Page 1

NHSC / NHDI

Resistive Element

Steam Humidifiers

Installation, Operation,

Maintenance, and

Troubleshooting Guide

NHSC

NHDI

IMPORTANT: Read and save these instructions. This

guide to be left with equipment owner.

Form #04-197-1 1505921

Page 2

Table Of Contents

INSTALLATION 1

RECEIVING & UNPACKING EQUIPMENT ................................1

PRE-INSTALLATION CHECKPOINT ...................................1

BASIC HUMIDIFIER CONFIGURATION..................................1

LOCATION & MOUNTING .........................................2

HUMIDIFIERS ·············································2

BLOWER PACKS ···········································3

STEAM DISTRIBUTORS AND SHORT ABSORPTION MANIFOLD ·················3

PLUMBING .................................................6

WATER SUPPLY LINE ········································6

DRAIN LINE ··············································6

STEAM LINE AND CONDENSATE RETURN LINE ··························7

ELECTRICAL................................................7

PRIMARY VOLTAGE SUPPLY WIRING TO HUMIDIFIER ······················7

PRIMARY VOLTAGE SUPPLY WIRING FROM HUMIDIFIER(S) TO BLOWER PACKS ·······7

LOW VOLTAGE CONTROL WIRING ·································9

CONTROL INSTALLATION ······································9

OPTIONAL MODULATION (CONTINUOUS CONTROLS)······················10

OPTIONAL MODULATION (CONTINUOUS CONTROL) PACKAGES BY NORTEC ········11

OPERATION 11

INTRODUCTION .............................................11

LAYOUT AND FUNCTION ........................................11

LEVEL REGULATION ········································11

STEAM GENERATION REGULATION································12

FLUSHING ··············································12

SCALE COLLECTOR TANK ·····································12

NHSC/ NHDI OPERATION ........................................12

STARTING OPERATION ·······································12

INTERROGATION OF THE OPERATING STATUS ···························14

MAINTENANCE..............................................17

NOTES ON MAINTENANCE .....................................17

DISMANTLING AND REASSEMBLYWORK .............................18

NOTES ON CLEANING........................................18

FAULT ELIMINATION ........................................19

SCALE TANK SERVICING ......................................20

REPLACING UNIT FUSES ......................................21

Page 3

RESETTING FAULT INDICATION“ERROR” .............................21

HEATING ELEMENT REPLACEMENTINSTALLATION INSTRUCTIONS ................21

TROUBLESHOOTING ··········································23

CONTROL CIRCUIT TERMINALBLOCK .................................25

PRE-START-UP CHECKLIST ......................................26

START-UP CHECKLIST .........................................27

MAINTENANCE CHECKLIST .......................................28

EXPLODED VIEWS ............................................30

WIRING DIAGRAMS ...........................................34

Page 4

INSTALLATION

.

as indicated on the spec label. Refer to local

codes.

RECEIVING & UNPACKING EQUIPMENT

1. Check packing slip to ensure ALL material has

been delivered.

2. All material shortages are to be reported to

NORTEC within 48 hours from receipt of

goods. NORTEC assumes no responsibility

for any material shortages beyond this period.

3. Inspect shipping boxes for damage and note

on shipping waybill accordingly.

4. After unpacking, inspect equipment for

damage and if damage is found, notify the

shipper promptly.

5. All NORTEC products are shipped on an

F.O.B. factory basis. Any and all damage,

breakage or loss claims are to be made

directly to the shipping company.

PRE-INSTALLATION CHECKPOINT

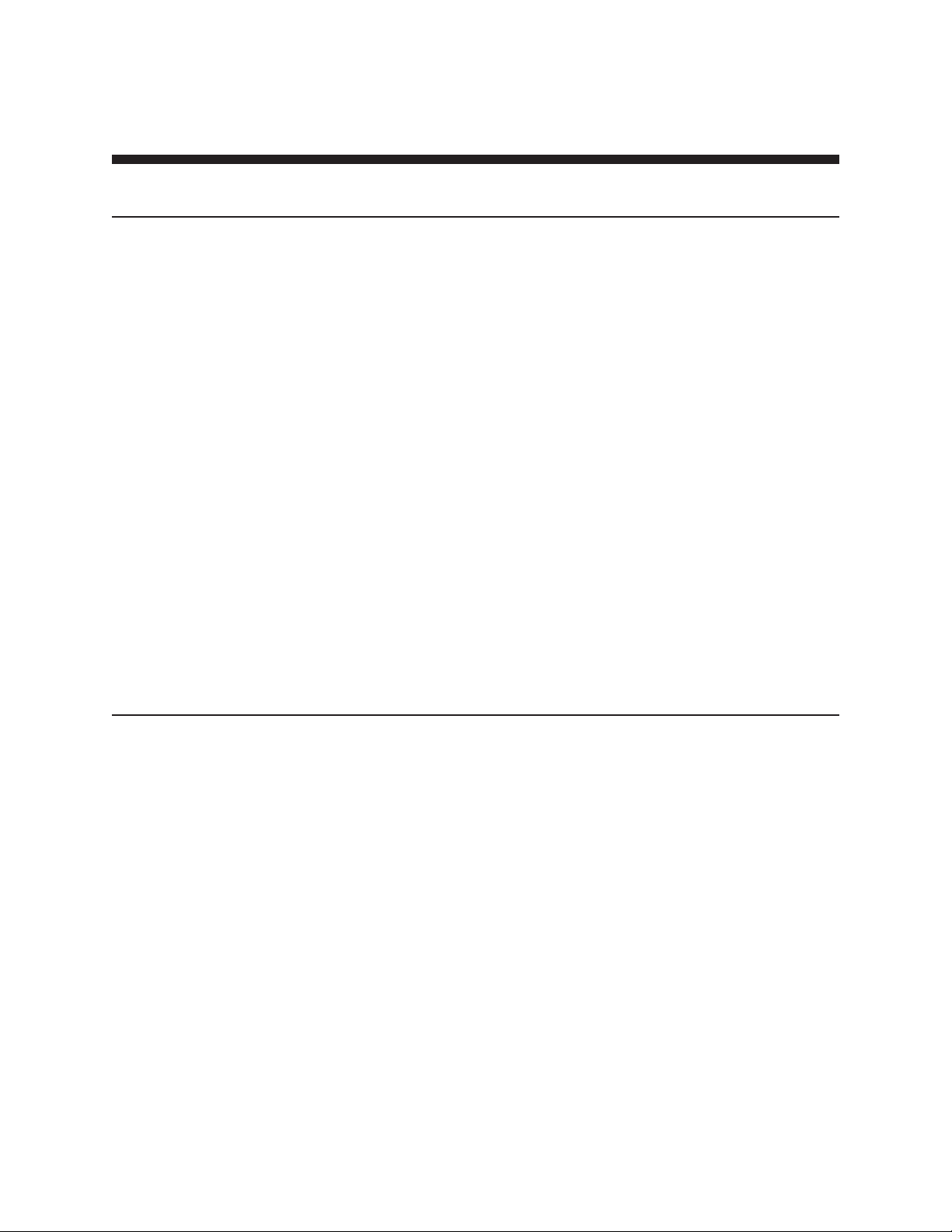

1. Ensure that available voltage and phase

corresponds with humidifier voltage and phase

as indicated on humidifier’s spec label (see

Figure #1).

3. Report any discrepancy immediately.

BASIC HUMIDIFIER CONFIGURATION

NORTEC NHSC / NHDI humidifiers share a

modular sheet metal cabinet. Each unit has a right

side electrical compartment. Each electrical

compartment has a hinge-down front door which is

removable from any partially or fully opened position.

Each electrical compartment has a screw-mounted

right side cover which can open for ease of electrical

connection. For safety, the door when closed keeps

the side cover from being opened.

Single units have a plumbing compartment

attached to the left side of the electrical. Double units

have a second plumbing compartment. Each

plumbing compartment has a hinge-down front door.

For safety, the door must be closed in order to engage

the safety interlock. To avoid any danger, never

operate the humidifier with a door off.

To open the doors, unlock, lift door up slightly and

pull top of door forward. Door will hinge 180 degrees

and hang straight down. To remove door, swing door

parallel to floor. Then lift up slightly and out. To

reinstall door, hold parallel to floor and insert hinge

pins at bottom.

2. Ensure that the dedicated external disconnect

is of sufficient size to handle the rated amps

Figure #1

NHSC / NHDI Series Humidifier

SteamOutlet

1.75" O.D.

Water

Supply

NOTE: NHDI does not have the scale collector tank.

