Page 1

Customer Care Solutions

Technical Documentation

SERVICE MANUAL

[NMP Part No. 0275893]

Model 6560

(RH-25 Series) Cellular Phones

Issue 1 Copyright © Nokia Corporation. All Rights Reserved

Page 2

Customer Care Solutions

Technical Documentation

Amendment Record Sheet

Amendment No Date Inserted By Comments

10/2003 J Fraser Issue 1

Issue 1 Copyright © Nokia Corporation. All Rights Reserved

Page 3

Customer Care Solutions

Technical Documentation

RH-25 (6560) Cellular Phones

Service Manual – Overall Manual Contents

Service Manual comprising

RH-25 Series Transceiver booklet comprising

Foreword

General

Parts

Service Software Instructions

Service Tools

Disassembly/Assembly

Troubleshooting - Baseband

Troubleshooting - RF

System Module

Schematics

Issue 1 Copyright © Nokia Corporation. All Rights Reserved

Page 4

This document is intended for use by qualified service personnel only.

Company Policy

Our policy is of continuous development; details of all technical modifications will be

included with service bulletins.

While every endeavour has been made to ensure the accuracy of this document, some

errors may exist. If any errors are found by the reader, NOKIA Corporation should be

notified in writing.

Please state:

Customer Care Solutions

Technical Documentation

IMPORTANT

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

Please send to: Nokia Corporation

CCS Technical Documentation

PO Box 86

FIN-24101 SALO

Finland

Issue 1 Copyright © Nokia Corporation. All Rights Reserved

Page 5

Customer Care Solutions

Technical Documentation

Warnings and Cautions

Please refer to the phone's user guide for instructions relating to operation, care and

maintenance including important safety information. Note also the following:

Warnings:

1. CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH

ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING

SYSTEMS. UNDER CERTAIN FAULT CONDITIONS, EMITTED RF ENERGY CAN

AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/

MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC

SYSTEMS TO RF ENERGY.

2. THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY

TO CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES EG PETROL STATIONS

(SERVICE STATIONS), BLASTING AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and that an

3. Ensure solder, wire, or foreign matter does not enter the telephone as

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are correctly

CELLULAR TELEPHONES, MAY INTERFERE WITH THE FUNCTIONALITY OF

INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR

THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY

QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO

INTERFERENCE.

anti-static wrist strap is worn.

damage may result.

re-fitted after servicing and alignment. Ensure all cables and wires are

repositioned correctly.

Issue 1 Copyright © Nokia Corporation. All Rights Reserved

Page 6

CCS Technical Documentation

RH-25 Series Transceivers

General Information

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation

Page 7

RH-25

General Information CCS Technical Documentation

Contents

Page No

Nokia Model 6560 (RH-25)........................................................................................... 3

Hardware Characteristics .............................................................................................3

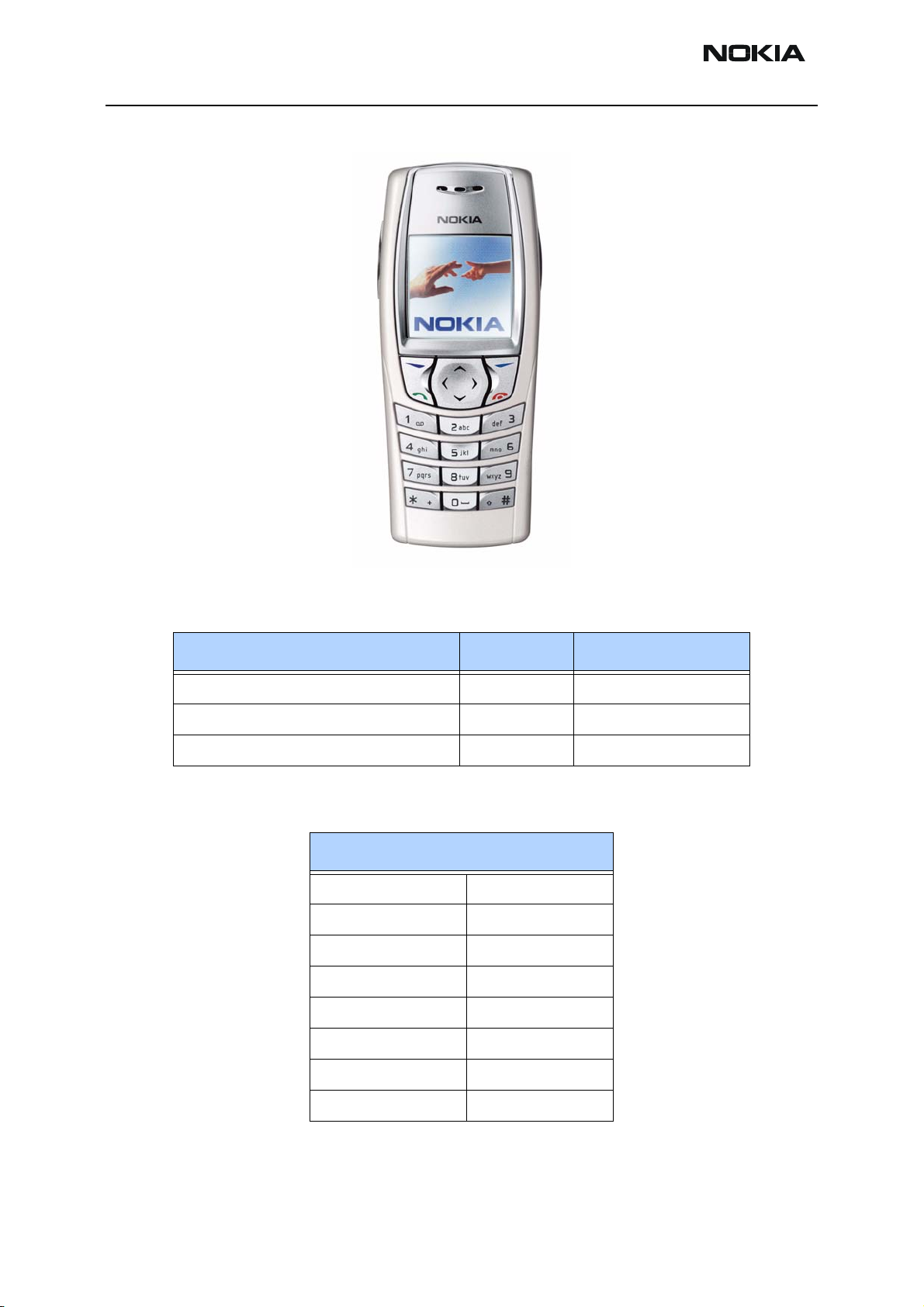

Model 6560 Handset ................................................................................................. 4

Sales Package ...............................................................................................................4

Module List ..................................................................................................................4

Supported Accessories .................................................................................................5

Technical Specifications ..............................................................................................5

General Specifications of Transceiver RH-25 .......................................................... 5

Page 2 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 8

RH-25

CCS Technical Documentation General Information

Nokia Model 6560 (RH-25)

RH-25 is a hand-portable dual band TDMA 850/1900 with AMPS. It has been designed

using DCT4 generation baseband (UEM/UPP), and RF (TACO) module, collectively referred

to as Stella processing engine.

The baseband module has been developed as part of the DCT4 common baseband.

RH-25 contains some baseband features that are new to the America's TDMA market.

These features include stereo FM receiver (offered as an accessory) and a MIDI (polyphonic ringing tones). RH-25 supports both two- and three-wire DCT3 chargers. The primary battery is the BLD-3 with a nominal capacity of 780 mAh.

Hardware Characteristics

• Hi-resolution (128x128) illuminated color display

• Active LCD pixel area: width 27.6mm X height 27.6mm

• Jack 4-style UI with four way navigation key; two soft key

• Support for internal semi-fixed battery (Janette type BLD-3)

• RTC backup battery support

• Audio amplifier and MALT speaker for MIDI support

• Ringing volume 100dB @ 5cm (MIDI tones through MALT speaker)

• Stereo FM receiver as an accessory

• IrDa port/interface

• Internal vibra

• Supports voice dial activation via headset button

• Six white TBSF LEDs for keyboard and two for LCD backlight

• 6-layer PWB, SMD with components on both sides of PWB

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 3

Page 9

RH-25

General Information CCS Technical Documentation

Model 6560 Handset

Sales Package

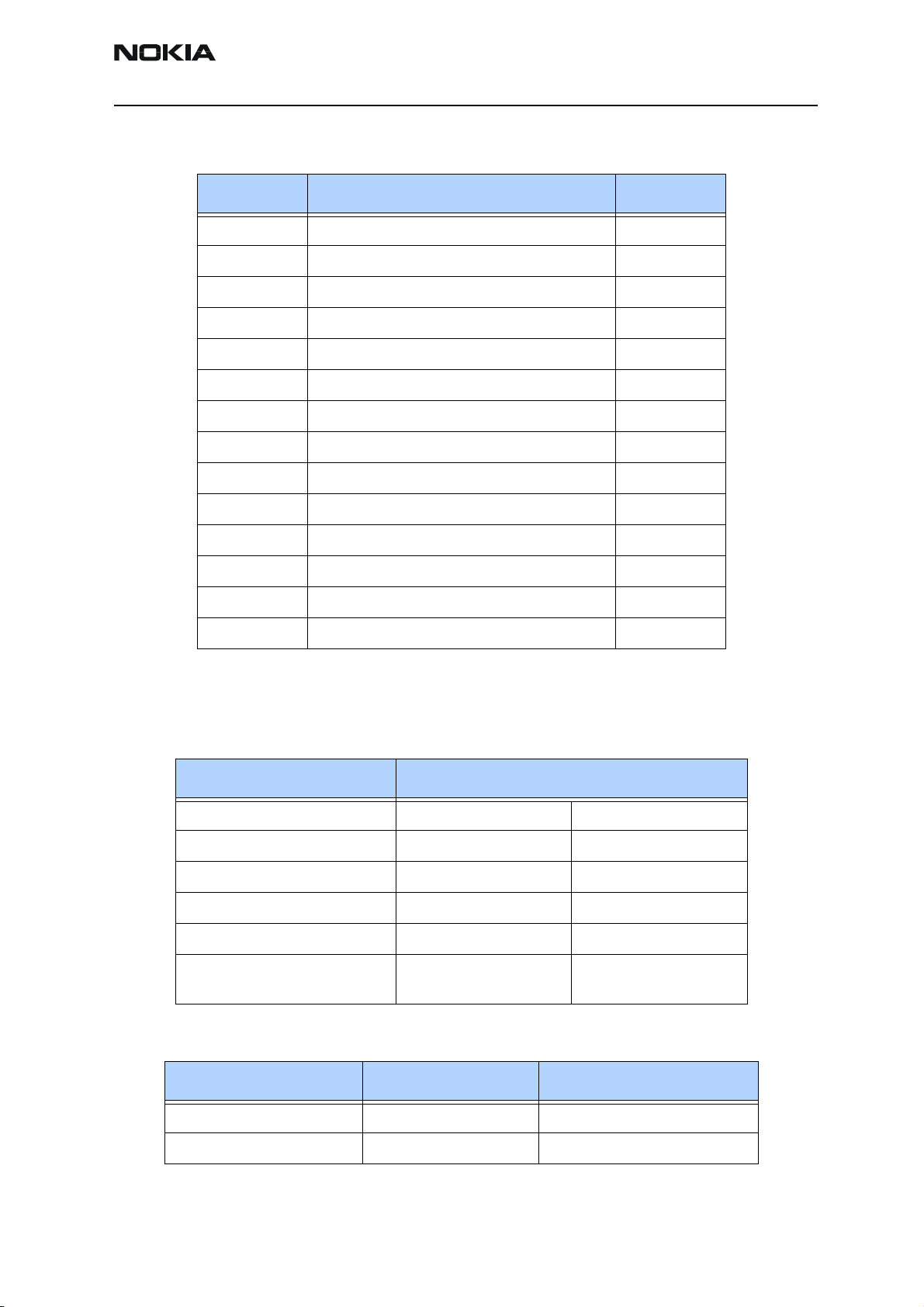

Transceiver RH-25 Customer-specific

Battery (780 mAh Li-Ion) BLD-3 0670352

Rapid Performance Charger (US plug) ACP-12U 0675303

Module List

Name: Type Code Material Code

RH-25 (Nokia 6560)

