Page 1

CONFIDENTIAL 1 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Repair-Hints

8210/8850

NSM-2/3

HD 914/916

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 2

CONFIDENTIAL 2 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

GENERAL

-How to use this document

Put the QUICK REPAIR layouts behind this manual.

Now you are able to follow these specifications with graphical layouts and it is easier for you to find the

components and measurepoints.

-Component characteristics

Some components contain important data.

Several described steps are only practicable if you are able to reflash/ realign the phone and/or rewrite

IMEI/SIMlock in certain cases.

Please pay attention to separate notes.

-Underfills, broken balls, µBGA

It is not possible to change underfilled components. The trial will damage PCB surely.

All replaceable µBGA-components must be renewed after removing.

Check soldering points, remove oxidated solderings (broken balls) carefully by enclosing few new solder

before placing new components.

µBGA must be soldered only with µBGA-rework machines (e.g. Zevac / OK International).

Use only recommended Fluxtype and an appropriate amount of it.

Clean very careful the PCB after every rework and take great pains over the keyboard area.

Don´t make any loose wiring connections anywhere.

If it is necessary to change any item located under the metal shields, remove the shield

first, don´t cut partially or bend it.

-Realign after repair

Characteristics of spare parts are different.

To prevent additional faults after repair (eg. low standby time, loosing network etc…) it is necessary to

retune phone values after repair.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 3

CONFIDENTIAL 3 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Contents

GENERAL 2

INTRODUCTION 4

PHONE DOES NOT SWITCH ON 5

LOW STANDBY TIME 9

CONTACT SERVICE 11

PHONE SWITCHES OFF 12

NOT CHARGING 13

SIMCARD FAULTS 15

NO SERVICE 18

FREQUENCY LIST 27

INTERNAL AUDIO 28

USER INTERFACE 30

CLOCK TIME PROBLEMS 31

SIMLOCKS 32

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 4

CONFIDENTIAL 4 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

INTRODUCTION

IMPORTANT:

This document is intended for use by authorised NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA 8210/8850 phones.

It contains a lot of collected tips and hints, to find failures and repair solutions easily.

It will also give support to the inexperienced technicians.

Saving process time and improving the repair quality is the aim of using this document.

We have built it up based on fault symptoms (listed in "Contents") followed by detailed description for further

analysis.

It is to be used additionally to the service manual and other service information like Service Bulletins,

for that reason it doesn't contain any circuit descriptions or schematics.

All measurements are made using following equipment:

Nokia repair SW : WinTesla Version 6.43

DLL version : NSM2 03.11.00- 25.05.2000

Nokia Module Jig : MJS 9

Digital multimeter : Fluke 73

Oscilloscope : Hitachi V-1565; Fluke PM 3380A/B

Spectrum Analyzer : Advantest R3361C with an analogue probe

RF-Generator / : Rohde & Schwarz CMD 53

GSM Tester

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If any errors

are found by the reader, NOKIA should be notified in writing, using following procedure:

Please state:

Title of the Document + Issue Number/Date of publication

Page(s) and/or Figure(s) in error

Please send to: Nokia GmbH

Service & Analysis Center Europe

Meesmannstr.103

D-44807 Bochum / Germany

Email: training.sace@nokia.com

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 5

CONFIDENTIAL 5 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

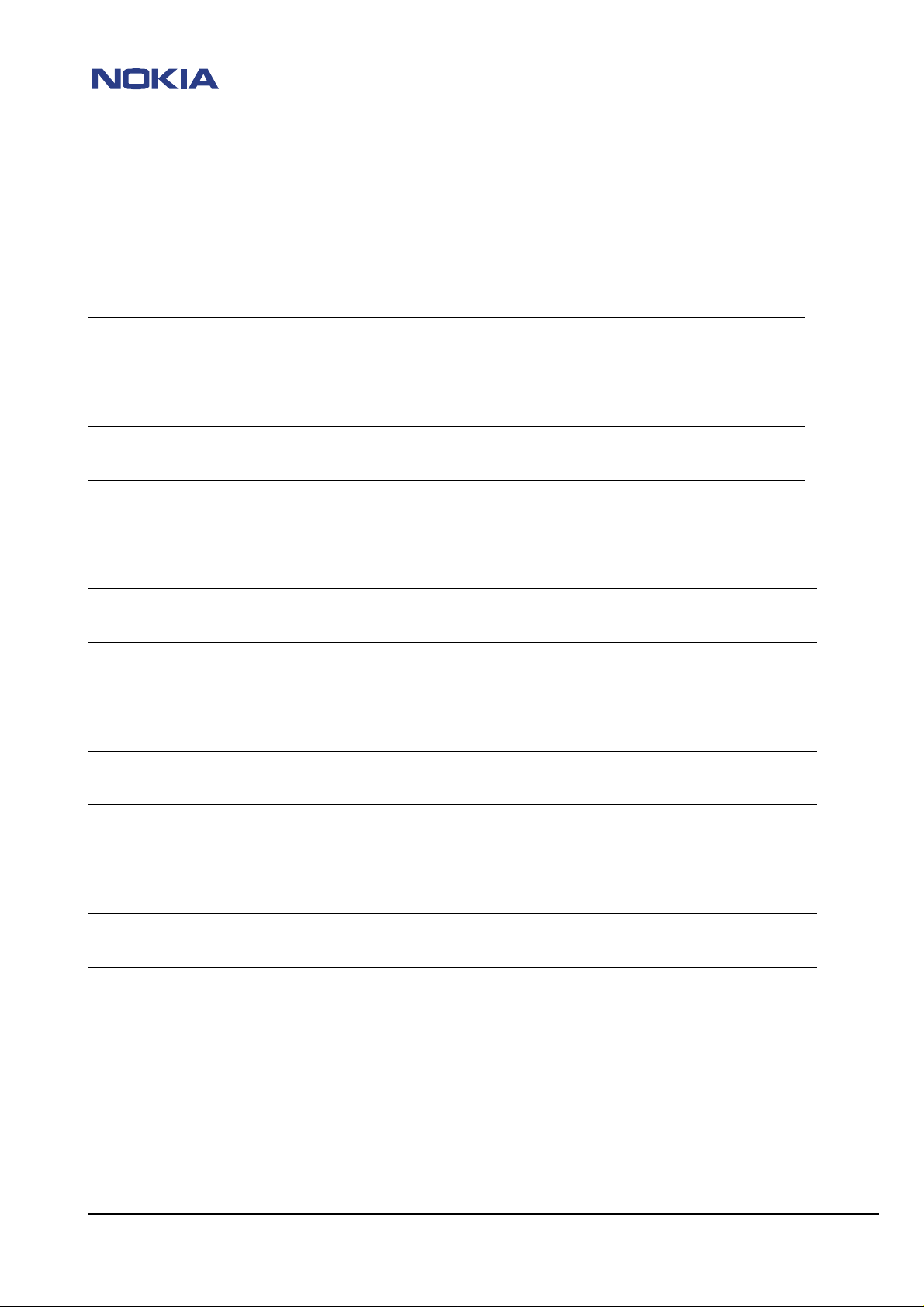

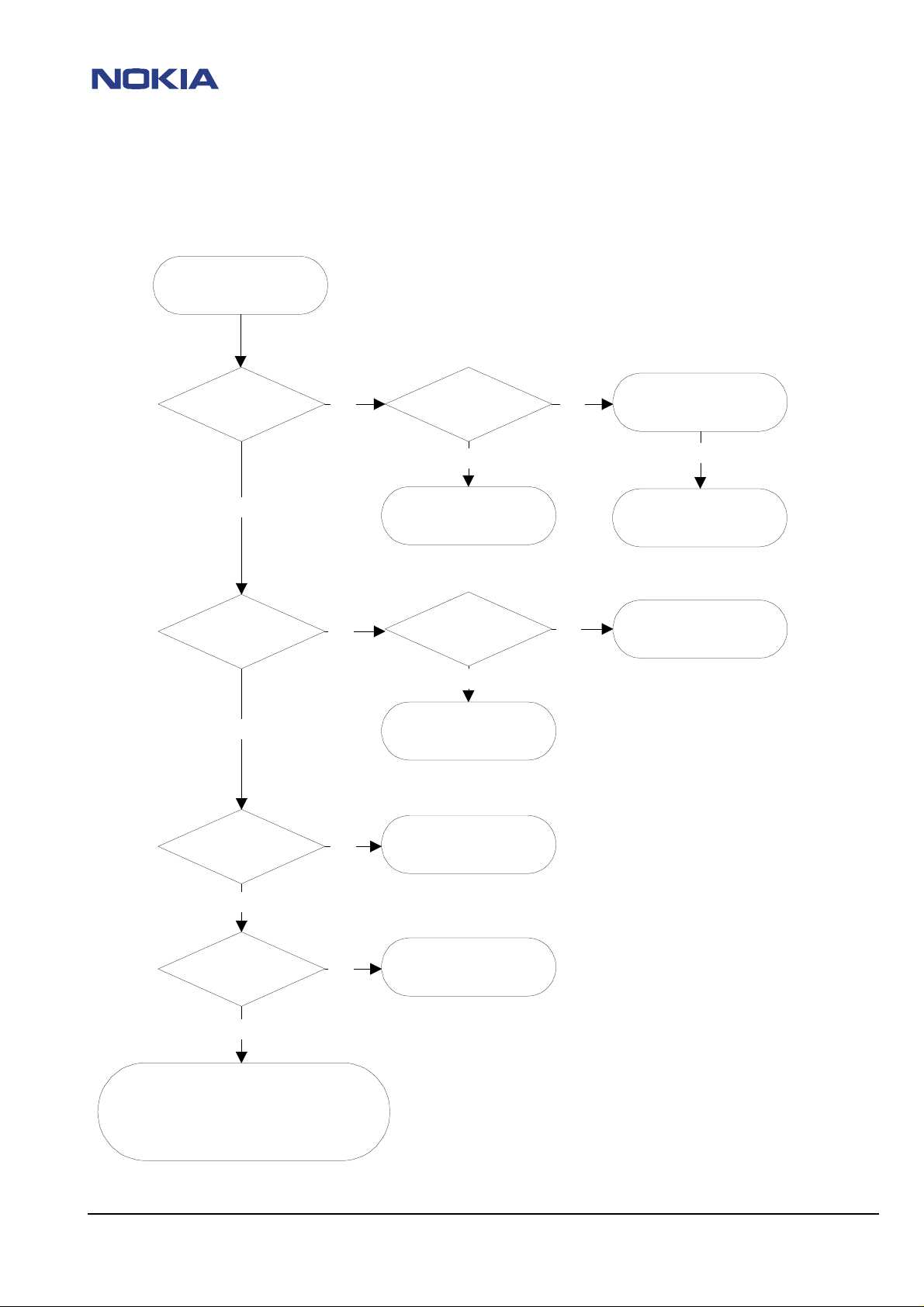

PHONE DOES NOT SWITCH ON

Check current consumption

OFFSTATE: 0-1mA SLEEPMODE: 1-4mA

Call mode: 130-400mA. If too high continue

with section "low standby/operation mode

time"

Check Vb~4V at C129

OK

Check if PWRONX at S330 drops to 0V

during pressing the powerswitch

OK

Check 32,768kHz at J228 3,2Vpp

squarewave

OK

Check Vbb 2,8V at C107

OK

Check Vxo 2,8V at C152

OK

Check Vref 1,5V at C106

nOK

nOK

nOK

nOK

nOK

nOK

Check X101 if bend or soiled, also

check L103

Check/change S330,R118

Check/change B100, R100/102/154,

C101/102/113

Check resistance of line to GND,

value should ~60k, if line ok, change

Check resistance of line to GND,

value should ~45k, if line ok, change

Check resistance of line to GND,

value should ~50k, if line ok, change

N100

N100

N100

nOK

Change N100

Check PURX 2.8V at J227 after pressing

Check 13MHz REFCLK at C213,~800mVpp

© 2000 NMP

OK

Check SLEEPX 2,8V at J226

OK

powerswitch

OK

OK

Try to flash the phone

nOK

nOK

nOK

nOK

MAD is faulty in all probability.

