Page 1

Programmes After Market Services

NSD-5 Series Transceivers

10. Troubleshooting

Issue 1 05/02 Nokia Corporation

Page 2

NSD-5

10. Troubleshooting P AMS Technical Documentation

Page 2 Nokia Corporation Issue 1 05/02

Page 3

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Contents

Page No

Troubleshooting............................................................................................................. 5

Baseband Troubleshooting............................................................................................. 5

Main Circuit Sections..................................................................................................... 5

Power Circuitry ............................................................................................................5

CCONT ........................................................................................................................5

Vbat ..............................................................................................................................5

Vref ..............................................................................................................................5

Linear Regulators .........................................................................................................5

1. Vbb........................................................................................................................ 5

2. RF Regulators (VR1–VR7)................................................................................... 6

3. V2V (VMAD) ....................................................................................................... 6

Switch mode regulator .................................................................................................6

1. V5V (+5V_POWER) ............................................................................................ 6

2. VSIM (3V_5V) ..................................................................................................... 6

A/D Conversion......................................................................................................... 6

Watchdog .................................................................................................................. 7

Serial bus................................................................................................................... 7

Clocks ..........................................................................................................................7

Sleep Clock ............................................................................................................... 7

System Clock............................................................................................................. 7

CDMA clock............................................................................................................. 7

Charging Circuit ..........................................................................................................7

CAFE ...........................................................................................................................8

Microphones.............................................................................................................. 8

Earpiece and XEAR .................................................................................................. 8

Transmit and Receive RF Signals............................................................................. 8

MAD4 ..........................................................................................................................8

DSP............................................................................................................................ 8

MCU.......................................................................................................................... 9

Memories .....................................................................................................................9

Troubleshooting Instructions ....................................................................................... 10

Check System Clock ............................................................................................... 11

Check Sleep Clock.................................................................................................. 12

In the Field .............................................................................................................. 12

Power Supplies........................................................................................................ 12

Phone is Totally Dead ................................................................................................13

Phone Won’t Power Up .............................................................................................13

Power Doesn’t Stay on or Phone is Jammed .............................................................14

Flash Programming Fails ...........................................................................................14

Audio failures ............................................................................................................14

Battery Will Not Charge ............................................................................................18

Baseband Test Points .................................................................................................19

Baseband Test Point Layout (Top side view) ............................................................21

Baseband Test Points Layout (Bottom side View A) ................................................22

Baseband Test Points Layout (Bottom side View B) ................................................23

RF Troubleshooting ..................................................................................................... 24

Purpose ......................................................................................................................24

Issue 1 05/02 Nokia Corporation Page 3

Page 4

NSD-5

10. Troubleshooting P AMS Technical Documentation

Introduction ................................................................................................................24

Reference Documents ................................................................................................24

WinTesla General Set Up ............................................................................................ 25

CDMA Fault-finding Set Up .....................................................................................25

Synthesizer Tuning Menu ..........................................................................................26

Tuning AFC............................................................................................................. 26

Description of Test.................................................................................................. 26

Definition of Result................................................................................................. 27

Manual Verification ................................................................................................ 27

Synthesizer Troubleshooting .....................................................................................27

Test Points............................................................................................................... 29

Trouble Case 1: Tx VHF LO Power < -20dBm ........................................................29

Trouble Case 2: Rx VHF LO Power < -12dBm ........................................................30

Trouble Case 3: UHF LO Power < -5dBm ................................................................30

Trouble Case 3: Rx UHF LO Power < -5dBm ..........................................................30

TX Tuning .................................................................................................................35

Description of Test.................................................................................................. 35

Definition of Result................................................................................................. 36

Manual Verification ................................................................................................ 36

TX Troubleshooting Flowchart .................................................................................38

1900 PCS Tuning Rx IF AGC ...................................................................................40

Description of Test.................................................................................................. 40

Definition of Result................................................................................................. 41

Manual Verification ................................................................................................ 41

1900 PCS Tuning Rx IF Compensation ....................................................................42

Description of Test.................................................................................................. 42

Definition of Result................................................................................................. 42

Manual Verification ................................................................................................ 43

RX Troubleshooting ..................................................................................................45

Troubleshooting ...................................................................................................... 45

Rx VHF LO Measured at RIF Pin 20 with a Hi Z Probe........................................ 46

RX Troubleshooting Flowchart .................................................................................46

Test Points .................................................................................................................46

Page 4 Nokia Corporation Issue 1 05/02

Page 5

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Troubleshooting

Baseband Troubleshooting

Each main portion of the circuit will be described in enough detail for the troubleshooter

to determine whether or not that part of the circuit being evaluated is functional. It will

be helpful to use the placement diagram, which illustrates all of the necessary testpoints

in the baseband circuit, to troubleshoot the phone. The placement diagram is intended to

be used concurrently with this document. Herein, TPD refers to Test Point Designation.

Main Circuit Sections

Power Circuitry

There are two ASICs in the baseband section, which supply power to most of the phone.

CCONT is the main power management ASIC. Two discrete linear regulators are used as

well.

CCONT

Vbat

Vref

CCONT is the main power management ASIC. Its features include eight 2.8V linear regulators, a linear regulator with adjustable output, a reference voltage output, a 5V switch

mode regulator, an 8-channel A/D converter, and 32kHz clock circuitry. Each of the main

functions and signals is described below, including information on how to verify correct

operation.

CCONT is powered directly from the battery voltage (Vbat). Since CCONT is a uBGA, the

physical connection of CCONT’s power pins cannot be verified. Vbat must be checked

instead at the closest external component, which is shown as TPD. Valid voltages are

3.2 – 4.2V and should always be powered, assuming voltage is applied to the

battery terminals.

Vref is used as a reference voltage both internal and external to CCONT. It is switchable

between the nominal voltages of 1.500V and 1.251V, with the default at power-up being

1.500V. The phone uses the 1.251V reference, so once flash software is running, Vref

should switch to 1.251V.

