Page 1

Customer Care Solutions

Technical Documentation

SERVICE MANUAL

[NMP Part No. 0275864]

Model 6585

(RH-34 Series) Cellular Phones

Issue 1 Copyright © 2003 Nokia Corporation. All Rights Reserved

Page 2

Customer Care Solutions

Technical Documentation

Amendment Record Sheet

Amendment No Date Inserted By Comments

11/2003 J Fraser Issue 1

Issue 1 Copyright © 2003 Nokia Corporation. All Rights Reserved

Page 3

Customer Care Solutions

Technical Documentation

RH-34 (6585) Cellular Phones

Service Manual – Overall Manual Contents

Service Manual comprising

RH-34 Series Transceiver booklet comprising

Foreword

General

Parts

Service Software Instructions

Service Tools

Disassembly/Assembly

Troubleshooting - Antennas

Troubleshooting - Baseband

Troubleshooting - FM Radio

Troubleshooting - GPS

Troubleshooting - RF (Part 1 and Part 2)

System Module

Schematics

Issue 1 Copyright © 2003 Nokia Corporation. All Rights Reserved

Page 4

This document is intended for use by qualified service personnel only.

Company Policy

Our policy is of continuous development; details of all technical modifications will be

included with service bulletins.

While every endeavour has been made to ensure the accuracy of this document, some

errors may exist. If any errors are found by the reader, NOKIA Corporation should be

notified in writing.

Please state:

Customer Care Solutions

Technical Documentation

IMPORTANT

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

Please send to: Nokia Corporation

CCS Technical Documentation

PO Box 86

FIN-24101 SALO

Finland

Issue 1 Copyright © 2003 Nokia Corporation. All Rights Reserved

Page 5

Customer Care Solutions

Technical Documentation

Warnings and Cautions

Please refer to the phone's user guide for instructions relating to operation, care and

maintenance including important safety information. Note also the following:

Warnings:

1. CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH

ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING

SYSTEMS. UNDER CERTAIN FAULT CONDITIONS, EMITTED RF ENERGY CAN

AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/

MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC

SYSTEMS TO RF ENERGY.

2. THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY

TO CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES EG PETROL STATIONS

(SERVICE STATIONS), BLASTING AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and that an

3. Ensure solder, wire, or foreign matter does not enter the telephone as

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are correctly

CELLULAR TELEPHONES, MAY INTERFERE WITH THE FUNCTIONALITY OF

INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR

THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY

QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO

INTERFERENCE.

anti-static wrist strap is worn.

damage may result.

re-fitted after servicing and alignment. Ensure all cables and wires are

repositioned correctly.

Issue 1 Copyright © 2003 Nokia Corporation. All Rights Reserved

Page 6

CCS Technical Documentation

RH-34 Series Transceivers

General Information

Issue 1 11/2003 Confidential ©2003 Nokia Corporation

Page 7

RH-34

General Information CCS Technical Documentation

Contents

Page No

Handportables ................................................................................................................ 3

Sales Package ...............................................................................................................4

Module List ..................................................................................................................4

Technical Specifications ..............................................................................................4

General Specifications of Transceiver RH-34 .......................................................... 4

Supported Accessories .............................................................................................. 5

Page 2 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 8

RH-34

CCS Technical Documentation General Information

Handportables

The Nokia 6585 (RH-34) offers a CDMA trimode (1900/800 MHz CDMA plus 800 AMPS

engine supporting 1XRTT. The RH-27 features an integrated FM radio, high-speed data

support, IR support, and RUIM.

RH-34 contains a 128 x 128 color display and has changeable display fonts. There is an

internal antenna, GPS (E-911) support, MIDI ringing tones, and an internal vibra.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 3

Page 9

RH-34

General Information CCS Technical Documentation

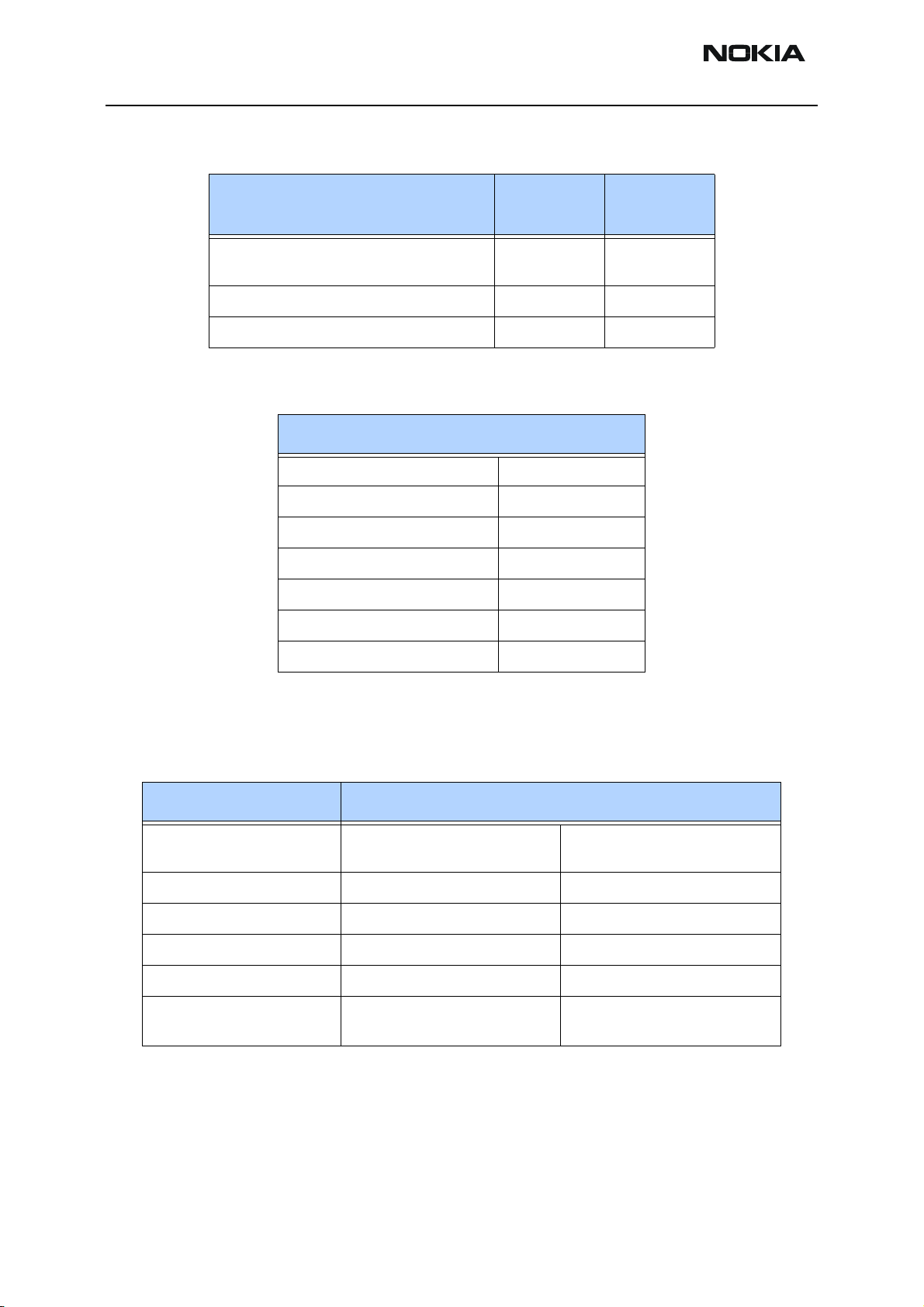

Sales Package

Module List

Name

Transceiver RH-34 Customer-

Battery (780 mAh Li-Ion) BLD-3 0670352

Rapid Performance Charger (US plug) ACP-12U 0675303

Type

Code

Material

Code

speciic

RH-34 (Nokia 6585)

A-cover assy 9458989

Keymat 9792498

Screws 6290107

Display 9517289

PWB assy 0202094

C-cover module 9491335

Battery 0670352

Technical Specifications

General Specifications of Transceiver RH-34

Parameter Specifications

Cellular system CDMA/AMPS, IS-19C, IS-98

IS-2000

TX frequency band 824.04 ... 848.97 MHz 1850 ... 1910 MHz

RX frequency band 869.04 ... 893.91 MHz 1930 ... 1990 MHz

Number of RF channels 832 1200

Channel spacing 30 kHz 50 kHz

Power levels -50dBm to +25dBm CDMA,

+8dBm to +26dBm AMPS

PCS J-STD-018, J-STD-008,

IS2000

-50dBm to +23dBm

Page 4 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 10

RH-34

CCS Technical Documentation General Information

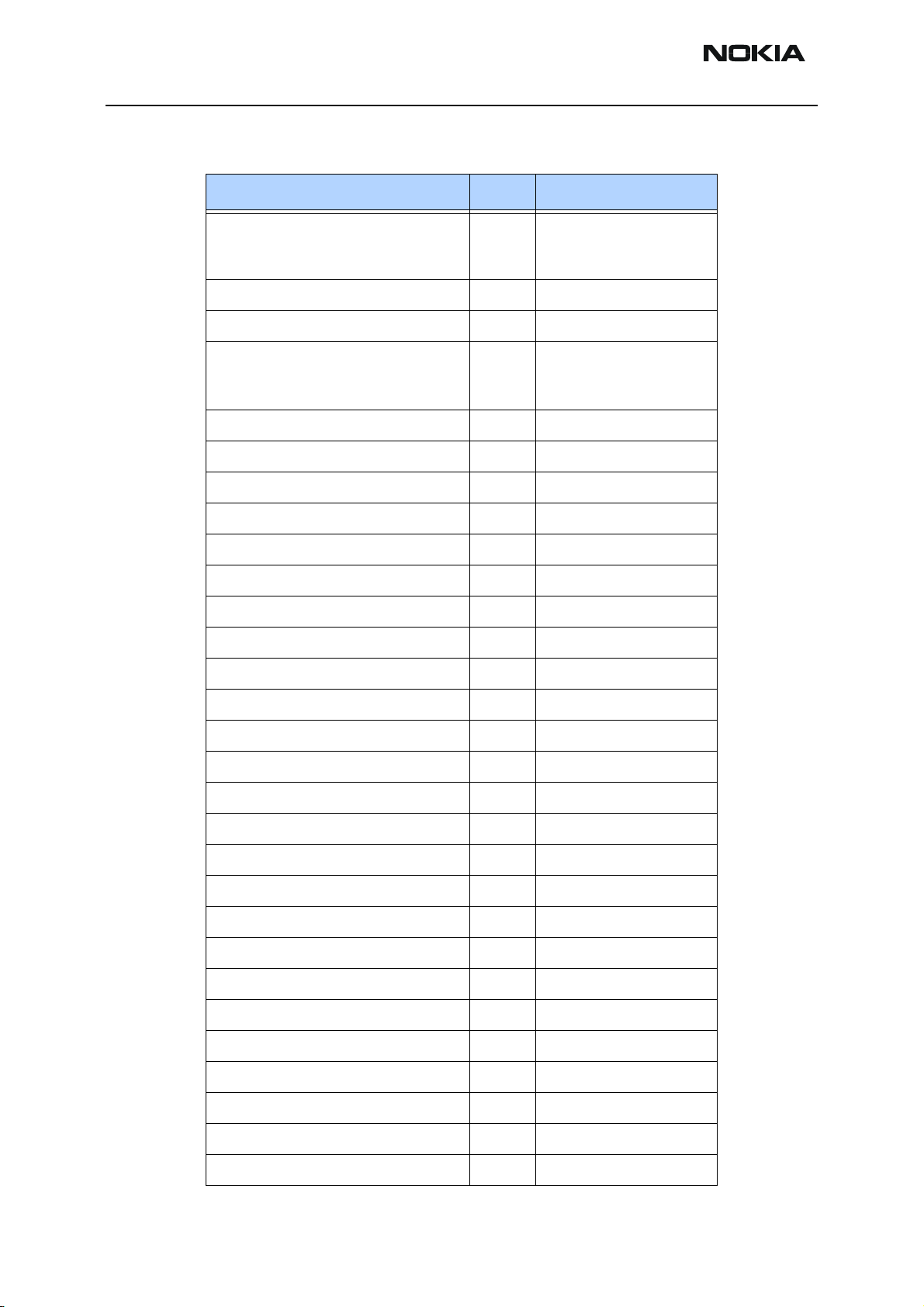

Parameter Mode Value and unit

Talk time Analog up to 50min.

Talk time Digital up to 2.4 hours

Standby time Analog up to 20 hours

Standby time Digital up to 10 days

Dimensions:

length

width

Weight 86.7 g - 3.1 ounces

105.8 mm - 4.17 inches

44.8 mm - 1.77 inches

Supported Accessories

Type Name Code

BLD-3 Standard 780 mAh Li-ion Battery 0670352

ACP-7U AC Travel Charger (US) 108-132 Vac 0675143

ACP-8U AC Charger 0675196

ACP-12U Rapid Performance Charger (US) 0675303

DDC-1 Spare Battery Charger 0675243

DCV-15 Desk stand with one-button synchronization 0675326

CARK-143 Advanced car kit 0080686

BHF-1 Headrest handsfree 0273278

LPS-4 Loopset 0630443

LCH-12 Cigarette Lighter Charger 0675328

HDB-4 Boom Headset 0694094

HS-5 Earbud Headset 0694121

HDS-3 FM Stereo Headset 0694093

HS-3 Fashion Stereo Headset 0694156

HS-10 Retractable Headset 0694126

DKU-5 USB cable 0273870

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 5

Page 11

RH-34

General Information CCS Technical Documentation

Page 6 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 12

CCS Technical Documentation

RH-34 Series Transceivers

Parts Lists

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation

Page 13

RH-34

Parts Lists CCS Technical Documentation

Contents

Page No

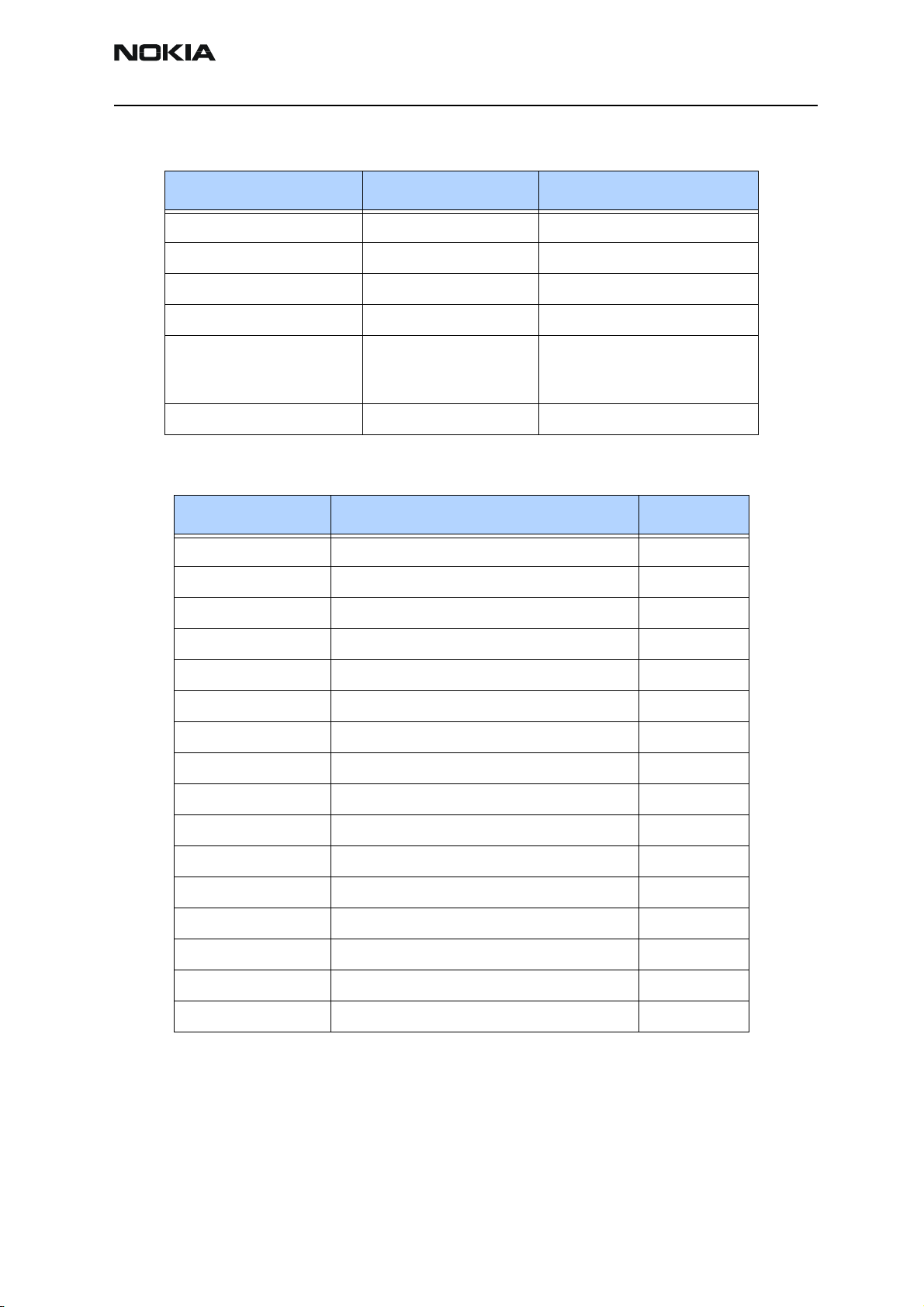

Exploded View............................................................................................................... 3

Assembly Parts of Basic Transceiver RH-34 ..............................................................4