A-cover assy 9491436

Keymat 9791041

Screws 6290171

Display 4850291

C-cover Module 9491370

Antenna Assy 0660298

Battery 0670352

B-cover 9653696

Page 4 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 10

RH-25

CCS Technical Documentation General Information

Supported Accessories

Type Name Code

BLD-3 Standard 780 mAh Li-ion Battery 0670352

ACP-7U AC Travel Charger (US) 108-132 Vac 0675143

ACP-8U AC Charger 0675196

ACP-12U Rapid Performance Charger (US) 0675303

DDC-1 Spare Battery Charger 0675243

CA-8 Advanced Car Kit 0080932

BHF-1 Headrest handsfree 0273278

LPS-4 Loopset 0630443

LCH-12 Cigarette Lighter Charger 0675328

HDB-4 Boom Headset 0694094

HS-5 Earbud Headset 0694121

HDS-3 FM Stereo Headset 0694093

HS-3 Fashion Stereo Headset 0694156

HS-10 Retractable Headset 0694126

Technical Specifications

General Specifications of Transceiver RH-25

Parameter Specifications

Cellular system TDMA 800 and AMPS TDMA 1900

RX frequency band 869.01-893.97MHz 1930.05 - 1989.99MHz

TX frequency band 824.01-848.97MHz 1850.01 - 1909.95MHz

Number of RF channels 832 1999

Channel spacing 30KHz 30KHz

Power levels -5 - +28dBm /

0.3mW - 630mW

-5 - +28dBm /

0.3mW - 630mW

Parameter Mode Value and unit

Talk time Analog 2 hrs

Talk time Digital 5 hrs

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 5

Page 11

RH-25

General Information CCS Technical Documentation

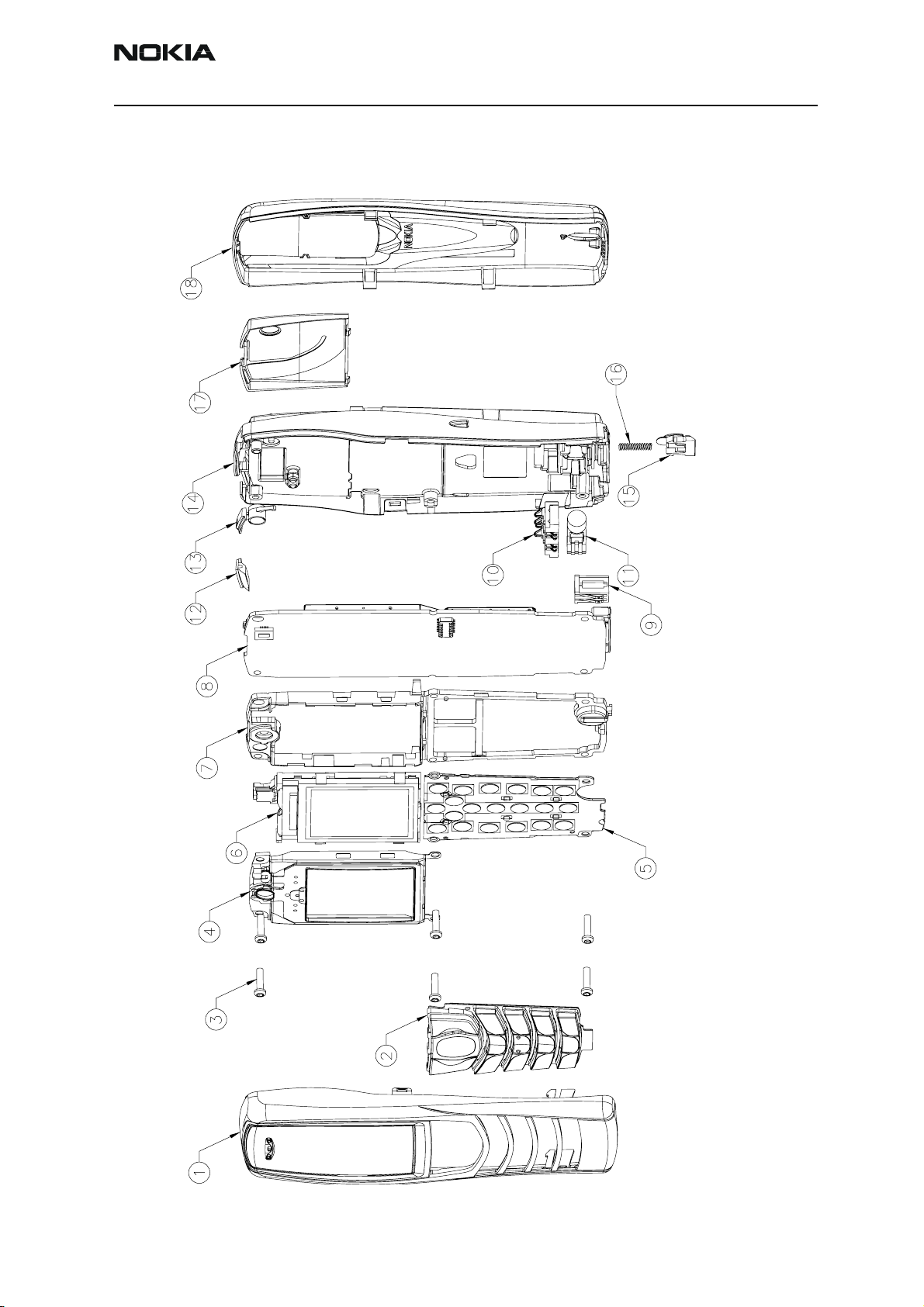

Parameter Mode Value and unit

Standby time Analog 60 hrs

Standby time Digital 371 hrs

Dimensions W=105.8mm L=44mm

Weight with BLD-3 battery 88.36g

Page 6 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 12

CCS Technical Documentation

RH-25 Series Transceivers

Parts Lists

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation

Page 13

RH-25

Parts Lists CCS Technical Documentation

Contents

Page No

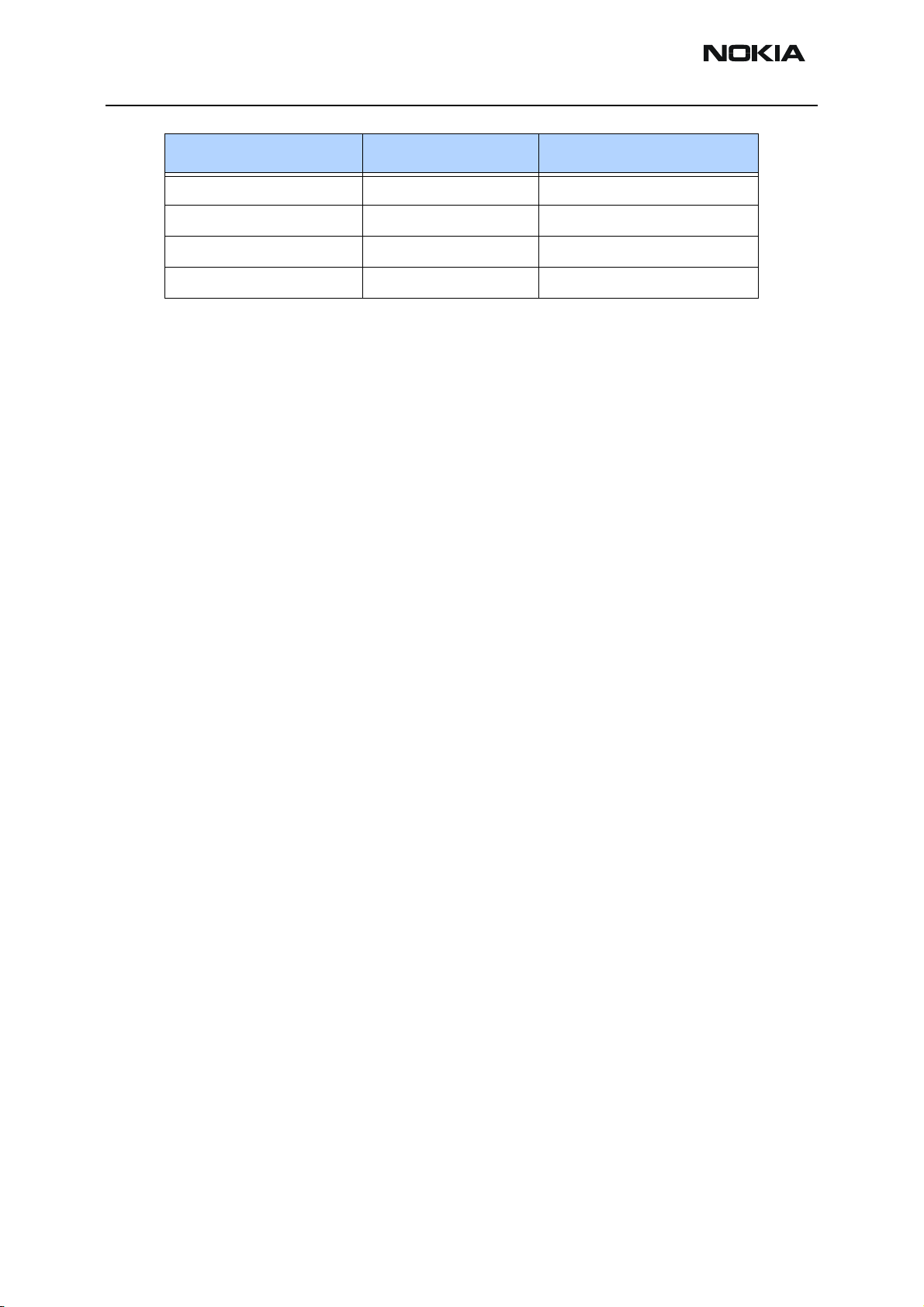

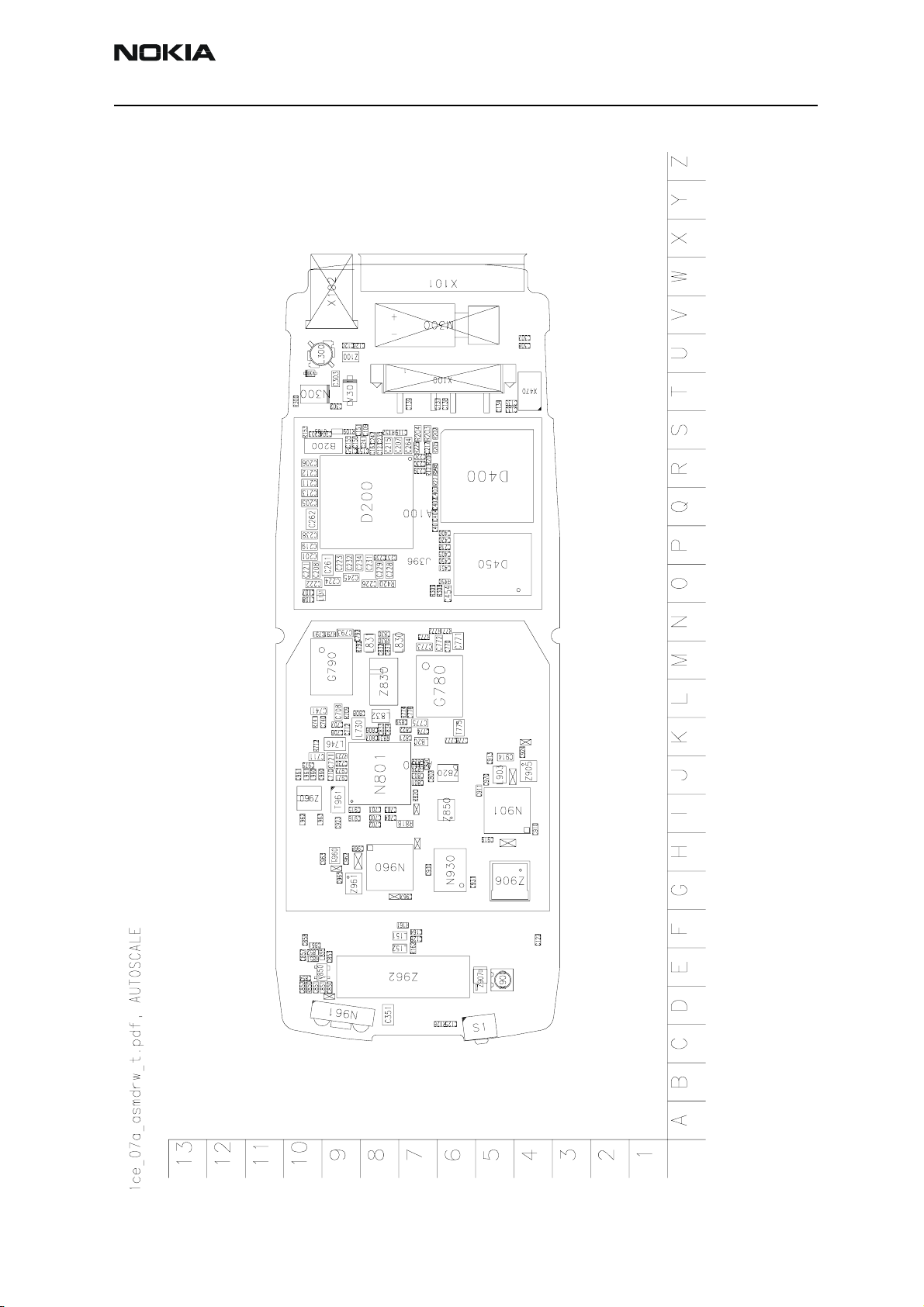

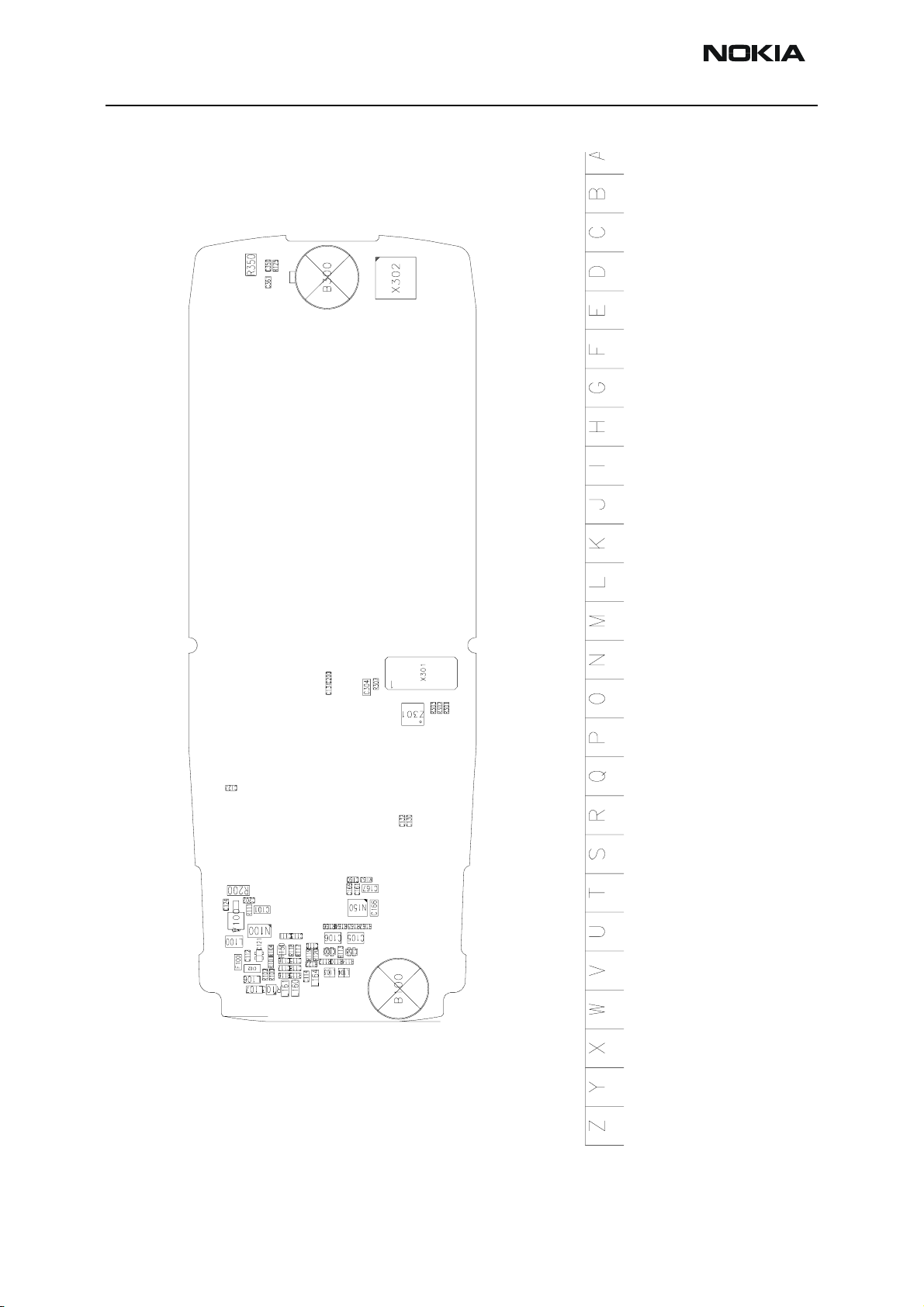

Exploded View............................................................................................................... 3

Assembly Parts of Basic Transceiver RH-25 ..............................................................4

Component Layout — Bottom ...................................................................................6

Parts Lists....................................................................................................................... 7

RH-25 (6560) — EDMS Issue 2.17 Code: 0202123 ...................................................7

Page 2 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 14

RH-25

CCS Technical Documentation Parts Lists

Exploded View

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 3

Page 15

RH-25

Parts Lists CCS Technical Documentation

Assembly Parts of Basic Transceiver RH-25

Item Qty Code Description

1 1 9491436 A-Cover (silver) DMC06279

2 1 9791041 Keymat (Latin) DMC06339

3 6 6290171 Screws M1.8x8mm DMC05300

4 1 9517301 Display Shield Assembly DMC06343

5 1 0210109 UI Board DMC06893

6 1 4850291 LCD Module DHS02568

7 1 9467111 LCD Frame DMC06344

8 1 9854768 PWB Engine DMF00140

9 1 5400243 DC Jack DNS04390

10 1 5409153 Battery Connector DNS01587

11 1 6800057

6800069

12 1 9453145 IR Window DMD10692

13 1 9790989 Power Key DMD10693

14 1 9491370 C-Cover DMC06323

15 1 9790990 Release Button DMD10665

16 1 9510845 Spring DNS05685

17 1 0660298 Antenna Assembly DMC06335

18 1 9491446 B-Cover Assembly (silver) DMC06280

Vibra Motor (Nomiki) DNS04642

Vibra Motor (Matsushita)

