Page 1

Important:

Read and save these instructions. This guide to be left with equipment owner.

2560599-D| 05 JUN 2014

Modbus

Installation and

Operation Manual

Using Modbus with Nortec

Humidifiers. Includes installation,

operation maintenance and

troubleshooting information.

Page 2

Nortec Humidity Ltd.

Nortec Humidity Ltd

Nortec Humidity Ltd

Thank you for choosing Nortec.

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Proprietary Notice

This document and the information disclosed herein are proprietary data of

document nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorization of

recipient’s equipment.

., except to the extent required for installation or maintenance of

Neither this

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2014,

. All rights reserved.

Page 3

Contents

2 Introduction

2 Requirements

2 Wiring Connections

10 Addressing and

Communication

10 NH-EL

15 NHTC

21 GSTC

25 SETC

29 MHTC

33 MES2 and RH2

39 NHRS

42 Troubleshooting

Page 4

CAUTION: Servicing

CAUTION: Electrical

CAUTION: Installation

• Disconnect main power before any servicing.

• The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

• During and following operation of the humidifier, the steam and components in

contact with the steam such as the blower pack, steam lines, steam distributors,

and condensate lines can become hot and can burn if touched.

• Nortec Humidity Ltd does not accept any liability for installations of humidity

equipment installed by unqualified personnel or the use of

parts/components/equipment that are not authorized or approved by Nortec

Humidity Ltd.

• All electrical work should be done according to local and national electrical code.

• Electrical connection to be performed by a licensed electrician.

• Do not mount on hot surfaces.

• Do not mount in area where freezing can occur.

• Do not mount on vibrating surface.

• Do not mount on floor.

• Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to

operate. Nortec highly recommends the use of a duct high limit humidistat.

Modbus Installation | 1

Page 5

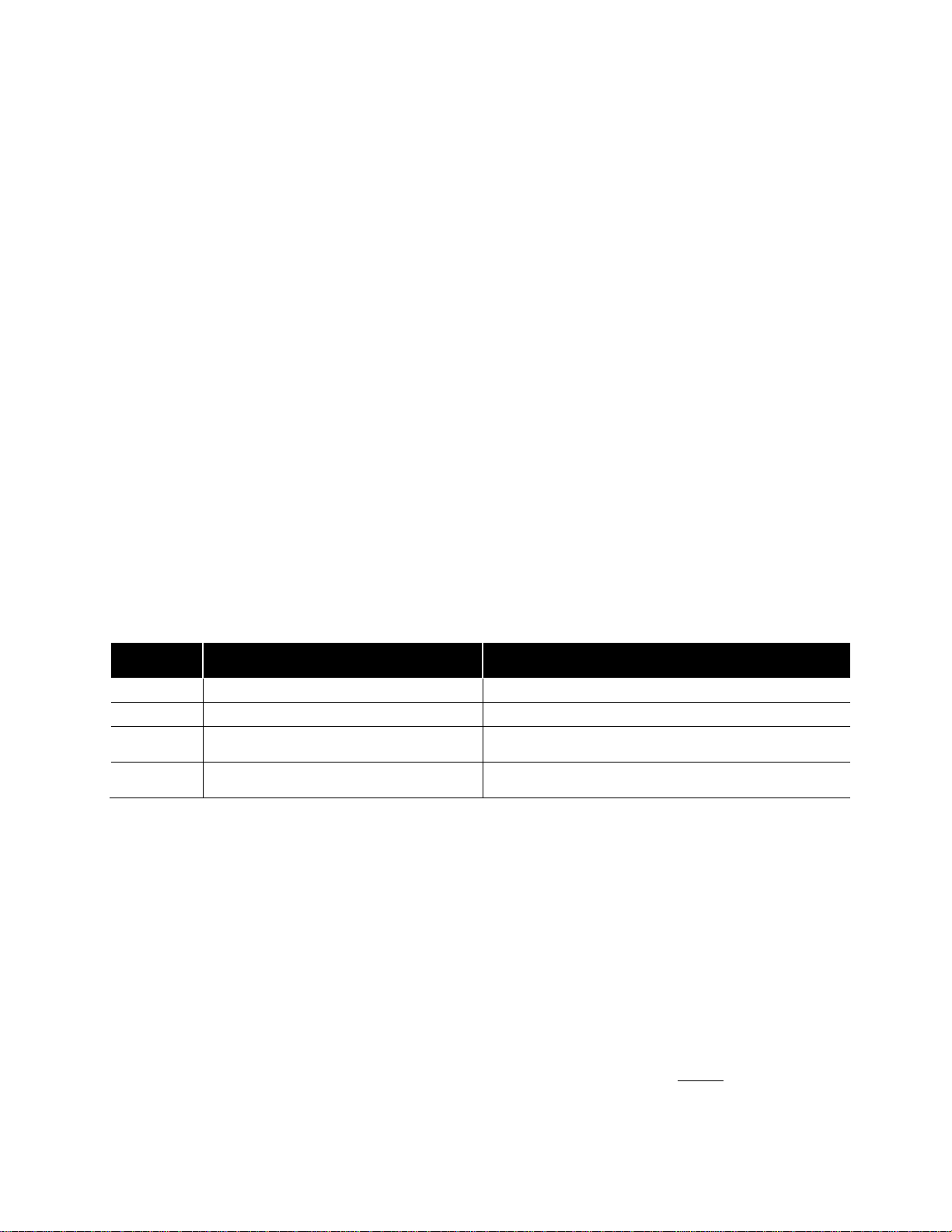

Part

Number

Required adapter board and terminals for Modbus

connections.

Required TTL converter for NHRS Modbus

connections.

Introduction

Many Nortec humidifiers feature control boards that include Modbus RTU and can connect to

Modbus networks right out of the box. This document describes how to connect these

humidifiers to such a network and defines the parameters that may be monitored.

Please note that there are differences between Modbus RTU and Modbus TCP. Nortec

humidifiers are Modbus RTU capable and require a gateway (by others) for Modbus TCP

networks. Contact the factory for more information on Modbus TCP communications.

Requirements

NH-EL Humidifiers are capable of Modbus RTU and require no additional hardware for this

connection.

Nortec humidifiers that feature that Total Controller (“TC”) control boards are also capable of

Modbus RTU. These include the NHTC, the GSTC, SETC, and MHTC humidifiers.

Additionally, the RH2 and MES-2 models feature a digital control board that supports Modbus,

however these models require an adapter board to provide the Modbus interface. Finally, the

NHRS also supports Modbus communications; however a TTL converter is required for this

functionality. Refer to following table for more information, items described as “optional” are

for convenience (but not required for Modbus), while items listed as required are needed for

Modbus functionality:

Table 1: Modbus Accessories

Kit Name Kit Description

2553787 NHTC, GSTC, SETC Modbus Connection Optional adapter cable for NHTC, GSTC, SETC.

2560630 MHTC Modbus Interface Optional terminal block for MHTC Modbus interface.

2531585 Modbus Option for OEM Digital Board

2560631 NHRS Modbus converter

Please consult your local Nortec representative to orders connection kits.

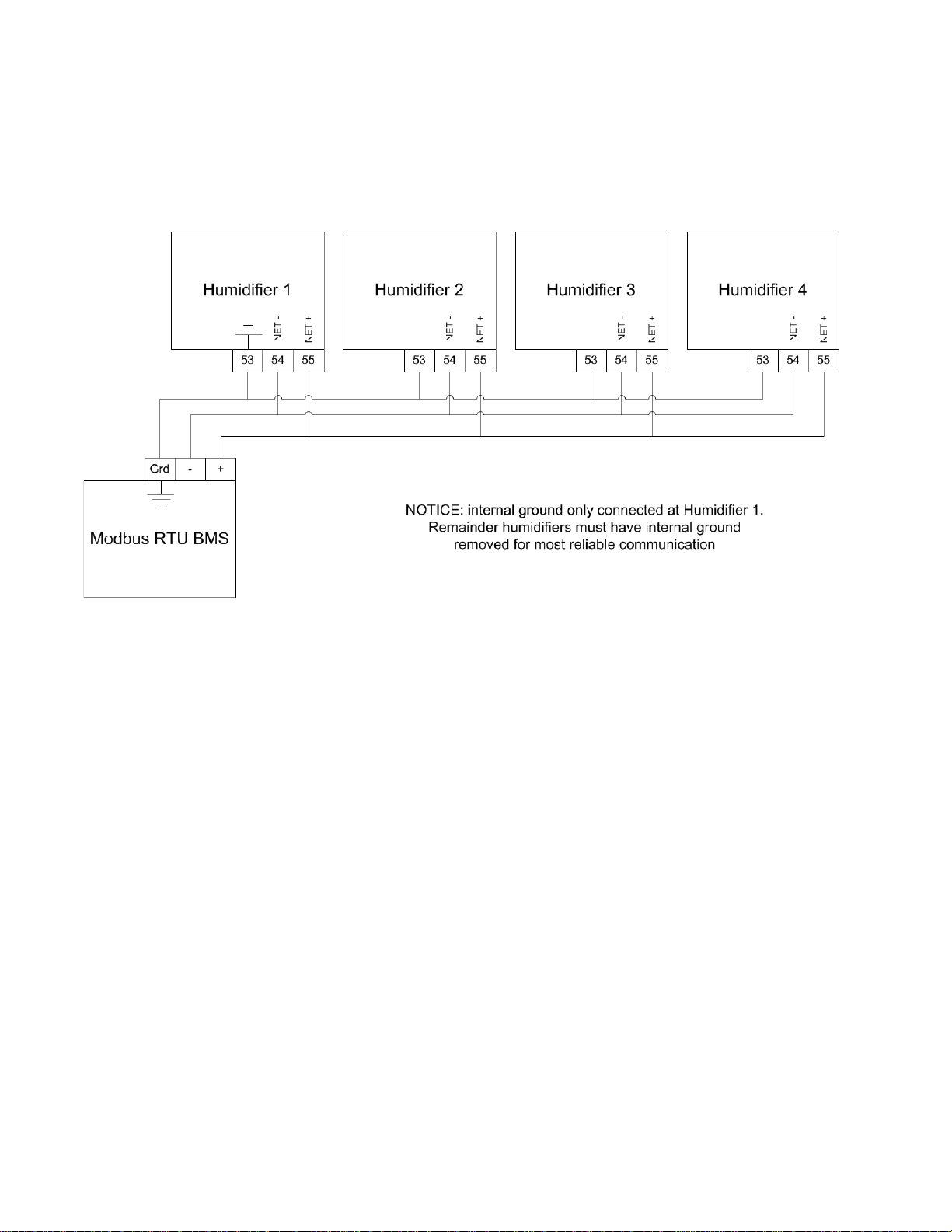

Wiring Connections

Using the correct wiring between the humidifier and the Modbus network is important to ensure

reliable communications and reduce the impact of electrical interference. The recommended

wire type is 18 -24 AWG, shielded twisted pair wire with 120 Ohm characteristic impedance. As

an alternative, CAT-5 (“Ethernet”) cable exceeds these specifications and may be used. In this

case, only two of the conductors and the wire shield will be used; care must be taken to isolate

any unused conductors.