Swap, because MAD is not

changeable

Change N100

Check Values around G830, N505

Continue with section "Flash update

and V800

not possible

Checked by:

CC Training Group

Approved by:

SACE

Page 6

CONFIDENTIAL 6 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Battery connector

Check if bent or soiled.

Clean pads of connector on PCB if soiled.

Power on/off switch S330 faulty

Check that PWRONX at S330 decreases to 0V during pressing the powerswitch.

B100

Check voltage at B100, both 1.6V DC.

Check 32.768kHz sinewave at C102, 700mVpp.

Check parts around B100- like R100, R102, R154, C101, C102.

Check sleepclock 32.768kHz squarewave at J228, 3.2Vpp.

G830 Reference oscillator faulty

Check Vcc 2.7V at C831 and Vcon (varies between 0.3V and 2.3V) at C832.

Check 26MHz Clk-frequency at C830, 900mVpp.

Check 13MHz Clk-frequency at C829, 300mVpp. If not ok, check values around N505.

Check 13MHz Clk-frequency at C213, 800mVpp. If not ok, check values around V800.

N100 CCONT faulty

Check Vb 3.6V at C129.

Check that PWRONX decreases to 0V at S330 when powerswitch is pressed. Also check R118.

Check 32.768kHz squarewave 3.2Vpp at J228.

Check 13MHz Clk-frequency at C213.

Check Vbb 2.8V at C107.

Check Vxo 2.8V at C152.

Check Vref 1.5V at C106.

Check SLEEPX 2.8V at J226.

Check PURX 2.8V at J227.

Probably broken solderings under CCONT N100. Replace CCONT with µBGA rework machine.

Note that it is necessary to run energy management calibration after changing CCONT!

D200 MAD faulty.

Check 32.768kHz squarewave at J228.

Check 13MHz Clk-frequency at C213.

Check Vbb 2.8V at C201.

Check SLEEPX 2.8V at J226.

Check PURX 2.8V at J227.

MAD is probably faulty, swap the unit, because MAD is not changeable.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 7

CONFIDENTIAL 7 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

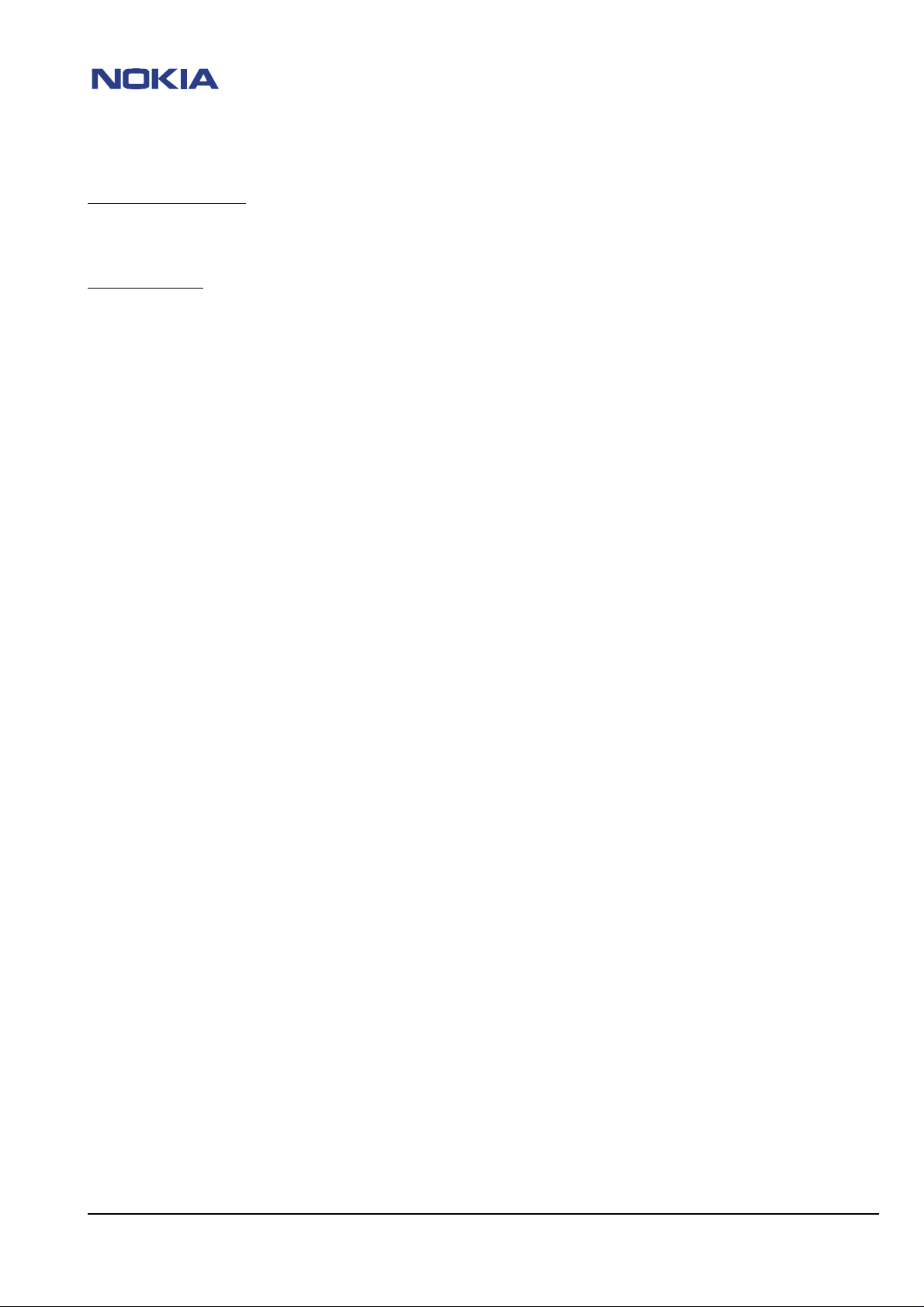

FLASH UPDATE NOT POSSIBLE

Check fault code

from prommer

MCU boot failure,

serial clock line failure, serial

data line failure

YES

Connect "watchdog disable"

R118 to GND

OK

Check Vbb 2.8V at C107, Vxo

2.8V at C152

OK

Check SLEEPX 2.8V

at J226

OK

nOK

nOK

NO

Algorithm code fail,

alias ID missing

Update FPS4 box

with latest flash

device list, try to

update again.

Continue with

section "phone does

not switch on"

MAD faulty

nOK

NO

External RAM failure

YESYES

Check values at D200, if OK,Swap, Combo Memory should

be the reason

© 2000 NMP

Check PURX 2.8V at

J227

OK

Check 13MHz RFCLK

at C213, ~800mVpp

OK

Check Mbus/Fbus lines

(J101-J103) for shorts to

GND. Also check

R109/201/203/215

OK

If error persists, PCB

or MAD should be

the reason.

nOK

nOK

Change CCONT

(N100)

Check values around

G830, N505, V800

Checked by:

CC Training Group

Approved by:

SACE

Page 8

CONFIDENTIAL 8 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Mbus / Fbus lines faulty

Check that there´s no short at J101- J103 to GND, resistance of lines should be between 60kOhm and 220kOhm.

ComboMemory

If “algorithm code / alias ID missing from prommer box” appears while flashing, make sure that your FPS4 box is updated

with the latest flash device list.

Contact service

If “contact service” appears while flashing, change C205 from 1µF to 2.2µF (Code 2610203) to stabilize flash programming

voltage.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 9

CONFIDENTIAL 9 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

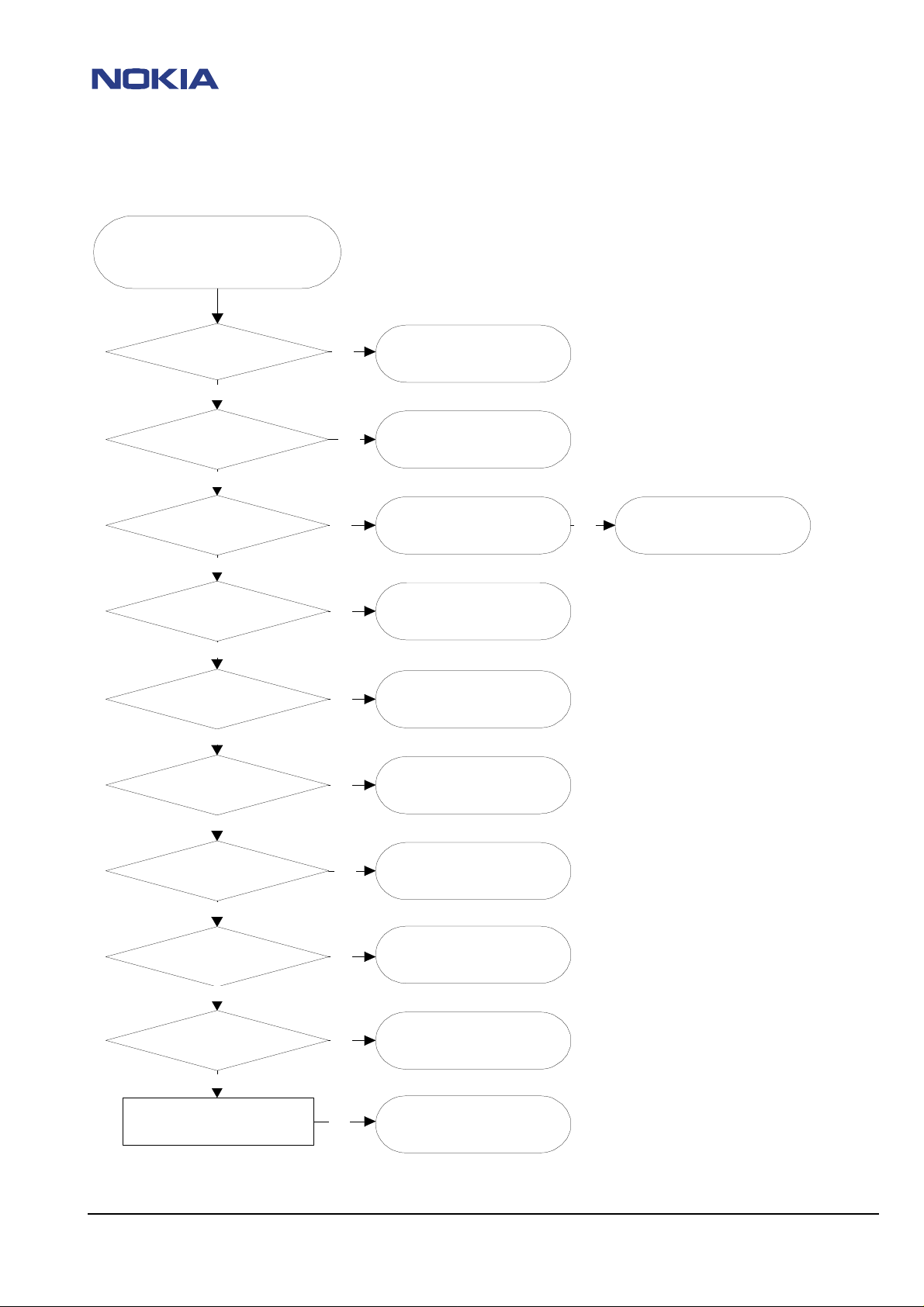

Low standby / operation mode time

Check power

consumption of

phone

Off state 0-1mA

OK

Sleepmode 1-4mA

OK

Check charging circuit, run

energy management calibration

nOK nOK

Lift L103

OK

Check capacitors in Vb line

or change

N100/101/220/310/401 if

necessary

nOK

Check resistance of output

voltage lines of CCONT to GND

nOK

OK

Change CCONT

nOK

Continue with section "not

charging"

