Norlake MF562 Installation Manual

BOTTOM MOUNT DISPLAY FREEZERS

Installation, Operation and

Maintenance Instructions

INSPECTION

When the equipment is received, all items should be carefully checked against the bill of lading to

insure all crates and cartons have been received. All units should be inspected for concealed

damage by uncrating the units immediately. If any damage is found, it should be reported to the

carrier at once, and a claim should be filed with the carrier. This equipment has been inspected and

tested in the Nor-Lake Manufacturing Facility and has been crated in accordance with transportation

rules and guidelines. Manufacturer is not responsible for freight loss or damage.

INSTALLATION

GENERAL

After the unit crate and base have been removed, locate the legs or casters found in the interior of

the cabinet. (Legs or casters are optional on these units.) Attach the legs or casters to the unit base

by screwing them into the same threaded fittings that were used to secure the crate base to the

cabinet. Insure that the legs or casters are screwed all the way into the base.

The condensing unit compressor is secured for shipping purposes. Remove the spring clips and

loosen the mounting bolts prior to operation. See the label attached to the condensing unit.

If for some reason the doors are not squared up on the cabinet, the doors can be adjusted. Opening

the door(s) and loosening the screws that hold both the top and bottom hinges to the cabinet can

accomplish this. After adjusting the door so that it is aligned correctly, tighten the screws to securely

hold the hinges in place.

LOCATION

The refrigeration system located at the bottom of the cabinet requires free air access for proper

operation. Allow a minimum four-inch clearance on the rear and sides of the cabinet. The cabinet

should also be leveled when it is placed in its final location. If legs or casters are not used with this

unit, it is required by NSF that the cabinet be sealed to the floor with an approved sealant such as

Dow Corning #732 silicone.

Physical Specifications

Unit Exterior Dimensions Refrigerant

Model Width x Depth x Height*

MF562 55" x 35-1/2" x 79-3/4" See Serial Tag

Note: Add 6 inches to the height for legs or 4-3/4 inches for casters

Type/Amt

01/03 053106

ELECTRICAL

Check the proposed outlet to be used to insure that the voltage, phase, and current carrying

capacity of the circuit from the electrical panel correspond to the requirements of the cabinet.

NEVER use an extension cord to wire any unit. On permanently connected cabinets, those not

furnished with a plug-in service cord, all inter-wiring between the electrical panel and the unit must

be done in accordance with the National Electric Code and all state and local codes. Refer to the

electrical data below and the Serial Tag for all pertinent electrical information.

Unit Type of

Model Connection

MF562 Permanent 115/208-230/60/1

Voltage/Hz/Phase

GENERAL OPERATION

This cabinet employs a unit cooler evaporator located inside the cabinet as the heat-removing

source. Through the refrigeration process, heat is captured in the evaporator, transferred to the

condensing unit at the bottom of the cabinet, and expelled to the surrounding outside air. It is

extremely important to allow a four-inch clearance on the sides and back of the unit for the

refrigeration process to function properly. To increase or decrease the internal cabinet temperature,

rotate the cold control, located on the unit cooler, to the desired temperature.

After shutting the door on freezer models, a short amount of time must be allowed before the door

can be reopened. This is due to the tight seal maintained between the door and the cabinet. Waiting a

few moments for the pressure to equalize permits the door to be opened easily.

