Page 1

Customer Care Solutions

NMM-3 Series Cellular Phones

5 - Disassembly Instructions

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-1

Company Confidential

Page 2

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

Table of Contents

Description Page No.

Disassembly Instructions

Disassembly Instructions ............................................................................................................... 3

Re-assembly Instructions .............................................................................................................. 11

Assembly of B-Cover Module ................................................................................................ 11

Assemble of UI Module ........................................................................................................... 14

Assembly of the ATO ................................................................................................................ 16

Assembly of the Transceiver .................................................................................................. 18

Visual Quality Check during Re-assembly ................................................................................ 20

Page 5-2 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 3

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

Disassembly Instructions

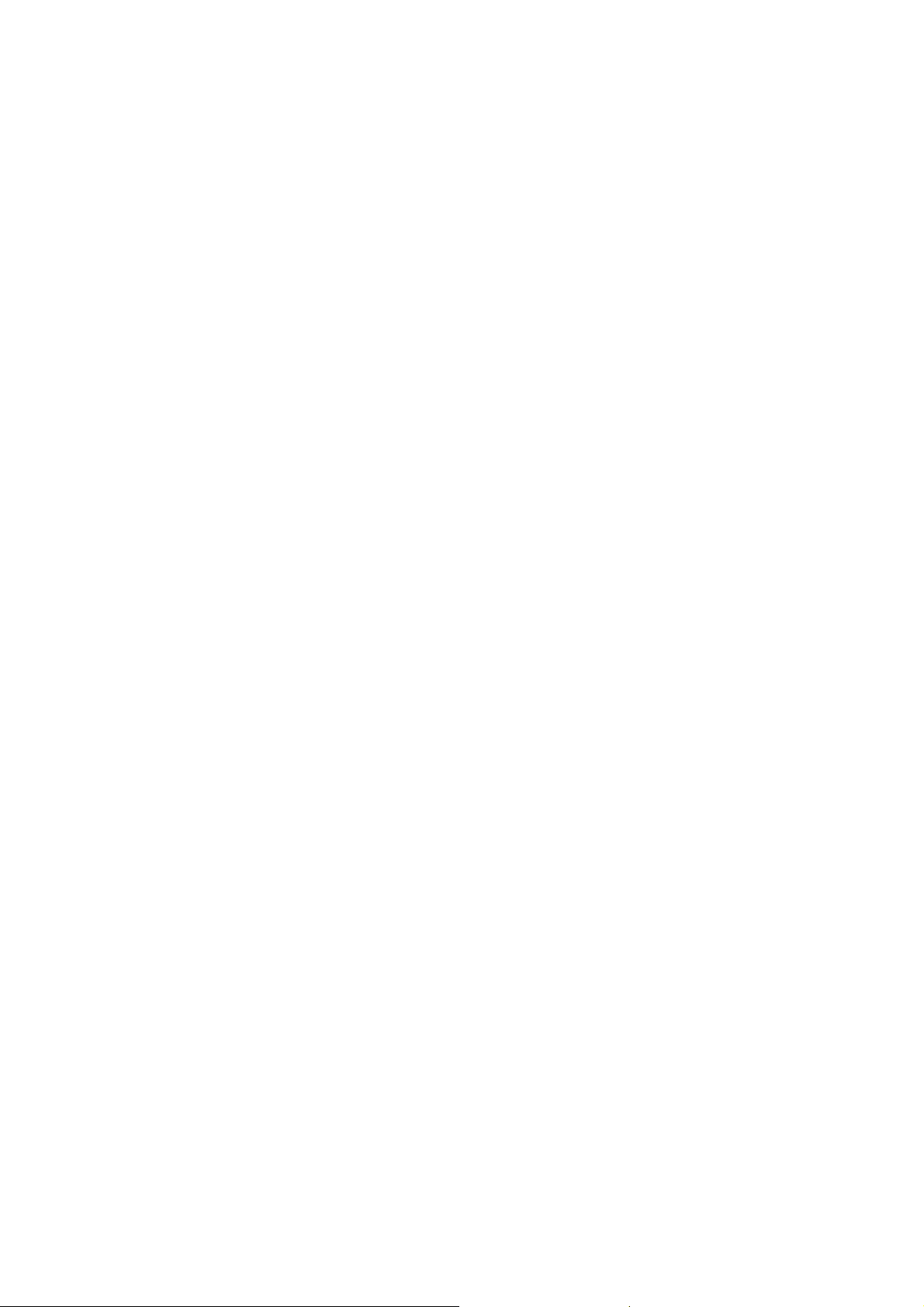

1. First remove LH Sleeve.

2. Now remove RH Sleeve.

1

2

3. Dismount C-Cover.

4. Pull up D-cover, which is attached

to B-cover with adhesive tape.

3

4

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-3

Company Confidential

Page 4

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

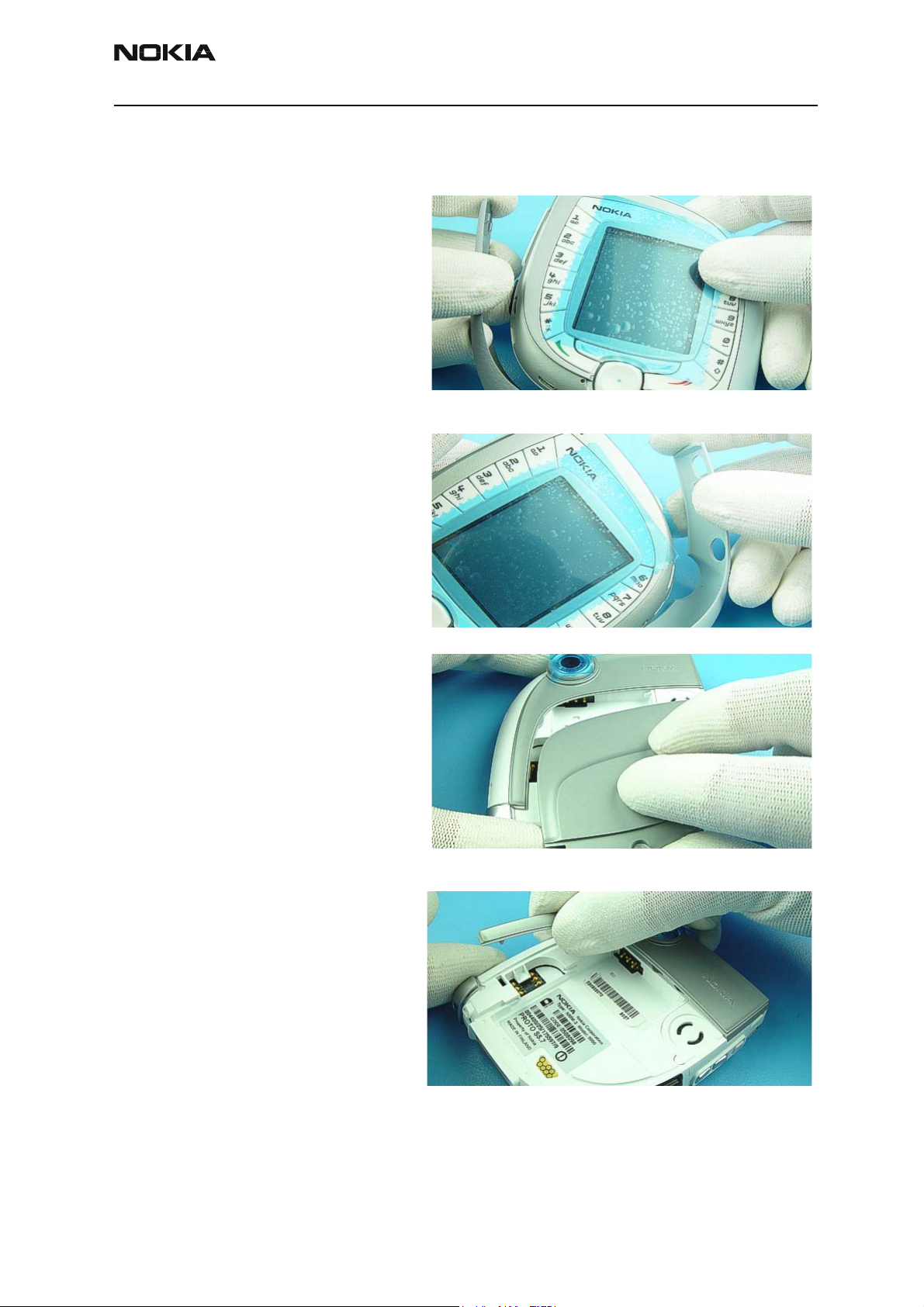

5. Unscrew Antenna screw. Use a new

Torx Plus screw and a torque of 26

Ncm for assembly.

