Norlake NBCF220/110-16A Installation Manual

3299720 / 160555

BLAST CHILLERS/FREEZERS CELLULES DE REFROIDISSEMENT RAPIDE/CELLULES MIXTES ABATIDORES/CONGELADORES RAPIDOS DE TEMPERATURA

USE AND INSTALLATION MANUAL

MANUEL D’UTILISATION ET D’INSTALLATION

MANUAL DE USO E INSTALACIÓN

06/15 Rev. A 160555

GB

FR

ES

Carefully read the instructions contained in the handbook. You may find important safety instructions and recommendations for use and maintenance.

Please retain the handbook for future reference.

The Manufacturer is not liable for any changes to this handbook, which may be altered without prior notice.

Lire avec attention les instructions contenues dans ce livret car elles fournissent d'importants renseignements pour ce qui concerne la sécurité, l'emploi et l'entretien.

Garder avec soin ce livret pour des consultations ultérieures de différents opérateurs.

Le constructeur se réserve le droit d'apporter des modifications à ce manuel, sans préavis ni responsabilité d'aucune sorte.

Lea atentamente las advertencias contenidas en este manual pues dan importantes indicaciones concernientes la seguridad, la utilización y el mantenimiento del aparato.

Rogamos guarde el folleto de instalación y utilización, para eventuales futuros usuarios.

El constructor se reserva el derecho de hacer modificas al actual manual, sín dar algún preaviso y sín responsabilidad alguna.

|

INDEX |

GENERAL INSTRUCTIONS ON DELIVERY |

....................................................................... 5 |

GENERAL WARNINGS .................................................................................................................................. |

5 |

LIST OF RULES ............................................................................................................................................. |

5 |

TRANSPORT AND HANDLING....................................................................................................................... |

5 |

UNPACKING ................................................................................................................................................ |

5 |

GENERAL SAFETY WARNINGS...................................................................................................................... |

6 |

INSTALLATION ............................................................................................................ |

7 |

PLATE DATA ................................................................................................................................................ |

7 |

MAX ROOM TEMPERATURE ........................................................................................................................ |

7 |

INSTALLATION............................................................................................................................................. |

8 |

DIMENSIONS .................................................................................................................................................................... |

9 |

TECHNICAL DATA............................................................................................................................................................ |

10 |

WIRING..................................................................................................................................................... |

11 |

CONDENSATE DRAIN................................................................................................................................. |

11 |

TESTING .................................................................................................................................................... |

11 |

CONTROL AND SAFETY SYSTEMS ............................................................................................................... |

12 |

REFRIGERANT MATERIAL SAFETY DATA SHEET .......................................................................................... |

12 |

DISPOSAL .................................................................................................................................................. |

13 |

STERILIZATION LAMP INSTALLATION......................................................................................................... |

13 |

PRINTER INSTALLATION ............................................................................................................................ |

13 |

OPERATION .............................................................................................................. |

14 |

GENERAL DESCRIPTION ............................................................................................................................. |

14 |

SETTING UP .................................................................................................................................................................... |

14 |

MACHINE LOADING........................................................................................................................................................ |

15 |

POSITION OF TRAYS........................................................................................................................................................ |

15 |

CORE PROBE................................................................................................................................................................... |

15 |

TEMPERATURES ............................................................................................................................................................. |

16 |

LENGTH .......................................................................................................................................................................... |

16 |

CONTROL PANEL ....................................................................................................................................... |

17 |

FIRST START-UP......................................................................................................................................... |

18 |

PROGRAM................................................................................................................................................. |

19 |

PROGRAM DESCRIPTIONS .............................................................................................................................................. |

19 |

STANDARD PROGRAMS.................................................................................................................................................. |

21 |

PROGRAM I.F.R. ............................................................................................................................................................. |

22 |

PROGRAM INFINITY........................................................................................................................................................ |

23 |

FAVORITE PROGRAMS.................................................................................................................................................... |

24 |

AUTOMATIC PROGRAMS ............................................................................................................................................... |

25 |

STORED PROGRAMS....................................................................................................................................................... |

27 |

MULTY ............................................................................................................................................................................ |

29 |

COOLING ........................................................................................................................................................................ |

30 |

FUNCTIONS ............................................................................................................................................... |

31 |

DEFROST......................................................................................................................................................................... |

31 |

SANITATION.................................................................................................................................................................... |

32 |

STORAGE ........................................................................................................................................................................ |

33 |

THAWING ....................................................................................................................................................................... |

34 |

PROVING (PROOFING) ................................................................................................................................................... |

36 |

PROBE HEATING ............................................................................................................................................................. |

38 |

** VIEW / EDIT PARAMETERS CYCLE.............................................................................................................................. |

40 |

3 |

3299720 /160555_GB |

HACCP....................................................................................................................................................... |

41 |

SETTINGS .................................................................................................................................................. |

50 |

LANGUAGE ..................................................................................................................................................................... |

50 |

SET DATE/CLOCK ............................................................................................................................................................ |

51 |

SECTOR........................................................................................................................................................................... |

52 |

MULTY ............................................................................................................................................................................ |

53 |

CYCLE CONTROL - AUTO OR MANUAL ........................................................................................................................... |

54 |

SERVICE..................................................................................................................................................... |

55 |

ALARMS.......................................................................................................................................................................... |

55 |

ALARMS TABLE ............................................................................................................................................................... |

56 |

RESET ALLARMI .............................................................................................................................................................. |

57 |

INPUTS OUTPUTS ........................................................................................................................................................... |

58 |

RESTORE......................................................................................................................................................................... |

59 |

PARAMETERS.................................................................................................................................................................. |

60 |

MAINTENANCE ......................................................................................................... |

61 |

MAINTENANCE AND CLEANING................................................................................................................. |

61 |

CLEANING THE CABINET................................................................................................................................................. |

61 |

CLEANING THE AIR CONDENSER .................................................................................................................................... |

62 |

STAINLESS-STEEL MAINTENANCE................................................................................................................................... |

62 |

DISCONTINUED USE ....................................................................................................................................................... |

63 |

EXTRAORDINARY MAINTENANCE.............................................................................................................. |

63 |

VIDEO BOARD AND ENCODER MAINTENANCE CHECKLIST ............................................................................................ |

63 |

MAINTENANCE OF PANEL BOARD.................................................................................................................................. |

64 |

CONDENSING SYSTEM MAINTENANCE .......................................................................................................................... |

65 |

REPLACEMENT CORE PROBE .......................................................................................................................................... |

66 |

WIRING DIAGRAM PLATE .......................................................................................................................... |

66 |

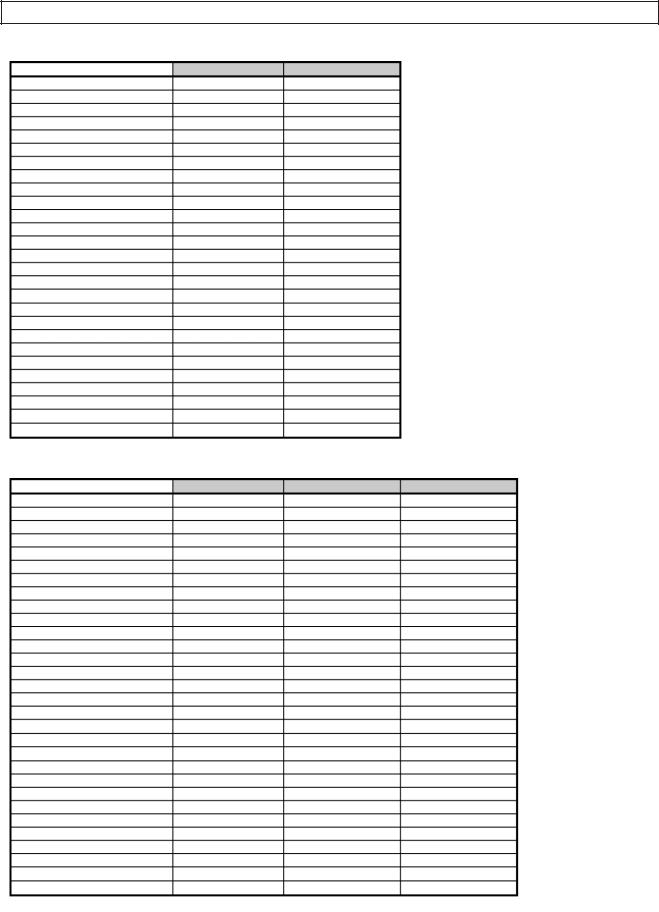

Annotate the emergency assistance number of specialised maintenance personnel.

Name and Surname |

Address |

Tel./fax no. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3299720 /160555_GB |

4 |

GENERAL INSTRUCTIONS ON DELIVERY

GENERAL WARNINGS

We assure you have made the best choice in purchasing our products and hope you will be fully satisfied with the performance. To this purpose, we recommend you strictly comply with the instructions and regulations contained in this handbook..

The user is required to carefully read the manual, always referring to it and conserving it in a known place, accessible to all operators.

The equipment is destined only for the function for which it was designed and, being for professional use, must be used only by qualified personnel.

The manufacturer declines all responsibility and any obligation to warranty if damage occurs to the equipment, persons or things, imputable to incorrect installation, inappropriate use by untrained personnel, non specific modifications or interventions, use of non original or non specific replacement parts, failure to observe, even partially, the indications found in this manual.

Please remember that no reproductions of this handbook are allowed. Due to our constant technological updating and research, the features described in this handbook may be altered without prior notice.

LIST OF RULES

The cooling cabinet we manufacture fully complies with the following regulations:

UL Listed for electrical safety – UL471 CSA C22.2.120

NSF standard 7 for sanitation

TRANSPORT AND HANDLING

For transportation and handling, all precautions necessary must be taken in order not to damage the equipment, referring to the indications found on the packaging of the same.

