Page 1

PAMS Technical Documentation

NPM–9 Series Transceivers

System Module & UI

Issue 1 02/2002 Nokia Corporation

Page 2

NPM–9

System Module & UI

PAMS Technical Documentation

CONTENTS

Transceiver NPM–9 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Modules 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Modes 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interconnection Diagram 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Module LA5 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Module 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Summary 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Characteristics 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulators and Supply Voltage Ranges 9. . . . . . . . . . . . .

External and Internal Signals and Connections 10. . . . . . . . .

Internal Signals and Connections 10. . . . . . . . . . . . . . . . . . . . .

FM Radio Interface 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal microphone 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal speaker 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC and DC Characteristics of RF–BB voltage supplies 12

AC and DC Characteristics of RF–BB digital signals 13. .

AC and DC Characteristics of RF–BB analogue signals 14

External Signals and Connections 15. . . . . . . . . . . . . . . . . . . .

UI (board–to–board) connector 15. . . . . . . . . . . . . . . . . . . .

LCD connector 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC connector 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headset connector 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM connector 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Description 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes of Operation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply Voltage Regulation 20. . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up and Reset 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/D Channels 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FM Radio 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IR Module 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup Battery 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM Interface 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buzzer 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Microphone 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UPP 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Block 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Module 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Frequency Plan 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC characteristics 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulators 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Diagram 30. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Nokia Corporation

Issue 1 02/2002

Page 3

NPM–9

PAMS Technical Documentation

RF characteristics 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter characteristics 31. . . . . . . . . . . . . . . . . . . . . . . .

Receiver characteristics 31. . . . . . . . . . . . . . . . . . . . . . . . . .

RF Block Diagram 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency synthesizers 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC function 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC–compensation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UI Board LU9 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD & Keypad Illumination 37. . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Speaker 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic Diagrams (at the back of the binder): LA5 layout 01 and LU9 layout 11

RF & BB (Version 0.0 Edit 2) for layout version 01 A–1. . . . . . . . . .

RF (Version 2.0 Edit 2) for layout version 01 A–2. . . . . . . . . . . . . . .

System Module & UI

BB Connections (Version 0.0 Edit 4) for layout version 01 A–3. . . .

System Connector (Version 1.3 Edit 162) for layout version 01 A–4

Audio Interface (Version 1.3 Edit 1) for layout version 01 A–5. . . .

UEM of BB (Version 2.0 Edit 1) for layout version 01 A–6. . . . . . . . .

Light Filtering (Version 2.0 Edit ) for layout version 01 A–7. . . . . .

Display and Keyboard Interface (Version 1.3 Edit 212) for layout version 01A–8

Infrared Module (Version 2.0 Edit 38) for layout version 01 A–9. .

FM Radio (Version 1.3 Edit 110) for layout version 01 A–10. . . . . . .

SIM Reader (Version 1.3 Edit 48) for layout version 01 A–11. . . . . .

UPP and decoupling capacitors (Version 2.0 Edit 91) for layout version 01A–12

Discrete capacitors for UPP (Version 1.3 Edit 10) for layout version 01 A–13

GSM RF – BB Interface (Version 1.3 Edit 35) for layout version 01 A–14

Flash Memory (Version 2.0 Edit 35) for layout version 01 A–15. . . .

Discrete capacitors for memory without VFlash1 (V. 1.3 Edit 10) layout 01A–16

Test pattern – 5 pin (Version 2.0 Edit 12) for layout version 01 A–17

Layout Diagram of LA5 – Top (Version 01) A–18. . . . . . . . . . . . . . . . .

Layout Diagram of LA5 – Bottom (Version 01) A–18. . . . . . . . . . . . . .

Testpoints of LA5 – Top (Version xx) A–19. . . . . . . . . . . . . . . . . . . . . . .

Testpoints of LA5 – Bottom (Version 01) A–19. . . . . . . . . . . . . . . . . . .

UI Board – LU9 for version 11 A–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Layout Diagram – LU9 for version 11 A–21. . . . . . . . . . . . . . . . . . . . . .

Issue 1 02/2002

Nokia Corporation

Page 3

Page 4

NPM–9

System Module & UI

PAMS Technical Documentation

This page intentionally left blank.

Page 4

Nokia Corporation

Issue 1 02/2002

Page 5

PAMS Technical Documentation

Transceiver NPM–9

Introduction

The NPM–9 is a dual band radio transceiver unit for the E–GSM900 and

GSM1800 networks. GSM power class is 4 and GSM1800 power class is

1. It is a true 3 V transceiver, with an internal antenna and vibra.

The NPM–9 phone includes integrated FM radio. Radio is used as a nor-

mal mono receiver. FM radio is highly integrated. Only few external com-

ponents are needed. Headset is used as an antenna for radio.

The transceiver has a full graphic display and the user interface is based

on a Jack style UI with two soft keys.

An internal antenna is used, there is no connection to an external anten-

na.

The transceiver has a low leakage tolerant earpiece and an omnidirec-

tional microphone, providing an excellent audio quality. The transceiver

supports a full rate, an enhanced full rate and a half rate speech decod-

ing.

NPM–9

System Module & UI

An integrated IR link provides a connection between two NPM–9 trans-

ceivers or a transceiver and a PC (internal data), or a transceiver and a

printer.

The small SIM ( Subscriber Identity Module ) card is located under the

battery. SIM interface supports both 1.8V and 3V SIM cards.

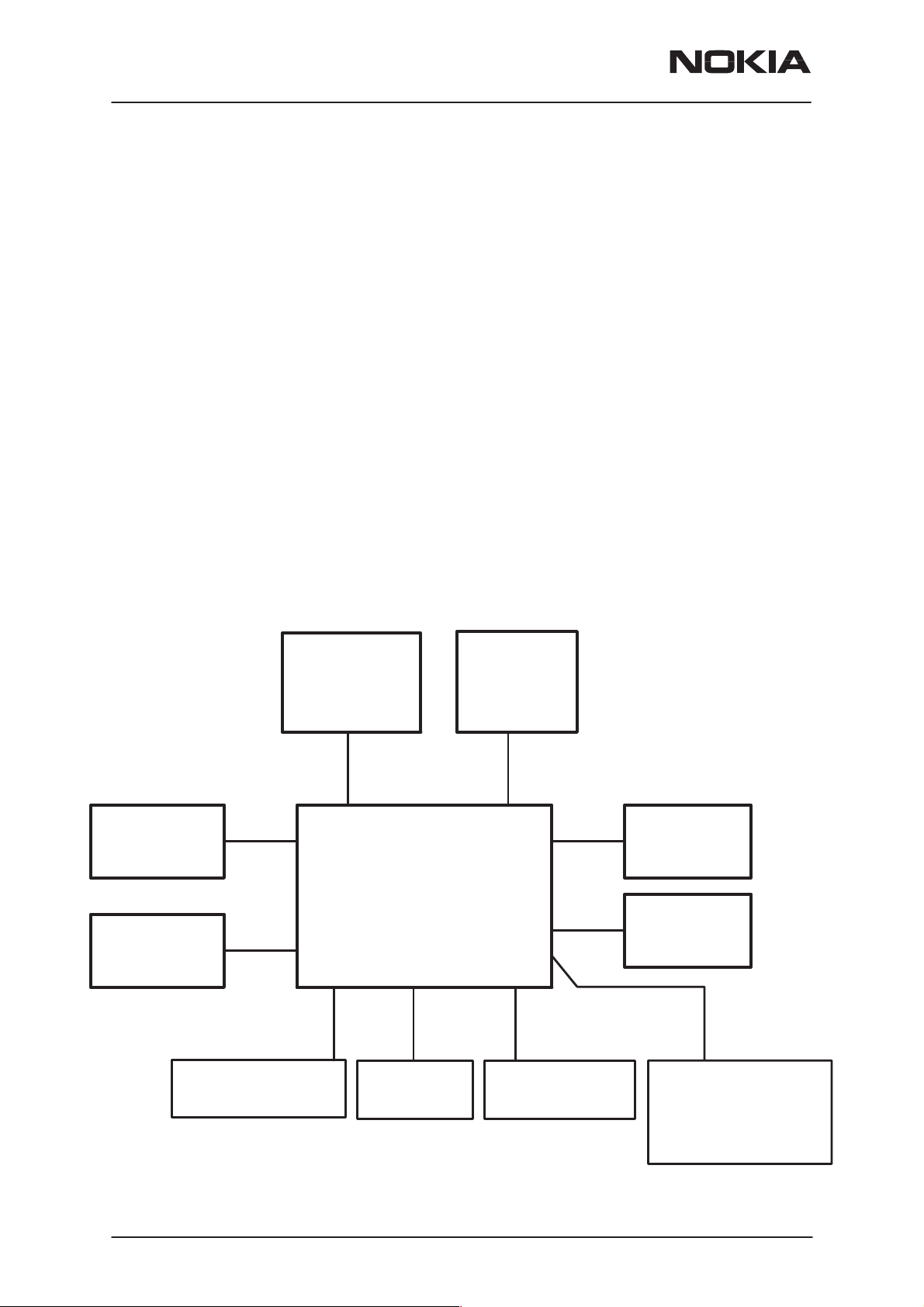

Electrical Modules

The radio module consists of Radio Frequency (RF) and baseband (BB).

User Interface (UI) contains display, keyboard, IR link, vibra, HF/HS con-

nector and audio parts. UI is divided into radio PWB LA5 and UI PWB

LU9. FM radio is located on the main PWB.

The electrical part of the keyboard is located in separate UI PWB named

LU9. LU9 is connected to radio PWB through spring connectors.

The System blocks provide the MCU, DSP, external memory interface

and digital control functions in UPP ASIC (Universal Phone Processor).

Power supply circuitry, charging, audio processing and RF control hard-

ware are in UEM ASIC (Universal Energy Management).

The purpose of the RF block is to receive and demodulate the radio fre-

quency signal from the base station and to transmit a modulated RF sig-

nal to the base station.

Issue 1 02/2002

Nokia Corporation

Page 5

Page 6

NPM–9

System Module & UI

Operation Modes

The transceiver has six different operation modes:

– power off mode – idle mode

– active mode – charge mode

– local mode – test mode

In the power off mode circuits are powered down and only sleep clock is

running.

In the idle mode only the circuits needed for power up are supplied.

In the active mode all the circuits are supplied with power although some

parts might be in the idle state part of the time.

The charge mode is effective in parallel with all previous modes. The

charge mode itself consists of two different states, i.e. the fast charge and

the maintenance mode.

The local and test modes are used for alignment and testing.

