Page 1

© Norgren 1996

Port

2.....1/4"

Relief Type

E.....Relieving with 60 psig (4.1 bar) integral relief valve

Gauge

N ....No gauge

R82 APPLICATION

The R82 cylinder gas pressure regulator is used in beer dispensing systems to control carbon dioxide pressure to the

beer keg. The R82 regulator with integral, preset, nonadjustable pressure relief valve meets the requirements of

ANSI-ASME F2.1-1975, Food, Drug and Beverage Equipment,

Proposed Section 9.7, Draught Beer Dispensing Equipment

and Related Components, (Seventh Draft dated October 17,

1980)

. The integral relief valve will, in the event of regulator

malfunction, limit the outlet pressure to help protect downstream equipment from an excessive overpressure condition.

R82 RELIEF TYPE

R82 regulators are relieving type regulators, and will therefore vent gas from the regulator body secondary chamber

when the regulator pressure adjusting screw is turned counterclockwise. Pressure downstream of the regulator will not

be reduced when the adjusting screw is turned counterclockwise because back-flow check valves must always be

installed in each regulator outlet line.

TECHNICAL DATA

Fluids: Carbon dioxide

Maximum primary (inlet) pressure: 3000 psig (206.9 bar)

Operating temperature: 0° to +140°F (-18° to +60°C)

Maximum outlet pressure adjustment limit: Factory set at 40

to 45 psig (2.8 to 3.1 bar)

Integral relief valve secondary (outlet), nonadjustable relief

cracking pressure setting: 60 psig ± 4 psig (4.1 ± 0.28 bar)

Materials:

Body: Brass

Bonnet: Zinc

Cartridge valve: Teflon, brass, stainless steel

Seals: Nitrile

Diaphragm: Acetal, nitrile

Relief valve: Brass, acetal, nitrile, aluminum

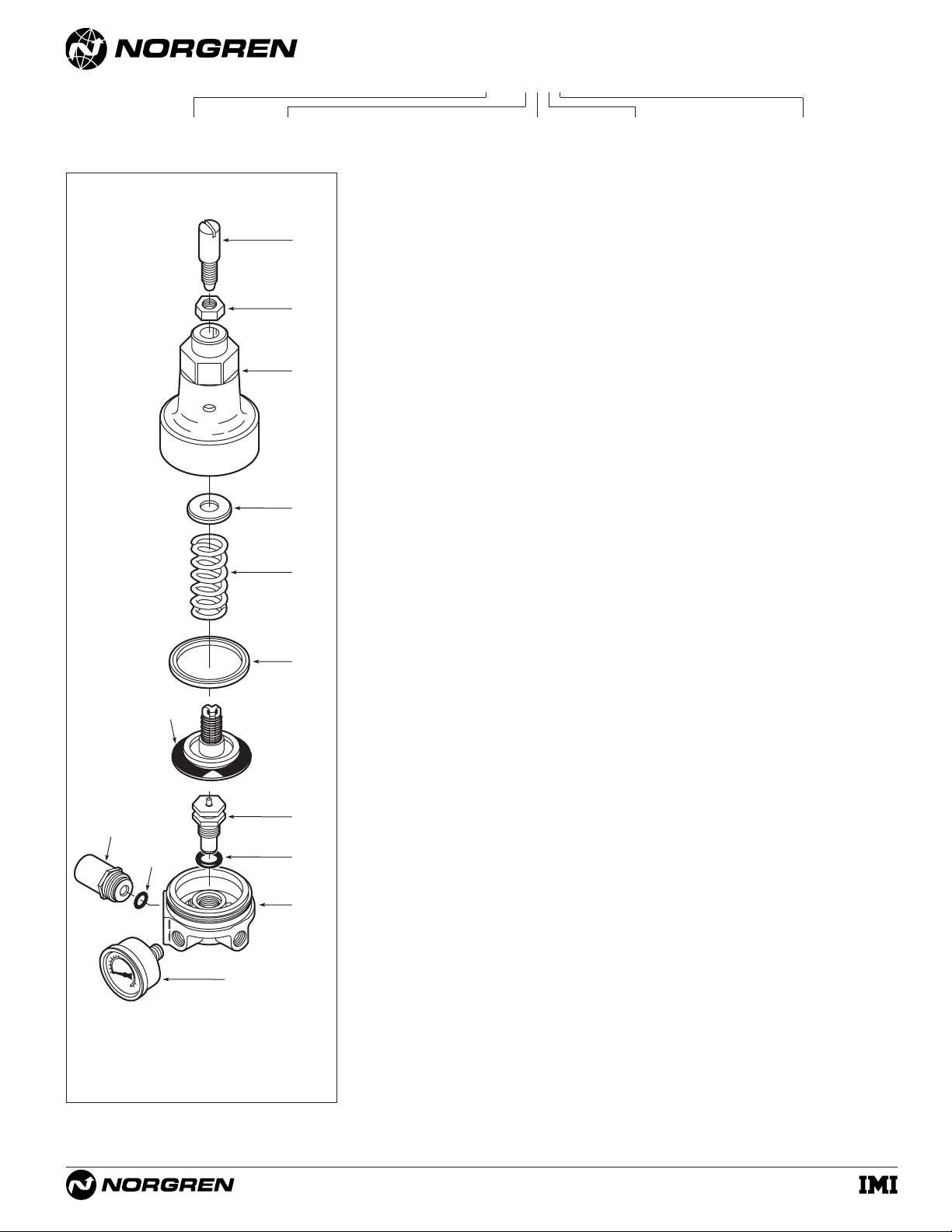

REPLACEMENT ITEMS

Diaphragm, relieving (7) ...............................................570-51

Cartridge valve (9, 10) ................................................5086-55

Relief valve (13, 14)*..................................................5779-56

*Relief valve is marked

60 PSIG RELIEF VALVE R82 and has

a brass body with a natural (silver colored) aluminum end

cap.

