Norgren R18 User Manual

Pilot Operated Regulator

R18 - 00 - X

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Port |

Relief Type |

Gauge |

||||

B.... |

1-1/2" |

R.... |

Relieving |

G.... |

With |

|

C.... |

2" |

N.... |

Non relieving * |

N.... |

Without |

|

* Do not use a feedback type pilot regulator with a non relieving R18 regulator.

TECHNICAL DATA |

6. Install a Norgren muffler (see Replacement Parts) in the |

|||

Fluid: Compressed air |

exhaust port of the R18 regulator. Installation of a muffler |

|||

Inlet pressure range: 0,7 bar (10 psig) minimum to 31 |

will reduce work area noise and protect R18 internal parts |

|||

bar (450 psig) maximum |

from contamination. |

Warning |

||

Operating temperature: -34° to +80°C (-30° to |

|

|

||

+175°F). Air supply must be dry enough to avoid |

Do not plug exhaust port of relieving type regulators. |

|||

ice formation at temperatures below +2°C (+35°F). |

Relief feature will fail if exhaust port is plugged. |

|||

Typical flow with 0,7 bar (100 psig) inlet pressure, 6,3 |

ADJUSTMENT |

|

|

|

bar (90 psig) set pressure, and a droop of 1 bar |

|

|

||

1. Before applying inlet pressure to regulator, turn pilot |

||||

(15 psig) from set: 944 dm3/s (2000 scfm) |

||||

regulator adjustment counterclockwise to remove all force |

||||

Gauge and pilot ports: |

||||

on regulating spring. |

|

|||

1/4" PTF with PTF main ports |

|

|||

2. Apply inlet pressure, then turn pilot regulator adjustment |

||||

G1/4 with ISO G main ports |

||||

clockwise to increase and counterclockwise to decrease |

||||

R1/4 with ISO Rc main ports |

||||

pressure setting. |

|

|

||

Exhaust port: |

|

|

||

3. Always approach the desired pressure from a lower |

||||

3/4" PTF with PTF main ports |

||||

pressure. When reducing from a higher to a lower setting, |

||||

G3/4 with ISO G main ports |

||||

first reduce to some pressure less than that desired, then |

||||

R3/4 with ISO Rc main ports |

||||

bring up to the desired pressure. |

||||

Materials: |

||||

|

|

NOTE |

||

Body, Bonnet,Bottom Plug, Valve: Aluminum |

|

|

||

With non-relieving regulators, make pressure |

||||

Elastomers: Nitrile |

||||

reductions with some air flow in the system. If made |

||||

|

||||

REPLACEMENT ITEMS |

under no flow (dead-end) conditions, the regulator |

|||

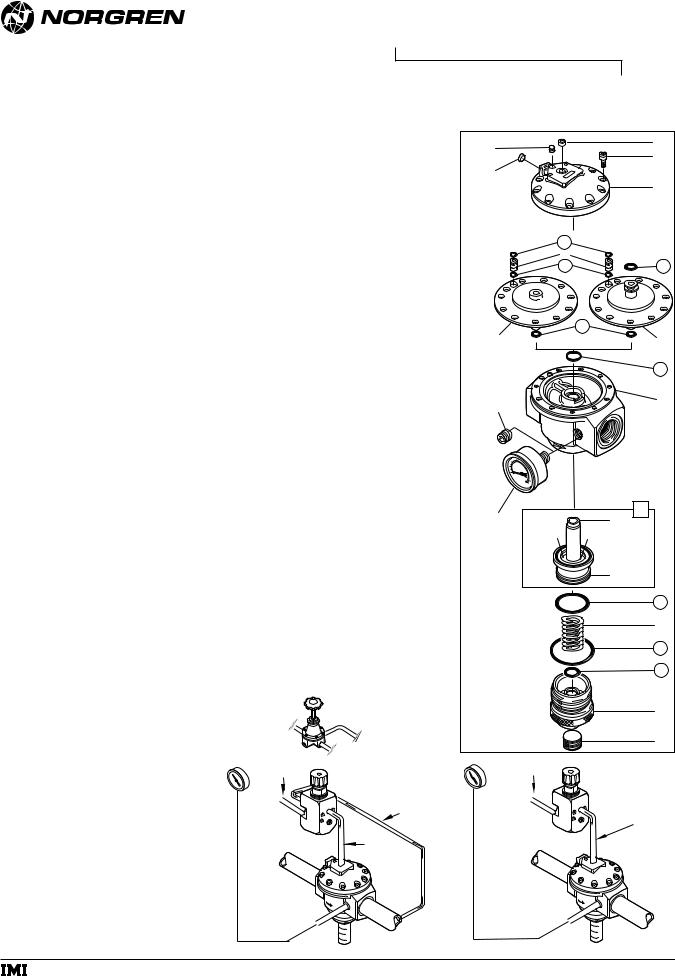

R18 service kit (items circled exploded view)..........5945-40 |

will trap the over-pressure in the downstream line. |

|||

Exhaust muffler |

DISASSEMBLY |

|

|

|

3/4 PTF ...............................................................MB006A |

|

|

||

1. Regulator can be disassembled without removal from air |

||||

R3/4 .....................................................................MB006B |

||||

line. |

|

|

||

|

|

|

||

INSTALLATION |

