Page 1

NH

TM

Series

NHTC / NHPC

ELECTRODE

STEAM HUMIDIFIER

Inst allation Manual

2522381-C

Page 2

PROPRIETARY NOTICE

This document and the information disclosed herein are proprietary data of

WALTER MEIER LTD. Neither this document nor the information contained herein

shall be reproduced used, or disclosed to others without the written authorization of

WALTER MEIER LTD., except to the exte nt required for installation or maintenance

of recipient’s equipment. All references to the NORTEC name should be taken as

referring to WALTER MEIER LTD.

LIABILITY NOTICE

WALTER MEIER LTD. does not accept any liability for installations of humidity equipment installed

by unqualified personnel or the use of parts/components/equipment that are not authorized or

approved by WALTER MEIER LTD.

COPYRIGHT NOTICE

Copyright 2008, WALTER MEIER LTD. All rights reserved.

SPECIFICATION LABEL LOCATION

The Specification Label for your NH Series Humidifier is located on the bottom of the unit. You will

find it attached to the skirt that separates the electrical and plumbing comp ar tments on the electrical

compartment side.

RECORD OF REVISIONS

For each revision, put the revised pages in your manual and disca rd the superseded pages. W rite the

revision number and revision date, date put in manual, and the incorporator’s initials in the applicable

columns on the Record of Revisions.

Revision

Number

Revision

Date

Date Put

In Manual By

Revision

Number

Revision

Date

Date Put

In Manual By

2008-08-28

Page 3

TABLE OF CONTENTS

Subject Page

10-00 INTRODUCTION

1. PREINSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

A. RECEIVING & UNPACKING EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. PACKAGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

B. HUMIDIFIER AND CONTROLS BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

C. DISTRIBUTOR BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

D. ACCESSORIES BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. PREINSTALLATION EQUIPMENT VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

10-10 INSTALLATION PROCEDURES

1. HUMIDIFIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

A. LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

B. MOUNTING WITH KEYHOLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

C. MOUNTING WITH WALL BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

D. WATER SUPPLY LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

E. DRAIN LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

F. STEAM RUNS AND CONDENSATE RETURNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

G. ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

H. CONTROL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

I. OPTIONAL OUTDOOR TEMPERATURE RESET FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

J. HUMIDITY TRANSDUCER SIGNAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

K. NETWORKING NHTCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

L. NORTEC ONLINE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

10-20 OPERATION

1. NHTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

A. NHTC COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

B. HUMIDIFIER START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

C. BASIC STEAM PRODUCTION METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

D. CYLINDER LIFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

E. SOFTWARE INITIAL SELF-TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

F. SOFTWARE FLOW CHART WITH DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

G. SELF-HELP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

H. SYSTEM MESSAGES AND LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

I. DOUBLE UNIT OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2. STEAM DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

A. STEAM DISTRIBUTOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

B. SAM-E OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

C. BLOWER PACK OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3. CONTROLS AND REMOTE COMMUNICATION (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

A. DIGITAL CONTROL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

B. DIGITAL TRANSDUCER OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

C. REMOTE CONNECTIONS (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

D. NORTEC LINKS OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

E. NORTEC ONLINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

10-30 MAINTENANCE PROCEDURES

1. NH ELECTRODE STEAM HUMIDIFIERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

A. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

B. WHEN TO REPLACE THE STEAM CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

C. EXTENDED SHUT-DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

D. COMPONENTS OF THE STEAM CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2008-08-28

Page 4

E. HOW TO REMOVE THE STEAM CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

F. MANDATORY CLEANING OF THE DRAIN VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

G. HOW TO INSTALL THE REPLACEMENT CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10-40 TROUBLESHOOTING

1. TROUBLESHOOTING NH ELECTRODE STEAM HUMIDIFIERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

A. PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

B. STARTING POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

C. NHTC/NHPC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

2. TROUBLESHOOTING DISTRIBUTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

A. TROUBLESHOOTING ATMOSPHERIC DISTRIBUTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

3. SAM-E TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

A. PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4. BLOWER PACKS TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

A. PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

5. DIGITAL ON/OFF HUMIDISTAT SENSOR CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

A. PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

6. 0-10V DIGITAL HUMIDISTAT SENSOR CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

A. PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

10-50 TECHNICAL

1. WIRING AND TERMINALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

A. HUMIDIFIER CONTROL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

B. NH WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

2. CHECK LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

A. PRE-NORTEC ONLINE START UP CHECKLIST WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

B. PRE-NORTEC LINKS START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

C. HUMIDIFIER MANDATORY PRE-START UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

D. HUMIDIFIER MANDATORY START-UP CHECKLIST AND QUICK REFERENCE . . . . . . . . . . . . . . . .73

E. PERIODIC MAINTENANCE CHECKLIST AND QUICK REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . 74

3. SPARE PARTS AND EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

A. ASD, BSD, CSD DISTRIBUTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

B. SAM-E SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

C. NH SERIES HUMIDIFIER SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

WARRANTY

2008-08-28

Page 5

LIST OF FIGURES

Figure Page

10-00 INTRODUCTION

Figure 1. NHTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Figure 2. Humidifier Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 3. Distributor Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 4. SAM-e Distributor Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 5. Remote Mounted Blower Pack Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 6. Typical NHTC Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

10-10 INSTALLATION PROCEDURES

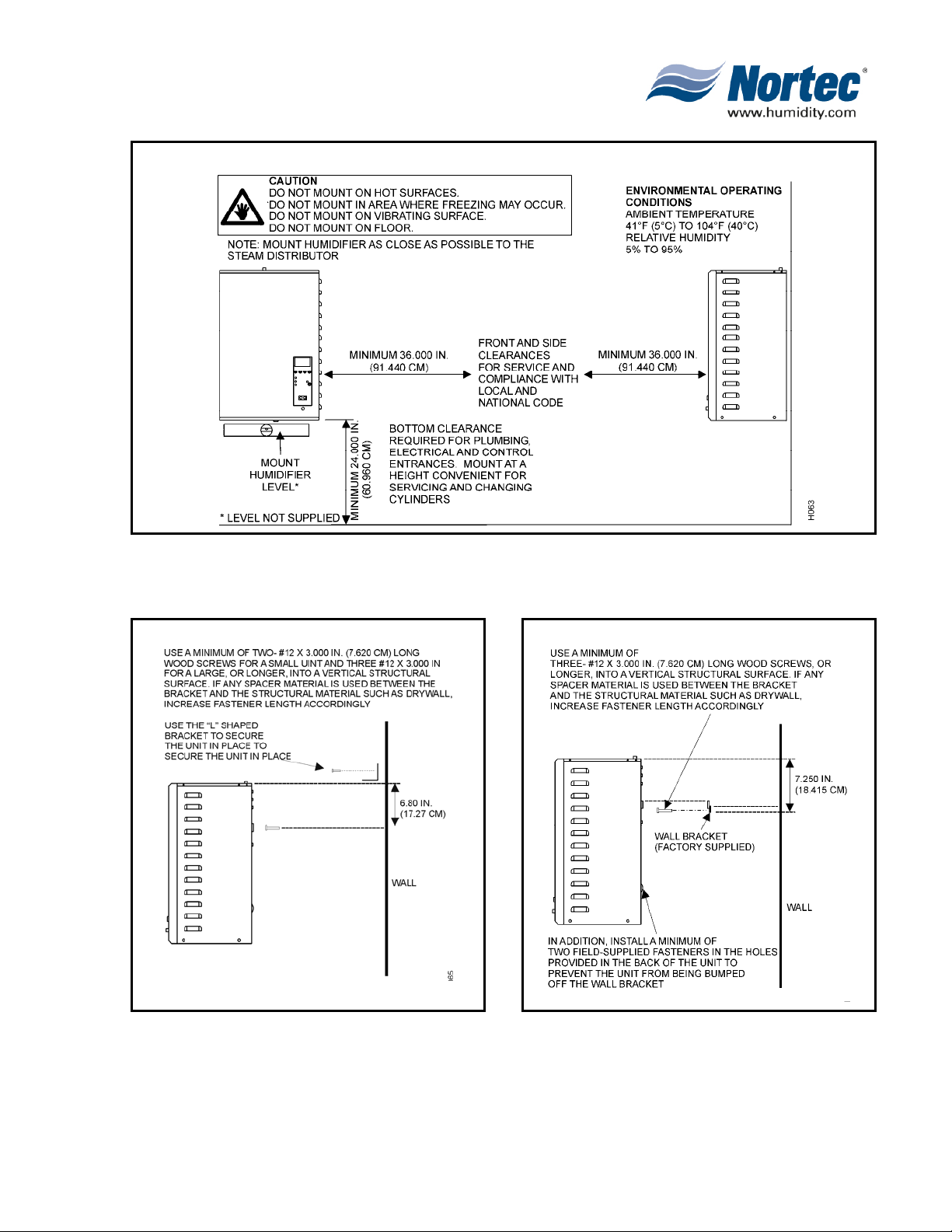

Figure 1. Clearances and Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 2. Mounting with Keyholes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 3. Mounting with Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

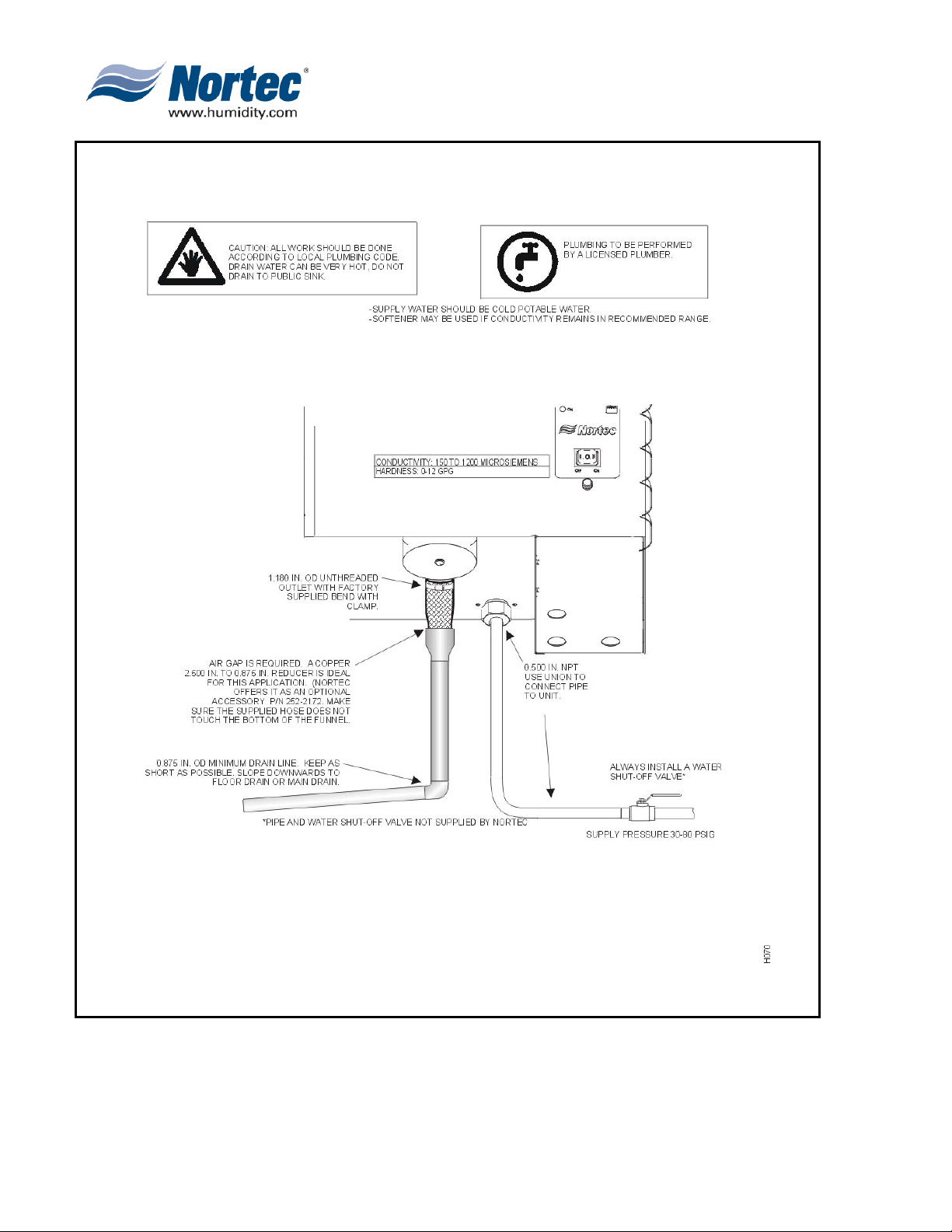

Figure 4. Drain Water and Supply Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