Make sure that the consignment has not been tampered with or damaged during transport.

UNPACKING

Installation must be carried out by authorized personnel.

After removing the packaging, ensure the integrity of the equipment and verify that all the parts or components are present and that the characteristics and state correspond to the specifications of the your order.

If not, please inform the retailer immediately.

Remove pvc protective film from all over the appliance.

Attention: all the packing material must be disposed of in accordance with the prevailing regulations in the country where the equipment is used and in any case must not be dispersed into the environment.

5 |

3299720 /160555_GB |

GENERAL SAFETY WARNINGS

The user is responsible for operations carried out on the equipment which do not comply with the indications in this manual, and periodic training of all personnel to work on the equipment is recommended.

List of some general warnings:

-do not touch the equipment with moist or wet hands or feet

-do not insert screwdrivers or kitchen tools or anything else between the guards and the parts in motion

-before any cleaning or maintenance operation, disconnect the equipment from the electrical mains

-do not pull on the power cord to disconnect the machine from the electrical mains

-during loading/unloading of product in the equipment use kitchen gloves

-use the needle probe to read the temperature at the core of the product, making sure to handle it with care

3299720 /160555_GB |

6 |

INSTALLATION

PLATE DATA

Make sure the technical wiring specifications comply with the ratings (i.e., V, kW, Hz, no. phases and mains power).

Please quote the product's serial number (shown on the rating plate) on any enquiry to the Manufacturer.

List of rates shown on the rating plate: |

I) |

Power defrost heater |

|

1) |

Model |

L) |

Condenser fan |

2) |

Manufacturer’s name and address |

M) |

Condenser fan FLA |

3) |

Insulation class |

N) |

Expanding fluid |

4) |

Year of production |

O) |

Refrigerant name |

5) |

Serial number |

P) |

Refrigerant quantity |

6) |

Electrical device casing protection rating |

Q) |

Climatic class |

A) |

Input voltage |

R) |

Fuse |

B) |

Electric current intensity |

S) |

MCA |

C) |

Frequency |

T) |

Evaporator fan |

D) |

Phase |

U) |

Evaporator fan FLA |

E) |

Compressor |

V) |

Design pressure |

F) |

Compressor RLA |

W) High side pressure |

|

G) |

Compressor LRA |

Z) |

Low side pressure |

H) |

Defrost heater |

|

|

MAX ROOM TEMPERATURE

Air-condenser units should not operate if room temperature is over 100°F. Above 90°F maximum output is not guaranteed.

Min. air circulation

|

Model |

|

|

Air q.ty |

|

|

|

|

[cfm] |

|

|

|

|

|

|

|

|

|

BC40A |

|

|

|

|

|

BCF48A |

650 |

|

||

|

BCF35A |

|

|

|

|

|

BC80A |

2.060 |

|

||

|

BCF99A |

|

|||

|

|

|

|

||

7 |

3299720 /160555_GB |

INSTALLATION

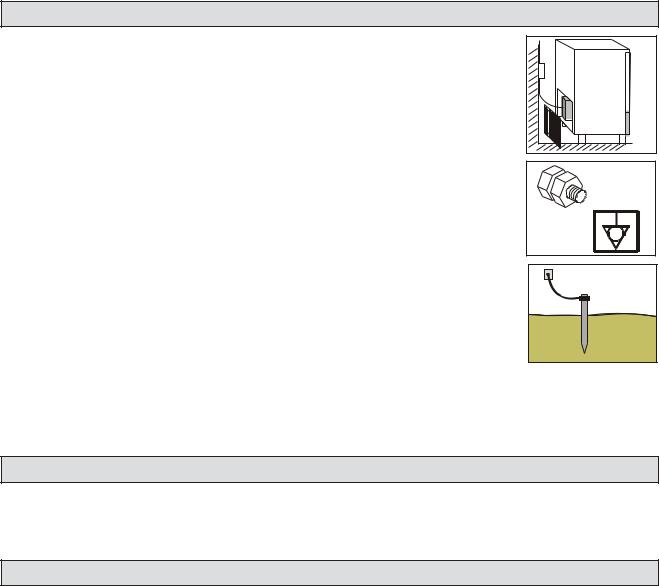

The appliance must be installed and tested in full compliance with accident-prevention regulations contained in national law and current guidelines. Installers are to comply with any current local regulations.

Place the appliance onto the required working site.

Avoid locations with exposure to direct sunlight.

Do not place the appliance in hot, poorly-ventilated rooms.

Do not place the refrigerated compartment near heat sources.

Leave a min. 4” clearance around the appliance on the sides where air inlet and outlet are located.

Level the appliance by means of adjustable feet.

WARNING: If the appliance is not properly levelled the performance and condensate drain may be hampered.

3299720 /160555_GB |

8 |

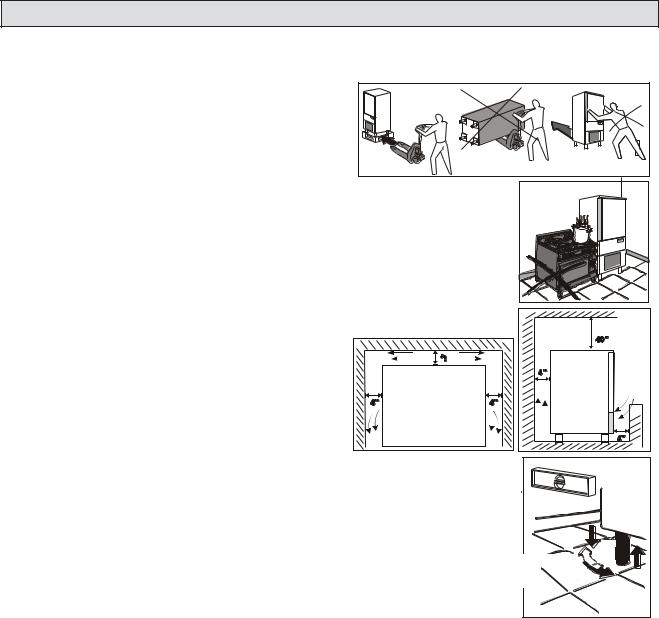

DIMENSIONS

Please refer to the dimensions of your own appliance.

BC40A |

|

|

|

|

|

|

|

BCF48A |

|

746,5 (29,38") |

|

|

|

1407 (55,39") |

|

|

|

|

|

720 (28,3") |

|

||

|

|

|

|

|

|

|

|

|

80 (3,15") |

|

|

|

|

|

|

|

60 |

|

625 |

60 |

|

600 |

|

|

(2,36") |

(24,6") |

(2,36") |

|

(23,62") |

|

|

740 (29,13) |

|

|

|

970 (38,19") |

|

|

|

|

|

|

|

|

|

|

|

|

150 (5,9") |

|

|

|

|

|

|

|

56,5 |

|

632 |

56,5 |

61,7 |

535 |

135,9 |

|

(2,22") |

(24,88") |

(2,22") |

(2,43") |

(21,06") |

(5,35") |

|

BCF35A |

|

|

|

|

|

|

1293,9 (50,94") |

|

|

|

|

|

|

|

|

|

|

929 (36,57") |

|

|

783,5 (30,84") |

||

|

|

|

|

|

|

||

690 (27,16") |

50 |

210 |

340 |

50 |

|

650 (25,59") |

|

840 (33,04") |

|

|

|||||

|

(1,97") |

(8,27") |

(13,87") |

(1,97") |

|

|

|

|

|

|

|

||||

150 (5,88") |

|

|

|

|

|

|

|

82,5 |

|

760 |

|

82,5 |

103,3 |

510 |

169,6 |

(3,23") |

|

(29,92") |

(3,23") |

(4,06") |

(20,07") |

(6,67") |

|

BC80A |

|

|

|

|

|

|

1562 (61,49") |

BCF99A |

|

800 (31,49") |

|

|

842,7 (33,17") |

||

|

|

|

|

|

|

||

|

75 |

|

650 |

75 |

|

700 (27,56") |

|

|

(2,95") |

(25,59") |

(2,95") |

|

|

|

|

|

1710 |

|

|

|

1860 |

|

|

|

(67,3") |

|

|

|

|

|

|

|

|

|

|

(73,23") |

|

|

|

|

|

|

|

|

|

|

|

|

150 (5,9") |

|

|

|

|

|

|

|

60 |

|

680 |

60 |

105,5 |

600 |

125,3 |

|

(2,36") |

(26,77") |

(2,36") |

(4,15") |

(23,62") |

(4,93") |

|

|

|

|

|

|

9 |

|

3299720 /160555_GB |

TECHNICAL DATA

Please refer to the technical data of your own appliance.

