Page 1

Nokia Customer Care

RH-29 Series Cellular Phones

6a - Baseband Troubleshooting

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 1

Company Confidential

Page 2

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Table of Contents

Page No

Introduction to RH-29 Troubleshooting ........................................................................................... 3

General guidelines for RH-29 troubleshooting ............................................................................3

Tools needed for troubleshooting ................................................................................................. 3

General guidelines............................................................................................................................. 3

Nominal current consumption ..........................................................................................................4

Troubleshooting Paths............................................................................................................................ 5

Dead or jammed device ......................................................................................................................5

Partially damaged device ...................................................................................................................6

Most common symptoms reported by customer .........................................................................6

Most common symptoms for audio problems........................................................................... 6

Symptoms related to energy management ................................................................................ 6

Problems related to UI module:..................................................................................................... 6

Most common RF related symptoms: .......................................................................................... 6

ASIC is changed ....................................................................................................................................7

UEM changed...................................................................................................................................... 7

UPP_WD2 changed ........................................................................................................................... 7

ZOCUS changed.................................................................................................................................. 7

Test points ..............................................................................................................................................7

“CONTACT SERVICE” on display ........................................................................................................8

1CK Baseband HW Subarea Troubleshooting.................................................................................. 9

Flashing troubleshooting .................................................................................................................... 9

Energy management troubleshooting ..........................................................................................11

Device does not stay on................................................................................................................ 11

General power checking ............................................................................................................... 12

Power key troubleshooting .......................................................................................................... 14

Clocks troubleshooting.................................................................................................................. 14

Charging checking.......................................................................................................................... 16

Energy management calibration ................................................................................................ 19

ADC-reading..................................................................................................................................... 20

Backup battery ............................................................................................................................... 21

SIM card .......................................................................................................................

Memory troubleshooting ..................................................................................................................26

Serial interface troubleshooting ....................................................................................................27

CBUS................................................................................................................................................... 27

FBUS ................................................................................................................................................... 28

MBUS.................................................................................................................................................. 28

MMC troubleshooting .......................................................................................................................29

Vibra .......................................................................................................................................................30

ZOCUS ....................................................................................................................................................31

UI Module Troubleshooting ............................................................................................................... 32

Keymat backlight ................................................................................................................................32

Keyboard problem ..............................................................................................................................33

Display blank ........................................................................................................................................34

Image on display not correct ..........................................................................................................35

Backlight does not turn on .............................................................................................................36

Handportable audio ............................................................................................................

Accessory Audio ..................................................................................................................................40

..................... 22

...............37

Page 2 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 3

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Introduction to RH-29 Troubleshooting

This document is intend to be a guide for localizing and repairing electrical faults in the

RH-29 device. First there is a brief guide for fault localizing. Then fault repairing is

divided into troubleshooting paths.

Before any service operation you must be familiar with the RH-29 product and module

level architecture. You have to also be familiar with the RH-29 specified service tools

such as the Phoenix service software, flashing tools and software.

General guidelines for RH-29 troubleshooting

Tools needed for troubleshooting

• Service tools (as listed at service tools chapter in service manual)

• Laboratory power supply with current indicator

• Oscilloscope

• Digital multimeter

General guidelines

If the device cannot be turned on by any means, see “dead device” troubleshooting

Current consumption (missing consumption) gives an idea whether the device is able to

start up.

Dropping supply voltage or very large current consumption indicates a short circuit

Check whether the connection with Phoenix works and what can be discovered with

Phoenix (ADC-readings, baseband self-test, BB-calibrations etc.)

Check baseband self-tests with Phoenix if “CONTACT SERVICE” is shown on the display.

Check visually display and rocker faults.

Force phone to LOCAL mode and make keyboard test by phoenix.

Check that board-to-board connector is OK, and connectors make good contacts.

If liquid damage, stop repairing!

Flash the phone before disassembling it, if the fault is not obvious and the Phoenix connection is OK.

Disassemble phone:

Try to locate failed module.

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 3

Company Confidential

Page 4

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Check failed module visually:

Mechanical damages?

Solder joints OK?

Continue with specific troubleshooting procedure for the module:

If there is an obvious fault, repair it before reflashing the device.

Flash first if a fault is not obvious.

If flashing is not working go to flashing troubleshooting.

Due to CSP packages short circuits or broken solder joints are not easily seen. If the

examined signal seems to be continuously in low or high level, then measure for possible

short circuit to ground (signal low) or to supply voltage (signal high) Note that if a problem is not found from any visible contact/component it can be under CSPs where the signal is connected.

Care must be taken when assembling and disassembling the transceiver. Failure to do

this may result in unnecessary damage to device.

Nominal current consumption

NOTE: Service tools need some amount of current to work.

The following current consumption values are measured from a complete RH-29.

Vbatt = 3.6V

Measured nominal currents are drawn from the main battery.

Measurements have been made with a current probe connected to an oscilloscope.

