Page 1

MES Electrode

Steam Humidifiers

Installation, Operation,

Maintenance, Spare Parts, and

Exploded Views Guide

IMPORTANT: Read and save this guide for future reference.

This guide to be left with equipment owner.

Form 07-111

Page 2

Page 3

Table of Contents

INSTALLATION 1

RECEIVING EQUIPMENT .........................................1

PRINCIPAL OF OPERATION .......................................1

WATER SUPPLY AND PLUMBING ....................................2

WATER CONNECTION ..........................................2

START-UP AND OPERATION .......................................2

CAPACITY ADJUSTMENT.........................................3

CYLINDER REPLACEMENT........................................3

WHEN TO REPLACE THE STEAM CYLINDER .............................3

REMOVING THE OLD CYLINDER ....................................4

INSTALLING THE NEW CYLINDER ....................................4

MAINTENANCE 4

EXTENDED SHUTDOWN .........................................4

TROUBLESHOOTING 4

TERMS USED ...............................................4

STARTING POINT .............................................5

DIAGNOSTIC PROCEDURES TROUBLESHOOTING GUIDE.......................7

SOFTWARE REQUIREMENT FOR MODBUS RTU ............................8

PHYSICAL DIMENSIONS DIAGRAM ...................................11

WIRING DIAGRAMS ...........................................12

SPARE PARTS LIST ...........................................14

EXPLODED VIEWS DIAGRAM ......................................15

Page 4

INSTALLATION

2

S

RECEIVING EQUIPMENT

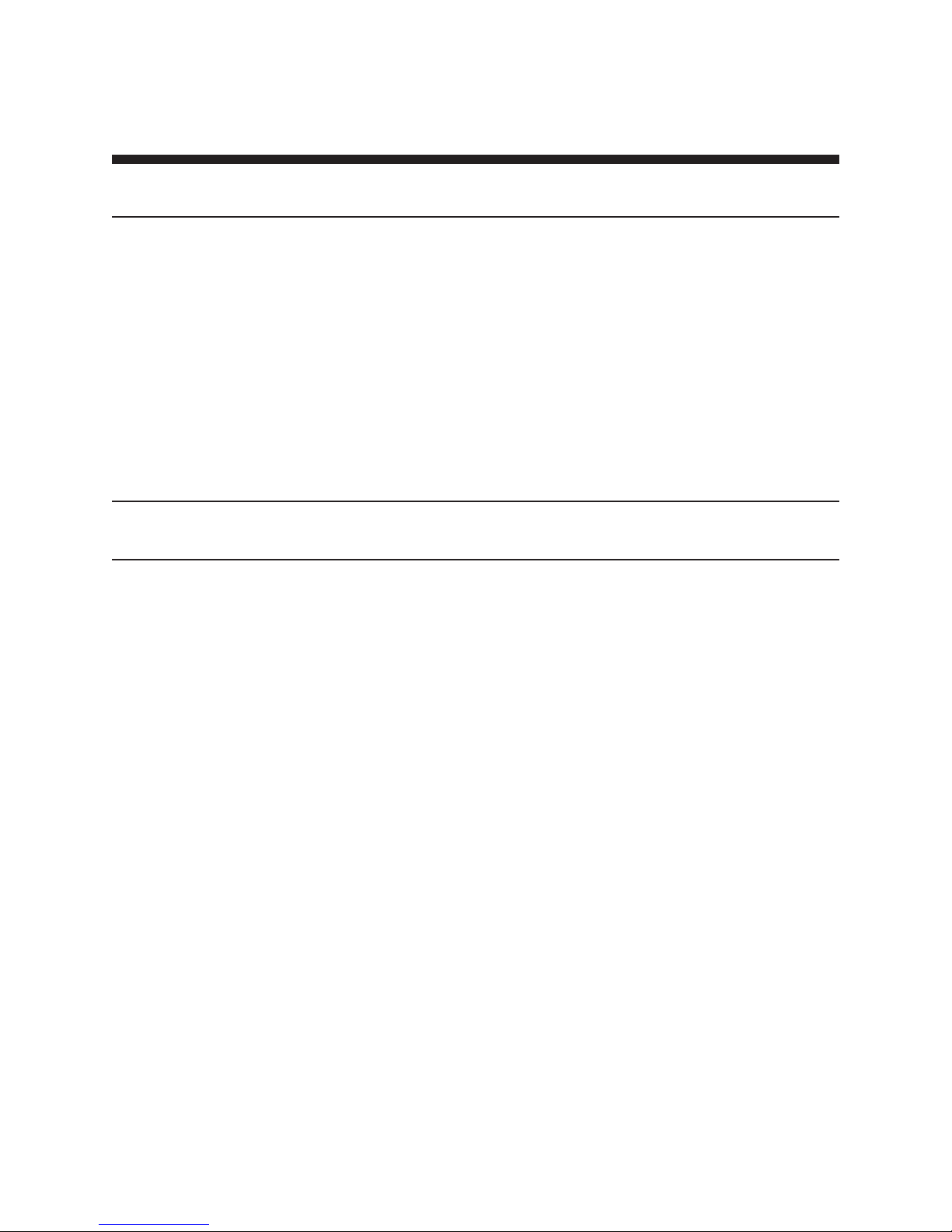

Figure #1

Operation Schematic

1. Check packing slip to ensure ALL material has

been received.

2. Inspect box for damage and note on shipping

waybill accordingly.

