Page 1

Important: Read and save these instructions. This guide to be left with equipment.

MES2

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for the MES2 Electrode

Steam humidifier

2554140-B|

24 OCT 2011

Page 2

Thank you for choosing Nortec.

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Proprietary Notice

This document and the information disclosed herein are proprietary data of WALTER MEIER LTD. Neither this

document nor the information contained herein shall be reproduced, used, or disclosed to others without the

written authorization of WALTER MEIER LTD., except to the extent required for installation or maintenance of

recipient’s equipment. All references to the Nortec name should be taken as referring to WALTER MEIER LTD.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2011, WALTER MEIER LTD. All rights reserved.

Page 3

Contents

1 Introduction

2 Receiving and Unpacking

3 MES2 Models

6 Options and Accessories

7 Humidifier Components

9 Humidifier Schematic

9 How the Humidifier Works

11 Installation

12 Typical MES2 Installation

13 Location

14 Mounting

15 Plumbing

16 Steam Lines and Condensate

Returns

31 Maintenance and

Servicing

32 Required Maintenance

36 Extended Shutdown

37 Maintenance Checklist

39 Troubleshooting

41 General Troubleshooting

43 MES2 Faults

45 Wiring Diagram

46 Spare Parts

50 Warranty

19 Primary Voltage Wiring

20 Control Wiring

21 Modbus Wiring

22 MES2 Installation Checklist

23 Operation

24 User Interface

25 Humidifier Configuration

27 Modbus Configuration

30 Start Up Procedure

Page 4

Introduction

CAUTION: Servicing

Disconnect main power before performing any servicing.

The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

During and following operation of the humidifier, the steam and components in

contact with the steam such as the steam lines, steam distributors, cylinders, and

condensate lines can become hot and can burn if touched.

Walter Meier does not accept any liability for improperly installed humidity

equipment or the use of parts/components/equipment that are not authorized or

approved by Walter Meier.

CAUTION: Electrical

All electrical work should in accordance with the local electrical code in location

where the humidifier will finally be operated.

CAUTION: Plumbing

Drain water from humidifier can be very hot. Do not drain to public sink.

All plumbing work should be in accordance with local plumbing code in location

where the humidifier will finally be operated.

CAUTION: Installation

Do not mount on hot surfaces

Do not mount in area where freezing can occur

Do not mount on vibrating surface

The MES2 produces steam at atmospheric pressure. No devices which could block

steam output should be connected to the steam outlet.

Steam lines must be installed so that no restriction can produce backpressure in

the humidifier.

Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to

operate. Nortec highly recommends the use of a duct high limit humidistat and air

proving switch.

1 | Introduction

Page 5

Receiving and Unpacking

1 Check packing slip to ensure ALL material has been delivered.

2 All material shortages are to be reported to Nortec within 48 hours from receipt of goods.

Nortec assumes no responsibility for any material shortages beyond this period.

3 Inspect shipping boxes for damage and note damages on shipping waybill accordingly.

4 After unpacking, inspect equipment for damage and if damage is found, notify the shipper

promptly.

5 All Nortec products are shipped on an FOB factory basis. Any and all damage, breakage or

loss claims are to be made directly to the shipping company.

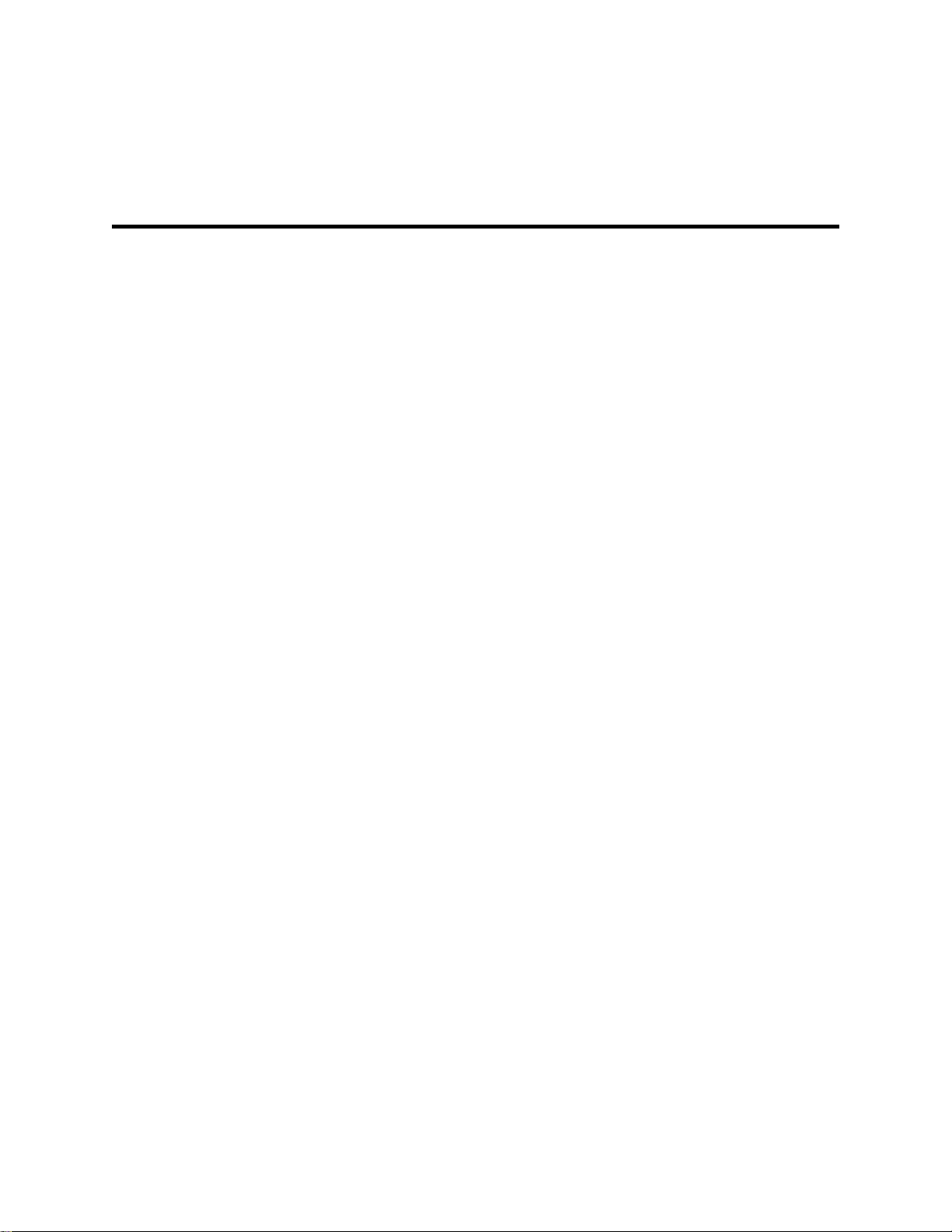

Before Installation

1 Ensure that available voltage and phase corresponds with humidifier voltage and phase as

indicated on humidifier’s specification label.

2 Ensure that the dedicated fused disconnect provided for the humidifier is of sufficient size to

handle the rated amps as indicated on the specification label.

3 Ensure sufficient clearances will be available as described in “Location” on page 13.

4 Ensure steam lines can be routed to distributor as described in Steam Lines and

Condensate Returns on page 16.

Figure 1: Specification Label Location

Introduction | 2

Page 6

MES2 Models

Open

Elect

ricalClosed

Elect

ric

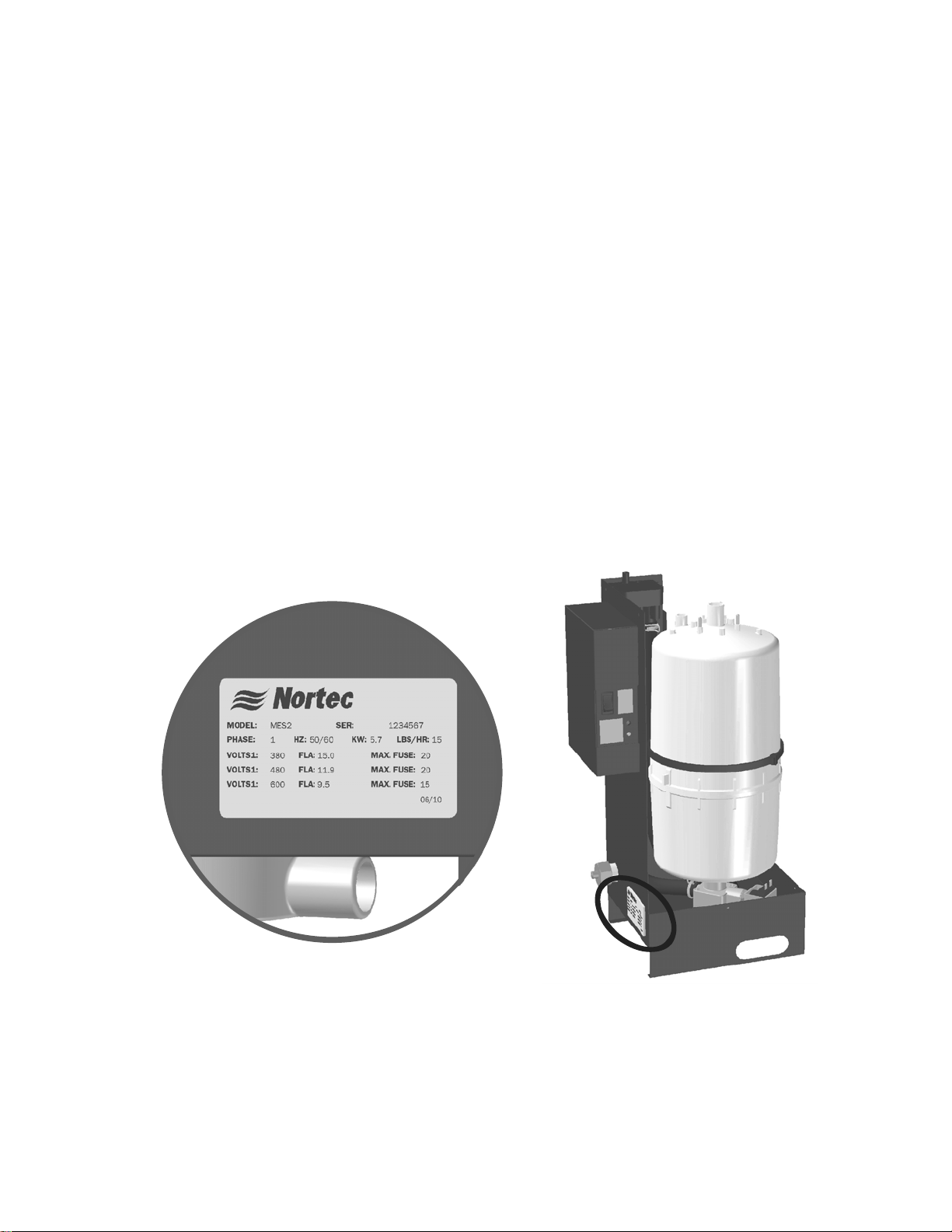

The MES2 is the most advanced OEM steam humidifier available and provides steady and

reliable humidification using the same proven cylinder technology as Nortec’s commercial

NHTC. The MES2 is offered in 5 models corresponding to control configurations as shown in

Figure 2. The remote configurations include 8 ft (2.4 m) of wiring for connecting the controls

to the plumbing cabinet. The Primary Voltage Wiring (PVW) model provides 8 feet of primary

wiring for connection to the contactor.

RemoteAttached Attached PVW

N/A

(ATT OE)

al

(ATT CE) (ATT CE PVW)

Figure 2: MES2 Models

The MES2 is available in 6 capacities ranging from 5 to 30 lb/hr (2.3 to 13.6 kg/hr) for

operation on a range of voltages and phases as outlined in Table 1: MES2 Part Numbers and

Electrical Data. The 6 capacities are packaged in 4 different cabinet sizes as shown in Figure 3.

