Noritz N-084M-DV-CA Installation Manual

Owner’s Guide and

Installation Manual

Model N-084M-DV-CA

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

-Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

•Immediately call your gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

CERTIFIED

R

Low NOx

Approved by SCAQMD

SAR8210-1

Thank you for purchasing this Noritz Gas Water Heater. Before using, please:

Read this manual completely for correct installation and operation instructions.

Completely fill out the warranty registration card (included separately) and

mail the detachable portion to Noritz America Corporation.

Keep this manual (and the remainder of the warranty registration card) where it

can be found whenever necessary.

NORITZ America Corporation

*SAR8210 T*

Contents

Contents ........................................................................................................ 2

Owner's Guide

Important Safety Information.......................................................................3

General Parts

Main Unit....................................................................................................8

Remote Controller .................................................................................... 9

Initial Operation ........................................................................................... 11

Setting and Using the Water Heater...........................................................12

Flow Meter Alarm......................................................................................... 14

Muting the Remote Controller .................................................................... 16

Preventing Damage from Freezing ............................................................ 17

Regular Maintenance...................................................................................19

Troubleshooting .......................................................................................... 21

Follow-up Service ........................................................................................ 25

Specifications .............................................................................................. 26

External Outfitting ....................................................................................... 27

Combustion Unit and Gas Route ............................................................... 29

Hot-Water Feed Route ................................................................................. 31

Electronic Control Unit................................................................................33

Electronic Control Unit, Remote Controller and Attached Set................ 34

Installation Manual ...................................................................................... 35

10. Water Piping........................................................................................... 48

11. Plumbing Applications.......................................................................... 49

12. Electrical Wiring .................................................................................... 50

13. Maintenance........................................................................................... 54

14. Trial Operation ....................................................................................... 54

15. Dimensions and Wiring Diagram ......................................................... 55

16. Multi-System .......................................................................................... 57

Remote Controller Installation Guide ........................................................ 61

2

1. Included Accessories............................................................................36

2. Optional Accessories............................................................................ 36

3. Quick Connect Multi System Installation ............................................ 37

4. Before Installation ................................................................................. 38

5. Choosing Installation Site .................................................................... 39

6. Installation Clearances ......................................................................... 40

7. Installation..............................................................................................42

8. Vent Pipe Installation ............................................................................ 42

9. Gas Piping.............................................................................................. 46

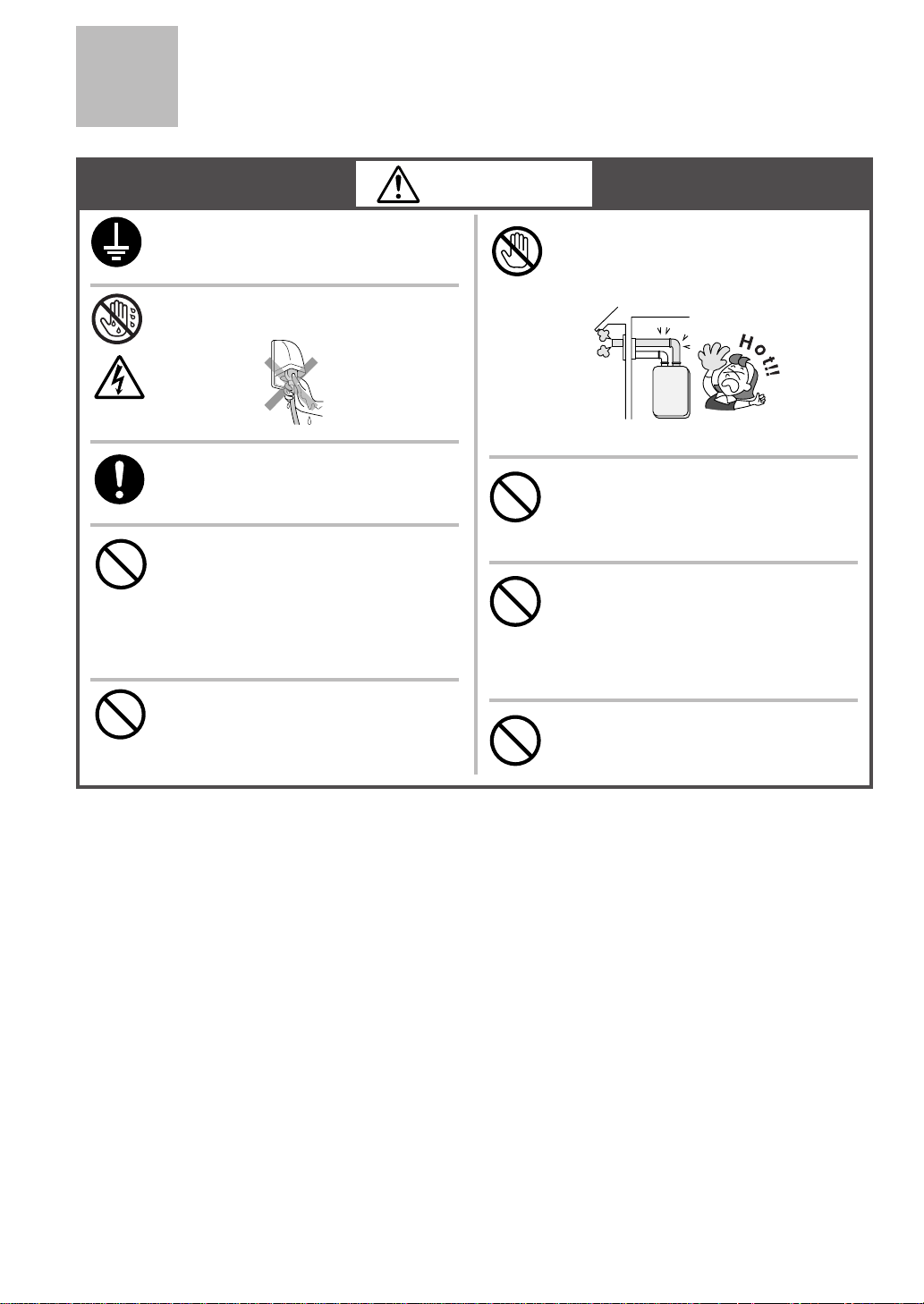

Important Safety Information-1

To prevent damage to property and injury to the user, the icons shown below will be used to warn of

varying levels of danger.

Every indication is critical to the safe operation of the water heater and must be understood and

observed.

Potential dangers from accidents during installation and use are divided into the following three

categories. Closely observe these warnings; they are critical to your safety.

Icons warning of risk level

Danger

Warning

Caution

Remarks

Other icons

Electric

Shock.

Prohibited

If you detect a gas leak:

1. Do not try to light any appliance

2. Do not touch any electrical

switch; do not use any phone in

your building.

3. Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

4. If you cannot reach your gas

supplier, call the fire department.

Denotes content that may result in instantaneous fire, serious injury

and even death when ignored.

Denotes content that may result in fire, serious injury and even

death when ignored.

Denotes content that may result in bodily injury and physical

damage when ignored.

The content following this icon is necessary to understand for safe

and easy use of this water heater.

High

Temperature.

No flame.

Be sure

to do.

Don’t

touch.

Danger

Ground.

Don’t

disassemble

the equipment.

Do not use the water heater if

the intake/exhaust pipe is

displaced, has holes, or is

corroded.

Don’t touch

with a wet

hand.

3

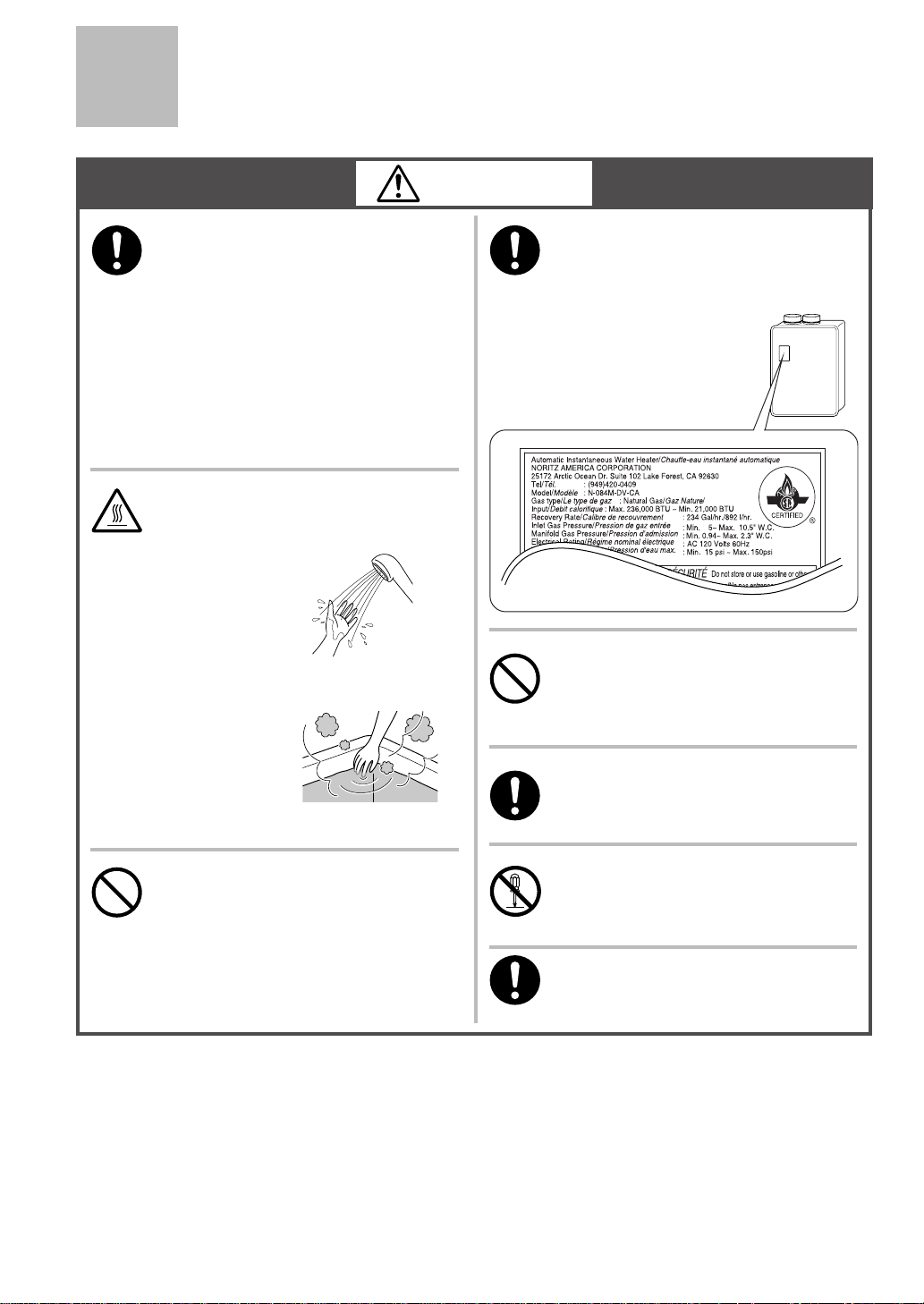

Important Safety Information-2

Warning

If you detect abnormal combustion

or abnormal odors, or during an

earthquake, tornado or fire:

1. Turn off the hot water supply

2. Turn off the power to the water

heater

3. Turn off gas and water at the main

4. Consult the nearest Noritz agent

Check the temperature of the

running hot water before

entering the shower.

Check the temperature before

stepping into the bath tub.

Be sure the gas/power supplied

matches the gas on the rating

plate.

For Natural Gas

Do not allow small children to play

unsupervised in the bathroom.

Do not allow small children to

bathe unsupervised.

4

Do not turn off the water heater or

change the water temperature while

someone is using.

Consult the nearest Noritz agent if

the water heater location needs to

be changed.

Contact a qualified service

technician for any necessary

repairs, service or maintenance.

Contact Noritz before using with

a solar pre-heater.

