Page 1

NHL-2NA Series Transceiver

Troubleshooting Instructions

Issue 2 11/02 Copyright ¤Nokia. All rights reserved

Page 2

Troubleshooting Instructions CCS Technical Documentation

[This page left intentionally blank]

Page 2 Copyright ¤Nokia. All rights reserved. Issue 2 11/02

Page 3

CCS Technical Documentation

Table of Contents

Baseband Troubleshooting............................................................................................. 3

Introduction ..................................................................................................................3

General guidelines for NHL-2NA system troubleshooting .........................................3

Troubleshooting paths .................................................................................................6

LG4 Baseband HW subarea troubleshooting ............................................................10

Energy management troubleshooting ........................................................................12

IR interface ................................................................................................................24

Sensors troubleshooting .............................................................................................26

Proximity Detector .....................................................................................................27

Ambient Light Detector .............................................................................................33

SIM card ....................................................................................................................39

Audio .........................................................................................................................43

Memory troubleshooting ...........................................................................................47

Baseband serial interface troubleshooting .................................................................48

Hall sensor troubleshooting .......................................................................................51

Display backlights troubleshooting ...........................................................................52

Bluetooth troubleshooting .........................................................................................53

Needed actions if ASIC is changed.............................................................................. 56

UEM changed ............................................................................................................56

AEM changed ............................................................................................................56

UPP_WD2 changed ...................................................................................................56

Flash0 changed ..........................................................................................................56

RF component changed .............................................................................................56

Test points and pin orders............................................................................................ 57

Test points in BaseBand area (LG4_06_02) ..............................................................57

Connectors pin order ..................................................................................................59

RF Troubleshooting ..................................................................................................... 63

Introduction ................................................................................................................63

RF Key component placement ...................................................................................64

Fault finding test point locations ...............................................................................65

Receiver .....................................................................................................................66

Transmitter .................................................................................................................73

Common ....................................................................................................................79

Receiver tunings ........................................................................................................85

Transmitter Tunings .................................................................................................100

Appendix.................................................................................................................... 108

Frequency mappings ................................................................................................108

UI Troubleshooting.................................................................................................... 117

Introduction ..............................................................................................................117

UI module troubleshooting cases .............................................................................117

Grip-Module Troubleshooting................................................................................... 121

Introduction ..............................................................................................................121

Backlight ..................................................................................................................122

Current Gauge ..........................................................................................................123

Vibra ........................................................................................................................124

Keyboard ..................................................................................................................125

Hall Sensor ...............................................................................................................126

Issue 2 11/02 ¤Nokia Corporation Page 1

Page 4

CCS Technical Documentation

Camera Troubleshooting Instructions........................................................................ 127

Background, tools and terminology .........................................................................127

Image taking conditions effect to image quality ......................................................128

Camera construction ................................................................................................134

Image quality analysis .............................................................................................135

Fault finding trees ....................................................................................................141

Page 2 ¤Nokia Corporation Issue 2 11/02

Page 5

CCS Technical Documentation

Baseband Troubleshooting

Introduction

This document is intended to be a guide for localising and repairing electrical faults in

the NHL-2NA device. First there is a brief guide for fault localising. Then fault repairing is

divided into troubleshooting paths.

Before any service operation you must be familiar with the NHL-2NA product and module level architecture. You also have to be familiar with the NHL-2NA specified service

tools such as the Phoenix service software, flashing tools and software.

General guidelines for NHL-2NA system troubleshooting

Tools needed for troubleshooting

• Service tools (as listed at service tools chapter in service manual)

• Laboratory power supply with current indicator

• Oscilloscope

• Digital multimeter

General guidelines

General notes about the NHL-2NA product:

• Large colour display

• Keyboard on grip part, rocker, two softkeys and application key under display +

side keys (power key and IHF enabling key)

• Flex cable carries signals between LG4 and LS4 boards. Battery and charger plug

is in grip part, so if the flex is damaged phone cannot be powered on.

• UI-module (display, backlights etc.) is also connected to LG4 module with flex

cable.

• If the component reference is under 100, component is located at the LS4 board.

And if the component reference is over 100, component is located at the LG4

board.

When you get a faulty NHL-2NA device and you start to troubleshoot it, first check the

following items:

• If the device cannot be turned on by any means, see “dead device” troubleshooting

• Current consumption (missing consumption) gives an idea wether the device is

able to start up.

• Dropping supply voltage or very large current consumption indicates a short circuit

• Check wether the connection with Phoenix works and what can be discovered

with Phoenix (ADC-readings, baseband selftest, bb-calibrations etc.)

• Check baseband selftests with Phoenix if “CONTACT THE RETAILER.” is shown on

the display.

• Check visually display and rocker faults

• Force phone to LOCAL mode and make keyboard test by phoenix

Issue 2 11/02 ¤Nokia Corporation Page 3

Page 6

CCS Technical Documentation

• Check that board-to-board connector, hotbar and adapter connections are OK,

and connectors make good contacts.

• If liquid damage, stop repairing!

If some module (eg. Camera, display, grip) is not working:

• Try working module

If this not helping

• Check supply voltages for failed module

• Check clock(s) for failed module

=> Go to relevant chapter of this document

Flash phone before disassembling it if fault is not obvious and Phoenix connection is

OK.

Dissasemble phone:

Try to locate failed module, is it LG4, LS4, UI or camera module.

• Check failed module visually:

Mechanical damages?

Solder joints OK?

Continue with specific troubleshooting procedure for the module:

• If there is an obvious fault, repair it before reflashing the device

• Flash first if a fault is not obvious

If flashing is not working go to flashing troubleshooting

Due to CSP packages short circuits or broken solder joints are not easily seen. If the

examined signal seems to be continuously in low or high level, then measure for possible

short circuit to ground (signal low) or to supply voltage (signal high) Note that if a problem is not found from any visible contact/component it can be under CSPs where the signal is connected.

Care must be taken when assembling and disassembling the tranceiver. Failure to do this

may result in unnecessary damage to device.

NOTE! if some ASIC is changed see chapter Bluetooth troubleshooting

Nominal current consumption

NOTE: Service tools need some amount of current to work. (FLA-21: 1-2mA and MJF-9Q:

2-6mA

Page 4 ¤Nokia Corporation Issue 2 11/02

Page 7

CCS Technical Documentation

The following current consumption values are measured from a complete NHL-2NA.

Vbatt = 3.8 – 4.2V

Measured nominal currents are drawn from the main battery.

Measurements have been made with a current probe connected to an oscilloscope.

Operating mode

Idle (BT off) 4-8 mA

2w audio call (backlights off) channel37 300-340mA

Viewfinder + nominal backlights 232mA

Current consumption

Issue 2 11/02 ¤Nokia Corporation Page 5

Page 8

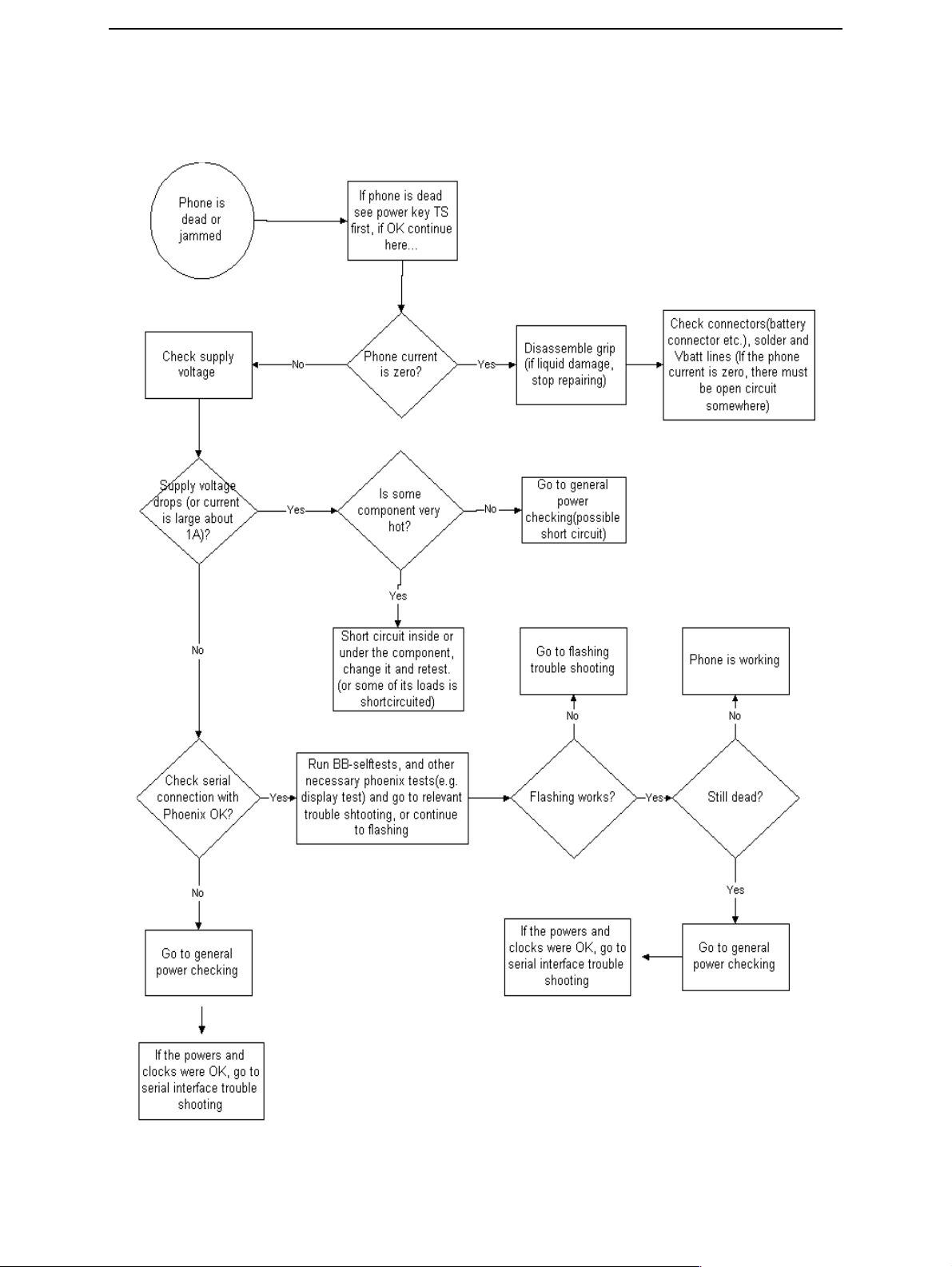

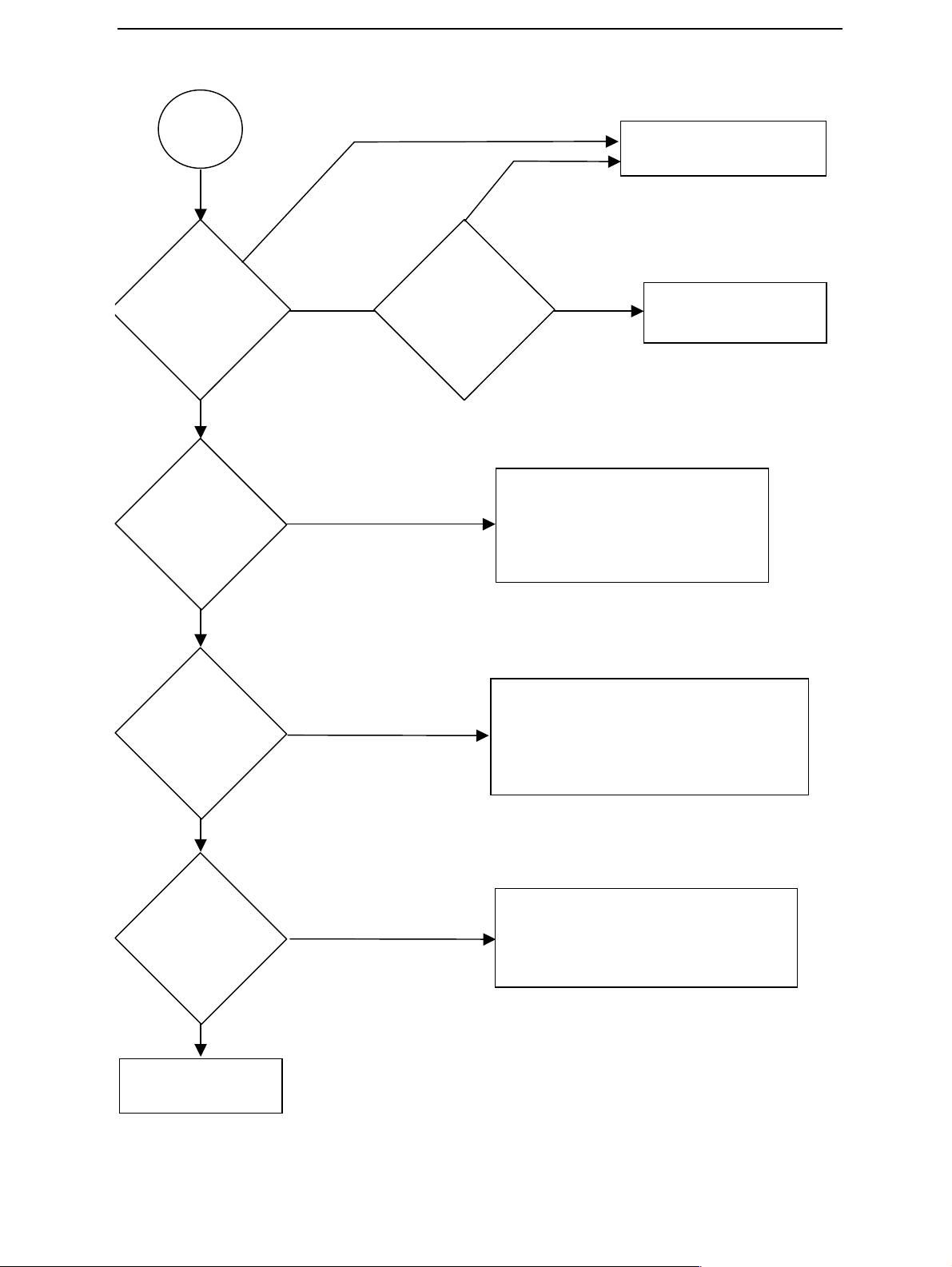

Troubleshooting paths

Dead or jammed device

CCS Technical Documentation

Page 6 ¤Nokia Corporation Issue 2 11/02

Page 9

CCS Technical Documentation

Partially damaged device

If the device is working, but some functionality is missing try to localize where the problem is and see relevant part of this manual. If, for example, audio is not working see

chapter Audio Troubleshooting, if charging is not working see chapter Charging Troubleshooting, etc.

Most common symptoms reported by customer

In this section is described most common symptoms reported by customers when the

device is brought to service. Some tips where the trouble can be found are also given.

