Page 1

NH

TM

Series

Outdoor

ELECTRODE

STEAM HUMIDIFIER

Out door Model

Inst allation Manual

2531550-B

Page 2

PROPRIETARY NOTICE

This document and the information disclosed herein are proprietary data of W alter Meier. Neither this

document nor the information contained herein shall be reproduced used, or disclosed to others

without the written authorization of Walter Meier, except to the extent required for installation or

maintenance of recipient’s equipment. All references to the NORTEC name should be taken as

referring to Walter Meier (Climate USA) Inc. and Walter Meier (Climate Canada) Ltd.

LIABILITY NOTICE

Walter Meier does not accept any liability for installations of humidity equipment installed by

unqualified personnel or the use of parts/component s/equipment that are not authorized or approved

by Walter Meier.

COPYRIGHT NOTICE

Copyright 2008, Walter Meier (Climate USA) Inc. and Walter Meier (Climate Canada) Ltd. All rights

reserved.

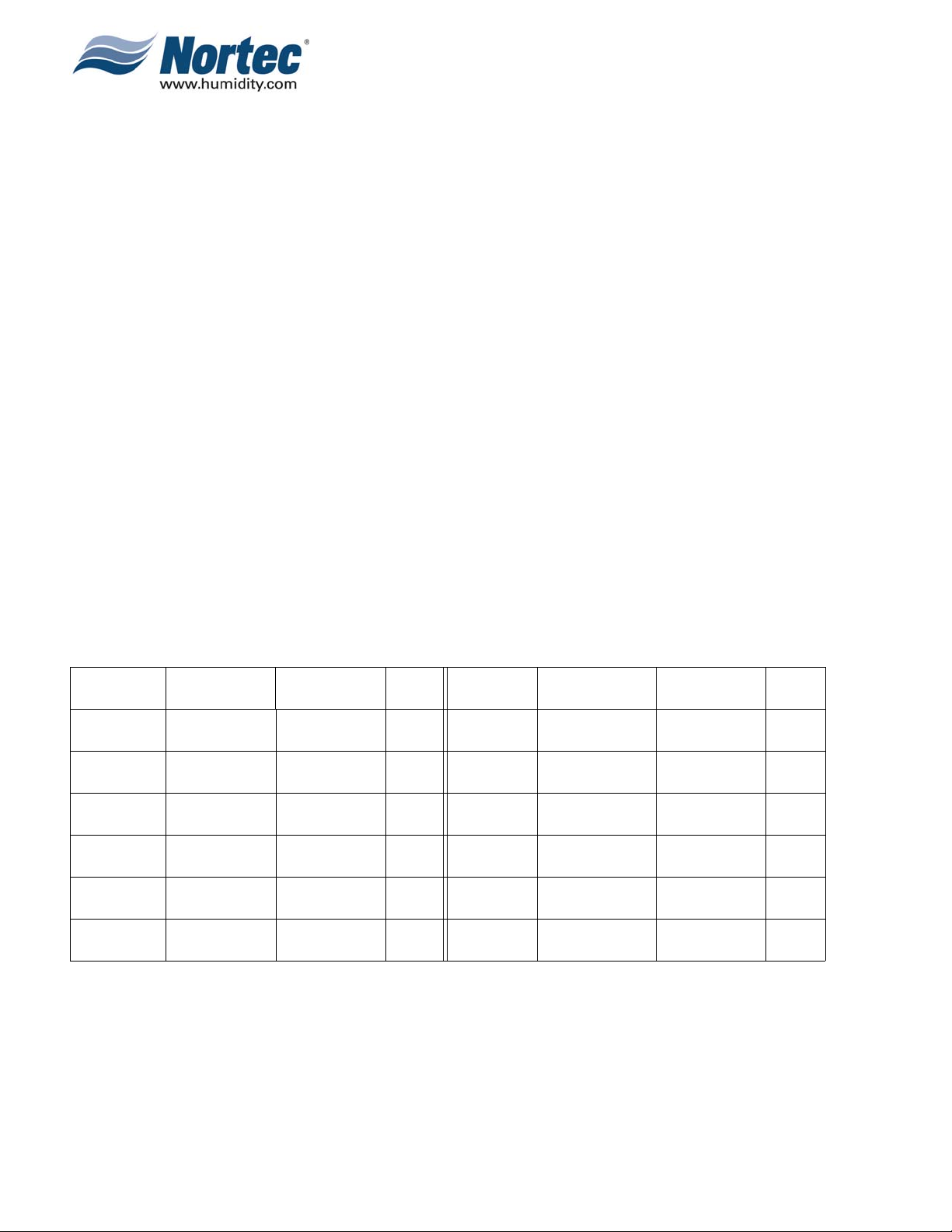

RECORD OF REVISIONS

For each revision, put the revised pages in your manual and disca rd the superseded pages. W rite the

revision number and revision date, date put in manual, and the incorporator’s initials in the applicable

columns on the Record of Revisions.

Revision

Number

Page Number Date Put

In Manual By

Revision

Number

Revision

Date

Date Put

In Manual By

2008-10-01

Page 3

TABLE OF CONTENTS

Subject Page

10-00 INTRODUCTION

1. PREINSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

A. ABOUT THIS GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. RECEIVING AND UNPACKING EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2. PACKAGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. HUMIDIFIER SKID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

C. DISTRIBUTOR BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

D. ACCESSORIES BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. PREINSTALLATION EQUIPMENT VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

A. EQUIPMENT VERIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

B. MOVING AND HANDLING THE HUMIDIFIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

10-10 INSTALLATION PROCEDURES

1. HUMIDIFIER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

A. LOCATION & MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B. AIR HANDLING MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

C. CURB MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

D. WALL MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

E. ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

F. WATER SUPPLY LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

G. DRAINL LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

H. AUXILIARY DRAINS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

I. STEAM LINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2. IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

B. HEATER AND FAN SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

C. FREEZE PROTECTION SYSTEM (OPTIONAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

D. SERVICING ELECTRODE STEAM CYCLINDER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

E. SERVICING NHRS WITH SCALE MANAGEMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

F. CLEANING DUST AND POLLEN DEPOSITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

G. RESTARTING AFTER FREEZING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3. OPERATION AND ADDITIONAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

A. OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

B. ADDITIONAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4. WEATHER DESIGN DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

A. WEATHER DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

10-20 TECHNICAL

1. SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

10-30 WIRING DIAGRAMS

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

WARRANTY

2008-10-01

Page 4

LIST OF FIGURES

Figure Page

10-00 INTRODUCTION

Figure 1. Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 2. Distributor Box Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 3. SAM-e Distributor Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4. Remote Mounted Blower Pack Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

10-10 INSTALLATION PROCEDURES

Figure 1. Recommended Clearances and Curb Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Figure 2. Typical Air Handling Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 3. Typical Rooftop Curb Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 4. Typical Wall Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 5. Normally Open / Normally Closed Valve Arrangement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 6. 3-Way Valve Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10-20 TECHNICAL

Figure 1. NHRS Outdoor Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 2. NHTC Oudoor Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

LIST OF TABLES

Table Page

10-10 INSTALLATION PROCEDURES

Table 1. Weather Design Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2008-10-01

Page 5

THIS PAGE INTENTIONALLY LEFT BLANK

2008-10-01

Page 6

10-00

INTRODUCTION

10-00

Page 1

2008-10-01

Page 7

1. PRE-INSTALLATION

A.

ABOUT THIS GUIDE

(1) This guide is intended as a supplement for the NH Series Installation Guide.

The NH Series Installation guide is included with all NH Series humidifiers and

contains information on installation, operation, and maintenance that applies to

both indoor and outdoor models. This guide contains supplementary information

that pertains specifically to the NH Series Outdoor humidifiers.

(2) For information on the installation of controls, interior piping, interior wiring,

distribution systems please refer to the NH Series Installation Guide.

(3)

The operation and control of the NH Outdoor Series is identical to the indoor

series. Please refer to the NH Series Installation guide for information on operating

your humidifier.

(4)

The maintenance items described in this guide are specific to the outdoor model

and must be performed IN ADDITION to the regular maintenance that an indoor

model would require. Please refer to the NH Series Installation guide for other

regular maintenance items.

B. RECEIVING & UNPACKING EQUIPMENT

(1) Check packing slip to ensure ALL material has been delivered.

(2) All material shortages are to be reported to NORTEC within 48 hours from receipt

of goods. NORTEC assumes no responsibility for any material shortages beyond

this period.

(3) Inspect shipping boxes for damage and note damages on shipping waybill

accordingly.

(4) After unpacking, inspect equipment for damage and if damage is found, notify the

shipper promptly.

(5)

All NORTEC products are shipped on an FOB factory basis. Any and all damage,

breakage or loss claims are to be made directly to the shipping company.

2. PACKAGING

A.

GENERAL

(1) The equipment packaging is standardized in that each box in the shipment will

always have the same contents. The following paragraphs identify the contents

of each box.

B.

HUMIDIFIER SKID

(1) Typically the NH Series Outdoor Humidifier ships on a skid (shown in Figure 1).

Controls and accessories are shipped separately in a box. The contents of the box

will be listed on the outside of the box.

C.

DISTRIBUTOR BOX

(1) Depending on the equipment ordered any of the following distributor box

configurations may be received:

2008-10-01

10-00

Page 2

Page 8

(a) For equipment received if an ASD, BSD, CSD distributor(s) is ordered refer to

Figure 2.

(b) For equipment received if a SAM-e distributor is ordered refer to Figure 3.

(c)

For equipment received if a RMBP is ordered refer to Figure 4.

D.

ACCESSORIES BOX

(1) Additional accessories such as drain water coolers and filters are shipped in a

separate box. Smaller accessories that would fit in the humidifier box are put in the

humidifier box and the box is identified as containing such.

10-00

Page 3

2008-10-01

Page 9

Figure 1. Humidifier

Figure 2. Distributor Box Contents

Figure 3. SAM-e Distributor Box

Figure 4. Blower Pack Box Contents

10-00

Page 4

2008-10-01

Page 10

3. PRE-INSTALLATION

A. EQUIPMENT VERIFICATION

(1) Ensure that available voltage and phase corresponds with humidifier voltage and

phase as indicated on humidifier’s specification label.

(2) Ensure that the dedicated external fuse disconnect is of sufficient size to handle

the rated amps as indicated on the specification label. Refer to local codes.

(3) Report any discrepancy immediately to the site engineer.

(4) Location and mounting is described in Chapter 10-10.

(5) Typical installation is described in Chapter 10-10.

B. MOVING AND HANDLING THE HUMIDIFIER

(1) The NH Outdoor Series humidifier is bolted to a shipping skid for easy

transportation. While still attached the skid, the humidifier can be lifted to a rooftop

or other location using a forklift or crane. The unit can also be positioned for wall

mounting using a forklift as long as the skid is attached, although it may be easier

to manually lift the unit onto its wall brackets. Installation on a curb requires guide

lifting of the unit. Observe the following precautions when moving and positioning

the humidifier:

(a) When lifting by crane, ensure that the unit is protected from physical damage

by the tethers and lifting equipment.

(b) When lifting by forklift, ensure that unit is properly balanced and secured to

prevent tipping.

(c) Use proper lifting techniques when manually lifting. Often several people will

be required to lift the unit.

(d) Remove the cabinet doors before manually lifting the unit.

(e) Ensure that the humidifier is the proper model, capacity, and voltage for the

specific location.

10-00

Page 5

2008-10-01

Page 11

THIS PAGE ITENTIONALLY LEFT BLANK

10-00

Page 6

2008-10-01

Page 12

10-10

INSTALLATION

PROCEDURES

10-10

Page 7

2008-10-01

Page 13

1.

HUMIDIFIER INSTALLATION

A.

LOCATION AND MOUNTING

(1) NH Outdoor Series humidifiers are UL listed for outdoor installation and come

complete with internal cooling for the electronics. An internal heater is standard

and ensures the enclosure remains at proper operating temperatures.

Additionally, a freeze protection system is available for use in cold climates.

