Page 1

Customer Care Solutions

NMM-3 Series Transceivers

4 - Service Tools

Issue 1 (11/2003) Copyright 2003 Nokia Corporation

Company Confidential

Page 2

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

Table of Contents

Page No

JBV-1 Docking Station and MJF-29 Adapter................................................................................... 3

MJS-84 Module Jig .................................................................................................................................4

MJS-85 Soldering Jig .............................................................................................................................5

SRT-6 Opening Tool ................................................................................................................................5

SRT-11 Camera Removal Tool.............................................................................................................. 6

FPS-8 Flash Prommer (Sales Pack) ..................................................................................................... 6

ACF-8 Universal Power Supply .............................................................................................................7

FPS-8C Parallel Flash Prommer (Sales Pack) ................................................................................... 7

FLS-4S POS (Point Of Sale) Flash Device (Sales Pack).................................................................. 8

FLA-45 POS (Point Of Sale) Flash Loading Adapter....................................................................... 8

FLC-2 DC Cable ........................................................................................................................................ 9

AXS-4 Service Cable ............................................................................................................................ 10

XCS-1 Service Cable ..............................................................................................................................10

SW Security Device PKD-1 ............................................................................................................... 11

PCS-1 Power Cable .............................................................................................................................. 11

CA-24RS RF Cable................................................................................................................................ 12

XRF-1 RF Cable...................................................................................................................................... 12

DAU-9S MBUS Cable........................................................................................................................... 13

SCB-3 DC Cable..................................................................................................................................... 13

XCS-4 Modular Cable.......................................................................................................................... 14

Printer Cable .......................................................................................................................................... 14

Appendix 4-A Guideline For First Lead Free Products........................................................... 15

