Page 1

CCS Technical Documentation

RH-25 Series Transceivers

Troubleshooting - Baseband

Issue 1 10/2003 Confidential © 2003 Nokia Corporation

Page 2

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Contents

Page No

Baseband Top-Level Description................................................................................... 4

Baseband Block Diagram ............................................................................................4

Environmental Specifications ......................................................................................5

Normal and Extreme Voltages.................................................................................. 5

Temperature Conditions............................................................................................ 5

Humidity.................................................................................................................... 5

Frequencies in Baseband .............................................................................................5

Infrared Interface (IrDA) .............................................................................................6

Energy Management ....................................................................................................6

Power Supply Modes ................................................................................................ 6

Battery BLD-3........................................................................................................... 7

Power Distribution .................................................................................................... 8

DC Characteristics .......................................................................................................9

Audio Circuitry ..........................................................................................................10

Audio Block Diagram ................................................................................................11

Earpiece................................................................................................................... 11

Microphones............................................................................................................ 11

Integrated Hands-free (IHF).................................................................................... 12

Audio Accessory Receive Path ............................................................................... 12

Audio Control Signals............................................................................................. 12

Acoustics ....................................................................................................................12

Earpiece Acoustic.................................................................................................... 12

IHF Speaker Acoustics............................................................................................ 12

Microphone Acoustics............................................................................................. 13

Vibra Motor............................................................................................................. 13

Audio Modes .............................................................................................................13

Handportable Mode................................................................................................. 13

Integrated Hands-free Audio Mode......................................................................... 14

Headset Audio Mode............................................................................................... 14

Loop set Audio Mode.............................................................................................. 15

External Hands-free Audio Mode........................................................................... 15

System Connector Interface......................................................................................... 15

System Connector ......................................................................................................15

Accessory Control Interface (ACI) ............................................................................16

Signal flow on ACI line - ACI-ASIC accessory inserted........................................ 17

Signal flow on ACI line - Non ACI-ASIC accessory inserted................................ 18

FBUS....................................................................................................................... 18

VOUT (Accessory Voltage Regulator)................................................................... 19

HookInt ......................................................................................................................20

Charging ....................................................................................................................20

DC-Plug................................................................................................................... 20

VCHAR Pins of System Connector........................................................................ 20

Voltages and Currents ................................................................................................22

Main Troubleshooting Diagram ................................................................................23

Phone is Dead ............................................................................................................25

Flash Programming Fault .........................................................................................26

Page 2 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 3

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Flash Programming Does Not Work .........................................................................27

Phone is Jammed .......................................................................................................30

Charger Faults ............................................................................................................32

Audio Faults ...............................................................................................................33

Keypad Fault ..............................................................................................................34

Display Fault ..............................................................................................................36

Accessory Faults ........................................................................................................37

Illumination Faults .....................................................................................................38

IrDa Fault ...................................................................................................................39

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 3

Page 4

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Baseband Top-Level Description

RH-25 is a handportable dual band TDMA and AMPS DCT-4 generation phone for the

smart classic segment.

The RH-25 Baseband consists of the DCT4 common Baseband chipset having some product-specific blocks of its own, such as pop-port system connector (also unofficially

known as "Tomahawk"), IHF, IrDA, and a color display.

The Baseband engine consists basically of two major ASICs:

• Universal Energy Management IC (UEM), including the analog audio circuits, the

charge control, and the voltage regulators.

• Universal Phone Processor (UPP), containing DSP, MCU, and some internal memory.

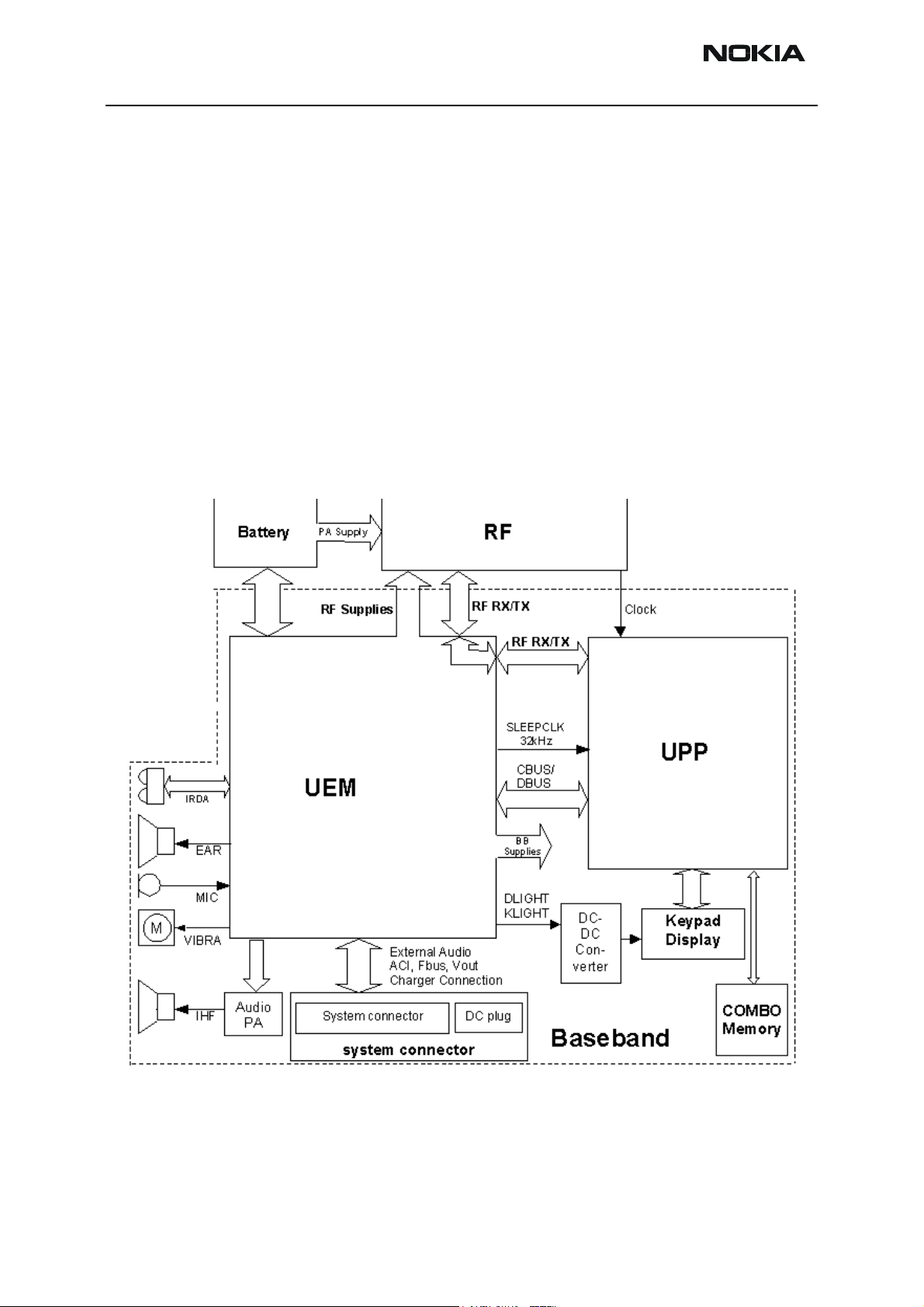

Baseband Block Diagram

The system block diagram below shows the main BB functional blocks.

Figure 1: Baseband block diagram

Page 4 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 5

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Environmental Specifications

Normal and Extreme Voltages

Following voltages are assumed as normal and extreme voltages for the BLD-3 battery

used in RH-25:

• Nominal voltage: 3.6 V

• Lower extreme voltage: 3.1 V

• Higher extreme voltage (fast charging): 4.4 V

Temperature Conditions

Operational temperature range (all specifications met within this range)

-10°C..+55°C

Functional temperature range (Reduced performance) -30°C..+70°C

Storage temperature range: -30°C..+85°C

Humidity

Relative humidity range is 5...95%.

The Baseband module is not protected against water. Condensed or splashed water may

cause interim or permanent phone malfunction.

Submergence of the phone in water will likely cause permanent damage to the phone.

Frequencies in Baseband

There are several clock frequencies at the baseband part. The following table lists all

available frequencies. The asynchronous and diagnostic busses are not included.

