Page 1

Programmes After Market Services

NHP-2 Series Transceivers

9. Troubleshooting

Issue 1 05/2002 Nokia Corporation

Page 2

NHP-2

9. Troubleshooting PAMS Technical Documentation

Page 2 Nokia Corporation Issue 1 05/2002

Page 3

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Contents

Page No

Transceiver Troubleshooting ......................................................................................... 5

Baseband Description ..................................................................................................5

BB and RF Architecture............................................................................................ 6

Power Up and Reset.................................................................................................. 6

Troubleshooting ........................................................................................................ 8

Phone is totally dead ............................................................................................... 11

Phone Doesn’t Stay On or Phone is Jammed.......................................................... 12

Flash programming ................................................................................................. 14

Flash programming ................................................................................................ 18

Charging Operation................................................................................................. 19

Charger troubleshooting.......................................................................................... 22

Display and Keyboard............................................................................................. 23

Display faults........................................................................................................... 24

Keypad faults........................................................................................................... 27

Audio....................................................................................................................... 29

Accessories.............................................................................................................. 30

Audio Troubleshooting ........................................................................................... 31

Microphone failure.................................................................................................. 32

Vibra failure ............................................................................................................ 33

Buzzer failure.......................................................................................................... 34

Receiver fault finding ................................................................................................35

General instructions for RX troubleshooting.......................................................... 35

Path of the received signal ...................................................................................... 35

Fault finding charts for receiver chain .................................................................... 36

Cell CDMA............................................................................................................. 39

Troubleshooting 128.1 MHz IF Saw Filter............................................................. 39

PCS.......................................................................................................................... 39

Transmitter fault finding ............................................................................................43

General instructions for TX troubleshooting .......................................................... 43

Path of the transmitted signall................................................................................. 43

Fault finding charts for transmitter.......................................................................... 44

AMPS...................................................................................................................... 44

Cell CDMA............................................................................................................. 46

PCS (only dualbander)............................................................................................ 47

Synthesizer fault finding ............................................................................................51

19.2 MHz reference oscillator................................................................................. 51

Fault finding chart for 19.2 MHz oscillator ............................................................ 52

RX VHF VCO......................................................................................................... 52

Fault finding chart for RX VHF VCO .................................................................... 53

TX VHF Synth........................................................................................................ 53

Fault finding chart for TX VHF VCO..................................................................... 54

UHF Synthesizer..................................................................................................... 54

Fault finding chart for UHF Synthesizer ................................................................ 55

Test Point Diagrams................................................................................................ 56

Issue 1 05/2002 Nokia Corporation Page 3

Page 4

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Page 4 Nokia Corporation Issue 1 05/2002

Page 5

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Transceiver Troubleshooting

Baseband Description

The baseband module is a CDMA dual-band engine. Baseband architecture is based on

the DCT4 Apollo engine. The baseband consists of three new ASICs: Universal Energy

Management (UEM), Universal Phone Processor (UPP), and Flash 64 Megabit.

The baseband architecture supports a power-saving function called “sleep mode”. This

sleep mode shuts off the VCTCXO, which is used as a system clock source for both RF and

Baseband. During the sleep mode, the system runs from a 32 kHz crystal. The phone is

wakened by a timer running from this 32 kHz clock supply. The sleep time is determined

by network parameters. Sleep mode is entered when both the MCU and the DSP are in

standby mode and the normal VCTCXO clock is switched off.

NHP-2 supports both three- and two-wire types of DCT3 chargers. There is a separate

PWM output for controlling the three-wire charger. Charging is controlled by the UEM

ASIC and by EM SW running in the UPP.

