Page 1

Customer Care Solutions

Technical Documentation

6-Troubleshooting Instructions

Issue 1 11/2004 COMPANY CONFIDENTIAL 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 2

CCS Technical Documentation

RM-12

[This page intentionally blank]

2 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 3

Introduction to RM-12 troubleshooting .........................................................................2

General guidelines for RM-12 troubleshooting ............................................................. 2

Tools needed for troubleshooting ............................................................................... 2

General guidelines .......................................................................................................2

RF Troubleshooting ....................................................................................................... 3

Introduction to RF troubleshooting .............................................................................3

RF Key component placement ....................................................................................4

RF Measurement points .............................................................................................. 5

EGSM900, GSM1800 & GSM1900 Transmitter .......................................................... 6

General instructions for Tx troubleshooting ...............................................................6

Additional information for EDGE troubleshooting ..................................................12

EGSM900, GSM1800 and GSM1900 Receiver .......................................................... 21

General instructions for Rx troubleshooting ............................................................. 21

Synthesizer .................................................................................................................. 28

General instructions for synthesizer troubleshooting ................................................ 28

Baseband troubleshooting ........................................................................................... 33

Partially damaged device ..........................................................................................33

Most common symptoms reported by customer .......................................................33

Dead or jammed device troubleshooting .................................................................. 35

ASIC is changed ........................................................................................................ 40

Test points .................................................................................................................40

Selftests / “Contact service” on display ....................................................................40

Flashing troubleshooting ........................................................................................... 44

Power troubleshooting .............................................................................................. 47

Audio troubleshooting ............................................................................................... 53

Display troubleshooting ............................................................................................60

Pixel defects ..............................................................................................................65

Backlight troubleshooting (1) ................................................................................... 67

Backlight troubleshooting (2) ................................................................................... 68

Backlight troubleshooting (3) ................................................................................... 69

Hall sensor troubleshooting ......................................................................................70

Keyboard troubleshooting ......................................................................................... 71

Camera Module Troubleshooting ............................................................................. 72

Camera construction .................................................................................................79

Camera fault finding diagrams .................................................................................. 86

FM Radio troubleshooting ........................................................................................ 89

USB Problems (1) .....................................................................................................93

USB Problems (2) .....................................................................................................94

BC3 Bluetooth Troubleshooting ............................................................................... 95

MMC Troubleshooting (1) ........................................................................................ 99

MMC Troubleshooting (2) ...................................................................................... 100

Accessory troubleshooting ...................................................................................... 101

SIM troubleshooting ...............................................................................................102

Vibra Troubleshooting ............................................................................................106

Clocks and Reset troubleshooting ........................................................................... 107

Page 4

RM-12

CCS Technical Documentation

Introduction to RM-12 troubleshooting

This document is intended to be a guide for localising and repairing electrical faults in the RM12 device. First there is a brief guide for fault localising. Then fault repairing is divided into troubleshooting paths.

Before any service operation you must be familiar with the RM-12 product and module level

architecture. You have to also be familiar with the RM-12 specified service tools such as the

Phoenix service software, flashing tools and software.

General guidelines for RM-12 troubleshooting

Tools needed for troubleshooting

• Service tools (as listed at service tools chapter in service manual)

• Laboratory power supply with current indicator

• Oscilloscope

• Digital multimeter etc. normal equipments

General guidelines

If the device cannot be turned on by any means, see “Dead device” troubleshooting.

Current consumption (missing consumption) gives an idea whether the device is able to start

up.

Dropping supply voltage or very large current consumption indicates a short circuit.

Check whether the connection with Phoenix works and what can be discovered with Phoenix

(ADC-readings, baseband selftest, bb-calibrations etc.).

Check display, keyboard and rocker faults visually.

Force phone to LOCAL mode and make keyboard test by Phoenix.

NOTE! If liquid damage, stop repairing.

Flash phone before disassembling it if fault is not obvious and Phoenix connection is OK.

Continue with specific troubleshooting procedure for the current fault.

If flashing does not work go to “Flashing” troubleshooting.

Due to CSP packages short circuits or broken solder joints are not easily seen. If the examined

signal seems to be continuously in low or high level, then measure for possible short circuit to

ground (signal low) or to supply voltage (signal high). Note that if a problem is not found from

any visible contact/component, it can be under CSPs where the signal is connected.

Care must be taken when assembling and disassembling the transceiver. Failure to do this may

result in unnecessary damage to the device.

NOTE! If an ASIC is changed, see “ASIC Changed” troubleshooting flow chart.

Issue 1 11/2004 COMPANY CONFIDENTIAL 2

Copyright © 2004 Nokia. All Rights Reserved.

Page 5

RM-12

CCS Technical Documentation

RF Troubleshooting

Introduction to RF troubleshooting

Measurements should be done using Spectrum analyzer with high-frequency high-impedance

passive probe (LO-/reference frequencies and RF power levels) and Oscilloscope with a 10:1

probe (DC-voltages and low frequency signals).

The RF-section is build around one RF-ASIC (HELGO N7300). For easier troubleshooting, this

RF troubleshooting document is divided into sections.

Before changing HELGO, please check the following things: supply voltages are OK and serial

communication coming from baseband to HELGO.

Please note that the grounding of the PA module is directly below PA-module so it is difficult to

check or change. Most RF semiconductors are static discharge sensitive! So ESD protection must be taken care of during repair (ground straps and ESD soldering irons). HELGO and

PA are moisture sensitive so parts must be pre-baked prior to soldering.

Apart from key components described in this document, here are a lot of discrete components

(resistors, inductors and capacitors) the troubleshooting of which is done by checking if sold ering of the component is done properly (for factory repairs checking if it is missing from PWB).

Capacitor can be checked for shortening and resistors for value by means of an ohmmeter, but

be aware that in-circuit measurements should be evaluated carefully.

Please be also aware that all measured voltages or RF levels in this document are rough figures. Especially RF levels vary due to different measuring equipment or different grounding of

the used probe. When using RF probe, usually a good way is to use metallic tweezers to connect probe ground to PWB ground as close to measurement point as possible.

Note! If the measurement values of RM-12 are as mentioned in this RF troubleshooting guide, but

there are still difficulties making calls with the device, then check the antenna contacts in PWB.

3 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 6

RM-12

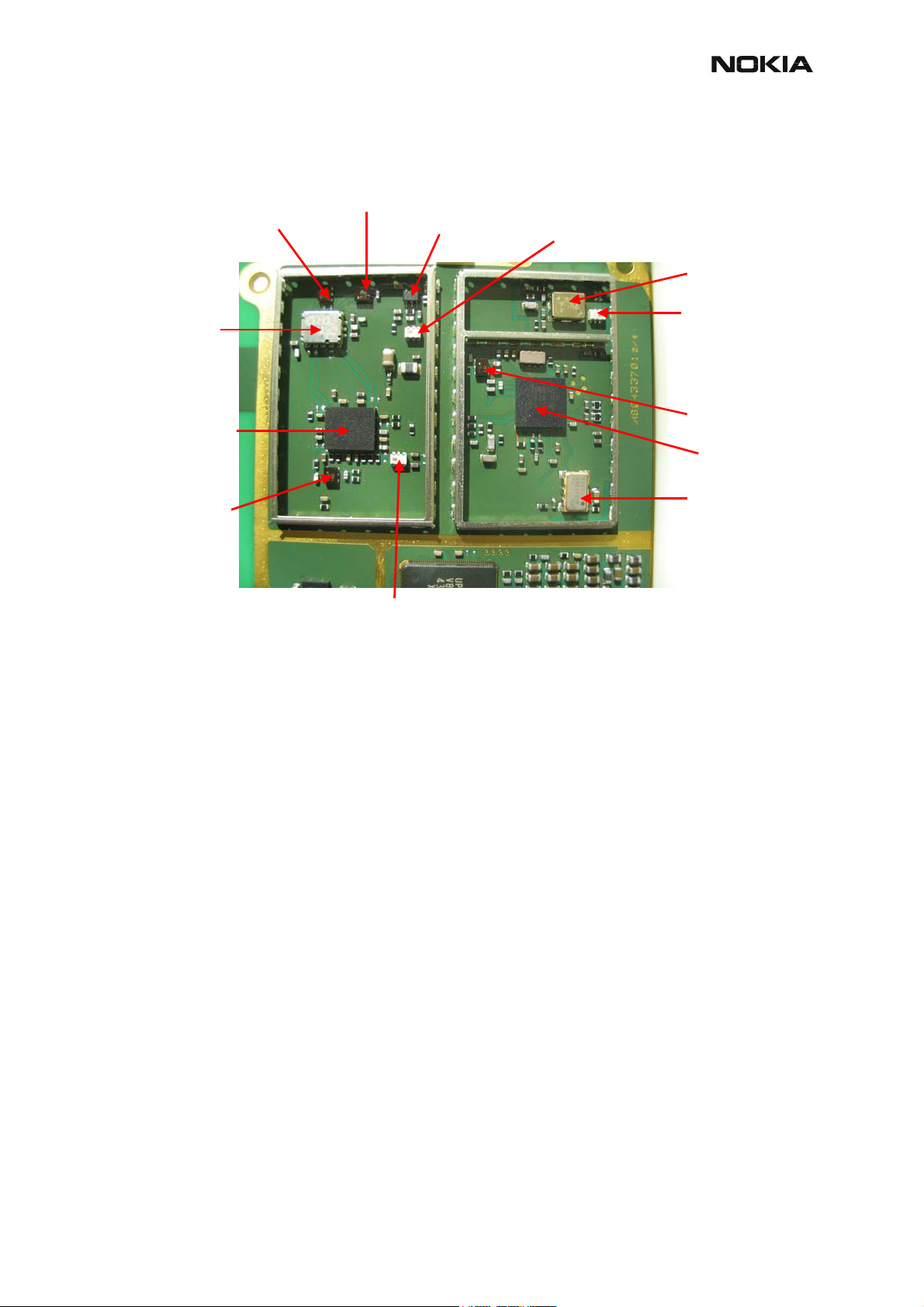

RF Key component placement

1900 RX SAW

900 RX SAW

CCS Technical Documentation

1900 LNA 1900 RX balun

4GHz VCO

Antenna

Switch Module

Power Amplifier

900 TX SAW

VCO balun

1800 RX SAW

Helgo86

RF ASIC

26 MHz VCTCXO

1800/1900 TX balun

Figure 1: Component placement 1

Issue 1 11/2004 COMPANY CONFIDENTIAL 4

Copyright © 2004 Nokia. All Rights Reserved.

Page 7

CCS Technical Documentation

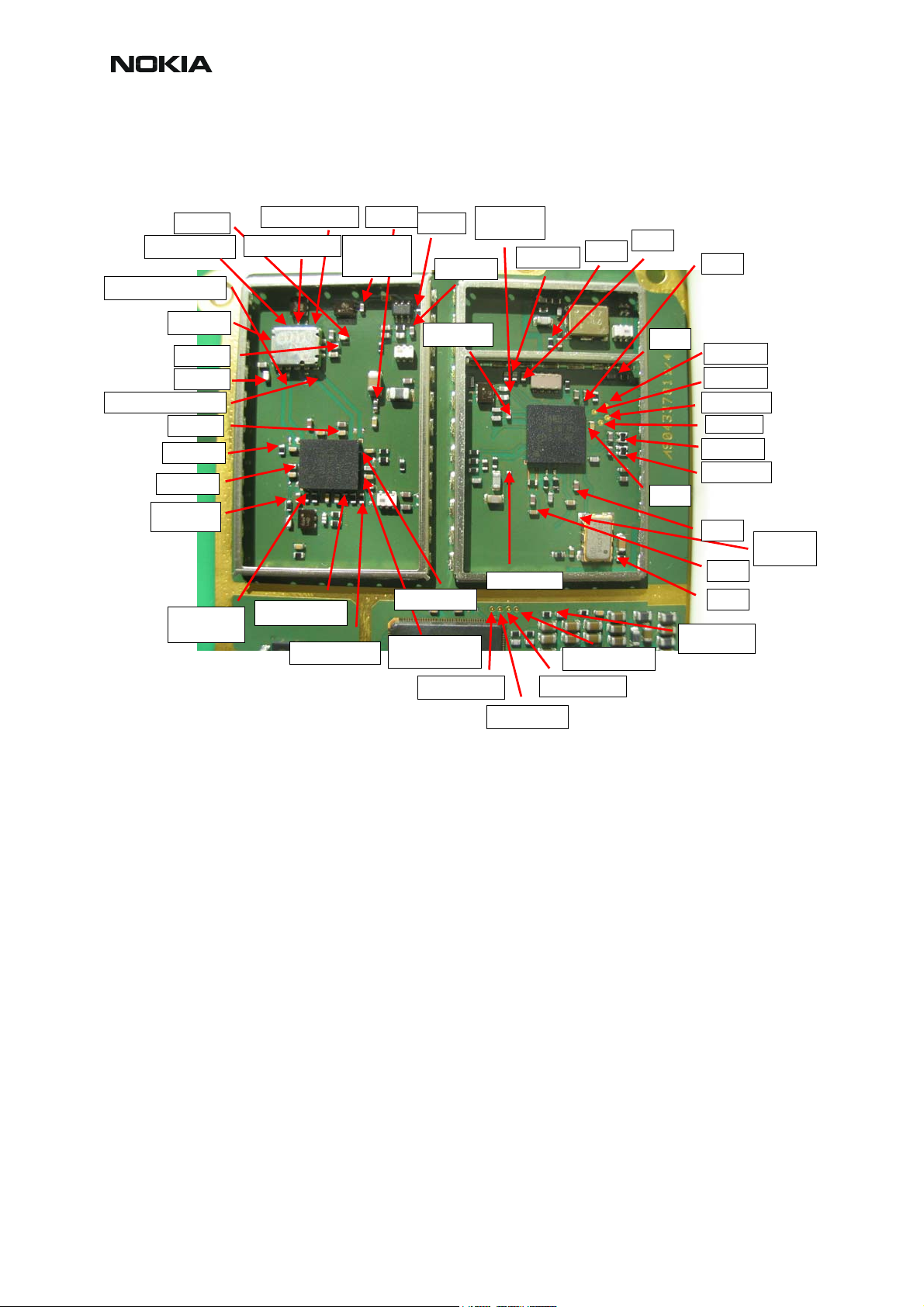

RF Measurement points

RM-12

VANT_3

ASM_in_900TX

To antenna

VANT_2

VANT_1

ASM_in_1800/1900TX

Mode

Iref_900

VTXB_900

PA_in_900

VPCTRL_900

ASM_out_1900RX

ASM_out_1800RXASM_out_900RX

VPCTRL_1800/1900

PA_in_1800/1900

VBAT

RX_1900_saw

_out

LNA_P

1900_RX_In

Iref_1800_1900

VTXB

_1800_1900

LNA_VCC

1800_RX_In

VPECTRL3(ALC)

900_RX_In

VR7

RFBusEna1/J7306

VR4

TXC

VR5

VR6

RXQ/J7303

RXI/J7302

TXP/J7300

TXA/J7301

TXQP/QN

TXIN/TXIP

VR1

VR2

VR3

26MHz to BB

VCTCXO

26Mhz out

RFBusReset/J7307 RFBusData/J7304

RFBusClk/J7305

Figure 2: Measurement points

5 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 8

RM-12

CCS Technical Documentation

EGSM900, GSM1800 & GSM1900 Transmitter

General instructions for Tx troubleshooting

Kindly refer to the Service Software Section, Service Concept diagram.

Connect test jig to computer with DAU-9S cable or to FPS-8 Flash Prommer with XCS-4 mod-

ular cable.

Make sure that you have PKD-1 dongle connected to computer’s parallel port.

Connect DC power supply to module test jig with FLC-2 cable.

NOTE! When repairing or tuning transmitter use external DC supply with at least 3A current capability. Set the DC supply voltage to 4.2V.

Connect an RF-cable to the module test jig (MJ-32) RF connector and to measurement equipment or at least a 10dB attenuator, otherwise the PA may be damaged. Normally a spectrum

analyzer is used as measurement equipment.

NOTE! Normally Spectrum analyzer maximum input power is +30dBm. It is recommended to use

10dB attenuator on Spectrum analyzer input to prevent damage.

Set the phone module to test jig and start Phoenix service sofware.

Initialize connection to phone. (Use FBUS driver when using DAU9S, COMBOX driver when

using FPS-8.)

Select product from the menu:

File -> Choose product -> RM-12

From toolbar, set operating mode to "Local"

Activate RF controls window from the menu:

Testing -> RF Controls

From the RF controls window:

• Select band "GSM900" or "GSM 1800" or "GSM1900" (Default = "GSM900")

• Set Active unit to "Tx" (Default = "Rx")

• Set Operation mode to "Burst" (Default = "Burst")

• Set Tx data type to "Random" (Default = "All1")

• Set Rx/Tx channel to 37 on GSM900 band or 700 on GSM1800 band or 661 on

GSM1900 (Defaults)

• Set Tx PA mode to "Free" (Default)

• Set power level to 5 (Default = 19) on GSM900 or to 0 (Default = 15) on

GSM1800 or GSM1900

Issue 1 11/2004 COMPANY CONFIDENTIAL 6

Copyright © 2004 Nokia. All Rights Reserved.