3. After unpacking, inspect unit for damage and if

damage is found, advise shipper as soon as

possible.

4. Inspect unit (humidifier) to ensure it is the

correct model, phase, and voltage. If any are

incorrect, advise the factory or your local

representative immediately.

NOTE: All products are shipped on an F.O.B.

factory basis. Any and all damage, loss, or breakage

claims are to be made directly to the shipping

company.

The NORTEC MES Series electrode humidifier is

the culmination of many years of research and

development in the electrode humidifier industry. This

unit has been built by skilled craftspeople and

thoroughly tested before shipment and should, if the

following instructions are observed, provide many

years of trouble-free operation.

FOR HUMIDIFIERS INSTALLED IN THE CITY

OF LOS ANGELES: A city of Los Angeles approved

spring-loaded double ball CHECK VALVE should be

supplied and installed by the contractor on each of the

potable water inlets to each humidifier.

Recommended valve manufacturer: Watts

Regulator (phone 508-688-1811), model #7, size 3/8”

NPT inlet and outlet.

CONDENSATE RETURN

(OPTIONAL)

FILL

CUP

1. INLET CHAMBER

. FILL CHAMBER

3. WATER OVERFLOW

CHAMBER (SAFETY DRAIN

IN CASE OF FILL VALVE/

CONTROL BOARD FAILURE)

STRAINER

TAP

WATER

SUPPLY

FILL

VALV E

CONNECTION

1

DRAIN

1” AIR

GAP

3

2

DRAIN

VALV E

DRAIN CANAL

(OPEN TO ATMOSPHERE)

STEAM HOSE

ELECTRODE

CYLINDER

DRAIN

PAN

An electronic timer uses the rate of amp fall to

determine the water level. The objective is to

concentrate current-carrying minerals in the cylinder

so that a smaller volume of water is required to

produce the rated steam output.

This achieves the longest life for the disposable

cylinder because of minimal electrode coverage and

use of less energy because the high concentration

allows a minimal drain rate.

Each drain line from these humidifiers shall be

routed, without dips or sags, to terminate above the

flood level rim of a City of Los Angeles approved

indirect waste receptor.

No combustible materials shall be placed in the

duct and/or the air plenum.

PRINCIPAL OF OPERATION

When the humidistat calls, the cylinder fills to

100% of the Full Load Amperage (F.L.A.) or to the top

of the cylinder, whichever comes first. See Figure #1.

If it reaches 100% F.L.A. the water heats and boils

away to a level giving 80% F.L.A.

When 80% F.L.A. is reached, the fill valve will

open refilling cylinder to 100% F.L.A. On occasion,

the drain valve will also come on if water level is too

low, indicating too high a concentration and the

requirement for a dilution of the water in the cylinder.

If the water reaches top of cylinder before 100%

F.L.A., the fill valve shuts off via the sensor and

fill-boil-fill-boil cycle continues, cycling off the red high

water sensor light until the concentration becomes

high enough to reach 100% F.L.A. The above

described control process will then take over.

-1-

Page 5

WATER SUPPLY AND PLUMBING

n

1. The fill valve is sized for an extended water

pressure range of 30 to 80 psi.

2. For cases below 30 psi add a pressure boost

pump, notify the factory and a fill valve with an

oversized orifice will be supplied.

are designed for water pressure from 30 to 80

psi and are protected by the built-in strainer.

4. For inlet water pressure outside this range, the

factory should be contacted. (See Water

Supply and Plumbing section of this manual.)

START-UP AND OPERATION

3. For cases above 80 psi, install a pressure

reducing valve in the water feed line to the

unit.

4. With extremely dirty or muddy water sources,

e.g., some well sources, ensure proper

filtration by adding an external filter to the

water line entering the unit. (Consult factory

for accessories such as filters.)

5. DO NOT use completely demineralized water

with this unit as it is the minerals that allow the

electrode principle to work.

6. DO NOT use a hot water source as it will

cause deposits that will eventually block the fill

valve orifice.

