Norgren Roundline Plus Stainless Steel Body Actuators User Manual

Roundline Plus

Stainless Steel Body Actuators

5/16" to 3" bore

Single and Double acting actuators

Full range of bore sizes

ACTUATORS

All essential models

Optional Ecology seal

Technical data

Medium:

Filtered, lubricated or nonlubricated, compressed air

Maximum Operating

Pressure:

250 psig (17.2 bar)

Temperature Range*:

Standard Nitrile Seals:

-20° to 200°F (-29° to 93°C)

Viton/High temp Seals:

-20° to 400°F (-29° to 205°C)

*With dew point of supply air less than air

temperature below 35°F (2°C)

Lubrication:

All Roundline Plus cylinders are

pre-lubricated during assembly

with a Teflon

®

based grease for

non-lube service and long life.

Materials

Cylinder Body:

304 Stainless Steel

Head and Cap:

Aluminum Alloy

Piston Rod:

Stainless steel in double rod

cylinders, and 5/16", 7/16", and

9/16" bores. Chrome plated

steel in all other bore sizes

Rod Bearing: Oil Impregnated

Sintered Bronze

Piston: Aluminum Alloy or

stainless steel

Rod & Piston Seals: Nitrile

Pivot Bracket, Rod Clevis, Foot

Bracket, Mounting Nut: Bright Zinc

Plated Carbon Steel

Options selector

Series

Roundline Plus RP

Roundline Plus with

Ecology seals* *ERP

Bore Size

5/16" 031

7/16" 043

9/16" 056

3/4" (E) 075

7/8" 087

1-1/16" (E) 106

1-1/4" (E) 125

1-1/2" (E) 150

1-3/4" 175

2" (E) 200

2-1/2" (E) 250

3" (E) 300

Available with Ecology Seals

E -

Stroke

Increments of 1/16" up to

a maximum. See table

Mounting Options

Single Acting Nose SAN

Single Acting Pivot SAP

Single Acting Front Block SBF

Single Acting Rear Block SBR

Single Acting Front Trunnion STF

Single Acting Rear Trunnion STR

Single Acting Non-Rotating Nose NRN

Single Acting Non-Rotating Pivot NRP

Reverse Acting Nose RAN

Reverse Acting Pivot RAP

Reverse Acting Front Block RAF

(available in 3/4", 1-1/16" & 1-1/2” only)

Reverse Acting Rear Block RAR

Double Acting Nose DAN

Double Acting Pivot DAP

Double Acting Double End Mount DAD

Double Acting Front Block DAF

Double Acting Rear Block DAR

Double Acting Front Trunnion DFT

Double Acting Rear Trunnion DRT

Double Acting Double Rod End DRD

RP 075 x 2.50 - DAN - PS

Mounting Options

Adjustable Cushion Head End CH†††

Adjustable Cushion Cap End CC†††

Adjustable Cushion Both Ends CB†††

Bumpers UB

Alternate Port Location PL(__)

Side Ported End Cap (DAN, SAN, and PC

DAFmodels only, note length adder)

Magnetic Piston PS

Switch Rail and location M1,M2,

Non-Adjustable cushion head end NH*

Non-Adjustable cushion cap end NC*

Non-Adjustable cushions both ends NB*

No Flats (no plain rod stick out) NF**

No Rod Thread PR

No Pin NP

Pivot Bushing (no pin) PO

Non-Standard Male Thread TM(__)

Non-Standard Female Thread FT(__)

Thread extension over standard TX†(__)

(specify additional length)

Rod extension over standard RX†(__)

(specify additional length)

Stainless Steel piston rod SS

(standard on certain models)

Viton/High Temperature Seals HT

Rod Wiper (not available with HT) RW

* ERP, ecology cylinders come complete with nonadjustable cushions both ends (NH, NC, NB, options not

required in model number of ERP cylinder). ERP on DAP,

DAF, DAD, and DAN models only (add PC option length

adder to DAN models)

** Available only on 1-1/16" bore - RAN and RAP, mounts.

† Male thread extension only. Consult factory for negative

thread or rod extensions.

††† Available on 075, 106, 150, 200, 250 & 300 Bores.

Maximum Stroke Lengths††

Bore Single &

Reverse Acting Double

5/16" 4 12

7/16"-9/16" 12 36

3/4"-1-3/4" 12 36

2" 4 36

2-1/2"-3" - 36

†† Consult factory for longer stroke lengths.

M3,M4

Acting

ACT-134

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

Roundline Plus Stainless Steel Body Actuators

1

Oil impregnated sintered bronze Rod Bearing provides

exceptional rod support, and optimal cycle life

Solid aluminum Piston is strong yet lightweight

5

for low inertia

Chrome plated carbon steel Piston Rod for strength,

2

smooth operation, and long life (stainless steel Piston

Rod on 5/16, 7/16, 9/16 and all Double Rod cylinders)

3

Lip-Type nitrile Rod Seal, pressure energized and

Lip-type nitrile Piston Seals are wear compensating

6

for long life

7

304 stainless steel Cylinder Body with polished I.D.

ensures smooth performance and outstanding life cycle

wear compensating

4

Head and Cap are solid aluminum alloy for strength

and durability

1

3

2

4

Ecology Roundline Plus - ERP Model

The ERP model is the cost effective answer to load deceleration

and faster through cushion performance.

1

IMPACT DAMPENING ECOLOGY PISTON SEALS

Increased load capabilities and cycle rates

»

»

Vibration and noise reduction

»

»

2

PRE-ENGINEERED NON-ADJUSTABLE CUSHION

Tamper resistant

»

»

Increased performance

»

»

6

5

7

*Note: Single acting cylinders (not shown) use

springs manufactured from music wire to provide

millions of trouble free cycles.

1

ACTUATORS

4

2

Roundline Ecology Piston Seal Option (ERP)

The Ecology (Impact Dampening) Piston Seal option is available on select inch bore size Roundline cylinders in DAP, DAD, and DAN configurations. This

option includes non-adjustable air cushions on both the extend and retract stroke of the cylinder. By including the Ecology Piston Seal option, cylinders can

be specified based on weights of load being carried and speed of load. This is shown in the table below.

Energy Absorption Capacity of the Impact Dampening Piston Seal

This chart represents the energy absorption capacity of the Impact Dampening piston seals with standard Non-Adjustable air cushions. The values given

are usable pounds stoppable at stated piston speeds.