Page 9

CCS Technical Documentation

g

g

p

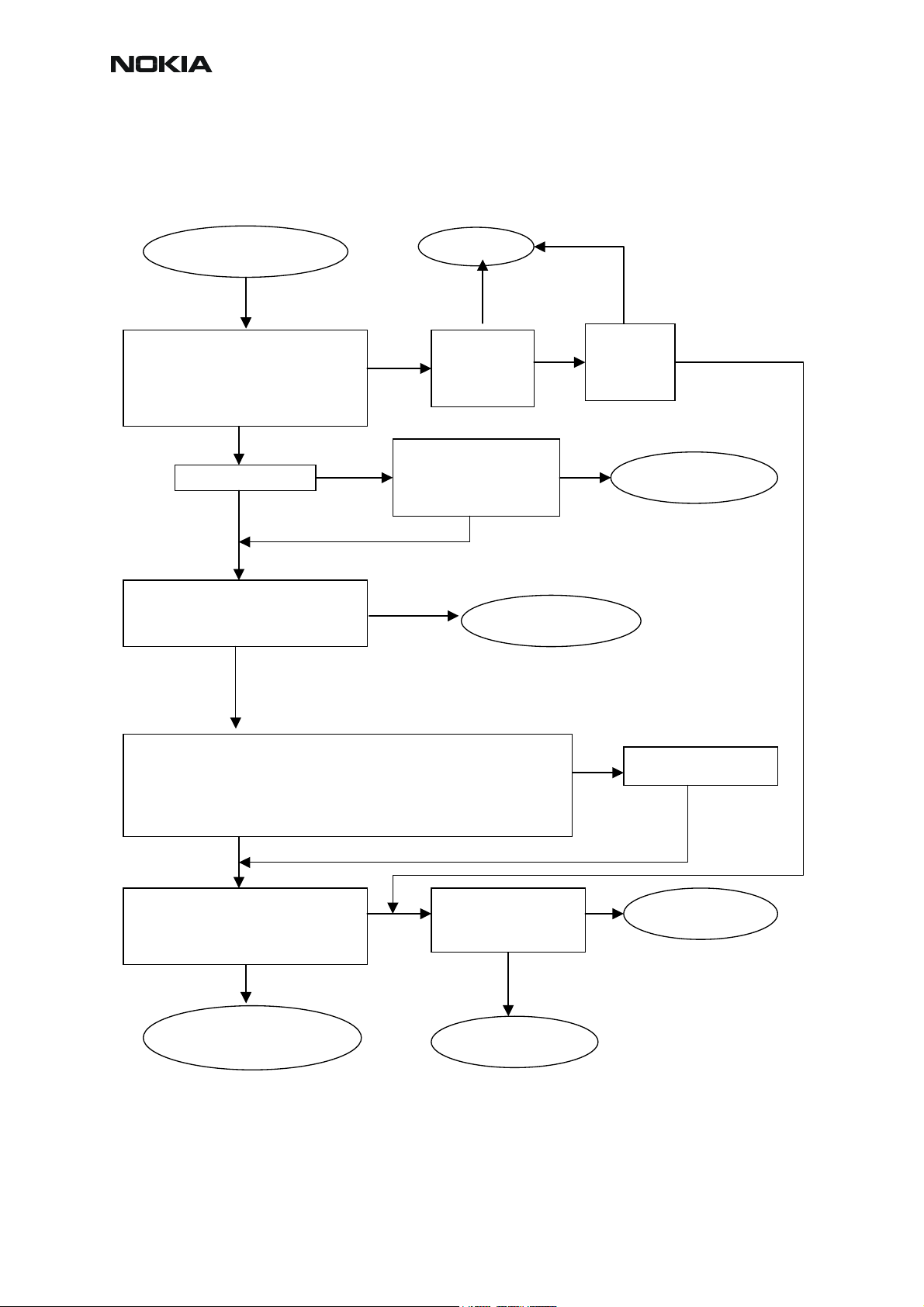

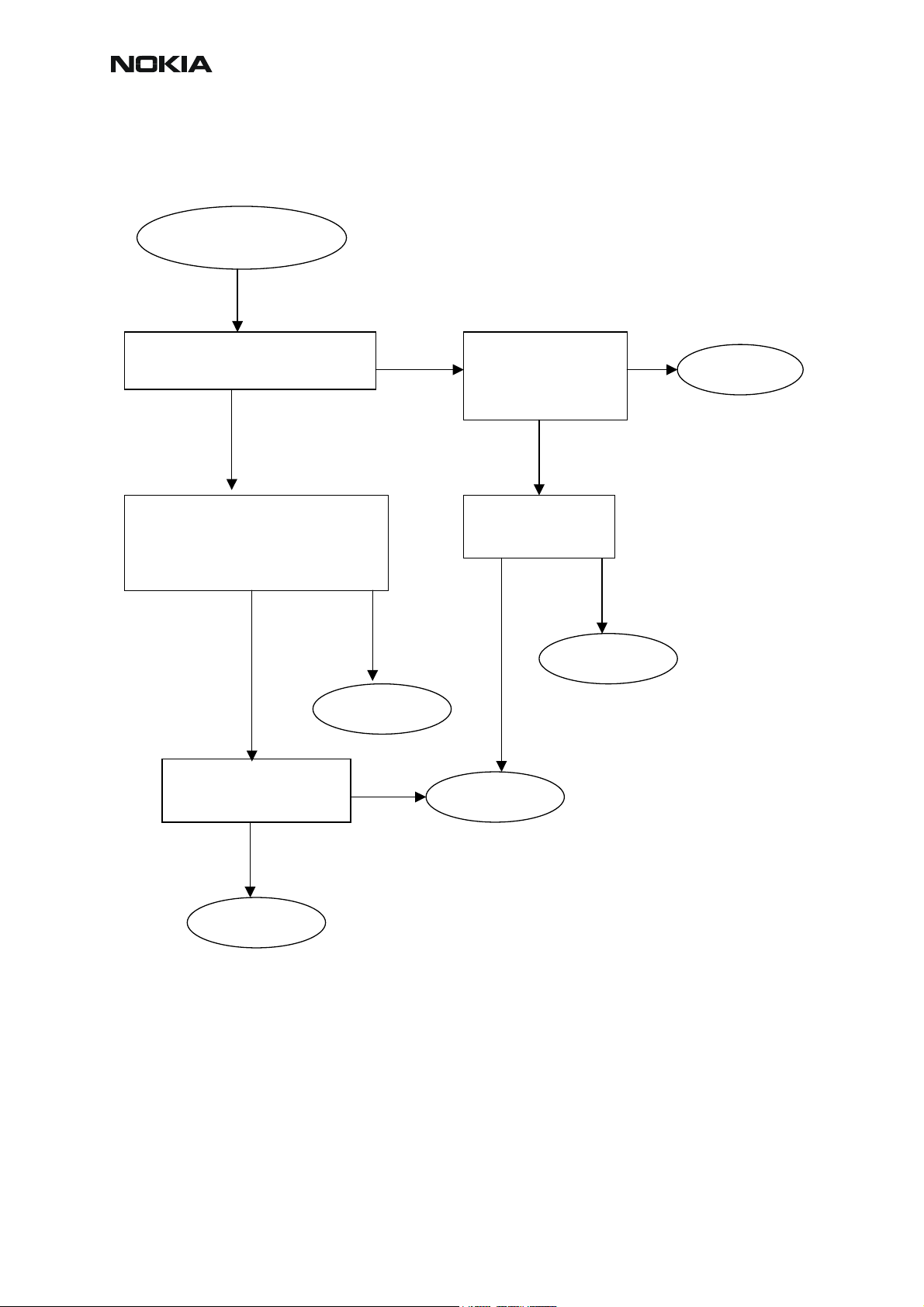

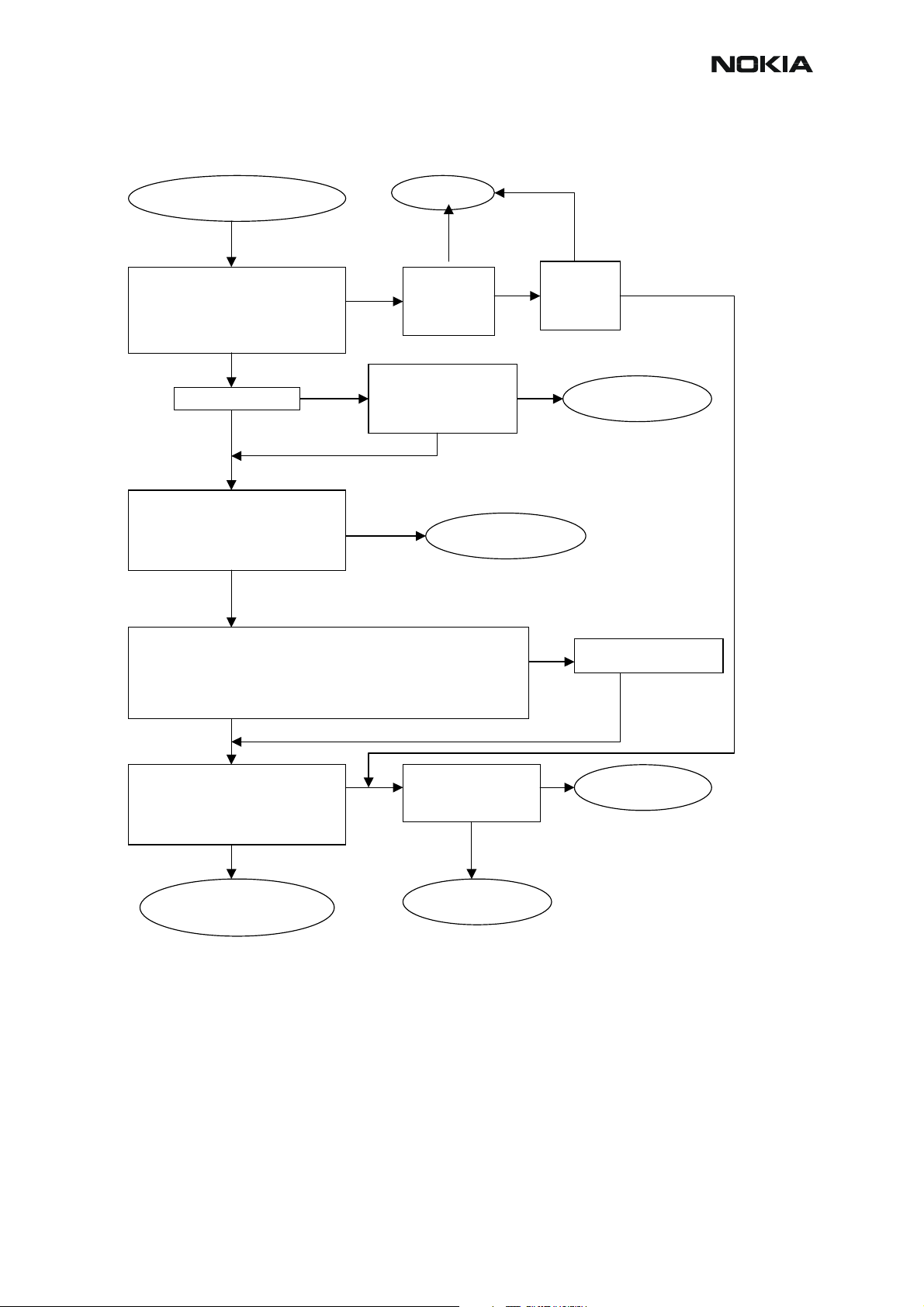

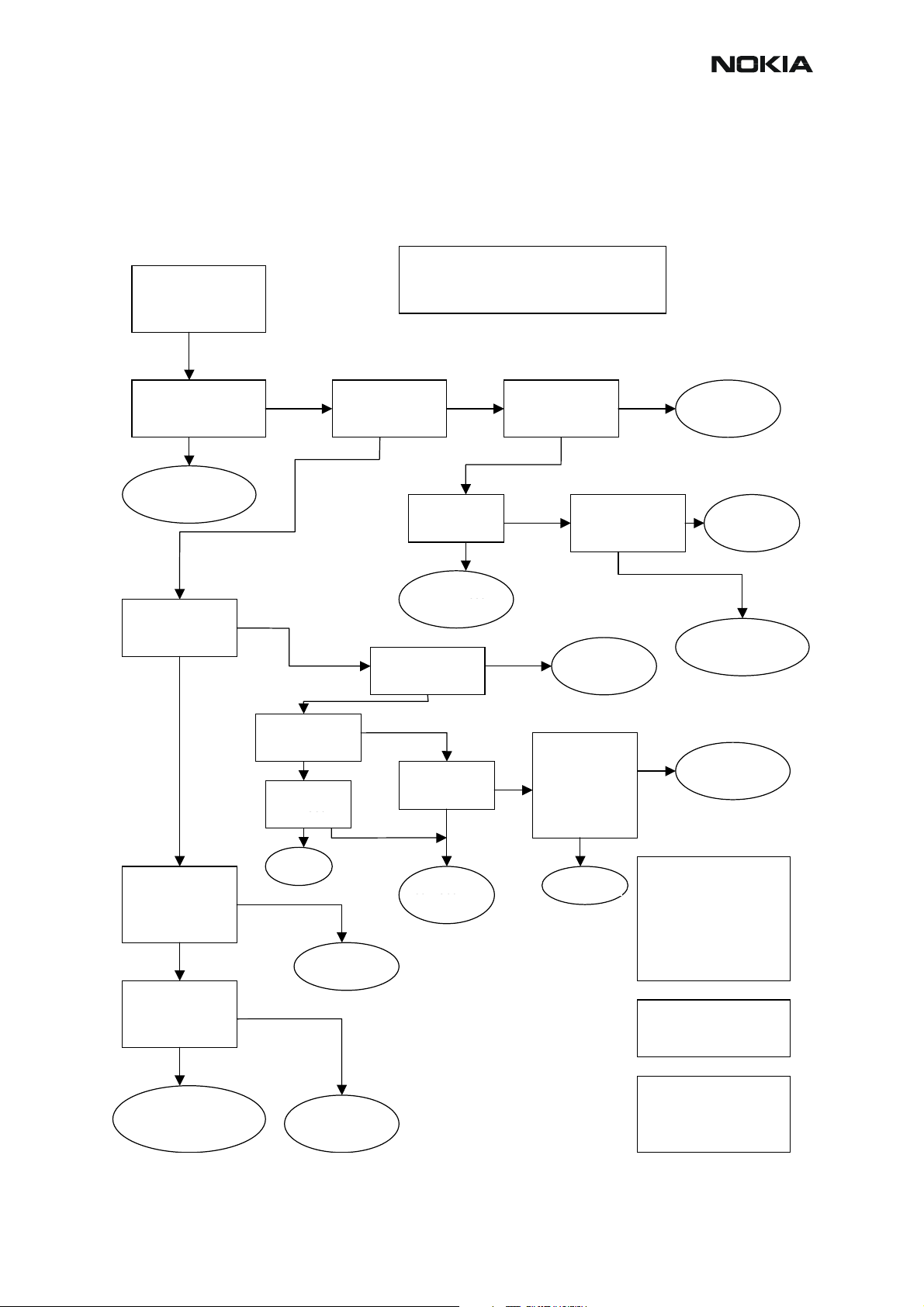

Transmitter troubleshooting diagrams

Yes

Yes No

Check output signal level:

+32…+33dBm@897.4MHz(GSM900)

+29…+30dBm@1747.8 and 1880MHz

(GSM1800&1900)

OK?

No

No Yes

Yes No

Check with RF probe signal level on

PA input: ~ -1…+5dBm

OK?

No

Yes

Start TX power level tuning and check tuned coefficient values:

Highest level ~0.655…0.831(GSM900); ~0.567…0.782(GSM1800&1900)

Yes

Lowest level ~0.166…0.196(GSM900); ~0.176…0 .225(GSM1800&1900)

Base level ~0.137…0.166(GSM900); ~0.132…0.161(GSM1800&1900)

Major differences?

No

Check control voltage with

Yes

oscilloscope:

PA Ctrl voltage >1.5V peak

No

OK?

Yes No

TX Troubleshooting

TX signal found?

PA & Antenna Switch

troubleshooting

Figure 3: Transmitter troubleshooting

TX OK

Check

all power

levels,

OK?

Check output signal

on 500MHz span

Signal found on incorrect

frequency?

Helgo

troubleshootin

Yes

Check control loop

components

OK?

Replace faulty

com

onents

Tune

TX power

levels,

OK?