Scale

Collector

Tank

Spec

Label

Drain

Valve

Optional SSR

Cooling Fans

Keypad

Display

Power and

Control

Wiring

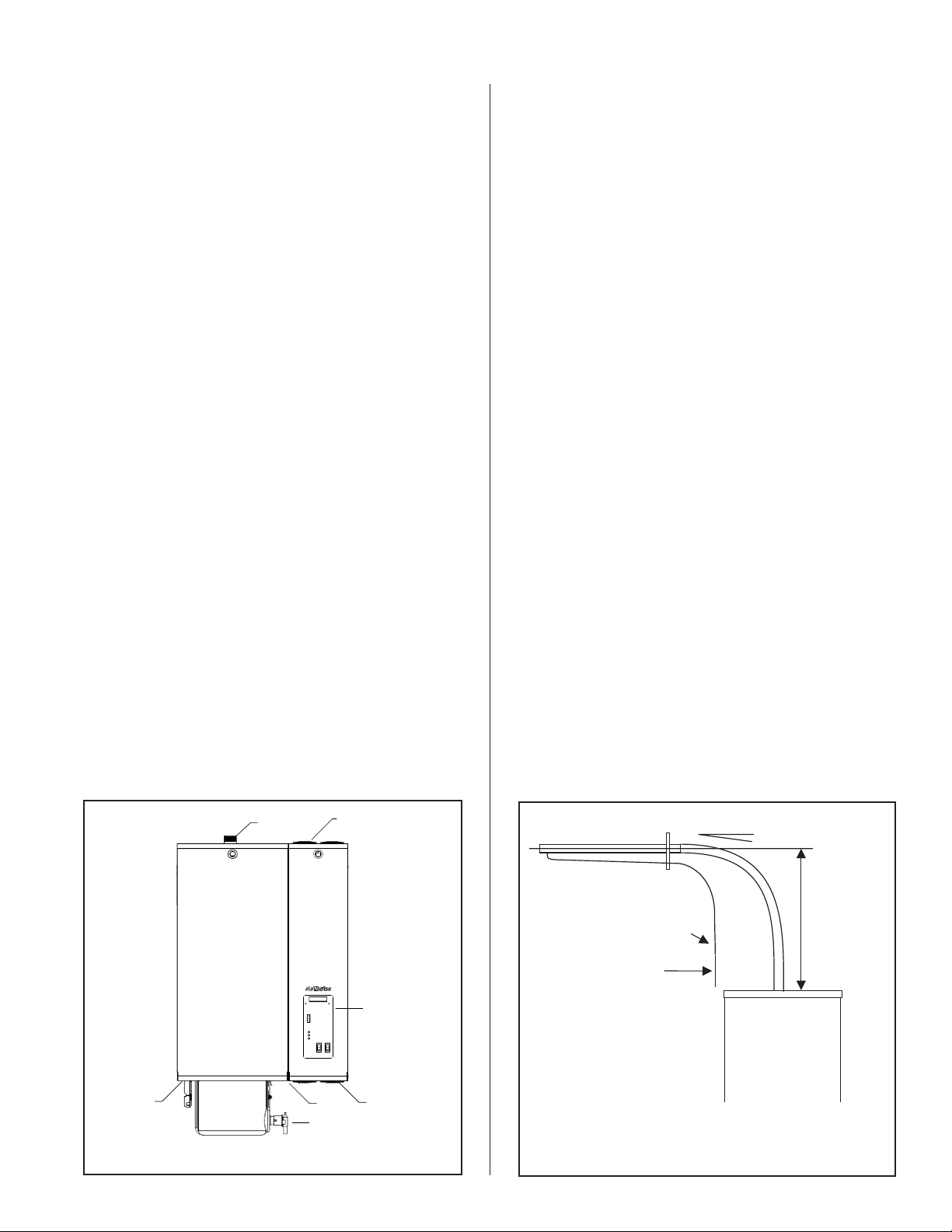

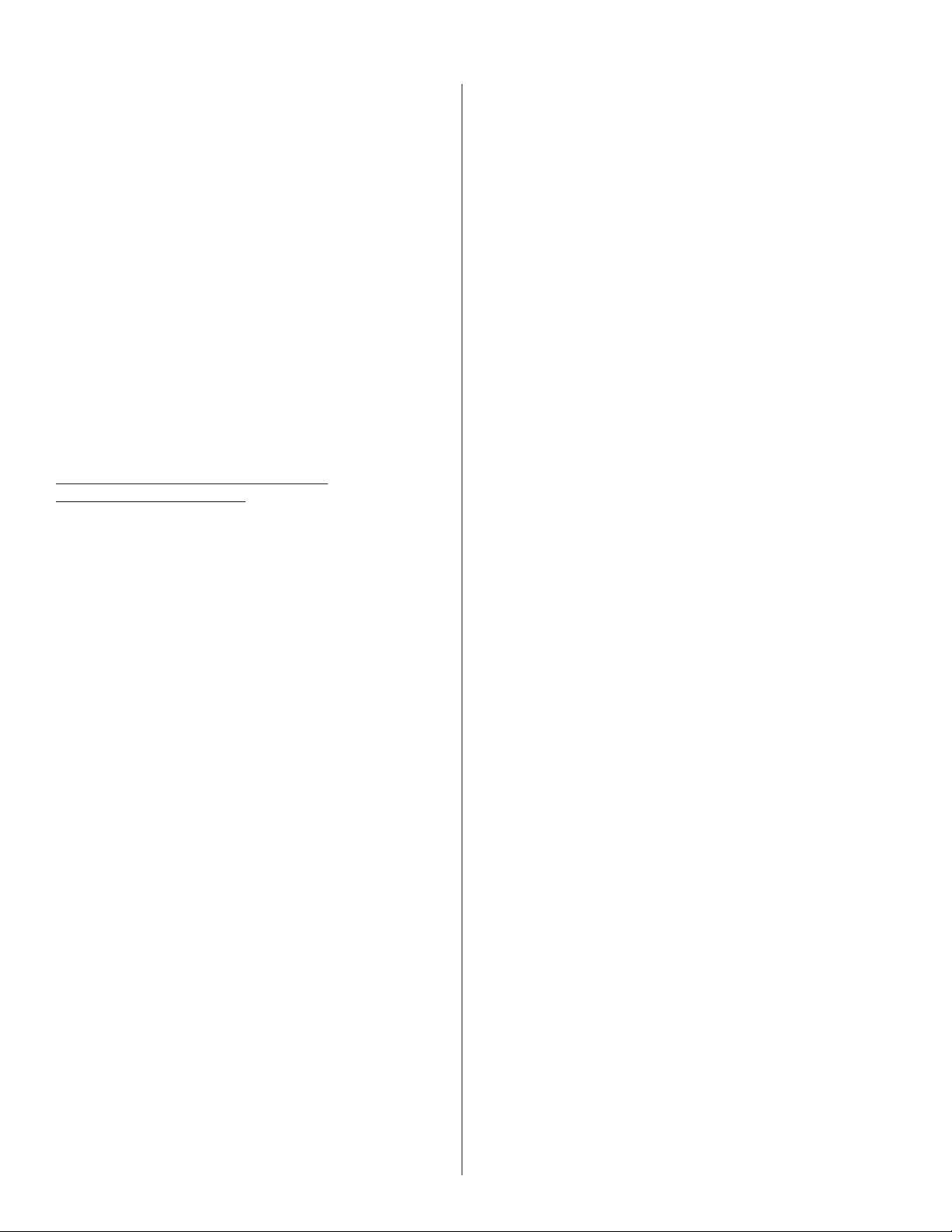

Figure #2

Minimum Steam Line Clearance

Min. 10 Degree Slope

Min. 12"

Trap

* See Section On

Condensate

Return Line

NOTE: Trap must be 3' minimum down from steam distributor

If not, condensate must be routed to drain.

-1-

Page 5

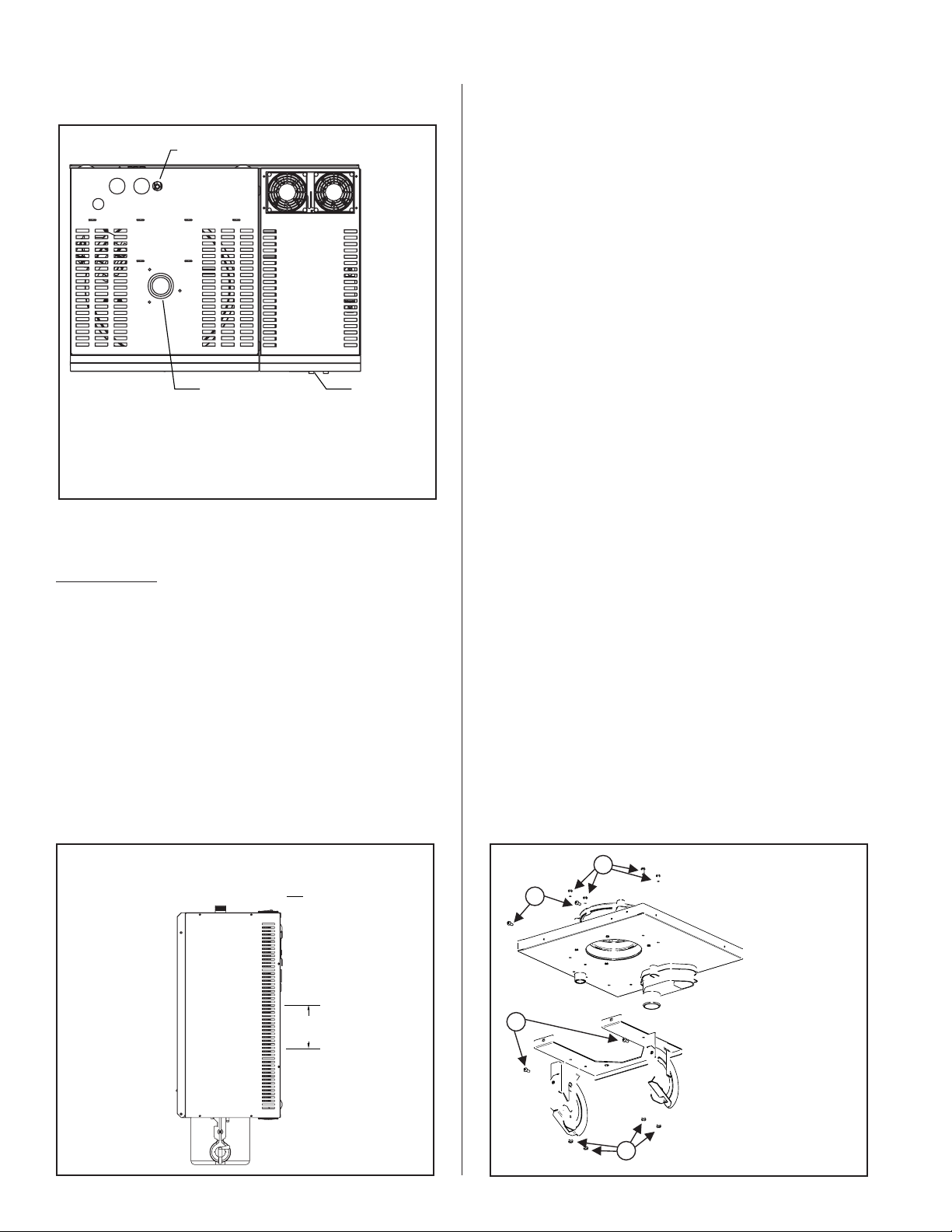

Figure #3

Clearance Required (Top View)

Condensate Return

Steam Outlet

NOTE: Local and national codes may deviate, please

consult applicable codes for clearance requirements.

Right side min. 36" side clearance. Min. 36" frontal

clearance recommended see note.

Top 12” Min, Bottom 12” Min, and Left Side 2” Min.

LOCATION & MOUNTING

HUMIDIFIERS

Right Side

Front

1. Location of the humidifier should be below and

as close as possible to the steam distributor

location. If possible, DO NOT locate humidifier

any further than absolutely necessary from

steam distributor location, as controllability

and net output will be reduced as a result of

heat loss through the steam hose (see Steam

Distribution Engineering Manual).

2. Where possible, mount humidifier at a height

convenient for servicing.

3. Wall mounting bracket provided should be

securely attached horizontally and open edge

facing upwards, using field-supplied fasteners.

For a single unit, use a minimum of 4 - #12 x

3” long wood screws. For a double unit, use a

minimum of 6 - #12 x 3” long wood screws.

These screws must be fastened securely on a

2 x 4 wood stud or equivalent support. If any

spacer material is used between the bracket

and the structural material such as drywall,

increase fastener length accordingly. In

addition, install a minimum of 2 field supplied

fasteners in the holes provided in the back of

the unit to prevent the unit from being bumped

off the wall bracket. See Figure #4.

NHSC / NHDI Series humidifiers are designed to

mount on a suitable wall or vertical surface. Do not sit

the unit on floor due to clearances required for

plumbing, electrical, and control entrances. The

clearance dimensions shown in this manual are for

reference only and are the minimum required for

maintenance of the humidifier. Local and National

Codes should be consulted prior to final location and

installation of the humidifier. NORTEC will not accept

responsibility for installation code violations.

Figure #4

Wall Bracket Mounting

Frontal clearance min. 36" (91 cm)

Right side clearance min. 36" (91 cm)

Left side clearance min. 2" (5 cm)

Wall

7.7"

(19.6 cm)

4. Mount unit on hanging bracket after ensuring

the bracket is properly anchored to the wall.

Raise the unit and place it on the hanging

bracket ensuring that the flanges in the

mounting bracket are properly aligned and

centered with the flanges of the unit. Push the

unit in towards the wall to properly interlock

the two flanges. Note: This will result in the

unit shifting slightly down. Ensure that the

hanging bracket’s flanges are fully engaged

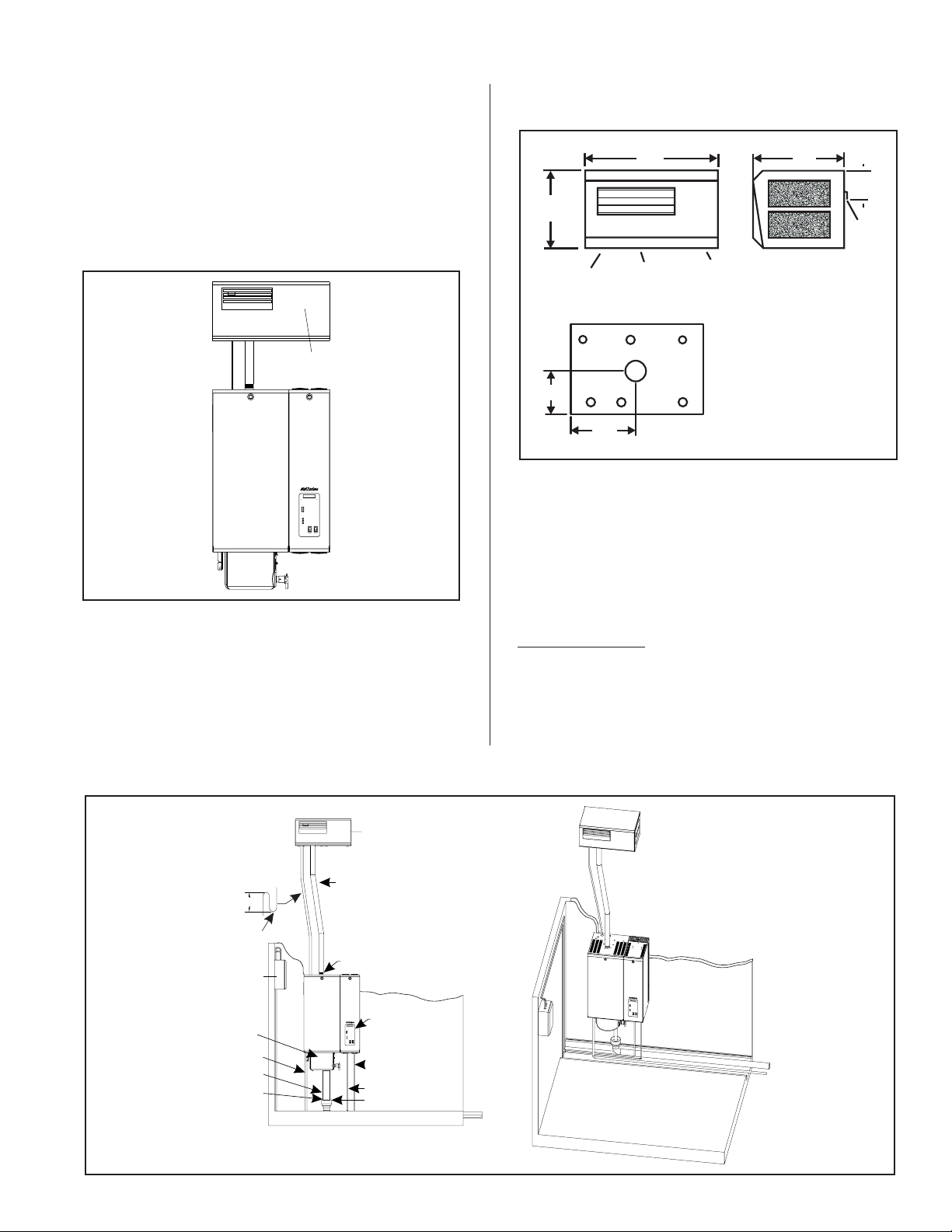

Figure #5

Installation of the Scale Tank Bracket (NHSC only)

1.

