Nortec MH, MHTC Reflow, MHTC Flow, MHB Engineering Manual

Your guide to selecting and specifying Nortec evaporative humidifiers / air coolers

2558982-D | 24 OCT 2011

MH

Series

Engineering

Manual

Includes technical specifications,

guidelines, and options for selection

and application of MHTC / MHB

Evaporative humidifiers / air coolers

Thank you for choosing Nortec.

Proprietary Notice

This document and the information disclosed herein are proprietary data of WALTER MEIER LTD. Neither this

document nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorization of WALTER MEIER LTD., except to the extent required for installation or maintenance of

recipient’s equipment. All references to the Nortec name should be taken as referring to WALTER MEIER LTD.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2011, WALTER MEIER LTD. All rights reserved.

Contents

1 Introduction

1 The MHTC/MHB Evaporative

Humidifier / Air Cooler

1 How the MH works

2 Humidification / Cooling

4 MH Models

6 MH Humidifier Features

7 MH Components

9 MH Specifications and

Dimensions

13 Specifying the MH

14 MH Specification Checklist

15 MH Model

29 MH Installation

Requirements

30 Location – Duct Module

31 Location – MHTC Reflow

Hydraulic Unit

32 Plumbing

34 Electrical

35 MHTC/ MHB Controls

39 Control Wiring

36 Nortec Controls

39 Control Location

41 Nortec Links XPS (MHTC Only)

44 Warranty

15 Duct Module Size

15 Number of Stages

15 Media Boxes Thickness

17 Humidification Load

19 Specifying for Air Cooling

21 MH Controls

21 MH Series Options and

Accessories

24 Sample Specification

The MHTC/MHB Evaporative Humidifier / Air Cooler

The MHTC / MHB is an evaporative type humidifier / air cooler that provides humidifier and

cooling adiabatically. The MHTC/MHB uses evaporative media that is placed in the air stream

of an air handler or duct. The media is wetted with potable, RO, or DI water. The energy in the

air passing through the media evaporates some of the water. The result is an increase in the

humidity of the air and a decrease in the temperature of the air.

The main applications of MH series humidifiers / air coolers are either humidification of

buildings which have a high humidification load and which can also benefit from the adiabatic

cooling effect or simply the adiabatic cooling of air for building temperature control. Since the

MH depends on the energy in the air passing through the evaporative media to evaporate water,

the MH requires inlet air that is warm and dry for most efficient operation.

MH Media

One of the most unique features of all MH series humidifiers / air coolers is their patented

synthetic v-profile evaporative media which does not break down over time and release

microscopic fibers which could be a health hazard. In addition the MH media is treated with an

antimicrobial agent and meets UL900 Class 1 flame and smoke in the USA, ULC-S111-07 Class

2 in Canada making it the best media available for evaporative humidification / air cooling.