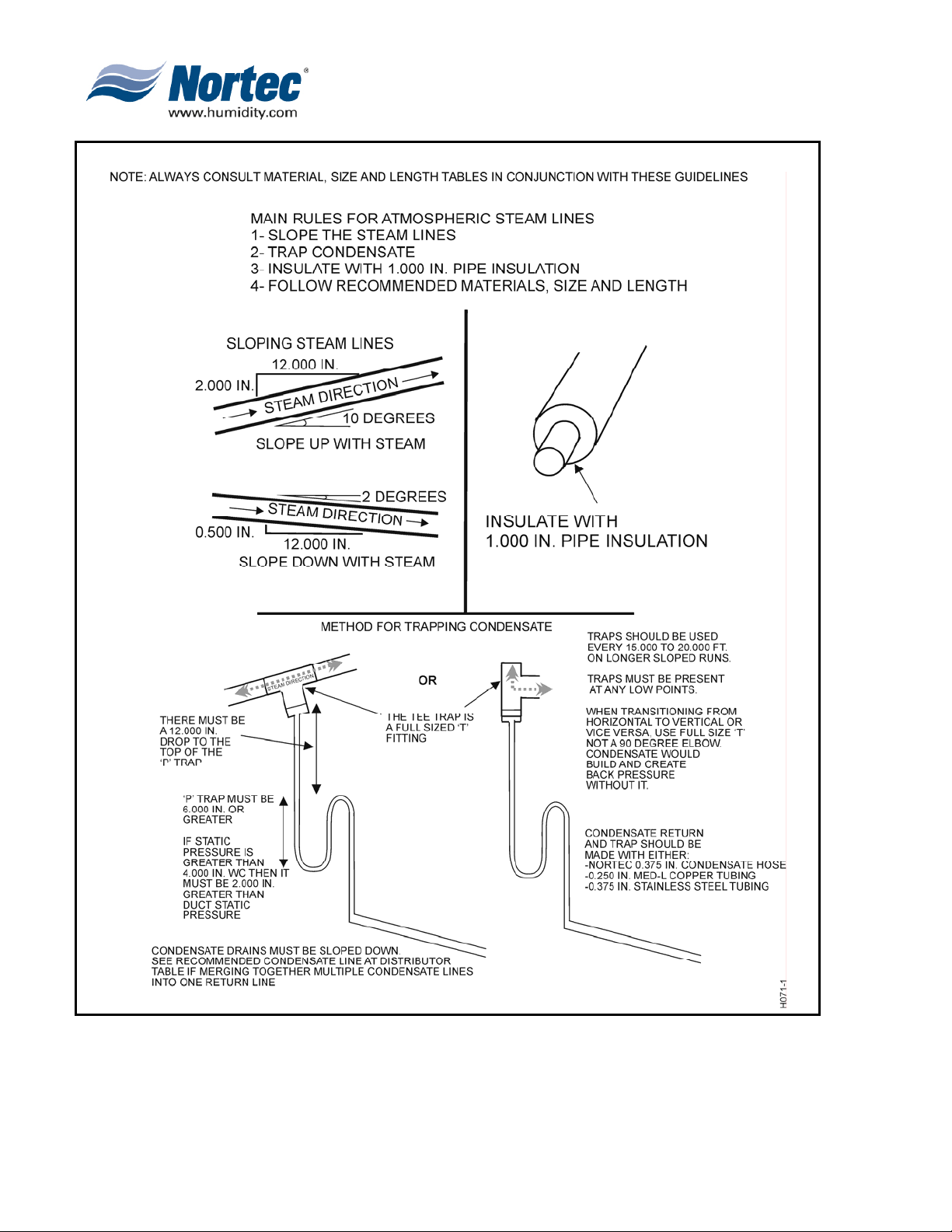

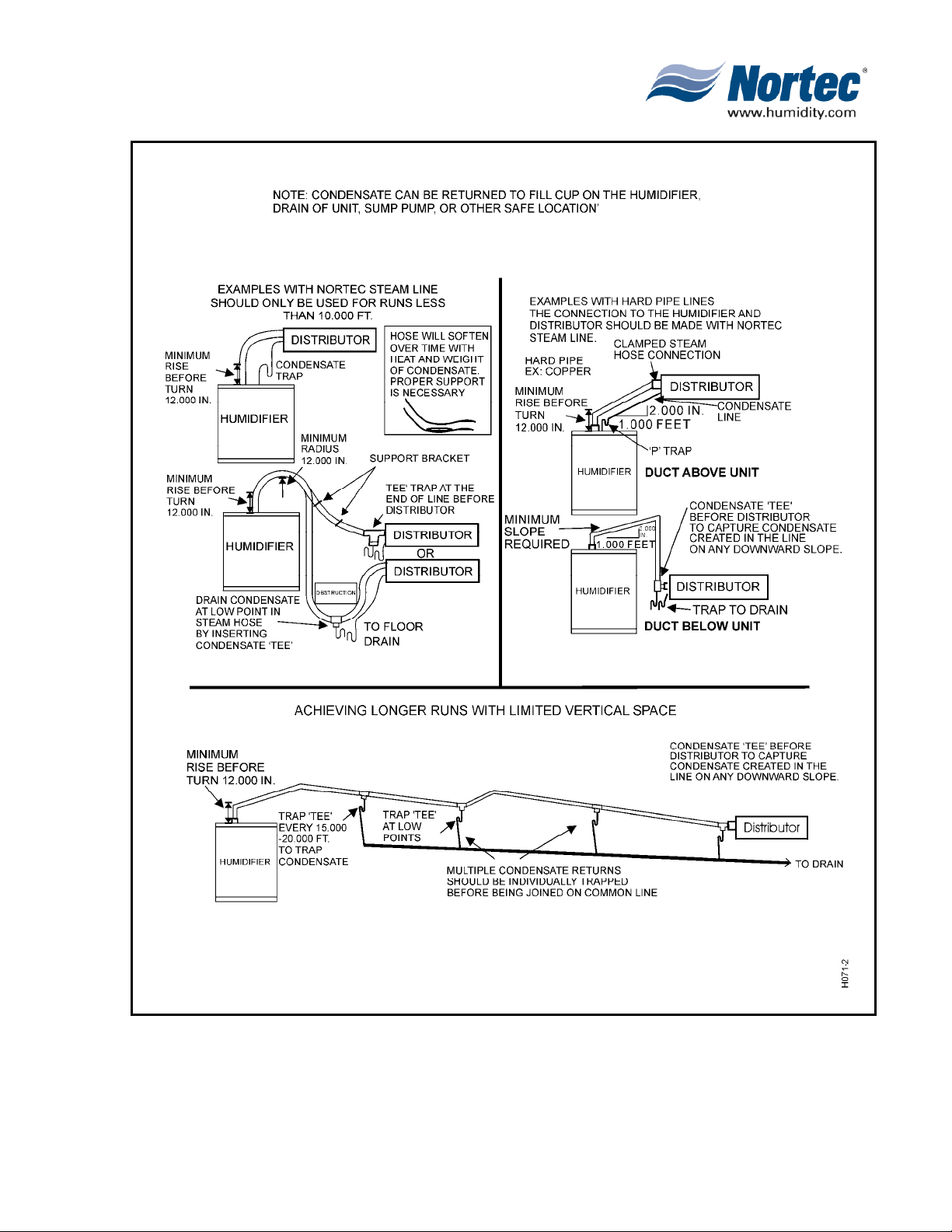

Figure 5. Steam Run and Condensate Return Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 6. Steam Run and Condensate Return Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 7. Primary Voltage Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 8. On-Off Control Guidelines and Low Voltage Terminal Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 9. NORTEC Control Guidelines and Wiring (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 10. Setpoint Versus Outdoor Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 11. NORTEC Humid ity T r ansducer Guidelines and Wiring (Optional) . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 12. Networking NHTC s (Optiona l) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 13. NORTEC On Line Installation Guidelines (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

10-20 OPERATION

Figure 1. NHTC Components (Front View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 2. NHTC Components (Side View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 3. Humidifier Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 4. Drain Rate Versus Water Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 5. Capacity Setting and Cylinder Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 6. Basic Steam Production Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 7. Software Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Figure 8. Steam Distributor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 9. SAM-e Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 10. Blower Pack Operation and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 11. NORTEC Digital Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Figure 12. Difference from Setpoint in Relation to Demand Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Figure 13. Duct and Wall Mounted Transdu cer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

10-30 MAINTENANCE PROCEDURES

Figure 1. Cylinder Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 2. Cylinder Removal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 3. Drain Valve Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 4. Cylinder Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10-50 TECHNICAL

Figure 1. NHTC/NHPC Double Unit Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Figure 2. NHTC/NHPC Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure 3. Distributor Exploded View and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Figure 4. SAM-e Exploded View and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Figure 5. NHTC/NHPC Plumbing Compartment Exploded View and Spare Parts . . . . . . . . . . . . . . . . . . . . .77

Figure 6. NHTC/NHPC Electrical Compartment Exploded View and Spare Parts . . . . . . . . . . . . . . . . . . . . .80

2008-08-28

Page 6

LIST OF TABLES

Table Page

10-10 INSTALLATION PROCEDURE

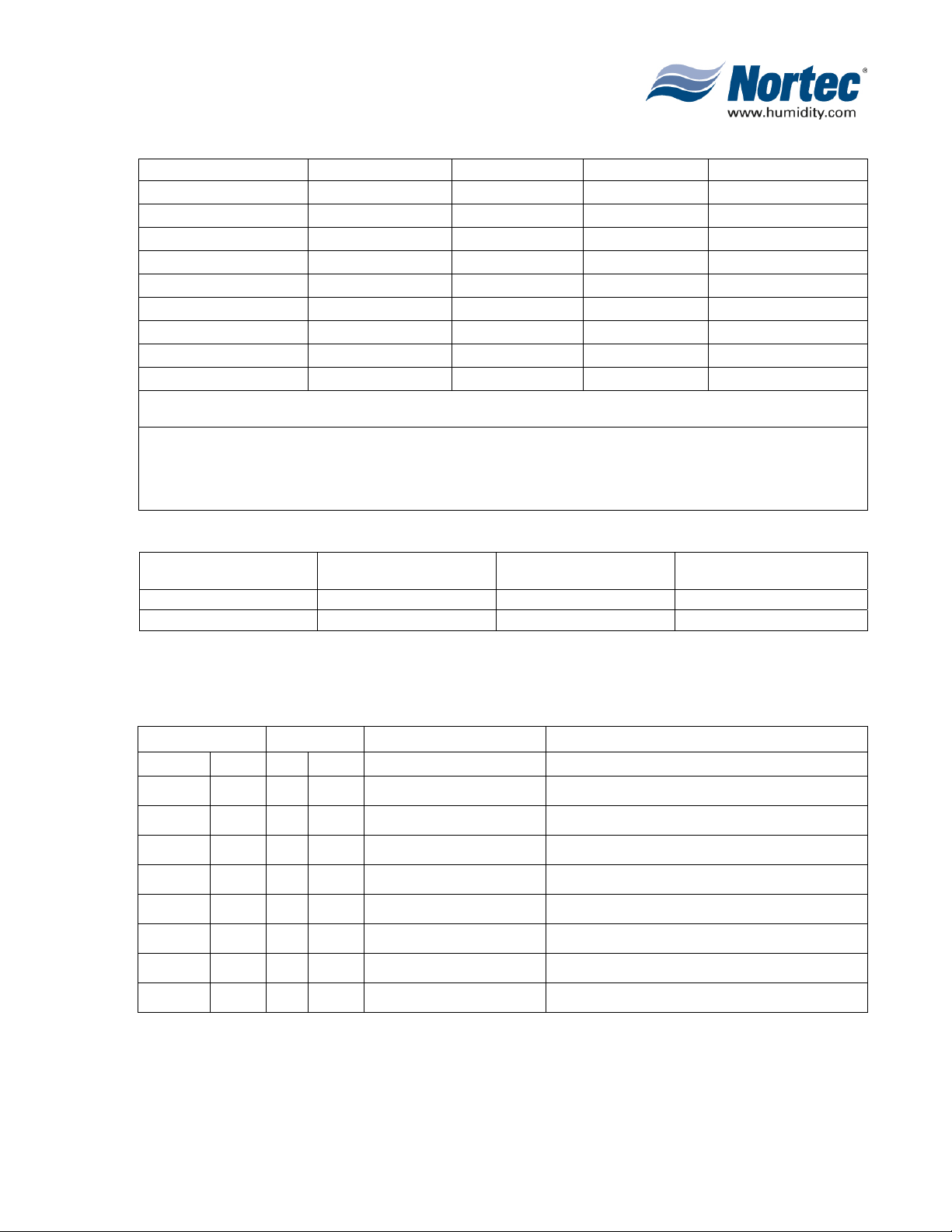

Table 1. Maximum Recommended Length of Steam Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 2. Steam Line Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 3. Recommended Material and Size for Steam Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 4. Recommended Condensate Line at Distributor(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table 5. Equivalent Length Elbow and T-Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table 6. Humidifier and Distributor Inlet/Outlet Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10-20 OPERATION

Table 1. NHTC / NHPC Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-30

Table 2. Self-Test Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 3. Signal Light Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Table 4. Status Messages with LED State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

10-40 TROUBLESHOOTING

Table 1. Troubleshooting Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Table 2. Ensuring A Demand Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table 3. NH System Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Table 4. Term Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

10-50 TECHNICAL

Table 1. Controller and Sensor Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Table 2. NHTC/NHPC Plumbing Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 3. NHTC/NHPC Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

2008-08-28

Page 7

2008-08-28

Page 8

10-00

INTRODUCTION

10-00

Page 1

2008-08-28

Page 9

Figure 1. NHTC

10-00

Page 2

2008-08-28

Page 10

1. PRE-INSTALLATION

A. RECEIVING & UNPACKING EQUIPMENT

(1) Check packing slip to ensure ALL material has been delivered.