Frequency Context UPP UEM Flash Comments

54 MHz Memory clock X X

19.44 MHz RF clock X

13MHz DBUS, RFBusClk X X

Up to 1MHz RFConvClk X X

Table 1: Frequency List

1.08MHz CBUS Clock X X AMPS mode: 1.25MHz

32kHz Sleep Clock X

1.2kHz ACI X X

1.625MHz

up to 6.5MHz

Display IF X Frequency depends on

SW

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 5

Page 6

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Infrared Interface (IrDA)

RH-25 supports data connectivity via an infrared link. An IR module is integrated into

the phone, connected to the IR interface of the UPP ASIC.

Energy Management

The energy management of RH-25 is based on BB 4.0 architecture. A semi-fixed battery

(BLD-3) supplies power primarily to UEM ASIC and the RF PA. UEM includes several regulators to supply RF and baseband. It provides the energy management including power

up/down procedure.

Power Supply Modes

The functional behavior of the UEM can be divided into seven different states. Since the

UEM controls the regulated power distribution of the phone, each of these states affects

the general functionality of the phone:

•No supply

• Backup

•Power off

• Reset

•Power on

• Sleep

•Protection

The different states of the UEM are detailed in the sections below.

No Supply

In the NO_SUPPLY mode, the UEM has no supply voltage (VBAT < V

V_BU

tery are either disconnected or both discharged to a low voltage level.

The UEM will recover from NO_SUPPLY into RESET mode if the VBAT voltage level rises

above the V

Backup

In BACK_UP mode the main battery is either disconnected or has a low voltage level

(VBAT < V

and VBACK <

MSTR

). This mode is due to the fact that both the main battery and the backup bat-

COFF-

level by either reconnecting the main battery or charge it to such level.

MSTR+

and VBACK > V_BU

MSTR-

COFF+

).

The regulator VRTC that supplies the real-time clock is disabled in BACK_UP mode.

Instead the unregulated backup battery voltage VBACK supplies the output of the VRTC.

All other regulators are disabled and the phone has no functionality.

The UEM will recover from BACK_UP mode into RESET mode if VBAT rises above V

MSTR+

Power Off

In order for the UEM to be in PWR_OFF mode, it must have supply voltage (VBAT >

V

MSTR+

).

Page 6 © 2003 Nokia Corporation Confidential Issue 1 10/2003

.

Page 7

RH-25

CCS Technical Documentation Troubleshooting - Baseband

The regulator VRTC regulator is enabled and supplying the RTC within the UEM. The UEM

will enter RESET mode after a 20 ms delay whenever one of the below listed conditions is

logically true:

• The power button is activated

• Charger connection is detected

• RTC alarm is detected

The UEM will enter PWR_OFF from all other modes except NO_SUPPLY and BACK_UP if

the internal watchdog elapses.

Reset

When the UEM enters RESET mode from PWR_OFF mode, the watchdog is enabled. If the

VBAT fails to rise above the power-up voltage level V

(3.1 V) before the watchdog

COFF+

elapses, the UEM will enter PWR_OFF mode. Otherwise, after a 200 ms delay, the regulator VFLASH1 will be enabled and after an additional delay of 500 µs, the regulators

VANA, VIO, VCORE, and VR3 will be enabled. All other regulators( i.e., VFLASH2, VSIM,

VR1, VR2, and VR4 - VR7) are software controlled and disabled by default. After an additional delay of 20 ms, the UEM enters PWR_ON mode.

Power On

In PWR_ON, the UEM is fully functional in the sense that all internal circuits are powered up or can be by means of software. The UEM will enter PWR_OFF mode if VBAT

drops below V

enter PWR_OFF mode if either of the watchdogs Operational State Machine (approx. 100

µs), Security (32 sec.), or Power Key (4 sec.) elapses or if any of the regulators trigger the

thermal protection circuitry

Sleep

The UEM can be forced into SLEEP mode by the UPP by setting the input SLEEPX low for

more than 60 µs. This state is entered when the external UPP activity is low (phone in

sleep) and thereby lowering the internal current consumption of the UEM. The regulator

VANA is disabled and VR1 - VR7 are either disabled or in low quiescent mode.

From SLEEP the UEM enters PWR_ON if SLEEPX goes high, PWR_OFF mode if watchdog

elapses or BACK_UP mode if VBAT drops below V

Protection Mode

The UEM has two separate protection limits for over temperature conditions: one for the

charging switch and one for the regulators. The temperature circuitry measures the onchip temperature. In case of charging over temperature, the circuit turns the charging

switch off. In case of over temperature in any of the regulators, the UEM powers off.

for a period of time longer than 5 µs. The UEM will furthermore

COOF-

.

MSTR-

Battery BLD-3

RH-25 uses the BLD-3 Li-ion battery with a capacity of 780mAh. BLD-3 is a case-less

battery; the main advantage of a case-less battery type is the overall size, particularly

the thickness and the number of contact terminals.

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 7

Page 8

RH-25

Troubleshooting - Baseband CCS Technical Documentation

BLD-3 has a four-pin connector. BSI resistor value is 75Kohm.

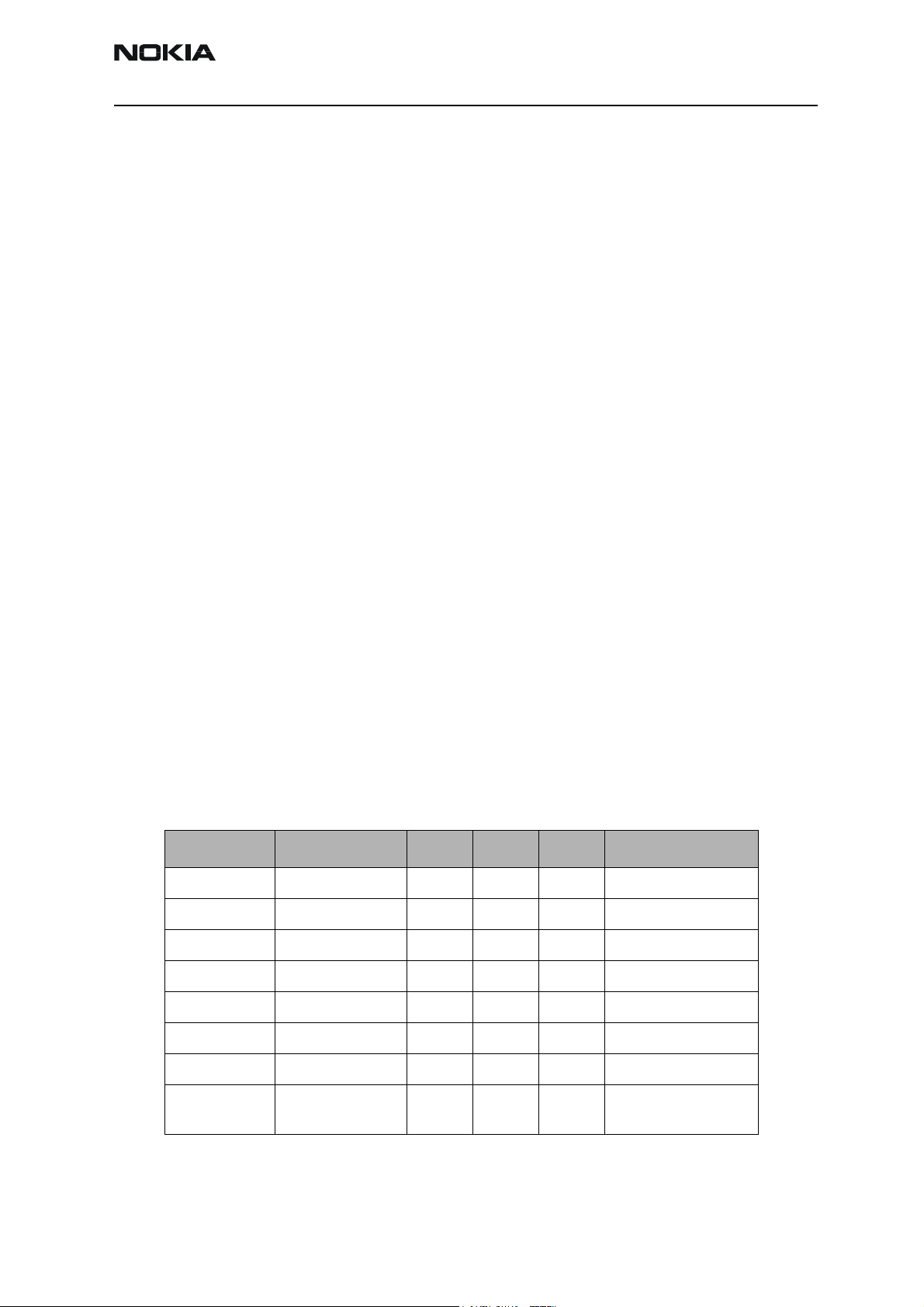

Power Distribution

Under normal conditions, the battery powers the baseband module. Individual regulators

located within the UEM regulate the battery voltage VBAT. These regulators supply the

different parts of the phone. Eight regulators are dedicated to the RF module of the

phone, and six to the baseband module.