Page 4 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 16

RH-25

CCS Technical Documentation Parts Lists

Component Layout — Top

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 5

Page 17

RH-25

Parts Lists CCS Technical Documentation

Component Layout — Bottom

Page 6 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 18

RH-25

CCS Technical Documentation Parts Lists

Parts Lists

RH-25 (6560) — EDMS Issue 2.17 Code: 0202123

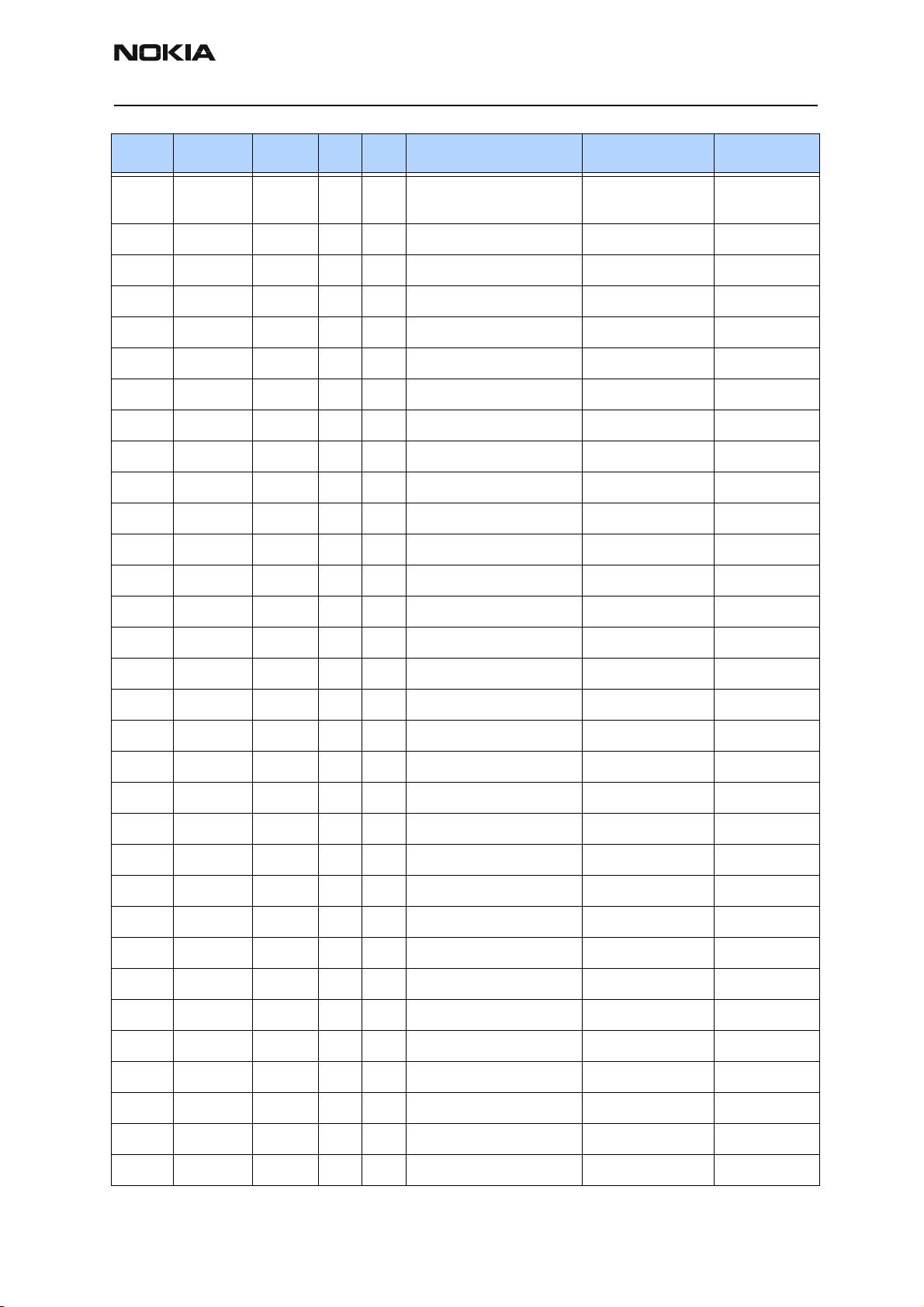

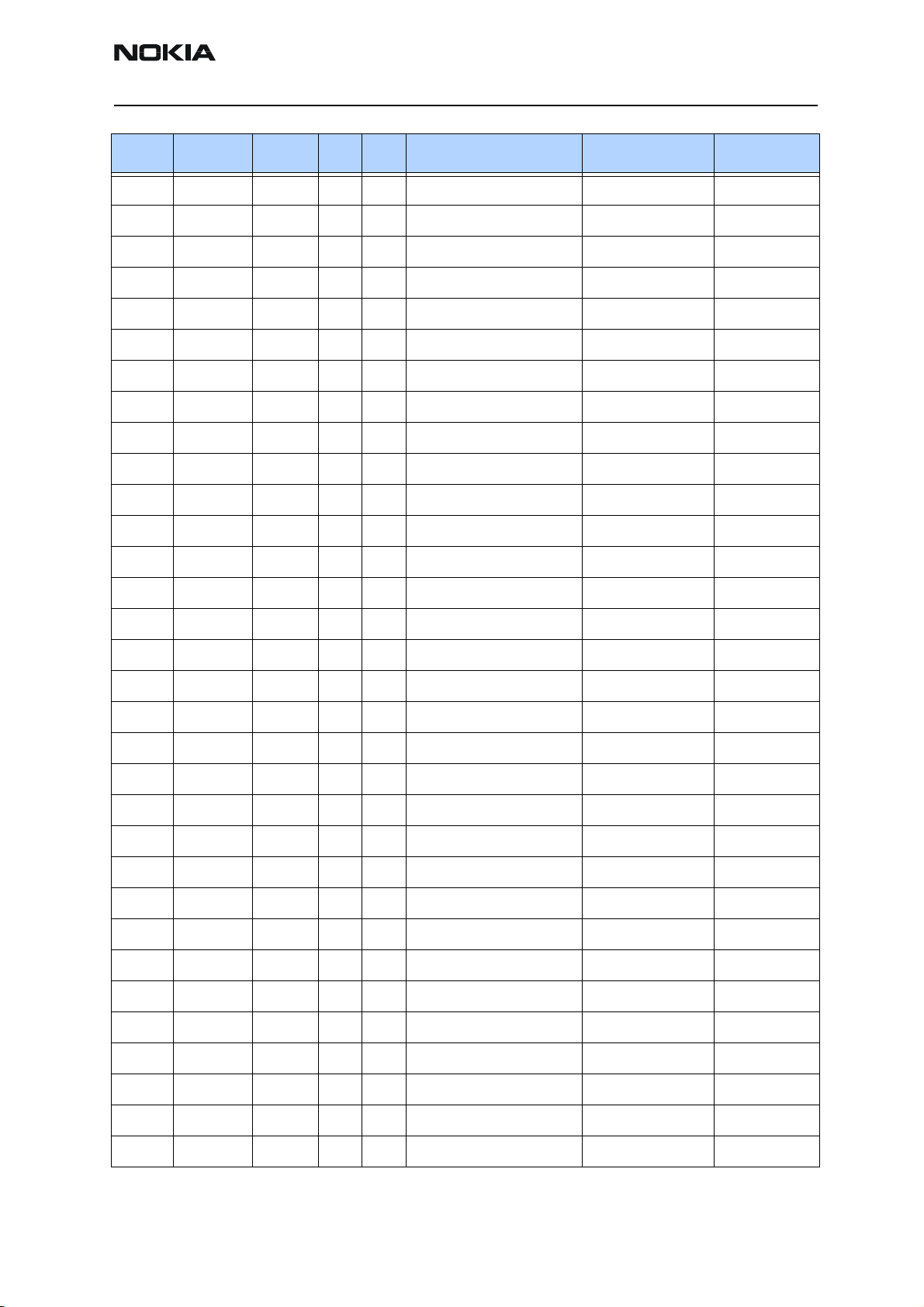

Item Code Side X Y Description Value Type

R100 1430726 Bottom V 9 chip res 0W06 100R J 0402

R101 1430726 Bottom V 9 chip res 0W06 100R J 0402

R102 1430726 Bottom V 9 chip res 0W06 100R J 0402

R103 4120011 Bottom V 9 ZDIX4 IP4043CX5 CA 14V2 10W CSP5

R104 1430812 Bottom U 9 chip res 0W06 220K J 0402

R109 1430804 Top S 9 chip res 0W06 100K J 0402

R110 1825033 Bottom V 7 chip varistor VWM14V VC46V 0402

R111 1430804 Bottom T 9 chip res 0W06 100K J 0402

R112 1825033 Bottom V 7 chip varistor VWM14V VC46V 0402

R113 1825033 Bottom V 7 chip varistor VWM14V VC46V 0402

R114 1825033 Bottom V 7 chip varistor VWM14V VC46V 0402

R115 1825033 Bottom V 8 chip varistor VWM14V VC46V 0402

R116 1825033 Bottom V 8 chip varistor VWM14V VC46V 0402

R117 1430762 Bottom U 8 chip res 0W06 2K2 J 0402

R118 1430762 Bottom U 8 chip res 0W06 2K2 J 0402

R119 1430762 Bottom V 8 chip res 0W06 2K2 J 0402

R120 1430762 Bottom V 7 chip res 0W06 2K2 J 0402

R121 1430804 Top R 7 chip res 0W06 100K J 0402

R122 1430762 Bottom V 8 chip res 0W06 2K2 J 0402

R125 1430778 Bottom D 8 chip res 0W06 10K J 0402

R126 1825033 Top D 6 chip varistor VWM14V VC46V 0402

R150 1620031 Bottom U 8 res network 0W06 2X1K0 J 0404

R152 1430784 Top S 8 chip res 0W06 15K J 0402

R153 1430778 Top S 10 chip res 0W06 10K J 0402

R161 1825033 Top F 7 chip varistor VWM14V VC46V 0402

R162 1825033 Top E 7 chip varistor VWM14V VC46V 0402

R163 1430764 Bottom T 6 chip res 0W06 3K3 J 0402

R164 1430710 Bottom U 7 chip res 0W06 22R J 0402

R165 1430710 Bottom U 6 chip res 0W06 22R J 0402

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 7

Page 19

RH-25

Parts Lists CCS Technical Documentation

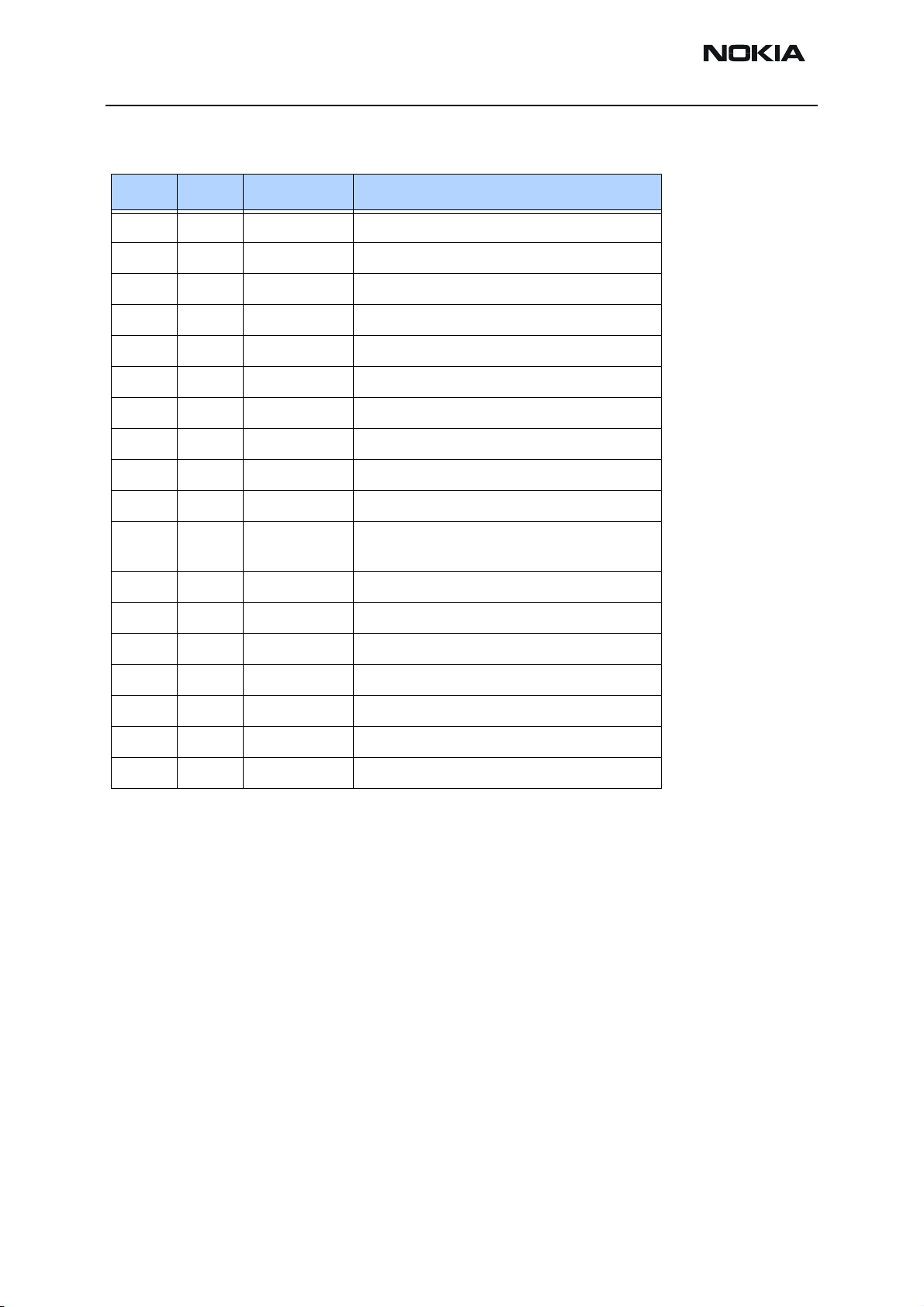

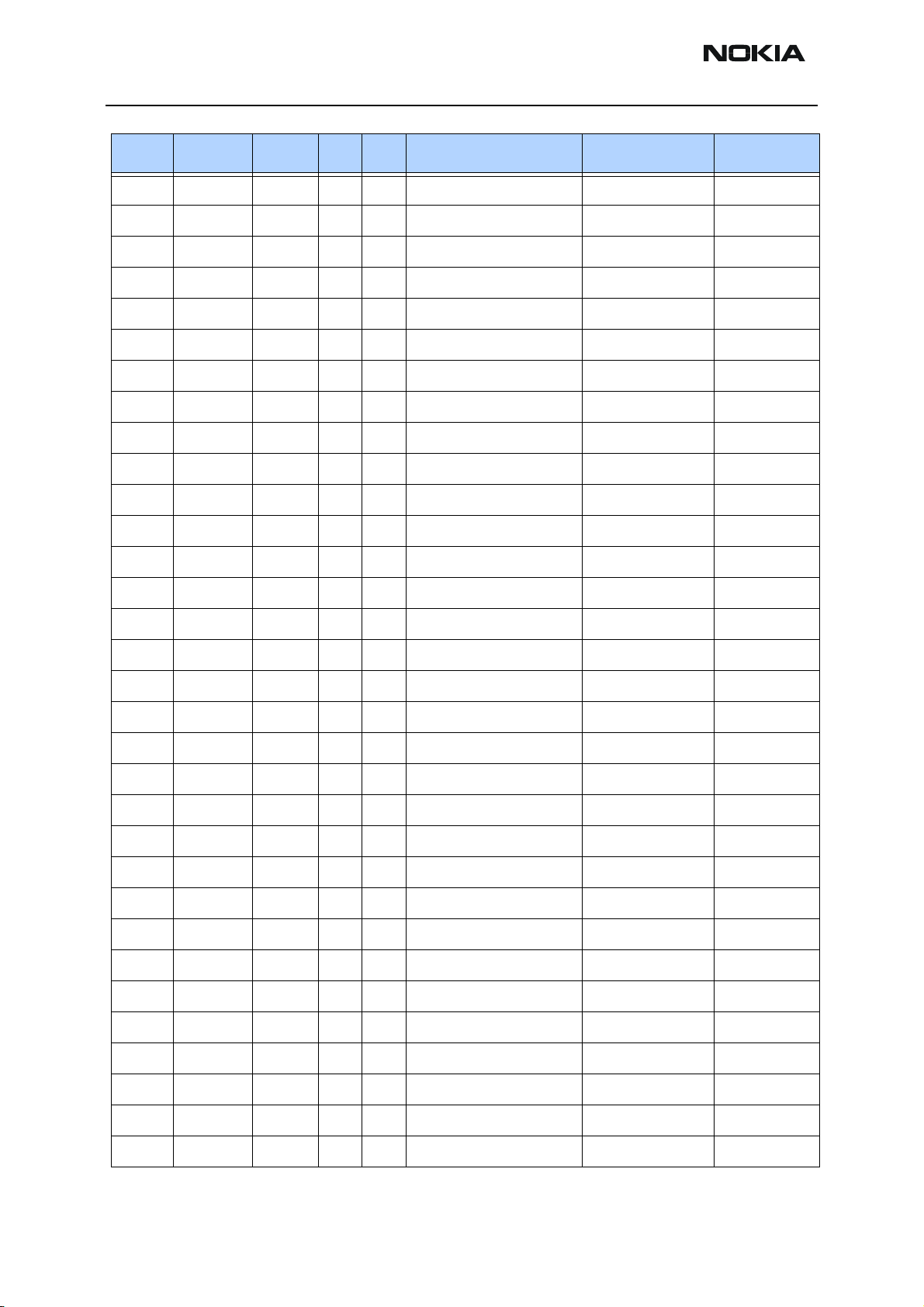

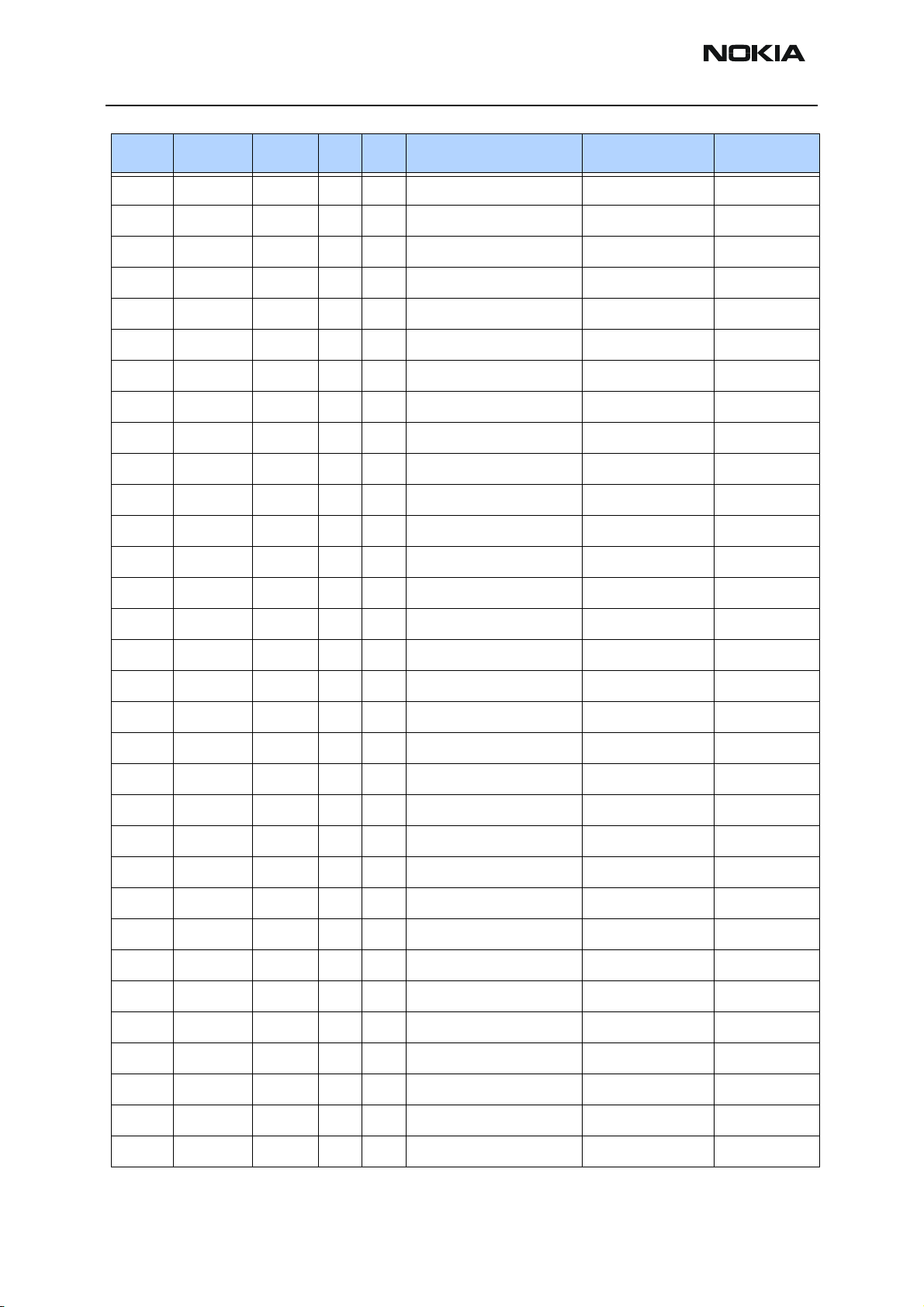

Item Code Side X Y Description Value Type

R166 1430710 Bottom U 7 chip res 0W06 22R J 0402

R167 1430710 Bottom U 6 chip res 0W06 22R J 0402

R200 1414605 Bottom T 9 chip res 0W25 0R22 J 0805

R202 1430804 Top S 7 chip res 0W06 100K J 0402

R203 1430087 Top S 7 chip res 0W06 100K J 0603

R204 1430087 Top S 7 chip res 0W06 100K J 0603

R205 1430770 Top S 7 chip res 0W06 4K7 J 0402

R206 1430804 Top R 7 chip res 0W06 100K J 0402

R225 1430770 Top S 7 chip res 0W06 4K7 J 0402

R226 1430690 Top R 7 chip res jumper 0R0 0402

R227 1430690 Top R 7 chip res jumper 0R0 0402

R300 1430712 Top T 10 chip res 0W06 27R J 0402

R301 1430734 Bottom O 4 chip res 0W06 220R J 0402

R302 1430734 Bottom O 4 chip res 0W06 220R J 0402

R303 1430734 Bottom O 4 chip res 0W06 220R J 0402

R307 1825033 Bottom O 6 chip varistor VWM14V VC46V 0402

R308 1430740 Top O 6 chip res 0W06 2K2 J 0402