Operating mode Current consumption

Idle 90 mA

2w audio call (backlights off) 250 mA

Page 4 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 5

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

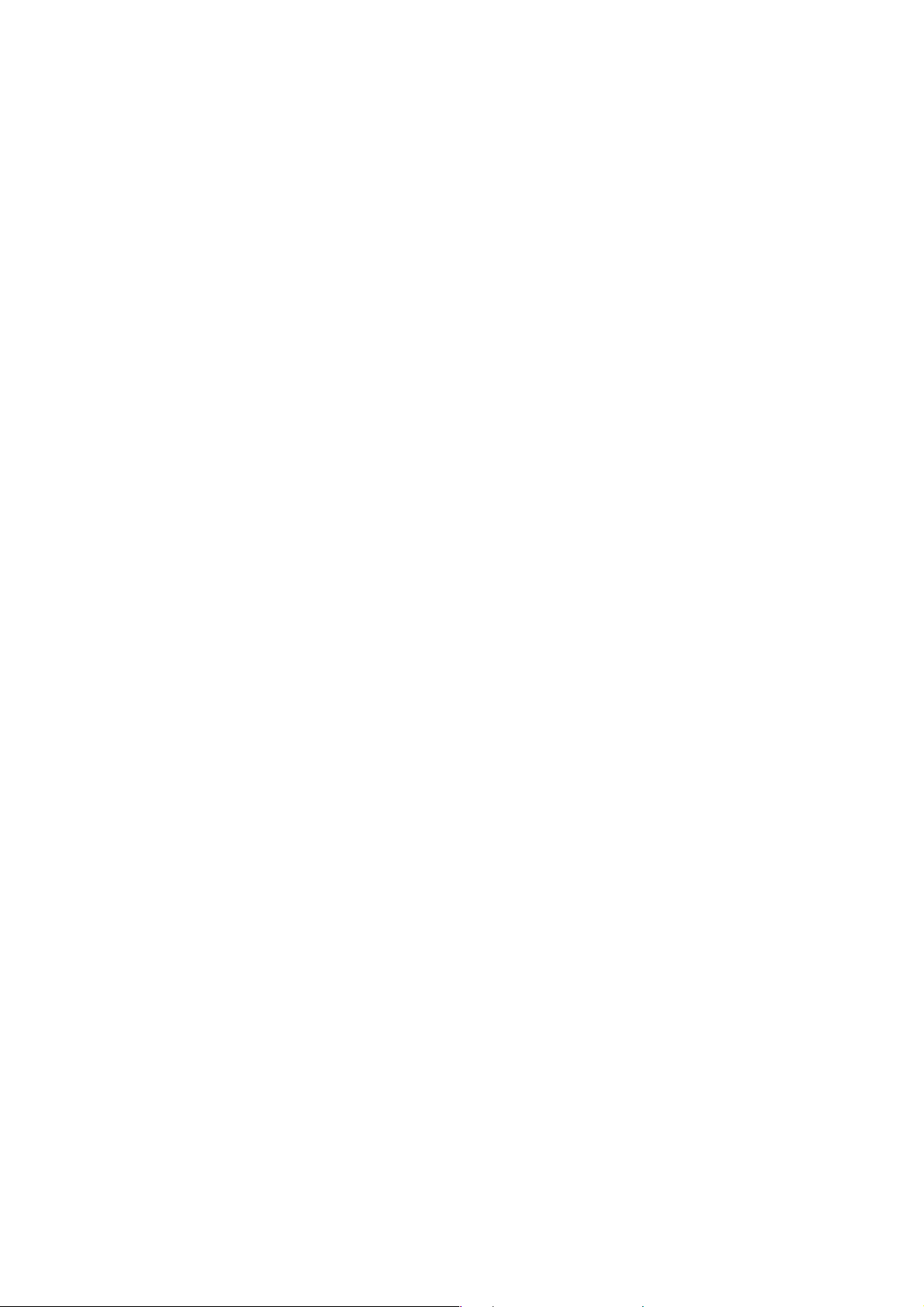

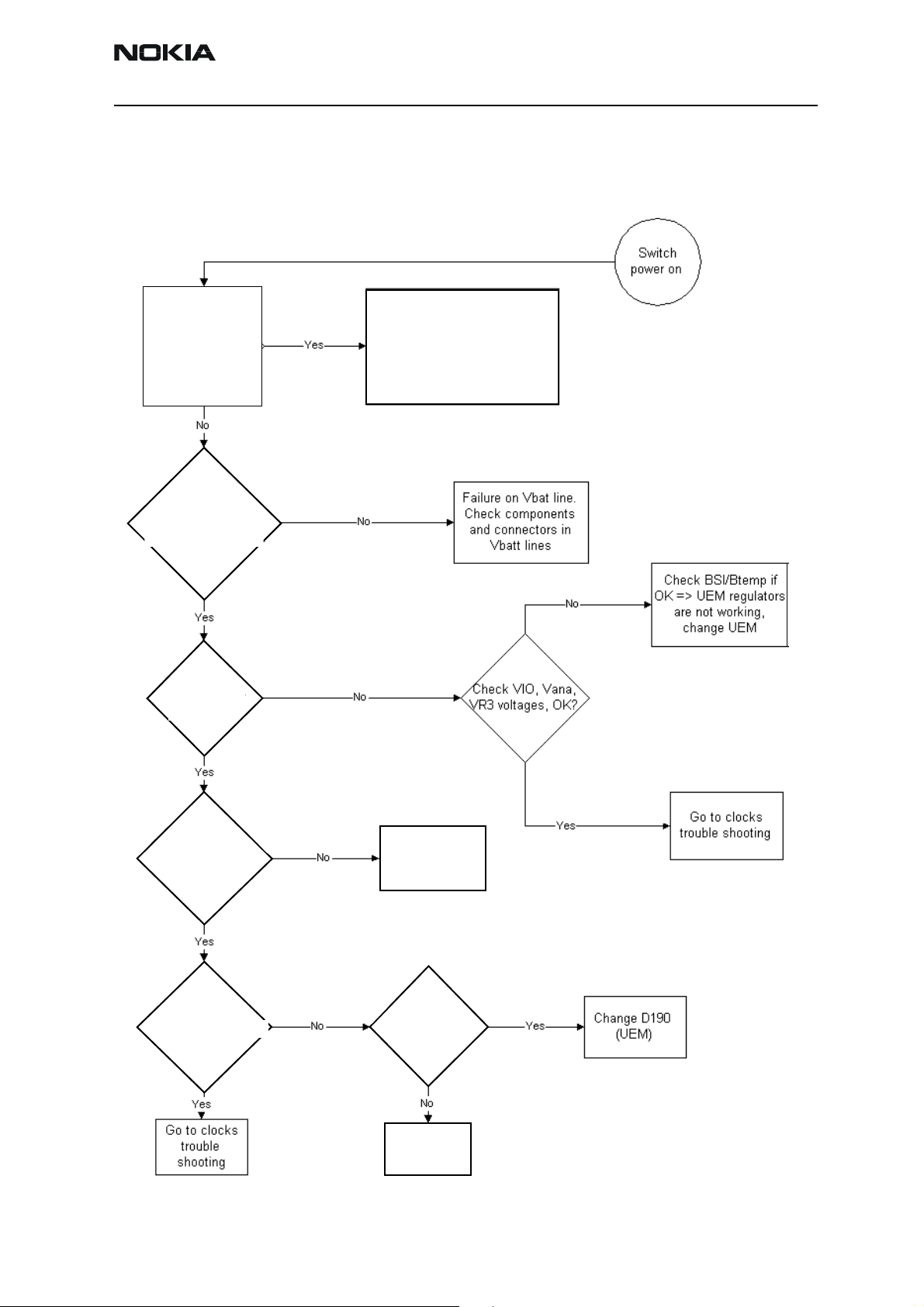

Troubleshooting Paths

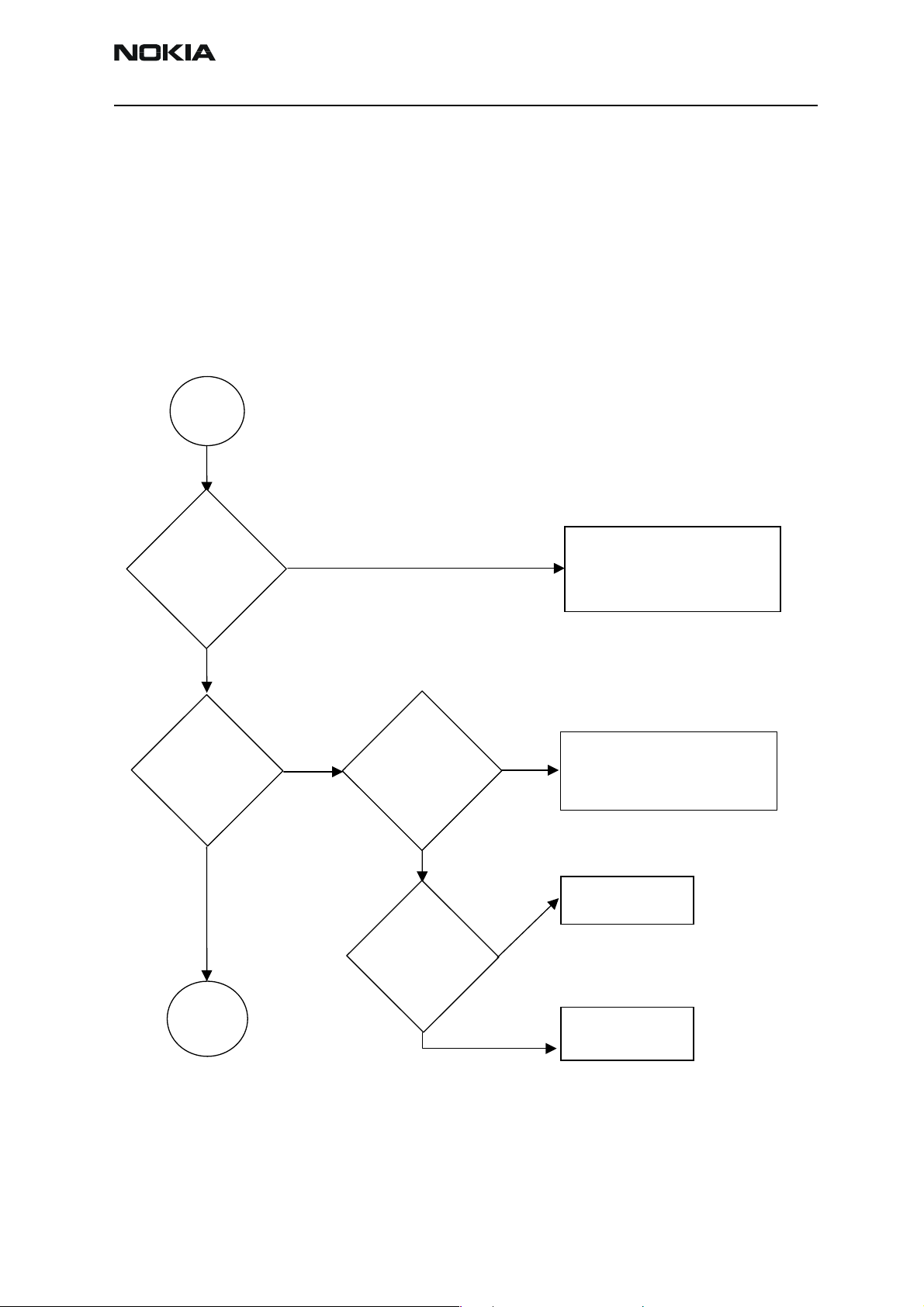

Dead or jammed device

Disassemble

yes

Check UI

connector

Replace

UI module

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 5

Company Confidential

Page 6

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Partially damaged device

If the device is working, but some functionality is missing try to localize where the problems is and see relevant part of this manual. E.g audio is not working see “Audio Troubleshooting”, if charging is not working see chapter Charging troubleshooting etc.

