Nordyne MGHA-056A AB FC-02, MGHA-070A AA FC-01, MGHA-056A AB FC-01, MGHA-056A AA FC-01, MGHA-070A AA FC-02 Installation Instructions Manual

...

Some of the info we offer in our downloads can be quite old. It’s rare that prices

for parts are listed in manuals, but if you see any please ignore them as the

prices are probably obsolete.

Most manuals contain parts lists and diagrams. The older the unit, the more

you’ll find obsolete parts. In same cases the parts may still be available, but

under a new part number. In other cases a generic part may be suitable for use.

For help in finding parts, please visit our parts store at

www.HVACpartstore.com.

Please note that specifications and illustrations are subject to change without notice and without

incurring obligations.

The information contained in this download is for the use of qualified individuals who have been

trained to interpret this data. All repairs on HVAC equipment should be performed by a qualified

technician. In some states, counties or cities, the law states that repairs must only be done by

licensed individuals. Persons not legally or technically qualified should not attempt to interpret

this information or perform any repairs

.

Downflow, DirectVent (Sealed Combustion)

Forced

Air

Gas

and

Oil Furnaces

Installation Instructions/Owners Manual

Includes

Warranty and Replacement Parts

Ust

Series MG, MM,

MS

and MB

For

installatlon

In:

1,

Manufactured Homes

2 AecreatioMI Vehicles, Park Models. Manulaetured Buildings

3.

Modular HomesIBuildings

4 Slle ConstructIOn

-ResidenllaliCommerclal

FOR YOUR SAFETY

Do

not5tore0rlisegasali""orothe

rflammableIIapors and

IIq

1I1d

5

in Ihe vK:,nity01thisorany

other

appliar>ce

A WARNING:

Improper Inslallatlon, adjustment,

slter.lion,

service

or

ma;nlenanCfO

can

cauSe

Injuryorproperty

damsg<!. ReIer

10

this manual.

for

assistance or additionallnlormatlon consult

a

qualilied

installer, aervice agencyorthe

gas

supplier.

FORYOUR SAFETY

WHATTO DO IFYOU

SMELL

GAS

00

not Iry to

IIgl11

any appliance.

• Do not touch any electncal swuch: do not

use

any phoneInyour

bu,ldlng

• Immediatelycali your gas supplier from a ne,ghbor's phooe, Follow

the gas supplier's inSlrUClions.

If you cannot reach your gas supplier. call tile tire department

A WARNING:

Should

overheating

occur,orthe

gas

supply

lailto

shut

011,

shul

011

the

manualg8S

valvetothe

appliance

belore

6hutlingoNlha

electrical

supply.

AWARNING:

00

not

use

this

Bpplianceilany

part

has been

submerged

under

water.

Immediately

calla

ql1lllilied

service

techniciantoinspecl

tile

appliance andtoreplace

any

pan01the

conlrol

system and

any gas

control

that

has

been submerg<ld underwater.

Leave these

instrue!ions

with

the

homeowner.

Advise

unit

owner/user

to

lollow

the

maintenance

recommendations

outlined. Have a

qualilil!d

service

technician

periodically

check

all

wiring

connections

and

service

unit

as needed.

NORDYNE

mamJ1ac'ur6r

01

/

.-..... .

,.

11.11 "

IQII

..

,~

MIIIE&

prooucrs

-

--

These instructoons are primarily intended to assist qualified mdiv,duals experienced m the proper installat,on of heat,ng and!

or

air condiliOnlng apphances. Some localcodesrequire lICensed installation service personnel forlhls type ofequIpment. Read

alllnstrlJCtlo~

carelully before starting the Installation

TABLE

OF CONTENTS

WARRANTY,.

SPECIFICATIONS.

.,

, ,.,., ,.,.

OWNERS INFORMATION ...

MANUFACTURER WARRANTY, OWNER RESPONSIBILITY

..

INSTALLATION

STANDARDS.

UNIT LOCATION ..

MINIMUM CLEARANCES,

RETURN

AIR

PROViSiONS.....

AIR

DISTRIBUTION SYSTEMS

..

ROOF JACK SELECTION

DUCT CONNECTOR SELECTION

INSTALLATION.".....

FLOOR OPENING AND FUEL LINE HOLE

CEILING AND ROOF OPENINGS

DUCT OPENINGS ......

FURNACE MOUNTING

PLATE.

DUCT CONNECTOR

..

FURNACE

.""

.

ROOF

JACK.

."

" "...

INSTALLATION

OF

TRANSIT_MODE VENTING SYSTEM

ELECTRICAL WIRING

FUEL PIPING.

LIGHTING AND FURNACE SHLIT DOWN

STANDING PILOT

(MGHA

MGHB,

MGBB).

SEOUENCEOFOPERATION-STANDING PILOT

DIRECT IGNITION IMMHA, MMHB. MMBB, MBHA. MBBA)

..

SEQUENCEOFOPERATION_DIRECT IGNITION

INSTRUCTIONS-GAS GUN (MBHA. MBBA)

INSTRUCTIONS-OIL GUN IMSHA MSBA)

__

SEQUENCE OF OPERATION OIL GUN

SEOUENCE OF OPERATION GAS GUN

SERVICE GUIDE

BURNER ADJUSTMENT

GAS CONVERSION,

TROUBLESHOOTING

MAINTENANCE

ACCESSORIES

WIRING DIAGRAMS,

REPLACEMENT PARTS LIST IMG, MM)

REPLACEMENT PARTS LIST

1MB

MSI '

............... " 4

. 5

,

....

,7

..,..,7

...,

".

..

e

..............

. e

,

..

...." 9

'"

.....

11

"

"

"

......

12

"

... 12

......" 13

"

"

"

"

.

.17

H

."

19

"

"

.~

"

"

~

.,,22

"

.."..

, ........ , ,..""".

,,,22

....................,

..,..

,22

"

,.., ,,24

."..25

............ 27

..

~

..

39

•

MGHA-

~!j§

AA

Fe

-02

"""'''00

~

1

,:L"m~,

M-Mobile Home

0\

or

02

Fuel. Type01Combu.lion

Special Uae

G·G"".

Direct Vent. ATM Burner

HR-HOl

Su~ace.

Dlrecl Ign,Ii<ln. 100% Shut·OII

B·Gas, Dlreci Vent, Gun Burner FC-Field

Corw,,~ible

M·Gas, Duecl Venl, Induced Dralt FO·Q;I

S·OiI. Direct

VenT.

Gun Burner po-Starnlard Pilot

w~nduce<l

Dralt

Comfort

Mode

.;::

"

HA·AJC

Adaptable

HB·

3

T""

AJC

Rea<tytw"" rolav

BA_AlC

Adaptable

up to 4 tons

BB-

4 Ton

AJC

RM<tylwltl1

relay

C.l>i",,1

Oimen.ion.IH~W~0)

A-56- < 19,314-.23_314-)

B_W

COli

Callitv

176-x19·314"

x 23·314")

L Efe<:lrlcal

Coda

HMling

Capacily

A·1PHi60

HlI120

VAC

Input. BTUH 1000'0)

Tabla

2.

Modell<!onliti""li"n

NORDYNE-manulaclurer

ollntertherm

and

Miller

produCIS.

-------

--------------_0

THIS

WARRANTY1$EFFECTIVEONFURNACES

INSTALLED

AFTER

JANUARY"1994

NORDYNE

LIMITED WARRANTY

Gas, Oil, Electrical Furnaces and Electrical Heat Modules

installed in a Manufactured Home.

Repls.c.ment

""",

cove'ogo

R~"""",'

""""

"""1Ii1od

""""'

lho trrtrl$

Of

tt-o,

...

"....

Iy

'-

'.nlod

Of'<-!

lOr

thO

'''''''''ndo'

of

"'"..,,,,,I

c""o"'\10 0'

tho

<lelK

""",

,0plac.O

.PPLI.NCE

TRADE·IN OPTION

If •

,.placomon'Oea1

.,chorl'}O'

...

nol

"".,Ia~

'O'

tI>.

mo<Ie<

',"naco

NORDYNE

INC.,,;r1

no!,......

0

,.,LInd

lor

t'>etum.>oo.

bu'

.............

C'_

to a NOIlDYNE

INC

<ll<t"""'o<

to,

....

hoa'

.'dlango'

TtHI

0'''''

,,;,

bo

pa.sed

'"

thO..""'.

""""""

II>tfI'"_

<>uri"""""

o!

tho

.........,.

_ bo

...-

'0

....

p"o-cI'W.'

ot

a

<>ow

""nac.

'T IS

HIE

SDLE RESPONSlB,UTY OF

THE

OWNERIUSEROFTHE

.PPLIANCE TO SEE

THaT

THE

APPLI.NCEISPROPERLY

M.IN·

T.INED

.ND

SERVICED OUR'NG

TNE

UFEOFTHE

.PPLI.NCE.

F.ILURE TO

H.~E

NOR

....

L

SER~ICE

.ND

....

