Noritz NRC98-OD, NRC83-OD Installation Manual

Potential dangers from accidents during installation and use are divided into the following three

categories. Closely observe these warnings, they are critical to your safety.

Prohibited

Disconnect

Power

Ground

Be sure to do

WARNING:

If the information in this manual is not followed exactly, a re or explosion may result

causing property damage, personal injury or death.

NORITZ AMERICA

CORPORATION

Installation Manual

CONDENSING TANKLESS GAS WATER HEATER

NRC98-OD

(Outdoor Installation)

NRC83-OD

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

DANGER

WARNING

CAUTION

SBA8677-2

Rev. 03/13

Requests to Installers

• In order to use the water heater safely, read this installation manual carefully, and follow the installation instructions.

• Failures and damage caused by erroneous work or work not as instructed in this manual are not

covered by the warranty.

• Check that the installation was done properly in accordance with this Installation Manual upon

completion.

•

After completing installation, please either place this Installation Manual in a plastic pouch and

attach it to the side of the water heater (or the inside of the pipe cover or recess box if applicable),

or hand it to the customer to retain for future reference. Also, be sure to ll in all of the required

items on the warranty and to hand the warranty to the customer along with the Owner's Guide.

CAUTION

FOR USE IN RESIDENTIAL APPLICATIONS.

I

nstallation must conform with local codes, or in the absence of local codes, the

National Fuel Gas Code, ANSI Z223.1/NFPA 54- latest edition and/or CSA B149.1,

Natural Gas and Propane Installation Code (NSCNGPIC).

Noritz America reserves the right to discontinue, or change at any time, the

designs and/or specications of its products without notice.

CERTIFIED

R

*SBA8677*

Low NOx

Approved by

SCAQMD

14 ng/J or 20 ppm

(Natural Gas Only)

2

1.

Included Accessories

The following accessories are included with the unit.

Check for any missing items before starting installation.

Q’ty

ShapePart

1

each

Part Shape

Q’ty

3

1

Remote Controller

(See p. 19)

Remote Controller

Cord (6ft (2m))

1

2.

Optional Accessories

The accessories listed below are not

included with the units, but may be necessary

for installation.

Cross Recessed

Head Screw

Quick Connect Cord

(QC-2)

Q’ty

ShapePartPart Shape

Q’ty

1

1

Remote Controller

Cord (26ft (8m))

1

Isolation V alves

(includes pressure

relief valve)

Pipe Cover

(PC-3S)

1

1

Recess Box

(RB-900)

1

Remote Controller

Outdoor

Junction Box

Owner's Guide, Warranty,

Installation Manual

(this document)

3

G

Quick Connect

Cord

Remote Controller Cord

Gas Supply Piping

Cold Water Supply

Hot Water

Remote Controller

Terminal Block

Cord

Connector

Cord

Connector

3.