The regulator VCORE is likewise adjustable and controlled by registers written by the

MCU. VCORE supplies the core of the UPP and can be adjusted on the fly by the MCU if

DSP capacity is inadequate. Higher VCORE supply (1.8 V) results in faster core operations

in the UPP.

Regulators VANA, VFLASH1, and VIO are solely controlled by the UEM and cannot be

enabled or disabled by the MCU. Furthermore, VFLASH1 and VIO are both ON, though in

low quiescent mode when phone is in sleep mode. An output current of 500 µA can be

drawn from the regulators. VIO supplies the UPP, FLASH and LCD, VFLASH1 supplies LCD

and the IrDA module. VANA is supplying analog parts internally in the UEM as well as the

baseband audio circuitry and pull-up resistors on the input of the UEM slow AD converters.

System connector provides a voltage to supply accessories. The white LED's need a higher

voltage supply as the battery can provide in bad condition. Separate external regulators

supply both consumers.

The regulators VR1A, VR1B, VR2 - VR7 and IPA1 - IPA4 are controlled by the DSP via

the DBus. VR4 - VR7 are controlled by the UEM as well and are disabled in sleep regardless of DSP writings.

VBAT/VBATTRF is furthermore distributed, unregulated, to the RF power amplifier, audio

power amplifier and external baseband regulators.

The CHACON module in the UEM controls the charging of the main battery. Furthermore

it contains a 3.2 Vdc regulator for charging of the backup battery and a 1.8 Vdc regulator

supplying the internal real time clock.

Page 8 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 9

RH-25

V

CCS Technical Documentation Troubleshooting - Baseband

Baseband

UEM

RF Regulators

VR1A

VR1B

VR2-7

6

SIM

VSIM

Battery

BAT

LED

regulator

ACC

regulator

PA Supply

VCORE

Baseband

Regulators

RTC

CHACON

VOUT

Tomahawk System Connector

VANA

VIO

VFLASH1

VFLASH2

Figure 2: Baseband power distribution

IHF PA

UPP

FLASH

LCD

Backup

battery

LED

Keyboard/display

IRDA

DC Characteristics

The following table reflects the specifications of voltage and current regulators within

the UEM:

Regulator Target

VR1A RF 4.6 4.75 4.9 0 10

4

VR2

VR3 RF 2.70 2.78 2.86 0.1 20

VR4 RF 2.70 2.78 2.86 0.1 50

VR5, VR6

VR7 RF 2.70 2.78 2.86 0.1 45

VrefRF01 RF 1.334 1.35 1.366 - 0.1

Table 2: UEM regulator outputs

Output Voltage (V) Output Current

(mA)

Min Typ Max Min Max

RF 2.70 2.78 2.86 0.1 100

0.1

1

RF 2.70 2.78 2.86 0.1 50

0.1

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 9

Page 10

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Output Voltage (V) Output Current

Regulator Target

Min Typ Max Min Max

1

VIO

2

VSIM

VANA BB 2.70 2.78 2.86 0.005 80

2

VCORE

VFLASH1 BB 2.70 2.78 2.86 0.005

VFLASH2

3

BB 1.72 1.8 1.88 0.005

BB 1.745

2.91

BB 1.000

1.235

1.425

1.710

0.974

1.215

1.410

1.692

BB 2.70 2.78 2.86 0.005 40

1.8

3.0

1.053

1.3

1.5

1.8

1.053

1.3

1.5

1.8

1.855

3.09

1.106

1.365

1.575

1.890

1.132

1.365

1.575

1.890

0.005

0.005

0.005

0.005

0.005

0.005

0.005

70

85

100

120

0.005

(mA)

150

0.500

25

0.500

70

85

100

120

200

200

200

200

70

1.5

1 The second current value indicates the maximum possible output current of the

regulator when in low quiescent mode.

2 The output voltages are split into two different current categories. The upper part

is the lower range of output current, and the lower part is the higher range of

output current.

3 Condition in sleep-mode depends on MCU writings to UEM regulator register

solely.

4 Condition in sleep-mode depends on DSP writings to UEM register.

When the accessory regulator, N100, is active, it will turn Vout ON (2.8V) and provide

70mA current.

Audio Circuitry

This section describes the audio-HW inside the Baseband. (External audio components

and acoustics are not considered with the details in this section.)

The main topology comes from other phones using BB4.0 engine, where the audio-HW is

mostly integrated into the UEM-ASIC. The biggest difference is that RH-25 has integrated hands-free (IHF).