Page 4-2 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 3

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

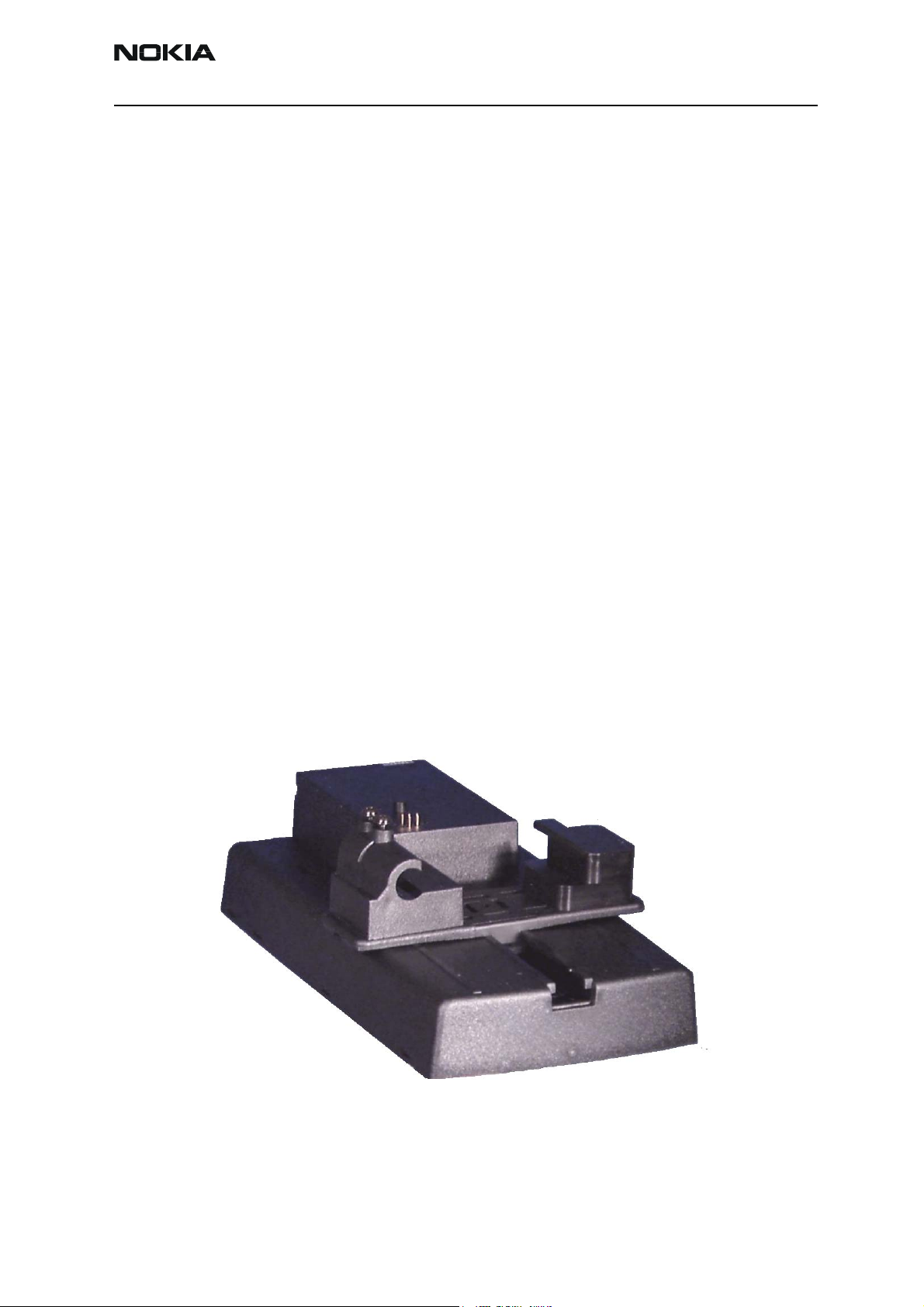

JBV-1 Docking Station and MJF-29 Adapter

The JBV-1 Docking Station has been designed for calibration and software update use.

The MJF-29 Docking Station Adapter makes signal connections to the phone. JBV-1 and

MJF-29 are used as one unit.

JBV-1 main electric functions are:

• adjustable VBATT calibration voltage, current measurement limit voltage ”VCHAR”,

current measurement calibration current ”ICHAR”

• adjustable ADC calibration voltage for BSI

• BSI calibration resistor

• FBUS signal routing to handset

• controlled via FBUS or USB

• Programming Pass / FAIL indication

In calibration mode JBV-1 is powered by external supply set at 11-16V DC. During flashing power is supplied from the FPS-8 or FLS-4S.