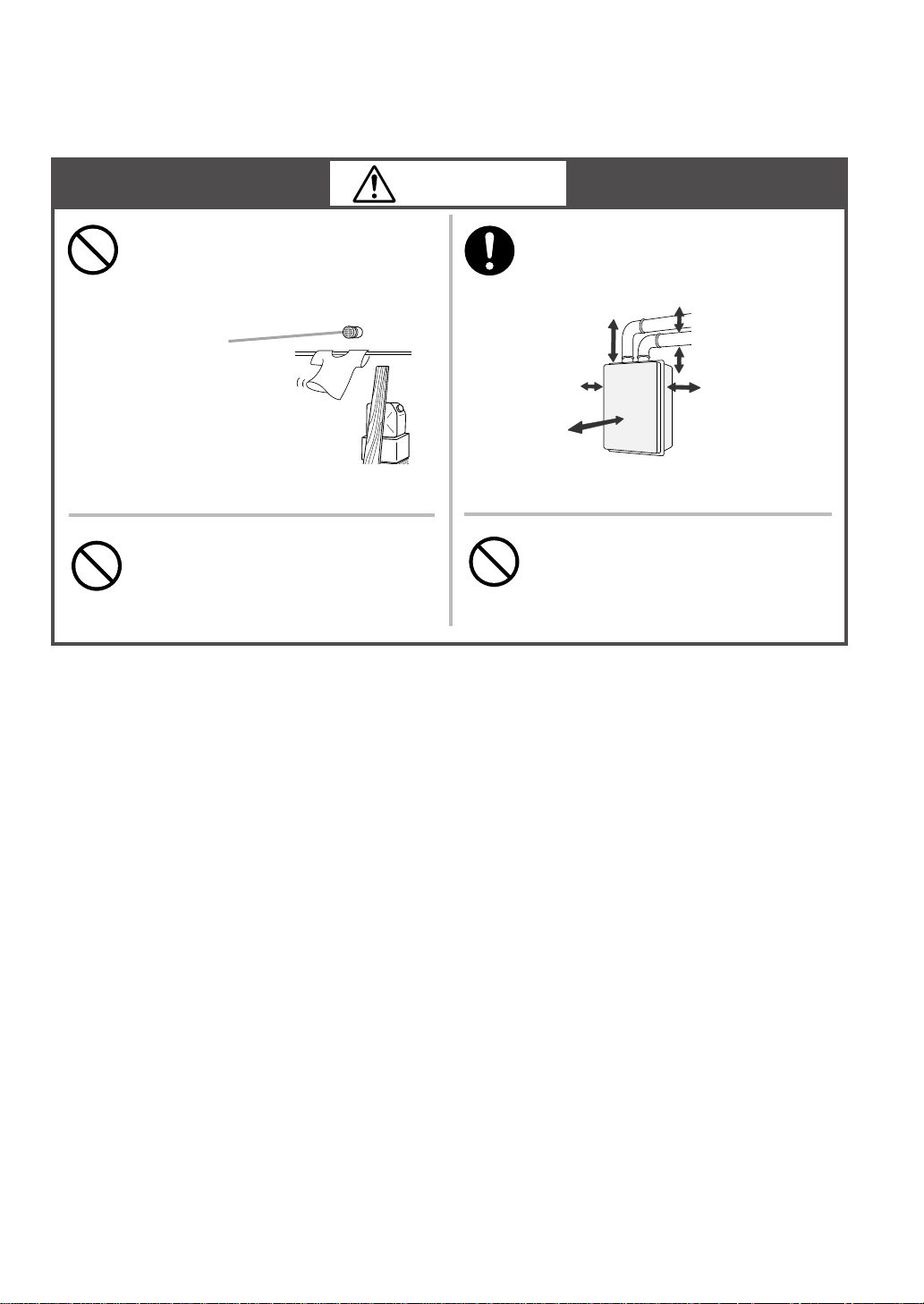

Warning

Do not place combustibles such as

laundry, newspapers, oils etc. near

the heater or the exhaust vent

terminal.

Vent terminal

Do not use combustible chemicals

such as oil, gasoline, benzene etc.

in the vicinity of the heater or the

exhaust vent terminal.

Leave the proper clearance between

the water heater and nearby objects

(trees, timber, boxes with flammable

materials etc.).

Upper:

Min. 50mm (2")

Left side:

Min. 50mm (2")

Front:

Sug. 600mm* (24"*)

Indicates suggested clearances for

*

maintenance.

Do not place or use a spray can

near the heater or the exhaust vent

terminal.

Sug.80mm (3")

from vent pipe*

Right side:

Min. 50mm (2")

5

Important Safety Information-3

Caution

Be sure to electrically ground the

unit.

Do not touch the power cord with

wet hands.

Keep power cord free of dust.

Do not use a broken or modified

power cord. Do not bind, bend or

stretch power cords.

Do not scratch, modify, or subject

them to impact or force.

Do not use the water heater for

other than hot water supply, shower

and bath.

Do not touch the exhaust vent pipe

during or immediately after operation of the water heater.

Do not use hair spray or spray

detergent in the vicinity of the

heater.

If this unit will be installed in a salon or other location where hair

spray or aerosols will be used, locate the unit away from where

these products are used.

Do not install in locations where

excessive dust or debris will be

in the air.

6

Remark

Do not drink water that has been inside the

unit for an extended period of time. Do not

drink the first use of hot water from the unit

in the morning.

Clean the filter on the water inlet as frequently as required by the quality of

your local water.

Keep the area around the unit clean.

If boxes, weeds, cobwebs, cockroaches etc. are in

the vicinity of the unit, damage or fire can result.

Do not install the equipment where the exhaust will blow on walls or windows.

Treat hard, acidic or otherwise impure

supply water with approved methods to

ensure full warranty coverage.

Problems resulting from scale formation

are not covered by the warranty.

Do not disassemble the remote controller.

Do not use benzene, oil or fat detergents to

clean the remote controller.

This may cause deformation.

Do not get the remote controller wet.

Although it is water resistant, too much water can

cause damage.

Do not splash water on the remote controller. Do not expose the remote controller to

steam.

Do not locate the remote controller near stoves or

ovens, this may cause damage or failure.

Preventing damage from freezing ( p.17)

Damage can occur from frozen water within the

device and pipes even in warm environments.

Be sure to read below for appropriate measures.

Repairs for damage caused by freezing are not

covered by the warranty.

Check ignition during use and extinction after use.

This unit is only approved for installation

up to 1300m (4500 ft.) above sea level.

For installations at higher elevations, contact Noritz America for instructions.

Do not use parts other than those specified

for this equipment.

Take necessary measures to prevent freezing of water and leakage of gas when leaving the unit unused for long periods of time.

( p.18)

If it is snowing, check the exhaust gas vent

and exhaust vent terminal for blockage.

