Page 1

NHL-2NA Series Transceivers

System Module LG4 and Grip

Module LS4

Issue 2 11/02 ¤Nokia Corporation

Page 2

System Module LG4 and Grip Module LS4 CCS Technical Documentation

This page intentionally left blank.

Page 2 ¤Nokia Corporation Issue 2 11/02

Page 3

CCS Technical Documentation System Module LG4 and Grip Module LS4

Table of Contents

Page No

Abbreviations ................................................................................................................. 6

LG4 System Module ...................................................................................................... 8

IIntroduction ................................................................................................................8

Technical overview ........................................................................................................ 8

LG4 features ................................................................................................................8

Component placement and PWB outline .....................................................................8

Block diagram .............................................................................................................. 12

UI Interface ................................................................................................................12

Baseband Technical Summary..................................................................................... 13

Functional Description................................................................................................. 14

BB Description ..........................................................................................................14

Memory Configuration............................................................................................ 14

Energy Management ............................................................................................... 14

Modes of Operation ...................................................................................................15

Voltage limits .......................................................................................................... 15

Clocking Scheme .......................................................................................................16

UPP_WD2 voltage/clock frequency adjusting........................................................ 16

Power Distribution, Control and Reset ......................................................................17

Power-up sequence (Reset mode) ........................................................................... 18

Powering off............................................................................................................ 18

Controlled powering off .......................................................................................... 18

Uncontrolled powering off ...................................................................................... 18

Watchdogs............................................................................................................... 18

Charging .................................................................................................................. 19

Chargers .................................................................................................................. 19

Battery ..................................................................................................................... 19

Back-up battery and real time clock ..........................................................................20

Baseband Measurement A/D Converter ....................................................................20

NHL-2NA BB Features & HW interfaces ................................................................... 21

NHL-2NA BB User interface ....................................................................................21

UI-Module Interface................................................................................................ 21

Power Key ............................................................................................................... 21

Grip Interface .......................................................................................................... 21

Bluetooth ....................................................................................................................23

IR ...............................................................................................................................23

SIM Interface .............................................................................................................23

NHL-2NA Audio Concept .........................................................................................24

Earpiece................................................................................................................... 24

Microphone ............................................................................................................. 25

IHF Amplifier and Speaker ..................................................................................... 25

External Audio interface ......................................................................................... 26

Camera Interface ........................................................................................................26

Proximity Sensor .......................................................................................................27

Proximity Detector components ................................................................................28

Lightguides.............................................................................................................. 28

IRED........................................................................................................................ 28

Photodiode............................................................................................................... 28

Issue 2 11/02 ¤Nokia Corporation Page 3

Page 4

System Module LG4 and Grip Module LS4 CCS Technical Documentation

HW Implementation................................................................................................ 28

Ambient Light Sensor ................................................................................................30

Flashing ......................................................................................................................31

Connections to Baseband ........................................................................................ 31

Testing interfaces .......................................................................................................32

Extreme Voltages ......................................................................................................33

Temperature Conditions ............................................................................................33

Humidity and Water Resistance ................................................................................33

RF Module .................................................................................................................34

Functional block descriptions.................................................................................. 34

The Frequency synthesizer...................................................................................... 34

RF Frequency Plan .................................................................................................. 36

DC characteristics ................................................................................................... 37

Regulators................................................................................................................ 37

Power Distribution Diagram ................................................................................... 38

RF characteristics .................................................................................................... 39

RF Block Diagram .................................................................................................. 40

Voltage Supplies and References ..............................................................................41

Receiver .....................................................................................................................43

Transmitter .................................................................................................................44

AGC strategy........................................................................................................... 45

AFC function........................................................................................................... 47

DC-compensation.................................................................................................... 48

Power control with analog temperature compensation scheme .............................. 48

Grip Module................................................................................................................. 50

Abbreviations .............................................................................................................50

Introduction ................................................................................................................50

General Interface between Grip and Transceiver ......................................................53

Grip Keyboard ...........................................................................................................56

Electrical implementation ....................................................................................... 56

Unit limits................................................................................................................ 57

Vibra ..........................................................................................................................57

Electrical interface .....................................................................................................57

Current Gauge ............................................................................................................59

Interfacing the current gauge................................................................................... 59

Backlight ....................................................................................................................61

Electrical interface................................................................................................... 61

Hall Sensor and Magnet .............................................................................................62

Magnet..................................................................................................................... 62

DC Jack and Battery Connector ................................................................................63

Electrical interface................................................................................................... 63

Table of Schematic Diagrams

Page No

RF-BB connection diagram 1

Accessories interface diagaram 2

AEM diagram 3

Baseband Diagram 4

BB-RF Interface diagram 5

Page 4 ¤Nokia Corporation Issue 2 11/02

Page 5

CCS Technical Documentation System Module LG4 and Grip Module LS4

SIM card interface diagram 6

CPU Diagram 7

IR module diagram 8

LPRF diagram 9

Memories diagram 10

Power Diagram 11

RF Diagram 12

Test Interface 13

UEM Diagram 14

User Interface Diagram 15

Parts Placement Diagram LG4_07 16

Issue 2 11/02 ¤Nokia Corporation Page 5

Page 6

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Abbreviations

ADC Analog-Digital Converter

AEM Auxiliary Energy Management ASIC

AFC Automatic Frequency Control

ALG Ambient Light Guide

ALS Ambient Light Sensor

ARM Processor architecture

ASIC Application Specific Integrated Circuit

BB Baseband

BLUETOOTH, BT Bluetooth

BSI Battery Size Indicator

CBus Control Bus connecting UPP_WD2 with AEM and UEM

CCI Camera Control Interface

CCP Compact Camera Port

CMT Cellular Mobile Telephone (MCU and DSP)

CPU Central Processing Unit

CSP Chip Scale Package

CTSI Clocking Timing Sleep Interrupt

DAC Digital-Analog Converter

DAI Digital Audio Interface

DBUS Data Bus

DCN Offset Cancellation contol signal

DIF Display InterFace

DLL Dynamic Link Library

DRC Dynamic Range Controller

DSP Digital Signal Processor

EFR Enhanced Full Rate

EGSM Extended – GSM

EQ Equalizer

EXT RF External RF

GPRS General Packet Radio Service

GSM Groupe Special Mobile/Global system mobile

HF Hands free

HFCM Handsfree Common

HS Handset

HSCSD High Speed Circuit Switched Data

I/O Input/Output

IHF Integrated hands free

IC Integrated Circuit

IR Infra red

IRED InfraRed Emitting Diode

IrDA Infrared Association

LCD Liquid Crystal Display

LG4 NHL-2NA Main PWB module

LNA Low Noise Amplifier

MCU Micro Controller Unit

MIC, mic Microphone

PA Transmit Power Amplifier

Page 6 ¤Nokia Corporation Issue 2 11/02

Page 7

CCS Technical Documentation System Module LG4 and Grip Module LS4

PC Personal Computer

PDA Pocket Data Application

PWB Printed Wiring Board

RF Radio Frequency

RFBUS Control Bus For RF

SDRAM Synchronous Dynamic Random Access Memory

SIM Subscriber Identity Module

UI User Interface

UEM Universal Enefry Management

VGA Video Graphic Array

VCXO Voltage Controlled Crystal Oscillator

VCTCXO Voltage Controlled Temperature Compensated Crystal Oscillator.

VCM Voltage Controlled Module

VGA Video Graphics Array

Issue 2 11/02 ¤Nokia Corporation Page 7

Page 8

System Module LG4 and Grip Module LS4 CCS Technical Documentation

LG4 System Module

IIntroduction

This is the module specification of LG4 which is the main electronics module in NHL-2NA

GSM dual band phone. NHL-2NA phone is also nick named as Nokia 7650. The sales

name is Nokia 7650.

Technical overview

LG4 features

• Dual band GSM tranceiver. EGSM900 and GSM1800 bands with GPRS class 6 and

HSCSD data capability

• BB release is Galaxy WD2, main ASIC UPP_WD2

• RF release is Gemini premium release for Lilly (but shrinked)

• Bluetooth, based on BT102 module

• IR, HW capable for 1Mbit data speed

• Proximity sensor for controlling integrated handsfree feature (IHF)

