System Controller

*SHA8754 C*

SC-201-6M INT

Installation Manual

Potential dangers from accidents during installation and use are divided into the following two

categories. Closely observe these warnings, they are critical to your safety.

WARNING

NOTICE

Denotes content that may result in fi re, serious bodily injury and even death

when ignored.

Denotes content that may result in bodily injury and physical damage when

ignored.

Requests to Installers

WARNING

Failures and damage caused by erroneous work or work not as instructed in this manual are not

covered by the warranty.

Refer to installation manual attached to the appliance as well.

Check that installation was done in accordance with this Installation Manual upon completion.

After completion of installation, be sure to hand this Installation Manual to the customer.

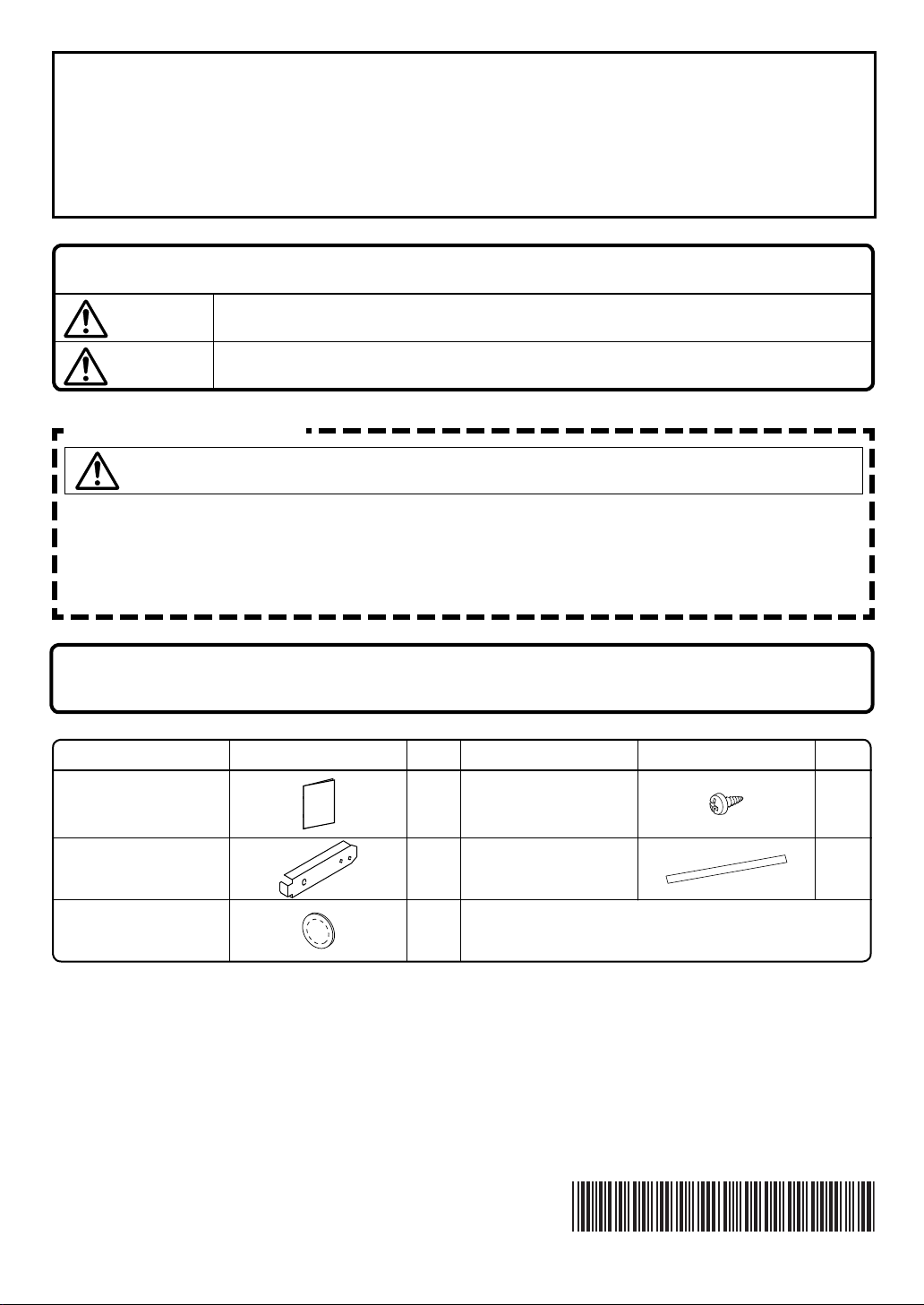

1.Included Accessories

Part Shape Q'ty Part Shape Q'ty

Installation Manual

(This document)

In order to use this product safely, read this installation manual carefully and

follow the installation instructions.

The following accessories are included with

this product. Check for missing items before

installing.

13

Tapping Screw

4 x 8

System Controller

Mounting Plate

Cord Bushing

*1 Use the vinyl ties for loose electrical wiring inside the unit.