Check capacitors

C702-704, C754/755

nOK

Change N702

Check components in

corresponding lines

Please note that standby time also depends

(Paging-Repeat-Period), signal strengh

(min.-98dBm), location updates and not at

© 2000 NMP

OK

Calibrate RX/TX values of the

phone

OK

on network side, like PRP

least users handling of phone.

nOK

Continue with section "RX/TX

faults"

Checked by:

CC Training Group

Approved by:

SACE

Page 10

CONFIDENTIAL 10 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Check the current consumption in different operation modes:

Funktion mode Minimum current in mA Maximum current in mA

Off state 0 1

Sleep mode 1 4

Call mode GSM 900 140 400

Call mode GSM 1800 130 370

Off state current fail

Lift L103 to define the fault if off state current is not ok.

If current is still not ok, lift C702/703/704 and C754/755 one by one.

If fault remains, change power amplifier N702, which is the reason in most cases.

If current is ok after removing L103, resolder it. After that you have to check capacitors in Vb line

(C100,C105,C129,C142,C165…).

If fault remains, change N100, N101, N220, N310 or N401. In most cases CCONT (N100) is responsible for this fault.

Sleep mode current fail

Check resistance of every output voltage line of CCONT (N100) to GND. The values should be higher than 10kOhm,

except Vsyn1 ( 3kOhm ) and Vsyn2 ( 0.9kOhm ).

If resistance of any line is not ok, check/change parts of this line.

If resistance of all lines is ok, change CCONT (N100).

If the standby/operation mode time is still not ok, check the charging circuit and run the energy management calibration.

It can also be necessary to calibrate the RX/TX values of the phone.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 11

CONFIDENTIAL 11 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

CONTACT SERVICE

This fault means that the phone software is able to run and thus the watchdog of CCONT (N100) can be served.

Selftest functions run when power is switched on and software is executed from ComboMemory.

If any selftest fails, a “Contact Service“ text is shown on LCD.

Possible failures:

MCU ROM Checksum failed

Try to flash the phone. If not ok after flashing, probably ComboMemory is faulty, which is not changeable.

CCONT Interface failed

Probably broken solderings under CCONT (N100).

If CCONT is not underfilled, replace it with µBGA rework machine.

If not ok after reworking the CCONT, probably MAD or PCB faulty.

Note that you have to run energy management calibration after changing CCONT!

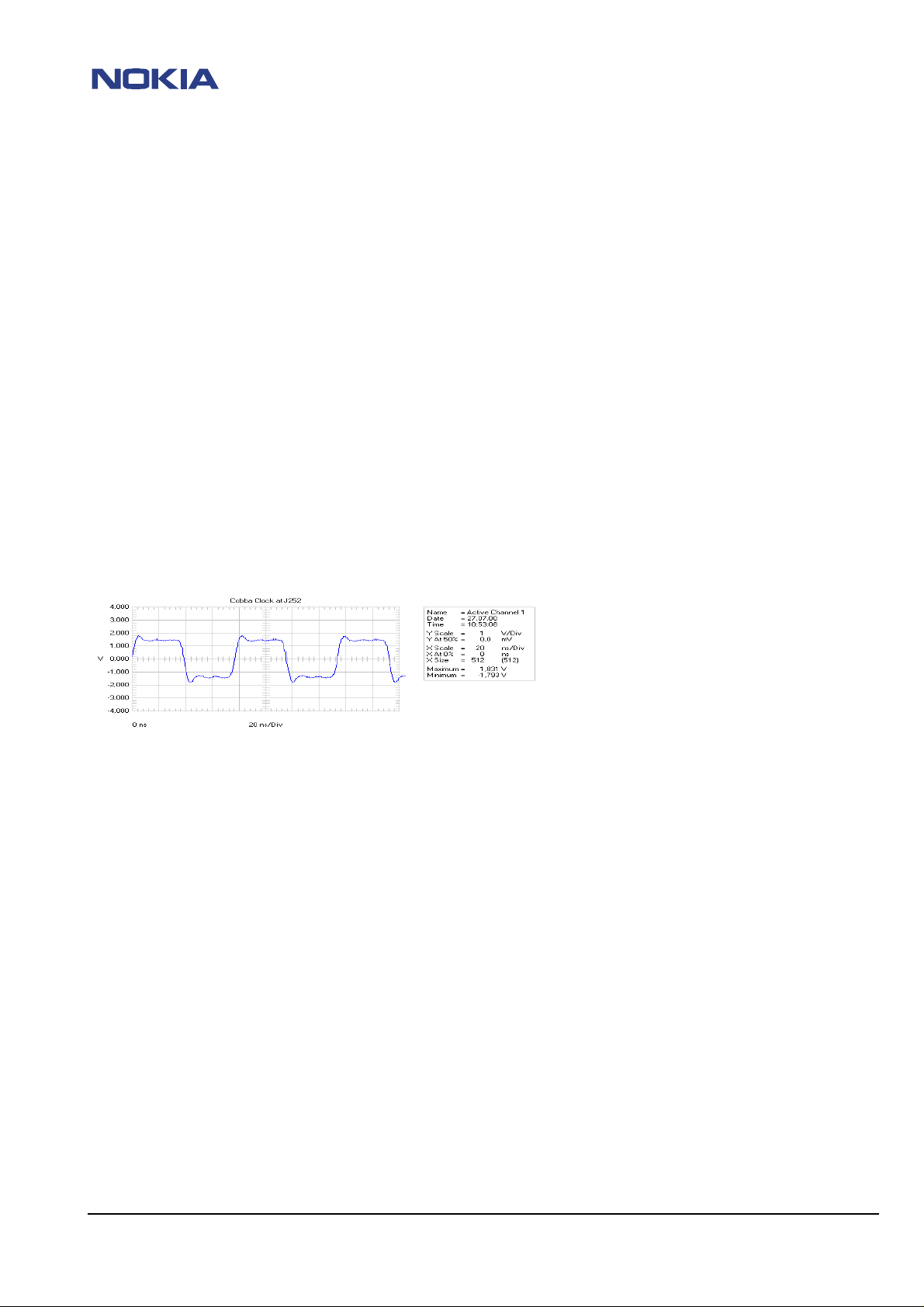

COBBA parallel/serial failed

Check Vbb 2.8V at C201 and VCOBBA 2.8V at C248.

Check COBBAClk at J252.

Probably broken solderings under COBBA (N250) – replace COBBA. If fault remains, MAD or PCB faulty.

Note: IMEIdata and SIMlock must be rewritten after COBBA- change, also retune RF-values.

DSP alive test failed.

In most of all DSP alive selftest failures MAD is faulty, which is not changeable.

Eeprom tune checksum failed

Use WinTesla to check if phonedata like Imei, product-code or PSN are corrupted.

If phone data is ok, try to reset the phone. If phone data is not ok or fault remains after reset, ComboMemory is faulty

in all probability.

RTC Battery failed

First try to charge RTC battery by switching on the phone for 10 to 15 minutes.

If fault remains, check contact springs of battery, bend them if nessecary.

(Also see NSM-2 Service Bulletin 20).

In some cases it can be necessary to change RTC battery and/or CCONT (N100).

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 12

CONFIDENTIAL 12 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

PHONE INTERMITTENT SWITCHES OFF/ DOESN’T SWITCH ON

Check mechanical appearance of connector X101.

Check that pads of X101 on PCB are clean.

Check amplitude of 32.768kHz at J228, 3.2Vpp squarewave, probably broken solderings under CCONT N100.

Remove CCONT if not underfilled and replace it with µBGA rework machine.

The same problem may cause N505, because the reference oscillator G830 (26MHz) is divided to 13MHz

system clock by HAGAR N505. If broken solderings exist under HAGAR, rework as described above.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 13

