Page 1

Nokia Customer Care

7 - System Module

ISSUE 1 11/04 Copyright © 2004 Nokia. All Rights Reserved

Page 2

RM-14

Nokia Customer Care 7 - System Module

[This page left intentionally blank]

2 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 3

RM-14

7 - System Module Nokia Customer Care

Table of Contents

Page No

Abbreviations ......................................................................................................6

General Description............................................................................................9

Feature list ......................................................................................................... 9

HW specific features: ....................................................................................... 9

UI features .......................................................................................................9

Technical Specifications .................................................................................. 10

Normal and extreme voltages.......................................................................... 10

Temperature conditions................................................................................... 10

Humidity........................................................................................................... 11

Vibration........................................................................................................... 11

ESD strength.................................................................................................... 11

HW Architecture Description ...........................................................................12

GSM Cellular Engine .....................................................................................12

RTC Circuitry .................................................................................................12

Zocus .............................................................................................................13

Power Management .......................................................................................... 14

HW reset switch............................................................................................... 14

Safety protected battery mode .......................................................................14

UEMEK............................................................................................................ 15

Internal regulator.............................................................................................. 16

External regulators........................................................................................... 17

VCORE SMPS ............................................................................................... 17

Bluetooth regulator .........................................................................................18

White Led Driver ............................................................................................ 18

Filter Components ..........................................................................................18

Power distribution ............................................................................................ 19

Battery connector............................................................................................. 20

Battery.............................................................................................................. 20

Charger interface............................................................................................. 21

System Connector ............................................................................................ 22

Interfaces ...........................................................................................................23

Camera............................................................................................................ 23

SIM interface.................................................................................................... 23

Flash Pads Pattern ........................................................................................23

Connectivity....................................................................................................... 25

IrDA.................................................................................................................. 25

IrDA Tiku EDGE Interface .............................................................................. 25

ISSUE 1 11/04 COMPANY CONFIDENTIAL 3

Copyright © 2004 Nokia. All Rights Reserved.

Page 4

RM-14

Nokia Customer Care 7 - System Module

Audio..................................................................................................................26

Display unit ...................................................................................................... 26

Mounting ........................................................................................................26

Engine Interface .............................................................................................26

Keyboard/UI..................................................................................................... 26

UI module .......................................................................................................26

Rotator ...........................................................................................................27

Function during use .......................................................................................27

Slide switch...................................................................................................... 29

LED driver........................................................................................................ 29

Generel circuit description .............................................................................30

Driving display and UI backlight ..................................................................... 30

Driving RGB LED ........................................................................................... 30

RF Module Introduction.................................................................................... 31

RF Frequency Plan............................................................................................ 32

Regulators ......................................................................................................... 33

Power Distribution ............................................................................................35

RF Characteristics ............................................................................................ 36

RF Block Diagram . ............................................................................................ 38

Frequency Synthesizers................................................................................... 39

Receiver........................................................................................................... 39

Transmittter...................................................................................................... 39

Front end.......................................................................................................... 39

Power amplifier................................................................................................ 40

RF ASIC Helgo ................................................................................................ 41

AFC function.................................................................................................... 41

List of Figures

Page No

Fig 1 RTC supply circuit.......................................................................................11

Fig 2 Zocus Circuit ...............................................................................................12

Fig 3 HW Reset circuit .......................................................................................... 14

Fig 4 Power Supply Overview..............................................................................15

Fig 5 SIM Filtering.................................................................................................17

Fig 6 Power Distribution.......................................................................................18

Fig 7 The connector............................................................................................. 19

Fig 8 BL-8N Battery.............................................................................................. 19

Fig 9 Charger Circuit............................................................................................20

Fig 10 TIKU/UEMEK SIM Interface Connections................................................. 22

Fig 11 FINUI and LABEL I/F ................................................................................ 23

Fig 12 Schematic for UI module............................................................................ 25

4 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 5

RM-14

7 - System Module Nokia Customer Care

Fig 13 Function during use.................................................................................... 26

Fig 14 The switch................................................................................................. 28

Fig 15 LED driver................................................................................................. 29

Fig 16 Figure 13 RF Frequency Plan....................................................................31

Fig 17 Power distribution diagram......................................................................... 34

Fig 18 RF Block Diagram.....................................................................................37

Fig 19 Front end................................................................................................... 40

Fig 20 Power Amplifier.........................................................................................40

ISSUE 1 11/04 COMPANY CONFIDENTIAL 5

Copyright © 2004 Nokia. All Rights Reserved.

Page 6

RM-14

Nokia Customer Care 7 - System Module

Abbreviations

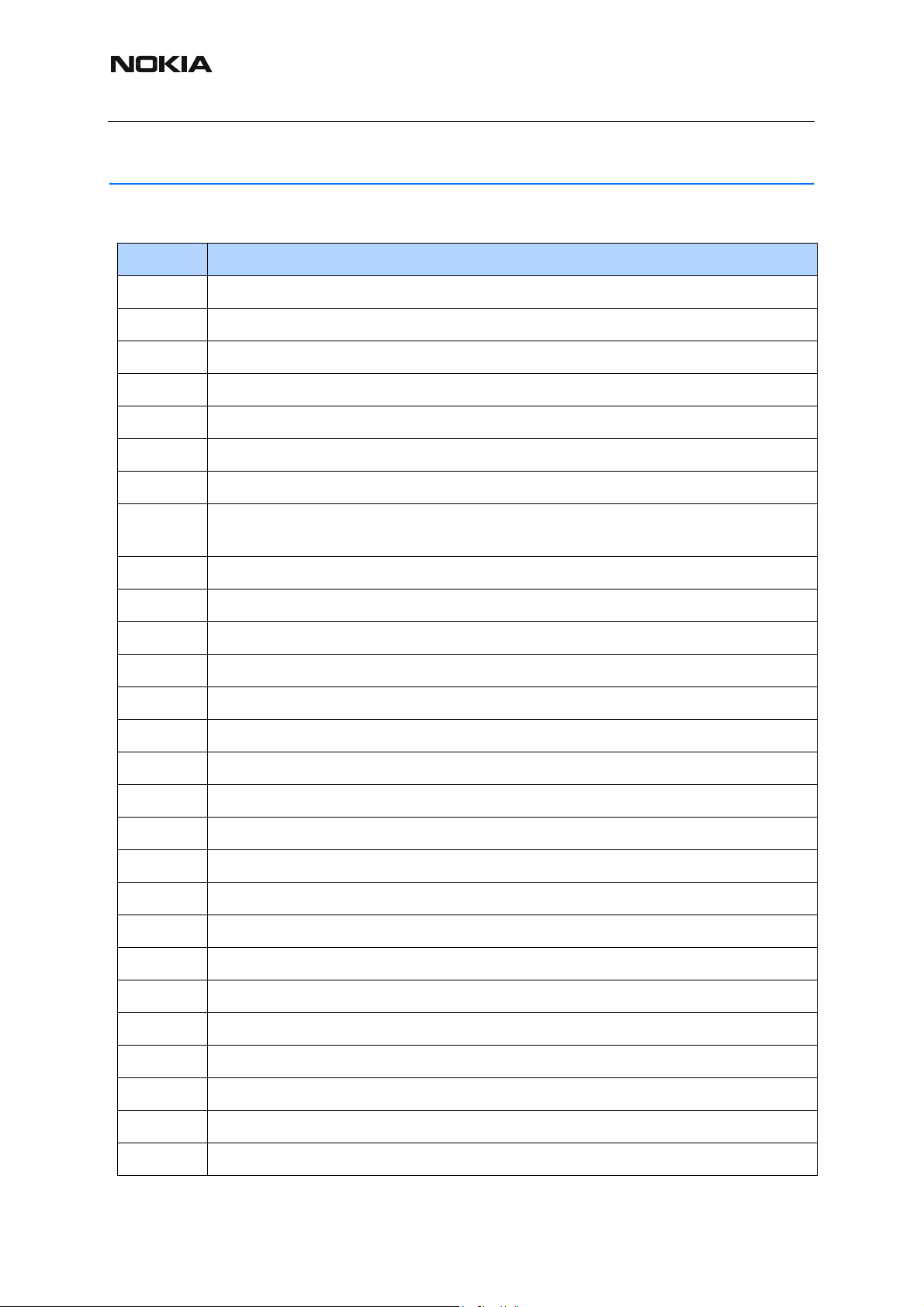

Abbr. Description

ACI Accessory Control Interface

ADC Analog to digital converter

ASIC Application Specific Integrated Circuit

ASIP Application Specific Integrated Passive

ADSP Application DSP (expected to run high level tasks)

ARM Advanced RISC Machines

ARM915 ARM9TDMI Core, Caches, MMU’s

ARM925 ARM915 + WinCE Compatible MMU (WinCE is a hardwareprogrammed option

which will not be enabled for Tiku.)