When troubleshooting use these tips and follow the given troubleshooting path.

Most common symtoms for audio problems can be:

“Earpice sound is missing”

”Handsfree sound is missing”

”Headset is not recognized”

”Microphone is not working”

”Volume cannot be adjusted”

” Ringing tones do not work”

”Audio volume too low”

If symptom is something like above see audio troubleshooting.

Most common symptoms for Irda and bluetooth problems can be:

“Irda does not work or it does not make a connection”

”Bluetooth does not work or connection cannot be established”

If symptoms are something like those, start to follow Irda or bluetooth

troubleshooting guidelines gave relevant chapters.

Symptoms related to energy management:

“Phone does not stay on”

”Charging is not working”

”Time is lost during battery change or short main battery removal”

”Charging takes too long”

”Operating time is very short”

These symptoms lead to relevant part of energy managemant troubleshooting

If the sensor/sensors are out of order description of symptoms can be like below:

“IHF is not disabled automatically when phone is put near ear”

“IHF cannot be enabled”

“Backlight is always ON or OFF”

“Backlight of display does not go OFF”

Issue 2 11/02 ¤Nokia Corporation Page 7

Page 10

In cases above see Chapter Sensors Troubleshooting or Backlight Troubleshooting

Problems in UI-module:

“UI-module keypad is not working”

”Joystick is not working”

”Backlight is dim”

”Baclight not even”

”Backlight is blinking”

”Keypad or display backlight is not working”

”Display related problems”

See UI- module troubleshooting.

Most common RF related symptoms:

“Call cannot be made”

”Phone does not find signal”

”Call is often dropped”

CCS Technical Documentation

See RF troubleshooting

Problems with camera can cause symptoms as:

“Bad image quality”

”Picture cannot be taken”

See camera module troubleshooting

Problems in LS4 can cause symptoms below:

”Backlight of grip is dim”

”Baclight of grip not even”

”Backlight of grip is blinking”

”Grip keypad is not working”

”Vibra is not working or is noisy etc.”

See grip- module troubleshooting.

Contact the retailer” on display

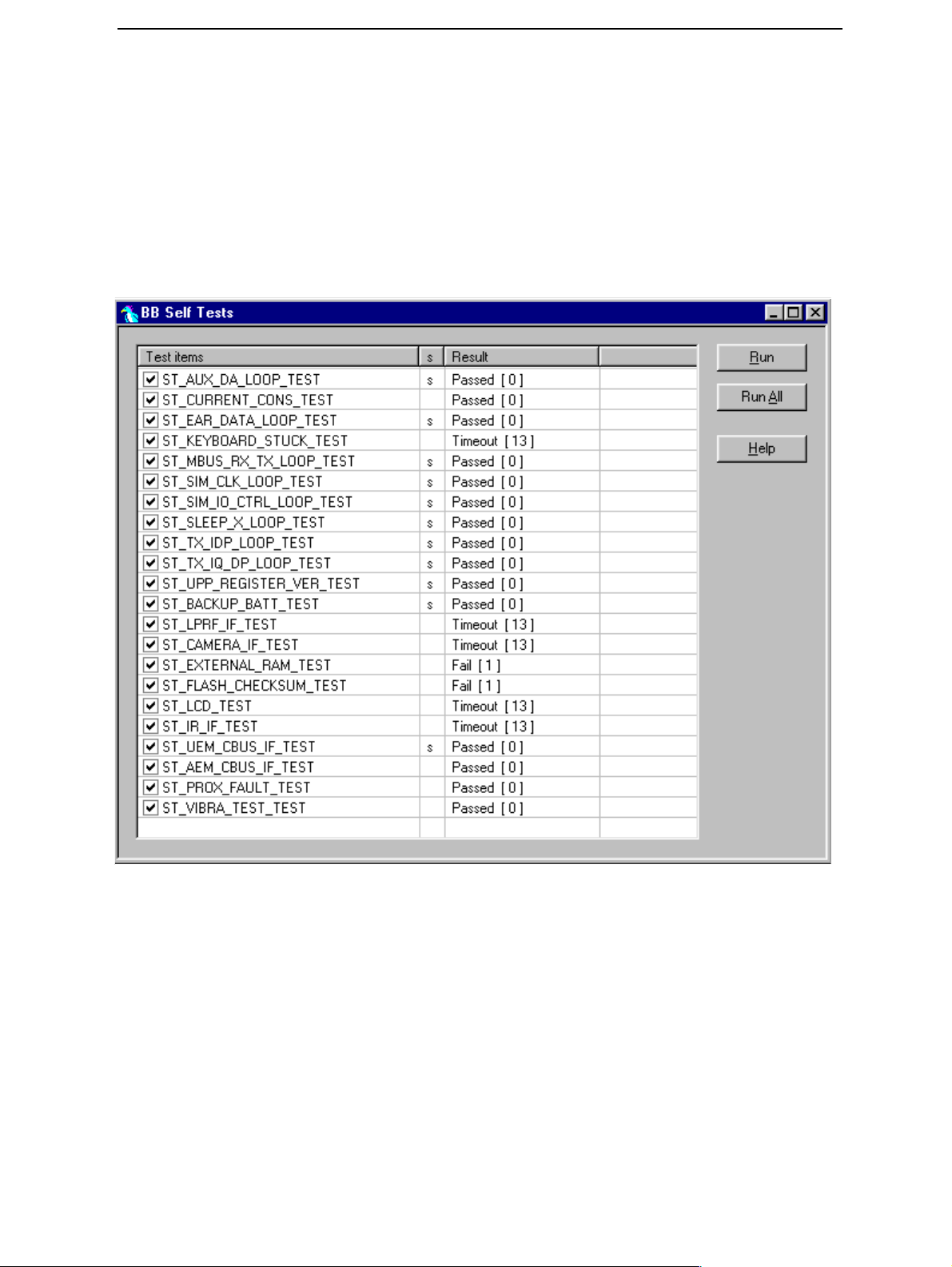

“Contact the retailer.” on display (Self-tests by Phoenix)

Display information: “Contact the retailer”

Page 8 ¤Nokia Corporation Issue 2 11/02

Page 11

CCS Technical Documentation

This fault means that software is able to run and thus the watchdog of UEM can be

served.

Selftest functions are executed when the phone is powered on and if one or more selftest functions fail, the message “Contact the retailer” is shown on the display.

MCU selftest cases can be split into two categories: The ones that are executed during

power up and the ones that are executed only with a PC connected. These tests and the

items included are as follows:

Figure 1: BB selftest-tool

If a selftest fails, see relevant chapter in this troubleshooting manual.

Issue 2 11/02 ¤Nokia Corporation Page 9

Page 12

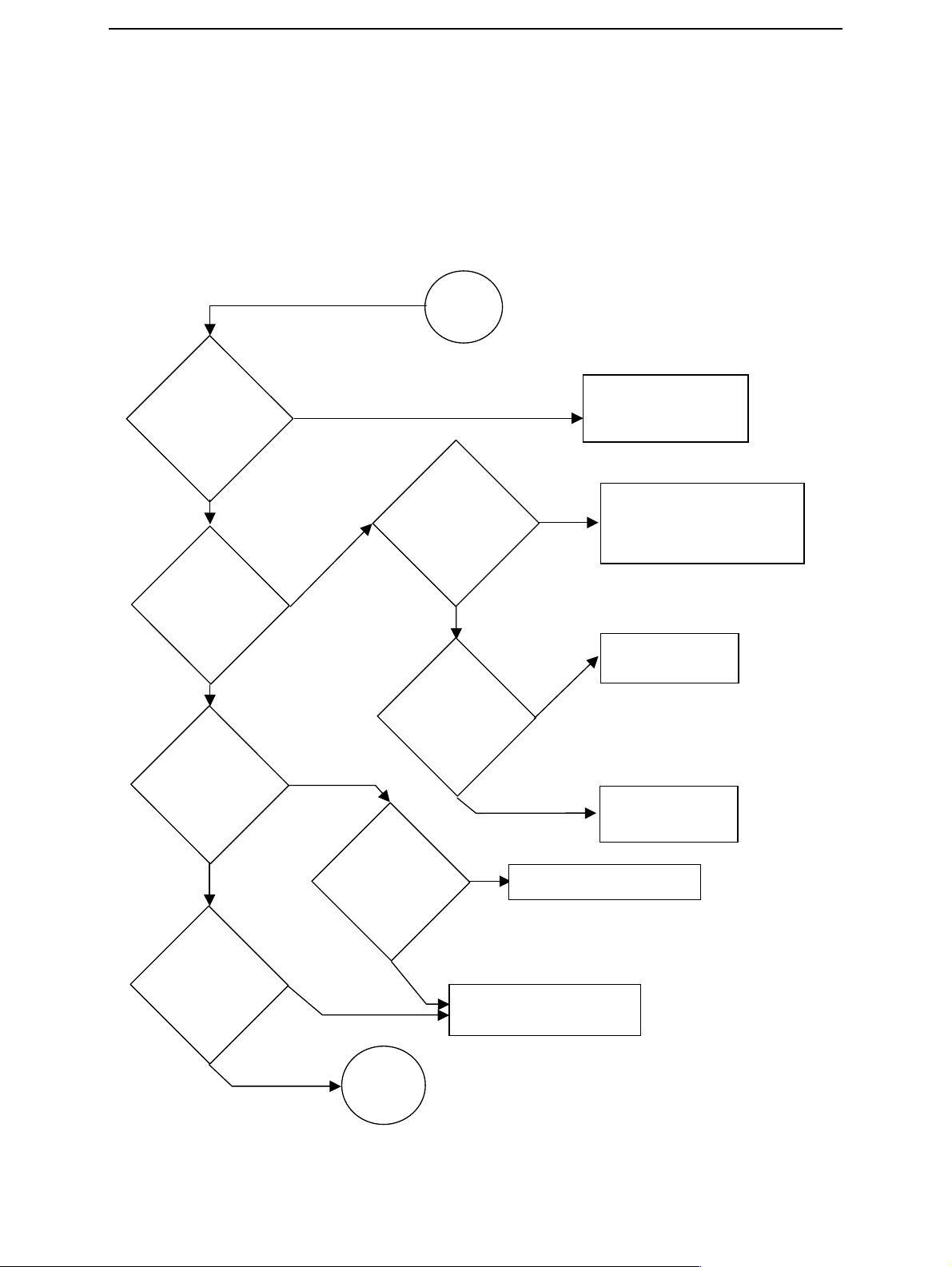

LG4 Baseband HW subarea troubleshooting

B

C

Flashing troubleshooting

NHL-2NA has three memory components installed on the main pwb. The best indication

of which one is causing problems can be obtained by flashing the device. It has to be

kept in mind that all three memory components are interfaced with UPP WD2 asic that

might itself have some problems. The necessary steps are described below. Phoenix error

messages during flashing greatly help on defining what is wrong. To be able to flash the

device, most device BB area components must function properly.

Flashing

faults

CCS Technical Documentation

C101 "Boot

timeout" or

C102 "boot start

txd fail"

message

?

No

C103

"Boot serial line

fail" message

?

No

C106

"Secondary

receive fail"

message

?

Yes

Yes

Yes

Measure BSI

pulse during

flash

programming

Is it ok?

Yes

Measure

I_FBUS_TX(J121)

line during flash

programming is it

1.8V?

Yes

No

Check connections

Check BB voltages

heck clocks

Check BSI line

attery connector, flex,

C239, Z383, R384

Change

UEM(D190)

No

Change UPP

WD2(D100)

No

Change UEM(D190)

Change

UPP_WD2(D100)

No

C202

"Algorithm

send" or C281

"phone message

chksum" fail

?

No

Sleep

clock(J101) ok ?

Yes

Yes

Flashing

faults page

2

Page 10 ¤Nokia Corporation Issue 2 11/02

Page 13

CCS Technical Documentation

C

Flashing

faults page

2

No

C108

"Prommer

message about

sdram failure"

?

No

Yes and sdram

allready changed

Yes

No

Activity in sdram

clk(J108) pad?

Yes

Change

UPP_WD2(D100)

Change

SDRAM(D312)

A204

"Wrong

manufacturer ID

and device ID"

message

?

No

C385

"Data block

handling timeout"

message

?

No

C586

"Phone fail

responce" or C684

"Data blok Nak"

message

?

Yes

Yes

Yes

hange Flash Chip according

to Phoenix messages

If both chips report wrong

ID's -> change

UPP_WD2(D100)

Bluetooth module is unable to start

flashing ->

Check V590,R591,R593-596,C594

and C595 -> still not ok

-> change BT module

Check flash0 bypass caps, check

Vpp connection to flasher, Check

R314(4.7k)

Ok->Change flash0(D311)

No

Flashing

successful/Retest

Issue 2 11/02 ¤Nokia Corporation Page 11

Page 14

Energy management troubleshooting

Device does not stay on

If the device is switched off without any visible reason, there may be problems in the following areas:

• UEM watchdog problem (WD is not updated by SW)

• BSI line problem (BSI line is floating => contact failure)

• Battery line problem

• Soldering problem

The most likely reason is UEM WD (watchdog), which turns the device off after about 32

seconds if SW is jammed.

This may be caused by a SW problem, UPP_WD2 problem (Not server by SW), UEM, AEM

or memory malfunctions.

The following tests are recommended:

CCS Technical Documentation

• General power checking

•Clocks

•Memory testing

• Serial Interface

If there is something wrong in BSI line, the device seems to be dead after the power key

is pressed. However the regulators of the device are on a few seconds before the powerdown.

This mode can easily be detected from the current consumption of the device. After a

few seconds the current consumption drops almost to 0 mA.

In this case check components listed below or soldering:

Battery connector X002

Grip connector X001 (especially pin number 27)

Hotbar soldering X380 (especially pin number 5)

EMI-filter Z383 (especially pins number A4 and E4)

UEM D190 (pin number C2)

If phone boots to TEST or LOCAL mode with normal battery, BSI or Btemp or both lines

are short circuited to ground. Check varistors, EMI-filter and filtering capacitors, which

are located to BSI and Btemp lines.