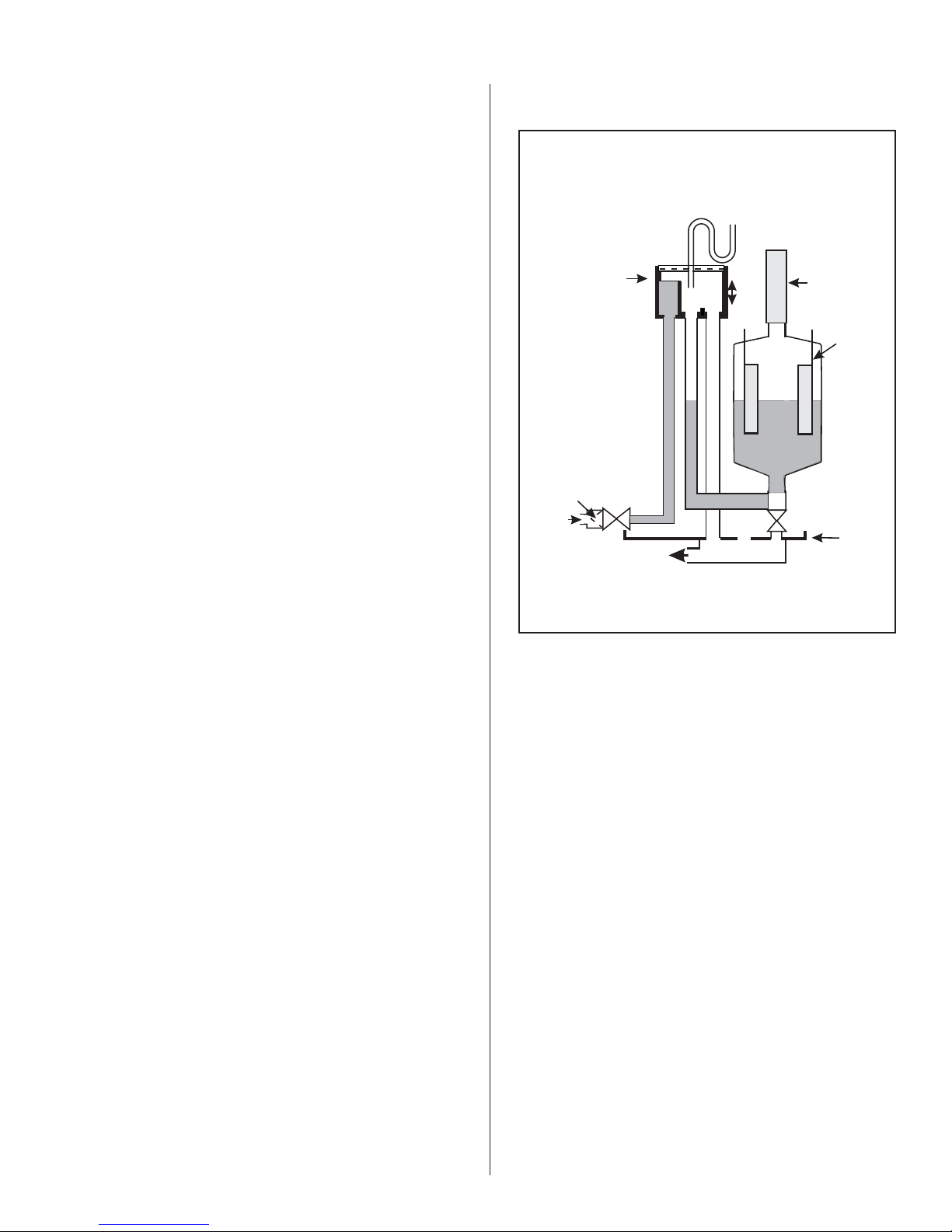

Figure #2

Bottom View of MES Series Unit

3/8" Cold Water

Olive Connection

Ambient temperature location for humidifier:

·

41ºF - 104ºF (5ºC - 40ºC).

Relative humidity location for humidifiers:

·

5% rh - 80% rh.

Check to see that the unit is securely mounted on

a level surface with the proper drain and water supply.

Check for correct voltage with appropriately sized

service. Check that the steam distributor, steam

supply hose, and condensate line are correctly

installed and routed back to the unit. Ensure that the

external control humidistat is located in an area to

properly sense the relative humidity to be maintained

by the humidifier, and that the interconnecting low

voltage wires between the humidistat and the unit’s

control terminal strip are in accordance with the wiring

diagram.

Check all electrical connections for wires which

may have become loose in shipping. Components

damaged due to loose connections are NOT under

warranty.

Check electrode plugs to ensure they are pressed

firmly onto the electrode pins. Important: Loose

connections will cause overheating of the cylinder

plugs, possibly melting the plugs and/or cylinder.

Use 7/8" I.D. Hose From Factory

WATER CONNECTION

1. A copper compression olive type coupling for

1/4" O.D. soft copper tubing is provided with

unit and requires no soldering for the water

connection to the unit. See Figure #2.

2. An isolating valve should ALWAYS be placed

in the feed water line allowing service of the fill

valve.

3. Each unit is fitted with a fill solenoid valve

located on the base drain pan. Flow orifices

7/8" Drain

Connectio

Open the isolating valve in the feed water line to

the unit.

Make sure the humidistat is set high enough to call

for humidification.

Turn on the main disconnect in the primary service

feeding the unit and check that unit has power at the

primary terminal block.

PUSH THE AUTO ON/OFF/DRAIN SWITCH TO

“ON”.

Water will start to enter the cylinder through its

bottom port and rise in the cylinder to a point

determined by the solid-state control circuitry.

It is not unusual upon initial start-up for the

water to fill the cylinder and cycle on the red high

water sensor light.

-2-

Page 6

The red light simply acts as a safety to shut off the

fill valve and prevent over-filling. With the red light on,

the water in the cylinder will continue to heat and, after

a few minutes, start to boil. After the boiling action of

the water has lowered the water level below the

sensor at the top of the cylinder, the red light will go

out and the fill solenoid will again open until the

cylinder is again full.

This cycling of the red light and fill valve will

continue until the unit’s full output capacity is reached

after which the water level will automatically lower

itself in the cylinder. (The increased concentration

allows for lower electrode coverage while maintaining

the same output.) When a stabilized condition is

reached the water will be boiling close to the cylinder

seam level. The solid state circuitry will maintain the

proper concentration in the cylinder by introducing

short drains only when necessary.

If the cylinder is manually drained the above

process will repeat itself.

