Page 1

Downfl ow, Direct Vent (Sealed Combustion)

Forced Air Gas & Oil Furnaces

Installation Instructions

Series M1B, M1G, M1M & M5S

For installation in:

• Manufactured Homes

• Recreational Vehicles, Park Models, &

Manufactured Buildings

• Modular Homes/Buildings

ATTENTION INSTALLERS:

It is your responsi b il i ty to k no w th i s pro du ct

better than your customer. This includes

being able to install the product according

to strict safety guidelines and instructing the

customer on how to operate and maintain the

equipment for the life of the product. Safety

should always be the deciding factor when

installing this product and using common

sense plays an important role as well. Pay

attenti on to all safety warni ngs and any other

special notes highlighted in the manual.

Improper installation of the furnace or failure

to follow safety warnings could result in

serious injury, death, or property damage.

These instructions are primarily intended

to assist qualifi ed individuals experienced

in the proper installation of this appliance.

Some local codes require licensed

installation/service personnel for this type

of equipment. Please read all instructions

carefully before starting the installation.

Return these instructions to the customer’s

package for future reference.

!

WARNING:

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Leave the building immediately.

• Immediately call your gas supplier

FIRE OR EXPLOSION HAZARD

• Failure to follow safety warnings

exactly could result in serious

injury or property damage.

• Installation and service must

be performed by a qualified

installer, service agency or the

gas supplier.

from a neighbors phone. Follow

the gas suppliers instructions.

• If you cannot reach your gas

supplier, call the fi re department

DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

• Do not store or use gasoline

or other fl ammable vapors and

liquids in the vicinity of this or

any other appliance.

Page 2

SAFETY INFORMATION .............................. 3

REQUIREMENTS & CODES ........................ 3

GENERAL INFORMATION ........................... 5

Warranty Information ................................ 5

Minimum Clearances ............................... 5

Applications ............................................. 6

Unit Location ............................................ 6

CIRCULATING AIR REQUIREMENTS ......... 7

Return Air Connections ........................... 7

Supply Air Connections ............................ 7

Operating Instructions - Oil Gun ..............22

Operating Instructions - Gas Gun ............22

How to Shut Off Gas - Gas Gun ...........22

Burner Adjustments .................................22

Gas Pressure .......................................22

Pilot Flame ...........................................22

Combustion Air ........................................23

Gas Gun ...............................................23

Oil Gun .................................................23

Electrode Setting - Oil Gun ......................23

Switching Honeywell (R7184) Ignition from

Interrupted to Intermittent ........................23

FURNACE INSTALLATION .......................... 8

General Information .................................. 8

Requirements & Codes ............................ 8

Locating & Cutting Duct Openings .......... 8

Standard Duct Connector Installation ....... 9

Alternate Attachment Method ...............10

Round Duct Connector Installation ..........10

Installing the Furnace ..............................10

ROOF JACK INSTALLATION ......................11

Roof Jack Selection .................................11

Application Notes .....................................11

Locating & Cutting Roof Openings ..........12

Installing the Roof Jack ............................13

Installation of Transit-Mode Vent System .13

Manufactured Home Factory.................13

ELECTRICAL INFORMATION .....................14

Line Voltage Wiring ..................................14

Connecting Power Supply Wires ...........15

Low Voltage Wiring ..................................15

Connecting Thermostat Wires ...............15

Verifying Anticipator Setting ..................15

Grounding ................................................15

FUEL SUPPLY AND PIPING .......................16

Oil Tank & Piping Istallation .....................17

One Line System ..................................17

Two Line System ...................................17

Fuel Line Hook Up ..................................17

Leak Check .............................................18

Priming Honeywell R7184 ......................18

Priming Beckett 7505 ..............................18

Fuel Oil Type ...........................................18

Conversion to Propane Gas ...................18

Atmospheric & Direct Ignition ..............18

High Altitude Conversion ........................19

Flue Gas Sampling .................................19

STARTUP & ADJUSTMENTS .....................20

Lighting Instructions - Pilot Models ..........20

How to Shut Off Gas - Pilot Models ......21

Operating Instructions - Direct Ignition ...21

How to Shut Off Gas - Direct Ignition ...22

OPERATING SEQUENCE ...........................24

Standing Pilot ..........................................24

Standing Pilot w/ Induced Draft Blower ...24

M1 Models - Direct Ignition ......................24

Oil Gun Models ........................................24

Gas Gun Models ......................................24

FURNACE CONTROLS & FUNCTIONS .....25

Furnace On-Off Switch ............................25

Limit Control ............................................25

Gas Valve.................................................25

Roll Out Switch - M1G .............................25

Oil Burner Primary Control ......................25

Summer Cooling - B,C,D Series ..............25

TROUBLESHOOTING .................................26

Standing Pilot Models ..............................26

Direct Ignition Models ..............................26

Oil Gun Models ........................................27

OPTIONAL ACCESSORIES ........................28

MAINTENANCE ...........................................30

Homeowner Information ..........................30

Installer Information Information ..............30

FIGURE & TABLES ......................................31

Table 10 - Furnace Specifi cations ........31

Table 11 - Orifi ce Sizes - High Alt. ........32

Table 12 - Blower Speed Selection .......32

Gas Information .......................................33

Table 13 - Gas Flow Rates ...................33

Table 14 - Gas Pipe Capacities ............33

Wiring Diagrams ......................................34

Fig. 39 - Gas Furnace - 056, 070 .........34

Fig. 41 - Standing Pilot - 077, 090 ........35

Fig. 42 - Gas Furn. w/ac 056, 070 ........36

Fig. 43 - Standing Pilot. w/ac 077, 090 .37

Fig. 44 - Gas Only (M1M Models) ........38

Fig. 45 - Gas & Oil (M1B & M5S) .........39

Installation Checklist ................................40

2

Page 3

SAFETY INFORMATION

Safety markings are used frequently throughout

this manual to designate a degree or level

of seriousness and should not be ignored.

WARNING indicates a potentially hazardous

situation that if not avoided, could result in

personal injury or death. CAUTION indicates

a potentially hazardous situation that if not

avoided, may result in minor or moderate injury

or property damage.

WARNING:

WARNING:

Do not use this appliance if any

part has been submerged under

water. Immediately call a qualifi ed

service technician to inspect the

appliance and to replace any part

of the control system and any gas

control that has been submerged

underwater.

The safety information listed

below must be followed during the

installation, service, and operation

of this furnace. Failure to follow

safety recommendations could

result in possible damage to the

equipment, serious per

or death

• Use only with type of gas approved for this

furnace. Refer to the furnace rating plate.

• Install this furnace in accordance to the

minimum clearances to combustible materials

listed in Table 1 (page 5).

• Provide adequate combustion air to the furnace

space as specifi ed on page 23.

• Combustion products must be discharged

outdoors. Connect this furnace to an approved

vent system, as specifi ed on pages 13 - 14.

• Never test for gas leaks with an open fl ame.

Use a commercially available soap solution to

check all connections (page 18).

• This furnace is designed to operate with a

maximum external pressure rise of 0.5 inches

of water column. Consult Table 8 (page 38),

and the rating plate for the proper circulating

air fl ow and temperature rise.

NOTE: It is important that the duct system be

designed to handle the desired fl ow rate and

external pressure rise. An improper ly designed

duct system can result in nuisance shutdowns,

and comfort or noise issues.

• This furnace may not be used for temporary

heating of buildings or structures under

construction.

• When supply ducts carry air circulated by the

furnace to areas outside the space containing

the furnace, the return air shall also be handled

by duct(s) sealed to the furnace casing and

terminating outside the space containing the

furnace. See page 14.

.

sonal injury

Notice to Installer

Installer is advised to carefully follow all

instructions and warnings in this manual to insure

maximum performance, safety, and operating

efficiency of these appliances. Improper

installation may create hazardous conditions,

and will void the appliance warranty.

WARNING:

PROPOSITION 65 WARNING:

This product contains chemicals

known to the state of California

to cause cancer, birth defects or

other reproductive harm.

REQUIREMENTS AND CODES

This furnace must be installed in accordance with

these instructions, all applicable local building

codes and the current revision of the National

Fuel Gas Code (NFPA54/ANSI Z223.1) or the

Natural Gas and Propane Installation Code,

CAN/CGA B149.1.

CE générateur d’air chaud doit être installé

conformément aux instructions du fabricant

et aux codes locaux. En l’absence de code

local, respecter la norme ANSI Z223.,1,

institulé National Fuel Gas Code ou les codes

d’installation CAN/GCA-B149.

The Commonwealth of Massachusetts requires

compliance with regulation 248 CMR 4.00 and

5.00 for installation of through – the – wall vented

gas appliances as follows:

1. For direct-vent appliances, mechanicalvent heating appliances or domestic hot

water equipment, where the bottom of the

vent terminal and the air intake is installed

below four feet above grade the following

requirements must be satisfi ed:

3

Page 4

a.) A carbon monoxide (CO) detector and

alarm shall be placed on each fl oor

level where there are bedrooms. The

detector shall comply with NFPA 720

(2005 Edition) and be mounted in the

living area outside the bedroom(s).

b.) A (CO) detector shall be located in

the room that houses the appliance or

equipment and shall:

• Be powered by the same electrical

circuit as the appliance or equipment.

Only one service switch shall power

the appliance and the (CO) detector;

• Have battery back-up power;

• Meet ANSI/UL 2034 Standards

and comply with NFPA 720 (2005

Edition); and Approved and listed

by a Nationally Recognized Testing

Laboratory as recognized under 527

CMR.

c.) A Product-approved vent terminal must

be used, and if applicable, a productapproved air intake must be used.

Installation shall be in strict compliance

with the manufacturer’s instructions. A

copy of the installation instructions shall

remain with the appliance or equipment

at the completion of the installation.

d.) A metal or plastic identifi cation plate shall

be mounted at the exterior of the building,

4 feet directly above the location of vent

terminal. The plate shall be of suffi cient

size, easily read from a distance of eight

feet away, and read “Gas Vent Directly

Below”.

2. For direct-vent appliances, mechanical

vent heating appliances or domestic hot

water equipment where the bottom of the

vent terminal and the air intake is installed

above four feet above grade the following

requirements must be satisfi ed:

a.) A (CO) detector and alarm shall be

placed on each fl oor level where there

are bedrooms. The detector shall comply

with NFPA 720 (2005 Edition) and be

mounted in the living area outside the

bedroom(s).

b.) The (CO) detector shall:

• Be located in the room that houses

the appliance or equipment;

• Be hard-wired, batter y powered or both.

• Shall comply with NFPA 720 (2005

Edition).

c.) A product-approved vent terminal must

be used, and if applicable, a productapproved air intake must be used.

Installation shall be in strict compliance

with the manufacturer’s instructions. A

copy of the installation instructions shall

remain with the appliance or equipment

at the completion of the installation.

The information listed below is for reference

purposes only and does not necessarily have

jurisdiction over local or state codes. Always

consult with local authorities before installing

any gas appliance.