SHA8754-5

Rev. 10/09

*1

Vinyl Tie

1

- 1 -

31

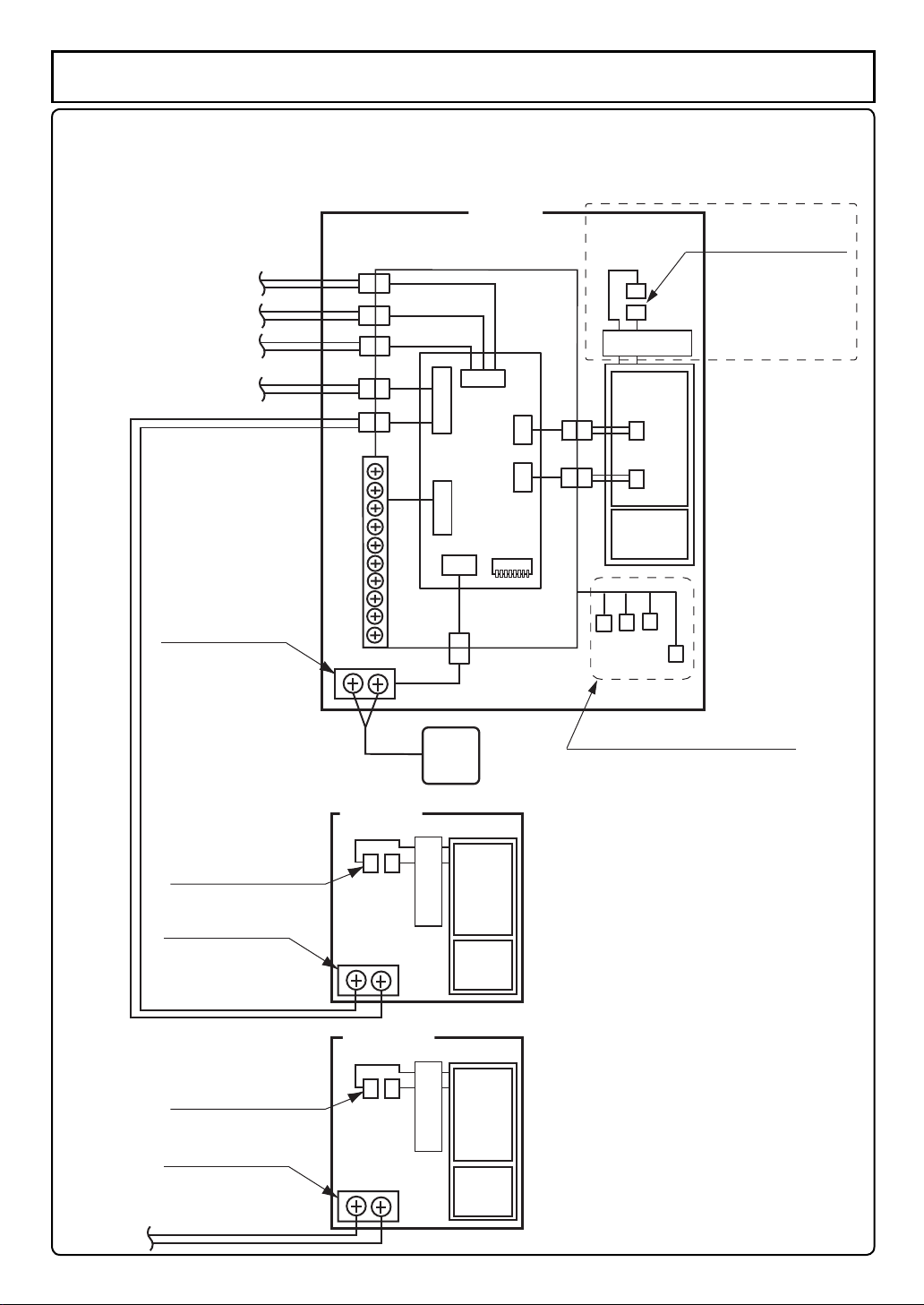

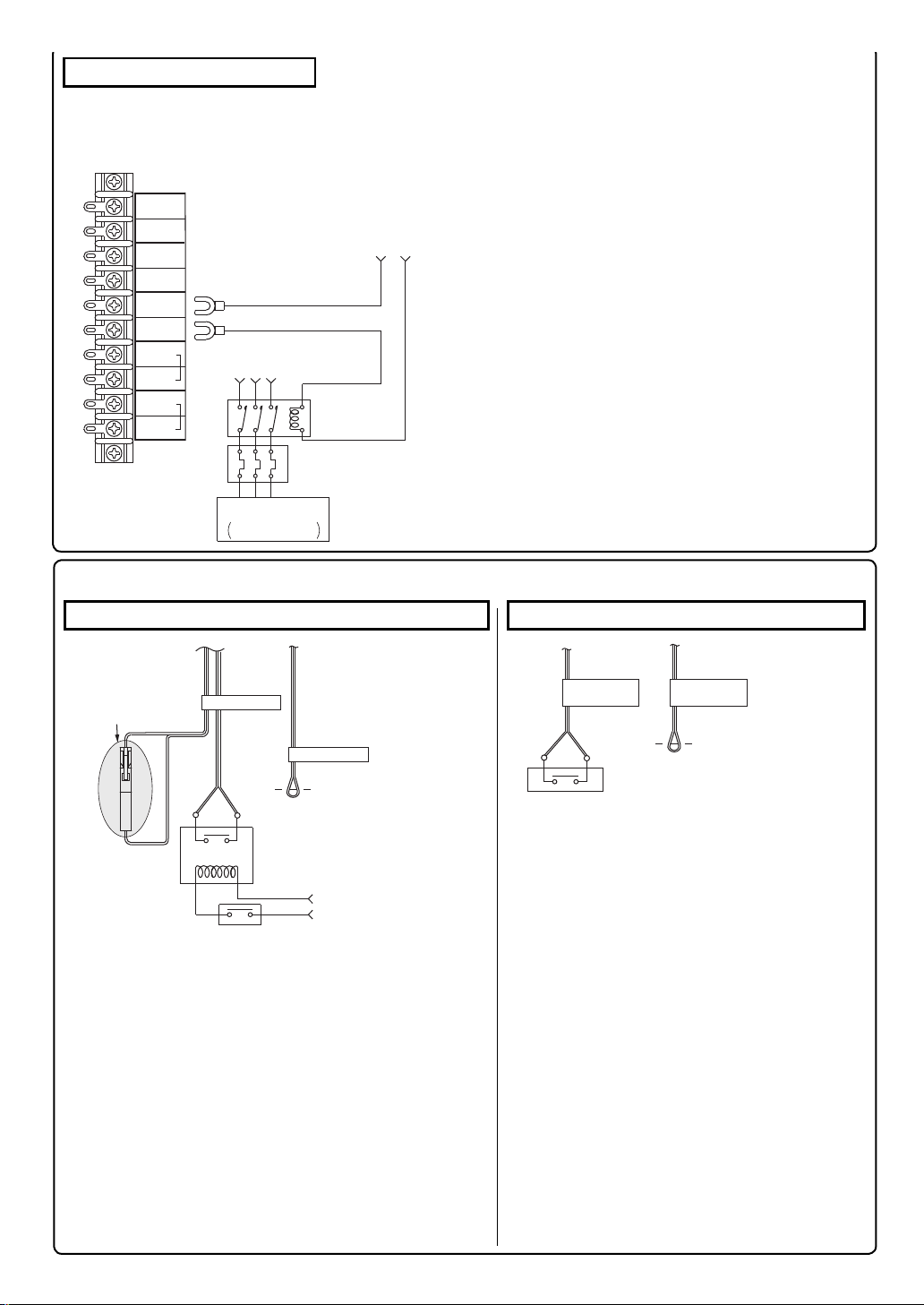

Multi-System Wiring

* Connect these to the

remote control terminal

block in each unit

No.6

No.5

No.4

No.3

No.2

Unit 1

System Controller

DIPSW

12345678

*N-132M(-ASME),N-1321M-ASME, NC380-SV-ASME

N-084M(-DV)(-ASME),N-0841MC(-DV),NCC199-SV(-DV)

