Page 1

nokia

Service & Analysis Center Europe

SACE CC Training Group

Phone doesn´t switch on

-. Check current consumption: Off state 0-1mA, sleep mode 1-4mA, if too high continue with section “low standby / operation mode time".

1. Check connector X101 if bend or soiled.

2. Check Vb 3.6V at C129. If not ok, check L103.

3. Check if PWRONX at S330 drops to 0V during pressing powerswitch. If not ok, check/change S330, R118.

4. Check 32.768kHz at J228, 3.2Vpp squarewave. Ok, go to 6.

5. Check/change B100, R100, R102, R154, C101, C102, C113, change CCONT (N100) if necessary.

6. Check Vbb 2.8V at C107. If not ok, check resistance of line to GND or change CCONT (N100).

7. Check Vxo 2.8V at C152. If not ok, check resistance of line to GND or change CCONT (N100).

8. Check Vref 1.5V at C106. If not ok, check resistance of line to GND or change CCONT (N100).

9. Check SLEEPX 2.8V at J226. If not ok, MAD is faulty in all probability. Swap the phone because MAD is not changeable.

10. Check PURX 2.8V at J227 after pressing powerswitch. If not ok, change CCONT (N100).

11. Check 13MHz Clk-frequency at C213, approx. 800mVpp. If not ok, check values around G830, N505 and V800.

-. Try to flash the phone. If not ok, continue with section “Flash update not possible".

Flash update not possible

-. Check if fault code from prommer is one of the following :

A: External RAM failure :

-. Check values at D200, if OK, swap unit, ComboMemory faulty.

B: Algorithm code fail / alias ID missing:

-. Update FPS4 box with latest flash device list, try to update again. If fault persists, check values at D200, if OK, swap

the unit,- ComboMemory is faulty.

C: MCU boot failure, serial clock / data line failure

-. Connect “watchdog disable” R118 to GND.

1. Check Vbb 2.8V at C107 and Vxo 2.8V at C152. If not ok, continue with section “phone doesn't switch on".

2. Check SLEEPX 2.8V at J226. If not ok, MAD faulty in all probability. Swap the phone because MAD is not changeable.

3. Check PURX 2.8V at J227. If not ok, change CCONT (N100).

4. Check 13MHz REFCLK at C213, approx. 800mVpp. If not ok, check values around G830, N505 and V800.

5. Check resistance of Mbus/Fbus lines (J101-J103) to GND. Also check R109, R201, R203, R215.

If update still not possible: Swap, MAD or PCB should be the reason.

Low standby / operation mode time

-. Check power consumption of phone: off state 0-1mA.

1. Lift L103, current consumption still to high: check C702/703/704 and C754/755. If failure persists, change N702.

If current is OK after removing L103: Resolder it: Vb line faulty.

2. In most cases CCONT (N100) is the reason. If fault persists after changing CCONT, probably N101, N220, N310, N401 faulty, also possible

that capacitor in Vb line Is faulty (eg C100, C105, C129, C142…).

-. Check current in sleep mode: 1-4mA.

-. Check resistance of output voltage lines of CCONT to GND.

-. Change components in corresponding lines if resistance is not ok. If resistance of lines is ok, but sleep mode current is still too high, change CCONT (N100).

-. Check charging circuit, run energy management calibration. If calibration is not ok, continue with section “Not charging".

-. Calibrate RX / TX values of the phone. If calibration not ok, continue with section “RX / TX faults”.

Note that the standby time also depends on network side and the users handling of the phone, eg lights on/off, memory activities, games…

Contact Service

A: MCU ROM Checksum failed:

-. Try to flash the phone. If not ok after flashing, probably ComboMemory faulty, which is not changeable.

B: Ccont Interface failed:

-. Probably broken solderings under CCONT (N100). Replace CCONT (if not underfilled) with µBGA rework machine.

-. If not ok after reworking the CCONT, probably MAD or PCB faulty.

Note that it is necessary to run energy management calibration after changing CCONT!

C: Cobba parallel/serial failed:

1. Check Vbb 2.8V at C201 and Vcobba 2.8V at C248

2. Check CobbaClk at J252, probably broken solderings under COBBA (N250). Replace COBBA with µBGA rework machine.

If fault remains probably MAD or PCB faulty

D: DSP Alive failed

-. In most of all DSP alive selftest failures MAD is faulty, which is not changeable.

E: Eeprom tune checksum failed

-. Use Wintesla to check if phonedata like Imei, product-code or PSN are corruped

If phone data is ok, try to reset the phone. If phone data is not ok or fault remains

after reset ComboMemory is faulty in all probability

F: RTC Battery failed

-. First try to charge RTC battery by assembling battery to the phone for 10 to 15 minutes.

If fault remains, check contact springs of battery, bend them if nessecary.

(see also NSM2 service bulletin 20)

-. In some cases it can be necessary to change CCONT (N100) or CHAPS (N101).

Phone intermittend switches off

1. Check mechanical appearance of connector X101, change if necessary make sure that pads of X101 on PCB are clean.

2. Check amplitude of 32.768kHz at J228, 3.2Vpp squarewave, if not ok, check parts around B100, probably broken solderings under CCONT (N100).

-. Remove CCONT if not underfilled, replace sparepart with µBGA rework machine and run energy management calibration. The same problem may cause N505,

because the reference oscillator G830 (26MHz) is divided to 13MHz system clock by Hagar N505.

-. If you suppose broken solderings under Hagar, rework as described above.