Model |

BC40A |

BC80A |

Gross weight [lb] |

276 |

496 |

Net weight [lb] |

254 |

440 |

Dimensions |

29,38”x28,3”x38,19” |

31,49”x33,17”x73,23” |

Capacity |

48 |

100 |

Mass /cycle [lb] (+194°Fψ+37°F) |

||

Net internal volume [cuft] |

2,55 |

5,52 |

Grids |

3 |

3 |

Power supply |

220 ~ |

220 ~ |

Voltage [V] |

||

Frequency [Hz] |

60 |

60 |

Phase |

1 ph |

3 ph |

Intensity [A] |

6,5 |

11 |

Power input [W] |

1051 |

2972 |

Refrigerating unit |

1083 |

4152 |

Refrigerating power [W] |

||

Evaporation temperature [°F] |

14 |

14 |

Cooling temperature [°F] |

+194ψ+37 |

+194ψ+37 |

Cooling time [min] |

90 |

90 |

Condensation temperature [°F] |

+130 |

+130 |

Max room temperature [°F] |

+90 |

+90 |

Compressor type |

Ermetic |

Ermetic |

Refrigerant |

R404A |

R404A |

Refrigerant qty [lb] |

3 |

4,4 |

Condesation air |

Air |

Air |

Noise [dB] (A) |

65 |

72 |

IFR |

ξ |

ξ |

Multi-detector probe |

ξ |

ξ |

Model |

BCF48A |

BCF35A |

BCF99A |

Gross weight [lb] |

286 |

297 |

496 |

Net weight [lb] |

264 |

264 |

440 |

Dimensions |

29,38”x28,3”x38,19” |

36,57”x33,04”x30,84” |

31,49”x33,17”x73,23” |

Capacity |

48 |

35 |

100 |

Mass /cycle [lb] (+194°Fψ+37°F) |

|||

Mass /cycle [lb] (+194°Fψ0°F) |

28 |

22 |

60 |

Net internal volume [cuft] |

2,55 |

2,55 |

5,52 |

Grids |

3 |

3 |

3 |

Power supply |

220 ~ |

220 ~ |

220 ~ |

Voltage [V] |

|||

Frequency [Hz] |

60 |

60 |

60 |

Phase |

1 ph |

1 ph |

3 ph |

Intensity [A] |

6 |

6 |

8,5 |

Power input [W] |

1139 |

1122 |

2625 |

Refrigerating unit |

1054 |

1054 |

3136 |

Refrigerating power [W] |

|||

Evaporation temperature [°F] |

-22 |

-22 |

-22 |

Cooling temperature [°F] |

+194ψ+37 |

+194ψ+37 |

+194ψ+37 |

Cooling time [min] |

90 |

90 |

90 |

Freezing temperature [°F] |

+194ψ0 |

+194ψ0 |

+194ψ0 |

Freezing time [min] |

240 |

240 |

240 |

Condensation temperature [°F] |

+130 |

+130 |

+130 |

Max room temperature [°F] |

+90 |

+90 |

+90 |

Compressor type |

Ermetic |

Ermetic |

Ermetic |

Refrigerant |

R404A |

R404A |

R404A |

Refrigerant qty [lb] |

3 |

3 |

4,4 |

Condesation air |

Air |

Air |

Air |

Noise [dB] (A) |

65 |

65 |

72 |

IFR |

ξ |

ξ |

ξ |

Multi-detector probe |

ξ |

ξ |

ξ |

3299720 /160555_GB |

10 |

WIRING

The connection to power supply may be carried out at the back of the appliance after removing the protection grid.

All wiring cables are to comply with the ratings shown on the technical specifications

Cables are to be connected to the no potential difference terminal.

The grounding cable is to be directly connected to a good grounding system.

The guarantee will cease and the Manufacturer will not be liable for any damage to appliances or operators arising from the non-compliance with the and tamperings to any part of the appliance (electric, thermodynamic or hydraulic plant).

CONDENSATE DRAIN

The equipment has a condensation collection tray. The tray is extractable from the lower part of the equipment.

TESTING

Should the appliance have been transported horizontally instead of a vertical position DO NOT START THE APPLIANCE IMMEDIATELY. WAIT FOR AT LEAST 24 HOURS BEFORE OPERATING.

The manufacturer declines any responsibility and any warranty obligation if damage occurs to the equipment imputable to transportation in a horizontal position.

Carry out the following checkings:

1)Outside temperatures must be included between 59°F and 100°F.

2)Turn on the appliance and wait 30 minutes before the use if the external temperature is “low”.

3)Check power input

4)Carry out at least one full quick cooling cycle

11 |

3299720 /160555_GB |

CONTROL AND SAFETY SYSTEMS

The following information concerns skilled staff only.

Door micro-switch: Prevents the appliance from working when the door is open

Overall protection fuses: Protect the whole power circuit from and short-circuits and overloads

Compressor thermal relay: Operates in case of an overload or working failures

Motor-fan thermal relay: Operates in case of an overload or working failures

Safety pressure-switch: Operates in case of coolant over-pressure

Cabinet temperature control: Is run by NTC probe through the relevant electronic card

Core temperature control: Is run by PT100 probe through an electronic card

Electronic boards: based on the parameters entered they command and control any devices connected to the equipment.

REFRIGERANT MATERIAL SAFETY DATA SHEET

1) |

R404a: fluid components |

|

|

|

ξ |

trifluoroethane |

(HFC |

143a) |

52% |

ξ |

pentafluoroethane |

(HFC |

125) |

44% |

ξ |

tetrafluoroethane |

(HFC |

134a) |

4% |

GWP = 3750

ODP = 0

2) Hazard identification

Overexposure through inhalation may cause anaesthetic effects. Acute overexposure may cause cardiac rhythm disorders and sudden death. Product mists or sprays may cause ice burns of eyes and skin.

3) First aid procedures

ξInhalation: keep injured person away from exposure, warm and relaxed. Use oxygen, if necessary. Give artificial respiration if respiration has stopped or is about to stop. In case of cardiac arrest give external cardiac massage. Seek immediate medical attention

ξSkin: use water to remove ice from affected areas. Remove contaminated clothes. CAUTION: clothes may adhere to skin in case of ice burns.

In case of contact with skin, wash with copious quantities of lukewarm water. In case of symptoms (irritation or blisters) seek medical attention.

ξEyes: immediately wash with ocular solution or fresh water, keeping eyelids open for at least 10 minutes. Seek medical attention.

ξIngestion: it can cause vomit. If conscious, rinse mouth with water and drink 200-300 ml of water. Seek medical attention

ξOther medical treatment: symptomatic treatment and support therapy when indicated. Do not administer adrenaline or sympatheticomimetic drugs after exposure, due to the risk of arrhythmia and possible cardiac arrest.

4) Environmental data

Persistence and degradation

ξHFC 143a: slow decomposition in lower atmosphere (troposphere). Duration in atmosphere is 55 years.

ξHFC 125: slow decomposition in lower atmosphere (troposphere). Duration in atmosphere is 40 years.

ξHFC 134a: relatively rapid decomposition in lower atmosphere (troposphere). Duration in atmosphere is 15.6 years

ξHFC 143a, 125, 134a: does not affect photochemical smog (not included in volatile organic

components – VOC – as established in the UNECE agreement). Does not cause ozone rarefaction. Product exhausts released in the atmosphere do not cause long-term water contamination.

3299720 /160555_GB |

12 |

DISPOSAL

WASTE STORAGE

At the end of the product life, avoid release to the environment. The doors should be removed before disposal. Temporary storage of special waste is permitted while waiting for disposal by treatment and/or final collection. Dispose of special waste in accordance with the laws in force with regard to protection of the environment in the country of the user.

PROCEDURE FOR ROUGH DISMANTLING THE APPLIANCE

Countries have different legislation; provision laid down by the laws and the bodies of the

countries where the demolition takes place are therefore to be observed. A general rule is to deliver the appliance to collection and demolition centers. Dismantle the refrigerator grouping together the components according to their chemical nature. The compressor contains lubricating oil and refrigerant,

which may be recycled. The refrigerator components are considered special waste, which can be assimilated with domestic waste. Make the appliance totally unusable by removing the power cable and any door locking mechanisms in order to avoid the risk of anyone being trapped inside.

DISMANTLING OPERATIONS SHOULD BE CARRIED OUT BY QUALIFIED PERSONNEL.

The improper disposal of Waste Electrical and Electronic Equipment is liable to punishment under the relevant laws in the countries where the offence is committed.

Waste electrical and Electronic Equipment may contain hazardous substances with potential harmful effects on the environment and human health. You are urged to dispose of them properly.

STERILIZATION LAMP INSTALLATION

The sterilization lamp kit is not supplied as standard equipment.

Should you purchase the kit, please follow the installation instructions to install.

PRINTER INSTALLATION

The printer is not supplied as standard equipment .

Should you purchase the printer, please follow the installation instructions to install.

13 |

3299720 /160555_GB |

OPERATION

GENERAL DESCRIPTION

This unit is capable of reducing the internal temperature of the contents from 135°F (57°C) to 40°F (4°C) with in 4 hours, in order to conserve it for a long period of time without altering the organoleptic characteristics. Machine capacity as to the quantity to be cooled depend on the model purchased.

SETTING UP

Before setting to operation thoroughly clean the cooling cabinet with a suitable detergent or sodium bycarb dissolved in lukewarm water. Clean the appliance inside to remove any condensate caused by the Manufacturer's final testing.

Cooling and freezing speed depends on the following factors:

a)container shape, type and material;

b)whether container lids are used;

c)foodstuff features (density, water contents, fat contents);

d)starting temperature;

e)thermal conduction inside the foodstuffs.

Positive /Negative quick cooling time depends on type of foodstuffs to be processed.

In general the programs the machine is equipped with are based on the chamber temperature management, the fan speed and the chilling time, in any case never exceed 7lb of load (for 12”x20” pans) or 15lb of load (for 18”x26” pans) and a thickness of 2” in negative chilling phase and 3” in positive chilling phase (table 2).

Check that the positive chilling program, up to +37°F at the product core, does not take more than 90 minutes and that the negative chilling program, up to 0°F at the product core, does not take more than 4 hours.

We recommend pre-chilling the work chamber before beginning with a chilling program and not covering the food during the program in order not to increase times.

We recommend using the core probe in order to have the exact core temperature reading. Do not stop the cycle before reaching a temperature of +37°F during positive quick cooling and 0°F during negative quick cooling.