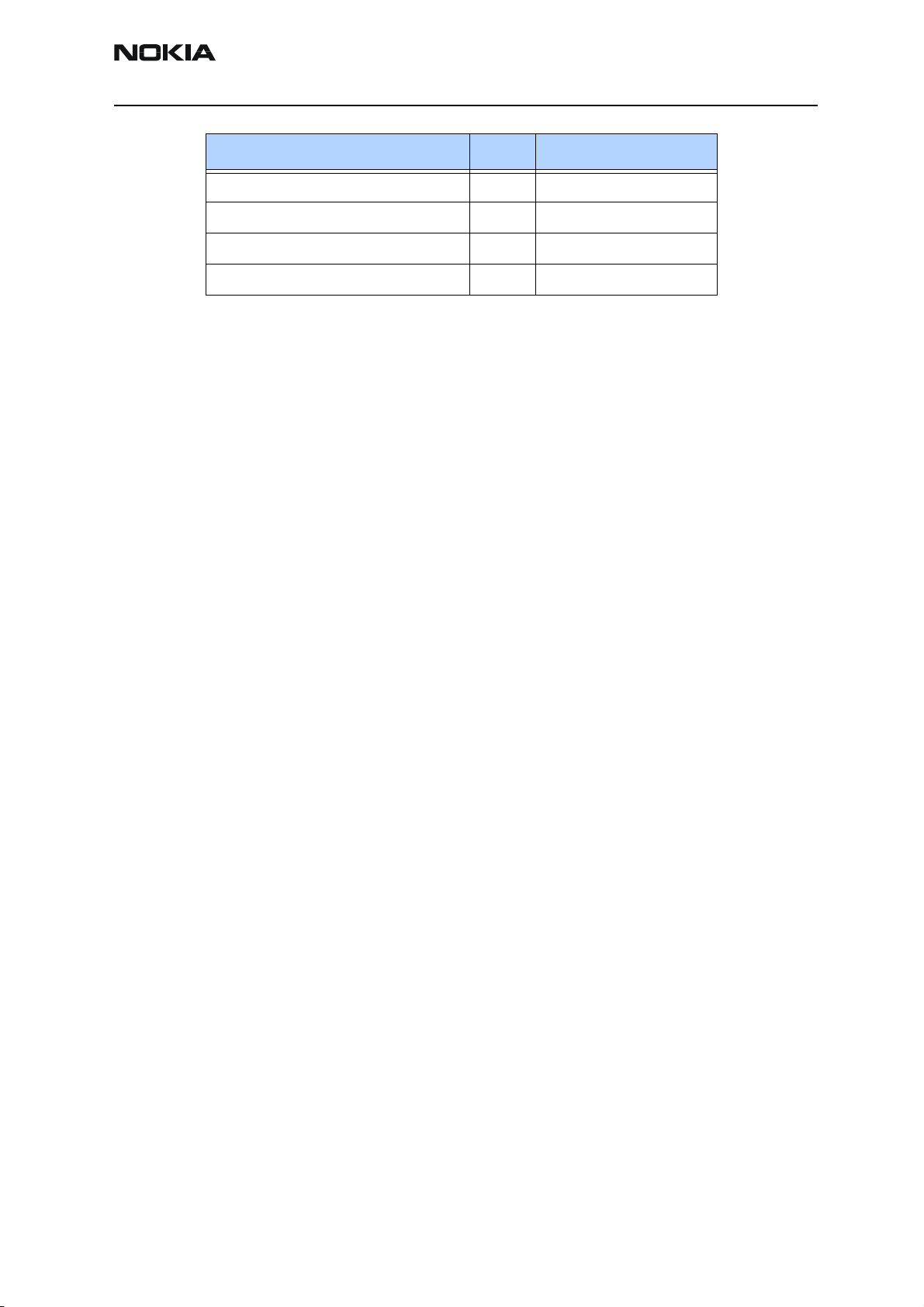

Component Layout — Top ..........................................................................................6

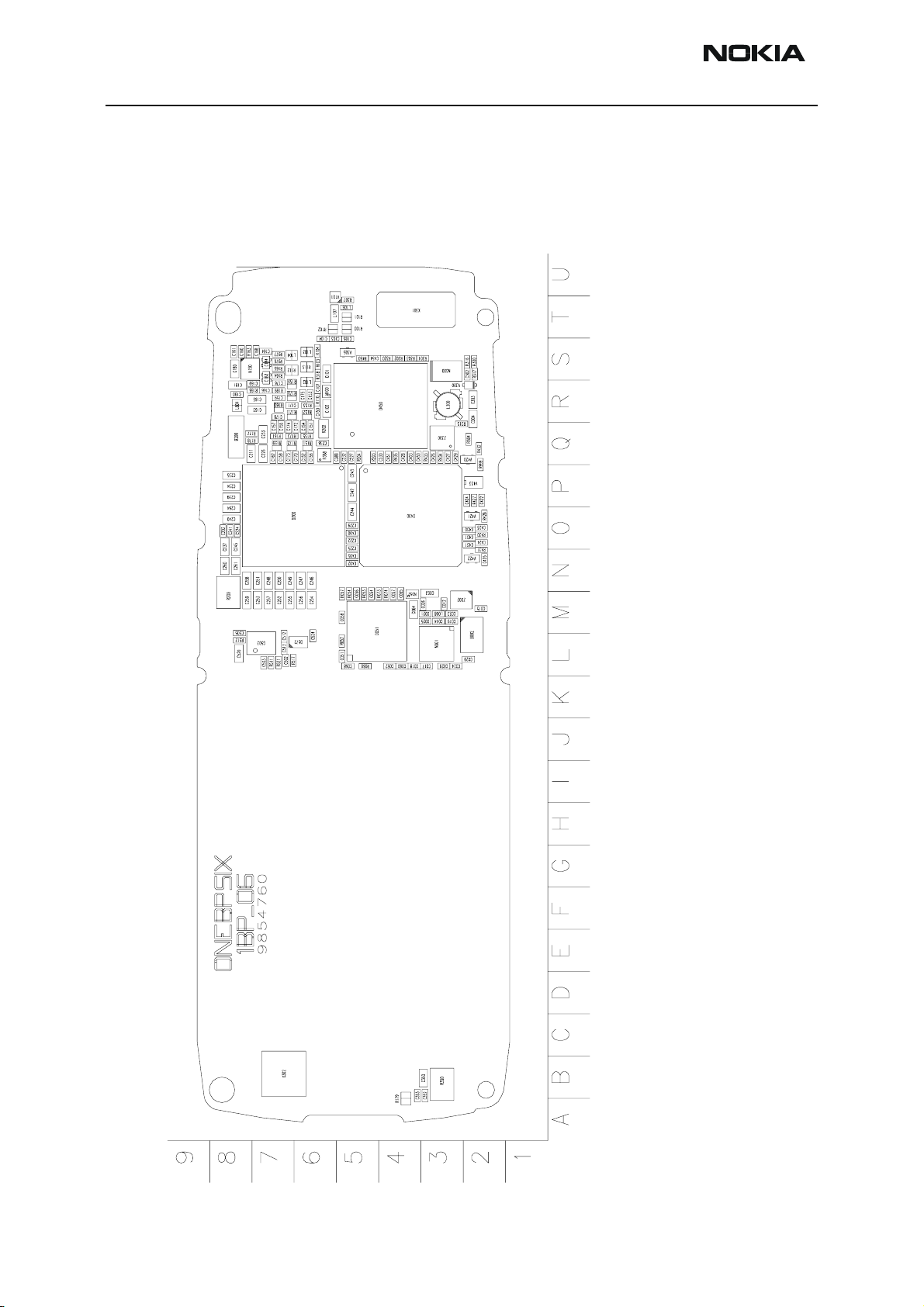

Component Layout — Bottom ....................................................................................7

Component Values — Top .........................................................................................8

Component Values — Bottom .....................................................................................9

Parts List ...................................................................................................................... 10

RH-34 (6585) — EDMS Issue 9.4 Code: 0202124 ...................................................10