Combustion and Ventilation Air

• US: National Fuel Gas Code (NFGC), Air for

Combustion and Ventilation

• CANADA: Natural Gas and Propane Installation Codes (NSCNGPIC), Venting Systems

and Air Supply for Appliances

Duct Systems

• US and CANADA: Air Conditioning Contractors

Association (ACCA) Manual D, Sheet Metal

and Air Conditioning Contractors National

Association (SMACNA), or American Society

of Heating, Refrigeration, and Air Conditioning

Engineers (ASHRAE) Fundamentals Handbook

Electrical Connections

• US: National Electrical Code (NEC) ANSI/

NFPA 70

• CANADA: Canadian Electrical Code CSA

C22.1

Gas Piping and Gas Pipe Pressure Testing

• US: NFGC and National Plumbing Codes

• CANADA: NSCNGPIC

General Installation

• US: Current edition of the NFGC and the

NFPA 90B. For copies, contact the National

Fire Protection Association Inc., Batterymarch

Park, Quincy, MA 02269; or American Gas

Association, 400 N. Capitol, N.W., Washington

DC 20001 or www.NFPA.org

• CANADA: NSCNGPIC. For a copy, contact

Standard Sales, CSA International, 178

Rexdale Boulevard, Etobicoke (Toronto),

Ontario, M9W 1R3 Canada

Safety

• US: (NFGC) NFPA 54–1999/ANSI Z223.1 and

the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B.

• Federal Manufactured Home Constructions

& Safety Standard (H.U.D. Title 24, Part

3280.707[a][2])

• The Standard for Manufactured Home

Installations (Manufactured Home Sites,

Communities, and Set-Ups) ANSI A225.1 and/

or CAN/CSA-2240 MH Series).

4

Page 5

• American National Standard (ANSI-119.2/

NFPA-501C) for all recreational vehicle

installations.

• CANADA: CAN/CGA-B149.1 and .2–M00

National Standard of Canada. (NSCNGPIC)

GENERAL INFORMATION

Manufacturer Warranty - Owner’s

Responsibilities

It is the sole responsibility of the homeowner to

make certain the gas furnace has been correctly

set up and converted to the proper fuel (L.P. gas

or Natural gas) and adjusted to operate properly.

All gas furnaces are manufactured for Natural gas

and must be fi eld converted when using L.P. gas.

CAUTION:

• Do Not alter or modify this furnace

or any of its components.

• Never attempt to repair damaged

or inoperable components. This

may cause unsafe operation, explosion, fi re and/or asphyxiation.

• If furnace malfunctions or does

not operate properly, contact a

qualifi ed service agency or gas

utility for assistance.

A warranty certifi cate with full details is included

with these instructions. However, NORDYNE

will not be responsible for any costs found

necessary to correct problems due to improper

setup, improper installation, furnace adjustments,

improper operating procedure on the part of the

user, etc. Carefully review these responsibilities

with your manufactured housing dealer, service

company or gas supplier. Some specifi c examples

of service calls which cannot be included in

warranty payments are:

• Converting the furnace to use another type of

gas.

• Repairing duct work in the home found to be

faulty.

• Correcting wiring problems in the electrical

circuit supplying the furnace.

• Resetting circuit breakers, blown fuses or other

switches.

• Correcting problems due to improper gas

supply pressure to the furnace.

• Providing instructional training on how to light

and operate the furnace.

• Furnace problems caused by installation of an

air conditioner, heat pump or other air comfort

devices.

• Adding a Roof Jack extension because of

unusual wind and/or snow conditions.

• Revising installation of the furnace flue

assembly (Roof Jack).

• Adjusting or calibrating of thermostat.

• Any construction debris which falls into fl ue

system.

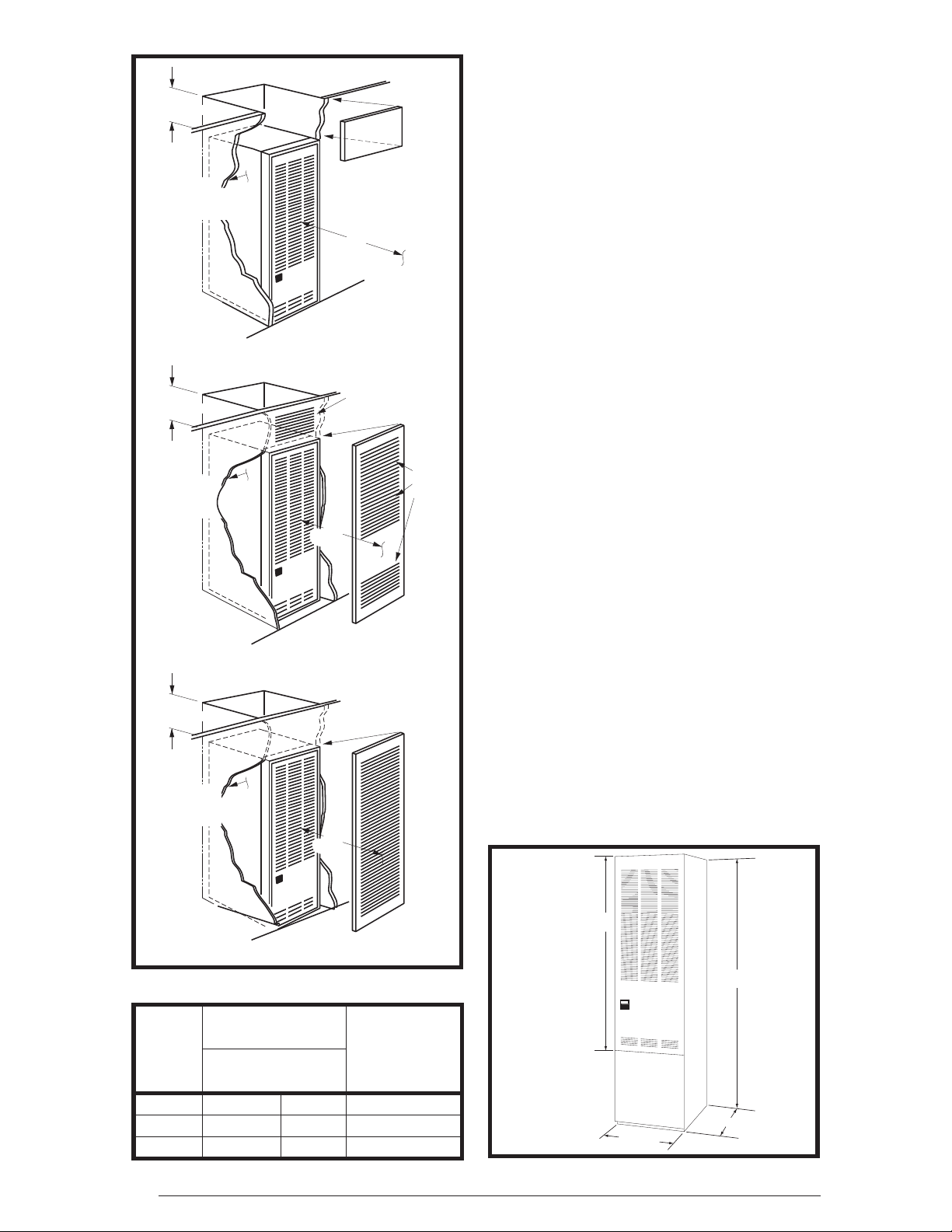

Minimum Clearances

This heating appliance must be installed with

clearances not less than the minimums listed

in Table 1. This furnace must be installed with

ample clearance for easy access to the air fi lter,

blower assembly, bur ner assembly, controls, and

vent connections. See Figures 1 - 3 (page 6).

• The dimensions of the room or alcove must be

able to accommodate the overall size of the

furnace and the installation clearances listed

in Table 1 and in Figure 4 (page 6).

• Alcove installations: minimum 18” clearance

at front of furnace shall be provided for future

servicing. A removable access panel should

be installed between top of the furnace door

frame and the ceiling.

• Closet installations must use a louvered door

having a minimum free area of 235 sq. in. when

located 6” from furnace or 390 sq. in. for 5 ton

ready M1/M5 furnaces. For special clearance

between 1” and 6”, requirements are a louvered

door with a minimum of 250 sq. in. free area,

with the openings in the closet door in line with

the louvered openings in the furnace door. A

fully louvered closet door may be used. See

Circulating Air Requirements (page 7).

ALL MODELS CLOSET ALCOVE

Front 6” 18”

Back 0” 0”

Sides 0” 0”

Roof Jack 0” 0”

To p 6 ” 6 ”

Top and Sides of Duct 0” 0”

Bottom of Duct

B Cabinet 0” 0”

A Cabinet

(w/ coil box)

A Cabinet

(w/o coil box)

Table 1. Minimum Clearances

0” 0”

1/4” 1/4”

5

Page 6

6" (152 mm)

Top Clearance

0" Side

Clearance

to Furnace

Cabinet

6" (152 mm)

Top Clearance

0" Side

Clearance

to Furnace

Cabinet

6" (152 mm)

Top Clearance

0" Side

Clearance

to Furnace

Cabinet

Removable access

panel should be

installed above

furnace door frame

to access roof jack

18"

(457 mm)

Figure 1. Alcove Installation

Provide min. 235

sq. in. (1516 cm )

open free area in

front or side wall

6"

(152 mm)

CLOSET DOOR

Figure 2. Closet Installation

Provide min. 250

sq. in. (1613 cm )

open free area in

front or side wall

1"

(25 mm)

Nearest

Wall or

Partition

2

or

In closet

door

located

at top,

center

or bottom

2

or

in closet

door

a fully

louvered

door may

be used

Applications

M1 Series gas and M5 Series oil furnaces are

listed direct vent (sealed combustion), downfl ow

heating appliances for manufactured (mobile)

homes, recreational vehicles, and for use in

residential/modular/commercial construction.

The furnace must be located so that venting can

be properly achieved.

Air conditioning may be added to structures with

M1/M5 series furnaces using air conditioning or

conventional units. This Installation Instruction

manual includes special requirements for

incorporation of air conditioning equipment to the

M1/M5 series of furnaces. See Tabel 12 (page 32).

Multi-speed blower assemblies shown in Table

2, have been certifi ed for fi eld installation in M1/

M5 Series furnaces.

Unit Location

• The furnace shall be appropriately located to

the supply and return air distribution system

(See Page 7). Sides and back of the furnace

may be enclosed by wall framing. See Minimum

Clearances (page 2) and Figures 1- 3.

• The furnace installation is only intended for

free air return through the furnace door louvers.

DO NOT connect a ducted return air system

directly to the furnace. Improper installation

may create a hazard and damage equipment,

as well as void all warranties.

• Furnace may be installed on combustible

flooring when using NORDYNE Duct

Connectors. See pages 9 & 10.

• When installed in a residential garage, the

furnace must be positioned so the burners and

the source of the ignition are located no less

than 18 inches above the fl oor and protected

from physical damage by vehicles.

CLOSET DOOR

Figure 3. Special 1” Clearance

Blower / Motor

Part

No.

Assembly

Blower

Wheel

Motor

(Hp)

A/C Capacity

(Tons)

903773 10 x 8 1/4 2, 2½ & 3

903413 11 x 8 1/2 2, 2½, 3 & 4

903890 11 x 8 3/4 2, 2½, 3, 4 & 5

Table 2. Blower Assemblies

6

“A”- 56"

“A” Model

w/o Coil

Cabinet

“B” Model

w/Coil

Cabinet

“B”- 76"

23 3/4"

19 3/4"

Figure 4. Overall Dimensions

Page 7

CIRCULATING AIR REQUIREMENTS

WARNING:

Do not allow combustion products

to enter the circulating air supply.

Failure to prevent the circulation

of combustion products into the

living space can create potentially

hazardous conditions including

carbon monoxide poisoning that

could result in personal injury or

death.