Tab.2

|

Model |

|

|

Max. output/cycle |

|

|

Standard of |

|

|

|

Capacity |

|

|

h |

|

||

|

|

|

|

|

shelves |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+194[°F]ψ+37[°F] |

+194[°F]ψ0[°F] |

|

|

|

|

|

n° max |

|

|

|

|

|

|

|

BC40A |

|

48[lb] |

- |

|

3 |

|

6 |

|

12“x20“ |

|

1,5“ |

|||||

|

BCF48A |

|

48[lb] |

28[lb] |

3 |

|

6 |

|

12“x20“ |

|

1,5“ |

||||||

|

BCF35A |

|

35[lb] |

22[lb] |

3 |

|

10 |

|

12“x20“ |

|

1,5“ |

||||||

|

BC80A |

|

100[lb] |

- |

|

3 |

|

12 |

|

12“x20“ |

|

1,5“ |

|||||

|

BCF99A |

|

100[lb] |

60[lb] |

3 |

|

12 |

|

12“x20“ |

|

1,5“ |

||||||

3299720 /160555_GB |

14 |

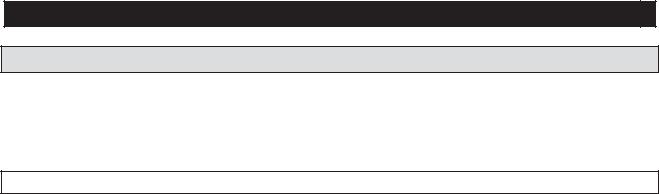

MACHINE LOADING

Do not pile up foodstuffs to be cooled. Thickness should be lower than 2” in negative quick cooling and lower than 3” in positive quick cooling.

Make sure air circulation is not hampered between food trays.

The grid-holding frame (included in those models which include trolleys) is to be located at the centre of the cabinet.

0,19”-0,79” |

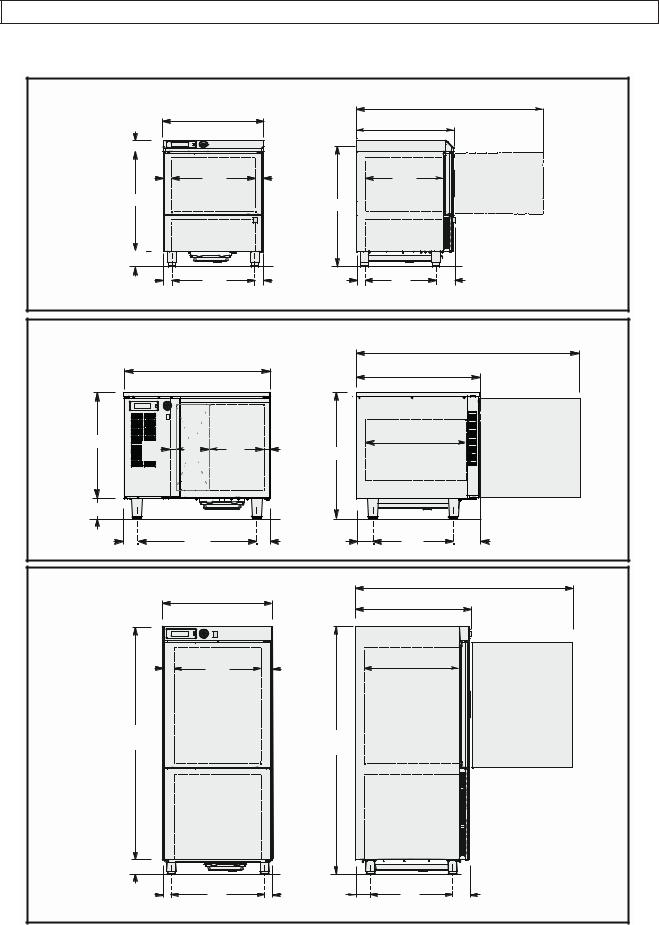

POSITION OF TRAYS

Place the trays as close to the evaporator as possible.

If the cabinet is not full place the trays at equal distance from one another.

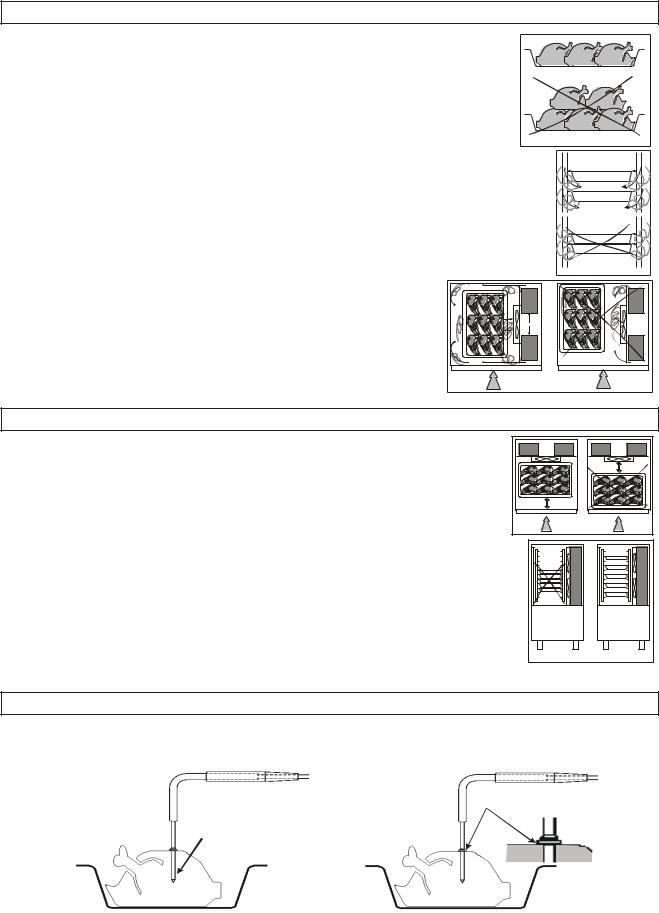

CORE PROBE

For proper position of the probe, refer to the following pictures.

S O N D A A S IN G O LO |

|

|

|

|

|

|

|

|

|

|

SONDA A M ULTIPLO |

|

|

|

||||

SINGLE-DETECTOR |

|

|

|

|

|

|

|

|

|

|

MULTI-DETECTOR |

|

|

|

||||

R IL E VA M E N TO |

|

|

|

|

|

|

|

|

|

|

RILEVAMENTO |

|

|

|

||||

PROBE |

|

|

|

|

|

|

|

|

|

|

PROBE |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PRODUCT SURFACE |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S UP ER FICIE PR O D O T TO |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PRODUCTCU R E PR OCORED O T TO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

3299720 /160555_GB |

TEMPERATURES

Do not leave the cooked products that are to be chilled/frozen at room temperature. Avoid humidity losses, which will be detrimental to the conserved fragrance of the product.

We recommend beginning the chilling/freezing program as soon as the preparation or cooking phase has ended, being careful to insert the product into the equipment at a temperature no lower than +160°F. The cooked product can enter the equipment even at very high temperatures, greater than +212°F, as long as the chamber has been pre-chilled.

In any case it should be taken into consideration that the program reference times always start from a temperature of +194°F, in positive chilling from +194°F to +37°F and in negative chilling from +194°F to 0°F.

LENGTH |

|

|

|

|

|

|

Cooled or frozen processed foodstuffs may be stored in a refrigerator for 5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

days of processing with no quality alterations. |

A |

|

|

|

|

|

|

|

|

|

|

|

|

For best results we recommend keeping temperature constant throughout the |

B |

|

|

|

|

|

storing (32°F to 39°F), according to the various commodities. |

|

|

|

|

|

|

Storing time may be increased to approx. two weeks by using vacuum |

C |

|

|

|

||

|

|

|||||

processing. |

|

|

|

|

|

|

After a negative quick cooling cycle, foodstuffs may be stored safely for 3 to 18 |

|

|

|

|

|

|

months, according to the type of foodstuff processed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

We strongly recommend keeping storing temperature at -4°F or below. |

|

|

|

|

|

|

The cooled product should be wrapped in a specific film for foodstuffs (better still, vacuum stored) and provided with a sticker reporting the content [A], date of processing [B] and expiry date [C] written in permanent type ink.

3299720 /160555_GB |

16 |

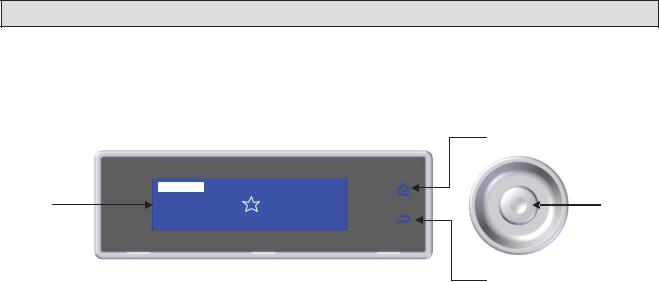

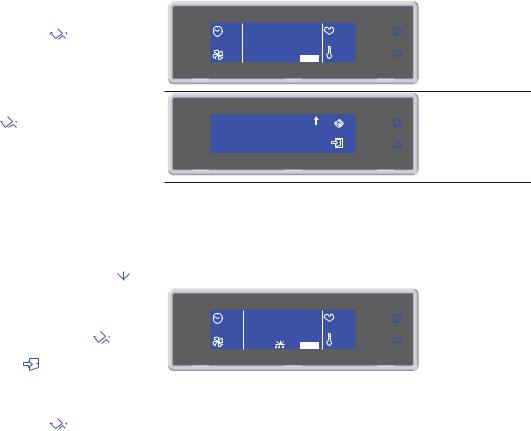

CONTROL PANEL

The illustration shows the equipment control panel, while the list indicates the description and functionality of the individual commands.