Copyright © 2000 Nokia Mobile Phones. All rights reserved

CONFIDENTIAL

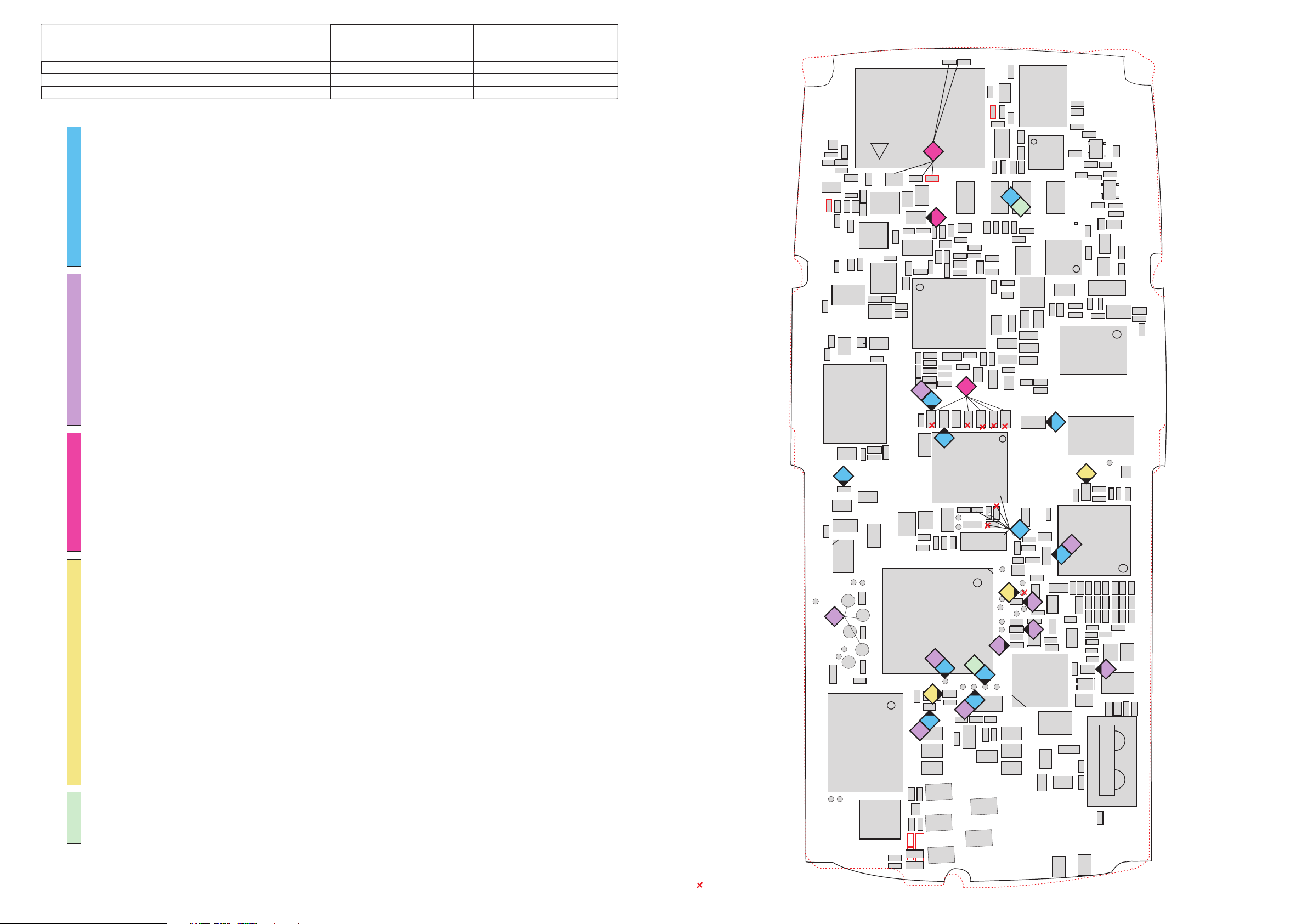

Baseband part 1

NSM-2/3

System Module RM7/RM7L

1(5)

Version 1.0 Approved

11.10.2000

NSM-3 differences in red

Measurepoint for GND-connected components

R723R723

C862C862

V801V801

C782C782

C788C788

C220C220

C864C864

R723R723

R807R807

5

C212C212

C212C212

C212C212

C760C760

L506L506

L503L503

C863C863

R758R758

C785C785

C805C805

VCOVCO

C802C802

3

R118R118

V350V350

C116C116

N220N220

J101

C758C758

R756R756

R757R757

C759C759

R711R711

N600N600

R755R755

R712R712

R805R805

G800G800

J102

J103

R211R211

ComboMemoryComboMemory

R751R751

R710R710

R801R801

V360V360

C206C206

C217C217

C209C209

C209C209

D210D210

C790C790

Z700Z700

C860C860

C783C783

T800T800

C804C804

R802R802

C801C801

C205C205

C205C205

M300M300

T700T700

R700R700

Z671Z671

C803C803

R704R704

C755C755

R284R284

R283R283

C799C799

C560C560

C550C550

Pwr. AmpPwr. Amp

C741C741

L504L504

V116V116

L752L752

R740R740

C704C704

L103L103

C286C286

R285R285

R284R284

R283R283

L284L284

L283L283

L505L505

C211C211

C281C281

N702N702

C742C742

T740T740

R975R975

C793C793

R800R800

11

C206C206

C218C218

C204C204

4

C285C285

R286R286

L284L284

L283L283

L751L751

C108C108

Mad2Mad2

1

C703C703

R741R741

C561C561

R974R974

C535C535

R564R564

R533R533

77

C152C152

C131C131

J226

11

C119C119

C213C213

1111

C754C754

C702C702

11

C541C541

C670C670

C747C747

R541R541

R744R744

C714C714

R791R791

R532R532

C746C746

R790R790

C557C557

R671R671

C792C792

R792R792

N505N505

HagarHagar

C562C562

C533C533

C564C564

R563R563

R565R565

C534C534

22

C153C153

C133C133

C106C106

C720C720

\\

C743C743

L553L553

R754R754

R763R763

C733C733

V730V730

C730C730

R732R732

R764R764

R763R763

R732R732

C630C630

L631L631

C631C631

L600L600

C600C600

C601C601

R510R510

C510C510

C531C531

C530C530

C532C532

R530R530

C540C540

C521C521

R546R546

C150C150

C154C154

C151C151

Z670Z670

C761C761

C614C614

C645C645

C163C163

C162C162

11

1

R730R730

R731R731

C731C731

T630T630

T600T600

C523C523

C522C522

C520C520

C513C513

C512C512

C511C511

C833C833

R833R833

C830C830

C129C129

C700C700

L510L510

R611R611

22

GSM+

GSM+

V800V800

R879R879

C615C615

R834R834

R830R830

R613R613

V904V904

C610C610

R610R610

C613C613

R643R643

C644C644

R645R645

V903V903

R640R640

C643C643

C640C640

C612C612

C611C611

R614R614

V907V907

Z600Z600

C620C620

VCTCXOVCTCXO

C621C621

V905V905

C642C642

L800L800

C834C834

C835C835

C832C832

C831C831

R831R831

C836C836

R832R832

G830G830

C165C165

Z620Z620

PCN

PCN

C879C879

88

CcontCcont

N100N100

R269R269

11

C248C248

L272L272

L271L271

C291C291

C292C292

N250N250

C261C261

C251C251

C259C259

C253C253

C257C257

C258C258

C257C257

C262C262

C275C275

C276C276

C263C263

C258C258

R267R267

C294C294

R268R268

C295C295

C261C261

C255C255

C296C296

C297C297

55

N401N401

C110C110

C406C406

R403R403

R404R404

N400N400

R270R270

C249C249

C102C102

R100R100

R128R128

C113C113

C132C132

C101C101

R154R154

C208C208

C102C102

C202C202

D200D200

2

99

C201C201

R101R101

R103R103

C127C127

33

2

J227

1010

R104R104

C128C128

B100B100

J228

C103C103

V104V104

C120C120

R122R122

22

R203R203

R216R216

R215R215

C203C203

R201R201

55

4444

C114C114

R125R125

R124R124

V104V104

C161C161

C140C140

R272R272

C268C268

V250V250

V252V252

R131R131

66

V100V100

C293C293

C400C400

COBBACOBBA

11

C266C266

C265C265

C247C247

C274C274

C276C276

C278C278

R252R252

V251V251

R274R274

R274R274

R260R260

C109C109

C104C104

R109R109

C276C276

C142C142

C405C405 C401C401

55

R120R120

R111R111

R205R205

R110R110

C107C107

C160C160

C121C121

V101V101

J252

55

R271R271

R277R277

C105C105

55

R258R258

N101N101

ChapsChaps

L104L104

F101F101

Page 2

nokia

Service & Analysis Center Europe

SACE CC Training Group

Internal audio faults

A: No audio from speaker

-. Check resistance of speaker (30 Ohm), change speaker if bend or soiled.

1. Check connection between speakerpads on PCB and C291/292, if not ok, check L271,272. Check for shorts to GND (>1M).

2. If fault persists, change COBBA (N250). Note that it is necessary to align RX / TX values and rewrite SIMlock-data after changing COBBA!

B: Microphone doesn't work

-. Check impedance of microphone (0,5-1kOhm), change if necessary.