• Handsfree, headset and earpiece audio connections

• VGA camera module connected with spring connector to LG4

• Ambient light sensor for controlling display and keyboard backlights

• Color display interface

• Flex cable interface to LS4 Grip module

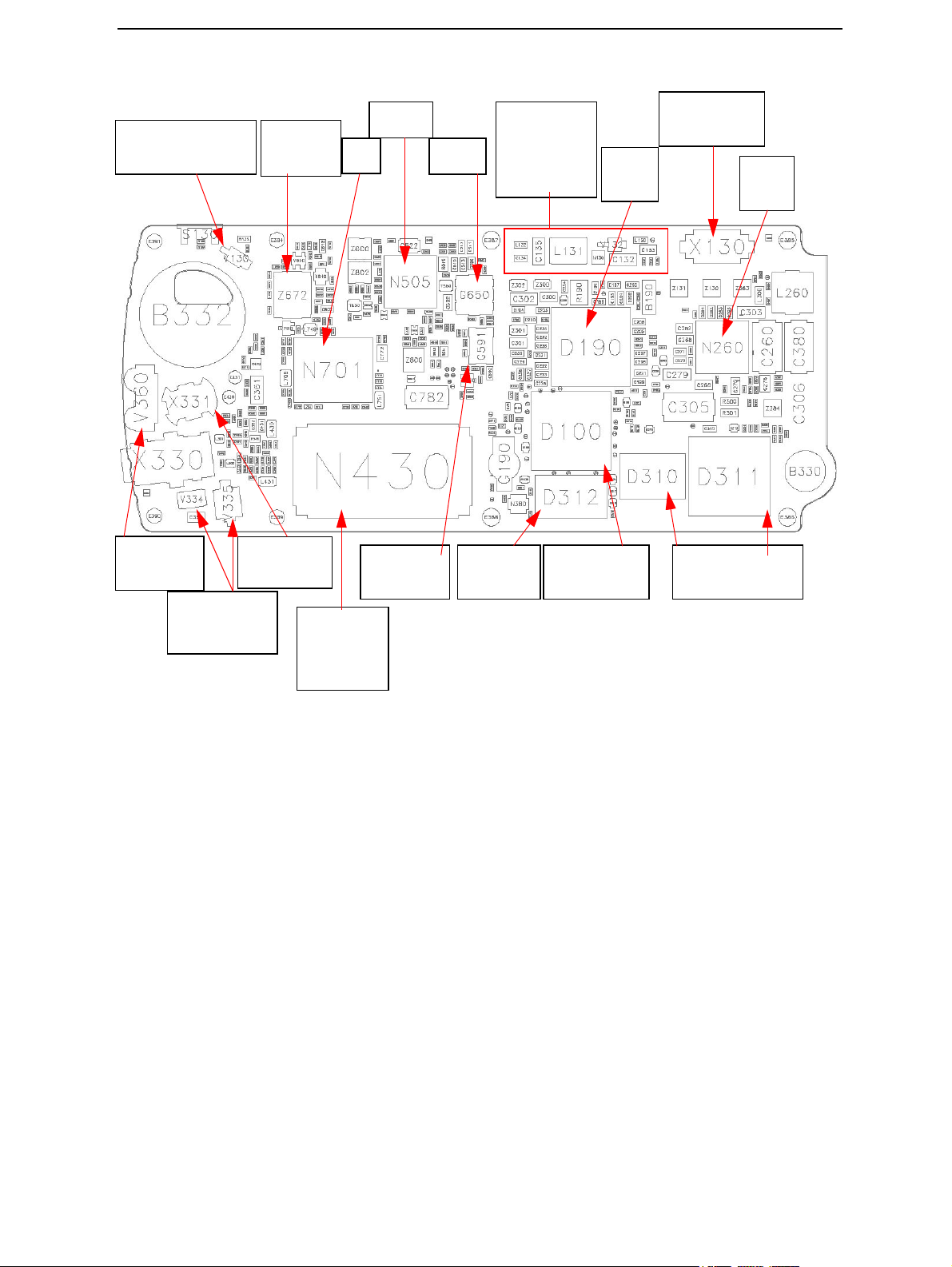

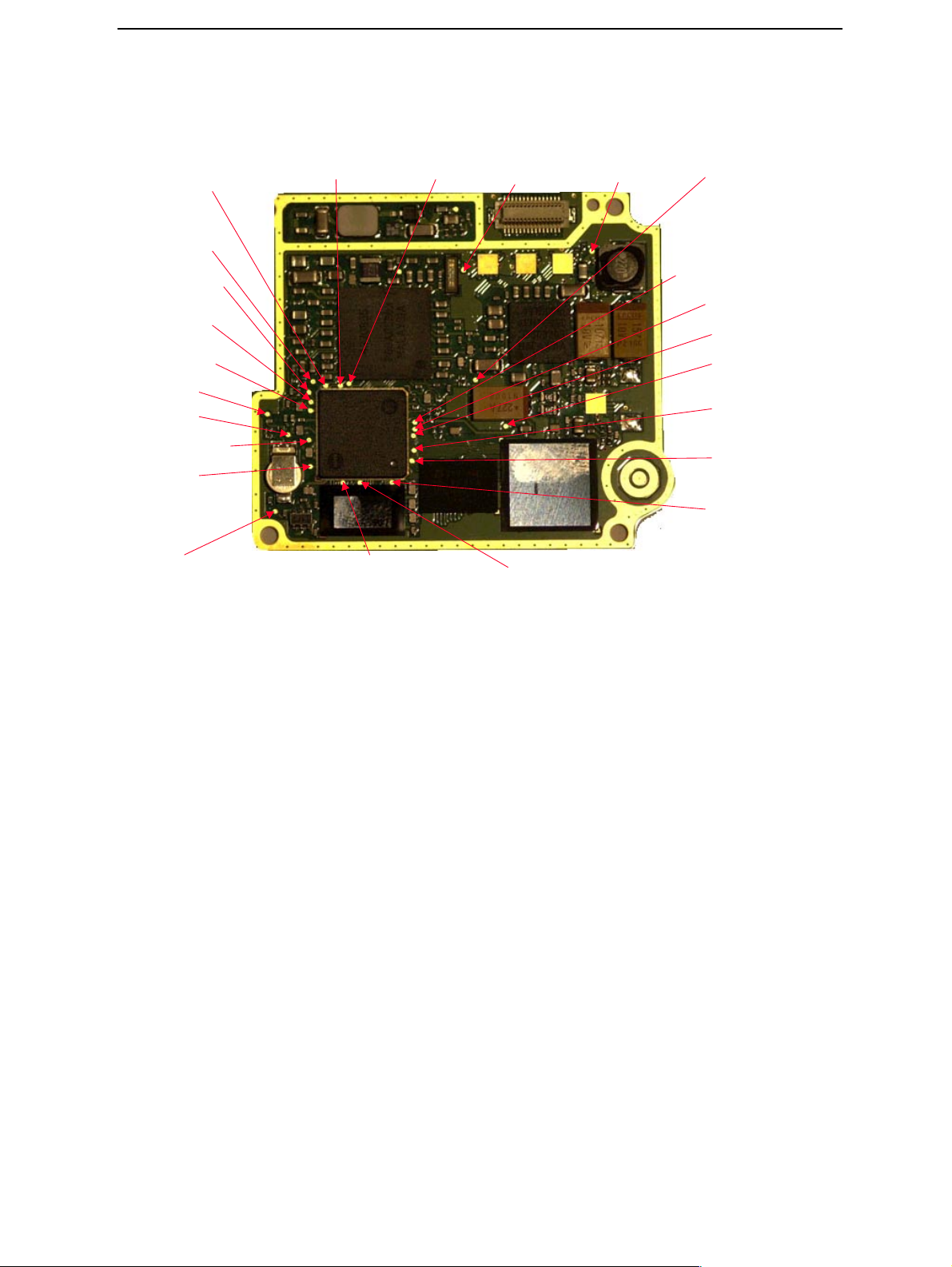

Component placement and PWB outline

Components are placed only on one side of the LG4 module.

Figure 1 shows LG4 module from component side, main components are listed.

Page 8 ¤Nokia Corporation Issue 2 11/02

Page 9

CCS Technical Documentation System Module LG4 and Grip Module LS4

r

r

Figure 1: Main components on LG4

UI module

connecto

AEM

Ambient light

senso

Antenna

switch

PA

Hagar

VCO

UI module

backlight

DC/DC

UEM

IR

Module

Proximity

sensor

Earpiece

Bluetooth

module,

BT102

VCTCXO

64Mbit

SDRA

UPP_WD2

32 + 128

Mbit flashes

Issue 2 11/02 ¤Nokia Corporation Page 9

Page 10

System Module LG4 and Grip Module LS4 CCS Technical Documentation

p

g

p

p

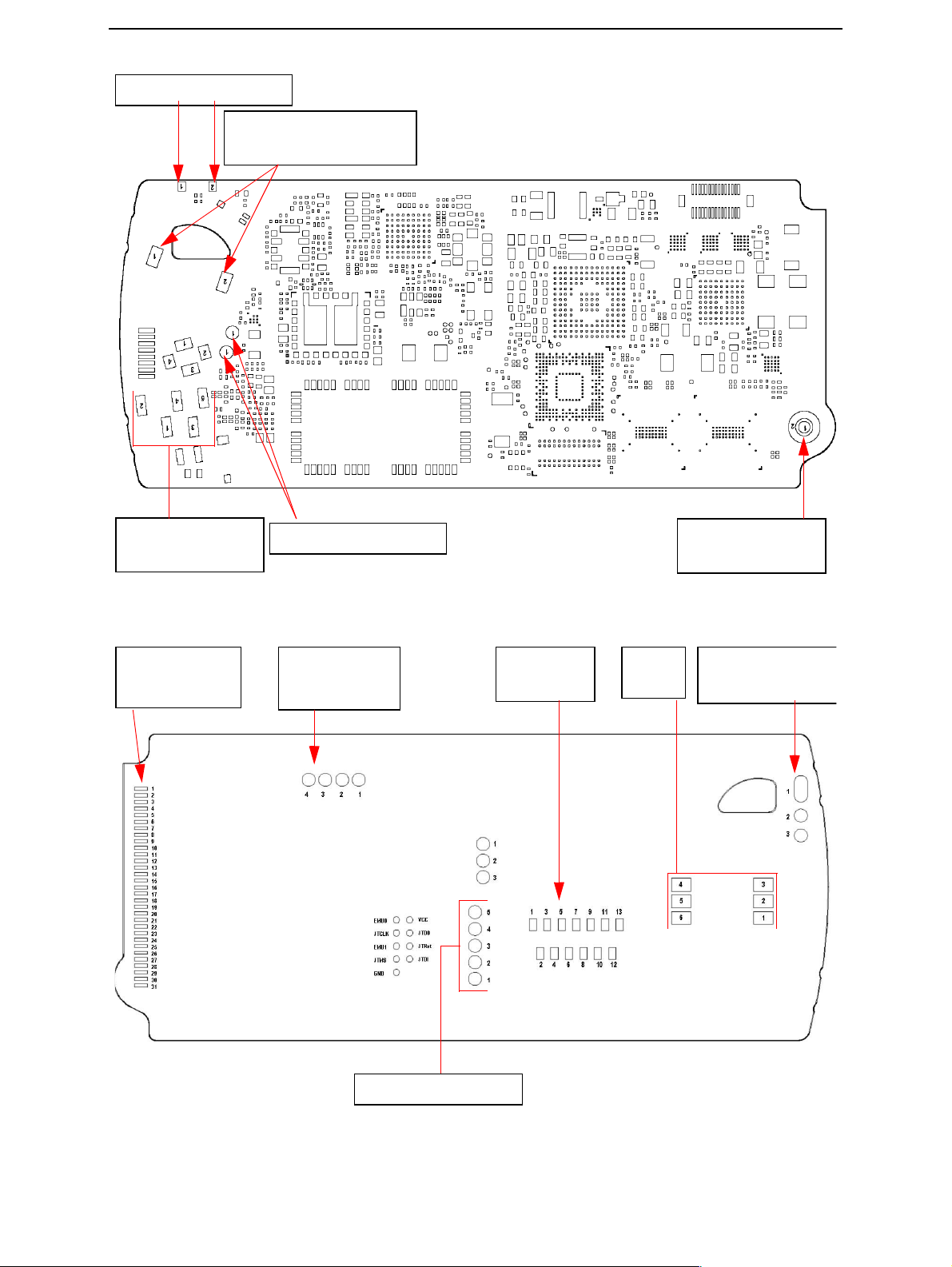

Figure 2: Spring connection pads on top side of LG4

Power switch pads

Integrated handsfree

speaker pads

Headset

connector pads

Flex solder

pads, Grip IF

BT antenna pads

Microphone

ads

Figure 3: Spring connection pads on back side of LG4 and flex cable solder pads

Prod testing:

Powering

Camera

ads

SIM

GSM antenna

ads

Production testin

Page 10 ¤Nokia Corporation Issue 2 11/02

Page 11

CCS Technical Documentation System Module LG4 and Grip Module LS4

Figure 4: Test points in LG4 baseband

Test points of BB

)

J140

(VBAtt)

J262 (UEMRst)

J114 (FLDEX) (mem cntr)

J113 (FLCS0X)

J109 (FLADa0)

J105 (AEMSleepX

J111 (FLCS1x)

J120 (RxQD)

J117 (TxQD)

RF: J118 (AuXDA)

J119 (RxID)

J110 (VcoreA)

J102 (SleepX)

J103 (PURX)

J104 (UEMInt)

J116 (TxID)

J270

(GenV battIO

J138 (Vctrl (camera)

J100 (RFClk)

J101 (Sleepclk)

J106

(SDRDa0)

J115 (FlClk)

J07

(SDR Ad0)

J108

(SDRAMClk)