BB Baseband

BB4.5 Common BaseBand 4.5 program

BC02 Bluetooth module by CSR

BL-8N Battery type.

BlueBird Bluetooth interface program to CSR.

CCP Compact Camera Port

CDSP Cellular DSP (expected to run low level tasks)

CIF Common Intermediate Format (352x288 pixels)

COF Chip on foil

COG Chip On Glass

CP Co-processor

CSR Cambridge Silicon Radio

CSTN Color Super Twisted Nematic

CTSI Clock Timing Sleep and Interrupt block of Tiku

DCT4.5 Digital Core Technology, generation 4.5

DSP Digital Signal Processor

DUT Device under test

EMC Electro Magnetic Compatibility

ESD Electro Static Discharge

6 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 7

RM-14

7 - System Module Nokia Customer Care

FR Full Rate

FSTN Film compensated Super Twisted Nematic

GSM Global System Mobile

HW Hardware

IF Interface

IHF Integrated Hands Free

IMEI International Mobile Equipment Identity

IR Infrared

IrDa Infrared Data Association

LCD Liquid Crystal Display

LDO Low Drop Out

LED Light Emitting Diode

LPRF Low Power Radio Frequency

MCU Microprocessor Control Unit

NTC Negative temperature Coefficient, temperature sensitive resistor used as an

temperature sensor.

PA Power Amplifier (RF)

PDA Personal Digital Assistant

PDRAM Program/Data RAM (on chip in Tiku)

Phoenix SW tool of DCT4.x

PUP General Purpose IO (PIO), USARTS and Pulse Width Modulators

PWB Printed Wired Board

RHEA TI bus from Lead3

RTC Real Time Clock, small circuitry that keeps track of updating the clock counter

and the calendar.

SARAM Single Access RAM

SIM Subscriber Identification Module

SW Software

SWIM Subscriber / Wallet Identification Module

TCXO Temperature Controlled Chrystal Oscillator

Tiku UPP (Universal Phone Processor), Official Tiku3G

TI Texas Instruments, American company

ISSUE 1 11/04 COMPANY CONFIDENTIAL 7

Copyright © 2004 Nokia. All Rights Reserved.

Page 8

RM-14

Nokia Customer Care 7 - System Module

UEME Universal Energy Management Enhanced

UI User Interface

USB Universal Serial Bus

USWIM UMTS Subscriber / Wallet Identification Module

USIM UMTS Subscriber Identification Module

UPP Universal Phone Processor

UPP_WD2Communicator version of DCT4 system ASIC

VIA Versatile Interface Architecture (on chip bus structure)

Copper plated, drilled connection between layers in a PWB

WCDMA Wide Band Code Division Multiple Access, Third Generation (3G) of Mobile Tel-

ephones

Zocus Zero Ohm Current Sensor, Current measuring device. It measures the current

from and to the battery . It is used by the EM SW for calculating the left over pow-

er in the battery.

8 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 9

RM-14

7 - System Module Nokia Customer Care

General Description

■ Feature list

HW specific features:

- Monoblock phone

- Tripleband Engine (900, 1800, 1900)

- GPRS/EGPRS MSC 10 (4+1, 3+2)

- FR, EFR, AMR codecs

- Integrated VGA Camera

- Display: 208x104 pixels, transmissive and mirror (on film) effect

- MMS (Multi Media Messaging), Java MIDP2.0, SyncML1.1.1 and X-HTML

- Intergrated MP3 file support

- Bluetooth

- IR

- FM Radio

- IHF

- Rotator with limited UI input keys: Upper Soft Key, Lower Soft Key, SEND/END keys

- Mono (Plug'n'play) Accessory support

- Slide for receiving call

- Fixed battery

UI features

Bearers supported:

− EDGE

−CSD, HSCSD

−GPRS

−Bluetooth

ISSUE 1 11/04 COMPANY CONFIDENTIAL 9

Copyright © 2004 Nokia. All Rights Reserved.

Page 10

RM-14

Nokia Customer Care 7 - System Module

Technical Specifications

These figures are a summary of the SPR-requirements.

■ Normal and extreme voltages

Following voltages are assumed as normal and extreme voltages for used battery:

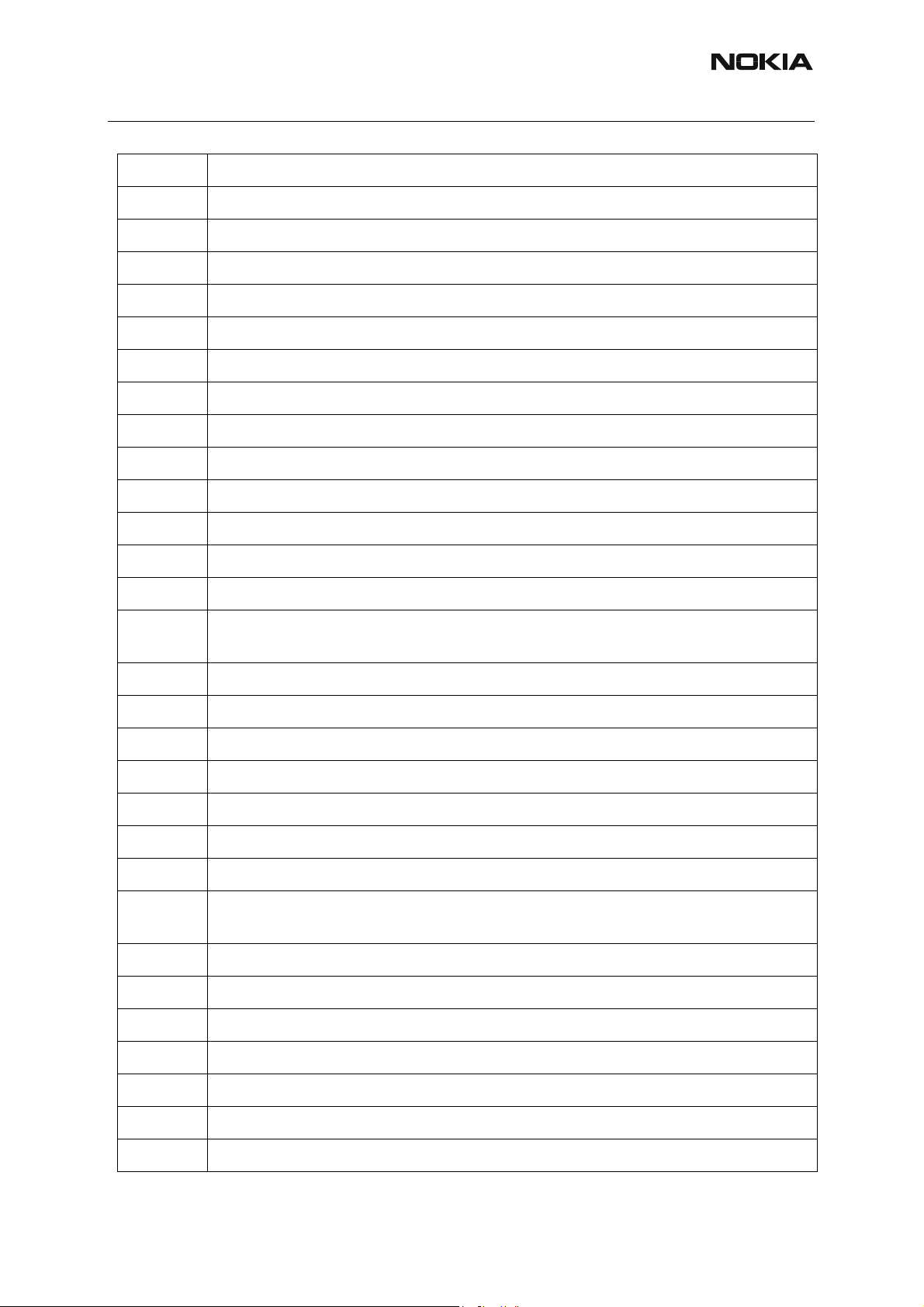

Table 1: Normal and extreme voltages

Voltage Voltage [V] Condition

General Conditions

Nominal voltage 3.90

a

Lower extreme voltage 3.3

Higher extreme voltage 4.30

HW Shutdown Voltages

Vmstr+ 2.1 ± 0,1 Off to on

Vmstr- 1.9 ± 0,1 On to off

SW Shutdown Voltages

Sw shutdown 3.1 In call

Sw shutdown 3.2 In idle

Min Operating Voltage

Vcoff+ 3.1 ± 0,1 Off to on

Vcoff- 2.8 ± 0,1 On to off

HW-Reset Demands

Min 1.0V

Max --

a. The nominal voltage is defined as being 15% higher than lower extreme voltage. TA will test with this nominal voltage

at an 85% range (0.85 x 3.9V ª 3.3V)

b. This limit is set to be above SW shutdown limit in TA.

b

c

d

c. During fast charging of an empty battery, this voltage might exceed this value. Voltages between 4.20 and 4.60 might

appear for a short while

d. The minimum Battery cell voltage required for the reset circuitry to turn on. This is not confirmed by measures at pt..