6. The Corner Piece fits very tight, so

it needs some extra force to separate

it from the B-cover with the SRT-6.

5

6

7. The A-cover is fixed with several

plastic clips. Start with the clip near

to the system connector.

8. Loosen the clips anti-clockwise by

using the SRT-6 as a lever. Do not

twist the SRT-6 because this could

cause damage to the cover.

7

8

Page 5-4 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 5

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

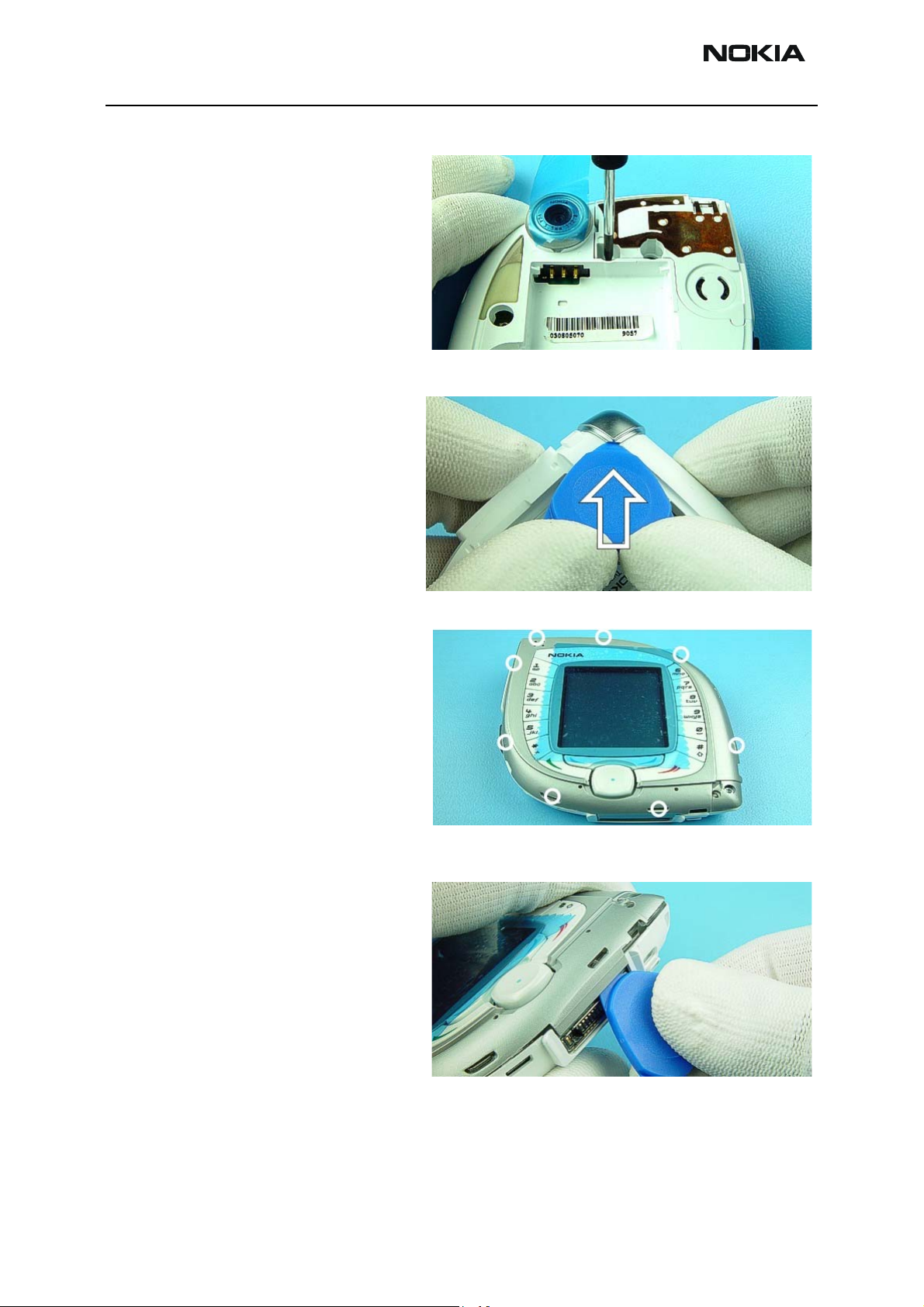

9. Remove A-cover.

10. Unscrew the six Torx Plus screws

using the order shown. For assembly

the reverse order and a torque of 19

Ncm has to be used for an old Bcover and 22 Ncm for a new B-cover.

No electric or air driver are allowed

to be used for assembly.

9

10

11. Unlock the three clips from the UI

Assembly, as indicated.

12. If unlocking doesn’t work check

that the Antenna screw has been

removed.