INTEN.NCE PER·

FORMED

ON

THE

.PPUaNCE

....

YVOlD

.HIS

W.RR.NTV,

HEaT

UCH.HGER

IGAS

.ND

Oll

FURN.CES),

Hoat

.'Ch<InIIOrs

wt>och

t~.

"""

to

,,,

..

a.

••

""""""0

I,,,,,,

...

OOVOI'go

,I

o

Hit

c",,_

...

cooO<,,",,"' w

••

~10<110

'

...

t",,''OC'

<I"c<

""""""

"'1011<"11'

"""'"'

_..,.,

_,

""

"'"

1_

•.

,ttl>t

....

'

'''''''''ngot

in

...

oppOonc.

ton

"""

10 ,..lKl

"

ma"''''0<""""mo,,,'-oo

.tlr'....

.Xj>O'o_ o!

....

fiIII1

ya'

o!

oovo'OI/O"""'"

pan.

bul

""""

Iho

..

>1t>

"OUII"""'"

ya,o!

....

pan. NORDVNE

INC

.....

pr<Mdo.

NOROYNE

'NC

[>._.

,_,ulOn,

.....

,UChlIngo,atno

0"'-'9"

wntch

....

tie

"""""0<1

10

on

""""",t",,

H"""*

hrm

lor

"",la1>OO

"""

~

oppUan:r r,toght

""",~.

lor

,""

"""''''''''-''\lO'

......., _

....

01

thO

""""",tuM,

ot

"'"

ow>_..

Ubor

"""'9'" "

,opla<o

_

"".t

.""hangooott., tho _ yeo,

..

....

,...,.,.....,..

....

Of

'ho

_rl

...

,

ot

tho

opprlallCO

B"Y'I'

protoe'""

pion,

.'.

av",I.~,"

'h,ough

yoo,

NOADYNE INC

o.,""'u'o<.

fix'

pion

p''''''do.

yoo w,tIl

ad<l""".1

yea"

ol

..,"'".

protec,,,,n.

rho

bu-y

..

1""'''''''''''

pia"

"""IbepmChaS""

wit"'"

180

day>

I,,,,,, tho oat<

,he

luma""

woo

"."IIe<l.

Conlac1.

NOROYNE

INC

DlSlnOOlO,'"roo'

.re.

fOtmo,.

do,.

....

Tho

homeown,,,

poe'.1

,uppllo<l w,'

h",ISProdUCl

h;>,.

1<$,

ol NOR

DVNEINC

o.s"tl"'""

lOt

YOU'

,~'.ronco

T

<I

""'.,n

warran'y.."',,'"

And

,.pI""",.,.",

pan.

, Tho""'\1"')'

,oad

'ho

,pplr.aOCB

warran'y

in,,,,,,,,,,,,,,,.

2

M.k.

oil,."",,,

""""",

,.""""""ndo<l",

'!wi

nc.rr..ow<>or's

"",,,ual

""ppIIBd

""'h

'Ml.POIIa""o

3

II

'ho

p,""'-m

,"I

po

..

"IS.

oontO<:!

'''''

wMCOIoo,..,

WhO

in

..

alod

'ho

'PP~.OCB.

'"

4

COnlllC'

Ihe

comp,my

f,om

whICh

you

p<Jfch

....<I,tHI

opplio"".

10'

...

"'a,,,,<,0'tho

0OO"4"lny

..

ho

in"allt<l

tho

II>ml>C.

S,

111c«tho'

a","ance..ne.<I""

c",,'acla

NORDYNE

'NC

o.st~"'Ot

,n

\'OU'

are.

IS<>••"""""'"

ItS'),

6

II

oil.,

loIIowltlQ

'''''

.""".d••

c'''''''",

you

a'e

.,,1

na....-.g

dolllCulty.

conloct '

...

NOADYNE

INC

Tecr.-.ca.1

S<>"'lCe

~paNmen'ln

S1.

Loo,..

'-10

T.cnnic.1

~fvi<:.

Dop..lmonl

NORDVNE INC

PO

8".

46yn

St.Louio,

'-10 63146-6Y11

JI4·a1a~200

(NOl.: colll•

.,I

c.ll.

will

nolbeoe".p'.dl

C.UTION:

U50

o! •

,.

r>'ICO

fl""

00'

,,"'ho"'""0'OIl

P'O"OO

by

NORDYNE

'NC,

may

'.""'

....

""'"

ondIor

PO"'"

""""JO'''

.,c

...

o! NORDYN" INC:.

_

".","'y

o"""',nco

."I'.ocn..""

..cnatgo'

"'.

"'"

,.,..,.,...

~'yOf

"

..

_'-UHf.

"""

no!

pOyablo oy

NORDYNE

'NC

.....1...

''''''

'"

part.

O'

U.,.,,,,,,

to

\Ill,

"I'r>Ur>co

001

C<J<nP'l"'"

""'"

'IORDYNE

INC:.

""'9"

0""'0<

""",",,,,,,

""",.icot""",

wntch

'.-'

"'"

"",

"""'..<.<

_rsoly

onoet

"'"

"'"

",,"'.''''11

etIO,oct.""""

...

,

v<>d

...

w""aOly

In

ad,,,,,,,,

'"

P'"""""ll

....

,"""'.

f"m

'"""on"_w,,,""ty

,opI&<:omon'

pOrt

• fIORD>NE

INC

dl,U."",,";1

poy

....

5Or>'ICO

firm

....

W>or

"""'I/O'

based

00 NORDYNE

INC:,..orranty

Iat>or,...

prooJ'am. Tho

labor

....

bo

paid

lor

_k

perfort!*l

<lur1ng

....

iomdoo

w",,,.,,ty

pe,,,,,,

wntch

" two ....

""

from

tho

""too!purcnas.

ot

....

__

•.

FI~E

YEAR

P.RTS

.ND

rwD

YEaR

L.8DR

COVER.GE,

If

""Y

p'-rt01""

_"""'.

t.., """ " "",..,..'"

rnato

,.,

0<

_.~

ur.oo,

""'_

""

.M

,.""".

,,;"""

I,..

yO""

'rom

oa,.

o!

....

00_

PO''''''''

oa,.

ot

"",

OfIr>Unc.

I'"

"""'"'"..

'"""

_nco

....

.-..taIoO.,""",

~I

oq..o~),

"

NORDYNE

INC

Do'''"'''O'

WJI

'uwIY"'oplac..".ro

pan,

~

,oq..o,"",

.,

no

Ch'''I/0.'""..""or."

aLJI"""".<I

or""",

Orm.

F'toghl ChatI/O' lor ....

,.".."...-

0""or....

""*

"spoo

....

~ty

01

....

appbatIC.

""""',

THIS

WARRANTY

DOES

NOT

COVER,

, Con""'"11

....

Iu~. trom

"""

f","

10 or>olhor

• "'dillS,.g tNI

_,

onll<,pa'or onhilhorroos'"

J

""y

_'0"'''10'..".""traM.

",".,oneo

""",_Iho

irwdo

and

OOJ"Id.ofthe

""""OJ'.

•

Notmal

maonlonAnCO,

ouch.,

001

""'LV.

rer:<a<_n!.

bI,.,

,~."""",

.oo.

LIMJTATIONS:

n",

....

rron'Y

""..-os

""'Y"

NOROYNE

INC

oppI",,",.,

in'laIIed

"""

_,.,ed

..,.,...

...

oont

.......tal

USAaMC"""""

..,

acoordanco

...

m

NOAOYNE

INC,

~~fIo:a1lOnS"""

onlho&ppllar>co

dola

pIoto!

!.abo!

and nstrucl>Dn.

"'I»'*'

_

tho

&ppIoance:

on<!

""".

not

COIIor

I

.....

duo

10

~t,

..

>USe,

otIo.o.

tavory

~I>O<I,

or....,., .

'"

oppIianco <:ootrols req<Jrod

10

.d.""

"'"

owl

•..,.

"""'.,00<>10

....

strucl",~

"'zo,

9~ophi<:

Ioc._

0'I......

""o<y

Tr..

warranty

go"'"

you

""""fic

......

r<gnI<

,""

y<>.J

may hlI""

01_

,,!jilt.

wntch

v.",

~om

,ta'o'o

,ta,

•.

Some,..,

..

00

oo'llilow

10m..""",

""

""'"

Ion<)

an

~

w..,.royI....

or

""

tho

.,c<.,"'"

0'

~",1a"""

of

"""""'

...

or

0"",<>QUO

"'ra1""rnaI/O', so thO.oovo

10m.."""

<.<

.'0"""'"

rnay

00'

aPI'iY

to you

"fr..

lOa,

,...,ty"

....

only

..

pr

...

w'''.'''Y"""',

",,"""nc.

_ 00

"'

.....

"."maro.

"1"."""_

or

.go.."""'t

by

'"y

PO'''''''

5IIllI

..

>1Ii"

or

"'"""-"\l

""

flO

R

DYNE

INC

.•

"1'

im<>lo-:l

10""""''''",

including

mo"""""·

a"",ty,"'o

OmllOO

'0 tho.-.tIIIi

~\'O

,."