CONFIDENTIAL 13 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

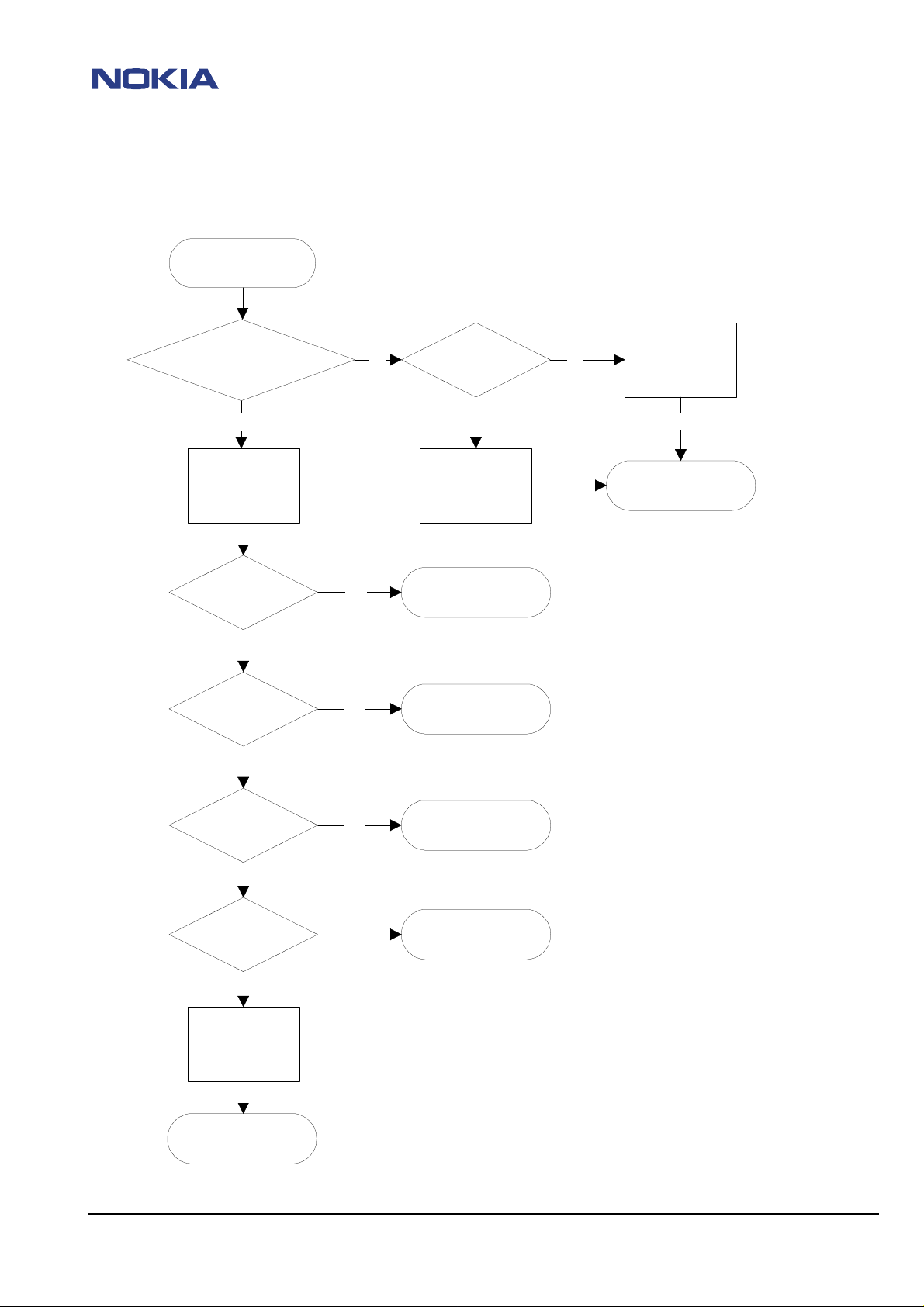

Not charging

Nothing happens if charger is

connected

check voltage level at R103>0,4V if

charger is connected

OK

Change N101/100

"not charging" appears on LCD

run energy management calibration

OK

nOK

Check/change X110,F101,

V100, R103/104

Try to charge after

calibration

Failure messages

Battery temperature failed

Battery size failed

Battery voltage failed

charge current failed

charge voltage failed

Check X101,

R120/122, change

N100

Check X101,

R120/122, change

N100

Change N100

Check R131, change

N100/101

Check Vcharge at voltage

divider R103/104

nOK

Check X110,V100, F101,

L104, change N101

Change N100

OK

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 14

CONFIDENTIAL 14 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

X110 DC/HS connector, X101 battery connector

Check mechanical appearance of connectors, make sure that pads for connectors on PCB are clean.

F101 faulty

Check resistance of F101 (0 Ohm).

Vcharge line shorted to GND.

Check resistance of Vcharge line at F101 to GND (50 kOhm).

If resistance is not ok, remove L104 and check again.If resistance is still not ok, V100 faulty in all probability.

If resistance is ok now, C103/C114 or N101 should be the reason.

N100 faulty

Change CCONT (N100) if any A/D value is out of limit while DC voltage is ok.

If DC voltages are not ok, check corresponding voltage dividers and battery connector X101 and run energy management

calibration.

Energy management calibration

Run calibration if charging stops too early, if message “not charging” appears on LCD or any part in the charging

circuit has been replaced.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 15

CONFIDENTIAL 15 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

SIMCARD FAULTS

"Insert SIMcard"

Check X302 if bend or soiled,

check contact pads on PCB

OK

Check Signals at V104:

Pin1 SIMCLK

pin3 VSIM

pin4 SIMData

pin5 SIMRST

"SIMcard not accepted" appears

on LCD

nOK

nOK

Change X302, clean PCB if

necessary

Check R124/125/128,

resistance of SIMlines to

GND. Change V104, N100

if necessary

nOK

Probably MAD or PCB

faulty

© 2000 NMP

Compare SIMlock data

with listed entries of

respective prod.-code with

WinTesla

nOK

Rewrite SIMlock data with NOKIA SECURITY

PASSWORD or send phone to SACE. If SIMlock is

corrected or inactive, but fault remains, change

COBBA (N250) and rewrite SIMlock

OK

Simlock is OK. If the Msin data field is

closed to a special IMSI number range,

only the operator is allowed to open the

SIMlock. Also see general SB65

Checked by:

CC Training Group

Approved by:

SACE

Page 16

CONFIDENTIAL 16 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

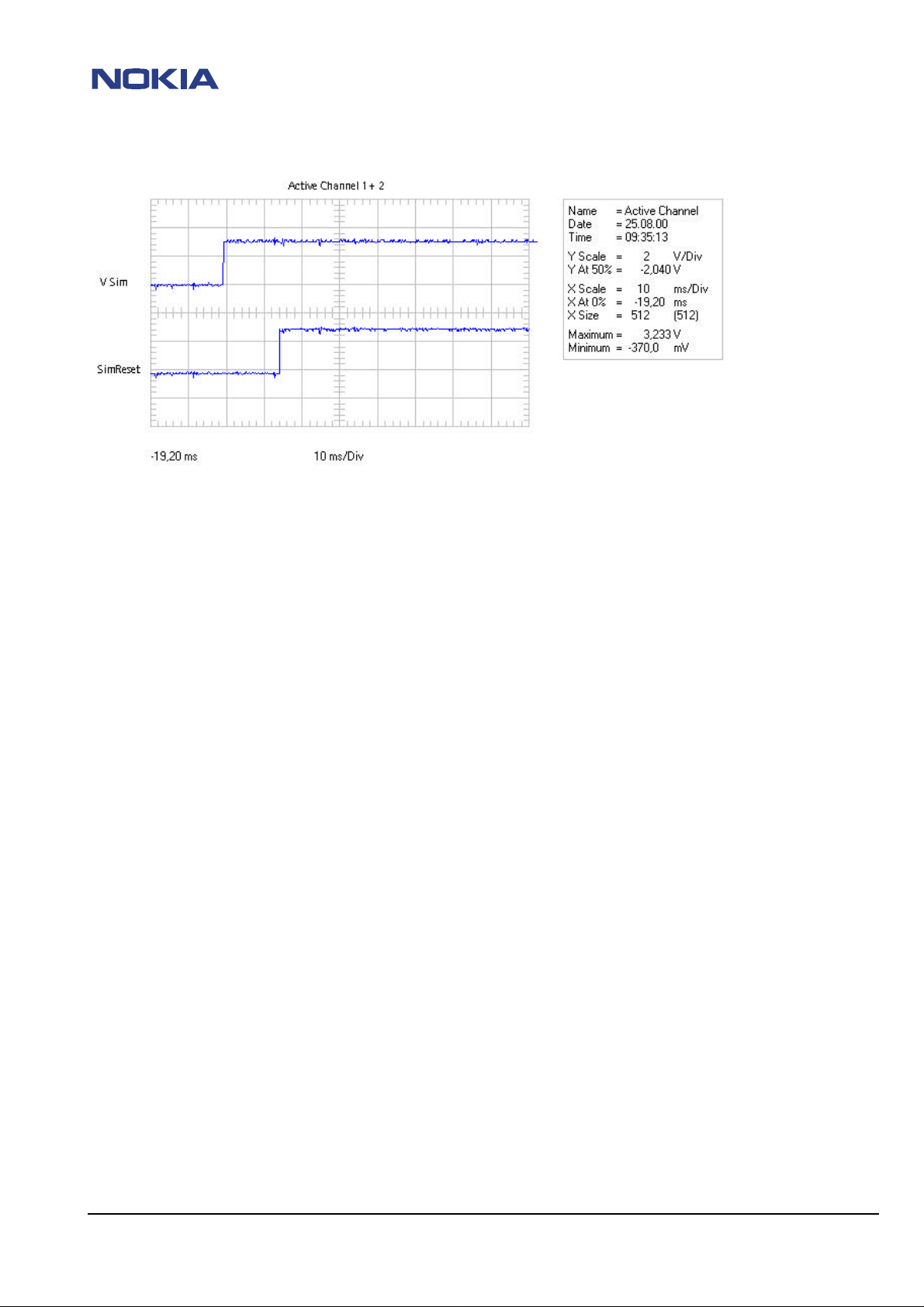

VSIM after switching on the phone without SIMcard. CCONT pulses up VSIM four times, at first the amplitude is 3 Volt, the next

three times 5 Volt.

If the phone is switched on with SIMcard, Vsim stays on level with which SIMcard works, expected that SIMcard is not dirty

or damaged.

Please Note: SIMclock and SIMdata are only present when SIMcard is active, for example if phone registers to network.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 17

CONFIDENTIAL 17 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

SIMReset is low-active, that means that the SIMcard will be reseted when SIMReset is 0 Volt. This is the case after switching

on the phone ( diagram above ). While Vsim is already high, SIMReset keeps low for a few milliseconds – in this time the card

will be reseted.

X 302 SIMcard Reader

Check if bent or soiled, change if necessary.

Make sure that SIMreader´s pads on PCB are clean and check/add twin rip (NSM-2 only,- see SB 012).

V 104 faulty

Check resistance of SIMlines to GND, value shouldn’t decrease 200kOhm.

Check also R124/125/128, C127/128.

CCONT (N100) faulty

Check SIMClock, SIMData, SIMReset and Vsim.

Probably broken solderings under CCONT (N100). Remove CCONT and replace it with µBGA rework machine.

Run energy management calibration after changing CCONT!

COBBA (N250) faulty

If „SIM card not accepted“ appears on LCD, but SIMlock-settings are ok or no SIMlock is set, it is necessary to change

COBBA (N250).

Note that you have to rewrite SIMlock-data and tune RX/TX-values of the phone after changing the COBBA.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 18

CONFIDENTIAL 18 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

NO SERVICE

First of all: Calibrate RX/TX values to define the fault.

No or too low TX power GSM 900

Use WinTesla to set phone into following mode: “Initialise/ Local mode/Testing/ RF Controls/ active unit TX, Ch.60”.

Check 26MHz reference oscillator at C830, 700mVpp, frequency deviation < 100Hz.

Check TXI/Q signals at R541/546, refer to signals shown on next pages.

If not ok, check values at COBBA (N250)- see below.

Check 902 MHz at T700 pin 4 and 6. If not ok, check signals at HAGAR (N505)- see below.

Check 902 MHz at N702 pin 8. If not ok, check parts like T700, Z700, Z671 or V801.

Check 902 MHz at L553 pin 1. If not ok, check values at N702.

Check 902 MHz at J600 (Antenna pad). If not ok, check L553 in & out, also check signal at Z670 in & out and TXVGSM

(2,8Vpp squarewave) at R671 (sets Z670 to TX-mode).

COBBA N250 faulty

Check Vbb (2.8V) at C201 and VCOBBA (2.8V) at C248.

Check 13MHz COBBAclk at J252 (see diagram in chapter „Contact Service“).

Probably broken solderings under COBBA (N250). Replace COBBA with µBGA rework machine and retune RX/TX values.

HAGAR N505 faulty

Check voltages at HAGAR :

Vtcxo 2.8V at C550.

Vchp 4.8V at C560

Vsynte 2.8V at C561

VRXrf 2.8V at C557

Vlna 2.8V at C562

Vref 1.35V at C535

Check 26MHz reference oscillator at C830, 700mVpp.