(2) All material shortages are to be reported to NORTEC within 48 hours from receipt

of goods. NORTEC assumes no responsibility for any material shortages beyond

this period.

(3) Inspect shipping boxes for damage and note damages on shipping waybill

accordingly.

(4) After unpacking, inspect equipment for damage and if damage is found, notify the

shipper promptly.

(5) All NORTEC products are shipped on an FOB factory basis. Any and all damage,

breakage or loss claims are to be made directly to the shipping company.

2. PACKAGING

A. GENERAL

(1) The equipment packaging is standardized in that each box in the shipment will

always have the same contents. The following paragraphs identify the contents of

each box.

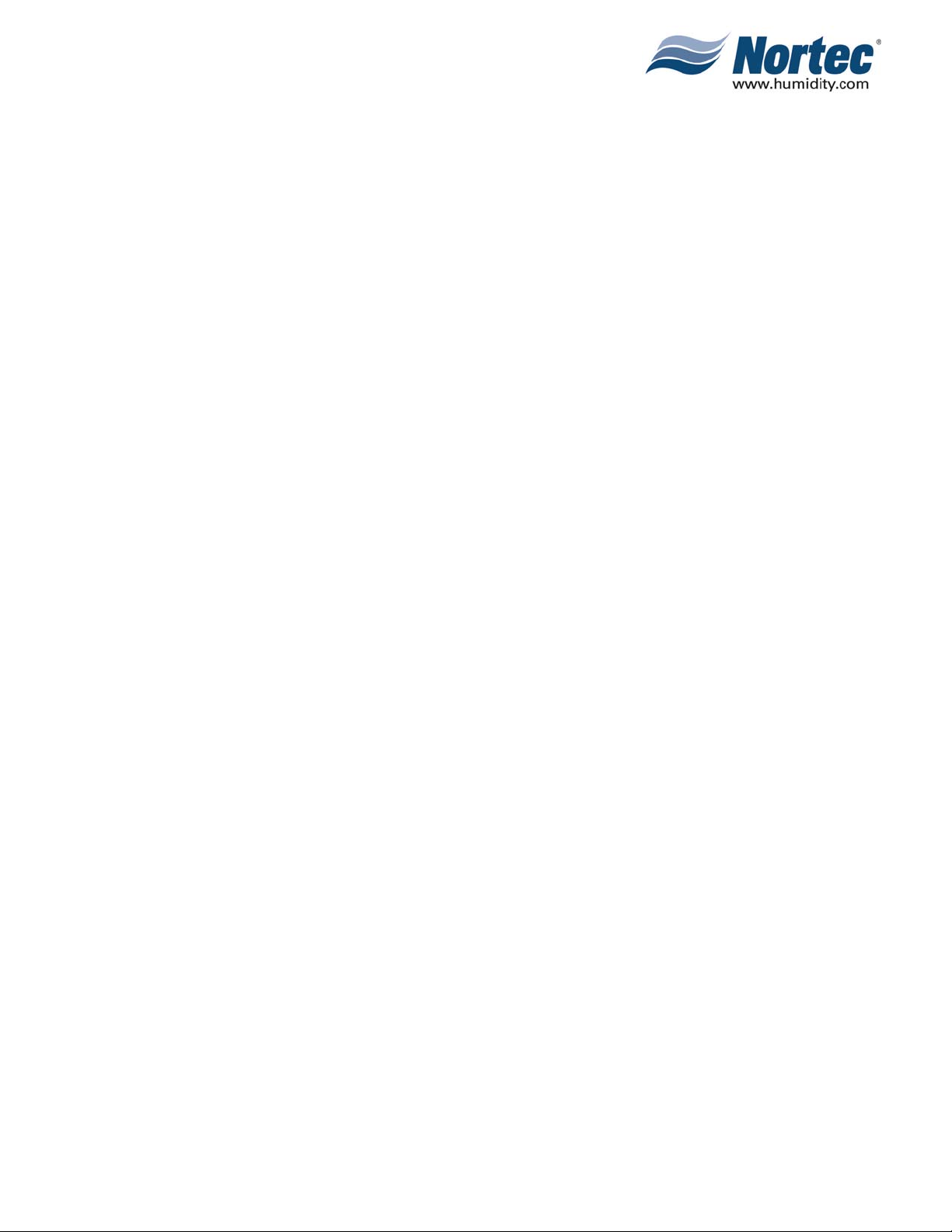

B. HUMIDIFIER AND CONTROLS BOX

(1) The typical equipment found in the humidifier and controls box is shown in Figure

2. The contents of the box are listed on the box. If controls are ordered they will be

listed and small accessories that fit into the box will also be listed on the box.

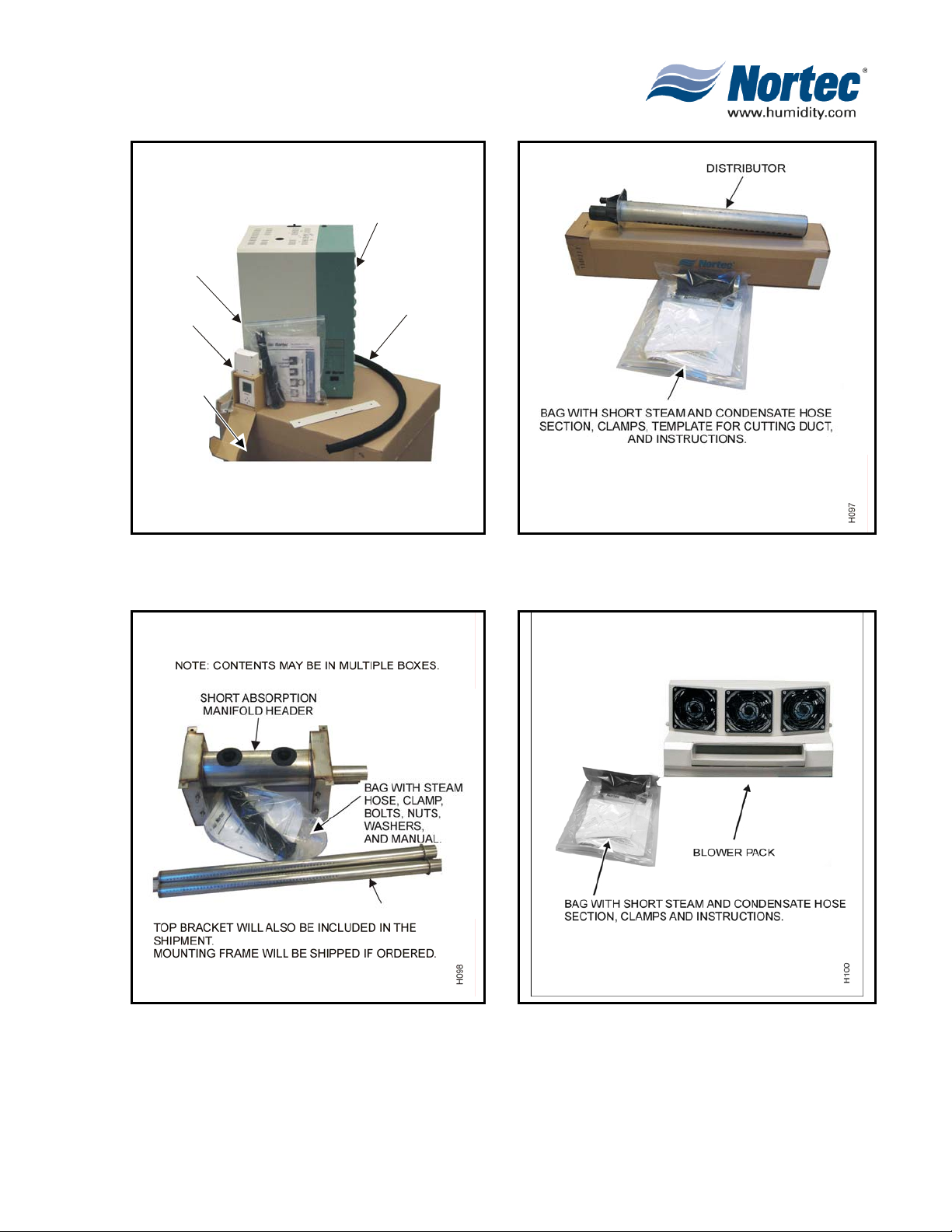

C. DISTRIBUTOR BOX

(1) Depending on the equipment ordered any of the following distributor box

configurations may be received:

a. For equipment received if an ASD, BSD, CSD distributor(s) is ordered refer to

Figure 3.

b. For equipment received if a SAM-e distributor is ordered refer to Figure 4.

c. For equipment received if a RMBP i s ordered refer to Figure 5.

D. ACCESSORIES BOX

(1) Additional accessories such as DWC, DWSP, Filter, and Fill cup extension kits are

shipped in a separate box. Smaller accessories that would fit in the humidifier box

are put in the humidifier box and the box is identified as containing such.

10-00

Page 3

2008-08-28

Page 11

BAG WITH

MANUAL,

CLAMPS,

HOSE SECTION

CONTROLS

(IF ORDERED

ONLY)

BOX WITH

ABBREVIATED

INSTRUCTIONS

AND BOX

CONTENT

STICKERS

Figure 2. Humidifier Box

HUMIDIFIER

STEAM HOSE

SECTION (NOT

SUPPLIED IF BUILT

ON BLOWER PACK

ORDERED)

H096

Figure 3. Distributor Box

Figure 4. SAM-e Distributor Box

Figure 5. Remote Mounted Blower Pack Box

10-00

Page 4

2008-08-28

Page 12

3. PREINSTALLATION EQUIPMENT VERIFICATION

A. GENERAL

(1) Ensure that available voltage and phase corresponds with humidifier voltage and

phase as indicated on humidifier’s specification label.

(2) Ensure that the dedicated external fuse disconnect is of sufficient size to handle

the rated amps as indicated on the specification label. Refer to local codes.

(3) Report any discrepancy immediately to the site engineer.

(4) Location and mounting is described in Chapter 10-10.