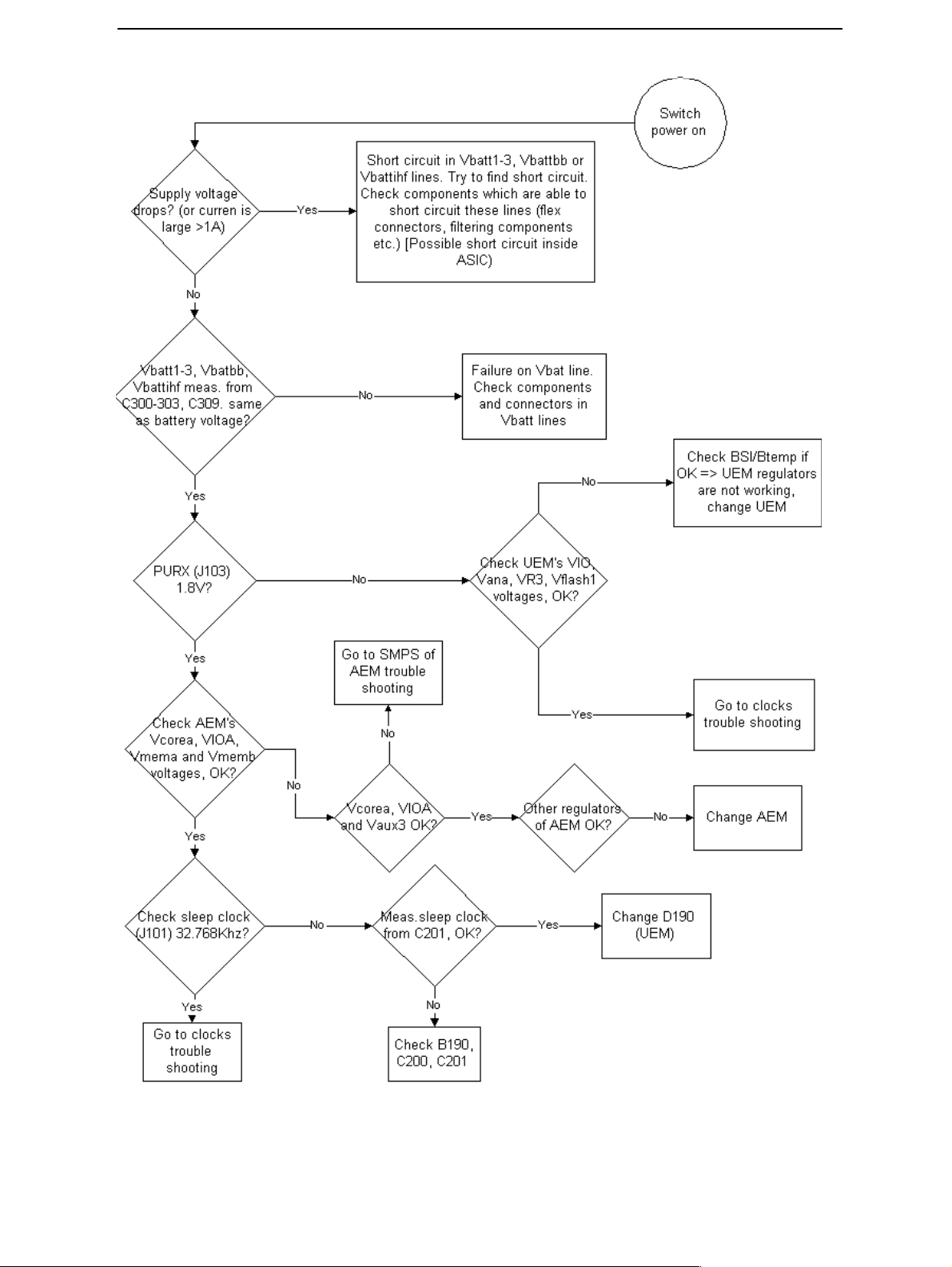

General power checking

Use service tool FLA-21. Battery voltage should be atleast 3.6V. After phone disassembly,

use module jig MJS-9Q.

Page 12 ¤Nokia Corporation Issue 2 11/02

Page 15

CCS Technical Documentation

.

Issue 2 11/02 ¤Nokia Corporation Page 13

Page 16

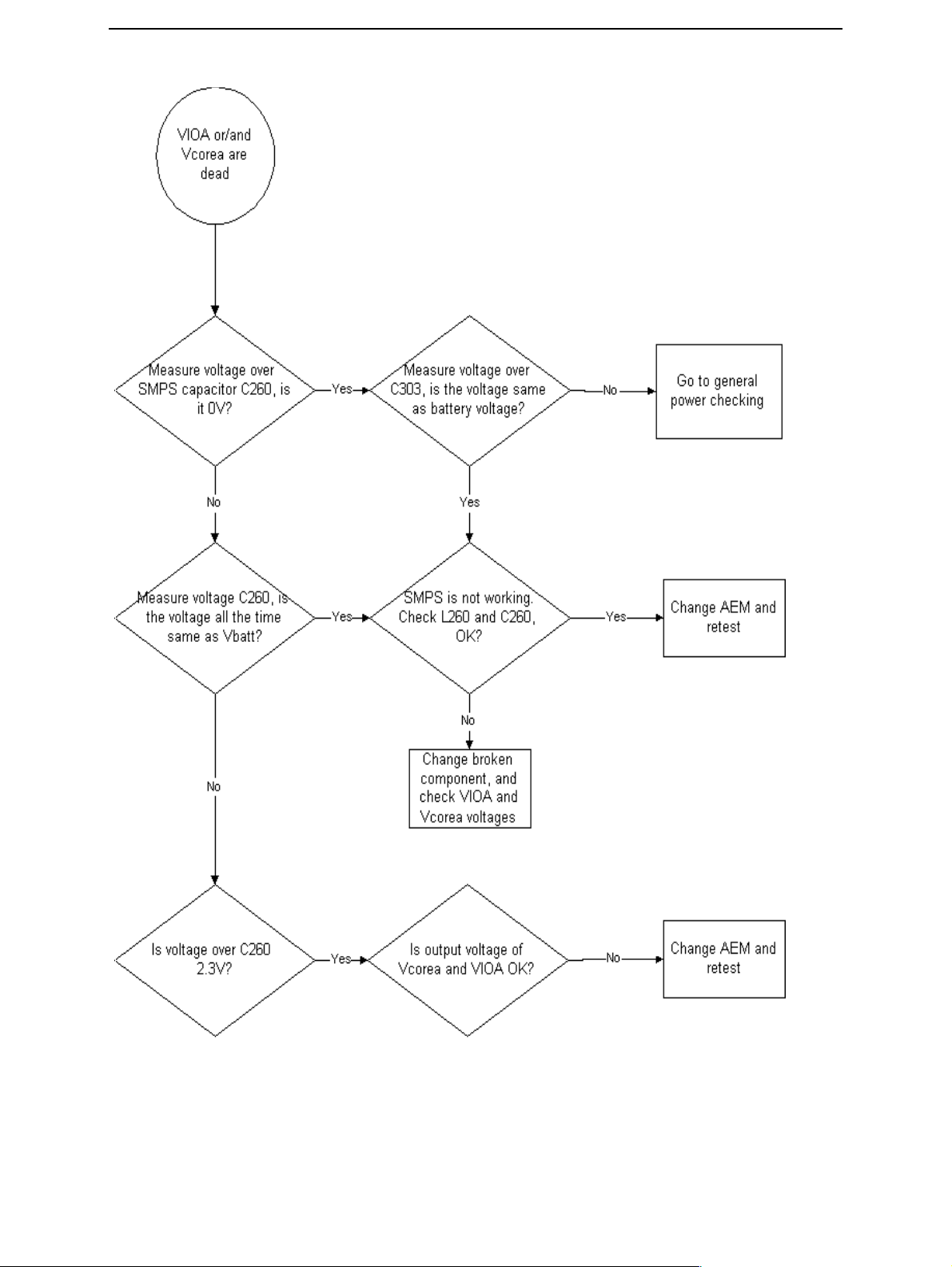

SMPS of AEM troubleshooting

CCS Technical Documentation

Page 14 ¤Nokia Corporation Issue 2 11/02

Page 17

CCS Technical Documentation

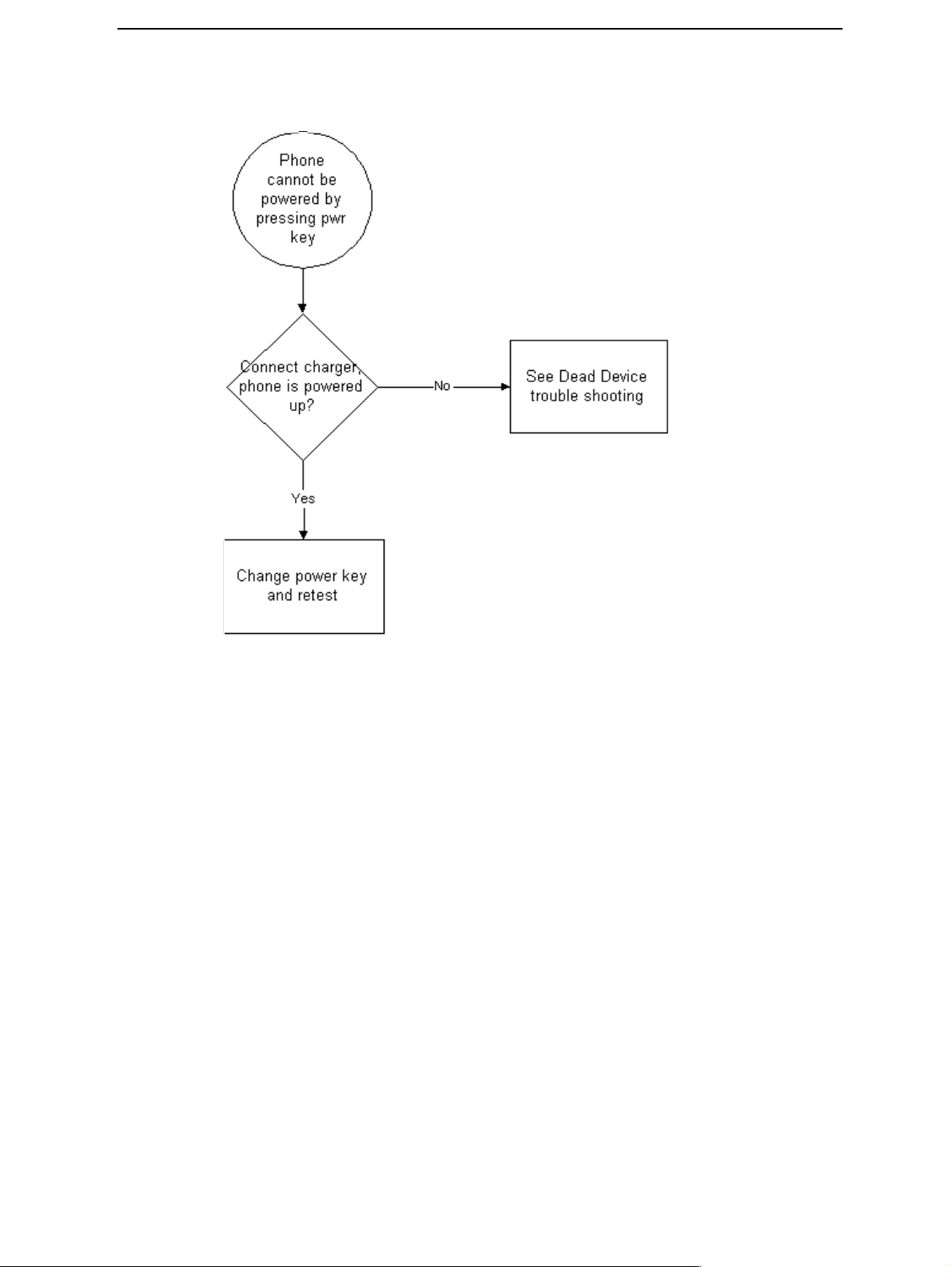

Power key troubleshooting

Issue 2 11/02 ¤Nokia Corporation Page 15

Page 18

Clocks troubleshooting

C

S

S

C

S

D

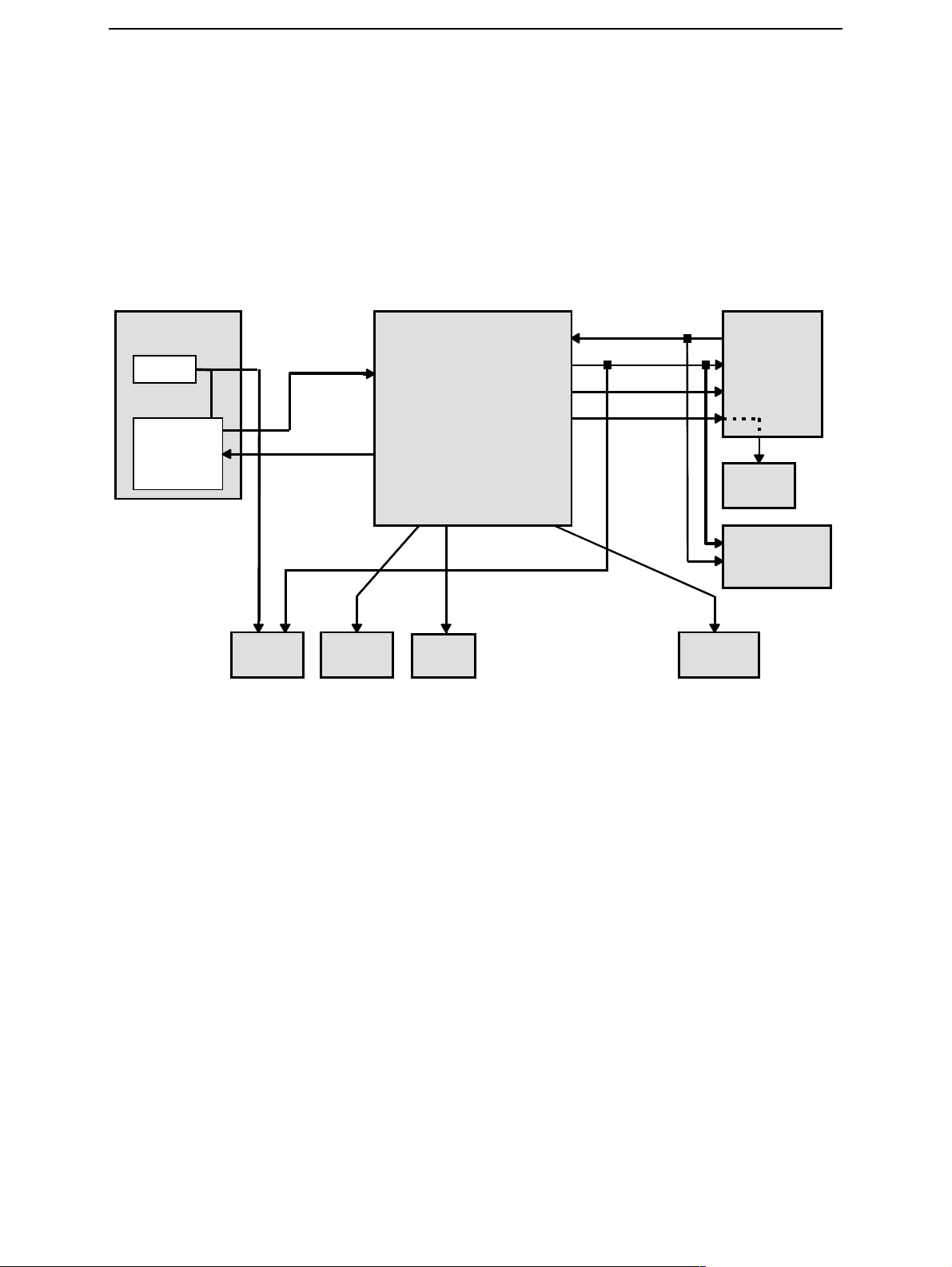

The main clock signal for the baseband is generated from the voltage and temperature

controlled crystal oscillator VCTCXO (G591). This 26 MHz triangle wave clock signal is

supplied to OSC_IN pin of HAGAR. Inside HAGAR the clock frequency is divided to 13

MHz and then fed to RFCLK pin of UPP_WD2 and Bluetooth.