Issue 2 11/02 ¤Nokia Corporation Page 11

Page 12

System Module LG4 and Grip Module LS4 CCS Technical Documentation

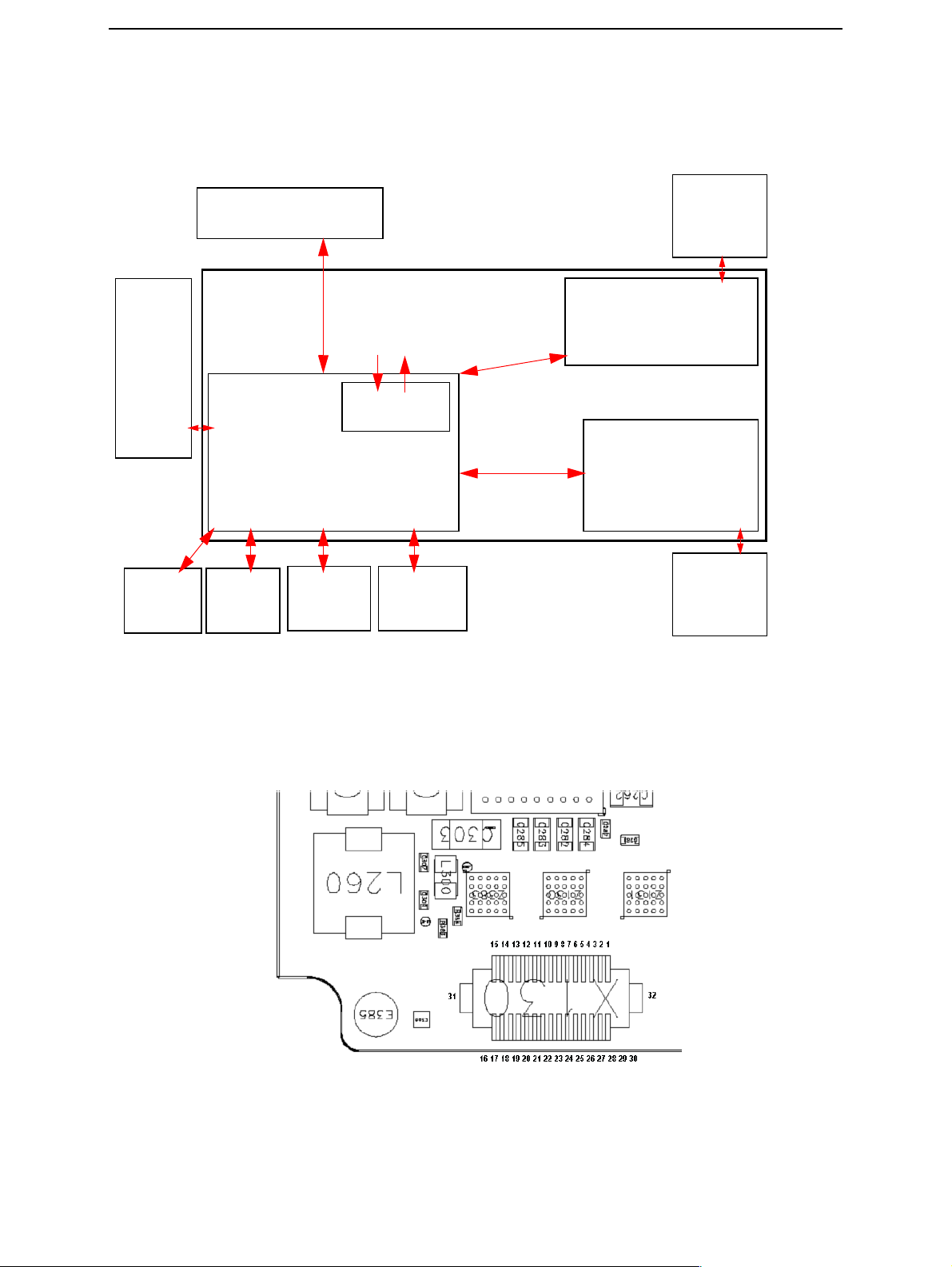

Block diagram

Below is the block diagram of LG4 module. External interfaces are drawn as arrows crossing LG4 border.

Figure 5: Block diagram of LG4

BT

antenna

Flex

to LS4

(Grip)

Flashing & Testing

LG4 module

BB

Sensors

Bluetooth

RF

VGA

camera

UImodule

Audio

SIM card

GSM

antenna

UI Interface

UI module interface pin numbering is presented in figure below. UI interface details are in

UI-module specification.

Figure 6: UI connector pin numbering on LG4 side

Page 12 ¤Nokia Corporation Issue 2 11/02

Page 13

CCS Technical Documentation System Module LG4 and Grip Module LS4

Baseband Technical Summary

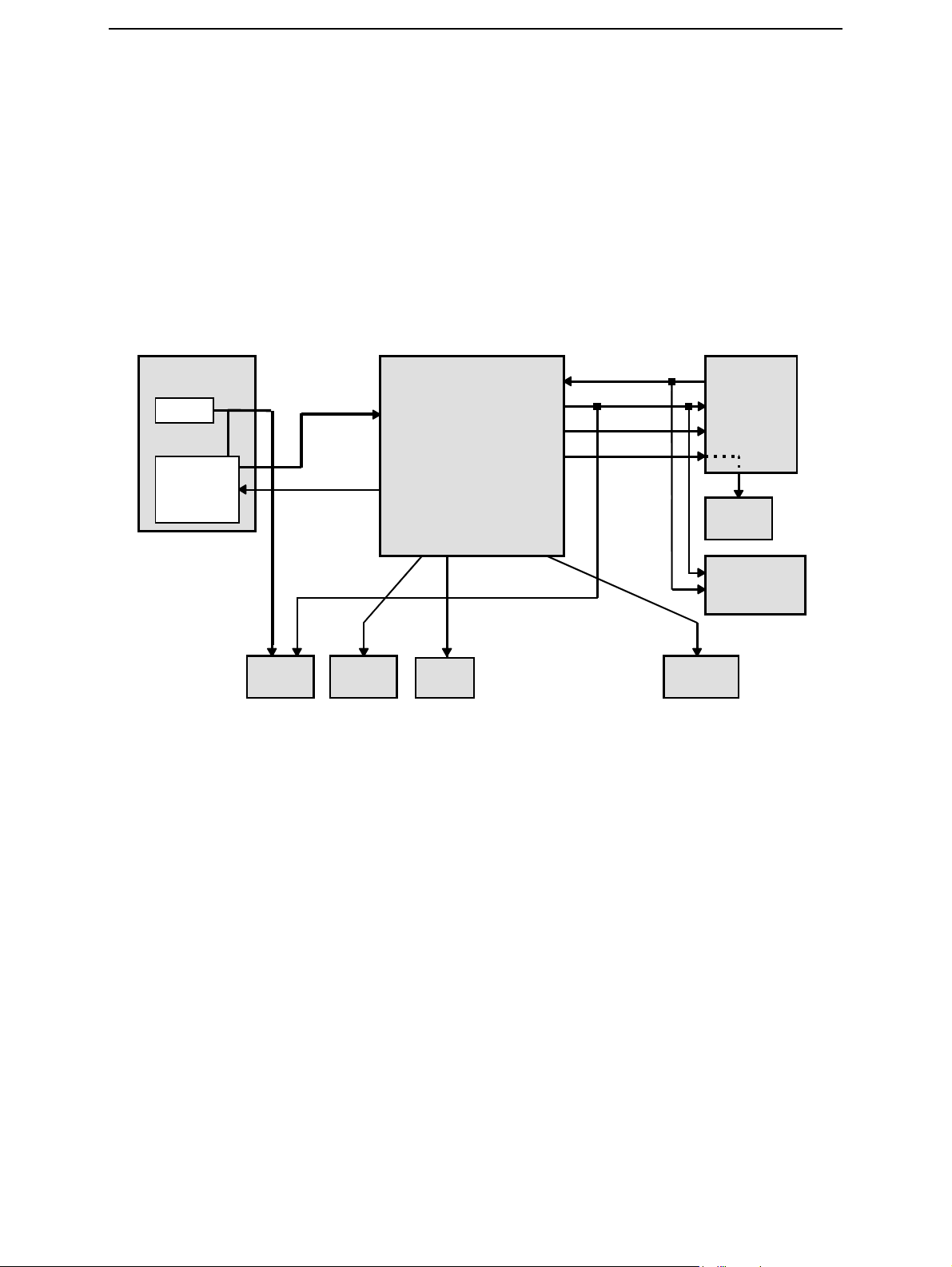

The heart of the BB is UPP_WD2, which includes MCU, DSP and Digital Control Logic.

Powering handled by Using AEM ASIC and UEM ASIC. There is Flash Memory 128Mbit +

32Mbit Flashes (20 Mbytes) and 64 Mbit (8 Mbytes) SDRAM. So there is a total of 28

Mbytes of Memory Capacity.

In BB there is an integrated Handsfree Audio Amplifier In AEM. There are two Audio Elements (Earpiece 8 mm and Speaker 16 mm) and External Galvanic Headset (DCT4) interface. IHF Speaker is also used to handle the Ringing tone. For IHF automated off function

there is proximity Sensor. In NHL-2NA there is only one microphone for both modes HS

and IHF.

For Data connectivity there is 1Mbit IR Module (IrDA compatible) and Bluetooth.

Display is MD-TFD type Color Display with 4096 Colors and 176x208 pixels with Backlight. Keyboard is partially in UI-Module and Partially in Grip-Module. Also there is This

Navigation Key Feature in UI-Module.

For imaging purposes BB supports VGA camera via CCP interfaces, which are integrated

in UPP_WD2.

Issue 2 11/02 ¤Nokia Corporation Page 13

Page 14

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Functional Description

BB Description

Core is based on UPP_WD2 CPU, which is a special version of the DCT4 UPP ASIC.

UPP_WD2 takes care of all the signal processing and operation controlling tasks of the

phone as well as all PDA tasks.

For Power management there are two Asics for controlling energy management and supplying current and different voltages; UEM and AEM. UEM and SW have the main control of the system voltages and operating modes and AEM acts as an auxiliary source of

voltages and current. The main reset for the system is generated by the UEM.

The interface from the RF and audio sections is handled also by UEM. This ASIC provides

A/D and D/A conversion of the in-phase and quadrature receive and transmit signal

paths and also A/D and D/A conversions of received and transmitted audio signals. Data

transmission between the UEM, AEM and RF and the UPP_WD2 is implemented using

different serial connections (CBUS, DBUS and RFBUS). Digital speech processing is handled by UPP_WD2 ASIC. Internal HF with proximity sensor functionality is implemented

inside the AEM ASIC.

A real time clock function is integrated into UEM, which utilizes the same 32kHz-clock

source as the sleep clock. A rechargeable battery provides backup power to run the RTC

when the main battery is removed. Backuptime is 20 Hours.

Memory Configuration

NHL-2NA uses two kinds of memories, Flash and SDRAM. These Memories have their

own Dedicated buses in UPP_WD2.

Synchronous DRAM is used as working memory. Interface is 16 bit wide data and 14 bit

Address. Memory clocking speed is 104 MHz. The SDRAM size 64Mbits (4Mx16).

SDRAM I/O is 1.8 V and core 2.78 V supplied by AEM’s regulators VIOA and VMEMA. All

memory contents are lost if the supply voltage is switched off.

Multiplexed Flash Memory Interface is used to store the MCU program code and User

Data. The memory interface is a burst type FLASH with multiplexed address/data bus.

Both I/O and core voltage are 1.8 V supplied by AEM’s VMEMB.

Energy Management

The master of EM control is UEM and with SW they have the main control of the system

voltages and operating modes. AEM (Auxiliary Energy Management) acts as an auxiliary

source of voltages and current.