5 lb/hr

(2.3 kg/hr)

10 lb/hr

(4.5 kg/hr)

(REM OE)

(REM CE)

15 - 20 lb/hr

(6.8 - 9 .1 kg/hr)

25 - 30 lb/hr

(11.4 - 13.6 kg/hr)

Figure 3: MES2 Capacities and Cabinets

3 | Introduction

Page 7

A

S

V

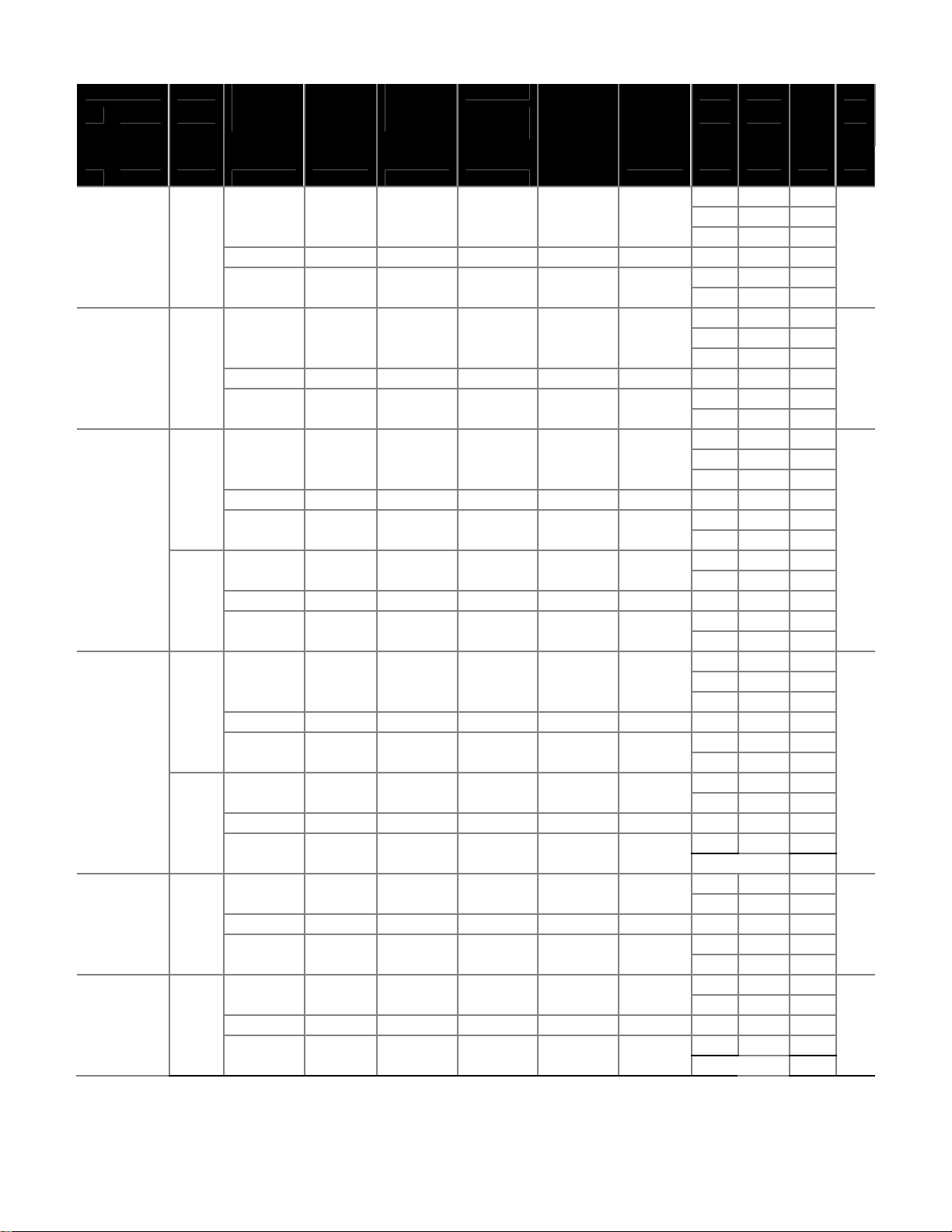

Table 1: MES2 Part Numbers and Electrical Data

Capacity Phase Attached

Closed

lb (kg) ATT OE ATT CE REM OE REM CE

Open

Elec.

5 (2.3) 1 2550262 3E+06 2550264 2550265 2550266 102 208 8.2 15 1.7

2550267 3E+06 2550269 2550270 2550271 103 380 4.5 15

2550272 3E+06 2550274 2550275 2550276 104 480 3.5 15

10 (4.5) 1 2550277 3E+06 2550279 2550280 2550281 202 208 16 25 3.4

2550282 3E+06 2550284 2550285 2550286 203 380 8.9 15

2550287 3E+06 2550289 2550290 2550291 204 480 7.1 15

15 (6.8) 1 2550300 3E+06 2550302 2550303 2550304 321 208 25 40 5.1

2550305 3E+06 2550307 2550308 2550309 305 380 13 20

2550310 3E+06 2550312 2550313 2550314 309 480 11 15

3 2550315 3E+06 2550317 2550318 2550319 303 208 14 20

2550320 3E+06 2550322 2550323 2550324 311 380 7.7 15

2550325 3E+06 2550327 2550328 2550329 311 480 6.1 15

20 (9.1) 1 2550340 3E+06 2550342 2550343 2550344 321 208 33 50 6.8

2550345 3E+06 2550347 2550348 2550349 305 380 18 30

2550350 3E+06 2550352 2550353 2550354 309 480 14 25

3 2550355 3E+06 2550357 2550358 2550359 303 208 19 30

2550360 3E+06 2550362 2550363 2550364 311 380 10 15

2550365 3E+06 2550367 2550368 2550369 311 480 8.2 15

25 (11.4) 3 2553765 3E+06 2553767 2553768 2553769 421 208 24 35 8.5

2553770 3E+06 2553772 2553773 2553774 407 380 13 20

2553775 3E+06 2553777 2553778 2553779 411 480 10 15

30 (13.6) 3 2550370 3E+06 2550372 2550373 2550374 421 208 28 40 10

2550375 3E+06 2550377 2550378 2550379 407 380 16 25

2550380 3E+06 2550382 2550383 2550384 411 480 12 20

Attached

Closed

Elec.

Remote

Open

Elec.

Remote

Elec.

ttached

Closed

Elec. PVW

ATT CE

PVW No. V A A KW

tandard

Cylinder

olts Amps Max

Ext

Fuse

240 7.1 15

277 6.1 15

600 2.8 15

240 14 20

277 12 20

600 5.7 15

240 21 30

277 18 30

600 8.5 15

240 12 20

600 4.9 15

240 28 45

277 25 35

600 11 20

240 16 25

600 6.5 15

240 20 30

600 8.2 15

240 25 40

600 9.8 15

KW

Introduction | 4

Page 8

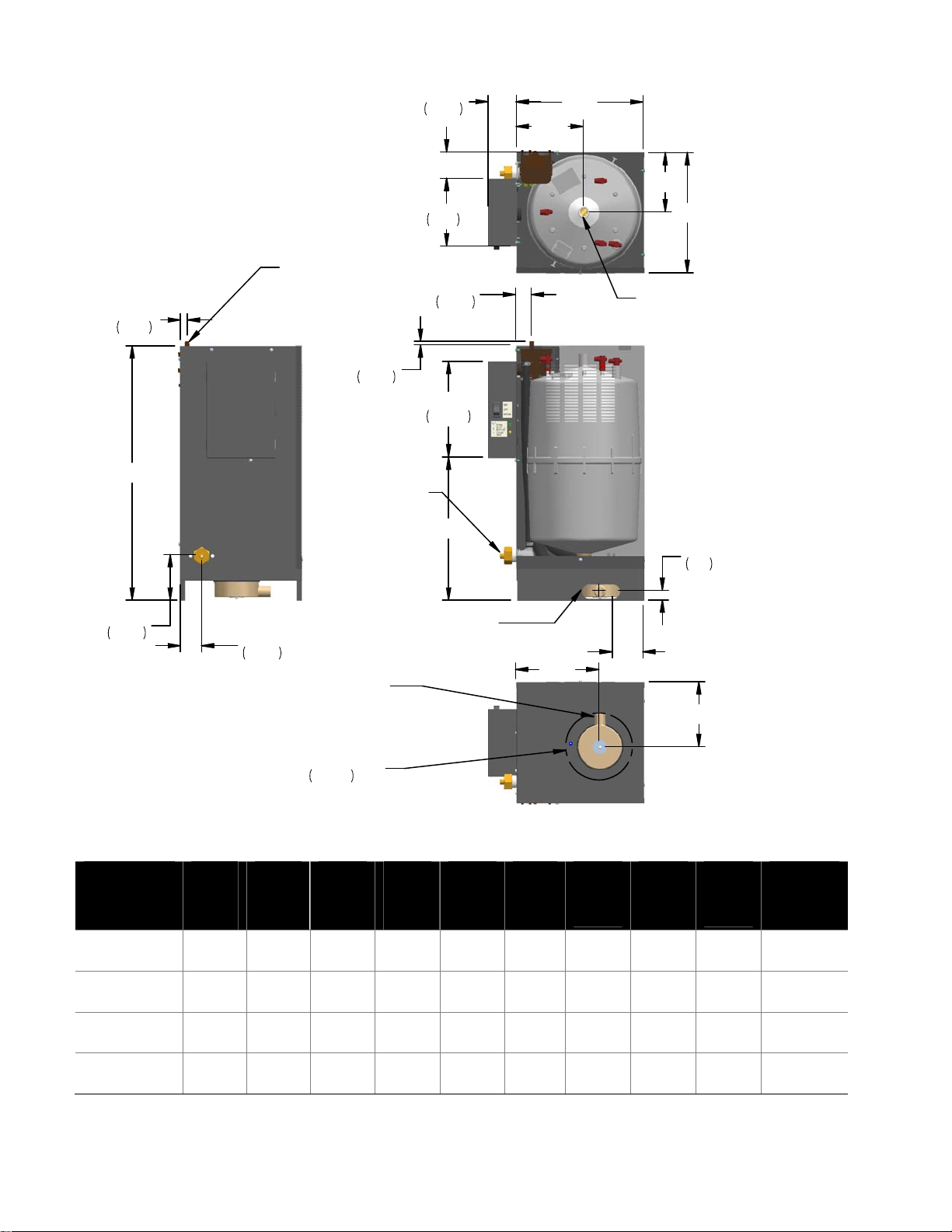

MES2 Dimensions / Weights

0.34 (9 mm)

Condensate

0.57

1. 4

C

Re t ur n

0.30

0.8

1/ 8 NPT

Fill Connection

2.30

5.8

F

5.50

14

1. 2 8

3.3

7.79

19 .8

G

D

A

E

B

0.875 (22 mm)

St e am Out l et

0.80

2

O

3.70

9.4

1. 7 3

4.4

1.12 x 2.0 (2.85 x 5.1) Slot

Both Cabinet Sides

H

0.875 (22 mm)

O

Drain Outlet

5.45

O

13 .8

Rotate 360

v

to

Desired Position

Note: Unless otherwise specified dimensions are in inches (cm). Tolerance ±0.1 in. (0.25 cm)

Capacity

lb/hr (kg/hr) A Width B Depth C Height

5

(2.3)

10

(4.5)

15-20

(6.8 – 9.1)

25-30

(11.4 – 13.6)

Note: * Steam Outlet is not centered on MES2 5 & 10 lb/hr (2.3 & 4.5 kg/hr) models.

** Weights given for MES2 with enclosed electronics and optional plumbing enclosure. Full Weight is weight with cylinder full of

water. Full weight may exceed this value at end of cylinder life depending on the amount of scale and its composition.

7.5

(19)

7.5

(19)

8.9

(22.6)

10.3

(26.2)

6.4

(16.3)

6.4

(16.3)

7.9

(20.1)

9.8

(24.9)

12.7

(35.3)

16.8

(42.7)

20.0

(50.8)

20.7

(52.6)

D*

Steam

Outlet

4.2

(10.7)

4.2

(10.7)

5.1

(13)

5.5

(14)

E*

Steam

Outlet

5.1

(13)

5.1

(13)

4.0

(10.2)

4.9

(12.5)

F

Elec.

Pos.

0.3

(0.8)

0.3

(0.8)

1.1

(2.8)

2.2

(5.6)

G

Elec.

Height

4.9

(12.5)

8.0

(20)

11.2

(28.5)

11.6

(29.5)

2.5 (6.4) MES2 25 - 30

1.5 (3.8) MES 5 - 20

J

H

Drain

Center

5.6

(14.2)

5.6

(14.2)

6.4

(16.3)

6.8

(17.3)

J

Drain

Center

3.4

(8.6)

3.4

(8.6)

4.2

(10.7)

5.2

(13.2)

Net/Full

Weight**

lb (kg)

10.7/14.2

(5/6.6)

12.4/18.4

(5.8/8.5)

16.5/30.5

(7.8/14.2)

20.2/43.2

(9.5/20.0)