N-0842MC(-DV)

NC199-OD(-DVC)

N-0931M(-DV, -OD)(-ASME) ,NC250-SV(-DV)-ASME only

Disconnect this

connector

Disconnect for

system controller

89

90

90

B5

B5

PCB

102

Power

PCB

*Remote control

terminal block

*Disconnect this

connector

Remote control

terminal block

Remote Controller Cord

*Disconnect this

connector

Remote control

terminal block

Remote Controller Cord

Unit 2

Unit 3-6

Remote

Controller

PCB

Disconnect for

system controller

Power

PCB

PCB

Disconnect for

system controller

Power

PCB

System select connectors

* The remote control terminal

location may differ depending on

the unit.

* The connector location may

be slightly different on the

actual circuit board than in

these illustrations.

- 2 -

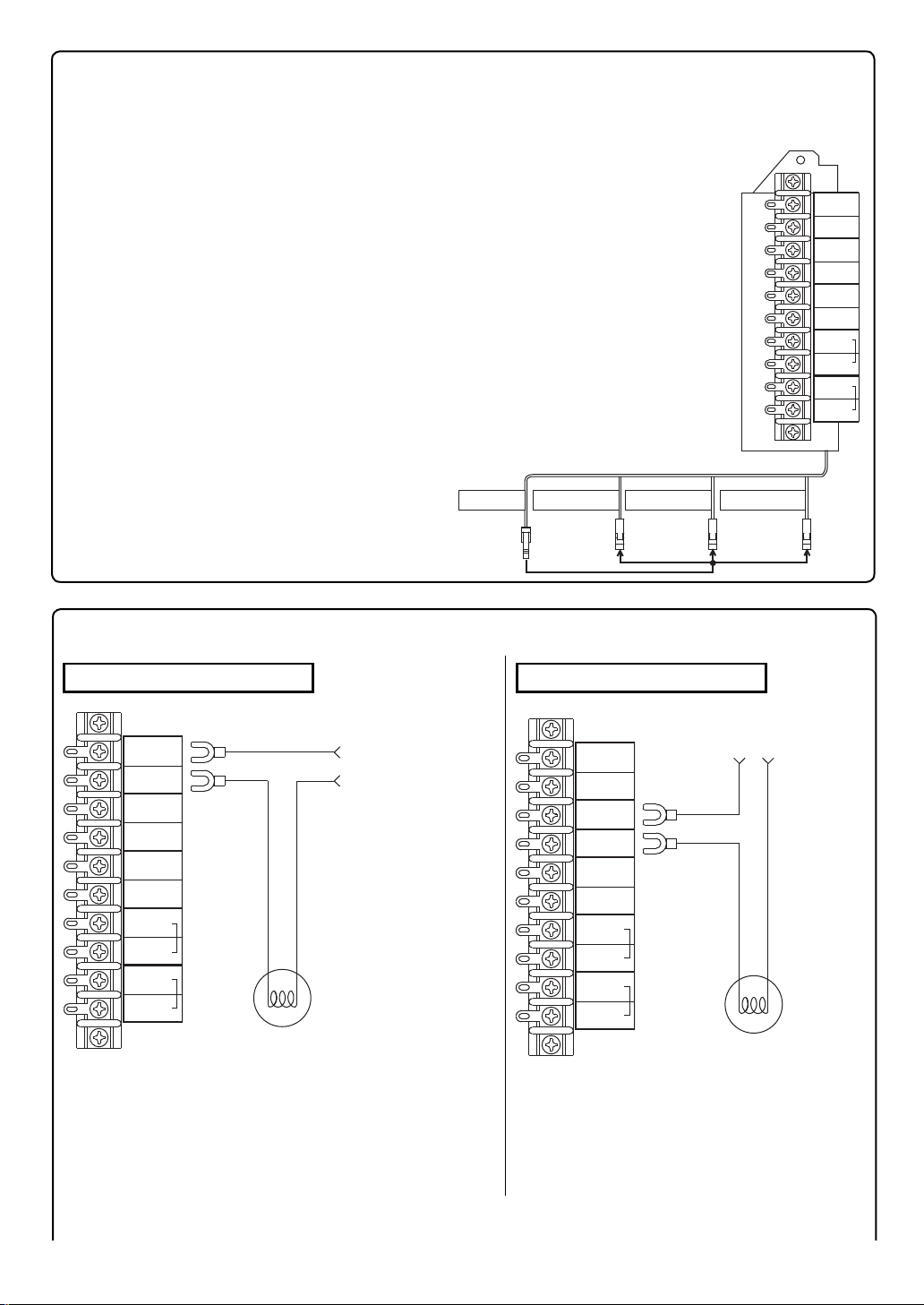

System Select Connectors

M

A

X

100W

Connect to

terminals

AC Power Supply

AC100-240V

Under 100W

Warning Light

1

2

Warning

Light

Warning

Light

Operation

Relay

Operation

Relay

Fan

Fan

Pump

1

Pump

Pump

2

Pump

If this system will be installed with a recirculation system, a storage system,

or with a fi ltration system, plug the selecter in to the connector

that corresponds to that type of system.

*If none of these circulating systems are used, do not connect the selecter.

If the units will be installed in a (1)

recirculation system:

Connect the selecter to the connector

labeled "Recirculation System" (1).

If the units will be installed with a (2)

storage tank:

Connect the selecter to the connector

labeled "Storage System" (2).

If the units will be installed with a water (3)

fi ltration system:

Connect the selecter to the connector

labeled "Filtration System" (3).

Selecter

Filtration System

Storage System

Recirculation

System

Warning

Light

Warning

Light

Operation

Relay

Operation

Relay

Fan

Fan

Pump1

Pump1

Pump2

Pump2

M

100W

A

X

(1)(2)(3)

System Controller Terminals (Optional Connections)

Operation LightWarning Light

A warning light can be connected to the system as •

above to warn of any abnormal operation.