Page 2 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 14

RH-34

CCS Technical Documentation Parts Lists

Exploded View

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 3

Page 15

RH-34

Parts Lists CCS Technical Documentation

Assembly Parts of Basic Transceiver RH-34

Item Qty Code

Window 1 9459246

9459247

9459248

Acoustic Fabric 1 9481098

A-Cover Blank 1 9453332

Keymat Assy 1 9791255

9791244

9791245

Screws 6 6290107

Display Shield Assy 1 9517370

UI PWB Assy (domesheet included) 1 0202222

LCD Frame plated 1 9467121

Speaker foam gasket 1 9481158

Microphone 1 5140263

LCD 1 4850291

Baseband shield assembly 1 9517329

Main engine 1 0202094

Volume key 1 9453377

Power key 1 9453133

IR window 1 9453137

Universal headset jack 1 5469801

IHF lid 1 9460573

IHF pins 2 9560164

DC jack 1 5400243

Vibra 1 6800057

Release button 1 9452502

Release spring 1 9511021

C-Cover blank 1 9453143

IHF speaker damper 1 9480909

IHF speaker 1 5140253

Pogo pins 2 5400319

IHF speaker gasket 1 9481118

GPS radiator 1 9560309

Page 4 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 16

RH-34

CCS Technical Documentation Parts Lists

Item Qty Code

Antenna Assy 1 0660301

Battery (BLD-3) 1 0670352

Logo badge 1 9430474

B-Cover 1 9453142

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 5

Page 17

RH-34

Parts Lists CCS Technical Documentation

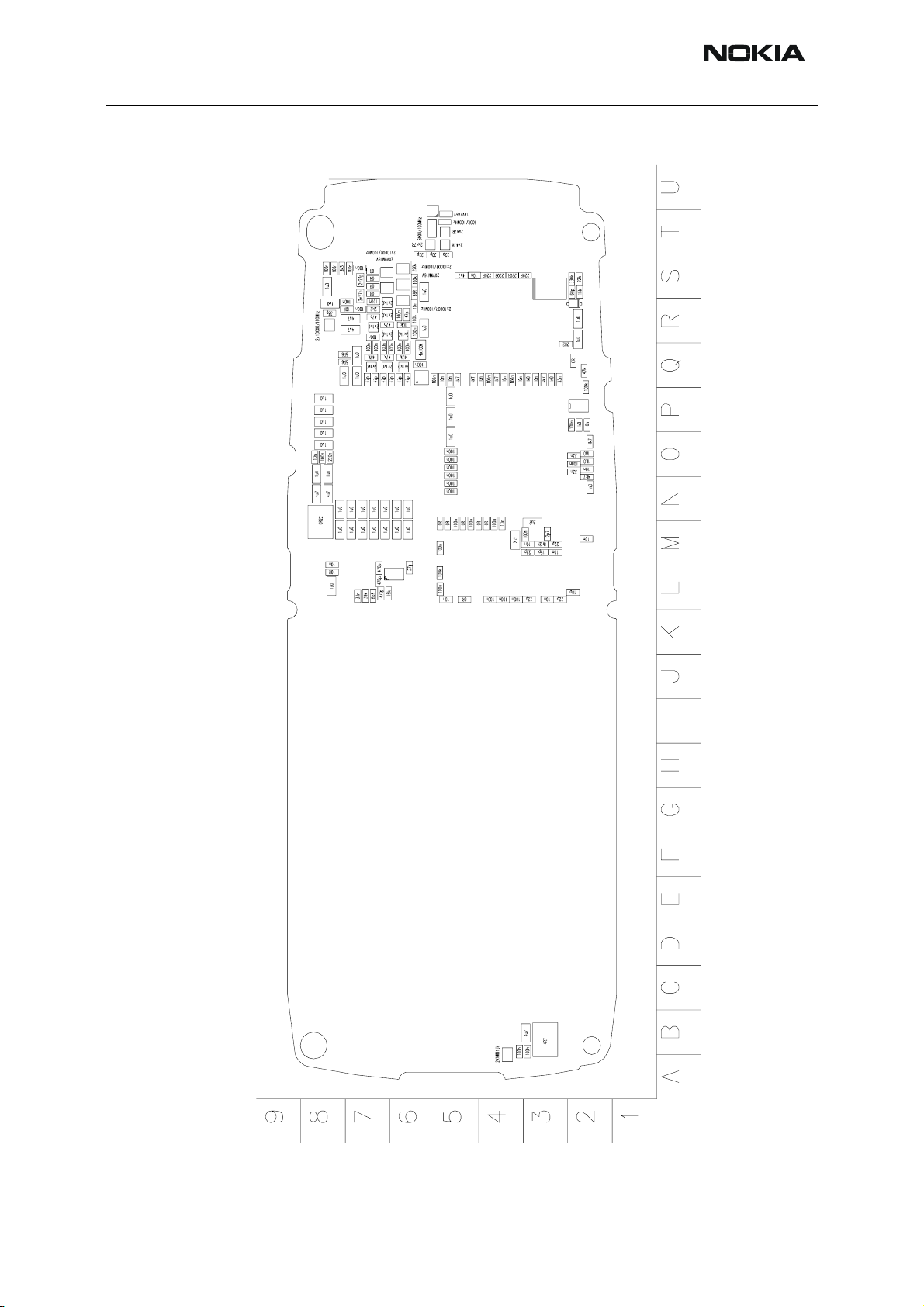

Component Layout — Top

Page 6 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 18

RH-34

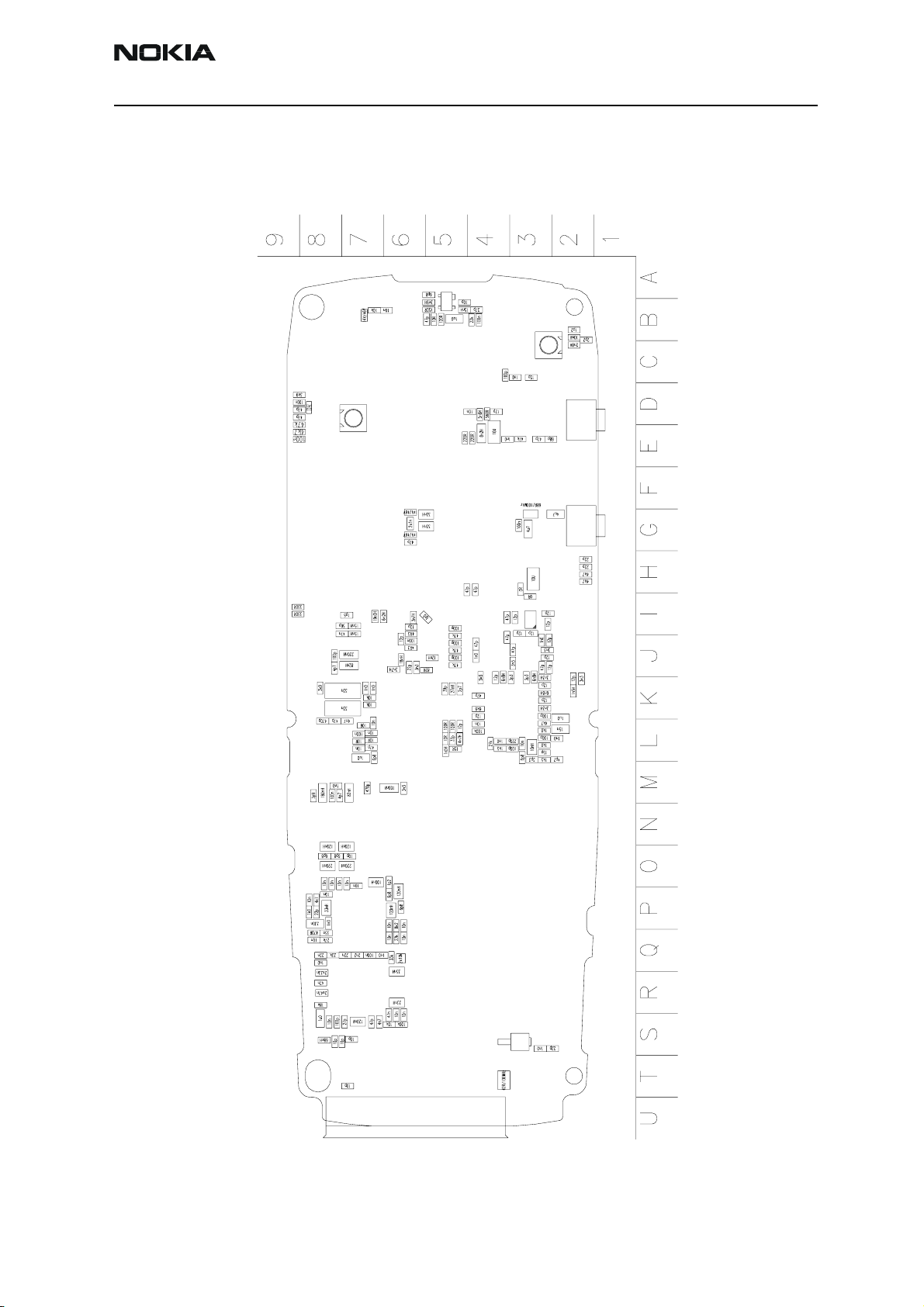

CCS Technical Documentation Parts Lists

Component Layout — Bottom

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 7

Page 19

RH-34

Parts Lists CCS Technical Documentation

Component Values — Top

Page 8 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 20

RH-34

CCS Technical Documentation Parts Lists

Component Values — Bottom

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 9

Page 21

RH-34

Parts Lists CCS Technical Documentation

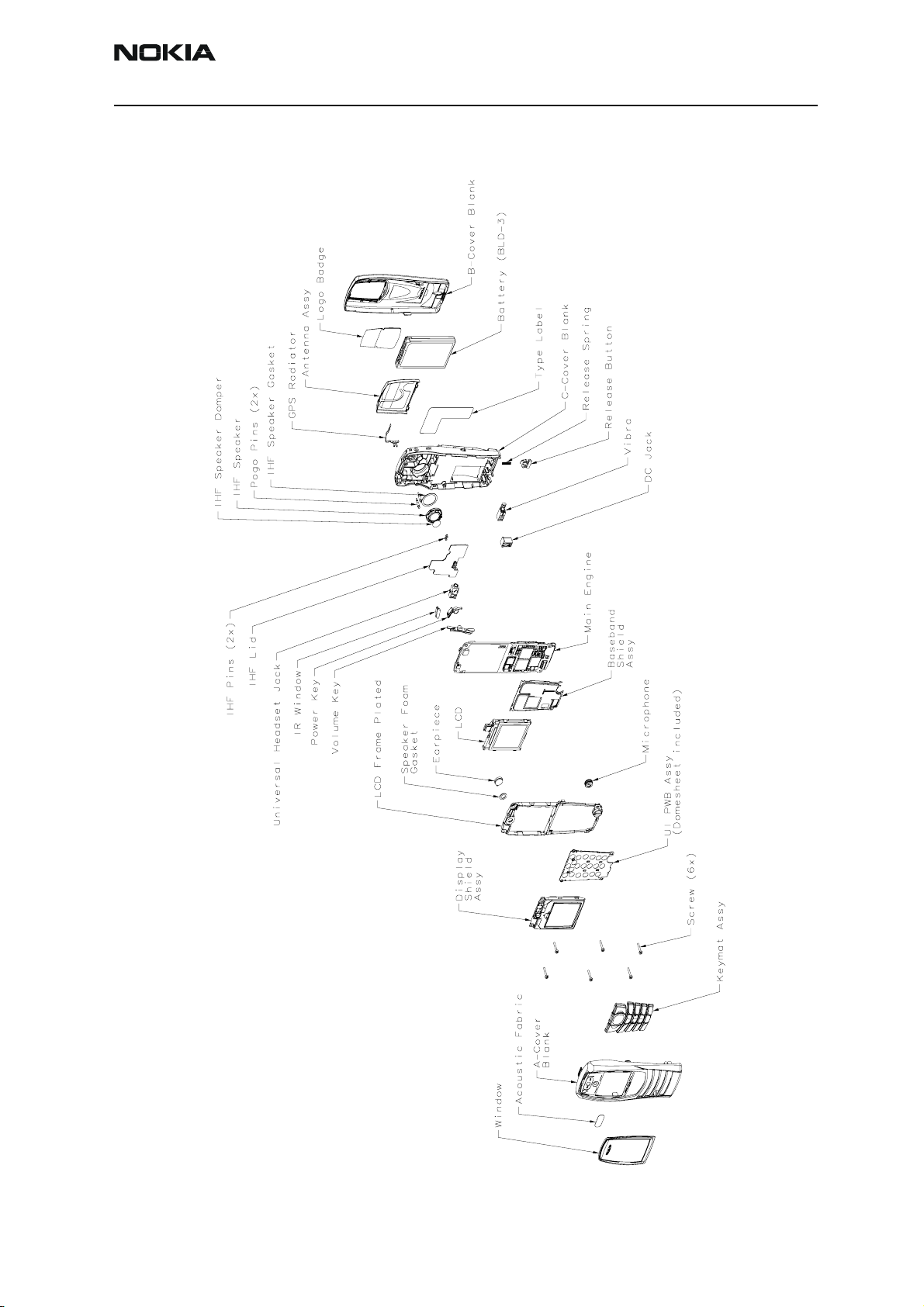

Parts List

RH-34 (6585) — EDMS Issue 9.4 Code: 0202124

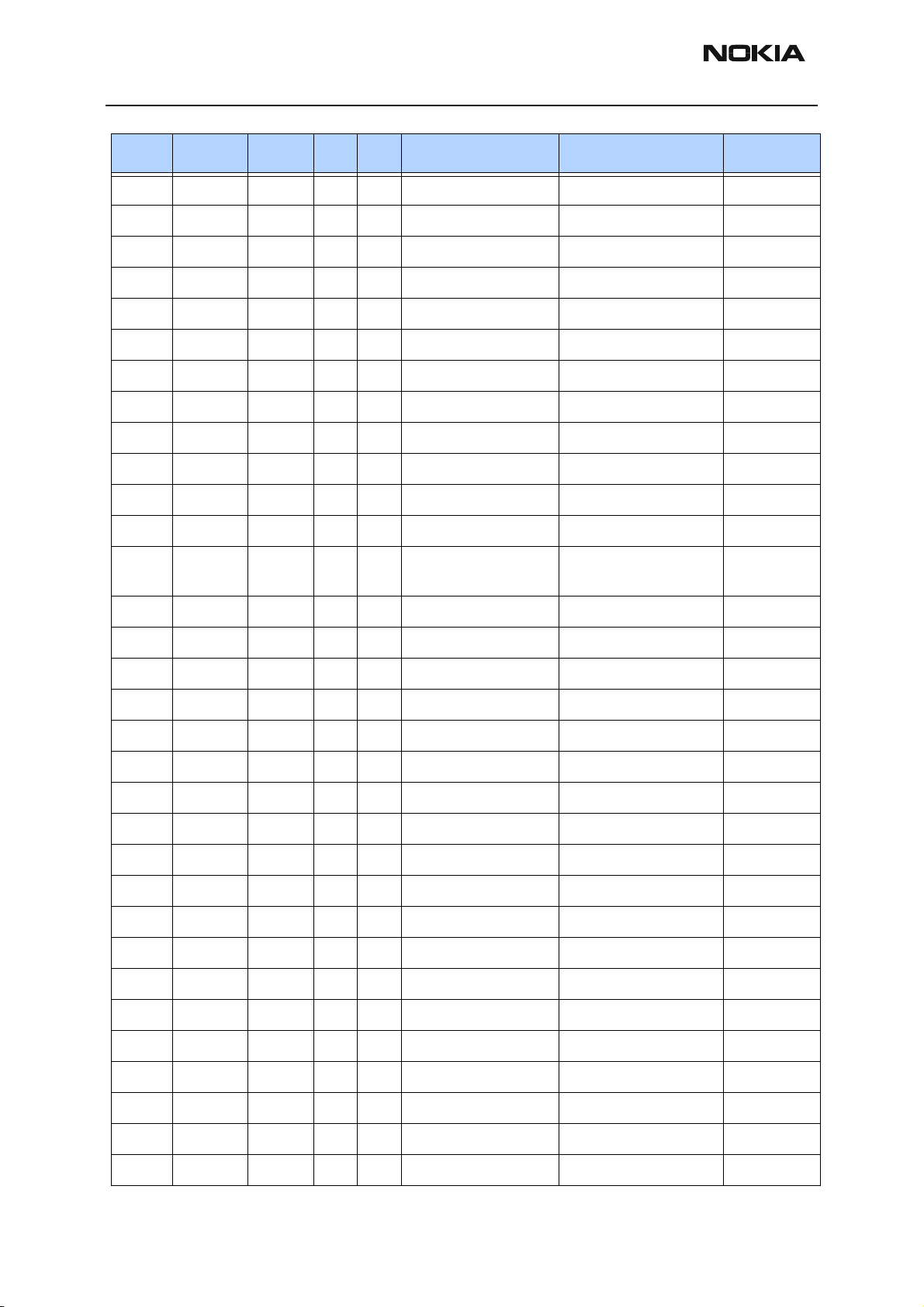

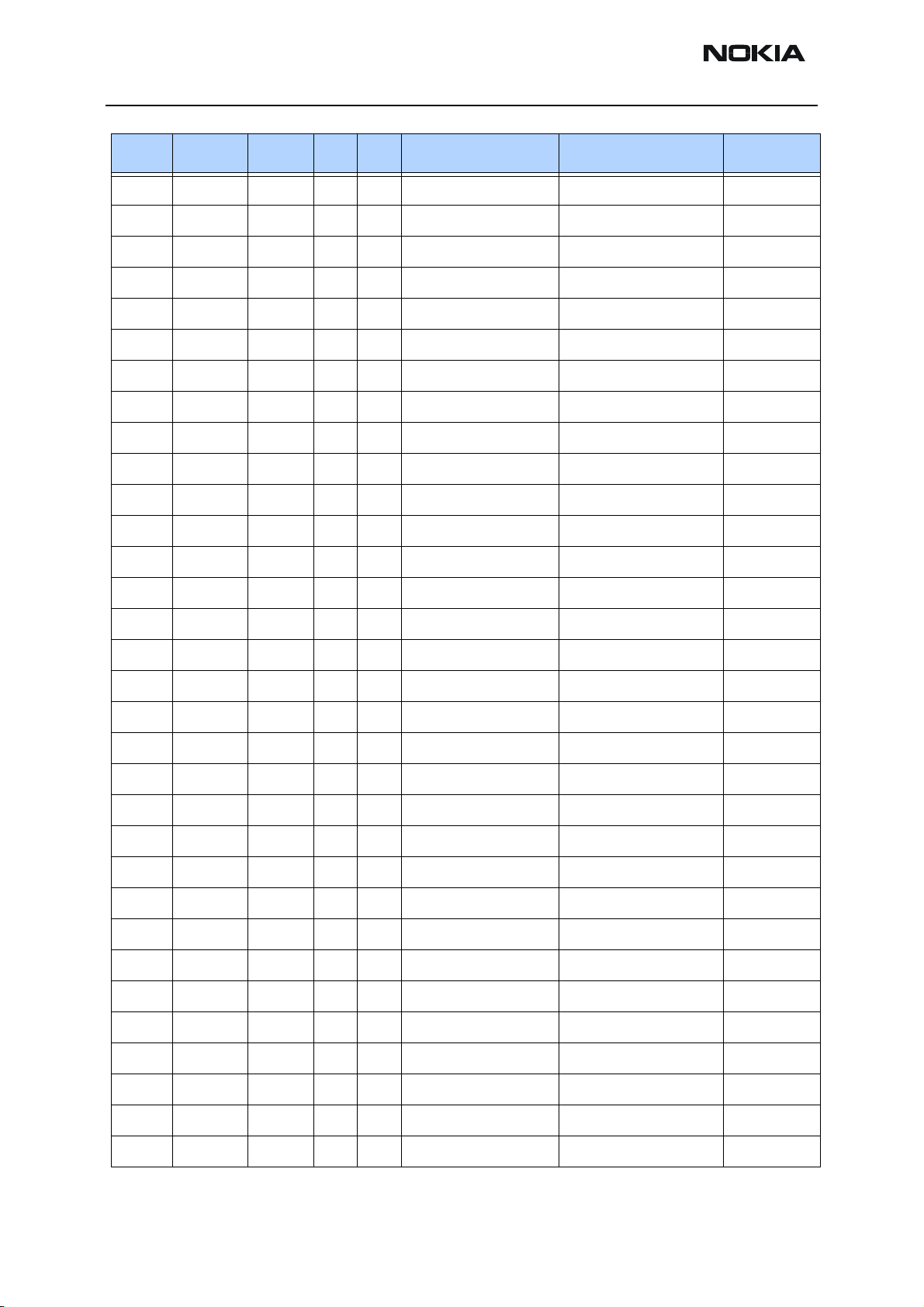

Item Code Side X Y Description Value Type

R001 1430788 Bottom B 4 chip res 0W06 22K J 0402

R002 1430728 Bottom B 5 chip res 0W06 120R J 0402

R003 1430700 Bottom B 5 chip res 0W06 10R J 0402

R004 1430730 Bottom B 5 chip res 0W06 150R J 0402

R052 1430804 Top L 5 chip res 0W06 100K J 0402

R053 1430690 Top M 5 chip res jumper 0R0 0402

R054 1430690 Top M 5 chip res jumper 0R0 0402

R057 1430690 Top M 5 chip res jumper 0R0 0402

R060 1430690 Top L 5 chip res jumper 0R0 0402

R073 1430690 Top M 5 chip res jumper 0R0 0402

R074 1430690 Top M 4 chip res jumper 0R0 0402

R100 1620027 Top T 5 res network 0W06 2X47R J 0404

R101 1620027 Top T 5 res network 0W06 2X47R J 0404

R102 1620027 Top T 6 res network 0W06 2X47R J 0404

R103 1430804 Top S 6 chip res 0W06 100K J 0402

R104 1430812 Top S 6 chip res 0W06 220K J 0402

R110 1430804 Top R 6 chip res 0W06 100K J 0402

R112 1825031 Top S 7 varistor array 2XVWM16V VC50 0405

R113 1825031 Top S 6 varistor array 2XVWM16V VC50 0405

R150 1620031 Top R 7 res network 0W06 2X1K0 J 0404

R151 1620031 Top Q 6 res network 0W06 2X1K0 J 0404

R152 1620031 Top R 6 res network 0W06 2X1K0 J 0404

R153 1430778 Top R 6 chip res 0W06 10K J 0402

R155 1430796 Top Q 6 chip res 0W06 47K J 0402

R159 1620031 Top Q 7 res network 0W06 2X1K0 J 0404

R160 1620031 Top R 7 res network 0W06 2X1K0 J 0404

R161 1430796 Top Q 7 chip res 0W06 47K J 0402

R162 1430766 Bottom D 9 chip res 0W06 3K9 J 0402

R163 1430764 Top S 8 chip res 0W06 3K3 J 0402

Page 10 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 22

RH-34

CCS Technical Documentation Parts Lists

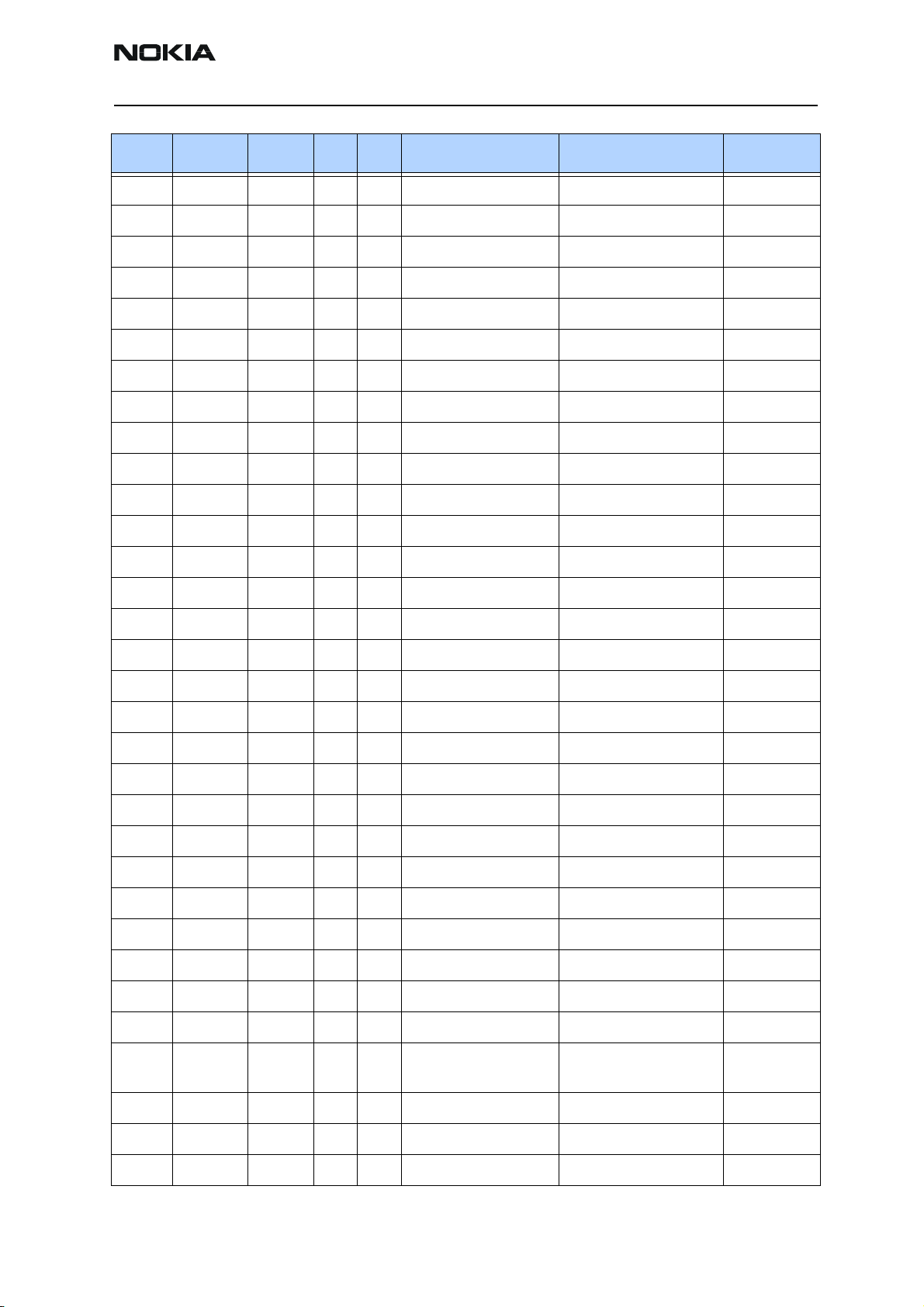

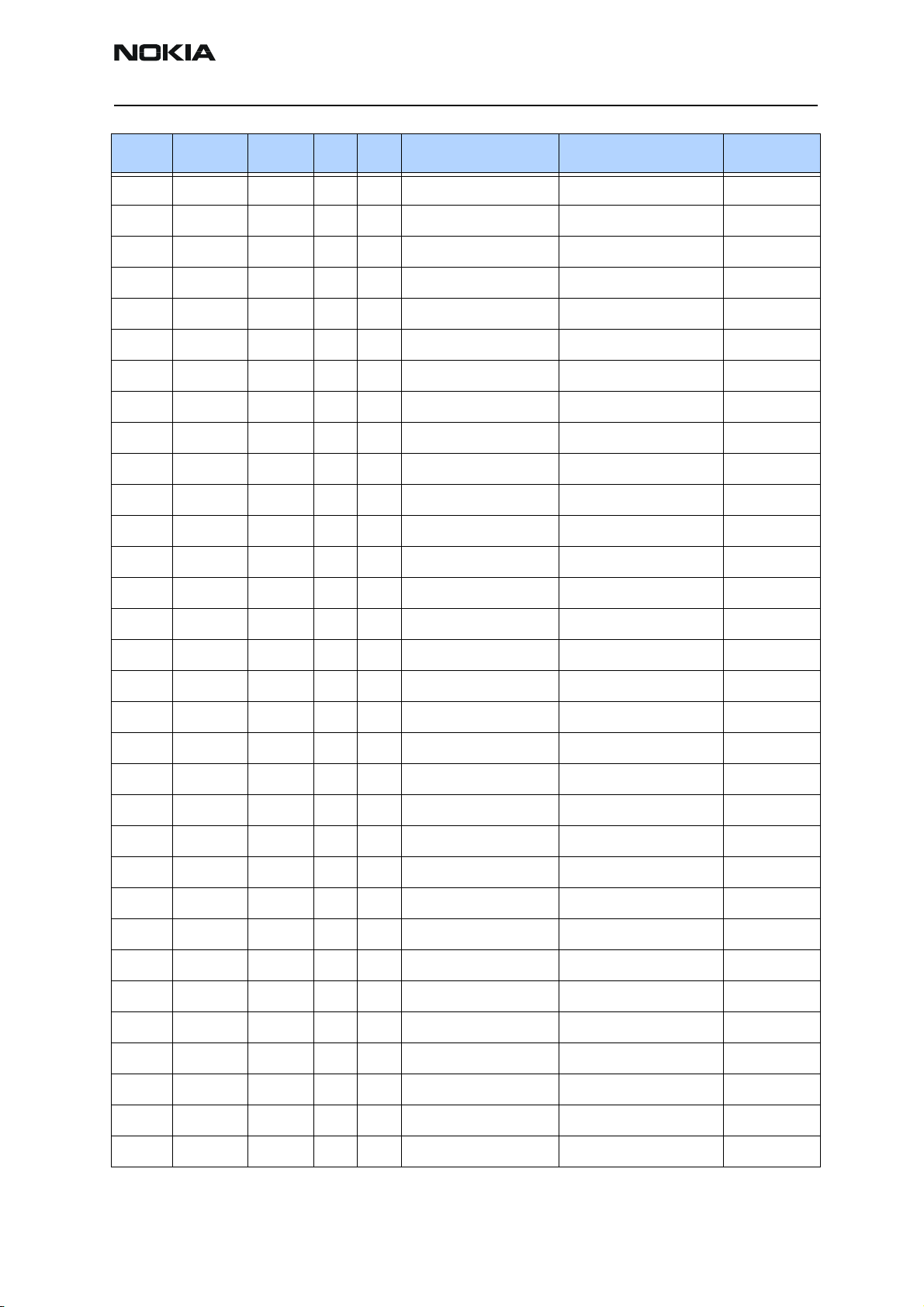

Item Code Side X Y Description Value Type

R164 1430700 Top S 7 chip res 0W06 10R J 0402

R165 1430700 Top S 7 chip res 0W06 10R J 0402

R166 1430700 Top R 7 chip res 0W06 10R J 0402

R169 1430762 Top R 7 chip res 0W06 2K2 J 0402

R170 1620031 Top R 7 res network 0W06 2X1K0 J 0404

R171 1620031 Top R 7 res network 0W06 2X1K0 J 0404

R172 1620031 Top Q 7 res network 0W06 2X1K0 J 0404

R173 1430875 Top Q 7 chip res 0W06 47K D 50PPM 0402

R177 1430693 Top Q 8 chip res 0W06 5R6 J 0402

R178 1430693 Top Q 8 chip res 0W06 5R6 J 0402

R179 1825031 Top A 4 varistor array 2XVWM16V VC50 0405

R180 1825033 Bottom G 6 chip varistor VWM14V VC46V 0402

R181 1825033 Bottom G 6 chip varistor VWM14V VC46V 0402

R183 1430770 Bottom E 9 chip res 0W06 4K7 J 0402

R185 1430690 Bottom D 8 chip res jumper 0R0 0402

R200 1419003 Top M 8 chip res 0W5 0R22 J 200PPM 1210

R202 1620043 Top Q 6 res network 0W03 4X100K J 0804

R203 1430770 Top Q 5 chip res 0W06 4K7 J 0402

R204 1430770 Top Q 5 chip res 0W06 4K7 J 0402

R220 1430690 Bottom I 3 chip res jumper 0R0 0402

R222 1430690 Bottom H 3 chip res jumper 0R0 0402

R300 1430788 Top S 2 chip res 0W06 22K J 0402

R301 1430742 Top S 3 chip res 0W06 390R J 0402

R302 1430742 Top S 4 chip res 0W06 390R J 0402

R304 1430690 Top Q 2 chip res jumper 0R0 0402

R306 1430770 Bottom B 7 chip res 0W06 4K7 J 0402