All return ductwork must be secured

to the furnace with sheet metal screws.

For installations in confi ned spaces,

all return ductwork must be adequately

sealed. The joint between the furnace

and the return air plenum must be

air tight.

The surface that the furnace is

mounted on must provide sound

physical support of the furnace with

no gaps, cracks or sagging between

the furnace and the fl oor or platform.

Return air and circulating air ductwork

must not be connected to any other

heat producing device such as a

fireplace insert, stove, etc. This

may result in fi re, explosion, carbon

monoxide poisoning, personal injury,

or property damage.

Return Air Connections

U.S.A. home manufacturers shall comply with

all of the following conditions to have acceptable

return air systems for closet installed forced air

heating appliances:

• The return air opening into the closet shall not

be less than specifi ed in the appliance’s listing.

• The cross-sectional area of the return duct

system leading into the closet, when located

in the fl oor or ceiling shall not be less than 235

square inches (or 390 square inches for 5 ton

ready M1/M5 Furnaces).

CAUTION:

HAZARD OF ASPHYXIATION: Do not

cover or restrict return air opening.

• Means shall be provided that prevent

inadvertent closure of fl at objects placed over

the return air opening located in the fl oor of the

closet (versus the vertical front or side wall).

• The total free area of openings in the fl oor or

ceiling registers serving the return air duct

system must be at least 235 sq. in. At least

one register should be located where it is not

likely to be covered by carpeting, boxes and

other objects.

• Materials located in the return duct system

must have a fl ame spread classifi cation of

200 or less. This includes a closet door if the

furnace is in a closet.

• Noncombustible pans having 1” upturned

fl anges are located beneath openings in a

fl oor duct system.

• Wiring materials located in the return duct

system shall conform to Articles 300-22 of the

National Electrical Code (ANSI C1/NFPA-70).

• Gas piping is not run in or through the return

duct system.

CAUTION:

HAZARD OF ASPHYXIATION:

Negative pressure inside the

closet, with closet door closed

and the furnace blower operating

on high speed, shall be no more

negative than minus 0.05 inch

water column.

• Test the negative pressure in the closet with

the air-circulating fan operating at high speed

and the closet closed. The negative pressure is

to be no more negative than minus 0.05 inch

water column.

• Air conditioning systems may require more

duct register and open louver area to obtain necessary airflow. Use NORDYNE’s

certiduct program to determine proper duct

size for A/C.

Supply Air Connections

For proper air distribution, the supply duct system

must be designed so that the static pressure

measured external to the furnace does not

exceed the listed static pressure rating shown

on the furnace rating plate.

7

Page 8

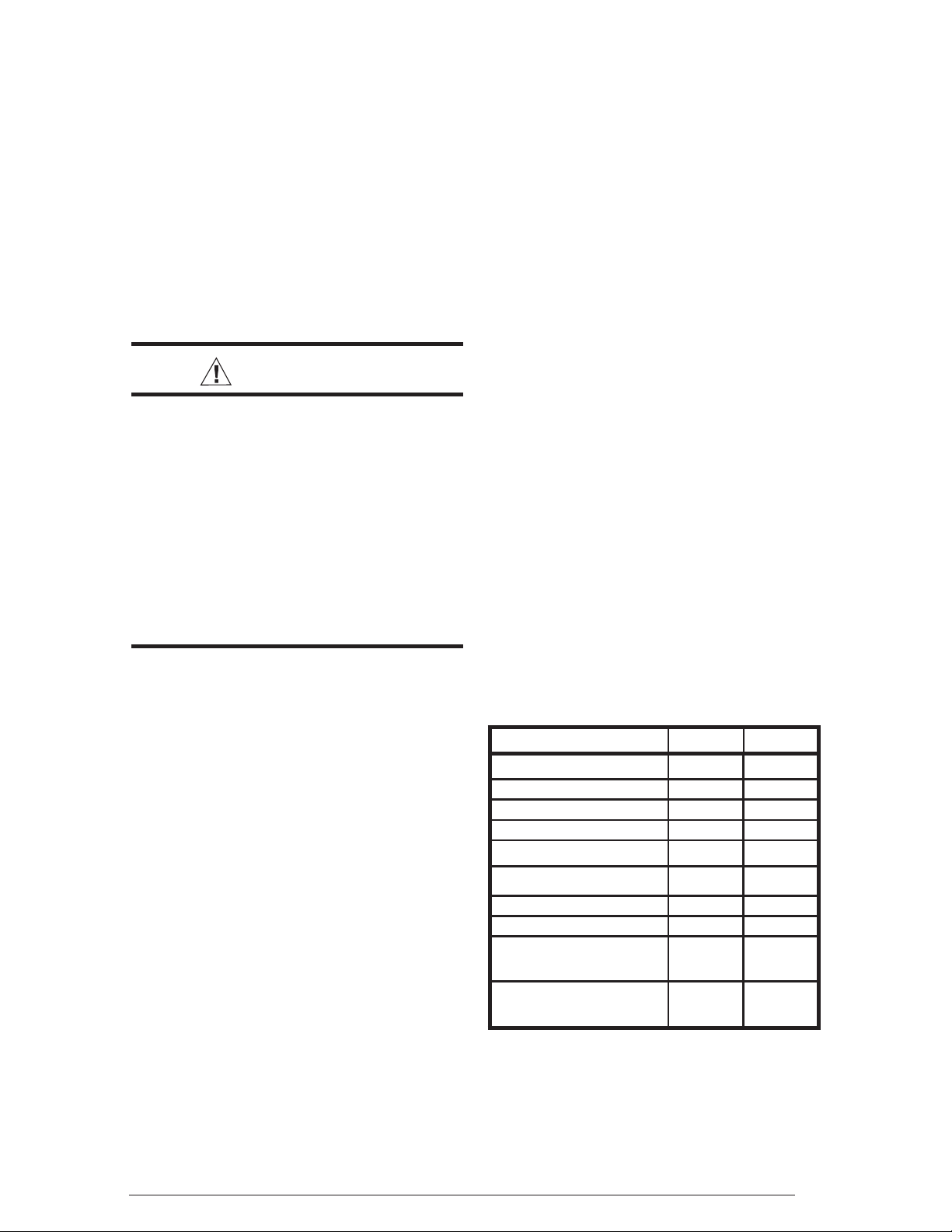

Location, size, and number of registers should

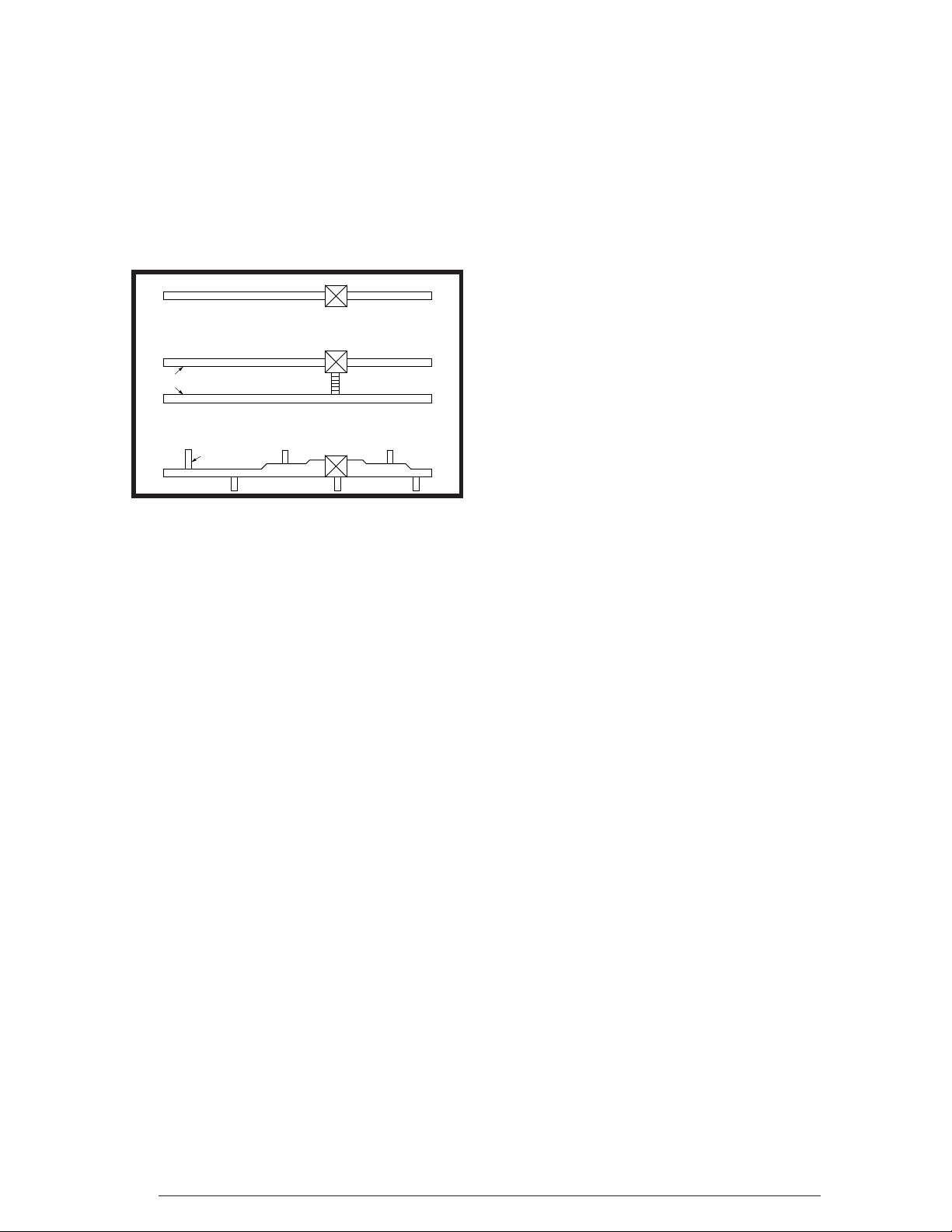

A Single trunk duct

B

Dual trunk duct

w/crossover connector

C

Transition duct

w/branches

be selected on the basis of best air distribution

and fl oor plan of the home. The supply air must

be delivered to the heated space by duct(s)

secured to the furnace casing, running full

size and without interruption.

• The M1 Series gas and M5 Series oil furnace

is certifi ed for use on wood fl ooring or supports,

but must be installed on top of a duct connector.

This factory supplied accessory must be

installed in the fl oor cavity and attached to the

supply air duct before the furnace is installed.

Three typical distribution systems are shown

in Figure 5. The location, size, and number of

registers should be selected on the basis of

best air distribution and fl oor plan of the home.

Figure 5. Typical Supply Duct System

FURNACE INSTALLATION

NOTE: These Installation procedures are

suggested for typical furnace installations.

Since all installations are different from each

other, the sequence of instructions may differ

from the actual installation. Only qualifi ed HVAC

technicians should install this furnace.

General Information

• The furnace must be leveled at installation and

attached to a properly installed duct system. Do

not use the back of the furnace for return

air. See page 7 for circulating requirements.

• The furnace must be installed so that all

electrical components are protected from

water.

• The dimensions of the room or alcove must be

able to accommodate the overall size of the

furnace and the installation clearances listed

in Table 1 and Figure 3 (page 6)

• The furnace must be installed upstream from

a refrigeration system.

• The plenum attached to the A/C coil box and

ductwork within 3 ft. of the furnace must be

installed so that surfaces are at least 1/4” from

combustible construction.