R309 1430740 Top O 7 chip res 0W06 2K2 J 0402

R350 1413850 Bottom D 9 chip res 0W125 4R7 J 0805

R420 1430268 Top O 8 chip res 0W06 27K F

100PPM

R450 1430770 Top O 6 chip res 0W06 4K7 J 0402

R709 1430700 Top L 9 chip res 0W06 10R J 0402

R712 1430700 Top K 10 chip res 0W06 10R J 0402

R721 1430796 Top J 9 chip res 0W06 47K J 0402

R741 1430796 Top K 10 chip res 0W06 47K J 0402

0603

R771 1430786 Top N 6 chip res 0W06 18K J 0402

R772 1430726 Top N 7 chip res 0W06 100R J 0402

R773 1430700 Top N 7 chip res 0W06 10R J 0402

R774 1430700 Top L 7 chip res 0W06 10R J 0402

R791 1430778 Top N 9 chip res 0W06 10K J 0402

R792 1430700 Top M 9 chip res 0W06 10R J 0402

Page 8 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 20

RH-25

CCS Technical Documentation Parts Lists

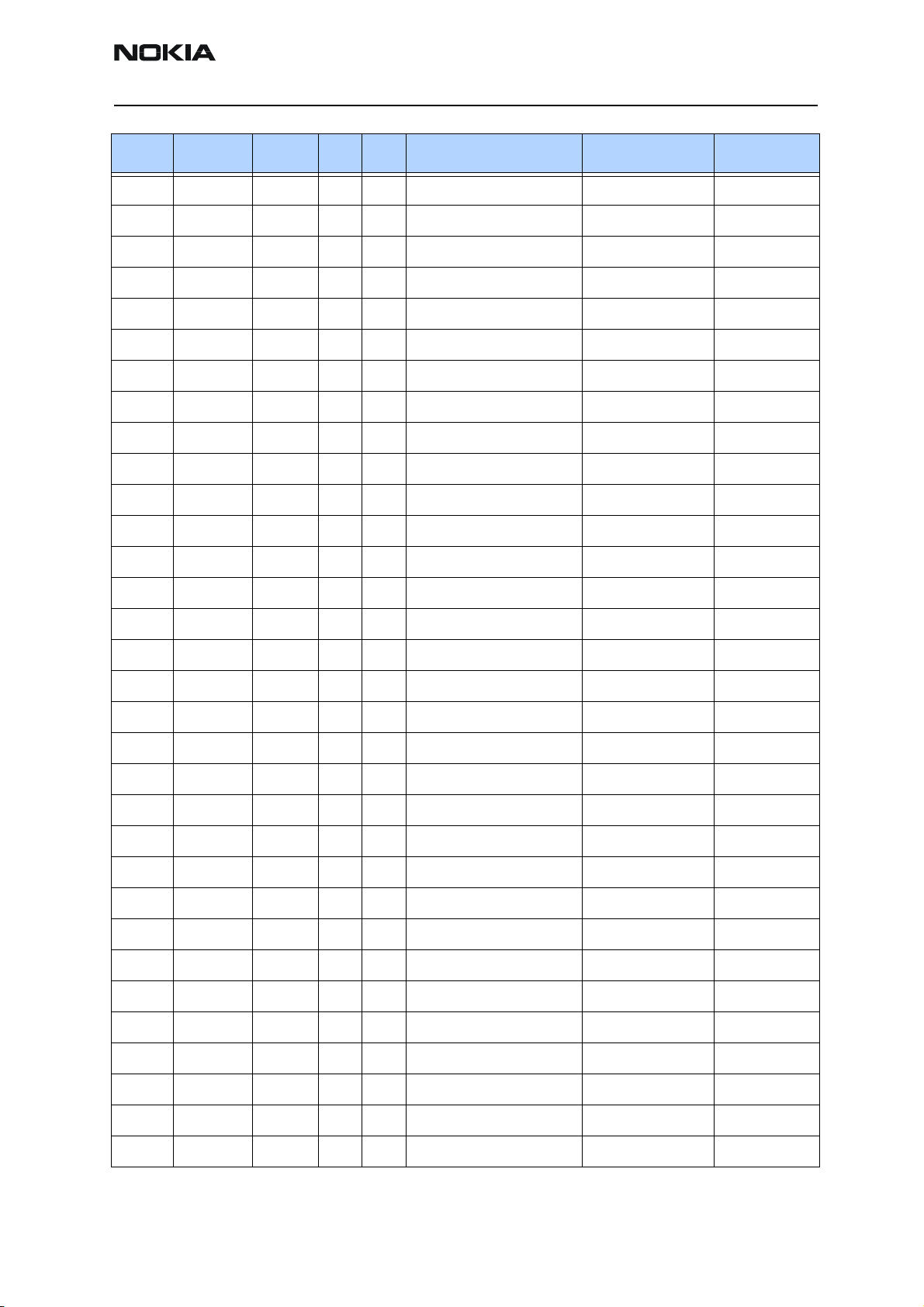

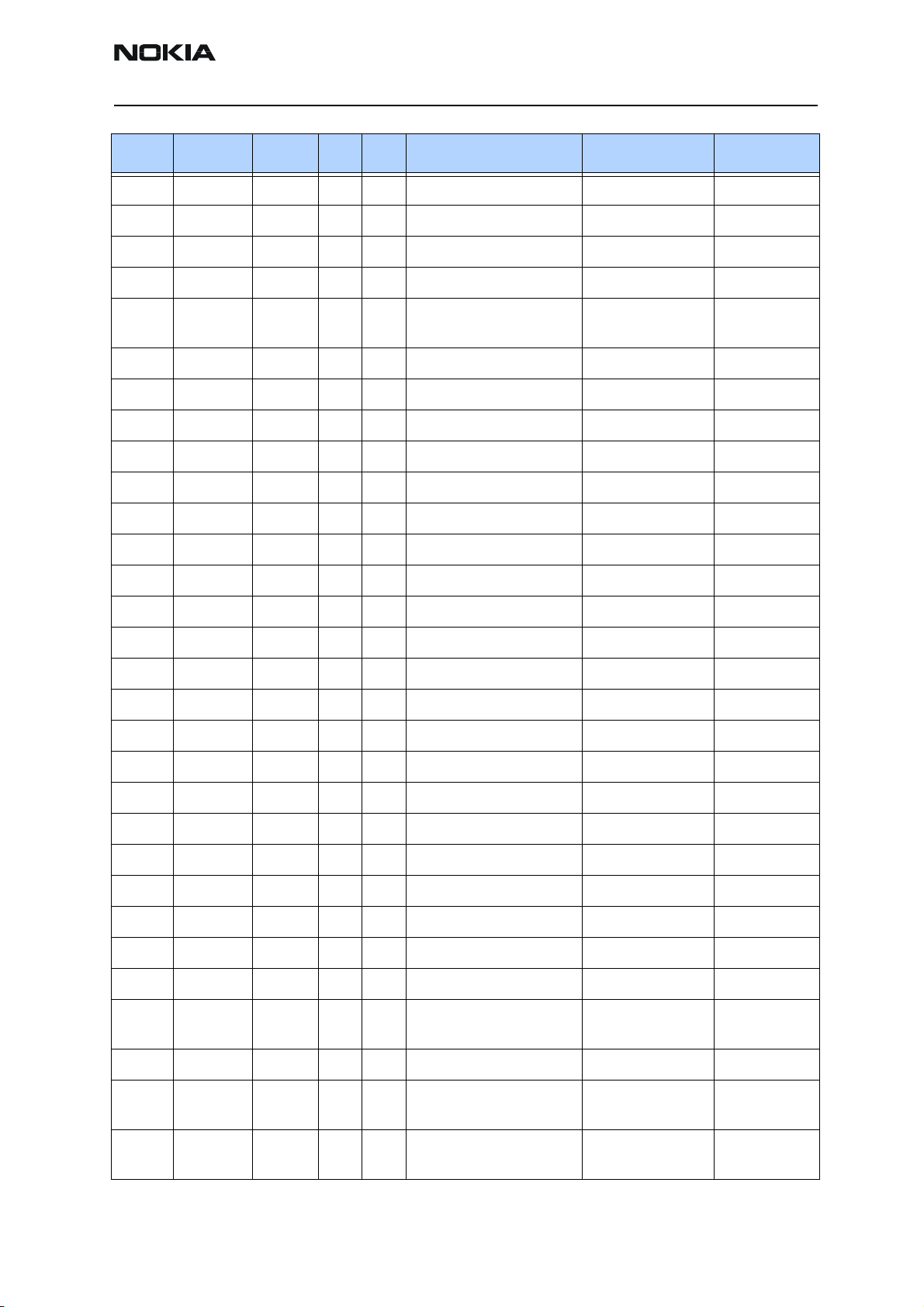

Item Code Side X Y Description Value Type

R818 1430268 Top I 7 chip res 0W06 27K F

100PPM

R820 1430740 Top I 7 chip res 0W06 2K2 J 0402

R830 1430832 Top N 8 chip res 0W06 2K7 J 0402

R831 1430734 Top K 8 chip res 0W06 220R J 0402

R850 1430798 Top D 10 chip res 0W06 56K J 0402

R851 1430734 Top E 10 chip res 0W06 220R J 0402

C100 2315201 Bottom V 7 chip array NP0 2X27P K 25V 0405

C101 2320481 Bottom T 9 chip cap X5R 1U K 6V3 0603

C102 2320481 Bottom V 9 chip cap X5R 1U K 6V3 0603

C103 2320544 Top S 9 chip cap NP0 22P J 50V 0402

C105 2312201 Bottom U 6 chip cap X5R 4U7 K 6V3 T=0.95 0805

C106 2312201 Bottom U 7 chip cap X5R 4U7 K 6V3 T=0.95 0805

C107 2320544 Top O 10 chip cap NP0 22P J 50V 0402

C108 2320544 Top O 10 chip cap NP0 22P J 50V 0402

0603

C109 2320783 Top S 8 chipcap X7R 100N K 16V 0603

C110 2320546 Bottom U 8 chip cap NP0 27P J 50V 0402

C111 2320544 Bottom U 8 chip cap NP0 22P J 50V 0402

C112 2320778 Bottom V 9 chip cap X7R 10N K 16V 0402

C113 2320544 Bottom U 8 chip cap NP0 22P J 50V 0402

C114 2320544 Bottom V 8 chip cap NP0 22P J 50V 0402

C115 2320756 Bottom V 8 chip cap X7R 3N3 K 50V 0402

C116 2320756 Bottom V 8 chip cap X7R 3N3 K 50V 0402

C117 2320544 Bottom V 8 chip cap NP0 22P J 50V 0402

C118 2320544 Bottom V 8 chip cap NP0 22P J 50V 0402

C119 2320744 Top S 7 chip cap X7R 1N0 K 50V 0402

C120 2320536 Top U 9 chip cap NP0 10P J 50V 0402

C121 2315201 Bottom V 9 chip array NP0 2X27P K 25V 0405

C122 2320805 Top F 4 chip cap X5R 100N K 10V 0402

C123 2320544 Top S 8 chip cap NP0 22P J 50V 0402

C124 2320744 Bottom T 10 chip cap X7R 1N0 K 50V 0402

C125 2320544 Top D 6 chip cap NP0 22P J 50V 0402

C126 2320536 Top U 9 chip cap NP0 10P J 50V 0402

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 9

Page 21

RH-25

Parts Lists CCS Technical Documentation

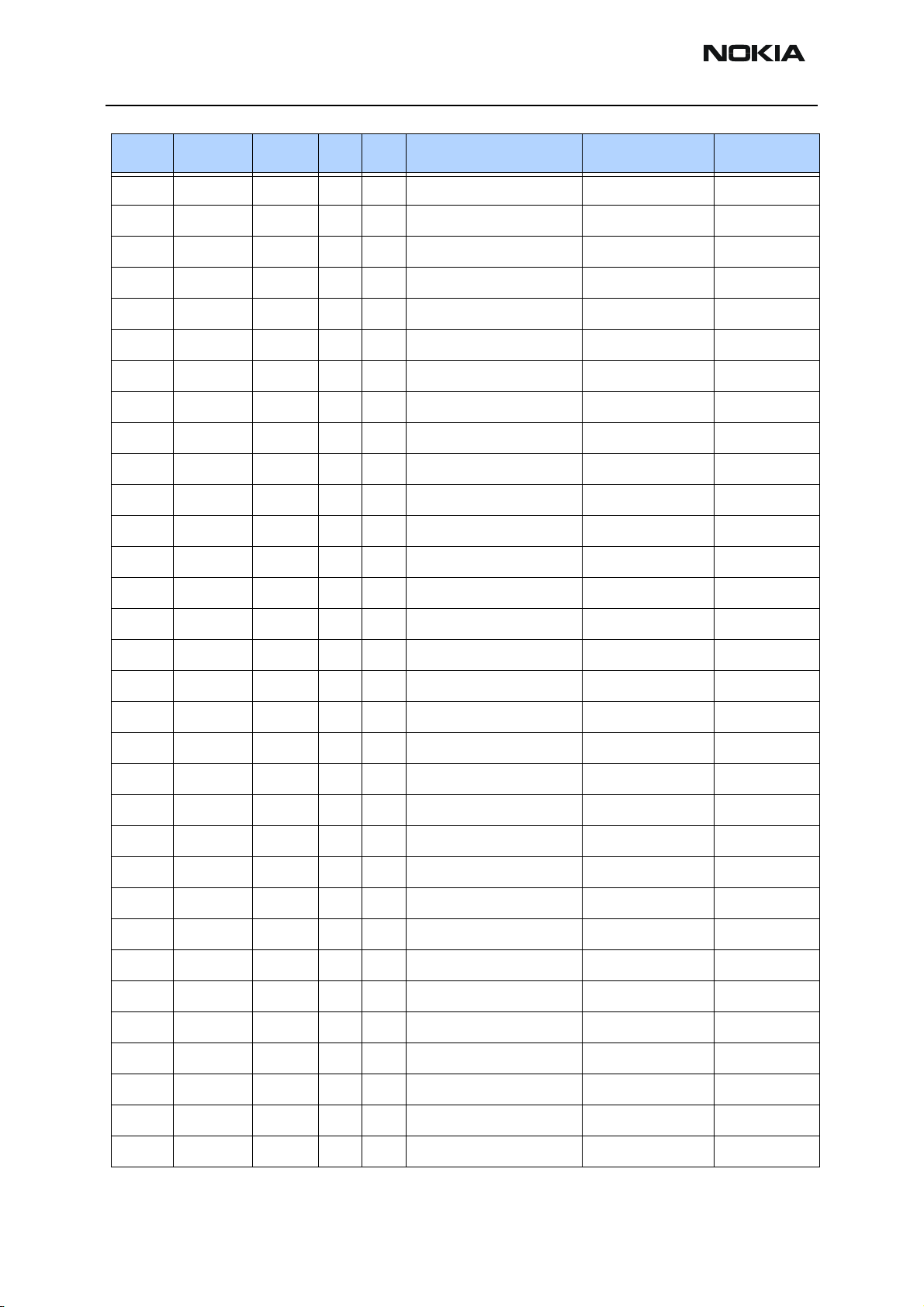

Item Code Side X Y Description Value Type

C127 2320546 Bottom Q 10 chip cap NP0 27P J 50V 0402

C128 2320596 Top F 7 chip cap X7R 3N3 J 50V 0402

C130 2320552 Bottom R 5 chip cap NP0 47P J 50V 0402

C131 2320552 Bottom O 7 chip cap NP0 47P J 50V 0402

C132 2320552 Bottom R 5 chip cap NP0 47P J 50V 0402

C133 2320544 Top T 5 chip cap NP0 22P J 50V 0402

C134 2320544 Top T 5 chip cap NP0 22P J 50V 0402

C135 2320544 Top T 5 chip cap NP0 22P J 50V 0402