Check Vref at TPD. Valid voltages are 1.478 – 1.523V and 1.244 – 1.258V, respectively.

Linear Regulators

1. Vbb

Vbb supplies power to most of the baseband circuitry. This regulator should be on at all

times during CCONT’s power on, reset, and sleep modes. Nominal voltage is 2.8V, but

anything in the range 2.7 – 2.87V is valid. Vbb is found at TPD30.

Issue 1 05/02 Nokia Corporation Page 5

Page 6

NSD-5

10. Troubleshooting P AMS Technical Documentation

2. RF Regulators (VR1–VR7)

VR1 through VR6 are referred to as the RF regulators. Most are switchable, and all should

be within 2.67 – 2.85V when they are on (2.8V nominal). VR1 and VR6 are always on during CCONT’s power on mode. The rest of the regulators are switchable and are normally

on during one or more of the various phone states, but may be turned on at any time

with the service software in order to verify their output. The RF regulators can be

checked at the following test points.

a) VR1 – TPD

b) VR1_SW – TPD

c) VR2 – TPD

d) VR3 – TPD

e) VR4 – TPD

f) VR5 – TPD

g) VR6 – TPD

h) VR7 - TPD

3. V2V (VMAD)

The V2V (VMAD) regulator is intended to power the MAD4 ASIC core. The output is

adjustable from 1.3V to 2.65V in 0.225V steps, and is used with MAD4 ver 3 (but not

MAD4 ver 2). The output at V2V, when MAD4 ver 3 is mounted, should be 1.750V ±5%

and can be checked at TPD27.

Switch mode regulator

1. V5V (+5V_POWER)

V5V is a 5V switch mode regulator, which always remains on during CCONT power on

mode. Valid voltages are 4.8V to 5.2V, and it can be checked at TPD2.

2. VSIM (3V_5V)

VSIM is powered by the same switch mode regulator as V5V; however, it is switchable

between 3V and 5V. The phone uses VSIM as the 3V FLASH programming voltage, so it

should remain off unless the phone is being flashed. Valid voltages are 2.8V to 3.2V, and

it can be checked at TPD1.

A/D Conversion

CCONT contains a 10–bit A/D converter that is multiplexed between eight different

inputs. They are used mainly for battery and charger monitoring. The eight inputs are:

Vbat (battery voltage), ICHAR (charger current), VCHAR (charger voltage), BSI (battery

type), BTEMP (battery temperature), VCXOTEMP (PA temperature), and EAD (accessory

Page 6 Nokia Corporation Issue 1 05/02

Page 7

NSD-5

PAMS Technical Documentation 10. Troubleshooting

detection). These readings can be accessed through the service software. Check for

shorts or opens on the resistor networks connected to these signals if the flash align test

software reports that they are out of range.

Watchdog

CCONT’s watchdog circuitry consists of an 8-bit down counter that causes CCONT to

power down when zero is reached. The counter may be reset by loading a new, non–zero

value into the watchdog register via CCONT’s serial bus. It is difficult to verify the watchdog function, but the serial bus may be verified.

There is a watchdog disable pin, which allows the watchdog timer to expire without

shutting down the phone. This pin is mainly used as one of the methods to turn on

CCONT from power off mode. While the phone’s power key is pressed, this pin should be

pulled low and can be checked at TPD 26 using a 70k resister. The watchdog can be disabled by pulling down the above-mentioned pin (WD_DIS) by shorting TPD 26 and

ground.

Serial bus

Since the serial bus is used to control almost all of CCONT’s functions, any shorts or open

circuits on these three lines would cause CCONT to be completely nonfunctional. The

main symptoms are the following:

CCONT will turn on when the power key is pressed (verify this by checking Vbb), but will

then power off after 32 seconds. All three serial bus signals (CCONTCSX,

UIF_CCONT_SDIO, and UIF_CCONT_SCLK) should toggle when attempting to write to a

CCONT register.

Note: If the LCD does not come on during this time, it may indicate that the serial bus is functional,

but the phone does not have valid flash code.