Product Code

JBV-1 Docking Station: 0770298

MJF-29 Docking Station Adapter: 0770592

View of MJF-29

Figure 1: MJF-29

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-3

Company Confidential

Page 4

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

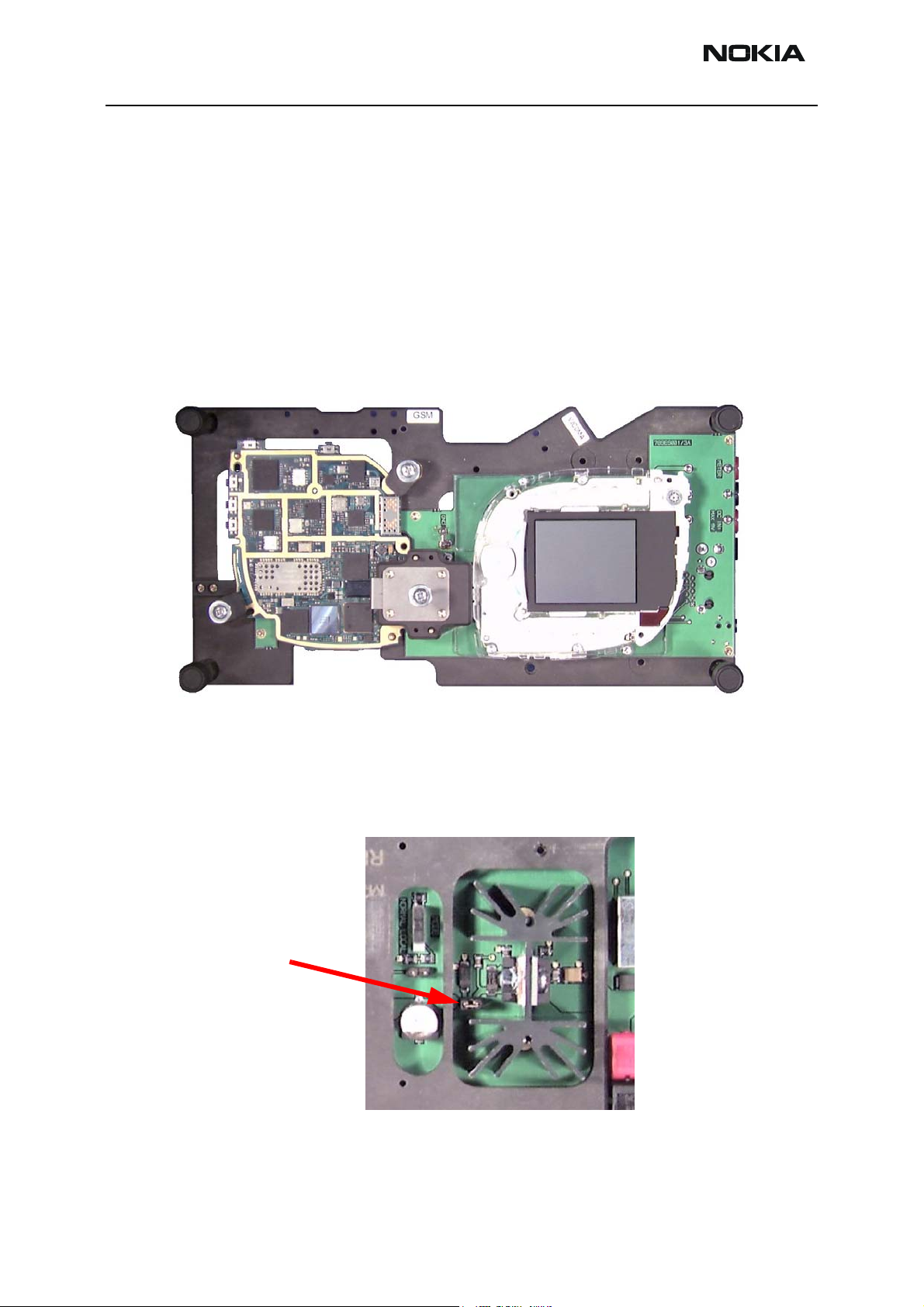

MJS-84 Module Jig

The MJS-84 Module Jig is used for faultfinding and testing the following modules:

• User Interface

• Baseband and RF on system module

Product Code

MJS-84 Module Jig: 0770590

View of MJS-84

Figure 2: MJS-84

*Note: Power to the MJS-84 can be supplied in three ways; 5V to 9V connected to the jack

or ‘DC IN’ banana socket or Vbat direct (3.2V to 4.2V) via the ‘METER’ connector (using

this method the jumper must be removed otherwise excessive current will be drawn

through the jig current sink. See Figure 3).

Figure 3:

Jumper

A charger can be connected to the charger jack, ensure that the phone supply is connected to the ‘DC IN’ and that the jumper is also connected.