In/Sec 3/4 1-1/16 1-1/4 1-1/2 2 2-1/2

6 36.6 62.3 74.5 115.5 258.9 421.1

12 5.6 15.6 18.6 28.9 64.7 105.3

18 2.5 6.9 8.3 12.8 28.8 46.8

24 1.4 3.9 4.7 7.2 16.2 26.3

30 0.9 2.5 3.0 4.6 10.4 16.8

36 0.6 1.7 2.1 3.2 7.2 11.7

42 0.5 1.3 1.5 2.4 5.3 8.6

48 0.3 1.0 1.2 1.8 4.0 6.6

54 0.3 0.8 0.9 1.4 3.2 5.2

60 0.2 0.6 0.7 1.2 2.6 4.2

Cylinder Bore

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

The figure above represents total stroke loss (both ends) for the pressure

indicated for new cylinders. The impact dampening seals will take some

compression set during operation of the cylinder and the stroke loss will

decrease. To determine stroke loss for either head or cap divide the value

shown by 2.

Effect of Impact Dampening Seals on Total Stroke of Cylinders

PSI 3/4 1-1/16 1-1/4 1-1/2 2 2-1/2

0 .11 .12 .12 .14 .15 .17

20 .08 .09 .09 .10 .10 .12

40 .05 .06 .06 .07 .07 .08

60 .03 .04 .04 .04 .04 .05

80 .01 .02 .02 .02 .02 .02

100 0 0 0 0 0 0

Cylinder Bore

ACT-135

Roundline Plus Stainless Steel Body Actuators

Dimensions in inches

Force Factor Data

Bore Code Force Factor (Area)

5/16" (031) 0.077 0.064

7/16" (043) 0.15 0.12

9/16" (056) 0.25 0.22

3/4" (075) 0.44 0.39

ACTUATORS

7/8" (087) 0.6 0.55

1-1/16" (106) 0.89 0.81

1-1/4" (125) 1.23 1.08

1-1/2" (150) 1.77 1.62

1-3/4" (175) 2.41 2.21

2" (200) 3.14 2.84

2-1/2" (250) 4.91 4.61

3" (300) 7.07 6.63

Force Output Formula

Cylinder Output Force = Force Factor (area) x Air Line Pressure (psi)

Ex: 1-1/16 bore cylinder operating at 80 psi:

Force exerted on the extend: 0.89 x 80 = 71.2 lbs.

Force exerted on the retract: 0.81 x 80 = 55.2 lbs.

Extend Retract

Approximate Spring Forces (lbs.)

Bore Code Relaxed (lbs) Compressed (lbs)

5/16" (031) 0.5 1

7/16" (043) 1 2

9/16" (056) 2 4

3/4" (075) 3 6

7/8" (087) 3 6

1-1/16" (106) 3 6

1-1/4" (125) 7.5 15

1-1/2" (150) 7 14

1-3/4" (175) 11 24

2" (200) 15 30

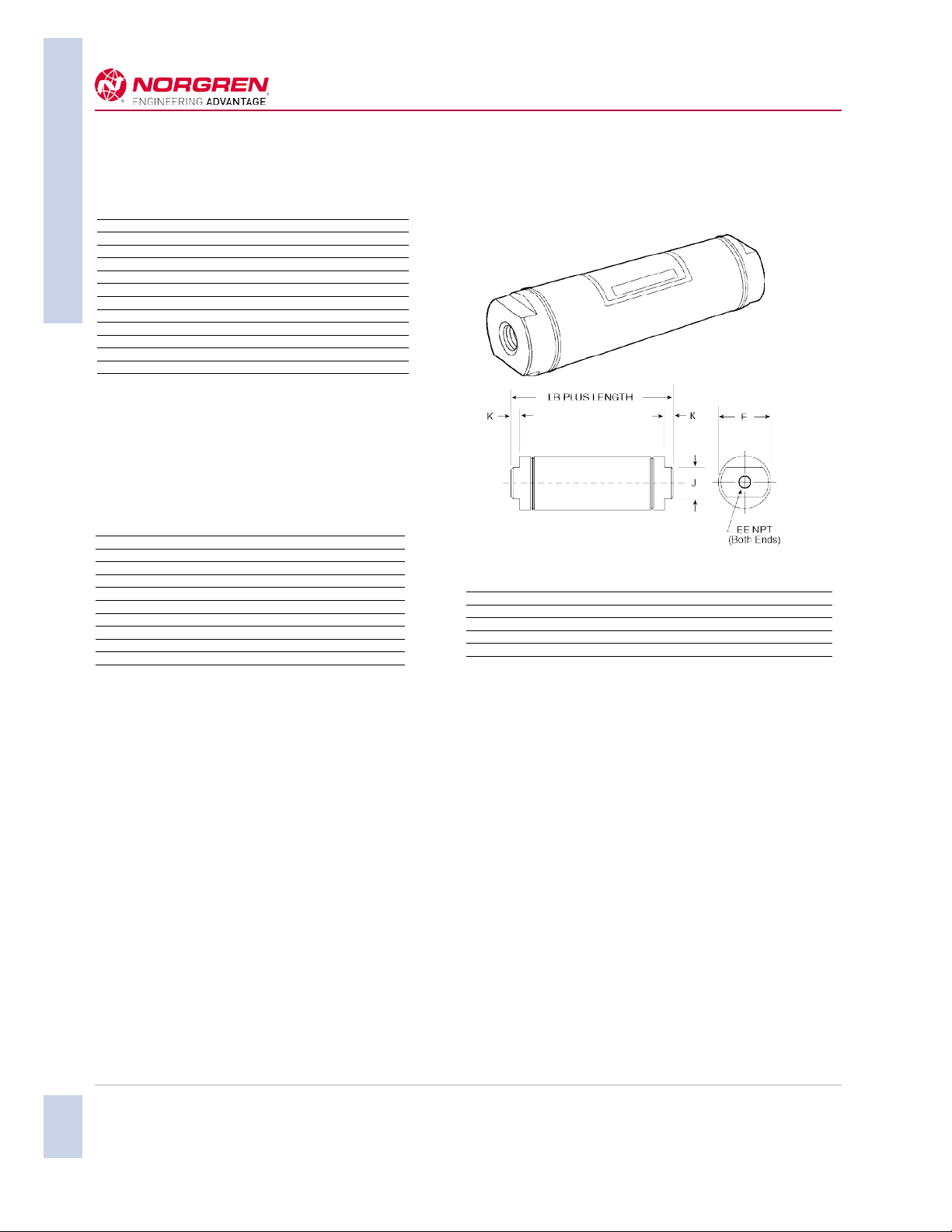

Air Reservoir

Air Reservoirs are made of the same high-quality stainless steel as the

Series RP Cylinders.

Bore E EE J K LB Standard Internal

3/4" 0.813 1/8" 0.625 0.187 1.938 1" increments thru 4"

1-1/16" 1.125 1/8" 0.875 0.187 2.375 1" increments thru 8"

1-1/2" 1.562 1/8" 0.875 0.250 2.250 1" increments thru 16"

2" 2.080 1/4" 1.250 0.312 2.875 1" increments thru 16"

2-1/2" 2.610 1/4" 1.750 0.312 2.875 1" increments thru 24"

Dimensions — All Dimensions in Inches

Lengths

ACT-136

How to Order

Example:

1-1/16" bore air reservoir with a 3" internal length would be ordered as

follows: AR-1-1/16 x 3

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

Roundline Plus Stainless Steel Body Actuators

CH,CC,CB - Adjustable Cushions

Available only on DAN, DAP, and DAD models.