Clocks

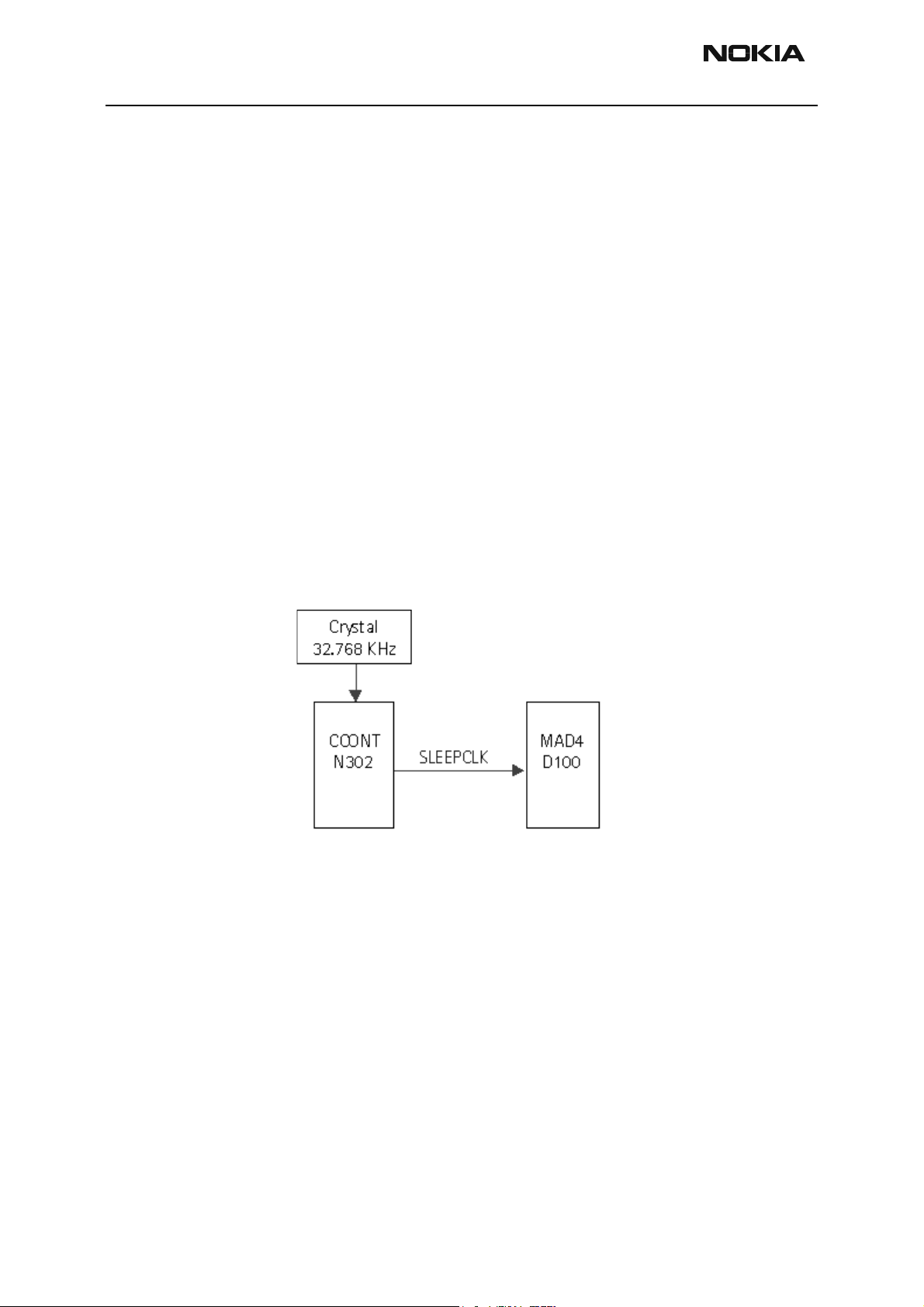

Sleep Clock

The 32kHz sleep clock is generated by CCONT, and can be checked at TPD32. The 32kHz

square wave will be present only after the phone is turned on.

System Clock

The 19.2MHz system clock is generated by the VCTXO in the RF section, and then squared

in CAFE. Check TPD11, which should be a 2.8V squarewave. This clock is not active during

the phone’s sleep mode (CLK_EN is low during sleep mode).

CDMA Clock

The CDMA clock is 9.8MHz and is generated in CAFE with a PLL. This should be a 2.8V

squarewave and can be verified at TPD10.

Charging Circuit

The charging switch, CHAPS, is controlled by a PWM from CCONT. This PWM can be at

Issue 1 05/02 Nokia Corporation Page 7

Page 8

NSD-5

10. Troubleshooting P AMS Technical Documentation

1Hz or at 32Hz, with varying duty cycles, and should only be active when a charger is

detected. The frequency depends on charger type. To verify correct operation of CHAPS,

monitor the charging current (ICHAR) with the service software. When the PWM is off,

current should be approximately 200uA. When the PWM is on, it must be greater than

approximately 300mA.

CAFE

The CAFE ASIC performs various functions with respect to the RF circuitry and audio. It

digitizes the analog voice signals from the microphone as well as converts received digital data to voice signals to be sent to the earpiece. This also includes accessory microphones and speakers. It also generates and decodes I and Q data for CDMA signals. CAFE

also acts as a clock squaring circuit and CDMA clock generator.

Microphones

The internal microphone is biased using transistor V280, which is powered by VR1_SW.

MICP should be about 1.7VDC, and MICN should be about 0.4VDC. Internal microphone

bias should only be active during a call. The XMIC is biased by the AUXOUT signal

through R240 and R241. The AUXOUT output provides 1.5V bias voltage to the external

microphone.

Earpiece and XEAR

The internal earpiece is driven differentially (EARP and EARN). The DC voltage on these

two pins is 1.35V. The difference in the DC voltage between these two pins should not be

more than 50mV.

The XEAR signal drives audio to the external accessories. The CAFE signal name is HF. The

DC level on this pin should be 1.35V. HFCM should also be at 1.35V. The difference in DC

voltage between these two pins should not be more than 50mV.

Note that SGND is the return path for XMIC and XEAR.

Transmit and Receive RF Signals

In CDMA mode, receive I and Q channel RF signals [RXIQ(3:0)] come into CAFÉ pins.

C201, C202, C203, and C204 can also be checked for these signals since they are in series

with the CAFÉ pins. Transmit I and Q RF signals [TXIQ(3:0)] can be seen at C205, C206,

C207, and C208.

MAD4

The MAD4 ASIC is the core of the baseband functionality and basically contains the DSP,

MCU, and CDMA logic. The DSP is used to perform functions such as RF control, DTMF

tone generation, and implementation of the vocoder. The MCU is used to perform functions that do not require as much power — higher-level functions such as UI software

(key presses, backlighting, LCD functions, etc.) and mode control.

DSP

The DSP sends control signals to the RF via PDMs. In order to control RF parameters such

as TX_LIM_ADJ, a continuously variable analog signal must be used. Since the DSP out-

Page 8 Nokia Corporation Issue 1 05/02

Page 9

NSD-5

PAMS Technical Documentation 10. Troubleshooting

puts only digital signals, a PDM RC circuit is used to convert the digital output signal to

an average analog voltage. A PDM line will always have a series resistor followed by a

shunt capacitor. The output of the MAD4 PDM lines will appear as squarewave signals.

However, after the shunt capacitor, the signals will appear to be DC with perhaps a slight

ripple. The RC circuit acts as an integrator in order to yield the average value (DC) of the

squarewave signal.

The transmit data bus (TXD(7:0)) is 8 bits wide. In CDMA mode, this bus is multiplexed

between sending I and Q data. The signals required to transfer TX data are

CAFE_TX_GATE, CLK9M80, and IQSEL. CAFE_TX_GATE must be high to transfer data, and

the data is clocked by CLK9M80, which is running at 9.8MHz.