Regardless of which wire type is used ensuring the correct shield terminations is necessary to

prevent electrical interference. The wire shield should be terminated at either the humidifier or

the Modbus system, but not both. This allows induced current to “drain”; if the shield is

terminated at both ends it will function as a conductor and can actually increase electrical

interference. To minimize signal loss a wire run should not exceed 2000 feet. Additionally, to

ensure communication reliability, it is recommended that no more than 8 humidifiers are

2 |Modbus Installation

Page 6

connected to a single chain/bus. The humidifiers should be the same type but do not need to

be the same capacity. For example it is not recommended to have an NHTC and a GSTC as part

of the same chain, but it is acceptable to have an NHTC-200 and an NHTC-30 as part of the

same chain. Connecting additional non-Nortec equipment into a Modbus chain is possible;

however it is important to ensure that all devices are operating with identical baud rate, parity,

and stop bits, and that each device has a unique Modbus address.

Figure 1: Example Daisy Chain Diagram for NH-EL, NHTC, GS, SE

Modbus Installation | 3

Page 7

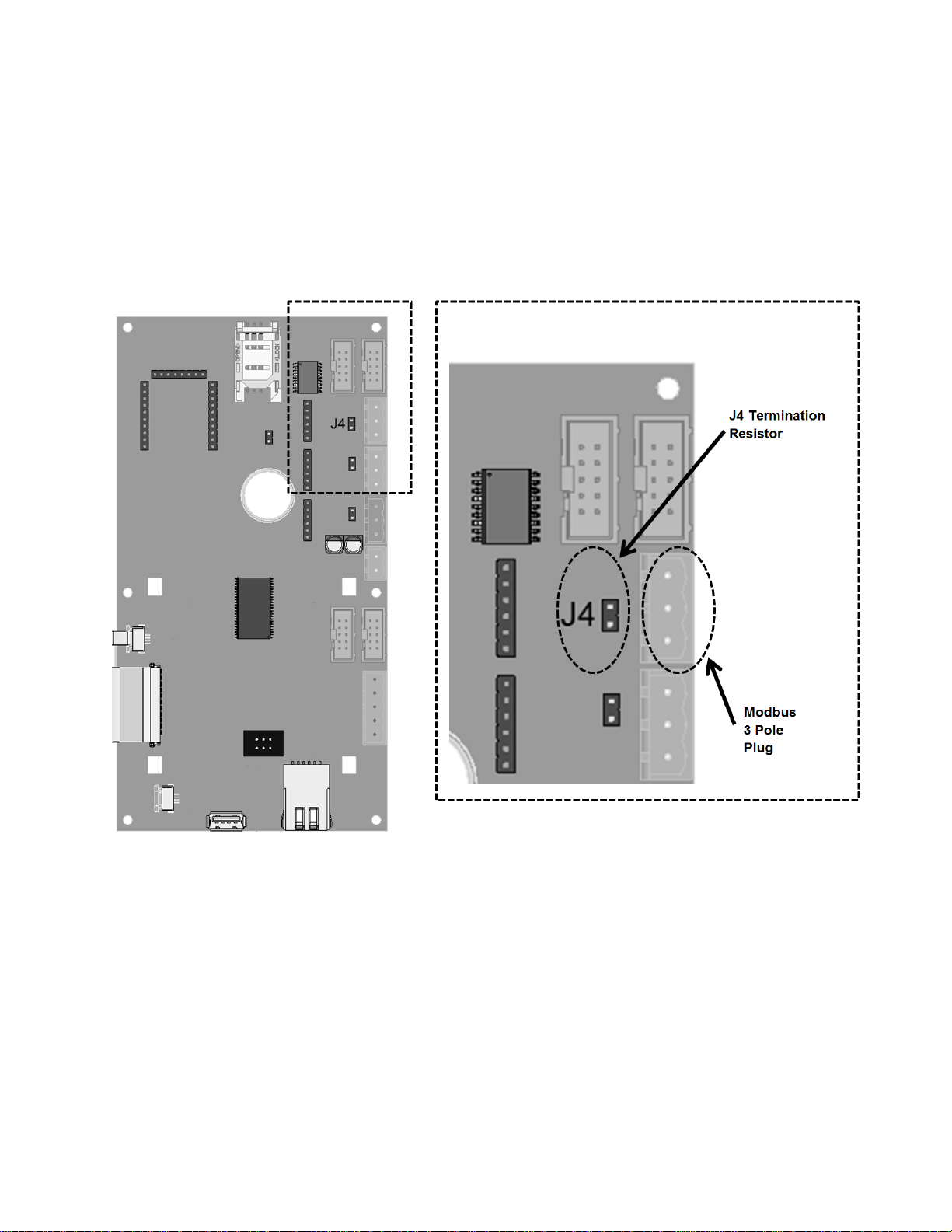

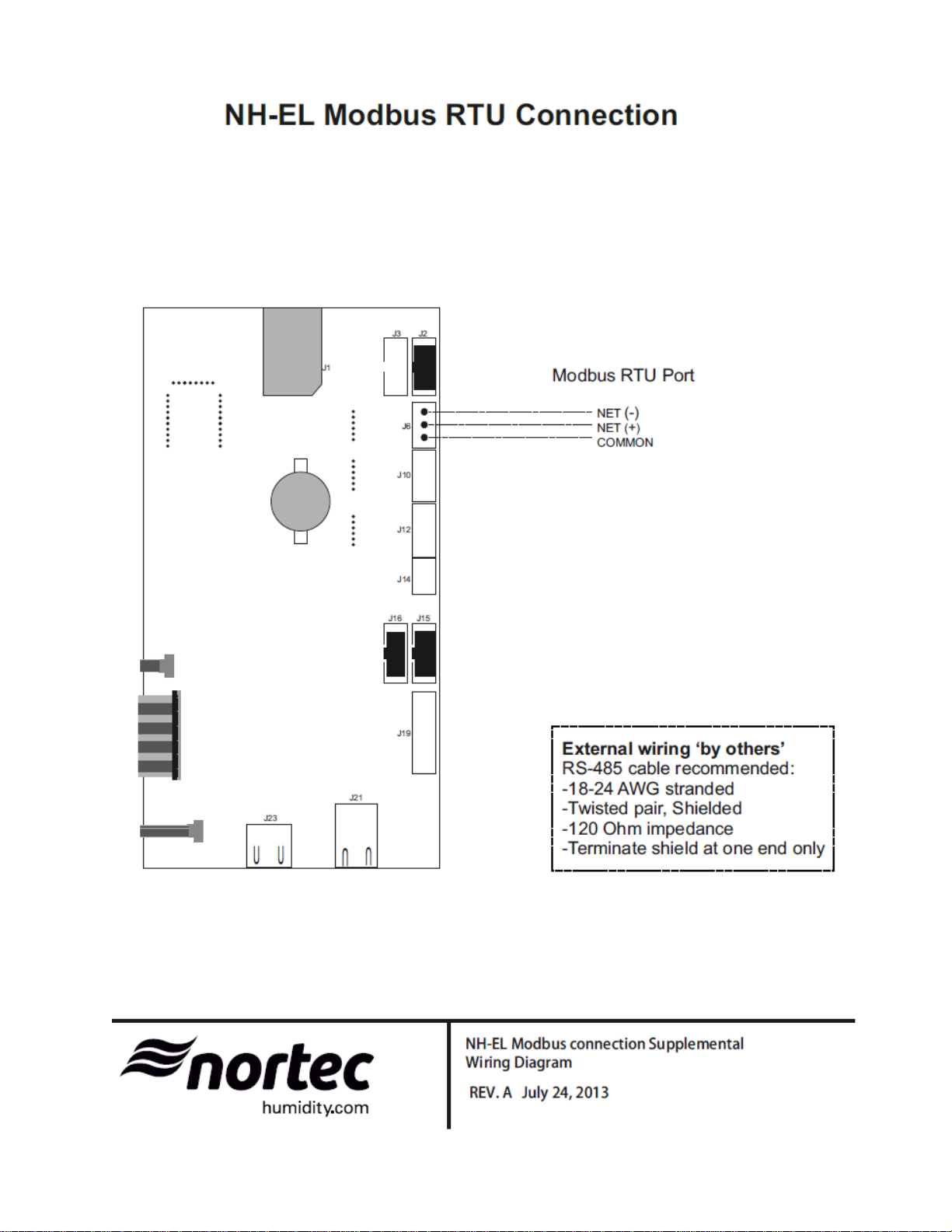

NH-EL Models

The NH-EL models use a 3 pole connector on the main processor card for Modbus connection.

This 3 pole connector is provided with all NH-EL and connections can be made directly to this

plug. Refer to Figure 2 and Figure 3 for connection location and wiring.

Please note: there is a 120 Ohm termination resistor available on board. When the jumper J4

is on, 120 Ohm is enabled. When the jumper J4 is off, 120 Ohm is disabled.

4 |Modbus Installation

Figure 2: NHEL Modbus 3 Pole Plug Location

Page 8

Note

NHTC, GSTC, SETC, and MHTC Models

The NHTC, GSTC, SETC, and MHTC models use a multifunction RJ45 plug on the mainboard to

provide Modbus communications. Connections can be made directly to this plug or,

alternatively, using one of accessories listed above.