• The cabinet plug must always be used to close

the hole in the side of the furnace when rotating

the inducer.

M1/M5 models must be installed with the Nordyne

•

A/C coil box which are listed according to the

cabinet size of the furnace: “B” cabinet - 920169,

“C” cabinet - 920171, and “D” cabinet - 920172.

8

Requirements and Codes

Installer must be familiar with and comply with

all codes and regulations applicable to the

installation of these heating appliances and

related equipment. In the absence of local codes,

the installation must be in accordance with the

current provisions of one or more of the following

standards.

• Federal Manufactured Home Constructions

& Safety Standard (H.U.D. Title 24, Part

3280.707[a][2])

• American National Standard (ANSI-119.2/

NFPA-501C) for all recreational vehicle

installations.

• American National Standard (ANSI-Z223.1/

NFPA-54) and/or CAN/CSA B149 for all gasfi red furnace models.

• American National Standard (ANSI-Z95.1/

NFPA-31) and/or CSA B139 for all oil-fi red

furnace models.

• American National Standard (ANSI-C1/NFPA-

70) and/or CSA 22.1 Canadian Electric Code

Part 1 for all electrical fi eld wiring.

• Units have been researched under standards

UL 307A & B, UL727-1999, ANSI Z21.47b/

CSA 2.3b-2008, and CSA B140.10.

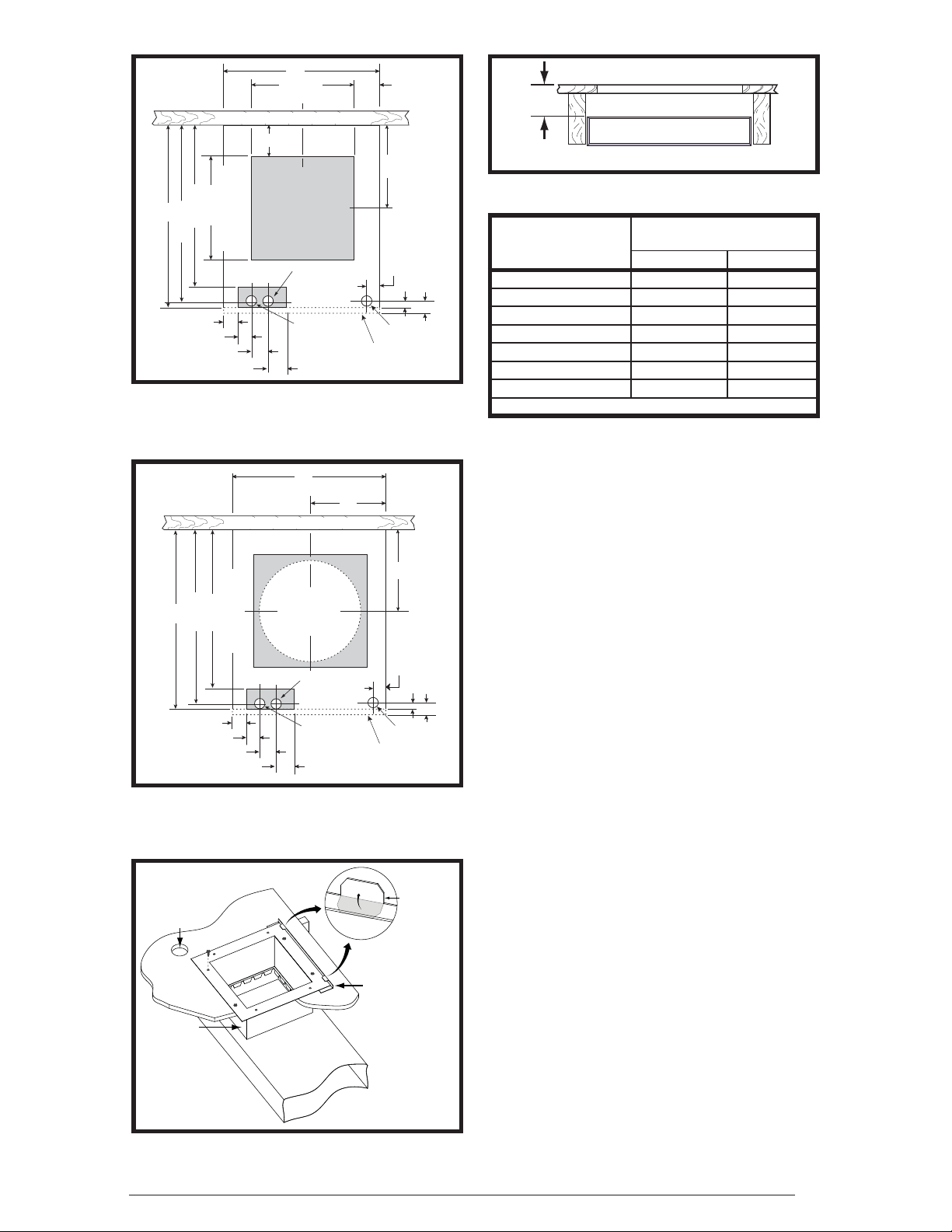

Locating and Cutting Duct Openings

Floor cut-outs and fuel line holes must be carefully

located to avoid misalignment of the furnace,

and vent piping. To locate standard ducts see

Figure 6 (page 9). For round ducts, see Figure 7.

1. Measure 10” from the rear wall or alcove and

mark the centerline of the cut-out on the fl oor.

2. Using the centerline as a starting point, draw

the rest of the duct cut-out to the dimensions

shown in Figures 6 or 7.

3. Cut out the fl oor opening 1/16” larger than

the actual cutout drawn. This will allow some

clearance when installing the duct connector.

4. Measure from the top of the fl oor down to the

top of the supply air duct to obtain the depth of

the fl oor cavity. NOTE: The depth of the fl oor

cavity shown as “X” in Figure 9 (page 9) will

determine the correct duct connector.

5. Determine which duct connector to use from

Table 3 (page 9).

Measure and drill gas hole. and cut out for cooling

6.

coil (if applicable). See Figures 6 or 7 (page 9).

Page 9

20"

14 1/2"

C

L

REAR WALL OF CLOSET OR ALCOVE

2 1/4"

FLOOR CUT-OUT

24"

21 3/4"

14 1/2"

23 1/4"

C

L

1 3/4"

3/4"

1 7/8"

FOR STANDARD

DUCT CONNECTORS

FURNACE OUTLINE

C

C

L

L

2 7/8"

CUT-OUT FOR

OPTIONAL

COOLING COIL

ALT FUEL-LINE

ENTRY 1 1/4" Dia.

1 3/4"

C

L

FURNACE

OUTER

DOOR

Figure 6. Cut-Out Dimensions for

Standard Duct Connectors

2 3/4"

10"

C

L

3/4"

FUEL

LINE

“X”

FLOOR

CAVITY

FLOOR OPENING

SUPPLY AIR DUCT

Figure 9. Floor Cavity

If Floor Cavity

“X” is:

7/8” / (22) 901987A 904008

C

L

2"

2” / (51) 901988A 904009

4-1/4” / (108) 901989A 904010

6-1/4” / (159) 901990A 904011

8-1/4” / (210) 901991A 904012

10-1/4” / (260) 901992A 904013

12-1/4” / (311) 901993A 904014

Note: Dimensions shown as Inches / (Millimeter)

Duct Connector

Type & Part Number

Standard Duct Round Duct

Table 3. Duct Connector Sizes

20"

C

L

10"

REAR WALL OF CLOSET OR ALCOVE

FLOOR

CUT-OUT FOR

24"

C

L

23 1/4"

21 3/4"

1 3/4"

3/4"

1 7/8"

2 7/8"

ROUND DUCT

(14 1/4” DIAMETER)

FURNACE OUTLINE

CUT-OUT FOR

C

C

L

L

COOLING COIL

ALT FUEL-LINE

ENTRY 1 1/4" Dia.

OPTIONAL

C

L

FURNACE

C

L

OUTER

DOOR

1 3/4"

Figure 7. Cut-Out Dimensions for

Round Duct Connectors

Hole for

Gas Line

Duct

Connector

Wood Floor

Connector

Tabs

Supply

Air Duct

Mounting Plate

10"

C

L

3/4"

FUEL

2"

LINE

Bend tabs

up 90°

Standard Duct Connector Installation

The standard duct connector is designed for use

on ducts 12” in width. However ducts narrower

than 12” may not allow suffi cient clearances

for this type of installation. For an alternate

installation method, see page 10.

1. Center the duct connector in the fl oor opening

with bottom tabs resting on top of the supply

air duct.

Mark the cut-out area on the supply air duct by

2.

tracing around the connector tabs (Figure 8) of the

duct connector.

3. Remove the duct connector and cut out the

marked area of the supply air duct 1/4” larger

the actual cutout drawn.

4. Install the duct connector back in the fl oor

opening with the bottom tabs extending into

the supply air duct.

5. Install the mounting plate (Figure 8) under

the back side of the duct connector. Align the

screw holes in both components.

6. Secure the duct connector and the mounting

plate to the wood fl oor with appropriate size

screws.

7. Bend the connector tabs on the bottom of

the duct connector upwards and as tight as

possible against the supply air duct.

8. Bend both tabs on the mounting plate up 90°.

See Figure 10, (page 10)

9. Seal all connections with industrial grade

sealing tape or liquid sealant.

Figure 8. Standard Duct Connector In-

stalled

NOTE: Requirements for sealing ductwork

vary from region to region. Consult with local

codes for requirements specifi c to your area.