Page 14 ¤Nokia Corporation Issue 2 11/02

Page 15

CCS Technical Documentation System Module LG4 and Grip Module LS4

Modes of Operation

NHL-2NA employs several hardware & SW controlled operation modes. Main Modes are

described below.

• NO_SUPPLY mode means that the main battery is not present or its

voltage is too low (below UEM master reset threshold) and back-up battery voltage is too low.

• In BACK_UP mode the main battery is not present or its voltage is too

low but back-up battery has sufficient charge in it.

• In PWR_OFF mode the main battery is present and its voltage is over

UEM master reset threshold. All regulators are disabled.

• RESET mode is a synonym for start-up sequence and contains in fact

several modes. In this mode regulators and oscillators are enabled and

after they have stabilized system reset is released and PWR_ON mode

entered.

• In PWR_ON mode SW is running and controlling the system.

• SLEEP mode is entered from PWR_ON mode when the system’s activity is low (SLEEPX and AEMSLEEPX controlled by SW).

• FLASHING mode is for production SW download.

Voltage limits

In the following the voltage limits of the system are listed. These are also controlling system states.:

Parameter Description Value

V

MSTR+

V

MSTR-

V

COFF+

V

COFF-

V_BU

COFF+

Master reset threshold (rising) 2.1 V (typ.)

Master reset threshold (falling) 1.9 V (typ.)

Hardware cutoff (rising) 3.1 V (typ.)

Hardware cutoff (falling) 2.8 V (typ.)

Back-up battery cutoff (rising) 2.1 V (typ.)

V_BU

SW

COFF

COFF-

Back-up battery cutoff (falling) 2.0 V (typ.)

SW cutoff limit (> regulator drop-out limit) MIN! 3.15 V SW changeable

The master reset threshold controls the internal reset of UEM. If battery voltage is above

, UEM’s charging control logic is alive. Also, RTC is active and supplied from the

V

MSTR

main battery. Above V

UEM allows the system to be powered on although this may

MSTR

not succeed due to voltage drops during start-up. SW can also consider battery voltage

Issue 2 11/02 ¤Nokia Corporation Page 15

Page 16

System Module LG4 and Grip Module LS4 CCS Technical Documentation

too low for operation and power down the system.

Clocking Scheme

A 26 MHz VCTCXO is used as system clock generator in GSM. During the system start-up,

UEM and AEM use their own RC-oscillators to generate timing for state machines. All

clock signals of the engine are illustrated in following figure.

In PWR_ON mode, SW must configure CBUS clock (1MHz) to be active all the time, as

this clock is used in AEM as digital clock and for the SMPS. Bluetooth uses 26 MHz analog clock.

Figure 7: NHL-2NA Clocking.

RF

26 MHz

VCXO

RF-ASIC

(Hagar)

RFClk

13 MHz

RFBusCl

UPP_WD2 UEM

SleepClk

CBusCl

DBusCl

SIMCl

SIM

Flash

Clk

LPRF

FLASHes

CAMERA

In SLEEP mode the VCTCXO is off. UEM generates low frequency clock signal (32.768

kHz) that is fed to UPP_WD2, Bluetooth and AEM.

UPP_WD2 voltage/clock frequency adjusting

The systems of the BB make it possible to adjust both clock frequency and the core voltage of the main ASIC. Here is a rough description of the Clocking Scheme.

No external clock is available for UPP_WD2 before VCTCXO starts. As reset is released,

the VCTCXO is running and MCU uses the 13 MHz clock while DSP is in reset. There are

three identical DPLL's, for MCU, for DSP and for accessory interfaces, which can be controlled independently. The clock for MCU can be up to 104 MHz and 117 MHz is maximum clock Frequency for the DSP. These clock signals are used either directly (SDRAM IF)

or divided down for the interfaces (e.g. flash IF).

SDRAM

Clk

SDRAM

AEM

Page 16 ¤Nokia Corporation Issue 2 11/02

Page 17

CCS Technical Documentation System Module LG4 and Grip Module LS4

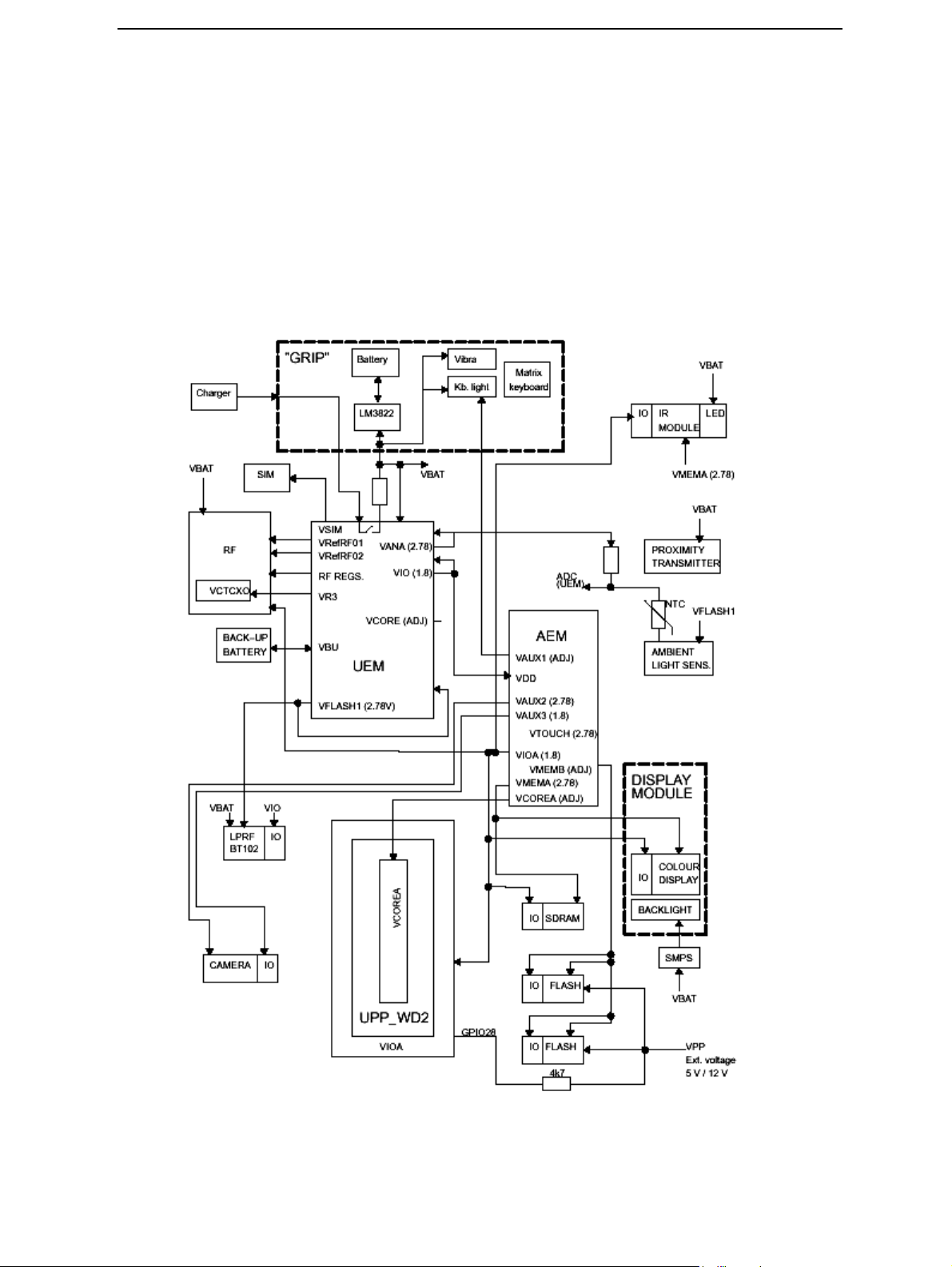

Power Distribution, Control and Reset

All power (except backup battery power) is drawn from BLB-2 Li-Ion battery located in

the Grip part of the phone. Power goes through LM3822 current gauge which is used for

current measurement and thus for remaining operating time estimation.

LG4 board contains two power ASIC’s UEM and AEM which contain the regulators

needed for generating the different operating voltages. In addition there is a SMPS in

LG4 generating the operating voltage for display module backlighting. In LS4 keyboard

the backlight is powered with a current pump.

Figure 8: Power distribution diagram

Issue 2 11/02 ¤Nokia Corporation Page 17

Page 18

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Power-up sequence (Reset mode)

RESET mode can be entered in four ways: by inserting the battery or charger, by RTC

alarm or by pressing the power key. After voltage appearing at UEM’s pin UEMRSTX (connected to AEM’s pin REFENA) is used as indication for AEM to start up HW regulators.

Also VCTXO is Powered up by using VR3 (UEM). After the 220 ms delays regulator are

configured and UEM enters PWR_ON mode and system reset PURX is released.

During system start-up, in RESET state, the regulators are enabled, and each regulator

charges the capacitor(s) at the output with the maximum current (short circuit current)

it can deliver. This results in battery voltage dropping during the start-up. When a battery with voltage level just above the hardware cutoff limit is inserted, the system may

not start due to excessive voltage dipping. Dropping below 2.8 V for longer than 5 us

forces the system to PWR_OFF state.

Powering off

Controlled powering off is done when the user requests it by pressing power-key or when

the battery voltage is falling too low. Uncontrolled powering off happens when battery is

suddenly removed or if over-temperature condition is detected in regulator block while

in RESET mode. Then all UEM’s regulators are disabled immediately and AEM’s regulators

are disabled as VDD supply disappears.

Controlled powering off

For NHL-2NA powering off is initiated by pressing the power key and Power off sequence

is activated in UEM and SW. Basically Power key cause UEM Interrupt to UPP_WD2 and

SW sets Watchdog time value to zero and as this happens, PURX is forced low and all

regulators are disabled.

If the battery voltage falls below the very last SW-cutoff level, SW will power off the

system by letting the UEM’s watchdog elapse.

If thermal shutdown limit in UEM regulator block is exceeded, the system is powered off.

System reset PURX is forced low. AEM has its own thermal limit for regulators. Whenever

the limit is exceeded, an interrupt is given to UPP_WD2 and SW should immediately

power off the whole system. AEM will disable its regulators in any case by itself after 10

ms delay (uncontrolled powering off).

Uncontrolled powering off

This happens when the battery is suddenly removed and is problematic as data may corrupt in memories. UEM’s state machine notices battery removal after battery voltage has

been below V

COFF-

regulators are disabled. AEM’s regulators except for VCOREA, VIOA, VMEMA and VMEMB

are disabled as PURX goes low. These regulators stay enabled as long as there is voltage

present at pin VDD (from UEM’s VIO).

for 5 us and enters PWR_OFF mode. PURX is set low and all UEM’s

Watchdogs

There are three watchdogs in UEM. First one is for controlling system power-on and

power-down sequences. The initial time for this watchdog after reset is 32 s and the

Page 18 ¤Nokia Corporation Issue 2 11/02

Page 19

CCS Technical Documentation System Module LG4 and Grip Module LS4

watchdog can not be disabled. The time can be set using a register. This watchdog is used

for powering the system off in a controlled manner. The other one is for security block

and is used during IMEI code setting. The third one is a power key watchdog. It is used to

power off the system in case SW is stuck and the user presses the power key. This WD is

SW configurable.