7

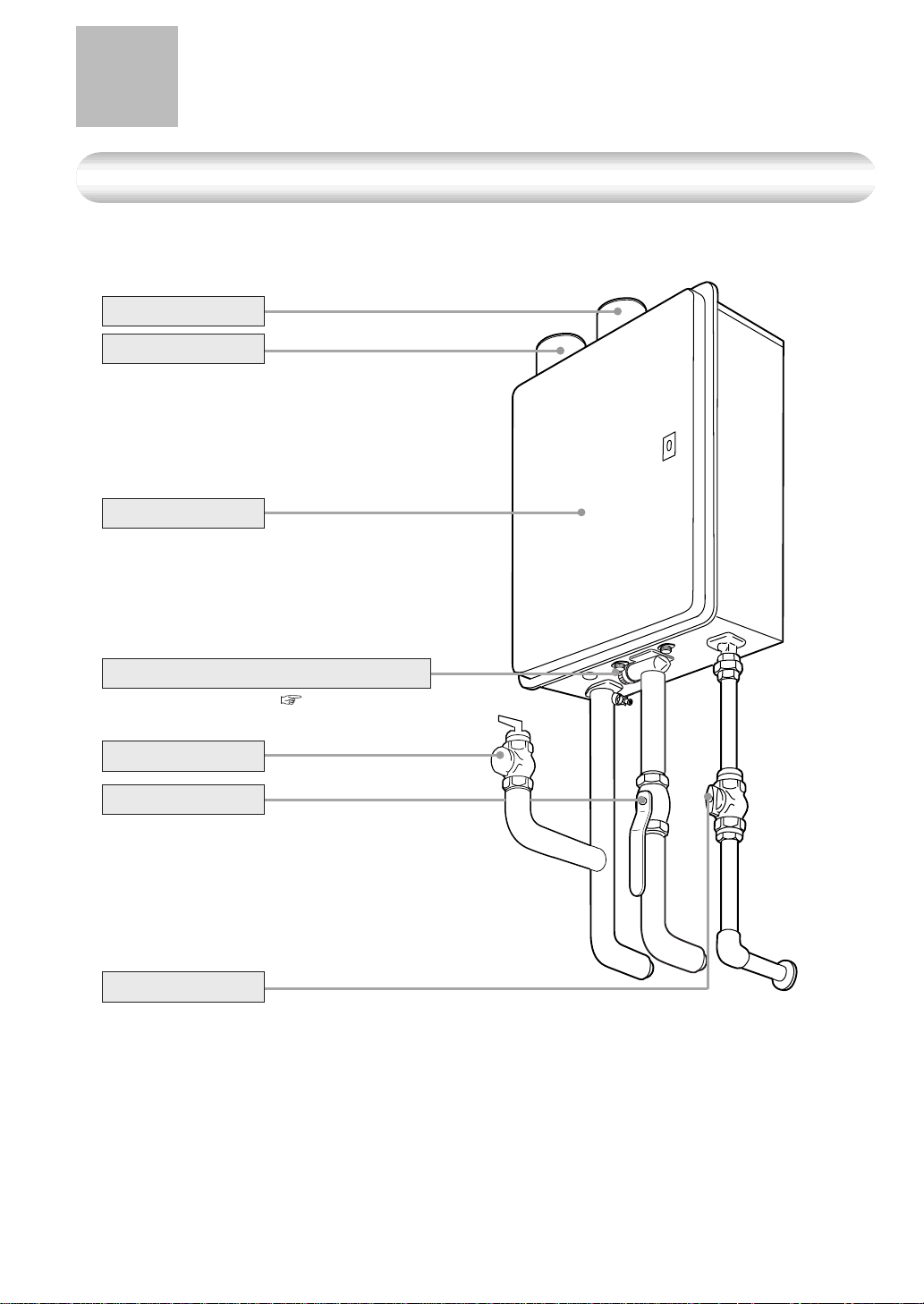

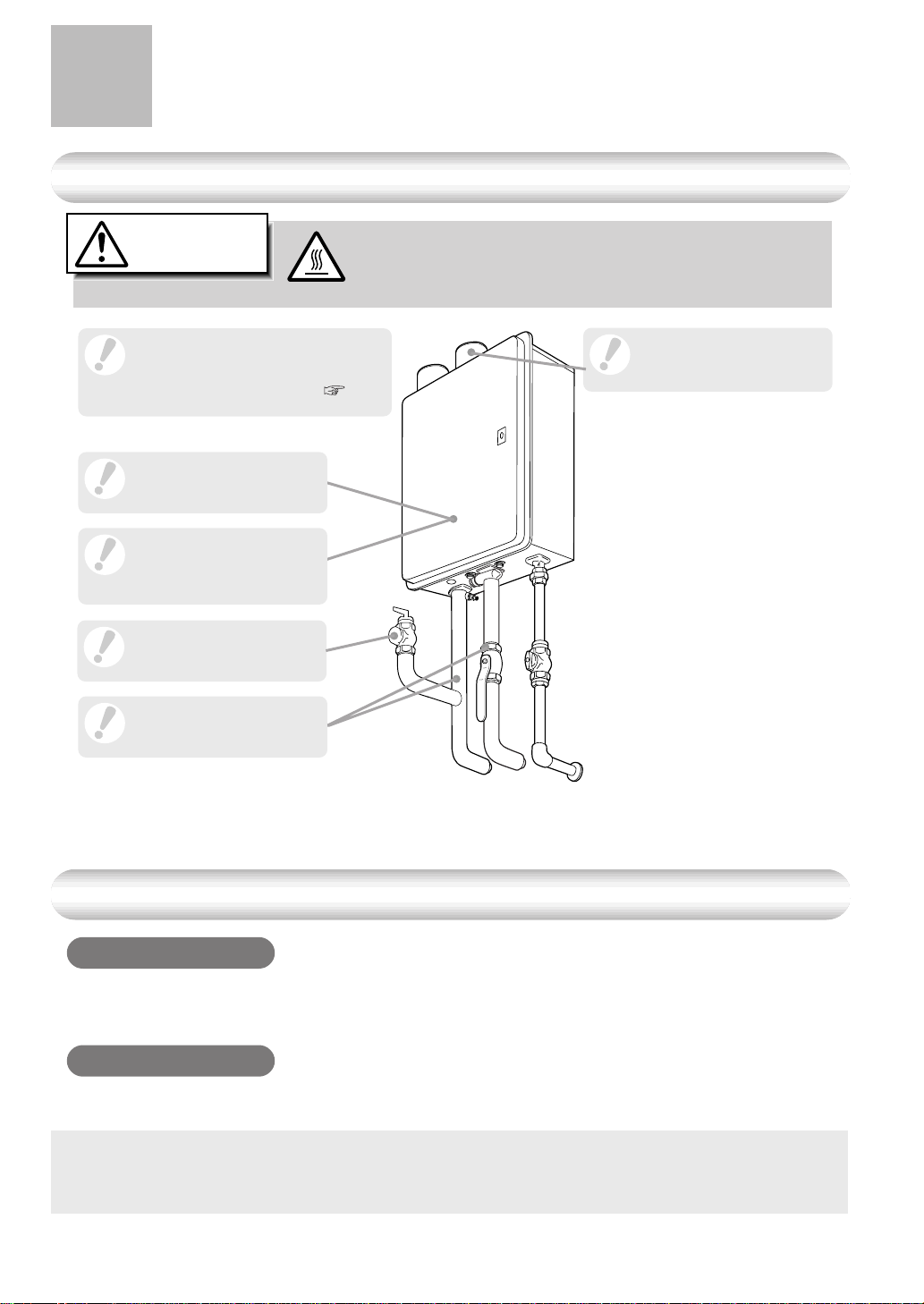

General Parts

Main Unit

Indoor Wall Mounted, Power Vented Model

Flue Collar

Intake pipe

Front Cover

Water Drain Valve (with Water Filter)

(Inside Water Inlet) ( p.20)

Pressure Relief Valve

Water Supply Valve

Gas Supply Valve

* The above illustration shows an example of installation.

The exact installation configuration may be slightly different.

8

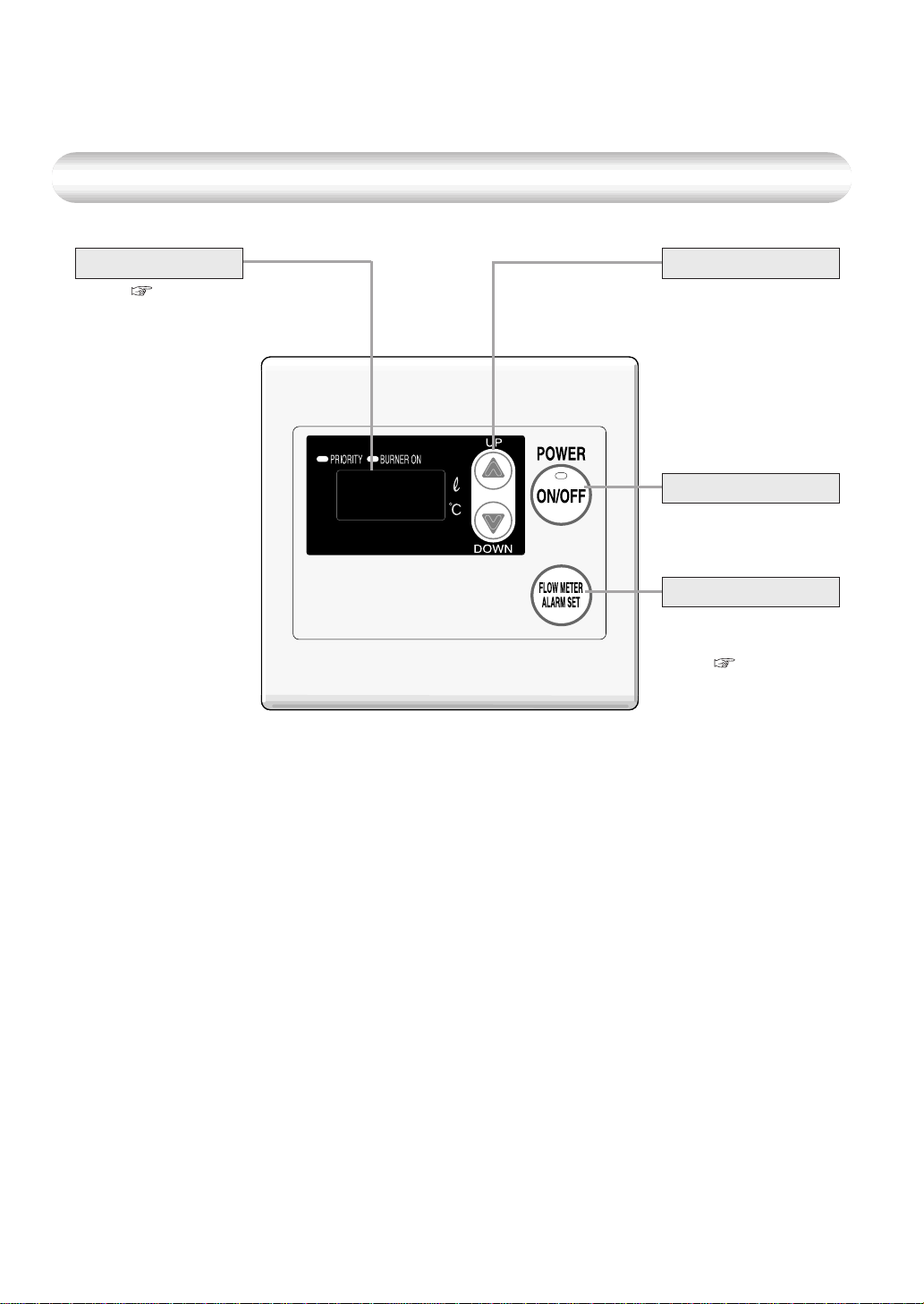

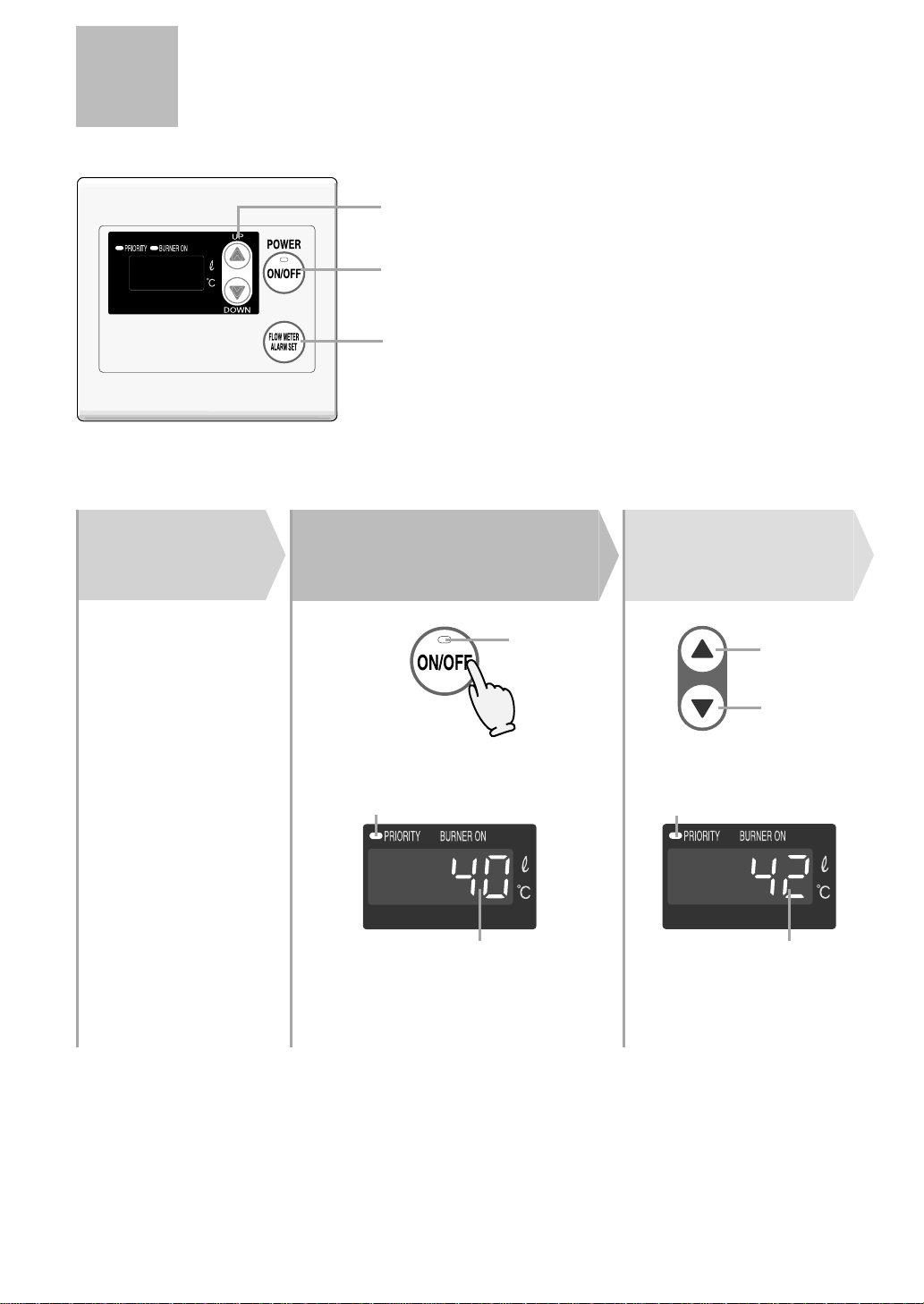

Remote Controller (RC-7646M-2)

Display

( next page)

Setting Buttons

For setting the hot

water temperature,

the flow meter alarm,

and other settings.

Power On/Off Button

For turning the

heater on and off.

Flow Meter Alarm Set Button

For setting the flow

meter alarm.

( p.14 and 15)

* Before use, remove the protective sheet from the remote controller surface.

*

The unit has been shipped from the factory with the remote control set at 40°C (104°F).