A

SOFT+37°F |

SOFT 0°F |

HARD +37°F |

HARD 0°F |

IFR |

INFINITY |

|

MENU |

B

D

C

A–Display: Displays all the information relative to the menus on the board and the application in progress.

B– HOME button: In any context, if enabled, this allows the user to return immediately to the main screen. If the button is enabled this is indicated by the corresponding back lighting.

C– BACK button: During navigation this button allows the user to return to the previous level in the menu structure, while when any cycle is in progress, it allows the user to modify the control parameters of the process in progress, temporarily saving the modified values.

D– Knob: The clockwise and anticlockwise turning of the knob allows the user to navigate through the various menus on the display, while pressing it allows access to the selected item.

The RGB LED bar, built into the door handle, takes on a different color depending on the process in progress:

-Stand-by: low intensity steady light blue light

-Chilling/freezing cycle (including infinity, Multy) Defrost and Cooling, in progress: high intensity flashing light blue light

-Conservation in progress: high intensity steady light blue light

-Freezing in progress: high intensity steady red light

-Sanitation in progress: low intensity steady red light

-Fault: steady yellow light

17 |

3299720 /160555_GB |

FIRST START-UP

At the first start-up the operator will be asked to choose the language and the sector.

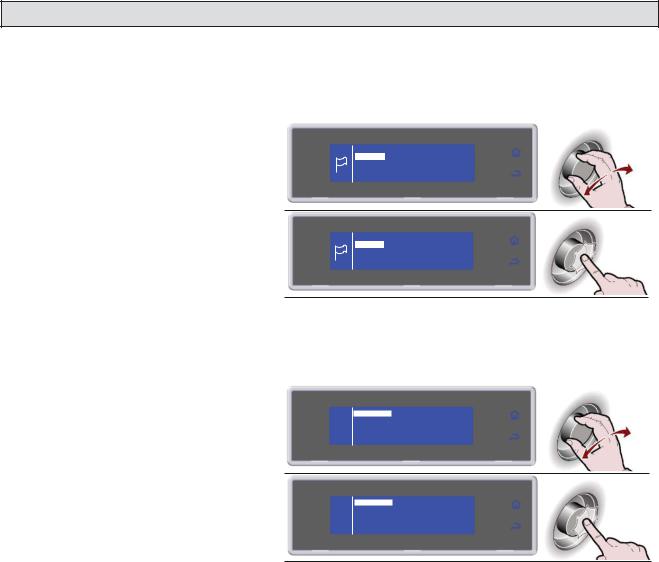

LANGUAGE SETTING

1.Select LANGUAGE by rotating the knob

2.Press the knob to confirm the selected language

The language can also be changed later (see page 50)

ITALIANO DUTCH ENGLISH DANSK

FRANCAIS SVENSKA DEUTSCH NORSK ESPANOL

ITALIANO DUTCH ENGLISH DANSK

FRANCAIS SVENSKA DEUTSCH NORSK ESPANOL

SECTOR SETTING

1.Select the SECTOR by rotating the knob

2.Press the knob to confirm the selected sector

The sector can also be changed later (see page 52)

CATERING

PASTRY

BAKERY ICE CREAM

CATERING

PASTRY

BAKERY ICE CREAM

3299720 /160555_GB |

18 |

|

PROGRAM |

|

|

|

|

|

PROGRAM DESCRIPTIONS |

|

|

|

|

PROGRAM |

DESCRIPTION |

|

|

STANDARD PROGRAMS |

|

|

Cycle carried out through probe at the core or time, suitable for chilling foods up to +37°F, |

|

SOFT +37°F |

using a chamber temperature of about 34°F. |

|

Cycle suitable for delicate products such as mousse, creams, desserts, vegetables or |

||

|

||

|

foods that are not very thick |

|

|

Cycle carried out through probe at the core or time, suitable for chilling foods up to +37°F, |

|

HARD +37°F |

using a chamber temperature varying from 5°F to 34°F. |

|

|

Cycle suitable for very dense products, with high grease content or large sized products |

|

IFR |

I.F.R. is the patented positive blast chilling system that automatically optimises the process |

|

for any type of food, no matter the size and quantity, chilling its surface thanks to the use of |

||

|

a multipoint, three sensor needle probe |

|

|

Cycle carried out through probe at the core or time, suitable for freezing foods up to 0°F, |

|

SOFT 0°F |

using a chamber temperature varying from 34°F to -40°F. |

|

|

Cycle suitable for leavened products, baked or cooked foods that are not very thick |

|

|

Cycle carried out through probe at the core or time, suitable for freezing foods up to 0°F, |

|

HARD 0°F |

using a chamber temperature that can reach -40°F. |

|

|

Cycle suitable for raw or cooked, large size foods |

|

INFINITY |

Time chilling/freezing cycle with infinite duration, suitable for cooling various type food |

|

pans. The temperature at the core can be checked |

||

|

||

|

AUTOMATIC PROGRAMS +37°F - CATERING |

|

LASAGNE |

Cycle dedicated to chilling of lasagne |

|

SOUPS AND SAUCES |

Cycle dedicated to chilling of soups and sauces |

|

RICE AND PASTA |

Cycle dedicated to chilling of rice and pasta |

|

MEAT |

Cycle dedicated to chilling of meat |

|

FISH |

Cycle dedicated to chilling of fish |

|

COOKED VEGETABLES |

Cycle dedicated to chilling of cooked vegetables |

|

HOT PASTRY |

Cycle dedicated to chilling of hot pastry products |

|

DRY PASTRY |

Cycle dedicated to chilling of dry pastry products |

|

WALNUTS VEAL |

Cycle dedicated to chilling of walnuts veal |

|

|

AUTOMATIC PROGRAMS 0°F - CATERING |

|

LASAGNE |

Cycle dedicated to freezing of lasagne |

|

SOUPS AND SAUCES |

Cycle dedicated to freezing of soups and sauces |

|

RICE AND PASTA |

Cycle dedicated to freezing of rice and pasta |

|

MEAT |

Cycle dedicated to freezing of meat |

|

FISH |

Cycle dedicated to freezing of fish |

|

COOKED VEGETABLES |

Cycle dedicated to freezing of cooked vegetables |

|

RAW VEGETABLES |

Cycle dedicated to freezing of raw vegetables |

|

PASTRY |

Cycle dedicated to freezing of pastry products |

|

RAW FISH |

Cycle dedicated to freezing of raw fish |

|

SUSHI |

Cycle dedicated to freezing of Sushi |

|

ANISAKIS 24h* |

It is a special blast freezing cycle that enables preventive and total food preservation and |

|

restoration. Once the probe reads -4°F at the food core, the appliance will automatically |

||

|

start the "devitalization phase for 24 hours” |

|

ANISAKIS 15h* |

it is a special blast freezing cycle that enables preventive and total food preservation and |

|

restoration. Once the probe reads -31°F at the food core, the appliance will automatically |

||

|

start the "devitalization phase for 15 hours” |

|

OPISTORKIS 24h |

It is a special blast freezing cycle that enables preventive and total food preservation and |

|

restoration. Once the probe reads -4°F at the food core, the appliance will automatically |

||

|

start the "devitalization phase for 24 hours” |

* Tested and validated in cooperation with: University of Naples Federico II - Department of Zootechnical Sciences and Food inspection and the University Research laboratory at the wholesale fish market of Pozzuoli, Naples

19 |

3299720 /160555_GB |

|

AUTOMATIC PROGRAMS +37°F - PASTRY SHOP |

DOUGH SHEETING |

Cycle dedicated to chilling of sheet dough |

MIXING IN DIE |

Cycle dedicated to chilling of moulded dough |

CREAM |

Cycle dedicated to chilling of creams |

LEAVENED |

Cycle dedicated to chilling of leavened products |

LEAVENED +50°F |

Cycle dedicated to chilling of leavened products +50°F |

SHORT PASTRY |

Cycle dedicated to chilling of shortcrust dough |

STUFFED PRODUCTS |

Cycle dedicated to chilling of filled products |

TARTS |

Cycle dedicated to chilling of tarts |

BRIOCHE |

Cycle dedicated to chilling of brioche |

PANNA COTTA |

Cycle dedicated to chilling of panna cotta |

YOGURT BOX |

Cycle dedicated to preparing of yogurt |

|

AUTOMATIC PROGRAMS 0°F - PASTRY SHOP |

|

DOUGH SHEETING |

Cycle dedicated to freezing of sheet dough |

|

MIXING IN DIE |

Cycle dedicated to freezing of moulded dough |

|

TARTS |

Cycle dedicated to freezing of tarts |

|

MOUSSE |

Cycle dedicated to freezing of mousse |

|

CROISSANT |

Cycle dedicated to freezing of croissants |

|

ICE CREAM |

Cycle dedicated to freezing of ice cream |

|

|

AUTOMATIC PROGRAMS +37°F - BAKERY |

|

TARTS |

Cycle dedicated to chilling of tarts |

|

BAKED BREAD |

Cycle dedicated to chilling of baked bread |

|

CREAM |

Cycle dedicated to chilling of creams |

|

LEAVENED |

Cycle dedicated to chilling of leavened products |

|

|

AUTOMATIC PROGRAMS 0°F - BAKERY |

|

COOKED TARTS |

Cycle dedicated to freezing of baked tarts |

|

RAW TARTS |

Cycle dedicated to freezing of unbaked tarts |

|

BAKED BREAD |

Cycle dedicated to freezing of baked bread |

|

UNCOOKED BREAD |

Cycle dedicated to freezing of unbaked bread |

|

|

AUTOMATIC PROGRAMS +37°F - ICE CREAM PARLOUR |

|

PANNA COTTA |

Cycle dedicated to chilling of panna cotta |

|

YOGURT BOX |

Cycle dedicated to preparing of yogurt |

|

|

AUTOMATIC PROGRAMS 0°F - ICE CREAM PARLOUR |

|

ICE CREAM -7°F |

Cycle dedicated to freezing of ice cream -7°F |

|

ICE CREAM |

Cycle dedicated to freezing of ice cream |

|

COMPLETE MOUSSE |

Cycle dedicated to freezing of complete mousse |

|

MOUSSE |

Cycle dedicated to freezing of mousse |

|

FROZEN DESSERT |

Cycle dedicated to freezing of frozen dessert |

|

|

MULTY PROGRAM |

|

MULTY |

Time chilling/freezing cycle, organized by load levels, with possibility of needle probe |