Figure 4: MES2 Dimensions and Weights

5 | Introduction

Page 9

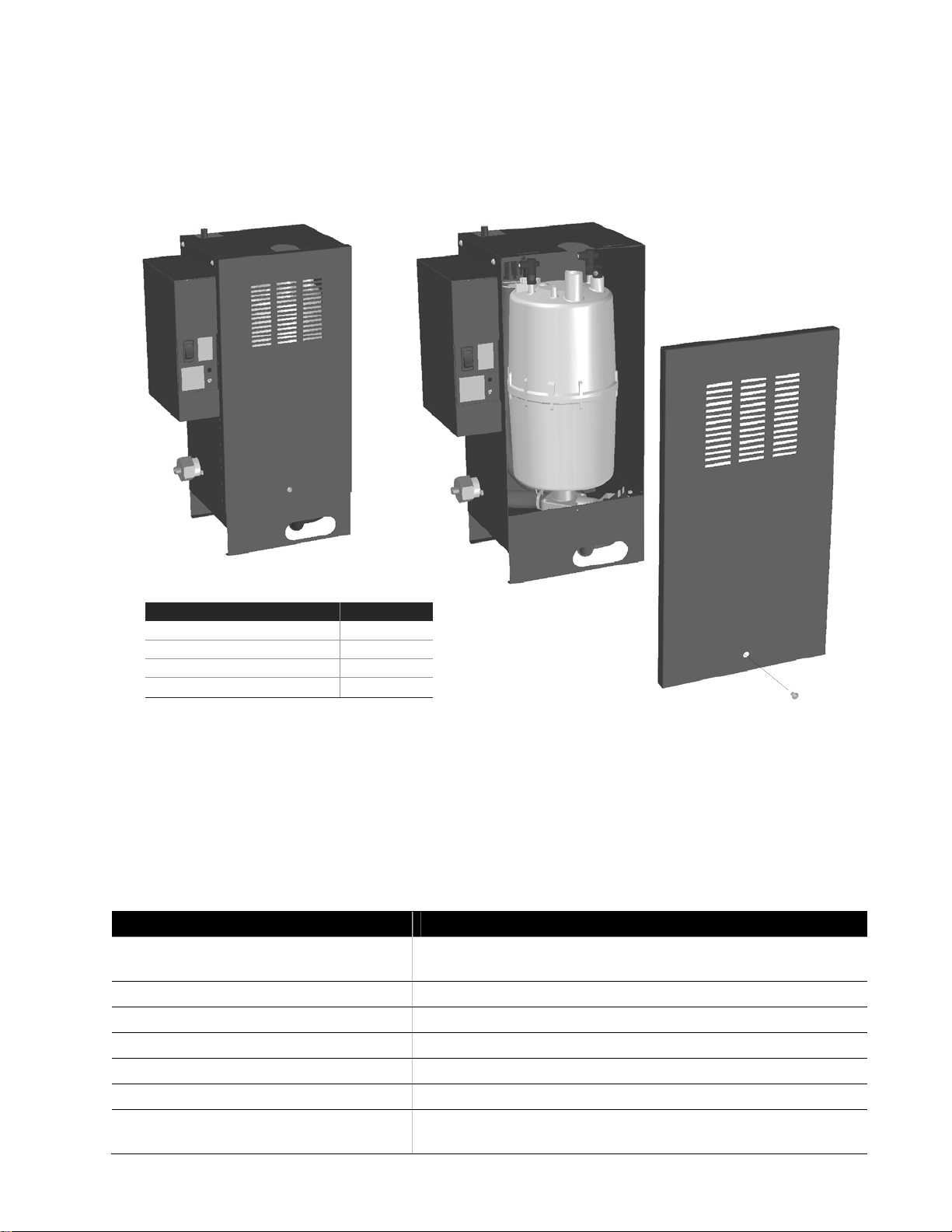

Options and Accessories

An enclosed plumbing option is available for each MES2 cabinet size. The option consists of a

fixed cabinet with an easily removable door for servicing. Figure 5 shows the enclosed

plumbing option installed on a 10 lb/hr MES2 ATT CE.

Enc losed P lumbing Part N umber s

Capacity Part No.

5 lb/hr (2.3 kg/hr)

10 lb/hr (4.5 kg/h r)

15, 20 lb/hr (6.8, 9.1 kg/hr)

25, 30 lb/hr (11.4, 13.6 kg/hr)

2554073

2554074

2554075

2554076

Figure 5: Enclosed Plumbing Option

Nortec also provides a complete line of options and accessories for every humidification

application. The following table lists some of the most common accessories available for use

with the MES2 humidifier. Refer to the installation instructions that come with the accessories

for their proper installation and operation.

Table 2: Options and Accessories

Option / Accessory Used For

Modbus Interface Controlling humidifier operation via Modbus (See Modbus Wiring

on page 21 and Modbus Configuration on page 27).

Enclosed Plumbing See above.

Steam Distributors Adding steam into air ducts.

On/Off or Modulating Control Humidistats Controlling the output of the humidifier based on sensed RH.

Air Proving Switch Insuring humidification only occurs when air is moving in a duct.

Steam Hose Connecting humidifier to steam distributor.

Condensate Hose Collecting and draining condensate that collects in steam

distributors and steam distribution lines.

Introduction | 6

Page 10

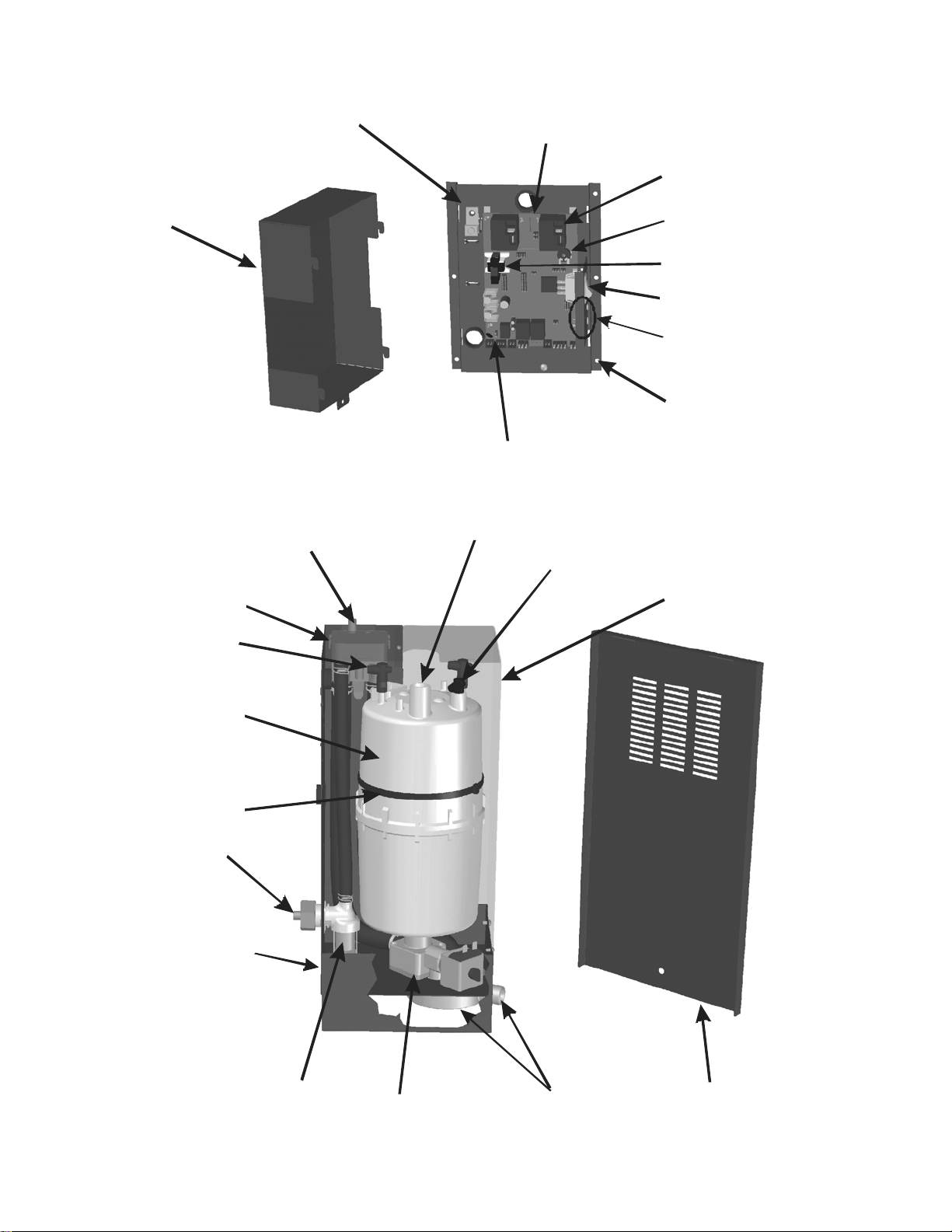

p

Humidifier Components

Ground Clam

Control Board

Power Relay

Electrical Cover

Fill Cup

Cyl i nder Plug

Condensate Return

Capaci ty A djustment

Potentiometer

Current Sensor

On/Off/Drain Switch

Status Lights

Bracket, Remote

El ectrical

Control Connection

Terminals

Steam Outl et

High Water Sensor

Plug

Pl umbing

Enc losure

(Optional)

Cyl i nder

Cyli nder

Tie Wrap

Fill Inlet

Drain Pan

Fill Valve

Drai n Valve

Drain Outlet

Drain Canal

Figure 6: MES2 Components

Pl umbing

Door

(Optional)

7 | Introduction

Page 11

Table 3: MES2 Components

Component Function of Component

Bracket, Remote

Electrical

Capacity Adjustment

Potentiometer

Condensate Return

Control Connection

Terminals

Current Sensor

Cylinder

Cylinder Plug

Cylinder Tie Wrap

Drain Outlet / Canal

Drain Pan

Supports the control components for MES2 models which have remote

electronics (REM).

Adjusts the maximum output of the humidifier from 100% down to 20%.

See Figure 22: Capacity Potentiometer Adjustment on page 26.

Provides a connection to return condensate to humidifier.

Terminals on the control board for connecting external controls to

humidifier.

Measures the amount of current flowing through the cylinder’s

electrodes.

Holds electrodes in water. Current between electrodes generates heat

used to generate steam.

Power connectors to electrodes in cylinder. Installer must connect wires

from contactor to cylinder plugs. (PVW model has wires installed).

Holds cylinder in place, reusable.

Combines cylinder drain water and fill cup overflow into a single drain

outlet.

Collects any water which may leak from water connections and routes it

to drain.

Drain Valve

Control Board

Electrical Cover

Fill Cup

Fill Inlet

Fill Valve

Ground Clamp

High Water sensor

Plug

On/Off/Drain Switch

Plumbing

Enclosure/ Door

Power Relay

Drains water from humidifier.

Controls all functions of the humidifier’s operation and provides input

and output connections to humidifier components.

Covers the control board and wiring on MES2 models with closed

electrical (CE).

Provides an air gap for backflow prevention.

1/8 NPT brass fitting for connecting supply water to the humidifier.

Controls flow of water into humidifier.

Electrical ground connection for humidifier.

Used to detect max water level in cylinder.

Turns power on/off to humidifier controller and drains the cylinder for

servicing. Note: Turn off humidifier disconnect to shut off primary power

to the humidifier.

The optional plumbing enclosure completely encloses the humidifiers

water components.

Turns on/off power to the contactor (supplied by others) based on a

signal from the humidifier’s controller (mounted on control board).

Status Lights

Steam Outlet

Indicate if the humidifier is operating. If the humidifier is shut down on a

fault the yellow LED flashes in sequence to indicate the fault that

occurred.

Outlet for steam generated by the humidifier. Connect to the outlet with

a steam hose and hose clamp.

Introduction | 8

Page 12

r

Humidifier Schematic

Air Gap

1.25 in.

(3.2 cm)

Steam Line

Steam Distributo

Condensate Return

Current Sensor

Power Relay

24 VAC

Drain Valve

External Air

Gap

Control Board

To

Contactor

Fill Cup

Cylinder

Overflow

High

Water

Sensor

Electrodes

From

Contactor

Fill Valve

Internal Air

Gap

Drain Canal

Figure 7: Humidifier Schematic

How the Humidifier Works

The MES2 is an atmospheric steam generator that uses heat generated by electrical current

flowing between submerged electrodes to generate steam. The MES2 is designed for air

humidification via steam distributor.

Steam Generation

If the MES2 is configured for On/Off operation then as soon as the safety loop between

terminal 1 and 2 is closed the humidifier assumes 100% demand, closes the power relay on

the control board, and measures the current flowing through the power wire routed through

the control board’s current sensor. If it is configured for modulating operation it waits for a

demand signal and for the safety loop between terminal 1 and 2 to be closed.

9 | Introduction

Page 13

If the demand is lower than the actual output the inlet valve is kept closed and output is

reduced by letting the water level in the cylinder decrease by evaporation.

If demand is higher than the actual output after a brief delay the fill valve is activated and

water flows into the fill cup. Water from the fill cup flows into the bottom of the cylinder

through a hose connected to the drain valve housing.

Note: The cylinder is gravity fed from the fill cup. If backpressure from the steam line is too

high it will cause water to back up in the fill cup and flow down the overflow line to the

drain.

A soon as the water in the cylinder comes in contact with the energized electrodes current

flows through the water. The resistance of the water to the electrical current generates heat

and in turn steam. The more electrode that is covered by water the higher is the current and

output. The unit continues to fill until the current matches demand or the high water sensor

detects a high water level.

The MES2 repeats the fill and boil down cycle repeatedly to match output to demand.

Over time minerals in the water will adhere to the cylinder’s electrodes. The humidifier will

automatically fill to a higher water level to maintain full capacity during the life of the

cylinder. Eventually because of scale formation it will no longer be possible for the

humidifier to reach its full capacity. The MES2 software monitors this condition and when

detected will stop operating and flash the yellow LED in a repeating sequence of 4 flashes.

Drains

As steam is produced minerals are left behind increasing the conductivity of the water. The

MES2’s patented auto adaptive cycle will monitor the water conductivity and perform drains

to maintain the water at optimal conductivity for peak performance.

The auto adaptive cycle provides the longest cylinder life in combination with keeping the

tightest control and most efficient use of water during the entire cylinder life.

Steam Distribution

The most common method for adding the steam into the air is to mount a steam distributor in a

supply air duct as shown in Figure 7: Humidifier Schematic. In an air handler the best location

for introducing the steam is after the heating coil where the air will be at its lowest humidity.