■ Temperature conditions

(1) Operational temperature range (all specifications met within this range)

–10°C +55°C

(2) Functional temperature range (Reduced performance)

–30°C +70°C

(3) Storage temperature range:

–30°C +85°C

10 COMPANY CONFIDENTIAL ISSUE 1 11/04

1

Copyright © 2004 Nokia. All Rights Reserved.

Page 11

RM-14

7 - System Module Nokia Customer Care

Temperatures at –10°C, +25°C and +55°C are used for cpk analysis.

The baseband module complies with the SPR4 Operating Conditions.

■ Humidity

Relative humidity range is 5...95%.

The BB module is not protected against water . Condensed or spla shed water might cause mal-

function. Any submerge of the phone will cause permanent damage. Long-term high humidity,

with condensation, will cause permanent damage because of corrosion.

The baseband module complies with the SPR4 Operating Conditions.

■ Vibration

The baseband module complies with the SPR4 Operating Conditions.

■ ESD strength

The baseband module complies with the SPR4 Operating Conditions.

ISSUE 1 11/04 COMPANY CONFIDENTIAL 11

Copyright © 2004 Nokia. All Rights Reserved.

Page 12

RM-14

Nokia Customer Care 7 - System Module

HW Architecture Description

GSM Cellular Engine

The BaseBand Engine consists of the TEMS (TikuEdge Memory Stacked Package) concept

and UEMEK. The TEMS concept combines all memory components in one package, which is

stacked on top of the TikuEdge. The memory combines 128Mbit NOR Flash, 512Mbit NAND

Flash and 128Mbit SDRAM in one package. The TikuEdge is also implemented in a stacked

package in which all pin connections are available on bottom pinout, and memory interface on

top pin out (POP I/F).

The energy manegement related part of the microBB4.5 engine is the UEMEK.

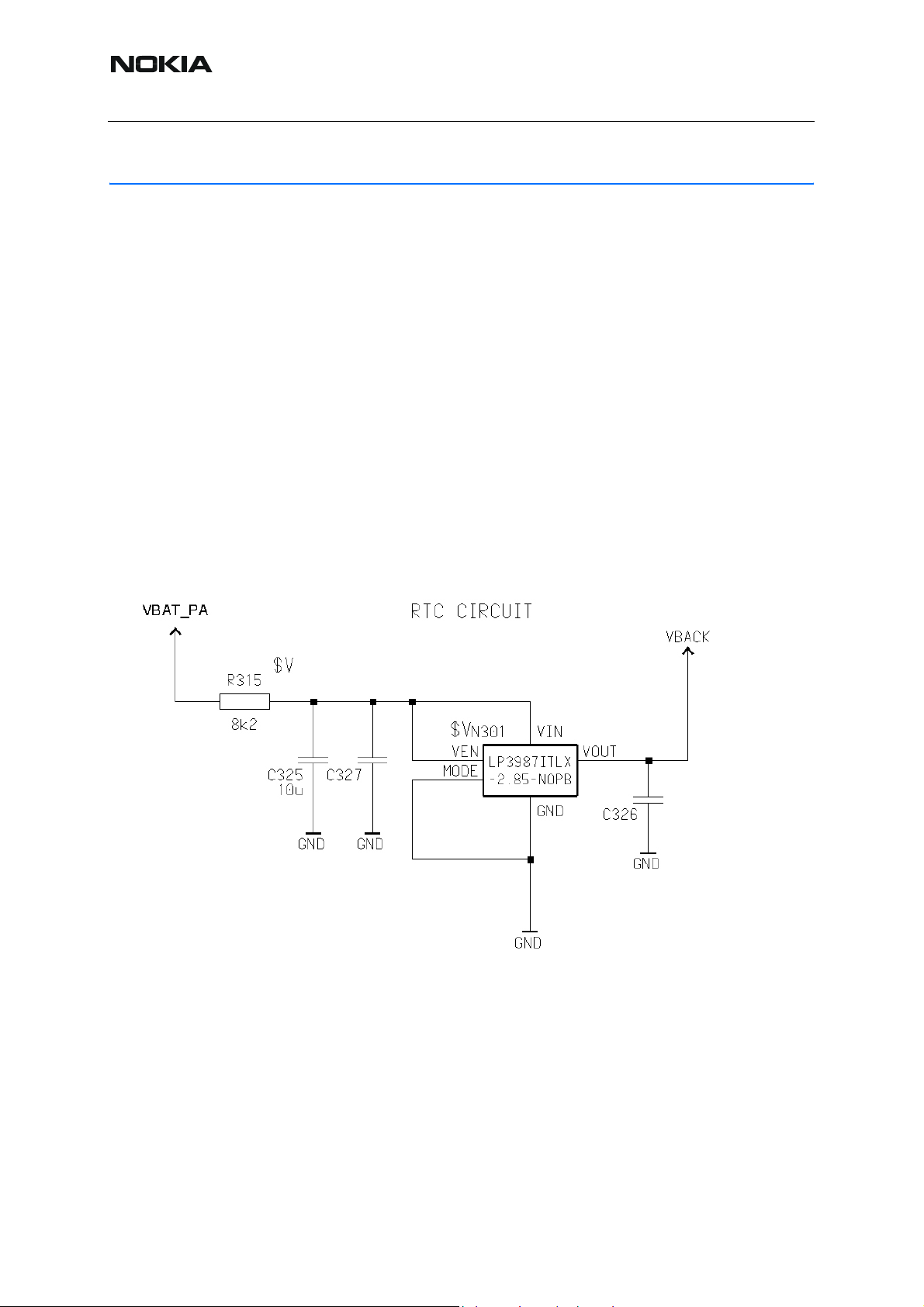

RTC Circuitry

Therefore a voltage regulator is used to supply the RTC circu it via the battery . The circu it looks

as follows:

Figure 1: RTC supply circuit

This is used in sleep mode where it is able to source 3mA. The supply VBAT_PA is byp assing

the HW switch, and therefore will have contact to the battery also whe n the SIM drawer is pulled

out.

The circuit will give a long back up time. Capacity on the battery when it has been discharged

to engine cut off (3,1V) is still 2.2mAh before battery voltage reaches 2,9V. This gives a back

up time of approx:

71 hours.