Page 10 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 11

RH-25

CCS Technical Documentation Troubleshooting - Baseband

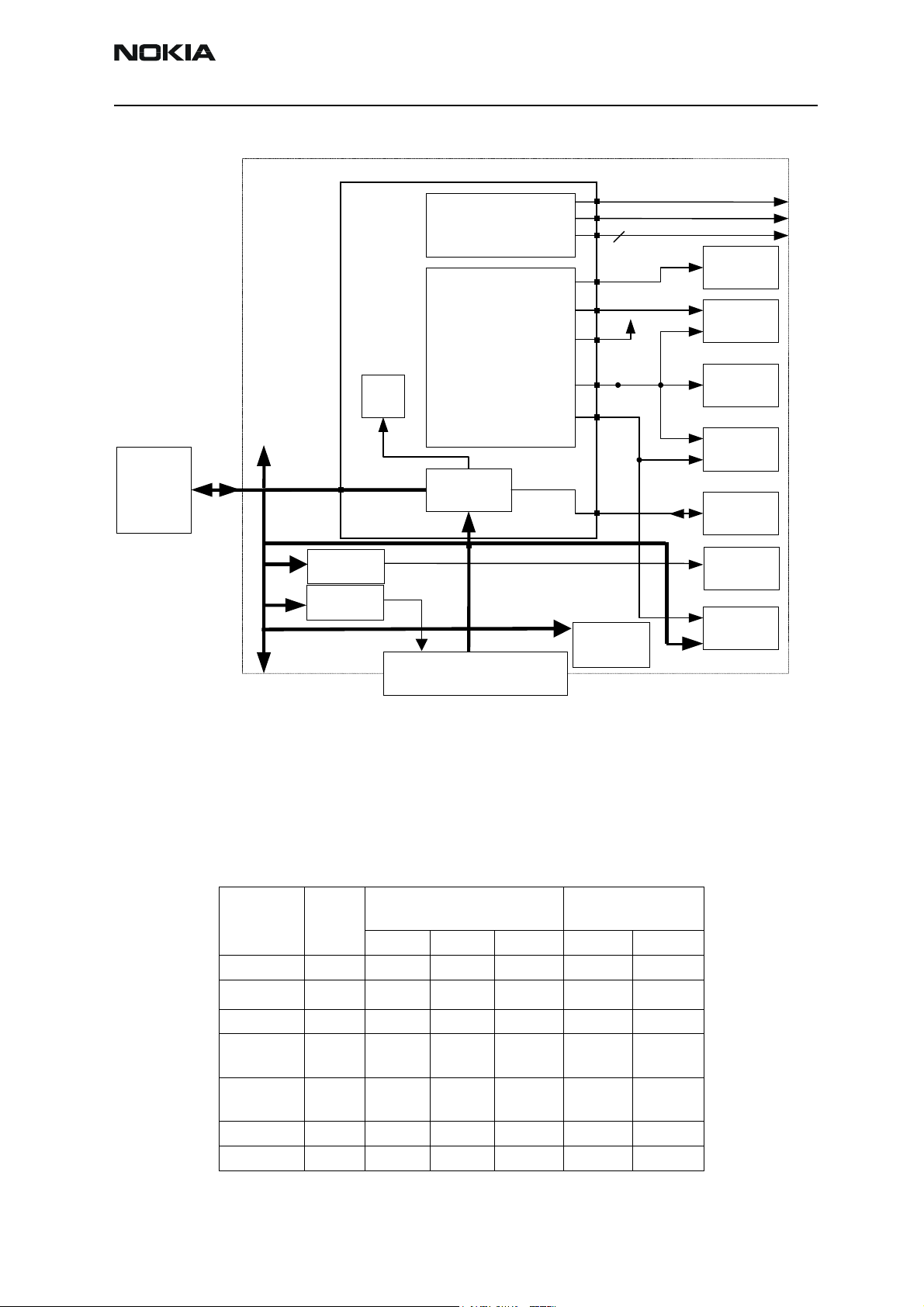

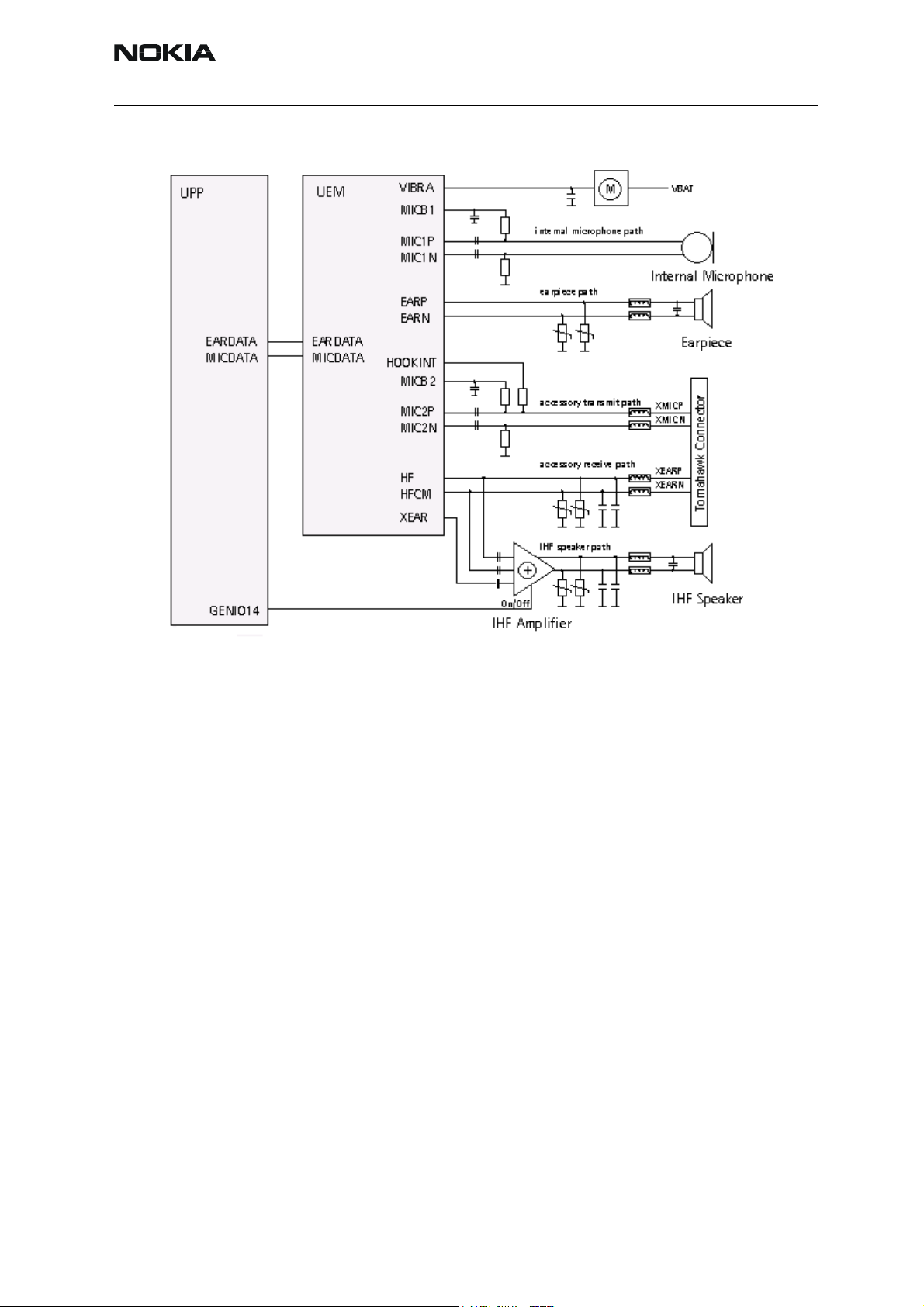

Audio Block Diagram

Earpiece

RH-25 uses an earpiece, which is also referred to as a PICO speaker. This is a 32 ohm

speaker with the diameter of 8 mm.

Earpiece is fed by the differential signals EARP and EARN from UEM. The signals run

quite directly from UEM to the earpiece, only some passive ands EMC protection components are needed

The external earpiece signals are fed by the HF and HFCM pins.

The level (swing) of earpiece-signals can be adjusted by register values inside UEM. These

signals have a common voltage level of 1.35 V (0.8 V for HF) at UEM pins.

Microphones

An EMC-improved type of microphone is used as internal microphone in RH-25, diameter

of which is 2.2mm.

Internal microphone circuitry is driven single-ended. Microphone needs bias voltage,

which is provided by UEM and is fed through a resistor to the microphone. A resistor is

also needed to the other side of the microphone, (i.e., between microphone and GND), in

order to provide the differential signals to UEM. Audio signals are AC-coupled from the

microphone.

Figure 3: Audio block diagram

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 11

Page 12

RH-25

Troubleshooting - Baseband CCS Technical Documentation

For the external microphone a differential input is used.

MIC1N and MIC1P (audio signals) and MICB1 (bias voltage) are used for the internal

microphone. MIC2N and MIC2P and MICB2 are used for external microphone.

Integrated Hands-free (IHF)

The speaker used for IHF is a 16 mm diameter speaker with 8 Ohm impedance, also

known as a MALT speaker.

IHF circuitry uses differential outputs from UEM.

Depending on the audio mode, the IHF amplifier is driven either from UEM HF / HFCM or

XEAR audio outputs. The IHF audio power amplifier (APA) LM4855 has a bridge-tied-load

(BTL) output in order to get the maximum use of supply voltage. The supply voltage for

driving circuitry of speaker is VBAT, thus the swing across the speaker is (VBAT.

The shutdown of the IHF PA is controlled by UPP using GENIO14.

Audio Accessory Receive Path

In RH-25, the accessory receive path is directly driven from UEM HF / HFCM differential

audio outputs, the output signal complies with the Pop-port accessory interface.

For EMC protection, ferrites are connected in series to the earpiece; for ESD protection,

varistors are used.

Audio Control Signals

The HEADINT signal is needed for recognizing the external device (e.g., headset) connected to the system. The recognition is based on the ACI-pin on the system connector,

which is shorted to ground inside the external device.

The button of the external device generates HOOKINT. This is used to answer or to end a

phone call.

Acoustics

Earpiece Acoustic

RH-25 uses the PICO 8mm earpiece.

This earpiece is mounted into the UI-shield assembly, the sealing of the front volume is

achieved using a foam gasket mounted on the front of the speaker. The UI shield is sealed

using a rubber sealing between UI shield and A-cover to create an acoustic path.

IHF Speaker Acoustics

The MALT speaker is used in RH-25 for integrated hands-free and ringing tone applications.

The IHF speaker is mounted to the IHF enclosure on a foam sealing ring. The IHF enclo-

Page 12 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 13

RH-25

CCS Technical Documentation Troubleshooting - Baseband

sure provides the needed back volume for the speaker. The IHF enclosure is closed with

the IHF lid, which is carrying the IHF pins to contact the IHF speaker.

The sealing of the effective acoustic volumes is achieved using ultrasonic welding to

bond the IHF lid and the IHF enclosure permanently.

To provide long-term reliability, additionally the IHF lid is heat stacked to the IHF enclosure. There is a dust membrane mounted inside the acoustic chamber that provides dust

and drop protection.

Due to ultrasonic welding of the IHF enclosure, it cannot be disassembled and, in case of

failure, the C-cover assembly should be replaced as one complete assembly.

Microphone Acoustics

A standard microphone module is used. This module is embedded into a rubber boot and

connected to the RH-25 system module by spring contacts.