R307 1825033 Top T 5 chip varistor VWM14V VC46V 0402

R309 1430740 Bottom I 9 chip res 0W06 330R J 0402

R310 1825033 Bottom B 7 chip varistor VWM14V VC46V 0402

R311 1430770 Bottom H 2 chip res 0W06 4K7 J 0402

R312 1430770 Bottom H 2 chip res 0W06 4K7 J 0402

R315 1430691 Top Q 3 chip res 0W06 2R2 J 0402

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 11

Page 23

RH-34

Parts Lists CCS Technical Documentation

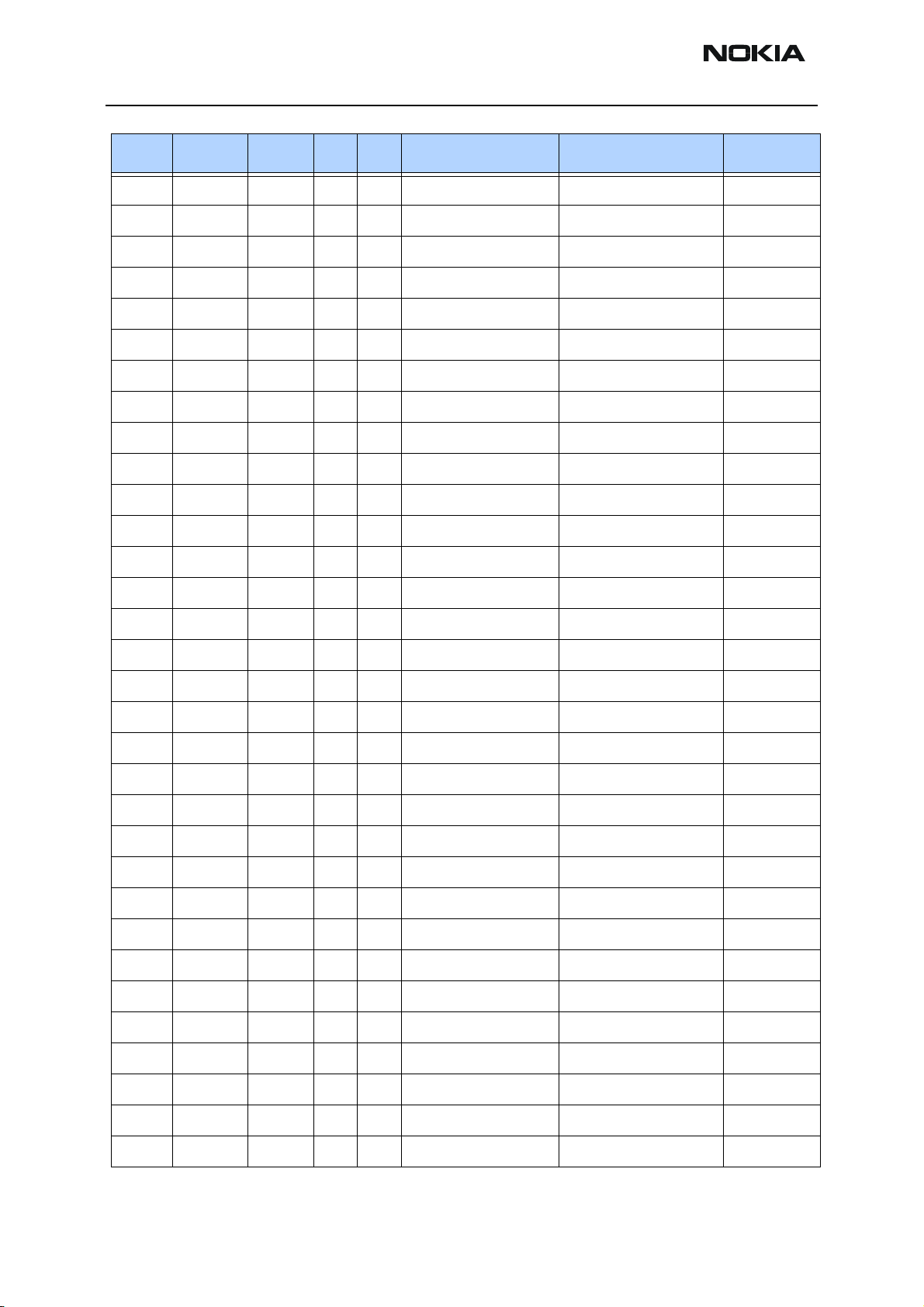

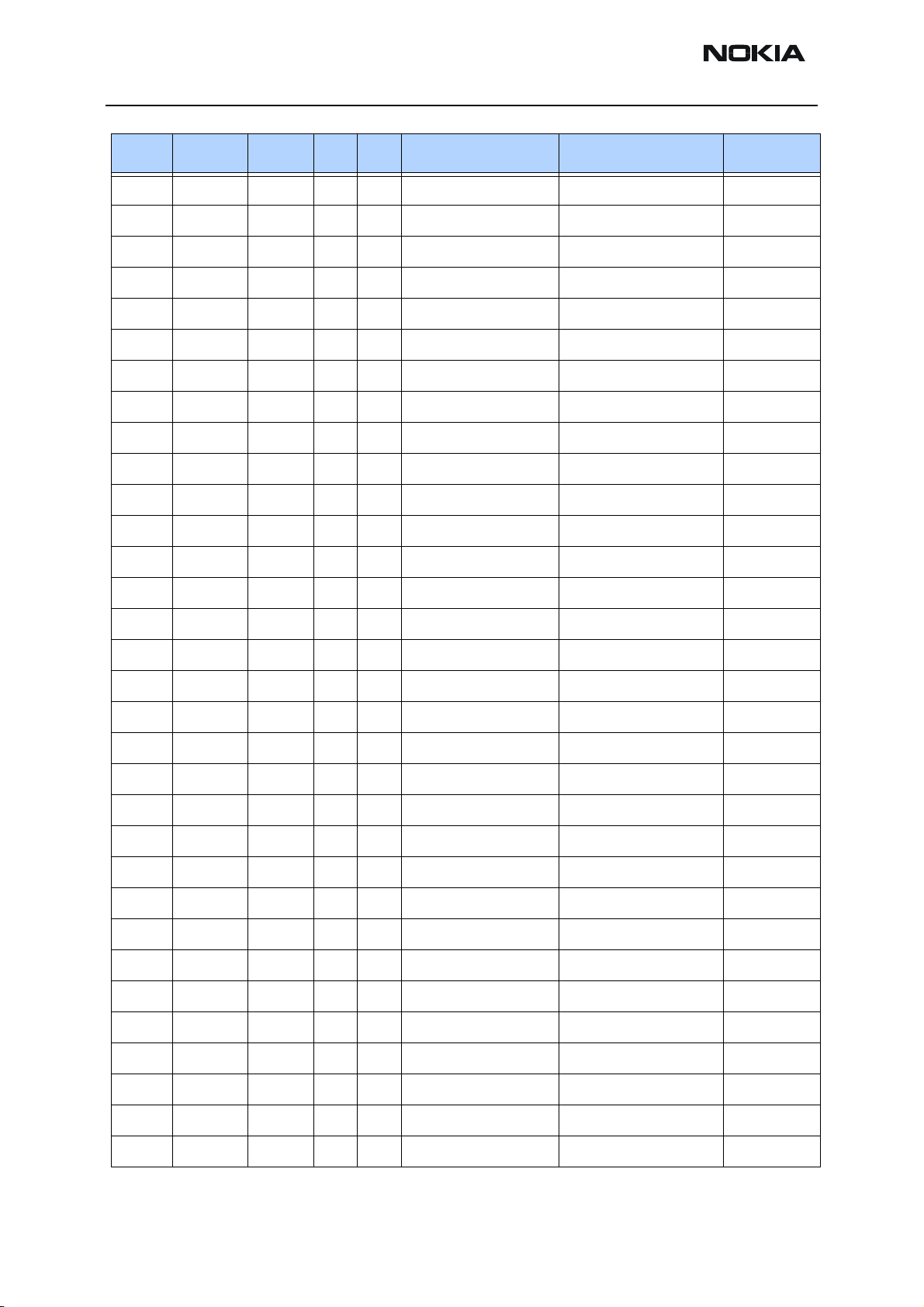

Item Code Side X Y Description Value Type

R316 1430816 Top S 2 chip res 0W06 330K J 0402

R317 1430784 Top S 2 chip res 0W06 15K J 0402

R318 1430726 Top S 6 chip res 0W06 100R J 0402

R320 1430742 Top S 4 chip res 0W06 390R J 0402

R321 1430740 Bottom I 9 chip res 0W06 330R J 0402

R350 1419009 Top B 3 chip res 0W5 4R7 J 220PPM 1210

R357 1430792 Bottom Q 6 chip res 0W06 33K J 0402

R359 1430778 Bottom S 6 chip res 0W06 10K J 0402

R360 1430804 Bottom S 6 chip res 0W06 100K J 0402

R361 1620019 Bottom Q 3 res network 0W06 2X10K J 0404

R367 1430786 Bottom R 8 chip res 0W06 18K J 0402

R369 1430792 Bottom Q 8 chip res 0W06 33K J 0402

R388 4120071 Top Q 6 ASIP EMIF03-SIM01

SIM Filter

R427 1430754 Top P 2 chip res 0W06 1K0 J 0402

R428 1430770 Top O 2 chip res 0W06 4k7 J 0402

R430 1430754 Top O 2 chip res 0W06 1K0 J 0402

R431 1430770 Top N 2 chip res 0W06 4K7 J 0402

R432 1430796 Top Q 2 chip res 0W06 47K J 0402

R433 1430754 Top Q 2 chip res 0W06 1K0 J 0402

R434 1430770 Top Q 3 chip res 0W06 4K7 J 0402

R435 1430770 Top Q 4 chip res 0W06 4K7 J 0402

R450 1430770 Top S 5 chip res 0W06 4K7 J 0402

R501 1430700 Bottom L 7 chip res 0W06 10R J 0402

R503 1430778 Bottom K 7 chip res 0W06 10K J 0402

R505 1430700 Bottom L 5 chip res 0W06 10R J 0402

BGA8

R506 1430706 Bottom L 5 chip res 0W06 15R J 0402

R508 1430766 Bottom K 8 chip res 0W06 3K9 J 0402

R509 1430726 Bottom L 5 chip res 0W06 100R J 0402

R511 1430794 Top L 7 chip res 0W06 39K J 0402

R512 1430700 Top L 8 chip res 0W06 10R J 0402

R513 1430700 Bottom L 7 chip res 0W06 10R J 0402

R515 1430700 Bottom L 7 chip res 0W06 10R J 0402

Page 12 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 24

RH-34

CCS Technical Documentation Parts Lists

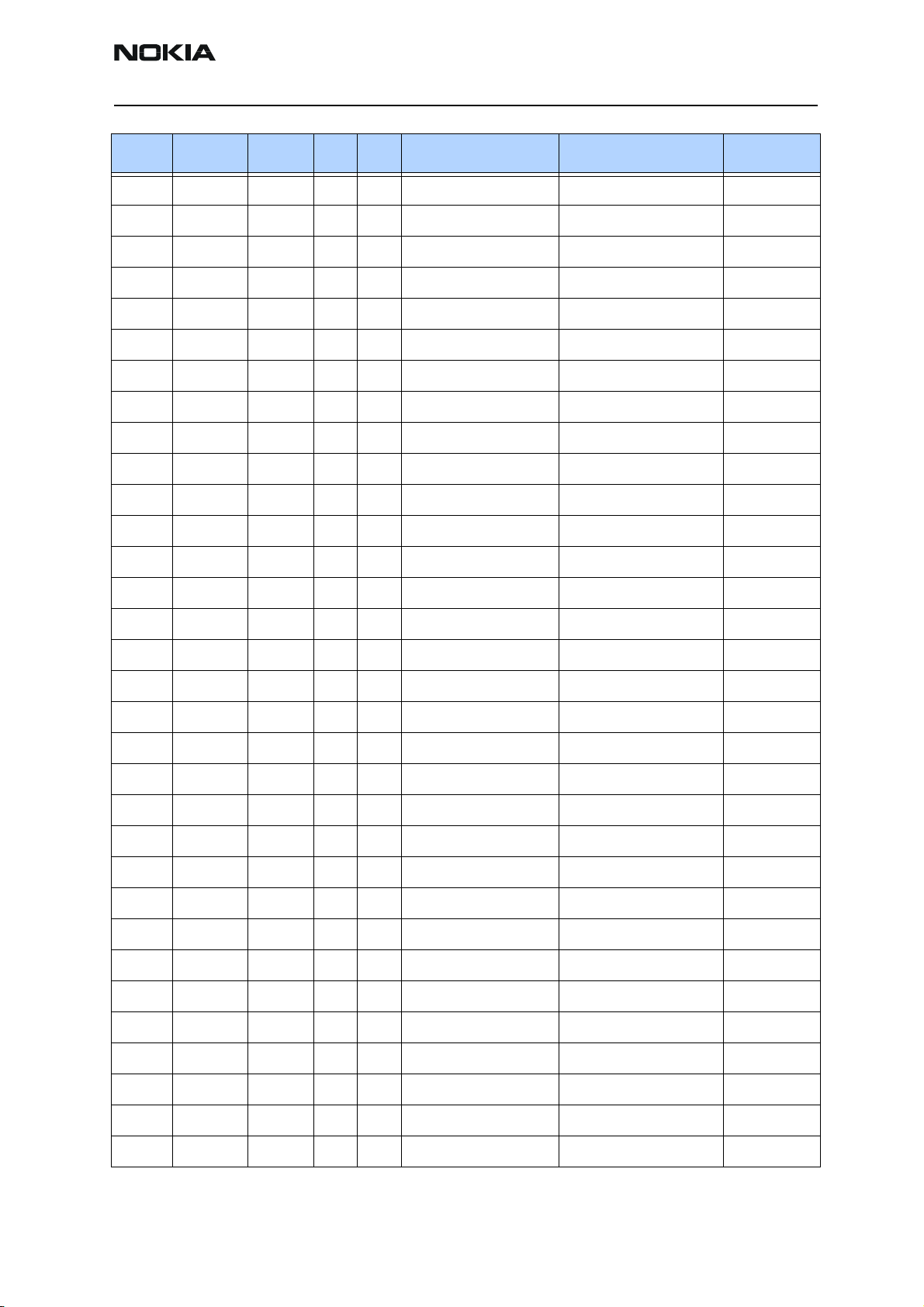

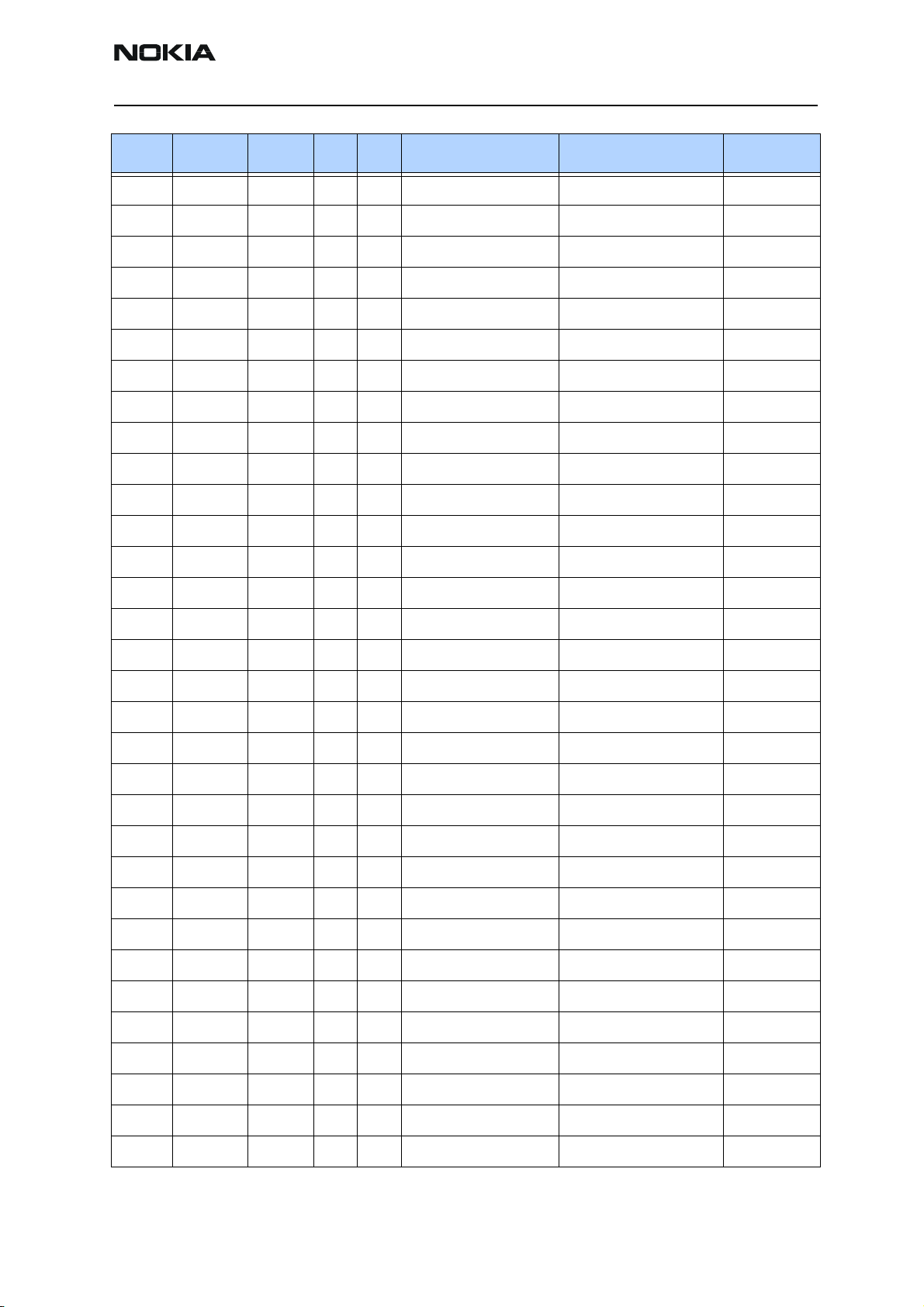

Item Code Side X Y Description Value Type

R517 1430784 Top L 7 chip res 0W06 15K J 0402

R519 1430726 Bottom L 5 chip res 0W06 100R J 0402

R521 1430774 Top L 7 chip res 0W06 6K8 J 0402

R550 1430778 Bottom K 7 chip res 0W06 10K J 0402

R601 1430758 Bottom L 4 chip res 0W06 1K5 J 0402

R602 1430790 Bottom L 4 chip res 0W06 27K J 0402

R604 1430772 Bottom K 4 chip res 0W06 5K6 J 0402

R605 1430754 Bottom L 3 chip res 0W06 1K0 J 0402

R606 1430754 Bottom L 3 chip res 0W06 1K0 J 0402

R607 1430770 Bottom L 3 chip res 0W06 4K7 J 0402

R609 1430758 Bottom L 3 chip res 0W06 1K5 J 0402

R611 1430804 Bottom L 4 chip res 0W06 100K J 0402

R621 1430774 Bottom K 4 chip res 0W06 6K8 J 0402

R701 1430762 Bottom Q 6 chip res 0W06 2K2 J 0402

R702 1430754 Bottom P 8 chip res 0W06 1K0 J 0402

R703 1430744 Bottom Q 8 chip res 0W06 470R J 0402

R704 1430770 Bottom P 8 chip res 0W06 4K7 J 0402

R705 1430790 Bottom Q 8 chip res 0W06 27K J 0402

R706 1430776 Bottom P 6 chip res 0W06 8K2 J 0402

R707 1430724 Bottom J 5 chip res 0W06 82R J 0402

R750 1430681 Bottom J 6 chip res 0W06 4R3 J 0402

R764 1430796 Bottom J 5 chip res 0W06 47K J 0402

R765 1430796 Bottom J 5 chip res 0W06 47K J 0402

R768 1430796 Bottom J 5 chip res 0W06 47K J 0402

R769 1430681 Bottom I 6 chip res 0W06 4R3 J 0402

R801 1430734 Bottom E 5 chip res 0W06 220R J 0402

R802 1430746 Bottom D 4 chip res 0W06 560R J 0402

R803 1430734 Bottom E 4 chip res 0W06 220R J 0402

R808 1820039 Bottom E 3 NTC RES 0W1 47K J

B=4050+-3%

R976 1430700 Top S 7 chip res 0W06 10R J 0402

R977 1430700 Top S 7 chip res 0W06 10R J 0402

R999 1430804 Top Q 2 chip res 0W06 100K J 0402

0402

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 13

Page 25

RH-34

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C001 2320518 Bottom B 2 chip cap NP0 1P8 C 50V 0402

C002 2320520 Bottom B 2 chip cap NP0 2P2 C 50V 0402

C004 2320805 Bottom B 4 chip cap X5R 100N K 10V 0402

C005 2320546 Bottom B 4 chip cap NP0 27P J 50V 0402

C006 2320536 Bottom B 5 chip cap NP0 10P J 50V 0402

C007 2320481 Bottom B 5 chip cap X5R 1U K 6V3 0603

C008 2320552 Bottom B 5 chip cap NP0 47P J 50V 0402

C009 2320532 Bottom A 5 chip cap NP0 6P8 C 50V 0402

C012 2320522 Top M 3 chip cap NP0 2P7 C 50V 0402

C014 2320540 Top M 3 chip cap NP0 15P J 50V 0402

C015 2320778 Top M 2 chip cap X7R 10N K 16V 0402

C017 2320544 Top L 3 chip cap NP0 22P J 50V 0402

C018 2320805 Top L 4 chip cap X5R 100N K 10V 0402

C019 2320620 Top M 3 chip cap X7R 10N J 16V 0402

C020 2320620 Top L 3 chip cap X7R 10N J 16V 0402

C021 2320620 Top M 3 chip cap X7R 10N J 16V 0402

C023 2320544 Top M 3 chip cap NP0 22P J 50V 0402

C024 2320544 Top L 3 chip cap NP0 22P J 50V 0402

C025 2320544 Top M 3 chip cap NP0 22P J 50V 0402

C026 2320805 Top M 3 chip cap X5R 100N K 10V 0402

C029 2320536 Top L 2 chip cap NP0 10P J 50V 0402

C051 2320805 Top L 5 chip cap X5R 100N K 10V 0402

C052 2320805 Top L 4 chip cap X5R 100N K 10V 0402