PAMS Technical Documentation

Interconnection Diagram

Keyboard

module

SIM Battery

Radio

Module

LA5

Antenna

Display

Charger

Page 6

MIC

IR Link

Nokia Corporation

Earpiece

HF

+

FM antenna

Issue 1 02/2002

Page 7

PAMS Technical Documentation

System Module LA5

Baseband Module

The baseband architecture supports a power saving function called ”sleep

mode”. This sleep mode shuts off the VCTCXO, which is used as system

clock source for both RF and baseband. During the sleep mode the sys-

tem runs from a 32 kHz crystal. The phone is waken up by a timer run-

ning from this 32 kHz clock supply. The sleep time is determined by net-

work parameters. Sleep mode is entered when both the MCU and the

DSP are in standby mode and the normal VCTCXO clock is switched off.

NPM–9 supports both three and two wire type of Nokia chargers. Three

wire chargers are treated like two wire ones. There is not separate PWM

output for controlling charger but it is connected to GND inside the bottom

connector. Charging is controlled by UEM ASIC (Universal Energy Man-

agement) and EM SW running in the UPP (Universal Phone Processor).

NPM–9

System Module & UI

BLB–2 Li–ion battery is used as main power source for the phone.

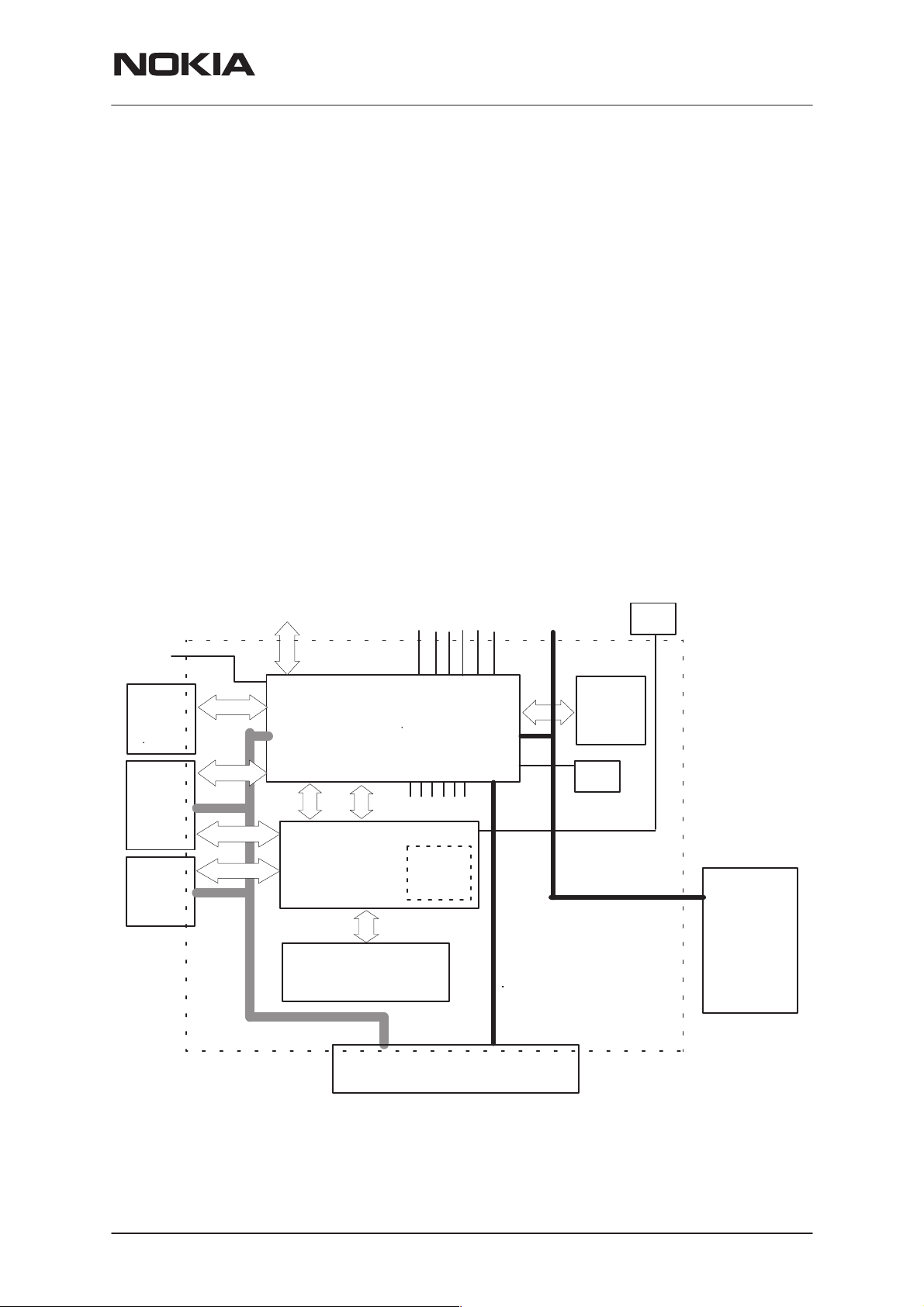

Block Diagram

TX/RX SIGNALS

PWR

IR

FM

radio

UI

Digital Control

UPP

FLASH MEMORY

RF SUPPLIES

UEM

BB SUPPLIES

RAM

PA SUPPL Y

32kHz

CLK

SLEEP CLOCK

SIM

VBAT

13MHz

CLK

SYSTEM CLOCK

BATTERY

BASEBAND

UPP ASIC (Universal Phone Processor) provides the MCU, DSP, external

memory interface and digital control functions. UEM ASIC (Universal En-

ergy Management) contains power supply circuitry, charging, audio proc-

essing and RF control hardware.

Issue 1 02/2002

EXT. AUDIO

HS–connector

Charger

connector

Nokia Corporation

Page 7

Page 8

NPM–9

System Module & UI

Technical Summary

Baseband is running from power rails 2.8V analog voltage and 1.8V I/O

voltage. UPP core voltage Vcore can be lowered down to 1.0V, 1.3V and

1.5V. UEM includes 6 linear LDO (low drop–out) regulators for baseband

and 7 regulators for RF. It also includes 4 current sources for biasing pur-

poses and internal usage. UEM also includes SIM interface which has

supports both 1.8V and 3V SIM cards.

Note: 5V SIM cards are no longer supported by NPM–9 baseband.

A real time clock function is integrated into the UEM which utilizes the

same 32kHz clock supply as the sleep clock. A backup power supply is

provided for the RTC which keeps the real time clock running when the

main battery is removed. The backup power supply is a rechargeable sur-

face mounted capacitor. The backup time with the capacitor is 30 minutes

minimum.

The analog interface between the baseband and the RF section is han-

dled by a UEM ASIC. UEM provides A/D and D/A conversion of the in–

phase and quadrature receive and transmit signal paths and also A/D and

D/A conversions of received and transmitted audio signals to and from

the user interface. The UEM supplies the analog TXC and AFC signals to

RF section according to the UPP DSP digital control. Data transmission

between the UEM and the UPP is implemented using two serial busses,

DBUS for DSP and CBUS for MCU. RF ASIC, Hagar, is controlled

through UPP RFBUS serial interface. There is also separate signals for

PDM coded audio. Digital speech processing is handled by the DSP in-

side UPP ASIC. UEM is a dual voltage circuit, the digital parts are running

from the baseband supply 1.8V and the analog parts are running from the

analog supply 2.78V also VBAT is directly used by some blocks.

PAMS Technical Documentation

The baseband supports both internal and external microphone inputs and

speaker outputs. UEM also includes third microphone input which is used

in NPM–9 for FM radio. Input and output signal source selection and gain

control is done by the UEM according to control messages from the UPP.

Keypad tones, DTMF, and other audio tones are generated and encoded

by the UPP and transmitted to the UEM for decoding. A buzzer and exter-

nal vibra alert control signals are generated by the UEM with separate

PWM outputs.

NPM–9 has two external serial control interfaces: FBUS and MBUS.

These busses can be accessed only through production test pattern.

EMC shielding for baseband is implemented using a metallized plastic

frame and UI PWB ground plane. On the other side the engine is shielded

with PWB grounding. Heat generated by the circuitry will be conducted

out via the PWB ground planes.

NPM–9 radio module is implemented to 8 layer PWB. UI module is divid-

ed between main PWB LA5 and separate UI PWB LU9.