9

Page 10

DUCT CONNECTOR

SUPPLY

AIR DUCT

Duct connector tabs

Narrow

Duct

Duct

Flap

Staples or sheet metal screws

Narrow

Duct

BEND TABS TIGHTLY

AGAINST SUPPLY AIR DUCT

Figure 10. Duct Connector Tabs

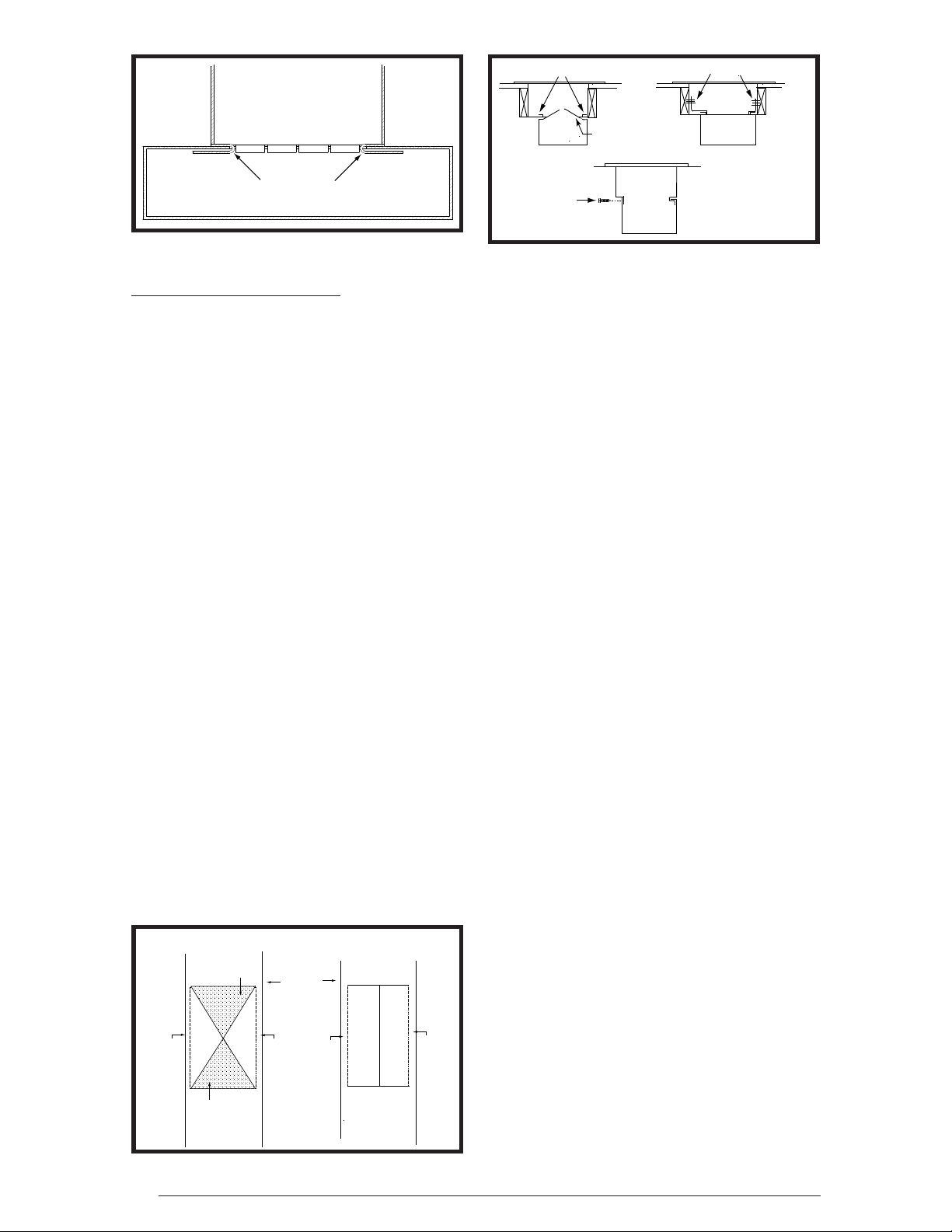

Alternate Attachment Method

The standard duct connector is designed for

use on ducts 12” in width. However if there is

insuffi cient clearance to bend the duct connector

tabs, this alternate attachment method may be

used.

1. Score and cut the top of the supply air duct as

indicated in Option 1 or Option 2 (Figure 11).

With Option 1 choice, cut out the metal from

the shaded area.

2. Fold the two fl aps (Options 1 or 2) up to form

the opening for the duct connector.

3. Install the duct connector with the bottom tabs

extending into the supply air duct.

4. Bend the tabs on the bottom of the duct

connector upwards and as tight as possible

against the supply air duct (Figure 12).

5. Form the fl aps (Options 1 or 2) up against the

duct connector as tight as possible.

6. Secure the duct connector fl aps to the supply air

duct with staples (3 minimum) or if a 2x block/

joist is not provided, use sheet metal screws

(2 minimum). NOTE: The duct connector tabs

may be attached to the air duct with sheet

metal screws or other suitable fasteners as

long as the duct connector and the air duct

are securely attached.

7. Seal all connections with industrial grade

sealing tape or liquid sealant.

NOTE: Requirements for sealing ductwork

vary from region to region. Consult with local

codes for requirements specifi c to your area.

Duct

Sheet metal

screws

Connector

Narrow

Duct

Figure 12. Narrow Ducts

Round Duct Connector Installation

1. Apply a bead of caulking, mastic, or other

approved sealant around bottom side of

connector.

2. Install and center the duct connector in the

fl oor opening.

3. Install the mounting plate under the back side

of the duct connector. See Figure 13 (page 11).

NOTE: Align the screw holes in both

components.

4. Secure the duct connector and the mounting

plate to the wood fl oor with appropriate size

screws.

5. Connect the round supply duct to the underside

of the duct connector and secure them with

fi eld supplied sheet metal screws.

6. Seal all connections with industrial grade

sealing tape or liquid sealant.

NOTE: Requirements for sealing ductwork

vary from region to region. Consult with local

codes for requirements specifi c to your area.

Installing The Furnace

Sides and back of the furnace may be enclosed

by wall framing such as in a closet or alcove. The

dimensions of the room or alcove must be able

to accommodate the overall size of the furnace

and the installation clearances outlined on page

2 and Figures 1 - 4 (page 6). The furnace shall

be appropriately connected to the supply and

return air distribution system as shown in Figures

14 & 15 (page 11).

OPTION 1 OPTION 2

Remove

this

Cut Here

Cut Here

Cut Here

Cut Here

Fold Flap Here

Remove

this

Flap

Flap

Cut Here

Cut Here

Supply

Air Duct

Fold Flap Here

Fold Flap Here

Figure 11. Narrow Air Duct Openings

10

Cut Here

Cut Here

Cut Here

Fold Flap Here

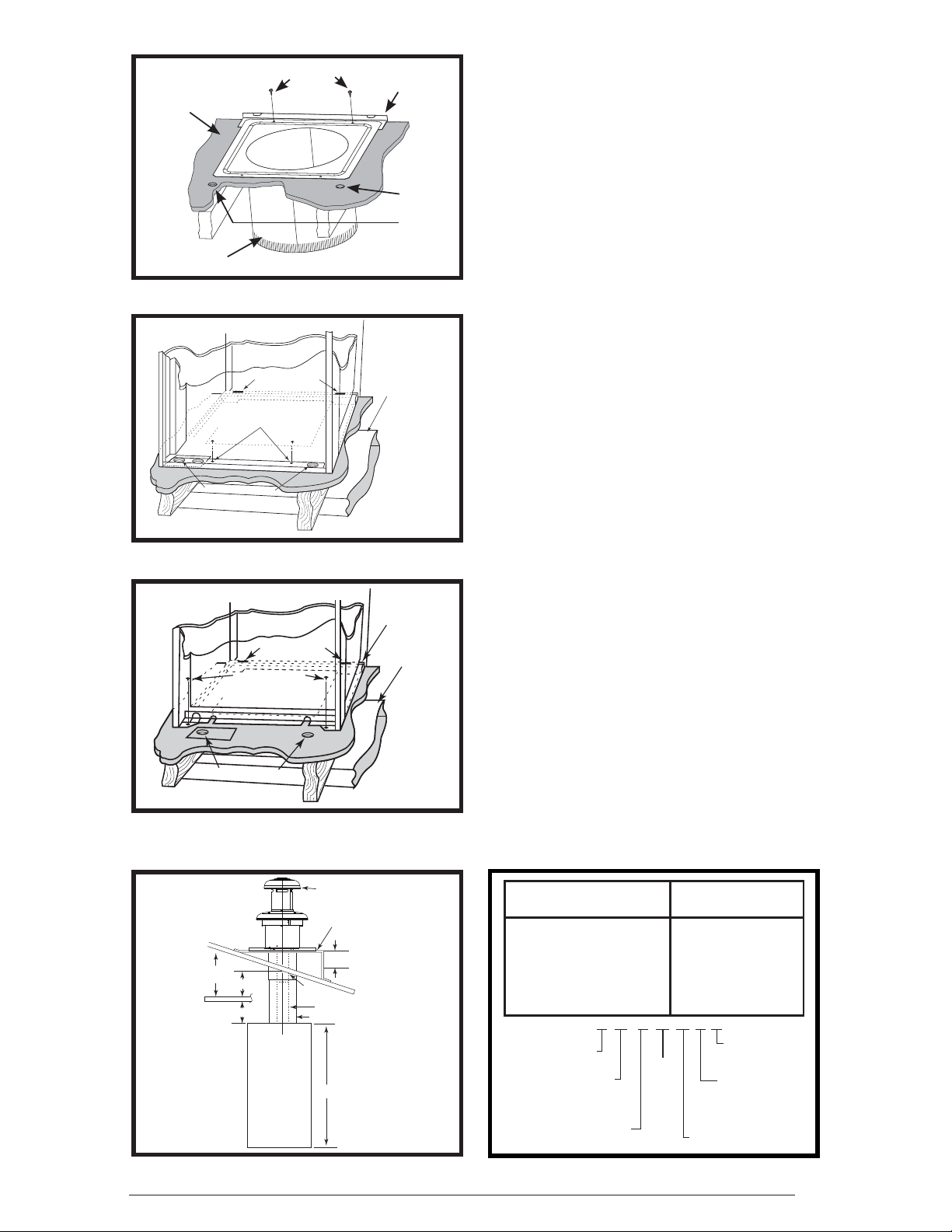

1. Remove furnace outer door(s) and bottom fuel

line knockout.

2. Place furnace onto duct connector and center

with fl oor opening.

3. Slide onto mounting plate. (Bottom rear slots

on furnace should engage with mounting plate

tabs.)

4. Secure front with one (1) fastener at each

corner (Figures 14 or 15).

NOTE: Additional fasteners may be used at rear,

sides or through door frame, as desired, to secure

furnace to closet or alcove framing.

Page 11

DUCT

CONNECTOR

SCREWS

MOUNTING

PLATE

ROOF JACK INSTALLATION

Required ceiling and roof cut-out openings (see

Figure 11) must be carefully located to avoid

misalignment of the furnace and Roof Jack.

Note: Install only Roof Jack Assemblies listed

in Table 4 on this heating appliance.