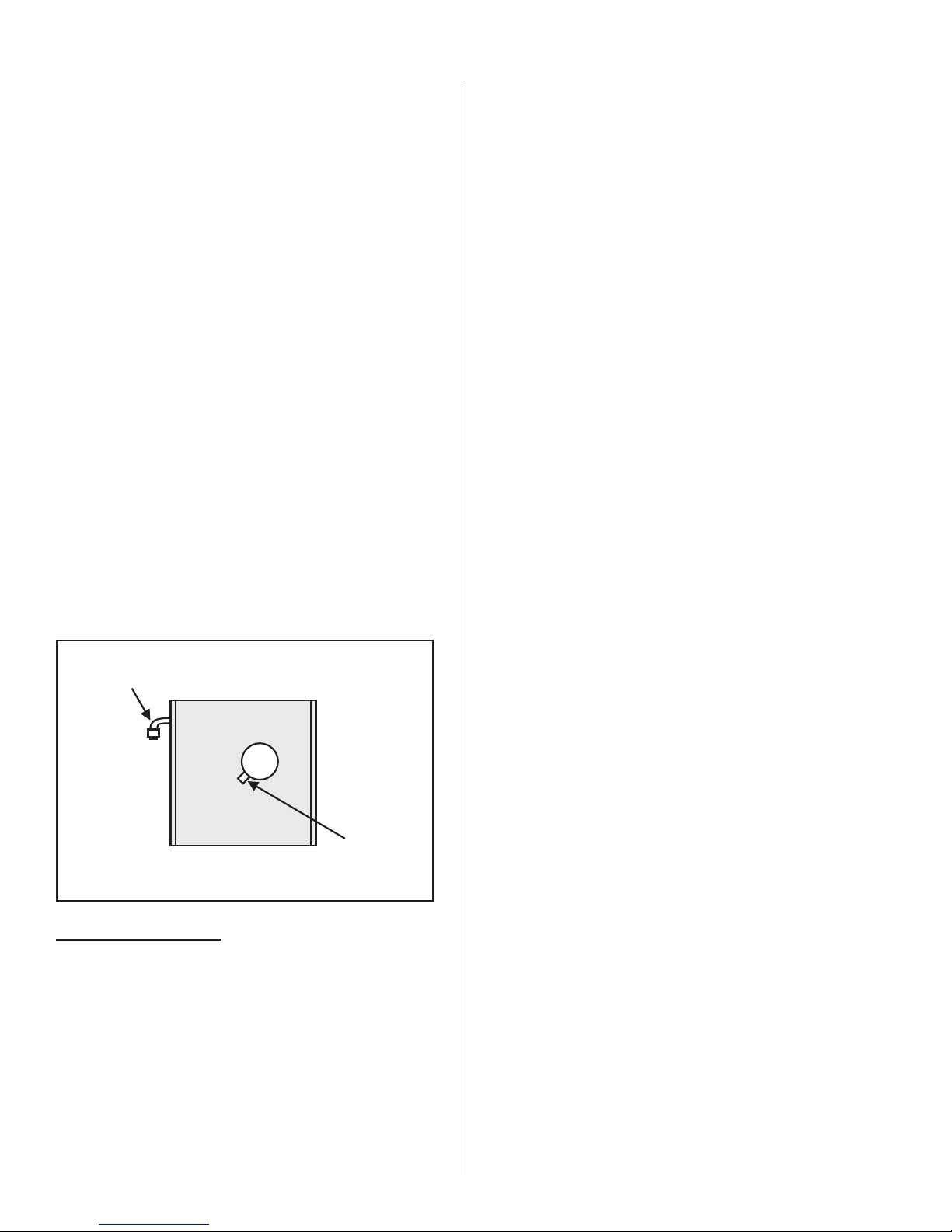

Low Water Conductivity

Figure #4

MES Adjustable Pot

CYLINDER REPLACEMENT

After an extended period of operation, in

accordance with life expectancy information, the

cylinder is completely used as indicated by the red

high water sensor light illuminated on the cabinet.

When this condition is reached, a new replacement

cylinder is to be installed.

Should normalization of the unit be required

immediately after start-up, the installer may speed up

the process by artificially increasing water conductivity.

During a fillcycle, the installer should dissolve half a

teaspoon of table salt (no more) in a cup of water and

add it to the cylinder by means of the fill cup attached

to the plumbing section.

Open the plumbing compartment and add salt

solution through cylinder outlet. Excessive amounts of

salt will result in erratic operation of the unit; however,

normalization of the unit will occur automatically

through the solid-state control sequence.

CAPACITY ADJUSTMENT

The MES Series of humidifiers come with

adjustable capacity (AC) PC boards. These boards

have a pot to adjust the output from 20 to 100%. See

Figures # 3 and 4.

Figure #3

MES Adjustable Pot

NOTE: Red light may come on during initial

start-up but does not mean cylinder replacement. See

Start Up and Operation section of this manual.

Figure #5

Cylinder Removal

Ad ustable

Adjustable

Capacity Pot

Capacity Pot

Consult factory or agent for replacement. Quote

the cylinder model from the white 3-digit label on the

cylinder or quote model, voltage, and serial number

from unit specification label.

WHEN TO REPLACE THE STEAM CYLINDER

The steam cylinder is disposable and must be

replaced at the end of cylinder life. Cylinder life is

-3-

Page 7

dependent on water supply conditions and humidifier

usage. Failure to replace the cylinder at the end of

cylinder life may result in unit damage. Walter Meier

(NORTEC) is not responsible for any damages

resulting from, or attributable to, the failure to replace a

used cylinder (see Manufacturer’s Warranty).