When this light fl ashes, check for an error code on

the remote controller and diagnose accordingly.

- 3 -

M

A

X

An operation light can be connected •

to the system controller as above in

order to indicate when power has been

turned on to the system.

Warning

Light

Warning

Light

Operation

Relay

Operation

Relay

Fan

Fan

Pump

Pump

Pump

Pump

100W

AC Power Supply

AC100-240V

Under 100W

Connect to

terminals

1

1

2

2

Operation Light

For connection to

Pump 1, see 1)

←

M

A

X

Circulation Pump

100W

1

2

Operation

Relay

Operation

Relay

Fan

Fan

Pump

1

Pump

Pump

2

Pump

Warning

Light

Warning

Light

Single phase AC120V or

Three phase AC240V pump voltage etc.

Relay

Thermal Relay

AC Power Supply

AC100-240V

Under 100W

Circulation Pump Terminals

Use these terminals to control the pump in any circulating system.•

Connected this way, the system controller will control the function of the pump.

Use a normally open relay to supply power to the pump. Use a thermal relay if necessary.•

When operating with 1 circulation pump(1)

AC Power Supply

1

1

2

2

AC100-240V

Under 100W

Single phase AC120V or

Three phase AC240V pump voltage etc.

Relay

Thermal Relay

Circulation Pump

Warning

Light

Warning

Light

Operation

Relay

Operation

Relay

Fan

Fan

Pump

Pump

Pump

Pump

M

100W

A

X

*If there is only one pump, connect to "Pump 1" terminals.

If two circulating pumps will be used:(2)

Connect as below if two circulating pumps will be used. The two pumps can be set to alternate

with a dipswitch change. (Refer to the "Dipswitch Settings" section.)

*Do not connect both Pump 1 and Pump 2 to the same terminal block.

* After connecting as shown above, set dipswitch 3 to "OFF".

(Refer to the "Dipswitch Settings" section.)

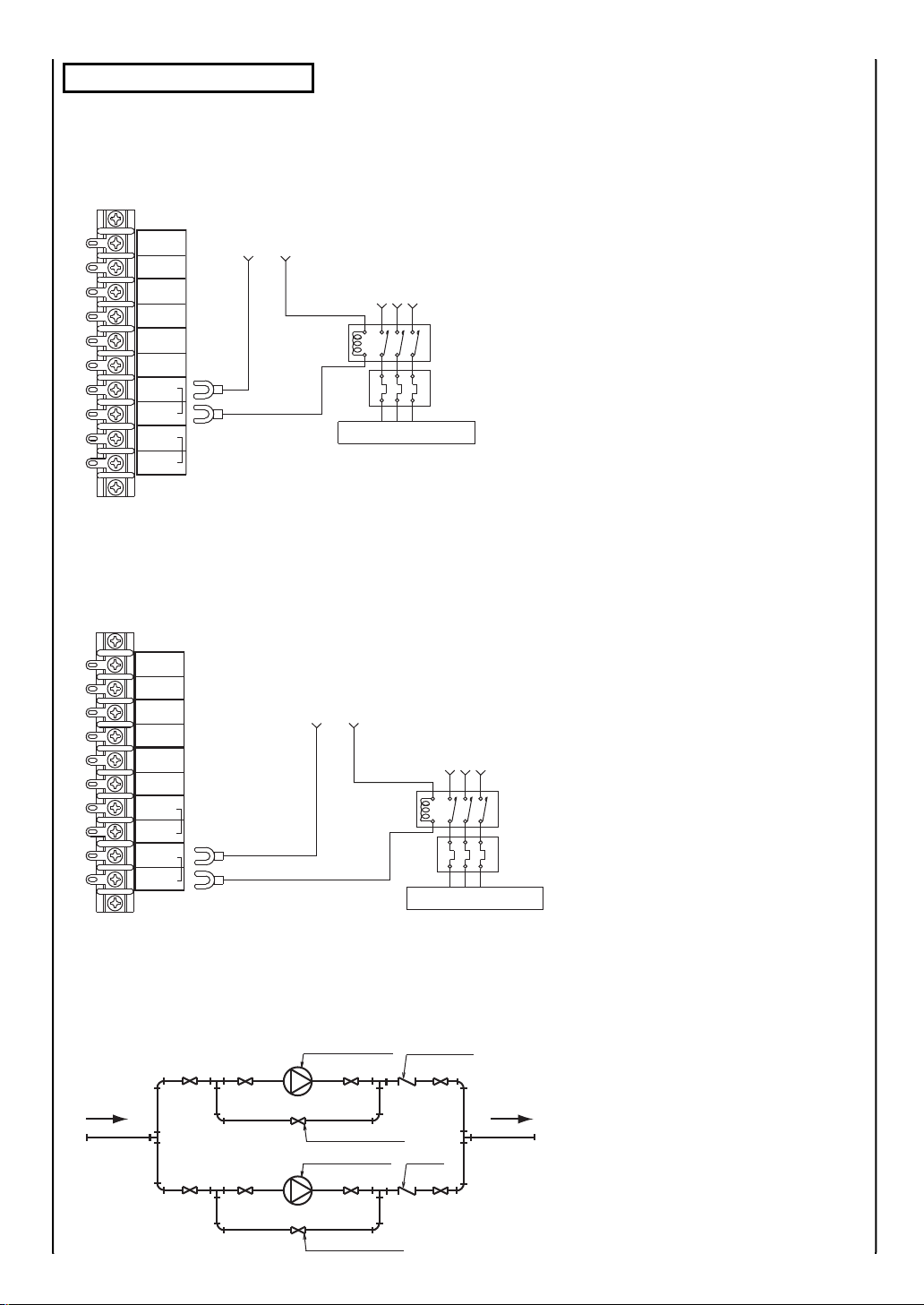

Piping diagram for parallel pipe installation•

Circulation pump

Flow control valve

Circulation pump

Check valve

Check

value

Adjust the pump fl ow with the fl ow control

valves.

If multiple pumps are used, control the fl ow of

Flow control valve

- 4 -

each pump with separate valves.

Exhaust Fan Terminal

M

A

X

100W

Connect to

terminals

Exhaust Fan

Ventilation Fan

Three phase AC240V etc

Single phase AC120V

Thermal

Relay

1

2

Operation

Relay

Operation

Relay

Fan

Fan

Pump

1

Pump

Pump

2

Pump

Warning

Light

Warning

Light

Relay

AC Power Supply

AC100-240V

Under 100W

These terminals will close when any of the units are heating or when the fan on any of the units is •

blowing. These terminals can be used to control an exhaust fan or damper in this way.