3. Check mechanical condition of connector X280 (8850 only).

4. Check MicBias at L287, 2.4V on active microphone (see Layout). If not ok, check values around V250.

5. Check connection between L287 and C263 (470 Ohm).

6. If fault remains, change COBBA (N250). Note that it is necessary to align RX / TX values and rewrite SIMlock-data after changing COBBA!

Clock time problems

A: Clock time has to be corrected in short periods

1. Check amplitude and frequency of sleepclock oscillator at J228, should be 3.2Vpp squarewave at 32.768kHz.

If not ok, change B100 or check parts like R100, R102, R154 and C101, C102, C113.

B: Clock time is lost after removing battery

-. Check contact springs of battery, bend them if nessecary (see also NSM-2 service bulletin 20) or change RTC-battery.

Bending of springs should be always done, also with new batteries.

If fault persists, probably CCONT (N100) or CHAPS (N101) faulty. Note that you have to run energy management calibration after changing CCONT.

Not charging

A: Nothing happens if charger is connected

-. Check mechanical appearance of connector X110.

1. Check resistance of fuse F101.

2. Check resistance of Vcharge line to GND, value should be around 50kOhm. If not ok, check/change V100, C103/114.

3. Check / Change N101, N100.

B: “not charging" appears on LCD

-. Run energy management calibration. If it works without failuremessage, try to charge after calibration.

C: Battery temperature failed

4. Check X101, R120/122 or change CCONT (N100).

D: Battery size failed

5. Check X101, R120/122 or change CCONT (N100).

-. Battery voltage failed: Change CCONT (N100).

E: Charge current failed

6. Check / change R131, N101, N100.

-. Charge voltage failed:

7. Check Vcharge at voltage divider R103/104. If ok change CCONT (N100).

8. If not ok, check parts like X110, V100, F101, L104 or change N101.

SIMcard faults

A: Insert SIM card

-. Check X302 if bend or soiled, change if necessary.

1. Make sure that pads for SIMcard-reader on PCB are clean.

2. Check V104: Pin 1-SIMclock, pin 3-VSIM, pin-4 SIMdata, pin 5-SIMreset, also check R124, R125, R128.

3. Check resistance of SIMlines to GND, change V104, C127/128 if necessary.

4. Probably broken solderings under CCONT (N100). Remove CCONT if not underfilled, replace sparepart with µBGA rework machine and run energy management

calibration.

-.. If fault persists, probably Mad or PCB faulty.

B: SIMcard not accepted

-. Use Wintesla to open quick/RF info window, compare shown SIMlock-data with the listed entries of the respective productcode.

-. If shown SIMlock-data is the same as in the list, SIMlock is ok.

Probably Msin data field is closed to special Imsi number range can be opened only by operator! (refer to general SB 65).

-. If shown SIMlock-data is not the same as in the list or somehow corrupted rewrite SIMlock-data with Nokia security password or send phone to SACE.

-. If SIMlock is corrected or inactive but fault remains, probably broken solderings under COBBA (N250). Change COBBA, align RX / TX values and rewrite SIMlock-data

once more.

UI faults

A: Backlight failure (Also see measurement points on page 4)

1. Check voltage at pin 7 and 15 of N310 (see layout)- should be 2,8V when lights are on. If not ok, there could be a break between D200 and N310, or Mad is faulty

2. Check Vb 3.6V pin 1 of N310 and Vbb 2.8V pin 2 of N310. (See layout)

3. Check resistance of R310 and R311. (See layout)

4. Check Vb at LED´s V320-325 and V331-340. (See layout)

5. If keypad backlight is not bright enough, change resistor R311 (see layout) from39kOhm to 10kOhm (also see NSM 2 service bulletin 23).

B: Vibra failure

-. Check version of vibramotor, add support tape if necessary (see also NSM-3 service bulletin 11).

6. Check Vb 3.6V at V350.

7. Check Vb 3.6V pin 1 and Vbb 2.8V pin 2 of N310. (See layout)

8. Check vibra signal at pin 16 of N310. If not ok, check vibra_cnt at pin 19 of N310. (See layout)

If signal is ok at pin19, change N310, else there is a break between D200 and N310, or MAD is faulty.

C: Display failure

-. If line segments missing or no display function at all, check mechanical appearance of display, change it if necessary.

Copyright © 2000 Nokia Mobile Phones. All rights reserved

CONFIDENTIAL

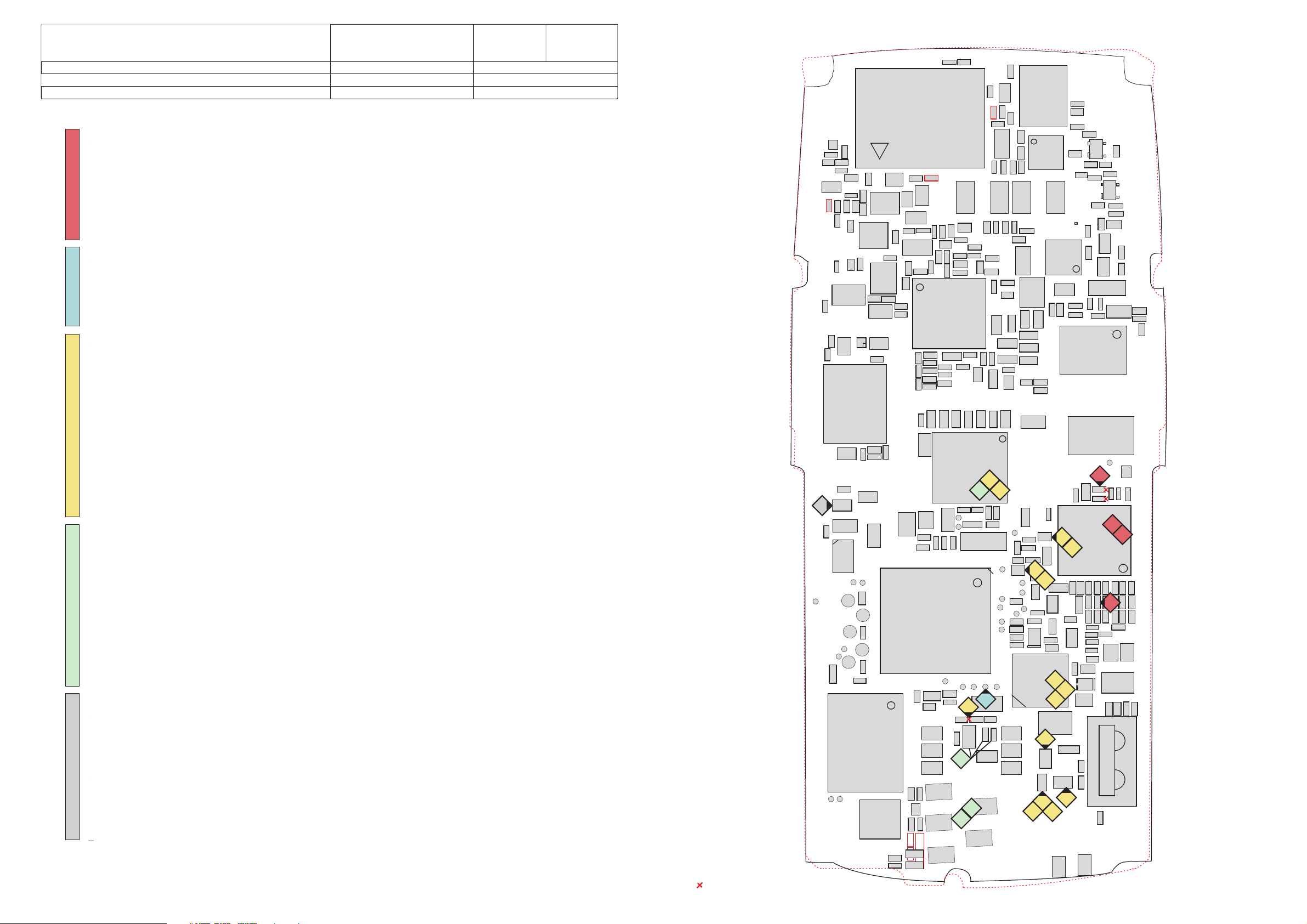

Baseband part 2

NSM-2/3

System Module RM7/RM7L

2(5)