Refer to figure 4 for information on the wiring connections for these units.

: This instruction manual covers the connections and points for the GSTC B+ and SETC B+

models only. Older models, manufactured pre-2009 do not include the RJ45 plug and require

an additional interface cable. Contact Nortec for information on connecting these units.

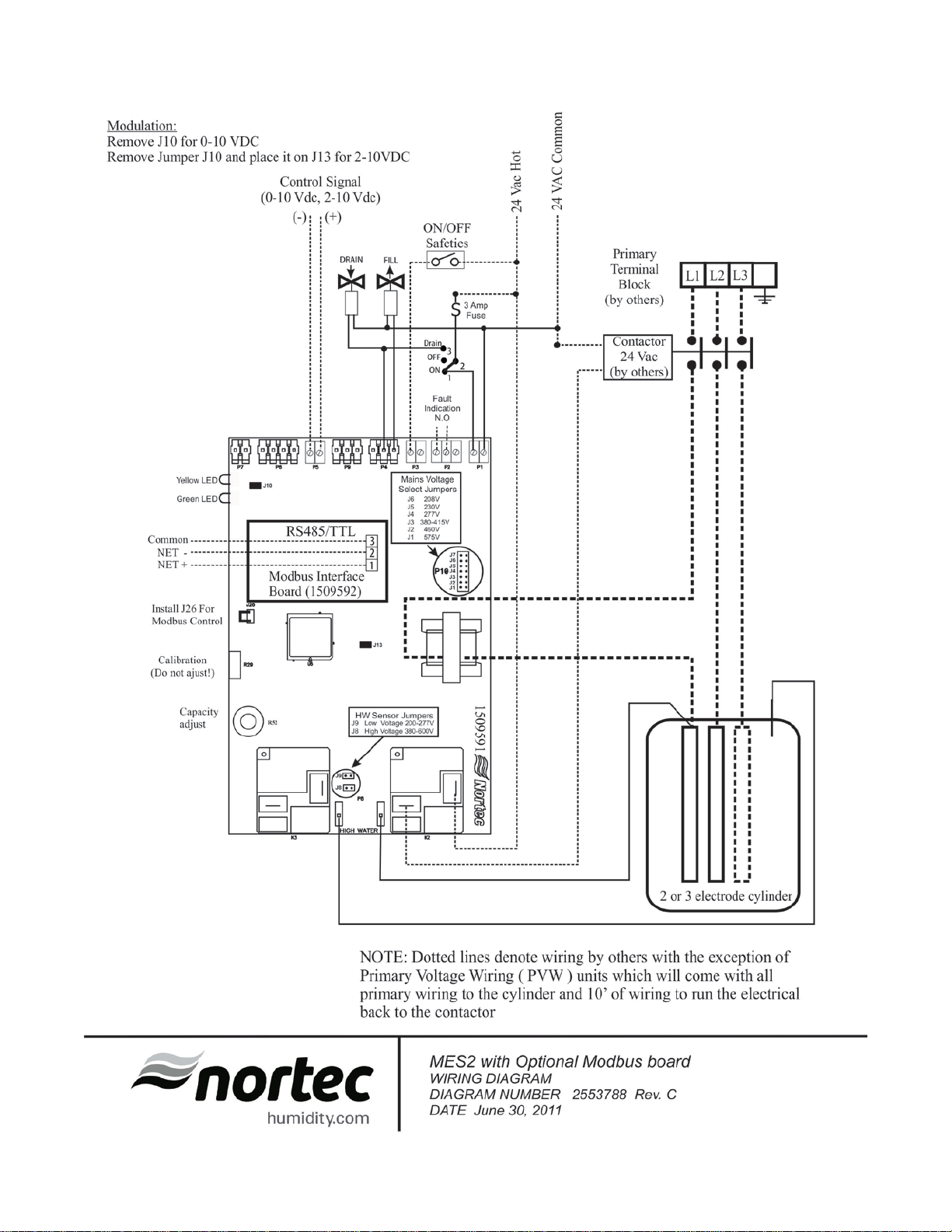

MES2 and RH2 Models

The MES2 and RH2 models require a Modbus support board to provide a connection point. This

board can be factory installed if indicated at time of order, or retrofit to existing units in the field.

Refer to Figure 5 for information on the wiring connections for these units.

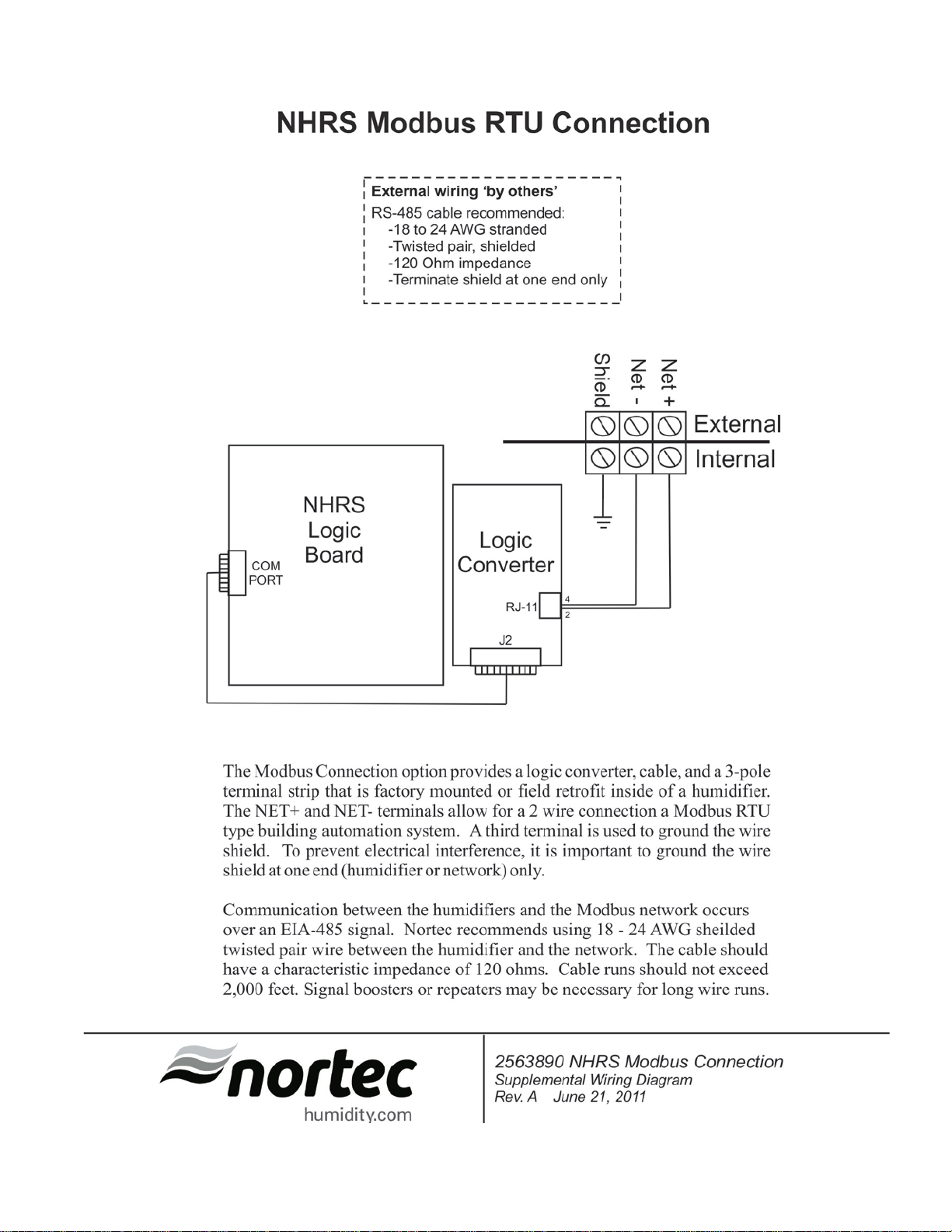

NHRS Models

The NHRS models require a Modbus kit to translate information from the processor board into

Modbus RTU information. This kit can be factory installed if specified at time of order or retrofit

to existing units in the field. Refer to figure 6 for information on the wiring connections for these

units.

Modbus Installation | 5

Page 9

6 |Modbus Installation

Figure 3: NH-EL Modbus Wiring Diagram

Page 10

Figure 4: TC Modbus Wiring Diagram

Modbus Installation | 7

Page 11

8 |Modbus Installation

Figure 5: MES2 and RH2 Modbus Wiring Diagram

Page 12

Figure 6: NHRS Modbus Wiring Diagram

Modbus Installation | 9

Page 13

Modbus Communication Set-up

1

2

3

4

5

Note: By default, Modbus is disabled. To enable Modbus, select

Modbus

under

Modbus

Parameters

. Select ON and confirm the selection by pressing the

Check Mark

button.

6

7

Addressing and Communications

Once the humidifier has been wired to the network, control variables must be mapped to allow

for control of the humidifier. The specific variables and communications requirements for each

humidifier are described in the following sections.

NH-EL Electrode Steam Humidifiers

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate either through the Modbus or BACnet interface.

The default Modbus address for an NH-EL is 10. If multiple units were included on an order, the

addresses of individual units may vary. To view or change the Modbus address:

Press the Menu icon on the lower left corner of the screen, to access the menu.

When prompted for a password, enter 0335 using the number pad. Press the Check Mark

icon to confirm.

Select the Configuration menu.

Select the Comms. menu.

Using the navigation buttons on the top right of the screen, scroll down to the Modbus

Parameters.

Select the Modbus Address setting. Using the Up and Down arrows, select a value between

1 and 247 inclusive as desired and press the Check Mark button to confirm the selection. It

is recommended to leave the parity and baud rate settings to their factory defaults (Even

and 9600 respectively) unless communication problems occur.

Press Back repeatedly until you return to the home screen.