There is also a ”soft watchdog” in UPP_WD2. It is used to reset the chip in case software

gets stuck for any reason. The Bluetooth module also contains a watchdog.

Charging

Charging controls and charge switch is in UEM. There are three different charging

modes; charging empty battery (start-up charge mode), PWM charging mode (without

SW control) and SW controlled charging.

UEM digital part takes care of charger detection (generates interrupt to UPP_WD2),

pulse width modulated charging control (for internal charge switch and external performance charger) and over voltage and current detection. SW using registers controls all

these.

Chargers

Battery

NHL-2NA BB is supporting a standard charger (two wires) or fast (performance) charger

(three wires), Chargers ACP-7, ACP-8 and ACP-9 and ACP-12, Cigarette Charger LCH-8

are supported.

With the standard version the PWM signal is set to 1 Hz, while with fast charger it is set

to 32 Hz. Also PWM signal is connected from UEM pin to the charger’s control input.

Due to high current consumption of the NHL-2NA BB, a performance charger ACP-8 is

needed.

NHL-2NA Battery is a detachable, semi-fixed Lithium-Ion BLB-2 battery. Other batteries

are allowed to use but NOT charged. Nominal voltage is thus 3.6-3.7 V (max charging

voltage 4.1-4.2 V).

The interface consists of four pins: VBAT, GND, BSI and BTEMP. Pull-down resistor inside

of the batteries (BSI signal) recognizes the battery types. Voltage level at BSI line is measured with using Em's AD-converter.

Issue 2 11/02 ¤Nokia Corporation Page 19

Page 20

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Back-up battery and real time clock

Real time clock (RTC), crystal oscillator and back-up battery circuitry reside in UEM. A

register in UEM controls back-up battery charging and charging is possible only in

POWER_ON State.

Baseband Measurement A/D Converter

The UEM contains 11 channels A/D converter, which is used for different Baseband measurement purposes. The resolution of A/D converter is 10 bits. Converter uses the CBUS

interface clock signal for the conversion. An interrupt will be given to the MCU at the

end of the all measurement. Converter is used for following purposes.

• Battery Voltage Measurement A/D Channel (Internal)

• Charger Voltage Measurement A/D Channel (Internal)

• Charger Current Measurement A/D Channel (Internal)

• Battery Temperature Measurement A/D Channel (External)

• Battery Size Measurement A/D Channel (External)

• Light Sensor Measurement A/D Channel (External)

• PA Temperature measurement A/D Channel (External)

• VCTCXO Temperature measurement A/D Channel (External)

There is also auxiliary AD converter in UEM, which is used to monitor RF functions. Converter is controlled directly by UPP DSP. Converter can be used for following purposes:

VCXO Temperature measurement A/D Channel (if not used in normal AD)

PA Temperature measurement A/D Channel (if not used in normal AD)

Page 20 ¤Nokia Corporation Issue 2 11/02

Page 21

CCS Technical Documentation System Module LG4 and Grip Module LS4

NHL-2NA BB Features & HW interfaces

NHL-2NA BB User interface

UI-Module Interface

Interface is for Color Display 176 x 208 (X3) resolution and backlight is white LED with

lightguide. Also Part of Keyboard is locating in module with Navigation Key. Display is

connected to LG4 by 30-pin Board-to-Board connector. Interface includes also power

rails for UI and Backlight. Interface uses GPIO pins of UPP_WD2.

Power Key

PWROnx of UEM is pulled up to battery voltage by a current source inside UEM. Pressing

PWR-Key connects UEM PWRONX-pin to ground via resistor. The power key has also a

reset function: while removing battery is difficult, a reset can be accomplished by pressing this key for longer time. Power key is connected to main PWB via spring contacts.

Grip Interface

Grip Interface includes Matrix Keyboard & Backlight, Battery interface, Vibra Interface,

Charger interface, Current Gauge interface.

Hall Sensor and Magnet

NHL-2NA is using Hall sensor TLE 4917 (NMP code 4341087) and magnet to find out the

open/close position of the grip. The hall sensor component is in the LG4 BB area and the

magnet is in the grip module. See locations of the sensor and magnet below, figure 9.

As the grip is closed, the hall sensor and magnet are against each other. At this position

the output of the hall sensor is high. As the grip is open and sensor and magnet are separated, the output is low. This low level gives the information to processor that grip is

open.

Figure 9: Locations of the sensor and magnet

Transceiver

LG4

Hall sensor

Grip

LS4

Magnet

Sensor needs 2.7V for operation and that's why Vflash1 voltage is needed to be connected to Vs pin. PRG pin is needed to be connected GND that output is zero as magnet

and sensor are separated. See Principle of the connection of the hall sensor below.

Issue 2 11/02 ¤Nokia Corporation Page 21

Page 22

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Figure 10: Principle of the connection of the hall sensor

Vflash1

100nF

PRG GND GND

Vs GND Q

GenIO25

10pF

UPP_WD2

Pins list of Hall sensors:

Pin Min Nom Max Pin number

Vs 2.4 V 2.7 V 3.5 V 1

GND 0 V 2, 4, 5

Q 0 V 1.8 V 3

PRG 0 V 3.7 V 6

Page 22 ¤Nokia Corporation Issue 2 11/02

Page 23

CCS Technical Documentation System Module LG4 and Grip Module LS4

A

Bluetooth

Bluetooth provides a fully digital link for communication between a master unit and one

or more slave units. The system provides a radio link that offers a high degree of flexibility to support various applications and product scenarios. Data and control interface for

a low power RF module is provided. The transmission is half-duplex. Air bit rate is 812.5

kbit/s.

IR

NHL-2NA BB uses TDFU5102 1Mbit IrDA 1.1 compatible module. Module interface signals are Tx (Transmitted Data), Rx (Received Data) and SD (ShutDown). IR transmission data speed can be from 9.6 kbit/s to 1.15 Mbit/s. The communication over the

IR is always started using bit rate 9.6 kbit/s. and the maximum we use is 115kbit/s.

Digital part is powered with 2.78 V by VMEMA and the LED by VBAT (nom. 4.2 V).

VMEMA is fully SW-controlled regulator. More details of the module can be found out

from IR specification under EDMS. See figure 11 for

Figure 11: IR connected to UPP_WD2

SIM Interface

The SIM interface is located in two chips (UPP_WD2 and UEM). In UEM there is only

support for one SIM card. The interfaces support both 1.8 V and 3 V SIM cards. Adjustable SIM regulator (1.8V/3.0V) is located in UEM and can be controlled by SW.

UPP_WD2

I IR

Block

1.8V

EM

2.7V

Module

TDFU5102

VCC

IREDA

RXD

TXD

SD

GND

IREDC

The data communication between the card and the phone is asynchronous half duplex.

The clock supplied to the card is in GSM system 1.083 MHz or 3.25 MHz. The data

baudrate is SIM card clock frequency divided by 372 (by default), 64, 32 or 16.

Issue 2 11/02 ¤Nokia Corporation Page 23

Page 24

System Module LG4 and Grip Module LS4 CCS Technical Documentation

NHL-2NA Audio Concept

NHL-2NA Audio's includes Earpiece, microphone, and headset connector, Integrated

Handsfree (IHF) with proximity sensing. IHF have high quality Audio with DCT4 Enchantments. Headset is DCT4 monoheadset with/-out button. For IHF versus Earpiece function

there is proximity sensor option, which detects if close to head, it switches IHF off. It can

be turned ON Manually by pressing the voice key. In NHL-2NA Audio Blocks there is

NHL-2NA BB Audio block diagram. Audio's are based on ASIC's UPP_WD2 and UEM.

Figure 12: NHL-2NA Audio Blocks

Earpiece

This Asic's readily support normal audio functionality. Between UPP_WD2 and UEM the

audio signals are transferred in digital format using signals MICDATA and EARDATA. The

microphone is connected to UEM and the headset output of UEM is fed also to AEM

audio amplifier. So actual IHF situation the signal is also existing in Headset signals.

NHL-2NA audio SW controls IHF amplifier power off when uses headset because both

use same audio lines (HF and HFCM). Ringing tones and warning/info tones are to be

produced with the IHF speaker also.

The earpiece to be used in NHL-2NA is an 8-mm Pico earpiece. It has 32: continuous

impedance and continuos power 8 mWatts. It Contacts to PWB Special adapter via

springs. It's driven by differential signals from UEM (EARP & EARN)

Page 24 ¤Nokia Corporation Issue 2 11/02

Page 25

CCS Technical Documentation System Module LG4 and Grip Module LS4

Microphone

The microphone capsule for NHL-2NA is a WM64MN capsule. Its sensitivity is -41db

Nominal and it's provided encapsulated in housing of neoprene. Contacts are done by

springs.

Two inputs are used from UEM, one for normal internal microphone and a second for

headset. The third microphone input is not used, so it must connected to ground. Microphone bias block in UEM generates bias voltages for handportable and HandsFree/headset microphones. For both microphone bias outputs (MICB1 & MICB2) the minimum

output voltage is 2.0 Volts and maximum output current is 600 PA. Microphone bias

block also includes a low pass filter for the reference voltage used as an input for the

MICB1&2 amplifiers.

IHF Amplifier and Speaker

The speaker to be used in NHL-2NA is a 16mm 8: speaker. It can handle 0.2 Watts nominal Power and Peak power 0.4 Watts. Component has molded neoprene gasket and its

contact to PWB via springs.

HF and HFCM lines of UEM are use to drive AEM IHF amplifier. IHF amplifier consists of

four blocks: gain setting stage, power amplifier, and comparator and Bias VCM generation. There is also some digital logic, which is integrated to other digital parts of AEM.

Power amplifier is a differential opamp. The differential output is intended to HandsFree

speaker. HandsFree amplifier load impedance is 8 ohm.

The outputs go into a high impedance state when powered down. The amplifier can be

enabled and shut down by control register.

SW realizes IHF and earpiece volume control mainly in AEM. For maximum signal–to–

noise performance it is preferable to set the gain of UEM’s earpiece driver to some fixed,

close–to–maximum value and use lower gain setting for AEM audio amplifier. Gain setting can be done in 2 dB steps, from –40 to +6 dB. Output sound pressure level of the

internal HandsFree speaker is controlled by the proximity sensor and SW (CBus is used

for controlling). Proximity sensor activity changes the gain automatically.

The schematic around the AEM IHF amplifier is presented in NHL-2NA schematics. The

schematic shows all the filtering needed and also protection components against ESD

and EMC.EMC and ESD Filtering component must be as near as possible to earphone

pads of the phone. Audio input lines components DC decoupling capacitors and EMC

capacitor must be located near to AEM.

The supply voltage for the IHF amplifier is filtered directly from the battery voltage. The

size of the capacitance needed for smoothing the voltage is High-Pass filter consist of

two parallel 220uF capacitors to ground with 2x2.2Ohm parallel in Series in VBAT line.

Issue 2 11/02 ¤Nokia Corporation Page 25

Page 26

System Module LG4 and Grip Module LS4 CCS Technical Documentation

External Audio interface

In NHL-2NA there is Headset Connector which is fully differential 4–wire connection.