Page 4-4 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 5

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

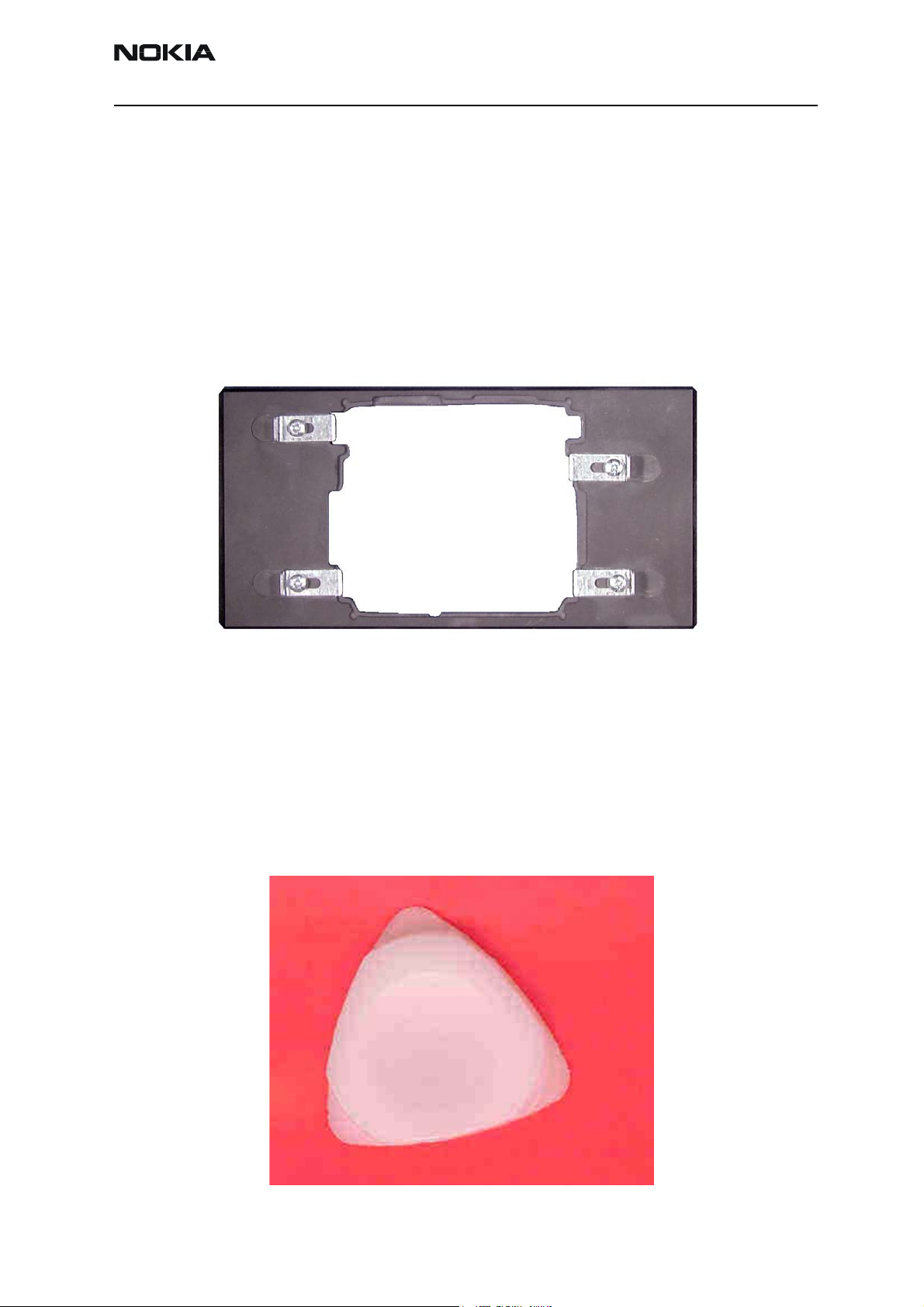

MJS-85 Soldering Jig

The Soldering Jig MJS-85 is used to support the engine module during soldering and

rework.

Product Code

MJS-85 Soldering Jig: 0770591

View of MJS-85

Figure 4: MJS-85

SRT-6 Opening Tool

The Opening Tool is to assist in the mechanical disassembly of the NMM-3.