C054 2320805 Top M 5 chip cap X5R 100N K 10V 0402

C056 2320805 Top M 5 chip cap X5R 100N K 10V 0402

C057 2320805 Top M 4 chip cap X5R 100N K 10V 0402

C058 2320805 Top M 5 chip cap X5R 100N K 10V 0402

C060 2320805 Top L 4 chip cap X5R 100N K 10V 0402

C063 2316001 Top M 3 chip cap X5R 2U2 K 6V3 0603

C064 2316001 Top M 4 chip cap X5R 2U2 K 6V3 0603

C065 2320620 Top M 4 chip cap X7R 10N J 16V 0402

C068 2320778 Top L 5 chip cap X7R 10N K 16V 0402

Page 14 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 26

RH-34

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

C101 2320481 Top S 6 chip cap X5R 1U K 6V3 0603

C102 2320481 Top R 6 chip cap X5R 1U K 6V3 0603

C103 2320544 Top S 6 chip cap NP0 22P J 50V 0402

C104 2320544 Top S 6 chip cap NP0 22P J 50V 0402

C105 2320544 Top S 5 chip cap NP0 22P J 50V 0402

C106 2320744 Bottom S 3 chip cap X7R 1N0 K 50V 0402

C107 2320778 Top R 6 chip cap X7R 10N K 16V 0402

C108 2320552 Bottom H 5 chip cap NP0 47P J 50V 0402

C109 2320552 Bottom G 6 chip cap NP0 47P J 50V 0402

C110 2320544 Bottom S 2 chip cap NP0 22P J 50V 0402

C111 2320552 Bottom H 4 chip cap NP0 47P J 50V 0402

C112 2320536 Bottom S 7 chip cap NP0 10P J 50V 0402

C113 2320536 Bottom S 7 chip cap NP0 10P J 50V 0402

C114 2320536 Bottom T 7 chip cap NP0 10P J 50V 0402

C115 2320536 Bottom S 8 chip cap NP0 10P J 50V 0402

C150 2320805 Top R 6 chip cap X5R 100N K 10V 0402

C151 2320805 Top Q 6 chip cap X5R 100N K 10V 0402

C152 2320552 Top R 6 chip cap NP0 47P J 50V 0402

C153 2320552 Top R 6 chip cap NP0 47P J 50V 0402

C154 2320805 Top Q 6 chip cap X5R 100N K 10V 0402

C155 2320805 Top Q 7 chip cap X5R 100N K 10V 0402

C156 2320552 Top Q 6 chip cap NP0 47P J 50V 0402

C157 2320805 Top Q 7 chip cap X5R 100N K 10V 0402

C158 2320552 Top Q 7 chip cap NP0 47P J 50V 0402

C159 2320552 Top R 7 chip cap NP0 47P J 50V 0402

C160 2320805 Top S 8 chip cap X5R 100N K 10V 0402

C161 2320805 Top S 8 chip cap X5R 100N K 10V 0402

C162 2320552 Top Q 7 chip cap NP0 47P J 50V 0402

C163 2320505 Top R 7 chip cap X5R 4U7 K 6.3V 0603

C164 2320805 Top S 7 chip cap X5R 100N K 10V 0402

C165 2320505 Top R 7 chip cap X5R 4U7 K 6.3V 0603

C166 2320805 Top R 7 chip cap X5R 100N K 10V 0402

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 15

Page 27

RH-34

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C167 2320552 Bottom D 9 chip cap NP0 47P J 50V 0402

C168 2320805 Top S 7 chip cap X5R 100N K 10V 0402

C169 2320805 Top R 7 chip cap X5R 100N K 10V 0402

C170 2320552 Top Q 6 chip cap NP0 47P J 50V 0402

C171 2320552 Top R 7 chip cap NP0 47P J 50V 0402

C172 2320805 Top Q 6 chip cap X5R 100N K 10V 0402

C173 2320552 Top Q 7 chip cap NP0 47P J 50V 0402

C174 2320805 Top Q 7 chip cap X5R 100N K 10V 0402

C175 2320805 Top R 6 chip cap X5R 100N K 10V 0402

C176 2320805 Top R 7 chip cap X5R 100N K 10V 0402

C177 2320552 Bottom D 9 chip cap NP0 47P J 50V 0402

C179 2320805 Bottom D 9 chip cap X5R 100N K 10V 0402

C180 2320481 Top S 8 chip cap X5R 1U K 6V3 0603

C181 2320481 Top R 8 chip cap X5R 1U K 6V3 0603

C182 2320805 Bottom E 9 chip cap X5R 100N K 10V 0402

C183 2315201 Top S 7 chip array NP0 2X27P K 25V 0405

C184 2315201 Top S 7 chip array NP0 2X27P K 25V 0405

C185 2315205 Bottom G 6 chip array X5R 2X1N M 16V 0405

C190 2320548 Top R 8 chip cap NP0 33P J 50V 0402

C202 2320778 Top O 8 chip cap X7R 10N K 16V 0402

C211 2320481 Top Q 8 chip cap X5R 1U K 6V3 0603

C222 2320805 Top O 5 chip cap X5R 100N K 10V 0402

C224 2320143 Top O 8 chip cap X5R 220N K 6.3V 0402

C225 2320805 Top O 5 chip cap X5R 100N K 10V 0402

C226 2320481 Top Q 7 chip cap X5R 1U K 6V3 0603

C227 2320778 Top Q 5 chip cap X7R 10N K 16V 0402

C229 2320805 Top O 5 chip cap X5R 100N K 10V 0402

C230 2320778 Top Q 4 chip cap X7R 10N K 16V 0402

C232 2320778 Top Q 5 chip cap X7R 10N K 16V 0402

C233 2320481 Top Q 7 chip cap X5R 1U K 6V3 0603

C234 2320481 Top P 8 chip cap X5R 1U K 6V3 0603

C235 2320481 Top P 8 chip cap X5R 1U K 6V3 0603

Page 16 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 28

RH-34

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

C237 2320481 Top O 8 chip cap X5R 1U K 6V3 0603

C238 2320805 Top Q 6 chip cap X5R 100N K 10V 0402

C239 2320481 Top P 8 chip cap X5R 1U K 6V3 0603

C240 2320481 Top O 8 chip cap X5R 1U K 6V3 0603

C241 2320805 Top O 8 chip cap X5R 100N K 10V 0402

C242 2320481 Top P 5 chip cap X5R 1U K 6V3 0603

C243 2320481 Top P 5 chip cap X5R 1U K 6V3 0603

C244 2320481 Top O 5 chip cap X5R 1U K 6V3 0603

C245 2320481 Top O 8 chip cap X5R 1U K 6V3 0603

C246 2320481 Top N 6 chip cap X5R 1U K 6V3 0603

C247 2320481 Top N 6 chip cap X5R 1U K 6V3 0603

C248 2320481 Top N 7 chip cap X5R 1U K 6V3 0603

C249 2320481 Top N 7 chip cap X5R 1U K 6V3 0603

C250 2320481 Top N 7 chip cap X5R 1U K 6V3 0603

C251 2320481 Top N 7 chip cap X5R 1U K 6V3 0603

C252 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C253 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C254 2320481 Top M 6 chip cap X5R 1U K 6V3 0603

C255 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C256 2320481 Top M 6 chip cap X5R 1U K 6V3 0603

C257 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C258 2320481 Top N 8 chip cap X5R 1U K 6V3 0603