PO""" o!

.,.,..a"...,ty.

NOR·

DYNE

INC.

"no!

h"'''.

tor

any oonstqL

..

nMl

0'

"""""'laI

c..ngo,

causo"byany

""toe''"""

",,"~.nc

•.

•

NORDVNE

INC, "",,oN. , oppliatw:o

.~.,,,

I duo'"<loIOClS"

mo.t~","11>'ld

w",'"",nS/>ol>

,

""'mal

u

urvteo

kY

Iho benolJt

of

hi

o<9'Ia'

""",",-uw, only, as

••

, forth Iow.

ISub_

O'WJlers

""1

ot>toin

.....

"''''nly

",_

"'-Y

cootaclNORDYNE

INC.

irl

wr~oy

.,""v.

"'"

~"

...

fnod)_

Th<s

w,,,.roy,,

v<>d

"'ho..""'

_,

....

t

..

atll,""'"....

appI.aoco

hlI' """'" ,",oov"".

llit.,""0'"",oc""

t

f

r

NonCE

TO INSTALLER

Installerisadvisedtofollow carefully all instruc1ions

and

warnings in this

manualtoinsure

maximum

performance,

safety.and operahngefficiency01these

appliances,

Improper

installation

may

create

hazardous

conditions.

and

will void

the appliance warramy_

1.

SPECIFICATIONS

GENERAL DESCRIPTION

MG. MM,

MS,

andMBSeries gas and oil fumaces are U.L.

Listed and

CSA

certified direct

vent

(sealed combustion).

downflow

healing

and

appliances (or manufactured (mobile)

homes. recrealional vehICles. and for

useInresidentiaV

modular/commercial

construction,

The

furnace

must

be

located so that

venting

canbeproperty achieved,

"A"

cabinet

models

may

be

Installed with Optional Coil

CalJlnet

Model

'911969

for

air

condltloning_

Mulli·spe&d. healinglcoolinQ

blowers

1/3HP(pin 9019981

are

lactory'provldedOnMGBB.

MMBB,

MSBA,

and

MBBA

models.

Add~ionally.

blowermodels

113HP(pin

901998) and

1/2

HP

(pin 901999) are

cerl~led

lor

held

inSlaliatlon in

tumacemodelsMG(H,B}(A,B);MM(H.B)(A,B);MS{H.B)(A,B):

and MB(H,B)

(A,B}when

use<J

inconlunct,on

w~h

2,wlre

relay

(pin 9019S4);

5·w"e

relay (pin 901995):

and

2·wire relay

used wllh

AlC

ready units

(MG(H.B)B

and

MM(H.B)B (pin

902649).

GA.

"_"000....

AG.

.•

"."

........

_

..

,....,.

_"'''-0)-

_ .•' ....r

_"'''-0)-

-

..

'"

-

"--

"

" "

...

~

..

""

"""""

..

,.

..

"

'0'

-_.

~

,

"

" "

"

..

" "

•

-~

..

.....

L'

..

"

.,',

0."

• 0"

_.T""",_

".

..,

"-,,

".

.,

..

"

"B" cab,nel

models

are tactory eqUipped with a lJuilHn coil

cavity

'CSA

1"",,,,'OIJtolIl

TKlle

4.

Ga.

Almo.pheric

Furnece.

liZ'"

NFPT

Gas \falvt Inlet

DESCRIPTION

DOS

'''''COO

ORA

....,

""'OCT"'''''''"

.'00'''_'.

$Iaoo,og P,lol

Eieclrn:

Ignl!lonJIon

_

....

,"-"

-"-"

....

,

_

.........

,

_"-",',0,

AIC

'daOlllbl,

Hal

$!IIMC";

r4JC

readv w're/,jy

-

."

"

.

-

~-

•

"

"

""".,

MGHA-05M (A,6)FC

MMHB-<l56A

IA.BIHR

~-

.,

..

"

,,,,,.,

MGHA-O?OA

(A,BIFC

MMH6·0?OA

(A.B)HR

_0.0.

••

MGHA-O??A

(A,BIFC

-

•

,

•

..

MMHB-onA

(A.B)HR

..

" " "

•

MGHA·090A

IA_BIPO

MMHB-09OA

(A_BlHR

_I

.......

,,·os

""

,,.

,>-I,

SraMmg

PliOI

3

100

EI'Clric ignilion •

1M

·CS.

~'Outpul

NC

agaglablll wlrelav

HoI

SUrfllC,1NCrudy

wlrei,y

Tabl,

5.

Ga.

Forced

Dr.ft.

Direcl Ignition

MGHB-05M IA.BIFC MMBB·056A6HR

""••""

""-0...

n_.e

..

MGHB-O?OA

(A,6IFC MMB6·070A6HR

.•

"""

.........

MGHB-onA (A,6IFC

MMB6·0nA6HR

........

,..,

-."-",

....

...........

"

-.

......

,

- - - -

MGHB-090A (A,6IPQ MMB6-000 A6

HR

""w"

...,w,.

...""

.

_00

-

••

-

••

StaMmg P,lot

,,~

Gas Gun

!l!C

r4dagla/*'

--

" "

•

•

NC

IIddOI.lQlft

wl",tay

MBHA-06SA

(A.BlFC

._-

"

•

,

"

-~.

MGBB-056ABFe

MBHA-oaSA

IA_BIFC

"

"

"

MGBB·070ABFC

Gu

Gun 4

1<10

NC

ild.lglabi,

'0

"

•

MGBB·onA6FC

MBBA·06M IA.SIFC

"'-''''''

•••

..

'"

.

MBSA·OSSA

'A.S'FC -

..

.

..

MGBB·09OABPO

....

'''"'''.00

"-,,

"os

".,

,,-os

EI,ctt'"

IgM.""

Oji

Gun

r41C

Milglam,

Hoi

S"'tace/r4/C i1aapw>!e MSHA-066A {A,B)FO

Table6.Gas A &

Oil

Gun Furnace.

MMHA-~A

IA.BIHR

MSHA-08SA IAB\FO

For

Tables

4

".

MMHA-070A IA.BIHR

Or/

aim.

roa

NC

"<I4mobl,

Eleclr>cal

Supply , ,'"120

\ro~s.

roHz. IIPH

MMHA-OnA (A.BIHR

MSBA-066A (A.B)FO

FuseorBreaker

15

Amps

MMHA-09OA

iA.BIHR

Th-errnosla.

C"cuiL

24

\ro~s,

roH •.15\rAe

MSBA-OSSA

IA_BlFO

Nom.

Anh::>palot

Sell'''9

"""""

..

""

..."..

...... ""_..,,

0.4

see

11>&

lumaee

labtllor

listed opuonal

aor

c""d~jomn9

equipment.

NORDYNE·

manufacturerofIntertherm

and

Miller

products.

_

----.

ABOUT

YOUR

CENTRAL

FURNACE

SYSTEM

Some specifIC examples of service calls whieh cannOI

be

Includedinwalfanly

payments

a'e'

A CAUTION:

COOn:otuty

..........

1hese

respon$IbIlIIlf"""'vo..-

rnanoJIaoctured

housng

dealer.

servK:fl

COI'l"CI3nyor

gas

suppIIe.

IOtnere_

be

no

1nISI.IRderstandu>g

al

a

tal"

,.....

1,

ConvelltngtMtumace10use anorhe. 1ypeotgas.

2 Repalnng

dld

work ,n the

home

tound to belautry

3 Correcl<f'l9 wmng proDlems In

Ina

elecr"cal

Cltcu,1

su~ngthelun;ace

4 Resenltlg

clrl;:\'"

I>leal<etsororne.

SWl1Cne.s

5 Com!c::IlnQprotllemsolHltomprope'gaaSUpplyP<flSUre

I<}

rne tumace,

6 Prow:I,ng Instructo::ltlal

tra,""'9

on

how

10

hgl\!and operate

the

lumace

7. Furnace

problems

caused

by

InslaHallon01an a,r

cond~""",r,

hear

pumpororner

a"

cornlOr1

d8Vrce1;.

8 AcId"'ll a Rool.Jack extensoon

llKa

.....

01

.........

1

WIfld

--,

9

ReVOSIfI9

IOStalla.lX:ln

oIl1le

lurnaceI....

~

(Roo!

-

10 AdjusI"'II

or

calbrarrng

01

tMrrnosla1

The manufacturerotrhls tutnllCe has been Involved in lhe

de~n

01

productstor tile manufacru'edhOrne ,ndusrry

Since

ItIe t,rsI mobile horneorIra.....

wn

001".

NOROVNE

ongon"..:t

rile

_I&d

comtlU$l'On tySrem. whodl

separales the

tumace

combus\lOn

s~em

rrom the

IMtlg

......01the

home,

now.

Slandllldtor rile

manutectu.-d

I\ome

'ndusuy

NOROVNE

etIQItlHlS

<18

...