The microphone is placed close to the system connector. The sound port of the microphone is located towards the bottom of the phone.

Vibra Motor

A vibrating alerting device is used to generate a vibration signal for an incoming call.

This vibra is located in the bottom section of the phone.

The vibrator is driven by the UEM output VIBRA, and controlled with a PWM signal. The

supply of the vibra is taken from the battery voltage of the phone.

Audio Modes

The following audio configurations can create the audio modes:

• Handportable

• Integrated hands-free

• Headset

• Loop set

• External hands-free

The following audio sources have to be routed according to the active audio mode:

• Speech

• Ringing tones / SMS tones

• Keypad tones

• Error tones / Warning tones

• Game tones

Handportable Mode

In handportable mode, earpiece path and internal microphone path are in use. The audio

sources are routed according to the following table:

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 13

Page 14

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Table 3: Handportable mode audio routing

Audio Source Earpiece

Speech X X

Ringing tones, SMS tones X

Keypad tones X

Warning/Error tone X

Game tones X

Internal

Microphone

Integrated Hands-free Audio Mode

In integrated hands-free mode, IHF path and internal microphone path are used. The

audio sources are routed according to the following table:

Table 4: IHF mode audio routing

Audio Source Earpiece

Speech X X

Ringing tones, SMS tones X

Internal

Microphone

IHF

speaker

IHF speaker

Accessory

receive path

Accessory

receive path

Accessory

transmit path

Accessory

transmit path

Keypad tones X

Warning/Error tones X

Game tones X

Headset Audio Mode

In headset mode, accessory receive path and accessory transmit path are used. RH-25

supports the following headsets:

HDB-4: HS-10, HS-5, and HS-2R headsets

The audio sources are routed according to the following table:

Table 5: Headset audio mode routings

Audio Source Earpiece

Speech X X X

Ringing tones, SMS tones X X

Keypad tones X

Internal

Microphone

IHF speaker

Accessory

receive path

Accessory

transmit path

Warning/Error tones X

Game tones X

Page 14 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 15

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Loop set Audio Mode

In loop set mode, accessory receive path and accessory transmit path are used. RH-25

supports the loop set LPS-4.:

Table 6: Loop set mode audio routing

Audio Source Earpiece

Speech X X

Ringing tones, SMS tones X X

Keypad tones X

Warning/Error tones X

Game tones X

Internal

Microphone

IHF speaker

Accessory

receive path

External Hands-free Audio Mode

In external hands-free mode, accessory receive path and accessory transmit path are

used. RH-25 supports external hands-free accessories:

BHF-1: Basic car hands-free kit

Table 7: External hands-free mode audio routing

Audio Source Earpiece

Speech X X

Internal

Microphone

IHF speaker

Accessory

receive path

Accessory

transmit path

Accessory

transmit path

Ringing tones, SMS tones X

Keypad tones X

Warning/Error tones X

Game tones X

System Connector Interface

System Connector

The system connector in RH-25 is called Pop-Port System Connector (unofficial name:

"Tomahawk"). It is a galvanic interface between phone and accessories.

Compared with previous system connector versions, four new functions are introduced

with the Pop-port system connector interface:

• Accessory Control Interface (ACI)

•Power Out

• Stereo audio output

• Universal Serial Bus (USB).

USB functionality and stereo audio output of the Pop-port are not supported in RH-25.

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 15

Page 16

RH-25

N

Troubleshooting - Baseband CCS Technical Documentation

Pop-port system connector is mechanically and electrically not backward-compatible

with any earlier Nokia accessory interfaces, except the charger connector.

ACI

Vout

Charge

Charge GND

Shielding GND

Fbus TX

Fbus RX

XMIC N

XMIC P

DATA GND

HSEAR_L_P

HSEAR_L_N

HSEAR_R_N

Figure 4: Tomahawk (Pop-port) system connector

Table 8: Tomahawk system connector interface description

Pin # Signal Notes

1 VCHAR Charger input line

2 GND Charge ground

3 ACI Insertion and removal detection/ Serial data bi-

directional 1 kbit/s

4 Vout Accessory power supply

5 Not used in RH-25

6 FBUS_RX Serial data from accessory to phone / 115 kbit/s

7 FBUS_TX Serial data from phone to accessory / 115 kbit/s

HSEAR_R_P

Shielding GND

8GND Data ground

9 XMIC N Negative audio in signal

10 XMIC P Positive audio in signal

11 HSEAR_L_N Negative left channel audio out signal

12 HSEAR_L_P Positive left channel audio out signal

13 HSEAR_R_N Negative right channel audio out signal

14 HSEAR_R_P Positive right channel audio out signal

Accessory Control Interface (ACI)

ACI is a point-to-point, master-slave, and bi-directional serial bus. It has three features:

• The insertion and removal detection of an accessory device

• Acting as a data bus, intended mainly for control purposes

• The identification and authentication of accessory type which is connected

The accessories are detected by the HeadInt signal when the plug is inserted.

Max bandwidth from the phone

Max bandwidth from the phone

Page 16 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 17

RH-25

d

+

t

K

)

t

g

r

y

K

CCS Technical Documentation Troubleshooting - Baseband

Normally when no plug is present, the pull-up resistor 100k pulls up the HeadInt signal

to VFLASH1. If the accessory is inserted, the external insertion and removal resistor

works as voltage divider and decreases the voltage level below the threshold Vhead.

The comparator output will be changed to high state causing an interrupt.

If the plug is removed, the voltage level of HeadInt increases again to VFLASH1. This

voltage level is higher than the threshold of the comparator and therefore its output will

be changed to low. This change leads to an interrupt. These HeadInt interrupts initiate

the accessory detection or removal sequence.

If no accessory is inserted / connected, the only active part on the Pop-port interface is

the ACI line.

ACI Accessor

Insertion &

Removal

detection

56

Data

GND

Accessory

Detect

VFLASH1

VFLASH1

4k7

UEM

HookInt

-

Vhea

MBUS

HeadIn

VFLASH1

47R 47R

ProdTP7

PHONE

100

ACI

ChargeGND

VBAT

Voltage

en

ulato

Re

UPP

GenIo(0

Figure 5: Principle schematics of ACI accessory and engine

Signal flow on ACI line - ACI-ASIC accessory inserted

1. Accessory is connected (insertion and removal resistor connect to ACI line)

1a) Phone gets HeadInt interrupt after 20ms check that ACI line is still low (<Vhead min)

2. Connect MBUS with HeadInt line (MBUS switch)

2a) If the phone detects a HeadInt interrupt from low to high transition in 20ms time-

frame, then an advanced accessory is connected

3. ACI chip reset (3000- 4000us)

4. Power up delay (50-400us)

5. Start bit (50us)

Vou

ACI

ASIC

VCC

6. Learning sequence (567-1700us)

7. ACI communication

8. MBUS is disconnected from HeadInt line (MBUS switch). After every communication.

9. Accessory is removed (no insertion and removal resistor on ACI line) --> phone gets

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 17

Page 18

RH-25

Troubleshooting - Baseband CCS Technical Documentation

HeadInt interrupt from ACI line low to high transition.

9a) If no HeadInt interrupt comes in the next 100ms, the accessory is really removed and

the phone goes in the state "no accessory".