Use a relay to provide power to the fan or damper. Use an additional thermal relay if necessary.•

Pressure Switch/Safety Shutoff Switch and External Operation Switch Connections

Pressure Switch/Safety Shutoff Switch Connection

Please remove

this connector

when Wind Pressure

SW are connected.

A pressure switch or other safety device can be •

installed to shut down the system under unsafe

or improper operation.

Please use a low voltage (15V) junction, normally •

open relay.

This terminal is short circuited at time of •

shipment.

In order to use this feature, cut the wire labeled

"Pressure Switch", connect it to the relay, and

disconnect the connector

Pressure Switch

15V 3.3mA

* Using the Noritz remote

Relay

controller cord, the cord

can be extended to

500m (1500ft.) maximum.

Pressure SW

Pressure Switch

Cut wire

Power Supply

Connecting the external operation switch

External

Operation Switch

External operation SW

External

Operation Switch

Cut wire

15V 3.3mA

* Using the Noritz remote

controller cord, the cord

can be extended to

500m (1500ft.) maximum.

Follow this procedure to use an external •

switch to turn power on and off to the unit

instead of the remote controller.

The power to the units will be on (1)

when the external switch is turned on

(closed).

The power to the units will be off when (2)

the external switch is turned off (open).

Use a low voltage (15V) junction.•

If the units are installed with a recirc *

ulation system,a storage tank or a

fi ltration system, the pump will also turn

on or off with this switch.

- 5 -

Multi-System

A. Installation without a recirculation system

* Do not connect to

* Disconnect this connector

Disconnect this Connector

*N-132M(-ASME),N-1321M-ASME,NC380-SV-ASME

N-084M(-DV)(-ASME),N-0841MC(-DV),NCC199-SV(-DV)

N-0842MC(-DV)

NC199-OD(-DVC)

N-0931M(-DV, -OD)(-ASME),NC250-SV(-DV)-ASME only

System Select Connector

on units 2-6 also.

"Disconnect for system controller" tag

Remote Controller

the connector.

Gas pipe

G

Pipe

Cold Water Supply

(1 1/4"-2")

Unit

No.1

System Controller

Unit No.2

Unit No.6

(1 1/4"-2")

Hot Water Pipe

- 6 -

Insulate or apply heating materials to both the cold water supply piping and the hot water piping to prevent freezing during cold •

weather and to prevent heat loss through the piping.

B-1. Example of Recirculation with a Multi-System

This system will make hot water more quickly available to remote fi xtures.

The pump will circulate water through the loop until the entire loop is warm, and then the system

controller will turn off the pump until the loop cools down.

(1 1/4"-2")

Size the water supply piping to

Water supply

*

allow for maximum flow rates

Gas Pipe

of the units.

G

Circulation Pump 2

(If Necessary)

When installing 2 pumps in parallel

Remote Controller

Circulation Pump 1

* Set dipswitch 3 to "OFF".

(See page of Dipswitch Settings)

Connect to the "Recirculation System"

Disconnect this Connector

* Also disconnect this connector on units 2-6

"Disconnect for system controller" tag

* N-132M(-ASME),N-1321M-ASME,NC380-SV-ASME

N-084M(-DV)(-ASME),N-0841MC(-DV),NCC199-SV(-DV)

N-0842MC(-DV)

N-0931M(-DV, -OD)(-ASME),NC250-SV(-DV)-ASME only

Unit 1

Unit 2

System Controller

connector.

System select connector

Expansion

Tank

(3/4"-1 1/4")

Hot Water Return Line

Size the pump to provide at least 8L/min. (2 GPM) @ 3m (30 kpa (10 feet)) of head + piping *

losses through the system. Turn the power button "ON" and check the maintenance monitors on

the unit to make sure the pump is providing adequate fl ow.

Make sure that the fl ow rate is not greater than 1.2m/sec. (4 ft./sec.).•

(3/4": 20L/min. (5 GPM), 1 1/4": 50L/min. (13 GPM))

If the fl ow is too low, the recirculation loop temperature will not be warm enough, if the fl ow is too

high, the lifetime of the unit will be reduced.

If there are multiple circulation loops, try to make the fl ow rate 3 - 5L/min. (.75 - 1.25 GPM) in *

each loop.

Use copper or stainless water piping for the entire system.*

(1 1/4"-2")

Unit 6

Hot Water

Hot Water

Supply

- 7 -

B-2. Example of Installation with a Storage Tank and Recirculation System

The pump will push water through the Multi-System to heat up the tank.

When the return temperature is high, the fl ow within the device will be limited to 10L/min. (2.6 GPM)*.

(For the 84M, the fl ow will be limited to 1.3 GPM.)

(For the KM3211WH and (L)WH(X)56, the fl ow will be limited to 5L/min.)

Hot WaterSupply

Return line

circulation pump

Hot water supply line

(Copper or Stainless Pipe)

(Copper or Stainless Pipe)

* If the tank thermostat will control the pump,

set dipswitch 2 to OFF. (See page of Dipswitch Settings)

Do not connect more than one pump to the tank thermostat.

Thermostat

Relief Valve

Hot water return line

F).

°

Hot Water

Storage Tank

G

Gas Pipe

* Set dipswitch 3 to OFF.

(See page of Dipswitch Settings)

Option 1-Tank

Remote

Controller

Thermostat Control

Option 2-Unit

Control

Pump Control

Wires (use an

external relay,

see page 4)

(if Necessary)

Storage Tank Circulation Pump 2

The system controller will stop the units from heating when the tank is up to temperature,

and the unit will cut the flow through it to 10L/min. (2.6 GPM.)

(For 84M, the flow is limited to 1.3 GPM.)

(For KM3211WH and (L)WH(X)56, the flow is limited to 5L/min.)

When installing 2 pumps in parallel

Install the plumbing so that a change in flow will not damage the pump.

disconnect this

System select connector

Connect to the “Sto-

rage system”

"Disconnect for system

Controller" tag

connector on units 2-6

* Also

connector"

Disconnect this Connector

* N-132M(-ASME),N-1321M-ASME,NC380-SV-ASME

N-084M(-DV)(-ASME),N-0841MC(-DV),NCC199-SV(-DV)

N-0842MC(-DV)

N-0931M(-DV, -OD)(-ASME),NC250-SV(-DV)-ASME only

Cold Water Supply

* Size the water supply piping to

allow for maximum flow rates

of the building.