Product Code

SRT-6 Opening Tool: 0770431

View of SRT-6

Figure 5: SRT-6

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-5

Company Confidential

Page 6

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

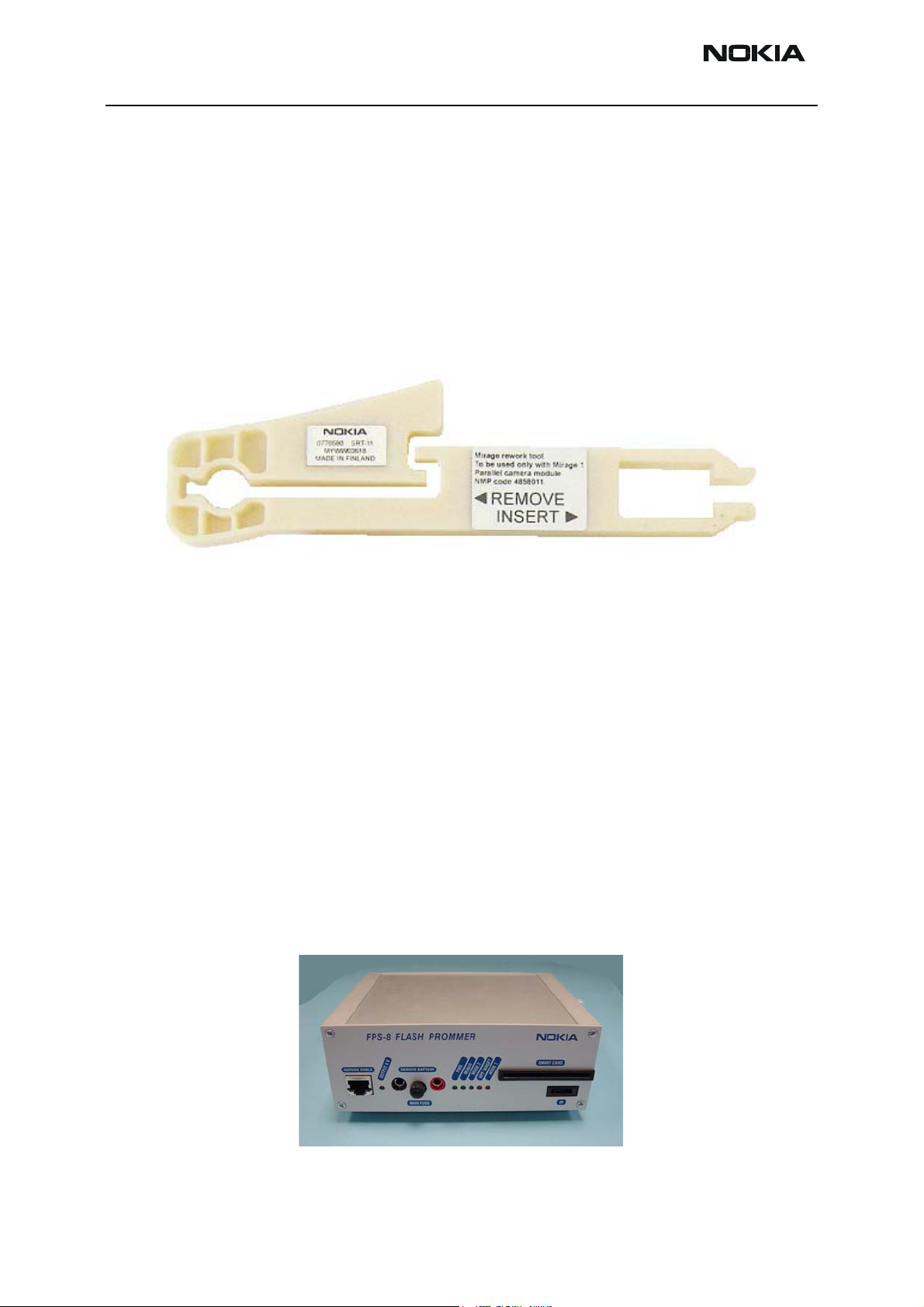

SRT-11 Camera Removal Tool

The Camera Removal Tool SRT-11 is used to remove the camera from its locking connector.

Product Code

SRT-11 Camera Removal Tool: 0770580

View of SRT-11

Figure 6: SRT-11

FPS-8 Flash Prommer (Sales Pack)

The FPS-8 Flash Prommer in conjunction with JBV-1 / MJS-84 is used for programming

and updating the phone software. Power is supplied to FPS-8 from the Universal Power

Supply.