MCU

The MCU is used to perform functions that require less processing power than the DSP. It

runs UI software and mode control; interfaces to MBUS; downloads code to flash; reads

and writes the EEPROM; controls charging; and interprets A/D data from CCONT.

Memories

MAD4 interfaces to three memories — Flash, SRAM, and EEPROM. All of them are powered by 2.8V (Vbb). During Flash programming, Vpp (signal name is Vff_flash on schematic) is driven to Flash memory.

Issue 1 05/02 Nokia Corporation Page 9

Page 10

NSD-5

10. Troubleshooting P AMS Technical Documentation

Troubleshooting Instructions

The first thing to do is to carry out a thorough visual check of the module. Make sure

that there is no mechanical damage and that solder joints are okay. Most failures will be

the result of SMD errors. Common errors include: solder placed where it shouldn’t be,

parts sliding off their pads, or parts placed incorrectly. A good visual inspection will pinpoint a large percentage of failing phones.

Before changing anything, also check all supply voltages and the system clock/sleep

clock.

The Troubleshooting Instructions section contains five modules:

- How to check/fix the system/sleep clock

- How to check/fix the power supplies

- How to check/fix the flashing faults

- How to check/fix the audio faults

- How to check/fix the charger faults

Page 10 Nokia Corporation Issue 1 05/02

Page 11

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Check System Clock

Figure 1: System clock picture

Issue 1 05/02 Nokia Corporation Page 11

Page 12

NSD-5

10. Troubleshooting P AMS Technical Documentation

Check Sleep Clock

Figure 2: Sleep clock picture

In the Field

Although solder joints may be adequate to pass manufacturing requirements, they may

not withstand mechanical stress or heat cycling. Cracked or broken solder may cause

failures to occur as the result of simple use. Reflowing some of the major components

may fix problems where the phone exhibits strange behavior (some buttons may not

work, the phone doesn’t ring, or the phone doesn’t power on).

Power Supplies

Measure the power supplies. Test points are illustrated in the baseband test points table

and the layout diagram.

Page 12 Nokia Corporation Issue 1 05/02

Page 13

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Power up sequence test:

CCONT digital parts keep MAD4 in reset by keeping PURX down for a delay of 62ms.

Here is the start-up sequence picture:

Ch1 = PWRONX

Ch2 = SLEEPCLK

Ch3 = PURX

Ch4 = RESETX

Phone is Totally Dead

The phone doesn’t take current at all when the power switch is pressed or when the

watchdog disable pin (TPD331) is grounded.

Make sure that the battery voltage you use is within specification (i.e., 3.2 - 4.2V). If the

voltage is lower than that, CCONT hardware (N302) prevents power on.

If the battery voltage is within the specification, change the CCONT (N302).

High current: This indicates that the problem is likely the result of a shorted component.

Check the orientation of major components (including RF) and check for shorts. Likely

components are those that are powered directly from Vbat such as CCONT, the PAs, and

various capacitors.

Low current: This indicates that CCONT is now powering on. Verify CCONT circuitry.

Phone Won’t Power Up

Do a visual inspection. Verify that all parts are on the board correctly, and that none is

missing. Phone won’t power up often is related to VCTCXO solder joints cracking and no

19.2MHz to the BB.

Issue 1 05/02 Nokia Corporation Page 13

Page 14

NSD-5

10. Troubleshooting P AMS Technical Documentation

Check that the 32kHz clock turns on when attempting to power up.

Check the power circuitry. This includes Vbat, Vref, and all of the linear regulators.

Power Doesn’t Stay on or Phone is Jammed

If this type of fault occurs after flash programming, there are most likely open joints in

ICs. Solder the IC joints. Normally, the power will be switched off by CCONT(N302) after

30 seconds if the CCONT watchdog cannot be served by software. This updating can be

seen with an oscilloscope at CCONTCSX(TPD334). In normal cases, there is a short pulse

from “1” to “0” every 8 seconds.

Because of underfill, check the supply voltages, clock signals, and power sequence. If the

power sequence fails, there are some open connections under MAD4 or compomemory. If

everything appears to be correct, it is best to erase the flash memory and try to reput the

software to the phone again.

Flash Programming Fails

The flash programming can be done via flash connector X052 or via dedicated PCB pads

(J56,J57). In production, the first programming is done via flash connector. After this, the

flash connector is cut away; as a result, the programming must be done via PCB pads visible through the shield under the battery. The fault-finding diagrams for flash programming are shown in the start-up sequence diagram.

In the case of flash programming errors, the flash prommer may provide some information about a fault. The fault information messages could be:

- MCU doesn’t boot

- Serial clock line failure

- Serial data line failure

- External RAM fault

- Algorithm file or alias ID not found

- MCU flash Vpp error

Flash: Failure to flash is the main baseband failure. Check all the CCONT regulators,

especially Vbb, VR1, and VR6 for shorts. Check clocks and reset circuitry. Check for shorts

on the address, data, and chip enable lines on the memories and MAD4. If a short is

detected, it may be that it is beneath the BGA flash and may have to be replaced.

Note: Unfortunately there is no ROM software that can be run when the phone does not

flash. Typically, this software would be used to test all of the interfaces between MAD4

and its peripherals. Therefore, it must be visually (or by ohmeter) determined whether

there is a possible short between two or more of the address or data lines.

Audio failures

If audio fails to be heard from the earpiece (or XEAR), check the following:

Check earpiece contacts.

Page 14 Nokia Corporation Issue 1 05/02

Page 15

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Verify that the CAFÉ EARP and EARN bias is on. If necessary, check the entire receive

path—Rx voice data comes from the RF through the RXIQ bus (CDMA), then to MAD4

through RXD (11:0) (Refer to schematic).

The Rx voice data then goes back to CAFE on CAFESIO (0), and then to the earpiece or

XEAR. CAFESIO (2) must also be active.

Conversely, if the transmit audio is not working, the fault could be anywhere in the

transmit path. Check the following:

Check microphone contacts.