Check TXI/Q signals at R541 and R546.

Check Sdata at J237, Sclk at R205 and Sena at R206 – refer to signals shown on next pages.

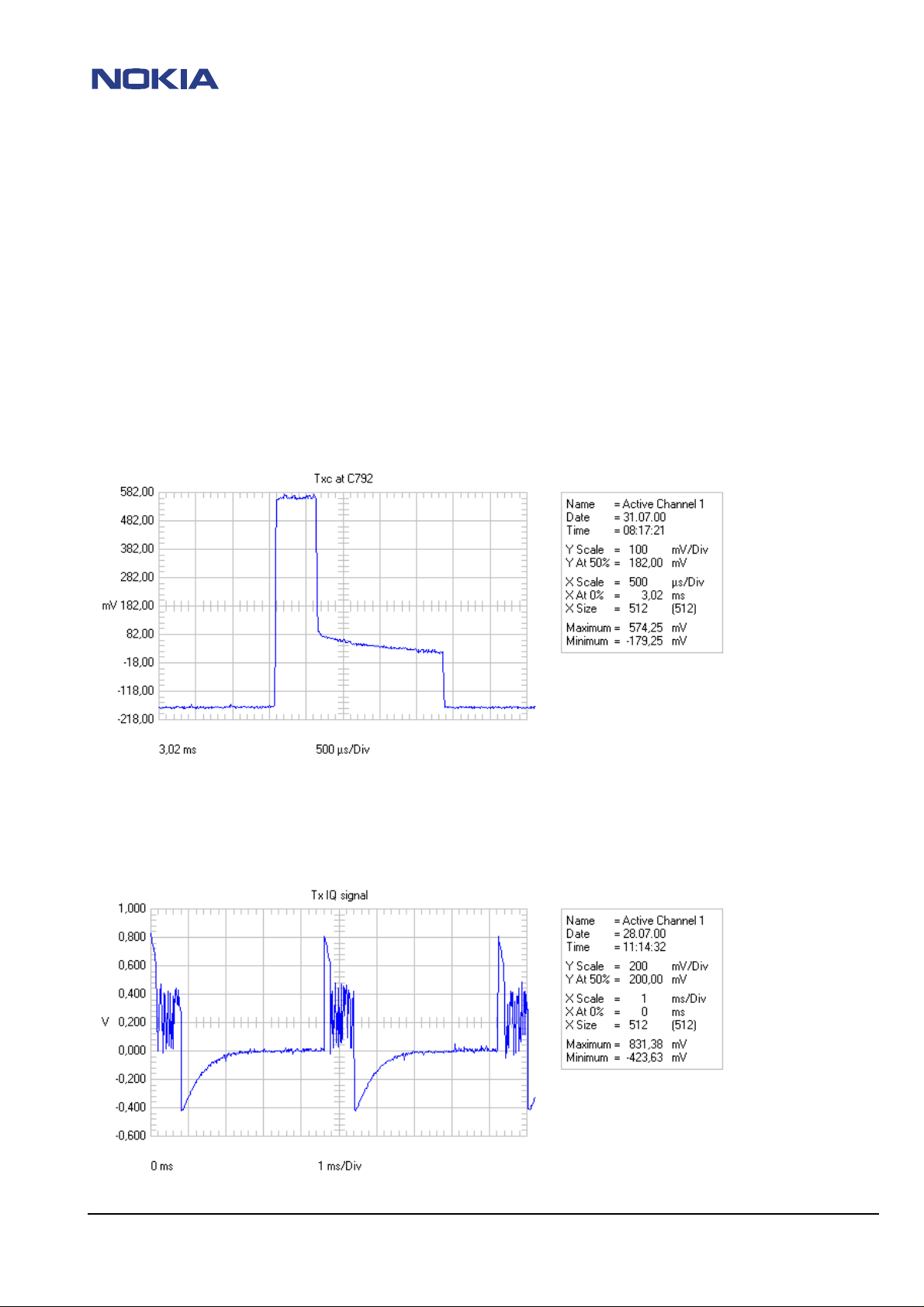

Check TXC at C792 (diagram on next page).

Check TXP at pad of R745, 2.8Vpp squarewave/ 217Hz. (R745 is not assembled, you can find the pads of it

between R791 and R541. TXP is measurable at the pad located near to R744).

Check frequency of SHF oscillator – refer to frequencies worksheet.

If all values are ok, but low or even no TX signal is measurable at T700, probably HAGAR has broken solderings or defect.

Replace HAGAR with µBGA rework machine and align RX/TX values.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 19

CONFIDENTIAL 19 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

26MHz reference oscillator faulty

Check Vcc 2.7V at C831 and Vcon (varies between 0.3V and 2.3V) at C832.

If frequency deviation is higher than +/- 100 Hz, it is necessary to change the oscillator.

Check appearance and pads of R832.(AFC-line).

G800 SHF oscillator faulty

Check frequency of oscillator if possible – refer to frequencies worksheet on page 27. If you have no possibility

to check frequency (~4GHz), check oscillator by measuring Vcc at C804 ( 2.8V) and Vc at C803, which varies between

0.7V and 3.8V, dependent on the used channel. If Vc is ~4.8V, the oscillator doesn’t work in all probability.

The amplitude of TXC depends on the chosen powerlevel. It varies between 0,4Vpp on powerlevel 19

and 1,6Vpp on powerlevel 5.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 20

CONFIDENTIAL 20 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 21

CONFIDENTIAL 21 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

N702 power amplifier faulty

Check TX power signal at pin 8 of N702.

Check TXVGSM at pin 1 of N702 (2.8Vpp squarewave/ 217Hz).

Check Vapc at pin 7 of N702 (1- 1.6Vpp depending on powerlevel).

Check Vbatt at pin 3 and 6 of N702.

If all values are ok but still there´s no or too low TX power measurable at L553 pin 1, change N702.

Z670 Diplexer faulty

Check TX power signal at pin 7 of L553.

Check TXVGSM 2.8Vpp squarewave at R671 (near HAGAR).

If all values are ok but still there´s no or too low TX power signal at J600 (Antenna pad), check solderings of Z670.

If it is necessary to change Z670, don’t forget to replace foam on sparepart. (NSM-2 only, see also Service Bulletin 22).

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 22

CONFIDENTIAL 22 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

No or too low TX power GSM 1800:

Use WinTesla to set phone in following mode:

Initialise/Product/Band/PCN/Testing/RF Controls/active unit TX Ch.700.

To find a fault in GSM 1800 TX mode, you can proceed almost the same way as described for GSM 900:

Check 26MHz reference oscillator at C830, 700mVpp, frequency deviation < 100Hz.

Check TXI/Q signals at R541/546. If not ok, check signals at COBBA (N250).

Check 1747.8 MHz at T740 pin 4 and 6. If not ok, check signals at HAGAR (N505).

Check 1747.8 MHz at N702, pin 8. If not ok, check parts like T740, Z671 or V801.

Check 1747.8 MHz at L553 pin 3. If not ok, check values at N702.

Check 1747.8 MHz at J600 ( Antenna pad ). If not ok, check L553 in & out, signal at

Z670 in & out and TXVDCS (2.8Vpp squarewave) at R670 (sets Z670 to TX-mode).

No RX- calibration GSM 900 possible.

Use WinTesla to set phone in following mode: Initialise/Local mode/Testing/RF Controls/active unit RX Ch.60, burst mode.

Set RF- generator to a high RF- level output, e.g. –40dBm.

Check 26MHz reference oscillator at C830, 700mVpp, frequency deviation < 100Hz .

Check 947MHz at Z620 in & out. If not ok, check signals at Z670.

Check 947MHz at C610. If not ok, check values at V904 and V907.

Check 947MHz at both sides of L600. If not ok, check Z600, T600.

Check RXI/Q signal at R530. If not ok, check signals at HAGAR N505.

If signal at R530 is ok but still no RX-calibration possible, check signals at COBBA (N250). Probably MAD faulty.

Diplexer (Z670) faulty

Check 947MHz at J600 ( Antenna pad ).

Check 947MHz at C614. If not ok, check solderings of Z670. If it is necessary to change Z670, don’t forget to replace foam

on sparepart. (NSM-2 only, see also Service Bulletin 22).

HAGAR (N505) faulty.

Check voltages at HAGAR :

Vtcxo 2.8V at C550.

Vsynte 2.8V at C561.

Vlna 2.8V at C562.

Check 26MHz reference oscillator at C830, 700mVpp, frequency deviation < 100Hz.

Check 947MHz at both sides of L600.

Check Sdata at J237, Sclk at R205 and Sena at R206, see diagrams in section TX-faults.

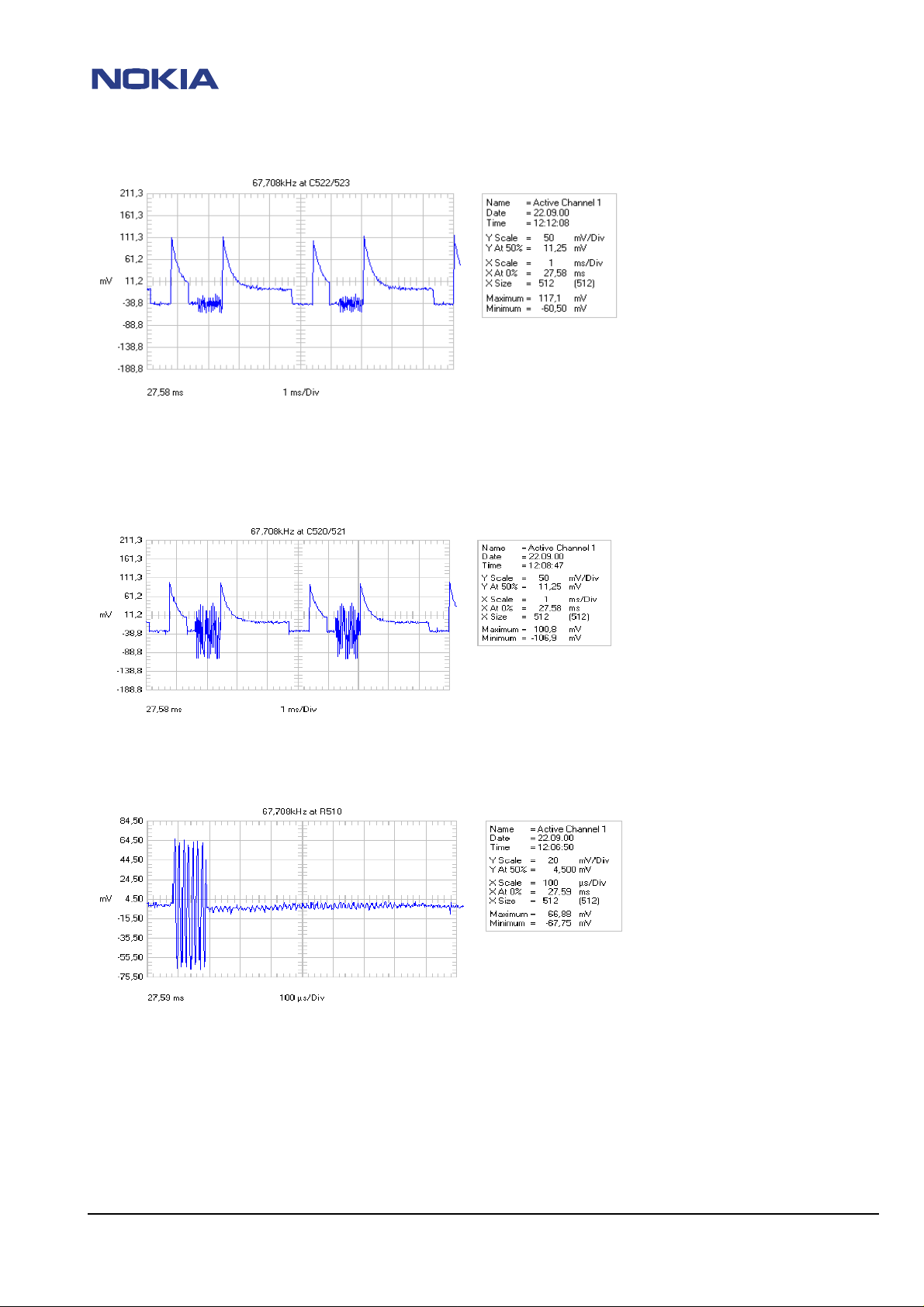

Check 67.708kHz at C522/523 (burst mode, input level –65dBm).

