Noritz SC-301-6M-EXT Installation Manual

System Controller

CAUTION

SC-301-6M-EXT

In order to use this product safely,

read this installation manual carefully

and follow the installation instructions.

Installation Manual

Potential dangers from accidents during installation and use are divided into the following two categories. Closely

observe these warnings, they are critical to your safety.

WARNING

CAUTION

WARNING indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Requests to Installers

WARNING

•

Failures and damage caused by erroneous work or work not as instructed in this manual are not covered by the warranty.

• Refer to installation manual attached to the appliance as well.

• Check that installation was done in accordance with this Installation Manual upon completion.

• After completion of installation, be sure to hand this Installation Manual to the customer.

• When you fasten the screws on the terminals (Warning lamp terminal and so on),do not use electric drivers,

impact drivers and so forth.Tightening with excessive force may cause the terminals to be damaged and lead

to failures.

In order to use this product safely, read this installation manual carefully and follow

the installation instructions.

Contents

1. Included Accessories .................................................2

2. Required Accessories ................................................2

3. Introduction ................................................................3

4. Installing the System Controller .................................4

5. Wiring Diagram, System Diagram.............................. 6

6. Remote buttons and display overview .......................7

7. Remote initial setup ...................................................9

8. Recirculation Pump Timer Setup .............................13

9.

System Check Button

10. Maintenance Monitors and Additional Settings

11. Additional Remote features

12. Additional System Controller Features

13. System design, Gas, and Water piping

14. Follow-up Service

.................................................. 15

.........

..........................................

.......................

......................

..........................................................

16

18

20

24

28

If at any time during the installation and setup of this product you have questions or concerns, please contact Noritz America

Engineering & Service at 866-766-7489 or visit http://support.noritz.com/.

SBA8939

Rev. 5/12

──

*SBA8939*

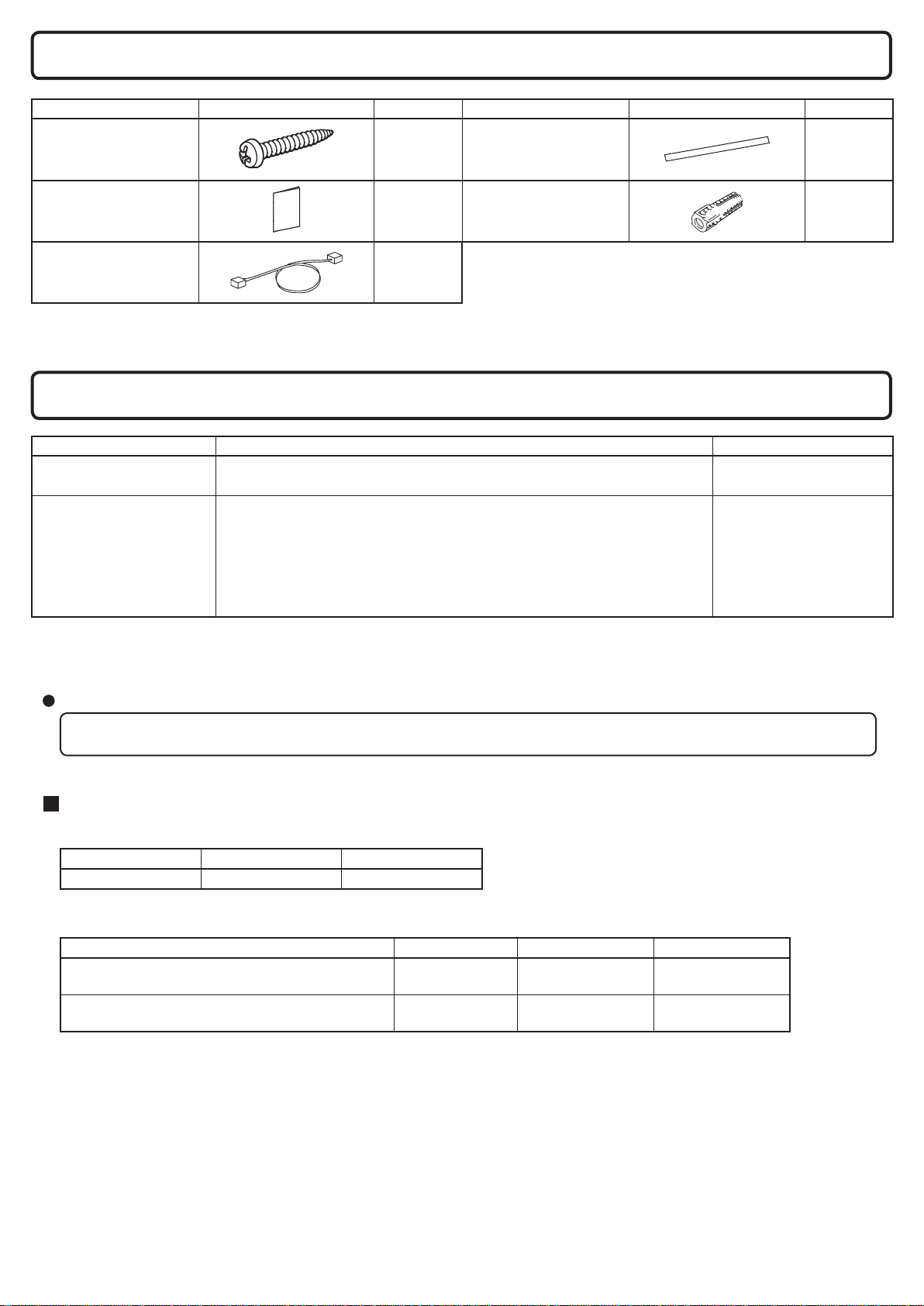

1. Included Accessories

Part Shape Qty Part Shape Qty

Tapping Screw

Check for any missing items

before starting installation.