C137 2320552 Top T 6 chip cap NP0 47P J 50V 0402

C138 2320552 Top T 6 chip cap NP0 47P J 50V 0402

C139 2320552 Top T 7 chip cap NP0 47P J 50V 0402

C151 2320783 Top S 9 chip cap X7R 100N K 16V 0603

C155 2320783 Top S 9 chip cap X7R 100N K 16V 0603

C156 2320783 Top S 9 chip cap X7R 100N K 16V 0603

C157 2320560 Top R 9 chip cap NP0 100P J 50V 0402

C158 2315201 Bottom V 7 chip array NP0 2X27P K 25V 0405

C159 2320560 Top R 8 chip cap NP0 100P J 50V 0402

C160 2320805 Bottom T 6 chip cap X5R 100N K 10V 0402

C161 2320805 Bottom T 6 chip cap X5R 100N K 10V 0402

C163 2320805 Top S 8 chip cap X5R 100N K 10V 0402

C164 2320596 Top F 7 chip cap X7R 3N3 J 50V 0402

C166 2320481 Bottom T 6 chip cap X5R 1U K 6V3 0603

C167 2320481 Bottom T 6 chip cap X5R 1U K 6V3 0603

C169 2320805 Bottom T 7 chip cap X5R 100N K 10V 0402

C200 2320552 Bottom N 7 chip cap NP0 47P J 50V 0402

C201 2320481 Top P 10 chip cap X5R 1U K 6V3 0603

C202 2320548 Bottom T 9 chip cap NP0 33P J 50V 0402

C203 2320536 Top S 10 chip cap NP0 10P J 50V 0402

C204 2320536 Top S 9 chip cap NP0 10P J 50V 0402

C205 2320481 Top Q 10 chip cap X5R 1U K 6V3 0603

C206 2320481 Top R 10 chip cap X5R 1U K 6V3 0603

C207 2320481 Top S 8 chip cap X5R 1U K 6V3 0603

Page 10 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 22

RH-25

CCS Technical Documentation Parts Lists

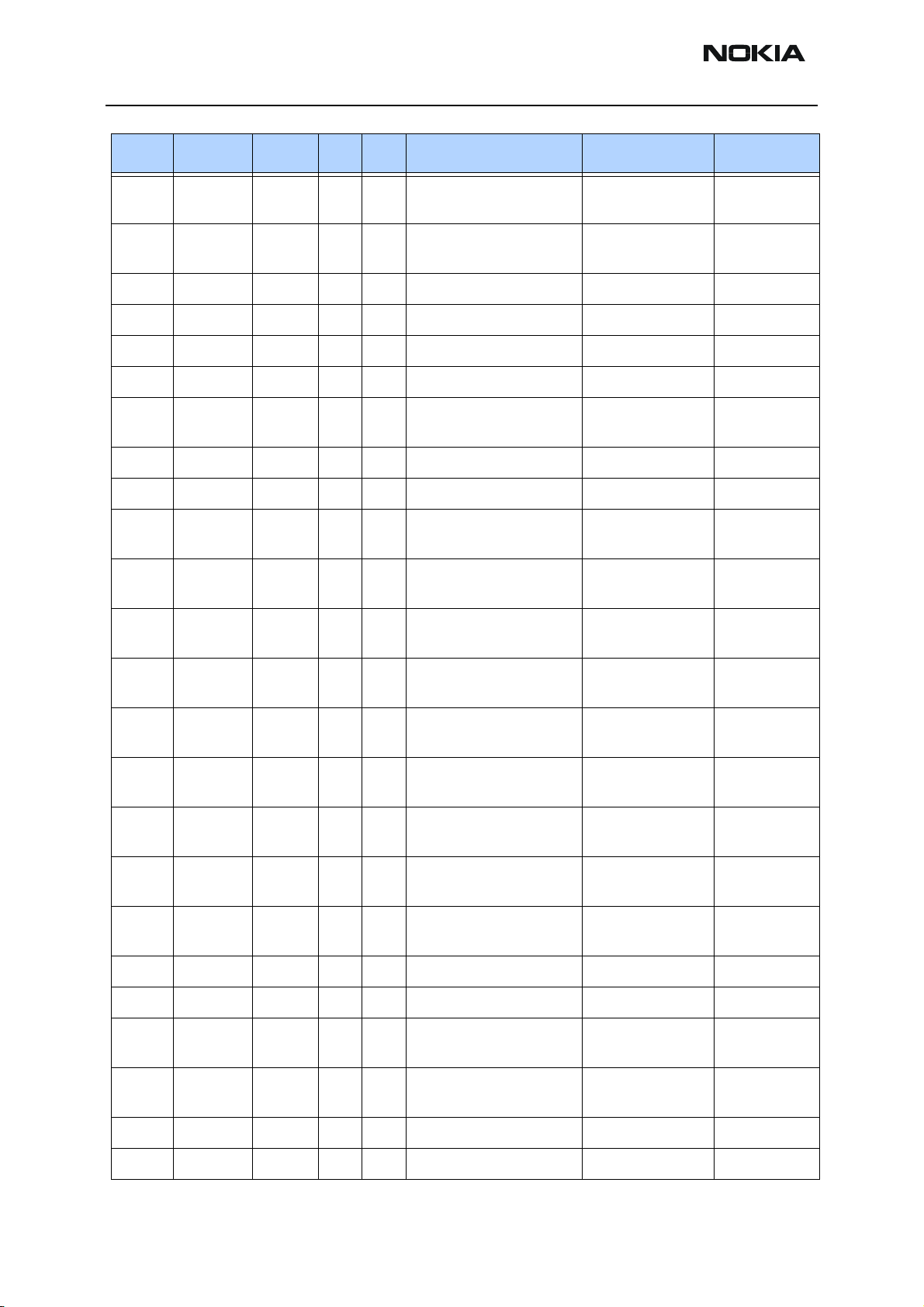

Item Code Side X Y Description Value Type

C208 2320481 Top O 10 chip cap X5R 1U K 6V3 0603

C211 2320481 Top R 10 chip cap X5R 1U K 6V3 0603

C212 2320481 Top R 10 chip cap X5R 1U K 6V3 0603

C213 2320481 Top Q 10 chip cap X5R 1U K 6V3 0603

C215 2320481 Top S 8 chip cap X5R 1U K 6V3 0603

C217 2320778 Top S 7 chip cap X7R 10N K 16V 0402

C218 2320805 Top P 6 chip cap X5R 100N K 10V 0402

C219 2320125 Top P 10 chip cap X5R 1U K 16 V 0603

C220 2320778 Top R 7 chip cap X7R 10N K 16V 0402

C221 2320481 Top O 10 chip cap X5R 1U K 6V3 0603

C222 2320481 Top O 10 chip cap X5R 1U K 6V3 0603

C223 2320481 Top P 9 chip cap X5R 1U K 6V3 0603

C224 2320481 Top O 9 chip cap X5R 1U K 6V3 0603

C226 2320481 Top O 8 chip cap X5R 1U K 6V3 0603

C228 2320481 Top O 8 chip cap X5R 1U K 6V3 0603

C229 2320481 Top O 8 chip cap X5R 1U K 6V3 0603

C230 2320778 Top R 7 chip cap X7R 10N K 16V 0402

C231 2320481 Top P 8 chip cap X5R 1U K 6V3 0603

C232 2320481 Top P 9 chip cap X5R 1U K 6V3 0603

C234 2320481 Top P 9 chip cap X5R 1U K 6V3 0603

C235 2320805 Top S 8 chip cap X5R 100N K 10V 0402

C236 2320805 Top P 8 chip cap X5R 100N K 10V 0402

C237 2320805 Top P 8 chip cap X5R 100N K 10V 0402

C238 2320491 Top P 10 chip cap X7R 220N K 10V 0603

C239 2320805 Top R 7 chip cap X5R 100N K 10V 0402

C241 2320544 Top S 8 chip cap NP0 22P J 50V 0402

C242 2320544 Top S 8 chip cap NP0 22P J 50V 0402

C245 2320481 Top O 9 chip cap X5R 1U K 6V3 0603

C261 2312243 Top O 9 chip cap X5R 4U7 K 6V3 0805

C262 2312243 Top Q 10 chip cap X5R 4U7 K 6V3 0805

C264 2320481 Top S 7 chip cap X5R 1U K 6V3 0603

C302 2320556 Top T 9 chip cap NP0 68P J 50V 0402

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 11

Page 23

RH-25

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C303 2320125 Top T 9 chip cap X5R 1U K 16 V 0603