11

12

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-5

Company Confidential

Page 6

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

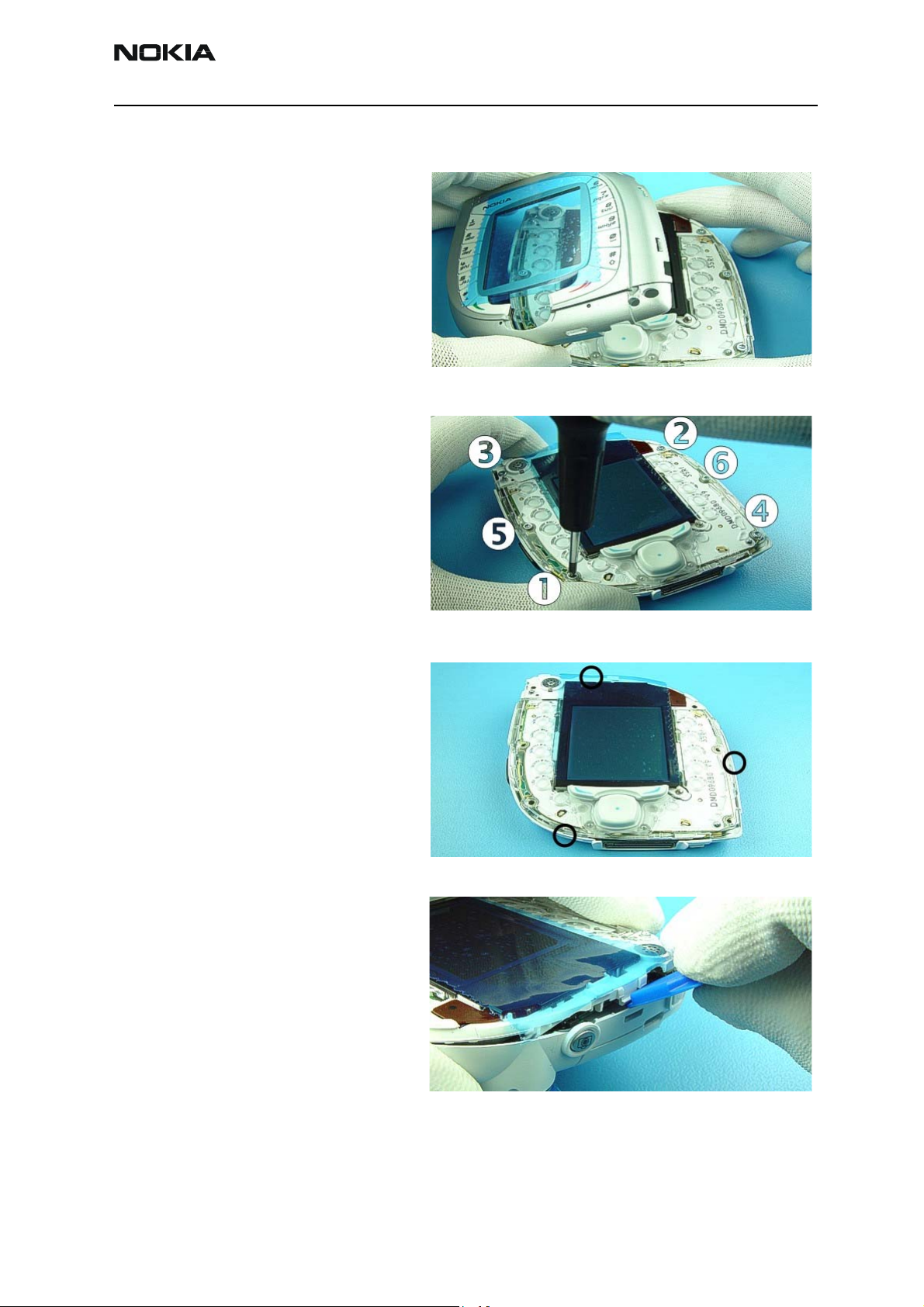

13. Remove UI Assembly.

14. After opening the side clips the

Lightguide can be removed.