9

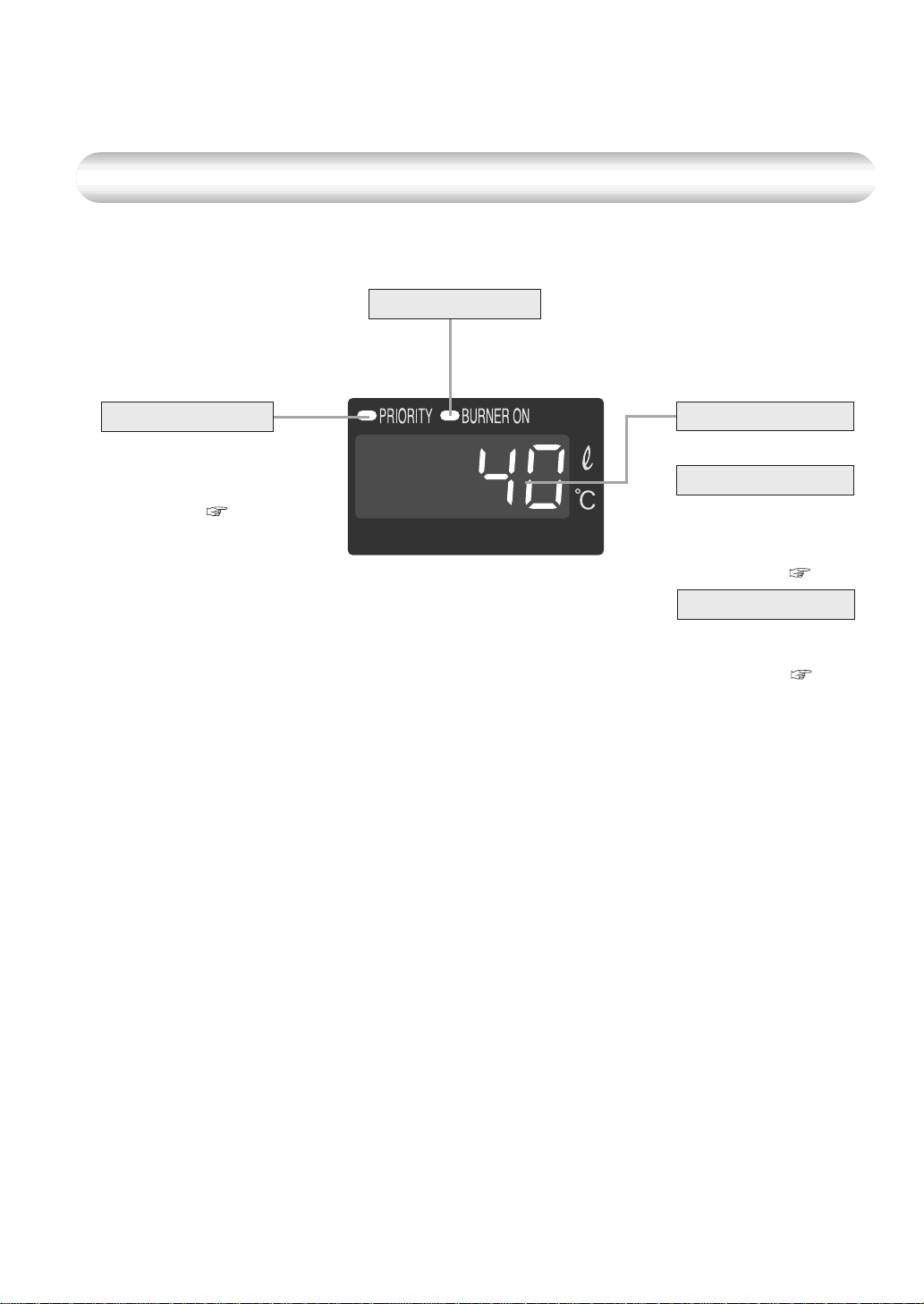

Display

The illustration below shows the remote controller display. What is actually displayed

depends on how the water heater is set.

Burner On Indicator

Priority Indicator

When this indicator

is lit, the hot water

temperature can be

set. ( p.13)

Temperature Setting

(Ex.: 40°C (104°F))

Flow Meter Setting

The display will flash

after hitting the flow

meter alarm set button.

( p.15)

Error Code

A number will flash if

a failure occurs.

( p.24)

10

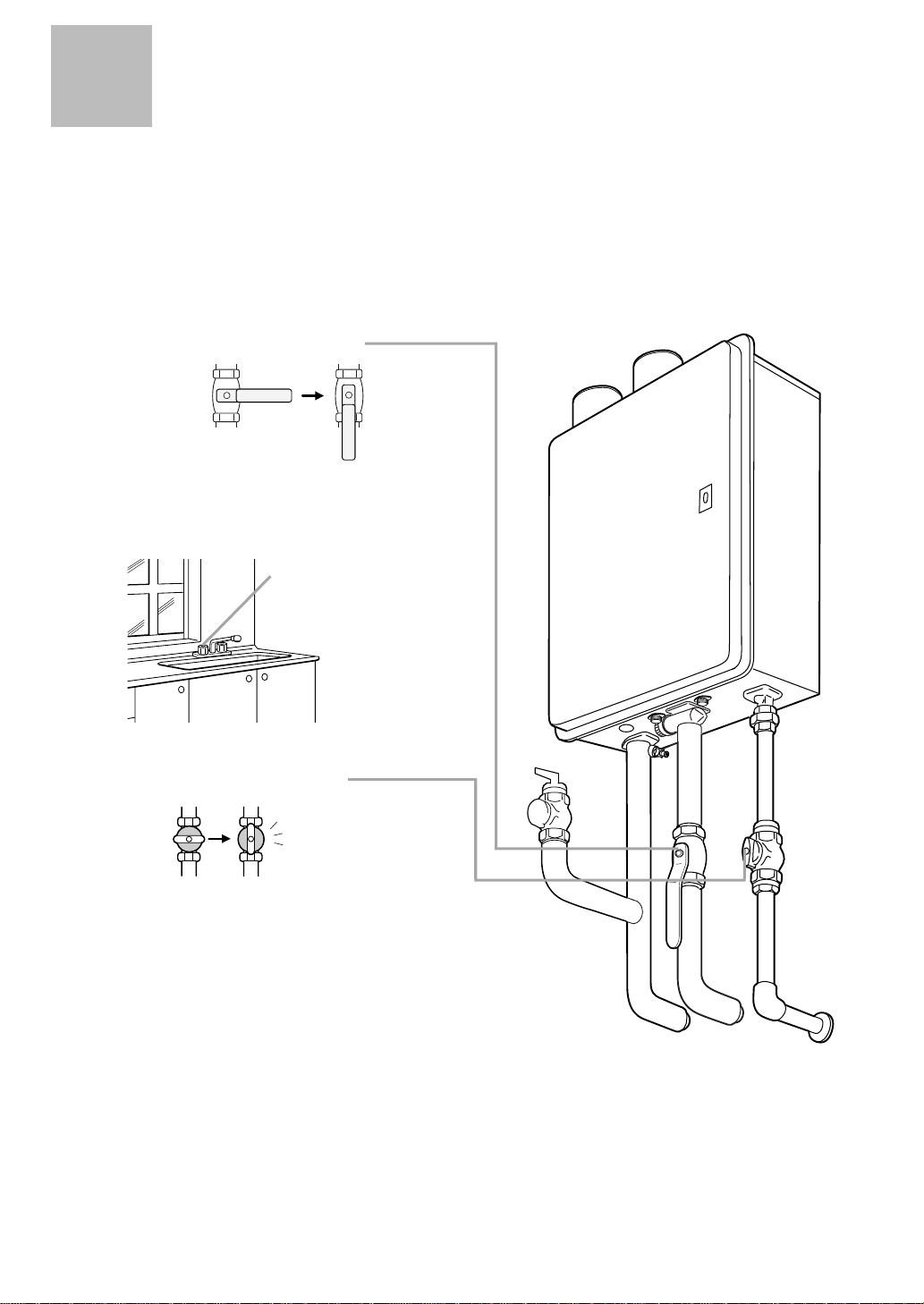

Initial Operation

Before the first use of your water heater, make the following preparations.

Follow steps 1 through 4.

Open the water supply valve.

1

CLOSED

Open a hot water fixture to confirm that

water is available, and then close the

2

fixture again.

Hot water fixture

OPEN

Open the gas supply valve.

3

Turn on the power.

4

11

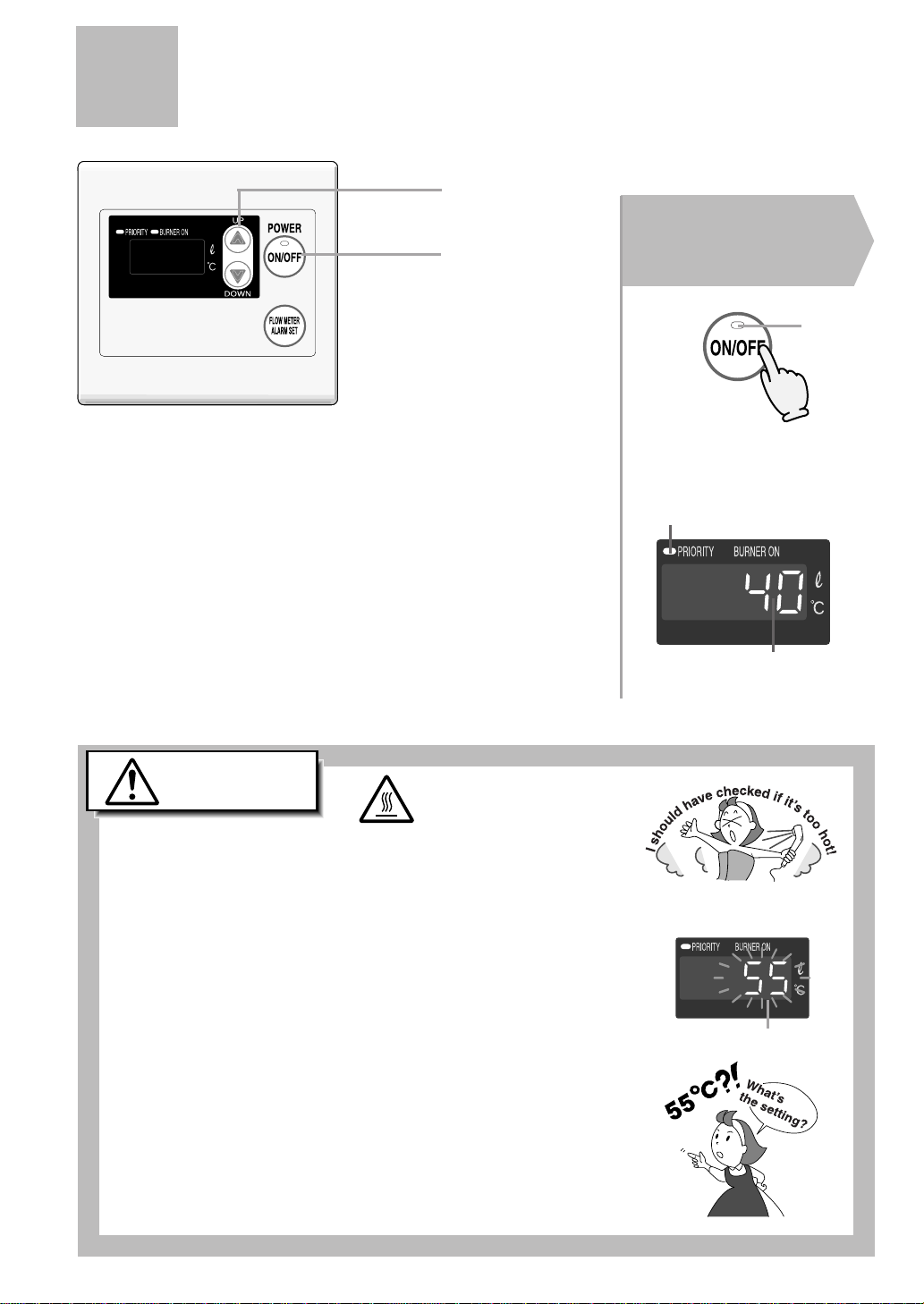

How to Use

Setting and Using the Water Heater

(Starting with the Power Off)

2

Press the Power

On/Off Button.

1

1

The temperature will be

displayed on the remote

control thermostat.

On

On

Caution

To prevent scalding:

High Temperature

Temperatures above 55°C (131°F) can scald.

•Check the water temperature by hand before bathing or

showering.

• When setting the unit to 55°C (131°F) or higher,

thetemperature display will flash for 10 seconds as a

high temperature warning.

• Take caution when using the unit again after setting to

55°C (131°F) or higher. Always check the set

temperature before use.

• Do not allow anyone to change the water temperature

while hot water is running.