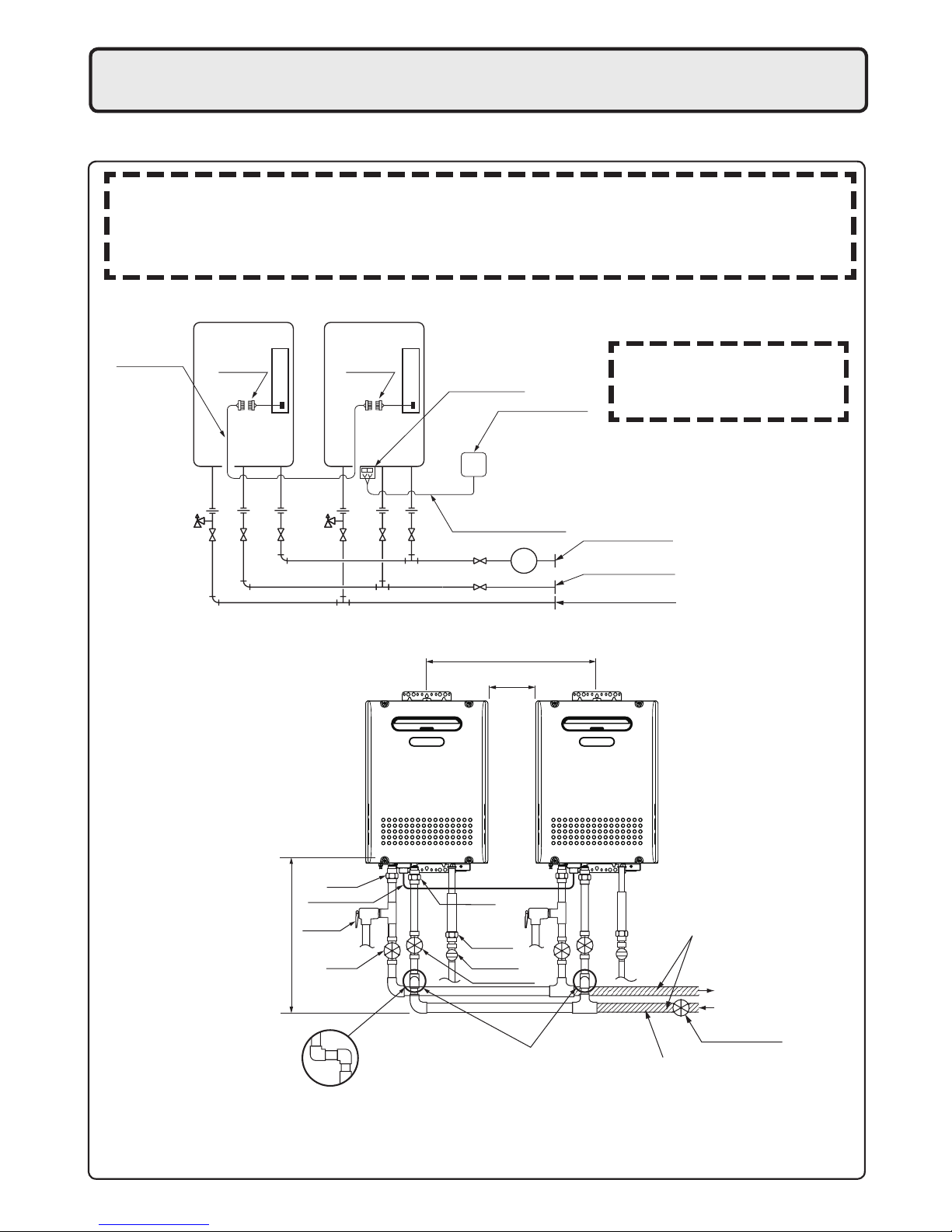

Quick Connect Multi System Installation

• The Quick Connect Multi System allows the installation of two units together utilizing only the Quick

Connect Cord.

Typical Plumbing

* When connecting two units, use only a

single remote controller.

Note: Connect the remote

controller to only one

of the units.

System Diagram

• Insulate the hot water piping to prevent heat loss. Insulate and apply heating materials to the

cold water supply piping to prevent heat loss and freezing of pipes when exposed to excessively

cold temperatures.

Union

Make this distance as short as possible.

* The hot water temperature will

become unstable as the pipe

length increases.

Quick Connect

cord

Union

Gas Valve

Union

Shutoff

Valve

Shutoff Valve

Hot Water

Cold Water

Leave enough clearance around the plumbing to

apply insulation. It will be necessary to add

bends to the piping to ensure that this clearance

is available.

Pressure

Relief

Valve

Shutoff Valve

Size the piping to allow for the

maximum flow rates of the units.

The backflow preventer is

put up before it diverges.

Distance at center: 20.3 - 36.3 in. (515 - 922mm)

Distance on sides

2 - 18 in. (50 - 457mm)

The Quick Connect Cord is 6 ft.(2m) long. Install the units 2-18" (50 - 457mm) apart from each

other to ensure the cord will be able to reach between the units. (See Typical Plumbing diagram).

(If the distance between the two units is too great, not only will the cord not be able to reach,

but the water temperature may also become unstable because of the difference in pipe length

between the two units).

4

Check the Gas

• Check that the rating plate indicates the

correct type of gas.

• Check that the gas supply line is sized for

180,000 Btuh for NRC98-OD, 157,000 Btuh

for NRC83-OD.

Check the Power

• The power supply required is 120VAC, at 60Hz.

May result in re or electric shock.

Use Extreme Caution if Using With a Solar Pre-Heater

• Using this unit with a solar pre-heater can lead to unpredictable output temperatures and

possibly scalding. If absolutely necessary, use mixing valves to ensure output temperatures do

not get to scalding levels. Do not use a solar pre-heater with the quick-connect multi-system.

4.

Before Installation

Do Not Use Equipment for Purposes Other Than Those Specied

• Do not use for other than increasing the temperature of the water supply, as unexpected accidents

may occur as a result.

Check Water Supply Quality

• If the water supply is in excess of 12 grains per gallon (200 mg/L) of hardness, acidic or otherwise

impure, treat the water with approved methods in order to ensure full warranty coverage.