Steam Line

The steam line between the cylinder steam outlet and the distributor may be Nortec steam

hose, copper pipe, or stainless steel pipe or tube. The MES2 is an atmospheric steam

generator so it is very important no restrictions are present in the steam line and that the steam

line is sized properly to carry the full output capacity of the humidifier. See Steam Lines and

Condensate Returns on page 16 for information on selecting steam lines.

Condensate Return

Whenever steam is generated, condensate is formed in the distribution system and steam

distributor. Insulating steam lines is one important way to reduce the amount of condensate

formed. Steam lines are sloped so that condensate does not collect in the lines and create a

restriction to steam flow. The condensate must be collected and removed from the system so

that it does not build up and leak into the duct or air handler. Condensate can be returned to

the MES2 fill cup to reduce water waste or can be fed to drain.

Introduction | 10

Page 14

Installation

12 Typical MES2 Installation

13 Location

14 Mounting

15 Plumbing

16 Steam Lines and Condensate Returns

19 Primary Voltage Wiring

20 Control Wiring

21 Modbus Wiring

22 MES2 Installation Checklist

11 | Installation

Page 15

/Of

f

f

y

A

f

A

C o n t

t o

r

r

L1

r

r

r

r

A

r

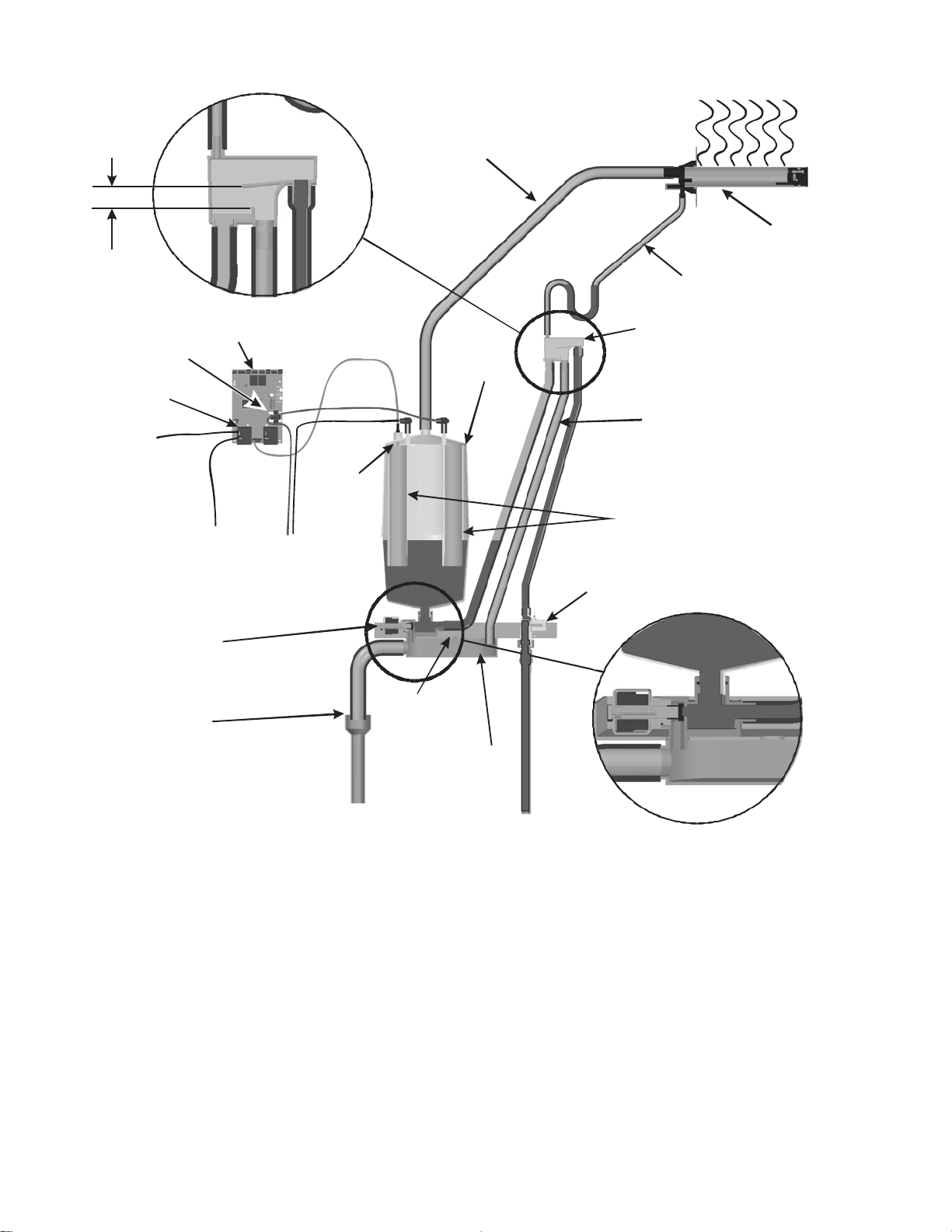

Typical MES2 Installation

Control

Wiring

Pg 20

Steam

Distribution

Page 16-18

12 in. (30 cm)

min. radius*

1 ft (30 cm)

min. before

any bend*

2 in. (5 cm)

min.

1 ft (30 cm)

Support

brackets*

Condensate

trap

E

n

e

a

g

i

c

z

e

Steam Line

O

(

2

L

S

4

n

o

a

V

o

e

p

C

t

)

Front side

clearance required

for cylinder removal.

Power Relay

On/Of

Drain

Switch

Fuse

2

4

V

C

Location

Mounting

Pg 13

Fill

Line

36 in. (90 cm)

recommended

Drain

Line

Plumbing

Primary

Voltage

Pg 15

Pg 19

1/8 in.

NPT

Cold Potable Water

30 - 80 PSIG

0.875 in.

(22 mm).

OD

ir gap

recommended

Drain

7/8 in. Min.

Note:

Single Phase

Connection Shown

L2

Disconnect Contacto

Current transforme

* Dimensions and brackets are recommendations based on best practice. OEM must verify operation if they are not followed or used.

Cylinde

plug with

white

marke

Figure 8: Typical Humidifier Installation

Installation | 12

Page 16

Location

Mount to structural member or on surface capable of supporting the humidifier’s operating

weight (see Figure 4: MES2 Dimensions and Weights). The humidifier may be set on its base but

clearance must be provided for the drain line to be sloped adequately. In general clearance is

not required around the humidifier except for maintenance access and electrical and plumbing

connections.

The clearance dimensions shown are recommendations based on best practice. OEM must

verify operation if they are not followed.

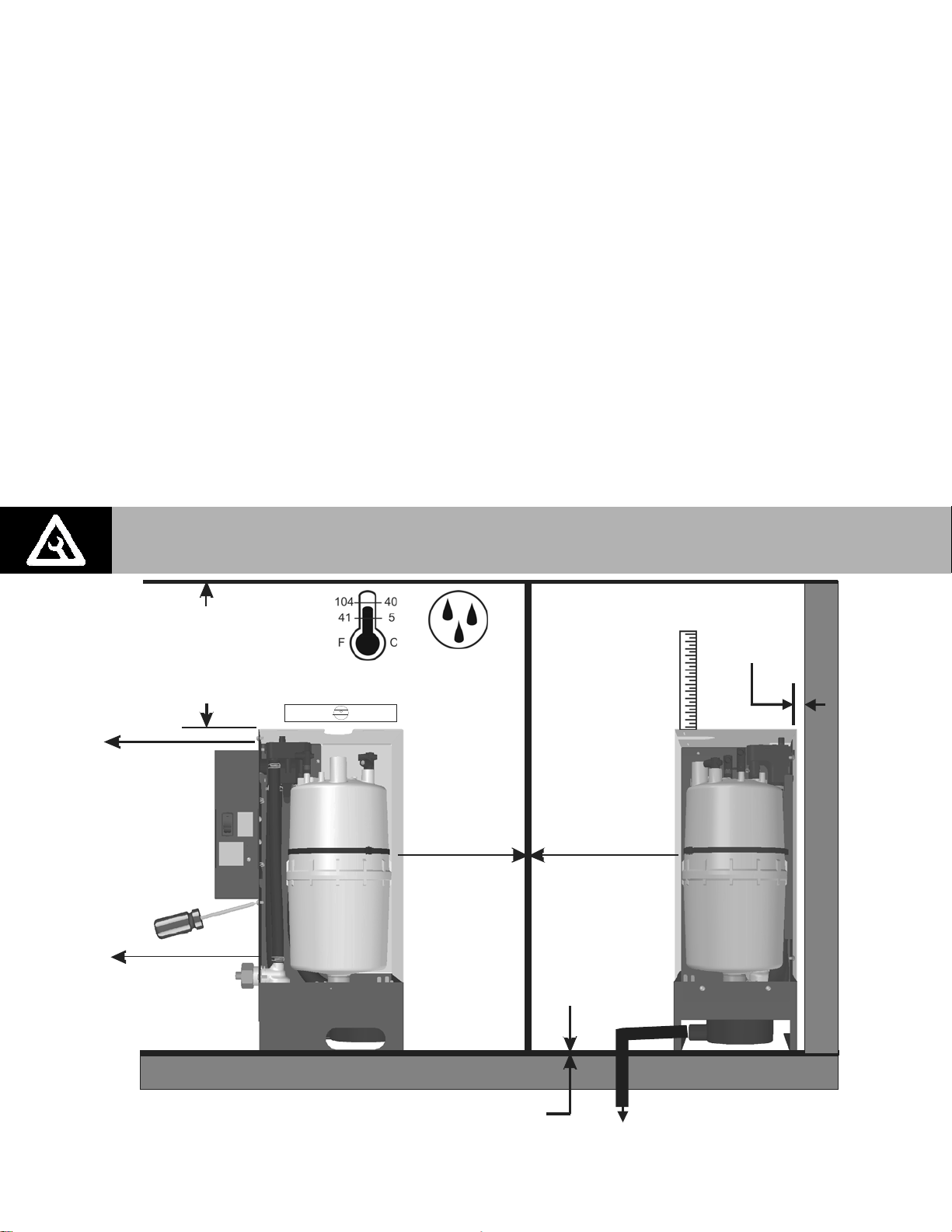

Install only in areas with ambient temperature 41-104°F (5–40°C) relative humidity 5 -

95%.

When possible install below the steam distributor. If mounted above the steam distributor

take care to provide proper steam line routing and proper condensate traps.

DO NOT locate the humidifier any further then absolutely necessary from the steam

distributor location as net output will be reduced as a result of heat loss through the steam

line.

The main service access required is for changing the cylinder. This access can be from the

front or right side. Right side service access is not possible with the optional plumbing

enclosure.

Note: Nortec recommends a vertical drop from the drain outlet and an air gap as close

as possible to the drain outlet to insure proper draining of the humidifier.

8 in. (20 cm)*

left side clearance

for remova l of cover

on attached closed

electronics models

0.5 in. (1.3 cm)*

top clearance

access hole required

for steam outlet and

optional condensate

return to fill cup.

only.

0 in . (0 cm)

access ho le or

additional clearance

required for fill

connection

Mount level

5-95%

in. ( cm)

00

side clearance

for front cylinder

cylinder removal

remo val

36 in. (92 cm)*

side clearance

for right side

only.

Note:

side cylinder

removal not

possib le with

enclosed

pluming option.

As close as

possible to steam

distributor

in. (92 cm)

36 *

front clearance

for front cylinder

remo val and/or fo r

attached electronics

models only.

0 in. (0 cm)

front clearance

for right side

cylinder removal

0.2 (0.5 cm)*

for fill cu p

tabs.

* Dimensions are recommendations based on best practice. OEM must verify operation if they are not followed.

13 | Installation

Access for properly sloped drain required.

0 in (0 cm) bottom clearance.