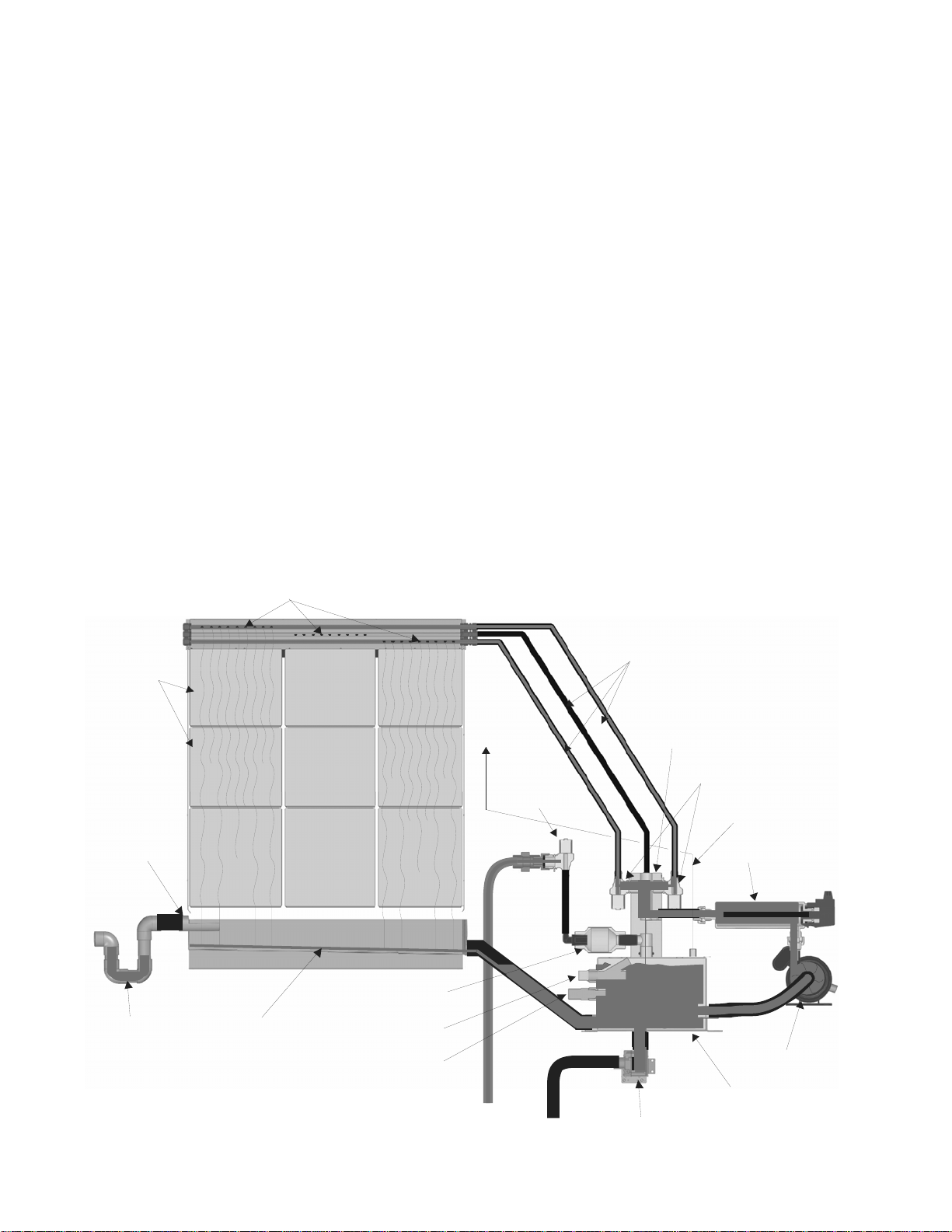

How the MH works

Media

Boxes

Overflow

Spray Bars

Stage 1 Stage 2 Stage 3

Check Valve

To duct

Fill Valve

Spray Bar Lines

Staging Manifold

Staging Valve s

Pressure

Equaliza t ion line

UV Light

P Trap

Drain Pan

1 | The Nortec MHTC / MHB

Float

Conductivity

Sensor

Drain

Figure 1: MHTC Reflow Schematic

Pump

Reservoir

Drain Valve

d

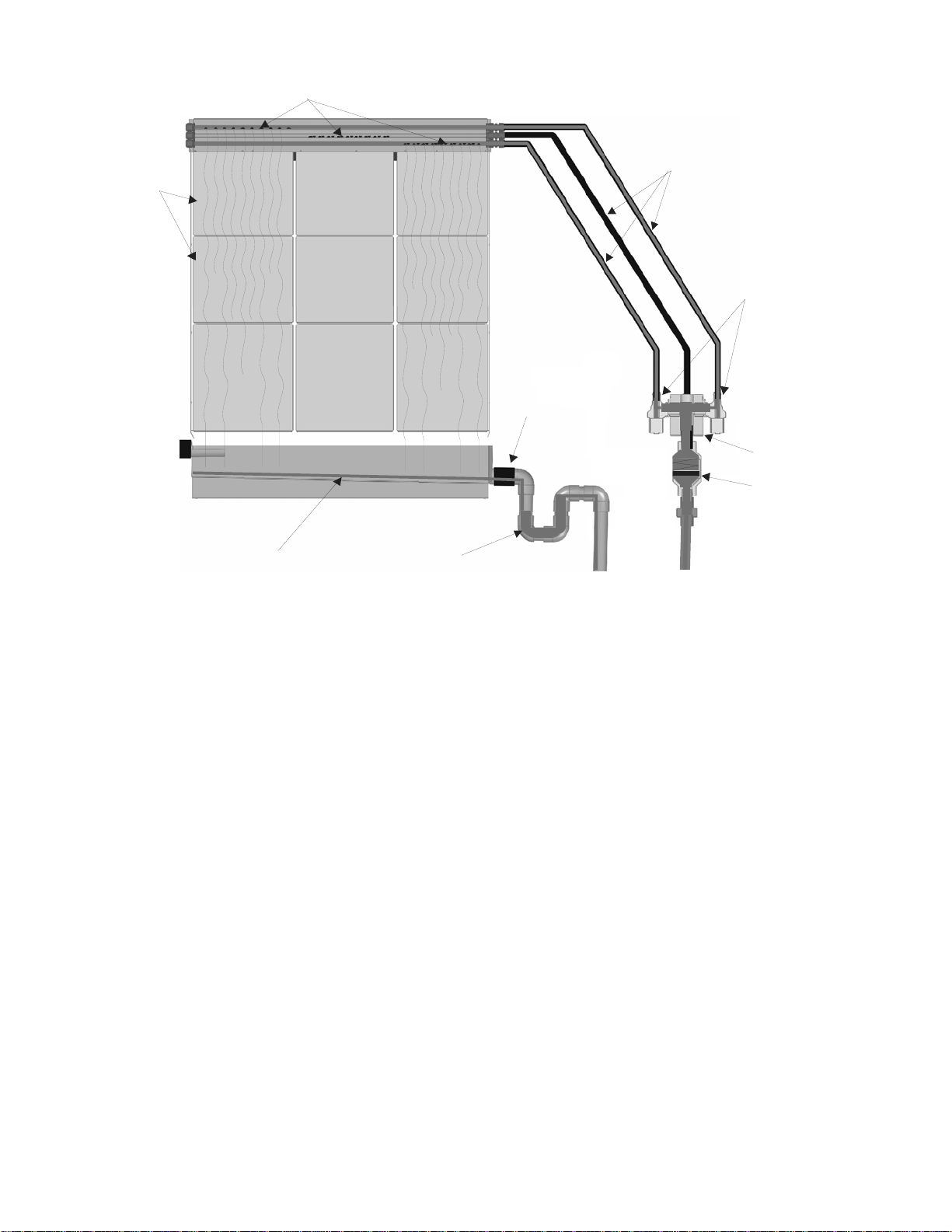

Spray Bars

Media

Boxes

Stage 1 Stage 2 Stage 3

Drain Pan

P Trap

Spray Bar Lines

Staging Valves

Drain

Staging Manifol

Check Valve

Figure 2: MHTC Flow / MHB Schematic

Humidification / Cooling

When a demand is received, the MH will;

MHTC Reflow - turn on its pump and UV light and after a short delay activate staging valves

as required to meet demand. Water will flow through the UV light, staging manifold, open

staging valves, and spray bar lines to the spray bars.

MHTC Flow / MHB – Activate staging valves as required to meet demand. Water will flow

through the staging manifold, open staging valves, and spray bar lines to the spray bars.

Each spray bar has a series of holes which allow water to flow out over a section of

evaporative media. As Water runs down the evaporative media some of it is evaporated by

air passing through the media. As a result of the evaporation the humidity of the air is

increased and the temperature of the air is decreased.

Any water that is not evaporated collects in the drain pan and;

MHTC Reflow - flows back to the hydraulic unit reservoir to be recirculated. As water is

evaporated the water level in the reservoir decreases and the float opens. The MH then

refills until the float is closed.

MHTC Flow / MHB – flows down to drain. The MHTC Flow / MHB does not have a reservoir

or pump and water simply flows through the staging valves when they are open using supply

water pressure to generate flow.

During operation the controller responds to changes in demand by opening and closing

staging valves. This allows the MH to match its output to demand.

The Nortec MHTC / MHB | 2

When demand is satisfied the MH will;

MHTC Reflow – turn off all staging valves and after a delay turn off the UV light and pump.

MHTC Flow / MHB – turn off all staging valves.

Water Management (MHTC Reflow only)

During the evaporation process minerals are left behind by the evaporated water resulting in

an increase in concentration in the remaining water. To prevent minerals from collecting in

and fouling the evaporative media more water is supplied to the media than can be

evaporated. The unevaporated water carries the minerals left by evaporated water to the

reservoir.

To prevent the mineral concentration from increasing to the point where excess water can

no longer dissolve minerals left in the media by evaporated water, the MH will periodically

flush the reservoir. The method used to determine when to flush the tank is configured

using display and keypad. Two triggers can be set.

Trigger 1

Time – The MHTC flushes the tank at a specific time every day.

Periodic – The MHTC flushes the tank after a fixed number of operating hours.

Demand - The MHTC flushes the tank after a fixed number of weighted hours ( weighted

hours = hours of operation x demand% )

Trigger 2

Cycle – The MHTC flushes the tank after a fixed number of fill cycles.

μSSensor (requires optional conductivity sensor)– Flushes the tank when the conductivity

sensor indicates the concentration of minerals exceeds a configured maximum value.