Issue 1 05/2002 Nokia Corporation Page 5

Page 6

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

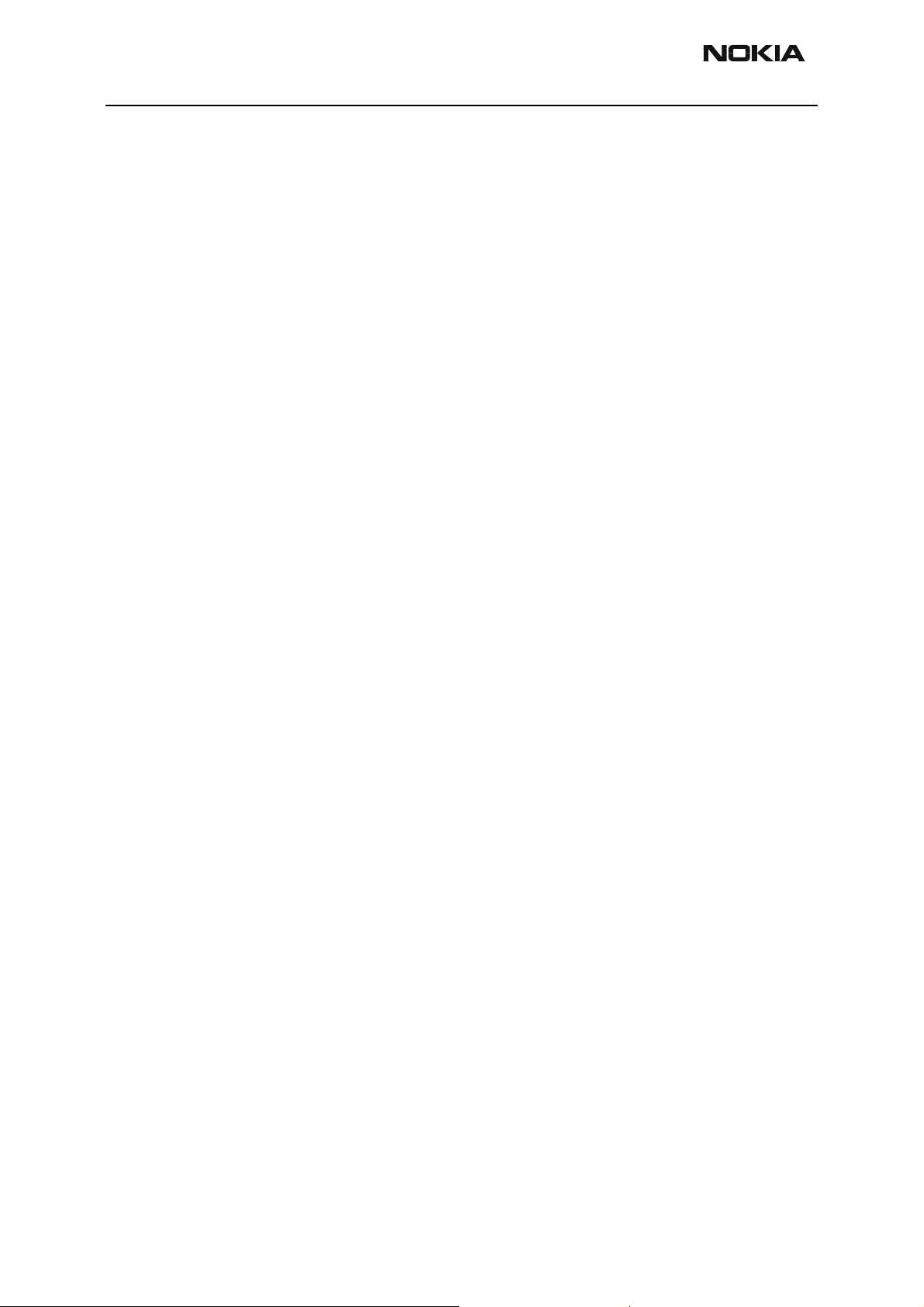

BB and RF Architecture