REMOVING THE OLD CYLINDER

See Figure # 5.

n

1. Turn off the water supply to unit.

2. The old cylinder must be drained completely

before removing. This is done by pushing the

auto on/off/drain switch to the “drain” position.

3. When completely drained, push the auto

on/off/drain switch to the “off” position.

4. Open the main disconnect during the entire

cylinder change operation.

7. The cylinder is now ready to be lifted out of

the unit.

INSTALLING THE NEW CYLINDER

1. The reverse procedure should be followed to

install a new cylinder. The main disconnect is

to be left open until the cylinder is completely

installed and reconnected.

2. Ensure that the cylinder mounting stubs are

seated properly in the allotted side mounting

slots within the unit.

3. The white sensor plug on all units is for the

sensor pin, which always goes on the single

pin offset from the others. See Figure # 6.

4. Ensure that cylinder plugs are very snug on

the pins. Replace any loose fitting plugs as

these may result in hazardous operation.

5. The power wires to the cylinder are attached

by cylinder plugs to the electrode pins on top of

the cylinder. Pull these plugs vertically off the

pins. See Figure # 5.

6. Using slot screwdriver, loosen the steam hose

clamp(s) and pull steam hose off vertically.

Figure #6

Plugs

White

Sensor Plug

Cylinder Pin

Sensor Pin

Cylinder Pin

Sensor Pin

Cylinder

Plug

1Ø

3Ø

Cylinder Pin

Cylinder Pin

MAINTENANCE

WARNING! The plumbing and electrical

compartments contain high voltage components and

wiring. The access cover is attached with screws.

Access should be limited to authorized personnel

only.

EXTENDED SHUTDOWN

Before disconnecting power to the humidifier for a

period of extended shutdown, ALWAYS DRAIN the

cylinder first. Otherwise, the electrodes are subject to

harmful corrosion which drastically shortens the

cylinder life. Do NOT leave the switch in the DRAIN

position indefinitely as the drain coil could burn out.

Leave the switch in the OFF position and “open” the

main external fused disconnect to stop power to the

humidifier. Close the shut off valve in the water

supply line feeding the humidifier.

TROUBLESHOOTING

TERMS USED

F.L.A. (Full Load Amps): Refers to amps listed

on the humidifier specification label.

Cylinder Pin

SHORT CYCLING: When the ‘on time’ of the

humidifier is less than ten minutes upon a call for

humidity. To correct short cycling, all humidifiers have

a capacity adjustment which allows the output of the

humidifier to be reduced to as low as 20% of rated

output, thus extending the ‘on time’ required to

maintain output.

-4-

Page 8

FOAMING: The phenomenon which can occur in

water when impurities, already in the water reach an

excess concentration as a result of boiling away pure

water and the continued boiling action agitating the

contained water. The humidifier electronics are

designed to prevent this occurrence although in

extreme cases, water will foam with little concentration

making it necessary to have the drain time of the

water, contained in the cylinder, increased. Foaming

is normally caused by short cycling, a restricted drain,

or back pressure. The foam, generated in these

instances, is conductive and may lead to false full

cylinder indication if the level of the foam approaches

the top of the cylinder.

BACK PRESSURE: The restriction of steam flow

caused by long steam runs, improperly sloped steam

lines, elbows changing the direction of steam flow from

horizontal to vertical without a drain leg, any plumbing

detail allowing the accumulation of condensate,

undersized steam line, improper steam distributor,

downward air flow onto the distributor causing excess

static pressure at the steam outlets, or high static

pressure ducts (not probable). To overcome excess

static pressure in the duct, a fill cup extension kit

should be used. In down flow applications, a down

flow distributor should be used, but in some cases the

fill cup extension will also be required.

3. The low voltage 3 amp fuse located in the

control box could be blown.

4. The contactor holding coil could be open or

shorted.

5. The switch could be defective.

Recheck that the “auto on/off/drain” switch is still

at “on”. If it is, then shut off the main disconnect and

check fuses or breaker of the main disconnect. If they

are serviceable, turn power back on.

To test for a defective “auto on/off/drain” switch,

connect a wire from the fuse directly to terminal 6 on

the external controls strip. If the contactor activates,

the “on” side of the switch is defective. If the contactor

does not activate, the PC board could be defective.

If the 3 amp control fuse blows when the wire from

the fuse touches terminal 6 on the external controls

strip, contactor holding coil could be shorted. Replace

contactor if necessary.

After the necessary components have been

replaced and the contactor pulls in, there is line

voltage to the cylinder and the control sequence can

begin.

RESET UNIT (HUMIDIFIER): To reset the

humidifier, the auto on/off/drain switch at the front of

the humidifier should be switch to the “Off” position for

a minimum of five seconds and then switched back to

the “On” position.

MONITORED LEG: Refers to the primary wire to

the cylinder which loops through the current sensing

devise of the main PCB. This wire is terminated at the

red cylinder plug at the cylinder.

STARTING POINT

Auto On/Off/Drain switch in “On” position - unit

will not fill:

When the on/off control circuit is made and the

“auto on/off/drain” switch is pushed to “on”, the 24 volt

holding coil of the primary contactor should energize.

The resulting magnetic pull closes the high voltage

contacts with a distinct and audible “clunk”. If the

contactor will not make, then inspect the following

while referring to the wiring diagram:

1. Check for 24 Vac across terminals 18 and 26

on PC board.