Version 1.0 Approved

11.10.2000

NSM-3 differences in red

Measurepoint for GND-connected components

6

R723R723

C862C862

V801V801

C782C782

C788C788

C220C220

C754C754

C702C702

Pwr. AmpPwr. Amp

N702N702

R723R723

C760C760

L506L506

L503L503

C790C790

C758C758

R756R756

C864C864

R755R755

C863C863

R757R757

R758R758

C759C759

R711R711

C785C785

N600N600

R807R807

C805C805

VCOVCO

C802C802

R118R118

V350V350

C116C116

N220N220

C212C212

C212C212

C212C212

R211R211

R805R805

G800G800

R712R712

R801R801

V360V360

C206C206

C217C217

C209C209

C209C209

C755C755

R751R751

Z671Z671

R710R710

Z700Z700

R704R704

T700T700

C860C860

R700R700

C783C783

T800T800

C804C804

C803C803

R802R802

C801C801

C205C205

C205C205

ComboMemoryComboMemory

D210D210

C799C799

C560C560

C550C550

C741C741

L504L504

V116V116

L752L752

C704C704

R740R740

L103L103

L505L505

C211C211

C742C742

T740T740

R975R975

C793C793

R800R800

C206C206

C218C218

C204C204

L751L751

C703C703

C561C561

R974R974

C535C535

R564R564

R533R533

C108C108

C131C131

Mad2Mad2

C119C119

C213C213

C541C541

C670C670

C747C747

R541R541

R744R744

C714C714

R791R791

R532R532

C746C746

R790R790

R563R563

R565R565

C534C534

C106C106

C208C208

R671R671

N505N505

C533C533

C132C132

C557C557

C792C792

R792R792

C562C562

C564C564

C153C153

C133C133

CcontCcont

N100N100

R128R128

C113C113

R154R154

C102C102

R741R741

HagarHagar

C152C152

C202C202

D200D200

C201C201

R101R101

7

R103R103

R104R104

C128C128

C127C127

2

C286C286

C285C285

M300M300

R284R284

R283R283

R285R285

R284R284

R283R283

L284L284

L283L283

C281C281

R286R286

L284L284

L283L283

3

1

L631L631

R530R530

C154C154

4

B100B100

C103C103

V104V104

C720C720

\\

C743C743

L553L553

R754R754

R763R763

C761C761

C733C733

V730V730

C730C730

R732R732

C162C162

R764R764

R763R763

R732R732

R730R730

C731C731

C630C630

C631C631

L600L600

C600C600

C601C601

C520C520

R510R510

C510C510

C531C531

C530C530

C532C532

C540C540

C521C521

R546R546

C150C150

C151C151

3

6

C102C102

R100R100

C101C101

C120C120

R122R122

R203R203

R216R216

R215R215

C203C203

R201R201

1

C114C114

R125R125

R124R124

V104V104

Z670Z670

C700C700

L510L510

C614C614

Z620Z620

C645C645

C163C163

R731R731

T630T630

T600T600

C523C523

C522C522

C513C513

C512C512

C511C511

C833C833

R833R833

C830C830

C129C129

C140C140

R120R120

R111R111

R205R205

R110R110

C160C160

4

C121C121

V101V101

R271R271

R277R277

C105C105

N101N101

ChapsChaps

F101F101

1

8

R611R611

R613R613

V904V904

C615C615

C644C644

Z600Z600

PCN

PCN

GSM+

GSM+

V800V800

C879C879

R879R879

R834R834

R830R830

VCTCXOVCTCXO

C610C610

R610R610

C613C613

R643R643

R645R645

V903V903

R640R640

C643C643

C640C640

C612C612

C611C611

R614R614

V907V907

C620C620

C621C621

V905V905

C642C642

L800L800

C834C834

C835C835

C832C832

C831C831

R831R831

C836C836

R832R832

G830G830

C165C165

R269R269

1

C248C248

L272L272

L271L271

C291C291

C292C292

N250N250

C261C261

C251C251

2

6

C259C259

C253C253

C257C257

C258C258

C262C262

C275C275

C276C276

C263C263

R268R268

C257C257

5

C258C258

R267R267

C294C294

C295C295

C261C261

C255C255

C296C296

C297C297

N401N401

C110C110

C406C406

R403R403

R404R404

N400N400

C249C249

C161C161

COBBACOBBA

4

C107C107

5

C266C266

C265C265

5

C268C268

V250V250

V252V252

R258R258

R272R272

3

8

R131R131

C247C247

C274C274

C276C276

C278C278

C293C293

R252R252

V251V251

R274R274

R274R274

R260R260

C109C109

C104C104

R109R109

C276C276

6

C142C142

8

C400C400

L104L104

C405C405 C401C401

V100V100

8

2

R270R270

Page 3

nokia

Service & Analysis Center Europe

SACE CC Training Group

NO TX GSM900

1. Check 26MHz RFCLK at C830(700mVpp), frequency deviation <100Hz.

2. Check TxIQ signals at R541/546. If ok, go to 4.

3. Check Vbb 2,8V at C201and VCOBBA (2,8V) at C248, check COBBACLK at J252,

probably COBBA (N250) faulty or broken soldered.

4. Check 902MHz at T700 pin 4 and 6. If ok, go to 6.

5. Check supply voltages for HAGAR(N505) at C535 (1,35V), C550 (2,8V), C557 (2,8V), C560 (4,8V), C561 (2,8V), C562 (2,8V).

6. Check Sdata at J237, SCLK at R205,SENA at R206, TXC at C792.

7. Check TXP at pad of not assembled R745 (between R791/541).

8. Check frequency of G800 (SHF) at C788 (TX-Ch.60-3608MHz) if possible, otherwise you can check Vcc at C804(2,8V) and Vc at C803

which varies between 0,7-3,8V. If Vc =4,8V, the oscillator doesn`t work.

If values are OK but no TX signal at T700, pobably HAGAR(N505) is faulty or broken soldered.

9. Check 902MHz at N702,pin8. If not OK, check T700,Z700/671, V801.

10. Check 902MHz at L553 pin1. If not OK, check Vbatt at pin 3 and 6 of N702, also check TXV_GSM 2,8Vpp

squarewave at N702,pin2 and Vapc 1-1,6Vpp squarewave at N702,pin7 depending on TX powerlevel.

11. Check 902MHz at J600 (Antenna pad).If not, check L553 in/out, Z670 in/out, TXVGSM at R671.

NO TX GSM1800

1. Check 26MHz RFCLK at C830(700mVpp), frequency deviation <100Hz.

2. Check TxIQ signals at R541/546.If ok, go to 4.

3. Check Vbb 2,8V at C201and VCOBBA (2,8V) at C248, check COBBACLK at J252,

probably COBBA(N250) faulty or broken soldered.