Most common symptoms reported by customer

In this chapter is described most common symptoms reported by customers when the

device is brought in for service. Some tips where the trouble can be found are given also.

When troubleshooting use these tips and follow the given troubleshooting path.

Most common symptoms for audio problems

“Earpiece sound is missing”

”Handsfree sound is missing”

”Headset is not recognized”

”Microphone is not working”

”Volume cannot be adjusted”

” Ringing tones does not work”

”Audio volume too low”

If symptom is something like above see audio troubleshooting.

Symptoms related to energy management

“Phone does not stay on”

”Charging is not working”

”Time is lost during battery change”

”Charging takes too long”

”Operating time is very short”

These symptoms lead to relevant part of energy management troubleshooting

Problems related to UI module:

“UI-module keypad is not working”

”Backlight is dim”

”Backlight not even”

”Backlight is blinking”

”Keypad or display backlight is not working”

”Display related problems”

See UI- module troubleshooting.

Most common RF related symptoms:

“Call cannot be made”

”Phone does not find signal”

”Call is often dropped”

See RF troubleshooting

Page 6 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 7

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

ASIC is changed

ASIC’s can be changed only at a defined service level.

UEM changed

If UEM is changed baseband calibrations should be made. New IMEI must be programmed also. ZOCUS calibration is not necessary.

UPP_WD2 changed

IMEI must be reprogrammed.