This procedure is summarized below:

Main Menu > 0335 > Configuration > Comms. Menu > Modbus Parameters >

Addr: 10 (1 – 247 acceptable)

Parity: Even (None, Even, Odd)

Baud Rate: 9600 (9600, 19200, 38400, 115200)

10 |Modbus Installation

Page 14

Control Signal Setting

1

2

3

4

Note: Refer to the CONTROL SETTING section of the NH Series Installation and Operation

Manual for more information on the above settings.

5

Modbus Parameters

By default the humidifier is configured operate on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its Modbus or BACnet interface.

To adjust this setting:

Press the Menu icon on the lower left corner of the screen, to access the menu.

When prompted for a password, enter 0335 using the number pad. Press the Check Mark

icon to confirm.

Select the Configuration menu.

Select the Control Settings menu. The following settings can be adjusted:

Source

Control Mode

Control Channels

Analog: Use hardwired control signal

Modbus: Write control signal through Modbus interface

Demand: Use a demand control signal

RH P: Use a sensor value and proportional

RH PI: Use a sensor value and proportional-integral control band

Single: Use a signal channel control signal

Dual: Use a dual channel control signal

Press Check Mark to confirm choice and then Back repeatedly to return to the home screen

when complete.

This procedure is summarized below:

Main Menu > 0335 > Configuration > Control Settings >

Source: Analog, Modbus,

Control Mode: Demand, RH P, or RH PI

Control Channels: Single or Dual

The NH-EL uses the following parameters for Modbus communication:

Signaling Type EIA-485

Transmission Mode RTU

Baud Rate 9600

Data Bits 8

Stop Bits 1

Parity Even

Address / Unit Number 10*

*Default, may vary for multi-unit orders.

It is important to note that the signaling type, transmission mode, data bits and stop bits cannot

be modified. Parity, baud rate and unit address can be modified as required.

Modbus Installation | 11

Page 15

Parameter

Name

Description

Modbus

Addr.

Type

Format

Range

Unit

R/W

Details

Write RH or

cylinder A

Requires Modbus or

primary control signal

Requires Modbus or

operation mode

Requires Modbus or

enabled

Requires Modbus or

operation mode

Limits output to

only)

Limits output to

only)

BMS timeout

BACnet

It is recommend to not

the factory default (300)

Remotely disable

for the unit

Writes the

for cylinder A

Use only when sending

primary space setpoint

Writes the

for cylinder A

The following points may be mapped for control:

Dinput_A1

Dinput_A2

Dinput_B1

Dinput_B2

Manual_

Capcity_A

Demand signal

value to control

channel 1 for

Write RH or

Demand signal

value to control

channel 2 for

cylinder A

Write RH or

Demand signal

value to control

channel 1 for

cylinder B

Write RH or

Demand signal

value to control

channel 2 for

cylinder B

Sets a manual

capacity limit

restriction for

cylinder A

40005

40006

40010

40011

40002

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Integer 0 - 100 % Write

Integer 0 - 100 % Write

Integer 0 - 100 % Write

Integer 0 - 100 % Write

Integer 0 - 100 % Write

BACnet to be enabled.

For most common

configurations, this is the

BACnet to be enabled.

Only applies to NH-EL150 and NH-EL-200 with

cylinders in independent

BACnet to be enabled.

Only applies to NH-EL150 and NH-EL-200 with

dual channel control

BACnet to be enabled.

Only applies to NH-EL150 and NH-EL-200 with

cylinders dual channel

control enabled and

cylinders in independent

percentage of total

cylinder capacity for

cylinder A (NH-EL-150

and NH-EL-200 models

Manual_

Capcity_B

BMS_

Timeout

Remote_

Disable

SP_Chan_A

1

SP_Chan_A

2

Sets a manual

capacity limit

restriction for

cylinder B (if

present)

for Modbus and

steam production

desired space

setpoint for

control channel 1

desired space

setpoint for

control channel 2

40007

40013

40001

40003

40004

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Integer 0 - 100 % Write

Integer 0 - 300 s Write

Integer 0 or 1 - Write

Integer 0 - 95 % Write

Integer 10 - 95 % Write

percentage of total

cylinder capacity for

cylinder B (NH-EL-150

and NH-EL-200 models

change the value from

0 = Idle/Humidify

1 = Disable

RH values to Dinput_A1.

For most common

configurations this is the

Use only when sending

RH value to Dinput_A2

with dual channel control

enabled

12 |Modbus Installation

Page 16

Use only with NH-EL-

mode

Use only with NH-EL-

mode

0 = Analog

4 = LonWorks

1 = Demand

3 = RH PI

Selects method

channels

Displays channel 1

capacity for cylinder A

Displays channel 2

capacity for cylinder A

Displays channel 1

200 models only)

Displays channel 2

200 models only)

Reads the status

A

Reads the status

B

SP_Chan_B

1

SP_Chan_B

2

Signal_

Source

Control_

Mode

Control_

Channel

Writes the

desired space

setpoint for

control channel 1

for cylinder B

Writes the

desired space

setpoint for

control channel 2

for cylinder B

Selects signal

source to control

unit

Selects method

to control unit

to control

40008

40009

40014

40015

40016

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Integer 0 - 95 % Write

Integer 10 - 95 % Write

Integer 0 - 4 - Write

Integer 1 - 3 - Write

Integer 0 - 1 - Write

150 and NH-EL-200

models when sending

RH value to Dinput_B1

and cylinders are in

independent operation

150 and NH-EL-200

models when sending

RH value to Dinput_B2

with dual channel

control enabled and

cylinders are in

independent operation

1 = Modbus

2 = BACnet/IP

3 = BACnet/MS

2 = RH P

0 = Single Channel

1 = Dual Channel

Input_A1

Input_A2

Input_B1

Input_B2

Blower_

Pack_A

Blower_

Pack_B

Displays channel

1 demand for

cylinder A

Displays channel

2 demand for

cylinder A

Displays channel

1 demand for

cylinder B

Displays channel

2 demand for

cylinder B

of the blower

pack for cylinder

of the blower

pack for cylinder

30004

30005

30014

30015

30008

30018

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Integer 0 - 100 % Read

Integer 0 - 100 % Read

Integer 0 - 100 % Read

Integer 0 - 100 % Read

Integer 0 or 1 - Read

Integer 0 or 1 - Read

demand/sensed RH as

a percentage of cylinder

demand/sensed RH as

a percentage of cylinder

demand/sensed RH as

a percentage of cylinder

capacity for cylinder B

(NH-EL-150 and NH-EL-

demand/sensed RH as

a percentage of cylinder

capacity for cylinder B

(NH-EL-150 and NH-EL-

0 = Open

1 = Closed

0 = Open

1 = Closed

Fan_

Activate_A

Indicates if air

handle or

furnace is

activated for

cylinder A

30009

Input

Register

Integer 0 or 1 - Read

Modbus Installation | 13

0 = Not Activated

1 = Activated

Page 17

Indicates if air

cylinder B

Reads the status

unit

Reads the status

request on the unit

0 = No Service

1 = Service Required

0 = Humidifying

9 = Fault

0 = Humidifying

9 = Fault

Demand Mode:

PID calculation

Demand Mode:

PID calculation

Reads the status

for cylinder A

Reads the status

for cylinder B

Displays the total time

running since last reset

Displays the total time

running since last reset

Reads the

cylinder A

An equated run time

System_Demand_A

Reads the

cylinder B

An equated run time

System_Demand_A

Fan_

Activate_B

Do_Fault_

A

Do_

Service_A

Humidifier

_Status_A

Humidifier

_Status_B

handle or furnace

is activated for

of a fault on the

of a service

Reads the status

of the unit for

cylinder A

Reads the status

of the unit for

cylinder A

30019

30025

30024

30003

30026

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer 0 - 9 - Read

Integer 0 - 9 - Read

0 = Not Activated

1 = Activated

0 = No Fault

1 = Fault

Required

1 = Idle

2 = Idle Drain

3 = Keepwarm

4 = Filling

5 = Draining

6 = Disabled

7 = Safety Loop

8 = Warning

1 = Idle

2 = Idle Drain

3 = Keepwarm

4 = Filling

5 = Draining

6 = Disabled

7 = Safety Loop

8 = Warning

System_

Demand_A

System_

Demand_

B

Safety_

Loop_A

Safety_

Loop_B

Run_Time

_A

Run_Time

_B

Weighted_

Hours_A

Weighted_

Hours_B

Reads the demand

for cylinder A

Reads the demand

for cylinder A

of the safety loop

of the safety loop

Reads operating

time for cylinder A

Reads operating

time for cylinder B

weighted time for

weighted time for

30006

30016

30007

30017

30010

30020

30011

30021

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Integer 0 – 100 % Read

Integer 0 – 100 % Read

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer 0 - 5000 Hrs Read

Integer 0 - 5000 Hrs Read

Integer 0 - 5000 Hrs Read

Integer 0 - 5000 Hrs Read

Summation of Input_A1

and Input_A2

RH Mode:

Summation of Input_B1

and Input_B2

RH Mode:

0 = Open

1 = Closed

0 = Open

1 = Closed

cylinder A has been

cylinder B has been

based on Run_Time_A x

based on Run_Time_A x

14 |Modbus Installation

Page 18

Modbus Address

1

2

3

4

5

Note: Do NOT modify other settings in the Factory settings manual. Adjusting other settings

can cause serious damage to the humidifier.

6

7

NHTC Electrode Steam Humidifiers

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate through the Modbus interface.

The default Modbus address for an NHTC is 1. If multiple units were included on an order, the

addresses of individual units may vary. To view or change the unit number:

Press the Menu key to access the menu.

When prompted for a password, enter 0459 using the arrow keys. Press Set to confirm.

Select the Factory Settings menu and press the Set key.

Select the Core Parameters menu and press the Set key.

Select the Modbus Parameters menu and press the Set key.

Select the Address setting and press Set to modify. Enter a value between 1 and 127

inclusive as desired and press Set to confirm the solution. It is recommended to leave the

parity and timeout settings to their factory defaults (Even and 300 respectively) unless

communication problems occur.

Press Esc repeatedly until you return to the home screen.