*1

3

Vinyl Tie

3

Installation Manual

(this document)

Insulated Cords

*1 : Use the included vinyl tie to bind any excess length of wire

1 Wall Anchor 3

2

2. Required Accessories

Name Usage Qty

Remote controller

RC-9018M

Remote controller Cord

RC-CORD10

RC-CORD26

CAUTION : Be sure to use the remote controller cord as listed above. If a different cord is used, the equipment may fail or not operate

properly.

* Always necessary. 1

-The communication cord between the system controller and the

remote controller can be lengthened up to a maximum total length

of 450 feet.

-The communication cord between the system controller and each

water heater can be lengthened up to a maximum total length of 45

feet.

Total number of units

in system - 1

When two or more multi-unit systems are installed in parallel

One remote controller is necessary for each multi-unit system (i.e. 3 multi-unit systems will require 3 system

controllers and 3 remote controllers). Each system will have separately wired remote controller cords.

For the combined use pattern

A. When there is no circulation pipe (standard type)

Number of units System controller Remote controller

1 to 6 SC-301-6M RC-9018M

B. When there is a circulation pipe

Condition Number

Recirculation type

(circulation heat-retention with external pump)

Storage Tank Recirculation type

(circulation heat-retention with external pump)

of units

1 to 6 SC-301-6M RC-9018M

1 to 6 SC-301-6M RC-9018M

System controller Remote controller

──

3. Introduction (see list of points below)

<Recirc>

<Tank recirc>

Introduction to the “SC-301-6M” System Controller

Overview

This manual is intended to provide instruction for the installation, operation, and features of the SC-301-6M system

controller. It is divided into 4 main sections:

1. Installation of the SC-301-6M system controller

2. Initial programming of the RC-9018M remote controller

3. Additional features of the RC-9018M remote controller and the SC-301-6M system

controller

4. Plumbing diagrams and general information about water and gas piping

Please read this manual carefully and follow the instructions as written. If you have any questions, please contact

Noritz Engineering & Service at 866-766-7489 or visit http://support.noritz.com/.

Basic Operation

The SC-301-6M system controller is used to combine 1 to 6 Noritz heaters into a single “multi-unit system” The system

controller stages units on and off based on hot water demand and rotates their operation to ensure even usage. It also

has two additional modes which optimize the system for operation with a recirculation line or storage tank.

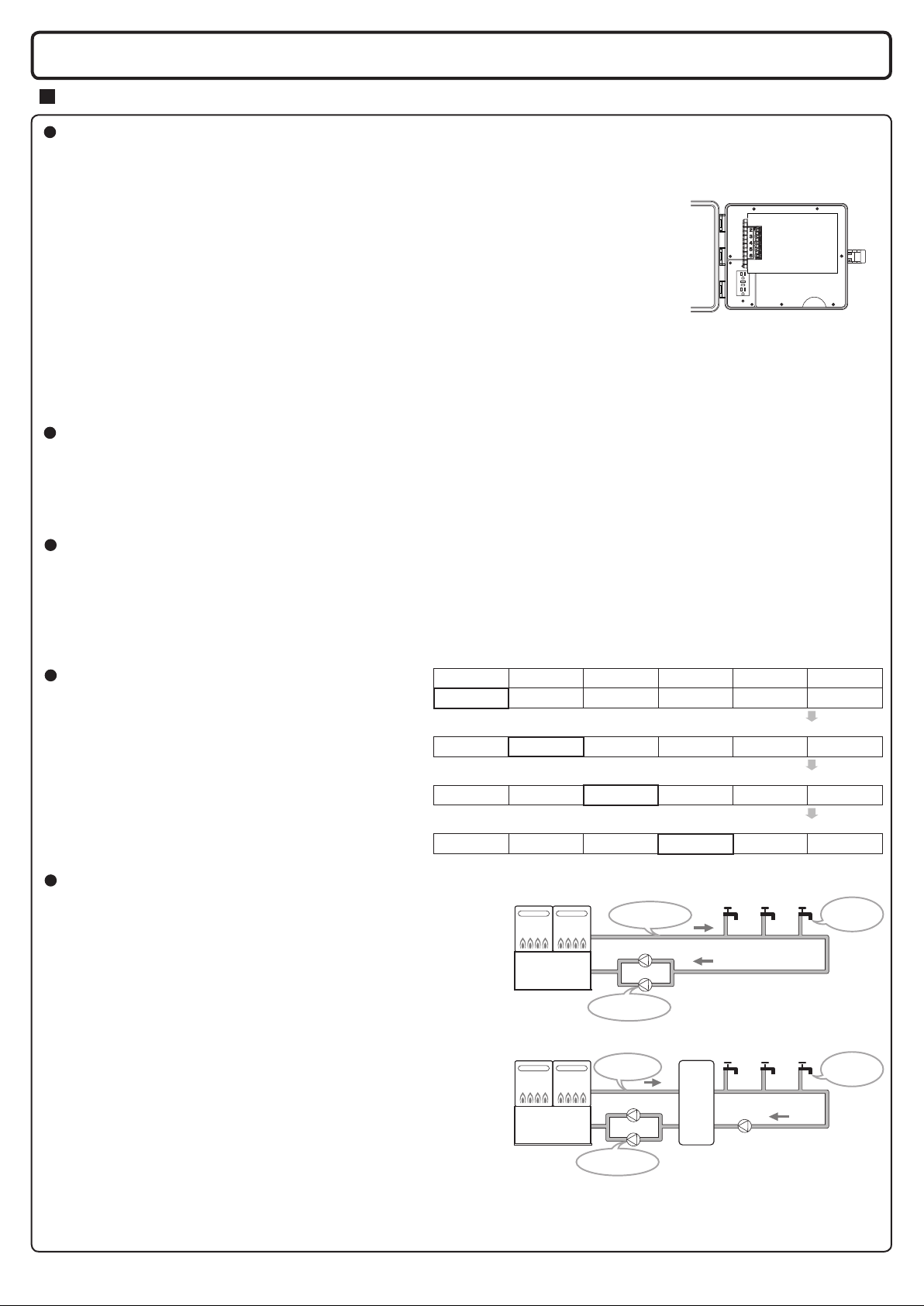

Unit Staging

Staging allows the multi-unit system to track hot water demand from the minimum ow rate of a single unit up to the

maximum output of several units. When the primary ring heater reaches ~50% of its maximum output, the system

controller activates the next unit in the system. When both these units reach ~50% of their maximum output, a third

unit is activated and so on. The SC-0-6M may also be congured to activate two heaters during primary ring to

allow for rapid initial hot water demand.