2. Jumper the humidistat on external control

terminal strip. If contactor operates, then

control system is at fault.

Approximately 30 seconds after the contactor pulls

in, the fill valve coil should energize. There is also a

visible fill relay on the printed circuit board. It is the

one located farthest from the C.T. core. The points on

this relay must be touching in order for the fill valve coil

to be energized.

If the points will not touch after the built-in time

delay, then the sensor input may be interfering. To

confirm, remove the black and red sensor wires from

the terminals 6 and 10 on the PC board. Wait 30

seconds and if the fill relay points not touch, then

sensor should be replaced. If they do not touch, then

the basic PC board could be faulty. To confirm,

disconnect the red wire from terminal 18 and touch it

to terminal 14. If the fill valve coil activates then the

basic PC board should be replaced. If it still does not

activate then the fill valve coil should be replaced.

Having changed the necessary components, water

starts filling the cylinder and begins to submerge the

electrodes. Because of the high voltage across the

electrodes, the water can now conduct electricity.

Red “Change Cylinder” light on - Water at top of

cylinder:

This is a common occurrence on start-up. See

Start-Up and Operation section of this manual.

-5-

Page 9

If the cylinder is old, it indicates end of cylinder life.

Time to replace the cylinder. See “When To Replace

The Steam Cylinder” section of this manual.

Red “Change Cylinder” light on - Water NOT at top

of cylinder:

Water foaming to top of cylinder causing false full

cylinder indication. This also may be accompanied by

arcing (flashing) inside cylinder. Refer to “Terms

Used” regarding foaming.

Water remains at high level and won’t concentrate:

This is normal on cold start-up and can be

accelerated by adding maximum 1/2 tsp. of dissolved

salt to the cylinder (through the plastic fill cup) on fill

cycle. See “Low Water Conductivity” section of this

manual.

If unit has been operating extensively, observe for

normal fill-boil-fill-boil cycle; no drain should be

occurring. If drain occuring, check for leaking drain

valve or back pressure.

Water beyond top of cylinder up into spout:

If the red light is not on and fill is still activated,

jumper across the connection of sensor on basic PC

board. If fill remains on when connection is jumped,

then basic PC board is faulty. If fill shuts off, then

verify primary voltage to cylinder (contactor

energized). If primary voltage is present, the high

water sensor PCB is defective.

Unit drains continually:

May be caused by foaming and/or back pressure,

or leaking drain valve.

Cylinder is almost empty, check for magnetic pull

on drain solenoid indicating miswiring. If no pull, drain

actuator is blocked open; remove, disassemble and

clean.

If drain is occurring through activated drain valve,

valve is miswired or electronics are faulty - consult

factory.

If drain is occurring through the overflow on the fill

cup, this is due to abnormal restriction on the steam

line and back pressure forces water out of the cylinder;

therefore, water cannot concentrate and level must

stay high; review installation of steam line to ensure no

blockages or excessive static pressure in air system.

-6-

Page 10

DIAGNOSTIC PROCEDURES - TROUBLESHOOTING GUIDE

Unit Status Lamp

Yellow Green

On On Maximum water level

Off Off No power to the

1 flash

sequence

Off Excess current.

Symptom Corrective actions

inside cylinder.

board.

Operating amperage

exceeded 130% of

rated amps. Water is

drained from the

cylinder (drain valve

on for 10 min.).

This usually happens on initial start-up after replacing the cylinder

(normal).

Water is concentrated with minerals inside the cylinder.

Let unit run, yellow light will disappear when the unit is at full

output. This may take a day or two.

Check for main power supply fault.

Turn power switch to ‘Drain’ position. If drain valve is activated

(sound of solenoid), check connection to the board or board itself.

When no sound present, check fuse (replace with 3.0 A if needed),

transformer (voltage should be present between fuse holder and

ground screw).

Check drain valve operation, drain time, possible drain

restrictions.

Check if fill valve leaks (not holding supply water).

Back pressure may also cause very conductive water conditions.

Was the humidifier short cycling?

Check for short cycling.

Water conductivity too high.

2 flashes in

sequence

4 flashes in

sequence

Off No current

detection for 30

minutes with

continuous call for

humidity.

Off End of cylinder life -

change cylinder.

Check water level in the cylinder - should be more than ¼ full. If

not check fill rate, 24 VAC voltage on fill valve terminals (unit must

be on with call for humidity - green light steady on). Verify fresh

water supply to the humidifier. Leaking drain valve can be at fault

(minerals blocking the plunger).

If cylinder is more than ¼ full, check primary power, connections to

the cylinder, continuity of wires to cylinder.

Are power wires connected to proper terminals on the cylinder?

(Color coding)

Possibly wrong cylinder type.

Low water conductivity.

Check water level in the cylinder, should be about ¾ full.

Check for foaming if water level lower or cylinder life shorter than

expected.

Change cylinder, clean drain valve.

-7-

Page 11

Modbus addresses:

4XXXX - R/W

3XXXX - R

SOFTWARE REQUIRMENTS FOR MODBUS RTU

Command Description MODBUS

Output Control

Set Output Sets the desired steam output

Force Drain When written to (FF), will interrupt

OFF

Disables the

humidifier and

places the

humidifier in

standby mode

After a microprocessor reset, the

default setting for Output Control

shall be OFF.

from 0-100%

This value shall be zero after a

microprocessor reset

the humidification process and

activate the humidifier drain valve.