WARNING

CAUTION

5.

Choosing Installation Site

* Locate the appliance in an area where leakage from the unit or connections will not result in damage

to the area adjacent to the appliance or to the lower oors of the structure. When such locations can-

not be avoided, it is recommended that a suitable drain pan, adequately drained, be installed under

the appliance. The pan must not restrict combustion air ow.

DANGER

Indoor

• This water heater is for outdoor installation only.

Never install it indoors.

Do not enclose the termination with corrugated

metal or other materials.

This will cause carbon monoxide

poisoning and a potential re

hazard.

5

• Avoid places where res are common, such as those where gasoline,

benzene and adhesives are handled, or places in which corrosive gases

(ammonia, chlorine, sulfur, ethylene compounds, acids) are present.

Using the incorrect voltage may result in re or cracking.

• Avoid installation in places where dust or debris will accumulate.

Dust may block the air-supply opening, causing the performance of the

device fan to drop and incomplete combustion to occur as a result.

• Avoid installation in places where special chemical agents

(e.g., hair spray or spray detergent) are used.

Ignition failures and malfunction may occur as a result.

• Carbon Monoxide Poisoning Hazard. Do not install this water heater in a

mobile home, recreational vehicle or on a boat.

• Install the water heater in a location where it is free from obstacles and

stagnant air.

• Consult with the customer concerning the location of installation.

• Do not install the water heater near staircases or emergency exits.

• Do not install the water heater where the exhaust will blow on outer walls

or material not resistant to heat. Also consider the surrounding trees and

animals.

The heat and moisture from the water heater may cause discoloration of

walls and resinous materials, or corrosion of aluminum materials.

• Do not locate the vent termination directed towards a window or any

other structure which has glass or wired glass facing the termination.

• Install in a location where the exhaust gas ow will not be affected by

fans or range hoods.

• Take care that noise and exhaust gas will not affect neighbors.

Avoid installation on common walls as the unit will make some operational noises while it is running.

• Avoid installation where the unit will be exposed to excessive winds.

• Before installing, make sure that the vent termination will have the proper

clearances according to the National Fuel Gas Code (ANSI Z223.1).

Prohibited

WARNING

CAUTION

Prohibited

State of California: The water heater must be braced, anchored or strapped to avoid moving during an

earthquake. Contact local utilities for code requirements in your area or call: 1-866-766-7489 and request instructions.

The Commonwealth of Massachusetts:

1) The outdoor units (OD) can only be used if they are for summer use only.

2) The water heater can be used for hot water only and not in a combination of domestic and space

heating.

6

6.

Installation Clearances

Before installing, check for the following:

Install in accordance with relevant building and mechanical codes, as well as any local, state or

national regulations, or in the absence of local and state codes, to the National Fuel Gas Code

ANSI Z223.1/NFPA 54 – latest edition. In Canada, see NSCNGPIC for detailed requirements.