Figure 1: NHP-2 Power Distribution

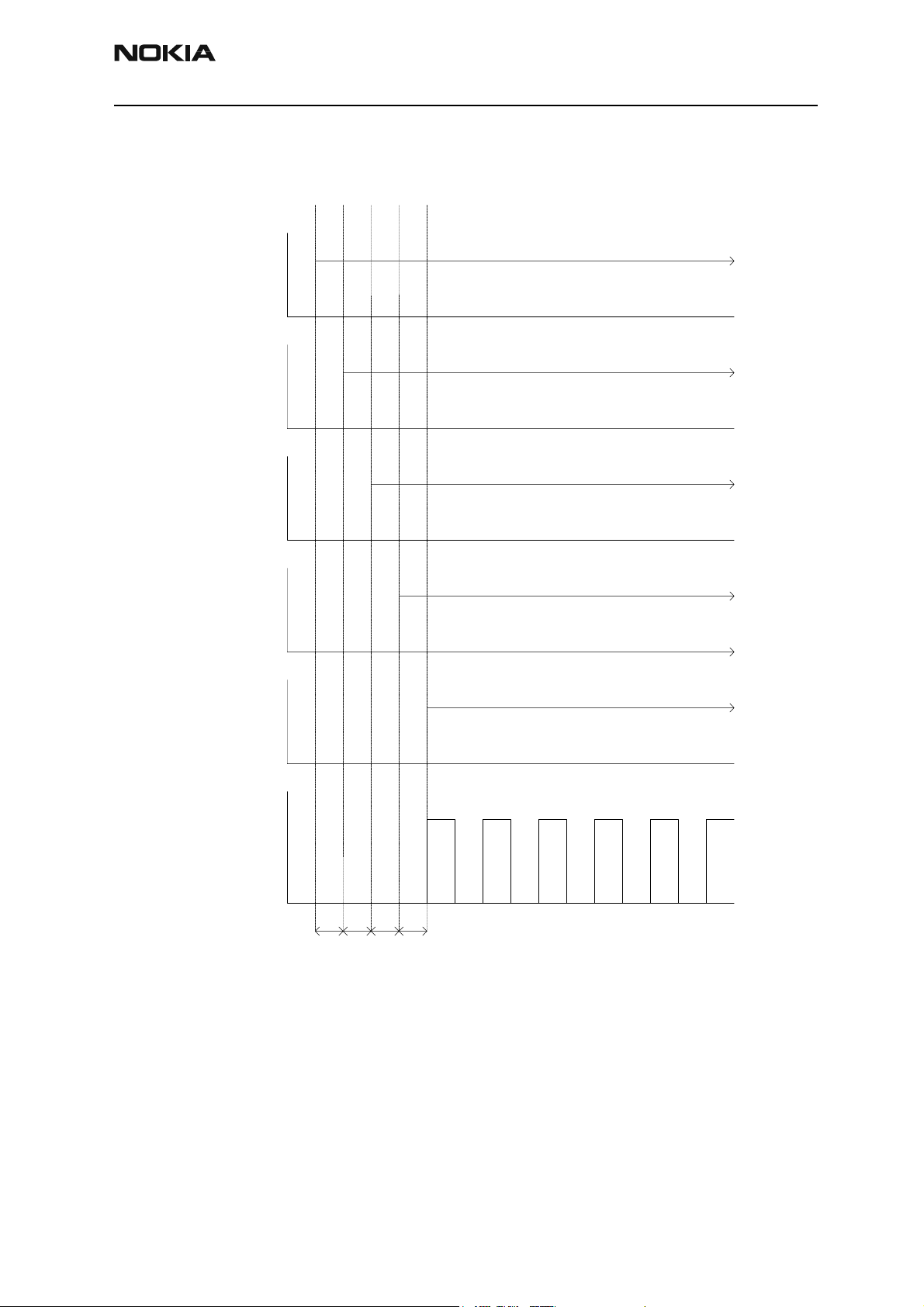

Power Up and Reset

Power up and reset is controlled by the UEM ASIC. There are three ways to power up the

baseband module:

1 Power Button (grounding the PWRONX pin of the UEM).

Page 6 Nokia Corporation Issue 1 05/2002

Page 7

NHP-2

PAMS Technical Documentation 9. Troubleshooting

2 Connect the charger to the charger input.

3 RTC Alarm (when the RTC logic has been programmed to give an alarm).

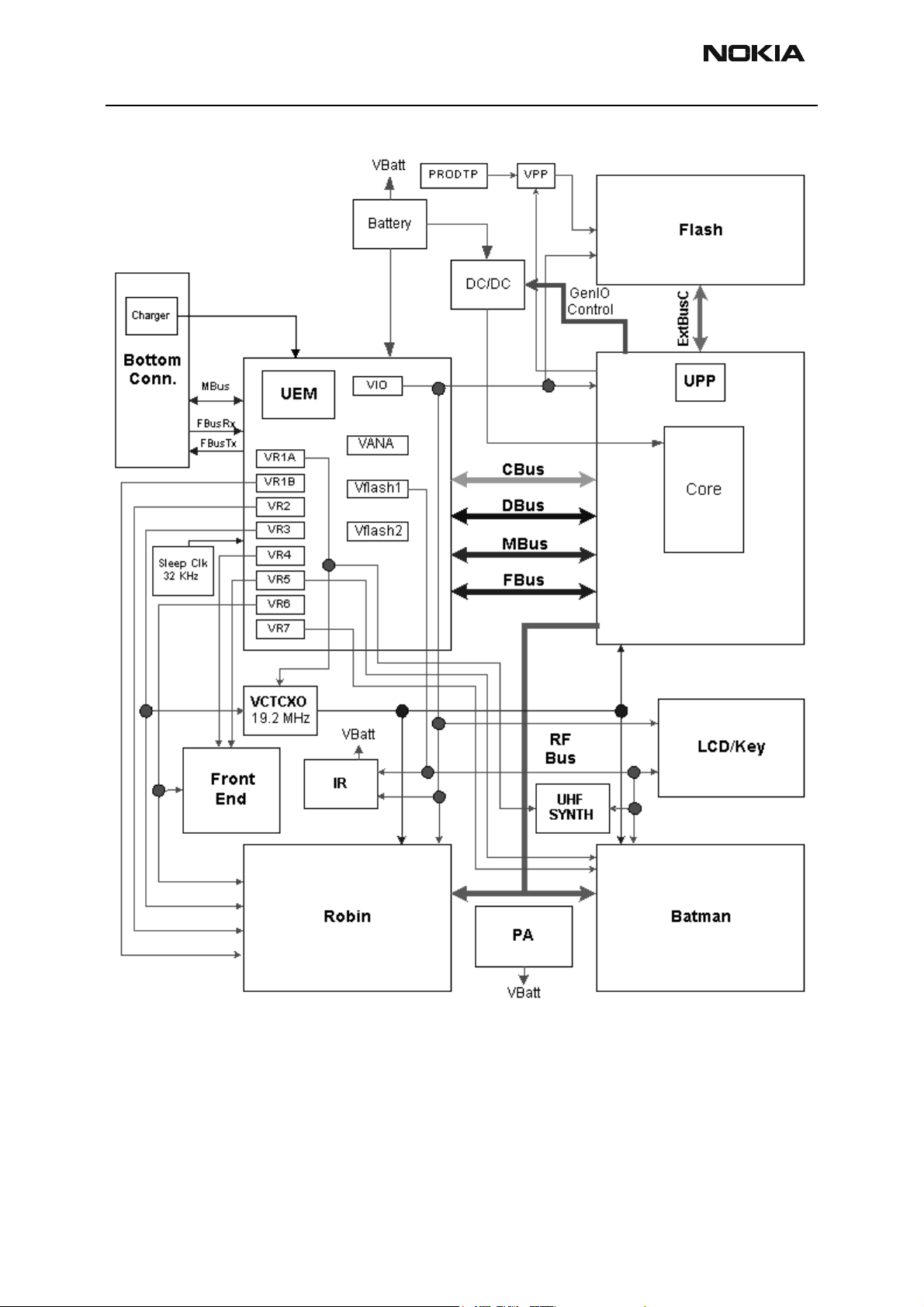

Reference signal

PwrOnX

Charger Detection

RTC

UEMRSTX

VFlash1

VIO

VCORE

VANA

VR3

19.2MHz Clk

PURX

32kHz XTAL

t1 t2 t4t3

t1 = 20ms

t2 = 200ms

t3 = 500us

t4 = 20ms

Figure 2: UEM start-up sequence from reset to power-on mode

Issue 1 05/2002 Nokia Corporation Page 7

Page 8

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Troubleshooting

First, carry out a thorough visual check of the module. Make sure that:

- there are no mechanical damages

- solder joints are OK

Before changing anything, ALL SUPPLY VOLTAGES AND SYSTEM CLOCK / SLEEP CLOCK

should be checked.