100«I

lilt'

I~I

central healing

system and

tne

t'rsl cenlral ail con;lft,oner

tor

.....nu1ac1ured

.,~,

NOROYNEISdedlcel&d

10

~g

rotl$CUSlomtrstheln:!'Sl

healing

"tid

ooohng

comlorl

pclSSlbIe,

NOAOVNE

COO5Iantly

seeks

10

lunne.

ret

....

Il$

procIlIelS

10

QOf'IlIfIUOUsIy

prOVIde

excePloona'

c:orRoI1

Folow

tne

0tlIIr\JdI0flS

on

U.

000lcIel

caretuly

and

U.

appIIilnCe

Wlil

pn:lIIIOt ITIllny yeats

01

supeoor

pertormence

d you....sl'110 cool

rour

hOrne .utomelJCally

""'"

a centrel

...

COf'<!llIOfW>g

sysIem

~1~le

IIlI!

exce!lenl NOROVNE

~

systems avallabie from )'OUt heatrog

and

cooiono;I

conlracror

TheM

')'$lams

are GUIQIlI(110 WQrIl

be$!

wei

yourNOFlOVNEI.....-..ce.ndl\elle_ca~

..

9"_,ed

IOdeWe.opIImUmptrlol .....nce

wMnlTlllledWltllNOAOVNE

fTIoV"daetured IlOme lumac

..

NOROVNE

alSOoftersWll-.hHter5.

t

~

__

""lin;

system5 specllleelly Geso;Jf'ld lor

........

ilCI

...

ed hoosIng

aooIIca1lORS

Cheek

WIth

your

motIde

home

dealer.

your

heahflg

and

COOhng

contraclO,

or

)'Ou' dlSlrll:>Ulor

10'

'nlI'lrmallOn-

Wrote

dlreclty1011I41

tiOClory

{PO

eo.

-46911,St

lOUIS.

MO

631461 d you are

nol

allie10locate a source

lor

NOROVNE manuliOClu'ed l.ou

...

'\9

produe\Sonyoura...

•

•

•

Never

anempt

to

alter

or

modify

thl.

fumace

or

My

01

Its

components.

Never

attempt

to

repair

damaged

or

Inoperable

components.

Such

acllon

should

ClUM

un,.fe

operation,

explosion

and/or

fire

uphyxiatian.

" •

malfunction

has

occurred,

orIfyou

.HI

that

the

furnacei.not

operating

a.

tt

should,

contactaquaUlied

Hrvica

BiJIlncy

or

gas

1Jt1l1ty

for

assist.nce.

4.

INSTALLATION

STANDARDS

Installer shan be tal'l'llbar

....

11I

and

~

WlthaMCOGel

and

...gulanons apphcable

10

lhe

onslallal.oon011_

heatrog

appIlances

and

relale<1

equoprnent In

Ioeu

01

local

codes,

tlla

inslallal.oon shan

be

on

accordance Wllhmecu.renl pr(MSOOI'lI

01

one

or

more

or

the

lo1lowtng standards.

a.

Federal ManulaClumd

Hom.-

C()n$tTUeloons

& Sately

Standard (H.U,D, Title 24,

Pall

260)

b. Amencan NatIOnal

Slandard

jANSI.119.2iT11FPA,

501

C) 10'

al

fec,eatlOMl

~l'IIele

Ins'-llalOOns.

c. Aml'ncanNalKJnaI

$landa'd

(ANSI·Z223,liTIIFPA·$t)

and/orC

...

NlCGA614910ra~98S·t"edtu'nace models.

d. Amencan NallOnal Standard (ANSI·Z95, I

iTIIFP

...

·3l)

andlo'

CSA

8139

10' all o,I·I"ed tumace moOels,

e Amer.canNallOnal Slanda,d(ANSI·CI iTIIFPA-70) and/

Of

CSA 22,1 Canadian EJectnc

CoOl

PM

1 to,

an

electneal frek' w,nng

I urms have been ,nvest,gated under slandards UL

NOROYNE·

m.nul.clurer

ollntert;rei~

grimIer

prOducts.

_

3.

MANUFACTURER

WARRANTY.

OWNER'S

RESPONSIBIUTIES

A warriltl1y cen,hcate Wllh

lui

datallsII'ncluded

w~h

these

,nSlructoons. Howeve., NORDVNE

WlII

nol

be

responSlbH!

lor

any

COSIS

foundneee$$!

rytocorrectprotll-ems (lue to'mproper

setup,

""pfoper

Itlslalllll>On.

lu.nace

adjustments,

~roper

operallng p,ocedufe on tile pan or the user, etc

IllS

1IIeso..

responM>lhty01rhe

hOm&OWfler

tomake canaon

me

gas

rumace has

been

correc:I'y

WIuPan(l convened

10

the proper

lue1lLP

gasorNalu-ral gaS) and a(llusled

10

operal"

prOl*rIy

..

~s

rumaces are manulaclure(l

lor

Naturalgas andmU$l~tMllll convened

wilen

us'ngl,P,

gas

5.

UNIT LOCATION

The lurnace shallbeappropnately located to the supply and

retum air dIstribution system. (See "AIR DISTRIBUTION".

Page9)Sides and backof the furnace maybeeoclosed

by

wall framing. (See "Minimum Clearances: Table7.and

Figures 3 through 5.)

The furnace installationisonly ,ntended for free air retum

Ihmugh the furnace door louvers. DO NOT connect a dueled

returna"sySlem directlytothe fumace. Improper installalion

may create a hazard and damage equIpment, as wellasvoid

all warranties.

Furnace maybe InstalledoncombustiblefloOring when

USing

5elles-458 Duct Connectors (see Table10and FIgures 10·

17).

6.

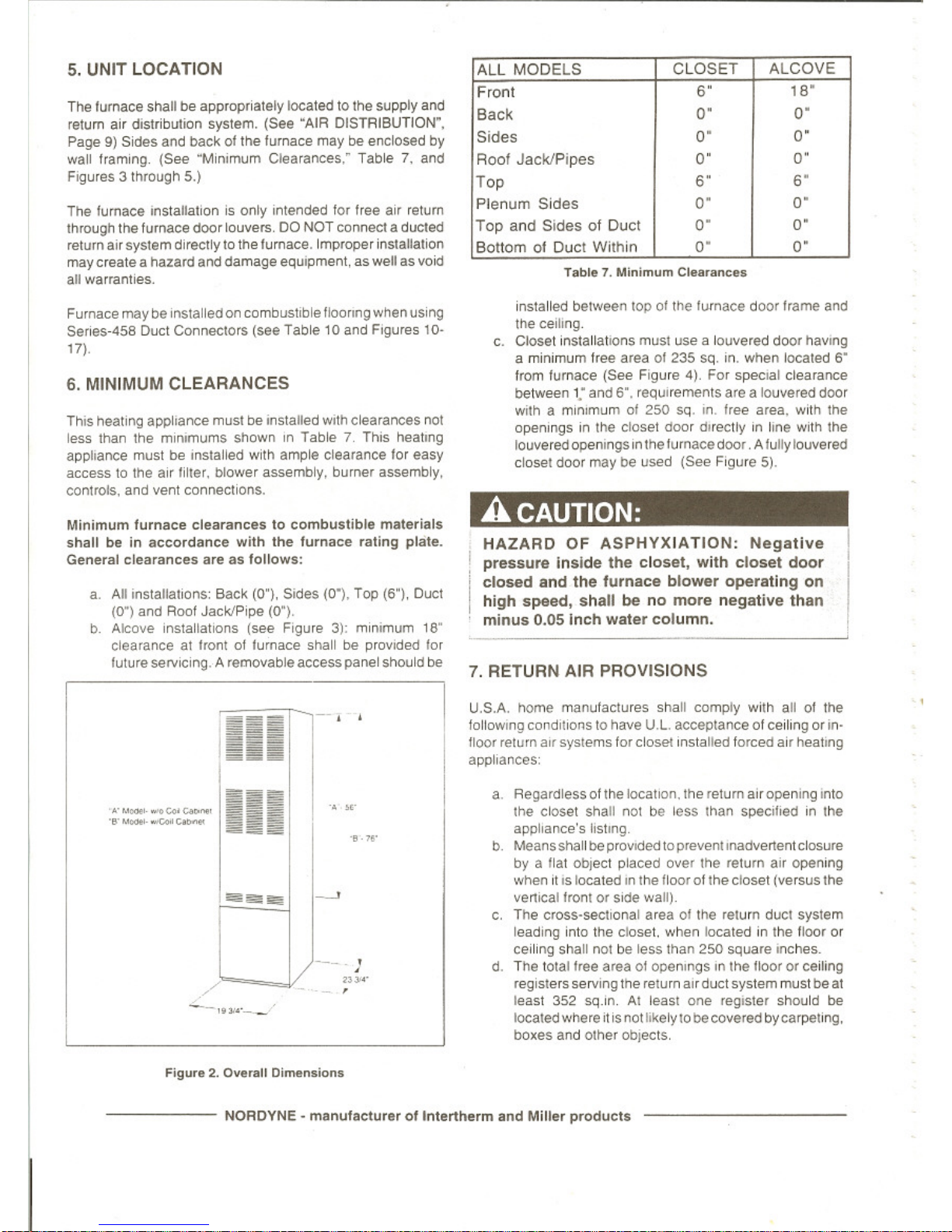

MINIMUM CLEARANCES

Th,s heat",," apphance mustbeInstalled

WIth

clearances

not

less than the minImUms shownInTable7.ThIS

heatIng

appliance mustbeInstalled

With

ample clearance

lor

easy

acceSStothe air lilter. blower assembly. burner assembly.

controls, and vent connections.