Figure 13: External Audio Connector

2. XEARN

4. XEARP

5. HEADINT

3. XM ICP

1. XM ICN

The Handsfree (HF) driver in UEM is meant for headset. In NHL-2NA case the output is

driven in fully differential mode. In the fully differential mode HF pin is the negative output and HFCM pin is the positive output. The gain of the Handsfree driver in the differential mode is 6 dB. The earpiece (EARP, EARN) and headset (HF, HFCM) signals are

multiplexed so that the outputs can not be used simultaneously. Minimum resistive and

maximum capacitive loading between HF and HFCM outputs are 30ohm

and 10nF. The

HF and HFCM amplifiers include a transient suppression circuitry, which prevents

unwanted spikes in HF and HFCM outputs when switching on and off the amplifiers.

The plug opens a mechanical switch inside the connector between HF and HeadInt lines.

The HeadInt line will be pulled up to 2.7V by internal resistor when the switch is open.

When not having the plug inserted the voltage in the HeadInt line will be <0.8 V caused

by internal pull down resistor in the HF line.

Camera Interface

NHL-2NA camera type is a Still camera with viewer option. Camera resolution is VGA.

The Camera module is connected by springs to PWB.

Camera interface is serial CCP, which is unidirectional interface; the control information

to camera is transmitted through I2C bus. The I2C is implemented purely by SW using

general purpose I/Os.

CCP interface consists of differential type of clock signal and one data signal. CCP

enables the use of high data rates with low EMI; maximum transfer capacity is 104 Mbit/

s, which means that transferring VGA (640x480) images at 15 fps is possible. CCP has

three image data operating modes: 8-bit, 10-bit and 12-bit ones.

AEM includes two dedicated regulators for powering internal camera, 2.78V for logic and

sensor and 1.8V for I/O.

More about camera module later in this section.

Page 26 ¤Nokia Corporation Issue 2 11/02

Page 27

CCS Technical Documentation System Module LG4 and Grip Module LS4

Proximity Sensor

Proximity Detector is used to deactivate IHF when something is close to the phone. Proximity detection is based on detecting level of reflected IR radiation. Detection distance

varies depending on the reflecting surface. System is calibrated to detect 20% diffuse

reflectance targets, parallel to the phone, at 50mm distance. Detection distance may

change due to wearing; minimum detection distance allowed is 30mm.

Figure 14: Proximity Detector Principle

Reflective Su rface

Li

gh

tg

ui

IR-LE D IR-Detector

Li

gh

tg

ui

Cover

PWB

Proximity Detector has also a self-monitoring feature, which is used to detect possible

failures in the Proximity Detector. Proximity Detector Principle figure describes the

mechanical concept of the Proximity Detector, Pulse levels shows signal levels.

Figure 15: Pulse levels

Proxi mity det ect

pulse

Self-test

puls e

Detecti on Treshold

Fault Treshol d

Faul t detect

puls e

Proximity detector interface is in AEM (Auxiliary Energy Management ASIC), other components of the proximity detector are optoelectrical components and optics.

The proximity detector block on AEM consists of digital and analog part. Digital logic is

included in digital part of AEM, and it is controlled through proximity detector control

register.

Analog part includes a current source for the emitter and a transinpedance amplifier,

high pass filter to filter off up to 2mA DC-current, gain-controllable amplifier and two

Issue 2 11/02 ¤Nokia Corporation Page 27

Page 28

System Module LG4 and Grip Module LS4 CCS Technical Documentation

comparators with adjustable thresholds in the receiver.

Proximity detector block enables several pulse width and pulse frequency selections and

emitter current can be controlled with a current sensing resistor. In NHL-2NA emitter

current is 100mA, pulse width 8Ps and pulse frequency 500/2000Hz.

Proximity Detector components

Lightguides

Lightguides are needed to guide emitted IR radiation outside the phone as well as to

guide the reflected pulses into the phone to the photodiode. Half angle of the emitted

radiation is 10q. This means, that most of the emitted radiation is reflected from a circle

that has diameter 20mm, when the target is at 50mm distance. Receiver lightguide collects radiation and guides it to the photodiode. Optical insulator, made of black rubber,

surrounds the photodiode so that it cannot receive any radiation that is reflected inside

the phone.

Self-monitoring signal is created with small reflector areas and curved top surfaces in

the lightguides. Reflectors are placed inside the phone, so that they are subject to as little wearing as possible.

IRED

The IRED type is CL-200-IR-X-TU (NMP CODE 4860009), which has high radiant intensity

and relatively small half angle (28°). Maximum forward current is 100mA (pulsed 1A) and

V

=1.3V. Rise Time is 2Ps, total radiant intensity 12mW (at 50mA current) and peak

f

radiant intensity at 950nm.

Photodiode

The photodiode is BPW34FS (NMP CODE 486J830). It has peak sensitivity at 950nm and

filtering for visible light. Photodiode receives radiation from 60° half angle and its rise

time is 20ns.

HW Implementation

The implementation of the proximity sensor is described in figure 16. Note that VTOUCH

is connected externally to VANA.

Page 28 ¤Nokia Corporation Issue 2 11/02

Page 29

CCS Technical Documentation System Module LG4 and Grip Module LS4

Figure 16: Proximity sensor implementation

VTOUCH

(2.78V)

VBAT

VANA

(2.78V)

AEM

IRED

4.7 Ohm

PRXdrv

PRXin

IR Detector

GNDANA

PRXrec

COFF CF1 CF2

100nF 220pF 220pF

Issue 2 11/02 ¤Nokia Corporation Page 29

Page 30

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Ambient Light Sensor

Ambient Light Detector (ALD) is used as a power saving feature.

Ambient Light Detector (ALD) measures illuminance on the display (ambient light). User

can select the limit, above which display backlight is not needed. In practice, two limits

are used in software to produce hysteresis. Hysteresis is needed to prevent backlight

from blinking. Backlight can be switched ON only when ambient light level is below

lower limit. Backlight is switched OFF, when ambient light level exceeds higher limit.

Figure 17: Ambient light sensor implementation

Ambient

Light

Optical

Lense

VFlash1

2.78 V

Pull-up

resistor

100 kOhm

Phototransistor

Siemens

LS

UEM

VCXOTEMP

VANA

2.78 V

Pull-up

resistor

100 kOhm

NTCResistor

Page 30 ¤Nokia Corporation Issue 2 11/02

Page 31

CCS Technical Documentation System Module LG4 and Grip Module LS4

V

Flashing

SW download in service is impelemented by custom tools and SW, kindly refer to Service

Software Instructions and Service Tool section of the manual.

Connections to Baseband

NHL-2NA type flash programmer FPS-8 is connected to the baseband directly in Production Tester, by using service cable and FLA-21 or Module jig to connect to test pads. With

assembled devices the testpads can be accessed by opening the grip with a special tool.

Figure 18: Flash programming connections

PurX

PC

LPT1

Serial2(AXS-4)

FPS 8 ONLY)

Centronics

FPS-8 /FLS-4S

(

ACF-8

COM2

COM1

Phone

service cable

2.78V

Vpp

Gnd

BSI

MBUS

FBUS_RX

FBUS_TX

cc

UEM

MBUS

FBUS

BSI

GND

TXRX

Flashing interface

FBUS_TX MBUS

FBUS_RX

2.78V

VPP

MBUS_RX

MBUS_TX

FBUS_RX

FBUS_TX

1.8V

UPP_WD2

4k7

Vpp

Flash

= DCT4 Accessories

= Phone

FPS-8 can also supply Vcc during flash programming i.e. service box’s or service battery’s

Vcc can be connected to FPS-8 by banana plugs but external power supply can be also

used during flash programming. shows how flash programming equipment is connected.

Note that Vcc connected to FPS-8/FLS-4S is preferred.

The flash programming interface uses following external signals:

1 FBUS RX (accessed from test pad pattern)

2 FBUS TX (accessed from test pad pattern)

3 MBUS (accessed from test pad pattern)

Issue 2 11/02 ¤Nokia Corporation Page 31

Page 32

System Module LG4 and Grip Module LS4 CCS Technical Documentation

4 BSI (accessed from battery connector)

5 Vcc (accessed from battery connector)

6 Ground (accessed from test pad pattern and battery connector)

7 Vpp (accessed from test pad pattern)

In HDB15 BB Vpp routing is based on common DCT4 solution. In this solution the use of

higher Vpp voltage is enabled at FLALI phase in production and in after sales if so

wanted.

External voltage (Vpp) is used during flash programming in production and possibly in

aftersales to speed up the process. In production, the usage of external programming

voltage is a necessity but in after sales the usage of external programming voltage does

not necessarily bring any noticeable improvement to flash programming time.

Testing interfaces

In NHL-2NA BB Interfaces Because of Camera, larger memory, sensors there are some

specific testing done and also because of flagship concept there is difference of physical

Interfaces

Table 1: Testing interface Electrical Specifications

Pin Name Dir Parameter Min Typ Max Unit Notes

1 MBUS <-> Vol 0 0.2 0.3*VFlash1 V

Vil (From Prommer) 0 0.2 0.3*VFlash1 V

Voh 0.7*VFlash1 2.7 0.7*VFlash1 V

Vih(From Prommer) 0.7*VFlash1 2.7 VFlash1 V

2 FBusTx -> Vol 0 2.7 0.3*VFlash1 V

Voh 0.7*VFlash1 2.7 VFlash1 V

3 FBusRx <- Vil (From Prommer) 0 2.7 0.3*VFlash1 V

Vih(FromPrommer) 1.89 2.7 VFlash1 V

Abs. Max. Voltage to

Test Pad Referenced

to GND

4 VPP To Phone 0 / 2.8 / 12

-0.3V 3.0 V Absolute

Max Voltage

limits to

MBUS/FBUS

+/-3%

V Prommer

Select

4 VPP

4 VPP To Phone 0 / 2.8 / 12

+/-3%

5 GND 0 V VBAT

V Prommer

Select

4 VPP

GROUND

Note1: VFlash1 is 2.78 +/- 3%

Page 32 ¤Nokia Corporation Issue 2 11/02

Page 33

CCS Technical Documentation System Module LG4 and Grip Module LS4

Table 2: Electrical Specifications for Power Supply Interface in Prod Testing

Pin Name Min Typ Max Unit Notes

1 VBAT 0 3.6 5.1 V

2 BSI 0 2.78 VFlash1 V Internal pullup

3 BTEMP 0 3.0 VAna V Internal pullup

4 GND 0 V

Note 1: VAna & VFlash1 = 2.78 +/-3%

Extreme Voltages

Lithium-Ion battery BLB-2 (1 cell):

• Nominal voltage is 3.6V

• Lower extreme voltage is 2.8V (cut off voltage)

• Higher extreme voltage is 4.2V (charging high limit voltage)

Temperature Conditions

Specifications are met within range of –10C to +55C ambient temperature. Reduced

operation between [-25] and [+60]. Storage temperature range is of –40C to +85C

according to Nokia specifications.

Humidity and Water Resistance

Relative humidity range is 5 … 95%. Condensed or dripping water may cause intermittent malfunctions. Protection against dripping water have to be implemented in (enclosure) mechanics. Continuous dampness will cause permanent damage to the module.

Issue 2 11/02 ¤Nokia Corporation Page 33

Page 34

System Module LG4 and Grip Module LS4 CCS Technical Documentation

RF Module

Functional block descriptions

The block diagrams of direct-conversion receiver and transmitter RF section are

described in the following figure. The illustration shows the RF-IC ( both RX and TX

functions ), power amplifier ( PA ), TX-SAW filter, VCO, VCTCXO module, discrete LNA

stages and SAW-filters for receive bands.