Microphone bias.

Tx voice data is transferred from CAFÉ to MAD4 on CAFESIO (1). CAFE-SIO (2) must also

be active. Tx voice data is then sent back to CAFÉ on the TXD bus (See schematic).

Tx voice data is then sent to RF on the TXIQ bus.

Issue 1 05/02 Nokia Corporation Page 15

Page 16

NSD-5

10. Troubleshooting P AMS Technical Documentation

Page 16 Nokia Corporation Issue 1 05/02

Page 17

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Issue 1 05/02 Nokia Corporation Page 17

Page 18

NSD-5

10. Troubleshooting P AMS Technical Documentation

Battery Will Not Charge

If the battery won’t charge (phone doesn’t allow the battery to charge), check CHAPS

and the charging circuit. It may also be necessary to verify the A/D functionality of

CCONT since this is the method of detecting battery type, charger type, etc.

Page 18 Nokia Corporation Issue 1 05/02

Page 19

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Baseband Test Points

Test

point

1 VSIM CCONT regulator output (2.8V-3.2V) From CCONT to FLASH

2 V5V CCONT regulator output (typical 5V) From CCONT to RF transmitter

3 EEPROMSDA EEPROM access serial data From MAD4 to EEPROM

4 EEPROMSCLK EEPROM access serial clock From MAD4 to EEPROM

5 CCONT_INT CCONT interrupt From CCONT to MAD4

6 MBUS Maintenance bus serial signal Bi-directional serial bus to MAD4

7 FBUS_TX Flash bus Tx signal Serial bus from MAD4 to the bot-

8 FBUS_RX Flash bus Rx signal Serial bus from the bottom con-

9 PWM PWM From CCONT to CHAPS

10 CLK9M83 9.83MHz square waveform From CAFE to MAD4

11 CLK19M20 19.2MHz square waveform From CAFE to MAD4

Signal name General characteristics General signal destination

and the bottom connector

tom connector

nector to MAD4

12 DATA(0) Data bus(0) From MAD4 to FLASH and SRAM

13 ADD(0) Address bus(0) From MAD4 to FLASH and SRAM

14 MEM(2) Write enable signal (active low) From MAD4 to FLASH, SRAM

15 MEM(1) SRAM select signal From MAD4 to SRAM

16 MEM(0) FLASH ROM select signal From MAD4 to FLASH

17 MEM(3) Read enable signal (active low) From MAD4 to FLASH, SRAM

18 RESETX Reset signal (active low) From MAD4 to CAFE

19 PWRONX Power ON (active low) From UI power key to MAD4 and

CCONT

20 CLK_EN VCTCXO enable signal From MAD4 to FLASH, CCONT, and

CAFE

21 UIF_CCONT_SCLK LCD and CCONT serial bus clock From MAD4 to LCD and CCONT

22 PURX Power up reset signal (active low) From CCONT to MAD4

23 SLEEPCLK 32.768KHz typical square waveform From CCONT to MAD4

24 CCONTCSX CCONT chip select signal From MAD4 to CCONT

25 UIF_CCONT_SDIO LCD and CCONT serial bus data From MAD4 to LCD and CCONT

26 WD_DIS Watchdog disable (active low) CCONT test point for phone diag-

nosis mode

27 Vmad MAD4 supply voltage From CCONT to MAD4

Issue 1 05/02 Nokia Corporation Page 19

Page 20

NSD-5

10. Troubleshooting P AMS Technical Documentation

Test

point

28 Vref CCONT regulator output (typical 1.244V) From CCONT to CAFE and battery I/

29 CRB 32.768KHz From 32K crystal to CCONT

30 Vbb Baseband supply voltage (2.8V typical) From CCONT to MAD4 and memo-

31 VR3 CCONT regulator output 2(typical 2.8V) From CCONT to RF receiver

32 VR4 CCONT regulator output 2(typical 2.8V) From CCONT to RF transmitter

33 VR2 CCONT regulator output 2(typical 2.8V) From CCONT to RF receiver

34 VR5 CCONT regulator output 2(typical 2.8V) From CCONT to RF transmitter

35 VR6 CCONT regulator output 2(typical 2.8V) From CCONT to CAFE

36 VR1 CCONT regulator output 2(typical 2.8V) From CCONT to 19.2MHz VCTCXO

37 VR1_SW 2.75V (MIC bias) From CCONT to V201 to CAFE

38 Vbat Battery voltage (3.2-4.2V)

Signal name General characteristics General signal destination

F

ries

From battery to CCONT and other

(3.1-5.2V with charger connected)

various parts of the phone

39 L_GND 0V From bottom connector through an

inductor to phone ground

40 V_IN Charger input (ACP-8:6V, LCH-9:8.3V

typical)

41 MICP Mic differential positive signal From bottom connector to CAFE

42 MICN Mic differential negative signal From bottom connector to CAFE

43 EAD_HEADINT Headset interrupt signal From bottom connector to MAD4

44 XEAR External ear output From CAFE to bottom connector

45 XMICN Mic external signal From bottom connector to CAFE

46 XMICP Mic external signal From bottom connector to CAFE

47 VR7 CCONT regulator output 2(typical 2.8V) From CCONT to RF transmitter

From bottom connector to CHAPS

internal microphone input

internal microphone input

external microphone input

external microphone input

Page 20 Nokia Corporation Issue 1 05/02

Page 21

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Baseband Test Point Layout (Top side view)

Issue 1 05/02 Nokia Corporation Page 21

Page 22

NSD-5

10. Troubleshooting P AMS Technical Documentation

Baseband Test Points Layout (Bottom side View A)

Page 22 Nokia Corporation Issue 1 05/02

Page 23

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Baseband Test Points Layout (Bottom side View B)

Issue 1 05/02 Nokia Corporation Page 23

Page 24

NSD-5

10. Troubleshooting P AMS Technical Documentation

RF Troubleshooting

Purpose

This section is intended to help the troubleshooter quickly determine and fix problems

with NSD-5 phones that have failed in the field.