WARNING

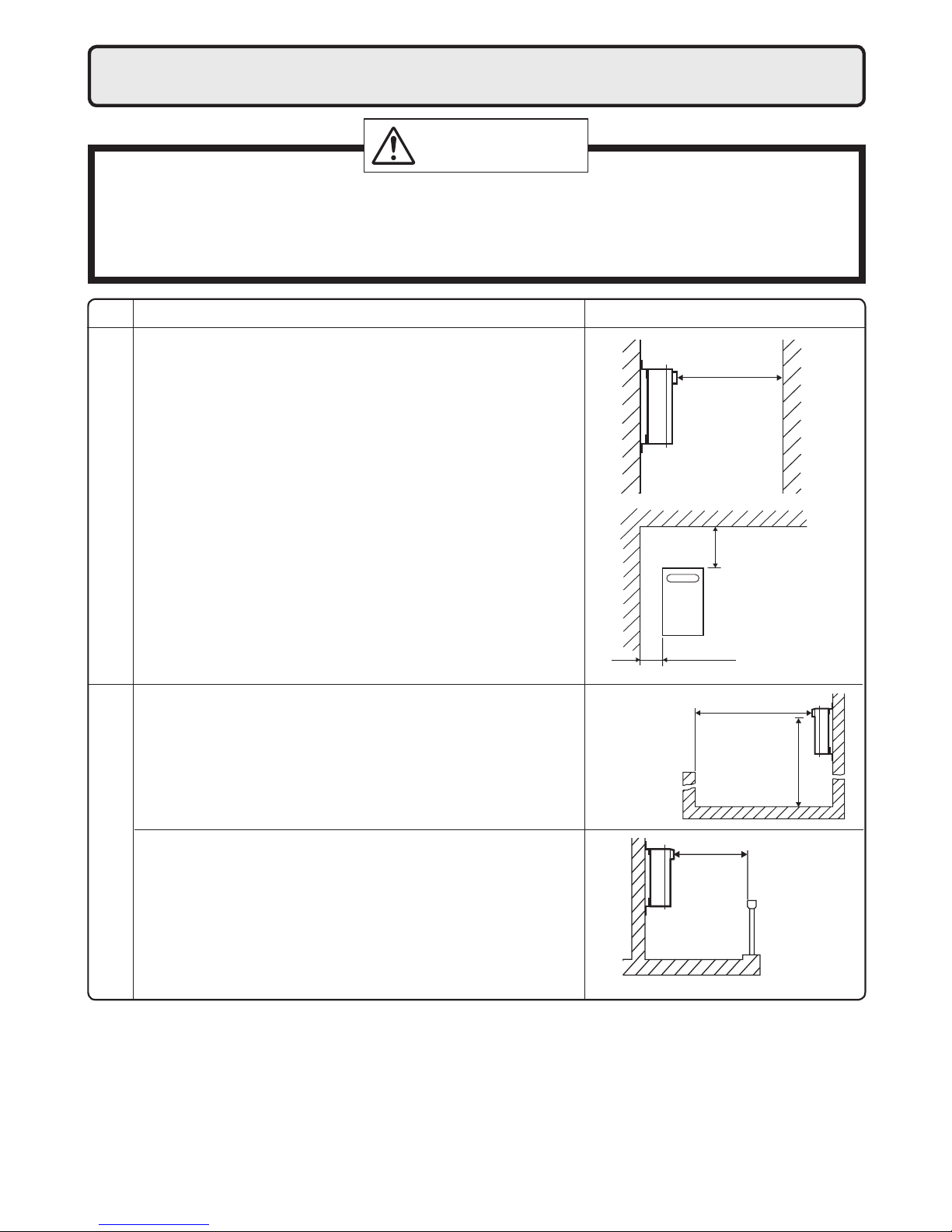

Item Check

• When installing the unit on a balcony, etc., secure an

evacuation route of 24" (600mm) or more in width.

• Provide clearance of 24" (600mm) or more in front of

the unit to facilitate inspection and repair. Do install the

unit such as the wall of the second oor where the unit

is out of reach.

• When installing the unit in a common side corridor, provide

a clearance of 47" (1,190mm) or more in front of the unit.

• Set the bottom edge of the exhaust port about

84" (2,130mm) from the corridor oor.

Handrail

common side

corridor

balcony, etc.

Handrail

about 84"

(2,130mm)

• Maintain the following clearance from both combustible

and non-combustible materials.

24" (600mm)

or more

36" (900mm)

or more

Surrounding the area of installation

24" (600mm)

or more

47" (1,190mm) or more

Required Clearances From Heater

Illustration

6" (150mm)