After 20 minutes the controller will

reset this value (00).

After a microprocessor reset, the

default setting shall be (00)

ON

Enables the

humidifier

(humidifier will

operate based

on the SET

OUTPUT

command

input)

address

40262 255: inhibit actions of

40264 Remotely set humidity reading

40276 255 will start the process, 0

Details

humidifier

0: allow normal operation

over network. Value of 0 to

100 (per cent). If no network

signal for N minutes, reverts to

0.

will be accepted, to clear if the

request has not been cleared

itself

Set MODBUS address* Change the humidifier controller’s

MODBUS address.

Range is 1-247.

This setting shall be non-volatile

with a default setting of 1.

Set MODBUS Baud rate* Changes the humidifier’s baud

rate.

Range is 4800, 9600, and 19200

B/sec.

This setting shall be non-volatile

with a default value of 9600 B/sec.

Set MODBUS parity* Change the humidifier controller’s

MODBUS parity.

Range is None, Even, Odd

This setting shall be non-volatile

with a default setting of Even.

-8-

40550 The value changes will only

take effect following a

hardware reset of the control

board.

40552 The value changes will only

take effect following a

hardware reset of the control

board

40554 The value changes will only

take effect following a hard

ware reset of the control board

-

Page 12

Reset Run Hour Counter Resets the humidifier controller’s

run hour counter to zero hours

40560 255 will start the run hours

counter process.

0 will be accepted to clear the

run hours counter.

Current damping Buffers the measured current 40510 From 0 to maximum

(depending on software ability)

Electrode current The value of the electrode current

in Amps

30850 Hex value representing the

humidifies current in amps

Resolution: 0.10 amps

Example:

015F (hex) = 35.1 Amps

Steam output The current steam output in Kg/Hr.

or LBS/hr

30860 Hex value representing the

humidifies steam output in

kg/hr

See UNITS (Modbus 40031)

Resolution: 0.10 kg or LBS

Example:

013B (hex) = 31.5 kg/hr or

LBS/hr

Run hour counter The number of hours the

humidifier has been in operation

since the last time the run hour

counter was reset

30414 Hex value representing the

number of humidifier oper

additional hours since the last

reset.

Resolution: 5 minutes

Maximum count: 5460 Hours.

Example:

07D0 = 2000 hours

Firmware version The firmware version of the

humidifier controller

Humidifier state Describes the current state of the

humidifier and it’s I/O’s

Contactor ON/OFF

Fill Valve ON/OFF

Drain Valve ON/OFF

Maximum production The rated maximum steam

production for the humidifier

Alarms The humidifier shall describe any

faults

Too long to fill

Excess Current

End of cylinder life

No current

30361 Packed BCD version 3.52

would be 0x0352

30800 Bit Allocation

Note More than one bit can be

active at any time.

Contactor on = 1

Fill valve on = 2

Drain valve on = 4

30802 Value written into Unit type

(40600) is also stored here

30364 Bit Allocation

Note More than one bit can be

active at any time.

Too long to fill = 1

Excess current = 2

End of cylinder life = 4

No Current = 8

-9-

Page 13

Units Required by the control board for

capacity calculations

40031 0: 0-1. 0=LBS, 1=KG

Unit type Required by the control board for

current and capacity calculations

Unit voltage Required by the control board for

current and capacity calculations

406000 Depending on the setting in

UNITS (Modbus: 40031)

Hex value representing

maximum unit capacity (100%

fill off amps)

40610 Format is Hexadecimal

numeration table (see below)

Hex Value Unit Type

0 110-120

1 208

2 220-240

3 230

4 277

5 347

6 380

Unit phase Required by the control board for

current and capacity calculations.