Page 8

Nokia Corporation

Issue 1 02/2002

Page 9

PAMS Technical Documentation

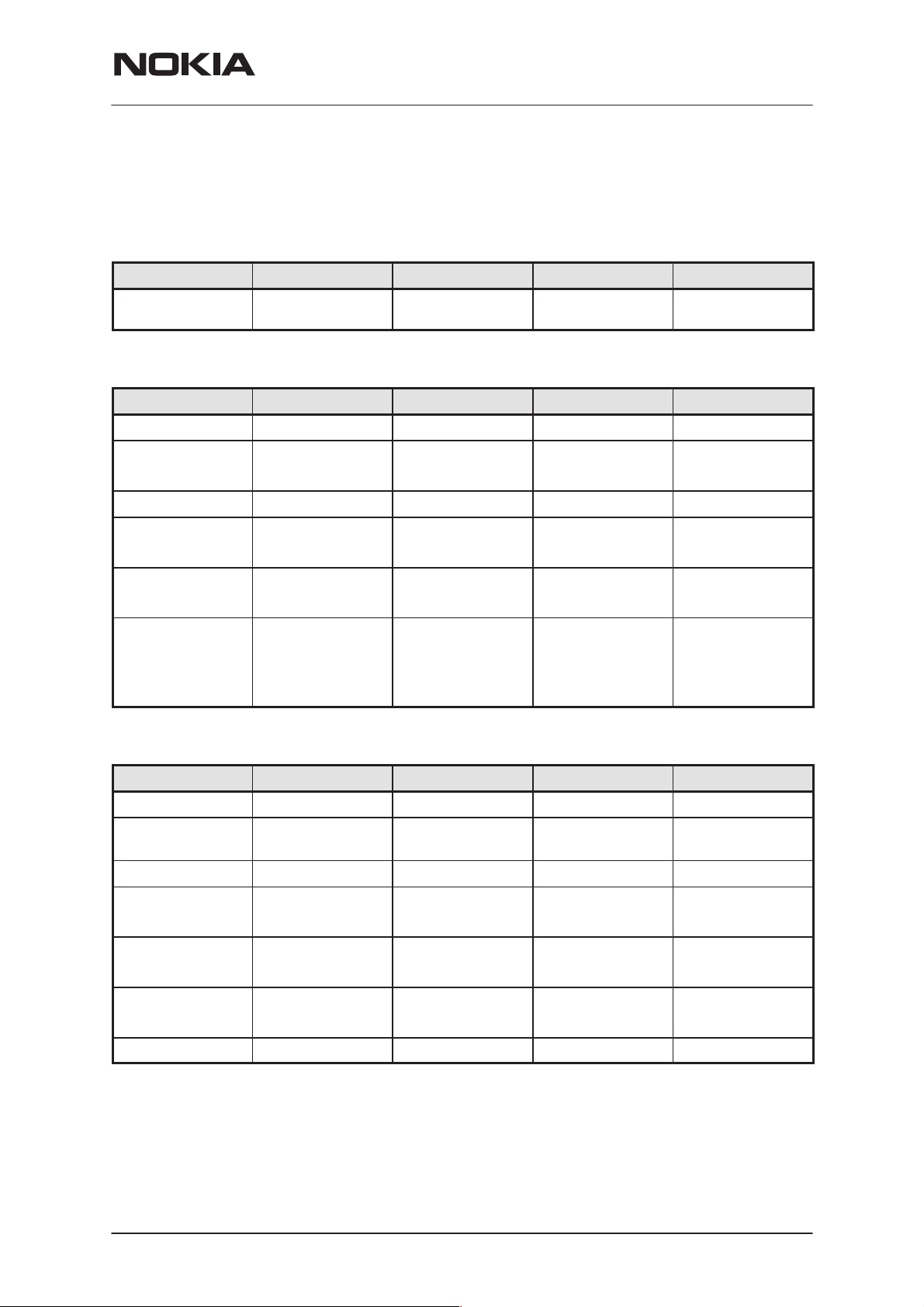

DC Characteristics

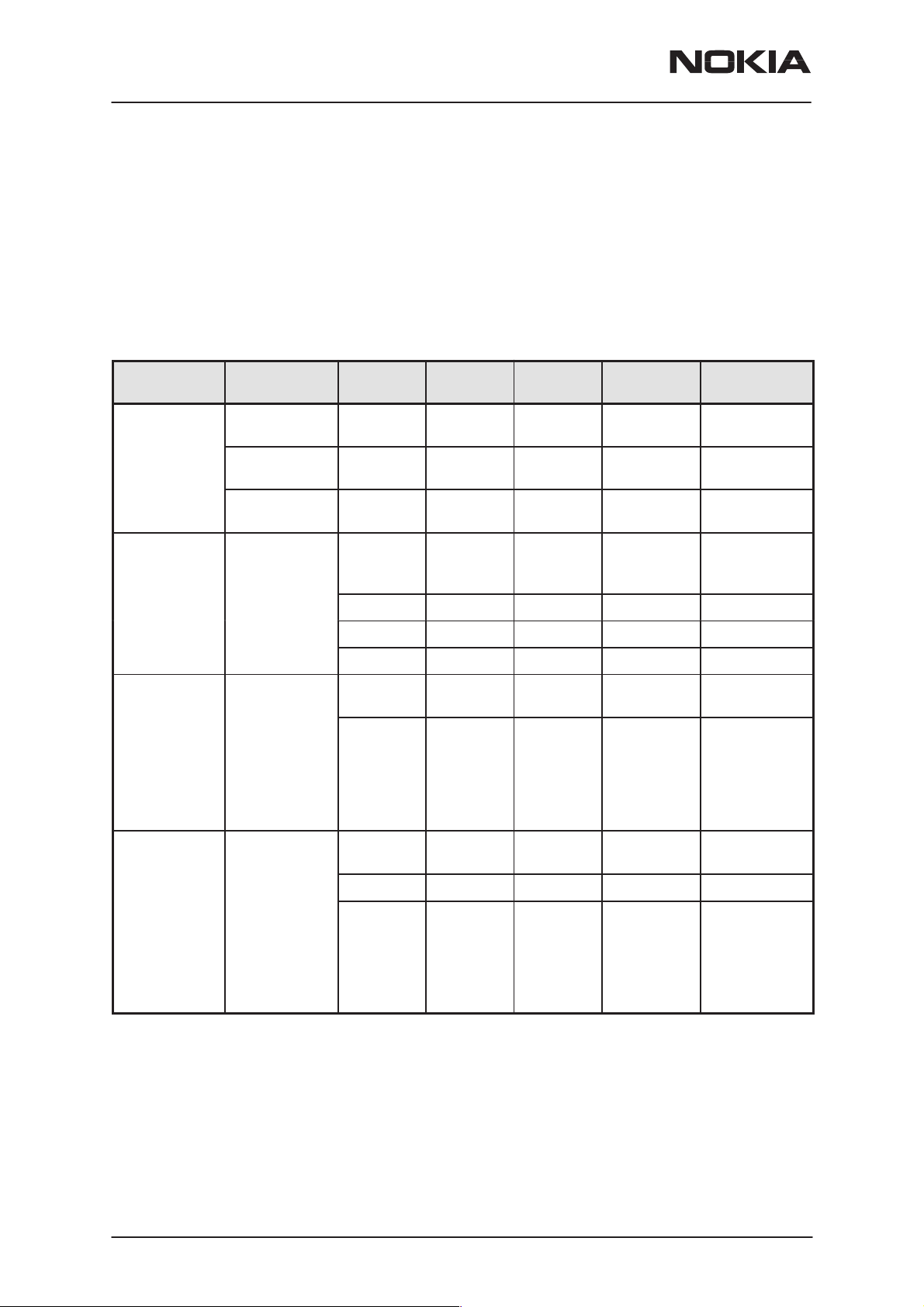

Regulators and Supply Voltage Ranges

Battery Voltage Range

Signal Min Nom Max Note

NPM–9

System Module & UI

VBAT 3.1V 3.6V 4.2V (charging

high limit voltage)

BB Regulators

Signal Min Nom Max Note

VANA 2.70V 2.78V 2.86V I

VFLASH1 2.70V 2.78V 2.86V I

VFLASH2 2.70V 2.78V 2.86V I

VSIM 1.745V

2.91V

1.8V

3.0V

1.855V

3.09V

VIO 1.72V 1.8V 1.88V I

VCORE 1.0V

1.235V

1.425V

1.710V

1.053V

1.3V

1.5V

1.8V

1.106V

1.365V

1.575V

1.890V

RF Regulators

3.1V SW cut off

= 80mA

max

= 70mA

max

I

= 1.5mA

Sleep

= 40mA

max

I

= 25mA

max

I

= 0.5mA

Sleep

= 150mA

max

I

= 0.5mA

Sleep

I

= 200mA

max

I

= 0.2mA

Sleep

Default value =

1.5V

Signal Min Nom Max Note

VR1A 4.6V 4.75V 4.9V I

VR2 2.70V

3.20V

2.78V

3.3V

2.86V

3.40V

VR3 2.70V 2.78V 2.86V I

VR4 2.70V 2.78V 2.86V I

VR5 2.70V 2.78V 2.86V I

VR6 2.70V 2.78V 2.86V I

VR7 2.70V 2.78V 2.86V I

max

I

max

max

max

I

Sleep

max

I

Sleep

max

I

Sleep

max

= 10mA

= 100mA

= 20mA

= 50mA

= 0.1mA

= 50mA

= 0.1mA

= 50mA

= 0.1mA

= 45mA

Issue 1 02/2002

Nokia Corporation

Page 9

Page 10

NPM–9

System Module & UI

PAMS Technical Documentation

External and Internal Signals and Connections

This section describes the external and internal electrical connection and

interface levels on the baseband. The electrical interface specifications

are collected into tables that covers a connector or a defined interface.

Internal Signals and Connections

FM Radio Interface

BB Signal FM Radio

Signal

VFLASH2

GenIO(3) FMClk

GenIO(8) FMWrEn

Vcc1 2.7V 2.78V 2.86V max. Icc1

Vcc2 2.7V 2.78V 2.86V max. Icc2

VDD 2.7V 2.78V 2.86V max. IDD

Min Nom Max Condition Note

19mA

800uA

3mA

1.4V

0

30ppm Stability

1.4V

0V

20µs t

1.8V 1.88V

0.4V

75581 kHz Frequency In GSM

2 µs t

1.8V 1.88V

0.4V

High

Low

rise

High

Low

wd

Reference

clock for FM

radio module

rise / fall time

FMWrEn

before rising

edge of

FMCtrlClk

(write operation)

high

GenIO(11) FMCtrlClk

Page 10

1.4V

0

50 ms t

1.8V 1.88V

0.4V

1 µs tr / t

Nokia Corporation

High

Low

start

max. 300kHz

f

rise / fall time

FMCtrlClk

delay after

switching on

the VFLASH2

(oscillator running)

Issue 1 02/2002

Page 11

PAMS Technical Documentation

out ut

NPM–9

System Module & UI

BB Signal

Signal

GenIO(12) FMCtrlDa

1.4V

0

10 µs t

1.5 µs t

GenIO(27) FMTuneX 1.4V

0

1.8V 1.88V

0.4V

14us t

1.8V 1.88V

0.4V

High

Low

da

shift

hold

High

Low

NoteConditionMaxNomMinFM Radio

Bidirectional

shift register

available after

”search

ready”

data available

after

FMCtrlClk

rising edge (read

operation)

FMCtrlDa

sta-

bile after

FMCtrlClk

rising edge

(write operation)

from FM module to UPP

(FMCtrlClk =

’1’)

MIC3P FMAudio

228mV

pp

326mV

pp

460mV

pp

50dB S/N

2% Harmonic

Internal microphone

Signal Min Nom Max Condition Note

MICP

200mV

pp

2.0 V 2.1 V 2.25 V DC

MICN 2.0V 2.1V 2.25V DC

Internal speaker

Signal Min Nom Max Condition Note

EARP

0.75V 0.8V

EARN

0.75V 0.8V

2.0 V

0.85V

2.0 V

0.85V

pp

pp

distortion

AC

AC

DC

AC

DC

2.2kΩ to

MIC1B

Differential

p

(V

= 4.0

diff

Vpp)