In SLEEP mode the VCTCXO is off. UEM generates low frequency clock signal (32.768

kHz) that is fed to UPP_WD2, Bluetooth and AEM.

CCS Technical Documentation

RF

VCXO

RF-ASIC

(Hagar)

LPRF

RFClk

13 MHz

RFBusCl

Flash

Clk

FLASHes

UPP_WD2 UEM

leepClk

BusCl

BusCl

IMCl

SIM

AEM

DRAM

lk

CAMERA

SDRAM

When the flashing of the device does not succeed, but powering is OK, follow these

instructions.

Note: The absence of clocks may indicate that the device (put phone to LOCAL mode

when the sleep is not allowed or press buttons so that phone is not in sleep mode) is in

sleep mode. Make sure that the device is not in sleep during RF clock measuring.

Ω

IMPORTANT: Clock signals have to be measured with 1M

(or greater) probes!

Page 16 ¤Nokia Corporation Issue 2 11/02

Page 19

CCS Technical Documentation

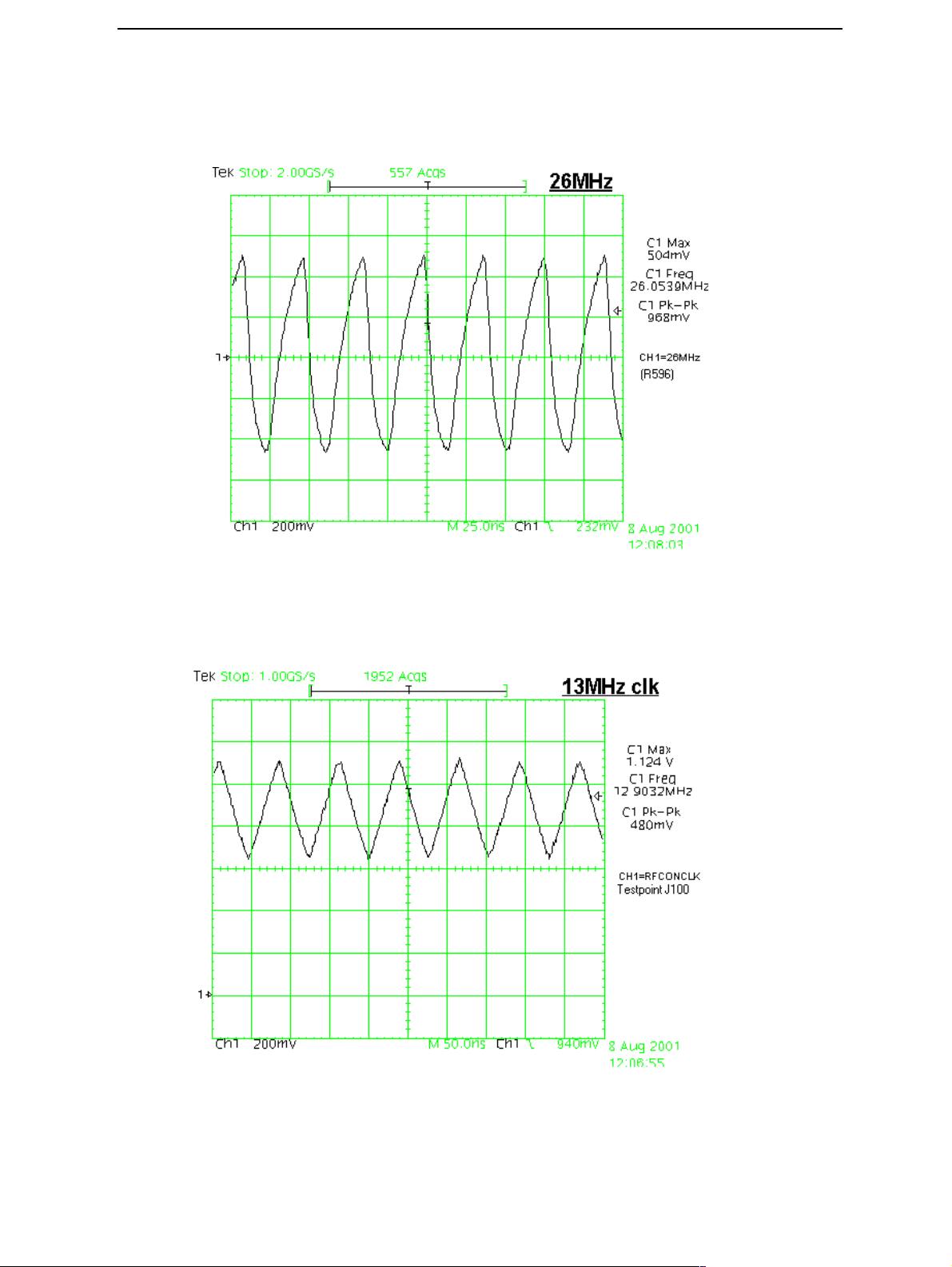

1 Measure signal from R596. This should be 26Mhz clock signal. See figure below.

If the clock not exist, check voltage from C662, it should be 2.78V (UEM regulator VR3). If voltage is OK, check G591 and other componets around it.

Figure 2: 26 Mhz clock

2 Check 13Mhz Rfclk from testpoint J100. See figure below. Offset should be

about 900mV. If the offset does not exist something is broken inside UPP_WD2

or DC-filtering capacitor in series on trace.

Figure 3: 13 MHz clock

Issue 2 11/02 ¤Nokia Corporation Page 17

Page 20

CCS Technical Documentation

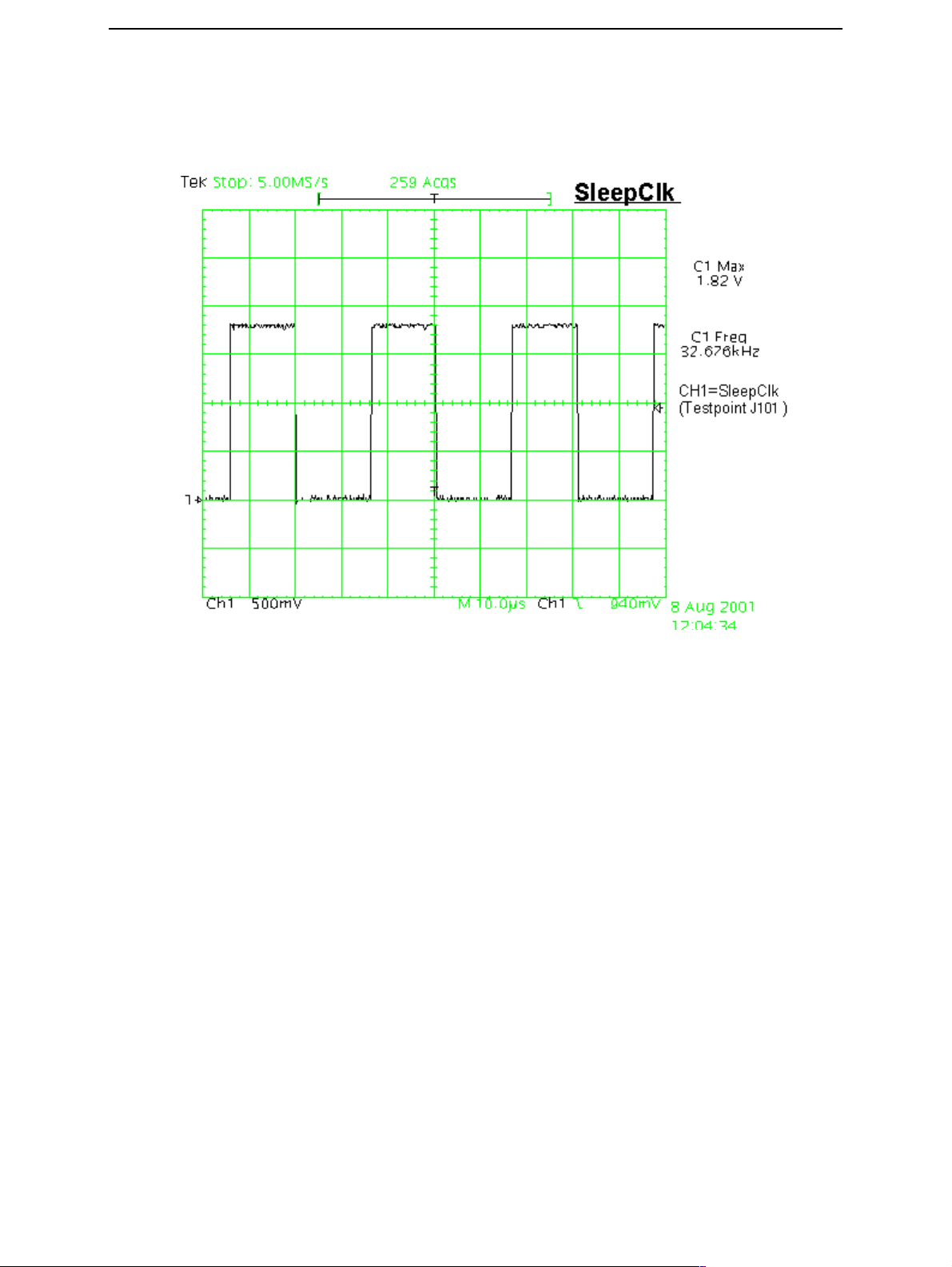

3 Check is the crystal oscillator (B190) oscillating at 32.768kHz frequency. If not

change B190. If OK measure sleepclk from testpoint J101. Frequency should be

the same 32.678kHz (see figure below.) If not change UEM.