(2) The NH Outdoor Series humidifiers can be mounted on an air handler, on an

appropriately sized curb, or on a wall or vertical surface. The clearance

dimensions shown in this guide are for reference only and are the minimum

required for maintenance of the humidifier. Local and National Codes should be

consulted prior to final location and installation of the humidifier. NORTEC cannot

accept responsibility for installation code violations. The minimum required

maintenance clearances are shown in Figure 1.

(3) Humidifiers typically operate in the cold winter months. As a result they should be

located where it is safe and convenient for maintenance personnel to service the

unit. This is essential as it may be less desirable to service the unit during

inclement weather. The warranty does NOT cover damage resulting to humidifier

as a result of neglect or freezing. NH Outdoor series should NOT be installed on a

rooftop in severe climates or where temperatures reach below 14°F (-10°C).

Please refer to Table 1: Weather Design Data in this document.

(4)

It is also important to consider the length and location of the humidifier steam line

that will result from the installation. Consult section 10-10 in the NH Series Indoor

Installation guide for further information on steam lines.

B. AIR HANDLER MOUNTING

(1) The NH outdoor series features provisions for hanging on brackets (supplied).

This allows the unit to be mounted directly to a vertical wall on an air handler unit.

This installation is advantageous since the steam piping is shorter, and hence the

condensate losses and backpressure are minimized. Typical air handler

installations are shown in Figure 2. Additionally, observe the following precautions

when installing the humidifier:

(a) Ensure that the surface selected to mount the humidifier is structurally sound

and capable of supporting the entire weight of the humidifier when in

operation.

(b) For minimum required maintenance clearances see Figure 1.

(c) Wall mounting bracket provided should be securely attached horizontally with

open edge upwards, using field-supplied fasteners.

(d) Using proper lifting techniques, lift the humidifier onto the brackets to mount

it. Several people may be required to lift the unit.

(e) Ensure that both the bracket and humidifier are mounted level.

(f) Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of the humidifier.

10-10

Page 8

2008-10-01

Page 14

C. CURB MOUNTING

(1) The integral base of the NH Outdoor models is designed to mount on a curb. The

curb must be built to structurally support the entire weight of the humidifier when in

operation. Required curb dimensions are given in Figure 1. Typical curb mounting

installations are shown in Figure 3. Additionally, observe the following precautions

when installing the humidifier:

(a) The NH Outdoor unit is shipped on a skid to allow for lifting by a forklift.

When lifting by this method, ensure that the forks extend across the entire

skid to prevent tipping or damage to the unit.

(b) Ensure that the humidifier is mounted level.

(c) The pan in the bottom of all outdoor models has a pipe chase for routing of

services into the humidifier from below.

(d) If the humidifier will be roof mounted, it is not necessary to make the hole in

the roof the same size as the curb, the curb drawing shows the size and

location of the pipe chase required. The pipe chase should be sealed when

installation is complete to ensure positive or negative pressure from the

building.

(e) When mounting the unit in cold climates, ensure the lowest point of the air

louvers is 12” above any surface when snow or ice could accumulate.

Remove excessive ice and snow as necessary.

(f) Final installation of the humidifier is accomplished by manually lifting the unit

into position on the curb. Ensure that proper lifting techniques are used.

Several people may be required to lift the unit.

(g) The base of the humidifier is predrilled to allow the unit to the screwed to a

curb. Ensure that the unit is securely fastened to the curb in this manner.

(h) Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of the humidifier.

(i) If possible, DO NOT locate humidifier any further than absolutely necessary

from steam distributor location as net output will be reduced as a result of

heat loss through steam line.

D. WALL MOUNTING

(1) A third option for installation involves mounting the humidifier on an exterior wall or

other vertical surface. This method requires holes to be drilled into the wall to

accommodate the steam lines, which exit from the rear of the humidifier. Typical

wall mounting installations are shown in Figure 4. If this method is selected, utilize

the provided brackets in a similar manner as if the installation was on an air

handler. Additionally, observe the following precautions:

(a) Ensure that the surface selected to mount the humidifier is structurally sound

and capable of supporting the entire weight of the humidifier when in

operation.

10-10

Page 9

2008-10-01

(b) For minimum required maintenance clearances see Figure 4.

Page 15

(c) Wall mounting bracket provided should be securely attached horizontally with

open edge upwards, using 5/16” x 3” (minimum) flat head screws. (See

Figure 4).

(d) Using proper lifting techniques, lift the humidifier onto the brackets to mount

it. Several people may be required to lift the unit.

(e) Ensure that both the bracket and humidifier are mounted level.

(f) Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of the humidifier.

10-10

Page 10

2008-10-01

Page 16

FRONT VIEW

B

BACK VIEW

D

E

STEAM LINE

CONNECTION

1.750inch OD

FILL WATER LINE,

SINGLE OR DOUBLE,

1/2" NPT B Y OTHE RS

A

EXPLODED VIEW

TOP

BOTTOM VIE W

SECONDARY FILL LINE

ONLY FOR NHRS.

1/2" NPT BY OTHERS

LEFT

RIGHT

C

KNOCKOUT FOR

OPTIONAL

WATER INLET

5"

(12.7cm)

G

F

ROOF PIPE

CHASES

FRONT

Model Dim. A Dim. B Dim. C Dim. D Dim. E

** 0-50lbs 34.7" (88.1cm) 25.0" (63.5cm) 15.5" (39.4cm) 3.4" (8.6cm) 7.9" (20.1cm)

50-100lbs 55.1" (140.0cm) 30.0" (76.2cm) 20.4" (51.8cm) 3.1" (7.8cm) 12.75" (32.4cm)

100-200lbs 55.1" (140.0cm) 46.0" (116.8cm) 20.4" (51.8cm) 3.1" (7.8cm) 12.75"/28.75" (32.4cm/73.1cm)

NHRS humidifiers under 50lbs/hour requ ire a medium Outdoor Enclosure

KNOCKOUT FOR

POWER LINE AND

HOLES F OR CONTROL

WIRING

ROOF CURB

BY OTHERS

5"

(12.7cm)

4"

(10.16cm)

3 3/4" MAX

(9.5cm)

** 0-50lbs 20.1" (51.1cm) 13.3" (33.8cm) 15"(38.1cm) Min.

50-100lbs 25.1" (63.8cm) 18.1"(46.0cm) 15"(38.1cm) Min.

