Page 1

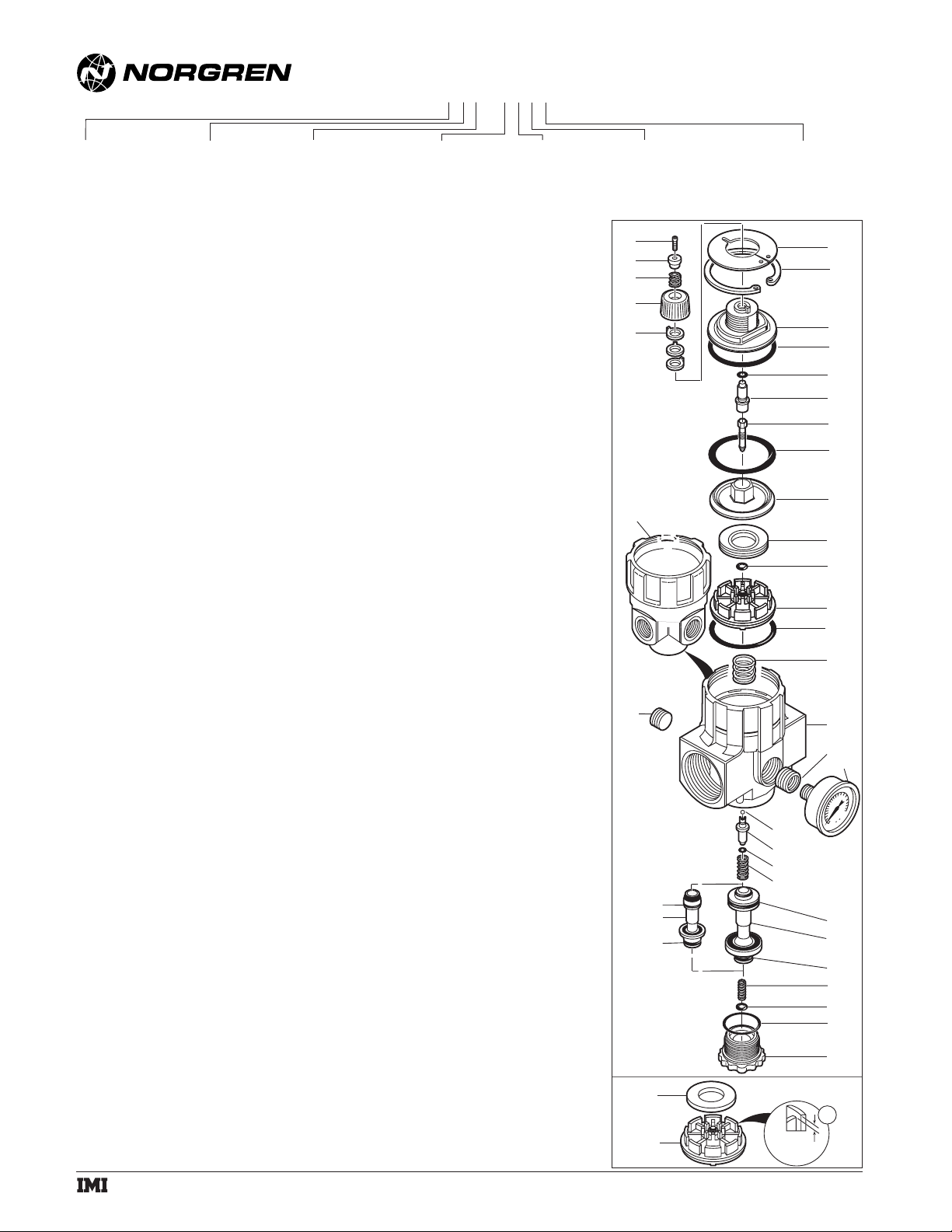

4.Use retaining ring pliers to remove the top plate (6)

and retaining ring (7). Pull cap (8) and o-ring (9) from

body.

5.Unscrew socket head screw (1), then remove button

(2), spring (3), knob (4), tumblers (5), coupling (10),

and o-ring (11).

6. Remove, as an assembled unit, the adjusting screw

(12) with upper and lower piston assemblies (items

13 thru 19). Remove spring (20).

7. Unscrew the adjusting screw (12), then separate

upper and lower piston assemblies (items 13 thru

19). The adjusting screw has left hand threads.