Available on bore sizes: 3/4”, 1-1/16”, 1-1/2”, 2”, 2-1/2”, 3”

Position #4 standard

UB - Bumpers

• Standard on 5/16”, 7/18”, 1-1/4”, and 1-3/4” bore sizes.

• The UB option will increase the overall length on all other bore sizes (see

chart for length changes).

• Single acting models will have one bumper on the piston side opposite the

spring.

• Bumpers are not included or available on ERP Ecology Seal models.

• When the HT high temperature option is ordered on these bore sizes, the

bumpers are omitted and may change the overall length of the cylinder

(except 5/16” bore, bumpers are not omitted).

• See “HT” Option below for further explanation of HT and UB in combination.

Bore Increase in cylinder length due to the UB option

5/16" Std Std Std Std

7/16" 0.062 0.125 0.188 0.25

9/16" 0.062 0.062 0.125 0.125

3/4" 0.125 0.125 0 0

7/8" Std Std Std Std

1-1/16" 0.125 0.125 0.125 0.5*

1-1/4" Std Std Std Std

1-1/2" 0.125 0.125 0.125 0.125

1-3/4" Std Std Std Std

2" 0.125 0.125 0.250 0.250

2-1/2" 0.125 0.125 0.250 0.250

3" 0.125 0.125 0.250 0.250

* When the UB and PS options are in combination on an 1-1/16" bore, double rod end, only the

bumper length should be added. All other models and bore sizes should add the UB length and

the PS length together.

Single Reverse Double Double

Acting Acting Acting Rod End

HT - High Temperature Seals (Viton)

• For service up to 400°F

• Not available with RW rod wiper option.

• When ordered with the UB bumper option, bumpers will also be rated to 400°F.

• For cylinders where bumpers are standard, opting for HT will omit the

bumpers and may decrease the overall length of the cylinder (except 5/16”

bore). See chart below for length changes.

• For cylinders where bumpers are standard, if high temp bumpers are required,

reference both HT and UB in the model number. This will provide high temp

seals and bumpers and not change the overall length of the cylinder (except

5/16” bore).

• On the 5/16” bore, bumpers are always standard, and never omitted.

Additionally, high temperature bumpers are not available on this bore size.

As a result, with the HT option, the 5/16” bore cylinder is rated to 200°F.

Decrease in Overall length due to HT option (in.)

Bore Single Reverse Double Double

Acting Acting Acting Rod End

5/16" 0.000 0.000 0.000 0.000

7/8" 0.090 0.125 0.220 0.250

1-1/4" 0.125 0.125 0.190 0.250

1-3/4" 0.125 0.125 0.250 0.250

1

PL(__) - Alternate Port Location

Designate location on head and cap

respectively. For example: L(12) =

Head port location 1, and Cap port

4

2

location 2.

3

PC - Side ported end cap (DAN and SAN models only)

Port will be on the side of the end cap and in line with the head

end port. Overall length of the cylinder will increase.

Change in overall length due to the PC option.

Bore Length Increase

5/16" 0.2

7/16" 0.19

9/16" 0.03

3/4" 0.44

7/8" 0.28

1-1/16" 0.25

1-1/4" 0.31

1-1/2" 0.19

1-3/4" 0.56

2" 0.38

2-1/2" 0.38

3" 0.44

PS - Magnetic Piston

A magnet on the piston may increase the length of

the cylinder. See chart below for length adders.

Bore Single & Double Double

5/16" 0.150 0.150 N/A

7/16" 0.200 0.250 0.250

9/16" 0.125 0 0

3/4" 0.125 0 0

7/8" 0.125 0.125 0.125

1-1/16" 0.125 0 0.125**

1-1/4" 0.125 0 0

1-1/2" 0.125 0 0

1-3/4" 0.125 0 0

2" 0.125 0 0

2-1/2" - 0 0

3" - 0 0

* When the UB and PS options are in combination on an 1-1/16" bore,

double rod end, only the bumper length should be added. All other

models and bore sizes should add the UB length and the PS length

together.

** Ecology piston seal adds .375" to the overall length when combined

Increase in cylinder length with the PS option

Reverse Acting Acting Rod End

with PS option on the 1-1/16" bore DRD model only.