Previous set

temperature

(Ex.: 40°C (104°F))

Remote Controller Display

Flashes for 10 sec

12

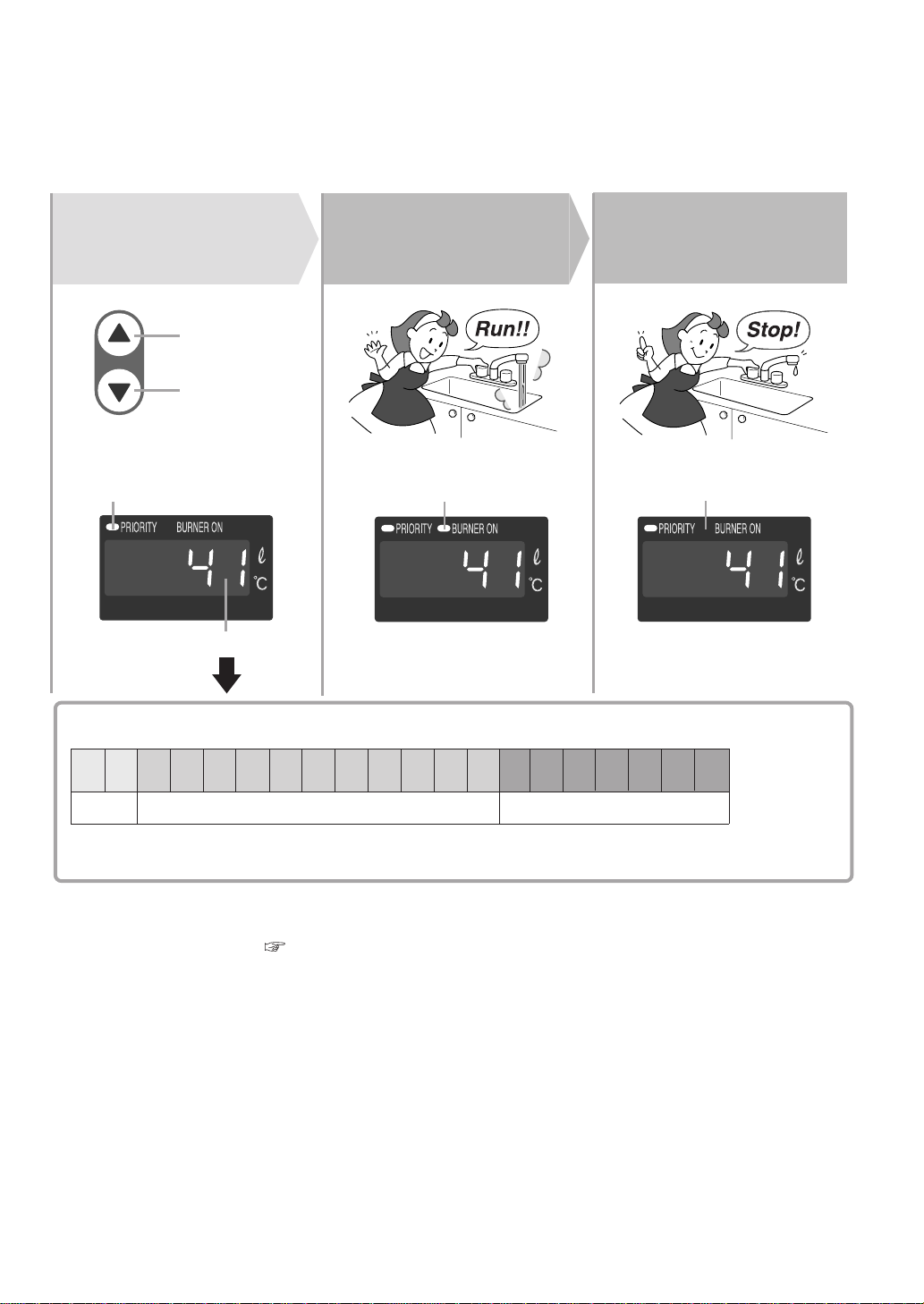

Set temperature.

2

Always check the

temperature setting

(

before use.

Hot

Cold

)

Turn on hot

water.

3

Turn off the hot

water.

4

Check the indicator lights.

Water temperature

The temperature settings below are examples. The temperature setting

(°C (°F)

37 38 39 40 41 42 43 44 45 46 47 48 50 55 60 65 70 75 80 83

(99) (100) (102) (104) (106) (108) (109) (111) (113) (115) (117) (118) (122) (131) (140) (149) (158) (167) (176) (181)

Faire la

vaisselle, etc.

*Initial factory setting is 40°C (104°F).

* For most residential applications, the recommended setting temperature is 50°C (122°F) or less.

For applications that occasionally require a higher temperature setting, locate the remote controller

in a convenient location ( p.61).

* Consult local codes for minimum operating temperatures.

:

necessary depends on the usage, the length of piping and the time of year.

Douche, alimentation en eau chaude, etc.

On

Off

)

Température élevée

If fixtures incorporate mixing valves,

set the temperature higher than usual.

13

How to Use

Flow Meter Alarm

2,3

1

3

(Starting with the power off)

Preparation

1. Plug the bath drain.

Press the Power

On/Off Button

1

On

The temperature will be displayed

on the remote control thermostat.

On

Previous set temperature

(example:40°C (104°F))

Set temperature.

Always check

2

temperature setting

(

before use.

Hot

Cold

Check the indicator lights.

Water temperature

)

14

An alarm will sound for ten

seconds when the flow

reaches the set level.

The water will continue to run unless it is

manually turned off.

To set the flow meter alarm:

Water Temperature

The temperatures settings below are only examples. The

:

(°C (°F)

37 38 39 40 41 42 43 44 45 46 47 48

(99) (100) (102) (104) (106) (108) (109) (111) (113) (115) (117) (118)

temperature setting necessary will depend on the usage,

the length of piping and the time of year.

Warmer HotWarm

* Initial factory setting: 40°C (104°F)

)

Adjust flow meter

3

alarm setting.

Press the flow meter alarm set button

(the setting will flash on the display)

and adjust with the setting buttons.

Increase

Decrease

Choose the flow meter alarm setting from the

following options: 38 - 260 L (10 - 60 gallons) (In

20 L (5 gallons), 300 L (80 gallons), 340 L (90

gallons), 380 L (100 gallons), 990 L (262 gallons).)

The alarm will not sound if it

Note:

is set for 990L(262gallons).

Turn on hot

water.

4

On

Turn off the hot

water when the

5

alarm sounds.

The alarm will sound when

the set level has been

reached. Stop the water.

The alarm will not

Note:

sound if it is set for

990L (262gallons).

Off

Flow meter setting will be flashing

(ex. 180L (48gallons))

* The level can only be adjusted

while the indicator is flashing.

* After ten seconds, the remote

will again display the temperature.

If the flow meter alarm is being used to indicate when a tub is full:

• If any hot water is being used besides what is going into the tub, the alarm will sound before

the tub is full.

• If there was water in the tub before the fill began, or if the water is not shut off manually when

the alarm sounds, the tub may overflow.

• If there was water in the tub before the fill began, the temperature in the tub after it is full may

be different from the temperature setting.

15

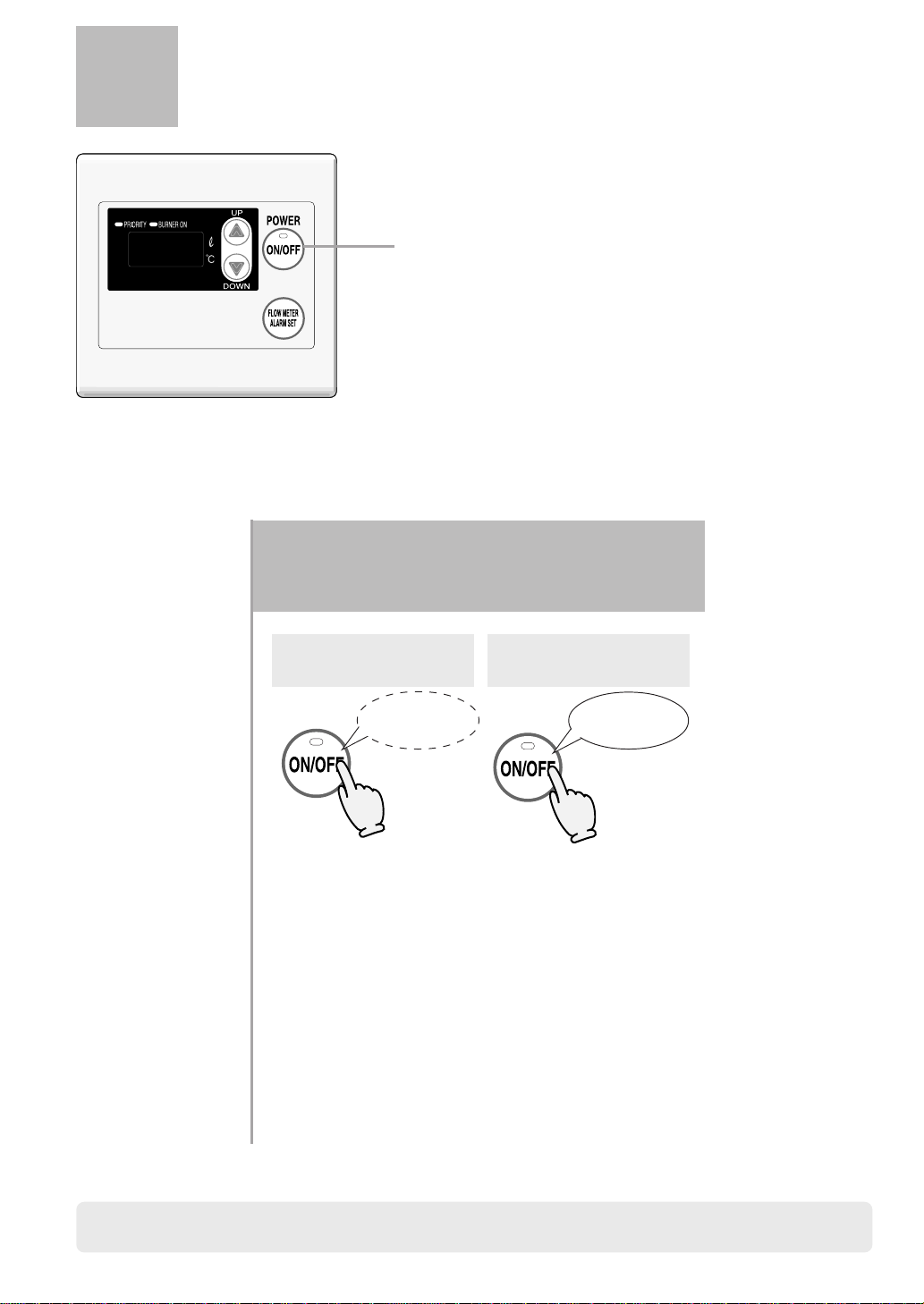

How to Use

Muting the Remote Controller

The remote controller will emit a sound

when any button is pushed. This sound

can be muted if it is desired.

* Initial factory setting is with sound.

1

With the remote controller

off, hold the Power On/Off

1

Button for five seconds.

Muted

No sound

after 5 sec.

Sound

Tone sounds

after 5 sec.

16

The flow meter alarm cannot be muted.

Preventing Damage from Freezing-1

Remarks

* Damage can occur from frozen water within the device and pipes even

in warm environments. Be sure to read below for appropriate measures.

* Repairs for damage caused by freezing are not covered by the warranty.

Freezing is prevented within the device automatically by the freeze-prevention heater

Freezing cannot be prevented when the power is disconnected. Do not remove the power plug

from the wall outlet.

(Freezing will be prevented regardless of whether the operation switch is ON or OFF.)

* The freeze prevention heaters will not prevent the plumbing external to the unit from freezing.

Protect this plumbing with insulation, heat tape or electric heaters, solenoids, or pipe covers.

If there remains a freezing danger, contact the nearest Noritz agent.

Take the measures below for extremely cold temperatures*.

*(outside temperature including wind chill factor less than -15°C (5°F))

This method can protect not only to the heater, but also to the water supply,

water piping and mixing valves.

1. Turn the unit on with the Power Button on the Remote Controller.

2. Close the gas supply valve.

3. Open a hot water fixture and let it run for approx. 1 minute, and

then check that the number 11 is flashing on the remote controller

display.

* If multiple units are being used, drain one minute for each unit.

* It is possible that a different number may be displayed on the

remote controller, but as long as it is flashing, you may continue.

4. Partially close the hot water fixture, but keep a small amount of hot

water running. (400cc (0.1gallon)/minute or about 4mm (0.2") thick.)

* If there is a mixing valve, set it to the highest level.

* When linking multiple units, discharge water equivalent to

400cc (0.1 gallon)/minute per unit.

5. The flow may become unstable from time to time. Check the flow

30 minutes later.

Hot Water Fixture

4mm (0.2") thick

* Remember to set mixing valves and fixtures to their original levels before using the unit again

to prevent scalding.

* If there is still a chance that the unit will freeze, drain the unit as on the next page.