Make sure o-ring (18) remains attached to the lower

piston (17). If not, retrieve it from inside the upper

piston (13).

8. Unscrew bottom plug (21) to gain access to the

parts (22 thru 33) located in the lower portion of the

body.

CLEANING

1.Clean parts with warm water and soap.

2.Rinse and dry parts. Blow out internal passages in

body (34, 35) with clean, dry compressed air.

3.Inspect parts. Replace those found to be damaged.

ASSEMBLY

1. Lubricate o-rings, o-ring sealing surfaces, and the

adjusting screw threads (12) with a small amount of

good quality o-ring grease.

2. Assemble the lower piston (16*, 17, 18,19), the

regulating spring (15), and upper piston (13, 14),

then turn the adjusting screw (12) into the assembly

until the tip of the screw is flush with the bottom of

the lower piston (17). The adjusting screw has left

hand threads. Place spring (20) in position in the

body, then place the upper and lower piston

assembly (items 12 thru 19) in the body.

3. Insert coupling (10) and o-ring (11) into cap (8).

Place tumblers (5), knob (4), spring (3), and button

(2) in position and secure with screw (1). Make

sure button (2) is installed with the large end

(marked A) up. Place o-ring (9) in position on the

cap (8), then place the cap and knob assembly

(items 1 thru 5, and 8 thru 11) in body, making sure

coupling (10) engages the adjusting screw (12).

4. Use retaining ring pliers to install retaining ring (7),

then install and top plate (6).

WARNING

Make sure retaining ring (7) is fully seated in the

groove in the body.

5. Install the lower section parts (items 21 thru 33)

into body (34 or 35).

6. Torque Table

Item Inch-Pounds (Nm)

21 (Bottom plug) 20 to 30 (2.3 to 3.4)

1 (Screw

)

3 to 4 (0.3 to 0.5). Screw head

must not extend more than

0.050" (1.3 mm) above top of

button (2).

7. Set the R24 for normal operation as described in

paragraph 1-2, page 2 before it is returned to

service.

* Item 16, washer, is used only with 1/4", 3/8", and

1/2" ported R24 regulators manufactured from

September, 1993 to March, 1994. The design of the

piston (17) was changed in early 1994, and washer

(16) was eliminated. The washer support ribs on the

early pistons (Detail A of exploded view) are

recessed approximately 0.188" (5mm) to

accommodate washer (16). The support ribs on

current pistons are recessed approximately 0.063

(2mm). Discard washer (16) when replacing the

early piston with a current piston.

IM-414.210.01

(2/02)

Replaces NIP-243

© Norgren 2002

TECHNICAL DATA

Fluid: Compressed air

Maximum inlet pressure: 300 psig (20 bar)

Operating temperature: 0° to +150°F (-20° to +80°C)

Air supply must be dry enough to avoid ice

formation at temperatures below +35°F (+2°C).

Typical flow at 150 psig (10 bar) inlet pressure, 90 psig

(6.3 bar) set pressure, and 15 psig (1 bar) droop

from set:

1/2" ports: 200 scfm (94 dm

3

/s)

1-1/4" ports: 700 scfm (330 dm

3

/s)

Maximum bleed rate at 50 psig (3.5 bar) outlet

pressure: 0.031 scfm (0.015 dm3/s). Maximum bleed

rate occurs under dead-end (no flow) conditions.

Port sizes:

Main Gauge

1/4" 1/4"

3/8" 3/8"

1/2", 3/4", 1", 1-1/4" 1/2"

Thread type: PTF, ISO G, or ISO Rc

Materials:

Body, top cap: Zinc

Main valve, adjusting screw: Brass

Pilot valve, relief valve, bottom plug: Acetal

Elastomers: Nitrile

REPLACEMENT ITEMS

Service kit - 1/4", 3/8" 1/2" ported regulators (Items 9,

11, 12, 14, 18, 19, 22 thru 26, 28, 29, 33).....5292-52

Service kit - 3/4", 1", 1-1/4" ported regulators (Items 9,

11, 12, 14, 18, 19, 23 thru 26, 30 thru 33) ....5292-53

PANEL MOUNTING DIMENSIONS

Panel mounting hole diameter: 1.26" (32 mm)

Maximum panel thickness: 0.12" (3 mm)

INSTALLATION

1.Shut off air pressure. Install regulator in air line -

● with air flow in direction of arrow on body,

● upstream of lubricators and cycling valves,

● as close as possible to the device being serviced.