|

reading, providing the time for each level |

||

|

||

|

BANQUETING PROGRAM |

|

BANQUETING |

Cycle dedicated to the catering sector, excellent for preparation of banqueting products |

|

|

VACUUM PROGRAM |

|

VACUUM |

Cycle dedicated to the catering sector for preparation of products before a vacuum-packing |

|

phase |

||

|

||

|

THAWING PROGRAM |

|

THAWING |

Cycle carried out by means of temperature probe or by time, dedicated to controlled food |

|

defrosting |

||

|

||

|

PROVING PROGRAM |

|

PROVING (PROOFING) |

Time cycle, dedicated to direct leavening of foods |

|

RETARDER PROVING |

Time cycle, dedicated to scheduled leavening of foods |

|

|

SMART ON PROGRAM |

|

|

Cycle with automatic start. |

|

SMART ON |

Once a hot product is inserted if an increase in the chamber temperature is detected, after |

|

5 minutes a Soft +37°F cycle will start, either by probe or time, based on whether or not the |

||

|

||

|

needle is used. |

|

3299720 /160555_GB |

20 |

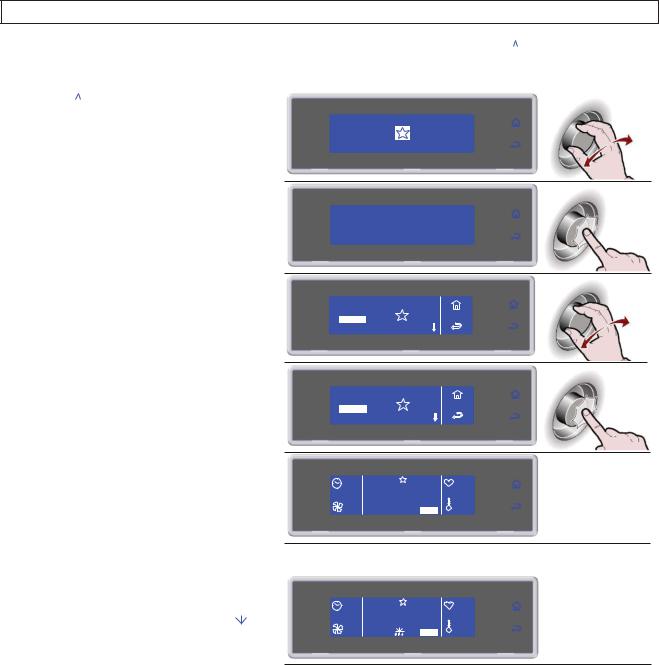

STANDARD PROGRAMS

Chilling/freezing cycles pre-set by the manufacturer which can be activated by selecting them directly from the initial screen, SOFT +37°F, HARD +37°F, SOFT 0°F and HARD 0°F.

During execution of the cycle the parameters can be viewed and modified temporarily. The new values will be valid exclusively for the cycle in progress.

1.Select the desired cycle by rotating the knob

2.Press the knob to activate the selected cycle

During the cycle it is possible:

-to view and modify the default parameters by selecting SET (see page 40)

-to stop the cycle by selecting STOP

Note: the modified parameters will be saved only for the cycle in progress

SOFT +37°F |

SOFT 0°F |

|

HARD 0°F |

HARD +37°F |

|

IFR |

INFINITY |

|

MENU |

SOFT +37°F |

SOFT 0°F |

|

HARD 0°F |

HARD +37°F |

|

IFR |

INFINITY |

|

MENU |

90' HARD +37°F |

+80°F |

||

100% |

SET |

STOP |

+75°F |

|

|

||

3.Cycle ended, automatic conservation phase

During conservation it is possible:

- |

to view and modify the default parameters by |

|

END CYCLE +80°F |

|

|

selecting SET (see page 40) |

- - |

||

- |

to activate a manual defrost by selecting |

100% |

CONSERVE |

|

SET |

STOP |

|||

|

|

|

|

+75°F |

- |

to stop the cycle by selecting STOP |

|

|

|

Note: the modified parameters will be saved only for the cycle in progress.

If not required, manual defrosting is not performed

21 |

3299720 /160555_GB |

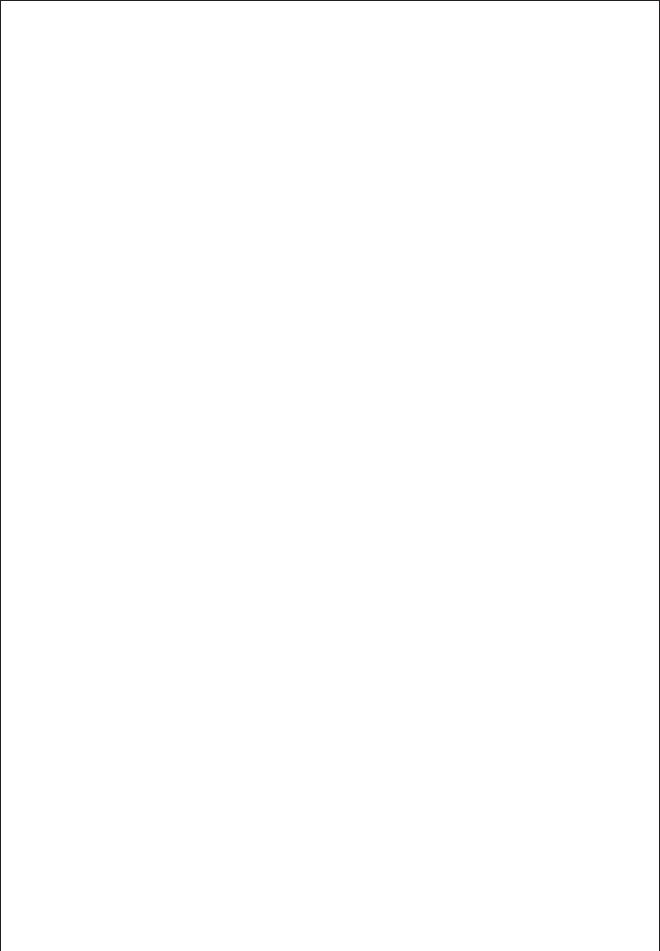

PROGRAM I.F.R.

The IFR is an innovative patented system of positive quick cooling which allows the cycle optimized for each type of foodstuffs by preventing superficial freezing. Temperatures are detected by a three-sensor multipoint needle probe. The position

inside the foodstuff is determined univocally by a reference disk located along the needle. (ref. par. “Core probe”).

1.Select the desired cycle by rotating the knob

2.Press the knob to activate the selected cycle

During the cycle it is possible:

-select SET to change the fan speed

-to stop the cycle by selecting STOP

Note: the modified value will only be saved for the cycle in progress

3.Cycle ended, automatic conservation phase

During conservation it is possible:

-to view and modify the default parameters by selecting SET (see page 40)

-to activate a manual defrost by selecting

-to stop the cycle by selecting STOP

Note: the modified parameters will be saved only for the cycle in progress.

If not required, manual defrosting is not performed

SOFT +37°F |

SOFT 0°F |

|

HARD +37°F |

HARD 0°F |

|

|

|

INFINITY |

IFR |

||

|

|

MENU |

SOFT +37°F |

SOFT 0°F |

|

HARD +37°F |

HARD 0°F |

|

|

|

INFINITY |

IFR |

||

|

|

MENU |

- - |

|

IFR |

+80°F |

|

|

|

|

100% |

SET |

|

+75°F |

|

|

STOP |

- - END CYCLE |

+80°F |

|||

100% |

CONSERVE |

+75°F |

||

SET |

STOP |

|||

|

|

|||

3299720 /160555_GB |

22 |

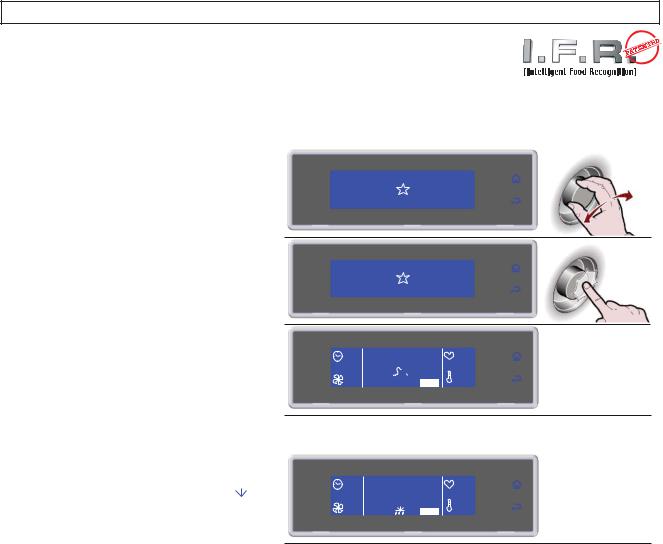

PROGRAM INFINITY

Time chilling/freezing cycle with infinite duration, suitable for cooling various type food pans. The temperature at the core can be checked.