12 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 13

RM-14

7 - System Module Nokia Customer Care

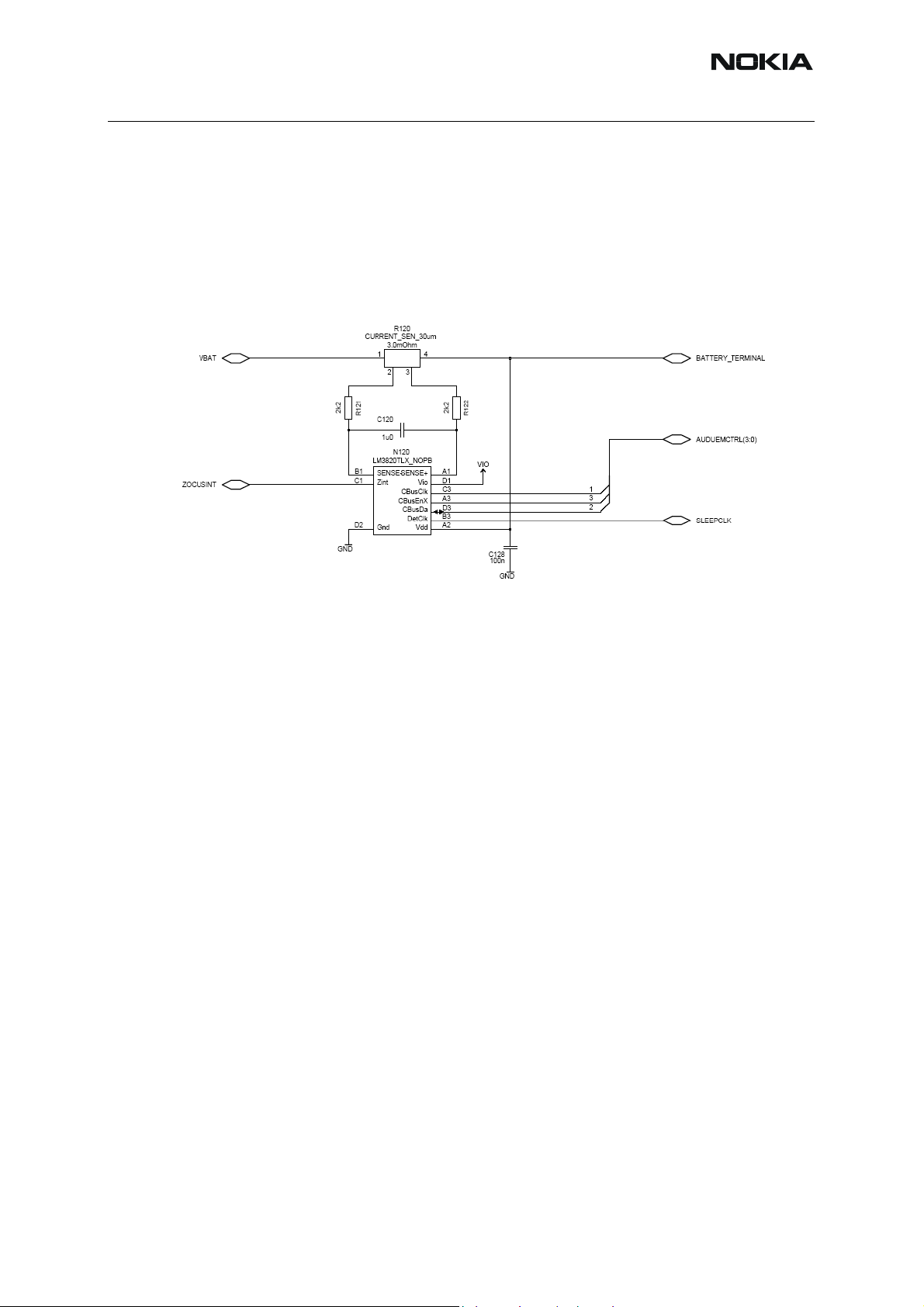

Zocus

The Zocus device (LM3820) is a precision current sensor, used by energy management software to determine the current consumption in the mobile phone.

Figure 2: Zocus Circuit

ISSUE 1 11/04 COMPANY CONFIDENTIAL 13

Copyright © 2004 Nokia. All Rights Reserved.

Page 14

RM-14

Nokia Customer Care 7 - System Module

Power Management

■ HW reset switch

Since the RM-14 project is equipped with a “fixed battery”, a need of a specific HW reset solution is required, since this is no longer possible by removing the battery. This request is meet

by the implementation of a power cut-of f switch that disconnects the battery power from the rest

of the phone. This switch is implemented by 2 P-Channel MOSFET’s inserted in the battery

power line.

RTC backup:

A minimum of 10 minutes power supplied to the RTC circuit is required.

Dead battery charge:

A battery safety circuit is protected by battery cell, which must be re-enabled.

Description:

The circuit depicted in HW Reset circuit-figure is connected to battery at “VBAT” and to the

phone at VBA T_OUT. The switch referred to as “SW” illustrates the switch, which enables power, supplied to the phone. This is implemented as a normally open switch in the SIM can. Its

function is to open when SIM-card is inserted and close whenever it’s extracted.

Beside of the PA-Module implementation, the rest of the phone will be powered from the

VBAT_OUT.

Safety protected battery mode

This mode implies a battery that has its cell disconnected from battery terminals by the batt eries own protection circuit .

When the protection circuit is disabled, the battery cell voltage is visible at the ba ttery terminals.

This means that the voltage of VBA T_OUT equals the battery cells whereas this must be higher

than the Gate-Source threshold voltage of Q1-2.

14 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 15

RM-14

7 - System Module Nokia Customer Care

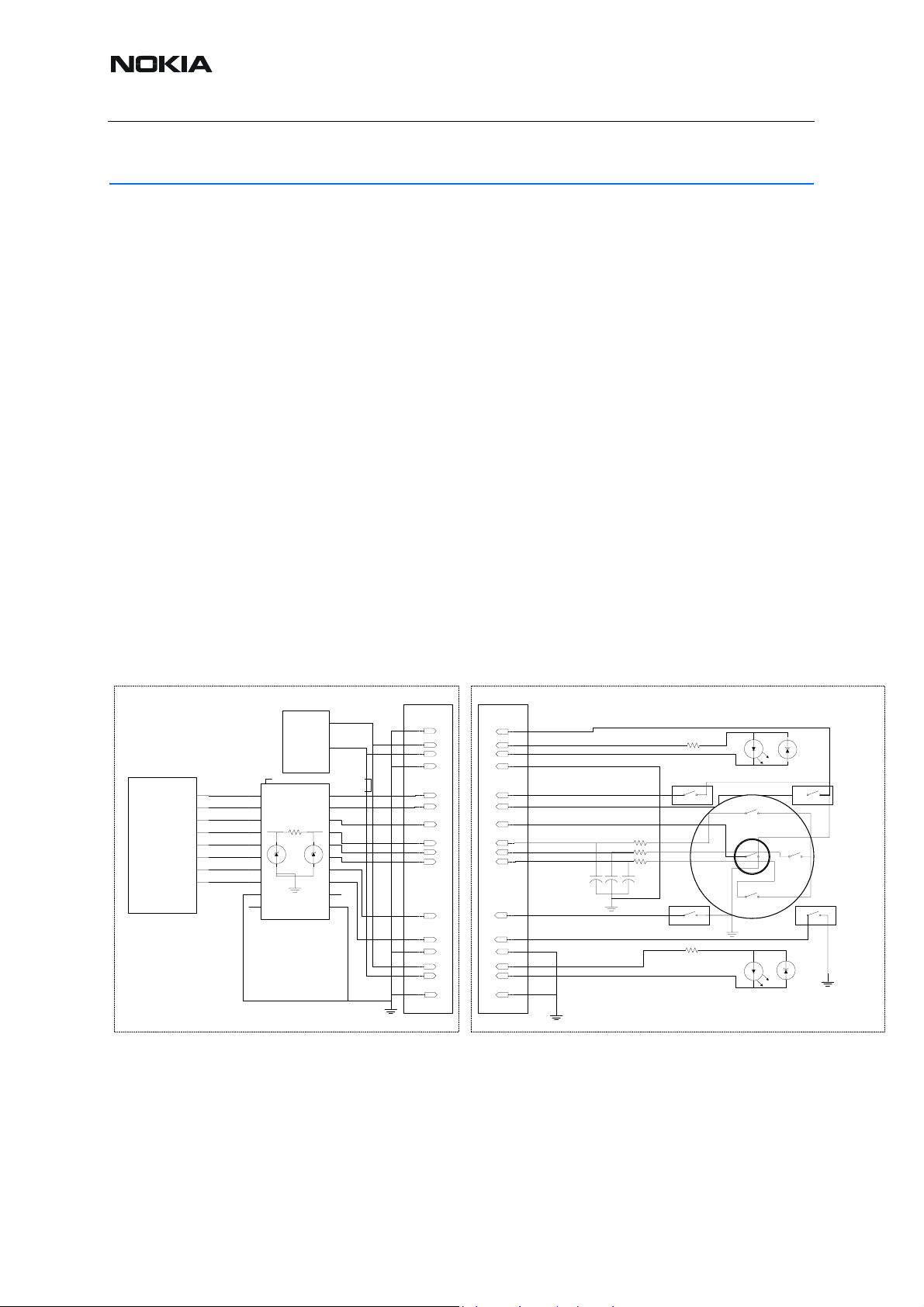

Figure 3:HW Reset circuit

■ UEMEK

The UEMEK is providing the power for the phone. It consist of the following regulators:

− BB 8 voltage regulators

− RF 7 voltage regulators, 2 current regulators

The BB regulators in the UEMEK are controlled by MCUSW except VANA, VFLASH1, VIO,

which are controlled by the UEMEK itself. The RF regulators are controlled by DSPSW except

VR3, which is controlled by the UEMEK.

An external regulator (SMPS) provides the core voltage for the phone processor (T ikuEDGE).

ISSUE 1 11/04 COMPANY CONFIDENTIAL 15

Copyright © 2004 Nokia. All Rights Reserved.

Page 16

RM-14

Nokia Customer Care 7 - System Module

The inputs of the UEMEK regulators are filtered by a coil / capacitor filter. Some of the inputs

are joined together..

Figure below shows the connections in the different filters.

VIO regulator is overloaded in sleep mode (this issue is inherited from Nokia 6230). Due to

peak currents on display and SDRAM the maximum output current for VIO regulator (2mA) is

exceeded.