2.

1) Line up holes in bracket with

3.

1.

holes in drain pan. Fasten the

bracket to the drain pan using

the four Nylon lock nuts

provided.

2) Fasten the front of bracket

with the two #10-24 self tapping

screws provided.

3) The two locking screws for the

bracket should already be

installed.

-2-

Page 6

and visible from within the plumbing section of

the unit, and that the unit’s flanges are

properly contained within the wall bracket.

5. Install tank bracket. See Figure #5. (NHSC

Version only). Mounting the scale tank. (NHSC

Version only).

Figure #6

Remote Mounted Blower Pack

Figure #7

Remote Mounted Blower Packs (RMBP)

23.0"

(58.4 cm)

11.0"

(28.0 cm)

Condensate

Steam

Power

14.2"

(36.2 cm)

2.9"

(7.3 cm)

Wall

Mounting

Bracket

Remote

Mounted

Blower Pack

Scale

Collector

Tank

6. Make sure humidifier is level.

7. DO NOT mount humidifier on hot surfaces.

8. If humidifiers are mounted on roof, a

thermostatically ventilated weatherproof

Typical Remote Mounted Blower Pack Installation

Figure #8

Dimensions Shown

Are Steam Line Connections

Allow Minimum 12" (31 cm)

7.7"

(19.5 cm)

7.2"

(18.2 cm)

Clearance On Each Side

cabinet provided by others should be used.

Consult factory.

9. DO NOT mount humidifiers on vibrating

surfaces or duct work.

BLOWER PACKS

1. Blower packs are an optional accessory used

to directly distribute steam to localized areas

(such as computer rooms) or in structures that

do not have a built-in air distribution system.

Remote Mounted Blower

Packs (RMBP) Only

NHSC

uses Nortec steam

hose 1.75" O.D.or

stainless steel pipe.

uses Nortec steam

3"

Min. Trap

Height 3"

Required

Humidistat

Scale

Collector

Tank - NHSC

Water

Supply 3/8”

Drain Line

1.75” O.D.

Air

Gap

NHSC / NHDI using a Remote Mounted Blower Pack (RMBP)

NHDI

hose 1.75” O.D. or

stainless steel pipe.

Do not exceed 10 ft

when using steam hose.

Steam Line

Connection

LCD Keypad

Display with

LED Status

Low Voltage

Controls Wiring

24 Vac

Primary Wiring

Copper Funnel

Drain (by others)

-3-

Page 7

2. All NHSC / NHDI Series blower packs consist

of a steel cabinet containing: blower/motor

powered by voltage directly from the

humidifier, fuse, relay, speed select switch,

stainless steel steam distributor, supply air

grille with adjustable louvers, and a built-in

manual reset safety thermostat to turn off the

humidifier if the blower pack gets overheated.

Control thermostat, mounted on the steam

distributor, starts the fan when steam is

generated. When supply voltage differs from

voltage required to run blower motor, the

blower pack will contain the proper

transformer. All blower packs provide intake

air filters, if required.

3. For installation details about the blower pack,

please refer to the blower pack installation

manual located in the blower pack box, Form

#XX-277.

STEAM DISTRIBUTORS AND SHORT

ABSORPTION MANIFOLD

1.1. Steam distributors are an optional accessory

used to directly distribute steam to localized

areas (such as computer rooms) which are

served by ducted air. These distributors are

made of stainless steel and are mounted level

to the duct.

6. For installation details, please refer to the

installation manual located in the Steam

Distributor box, Form #XX-231.

7. For calculating absorption distances, refer to

H.E.L.P. Software or the Steam Distribution

Engineering Manual, Form #XX-232.

2. The SAM-e optional accessory has the same

function, to distribute steam inside a duct. The

only difference is that this system is designed

to reduce the absorption distance of the steam

in the duct by optimizing the steam

distributors.

3. Each cylinder requires its own steam line

and at least one distributor (do not join two

or more cylinders to one larger steam line).

Any cylinder’s steam line may be divided into

multiple branches to feed more than one

distributor. Steam supply line “tees” are

common stainless fittings that are available for

this purpose.

4. Steam distributor locations are typically as

follows: supply air duct, return air duct, air

handling unit. Proper location should

consider: air temperature, relative humidity

before the distributor, air velocity, dimensions

of the location, amount of steam being

introduced into the duct, downstream

obstructions, and surfaces vulnerable to

wetting.

5. The NHSC / NHDI can overcome 6” of W.C.

duct static pressure max. Consult the factory

if you exceed 6” of W.C.

-4-

Page 8

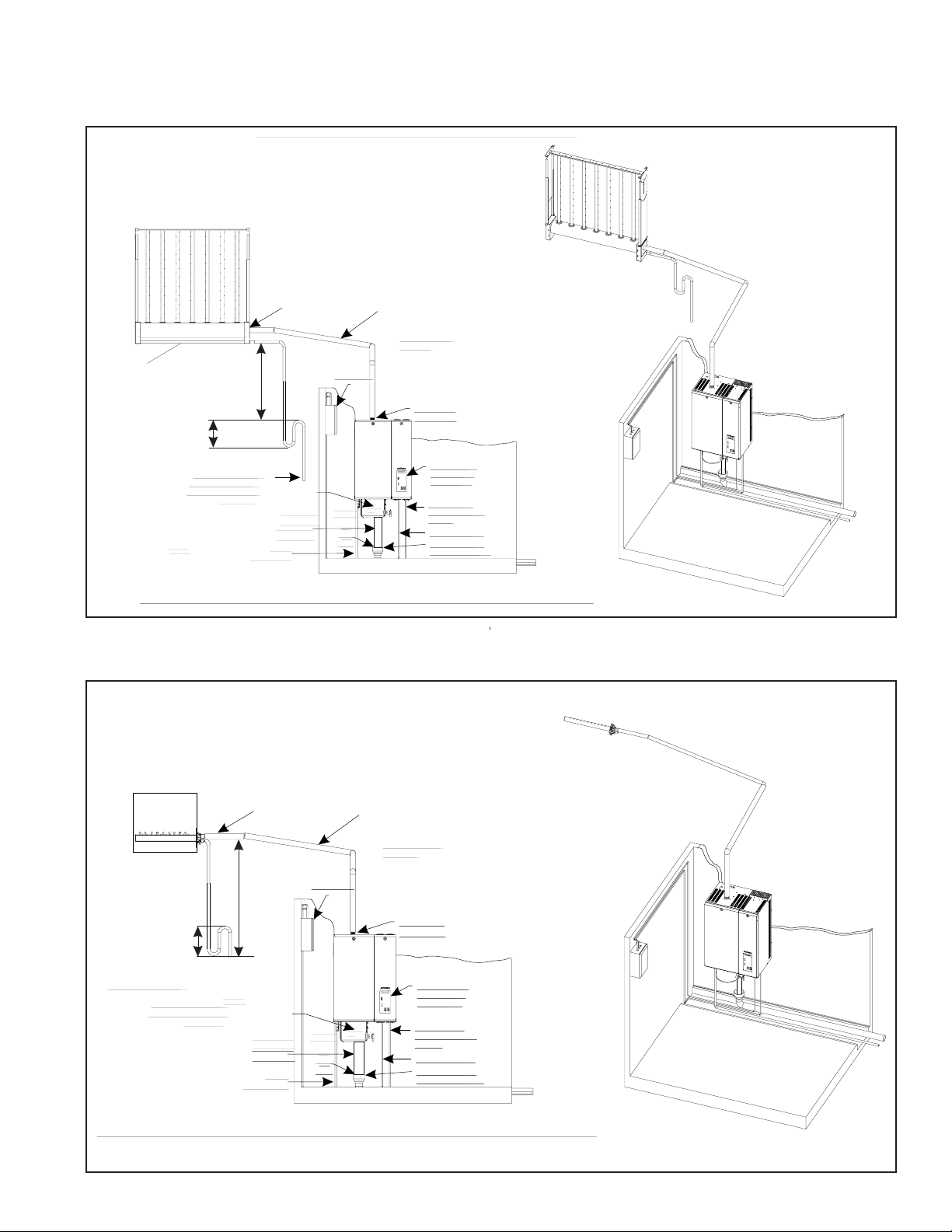

SAM-e

static pressure

Trap depth

2” greater

than duct

Min

24”

Condensate return

to floor drain, sump

pump or back to the

humidifier

Supply 3/8”

Steam

Inlet

Collector

Drain Line

1.75" O.D.

Water

Figure #9

Typical AHU / Duct Application using a SAM-e

NHSC

uses Nortec steam

hose 1.75” O.D. Or Med.

L Copper Insulated

NHDI

uses Nortec steam

hose 1.75” O.D. or

stainles steel pipe.

Do not exceed 10 ft

Gap

Air

when using steam hose.

Steam Line

Connection

LCD Keypad

Display with

LED Status

Low Voltage

Controls Wiring

24 Vac

Primary Wiring

Copper Funnel

Drain (by others)

Scale

Tank

NHSC

Humidistat

NHSC using a Short Absorption Manifold(SAM-e)in Duct/AHU

Figure #10

Typical Duct Application using Standard Distributor

NHSC

uses Nortec steam

hose 1.75” O.D. Or Med.

L Copper Insulated

NHDI

uses Nortec steam

hose 1.75” O.D. or

stainles steel pipe.

Do not exceed 10 ft

when using steam hose.

Steam Line

Connection

LCD Keypad

Display with

LED Status

Low Voltage

Controls Wiring

24 Vac

Primary Wiring

Copper Funnel

Drain (by others)

Condensate trap

must be 2” greater

than duct static

pressure.

Steam

Inlet

Min

24”

Scale

Collector

Tank

NHSC

Drain Line

1.75" O.D.

Water

Supply 3/8”

Humidistat

Air

Gap

NOTE: NHDI does not have the scale management system.

-5-

Page 9

PLUMBING

All water supply and drain line connections

should be installed in accordance with local

plumbing codes and should be copper or other

material suitable for potable water at 140ºF (60ºC).

WATER SUPPLY LINE - NHSC

1. The humidifier is intended to operate on

potable water.

2. Standard fill valves are sized for water

pressure ranging from 30 to 80 psig. For other

pressures, consult factory. This pressure

should be measured at the humidifier if the

water pressure is suspect.

3. ALWAYS supply and install a shut off valve in

the fill water supply line dedicated to the

humidifier to facilitate servicing. Use ½" OD

copper to within 4 feet of the humidifier.

Reduce to 3/8" OD and connect to the

factory-supplied 3/8" olive compression fitting

under the humidifier.

4. Same installation as #3, but add Drain Water

Cooler instead of fill.

#11). A field-supplied funnel (see Figure #12)

is recommended. It will prevent backup in the

drain pan and in the cylinder due to partially

blocked or badly installed drain lines. This

prevents rusting of the drain pan.

2. The NHSC scale collector tank is also

equipped with its own drain. It is

recommended to pipe, with a flex hose, the

scale collector tank to allow drainage, if

required while maintaining ease of servicing

(DO NOT HARDPIPE).

3. The drain line should not end in a sink used

frequently by personnel, or where plumbing

codes prohibit it. Route to a floor drain or

equivalent for safety reasons, since drain

water from humidifier can be very hot.