Storage Tank Circulation Pump 1

C (10

°

C or more, the dipswitch 4 is turned to OFF.

°

System Controller

Unit 6 Unit 2 Unit 1

(1 1/4"-2")

Storage tank return line

(Copper or Stainless Pipe)

- 8 -

(1 1/4"-2")

Storage tank supply line

(Copper or Stainless Pipe)

To achieve the highest recovery, size the storage tank circulation pump for maximum capacity. *

All USA MODELS : Refer to the Installation Manual provided with the water heater for sizing guidelines.

(L)WH(X)56, (L)WHC56, KM3211WH, BC3200RA : 32L/min. (each) @ 12 m of head + piping losses through the system.

Except USA model. (See page of Dipswitch setting.)

For the set temperature of the remote control, use the set temperature (of the thermostat) + about 6 *

When the recirculation loop set temperature is adjusted to 65 *

Verify that the supply pressure to the units is at least 0.2MPa (2 bar).

2.

Gas Piping

Follow the instructions from the gas supplier.

Gas Connection

Gas fl ex lines are not recommended unless•

they are sized for the maximum input

kW (Btu/h

Do not use piping with a diameter smaller than •

the size of the gas inlet to each unit.

After installation, check the gas line for any •

leaks before using.

3.Water Piping

The plumbing should be installed by a qualifi ed plumbing contractor according to all applicable •

codes and regulations.

Insulate or apply heating materials to the supply and hot water piping to prevent freezing during •

cold weather and to prevent heat loss through the piping.

Use a union coupling or fl exible pipe for connecting the units to ease service and maintenance.•

Refer to the system diagrams for supply and hot water pipe sizing. Do not install piping that is •

smaller than the inlet or outlet water connections on the units.

•

MJ) of each unit.

Ask a qualifi ed plumber to perform the installation. Observe all

applicable codes.

Gas Valve

Install a gas shutoff valve for every unit

installed.

Gas Meter

Select a gas meter capable of supplyingthe

entire kW (Btu/h

appliances that the meter serves. Size the gas

line for the entire kW (Btu/h

•

MJ) demand of all gas

•

MJ) demand also.

If using an expansion tank, make sure it is correctly sized for the system.•

Use only copper or stainless steel pipe for all plumbing.•

Keep the plumbing as simple as possible.•

Avoid using pipes in which air can accumulate.•

Use only approved materials, and have the installation inspected upon completion.*

- 9 -

Electrical Wiring4.

Do not connect electrical power to the unit until all electrical wiring has been completed.•

NOTICE

N-132M(-ASME), N-1321M-ASME, NC380-SV-ASME

When installing the system controller, take care not to damage the internal electrical components in the (1)

unit and tie off loose electrical cords with the included vinyl ties.**

Remove the connector from the circuit board to the remote controller terminal block in the unit.(2)

Connect this disconnected connector labeled 90 from the circuit board to the connector labeled 90

from the system controller.

Connect the connector from the remote controller terminal block to the connector from the system (3)

controller labeled “To remote controller terminal ”.

Connect the B5 connector from the system controller to the B5 connector of the unit.(4)

Use the remote controller cords and the cords included with the system controller to(5)

connect the system controller to the other units.

Unit 1 (The unit with the System Controller)

* The remote controller cord can be extended up to 100m (300 ft.).

Fix with accessory screw

If the remote controller is not connected to the system, the unit will default to • a

60 °C (140 °F) temperature setting.

System Controller

Connect to the connector No.90 of the unit.

Ground Wire

Connect with

accessory screw

Slide system contoroller

into the bracken in the

back of the case.

"To remote controller terminal "

tag

Connector color: red

No.2

Connector color: red

Clamp

* Remote Controller cord

(To a remote controller)

PCB

9090

B5B5

Remote Controller Cord

Connect to the connector

B5 of the unit.

"SYSTEM CONTROLLER" tag

"

Disconnect for system controller

Disconnect this Connector

Disconnect this connector

on units 2-6 also.

"To Gas Water Heater for Multi" tag

" tag

**Note: If remote controller RC-7647M or RC-7650M ( °C temperature display) is being used, an

adjustment to all water heaters connected to the system controller will be necessary.

Make this adjustment prior to making the electrical connections to the system controller.

Refer to page 14 for instructions.

Units 2-6

(Connect each unit to corresponding wires labeled 2-6 from the system controller)

Remote Controller Cord

No.2 To Unit 2

Clamp

No.6 To Unit 6

When installing 2 or more units

Install one remote controller cord for every unit connected to the system controller. Wire each unit

independently to the system controller keeping the overall length of the remote controller cord less

than 15m(45 ft.).

- 10 -

N-084M(-DV)(-ASME), KM3211WH, (L)WH(X)56

When installing the system controller, take care not to damage the internal electrical components in(1) the

unit and tie off loose electrical cords with the included vinyl ties.**

Remove the connector from the circuit board to the remote controller terminal block in the unit.(2)

Connect this disconnected connector labeled 90 from the circuit board to the connector labeled 90

from the system controller.

Connect the connector from the remote controller terminal block to the connector from the system (3)

controller labeled "To remote controller terminal ".

Connect the B5 connector from the system controller to the B5 connector of the unit.(4)

Use the remote controller cords and the cords included with the system controller to connect the (5)

other units to the system controller.

Unit 1

(The Unit with the System Controller)

The remote controller cord length*

When using one remote controller = Maximum length 100m (300ft.).

When using two remote controllers = within 50m (150ft.) each (KM3211WH only).

When using three remote controllers = within 20m (65ft.) each (KM3211WH only).

Please refer to the installation manual of the unit about version and quantity of remote controllers *

that can be connected.

Fix with accessory screw

Ground Wire

Connect with

accessory screw

Fix with accessory screw

System controller

Mounting Plate

Slide system controller

into the bracket in the

back of the case.

"To Gas Water Heater for Multi" tag

"To remote controller terminal " tag

System Controller

Connector color: red

Remote Controller Cord

Connect to the connector No.90 of the unit.

PCB

9090

No.2

Connector color: red

B5B5

Clamp

* Remote Controller cord

(To remote controller)

Connect to the connector

B5 of the unit.