Figure 4: Power Supply Overview

Charger

Section

Charger

Connector

Charger

Filter

Fuse 1.5A

BATT

VBAT

Zocus

Battery

■ Internal regulator

LM2708

Regulator

LP3987

Regulator

HW Reset

VBAT_PA

Switch

VCORE

2,8V REG

VBAT

TO RF

Bluetooth

BC02

Tiku

PA-Module

VBATBB

LM2795,

White Led

Driver

Current

Regulator

Audio

PA

Legend:

UEMEK

EMC Section

Ext. components

Display

BLight

KBoard

BLight

RGB Led

Buzzer

Tiku PLL

Filter 1

Filter 2

Filter 3

Filter 4

Filter 5

Filter 6

Filter 7

VAUX1

Regulator

VAUX2

Regulator

VAUX3

Regulator

VFLASH1

Regulator

VCORE

Regulator

VANA

Regulator

VIO

Regulator

VSIM

Regulator

VR1A/B

Regulator

VR3

Regulator

VR2

Regulator

VR4

Regulator

VR5

Regulator

VR6

Regulator

VR7

Regulator

VAUX1

VAUX2

VAUX3

VFLASH1

VCORE_LIN

VANA

VIO

VSIM

VR1A/B

VR3

VR2

VR4

VR5

VR6

VR7

Not used

Not used

Not used

LCD, IrDA, FM radio,

Camera analog

Camera Dig

UEME audio, RF

{

RX/TX conv.

Flash, SDRAM, LCD i/

o, NUT i/o, TIKU i/o,

{

BT i/o, Zocus i/o

SIM

RF Section

RF Section

Enable for BT clock

RF Section

RF Section

RF Section

RF Section

RF Section

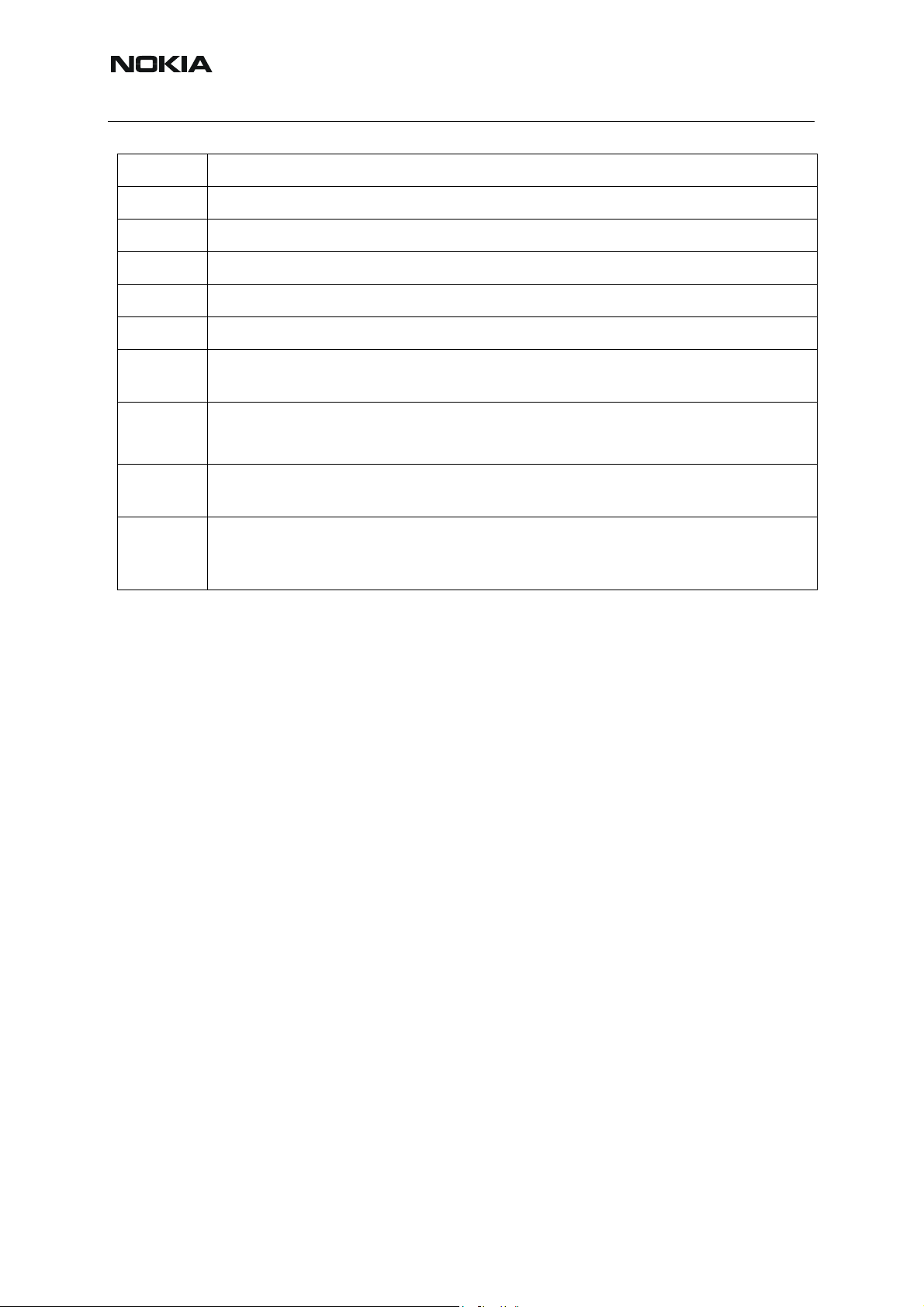

The following list shows the internal regulators:

Table 2: Internal Regulators

Name Voltage (V) Current (mA) Fil-

Comment

ter

Min Nom Max Max Sleep

Max

VANA 2.70 2.78 2.86 80 2 5uA minimum for stability.

Controlled by the UEMEK.

Disabled in Sleep mode.

VFLASH1 2.7

(2.61)

2.78 2.86

(2.95)

70 1.5 1 5uA minimum for stability.

Controlled by the UEMEK.

(Sleep indication)

16 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 17

RM-14

7 - System Module Nokia Customer Care

Name Voltage (V) Current (mA) Fil-

ter

Min Nom Max Max Sleep

Max

VIO 1.72 1.80 1.88 150 2 3 5uA minimum for stability.

VCORE

Camera

on

VAUX1 1.745

VAUX2 2.70 2.78 2.86 70 0.5 1 5uA minimum for stability.

VAUX3 2.70 2.78 2.86 20 0.5 1 5uA minimum for stability.

VSIM 1.745

VR1A/B 4.60 4.75 4.90 10 - 4 Disabled in Sleep mode. The

1.71 1.8 1.89 200 0.2 1 5uA minimum for stability.

2.91

2.91

1.80

3.0

1.80

3.00

1.855

3.09

1.855

3.09

50 0.5 1 Voltage level is set by

25 0.5 - 5uA minimum for stability.

Comment

Controlled by the UEMEK.

MCUSW is setting the voltage.

MCUSW.

maximum current is for 1 regulator active. If both are used,

maximum 5mA each.

VR2 2.70

(2.61)

VR3 2.70 2.78 2.86 20 - 4 100uA minimum for stability.

VR4 2.70 2.78 2.86 50 0.1 6 100uA minimum for stability.

VR5 2.70 2.78 2.86 50 0.1 7 100uA minimum for stability.

VR6 2.70 2.78 2.86 50 0.1 7 100uA minimum for stability.

VR7 2.70 2.78 2.86 45 - 7 100uA minimum for stability.

2.78

(2.78)

2.86

(2.95)

100 - 5 100uA minimum for stability.

Active during (Sleepmode).

Controlled by the UEMEK.

■ External regulators

VCORE SMPS

The VCORE regulator is based on the LM2708 step-down DC-DC converter . The regulator can

provide 350mA and can switch between 1.35 – 1.57V output voltag e. It can switch between low

power mode (Sleep) (linear mode) and full power mode (switched).

- Input voltage 2.7 – 5.5V

- Output voltage 1.35V – 1.57V

- External Sync input (PWM frequency between 500kHz and 750khz)

- Output current 517mA

ISSUE 1 11/04 COMPANY CONFIDENTIAL 17

Copyright © 2004 Nokia. All Rights Reserved.

Page 18

RM-14

Nokia Customer Care 7 - System Module

- Overload and thermal protection

Bluetooth regulator

An external regulator powers the BC02 module. The used regulator is a LP3987ITL by National

Semiconductor. The output voltage is 2.8V and the output current is 150mA continuously.

White Led Driver

A white led driver is implemented for display backlight and key_UI le’s. RGB Led Regulator

This regulator supplies the RGB led.

Filter Components

All connectors going to the “outside world” have filter components, ESD protection and EMC

reduction.

The Digital/Data lines on SIM have special d edicated filter ASIP . The belo w figure show the SIM

filtering.