4. Keep drain lines as short as possible. Keep

drain lines sloped down, not level and not

up since low spots in drain lines will

accumulate sediment and cause backup.

The drain line should be 2.0” O.D. copper pipe

or larger. Do not use plastic pipe for drain

lines. Consult factory.

DRAIN LINE - NHDI

WATER SUPPLY LINE - NHDI

1. Humidifier is intended to operate on Reverse

Osmosis (RO) water or De-ionized (DI) water

with a water conductivity of less than 20

Microsiemens.

2. Standard fill valves are sized for water

pressure ranging from 30 to 80 psig. For other

pressures, consult factory. This pressure

should be measured at the humidifier if the

water pressure is suspect.

3. ALWAYS supply and install a shut-off valve in

the fill water supply line dedicated to the

humidifier to facilitate servicing. Use ½" OD

plastic or stainless steel to within 4 feet of the

humidifier. Reduce plastic or stainless steel to

3/8" OD and connect to the factory-supplied

3/8" olive compression fitting under the

humidifier.

4. Same installation as #3, but add Drain Water

Cooler instead of fill.

DRAIN LINE - NHSC

1. Humidifier is equipped with a 1.5”" O.D.

unthreaded drain outlet on underside of drain

canal on bottom of the humidifier (see Figure

1. Humidifier is equipped with a 1.5” O.D.

un-threaded drain outlet on underside of drain

canal on bottom of the humidifier (see Figure

#6). A field-supplied funnel (see Figure #8) is

recommended. It will prevent backup in the

drain pan and in the cylinder due to partially

blocked or badly installed drain lines. This

prevents rusting of the drain pan.

2. The drain line should not end in a sink used

frequently by personnel, or where plumbing

codes prohibit it. If the Drain Water Cooler is

used with potable water then copper may be

used. Route to a floor drain or equivalent for

safety reasons, since drain water from

humidifier can be very hot. Verify with local

codes on DI and RO water. Drains should be

verified for their suitability for RO or DI water

and local codes should be checked.

3. Keep drain lines as short as possible. Keep

drain lines sloped down, not level and not

up since low spots in drain lines will

accumulate sediment and cause backup.

The drain line should be 2.0” O.D. S.S. pipe or

larger. Do not use plastic pipe for drain lines.

Consult factory.

-6-

Page 10

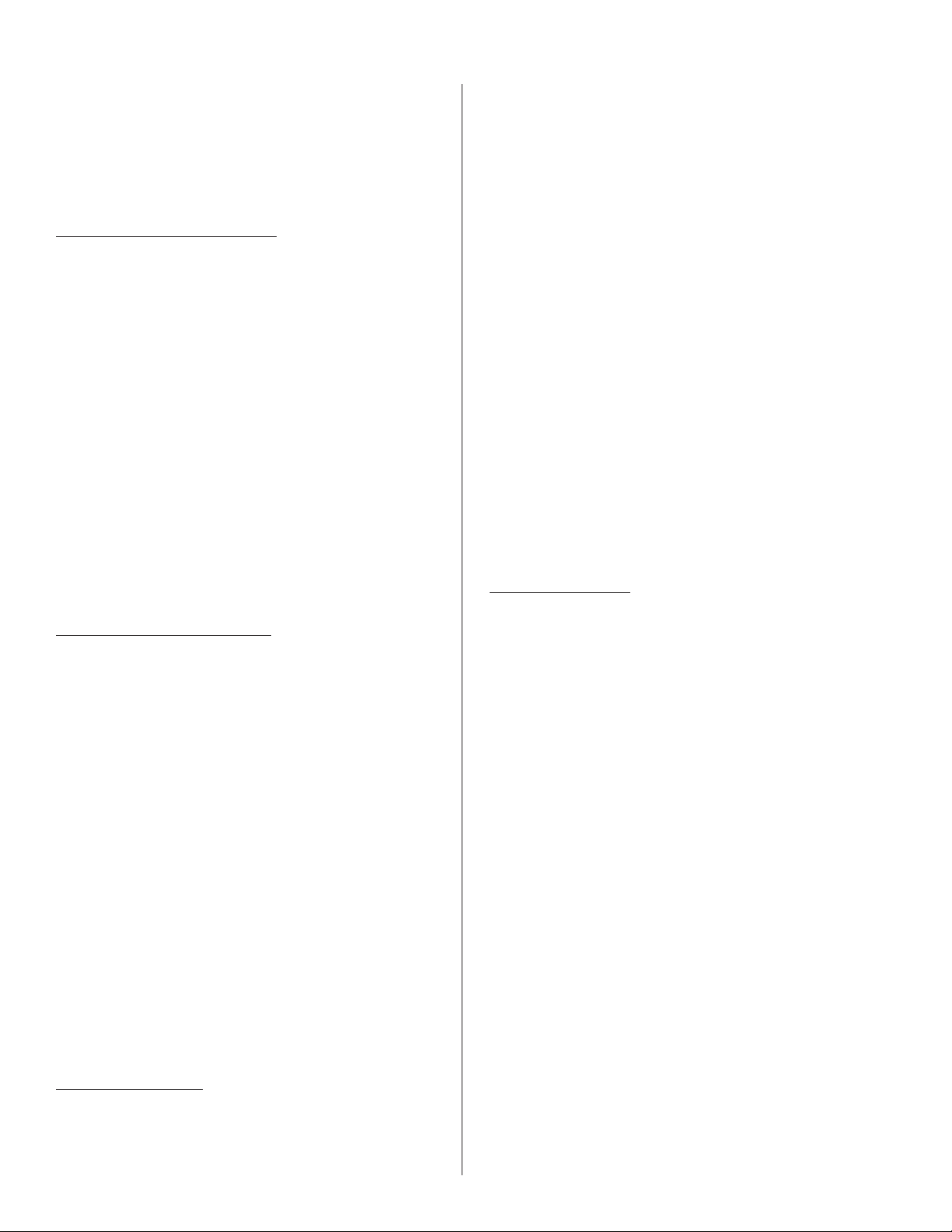

l

A

Supply Water

t

Connection

3/8“

Drain

Water Cooler

Connection 3/8”

Drain

Connection

1.5" O.D.

Figure #11

Drain Line Connection

NHSC

Scale

Collector

Tank

A

7.95

B

(58.4)

Model

010-090

135-180 Left

135-180 Right

23.0

(20.2)

A (in.)

1.7”

1.7”

1.7”

Figure #12

Drain Connection

B (in.)

5.4”

5.4”

20.3”

Power

Inlet

Controls

Inlet

Optional

Cooling Ki

for SSR

(consult

factory)

STEAM LINE AND CONDENSATE RETURN LINE

1. Refer to the installation manual of the steam

distribution system used in your application.

Steam Distributor Form #XX-231, SAM-e

Form #XX-249, and Blower Pack Form

#XX-277.

ELECTRICAL

PRIMARY VOLTAGE SUPPLY WIRING TO

HUMIDIFIER

1. Check and ensure that available voltage and

phase corresponds with operating voltage and

phase of humidifier as indicated on the

humidifier spec label, see Figure #1.

2. Ensure that an adequate power supply is

available to carry full humidifier amperage

drawn as specified by rated amps on the

humidifier spec label, reference to local codes.

3. A dedicated external disconnect must be

installed. Do not exceed the maximum circuit

protection amps as indicated on the

nameplate label.

ir

Gap

Clamp and1.5”ID Hose

Factory Supplied

Install aCopper Funnelfor theNHSC mode

and aStainless SteelFunnel forthe NHDI

model (byothers).

4. Connect ground wire to cabinet ground clamp.

Do not use neutral wire of four wire supply as

ground.

5. Single phase humidifiers may be run on three

phase power, but load may unbalance power

NOTE: Steam hose should not

reach bottom of the funnel.

Install a2” O.DCopper Pipefor theNHSC

model and2”O.D. Stainless SteelPipe for

the NHDImodel(by others).

grid.

6. External wiring sizes must be in accordance

with NEC and/or CEC and existing local

electrical codes and by-laws.

Figure #13

Drain Pump by others (if necessary)

PRIMARY VOLTAGE SUPPLY WIRING FROM

HUMIDIFIER(S) TO BLOWER PACKS

1. All blower packs are wired (by others) to be

powered from the humidifier.

Humidifier

2. As a safety feature, blower packs come

equipped with a manual reset safety

thermostat and relay built into the blower pack

cabinet. The manual reset thermostat turns

Recommended Model

Gould - Model SSH

Consult Factory

Floor

Surface

Line

Drain Line

off the humidifier if the blower pack gets

overheated. The control thermostat, mounted

on the steam distributor, starts the fan when

steam is generated.

3. All blower packs have high efficiency blowers

to minimize the frontal and overhead

clearance required to absorb the steam.

-7-

Page 11

(ACTUAL)

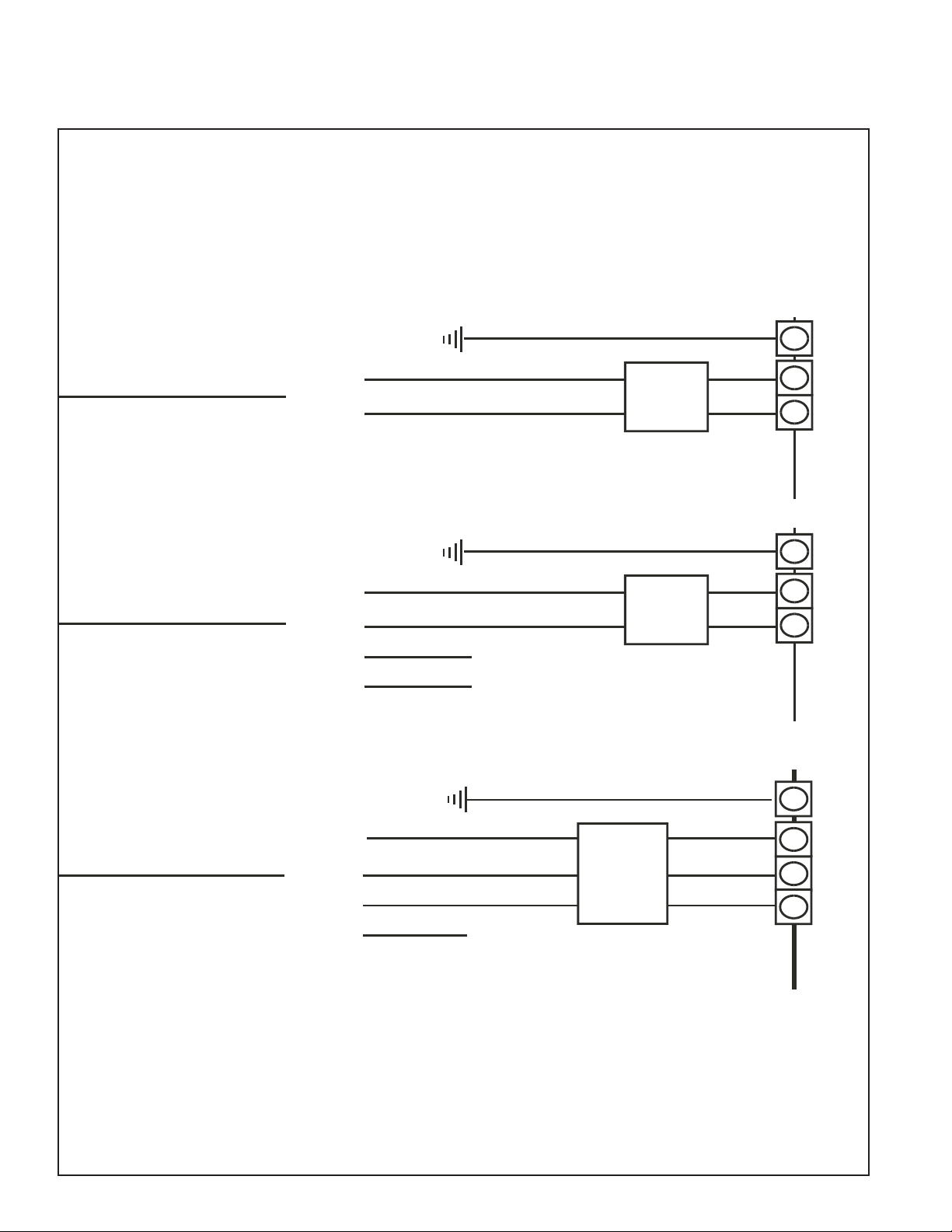

Figure #14

Primary Voltage Supply Wiring

PRIMARY (LINE) VOLTAGE WIRING TO UNITVOLTAGE

(BY OTHERS)

L1

L2

- Single Phase Unit.