100-200lbs 41.1" (104.4cm) 18.1" (46.0cm) 15"(38.1cm) Min.

Model Front Left Right Back(Curb Mount)

** 0-50lbs 24" (60.96cm) 0 20" (50.80cm) 6" (15.25cm)

50-100lbs 24" (60.96cm) 0 20" (50.80cm) 6" (15.25cm)

100-200lbs 38" (96.52cm) 0 20" (50.80cm) 6" (15.25cm)

POWER KNOCKOUTS

TO AND FROM

BRE A KER

Model Weight (lbs)

0-50 lbs

50-100lbs

100-200lbs

Model Dimension F Dimension G Curb Height

Minimum Required Clearance

Major Dimensions

137 lbs (62 kg)

206 lbs (93 kg)

Roof Curb Height

FRONT

99 lbs (45 kg)

10-10

Page 11

2008-10-01

NH Outdoor Enclosure Physical Data Sheet

Small/Medium/Large models

May 21 2008

Figure 1. Recommended Clearances and Curb Dimensions

Page 17

NH OUTDOOR TYPICAL AIR HANDLING UNIT INSTALLATION

STEAM LINE TO DISTRIB UTOR

AIR HANDLING

UNIT

INSULATED AND HEAT-TRACED

WATER SUPPLY (BY OTHERS)

CAN ALSO BE ROUTED THROUGH

PIPE-CHASE AND PROVIDED

PUNCHOUTS

3-WAY VALVE OR

NO-NC VALVE

ARRANGEMENT

(BY OTHERS)

MANUAL SHUT-OFF

FUNNEL WITH

AIR GAP

Figure 2. Typical Air Handling Unit Installation

DRAIN LINES

SEE FIGURE 8 FOR

MOUNTING DETAIL

PUNCHOUTS PROVIDED

FOR POWER WIRING

TO AND FROM BREAKER

NH OUTDOOR TYPICAL ROOFTOP CURB INSTALLATION

INSULATED STEAM LINE

(BY OTHERS)

PUNCHOUTS PROVIDED

FOR POWER WIRING

INSULATED AND HEAT-TRACED

WATER SUPPLY (BY OTHERS)

CAN ALSO BE ROUTED THROUGH

PIPE-CHASE AND PROVIDED

PUNCHOUTS

3-WAY VALVE OR

NO-NC VALVE

ARRANGEMENT

(BY OTHERS)

MANUAL SHUT-OFF

DRAIN LINES

FUNNEL WITH

AIR GAP

TO AND FROM BREAKER

Figure 3. Typical Rooftop Curb Installation

10-10

Page 12

2008-10-01

Page 18

10-10

Page 13

2008-10-01

Figure 4. Typical Wall Mount Installation

Page 19

E. ELECTRICAL INSTALLATION

(1) Only qualified personnel should install electrical wiring. All wiring must be in

accordance with national and local codes.

(2) Power and control wiring is to be routed into the humidifier through the pipe chase

in the base of the unit.

(3) A field supplied NEMA rated weatherproof disconnect switch must be mounted

external to the NH Outdoor unit to allow for power interruption during servicing

and/or maintenance. A mounting plate, located on the side of each outdoor model,

is available for mounting of the disconnect switch. Two electrical cutouts are

provided for routing the primary wiring from the disconnect switch to the main

power terminal strip inside the unit.

(4) Installation details for primary and low voltage control wiring are the same as for

indoor units.

F. WATER SUPPLY LINE

(1) The water supply line is critical to the proper operation of the humidifier.

Humidifiers primarily operate in the cold winter months when freezing is a serious

issue. To prevent freezing of the humidifier, a water supply line freeze protection

system should be ordered and used in conjunction with a normally open / normally

closed valve arrangement described below. NORTEC’s limited warranty does

NOT cover damage resulting from freezing.

(2) There are two alternative configurations for the supply line plumbing. The first

method involves using a normally open / normally close valve arrangement (see

Figure 5). The valves should be installed inside of the building to prevent freezing.

The water should flow from the supply through a normally closed valve. This valve

should always be closed unless energized by the humidifier. This prevents water

from flowing to the humidifier when there is no demand, or in the event of a power

failure. After the first valve the water should flow to a tee. The central branch of

the tee is to be plumbed to the humidifier. The remaining branch of the tee should

is to be connected to a normally open valve. This valve remains open to allow

water to drain back from the outdoor lines when there is no demand from the

humidifier or in the event of a power failure. When energized by the humidifier, this

valve will close and allow water to flow to the humidifier. With this configuration the

outdoor line will be empty unless the humidifier requests water. This effectively

eliminates the chance of water freezing in the outdoor portion of the line.

(3) The second method operates on the same principle as the first, however it

replaces the two-valve configuration with a single safety three-way water valve.

This valve is to be installed inside of the building. When the humidifier begins to

operate, it will energize this valve and send water to the humidifier. When the

humidifier is not in use, the valve will close the supply, and allow water in the

outdoor lines to flow to drain. See Figure 6 for details.

(4) The valves described above should operate on either a 24V or 110V signal and

should be wired to the appropriate terminals inside of the humidifier.

10-10

Page 14

2008-10-01

Page 20

(5) Additionally the following points should be considered:

(a) Each unit is supplied with a ½” NPT male connection to the fill valve. Refer to

the NH series indoor installation guide for allowable pressures and fill rates.

(b) ALL OUTDOOR LINES MUST BE PROPERLY HEAT TRACED AND

INSULATED TO PREVENT FREEZING

(c) It is recommended to install and additional guide shut off valve within the

building to allow isolation of the water to the unit for easy servicing. The

guide shut off valve must be accessible to service personnel.

10-10

Page 15

2008-10-01

Page 21

Figure 5. Normally Open / Normally Closed Valve Arrangement

10-10

Page 16

2008-10-01

Page 22

10-10

Page 17

2008-10-01

Figure 6. 3-Way Valve Arrangement

Page 23

G. DRAIN LINE

(1) NH Series Outdoor units require and external drain line to provide for draining from

the unit.