Minimum

furnace

clearancestocombustible

materialS

shallbeIn

accordance

with

Ihe

furnace

rallng

plate.

General clearances are as

follows:

a.

All IOstallat,ons; Back (0"), SIdes (0"). Top (6"), Duct

(0") and Roof Jack/Pipe (0")

b Alcove installations (see Ftgure

31:

minImum

18"

clearance at tront of turnace shall be provided lor

future sel\llcing. Aremovable accesspanel should be

III

ALL

MODELS

CLOSET

ALCOVE

Front

'"

""

Back

0"

0"

Sides

0"

0"

Roof

Jack/Pipes

0"

0"

Top

'"

'"

Plenum

Sides

0"

0"

Top

and

SidesofDuct

0"

0"

BottomofDUCI

WIthin

0"

0"

installed between top01the "..mace door

I'ame

and

the cell,ng

c. Closet installatIons

mUSI

use a Iouve'ed door

haVIng

a minImum free area of 235

sq,

on.

when Iocaled

S"

from fumace

l$a<>

Figure

4),

For

speCIal

clearance

between

1,"

and 6". reqUIrements are a louvered door

wllh a minimumof250 sq

,n

Iree a'ea.

With

the

openmgsInthe closet

Ooor

<mectlyinhne

wnh the

louveredopeOlngs

,n

thefurnacedoo' ,Afuliy louvered

c10sel

door mayoeuse<J

(Sa<>

Figure

51.

A CAUTION:

HAZARD

OF

ASPHYXIATION:

Negative

pressure

Inside

the

closet,

with

closet

door

closed

and

the

furnace

blower

operating

on

high

speed,

shall

be

no

more

negative

than

minus

0,05

Inch

water

column.

7.

RETURN AIR PROVISIONS

U.S.A. home manufactures shall comply W'lh ali of the

follOWIng

condilionsto have

U.L

acceptanceof ceilingorm·

floor return all systems for

clOSe!

Installed forced air heanng

appliances;

---

/

..

".

,

•

,,~

..

•

a Regardlessofthe location. the returnairopening mto

Ihe closet shall notbeleSS

lhan specliiedinlhe

appliance's I,stlng

b Meansshallbe provldedlOpreVenl lnadvenentclosure

by

a Ilat oblect placed ove' the returna"opening

whenItIS

located In Ihe lloor of Ihecloset (versus lhe

ven>eal

fronl or Side walil

c,

The cross"sechonal area01the relurn

dUCI

system

leading into the closet, when located in the floo,

Or

ceiling shall notbeless than 250 square ,nches.

d The total hee area ot open,ngs ,n the

Hoor

or ceiling

reglslersservingtne relurn airductsystem must be

at

least 352 sq.in.

AI

leasl one reglste, should

be

Iocaledwhereitisnotlikely

10becoveredby carpellng.

boxes and olhe,oblects,

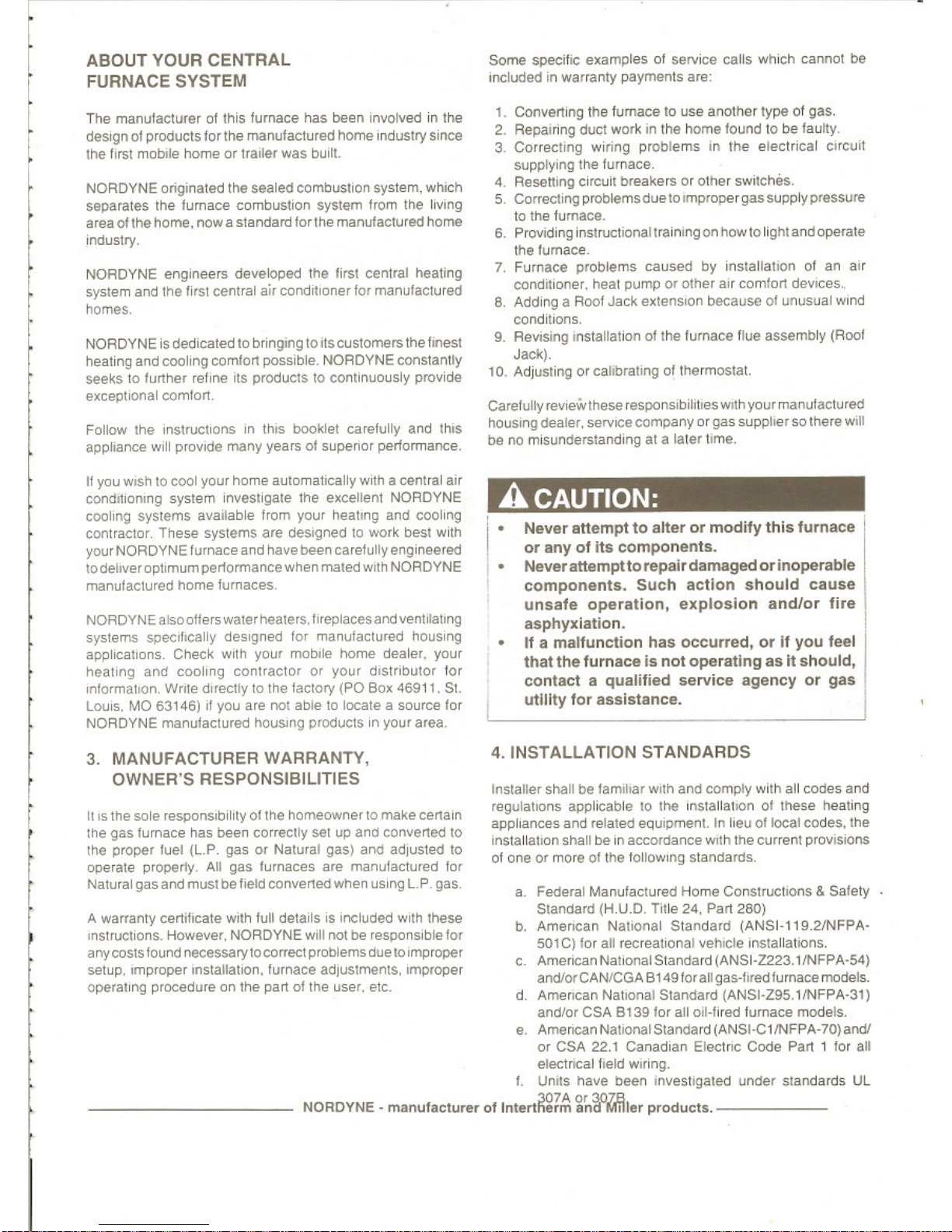

Figure2.Ove",11

Dimensions

NORDYNE - manufaClUreroflntertherm

Bnd

Miller

products

e Materials located

,1'1

the

,,,'um duct system have a

llam<!

spread class,hcal,on ot

200

or

~SS,

f.

Noncombustible pans

havrng1"upturned flanges a,e

located beneath opefllngs

,1'1

a floor duct syslem,

g.

Wiring malerials located in

the

return duct system

shall conform10Art,,,le" 300-22Ofthe NatIOnal

Electrical Code (ANSI C1INFPA-701.

h.

Gas

pipingISnot

run,nOr

Ihroug"

the

relum

dOCI

system,

Test

lt1e

negative

pressu,e

Illlhe closet

wilh

the

air-

circulating fan operatingath'gh speed and the closet

close<'l,

The

negatove pressure

IS

10

be

no

more

negatIve than m,nus 0.05 ioch water column.

For floor return systems.

tile

manutaclured home

manufacturer shall all,. a prominent ma,l"ng on

or

nea, the appliance whereItCanbeeasily read when

the

closet doorisopen. The marketlng sllall 'ead:

HAZARDOFASPHYXIATION:

00

not cover

or

restrict return air opening.

A

CAUTION:

Three typical drslnbut,on

systems

are

illustrated mF,gure6,

For proper air dlstribuhOn, Ihe supply duel system musl be

deSigned so

lhallhe

slatlC pressure

measured

e~le,"al

to

the furnace

does

nol

exceeolhe

Iisteo

stallC

pressure

raling

shown

on

lhe furnace rahng plale.

8. AIR DISTRIBUTION

SYSTEMS

Locanon, size.

and

number01reg,sters shouldbeselec1ed

on the basisof

beSI

aor

distnl>u!Jon

and

floor planofIhe home.

.

_.

w.,

o·

,--

Figure3.Alcove Instalillion

0·

....