- Single Phase Supply.

- Required Voltage Between L1 And L2.

- Load Balanced.

L1

L2

L3

Neutral

Ground

Ground

- Single Phase Unit.

- 3 Phase Supply.

- Required Voltage Between L1 And L2.

- Load Will Be Unbalanced.

Ground Wire

Dedicated

Disconnect

Ground Wire

Dedicated

Disconnect

Circuit

Breaker

Or

Circuit

Breaker

Or

Ground

Leg

2Pole

Te rm i na l

Block

E

I

X

N

T

T

Ground

Leg

2Pole

Te rm i na l

Block

E

I

X

N

T

T

Ground Wire

L1

L2

L3

Neutral

Ground

Dedicated

Circuit

Breaker

Or

Disconnect

- 3 Phase Unit.

- 3 Phase Supply.

- Required Voltage Between Any Two Legs.

- Load Will Be Balanced.

NOTE: VoltageAt TerminalBlock Must Be InAccordance With Spec. Label.

All Wiring ToBe InAccordance With Existing NationalAnd Local Electrical Codes.

-8-

Ground

Leg

3Pole

Te rm i na l

Block

E

I

X

N

T

T

Page 12

4, All blower packs require field wiring between

two pole primary voltage terminal blocks and

two low voltage control (class 1 circuit wiring

required) terminal strips; one of each located

in the humidifier and the remote blower pack

cabinet. To properly access the primary block

on the humidifier, it is necessary to open the

side pan. To connect the primary and control

(class 1 circuit wiring required) wiring, the

wiring is fed through the grommet provided in

the bottom of the blower pack. The terminal

block and strip are accessed by removing the

blower pack cover.

5. Field wiring of remote blower packs must

conform to national and local electrical codes.

Refer to wiring diagram supplied inside the

humidifier.

6. Use approved wire for power connection from

two pole terminal block of remote blower pack

to additional two pole terminal block inside

electrical section of humidifier.

7. Use approved wire to connect the ground

clamp of remote mounted blower pack to

ground clamp provided in the electrical section

of humidifier.

LOW VOLTAGE CONTROL WIRING

A - Wall or Duct Mounted Control On/Off

Humidistat: Wired to make on drop in humidity, break

on rise to set-point. Set to desired % RH. Can be a

make/break set of contacts from a Building Automation

System.

B - Duct Mounted Safety High Limit On/Off

Humidistat (if used): Wired to make on drop in

humidity, break on rise to safety set-point. Set to

approximately 85% RH as a safety to help prevent

saturation and wetting in the duct.

C - Duct Mounted Safety Air-Proving On/Off

Switch (if used): Wired to make with sensed air flow,

break when no air flow. Used as a safety to prevent

saturation when there is no airflow.

1. NORTEC offers various versions of A, B and

C to suit each application. In general, A is

essential, whereas B and C are highly

recommended in ducted applications.

2. Field wiring from humidistat to humidifier and

between devices should be 18 AWG or

heavier and kept as short as possible.

3. Low voltage control terminal strips are

provided in the electrical compartment.

Internal sides are factory wired. External

sides are to be field wired.

On-Off Controls

Figure #15

External Wiring of On/Off Controls

A

B

C

D

External

Internal

10

8

Controls are available from NORTEC as

accessories. If controls were not ordered with

humidifier, they must be supplied by others. The

following information is relevant to all controls, factory

supplied or otherwise.

A, B, C and D (described below) are to be wired in

series (only one path for current) across terminals 8

and 10 on the low voltage control terminal strip or

replaced with a jumper wire for constant operation.

Caution: this is the “hot” wire from the 24V control

transformer; it will blow the 3A fuse if any control field

wiring touches ground.

4. Each humidifier is supplied with a wiring

diagram inside.

D - Blower pack safeties

CONTROL INSTALLATION

1. Mount any wall humidistat (control or high

limit) over standard electrical box at height

similar to typical thermostat. Any wall

humidistat should be in location

representative of overall space being

humidified and not in path of blower pack or

air supply grille. Do not mount on a outside

wall where temperature fluctuation can affect

control response.

2. Mount duct humidistat in location

representative of overall air humidity, usually

in the return duct. Do not mount it directly in

front of steam distributor or in turbulent or

mixing zone. Mount it where humidity and

temperature are uniform and representative of

spaces being humidified.

3. Mount duct high limit humidistat

downstream of steam distributors far enough

that, under normal humidity and air flow

-9-

Page 13

temperature are uniform and representative of

s

spaces being humidified.

3. Mount duct high limit humidistat

downstream of steam distributors far enough

that, under normal humidity and air flow

conditions, steam will have been fully

absorbed (typically at least 10 feet). It must

be located to sense high humidity only when

uniform and representative air is

over-humidified or approaching saturation.

4. Mount duct air-proving switch so that it is

able to sense air flow or lack of it. Wire it to

make when air flow is sensed and break when

air flow fails.

5. Check operation of all on/off controls before

starting humidifier.

one of several control wiring diagrams. In all

cases, modulating signal interfaces through

control terminal strip to main pc board inside

humidifier.

4. For set-point control at the humidifier an

integrated controller can accept a direct

transducer signal. The accuracy of the

humidifier to changing conditions will be

dependant on the accuracy of the signal.

5. The modulation signal must increase from

minimum toward maximum as sensed RH

(actual RH) drops below desired RH (%RH

set-point). In response, humidifier’s steam

output will increase from minimum toward

maximum. When humidifier’s steam output

(lbs/hr) matches humidification load (lbs/hr),

modulation signal will stabilize.

6. Calibration of controls (on/off or modulation) in

the field may be necessary due to shipping

and handling. Verify humidistat accuracy

before commissioning system.

OPTIONAL MODULATION (CONTINUOUS

CONTROLS)

1. Read on/off controls section first since it is

necessary to all control systems.

2. Virtually any modulation (continuous control)

external hardware by others (as long as it has

%RH set-point circuitry) may be interfaced

with pre-specified factory-configured pc board

via the control terminal strip.

3. Modulation (continuous control) by others for

use with NHSC / NHDI humidifiers involves

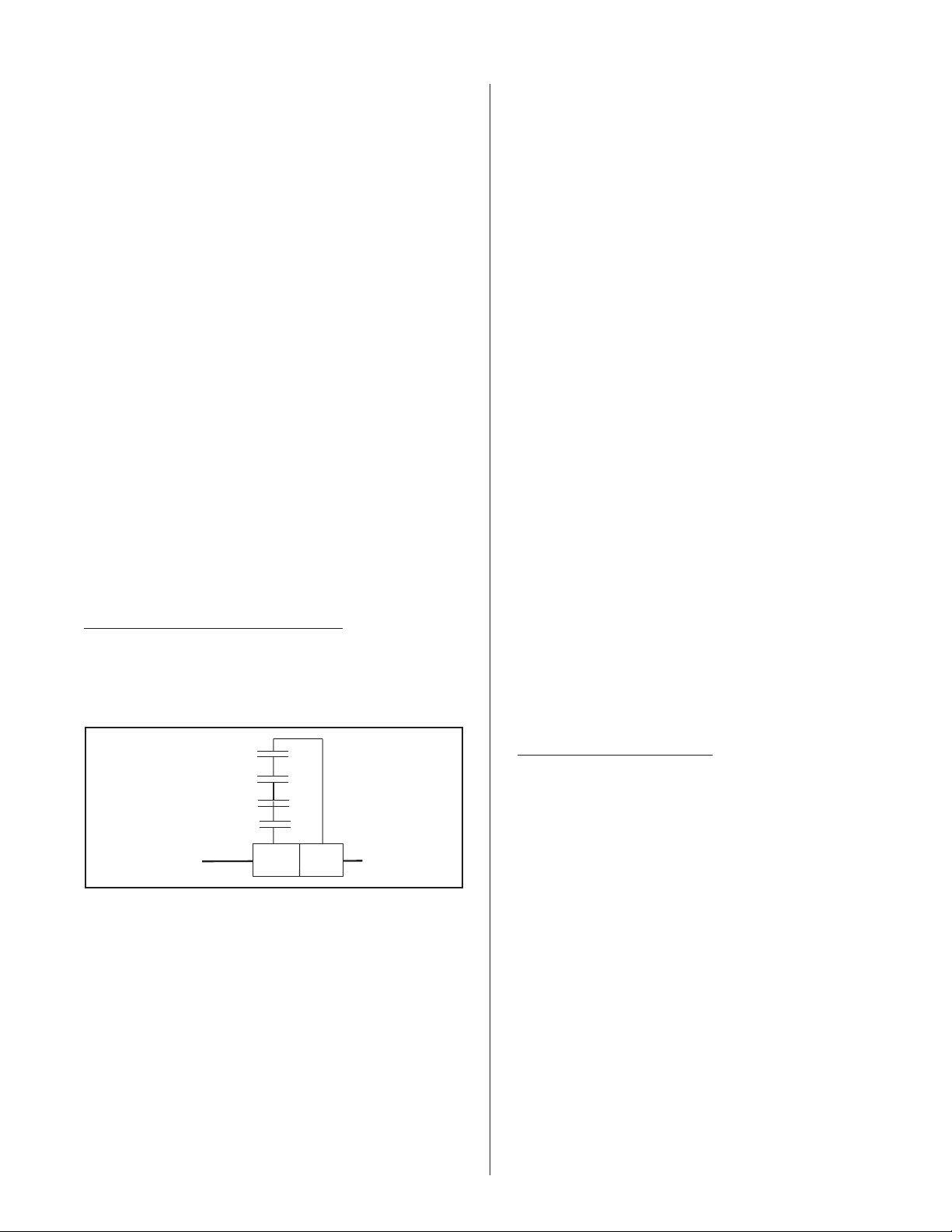

Figure #16

Generalized Modulation Wiring

NHSC / NHDI SERIES

CONTROL CIRCUI T T ERMINAL BLOCK

IMPORTANT: REA D THESE INSTRUCTI ONS CAREF ULLY BEFORE CONNECTING CONT ROL WIRI NG

Other On/Off

Devices

High Limit

Humidistat

Air Proving

Switch

Control

Humidistat

NOTE: If no On/Off

Control is used, then

A field jumper must

be connected across

8 and 10 in order for

humidifier to operate

NOTE: See Included Diagram(s) For Accessory Wiring Instructions

NHDI: Dry Points, rated 24 Vac/dc 1.0Amp

max. resistive load per Indicator

OPTIONAL REMOTE

STATUS PCB

K1 Steam

K2 Error

K3 Ser vice

K4 Unit ON

Optional external remote

indication. Any or all of these

remote indications can be

utilized. Refer to Trouble

Shooting Manual for system

status indication.

10

8

Optional

Modulation Control

See Diagram included

with unit for details

32 30 28

61

6. Field-wiring connections for modulation control

are to be made to external side of terminals

28, 30 and 32 on humidifier’s control terminal

strip. Always refer to the external control’s

wiring diagram factory supplied with each

NORTEC modulation control option.

7. Varying dc Voltage Modulation Signal

Powered by Others: NHSC / NHDI

humidifiers can be factory configured to accept

the following vdc signals: 0-10 vdc, 0-20 vdc,

1-5 vdc or 2-10 vdc. Wire according to

NORTEC supplied external wiring diagram

that comes with each modulation option. To

share the signal with more than one

humidifier, wire in parallel to each humidifier.

If a different signal is desired consult factory.

8. Varying dc milliAmp (mA) Modulation

Signal Powered by Others: NHSC / NHDI

humidifiers can be factory-configured to

accept a standard dc mA signal, if

pre-specified. Wire according to NORTEC

supplied external wiring diagram that comes

with each modulation option. Choose from

0-20 dc mA or 4-20 dc mA. To share the

signal with more than one humidifier consult

factory.

9.

Varying Resistance (W) Modulation by

Others: NHSC / NHDI humidifiers can be

factory configured to power a 3-wire varying

resistance modulation humidistat by others, if

pre-specified. Wire according to NORTEC

supplied external wiring diagram that comes

with each modulation option. Choose from

0-500W or up to 0-1000W. To share the signal

with more than one humidifier consult factory.