If water will not flow because it is frozen:

1. Close the gas and water valves.

2. Turn off the power button.

3. Open the water supply valve from time to time to check whether water is running.

4. When the water is flowing again, check for water leaks from the equipment and piping

before using.

If the heater or the piping is frozen, do not use the heater or it may get damaged.

17

Preventing Damage from Freezing-2

If the water heater will not be used for a long period of time,

Drain the water.

Drain the water as follows:

Caution

High Temperature

Drain water into a bucket to prevent water damage.

1. Close the gas valve.

2. (1) Turn the power on.

(2) Turn and leave open the hot water fixture for more than 1 minute and close.

*If multiple units are being used, drain one minute for each unit.

*An 11 Error Code may appear on the remote control.

This is not a malfunction of the unit. Do not turn Power ON/OFF Button OFF.

3. Close the water supply valve, disconnect

the electrical power supplied to the unit.

Do not touch with wet hands.

4. Fully open all hot water fixtures.

To avoid burns, wait until the equipment cools down

before draining the water. The appliance will remain hot

after it is turned off.

Fixture

Fixture

18

5. Open all drain plugs and drain the water out

of the unit.

6. When the water is completely drained, replace all drain

plugs and close the hot water fixtures.

Turning the Unit Back On

1. Check that all drain plugs are inserted.

2. Check that all hot water fixtures are closed.

3. Follow the procedure on p.11 “Initial operation”, steps 1 through 4.

Drain Plugs

Regular Maintenance-1

Periodic Inspection

Caution

High Temperature

For laundry, newspaper, timber,

Check

oil, spray cans and other

combustible materials. ( p.5)

For abnormal sounds

Check

during operation.

For abnormalities in

Check

external appearance,

discoloration or flaws.

For proper operation of

Check

pressure relief valve.

For water leaks from the

Check

equipment and piping.

To avoid burns, wait until the equipment cools down

before draining the water. The appliance will remain

hot after it is turned off.

For dust and soot in

Check

the flue terminal.

Periodic Maintenance

Equipment

Wipe the outside surface with a wet cloth, then dry the surface. Use a neutral detergent to

clean any stains.

Remote Controller

Wipe the surface with a wet cloth.

• Do not use benzene, oil or fatty detergents to clean the remote controller;

deformation may occur.

• The remote controller is water resistant but not water proof. Keep it as dry as possible.

19

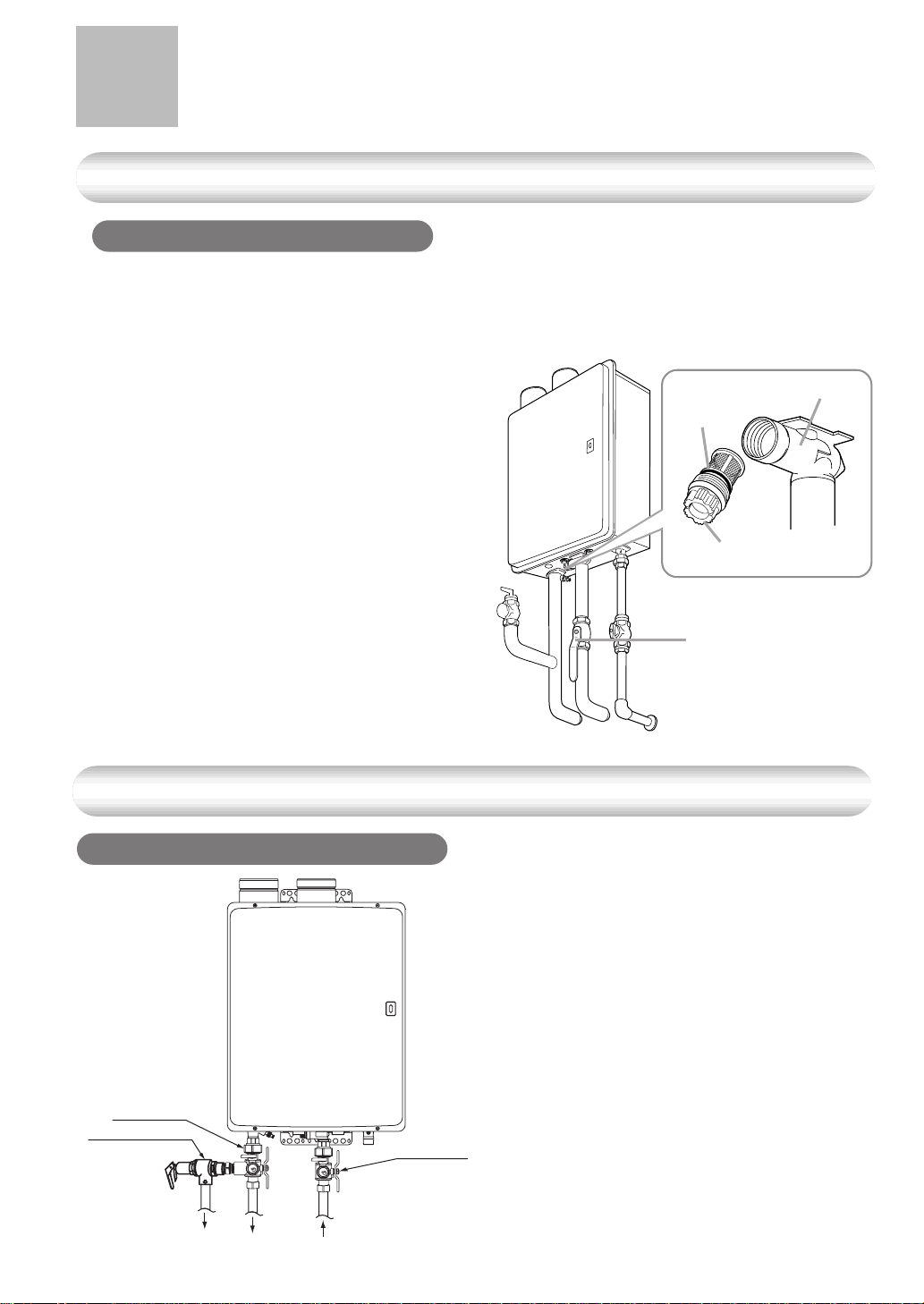

Regular Maintenance-2

Periodic Maintenance

Water Drain Valve (with Water Filter)

If the water drain valve (with water filter) is covered with debris, the hot water may not run

smoothly, or the unit may put out cold water. Check and clean the filter as explained below.

* To avoid burns, wait until the equipment cools down before draining the water.

The appliance will remain hot after it is turned off.

* Water will be discharged from the drain plug.

Place a container, etc. to receive the discharged

water.

1. Close the water supply valve.

2. Open all hot water fixtures.

3. Remove the inlet and outlet drain plugs (about

1L (0.3gallons) will drain out)

4. Take the water drain valve (with water filter) out

of the inlet. (See illustration to right).

5. Clean the water drain valve (with water filter) with

a brush under running water.

6. Replace the water drain valve (with water filter).

(Take care not to lose the packing.)

7. Close all hot water fixtures.

8. Open the water supply valve and check that

water does not leak from the drain plugs or water

drain valve (with water filter).

Optional Maintenance

Water Heater Service Valves (IK-WV-2)

Inlet

Packing

Drain Plug

(with filter)

Water Supply

Valve

20

Hot Water

Service Valve

Pressure Relief Valve

Drain

Water Outlet

Water Intlet

Cold Water

Service Valve

* Isolator valve kits may be purchased as an

accessory from Noritz (Part #IK-WV-2).

They allow for one man full diagnostic testing

and easy flushing of the system.

* The kit includes two full port isolation valves

and a pressure relief valve for the hot side.

Contact Noritz for more information.

Troubleshooting-1

Initial Operation

Unit does not attempt to ignite

when water is running.

Unit attempts to ignite but fails

Hot water is not available

when a fixture is opened.

• Is water running?

• Check for reversed plumbing or crossed pipes.

•Check the water drain valve filter. ( p.20 )

• Reset unit and try again. There may be air in the gas line.

• Have a professional check the gas supply pressure.

Temperature

•Are the gas and water supply valves fully open?

• Is the water supply cut off?

•Is the hot water fixture sufficiently open?

•

Is the gas being cut off by the gas meter ?

(Can other gas devices such as stoves be used?)

•(For LP) Is there enough gas in the tank?

(Can other gas devices such as stoves be used?)

• Is the water drain valve filter clogged? ( p.20)

• Is the power button turned on?

No water is available when

a fixture is opened.

The hot water is not the correct

temperature.

Water takes time to become hot

when turning the hot water fixture.

The water is too hot.

• Is the water supply cut off?

• Is the heater frozen?

•Is the hot water fixture sufficiently open?

• Have you allowed enough time for the cold water in the

pipes to drain out?

•Are the gas and water supply valves fully open?

• Is the water temperature setting appropriate?

( p.12 and p.13)

• If the water supply temperature is high, it is possible

for the temperature to be higher than the temperature

set on the remote controller.

• If only a small amount of hot water is demanded, it is

possible for the temperature to be higher than the

temperature set on the remote controller.

• If the supply water goes through a solar pre-heating

system, it is possible for the temperature to be higher

than the temperature set on the remote controller.

21

Troubleshooting-2

Temperature

The water is not hot enough.

The water is cold when only a

single fixture is open.

Fluctuations in hot water

temperatures.

The amount of hot water at a

certain fixture is not constant.

•Are the gas and water supply valves fully open?

• Is the water temperature setting appropriate?

• If the amount of hot water required is very high, it is

possible for the temperature to be lower than the temp erature set on the remote controller.

Decrease the amount of water passing through the unit

and the temperature should stabilize.

• The unit will not heat the water if the flow rate is less than

2.7L (0.7gallons) per minute.

Open the fixture more or open other fixtures so that a greater

flow passes through the unit, and the unit should begin

heating again.

• Set water temperature at 48°C (118°F) to 50°C (122°F).

This will allow you to use a higher flow of hot water thus

meeting the minimum flow requirement of 2.7L/min. (0.7gpm).

• Clean the water filter of any debris ( p. 20)

Amount of Hot W ater

•

When hot water is demanded at other fixtures, the amount

available may be reduced. The maximum flow available from

this unit is 32L/min. (8.4GPM) at a 7°C (45°F) temp. rise.

• Pressure fluctuations and other plumbing conditions can

cause the temperature and pressure at a fixture to be

unstable, but it should stabilize after a short time.

• There are some types of hot water taps that discharge large

volumes of hot water initially, but stabilize after time.

•To keep the temperature stable, the heater limits the

amount of water that can flow through it to a small

amount initially, but the amount increases over time.

( p.12 and p.13)

22

The amount of hot water in the tub

is less/more than the set amount.

The flow meter alarm does not

sound even when filled to the set

amount.

Amount of hot water available

has decreased over time.

•When hot water is used for other fixtures while filling the

bath tub, the tub will not fill as much.

• If there is water in the tub already, or when filling is stopped

and resumed, the tub will fill more.

•

The flow meter alarm is set to sound when hot water

is continuously discharged for the set volume of water. If mixing

valves are used, or if cold water is mixed with hot water at the

fixture, the tub will fill more than the setting of the flow meter

alarm.

• Is the water drain valve filter clogged? ( p.20)

Remote Controller

The light on the power button

does not come on.

The water temperature changes

after a power failure or when the

power is disconnected.

The fan can be heard after

operation is stopped.

A motor can be heard when turning

the unit ON or OFF, when opening

or closing a fixture, or after the unit

has been running for a while.

• Has there been a power failure?

•Is the power connected properly?

• The temperature setting and the flow meter alarm setting

may both need to be reset after a power outage.

Sounds

• These noises indicate the proper operation of devices

which are designed to let the unit reignite more quickly,

and ensure the water temperature is stable.

Other

The heater stops burning during

operation.

exhaust vent on a cold day.

The hot water is turbid.

Water leaks from the drain plugs

on the outlet.

• Are the gas and water supply valves fully open?

• Is the water supply cut off?

• Is the hot water fixture sufficiently open?

• Is the gas being cut off by the gas meter?

(Can other gas devices such as stoves be used?)

• (For LP) Is there enough gas in the tank?

(Can other gas devices such as stoves be used?)