Unit Rotation

The SC-301-6M system controller rotates operation

of the primary firing heater every 8 hours of

UNIT1 UNIT2 UNIT3 UNIT4 UNIT5 UNIT6

1st 2nd 3rd 4th 5th 6th

Rotation

combustion time or up to 24 hours of plug-in time.

This helps to ensure even usage of all units.

6th 1st 2nd 3rd 4th 5th

Rotation

5th 6th 1st 2nd 3rd 4th

Rotation

4th 5th 6th 1st 2nd 3rd

System Selection

The SC-301-6M allows the user to select two additional

system types: “Recirc” and “Tank recirc.” These settings

optimize performance with recirculation and storage tank

systems, and allow the system controller to operate one or two

pumps.

Water heater

Hot water is circulated

in the piping.

Pump

Pump

Instant hot

water is

available.

──

The system controller

operates these pumps.

Water heater

*

These diagrams are for illustration purposes only.

Hot water is circulated

to the tank.

Pump

Pump

The system controller

operates these pumps.

Hot water

storage

tank

Pump

Instant hot

water is

available.

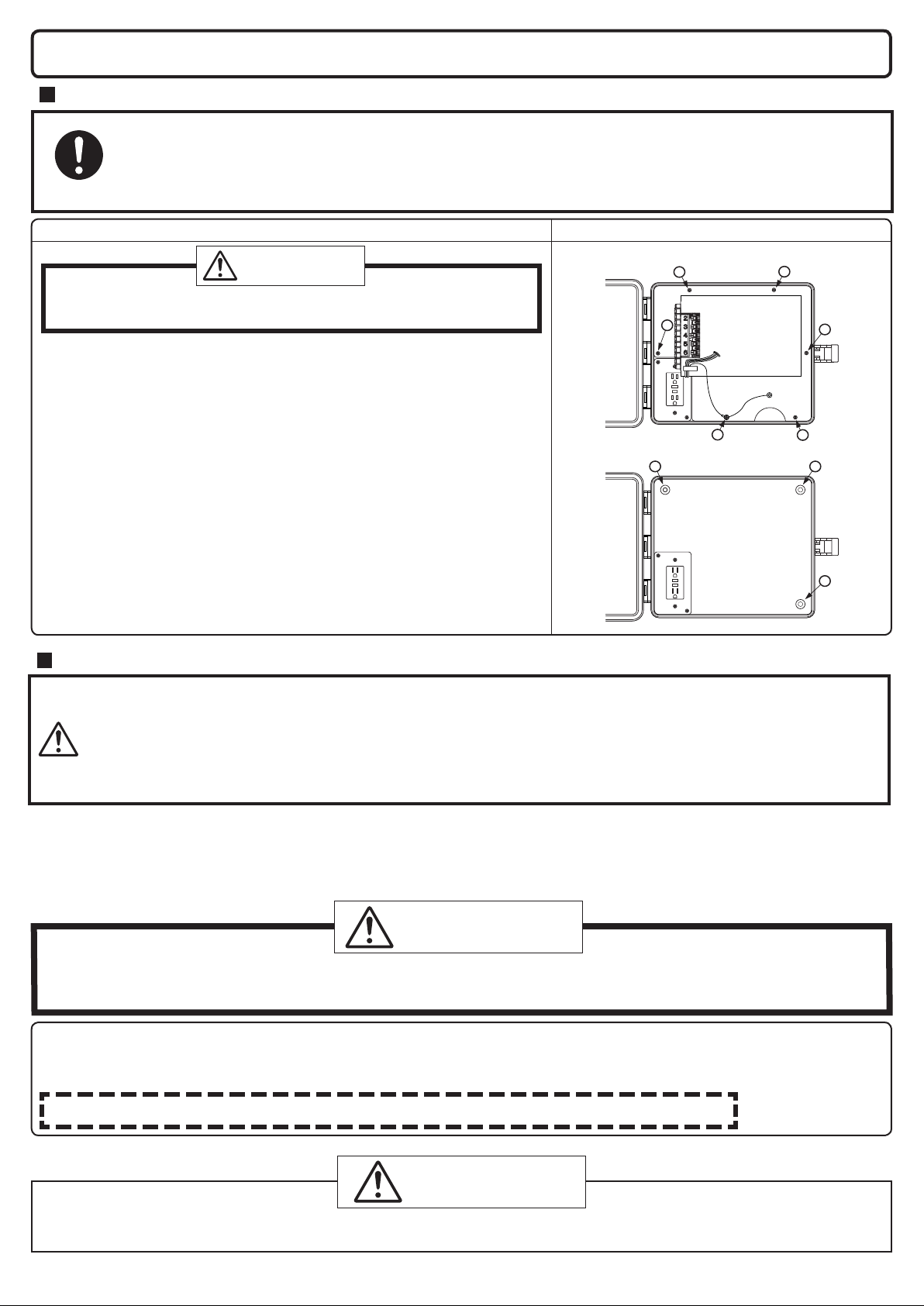

4. Installing the System Controller

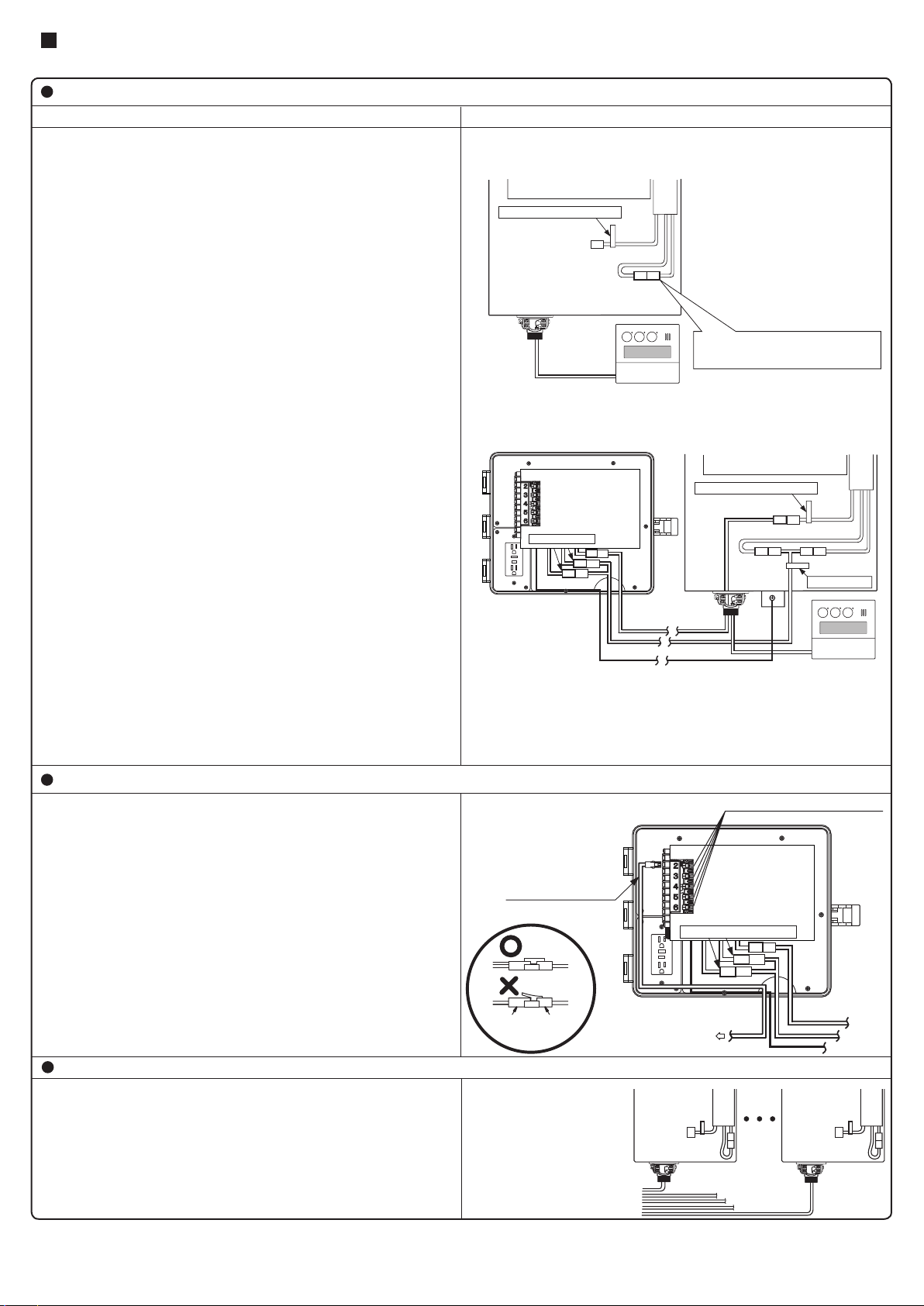

Figure 1: Removing the Sub-Panel

Securing to the wall

●

The weight of the device will be applied to the wall. If the strength of the wall is not sufcient, reinforcement

must be done to prevent the transfer of vibration.

●

Do not drop or apply unnecessary force to the device when installing. Internal parts may be damaged and

Be sure to do

may become highly dangerous.

●

Install the unit on a vertical wall and ensure that it is level.

Check

CAUTION

•

When installing with bare hands, take caution to not inict injury.

•

Be careful not to hit electrical wiring, gas, or water piping while drilling holes.

1. Remove the Sub-Panel by removing the six (6) screws as shown in

Figure 1. Pull the Sub-Panel out of the box.

* Remove the grounding wires, which are tightened on the sub-panel.

2. Three (3) mounting holes can be found once the Sub-Plate is removed

(Figure 2). Hold the box in position and use the three (3) included

mounting screws to secure the System Controller to a wall.

3. If mounting the box to drywall or masonry, use the provided wall an-