This procedure is summarized below:

Menu > 0459 > Factory Settings > Core Parameters > Modbus Parameters >

Parity: Even

Addr: 1 (Default, 1 – 127 acceptable)

Timeout: 300 seconds (Default, 5 – 600 acceptable)

Modbus Installation | 15

Page 19

Control Signal Setting

1

2

3

Note: Refer to the CONTROL SETTING section of the NH Series Installation and Operation

Manual for more information on the above settings.

4

By default the humidifier operation is configured on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its Modbus interface.

To adjust this setting:

Press the Menu key to access the menu.

When prompted for a password, enter 0335 using the arrow keys. Confirm the password

with set.

Select the Control Settings menu and press the Set key. The following settings can be

adjusted:

Source

REG Mode

MOD Mode

CNT Type Setting not relevant when writing control signal through Modbus.

Analog: Use hardwired control signal

Digital: Write control signal through Modbus interface

Demand: Use a demand control signal

RHp: Use a sensor value and proportional

RHpi: Use a sensor value and proportional-integral control band

Single CH: Use a signal channel control signal

Dual CH: Use a dual channel control signal

Press Esc repeatedly to return to the home screen when complete.

This procedure is summarized below:

Menu > 0335 > Control Settings >

Source: Analog or Digital

Reg Mode: Demand, RHp, or RHpi

Mod Mode: Single CH or Dual CH

CNT Type: As required

16 |Modbus Installation

Page 20

Modbus Parameters

Address / Unit Number

1*

The NHTC uses the following parameters for communication:

Signaling Type EIA-485

Transmission Mode RTU

Baud Rate 9600

Data Bits 8

Stop Bits 1

Parity Even

*Default, may vary for multi-unit orders.

It is important to note that the signaling type, transmission mode, baud rate, data bits and stop

bits cannot be modified. Parity and unit address can be modified as required.

Modbus Installation | 17

Page 21

Variable Name

Description

Addr.

Type

Format

Range

Uni

t

R/W

Details

Sets a

cylinder 1.

Sets a

present).

Write RH or

cylinder 1

Write RH or

cylinder 2

Requires network controls

mode

Write RH or

cylinder 1

Requires network controls

mode

Writes the

cylinder 1

Writes the

cylinder 2

Use only with NHTC-150

mode

Writes the

cylinder 1

The following points may be mapped for control:

CapLimitCyl1

CapLimitCyl2

RHDemCyl1

RHDemCyl2

RHDem2Cyl1

manual

capacity

restriction for

manual

capacity

restriction for

cylinder 2 (if

Demand

signal value

to control

channel 1 for

Demand

signal value

to control

channel 1 for

Demand

signal value

to control

channel 2 for

40026

41026

40264

41264

40265

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Integer

Integer

Integer 0 - 100 % Write

Integer 0 - 100 % Write

Integer 0 - 100 % Write

50-

100

50-

100

% Write

% Write

Limits output to

percentage of total

cylinder capacity

Limits output to

percentage of total

cylinder capacity for

cylinder 2 (NHTC-150 and

NHTC-200 models only)

Requires network controls

(NetSensor = 1), for most

common configurations

this is the primary control

signal

(NetSensor = 1), only

applies to NHTC-150 and

NHTC-200 with cylinders

in independent operation

Requires network controls

(NetSensor = 1), only

applies to NHTC-150 and

NHTC-200 with dual

channel control enabled

RHDem2Cyl2

Set1Cyl1

Set1Cyl2

Set2Cyl1

Write RH or

Demand

signal value

to control

channel 2 for

cylinder 2

desired space

setpoint for

control

channel 1 for

desired space

setpoint for

control

channel 1 for

desired space

setpoint for

control

channel 2 for

41265

40024

41024

40010

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Integer 0 - 100 % Write

Integer 30-95 % Write

Integer 30-95 % Write

Integer 30-95 % Write

(NetSensor = 1), only

applies to NHTC-150 and

NHTC-200 with cylinders

dual channel control

enabled and cylinders in

independent operation

Use only when sending RH

value to RHDem1, for

most common

configurations this is the

primary space setpoint

and NHTC-200 models

when sending RH value to

RHDem1 and cylinders are

in independent operation

Use only when sending RH

value to RHDem2 with

dual channel control

enabled

18 |Modbus Installation

Page 22

Use only with NHTC-150

mode

Remotely

cylinder 1

Used only for NHTC-150

255 = Disabled

Switches

control signal

Displays

cylinder 1

Displays channel 1

cylinder 1

Displays channel 1

200 models only)

Displays

cylinder 1

Displays channel 2

cylinder 1

Displays channel 2

200 models only)

Reads fault

status

Input

Register

0 or

255

0 = No Fault

255 = Fault Warning

Reads service

status

0 = Idle / Standby

Humidifying

Reads operating time for

hours = (Value x 5)/60

Writes the

desired space

Set2Cyl2

DisableCyl1

DisableCyl2

NetSensor

setpoint for

control

channel 2 for

cylinder 2

disable steam

production for

Remotely

disable steam

production for

cylinder 2

between hard

wired or

network

41010

40262

41262

40226

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Integer 30-95 % Write

Integer

Integer

Integer 0 or 1 - Write

0 or

255

0 or

255

- Write

- Write

and NHTC-200 models

when sending RH value to

RHDem2 with dual

channel control enabled

and cylinders are in

independent operation

0 = Normal operation

255 = Disabled

and NHTC-200 models.

Both cylinder 1 and 2

must be disabled to

completely disable

humidifier.

0 = Normal operation

1= Network sensor or

demand

0 = Wired sensor or wired

demand

Ch1DemCyl1

Ch1DemCyl2

Ch2DemCyl1

Ch2DemCyl2

Fault Warning

Service Warning

channel 1

demand for

Displays

channel 1

demand for

cylinder 2

channel 2

demand for

Displays

channel 2

demand for

cylinder 2

warning

30348

31348

30349

31349

30301

30300

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Integer

Integer

Integer

Integer

Integer

Integer

0 -

100

0 -

100

0 -

100

0 -

100

0 or

255

% Read

% Read

% Read

% Read

- Read

- Read

demand as a percentage

of cylinder capacity for

demand / output as a

percentage of cylinder

capacity for cylinder 2

(NHTC-150 and NHTC-

demand as a percentage

of cylinder capacity for

demand / output as a

percentage of cylinder

capacity for cylinder 2

(NHTC-150 and NHTC-

0 = No Service Warning

255 = Service Warning

Unit Status

Cyl1OpTime

Reads unit

status

Reads

operating

time for

cylinder 1

30312

30213

Input

Register

Input

Register

Integer

Integer

0 or

255

0 -

65535 5 min

- Read

255 = Active /

cylinder 1. Each number

Read

Modbus Installation | 19

is equivalent to 5 minutes

of operation. Time in

Page 23

Reads operating time

5)/60

11 = Security loop open

run for 72hrs

Unit will not run until

fault

Displays the

cylinders)

Cyl2OpTime

UnitStatus

Reads

operating

time for

cylinder 2

Displays

status

warnings

31213

31385

Input

Register

Input

Register

0 -

Integer

Integer 0-99 - Read

6553

5

5

min

Read

for cylinder 2 (NHTC150 and NHTC-200

only). Each number is

equivalent to 5 minutes

of operation.

Time in hours = (Value x

19 = Cylinder spent

warning

If status 19, unit will

have yellow service light

on and will continue to

CylSpent

SysTotalDem

Displays

cylinder end

of life fault

total demand

on system

(sum both

30378

30251

Input

Register

Input

Register

Integer 0-99 - Read

Integer

0 -

100

% Read

cylinder is replaced

19 = Cylinder spend

Sum of Steam Output

Cyl-1 and Cyl-2 in

percentage

20 |Modbus Installation

Page 24

Modbus Address

1

2

3

4

5

6

Control Signal Setting

GSTC Gas Fired Steam Humidifiers

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate through the Modbus interface.

The default Modbus address for a GSTC is 1. If multiple units were included on an order, the

addresses of individual units may vary.

To view or change the unit number:

Press the Menu key to access the menu.

When prompted for a password, enter 0335 using the arrow keys. Press Set to confirm.

Select the Control Settings menu and press the Set key.

Select the Modbus Parameters menu and press the Set key.

Select the Address setting and press Set to modify. Enter a value between 1 and 127

inclusive as desired and press Set to confirm the solution. It is recommended to leave the

parity and timeout settings to their factory defaults (None1 and 300 respectively) unless

communication problems occur.

Press Esc repeatedly until you return to the home screen.

This procedure is summarized below:

Menu > 0335 > Control Settings > Modbus Parameters >

Parity: None1

Addr: 1 (Default, 1 – 127 acceptable)

Timeout: 300 seconds (Default, 5 – 600 acceptable)

By default the humidifier is configured operate on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its Modbus interface.

Modbus Installation | 21

Page 25

1

2

3

Note: Refer to the

GSTC Total Controller Flow Chart

section of the GS Series Installation and

Operation Manual for more information on the above settings.

4

Modbus Parameters

Signaling Type

EIA-485

Transmission Mode

RTU

Baud Rate

9600

Data Bits

8

Stop Bits

1

Parity

None

Address / Unit Number

1*

To adjust this setting:

Press the Menu key to access the menu.

When prompted for a password, enter 0335 using the arrow keys. Confirm the password

with set.

Select the Control Settings menu and press the Set key. The following settings can be

adjusted:

Source:

REG Mode:

MOD Mode:

CNT Type: Setting not relevant when writing control signal through modbus.

Analog: Use hardwired control signal

Digital: Write control signal through modbus interface

Demand: Use a demand control signal

RHp: Use a sensor value and proportional

RHpi: Use a sensor value and proportional-integral control band

Single CH: Use a signal channel control signal

Dual CH: Use a dual channel control signal

Press Esc repeatedly to return to the home screen when complete.

This procedure is summarized below:

Menu > 0335 > Control Settings >

Source: Analog or Digital

Reg Mode: Demand, RHp, or RHpi

Mod Mode: Single CH or Dual CH

CNT Type: As required

The GSTC uses the following parameters for communication:

*Default, may vary for multi-unit orders.