-10-

Page 14

OPTIONAL MODULATION (CONTINUOUS

CONTROL) PACKAGES BY NORTEC

1. Modulation (continuous control) “packages”

are offered as accessories by NORTEC.

Power supply comes from inside NHSC /

NHDI humidifiers.

2. NORTEC provides the humidity set point

circuitry and sensor(s) for wall or duct

mounting or both as pre-selected when

ordering the option. NORTEC offers several

packages for NHSC / NHDI Series humidifiers.

Wire according to NORTEC supplied external

wiring that comes with each optional

modulation package.

control board. The humidifier’s operating status is

reported to the user by the green, red and yellow

indicator lights on the front of the unit.

The prerequisites for getting power and water into

the steam cylinder are as follows:

On/off switch must be switched on.

-

control circuit 8-10 must be made.

-

door interlock switch must be made (interlock switch

-

can be pulled out to operate unit).

Modulating signal must be calling.

-

Internal safeties must be made over temperature

-

switch and ground fault.

3. Optional modulation packages without

modulating safety high limit can use on-off

safety high limit. Refer to on-off controls

section.

4. All versions can use on-off safety air proving

switch. Refer to on-off controls section.

OPERATION

INTRODUCTION

The NORTEC NHSC Series humidifier is a

completely new design based on up-to-date

technology. The NHSC is designed to provide clean

steam humidification at an economical price.

The NHSC uses a micro-computer control system

for greater flexibility. The NHSC has a liquid crystal

display (LCD) to indicate system messages and

display RH.

LAYOUT AND FUNCTION

LEVEL REGULATION

The water level in the steam tank is continuously

monitored with the level unit.

The unit pulse fills based on steam production.

The pulse filling in the unit varies depending on the

water level detected by the float chamber.

One magnetic float monitors five different water

levels in the float chamber. The second float ensures

the water level is always above the heating elements.

The pressure equalizing pipe between the steam

connection and the level unit ensures that the water

levels are the same in the steam tank.

The NHSC humidifiers consist of a plumbing and

an electric compartment. In every case there is at

least one steam distributor (SD) for installation in air

ducts or blower packs (remote mounted: RMBP) for

direct space humidification.

Water enters the steam cylinder through the

bottom via the fill cup assembly when the 24 volt fill

valve solenoid is energized. The water is heated via

electric element and produces sterile steam for

distribution into the air.

Primary electric power is applied to the heating

elements in the steam cylinder when the on/off switch

is pushed on and all control options are calling. A

primary to 24 volt step-down transformer provides

power to the contactor holding coil(s) via the main

-11-

Page 15

STEAM GENERATION REGULATION

The steam is produced in the steam tank by

resistive heating element technology. An external or

the internal regulator for connection as required control

the steam production fully variably from 3 to 100%.

FLUSHING - NHSC ONLY

The evaporation process increases the

concentration of minerals in the water of the steam

cylinder. A suitable volume of water must be flushed

through the steam cylinder from time to time and

replaced by fresh water to ensure that this

concentration does not exceed a specific value

unsuitable for operation. The NHSC / NHDI steam

humidifier performs a flush cycle. This consists of the

following two forms of flushing.

Automatic flushing takes place as soon as the

•

water in the steam cylinder exceeds the upper

operating level (e.g. By foaming of the water).

Flushing is a time dependent process at

•

preselected time intervals.

Automatic or time-dependent flushing takes place

based on the water quality and the operating data.

SCALE COLLECTOR TANK - NHSC ONLY

The minerals precipitated by the evaporation

process accumulate at the bottom of the steam

cylinder. Units designed for operation with untreated

water are equipped with a scale collector tank located

directly underneath the steam cylinder. This way the

minerals do not accumulate in the steam cylinder but

mainly in the collector tank thus extending the service

intervals and reducing the maintenance costs.

NHSC / NHDI OPERATION

Ensure the valve on the NHSC mineral tank is

•

closed.

Switch on the steam humidifier main switch.

•

The steam humidifier carries out a system test.

The display below appears and the three LEDs light

for approx. 3 seconds.

test

If a fault is detected during the system test, a

corresponding fault message is triggered.

If the system test is successful, the steam cylinder

fills up and a float test is carried out (function check on

the level unit). The display below appears.

filling

Note: If a fault is detected during the float test, an

appropriate fault message is triggered

If the float test is successful, the NHSC / NHDI will

be in normal operating mode. The display below

appears and the green LED lights.

The following procedure should be carried out only

on the first occasion that the unit is operated:

NHSC/DI

ready

• Check the function of the steam humidifier:

•

Switch on the humidification by raising the set

humidity value on the humidity controller /

humidistat / NHSC / NHDI Display.

•

Switch off the humidification by lowering the set

humidity value on the humidity controller /

humidistat / NHSC / NHDI Display.

STARTING OPERATION

The following procedure should be carried out in order

to operate the steam humidifier:

•

Examine the steam humidifier and installation to

ensure it has been installed properly or for

possible damage.

Caution! Damaged units and units with

improper installation must not be operated.

•

Open the filter valve / shut-off valve in the water

feed line.

•

Switch on the external disconnect for the main

supply (Heating and control voltage).

•

Check for correct functioning of the monitoring

equipment (external safety network).

•

Set the desired humidity value on the humidity

controller/humidistat.

•

Make sure no leaks are present.

The heating current switches on as soon as the

humidity controller/humidistat demands humidity. The

yellow LED lights and steam is produced after a short

delay (approx. 5 minutes).

Operating status display on the unit

The operating status is displayed in the LED on

the unit as follows:

-12-

Page 16

Green LED lit: Unit producing steam

•

Yellow LED flashing: Major or minor servicing

•

due. The relevant notice is shown in the display.

Red LED flashing: There is a problem. The unit

•

is trying to solve the problem. The relevant

warning message appears in the display.

Red LED lit: Insoluble problem. The relevant

•

error message appears in the display.

Optional Remote operating and fault indication

If the steam humidifier is equipped with the

optional remote operating and fault indication

(option ”RFS”), the operating status will be shown as

follows:

K1 Steam (N/O) Normally open

K2 Error (N/O) Normally open

Or

(N/C) Normally closed

K3 Service (N/O) Normally open

Or

(N/C) Normally closed

K4 Unit On (N/O) Normally open

-13-

Page 17

INTERROGATION OF THE OPERATING

STATUS

The NHSC / NHDI operating and display unit has

a “display menu” from which various operating

parameters can be viewed.

Note: It is not possible to change the values on the

display level.

Operation

Call up the display level with <ê>or<é>.

<ê> next operating parameter.

<é> previous operating parameter.

Exit the display level with <Menu>

Internal Controller

Controller funct

off

Internal controller activated (”on”)/deactivated

(”off”)

Working Hours

elapsed time

623

Total of working hours elapsed since initial

commissioning of the steam humidifier.

Time Remaining to minor/major service

time to mainten.

600/1200

The time remaining (in hours) before the next

minor/major service.

Description of the operating parameters on the

display level

The following describes the individual operating

parameters that can be selected using the keys <ê>

and <é>, after the display level has been called up.

Steam Productions

steam-prod[%]

ref.=50/act=25

Current actual and nominal value of steam

production in percentage of total output.

Nominal value: Unit capacity x input signal value.

Actual value: max. Unit capacity x input signal

value x capacity limitation.

Note: If the internal controller is activated only the

actual value is shown.

Under the following conditions the actual value

may differ from the nominal value: upon activation of

the heating power, if capacity limitation is active during

the filling cycle of the steam cylinder.

Can be increased for poor water conditions or

decreased for good water conditions.

Figure #17

NHSC / NHDI Maintenance Intervals

Analog Input (humidity demand)

Analog input [%]

25

Current value of the signal applied to the analog

input in % of its max. value.

Note: If the internal controller is active the

displayed value corresponds to the current air humidity

(%rh).

-14-

Page 18

Note: The stated times are based on 100% steam

capacity. If the operation is at a lesser capacity, the

time should be extended accordingly. The servicing

intervals are set using the rotary switch “S2” on the

control board.

Drain Cycle

drain cycle

4: 120

The following indications are provided for the set

flushing interval:

Left: Switch setting on rotary switch “S1”

Right: Set flushing interval

Note: Water quality conditions resulting in

component failures are not covered under Nortec’s

standard warranty.

The factory settings are based on the following

water conditions when the unit leaves the factory.

Water

NHSC NHDI

Parameters

Conductivity 0-1500 MicroMhos 0-50 MicroMhos

Hardness 12 grains per gallon

(gpg)

0 grains per gallon

(gpg)

Note: The flushing interval is set on switch “S1” on

the control board.

Figure #18

NHSC / NHDI Drain Cycle Parameters

ValueSettings

Position Drai n Inte rval At 100%

S1 Steam Capacity

00Min.

1 720 Min.

2 360 Min.

3 180 Min.

4 120 Min.

560Min.

630Min.

720Min.

810Min.

95Min.

Factory Settings

NHSC - DI NHSC(S1) NHDI (S1)

Model Setting Setting

010 4 1

015 4 1

020 5 1

030 6 1

045 7 1

065 8 1

090 8 1

135 8 1

180 8 1

NHSC/NHDI

Main Board

Silica 12 parts per million

(ppm)

0 parts per million

(ppm)

PH 6.5-7.5 7

Chlorides > 50 parts per mil

lion (ppm)

> 25 parts per mil

lion (ppm)

Note: Should you have water conditions above the

stated parameters consult the factory for a new

blowdown setting to help improve your scale

management.

Chlorides

– High levels of chlorides will attack

stainless steel. The solution would be to add an in-line

carbon filter that will remove up to 99% of the

chlorides. Consult the factory for additional information

if your water contains high levels of chlorides.

Nortec recommends performing a semi-annual

water analysis to ensure optimal performance.

Stand-by Heating

stand-by heating

off

-

Drain

Interval (S1)

Example:

Position

4:120

NOTE: Approximately 1 liter or

0.26 gallons will drain during

these intervals. Drain Water

Cooling will be active during

these intervals to temper the

drain water to 140 degrees F (60

degrees C) or less.

LCD

Display

Duration between

drain cycles

Stand-by heating activated (”on”) deactivated

(”off”).

Note: If stand-by heating is active the water

temperature in the steam cylinder is constantly kept at

approximately 70ºC (158ºF) by the control board.

Capacity Limitation

power limit [%]

100

The set capacity limitation as a percentage of the

maximum capacity. Press both arrow keys at the

same time and a code will appear. Enter 8808 using

the arrow keys on the keypad and scroll down to the

-15-

Page 19

power limit screen. To change the power limit, simply

press the down aroow key to desired capacity and

press enter to save that new value. Press menu key

to exit parameter screen.

Inlet Valve Correction

inlet valve cor.

130

Set inlet valve correction (cycle ratio) in % of

standard setting value to balance out water pressure

variations.

Figure #19

NHSC / NHDI Control Interval

Soft Start

Soft Start

Off

Soft Start activated (on), consult factory.

Deactivated (off) factory set.

Demineral Mode

Demineral Mode

Off

Demineral mode activated (on), consult factory.

Deactivated (off) factory set.

Serial Interface

Serial Interface

Off

Serial Interface activated (on), consult factory.

Deactivated (off) factory set.

Full Drain Cycle

Full Drain Cycle activated (on), consult factory.

Deactivated (off) factory set.

Flush Cycle

Flush Cycle

Off

Flush Cycle activated (on), consult factory.

Deactivated (off) factory set.

Control Signal

analog signal

0 - 5v (poti)

Range of the active analog signal in V or mA,

respectively.

Note: The range of the analog signal may be

adjusted using the rotary switch “S3” on the control

board.

Software Version

software version

VX.XX

Current software version for the steam humidifier.

-16-

Page 20

Unit Type

machine type

xxlb/xxxV

Warning:

In order to eliminate faults, the steam

humidifier must be switched off and secured against

unintentional re-connection. Take care that the

electricity supply to the main contactor is disconnected

(check with voltage meter).

Only allow trained and qualified personnel to

repair faults. Faults relating to electrical installation

(e.g. change of unit fuse) must only be carried out by

authorized personnel.

Repair work and replacement of faulty

components must only be carried out by your service

technician!

NOTES ON MAINTENANCE

Figure #21

Major Maintenance - NHSC / NHDI

NHSC Maintenance

Complete cleaning

(between 600 - 6000

hours of operation)

- Unit indicates cleaning is

required.

- This cleaning normally occurs

once a year(depends on water

quality).

- The scale collector tank and the

stainless steel tank are removed

and cleaned.