4. Check 1747,8MHz at T740 pin 4 and 6. If ok, go to 6.

5. Check supply voltages for HAGAR(N505) at C535 (1,35V), C550 (2,8V), C557 (2,8V), C560 (4,8V), C561 (2,8V), C562 (2,8V).

6. Check Sdata at J237, SCLK at R205,SENA at R206, TXC at C792.

7. Check TXP at pad of not assembled R745 (between R791/541).

8. Check frequency of G800 at C788(TX-Ch.700-3495,6MHz) if possible, otherwise you can check Vcc at C804(2,8V) and Vc at C803

which varies between 0,7-3,8V. If Vc =4,8V, the oscillator doesn`t work.

If Values are OK but no TX signal at T740, pobably HAGAR(N505) is faulty or broken soldered.

9. Check 1747,8MHz at N702,pin8. If not OK, check T740, Z671, V801.

10. Check 1747,8 MHz at L553 pin3. If not OK, check Vbatt at pin 3 and 6 of N702, also check TXVDCS 2,8Vpp

squarewave at N702,pin1 and Vapc 1-1,6Vpp squarewave at N702,pin7 depending on TX powerlevel.

11. Check 1747,8MHz at J600 (Antenna pad).If not, check L553 in/out, Z670 in/out, TXVDCS at R670.

NO RX GSM900

1. Check 26MHz reference oscillator at C830, 700mVpp,frequency deviation < 100Hz

2. Check 947MHz at C645. If not ok check solderings of Z670, change if necessary and replace foam on sparepart.

(NSM 2 only)

3. Check 947MHz at C615. If not ok check/change Z620

4. Check 947MHz at C610. If not ok check values of LNA like Vlna 2,7V at R614 and LNA_G 0,7V at C611,change

V904/907 if necessary.

5. Check 947MHz at L600. If not ok check/change Z600, T600

6. Check RxIQ signal at R530. If not ok, check values at HAGAR(N505) supply voltages at

C560 (4,8V), C561 (2,8V), C562 (2,8V),

Check frequency of G800 at C788 (RX-Ch.60-3788MHz) if possible, otherwise you can check Vcc at C804(2,8V) and Vc at C803

which varies between 0,7-3,8V. If Vc =4,8V, the oscillator doesn`t work.

-. If all values are ok but no RxIQ signal at R530,

7. If signal at R530 is ok, but still no Rx-calibration possible,check values at COBBA(N250). Check Vbb 2,8V at C201 and

VCOBBA(2,8V) at C248, also check COBBACLK at J252, if values are ok, probably COBBA

solderings are broken.

NO RX GSM1800

1. Check 26MHz RFCLK at C830(700mVpp), frequency deviation <100Hz.

2. Check 1842,8MHz at C614. If not OK, check solderings of Z670, change if necessary and replace foam on

sparepart.(NSM-2 only).

3. Check 1842,8MHz at C644.If not OK, check/change Z620

heck 1842,8MHz at C640. If not ok check values of LNA like Vlna 2,7V at R614 and LNA_P 0,7V at

4. C

C642,change V903/905 if necessary.

5. Check 1842,8MHz at L631. If not ok check/change Z600, T630.

6. Check RxIQ signal at R530. If not ok check values at HAGAR(N505) like supply voltages at

C560 (4,8V), C561 (2,8V), C562 (2,8V), heck Sdata at J237, SCLK at R205,SENA at R206, RF_REF 1,2V at C534.

Check frequency of G800 at C788 (RX-Ch.700, 3685,6MHz)) if possible, otherwise you can check Vcc at C804(2,8V) and Vc at C803

which varies between 0,7-3,8V. If Vc =4,8V, the oscillator doesn`t work.

-. If all values are ok but no RxIQ signal at R530,

7. If signal at R530 is ok, but still no Rx-calibration possible,check values at COBBA(N250). Check Vbb 2,8V at C201 and

VCOBBA(2,8V) at C248, check also COBBACLK at J252, if values are ok, probably COBBA

solderings are broken.

CONFIDENTIAL

RF part

NSM-2/3

System Module RM7/RM7L

C535 (1,35V), C550 (2,8V), C557 (2,8V),

Sdata at J237, Sclk at R205 and Sena at R206, check RxRef 1,2V at C534,

pobably HAGAR(N505) is faulty or broken soldered.

C535 (1,35V), C550 (2,8V), C557 (2,8V),

c

pobably HAGAR(N505) is faulty or broken soldered.

3(5)