chors to secure the System Controller to a wall.

4. After the box has been properly mounted, use the removed screws to

reattach the Sub-Panel back onto the box.

* Do not to forget to tighten the grounding wires, which were removed

in the step 1, with the sub-panel.

5. Take waterproong measures so the water does not enter the building

from the screws used to mount the device.

• Make sure the unit is installed securely so that it will not fall or move

due to vibrations or earthquakes.

Electrical Wiring

Consult a qualied electrician for the electrical work.

Illustration

2

1

System Controller

Sub-Panel

6

Figure 2: Provided Mounting Holes

1

3

5

4

2

3

- Do not connect electrical power to all water heaters (do not turn ON the power supply) before all

electric wiring is completed. Otherwise, electric shock or failure of the water heater and system

controller may occur.

CAUTION

This appliance must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70. In Canada, the latest CSA C22.1 Electrical Code.

Caution:

Electrical Shock Hazard

Do not turn power on until electrical wiring is nished. Disconnect power before servicing.

Failure to do so may result in death or serious injury from electrical shock.

Ground

• Connect a grounding wire comes from the system controller to unit 1 (Refer to page 5).

An electrician should do this work.

Do not connect the ground to the city water or gas piping. Do not tie the ground to a telephone line.

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

Field wiring to be performed at time of appliance installation.

- If a remote controller cord is not connected, the temperature of the water heater is xed to 0°F

(50°C) and high-temperature hot water is discharged. So check it is surely connected.

- Be sure to tighten the screw to the terminal block manually and do not use an electric

screwdriver or impact driver. Otherwise, the terminal block may be damaged.

WARNING

CAUTION

Electrostatic discharge can affect electronic components. Take precautions to prevent electrostatic discharges from personnel

or hand tools during the system controller installation and servicing to protect the product’s electronic control.