Rail shown at

position M2

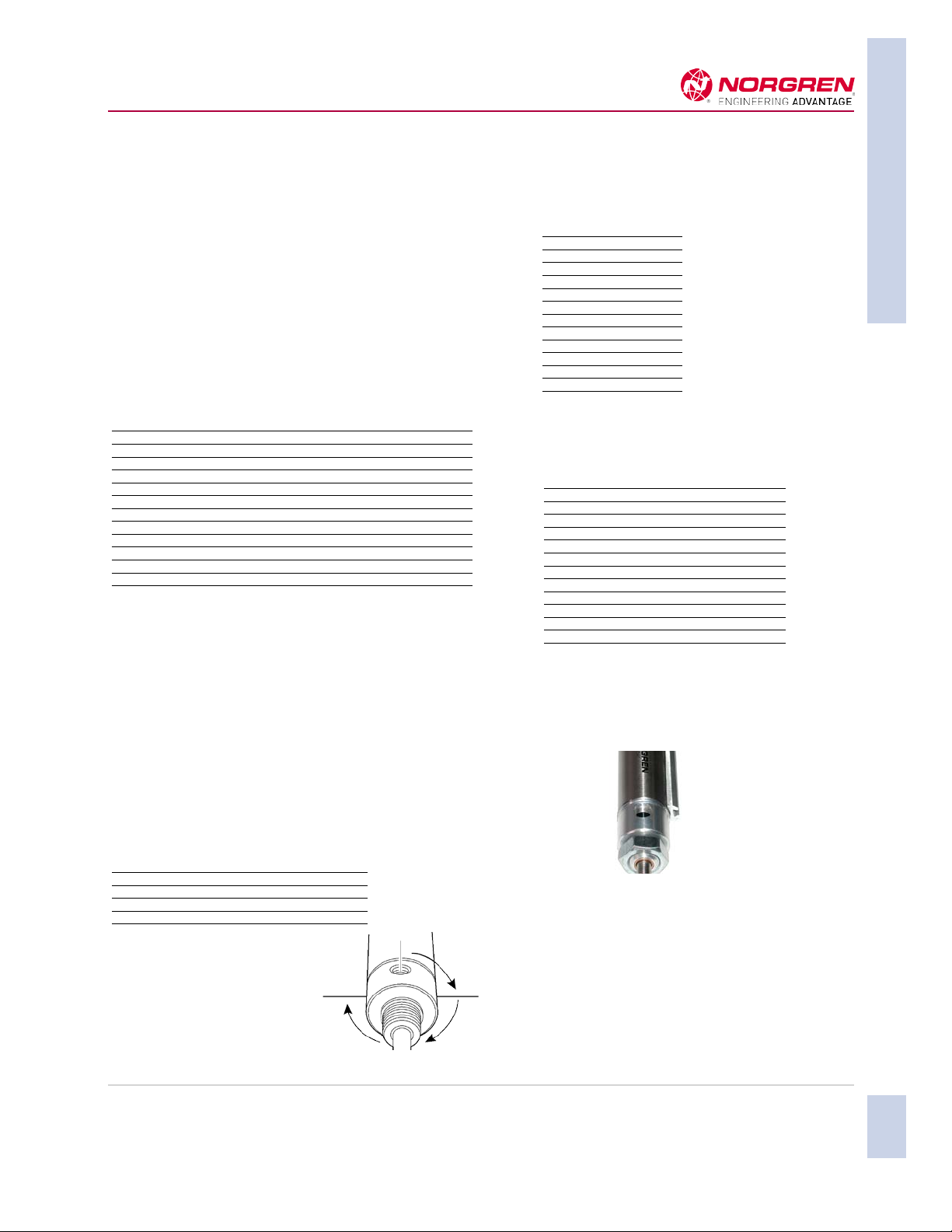

M1,M2,M3,M4 - Switch rail mounted and position

Switch rail will be mounted in position #1 for M1

option, Position #2 for M2 option, etc. Must also

reference the PS option in the cylinder model

number to receive a magnet on the piston.

A band style swtich bracket can be ordered as a

separate item instead of the switch rail. See switch

section for band style bracket information.

Switches ordered as separate items.

FT(__) - Female thread

Specify thread type in parentheses. Female rod

thread available on 1-3/4", 2", 2-1/2", 3" bores.