The sales pack includes: - FPS-8 Flash Prommer 0750123

- FPS-8 Activation Sheet 9359289

- Universal Power Supply 0680032

- AXS-4 Service Cable (D9-D9) 0730090

- Printer cable 0730029

Sales package code

FPS-8 Flash Prommer: 0080321

View of FPS-8

Figure 7: FPS-8

Page 4-6 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 7

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

ACF-8 Universal Power Supply

The ACF-8 Universal Power Supply is used to power FPS-8, it provides 2.1A at 6V DC.

Product Code

ACF-8 Universal Power Supply: 0680032

View of ACF-8

Figure 8:

FPS-8C Parallel Flash Prommer (Sales Pack)

The FPS-8C Parallel Flash Prommer is used with the JBV-1 / MJS-84. A maximum of 8

phones can be flashed simultaneously. The FPS-8C consists of eight SF11C programming

cards. SF11C card is functionally identical to FPS-8.

Sales package code

FPS-8C Parallel Flash Prommer: 0080396

View of FPS-8C

Figure 9: FPS-8C

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-7

Company Confidential

Page 8

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

FLS-4S POS (Point Of Sale) Flash Adapter (Sales Pack)

The FLS–4S POS Flash Adapter connects to the PC parallel port, it is used in conjunction

with the FLA-45 POS Flash Loading Adapter for programming and updating the phone

software. Power is supplied to the FLS-4S from a ACF-8 Universal power supply.

The sales pack includes:

• FLS-4S Flash Dongle See below

• User Guide

• ACF-8 Universal Power Supply 0680032

• Device Driver software

Product Code

FLS-4S Sales Pack – Europe/Africa 0080541

FLS-4S Sales Pack –APAC 0080542

FLS-4S Sales Pack –Americas 0080543

View of FLS-4S

Figure 10: FLS-4S

FLA-45 POS (Point Of Sale) Flash Loading Adapter

The FLA-45 POS Flash Loading Adapter FLA-48 is used in place of the phone’s normal

battery during service. It supplies a controlled operating voltage and is connected to the

FLS-4S when flash programming. Connection between the FLS-4S and FLA-45 is made

using the VCS1 cable.

Product Code

FLA-45 POS Flash Loading Adapter: 0775340

Page 4-8 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 9

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

View of FLA-45

Figure 11: FLA-45

FLC-2 DC Cable

The FLC-2 is used to supply a controlled operating voltage to FLA-48 adapter.

Product Code

FLC-2 DC Cable: 0730185

View of FLC-2

Figure 12: FLC-2

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-9

Company Confidential

Page 10

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

AXS-4 Service Cable

The AXS-4 D9-D9 Service Cable is used to connect two 9 pin D connectors e.g. between

PC and FPS-8. Cable length is 2 meters.

Product code

AXS-4 D9-D9 Service Cable: 0730090

View of AXS-4

Figure 13: AXS-4

XCS-1 Service Cable

The XCS-1 Service Cable is used to connect FLS-4 to FLA-48.

Product code

XCS-1 Service Cable: 0730218

View of XCS-1

Figure 14: XCS-1

Page 4-10 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 11

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

SW Security Device PKD-1

SW security device is a piece of hardware enabling the use of the service software when

connected to the parallel (LPT) port of the PC. Whithout the dongle present it is not possible to use the service software. Printer or any such device can be connected to the PC

through the dongle if needed.

Caution: Make sure that you have switched off the PC and the printer before making connections!

Caution: Do not connected the PKD-1 to the serial port. Product Code

SW Security Device PKD-1: 0750018

View of SW Security Device

Figure 15: PKD-1

PCS-1 Power Cable

The PCS-1 Power Cable (DC) is used to connect e.g. JBV-1 or MJS-31 to FPS-8.