Yes

No

Synthesizer

troubleshootin

Tune TX coefficient

values

Replace Helgo

RM-12

7 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 10

RM-12

CCS Technical Documentation

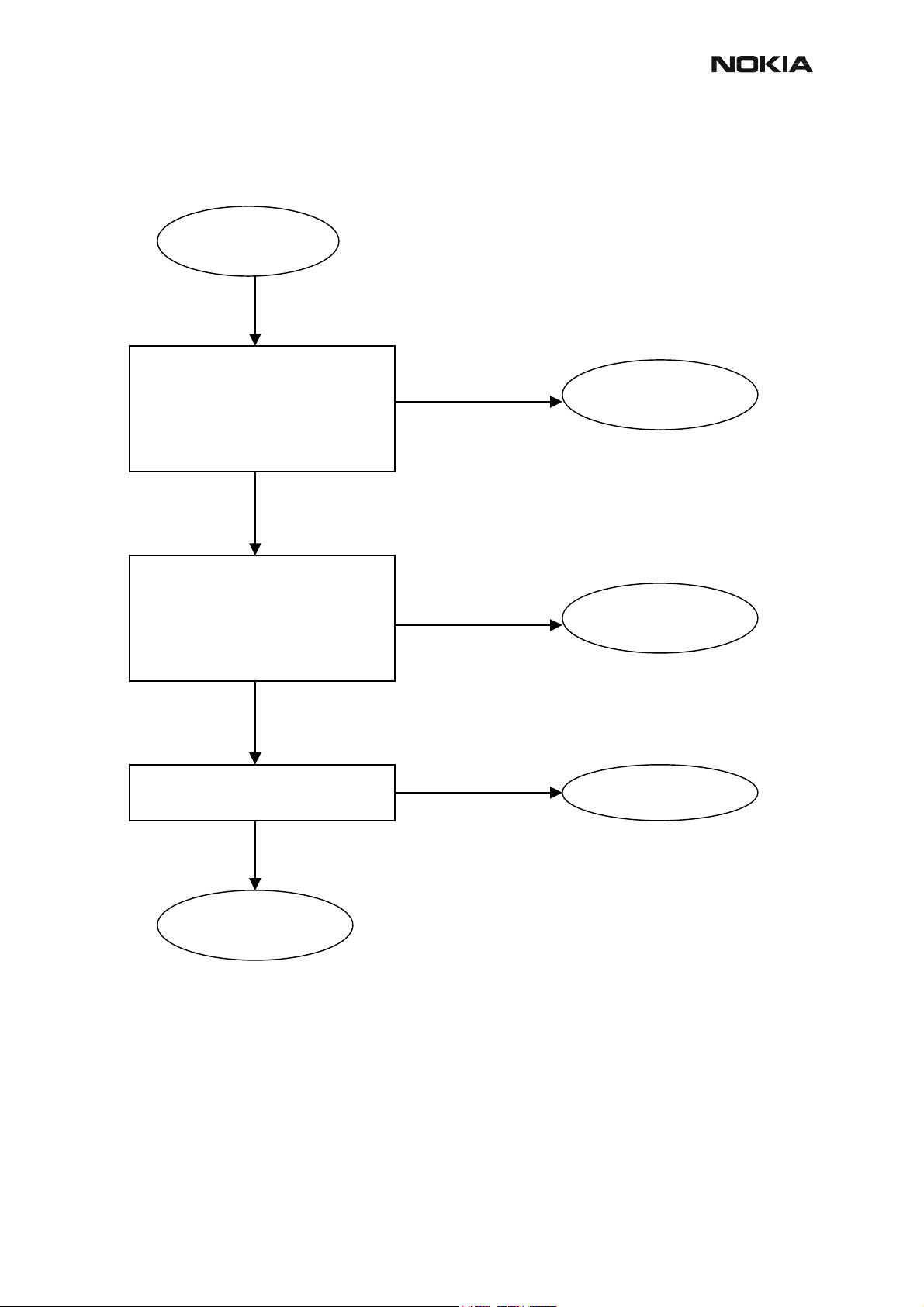

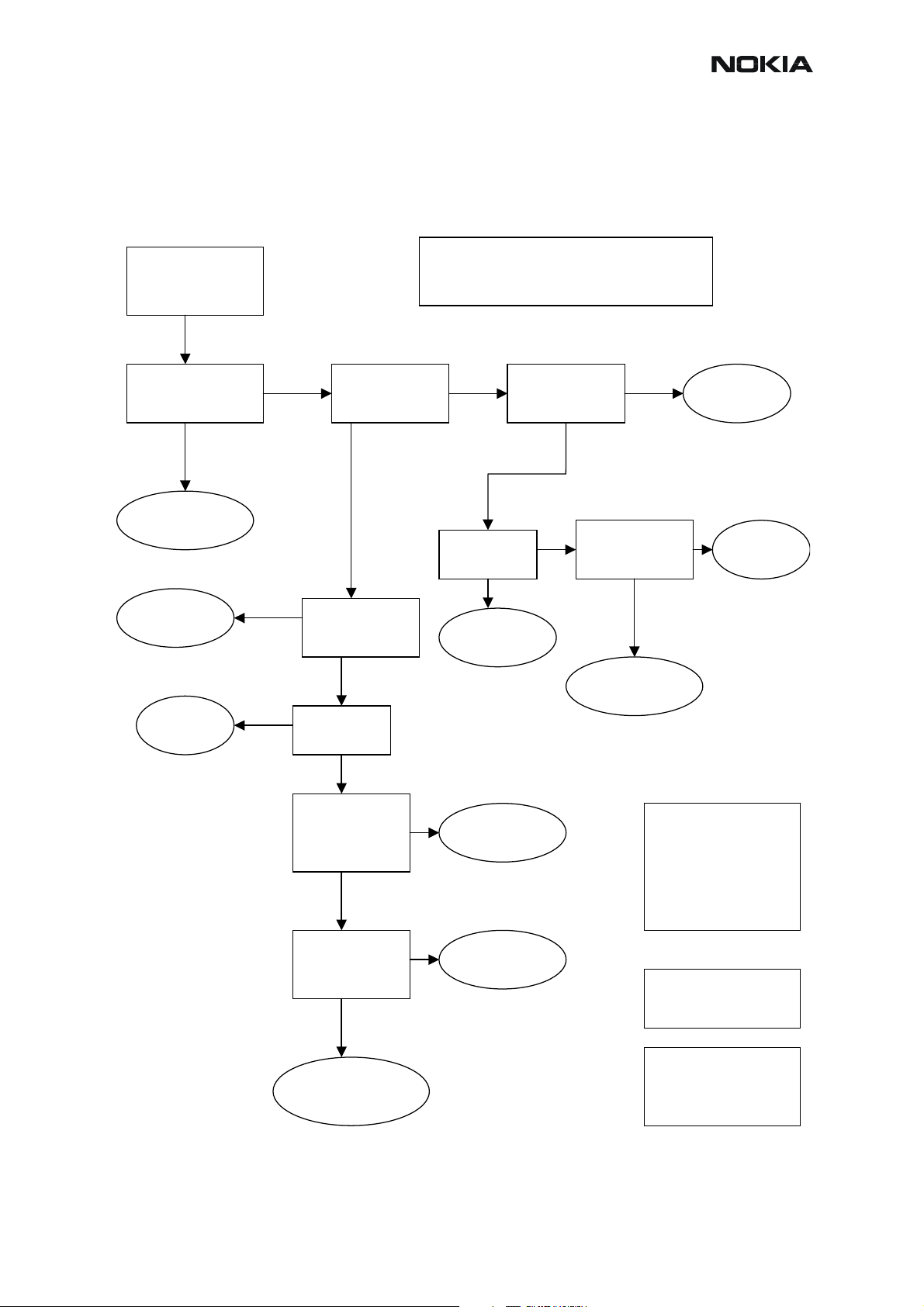

Figure 4: HELGO IC troubleshooting

Check with oscilloscope:

-TXI/TXQ signals

No

-VR1, VR2, VR4, VR5, VR6 =2.8V

-VrefRF01 = 1.35V

-Helgo serial interface

-TXP & TXC signals

OK?

Yes

Check with RF probe:

4G VCO signal output:

No

-3589.6MHz (GSM900)

-3495.6MHz (GSM1800)

-3760MHz (GSM1900)

Level > - 10dBm

OK?

Yes

Yes

Check modulator output components

OK?

No

HELGO IC

troubleshooting

Replace faulty

component(s)

Baseband

troubleshooting

Synthesizer

troubleshooting

Replace HELGO

Issue 1 11/2004 COMPANY CONFIDENTIAL 8

Copyright © 2004 Nokia. All Rights Reserved.

Page 11

CCS Technical Documentation

p

)

p

RM-12

Check with RF probe signal level on PA

Yes Yes

input ~ -1…+5 dBm

OK?

Yes No

Check with oscilloscope:

-VBATT ~4V

-VTXB = 2.8V pulsed

-VPCTRL_900/1800/1900

OK?

Yes

Yes

PA & Antenna Switch

troubleshooting

No

Check component s

around PA

OK?

No

Replace faulty

onent(s)

com

Figure 5: PA and Antenna Switch troubleshooting

Check with oscilloscope:

-VANT1 (GSM900)

-VANT2 (GSM1800)

-VANT3 (GSM1900)

OK?

Check VANT line

components

OK?

Yes No

Replace faulty

onent(s

com

Replace PA

Replace

HELGO

Replace ant.

switch

9 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 12

RM-12

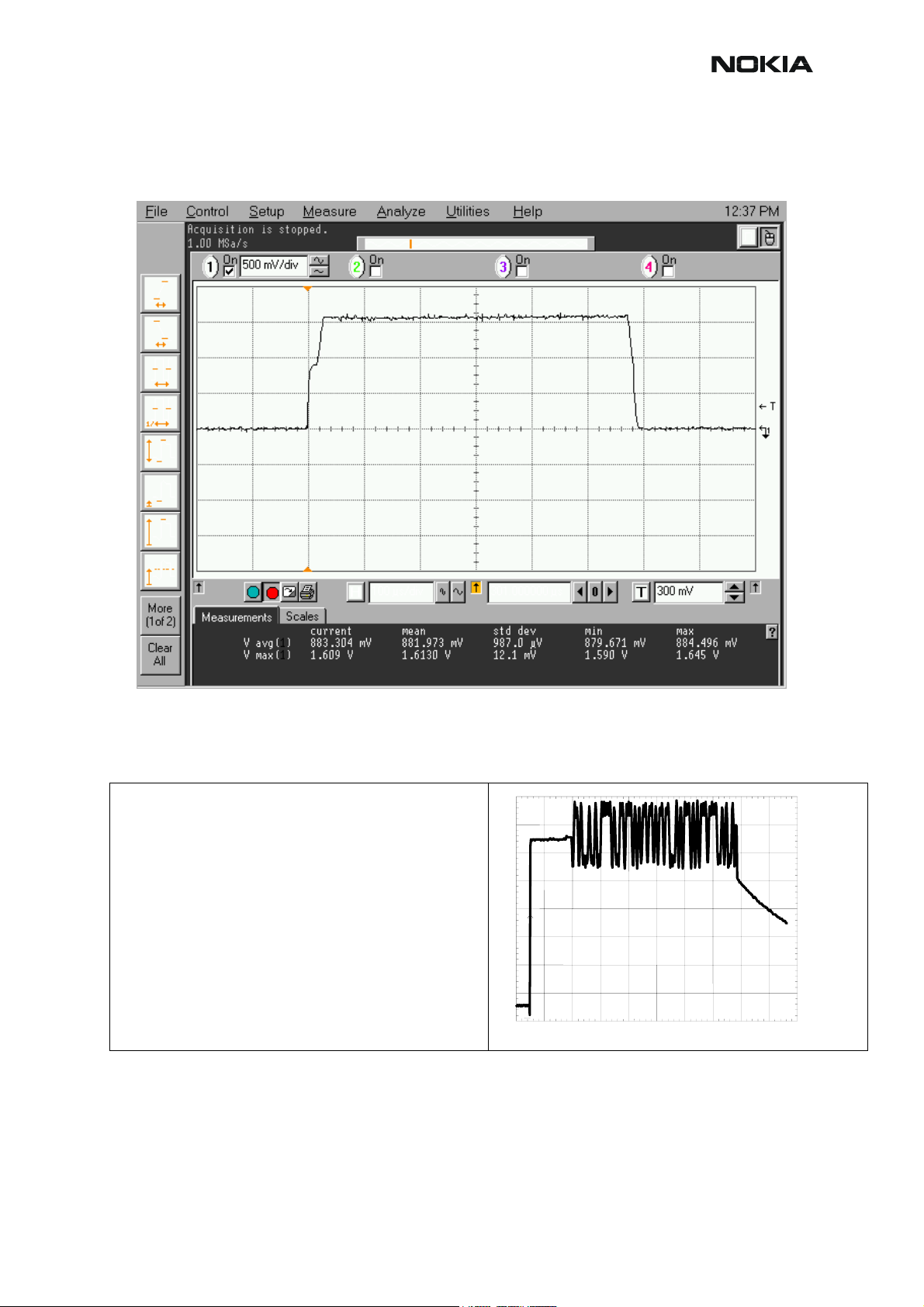

Pictures of transmitter signals

CCS Technical Documentation

Figure 6: Transmitter signals, VPCTRL

VPCTRL900 power level high at R7003

VPCTRL1800/1900 power level high at R7007

Figure 7: Transmitter signals

200mV/div

TX I/Q at R7304/7305 power level high Random data

100us/div

Issue 1 11/2004 COMPANY CONFIDENTIAL 10

Copyright © 2004 Nokia. All Rights Reserved.

Page 13

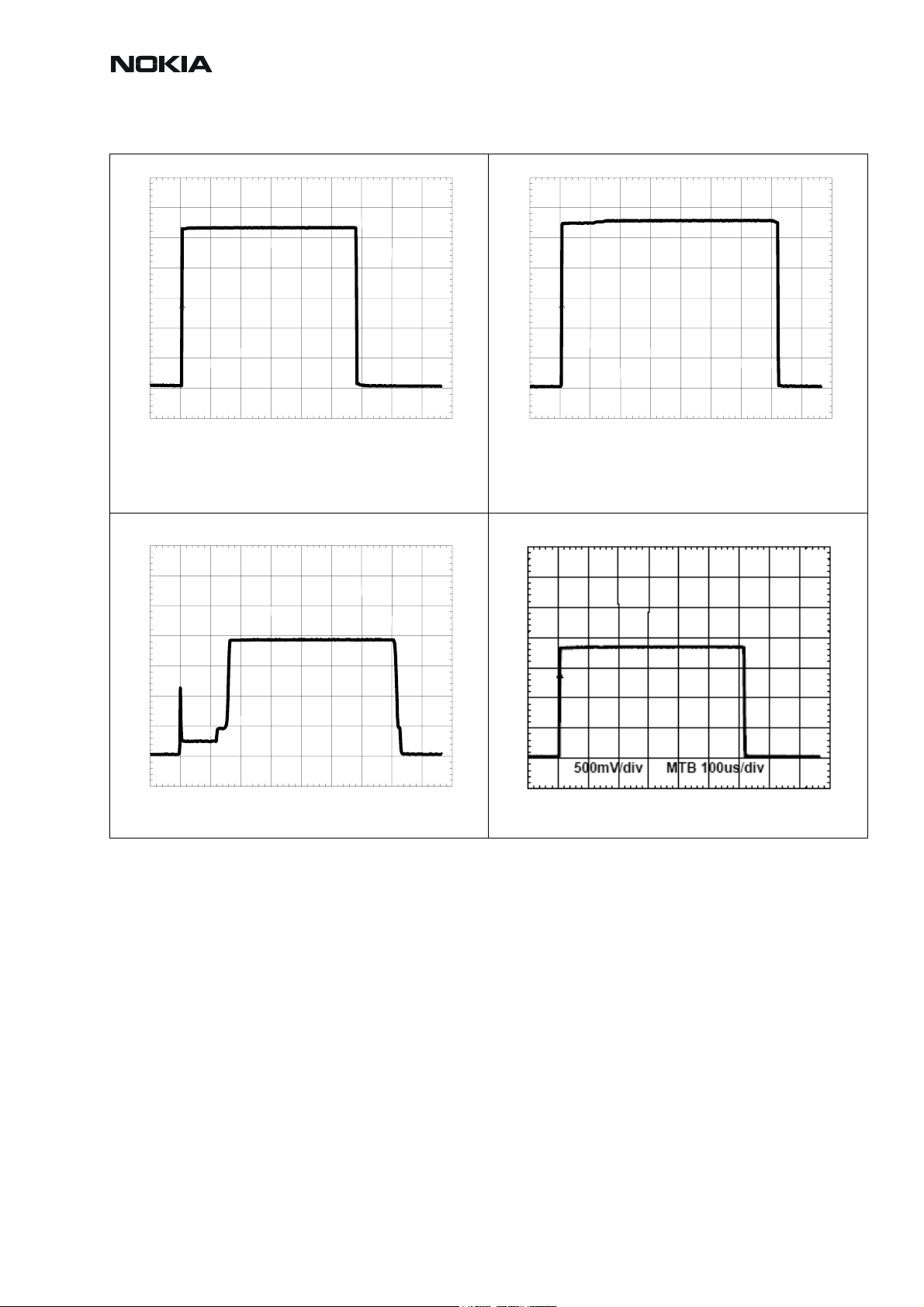

CCS Technical Documentation

RM-12

500mV/div 100us/div

VANT_1 / GSM900 TX at C7100

VANT_2 / GSM1800 TX at C7102

VANT_3 / GSM1900 TX at C7101 OV

(no signal/ Flatline on Oscilloscope screen)

500mV/div 100us/div

TXC at R7303

1

VTXB_900 at C7013

VTXB_1800_1900 at C7014

500mV/div 100us/div

TXP at J7300

11 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 14

RM-12

m

A

CCS Technical Documentation

Figure 8: Tx out signal, 900 band, burst mode, channel 37

Ref Lvl

Ref Lvl

34 dBm

34 dBm

34

21 dB Offset

30

20

10

0

-10

-20

-30

-40

-50

Marker 1 [T1]

28.46 dBm

897.38997996 MHz

RBW 100 kHz

VBW 100 kHz

SWT 2 s

1

RF Att 40 dB

Unit dB

A

1M

-60

-66

Center 897.4 MHz Span 2 MHz200 kHz/

Date: 28.APR.2003 15:09:42

Additional information for EDGE troubleshooting

EDGE mode troubleshooting differs slightly from basic GSM troubleshooting

Establish connection to the phone normally (see GSM900/1800/1900 troubleshooting instructions).

Select product from the menu:

File -> Choose Product -> RM-12

From toolbar, set operating mode to “Local”

Activate RF controls window from the menu:

Testing -> RF Controls

From the RF controls window:

• Select Band “GSM900” or “GSM1800” or “GSM1900”

(Default=”GSM900”)

Issue 1 11/2004 COMPANY CONFIDENTIAL 12

Copyright © 2004 Nokia. All Rights Reserved.

Page 15

CCS Technical Documentation

• Set Active unit to “Tx” (Default=”Rx”)

• Set Edge “On” (Default=”Off”)

• Set Operation mode to “Burst” (Default=”Burst”)

• Set Tx data type to “Alternate PN9” (Default=”All1”)

• Set Rx/Tx channel to 37 on GSM900 or 700 on GSM1800 or 661 on

GSM1900 (Defaults)

• Set power level to 8 (Default = 19) on GSM900 or to 2 (Default = 15) on

GSM1800 or GSM1900

NOTE! For GSM900, Edge power levels 5, 6 and 7 are not in use, and for GSM1800&1900, Edge

power levels 0 and 1 are not in use.

RM-12

13 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 16

RM-12

g

g

p

CCS Technical Documentation

Figure 9: Transmitter EDGE troubleshooting

TX EDGE Troubleshooting

Yes

Yes No

Check output signal level:

+24…+30dBm@897.4MHz(GSM900)

+22…+29dBm@1747.8 and 1880MHz

(GSM1800&1900)

OK?

No

No Yes

Yes No

No

Yes

Yes

No

Yes

No

Yes No

TX signal found?

Check with RF probe signal level on

PA input:

~-8dBm@PCL=8 (GSM900)

~-10dBm@PCL=2 (GSM1800&1900)

OK?

Start TX Edge power level tuning and check tuned coefficient values:

Highest level ~0.684…0.841(GSM900); ~0.763…0.860(GSM1800&190 0)

Lowest level ~0.333…0. 420(GSM900); ~0.323…0. 362(GSM1800&1900)

Base level ~0.273…0.313(GSM900); ~0.244…0.313(GSM1800&1900)

Major differences?

Check control voltages with

oscilloscope:

Pa Iref ~2V peak (GSM900)

Pa Iref ~2.1V peak (GSM1800@1900)

Mode ~1.8V OK?

PA & ant switch

EDGE troubleshooting

Yes

TX OK

Check

all power

levels,

OK?

Check output signal

on 500MHz span

Signal found on incorrect

frequency?

Helgo EDGE

troubleshootin

Check EDGE control

loop components

OK?