It is important to note that the signaling type, transmission mode, baud rate, data bits and stop

bits cannot be modified. Parity and unit address can be modified as required.

22 |Modbus Installation

Page 26

Variable

Name

Description

Addr

Type

Format

Range

Unit

R/W

Additional Details

Write RH or

channel 1

Write RH or

channel 2

Writes the

control channel 1

Writes the

control channel 2

Remotely

humidifier

0 = Demand Signal

Integral Control)

0 = Hard wired

value

Read RH or

1

Read RH or

2

Read space

control channel 1

Read space

control channel 2

Confirms remote

disable status

Input

Register

0 = Run

255 = Disable

The following points may be mapped for control:

RHDem1

RhDem2

Set1

Set2

Disable

InputType

Demand signal

value to control

Demand signal

value to control

desired space

setpoint for

desired space

setpoint for

disables the

Selects the

control type that

the humidifier

operates on

40264

40265

40024

40025

40262

40007

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Analog 0-100 % Write

Analog 0-100 % Write

Analog 30-95 % Write

Analog 30-95 % Write

Analog 0, 255 - Write

Analog

0,1,2,3

,

- Write

Requires network

controls

(NetSensor = 1)

Requires network

controls

(NetSensor = 1)

Use only when

sending RH value

to RHDem1

Use only when

sending RH value

to RHDem2

0 = Run

255 = Disable

1 = On/Off Signal

2 = RH Sensor

Value (Use

Proportional

Control)

3 = RH Sensor

Value (Use

Proportional-

NetSensor

RHDem1

RHDem2

Set1

Set2

Disable

Switches

between hard

wired or network

control signal

Demand signal

value from

control Channel

Demand signal

value from

control Channel

setpoint for

setpoint for

40226

30348

30349

40024

40025

30989

Holding

Register

Input

Register

Input

Register

Input

Register

Input

Register

Binary 0,1 - Write

Analog 0-100 % Read

Analog 0-100 % Read

Analog 30-95 % Read

Analog 30-95 % Read

Analog 0, 255 - Read

control signal

1 = Use Modbus to

write control signal

Displays signal

value as a

percentage

Displays signal

value as a

percentage

Only available for

InputType 2 or 3

Only available for

InputType 2 or 3

Modbus Installation | 23

Page 27

0 = Demand Signal

Integral Control)

0 = Hard wired

value

Read fault

status

Input

Register

0 = No Fault

1 = Fault Detected

0 = No Service

Required

Read

status

0 = Idle / Standby

Humidifying

0 = Communication

Communication

Read

hours of unit

Read

at humidifier)

Read 3 day

at humidifier)

SysDemand

Read system

demand

Displays output as

capacity

Read hours

service

Displays hours

next service.

Displays the status

1 = Closed

InputType

Confirms the

control type

that the

humidifier

operates on

40007

Input

Register

Analog 0,1,2,3 - Read

1 = On/Off Signal

2 = RH Sensor

Value (Use

Proportional

Control)

3 = RH Sensor

Value (Use

Proportional-

Confirms the

NetSensor

Fault

Service

Status

Connection

HourOpt

KeepWarm

system control

type

Read service

warning status

humidification

Read

connection

status

operational

keepwarm

option status

(enable/disable

40226

30301

30300

30302

40267

30350

30356

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Binary 0,1 - Read

Binary 0,1 - Read

Binary 0,1 - Read

Binary 0,1 - Read

Binary 0,1 - Read

Analog

Analog 0,1 - Read

0 -

Infinity

hrs Read

control signal

1 = Use Modbus to

write control signal

Warning

1 = Service

1 = Active /

Error

1 = Normal

Displays hours of

operation.

Bit0 - KEEPWARM

0 = Disabled

1 = Enabled

3DayDrain

ServHours

SecurityLoop

24 |Modbus Installation

drain option

status

(enable/disable

output /

before next

Displays status

of security loop.

30356

30347

30352

30364

Input

Register

Input

Register

Input

Register

Input

Register

Analog 0,1 - Read

Analog 0-100 % Read

Analog 500-0 hrs Read

Analog 0,1 - Read

Bit1 - 3 DAY DRAIN

0 = Disabled

1 = Enabled

percentage of

remaining until

of the security loop

on terminals 1 and

2. Loop must be

"closed" for

humidifier to

operate.

0 = Open

Page 28

Modbus Address

1

2

3

4

5

6

SETC Steam Exchange Humidifiers

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate through the Modbus interface.

The default Modbus address for a SETC is 1. If multiple units were included on an order, the

addresses of individual units may vary.

To view or change the unit number:

Press the Menu key to access the menu.

When prompted for a password, enter 0335 using the arrow keys. Press Set to confirm.

Select the Control Settings menu and press the Set key.

Select the Modbus Parameters menu and press the Set key.

Select the Address setting and press Set to modify. Enter a value between 1 and 127

inclusive as desired and press Set to confirm the solution. It is recommended to leave the

parity and timeout settings to their factory defaults (None1 and 300 respectively) unless

communication problems occur.

Press Esc repeatedly until you return to the home screen.

This procedure is summarized below:

Menu > 0335 > Control Settings > Modbus Parameters >

Parity: None1

Addr: 1 (Default, 1 – 127 acceptable)

Timeout: 300 seconds (Default, 5 – 600 acceptable)

Modbus Installation | 25

Page 29

Control Signal Setting

1

2

3

Note: Refer to the

SETC Humidifier Configuration

section of the SE Series Installation and

Operation Manual for more information on the above settings.

1

Modbus Parameters

Signaling Type

EIA-485

Transmission Mode

RTU

Baud Rate

9600

Data Bits

8

Stop Bits

1

Parity

None

Address / Unit Number

1*

By default the humidifier is configured operate on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its Modbus interface.

To adjust this setting:

Press the Menu key to access the menu.

When prompted for a password, enter 0335 using the arrow keys. Confirm the password

with set.

Select the Control Settings menu and press the Set key. The following settings can be

adjusted:

Source

REG Mode

MOD Mode

CNT Type Setting not relevant when writing control signal through Modbus.

Analog: Use hardwired control signal

Digital: Write control signal through Modbus interface

Demand: Use a demand control signal

RHp: Use a sensor value and proportional

RHpi: Use a sensor value and proportional-integral control band

Single CH: Use a signal channel control signal

Dual CH: Use a dual channel control signal

Press Esc repeatedly to return to the home screen when complete.

This procedure is summarized below:

Menu > 0335 > Control Settings >

Source: Analog or Digital

Reg Mode: Demand, RHp, or RHpi

Mod Mode: Single CH or Dual CH

CNT Type: As required

The SETC uses the following parameters for communication:

*Default, may vary for multi-unit orders.

It is important to note that the signaling type, transmission mode, baud rate, data bits and stop

bits cannot be modified. Parity and unit address can be modified as required.

26 |Modbus Installation

Page 30

Variable

Name

Description

Addr

Type

Format

Range

Unit

R/W

Additional Details

Write RH or

channel 1

Write RH or

channel 2

Writes the desired

control channel 1

Writes the desired

control channel 2

Remotely disables

the humidifier

Holding

Register

0 = Run

255 = Disable

0 = Demand Signal

Control)

Switches between

signal

0 = Hard wired control

control signal value

Read RH or

Channel 1

Read RH or

Channel 2

Read space

channel 1

Read space

channel 2

Confirms remote

disable status

Input

Register

0 = Run

255 = Disable

0 = Demand Signal

Control)

The following points may be mapped for control:

RHDem1

RhDem2

Set1

Set2

Disable

InputType

NetSensor

Demand signal

value to control

Demand signal

value to control

space setpoint for

space setpoint for

Selects the control

type that the

humidifier

operates on

hard wired or

network control

40264

40265

40024

40025

40262

40007

40226

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Analog 0-100 % Write

Analog 0-100 % Write

Analog 30-95 % Write

Analog 30-95 % Write

Analog 0, 255 - Write

Analog 0,1,2,3 - Write

Binary 0,1 - Write

Requires network controls

(NetSensor = 1)

Requires network controls

(NetSensor = 1)

Use only when sending RH

value to RHDem1

Use only when sending RH

value to RHDem2

1 = On/Off Signal

2 = RH Sensor Value (Use

Proportional Control)

3 = RH Sensor Value (Use

Proportional-Integral

signal

1 = Use Modbus to write

RHDem1

RHDem2

Set1

Set2

Disable

InputType

Demand signal

value from control

Demand signal

value from control

setpoint for control

setpoint for control

Confirms the

control type that

the humidifier

operates on

30348

30349

40024

40025

30989

40007

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Analog 0-100 % Read

Analog 0-100 % Read

Analog 30-95 % Read

Analog 30-95 % Read

Analog 0, 255 - Read

Analog 0,1,2,3 - Read

Displays signal value as a

percentage

Displays signal value as a

percentage

Only available for InputType

2 or 3

Only available for InputType

2 or 3

1 = On/Off Signal

2 = RH Sensor Value (Use

Proportional Control)

3 = RH Sensor Value (Use

Proportional-Integral

Modbus Installation | 27

Page 31

0 = Hard wired control

control signal value

Input

Register

0 = No Fault

1 = Fault Detected

Read service

warning status

Input

Register

0 = No Service Warning

1 = Service Required

Read

status

0 = Communication Error

Communication

Read operational

hours of unit

Input

Register

0 -

Infinity

Displays hours of

operation.

Read keepwarm

humidifier)

Read 3 day drain

humidifier)

SysDemand

Read system

output / demand

Input

Register

Displays output as

percentage of capacity

Read hours before

next service

Input

Register

Displays hours remaining

until next service.

Displays the status of the

1 = Closed

Confirms the

NetSensor

Fault Read fault status 30301

Service

Status

Connection

HourOpt

KeepWarm

3DayDrain

system control

type

humidification

Read connection

status

option status

(enable/disable at

option status

(enable/disable at

40226

30300

30302

40267

30350

30356

30356

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Binary 0,1 - Read

Binary 0,1 - Read

Binary 0,1 - Read

Binary 0,1 - Read

Binary 0,1 - Read

Analog

Analog 0,1 - Read

Analog 0,1 - Read

hrs Read

signal

1 = Use Modbus to write

0 = Idle / Standby

1 = Active / Humidifying

1 = Normal

Bit0 - KEEPWARM

0 = Disabled

1 = Enabled

Bit1 - 3 DAY DRAIN

0 = Disabled

1 = Enabled

ServHours

SecurityLoop

Displays status of

security loop.