Figure 19: RF block description

VR4

Antenna switch

Dir. Coupler

GSM

1800

E-GSM

900

DET

RX

SAW

TX

RX

SAW

TX

VtxLO_GS M

PA

VBATTRF

LNA

LNA

VtxB_DCS

VtxB_GSM

dB

-2

dB

-2

Last edit 12:39 1 3.12.00

Drawing85

VRF_RX

SAW

INP_P_RX

INM_P_RX

SAW

INP_G_RX

INM_G_RX

LNA_P

LNAB_P

LNA_G

LNAB_G

V_ANT_1/

V_ANT_2

2

VB_DET

VTXLO_G

VTX_B_P

VTX_B_G

OUTP_P_TX

OUTM_P_TX

OUTP_G_TX

OUTM_G_TX

Vpctrl_ fb

RF

Controls

Open collecto r

Open collecto r

DET

Vpctrl_g

Vpctrl_p

2

1/4

PWC

TXP

TXC

222

1/2

2

2

2

44

0dB

Cm_dtos_I

1/2

1/4

44

2

2 2

RX Filter

Calibration

8 / 18 dB

8 / 18 dB

Reset

Cp_dtos_I

DtoS

DtoS

64/65

CTRL

SDATA

Cp_f_I

Cm_f_I

Cp_f_Q

Cm_f_Q

Cp_dtos_Q

Cm_dtos_Q

BIQUAD

BIQUAD

NDIV

ADIV

HAGAR

SLE

SCLK

OUT_BB1_I

OUT_BB1_Q

I_DCN2_I

charge

pump

RDIV

I_DCN2_Q

C2_BB1_Q

C1_BB1_Q

VB_EXT

DCN2

DCN2

1/2

RF TEMP

SENSOR

RB_EXT

VF_RX

RXI

VREF_RX

RXQ

INP_LO/INM_LO

2

OUT_CP

loop

filter

VCP/GND_CP

2

VDIG

OSC_IN

26MHz

TOUT

VBB

VPRE

VLO

TXI_0/TXI_180

2

TXQ_0/TXQ_180

GNDRF_TX

GND_BB / GNDRF_RX / GND_L O / GND_PRE /

GND_CP / GND_ DIG / GND_ RX

RFTEMP

C1_BB1_I

C2_BB1_I

BB_Gain

0-40dB

BB_Gain

0-40dB

M

VREFRF01

RXI_P

RXI_N

VREFRF02

RXQ_P

RXQ_N

VR1

VCO

3dB

VR7

2

2

LPRFCLK

RFCLK

TXI_0/TXI_180

TXQ_0/TXQ_180

HGR_TEMP

RFBUSEN1

RFBUSCLK

RFBUSDA

RESET

VBATTRF

VR3

AFC

VR6

VR5

TXC

TXP

VR2

AFC

The Frequency synthesizer

The VCO frequency is locked using a PLL to a stable frequency source, which is a VCTCXO.

The VCTCXO is running at 26 MHz. The Temperature effect is controlled with AFC. The

AFC is generated with a 11 bit conventional DAC in UEM.

The physical PLL is located inside the HAGAR RF-IC and is controlled via serial bus. The

PLL synthesizer consists of the following blocks :

• 64/65 CML prescaler

• Programable R-, N- and A-dividers,

• Phase detector and charge pump

Page 34 ¤Nokia Corporation Issue 2 11/02

Page 35

CCS Technical Documentation System Module LG4 and Grip Module LS4

Figure 20: Phase locked loop

HAGAR

GSM1800

O2

3420 - 3840 MHz

E-GSM900

AFC

26 MHz

O4

SDATA

CTRL

SCLK

O64/65

SLE

NDIV

ADIV

RDIV

( O65 )

Reset

M

Charge

Pump

Loop

Filter

VCO

The SHF local signal generated by a VCO module is fed into prescaler. The prescaler is a

dual-modulus divider. The output of the prescaler is fed to N- and A- divider which produce the input to phase detector. The phase detector compares this signal to the reference signal (400 kHz) which is obtained by dividing the VCTCXO output by reference Rdivider. The output of the phase detector is connected to the charge pump which charges

or discharges integrator capacitor in the loop filter, depending on the phase of the measured frequency compared to the reference frequency.

The loop filter, VCO and VCTCXO are all external synthesizer building blocks.

The loop filter performs filtering of the pulses and generates DC control voltage to the

VCO. The loop filter also defines the step response of the PLL ( settling time ) and effects

the stability of the loop. That’s why integrator capacitor has got a resistor for phase

compensation. The other filter components are for sideband rejection.

The dividers are controlled via serial bus: SDATA is for data, SCLK is serial clock for the

bus and SLE is latch enable, which enables new data storage into dividers.

The transceiver LO signal is generated by VCO module. The VCO generates double frequency in GSM1800 and times four frequency in E-GSM900 compared to the actual RF

channel frequency. LO signal is divided by two or four in HAGAR ( depending on system

mode ).

This RF module comprises all RF functions of the engine. RF circuitry is located on one

side (B-side) of the PCB.

EMC leakage is prevented by using a metal B-shield, which screens the whole RF side

(included FM radio) of the engine. The conductive (silicon or metal) gasket is used

between the PCB and the shield. The metal B-shield is separated to three blocks. The first

one include the FM radio. The second block include the PA, antenna switch, LNAs and

dual RX SAW. The last block include the Hagar RF IC, VCO, VCTCXO, baluns and balanced

filters.

Issue 2 11/02 ¤Nokia Corporation Page 35

Page 36

System Module LG4 and Grip Module LS4 CCS Technical Documentation

The baseband circuitry is located on the A-side of the board, which is shielded with a

metallized frame and ground plane of the UI-board.

Maximum height inside on B-side is 1.8 mm. Heat generated by the circuitry is conducted out via the PCB ground planes and metallic B-shield

RF Frequency Plan

Figure 21: RF Frequency plan

925–960

MHz

1805–1880

MHz

1710–1785

MHz

880–915

MHz

f/4

f

f

HAGAR

f

f/2f/4

f

f/2

PLL

3420–

3840

MHz

26 MHz

VCTCXO

I–signal

I–signalI–signalI–signal

Q–signal

I–signal

Q–signal

RX

TX

Page 36 ¤Nokia Corporation Issue 2 11/02

Page 37

CCS Technical Documentation System Module LG4 and Grip Module LS4

DC characteristics

Regulators

List of the needed supply voltages :

Volt. source Load

VR1a PLL charge pump (4,8 V)

VR2 TX modulator

VR3 VCTCXO + buffer

VR4 HAGAR IC (LNAs+mixer+DTOS)

VR5 HAGAR IC (div+LO-buff+prescaler),

VR6 HAGAR (Vdd_bb)

VR7 VCO

VrefRF01 ref. voltage for HAGAR

VrefRF02 ref. voltage for HAGAR

Vbatt PA

Issue 2 11/02 ¤Nokia Corporation Page 37

Page 38

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Power Distribution Diagram

Figure 22: Power Distribution Diagram

UEM

VR

1

VR

2

VR

3

VR

4

VR

5

E-GSM900/GSM1800

LNA

VCTXCO

HAGAR

PLL charge pump

TX IQ modulator

VCTCXO buffer

RX Mixer

DTOS

Frequency dividers

Power

Detector

PLL

V

V

REF

REF

V

V

FLASH01

VR

VR

RF01

RF02

BATT

6

7

LO buffers

Prescaler

BB section

RX reference voltage

Reference voltage

VCO

PA

BT102

Page 38 ¤Nokia Corporation Issue 2 11/02

Page 39

CCS Technical Documentation System Module LG4 and Grip Module LS4

RF characteristics

Item Values (E-GSM / GSM1800)

Receive frequency range 925 ... 960 MHz / 1805...1880 MHz

Transmit frequency range 880 ... 915 MHz / 1710...1785 MHz

Duplex spacing 45 MHz / 95 MHz

Channel spacing 200 kHz

Number of RF channels 174 / 374

Power class 4 (2 W) / 1 (1 W)

Number of power levels 15 / 16

Transmitter characteristics

Item Values (E-GSM/GSM1800)

Type Direct conversion, nonlinear, FDMA/TDMA

LO frequency range 3520...3660 MHz / 3420...3570 MHz

Output power 2 W / 1 W peak

Gain control range min. 30 dB

Maximum phase error ( RMS/peak ) max 5 deg./20 deg. peak

Receiver characteristics

Item Values, E-GSM/GSM1800

Type Direct conversion, Linear, FDMA/TDMA

LO frequencies 3700...3840 MHz / 3610...3760 MHz

Typical 3 dB bandwidth +/- 91 kHz

Sensitivity min. - 102 dBm (GSM1800 norm.cond. only)

Total typical receiver voltage gain ( from

antenna to RX ADC )

Receiver output level ( RF level -95 dBm ) 230 mVpp, single-ended I/Q signals to RX ADCs

Typical AGC dynamic range 83 dB

86 dB

Accurate AGC control range 60 dB

Typical AGC step in LNA 30 dB GSM1800 25 dB EGSM

Usable input dynamic range -102 ... -10 dBm

RSSI dynamic range -110 ... -48 dBm

Compensated gain variation in receiving band +/- 1.0 dB

Issue 2 11/02 ¤Nokia Corporation Page 39

Page 40

System Module LG4 and Grip Module LS4 CCS Technical Documentation

RF Block Diagram

Figure 23: RF Block Diagram

RF_BB interface

Antenna Switch

PA LNA

LNA2, Mixer,

AGC, DTOS

Tx IQ modulator

RFtemp

Battery

RFI and Codec

BB & RF regulators

Charger switch

TXC Vreg

UEM

Tx I/Q

Rx I/Q

PLL, Dividers

Hagar

Bluetooth

26 MHz

AFC

RF_RF interface

VCO

4 GHz

26 MHz

VCTCXO

13 MHz

Codec samplesData to & from RF

RF control lines

UPP

MCU, ASIC & DSP

For further information see table on the next page.

Page 40 ¤Nokia Corporation Issue 2 11/02

Page 41

CCS Technical Documentation System Module LG4 and Grip Module LS4

Voltage Supplies and References

Signal

name

VBAT Bat-

VR1 UEM VCP Voltage 4.6 4.75 4.9 V Supply for varactor for

VR2 UEM VRF_TX Voltage 2.70 2.78 2.86 V Supply for part of trans-

From To Parameter Min Typ Max Unit Function

tery

PA &

UEM

Voltage 2.95 3.5 5.15 V Battery supply. Cut-off

Current 2000mA

Current drawn by

PA when ”off”

Current 2 10 mA

Noise density 200 nVrms/

Current 65 100 mA

Noise density

f=100Hz

f>300Hz

0.8 2 mA

sqrt(Hz

)

80

55

nVrms/

sqrt(Hz)

level of DCT4 regulators

is 3.04V. Losses in PWB

tracks and ferrites are

taken account to minimum battery voltage

level.

UHF VCO tuning.

mit strip. Supply for TX

I/Q-modulators.