Figure 9: Mounting Location / Clearance

Page 17

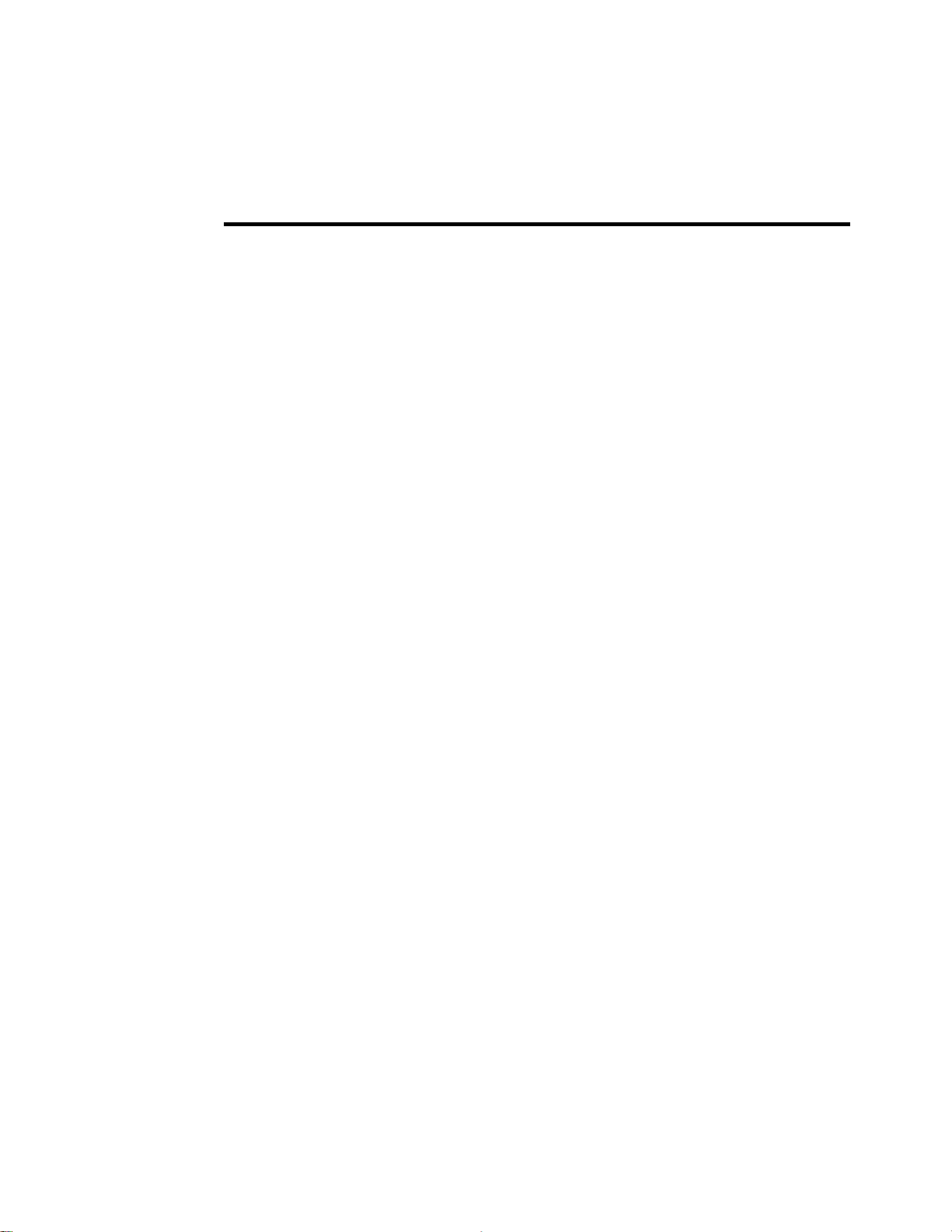

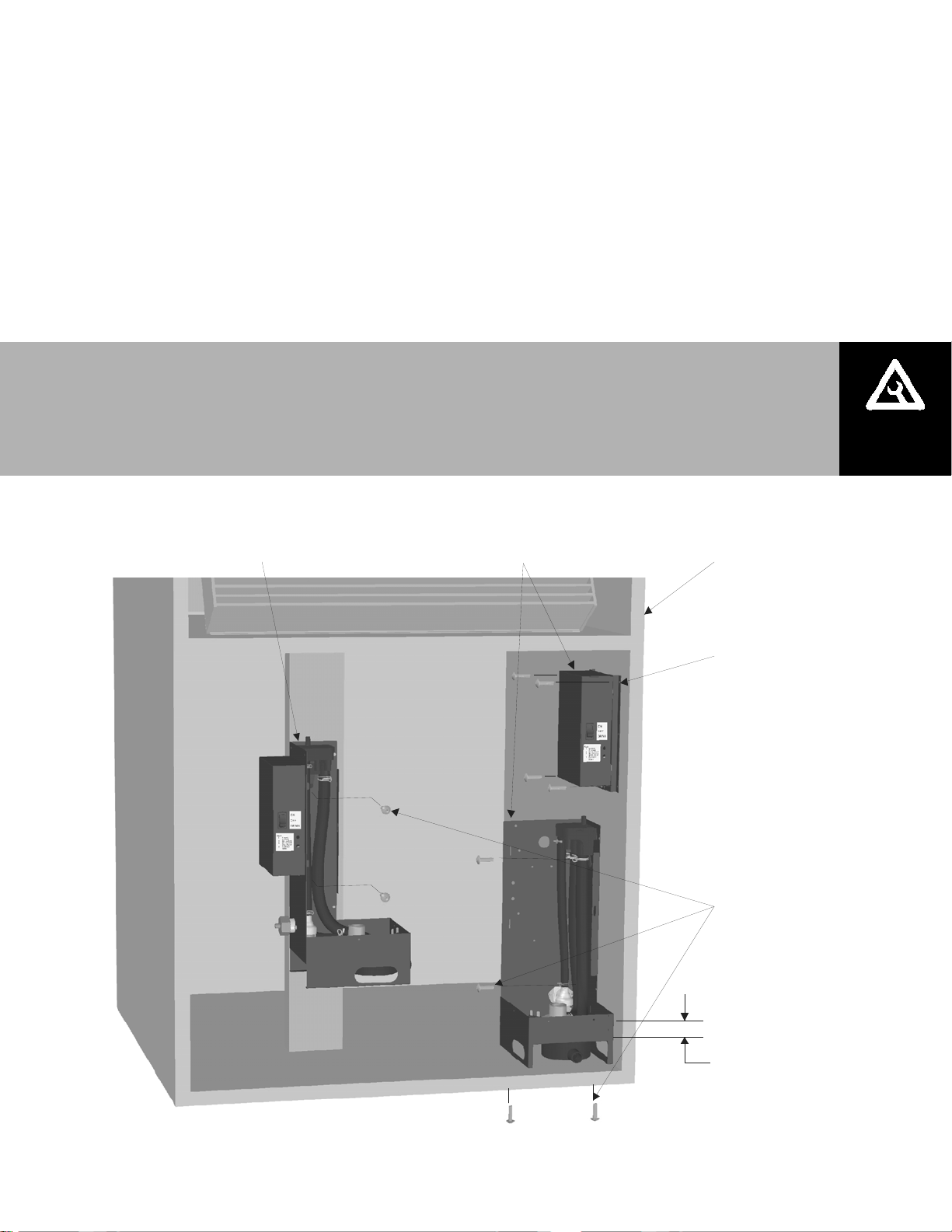

Mounting

1 The MES2 humidifier can be wall or floor mounted. No mounting holes are provided but can

be made anywhere in the base and sides of the cabinet at installation time.

2 Use a minimum of 2 x #8 screws mounted securely into structural surfaces.

3 Make sure the unit is level.

4 If enclosed plumbing option is installed then mounting screws can also be installed into the

plumbing enclosure.

5 It is the installer’s responsibility to insure that the humidifier is securely and safely mounted

in the air handler.

Note:

Installation methods shown are suggestions only actual mounting may differ and must

be verified by OEM.

When mounting to a vertical member by drilling holes in the cabinet, be careful not to

make any holes in the bottom 1 in (2.5 cm) of the drain pan.

MES2 Attached

Electronics

(Back Mounted)

MES2 Remote

Electronics

(Side/Base Mounted)

Air Handler

Remo te El ectr o n i cs

Mount using 4 s crews i

0.19 in. mounting holes

Plumbing

Drill holes in back ,

side, or base of c abinet

and sec ure with m in. of

2 x #8 Sc rews.

Figure 10: MES2 Mounting

Avoid drilling in

bottom 1 in (2.5 c m)

of drain pan.

Installation | 14

Page 18

A

r

f

r

Plumbing

1/8 in. NPT

fill connection.

0.875 in. (22 mm). OD

un-threaded outlet

Always install a water

All water supply and drain line connections should be installed in accordance with local

Supply water is recommended at 30 to 80 PSIG and 150-1200 Microsiemens (Hardness 0-

shut-off valve.

Use 1/2 in. OD coppe

to within 4 ft (1.2 m) o

humidifie

*Elbows, pipe, water shut-off valve, and air gap reducer not supplied by Nortec.

Figure 11: Water Supply and Drain Connection

plumbing codes.

12 GPG). Consult factory for water conditions outside of this range. Install water shut off

valve before humidifier to facilitate servicing.

Min. 7/8 in. OD drain line.

Ensure adequate slope to

handle flow.

ir gap recommended.

1 1/2 in. to 7/8 in.

Copper reducer is ideal.

(Nortec option P/N 2522172)

Hose must not touch the bottom

of the funnel.

The drain line should not end in a sink used frequently by personnel, or where plumbing

codes prohibit it. Route to a floor drain or equivalent for safety reasons.

Ensure drain line is adequately sized to provide free and easy draining and that an air gap is

installed as shown. A restricted drain can cause cylinder water to over concentrate and

result in poor operation.

If a drain is not located near the humidifier use a condensate pump rated for hot drain water

such as Nortec’s P/N 1429527.

15 | Installation

For humidifiers installed in some cities including the City of Los Angeles:

A city-approved spring-loaded double ball CHECK VALVE must be installed by

contractor on the potable water inlet to the humidifier. Recommended valve

manufacturer: Watts Regulator, Size 3/8” inlet and outlet, Model #7.

Each drain line from the humidifier must be routed, without dips or sags, to

terminate above the flood level rim of a city approved indirect waste receptor.

Page 19

Steam Lines and Condensate Returns

MAIN RULES FOR ATMOSPHERIC STEAM LINES

Slope the steam lines

Trap condensate (Use full size ‘T’ for Traps)

Condensate traps must be a minimum of 3 in. (15 cm) in height or duct static

pressure + 2 in. whichever is greater.

Steam lines must not have any restrictions which could cause back pressure.

1.0 in. (2.5 cm) pipe insulation recommended.

Follow recommended materials, size and length see tables.

Use Appropriate Slope Insulate Pipe

10 Degrees

m

a

e

t

S

1 ft (30 cm)

2 in.

(5 cm)

n

o

i

t

c

e

r

i

D

S

t

e

a

m

r

D

i

Note: Larger diameter lines should be used for steam runs longer than those listed. Contact Nortec for recommendation and

0.5 in.

(12 mm)

Steam Line

Material

Copper Tube 0-10 0-3 3/4 in MED-L Tubing (7/8 in. OD)

Stainless Steel

Tube

Nortec Hose < 10 < 3 Part Number 1328810 (7/8”)

instructions on proper installation of reducers for larger diameter steam lines.

Steam Output

(Lb/hr)

S

t

e

a

1ft (30 cm)

Table 5: Maximum Recommended Length of Steam Line

5 8

10 15

15

20

25

30

NOTE: 1 Contact Nortec for information on possible losses of other steam line diameters used for longer runs.

2 The use of steam line other then copper, stainless steel tube or Nortec supplied steam line will void the

warranty and may adversely affect the operation of the humidifier

e

o

t

i

c

m

D

i

Figure 12: Main Steam Line Requirements

Table 4: Recommended Steam Line Material

Steam Line Length

0-10 0-3

n

r

e

c

t

i

o

n

ft m

Distance

(ft)

20 2.0 3/4

25 2.5 3/4

2 Degrees

Steam Line Description

7/8 in. Tubing (0.049 W)

Possible Loss

(lb/hr)

1.0

1.5

1 in. (2.5 cm) pipe

insulation

Steam Line Size

(in)

3/4

3/41

1

1

Installation | 16

Page 20

e

12 in. (30 cm)

min drop to

top of ‘P’ Trap

P Trap min

6 in. (15 cm)

duct static

pressure + 2 in

whichever is

greater

Tee is same size

as steam line

or

Use a full size tee, not a 90

degree elbow for vertical

to horizontal transitions.

‘P’ Traps Use:

- NORTEC 0.375 in condensate hose

- 1/4 in Med-L copper tubing, or

- 0.375 in stainless steel tubing

Condensate drains must be sloped down.

Route to humidifier fill cup if possible.

Figure 13: Condensate Traps

12 in.(30 cm)

min. radius*

2 in. (5 cm)

min.

1 ft (30 cm)

before any

bend*

1 ft (30 cm)

Condensat

line

Support

brackets*

Condensate

trap

Connect condensate

hose to fill cup

or to drain.

Connect steam

hose to cylinder

* Dimensions and brackets are recommendations based on best practice. OEM must verify operation if they are not followed.

17 | Installation

Figure 14: Steam Distributor Above Humidifier (Hose)

Page 21

e

12 in.

(30 cm)

min. radius*

Support brackets*

Hose will soften

over time

proper support

Is necessary

1ft (30 cm)

min. before

any bend*

Obstruction

1 ft (30 cm)

Use full size condensate tee

at low point. Slope lines up

to “T” and immediately after it.

To drain

* Dimensions and brackets are recommendations based on best practice. OEM must verify operation if they are not followed.

Figure 15: Steam Distributor Below Humidifier With Obstruction (Hose)

2 in.

(5 cm)

min.

To drain

1 ft (30 cm) min.

(recommended)

No drop to

condensate

trap

No condensat

trap at vertical

transition

Steam line

not sloped

Figure 16: Common Steam Line Errors

Installation | 18

Page 22

L1

r

A

r

r

r

r

r

r

r

r

r

Primary Voltage Wiring

Note:

Ensure mains voltage and HWS

1

jumper settings match operating

voltage (see table below for setting,

see Figure 21 for jumper location).

Dedicated fused disconnect

2

must be installed. Fusing must

not exceed max circuit protection

as indicated on the specification

label.

Ensure that adequate powe

3

is available to carry full

humidifier amp draw as

indicated on the specification

label.