FUEL

LINE

HOLES

14” SUPPLY

CONNECTION

Figure 13. Round Duct Connector Installed

MTG. PLATE TABS

SECURE FURNACE

WITH 2 FASTENERS AT FRONT

CORNER HOLES

Knockout Over Holes

SUPPLY AIR DUCT

SLIDE FURNACE

ALL THE WAY BACK

ONTO MTG. PLATE

Figure 14. “A” & “B” Cabinet Furnaces

SLIDE FURNACE

BACK AGAINST

MTG. PLATE

MTG. PLATE TABS

SECURE FURNACE

WITH 2 FASTENERS

AT FRONT CORNER HOLES

FUEL LINE HOLES

SUPPLY

AIR DUCT

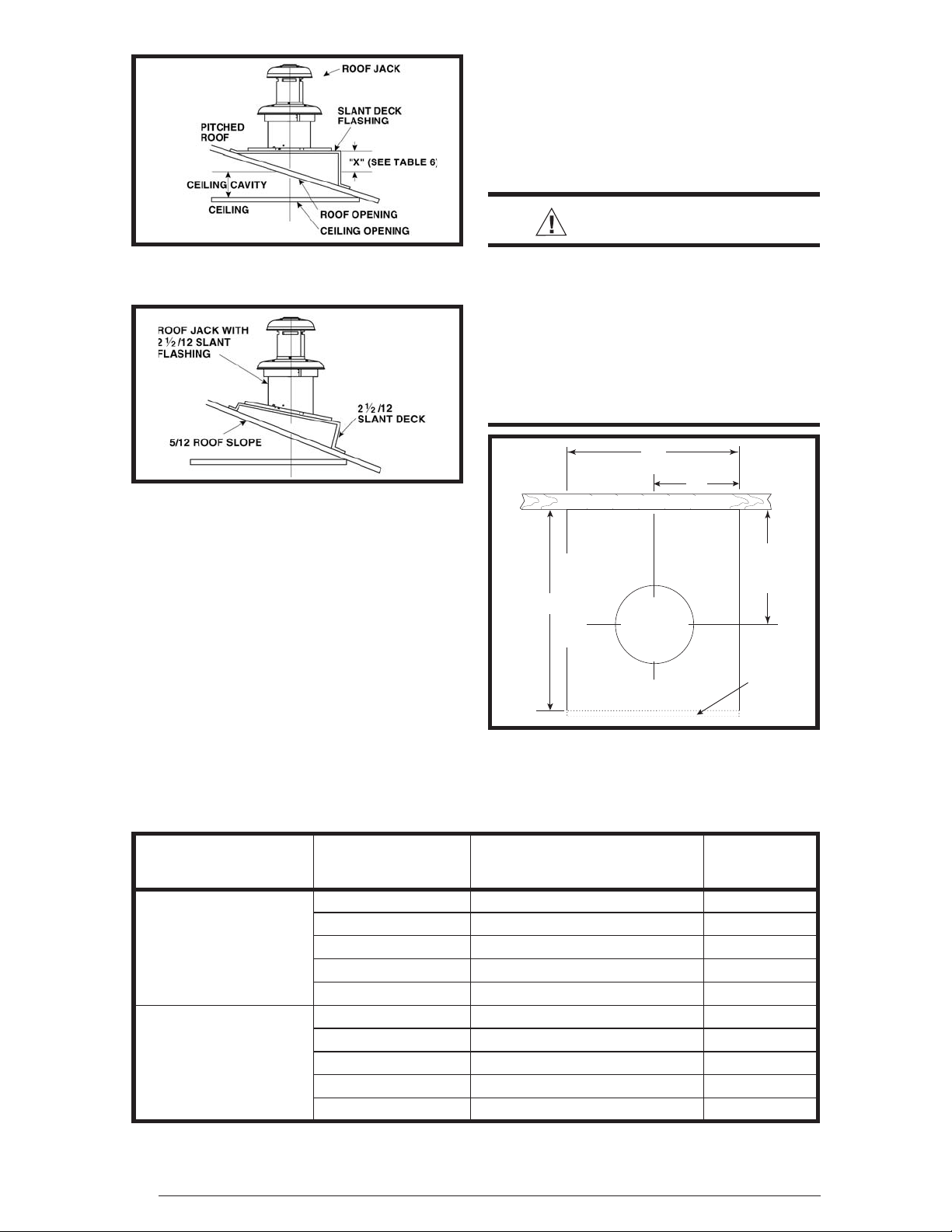

Roof Jack Selection

1. Determine depth of ceiling cavity from center

of roof opening to center of ceiling opening.

(See Dimension “A” in Figure 16.)

2. Determine ceiling height and subtract height

of furnace. (See Dimension “B” in Figure 16.)

3. Add dimensions A + B (and X from Table 5

and Figure 18 if slant deck fl ashing is used).

The total length of (A + B + X) must be within

the minimum and maximum range of one of

the Roof Jacks listed in Table 4.

Application Notes:

• FAW, FAWT, SAW and SAWT Series Roof

Jacks with a 5” diameter inner vent pipe may

be used with all models of M1 Series gas and

M5 Series oil furnaces.

F = Flat Flashing: fl exes from 0/12 to 1/12 roof

slope. See Figure 17 (page 12).

S = Slant Flashing: 2.5/12 Slope fl exes from

1/12 to 4/12 roof slope, 4/12 fl exes from

3/12 to 5/12. See Figure 18.

• Stainless steel roof jacks are available.

• M1/M5 furnaces may be used with roof jacks

as tall as 170” (except M1M 056 & M1B 066

models, which are limited to 120”). An internal

roof jack extension (p/n 901935 - 10”, p/n

903107 - 18”) can be used to increase roof

jack height. All connections inside the home

must be made below the ceiling.

Figure 15. “A” Cabinet Furnace on Coil

Cabinet

ROOF JACK

SLANT DECK

PITCHED

ROOF

CEILING

CAVITY

CEILING

“A”

“B”

Furnace

FLASHING

"X" (SEE TABLE 5)

Roof

Opening

Flue Pipe

Combustion Air Pipe

56" or 76"

Figure 16. Ceiling Cavity Depth

NOTE: If the roof jack crown is covered or blocked

with snow, the furnace will not operate properly.

MODEL NUMBER

(F,S)AW(T)1523-(0,2,4)(A,S) 15” - 23”

(F,S)AW(T)2135-(0,2,4)(A,S) 21” - 35”

(F,S)AW(T)2747-(0,2,4)(A,S) 27” - 47”

(F,S)AW(T)3563-(0,2,4)(A,S) 35” - 63”

(F,S)AW(T)5195-(0,2,4)(A,S) 51” - 95”

SSAW

F = FLAT FLASHING

S = SLANT FLASHING

AW= ALL WEATHER

TYPE:

BLANK = NON-TRANSIT

T= TRANSIT MODE

APPROX. LENGTH

BELOW FLASHING

47 - 2

T

27

MIN. ADJ.

LENGTH

MAX. ADJ.

LENGTH

FLUE STEEL TYPE

A= ALUMINIZED

S=STAINLESS

FLASHING

PITCH/12" RISE

0=FLAT

2=2.5/12

4=4/12

Table 4. Roof Jack Assemblies

11

Page 12

1. Locate center of Roof Jack opening, measure

CEILING

CUT-OUT FOR

FLUE AND

ROOF JACK

C

L

C

L

24"

20"

13 1/2"

REAR WALL OF CLOSET OR ALCOVE

10"

FURNACE

OUTER

DOOR

FURNACE OUTLINE

13 1/2” from the rear wall of closet or alcove

along the center line of furnace and fl oor

opening. See Figure 19.

2. Cut ceiling and roof holes as follows:

• Ceiling = 8 3/4” (222 mm) diameter

• Roof = 9 3/8” (238 mm) diameter

IMPORTANT:

Figure 17. Example of Flat Jack

with Flashing

Figure 18. Example of 2½/12 Slant Jack

with Flashing

If the home is located in regions where snow

accumulation exceeds 7” (HUD snowload zones)

use an external roof jack extension (p/n 901937).

Extensions are optional accessories and may be

purchased through your NORDYNE distributor.

Locating and Cutting Roof & Ceiling Openings

DO NOT ALLOW DEBRIS TO FALL INTO THE

FURNACE. THIS COULD CAUSE UNSAFE

OPERATION AND VOIDS THE FURNACE

WARRANTY. Use the top cap that comes with

the furnace packaging (or alternate protector) to

prevent debris from falling into the fur nace before

the fi nal roof jack connection is made

Refer to the installation

instructions provided with

optional air conditioning

packages when installing

furnaces with optional cooling

coil cabinet or with optional

C* series indoor coils.

Figure 19. Cut-Out Dimensions for

Flue & Roof Jack

12

ROOF JACK SERIES IF ROOF PITCH IS:

SLANT DECK

FLASHING NUMBER

“X” FACTOR

IS:

2” in 12” 903893 (2.5/12) 2-1/8”

2-1/2” in 12” 903893 (2.5/12) 2-1/2”

“F Series

3” in 12” 903894 (3/12) 2-7/8”

3-1/2” in 12” 903894 (3/12) 3-1/4”

4” in 12” 903895 (4/12) 3-5/8”

4-1/2” in 12” 903895 (2.5/12) 2-1/8”

5” in 12” 903895 (2.5/12) 2-1/2”

“S” Series (2.5 / 12

Pitch only)

Optional Deck Flashings for Flat and 2.5/12 Pitch Roof Jacks. 4/12 Pitch Roof Jacks not applicable.

5-1/2” in 12” 903894 (3/12) 2-7/8”

6” in 12” 903894 (3/12) 3-1/4”

6-1/2” in 12” 903895 (4/12) 3-5/8”

Table 5. Slant Deck Flashings

Page 13

Installing The Roof Jack

1. Apply caulking compound on underside of roof

fl ashing to form a continuous strip at least 3/8”

wide around the underside of the perimeter of

the fl ashing. See Figures 20 or 21.

2. Connect Roof Jack Assembly to the furnace.

Insert telescoping Roof Jack Assembly through

the opening cut on the roof.

3. Connect fl ue pipe to fl ue collar of furnace. See

Figure 22.

4. Connect combustion air pipe to furnace collar

with sheet metal screw (See Figure 22).

NOTE: It is recommended that the connection

of the combustion air pipe to the furnace be

made before the fl ashing is secured to the

roof to maintain alignment of roof jack and

furnace connections.

NOTE: For replacement furnaces, be sure

the inner fl ue pipe connects over the furnace

vent collar. DO NOT use a smaller diameter

inner fl ue pipe which could slide inside the

furnace vent collar and restrict the fl ow of

furnace fl ue products.

Secure roof jack with

appropriate fasteners

after connecting to

Caulk under roof

flashing to prevent

water leakage

Optional 2-piece ceiling

ring #902521

Secure lower roof

jack section with

no. 10 S.M. screws

Caulk under roof

ashing to prevent

water leakage

furnace

Figure 20. Flat Roof

Upper Roof Jack Section

Ceiling

Optional Slant

Deck Flashing

Secure ashing

with appropriate

fasteners

Roof

5. Attach Roof Flashing. If necessary, shift roof

fl ashing slightly in the roof opening so that

assembly is in alignment with furnace.

NOTE:

If fl ashing is mounted on 12 degree

angle, it may be necessary to adjust the angle

to match the roof pitch; (1/12 - 4/12 maximum).

6. Press down fi rmly on roof fl ashing (over

caulking) to make the seal with roof water tight.

7. Secure fl ashing with appropriate fasteners.

NOTE: For added protection against leaks, coat

the fl ashing plate and fasteners with approved

roofi ng compound.

Installation of Transit-Mode Venting System

Manufactured Home Factory

1. Furnace must be installed in accordance to

furnace installation manual.

2. Select appropriate Roof Jack from Table 4

(page 11).

3. Roof Jack (less upper Roof Jack crown), with

weather cap to be installed as described under

Install Roof Jack.

Ceiling

Figure 21. Pitched Roof

Figure 22. Combustion Air Pipe Connection

NOTE: Upper Roof Jack crown to be stored in

a prominent location inside manufactured home

until on-site installation.

13

Page 14

4. The four warning tags supplied must be

SCREWS

COMPLETED

ASSEMBLY

TO FURNACE

UPPER ROOF

JACK (CROWN)

INNER FLUE

PIPE

FLUE ASSEMBLY

OUTER PIPE

FLASHING

WEATHER CAP

installed as follows:

• To weather cap

• To fuel line connection point (Gas) or furnace

burner (Oil)

• To furnace fl ame observation door (Gas or

Oil)

• To furnace wall thermostat

5. Transit-mode weather cap to be removed and

upper Roof Jack crown installed (See Figure

24). Do Not Discard screws.

6. Place upper Roof Jack (crown) on to the fl ue

pipe assembly. NOTE: Make sure inside fl ue

pipe attaches over inner fl ue pipe and outer

Roof Jack pipe fi ts over outer pipe.

7. Secure in place using three (3), #10, 1/2” sheet

metal screws removed in step 5. Do not use

the same holes which secured the rain cap in

place.

8. Remove and discard venting system warning

tags.

WARNING:

Failure to properly secure the fl ue

pipe to the furnace may result in

fi re, explosion or asphyxiation

when operating the furnace.

ELECTRICAL INFORMATION

WARNING:

To avoid electric shock, personal

injury, or death, turn off the electric

power at the disconnect or the

main service panel before making

any electrical connections.