C259 2320481 Top M 8 chip cap X5R 1U K 6V3 0603

C260 2320505 Top N 8 chip cap X5R 4U7 K 6.3V 0603

C261 2320505 Top N 8 chip cap X5R 4U7 K 6.3V 0603

C264 2320481 Top O 8 chip cap XR5 1U K 6V3 0603

C270 2320505 Bottom G 3 chip cap X5R 4U7 K 6.3V 0603

C271 2310037 Bottom H 3 chip cap X5R 10U M 6V3 0805

C272 2320505 Bottom G 2 chip cap X5R 4U7 K 6.3V 0603

C273 2320805 Bottom G 3 chip cap X5R 100N K 10V 0402

C302 2320556 Top S 2 chip cap NP0 68P J 50V 0402

C303 2320125 Top R 2 chip cap X5R 1U K 16V 0603

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 17

Page 29

RH-34

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C304 2320125 Top R 2 chip cap X5R 1U K 16V 0603

C310 2320544 Bottom B 6 chip cap NP0 22P J 50V 0402

C311 2320544 Bottom H 2 chip cap NP0 22P J 50V 0402

C312 2320544 Bottom H 2 chip cap NP0 22P J 50V 0402

C350 2320505 Top B 3 chip cap X5R 4U7 K 6.3V 0603

C352 2320805 Top B 3 chip cap X5R 100N K 10V 0402

C353 2320805 Top B 4 chip cap X5R 100N K 10V 0402

C357 2320778 Bottom S 6 chip cap X7R 10N K 16V 0402

C358 2320785 Bottom S 6 chip cap X7R 47N K 10V 0402

C359 2320805 Bottom Q 7 chip cap X5R 100N K 10V 0402

C361 2320744 Bottom Q 8 chip cap X7R 1N0 K 50V 0402

C362 2320778 Bottom S 6 chip cap X7R 10N K 16V 0402

C363 2315261 Bottom R 8 chip array X5R 2X47N K 10V 0405

C364 2321007 Bottom Q 8 chip cap X7R 22N K 16V 0402

C365 2315209 Bottom R 8 chip array X5R 2X33N M 10V 0405

C366 2320785 Bottom R 8 chip cap X7R 47N K 10V 0402

C367 2320560 Bottom S 8 chip cap NP0 100P J 50V 0402

C370 2320760 Bottom S 7 chip cap X7R 4N7 K 25V 0402

C371 2320778 Bottom S 8 chip cap X7R 10N K 16V 0402

C372 2320481 Bottom S 8 chip cap X5R 1U K 6V3 0603

C373 2321007 Bottom Q 7 chip cap X7R 22N K 16V 0402

C374 2320744 Bottom Q 7 chip cap X7R 1N0 K 50V 0402

C375 2320752 Bottom Q 7 chip cap X7R 2N2 K 50V 0402

C378 2320546 Bottom S 7 chip cap NP0 27P J 50V 0402

C379 2320552 Bottom S 7 chip cap NP0 47P J 50V 0402

C388 2320805 Top Q 6 chip cap X5R 100N K 10V 0402

C400 2320805 Top O 5 chip cap X5R 100N K 10V 0402

C401 2320805 Top O 2 chip cap X5R 100N K 10V 0402

C402 2320805 Top N 5 chip cap X5R 100N K 10V 0402

C403 2320805 Top Q 4 chip cap X5R 100N K 10V 0402

C404 2320805 Top P 2 chip cap X5R 100N K 10V 0402

C405 2320805 Top N 5 chip cap X5R 100N K 10V 0402

Page 18 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 30

RH-34

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

C422 2320620 Top P 2 chip cap X7R 10N J 16V 0402

C423 2320744 Top O 2 chip cap X7R 1N0 K 50V 0402

C424 2320620 Top O 2 chip cap X7R 10N J 16V 0402

C425 2320744 Top N 2 chip cap X7R 1N0 K 50V 0402

C426 2320620 Top Q 3 chip cap X7R 10N J 16V 0402

C427 2320744 Top Q 3 chip cap X7R 1N0 K 50V 0402

C428 2320778 Top Q 4 chip cap X7R 10N K 16V 0402

C429 2320783 Top Q 3 chip cap X7R 33N K 10V 0402

C430 2320783 Top O 2 chip cap X7R 33N K 10V 0402

C431 2320783 Top O 2 chip cap X7R 33N K 10V 0402

C435 2320778 Bottom P 6 chip cap X7R 10N K 16V 0402

C450 2320778 Top Q 4 chip cap X7R 10N K 16V 0402

C451 2320805 Top Q 4 chip cap X5R 100N K 10V 0402

C454 2320778 Top S 5 chip cap X7R 10N K 16V 0402

C501 2320552 Bottom L 7 chip cap NP0 47P J 50V 0402

C502 2320576 Top L 7 chip cap X7R 470P J 50V 0402

C503 2320783 Top L 7 chip cap X7R 33N K 10V 0402

C504 2320620 Bottom L 7 chip cap X7R 10N J 16V 0402

C505 2320620 Top M 8 chip cap X7R 10N J 16V 0402

C507 2320620 Bottom L 7 chip cap X7R 10N J 16V 0402

C508 2420003 Bottom K 7 chip cap PPS 33N J 16V 1206

C509 2320584 Bottom K 7 chip cap X7R 1N0 J 50 V 0402

C510 2420003 Bottom K 7 chip cap PPS 33N J 16V 1206

C511 2320481 Bottom L 7 chip cap X5R 1U K 6V3 0603

C512 2320576 Top L 7 chip cap X7R 470P J 50V 0402

C513 2320576 Top L 7 chip cap X7R 470P J 50V 0402

C514 2320550 Bottom K 5 chip cap NP0 39P J 50V 0402

C515 2320552 Bottom L 8 chip cap NP0 47P J 50V 0402

C516 2320548 Bottom L 5 chip cap NP0 33P J 50V 0402

C517 2320576 Bottom L 8 chip cap X7R 470P J 50V 0402

C518 2320618 Bottom L 7 chip cap X7R 4N7 J 25V 0402

C519 2320522 Bottom K 5 chip cap NP0 2P7 C 50V 0402

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 19

Page 31

RH-34

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C520 2320481 Top L 8 chip cap X5R 1U K 6V3 0603

C521 2320805 Bottom L 7 chip cap X5R 100N K 10V 0402

C522 2320620 Bottom L 7 chip cap X7R 10N J 16V 0402

C524 2320546 Top L 6 chip cap NP0 27P J 50V 0402

C532 2320532 Bottom L 7 chip cap NP0 6P8 C 50V 0402

C550 2320584 Bottom K 7 chip cap X7R 1N0 J 50V 0402

C553 2320538 Bottom L 5 chip cap NP0 12P J 50V 0402

C602 2320633 Bottom L 3 chip cap NP0 220P J 25V 0402

C603 2320538 Bottom K 4 chip cap NP0 12P J 50V 0402

C605 2320560 Bottom K 3 chip cap NP0 100P J 50V 0402

C606 2320744 Bottom L 4 chip cap X7R 1N0 K 50V 0402

C607 2320620 Bottom L 4 chip cap X7R 10N J 16V 0402

C608 2320538 Bottom I 3 chip cap NP0 12P J 50V 0402

C611 2320538 Bottom J 3 chip cap NP0 12P J 50V 0402

C612 2320584 Bottom L 2 chip cap X7R 1N0 J 50V 0402

C613 2320109 Bottom L 2 chip cap X7R 15N J 25V 0603

C614 2320538 Bottom K 4 chip cap NP0 12P J 50V 0402

C618 2320602 Bottom L 2 chip cap NP0 4P7 C 50V 0402

C619 2320552 Bottom J 4 chip cap NP0 47P J 50V 0402

C621 2320744 Bottom J 4 chip cap X7R 1N0 K 50V 0402

C627 2320538 Bottom I 3 chip cap NP0 12P J 50V 0402

C629 2321011 Bottom L 3 chip cap NP0 8P0+/-0.5P 50V 0402

C630 2320604 Bottom L 3 chip cap NP0 18P J 50V 0402

C631 2320520 Bottom L 3 chip cap NP0 2P2 C 50V 0402

C632 2320560 Bottom L 3 chip cap NP0 100P J 50V 0402

C633 2320552 Bottom J 3 chip cap NP0 47P J 50V 0402

C634 2320596 Bottom K 2 chip cap X7R 3N3 J 50V 0402

C635 2320596 Bottom J 3 chip cap X7R 3N3 J 50V 0402

C637 2320560 Bottom L 3 chip cap NP0 100P J 50V 0402

C638 2320620 Bottom L 3 chip cap X7R 10N J 16V 0402

C639 2320596 Bottom J 3 chip cap X7R 3N3 J 50V 0402

C640 2320524 Bottom K 3 chip cap NP0 3P3 C 50V 0402

Page 20 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 32

RH-34

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

C642 2320524 Bottom K 3 chip cap NP0 3P3 C 50V 0402

C645 2320538 Bottom I 3 chip cap NP0 12P J 50V 0402

C646 2320538 Bottom K 3 chip cap NP0 12P J 50V 0402

C647 2320538 Bottom K 3 chip cap NP0 12P J 50V 0402

C648 2320744 Bottom J 3 chip cap X7R 1N0 K 50V 0402

C649 2320522 Bottom J 4 chip cap NP0 47P J 50V 0402

C650 2320538 Bottom I 3 chip cap NP0 12P J 50V 0402

C651 2320538 Bottom J 3 chip cap NP0 12P J 50V 0402

C652 2320481 Bottom K 2 chip cap X5R 1U K 6V3 0603

C660 2320538 Bottom K 2 chip cap NP0 12P J 50V 0402

C666 2320552 Bottom K 4 chip cap NP0 47P J 50V 0402

C677 2320552 Bottom J 3 chip cap NP0 47P J 50V 0402

C701 2320783 Bottom Q 8 chip cap X7R 33N K 10V 0402

C702 2320584 Bottom P 8 chip cap X7R 1N0 J 50V 0402

C703 2320805 Bottom Q 6 chip cap X5R 100N K 10V 0402

C704 2320778 Bottom P 6 chip cap X7R 10N K 16V 0402

C706 2320778 Bottom Q 8 chip cap X7R 10N K 16V 0402

C707 2320778 Bottom Q 6 chip cap X7R 10N K 16V 0402

C708 2320778 Bottom O 8 chip cap X7R 10N K 16V 0402

C710 2320778 Bottom P 8 chip cap X7R 10N K 16V 0402

C712 2320778 Bottom O 8 chip cap X7R 10N K 16V 0402

C714 2360001 Bottom P 8 chip cap X5R 330N K 10V 0603

C715 2320620 Bottom P 8 chip cap X7R 10N J 16V 0402

C716 2320544 Bottom P 8 chip cap NP0 22P J 50V 0402

C718 2320778 Bottom O 8 chip cap X7R 10N K 16V 0402

C722 2320778 Bottom O 7 chip cap X7R 10N K 16V 0402

C723 2320778 Bottom O 7 chip cap X7R 10N K 16V 0402

C740 2320544 Bottom O 7 chip cap NP0 22P J 50V 0402

C750 2320560 Bottom J 5 chip cap NP0 100P J 50V 0402

C753 2320560 Bottom I 5 chip cap NP0 100P J 50V 0402

C755 2320516 Bottom I 7 chip cap NP0 1P5 C 50V 0402

C756 2320560 Bottom J 5 chip cap NP0 100P J 50V 0402

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 21

Page 33

RH-34

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C757 2320554 Bottom I 7 chip cap NP0 56P J 50V 0402