2. Shut off inlet pressure to pilot regulator and to the R18. |

|||

1. Shut off air pressure. Install regulators in air line - |

Reduce pressure in inlet and outlet lines to zero. |

|||

● upstream of lubricators and cycling valves. |

3. Turn pilot regulator adjustment counterclockwise to remove |

|||

● at any angle. |

all force on regulating spring. |

|||

● install the R18 pilot operated regulator as close as |

4. Disassemble the R18 in general accordance with the item |

|||

possible to the device being serviced. |

numbers on exploded view. |

|||

● install the pilot regulator at any convenient, accessible |

CLEANING |

|

|

|

location. |

|

|

||

1. Clean parts with warm water and soap |

||||

2. Use pipe thread sealant on male threads only when |

||||

2. Rinse and dry parts. Blow out internal passages in body |

||||

making the following pipe connections. Do not allow |

||||

(22) with clean, dry compressed air. |

||||

sealant to enter interior of regulators. |

||||

3. Inspect parts. Replace those found to be damaged. |

||||

● Connect inlet and outlet air lines to R18 main ports |

||||

ASSEMBLY |

|

|

||

with air flow in direction of arrow on body. |

|

Note |

||

● Connect inlet and outlet air lines to pilot regulator main |

|

|

||

ports. The inlet port of the R40 and R41 is marked IN, |

Early and current diaphragms (16, 17) are not |

|||

and the outlet port is marked OUT. The direction of air |

interchangeable. When replacing a diaphragm, make |

|||

flow thru the 11-104 pilot is indicated by an arrow on |

sure the new one is identical to the used one. In |

|||

the bottom of the body. If desired, inlet air for the pilot |

addition, the bonnet (11) used with the current |

|||

regulator may be tapped from the R18 regulator at the |

diaphragm (17) has a hole drilled on the inside to accept |

|||

R18 port marked PRI. When the PRI port is used to |

the upper piston on the diaphragm. |

|||

supply air to the pilot regulator, inlet pressure to the |

1. Lubricate o-rings and surfaces in contact with o-rings with |

|||

R18 must not exceed the maximum rated pressure of |

||||

a light coat of good quality o-ring grease. |

||||

the pilot regulator. |

||||

2. Lubricate threads on bottom plug (24) with a small amount |

||||

● Connect the outlet of the pilot regulator to the port |

||||

of anti-seize compound. |

|

|||

marked PILOT on the R18 regulator. This is the pilot |

|

|||

3. Assemble the unit as shown on the exploded view. Hold |

||||

pressure line. |

||||

diaphragm (16, 17) against upper travel limit, then apply |

||||

3. Special Instructions for a Feedback Pilot Regulator: |

||||

increasing torque to the 10 bonnet screws in a crisscross |

||||

Connect one end of the feedback line to the feedback port |

||||

pattern. Apply final torque of 13,6 to 14,7 Nm (120 to 130 |

||||