ACTUATORS

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

ACT-137

Roundline Plus Stainless Steel Body Actuators

Dimensions in inches

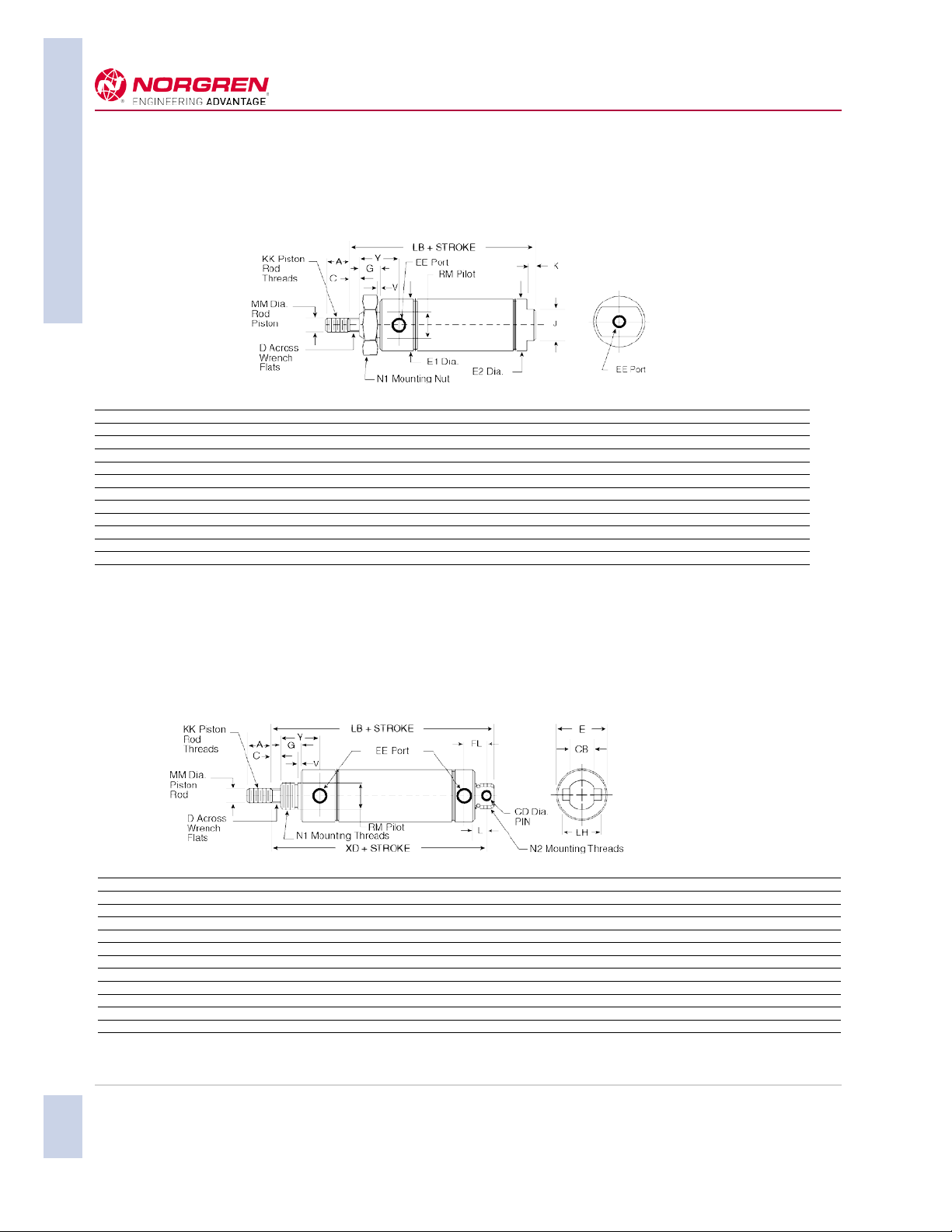

Double Acting (DAN) — Nose Mount

ACTUATORS

Bore A C D EE E1 E2 G J K KK LB MM N1 RM Y V

5/16" 0.38 N/A N/A 10-32 0.61 0.36 0.31 0.36 N/A 5-40 1.64 0.125 3/8-24 .371/.373 0.47 0.03

7/16" 0.50 N/A N/A 10-32 0.74 0.50 0.38 0.38 0.19 10-32 2.12 0.187 7/16-20 .434/.437 0.72 0.05

9/16" 0.50 N/A N/A 10-32 0.62 0.62 0.38 0.50 0.19 10-32 2.28 0.187 7/16-20 .434/.437 0.75 0.06

3/4" 0.50 N/A N/A 1/8 NPT 0.86 0.81 0.50 0.62 0.19 1/4-28 2.97 0.250 5/8-18 .621/.624 0.97 0.09

7/8" 0.50 N/A N/A 1/8 NPT 0.94 0.94 0.50 0.62 0.19 1/4-28 2.94 0.250 5/8-18 .621/.624 0.97 0.09

1-1/16" 0.50 N/A †N/A 1/8 NPT 1.12 1.12 0.50 0.88 0.19 5/16-24 3.12 0.312 5/8-18 .621/.624 1.06 0.09

1-1/4" 0.75 0.25 0.38 1/8 NPT 1.34 1.34 0.63 0.88 0.25 7/16-20 4.00 0.437 3/4-16 .746/.749 1.37 0.09

1-1/2" 0.75 0.25 0.38 1/8 NPT 1.56 1.56 0.63 0.88 0.25 7/16-20 3.69 0.437 3/4-16 .746/.749 1.25 0.09

1-3/4" 0.88 0.31 0.44 1/4 NPT 1.84 1.84 0.75 1.25 0.25 1/2-20 4.69 0.500 1-14 1.029/1.032 1.63 0.09

2" 0.88 0.38 0.50 1/4 NPT 2.08 2.08 0.81 1.25 0.31 1/2-20 4.69 0.625 1-1/4-12 1.372/1.375 1.46 0.12

2-1/2" 0.88 0.38 0.50 1/4 NPT 2.59 2.59 0.81 1.75 0.31 1/2-20 4.69 0.625 1-3/8-12 1.497/1.500 1.46 0.12

3" 1.25 0.38 0.63 3/8 NPT 3.12 3.12 1.00 2.00 0.31 5/8-18 5.25 0.750 1-1/2-12 1.622/1.625 1.71 0.19

†

1-1/16 bore with SS or PS option, C = 0.12 and D = 0.25. To remove the flats and plain rod stick out, specify NF in the model number.

Double Acting (DAP) — Pivot Mount

Bore A C CB CD D E EE FL G KK L LB LH MM N1 N2 RM V XD Y

5/16"* 0.38 N/A 0.25 0.125 N/A 0.61 10-32 0.34 0.31 5-40 0.19 2.19 0.39 0.125 3/8-24 3/8-24 .371/.373 0.03 2.03 0.47

7/16" 0.50 N/A 0.31 0.156 N/A 0.74 10-32 0.44 0.38 10-32 0.25 2.81 0.50 0.187 7/16-20 7/16-20 .434/.437 0.05 2.56 0.72

9/16"* 0.50 N/A 0.31 0.156 N/A 0.62 10-32 0.38 0.38 10-32 0.25 2.75 0.50 0.187 7/16-20 7/16-20 .434/.437 0.06 2.56 0.75

3/4" 0.50 N/A 0.38 0.250 N/A 0.86 1/8 NPT 0.62 0.50 1/4-28 0.34 4.03 0.75 0.250 5/8-18 5/8-18 .621/.624 0.09 3.75 0.97

7/8" 0.50 N/A 0.38 0.250 N/A 0.94 1/8 NPT 0.62 0.50 1/4-28 0.34 3.84 0.75 0.250 5/8-18 5/8-18 .621/.624 0.09 3.56 0.97

1-1/16" 0.50 0.12 0.38 0.250 0.25 1.12 1/8 NPT 0.62 0.50 5/16-24 0.34 4.12 0.75 0.312 5/8-18 5/8-18 .621/.624 0.09 3.84 1.07

1-1/4" 0.75 0.25 0.50 0.250 0.38 1.34 1/8 NPT 0.78 0.63 7/16-20 0.41 5.12 0.88 0.437 3/4-16 3/4-16 .746/.749 0.09 4.72 1.37

1-1/2" 0.75 0.25 0.62 0.375 0.38 1.56 1/8 NPT 0.81 0.63 7/16-20 0.50 4.75 1.00 0.437 3/4-16 3/4-16 .746/.749 0.09 4.38 1.25

1-3/4" 0.88 0.31 0.62 0.376 0.44 1.84 1/4 NPT 1.12 0.75 1/2-20 0.50 6.25 1.00 0.500 1-14 1-14 1.029/1.032 0.09 5.75 1.63

2"* 0.88 0.38 0.75 0.375 0.50 2.08 1/4 NPT 1.03 0.81 1/2-20 0.56 6.06 1.63 0.625 1-1/4-12 1-1/4-12 1.372/1.375 0.12 5.62 1.54

2-1/2"* 0.88 0.38 0.75 0.375 0.50 2.59 1/4 NPT 1.03 0.81 1/2-20 0.56 6.06 1.63 0.625 1-3/8-12 1-3/8-12 1.497/1.500 0.12 5.62 1.47

3"* 1.25 0.38 0.88 0.500 0.63 3.12 3/8 NPT 1.34 1.00 5/8-18 0.81 7.12 1.90 0.750 1-1/2-12 1-1/2-12 1.622/1.625 0.19 6.50 1.71