(2) ALL OUTDOOR PIPING SHOULD BE PROPERLY INSULATED AND HEAT

TRACED TO PREVENT FREEZING.

(3) Route the drain hose to a drain funnel inside the building to provide an air gap

before entering the main building drain/sewage system.

(4) Some units have a drain pump. Refer to the NH Indoor Installation Guide for flow

rates and pressures.

(5) Drain line should be capable of withstanding 200°F (93°C) temperatures.

(6) Internal drain water tempering will ensure a maximum of 140°F (60°C) during

normal operation.

(7) Optional low temperature drain water cooler is available to cool drain water to

120°F (49°C).

H. AUXILIARY DRAINS

(1) Auxiliary draining is part of the freeze protection system that is discussed in section

2C of this chapter.

(2) A second hose, 5/8” in diameter, extends from the bottom of the unit. This is the

auxiliary drain hose.

(3) This hose must be drained into an open funnel. It can share a funnel with the

primary drain line if necessary.

(4) ENSURE ALL AUXILIARY DRAIN HOSE IS PROPERLY HEAT TRACED A ND

INSULATED TO PROTECT FROM FREEZING.

(5) Auxiliary drain water temperature will be 50°F (10°C)

(6)

Additionally, the NHSC has an additional port to allow for guide draining of the

scale tank. It is recommended that this drain port be plumbed to a funnel in the

same manner as the other drains. This drain can share a funnel with the other

primary and auxiliary drains if desired.

I. STEAM LINES

(1) The steam outlet connection is located at the back of the NH Outdoor unit. Steam

hose(s) and clamps are supplied with the unit and are intended to provide a flexible

coupling outside of the unit to the building steam lines.

(2) NH Outdoor models can develop steam pressures up to 12” w.c. to overcome duct

and steam line pressures. Duct and line pressures about 12” w.c. will cause steam

to exit through the drain line.

(3) Steam lines can be routed to an air handler on a roof or pipe chased (external to

the unit) through an exterior wall or roof to enter the building.

(4) All steam lines must be insulated to reduce losses.

(5)

For steam line installation guidelines, consult the distribution system installation

10-10

Page 18

2008-10-01

Page 24

Y

W

T

T

guide (Steam Distributor Installation Guide Form #XX-231 and SAM-e Short

Absorption Manifold Form #XX-249).

2.

IMPORTANT INFORMATION

A.

GENERAL

OUR HUMIDIFIER OPERATES ON HIGH VOLTAGE AND CURRENTS,

HICH CAN CAUSE SERIOUS INJURY OR DEATH. ENSURE THAT

HE POWER TO THE UNIT IS OFF BEFORE PERFORMING ANY

SERVICE WORK ON THE HUMIDIFIER. ONLY QUALIFIED

PERSONNEL SHOULD PERFORM MAINTENANCE OR REPAIRS ON

HE HUMIDIFIER. DO NOT SERVICE THE HUMIDIFIER WHILE

STANDING ON WET OR ICY SURFACES, OR IN WET WEATHER.

IF THE HUMIDIFIER HAS BEEN IN OPERATION, INTERNAL

COMPONENTS CAN BE HOT ENOUGH TO CAUSE SERIOUS INJURY.

FULLY DRAIN THE UNIT AND ALLOW SUFFICIENT TIME FOR THE

UNIT TO COOL BEFORE PERFORMING ANY SERVICE WORK.

CAUTION

CAUTION

B.

HEATER AND FAN SYSTEM

(1) The NH Outdoor humidifiers feature an internal heating and cooling system to

maintain appropriate operating temperatures and protect the electronics during

adverse conditions.

(2) During the winter months when the temperatures are cooler, a 200 W heater and

fan system will automatically activate to keep the internals of the case at an

appropriate operating temperature. This heater is automatically controlled by an

internal thermostat, and cannot be manually activated.

(3) During the warm summer months, a weather shielded case fan will circulate air

throughout the case, cooling the electronics and maintaining operating

temperatures. This fan is automatically controlled by a thermostat, and cannot be

manually activated.

10-10

Page 19

2008-10-01

Page 25

A

A

WARNING

IT IS ESSENTIAL THAT THE FANS AND HEATERS BE INSPECTED

PERIODICALLY TO ENSURE THAT THEY CAN SPIN FREELY AND

HAVE NOT BECOME CLOGGED WITH DIRT, POLLEN, OR BY

NIMALS. THIS IS ESPECIALLY TRUE OF THE EXTERNAL CASE FAN

ND FAN SHROUD.

WARNING

IN COLD CLIMATES THE FREEZE PROTECTION SYSTEMS MUST BE

CORRECTLY INSTALLED AND FULLY FUNCTIONAL AT ALL TIMES.

HUMIDIFIER WARRANTY DOES NOT COVER DAMAGE RESULTING

FROM FREEZING OF THE HUMIDIFIER, SUPPLY LINES, DRAIN LINES,

OR STEAM DISTRIBUTION SYSTEM.

FREEZE PROTECTION SYSTEM (STANDARD)

C.

(1) Freeze protection is Standard for NH Outdoor units. This system prevents internal

water freeze-up, which may damage the humidifier.

(2) The system consists of an additional normally closed mechanical drain valve. This

valve is activated by a bi-metallic strip thermostat, which allows for it to operate in

the event of a power failure. When the thermostat detects that the water inside the

humidifier has cooled to 43°F (6°C), the valve opens allowing water to drain. The

freeze protection system drains water from steam cylinders, reservoirs, hoses, and

internal lines. Emptying the humidifier protects the hoses, fittings, valves,

cylinders, and fill cups from ice damage and prevents unit freeze up.

WARNING

ENSURE THAT THE FREEZE PROTECTION SYSTEM DRAIN HOSE IS

FREE OF KINKS OR BLOCKAGES THAT MAY PREVENT IT FROM

OPERATING.

WARNING

IN COLD CLIMATES THE FREEZE PROTECTION SYSTEMS MUST BE

CORRECTLY INSTALLED AND FULLY FUNCTIONAL AT ALL TIMES.