Issue 1 02/2002

Nokia Corporation

Page 11

Page 12

NPM–9

04V

tracks and ferrites

f

CO

Current

2 10

mA

tu

tuning

Su

Su ly for TX

VLO

buffers, rescaler

System Module & UI

PAMS Technical Documentation

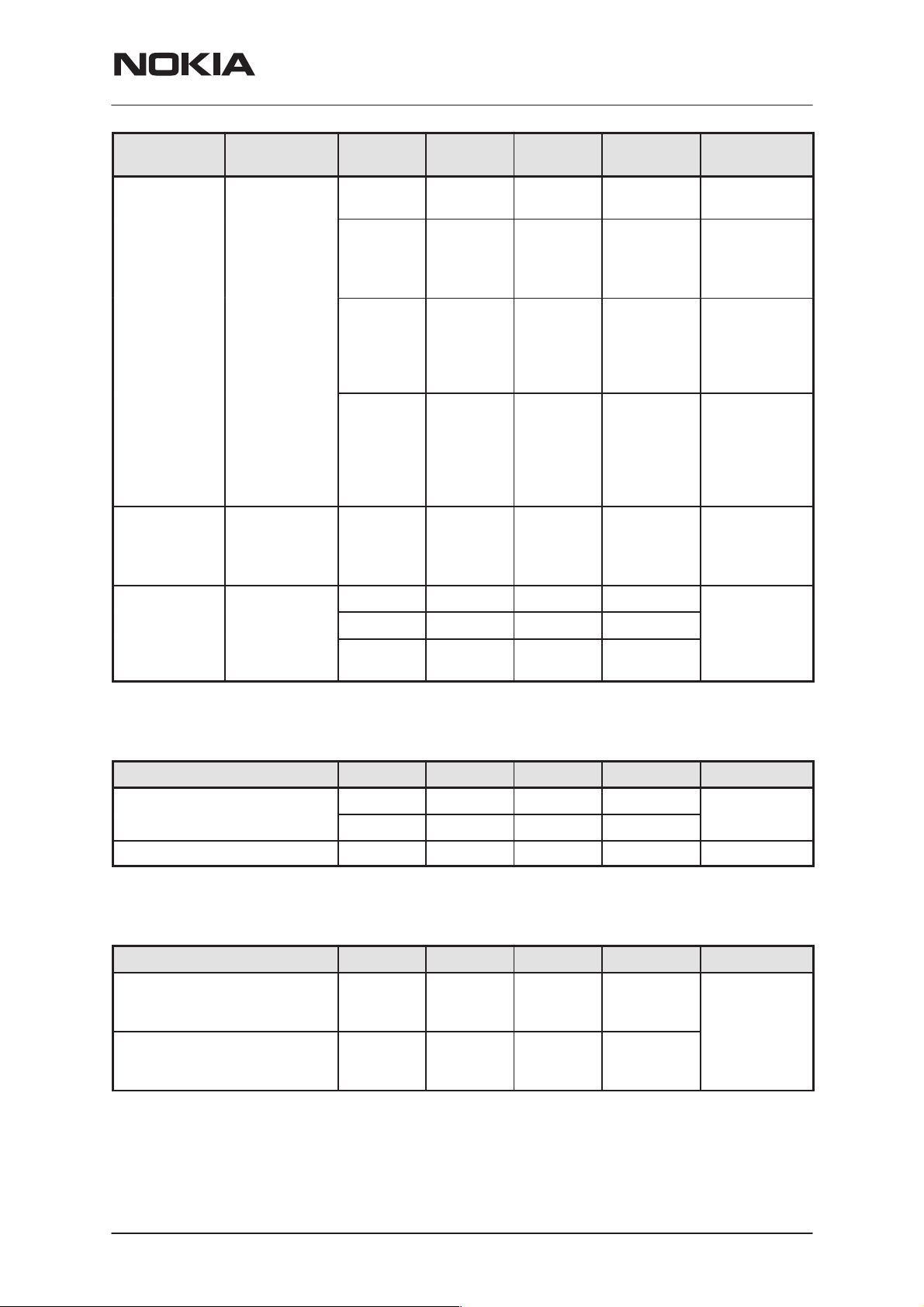

AC and DC Characteristics of RF–BB voltage supplies

Signal

name

VBAT Battery PA & UEM

VR1A UEM VCP

VR2 UEM VRF_TX

VR3 UEM VCTCXO

From To Parameter Min Typ Max Unit Function

Voltage 2.95 3.6 4.2 V

Current 2000 mA

Current drawn by

PA when ”off”

Voltage 4.6 4.75 4.9 V

Noise density 240 nVrms/

Voltage 2.70 2.78 2.86 V

Current 65 100 mA

Noise density

f=100Hz

f>300Hz

Voltage 2.70 2.78 2.86 V

0.8 2 uA

sqrt(Hz)

120 nVrms/

sqrt(Hz)

Battery supply .

Cut–off level of

regulators is 3.

Losses in pwb

tracks and ferrites

are taken account to

minimum battery

voltage level.

Supply for varactor

or UHF V

ning.

.

Supply for part of

transmit strip.

pply for TX

I/Q–modulators.

Supply for VCTCXO

.

VR4 UEM VRF_RX

VR5 UEM VDIG,

VPRE,

VL

VR6 UEM VBB

Current 1 20 mA

Noise density 240 nVrms/

sqrt(Hz)

Voltage 2.70 2.78 2.86 V

Current 50 mA

Noise density

f = 6 Hz

f = 60 Hz

f 600Hz

Voltage 2.70 2.78 2.86 V

Current 50 mA

Noise density

BW=100Hz...

100kHZ

Voltage 2.70 2.78 2.86 V

Current 50 mA

Noise density

BW=100Hz...

100kHz

5500

240 nVrms/

240 nVrms/

550

55

nVrms/

sqrt(Hz)

sqrt(Hz)

sqrt(Hz)

Supply for Hagar

RX; preamp., mixer,

DTOS

Noise density

decades 20dB/dec

from 6Hz to 600Hz.

From f >600Hz

maximum noise

density

RMS

/√Hz.

l

r

,

55nV

Supply for Hagar

PLL; dividers, LO–

ffr pr

Supply for Hagar

BB and LNA

Page 12

Nokia Corporation

Issue 1 02/2002

Page 13

PAMS Technical Documentation

CO

for RF–IC

density is

some digita

some digital arts of

Signal name

FromToParameter

Fun

ter

DC

ng?

name

VR7 UEM UHF VCO

System Module & UI

Voltage 2.70 2.78 2.86 V

Current 30 mA

NPM–9

FunctionUnitMaxTypMinParameterToFromSignal

Supply for UHF

V

VrefRF01 UEM VREF_RX

VrefRF02 UEM VB_EXT

Noise density

100Hz<f<2kHz

2kHz<f<10kHz

10kHz<f<30kHz

30kHz<f<90kHz

90kHz<f<3MHz

Voltage 1.334 1.35 1.366 V

Current 100 uA

Temp Coef –65 +65 uV/C

Noise density

BW=600Hz...

100kHz Note

Voltage 1.323 1.35 1.377 V

Current 100 uA

Temp Coef –65 +65 uV/C

Noise density

BW=100Hz...

100kHz

70

nVrms/

55

sqrt(Hz)

35

30

30

60 nVrms/

sqrt(Hz)

350 nVrms/

sqrt(Hz)

Voltage Reference

.

Note: Below

600Hz noise

allowed to

increase 20

dB/oct

Supply for RF–BB

digital interface and

l parts of

RF.

AC and DC Characteristics of RF–BB digital signals

Min Typ Max Unit

TXP

(RFGenOut3)

UPP PA &

RF–IC

”1” 1.38 1.88 V

”0” 0 0.4 V

Load Resistance 10 220 kohm

Load Capacitance 20 pF

Timing Accuracy 1/4 symbol

Input Characteristics

c-

tion

Tran

smit

ter

pow

er

amp

lifier

ena

ble /

N2

timi

??

Issue 1 02/2002

Nokia Corporation

Page 13

Page 14

NPM–9

ena

ena

data

data

d

cloc

cloc

(G

)

ag

Hag

circuits, AC

circuits, AC

System Module & UI

PAMS Technical Documentation

RFBusEna1X UPP RF–IC

RFBusData UPP RF–IC

RFBusClk UPP RF–IC

ParameterToFromSignal name

UnitMaxTypMin

”1” 1.38 1.88 V

”0” 0 0.4 V

Current 50 uA

Load resistance 10 220 kohm

Load capacitance 20 pF

”1” 1.38 1.88 V

”0” 0 0.4 V

Load resistance 10 220 kohm

Load capacitance 20 pF

Data frequency 10 MHz

”1” 1.38 1.88 V

”0” 0 0.4 V

Load resistance 10 220 kohm

Load capacitance 20 pF

Data frequency 10 MHz

Fun

c-

tion

RFb

us

ble

RFb

us

;

rea

/writ

e

RFb

us

k

RESET

ENIO6

UPP RF–IC

”1” 1.38 1.85 V

”0” 0 0.4 V

Load capacitance 20 pF

Load resistance 10 220 kohm

Timing accuracy 1/4 symbol

Res

et to

H

ar

AC and DC Characteristics of RF–BB analogue signals

Signal name From To Parameter Min Typ Max Unit Function

VCTCXO VCTCXO UPP

VCTCXOGnd VCTXO UPP DC Level 0 V Ground for

Signal amplitude 0.2 0.8 2.0 Vpp

Input Impedance 10 kohm

Input Capacitance 10 pF

Harmonic Content –8 dBc

Clear signal

window (no glitch)

Duty Cycle 40 60 %

200 mVpp

High stability clock

signal for the logic

coupled. Distorted

sine wave eg.

sawtooth.

reference clock

RXI/RXQ RF–IC UEM

Page 14

Nokia Corporation

Differential voltage

swing (static)

DC level 1.3 1.35 1.4 V

I/Q amplitude

missmatch

I/Q phase

missmatch

1.35 1.4 1.45 Vpp

0.2 dB

–5 5 deg

Issue 1 02/2002

RX baseband

signal.

Page 15

PAMS Technical Documentation

Programmable

voltage

opa

oam G1

NPM–9

System Module & UI

FunctionUnitMaxTypMinParameterToFromSignal name

TXIP / TXIN UEM RF–IC

TXQP /

TXQN

AFC UEM VCTCXO

Aux_DAC

(TxC)

UEM RF–IC Same spec as for TXIP / TXIN Differential

UEM RF

Differential voltage

swing (static)

DC level 1.17 1.20 1.23 V

Source

Impedance

Voltage Min

Max

Resolution 11 bits

Load resistance

and capacitance

Step settling time 0.2 ms

Voltage Min

Max 2.4

Source

Impedance

Resolution 10 bits

2.23 2.48 Vpp

200 ohm

0.0

2.4

1

0.1

V

2.6

kohm

100

nF

0.1 V

200 ohm

Programmable

voltage swing.

common mode

.

Between

TXIP–TXIN

quadrature phase

TX baseband

signal for the RF

modulator

Automatic

frequency control

signal for

VCTCXO

Transmitter power

control

Noise density

BW=100Hz...