ZOCUS changed

Zocus must be re-calibrated

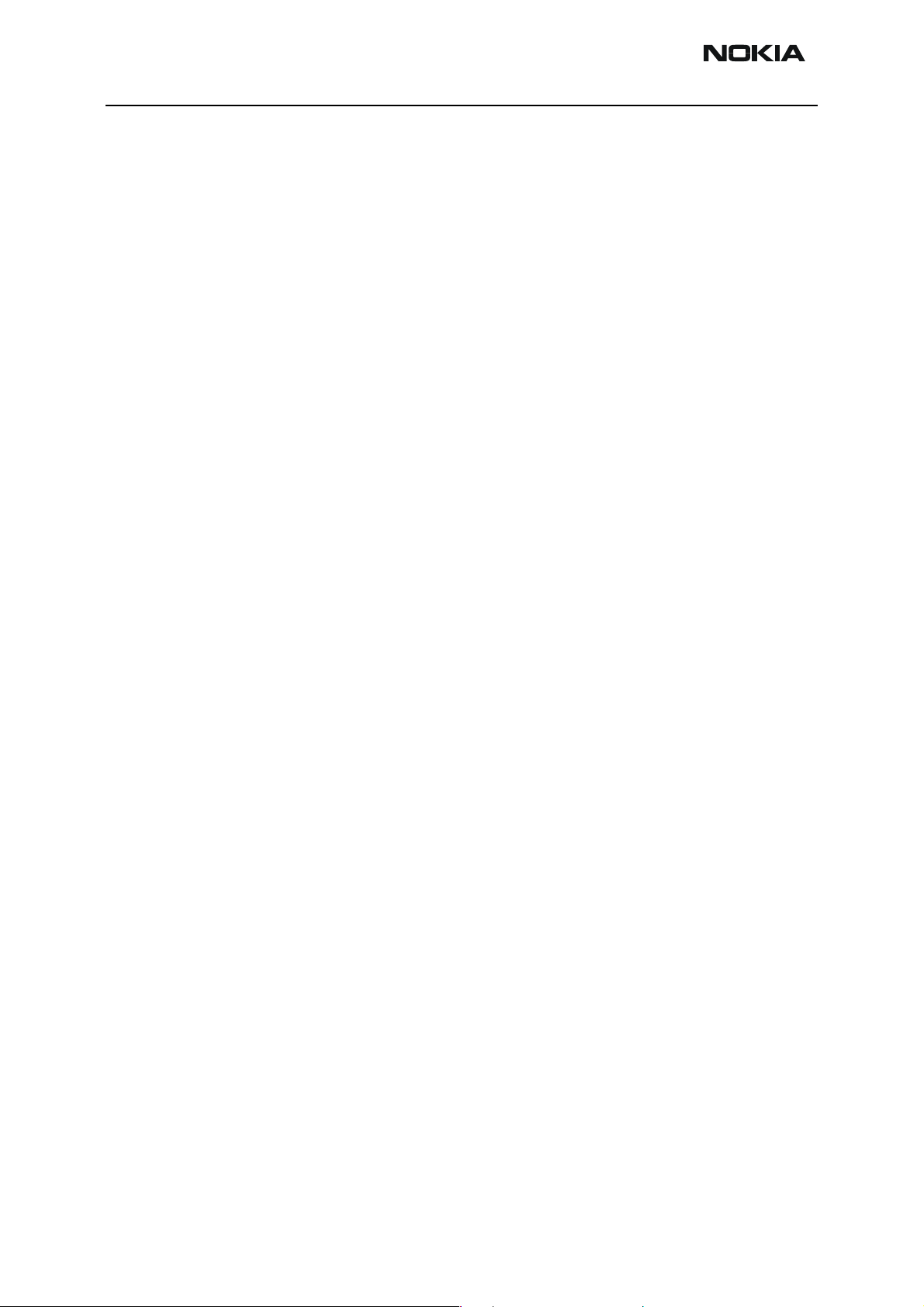

Test points

Test Point Signal Test Point Signal Test Point Signal

J109 UEMInt J203 TXQD J477 SIM IF

J123 SLEEPCLK J204 AUXD J482 MMC IF

J124 SLEEPX J311 FLASH CE J483 MMC IF

J125 PURX J312 FLASH CE J484 MMC IF

J170 RFCLK_I J314 SDRAMCLK J485 MMC IF

J190 EARDATA J315 FLASH CLK J487 MMC IF

J191 MICDATA J334 Shutdown

Audio PA

J192 SIMIODAI J390 Current sense

resistor

J193 SIMCLKI J391 Current sense

resistor

J194 SIMIOCTRL J392 Current sense

resistor

J195 MBUSTX J393 Current sense

resistor

J196 MBUSRX J470 SIM IF J496 MMC IF

J488 MMC IF

J490 MMC IF

J492 MMC IF

J493 MMC IF

J495 MMC IF

J197 FBUSTXI J471 SIM IF J497 MMC IF

J198 FBUSRXI J472 SIM IF J498 MMC IF

J199 RFCONVCLK J473 SIM IF J499 MMC IF

J200 RXID J474 SIM IF

J201 RXQD J475 SIM IF

J202 TXID J476 SIM IF

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 7

Company Confidential

Page 8

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

“CONTACT SERVICE” on display

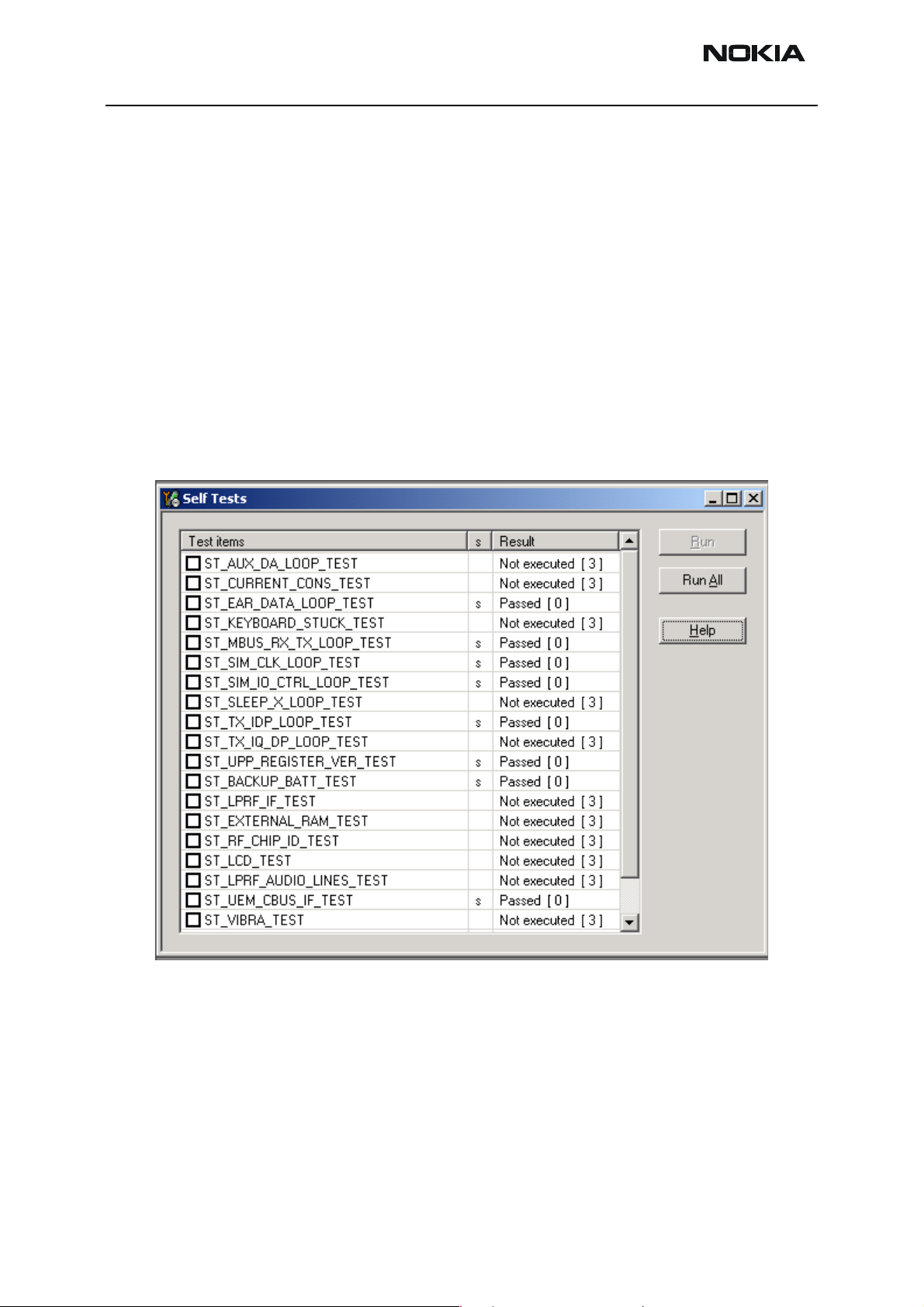

CONTACT SERVICE on display (Self-tests by Phoenix)

Display information: “Contact Service”

This fault means that software is able to run and thus the watchdog of UEM can be

served.

Self-test functions are executed when the phone is powered on and if one or more selftest functions fail, the message “Contact Service” is shown on the display.

MCU self-test cases can be split into two categories: The ones that are executed during

power up and the ones that are executed only with a PC connected. These test and the

items included are as follows:

If some self-test failed, see relevant chapter in this troubleshooting document.

Page 8 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 9

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

1CK Baseband HW Subarea Troubleshooting

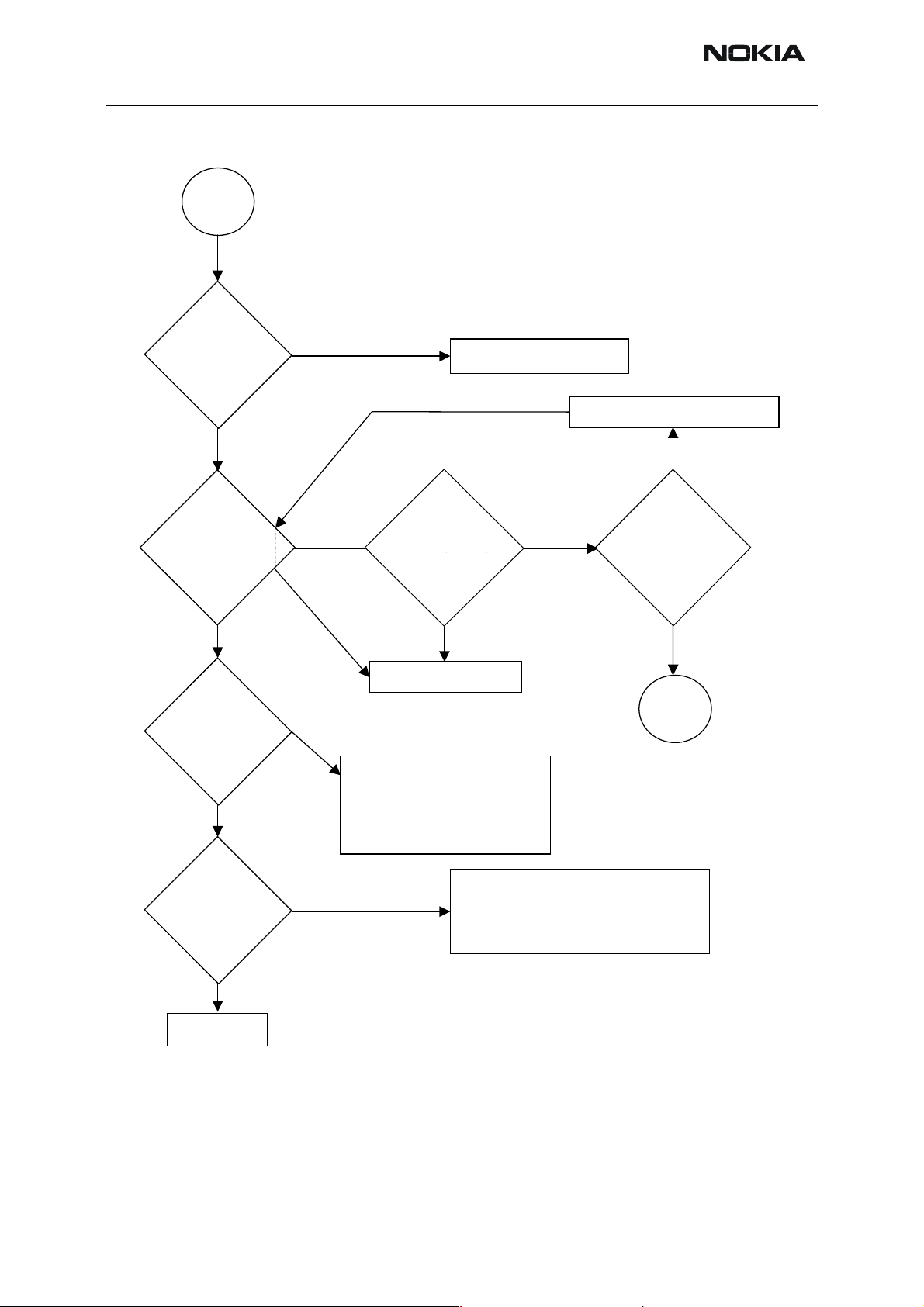

Flashing troubleshooting

RH-29 has three memory components installed on the main PWB. The best indication of

which one is causing problems can be obtained by flashing the device. It has to be kept

in mind that all three flashes are interfaced with UPP WD2 asic that might it self have

some problems. The necessary steps are described below. Phoenix error messages during

flashing greatly help on defining what is wrong. To be able to flash the device, most

device BB area components must function properly.

Flashing

faults

The phone does

not set Flashbus

TXD line high

after startup

No

The phone does

not set the

flashbus TXD

line low after the

startup

No

Memory

faults page

2

Yes

Yes

Measure BSI

pulse during

flash

programming

Is it ok?

Yes

Measure

FBUSTX line

during flash

programming is

it 1.8V?