Introduction

This document is written for use in conjunction with the WinTesla Tuning and Testing

software. Screen shots of the menu structures are shown throughout the document. This

document should be used in conjunction with the phone’s schematics which are referred

to in detail throughout.

WinTesla has three key menus:

Configure — Basic set up covered in WinTesla General Set Up

Testing — This menu allows switching on the phone in different modes

Tuning — This menu allows tuning and storing of data to eeprom

Tuning is described in four parts:

A description of the tuning: Describes the tuning process

Definition of result: What tuning is storing to eeprom

Manual Verification: How to use WinTesla to tune the phone

Troubleshooting: Outlines key components to be checked

Reference Documents

The phone’s schematics are essential for troubleshooting and are referred to in detail

throughout the document.

The following document may also be useful as a reference:

DRK00009-EN: Diagnostic Technicians Guide to Zim Flash/Alignment and Final/UI Tuning

and Testing

Page 24 Nokia Corporation Issue 1 05/02

Page 25

NSD-5

PAMS Technical Documentation 10. Troubleshooting

WinTesla General Set Up

Following connection of the phone to the PC COM port and starting WinTesla, select

Product from the main WinTesla menu and New from the drop-down menu. The ZIM

configuration will automatically be selected.

Select Configure from the main WinTesla menu and then choose Frequency Planning

from the drop-down menu. You then will be able to set up the default CDMA Channels.

The cable loss also should be entered. It is possible to enter a Tx and Rx cable loss separately; however, if a single cable is being used, then both losses should be the same.

CDMA Fault-finding Set Up

CDMA testing is started by selecting Testing from the main WinTesla menu and then

Issue 1 05/02 Nokia Corporation Page 25

Page 26

NSD-5

10. Troubleshooting P AMS Technical Documentation

selecting CDMA Tests from the drop-down menu. The “CDMA Testing” dialog box default

switches on both the transmitter in Rh

receiver ON, with the channel defined as “Mid” in the “Frequency Planning” dialog box.

PDMs may be adjusted on the “CDMA Testing” dialog box with the slider bars or by

entering a value in the appropriate boxes. The transmitter is switched off by inserting a

checkmark in the TX Off box. The Rho box switches on the CDMA IQ modulation. The

RX_IF_AGC is read by clicking the Read button. The LNA defaults to ON and can be

switched off by inserting a checkmark in the LNA box.

o mode (Tx with CDMA modulation) and the

Synthesizer Tuning Menu

WinTesla prompts you with equipment settings for all the tunings. At the end of the tuning sequence, WinTesla gives you the option of saving the new tuning values to EEPROM

or of exiting without saving the new values to EEPROM.

Tuning AFC

Description of Test

This test tunes the VCTCXO to exactly 19.2MHz using a DC voltage (C519 or TPD205)

controlled by the AFC PDM. The resulting PDM is stored to EEPROM. The CDMA IQ mod-

Page 26 Nokia Corporation Issue 1 05/02

Page 27

NSD-5

PAMS Technical Documentation 10. Troubleshooting

ulation is switched off. The output carrier is monitored with a spectrum analyzer. Click

on WinTesla Help for equipment set-up. The AFC PDM is tuned until the RF CW carrier

frequency is within +/-250Hz of 2073.1MHz (i.e., Channel 300).

Note: The Spectrum Analyzer must be connected to a high-stability, 10MHz reference at

the rear of the instrument. If this is not done, then the tuning will not be accurate.

Definition of Result

As a result of this tuning, the AFC PDM is stored to EEPROM, which puts the VCTCXO at

the correct frequency.

Manual Verification

Use WinTesla as follows:

1. Select Tuning from the WinTesla main menu and choose 1900 PCS and AFC... from

the drop-down menus.

2. The “Tuning AFC” dialog box is displayed. Use this box to adjust the Present AFC values, using the U

3. Select either the Save & Exit button or the No Save & Exit button when through.

p and Dn buttons or the PgUp or PgDn buttons.

Synthesizer Troubleshooting

The VCTCXO reference designator is G501. VR1 supplies 2.7V to the VCTCXO through

R501, decoupled with C561. The VCTCXO is controlled by a DC level from the AFC PDM in

MAD, connected to Pin1. The PDM is filtered by R141 and C141 in the baseband section

and by R504 and C507 in the RF section. Typically, a correctly tuned VCTCXO should have

approximately 1.5 volts on Pin 1.

Issue 1 05/02 Nokia Corporation Page 27

Page 28

NSD-5

10. Troubleshooting P AMS Technical Documentation

Adjustment of the AFC PDM from 0 to 511 should result in a voltage change on G501

Pin 1 of between 0.77 and 2.09 volts with approximately 45kHz change in the transmitter output frequency in the PCS band.

Selecting the “PCS AFC Tuning On” box disables the CDMA modulation, allowing AFC

tuning to be performed on the RF carrier feed through.

Page 28 Nokia Corporation Issue 1 05/02

Page 29

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Test Points

Test Point Signal Name General Characteristics General Signal Destination

C507-R504 AFC VCTCXO control voltage PDM from MAD4

R530-R501 VR1 2.7V supply to VCTCXO CCONT to VCTCXO

C519-C544 19.2MHz 19.2MHz from VCTCXO output VCTCXO output to CAFE and PLL IC’s

C518 Tx VHFLO VHF LO to TIF CELL CDMA 346.2MHz LO from PLL to TIF IC

C517 Rx VHFLO 256.2MHz VHF LO to RIF LO from PLL to RIF

19.2MHz measured at the output of the VCTCXO with a 10 Mohm probe. The figure

below shows the 19.2MHz signals measured by oscilloscope.

Requirements

Test Point Signal Name Specification

C507-R504 AFC 1.5 +/- 0.5V

C519-C544 19.2MHz 19.2MHz +/- 150Hz

C518 Tx VHF LO >

C517 Rx VHF LO >

C510 TX UHF LO >

C524 RX UHF LO > -5dBm

-20dBm

-12dBm

-5dBm

Trouble Case 1: Tx VHF LO Power < -20dBm

Check the DC level of V508.