C304 2320125 Bottom O 6 chip cap X5R 1U K 16 V 0603

C307 2320548 Top U 4 chip cap NP0 33P J 50V 0402

C308 2320560 Top U 4 chip cap NP0 100P J 50V 0402

C350 2320805 Bottom D 9 chip cap X5R 100N K 10V 0402

C351 2312243 Top D 8 chip cap X5R 4U7 K 6V3 0805

C361 2320805 Bottom D 9 chip cap X5R 100N K 10V 0402

C400 2320778 Top P 6 chip cap X7R 10N K 16V 0402

C401 2320805 Top P 7 chip cap X5R 100N K 10V 0402

C402 2320778 Top Q 7 chip cap X7R 10N K 16V 0402

C403 2320778 Top Q 7 chip cap X7R 10N K 16V 0402

C404 2320778 Top Q 7 chip cap X7R 10N K 16V 0402

C405 2320778 Top P 6 chip cap X7R 10N K 16V 0402

C420 2320744 Top P 6 chip cap X7R 1N0 K 50V 0402

C450 2320778 Top P 6 chip cap X7R 10N K 16V 0402

C451 2320805 Top O 6 chip cap X5R 100N K 10V 0402

C454 2320779 Top O 6 chip cap X74 100N K 16V 0603

C700 2320552 Top I 8 chip cap NP0 47P J 50V 0402

C701 2320536 Top I 8 chip cap NP0 10P J 50V 0402

C702 2320805 Top I 8 chip cap X5R 100N K 10V 0402

C703 2320536 Top I 8 chip cap NP0 10P J 50V 0402

C704 2320805 Top I 8 chip cap X5R 100N K 10V 0402

C706 2320552 Top K 9 chip cap NP0 47P J 50V 0402

C707 2320744 Top K 9 chip cap X7R 1N0 K 50V 0402

C708 2320481 Top L 9 chip cap X5R 1U K 6V3 0603

C710 2320740 Top J 9 chip cap X7R 680P K 50V 0402

C711 2320481 Top J 10 chip cap X5R 1U K 6V3 0603

C712 2320552 Top K 9 chip cap NP0 47P J 50V 0402

C720 2320564 Top J 9 chip cap NP0 150P J 50V 0402

C721 2322023 Top J 9 chip cap NP0 2N2 J 16V 0603

C740 2320564 Top K 9 chip cap NP0 150P J 50V 0402

C741 2322023 Top L 10 chip cap NP0 2N2 J 16V 0603

Page 12 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 24

RH-25

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

C770 2320580 Top M 6 chip cap X7R 680P J 50V 0402

C771 2480003 Top M 6 chip cap PPS 8N2 J 16V 0805

C772 2320495 Top M 6 chip cap NP0 1N0 J 50V 0603

C773 2320466 Top M 7 chip cap NP0 220P J 50V 0603

C774 2320536 Top K 7 chip cap NP0 10P J 50V 0402

C775 2320481 Top K 7 chip cap X5R 1U K 6V3 0603

C776 2320778 Top L 7 chip cap X7R 10N K 16V 0402

C777 2320536 Top K 6 chip cap NP0 10P J 50V 0402

C778 2320536 Top K 6 chip cap NP0 10P J 50V 0402

C791 2320805 Top N 10 chip cap X5R 100N K 10V 0402

C792 2320778 Top N 9 chip cap X7R 10N K 16V 0402

C793 2320481 Top N 9 chip cap X5R 1U K 6V3 0603

C801 2320552 Top J 7 chip cap NP0 47P J 50V 0402

C802 2320778 Top J 7 chip cap X7R 10N K 16V 0402

C803 2320536 Top J 7 chip cap NP0 10P J 50V 0402

C806 2320552 Top K 8 chip cap NP0 47P J 50V 0402

C807 2320536 Top K 8 chip cap NP0 10P J 50V 0402

C808 2320805 Top L 9 chip cap X5R 100N K 10V 0402

C820 2320552 Top J 7 chip cap NP0 47P J 50V 0402

C821 2320552 Top K 7 chip cap NP0 47P J 50V 0402

C822 2320805 Top K 7 chip cap X5R 100N K 10V 0402

C830 2320778 Top N 8 chip cap X7R 10N K 16V 0402

C831 2320602 Top M 8 chip cap NP0 4P7 C 50V 0402

C832 2320602 Top M 8 chip cap NP0 4P7 C 50V 0402

C833 2320536 Top K 8 chip cap NP0 10P J 50V 0402

C834 2320536 Top K 8 chip cap NP0 10P J 50V 0402

C850 2320536 Top D 9 chip cap NP0 10P J 50V 0402

C851 2320536 Top D 10 chip cap NP0 10P J 50V 0402

C852 2320584 Top D 10 chip cap X7R 1N0 J50V 0402

C853 2320554 Top E 9 chip cap NP0 56P J 50V 0402

C854 2320554 Top E 10 chip cap NP0 56P J 50V 0402

C857 2320536 Top E 10 chip cap NP0 10P J 50V 0402

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 13

Page 25

RH-25

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C858 2320584 Top F 10 chip cap X7R 1N0 J50V 0402

C859 2320536 Top K 7 chip cap NP0 10P J 50V 0402

C861 2320514 Top F 10 chip cap NP0 1P2 C 50V 0402

C910 2320744 Top I 4 chip cap X7R 1N0 K 50V 0402

C911 2320778 Top J 5 chip cap X7R 10N K 16V 0402

C913 2320560 Top J 5 chip cap NP0 100P J 50V 0402

C914 2320481 Top J 5 chip cap X5R 1U K 6V3 0603

C915 2320536 Top I 9 chip cap NP0 10P J 50V 0402

C916 2320805 Top I 9 chip cap X5R 100N K 10V 0402

C919 2320508 Top H 5 chip cap NP0 1P0 C 50V 0402

C923 2320604 Top I 9 chip cap NP0 18P J 50V 0402

C924 2320604 Top K 4 chip cap NP0 18P J 50V 0402

C930 2320536 Top H 7 chip cap NP0 10P J 50V 0402

C931 2320744 Top G 6 chip cap X7R 1N0 K 50V 0402

C960 2320536 Top J 10 chip cap NP0 10P J 50V 0402

C961 2320536 Top J 10 chip cap NP0 10P J 50V 0402

C962 2320536 Top H 9 chip cap NP0 10P J 50V 0402

C963 2320536 Top H 9 chip cap NP0 10P J 50V 0402

C965 2320508 Top G 9 chip cap NP0 1P0 C 50V 0402

C967 2320536 Top G 7 chip cap NP0 10P J 50V 0402

C968 2320778 Top H 9 chip cap X7R 10N K 16V 0402

C970 2320536 Top J 5 chip cap NP0 10P J 50V 0402

C971 2320536 Top J 9 chip cap NP0 10P J 50V 0402

C972 2320805 Top J 9 chip cap X5R 100N K 10V 0402

C975 2320560 Top J 10 chip cap NP0 100P J 50V 0402

L100 3203743 Bottom U 10 ferrite bead 0R03 42R/100MHz 3A 0805

L103 3203803 Bottom V 7 chip bead array 2X1000R 0R75 0405

L104 3203803 Bottom V 7 chip bead array 2X1000R 0R75 0405

L106 3203741 Bottom V 9 ferrite bead 0R5 600R/100MHz 0603

L107 3203741 Bottom V 9 ferrite bead 0R5 600R/100MHz 0603

L131 3203803 Top O 10 chip bead array 2X1000R 0R75 0405

L151 3645349 Top F 7 chip coil 33NH G Q40/250MHz 0603

Page 14 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 26

RH-25

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

L152 3645349 Top E 7 chip coil 33NH G Q40/250MHz 0603

L160 3203741 Bottom V 8 ferrite bead 0R5 600R/100MHz 0603

L161 3203741 Bottom V 8 ferrite bead 0R5 600R/100MHz 0603

L164 3203741 Bottom V 7 ferrite bead 0R5 600R/100MHz 0603

L300 3640119 Top U 10 Choke 22U M 1R4

0.33A

L730 3645093 Top K 9 chip coil 36N G Q55/500MHz 0805

L746 3645091 Top K 9 chip coil 22N G Q55/500MHz 0805

L820 3645211 Top K 7 chip coil 6N8 K Q27/250MHz 0603

L821 3646069 Top J 7 chip coil 33N J Q23/800MHz 0402

L822 3646063 Top J 7 chip coil 22N J Q28/800MHz 0402

L830 3643087 Top M 8 chip coil 180N J Q13/50MHz 0805

L831 3643087 Top M 8 chip coil 180N J Q13/50MHz 0805

L832 3645067 Top L 8 chip coil 330N J Q48/250MHz 0805

L851 3646005 Top D 9 chip coil 2N7+- 0N3 Q29/800MHz 0402

L852 3646067 Top E 10 chip coil 18N J Q29/800MHz 0402

L855 3646053 Top E 9 chip coil 4N7+-0N3 Q28/800MHz 0402

L903 3643085 Top J 5 chip coil 5N6+/-0N5 Q35 1.5A 0805

L960 3646083 Top J 10 chip coil 100N J Q16/300MHz 0402

3.3X3.3X1.5

L961 3646083 Top J 10 chip coil 100N J Q16/300MHz 0402

L962 3646083 Top I 10 chip coil 100N J Q16/300MHz 0402

L963 3646083 Top I 10 chip coil 100N J Q16/300MHz 0402

V100 4113721 Bottom U 9 TVS DI 1PMT16AT3 16V 175W PWRMITE

V300 4110475 Top T 10 SCH DI 1PS79SB31 200MA 30V SOD523

V850 4210189 Top E 10 TR BFP620

D200 4370825 Top Q 8 UEMK W-DOG ENA TO21 TFBGA168

D400 4370873 Top R 5 UPP8M V2.2 F751986B C035 UBGA144

D450 4341531 Top P 5 Combo 64M NOR+4M

SRAM

G780 4350279 Top L 6 VCO 2GHz 2.78V 10.5MA TDMA

G790 4510307 Top M 9 VCTCXO 19.44MHz+/-

2.5PPM

N100 4341063 Bottom U 9 REG 2.8V/150MA

(LP3985NOPB)

TBGA48

2.78V

SOT23-5

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 15

Page 27

RH-25

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

N150 4341417 Bottom T 6 AF Amp 85MW/5V

(LM4855ITLX)

N300 4341309 Top T 10 DC/DC CONV 350MA

(TK11851)

N801 4370915 Top J 8 TACO_V3.1 TZC8CRTT TFBGA108

N901 4350401 Top I 5 PW AMP RF9270 TDMA800

N930 4350267 Top H 6 Pwr Detector Module 800/1900MHz

N960 4350399 Top H 8 Pw Amp RF9271 TDMA1900

N961 4860171 Top D 9 IRDA 1.3 1.152MBIT/S

>2.4V 8PIN

Z100 3640085 Top U 9 FILT 470NF 16V OR03 2A 0805

Z301 4120031 Bottom O 5 EMI/ESD FILT EMIF10-1K010F1 BGA24

Z820 4510357 Top J 6 Saw Filt 881.5+-12.5MHz/

3DB

Z830 4511351 Top L 8 Saw Filt 135.54+-

0.013MHz

Z850 4511361 Top I 6 Saw Filt 1960+-30MHz/

4.5DB

USME18

SOP8

2.5X2

6X3.5MM

2X2.5

Z905 4511357 Top J 4 Saw Filt 836.5+-12.5MHz/

3.0

Z906 4512173 Top G 5 Dupl 824-849/869-

894MHz

Z907 4550117 Top E 5 Dupl 824-894/1850-

1990MHz

Z960 4511353 Top I 10 Saw Filt 180.51+-

0.015MHz

Z961 4511363 Top G 9 Saw Filt 1880+-30MHz/

5DB

Z962 4512171 Top E 7 Dupl 1850-1910/1930-

1990MHz

T775 4550153 Top K 6 Transf Balun 2060+-70MHz 2.0X1.25

T960 4550173 Top H 9 Trans Balun 1920+-70MHz 2X1.25

T961 3640429 Top I 9 Transf Balun 900 MHz +/- 100

MHz

B200 4510303 Top S 9 Crystal 32.768KHz+-

20PPM 12.

2.5X2

5X5X1.7

3.2X1.6

3X3MM

2.5X2X1

17X5

1206

5PF

F100 5119019 Bottom V 9 Sm Fuse F 1.5A 32V 0603

X101 5460061 Top W 6 Sm System Connector 14POL

Page 16 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 28

RH-25

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

X301 5469135 Bottom N 5 Sm Conn 2X8 SPR 50V 0.5A PWB/PWB

X302 5469175 Bottom D 5 Sm Conn 2X5F P0.5 PWB/PWB

X900 5429037 Top E 5 Sm Conn Fr Jack 50R 2W 6GHz

A100 9517299 Top Q 7 BB Shield Assy DMC06338 Hobbes

A900 9517302 Top J 7 RF Shield Assy DMC06337 Hobbes

S001 5409235 Top C 5 Sm Tact Sw Trav 0.2 4.1X3.55X

1.75

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 17

Page 29

RH-25

Parts Lists CCS Technical Documentation

Page 18 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 30

CCS Technical Documentation

RH-25 Series Transceivers

Service Software Instructions

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation

Page 31

RH-25

Service Software Instructions CCS Technical Documentation

Contents

Page No

Phoenix User’s Guide .................................................................................................... 3

Introduction ..................................................................................................................3

General Setup Procedure........................................................................................... 3

Hardware Requirements for using Phoenix .............................................................. 4

Installing Phoenix ........................................................................................................4

Installation Directions............................................................................................... 4

Software Support Bundles ...........................................................................................4

Starting a Phoenix Session ...........................................................................................5

Concepts.................................................................................................................... 5

Initial Session with Phoenix...................................................................................... 5

Scanning for a Product.............................................................................................. 6

Using Components.................................................................................................... 7

Using Profiles............................................................................................................ 7

Uninstalling Phoenix ...................................................................................................7

Uninstalling Phoenix version.................................................................................... 7

Page 2 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 32

RH-25

CCS Technical Documentation Service Software Instructions

Phoenix User’s Guide

Introduction

This section briefly describes how to install Phoenix and includes some basic information

on how to use the program. More detailed information can be found in the Phoenix Help

files. Each feature in Phoenix has its own Help file, which can be activated whil running

Phoenix. To activate a Help file while Phoenix is running, press the F1 key or the specific

feature’s Help button.

General Setup Procedure

Initial installation of Phoenix requires the complete Phoenix installation package. This

package, currently around 30 Megabytes in size, is provided on a CD-ROM disk. Because

of this large size, it is not recommended to download the file nor is it practical to provide

it on 3.5-inch floppy disks.

Install Phoenix by following the steps outlined on the material that comes with the disk.

It should be noted that installation of a Nokia dongle on the computer being loaded is

REQUIRED prior to beginning the installation of the software.

The software is packaged into an Installshield executable bundle. When the user doubleclicks on this file, the installation program provides on-screen instructions on how to

proceed. Standard installation, provided by selecting all default choices, is highly recommended. You may do a custom installation and place Phoenix into a special location on

your hard drive, but this is only recommended for experienced users.

It is necessary to reboot the computer after installing the software. The program will not

be usable until a reboot is performed. After reboot, the Phoenix icon is displayed on the

computer desktop. Double-clicking on this icon launches the program.

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 3

Page 33

RH-25

Service Software Instructions CCS Technical Documentation

Hardware Requirements for using Phoenix

Minimum Hardware Requirements

Processor 233 MHz

RAM1 64 MB

Disk space needed 50-100 MB

Supported Operating

Windows 95 Limited, no USB support

Windows 98

Windows NT 4.0 no USB support

Windows 2000 Professional version

Installing Phoenix

Before installing the software, verify:

• The dongle is attached to the parallel port for PKD version dongles, or an FLS-4 version

dongle is attached on either the parallel port or the USB port (if the computer supports

USB).

• Ensure that if the computer supports administrator rights (typically on Windows NT

and Windows 2000 installations) that access is enabled for the user performing the

Phoenix installation.