7 400

8 415

9 440-480

A 550-600

40620 Bit Allocation

Single phase = 1

Three phase = 2

Three phase (6 electrode) = 4

-10-

Page 14

MES

-11-

Page 15

-12-

Page 16

- 13-

Page 17

MES SERIES SPARE PARTS LIST - ELECTRICAL AND PLUMBING

1

1

1

1

2

1

1

2

1

1

2

1

1

2

1

1

2

1

1

4

1

1

1

1

4

1

1

1

1

4

1

1

1

1

4

1

1

1

1

4

MES-U 25 - 30 / 3Ph

MES-U 15 - 20 / 3Ph

380/

208/

380/

208/

380/

460/

230V

460/

230V

460/

575V

575V

575V

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

n/a

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

3

1

2

1

1

3

1

2

1

1

3

1

2

1

1

3

1

2

1

1

3

1

1

1

n/a

1

1

1

n/a

1

1

1

n/a

1

1

1

n/a

1

1

1

n/a

1

1

2

1

2

2

1

2

2

1

2

2

1

2

2

1

2

2

1

1

1

1

2

1

1

1

1

2

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MES-U 15 - 20 / 1Ph

MES-U5 - 10/ 1Ph

208/

380/

208/

NORTEC

Comments

230V

460/

230/

PA RT

575V

277V

NUMBER

1

1

1

1

1

1

1

1

1

1

1

Consult

Fac tor y

150 4150

135 4012B

1

n/a

1

n/a

1

n/a

135 4012R

135 4012Y

1

1

1

132 1216

1

1

1

163 1026

1

1

1

132 5064

1

1

1

132 5046

1

1

1

132 8810

1

1

1

132 6003

w/ocoil

1

1

1

145 6000

1

1

1

132 6002

w /o body

1

1

1

Specify Length 132 8860

3

3

3

132 5035

1

1

1

132 6004

2

1

1

2

1

1

2

1

1

145 5002

132 6002K1

132 1042BR

1

1

1

142 1050

1

1

1

1

132 1061

n/a

n/a

n/a

n/a

132 1062

1

1

1

Specify Length 132 8850

2

2

2

132 5023

2

2

2

145 5004

1

1

149 5072

1

1

132 6129

1

1

1

145 1003

2

2

2

Closed Plumbing 145 3079

1

1

1

Closed Plumbing 163 1014

2

2

2

132 3079

1

1

1

PVC * Electrical 132 3020

1

1

1

132 5253

1

1

1

132 3099

1

1

1

147 4994

1

1

1

132 8810

4

4

4

132 5007

1

1

1

132 3097

1

1

1

PVC * Electrical 147 3002

PVC * Electrical 163 1050

1

1

1

151 3003

1

1

1

1

1

1

1

1

1

Consult

Fac tor y

1509591

1509529

DESCRIPTION

Drain Canal Screw

Cylinder - To order replac ement cylinder, quote the 3-digit

number on the cyl. Being replaced or quote the unit

serial number, model and voltage from the spec label.

Cylinder Plug - Sensor H.W.S

Cylinder Plug 10AWG Spring Loaded - Black

Cylinder Plug 10AWG Spring Loaded - Red

Cylinder Plug 10AWG Spring Loaded - Yellow

1

2

3

4

NO

POS .

5

Drain Canal

6

Drain Canal Washer

Drain Canal Gasket

8

9

7

- -14-

Steam Hose Nominal 3/4" - Specif y Length

Fus e 3 A In- Lin e

Drain Valve Plastic Stuff ing Block

Drain Valve Body and Coil Ass embly

Drain Valve Hose and Overf low Hose

Drain Valve Body - As sembly

Drain Valve Coil Assembly - 24V A SCO2

Drain Hose Nominal 3/4" - 1 f t. length

11

10

Drain Valve Hose and Overf low Hose Spring Clamp

12

14

13

15

Drain Valve Spring & Core

Drain Valve Scr ew s

Drain Valve O-Ring

17

19

18

16

Fill Valve Hos e

Fill Cup

Fill Valve A ssembly #2

Fill Valve A ssembly #1

23

20

22

21

Fitting - 3/8" to 1/4" compression 90 degree

Grommet - Closed 7/8"

Fitting - 1" to 3/8"

Fill Valve Spring Clamp

Fill Valve Sc rew

26

24

25

Grommet - Closed 1-1/16"

Grommet - Open 7/8"

28

27

29

30

31

High Water Sensor PC Board A ss embly

Steam hose Clamp

Terminal Block 65A 1PH

Tie Wrap - Reusable

Sw itch -On/Of f

Ground Clamp

High Water Sensor Board Standof f

High Water Sensor Ligh and Lense

36

35

32

33

34

Terminal Block 65A 3PH

number on the board label, or, quote the unit ser ial number

PCB - To order replacement PC Board, quote the 7- digit

model and voltage from the spec label

MES-P Replacement PCB Board

MES-P Replacement Modbus driver board

37

39

40

38

41

42

43

Page 18

- 15-

Page 19

LIMITED WARRANTY

Walter Meier Inc. and/or Walter Meier Ltd. (hereinafter collectively referred to as

THE COMPANY), warrant for a period of two years from date of shipment, that THE

COMPANY’s manufactured and assembled products, not otherwise expressly

warranted (with the exception of the cylinder) are free from defects in material and

workmanship. No warranty is made against corrosion, deterioration, or suitability of

substituted materials used as a result of compliance with government regulations.

THE COMPANY’s obligations and liabilities under this warranty are limited to

furnishing replacement parts to the customer, F.O.B. THE COMPANY’s factory,

providing the defective part(s) is returned freight prepaid by the customer. Parts used

for repairs are warranted for the balance of the term of the warranty on the original

humidifier or 90 days, whichever is longer.

The warranties set forth herein are in lieu of all other warranties expressed or

implied by law. No liability whatsoever shall be attached to THE COMPANY until said

products have been paid for in full and then said liability shall be limited to the original

purchase price for the product. Any further warranty must be in writing, signed by an

officer of THE COMPANY.

THE COMPANY’s limited warranty on accessories, not of Walter Meier’s

manufacture, such as controls, humidistats, pumps, etc. is limited to the warranty of the

original equipment manufacturer from date of original shipment of humidifier.

THE COMPANY makes no warranty and assumes no liability unless the

equipment is installed in strict accordance with a copy of the catalog and installation

manual in effect at the date of purchase and by a contractor approved by THE

COMPANY to install such equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for

consequential damage or damage resulting directly from misapplication, incorrect sizing

or lack of proper maintenance of the equipment.

THE COMPANY retains the right to change the design, specification and

performance criteria of its products without notice or obligation.

Page 20

Walter Meier (Climate Equipment) Ltd.

2740 Fenton Road, Ottawa, Ontario K1T3T7

Walter Meier (Climate Equipment) Inc.

826 Proctor Avenue, Ogdensburg, New York 13669

Tel: 866 NORTEC 1 Fax: 613 822 7964

nortec@humidity.com www.humidity.com

PRINTED IN CANADA

Loading...

Loading...