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 23

CONFIDENTIAL 23 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

If signal is not ok, check VRXrf 2.8V at C557, check also Vchp 4.8V at C560 and frequency of G800 at C788

(RX Ch.60: 3788MHz) or change HAGAR (N505).

Check 67,708kHz at C520/521 (burst mode, input level –65dBm).

Check 67,708kHz at R510 (burst mode, input level –65dBm).

If signal is not ok at R510, check C510- C513 for shorts to GND, check resistance of R510

( 4 * 100R ) or change HAGAR (N505).

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 24

CONFIDENTIAL 24 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

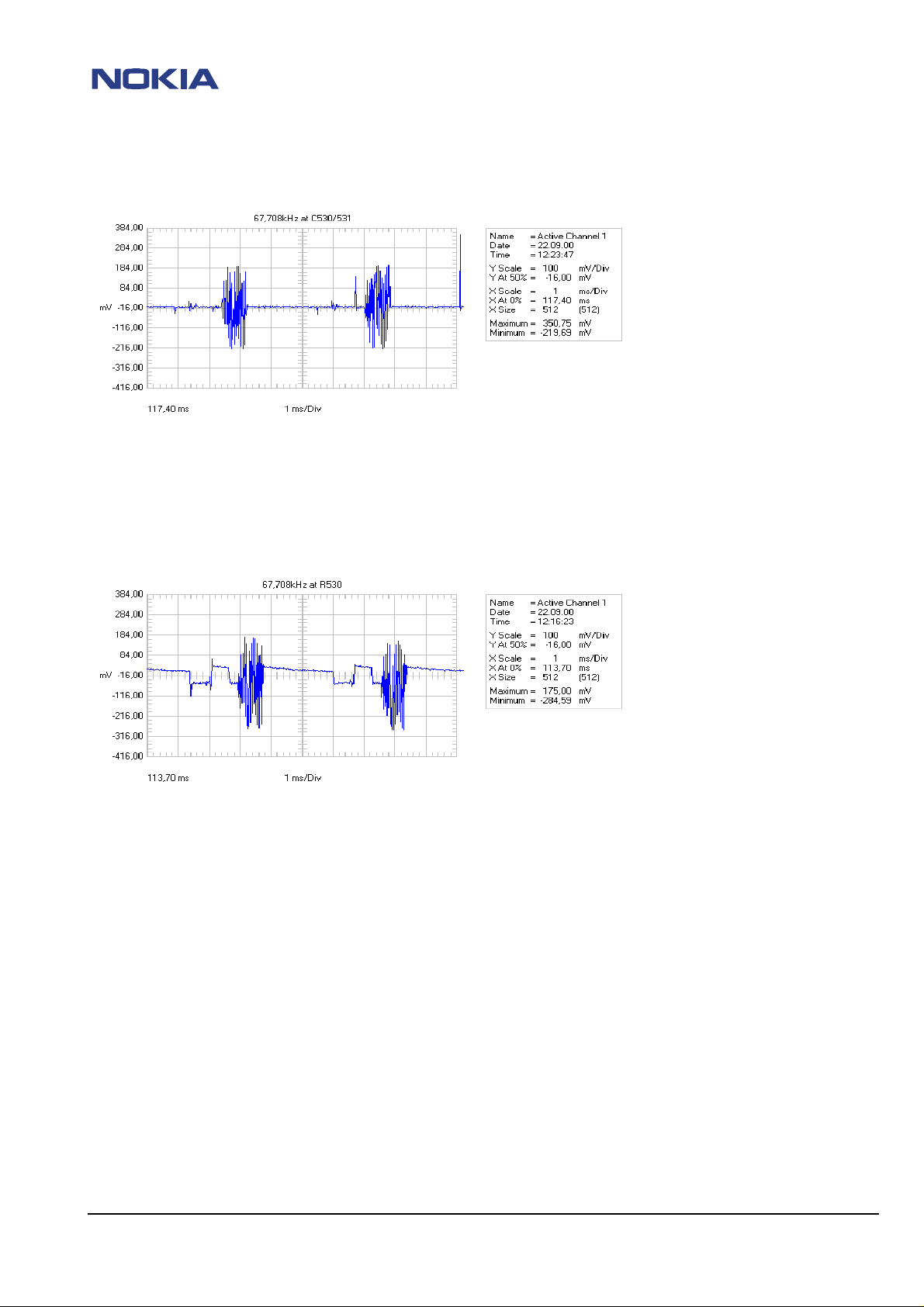

Check 67.708kHz at C530/531 (burst mode, input level –65dBm).

Check 67.708kHz at R530 (burst mode, input level –65dBm).

If signal is not ok at R530, check Vref 1,35V at C535, also check C530-C533 if broken or broken soldered, change HAGAR (N505)

if necessary.

COBBA (N250) faulty

Check Vbb 2,8V at C201 and VCOBBA 2.8V at C248.

Check COBBAclk at J252 (see diagram in chapter “Contact Service“).

Probably broken solderings under COBBA (N250). Remove COBBA, replace it with µBGA rework machine and retune

RX/TX values of the phone.

G830 26MHz reference oscillator faulty.

Check Vcc 2.7V at C831 and Vcon (varies between 0.3V and 2.3V) at C832.

If frequency deviation is higher than +/- 100 Hz, it is necessary to change the oscillator.

G800 SHF oscillator faulty

Check frequency of oscillator if possible – refer to frequencies worksheet (page 27)

If you have no possibility to check frequency, check oscillator by measuring Vcc at C804 (2,8V) and Vc at C803, which varies

between 0.7V and 3.8V.

If Vc is 4.8V, the oscillator doesn’t work in all probability.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 25

CONFIDENTIAL 25 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

No RX - calibration GSM 1800 possible.

Use WinTesla to set phone in following mode: Initialise/Product/Band/PCN

Testing/RF Controls/ active unit RX Ch.700, burst mode.

Set RF- Generator to a high RF- Level output, eg –40dBm.

To find a fault in GSM 1800 RX mode, you can proceed almost the same way as described for GSM 900:

Check 26MHz reference oscillator at C830, 700mVpp,frequency deviation < 100Hz

Check 1842.8MHz at Z620 in & out. If not ok check values at Z670.

Check 1842.8MHz at C640. If not ok check values at V903 and V905.

Check 1842.8MHz at both sides of L631. If not ok check Z600, T630.

Check RXI/Q signal at R530. If not ok check values at HAGAR (N505).

If signal at R530 is ok but still no RX-calibration possible, check signals at COBBA (N250), probably MAD faulty.

Low receiver signal strength indicator

Calibrate RX values of the phone.

Check if antenna pad on PCB is dirty or antenna spring is bend.

Check receivers signal strength indicator with a new antenna.

Bit error too high.

If bit error is too high, probably Z620 faulty. Change filter, retune phone values and check phone in call mode with a simulator.

Oxidized pads under COBBA

Check the module in call mode with a simulator.

Knock carefully around the COBBA with a nonmetallic item.

If errors like RX quality/level or TX power/phase/frequency appear, there are probably oxidized pads under COBBA. Remove COBBA,

tinplate oxidized pads carefully with flux and solder, replace COBBA with µBGA rework machine.

Note that you have to rewrite SIMlock-data and tune RX/TX-values of the phone after changing the COBBA.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 26

CONFIDENTIAL 26 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Faulty TX - spectrum

1) 3)

2) 4)

Pic.1: Normal spectrum

Pic.2: Spectrum with broken solderings under CCONT.

Spectrum turns to picture 1 if CCONT is pushed carefully with a nonmetallic item.

Pic.3: Spectrum of faulty COBBA (RSSI-Alignment not possible, TXI/Q faulty).

Pic.4: Spectrum of faulty oscillator G800, both COBBA or HAGAR can be the reason.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 27