1.Select the desired cycle by rotating the knob

4.Cycle ended, automatic conservation phase

During conservation it is possible:

-select SET to view and modify the chamber temperature and fan speed

-to stop the cycle by selecting STOP

Note: the modified values will be saved

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

HARD 0°F |

|

IFR |

|

|

|

INFINITY |

|

|

MENU |

|

SOFT +37°F |

SOFT 0°F |

|

HARD +37°F |

HARD 0°F |

|

IFR |

|

|

|

INFINITY |

|

|

MENU |

|

|

INFINITY |

+80°F |

|

|

|

||

100% |

SET |

STOP |

+75°F |

|

|

||

23 |

3299720 /160555_GB |

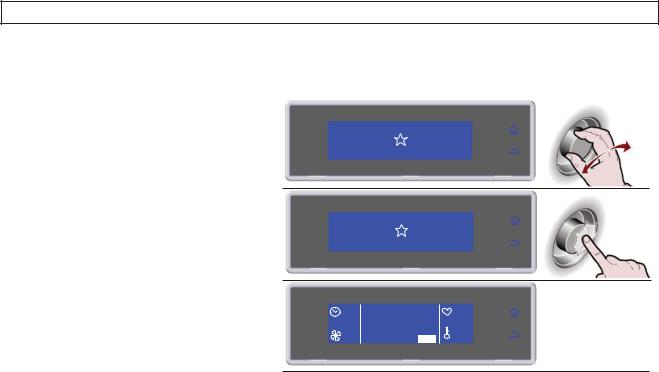

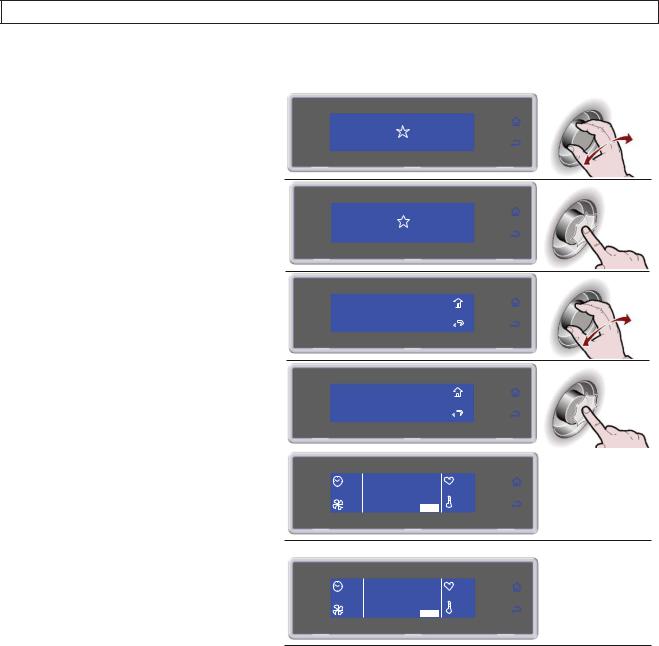

FAVORITE PROGRAMS

A library consisting in 10 cycles selected from those stored and labelled as favorites  (see page 27)

(see page 27)

1. Select  by rotating the knob

by rotating the knob

SOFT +37°F |

SOFT 0°F |

HARD +37°F |

HARD 0°F |

IFR |

INFINITY |

|

MENU |

2.Press the knob to enter section FAVORITE PROGRAMS

3.Select the desired cycle by rotating the knob

4.Press the knob to activate the selected cycle

During the cycle it is possible:

-to view and modify the default parameters by selecting SET (see page 36)

-to stop the cycle by selecting STOP

Note: the modified parameters will be saved only for the cycle in progress

SOFT +37°F |

|

|

SOFT 0°F |

HARD +37°F |

|

|

HARD 0°F |

|

|

||

IFR |

|

|

INFINITY |

|

|

||

|

MENU |

||

1 CICLO 1

2 CICLO 2

3 CICLO 3

4 CICLO 4

1 CICLO 1

2 CICLO 2

3 CICLO 3

4 CICLO 4

90' |

|

MEMO +37°F |

+80°F |

|

CICLO 3 |

||||

|

|

|||

100% |

SET |

STOP |

+75°F |

|

|

|

|||

5.Cycle ended, automatic conservation phase

During conservation it is possible:

-to view and modify the default parameters by selecting SET (see page 40)

-to activate a manual defrost by selecting

-to stop the cycle by selecting STOP

Note: the modified parameters will be saved only for the cycle in progress.

If not required, manual defrosting is not performed

- - |

|

MEMO +37°F |

+80°F |

|

END CYCLE |

||||

|

|

|||

100% |

CONSERVE |

+75°F |

||

SET |

STOP |

|||

|

|

|||

3299720 /160555_GB |

24 |

AUTOMATIC PROGRAMS

These programs are manufacturer recommended work cycles. During the cycle the parameters can be viewed, but not modified.

1. Select MENU by rotating the knob

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

2.Press the knob to enter section MENU

3.Select AUTOMATIC by rotating the knob

4.Press the knob to enter section AUTOMATIC

5.Select the type of desired cycle by rotating the knob

6.Press the knob to enter into the selected type of cycle

7.Select the desired cycle by rotating the knob

8.Press the knob to activate the selected cycle

9.Select the quantity of load to be treated, minimum, medium, maximum

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

|

AUTOMATIC |

FUNCTIONS |

|

|

|

|

STORED |

HACCP |

|

|

|

|

MENU |

||||

|

MULTY |

SETTING |

|||

|

|

|

|

||

|

COOLING |

SERVICE |

|

|

|

|

|

|

|

||

|

|

|

|

||

|

|

|

|

|

|

|

AUTOMATIC |

FUNCTIONS |

|

|

|

|

STORED |

HACCP |

|

|

|

|

MENU |

||||

|

MULTY |

SETTING |

|||

|

|

|

|

||

|

COOLING |

SERVICE |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

AUTOMATIC +37°F |

|

|

AUTOMATIC 0°F |

MENU |

|

BANQUETING |

||

AUTO |

||

VACUUM |

|

AUTOMATIC +37°F |

|

AUTOMATIC 0°F |

MENU |

BANQUETING |

AUTO |

VACUUM |

|

|

LASAGNE |

|

|

|

|

|

|

|

|

||

|

SOUPS AND SAUCES |

MENU |

|||

|

|

|

AUTO |

||

|

RICE AND PASTA |

||||

|

MEAT |

AUTO +37°F |

|||

|

|

|

|

||

|

|

|

|

|

|

|

LASAGNE |

|

|

|

|

|

|

|

|

||

|

SOUPS AND SAUCES |

MENU |

|||

|

RICE AND PASTA |

|

AUTO |

||

|

MEAT |

AUTO +37°F |

|||

|

|

|

|

|

|

|

|

|

|

|

|

RICE AND

PASTA

25 |

3299720 /160555_GB |

10.Press the knob to activate the selected cycle

During the cycle it is possible:

-to view the default parameters by selecting INFO

-to stop the cycle by selecting STOP

Note: the parameters cannot be modified

12.Cycle ended, automatic conservation phase

During conservation it is possible:

-to view the default parameters by selecting INFO

-to activate a manual defrost by selecting

-to stop the cycle by selecting STOP

Note: the parameters cannot be modified.

If not required, manual defrosting is not performed

3299720 /160555_GB

RICE AND

PASTA

45' |

|

AUTO +37°F |

+80°F |

|

RICE AND |

||||

|

|

|||

90% |

|

PASTA |

+75°F |

|

INFO |

STOP |

|||

|

|

|||

- - END CYCLE |

+80°F |

|||

100% |

CONSERVE |

+75°F |

||

SET |

STOP |

|||

|

|

|||

26

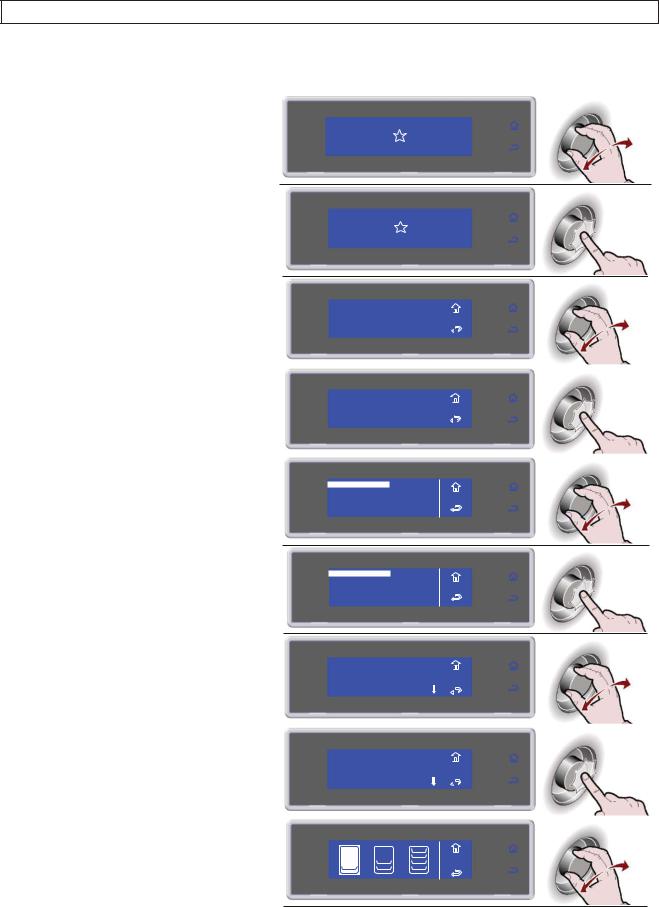

STORED PROGRAMS

These are 10 chilling cycles and 10 freezing cycles that can be configured based on the needs of the user, the names of which can be freely set.