DC level of pin 1 > 1V, pin2 0.7 -0.8V, pin 3 > 2V, between Pin 1 and Pin 2 from 0.6 to

0.8V

If not, change V508.

Issue 1 05/02 Nokia Corporation Page 29

Page 30

NSD-5

10. Troubleshooting P AMS Technical Documentation

Trouble Case 2: Rx VHF LO Power < -12dBm

Check the DC level of V506.

DC level of Pin 1 > 1V, Pin 2 0.7 0.8V, Pin3 > 2V, between Pin 1 and Pin 2 from 0.6 to

0.8V

If not, change V506.

Trouble Case 3: UHF LO Power < -5dBm

Check the DC level of V502.

DC level of Pin 1 > 0.5V, between Pin 1 and Pin 2 from 0.6 to 0.8V

If not, change V502.

Trouble Case 3: Rx UHF LO Power < -5dBm

Change G502.

Page 30 Nokia Corporation Issue 1 05/02

Page 31

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Start

Set to "Tuning A FC" Mode

Measure Antenna Port Frequency

=2073.1M Hz

+ / - 250Hz

Yes

Measure "CLK19M2RF" frequency

=19.2MHz + / -

150Hz

Yes

TX V H F L O te s t -> A

RX VH F L O te s t -> B

TX/R XUH F L O te s t - > C

No

No

Adjust AFC Value

Adjust AFC Value

A B C

Issue 1 05/02 Nokia Corporation Page 31

Page 32

NSD-5

10. Troubleshooting P AMS Technical Documentation

A

Measure TX VHF LO power at C518

> -20dBm B

No

Measure DC level of V508

pin 1>1V

pin2 >0.6V

pin3 >2V

Yes

Yes

No

Check

C515, C518, C511, L506

Change the V508

Page 32 Nokia Corporation Issue 1 05/02

Page 33

NSD-5

PAMS Technical Documentation 10. Troubleshooting

B

Measure RX VHF LO power at C517

> -12dBm

No

Measure DC level of V506

pin 1>1V

pin2 >0.6V

pin3 >2V

Yes

Yes

No

Change the V506

C

Check

C516, C517, C506, C569, L501

Issue 1 05/02 Nokia Corporation Page 33

Page 34

NSD-5

10. Troubleshooting P AMS Technical Documentation

C

Remove C704

Measure RX UHF

LO power at C524

> -5dBm

No

Measure DC level of

G502

pin 10>2 .7 V

Yes

Change G502

Set to CH300 in CDMA Tes ti ng mo de

Measure RX UHF LO frequency at

C524

=2088.1MHz

@ Ch600

+/-150Hz

Yes

Add C704

No

Yes

Measure SYN_LE1,

SYN_DAT, SYN_CLK

Displayed

waveforms?

No

D

Check MAD4

Page 34 Nokia Corporation Issue 1 05/02

Page 35

NSD-5

PAMS Technical Documentation 10. Troubleshooting

C

Remove L619

Measure TX UHF LO power at

Measure DC level of G502

Meas ure power level

C510

> -5dBm

No

pin 9 >2 .7V

Yes

at R517

> -5dBm

Yes

Set to CH300 in CDM A Testing Mode

Measure TX UHF LO frequency at C510

=2088.1MHz

@ Ch600

+/-150Hz

Yes

Add L619

No

No

Measure

SYN_LE1,

SYN_DAT,

SYN_CLK

Displayed

waveforms?

No

Yes

Measure DC level of V502

C521, C510, R517, R518, R516

TX Tuning

Description of Test

The RIF and TIF AGC is approximately a second-order curve; this curve is split into

16 segments for both Transmitter and Receiver. Offset and slope values are stored in

EEPROM for each of these 16 segments. The offset for the segments is computed from

Yes

pin 1> 0.5 V

Yes

Check

Check MAD4

Change G 50 2

No

Change the V502

END

Issue 1 05/02 Nokia Corporation Page 35

Page 36

NSD-5

10. Troubleshooting P AMS Technical Documentation

the 3-point calibration performed in this test. Then a second-order approximation is

made and the offset and slope computed.

TX_IF_AGC must be adjusted to achieve the correct power level for Point 1. When this is

done, the process must be repeated for Points 2 and 3.

Definition of Result

The results of the three-point tuning are the 16 slope and offset values, which are stored

to EEPROM RF_TUNE_PCS_TX_AGC_OFFSET_SLOPE_HANDLE.

Manual Verification

Use WinTesla as follows:

Page 36 Nokia Corporation Issue 1 05/02

Page 37

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Issue 1 05/02 Nokia Corporation Page 37

Page 38

NSD-5

10. Troubleshooting P AMS Technical Documentation

TX Troubleshooting Flowchart

Start

Set Tx to ON

Check LED OFF

Set Tx_IF_GAIN = 500

Measure the total current

>550mA

No

Set TX_IF_GAIN = 10

<250mA

No

Measure UHF_LO

<-8dBm

No

Measure VHF_LO

<-15dBm

No

Set TX_IF_GAIN = 500

Yes

Replace RF connector or duplexor

START

Yes

Replace PAM

START

Yes

See Synthesizer troubleshooting processor

Yes

See Synthesizer troubleshooting processor

Measure Tx_IF signal

Yes

<-15dBm

No

1

Replace TIF

START

Page 38 Nokia Corporation Issue 1 05/02

Page 39

NSD-5

PAMS Technical Documentation 10. Troubleshooting

1

Set Tx to

Measure voltage at N606 pin2 and pin3

>0.5V

Measure RF signal level at N606 output pin8

>-20dBm

Measure voltage at V609 pin 1

Yes

Replace Replace

Start

Replace

Yes

<1.8V

Measure voltage at V606 pin 5

Yes

<2.5V

See synthesizer troubleshooting processorStart

No

No

Yes

No

Yes

No

No

Start

Replace

Start

Replace

Replace

Measure RF output signal level at V609 pin3<0.6VMeasure voltage at V609 pin 3

Yes

Measure voltage at V603 pin 7

Yes

Measure voltage at N603 pin 6

Start

Start

<-10dBm

No

<0.5V

No

Yes

<0.5VSee Baseband troubleshooting processor

No

Measure voltage at N602 pin 3

Yes

Replace

Start

<2.5V

No

2

Issue 1 05/02 Nokia Corporation Page 39

Page 40

NSD-5

r

r

10. Troubleshooting P AMS Technical Documentation

2

Measure the difference RF power level at N602 pin 2 and RF power level at N602 pin 4