• This is normal. The white smoke is actually steam.White smoke comes out of the

• This is harmless. Small air bubbles appear as the

water is heated and depressurized rapidly to

atmospheric pressure.

•When the unit is under very high pressure, water will leak

from the drain plugs as a safety so that the unit is not

damaged by the high pressure.

23

Troubleshooting-3

Other

The water appears blue or

The bath tub/wash-basin has turned

blue

åÃè·ï\é¶Ç Ç®í≤Ç◊Ç≠ÇæÇ≥Ç¢ åÃè·ï\é¶Ç Ç®í≤Ç◊Ç≠ÇæÇ≥Ç¢

• This can be caused by a reaction of copper ions in the

water with fat particles (furring). This is not a health risk,

and the discloration of the tub or basin can be cleaned.

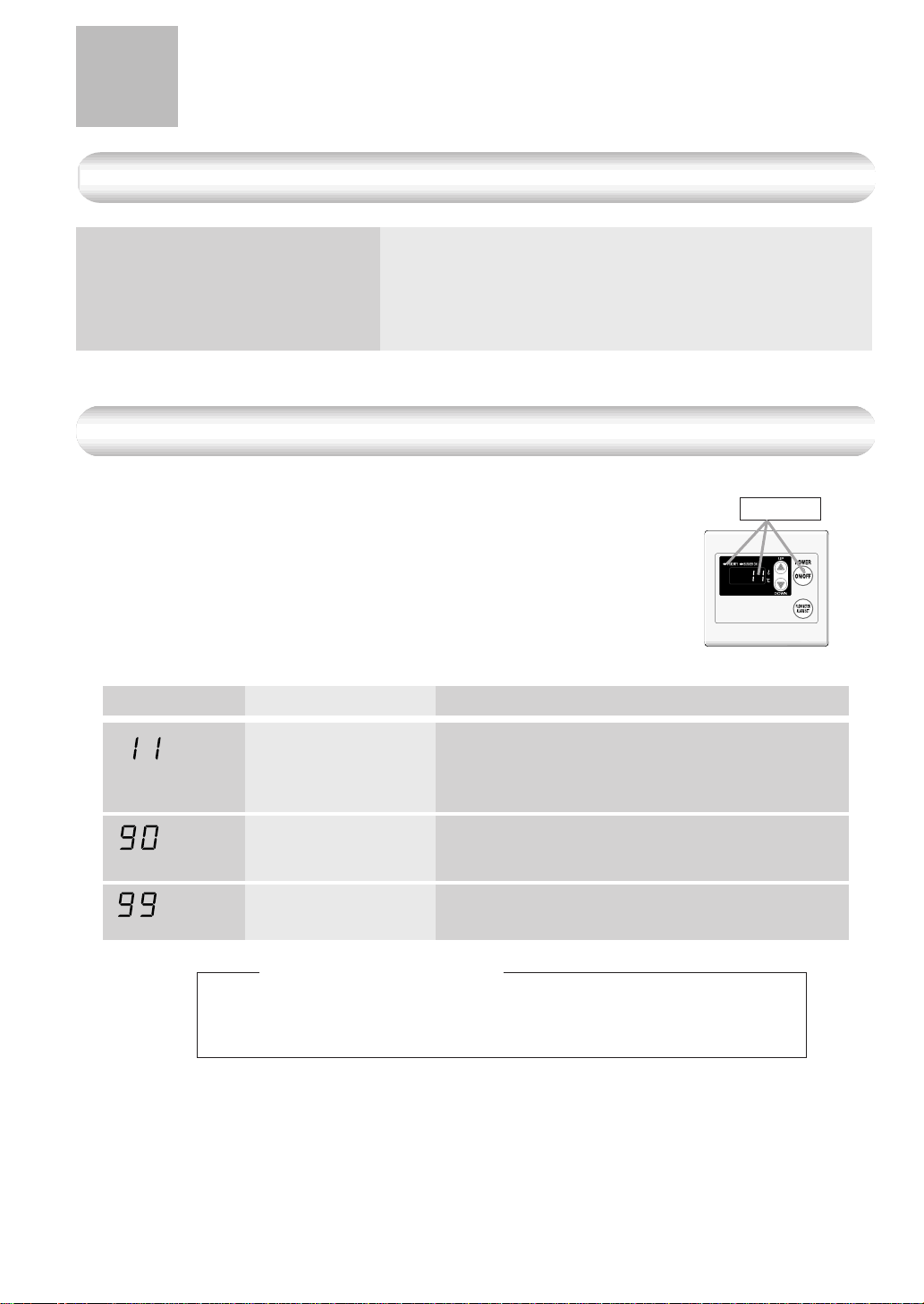

Check for an Error Code

If there is a problem with the unit, a numerical error code will flash on the remote controller.

If this occurs, take appropriate measures as listed below.

When an error code appears, the display and the operation light will flash

together.

Error Code Cause Action

Ignition error

Check whether the gas valve is open. Press the power

button to turn the unit off, open a hot water fixture,

and turn the unit back on. If the flashing number

doesn't return the problem is solved.

Flashing

Remote Controller

24

Abnormal combustion,

low gas supply pressure

Contact our sales agent if:

• Any other error code appears.

• An error code is indicated again after the above actions were followed.

• There are any other questions.

Have a professional check the gas supply pressure.

Contact the nearest Noritz agent.

Contact the nearest Noritz agent.Abnormal combustion

Follow-up Service

Requesting Service

First follow the instructions in the troubleshooting section (p.21 to p.24).

If the error is not corrected, contact our sales agent.

We will need to know:

The Model ................ (check the rating plate)

*See p.4 for the location of the label

Date of purchase ..... (see the warranty)

Details of problem... (flashing error codes,

etc., in as much detail as possible)

Your name, address, and telephone number

Desired date of visit

*A request for service may be rejected if the water heater is installed

in a location where working on the unit may be dangerous. Contact a

plumber.

Warranty

A warranty registration card is included separately.

Be sure that the plumber, date of purchase and other necessary items are filled in.

Read the content carefully, and keep the warranty card in a safe place.

For repairs after the warranty period, there will be a charge on any service, and service will only

be performed if the unit is deemed repairable.

Period of Time for Stocking Repair Parts

Noritz will stock repair and maintenance parts for this unit for a minimum of seven years after

production has ceased.

Reinstallation

If you want to reinstall the appliance at a different location, confirm that the gas and power

supply indicated on the rating plate are available at the new location. If you are not sure,

consult the local utility company.

If you move to a region that uses a different type of gas, conversion and adjustment of the

appliance will be necessary. This work must be performed by Noritz and will be charged for

even during the warranty period.

25

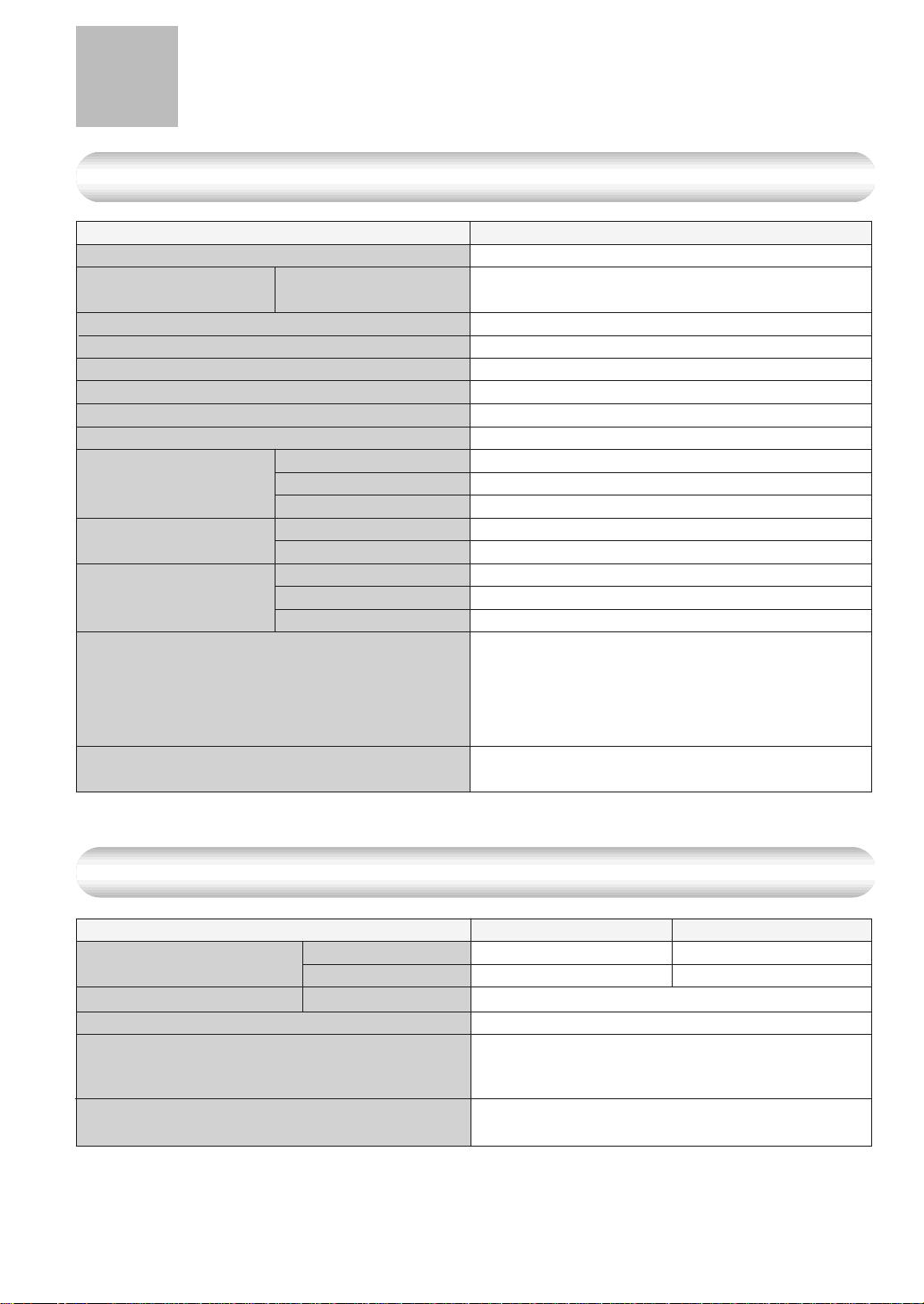

Specifications

Specifications

•Specifications may be changed without prior notice.

• The capacity may differ slightly, depending on the water

pressure, water supply, piping conditions, and water temperature.

Item

Model Name

Type

Ignition

Operating Pressure

Minimum Flow Rate

Dimensions (Height) x (Width) x (Depth)

Weight

Water Holding Capacity

Connection Sizes

Power Supply

Materials

Safety Devices

Accessories

Installation

Air Supply/Exhaust

Water Inlet

Hot Water Outlet

Gas Inlet

Supply

Consumption

Casing

Flue Collar

Heat Exchanger

Specification

N-084M-DV

Indoor Wall Hanging

Direct Vent/Sealed Combustion

Direct Ignition

15-150 PSI

2.7 L/min. (0.7 GPM)

615mm (24.2") x 465mm (18.3") x 239mm (9.4")

63 lbs.

1.1L (0.3Gallon)

3/4"

3/4"

3/4"

120 VAC (60Hz)

NG:86W, LP:92W, Freeze Prevention 135W

Zincified Steel Plate/Polyester Coating

Stainless Steel

Copper Sheeting, Copper Tubing

Flame Rod, Thermal Fuse, Pressure Relief Valve,

Lightning Protection Device (ZNR),

Electric Leakage Prevention Device (GFCI), Overheat

Prevention Device, Freezing Prevention Device,

Fan Rotation Detector

Remote Controller, Remote Controller Cord,

Anchoring Screws

26

Item

Gas

Consumption

Maximum Hot Water Capacity

Capacity Range

Temperature Settings

Default Temperature Options

Performance

Maximum Performance

NG

LP

7°C (45°F) Rise 32L/min. (8.4 Gal./min.)

236,000 btuh

236,000 btuh

2.7-32L/min. (0.7-8.4 Gal./min.)