These cycles already have default settings set up by the manufacturer: once modified by the user the new values can be saved in the memory and recalled at a subsequent start of that cycle.

10 of these programs can be made FAVORITES, organizing them based on the needs of the user.

1. Select MENU by rotating the knob

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

2.Press the knob to enter section MENU

3.Press the knob to enter section STORED

4.Press the knob to enter section STORED

5.Select the type of desired cycle by rotating the knob

6.Press the knob to enter into the selected type of cycle

7.Select the desired cycle by rotating the knob

8.Press the knob to activate the selected cycle

During the cycle it is possible:

-View, modify the default parameters and make it a favorite by selecting SET

-to stop the cycle by selecting STOP

Note: the modified parameters can be saved once the new value is inserted by selecting

otherwise, by selecting |

|

, the modifications |

|

will be active only for the cycle in progress.

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

|

AUTOMATIC |

FUNCTIONS |

|

|

|

|

|

STORED |

|

HACCP |

|

|

|

|

|

MENU |

||||

|

MULTY |

SETTING |

||||

|

|

|

|

|||

|

COOLING |

SERVICE |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|

|

|

|

AUTOMATIC |

FUNCTIONS |

|

|

|

|

|

STORED |

|

HACCP |

|

|

|

|

|

MENU |

||||

|

MULTY |

SETTING |

||||

|

|

|

|

|||

|

COOLING |

SERVICE |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

STORED +37°F

STORED 0°F MENU

STORED

STORED +37°F

STORED 0°F MENU

STORED

1 |

CICLO 1 |

|

|

|

|

|

|

|

|

|

|||

2 |

CICLO 2 |

|

MENU |

|||

3 |

|

|

|

STORED |

||

CICLO |

3 |

|||||

4 |

CICLO |

4 |

|

STOR.+37°F |

||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|

|

|

1 |

CICLO 1 |

|

|

|

|

|

|

|

|

|

|||

2 |

CICLO 2 |

|

MENU |

|||

3 |

|

CICLO 3 |

|

STORED |

||

|

|

STOR.+37°F |

||||

4 |

CICLO 4 |

|

||||

|

|

|

|

|||

|

|

|

|

|

|

|

27 |

3299720 /160555_GB |

If the modifications are saved the user will be asked to assign a name to the cycle. use the knob

to enter the name and press  to save it.

to save it.

To make a cycle a favorite, select MAKE FAVORITE, found at the end of the parameters list, and enter the desired position. The cycle will automatically overwrite the one in that position.

Save by selecting

90' |

|

STOR. +37°F |

+80°F |

|

CICLO 3 |

||||

|

|

|||

100% |

SET |

STOP |

+75°F |

|

|

|

|||

SOFT PHASE TIME |

60' |

|

|

|

SOFT PHASE FAN |

70% |

|

|

|

|

|

|||

STORAGE |

39°F |

|

|

|

MAKE FAVORITE |

|

_ |

|

|

|

|

|

|

|

|

|

|

|

|

9.Cycle ended, automatic conservation phase

During conservation it is possible:

-View, modify the default parameters and make it a favorite by selecting SET

-to activate a manual defrost by selecting

-to stop the cycle by selecting STOP

Note: the modified parameters can be saved once the new value is inserted by selecting

otherwise, by selecting |

|

the modifications will |

|

be active only for the cycle in progress.

If the modifications are saved the user will be asked to assign a name to the cycle. use the knob

to enter the name and press  to save it.

to save it.

If not required, manual defrosting is not performed

3299720 /160555_GB

- - |

|

STOR. +37°F |

+80°F |

|

END CYCLE |

||||

|

|

|||

100% |

CONSERVE |

+75°F |

||

SET |

STOP |

|||

|

|

|||

28

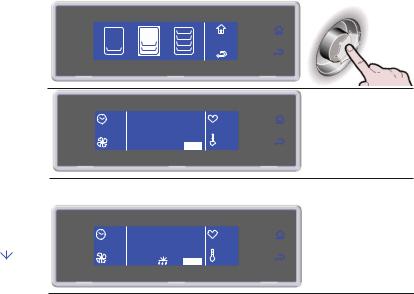

MULTY

Chilling/freezing cycle by time organized by load levels.

The number of levels available varies depending on the equipment.

1. Select MENU by rotating the knob

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

2. Press the knob to enter section MENU

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

3. Select MULTY by rotating the knob

AUTOMATIC |

FUNCTIONS |

|

|

|

|

|

STORED |

HACCP |

MENU |

||||

MULTY |

|

SETTING |

||||

|

|

|

|

|

||

COOLING |

SERVICE |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|

|

|

4.Press the knob to enter section MULTY

5.Enter the time for each level and confirm it with the knob

During the cycle it is possible:

-to view and modify the default parameters by selecting SET (see page 40)

-to stop the cycle by selecting

Note: the modified parameters will be saved

At the expiry of the set value for each individual level, the buzzer and the flashing value alert the user that the product can be withdrawn.

Once all the set times have expired, automatic conservation phase During conservation it is possible:

-to view and modify the default parameters by selecting SET (see page 40)

Note: the modified parameters will be saved

|

AUTOMATIC |

FUNCTIONS |

|

|

|

|

|

|

STORED |

HACCP |

MENU |

||||

|

MULTY |

|

SETTING |

||||

|

|

|

|

|

|

||

|

COOLING |

SERVICE |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

1 |

30' |

|

+80°F |

|

2 |

20' |

|

|

|

|

|

MENU |

||

3 |

0' |

|

|

MULTY |

4 |

0' |

SET |

+75°F |

5L |

5 |

0' |

|

||

|

|

1 |

30' |

|

+80°F |

|

2 |

20' |

|

|

|

|

|

MENU |

||

3 |

0' |

|

|

MULTY |

4 |

0' |

SET |

+75°F |

5L |

5 |

0' |

|

||

|

|

29 |

3299720 /160555_GB |

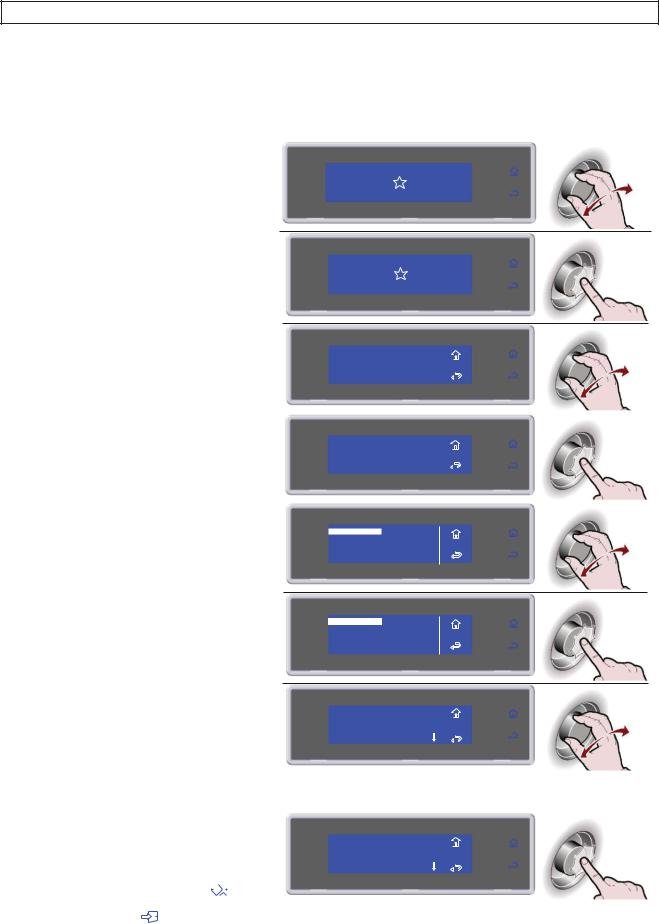

COOLING

It is advisable to run a cooling cycle prior to selecting any chilling cycle.

1. Select MENU by rotating the knob

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

2. Press the knob to enter section MENU

SOFT +37°F |

|

SOFT 0°F |

HARD +37°F |

|

HARD 0°F |

IFR |

|

INFINITY |

|

MENU |

|

3. Select COOLING by rotating the knob

AUTOMATIC |

FUNCTIONS |

|

|

|

|

||

STORED |

HACCP |

MENU |

|||||

MULTY |

SETTING |

||||||

|

|

|

|

||||

COOLING |

|

SERVICE |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

4.Press the knob to activate the selected cycle

During the cycle it is possible:

-to view and modify the default parameters by selecting SET (see page 40)

-to stop the cycle by selecting STOP

Note: the modified parameters will be saved only for the cycle in progress

|

AUTOMATIC |

FUNCTIONS |

|

|

|

|

|

|

STORED |

HACCP |

MENU |

||||

|

MULTY |

SETTING |

|||||

|

|

|

|

|

|||

|

COOLING |

|

SERVICE |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

- - |

COOLING |

+80°F |

|

|

|

||

100% |

SET |

STOP |

+75°F |

|

|

||

5.Cycle ended, automatic conservation phase

During conservation it is possible:

-to view and modify the default parameters by selecting SET (see page 40)

-to stop the cycle by selecting STOP

Note: the modified parameters will be saved only for the cycle in progress

- - END CYCLE |

+80°F |

|||

100% |

CONSERVE |

+75°F |

||

SET |

STOP |

|||

|

|

|||

3299720 /160555_GB |

30 |

Loading...

Loading...