In general more frequent drains result in less maintenance. The amount of water drained to

control mineral concentration in the recirculating water can be configured in the MHTC’s

software.

Pressure Equalization Line (MHTC Reflow only)

In order to ensure that water flows properly from duct module’s drain pan to the MHTC Reflow’s

reservoir a pressure equalization line must be installed between the reservoir and the duct

down stream of the duct module. The line ensures pressure in the reservoir and duct are equal

and water flows properly from the drain pan to the reservoir.

UV Light

A UV light is standard on the MHTC Reflow and optional on the MHTC Flow / MHB. The UV light

prevents bacteria in the supply water or reservoir from being introduced into the evaporative

media. It does not kill bacterial that may be introduced into the media in the air stream.

Box Drying / Box Washing

In order to prevent bacteria from growing in the evaporative media the MH includes a box drying

cycle that allows the media to dry out. The MH will periodically close all staging valves and allow

the media to dry out regardless of demand.

In order to wash minerals from and prolong media life the MH includes a wash cycle which turns

on all staging valves regardless of demand or control status and rinses the media.

3 | The Nortec MHTC / MHB

MH Models

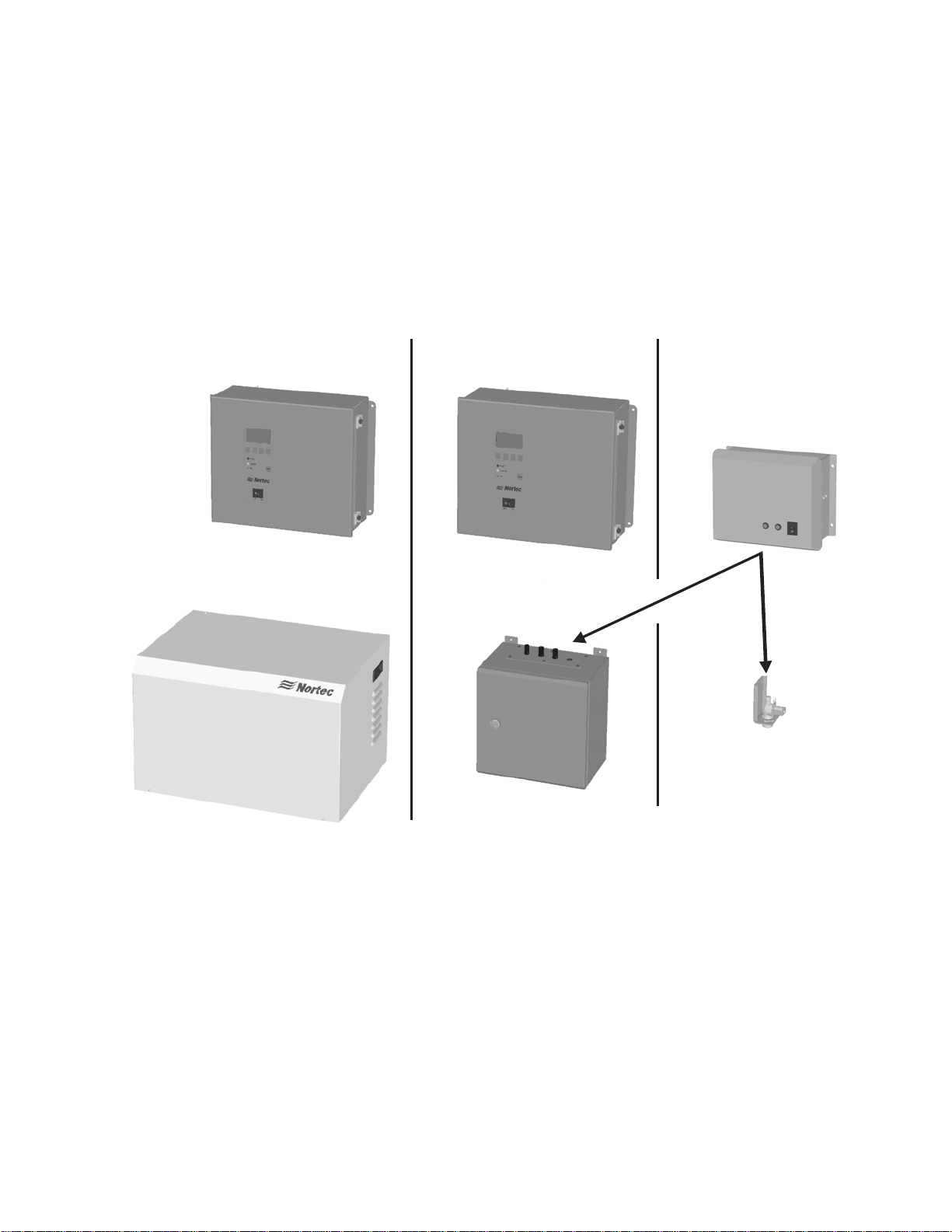

The MH2 is available in three models (see Figure 3: MH Models and Table Table 3: MH

Specifications).

MHTC Reflow - provides state of the art control technology with staged output to match

demand. The Reflow model also includes a hydraulic unit that provides maximum water

conservation by recirculating unevaporated water.

MHTC Flow - provides the same state of the art control technology including staging of

output to match demand but without the hydraulic unit for recirculating water.

MHB - provides basic operation without any user configurable features.

MHTC Reflow MHTC Flow MHB

OR

Single StageMult i S t age

Figure 3: MH Models

Each MH model is coupled with a duct module that contains the evaporative media used for

humidifying / cooling the duct air. The duct module is basically the same for each model with

the exception of the number of spray bars which are used for staging output.

The Nortec MHTC / MHB | 4

MHTC Reflow vs MHTC Flow and MHB

All units run a small excess of water over the media during operation to wash minerals away

and prolong media life. The MHTC Flow and MHB direct this water directly to drain, while the

MHTC REflow recaptures and reuses the water. The REflow is the most water efficient model

and recommended for good quality potable water and treated water types. Flow models are

recommended for areas with hard potable water, or where a central wastewater recovery

strategy is being used. See Table 1: MHTC Reflow / MHTC Flow / MHB Features for a listing of

the additional features provided by the MHTC Reflow.