37-50°C (99-122°F) (In 1°C intervals),

55-80°C (131-176°F) (In 5°C intervals),

83°C (181°C ) (20 Options)

50,55,60,80°C (122,131,140,176°F)

(Original is 50°C (122°F))

Minimum Performance

21,000 btuh

21,000 btuh

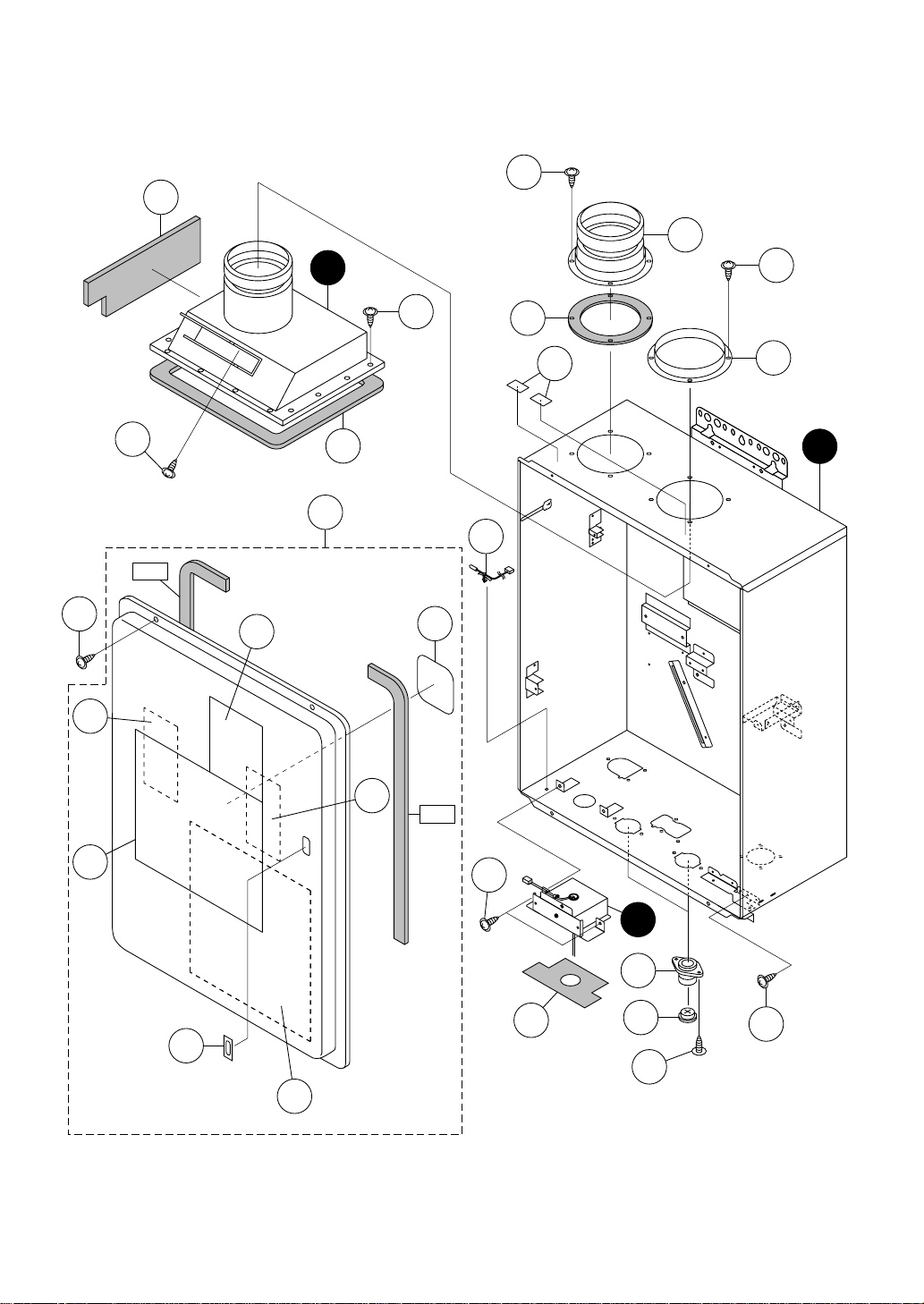

External outfitting N-084M-DV-CA

011

072

016

071

020

070

003

007

010

001

012

072

009

026

015

027

072

017

025

006

004

005

019

003

070

035

034

013

014

070

073

27

External outfitting N-084M-DV-CA

Part Nos. Part Names Order Nos. Q'ty/unit

001 N-084M-DV-CA Front-SET-AS SKA7142 1

003 Front packing L AAP AAPL017 2

004 Lamp seal plate DEC DECK008 1

005 Connection diagram label EJM EJMK001 1

006 Caution label CA ENG EHU EHUK010 1

007 Caution label 2 EAU EAUK004 1

009 Plug insulation sheet CRU CRUK002 1

010 Exhaust box FF CZV CZVF001 1

011 Heat insulator CZV CZVL002 1

012 Exhaust joint packing DHN DHNL003 1

013 Wiring coupling BXK BXKA022 2

014 Grommet CXP CXPA026 2

015 Intake pipe packing EHK EHKL084 1

016 Intake pipe BCU BCUF021 1

017 Intake flange BCU BCUF022 1

019 Caution label CA1 EHU EHUK008 1

020 Caution label CA2 EHU EHUK009 1

025 Case FF EJM EJMA011 1

026 Air themistor-300 BWC BWCH003 1

027 Intake/Exhaust label EJM EJMK031 1

034 Junction box set EHU EHUA008 1

035 Junction box packing EHU EHUL002 1

070 Cross recessed round-head collar N-tapping screw 4X8

071 Cross recessed truss type3 EVERTIGHT tapping screw with PW 4X12

072 Cross recessed round-head collar N-tapping screw 4X10

073 Cross recessed round-head collar type3 EVERTIGHT tapping screw 4X12

28

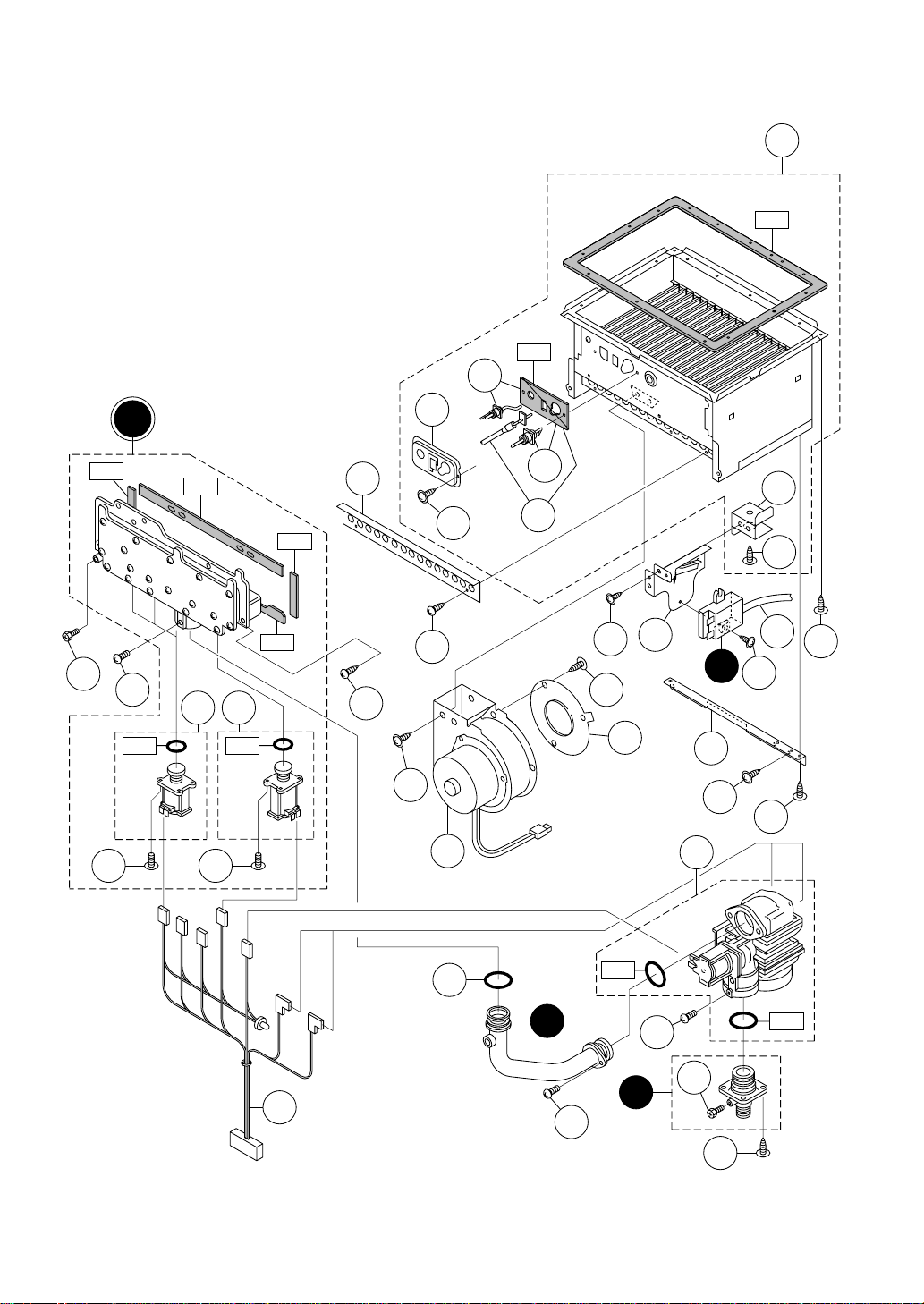

Combustion unit and gas route N-084M-DV-CA

102

101

100

109

171

117

175

110

172

116

175

105

126

117

118

112111

115114

170

070

173

070

119

103

104

070

070

141

132

122

125

070

128

176

131

070

129

173

072

127

121

120

172

121

124

172

123

171

073

29

Combustion unit and gas route N-084M-DV-CA

Part Nos. Part Names Order Nos. Q'ty/unit

100 Combustion tube set EAC SET-V SBP7302 1

101 Flame rod DLK SET-V SBA7506 1

102 Plug fixing plate(for N) DLK DLKL012 1

103 Ignition plug Q(N) SET-V SBA7504 1

104 Burner sensor DLK SET-V SBA7505 1

105 Plug fixing plate(for N) DLK DLKC009 1

109 Suction air joint packing DHN DHNL002 1

110 Manifold set15 EDM SET-AS SBE7875 1<LPG>

Manifold set24 EDM SET-AS SBE7874 1<NGA>

111 Solenoid S16L CRU SET-AS SAQ7346 3

112 Solenoid S24L CRU SET-AS SAQ7406 1

114 O-ring S30 type 1A SAD6433 3

115 O-ring S-38 SAD6372 1

116 Manifold seal packing top CRP CRPL002 1

117 Manifold seal packing side CRP CRPL004 2

118 Manifold seal packing bottom CRP CRPL003 1

119 Fan motor DKE DKEF030 1

120 Manifold pipe set EDM EDME006 1

121 O-ring P25.5 SAB1512 2

122 Gas mech S24DQ CRP SET-V SAQ7708 1

123 O-ring JASO 2028A 8590109 1

124 Gas fitting 20A SET EJH EJHE001 1

125 Mounting plate for burner case DLT DLTC001 1

126 Main damper 11 CRP CRPC052 1

127 Conduit R10 EDM EDMJ006 1

128 Igniter CRP CRPJ002 1

129 High-voltage cord 470 SAC1229 1

131 Mounting plate for igniter EAC EACC011 1

132 Mounting plate for igniter DTJ DTJA015 1

141 Bell-mouse 44 CRU CRUC045 1

30

170 Cross recessed round-head type3 EVERTIGHT tapping screw 5X16

171 Cross recessed hexagon head machine screw M4X8

172 Cross recessed round-head machine screw M4X8

173 Cross recessed round-head N-tapping screw 4X8

175 Cross recessed round-head SPAKmachine screw with guide M4X12

176 Cross recessed round-head collar N-tapping screw 4X12

Loading...

Loading...