HUMIDIFIER WARRANTY DOES NOT COVER DAMAGE RESULTING

FROM FREEZING OF THE HUMIDIFIER.

D. SERVICING ELECTRODE STEAM CYLINDER

(1) The cylinders inside of the NH electrode stream models have a finite life and must

be replaced periodically. The life span of the cylinder varies based on incoming

water conditions. The unit will indicate that it is time to change the cylinder by way

of a message displayed on the screen. The humidifier should be frequently

monitored ensure that the cylinder is changed when required to eliminate

downtime. An optional Remote Fault Indication Package (P/N: 2522170) is

10-10

Page 20

2008-10-01

Page 26

available to signal remotely that he humidifier requires service. If the NORTEC

OnLine option was ordered, cylinder change notices will be delivered via email.

(2)

Please refer to the NH Series Indoor Installation guide for further details on

replacing cylinders.

E. SERVICING NHRS WITH SCALE MANAGEMENT SYSTEM

(1) As with the indoor units, the scale collector tanks on the NHRS must be emptied

periodically based on supply water conditions. At a minimum NORTEC

recommends the tanks be emptied twice every year/season. Also, every third time

the tanks are cleaned, the cylinder and heating elements should be disassembled

and cleaned as well. This will ensure long and reliable operation of your NORTEC

humidifier.

(2) The procedure for changing the cylinder is similar to that of the indoor units with

two minor differences:

(a) The guide drain control is located on the back of the scale collector tank as

opposed to the side.

(b) When the tank has finished draining the hose clamps that secure the freeze

protection/ drain hoses to the tank need to be loosened and the hoses

removed. With the hoses disconnected the scale collector tank can be

removed and emptied. Ensure that the hoses are reconnected and secure

before restarting the humidifier.

(c) For further details please refer to the NHSC Installation Guide.

F. CLEANING DUST AND POLLEN DEPOSITS

(1) Dust, pollen, and animal nests must be periodically removed from the humidifier.

This is best accomplished with a vacuum or with compressed air. When cleaning

the humidifier focus on the following areas:

(a) Exhaust and heater fans

(b) Heater coil

(c) Case louvers

(d) Heat sinks (if applicable)

(e) Electronics

(f) Case floor

G. RESTARTING AFTER FREEZING

(1) In the unlikely event that the humidifier must be restarted after freezing, the

following procedure should be followed:

(a) Inspect all hoses, fittings, valves, and seals for cracking or damage. Since

water expands when it freezes, connections may have come loose, or fittings

may have cracked. If any parts are damaged contact your NORTEC

representative for replacement parts.

10-10

Page 21

2008-10-01

(b) Power the humidifier on. The heater and fan circuit will automatically power

on and begin to warm the case.

Page 27

(c) Once the unit has reached an appropriate temperature it will resume normal

operation.

3. OPERATION AND ADDITIONAL MAINTENANCE

A. OPERATION

(1) NH Outdoor series humidifiers are operated in the same manner as their indoor

counterparts. Please refer to the NH Series Installation guide for more details.

B. ADDITIONAL MAINTENANCE

(1) In addition to the maintenance items listed in this guide, the NH Series Installation

Guide lists other maintenance items that apply the entire NH Series (indoor and

outdoor). Refer to the NH Series Installation Guide for further details and

procedures.

4. WEATHER DESIGN DATA

A. WEATHER DATA

(1) The following weather design data is provided to assist in determining suitable

locations for rooftop mounting of the NH Series Outdoor models. Climates that see

very cold winter conditions are not good candidates for rooftop NH units. It is NOT

recommended to install the humidifier in areas that reach below 14°F (-10°C)

during January, or above 122°F (50°C) during July (see table below). These

harsh climates can cause required maintenance to be difficult to perform and

increase the risk of the humidifier freezing or overheating.

10-10

Page 22

2008-10-01

Page 28

A

A

A

Table 1. Weather Design Data

State/Province City

labama Birmingham 10 -12 81 61 66 95 35 84 56 68

Mobile 10 -12 -- -- -- 95 35 90 64 78

rizona Flagstaff -10 -23 83 58 -- 90 32 77 36 - Phoenix 25 -4 75 47 39 105 41 53 31 23

Yuma 30 -1 56 37 27 110 44 51 31 23

rkansas Little Rock 5 -15 80 67 68 95 35 85 55 59

California Eureka 30 -1 87 -- 77 90 32 92 -- 80

Fresno 25 -4 93 80 66 105 41 61 36 20

Los Angeles 35 2 63 46 51 90 32 85 50 54

Sacramento 30 -1 90 82 70 100 38 76 46 28

San Diego 35 2 76 58 60 85 29 86 68 65

San Francisco 35 2 84 68 70 85 29 92 75 78

Colorado Denver -10 -23 54 37 41 95 35 55 27 30

Grand Junction -15 -26 77 64 64 95 35 48 27 22

Pueblo -20 -29 67 44 48 95 35 73 34 35

Connecticut New Haven 0 -18 75 65 69 95 35 77 64 74

Delaware Wilmington 0 -18 77 62 70 95 35 80 52 69

District of Columbia Washington 0 -18 73 56 64 95 35 78 52 64

Florida Jacksonville 25 -4 89 56 75 95 35 85 57 76

Miami 35 2 87 59 75 91 33 83 64 76

Georgia Atlanta 10 -12 80 64 69 95 35 83 57 68

Augusta 10 -12 84 59 69 98 37 83 55 69

Savannah 20 -7 83 58 72 95 35 85 61 80

Idaho Boise -10 -23 82 75 74 95 35 54 34 23

Lewiston -5 -20 79 73 71 95 35 64 37 25

Illinois Cairo 0 -18 81 69 -- 98 37 83 57 - Chicago -10 -23 81 70 75 95 35 78 51 55

Peoria -10 -23 83 72 77 96 35 81 53 58

Indiana Fort Wayne -10 -23 84 75 81 95 35 84 53 58

Indianapolis -10 -23 83 72 78 95 35 84 54 60

Terre Haute 0 -18 82 70 76 95 35 77 50 56

Iowa Davenport -15 -26 -- -- -- 95 35 -- -- - Sioux City -20 -29 78 67 72 95 35 86 55 54