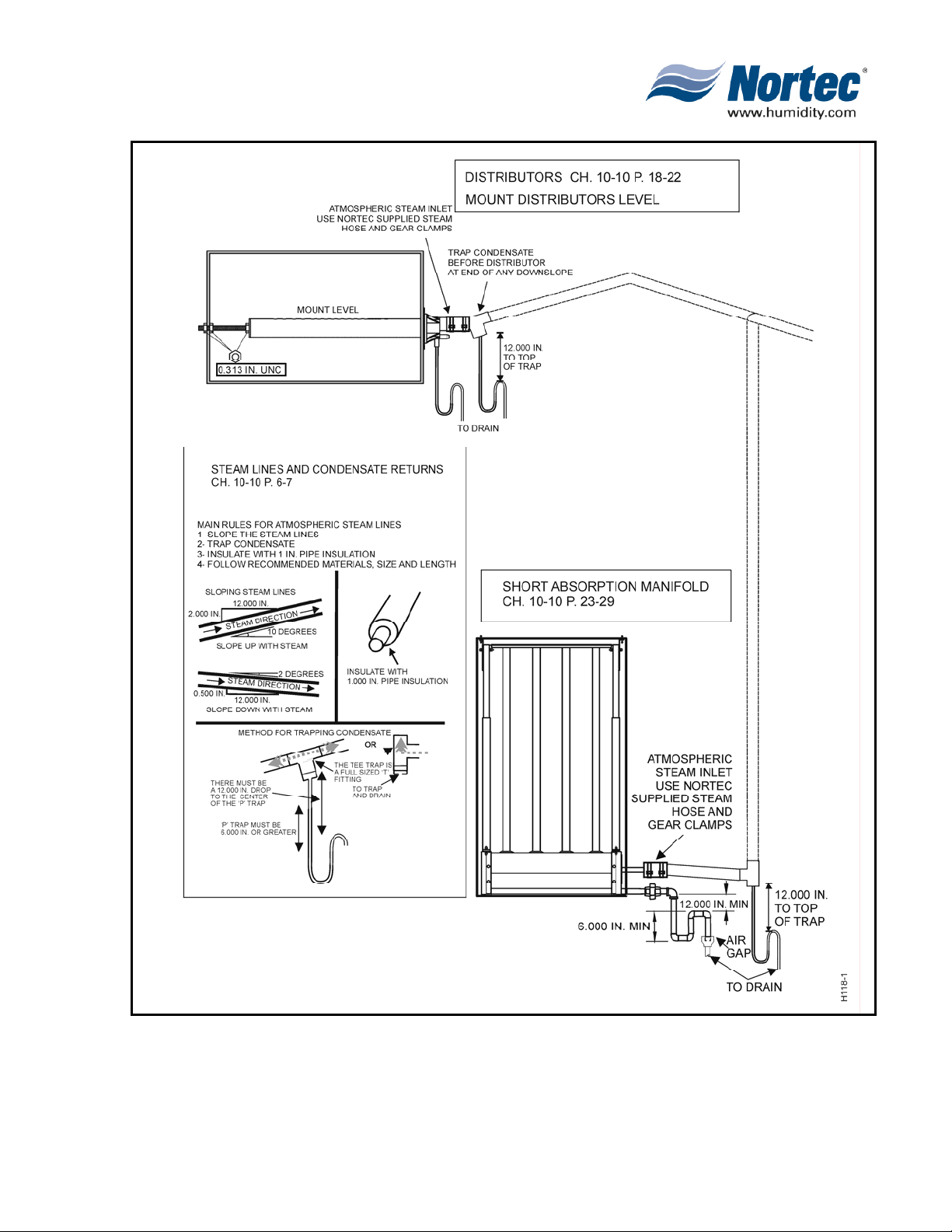

(5) Typical installation (See Figure 6.) shows the references to the appropriate

chapter of the manual.

10-00

Page 5

2008-08-28

Page 13

Figure 6. Typical NHTC Installation (Sheet 1 of 2)

10-00

Page 6

2008-08-28

Page 14

10-00

Page 7

2008-08-28

Figure 7. Typical NHTC Installation (Sheet 2 of 2)

Page 15

THIS PAGE INTENTIONALLY LEFT BLANK

10-00

Page 8

2008-08-28

Page 16

10-10

INSTALLATION

10-10

Page 9

2008-08-28

Page 17

1. HUMIDIFIER INSTALLATION

A. LOCATION

(1) The NORTEC NHTC series humidifier is designed to mount on a suitable wall or

vertical surface. Do not sit the unit on the floor due to clearances required for

plumbing and electrical connections. The clearance dimensions shown in this

manual are for reference only and are the minimum required for maintenance on

the humidifier. Local and national codes should be consulted before final location

and installation of the humidifier. NORTEC cannot accept responsibility for

installation code violations. See Figure 1 Clearances and Operating Conditions.

(2) The location of the humidifier should be below the steam distributor. DO NOT

locate the humidifier any further then absolutely necessary from the steam

distributor location as net output will be reduced as a result of heat loss through the

steam line.

(3) When possible, mount the NHTC humidifier at a height convenient for servicing.

B. MOUNTING WITH KEYHOLES

(1) The NHTC series humidifier is wall mounted using keyholes located on the back of

the unit’s cabinetry. The keyholes are spaced 16 inches apart center to center for

large units and 10.7 inches apart for small as per UL certification standard stud

spacing dictates.

(2) Use #12 x 3 in. screws. 2 screws are needed for a single unit (NHTC 010 to 100

lbs/hour). 3 screws are needed for a double unit (NHTC 150 to 200 lbs/hour). Insert

the screw 16 in. apart. Be sure the screws are level to each other. Proceed to

insert the screws into the studs until there is 1/4 in. of screw exposed. Ensure the

screws are properly anchored to the wall.

(3) Raise the unit. Align the keyholes on the back of the unit with the screws. Place the

screws through the keyholes. Make sure the unit is level then tighten the screws to

secure the unit in place.

(4) Once the unit is securely fixed to the wall, install the “L” shaped brackets into the

same studs the unit is attached to. Place the brackets on top of the unit, inline with

the studs. Using the appropriate sized wood screw fasten the “L” brackets to the

studs securing the unit from any upward motion. See Figure 2 Mounting with

keyhole.

C. MOUNTING WITH WALL BRACKET

(1) For NHTC units that mount using a Wall mounting bracket 3 x #12 3.0 inch wood

screws are to be used.

(2) Wall mounting bracket provided should be securely attached horizontally with open

edge upwards, using field-supplied fasteners. Be sure the bracket is mounted level

See Figure 3.

(3) If humidifiers are mounted on a roof, a thermostatically ventilated weather proof

cabinet should be used. Consult factory.

10-10

Page 10

2008-08-28

Page 18

D. WATER SUPPLY LINE

(4) All water supply and drain line connections should be installed in accordance with

local plumbing codes.

(5) For installation details see Figure 5 & 6.

E. DRAIN LINE

DRAIN WATER FROM HUMIDIFIER CAN BE VERY HOT.

(1) The drain line should not end in a sink used frequently by personnel, or

where plumbing codes prohibit it. Route to a floor drain or equivalent for

safety reasons.

(2) For installation details see Figure 4.

F. STEAM RUNS AND CONDENSATE RETURNS

(1) Tables 1 through 6 indicate what material and recommended length to use when

installing atmospheric steam lines. The lengths mentioned are equivalent feet and

therefore the full length of tubing with the addition of equivalent feet of elbows and

tees.

CAUTION

(2) Figure 5 illustrates the guidelines for installation, routing and trapping of steam

runs and condensate returns.

(3) Table 6 indicates steam outlet size of humidifier and steam inlet size of distributors.

10-10

Page 11

2008-08-28

Page 19

Figure 1. Clearances and Operating Conditions

Figure 2. Mounting with Keyholes

Figure 3. Mounting with Mounting Bracket

10-10

Page 12

2008-08-28

Page 20

10-10

Page 13

2008-08-28

Figure 4. Drain Water and Supply Connection

Page 21

Table 1. Maximum Recommended Length of Steam Line

Unit Size Steam Output Distance Possible Loss Steam Line Size

NH-005 5 lbs/hr 8 feet 1.0 lbs/hr 3/4

NH-010 10 lbs/hr 15 feet 1.5 lbs/hr 3/4

NH-020 20 lbs/hr 20 feet * 2.0 lbs/hr 3/4

NH-030 30 lbs/hr 25 feet * 2.5 lbs/hr 3/4

NH-050 50 lbs/hr 40 feet ** 4.0 lbs/hr 1 ½”

NH-075 75 lbs/hr 50 feet ** 5.0 to 10.0 lbs/hr 1 ½”

NH-100 100 lbs/hr 50 feet ** 5.0 to 10.0 lbs/hr 1 ½”

NH-150 150 lbs/hr 50ft/cylinder ** 5.0 to 10.0 lbs/hr 1 ½” cyl

NH-200 200 lbs/hr 50ft/cylinder ** 5.0 to 10.0 lbs/hr 1 ½” cyl

* Use one inch copper steam line for longer runs.

** Use two inch copper steam line for longer runs.

Notes: 1. This table gives the maximum recommended steam run by unit size.

2. The use of steam line other then copper, stainless steel tube or Nortec supplied steam line will void the

warranty and may adversely effect the operation of the humidifier

3. The NH-150 and NH-200 are dual units.

Table 2. Steam Line Materials

NORTEC Steam Line Copper Tube (Potable)

Stainless Steel Tube

(RO or DI)

Short Run < 10 feet (3m) yes yes yes

Long Run > 10 feet (3m) no yes yes

NOTE

Do not use plastic, steel, or black iron. Long runs affect accuracy of humidifier and its ability to quickly

respond to changes in demand when tight control is required.

Table 3. Recommended Materials and Sizes for Steam Runs

Unit Size

lbs/hr kg/hr ft m

Steam Run Steam Line Material Steam Line Description

0-30 0-13 0-10 0-3 Copper Tube 0.750 in MED-L Tubing (0.875 inch OD)

0-30 0-13 30+ 3+ Copper Tube 1.0 inch MED-L Tubing (1.125 inch OD)

0-30 0-13 0-10 0-3 Stainless Steel Tube 0.875 inch Tube x 0.049 inch thick

0-30 0-13 30+ 3+ Stainless Steel Tube 1.125 inch Tube x 0.049 inch thick

50-100 22-45 0-20 0-6 Copper Tube 1.500 in MED-L Tubing (1.625 inch OD)

50-100 22-45 20+ 6+ Copper Tube 2.0 inch MED-L Tubing (2.125 inch OD)

50-100 22-45 0-20 0-6 Stainless Steel Tube 1.750 inch Tube x 0.065 inch thick

50-100 22-45 20+ 6+ Stainless Steel Tube 2 inch Tube x 0.065 inch thick

NOTE

Options show in bold-italic font require that reducers be used at both ends. These extra large sizes are

to allow for better condensation removal in long steam runs. These sizes do not permit the use of hose

couplings to connect either humidifier or distributors.

Insulate steam lines with 1” pipe insulation.

10-10

Page 14

2008-08-28

Page 22

Figure 5. Steam Run and Condensate Return Installation Guidelines (Sheet 1 of 2)

10-10

Page 15

2008-08-28

Page 23

Figure 6. Steam Run and Condensate Return Installation Guidelines (Sheet 1 of 2)

2008-08-28

10-10

Page 16

Page 24

Table 4. Recommended Condensate Line at Distributor(s)

Dispersion Method Condensate Hose Copper Tube (Potable)

1 x Steam Distributor

0.375 inch

NORTEC 132-8840

0.375 inch

3 x Steam Distributor

NORTEC 132-8840

Note: *When using more then 1 steam distributor, the condensate line must be trapped before it is

joined together. See figure 4

0.250 inch. MED-L Tubing

(0.375 inch OD)

0.500 inch. MED-L Tubing

(0.875 inch OD)

Stainless Steel Tube

(RO or DI)

0.375 Tube 0.049 inch thick

0.650 Tube 0.049 inch thick

Table 5. Equivalent Lengths of Elbows and Tee Fittings

Nominal Tube

Diameter

0.750 / 0.875 in. 2 ft. 1 ft. 4 ft.

1.500 / 1.750 in. 3 ft. 6 in. 1ft. 9 in. 7 ft.

2.000 / 2.500 in. 4 ft. 6 in. 2 ft. 3 in. 10 ft.

Standard 90degree

Elbow

Standard 45 degree

Elbow Side Outlet Tee

Table 6. Humidifier and Distributor Inlet/Outlet Sizes

Humidifier Steam Outlet Distributor Steam Inlet

NH 5-30 0.875 in. OD ASD, BSD 0.875 inch OD

NH 50-100 1.75 in. OD CSD 1.75 inch OD

NH 150-200 Two 1.75 in. OD

SAM-e 1.75 inch OD*

mini SAM-e 0.875 or 1.75 inch OD**

NOTE: * SAM-e may have multiple 1.75 in. inlets depending on order.