Page 18 ¤Nokia Corporation Issue 2 11/02

Page 21

CCS Technical Documentation

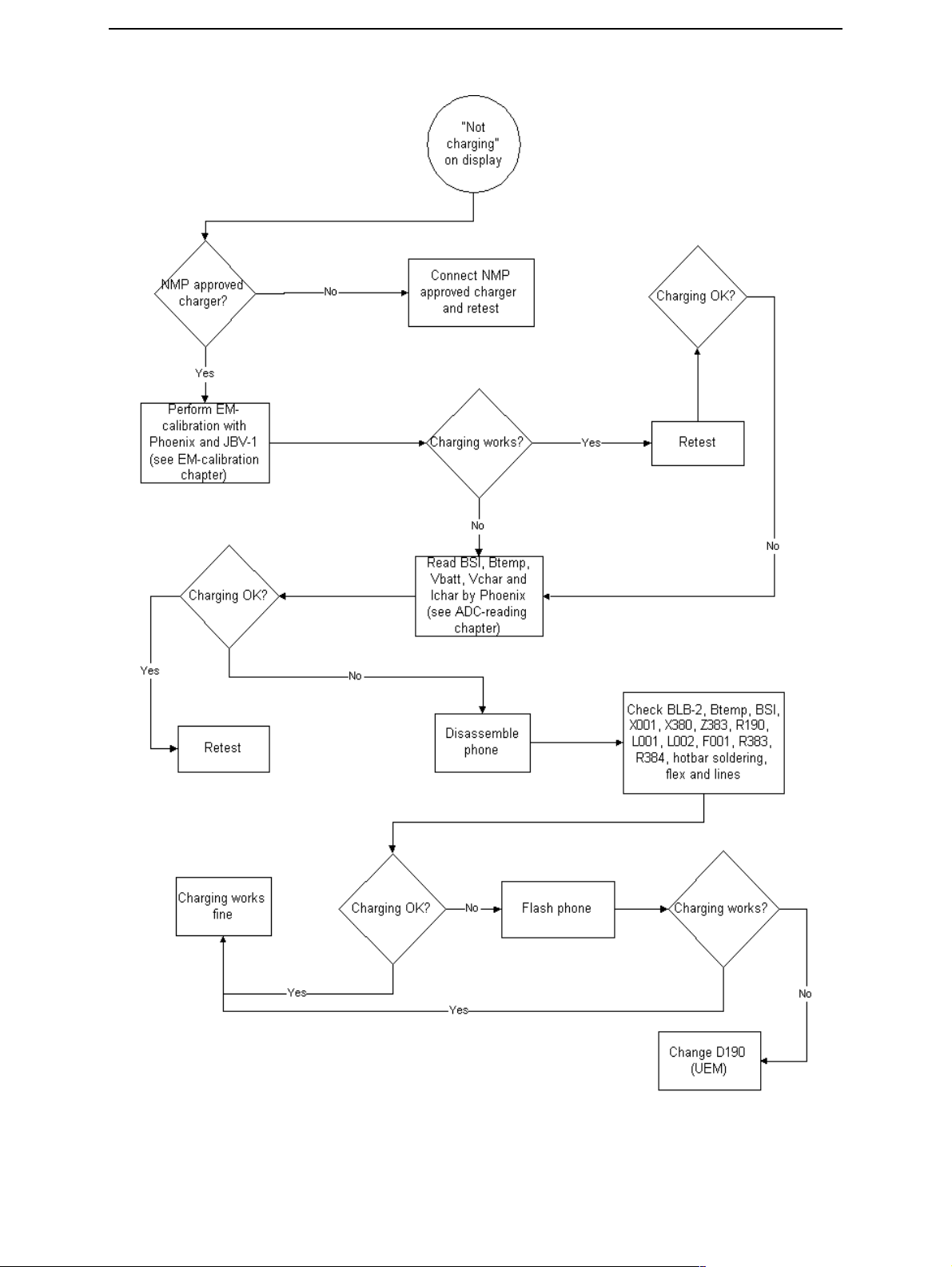

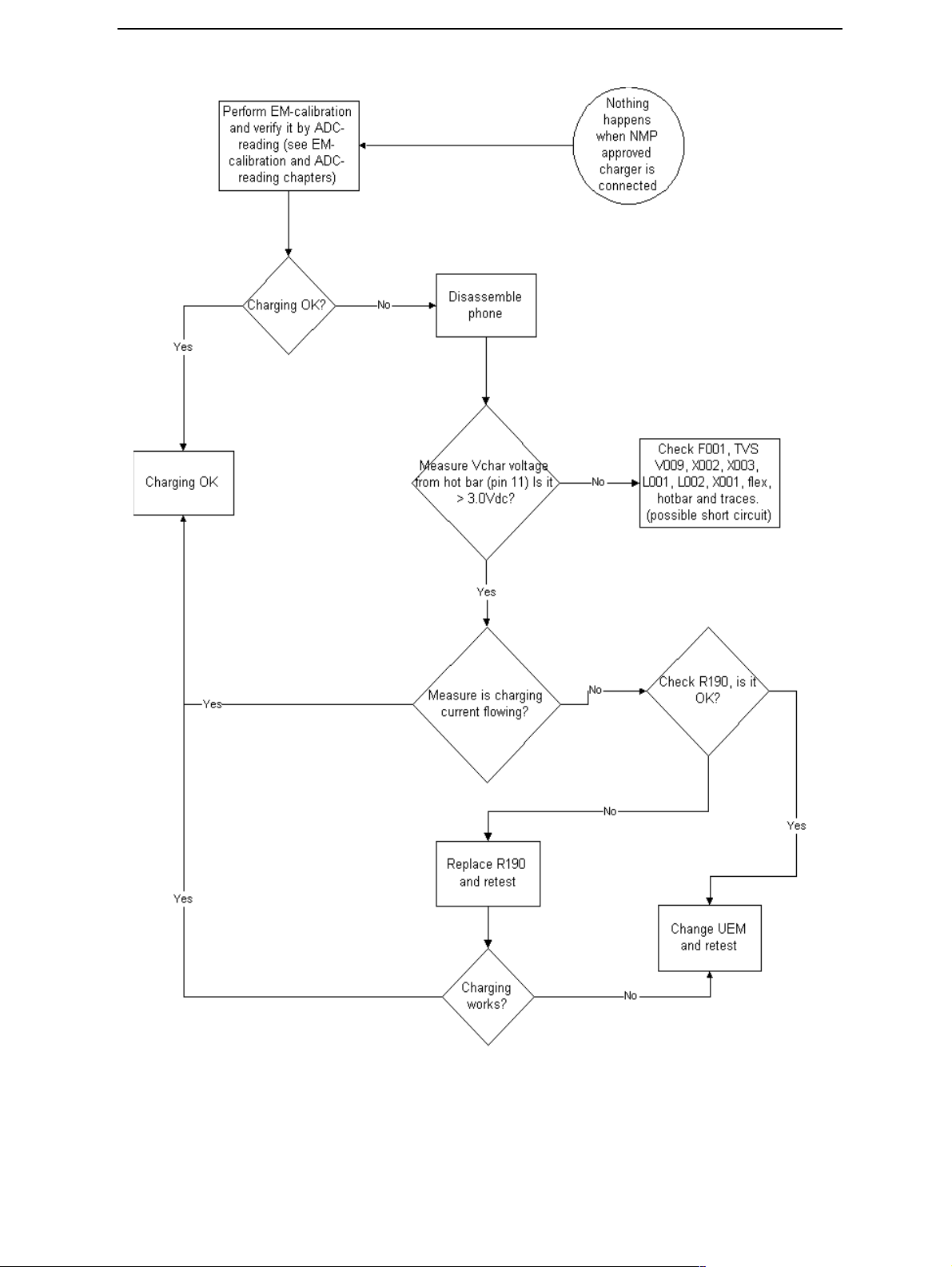

Charging checking

Use the BLB-2 battery and JBV-1 calibration set to test charging. (NOTE: power supply

cannot be charged if it not has a current sinking capability.) When you are charging

totally empty battery, remember that start-up charging might take a little bit longer time

than normal. During this time display is blank.

If charger is not NMP approved type and its current and voltage is not within NMP

charger window then software does not start charging and there is “NOT CHARGING” on

the display. Voltage should be between 5.5V - 9.3V and current between 200mA –

850mA

Remove and reconnect battery and charger few times before you start to measure

device. This check ensures that the fault really exists.

Issue 2 11/02 ¤Nokia Corporation Page 19

Page 22

CCS Technical Documentation

Page 20 ¤Nokia Corporation Issue 2 11/02

Page 23

CCS Technical Documentation

Issue 2 11/02 ¤Nokia Corporation Page 21

Page 24

Energy management calibration

During energy management calibration A/D-converter, BSI, Btemp, Battery voltage,

Charger voltage and Charger current are calibrated. For detailed information and

instructions see EM-calibration instructions in service manual.

Troubleshooting tips:

ADC-offset over limits:

Inspect BSI line, connectors (hotbar and board to board connector) and components in it

(Varistor R008, EMI-filter Z383, Pull-up resistor R384). If these are OK, change UEM.

BSI Gain over limits:

Inspect BSI line, connectors (hotbar and board to board connector) and components in it

(Varistor R008, Capacitor C002, EMI-filter Z383, Pull-up resistor R384). If these are OK,

change UEM.

Btemp Gain over limits:

Inspect Btemp line, connectors (hotbar and board to board connector) and components

in it (Varistor R006, Capacitor C010, EMI-filter Z383, Pull-up resistor R383). If these are

OK, change UEM.

CCS Technical Documentation

Vbatt offset and Gain:

Inspect Vbatt lines and component in it.

Vchar over limits:

Inspect components which are connected Vchar line: Filtering capacitors C005, C006,

C011, TVS V009, L001 and Fuse F001. If those are OK, Change UEM

Ichar over limits:

Inspect components which are connected at Vchar line: Filtering capacitors C005, C006,

C011, TVS V009, L001 and Fuse F001. If those are OK, First change current sense resistor

(R190), if calibration is not still successful change UEM.

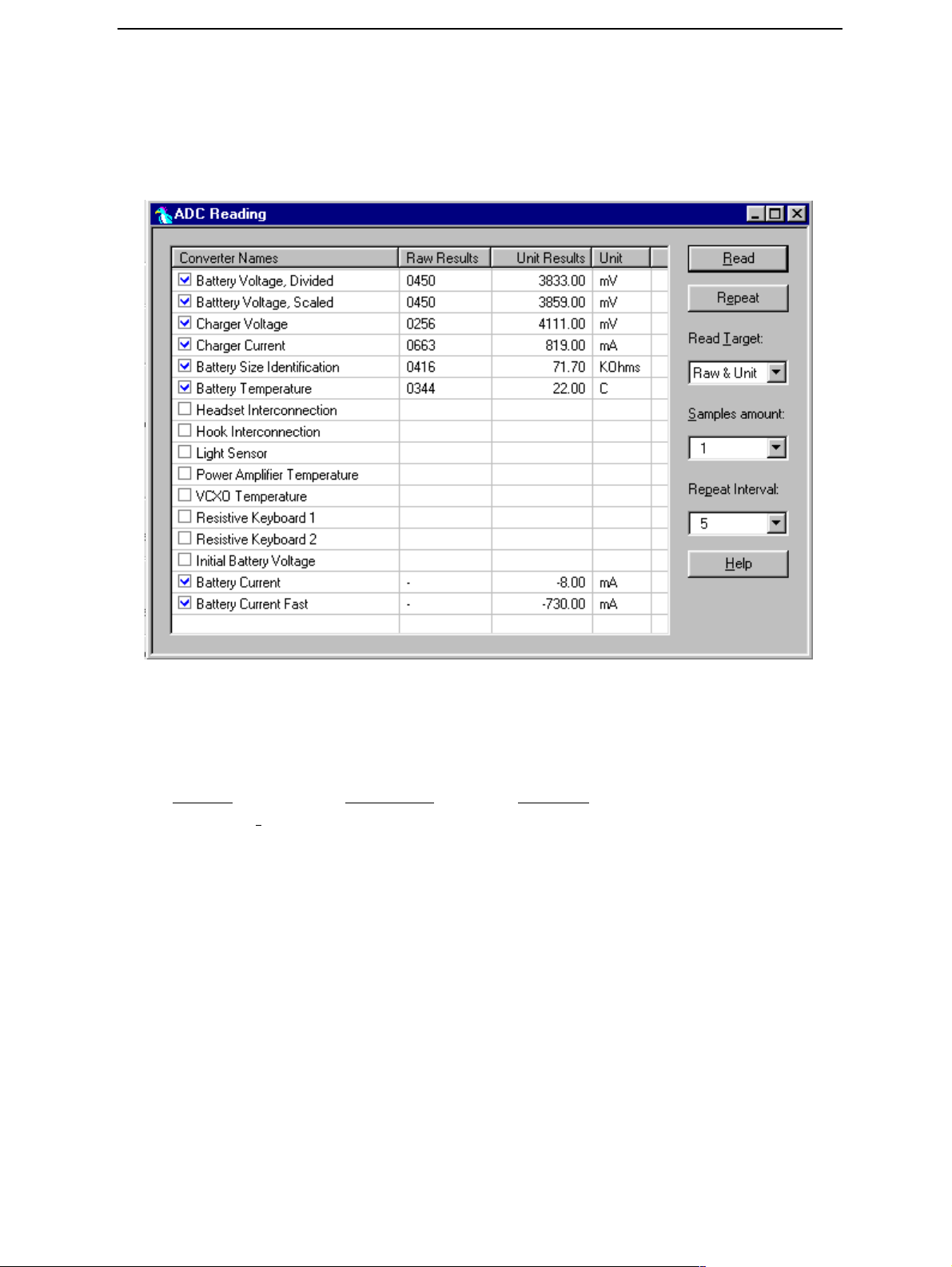

Calibration can be checked using ADC-redings. Known voltages, currents and resistances

are fed and read by ADC-readings, read values and known values can be compared.

Page 22 ¤Nokia Corporation Issue 2 11/02

Page 25

CCS Technical Documentation

ADC-reading

Divided and scaled battery voltage, Charger voltage, Charger current, BSI and Btemp values can be read by this tool. Read values few times before you can be sure that results

are accurate.

Figure 4: ADC-readings view

Note:: If Vbatt Scaled and Divided unit results are different default calibration values

are used. In this case perform EM-calibration to get full performance of phone.

Maximum tolerances are:

Reading

Vbatt SCAL 4.2V ± 25mV

Vchar 8.4V ± 40mV

Ichar 500mA ± 20mA

BSI 68k(BLB-2) ± 1.3kohm

Btemp 273K(47k) ± 5K

Backup battery

Symptom of backup battery fault is:

Real Time Clock loses the correct time during short main battery removal.

The same syptom can also be seen when the backup battery is empty. About 5 hours is

needed to fully charge the backup battery in the device. NOTE: Backup battery is charged

only the same time with main battery charging. Or when the device is LOCAL or TEST

mode.

Check point Tolerance

Issue 2 11/02 ¤Nokia Corporation Page 23

Page 26

CCS Technical Documentation

Always check that the backup battery visually for any leakage or any other visual defect.

Check that the backup battery is correctly mounted in the device before closing the

cover.

1 Check with Phoenix is backup battery OK

2 Measure the voltage of backup battery

• Normal operation when the voltage is > 2.0V

• Fully charged when the voltage is about 3.2V (because of large internal imped

ance voltage won’t stay above 3.0V a long time after charging is disabled)

3 Enable backup battery charging (start to charge main battery or boot device to

LOCAL or TEST mode)

4 Measure voltage of backup battery during charging, It should arise if it is not

3.2V, yet.

5 When the voltage is over 2.0V for sure, check backup battery with Phoenix.

-> If not OK then D190 is faulty.

6 Ensure that the RTC is running.

IR interface

0. IR test

1. IR test

s

e

y

2. IR ok

Re-flash,ifnot

working its

beyond

economical

repair

no 3. IR selftest

4. Remove Acover (refer to

disassebly

instructions)

5. Repeat IR

no

6. Replace IR

module, repeat

s

e

y

test

noyes

test

2. IR ok

o

n

e

y

s

4. Remove Acover

Replace A-

cover

5. Repeat IR

test

yes

soldering of

GND (pins 5

soldering of

serial resistors

and capacitors,

o

n

8. Check

Vcc and

and 8)

yes

10. Check

the rest of

the pins.

s

e

y

7. Replace

repeat test

7. Replace

serial resistors

and capacitors,

repeat test

no

Beyond

economical

repair

no

no

no

yes

9. Check

capacitors

C360-363

o

n

Fix and repeat

test

6. Replace IR

module and

test again

no

If test fails after

re-flash, phone

is beyond

economical

repair

2. IR ok

yes

PWB fail

s

e

y

no

Page 24 ¤Nokia Corporation Issue 2 11/02

Page 27

CCS Technical Documentation

0. At this point it is supposed that problem is in HW

1. Send something to another phone or laptop

2. Everything is ok

3. Activate phones IrDA selftest

4. Take off phones A-cover

5. Start test again from the beginning, there might be more than one fault...

6. Solder a new IrDA module to phone, start test again.

7. Replace resistors R360 – R363 and capacitors C360-C363

8. Vcc in pin 5 should be connected to VMEMA

9. Check capacitors C360-363 for shorts and open contacts

10. Pin 1 (Anode) should be at battery voltage, pin 2 (Cathode) should be floating, pin 3

(Tx), pin 4 (Rx), pin 7 (mode) should be grounded.

Issue 2 11/02 ¤Nokia Corporation Page 25

Page 28

Sensors troubleshooting

This part of document is written to help troubleshooting for proximity sensor and ambient light sensor in NHL-2NA. Both of them are calibrated in production, in FINUI tester.

AMS has possibility to calibrate proximity sensor at service points, ambient light sensor

is repaired in Bochum.

This document is ment to be used only in troubleshooting and does not provide information on basic functionality of the systems. Basic operating principle can be found in

chapter “System Module LG4 and Grip Module LS4”, calibration instructions can be

found in chapter “Service Software Instructions”.

CCS Technical Documentation

Page 26 ¤Nokia Corporation Issue 2 11/02

Page 29

CCS Technical Documentation

Proximity Detector

General notes

In the production proximity detector problems are best located from calibration results.

Before starting troubleshooting with the help of this section, user should familiarize to

the calibration instructions.

When the user brings the phone to the service point complaining that handsfree won’t

turn on, the problem can be either in the handsfree speaker circuitry, or in the proximity

detector. This chapter gives instructions how to repair the problem in the proximity

detector.

A good indicator that the proximity detector has caused disabling of the loudspeaker is,

that the phone has switched the audio back to the earpiece. If the audio is not switched

to the earpiece but also loudspeaker is not on, the problem is most likely in the handsfree

circuitry.

When the problem is located on the proximity detector, always replace lens module

before proceeding to detailed troubleshooting.

If the problem is not this simple, the best way to look for the problem is to use PD calibration results.

Remember that Proximity Detector has to be calibrated always when optocomponents or

optics are replaced! Calibration also has to be done, if AEM ASIC is replaced or if calibration settings are lost from PMM.

Proximity Detector components

From now on Proximity Detector will be referred to as PD.

Main components of PD are lenses, emitter (IRED CL-200-IR, V334, 4860009), RSENSE

4R3 (R347), receiver (photodiode BPW34FS, V335, 4864911) and a control block, which is

located on AEM ASIC (N226). Three external capacitors are part of the control block:

100n (C275) and 220p (C273 and C274).