CONFIDENTIAL 27 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

FREQUENCY LIST

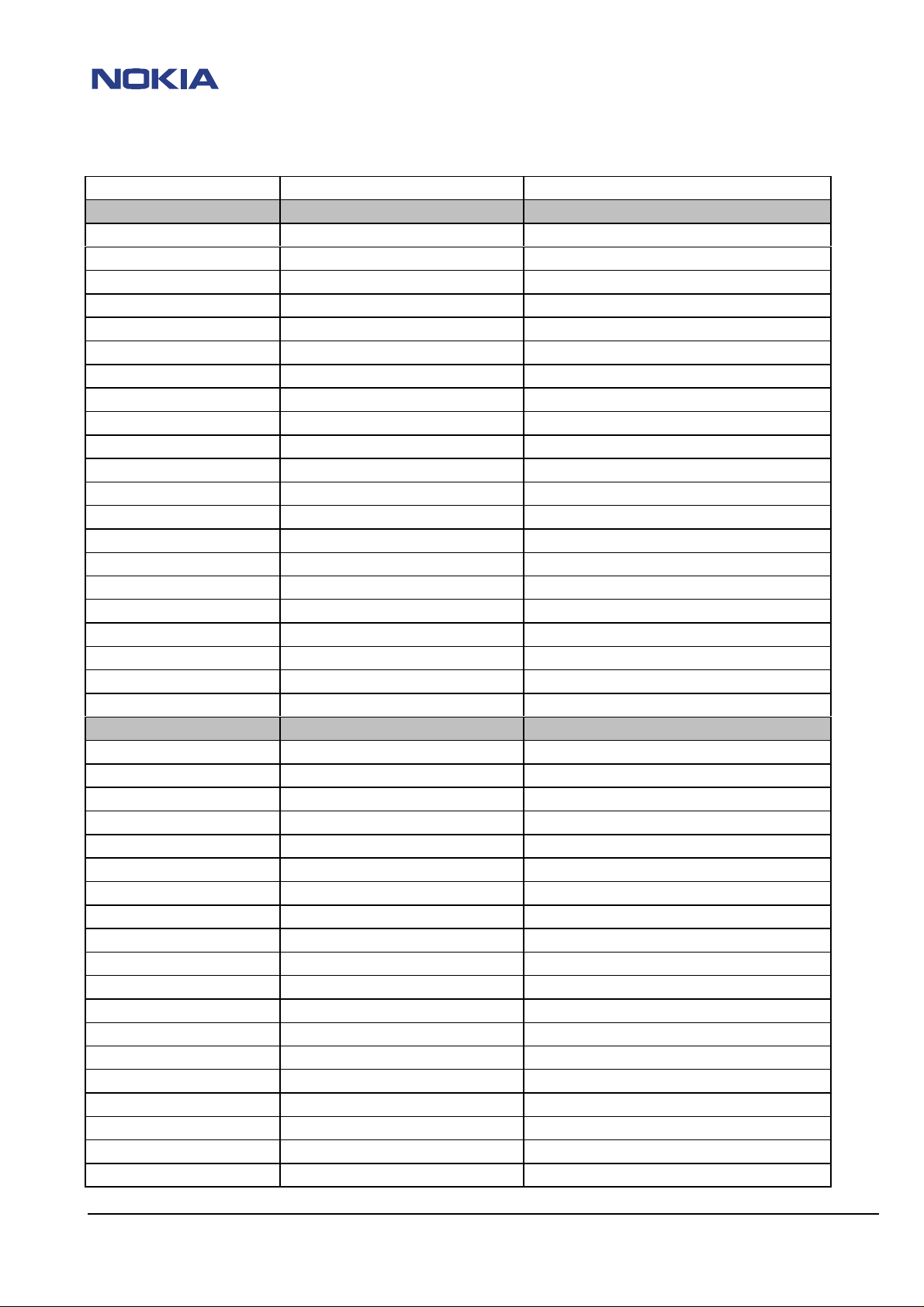

EGSM Channels & Frequencies

Channel TX RX VCO - TX VCO VCO - RX VCO

MHz MHz MHz VOLT MHz VOLT

975 880,2 925,2 3520,8 2,66 3700,8 1,46

976 880,4 925,4 3521,6 3701,6

977 880,6 925,6 3522,4 3702,4

978 880,8 925,8 3523,2 3703,2

979 881 926 3524 3704

980 881,2 926,2 3524,8 3704,8

981 881,4 926,4 3525,6 3705,6

982 881,6 926,6 3526,4 3706,4

983 881,8 926,8 3527,2 3707,2

984 882 927 3528 3708

985 882,2 927,2 3528,8 2,69 3708,8 1,51

986 882,4 927,4 3529,6 3709,6

987 882,6 927,6 3530,4 3710,4

988 882,8 927,8 3531,2 3711,2

989 883 928 3532 3712

990 883,2 928,2 3532,8 3712,8

991 883,4 928,4 3533,6 3713,6

992 883,6 928,6 3534,4 3714,4

993 883,8 928,8 3535,2 3715,2

994 884 929 3536 3716

995 884,2 929,2 3536,8 2,72 3716,8 1,56

996 884,4 929,4 3537,6 3717,6

997 884,6 929,6 3538,4 3718,4

998 884,8 929,8 3539,2 3719,2

999 885 930 3540 3720

1000 885,2 930,2 3540,8 3720,8

1001 885,4 930,4 3541,6 3721,6

1002 885,6 930,6 3542,4 3722,4

1003 885,8 930,8 3543,2 3723,2

1004 886 931 3544 3724

1005 886,2 931,2 3544,8 2,75 3724,8 1,61

1006 886,4 931,4 3545,6 3725,6

1007 886,6 931,6 3546,4 3726,4

1008 886,8 931,8 3547,2 3727,2

1009 887 932 3548 3728

1010 887,2 932,2 3548,8 3728,8

1011 887,4 932,4 3549,6 3729,6

1012 887,6 932,6 3550,4 3730,4

1013 887,8 932,8 3551,2 3731,2

1014 888 933 3552 3732

1015 888,2 933,2 3552,8 2,78 3732,8 1,66

1016 888,4 933,4 3553,6 3733,6

1017 888,6 933,6 3554,4 3734,4

1018 888,8 933,8 3555,2 3735,2

1019 889 934 3556 3736

1020 889,2 934,2 3556,8 3736,8

1021 889,4 934,4 3557,6 3737,6

1022 889,6 934,6 3558,4 3738,4

1023 889,8 934,8 3559,2 2,81 3739,2 1,7

0 890 935 3560 3740

Standard

1 890,2 935,2 3560,8 2,81 3740,8 1,7

60 902 947 3608 3 3788 2,01

124 914,8 959,8 3659,2 3,2 3839,2 2,34

512 1710,2 1805,2 3420,4 2,03 3610,4 0,84

700 1747,8 1842,8 3495,6 2,36 3685,6 1,3

885 1784,8 1879,8 3569,6 2,66 3759,6 1,77

VC at C803 VC at C803

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 28

CONFIDENTIAL 28 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

INTERNAL AUDIO FAULTS

No audio from speaker

Check resistance of speaker

(30R), change speaker if

bend or soiled

OK

Check connection between

speakerpads on PCB and

C291/292.

nOK

Check L271/272

OK

Check resistance of

speakerlines to GND, both

>1M

OK

Change COBBA N250

Microphone does not work

Check/change mic

Check connection L287 to

C263 (470R)

OK

Change COBBA (N250)

nOK

OK

Check connector X280 (8850

only!)

OK

Check micbias at L287 (2,4V) on

active mic

nOK

Check/change parts around V250

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 29

CONFIDENTIAL 29 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Speaker faulty

Check resistance of speaker ( 30 Ohm ).

Check mechanical appearance of speaker if audio signal is too quiet or distorted.

Ear N/P disconnection or short circuit to GND.

Check resistance of L271/272 ( 0 Ohm ).

Check resistance of lines to GND ( > 1MOhm ).

Microphone doesn’t work.

Check/change microphone.

Check connector X280 if bent or soiled (8850 only), change if necessary, also see SB-005.

Check microphone voltage at L287 (2,4V) on active micro.

Check connection between L287 and C263 ( 470 Ohm ).

Change COBBA (N250) if necessary.

TDMA – noise

If audio is distorted by TDMA – noise, make sure that PCB is clean.

Further more it is necessary to assemble the phone with a torque screwdriver with the required torque of 17 Ncm.

NSM-3: Try to change the mainframe assy, RF can, antenna.

NSM-2: Try to change the B-Cover and/or the speaker/ metal gasket and/or slide.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 30

CONFIDENTIAL 30 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

USER INTERFACE FAILURE

Display failure

Check mechanical appearance of display.

Check Vbb 2.8V at C330.

Probably MAD faulty.

Keypad no function

Check if contacts of domesheet / keymat are dirty.

Clean PCB if necessary, check surface of LCD-module (bend?).

Check resistance of ROW and COL lines between the keys.

Probably MAD faulty.

Backlight failure

Check KBlights 2.8V at pin 7/15 of N310. If not ok, there could be a break between D200 and N310, or MAD is faulty.

Check Vb 3.6V pin 1 and Vbb 2.8V pin 2 of N310.

Check resistance of R310 and R311.

Check Vb at LED´s V320-325 and V331-340.

If keypad backlight is not bright enough, change resistor R311 from 39kOhm to 10kOhm (See also NSM-2 service bulletin 23).

Buzzer failure

Check mechanical condition of buzzer.

Check Vb 3.6V at B301.

Check Vb 3.6V pin 1 and Vbb 2.8V pin 2 of N310

Check buzzer signal at pin 6 of N310.

Check buzzer_cnt signal at pin 3 of N310. If not ok, there could be a break between D200 and N310, or MAD is faulty.

Vibra failure (only for 8210)

Check version of vibramotor, add support tape if necessary (see also NSM-3 service bulletin 11).

Check Vb 3.6V at V350.

Check Vb 3.6V pin 1 and Vbb 2.8V pin 2 of N310.

Check vibra signal at pin 16 of N310. If not ok, check vibra_cnt at pin 19 of N310.

If signal is ok at pin 19, change N310, else there is a break between D200 and N310, or MAD is faulty.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 31

CONFIDENTIAL 31 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

CLOCK TIME PROBLEMS

Clock time has to be corrected in short periods.

Check amplitude and frequency of sleepclock oscillator at J228 (3,2Vpp squarewave at 32.768kHz).

If amplitude or frequency is not ok, change crystal B100. If fault persists, check parts around B100 like R100/102/154

and C101/102/113.

Clock time is lost after removing battery

Check mechanical appearance of RTC-battery, especially the angles of the batterysprings.

If necessary bend them as shown in the first picture for the plus (short) spring and in the second for the minus (longer) spring

with help of tweezers. Also see NSM2 service bulletin 20.

The bending of the battery-spring should be always done, also with new batteries!

After changing the RTC-battery it is necessary to charge it. This can easily be done

by putting the battery on the phone for 10 to 15 minutes (It is not necessary to switch on the phone).After that,

RTC-battery should be able to save the clocktime.

If the fault still remains, it is probably necessary to change CCONT (N100) or CHAPS (N101).

Note that you have to run energy management calibration after changing CCONT!