** mini SAM-e inlet is determined on order and may have two 1.75 in. OD inlets.

Blower Pack

0.875 inch OD or

1.75 inch OD

10-10

Page 17

2008-08-28

Page 25

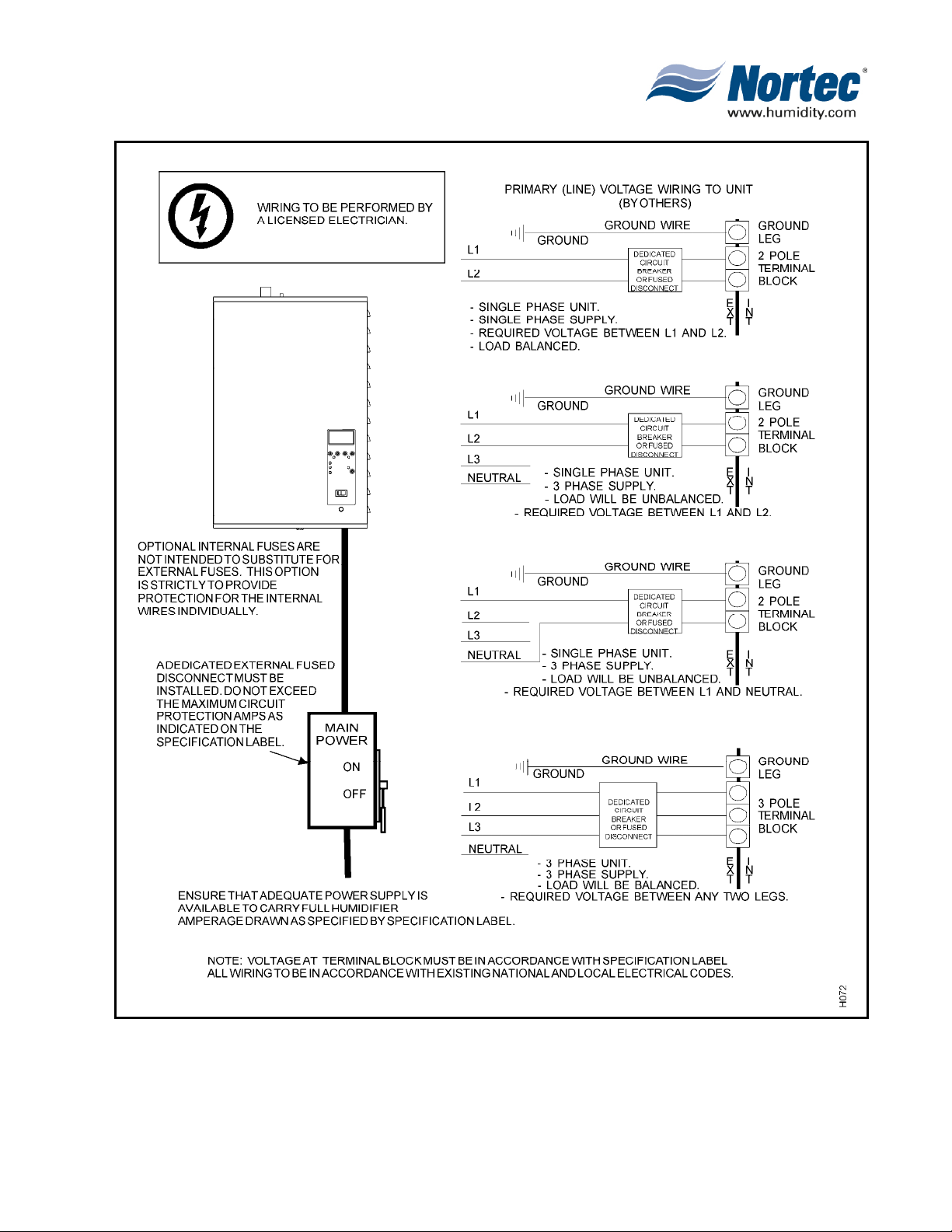

Figure 7. Primary Voltage Supply Wiring

10-10

Page 18

2008-08-28

Page 26

A

T

G. ELECTRICAL

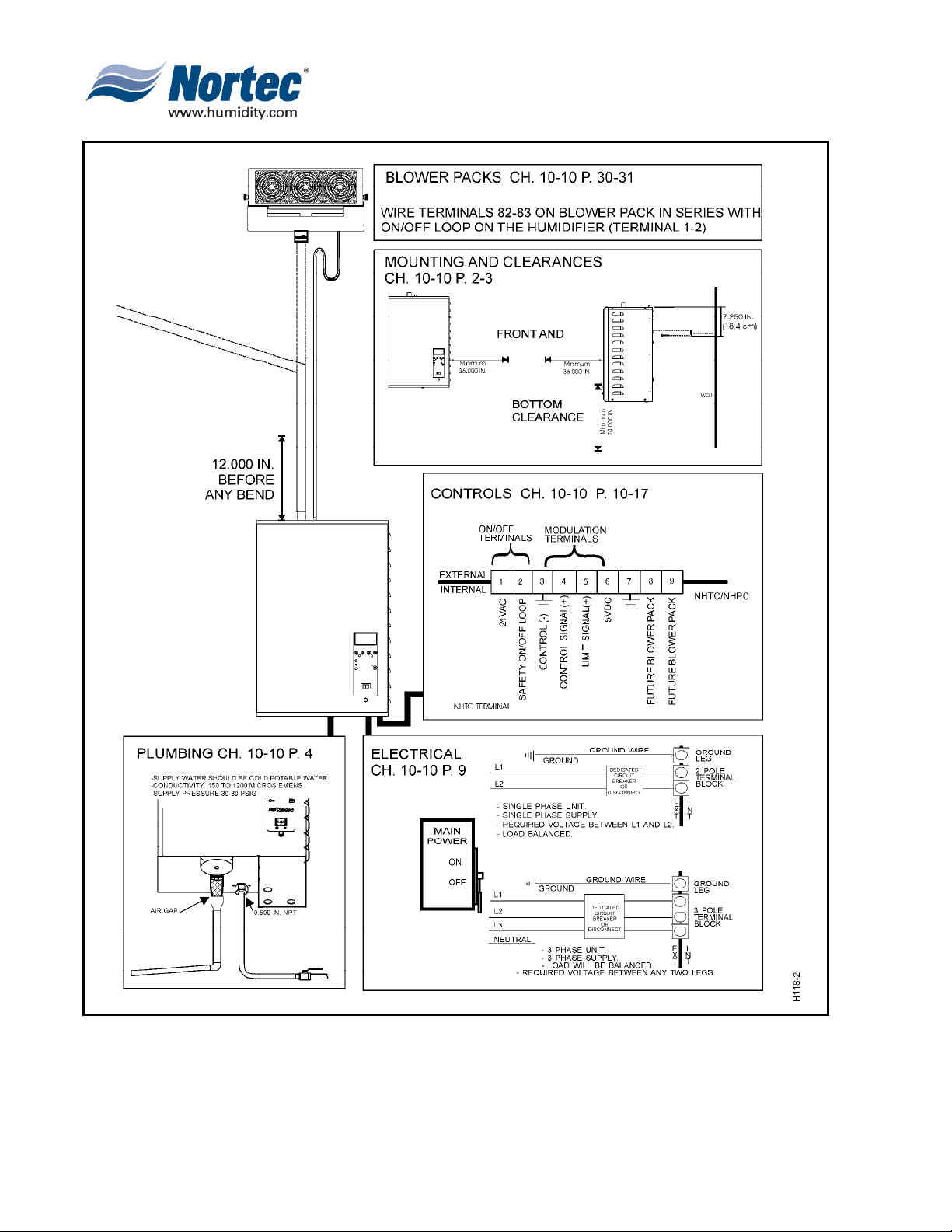

(1) Primary Voltage Supply Wiring to Humidifier

(a) Local electrical codes should always be followed when installing a NORTEC

Humidifier. Direct wiring to the high voltage terminal is shown in Figure 7.

H. CONTROL WIRING

(1) Controls are available from NORTEC as accessories. If controls were not ordered

with humidifier, they must be purchased or supplied by others. The following

information is relevant to all controls, factory supplied or otherwise.

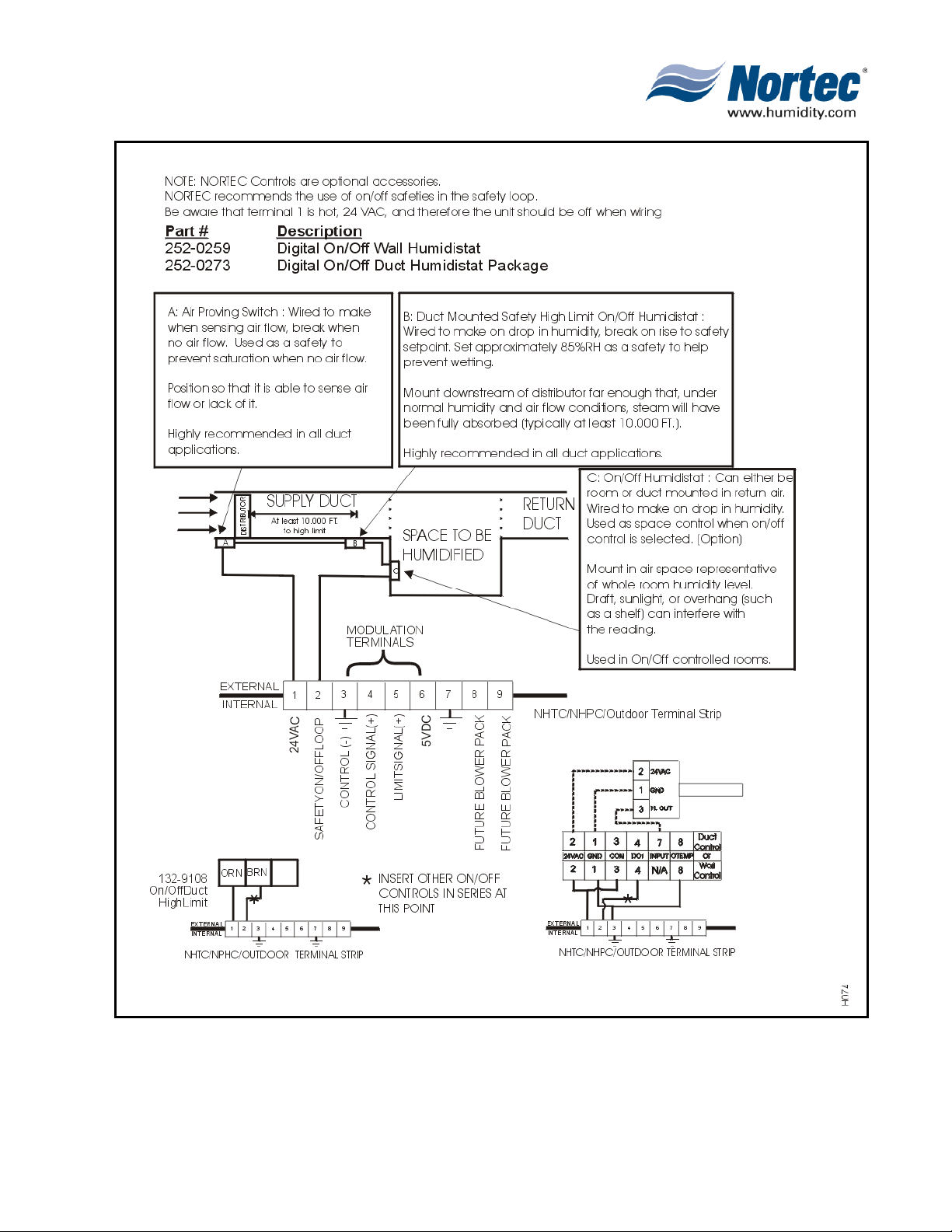

(a) On-Off Controls

CAUTION

REGARDLESS OF SELECTING ON/OFF OR MODULATING CONTROL

METHOD, NORTEC HUMIDIFIERS MUST HAVE A CLOSED CIR CUIT

CROSS ITS ON/OFF SECURITY LOOP CONTROL TERMINAL TO

OPERATE. NORTEC HIGHLY RECOMMENDS THE USE OF A HIGH

LIMIT HUMIDISTAT AND AN AIR PROVING SWITCH IN SERIES FOR

HIS FUNCTION.

The method and guidelines for installing on/off controls are displayed in

Figure 8. It can be combined with all control methods.

(b) Demand Signal Controls Installation

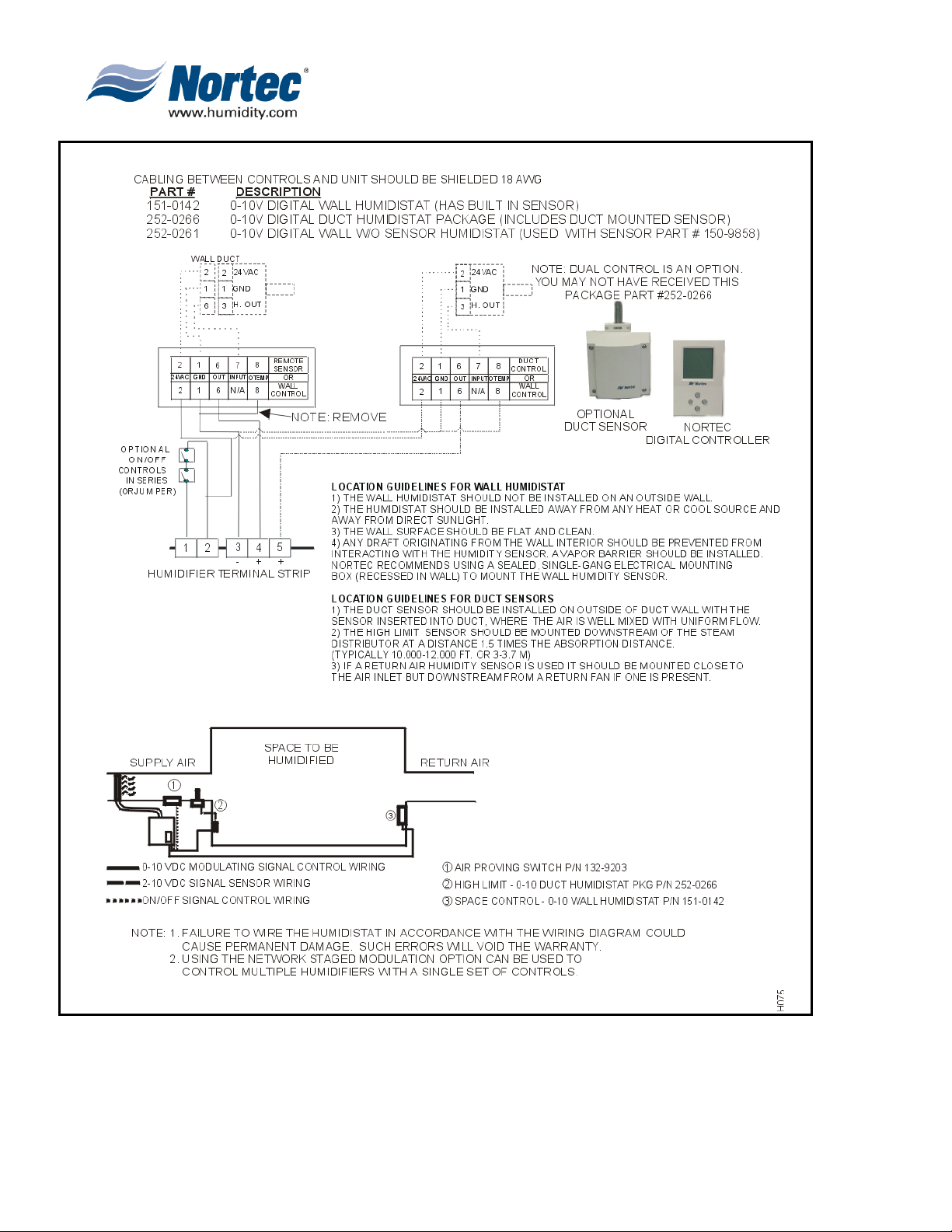

Figure 9 uses the Nortec optional Controllers to demonstrate the typical

demand signal installation.