13

14

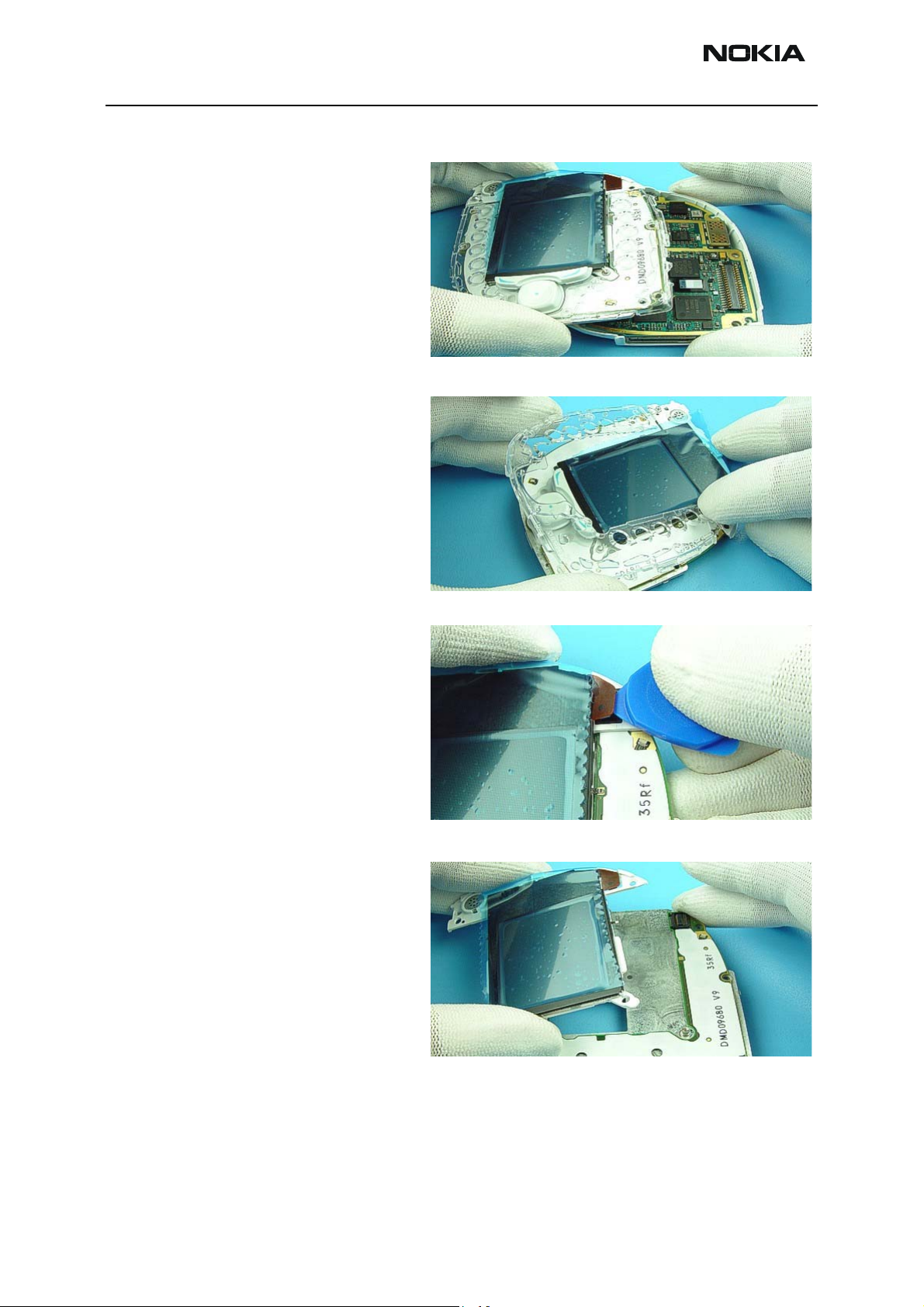

15. Carefully open LCD Connector

with the SRT-6. Do not damage the

sensitive flex foil.

16. Remove LCD.

15

16

Page 5-6 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 7

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

17. Press out Earpiece from guiding

pin side.

18. Separate UI PWB from Engine

Shield.

17

18

19. Dismount Engine module.

20. Use disassembly side of the SRT11 to remove the VGA Camera. Use

the other side of the SRT-11 for

assembly.

19

20

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-7

Company Confidential

Page 8

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

21. Lever out WCDMA Antenna from

B-cover.

22. Using a charger plug remove the

DC Jack.

21

22

23. Remove Vibra Motor, taking care

not to damage the spring contacts.

24. Unlock the side snaps to remove

the IT Window.

23

24

Page 5-8 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 9

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

25. Push out the Volume Keys, taking

care not to damage the silicon.

26. Remove the Microphone from its

guidance.

25

26

27. Remove Camera Shutter Key.

28. Remove Power Key.

27

28

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-9

Company Confidential

Page 10

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

29. Detach Camera Window by placing SRT-6 as shown and pressing

upwards forcefully.

30. Press out Rubber Gasket from the

outside.

29

30

31. There are two plastic clips, which

have to be unlocked before removing

GSM Antenna.

32. Finally remove HF Speaker with

tweezers.

31

32

Page 5-10 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 11

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

Re-Assembly Instructions

Assembly of B-Cover Module

1. Assemble the Handsfree Speaker

1

into the GSM antenna housing making sure to apply even pressure

around the circumference of the

device. Ensure the alignment feature