100kHz

Temp Coef –65 +65 uV/C

RFTemp RF UEM

Vbase RF UEM Voltage 2.7 V Detected voltage

Voltage at –20oC 1,57

Voltage at +25oC 1,7

Voltage at +60oC 1,79

800 nVrms/

sqrt(Hz)

V Temperature

NOTE; Assumed

power control

mp G=1

sensor of RF.

from PA power

level sensing unit

External Signals and Connections

UI (board–to–board) connector

Pin Signal Min Nom Max Condition Note

1 SLOWAD(2) 1.5V

0.1V

2 VBAT 3.0V 3.6V 4.2V Battery voltage

3 ROW(4) 0.7xVIO

0

2.7V

1.0V

1.8V

0.3xVIO

Flip closed

Flip open

High

Low

used for flip

identification

for leds

Keyboard ma-

trix row 4

Issue 1 02/2002

Nokia Corporation

Page 15

Page 16

NPM–9

System Module & UI

PAMS Technical Documentation

NoteConditionMaxNomMinSignalPin

4 ROW(3) 0.7xVIO

0

5 COL(2) 0.7xVIO

0

6 ROW(2) 0.7xVIO

0

7 COL(1) 0.7xVIO

0

8 ROW(0) 0.7xVIO

0

9 KLIGHT VBAT

10 ROW(1) 0.7xVIO

0

11 COL(3) 0.7xVIO

0

12 COL(4) 0.7xVIO

0

13 GND 0V

14 GND 0V

15 GND 0V

VIO

0.3xVIO

VIO

0.3xVIO

VIO

0.3xVIO

VIO

0.3xVIO

VIO

0.3xVIO

0.3xVBAT

VIO

0.3xVIO

VIO

0.3xVIO

VIO

0.3xVIO

High

Low

High

Low

High

Low

High

Low

High

Low

LED off

LED on

High

Low

High

Low

High

Low

Keyboard matrix row 3

Keyboard matrix column 2

Keyboard matrix row 2

Keyboard matrix column 1

Keyboard matrix row 0

two colour led

control

Keyboard matrix row 1

Keyboard matrix column 3

Keyboard matrix column 4

16 GND 0V

LCD connector

Pin Signal Min Nom Max Condition Note

1 XRES

2 XCS

3 GND 0V

4 SDA

0.8*VIO

0

100ns t

0.8*VIO

0

130ns t

130ns t

300ns t

0.8*VIO

0

0.7*VIO

0

100ns t

100ns t

VIO

0.22*VIO

VIO

0.22*VIO

VIO

0.22*VIO

VIO

0.3*VIO

Logic ’1’

Logic ’0’

rw

Logic ’1’

Logic ’0’

css

csh

csw

Logic ’1’

Logic ’0’

Logic ’1’

Logic ’0’

sds

sdh

Reset

Active low

Reset active

Chip select

Active low

XCS low before

SCLK rising

edge

XCS low after

SCLK rising

edge

XCS high pulse

width

Serial data

(driver input)

Serial data

(driver output)

Data setup time

Data hold time

Page 16

Nokia Corporation

Issue 1 02/2002

Page 17

NPM–9

PAMS Technical Documentation

5 SCLK

6 VDDI (VIO) 1.72V 1.8V 1.88V Logic voltage

7 VDD

(VFLASH1)

8 VOUT 9V Booster output,

0.8*VIO

0

250ns t

1 10ns t

1 10ns t

VIO

0.22*VIO

4.0MHz

Logic ’1’

Logic ’0’

Max frequency

scyc

shw

slw

2.72V 2.78V 2.86V Voltage supply

System Module & UI

NoteConditionMaxNomMinSignalPin

Serial clock input

Clock cycle

Clock high

Clock low

supply

Connected to

VIO

Connected to

VFLASH1

C=1uF connected to GND

DC connector

Pin Signal Min Nom Max Condition Note

2 VCHAR 7.0 V

RMS

8.4 V

RMS

9.2 V

RMS

850 mA

Fast charger

Charger positive input

1 CHGND 0 Charger ground

Headset connector

Pin Signal Min Nom Max Condition Note

5 XMICP

3 XMICN

4 XEARN

7 XEARP

1V

pp

100 mV

2.0 V 2.1 V 2.25 V DC

1V

pp

100 mV

0.75V 0.8V 0.85V DC

1V

pp

0.75V 0.8V 0.85V DC

pp

pp

G = 0dB

G = 20dB

G = 0 dB

G = 20dB

AC

1kΩ to MIC2B

1kΩ to GND

1V

5 HookInt 0V 2.86V

(VFLASH1)

6 HeadInt 0V 2.86V

(VANA)

Issue 1 02/2002

Nokia Corporation

pp

AC

Connected to

UEM AD–converter

Accessory

detection

Page 17

Page 18

NPM–9

System Module & UI

PAMS Technical Documentation

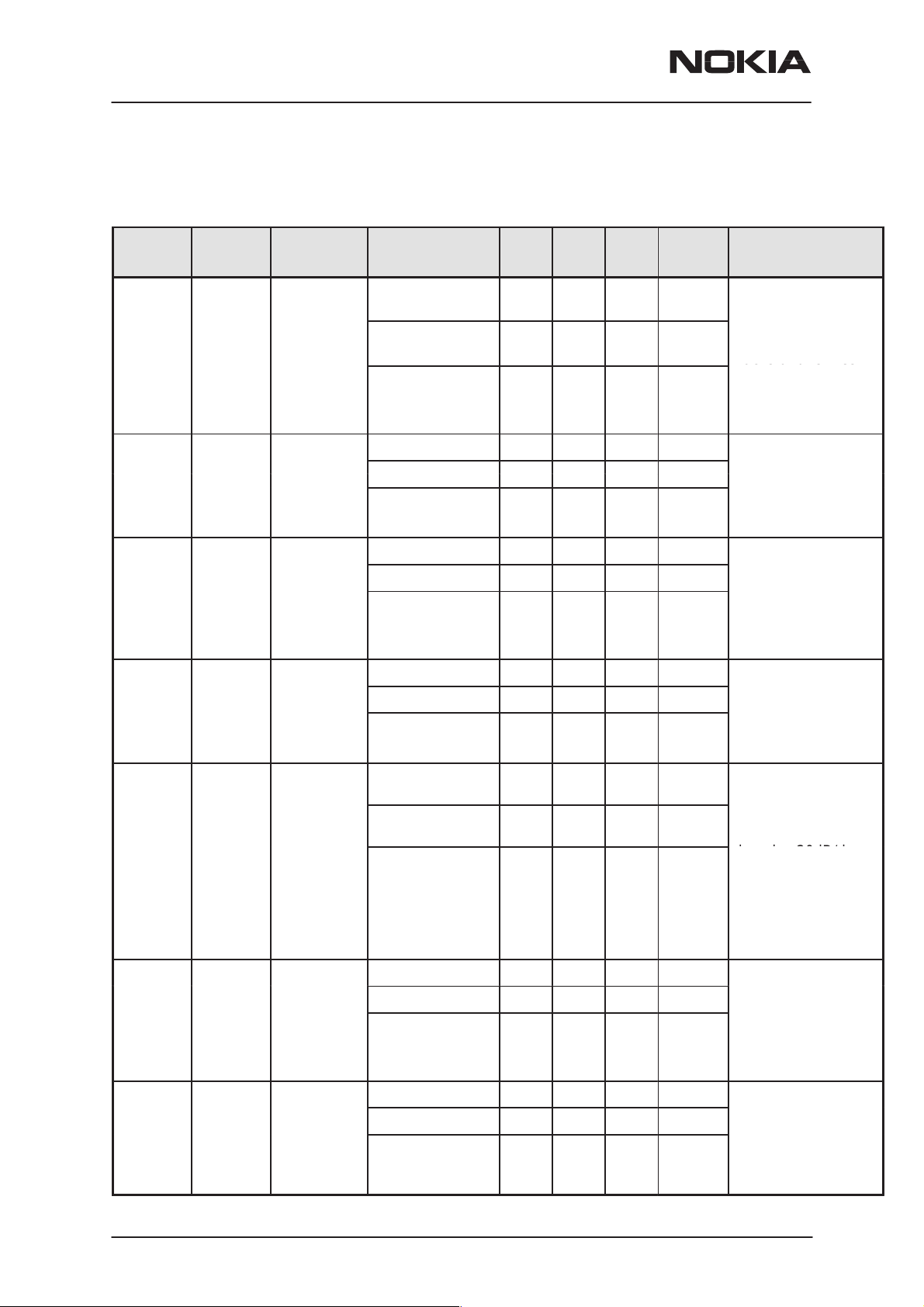

SIM connector

Pin Name Parameter Min Typ Max Unit Notes

1 VSIM

2 SIMRST

3 SIMCLK

4 DATA

1.8V SIM Card 1.6 1.8 1.9

3V SIM Card 2.8 3.0 3.2

1.8V SIM Card 0.9xVSIM

0

3V SIM Card 0.9xVSIM

0

Frequency 3.25 MHz

Trise/Tfall 50 ns

1.8V Voh

1.8V Vol

3 Voh

3 Vol

1.8V Voh

1.8V Vol

3 Voh

3 Vol

1.8V Vih

1.8V Vil

3V Vil

3V Vil

0.9xVSIM

0

0.9xVSIM

0

0.9xVSIM

0

0.9xVSIM

0

0.7xVSIM

0

0.7xVSIM

0

VSIM

0.15xVSIM

VSIM

0.15xVSIM

VSIM

VSIM

VSIM

0.15xVSIM

VSIM

0.15xVSIM

VSIM

0.15xVSIM

VSIM

0.15xVSIM

V Supply voltage

V SIM reset (output)

V

V SIM data (output)

SIM clock

SIM data (input)

Trise/Tfall max 1us

5 NC

6 GND GND 0 V Ground

Page 18

Nokia Corporation

Issue 1 02/2002

Page 19

PAMS Technical Documentation

Functional Description

Modes of Operation

LA5 baseband engine has six different operating modes:

– No supply

– Backup

– Acting Dead

– Active

– Sleep

– Charging

No supply

In NO_SUPPLY mode the phone has no supply voltage. This mode is due

to disconnection of main battery and backup battery or low battery voltage

level in both of the batteries.

Phone is exiting from NO_SUPPLY mode when sufficient battery voltage

level is detected. Battery voltage can rise either by connecting a new bat-

Backup

tery with VBAT > V

tery above V

MSTR+

MSTR+

.

NPM–9

System Module & UI

or by connecting charger and charging the bat-

In BACKUP mode the backup battery has sufficient charge but the main

battery can be disconnected or empty (VBAT < V

VBU

VRTC regulator is disabled in BACKUP mode. VRTC output is supplied

without regulation from backup battery (VBACK). All the other regulators

are disabled.

Acting Dead

If the phone is off when the charger is connected, the phone is powered

on but enters a state called ”Acting Dead”. To the user the phone acts as

if it was switched off. A battery charging alert is given and/or a battery

charging indication on the display is shown to acknowledge the user that

the battery is being charged.

Active

In the active mode the phone is in normal operation, scanning for channels, listening to a base station, transmitting and processing information.

There are several sub–states in the active mode depending on if the

phone is in burst reception, burst transmission, if DSP is working etc.

One of the sub–state of the active mode is FM radio on state. In that case

UEM audio blocks and FM radio are powered on. FM radio circuitry is

controlled by the MCU and 75kHz reference clock is generated in the

UPP. VFLASH2 regulator is operating.