Replace faulty

com

onents

Yes

Tune

TX power

levels,

OK?

Synthesizer

troubleshootin

Tune TX coefficient

values

No

Replace Helgo

Issue 1 11/2004 COMPANY CONFIDENTIAL 14

Copyright © 2004 Nokia. All Rights Reserved.

Page 17

CCS Technical Documentation

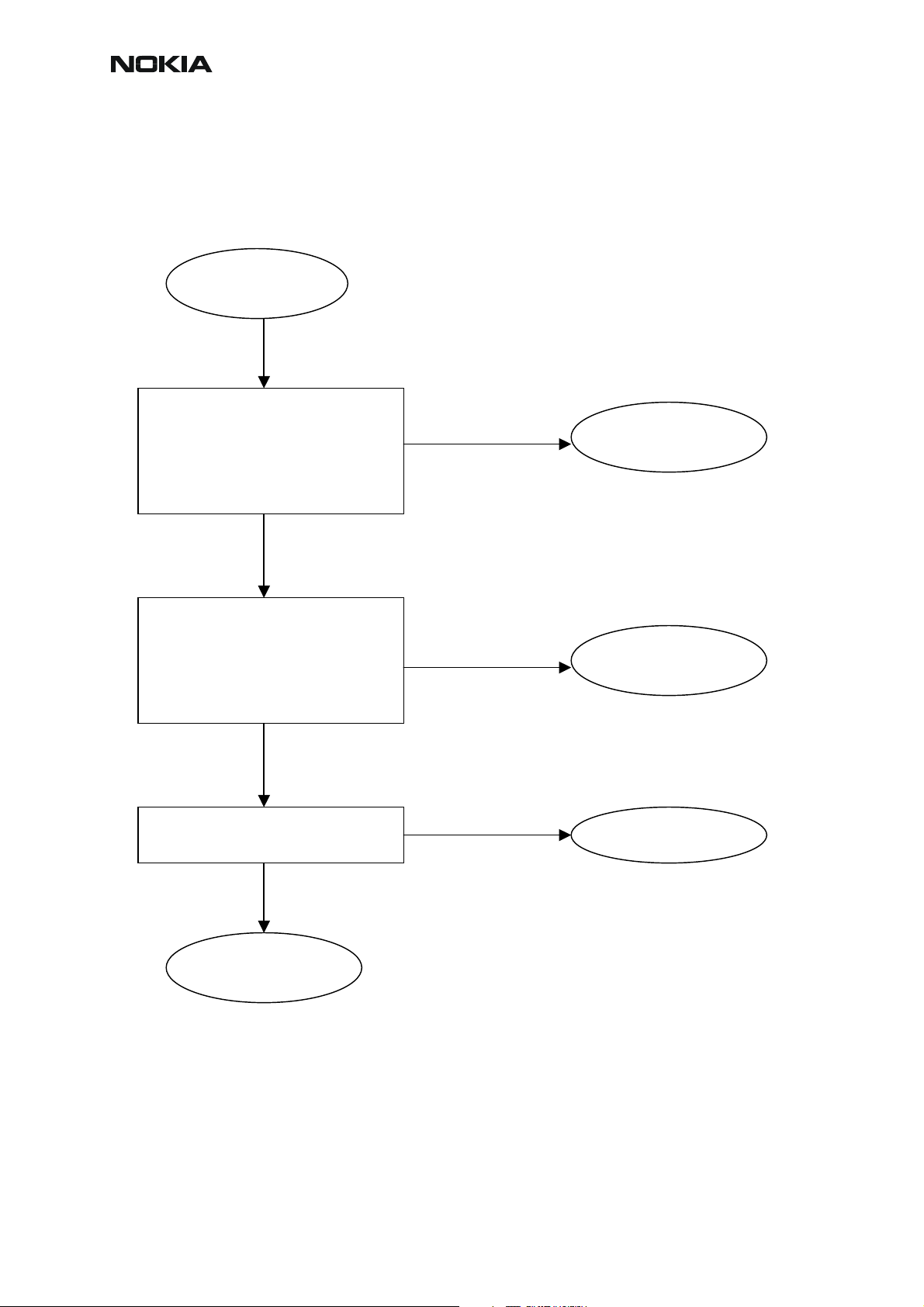

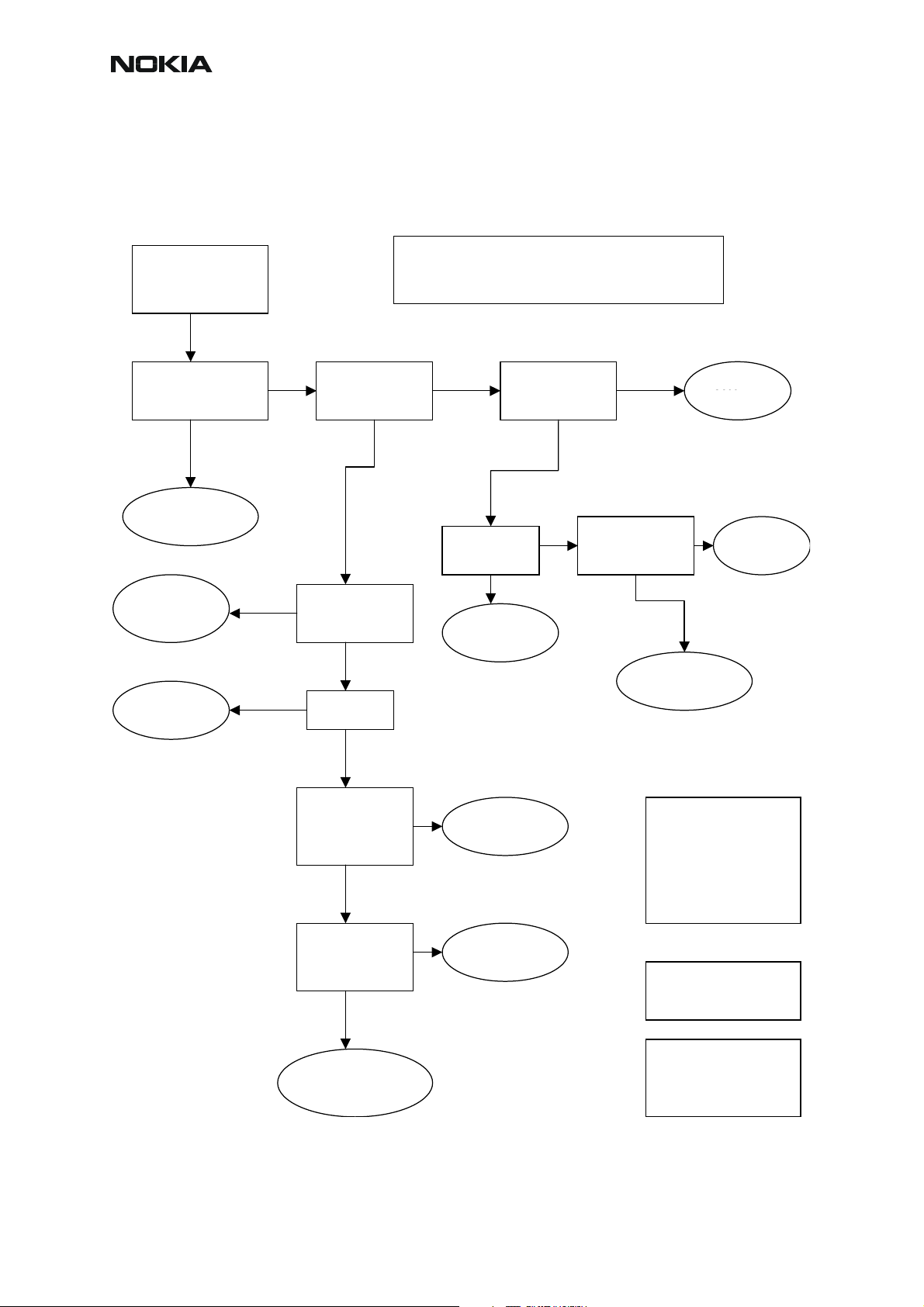

Figure 10: Helgo EDGE troubleshooting

Check with oscilloscope:

-TXI/TXQ signals

No

-VR1, VR2, VR4, VR5, VR6 =2.8V

-VrefRF01 = 1.35V

-Helgo serial interface

-TXP & TXC & TXA

OK?

Yes

Check with RF probe:

4G VCO signal output:

No

-3589.6MHz (GSM900)

-3495.6MHz (GSM1800)

-3760MHz (GSM1900)

Level > - 10dBm

OK?

Yes

Yes

Check modulator output components

and VPECTRL3 signal

No

Helgo EDGE

troubleshooting

Replace faulty

component(s)

Baseband

troubleshooting

Synthesizer

troubleshooting

Replace HELGO

RM-12

15 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 18

RM-12

p

)

p

)

CCS Technical Documentation

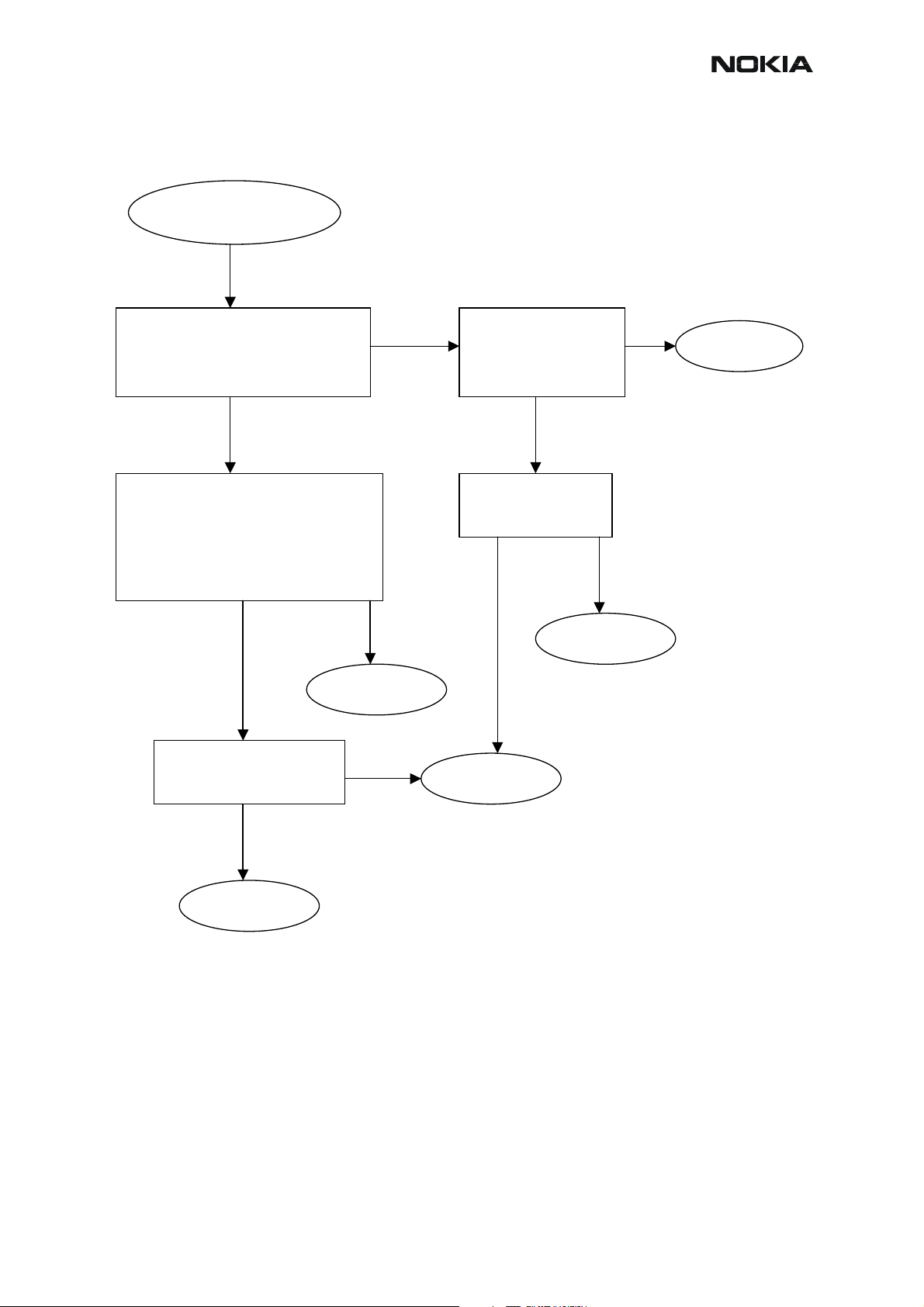

Figure 11: Pa & ant switch EDGE troubleshooting

PA & ant switch

EDGE troubleshooting

Check with RF probe signal level on PA

input:

~ -8dBm@PCL=8 (GSM900)

~ -10dBm@PCL=2 (GSM1800&1900)

OK?

Yes No

Check with oscilloscope:

-VBATT ~4V

-Iref _900 ~2V peak

-Iref_1800_1900 ~2.1V peak

-VTXB = 2.8V pulsed

-Mode = ~1.8V

OK?

No

Check components

around PA

OK?

Yes No

Yes

Replace PA

Yes Yes

Yes

Check with oscilloscope:

-VANT1 (GSM900)

-VANT2 (GSM1800)

-VANT3 (GSM1900)

OK?

Check VANT line

components

OK?

Replace

HELGO

Replace faulty

onent(s

com

Replace ant.

switch

No

Replace faulty

onent(s

com

Issue 1 11/2004 COMPANY CONFIDENTIAL 16

Copyright © 2004 Nokia. All Rights Reserved.