Yes

No

No

Check connections

Check BB voltages

Check clocks

Change UEM

Check BSI line

Check BSI line

Battery connector, flex,

Battery connector,

C239, Z383, R384

C381, R192 and C231

Change

UEM

Change UPP

WD2

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 9

Company Confidential

Page 10

RH-29 Company Confidential

g

6b - Baseband Troubleshooting Nokia Customer Care

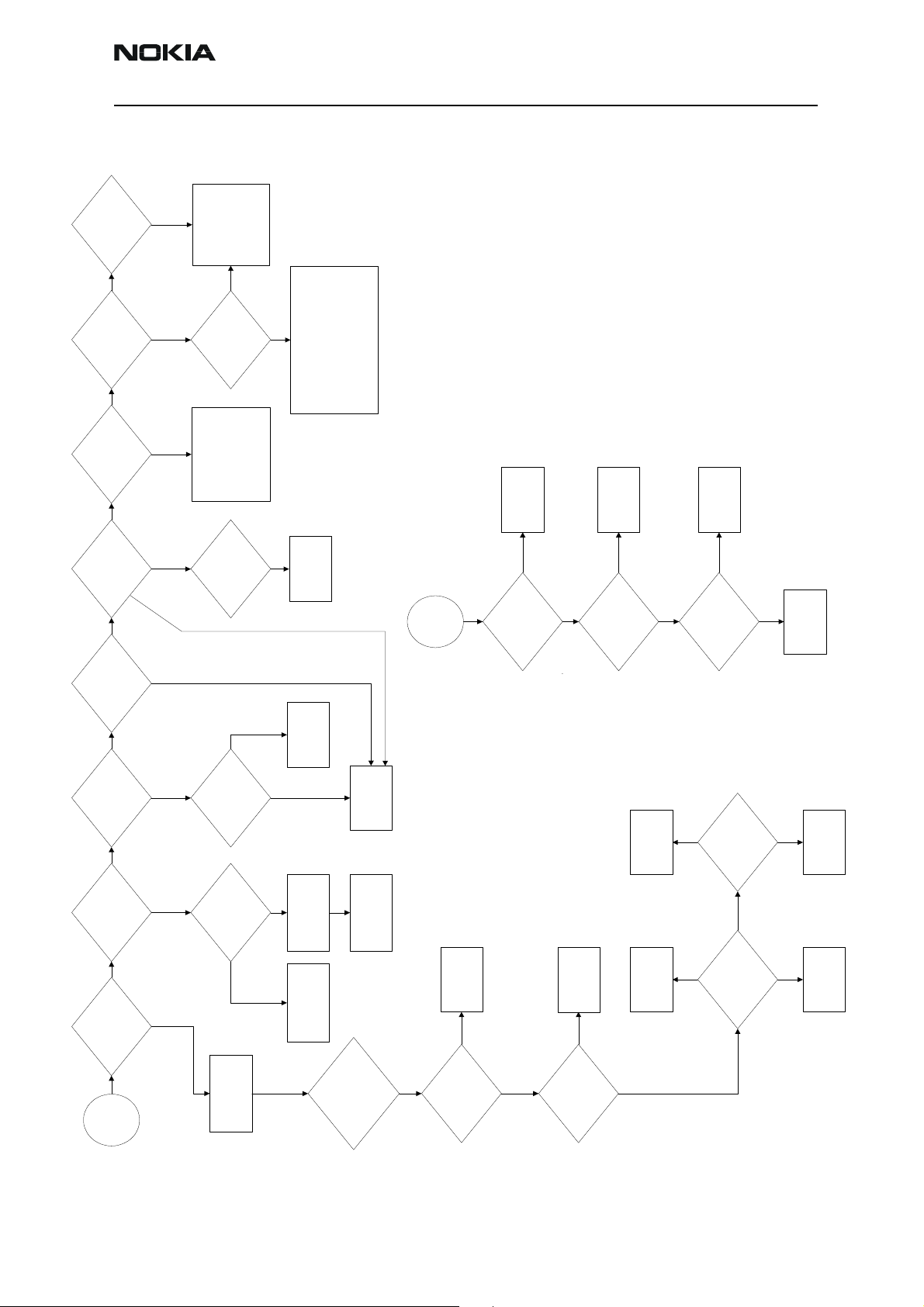

Memory

faults

page2

"Secondary

receive fail" or

"Algorithm send

failed"

messa

Prommer

message about

sdram failure?

manufacturer ID

and device ID

e?

No

No

Wrong

No

Yes

Yes

Yes

Change UPP_WD2

Activity in SDRAM

Activity in sdram

Clk path (R101)?

clk J108 pad?

(J314)?

No

Change UPP_WD2

Change Flash Chip

according to Phoenix

messages

If both chips report wrong

ID's -> change UPP_WD2

Yes

Change SDRAM

Yes

Voltages

Voltages

VmemA and

VmemA and

Vio OK?

VioA ok?

No

EM

troubles

"Flash informs

about a failure"

during flashing

No

Retest

Yes

Check flash0 bypass caps, check

Vpp connection to flasher, Check

Vpp resistor(4.7k)

Vpp resistor (R310)

Ok->Change flash0

Page 10 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 11

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

NAK" ?

C586 "Phone fail

response received"

or C684 "Data block

message ?

C385 "Data block

handling timeout"

OK ->flash (D311)

check R310 (4.7k)

Check flash byp ass

connection to flasher,

caps, check VPP R310

No

Yes

Flashing with option

"phone only" succesful ?

-> still not OK

->change BT module

Bluetooth module is unable to start flashing

-> check V601, R601,R602,R627 and C602

ID" ?

manufacture

A204 "Wrong

ID and device

SDRAM

failure" ?

message about

C108 "Prommer

C202 "Algorithm

send" or C281 "phone

C106 "Secondary

C103 "Boot serial line"

No No No No No No No

C101 "boot timeout "

Yes

Flashing

Yes

fail ?

message cheksum"

message ?

receive fail"

Fail ?

fail" message

or C102 "boot start txd

faults

and SDRAM

Change Flash chip

allredy

changed

Yes Yes Yes Yes Yes

Yes Yes Yes

Measure BSI

(D100)

according to phoenix

messages (typical D312)

if both chips report wrong

ID's -->change UPP WD2

Change

Yes

No Yes

Check BSI line

Change

Change UPP

Battery connector

SDRAM (D310)

fail

phone

Op.Start

UEM (D190)

Change

UPP WD2 (D100)

Doesn't help

Change

WD2 (D100)

(X382) and C381

UEM (D190)

Change

UEM (D190)

No

?

change flash

(128Mb) D311

Flashing starts ok

show error code C101

after 5s flashing stop's and

VIO C216 (1.8V),

UEMRSTX R431(VBAT)

and PURX J125(1.8)

Voltage VIO OK ?

OK ?

Sleep clock (J123)

is it ok ?

programming

pulse (X382,pin2

"middle") during flash

No

try flashing with

Check connections

powers from FPS-8

reflash

Change and

Yes

chips?

Broken flash-

Yes

No

Check N260

SMPS Regulator

No

?

VcoreA (1.5V)

Change

UEM (D190)

Yes

Current

mode ?

consumpti on

50mA in local

Check

XTAL ( B601)

Mjoelner (N601)

Change

UEM (D190)

Yes

Change

and reflash

UPP WD2 (D100)

Yes

No

OK

Sleep clock (J123)

NoNo

No

?

RFClk (C602)

Bias 800-1000mV ?

2.78V

Pulses to

(2.78V)

VR3(C212)

at power up ?

Change

UEM (D190)

Change

UPP WD2 (D100)

Yes Yes

Change

UPP WD2 (D100)

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 11

Company Confidential

Page 12

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Energy management troubleshooting

Device does not stay on

If the device is switched off without any visible reason, there may be problems in the following areas:

• UEM watchdog problem (WD is not updated by SW)

• BSI line problem (BSI line is floating => contact failure)

• Battery line problem

• Soldering problem

The most likely reason is UEM WD (watchdog), which turns the device off after about 32

seconds if SW is jammed.