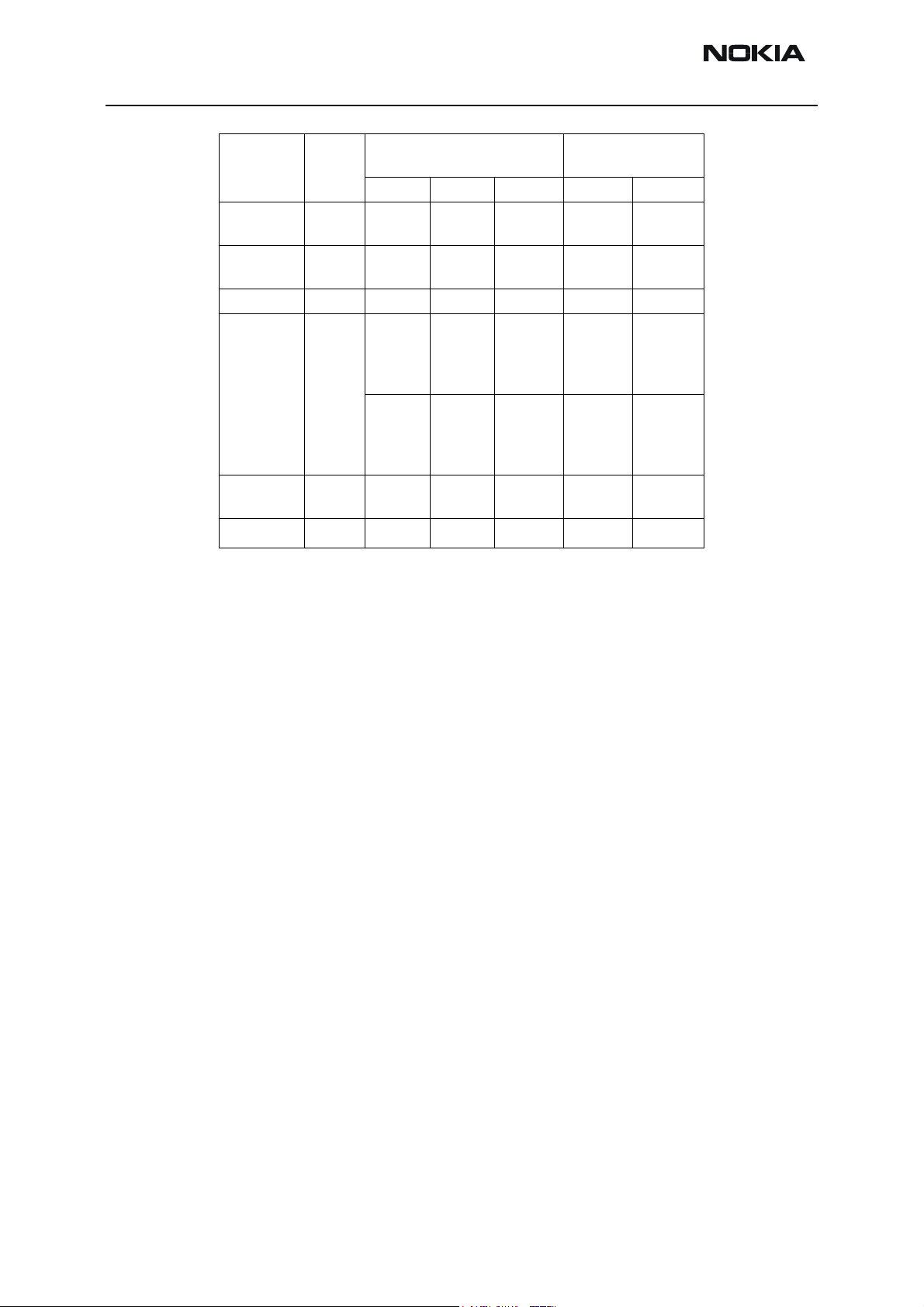

Table 9: Voltage levels

Signal Min Typ Max Unit Notes

V

FLASH1

V

head

Specified val-

2.7 2.78 2.86 V

1.75 1.9 2.05 V

Min Typ Max Unit

ues for levels

V

act_detect

0.83 1.13 V Voltage level if MBUS not connected to HeadInt

(MBUS switch open), but ACI accessory is

inserted.

V

V

high

low

2.45 2.71 V Voltage level after MBUS connected to HeadInt

<0.22*VDD V

Signal flow on ACI line - Non ACI-ASIC accessory inserted

V

headInt

V

FLASH1

V

head_min

1

20ms

2

1

a

V

low

3

Mono Headset is

recognized.

3

a

4

a

4

FBUS

Figure 6: Signal flow on ACI Line

1. Accessory is connected (insertion and removal resistor connect to ACI line)

1a) Phone gets HeadInt interrupt after 20ms check that ACI line is still low (<Vhead min)

2. Connect MBUS with HeadInt line (MBUS switch)

3. The 20 ms timer elapsed and no transition has been on HeadInt line

3a) Disconnect MBUS from HeadInt line

4. Accessory is removed. Phone gets HeadInt interrupt from ACI line low to high transition.

4a) If no HeadInt interrupt comes in the next 100ms, the accessory is really removed.

FBUS is an asynchronous data bus with separate TX and RX signals. Default bit rate of

the bus is 115.2 Kbit/s.

FBUS is used as additional communication channel from phone to accessory and vice

versa. There are two types of accessories which it uses:

Page 18 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 19

RH-25

CCS Technical Documentation Troubleshooting - Baseband

1. Nokia Serial Bus Accessory, AT mode

2. Fbus Phonet mode accessory

From HW-point of view, this does not make any difference.

Table 10: FBUS interface

Signal Parameter Min Typ Max Unit

FBUS_RX V

FBUX_TX V

IH

V

IL

OH

V

OL

VOUT (Accessory Voltage Regulator)

DCT4 chip set does not provide and power supply for accessories. To enable this, an

external LDO regulator is needed. This regulator is called Accessory Regulator.

The regulator input is connected directly to battery voltage (VBAT) and the output to

VOUT pin at system connector. The regulator is controlled by the GENIO(0) line of UPP.

With this signal, the regulator can be switched on and off.

The regulator can be supply up to150 mA. (Note: this exceeds the Pop-port minimum

requirement.)

VBAT

UPP

GenIO(0)

1.95 2.78 3.0 Vout

0 0.2 0.83

1.95 2.78 2.83

0 0.2 0.83

Tomahawk

bottom connector

Voltage

regulator

En

LP3985

VOUT

0.9R

DC resistance of ferrite

+ impedance of line and connector

Figure 7: Accessory power supply diagram

Table 11: Accessories power supply

Signal Min Nom Max Unit Note

Vout 2.63

2.56

GenIO(0) 1.4 1.88

2.80 2.88 V I = 70mA

Imax = 150mA

0.6 V High (ON)

0.6

Low (OFF)

The pull-down resistor on the enable input of the regulator is needed because in the

switch-off mode of the phone, the output level of the Genio(0) is not defined. Without

this resistor the output of the regulator can be floating.

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 19

Page 20

RH-25

Troubleshooting - Baseband CCS Technical Documentation

RH-25 supports fully differential external audio signals. A headset can be connected to

the Pop-port system connector. However, only Mono audio is supplied to accessories.

HookInt

This signal is used to detect whether a button in accessory is pressed or not. The hook

signal is generated by creating a short circuit (20 ohm) between the headset microphone

signals (XMICP and XMICN). In this case, an LP-filter is needed on the HookInt input to

filter the audio signal.

If no accessory is present, the HookInt signal is pulled up by the UEM resistor.

If an accessory is inserted and the microphone path is biased, the HookInt signal

decreases to 1.9V due to the microphone bias current flowing through the resistor. When

the button is pressed, the microphone signals are connected together, and the HookInt

input will get half of micbias dc value 1.1V. This change in DC level will cause the HookInt comparator output to change state, in this case from 0 to 1.

HookInt comparator reference is selected level is 1.35 V.

Normally micbias and hookint are enabled only when audios are routed to headset.

In order to recognize the Hook signal (button in headset or SyncButton in deskstand),

when the phone is in the sleep mode, it must be done by polling. That means the micbias

and the hookInt signal must be enabled in regular time intervals.

Charging

RH-25 can be charged via a DC-plug or charging pins on the system connector. It supports only 2-wire charging.

Table 12: Voltage levels Hook Int

Signal Min Nom Max Unit

VFLASH1 2.7 2.78 2.86 V

MICB2 2.0 2.1 2.25

600

Vhook1 1.25 1.35 1.45 V

V

uA

DC-Plug

RH-25 uses a 3.5mm DC-plug. It is possible to use a 3-wire charger, but the PWM inside

these chargers is not supported.

VCHAR Pins of System Connector

The VCHAR and ChargeGND pin are directly connected to the normal charger lines of the

Page 20 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 21

RH-25

CCS Technical Documentation Troubleshooting - Baseband

DC-plug.