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 32

CONFIDENTIAL 32 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

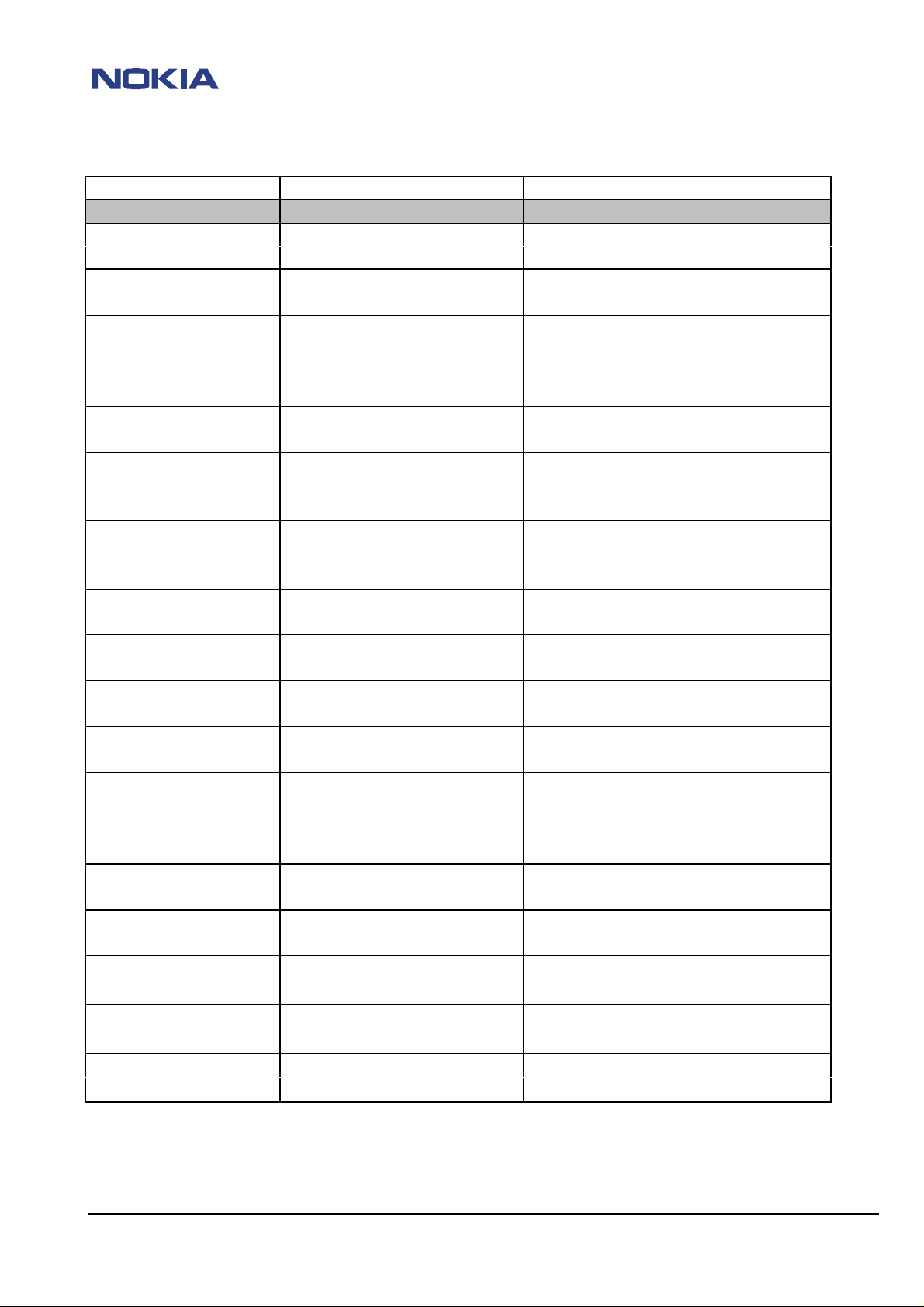

Product-Codes NSM - 2

06. Jul 00

Product-Code SIM-Lock Data Operator

0501899 APAC / BASIC TR

0502573 APAC - A

0502939 EURO - A

0502940 EURO-C

0503072 APAC-A

0503093 EURO-B

0503094

0503095

0503096

No SIM-Lock

MCC & MNC 00101

MSIN 0000000001

EURO-D

EURO-E

EURO-F

0503097 EURO-G

0503098 EURO-H

0503525 EURO-F

0503526 EURO-E

0503527 EURO-C ALS

0503528 EURO-D

0503529 APAC-B

0503530 APAC-C

0503595 APAC BOPOMOFO TR

0503596 APAC STROKE TR

0503597 APAC LATIN TR

0503612 APAC-C

Product-Codes NSM - 3 30. Aug 00

0502688 APAC / Basic TR

0502689 EURO - C

0503139 Basic TR "RED"

0503140 APAC STROKE

0503220 EURO - A

0503240 EURO - B

0503241

0503242

0503243

No SIM-Lock

MCC & MNC 00101

MSIN 0000000000

EURO - D

EURO - E

EURO - F

0503244 EURO - G

0503245 EURO - H

0503246 APAC - A

0503247 APAC - B / Blue

0503377 EURO - D / Russia

0503378 EURO - E / Hungary

0503379 EURO - F / Poland

0503380 EURO - I

0503381 EURO - C ALS

0503472 APAC Bopomofo

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 33

CONFIDENTIAL 33 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Product-Codes NSM - 3

Product-Code SIM-Lock Data Operator

0503473 APAC - A STROKE

0503474 APAC - C

0503475 APAC - C

0503491 Basic TR / APAC - B / STROKE Blue

0503974 EURO - C Network Monitoring

0504317 EURO - C Bouygues

0504415 Orange / Basic TR / Blue / Logo

0504416 Movistar / Basic TR / Grey / Logo

0504418 Basic TR "BLUE"

0504419 EURO - A Blue

0504422 EURO - D Blue

0504427 EURO - E Blue

0504428 EURO - F Blue

0504431 EURO - G Blue

0504432 EURO - H Blue

0504433

0504434

0504435

No SIM-Lock

MCC & MNC 00101

MSIN 0000000000

EURO - E Blue / Hungary

EURO - F Blue / Poland

EURO - C ALS Blue

0504436 EURO - C Blue

0504450 EURO - D Blue / Russia

0504451 EURO - B

0504573 Basic TR / TIM / Blue / Logo

0504578 EURO - C TIM

0504580 Basic TR / BLU / Blue / Logo

0504581 Basic TR / APAC / Bopomofo Blue

0504582 APAC - A

0504584 EURO - C / BLU

0504585 APAC - A STROKE Blue

0504586 Basic TR / Airtel / Grey / Logo

0504587 Basic TR / APAC-A / STROKE Blue

0504611 Basic TR / Amena / Grey / Logo

0504615 EURO - A / Amena

0504761 EURO - F / ERA Poland Blue

0504763 EURO - F / Centertel Poland

0504778 APAC - C Korea Blue

0504779 APAC - C NOKIA Blue

0504780 APAC - B Basic TR / Blue

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 34

CONFIDENTIAL 34 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

Product-Codes NSM - 3

Product-Code SIM-Lock Data Operator

0504339 MCC & MNC 20810 EURO - C

MSIN ?????????? SFR

0504344 MCC & MNC 26806 EURO - D

MSIN ?????????? TMN

0504369 MCC & MNC 20408 EURO - C

MSIN ?????????? KPN

0504372 MCC & MNC 23203 EURO - C

MSIN ?????????? Maxmobil

0504392 MCC & MNC 26801 EURO - D

MSIN ?????????? Telecel

0504417 MCC & MNC 21407 EURO - A

MCC & MNC 21402

MSIN ?????????? Movistar

0504437 MCC & MNC 23433 EURO - I

MCC & MNC 23486

MSIN ?????????? Orange

0504470 MCC & MNC 23201 EURO - C

MSIN ?????????? Mobilkom

0504504 MCC & MNC 26001 EURO - F

MSIN ?????????? Polcomtel

0504579 MCC & MNC 23205 EURO - C

MSIN ?????????? Connect

0504588 MCC & MNC 21401 EURO - A

MSIN ?????????? Airtel Club

0504591 MCC & MNC 23430 EURO - C

MSIN ?????????? One2One

0504760 MCC & MNC 26801 EURO - D

MSIN ?????????? Telecel ( Blue )

0504783 MCC & MNC 23205 EURO - C

MSIN ?????????? Connect ( Blue )

0504807 MCC & MNC 26806 EURO - D

MSIN ?????????? TMN ( Blue )

0505030 MCC & MNC 23203 EURO - C

MSIN ?????????? MaxMobil

0505161 MCC & MNC 23201 EURO - C

MSIN ?????????? Mobilkom

0505167 MCC & MNC 21403 EURO - A

MSIN ?????????? Amena Exclusivo

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 35

CONFIDENTIAL 35 (35)

NSM-2/3

Service & Analysis Center Europe Repairhints Version 2.0 Approved

SACE CC Training Group 2000-10-16

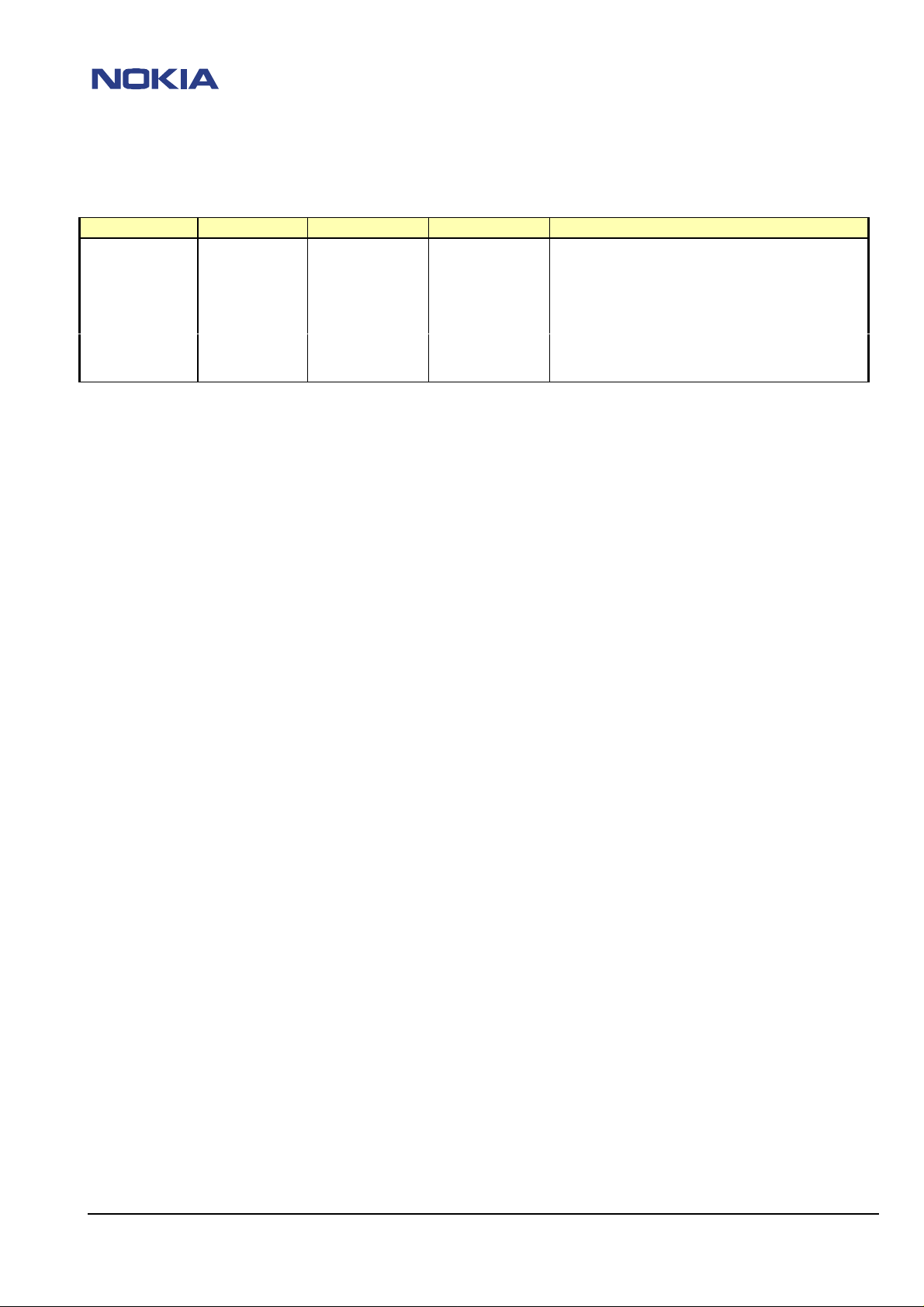

CHANGE HISTORY

Originator Status Version Date Comment

CC-TrainingGroup

CC-TrainingGroup

CC-TrainingGroup

CC-TrainingGroup

Draft 0.1 05.10.2000 First draft version for the repair group

Draft 0.3 09.10.2000 Comments of repairgroup added.

Approved 1.0 11.10.2000 First CC version.

Approved 2.0 16.10.2000 Frequency list added.

© 2000 NMP

Checked by:

CC Training Group

Approved by:

SACE

Loading...

Loading...