Version 1.0 Approved

11.10.2000

NSM-3 differences in red

C754C754

C702C702

8

7

9

R723R723

C760C760

R723R723

L506L506

C862C862

L503L503

C790C790

C758C758

V801V801

C864C864

C782C782

8

66

C788C788

8

R751R751

R756R756

R755R755

C863C863

R757R757

R710R710

R758R758

C759C759

R712R712

R711R711

C785C785

2

N600N600

C860C860

R807R807

R805R805

C805C805

66

G800G800

VCOVCO

1

Z700Z700

44

C783C783

T800T800

C804C804

99

T700T700

C755C755

Z671Z671

R704R704

44

R700R700

668

2

C799C799

6

4

C560C560

C550C550

Pwr. AmpPwr. Amp

L752L752

C741C741

R740R740

L504L504

8

6

6

6

6

C803C803

R801R801

R802R802

C802C802

C801C801

R118R118

V360V360

V350V350

C220C220

C116C116

C212C212

C212C212

C212C212

C205C205

C205C205

N220N220

C206C206

C217C217

C209C209

C209C209

R211R211

8

66

66

V116V116

ComboMemoryComboMemory

D210D210

M300M300

R284R284

R283R283

C704C704

L103L103

C286C286

R285R285

R284R284

R283R283

L284L284

L283L283

L505L505

8

C211C211

C281C281

N702N702

C742C742

T740T740

R975R975

C793C793

R800R800

R206R206

C218C218

C204C204

C285C285

R286R286

L284L284

L283L283

L751L751

Mad2Mad2

C703C703

C561C561

R974R974

C535C535

R564R564

R533R533

C108C108

C131C131

6

C119C119

C213C213

10

C670C670

6

R741R741

HagarHagar

66

C152C152

6

C202C202

66

6

3 4

C747C747

C714C714

R532R532

C746C746

R671R671

6

N505N505

66

C533C533

R563R563

R565R565

C534C534

66

C106C106

C132C132

6

C208C208

D200D200

33

77

77

C201C201

R101R101

22

C541C541

C102C102

R744R744

R790R790

C792C792

R792R792

6

C564C564

C133C133

CcontCcont

J237

33

R103R103

C127C127

5

R541R541

5

R128R128

22

R791R791

C557C557

55

C562C562

66

66 77

C153C153

N100N100

C113C113

R154R154

R104R104

C128C128

77

L631L631

R530R530

B100B100

C103C103

C531C531

C154C154

6

R124R124

V104V104

R732R732

C630C630

C631C631

R100R100

C101C101

7

C114C114

V104V104

1010

C743C743

R763R763

7

55

55

C530C530

C521C521

6

6

1010

\\

1

L553L553

3 5

R754R754

C733C733

V730V730

22

C730C730

R732R732

R764R764

R763R763

L600L600

C600C600

C601C601

R510R510

C510C510

C532C532

C540C540

C150C150

C151C151

C102C102

666

3

7

R125R125

R546R546

22

3

C720C720

C761C761

C162C162

C520C520

R203R203

R216R216

R215R215

C203C203

R201R201

7

R730R730

C731C731

22

R205R205

R205R205

C120C120

R122R122

2

C614C614

C645C645

C163C163

R731R731

C513C513

C512C512

C511C511

R833R833

T630T630

C523C523

C140C140

R111R111

R110R110

J252

C129C129

C160C160

R277R277

ChapsChaps

T600T600

C833C833

C121C121

V101V101

R271R271

C105C105

C522C522

C830C830

N101N101

Z670Z670

R120R120

F101F101

Z620Z620

L104L104

C107C107

R258R258

C161C161

R272R272

PCN

PCN

C879C879

C268C268

V250V250

V252V252

R131R131

V800V800

R879R879

11

V100V100

GSM+

GSM+

C293C293

C400C400

1111

R613R613

J600

V904V904

C610C610

44

R610R610

C613C613

R643R643

R645R645

V903V903

C615C615

1111

C700C700

L510L510

R611R611

33

C644C644

33

R640R640

C643C643

C640C640

4

C612C612

C611C611

R614R614

V907V907

Z600Z600

C620C620

R834R834

R830R830

VCTCXOVCTCXO

C621C621

V905V905

C642C642

L800L800

C834C834

C835C835

C832C832

C831C831

R831R831

C836C836

R832R832

G830G830

11

11

11

C165C165

7

R269R269

7

33

33

C248C248

L272L272

L271L271

C291C291

C292C292

N250N250

C261C261

C263C263

C251C251

C259C259

C253C253

C257C257

C258C258

C257C257

C262C262

C275C275

C276C276

C258C258

R267R267

C294C294

R268R268

C295C295

C261C261

C255C255

C296C296

C297C297

N401N401

R403R403

C406C406

C110C110

R404R404

C249C249

COBBACOBBA

C266C266

C265C265

C247C247

C274C274

C276C276

C278C278

R252R252

V251V251

R274R274

R274R274

C109C109

R260R260

C104C104

R109R109

C276C276

C142C142

N400N400

C405C405 C401C401

R270R270

Copyright © 2000 Nokia Mobile Phones. All rights reserved

Measurepoint for GND-connected components

Page 4

nokia

Service & Analysis Center Europe

SACE CC Training Group

66

C802C802

R118R118

V350V350

C

C116C116

2

2

20

20C

N

N

2

2

2

2

0

Vibra motor pinsVibra motor pins

C212C21

C

C

2

2

12C212

12C212

2

F

l

l

a

a

s

s

h

hF

R284R284

R283R283

Copyright © 2000 Nokia Mobile Phones. All rights reserved

0

C206C206

C

2

2

1

1

7

7C

C

C

C

C

2

2

2

2

09

09

09

09

R211R211

D2

D2

1

1

0

0

R2

R2

8

8

5

5

L284L284

L283L283

1

C

C

C

2

2

2

8

8

85C285

6

6

C2

C2

8

8

1

1

R

R

2

2

86

86

44

55

C7

C7

8

8

2

2

R8

R8

C

C

07

07

8

8

0

0

C

C

5

5

78

78

8

8

G

G

V

V

8

8

C

C

0

0

O

O

0

0

C

C

R

R

8

8

8

8

R802R802

0

0

0

0

3

3

1

1

C801C801

V360V360

0

0

0

0

5

5

5

5

C211C21

C213C213

V

V

1

1

1

1

6

6

C2

C2

C2

C2

C119C119

C204C204

M

M

20

20

ad2

ad2

0

0D

C201C201

R101R101

R103R103

R104R104

C

C

C

C

12

12

12

12

8

8

7

7

V104V104

DC & HS connector

DC & HS connector

5409095

5409095

SIM connector

SIM connector

5409117

5409117

R7

R7

2

2

3

3

R723

R723

L506L506

C862C862

L503L503

C758C758

V801V801

R756R756

C

C

R757R757

86

86

55

55

3

3

R7

C

C

58R7

58

7

7

5

5

9

9

R

R

R

R

7

7

C7

C7

7

7

1

1

1

1

8

8

1

1

2

2

5

5

N

6

6

0

0

0

0N

C860C860

R700R700

C783C783

R

R

8

8

0

0

5

5

T800T800

C804C804

20

20

6

6

C

C

10

10

8

8

C1

C

C

13

13

32

32C1

1

1

C

C

C

C

C

C

C218C218

20

20

1

1

2

2

02

02

0

0

8

8

2

2

D

C103C103

C114C114

R1

R

R

1

1

25

25R1

2

2

4

4

V

V

1

1

0

0

4

4

CONFIDENTIAL

Layout and connectors

NSM-2/3

System Module RM7/RM7L

33

22

11

1)SIMCLK

1)SIMCLK

2)RST

2)RST

3)VSIM

3)VSIM

4)GND

4)GND

5)VSIM

5)VSIM

6)DATA

6)DATA

P

P

wr

wr

.

.