This may caused by SW problem, UPP_WD2 problem (Not server by SW), UEM or memory

malfunctions.

The following tests are recommended:

• General power checking

• Clocks

• Memory testing

• Serial Interface

If there is something wrong in BSI line, the device seems to be dead after the power key

is pressed. However the regulators of the device are on a few seconds before the powerdown.

This mode can easily be detected from the current consumption of the device. After a

few seconds the current consumption drops almost to 0 mA.

In this case check component or soldering

• Battery connector X382

EMI-filter R381

UEM D190 (pin number C2)

If phone boots to TEST or LOCAL mode with normal battery, BSI is short circuited to

ground. Check EMI-filter and filtering capacitors, which are located to BSI.

Page 12 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 13

Company Confidential RH-29

C

(J

)

Nokia Customer Care 6b - Baseband Troubleshooting

General power checking

Use service tool SF-20. Battery voltage should be at least 3.6V. After phone disassembly,

use module jig MJ-21.

Supply voltage

drops? (or current

is large >1A)

Vbatt1-3, Vbatbb,

Vbattihf meas. from

300,C301 & C302

C301, C302 & C303

J125

PURX (PIN 44

?

)BT module)

Short circuit in Vbatt1-3,

Vbattbb or Vbattihf lines. Try to

find short circuit. Check

components which are able to

short circuit these lines,

(filtering components etc.)

Check Vcorea

and Vmema

voltages, OK?

Check sleep

123

clock (PIN 26 BT mod.)

32.768Khz?

See next page

Meas. from

C200, OK?

Check B190,

C199, C200

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 13

Company Confidential

Page 14

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Vcorea dead

Voltages at

C262, C263 and L260

(both sides), OK?

No

Change

L260 OK?

No

Change N260 and

Retest

Yes

Yes

Retest

Retest

Page 14 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 15

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Power key troubleshooting

Phone cannot

be powered by

pressing pwr

key

Clocks troubleshooting

Clocks include the following:

RF-clock

DBUS, CBUS clocks

Flash and SDRAM clocks

Sleep clock

Bluetooth clock

SIM clock

MMC clock

The main clock signal for the baseband is generated from the voltage controlled crystal

oscillator VCXO. This 26 MHz triangle wave clock signal is supplied to OSC_IN pin of

Mjoelner and out to UPPWD2. Inside UPPWD2 the clock frequency is divided to 13 MHz

Connect

charger, phone

is powered

up?

Yes

Change power key

and retest

No

See dead device

troubleshooting

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 15

Company Confidential

Page 16

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

and then fed to RFCLK.

UEM

SIM

ZOCUS

VCXO

RF-ASIC

Mjoelner

13 MHz

MMC

LPRFClk

analog 26 MHZ

BT

module

RFClk

26 MHz

RFBusClk

13 MHz

UPP_WD2

FlashClk

Max 40 MHz

Flash

memories

SDRAM

SleepClk 32 MHz

SDRAM

Max 104 MHz

CBusClk 1 MHZ

DBusClk

13 MHz

SIMClk

3.25 MHz

In SLEEP mode the VCXO is off. UEM generates low frequency clock signal (32.768 kHz)

that is fed to UPP_WD2, Bluetooth and ZOCUS.

When the flashing of the device does not succeed, but powering is OK, follow these

instructions.

Note: The absence of clocks may indicate that the device (put phone to LOCAL mode

when the sleep is not allowed or press buttons so that phone is not in sleep mode) is in

sleep mode. Make sure that the device is not in sleep during clocks measuring.

IMPORTANT: Clock signals have to be measured with 1MΩ (or greater) probes!

Measure signal from J170. This should be 26Mhz clock signal. See RF Troubleshooting for

further information.

Check the crystal oscillator (B190) is oscillating at 32.768kHz frequency. If not change

B190. If OK measure sleepclk from J123. Frequency should be the same 32.678kHz (see

Figure 1, “Sleep clock,” on page 17 below.) If not change UEM.

Page 16 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 17

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Figure 1: Sleep clock

(J123)

Charging checking

Use the BL6-C battery and JBV-1 calibration set to test charging. (NOTE: power supply

cannot be charged if it not has a current sinking capability.) When you are charging

totally empty battery, remember that start-up charging might take a little bit longer time

than normal. During this time display is blank.

If charger is not NMP approved type and its current and voltage is not within NMP

charger window then software does not start charging and there is “NOT CHARGING” on

the display. Voltage should be between 5.3V - 9.5V and current between 200mA –

900mA

Remove and reconnect battery and charger few times before you start to measure

device. This check ensures that the fault really exists.

(Refer to “Charging troubleshooting”)

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 17

Company Confidential

Page 18

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Figure 2: Charging troubleshooting

Check BL6-C, Btemp, BSI,

X382, R381, R390

Page 18 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 19

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Nothing

happens

ACP-12

when ACP-8

is connected

Measure Vchar

at V380. Is it

>3.0Vdc?

Replace R190

and retest

Check F380, L380,

V380, C382, C389

Check R190,

is it OK?

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 19

Company Confidential

Page 20

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Energy management calibration

During energy management calibration A/D-converter, BSI, Btemp, Battery voltage,

Charger voltage and Charger current are calibrated.

Limits for calculated calibration values are as follows:

Channel Low High

ADC Offset -50 50

ADC Gain 26000 29500

BSI Gain 860 1180

Vbatt Offset 2400 2600

Vbatt Gain 10000 11000

Vchar 57000 63000

Ichar 3600 5000

ADC-offset over limits:

Inspect BSI line and components in it (R381, Pull-up resistor R192). If these are OK,

change UEM.

BSI Gain over limits:

Inspect BSI line and components in it (R381, Pull-up resistor R192). If these are OK,

change UEM.

Vbatt offset and Gain:

Inspect Vbatt lines and component in it.

Vchar over limits:

Page 20 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 21

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Inspect components which are connected Vchar line: F380, L380 and V380.

Ichar over limits:

Inspect components which are connected at Vchar line. If those are OK, First change current sense resistor (R190), if calibration is not still successful change UEM.

Calibration can be checked using ADC-readings. Known voltages, currents and resistances are fed and read by ADC-readings, read values and known values can be compared.

ADC-reading

Divided and scaled battery voltage, Charger voltage, Charger current, BSI and Btemp values can be read by this tool. Read values few times before you can be sure that results

are accurate.

NOTE: IF Vbatt Scaled and Divided unit results are different default calibration values are

used. In this case perform EM-calibration to get full performance of phone.

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 21

Company Confidential

Page 22

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Maximum tolerances are:

Reading Check point Tolerance

Vbatt SCAL

Vchar 8.4V ± 40mV

Ichar 500mA ± 20mA

BSI 91k ± 1.3kohm

Btemp 47k

Backup battery

Symptom of backup battery fault is

Real Time Clock loses the correct time during short main battery removal.

The same symptom can also be seen when the backup battery is empty. About 5 hours is

needed to fully charge the backup battery in the device. NOTE: Backup battery is charged

only the same time with main battery charging. Or when the device is LOCAL or TEST

mode.

Always check the backup battery visually for any leakage or any other visual defect.

Check that the backup battery is correctly mounted in the device before closing the

cover.

4.2V ± 25mV

± 5% <+25

°C

Check with Phoenix that backup battery is OK

Measure the voltage of backup battery

• Normal operation when the voltage is > 2.0V

• Fully charged when the voltage is about 3.2V (because of large internal

impedance voltage won’t stay above 3.0V a long time after charging is

disabled)

Enable backup battery charging (start to charge main battery or boot device to LOCAL or

TEST mode)

Measure voltage of backup battery during charging, It should arise if it is not 3.2V, yet.

When the voltage is over 2.0V for sure, check backup battery with Phoenix.

-> If not OK then D190 is faulty.

Ensure that the RTC is running.

Page 22 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 23

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

SIM card

The whole SIM interface locates in two chips UPP_WD2 and UEM. UEM contains the SIM

interface logic level shifting. UPP provides SIMClk through UEM to the SIM. SIM interface supports both 3 V and 1.8 V SIMs.