● at any angle.

2.Connect piping to proper ports using pipe thread

sealant on male threads only. Do not allow sealant to

enter interior of regulator.

3.

Install a pressure gauge or plug the gauge ports.

Gauge ports can also be used as additional outlets for

regulated air.

4.Install a Norgren general purpose filter upstream of

the regulator.

ADJUSTMENT

1.Before applying inlet pressure to regulator, turn

adjustment (4) counterclockwise until knob stops.

2.Apply inlet pressure, then turn adjustment (4)

clockwise to increase and counterclockwise to

decrease pressure setting.

3.Always approach the desired pressure from a lower

pressure. When reducing from a higher to a lower

setting, first reduce to some pressure less than that

desired, then bring up to the desired pressure.

4. If desired, a maximum or minimum outlet pressure

adjustment limit may be set. See page 2 for

instructions.

DISASSEMBLY

1.Regulator can be disassembled without removal from

air line.

2.Shut off inlet pressure. Reduce pressure in inlet and

outlet lines to zero.

3.Turn adjustment (4) fully counterclockwise.

WARNING

Prior to performing step 4, make certain air

pressure upstream and downstream of the R24 is

zero psi.

R24

Installation & Maintenance

Instructions

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified. Do not use these units to control pressures outside of the specified ranges.

Special Purpose Regulator

Adjustable Pressure Limits - High Relief Flow

R24 - ★★★ - ★★★★

Thread Form

A....PTF

B....ISO Rc taper

G....ISO G parallel

Port

2....1/4" 6 ....3/4"

3....3/8 8 ....1"

4....1/2" A....1-1/4"

Spring (Outlet Pressure Range) *

C....5 to 30 psig (0.3 to 2 bar)

F ....5 to 60 psig (0.3 to 4 bar)

L....10 to 125 psig (0.7 to 8 bar)

S....10 to 250 psig (0.7 to 17 bar)

Type

R....Relieving piston

Gauge

G....With

N....Without

Option

0....Not applicable

Adjustment Type

0....Knob

a subsidiary of IMI plc

1

2

3

4

5

34

36

29

28

29

16

17

24

25

26

27

0.188"

(5mm)