Power up faults

Power-up sequence

UEM acts as a HW master during start up

1 VBATT limits: 2.1V for internal state machine, 3V triggering whole startup

2 Regulator sequencing

• Hw "core" regulators "on": VANA, VIO, VFLA SH1, VFLASH2, and

VCORE, which provide nominal voltages and curre nts according to

Table 1.

Page 8 Nokia Corporation Issue 1 05/2002

Page 9

NHP-2

PAMS Technical Documentation 9. Troubleshooting

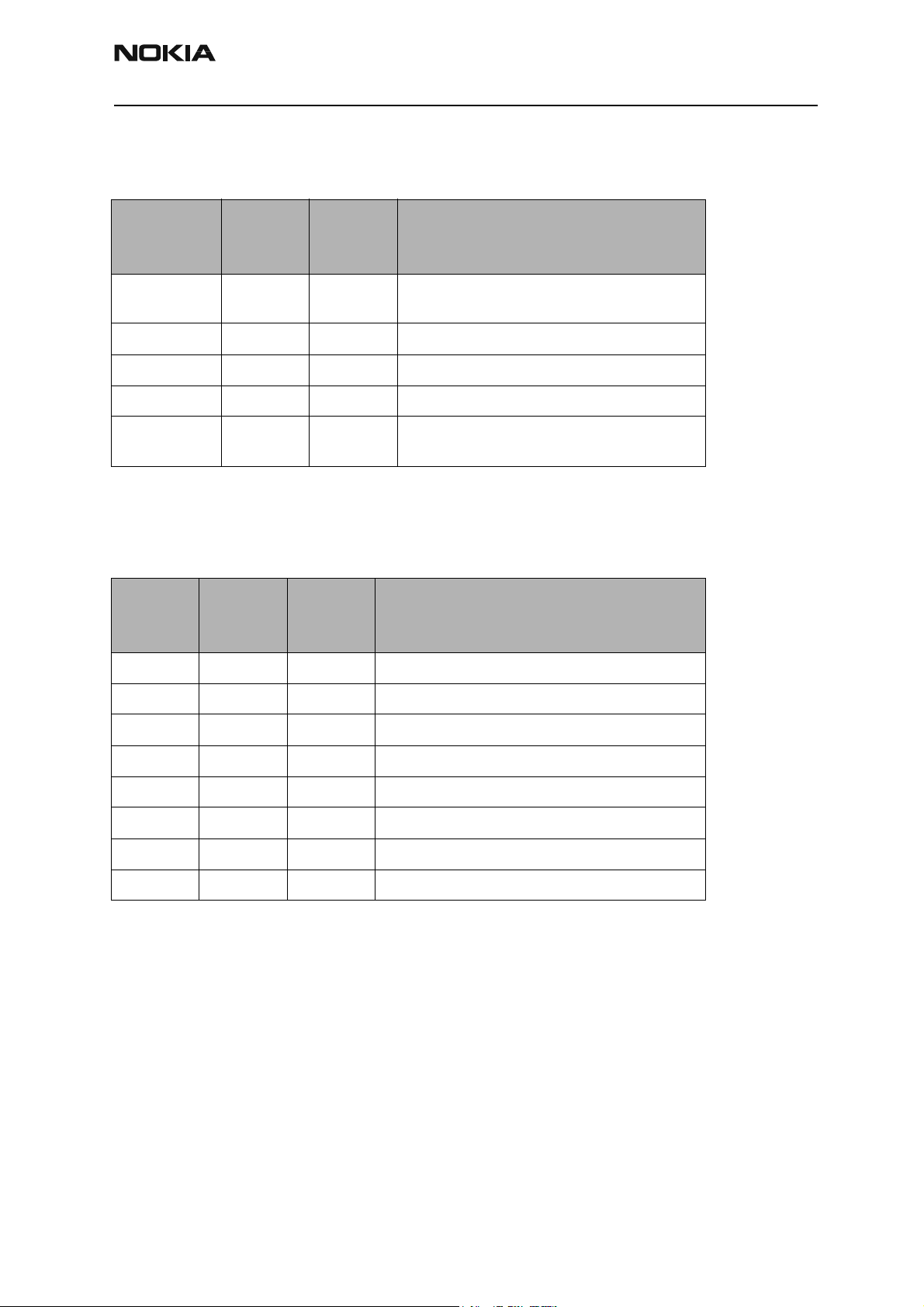

Table 1: Baseband regulators

Maximum

Regulator

VCORE (dc/dc) 300 1.5 Output voltage selectable 1.0V/1.3V/1.5V/1.8V.

VIO 150 1.8 Always enabled, except during power-off mode.

VFLASH1 70 2.78 Always enabled, except during power-off mode.

VFLASH2 40 2.78 Enabled only when data cable is connected.

VANA 80 2.78 Enabled only when the system is awake. (Off

current

(mA)

Vout (V) Notes

Power-up default: 1.5V

during sleep mode and power-off mode.)

• UEM supplies voltages VR1A, VR1B, VR2, VR3, VR4, VR5, VR6,

and VR7 for RF. See Table 2.

Table 2: RF regulators

Maximum

Regulator

VR1A 10 4.75 Enabled when receiver is on.

VR1B 10 4.75 Enabled when transmitter is on

VR2 100 2.78 Enabled when transmitter is on

VR3 20 2.78 Enabled when SleepX is high

VR4 50 2.78 Enabled when receiver is on

VR5 50 2.78 Enabled when receiver is on

VR6 50 2.78 Enabled when transmitter is on

VR7 45 2.78 Enabled when receiver is on

current

(mA)

Vout (V) Notes

3 Reset releasing delay

• Supply voltages stabilize to their UEM hw default value

• RFCLK grows to full swing