Yes

<12dB

No

Measure voltage at V604 pin3

Yes

>4.7V

END

StartReplace V602

No

Measure voltage at V604 pin 3

Yes

<4.9V

No

Measure voltage at V603 pin 4

<2.5V

No

Replace V604

Start

See baseband troubleshooting processo

Yes

See baseband troubleshooting processo

1900 PCS Tuning Rx IF AGC

Description of Test

The RIF and TIF AGC is approximately a second-order curve. This curve is split into

16 segments for both transmitter and receiver. Offset and slope values are stored in

Page 40 Nokia Corporation Issue 1 05/02

Page 41

NSD-5

PAMS Technical Documentation 10. Troubleshooting

EEPROM for each of these 16 segments. The offset for the segments is computed from

the three-point calibration performed in this test. Then, a second-order approximation is

made and the offset and slope computed.

This tuning is done by putting signal level 1 into the receiver. The RX_IF_AGC will then

automatically adjust for max CAFE input and the RX_IF_AGC is noted. This process is

then repeated for signal levels 2 and 3.

Definition of Result

The results of the three-point tuning are the 16 slope and offset values, which are stored

to EEPROM RF_TUNE_PCS_RX_AGC_OFFSET_SLOPE_HANDLE.

Manual Verification

Use WinTesla as follows:

Issue 1 05/02 Nokia Corporation Page 41

Page 42

NSD-5

10. Troubleshooting P AMS Technical Documentation

1900 PCS Tuning Rx IF Compensation

Description of Test

In this tuning, the receiver is calibrated at five different frequencies across the band.

WinTesla instructs the signal generator to be set at five specific frequencies and a fixed

amplitude. The RX_IF_AGC is adjusted by the phone’s software to make the best use of

the CAFE ADC. The setting of RX_IF_AGC then is read from the phone at each of the five

frequencies.

Definition of Result

The five different values of RX_IF_AGC are stored to EEPROM.

Page 42 Nokia Corporation Issue 1 05/02

Page 43

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Manual Verification

Use WinTesla as follows:

Issue 1 05/02 Nokia Corporation Page 43

Page 44

NSD-5

10. Troubleshooting P AMS Technical Documentation

Page 44 Nokia Corporation Issue 1 05/02

Page 45

NSD-5

PAMS Technical Documentation 10. Troubleshooting

RX Troubleshooting

Troubleshooting

Check components in the receiver chain from Duplexer Z727, LNA V701 and Mixer N701,

the 128.1MHz CDMA IF SAW filter Z728 and RIF N730. Check that the RX_IF_AGC RIF

Pin D2 changes as the receiver input signal level is adjusted. Check the Rx VHF LO RIF

C517. See plot diagram (following) and the Synthesizer Block.

Note: If any of these components are damaged and are replaced, then the Rx IF AGC second-order

curve must be returned.

Issue 1 05/02 Nokia Corporation Page 45

Page 46

NSD-5

10. Troubleshooting P AMS Technical Documentation

Rx VHF LO Measured at RIF Pin 20 with a Hi Z Probe

RX Troubleshooting Flowchart

Start

Measure the RF signal power gain

between V701 pin 1 and pin 3

See Baseband

troubleshooting

processor

>-10dB

Measure the Freq. of N701

Check the N730 Pin D1

No

>2.0V

Yes

Replace N730 Replace N730

No No

Pin6

128.1 MHz

Count Value

charged by RF_RX

level charging

End

No

Yes

No

Yes

Yes

Check the voltage at V701

Pin3 is>2.0V & Replace V701

Measure UHF_LO Power level at

N701 Pin4

See synthesize

No

Yes

troubleshooting

See synthesize

No

troubleshooting

>-10dBmCheck the RX_Count by WinTesla

Yes

Replace N701

Measure VHF_LO Power level

at N730 Pin D6

>-10dBm

processor

processor

Test Points

Signal Name General Characteristics General Signal Destination

AFC VCTCXO control voltage PDM from MAD4

VR1 2.7V supply to VCTCXO CCONT to VCTCXO

19.2MHz 19.2MHz from VCTCXO buffer VCTCXO buffer to CAFE and PLL IC’s

TX_LIM_ADJ Detector demand voltage PDM from MAD4 Pin 128 deector

circuit at RF output

1900 MHz PA Output RF output from PA check for short

RF output from PA

with phone switched OFF

Page 46 Nokia Corporation Issue 1 05/02

Page 47

NSD-5

PAMS Technical Documentation 10. Troubleshooting

Signal Name General Characteristics General Signal Destination

Tx VHF LO VHF LO to TIF PCS CDMA

436.2MHz

Tx UHF LO UHF LO up converter IC LO from 2GHz VCO to up converter

Rx VHF LO 256.2MHz VHF LO to RIF LO from PLL to RIF

RX_IF_AGC DC voltage proportional to signal

level into receiver in CDMA mode

LO from PLL to TIF IC

IC

AGC control voltage from MAD4

Pin A16 to RIF Pin D2

Issue 1 05/02 Nokia Corporation Page 47

Page 48

NSD-5

10. Troubleshooting P AMS Technical Documentation

Page 48 Nokia Corporation Issue 1 05/02

Loading...

Loading...