CIo"

to

F"

,.

o.-

,

figure4,Closet In.lallation

~

~----~--

"

~

~

~

:~~~:>".

ill

~

~

~

-<

r:'"

-""''''

~~~

"'''''''''

I

~~§

.-

>

02",

~~

~iiii~

r

~

~

iiii

~

(~S

~,

•

"'i'<''''

~:g,:§~

\.,

~i'<''''

"'~,...

II!

•

'-

"",a:

~

~L05E

~~

I,

,

"

[

flgur.6.Typical Supply

Duct

System

============~";O;;;";O;';";;;';~~m;;;.;";";'.;,;';":,rer

01

lnlerlherm

and

Miller

products.

_

9.

ROOF

JACK

SELECTION

,,-

This

;0<01

~'oo

above ceifing

Flashing

.!.ack

'-,.

,

111

/

/

C~vity

I

"~-

-

•

-,-

•

00

I

J

Furn"".

~-.

-

-'-

''''''

Ceding

Flal

Roo

Flue

PI~

CombuSl1

Air

Pipe

APPLICATION NOTES'

a.

FO, SO. SOT and FOT Senes Roof Jacks with a 5"

diameterinner vent pipe may be used with all models

ot

MG, MM. MS. andMBseries

gas and oillumaces,

b.

F_Flat, Flashing: Adjusts Irom

0112toat

least

1112

root slope

C,

S~Slant

Flashing tor

2.5112

Slope: adjusts

1112

to

41

12 root slope,

a Determ",e depth

ot

ceiling caVily trom

centel

of root

openlr>g

to center of ceiling opelllng, (See DimenSIon

"A"

in

Figure

7.)

b.

Determ",eceillngheight arid sublract height ottumace.

(See D,menslO/ls "B"

in

Figure 7.)

c.

AdddlmensOonsA+B (and Xfrom Table 9 and F'9ure

8 if stant deck flashing is used), The lotallength of

(A

+ B +X)Will

be

w~hin

the minimum and maximum

range of one of the Root Jacks

l>StedInTable 8.

Nole: Install only Root Jack Assemblies listedinTable 6

on

this Ileating appliance,

ROOF

JACK

EXTENSION

Figure

7. Rool Jack A

••

embfleo

Figure

8

~

"X"

(SEE

TABLE

~I

~

ROOf

JACK

SLANT DECK

FLASHING

ROOF

OPENING

CEILING

OPENING

CEILING

PITCHED

,~

ROOF

JACK

WITH

2',112

SLANT

FLASHING

Under some circumstances it maybedeSirable to raise the

Roof Jack by

USing

a furnace Root

lack

exlenslon (external

extensIOn pin 901937,IIIIernai extension pin 901935).

An

extenSIOn

or high

Wind

senes roof jack may helptosolve a

pilol outage caused by unusual wirld elleels because

of

geographICal features such as hiils. trees. tall buildings, etc

The extenSion

IS

availableas an opllonal accessoryand may

be purchased through your NQROYNE distributor.

,

I

,

MODEL

,

APPROX, ADJ.

NUMBER

LENGTHS'

BELOW FLASHING

F01323

-5

13- - 23-

F02343

-5

23" - 43"

501835

-5

18"-35"

502447

-5

24--47"

503253

-5 32" ·53"

504895

-5 48" - 95"

I

50T2442

-5

24"-42-

50T2745

-5 27" - 45"

50145B1

-5 45" - 81"

IFOT2846

-5

28" - 46-

2h

112

SLANT

DECK

SOT

~I

,

.....

."".....,

'"<L"''''_G

T"~T

""

0""'""

OT_

---

27

45

-5

L

6.7.;,",-

,...,TN

--

"'"GlN

5/12

ROOf

SLOPE

Tablee,Rool J..k A

....

mbl>e.

Fig~re

9.

NORDYNE -

manulacturer

ollntertherm

and

Miller

products

--------.

lop

0I5I4'PIY

Ulluel

(SH

Fogure

10)

b.

Seled

appropniIlemodltlt<omTable 10wtw;:hma\C11e'5

X~

01

the lloof

caVl1y,

To maJOffille

a"

deIlvery.remtlIIe reducer"C"

(Me

F"ilure

12JIOoblam

lhe largest open area

tNI

WIll

lIt lhe duetnloor

conSlruc1lOR.

11.INSTAL.L.ATION

Required floor.

ceol,ng.

and loot

CulOu!

openongs

must

be

carefully located to

aVOid

m'sallgnmenlotrhe

lurnace

and

Rool Jack (sef! Figures

13&'4),

Installahon procedules a'e

suggested

lor

typlCallumace Inslallat,ons and

r.ee<:l

not

be

Tolowed in ,he exact IIs'ed

seO

....nce

Flgu..-,O.

R.00f'I

CAVITY

C

I

__

IO•X

...

F9n

'Z_T_'OI

1-1

2~""~oC=r

IF

~ITCH

IS

FLASHING

NO

.X" FACTOI'lIS'

..

,

UN

0ut:1

~,

2·InI:!'"

901942

21/8"

(54MMj

rFloo<

cav,M

is. ConnI<:lOr

MOGel

NumD~r

(51mm/304mm)

718"

122/Ml1

458~01

901987

2 112·

on

12·

90194,

2

112"