10-10

Page 19

2008-08-28

Page 27

Figure 8.

On/Off Control Guidelines and Low Voltage Terminal Strip

10-10

Page 20

2008-08-28

Page 28

10-10

Page 21

2008-08-28

Figure 9. NORTEC Control Guidelines and Wiring (Optional)

Page 29

I. OPTIONAL OUTDOOR TEMPERATURE RESET FUNCTION

NOTE

Order outdoor temperature sensor separately, Part #252-0263.

(1) Each humidistat and controller is equipped with an integrated reset function that

will limit the setpoint during cold weather operation. This will prevent condensation

on windows and building structures. Figure 10 illustrates how the setpoint reset

feature operates.

(2) This feature is enabled by removing the jumper from terminals 8 and 1 on the

humidistat and wiring the outdoor temperature sensor to these terminals.

(3) When the outdoor temperature setback feature is in effect, the humidistat will

normally display the calculated setpoint limit based on the outdoor air temperature.

A snowflake will also be displayed to indicate cold weather operation. When any

key on the controller is pressed, the LCD screen will display the customer specified

setpoint for a short duration.

Figure 10. Setpoint Versus Outdoor Temperature

10-10

Page 22

2008-08-28

Page 30

J. HUMIDITY TRANSDUCER SIGNAL INSTALLATION

(1) Figure 11 displays the NORTEC optional humidity transducer installation.

K. NETWORKING NHTC

(1) The wiring of master/slave networks are explained in Figure 12. It allows operation

of multiple NHTCs with one control signal.

L. NORTEC ONLINE INSTALLATION

(1) An abbreviated recommended installation of NORTEC OnLine and its components

are shown in Figure 13.

10-10

Page 23

2008-08-28

Page 31

Figure 11. NORTEC Humidity Transducer Guidelines and Wiring (Optional)

10-10

Page 24

2008-08-28

Page 32

10-10

Page 25

2008-08-28

Figure 12. Networking NHTCs (Optional)

Page 33

Figure 13. NORTEC OnLine Installation Guidelines (Optional)

10-10

Page 26

2008-08-28

Page 34

10-20

OPERATION

10-20

Page 27

2008-08-28

Page 35

1. NHTC

A. NHTC COMPONENTS

(1) Refer to Figures 1 and 2 when reading Table 1.

B. HUMIDIFIER START-UP

(1) Figure 3 describes the method for powering up a humidifier and the cautions to take.

C. BASIC STEAM PRODUCTION METHOD

(1) Figure 6 describes the method the NH Series humidifier uses to produce pure clean

steam. The NORTEC NH electrode steam humidifier uses NORTEC’s patented AutoAdaptive cycle to calculate drains to maintain optimal performance. Figure 4 Drain Rate

vs Water Conductivity depicts an indication of drain amounts.

D. CYLINDER LIFE

(1) The output of all NH Series humidifiers is pure, clean steam; minerals originally in the

incoming water are left behind. These minerals will eventually coat the cylinder

electrodes. Therefore, the mineral content of the incoming water, the unit running time

and output capacity setting ultimately determine cylinder life. NORTEC’s cylinder life is

up to 2,000 hours of operation. Water chemistry and capacity can affect cylinder life.

(See Figure 5.) See Table 4 to identify the message which indicates when the cylinder

is at the end of its life.

Figure 1. NHTC Components (Front View)

Figure 2. NHTC Components (Side View)

10-20

Page 28

2008-08-28

Page 36

Table 1. NHTC/NHPC Components

Item Number Component Name Description

1 Steam Connector Used to allow easy replacement of cylinders without disconnecting

the steam line.

2 Condensate Return This inlet is to return condensate to the unit.

3 Fill Cup The fill cup allows isolation from the fill line by supplying an air gap.

It will also overflow any water that cannot enter the cylinder to drain.

4 Float Chamber (Optional) Detection OPTION – Used with the advanced foam detection

setting.

5 Manual Drain Button By pushing this button, manual drain is initiated with software

support. Software support supplies drain cooling if enabled and will

disable manual drain after 10 minutes.

6 Door Interlock The door interlock prevents the unit from running when the front

door is off. For startup and troubleshooting, pulling this interlock will

overide this safety feature.

7 Back-up Drain Back-up drain switch allows the draining of the cylinder without

electronic support.

8 Fill Valve The fill valve allows water to flow up to the fill cup. In units with

Drain Water Cooling to 120 degrees option, this valve is a dual

valve. The second valve is wired in parrallel with the drain valve to

quench the water with fresh cold water everytime the drain is

activated.

9 Drain Canal The drain canal allows all drainable water to accumulate into one

location to then be drained away.

10 Drain Valve Drain valve when energized will allow water to flow down to the

drain canal. When not energized, water flowing from the fill cup will

flow up into the cylinder.

1 1 Transformer The transformer converts the primary supply voltage to the required

24 VAC to the unit electronics. It is protected by a fuse to ensure

that the 24 VAC electronics are protected from surges or shorts.

12 On/Off Switch Turns the unit power on and off. Be aware that high voltage will still

enter the unit even though the 24VAC electronic are disabled. The

contactor will not be energized. Main shut-off should be open before

any servicing is performed.

13 Graphical Display and Menu

Buttons

14 Remote Relay Board (Optional) The remote relay board is a set of 4 dry contacts, rated for 24 VAC

15 NORTEC Cylinder The NOR T EC disposable cylinder contains electrodes that become

The graphical display and buttons are used to navigate through the

software. Use software flowchart as a reference.

1A, which activate in conjunction with humidifier on, steam

production, service and error conditions.

energized when the contactor is closed. This allows current to pass

through the water from one electrode to another, generating heat

within the water. The water then boils and the output is clean pure

steam.

10-20

Page 29

2008-08-28

Page 37

Table 1. NHTC/NHPC Components (cont)

Item Number Component Name Description

17 Cylinder Plug Cylinder plugs are press fit on cylinder electrode pins. These color

coded connections should fit snuggly, on same color pins. Replace

if loose or frayed.

18 Low Voltage T erminal Strip The low voltage terminal strip is the location at which all controls are

connected. See Installation for details.

19 Driver Board The driver board(s) is the housing of all fuses and relays. It is

connected to the total controller, and monitor and activate all

humidifier states.

20 Contactor The contactor(s) when energized allow main power to energize the

cylinder electrodes, allowing current to pass, boiling the water.

21 NORTEC OnLine Module

(Optional)

NORTEC ONLINE OPTION NHTC ONLY. This module allows the

NHTC to be connected to the internet and communicate information

to NORTEC via the internet. See NORTEC OnLine operation for

details. NHTC only

22 Links Module

(Optional)

23 Network Terminal Strip The network terminal strip allows up to 13 NHTC units to be

24 Fuse Holder OPTIONAL FUSE PACKAGE provides protection of individual high

25 High Voltage Terminal Strip Connection point of main power lines to the humidifier from the

26 Total Controller The total controller board (hidden in this view) is part of the

NORTEC LINKS OPTION NHTC ONLY This module allows the

NHTC to communicate with a BMS system using the

communication protocol requested at order. See NORTEC Links

operation for details. NHTC only

connected on one Links module and eight OnLine modules. See

Installation of NORTEC Links and OnLine for details on wiring

humidifier networks.

voltage lines in the humidifier and does not replace fuse and

external disconnect.

underside of the strip. It is accompanied by a ground terminal which

grounds the cabinet.

graphical display. It is the microcomputer that sends and collects

information from the driver boards, network modules and any other

humidifier connected to it.

10-20

Page 30

2008-08-28

Page 38

Figure 3. Humidifier Start-Up

10-20

Page 31

2008-08-28

Figure 5. Capacity Setting and Cylinder LifeFigure 4. Drain Rate Versus Water

Conductivity

Page 39

Figure 6. Basic Steam Production Method

10-20

Page 32

2008-08-28

Page 40

E. SOFTWARE INITIAL SELF-TEST

Table 2. Self-Test Messages

Graphic Display Explanation/Comments (What You Read)

NHTC START-UP:

INIT CYLINDER

NHTC START-UP:

READING CYLINDER DATA

SELF TEST CYLINDER

Inlet V a lve

ESC

SELF TEST CYLINDER

Drain Valve

ESC

SELF TEST CYLINDER

Heat Cont.

ESC

SELF TEST CYLINDER

Pump

ESC

SELF TEST CYLINDER

Bleed Valve

ESC

SELF TEST REMOTE

Steam Relay

ESC

SELF TEST REMOTE

Service Relay

ESC

SELF TEST REMOTE

Error Relay

ESC

SELF TEST REMOTE

Oper. Relay

ESC

The unit is beginning its bootup routine, along with powering up the EEPROM on the

SMART Cylinder

The unit reads the type of cylinder to provide maximum control of operation. If it

unable to do so it will skip the rest of the self-test and fault out.

Unit energizes the fill valve for 1 second.

Unit energizes the drain valve for 2 seconds.

Unit closes the contactor for 2 seconds.

Unit activates the pump (if present) for 2 seconds.

Unit activates the bleed valve (if present) for 2 seconds.

Unit activates the steam relay for remote fault indication package and green light.

Unit activates the service relay for remote fault indication package and yellow light.

Unit activates the error relay for remote fault indication package and red light.

Unit activates the unit on relay.

F. SOFTWARE FLOW CHART WITH DEFINITIONS

(1) The flow chart in Figure 7 depicts the software logic and definitions.

G. SELF-HELP

(1) The microcomputer applies corrective actions whenever its self-diagnostics identifies a

problem that it is able to correct by itself. If the corrective action is not successful then

it displays a system message. If the corrective action requires a service person, then

the microcomputer’s only resort is to stop the unit and display a system message. The

unit never stops unless it has to.

(2) After three days of no call from either the on/off controls or the modulating controls,

when active, the three-day drain active feature is automatically activated long enough

to drain all water from the steam cylinder. This NORTEC feature will prolong the life of

the cylinder. (User selectable, default is ON.)

10-20

Page 33

2008-08-28

Page 41

Figure 7. Software Flow Chart (Sheet 1 of 7)

10-20

Page 34

2008-08-28

Page 42

10-20

Page 35

2008-08-28

Figure 7. Software Flow Chart (Sheet 2 of 7)

Page 43

Figure 7. Software Flow Chart (Sheet 3 of 7)

10-20

Page 36

2008-08-28

Page 44

10-20

Page 37

2008-08-28

Figure 7. Software Flow Chart (Sheet 4 of 7)

Page 45

Figure 7. Software Flow Chart (Sheet 5 of 7)

10-20

Page 38

2008-08-28

Page 46

10-20

Page 39

2008-08-28

Figure 7. Software Flow Chart (Sheet 6 of 7)

Page 47

Figure 7. Software Flow Chart (Sheet 7 of 7)

10-20

Page 40

2008-08-28

Page 48

H. SYSTEM MESSAGES AND LIGHTS

(1) Table 3 describes general signal light status meanings.