Insert wires into cylinder plugs

4

and tighten with 2mm allen wrench

to11 in-lb.

Ensure both plumbing cabinet

5

and remote electrical bracket

(if present) are grounded. Use

ground wires if required.

6

with national and local

electrical codes.

Mains Voltage Jumper HWS Jumper

600

480

380

277

240

208

Remote Electrical Bracket

ground wire

Cabinet ground wire

Secure wires with tie

wraps to tabs provided

in mounting bracket

ll wiring to be in accordance

Mains Voltage and HWS Select

J1

J2

J3

J4

J5

J6

J8

J9

3 Phase

L3

L2

L1

Disconnect

1 Phase

Cylinder Plugs

Contacto

Ground Lug

(on cabinet ATT o

on bracket REM)

Cylinde

plug with

white

marke

Current

transforme

Cylinde

plug with

white

marke

L2

19 | Installation

Disconnect

Figure 17: Primary Power Connection

Contacto

transforme

Current

Page 23

f

r

r

r

f

r

r

Control Wiring

Contacto

Contacto

Ground

24 VAC

On/Of

Safety Loop

Control

Signal

Tie wrap

wires to tabs

provided

Mandatory Wiring:

Use min. 18 AWG and keep as short as possible.

24 VAC to fuse connected to On/Off/Drain switch

1

and to power relay 0.25 in. spade connectors.

,

Ground wire from humidifier ground to air handler

2

ground.

On/Off/Safety input (24 VAC) input to point 2 of P3.

3

Optional Wiring:

Modulating control input (0-10 or 2-10 VDC)to P5

4

(J10 must be removed for modulation).

500 ohm resistor between 1-2 of P5 for mA

5

modulating control input.

Remote Fault to P2.

6

Cut-out

in cove

for wiring

Electrical Cove

(Enclosed electrical

models only)

Power Relay

Fuse+Power Relay

Contacto

Remote Fault

P2

(NO)

On/Off (Safety Loop) 24VAC

P3

Control (+)

P5

Signal (-)

24 VAC

On/Of

Drain

Switch

Fuse

Figure 18: Control Wiring

Installation | 20

Page 24

B

r

The MES2 humidifier can be operated with either On/Off controls or On/Off Safety and one

modulating input. See On/Off or Modulating Control (J10) on page 26 to configure the MES2 for

modulation. For control wiring use minimum 18 AWG and keep as short as possible. For

Modbus wiring use 18-24 AWG shielded, twisted pair 120 Ω impedance cable.

Remote fault indication is provided via a normally open relay which is closed when the controller

is in a fault condition. The dry contact may be connected to maximum of 1 amp at 24 VAC or 24

VDC.

Note: Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to operate.

Nortec highly recommends the use of a high limit humidistat and an air proving switch

in series for this function.

Modbus Wiring

The optional Modbus interface board can be installed onto the MES2 control board to provide

Modbus control of the MES2. In order for Modbus control to be active a jumper must be

installed on J26 of the control board. See Modbus Configuration on page 27 for information on

configuring Modbus communication.

Note:

1

Requires optional Modbus board

(PN 1509592)

2

120 Ω impedance cable.

3

4

control.

Use 18-24 AWG shielded, twisted pai

Connect shield at one end only.

J26 must be installed for Modbus

(Optional)

Modbus

RS485

Connection

Common

Modbus

Board

A

Figure 19: Modbus Wiring

21 | Installation

Page 25

MES2 Installation Checklist

Unit Serial #: _________________ No. of humidifiers: _______ Tag: _______________

Unit type: _______ __________ Voltage: ________V/_____ph

Cylinder type: Customer/Job: Address:

WATER QUALITY:

Well water City water

POWER:

Voltage, amp, fuse per Spec Label: yes no

Jumper 1-6 setting _________________

Jumper 8/9 settting ________________

Disconnect switch yes no

HUMIDIFIER MOUNTING: (Clearances around the unit Acceptable Obstruction)

Humidifier level. Cylinder removal clearance

STEAM LINE(S):

Material Diameter / Size

Slope up (min 2 in/ft). Slope down (min 0.5 in/ft)

Low point condensate traps No hose kinks / Restrictions

Type of Insulation if installed

CONDENSATE LINE(S):

P Trap min 6 in or duct press + 2 in P Trap sufficient drop to ensure flow

WATER LINE:

1/2 in to within 4ft of unit Water pressure: 30-80 psig

DRAIN LINE:

Diameter / Size ______________ Air gap within 3 ft of the unit

CYLINDER:

Seated in drain valve and secured yes no

WIRING:

Wiring connections and connectors secured yes no

CONTROLS:

On / Off / Security loop devices working correctly yes no

Jumper J10 set to

Modulating (removed)

Or

On/Off (installed)

Jumper J26 set to

Terminal block input control (removed)

Or

Modbus control (installed)

Inspected by: Date of inspection: ______/_______/______

Company:

Installation | 22

Page 26

Operation

24 User Interface

24 LED Status Lights

24 On/Off Drain Switch

25 Humidifier Configuration

26 Capacity Adjustment

26 Mains Voltage Select (J1 to J6)

26 High Water Sensor Voltage (J8 and J9)

26 On/Off or Modulating Control (J10)

26 Modulation Offset (J13)

27 Ground Fault Interrupt (GFI) (J15)

27 Modbus Control (J26)

27 Modbus Configuration

27 Modbus Addresses

30 Start Up Procedure

23 | Operation

Page 27

r

r

User Interface

LED Status Lights

The MES2 user interface includes 2 LED’s which provide information about the humidifier’s

current status.

On/Off/Drain

(Turns humidifie

On/Off and drains

Switch

the cylinder)

Green LED On

Indicates steam is being

produced

Green LED Blinking

Indicates humidifier is on

but there is no requirement

for humidity.

Yellow LED On

Indicates that water level is

high

Yellow LED Flashing

(LED will flash fixed numbe

of times then pause.)

Indicates the controller has

detected a fault and has shut down.

Number of flashes indicates

which fault. See

Troubleshooting for more

information.

Figure 20: User Interface

Yellow LED Steady On

When the yellow LED is steady on (not flashing) it indicates that the high water sensor

has interrupted filling of the cylinder. The LED is on for information only and unless it

persists for an extended period of time it does not require any action.

On/Off Drain Switch

The On/Off Drain switch turns on power to the MES2 control board or to the MES2’s drain valve.

For normal operation the switch should be set to the On position.

To manually drain the humidifier set the switch to the drain position until the cylinder is

completely empty then turn the switch off. Do not leave the switch in the drain position for

extended periods of time.

When servicing the humidifier the switch should be set to Off and the fused disconnect or

breaker should be turned to Off.

Operation | 24

Page 28

V

V

V

V

V

V

V

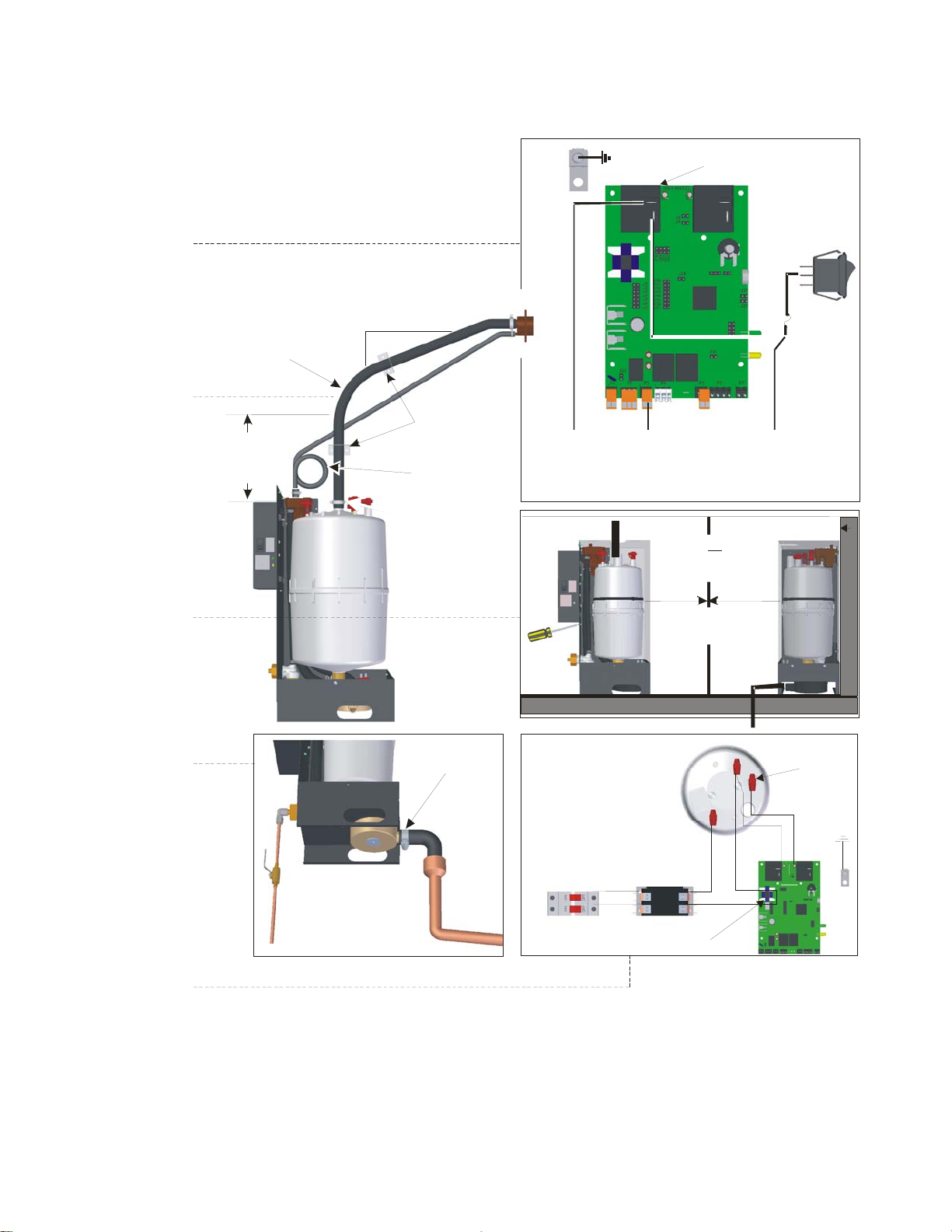

Humidifier Configuration

The MES2 is factory configured to operate under most conditions without the need for any

changes to its configuration. If required several settings can be made using jumpers on the

MES2’s control board. The output of the MES2 can also be reduced by using a potentiometer

on the MES2’s control board. See Figure 21: MES2 Control Board Jumpers for location of

jumpers and the capacity adjustment potentiometer.

Note: Nortec recommends not making any configuration changes unless they are required and

that any changes to the MES2’s settings be performed by a qualified technician.

J1 - J6

Mains

Voltage

Select

P11

J8 & J9

HWS Voltage

Potentiometer

Capacity

Adjustment

P11 (2-3)

Disable Self Test

J26

Modbus

Control

J13 & J15

Modulation

Offset & GFI

J10

On/Off or

Modulating

Figure 21: MES2 Control Board Jumpers

Table 6: MES2 Control Board Jumpers

Jumper Installed Removed

J1 550-600

J2 440-480

J3 380-415

J4 277

J5 220-240

J6 200-208

J8 HWS setting for 380-600 V

J9 HWS setting for 200-277

J10 On/Off Operation

J13 2-10 VDC or 4-20 mA* modulation

J15 GFI on, power relay off during drain

J26 Modbus control enabled

P11 (2-3) Self test at start up disabled

* mA modulation control requires a 500 ohm resistor installed between pins 1-2 of P5 control signal input terminal (see Figure 18:

Control Wiring.

0-10 VDC or 0-20 mA* modulation

GFI off power relay on during drain

Modbus Control disabled

Self test at start up enabled

No Affect

No Affect

No Affect

No Affect

No Affect

No Affect

No Affect

No Affect

Modulating Operation

25 | Operation

Page 29

Caution: Never adjust jumpers other than those listed in this section. Other jumpers are

factory set and must not be changed.

Capacity Adjustment

The Capacity adjustment potentiometer can adjust the capacity of the humidifier between 100%

and 20% of its rated output. (Factory setting = 100% output)

Figure 22: Capacity Potentiometer Adjustment

100%20%

Mains Voltage Select (J1 to J6)

The jumper setting must be set to match the operating voltage of the humidifier. The MES2 is

factory calibrated to provide maximum output over a range of operating voltages depending on

the setting of J1 to J6. Changing the jumper location sets the fill off amps of the humidifier to

correspond to that required at its operating voltage. One jumper only must be installed on J1 to

J6. See Table 6 for correct jumper placement.

High Water Sensor Voltage (J8 and J9)

The MES2 detects high water by measuring current flowing to its high water sensor pin (Cylinder

plug with white marker). To insure accurate detection of current, the High Water Sensor (HWS)

circuit must be configured using J8 and J9 to match the operating voltage. A jumper must be

installed on either J8 or J9, not on both. See Table 6 for correct jumper placement.

On/Off or Modulating Control (J10)

The MES2’s output can be controlled by either an On/Off humidistat or a modulating

humidistat. To set the MES2 to operate with a modulating humidistat remove Jumper J10.