- Check all plumbing and

electrical components for any

issues.

MAINTENANCE

All maintenance work must be performed by

adequately qualified and trained personnel familiar

with the dangers involved. Ascertaining the

qualifications is the customer’s responsibility.

Instructions and details concerning the

maintenance work must be observed and adhered to

without fail.

Only the type of maintenance work outlined in this

documentation must be carried out.

Figure #20

Minor Servicing - NHSC ONLY

To safeguard reliable operation, the maintenance

of the NHSC should be devised in three stages. A

distinction is made here between periodic inspections,

minor servicing and major maintenance of the

steam-air humidifier.

The intervals required between minor servicing

and major maintenance depend on the water quality

and the quality of steam generated and can be

pre-selected on the rotary switch “S2” on the control

board. After expiry of the selected interval, the yellow

LED flashed and an appropriate message alternates

with the normal operation indication.

The following is an overview of the work that

should be undertaken for the three maintenance

stages.

Periodic Inspections

When Once per week

Work Inspect the water and steam

installations for correct sealing and any

possible damage.

Use original spare parts exclusively to replace

defective parts.

Before maintenance is initiated, the steam

humidifier must be taken out of operation in

accordance with instructions in the manual and

protected against unintentionally switching on the

humidifier.

Inspect the drain line for soiling.

Inspect the electrical installation for

loose cables and damaged

components.

Inspect the humidifier for irregularities

both external and internal.

-17-

Page 21

Minor Maintenance

Work Carry out the periodic inspection items.

When The yellow LED flashes and the

message “minor servicing due”

appears, alternating with the normal

operation indication.

Work Carry out the periodic inspection items.

Empty the steam cylinder and clean the

scale collector tank.

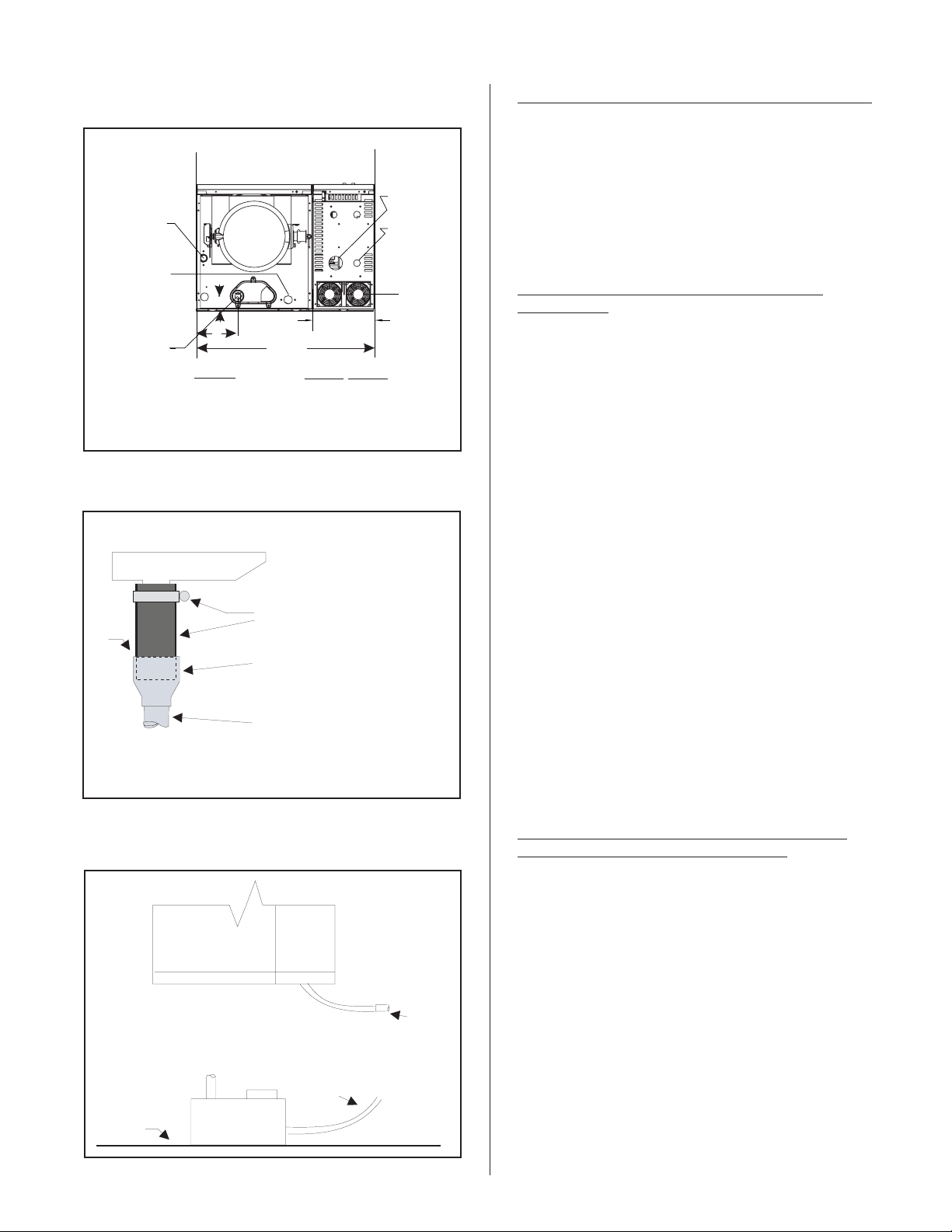

Figure #22Scale Tank Removal

1.

5.

3.

2.

4.

1.

Turn unit off.

2.

Drain unit and scale tank.

3.

Unlock support bracket by removing locking screws.

4.

Open both mechanisms by rotating counter clockwise until opening is visible.

5.

Place scale tank on support bracket.

6.

Rotate bracket to close mechanism and raise scale tank. Note ensure scale

tank lines up with opening at the bottom of the drain pan when raising.

7.

Lock mechanism by re-inserting the two locking screws.

Empty the steam tank.

Clean the scale collector tank (NHSC

Only).

Dismantle and clean the steam

cylinder.

Dismantle and clean the liner (NHSC

Only).

Clean the unit inner chamber.

Inspect the components inside the unit

for damage.

Resetting Minor and Major Maintenance

In order to return the steam humidifier to normal

operation after minor or major maintenance is

complete, you must press and hold down the drain

switch while turning the unit in the OFF position for

approxiamately 10 seconds. Then turn the unit switch

back onfor 10 seconds and release the drain switch

and the LCD message will return to normal.

DISMANTLING AND REASSEMBLY WORK

Major Maintenance

When The yellow LED flashed and the

message “major maintenance due”

appears, alternating with the normal

operation indication.

Removal of the scale collector tank - NHSC Only

Caution!

Before commencing any dismantling

work, the humidifier is to be taken out of operation as

previously described.

NOTES ON CLEANING - NHSC Only

Cleaning the steam cylinder, scale collector tank,

and steam cylinder liner.

Whenever possible, clean off any mineral coating

that has formed.

Wash parts with lukewarm soap suds and then

rinse off well. Note: if the components are heavily

scaled, place them in 8 percent formic acid until the

scale has dissolved. Then treat components as

previously described.

Cleaning the heating elements

Immerse cover with heating elements fitted to 1”

(2 cm) below the rim of the cover in a container with 8

percent formic acid. Ensure electrical wires do not

make contact (do not fully submerge). Allow the acid

to take effect until the scale coating has dissolved.

-18-

Page 22

Note: The heating elements do not have to be entirely

free from scale.

Then rinse heating elements thoroughly with fresh

water.

Warning! Ensure that the electrical connections

remain dry.

Turn on the humidifier with the unit switch.

Continue to depress the blow-off pushbutton until

the system test has finished (approx. 10 seconds).

FAULT ELIMINATION

Fault indication

Warning! Do not remove scale coating on the

heating elements with tools (screwdriver, scraper, etc.)

or by striking. This could damage the heating

elements.

Cleaning the interior of the unit

Wipe down components inside the unit with a

damp cloth (clean water). Severely scaled

components, e.g. the inlet funnel and the blow-off

pump, should be cleaned using commercially available

cleaning and descaling agents.

Warning! The electrical connections and

electronic components must remain dry.

Notes on Cleaning Agents

Warning! Formic acid is harmless to the skin but it

attacks the mucous membranes. Protect the eyes and

respiratory tracts from contact with the acid and its

vapor (wear goggles and work in a well ventilated

room or outside).

The use of disinfectants is only permitted if they

leave no toxic residues. The components must be

rinsed thoroughly with water after cleaning in all cases.

Caution! Do not use any solvents, aromatized

or halogenized hydrocarbons, or other aggressive

substances for cleaning purposes.

In case of malfunction during operation, the

humidifier control checks whether there is a temporary

problem (e.g. water supply interrupted for a short time)

or whether it can resolve the problem by taking

necessary measures. Such malfunctions set the unit

into the “Alarm” status (fault elimination). The red

LED flashes and an alarm message appears in the

display alternating with the notice “recovering -

please wait”.

Note: If the cause of the malfunction disappears of

its own accord or if the controls can repair the

malfunction, the alarm message will automatically

switch off.

Note: If the unit is in display or setting level the

alarm message in the display will be suppressed.

If the controller, after several attempts, fails to

solve the problem (number of attempts depends on the

type of malfunction) or if the problem obstructs further

operation, the heating voltage is interrupted via the

main contactor. The red LED stays lit and an error

message appears in the display alternating with the

notice “Please turn off unit”.

Note: If the unit is in the display or setting level the

error message in the display will be suppressed.

The information and instructions regarding

cleaning agents are to be strictly observed and

implemented. In particular: Information relating to the

protection of personnel, environmental conservation

and restrictions regarding usage should be adhered to.

In all cases, local regulations relating to

environmental protection must be implemented.

To reset the maintenance indication

When maintenance work has been completed, the

maintenance display can be reset as follows:

Turn on the service switches in the main supply

line.

With the unit switched off depress and hold the

drain switch.

-19-

Page 23

2

ON

OFFDRAIN

1

Scale

Tank

Collector

T

ank support

6

PN: 150-5913 Rev. A

SCALE COLLECTOR TANK SERVICING

1. Drain Cylinder.

2. Turn off the unit.

water

3. Open manual drain valve on Scale Tank to drain remaining

4. Disconnect hose connection on scale tank.

mechanism.

5. Remove locking screws on the front of the Scale

-20-

6. Lower and remove Scale Tank.

7. Visually inspect cylinder, heating elements and o-ring. Clean or

replace if necessary.

Note: Scale collector tank has to be removed after 5000 hours

or 3 years, whichever comes first.

Scale tank last replaced on:

Page 24

REPLACING UNIT FUSES

Open the plumbing door.

3.

Warning! Before replacing the unit fuse the

steam humidifier must be switched off and

secured against unintentional re-connection. Take

care that the electricity supply to the main contactor is

disconnected (check with voltage tester).

Warning! Electronic components are very

sensitive to electrostatic discharge. To protect these

components, measures must be taken against

damage from electrostatic discharge when replacing

the unit fuse (ESD protection).

The unit fuses may only be replaced by trained

and qualified personnel.

Important! If the unit fuse blows this is generally

due to a faulty unit component. Therefore you should

check these components before replacing the fuse

(see table below).

Only use the correct type of fuse according to the

following table.

Warning! It is not permitted to use repaired fuses.

Let unit tank cool down if needed.

4.

Remove steam hose by loosening gear clamp.

5.

Disconnect temperature switch. Note there is

6.

no polarity with this cable.

Remove gear clamp and remove tank from the

7.

unit

8. Undo cylinder tank strap and remove tank

from unit.

9. Remove lid clamp, open lid and identify

heating elements to be replaced.

10. Remove the nut, washer, plug and gasket

from the top of heating element you are

replacing. Note: Save the hardware for

installing the new heating element.

11. Note the heating element orientations, and

remove heating element by pulling it down

through the lid.

Fuse Specification Before replacing,

F1 on supply

module

F2 on supply

module

F5 on control

board

RESETTING FAULT INDICATION “ERROR”

In order to return the steam humidifier to operation

after fault indication error, you must press and hold

down the drain switch while turning the unit in the off

position for approximately 10 seconds. Then turn the

unit switch back on and release the drain switch after a

10 second interval.