(~MM)

l'" 151/Ml)

453902

901988

{64mm/304mml

4

114·

(108mm\

458903

901989

3·

on

'2"

90,940

2

718"

(73MM)

6

114"

(\5!1r1m\

458904

901990

{76mml304mml

8 fl4"

(211;lmm1

458905

901\191

3 '12"

on

'2"

901939

3

114"

(83MM)

'A

,,..

(26Onwn)

.~~

9011192

(89""nI304mml

121(4·

1311"",,)

458907

901993

4"

on

12"

90\938

3 5/8"

(92/o1MJ

(lQ2rnm/J.04mml

T_

10.

Duel

Cor._lI:>n

S"on12'"

U

...

90194\

2

11'2"

(64MMJ

{127"""~"""1

WIth

......

MYIn'iJ

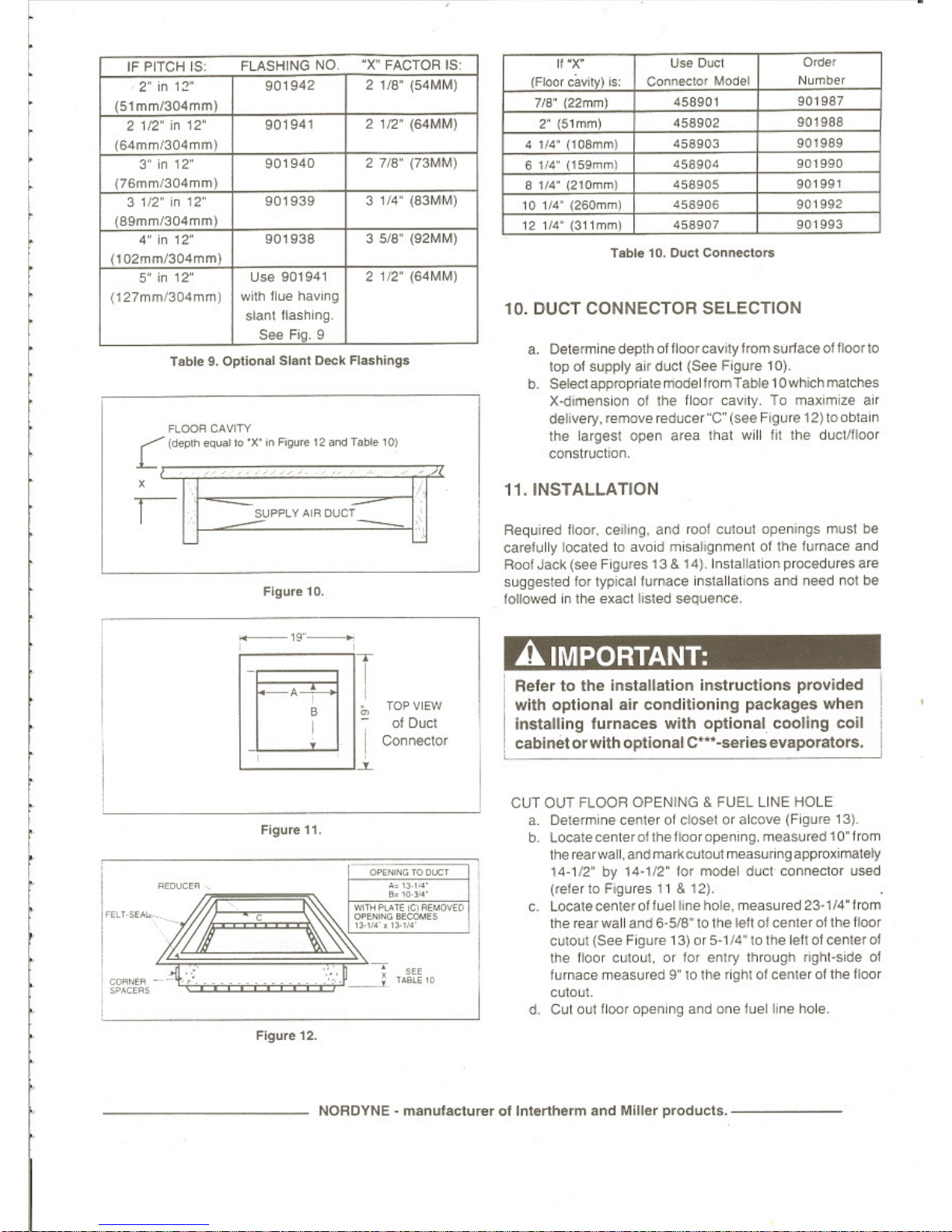

10. DUCT CONNECTOR SELECTION

"""

.....

.

""...Ell

'

a.

Del~dep(h

01Iloo<

cawytromsurlace

0I11oor1O

r

r

t

[

l

r

A IMPORTANT:

Reiertothe

inatallalion

Inalructlona

provided

with

optional

air

conditioning

packages when

Installing

furnaces

with

optional

cooling

coil

cablnetorwith

optional

C'"

"""es

evaporators.

_.-

.~.

Rgu..-l1.

"'''4'

•••

.........

1(0(:

"'l_

-_.

,,.,,

.

,,.

...

CUT

OUT

flOOR

OPENING

& FUEL LINE

HOlE

"'.

Det

.......

~e<

~

etoMt

Of

aJeQvoe (Fogure 1

J)

b Locatecenle<

~1helloorope<Wlg

.

..-sured

10" lrom

there.arwal!.andll'lllll<e>*llAmeasunngawoOXli,ralety

14-1/2" by

""1/2"

lor

r\""IOdII'I

d\lCI

co

..

...ao<

used

(<eter10FIgUf8S

11

&

12)

.

c.

Locateceote<01lue!

...

hole.

measured

23-1/4"

lrom

1I1e

rear will and

&-518"10

Ille

Ie/I

~

centerIII

tIE

IlDor

CUlout

(SH

Fogure

13)or5·114"

10

lhe

leh01<:ente'

III

me IIoor Culout.

or

IOf

efllry mrougtl ngM·SIde

01

furnace measurf(l 9"10rl'\f

.igt11

ot

~Ier

01

the

noor

culOul.

d

CUI

out

Hoor

QPe"'ng and

OI"H!!~

~ne

hole.

Figure

12.

- NORDVNE"

menllt.clur••ollntertherm

and

Miller

prodllcl

•.

_

..

_-'

...

-

...

.......

_-'"

~.-

b. GeI1lel'

ouct

connec1Of

.nd

pu$h

I)adl

.QalO'lSl

.ea.

edge

01

I'Ioor

opel

'"

og

C.

Mark CUlOIA

1oc:a1Kln

(tab

am)

and

rerTIOW! duel

,-

d_

Cut out duel

opetWlg

1!."

IiIrger tNln

....

marl<ed

.

flllu.a

16.0...

1Connector

,

I I

,

..

,.'

-_

........

--

~

.

~

.

-

•

•

-'

~

-

".

....

"

...

-

,

'0

"-

.

~-

•

_0

-0

•

"

...

..............

.-

..'".-.u.

01'

<LOS,,,""...

""""

.

I

..."""

.OHMIl

,

.""

DUC'

""""-

,

""-,

."".-

I

,

....

'-'

..

•

•

/N:'

,

-

-

•

<F<f~~

,

-

J"

...~,..'•.

~

,-

,

"""'"CI.~_

--

~-

•

~-

-

-

•

,

,

•

~

-

-------.-

'.

-----.-::

,

-

..-..

..........

--

•

•

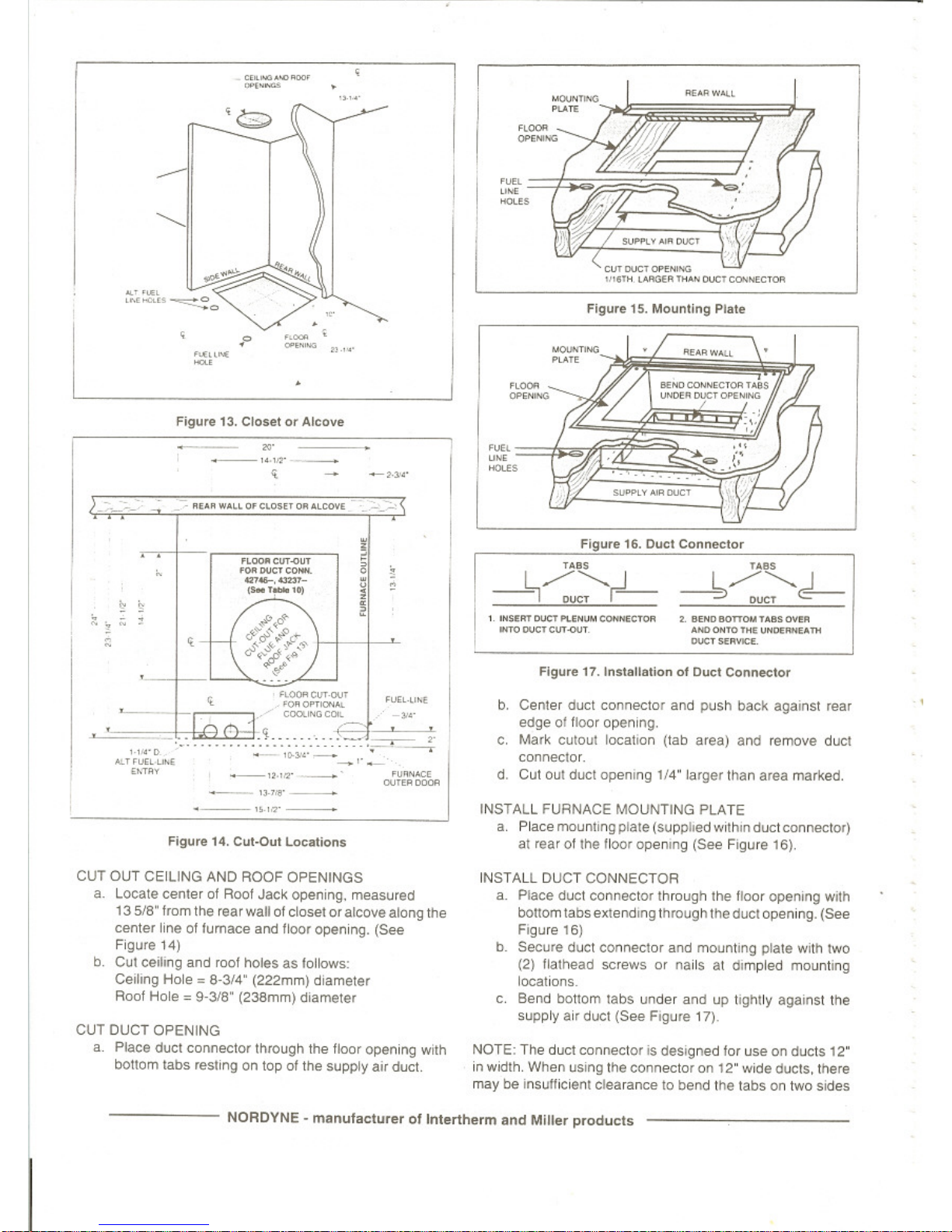

Flgou" 13. Closet

0'

Ako

...

...

""

..1•.

Cul-Out

I

oc:_

INSTALL FURNACE MOUNTING

ptA

TE

il-

Place

mounlIn§l

pa.

..

(S\lJlDlIed

W<Itwl

ouct

t<:A.."""""

ill

rear

ollhe

IIoor

opel-Ill

(See

Fogu.e 16).

ClIT

0lIT

CEILING AND ROOF OPENINGS

._ Lox.al.

<:enl.'

04

Roo!

Jack

openong.

measu

..

d

13

5/8"from

lhe

IU'

wd

04

dosel

CO"

~

8loog l1Ie

cen1et

"""

of

tumillCfl and

1100<

openong.

(See

Ff{j

.....

,.)

b

CUI

QeWlg

and

root

holes

as tallows,

CeUlg

Hole.

8·3/."

(222mml

d'amete'

Roo!

Hole.

g.3Jll" (238mm) d<ameter

CUT DUCT OPENING

a

P~c.

dUCl

connector through the floor opening

Wllh

bOnom

labs

'eSllng on topofthe

supply.It

duct.

INSTAll.

DUCT CONNECTOFl

..

Place duel connector lhrougll

lhe

IIoor

opel_ogWllh

bolIom

labs1!1Iendo:'lg

ll1fOo.1O/1lhe

ducl

~I

,"ig.

(See

Figure

15)

b Secure d...et conneclOf and mountmg plate

WIlh

two

(21

!lathead .crewso.nails aI (IImpled

mount"'9

locations

C Bend bonom labs

uode.

anduptlglltly

aQall1st

tile

SllPPly."

dUCI

(See

Figure 17)

NOTE,

Tile

d...et connecto.,s deSigned for use

on

ducts

12·

in

wJd1h.

When