or more

7

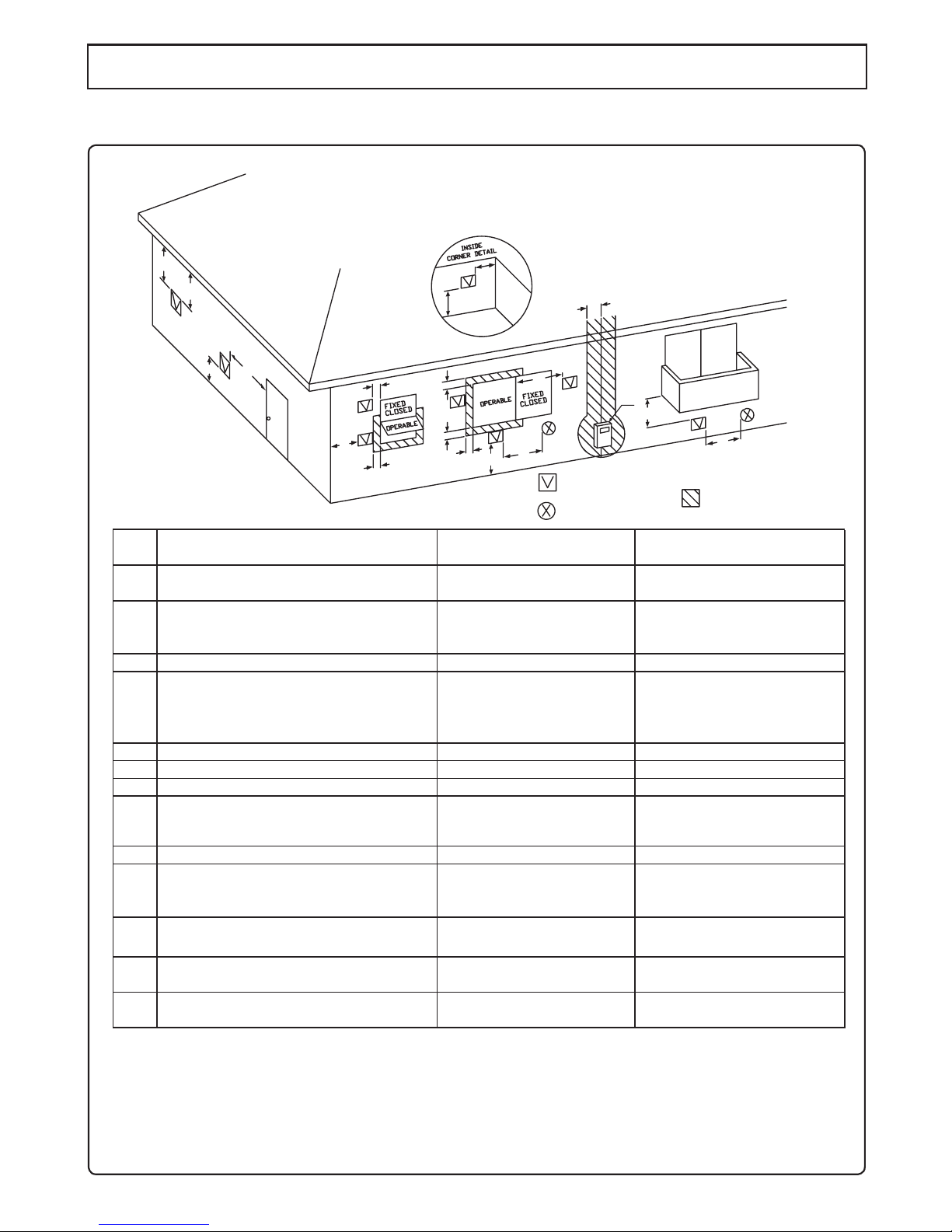

Clearance Requirements from Vent Terminations to Building Openings

* All clearance requirements are in accordance with ANSI Z21.10.3 and the National Fuel Gas Code,

ANSI Z223.1 and in Canada, in accordance with NSCNGPIC.

DescriptionRef

A=

Clearance above grade, veranda, porch,

deck, or balcony

B=

Clearance to window or door that may

be opened

C=

Clearance to permanently closed window

D=

Vertical clearance to ventilated soffit

located above the terminal within a

horizontal distance of 2 feet (61 cm)

from the center line of the terminal

*

E=

Clearance to unventilated soffit

*

F=

Clearance to outside corner

*

G=

Clearance to inside corner

*

H=

Clearance to each side of center line

extended above meter/regulator assembly

3 ft (91 cm) within a height

15 ft (4.5 m) above the

meter/regulator assembly

I=

Clearance to service regulator vent outlet

3 ft (91 cm)

J=

Clearance to nonmechanical air supply

inlet to building or the combustion air inlet

to any other appliance

K=

Clearance to a mechanical air supply inlet

6 ft (1.83 m)

L=

Clearance above paved sidewalk or paved

driveway located on public property

Clearance under veranda, porch, deck,

or balcony

7 ft (2.13 m)†

M=

1

In accordance with the current CSA B149.1 Natural Gas and Propane Installation Code

2

In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code

† A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single

family dwellings and serves both dwellings.

‡ Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

* Clearance in accordance with local installation codes and the requirements of the gas supplier.

Clearance to opposite wall is 24 inches (60 cm).