on the device is aligned to the relevant feature in the antenna housing.

Note: Ensure the contacts are

avoided and the speaker gauze is first

fitted to the GSM antenna module.

2

2. Snap the GSM antenna module

onto the B-Cover module ensuring

the clip nearest the camera window is

engaged first, whilst taking care to

ensure the speaker contacts are

aligned inside the B-Cover aperture

before all clips are assembled to avoid

any damage to them.

Note: The GSM antenna module will

not sit parallel to the B-Cover when it

is assembled. There will be a gap next

to the speaker - this is normal.

3. Fit the camera window gasket/

3

boot onto the B-Cover moulding

ensuring first that the B-Cover is

internal side up so you can see the

alignment of the gasket with the

three alignment clips into the BCover recesses.

Note: Ensure that the annulus of the

camera boot is concentric with the BCover camera annulus.

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-11

Company Confidential

Page 12

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

4. Turn the B-Cover over once the

4

boot is aligned and push the boot

retention clips into the recesses in

the B-Cover so they are visible from

the outside of the B-Cover.

5. Assemble the camera window

6

adhesive to the camera window

annulus on the B-Cover, ensuring it is

centrally fitted and the yellow backing tape is removed.

6. Align the camera window to the

B-Cover using the alignment feature

in both the window and the B-Cover.

Press down on the edges of the window (taking care not to damage it)

until all three clips snap home to the

B-Cover.

Note: Ensure the B-Cover is supported underneath when the window is assembled. Assembly

force must be at least 60N/cm² for at least 6 seconds.

7. Take an IR window and snap it into

7

the B-Cover ensuring that it is orientated the correct way around. Assemble the right hand side clip first into

the B-Cover then snap the second

clip into place.