(Factory setting = jumper Installed, On/Off operation)

J10 Removed– Modulating operation, the controller monitors the demand signal on

terminal point 4 of the control terminal strip and adjusts humidifier output to match it. For

mA control install a 500 ohm resistor across pins 1 and 2 of P5 control signal input terminal.

J10 Installed - The MES2 is configured for On/Off operation. The controller will ignore any

modulating signals even if they are connected.

Modulation Offset (J13)

The MES2 controller can be configured to work with a modulating humidistat with 4-20 mA or 210 VDC output. Modulation offset can be configured with jumper 13. (Factory setting = Jumper

Removed, 0-10 VDC or 0-20 mA control signal). See Table 6 for correct jumper placement.

Operation | 26

Page 30

Ground Fault Interrupt (GFI) (J15)

Ground current leakage can occur when the humidifier performs drains. With jumper J15 the

MES2 can be configured to turn off the power to the electrodes whenever a drain takes place.

See Table 6 for correct jumper placement.

Modbus Control (J26)

The MES2 can be controlled via its Modbus interface. When configured for Modbus control the

MES2 ignores On/Off and modulation control inputs on its control terminal strip and operates

strictly based on data received via Modbus. The Modbus interface can also be used to make

some configuration changes and to read the status of the MES2. See Table 7.

J26 Removed – The Modbus interface is turned off and the humidifier operates based on

control inputs at its terminal strip.

J26 Installed – The Modbus interface is turned on. The humidifier will operate strictly based

on control inputs received via Modbus and can be configured and queried using the Modbus

interface.

Disable Self Test (P11, 2-3)

On start up the MES2 performs a self test that activates all outputs briefly including the remote

fault output. To disable the self test the jumper installed on P11 pins 2-3 can be installed.

Modbus Configuration

Contact Factory – 1-866-NORTEC-1.

Modbus Addresses

The following table lists the MES2 parameters that are available via Modbus. 4XXXX

parameters can be read and written by the Modbus master. 3XXXX parameters are read only.

Table 7: Modbus Addresses

Function Description Address Details

Output

Control

Set Output Sets the desired steam output from 0-

OFF

Disables the humidifier and places the

humidifier in standby mode

ON

Enables the humidifier (humidifier will

operate based on the SET OUTPUT input)

100% This value shall be zero after a

microprocessor reset

40002 255: inhibit actions of humidifier

0: allow normal operation

40004 Remotely set humidity reading over

network. Value of 0 to 100 (per cent). If

no network signal for N minutes, reverts

to 0.

27 | Operation

Page 31

Table 7: Modbus Addresses (Continued)

Function Description Address Details

Force Drain When written to (FF), will interrupt the

humidification process and activate the

humidifier drain valve. After 20 minutes

the controller will reset this value (00).

After a microprocessor reset, the default

setting shall be (00)

Reset Run

Hour

Counter

Set Modbus

address

Set Modbus

Baud rate

Set Modbus

parity

Units Required by the control board for

Unit type Required by the control board for current

Unit voltage Required by the control board for

Unit phase Required by the control board for current

Electrode

current

Resets the humidifier controller’s run

hour counter to zero hours

Change the humidifier controller’s

MODBUS address. Range is 1-247. This

setting shall be non-volatile with a

default setting of 1.

Changes the humidifier’s baud rate.

Range is 4800, 9600, and 19200 B/sec.

This setting shall be non-volatile with a

default value of 9600 B/sec.

Change the humidifier controller’s

MODBUS parity. Range is None, Even,

Odd This setting shall be non-volatile with

a default setting of Even.

capacity calculations

and capacity calculations

current and capacity calculations

and capacity calculations

The value of the electrode current in

Amps

40005 255 will start the process, 0 will be

accepted, to clear if the request has not

been cleared itself

40006 255 will start the run hours counter

process. 0 will be accepted to clear the

run hours counter.

40201 The value changes will only take effect

following a hardware reset of the control

board.

40202 The value changes will only take effect

following a hardware reset of the control

board

40203 The value changes will only take effect

following a hardware reset of the control

board

40204 0=LBS, 1=KG

40205 Depending on the setting in UNITS

(Modbus: 40204) Hex value

representing maximum unit capacity

(100% fill off amps)

40206 Hex Value Unit Type

0 110-120

1 208

2 220-240

3 230

4 277

5 347

6 380

7 400

8 415

9 440-480

A 550-600

40207 Bit Allocation

Single phase = 1

Three phase = 2

Three phase (6 electrode) = 4

30104 Hex value representing the humidifies

current in amps Resolution: 0.10 amps

Example: 015F (hex) = 35.1 Amps

Operation | 28

Page 32

Function Description Address Details

Steam

output

Run hour

counter

Humidifier

state

Alarms The humidifier shall describe any faults

Maximum

production

Firmware

version

The current steam output in Kg/Hr. or

LBS/hr See UNITS (Modbus 40031)

The number of hours the humidifier has

been in operation since the last time the

run hour counter was reset

Describes the current state of the

humidifier and it’s I/O’s Contactor

ON/OFF Fill Valve ON/OFF Drain Valve

ON/OFF

Too long to fill Excess Current End of

cylinder life No current

The rated maximum steam production

for the humidifier

The firmware version of the humidifier

controller

30105 Hex value representing the humidifies

steam output in kg/hr Resolution: 0.10

kg or LBS Example: 013B (hex) = 31.5

kg/hr or LBS/hr

30106 Hex value representing the number of

humidifier operational hours since the

last reset. Resolution: 5 minutes

Maximum count: 5460 Hours. Example:

07D0 = 2000 hours

30107 Bit Allocation Note More than one bit

can be active at any time. Contactor on

= 1 Fill valve on = 2 Drain valve on = 4

30108 Bit Allocation Note More than one bit

can be active at any time.

Too long to fill = 1

Excess current = 2

End of cylinder life = 4

No Current = 8

30111 Value written into Unit type (40205) is

also stored here

30113 Packed BCD version3.52 would be

0x0352

29 | Operation

Page 33

Start Up Procedure

1 Examine the humidifier and installation for damage and or improper installation.

Warning: Damaged Units or improperly installed units must not be operated. Damaged or

improperly installed units may present a danger to persons and property.

2 If enclosed plumbing option is installed ensure that the front cover is in place and secured

with its retaining screw.

3 Open the supply water shut off valve.

4 Turn on the mains power using the installed disconnect.

5 Turn the On/Off switch to the “On” position.

The humidifier will perform a self-diagnostic sequence during which the LED’s and internal

components will be momentarily activated.

If an error is detected during the self-diagnostic sequence the humidifier will not start. The

yellow status LED will flash in sequence to indicate the detected fault. See Table 7:

Troubleshooting MES2 Faults on page 43 for information on diagnosing and correcting

faults.

After the system test the humidifier is in normal operation mode.

6 Check and adjust the control setpoint on the control and high limit humidistat.

7 When the external humidistat generates a demand for humidity and the security loop is

closed the green humidifying LED on the front of the humidifier will light up, the power relay

on the control board will engage, the fill valve will activate (after a delay) and the cylinder will

slowly fill with water.

Note: While the cylinder is filling with water there should be no water flowing down the drain. If

water is flowing down the drain it can indicate excessive backpressure or a leaking drain

valve. See chapter on troubleshooting starting on page 39.

8 It can take some time for the water to be heated up by the submerged electrodes and for

steam to be produced. Once the fill valve shuts off after reaching the appropriate water

level, the water in the cylinder will start to heat up until steam is generated.

Note: If operated on low conductivity water it may take several hours for the MES2 to

reach full output capacity. This is normal. During this time the humidifier will not perform

any drains and the conductivity of the water in the cylinder will increase.

Operation | 30

Page 34

Maintenance and

Servicing

32 Required Maintenance

32 Cylinder Spent Fault

32 Replacement Cylinder

33 Removing the Cylinder

34 Drain Valve Cleaning

35 Installing the New Cylinder

36 Extended Shutdown

36 Starting After Extended Shutdown

37 MES2 Maintenance Checklist

31 | Maintenance and Servicing

Page 35

r

f

r

Required Maintenance

The MES2 humidifier has been designed to require very little maintenance. Regular

maintenance consists of checking the humidifier to insure it is in good condition, replacing the

cylinder when the software advises that the cylinder is spent and cleaning out the drain valve

whenever the cylinder is replaced.

Cylinder Spent Fault

When the cylinder is spent the MES2 will stop operating and the yellow LED will flash in a

repeating pattern of 4 flashes. At this time the cylinder must be replaced. See Table 7:

Troubleshooting MES2 Faults on page 43 for more information on other flash sequences.

The steam cylinder is disposable and must be replaced at end of cylinder life. Cylinder life is

dependent on water supply conditions and humidifier usage.

Caution: Failure to replace the cylinder at the end of cylinder life will result in improper

operation and may result in damage to the humidifier. Nortec is not responsible for any

damages resulting from, or attributed to, the failure to replace a spent cylinder (see

Manufacturer’s Warranty).

Note: Nortec recommends keeping a replacement cylinder in stock throughout the

humidification season. This will prevent possible downtime when the humidifier reports

cylinder end of life.

Replacement Cylinder

The label on the existing cylinder identifies the cylinder type in its top left corner. When ordering

a cylinder always quote the three or five digit model number on the label, the humidifier’s serial

number, and the humidifiers voltage. Serial number and voltage are located on the

specification label on the left side of the humidifier.

Steam Outlet

Secure steam hose to

High Water Sensor Pin

Has a plastic collar

around it. Connect

orange high wate

sensor wire here.

outlet with hose clamp.

Electrode Pin

Connect color coded cylinde

plugs to pin with corresponding

color label. There may be 2 or 3

connections depending on

cylinder.

The spring loaded plug should

fit snugly on the pin. Replace i

loose or any signs of damage.

Label

Identifies cylinder type in

top left. Always replace

cylinder with the same

model.

Figure 23: MES2 Cylinder

Maintenance and Servicing | 32

Page 36

Removing the Cylinder

Warning

Check to see if yellow service LED is flashing (see Figure 20: User Interface on

page 24) then disconnect main power at the external disconnect before any

servicing.

The inside of the humidifier’s cabinet contains high voltage components and

wiring. Access should be limited to authorized personnel.

1 Drain the existing cylinder by switching the On/Off/Drain switch to the Drain position. Let

the humidifier drain until no more water is flowing out to drain (usually not more than 10

minutes).

2 Turn the humidifier On/Off/Drain switch to off.

3 Close supply water shut off valve.

4 Turn off power to the humidifier with the external disconnect.

5 If enclosed plumbing option is installed remove the screw securing the front cover.

6 Remove the cylinder plugs from the cylinder pins by pulling vertically.

7 Using a flat screwdriver loosen the hose clamp where the hose is connected to the cylinder.

8 Using a small flat screwdriver press the tab on the cable tie holding the cylinder in place and

pull the cable tie open.

9 Tip the top of the cylinder forward to pivot it out of the steam hose. When free of steam

hose lift the cylinder out.

Cylinder Plug

lift vertically

Hose Clamp

Tilt cylinder

forward to clear

hose and then

lift from drain

valve.

Cable Tie

On/Off/Drain Switch

33 | Maintenance and Servicing

Figure 24: Cylinder Removal

Page 37

Drain Valve Cleaning

Always clean the drain valve before installing a new cylinder. Scale from the spent cylinder may

have fallen into the drain valve and could prevent its proper operation. To properly clean the

drain valve it must be removed and disassembled.

Note: Be sure to reattach the green ground wire to reduce the risk of electrical shock.

1 Disconnect spade terminals from the drain valve.

2 Remove the screw holding the green ground wire and the two screws holding the valve to

the drain pan.

3 Squeeze the tabs of the spring clamp holding the hose to the drain valve and slide it up the

hose. Pull hose from drain valve. Lift the drain valve from the drain pan.

4 Unsnap red coil cap on solenoid and remove the solenoid from the valve.

5 Loosen brass nut holding actuator to plastic housing with a wrench and disassemble

actuator.

6 Clean actuator components and valve housing (inlet port, outlet port, and cylinder port). Put

new o-ring that was supplied with new cylinder into valve.

7 Reassemble actuator making sure tapered end of spring is oriented as shown Figure 26.

Tighten brass nut 1/4 turn past hand tight.

8 Clean out end of hose and reattach to valve. Slide hose clamp back in place and place valve

into drain pan.

9 Secure valve with 2 screws and attach green ground wire to solenoid.

Cylinder Port

and O-ring

Ground Wire

Hose and

Hose Clamp

Screws

Solenoid

Brass Nut

(Actuator)

Figure 25: Drain Valve

Spade Connectors

Maintenance and Servicing | 34

Page 38

Plunger

Spring

(Note Orientation)

Sleeve

and

Solenoid

Figure 26: Drain Valve Actuator Assembly

Installing the New Cylinder

CAUTION: Make sure the new cylinder is the same model as the one that was

removed. Model number is on top left corner of cylinder label.

1 Insert cylinder into drain valve. Tilt cylinder forward and fit end of steam hose to steam

outlet. Tip cylinder back into place.