30347

30352

30364

Input

Register

Analog 0-100 % Read

Analog 500-0 hrs Read

Analog 0,1 - Read

security loop on terminals

1 and 2. Loop must be

"closed" for humidifier to

operate.

0 = Open

28 |Modbus Installation

Page 32

Modbus Address

1

2

3

4

5

6

7

MHTC Evaporative Media Humidifiers

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate through the Modbus interface.

The default Modbus address for a MHTC is 1. If multiple units were included on an order, the

addresses of individual units may vary.

To view or change the unit number:

Press the Menu key to access the menu.

Select the User option and press Set.

When prompted for a password, enter 8808 using the arrow keys. Press Set to confirm.

Select the Settings menu and press the Set key.

Select the Modbus menu and press the Set key.

Select the Address setting and press Set to modify. Enter a value between 1 and 127

inclusive as desired and press Set to confirm the solution. It is recommended to leave the

parity and timeout settings to their factory defaults (None1 and 300 respectively) unless

communication problems occur.

Press Esc repeatedly until you return to the home screen.

This procedure is summarized below:

Menu > User > 8808 > Modbus >

Parity: None1

Addr: 1 (Default, 1 – 127 acceptable)

Timeout: 300 seconds (Default, 5 – 600 acceptable)

Modbus Installation | 29

Page 33

Control Signal Setting

1

2

3

4

Note: Refer to the

MHTC Humidifier Configuration

section of the MH Series Installation and

Operation Manual for more information on the above settings.

1

By default the humidifier is configured operate on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its Modbus interface.

To adjust this setting:

Press the Menu key to access the menu.

Select the User options and press Set.

When prompted for a password, enter 8808 using the arrow keys. Confirm the password

with set.

Select the Controls menu and press the Set key. The following settings can be adjusted:

Signal Source

Hum. Control

Control Sign Setting not relevant when writing control signal through Modbus.

Analog: Use hardwired control signal

Modbus: Write control signal through Modbus interface

External: Use a demand control signal

Int(p): Use a sensor value and proportional

int(pi): Use a sensor value and proportional-integral control band

Press Esc repeatedly to return to the home screen when complete.

This procedure is summarized below:

Menu > User > 8808 > Controls >

Signal Source: Analog or Modbus

Hum. Control: External, Int(p), or Int(pi)

Control Sign: As required

30 |Modbus Installation

Page 34

Modbus Parameters

Signaling Type

EIA-485

Transmission Mode

RTU

Baud Rate

9600 (cannot be changed)

Data Bits

8

Stop Bits

1

Parity

None

Address / Unit Number

1*

Variable

Name

Description

Addr

Type

Format

Range

Unit

R/W

Details

Writes a control

error.

Reads/Writes

setpoint

Used when

0 = Allow normal

humidifier

0 = Demand Signal

method)

The MHTC uses the following parameters for communication:

*Default, may vary for multi-unit orders.

It is important to note that the signaling type, transmission mode, baud rate, data bits and stop

bits cannot be modified. Parity and unit address can be modified as required.

The following points may be mapped for control:

CapLimit

RHDem1

Set1

Disable

Manual

Capacity Limit

Reads/writes

a control

signal to the

humidifier

the desired

space

Remotely

disables

humidifier

40008

40053

40005

40052

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Integer

Integer

Integer

Integer 0 or 1 - Write

30 100

0 -

100

10 -

90

% Write Limits unit output.

% Write

% Write

signal to the

humidifier. This input

only works if

humidifier is set to

network control

NetSensor set to 1)

in the control

settings. If the

system is set to

network control no

signal is detected,

the unit will display

the modbus timeout

Hum_Control = 2 or

3 only

humidifier operation

1 = Remotely

disables the

Selects the

Hum_Contr

ol

control type

that the

humidifier

operates on

40003

Holding

Register

Integer 0 - 3 - Write

1 = On/Off Signal

2 = RH Sensor Value

(Use Proportional

control method)

3 = RH Sensor Value

(Use ProportionalIntegral control

Modbus Installation | 31

Page 35

Switches

control signal

Indicates

stage 1

Indicates

stage 2

Indicates

stage 3

Indicates

status

Indicates

requirement

0 = No service

1 = Service required

Indicates fault

status

Input

Register

0 = No error

1 = Error(s) detected

Indicates

cycle status

Indicates

status

Displays

hours

Displays UV

hours

Displays unit

hours

Indicates

and 2)

Humidifier will only

1 = On

0 = Tank below full

1 = Tank full

Indicates

stages

NetSensor

Stage1Dem

Stage2Dem

Stage3Dem

Warning

Service

Fault

between hard

wired or

network

output from

humidifier

output from

humidifier

output from

humidifier

warning

maintenance

40002

30025

30026

30027

30015

30016

30017

Holding

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Integer 0 or 1 - Write

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer 0 or 1 - Read

0 = Wired Analog

Sensor/Demand

1 = Modbus/Remote

Sensor/Demand

0 = Inactive

1 = Active

0 = Inactive

1 = Active

0 = Inactive

1 = Active

0 = No warning

1 = Warning

required

Cleaning

TankDrain

PumpRunHr

UVRunHr

ServTime

Security

TankLevel

automatic

stage cleaning

automatic

tank drain

pump

operational

lamp

operational

operational

security loop

status

(humidifier

terminals 1

Max Level

Sensor

30018

30019

30100

30101

30102

30200

30202

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Input

Register

Integer 0 or 1 - Read

Integer 0 or 1 - Read

Integer

Integer

Integer

Integer 0 or 1 - Read

Integer 0 or 1 - Read

0 -

65535

0 -

65535

0 -

65535

10

min

10

min

10

min

Read

Read

Read

0 = Inactive

1 = Active

0 = Inactive

1 = Active

1Bit = 10min (max.

10’922h)

1Bit = 10min (max.

10’922h)

1Bit = 10min (max.

10’922h)

operate when

security loop is

closed.

0 = Off

level

System

Ready

32 |Modbus Installation

when the

humidifier is

ready to

commence

30013

Input

Register

Integer 0 or 1 - Read

0 = System busy

(cleaning or draining)

1 = System ready to

Humidify

Page 36

1

2

3

Jumper Position

Function

J26 Removed

Terminal strip control

J26 Installed

Modbus control

Signaling Type

EIA-485

Transmission Mode

RTU

Baud Rate

9600 (can be changed to 4800 bps or 19200 bps)

Data Bits

8

Stop Bits

1

Parity

Even

Address / Unit Number

1*

MES2 and RH2 Models

The default Modbus address for a humidifier is 1.

To view or change the unit number:

Establish Modbus communications and map desired points as indicated in the following

table.

Read the current Modbus address from variable 40201.

Change this address by writing the desired value to 40201. Values of 1 – 255 are

acceptable.

By default the MES2 and RH2 are configured operate on a control signal supplied through the

unit terminal strip. This can be changed to allow the humidifier to function entirely through its

Modbus interface. This is configured by removed Jumper 26 from the humidifier circuit board.

MES2 and RH2 Electrode Steam OEM Humidifiers

The MES2 and RH2 both use the following parameters for communication:

*Default, may vary for multi-unit orders.

Modbus Installation | 33

Page 37

Variable

Name

Description

Addr

Type

Format

Range

Unit

R/W

Details

0 = Disable operation of

Notes:

-

255 is written.

Imposes a

capacity.

0 = Normal operation

Notes:

normal operation.

Writes a

humidifier.

Default = 1. Values of 1 -

power cycled.

The following points may be mapped for control:

Configures

how

HumEnable

humidifier

responds to

modbus

controls

40003

Holding

Register

Integer 0,255 - Write

humidifier (Default Value)

255 = Allow operation of

humidifier within limits

specified by CapLimit

If a valid Modbus

message is not received

within the timeout

windows, this parameter

reverts to 0.

- This value cannot be set

when the FORCE DRAIN is

activated as. FORCE

DRAIN temporarily sets

this to value 0.

- Jumper J26 must be

installed to write any

parameter over the

Modbus. J26 sets it into

the control mode.

- Opening of the

hardwired security loop

(terminals 1 and 2) will

override operation even if

CapLimit

ForceDrain

ModAddress

maximum

output limit

as

percentage

of unit

Manually

initiates a

drain

period.

new

Modbus

address for

the

40004

40005

40201

Holding

Register

Holding

Register

Holding

Register

Integer

Integer 0, 255 - Write

Integer 1-255 - Write

25 100

% Write

Values outside of 25 100% return an error.

Default on startup = 25.

(Default)

255 = Initiate a 20

minute timer during which

the drain is active.

- During a force drain,

humidification ceases.

- Writing 0 during 20

minute period will cancel

the drain.

- After 20 minutes this

value will revert to 0 and

the humidifier will resume

255 are acceptable.

Changes to this variable

do not take effect until

the humidifier has been

34 |Modbus Installation

Page 38

Changes to this variable

2 = 19200 bps

Changes to this variable

2 = Odd parity

Allows the

e.

Requires that HumEnable

operation is complete.

Switches

units.

Value represents

written as 5. (Default = 8)

Reads the jumper (J1 thru

installed)

0 = Single phase

2 = 3 phase (6 electrode)

do not take effect until

Baud

Parity

Sets the

Modbus

baud rate

Set Modbus

Parity

40202

40203

Holding

Register

Holding

Register

Integer 0,1,2 - Write

Integer 0,1,2 - Write

the humidifier has been

power cycled.

0 = 4800 bps

1 = 9600 bps (Default)

do not take effect until

the humidifier has been

power cycled.

0 = No parity

1 = Even parity (Default)

RunHrReset

Units

Model

run hour

counter to

be reset to

0, typically

used

following

maintenanc

between

imperial

(lbs/hr) and

metric

(kg/hr)

Allows

writing of

humidifier

capacity to

match

model.