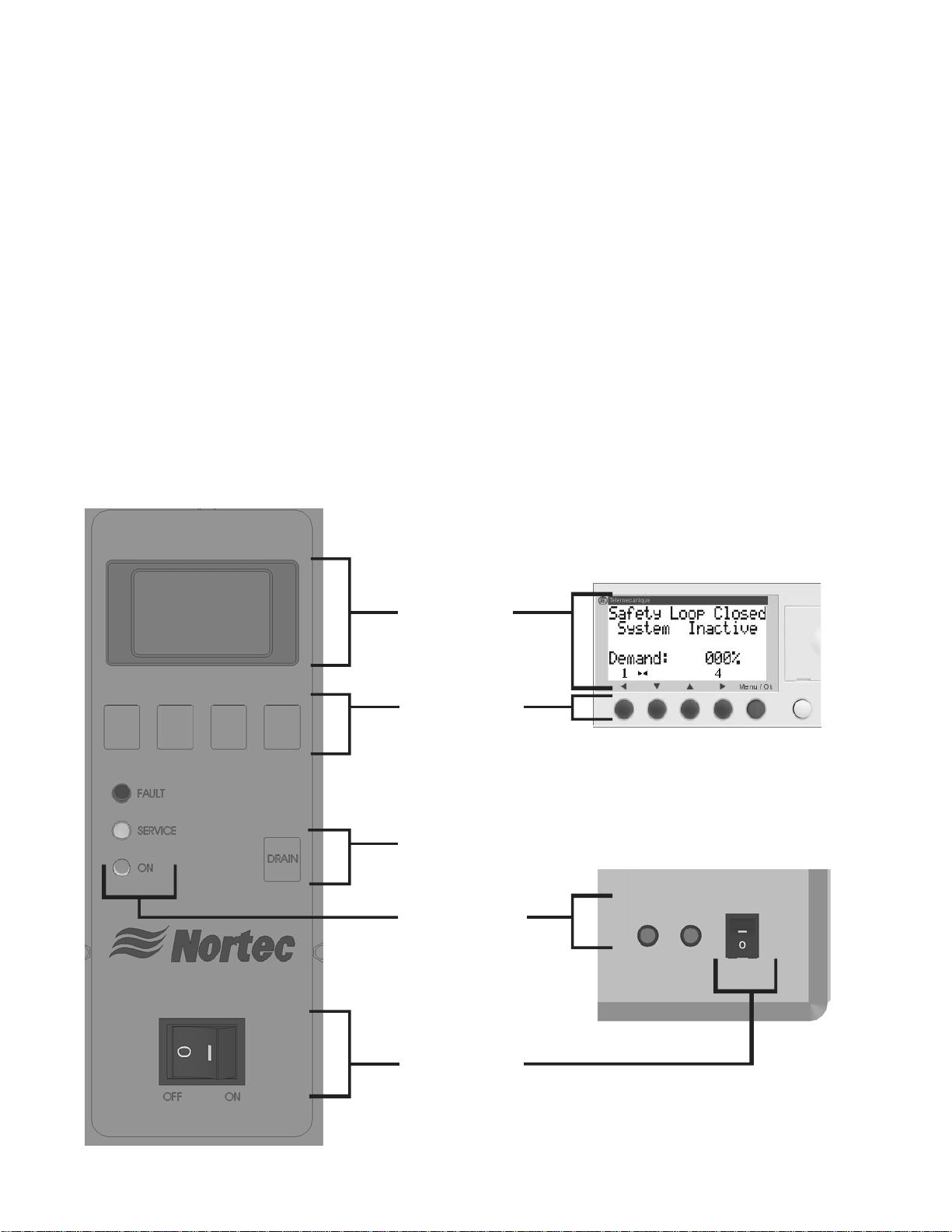

MHTC Flow vs MHB

The main difference between the MHTC Flow and the MHB model is in their controls and user

interface. The MHTC model’s Total Controller provides a graphic LCD screen and keypad,

accepts additional control signals and has optional building management system connectivity

(BACnet, Lonworks, Johnson N2, and Modbus). The MHB controls provide the basic

functionality required for operation. See Table 1: MHTC Reflow / MHTC Flow / MHB Features

for a listing of the two control systems features. Figure 4 shows the differences in the MHTC’s

and MHB’s user interface.

MHTC

MHB

LCD Display

Inside Control Box

Input Buttons

(MHTC used to

navigate screens

and for configuration,

MHB for factory

configuration only.)

Sof tware Drain

Button

(Initiates a software

controlled drain)

Status LEDs

Lights

Outside Control Box

5 | The Nortec MHTC / MHB

On/Off Switch

(Turns humidifier

On/Off)

Figure 4: MHTC and MHB User Interfaces

The MHTC LCD screen and keypad - allow easy configuration of all features of the MHTC

humidifier such as control signals, box washing / drying, tank flushing, maintenance reminders,

and others. The LCD screen also provides status information indicating current status and

configuration, service and fault messages, and troubleshooting information. One of the key

features of the MHTC controller is tracking operation and providing information about service

requirements to make it easy to service and maintain the MHTC.

MH Humidifier Features

From their patented evaporative media and modular design to the MHTC’s advanced control

system with optional internet based monitoring capability to the MHTC Reflows advanced water

conservation technology all MH models include many advanced features that set them apart

from other evaporative humidifiers / air coolers. The following list outlines some of the MH

series key features.