Kansas Dodge City -10 -23 78 57 61 95 35 77 45 52

Topeka -10 -23 78 64 67 100 38 85 54 54

Kentucky Louisville 0 -18 78 68 69 95 35 77 52 57

Louisiana New Orleans 20 -7 85 67 73 95 35 84 64 72

Shreveport 20 -7 83 67 66 100 38 86 56 62

Maine Portland -5 -21 81 65 74 90 32 78 58 76

Maryland Baltimore 0 -18 72 68 56 95 35 71 52 65

Massachusetts Boston 0 -18 72 59 67 92 33 72 55 70

Michigan Detroit -10 -23 82 71 77 95 35 74 50 56

Grande Rapids -10 -23 85 78 80 95 35 76 51 54

Minnesota Duluth -25 -32 78 74 74 93 33 87 61 66

Minneapolis -20 -29 82 72 75 95 35 82 54 54

Mississippi Vicksburg 10 -12 82 65 67 95 35 87 61 70

JANUARY

Temperature

Dry

Bulb

°F

Dry

Bulb

°C

JANUARY

Relative Humidity (% RH)

7:30

A.M.

1:30

P.M.

7:30

P.M.

JULY

Temperature

Dry

Bulb

°F

Dry

Bulb

°C

Relative Humidity (% RH)

7:30

A.M.

JULY

1:30

P.M.

7:30

P.M.

10-10

Page 23

2008-10-01

Page 29

Missouri Kansas City -10 -23 78 64 66 100 38 76 48 47

St. Louis 0 -10 77 65 68 95 35 73 50 55

Montana Billings -25 -32 67 73 60 90 32 65 40 33

Butte -20 -29 76 70 71 95 35 82 36 33

Nebraska North Platte -20 -29 80 62 66 85 29 84 50 46

Omaha -10 -23 82 68 73 95 35 80 51 51

Nevada Reno -5 -21 82 67 54 95 35 72 25 20

New Hampshire Concord -15 -26 78 60 69 90 32 80 49 69

New Jersey Atlantic City 5 -15 79 68 74 95 35 81 72 82

Newark 0 -18 72 79 65 95 35 75 51 65

Trenton 0 -18 73 62 68 95 35 77 55 68

New Mexico Albuquerque 0 -18 68 51 46 95 35 59 33 28

New York Albany -10 -23 75 63 71 93 34 79 52 64

Buffalo -5 -21 79 72 78 93 34 78 53 63

New York 0 -18 72 61 66 95 35 75 58 68

Rochester -5 -21 81 73 79 95 35 80 50 60

North Carolina Asheville 0 -18 82 59 69 93 34 88 56 73

Raleigh 10 -12 82 57 69 95 35 86 55 72

North Dakota Bismarck -30 -34 77 71 75 95 35 85 52 49

Ohio Cincinnati 0 -18 82 70 74 95 35 84 52 60

Cleveland 0 -18 81 72 79 95 35 79 52 58

Columbus -10 -23 83 71 76 95 35 78 52 60

Toledo -10 -23 79 72 75 95 35 76 52 59

Oklahoma Oklahoma City 0 -18 79 62 65 101 38 80 49 51

Oregon Baker -5 -21 83 81 78 90 32 69 68 36

Portland 10 12 87 82 78 90 32 86 63 48

Pennsylvania Harrisburg 0 -18 72 49 65 95 35 78 51 62

Philadelphia 0 -18 74 65 68 95 35 78 52 64

Pittsburg 0 -18 77 67 63 95 35 80 52 63

Scranton -5 -21 80 67 -- 95 35 77 50 -Rhode Island Providence 0 -18 73 60 67 93 34 79 57 73