Note: Ensure the front and back of

the window is not cosmetically damaged by wearing soft gloves when

pressure is applied to the window.

Page 5-12 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 13

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

8. Assemble the WCDMA antenna

8

into the B-Cover module ensuring the

antenna is engaged under the clip

nearest the battery bay wall before

the external clip is made by pushing

down on the antenna to clip it to the

B-Cover.

Note: Ensure the clips are engaged

by checking the clip is within the clip

aperture of the outside of the BCover. Ensure also that the metallization on the antenna is not scratched

or contaminated.

9. Assemble all electromechanical

9

devices into their specific apertures

(i)

provided for them in the B-Cover

module, including the vibra, microphone and DC Jack. Ensure each

device is fully assembled into their

individual cavities and in the correct

orientation as illustration opposite

indicates.

Note: Ensure the contacts on each

device are avoided and the DC Jack

snapped home.

9 (ii). Removing the microphone.

9

(ii)

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-13

Company Confidential

Page 14

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

9 (iii). Removing the Vibra Motor.

9

(iii)

10. Ensure each of the three keys is

10

fully assembled into their apertures.

Ensure the bottom of the key is

aligned into the B-Cover with the

face being pushed through the aperture in the B-Cover. The key flanges

must be tight up against the B-Cover

flange with no gap.

Assembly of UI Module

Note: Ensure the Class I faces of the

keys are not touched or damaged

during the assembly sequence.

1. Place the earpiece into the LCD

1

frame, ensuring the alignment feature on the device is aligned with the

slot in the frame. Press the device

into the frame.

Note: Ensure the metal body of the

earpiece is not distorted and the contacts are not deformed. Ensure the

earpiece is fully assembled into the

LCD frame.

Page 5-14 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 15

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

2. Assemble the UI PWB Module onto

2

the Engine shield ensuring the shield

is kept flat and not distorted or bent.

The PWB must be LED’s up and care

must be taken not to touch the board

to board connector pads.

Note: Ensure the datum pins on the

shield are not deformed.

3. Assemble the LCD module onto the

3

UI shield assembly, ensuring the clip

at the top & middle of the frame near

the ear piece is assembled first and

then the bottom frame location hole

is assembled over the shield pin.

Note: Ensure the LCD is kept flat at

all times and only ever handled from

the sides. The protective tape must be

kept on the LCD during handling and

assembly.

4. Clip the male LCD connector on

4

the LCD module into the female LCD

connector on the UI PWB, ensuring to

align the devices first. The connector

should snap into place.

Note: The connector must be assembled keeping it flat and applying even

pressure across the top of the rigidiser.

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-15

Company Confidential

Page 16

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

5. Place a Navi key assembly onto the

5

UI PWB, ensuring the alignment pips

on the bottom of the Navi key assembly are located into the holes in the

UI PWB.

Note: Ensure the Class I surfaces of

the Navi key are kept clean and

undamaged. These must be checked

before assembly.

6. Place a lightguide assembly onto

6

the UI module assembly, sliding the

top right lightguide tab under the

LCD frame first, then clipping the

right then left clips to the engine

shield and finally placing the top left

lightguide alignment hole over the

top left engine shield alignment pin.

Assembly of ATO Module

Note: Ensure the lightguide is not

distorted and the side clips are fully

assembled and not cracked. Also

ensure that all LED’s are within the

recesses in the lightguide provided for

them.

1. Assemble the engine PWB onto

the UI module (making sure the module is first placed LCD down). Ensure

the engine is located onto the engine

shield alignment pins.

Note: Ensure the board to board connector and camera assembly are

avoided by only holding the PWB

module in the designated areas indicated.

Protection Pad (not supplied)

Page 5-16 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 17

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

2. Assemble the camera into the

2

camera connector using the SRT-11

Camera Assembly tool.

Note: Ensure the alignment pip on

the SRT-11 Camera Assembly tool is

aligned with the pip on the camera

which is in turn aligned with the dot

on the camera connector assembly

before location and assembly. Also

ensure that the camera has all three

clips connected to the shield.