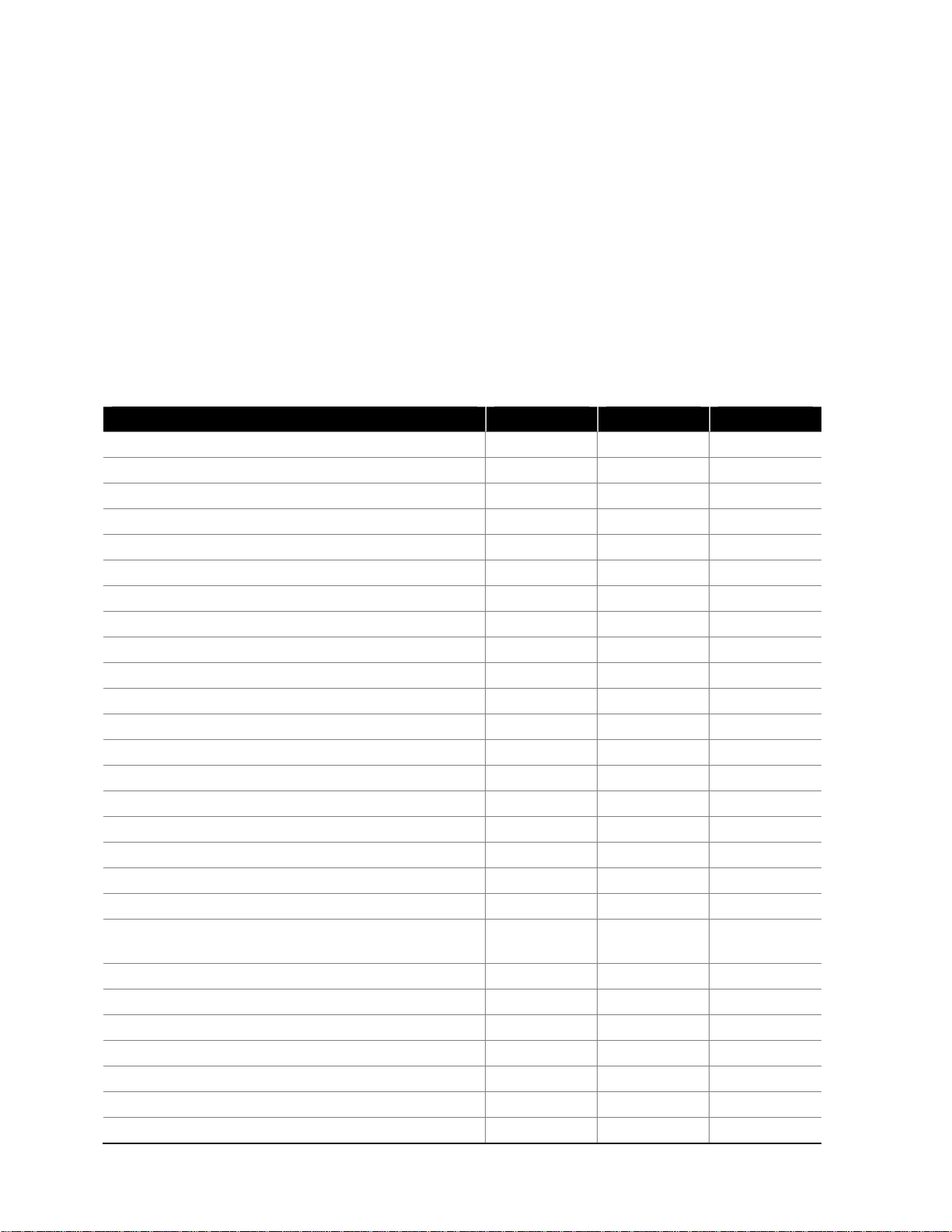

Table 1: MHTC Reflow / MHTC Flow / MHB Features

General MHTC Reflow MHTC Flow MHB

Patented synthetic V-profile evaporative media

Stainless steel duct / media box frames, and drain pan

Operates on DI/RO, Potable, Softened Water

Optional low pressure drop mist eliminator

Recirculating water system

Direct water system

Wash cycles and box drying

Step-Control 1,2, or 3 stage

Ultra violet water treatment

Installation / Maintenance

All electrical components outside of duct

Modular easy to change media boxes

Programable maintenance settings

Wide range of water management options

Electronics

Graphic display screen with keypad input

LED status indicators

Remote status via dry points

Staged output based on modulating signal

Proportional and integral internal control from humidity

sensor inputs

Manual capacity adjustment

On/Off operation

Compatible with all standard Industrial controls

BMS (Lonworks, BACnet, Johnson, Modbus)

Other

UL900 Class 1 Flame and Smoke USA

ULC-S111-07 Class 2 Flame and Smoke Canada X X X

X X X

X X X

X X X

Optional Optional Optional

X

X X

Configurable Configurable Factory Set

X X X

X Option Option

X X X

X X X

X X

X

X X

X X (2 lights)