Table 13: Charger input voltage levels

Signal Min Nom Max Unit Notes

Input voltage range

(fast charger)

Input voltage range

(standard charger)

5.5 8.4 9.3 VRMS 1 = 850mA

11 .1

7.9

-0.3 20 V Absolute maximum VCHAR voltage

16 Vpeak

VRMS

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 21

Page 22

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Voltages and Currents

Table 14: System connector interface signals

Pin # Signal Parameter Min Typ Max Unit Notes

1VCHAR 0 9

0.85

2 GND Charge ground

3 ACI Logic “0”

Logic “1”

4 Vout Output voltage

Current

5 Not used in RH-25

6 FBUX_RX Logic “0”

Logic “1”

7 FBUS_TX Logic “0”

Logic “1”

8 GND Data ground

9 XMIC N Differential

voltage swing

DC level

0

1.7

2.56 2.8

0

2.0

0

1.89

0.2

2.78

70

0.2

2.78

0.2

2.78

1Vpp

0.7

2.86

2.88

150

0.86

3.0

0.81

2.83

VDC

ADC

V Insertion and removal

detection/ Serial data

bi-directional 1 kbit/s

VDC

mA

V Serial data from

V Serial data from

VDC

70mA is specified as

the max current in the

Pop-port specification

accessory to phone /

115 kbit/s

phone to accessory /

115 kbit/s

Negative audio in signal

10 XMIC P Differential

voltage swing

DC level 2.05

11 HSEAR_L_N Differential

voltage swing

12 HSEAR_L_P Differential

voltage swing

13 HSEAR_R_N Differential

voltage swing

14 HSEAR_R_P Differential

voltage swing

1

2.1 2.25

400

1 Vpp Left channel negative

1 Vpp Left channel positive

1 Vpp Right channel nega-

1 Vpp Right channel positive

Vpp

VDC

uA

Positive audio in signal

audio out signal

audio out signal

tive audio out signal

audio out signal

Page 22 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 23

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Main Troubleshooting Diagram

Top

Phone totally dead

NO

Flash programming

doesn't work

NO

Phone doesn't start

up or phone is

jammed

NO

Charging doesn't

work

YES

YES

YES

YES

Phone

dead

Flash

faults

Phone

is

jammed

Charger

faults

NO

IrDa doesn't work IrDa fault

NO

YES

Top page 2

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 23

Page 24

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Top 2

Audio faults

NO

Display or LEDs not

working

NO

Keypad doesn't work

NO

Accessory doesn't

work

NO

YES

YES

YES

YES

Audio

faults

Display

faults

Keypad

faults

Access

ory

faults

Illumination doesn't

work

NO

YES

END

Illumina

tion

faults

Page 24 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 25

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Phone is Dead

Phone

is dead

Check X100

Is phone current

0 mA?

YES NO

(contacts,

solderings). Is it

OK?

YES

Change X100

NO

Phone current is

<50 mA

NO

Phone current is

~54 mA

YES

Is phone in Local

Mode?

Check power key Change if defective

YES

NO

Check all VBAT lines

Is flash

YES YES

programming

working OK?

NO

NO

Check X100, R203,

NO YES

R204, C217, and

C220. Replace if

defective.

Phone

is

jammed

Flash

faults

Change UEM

YES

End

NO

Change

defective part

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 25

Page 26

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Flash Programming Fault

Flash

faults

Is the FBUS TX line

HIGH after startup?

YES

Is FBUSTX line set

to LOW after it has

been HIGH?

YES

Wrong manufacturer

ID and device ID

Measure BSI pulse

NO NO

during Flash

programming. Is it

OK?

YES

Measure FBUSTX

line during Flash

operation (J491). Is it

NO

~1.8V?

NO

YES

YES

Check X100, R203,

R204, C217, and

C220. Replace if

defective.

Check R104. If OK,

change UEM

Change UPP

Change Flash

NO

Is phone totally

dead?

NO

Phone doesn't start

up or is jammed

NO

YES

YES

Phone

is dead

Phone

is

jammed

End

(retest)

Page 26 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 27

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Flash Programming Does Not Work

Flash programming procedure

1 The phone communicates with the prommer via the production test pattern,

using the following signals:

• FBUSTX (serial data to phone)

• FBUSRX (serial data from phone)

• MBUS (serial clock for FBUSRX)

• VPP (external flashing voltage for speed up flashing)

• The BSI line also is used when initializing flashing (battery connector)

2 When the phone is powered (VBAT>3V), the MBUS and FBUSTX lines are pulled

up internally by the phone.

3 The prommer sends a command to the UEM, using FBUSRX, to enter the Flash

mode. During the sending of this command, the prommer keeps the BSI line high

and MBUS is used as a serial clock.

4 When the Flash mode command is acknowledged, UEM enters the Flash mode

and releases reset (PURX) to MCU.

5 After reset is released, UPP checks if there is a request for the Bootstrap code

that resides in the UPP ROM.

6 The request for Bootstrap is the MBUS pulled down by the prommer (if the boot-

strap is not requested, the bootstrap code jumps to FLASH SW).

7 If the Bootstrap code is requested, UPP enters the Flash mode and sets FBusTX to

‘0’ as an acknowledgement to the prommer. This is an indication that UPP can

run, at least, the fixed Bootstrap code — although it is not able to run the FLASH

code. UPP then sends an UPP ID to the prommer via the FBUSTX line.

8 After the prommer has received the UPP ID, it sends a corresponding Secondary

Boot Code to the phone via FBUSRX. The Secondary Boot Code, when run in UPP,

requests UPP to send information to the prommer about the flash type and other

HW-related parameters about the device to be flashed.

9 The prommer then sends the Algorithm Code corresponding to the HW parame-

ters, and this algorithm, when run in UPP, takes over handling the MCUSW transfer to Flash.

10 To speed up flashing, 12 volts can be supplied to Vpp (by the prommer).

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 27

Page 28

RH-25

Troubleshooting - Baseband CCS Technical Documentation

11 The Flash program includes a package of MCU and DSP software and all default

parameters for the phone. The tuning values will be added/rewritten during the

Flash/Alignment phase.

Flash programming error codes

The various error codes can be seen from the FPS-8 Flash menu in Phoenix.

The underlined text in the following table indicates that the item under consideration is

being used for the first time in the flashing sequence.

Table 15: Flash programming error codes

Error Description Not working properly

C101 “The Phone does not set FbusTX line

high after the startup.”

C102 “The Phone does not set FbusTx line low

after the line has been high. The Prommer generates this error also when the

Phone is not connected to the Prommer.”

C103 “Boot serial line fail.” Mbus from Prommer->UEM->UPP(MbusRx)(SA1)

C104 “MCU ID message sending failed in the

Phone.”

C105 “The Phone has not received Secondary

boot codes length bytes correctly.”

C106 “The Phone has not received Secondary

code bytes correctly.”

Vflash 1

VBatt

BSI and FbusRX from prommer to UEM

FbusTX from UPP->UEM->Prommer(SA0)

PURX(also to Safari)

VR3

Rfclock(VCTCXO->Safari->UPP

Mbus from Prommer->UEM->UPP(MbusRx)(SA0)

FbusTx from UPP->UEM->Prommer(SA1)

BSI and FbusRX from prommer to UEM

FbusRX from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

FbusTx from UPP->UEM->Prommer

Mbus from Prommer ->UEM->UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

Mbus from Prommer->UEM->UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

C107 “The Phone MCU cannot start Secondary

code correctly.”

C586 “The erasing status response from the

Phone informs about fail.”

C686 “The programming status response from

the Phone informs about fail.”

Cx81 “The Prommer has detected a checksum

error in the message, which it has

received from the Phone.”

UPP

Flash

Flash

FbuxTx from UPP->UEM->Prommer

Page 28 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 29

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Table 15: Flash programming error codes

Error Description Not working properly

Cx82 “The PRommer has detected a wrong ID

byte in the message, which it has

received from the Phone.”

A204

Cx83

Cx84

Cx85

Cx87 “Wrong MCU ID.” RFClock

Startup for

flashing

“The flash manufacturer and device IDs

in the existing Algorithm files do not

match with the IDs received from the

target phone.”

“The Prommer has not received Phone

acknowledge to the message.”

“The Phone has generated NAK signal

during data block transfer.”

“Data block handling timeout.”

Required startup for flashing Vflash1

FbuxTx from UPP->UEM->Prommer

Flash

UPP

VIO/VANA?

Signals between UPP-Flash

Mbus from Prommer->UEM->UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

UPP(Vcore)

VBatt

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 29

Page 30

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Phone is Jammed

Phone is

jammed

Measure VIO,

VCORE, VFlash1,

VANA, and VR3

voltages. Are they

OK?

Measure 32kHz

Sleep Clk from test

point J404. Is it OK?

YES

Measure 19.44MHz

RF Clk from C420. Is

it OK?