C758 2320785 Bottom I 7 chip cap X7R 47N K 10V 0402

C759 2320602 Bottom J 8 chip cap NP0 4P7 C 50V 0402

C761 2320596 Bottom M 6 chip cap X7R 3N3 J 50V 0402

C763 2320538 Bottom I 6 chip cap NP0 12P J 50V 0402

C766 2320560 Bottom J 8 chip cap NP0 100P J 50V 0402

C767 2320576 Bottom M 7 chip cap X7R 470P J 50V 0402

C769 2320596 Bottom J 6 chip cap X7R 3N3 J 50V 0402

C770 2320514 Bottom O 6 chip cap NP0 1P2 C 50V 0402

C771 2320532 Bottom P 6 chip cap NP0 6P8 C 50V 0402

C772 2320532 Bottom P 6 chip cap NP0 6P8 C 50V 0402

C777 2320536 Bottom O 7 chip cap NP0 10P J 50V 0402

C778 2320532 Bottom O 8 chip cap NP0 6P8 C 50V 0402

C779 2320532 Bottom O 8 chip cap NP0 6P8 C 50V 0402

C781 2320526 Bottom M 8 chip cap NP0 3P9 C 50V 0402

C783 2320602 Bottom M 8 chip cap NP0 4P7 C 50V 0402

C784 2320584 Bottom M 8 chip cap X7R 1N0 J 50V 0402

C785 2320516 Bottom I 5 chip cap NP0 1P5 C 50V 0402

C786 2320805 Bottom M 8 chip cap X5R 100N K 10V 0402

C787 2320538 Bottom J 6 chip cap NP0 12P J 50V 0402

C788 2320805 Bottom J 6 chip cap X5R 100N K 10V 0402

C801 2320552 Bottom I 4 chip cap NP0 47P J 50V 0402

C802 2320538 Bottom I 3 chip cap NP0 12P J 50V 0402

C803 2320538 Bottom D 4 chip cap NP0 12P J 50V 0402

C807 2320778 Bottom D 4 chip cap X7R 10N K 16V 0402

C808 2320584 Bottom C 3 chip cap X7R 1N0 J 50V 0402

C809 2320540 Bottom C 3 chip cap NP0 15P J 50V 0402

C810 2320584 Bottom E 4 chip cap X7R 1N0 J 50V 0402

C811 2320556 Bottom E 3 chip cap NP0 68P J 50V 0402

C813 2320552 Bottom E 3 chip cap NP0 47P J 50V 0402

C814 2320560 Bottom C 4 chip cap NP0 100P J 50V 0402

C817 2310037 Bottom E 4 chip cap X5R 10U M 6V3 0805

Page 22 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 34

RH-34

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

L001 3646401 Bottom C 2 chip coil 2N J Q16/250MHz 0402

L002 3646009 Bottom B 2 chip coil 10N J Q30/800MHz 0402

L005 3646061 Bottom B 5 chip coil 15N J Q30/800MHz 0402

L006 3646051 Bottom B 5 chip coil 3N9+-0N3

Q28/800MHz

L008 3646055 Top M 3 chip coil 8N2 J Q28/800MHz 0402

L100 3203743 Bottom T 4 ferrite bead 0R03 42R/100MHz 3A 0805

L102 3203803 Top R 6 chip bead array 2X1000R 0R75 0405

L103 3203803 Top S 6 chip bead array 2X1000R 0R75 0405

L104 3203803 Top S 7 chip bead array 2X1000R 0R75 0405

L106 3203725 Top T 5 ferrite bead 600R/100MHz 0402

L107 3203741 Top T 6 ferrite bead 0R5 600R/100MHz 0603

L151 3645349 Bottom G 5 chip coil 33NH G Q40/250MHz 0603

L152 3645349 Bottom G 5 chip coil 33NH G Q40/250MHz 0603

L270 3203723 Bottom G 3 ferrite bead 0R35 68R/100MHz 0603

L271 3640163 Bottom H 2 choke 10U M 0.4A 0R8 3.3X3.3X1.3

L300 3640161 Top R 3 choke 22U M 0.33A 1R5 3.3X3.3X1.3

L351 3646081 Bottom S 8 chip coil 68N J Q17/300MHz 0402

0402

L356 3645349 Bottom R 6 chip coil 33NH G Q40/250MHz 0603

L357 3645349 Bottom R 6 chip coil 33NH G Q40/250MHz 0603

L358 3645233 Bottom S 7 chip coil 120N G Q32/150MHz 0603

L501 3646007 Bottom K 5 chip coil 27N J Q27/800MHz 0402

L507 3646043 Bottom L 5 chip coil 1N5+-0N3

Q33/800MHz

L520 3646221 Bottom L 5 chip coil 4N7+-0N3

Q7/100MHz

L603 3646225 Bottom K 4 chip coil 6N8 J Q7/100MHz 0402

L604 3646225 Bottom K 3 chip coil 6N8 J Q7/100MHz 0402

L609 3646047 Bottom K 3 chip coil 3N3+-0N3

Q28/800MHz

L610 3646047 Bottom K 3 chip coil 3N3+-0N3

Q28/800MHz

L611 3645219 Bottom L 3 chip coil 10N J Q31/250MHz 0603

L666 3646085 Bottom K 3 chip coil 6N8 K Q29/800MHz 0402

0402

0402

0402

0402

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 23

Page 35

RH-34

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

L667 3646043 Bottom K 2 chip coil 1N5+-0N3

Q33/800MHz

L701 3645223 Bottom P 8 chip coil 33N J Q40/250MHz 0603

L702 3646065 Bottom J 5 chip coil 12N J Q31/800MHz 0402

L750 3646415 Bottom I 7 chip coil 19N J Q24/250MHz 0402

L751 3646405 Bottom I 7 chip coil 6N2 J Q20/250MHz 0402

L752 3646061 Bottom I 7 chip coil 15N J Q30/800MHz 0402

L753 3645351 Bottom J 7 chip coil 220N J Q8/50MHz 0603

L754 3645189 Bottom M 6 chip coil 100N J Q12/100MHz 0603

L755 3646067 Bottom J 6 chip coil 18N J Q29/800MHz 0402

L757 3646061 Bottom I 7 chip coil 15N J Q30/800MHz 0402

L759 3645227 Bottom O 7 chip coil 100N J Q34/150MHz 0603

L760 3645229 Bottom P 6 chip coil 120N J Q32/150MHz 0603

L761 3645229 Bottom P 6 chip coil 120N J Q32/150MHz 0603

L762 3645195 Bottom M 7 chip coil 82N J Q12/100MHz 0603

0402

L764 3645301 Bottom M 8 chip coil 180N J Q13/100MHz 0603

L765 3645229 Bottom O 7 chip coil 120N J Q32/150MHz 0603

L766 3645229 Bottom O 8 chip coil 120N J Q32/150MHz 0603

L767 3645319 Bottom O 7 chip coil 220N J Q25/100MHz 0603

L768 3645319 Bottom O 8 chip coil 220N J Q25/100MHz 0603

L770 3645195 Bottom J 7 chip coil 82N J Q12/100MHz 0603

L771 3646099 Bottom J 6 chip coil 2N7+-0N3

Q29/800MHz

L773 3646099 Bottom I 6 chip coil 2N7+-0N3

Q29/800MHz

L801 3645191 Bottom E 4 chip coil 8N2 J Q10/100MHz 0603

L802 3646223 Bottom D 4 chip coil 5N6+-0N3 Q7/100MHz 0402

L804 3203803 Top R 8 chip bead array 2X1000R OR75 0405

V001 4210265 Bottom B 5 TR BFP620 LNA 65GHz NF.7Db SOT343

V100 4113721 Bottom S 3 TVS DI 1PMT16AT3 16V 175W PWRMITE

V101 4120011 Top T 6 ZDIX4 IP4043CX5 CA 14V2 10W CSP5

0402

0402

V300 4110475 Top R 2 SCH DI RB521S

V305 4219921 Top S 5 TR DTC143ZE N RBE4K7/47K 0A1 SC75

V356 4110965 Bottom R 6 CAP DI BB202 CT=2.5 FM 0R8 SOD523

Page 24 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 36

RH-34

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

V357 4110965 Bottom R 6 CAP DI BB202 CT=2.5 FM 0R8 SOD523

V420 4219921 Top Q 2 TR DTC143ZE N RBE4K7/47K 0A1 SC75

V421 4219921 Top O 2 TR DTC143ZE N RBE4K7/47K 0A1 SC75

V422 4219921 Top N 2 TR DTC143ZE N RBE4K7/47K 0A1 SC75

V423 4219937 Top P 2 TRX2 UMT1/PUMT1 P40V100MA SOT363

V601 4110921 Bottom L 2 CAP DI BBY57-02W 1/4 16/4P SOD523

V602 4112491 Bottom L 4 PIN DI BA892

V701 4110921 Bottom O 8 CAP DI BBY57-02W 1/4 16/4P SOD523

G502 4350329 Bottom L 6 VCO 986-1034/2040-

2140MHz 2.7V

G503 4510435 Top M 7 VCTCXO 19.2MHz+-2PPM 2.78V

2.2MA

D051 4370947 Top O 5 TWL5001 GPS BB ASIC V1.2

D200 4370825 Top O 7 UEMK W-Dog ENA TO21 TFBGA168

D400 4375019 Top R 4 UPP8M V3.5 F751542I UBGA144 C035

D450 4341501 Top R 4 Combo 128M NOR + 8M SRAM

TBGA48

D572 4341645 Top L 6 ULP Inverter 0.9-3.6V SC-70

N001 4370953 Top L 3 GPS RX TRF5101 PG2.1 PBGA-49

N052 4341421 Top M 4 VREG 2.8V/150MA

(LP3985ITLX)

N100 4341421 Top R 6 VREG 2.8V/150MA

(LP3985ITLX)

N150 4341417 Top S 8 AF Amp 85MW/5V

(LM4855ITLX)

N270 4341609 Bottom G 3 VREG PWM/LDO (NCP1501) MSOP8

N300 4341309 Top S 3 DC/DC Conv 350MA(TK11851) SOP8

N350 4860181 Bottom B 3 IRDA 1.3 1.152MBIT/S >2.4V 8PIN

N356 4341427 Bottom R 7 FM Receiver (TEA5767HN) LQFP40

USMD5

USMD5

USMD18

N502 4341295 Bottom K 5 FR Amp G5.5Db/2.1GHz(ULOBA) SC70-6

N507 4341395 Bottom L 8 1XPLL/SYNTH 2.5GHz(LMX231OU) MLF20

N601 4370857 Bottom K 3 ROBIND

SSBUP-Converter

N602 4370887 Bottom J 2 Hornet RF2357E7 PCS Driver

N603 4370885 Bottom J 4 Tomcat RF2356E4 CDMA 2000 SOT23-8

CDMA TFBGA

Amp

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 25

Page 37

RH-34

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

N605 4341311 Bottom I 3 Switch SPDT GAAS (SW-437) SC70-6

N701 4370851 Bottom P 7 BATMAND RFIC RCVR CDMA UFBGA84

N750 4375161 Bottom J 7 LNA/MIXER/

DOWNCNTR

N801 4350343 Bottom F 3 PW Amp RF9209E6.7 CDMA800

N802 4350377 Bottom D 3 PW Amp RF9318 CDMA190 (NIMBUS)

N806 4120091 Bottom D 4 ASIP STPAC01-F1 CDMA

B002 4510415 Top L 2 TCXO 16.368MHz+-1.5PPM

B200 4510303 Top Q 8 Crystal 32.768KHz+-20PPM 12.5PF

T603 4550211 Bottom K 2 TRANSF BALUN 1850-1990MHz SMD

T604 4550209 Bottom J 3 TRANSF BALUN 824-894MHz SMD

Z001 4550253 Bottom B 4 CER Filter 1575.42+-4MHz 3.5X3.5X2

Z002 4510367 Top M 3 SAW Filter 1575+-2MHz/2Db 2.6X2.1X1

Z300 4120031 Top Q 3 EMI/ESD FILT EMIF10-1K010F1 BGA24

Z601 4511331 Bottom I 2 Dual SAW Filter 1867/1892+-17.5MHz

Z604 4511275 Bottom I 8 SAW Filter 836.5+-12.5MHz/3.5Db 3X3

Alfred VQFN-24

BGA8

PWR DET

GPS

2.8V

Z750 4511423 Bottom J 8 SAW Filter 1960+-30MHz/3.2Db 2X1.6

Z751 4511309 Bottom J 7 SAW Filter 881.5+-12.5MHz/3Db 2.5X2

Z752 4510359 Bottom N 4 XTAL Filter 128.1MHz+-15KHz 3.8X3.8

Z753 4511429 Bottom N 4 SAW Filter 128.1+-0.615MHz 8.7X4.6

Z801 4510427 Bottom D 5 Isolator 1880+-30MHz 15Db 4X4X1.6

Z802 4510425 Bottom F 5 Isolator 836+-12.5MHz 12Db 5X5X1.8

Z803 4512175 Bottom F 6 DUPL 824-849/869-894MHz 5X5X1.5

Z804 4512191 Bottom D 2 DUPL 1850-1910/

1930-1990MHz

Z805 4550117 Bottom D 2 DIPL 824-894/

1850-1990MHz

S300 5209001 Bottom D 7 SM SW TACT SPST 12V 50 MA Side Key

S301 5209001 Bottom G 4 SM SW TACT SPST 12V 50 MA Side Key

S302 5409235 Bottom A 3 SM TACT SW TRAV 0.2 4.1X3.55X

F100 5119019 Bottom T 4 SM Fuse F 1.5A 32V 0603

5X5

3.2X1.6

1.75

X001 5420047 Bottom C 3 SM COAX CONN+SW F 50R 250V 6GHz

Page 26 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 38

RH-34

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

X100 5409141 Bottom H 4 SM Battery Connector 4POL SPR 12V 2A

X101 5460061 Bottom U 6 SM System Connector 14POL

X301 5469135 Top T 4 SM CONN 2X8 SPR 50V 0.5A PWB/PWB

X302 5469175 Top B 7 SM CONN 2X5F P0.5 PWB/PWB

X386 5409317 Bottom P 4 SM SIM CONN 2X3POL P2.54MM

X814 5420047 Bottom D 7 SM COAX CONN+SW F 50R 250V 6GHz

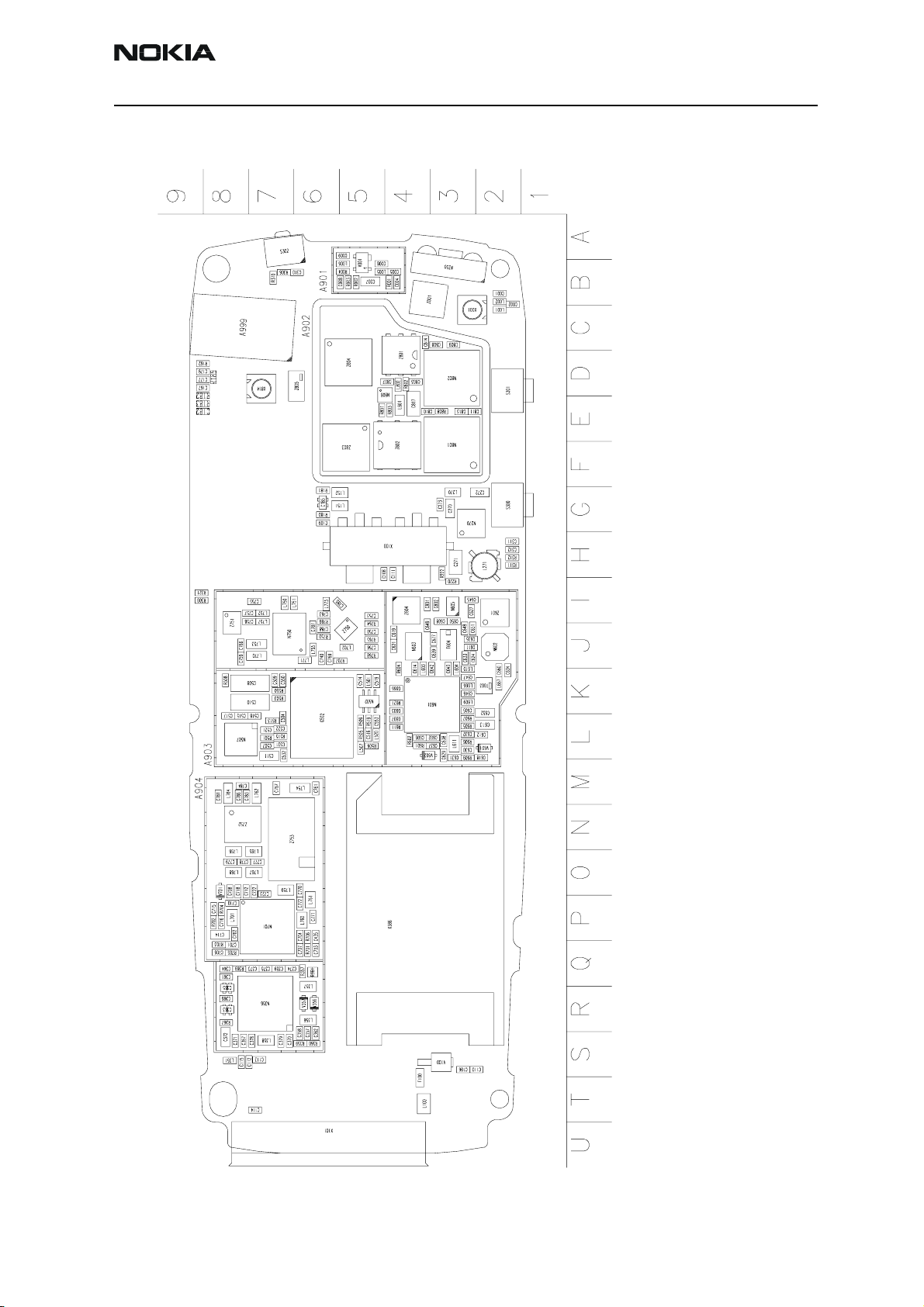

A901 9511194 CAN LNA DMD10501 RH-27

A902 9517280 CAN PA ASSY DMC06264 RH-27

A903 9517281 CAN RF ASSY DMC06208 RH-27

A904 9517282 CAN RF/RX ASSY DMC06207 RH-27

Issue 1 Amendment 12/2003 Confidential ©2003 Nokia Corporation Page 27

Page 39

RH-34

Parts Lists CCS Technical Documentation

Page 28 ©2003 Nokia Corporation Confidential Issue 1 Amendment 12/2003

Page 40

CCS Technical Documentation

RH-34 Series Transceivers

Service Software Instructions

Issue 1 11/2003 Confidential ©2003 Nokia Corporation

Page 41

RH-34

Service Software Instructions CCS Technical Documentation

Contents

Page No

Phoenix User’s Guide .................................................................................................... 3

Introduction ..................................................................................................................3

General Setup Procedure........................................................................................... 3

Hardware Requirements for using Phoenix .............................................................. 4

Installing Phoenix ........................................................................................................4

Installation Directions............................................................................................... 4

Software Support Bundles ...........................................................................................4

Starting a Phoenix Session ...........................................................................................5

Concepts.................................................................................................................... 5

Initial Session with Phoenix...................................................................................... 5

Scanning for a Product.............................................................................................. 6

Using Components.................................................................................................... 7

Using Profiles............................................................................................................ 7

Uninstalling Phoenix ...................................................................................................7

Uninstalling Phoenix version.................................................................................... 7

Diego User’s Guide........................................................................................................ 8

Introduction ..................................................................................................................8

General Setup Procedure........................................................................................... 8

Hardware Requirements for using Diego.................................................................. 9

Installing Diego ...........................................................................................................9

Installing.................................................................................................................... 9

Software Support Bundles .........................................................................................10

Starting a Diego Session ............................................................................................10

Concepts.................................................................................................................. 10

Initial Session with Diego and FLS-4S Dongle...................................................... 10

Scanning for a Product............................................................................................ 12

Using Components.................................................................................................. 12

Uninstalling Diego .....................................................................................................12

Uninstalling Diego version...................................................................................... 13

Page 2 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 42

RH-34

CCS Technical Documentation Service Software Instructions

Phoenix User’s Guide

Introduction

This section briefly describes how to install Phoenix and includes some basic information

on how to use the program. More detailed information can be found in the Phoenix Help

files. Each feature in Phoenix has its own Help file, which can be activated whil running

Phoenix. To activate a Help file while Phoenix is running, press the F1 key or the specific

feature’s Help button.

General Setup Procedure

Initial installation of Phoenix requires the complete Phoenix installation package. This

package, currently around 30 Megabytes in size, is provided on a CD-ROM disk. Because

of this large size, it is not recommended to download the file nor is it practical to provide

it on 3.5-inch floppy disks.

Install Phoenix by following the steps outlined on the material that comes with the disk.

It should be noted that installation of a Nokia dongle on the computer being loaded is

REQUIRED prior to beginning the installation of the software.

The software is packaged into an Installshield executable bundle. When the user doubleclicks on this file, the installation program provides on-screen instructions on how to

proceed. Standard installation, provided by selecting all default choices, is highly recommended. You may do a custom installation and place Phoenix into a special location on

your hard drive, but this is only recommended for experienced users.

It is necessary to reboot the computer after installing the software. The program will not

be usable until a reboot is performed. After reboot, the Phoenix icon is displayed on the

computer desktop. Double-clicking on this icon launches the program.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 3

Page 43

RH-34

Service Software Instructions CCS Technical Documentation

Hardware Requirements for using Phoenix

Minimum Hardware Requirements

Processor 233 MHz

RAM1 64 MB

Disk space needed 50-100 MB

Supported Operating

Systems

Windows 95 Limited, no USB support

Windows 98

Windows NT 4.0 no USB support

Windows 2000 Professional version

Notes

Installing Phoenix

Before installing the software, verify:

• The dongle is attached to the parallel port for PKD version dongles, or an FLS-4 version

dongle is attached on either the parallel port or the USB port (if the computer supports

USB).

• Ensure that if the computer supports administrator rights (typically on Windows NT

and Windows 2000 installations) that access is enabled for the user performing the

Phoenix installation.

• If a previous version of Phoenix has been installed, it may be necessary to first properly

remove that program prior to installing the new version. If installation is performed,

be sure to reboot the computer prior to continuing. See the section Uninstalling

Phoenix for instructions on how to uninstall.

Installation Directions

• Insert the CD-ROM disk into the computer drive

• Access the drive and double-click on the Phoenix software package found on the CD.

• Follow the on-screen prompts to conclusion.

Note that rebooting the computer may be necessary when completed.

Software Support Bundles

The Phoenix installation is auto-executable. You must obtain Software Support Bundles

Page 4 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 44

RH-34

CCS Technical Documentation Service Software Instructions

to load software upgrade files to customer-specific phone models.

These bundles are created by CCS and made available by AMS on the Partners Web Page

http://americas.partners.nokia.com. This web page is password-controlled; if you have

not registered as a user, contact Nokia Central Service in Melbourne, Florida.

Similar to the Phoenix installation, these Software Support Bundles are InstallShield executable packages. Just double-click on the package and it will auto-install.

No rebooting of the computer is required.

Starting a Phoenix Session

Concepts

When referring to Phoenix, Product is the cellular phone attached to the computer.

More specifically, it is the particular type of phone.

Connection is the type of cable used to attach the phone and the port on the computer

where it is attached. Refer to the Service Tools chapter for additional information.

The first time Phoenix is used, certain connection configurations must be made. Subsequent uses will rely on these selections and they will not need to be made again.

Initial Session with Phoenix

It is necessary to create the connection the first time Phoenix is used. Follow these simple steps:

Select Manage Connections… from the “File” drop-down menu.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 5

Page 45

RH-34

Service Software Instructions CCS Technical Documentation

Next click the Add… button to create a new connection.

When the Select Mode dialog box appears, you may then select either Wizard, which will

auto-detect your connection configuration, or Manual, which allows you to manually

select options to create the connection.

Once a connection is defined, make sure that the one to be used is moved to the top of

the list (use the up down arrows on the Manage Connections dialog box. Then click on

the Apply button. Close the window when finished.