* Pivot bushing included

ACT-138

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

Roundline Plus Stainless Steel Body Actuators

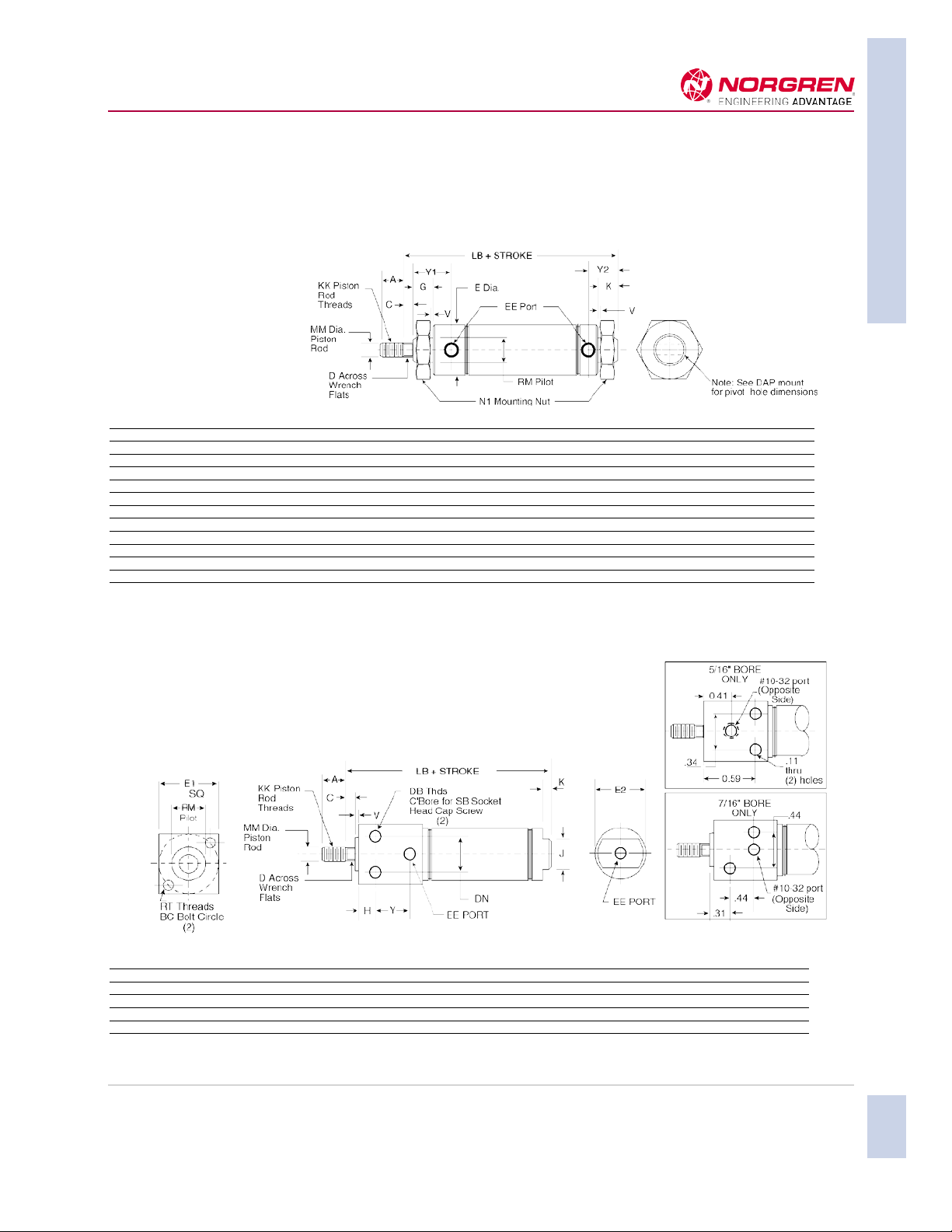

Double Acting (DAD) — Double End Mount

Bore A C D E EE G K KK LB MM N1 RM V Y1 Y2

5/16"* 0.38 N/A N/A 0.61 10-32 0.31 0.35 5-40 2.19 0.125 3/8-24 .371/.373 0.03 0.47 0.50

7/16" 0.50 N/A N/A 0.74 10-32 0.38 0.50 10-32 2.81 0.187 7/16-20 .434/.437 0.05 0.73 0.69

9/16"* 0.50 N/A N/A 0.62 10-32 0.38 0.44 10-32 2.75 0.187 7/16-20 .434/.437 0.06 0.75 0.57

3/4" 0.50 N/A N/A 0.86 1/8 NPT 0.50 0.62 1/4-28 4.03 0.250 5/8-18 .621/.624 0.09 0.97 0.90

7/8" 0.50 N/A N/A 0.94 1/8 NPT 0.50 0.62 1/4-28 3.84 0.250 5/8-18 .621/.624 0.09 0.97 0.90

1-1/16" 0.50 0.12 0.25 1.12 1/8 NPT 0.50 0.62 5/16-24 4.12 0.312 5/8-18 .621/.624 0.09 1.07 0.90

1-1/4" 0.75 0.25 0.38 1.34 1/8 NPT 0.63 0.81 7/16-20 5.12 0.437 3/4-16 .746/.749 0.09 1.37 1.18

1-1/2" 0.75 0.25 0.38 1.56 1/8 NPT 0.63 0.88 7/16-20 4.75 0.437 3/4-16 .746/.749 0.09 1.25 1.18

1-3/4" 0.88 0.31 0.44 1.84 1/4 NPT 0.75 1.00 1/2-20 6.25 0.500 1-14 1.029/1.032 0.09 1.63 1.62

2"* 0.88 0.38 0.50 2.08 1/4 NPT 0.81 1.00 1/2-20 6.06 0.625 1-1/4-12 1.372/1.375 0.12 1.46 1.47

2-1/2"* 0.88 0.38 0.50 2.59 1/4 NPT 0.81 1.00 1/2-20 6.06 0.625 1-3/8-12 1.497/1.500 0.12 1.46 1.47

3"* 1.25 0.38 0.63 3.12 3/8 NPT 1.00 1.43 5/8-18 7.12 0.750 1-1/2-12 1.622/1.625 0.19 1.71 1.96

* Pivot bushing included

Dimensions in inches

ACTUATORS

Double Acting (DAF) — Front Block Mount

Bore A BC C D DB DN EE E1 E2 H J K KK LB MM RM RT SB V Y

5/16" 0.38 N/A N/A N/A N/A N/A 10-32 0.50 0.36 N/A N/A N/A 5-40 1.72 0.125 N/A N/A N/A N/A N/A

7/16" 0.50 0.75 N/A N/A 8-32 N/A 10-32 0.75 0.50 N/A 0.38 0.19 10-32 2.12 0.187 0.437 8-32 N/A 0.06 N/A

3/4" 0.75 1.00 0.25 0.22 1/4-20 0.62 1/8 NPT 1.00 0.81 0.38 0.62 0.19 1/4-28 3.22 0.250 0.625 10-32 #10 0.09 0.50

1-1/16" 0.75 1.25 0.38 0.25 1/4-20 0.81 1/8 NPT 1.25 1.12 0.62 0.88 0.19 5/16-24 3.75 0.312 0.75 10-32 #10 0.09 0.54

1-1/2" 1.25 1.75 0.25 0.38 5-16-18 1.12 1/4 NPT 1.75 1.56 0.88 0.88 0.25 7/16-20 4.19 0.437 1.00 1/4-20 1/4 0.13 0.65

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

ACT-139