──

For NC1991 series

Unit 1

(The Unit with the Remote Controller)

P.C.B.

90

B5

"SYSTEM CONTROLLER" tag

90

Remove it for connecting

the system controller.

water heater connection terminal

Unit 1

* Circuit board is indicated as P.C.B.

Open the cover of the external remote controller cord terminal block of each water heater.

Construction work for unit 1 (Water heater to which remote controller is attached)

Operation Illustration

Open the front cover

1. Connect the remote controller cord to the external remote

(The Unit with the Remote Controller)

controller cord terminal block. (Refer to the remote controller

RC-9018M section of the installation manual).

2. Connect the opposite side of the remote controller cord that

"SYSTEM CONTROLLER" tag

was connected in the step 1 to the remote controller.

* Refer to the installation manual.

3. 1) Disconnect the connector 90 (white) from the P.C.B. of

the water heater.

B5

90

Use the insulated cord labeled “DVC ERV” and connect the

two connectors with the labeled end to the water heater.

Install the cord to the water heater and connect the

two connectors to the two disconnected connectors 90

(white) of the water heater.

Install the other end of the cord to the system controller.

2)

Connect the connector with the green/red wires to the

connector 90 (yellow) with a tag “to Connector 90” that

comes from the system controller.

Then, connect the connector with the black/white wires to

the connector 90 (yellow) with a tag “to Remote Controller

Terminal” that comes from the system controller.

3) Use the remaining insulated cord and connect the

connector to the water heater.

Install the cord to the water heater and connect the

connector to the connector B5 (white) with a tag

“SYSTEM CONTROLLER” that comes from the P.C.B.

of the water heater.

System Controller

Connector color: yellow

B5

90

90

4) Install the other end of the cord to the system controller.

Plug the cord into the connector B5 (white) labeled “to

connector B5” coming from the system controller P.C.B.

5) Pull a grounding wire in the junction box of Unit 1 and

tighten the round terminal of the grounding wire with a

grounding screw of the unit.

If there is a electrical conduit, place the grounding wire

in the electrical conduit.

(For the attachment to the junction box, refer to the

installation manual of the unit.)

P.C.B.

90

Remove it for connecting

the system controller.

P.C.B.

"SYSTEM CONTROLLER" tag

B5

90

90

"DVC ERV" tag

Construction work for each water heater (Unit 2 to 6: water heater to which the remote controller is not attached)

4.

Using the remote controller cord from each water heater, plug

the connector into the system controller plugs for units 2-6.

(The number of the remote controller cords necesary is

determinated by the total number of heaters minus one.)

1) Connect the connector for the communication cord

with unit 2 of the system controller with the connector

side of the remote controller cord.

The connector No.2 is for unit 2 and the connector No. 3 is

for unit 3.

Unit

Construction work of each water heater (

6. Connect Y terminal side of the remote controller cord that

was connected in the step 5 to the corresponding external

remote controller cord terminal block of unit 2 to 6.

Remote controller cord

(Required accessory)

Remote

water heater

controller

connection

cord

terminal

to the linked water heater

(system controller plug)

connector No.2

connector No.3

connector No.4

connector No.5

connector No.6

System Controller

Connector color: yellow

B5

90

90

2 to 6: water heater to which remote controller is not attached)

* Do not have to open

the front covers of

Unit 2 Unit 6

P.C.B.

these units.

For system controller

P.C.B.

* After all connections are made, replace the front cover of unit #1 (taking special care to do not crush any wires) and the

covers of the external remote controller cord terminal blocks of all connected water heaters.