Page 19

CCS Technical Documentation

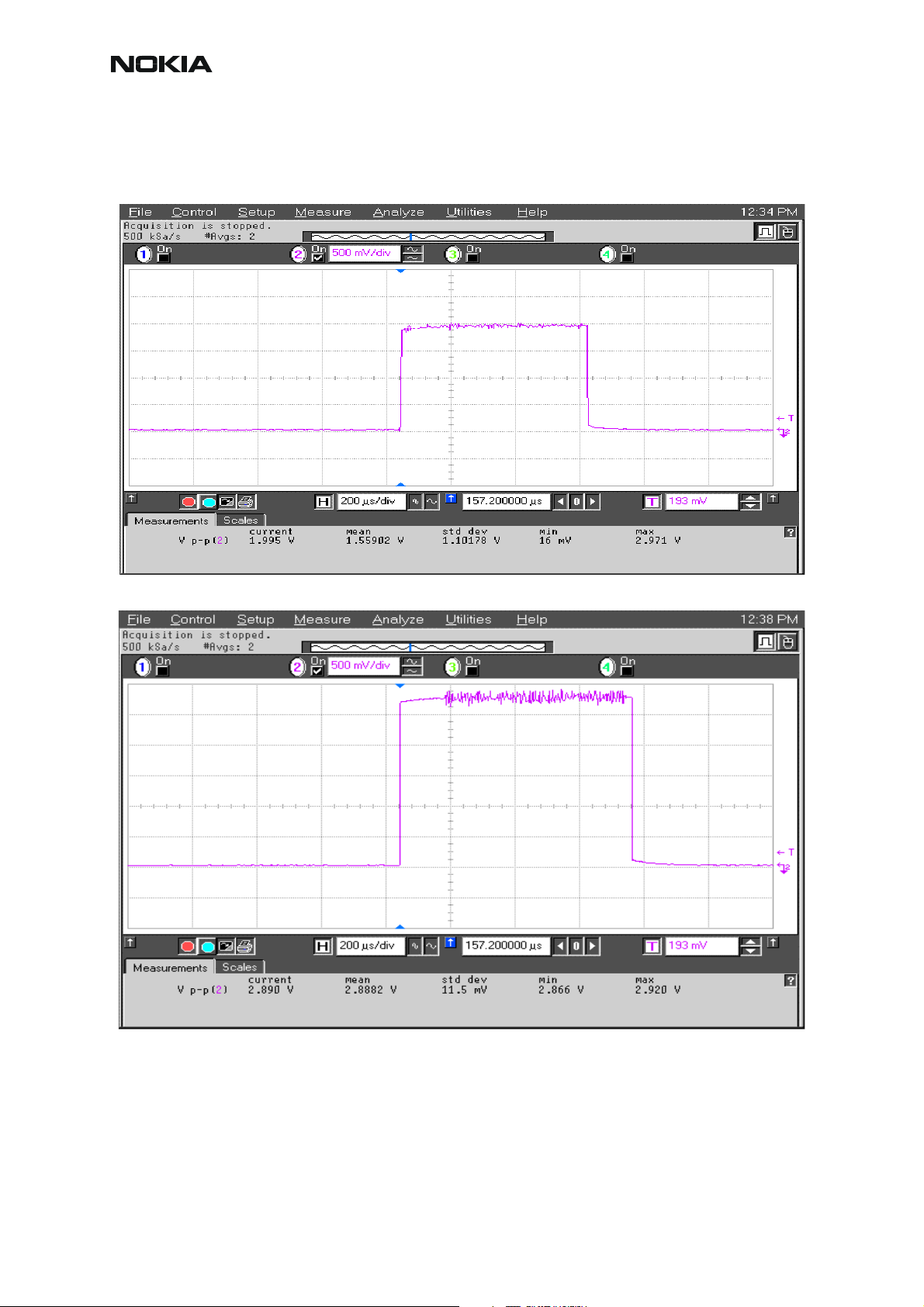

Pictures of EDGE transmitter signals

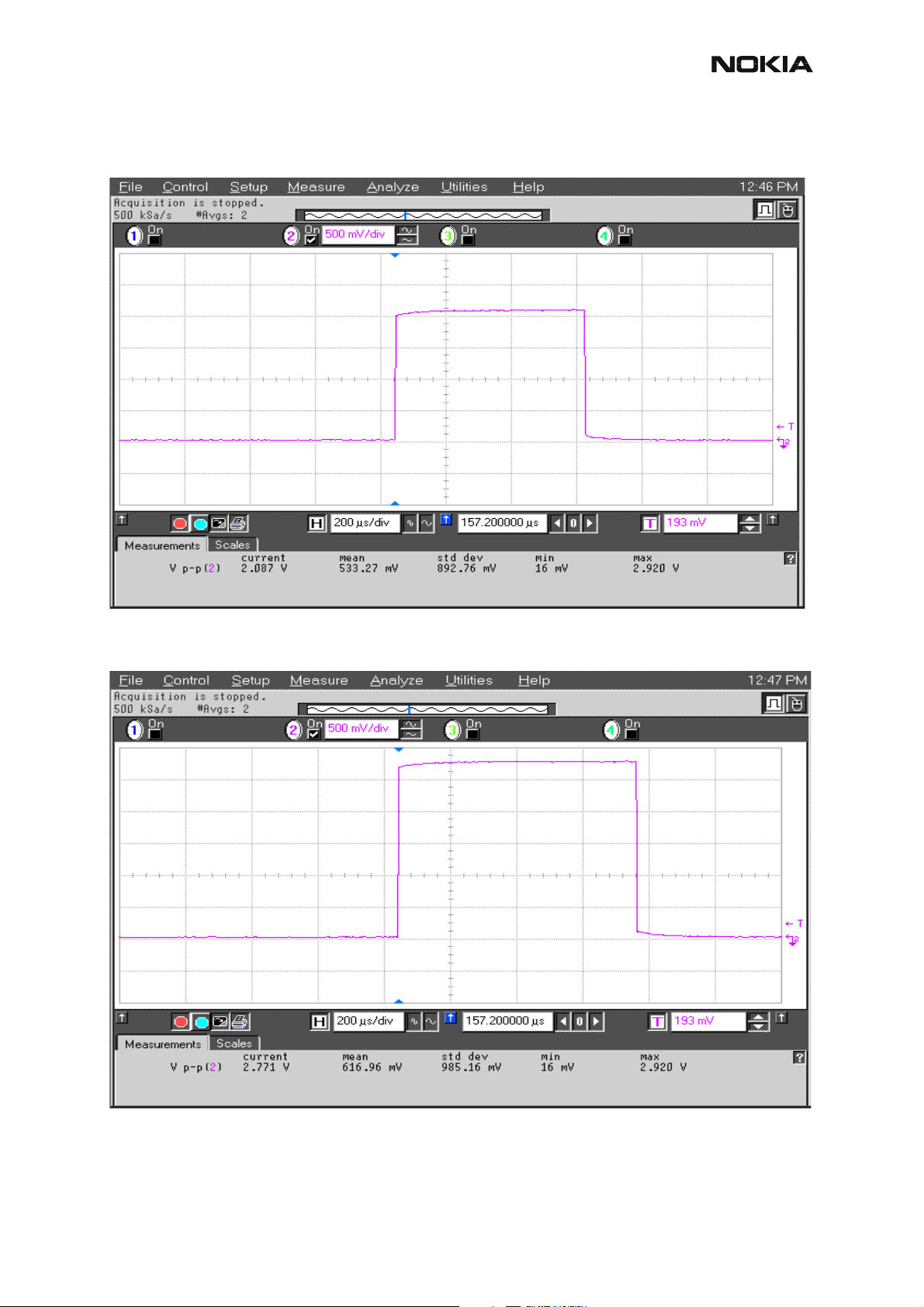

Figure 12: I_ref_900 power level 8 at R7019/C7001

RM-12

Figure 13: VTXB 900 power level 8 at C7013

17 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 20

RM-12

CCS Technical Documentation

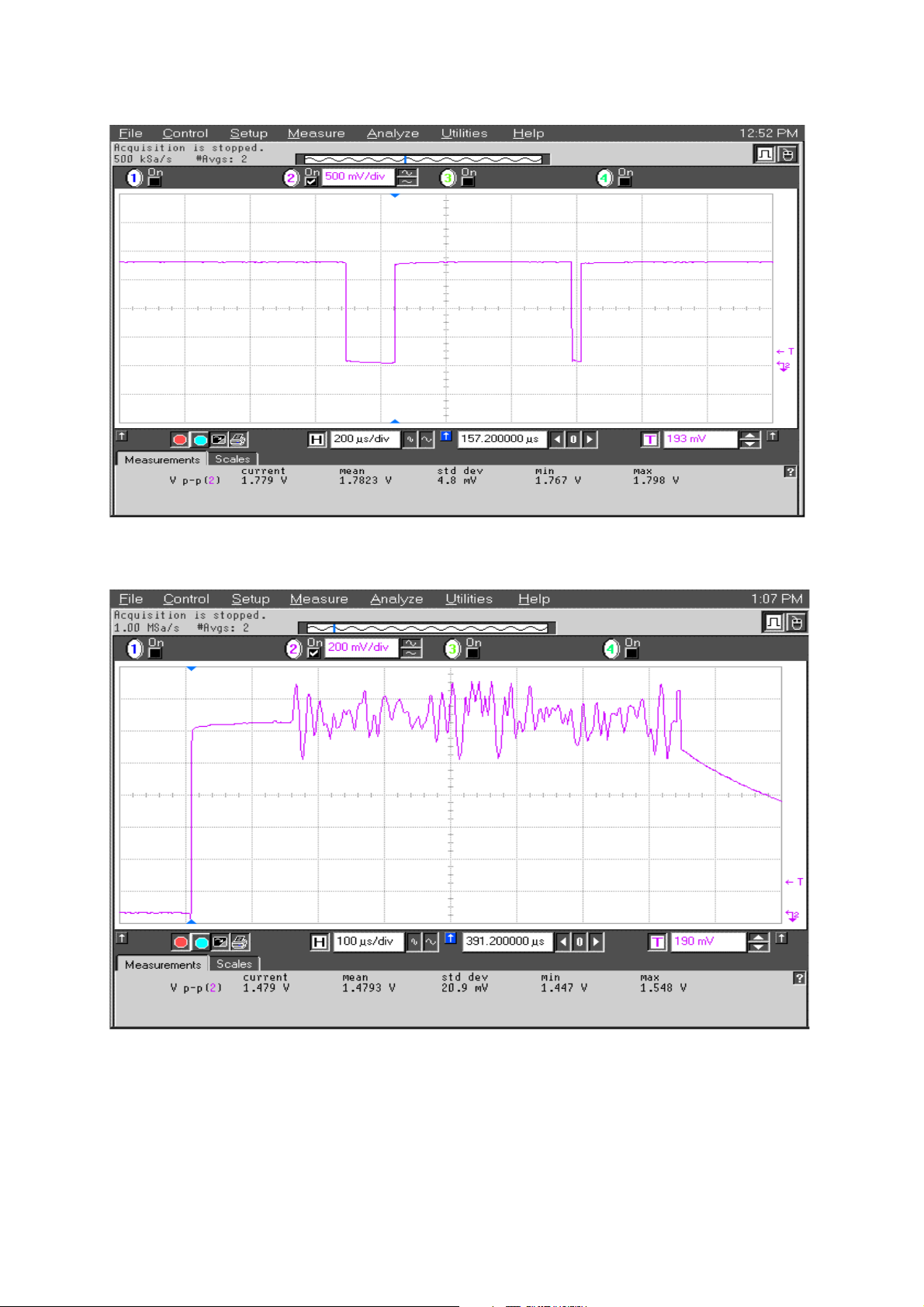

Figure 14: I_ref_1800/1900 power level 2 at R7017/C7000

Figure 15: VTXB 1800/1900 power level 2 at C7014

Issue 1 11/2004 COMPANY CONFIDENTIAL 18

Copyright © 2004 Nokia. All Rights Reserved.

Page 21

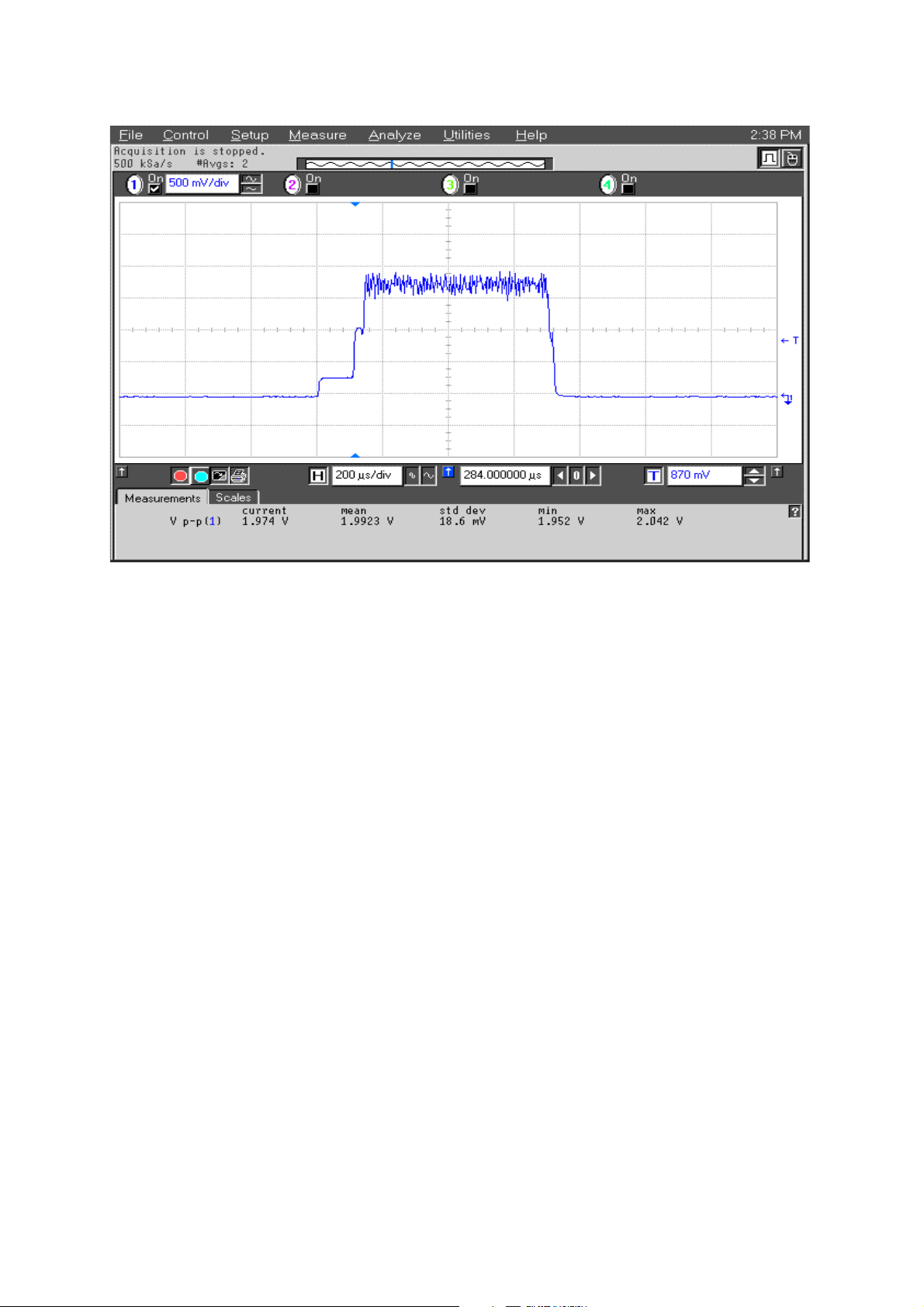

Figure 16: TXA 900/1800/1900 at C7309

Figure 17: TXI/TXQ signal at C7311/C7312/R7304/R7305

Page 22

Figure 18: VPECTRL3 (ALC) signal at C7309

Page 23

RM-12

CCS Technical Documentation

EGSM900, GSM1800 and GSM1900 Receiver

General instructions for Rx troubleshooting

Connect test jig to computer with DAU-9S cable or to FPS-8 Flash Prommer with XCS-4 modular cable.

Make sure that you have PKD-1 dongle connected to the computer’s parallel port.

Connect DC power supply to module test jig with FLC-2 cable.

Set the DC supply voltage to 4.2V.

Connect an RF-cable to the module test jig (MJ-32) RF connector and to RF signal generator.

Set the phone module to test jig and start Phoenix service sofware.

Initialize connection to phone. (Use FBUS driver when using DAU-9S, COMBOX driver when

using FPS-8.)

Choose product from the menu:

File -> Choose product -> RM-12

From toolbar, set operating mode to "Local"

Activate RF controls window from the menu:

Testing -> RF Controls

From the RF controls window:

• Select band "GSM900", "GSM 1800" or “GSM1900” (Default =

"GSM900")

• Set Active unit to "Rx" (Default = "Rx")

• Set Operation mode to "Burst" (Default = "Burst")

For continuous mode:

• Set Operation mode to "Continuous"

• Set AGC to "12: FEG_ON + DTOS_ON + BB_30=Vgain60” (maximum

gain setting used in normal mode)

(Default = "14: FEG_ON + DTOS_ON + BB_42=Vgain72")

• Set Rx/Tx channel to 37 on GSM900 band, 700 on GSM1800 band or

661 on GSM1900 (Defaults)

Apply 942.46771 MHz (channel 37 + 67.710 kHz offset), 1842.86771 MHz (channel 700 +

67.710 kHz offset) or 1960.06771 MHz (channel 661 + 67.71 kHz) –90 dBm signal to the RFconnector (remember to compensate for cable attenuation).

Issue 1 11/2004 COMPANY CONFIDENTIAL 21

Copyright © 2004 Nokia. All Rights Reserved.

Page 24

RM-12

CCS Technical Documentation

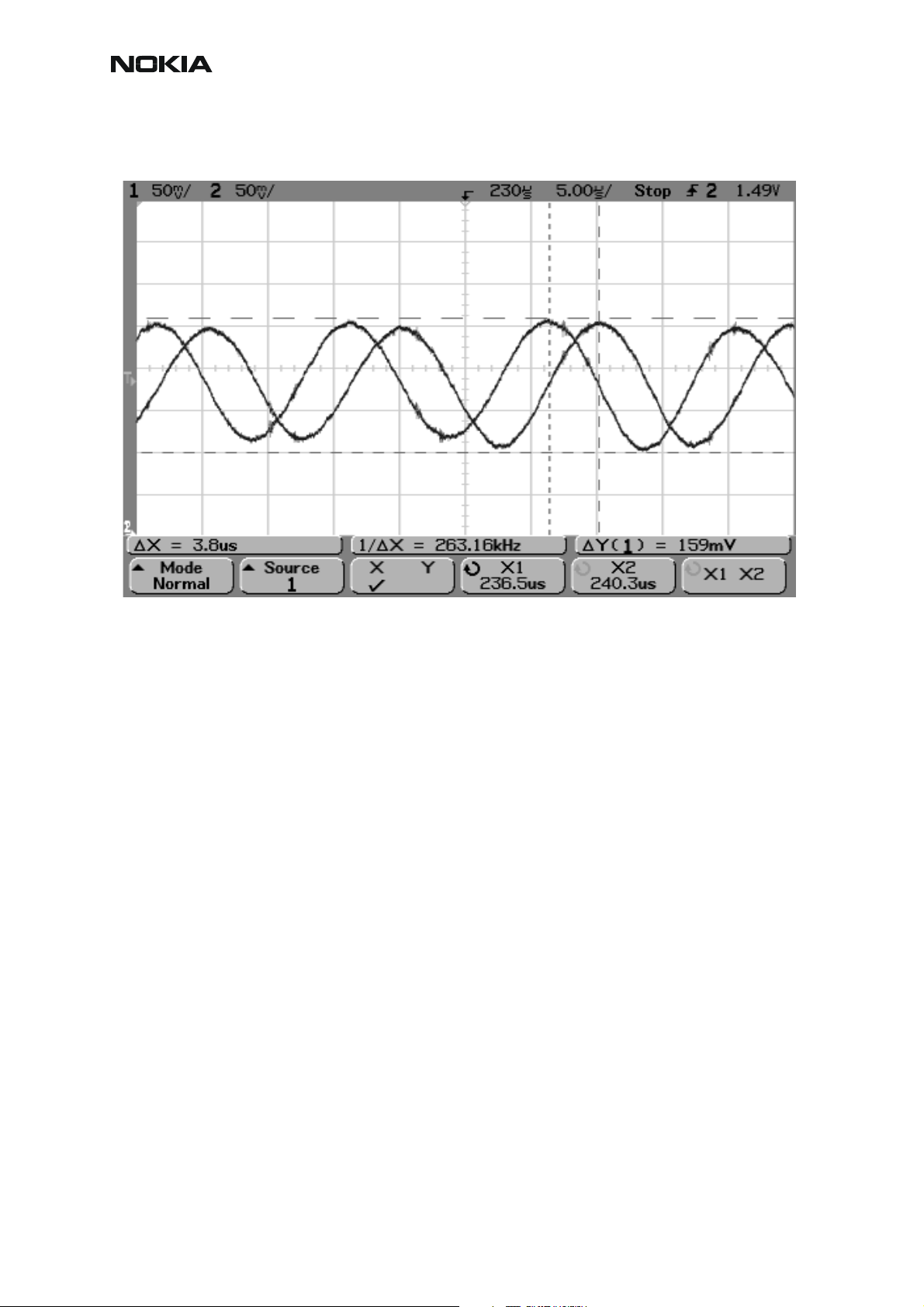

Measuring with an oscilloscope on "RXI" or "RXQ" following screens should be seen on a working GSM900, GSM1800 or GSM1900 receiver:

Figure 1: RX I/Q signal, burst mode, input level –90dBm

Receiver I or Q burst mode signal (channel 37) measured from testpoint RXI or RXQ with

942.46771 MHz signal, input level –90dBm at RF-connector.

Correct signal amplitudes approximately:

• GSM900~170mVpp

• GSM1800~140mVpp

• GSM1900~160mVpp

Signal part frequency 67.7kHz sine.

DC level of signal part is 1.35V. DC level can variate about +/-100mV between I and Q signals

and between different bands as well.