Roundline Plus Stainless Steel Body Actuators

Dimensions in inches

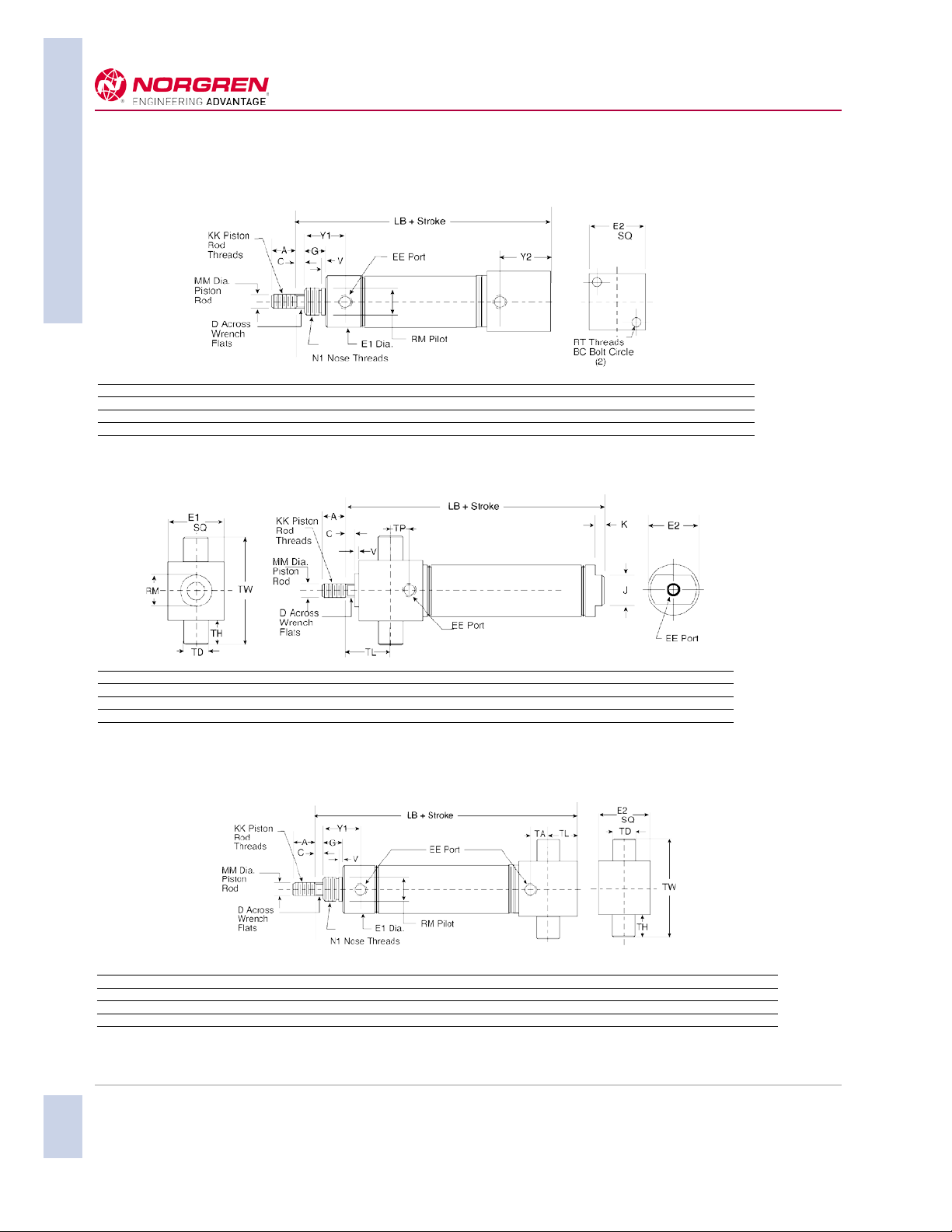

Double Acting (DAR) — Rear Block Mount

ACTUATORS

Bore A C D E1 E2 EE G KK LB MM N1 RM RT BC V Y1 Y2

7/16" 0.50 N/A N/A 0.75 0.75 10-32 0.38 10-32 2.44 0.187 7/16-20 .433/.437 8-32 0.75 0.05 0.72 0.34

3/4" 0.75 0.25 0.22 0.86 1.00 1/8 NPT 0.50 1/4-28 3.78 0.250 5/8-18 .621/.624 10-32 1.00 0.09 0.97 0.44

1-1/16" 0.75 0.38 0.25 1.12 1.25 1/8 NPT 0.50 5/16-24 4.00 0.312 5/8-18 .621/.624 10-32 1.25 0.09 1.06 1.25

1-1/2" 1.25 0.25 0.38 1.56 1.75 1/4 NPT 0.63 7/16-20 4.38 0.437 3/4-16 .746/.749 1/4-20 1.75 0.09 1.25 0.62

Double Acting (DFT) — Front Trunnion Mount

Bore A C D E1 E2 EE J K KK LB MM RM TD TH TL TP TW V

7/16" 0.50 N/A N/A 0.75 0.50 10-32 0.38 0.19 10-32 2.12 0.187 0.44 0.374 0.25 0.31 0.41 1.25 0.06

3/4" 0.75 0.25 0.22 1.00 0.81 1/8 NPT 0.62 0.19 1/4-28 3.22 0.250 0.62 0.500 0.38 0.69 0.53 1.75 0.09

1-1/16" 0.75 0.38 0.25 1.25 1.12 1/8 NPT 0.88 0.19 5/16-24 3.75 0.312 0.75 0.500 0.38 1.09 0.53 2.00 0.09

1-1/2" 1.25 0.25 0.38 1.75 1.56 1/4 NPT 0.88 0.25 7/16-20 4.19 0.437 1.00 0.500 0.38 1.19 0.59 2.50 0.12

Double Acting (DRT) — Rear Trunnion Mount

Bore A C D E1 E2 EE G KK LB MM N1 RM TA TD TH TL TW V Y1

7/16" 0.50 N/A N/A 0.75 0.75 10-32 0.38 10-32 2.44 0.187 7/16-20 .433/.437 0.09 0.374 0.25 0.25 1.25 0.05 0.72

3/4" 0.75 0.25 0.22 0.86 1.00 1/8 NPT 0.50 1/4-28 3.78 0.250 5/8-18 .621/.624 0.06 0.500 0.38 0.38 1.75 0.09 0.97

1-1/16" 0.75 0.38 0.25 1.12 1.25 1/8 NPT 0.50 5/16-24 4.00 0.312 5/8-18 .621/.624 0.06 0.500 0.38 0.38 2.00 0.07 1.06

1-1/2" 1.25 0.25 0.38 1.56 1.75 1/4 NPT 0.63 7/16-20 4.38 0.437 3/4-16 .746/.749 0.12 0.500 0.38 0.50 2.50 0.09 1.25

ACT-140

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

Roundline Plus Stainless Steel Body Actuators

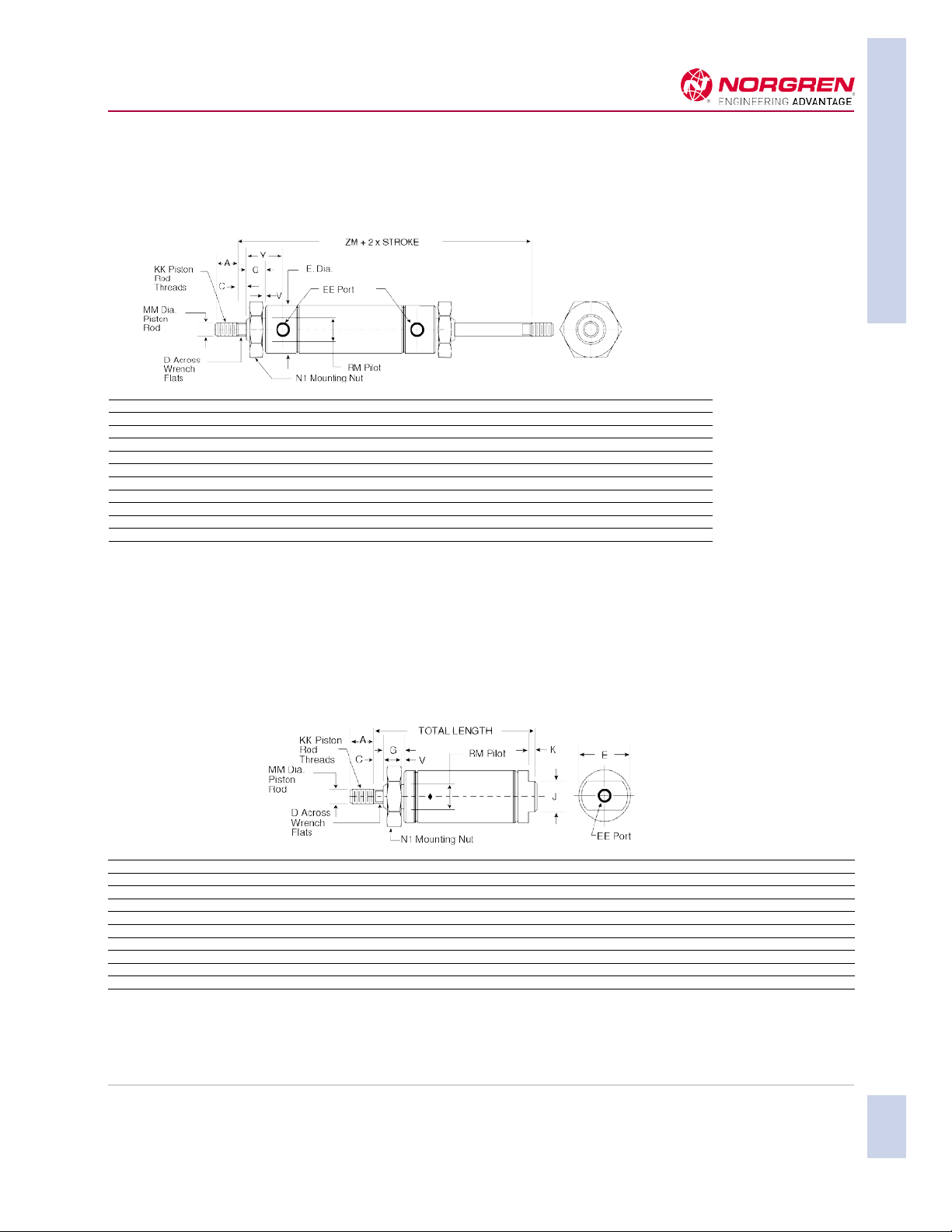

Double Acting Double Rod End (DRD) — Double End Mount

Bore A C D E EE G KK MM N1 RM V Y ZM

7/16" 0.50 N/A N/A 0.74 10-32 0.38 10-32 0.187 7/16-20 .434/.437 0.05 0.72 2.81

9/16" 0.50 N/A N/A 0.62 10-32 0.38 10-32 0.187 7/16-20 .434/.437 0.06 0.75 2.94

3/4" 0.50 N/A N/A 0.86 1/8 NPT 0.50 1/4-28 0.250 5/8-18 .621/.624 0.09 0.97 4.00