Figure 5:SIM Filtering

The Audio circuit: Earpiece, IHF, internal microphone and external speaker are filtered with discrete components (common mode reduction coils, Varistors, caps and resistors), where as the

external microphone uses differential mode mic. ASIP.

The 16 UEMEK BB & RF regulators are specified to have a decoupling cap of 1 uF ±20%.

18 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 19

RM-14

7 - System Module Nokia Customer Care

■ Power distribution

The connection of various power connection can be seen in the following overview.

Figure 6: Power Distribution

HF

Speaker

Vibra

"On Key"

CHARGER

PAOUTN

ESD

PAOUTP

ESD

BuzzO

PwrOnX

ESD

VR1A 4.75V

VR1B 4.75V

VR2

2.78V

VR3

2.78V / 3.6V

VR4

2.78V / 3.6V

VR5

2.78V / 3.6V

VR6

2.78V / 3.6V

VR7

2.78V / 3.6V

RF Regulators BB Regulators

VRefRF02

VRefRF01

VBack

VCharOut

BTEMP

RF CODECS

AUDIO CODEC

DIGITAL

BLOCKS

DIGITAL

BLOCKS

VBack

BSI

LS

PURX

SleepClk

SleepX

VCharIn

UEMEK

2.78V VAUX2

2.78V

VAUX3

VANA2.78V

VFLASH1

2.78V

1.8/3.0V

VSIM

VAUX11.8/3.0V

VCORE1.0-1.8V

1.8V

1,8V VIO

KLight

DLight

CALLED

UEMRstX

Vibra

ESD

RGB Led

Display

illumination

LCD Driver

LED

driver

RGB

Reg

IR

Module

SIM

CCP

Camera

Parallel

Display

Keyb Light

Rotator

FM Radio

Battery

BL-8N

BATT

VBAT

VXO

ZOCUS-C

HW Reset

Sw

HELGO

RF

PA_Module

TIKU

EDGE Memory

Stacked

(TEMS)

RFClock

BC02

2.8V

LP3987

1.5V

VCORE

LM2708

NewVision Jinx

Power Distribution Diagram

Ver. 0.1

18.02.2004

CONFIDENTIAL

Copyright © 2002 Nokia Mobile Phones

ISSUE 1 11/04 COMPANY CONFIDENTIAL 19

Copyright © 2004 Nokia. All Rights Reserved.

Page 20

RM-14

Nokia Customer Care 7 - System Module

■ Battery connector

The battery connector has two pogo pins one for VBA T (Pin A) and one f or GND (Pin B). There

are no connections for either BTEMP or BSI. Hence the temperature is measured with a NTC

on PWB opposite side of battery.

The connector has a dynamic movement area of 0.6 - 2.1mm with a force of 2.3 – 0.3N respectivly.

Figure 7: The connector

■ Battery

Type:BL-8N

Technology:Li-Ion. 4.2V charging. 3.1V cut-off

Capacity:700 mAh

The battery pack is designed for RM-14 .

The BSI resistor is placed on the main PWB as RM-14 supports only one battery capacity. Fur-

ther a BSI connection is added to the Flash interface.

The battery temperature is measured by a NTC resistor placed on the main PWB, opposite to

the Battery.

Battery pack has an impedance of 130 - 150mΩ (0 – 45

Figure 8: BL-8N Battery

o

C).

20 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 21

RM-14

7 - System Module Nokia Customer Care

Inside the battery, an over-temperature and an over-voltage protection circuit are present. Op-

o

erational temperatures of battery are –20 – 70

C in discharge mode.

Care should be taken with the temperature. If the battery is charged above 60 degrees Celsius,

overheating might occur.

■ Charger interface

RM-14 conforms to the global NMP Charger Interface.

Charging is controlled by the UEMEK. The charger connection is through the system connector

interface. The RM-14 baseband is designed to support both 2- and 3-wire type chargers.

Figure 9: Charger Circuit

ISSUE 1 11/04 COMPANY CONFIDENTIAL 21

Copyright © 2004 Nokia. All Rights Reserved.

Page 22

RM-14

Nokia Customer Care 7 - System Module

System Connector

The system connector in RM-14 is a plug and play connector.

The Plug & Play system connector supports the fully differential DCT4, 4-wire audio/co ntrol interface which includes:

Audio

- 2 -wire fully differential mono audio

- 2-wire differential mic input

Detection/controlling

- Headint passive brake switch

Not supported is:

- Pins for 2 -wire charging in cradles

Table 3: DC Plug pinlist

PinNo Pin Name Description Voltage levels, Current Comment

2 CHARGE Charger input 0-16,9V, 0,85A Max Voltage Peak from

AC-7 used.

1 GND Ground 0,85A

22 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 23

RM-14

7 - System Module Nokia Customer Care

Interfaces

■ Camera

The module has only one operating mode: Bayer mode (raw pixel data output). Thus viewfinder, video streaming, colour correction, white balance etc. must be handled in software.

■ SIM interface

The engine first tries to contact SIM card with 1.8V. If no response is given, 3.0V supply is tried

instead.

The whole SIM interface locates in two asics; TIKU and UEMEK.

Figure 10: TIKU/UEMEK SIM Interface Connections

SIM

C5C6C7

C1C2C3

UEMEK

SIMIF Block

C8

C4

SIMData

SIMClk

SIMRst

VSIM

BSI

GND GND

Data

SIMClk

SIMIO

UEMEK

Dig. Logic

Tiku

Data

SIMClk

SIMIO

UIF Block

UEMInt

CBusDa

CBusEnX

CBusClk

The internal clock frequency from the CTSI Block is 13 MHz in GSM.

Flash Pads Pattern

These are accessed through the SIM Can by removing the SIM draw’. There is no access to

the battery connector and hereby the battery, through this interface connection. The battery

cannot be charged when the POS adapter is inserted.

The power is supplied to the Engine for purposes of power supply during flashing only. Also,

this interface is used for flashing when battery is inserted, and hereby the I/F ensures that there

is no connection to battery.

ISSUE 1 11/04 COMPANY CONFIDENTIAL 23

Copyright © 2004 Nokia. All Rights Reserved.

Page 24

RM-14

Nokia Customer Care 7 - System Module

Figure 11: FINUI and LABEL I/F

24 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 25

RM-14

7 - System Module Nokia Customer Care

Connectivity

■ IrDA

RM-14 suppports data connectivity via the Infra Red lin k. The IR interface is integrated into the

TIKU and the main external component is the IR module. The datarate supported will be

1.152Mbit. The circuit around the module is the same as in Nokia 6230. However, since the IR

window due to design reasons is lifted in relations to the PWB an lig htguide has to connect the

IR light and the IR window . Thus the u p firing module TFDU5307 from Vishay has been selected, instead of the one used in Nokia 6230.

IrDA Tiku EDGE Interface

This interface receives data from, and transmits data to peripheral equipment. It transforms serial data to parallel data, for the MCU or DSP, and vice versa.

ISSUE 1 11/04 COMPANY CONFIDENTIAL 25

Copyright © 2004 Nokia. All Rights Reserved.

Page 26

RM-14

Nokia Customer Care 7 - System Module

Audio

The audio and vibrator functions are specified UI

■ Display unit

Mounting

The Display Unit interface is a parallel interface.

Engine Interface

A 24-pin connector provides the interface between the Display Unit and the Engine PWB.

■ Keyboard/UI

UI module

RM-14 is instead of a traditional alphanumerical keyboard equipped with a rotator. The user

interface is thus the rotator + 5 keys (upper soft key, lower soft key, send, end/power, select).

All this combined with backlight is called UI module.

The schematic of the complete UI-module can be seen below.

Figure 12: Schematic for UI module

ASIC

PWB

LED driver

circuit

10 line EMI filter

1kOhm

16 pin UIconnector

16 line

flexpiece

LED1+

Upper Soft Key

Lower Soft Key____________________________

TIKU P(00) row0

TIKU P(01) row1

TIKU P(02) row2

Send

LED2+

Rotator module

LED1-

GND

Sel

220 Ohm

(0402 comp)

1nF

(0402 comp)

PWRONX

LED2-

GND

68 Ohm

(0402 comp)

CL-510S-WD-D-T

SOFT LEFT SOFT RIGHT

SEND END

68 Ohm

(0402 comp)

Citizen

SwitchA

Select

SwitchC

CL-510S-WD-D-T

Citizen

SwitchB

5V6/15V/0J05

5V6/15V/0J05

(1825127)

Varistor

AVX TVS

(1825127)

Varistor

AVX TVS

In the middle of the rotator there is a select key. On top of this 4 keys are present, these are:

- Send

- End/power-key

26 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 27

RM-14

7 - System Module Nokia Customer Care

- Upper soft key

− Lower soft key

These are implemented so that they can be pressed (and detected) simultaneously.