─5─

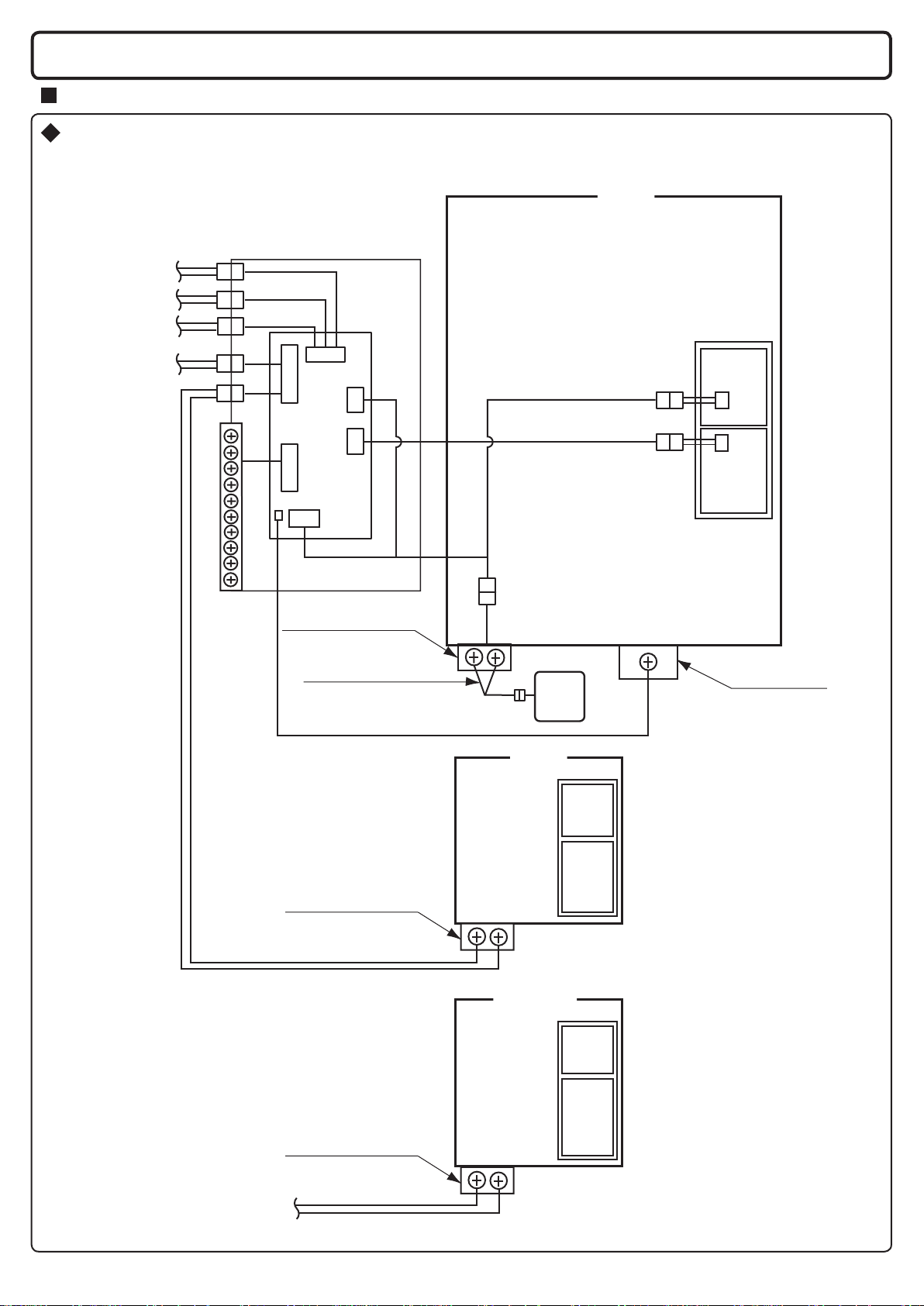

5. Wiring Diagram, System Diagram

Unit 1

Wiring Diagram (Multi-unit System Wiring)

When six units are installed

* Connect these to the remote control terminal block

in each unit

No.6

No.5

No.4

No.3

No.2

System Controller

Remote controller

terminal block

Remote Controller Cord

Grounding wire

Remote

Controller

909089

B5

102

Power

PCB

PCB

Junction box

Remote Controller

terminal block

Remote Controller Cord

Remote controller

terminal block

Remote Controller Cord

Unit 2

Units 3-6

PCB

Power

PCB

PCB

Power

PCB

* The remote controller terminal

location may differ depending on

the unit.

* To turn OFF the power supply

to the system controller, you will

need to cut power to both the

primary heater and all attached

heaters.

─6─

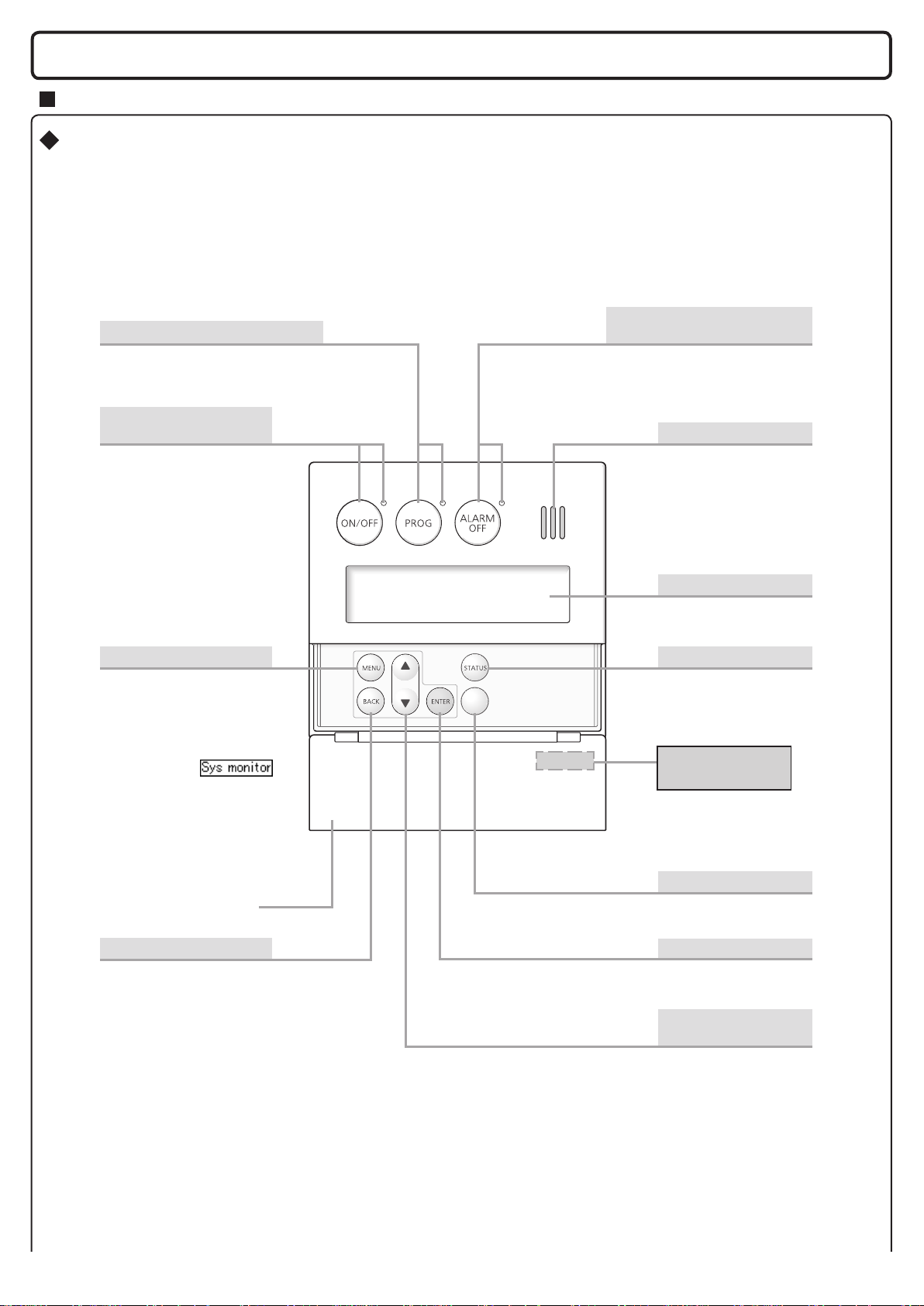

6. Remote button and display overview

Remote Controller (Required Accessories : RC-9018M)

The remote controller will emit a tone when a button is pressed.