12 in (30 cm)‡

*

12 in (30 cm)

36 in (91 cm)

*

*

*

*

*

*

*

*

3 ft (91 cm) above if within

10 ft (3 m) horizontally

*

12 in (30 cm)

4 ft (1.2 m) below or to side

of opening; 1 ft (30 cm)

above opening

36 in (91 cm)

4 ft (1.2 m) below or to side

of opening; 1 ft (30 cm)

above opening

US Non-Direct Vent

Installations

2

Canadian Non-Direct Vent

Installations

1

Vent Terminal

D

E

B

B

F

B

A

G

H

I

C

B

M

K

J

B

B

L

Air Supply Inlet

Area Where Terminal

is Not Permitted

A

8

Illustration

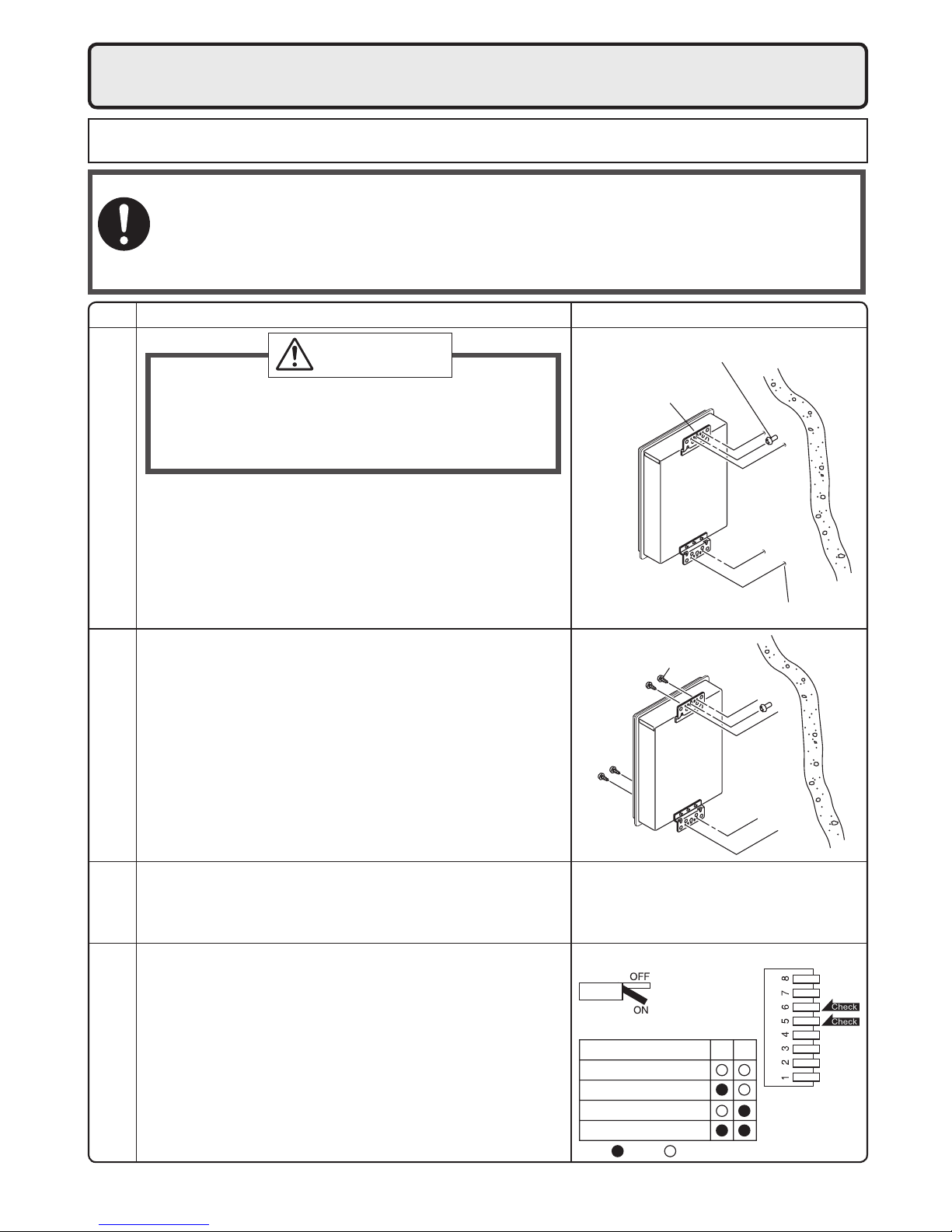

7.

Installation

Check

4. Drill holes for the remaining four screws.

5. Hang the unit again by the rst screw, and then

insert and tighten the remaining four screws.

6. Take waterproong measures so that water does

not enter the building from screws mounting the

device.

• Make sure the unit is installed securely so that it will

not fall or move due to vibrations or earthquakes.

Securing to the wall

1. Drill a single screw hole, making sure to hit a stud.

2. Insert and tighten the screw and hang the unit by

the upper wall mounting bracket.

3. Determine the positions for the remaining four screws

(two for the top bracket and two for the bottom), and

remove the unit.