Amp

C755C755

C741C741

r

r

a

a

C533C533

R122R122

R277R277

5

5

1

1C4

Amp

C704C704

L7

L7

L

L

5

5

75

75

1

1

2

2

L103L103

C

C

C

C

67

67

7

7

4

4

C742C742

7

7

0

0

T7

T7

C714C714

4

4

R

C

0

0

5

5

7

7

32

32R

4

4

R790R790

6C

6

R74

R

R

C792C792

6

6

1

1R74

71

71

R792R792

N

N

Ha

Ha

5

5

g

g

0

0

5

5

C

C562C562

5

5

31

31C

C564C564

R53

R53

C

C

5

5

0

0

21

21

C15

C1

C154C15

C

C

1

1

50

50C1

5

3C15

3

C

C

1

1

02

02

C1

C1

0

0

C4

0

0

5

4

1

1

C

C

1

1

40

40

R120R120

R111R111

R

20

20

R110R110

C

C

5R

5

1

1

0

0

7

7

C160C160

C120C120

C121C121

V1

V1

V

V

10

10

C268C268

0

0

1

1

1

1

V

2

2

5

5

0

0V

R271R271

V

C293C293

2

2

5

5

2V

2

V2

V2

5

5

1

1

R258R258

R272R272

C10

C10

4

4

R109R109

C276C276

C142C142

N4

C40

C40

0

0

5

5

0

0N4

R2

R2

7

7

0

0

C760C760

C

790C790

R7

R7

5

5

Z6

Z6

1

1

R

R

7

7

7

7

R710

R710

1

1

Z7

C

C

0

0

79

79

0Z7

0

9

9

R704R704

R

7

7

40

40R

T

T

L505L505

7

7

0

0

L5

L5

0

0

0

0

4

4

C560C560

C550C550

R

R

9

9

C561C561

7

7

5

5

R974R974

C

R563R563

7

7

9

9

C535C535

3

3C

R565R565

R8

R564R564

00

00R8

C534C534

R533R533

C

C

C

C

C

C

C

1

1

1

1

1

5

5

33C133

0

0

2

2

6

6

C

C

N

N

N1

N1

c

c

1

1

o

o

0

0

00

00

0

0

nt

nt

R1

R1

R128R128

C113C113

0

0

0

0

C101C101

R154R154

B110B110

R203

R203

R216R216

R215R215

C203C203

R201R201

N

N

Cha

Cha

N

1

1

1N

1

0

0

p

p

s

s

1

1

R

R

131

131

C400C400

L

L

1

1

0

0

4

4

F

F

F

1

1

1

1

0

0

01

01F

V100V100

1

1

V_BATTV_BATT

N

7

7

0

0

2

2N

C5

R541R541

41

41C5

R744R744

R791R791

C557C557

L631

L631

R

R

5

5

1

1

0

0

C510C510

C53

C53

0

0

C532C532

C540C540

R

R

546

546

C129C129

C

C

1

1

61

61

C26

C26

C26

C26

6

6

5

5

C2

76

76C2

C

C

27

27

8

8

R252R252

R274R274

R274R274

C109C109

C109C109

C110C11

C

C

4

4

0

0

0

6

6

B_TEMPB_TEMP

BSIBSI

C754C754

C702C702

R

R

R7

R7

R

76

76

732R73

6

6

4

4

2

3

3

C630C630

C631C631

L6

L6

C600C600

0

0

0

0

C601C601

C

5

5

C52

C52

2

2

2

2

3

3C

2

2

0

0

C513C513

C512C512

C511C511

C833C833

R833R833

C830C830

C

C

C

2

2

4

4

2

2

8

8

49

49C

C292C292

C

C

N25

OBB

OBB

0

0N25

A

A

C25

C25

C

C

C2

C2

C

C

261

261

2

2

5

5

4

4

9

9

3

3

7

7

C

C

C

C

C2

C

C

C

2

2

27

27

274C

274

2

2

62

62

76

76C2

6

6

3

3

5

5

R

R

C29

R

R

C

C

2

2

26

26

2

2

5

5

6

6

9

9

8

8

7

7

4

4C29

8

8

5

5

C261C261

C255C255

C29

C29

C

C

2

2

9

9

7

7

6

6

N401N4

01

R4

R4

R4

R4

0

0

0

0

4

4

3

3

\\

C7

L

L

5

5

4

4

53

53

3C7

3

R

7

7

5

5

C7

C7

4

4R

6

6

1

1

C733C733

C

C

6

6

V730V7

14

14

30

C6

C6

4

4

5

5

C7

C7

R

R

C

C

C

1

1

732

732

1

1

6

6

3

3

6

6

3

3C

0

0

2

2

R

R

7

7

30

30

R731R731

C731C731

P

GS

P

GS

C

C

T

6

6

N

N

M

3

3

0

0T

T

T

60

60

0

0

C

C

5

5

C291C291

C

258C

258

C

C

2

2

5

5

7

7

C

C

2

2

M

+

+

V800V800

C

R

879

8

8

879R

R834R834

79

79C

R830R830

V

V

C

C

8

8

T

T

30

30

C

C

X

X

O

O

C1

65C1

65

R269R269

L

L

L

C

C

2

2

2

2

2

2

7

7

7

7

51

51

2

2L

1

1

C2

C2

5

5

7

7

NSM-3 differences in red

300-399300-399

400-420400-420

200-220200-220

221-299221-299

400-900400-900

100-199100-199

Version 1.0 Approved

11.10.2000

BGNDBGND

Battery connector

Battery connector

5409093

5409093

Volume switchVolume switch

C

C

7

7

2

2

0

0

D

D

i

i

Z

Z

p

p

6

6

l

l

e

e

70

70

x

x

e

e

r

r

Z6

Z6

2

2

0

0

Z

600

600Z

C834

C834

5

5

R831R831

G

G

C700C700

L510L510

R611R611

R613R613

D

D

i

i

p

p

l

l

e

e

x

x

1

1C

C

6

6

20

20C

L800L800

C

C

83

83

6

6

1

1

C831C831

V9

V9

04

04

C615C615

R610R610

C613C613

R643R643

C644C644

R645R645

V903

V903

R640R640

C643C643

C640C640

C

C

6

6

1

1

2

2

C

R614R614

V90

V90

C

7

7

621

621C

V

V

9

9

C

05

05

642

642C

C832C832

C836C836

R

8

8

32

32R

UIUI

InfraredInfrared

BasebandBaseband

AudioAudio

RF-PartRF-Part

Power SupplyPower Supply

4(5)