• Electrical connections must be in compliance

with all applicable local codes with the current

revision of the National Electric Code (ANSI/

NFPA 70).

• For Canadian installations the electrical

connections and grounding shall comply with

the current Canadian Electrical Code (CSA

C22.1 and/or local codes).

Line Voltage Wiring

It is recommended that 115VAC line voltage be

supplied to the furnace from a dedicated branch

circuit containing the correct fuse or circuit

breaker for the furnace. See Table 10 (page 31).

IMPORTANT NOTE: An electrical disconnect

must be installed readily accessible from and

located within sight of the furnace. Refer to

the wiring diagram inside the control box

cover or Figures 40 - 45 (pages 34 - 39) for the

wiring of your particular unit. Any other wiring

methods must be acceptable to authority

having jurisdiction.

14

Figure 23. Roof Jack Crown

CAUTION:

Label all wires prior to disconnection

when servicing controls. Wiring errors

can cause improper and dangerous

operation. Verify proper operation

after servicing.

IMPORTANT NOTE: Proper line voltage

polarity must be maintained in order for the

control system to operate correctly. Verify

the incoming neutral line is connected to

the white wire and the incoming “hot” line is

connected to the black wire. The furnace will

not operate unless the polarity and ground

are properly connected as shown in Figure 25.

Route all electrical wiring to the left side of the

furnace. For installation of “A” Cabinet furnaces,

allow suffi cient slack in the wiring if an optional

cooling coil cabinet is added at a later time. Use

of copper conductors is recommended.

Page 15

Connecting Power Supply Wires

1. Remove the furnace control panel cover.

2. Route wires (115 VAC) through the strain

relief on the left side of the furnace control box

(see Figure 24).

3. Connect the hot wire to the black pigtail lead,

and the neutral wire to the white pigtail lead.

Secure all connections with suitable wire nuts.

4. Connect the ground wire to the grounding

screw.

5. Reinstall the control panel cover and secure

with the original mounting screws.

Low Voltage Wiring

The thermostat must be installed according

to the instructions supplied by the thermostat

manufacturer. Low voltage connections (24 VAC)

from the thermostat are wired to the terminal strip

on the integrated control in the furnace.

NOTE: The thermostat must not be installed on

an outside wall or any other location where its

operation may be adversely affected by radiant

heat from fi replaces, sunlight, or lighting fi xtures,

and convective heat from warm air registers or

electrical appliances. The nominal anticipator

setting is 0.4. (Refer to the thermostat literature

for additional information.)

Five-conductor thermostat wire is recommended

for 24 volt low-voltage circuit (2-wire is required

for furnace only; 5-wire for heating and optional

cooling systems). Refer to table 6 for thermostat

wire information.

Connecting Thermostat Wires

1. Insert 24 volt wires through the plastic grommet

just above the control panel.

2. Connect the thermostat wires to the furnace

low voltage pigtails (see Figure 25).

3. Connect low-voltage circuit to the wall

thermostat.

4. A hole may be made in the furnace cabinet

to ease thermostat wiring. Make sure that the

wiring is protected from the sharp edge of the

added hole.

Verifying Anticipator Setting

After the furnace is installed, check the thermostat

anticipator against the nominal setting of 0.4.

1. Connect the milliamp meter in series with one

of the gas valve’s low voltage terminals.

2. Energize the gas valve.

3. Read the value of the milliamps.

4. Adjust the heat anticipator of the thermostat

to the value on the milliamp meter.

If the heat

anticipator is set too high, the furnace may

delay turning on. If set too low, the furnace

may cycle frequently and not provide comfort

to the homeowner.

Recommended T’STAT Wire

Thermostat

Wire Gauge

Length (Unit to T’STAT)

2-Wire

(Heating)

5-Wire

(Heating/Cooling)

24 55 25

22 90 45

20 140 70

18 225 110

Table 6. Thermostat Wire Gauge

Thermostat

Rc

H

R

W

G

Y

Red

White

Green

Yellow

M1/M5 A/C

Ready Furnace

Red

White

Green

Grey

Figure 25. Thermostat Wiring For

A/C Ready Models

Grounding

WARNING:

On-Off

Switch

Blower

Plug

Powe r

Entry

On-Auto Switch

(Heating Models Only)

Thermostat Wires

Furnace

Control Box

To combustion

Blower or Flame

Roll-out Switch

To Gas Valve

or Burner

Figure 24. Control Panel (All Models)

To minimize personal injury,

the furnace cabinet must have

an uninterrupted or unbroken

electrical ground. The controls

used in this furnace require an

earth ground to operate properly.

Acceptable methods include

electrical wire or conduit approved

for ground service. Do not use gas

piping as an electrical ground!

15

Page 16

FUEL SUPPLY AND PIPING

WARNING:

All piping must conform with local

building codes, or in the absence

of local codes, with the most recent

edition of the National Fuel Gas

Code ANSI Z223.1 or (CAN/CGA

B149.1 or .2). Failure to follow all

safety warnings could result in

serious injury, death or property

damage.

This furnace may be installed with left or right

side gas entry. When connecting the gas supply,

provide clearance between the gas supply line

and the entry hole in the furnace casing to avoid

unwanted noise and/or damage to the furnace.

Typical gas service hookup for this furnace is

shown in Figure 26. Table 14 (page 37) lists

gas fl ow capacities for standard pipe sizes as a

function of length in typical applications based

on nominal pressure drop in the line.

IMPORTANT NOTES:

• Some local regulations require the

installation of a manual main shut-off

valve and ground joint union external to

the furnace (Figure 36). The shut-off valve

should be readily accessible for service

and/or emergency use. Consult the local

utility or gas supplier for additional

requirements regarding placement of the

manual main gas shut-off.

• Gas piping must never run in or through

air ducts, chimneys, gas vents, or elevator

shafts.

• Compounds used on threaded joints of gas

piping must be resistant to the actions of

-liquefi ed petroleum gases.

• The main gas valve and main power

disconnect to the furnace must be properly

labeled by the installer in case emergency

shutdown is required.

• Flexible gas connectors are not recommended for this furnace but may be used

if allowed by local jurisdiction. Only new

fl exible connectors may be used. DO NOT

reuse old fl exible gas connectors.

• A drip leg should be installed in the vertical

pipe run to the unit (Figure 36).

• All piping shall be black iron pipe, or

equivalently sized steel tubing. Internally

tinned copper tubing may be used for gas

supply systems.

Fuel line installations other than typical

installations shown in Figures 26 and 27

(page 17) must comply with the fuel piping

provisions stated in the Federal Manufactured

Home Standard (H.U.D. TITLE 24, PART 280)

and the National Fuel Gas Code (ANSI-Z223.1/

NFPA-54).

• Optional fuel inlet lines are available for all

gas furnace models to permit the addition of

a 1/2” F.P.T. shut-off valve above the fl oor.

NOTE: Shut-off valve must be designed and

listed for use with liquid petroleum (L.P. gas).

The gas supply to your home will either be Natural

Gas or L.P. (bottle gas). Your furnace is factory

equipped to operate on Natural Gas. If your gas

supply is L.P. (bottle gas), you must contact a

qualifi ed serviceman or gas supplier to convert

the furnace. Instructions for gas conversion are

listed on page 18. Factory installed orifi ce sizes

are listed in Table 10 (page 31).

For natural gas operation, the furnace is designed

for 7” W.C. inlet pressure. Pressure is reduced

to 3 1/2” W.C. by the pressure regulator in the

gas valve. The maximum inlet pressure for the

valve is 13” W.C.

On-Off-Fan

Switch

Control

Panel

Floor

Floor Cavity

To Gas

Supply

Figure 26. Typical Gas Piping

Alt. Fuel

Line Entry

16

Page 17

t

For L.P. gas, pressure to the gas valve must be

more than 11” W.C. but not more than 13” W.C.

Pressure is reduced to 10” W.C. by the pressure

regulator in the gas valve.

CAUTION:

Furnace conversion must be performed by a qualifi ed technician.

Improper conversion can cause

unsafe operation, explosion, fi re

and/or asphyxiation.

Oil Tank and Piping Installation

The following procedures are recommended as

good practice. However, requirements of local

codes and ordinances, H.U.D. Manufactured

Home and Safety Standards or National Fire

Protection Association must be satisfi ed, where

they apply, for an approved installation.

• Use a tank capacity suitable for the application

with a weatherproof, capped fi ll opening and

a shielded vent to let in air as fuel is used.

• The inside of the tank must be clean before

fi lling. All water, rust, sediment, and debris

must be fl ushed out.

• A fuel or tank gauge (Figure 27) is recommended for easy checking of the fuel level.

Check the gauge reading with a dipstick.

• Locate the storage tank conveniently near

the home. If the fuel tank is installed above

ground, the tank may rest 3 to 4 inches off

the ground. Fuel tanks may also be buried if

properly coated to resist corrosion. The vertical

dimension from the bottom of the fuel tank to

the fuel pump must not exceed 10 feet.

• Keep the tank fi lled, especially in the summer

to reduce the accumulation of condensation.

One Line System

The one line system is highly recommended

where vertical lift, from bottom of tank to pump,

is less than eight feet (Figure 27). A single line

hookup has the advantage of lower cost and

quieter operation.

Two Line System

If a two pipe system is used or if oil is taken from

the bottom of the tank, a fi lter is recommended.

A two line system should only be used if vertical

lift exceeds 8 feet.

1. Install the oil feed line as outlined in steps 1 - 6

below.

2. Install the oil pump bypass plug in the bottom

return port.

3. Route the return line up through the furnace

base to the return port of the pump. Route the

other end of the line to the tank, using 3/8”

O.D. copper tubing or 1/4” pipe with the ends

capped.

4. Insert the return line through the second

opening in the duplex bushing. If the bottom

of the tank is lower than the pump intake, the

tube should be inserted three or four inches

from the tank bottom. If the bottom of the tank

is higher than the pump intake, the return line

should extend not more than 8” inside the tank.

Fuel line Hook-Up

1. Use a 3/8” O.D. copper tubing for the fuel line.

NOTE: Cap the end with tape to keep out dirt

while the line is being routed.

2. Install duplex bushing for two 3/8” lines in the

top fi tting of the tank. See Figure 27.

3. Insert one end of the tubing through the duplex

bushing until it is three to fi ve inches from the

bottom drain. Tighten the bushing.

4. Route the line where it will not incur any

damage. Make bends gradual and avoid kinks

which might restrict oil fl ow.

Cordset

Pressure Adjustment

Screw

Becket

USE ONLY WITH

VALVE ON DELAY

A2EA-6520

4 GPH 100-150 PSI 3450 RPM

NO. 2 & LIGHTER FUEL

3 GPH 150-200 PSI 3450 RPM

NO. 2 FUEL

INLET

Made by Suntec

Exclusively for Beckett

If fuel pump fails to lift oil, check for air

leaks and tighten all fuel fittings. Reprime fuel pump by injecting fuel oil into

optional (top) return port. Replace return

port plug and repeat priming procedure.

Inlet Port

INLET

1/4 NPTF

BY-PASS

Bleed & Gauge Port

Return Port - Install 1/6” Bypass Pipe

Plug for 2-pipe System Only.

(Use 5/32” Allen Wrench)

Vent with cap

Gauge

3/8" Oil Supply Line

Guide

Pipe

End of Oil Supply Line

3" to 5" Above Bottom Drain

NOTE: Additional venting may be

required if tank is filled rapidly.