A

6

7

8

9

11

10

12

14

13

15

18

17

19

20

35

37

38

31

30

32

33

22

23

21

Page 2

R24

Installation & Maintenance

Instructions

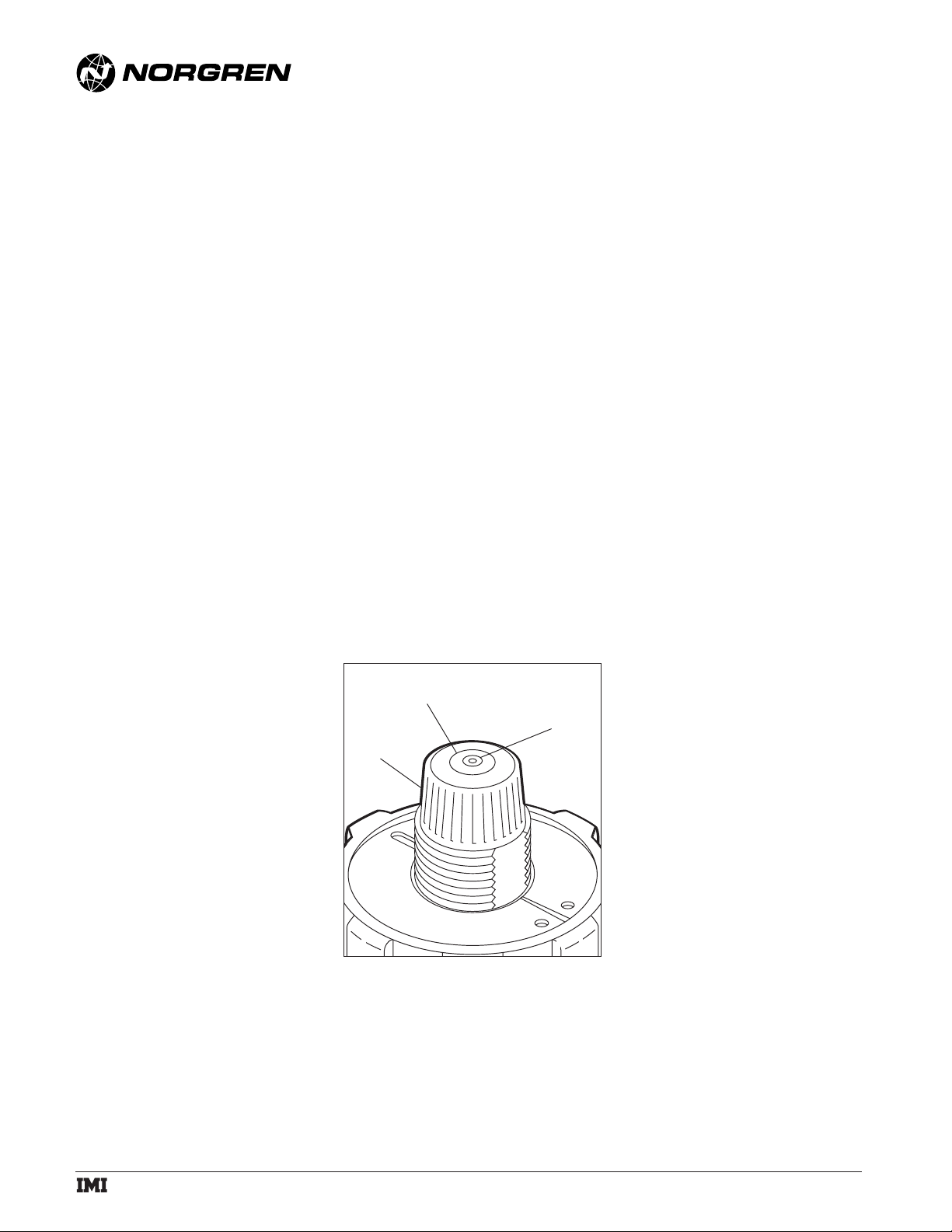

1-3. How to Set Outlet Pressure Limit

when the Pressure Set Button is in the

Tamper Resistant Position (Fig 1).

To Set a Maximum Pressure Limit:

1. With primary pressure applied to the R24, turn

adjusting knob clockwise until the desired maximum

outlet pressure is reached.

2. Hold adjusting knob, then use a 5/64" hex wrench

to loosen button screw 4 to 5 turns.

3. Depress and hold button screw, then turn adjusting

knob clockwise until it stops. Release button

screw.

4. Hold adjustment knob and tighten button screw. Do

not depress screw, as the adjustment limit will

be affected.

5. Turn adjusting knob fully counterclockwise.

To Set a Minimum Pressure Limit:

1. With primary pressure applied to the R24, turn

adjusting knob clockwise until the desired minimum

outlet pressure is reached.

2. Hold adjusting knob, then use a 5/64" hex wrench

to loosen button screw 4 to 5 turns.

3. Depress and hold button screw, then turn the

adjusting knob counterclockwise until it stops.

Release button screw.

4. Hold adjustment knob and tighten screw. Do not

depress screw, as the adjustment limit will be

affected.

WARNING

When the minimum adjustment limit is set

above zero, the upper limit of adjustment

increases correspondingly, and could possibly

approach inlet pressure.

1-2. Regulators Shipped from Factory:

● allow pressure adjustment throughout the entire

outlet pressure range as shown on the regulator

label and as listed in the model number description

at the top of page 1.

● have the red pressure set button (Figure 1) in the

tamper resistant position, preventing the accidental

setting of a pressure limit. When the button is in

the tamper resistant position, the letters TR are

visible on the button; when the button is in the

adjustable position, the letter A is visible.

1-2. Set the R24 for Normal Operation

(Fig 1).

Any time the R24 is disassembled and reassembled,

the adjusting knob must be reset for normal operation

(i.e., set to operate thru the entire outlet pressure

range as listed in the model number description at the

top of page 1).

1. Make sure the red pressure set button is in the

adjustable position (end marked A up). If the end

marked TR is up, reverse the position of the button

by performing steps 1 and 2 in paragraph 1-5,

Tamper Resistant Procedure, but reinstall the button

with the end marked A up.

2. Install the regulator in a compressed air test line

with gages installed for observing inlet and outlet

pressures. Inlet pressure should not exceed 250

psig (17.2 bar).

3.Turn adjusting knob fully counterclockwise (ccw),

then slowly apply inlet pressure while observing the

outlet pressure gage.