UPP & UEM SIM connections

GND

UPP

SIM

C5 C6 C7

C1C2C3

BSI line from battery

SIMCLK

SIMRST

BSI

SIMDATA

VSIM

GND

UEM

SIMIF

register

SIMIO

SIMClk

Data

UEM

digital

logic

SIMIO

SIMClk

Data

UIF Block

UEMInt

CBusDa

CBusEnX

CBusClk

The SIM power up/down sequence is generated in the UEM. This means that the UEM

generates the RST signal to the SIM. Also the SIMCardDet signal is connected to UEM.

The card detection is taken from the BSI signal, which detects the removal of the battery.

Monitoring of the BSI signal is done by a comparator inside UEM. The threshold voltage

is calculated from the battery size specifications.

The SIM interface is powered up when the SIMCardDet signal indicates ”card in”. This

signal is derived from the BSI signal. SW tries first to power up the SIM with 1.8 V. If this

doesn't succeed power up is repeated with VSIM switched to 3 V.

The data communication between the card and the phone is asynchronous half duplex.

The clock supplied to the card is in GSM system 1.083 MHz or 3.25 MHz. The data

baudrate is SIM card clock frequency divided by 372 (by default), 64, 32 or 16.

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 23

Company Confidential

Page 24

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Figure 3: SIM Power Up.

Ch1 Vsim

Ch2 Reset

Ch3 Clock

Ch4 I/O

Measured with

3Vsim

Figure 4: SIM answer to reset.

SIM answer to reset

CH1 = SIM_CLK

CH2 = SIM_RST

CH3 = SIM_I/O

CH4 = SIM_PWR

Measure points

SIM connector

Page 24 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 25

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Figure 5: SIM Clk 3.25MHz.

SIM_Clk_3.25MHz

CH1 = SIM_CLK

Measure points

SIM connector

Remember to check the two PHOENIX test cases before changing UPP!!!!

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 25

Company Confidential

Page 26

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

"Insert SIM Card" in device display although card is inserted

START

Perform

SIM BB self tests.

Are they OK?

Yes

Perform

Phoenix SIM tests.

Are they OK?

Yes

Is the SIM

Detection Reliable?

Yes

No

Check & clean battery

centre contact. Verify BSI

signal has a steady voltage.

Replace UEM

Perform

BB SIM self tests.

Are they OK?

Yes

Check SIM connector

Is it OK?

Yes

Measure VSIM.

Is it 1.8/3.0V when SIM

interface is powered

up?

Yes

NoNo

No

No

Replace UPP_WD2

Check & clean connector

contacts & pads

Replace connector

Measure VSIM

resistance to GND.

Is it low?

Yes

Check C470. Is it OK?

Yes

NoNo

No

Change UEM

Change VSIM

decoupler, C470

Problem solved?

Yes

END

No

Analyse signals & look for

errors in rise / fall times due

to wrong fitted / faulty

passives

Check SIM Power Up

sequencing. Is it OK?

Yes

No

Change SIM ASIP, R470

Check Clk, RST &

DATA at SIM connector.

Are the signals

present?

Yes

No

Check Clk,

RST & DATA between

UEM and the SIM ASIP.

Are the signals

present?

Yes

Change SIM ASIP, R496

R470

No

Change UEM

Page 26 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 27

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Memory troubleshooting

Most memory related errors are found through flashing the device, flashing the device is

therefore recommended before any of the steps described in this chapter. Check flashing

troubleshooting section first.

There are however a few memory related errors that cannot be found through flashing.

• - SDRAM(D310) partially damaged. This can mean that the SDRAM

component itself is partially damaged and all the memory locations cannot be successfully read or there is a soldering problem somewhere

either under UPP or SDRAM. There is a BB self test for testing SDRAM

component quite thoroughly, but the problem is that if SDRAM doesn't

function properly one may not be able to run those tests as SDRAM is

used during the device boot and self-test cannot be run if the device

hasn't booted.

• DEVICE may inform about being "out of memory " more often than it

should

• - flash1 (D312) is partially/totally damaged. During flashing the manufacturer, device and revision id's are read, but flashing is done based on

id's of the flash0 (D311). This means that one cannot see any error

messages displayed on Phoenix window during flashing if flash1 is failing. Id's are however displayed on the Phoenix window and successful

read of flash1 id's can be checked from there.

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 27

Company Confidential

Page 28

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Serial interface troubleshooting

CBUS

CBUS is a three wire serial interface between the main baseband components. The bus

consists of data, clock and bus_enable signals. In RH-29 the bus is connected from UPP

WD2 to ZOCUS, UEM and LPRF. UPP_WD2 takes care of controlling the traffic on the bus.

If the interface is faulty from the UPP WD2's end the phone won't boot properly as powering configurations don't work. Traffic on the bus can be monitored from three pins on

the LPRF module. Pins 34, 35 and 36.

In the pictures below CBUS traffic at boot up is shown. CbusEnx is connected to Ch1,

Cbus Da to Ch2 and CbusClk to Ch3.

CBUS_EN

CBUS_DATA

CBUS_CLK

If however you are able to get the phone to boot up and can reach Phoenix BB self tests

it is possible to test the functionality of each component attached to Cbus. Use

Page 28 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 29

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

ST_ZOCUS_CBUS_IF_TEST to test AEM Cbus interface

ST_UEM_CBUS_IF_TEST to test UEM Cbus interface

ST_LPRF_IF_TEST to test Bluetooth Cbus interface

If an error is found testing any of the above components you should replace the failing

component.

FBUS

FBUS is a two wire RX and TX interface between UPP and flash/test interface. The bus

goes through UEM which adjusts the voltage levels to suit UPP_WD2. The interface voltage level on the phone flash/test pad pattern is 2.78V and on the UPP WD2 end it is 1.8V.

The functionality of this interface should not affect the device boot into NORMAL, LOCAL

nor TEST modes. Phoenix tests can be performed through MBUS interface in the case of a

failure in FBUS interface. Flashing is not possible if there is a problem in FBUS.

MBUS

MBUS is a two wire RX and TX interface between UPP and UEM. From UEM the interface

continues to flash/test interface as a one wire interface. UEM also adjusts the voltage

levels. The interface voltage level on the phone flash/test pad pattern is 2.78V and on the

UPP WD2 end it is 1.8V. MBUS traffic between UPP WD2 and UEM can be tested with

PHOENIX (ST_MBUS_RX_TX_LOOP_TEST). Flashing is not possible if there is a problem in

MBUS.

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 29

Company Confidential

Page 30

RH-29 Company Confidential

J

J

6b - Baseband Troubleshooting Nokia Customer Care

MMC troubleshooting

Save Photo to known

working MMC

Replace R473

Yes

Does save

succeed

Yes

No

Phoenix

MMC test

Pass

Fail

Use CRO to examine Clk and CMD

signals at points MMC connector.

Are signals

present?

No

Yes

No MMC

failure

No Physical MMC

failure, reflash

Are signals

present @

490, J495

J481, J485

No

Yes

Replace R473

Is

connector

No

No MMC fault

found

No Physical MMC

failure, reflash

Yes

Are

signals

No

Replace R473

MMC

working?

No

Replace N470

Yes

Are signals

present @

490, J495

J481, J485

No

Replace UPP_WD2

End

Yes

MMC

working?

Yes

Replace N470

No

Page 30 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 31

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Vibra

There may be three kinds of problems with the vibra:

- it does not rotate

- It is noisy

- it is continuously on

Noisiness is usually caused by the contact of the rotating mass with surrounding

mechanics.

that C146 is

Check C145, C146,

C147

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 31

Company Confidential

Page 32

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

ZOCUS

Check

N380

Page 32 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 33

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

UI Module Troubleshooting

This document describes the troubleshooting of the UI module

If the problem is in the display or in the keymat PWB the entire UI module must be

replaced. However, the earpiece may be replaced (see audio troubleshooting).

Keymat backlight

If the keymat backlight is not functioning and the backlight driver voltage is generated

correctly on the 1CK module, then the problem is either in the connector or the UI module. Note that it is possible that one LED is dead while all others are working.

Check and

measure that

R610 is on its

place.

Measure from VKEYB

that voltage is ~Vbat

when the keyboard

backlight is turned on.