*

This Remote Controller is not resistant to water, steam, chemicals, or UV rays. Please install it in a location where it

will not be exposed to these conditions. If it must be installed outdoors, please use a weatherproof enclosure. Consult

the RC-9018M Installation Manual for details.

Alarm Off Button

Prog Button / Indicator (Red)

Activates the automatic water heater power

“ON” or “OFF” setting as determined by the

user selected schedule.

Power ON /OFF Button

/ Indicator (Green)

For turning the water heater

on/off.

Stops the tone that is emitted

when an error occurs.

(page 28.)

/ Indicator (Red)

Speaker

Menu Button

* Use to change system

settings or to return to

the home screen.

*

If you press the menu button

and press the temperature

setting buttons,

is sometimes displayed.

However, do not use this

mode as it is meant

for

installation or service

personnel only.

Cover shown in

the open position.

Back Button

Returns to the previous

screen while making system

settings or checking status.

Display Screen

(Next page)

Status Button

Check the status of the

system or the number of

installed units.

(page 15, 28.)

Remote Controller

Part Number

The part number is

printed on the surface

of the cover.

Lock Button

Locks remote controller

operation.

Conrms changes

made by the user.

Hot Water Temperature

Setting Buttons

For setting the hot water

temperature, and

other settings.

(page 19.)

Enter Button

──

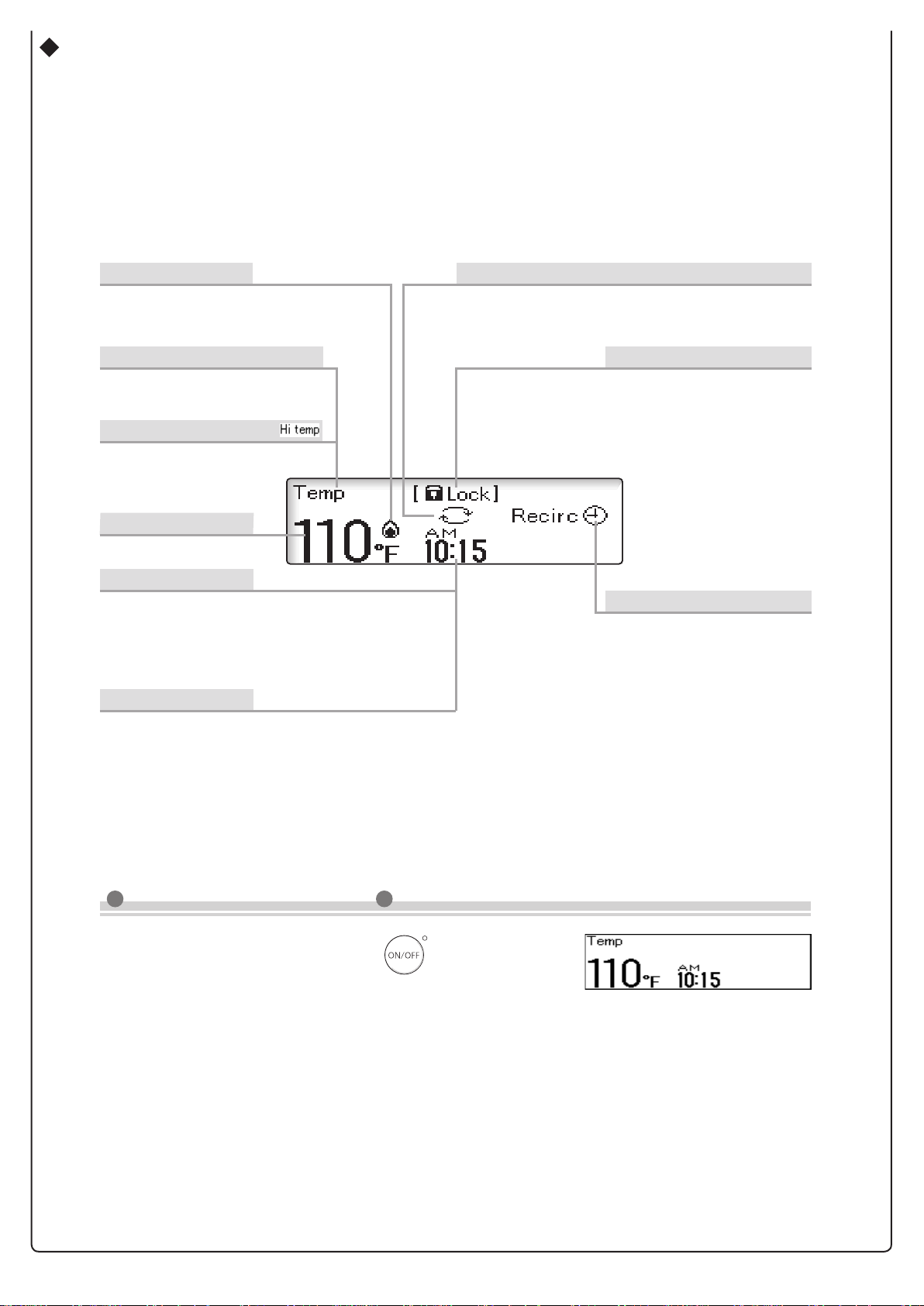

Screen Display

* The screen display shown below is for illustration purposes only.

The actual display will vary depending on how the water heater is being used.

* After a button is pressed, the display will gradually become darker to prevent unnecessary power consumption

by the remote controller.

Flame Symbol

The ame symbol is displayed during

combustion when using hot water or

recirculation functions.

Display for Temperature Setting

During normal operation, the set

temperature is displayed.

Display for High Temperature

Displays when the set temperature

is 5°F/55°C (°F) or higher.

Temperature Setting

(Ex.: 0°F)

Clock Display

(Ex.: AM10:15)

Normally the clock display is not shown when

the power ON/OFF button is "OFF".

* This setting can be changed so that the clock is displayed

even when the power button is turned "OFF".