X X

1-3 Stages 1-3 Stages 1 stage

X X

X X

X X X

X X

Option Option

X X X

The Nortec MHTC / MHB | 6

V

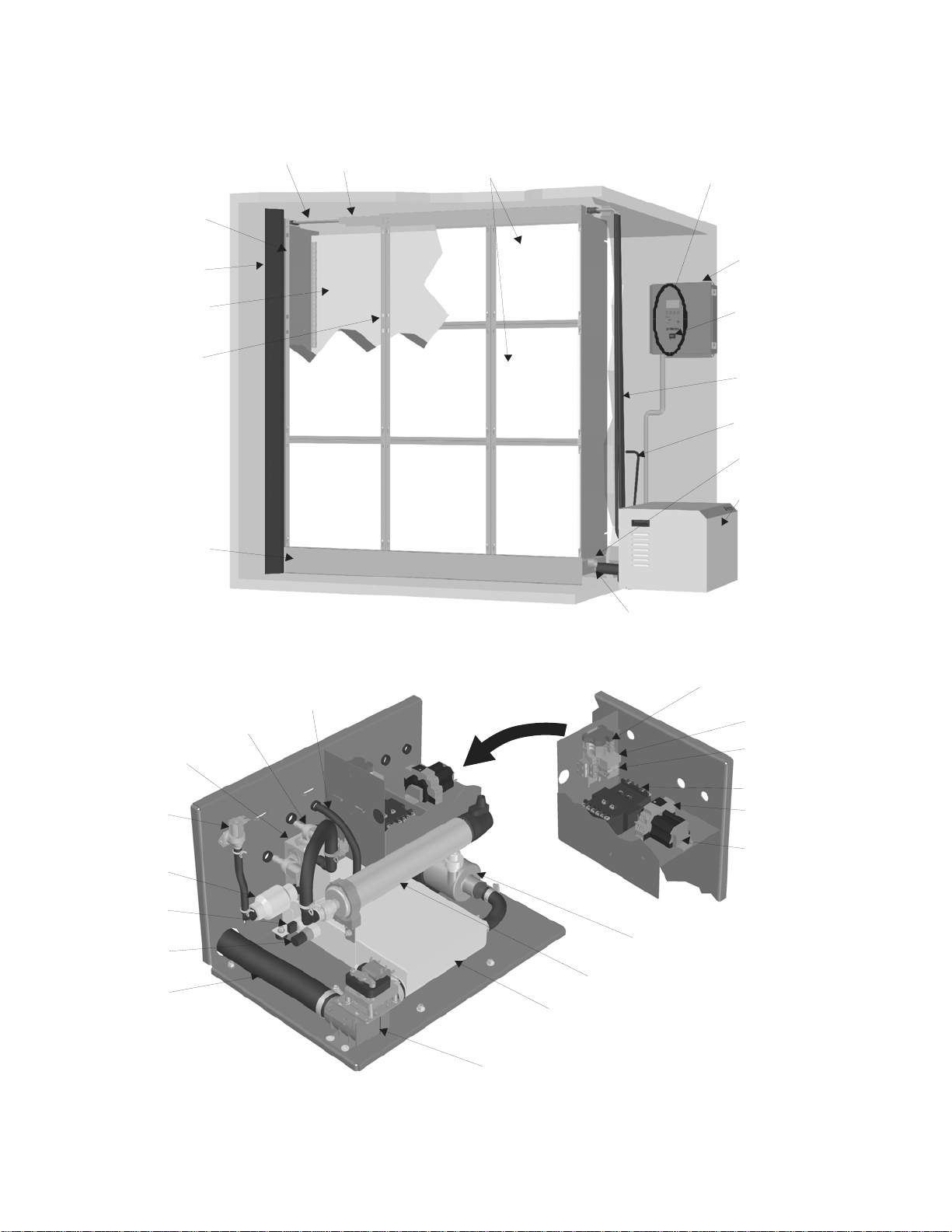

MH Components

Spray

Bars

Right

Side Panel

Duct Seal

Mist

Eliminator

Intermediate

Member

Drain

Pan

Equalization

Staging

Staging

Manifold

Fill

Valve

Check

Valve

Float

Conductivity

Sensor

Drain Outlet

Valve

7 | The Nortec MHTC / MHB

Pressure

Line

Spray Bar

Cap

Media Boxes

Reservoir

Drain Valve

Figure 5: MH Humidifier Components

Display and Keypad

Control

Box

On/Off Switch

Water Lines

Pressure

Equalization

Line

Drain

Overflow

Hydraulic

Unit

Drain Pan Drain

High Voltage

Terminal Block

Fuse Bloc k

Pump and U

Light Relay

Transformer

Conductivity

Transmitter

Low Voltage

Terminal

Block

(Hydraulic

Uni t )

Pump

UV Light

f

Description of Components

Table 2: Humidifier Components

Component Function of Component

Check Valve Provides back flow protection for supply water line.

Conductivity Sensor

/Transmitter

Control Box /

Display and Keypad

Drain Pan Collects unevaporated water from media for recirculation or draining.

Drain Pan Drain Drain pan connection to hydraulic unit reservoir.

Drain Outlet Drain connection from the hydraulic unit.

Drain Overflow Provides protection from overfilling the drain pan.

Drain Valve Drains water from the reservoir.

Duct Seal Prevents duct air flow from bypassing the humidifier.

Fill Valve Controls makeup water flow to humidifier based on float level.

Float Measures water level in reservoir to prevent over filling.

Fuse Block Overcurrent protection for pump and UV light.

High Voltage

Terminal Block

Hydraulic Unit Collects water from the drain pan and pumps, treats with UV light, and

Intermediate

Member

Low Voltage

Terminal Block

Media Boxes Surface from which water is evaporated for humidification/cooling.

Mist Eliminator Captures any water droplets that are carried off the media boxes with air

On/Off Switch Turns power On/Off to humidifier controller. Note: Turn off humidifier

Pressure

Equalization Line

Pump Pumps water from the reservoir to the media boxes.

Pump and UV Light

Relay

Reservoir Collects water from the drain pan for recirculation / draining.

Side Panel, Right Structural member supports media boxes and spray bar cap.

Spray Bar Cap/

Spray Bars

Staging Manifold /

Valve(s)

Transformer Steps primary voltage down to 24 VAC for the controller and internal

UV Light Eliminates any bacteria in the water being pumped to the media boxes.

Water Lines Supply water lines from hydraulic unit to spray bars.

Sensor measures conductivity of water in the reservoir. Transmitter

sends measured value to control box for use in water quality control.

Controls all functions of the humidifier’s operation and provides user

interface for configuration of the humidifier.

Primary voltage connection on hydraulic unit and in control box.

stages water to media. Fills and drains reservoir to control water quality.

Structural member supports media boxes.

Hydraulic Unit – connects control box inputs to the hydraulic unit.

Control Box – provides connection for control signals and safety loop.

Available in 8 in. (20 cm) or 12 in. (30 cm) thickness.

flow in high duct speed applications.

disconnect to shut off primary power to the humidifier.

Balances pressure in hydraulic unit reservoir with pressure in duct to

ensure proper water flow to reservoir from drain pan.

Turns on power to the UV light and pump based on signal from the

control box.

Distributes water to the media boxes and prevents water from spraying

anywhere else.

Controls flow o

water to media boxes based on demand.

components such as the fill valve and drain valve.

The Nortec MHTC / MHB | 8

t

t

MH Specifications and Dimensions

Table 3: MH Specifications

Voltage

Control signals

Max No. of Stages

Water supply

Water drain

Control accuracy

Supply water pressure

Supply water temperature

Water quality

Max. allowable air velocity through

media

Pressure drop

Ambient conditions (control unit)

Fire classification of evaporative media

MHB

120 VAC / 60 Hz 120 VAC / 60 Hz 120 VAC / 60 Hz

On/Off

Dry set of points

3 3 3

3/4 in. BPP, 1/2 in.

NPT adapter provided

2 in. (50.8 mm) OD

ube

Depends on air conditions, number of stages, and control setup

30-145 psi (2-10 Bar)

Tap water, reverse osmosis, softened or fully demineralized water.

1100 fpm (5.5 m/s) with mist eliminator.

Typically 0.44 IWC (250 Pa) @ 500 fpm (2.5 m/s) and 90% RH

34 –104 ºF (1- 40 ºC) Max 75% RH

UL900 Class 1 USA, ULC-S111-07 Class 2 Canada

MHTC

Flow

VDC 0-5, 1-5, 0-10,

2-10, 0-16, 3.2-16

mA 0-20, 4-20

1/2 in/ FPT 3/4 in. BPP, 1/2 in.

NPT adapter provided

2 in. (50.8 mm) OD

ube

41-113 ºF (5-45 ºC)

750 fpm (3.8 m/s)

MHTC

Reflow

VDC 0-5, 1-5, 0-10,

2-10, 0-16, 3.2-16

mA 0-20, 4-20

2 in (50.8 mm) ID

hose

4 x 5/16 in

(8 mm)