OK?

V165

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 33

Company Confidential

Page 34

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Keyboard problem

If the keyboard does not work, follow the troubleshooting chart below:

Change UPPWD2

Page 34 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 35

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Display blank

Check and change

V132 and Z130.

Display OK.

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 35

Company Confidential

Page 36

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Image on display not correct

MJ-21

display

Page 36 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 37

Company Confidential RH-29

C

R130

0

Nokia Customer Care 6b - Baseband Troubleshooting

Display backlight does not turn on

Display

not working

Display

LEDs OK?

C130

Check and replace

display module or

connectors.

133

Replace D13

and V130

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 37

Company Confidential

Page 38

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Hand portable audio

Start

Is earpiece

working?

Yes

Replace earpiece with

No

Place phone to MJ21 and set it to local mode.

MIC2(Amp1=0dB,MicGainCtrl=0dB), HP OUT

(GainCtrl=-6db), LOOPBACKANA on.

Measure DC-offset from earpiece pads.

new one. Does the

earpiece work now?

No

Use Phoenix audio test to set

Is it ~1.3V?

Yes

Measure MICB2 from MIC2P.

Is it ~2.1V?

Yes

Connect external audio signal

(1kHz sine 200mVp-p)

to MIC2P and gnd to MIC2N.

Yes

No

No

earpiece and

Check R341,X130

and lines. If OK,

change UEM.

Check L381,R337,R349

and lines. If OK,

change UEM.

Retest

UI module.

Measure signal from earpiece pads.

Is it ~180mV

Measure differential signal

over R336. (UEM )

Is it ~190mV

Check L381,R335,

C337 and lines.

No

No

?

p-p

?

p-p

Change UPP and retest.Yes

Change UEM and retest.Yes

Audio faults 2

Page 38 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 39

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Audio fault s 2

Is

microphone

working?

Yes

Replace microphone with

No

Place phone to MJ21 and set it to local

MIC1(MicGainCtrl=0dB), EAR(GainCtrl=

Measure differential signal over R340.

new one. Does the

microphone work now?

No

mode. Use Phoenix audio test to set

-26dB) and LOOPBACKANA on.

Measure MICB1 from MICP.

Is it ~2.0V?

Yes

Connect external audio signal

(1kHz sine 200mV

gnd to MICN.

Is it ~170mV

) to MICP and

p-p

p-p

Yes

?

Yes

No

No

Retest microphone.

Check R339,R350,

R340 and lines.

If OK, change UEM.

Check R338, C344,

R340 and lines.

If OK, change UEM.

Measure differential signal

from earpiece pads.

Is it ~225mV

Yes

Change UPP and retest.

?

p-p

No

Check R341, X130

and lines.

If OK, change UEM.

Audio fault s 3

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 39

Company Confidential

Page 40

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Replace IHF-lid.

Audio fault s 3

Check IHF-lid pogo pins.

Pins stuck?

No No Yes

Yes

Does MALT work?

Is MALT

working?

Yes

No

Place phone to MJ21 and set it to local mode. Use

Phoenix audio test to set MIC2(g1&g2),

HF+HFCM(g) a nd LOOPBACKANA on.

activate Boomer IHF. Connect external

audio signal ( 1kHz sine 200mVp-p)

AudioP and AudioN pads in MJ21.

Replace MALT.

Does the MALT work now?

No

Measure DC-offset from

C331,C332,R386 and R389.

Is it ~800mV?

Yes

Use Phoenix audio test to

to MIC2P and gnd to MIC2N.

Measure differential signal from

Is it ~450mV

No

?

p-p

Yes

No

Retest phone.

Check lines. If OK,

change UEM and retest.

Yes

Retest phone.

END

Measure J334 voltage.

Is it ~1.8V?

Yes

Me asure VAPA v oltage.

Is it near supply voltage?

Yes

Measure signal between C331 and C332.

Yes

?

p-p

?

p-p

Is it ~240mV

Measure signal between R330 and R331.

Is it ~240mV

Check R332, R333,

N330 and lines.

Replace defected and retest.

No

No

No

Change UPP

and retest.

Check L330

and lines,

retest.

Check C331,C332,

R330, R331 and lines.

Replace defected.

Page 40 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 41

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Accessory Audio

Start

Is

accessory

detection

working?

No

Replace connector X381.

Does detection work now?

No

Yes

Retest phone.

Yes

Check contacts of PWB.

Are those OK?

Yes

Place phone to MJ21.

Set phone to normal mode.

Measure HEADINT voltage from

L384 and J402 . Is it ~2.75V?

Yes

User may have used

unsopported accessory.

No

No

Solder a replacement

contact and retest.

Check L384 and line.

If OK, change UEM

and retest.

Accessory faults 2

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 41

Company Confidential

Page 42

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Accessory faults 2

Is

accessory

earpiece

working?

No

Place phone to MJ21 and set it to local

Replace accessory.

Does the earpiece work now?

No

mode. Use Phoenix audio test to set

MIC2(Amp1=0dB,MicGainCtrl=0dB),

HF+HFCM(GainCtrl=-6dB) and

LOOPBackAna on.

Yes

Accessory fault.

Yes

Measure DC-offset from R386, R389,

L382, HF and HFCM.

Is it ~810mV?

Yes

Measure MICB2 from MIC2P.

Is it ~2.1V?

Yes

Connect external audio signal

(1kHz sine 200mVp-p)

to MIC2P and gnd to MIC2N.

Measure differential

signal over R336.

Is it ~190mV

Yes

Measure differential signal from HF and HFCM.

Is it ~180mV

Yes

?

p-p

?

p-p

No

No

Check R386, R389,

No

No

L382 and lines. If OK,

change UEM.

Check L381,R337,R349

and lines. If OK,

change UEM.

Check L381, R335,

C337 and lines. If OK, verify

audio signal connection.

Change UEM and retest.

Change UPP and retest.

Accessory faults 3

Page 42 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Page 43

Company Confidential RH-29

Nokia Customer Care 6b - Baseband Troubleshooting

Accessory faults 3

Is

accessory

microphone

working?

No

Replace accessory. Does the

microphone work now?

No

Place phone to MJ21 and set it to local

mode. Use Phoenix audio test to

set MIC2(Amp1=0dB,MicGainCtrl=0dB),

HF+HFCM(GainCtrl=-6dB) and

LOOPBackAna on.

Yes

Accessory fault.

Yes

Measure MICB2 from MIC2P.

Is it ~2.1V?

Yes

Measure DC-offset from R386, R389,

L382, HF and HFCM.

Is it ~810mV?

Yes

Connect external audio signal

(1kHz sine 200mV

to MIC2P and gnd to MIC2N.

Measure differential signal

over R336.

Is it ~190mV

Yes

Measure differential signal over HF and HFCM.

Is it ~180mV

Yes

)

p-p

?

p-p

?

p-p

No

No

Check L381,R337,R349

and lines. If OK,

change UEM.

Check R386, R389,

No

L382 and lines. If OK,

change UEM.

Check L381, R335,

C337 and lines. If OK, verify

audio signal connection.

No

Change UEM and retest.

Change UPP and retest.

Accessory faults 4

Issue 1 05/2004 Copyright © 2004 Nokia Corporation Page 43

Company Confidential

Page 44

RH-29 Company Confidential

6b - Baseband Troubleshooting Nokia Customer Care

Accessory faults 4

Is

accessory

button

working?

No

Replace accessory. Does the

button work now?

No

Yes

Accessory fault.

Yes

Replace connector X381.

Does the button work now?

No

Place phone to MJ21 and set it to local

mode. Use Phoenix audio test to

set MIC2, Ear and LOOPBackAna on.

Measure voltage level from R334.

Is it ~2.1V?

Yes

Press HOOKINT

button in MJ21.

Measure voltage level from R334.

Is it ~1.0V?

Yes

Yes

No

No

Connector fault. Retest

after replacement.

Check R337,R349

and lines. If OK,

change UEM.

Check R334

and lines. If OK,

change UEM.

Retest phone.

End

Page 44 Copyright © 2004 Nokia Corporation Issue 1 05/2004

Company Confidential

Loading...

Loading...