Error Code

A number will ash if a

failure occurs. (page 28.)

(page 18.)

*

For systems that use recirculation operation, the symbol

is displayed when the power ON/OFF button is set to "ON".

*

It is displayed during the recirculation operation.

Display for Recirculation Operation

Locked Display

The lock symbol is displayed

when the remote controller is

locked.

The clock symbol is displayed

when the recirculation timer is

activated.

(page 19.)

Recirculation Timer

(page 13 - 14.)

Note: As shipped from the factory, the remote controller is set to display in °F and gallons.

To adjust the display to °C and liters, refer to the

page 12

.

What is the home screen?

The home screen is displayed when the button is "ON".

Normally, the hot water temperature and the clock, etc. are displayed.

<Home Screen Example>

──

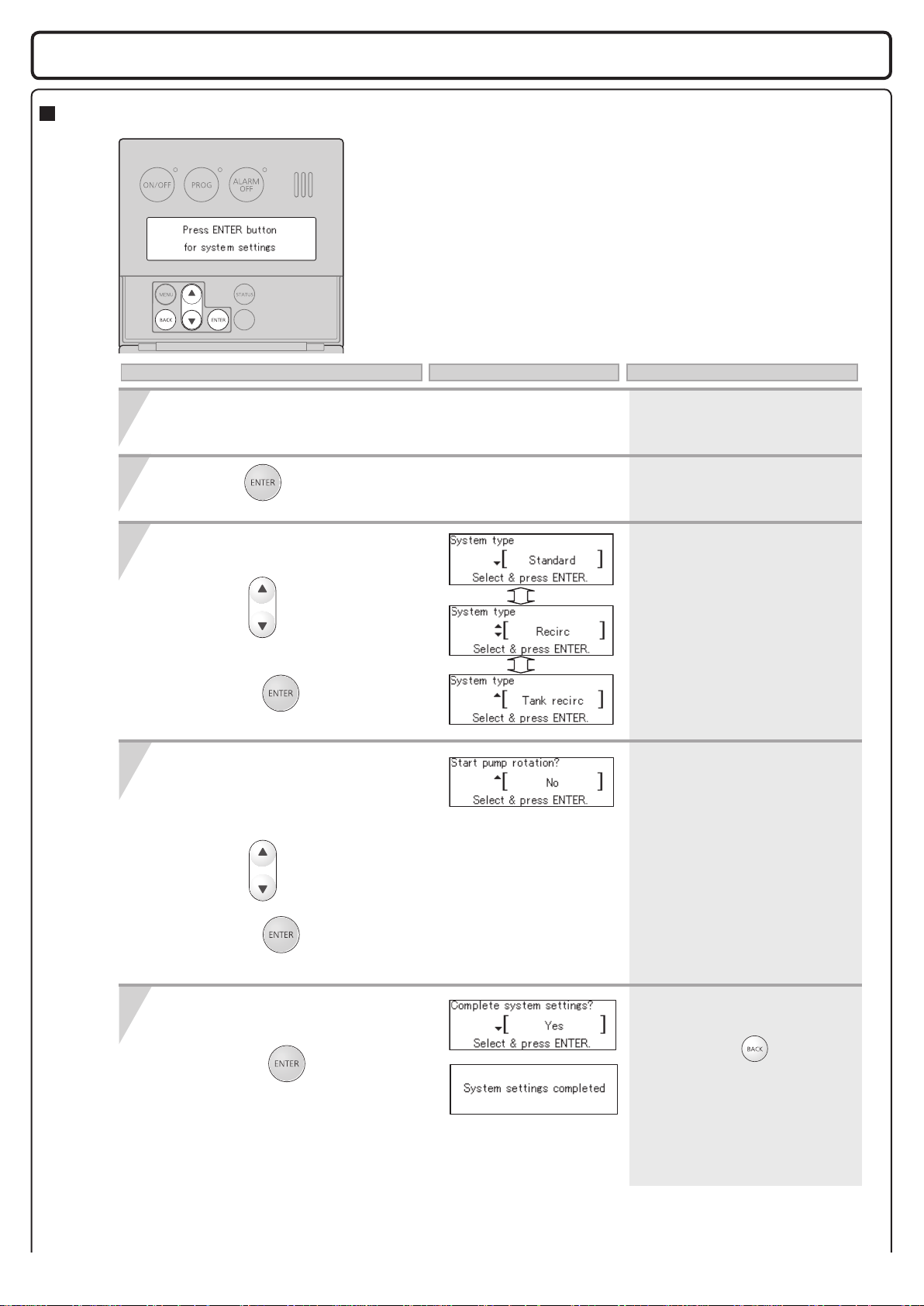

7. Remote initial setup

Initial Setting Procedure in the “System Settings” Screen

Note: When power is rst connected to the multi-unit system (system

controller and units), the remote enters an initial setting mode.

The following instructions explain how to perform an initial setting.

If you need to change these settings at a future date, follow the

instructions titled System Selection and Settings in the “Initial

Settings” Screen (page 10 - 12).

Operation Screen Display Description

Preparation

Press the

1

1) You will be prompted to choose

2

3

a system type.

2) Use the

to the correct system type.

3) Press the

select your system type.

1) If you chose the “Recirc.” or

“Tank Recirc.” systems, you

will be prompted to turn pump

rotation on or off (this setting

is set to “off” by default).

Connect power to all heaters in multi-unit system.

button on the remote.

buttons to navigate

(Standard, Recirc., or Tank Recirc.)

button to

* Note: only when you connect one/two

pumps to the system controller,you

need to select “Yes” or “No”.

4

2) Use the

yes (on) or no (off).

3) Press the

the pump rotation.

1) You will now be prompted to

“complete system setting.”

2) Press the

complete the system setting.

3) Once you choose “Complete

system settings?”, the

remote will display “System

settings completed”.

buttons to select

button to set

button to

──

* Note: if you chose standard system in

step 2 - 2), you will immediately go to

this prompt.

* You may use the

return to the previous menu at any

time.

button to

Loading...

Loading...