• Core is ready to run but waiting for PURX release

4 Reset releasing

• UPP releases the SLEEPX up to "non sleep" -state to prevent the

UEM switching the regulators "OFF"

Issue 1 05/2002 Nokia Corporation Page 9

Page 10

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

5 MCU starts running the Bootsrap Code

• written in stone/ UPP internal ROM

• the program checks if there exists any reason for FDL mode (Flash

Down Load)

• If there exists executable code in FLASH and there exists no reason

for FDL, the MCU starts running the MCU pro gram from FLASH.

6 MCU runs the FLASH MCU code the phone initialization, user interfaces, internal

blocks, etc.

• Core regulator voltage setting for required DSP speed

• Initializes the DSP and concerning hw

Releases DSP reset -> DSP starts running

1 Power key pressed

• After 20ms, UEM enters RESET MODE if VBAT>Vmstr+

• VFLASH1, Vana, Vcore, Vio, and VR3 goes high.

• VCTCXO enabled by VR3 -> RFClk 19.44 MHz running.

2 Purx released

• Purx released by UE M , U EM IN T go es high for 100 ms , Sle epX goes

high and SleepClk (32 KHz) starts running.

3 Software running

• Default value of V core is 1.5 V.

• Cbus (1.2MHz) and Dbus (9.6MHz) clocks start running.

Note! In case of power up faults, it's not possible to force phone on by disabling watchdog. Instead it's

recommended to use normal or single triggering on oscilloscope, so that it's possible to see if signal

goes to its normal value even for a while when power key is pressed.