Issue 2 11/02 ¤Nokia Corporation Page 27

Page 30

CCS Technical Documentation

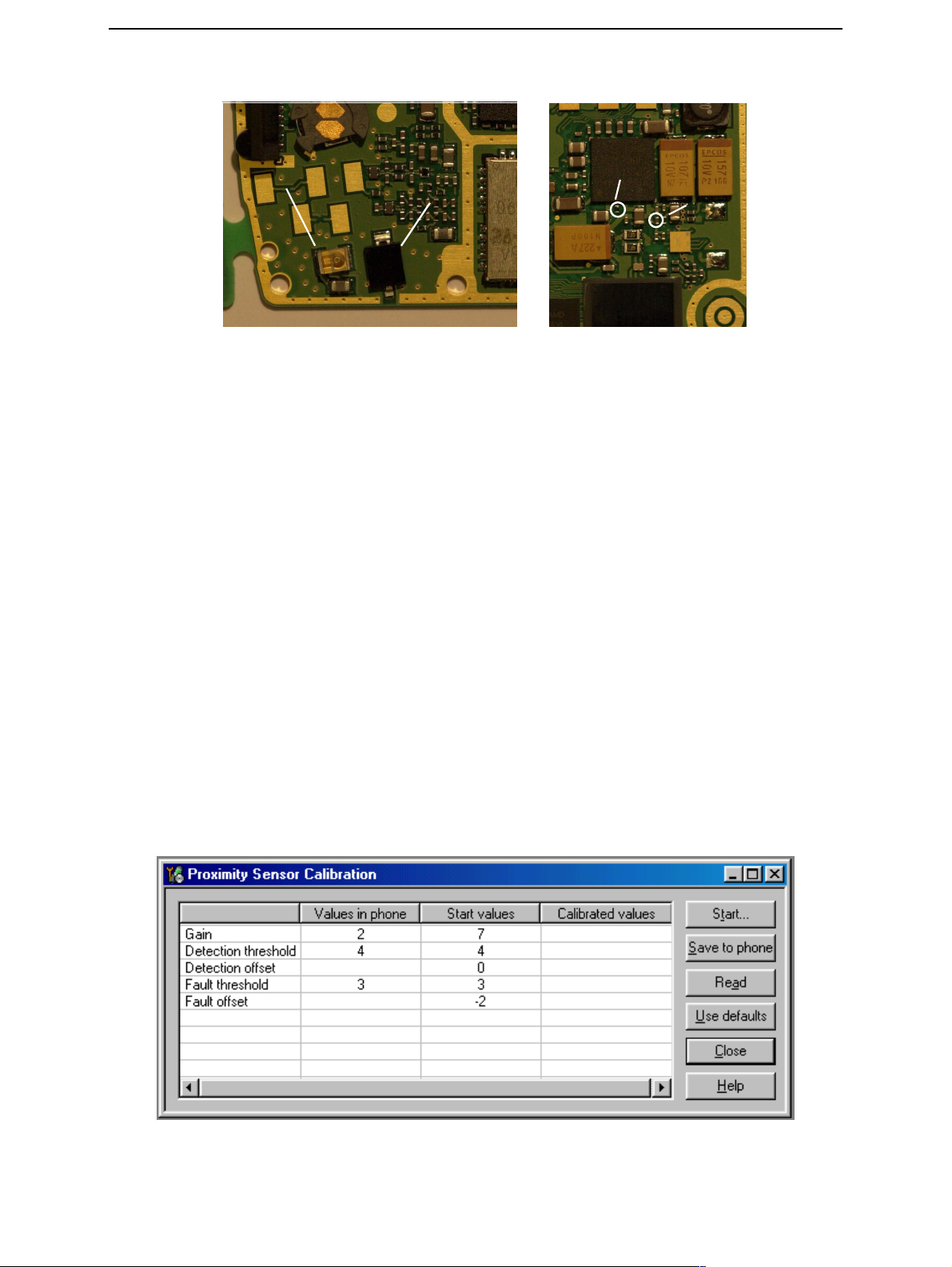

Figure 5: Most important receiver and transmitter components

V334 V335

Handsfree shuts down automaticallly in sunshine

It is normal, if this behaviour occurs only in high ambient light conditions, e.g. direct

sunlight, and no repair actions are needed. If this problem occurs also in low ambient

light conditions (outdoors when the phone is not facing the sun), check that capacitors

C273, C274 and C275 are placed correctly. Replace the lens module and recalibrate the

system.

PD calibration

Proximity Sensor Calibration tool is shown in the Figure 4 Proximity Sensor Calibration

tool. Parameters that are calibrated and saved to PMM are gain, detection threshold and

fault detection threshold. When you start the calibration tool, the values in the PMM are

shown in the left column. Second column shows start values used in calibration, they

are defined by R&D. Calibration consists of two phases. First gain and detection threshold are calibrated. If this calibration is finished successfully, software starts fault threshold calibration; fault threshold cannot be calibrated alone. Offset value(s) are used to

adjust the thresholds to compensate possible wearing of the PD. To help troubleshooting

phone SW response is one of the 13 messages that are explained in the next chapter.

Successful gain and detect threshold calibration tells that optoelectrical components are

OK. Note! Values in this picture might change.

R347

C275

Figure 6: Proximity Sensor Calibration tool

Page 28 ¤Nokia Corporation Issue 2 11/02

Page 31

CCS Technical Documentation

Troubleshooting with PD Calibration results

CALIB OK (0x00)

This is the response, when calibration is done successfully. Save calibration results to the

phone.

START ILLEGAL PARAMETER (0x01)

Calibration starts with rough check for start values. Detection threshold, gain and fault

detection threshold must be between 0 and 7; offset for both of them is from -7 to 7.

Default start parameters never fail to meet these limits. Check that correct limits are

used in the calibration SW (PC or Phoenix) and try calibration again.

PXM GAIN INT FAIL (0x02)

This should be impossible. If, however, you manage to get this error, try calibration again.

DET TR FAIL (0x03)

An error has occurred during calibration. Try calibration again. If no result is obtained in

three calibrations, replace proximity optics.

Another option is, that detection offset is too big for calibrated detection threshold. This

isn’t possible, if start values are correct. Use default start values.

OFFSET FAIL (0x05)

Selected offset could not be used with this calibration result. Check, that you have used

correct default offset. Then replace the optics.

DET NOT DONE (0x06)

Fault calibration can be done only directly after detect calibration. If, for example, the

phone was restarted between fault –and detect calibration, this error occurs. Repeat

whole calibration.

COMBINATION FAIL (0x07) / W OFF FAIL (0x08)

Calibrated detection threshold, fault detection threshold and detection offset form a

combination that is not allowed. Use default start values in calibration and check that

proximity rubber is OK. If this does not help, replace optics.

FAULT INT FAIL (0x09)

This error occurs, if self-monitoring signal is too small to exceed any fault threshold

(when offset is added). This error occurs also if there is a detection during fault threshold

calibration.

Issue 2 11/02 ¤Nokia Corporation Page 29

Page 32

CCS Technical Documentation

Is proximity optics and proximity rubber OK (visual check)? If not, replace optics. Check

calibration conditions and repeat calibration.

FAULT OVER LIMIT FAIL (0x10)

This error occurs in fault detection threshold calibration, if self-monitoring signal is

higher than each fault detection threshold. There are two reasons, that could cause this

failure:

Detection calibration is done without the calibration target or the target was too far

from the phone.

Fault calibration was done with the calibration target.

Check calibration conditions and repeat calibration.

GAIN MAX LIMIT FAIL (0x0B)

Gain value has reached its maximum limit, and there are no detections. This means, that

path from tx to rx is broken. Most probable is, that the failure is on the LG4. Figure 5

GAIN MAX LIMIT FAIL troubleshooting presents troubleshooting diagram for this failure.

Page 30 ¤Nokia Corporation Issue 2 11/02

Page 33

CCS Technical Documentation

S

G

Figure 7: GAIN MAX LIMIT FAIL troubleshooting

GAIN MAX

LIMIT FAIL

Was

reflectance

target

properly

placed?

YES

Disassemble the

phone to MJS-9Q

Check TX and RX

path, replace needed

components, fix solder

problems (1)

Try calibration in the

MJS-9Q

GAIN MAX

LIMIT

FAIL?

NO

NO

YES

Fix thetarget and

repeat calibration

Replace AEM

calibration

ave calibrated values

to the phone

Try calibration in the

MJS-9Q

Is

OK?

YES

NO

Follow respective

error message

AIN MAX

LIMIT

FAIL?

NO

YES

Beyond economical

repair

Reassemble the phone,

replace optics.

Is

calibration

OK?

YES

Save calibrated values

to the phone

1 PD TX line: RSENSE R347 is connected to GND and IRED V334 to Vbatt

RX line: photodiode V335 is connected to GND. See figure 5.

2 If there is no obvious fault, replace first V335, then V334. Try calibration in the

MJS-9Q in between.

Follow respective error

message

Issue 2 11/02 ¤Nokia Corporation Page 31

Page 34

CCS Technical Documentation

S

S

GAIN MIN LIMIT FAIL (0x0C)

There is a detection at each gain. IRED, RSENSE and photodiode are OK. Possible reasons

are shortcut in RSENSE, missing optical insulator or wrong start values in calibration.

Figure 8: GAIN MIN LIMIT FAIL troubleshooting

GAIN MIN

LIMIT FAIL

Is the

calibration

done

correctly?

YES

Disasseble the phone

to MJS-9Q

Proximity

rubber OK?

Screws

were tight?

YES

Is RSENSE

4R3 and

soldering

OK?

YES

NO Check correct start

values from Sensor

Calibration Instructions

and repeat calibration.

NO

NO

Replace

RSENSE

Is

calibration

OK?

YES

ave calibrated values

to the phone

NO

Follow respective

error message

Replace AEM

Try calibration in MJS9Q

GAIN MIN

LIMITFAIL?

YES

If you have checked

mechanics, RSENSE

and AEM the phone

is beond economical

repair

NO

Reassemble the phone,

replace proximity rubber

and optcs if needed

Is

calibration

OK?

YES

avecalibratedvalues

to the phone

NO

Follow respective

error message

Page 32 ¤Nokia Corporation Issue 2 11/02

Page 35

CCS Technical Documentation

Ambient Light Detector

General Notes

Ambient light sensor problems can be found during the calibration process or as problems with the display backlight and grip LEDs. The problem can also be in the NTC-resistor, which is used for temperature compensation of the ambient light detector. Before

starting troubleshooting according to these instructions, it must be ensured that the

problem really is in the ambient light detector. Other possibility is e.g. UI-module or

backlight powering itself. This can be checked easily, because light sensor can be turned

off.

Calibration of the Ambient Light Detector is needed always, when the phototransistor is

replaced.

Calibration system is described in chapter “Service Software Instructions”.

Figure 9: Ambient light detector calibration tool

Issue 2 11/02 ¤Nokia Corporation Page 33

Page 36

Ambient Light Detector

R

R

From now on the Ambient Light Detector will be referred to as ALD.

Main components of the ALD are phototransistor SFH3410 (V130, 4864901), pull-up

resistor 22kΩ (R131) and UEM (D190) ADC. There is also an NTC-resistor 47kΩ (R132,

1820037), which is used for temperature compensation. Temperature compensation is

done by SW.

CCS Technical Documentation

Figure 10: Ambient Light Sensor components

V130

(collector)

132

V130

(emitter)

131

Page 34 ¤Nokia Corporation Issue 2 11/02

Page 37

CCS Technical Documentation

r

p

Problems from the user point of view

“The sensor doesn’t control backlights of the phone”

Figure 11: ALD troubleshooting 1

“The light sensor never

controls backlights of

the phone.” “Backlight

alwayson.”

Is light

sensor set

on?

Yes

Are

backlights

off in bright

light? (1)

Yes

ALD circuitry is working

No

No

Set the sensor to

“Maximum”.

Use Phoenix to see

ADC-readings and

VCXOTEMP. Read the

sensor in bright light.

Does sensor

reading

change with

illumination?

(2)

Is

VCXOtemp

readind

around the

ight value?

Are ADCreadings

OK?

Yes

Yes

No

No

No

Disassemble the

phone to MJS-9Q

Disassemble the

phone to MJS-9Q

Replace UEM

Check pull-up resistor

and phototransistor (3)

Check pull-up resistor

and NTC resistor (4)

If this does not help, the

problem is beond economical

repair.

Yes

Reassemblethe

hone

Is ALD

mechanics

OK?

(5)

No

Replace A-cover

Yes

Calibratethe light

sensor

Issue 2 11/02 ¤Nokia Corporation Page 35

Page 38

CCS Technical Documentation

1 Set light sensor sensitivity to minimum. Illuminate sensor from close range with

very bright light.

2 Sensor ADC-reading should be <500 in bright light and in total darkness >900.

3 Check that resistance between sensor collector and VFLASH1 is 22kΩ (R131).

Check that resistance between collector and emitter of the ambient light sensor

changes, when illumination on the sensor (from ~5kΩ in high illuminance to

~500kΩ in total darkness) (V130). If phototransistor has to be replaced, the

detector has to be calibrated. Calibration can be done only with TDS-11 light

source.

4 NTC ( R132) resistance at room temperature is ~47kΩ.

5 Check following points: is opening on the black paint in the A-cover covered; is

light guide (integrated in the A-cover) broken?

Page 36 ¤Nokia Corporation Issue 2 11/02

Page 39

CCS Technical Documentation

V

r

“Backlights are never ON”

Figure 12: ALD troubleshooting 2

“Ba cklight is

never ON.”

IsBa c k lig h t

ON, when

Light Sensor

settingis

OFF?

Yes

Are

backlights

ON in

darkness?

Yes

AL Dcircu itryiswork in g

Ca libratethelight

sensor.

No

Go to Backlight

Troubleshooting

No No

UsePhoenix to see

ADC-readings and

VCXOTEMP

Does sensor

reading

change with

illum ination?

(2)

Yes

Is

CXOtemp

readind

around the

ight value?

No

Yes

Disasseblethe

phonetoMJS-9Q

Disassemblethe

phone to MJS-9Q

Check VFLASH1, pull-up

resistor and ambient light

)

sensor (3

Check pull-up resistor

andNTCresistor (4)

Calibratethelight

sensor.

Isthe

fun ctionality

OK?

No

Problem isbeyond

economical repair

Yes

Select default setting

for thelight sensor.

Issue 2 11/02 ¤Nokia Corporation Page 37

Page 40

CCS Technical Documentation

1 Set light sensor sensitivity to “minimum”. Cover ALD window for example with a

hand.

2 Sensor ADC-reading should be <500 in bright light and in total darkness >900.

3 Vflash1, measured at pull-up resistor pin, should be 2.78V. Check that resistor

R131 is placed, and it’s resistance is 22kΩ. Check that resistance between collector and emitter of the ambient light sensor changes, when illumination on the

sensor (from ~5kΩ in high illuminance to ~500kΩ in total darkness). If phototransistor has to be replaced, the detector has to be calibrated. Calibration can

be done only with TDS-11 light source.