The powerkey is implemented in the END key. Therefore this will be connected to the

PWRONX pin on the UEME.

Rotator

The connections from the rotator module (including keys) to the engine are:

Function Connecting IC Pin Level pressed/

unpressed

Upper soft key TIKU GPIO2 (col0) 0/Open

Lower soft key TIKU GPIO3 (col1) 0/Open

Select TIKU GPIO13 0/Open

Switch A TIKU GPIO10 -Switch B TIKU GPIO9 -Switch C TIKU GPIO8 -Send TIKU GPIO4 0/Open

End/Power UEME PWRONX 0/Open

Function during use

This consists of 3 switches which during rotation open and close in the following pattern:

Figure 13:Function during use

ISSUE 1 11/04 COMPANY CONFIDENTIAL 27

Copyright © 2004 Nokia. All Rights Reserved.

Page 28

RM-14

Nokia Customer Care 7 - System Module

In the following:

-contacts in rotator are CAPITAL LETTERS

-pins on TIKU are corresponding lowercase letters (Thus switch A corresponds to pin A on

TIKU).

If the system has been initalized following routine is present (starting at point 1):

System has enabled pin c (driven low), a and b are disabled (pulled high).

Pos. 1: Contact A and B are closed, C is open (pin a = hi, b = hi, c = lo).

Between 1 & 2: Rotating the wheel CW causes:

Contact A to open => Now only B is closed, (pin a = hi, b = hi, c = lo).

Pos. 2: Rotating further CW causes:

C to close => now B and C is closed, This causes a low interrupt on pin b (pin a = hi, b = lo, c

= lo).

New state in SW is set: (pin a = lo, b = hi, c = hi). Now ready for next step.

Between 2 & 3: Rotating further CW causes:

B to open => now only C is closed, (pin a = lo, b = hi, c = hi).

Pos. 3: Rotating further CW causes:

A to close => Now A and C are closed. This causes a low interrupt on pin c (pin a = lo, b = hi,

c = lo).

New state in SW is set: (pin a = hi, b = lo, c = hi). Now ready for next step.

Between 3 & 1: Rotating further CW causes:

contact C to open => Now only A is closed.

Pos.1: This is similar to the first position 1. The pattern is repeated.

This pattern will go on as long as the rotator is turned CW, and the switches open and close

regulairy.

This means:

-In between steps only one switch is closed. This switch stays closed while the 2 other are

changing state.

-Every time a switch closes a low interrupt is generated.

-When going CCW the same pattern will happen, but in opposite order.

-Every time an interrupt is generated a new state has to be set.

-If a false state occurs, initalization routine has to be run until a correct state is reached.

28 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 29

RM-14

7 - System Module Nokia Customer Care

Whether the rotator movement is CW (down) or CCW (up) can thus b e decoded by comparing

the interrupt pin with the stage of the last interrupt.

■ Slide switch

A switch is needed to detect the position of the slide.

Connection to the engine:

Connecting

pin

AuxDet UEME Output from Hall IC tells if slide is open or

This switch is implemented with a hall IC and a magnet. The hall IC is SH248CSP from Samsung.

Connecting ICFunction Open/

Closed

1/0

closed

Figure 14: The switch

The signal from the Hall IC is connected to the analog keyboard input (AuxDet) in the UEME,

as this also is an interrupt input. This allows the phone to wake up, by opening the phone.

Analog keyboard input is used due to interrupt possibilities and because the Hall IC requires a

minimum supply voltage of 2.7V.

The Hall solution requires a magnet, which is placed on top of Ha ll-IC, and is moved away from

the sensor with the moving mechanics, thus making a change of the magnetic field. The magnet has the dimensions 5x3x1 mm and is mounted in the top of the phone in the sliding part.

ISSUE 1 11/04 COMPANY CONFIDENTIAL 29

Copyright © 2004 Nokia. All Rights Reserved.

Page 30

RM-14

Nokia Customer Care 7 - System Module

■ LED driver

The general LED driver circuit looks as follows:

Figure 15: LED driver

Generel circuit description

The circuit is build around LM2795(NMP code: 4341425. This is a switched capacitor type step

up converter. It has 5 outputs. 4 of them are mirrored current sources (D1-D4), and the 5

the output from the chargepump(Pout).

th

is

Driving display and UI backlight

The mirrored current sources are used to drive the display backlight (D1-D3), and the backlight(D4) to the UI-module (rotator).

Driving RGB LED

The Pout output (from the chargepump) is fed to the RGB LED’s.

30 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 31

RM-14

7 - System Module Nokia Customer Care

RF Module Introduction

The RF module performs the necessary high frequency operations of the EGSM900/

GSM1800/GSM1900 tripleband (EDGE) engine in the RM-14 product.

Both the transmitter and receiver have been implemented by using direct conversion architecture, which means that the modulator and demodulator operate at the channel frequency.

The core of the RF is an application-specific integrated circuit, Helgo. Another core component

is a power amplifier module, which includes two amplifier chains, one for EGSM900 and the

other for GSM1800/GSM1900.

Other key components include:

• 26 MHz VCTCXO for frequency reference

• 3296-3980 MHz SHF VCO (super high frequency voltage controlled oscillator)

• front end module comprising a RX/TX switch and two RF bandpass SAW filters

• three additional SAW filters

The control information for the RF is coming from the baseband section of the engine through

a serial bus, referred later on as RFBus. This serial bus is used to pass the information about

the frequency band, mode of operation, and synthesizer channel for the RF.

In addition, exact timing information and receiver gain settings are transferred through the RFBus. Physically, the bus is located between the baseband ASIC called TIKU and Helgo.

The RF circuitry is located on both sides of the 8 layer PWB.

EMC leakage is prevented by using metal cans. The RF circuits are separated to four blocks:

− FM radio.

−PA, front end module and VCTCXO.

− Helgo RF IC, baluns and balanced filters.

− VCO

The baseband circuitry is located on both side of the board, which is shielded with a meallized

frame and ground plane of the UI-board.

ISSUE 1 11/04 COMPANY CONFIDENTIAL 31

Copyright © 2004 Nokia. All Rights Reserved.

Page 32

RM-14

Nokia Customer Care 7 - System Module

RF Frequency Plan

RF frequency plan is shown below. The VCO operates at the channe l frequen cy multiplie d b y

two or four depending on the frequency band of operation.

Figure 16: RF Frequency Plan

32 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 33

RM-14

7 - System Module Nokia Customer Care

Regulators

The transceiver baseband section has a multi function analog ASIC, UEM, which contains

among other functions six pieces of 2.78 V linear regulators and a 4.8 V switching regulator.

The seven regulators are named VR1 to VR7. VrefRF01 and VrefRF02 are used as the reference voltages for the Helgo, VrefRF01 (1.35V) for the bias reference and VrefRF02 (1.35V) for

the RX ADC (analog-to-digital converter) reference.

The regulators (except for VR7) are connected to the Helgo.