40006

40204

40205

Holding

Register

Holding

Register

Holding

Register

Integer 0, 255 - Write

Integer 0,1 - Write

Integer 0 - 30 - Write

is set to 0 (disabled) first

or ILLEGAL DATA error will

occur.

255 = Reset the run time

hours (reported in

RunHrs) to 0.

Value reverts to 0 after

0 = Imperial (lbs/hr)

1 = Metric (kg/hr)

Changes values reported

in Model (40205) and

SteamOutput (30105).

maximum unit capacity, in

lbs/hr, at 100% Fill Off

Amps.

Value cannot be written

while HumEnable = 255

(operational).

The MES-005 would be

Voltage Unit voltage 40206

Phase

Unit voltage

phases

40207

Holding

Register

Holding

Register

Integer

Integer 0,1,2 - Write

1 to

10

- Write

6) pin settings and

reports the voltage:

0: 110-120V (J6 installed)

1: 208V (J6 installed)

2: 220-240V (J5 installed)

3: 230V

4: 277V (J4 installed)

5: 347V

6: 380V (J3 installed)

7: 400V (J3 installed)

8: 415V (J3 installed)

9: 440-480V (J2 installed,

Default)

10: 550-600V (J1

1 = 3 phase (Default)

Modbus Installation | 35

Page 39

Write 255 to this register

read 0 (unit is disabled)

Each integer is a multiple

(disabled).

Each bit represents

in the register.

Units are defined in

in the register.

Steam production hours

12 = 60 minutes (1 hr)

Displays

version.

ForceReset

Resets the

controller

and restarts

in standby.

40007

Holding

Register

integer 0,255 - Write

to reset the control. The

controller will reset,

restart, and remain in

standby mode. After

completion:

- WasReset (40002 )will

read 255 (reset has

occurred)

- HumEnable (40003) will

TimeWindo

w

Current

SteamOutp

ut

Sets the

permissible

window for

modbus

data to be

written.

Displays

current

draw in

Amps.

Displays the

steam

output in

either

Metric of

Imperial

units.

40208

30104

30105

Holding

Register

Input

Register

Input

Register

Integer

Integer

Integer 0 - 300

0 -

255

0 -

12495

- Write

Amps Read

lbs/hr

kg/hr

Read

of 200mS. Maximum time

of 51 secs occurs when

the register reads 255.

A value of 0 disables the

timeout, but can only be

written with HumEnable

(40003) is set to 0

0.0024 Amps, therefore

1 Amp = 416 bits.

The Amp value does not

clear when security loop

is open and the

demand is 0. The last

detected value remains

Units (register 40204).

Unit includes decimal

point as integer value.

Example:

17 = 1.7 (kg/hr or

lbs/hr)

This variable does not

clear when the security

loop is open and the

demand 0. The last

detected value remains

RunHrs

Firmware

36 |Modbus Installation

Run hour

Counter

unit

firmware

30106

30113

Input

Register

Input

Register

Integer

Integer - - Read

0 -

24000

min Read

since last reset. Max

possible 2000 hrs of

operation. Each integer

is a multiple of 5

minutes. Example:

1 = 5minutes

Example: 352 = Version

3.52

Page 40

Significant bits: 1 (Bit

active.

The maximum amount

Model (40205).

Values are displayed as

jumper J10 is installed.

0 = (Amber LED 1 flash)

End of cylinder life.

Uses significant bits 0

(0 = High Water)

Status

Displays

status of

various

components

.

30107

Input

Register

Integer 0 - 128 - Read

0), 2 (Bit 1), 4 (Bit 2), 8

(Bit 3), 16 (Bit 4), 32

(Bit 5), 64 (Bit 6), 128

(Bit 7).

Bit 0 = Contactor

Bit 1 = Fill Valve

Bit 2 = Drain Valve

Bit 3 = Blower pack fan

Bit 4 = Collective fault

(see 30108 for details)

Bit 5 = Humidifier Active

A “1” in the appropriate

bit location indicates

that the component is

MaxOutput

Modulation

FaultCode

Displays the

maximum

capacity of

humidifier.

Displays the

value of

modulating

signal when

a local

modulating

humidistat

is used.

Indicates

the

presence of

a fault and

which fault

has been

detected.

30111

30102

30108

Input

Register

Input

Register

Input

Register

Integer 0 - 30 lbs/hr Read

Integer

Integer

01023

032768

- Read

- Read

of steam per hour that

the humidifier can

produce in lbs/hr. This

value is copied from

whole numbers with 2

decimals places.

Example:

1023 = 10.23 volts

500 = 5.00 volts

A constant value of

1023 can indicate the

Excess current.

1 = (Amber LED 3 flash)

High water level, no

current.

2 = (Amber LED 2 flash)

No current detected

3 = (Amber LED 4 flash)

CtrlStatus1

Describes

controller

hardware

and jumper

statuses.

30109

Input

Register

Integer

032768

- Read

through 15 (1, 2, 4, 8,

16, 32, 64, 128, 256,

512, 1024, 2048,

4096, 8192, 16384,

32768 respectively).

Bit 1 - Electrodes

passing current (0 = On)

Bit 2 - FAULT Relay (0 =

On)

Bit 3 - YELLOW LED

(1 = Illuminated)

Bit 4 - GREEN LED

(0 = Illuminated)

Bit 5 - FAN (1 = On)

Bit 8 - High Water Input

Modbus Installation | 37

Page 41

Bit 4 - MODBUS

Active)

CtrlStatus2

Hardware

status

Port D_E

30110

Input

Register

Integer

032768

- Read

Control Active

(0 = J26 installed)

Bit 9 - FILL (1 = Active)

Bit 10 - DRAIN (1 =

38 |Modbus Installation

Page 42

Modbus Address

1

2

3

4

5

Control Signal Setting

1

2

1

2

3

4

5

NHRS Electric Steam Humidifiers

After wiring connections have been completed, the humidifier needs to be setup to operate and

communicate through the Modbus interface.

The default Modbus address for a NHRS is 1. If multiple units were included on an order, the

addresses of individual units may vary.

To view or change the unit number:

Press both the ↑ and ↓keys simultaneously to access the menu.

When prompted for a password, enter 8808 using the arrow keys.

Scroll through the menu until and select the Modbus Address.

Enter a value between 1 and 127 inclusive as desired.

Press both the ↑ and ↓keys simultaneously to return to the main menu.

This procedure is summarized below:

↑ and ↓ > 8808 > Modbus Address > 1 to 127

By default the humidifier is configured operate on a hardwired control signal supplied through

the unit terminal strip. This can be changed to allow the humidifier to function entirely through

its Modbus interface.

To adjust this setting:

Establish Modbus communications and map points as indicated in the following table.

Write a value of 1 to address 40039. A value of 1 indicates control through Modbus, a value

of 0 indicates controls hardwire to terminal strip.

The control type can also be modified:

Press both the ↑ and ↓keys simultaneously to access the menu.

When prompted for a password, enter 8808 using the arrow keys.

Scroll through the menu until and select the Controller Func.

Select Off for a demand type control, or On for sensor (transducer) control.

Press both the ↑ and ↓keys simultaneously to return to the main menu.

Modbus Installation | 39

Page 43

Modbus Parameters

Signaling Type

EIA-485

Transmission Mode

RTU

Baud Rate

9600

Data Bits

8

Stop Bits

1

Parity

None

Address / Unit Number

1*

The NHRS uses the following parameters for communication:

*Default, may vary for multi-unit orders.

40 |Modbus Installation

Page 44

Variable

Name

Description

Addr

Type

Format

Range

Unit

R/W

Details

Set a manual

for the humidifier

Limits output to

capacity

Write RH or Demand

humidifier

Writes the desired

controls

Switches between

signal

1 = Use Modbus to write

wired demand signal

Read RH or Demand

humidifier

Read space setpoint

controls only)

Reads the manual

for humidifier

1 = Use Modbus to write

wired demand signal

SysDeman

d

Read system ouput

/ demand

Input

Register

Displays output as

percentage of capacity

Read operation

hours of unit

Input

Register

0infinity

Displays cumulative

hours since startup

Read minor

remaining

Read major

remaining

Read humidification

status

Input

Register

0 = Idle / Standby

1 = Active / Humidifying

Read service

warning status

Input

Register

0 = No Service Warning

1 = Service Required

Input

Register

0 = No Fault

1 = Fault Detected

0 = Demand Signal

("Transducer Control")

Read

status

0 = Communication Error

Communications

The following points may be mapped for control:

CapLimit

RHDem

Set

NetSensor

RHDem

Set

CapLimit

NetSensor

capacity restriction

signal value to

space setpoint

when using sensor

hard wired or

network control

signal value from

(sensor type

capacity restriction

Confirms humidifier

control mode

40006

40038

40024

40039

40008

40024

40006

40039

Holding

Register

Holding

Register

Holding

Register

Holding

Register

Input

Register

Input

Register

Input

Register

Input

Register

Integer 50-100 % Write

Integer 0-100 % Write

Integer 30-95 % Write

Integer 0,1 - Write

Integer 0-100 % Read

Integer 30-95 % Read

Integer 50-100 % Read

Integer 0,1 - Read

percentage of total

Requires network

controls (NetSensor = 1)

Use only when sending

RH value to RHDem

sensor or demand value

0 = Hard wired sensor or

Used with hardwired or

network control signal

Sensor controls only, not

for demand type controls

Adjust using writeable

CapLimit variable

sensor or demand value

0 = Hard wired sensor or

40007

HourOpt

SmallHrs

LargeHrs

Status

Service

Fault Read fault status 40035

InputType

Connection

maintenance hours

maintenance hours

Read control signal

mode

communication

40009

40013

40015

40036

40037

40025

40015

Input

Register

Input

Register

Input

Register

Input

Register

Integer 0-100 % Read

Integer

Integer 0-6000 hrs Read

Integer 0-6000 hrs Read

Integer 0,1 - Read

Integer 0,1 - Read

Integer 0,1 - Read

Integer 0,1 - Read

Integer 0,1 - Read

hrs Read

Displays hours until next

minor maintenance

Displays hours until next

major maintenance

1 = RH Sensor Signal