on the pilot regulator. The feedback port on the R41 is |

||||

inch-pounds). Tighten bottom plug (24) hand tight. |

||||

marked FDBK. The 11-104 has two 1/8" PTF feedback |

||||

|

|

|

||

ports. Plug the unused feedback port. Connect the other |

|

|

|

|

end of the feedback line to a gauge port on the R18 or, if |

|

|

11-104 FEEDBACK |

|

maximum precision pressure regulation is desired, to the |

|

|

||

Inlet |

|

PILOT REGULATOR |

||

application point downstream of the R18. Keep the |

|

|||

Air |

|

|

||

feedback line as short as possible and unrestricted. Use |

|

Feedback |

||

1/4" or 3/8 "OD copper tube for the feedback line. Plug |

|

|

Line |

|

unused gauge ports. |

|

|

||

|

|

|

||

Warning - Feedback Pilot Regulators |

|

|

Pilot Pressure Line |

|

Norgren manufacturers two feedback pilot regulator |

Inlet |

|

|

|

types (the R41 and the 11-104). Use the R41, the 11- |

Air |

R41 FEEDBACK |

||

104-002, or the 11-104-003 feedback pilot regulator to |

|

|

PILOT REGULATOR |

|

control outlet pressures greater than 100 psig (7 bar). |

|

|

||

|

|

|

||

Use the Norgren 11-104-001 feedback pilot regulator |

|

|

|

|

to control outlet pressures at or less than 100 psig (7 |

|

|

Feedback |

|

bar). |

|

|

Line |

|

The feedback line must sense R18 outlet pressure |

|

|

Pilot |

|

and must be connected before turning on air pressure. |

|

|

||

Inlet |

|

Pressure |

||

If the feedback line is not connected, R18 outlet |

|

|||

Air |

|

Line |

||

pressure will rapidly increase to inlet pressure when |

|

|||

the feedback pilot adjusting knob is turned clockwise. |

|

|

|

|

4. Install a pressure gauge in a gauge port on the R18, or to the |

|

|

|

|

application point downstream of the R18. Do not connect the |

R18 PILOT |

|

||

gauge to the pilot pressure line, as this pressure is not the |

OPERATED |

|

||

same as the R18 outlet pressure. Locate the gauge next to |

REGULATOR |

|

||

the pilot regulator. Plug unused gauge ports. |

|

|

|

|

5. Install a general purpose filter upstream of the regulator. |

|

|

Outlet |

|

|

|

|

Air |

|

© Norgren 2001 |

Figure 1. Feedback Pilot Installation |

|||

a subsidiary of IMI plc

R18

Installation & Maintenance

Instructions

|

Thread Form |

|

|

A....PTF |

|

|

B....ISO Rc taper |

|

|

G....ISO G parallel |

|

8 |

7 |

|

10 |

||

|

||

9 |

|

|

|

11 |

|

12 |

|

|

13 |

|

|

14 |

15 |

|

16 |

18 |

|

17 |

||

|

||

|

19 |

|

21 |

22 |

|

|

20 |

29 |

33 |

|

30 |

31 |

|

32 |

28

|

27 |

|

26 |

|

25 |

|

24 |

|

23 |

Inlet Air |

R40 CONVENTIONAL |

|

PILOT REGULATOR |

|

Pilot |

|

Pressure |

Inlet Air |

Line |

|

|

|

R18 PILOT |

|

OPERATED |

|

REGULATOR |

|

Outlet |

|

Air |

Figure 2. Conventional Pilot Installation

IM-350.230.01 (5/01)

Loading...

Loading...