22 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 25

RM-12

CCS Technical Documentation

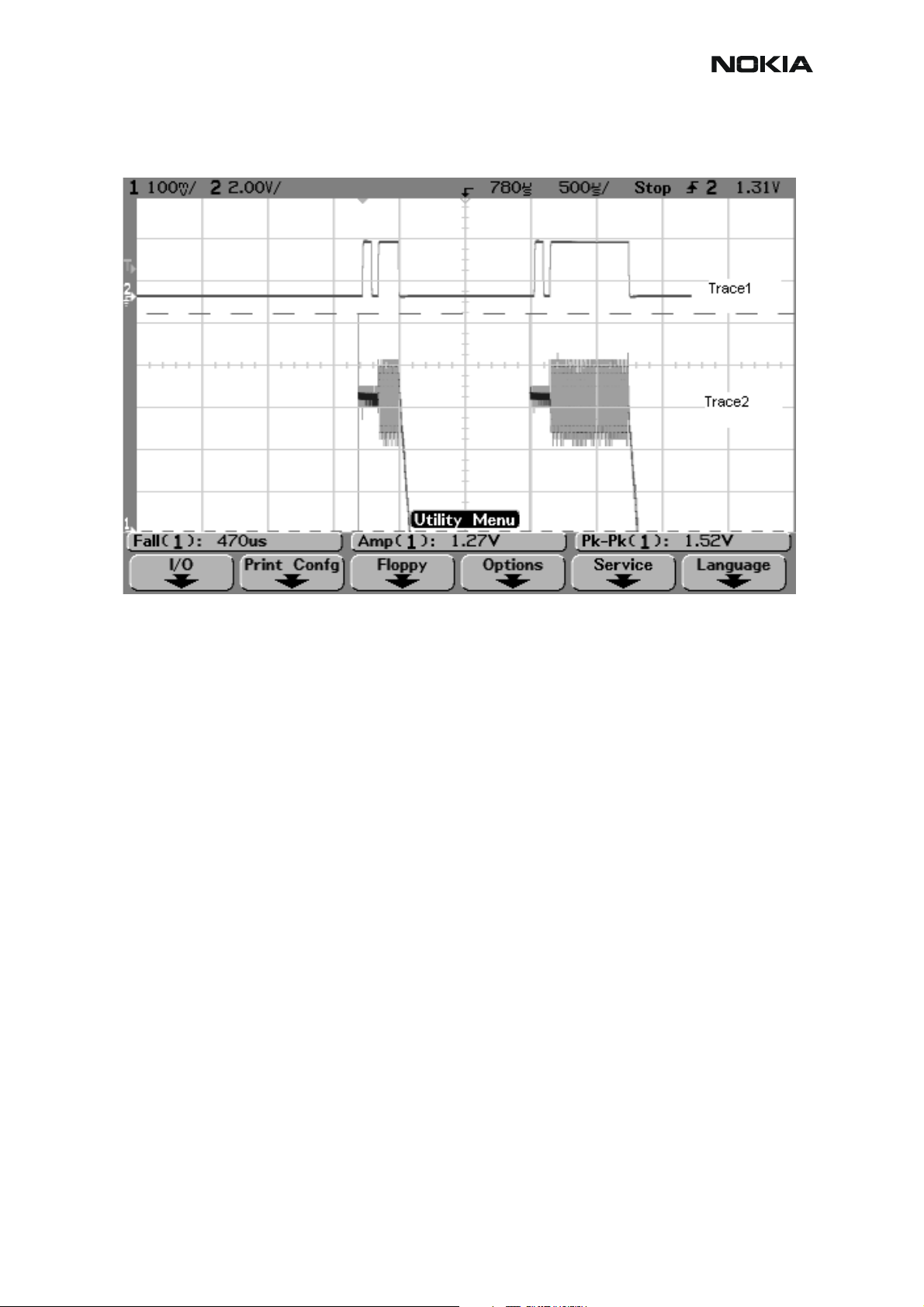

Figure 2: GSM1900 RX I or Q signal (trace2), burst mode

GSM1900 receiver burst mode I or Q signal at ch 661 with input signal 1960.067MHz, level –

90 dBm at RF-connector.

Trace2: With wider time scaling both monitoring and own RX bursts are seen, 1

nd

is monitoring and 2

burst (longer) is own RX burst.

st

burst (shorter)

Trace1: External LNA VCC supply voltage at burst mode, input level –90 dBm. Measured from

testpoint LNA_VCC.

Issue 1 11/2004 COMPANY CONFIDENTIAL 23

Copyright © 2004 Nokia. All Rights Reserved.

Page 26

CCS Technical Documentation

Figure 3: RX I&Q, phase difference 90 deg between signals

RM-12

Detailed view of GSM900 continuous mode RX I and Q signals measured from testpoints RXI

and RXQ simultaneously.

Used channel 37, input signal 942.46771 MHz, level –90 dBm at antenna port, AGC setting 12.

Phase difference should be 90 degrees between RX I and Q signals at all bands.

24 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 27

RM-12

A

q

A

–

A

)

A

Troubleshooting diagram for GSM900 receiver

Phone in “Continuous” mode, AGC setting “12”..

CCS Technical Documentation

pply –90dBm

942.46771MHz signal

from generator to

antenna connector

Osilloscope at RX_I

signal 170mVpp DC

offset 1.35***

Fre

uency 67.7kHz

Rx 900 chain

functional

Check

L809,L810

L7104, L7103

Figure 4: GSM900 receiver troubleshooting

Note! Generator level can be set higher if

needed. Just note that levels will be different

in whole chain respectively.

Spectrumanalyzer:

ntenna Switch

output GSM900

88dBm

Spectrumanalyzer:

HELGO inputs

GSM900 –89dBm

Oscilloscope

VANT_1…3 0V

Check Antenna

Switch Z800

Spectrumanalyzer:

ntenna Switch

input –88dBm

Z7100

Oscilloscope:Check

HELGO serial

interface (burst

mode

Check

C809

X7100

Check

Baseband

Check SAW

Z809

Z7101

Check SAW

filter output

Oscilloscope:

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Spectrumanalyzer:

4G VCO output

3769.6MHz

~-30dBm*

Check HELGO

N500

N7300

Check

Baseband

Synthesizer

troubleshooting

Check HELGO

N500

N7300

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the nearest

PWB ground). Reading

value is represented without

+26 dB compensation.

* Spectrumanalyzer reading

with 1 kohm passive probe

(right value add +26dB)

*** DC-level of RXI/RXQ in

continuous mode will

decrase slowly. The original

level can be rest ored by

rewriting gain set

ll spectrumanalyzer

Issue 1 11/2004 COMPANY CONFIDENTIAL 25

Copyright © 2004 Nokia. All Rights Reserved.

Page 28

CCS Technical Documentation

A

q

A

A

)

A

Troubleshooting diagram for GSM1800 receiver

Phone in “Continuous” mode, AGC setting “12”.

RM-12

pply –90dBm

1842.86771MHz signal

from generator to

antenna connector

Osilloscope at RX_I

signal 170mVpp DC

offset 1.35***

Fre

uency 67.7kHz

Rx 1800 chain

functional

Z7102,

Check Z808,

L838,L839

L7105, L7106

Figure 5: GSM1800 receiver troubleshooting

Note! Generator level can be set higher if needed.

Spectrumanalyzer

ntenna Switch

output, GSM1800

-88dBm

Spectrumanalyzer

HELGO inputs

GSM1800 –88dBm

Just note that levels will be different in whole chain

respectively.

Spectrumanalyzer

input –84dBm

Oscilloscope

VANT_1…3 0V

Check Antenna

Z7100

Switch Z800

ntenna Switch

Oscilloscope:Check

HELGO serial

interface (burst

mode

Check

C809

X7100

Check

Baseband

Check Z808

Z7102

Check SAW

filter output

Oscilloscope

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Spectrumanalyzer

4G VCO output

3685.6MHz

~-30dBm*

Check HELGO

N500

N7300

Check

Baseband

Synthesizer

troubleshooting

Check HELGO

N500

N7300

ll spectrumanalyzer

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the nearest

PWB ground). Reading

value is represented without

+26 dB compensation.

* Spectrumanalyzer reading

with 1 kohm passive probe

(right value add +26dB)

*** DC-level of RXI/RXQ in

continuous mode will

decrase slowly. The original

level can be restored by

rewriting gain set

26 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 29

RM-12

A

q

A

p

A

)

A

Troubleshooting diagram for GSM1900 receiver

Phone in “Continuous” mode, AGC setting “12”.

Figure 6: GSM1900 receiver troubleshooting

pply –90dBm

1960.06771MHz signal

from generator to

antenna connector

Note! Generator level can be set higher

if needed. Just note that levels will be

different in whole chain respectively.

CCS Technical Documentation

Osilloscope at RX_I

signal 160mVpp DC

offset 1.35***

uency 67.7kHz

Fre

Rx 1900 chain

functional

Spectrumanalyzer:

HELGO inputs

GSM1900 –88dBm

Check LNA

output from C829

–84dBm

Check Balun

T701 output

Z7104

C808, C807

C7111, C7112

C7110

Spectrumanalyzer:

ntenna Switch

outputs, GSM1900

ut -88dBm

SAW in

Oscilloscope:

VANT_3 2.7V

VANT_1/2 0V

Spectrumanalyzer:

RX_SAW_out –

90dBm (C826)

(C7108)

Oscilloscope:

LNA_VCC 2.6

LNA_P 0V

Check Antenna

Switch Z800

Z7100

Spectrumanalyzer:

ntenna Switch

input –84dBm

Oscilloscope:Check

HELGO serial

interface (burst

mode

Check Z806

Oscilloscope:

Check R800,

R7100

R810, L800

R7101, L7107

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Z7103

Check

C809

X7100

Check

Baseband

Check HELGO

N500

N7300

Check Baseband

Oscilloscope:

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Spectrumanalyzer:

4G VCO output

3920 MHz

~-30dBm*

Check HELGO

N500

N7300

Check

Balun

Check

Baseband

Synthesizer

troubleshooting

C7111,

Check C808,

L805, C807

L7108, C7112

Check

HELGO N500

N7300

ll spectrumanalyzer

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the nearest

PWB ground). Reading

value is represented without

+26 dB compensation.

* Spectrumanalyzer reading

with 1 kohm passive probe

(right value add +26dB)

*** DC-level of RXI/RXQ in

continuous mode will

decrase slowly. The original

level can be restored by

rewriting gain set

Issue 1 11/2004 COMPANY CONFIDENTIAL 27

Copyright © 2004 Nokia. All Rights Reserved.

Page 30

RM-12

CCS Technical Documentation

Synthesizer

General instructions for synthesizer troubleshooting

Connect test jig to computer with DAU9S cable or to FPS-8 Flash Prommer with XCS-4 modular cable.

Make sure that you have PKD-1 dongle connected to the computer’s parallel port.

Connect DC power supply or FPS-8 to module test jig with PCS-1 cable.

Set the DC supply voltage to 4.2V.

Set the phone module to test jig and start Phoenix service sofware.

Initialize connection to phone. (Use FBUS driver when using DAU9S, COMBOX driver when

using FPS-8.)

Select product from the menu:

File -> Choose product -> RM-12

From toolbar, set operating mode to "Local"

Activate RF controls window from the menu:

Testing -> RF Controls

From the RF controls window:

• Select band "GSM900", "GSM 1800" or "GSM1900" (Default =

"GSM900")

• Set Active unit to "Rx" (Default = "Rx")

• Set Operation mode to "Continuous" (Default = "Burst")

• Set Rx/Tx channel to 37 on GSM900 band, 700 on GSM1800 band, 661

on GSM1900 band (Defaults)

28 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 31

RM-12

Synthesizer

troubleshooting

Yes

CCS Technical Documentation

Figure 7: Synthesizer troubleshooting diagram

*(When 2.5kOhm passive probe is used,

correct the measurement by +34 dB

Set with RF controls:

Active Unti = Rx

Operation mode = Continuous

Check with RF probe:

-4G VCO out signal

- 3589.6 MHz (GSM900)

-3495.6 MHz (GSM1800)

- 3760 MHz (GSM1900)

Level >-10dBm (*

OK ?

No

VCO out signal level<-10dBm

No

Check output signal on

1 GHz span

Signal found on

incorrect frequency ?

Yes

Yes

Synthesizer

OK

Yes

Check with oscilloscope:

-4G VCO Vcc = 2.7V

No

Check balun

output levels and

solder joints

OK ?

No

Replace

faulty

component(s)

OK ?

No

Yes

Yes

Baseband

troubleshooting

Replace

VCO

Check with oscilloscope:

VCO control voltage

from VCO pin

0V ?

No

Check with oscilloscope:

VCO control voltage

from VCO pin

>4.0 V ?

Yes

Check balun

output levels and

solder joints

OK ?

Yes

Check VCO control

loop components

Yes

OK ?

Replace

VCO

No

Replace

faulty

component(s)

No

Issue 1 11/2004 COMPANY CONFIDENTIAL 29

Copyright © 2004 Nokia. All Rights Reserved.

Page 32

CCS Technical Documentation

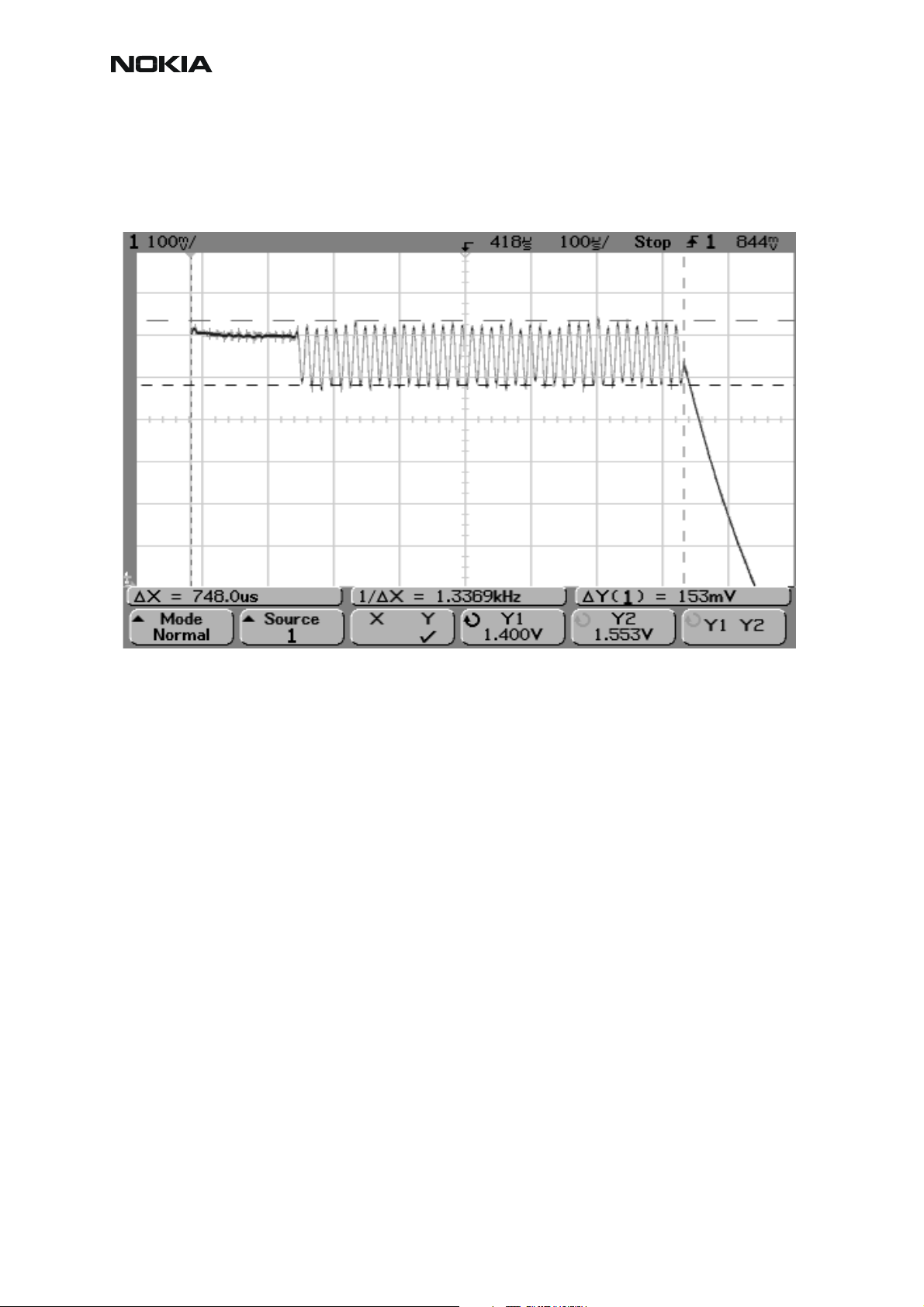

Pictures of synthesizer signals

Figure 8: 26MHz at G7200 pin out

RM-12

Figure 9: 26MHz RFCLK at R2902/C2902

30 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 33

RM-12

CCS Technical Documentation

Figure 10: 1800 TX, channel 512, burst mode

Figure 11: 1900 RX, channel 810, continuous mode

Issue 1 11/2004 COMPANY CONFIDENTIAL 31

Copyright © 2004 Nokia. All Rights Reserved.