• The weight of the device will be applied to the wall. If the strength of the wall is not suf-

cient, reinforcement must be done to prevent the transfer of vibration.

• Do not drop or apply unnecessary force to the device when installing. Internal parts may

be damaged and may become highly dangerous.

• Install the unit on a vertical wall and ensure that it is level.

Locating Screw Holes

Mounting

Structure

• When installing with bare hands, take caution to

not inict injury.

• Be careful not to hit electrical wiring, gas, or water

piping while drilling holes.

Item

CAUTION

Be sure to do

Mounting Bracket

(upper)

Anchoring Screw

(Arrangement at the eld)

Location of Screw Hole

Locating Screw Holes

Installations at Elevations

Above 2,000 ft.

• Adjust the dip switches as illustrated in the table to

the right if this water heater is installed at an altitude

of 2000 ft. (610m) or higher.

• Disconnect power to the water heater before chang-

ing the dip switches. Failure to perform this step will

result in a "73" code displayed on the remote controller and a cease in operation. If this occurs, discon-

nect, then reconnect power to the water heater to

reset the system.

Note : Please refer to page 19 for the location of the

dip switch bank.

* Do not change any other dipswitches.

* High elevation adjustment.

65

2,001 - 4,000 ft (611 - 1,220m)

0 - 2,000 ft (0 - 610m)

ON= OFF=

4,001 - 6,000 ft (1,221 - 1,830m)

6,001 - 8,000 ft (1,831 - 2,440m)

9

Gas Meter

Select a gas meter capable of supplying the entire

btuh demand of all gas appliances in the building.

Gas Connection

• Do not use piping with a diameter smaller than

the inlet diameter of the water heater.

• Gas flex lines are not recommended unless

they are rated for 180,000 btuh(NRC98-OD),

157,000 btuh(NRC83-OD).

• Install a gas shutoff valve on the supply line.

• Use only approved gas piping materials.

Follow the instructions from the gas supplier.

Gas Pressure

Size the gas line according to total btuh demand

of the building and length from the meter or

regulator so that the following supply pressures

are available even at maximum demand:

Natural Gas Supply Pressure

Min. 4" WC

Max. 10.5" WC

LP Gas Supply Pressure

Min. 8" WC

Max. 14" WC

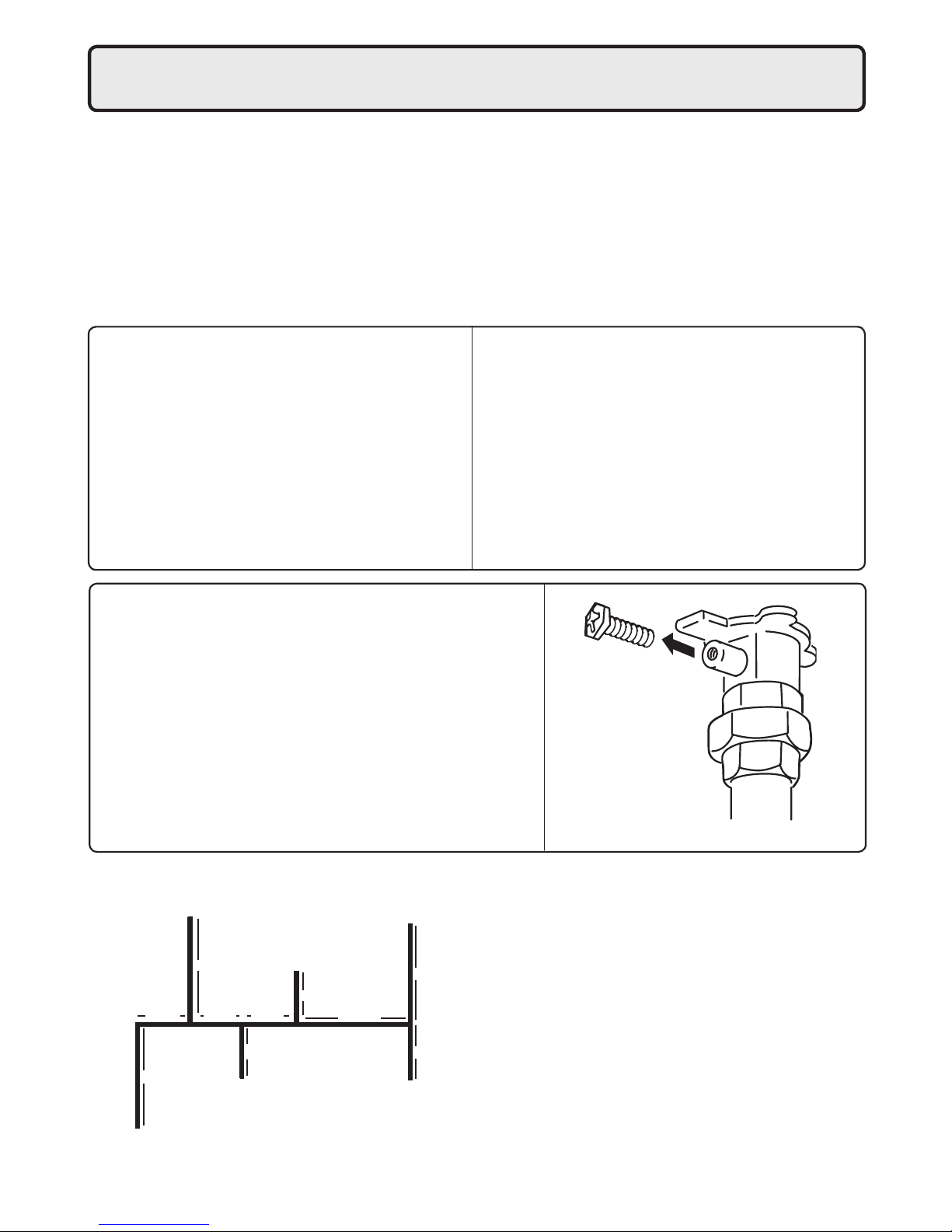

8.

Gas Piping

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1⁄2 psig (3.5 kPa).

The Appliance must be isolated from the gas supply piping system by closing its individual manual shut-

off valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than

1

⁄2 psig (3.5 kPa).

The appliance and its gas connections must be leak tested before placing the appliance in operation.

The inlet gas pressure must be within the range specied. This is for the purposes of input adjustment.

In order to choose the proper size for the gas line, consult local codes or the National Fuel Gas Code

ANSI Z223.1.

Natural Gas

Meter

**See next page for the pipe capacity charts.

Noritz Condensing Tankless Gas Water Heater

(NRC98-OD 180,000 Btuh)

(NRC83-OD 157,000 Btuh)

Clothes Dryer

(35,000 Btuh)

Barbecue

(50,000 Btuh)

Gas Range Stove

(65,000 Btuh)

10' (3m)

10' (3m)

10' (3m)

10' (3m)

5' (1.5m)

5' (1.5m)

5' (1.5m)

5' (1.5m)5' (1.5m) 5' (1.5m)

Gas Fireplace

(25,000 Btuh)

Instructions

1. Size each outlet branch starting from the furthest

using the Btuh required and the length from the

meter.

2. Size each section of the main line using the

length to the furthest outlet and the Btuh

required by everything after that section.

Sample Gas Line

Sample Calculation

Outlet A: 45' (13.5m) (Use 50' (15m)), 50,000 Btuh requires 1/2"

Outlet B: 40' (12m), 65,000 Btuh requires 1/2"

Section 1: 45' (13.5m) (Use 50' (15m)), 115,000 Btuh requires 3/4"

Outlet C: 30' (9m), 35,000 Btuh requires 1/2"

Section 2: 45' (13.5m) (Use 50' (15m)), 150,000 Btuh requires 3/4"

Outlet D: 25' (7.5m) (Use 30' (9m)), 25,000 Btuh requires 1/2"

Section 3: 45' (13.5m) (Use 50' (15m)), 175,000 Btuh requires 1"

Outlet E: 25' (7.5m) (Use 30' (9m)),

180,000 Btuh requires 3/4" (NRC98-OD),

157,000 Btuh requires 3/4" (NRC83-OD)

Section 4: 45' (13.5m) (Use 50' (15m)), 355,000 Btuh requires 1-1/4"

Section 3 Section 2

Section 1

Outlet A

Outlet B

Outlet C

Outlet D

Outlet E

Section 4

Measuring Gas Pressure

In order to check the gas supply pressure to the unit, a

tap is provided on the gas inlet. Remove the hex head

philips screw from the tap, and connect a manometer

using a silicon tube.

In order to check the gas manifold pressure, a pair of

taps are provided on the gas valve inside the unit.

The pressure can be checked either by removing the hex

head philips screw and connecting a manometer with a

silicon tube, or by removing the 1/8" NPT screw with an

allen wrench and connecting the appropriate pressure

gauge.

Loading...

Loading...