USing

the connector

on

12" w,(le ducts, there

may be insuMicienl clearance to bend tne tabs

on

two s,aes

-------

NORDYNE -

manufaclur.r

ollnt.rlhe'm

and

Miller

p.oducts

•

•

INSTALL ROOF JACK

c Stide

bacl<

01'10

m:lOnli"ll

plale untit snug. (Bot1om

"'Ilr

stolS on

lumace

should e"<Jall€' with mount''''J

plate 18bs.)

d. Secure front with ooe (1) screw al

each

comer

(Set!

Figu,es

20

or

2t),

Apply Caulkmg to Roof FlashIng. Apply caUlkIng

compDl'n(!

on

Undersideofrootflashing,lDformacon\lnuousstnpatleasl

3/B" wKle

(see

Figure 22) around

the

unde""de

of the

penmelerofthe Hasnln9, Connect Rool

Jack

AssemblytoIhe

fumace.lnsell

telescop<ng

ROOf

Jack

Assemblylhrough

tile

opelll"ll

CUI

on the rool. Connect flue ll'Pl! 10 llue coHar

of

fumace, Connect combustIOn air

P<Pl!

to

lumac

.. collar with

sheet melal

SCrew

(See

Flgufe 23). II is rocommende<! that

the

connection of

the

combuSlIon

alf

p,pe to the Iurnace be

maoe

betore the flashIng is secUfeo to

tt>e

roof10maintain

alignment

01

roof jack and turnace COflIlllCIIOIlS.

NOTE: Addiloonallasteners

may

be

used

al

rear,

SlOeS

or

T1lfOUgh

(100<

frame.as(les"ect,10 secure

lurnace

tocloset

or

aICO"" framIng.

..

-

............

-",,-';."-;

...

\.\_'!"-

'

..

~-."",

---

'._'_.-

-

--v.R2,.t-

_

..

~

-'.

".'

'0"

_.

•

,"

-

......

---'-"

---_.-

u-~

~

r

f

Figure

1lI.

Olille

dllC1

conne<:lO'. In

such

CaseS too

tabs

maybeattached

to

the

sides

01

the

ductbyUSing

sheel

melal

screws

or other

sUitable

lasteners.

(SeeF'gure

18)

NOTE: Forreplacement lumaces,

bes"re

the

Innerllue

pipe

connects

overlhe

fumaceventcollar.00NOT

uae..amaller

diameler

inner

Ilue

pipe

Which

could

alid..inside

lhe

lurnace

vent

collar

and

reslricllhe

Ilow01lumac..lIue

producls.

FiGure

21.

"A"

Callin..t

Fum""

.. on

"196'

Coil Ceblnel

--

....'......

y'"""

'""OM",

"."

•

--

...'...w••

'"""

""toM'

.....

"

IIJI'

•

"'

....

.,,,-

-,.

~o~"~"'_

.,~~~

•

«_

'..-.co

~"',"""'ws

."

....

'

"""/:

""'

..

."-.-

...

C>

.

'"""

.-"0,,,,_,,,,

..._..

c..ooo_.

~.

"

~"""",,,WS

.,,""",

=-0._..

}

."

Figure

20.

-A"&-B"

Ceblnel Furn..:

..

It tapeIS

Use<110

provide a

bene'

seal.,tshouldbeapproved

by

applicable natKlOllIOflOCal

codes

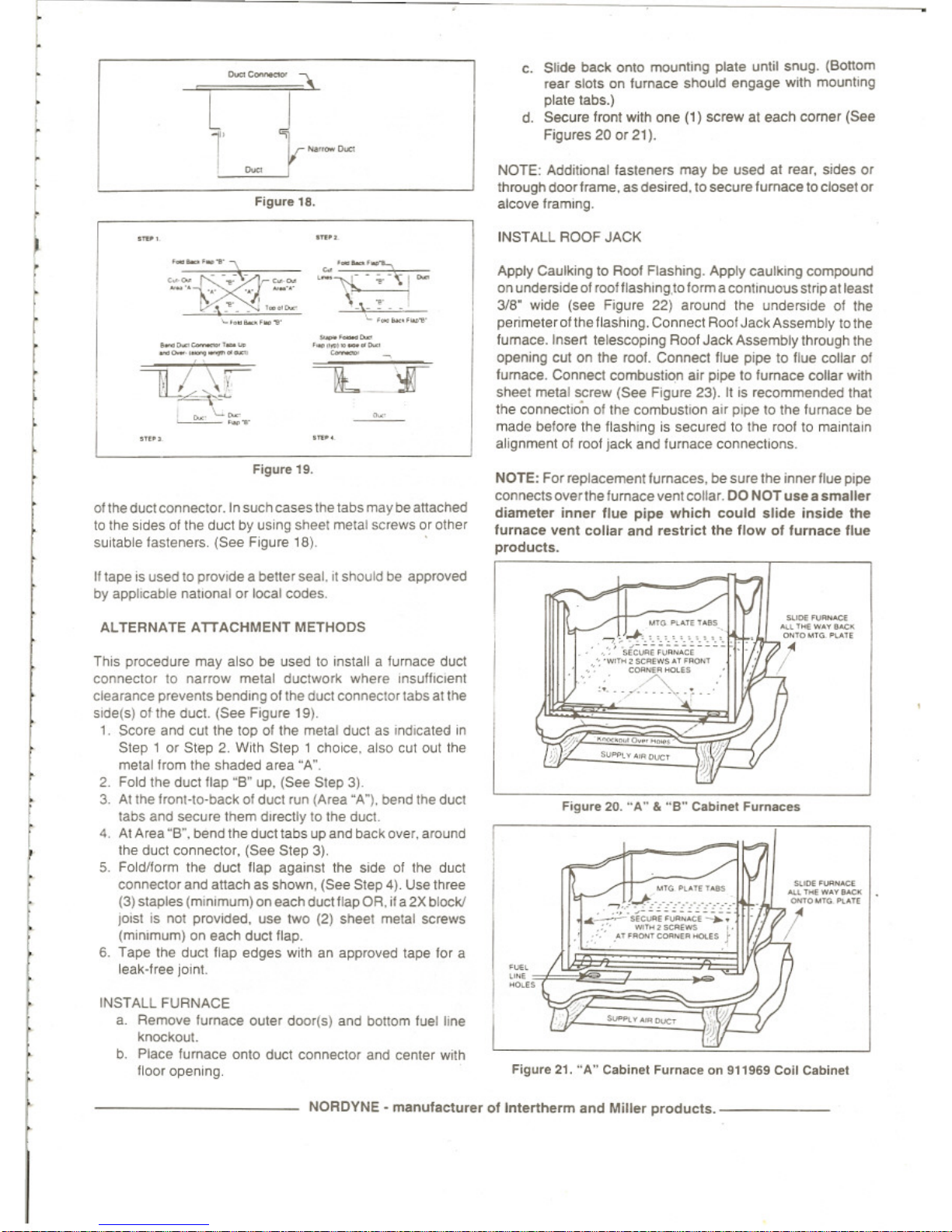

Til,s procedure

may

also be used10,nstall a furnace

dUel

ccmnector 10 narrow

melal

dUClwor1<

whe'e

Insulh"",n1

c~a,ance

prevents bending

of

lhe

Que!

ccone<:IO'

tabs

at the

sKleis)

01

the

duct

(See

F'!lure 19)

1 SCore

and

Cui the top

01

the

metal

ductasIndICated

,n

Slep'

or

Step 2. With Slep ,

chOICe.

also cut

001

the

melal from the shaded

a,ea

"A"

2 Fold the duct

Hap

-go

up.

(See

Step 3l

3.

At the

fronHp·Di!ckofdUCI

run

(Area

"A"),

oer>d

the

dUCI

labs

and

secUfe u

....md<re<:lly

to

the

duel

4AtArea"S",

bend

the dUCl1abs up

an<!

back

o"e"

around

'he

duct

connectO'.lSet!

Step 3),

5.

Foict/lorm the

duel

flap

a'1a"ut

the

sode

ot the duet

COMedO,

an<!

attach as

s!>Own,

(Set! Step 4). Use Ih,,,,,

(3) staples(mlnomum)oneachduct flap OR.

~

a2Xblock/

""stis1101

p<0\fItIe<l. use two (2) Sr.eel metal screws

(minImum) on each

duct

llap.

6.

Tape

the duel flap edges

With

an approved tape tor a

leak·f,ee

jomt

ALTERNATE

ATTACHMENT

METHODS

INSTALL FURNACE

a. Remove furnace

oute,

doorlsj

an<!

b<:1lI0m

tvet tIne

knockout

b,

Place fumace onlO duct connectO' and center

w~h

floo, opening

NORDYNE·

manufactu,eroftnlertf\erm

and

Millar

producls.

_

Loading...

Loading...