2" Duplex

Bushing

2" Fill

Drain

Top of Tank

Shut-off

Valve

Optional

Fuel

Filter

8 ft.

Alternate

Fuel Line

Entry

Furnace

Control

Panel

Bypass Solenoid Valve

Nozzle Port

3/16 Flare Fitting

Oil

Flue Gas

Sampling

Hole

On-Off-Fan

Switch

Oil-Gun

Burner

Floor

Floor Cavity

Inlet Port

1/4 NPTF

Figure 27. Typical Oil Piping for Above Ground (Single-Line) Supply

17

Page 18

5. Open the furnace door and connect the oil line

to the intake port on the pump. Tighten other

port plugs on the pump. NOTE: Verify the oil

line is airtight! Air leaks can cause the pump

to lose prime and will create other problems

such as nozzle failure, odors, rumbling noise,

and false safety shutdown.

6. Insert the short length of the copper tube level

with the bottom of the duplex bushing. Form

the tube into an inverted “U” to serve as a vent.

to a dedicated pump prime mode, during

which the motor, igniter and valve are powered

for 4 minutes. The yellow LED will be on.

NOTE: If prime is not established during the

four minute pump prime mode, repeat step 3

until the oil pump is fully primed.

4. When oil fl ow is clear and free of air bubbles,

close air-bleed valve and tighten. (Time to

bleed air out will vary depending on length of

oil line, number of bends, etc.)

Leak Check

To eliminate problems caused by air in the oil

line, all connections in the oil supply line and

all plugs, nuts, and fi ttings on the pump must

be airtight. NOTE: This includes the nut that

covers the pressure adjustment. It is important

that the hook-up be done carefully and with a

good fl aring tool.

Prepare the burner for priming by attaching a

clear plastic hose over the bleed port fi tting and

fully opening the pump bleed port. Use a suitable

container to collect purged oil.

To ensure continuous operation, use a wire to

jump terminals T- T (or F-F) on the primary control

while burner is running.

After the piping to the furnace is complete, all

connections must be tested for leakage. This

includes pipe connections at the main gas valve,

emergency shutoff valve and each joint or union.

The soap and water solution can be applied using

a small paintbrush. If any bubbling is observed,

the connection is not sealed adequately and must

be retightened. Repeat the tightening and soap

check process until bubbling ceases.

Priming furnaces equipped with Honeywell

R7184 primary control:

1. While the ignition is on, press for 1/2 second

(or less), and release the reset button. The

lockout time will be extended to 4 minutes.

2. If prime is not established within the 4 minutes,

the control will lock out. Press the reset button

to reset the control.

3. Repeat steps 1 & 2 (if needed) until the oil

pump is fully primed.

Priming furnaces equipped with the Beckett

7505 primary control:

1. After the burner starts, press and hold the

reset button until the yellow LED turns on (15

seconds). This indicates that the button has

been held long enough.

2. Release the reset button. The yellow LED will

turn off and the burner will start up again.

3. At burner start up, click the reset button while

the igniter is still on. This transitions the control

18

Fuel Oil Type

Do not use fuel oil heavier than Grade No. 2.

Grade No. 1 may be used where the oil supply

is subject to low temperatures.

DO NOT USE GASOLINE, CRANKCASE OIL,

OR ANY OIL CONTAINING GASOLINE.

WARNING:

Failure to keep supply of oil clean

by various procedures described

above may cause failure of certain

components such as the fuel pump

gears, check valve, shaft seal, or

burner nozzle which may result in

a burner fi re.

Conversion to Propane (LP) Gas

This gas fi red heating appliance was shipped from

the factory for use with natural gas. However, the

appliance can be converted for use with LP gas.

Use the following procedure for gas conversion

of the burner. See Table

Atmospheric and Direct Ignition Furnaces

1. Follow the instructions “How to Shut Off Gas”

on pages 21 or 22.

2. Disconnect the gas pipe union and the electrical

wires connected to the gas valve.

3. Remove the pilot tube and thermocouple from

the gas valve (M1G).

4. Remove the gas valve assembly:

a. Remove screw(s) from gas valve bracket.

Gas valve and spud may be removed.

Orifi ce is located at the end of the spud

(M1G or M1M) or remove three (3) bolts

from U-shaped manifold plate and orifi ce

assembly (M1B).

5. Replace the main orifi ce with the L.P. gas

orifi ce supplied in the envelope located by the

gas valve. Verify the orifi ce size matches the

nameplate or Table 10 (page 31). NOTE: It is

not necessary to convert the pilot orifi ce.

Page 19

6. For Honeywell gas valves with the regulator

converter (Figure 28, page 19):

a. Unscrew the pressure regulator cap and

check for the letters NAT or LP.

b. Invert the cap and tighten until snug.

7. For Robertshaw gas valves with the regulator

converter (Figure 29):

a. Remove the black cover and unscrew the

converter located on top of the gas valve.

b. Invert the converter: for LP the red ring will

be located at the bottom and the LP stamping

on the converter will appear right side up.

c. Screw converter back into the regulator,

hand tight plus 1/8 turn. Replace the black

cover on the converter top to protect the

threads.

8. Reassemble the burner assembly into the

furnace.

9. Reconnect the gas piping and electrical wires

to the gas valve.

10. Open the manual shut-off valve and follow

the Lighting and Operating instructions on

page 22.

PRESSURE

REGULATOR

CAP

T

A

N

T

T

N

A

A

N

T

OR

N

A

OTHER SIDE

Figure 28. Honeywell Gas Valve

LP Gas

Configuration

Red

P

L

OF CAP

M11678

L

P

High Altitude Conversion

High altitude conversion with this furnace

depends on the installation altitude and the

heating value of the gas. The installation of this

furnace at altitudes above 2,000 feet must meet

the requirements of the National Fuel Gas Code

or local jurisdiction. In Canada, the requirements

for high altitude are different and governed by

CGA B149.1. Please consult your local code

authority.

WARNING:

The reduction of input rating necessary for high altitude installation

may only be accomplished with

factory supplied orifi ces. Do not

attempt to drill out orifi ces in the

fi eld. Improperly drilled orifi ces

may cause fi re, explosion, carbon

monoxide poisoning, personal

injury or death.

This furnace is shipped from the factory with

orifi ces and gas regulator settings for natural gas

operation at sea level altitudes. At 2000 feet, the

NFGC requires that this appliance be derated

4% for each 1000 feet of altitude. For example,

the input needs to be reduced 8% at 2,000 feet,

12% at 3,000 feet and etc. This deration is in

reference to the input rate and gas heating value

at sea level. See Table 12 (page 32).

Black Cover

Natural Gas

Configuration

Figure 29. Robertshaw Gas Valve

Flue Gas Sampling

It may be necessary to take fl ue gas sampling

from oil and gas furnaces (M5S and M1B Series

Models) in order to check the performance after

furnace installation. A fl ue gas sample may

be taken from the heat exchanger, which is

located behind the hole of the top-front of blower

compartment.

1. Turn off all electric power to the appliance.

2. Remove the black plastic cap located above

the blower. Do not discard cap.

3. Drill a hole through the top of the blower

compartment. NOTE: Hole diameter should

be same size as sampling tube.

4. Insert sampling tube through the drilled hole

and into the heat exchanger.

5. After a complete check and adjustment

of furnace performance, seal the drilled

hole with a screw larger than the hole.

NOTE: Seal the screw threads with silicon

sealant - rated at least 500° F.

6. Plug the outside hole with the plastic cap

removed in step 3.

19

Page 20

STARTUP AND ADJUSTMENTS

PLEASE READ ALL SAFETY INFORMATION

BEFORE LIGHTING THE FURNACE

WARNING:

FIRE OR EXPLOSION HAZARD

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Leave the building immediately.

• Immediately call your gas supplier

from a neighbors phone. Follow the

gas suppliers instructions.

• If you cannot reach your gas

supplier, call the fi re department.

WARNING:

Before placing the furnace in

service, it must be checked to

ensure it is equipped for the type

of gas being used. The burner fl ame

must be observed and adjusted

if necessary. Failure to observe

this caution may result in unsafe

operation, explosion and/or fi re, or

asphyxiation. See the Gas Supply

and Combustion Air sections.

Lighting Instructions - Standing Pilot Models.

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance.

3. Remove the furnace door.

4. Push in and move the gas control lever to the

OFF positon (Figure 30). DO NOT FORCE!

5. Wait 10 minutes to clear out any gas. If you smell

gas, STOP! and read the Safety Information.

If you don’t smell gas, proceed to step 6.

6. Find pilot - follow metal pilot tube from gas

control valve. Open hinged fi re observation

door. The pilot is found at the end of the pilot

tube just left of the pilot shield (Figure 31).

7. Lightly depress the gas control lever and move

it to the ON position. Release and move the

lever to the PILOT position.

8. Move the control lever to SET and hold.

Immediately light the pilot with a match.

Continue to hold the control lever for about one

(1) minute after the pilot is lit. NOTE: The pilot

fl ame is adjustable by turning the adjustment

screw located on the gas valve with a small

screwdriver. See Figure 29.

9. Release the lever and it will spring back to the

PILOT position. NOTE: Pilot should remain lit.

If it goes out, repeat steps 4 through 8 above. If

the lever does not spring back when released,

immediately call your service technician or gas

supplier. If the pilot will not stay lit after several

tries, move the gas control lever to OFF and

call your service technician or gas supplier.

10. Move the gas control lever to ON.

11. Turn on all electric power to the furnace.

• The fi rst lighting of the furnace after any

home setup must be performed by a

qualifi ed service technician.

• If this appliance has a pilot that must be lit by

hand, follow these instructions exactly.

• BEFORE LIGHTING: Smell all around the

furnace for gas and next to the fl oor. Some

gas is heavier than air and may settle on the

fl oor.

• Use only your hand to push in the gas control

lever. Never use tools. If the lever will not push in

by hand, don’t try to repair it. Force or attempted

repair may result in a fi re or explosion. Call a

qualifi ed service technician.

• Do not use this furnace if any part has been

under water. Immediately call a service

technician to inspect the furnace and to replace

any part of the gas valve or control system

which has been under water.

20

Gas Control Lever

Figure 30. Standing Pilot Valve

PILOT

BRACKET

Figure 31. Lighting The Furnace

Pilot Position

Set Position

Page 21

12. Set the thermostat mode to HEAT or a desired

GAS CONTROL KNOB

temperature setting and then ON.

WARNING:

Close the hinged fi re door. If door

is left open or spring is broken it

may allow products of combustion

into the living space by the furnace

blower, resulting in possible

asphyxiation.

13. Replace the furnace door.

NOTE: In the event of any fl ashback or explosion,

immediately shut off the furnace and call your

service technician.

WARNING:

Should overheating occur, or the gas

supply fails to shut off, shut off the

manual gas valve to the furnace before

shutting off the electrical supply.

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance.

3. Remove the furnace door and turn off the gas

valve:

• Honeywell: push in and turn the gas control

knob clockwise to OFF (Figure 32)

• Robertshaw: push the gas control lever to

the OFF position (Figure 33). Do not force!

4. Wait ten (10) minutes to clear out any gas. If

you smell gas, STOP! and follow the Safety

Information on page 19. If you do not smell

gas, proceed to next step 5.

5. Set the thermostat MODE the ON position.

6. Turn the gas valve ON:

• Honeywell: push in and turn gas control