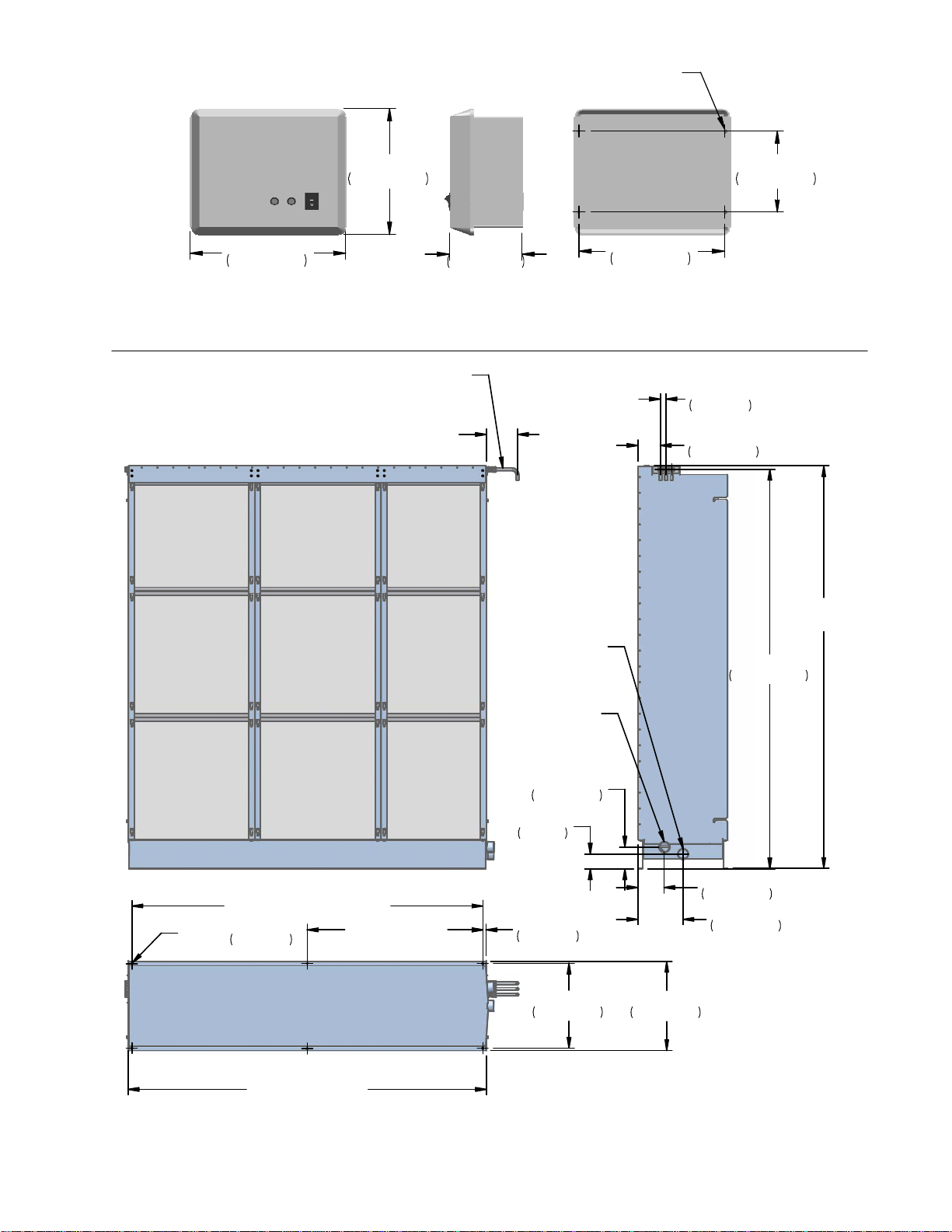

12.0 in.

30.5 cm

O

16.7 in.

42.5 cm

17.5 in.

44.4 cm

Figure 6: MHTC Reflow/Flow Control Box Dimensions

6.2 in.

15.6 cm

14.3 in.

36.3 cm

9 | The Nortec MHTC / MHB

4 x 0.31 in.

(8 mm)

O

9.3 in.

23.6 cm

11.5 in.

29.2 cm

5.4 in.

13.6 cm

6.0 in.

15.2 cm

10.75 in.

27.3 cm

Figure 7: MHB Control Box Dimensions

12 in. (30 cm) Supplied

Cut to Desired Length

1-3 x Spray Bar

1/2 in. (12.7 mm)

Tube

1.0 in.

2.7 cm

TYP

4.2 in.

10.7 cm

2.0 in (50.8 mm)

2 in. (50.8 mm)

Drain

Tube

Overflow

Tube

H=24 - 144 in.

(0.6 - 3.7 m)

74.6 in.

189.6 cm

W - 1.2 in (W - 3.2 cm)

O

0.2 in.

0.6 cm

6 X

W/2 - 0.6 in.

(W/2 - 1.6 cm)

4.1 in.

10.3 cm

2.8 in.

7 cm

0.6 in.

1.6 cm

4.9 in.

12.5 cm

8.4 in.

21.5 cm

15.8 in.

40.2 cm

16.6 in.

42.3 cm

W = 24 - 144 in.

(0.6 - 3.6 m)

Figure 8: MH Duct Module Dimensions

The Nortec MHTC / MHB | 10

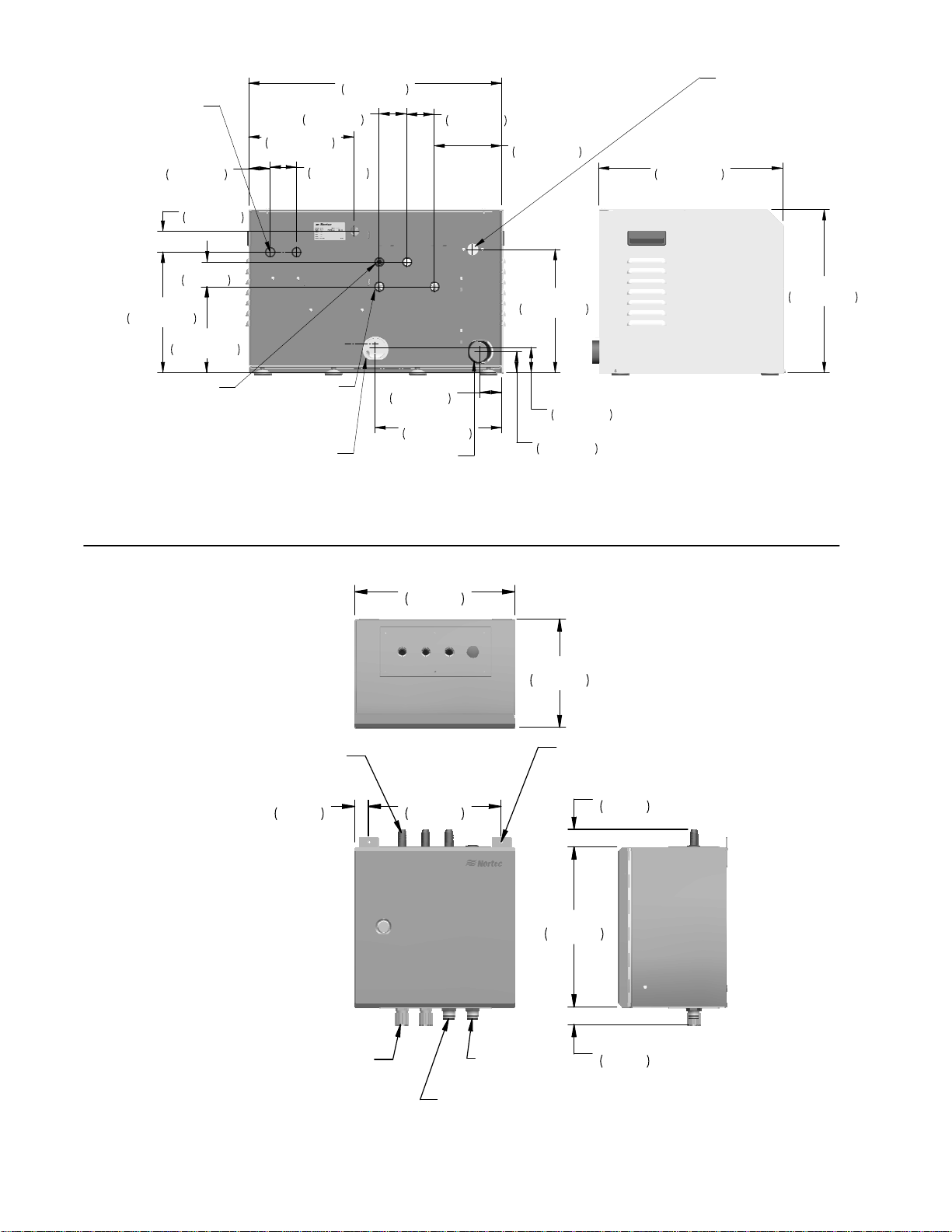

Electrical

3 x 7/8 in.