VR3 UEM VCTCXO Voltage 2.70 2.78 2.86 V Supply for VCTCXO

Current 1 20 mA

Noise density 200 nVrms/

sqrt(Hz

)

VR4 UEM VRF_RX Voltage 2.70 2.78 2.86 V Supply for Hagar RX;

Current 50 mA

Noise density

f=100..10kHz

f=100kHz

VR5 UEM VDIG,

VPRE,

VLO

VR6 UEM VBB Voltage 2.70 2.78 2.86 V Supply for Hagar BB and

Voltage 2.70 2.78 2.86 V Supply for Hagar PLL;

Current 50 mA

Noise density

BW=100Hz to

100kHZ

Current 50 mA

20020nVrms/

sqrt(Hz)

200 nVrms/

sqrt(Hz

)

preamp., mixer,

DTOS

Noise density should

have -20dB/G slope after

10kHz corner frequency

dividers, LObuffers, prescaler,

LNA

Noise density

BW=100Hz to

100kHz

200 nVrms/

sqrt(Hz

)

Issue 2 11/02 ¤Nokia Corporation Page 41

Page 42

System Module LG4 and Grip Module LS4 CCS Technical Documentation

VR7 UEM UHF VCO Voltage 2.70 2.78 2.86 V Supply for UHF VCO

Current 30 mA

Noise density

100Hz<f<2kHz

2kHz<f<10kHz

10kHz<f<30kHz

30kHz<f<90kHz

90kHz<f<3MHz

70

55

35

30

30

nVrms/

sqrt(Hz)

VrefRF01UEM VREF_RX Voltage 1.3341.35 1.366V Voltage Reference for

RF-IC.

Note:Below 600Hz noise

Current 100 mA

Temp Coef -65 +65 uV/C

Noise density

BW=600Hz to

100kHz Note

55 nVrms/

sqrt(Hz

)

density is allowed to

increase 20 dB/oct

VrefRF02UEM VB_EXT Voltage 1.3341.35 1.366V Supply for RF-BB digital

interface and some dig-

Current 100 mA

ital parts of RF.

Temp Coef -65 +65 uV/C

Noise density

BW=100Hz to

100kHz

400 nVrms/

sqrt(Hz

)

Page 42 ¤Nokia Corporation Issue 2 11/02

Page 43

CCS Technical Documentation System Module LG4 and Grip Module LS4

Receiver

Figure 24: NHL-2NA Receiver chain

The receiver is a direct-conversion, dual-band linear receiver. RF signal energy gathered

st

by the antenna is fed via the antenna switch module to the 1

and MMIC LNAs. The RF antenna switch module provides for upper- and lower-band

operation. The signal having been amplified by the LNA is then fed to 2

RX bandpass SAW filters

nd

RX bandpass

SAW filters. Both of these 2nd RX bandpass SAW filters have UNBAL/BAL configuration to

achieve the balanced feed for HAGAR. The discrete LNAs have three gain levels. The first

one is maximum gain, the second one is about -30dB ( GSM1800 ) and –25dB ( EGSM900 ) below maximum gain and the last one is off state. The LNA gain selection is

controlled directly by HAGAR.

The performance of the RX bandpass SAW filters are mainly responsible for defining the

receiver's blocking characteristics against spurious signals outside passband and the protection against spurious responses.

The differential RX signal is amplified and mixed directly down to BB frequency in

HAGAR. The LO signal is generated with external VCO. This VCO signal is divided by 2 (

GSM1800 ) or by 4 ( E-GSM900 ). The PLL and dividers are internal to the HAGAR IC.

From the mixer output to ADC input RX signal is divided into I- and Q-signals. Accurate

phasing is generated in LO dividers. After the mixer DTOS amplifiers convert the differential signals to single ended.

The DTOS has two gain stages. The first one has constant gain of 12dB and 85kHz cut off

frequency. The gain of second stage is controlled with control signal g10. If g10 is high

(1) the gain is 6dB and if g10 is low (0) the gain of the stage is -4dB. The active channel

filters in HAGAR provide selectivity for channels (-3dB @ r 91 kHz typ.). The integrated

baseband filter inside HAGAR is an active-RC-filter with two off-chip capacitors. Large

RC-time constants are needed in the channel select filter of the direct-conversion

receiver and are achieved with large off-chip capacitors because the impedance levels

could not be increased due to the noise specifications.

The baseband filter consists of two stages, DTOS and BIQUAD. DTOS is differential to single-ended converter having 8dB or 18dB gain. BIQUAD is modified Sallen-Key Biquad.

Integrated resistors and capacitors are tunable. These are controlled with a digital con-

Issue 2 11/02 ¤Nokia Corporation Page 43

Page 44

System Module LG4 and Grip Module LS4 CCS Technical Documentation

trol word. The correct control words that compensate for the process variations of integrated resistors and capacitors and of tolerance of off chip capacitors are found with the

calibration circuit.

The next stage in the receiver chain is AGC-amplifier, also integrated into HAGAR. AGC

has digital gain control via serial mode bms. AGC-stage provides gain control range (40

dB, 10 dB steps) for the receiver and also the necessary DC compensation. Additional 10

dB AGC step is implemented in DTOS stages.

DC compensation is made during DCN1 and DCN2 operations ( controlled via serial bus ).

DCN1 is carried out by charging the large external capacitors in AGC stages to a voltage

which effect a zero dc-offset. DCN2 set the signal offset to constant value ( V

1.35 V ). The V

RF_02 signal is used as a zero level to RX ADCs.

ref

ref

RF_02

Single ended filtered I/Q-signal is then fed to ADCs in BB. Input level for ADC is 1.45 V

max.

Rf-temp port is intended to be used for compensation of RX SAW filters thermal behavior. This phenomena will have impact to RSSI reporting accuracy. The current information is -35ppm/C for center frequency drift for all bands. This temperature information

is a voltage over two diodes and diodes are fed with constant current.

Transmitter

Transmitter chain consists of two final frequency IQ-modulators for upper and lower

band, a dual power amplifier and a power control loop.

I- and Q-signals are generated by baseband. After post filtering (RC-network) they go

into IQ-modulator in HAGAR. There are separate outputs one for EGSM and one for

GSM1800.

In EGSM branch there is a SAW filter before PA to attenuate unwanted signals and

wideband noise from the Hagar IC.

The final amplification is realized with dual band power amplifier. It has two different

power chains: one for EGSM and one for GSM1800. PA is able to produce over 2 W (0

dBm input level) in EGSM band and over 1 W (0 dBm input level) in upperband band into

50 ohm output . Gain control range is over 45 dB to get desired power levels and power

ramping up and down.

pp

Power control circuitry consists of discrete power detector (common for lower and

upperband) and error amplifier in HAGAR. There is a directional coupler connected

between PA output and antenna switch. It is a dual band type and has input and outputs

for both systems. Directional coupler takes a sample from the forward going power with

certain ratio. This signal is rectified in a schottky-diode and it produces a DC-signal after

filtering.

Page 44 ¤Nokia Corporation Issue 2 11/02

Page 45

CCS Technical Documentation System Module LG4 and Grip Module LS4

AGC strategy

The AGC-amplifier is used to maintain the output level of the receiver in within a certain

range. The AGC has to be set before each received burst with pre-monitoring or without

pre-monitoring. In pre-monitoring, the receiver is switched on roughly 130µs before the

burst begins, DSP measures received signal level and adjusts AGC-amplifiers via serial

bus.

With this particular receiver architecture, there is 50 dB of accurate gain control in 10

dB steps and large LNA step ( approximately 25dB for E-GSM900 and 30 for GSM1800).

LNA AGC step size depends on channel to some extent.

In practice, this results in 6 accurate AGC steps and 2/3 non-accurate steps available to

the UPP depending on the band.

Because of the requirement from the GSM specifications that each MS should be able to

measure and report it's RSSI accurately when receiving levels below –48dBm, and due to

the fact that the LNA step is not accurate, the LNAs should always be in the ON state in

this situation. For all signals in excess of –48dBm the MS will report a constant value.

Step no. AGC Step value AGC Gain

1 0 -4 OFF -7 -11

2 1 +6 OFF -7 -11

3 2 +16 OFF -7 -11

4 3 -4 ON +18 +19

5 4 +6 ON +18 +19

6 5 +16 ON +18 +19

7 6 +26 ON +18 +19

8 7 +36 ON +18 +19

9 8 +46 ON +18 +19

Front-end LNA

state

Front-end

LNA gain

E-GSM900 GSM1800

Issue 2 11/02 ¤Nokia Corporation Page 45

Page 46

System Module LG4 and Grip Module LS4 CCS Technical Documentation

Figure 25: Gain control of E-GSM900

ADC input

voltage

[ mV

p-t-p

]

B

d

4

B

B

d

6

6

3

+

B

d

6

4

+

2

+

LNA gain = +18dB ( E-GSM900 ) LNA gain = -7dB ( E- GSM900 )

Accurate gain c ontrol region

Accurate RSSI requirment range

B

d

d

6

1

+6dB

+

DtoS gain = ? dB DtoS gain = ? dB

B

d

4

-

dB

6

+

-

Receiver chain

gain

[ dB ]

64

54

44

34

24

14

-1

-11

-100 -90 -80 -70 -60 -50 -40 -30 -20 -10 0

-110

18+46=64

18+36=54

18+26=44

18+16=34

18+6=24

18-4=14

-7+6=--1

RF signal

[ dBm ]

-7-4=-11

-110 -100 -90 -80 -70 -60 -50 -40 -30 -20 -10 0

RF signal

[ dBm ]

Page 46 ¤Nokia Corporation Issue 2 11/02

Page 47

CCS Technical Documentation System Module LG4 and Grip Module LS4

Figure 26: Gain control of GSM1800

ADC input

voltage

p-t-p

[ mV

]

B

d

4

-

6dB

B

B

B

d

6

6

3

2

+

B

d

6

4

+

+

LNA gain = +19dB ( GSM1800 ) LNA gain = -11dB ( GSM1 800 )

Accurate gain control region

Accurate RSSI requirment range

B

d

d

6

1

+6dB

+

DtoS gain = ? dB DtoS gain = ? dB

4

-

1

d

+

dB

6

+

Receiver chain

gain

[ dB ]

65

55

45

35

25

15

5

-5

-15

-100 -90 -80 -70 -60 -50 -40 -30 -20 -10 0

-110

19+46=65

19+36=55

19+26=45

19+16=35

19+6=25

19-4=15

-11+16=5

-11+6=--5

RF signal

[ dBm ]

-11-4=-15

-110 -100 -90 -80 -70 -60 -50 -40 -30 -20 -10 0

RF signal

[ dBm ]

AFC function

The AFC is used to lock the transceivers clock to frequency of the base station. The AFC

voltage is generated in baseband using an 11 bit DAC where an RC-filter is placed on the

AFC control line to reduce the noise from the converter. The settling time requirement

Issue 2 11/02 ¤Nokia Corporation Page 47

Page 48

System Module LG4 and Grip Module LS4 CCS Technical Documentation

for the RC-network comes from signaling, i.e. how often PSW slots occur. They are

repeated after 10 frames. The AFC tracks the base station frequency continuously which

enables the transceiver to have a stable frequency reference.

The settling time requirement is also determined from the allowed start up-time. When

the transceiver is in sleep mode and ”wakes-up" to receive mode, there is only about 5

ms for the AFC voltage to settle. When the first burst is received, the system clock has to