"

Disconnect for system controller

Disconnect this Connector

Disconnect this connector

on units 2-6 also.

*N-084M(-DV)(-ASME) only

" tag

**Note: If remote controller RC-7647M or RC-7650M ( °C temperature display) is being used, an

adjustment to all water heaters connected to the system controller will be necessary.

Make this adjustment prior to making the electrical connections to the system controller.

Refer to page 14 for instructions.

Units 2-6

(Connect each unit to corresponding wires labeled 2-6 from the system controller)

Remote Controller Cord

No.2 To Unit 2

No.6 To Unit 6

Clamp

When installing 2 or more units

Install one remote controller cord for every unit connected to the system controller. Wire each unit

independently to the system controller keeping the overall length of the remote controller cord less

than 15m(45 ft.).

- 11 -

N-0931M(-DV, -OD)(-ASME), NC250-SV(-DV)-ASME

N-0841MC(-DV), NCC199-SV(-DV), N-0842MC(-DV), (L)WHC56, BC3200RA

When installing the system controller, take care not to damage the internal electrical components (1)

in the unit and tie off loose electrical cords with the included vinyl ties.**

Remove the connector from the circuit board to the remote controller terminal block in the unit.(2)

Connect this disconnected connector labeled 90 from the circuit board to the connector labeled 90

from the system controller.

Connect the connector from the remote controller terminal block to the connector from the system (3)

controller labeled "To remote controller terminal ".

Connect the B5 connector from the system controller to the B5 connector of the unit.(4)

Use the remote controller cords and the cords included with the system controller to connect the (5)

other units to the system controller.

Unit 1

(The Unit with the System Controller)

The remote controller cord length*

When using one remote controller = Maximum length 100m (300ft.).

When using two remote controllers = within 50m (150ft.) each (BC3200RA only).

When using three remote controllers = within 20m (65ft.) each (BC3200RA only).

Please refer to the installation manual of the unit about version and quantity of remote controllers *

that can be connected.

Fix with accessory screw

Ground Wire

Connect with

accessory screw

Slide system controller

into the bracket in the

back of the case.

"To Gas Water Heater for Multi " tag

"To remote controller terminal " tag

System Controller

Connector color: red

No.2

Connector color: red

Remote Controller Cord

Connect to the connector No.90 of the unit.

Connect to the connector

PCB

9090

B5B5

* Remote Controller cord

(To remote controller)

B5 of the unit.

"

Disconnect for system controller

Disconnect this Connector

Disconnect this connector

on units 2-6 also.

Except (L)WHC56, BC3200RA

"SYSTEM CONTROLLER" tag

Clamp

" tag

**Note: If remote controller RC-7647M or RC-7650M ( °C temperature display) is being used, an

adjustment to all water heaters connected to the system controller will be necessary.

Make this adjustment prior to making the electrical connections to the system controller.

Refer to page 14 for instructions.

Units 2-6

(Connect each unit to corresponding wires labeled 2-6 from the system controller)

Remote Controller Cord

No.2 To Unit 2

No.6 To Unit 6

Clamp

The location of the terminals will either be inside the unit or external to the unit.*

When installing 2 or more units

Install one remote controller cord for every unit connected to the system controller. Wire each unit

independently to the system controller keeping the overall length of the remote controller cord less

than 15m(45 ft.).

- 12 -

The installer should test operate the system, explain to the

5. T rial Operation

Connect electrical power to each of the units.(1)

Open the gas shutoff valve, the main water valve, and the water shutoff valves on all of the units.(2)

Turn the power ON with the remote controller. (The Operation Lamp will light up.)(3)

Slowly open a hot water fi xture and confi rm that the units ignite in sequence and that the Burner (4)

On Lamp on the remote controller lights.

If an "11" or "12" error code fl ashes on the remote controller, there may be air in the gas line.•

Hit the Power Button ON and OFF a few times and then open the fi xture again to try igniting the

unit again.

If this fi xture does not cause all of the units to ignite, test the rest of the units by switching which •

the primary unit by pressing either the Maximum or Minimum Manifold Pressure Set Button on the

circuit board of the unit.

Operate all of the units and confi rm that the water temperature corresponds to the temperature set •

on the remote controller. Set the remote to the lowest temperature to maximize water fl ow.

If the water temperature is hotter than the set temperature, check to make sure that the remote is

connected to the system controller, and that the system controller is connected to the other units.

If the units do not operate properly, refer to the Troubleshooting section of the Owner's Manual.•

After the test operation, clean any debris off of the fi lter on the water inlet.*

customer how to use the units, and give the owner the Installation

and Operation Manual before leaving the installation.

Checking Water Flow (Maintenance Monitors) Necessary only for recirculation systems

is

N-084M(-DV)(-ASME), N-132M(-ASME), N-1321M-ASME, NC380-SV-ASME, N-0931M(-DV,-OD)(-ASME),

NC250-SV(-DV)-ASME, N-0841MC(-DV), NCC199-SV(-DV), N-0842MC(-DV)

Turn the Power button "ON".(1)

Press the temperature up and down buttons (2) △ and ▽

simultaneously for more than 2 seconds.

(The remote control will display the maintenance monitors.)

"Unit No.", "Data No." and "Data" are displayed on the remote *

controller temperature display.

Press the "FLOW METER ALARM SET" button to change (3)

which unit's information in being displayed.

(The combustion lamp of the selected unit will fl ash twice.)

When switching "Unit No.", the display will change from *

"5C→01→Data No."→"01→02→Data No."→"02→03 →

Data No."• • •"(Last Unit)No.→5C→OFF" when the "FLOW

METER ALARM SET" button is pressed.

If the "FLOW METER ALARM SET" button is not pushed to

change the Unit No., the Data No. for that Unit will then be

displayed on the remote controller.

Press the temperature up or down buttons (4) △ or ▽ to select

Data No.14. The water fl ow through that heater will be

displayed.

Repeat (2) - (3) for all water heaters. Adjust so that the total (5)

water fl ow of all devices is 2 GPM or more.

Press the temperature up and down buttons (6) △ and ▽

simultaneously for over 2 sec. to return to the temperature

display.

Temperature display

Flow Meter Alarm

Set Button

Temperature switch

(Changing the Data No.)

(Device No., Data No., Data)

Power Button

(Device No.)