2 Secure cylinder with the reusable cable tie. Tighten hose clamp being careful not to over

tighten and crush the plastic cylinder steam outlet.

3 Attach color-coded cylinder plugs to the corresponding color-coded cylinder pin. Push down

completely. Connect high water sensor plug. Spring-loaded plugs should fit snuggly onto

the cylinder pin. Replace if they are loose or damaged.

4 If enclosed plumbing option is installed replace the humidifier cover and secure with screw.

5 Turn on power to humidifier with the external disconnect.

6 Open supply water shut off valve.

7 Turn the humidifier On/Off /Drain switch to On.

35 | Maintenance and Servicing

Page 39

Extended Shutdown

Should it be required to disconnect power to the humidifier for a period of extended shut-down,

always drain the cylinder first. Otherwise, the electrodes are subject to harmful corrosion which

drastically shortens the cylinder life.

1 Switch the On/Off/Drain Switch to the Drain position.

2 Wait until the humidifier is completely drained (usually takes less than 10 minutes).

3 Turn the On/Off /Drain switch to the off position.

4 Shut off power to the humidifier with the external disconnect.

5 Close the supply water shut-off valve.

Caution:

Do not leave the switch in the DRAIN position indefinitely as the drain coil could burn

out.

When disconnecting power to the humidifier for an extended period of time drain the

cylinder first to prevent harmful corrosion.

Note: As long as the MES2 is powered, it will automatically drain the cylinder when there

has not been a call for humidity for an extended period of time. This feature will reduce or

prevent the possibility of corrosion of the electrodes and the accumulation of algae and

bacteria growing in the cylinder. The cylinder will remain empty until there is a call for

humidity at which time the fill valve will open and refill the cylinder. The unit will go

through its normal process for optimum operation.

Starting After Extended Shutdown

1 Check to see the humidifier has not been damaged and the installation has not been

altered.

2 Open the supply water shut-off valve.

3 Turn on the power to the humidifier with the external disconnect.

4 Turn the On/Off/ Drain switch to the On position.

5 Follow the start up procedure in the section titled Start Up Procedure on page 30.

Maintenance and Servicing | 36

Page 40

MES2 Maintenance Checklist

Model #: _________________

Serial #: _________________ Tag: ________

Cylinder #:

CHECK CYLINDER

Cylinder spent), yellow LED flashing 4 times in sequence.

(If Yellow LED is On and cylinder is not new then cylinder will have to be replaced soon.)

REPLACE CYLINDER

Cylinder drained.

Disconnect open, On/Off/Drain switch off, water shut off valve closed, cover removed.

Cylinder removed

Drain valve removed / cleaned / new O-Ring installed

Drain valve cleaned / installed / ground wire attached.

New Cylinder Installed New cylinder model #

Cylinder plug colors match cylinder dots.

Cylinder plugs snug and in good condition.

High Water Sensor plug snug and in good condition.

Steam hose attached.

Cover replaced, water shut off valve open, On/Off /Drain switch On, Disconnect Closed

(Should be same as removed cylinder)

SYSTEM CHECK

Yellow Led flashing? No Yes Flash Sequence?

(See Troubleshooting Chapter for actions if yellow LED is flashing)

Primary power disconnect turned off

Cylinder plugs snug and in good condition.

Electrical wiring not loose and in good condition,

Steam hoses and steam lines in good condition / No kinks in hose,

No Signs of water leaking around humidifier, steam line, condensate returns,

Cover replaced, water shut off valve open, On/Off /Drain switch On, Disconnect Closed

Inspected by: Date of inspection: _______/_______/______

Company:

37 | Maintenance and Servicing

Page 41

Maintenance and Servicing | 38

Page 42

Troubleshooting

40 Organization of Troubleshooting Chapter

40 Troubleshooting Requirements

41 General Troubleshooting

41 Humidifier

42 Steam Distributors

42 Modbus

42 MES2 Faults

43 LED Flash Sequence

43 Clearing a Fault

45 MES2 Wiring Diagram

39 | Troubleshooting

Page 43

Organization of Troubleshooting Chapter

The troubleshooting chapter is broken down into 2 sections.

General Troubleshooting Deals with troubleshooting incorrect humidifier operation,

steam line and plumbing issues without any control

software faults.

Humidifier Warnings and Faults Deals with faults that are generated by the humidifier’s

control software.

CAUTION: Be aware, when troubleshooting, that the humidifier is powered by high voltage

and familiarity with both good practices and wiring of the humidifier is recommended.

Any troubleshooting should be done by qualified personnel.

NOTE:

Check if yellow service LED is flashing before turning off the humidifier to determine if

a fault has occurred. See Figure 20 on page 24 and Table 7 on page 43.

Most humidifier faults are not caused by faulty equipment but rather by improper

installation. A complete fault diagnosis always involves a thorough examination of the

entire system. Often, the steam hose connection has not been properly executed, or

the fault lies with the humidity control system.

Troubleshooting Requirements

Ensure the installation meets the installation requirements outlined in the Installation

Chapter of this manual.

Familiarize yourself with the operation of the humidifier by reading the Operation Chapter on

page 24 and the section describing How the Humidifier Works on page 9 in this manual.

A generic copy of the MES2 wiring diagram is included at the end of this chapter for

reference purposes.

When contacting your local representative or Nortec for troubleshooting assistance, please

ensure the serial number has been obtained for reference purposes.

Troubleshooting | 40

Page 44

General Troubleshooting

The following section provides general guidelines for troubleshooting the MES2 humidifier and

auxiliary components. For detailed troubleshooting information refer to the manuals that were

provided with auxiliary equipment and to Table 7: Troubleshooting MES2 Faults on page 43.

Humidifier

Table 6: General Troubleshooting

Symptom Cause Corrective Action(s)

Nothing happens when On/Off

switch is turned on.

Humidifier will not humidify or

not reaching RH setpoint

1 Fuse blown 1 Check inline fuse between

On/Off/Drain switch and control

board.

2 Incorrect Voltage 2 Check voltage supplied to

On/Off/Drain switch is 24 VAC.

3 Mains power turned off 3 Turn on mains power.

1 Safety loop open. No 24 VAC at

2.

2 No demand signal (If J10

removed for modulation)

3 Not configured correctly for

On/Off or modulating control

4 Capacity has been manually

limited

1a Check if there is 24 VAC at point 2 of

Terminal P3 on the control board.

1b Check if air handler is outputting 24

VAC run signal.

1c Check wiring and operation of On/Off

devices connected in series between

output calling for humidity and point 2

of terminal P3.

2 Check voltage between P5 and

ground. 25% of full-scale signal must

be present for humidifier to start.

3 Check that J10 on control board is

removed for modulating control and

installed for On/Off control.

4 Check Manual Capacity adjustment

potentiometer. Clockwise increases

capacity.

Humidifier has faulted and

yellow LED is flashing

41 | Troubleshooting

5 Low conductivity water

6 Humidifier undersized

1 Software has detected an

abnormal condition

5 Check if yellow LED is on. If operated

on low conductivity water it may take

several hours for the MES2 to reach

full output capacity. This is normal.

During this time the humidifier will not

perform any drains and the

conductivity of the water in the

cylinder will increase.

1 Refer to Table 7: Troubleshooting

MES2 Faults.

Page 45

Steam Distributors

Symptom Cause Corrective Action(s)

Distributor spitting out water

1 Distributor not level 1 Use support at end of distributor to

ensure it is level.

2 “P” Trap too close to distributor 2 “P” Trap must be a minimum of 12 in

(30 cm) below the distributor to

ensure flow. Relocate if required.

3 Condensate line not sloped

sufficiently

4 Trap blocked 4 Check that water flows through trap.

5 Steam line not insulated 5 If steam line is long condensate build

6 Incorrect steam line installation 6 Check that steam line has been

7 Humidifier foaming and foam

carried up steam line.

3 Sufficient slope to insure flow is

required. Reinstall if required.

Clear out if blocked.

up could overload distributor

condensate port. Insulate line to

improve efficiency and install

additional condensate traps as

required.

installed with condensate traps and

slope per installation instructions on

page 16.

7a Check if foaming caused by short

cycling.

7b Check if foaming caused by blocked

or restricted drain.

7c Check if steam line is causing back

pressure and preventing proper filling.

Condensation in Air Handler 1 Installation clearances not

observed

2 Design conditions changed 2 Check supply air temperature and

3 High limit not functioning 3 Check setting and operation of high

Modbus

Symptom Cause Corrective Action(s)

No Modbus Communication

1 Incorrect Wiring 1a Use 18/24 AWG Shielded Twisted

2 Incorrect Communication

Parameters

3 Noise interference 3a Route data cable away from noise

1 Refer to distributor installation manual

for required clearances. Relocate

distributor if required.

humidity to determine if conditions

have changed.

limit. Replace if defective.

Pair, 120 Ω cable.

1b. Connect shield to one end only.

1c. Check polarity of data wires.

2 Defaults are 9600 B/sec, Modbus

Address 1, Even Parity

generating devices.

3b Install an RS485 repeater.

Troubleshooting | 42

Page 46

MES2 Faults

The self-diagnostic system built into the MES2 is continually monitoring the operation of the

humidifier. When an abnormal condition occurs that cannot be self corrected by the software

the MES2 will turn off power to the cylinder, drain the cylinder, and annunciate the fault using

the yellow status LED.

LED Flash Sequence

To differentiate between different fault conditions the yellow LED is flashed in different

sequences. Table 7 lists MES2 faults, their meaning, possible causes, and corrective actions.

Clearing a Fault

Check the flash sequence against the list of fault messages and take any necessary actions

to correct the cause(s) as outlined in Table 7: Troubleshooting MES2 Faults.

Power cycle the humidifier with the On/Off switch. Wait 3 seconds between off and on.

Table 7: Troubleshooting MES2 Faults

Yellow LED System Detected Cause Corrective Action(s)

1 flash

Excess Current

Current has exceeded

130% of max

1 Drain blocked water over

concentrated

2 Drain solenoid not energized,

water over concentrated

3 Filling too fast, fill valve

damaged

4 Water supply too conductive 4a Contact Nortec

5 Humidifier short cycling 5a Check if high limit or other

1 Clean the drain line and drain

valve.

2 Check and correct wiring to

drain valve.

3 Check fill rate and replace the

fill valve if needed.

representative for

recommendation on alternate

cylinder

4b Change the water supply

On/Off control is cycling

On/Off in less than 5

minutes. Check location and

setting of high limit.

5b Reduce the output by

turning down the capacity

potentiometer.

5c If modulating control check

if controller Pband too tight.

5d Check for temperature

swings.

43 | Troubleshooting

6 Wrong cylinder installed 6 Install correct cylinder model

7 Cylinder Spent but not

detected by software

8 Condensate from other

source

9 Back pressure 9 Eliminate back pressure

7 Replace the cylinder (see

maintenance chapter)

8 Remove condensate returns

other than from steam line.

Page 47

Table 7: Troubleshooting MES2 Faults (Continued)

Yellow LED System Detected Cause Corrective Action(s)

2 flashes

No Current

Fill valve activated for

long time but high water

level not reached.

Fill should be faster than

1” per minute.

1 Drain valve leaking or stuck

open

1 Clean drain valve or replace

(see maintenance chapter)

2 Water shut off valve closed 2 Open shut off valve

3 Fill Valve strainer blocked 3 Clean out strainer on fill valve

4 High system back pressure 4a Check for kinked hose

4b Check for proper

condensate removal (see

installation chapter)

5 High water sensor not

connected

5 Check that cylinder plug with

white marker is connected to

short electrode with a plastic

collar around it and to control

board.

6 Low water conductivity 6a Check conductivity of water.

If less than 150

microsiemens contact factory

for recommendation.

6b Add 1/4 teaspoon of salt to

fill cup and restart unit.

1 Primary wire not looped

through current transformer.

1 Open disconnect, rewire

primary wire through current

transformer.

3 flashes

4 flashes

No Current, High Water

Water level at top of

cylinder with no current

Cylinder Spent

Electrodes covered with

scale.

2 1 phase of 3 phase supply

blown

3 High water sensor plug is on

an electrode pin.

4 Cylinder plugs installed

incorrectly

1 Cylinder electrodes are

calcified.

2 Software incorrectly detected

cylinder is spent

2 Check that all phases are

energized.

3 Install high water senor plug

on cylinder pin with collar

around it.

4 Check that cylinder plugs

colors match markers next to

electrodes on cylinder and

that white marked cylinder

plug is connected to pin with

collar around it.

1 Replace cylinder with same

model number (see

maintenance chapter)

2a If fault has occurred shortly

after start up then check for

low water conductivity. (See 2

flashes cause 6)

2b Check if water in cylinder is

foaming. If yes see 1 flash Excess current causes.

Troubleshooting | 44

Page 48

MES2 Wiring Diagram

Modulation:

Remove J10 for 0-10 VDC

Remove Jumper J10 and place it on J13 for 2-10VDC

Control Signal

(0-10 Vdc, 2-10 Vdc)

(-) (+)

DRAIN

FILL

ON/OFF

Safties

S

3 Amp

Fuse

24 Vac Hot

24 VAC Common

Primary

Terminal

Block

(by others)

L1

L2 L3

Yellow LED

Green LED

Common

B

A

Install J26 For