6.3 A,

slow-acting

1A,

quick-acting

50mA,

quick-acting

check

Drain pump (blocked

or coil faulty)

Inlet valve (blocked

or coil faulty)

Control signal

HEATING ELEMENT REPLACEMENT

INSTALLATION INSTRUCTIONS

12. Place gasket from step 15 on new heating

element and install new heating element by

inserting it into the lid from the bottom

ensuring orientation matches previous heating

element.

13. Re-install gasket, plug, washer, and nut.

Tighten assembly

14. Connect element pins into the male connector

by pushing in the pins and they should lock

into place, pull to ensure.

15. Ensure all heating element fastening nuts are

tight.

16. Re-install cylinder tank lid, clamp on cylinder

and re-install the tank in the unit. Take care to

ensure that the tank is level in the base and

that the connecting components are aligned.

17. Fasten the cylinder into position using the

cylinder strap.

18. Re-connect steam hose and clamp to steam

output coupling.

Drain unit.

1.

Turn off the unit, and disconnect primary

2.

power to the unit.

19. Connect female connector to the male

connector.

-21-

Page 25

Figure #23

Element Pins

Heating Element

20. Connect temperature switch cable. Note: This

cable is not polarity sensitive.

21. Double-check all the connections.

22. Turn the unit on.

23. Allow unit to fill.

24. Inspect unit operation and check for leaks.

25. Close and lock plumbing door.

-22-

Page 26

TROUBLE-SHOOTING

Most operational malfunctions are not caused by faulty equipment but rather by improper installation or disregard

for planning guidelines. Therefore, a complete fault diagnosis always involves a thorough examination of the entire

system. Often, the steam hose connection has not been properly executed or the fault lies with the humidity control

system. The following table gives a list of possible malfunctions, the appropriate alarm or error message, details of

their cause, and notes on how to deal with each problem.

Malfunction / Indication Cause Remedy

Min. Filling time too short

Error code: 1A/1B

Alarm 1A

filling time

Error 1B

filling time

Internal safety chain interrupted

Error code: 2A/2B

Alarm 2A

safety chain int

Error 2B

safety chain int

Max. Filling time exceeded (alarm

message only)

Error code: 3A/3B

Alarm 3A

water supply

Water feed to steam cylinder heavily

calcified.

Level in steam cylinder and level unit

do not match.

Connection to over-temperature

switch on steam cylinder broken or

over-temperature switch faulty.

Steam cylinder overheating,

over-temperature switch has

responded.

Flat-band cable between control and

power board interrupted or not

connected.

Water feed blocked (main water tap

closed, filter valve closed or blocked).

Water pressure too low.

Inlet valve does not open, filter sieve

in Inlet valve blocked or inlet valve

faulty.

Feed hoses into the steam humidifier

not connected or kinked.

Level unit not connected.

Float in the level unit sticking or level

unit faulty.

Carry out major servicing.

Check connections or replace

over-temperature switch.

Inspect steam cylinder, clean if

necessary. Replace over-temperature

switch.

Inspect connections, connect or

replace flatband cable.

Check water feed, open main water

tap, open or clean filter valve.

Raise water pressure (range 1-10

bar).

Inspect electrical connections and

fuse F2 on supply module. Clean filter

sieve or replace Inlet valve.

Inspect hoses into unit and connect if

necessary. Replace faulty hoses.

Connect level unit.

Clean or replace level unit.

Max. Boil down rate too long

Error code: 4A/4B

Alarm 4A

steam time

Error 4B

steam time

Max. Drain time exceeded

Error code: 5A/5B

Alarm 5A

drain

Error 5B

drain

Individual heating elements faulty.

Main voltage too low or failure of a

phase (L1, L2 or L3).

Steam line too long or not insulated.

Drain pump not connected or faulty.

Outlet line from unit kinked or

blocked.

Water outlet blocked (external outlet

line or siphon blocked.

Hose to level unit blocked.

-23-

Replace faulty heating elements.

Replace fuses on power board.

Check main voltage and

connections.

Maintain maximum line lengths

(max. 15’). Insulate steam lines.

Connect or replace drain pump.

Inspect outlet line from unit, replace if

necessary.

Clean water outlet line and siphon.

Clean or replace hose.

Page 27

Malfunction / Indication Cause Remedy

Invalid level

Error code: 6A/6B

Alarm 6A

level indicat

Error 6B

level indicat

Steam pressure (error only)

Error code: 7A/7B

Alarm 7A

communication

External safety chain interrupted

Error code: none

safety chain

external A

mains failure

B

Level unit faulty.

Magnetic field in vicinity of level unit.

Steam hose blocked or restricted

(water trap).

Pressure balance adapter into steam

connection fitting blocked.

Duct pressure too high (>1500 Pa).

Ventilator lock open.

Automatic flow control has

responded.

Safties are open.

Main failure on Unit B. Inspect voltage supply to Unit B.

Replace level unit.

Eliminate magnetic field.

Inspect steam hose, clean if

necessary and install correctly.

Remove adapter and clean opening

with a needle.

Inspect ventilation settings.

Switch on ventilator/ventilation

system.

Inspect ventilator/filter of ventilation

system.

Servicing, inspect system if

necessary.

LEGEND

A = Circuit 1

B= Circuit 2 (double unit 2nd

cylinder)

-24-

Page 28

NHDI: Dry Points, rated 24 Vac/dc 1.0 Amps

max. resistive load per Indicator

OPTIONAL REMOTE

ST AT US PC B

Optional

K1 St e a m

status indication.

indication. Any or all of these

remote indications can be

utilized. Refer to Trouble

Shooting Manual for system

INSTALLATION INSTRUCTIONS

ACCESSORY

DIAGRAM No. 1508104 Rev. A Nov. 21, 2003

K3 Se r v i c e

K2 E r r o r

K4 U n i t O N

Optional external remote

61

NHSC / NHDI SERIES

CONTROL CIRCUIT TERMINAL BLOCK

NOTE: See Included Diagram(s) ForAccessory Wiring Instructions

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY BEFORE CONNECTING CONTROL WIRING

with unit for details

Modulation Control

See Diagram included

32 30 28

10

8

Air Proving

Hig h Lim it

OtherOn/Off

Devic es

Hum idistat

Sw i tc h

Control

Hum idistat

ield jumper must

NOTE: If no On/Off

Control is used, then

be connected across

8 and 10 in order for

af

humidifier to operate

-25-

Page 29

NHSC / NHDI Electric Steam Humidifier

Humidifier Mandatory Pre-Start-up Checklist (p.1 of 2)

Unit Serial #: ________ # of humidifiers: _____ Tag:_____________

Unit type: NHSC / NHDI

Customer/Job:_______________ Address: __________________________________________________

Inspected by: _____________ Date of inspection: ___/___/___

______________________________________________________________________________________________

W

WATER QUALITY:

- Well water r -City water r -Softened water r

- Conductivity: _______mhmos - Hardness: _____gr. –Silica____ppm

Voltage: _____V/___ph Steam output: ____lbs./hr

HUMIDIFIER MOUNTING:

Clearances around the unit Acceptable Obstruction

- Front (door opens freely?) 3ft min

- Top (steam lines) 1ft min r ____________________

- Bottom (fill, drain, controls) 1ft min

- Right (main pwr) 3ft min

- Left (main pwr) 2” min

- Ensure the scale tank bracket is locked in place

r _______________

r ____________________

r ____________________

r ____________________

r

STEAM LINES: CONDENSATE LINES:

- Slope up 2” per 12” r - Slopped back to drain r

- Slope down ½” per 12” r - Trapped 2” more than static duct pressure r

- Traps r - Size _______

- Insulated

- Length/Size ____________

- 90 deg. elbows qty: ____ - 45 deg. Elbows qty: ____

- Can condensate be trapped anywhere in the steam line? Yes

r

r no r

WATER LINES:

-½” at max 4ft from the unit - 3/8” connection at fill

-water pressure: 30-80psig

DRAIN LINES:

-Air gap located within 3ft of the unit r - Slopped to drain r -Size:________

WIRING:

No loose wires around the unit or on the PC board? Yes r no r

CONTROLS:

Installed Location / Wiring /Setting

- High limit:

- Air proving:

- Mod controller:

- Other:

r _____________________

r _____________________

r _____________________

r _____________________

POWER

- Voltage, amperage rating and fuse corresponds to Spec Label r

- Disconnect switch located close to humidifier r

Field contact:___________________________ Signature:_______________________________

Page 30

NHSC / NHDI Electric Steam Humidifier

Humidifier Mandatory Start-up Checklist (p. 2 of 2)

Unit Serial #: ________ # of humidifiers: _____ Tag: _____________

Unit type: NHSC / NHDI

Customer/Job: _______________ Address: _________________________________________________

Start-up by: _____________ Date of start-up: ___/___/___

______________________________________________________________________________________

Voltage: _____V/___ph Steam output: ____lbs./hr

1. PRELIMINARY:

- Pre-start-up checklist completed? yes r no r

If no, return to Pre-Start-up Checklist before going on with start-up procedure.

2.START-UP PROCEDURE:

The prerequisites for getting power and water into the steam cylinder are as follows:

- check that main breaker is on and power is at the unit

- check that main water shut-off valve is open

- on/off/drain switch must be switched on

- control circuit 8-10 must be made

- modulation humidistat, if present, must be calling

- door interlock switch must be made (interlock switch can be pulled out to operate unit)

The unit will undergo a System Test

will fill and the float test will be carried out. If everything ok, the green light will come on and the display will

show NHDI or NHSC Ready

.

to ensure integrity of all the components. If the test is successful, the unit

3. OPERATIONAL CHECK:

-Switch on the humidification by raising the humidity set point on the humidistat/controller.

-Switch off the humidification by lowering the humidity set point on the humidistat/controller.

-Check for correct functioning of the external monitoring safeties such as air proving and high limit.

-When check complete: Set the desired humidity level.

Remarks:__________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________.

-27-

Page 31

NHSC / NHDI Electric Steam Humidifier

Maintenance Checklist (p.1 of 2)

Unit Serial #: ________ # of humidifiers: _____ Tag: _____________

Unit type: NHSC / NHDI

Customer/Job: _______________ Address: _________________________________________________

Maintenance by: _____________ Date of maintenance:___/___/___

______________________________________________________________________________________

Type of maintenance:

Voltage: _____V/___ph Steam output: ____lbs./hr

Periodic maintenance, once per week:

- Inspect water and steam installation lines for leaks

- Inspect drain lines for clogging

- Inspect electrical installation for loose cables and damaged components.

- Inspect the humidifier for damage.

Minor servicing, when the yellow LED flashes and display indicates minor maintenance due:

- Carry out periodic inspection items

- Empty the steam cylinder and clean the mineral collector.

Major servicing, when the yellow LED flashes and display indicates major maintenance due:

- Carry out periodic inspection items

- Empty the steam cylinder and clean the mineral collector.

- Dismantle and clean the steam cylinder

- Clean the unit inner chamber

- Inspect the inside components for damage.

Note: Time interval between minor and major are set through rotary switch #2 on the control board.

Cleaning recommendations for the Steam cylinder, mineral collector tank (NHSC Only) and

steam cylinder (NHSC Only) insert:

- Drain unit completely including mineral collector tank drain

- Remove lime collector tank, remove steam cylinder

- Whenever possible, chip off or scrape off any scale coating

- Wash and rinse parts with lukewarm soap water (If components are heavily scaled, place them

in 8% formic acid until the scale has dissolved. Then treat components as previously described.)

Cleaning recommendations for heating elements:

- Wash and rinse heating with lukewarm soap water (If components are heavily scaled, place

them in 8% formic acid until the scale has dissolved. Then treat components as previously described.)

Warning: On no account remove scale coating on the heating element with tools or by striking. This

could damage the heating element.

Cleaning recommendations for internal plumbing components:

- Wipe down components inside the unit with a damp cloth (clean water).

- Severely scaled components should be cleaned using commercially available cleaning and

de-scaling agents.

Warning: Ensure electrical connections remain dry!!!

For more information on cleaning agents and formic acid, review notes in the installation manual.

-28-

Page 32

NHSC / NHDI Electric Steam Humidifier

Maintenance Checklist (p.2 of 2)

Note: In all cases, local regulations relating to environmental protection must be implemented.

How to reset the maintenance indication:

- Switch on the services in the main supply lines.

- With the unit switch off, depress and hold the drain switch.

- Switch on the steam humidifier with the unit switch

- Continue to depress the drain button until the system test has finished (approx 10 sec.)

Comments:

________________________________________________________________________________________

________________________________________________________________________________________