7/8" 0.50 N/A N/A 0.94 1/8 NPT 0.50 1/4-28 0.250 5/8-18 .621/.624 0.09 0.97 3.91

1-1/16" 0.50 0.12 0.25 1.12 1/8 NPT 0.50 5/16-24 0.312 5/8-18 .621/.624 0.09 1.06 4.00

1-1/4" 0.75 0.25 0.38 1.34 1/8 NPT 0.63 7/16-20 0.437 3/4-16 .746/.749 0.09 1.37 5.56

1-1/2" 0.75 0.25 0.38 1.56 1/8 NPT 0.63 7/16-20 0.437 3/4-16 .746/.749 0.09 1.25 5.12

1-3/4" 0.88 0.31 0.44 1.84 1/4 NPT 0.75 1/2-20 0.500 1-14 1.029/1.032 0.09 1.94 6.56

2" 0.88 0.38 0.50 2.08 1/4 NPT 0.81 1/2-20 0.625 1-1/4-12 1.372/1.375 0.12 1.46 6.56

2-1/2" 0.88 0.38 0.50 2.59 1/4 NPT 0.81 1/2-20 0.625 1-3/8-12 1.497/1.500 0.12 1.46 6.56

3" 1.25 0.38 0.63 3.12 3/8 NPT 1.00 5/8-18 0.750 1-1/2-12 1.622/1.625 0.19 1.71 7.31

Dimensions in inches

ACTUATORS

Single Acting Spring Return (SAN) — Nose Mount

Bore A C D E EE G J K KK MM N1 RM V Total Length

5/16" 0.38 N/A N/A 0.36 10-32 0.25 N/A N/A 5-40 0.125 1/4-28 .309/.312 0.03 1.12 + (0.75 per 1/2" of stroke)

7/16" 0.50 N/A N/A 0.50 10-32 0.31 0.38 0.19 10-32 0.187 3/8-24 .369/.373 0.05 1.31 + (0.94 per 1/2" of stroke)

9/16" 0.50 N/A N/A 0.62 10-32 0.38 0.50 0.19 10-32 0.187 7/16-20 .434/.437 0.06 1.53 + (1.62 per 1" of stroke)

3/4" 0.50 N/A N/A 0.81 1/8 NPT 0.44 0.62 0.19 1/4-28 0.250 1/2-20 .494/.498 0.08 1.50 + (1.69 per 1" of stroke)

7/8" 0.50 N/A N/A 0.94 1/8 NPT 0.50 0.62 0.19 1/4-28 0.250 5/8-18 .621/.624 0.09 1.84 + (1.56 per 1" of stroke)

1-1/16" 0.50 N/A†N/A 1.12 1/8 NPT 0.50 0.88 0.19 5/16-24 0.312 5/8-18 .621/.624 0.07 1.94 + (1.56 per 1" of stroke)

1-1/4" 0.75 0.25 0.38 1.34 1/8 NPT 0.63 0.88 0.25 7/16-20 0.437 3/4-16 .746/.749 0.09 2.66 + (1.81 per 1" of stroke)

1-1/2" 0.75 0.25 0.38 1.56 1/8 NPT 0.63 0.88 0.25 7/16-20 0.437 3/4-16 .746/.749 0.09 2.44 + (1.69 per 1" of stroke)

1-3/4" 0.88 0.31 0.44 1.84 1/4 NPT 0.75 1.25 0.25 1/2-20 0.500 1-14 1.029/1.032 0.09 2.97 + (2.00 per 1" of stroke

2" 0.88 0.38 0.50 2.08 1/4 NPT 0.81 1.25 0.31 1/2-20 0.625 1-1/4-12 1.372/1.375 0.12 Consult Factory

†

1-1/16 bore with SS or PS option, C = 0.12 and D = 0.25. To remove the flats and plain rod stick out, specify NF in the model number.

Norgren.com/usa – 303.794.2611 – help@amer.norgren.com

ACT-141

Loading...

Loading...