Table 3. Signal Light Status

Yellow Green Red

OFF OFF OFF Unit is on standby or humidifier has just been energized but has not sensed

production of steam yet.

OFF ON OFF Humidifier senses production of steam.

ON OFF OFF An attention state exists that should not prevent the unit from producing steam

when the controls call for it. Check the message on the screen to try to correct it.

ON ON OFF Prepare to replace cylinder or normal startup operation. May also indicate an

attention during operation. Check the message on the screen to try to correct it.

BLINK OFF OFF Manual Drain On with software drain switch.

OFF BLINK OFF Unit sees a demand, but safeties are open.

OFF OFF ON Operation fault (unit will not run).

(2) Table 4 describes common status messages and the lights displayed for each and their

meaning. For a list of warnings and faults, see Chapter 10-40 Troubleshooting.

I. DOUBLE UNIT OPERATION

(1) The unit will report only one cylinder at a time if the unit was ordered without coupled

circuits. You will notice on the screen the indication of which cylinder you are

monitoring and in the lower right the option to monitor the alternate cylinder.

10-20

Page 41

2008-08-28

Page 49

Table 4. Status Messages with LED State

NHTC Display Message LED state System Action

Idle None Unit is made idle.

Humidifying GRN (after steam

production starts)

MANUAL DRAIN: ON YEL (blink) The drain valve is activated.

SAFETY LOOP; OPEN GRN

(blink)

LEVEL SENSOR; ON None Deactivates the fill valve to prevent overfilling.

KEEP WARM ACTIVATED None Keep Warm feature activated, it has closed the

The unit has closed the contactor and is sending

current to the cylinder to humidify.

Steam production stopped.

contactor to warm the water.

W19: Cylinder spent YEL, GRN The electronics allow the cylinder to be reset up

to four times before locking out the humidifier.

E19: Cylinder spent YEL, RED Humidifier interrupts operation and the fault relay

is activated.

FOAM: FULL TANK FLUSHING None The unit will initiate a flush of the cylinder and

resume operation.

10-20

Page 42

2008-08-28

Page 50

Symptom Diagnosed Probable Cause Corrective Action

Unit is awaiting a demand or

control signal.

This is normal when there is no need for

humidity. If you believe there is a need for

humidity, and the unit should not be idle,

refer to troubleshooting

Normal Operation

The unit is now boiling water in

the cylinder and filling as

necessary.

This is not a fault or warning. It

is an indication that the manual

drain switch has been activated.

Safety loop circuit (terminal 1

and 2) is open.

Water has reached the top of

the cylinder and has activated

the high water sensor. This is

not an error or fault, but is

normal on start-up and at the

end of a cylinder life span.

Keep Warm feature is enabled

and proceeding to a Keep Warm

Cycle.

This is normal when there is a need for

humidity. If you believe there is no need for

humidity, and the unit should idle, refer to

troubleshooting

Manual drain switch has been activated. Press Manual Drain button again to

One or more of the safety devices is open

as the result of a device failure, improper

installation or an unsafe condition has been

detected.

1. Normal on start-up with a new cylinder

or a cylinder that has been completely

drained because of an extended off

period. This condition can last several

hours until the water in the cylinder has

concentrated or the electrodes can no

longer provide rated capacity or

adjusted capacity. Water level

automatically rises to meet the demand.

2. Foaming can also cause an invalid high

water indication.

Unit is entering the Keep Warm cycle. The

unit has been inactive for a given period

and is keeping the water warm.

Normal Operation

stop the drain action.

Determine which device is preventing

continuity of the safety loop circuit, and

verify that it is functioning properly and

is properly installed and calibrated.

If foaming is determined to be the

cause of the high water indication,

consult your local representative about

possible adjustment and/or a foam

detection kit. If not foaming, consider it

normal operation unless water level is

not at the top of the cylinder.

Normal for unit with Keep Warm setting

activated.

Electronics have determined

cylinder is spent. Within the next

72 hours the humidifier will stop.

Electronics have determined

that the cylinder is spent.

The electronics has detected

foaming within the cylinder (only

for units with the optional Foam

Detection Package).

10-20

Page 43

2008-08-28

The cylinder must be replaced with the

same type and model.

The cylinder must be replaced with the

same type and model.

The unit has detected a foaming condition

within the cylinder.

When ordering a new cylinder, quote

the model number presently installed in

the humidifier.

When ordering a new cylinder, quote

the model number presently installed in

the humidifier.

The unit will initiate corrective action on

its own.

Page 51

2. STEAM DISTRIBUTION

A. STEAM DISTRIBUTOR OPERATION

(1) Figure 8 describes the method by which the steam distributor releases pure clean

steam into the duct while collecting condensate and removing it by the condensate

return.

B. SAM-e OPERATION

(1) Figure 9 describes the method by which the Short Absorption Manifold releases pure

clean steam into the duct while collecting condensate, removing it by condensate

return and ensuring short absorption distance.

C. BLOWER PACK OPERATION

DURING AND FOLLOWING OPERATION OF THE HUMIDIFIER, THE

STEAM AND COMPONENTS IN CONTACT WITH THE STEAM ON THE

BLOWER PACK CAN BECOME HOT AND CAN BURN IF TOUCHED.

(1) Figure 10 describes the method by which the blower pack distributes the pure clean

steam directly into the space required. It also describes the adjustments that can be

made to conform to the specific situation.

WARNING

Figure 8. Steam Distributor Operation

10-20

Page 44

2008-08-28

Page 52

Figure 9. SAM-e Operation

10-20

Page 45

2008-08-28

Figure 10. Blower Pack Operation and Adjustments

Page 53

3. CONTROLS AND REMOTE COMMUNICATION (OPTIONAL)

A. DIGITAL CONTROL OPERATION

(1) Figure 11 shows the components of the NORTEC Controller and how to adjust the

setpoint.

(2) In the case of a modulating NORTEC Controller, Figure 12 shows the relation between

the difference from setpoint to %rh in the room and the 0-10 V DC demand signal sent

out. From this basis the NORTEC Controller uses its PI algorithm to adjust its demand

signal in accordance with the history of the environment. This type of control allows for

tighter and more precise control.

B. DIGITAL TRANSDUCER OPERATION

(1) The NORTEC digital transducers, shown in Figure 13, are designed to sense humidity

in duct or in room respectively, and report it back to a controller or the NHTC directly.

Required humidifier output is determined by controller or humidifier.

C. REMOTE CONNECTIONS (OPTIONAL)

CAUTION

NORTEC DOES NOT RECOMMEND USING THE DRY RELAY

CONTACTS WITH ANYTHING MORE THAN 24 VAC, 1 AMP.

(1) The NHTC reports the signal light status, in Table 3, by closing the supplied dry contact

relays which can be wired back to a BMS or monitoring station. This method of

monitoring is not as informative as the actual display, but alerts you to the general

status of the unit.

Figure 11. NORTEC Digital Controller

10-20

Page 46

2008-08-28

Page 54

D. NORTEC LINKS 2 OPERATION

(1) NORTEC LINKS 2 is an option that can be integrated with the NHTC. This allows a

BMS to monitor and in the right configuration, control the humidifier. For additional

information about NORTEC Links and its operation and configuration, go to

www.humidity.com

(2) Table 5 contains a list of NORTEC LINKS 2 variable definitions. For a complete list,

contact the factory.

E. NORTEC ONLINE OPERATION

(1) NORTEC OnLine is an option that can be integrated with the NHTC. This allows a user

to log onto the internet, go to www.norteconline.com

their unit from any computer with an internet connection. (See Figure 14)

(2) After initially logging into the NORTEC OnLine server the user will be presented with a

list of humidifiers currently registered with the Server program. Each humidifier will be

listed with a unit type identifier, a serial number and an address descriptor.

(3) By clicking on the humidifier name, the user will then be brought to a status screen with

an image of the selected humidifier.

(4) Figure 14 shows a typical NORTEC OnLine Monitoring Screen. Use this manual in

combination with NORTEC OnLine to be able to monitor and understand the settings

possible through the NORTEC OnLine Interface.

and look up the NORTEC LINKS 2 manual.

and log in to allow them to monitor

Figure 12. Difference from Setpoint in

Relation to Demand Signal

10-20

Page 47

2008-08-28

Figure 13. Duct and Wall Mounted

Transducer

Page 55

THIS PAGE INTENTIONALLY LEFT BLANK

10-20

Page 48

2008-08-28

Page 56

10-30

MAINTENANCE

PROCEDURES

10-30

Page 49

2008-08-28

Page 57

MAINTENANCE PROCEDURES

1. NH ELECTRODE STEAM HUMIDIFIERS

Typical tools required for any maintenance procedure:

- Slotted Screwdriver

- Small Slotted Screwdriver

- Phillips Screwdriver

- Needle-Nose Pliers

- Wrench

A. MAINTENANCE

WARNING

DISCONNECT MAIN POWER BEFORE ANY SERVICING.

WARNING

THE PLUMBING AND ELECTRICAL COMPARTMENTS CONTAIN HIGH

VOLTAGE COMPONENTS AND WIRING. ACCESS SHOULD BE

LIMITED TO AUTHORIZED PERSONNEL ONLY.

(1) The NHTC and its components are a very low maintenance system. The only

maintenance normally required is to change the cylinder, clean out the drain valve

assembly, clean out the inlet valve screen and know the procedure for extended shutdown and start-up.

B. WHEN TO REPLACE THE STEAM CYLINDER

(1) The steam cylinder is disposable and must be replaced at end of cylinder life. Cylinder

life is dependent on water supply conditions and humidifier usage. Failure to replace

the cylinder at the end of cylinder life will cause the unit to lock out. NORTEC is not

responsible for any damages resulting from, or attributed to, the failure to replace a

spent cylinder (see Manufacturer’s Warranty). There are many indications, each of

which signifies the end of cylinder life. See 10-20 Operation, Table 4, for details on how

the unit functions and determines end of cylinder life.

C. EXTENDED SHUT-DOWN

(1) As long as the NHTC is powered, it will automatically drain the cylinder when there has

not been a call for humidity for an extended period of time. This feature will reduce or

prevent the possibility of corrosion of the electrodes and the accumulation of algae and

bacteria growing in the cylinder. The cylinder will remain empty until there is a call for

humidity at which time the fill valve will open and refill the cylinder. The unit will go

through its normal process for optimum operation.

(2) Should it be required to disconnect power to the humidifier for a period of extended

shut-down, always drain the cylinder first. Leave the switch in the OFF position and

‘open’ the main external fused disconnect to stop power to the humidifier. Close the

shut-off valve in the water supply line feeding the humidifier.

10-30

Page 50

2008-08-28

Page 58

D. COMPONENTS OF THE STEAM CYLINDER

(1) Consult Figure 1 for NORTEC cylinder components.

10-30

Page 51

2008-08-28

Figure 1. Cylinder Components

Page 59

E. HOW TO REMOVE THE STEAM CYLINDER

(1) Consult Figure 2 for removal of the steam cylinder.

Figure 2. Cylinder Removal Procedure

10-30

Page 52

2008-08-28

Page 60

F. MANDATORY CLEANING OF THE DRAIN VALVE

(1) Always clean the drain valve before installing a new cylinder since the valve port may

be as dirty as the used cylinder. Figure 3 describes the process of removing and

cleaning the drain valve. Perform paragraph E. before proceeding.

10-30

Page 53

2008-08-28

Figure 3. Drain Valve Maintenance

Page 61

G. HOW TO INSTALL THE REPLACEMENT CYLINDER

(1) Consult Figure 4 to install the replacement cylinder.

Figure 4. Cylinder Replacement Procedure

10-30

Page 54

2008-08-28

Page 62

10-40

TROUBLESHOOTING

10-40

Page 55

2008-08-28

Page 63

1. TROUBLESHOOTING NH ELECTRODE STEAM HUMIDIFIERS

A. PREPARATION

(1) Ensure the installation detail conform to installation requirements.

(2) Understanding the Principle of Operation and the software menus is an asset when

troubleshooting. This information is found in chapter 10-20 Operation and can be

elaborated on by your local representative.

(3) When contacting your local representative or NORTEC for troubleshooting assistance,

please ensure the serial number has been obtained for reference purposes.

(4) Whenever the troubleshooting steps indicate a problem with the main pc-board, first

check all connections at the main PCB (including the ribbon cable connections at the

center of the main PCB) before ordering replacements.

B. STARTING POINT

(1) Table 1 checkpoints will allow for faster troubleshooting. Ensuring that all these steps

are taken is good practice when beginning to troubleshoot the NH series humidifier.

Check your symptom and verify all points before ordering any replacement parts or

contacting your local representative. Use the wiring diagram when necessary for

clarification.

NOTE

Wiring diagrams on unit supersedes diagrams in this manual.