C754C754

L505L505

C211C211

C281C281

N702N702

C742C742

T740T740

R975R975

C793C793

R800R800

R206R206

C218C218

C204C204

C285C285

R286R286

L284L284

L283L283

L751L751

C535C535

C108C108

MADMAD

C703C703

R741R741

C561C561

R974R974

R564R564

R533R533

C152C152

C131C131

J226

C119C119

C213C213

C702C702

C541C541

C670C670

C747C747

R541R541

R744R744

C714C714

R791R791

R532R532

C746C746

R790R790

C557C557

R671R671

C792C792

R792R792

N505N505

HAGARHAGAR

C562C562

C533C533

C564C564

R563R563

R565R565

C534C534

C106C106

C208C208

C202C202

R530R530

C153C153

C133C133

CCONTCCONT

N100N100

R128R128

C113C113

C132C132

J121

R154R154

J237

C102C102

D200D200

J223

C201C201

J227

R101R101

R103R103

R104R104

C128C128

C127C127

L631L631

C531C531

C154C154

B100B100

J122

J250

J251

J256

J253

J228

C103C103

R124R124

V104V104

R732R732

C630C630

C631C631

R100R100

C101C101

C114C114

V104V104

C743C743

R763R763

C733C733

R732R732

R763R763

L600L600

R510R510

C530C530

C521C521

C150C150

C102C102

J239

R125R125

\\

R754R754

V730V730

C730C730

C600C600

C601C601

C510C510

C532C532

J257

J252

J255

C720C720

C615C615

R834R834

R830R830

C700C700

L510L510

R611R611

Z600Z600

J600

R613R613

V904V904

C610C610

R610R610

C613C613

R643R643

C644C644

R645R645

V903V903

R640R640

C643C643

C640C640

C612C612

C611C611

R614R614

V907V907

C620C620

VCTCXOVCTCXO

C621C621

V905V905

C642C642

L800L800

C834C834

C835C835

C832C832

C831C831

R831R831

C836C836

R832R832

G830G830

L553L553

R764R764

Z670Z670

C761C761

C614C614

Z620Z620

C645C645

C163C163

C162C162

R730R730

R731R731

C731C731

C520C520

PCN

PCN

GSM+

T630T630

C523C523

GSM+

T600T600

V800V800

C879C879

R879R879

C522C522

C513C513

C512C512

C511C511

C540C540

R546R546

C833C833

R833R833

C830C830

C151C151

C120C120

R122R122

R203R203

R216R216

R215R215

C203C203

R201R201

J104

R205R205

C129C129

C140C140

R111R111

R110R110

C160C160

J254

R277R277

ChapsChaps

C121C121

V101V101

R271R271

C105C105

C161C161

R120R120

C107C107

C268C268

V250V250

V252V252

C293C293

R258R258

R272R272

N101N101

C165C165

C291C291

C292C292

N250N250

C261C261

R269R269

L272L272

L271L271

C251C251

C259C259

C253C253

C257C257

C258C258

C257C257

C262C262

C275C275

C276C276

C263C263

C258C258

R267R267

C294C294

R268R268

C295C295

C261C261

C255C255

C296C296

C297C297

N401N401

U53

C248C248

C249C249

COBBACOBBA

C266C266

C265C265

C247C247

C274C274

C276C276

C278C278

R252R252

V251V251

R274R274

R274R274

R260R260

C109C109

C104C104

R109R109

C276C276

C110C110

C142C142

R131R131

C400C400

L104L104

F101F101

C405C405 C401C401

V100V100

C406C406

R403R403

R404R404

N400N400

R270R270

C342C342C342C342

C330C330C330C330

B301B301

C310C310

99

33

V325V325

V321V321

V323V323

NSM-3

N301N301N301N301

11

N310N310N310N310

C331C331C331C331

22

55

R311R311R311R311

R351R351R351R351

R310R310R310R310

R350R350R350R350

R353R353R353R353

R352R352R352R352

V324V324V324V324

R723R723

C760C760

R723R723

L506L506

V320V320

V324V324

V322V322

V336V336V333V333

C862C862

V801V801

C782C782

L503L503

C790C790

C758C758

R751R751

R756R756

C864C864

R755R755

C863C863

R757R757

R710R710

R758R758

C759C759

R712R712

R711R711

C785C785

N600N600

C860C860

Z700Z700

C783C783

T700T700

R700R700

Z671Z671

R704R704

C755C755

C799C799

C560C560

C550C550

Pwr. AmpPwr. Amp

C704C704

L752L752

L103L103

C741C741

R740R740

L504L504

4

R807R807

R805R805

C805C805

C802C802

N220N220

J110

ComboMemoryComboMemory

T800T800

C804C804

G800G800

C803C803

R801R801

R802R802

C801C801

V360V360

V116V116

C205C205

C205C205

J242

C206C206

C217C217

J101

C209C209

C209C209

R211R211

D210D210

C286C286

R284R284

R283R283

R285R285

R284R284

R283R283

L284L284

L283L283

M300M300

V335V335V332V332

C788C788

VCOVCO

C

C

6

6

1

1

0

0

V331V331

B301B301

C310C310

V325V325

V321V321

V323V323

NSM-2

V334V334

5

L287L287

4

C287C287

R287R287

R118R118

C342C342C342C342

C330C330C330C330

99

33

N301N301N301N301

11

N310N310N310N310

C331C331C331C331

22

55

R311R311R311R311

R351R351R351R351

R310R310R310R310

R350R350R350R350

R353R353R353R353

R352R352R352R352

V324V324V324V324

V350V350

C220C220

C116C116

J241

J103

J230

V320V320

V322V322

J102

J235

J120

C212C212

C212C212

C212C212

4

V333V333

V337V337

V332V332

V340V340

V331V331

S300S300

V336V336

V338V338

V335V335

J236

V339V339

V334V334

5

R287R287

L287L287

C287C287

4

J260

X280X280

Page 5

nokia

Service & Analysis Center Europe

SACE CC Training Group

Z670Z670

C720C720

L553L553

\\

C743C743

C754C754

C702C702

L510L510

R611R611

C700C700

C761C761

R754R754

C733C733

N702N702

Pwr. AmpPwr. Amp

C614C614

R613R613

V730V730

R723R723

C610C610

V904V904

C615C615

Z620Z620

C645C645

C760C760

R723R723

R610R610

C613C613

C163C163

C162C162

C730C730

R732R732

L506L506

C862C862

C790C790

L503L503

CONFIDENTIAL

Measurements

NSM-2/3

Version 1.0 Approved

11.10.2000

5(5)

System Module RM7/RM7L

R832R832

C836C836

C832C832

C621C621

R640R640

C640C640

V903V903

R643R643

R645R645

C644C644

R614R614

V907V907

C612C612

C643C643

C611C611

V905V905

C620C620

Z600Z600

GSM+

GSM+

PCN

PCN

T600T600

C642C642

T630T630

R731R731

C731C731

R730R730

R764R764

R763R763

R732R732

R791R791

R541R541

R744R744

C541C541

C746C746

C747C747

C714C714

R532R532

C670C670

L751L751

C704C704

L752L752

C755C755

Z671Z671

R751R751

R710R710

R755R755

R756R756

R757R757

C758C758

C863C863

R758R758

L103L103

C759C759

C742C742

C799C799

Z700Z700

T740T740

C741C741

C630C630

C557C557

R790R790

R704R704

R712R712

R711R711

L631L631

C792C792

R671R671

R741R741

R740R740

C785C785

C631C631

R792R792

L505L505

T700T700

C600C600

L600L600

L504L504

V801V801

L800L800

V800V800

N600N600

C835C835

C834C834

R834R834

R879R879

C879C879

C601C601

N505N505

HagarHagar

C560C560

R700R700

C860C860

C782C782

C831C831

C522C522

C523C523

C520C520

R510R510

C550C550

C783C783

R831R831

R830R830

G830G830

VCTCXOVCTCXO

C513C513

C512C512

C510C510

C530C530

C531C531

C562C562

C533C533

C561C561

R975R975

T800T800

R805R805

C805C805

R807R807

C788C788

C165C165

C830C830

C833C833

C511C511

R833R833

R546R546

C540C540

C532C532

C521C521

R530R530

C564C564

R565R565

C534C534

R563R563

R564R564

R533R533

R974R974

C535C535

R800R800

C793C793

C804C804

C151C151

C150C150

C154C154

C153C153

C133C133

C106C106

C152C152

C206C206

C129C129

N100N100

CcontCcont

C108C108

C803C803

R802R802

C801C801

R801R801

G800G800

VCOVCO

C802C802

R269R269

C251C251

L271L271

L272L272

C248C248

C249C249

C291C291

C292C292

N250N250

COBBACOBBA

C161C161

C140C140

C102C102

R100R100

C113C113

R128R128

C132C132

C131C131

V116V116

V360V360

R118R118

V350V350

C101C101

R154R154

C205C205

C205C205

C116C116

C220C220

R120R120

R111R111

R205R205

C102C102

C208C208

C202C202

C218C218

C107C107

R110R110

B110B110

C204C204

N220N220

C257C257

C258C258

C253C253

C259C259

C261C261

C247C247

C266C266

C265C265

C121C121

C160C160

C120C120

R122R122

C268C268

V101V101

V101V101

C257C257

C206C206

C275C275

C276C276

C262C262

C263C263

C274C274

C276C276

V250V250

R203R203

C258C258

C294C294

C295C295

R267R267

R268R268

C278C278

C293C293

V252V252

R271R271

R277R277

R216R216

D200D200

Mad2Mad2

C261C261

R252R252

C105C105

C217C217

C255C255

R274R274

V251V251

R215R215

C203C203

C297C297

C296C296

R274R274

R258R258

R272R272

R201R201

C109C109

C109C109

R109R109

C104C104

N1N1

N101N101

ChapsChaps

C209C209

C209C209

C212C212

C212C212

C212C212

N401N401

R211R211

R403R403

R404R404

C406C406

C110C110

C276C276

C142C142

R131R131

C114C114

C103C103

R104R104

R103R103

C201C201

R101R101

C213C213

C119C119

C211C211

ComboMemoryComboMemory

R125R125

R124R124

C128C128

C127C127

D210D210

N400N400

C405C405 C401C401

C400C400

L104L104

V104V104

V104V104

F101F101

F101F101

R270R270

V100V100

C281C281

R286R286

R285R285

L283L283

L284L284

R283R283

R284R284

C285C285

C286C286

M300M300

Copyright © 2000 Nokia Mobile Phones. All rights reserved

Loading...

Loading...