(22 mm)

11.5 in.

29.2 cm

Press. Equal.

1/2 in. (13 mm)

2.0 in.

5.2 cm

2.0 in.

5.1 cm

2.4 in.

6 cm

8.2 in.

20.8 cm

Hose Barb

2.6 in.

6.7 cm

10.0 in.

25.5 cm

2.5 in.

6.4 cm

Spray Bar

Connections

1-3 x 1/2 in.

(13 mm) Hose Barb

Drain Pan

Connection

2 in. Tube

24.1 in.

61.3 cm

2 in. ID Hose

2.1 in.

5.3 cm

12.1 in.

30.7 cm

Drain

2.6 in.

6.7 cm

6.4 in.

16.4 cm

11.8 in.

29.9 cm

2.4 in.

6.1 cm

2.0 in.

5.2 cm

Water Inlet

3/4 in BSP

(1/2 in. NPT

Adapter

provided)

17.6 in.

44.6 cm

15.6 in.

39.5 cm

Figure 9: MHTC Reflow Hydraulic Unit Dimensions

11.87

30.15

8.05

20.45

1 - 3 x 1/2 in. OD

Barbed Hose

1.00

2.55

9.87

25.07

2 x 1/4 in.

(6.4 mm)

O

1.31

3.33

11.88

30.16

2 x Water T ight

Electrical Connection

Figure 10: MHTC Flow/MHB Multi Stage Hydraulic Unit Dimensions

11 | The Nortec MHTC / MHB

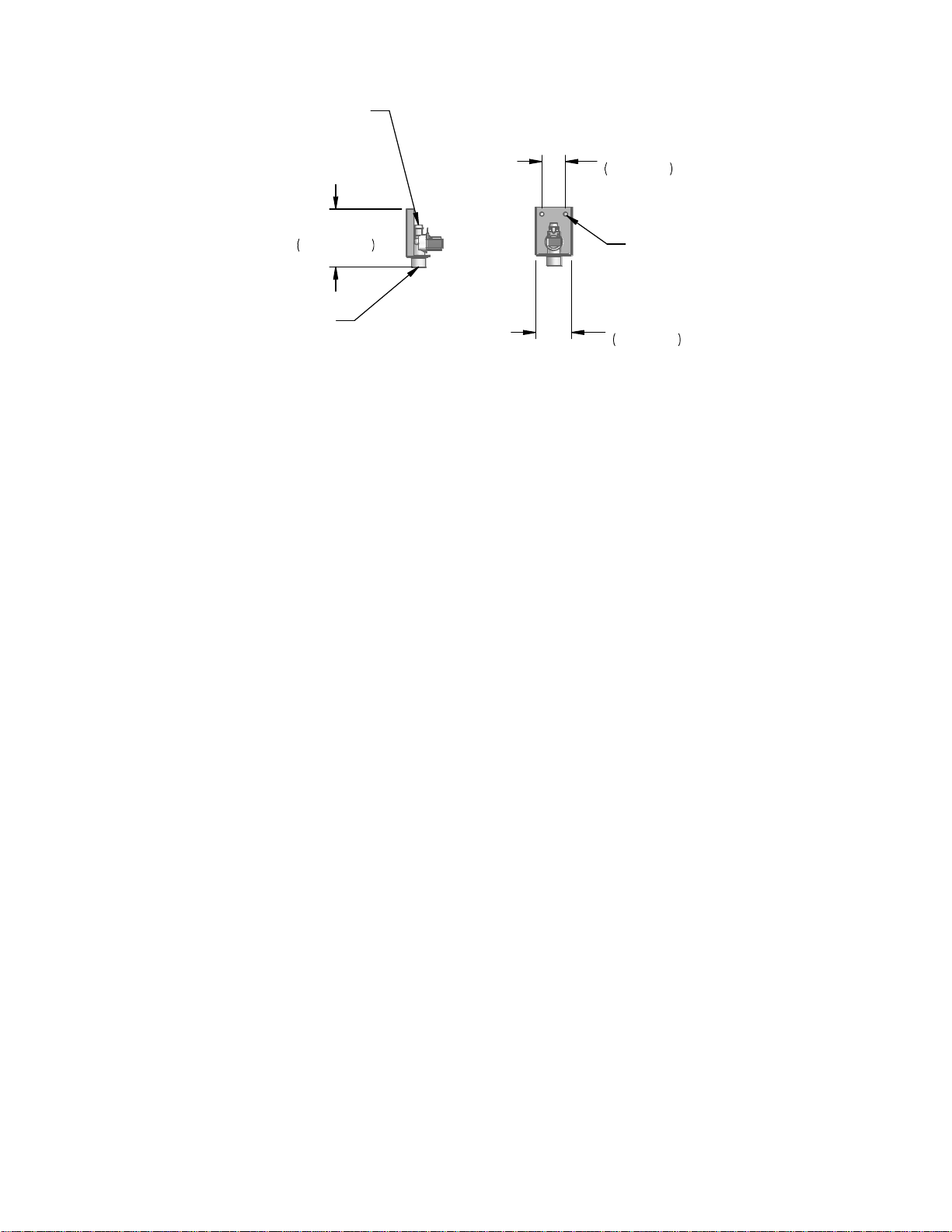

Strain Relief

Drain

1/2 in. NPT

Water Inlet

1/2 in. NPT

1.32

3.36

Spray Bar

Connection

1/2 in (13 mm)

Hose Barb

1.8 in.

4.4 cm

4.3 in.

10.9 cm

2 x 0.3 in.

(7.6 mm)

O

Water Inlet

3/4 in GHT

2.7 in.

6.8 cm

Figure 11: MHB Single Stage Hydraulic Unit

The Nortec MHTC / MHB | 12

Loading...

Loading...