WARNING

BE AWARE, WHEN TROUBLESHOOTING, THAT THE HUMIDIFIER IS

POWERED BY HIGH VOLTAGE AND FAMILIARITY WITH BOTH GOOD

PRACTICES AND WIRING OF THE HUMIDIFIER IS RECOMMENDED.

ANY TROUBLESHOOTING THAT REQUIRES OPENING THE CABINET

SHOULD BE DONE BY QUALIFIED PERSONNEL.

C. NHTC/NHPC

(1) The self-diagnostic system built into the NHTC is continually checking the status of the

electrical circuits to the fill valve, drain valve, primary voltage contactor, high water

sensor and steam cylinder. The modulating signals from external humidistat and

reduced manual capacity settings are taken into consideration. When problem

symptoms are found, the NHTC/NHPC will take self-corrective actions, if applicable. It

will, if necessary, respond by shutting itself down. Table 3 describes some of the

conditions the NH unit can detect and warn or protect itself against. Table 4 contains a

definition of the terms used in this section.

10-40

Page 56

2008-08-28

Page 64

System What to Check Why

Nothing is happening when the

on/off switch is turned on

Table 1. Troubleshooting Symptoms

Main power is on and matches the

specified voltage on the specification label.

No, or improper voltage can cause the

electronics or components not to respond.

The unit will not fill or fills very

slowly (less then 1” per minute)

24 VAC output from the step-down

transformer. Check high and low voltage.

Ensure that fuses in the humidifier and on

the electronic boards are good. Ensure

that 24 VAC is getting to the main board.

Door interlock open. The door interlock has malfunctioned.

Water supply is on and water pressure is

between 30 to 80 psig

Unit is getting a demand signal or the unit

is producing the required steam capacity.

See ensuring demand T able 2.

No leak at drain valve or around cylinder.

Check for water coming out of the drain.

Check the fill valve inlet.

Check fill valve strainer.

Check optional inline filter.

24 VAC is required to power nearly all the

components of the humidifier, including the

electronics.

The fuses are in place to prevent damage

to the electronics. If there was a surge the

fuse may have blown to prevent damage

to the unit.

The proper water volume and pressure

must be available as the valves in the NH

unit rely on its pressure to control volume

and operation. NORTEC recommends 55

to 60 PSIG.

The unit will not activate the fill valve

without a demand for humidity. It will also

only fill as necessary once there is a

demand. Once it reaches the requested

demand, it will stop filling.

The cylinder is held in by gravity and

sealed by an O-ring. If not properly seated,

it could leak and prevent the unit from

filling.

Drain stuck open

Unit will not humidify or is not

reaching requested capacity.

Unit has faulted or has a

warning

10-40

Page 57

2008-08-28

Pressure in the steam line could also

prevent filling causing the water in the fill

cup to overflow to drain.

Strainer is clogged.

Fill valve may also be restricted after

capturing debris in its filter.

Unit is getting a demand signal. Refer to

Table 2.

Capacity is manually limited. The unit will not surpass the capacity

Cylinder is full. The unit will not fill further than a full

Check Table 3, Faults and Warning Codes Each code is identified and each has

Unit will not send power to the cylinder

without a demand and safeties met.

dictated by the user in the software.

cylinder. Operation requires it to try to

concentrate the conductivity, which may

take several hours, before it reaches full

capacity.

individual causes and solutions.

Page 65

Table 2. Ensuring A Demand Signal

Check Why and How

Safety Loop (terminal 1

and 2) is closed

Channel 1 has a signal. Whether for on/off or modulating, a voltage potential signal must be present between

Channel 2 has a signal Only applicabl e if configured to accept dual channel input.

The safety loop is checked to ensure that it is safe to operate. Checking to see 24 VAC from

terminal 1 to ground, and terminal 2 to ground should indicate whether is closed.

If found to be open, isolate which component in the safety loop is open to solve the issue. If

suspect, confirm that it is connected and operating properly.

terminal 3 and 4 for the humidifier temperature.

If on/off there should be 5 VDC.

If VDC modulating, at least 25% of total possible signal must be present.

If mA controlled, at least 25% of total possible signal must be present.

If Transducer signals, the unit setpoint must be higher then the sensed room RH signal.

If VDC modulating, at least 25% of total possible signal must be present.

If mA controlled, at least 25% of total possible signal must be present.

If Transducer signals, the high limit setpoint must be higher than the sensed RH signal.

2. TROUBLESHOOTING DISTRIBUTORS

CAUTION

KEEP IN MIND WHEN TROUBLESHOOTING DISTRIBUTORS THAT

THEY ARE BEING USED WITH STEAM AND THEREFORE, ARE AND

CAN REMAIN VERY HOT DURING THE TROUBLESHOOTING

PROCESS.

A. TROUBLESHOOTING ATMOSPHERIC DISTRIBUTORS

(1) If the distributor is spitting out water, ensure that the distributor is installed level and

check the condensate return for proper slope, check head above the trap, and check

the trap that it is clear of obstructions.

(2) If the distributor is condensing inside the duct, make sure the installation clearances

are as indicated in Chapter 10-10 Installation, and make sure that the design conditions

have not changed. If over humidification of the duct results, check controls and safeties

(ensure safeties are properly installed and functioning).

3. SAM-e TROUBLESHOOTING

A. PROCEDURE

(1) If the SAM-e is spitting out water, ensure that the distributor is installed per instructions

in Chapter 10-10 Installation and check the condensate return for proper slope and trap

and that it is clear of obstructions. The condensate return must be the lowest point of

the SAM-e header.

10-40

Page 58

2008-08-28

Page 66

(2) If the SAM-e is condensing inside the duct, make sure that the design conditions have

not changed.

(3) If grommets leak, make sure the tubes are firmly inserted, if cracks or damage are

found, replace grommet.

4. BLOWER PACKS TROUBLESHOOTING

A. PROCEDURE

(1) An optional blower pack (BP), ensure power supplied to blower pack either from

humidifier or other source, if present, gets its primary voltage from inside the humidifier.

This way, only one external power source has to be connected to the equipment.

Confirm this power source before troubleshooting the blower pack.

(2) Ensure blower pack is installed per Chapter 10-10 Installation.

(3) If fans are not functioning, confirm safety is not open. Fans are only ON when steam is

being discharged.

5. DIGITAL ON/OFF HUMIDISTAT SENSOR CALIBRATION

A. PROCEDURE

(1) The humidity sensor is factory calibrated, however, it can be field recalibrated.

(a) The calibration routine can be accessed by pressing and holding down the option

button for five seconds. A new screen will appear with the calibration adjustments.

(b) Press the up or down buttons until the text calH appears on the LCD screen.

(c) To adjust the calibration press the Option button. The screen should load to

display the current calibration trim. The calibration trim can be adjusted by

pressing the up or down buttons to the desired level and then pressing the option

button to confirm the settings.

(d) Press the Power button to return to the normal display.

NOTE

A properly calibrated hygrometer should be used in conjunction with any calibration

procedure.

10-40

Page 59

2008-08-28

Page 67

Table 3. NH System Messages

NHTC Display Message LED state System Action Symptom Diagnosed

E5: Cylinder B Controller

missing

E6: Extendet Missing RED Humidifier activates its fault

E7: CPU CRC fault RED Humidifier activates its fault

W11: Safety Loop Open GRN Humidifier goes on standby. O N/OFF controls wired between

W12: Cylinder Max Level NONE Fill valve inte rrupted. Water at top of cylinder.

E12: Cylinder max Level no

current

W13: Fill Timeout GRN

RED Humidifier is in standby until

problem corrected.

relay and interrupts its operation

until communication is fixed.

relay and interrupts operation.

RED Humidifier activates its fault

relay and interrupts its

operation.

The humidifier will attempt to

blink

clear any debris by pulsing the

drain valve.

On power up, the controller cannot

detect the driver board for cylinder B.

The slave unit is not in communication

with the master unit. Master unit

powered?

Problem with the processor hardware

or software.

terminal 1 and 2 are open.

The high water sensor is activated but

no current is measured in cylinder.

The fill valve has been activated for an

extended period of time but water has

not reached the sensor.

E13: Fill: Timeout RED The fill valve has been activated

for an extended period of time

but has not reached the sensor.

W15: Over current YEL The drain is activated to

decrease the water level in the

cylinder.

E15: Over Current RED Humidifier interrupts operation

and the fault relay is activated.

W16: Excess Current YEL Humidifier interrupts operation

and the fault relay is activated.

E16: Excess Current RED Humidifier interrupts operation

and the fault relay is activated.

Humidifier stops operation and the

fault relay is activated.

Measured current in the cylinder has

exceeded 115% of rated output.

Measured current in the cylinder has

exceeded 115% of rated output.

Measured current in the cylinder has

exceeded 115% of rated output.

Measured current in the cylinder has

exceeded 130% of rated output.

10-40

Page 60

2008-08-28

Page 68

Probable Cause Corrective Action

1. The driver board is damaged.

2. Controller is not configured correctly.

1. The master unit is not configured correctly.

2. Is the RJ12 cable damaged?

3. Is an incorrect RJ12 cable used?

4. J2 ports on driver boards are not connected.

The electronics of the main PCB have diagnosed the main

PCB (itself) as defective.

1. Current measurement core loose on driver board?

2. Primary wire not looped through CT core?

3. High water sensor plug is on an electrode pin.

1. Is the drain stuck open?

2. Check system backpressure.

3. Is the water supply closed?

4. Drain leaking?

1. Is the water supply closed?

2. Is the drain leaking?

3. Check the system backpressure.

1. Is the drain blocked?

2. Is the cylinder filling too fast?

3. Was the wrong fill valve supplied?

4. Is there scale in the cylinder?

5. Is the water too conductive?

6. Is the wrong cylinder supplied?

7. Is the cylinder spent?

1. Replace the driver board.

2. Verify that the humidifier is a double unit.

3. Check that the driver board ribbon cable is connected

to the main board.

1. Verify configuration settings for the units.

2. Replace the RJ12 cable.

3. Replace with correct cable.

4. Check all connections to the processor board.

Reset humidifier and monitor display. If Error reoccurs

within one minute of resetting the unit, the problem is with

the main PCB. If the Error is not repeated, the primary

power to the unit is suspect.

1. Connect CT core.

2. Interrupt main power and rewire CT core.

3. Install high water plug on shrouded pin.

1. Clean drain valve or replace.

2. Install fill cup extension kit if required.

3. Open water supply.

4. Clean drain valve.

1. Open water supply.

2. Clean drain valve.

3. Clean drain valve or replace.

4. Install fill cup extension kit if required.

1. Clean the drain line.

2. Replace the fill valve.

3. Replace the fill valve.

4. Rinse the cylinder.

5. Change water supply.

6. Install the correct type of cylinder.

7. Replace the cylinder.

1. Is the drain blocked?

2. Is the drain restricted?

3. Is the cylinder filling too fast?

4. Was the wrong fill valve supplied?

5. Is there scale in the cylinder?

6. Is the water too conductive?

7. Was the wrong cylinder supplied?

1. Is the drain blocked?

2. Is the drain restricted?

3. Is the cylinder filling too fast?

4. Was the wrong fill valve supplied?

5. Is there scale in the cylinder?

6. Is the water too conductive?

1. Is the drain blocked?

2. Is the drain restricted?

3. Is the cylinder filling too fast?

4. Was the wrong fill valve supplied?

5. Is there scale in the cylinder?

6. Is the water too conductive?

10-40

Page 61

2008-08-28

1. Clean the drain line.

2. Clean the drain line.

3. Replace the fill valve.

4. Replace the fill valve.

5. Rinse the cylinder.

6. Change the water supply.

7. Install correct cylinder type.

1. Clean the drain line.

2. Clean the drain line.

3. Replace the fill valve.

4. Replace the fill valve.

5. Rinse the cylinder.

6. Change the water supply.

1. Clean the drain line.

2. Clean the drain line.

3. Replace the fill valve.

4. Replace the fill valve.

5. Rinse the cylinder.

6. Change the water supply.

Page 69

Table 3. NH System Messages (cont)

NHTC Display Message LED state System Action Symptom Diagnosed

E17: Req off current RED Humidifier interrupts operation

and the fault relay is activated.

W18: Foam YEL System will activate selected

foam algorithm. (See Figure 7.)

E18: Foam RED System will activate selected

foam algorithm. (See Figure 7.)

W19: Cylinder spent YEL T he electronics allow the

cylinder to be reset up to four

times before locking out the

humidifier.

E19: Cylinder spent YEL, RED Humidifier interrupts operation

and the fault relay is activated.

W20: Conductivity too low YEL Humid ifier will continue to

operate on this water supply.

W23: Control sensor broken YEL Humidifier put on standby. After

a timeout period, this warning

becomes a fault.

With no system demand, current is

detected in the cylinder.

System has detected foaming and will

attempt to self correct if foam mode is

active.