Product Code

PCS-1 Power Cable: 0730012

View of PCS-1

Figure 16: PCS-1

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-11

Company Confidential

Page 12

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

CA-24RS RF Cable

RF cable CA-24RS is used to connect e.g. ............................................... to RF measurement

equipment.

Product code

CA-24RS RF Cable: 0730315

View of CA-24RS

Figure 17: CA-24RS

TBD

XRF-1 RF Cable

RF cable XRF-1 is used to connect e.g. MJS-51, CPL-5, TDS-10 or RA7 to RF measurement

equipment..

Product code

XRF-1 RF Cable: 0730085

View of XRF-1

Figure 18: XRF-1

Page 4-12 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 13

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

DAU-9S MBUS Cable

The MBUS Cable DAU-9S has a modular connector, and is used with between PC’s serial

port and e.g. MJS-51, FLA-48, or JBV-1

Product Code

DAU-9S MBUS Cable: 0730108

View of DAU-9S

Figure 19: DAU-9S

SCB-3 DC Cable

The DC Cable SCB-3 is used to connect e.g. JBV-1 to the phone.

Product Code

SCB-3 DC Cable: 0730114

View of SCB-3

Figure 20: SCB-3

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-13

Company Confidential

Page 14

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

XCS-4 Modular Cable

XCS-4 is a shielded cable (one specially shielded conductor) modular cable for flashing

and service purposes.

Product code

XCS-4 Modular Cable: 0730178

View of XCS-4

Figure 21: XCS-4

Printer Cable

This cable is used to connect the PC to FPS-8.

Product code

Printer Cable: 0730029

View of Printer Cable

Figure 22: Printer Cable

Page 4-14 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 15

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

Appendix 4-A Guideline For First Lead Free Products

CONTENTS

1. Scope

2. SnPb / Pb Free Process

2.1 Pb (Sn62Pb36Ag2) Product

2.2 Pb Free (Sn95.5Ag3.8Cu0.7) Product

2.3 Mixed Component Product

3. Rework Method

4. Rework Material

5. Rework Equipment and Tools

5.1 Manual Soldering Using Soldering Iron

5.2 Manual and Semi-automatic Hot Gas Soldering

6. Rework Station Heating Profile

6.1 Profile Measurement Method on PWBs for Rework Station

6.2 Measuring procedure

6.3 Sample Profile

1. Scope

This guideline is designed to be used in NMP manufacturing. It is the first guideline for

lead free rework process for product programs. Specific work instructions must be created on the basis of this guideline. This document will be updated all the time.

Specifications, parameters and work methods are not described in this, so document follow other MES specifications.

2. SnPb / Pb Free Process

The paste used in the production process also defines the process. If a process makes use

of paste that contains lead, it is called a normal process, whereas a process relying on

lead free paste is called a lead-free process.

2.1 Pb (Sn62Pb36Ag2) Product

In rework, use is made of paste containing Pb, with Pb solder wire. The rework station

uses the Pb-process profile.

2.2 Pb Free (Sn95.5Ag3.8Cu0.7) Product

In rework, only Pb-free paste, solder wire and Pb-free components are used. The rework

station uses the Pb-free process profile.

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-15

Company Confidential

Page 16

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

2.3 Mixed Component Product

This process uses Pb-free paste, but all components are not Pb free yet. In rework, Pbfree paste and Pb-free solder wire are used. The rework station uses the Pb-free process

profile.

3. Rework Method

Rework methods are the same as in Pb-process. Components that cannot be repaired

with soldering iron are repaired at the rework station. Rework station heating profile

shall be made to each products and components.

Electromechanical components may be damaged if the temperature exceeds 260 °C.

NOTE: Reservations are made for project specific rework limitations.

4. Rework Material

Same fluxes and solder wicks can be used as in Pb-process.

Solder wires and paste shall be a lead free.