• If a previous version of Phoenix has been installed, it may be necessary to first properly

remove that program prior to installing the new version. If installation is performed,

be sure to reboot the computer prior to continuing. See the section Uninstalling

Phoenix for instructions on how to uninstall.

Systems

Notes

Installation Directions

• Insert the CD-ROM disk into the computer drive

• Access the drive and double-click on the Phoenix software package found on the CD.

• Follow the on-screen prompts to conclusion.

Note that rebooting the computer may be necessary when completed.

Software Support Bundles

The Phoenix installation is auto-executable. You must obtain Software Support Bundles

Page 4 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 34

RH-25

CCS Technical Documentation Service Software Instructions

to load software upgrade files to customer-specific phone models.

These bundles are created by CCS and made available by AMS on the Partners Web Page

http://americas.partners.nokia.com. This web page is password-controlled; if you have

not registered as a user, contact Nokia Central Service in Melbourne, Florida.

Similar to the Phoenix installation, these Software Support Bundles are InstallShield executable packages. Just double-click on the package and it will auto-install.

No rebooting of the computer is required.

Starting a Phoenix Session

Concepts

When referring to Phoenix, Product is the cellular phone attached to the computer.

More specifically, it is the particular type of phone.

Connection is the type of cable used to attach the phone and the port on the computer

where it is attached. Refer to the Service Tools chapter for additional information.

The first time Phoenix is used, certain connection configurations must be made. Subsequent uses will rely on these selections and they will not need to be made again.

Initial Session with Phoenix

It is necessary to create the connection the first time Phoenix is used. Follow these simple steps:

Select Manage Connections… from the “File” drop-down menu.

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 5

Page 35

RH-25

Service Software Instructions CCS Technical Documentation

Next click the Add… button to create a new connection.

When the Select Mode dialog box appears, you may then select either Wizard, which will

auto-detect your connection configuration, or Manual, which allows you to manually

select options to create the connection.

Once a connection is defined, make sure that the one to be used is moved to the top of

the list (use the up down arrows on the Manage Connections dialog box. Then click on

the Apply button. Close the window when finished.

You can now proceed with the normal initiation of a session by selecting a product or

scanning for a product.

Scanning for a Product

Many features of this program are product-specific. Therefore it is necessary to configure Phoenix for the product on which you will be working at the beginning of the session.

Scan Product – Choose Scan Product from the drop-down menu list and Phoenix will

automatically scan for product and select the necessary configurations. The status bar

Page 6 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 36

RH-25

CCS Technical Documentation Service Software Instructions

at the bottom will indicate if the product was found and its type.

Using Components

When working with Phoenix, tasks are generally managed by specific software components. From the menu, select the desired component or task to be performed.

“Opening a component” is defined as opening a tool window within Phoenix. When this

window is opened, Phoenix also opens a toolbar for it and adds component-specific

menu items in the Window menu.

Using Profiles

Phoenix’s Profile feature allows product, connection and currently open components to

be stored into permanent storage by creating a profile file with a name of your choice

followed by an .nmp file extension for later retrieval.

Saved profiles makes it easy to configure Phoenix into a desired configuration with

favorite windows already opened and ready to go.

Opening and saving profiles is done via menu commands found in the File drop-down

menu: Open Profile and Save Profile.

Profiles are stored into a disk file with user-defined names. As a result, there can be

multiple profiles for different repeated tasks or user preferences.

Uninstalling Phoenix

As mentioned in the Installing Phoenix section, it may be necessary or desirable to

remove Phoenix. Care must be taken to follow this procedure. Failure to remove the

program properly will cause misconfiguration of the computer’s registry.

Uninstalling Phoenix version

• Access the computer’s “Control Panel” section, selectable from the Start button or the

“My Computer” desktop icon

• Select the “Add/Remove Programs” icon

• Select the Phoenix version to be removed, and click the Add/Remove button

• Click on the OK button to begin the process of removal

• Follow the on-screen instructions

Be sure to reboot the computer when finished.

Issue 1 10/2003 Company Confidential ©2003 Nokia Corporation Page 7

Page 37

RH-25

Service Software Instructions CCS Technical Documentation

Page 8 ©2003 Nokia Corporation Company Confidential Issue 1 10/2003

Page 38

CCS Technical Documentation

RH-25 Series Transceivers

Service Tools

Issue 1 10/2003 Confidential © 2003 Nokia Corporation

Page 39

RH-25

Service Tools CCS Technical Documentation

Contents

Page No

Service Tools.................................................................................................................. 3

6560 .............................................................................................................................3

Flashing and Testing Setups .......................................................................................... 8

FPS-8 Flash Prommer for Heavy Flash .......................................................................8

FPS-8C Flash Prommer for Heavy Parallel Flash .......................................................8

User Instructions ............................................................................................................ 9

DA-15 / SA-16 .............................................................................................................9

SF-15 ..........................................................................................................................11

Page 2 ©2003 Nokia Corporation Confidential Issue 1 10/2003

Page 40

RH-25

CCS Technical Documentation Service Tools

Service Tools

6560

Photo Code Service Tool Code Description

MJ-16 Module Jig 0770575 This jig allows phone

PWB-level service and

troubleshooting. Electric currents should be

protected against

over-voltage and

over-current.

FLS-4S POS Flash Adapter 0080543 The Point of Sale

(POS) flash is a lowcost software upgrade

tool. This requires the

XCS-1 cable and

ACP-8U for operation.

FPS-8 Flash Prommer 0080321 The Flash Prommer

FPS-8 is used for

flash.

FPS-8C Heavy Flash Prommer 0080396 The Heavy Flash

Prommer FPS-8C is

used for heavy parallel flashing.

Issue 1 10/2003 Confidential ©2003 Nokia Corporation Page 3

Page 41

RH-25

Service Tools CCS Technical Documentation

Photo Code Service Tool Code Description

JBV-1 Docking Station 0770298 The Docking Station

and the Docking Station Adapter (DA-15)

are needed for Mbus,

Fbus, RF, and audio

connections.

This setup allows connection between flash

prommers. When the

audio box is connected, it has to be

connected to the

phone’s audio connector.

DA-15 Docking Station

Adapter

CPL-1 Coupler 0770287 The coupler has been

JBA-8 Audio Box 0770320 The Audio Box is

0770624 The Docking Station

can be powered by

FPS-8 or external

power supply.

NOTE: SEE USER

INSTRUCTIONS FOR

DA-15 on page 9.

developed for antenna

go/no go testing.

needed for audio connections. The box

must support DCT4

Janette audios. JBA-8

provides an interconnection between the

phone’s system connector (XEAR, XMIC)

through a fixed audio

cable and audio tester

with a BNC-BNC

coax. Connection to a

PC can be made with

the service battery,

through a DAU-9

cable.

Page 4 ©2003 Nokia Corporation Confidential Issue 1 10/2003

Page 42

RH-25

CCS Technical Documentation Service Tools

Photo Code Service Tool Code Description

SF-15 Flash Adapter 0770625 SF-15 allows a con-

tinuous maximum

power supply for the

phone from an external power supply, the

ACP-8.

NOTE: SEE USER

INSTRUCTIONS FOR

SF-15 ON PAGE 11.

Note: SF-15 is not to

be used for handset

testing; it is only

designed for flashing.

AXP-8 Printer Cable 073F000 The Parallel Printer

Cable connects the

parallel connector of

the PC and the parallel input of the FPS-8.

AXS-4 D9-D9 Cable 0730090 The AXS-4 D9-D9

service cable is used

to connect two 9-pin

connectors (e.g.,

between PC and

FPS-8). AXS-4 length

is 2 meters

CA-X Audio Cable TBD The audio cable con-

nects to the audio box

JBA-8.

SCB-3 DC Cable 0730114 The DC Cable SCB-3 is

used to connect the

docking station to the

charger connection

(Vin) of the phone to

conduct the charger

calibration service

procedure.

Issue 1 10/2003 Confidential ©2003 Nokia Corporation Page 5

Page 43

RH-25

Service Tools CCS Technical Documentation

Photo Code Service Tool Code Description

DAU-9S Mbus Cable 0730108 The Mbus Cable has a

modular connector

and is used with the

service audio box

JBA-4 or a modular

T-adapter.

PCS-1 Power Cable 0730012 The Power Cable

PCS-1 is used to connect the service tools

(JBV-1, MJF-23) to

an external power

supply.

XRF-1 RF Cable 0730085 The XRF-1 cable con-

nects a service tool

and RF measurement

equipment.

XCS-4 Mbus/Fbus Cable 0730178 The XCS-4 Service

Cable is a modular

cable for flashing

DCT4 products.

Page 6 ©2003 Nokia Corporation Confidential Issue 1 10/2003

Page 44

RH-25

CCS Technical Documentation Service Tools

Photo Code Service Tool Code Description

PKD-1 SW Security Device 0750018 SW security device

PKD-1 is hardware

device that, when

connected to the parallel (LPT) port of the

PC, enables the use of

the service software.

Without the dongle

present, it is not possible to use the service software. Printers

or other peripheral

devices can be connected to the PC

through the dongle, if

needed.

Caution: Make sure

that you have

switched off the PC

and the printer before

making connections!

Caution: Do not connect the PKD-1 to the

serial port. You may

damage your PKD-1!

CA-13RS RF Probe 0730300 Spare part for RF

probe used in SA-16

and MJ-16.

SA-16 RF Adapter 0770577 The SA-16 adapter is

used with the DA-15

docking station

adapter, and is needed

for proper RF connection. The adapter

allows galvanic connections to assembled handset RF

switches. The adapter

permits the handset

to be connected to RF

measuring and test

equipment during test

and repair and can be

used with covers on or

off.

Issue 1 10/2003 Confidential ©2003 Nokia Corporation Page 7

Page 45

RH-25

Service Tools CCS Technical Documentation

Flashing and Testing Setups

FPS-8 Flash Prommer for Heavy Flash

The FPS-8 flash prommer is used for heavy flashing. The sales pack product code is

0080321.

FPS-8C Flash Prommer for Heavy Parallel Flash

The FPS-8C flash prommer is used for heavy parallel flashing. The sales pack product

code is 0080396.

Page 8 ©2003 Nokia Corporation Confidential Issue 1 10/2003

Page 46

RH-25

CCS Technical Documentation Service Tools

User Instructions

DA-15 / SA-16

Follow these instructions to avoid damage to the adapter or the phone.

Note: Using the adapter in any way other than described here may harm important pins

and connectors of the adapter. It cannot be used like the FLA-13 for 3520/3560 products.

1 Lock bottom of phone onto the jig.

2 In an arching motion, push phone downward.

3 Push phone down until locks engage.

Issue 1 10/2003 Confidential ©2003 Nokia Corporation Page 9

Page 47

RH-25

Service Tools CCS Technical Documentation

4 Push the probe up from the bottom (photo at left below) and then engage the

locking mechanism (right).

To remove adapter, follow the inverse order of the installation in Steps 1 through 4.

Page 10 ©2003 Nokia Corporation Confidential Issue 1 10/2003

Page 48

RH-25

CCS Technical Documentation Service Tools

SF-15

Follow these instructions to avoid causing any damage to the adapter or the phone.

Note: Using the adapter in any other way may harm the important pins and connectors of

the adapter. It cannot be used like the MJF-2 for 3520/3560 products.

1 Lock bottom of the SF-15 onto the phone.

2 In an arching motion, push the phone and the SF-15 together until the locks

engage.

Issue 1 10/2003 Confidential ©2003 Nokia Corporation Page 11

Page 49

RH-25

Service Tools CCS Technical Documentation

3 To remove, press the tabs on BOTH sides to release.

Page 12 ©2003 Nokia Corporation Confidential Issue 1 10/2003

Page 50

CCS Technical Documentation

RH-25 Series Transceivers

Disassembly

Issue 1 10/2003 Confidential ©Nokia Corporation

Page 51

RH-25

Disassembly CCS Technical Documentation

ESD Protection

Disassembly Instructions

Step-by-Step Disassembly Instructions (Model 6560)

Push the Release Button to the left before pulling up

the B-Cover. Remove the battery.

Unscrew the six T6 screws, using the shown order. For

assembly, the reverse order (i.e., labeled number 6 is first

screw for assembly) and a torque of 17Ncm must be

used.

Unlock the top guidance to remove the A-Cover.

As noted in the figure above, separate the two halves

from the side with connector while keeping the opposite side in place. This will cause less stress on the connector than removing perfectly straight.

Page 2 ©Nokia Corporation Confidential Issue 1 10/2003

Page 52

RH-25

CCS Technical Documentation Disassembly

Step-by-Step Disassembly Instructions (Model 6560)

Remove the modules from the C-cover and unplug the

display connector by pulling the modules apart carefully.

Open the snaps on both sides of display shield (two on

each side).

Microphone may be removed; however, it must be

replaced with a new part! When assembling new part,

pay special attention not to touch spring contacts as

they are easily damaged.

The Display Shield is hooked at the bottom edge.

Press the LCD off of the LCD Frame. Use a clean cloth

as shown above.

Bend the frame a bit, shift the UI Board Module to the

right and then pull it up.

Issue 1 10/2003 ©Nokia Corporation Confidential Page 3

Page 53

RH-25

Disassembly CCS Technical Documentation

Step-by-Step Disassembly Instructions (Model 6560)

To remove the DC Jack, insert tweezers between the

spring contacts and under the jack. You will need to

use some force to pull the jack upward.

Grip the Vibra Motor as shown above and pull it off of

its guidance.

Battery connector may be removed with a small pair of

needle nose pliers. Grasp connector between contacts

and pull straight up. If contacts are bent even slightly

during this procedure, replace with new part.

You can remove the infrared window with your fingers.

The Power Key must first be unlocked on the lower side

(see inset).

Unlock Antenna on both sides with a small screwdriver

or black stick.

The Antenna Pogo Pins can be removed by using the

torx driver to push them through the C-Cover.

Page 4 ©Nokia Corporation Confidential Issue 1 10/2003

Page 54

RH-25

CCS Technical Documentation Disassembly

Step-by-Step Disassembly Instructions (Model 6560)

The release button may be removed with fingers or

with black stick. Once removed, a new button must be

used as the retaining clips will have been weakened.

Assembly Instructions

Use the Disassembly Instructions in the reverse order to reassemble the handset.

Issue 1 10/2003 ©Nokia Corporation Confidential Page 5

Page 55

RH-25

Disassembly CCS Technical Documentation

Page 6 ©Nokia Corporation Confidential Issue 1 10/2003

Page 56

CCS Technical Documentation

RH-25 Series Transceivers

Troubleshooting - Baseband

Issue 1 10/2003 Confidential © 2003 Nokia Corporation

Page 57

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Contents

Page No

Baseband Top-Level Description................................................................................... 4

Baseband Block Diagram ............................................................................................4

Environmental Specifications ......................................................................................5

Normal and Extreme Voltages.................................................................................. 5

Temperature Conditions............................................................................................ 5

Humidity.................................................................................................................... 5

Frequencies in Baseband .............................................................................................5

Infrared Interface (IrDA) .............................................................................................6

Energy Management ....................................................................................................6

Power Supply Modes ................................................................................................ 6

Battery BLD-3........................................................................................................... 7

Power Distribution .................................................................................................... 8

DC Characteristics .......................................................................................................9

Audio Circuitry ..........................................................................................................10

Audio Block Diagram ................................................................................................11

Earpiece................................................................................................................... 11

Microphones............................................................................................................ 11

Integrated Hands-free (IHF).................................................................................... 12

Audio Accessory Receive Path ............................................................................... 12

Audio Control Signals............................................................................................. 12

Acoustics ....................................................................................................................12

Earpiece Acoustic.................................................................................................... 12

IHF Speaker Acoustics............................................................................................ 12

Microphone Acoustics............................................................................................. 13

Vibra Motor............................................................................................................. 13

Audio Modes .............................................................................................................13

Handportable Mode................................................................................................. 13

Integrated Hands-free Audio Mode......................................................................... 14

Headset Audio Mode............................................................................................... 14

Loop set Audio Mode.............................................................................................. 15

External Hands-free Audio Mode........................................................................... 15

System Connector Interface......................................................................................... 15

System Connector ......................................................................................................15

Accessory Control Interface (ACI) ............................................................................16

Signal flow on ACI line - ACI-ASIC accessory inserted........................................ 17

Signal flow on ACI line - Non ACI-ASIC accessory inserted................................ 18

FBUS....................................................................................................................... 18

VOUT (Accessory Voltage Regulator)................................................................... 19

HookInt ......................................................................................................................20

Charging ....................................................................................................................20

DC-Plug................................................................................................................... 20

VCHAR Pins of System Connector........................................................................ 20

Voltages and Currents ................................................................................................22

Main Troubleshooting Diagram ................................................................................23

Phone is Dead ............................................................................................................25

Flash Programming Fault .........................................................................................26

Page 2 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 58

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Flash Programming Does Not Work .........................................................................27

Phone is Jammed .......................................................................................................30

Charger Faults ............................................................................................................32

Audio Faults ...............................................................................................................33

Keypad Fault ..............................................................................................................34

Display Fault ..............................................................................................................36

Accessory Faults ........................................................................................................37

Illumination Faults .....................................................................................................38

IrDa Fault ...................................................................................................................39

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 3

Page 59

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Baseband Top-Level Description

RH-25 is a handportable dual band TDMA and AMPS DCT-4 generation phone for the

smart classic segment.