INSTALLATION – Also refer to ANSI-ASME F2.1-1975, Food,

Drug and Beverage Equipment,

Proposed Section 9.7,

Draught Beer Dispensing Equipment and Related

Components.

This regulator has two primary (inlet) ports marked PRI, and

two secondary (outlet) ports marked SEC (secondary).

1. Connect the high pressure supply to either of the

PRI

ports. The other primary port can be plugged, used as a

manifold port to another regulator, or used for a primary

pressure gauge. Use a U.L. listed gauge.

2. Connect outlet lines which lead to the downstream system

to either of the

SEC ports. The other secondary port can be

plugged, used as an additional secondary outlet, or used

for a secondary pressure gauge. Use a U.L. listed gauge.

WARNING

Never connect the high pressure supply to the regulator ports

marked

SEC. Never connect the outlet lines to the regulator

ports marked

PRI. Improper connections will expose the

downstream system to excessive pressure, resulting in equipment damage and/or personal injury. Before turning on gas

pressure, turn regulator adjusting screw (2) fully counterclockwise.

ADJUSTMENT

1. Turn regulator adjusting screw (2) fully counterclockwise.

2. Turn on gas pressure.

3. Turn adjustment clockwise to increase secondary (outlet)

pressure setting. Turn adjustment counterclockwise to

decrease pressure setting.

4. Always approach the desired pressure from a lower pres-

sure. When reducing from a higher to a lower setting, first

reduce to some pressure less than that desired, then bring

up to the desired pressure.

5. Tighten lock nut (3) to secure pressure setting.

DISASSEMBLY

1. Shut off inlet pressure. Reduce pressure in inlet and outlet

lines to zero.

2. Turn regulator adjusting screw (2) fully counterclockwise.

3. Unit can be disassembled without removal from air line.

4. Disassemble in general accordance with the item numbers

on exploded view. Use 5/8" socket to remove cartridge

valve (9).

CLEANING

1. Clean parts with warm water and soap.

2. Rinse and dry parts. Blow out internal passages in body

with clean, dry compressed air.

3. Inspect parts. Replace those found to be damaged.

NOTE

Cartridge valve (9) is factory sealed and is not repairable.

Relief valve (13) is not adjustable or repairable. Replace these

parts if not sealing properly. Use only the specified Norgren

parts for replacement. Do not use damaged or inoperative

parts or assemblies. Maintain strict cleanliness when

reassembling regulator.

ASSEMBLY

1. Lubricate threads and tip of adjusting screw (2), with a

light, even coat of Lubriplate Aero.

2. Lubricate bonnet threads (1), with a light, even coat of

Led-Plate 250.

3. Lubricate o-rings (10, 14) with a light coat of Dow Corning

DC 44 silicone grease.

4. Assemble the unit as shown on the exploded view.

5. Torque Table

Item Torque

9 (Cartridge valve) 45 to 65 in-lbs (5 to 7 Nm)

1 (Bonnet) 25 to 30 ft-lbs (34 to 40 Nm)

13 (Relief valve) 40 to 80 in-lbs (4.5 to 9 Nm)

WARNING

For safety in system applications using Model R82 Regulators,

the following procedures must be followed.

1.Pressure relief valves of sufficient capacity must always be

used in the secondary (outlet) lines downstream of each

pressure regulator, whether as an integral part of the regulator, as is the case with Norgren Model R82 Regulators, or

separately installed elsewhere in the outlet lines. Do not

remove or attempt to adjust, plug, block or otherwise defeat

the purpose of the relief valve. The integral pressure relief

valve used on the R82 regulator is preset and marked

60 PSIG. Replace only with the same 60 psig relief valve,

part number 5779-56. See REPLACEMENT ITEMS for

description of relief valve color coding. Failure to provide a

pressure relief valve of sufficient capacity to hold outlet

pressure below the lowest working pressure rating of any

piece of equipment installed in the outlet lines can result in

equipment damage and/or personal injury.

2.A back flow check valve must always be installed at the reg-

ulator outlet and/or other points in the system as specified

for draught beer dispensing equipment to prevent reverse

flow through the regulator and possible introduction of liquids and other contaminants into the regulator.

4.Regulators must not be used where temperature or pres-

sure may exceed those specified in the

TECHNICAL DATA

paragraph.

4.These regulators are not intended for use in life support

systems.

5.The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be used

in conjunction with these products and if inaccurate indications may be hazardous to personnel or property, the gauge

should be calibrated before initial installation and at regular

intervals during use. For gauge standards refer to ANSI

B40.1.

Thread

A ....PTF

Spring (Outlet pressure adjustment range) *

E...2 to 45 psig (0.14 to 3.1 bar)

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified. Do not use these units to control pressures outside of the specified ranges.

5400 South Delaware Street, Littleton, CO 80120-1663 Phone 303-794-2611 Fax 303-795-9487

Installation & Maintenance

Instructions

U.L. Listed Cylinder Gas Regulator

for Controlling Pressure to the Beer Keg

in Beer Dispensing Systems

R82 -

★00 - ★★★★

NIP-254 (11/96) Supersedes 5/96

13

14

2

3

1

4

5

6

7

9

10

11

12

Loading...

Loading...