Page 34

CCS Technical Documentation

g

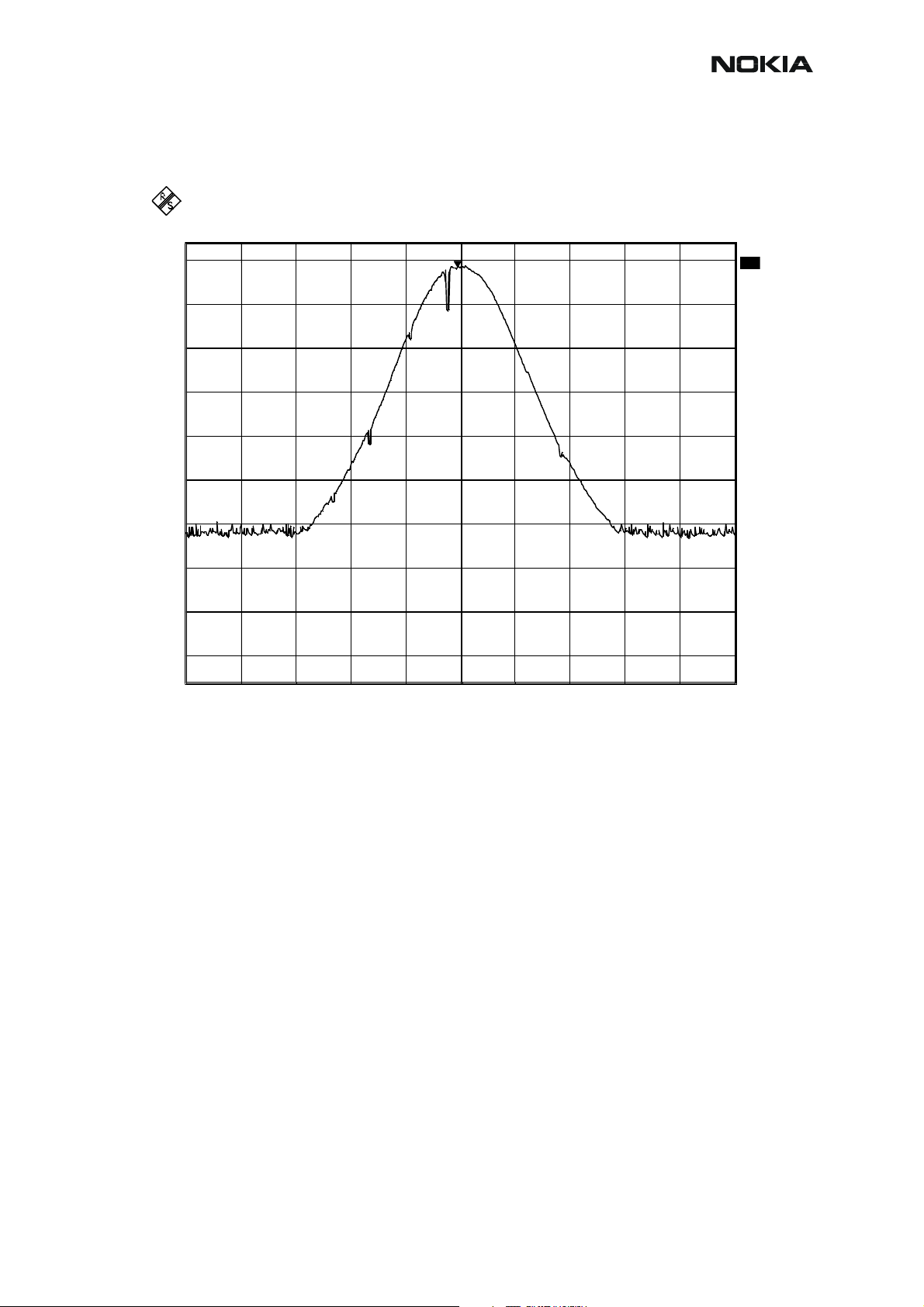

Figure 12: VCO output, 1800 band, ch700, RX on, continuous output

RM-12

RF test points

Signal Test Point Parameter Characteristics Note Function

TXP J7300 "1" and "0" 1.8/0 V digital signal Power amplifier enable

TXA J7301 "1" and "0" 1.8/0V digital signal Power control loop enable

RXI/RXQ J7302/J7303 voltage swing (static) 1.4Vpp DC level 1.4V Received demodulated I -and Q sign als

RFBus Data J7304 "1" and "0" 1.8/0V digital signal data frequency max. 10MHz RFBUs data; read/write

RFBusClk J7305 "1" and "0" 1.8/0V digital signal data frequency max. 10MHz RF Bus clock

RFBus Ena1 J7306 "1" and "0" 1.8/0V digital signal RFBus enable

RESET J7307 "1" and "0" 1.8/0V digital signal Reset to Helgo

RF GSM component alignment

Helgo (N7300) YES YES YES YES YES YES

PA (N700) NO NO NO NO YES YES

ASM (Z7100) NO YES YES YES YES YES

VCO (G7201) NO NO NO NO YES NO

TX SAW (Z7000) NO NO NO NO NO NO

RX LNA (V7100) NO YES YES NO NO NO

RX SAW (Z7101,Z7102,Z7103) NO YES YES NO NO NO

32 COMPANY CONFIDENTIAL Issue 1 11/2004

RX Channel Select Filter CalRX Cal RX Band Filter Response Cal RX DtoS Balance Cal TX IQ Tuning TX Power Level Tunin

Copyright © 2004 Nokia. All Rights Reserved.

Page 35

RM-12

Nokia Customer Care

Baseband troubleshooting

Partially damaged device

If the device is working, but some functionality is missing, try to localise the problem(s) and see

a relevant part of this manual. For example, if audio is not working see “Audio Troubleshooting”,

if charging is not working see “Charging troubleshooting”, and so on.

Most common symptoms reported by customer

Here you can find some common symptoms reported by customers when the device is brought

in for service. Some tips for locating the problem are also given. When troubleshooting, use

these tips and follow the given troubleshooting path.

Most common symptoms for audio problems

• “Earpiece sound is missing”

• ”Handsfree sound is missing”

• ”Microphone is not working”

• ”Ringing tones do not work”

• ”Audio volume too low”

• “IHF does not work”

If the symptom is one of the above, see “Audio troubleshooting”.

Most common symptoms for Bluetooth problems

• ”Bluetooth does not work or connection cannot be established”

Follow “Bluetooth troubleshooting” guidelines.

Symptoms related to energy management

• “Phone does not stay on”

• ”Charging is not working”

• ”Time is lost during battery change”

• ”Charging takes too long”

• ”Operating time is very short”

With these symptoms, follow “Power troubleshooting”.

Issue 1 11/2004 COMPANY CONFIDENTIAL 33

Copyright © 2004 Nokia. All Rights Reserved.

Page 36

CCS Technical Documentation

Problems related to UI-module

• “Touch Screen is not working”

• “Touch Screen is working unreliably”

• “Keypad is not working”

• ”Rocker is not working”

• ”Backlight is dim”

• ”Backlight not even”

• ”Backlight is blinking”

• ”Keypad or display backlight is not working”

RM-12

• ”Display-related problems”

See “UI troubleshooting”.

Most common RF-related symptoms

• “Call cannot be made”

• ”Phone does not find signal”

• ”Call is often dropped”

See “RF troubleshooting”.

Problems related to camera

• “Bad image quality”

• ”Picture cannot be taken”

See “Camera module troubleshooting”.

34 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 37

RM-12

Dead or jammed device troubleshooting

Dead phone

Place service

battery via

ammeter=

Power On

Nokia Customer Care

Yes

Any image on

screen

Yes

Normal

operation

No No

No

Ammeter

>> 0 mA

Yes

Connect PC to

Phone using DAU-

9S cable.

Scan product

RM-12

found

Yes

Normal

operation

No

Flash the phone Succeed

Go to/visit display

No

troubleshooting

Normal

operation

No

No

Go to power

troubleshooting

Go to OMAP1510

troubleshooting

Yes

Yes

Yes

End test

Issue 1 11/2004 COMPANY CONFIDENTIAL 35

Copyright © 2004 Nokia. All Rights Reserved.

Page 38

CCS Technical Documentation

OMAP1510 (1)

Start

Booting

problems?

Yes

Visit APE Power

troubleshooting

APE Power

OK/fixed,

problem

solved?

No

Check resistor

R4806, replace

if needed.

Problem

solved?

RM-12

Yes

Yes End

No

No

Visit APE clock

troubleshooting

Vis it SDRAM

troubleshooting

Was it a

SDRAM

problem?

No

Yes

APE clocks/

reset OK/fixed,

problem

solved?

No

Go to /(visit) APE

NAND

troubleshooting

Was it a NAND

problem?

Yes

End

Yes

End

No

Replace

engine board.

OMAP1510 D4800

36 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 39

RM-12

SDRAM (1)

Start

Run

ST_APE_RAM_

TEST, with

Phoenix.

Result?

All signals in this

troubleshooting are in

range 0 - V18

Problem

Pass

occurs only in

heat or cold?

No

Use cold spray/

hot air to SDRAM device

or customer feedback

Phone might been

dropped, solder

Yes

balls cracked,

replace D5080

Nokia Customer Care

Fail

Measure

SDRAM

voltage V18 at

C5083

Correct

Measure SDCLK

Measure

SDCLK

frequency at

frequency at

R4808 = 75MHz,

R4808

(1.8V).

>70MHz?, level

0 - ~V18

No

Go to SDRAM

troubleshooting

page 2

Incorrect

Yes

Go to OMAP1510

troubleshooting

Check and replace

if needed C5083-

Check C5083 - C5089.

C5089, res ist ance

>>1Mohm

Correct

Phone might been

dropped, solder

balls cracked,

replace D5080

Measure

SDRAM

voltages V18

at C5083

Incorrect

Correct

Visit APE Power

troubleshooting

Measure

SDRAM

voltages V18

at C5083

Incorrect

Change SDRAM

D5080

Issue 1 11/2004 COMPANY CONFIDENTIAL 37

Copyright © 2004 Nokia. All Rights Reserved.

Page 40

CCS Technical Documentation

SDRAM (2)

From SDRAM

troubleshooting

page 1

Replace

Inspect R4808

value, approx

22ohm

No

R4808 and

measure

SDCLK

frequency

>>70Mhz

Yes

Rerun

ST_APE_RAM_

TEST with

Phoenix

Fail

Change SDRAM

D5080

RM-12

Yes

No

Problem

occurs while

booting?

Yes

Go to Seija/NAND

troubleshooting

Pass

No

Go to OMAP1510

troubleshooting

38 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 41

RM-12

APE flash

Nokia Customer Care

All signals in this

troubleshooting are in

range 0 - V18

Busy# signal rises

at latest after

1055us after

RSTIN# rises.

However, the Busy#

can be high before

RSTIN# rises, but this

is not taken into account.

Start

Measure

MDOC Busy#

at R4801 and

RSTIN# at

J4803

RSTIN# stays low

Measure

MPU_nReset at

R4802, low to

high transition?

Stays low

Yes

Backup user data before

MDOC troubleshooting, if

Boot phone.

Use oscilloscope.

Busy#

stays low

Go to OMAP1510

troubleshooting

possible

Check resistor

R4801

~10k

Yes

Check MDOC

core voltage at

C5000, V28

Correct

voltages

No

Replace resistor

R4801 and rerun

first test

Voltage levels

invalid

Check

resistors

R5000 and

R5001,

both ~10k

Yes

Measure

CS0# at J4805

and OE#

J4802,

toggling?

Yes

Memory

corrupted, reflash,

or replace MDOC

D5000

Replace damaged

No

Go to OMAP1510

No

Go to APE reset

troubleshooting

resistor(s)

troubleshooting

Check MDOC

I/O voltage at

C5001,

V18

Correct

voltages

Check

resistors

R5000 and

R5001,

both ~10k

Yes

MDOC damaged,

replace D5000

Voltage

level

invalid

No

Go to APE Power

troubleshooting

Replace damaged

resistor(s)

Issue 1 11/2004 COMPANY CONFIDENTIAL 39

Copyright © 2004 Nokia. All Rights Reserved.

Page 42

RM-12

CCS Technical Documentation

ASIC is changed

ASICs can be changed only at a defined service level.

• If UEM is changed

If UEM is changed, baseband calibrations should be made. IMEI must be prog rammed also.

• If UPP8M is changed

If UPP is changed, there is no need to flash the phone.

• If Zocus is changed

If Zocus is changed, it must be calibrated.

• Nor flash changed

If CMT Nor flash is changed, re-flash the phone. IMEI must be programmed also.

• SDRAM changed

If SDRAM is changed, there is no need to flash the phone.

• MDOC flash changed

If MDOC memory is changed, User data needs to be back-upped if possible. Re-flash the

phone.

• Touch screen controller

If touch screen controller or display module is changed, calibrations should be made.

•BT

If BT chip is changed, there is no need to flash the phone.

Test points

Test point locations and possible signal levels are listed in the Schematics chapter of this Service Manual.

Selftests / “Contact service” on display

MCU selftest cases can be split into two categories: ones that are executed during power up

and ones that are executed only with a PC connected.

“CONTACT SERVICE” on display means that software is able to run and thus the watchdog of

UEM can be served. Selftest functions are executed when the phone is powered on a nd if one

or more selftest functions fail, the message “Contact Service” is shown on the display.

40 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 43

RM-12

Nokia Customer Care

PC selftests are listed below:

Table 1: PC selftests

Test Description

ST_AUX_DA_LOOP_TEST This function tests the connection of

AuxDa and UemInt signals between

UPP and UEM.

ST_EAR_DATA_LOOP_TEST This function tests the connection of

EarData and MicData signals between

UPP and UEM.

ST_KEYBOARD_STUCK_TEST This function tests if some key is

stucked.

ST_MBUS_RX_TX_LOOP_TEST

ST_SIM_CLK_LOOP_TEST

ST_SIM_IO_CTRL_LOOP_TEST

ST_SLEEP_X_LOOP_TEST

ST_TX_IDP_LOOP_TEST

This function tests the connection of

MBusTx and MBusRx signals between

UPP and UEM.

This function tests the connection of

SimClk and SimIODa signals between

UPP and UEM. This test requires also

that SimIOCtrl signal can be set to high

state.

This function tests the connection of

SimIOCtrl and SimIODa signals

between UPP and UEM. This test

requires also that SimClk signal can be

switched.

This function tests the connection of

SleepX and SleepClk signals between

UPP and UEM.

This function tests the connection of

TxIdp and RxIdp signals between UPP

and UEM.

ST_TX_IQ_DP_LOOP_TEST

This function tests the connection of

TxQdp and RxQdp signals between

UPP and UEM.

ST_BACKUP_BATT_TEST

This function tests if the backup battery

was ok during power-up.

ST_LPRF_IF_TEST

This test verifies, whether BT MCM

internal selftests are o.k.

Issue 1 11/2004 COMPANY CONFIDENTIAL 41

Copyright © 2004 Nokia. All Rights Reserved.

Page 44

CCS Technical Documentation

RM-12

Table 1: PC selftests

ST_CAMERA_IF_TEST

Purpose of this test is to verify the cam-

era data and I2C lines. I2C interface test

and camera activation is done first and

then camera sends test picture to the

OMAP.

ST_WARRANTY_TEST

This function tests the Warranty Infor-

mation State.

ST_FLASH_CHECKSUM_TEST

This test computes the checksums over

flash ROM areas and compares them to

the pre-calculated checksums in flash

header.

ST_RADIO_TEST

Purpose of this test is to check that radio

data line is working properly.

ST_LPRF_AUDIO_LINES_TEST

This test verifies the LPRF audio lines.

ST_UEM_CBUS_IF_TEST This test verifies the CBUS connection

of CBUSCLK, CBUSDA, and CBUSENX

signals between UPP and UEM.

ST_VIBRA_TEST This test verifies the vibra lines.

ST_SLEEPCLK_FREQ_TEST Purpose of this test is to check the basic

functionality of

ST_SLEEPCLK_FREQ_TEST.

ST_CURRENT_GAUGE_IF_TEST Purpose of this test is to check that

ST_CURRENT_GAUGE_IF_TEST is

working in real HW environment. Test

uses current gauge registers to verify,

that correct HW-module is in place and

working properly.

ST_CMT_APE_WAKEUP_TEST Purpose of this test is to check that

ST_CMT_APE_WAKEUP_TEST is

working properly.

ST_MAIN_LCD_IF_TEST Purpose of this test is to check that dis-

play interface (OMAP and LCD) is work-

ing properly.

ST_TOUCH_STUCK_TEST Purpose of this test is to check that

touch interface is working properly.

ST_APE_DAC_CTRL_IF_TEST Purpose of this test is to check connec-

tions (I2C lines) between APE and DAC.

Audio driver provides the test interface.

42 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 45

RM-12

Nokia Customer Care

Table 1: PC selftests

ST_APE_RAM_TEST Purpose of this test is to check that

ST_APE_RAM_TEST is working prop-

erly. Test starts RAM testing and loops

the result until response from APE boot-

code is received.

ST_APE_POST_CODE_TEST Purpose of this test is to check that

ST_APE_POST_CODE_TEST is (boot-

code) working properly.

ST_BT_WAKEUP_TEST Purpose of this test is to check that

UART interface from the OMAP to the

Bluetooth module. The Bluetooth ASIC

self-test runs automatically as part of the

boot-up sequence. It is based on the

assumption that UART communication

is required to successfully run the initiali-

sation sequence. It cannot be assumed

that if the connection works if a UART

command is sent to the Bluetooth ASIC.

Therefore, the Bluetooth ASIC must

send the status information (OK/Not OK)

to the test server in the boot sequence.

ST_XABUS_TEST Purpose of this test is to check that

ST_XABUS_TEST is working in real HW

environment. Test checks the communi-

cation bus between CDSP and Applica-

tion DSP and therefore this test cannot

be executed in MOSIM environment.

Also ST_FAIL situation would be too dif-

ficult to simulate comparing to benefits.

ST_PWR_KEY_TEST Purpose of this test is to check that pwr

key is working properly.

Issue 1 11/2004 COMPANY CONFIDENTIAL 43

Copyright © 2004 Nokia. All Rights Reserved.

Page 46

CCS Technical Documentation

Flashing troubleshooting

Flashing does

not work

Check cables and

flashing adapter. Verify

that you have the right

data package

From APE flashing

troubleshooting

RM-12

From the CMT

flashing

troubleshooting

OK? No

Go to CMT

flashing

troubleshooting

RM-12

Check Nokia 7710

flashing

instructions

44 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 47

RM-12

APE Flashing

From the CMT

flashing

troubleshooting

Flashing

stalls. "ADL ->

sending code: x%"

(x<100) ?

No

Yes

Nokia Customer Care

Go to NAND

troubleshooting

Run

ST_APE_POST_

CODE_TEST with

Phoenix

pass

Go to USB

troubleshooting

Reflash

Fail

Phone starts

to boot, but jams

after a while ?

No, totally dead device

Go to APE power

troubleshooting

Yes

CMT functionality

OK and automatically

ran self tests passed?

Yes

Go to OMAP1510

troubleshooting

No

Go to CMT

troubleshooting

Issue 1 11/2004 COMPANY CONFIDENTIAL 45

Copyright © 2004 Nokia. All Rights Reserved.

Page 48

CCS Technical Documentation

CMT flashing

Note! OMAP, UEM and UPP are unchangeable.

From the top

level

Measure FBUS

and BSI signals

while flashing

FBUS TX is

HIGH during

flashing?

No

BSI pulse

exists during

flashing?