PASTE:

Multicore Solders 96SCLF300AGS88.5 7600033

SOLDER WIRE:

Solder wire NMP code

Multicore Solders Crystal 502 Ecosol TSC 96SC Not available

Other diameter Process ongoing

FLUXES:

Multicore Multifix 450-01 7540021

Multicore MF-X33S07 7540019

Multicore Multifix 5ML/5CC for dispenser 7540023

Paste NMP code

Flux NMP code

SOLDER WICKS:

Wick Diameters NMP code

Multicore No Clean Desoldering Wick 0.5mm 7600023

Multicore No Clean Desoldering Wick 0.8mm 7600600

Multicore No Clean Desoldering Wick 1.5mm 7600601

Page 4-16 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 17

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

5. Rework Equipment and Tools

The same soldering irons and hot air guns can be used as in the Pb-process.

Studies are being made on the capability of rework stations approved for a process that

contains lead ( Zevac / Airvac, Metcal BGA 3000 series) to see how they perform in connection with the lead-free process.

(The performance of Zevac with a lead-free process would seem adequate. In the case of

Metcal Series BGA 3000 equipment, minimum temperature may be the limiting factor.)

More info about tool requirements will be updated later on.

5.1 Manual Soldering Using Soldering Iron

Parameter Specification

Tip diameter

Tip temperature for soldering

SMD components

Selected to fit application

+380 °C ± 10 °C max. (tip temperature in idle

mode, not in contact with soldering location)

or: Metcal 700 Series soldering tip

5.2 Manual and Semi-automatic Hot Gas Soldering

Parameter Specification

Max. air temperature/time

measured at PWB surface

+260 °C/30 s

6. Rework Station Heating Profile

When creating the heating profile, the main requirement is that the profile meets the

Pb-free reflow profile specifications. The shape and length of the profile might differ

depending on component type (e.g. shields, big ground area).

All profiles shall fulfill the Pb Free Reflow Soldering Profile Specification.

Table 1: Process key parameter

Item Specification

Melting point 217 °C

Time above 217 °C 35…60 s

Time above 230 °C 25…50 s

Peak temperature

(Temperature between component and PWB)

Component surface temperature Max. 260 °C

232…250 °C

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-17

Company Confidential

Page 18

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

6.1 Profile Measurement Method on PWBs for Rework Station

Needed equipment: Product PWB, CSP component, 3 pcs. K-type thermocouples, data

logger, e.g. Datapaq, glue or Kapton tape.

Thermocouples should be placed in 3 positions on product: one on top of component surface, one between component and PWB and one beneath the PWB.

To start, drill holes from beneath the PWB under the BGA . The temperature for the profile is measured using K-type thermocouple between the component and the PWB. Insert

thermocouple probes through the hole so that the probe is properly located between the

PWB and component.

To attach thermocouple to PWB surface (solder land) or on small component, use small

amounts of high melting point solder. The melting point of the solder must be higher

than 260 °C. To attach thermocouple on top of a component, use a small amount of

appropriate, temperature resistant glue or heat resistant tape (Kapton).

6.2 Measuring procedure

• To start, adjust PWB with thermocouples to rework station and connect

the thermocouple cables to datalogger.

• Choose right heating profile. Start profile and wait when profiling will

end.

• Download information to Pc. Analyzed information and compare it

against to specification.

• Make temperature adjustment in rework station if needed and repeat

profile again.

• Analyzed information.

6.3 Sample Profile

The following profile is a made for an 6620 (RH-20) PA component and meets the specification requirements.

Example of thermocouple attachment

Page 4-18 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Page 19

Company Confidential NMM-3

CCS Technical Documentation 4 - Service Tools

Datapaq profile. Green (upper) profile is component surface temperature (max. 260 °C)

and red (lower) profile is measured between component and PWB (max. 237 °C)

Issue 1 (11/2003) Copyright 2003 Nokia Corporation Page 4-19

Company Confidential

Page 20

NMM-3 Company Confidential

4 - Service Tools CCS Technical Documentation

This page has deliberately been left blank

Page 4-20 Copyright 2003 Nokia Corporation Issue 1 (11/2003)

Company Confidential

Loading...

Loading...