South Carolina Charleston 15 -9 87 55 76 95 35 88 64 82

Columbia 10 -12 81 57 65 95 35 83 56 68

South Dakota Huron -20 -29 79 72 76 95 35 86 52 49

Rapid City -20 -29 71 69 67 95 35 71 42 40

Tennessee Knoxville 0 -18 83 65 69 95 35 83 55 66

Memphis 0 -18 82 67 73 95 35 85 55 59

Texas Amarillo -10 -23 71 51 52 100 38 77 43 42

Corpus Christi 20 -7 88 66 75 95 35 93 58 68

Dallas 10 -12 81 62 62 100 38 79 50 47

El Paso 10 -12 63 45 39 100 38 60 37 30

Houston 20 -7 85 66 73 95 35 90 58 66

San Antonio 20 -7 82 60 59 100 38 88 49 45

Utah Salt Lake City -10 -23 80 71 72 95 35 56 27 23

Vermont Burlington -10 -23 81 69 78 90 32 76 54 67

Virginia Richmond 15 -9 84 60 68 95 35 81 57 72

Washington Seattle 15 -9 86 80 74 85 29 86 63 47

Walla Walla -5 -21 80 74 78 95 35 50 33 22

West Virginia Charleston 0 -18 79 64 70 95 35 88 53 67

Parkersburg -10 -23 82 66 74 95 35 80 52 65

Wisconsin Green Bay -15 -26 75 68 73 95 35 85 58 64

Milwaukee -15 -26 76 70 73 95 35 81 58 64

10-10

Page 24

2008-10-01

Page 30

A

Wyoming Cheyenne -15 -26 59 48 55 95 35 73 36 40

lberta Calgary -29 -34 71 87 31 34

Edmonton -29 -34 75 86 30 42

Grande Prairie -43 -42 80 84 29 38

Lethbridge -32 -36 66 91 33 30

Medicine Hat -30 -34 73 96 36 31

British Columbia Estevan Point 17 -8 84 87 31 32

Fort Nelson -40 -40 79 94 34 32

Penticton 0 -18 81 85 29 44

Prince George -37 -38 82 73 23 53

Prince Rupert 11 -12 87 80 27 54

Vancouver 15 -9 87 80 27 41

Manitoba Brandon -29 -34 73 90 32 50

Churchill -40 -40 76 79 26 57

The Pas -35 -37 77 85 29 54

Winnipeg -29 -34 78 90 32 50

New Brunswick Campbellton -18 -28 77 87 31 54

Fredericton -16 -27 72 89 32 47

Moncton -12 -24 82 88 31 52

Saint John's -12 -24 82 81 27 62

Newfoundland Corner Brook -10 -23 84 84 29 47

Gander -5 -21 76 85 29 45

Goose Bay -26 -32 85 86 30 42

St. John's 1 -17 79 26 60

N.W.T. Frobisher -45 -43 77 63 17 67

Resolute -49 -45 71 54 12 81

Yellowknife -49 -45 82 78 26 50

Nova Scotia Halifax 0 -18 83 83 28 50

Sydney 1 -17 84 84 29 56

Yarmouth 5 -15 83 76 24 70

Ontario Thunder Bay -27 -33 80 86 30 52

Hamilton 0 -18 75 91 33 52

Kaspuskasing -30 -34 79 87 31 52

Kingston -11 -24 85 29 69

Kitchener -3 -19 84 88 31 58

London 0 -18 80 90 32 53

North Bay -20 -29 77 87 31 46

Ottawa -17 -27 90 32 50

Peterborough -13 -25 77 90 32 53

Sioux Lookout -33 -36 78 65 18 69

Sudbury -20 -29 81 89 32 44

Timmins -33 -36 79 90 32 45

Toronto -3 -19 82 90 32 56

Windsor -3 -16 92 31 51

Sault Ste. Marie -20 -29 88 29 48

P.E.I. Charlottetown -6 -21 86 84 29 57

Quebec Knob Lake -40 -40 79 55 13 70

Mont Joli -11 -24 75 62 17 71

Montreal -16 -27 88 31 58

Port Harrison -39 -39 76

Quebec City -19 -28 81 86 30 60

Sept-Iles -27 -33 80 27 47

10-10

Page 25

2008-10-01

Page 31

Sherbrooke -18 -28 87 31 58

Trois Rivieres -18 -28 88 31 58

Saskatchewan Prince Albert -41 -41 77 88 31

Regina -34 -37 81 92 33

Saskatoon -34 -37 76 90 32

Swift Current -29 -34 79 93 34

Yukon Territory Dawson -56 -49 76 57 14 60

Whitehorse -45 -43 82 78 26 40

Table Source: ASHRAE

10-10

Page 26

2008-10-01

Page 32

10-20

TECHNICAL

10-20

Page 27

2008-10-01

Page 33

Figure 1. NHRS Outdoor Exploded View

10-20

Page 28

2008-10-01

Page 34

10-20

Page 29

2008-10-01

Figure 2. NHTC Outdoor Exploded View

Page 35

THIS PAGE INTENTIONALLY LEFT BLANK

10-20

Page 30

2008-10-01

Page 36

10-30

WIRING DIAGRAMS

10-30

Page 31

2008-10-01

Page 37

Figure 1. Wiring Diagram NHTC Outdoor

10-30

Page 32

2008-10-01

Page 38

10-30

Page 33

2008-10-01

Figure 2. Wiring Diagram NHRS Outdoor (Single)

Page 39

Figure 3. Wiring diagram NHRS Outdoor (Double)

10-30

Page 34

2008-10-01

Page 40

THIS PAGE INTENTIONALLY LEFT BLANK

Page 41

WARRANTY

(1) Walter Meier Inc. and/or Walter Meier Ltd. (hereinafter collectively referred to as THE

COMPANY), warrant for a period of two years after installation or 30 months from

manufacturer’s ship date, whichever date is earlier, that THE COMPANY’s

manufactured and assembled products, not otherwise expressly warranted (with the

exception of the cylinder), are free from defects in material and workmanship. No

warranty is made against corrosion, deterioration, or suitability of substituted materials

used as a result of compliance with government regulations.

(2) THE COMPANY’s obligations and liabilities under this warranty are limited to furnishing

replacement parts to the customer, F.O.B. THE COMPANY’s factory, providing the

defective part(s) is returned freight prepaid by the customer. Parts used for repairs are

warranted for the balance of the term of the warranty on the original humidifier or

90 days, whichever is longer.

(3) The warranties set forth herein are in lieu of all other warranties expressed or implied

by law. No liability whatsoever shall be attached to THE COMPANY until said produ cts

have been paid for in full and then said liability shall be limited to the original purchase

price for the product. Any further warranty must be in writing, signed by an officer of

THE COMPANY.

(4) THE COMPANY’s limited warranty on accessories, not of the companies manufacture,

such as controls, humidistats, pumps, etc. is limited to the warranty of the original

equipment manufacturer from date of original shipment of humidifier.

(5) THE COMPANY makes no warranty and assumes no liability unless the equipment is

installed in strict accordance with a copy of the catalog and installation manual in effect

at the date of purchase and by a contractor approved by THE COMPANY to install

such equipment.

(6) THE COMPANY makes no warranty and assumes no liability whatsoever for

consequential damage or damage resulting directly from misapplication, incorrect

sizing or lack of proper maintenance of the equipment.

(7) THE COMPANY makes no warranty and assumes no liability whatsoever for damage

resulting from freezing of the humidifier, supply lines, drain lines, or steam distribution

systems.

(8) THE COMPANY makes no warranty and assumes no liability whatsoever for

equipment that has failed due to ambient conditions when installed in locations having

climates below 14°F (-10°C) during January or above 104°F (40°C) during July. (See

Table 1: Weather Design Data above).

(9) THE COMPANY retains the right to change the design, specification and performance

criteria of its products without notice or obligation.

Page 42

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Cylinder Replacement Date (MM/DD/YYYY)

U.S.A.

Walter Meier (Climate USA) Inc.

826 Proctor Avenue

Ogdensburg, NY 13669

TEL: 1-866-NORTEC-1

EMAIL: northamerica.climate@waltermeier.com

WEBSITE: www.humidity.com

CANADA

Walter Meier (Climate Canada) Ltd.

2740 Fenton Road

Ottawa, ON K1T 3T7

TEL: 1-866-NORTEC-1

FAX: (613) 822-7964

Authorized Agent:

Loading...

Loading...