3. Assemble the B-Cover module

3

onto the UI & PWB modules. Locate

the top of the phone first to avoid

damage to the camera and camera

shield and so the two alignment pins

on the engine shield find their location holes in the B-Cover.

Protection Pad (not supplied)

Note: Ensure the alignment of the B-

Cover module is correct by aligning it

gently before the clipping of the two

modules. Take extra care as this is a

blind assembly.

4. Clip all three UI module to B-Cover

4

module clips together ensuring the

top clip is made first followed by the

clip by the system connector and

then finally the clip on the side.

Note: Ensure pressure is only applied

directly above the clips.

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-17

Company Confidential

Page 18

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

5

5. Assemble the 7th screw into the

back of the B-Cover making sure not

to damage the B-Cover. This screw

must be a new 5.3mm x 1.6mm T6

(IP6) machine screw (NMP 6150905)

with an orange threadlock patch

applied with a torque of 26 Ncm.

Note: Only use a hand torque driver.

6. Assemble the 6 screws into the

6

ATO in the order indicated opposite.

Using new 9.0mm x 1.6mm T6 Remform screws (NMP 6150903). A

torque of 19 Ncm must be applied to

these screws when an old B-cover is

re-used and 22 Ncm for a new cover.

Assembly of Transceiver

Ensure the screws heads are sitting

flush on the lightguide or LCD frame.

Note: Only use a hand torque driver.

1. Assemble the A-Cover module

1

onto the ATO module using the clipping sequence outlined opposite,

ensuring clip number one is slid onto

the lightguide clip (pressure must

only be applied to the edge of the ACover over the clips and NOT over the

LCD).

Note 1: Each of the clips must be

checked for correct assembly in

which case the clip must be fully visible within the A-Cover aperture.

Make sure the blind clip over the system connector (9) is also assembled.

Note 2: Make sure the LCD protective tape is removed before assembly of A-Cover module.

Page 5-18 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Page 19

Company Confidential NMM-3

CCS Technical Documentation 5 - Disassembly Instructions

2. APAC ONLY - The tamper proof

2

label must be fitted across the split

line of the A-Cover and B-Cover in

the place indicated in the illustration

opposite.

3. Assemble the corner piece onto

3

the ATO module ensuring the top side

is placed in its retention recess within

the A-Cover first. Pushing the corner

piece downwards snaps the bottom

clip home.

Note: Be sure to only apply pressure

to the corner piece and that the component is the correct way around.

4. Assemble the D-Cover module to

4

the ATO module by firstly removing

the protective tape from the adhesive

at the back of the D-Cover and then

clipping the D-Cover clips to the ATO

in order shown opposite.

Note: Apply light pressure across the

D-Cover once assembled to ensure

the adhesive takes. Ensure gloves are

used and the cosmetic Class I painted

surface of the D-Cover is not damaged or contaminated in any way.

Issue 1 (11/2003) Copyright 2003 Nokia Corporation. Page 5-19

Company Confidential

Page 20

NMM-3 Company Confidential

5 - Disassembly Instructions CCS Technical Documentation

Visual Quality Checks during Re-assembly

• Ensure the window in the A-Cover module has no contamination, scratches or

wear in the viewing area of any kind

• Ensure the camera window viewing area is clear of contaminants or defects

• Ensure the corner piece is correctly fitted and free from contaminants or defects

• Ensure the side keys all depress

• Ensure all 7 screws are fitted and fully assembled

• Ensure the keymat and navi key are free from contaminants or defects

• Ensure the C and D-Covers as well as the painted surface on the A-Cover are free

from contaminants or defects

• Ensure all nine A-Cover clips are fully assembled

• Ensure the window border colour is the same colour as the A-Cover

• Ensure the window has protective tape fitted

• Ensure the camera window has protective tape fitted

• Ensure none of the A-Cover clips are broken

• Ensure all three UI module to B-Cover module clips are made

• Ensure there is no contamination or damage in the B-Cover battery bay area

• Ensure the LCD protective tape and D-Cover adhesive backing tapes have been

removed

• Ensure the phone is free from dust or hairs

Page 5-20 Copyright 2003 Nokia Corporation. Issue 1 (11/2003)

Company Confidential

Loading...

Loading...