- 13 -

Checking Water Flow (Maintenance Monitors)

(L)WH(X)56, (L)WHC56, KM3211WH, BC3200RA

Necessary only for recirculation systems

Power On/Off Button

Display

Set Button

Speaker

The Power On/Off Button can be set to either "ON" or "OFF" unit operation will not be affected by this setting.

However, be sure to set the Power On/Off Button to “ON” after turning on the power.

<Display procedure>

Press and hold both the up [(1) ▲] and down [▼] select buttons simultaneously for more than fi ve seconds.

“Maintenance Monitor” display will appear along with the data no. and data.(2)

Displaying data and switching data no.(3)

Press the up [a) ▲] select button to switch display to the next item no. Press the down [▼] set button to

switch display to the previous data no.

Press the set button to switch to the mode for changing the ten’s digit. Use the select buttonsb)

[▲] and [▼] in the same manner as 1) to make changes.

When pressing the setting button again:c)

If the data no. is 03, the microcomputer name of the remote controller is displayed. When the set •

button is pressed again, the unit will return to the mode of 1).

If the data no. is other than 03, the unit will return to the mode of 1).•

During maintenance monitors are displaying, the hot water temperature and other settings cannot be

adjusted.

Press the temperature up or down buttons [(4) ▲] or [▼] to select Data No.14. The water fl ow through that

heater will be displayed.

Repeat (3) - (4) for all water heaters. Adjust (so that) the total water fl ow of all devices is 8L/min. or more.(5)

<Returning to Normal Mode>

For releasing the indication, press and hold both up [(1) ▲] and down [▼] of select buttons simultaneously more

than two seconds, or leave it alone for more than 10 minutes.

Selection Button

Display No. and Unit No.

Display Unit No.

5C SC-201

01 Unit 1

02 Unit 2

•

•

•

06 Unit 6

•

•

•

Water Heater Dipswitch Settings (When using remote controller RC-7647M or RC-7650M)

N-084M(-DV)(-ASME), N-132M(-ASME), NC380-SV-ASME, N-1321M-ASME, N-0931M(-DV,-OD)(-ASME),

NC250-SV(-DV)-ASME, N-0841MC(-DV),NCC199-SV(-DV), N-0842MC(-DV), NC199-OD(-DVC)

When using remote controller RC-7647M or RC-7650M ( °C temperature display), a dipswitch change will be

necessary on all water heaters connected to the system controller. Refer to the below instructions to make the

adjustment. A remote controller will need to be connected to the water heater being adjusted.

Connect electrical power to the water heater and wait 10 seconds before proceeding to step 2.(1)

Within the fi rst ten minutes of connecting electrical power, before turning on the operation button, hit the [(2) ▲]

or [▼] button on the remote controller and hold until the display blinks "99". If "99" does not blink on the

remote controller, unplug the water heater and try again.

Use the [(3) ▲] or [▼] button on the remote controller to scroll to the appropriate dipswitch number as indicated

below.

Press the "FLOW METER ALARM SET" button for 0.5 sec to change the setting ON/OFF:(4)

ON: "priority" lamp fl ashes.

OFF: "priority" lamp goes off.

For models N-084M(-DV)(-ASME), N-132M(-ASME), N-1321M-ASME, NC380-SV-ASME:(5)

Change "A8" from OFF to ON. Do not adjust any other dipswitches!

For models

Change "2F" from OFF to ON. Do not adjust any other dipswitches!

When the dipswitch has been adjusted, confi rm the setting by pressing and holding both the [(6) ▲] and [▼]

buttons on the remote controller until the controller emits a beeping noise. The new setting will be lost if this

is not done.

Repeat this entire procedure for every water heater that will be connected to the system controller.(7)

N-0931M(-DV,-OD)(-ASME), N-0841MC(-DV), NC250-SV(-DV)-ASME, NCC199-SV(-DV), NC199-OD(-DVC):

- 14 -

Dipswitch Settings

N-084M(-DV)(-ASME), N-132M(-ASME), N-1321M-ASME, NC380-SV-ASME, N-0931M(-DV,-OD)(-ASME),

NC250-SV(-DV), N-0841MC(-DV), NCC199-SV(-DV), N-0842MC(-DV)

Disconnect the power to the units before changing the dipswitches.

(Otherwise, settings will not take effect.)

Dipswitch SW8SW7SW6SW5SW4SW3SW2SW1

Pump

abnormality

detection

Pump

rotation

NoYes

YesNo

Set temperature

* All dipswitches are set to ON from the factory.

SW2: Pump abnormality detection

Set to OFF if the pump will not be connected to the system controller, but instead the pump will

be controlled by an external control device.

SW3: Pump rotation

Set to OFF if using 2 pumps.

SW4: If the switch is set to OFF, and the Power Button is turned OFF and ON, the unit will accept

°

125

F return water (if the unit is set at that temperature or higher).

When the dipswitch is ON, the unit will allow the standard return temperature.

* Do not change any other dipswitches.

OFF

ON

1 2345678

- 15 -

Dipswitch Settings

(L)WH(X)56, (L)WHC56, KM3211WH, BC3200RA

Disconnect the power to the units before changing the dipswitches.

(Otherwise, settings will not take effect.)

Dipswitch SW8SW7SW6SW5SW4SW3SW2SW1

Pump

abnormality

detection

Pump

rotation

60 C recovery

during

hightemperature

setting

Power Button

works with

circulation

Yes

No

YesNo

Set temperature Independence

Interlock

* All dipswitches are set to ON from the factory.

SW2: Pump abnormality detection

Set to OFF if the pump will not be connected to the system controller, but instead the pump will

be controlled by an external control device.

SW3: Pump rotation

Set to OFF if using 2 pumps.

SW4: The setting temperature which the Power Button is turned ON, and OFF when the setting is

high temperature.

When the setting temperature is changed above 60°C, turn the Power Button OFF once, then

60°C is displayed when turning the Power Button ON again. (When the dipswitch is ON.)

When the dipswitch is switched to OFF, the temperature will remain at the previous setting.

(before the Power Button is turned to ON.)

SW5: Behavior when turning on the Power Button with remote controller or external operation

terminal.

When the dipswitch is set to ON, the Power Button and the circulation switch are turned ON at

the same time.

When the dipswitch is turned to OFF, only the Power Button is turned to ON.

* Do not change any other dipswitches.

OFF

ON

1 2345678

- 16 -

Loading...

Loading...