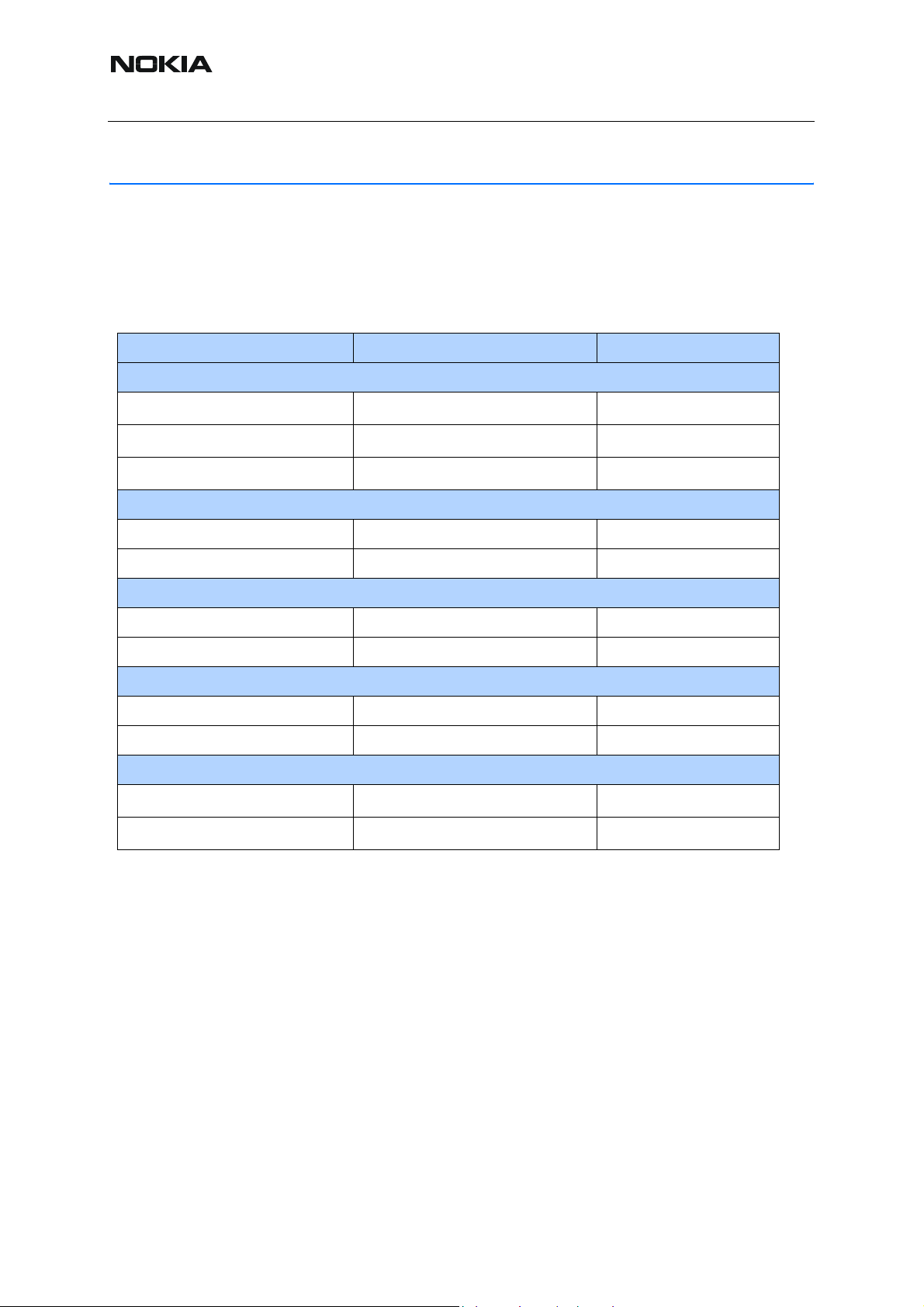

List of the needed supply voltages

Volt. Source Load

VR1 PLL charge pump (4.8 V)

VR2 TX modulators, VPECTRL3s (ALC), driver

VR3 VCTCXO, synthesizer digital parts

VR4 Helgo pre-amps, mixers, DtoS

VR5 dividers, LO-buffers, prescaler

VR6 LNAs, Helgo baseband (Vdd_bb)

VR7 VCO

VrefRF01 ref. Voltage for Helgo

VrefRF02 ref. Voltage for Helgo

Vbatt PA

Typical Current Consumption

The table below shows the typical current consumption in different operation modes.

Operation mode Current consumption Notes

Power OFF < 10 uA

RX, EGSM900 75 mA, peak

RX, GSM1800/

GSM1900

ISSUE 1 11/04 COMPANY CONFIDENTIAL 33

70 mA, peak

Copyright © 2004 Nokia. All Rights Reserved.

Page 34

RM-14

Nokia Customer Care 7 - System Module

TX, power level 5,

EGSM900

TX, power level 0,

GSM1800/GSM1900

1700 mA, peak

1000 mA, peak

34 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 35

RM-14

7 - System Module Nokia Customer Care

Power Distribution

Power Distribution Diagram

Figure 17:Power distribution diagram

ISSUE 1 11/04 COMPANY CONFIDENTIAL 35

Copyright © 2004 Nokia. All Rights Reserved.

Page 36

RM-14

Nokia Customer Care 7 - System Module

RF Characteristics

Main RF Characteristics

Parameter Unit and value

Cellular system EGSM900/GSM1800/GSM1900

RX Frequency range EGSM900: 925 ... 960 MHz

GSM1800: 1805...1880 MHz

GSM1900: 1930...1990 MHz

TX Frequency range EGSM900: 880 ... 915 MHz

GSM1800: 1710 ...1785 MHz

GSM1900: 1850 …1910 MHz

Duplex spacing EGSM900: 45 MHz

GSM1800: 95 MHz

GSM1900: 80 MHz

Channel spacing 200 kHz

Number of RF channels EGSM900: 174

GSM1800: 374

GSM1900: 300

Output Power EGSM900: GSMK 5…33 dBm

EGSM900: 8-PSK 5…27 dBm

GSM1800: GSMK 0…30 dBm

GSM1800: 8-PSK 0…26 dBm

GSM1900: GSMK 0…30 dBm

GSM1900: 8-PSK 0…26 dBm

Number of power levels GMSK EGSM900: 15

GSM1800: 16

GSM1900: 16

Number of power levels 8-PSK EGSM900: 12

GSM1800: 14

GSM1900: 14

Transmitter Characteristics

Item Values (EGSM900/1800/1900)

Type Direct conversion, nonlinear, FDMA/TDMA

LO frequency range EGSM900: 3520...3660 MHz (4 x TX freq)

GSM1800: 3420...3570 MHz (2 x TX freq)

GSM1900: 3700...3820 MHz (2 x TX freq)

36 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 37

RM-14

7 - System Module Nokia Customer Care

Output power

(EGSM900/GSM1800/GSM1900)

Receiver Characteristics

Item Values, EGSM900/1800/1900

Type Direct conversion, Linear, FDMA/TDMA

LO frequencies EGSM900: 3700...3840 MHz (4 x RX freq)

Typical 3 dB bandwidth +/- 91 kHz

Sensitivity min. - 102 dBm (normal condition)

Receiver output level (RF level -95 dBm) 230 mVpp, single-ended I/Q signals to RX

GMSK 33/30/30 dBm

8-PSK 27/26/26 dBm

GSM1800: 3610...3760 MHz (2 x RX freq)

GSM1900: 3860...3980 MHz (2 x RX freq)

ADCs

ISSUE 1 11/04 COMPANY CONFIDENTIAL 37

Copyright © 2004 Nokia. All Rights Reserved.

Page 38

RM-14

Nokia Customer Care 7 - System Module

RF Block Diagram

The block diagram of the RF module can be seen in Figure 15. The detailed funct ional description is given in the following sections.

Figure 18: RF Block Diagram

Helgo

38 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 39

RM-14

7 - System Module Nokia Customer Care

Frequency Synthesizers

The VCO frequency is locked by a PLL (phase locked loop) into a stable frequency source given by a VCTCXO, which is running at 26 MHz.

The frequency synthesizer is integrated in Helgo except for the VCTCXO, VCO, and the loop

filter.

■ Receiver

Each receiver path is a direct conversion linear receiver. From the antenna the received RFsignal is fed to a front-end module where a diplexer first divides the signal to two separate p aths

according to the band of operation: either lower, EGSM900 or upper, GSM1800/GSM1900

path.

Most of the receiver circuitry is included in Helgo.

■ Transmittter

The transmitter consists of two final frequency IQ-modulators and power amplifiers, for the lower and upper bands separately, and a power control loop. The IQ-modulators are integrated in

Helgo, as well as the operational amplifiers of the power control loop. The two power amp lifiers

are located in a single module with power detector.

■ Front end

The front end features include:

- Antenna 50 ohm input

- RX EGSM900 balanced output

- RX GSM1800 balanced output

- RX GSM1900 single ended output

- TX GSM900 single ended 50 ohm input

- TX GSM1800/GSM1900 single ended 50 ohm input

- 3 control lines from the Helgo

ISSUE 1 11/04 COMPANY CONFIDENTIAL 39

Copyright © 2004 Nokia. All Rights Reserved.

Page 40

RM-14

Nokia Customer Care 7 - System Module

Figure 19: Front end

■ Power amplifier

The power amplifier features include:

50 ohm input and output, EGSM900 and GSM1800/GSM1900

Internal power detector

GMSK and EDGE mode

Figure 20: Power Amplifier

40 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Page 41

RM-14

7 - System Module Nokia Customer Care

■ RF ASIC Helgo

The RF ASIC features include

Balanced I/Q demodulator and balanced I/Q modulator

Power control operational amplifier, acts as an error amplifier

The signal from VCO is balanced, frequencies 3296 to 3980 MHz

Low noise amplifiers (LNAs) for EGSM900 and GSM1800 are integrated.

The Helgo can be tested by test points only.

■ AFC function

AFC is used to lock the transceiver’s clock to the frequency of the base station.

ISSUE 1 11/04 COMPANY CONFIDENTIAL 41

Copyright © 2004 Nokia. All Rights Reserved.

Page 42

RM-14

Nokia Customer Care 7 - System Module

[This page left intentionally blank]

42 COMPANY CONFIDENTIAL ISSUE 1 11/04

Copyright © 2004 Nokia. All Rights Reserved.

Loading...

Loading...