You can now proceed with the normal initiation of a session by selecting a product or

scanning for a product.

Scanning for a Product

Many features of this program are product-specific. Therefore it is necessary to configure Phoenix for the product on which you will be working at the beginning of the session.

Scan Product – Choose Scan Product from the drop-down menu list and Phoenix will

automatically scan for product and select the necessary configurations. The status bar

Page 6 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 46

RH-34

CCS Technical Documentation Service Software Instructions

at the bottom will indicate if the product was found and its type.

Using Components

When working with Phoenix, tasks are generally managed by specific software components. From the menu, select the desired component or task to be performed.

“Opening a component” is defined as opening a tool window within Phoenix. When this

window is opened, Phoenix also opens a toolbar for it and adds component-specific

menu items in the Window menu.

Using Profiles

Phoenix’s Profile feature allows product, connection and currently open components to

be stored into permanent storage by creating a profile file with a name of your choice

followed by an .nmp file extension for later retrieval.

Saved profiles makes it easy to configure Phoenix into a desired configuration with

favorite windows already opened and ready to go.

Opening and saving profiles is done via menu commands found in the File drop-down

menu: Open Profile and Save Profile.

Profiles are stored into a disk file with user-defined names. As a result, there can be

multiple profiles for different repeated tasks or user preferences.

Uninstalling Phoenix

As mentioned in the Installing Phoenix section, it may be necessary or desirable to

remove Phoenix. Care must be taken to follow this procedure. Failure to remove the

program properly will cause misconfiguration of the computer’s registry.

Uninstalling Phoenix version

• Access the computer’s “Control Panel” section, selectable from the Start button or the

“My Computer” desktop icon

• Select the “Add/Remove Programs” icon

• Select the Phoenix version to be removed, and click the Add/Remove button

• Click on the OK button to begin the process of removal

• Follow the on-screen instructions

Be sure to reboot the computer when finished.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 7

Page 47

RH-34

Service Software Instructions CCS Technical Documentation

Diego User’s Guide

Introduction

This section briefly describes how to install Diego and includes some basic information

on how to use the program. More detailed information can be found in the Diego Help

files. Each feature in Diego has its own Help file, which can be activated while running

Diego. To activate a Help file while Diego is running, press the F1 key or the specific feature’s Help button.

Diego is designed to be used by point of sales locations. Ease of use and minimal operator decision-making were key factors in the design. Additionally, this Diego version is

compatible with current-generation phones (DCT3 versions such as 5185i, 5170i, 5180i,

6185i, and 3285) and DCT4 versions such as the 6385.

General Setup Procedure

Initial installation of Diego requires the complete Diego installation package. This package, currently around 18 megabytes in size, is provided on a CD-ROM disk. Because of

this large size, it is not recommended to download the file nor is it practical to provide it

on 3.5-inch floppy disks.

Install Diego by following the steps as outlined on the material that comes with the disk.

It should be noted that installation of a Nokia dongle on the computer being loaded is

REQUIRED prior to beginning the installation of the software.

The software is packaged into an InstallShield executable bundle. When the user double-clicks on this file, the installation program provides on-screen instructions on how to

proceed. Standard installation, provided by selecting all default choices, is highly recommended. You may do a custom installation and place Diego into a special location on

your hard drive; however, this is only recommended for experienced users.

It is necessary to reboot the computer after installing the software. The program is not

usable until a reboot is performed. After reboot, the Diego icon is included on the computer desktop. Double-clicking on this icon launches the program.

Page 8 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 48

RH-34

CCS Technical Documentation Service Software Instructions

Hardware Requirements for using Diego

Minimum Hardware Requirements

Processor 233 MHz

RAM1 64 MB

Disk space needed 50-100 MB

Supported Operating

Systems

Windows 95 Limited, no USB support

Windows 98

Windows NT 4.0 no USB support

Windows 2000 Professional version

Notes

Installing Diego

Before installing the software, verify:

• An FLS-4 version dongle is attached to either the parallel port or the USB port (if the

computer supports USB). An FLS-2D may be used; however, the FLS-2D does not support the new generation DCT-4 version phones.

• Ensure that if the computer supports administrator rights (typically on Windows NT

and Windows 2000 installations) that access is enabled for the user performing the

installation.

• If a previous version of Diego has been installed, it may be necessary to first properly

remove that program prior to installing the new version. If installation is performed,

be sure to reboot the computer prior to continuing. See Uninstalling Diego for

instructions on how to uninstall.

Installing

• Insert the CD-ROM disk into the computer drive.

• Access the drive and double-click on the Diego software package found on the CD.

• Follow the on-screen prompts to conclusion.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 9

Page 49

RH-34

Service Software Instructions CCS Technical Documentation

Note that rebooting the computer will be necessary when completed.

Software Support Bundles

The Diego installation is auto-executable. You must obtain Software Support Bundles to

load software upgrade files to customer-specific models.

These bundles are created by CCS and made available by AMS on the Partners Web Page

http://americas.partners.nokia.com . This web page is password-controlled; if you have

not registered as a user, contact Nokia Central Service in Melbourne, Florida.

Similar to the Diego installation, these packages are executable packages. Just doubleclick on the package, and it will auto-install.

No re-booting of the computer is required.

Starting a Diego Session

Concepts

When referring to Diego, Product is the cellular phone attached to the computer. More

specifically, it is the particular type of phone.

Connection is the type of cable used to attach the phone and the port on the computer

where it is attached. Refer to the Service Tools chapter for more information.

The first time Diego is used, certain connection configurations must be made. Subsequent uses will rely on these selections and they will not need to be made again.

Initial Session with Diego and FLS-4S Dongle

You must configure the Virtual Port Connection in Diego the first time Diego is launched.

The FLS-4 dongle uses virtual port, which eliminates the need to use the serial port (as

the FLS-2D does). During the installation of the FLS-4 drivers (included in the Diego

installation package), a virtual COM port is set to the next available COM port number.

This port selection must be put into the Diego configuration.

Follow these simple steps:

Page 10 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 50

RH-34

N

CCS Technical Documentation Service Software Instructions

Select “My Computer” desktop icon and click on the “FLS Virtual Port” icon.

Make note of the Virtual Port Assignment (COM 2 in this example).

Next select “Add…” to create a new connection.

ote: COM port settings can

only be entered or changed if

the auto-connection feature of

Diego is disable (as indicated

by the grey Status box).

To disable the auto-connect

click on this icon in the tool

bar:

Note: COM port settings can only be entered or changed if the auto-connection feature of Diego is

disabled (as indicated in the grey Status box). To disable the auto-connect feature, click on this icon in

the toolbar.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 11

Page 51

RH-34

Service Software Instructions CCS Technical Documentation

Select the Virtual COM port setting. Then press the Apply button.

You can now proceed with the normal initiation of a session.

Scanning for a Product

Many features of this program are product-specific. Therefore, it is necessary to configure Diego at the beginning of a session for the product on which you will be working.

Scanning of the product can be done manually or automatically. The default setting is

automatic. This setting can be changed to manual in the “settings” – “general” box. In

automatic mode, Diego will automatically scan for a product at a periodic rate. The scan

rate is defaulted to every 5 seconds, but it can be changed to a different frequency in the

Setup menu.

To manually scan for a product, click on the “Settings” icon as noted above.

Using Components

When working with Diego, tasks are generally managed by specific software components. From the icons displayed on the left side of the screen, select the desired component or task to be performed.

“Opening a component” is defined as opening a tool window within Diego. When this

window is opened, Diego also opens a task box for it, which includes component-specific menu items.

Uninstalling Diego

As mentioned in the Installing Diego section, it may be necessary or desirable to remove

Diego. Care must be taken to follow this procedure. Failure to remove the program

properly will cause misconfiguration of the computer’s registry.

Page 12 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 52

RH-34

CCS Technical Documentation Service Software Instructions

Uninstalling Diego version

• Go to the computer’s “Control Panel”, selectable from the Start button or the “My

Computer” desktop icon.

• Select “Add/Remove Programs” icon.

• Select the Diego version to be removed, and click the Add/Remove button.

• Click on the OK button to begin the process of removal.

• Follow the on-screen instructions.

Be sure to reboot the computer when finished.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 13

Page 53

RH-34

Service Software Instructions CCS Technical Documentation

Page 14 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 54

CCS Technical Documentation

RH-34 Series Transceivers

Service Tools

Issue 1 11/2003 Confidential ©2003 Nokia Corporation

Page 55

RH-34

Service Tools CCS Technical Documentation

Contents

Page No

Model 6225 Service Tools............................................................................................. 3

Flashing and Testing Setups .......................................................................................8

Flashing, Testing, and Tuning with Covers on ............................................................8

Service Setup 1.......................................................................................................... 9

Service Setup 2........................................................................................................ 10

Service Setup 3........................................................................................................ 11

Automated Tuning and Alignment ............................................................................12

Automated Tuning and Alignment Equipment List................................................ 13

GPS Testing Engine ...................................................................................................13

GPS Testing Equipment.......................................................................................... 14

Page 2 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 56

RH-34

CCS Technical Documentation Service Tools

Model 6585 Service Tools

JBV-1 Docking Station DA-12 Docking Station Adapter

0770298 0770603

The Docking Station and the Docking Station Adapter

are needed for Mbus, Fbus, RF, and audio connections.

This setup allows connection between flash prommers.

When the audio box is connected, it has to be connected to the phone’s audio connector. The Docking

Station can be powered by FPS-8 or external power

supply.

The flash adapter allows FBUS/MBUS connections for

flashing.

JBA-12 Audio Box CPL-8 GPS/RF Coupler

0770536 0770475

The JBA-12 is required for audio testing at authorized

service centers.

CPL-8 allows testing of the GPS antenna at AMS locations.

Shield Box JSX-1A is required.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 3

Page 57

RH-34

Service Tools CCS Technical Documentation

JSX-1A Shield Box DKU-5F Flash Cable

0770346 0780738

The Shield Box allows RF radiated tests and antenna

testing. Contact the Americas AMS in Melbourne, FL

for more information on how to obtain one..

For use with the Spirent UPST and UMPP service software.

Note: The cable cannot be used as a straight through

USB connection cable.

FPS-8 Flash Prommer ADS-8 Audio Cable

0080321 0730268

The Flash Prommer FPS-8 is used for heavy flash. The Audio Cable connects to the Audio Box (JBA-12).

Page 4 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 58

RH-34

CCS Technical Documentation Service Tools

XCS-4 Mbus/Fbus Cable CA-5S DC Service Cable

0730178 0730283

XCS-4 Service Cable is a modular cable for flashing

DCT4 products.

The DC Service Cable (CA-5S) connects the docking

station (JBV-1) to the charger connection (Vin) of the

phone to conduct EM calibration.

Note: CA-5S replaces the SCB-3 cable (0730114).

PCS-1 Power Cable XRS-6 RF Cable

0730012 0730231

The PCS-1 Power Cable is used to connect the service

tools (JBV-1, DA-12) to an external power supply.

The XRS-6 Cable is used to connect service tools to RF

measuring equipment.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 5

Page 59

RH-34

Service Tools CCS Technical Documentation

FLS-4S POS Flash Dongle DAU-9T FBUS Data Cable

0080543 0730267

The Point of Sale (POS) flash is a low-cost software

upgrade tool. This requires XCS-1 cable and ACF-8 for

operation.

FBUS cable DAU-9T provides a connection from the

serial port of the computer to the system connector of

the phone.

DAU-9S Cable (DB-9-Mode-10) CA-25RS RF Test Probe

0730108 0730316

DAU-9S is a general-purpose communications cable. The CA-25RS allows testing of the CDMA RF.

Page 6 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 60

RH-34

CCS Technical Documentation Service Tools

CA-22DS Service Connector MJ-18 Module Jig

0730311 0770599

This cable is used with FLS-4S or FLC-20 for bottomconnector flashing.

PKD-1 SW Security Device

0750018

SW security device (PKD-1) is a hardware device that,

when connected to the parallel (LPT) port of the PC,

enables the use of service software. Without the dongle present, it is not possible to use the service software. Printers or other peripheral devices can be

connected to the PC through the dongle, if needed.

Caution: Make sure that you have switched off the PC

and the printer before making connections!

This jig allows phone PWB-level service and troubleshooting for authorized service centers.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 7

Page 61

RH-34

Service Tools CCS Technical Documentation

Flashing and Testing Setups

POS Flash Setup 1 POS Flash Setup 2

FLC-20 and CA-22DS DKU-5F

POS Flash Setup 3 Service Center Flash Setup 4

FLS-4S and CA-22DS FPS-8 prommer, JBV-1, and DA-12

Flashing, Testing, and Tuning with Covers on

Tightened performance specifications require more precise equipment and methods for

testing and alignment. Manual tuning can’t provide accurate results for the RH-34,

which means that this test has to be automated.

These setups are intended to be with with the Phoenix Service Software. Both manual

testing and automated tuning are permitted with Phoenix Service Software.

Page 8 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 62

RH-34

CCS Technical Documentation Service Tools

Service Setup 1

Item Name Type Code

Docking Station JBV-1 0770298

1 Docking Station Adapter DA-12 0770603

2 DC Power Cable PCS-1 0770012

3 Modular Cable XCS-4 0730178

4 Flash Prommer Box FPS-8 0080321

5 Printer Cable

(included with FPS-8)

6 D9-D9 Cable

(included with FPS-8)

7 SW Protection Key PKD-1 0750018

8 AC Charger ACP-8F 0680032

CA-10DS 0730298

AXS-4 0730090

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 9

Page 63

RH-34

Service Tools CCS Technical Documentation

Service Setup 2

Item Name Type Code

1 Module Jig MJ-18 0770599

2 DC Power Cable PCS-1 0730012

3 RF Antenna Cable XRS-6 0730231

4 Service MBUS Cable DAU-9S 0730108

5 SW Protection Key PKD-1 0750018

Page 10 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 64

RH-34

CCS Technical Documentation Service Tools

Service Setup 3

Item Name Type Code

1 Docking Station JBV-1 0770298

2 Docking Station Adapter DA-12 0770603

3 DC Service Cable CA-5S 0730283

4 RF Antenna Cable XRS-6 0730231

5 DC Power Cable PCS-1 0730012

6 Service MBUS Cable DAU-9S 0730108

7 SW Protection Key PKD-1 0750018

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 11

Page 65

RH-34

Service Tools CCS Technical Documentation

Automated Tuning and Alignment

This setup is used for tuning of the handset at Nokia Authorized Service Centers..

Page 12 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 66

RH-34

CCS Technical Documentation Service Tools

Automated Tuning and Alignment Equipment List

Item Name MFR Model # QTY Comment

1 Vector Signal Analyzer Agilent E4406A 1 Options B78, BAC and BAE

2 Signal Generator Agilent E4421B 1 Digital signal generator with

high stability oscillator and high

spectral purity

3 Momentum Series Agilent 8960C 1 CDMA tester for IS-95, IS-2000,

and AMPS protocols

4 Power Supply Keithly K2306 2 Programmable with sense wire

5 Win2000 PC Dell with Pentium III or above,

network card, 256M RAM, 20GB

HD, CD-ROM, etc.

6 NI-GPIB Interface NI GPIB-USB-A 2 USB to GPIB adapter (184983G-

01)

7 Docking Station Nokia JBV-1 1 Consult your local Nokia After

Market Services office for more

information

8 RF Switches Green Hill TVi9901 1 Consult your local Nokia After

Market Services office for more

information

Note: A Test Sequence File is required to perform “Auto tune” on this phone. In addition, Phoe nix needs to have the Auto Tune function installed. Consult you local Nokia After Market Services office more information.

GPS Testing Engine

This setup will be used for testing of the GPS Engine at Nokia Authorized Service Centers.

Both Galvanic and Radiated tests will be supported. The GPS Test component in Phoenix

will provide functionality to perform these tests. Refer to the Troubleshooting - GPS section for more details regarding GPS Engine troubleshooting.

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 13

Page 67

RH-34

Service Tools CCS Technical Documentation

DA-12

DA-12

releaselatest

GPS Testing Equipment

• Power Supply

Figure 1: GPS Galvanic Testing

Figure 2: GPS Radiated Testing

• Signal Generator up to 2 GHz

• Computer (Pentium 3, W2000)

Page 14 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 68

RH-34

CCS Technical Documentation Service Tools

• JBV-1 Docking Station

• DA-12 Docking Station Adaptor

• PCS-1 DC Power Cable

• DAU-9S M/F-Bus Cable

• RF Test Cables (for GPS RF Port)

• Latest Release Phoenix AMS version w/ GPS Test Component

Issue 1 11/2003 Confidential ©2003 Nokia Corporation Page 15

Page 69

RH-34

Service Tools CCS Technical Documentation

Page 16 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 70

CCS Technical Documentation

RH-34 Series Transceivers

Disassembly/Assembly

Issue 1 11/2003 Confidential ©2003 Nokia Corporation

Page 71

RH-34

Disassembly/Assembly CCS Technical Documentation

Step-by-Step Disassembly Instructions

Alway use ESD protection

Disassembly Instructions

Step-by-Step Disassembly Instructions (Model 6585)

1. Push the Release Button to the left before pulling up

the B-Cover. Remove the battery and the SIM card.

2. Unlock the top guidance to remove the A-Cover.

3. Unscrew the six T6 screws, using the shown order.

For assembly, the reverse order and a torque of 17Ncm

must be used.

4. Remove the modules from the C-cover and unplug

the display connector by pulling the modules apart

carefully.

Page 2 ©2003 Nokia Corporation Confidential Issue 1 11/2003

Page 72

RH-34

CCS Technical Documentation Disassembly/Assembly

Step-by-Step Disassembly Instructions (Model 6585)