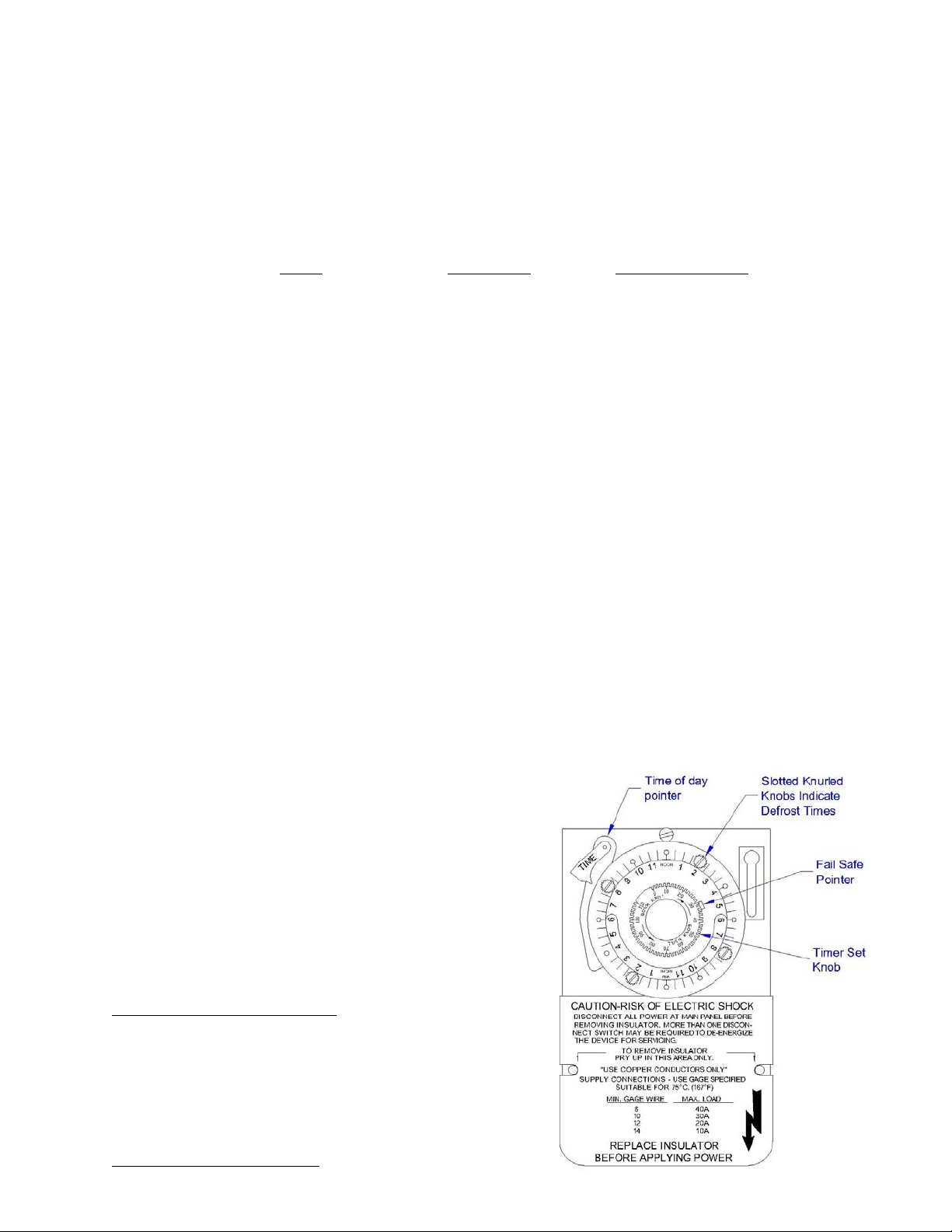

A positive defrost is required to remove frost from the coil in freezer models. This is accomplished

by energizing heaters during the defrost cycle that are positioned on the coil surface. The time clock,

shown below, is factory set to allow four defrosts per day. Note: Adjustment of the correct time o f

day will be required to maintain these defrost periods. As the preset defrost time is reached, the time

clock automatically terminates the refrigeration process by turning off the condensing unit and unit

cooler fan motors, and energizes the defrost heaters. As the coil temperature increases, the frost

begins to melt producing water that runs down the coil to the unit cooler drain pan and exits through

the drain tube to the vaporizer. After all the frost has

been removed and the coil temperature reaches

approximately 50°F, the defrost is terminated through

the action of the defrost termination control located on

the unit cooler, and the refrigeration process resumes.

In order to insure that any excess water remaining on

the coil is not sprayed into the cabinet interior, and all

heat generated by the defrost is removed, the unit

cooler fans will not operate until the coil

temperature reaches approximately 25°F.

TIME CLOCK ADJUSTMENTS

Setting the correct time of day: To set the correct time

of day, simply rotate the small inner-dial

counterclockwise until the correct time of day on the

large dial is opposite the "time" indicator. In referring to

the drawing of the time clock, the correct time of day

shown is 7:30 a.m.

Number of defrosts per day: The timer is factory set to

Loading...

Loading...