COFF

MSTR

and VBACK >

).

In active mode the RF regulators are controlled by SW writing into UEM’s

registers wanted settings: VR1A can be enabled or disabled. VR2 can be

enabled or disabled and its output voltage can be programmed to be

Issue 1 02/2002

Nokia Corporation

Page 19

Page 20

NPM–9

System Module & UI

2.78V or 3.3V. VR4 –VR7 can be enabled or disabled or forced into low

quiescent current mode. VR3 is always enabled in active mode.

Sleep mode

Sleep mode is entered when both MCU and DSP are in stand–by mode.

Sleep is controlled by both processors. When SLEEPX low signal is detected UEM enters SLEEP mode. VCORE, VIO and VFLASH1 regulators

are put into low quiescent current mode. All RF regulators are disabled in

SLEEP. When SLEEPX=1 is detected UEM enters ACTIVE mode and all

functions are activated.

The sleep mode is exited either by the expiration of a sleep clock counter

in the UEM or by some external interrupt, generated by a charger connection, key press, headset connection etc.

In sleep mode VCTCXO is shut down and 32 kHz sleep clock oscillator is

used as reference clock for the baseband.

Charging

PAMS Technical Documentation

The battery voltage, temperature, size and current are measured by the

UEM controlled by the charging software running in the UPP.

The charging control circuitry (CHACON) inside the UEM controls the

charging current delivered from the charger to the battery. The battery

voltage rise is limited by turning the UEM switch off when the battery voltage has reached 4.2 V. Charging current is monitored by measuring the

voltage drop across a 220 mOhm resistor.

Supply Voltage Regulation

Supply voltage regulation is controlled by UEM asic. There are six separate regulators used by baseband block.

BB Regulators

Signal Min Nom Max Note

VANA 2.70V 2.78V 2.86V I

VFLASH1 2.70V 2.78V 2.86V I

VFLASH2 2.70V 2.78V 2.86V I

VSIM 1.745V

2.91V

VIO 1.72V 1.8V 1.88V I

VCORE 1.0V

1.235V

1.425V

1.710V

1.8V

3.0V

1.053V

1.3V

1.5V

1.8V

1.855V

3.09V

1.106V

1.365V

1.575V

1.890V

= 80mA

max

= 70mA

max

I

= 1.5mA

Sleep

= 40mA

max

I

= 25mA

max

I

= 0.5mA

Sleep

= 150mA

max

I

= 0.5mA

Sleep

I

= 200mA

max

I

= 0.2mA

Sleep

Default value =

1.5V

Page 20

Nokia Corporation

Issue 1 02/2002

Page 21

PAMS Technical Documentation

Battery

Li–ion battery pack BLB–2 is used in NPM–9.

Nominal discharge cut–off voltage 3.1V

Nominal battery voltage 3.6V

Nominal charging voltage 4.2V

Pin numbering of battery pack

Signal name Pin number Function

VBAT 1 Positive battery terminal

BSI 2 Battery capacity measurement (fixed resistor inside the

BTEMP 3 Battery temperature measurement (measured by ntc

GND 4 Negative/common battery terminal

NPM–9

System Module & UI

battery pack)

resistor inside pack)

BLB–2 battery pack pin order

Power Up and Reset

Power up and reset is controlled by the UEM ASIC. NPM–9 baseband

can be powered up in following ways:

1. Press power button which means grounding the PWRONX pin of the

UEM

2. Connect the charger to the charger input

3. Supply battery voltage to the battery pin

4. RTC Alarm, the RTC has been programmed to give an alarm

1 (+)2(BSI)3(BTEMP)4(GND)

After receiving one of the above signals, the UEM counts a 20ms delay

and then enters it’s reset mode. The watchdog starts up, and if the battery

voltage is greater than Vcoff+ a 200ms delay is started to allow references etc. to settle. After this delay elapses the VFLASH1 regulator is enabled. 500us later VR3, VANA, VIO and VCORE are enabled. Finally the

PURX (Power Up Reset) line is held low for 20 ms. This reset, PURX, is

fed to the baseband ASIC UPP, resets are generated for the MCU and

Issue 1 02/2002

Nokia Corporation

Page 21

Page 22

NPM–9

System Module & UI

the DSP. During this reset phase the UEM forces the VCTCXO regulator

on regardless of the status of the sleep control input signal to the UEM.

The FLSRSTx from the ASIC is used to reset the flash during power up

and to put the flash in power down during sleep. All baseband regulators

are switched on at the UEM power on except SIM and VFLASH2 regulators which are controlled by the MCU. The UEM internal watchdogs are

running during the UEM reset state, with the longest watchdog time selected. If the watchdog expires the UEM returns to power off state. The

UEM watchdogs are internally acknowledged at the rising edge of the

PURX signal in order to always give the same watchdog response time to

the MCU.

A/D Channels

The UEM contains the following A/D converter channels that are used for

several measurement purpose. The general slow A/D converter is a 10 bit

converter using the the UEM interface clock for the conversion. An interrupt will be given at the end of the measurement.

PAMS Technical Documentation

The UEM’s 11–channel analog to digital converter is used to monitor

charging functions, battery functions, voltage levels in external accessory

detection inputs, user interface and RF functions.

When the conversion is started the converter input is selected. Then the

signal processing block creates a data with MSB set to ’1’ and and others

to ’0’. In the D/A converter this data controls the switches which connect

the input reference voltage (VrefADC) to the resistor network. The generated output voltage is compared with the input voltage under measurement and if the latter is greater, MSB remains ’1’ else it is set ’0’. The following step is to test the next bit and the next...until LSB is reached. The

result is then stored to ADCR register for UPP to read.

The monitored battery functions are battery voltage (VBATADC), battery

type (BSI) and battery temperature (BTEMP) indication.

The battery type is recognized through a resistive voltage divider. In

phone there is a 100kOhm pull up resistor in the BSI line and the battery

has a pull down resistor in the same line. Depending on the battery type

the pull down resistor value is changed. The battery temperature is measured equivalently except that the battery has a NTC pull down resistor in

the BTEMP line.

KEYB1&2 inputs are used for keyboard scanning purposes. These inputs

are also routed internally to the miscellaneous block. In NPM–9 KEYB1

input is used for flip detection.

Page 22

The HEADINT and HOOKINT are external accessory detection inputs

used for monitoring voltage levels in these inputs. They are routed internally from the miscellaneous block and they are connected to the converter through a 2/1 multiplexer.

The monitored RF functions are PATEMP and VCXOTEMP detection. PATEMP input is used to measure temperature of the RFIC, Hagar. VCXOTEMP is not used in NPM–9.

Nokia Corporation

Issue 1 02/2002

Page 23

PAMS Technical Documentation

FM Radio

FM radio circuitry is implemented using highly integrated radio IC,

TEA5757. Only few external components like filters, discriminator and capacitors are needed.

TEA5757 is an integrated AM/FM stereo radio circuit including digital tuning and control functions. NPM–9 radio is implemented as superheterodyne FM mono receiver. FM stage of the TEA5757 incorporates a tuned

RF stage, a double balanced mixer, one pin oscillator and is designed for

distributed IF ceramic filters. IF frequency is 10.7 MHz.

Channel tuning and other controls are controlled by the MCU. Reference

clock, 75kHz, is generated by the UPP CTSI block.

FM radio circuitry is controlled through serial bus interface by the MCU

SW. TEA5757 informs MCU when channel is tuned by setting

signal to logic ’0’.

Digital Interface

NPM–9

System Module & UI

FMTuneX

UPP TEA5757

GenIO(3)

GenIO(12)

GenIO(11)

GenIO(8)

GenIO(27)

NOTE:

FMCtrlClk

needs to be set to logic ’1’ when data is not written or

FMClk

FMCtrlDa

FMCtrlClk

FMWrEn

FMTuneX

read. This is required for correct operation of the

FM radio audio & antenna connections

Bottom

Connector

1000Ω@100MHz

XTAL

VIO

DATA

BUS–CLK

WR–EN

VIO

MO/ST

FMTuneX

signal.

UEM TEA5757

XEARP

XEARN

Issue 1 02/2002

1n

1n

18pF18pF

72nH

Nokia Corporation

HF

MIC3

HFCM

100nF

3.9nF

4.7kΩ

AFLO

100kΩ

FM_RFI

Page 23

Page 24

NPM–9

System Module & UI

IR Module

The IR interface, when using 2.7V transceiver, is designed into the UEM.

The IR link supports speeds from 9600 bit/s to 1.152 MBit/s up to distance of 1m. Transmission over the IR if half–duplex.

The lenght of the transmitted IR pulse depends on the speed of the transmission. When 230.4 kbit/s or less is used as a transmission speed, pulse

length is maximum 1.63us. If transmission speed is set to 1.152Mbit/s the

pulse length is 154ns according to IrDA specification.

Backup Battery

Backup battery is used in case when main battery is either removed or

discharged. Backup battery is used for keeping real-time clock running for

minimum of 30 minutes.

Rechargeable backup battery is connected between UEM VBACK and

GND. In UEM backup battery charging high limit is set to 3.2V. The cut–

off limit voltage (V

charging is controlled by MCU by writing into UEM register.

BUCoff–

PAMS Technical Documentation

) for backup battery is 2.0V. Backup battery

Polyacene SMD battery type is used. The nominal capacity of the battery

is 0.2 mAh.

SIM Interface

UEM contains the SIM interface logic level shifting. SIM interface can be

programmed to support 3V and 1.8V SIMs. SIM supply voltage is selected by a register in the UEM. It is only allowed to change the SIM supply voltage when the SIM IF is powered down.

The SIM power up/down sequence is generated in the UEM. This means

that the UEM generates the RST signal to the SIM. Also the SIMCardDet

signal is connected to UEM. The card detection is taken from the BSI signal, which detects the removal of the battery. The monitoring of the BSI

signal is done by a comparator inside UEM. The comparator offset is

such that the comparator output do not alter state as long as the battery

is connected. The threshold voltage is calculated from the battery size

specifications.

The SIM interface is powered up when the SIMCardDet signal indicates

”card in”. This signal is derived from the BSI signal.

Parameter Variable Min Typ Max Unit

SIMCARDet, BSI comparator Threshold Vkey 1.94 2.1 2.26 V

SIMCARDet, BSI comparator Hysteresis (1) Vsimhyst 50 75 100 mV

The whole SIM interface locates in two chip UPP and UEM.

The SIM interface in the UEM contains power up/down, port gating, card

detect, data receiving, ATR–counter, registers and level shifting buffers

logic. The SIM interface is the electrical interface between the Subscriber

Identity Module Card (SIM Card) and mobile phone (via UEM device).