4 NTC ( R132) resistance at room temperature is ~47kΩ.

Page 38 ¤Nokia Corporation Issue 2 11/02

Page 41

CCS Technical Documentation

SIM card

The whole SIM interface locates in two chips UPP_WD2 and UEM. UEM contains the SIM

interface logic level shifting. UPP provides SIMClk through UEM to the SIM. SIM interface supports both 3 V and 1.8 V SIMs. There is an EMI component on lg4 between the

sim card and UEM which isn't shown in the below picture. One pullup resistor is also on

board at simdata line, which isn't shown in the picture.

Figure 13: UPP WD2 & UEM SIM connections

GND

UPP

SIM

C5 C6 C7

C1C2C3

BSI line from battery

SIMCLK

SIMRST

BSI

SIMDATA

VSIM

GND

UEM

SIMIF

register

SIMIO

SIMClk

Data

UEM

digital

logic

SIMIO

SIMClk

Data

UIF Block

UEMInt

CBusDa

CBusEnX

CBusClk

The SIM-power up/down sequence is generated in the UEM. This means that the UEM

generates the RST signal to the SIM. Also the SIMCardDet signal is connected to UEM.

First the SW attempts to power up the SIM with 1.8 V. If this does not succeed power up

is repeated with VSIM switched to 3 V.

The data communication between the card and the phone is asynchronous half duplex.

The clock supplied to the card is in GSM system 1.083 MHz or 3.25 MHz. The data

baudrate is SIM card clock frequency divided by 372 (by default), 64, 32 or 16.

Issue 2 11/02 ¤Nokia Corporation Page 39

Page 42

Figure 14: SIM Power Up.

CCS Technical Documentation

Ch1 Vsim

Ch2 Reset

Ch3 Clock

Ch4 I/O

Measured with

3Vsim

Figure 15:

SIM answer to reset

-Ch1 Vsim

-Ch2 sim_data

–Ch3 sim_clk

–Ch4 sim_reset

Page 40 ¤Nokia Corporation Issue 2 11/02

Page 43

CCS Technical Documentation

Figure 16: SIM Clk 3.25MHz

Issue 2 11/02 ¤Nokia Corporation Page 41

Page 44

CCS Technical Documentation

"Insert SIM Card" in device display allthough card is inserted

Sim card

faults

Check sim BB

self tests. Are

they ok?

Yes

Check SIM

connector

Is it ok?

Yes

Measure VSIM

voltage from jig

is it 1.8/3.0V at

powerup?

No

No

No

Either UPP_WD2 or UEM is

faulty. Change UEM first

and if still fails the tests

change UPP_WD2

Clean pwb pads and

connector / change

connector

Check Vsim resistance to

gnd (no power) if low ->

measure C470 -> if ok

change R470 -> still not

ok -> change UEM

Yes

No

Check SIM

power up

sequence

Is it ok?

Check Vsim resistance to

gnd (no power) if low ->

measure C470 -> if ok

change R470 -> still not

ok -> change UEM

Page 42 ¤Nokia Corporation Issue 2 11/02

Page 45

CCS Technical Documentation

Audio

Microphone

Issue 2 11/02 ¤Nokia Corporation Page 43

Page 46

Earpiece

CCS Technical Documentation

Check that holes are not covered.

Page 44 ¤Nokia Corporation Issue 2 11/02

Page 47

CCS Technical Documentation

IHF

In the case of IHF fault the reason can be found from integrated hands free itself or

proximity sensor. Proximity sensor disables IHF if phone is too near some object. It is possible if the proximity sensor is faulty IHF can not be enabled even if it is working fine.

Issue 2 11/02 ¤Nokia Corporation Page 45

Page 48

Accessory detection troubleshooting

CCS Technical Documentation

Page 46 ¤Nokia Corporation Issue 2 11/02

Page 49

CCS Technical Documentation

Memory troubleshooting

Most memory related errors are found through flashing the device, flashing the device is

therefore recommended before any of the steps described in this chapter. Check flashing

troubleshooting section first.

There are however a few memory related errors that cannot be found through flashing.

• SDRAM partially damaged

This can mean that the sdram component itself is partially damaged and all the

memory locations cannot be successfully accessed or there is a soldering problem

somewhere either under UPP or sdram.

Sdram fault

suspected

Yes

Run sdram BB selftest

If fail -> change sdram ->

retest -> if still fails ->

change UPP WD2

Change

sdram

No

Does the phone

boot to local

mode?

• flash1 (D310) is partially/totally damaged

During flashing the manufacturer, device and revision id's are read, but flashing

is done based on id's of the flash0 (D311). This means that one cannot see any

error messages displayed on Phoenix window during flashing if flash1 is failing.

Id's are however displayed on the Phoenix window and successful read of flash1

id's can be checked from there. One good way to test flash1 functionality is to

format it(from Phoenix).

Issue 2 11/02 ¤Nokia Corporation Page 47

Page 50

Baseband serial interface troubleshooting

CBUS

CBUS is a three wire serial interface between main baseband components. The bus consists of data, clock and bus_enable signals. In NHL-2NA the bus is connected from UPP

WD2 to AEM, UEM and the BT module. UPP_WD2 takes care of controlling the traffic on

the bus.

If the interface is faulty from the UPP WD2's end the phone will not boot properly as

powering configurations do not work. Traffic on the bus can be monitored from three

pins on the BT module. Pins are shown below.

Figure 17: CBUS measuring points

CCS Technical Documentation

CBusClk

CBusDa

CBusEnx

Page 48 ¤Nokia Corporation Issue 2 11/02

Page 51

CCS Technical Documentation

In the pictures below CBUS traffic at bootup is shown. CbusEnx is connected to Ch1,

Cbus Da to Ch2 and CbusClk to Ch3. The lower is just a more detailed picture of a write

command (to AEM).

However, if you are able to get the phone to boot up and can reach Phoenix BB self tests

it is possible to test the functionality of each component attached to Cbus. Use:

• ST_AEM_CBUS_IF_TEST to test AEM Cbus interface

• ST_UEM_CBUS_IF_TEST to test UEM Cbus interface

• ST_LPRF_IF_TEST to test Bluetooth Cbus interface

If an error is found testing any of the abowe components you should replace or re-solder

the failing component.

Issue 2 11/02 ¤Nokia Corporation Page 49

Page 52

FBUS

MBUS

CCS Technical Documentation

FBUS is a two wire RX and TX interface between UPP and flash/test interface. The bus

goes through UEM which adjusts the voltage levels to suit UPP_WD2. The interface voltage level on the phone flash/test pad pattern is 2.78V and on the UPP WD2 end it is 1.8V.

The functionality of this interface should not affect the device boot into NORMAL, LOCAL

nor TEST modes. Phoenix tests can be performed through MBUS interface in the case of a

failure in FBUS interface. Flashing is not possible if there is a problem in FBUS interface.

MBUS is a two wire RX and TX interface between UPP and UEM. From UEM the interface

continues to flash/test interface as a one wire interface. UEM adjusts the voltage levels.

The interface voltage level on the phone flash/test pad pattern is 2.78V and on the UPP

WD2 end it is 1.8V. MBUS traffic between UPP WD2 and UEM can be tested with PHOENIX (ST_MBUS_RX_TX_LOOP_TEST). Flashing is not possible if there is a problem in

MBUS.

Page 50 ¤Nokia Corporation Issue 2 11/02

Page 53

CCS Technical Documentation

Hall sensor troubleshooting

There might be two kind of malfunction concerning Hall sensor; The out put of the Hall

sensor keeps to high or low regardless the position of the magnet.

Hall sensor

malfunction

Phone thinks grip is

open all the time

Check that magnet is

in its place and it's as

effective as specified

Measure that N380 is

properly soldered and it

has ~2.78V in pin 1. Pin

3 should be down when

magnet is not above the

component. ~1.8V

when magnet is above

it.

no

Phone thinks grip is

closed all the time

yes

Change the N380 to a

new one and retest.

Hall sensor works

Issue 2 11/02 ¤Nokia Corporation Page 51

Page 54

Display backlights troubleshooting

CCS Technical Documentation

Page 52 ¤Nokia Corporation Issue 2 11/02

Page 55

CCS Technical Documentation

Bluetooth troubleshooting

BT Failure

Part I

(Flashing problems)

Attempt to re-flash

the phone

Do you have

any FPS-8

errors?

Yes

No

Does the

phone's main

SW flash

correctly?

Yes

Does the BT

SW flash

correctly?

Yes

BT Flashing OK!

No

No

Go to Calypso's

'Flashing'

Troubleshooting

Section

1) Replace

BT MCM

2) Attempt to

Flash Phone

Issue 2 11/02 ¤Nokia Corporation Page 53

Page 56

BT Failure

Part II

(BER Failure)

Test Pogo-Pin

connection to BT

antenna

with multimeter

Are the Pogo-

Pins electrically

connected to

BT antenna

(i.e. short

circuit)?

Yes

Visually check BT

antenna

CCS Technical Documentation

Replace

No

BT antenna

(i.e.new chassis)

Go to

BT Failure

Part III

No

Is BT antenna

attached

properly to

chassis?

Yes

Check soldering of

BT MCM with

microscope

Is BT MCM

propely

soldered to the

PWB?

No

Is BER < =

0.1%?

Yes

BT OK!

Yes

Yes

Is soldering so

bad that you

No Yes

must remove

BT MCM?

No

Re-solder

BT MCM

Production Only

Replace BT MCM

Re-Flash phone

using option

BT ONLY

Can you make

a connection to

BT Box?

No

Go to

BT Failure

Part III

Page 54 ¤Nokia Corporation Issue 2 11/02

Page 57

CCS Technical Documentation

BT Failure

Part III

(BER Failure)

Check VCC

(Pins 52, 53, 54)

with O-scope

Does VCC =

2.95 - 5.2

VDC?

No

Yes

Does Ripple

Voltage

< = 400mVpp?

Yes

Check VREG

(Pin 6)

with O-scope

Does VREG =

2.7-3.3VDC?

Yes

Does Ripple

Voltage

< = 30mVpp?

No

No

Check

VBAT / L430 /

C431

No

Check

VFLASH1 / L431

Check SYSCLCK

(Pin 50 )

with O-scope

Does Vin =

300-900mVpp?

Yes

Does Freq. =

26MHz?

No

Check

VCTCXO

No

Buffer Section

Yes

Yes

1) Replace

Can you make

a connection to

BT Box?

No

1) Replace

BT MCM

2) Flash Phone

using 'BT ONLY'

Yes No

Is BER < =

0.1%?

Yes

BT OK!

BT MCM

2) Flash Phone

using 'BT ONLY'

Issue 2 11/02 ¤Nokia Corporation Page 55

Page 58

Needed actions if ASIC is changed

UEM changed

If UEM is changed baseband calibrations should be made. IMEI has to be rebuilt to the

phone.

AEM changed

If AEM is changed proximity and ambient light sensor calibrations should be achieved.

UPP_WD2 changed

Device has to be reflashed.

Flash0 changed

IMEI has to be reprogrammed. Has to be flashed (naturally). IMEI has to be rebuilt to the

phone.

CCS Technical Documentation

RF component changed

If any RF component changed, RF calibration(tuning) has to be done.

Page 56 ¤Nokia Corporation Issue 2 11/02

Page 59

CCS Technical Documentation

Test points and pin orders

Test points in BaseBand area (LG4_06_02)

J100 RFclk

J101 Sleepclk

J102 SleepX

J103 PURX

J116 Txid

J117 Txqd

J118 Auxda

J119 Rxid

J120 Rxqd

J104 UEMint

J105 AEMSleep

J110 DSPVcc

J106 SDRda0

J107 SDRad0

J108 SDRclk

J109 FLDa0

J 111 F LXS 1x

J113 FLCS0x

J114 FLOEX

J115 FLClk

J121 I_FBUS_TX

J381 Vbatt

J270 GenVbattIO

J262 Refen

Issue 2 11/02 ¤Nokia Corporation Page 57

Page 60

CCS Technical Documentation

Page 58 ¤Nokia Corporation Issue 2 11/02

Page 61

CCS Technical Documentation

Connectors pin order

UI-connector

Pin

no.

1 VDD IN 2.78 V Voltage supply

2 GND 0 V System ground

3 D4 IN

4 D0 IN

5 A0 IN V H: data

6 GND 0 V System ground

7 VDDI IN 1.8 V Logic voltage supply

8 D1 IN

9 D2 IN

Signal name Type Typical Unit Description

V Data to write

OUT

OUT

OUT

OUT

V Data to read

V Data to write

V Data to read

L: command

V Data to write

V Data to read

V Data to write

V Data to read

10 D3 IN

OUT

11 Rocker3 200 mOhm

12 Rocker2 200 mOhm

13 GND 0 V System ground

14 Rocker5 200 mOhm

15 Rocker4 200 mOhm

16 Rocker1 200 mOhm

17 V

18 V

19 Row1 IN/

20 Row0 IN/

+ IN/

LED

- IN/

LED

4.5 V LED, positive terminal

OUT

0 V LED, negative terminal

OUT

OUT

OUT

V Data to write

V Data to read

Ohm Tracking resistance

mA Drive current

Ohm Tracking resistance

mA Drive current

mA Drive current

Issue 2 11/02 ¤Nokia Corporation Page 59

Page 62

CCS Technical Documentation

21 Col1 IN/

OUT

22 Col0 IN/

OUT

23 GND 0 V System ground

24 RESX IN V Reset

25 D5 IN

OUT

26 D6 IN

OUT

27 D7 IN

OUT

28 GND 0 System ground

29 RDX IN L: read

Ohm Tracking resistance

mA Drive current

Ohm Tracking resistance

mA Drive current

(active low)

V Data to write

V Data to read

V Data to write

V Data to read

V Data to write

V Data to read

(active low)

30 WRX IN L: Write

(active low)

Page 60 ¤Nokia Corporation Issue 2 11/02

Page 63

CCS Technical Documentation

Board to board connector

See System Module LG4 and Grip Module LS4”.

Pin order of spring connectors

Issue 2 11/02 ¤Nokia Corporation Page 61

Page 64

CCS Technical Documentation

Page 62 ¤Nokia Corporation Issue 2 11/02

Page 65

CCS Technical Documentation

RF Troubleshooting

Introduction

Measurements should be done using Spectrum Analyzer with high-frequency 1kW (20:1)

passive probe (LO-/reference frequencies and RF-power levels) and Oscilloscope with a

10:1 probe (DC-voltages and low frequency signals).

Please note that the grounding of the PA-module is directly below PA-module so it is difficult to check or change. Most RF semiconductors are static discharge sensitive! So

ESD protection must be taken during repair (ground straps and ESD soldering irons). The

Hagar IC is moisture sensitive so parts must be pre-baked prior to soldering.