YES

Check VBATT1-6,

NO NO

VIO, VCORE,

VFlash1, VANA , VR3

lines. Are they OK?

YESYES

NO

Measure Sleep Clk

from B200. Is it OK?

YES

NO

Measure 19.44MHz

NO NO

RFClk from G790. Is

it OK?

YES

Check BSI/BTEMP

lines and VBATT

lines

Check BSI/BTEMP

lines. If OK, UEM

regulators are not

working. Change

UEM.

Check B200, C203,

and C204

Change UEM

Check G790. If not

OK, change.

Check R420. If OK,

change N801.

Measure PURX

signal from test

point J402. Is it

NO

Change UEM

~1.8V?

YES

Phone is

jammed,

page 2

Page 30 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 31

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Phone is

jammed,

page 2

Measure 13MHz Clk

Phone shutdown

after 30 seconds

NO

Measure 1.08MHz

Clk signal from test

point J406. Is it OK?

YES NO

DBUSCLK signal

from test point J413.

Is it OK?

NO

Change UPP

YES

Read phone info. Is

it OK?

YES

END

Measure FBUSRX

NO NO

signal during phone

info read from test

point J412. Is it OK?

YES

Measure FBUSTX

signal during phone

info read from test

NO

point J411. Is it OK?

YES

Change UEM

Change UPP

Change UEM

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 31

Page 32

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Charger Faults

Charger

faults

Battery bars are

working (scroll)

NO

Measure voltage

over V100 (TVS). Is

it > 3.0 V?

YES

Read BTEMP

value. Compare it

to ambient

temperature. Is it

~25C?

YES

Measure charger

current through

F100. Is it

~350...390mA (with

ACP-7)?

Check X102,

NO

F100, L100,

V100, C124, C127

and line.

Check X100,

C137, C138,

NO

R203, R205,

C217 and line.

Are they OK?

Check R200. Is

NO

it OK?

YES

NO

Change defective

part (if any),

recalibrate charge

current/voltage.

Recalibrate

BTEMP with

YES

Phoenix SW.

defective part,

recalibrate and

YES

Change UEM

Retest

Retest.

Retest

Change

retest

YES

NO

END

Change

defective part,

recalibrate

charge current/

voltage. Retest.

Page 32 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 33

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Audio Faults

Audio

faults

Is the earpiece

working?

YES

NO YES

Change earpiece. Is

it working now?

NO

Set phone in LOCAL mode.

Use Phoenix A udio test. Set

EXT IN, HP OUT, LOOP ON

Measure DC offset voltage

from earpiece pads. Is it

NO

~1.38V?

YES

Measure MIC2B

voltage from XMICP

NO

(L102). Is it ~2.2V?

YES

Connect EXT audio signal

(1kHz sine, 200mVpp) in

XMICP and GND in XMICN.

Retest earpiece

Check L131, C107,

C108 and lines. If OK,

change UEM.

Check C159, R150,

C115, C118, R115, L160

and line. If OK, change

UEM.

Measure sine signal from

earpiece pads. Is it

~880mVp-p?

YES

END

Change UPP

and retest

Measure sine signal from

NO YES

R117 and R118 (UEM). Is it

~130mVp-p?

NO

Check C155, C156,

C113, C111, R117,

R118, R150 and lines

Change

UEM

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 33

Page 34

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Keypad Fault

Keypad

faults

Is the power key

working?

YES

Keypad

faults,

page 2

NO NO

Measure voltage

from S1. Is it high?

YES

Measure voltage

from S1 when power

YES

key is pressed. Is it

high?

NO

Phone

is

jammed

Check R125, C125,

and S1. If OK,

change UEM

Check S1. Is it

OK?

NO

YES

Phone

is dead

Change S1

Page 34 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 35

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Keypad

faults,

page 2

Are UI modules keys

working?

NO

Try to change UI

PWB. Are the keys

working now?

NO

Check X301 (solder

joints and spring

contacts). Is it OK?

YES

Measure ROW0 ROW4 lines from

X301. Is voltage level

~1.8V?

YES

Measure SLEEPX

signal from test

point J403 when key

is pressed. Is

voltage level ~1.8V?

YES

NO

NO

Retest failing UI

module

Change X301

NO

Check lines ROW0 -

ROW4 from X301. If

OK, change Z301. If

it still fails, change

UPP

YES

When keypad is

pressed, are the

LEDs turned on?

NO

Illuminati

END

on faults

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 35

Page 36

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Display Fault

Display

faults

Try to change UI

Does the display

start?

NO YES

module. Is the

display working

now?

NO

Retest failing UI

module

YES

Check X302 (solder

joints). Is it OK?

Measure VDD (2.7V)

and VDD1 (1.8V). Are

they OK?

YES

Measure RESX

(J306) and CSX

(J307) signals. Are

voltage levels

~1.8V?

YES

Measure SDA (J308)

and SCLK (J309)

signals. Are voltage

levels ~1.8V?

NO

NO

NO

NO

Change X302

Check X302 and

lines again. If OK,

change UEM.

Check X302 and

lines again. If OK,

change UPP.

Check X302, R308,

R309 and lines. If

OK, change UPP.

YES

Are the display LEDs

END

working when key is

pressed or enabled

by Phoenix SW?

NO

Illumination

faults

Page 36 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 37

RH-25

CCS Technical Documentation Troubleshooting - Baseband

Accessory Faults

Accessory

faults

Is accessory

detected when

connected to system

connector?

YES

Check system

NO NO

connector (X101)

(solderings, contact

plates). Is it OK?

YES

Measure ACI line

(pin3). Is it

NO

~0.83...1.13V?

YES

Measure VOUT

voltage (pin4). Is it

~2.8V?

YES

NO

Retest

Repair solderings

or check contact

plates if dirty.

Retest.

Check ACI line (L106,

R103, R102, R109,

C103). If not OK,

change defective part

and retest.

Check VOUT line (N100,

L107, R103, C101, C102,

C112). If not OK,

change defective part

and retest.

ACI Accessory

END

Measure ACI line

(pin3). Is it ~0V?

YES

Measure VOUT

voltage (pin4). Is it

~0V?

YES

Retest

Check ACI line (L106,

R103, R102, R109,

NO

C103). If not OK,

change defective part

and retest.

Check that regulator

N100 enable pin is LOW

NO

state. If not OK, check

ACI line again.

Non-ACI Accessory

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 37

Page 38

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Illumination Faults

Illumination

faults

Are the display LEDs

working?

YES

Are the keyboard

LEDs working?

YES

Try to change display.

Are LEDs working now?

NO

NO

Check X302 (solder

joints). Is it OK?

YES

Measure VLED+ and VLED-.

VLED+ =~7.5V and VLED- =~0.5V

when LED driver is enabled. Are

they OK? (Notice: VLED+=VBATT

when driver is disabled).

YES

Try to change UI PWB. Are the

NO

LEDs working now?

YES

Check X301 (solder joints). Is it OK?

YES

Measure VLED+.

VLED+=~7.5V when LED

driver is enabled. Is it OK?

YES

YES

NO

YES

NO

Retest failing

Change X302

Check N300,

L300, V300,

NO

R300, C303,

C304. If not OK,

change defective

Retest failing UI

Check X302,

NO

R308, R309 and

lines. If OK,

change UPP.

Check N300,

L300, V300, R300,

C303, C304. If not

OK, change

defective part.

display

part.

PWB

Check LEDs in UI PWB. Are they OK?

NO

Change

defective parts

END

YES

Retest

Page 38 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Page 39

RH-25

CCS Technical Documentation Troubleshooting - Baseband

IrDa Fault

IrDa fault

Go to infrared menu and

Does the IrDa work?

press Select. Do you see

NO YES

the IrDa icon blinking on

the display?

NO

Retest IrDa of

phone

YES

Can you send and

receive vcard

between another

RH-25 phone?

YES

Check N961 (solder

joints). Is it OK?

Measure VBAT at pin 1

of N961 and verify if it

is between 3.6~4.2V

NO

Reflash phone and

retest IrDa

YES

YES

NO

NO

Change N961

Check C302,

R300, L300,

V300, C304, and

C303. If not OK,

change defective

part.

END

Issue 1 10/2003 Confidential © 2003 Nokia Corporation Page 39

Page 40

RH-25

Troubleshooting - Baseband CCS Technical Documentation

Page 40 © 2003 Nokia Corporation Confidential Issue 1 10/2003

Loading...

Loading...