The RH-25 Baseband consists of the DCT4 common Baseband chipset having some product-specific blocks of its own, such as pop-port system connector (also unofficially

known as "Tomahawk"), IHF, IrDA, and a color display.

The Baseband engine consists basically of two major ASICs:

• Universal Energy Management IC (UEM), including the analog audio circuits, the

charge control, and the voltage regulators.

• Universal Phone Processor (UPP), containing DSP, MCU, and some internal memory.

Baseband Block Diagram

The system block diagram below shows the main BB functional blocks.

Figure 1: Baseband block diagram

Page 4 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 60

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Environmental Specifications

Normal and Extreme Voltages

Following voltages are assumed as normal and extreme voltages for the BLD-3 battery

used in RH-25:

• Nominal voltage: 3.6 V

• Lower extreme voltage: 3.1 V

• Higher extreme voltage (fast charging): 4.4 V

Temperature Conditions

Operational temperature range (all specifications met within this range)

-10°C..+55°C

Functional temperature range (Reduced performance) -30°C..+70°C

Storage temperature range: -30°C..+85°C

Humidity

Relative humidity range is 5...95%.

The Baseband module is not protected against water. Condensed or splashed water may

cause interim or permanent phone malfunction.

Submergence of the phone in water will likely cause permanent damage to the phone.

Frequencies in Baseband

There are several clock frequencies at the baseband part. The following table lists all

available frequencies. The asynchronous and diagnostic busses are not included.

Frequency Context UPP UEM Flash Comments

54 MHz Memory clock X X

19.44 MHz RF clock X

13MHz DBUS, RFBusClk X X

Up to 1MHz RFConvClk X X

Table 1: Frequency List

1.08MHz CBUS Clock X X AMPS mode: 1.25MHz

32kHz Sleep Clock X

1.2kHz ACI X X

1.625MHz

up to 6.5MHz

Display IF X Frequency depends on

SW

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 5

Page 61

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Infrared Interface (IrDA)

RH-25 supports data connectivity via an infrared link. An IR module is integrated into

the phone, connected to the IR interface of the UPP ASIC.

Energy Management

The energy management of RH-25 is based on BB 4.0 architecture. A semi-fixed battery

(BLD-3) supplies power primarily to UEM ASIC and the RF PA. UEM includes several regulators to supply RF and baseband. It provides the energy management including power

up/down procedure.

Power Supply Modes

The functional behavior of the UEM can be divided into seven different states. Since the

UEM controls the regulated power distribution of the phone, each of these states affects

the general functionality of the phone:

•No supply

• Backup

•Power off

• Reset

•Power on

• Sleep

•Protection

The different states of the UEM are detailed in the sections below.

No Supply

In the NO_SUPPLY mode, the UEM has no supply voltage (VBAT < V

V_BU

tery are either disconnected or both discharged to a low voltage level.

The UEM will recover from NO_SUPPLY into RESET mode if the VBAT voltage level rises

above the V

Backup

In BACK_UP mode the main battery is either disconnected or has a low voltage level

(VBAT < V

and VBACK <

MSTR

). This mode is due to the fact that both the main battery and the backup bat-

COFF-

level by either reconnecting the main battery or charge it to such level.

MSTR+

and VBACK > V_BU

MSTR-

COFF+

).

The regulator VRTC that supplies the real-time clock is disabled in BACK_UP mode.

Instead the unregulated backup battery voltage VBACK supplies the output of the VRTC.

All other regulators are disabled and the phone has no functionality.

The UEM will recover from BACK_UP mode into RESET mode if VBAT rises above V

MSTR+

Power Off

In order for the UEM to be in PWR_OFF mode, it must have supply voltage (VBAT >

V

MSTR+

).

Page 6 © 2003 Nokia Corporation Confidential Issue 1 10/2003

.

Page 62

RH-25

CCS Technical Documentation Troubleshooting - Baseband

The regulator VRTC regulator is enabled and supplying the RTC within the UEM. The UEM

will enter RESET mode after a 20 ms delay whenever one of the below listed conditions is

logically true:

• The power button is activated

• Charger connection is detected

• RTC alarm is detected

The UEM will enter PWR_OFF from all other modes except NO_SUPPLY and BACK_UP if

the internal watchdog elapses.

Reset

When the UEM enters RESET mode from PWR_OFF mode, the watchdog is enabled. If the

VBAT fails to rise above the power-up voltage level V

(3.1 V) before the watchdog

COFF+

elapses, the UEM will enter PWR_OFF mode. Otherwise, after a 200 ms delay, the regulator VFLASH1 will be enabled and after an additional delay of 500 µs, the regulators

VANA, VIO, VCORE, and VR3 will be enabled. All other regulators( i.e., VFLASH2, VSIM,

VR1, VR2, and VR4 - VR7) are software controlled and disabled by default. After an additional delay of 20 ms, the UEM enters PWR_ON mode.

Power On

In PWR_ON, the UEM is fully functional in the sense that all internal circuits are powered up or can be by means of software. The UEM will enter PWR_OFF mode if VBAT

drops below V

enter PWR_OFF mode if either of the watchdogs Operational State Machine (approx. 100

µs), Security (32 sec.), or Power Key (4 sec.) elapses or if any of the regulators trigger the

thermal protection circuitry

Sleep

The UEM can be forced into SLEEP mode by the UPP by setting the input SLEEPX low for

more than 60 µs. This state is entered when the external UPP activity is low (phone in

sleep) and thereby lowering the internal current consumption of the UEM. The regulator

VANA is disabled and VR1 - VR7 are either disabled or in low quiescent mode.

From SLEEP the UEM enters PWR_ON if SLEEPX goes high, PWR_OFF mode if watchdog

elapses or BACK_UP mode if VBAT drops below V

Protection Mode

The UEM has two separate protection limits for over temperature conditions: one for the

charging switch and one for the regulators. The temperature circuitry measures the onchip temperature. In case of charging over temperature, the circuit turns the charging

switch off. In case of over temperature in any of the regulators, the UEM powers off.

for a period of time longer than 5 µs. The UEM will furthermore

COOF-

.

MSTR-

Battery BLD-3

RH-25 uses the BLD-3 Li-ion battery with a capacity of 780mAh. BLD-3 is a case-less

battery; the main advantage of a case-less battery type is the overall size, particularly

the thickness and the number of contact terminals.

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 7

Page 63

RH-25

Troubleshooting - Baseband CCS Technical Documentation

BLD-3 has a four-pin connector. BSI resistor value is 75Kohm.

Power Distribution

Under normal conditions, the battery powers the baseband module. Individual regulators

located within the UEM regulate the battery voltage VBAT. These regulators supply the

different parts of the phone. Eight regulators are dedicated to the RF module of the

phone, and six to the baseband module.

The regulator VCORE is likewise adjustable and controlled by registers written by the

MCU. VCORE supplies the core of the UPP and can be adjusted on the fly by the MCU if

DSP capacity is inadequate. Higher VCORE supply (1.8 V) results in faster core operations

in the UPP.

Regulators VANA, VFLASH1, and VIO are solely controlled by the UEM and cannot be

enabled or disabled by the MCU. Furthermore, VFLASH1 and VIO are both ON, though in

low quiescent mode when phone is in sleep mode. An output current of 500 µA can be

drawn from the regulators. VIO supplies the UPP, FLASH and LCD, VFLASH1 supplies LCD

and the IrDA module. VANA is supplying analog parts internally in the UEM as well as the

baseband audio circuitry and pull-up resistors on the input of the UEM slow AD converters.

System connector provides a voltage to supply accessories. The white LED's need a higher

voltage supply as the battery can provide in bad condition. Separate external regulators

supply both consumers.

The regulators VR1A, VR1B, VR2 - VR7 and IPA1 - IPA4 are controlled by the DSP via

the DBus. VR4 - VR7 are controlled by the UEM as well and are disabled in sleep regardless of DSP writings.

VBAT/VBATTRF is furthermore distributed, unregulated, to the RF power amplifier, audio

power amplifier and external baseband regulators.

The CHACON module in the UEM controls the charging of the main battery. Furthermore

it contains a 3.2 Vdc regulator for charging of the backup battery and a 1.8 Vdc regulator

supplying the internal real time clock.

Page 8 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 64

RH-25

V

CCS Technical Documentation Troubleshooting - Baseband

Baseband

UEM

RF Regulators

VR1A

VR1B

VR2-7

6

SIM

VSIM

Battery

BAT

LED

regulator

ACC

regulator

PA Supply

VCORE

Baseband

Regulators

RTC

CHACON

VOUT

Tomahawk System Connector

VANA

VIO

VFLASH1

VFLASH2

Figure 2: Baseband power distribution

IHF PA

UPP

FLASH

LCD

Backup

battery

LED

Keyboard/display

IRDA

DC Characteristics

The following table reflects the specifications of voltage and current regulators within

the UEM:

Regulator Target

VR1A RF 4.6 4.75 4.9 0 10

4

VR2

VR3 RF 2.70 2.78 2.86 0.1 20

VR4 RF 2.70 2.78 2.86 0.1 50

VR5, VR6

VR7 RF 2.70 2.78 2.86 0.1 45

VrefRF01 RF 1.334 1.35 1.366 - 0.1

Table 2: UEM regulator outputs

Output Voltage (V) Output Current

(mA)

Min Typ Max Min Max

RF 2.70 2.78 2.86 0.1 100

0.1

1

RF 2.70 2.78 2.86 0.1 50

0.1

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 9

Page 65

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Output Voltage (V) Output Current

Regulator Target

Min Typ Max Min Max

1

VIO

2

VSIM

VANA BB 2.70 2.78 2.86 0.005 80

2

VCORE

VFLASH1 BB 2.70 2.78 2.86 0.005

VFLASH2

3

BB 1.72 1.8 1.88 0.005

BB 1.745

2.91

BB 1.000

1.235

1.425

1.710

0.974

1.215

1.410

1.692

BB 2.70 2.78 2.86 0.005 40

1.8

3.0

1.053

1.3

1.5

1.8

1.053

1.3

1.5

1.8

1.855

3.09

1.106

1.365

1.575

1.890

1.132

1.365

1.575

1.890

0.005

0.005

0.005

0.005

0.005

0.005

0.005

70

85

100

120

0.005

(mA)

150

0.500

25

0.500

70

85

100

120

200

200

200

200

70

1.5

1 The second current value indicates the maximum possible output current of the

regulator when in low quiescent mode.

2 The output voltages are split into two different current categories. The upper part

is the lower range of output current, and the lower part is the higher range of

output current.

3 Condition in sleep-mode depends on MCU writings to UEM regulator register

solely.

4 Condition in sleep-mode depends on DSP writings to UEM register.

When the accessory regulator, N100, is active, it will turn Vout ON (2.8V) and provide

70mA current.

Audio Circuitry

This section describes the audio-HW inside the Baseband. (External audio components

and acoustics are not considered with the details in this section.)

The main topology comes from other phones using BB4.0 engine, where the audio-HW is

mostly integrated into the UEM-ASIC. The biggest difference is that RH-25 has integrated hands-free (IHF).

Page 10 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 66

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Audio Block Diagram

Earpiece

RH-25 uses an earpiece, which is also referred to as a PICO speaker. This is a 32 ohm

speaker with the diameter of 8 mm.

Earpiece is fed by the differential signals EARP and EARN from UEM. The signals run

quite directly from UEM to the earpiece, only some passive ands EMC protection components are needed

The external earpiece signals are fed by the HF and HFCM pins.

The level (swing) of earpiece-signals can be adjusted by register values inside UEM. These

signals have a common voltage level of 1.35 V (0.8 V for HF) at UEM pins.

Microphones

An EMC-improved type of microphone is used as internal microphone in RH-25, diameter

of which is 2.2mm.

Internal microphone circuitry is driven single-ended. Microphone needs bias voltage,

which is provided by UEM and is fed through a resistor to the microphone. A resistor is

also needed to the other side of the microphone, (i.e., between microphone and GND), in

order to provide the differential signals to UEM. Audio signals are AC-coupled from the

microphone.

Figure 3: Audio block diagram

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 11

Page 67

RH-25

Troubleshooting - Baseband CCS Technical Documentation

For the external microphone a differential input is used.

MIC1N and MIC1P (audio signals) and MICB1 (bias voltage) are used for the internal

microphone. MIC2N and MIC2P and MICB2 are used for external microphone.

Integrated Hands-free (IHF)

The speaker used for IHF is a 16 mm diameter speaker with 8 Ohm impedance, also

known as a MALT speaker.

IHF circuitry uses differential outputs from UEM.

Depending on the audio mode, the IHF amplifier is driven either from UEM HF / HFCM or

XEAR audio outputs. The IHF audio power amplifier (APA) LM4855 has a bridge-tied-load

(BTL) output in order to get the maximum use of supply voltage. The supply voltage for

driving circuitry of speaker is VBAT, thus the swing across the speaker is (VBAT.

The shutdown of the IHF PA is controlled by UPP using GENIO14.

Audio Accessory Receive Path

In RH-25, the accessory receive path is directly driven from UEM HF / HFCM differential

audio outputs, the output signal complies with the Pop-port accessory interface.

For EMC protection, ferrites are connected in series to the earpiece; for ESD protection,

varistors are used.

Audio Control Signals

The HEADINT signal is needed for recognizing the external device (e.g., headset) connected to the system. The recognition is based on the ACI-pin on the system connector,

which is shorted to ground inside the external device.

The button of the external device generates HOOKINT. This is used to answer or to end a

phone call.

Acoustics

Earpiece Acoustic

RH-25 uses the PICO 8mm earpiece.

This earpiece is mounted into the UI-shield assembly, the sealing of the front volume is

achieved using a foam gasket mounted on the front of the speaker. The UI shield is sealed

using a rubber sealing between UI shield and A-cover to create an acoustic path.

IHF Speaker Acoustics

The MALT speaker is used in RH-25 for integrated hands-free and ringing tone applications.

The IHF speaker is mounted to the IHF enclosure on a foam sealing ring. The IHF enclo-

Page 12 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 68

RH-25

CCS Technical Documentation Troubleshooting - Baseband

sure provides the needed back volume for the speaker. The IHF enclosure is closed with

the IHF lid, which is carrying the IHF pins to contact the IHF speaker.