Apart from key-components described in this document here are a lot of discrete components (resistors, inductors and capacitors) which troubleshooting is done by checking if

soldering of the component is done properly, for factory repairs (checking if it is missing

from PCB). Capacitors can be checked for shortening and resistors for value by means of

an ohmmeter, but be aware in-circuit measurements should be evaluated carefully.

Please be aware that all measured voltages or RF levels in this document are rough

figures. Especially RF levels varies due to different measuring equipment or different

grounding of the used probe.

All tuning must be done with Phoenix Service Software, version 02.90.001, or later.

Issue 2 11/02 ¤Nokia Corporation Page 63

Page 66

RF Key component placement

CCS Technical Documentation

Page 64 ¤Nokia Corporation Issue 2 11/02

Page 67

CCS Technical Documentation

9

T

TXQTXIR

R

R

Fault finding test point locations

900 LNAB_G

900 ASM RX

900 LNAi/p

1800 ASM RX

1800 LNAi/p

900 PAo/p

1800 PAo/p

900 LNAo/p

900 PABIAS

900 LNA_G

900 SAWi/p

1800 SAWi/p

1800 SAWo/p

1800 LNA_P

1800 PACONTROL

900 TXBALUN i /p

1800 LNAB_P

1800 PABIAS

00 SAWo/p

1800 TXFILTi/p

VR6

VCO BALUN o/p

900 PACONTROL

VR2

1800 PAi/p

900 PAi/p

XC

RX_I

VrefRF02

eset

VCO VCC

4G VCO o/p

VCO CONT ROL

VrefRF01

FBusClk

FBusEna1

VCT CXO o/p

RFBusDa ta

Issue 2 11/02 ¤Nokia Corporation Page 65

Page 68

Receiver

General description

CCS Technical Documentation

The receiver is a direct-conversion, dual-band linear receiver. RF signal energy gathered

by the antenna is fed via the antenna switch module to the 1

st

RX bandpass SAW filters

and MMIC LNAs. The RF antenna switch module provides for upper- and lower-band

operation. The signal having been amplified by the LNA is then fed to 2nd RX bandpass

SAW filters. Both of these 2nd RX bandpass SAW filters have UNBAL/BAL configuration to

achieve the balanced feed for HAGAR. The discrete LNAs have three gain levels. The first

one is maximum gain, the second one is about -30dB ( GSM1800 ) and –25dB ( EGSM900 ) below maximum gain and the last one is off state. The LNA gain selection is

controlled directly by HAGAR.

The performance of the RX bandpass SAW filters are mainly responsible for defining the

receiver's blocking characteristics against spurious signals outside passband and the protection against spurious responses.

The differential RX signal is amplified and mixed directly down to BB frequency in

HAGAR. The LO signal is generated with external VCO. This VCO signal is divided by 2 (

GSM1800 ) or by 4 ( E-GSM900 ). The PLL and dividers are internal to the HAGAR IC.

From the mixer output to ADC input RX signal is divided into I- and Q-signals. Accurate

phasing is generated in LO dividers. After the mixer DTOS amplifiers convert the differential signals to single ended.

The DTOS has two gain stages. The first one has constant gain of 12dB and 85kHz cut off

frequency. The gain of second stage is controlled with control signal g10. If g10 is high

(1) the gain is 6dB and if g10 is low (0) the gain of the stage is -4dB. The active channel

filters in HAGAR provide selectivity for channels (-3dB @ ± 91 kHz typ.). The integrated

Page 66 ¤Nokia Corporation Issue 2 11/02

Page 69

CCS Technical Documentation

baseband filter inside HAGAR is an active-RC-filter with two off-chip capacitors. Large

RC-time constants are needed in the channel select filter of the direct-conversion

receiver and are achieved with large off-chip capacitors because the impedance levels

could not be increased due to the noise specifications.

The baseband filter consists of two stages, DTOS and BIQUAD. DTOS is differential to single-ended converter having 8dB or 18dB gain. BIQUAD is modified Sallen-Key Biquad.

Integrated resistors and capacitors are tunable. These are controlled with a digital control word. The correct control words that compensate for the process variations of integrated resistors and capacitors and of tolerance of off chip capacitors are found with the

calibration circuit.

The next stage in the receiver chain is AGC-amplifier, also integrated into HAGAR. AGC

has digital gain control via serial mode bms. AGC-stage provides gain control range (40

dB, 10 dB steps) for the receiver and also the necessary DC compensation. Additional 10

dB AGC step is implemented in DTOS stages.

DC compensation is made during DCN1 and DCN2 operations ( controlled via serial bus ).

DCN1 is carried out by charging the large external capacitors in AGC stages to a voltage

which effect a zero dc-offset. DCN2 set the signal offset to constant value ( V

1.35 V ). The V

RF_02 signal is used as a zero level to RX ADCs.

ref

RF_02

ref

Single ended filtered I/Q-signal is then fed to ADCs in BB. Input level for ADC is 1.45 V

max.

Rf-temp port is intended to be used for compensation of RX SAW filters thermal behavior. This phenomena will have impact to RSSI reporting accuracy. The current information

is -35ppm/C for center frequency drift for all bands. This temperature information is a

voltage over two diodes and diodes are fed with constant current.

E-GSM900

E-GSM900 RX Troubleshooting Setup steps

1 Place the phone in the test jig

2

3

4

5

6

File → Choose Product → Calypso

From 'Toolbar' set operating mode to Local

Maintenance → Testing → RF Controls

Select band 'GSM900'

Set Active unit to 'Rx'

pp

7

8

9

Set Operation mode to 'Continuous'

Set AGC to '8:FEG ON +46 dB'

Set Rx/Tx channel to 37

Issue 2 11/02 ¤Nokia Corporation Page 67

Page 70

CCS Technical Documentation

Page 68 ¤Nokia Corporation Issue 2 11/02

Page 71

CCS Technical Documentation

S

S

C

Troubleshooting diagram for GSM900 receiver:

Apply –90dBm

942.46771MHz

signal from generator

to antenna connector

Yes

Oscilloscope at RX_I

Signal 700mVpp

DC offset 1.35V

Frequency 67.7kHz

No

Change

generator

level to

–50dBm

Yes No

Spectrumanalyzer

900 SAW i/p

-61 dBm

pectrumanalyzer

900 ASM RX

-80 dBm

No

Check

Antenna

switch

Z672

EGSM RX chain

functional

Yes

Yes

Yes

Oscilloscope

LNA_G2.6V

LNAB_G 2.7V

Yes

pectrumanalyzer

900 LNA o/p

–57 dBm

No

Oscilloscope

900LNAo/p2.6V

900LNAi/p0.8V

Yes

Check V610,

C597, L566, L567

No

Yes

No

Oscilloscope

VR4 2.7V

Check Hagar

serial interface

Check R612

Yes

Check Hagar

N505

Check C610

heck V610,

L610, R616

No

Check

Baseband

Spectrumanalyzer

900 SAW o/p

-66 dBm

Yes

Oscilloscope

VR4 2.7V

Check Hagar

serial interface

(burst mode)

Yes

Spectrumanalyzer

VCO o/p

3769.6MHz

∼-37 dBm (*

Yes

Check Hagar

N505

No

Check Z600,

C599, C601, L600

No

Check Baseband

No

Synthesizer

troubleshooting

All spectrumanalyzer

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the

nearest PWB ground).

Reading value is

represented without +26

dB compensation.

* Spectrumanalyzer

reading with1 kohm

passive probe (right

valueadd+26dB)

Issue 2 11/02 ¤Nokia Corporation Page 69

Page 72

GSM1800

GSM1800 RX Troubleshooting Setup steps:

CCS Technical Documentation

1 Place the phone in the test jig

2

3

4

5

6

7

8

9

File → Choose Product → Calypso

From 'Toolbar' set operating mode to Local

Maintenance → Testing → RF Controls

Select band 'PCN'

Set Active unit to 'Rx'

Set Operation mode to 'Continuous'

Set AGC to '8:FEG ON +46 dB'

Set Rx/Tx channel to 700

Page 70 ¤Nokia Corporation Issue 2 11/02

Page 73

CCS Technical Documentation

S

S

1

C

R

Troubleshooting diagram for GSM1800 receiver

Apply –90dBm

1842.86771MHz

signal from generator

to antenna connector

Yes

Oscilloscope at RX_I

Signal 700mVpp

DC offset 1.35V

Frequency 67.7kHz

Yes

GSM1800 RX chain

functional

No

Change

generator

level to

–50dBm

Yes No

Spectrumanalyzer

1800 SAW i/p

-66 dBm

Yes

pectrumanalyzer

1800 ASM RX

-82 dBm

Yes

No

Check

Antenna

switch

Z672

Spectrumanalyzer

1800 SAW o/p

-71 dBm

No

Oscilloscope

LNA_P0V

LNAB_P 2.6V

Yes

pectrumanalyzer

800 LNA o/p

–58 dBm

No

Oscilloscope

1800 LNA o/p 2.6V

1800 LNA i/p 0.8 V

Yes

Check V640,

C632

Check Z802,

C630, C631, L630

No

Yes

No

Oscilloscope

VR4 2.7V

Check Hagar

serialinterface

(burst mode)

Check Hagar

N505

Check C640

heck V640,

642, L640,

R646

Yes

No

Check

Baseband

Yes

No

Oscilloscope

VR4 2.7V

Check Hagar

serial interface

(burst mode)

Yes

Spectrumanalyzer

VCO o/p

3685.6MHz

∼-33dBm(*

Yes

Check Hagar

N505

No

Check Baseband

Synthesizer

troubleshooting

All spectrumanalyzer

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the

nearest PWB ground).

Reading value is

represented without +26

dB compensation.

* Spectrumanalyzer

reading with 1 kohm

passiveprobe(right

value add +26dB)

Issue 2 11/02 ¤Nokia Corporation Page 71

Page 74

Picture of RX signal

CCS Technical Documentation

Figure 1: Example of RX_I (or RX_Q) signal at –90dBm signal level

Page 72 ¤Nokia Corporation Issue 2 11/02

Page 75

CCS Technical Documentation

Transmitter

General description

The transmitter chain consists of two final frequency I/Q-modulators, one for E-GSM900

and the other for the GSM1800 band, a dual power amplifier and a power control loop.

The I- and Q-signals are generated by baseband. After post filtering ( RC network) they

go into IQ-modulator in HAGAR. The LO signal for the modulator is generated by the

external VCO and is divided by 2 or by 4 depending on the system mode. There are separate outputs one for E-GSM900 and one for GSM1800.

In the E-GSM900 branch, a SAW filter is placed before PA to attenuate unwanted signals

and wide-band noise from the HAGAR IC.

The final amplification is realized with dual band power amplifier. It has two separate

power chains one for E-GSM900 and one for GSM1800. The PA is capable of producing

in excess of 2 W ( 0 dBm input level ) in the E-GSM900 band and over 1 W ( 0 dBm input

level ) in the GSM1800 band assuming a 50 W output. The gain control range is over 45

dB to achieve the desired power levels and power ramp/decay performance.

Harmonics generated by the nonlinear PA are filtered out with filtering inside the

antenna switch -module.

Issue 2 11/02 ¤Nokia Corporation Page 73

Page 76

Power control circuitry consists of discrete power detector ( common to E-GSM900 and

GSM1800 bands ) and error amplifier internal to HAGAR. There is a directional coupler

connected between PA output and antenna switch. It is a dual-band type and has input

and outputs for both systems. Dir. coupler takes a sample from the forward going power

with certain ratio. This signal is rectified using a Schottky-diode and produces a DC-signal after filtering.

E-GSM900

CCS Technical Documentation

Figure 2: E-GSM900 TX Troubleshooting Setup steps

1 Place the phone in the test jig

2

3

4

5

6

7

8

9

10

11

File → Choose Product → Calypso

From 'Toolbar' set operating mode to Local

Maintenance → Testing → RF Controls

Select band 'GSM900'

SetActiveunitto'Tx'

SetOperationmodeto'Burst'

Set TX data type to 'Random'

Set Rx/Tx channel to 37

Set Tx PA mode to 'Free'

Set power level to 5

Page 74 ¤Nokia Corporation Issue 2 11/02

Page 77

CCS Technical Documentation

GSM1800

Figure 3: GSM 1800 TX Troubleshooting Setup steps

1 Place the phone in the test jig

10

11

2

3

4

5

6

7

8

9

File → Choose Product → Calypso

From 'Toolbar' set operating mode to Local

Maintenance → Testing → RF Controls

Select band 'PCN'

SetActiveunitto'Tx'

SetOperationmodeto'Burst'

Set TX data type to 'Random'

Set Rx/Tx channel to 700

Set Tx PA mode to 'Free'

Set power level to 0

Issue 2 11/02 ¤Nokia Corporation Page 75

Page 78

Fault finding tree

CCS Technical Documentation

Tx troubleshooting

Check output signal level

from antenna connector

+32dBm@897.4MHz (GSM900)

+29dBm@1747.8MHz (PCN1800)

OK?

NO

Tx signal found?

YES

Check with RF probe signallevel

on PA input

-6 dBm on 900 PA i/p

-23 dBm on 1800 PA i/p

OK?

YES

StartTX power level

tuning and check

tuned DAC values:

Highestlevel

Highestlevel

Lowestlevel

~

~

600(PCN1800)

Base level

700(GSM900)

~

170

~

150

NO

NO

Tx OK

YES

Check all

YES

NO

powerlevels

OK?

Check output signal

on 500MHz span

Signal found on

incorrect frequency?

Check GSM tx filter/

PCNtx balun input level

-9 dBm on 900 FILT i/p

-24 dBm on 1800 BALUN i/p

OK?

YES

Replace faulty

components

YES

NO

Tune TX DAC

values

YES

Tune TX power

levels OK?

YES

NO

Synthesizer

troubleshooting

Hagar

troubleshooting

Majordifferences?

NO

Check with oscilloscope

900&1800PACONTROL

>2.4V peak

OK?

YES

PA&ant.switch

troubleshooting

NO

Check powercontrol

loop components

OK?

NO

Replace faulty

components

YES

Replace HAGAR

Page 76 ¤Nokia Corporation Issue 2 11/02

Page 79

CCS Technical Documentation

Example of TX signals

Figure 4: Example of TXI signal

Figure 5: Example of TXQ signal

Figure 6: Example of VC2 signal

Issue 2 11/02 ¤Nokia Corporation Page 77

Page 80

CCS Technical Documentation

Figure 7: Example of 900/1800 PA BIAS signal

Figure 8: Example of 900/1800 PA CONTROL signal

Figure 9: Example of 900 TX burst from antenna connector

*

RBW 100 kHz

*

*

Ref 40 dBm

Offset 13 dB

40

30

1AP

CLRWR

20

10

0

-10

-20

-30

-40

-50

-60