If outlet pressure is indicated with the knob fully

ccw:

a. Depress and hold the pressure set button, then

turn adjusting knob clockwise (cw) until it stops

and release button.

b. Turn adjusting knob ccw until outlet pressure

reaches zero. If outlet pressure does not reach

zero when knob is turned fully ccw, repeat steps (a)

and (b) until it does.

c. When outlet pressure reaches zero, turn knob

an additional 1/4 turn ccw. Depress pressure set

button, then turn knob fully ccw and release

button.

d. Turn knob slowly cw and verify that outlet pressure

starts after knob is turned 1/4 turn. Fine

adjustment can be made by depressing the

pressure set button and turning knob cw or ccw

as needed.

If outlet pressure is not indicated with the knob

fully ccw:

a. Turn adjusting knob clockwise (cw) until outlet

pressure is indicated.

b. If outlet pressure is not indicated when the knob is

turned fully cw, depress pressure set button, then

turn adjusting knob ccw until it stops and release

button. Repeat steps (a) and (b) until outlet

pressure is indicated when the knob is turned cw.

c. When outlet pressure starts, turn knob ccw 1/4

turn. Depress pressure set button, then turn knob

fully ccw and release button.

d. Turn knob slowly cw and verify that outlet pressure

starts after knob is turned 1/4 turn. Fine

adjustment can be made by depressing the

pressure set button and turning knob cw or ccw as

needed.

After the regulator is set for normal operation, the

adjusting knob may be set to limit the maximum or the

minimum adjustable pressure setting of the regulator.

For example, a regulator with a 10 to 125 psig outlet

pressure range could be set to limit the maximum

outlet pressure to 90 psig, or it could be set to limit the

minimum outlet pressure to 25 psig.

IM-414.210.02

(2/02)

Setting Outlet Pressure Adjustment Limits

On The R24

© Norgren 2002

1-4. How to Set Outlet Pressure Limit

when the Pressure Set Button is in the

Adjustable Position (Fig 1).

To Set a Maximum Pressure Limit:

1. With primary pressure applied to the R24, turn

adjusting knob clockwise until the desired

maximum outlet pressure is reached.

2. Depress and hold button screw, then turn the

adjusting knob clockwise until it stops. Release

button screw.

3. Turn adjusting knob fully counterclockwise.

To Set a Minimum Pressure Limit:

1. With primary pressure applied to the R24, turn

adjusting knob clockwise until the desired

minimum outlet pressure is reached.

2. Depress and hold button screw, then turn the

adjusting knob counterclockwise until it stops.

Release button screw.

WARNING

When the minimum adjustment limit is set

above zero, the upper limit of adjustment

increases correspondingly, and could possibly

approach inlet pressure.

1-5. Tamper Resistant Procedure (Fig 1).

Adjustment limits can be made tamper resistant by

reversing the position of the red pressure set button

so the end marked TR is up. To reverse the button:

1. Apply minimum 25 psig (1.7 bar) to the regulator.

Turn adjusting knob fully clockwise, then hold

adjusting knob and and remove button screw

using a 5/64" hex wrench. Do not depress

screw, as the adjustment limit will be affected.

Remove button, then reinstall with the end

marked TR up.

2. Install button screw, taking care not to push screw

in when tightening. Turn adjusting knob fully

counterclockwise.

1-6. Warning.

These products are intended for use in industrial

compressed air systems only. Do not use these

products where pressures and temperatures can

exceed those listed under Technical Data.

If outlet pressure in excess of the regulator

pressure setting could cause downstream equipment

to rupture or malfunction, install a pressure relief

device downstream of the regulator. The relief

pressure and flow capacity of the relief device must

satisfy system requirements.

The accuracy of the indication of pressure gauges

can change, both during shipment (despite care in

packaging) and during the service life. If a pressure

gauge is to be used with these products and if

inaccurate indications may be hazardous to

personnel or property, the gauge should be

calibrated before initial installation and at regular

intervals during use.

Before using these products with fluids other than

air, for non industrial applications, or for life-support

systems consult Norgren.

Figure 1. R24 Pressure Set Button

RED PRESSURE SET BUTTON

TR = Tamper Resistant Position

A = Adjustable Position

ADJUSTING

KNOB

BUTTON

SCREW

a subsidiary of IMI plc

Loading...

Loading...