Page 24

Nokia Corporation

Issue 1 02/2002

Page 25

PAMS Technical Documentation

The data communication between the card and the phone is asynchronous half duplex. The clock supplied to the card is in GSM system 1.083

MHz or 3.25 MHz. The data baud rate is SIM card clock frequency divided by 372 (by default), 64, 32 or 16. The protocol type, that is supported, is T=0 (asynchronous half duplex character transmission as defined in ISO 7816–3).

NPM–9

System Module & UI

SIM

C5 C6 C7

C1C2C3

From Battery Type contact

C8

C4

The internal clock frequency from UPP CTSI block is 13 MHz in GSM.

Thus to achieve the minimum starting SIMCardClk rate of 3.25 MHz (as is

required by the authentication procedure and the duty cycle requirement

of between 40% and 60%) then the slowest possible clock supplied to the

SIM has to be in the GSM system clock rate of 13/4 MHz.

SIMDATA

SIMCLK

VSIM

BSI

SIMRST

GND

UEM

SIMIF

register

SIMIO

SIMClk

Data

UEM

digital

logic

GND

SIMIO

SIMClk

Data

UPP

UIF Block

UEMInt

CBusDa

CBusEnX

CBusClk

Buzzer

Buzzer is used to generate alerting tones and melodies to indicate incoming call. It is also used to generate keypress and warning tones for the

user. Buzzer is controlled by PWM (Pulse Width Modulation) signal generated by the buzzer driver of the UEM. Target SPL is 100dB (A) at 5cm.

Internal Microphone

The internal microphone capsule is mounted in the bottom connector. Microphone is omnidirectional. The internal microphone is connected to the

UEM microphone input MIC1P/N. The microphone input is asymmetric

and microphone bias is provided by the UEM MIC1B. The microphone

input on the UEM is ESD protected. Spring contacts are used to connect

the microphone contacts to the main PWB.

Issue 1 02/2002

Nokia Corporation

Page 25

Page 26

NPM–9

System Module & UI

UEM

MIC1B

MIC1N

PAMS Technical Documentation

22pF 100nF

33nF

2k2

UPP

33nF

MIC1P

2k2

600Ω@100MHz

27pF

22pF

UPP (Universal Phone Processor) is the digital ASIC of the baseband.

UPP includes 8MBit internal RAM, ARM7 Thump 16/32–bit RISC MCU

core, LEAD3 16–bit DSP core, ROM for MCU boot code and all digital

control logic.

Main functions of the custom logic are:

1. Interface between system logic and MCU/DSP (BodyIf)

2. Clocking, timing, sleep and interrupt block (CTSI) for system

timing control

3. MCU controlled general purpose USART, MBUS USART and

general purpose IOs (PUP).

4. SIM card interface (SIMIf)

5. GSM coder (Coder)

6. GPRS support (GPRSCip)

7. Interfaces for keyboard, LCD and UEM (UIF)

8. Accessory interface for IrDA SIR, IrDA FIR and LPRF (AccIf)

9. SW programmable RF interface (MFI)

10. Programmable serial interface for Hagar RFIC (SCU)

11. Test interface (TestIf)

Memory Block

For the MCU UPP includes ROM, 2 kbytes, that is used mainly for boot

code of MCU. To speed up the MCU operation small 64 byte cache is

also integrated as a part of the MCU memory interface. For program

memory 8Mbit (512 x 16bit) PDRAM is integrated. RAM block can also be

used as data memory and it is byte addressable. RAM is mainly for MCU

purposes but also DSP has also access to it if needed.

Page 26

Nokia Corporation

Issue 1 02/2002

Page 27

PAMS Technical Documentation

MCU code is stored into external flash memory. Size of the flash is 64Mbit

(4096 x 16bit) The NPM–9 baseband supports a burst mode flash with

multiplexed address/data bus. Access to the flash memory is performed

as 16–bit access. The flash has Read While Write capabilities which

makes the emulation of EEPROM within the flash easy.

NPM–9

System Module & UI

Issue 1 02/2002

Nokia Corporation

Page 27

Page 28

NPM–9

System Module & UI

RF Module

This RF module takes care of all RF functions of the engine. RF circuitry

is located on one side (B–side) of the PWB.

EMC leakage is prevented by using a metal B–shield, which screens the

whole RF side (included FM radio) of the engine. The conductive (silicon

or metal) gasket is used between the PWB and the shield. The metal

B–shield is separated to three blocks. The first one include the FM radio.

The second block include the PA, antenna switch, LNAs and dual RX

SAW. The last, but not least, block include the Hagar RF IC, VCO,

VCTCXO, baluns and balanced filters. The blocks are divided on the basis that the attenuation between harmonics of the transmitter and the

VCO signal (including Hagar IC) is a high (over 100dB). The VCO and TX

outputs of the Hagar RF IC are located one another as far as possible. In

order to guard against the radiated spurious inside blocks, the RF transmission lines are made with striplines after PA.

PAMS Technical Documentation

The baseband circuitry is located on the A–side of the board, which is

shielded with a metallized frame and ground plane of the UI–board.

Maximum height inside on B–side is 1.8 mm. Heat generated by the circuitry will be conducted out via the PWB ground planes and metallic

B–shield

RF Frequency Plan

925–960

MHz

1805–1880

MHz

f/4

HAGAR

I–signal

I–signalI–signalI–signal

Q–signal

f

f

RX

f/2f/4

f

f/2

f

3420–

PLL

3840

MHz

Page 28

1710–1785

MHz

880–915

MHz

Nokia Corporation

26 MHz

VCTCXO

I–signal

Q–signal

TX

Issue 1 02/2002

Page 29

PAMS Technical Documentation

DC characteristics

Regulators

Transceiver has a multifunction power management IC on baseband section, which contains among other functions; 7 pcs of 2.78 V regulators

and 4.8V up–switcher for charge pump.

All regulators can be controlled individually with 2.78 V logic directly or

through control register. In GSM direct controls are used to get fast

switching, because regulators are used to enable RF–functions.

Use of the regulators can be seen in the Power Distribution Diagram.

VrefRF01and VrefRF02 are used as the reference voltages for HAGAR

RF–IC, VrefRF01 (1.35V) for bias reference and VrfeRF02 (1.35V) for RX

ADC’s reference.

Regulators (except VR2 and VR7) are connected to HAGAR. Different

modes were switched on by the aid of serial bus.

NPM–9

System Module & UI

List of the needed supply voltages :

Volt. source Load

VR1 PLL charge pump (4,8 V)

VR2 TX modulator

VR3 VCTCXO + buffer

VR4 HAGAR IC (LNAs+mixer+DTOS)

VR5 HAGAR IC (div+LO–buff+prescaler),

VR6 HAGAR (Vdd_bb)

VR7 VCO

VrefRF01 ref. voltage for HAGAR

VrefRF02 ref. voltage for HAGAR

Vbatt PA

Issue 1 02/2002

Nokia Corporation

Page 29

Page 30

NPM–9

System Module & UI

Power Distribution Diagram

PAMS Technical Documentation

SOURCE

VR1

VR2

VR3

VR4

VR5

4.75 V +/– 3.2 %

10 mA

2.78 V +/– 3 %

100 mA

2.78 V +/– 3 %

20 mA

2.78 V +/– 3 %

50 mA

2.78 V +/– 3 %

50 mA

LOAD

Charge pump in HAGAR

TX IQ modulator, power

control opamp in

Hagar

VCTCXO

VCTCXO buffer in Hagar

E–GSM & DCS LNA

RX mixer in Hagar

DTOS in Hagar

PLL in Hagar

UEM

VR6

VR7

VrefRF01

VrefRF02

2.78 V +/– 3 %

50 mA

2.78 V +/– 3 %

50 mA

1.35 v +/– 1.15 %

< 100 ua

1.35 V +/– 2 %

< 100 ua

Dividers in Hagar

LO buffers in Hagar

Prescaler in Hagar

Power detector

BB section in Hagar

SHF VCO Module

Ref. volt. for Hagar RX

Ref. volt. for Hagar

Page 30

VBATT

3.2 – 4.5 V

1700 mA (max)

Nokia Corporation

Dual PA module

Issue 1 02/2002

Page 31

PAMS Technical Documentation

System Module & UI

RF characteristics

Item Values (E–GSM / GSM1800)

Receive frequency range 925 ... 960 MHz / 1805...1880 MHz

Transmit frequency range 880 ... 915 MHz / 1710...1785 MHz

Duplex spacing 45 MHz / 95 MHz

Channel spacing 200 kHz

Number of RF channels 174 / 374

Power class 4 (2 W) / 1 (1 W)

Number of power levels 15 / 16

Transmitter characteristics

Item Values (E–GSM/GSM1800)

Type Direct conversion, nonlinear, FDMA/TDMA

LO frequency range 3520...3660 MHz / 3420...3570 MHz

Output power 2 W / 1 W peak

Gain control range min. 30 dB

Maximum phase error ( RMS/peak ) max 5 deg./20 deg. peak

NPM–9

Receiver characteristics

Item Values, E–GSM/GSM1800

Type Direct conversion, Linear, FDMA/TDMA

LO frequencies 3700...3840 MHz / 3610...3760 MHz

Typical 3 dB bandwidth +/– 91 kHz

Sensitivity min. – 102 dBm (GSM1800 norm.cond. only)

Total typical receiver voltage gain ( from antenna

to RX ADC )

Receiver output level ( RF level –95 dBm ) 230 mVpp, single–ended I/Q signals to RX ADCs

Typical AGC dynamic range 83 dB

Accurate AGC control range 60 dB

Typical AGC step in LNA 30 dB GSM1800 25 dB EGSM

Usable input dynamic range –102 ... –10 dBm

RSSI dynamic range –110 ... –48 dBm

Compensated gain variation in receiving band +/– 1.0 dB

86 dB

Issue 1 02/2002

Nokia Corporation

Page 31

Page 32

Page 32

Nokia Corporation

PCN

Dual SAW

EGSM

LNA

LNA

SAW

SAW

HAGAR

f/2

NPM–9

RF Block Diagram

I

Q

VrefRF01

System Module & UI

f

VrefRF02

CTRL

SERIAL CTRL

BUS

Issue 1 02/2002

ANT SW

Coupler

Dual PA

SAW

PCN

EGSM

f/2

f

PLL

SHF

VCO

f

f/2

13 MHz

f/2

to ASIC

f

f/2

f

26 MHz

VCXO

AFC

TXC

TXP

TXIP

TXIN

TXQP

TXQN

RF_temp

PAMS Technical Documentation

Page 33

PAMS Technical Documentation

Frequency synthesizers

VCO frequency is locked with PLL into stable frequency source, which is

a VCTCXO–module ( voltage controlled temperature compensated crystal

oscillator ). VCTCXO is running at 26 MHz. Temperature drifting is controlled with AFC ( automatic frequency control ) voltage. VCTCXO is

locked into frequency of the base station. AFC is generated by baseband

with a 11 bit conventional DAC. 13MHz VCTCXO can also be used if multislot operations is not needed. If more than 1(RX)+1(TX) slot is wanted

settling times have to be less than 300us from channel to channel. This

can be achieved when PLL loopbandwith is ~35kHz. Noise coming from

the loop and noise from dividers (20*logN) increases rms phase error

over 3 degrees which is the maximum for synthesizer.