RM-12

Check BSI line

including X2020,

No

R2035, C2020,

R2201, C2225 and

R2202

Yes

IS FBUS TX set LOW

after it has been

HIGH

Yes

Check Phoenix

Prommer Tool

window

information

Wrong

Manufacturer

ID or

Device ID

No

Is FBUSTX

~1.8V during

flashing

Yes

No

Yes

No

Check R2025, if

OK change UEM

Change UPP

(D2800)

Change flash

(D3000)

Go to APE flashing

troubleshooting

Reflash

46 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 49

RM-12

Power troubleshooting

Nokia Customer Care

Table 2: Power troubleshooting

Regulator

reference

Output

name

Output

voltage

Test point Supply to

N4201 V15 1.57 C4214 D4800 Omap1510 core

N4202 V18 1.8 C4212 D4800 Omap 1510 io, D5080

SDRAM, D5000, MDOC, camera

N4200 V28 2.8 C4202 D4800 Omap 1510 io, camera con-

verter, display module, N4400

touch controller

N5200 VMMC 3 C5202 MMC

N2000 Vout 2.8 C2000 Pop-port

N2001 V33 3.3 C2005 D4800 Omap 1510 USB

D4420 VLED 10..11V C4424 Backlight, keylight

Issue 1 11/2004 COMPANY CONFIDENTIAL 47

Copyright © 2004 Nokia. All Rights Reserved.

Page 50

CCS Technical Documentation

CMT

Note! OMAP, UPP and UEM are unchangeable.

NO power

up

Connect service

battery to phone

and measure

current when

powering on

RM-12

Current rises

over 100mA but

drops down

NO

Current short

NO

Current 0mA all

the time

NO

Disassemble

phone

Check CMT

voltages:

C2232=2.8V,

C2202=2.8V,

C2204=1.8V,

C2205=1.5V

All Voltages ok

w he n power

button pressed

YES

YES Flash phone SW

NO

YES

Disassemble

phone and check

visually possible

shortcircuits and

YES

damaged or over

heated

components

Check Battery

YES

NO

connector

C2232=2.8V to

RF, C2202=2.8V

to R2201 and

N4201,

C2204=1.8V to

D2800 and D3000,

C2205=1.5V to

D2800

Current rises

over 100mA but

drops down

Any damaged

component found

and changed

Remowe RF VBAT

NO

NO

Change damaged

component on

voltage not in

spec.

YES

filter L7000

Perform EM

calibration with

Phoenix and

JBV-1

All Voltages ok

w he n power

button pressed

Current short Goto RF checkingNO

YES

Change R2036,

Current short

YES

CSP compone n t

on VBATT:

N2000, N2070,

N2100, N2200,

N4200, N4201,

N4202, N5200

Change UEM

NO

D2200

Check CMT Res e t

and clocks.

YES

48 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 51

RM-12

Charging

Not

charging

Connect

service battery

and read BSI

by Phoenix

75kohm

100kohm

YES

Connect charger

and read Vchar

voltage by

Phoenix ACP-12

5.7V

NO

Note! OMAP, UEM and UPP are unchangeable.

Perform EM

calibration by

NO

NO

YES Flash phone SW

Phoenix and

JBV-1

Charging OK

Read BSI b y

Phoenix. With

servce battery

100kohm

75kohm

YES

YES

Flash phone SWNO

Read BSI b y

Phoenix. With

servce battery

75kohm

100kohm

YES

Change R2201

and R2202

Nokia Customer Care

Disassemble

NO

phone and check

Battery contacts .

R2202, Norma l

NO

Phone in jig.

Measure

voltage on

mode 1.3V

Perform EM

calibration by

Phoenix and

JBV-1

Connect charger

and read Vchar

voltage by

Phoenix ACP-12

5.7V

NO

Flash phone SW

Charging OK

NO

NO

Charging OKYES

Charging OK

Disassemble

phone and change

NO Charging OK

Measure Vchar

from fuse F2020

5.7V

YES

YES

R2200

NO

Measure Vchar

from fuse F2020

calibration by

Change fuse

F2020

5.7V

NO

Perform EM

Phoenix and

JBV-1

NO

NO

Change UEM

D2200

Charging OK

Disassemble

phone. Check

charger connector.

Measure Vchar

from L2020 5.7V

Change fuse

F2020 and V2020.

NO

YES

Change L2020

Issue 1 11/2004 COMPANY CONFIDENTIAL 49

Copyright © 2004 Nokia. All Rights Reserved.

Page 52

CCS Technical Documentation

APE

RM-12

Power on

Supply voltage

drops(or current

is large)?

NO

Measure VBAT

from input filters

C4200, C4209,

L4203(both sides)

OK?

YES

Check

V28(~2.8V),

OK?

YES

Visit APE reset

troubleshooting

YES

NO

NO

Note! OMAP, UEM and UPP are unchangeable.

Short circuit in

VBAT line

Failure on VBAT

line, check

components and

connectors

Check

enable(VIO),

high (1.8V)?

NO

UEM fault

YES

Change V28

regulator(N4200)

and retest, OK?

NO

Shortcut in V28

line

Check SYNC/

MODE fr o m

R4202 (both

sides), High

(>2V)?

YES

Check

V15(~1.57V),

OK?

YES

Check V18

(~1.8V), OK?

YES

END

R4200 or

Faulty V1600 or

NO

NO NO

R4202, change

and retest

V15 > 1.62V ?

V18 >1.89V ?NO

No

Check

enable (VIO),

high (1.8V)?

NO

UEM fault

YES

NO

Check enable

(VFLASH1),

high (2.8V)?

NO

UEM fault

Check

ref. voltage

at C4211,

1.35V ?

NO

Ref .

voltage found

at either end of

L4200 ?

YES

YES

YES

YES

Check

voltage at L4201

(both sides low),

~0V ?

Change coil and

retest V15

YES

Check

voltage at L4202

(both sides low),

<1V ?

Change filter

(L4200)

NO

YES

NO

Change coil and

retest V18

Change SMPS

chip(N4201) and

retest, OK?

Shortcut in V15

YES

NO

line

Change SMPS

chip (N4202)

and retest, OK?

NO

Shortcut in

V18 line

50 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 53

RM-12

APE Clocking

APE clocks

trouble

shooting

Clk32k (J4815):

Voh ~ 2.8V &

f ~ 32.768kHz ?

(Figure 1)

Nokia Customer Care

Reflash the phone

SleepClk ( J2802):

No

Voh ~ 1.8V &

f ~ 32.768kHz ?

(Figure 2)

first and check that

Clk32k is not shorted

to GND or some

Yes

power line. If Clk32k

still doesn't w ork,

change UEM

Yes

12Mhz clock

(C4800, OSC1_IN):

Vpp ~ 1.7V &

f ~ 12.0MHz ?

(Figure 3)

Yes

Check that

(C4800, OSC1_IN)

DC-offset ~ 720mV

(C4802, OSC1_OUT)

DC-offset ~760mV

(Figures 3&4)

Yes

Solder joints of

C4800, C4801,

C4802 and B4800

OK ?

Yes

Measure

resistance over

C4801.

R >>1M ?

Yes

NoNo

No

No

Go to CMT clock s

troubleshooting

Solder joints of

OMAP151 0

damaged

Fix solder joints

Check solder joints

of V6031 and

replace the

component, if

necessary.

No

Change B4800. If

Check completed

this doesn't help,

change C4800,

C4801 and C4802.

Issue 1 11/2004 COMPANY CONFIDENTIAL 51

Copyright © 2004 Nokia. All Rights Reserved.

Page 54

CCS Technical Documentation

APE Reset

APE reset

trouble

shooting

Switch power on

by connecting

power to battery

terminals of the

phone

Low to

high transition

on PURX

(N4800, pin #3) &

Voh ~ 1.8V ?

(Fig. 5)

No

Go to CMT

troubleshooting

RM-12

Yes

Low to

high transition

on MPU_nRes e t

(N4800, pin #1) &

Voh ~ 2.8V ? PURX to

MPU_nReset delay should

be 65-195ms!

(Fig. 5)

Yes

Check completed

Note!!!

Only probes having input impedance of

10Mohm or greater should be used when

measuring MPU_nRese t.

R4802 ~100k

No Yes

& solder joints

OK ?

No

Fix solder joints or

change R4802

Check the solder

joints of N4800

and change the

chip, if necessary.

52 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 55

RM-12

Audio troubleshooting

Earpiece

Earpiece doesn't work

Nokia Customer Care

STAR T

Check that ear piece

adapter module is held

by 4 snaps properly.

Is it OK?

YES

Check connector X 100

on A- frame assembly .

Is it OK?

YES

Set Phoenix Audio Routing

to earpiece (HpEar) f rom a

working audio input MIC1

(HpMic) or MIC2 (HdMic).

Ensure that suitable MIC

Bias is set on.

YES

Note! OMAP, UEM and UPP are unchangeable.

NO

NO

Change earpiece

adapter module . Check

and clean also contact

pads f or the earpiece.

Change new A-f rame

assembly .

Is DC bias

(~1.3Vdc at B100)

OK?

Are audio signals

from UEM to the

earpiece p ads ok?

Does the audio work

in a call?

YES

END

NO

Check L100, R100,

R101, C100, R2101.

Change com ponent s if

needed.

Chec k L100, R100,

R101, C100, R2101.

Change component s if

needed.

Change UPP

Is DC bias

(~1.3Vdc at B100)

OK?

YESYES

Are audio signals

from UEM to the

earpiece p ads ok?

YESYES

NONO

NONO

Change UEM

Change UEM

Issue 1 11/2004 COMPANY CONFIDENTIAL 53

Copyright © 2004 Nokia. All Rights Reserved.

Page 56

CCS Technical Documentation

Headset Microphone

External MIC doesn't work

START

RM-12

Check sy stem

connector and PWB

contacts .

Are they OK?

YES

Connect a working

Pop-Port headset to

the system connector

Set Phoenix Audio

Routing f r om MIC2

(Hd MIC) to a working

audio output (HpEar or

XEar). Ensure MIC

Bias (MICB2) i s set

on.

YES

Is MIC Bias 2.1V

present at R 2130?

NO

Clean c ont acts

and replace

system

connec t or

(X2021)

Check R2005, R2122,

R2123, R2130, C2022,

C2012, C2013, C2128,

C2129 and C2137.

Change component s if

needed.

Is MIC Bias 2.1V

present at R2130?

YESYES

NONO

Change UEM

Check audio path through

Are audio signals

fro m system

connector to UEM

OK?

YES

Does the audio work

during a call?

NO

L2003, R2005, R2125,

C2022, C2013, C2012,

C2124. Check also Hookint

route trough R2121 and

C2120. Change needed

com ponent s.

Change UPP

Are audio signals

fro m sys tem

connector to UEM

OK?

YES

NONO

Change UEM

YES

END

54 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 57

RM-12

P

Headset speaker (1)

External Earpiece doesn't work

Nokia Customer Care

STAR T

Chec k system connector

and PWB contacts.

Ar e t he y O K ?

YES

Connect a working

Pop-Port headset to the

system connect or

Play MIDI, AAC or

MP3 playback fi le

fr o m Headset (HS).

Ensure that volume

level is high enough.

Is HS speaker

working?

YES

NO

NO

Note! OMAP, UEM and UPP are unchangeable.

Clean contacts

and replace

system

connec t or

(X2021)

Check audio path from the

Is the DC bias

f rom Audio PA to

system connect or

OK? (~1.8Vdc at

X2021's pin

11,12,13, 14)

YES

NO

system connector to th e

Audio PA (L2004, L2005,

R2026, R 2027, R 20 32, R 2033,

C2036, C 2027, C 20 11, C 2010,

C2009, C 2008, R 20 28, R 2029,

R2030, R 2031).

Change components if

needed.

Is the DC bias

from Audio PA to

system connect or

OK? (~1.8Vdc at

X2021's pin

11,12,13, 14)

NO

Change Audio

(N2100)

ee the following flow chart,

Is the DC bias

from CODEC to

Audio PA

(~1.4Vdc at C2104

and C2105)

OK?

YES

Is digital audio

signal from OMAP

to CO DEC present

at J4100?

YES

Change audio

CODEC

(N4100)

NO

Change OMAP

(D4800)

Are the CODEC

Control-s ignals

(at R4800) OK?

YES

Change Audio

CODEC (N4100)

NONO

Change OMAP

(D4800)

Issue 1 11/2004 COMPANY CONFIDENTIAL 55

Copyright © 2004 Nokia. All Rights Reserved.

Page 58

CCS Technical Documentation

Headset speaker (2)

See the previous flow chart

RM-12

YES

Set Phoenix Audio Routing

from a working MIC input

MIC1 (HpMic) or MIC2

(HdMic) to XEAR. Ensure

the correct MIC bias is on.

Is the DC bias

seen at XEAR

output of the

UEM?

(at C4104)

YES

Are audio signals

fr o m UE M O K ?

(at C4104, R4100,

C4105)

YES

Note! OMAP, UEM and UPP are unchangeable.

NO

NO

Change

UEM

Change

UEM

Does audio work in

a call?

YES

END

NO

Change

UPP

56 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 59

RM-12

P

Internal Hands Free Speaker (1)

IHF doesn't work

Nokia Customer Care

START

Check I H F spe aker ,

contacts and PWB pads

Are they OK?

YES

Pl a y MI D I , A A C o r

MP3 play back fi l e from

IHF. Ensure that

vo l u m e lev el is high

enough.

Is IHF speaker

working?

NO

NO

Note! OMAP, UEM and UPP are unchangeable.

Clean contacts an d

replace IHF speaker

(B2120)

Is the DC bias

from Audio PA to

IHF-speaker pads

OK? (~1.8Vdc at

B2120)

NO

Check audio path from the

IHF-speake r to the Audio PA

(L2101, R2102, C2134, C 2148).

Change component s if needed.

Is the DC bias

from Audio PA to

IHF-speaker pads

OK? (~1.8Vdc at

B2120)

NO

Change Audio

(N2100)

YES

Is the DC bias

from CODE C to

Audio PA (~ 1.4Vdc

at C2107)

OK?

YES

Is digital audio

signal from OMAP

to CO DEC present

at J4100?

YES

Change audio

CODEC

(N4100)

YES

NO

Change OMAP

(D4800)

Ar e the CO DEC

Cont rol-s ignals

(at R4800) OK?

YES

Change Audio

CODEC (N4100)

NONO

Change OMAP

(D4800)

See the following flow chart,

Issue 1 11/2004 COMPANY CONFIDENTIAL 57

Copyright © 2004 Nokia. All Rights Reserved.

Page 60

CCS Technical Documentation

Internal Hands Free Speaker (2)

See the previous flow chart

Set Phoenix Audio Routing

(HdMic) to XEAR. Ensure

YES

from a working MIC input

MIC1 (HpMic) or MIC2

the correct MIC bias i s

on.

Is the DC bias

seen at XEAR

output of the

UEM?

(at C4104)

Note! OMAP, UEM and UPP are unchangeable.

NO

Change

UEM

RM-12

YES

Are audio signals

fr o m UE M O K ?

(at C4104, R4100,

C4105)

YES

Does audio work in

a call?

YES

END

NO

NO

Change

UEM

Change

UPP

58 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 61

RM-12

Microphone

Microphone doesn't work

Nokia Customer Care

START

Check MIC module and

PWB contact s.

Are they OK?

YES

Set Phoeni x Audio

Routing from MIC1

(HpMic) to a w orking

audio output (HpEar or

XEAR). Ens ure MIC

Bias (M ICB1) is set on.

YES

Is MIC Bias 2.1V

present at R 2128?

Note! OMAP, UEM and UPP are unchangeable.

NO

Clean contacts

and replace

MIC module

(B2115)

Check R2126, R2124,

R2128, R2129, C2122,

C2125, C2126, C2127,

C2133. Change

com ponent s if needed.

Is MIC Bias 2.1V

present at R2128?

NONO

Change UEM

YESYES

Check R2126, R2124,

Are audio signals

from MI C to UEM

OK?

YES

Does the audio work

in a call?

NO

R2128, R2129, C2122,

C2125, C2126, C2127,

C2133. Check als o

R2127. Change

com ponent s if needed.

Change UPP

Are audio signals

from MIC to UEM

OK?

YES

NONO

Change UEM

YES

END

Issue 1 11/2004 COMPANY CONFIDENTIAL 59

Copyright © 2004 Nokia. All Rights Reserved.

Page 62

CCS Technical Documentation

Display mod

ule

Display troubleshooting

Display module

troubleshooting.

troubleshooting.

Main level

Main level.

Start

RM-12

Blank display. Wrong colors. Chancing

colors, lines or areas. Backlight OK.

Display electrical problems,

connection problems

Goto Blank Display

Troubleshooting

Touchscreen

is not working.

Goto Touchscreen

Troubleshooting

Problem type?

Display optical problems.

Illumination is not working,

partially working or not even.

Pixel defects.

Goto Faulty Display

Troubleshooting

Display is dimm,

key leds not ok

Goto Backlight

Troubleshooting

60 COMPANY CONFIDENTIAL Issue 1 11/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 63

RM-12

Blank Display (1)

Start

Check for bad

connections/

broken

connector.

Fault in

connectors

Nokia Customer Care

Connections

OK

Clean/replace

connector from

phone.

Working?

Yes

End

Measure V28

No

from L4427.

Voltage OK?

Check

C4439-C4440,

L4427

components

OK?

Replace

broken

components.

Display

working?

Yes

Yes

No

L4427 = 0V

No

Go to Power

troubleshooting

No

Try with

another display

module. Display

working?

No

Inspect EMI

components

Z4421-Z4423 and

display clock

filtering capacitor

C4444 for poor

soldering.

Yes

Use oscilloscope and tap

touchscreen before

measuring (clock is not

active in partial mode)

display module.

Change new

Calibrate

touchscreen

End

Yes

No

Goto OMAP

troubleshooting

Flash phone.

Display OK?

Yes

End

No clock

Measure

display clock

from C4444.

12.5MHz clock detected

Go to blank

display

troubleshooting

Issue 1 11/2004 COMPANY CONFIDENTIAL 61

Copyright © 2004 Nokia. All Rights Reserved.

Page 64

CCS Technical Documentation

Blank Display (2)

Continues from

blank display

troubleshooting

page1

Start phone with

display flex

disconnected.

Measure

X4423 pins #9

#10 #11 with

oscilloscope

RM-12

Toggling

Start phone again with

display flex connected

and retest.

No toggling

Replac e

Z4421 EMI

filter.

Display

working?

Yes

No

Measure

X4423 pins

#15 and

#30 w ith

oscilloscope

No toggling

Replace

Z4422 and

Z4423 EMI

filter. Display

working?

Pins are display data

lines. There should be

data toggling if phone