R

f

ref

f_out /

M

PHASE

DET.

CHARGE

PUMP

NPM–9

System Module & UI

26 MHz frequency reference

AFC–controlled VCTCXO

LP

f_out

VCO

Kd

M

Kvco

M = A(P+1) + (N–A)P=

= NP+A

PLL is located in HAGAR RF–IC and is controlled via serial RFBus. There

is 64/65 (P/P+1) prescaler, N– and A–divider, reference divider, phase detector and charge pump for the external loop filter. SHF local signal, generated by a VCO–module ( VCO = voltage controlled oscillator ), is fed

thru 180deg balanced phase shifter to prescaler. Prescaler is a dual modulus divider. Output of the prescaler is fed to N– and A–divider, which

produce the input to phase detector. Phase detector compares this signal

to reference signal (400kHz), which is divided with reference divider from

VCTCXO output. Output of the phase detector is connected into charge

pump, which charges or discharges integrator capacitor in the loop filter

depending on the phase of the measured frequency compared to reference frequency.

Loop filter filters out comparison pulses of phase detector and generates

DC control voltage to VCO. Loop filter defines step response of the PLL (

settling time ) and effects to stability of the loop, that’s why integrator capacitor has a resistor for phase compensation. Other filter components

are for sideband rejection. Dividers are controlled via serial bus. RFBusData is for data, RFBusClk is serial clock for the bus and RFBusEna1X is

a latch enable, which stores new data into dividers.

LO–signal is generated by SHF VCO module. VCO has double frequency

in GSM1800 and x 4 frequency in EGSM compared to actual RF channel

Issue 1 02/2002

Nokia Corporation

Page 33

Page 34

NPM–9

System Module & UI

frequency. LO signal is divided by two or four in HAGAR (depending on

system mode).

Receiver

Receiver is a direct conversion, dual band linear receiver. Received RF–

signal from the antenna is fed via RF–antenna switch module to 1st RX

bandpass RF–SAW filters and MMIC LNAs (low noise amplifier). RF–antenna switch module contains upperband and lowerband operation. The

LNA amplified signal is fed to 2nd RX bandpass RF–SAW filters. Both 2

RX bandpass RF–SAW filters have un–bal/bal configuration to get the

balanced (balanced) feed for Hagar.

Discrete LNAs have three gain levels. The first one is max. gain, the second one is about –30dB(GSM1800) and –25dB(EGSM900) below max.

gain and the last one is off state. The gain selection control of LNAs

comes from HAGAR IC.

RX bandpass RF–SAW filters define how good are the blocking characteristics against spurious signals outside passband and the protection

against spurious responses.

PAMS Technical Documentation

nd

Differential RX signal is amplified and mixed directly down to BB frequency in HAGAR. Local signal is generated with external VCO. VCO signal is

divided by 2 (GSM1800) or by 4 (E–GSM900). PLL and dividers are in

HAGAR–IC.

From the mixer output to ADC input RX signal is divided into I– and

Q–signals. Accurate phasing is generated in LO dividers. After the mixer

DTOS amplifiers convert the differential signals to single ended. DTOS

has two gain stages. The first one has constant gain of 12dB and 85kHz

cut off frequency. The gain of second stage is controlled with control signal g10. If g10 is high (1) the gain is 6dB and if g10 is low (0) the gain of

the stage is –4dB.

The active channel filters in HAGAR provides selectivity for channels

(–3dB @ +/–91 kHz typ.). Integrated base band filter is active–RC–filter

with two off–chip capacitors. Large RC–time constants needed in the

channel select filter of direct conversion receiver are produced with large

off–chip capacitors because the impedance levels could not be increased

due to the noise specifications. Baseband filter consists of two stages,

DTOS and BIQUAD. DTOS is differential to single–ended converter having 8dB or 18dB gain. BIQUAD is modified Sallen–Key Biquad.

Integrated resistors and capacitors are tunable. These are controlled with

a digital control word. The correct control words that compensate for the

process variations of integrated resistors and capacitors and of tolerance

of off chip capacitors are found with the calibration circuit.

Page 34

Next stage in the receiver chain is AGC–amplifier, also integrated into HAGAR. AGC has digital gain control via serial mode bus. AGC–stage provides gain control range (40 dB, 10 dB steps) for the receiver and also the

necessary DC compensation. Additional 10 dB AGC step is implemented

in DTOS stages.

Nokia Corporation

Issue 1 02/2002

Page 35

PAMS Technical Documentation

DC compensation is made during DCN1 and DCN2 operations (controlled

via serial bus). DCN1 is carried out by charging the large external capacitors in AGC stages to a voltage which cause a zero dc–offset. DCN2 set

the signal offset to constant value (VrefRF_02 1.35 V). The VrefRF_02

signal is used as a zero level to RX ADCs.

Single ended filtered I/Q–signal is then fed to ADCs in BB. Input level for

ADC is 1.45 Vpp max.

Rf–temp port is intended to be used for compensation of RX SAW filters

thermal behavior. This phenomena will have impact to RSSI reporting accuracy. The current information is –35ppm/C for center frequency drift

for all bands. This temperature information is a voltage over two diodes

and diodes are fed with constant current.

Transmitter

Transmitter chain consists of two final frequency IQ–modulators for upper

and lower band, a dual power amplifier and a power control loop.

NPM–9

System Module & UI

I– and Q–signals are generated by baseband. After post filtering (RC–network) they go into IQ–modulator in HAGAR. LO–signal for modulator is

generated by VCO and is divided by 2 or by 4 depending on system

mode. There are separate outputs one for EGSM and one for GSM1800.

In EGSM branch there is a SAW filter before PA to attenuate unwanted

signals and wideband noise from the Hagar IC.

The final amplification is realized with dual band power amplifier. It has

two different power chains one for EGSM and one for GSM1800. PA is

able to produce over 2 W (0 dBm input level) in EGSM band and over 1

W (0 dBm input level) in upperband band into 50 ohm output . Gain control range is over 45 dB to get desired power levels and power ramping

up and down.

Harmonics generated by the nonlinear PA are filtered out with filtering inside the antenna switch –module.

Power control circuitry consists of discrete power detector (common for

lower and upperband) and error amplifier in HAGAR. There is a directional coupler connected between PA output and antenna switch. It is a dualband type and has input and outputs for both systems. Dir. coupler takes

a sample from the forward going power with certain ratio. This signal is

rectified in a schottky–diode and it produces a DC–signal after filtering.

The possibility to improve efficiency in low power levels has been specified in power amplifier module. The improved efficiency will take place on

power level 7 and lower in EGSM. For this option there is control input

line in PA module.

AFC function

AFC is used to lock the transceivers clock to frequency of the base station. AFC–voltage is generated in BB with 11 bit DA–converter. There is a

Issue 1 02/2002

Nokia Corporation

Page 35

Page 36

NPM–9

System Module & UI

RC–filter in AFC control line to reduce the noise from the converter. Settling time requirement for the RC–network comes from signalling, how

often PSW ( pure sine wave ) slots occur. They are repeated after 10

frames. AFC tracks base station frequency continuously, so transceiver

has a stable frequency, because changes in VCTCXO–output don’t occur

so fast ( temperature ).

Settling time requirement comes also from the start up–time allowed.

When transceiver is in sleep mode and ”wakes” up to receive mode ,

there is only about 5 ms for the AFC–voltage to settle. When the first

burst comes in system clock has to be settled into +/– 0.1 ppm frequency

accuracy. The VCTCXO–module requires also 5 ms to settle into final

frequency. Amplitude rises into full swing in 1 ... 2 ms, but frequency settling time is higher so this oscillator must be powered up early enough.

DC–compensation

DC compensation is made during DCN1 and DCN2 operations (controlled

via serial bus). DCN1 is carried out by charging the large external capacitors in AGC stages to a voltage which cause a zero dc–offset. DCN2 set

the signal offset to constant value (RXREF 1.35 V). The RXREF signal is

used as a zero level to RX ADCs.

PAMS Technical Documentation

Page 36

Nokia Corporation

Issue 1 02/2002

Page 37

PAMS Technical Documentation

UI Board LU9

NPM–9 consists of separate UI board, named as LU9, which includes

contacts for the keypad domes and LEDs for keypad illumination. UI

board is connected to main PWB through 16 pole board–to–board connector with springs. Signals of the connector are described in section External and Internal Signals and Connections.

5x4 matrix keyboard is used in NPM–9. Key pressing is detected by scanning procedure. Keypad signals are connected UPP keyboard interface.

When no key is pressed row inputs are high due to UPP internal pull–up

resistors. The columns are written zero. When key is pressed one row is

pulled down and an interrupt is generated to MCU. After receiving interrupt MCU starts scanning procedure. All columns are first written high and

then one column at the time is written down. All other columns except one

which was written down are set as inputs. Rows are read while column at

the time is written down. If some row is down it indicates that key which is

at the cross point of selected column and row was pressed. After detecting pressed key all register inside the UPP are reset and columns are

written back to zero.

NPM–9

System Module & UI

LCD & Keypad Illumination

In NPM–9 blue leds are used for LCD and keypad illumination. For LCD

illumination four leds are used and for keypad six leds.

Current through leds is controlled by transistor circuitry. External transistor driver circuitry is used as constant current source in order to prevent

any change in battery voltage be seen as changing led brightness. Battery voltage is changing for example during charging depending on a

charger, battery type and age.

VBATT

10R

Keypad leds

VBATT

VBATT

15R

LCD leds

KLight

Issue 1 02/2002

Nokia Corporation

330R

Page 37

Page 38

NPM–9

System Module & UI

LEDs are controlled by the UEM PWM outputs. Both LEDs are controlled

KLight

by

biasing the transistor and limiting the current by resistors. Current is set

separately to keyboard and LCD leds.

Internal Speaker

The internal earpiece is a dynamic earpiece with an impedance of 32

ohms. The earpiece is low impedance one since the sound pressure is to

be generated using current and not voltage as the supply voltage is restricted to 2.7V. The earpiece is driven directly by the UEM and the earpiece driver in UEM is a bridge amplifier.

UEM

PAMS Technical Documentation

output of the UEM. Current flow through the LEDS is set by

EARP

EARN

22Ω

22Ω

1000Ω@100MHz

1000Ω@100MHz

27pF 27pF

Page 38

Nokia Corporation

Issue 1 02/2002

Loading...

Loading...