Page 10 Nokia Corporation Issue 1 05/2002

Page 11

NHP-2

PAMS Technical Documentation 9. Troubleshooting

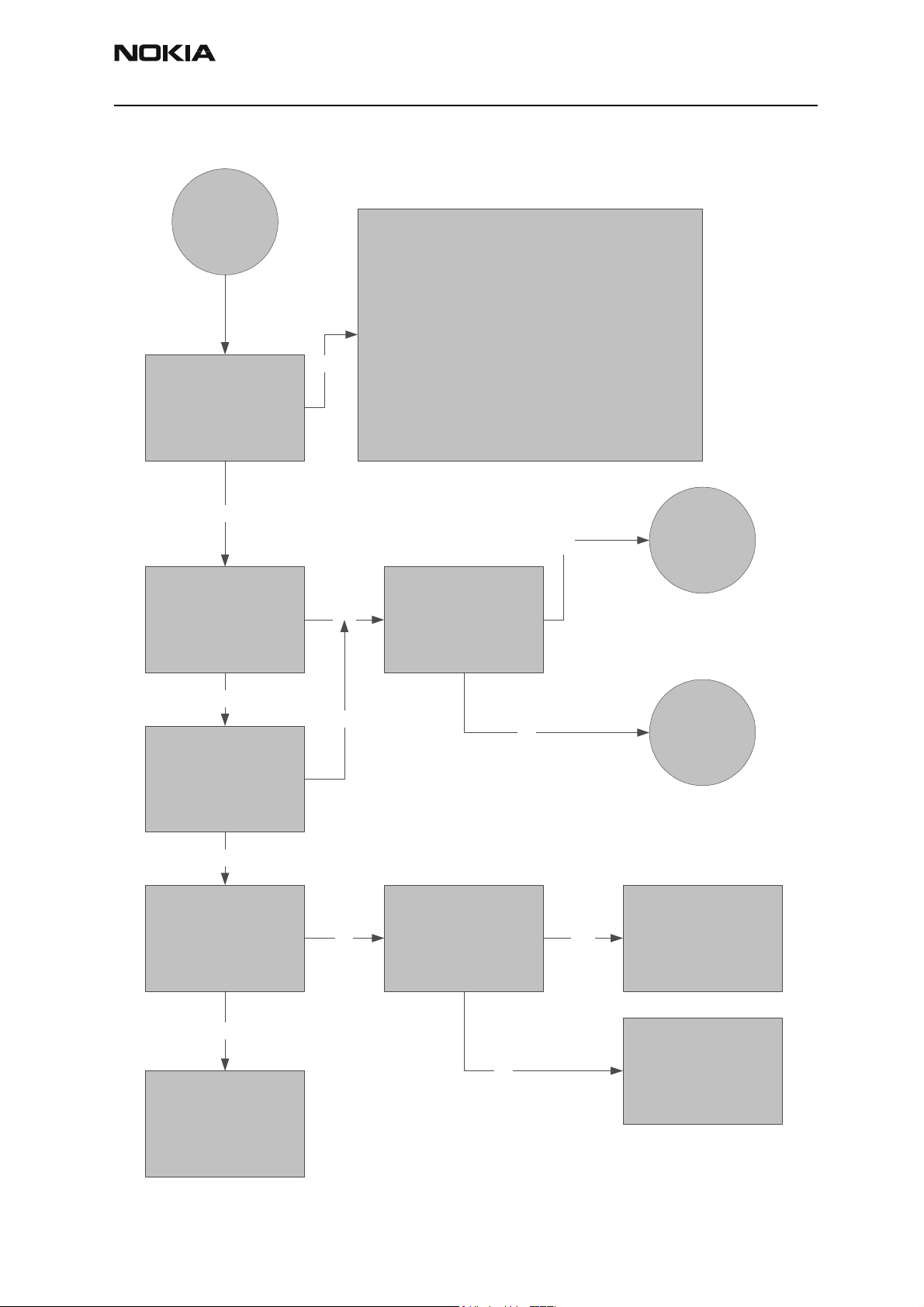

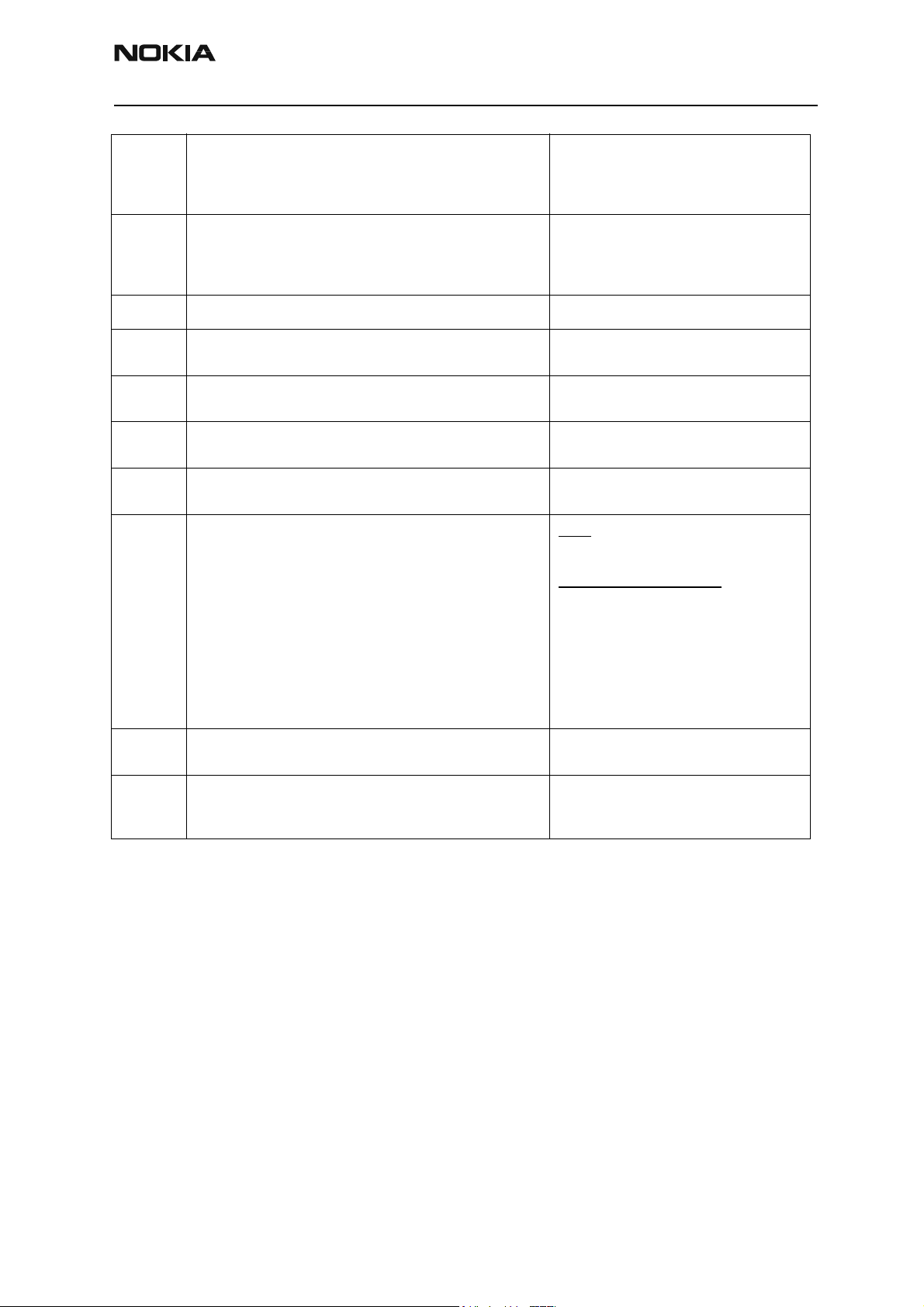

Phone is totally dead

Phone is dead

-If current is zero, check X101 solder and VBATT lines

-If current is too high, check for shorts

-Make sure all BB regulators are at their respective

voltage levels (e.g. , VANA, VIO, VCORE (DC-DC),

VFlash1, and VR3. See phone's top view diagram for

Yes

Phone current is zero

or too high?

test points

-Make sure the System Clk is 19.2 MHz and that the

Sleep Clk is 32 KHz

-Make sure PURX and SleepX signals are high (1.8V)

No

Phone current is < 30 mA

No

Phone current is <= 35 mA

Yes

Is phone in Local Mode?

Yes

No

Is phone flash programming

OK?

No

Check BSI line X101, R202,

R206, C230, C109.

Are they OK?

Yes

Phone is

jammed

Flash faults

YesNo

Change UEM

Yes

No

OK restart

Repair

Issue 1 05/2002 Nokia Corporation Page 11

Page 12

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

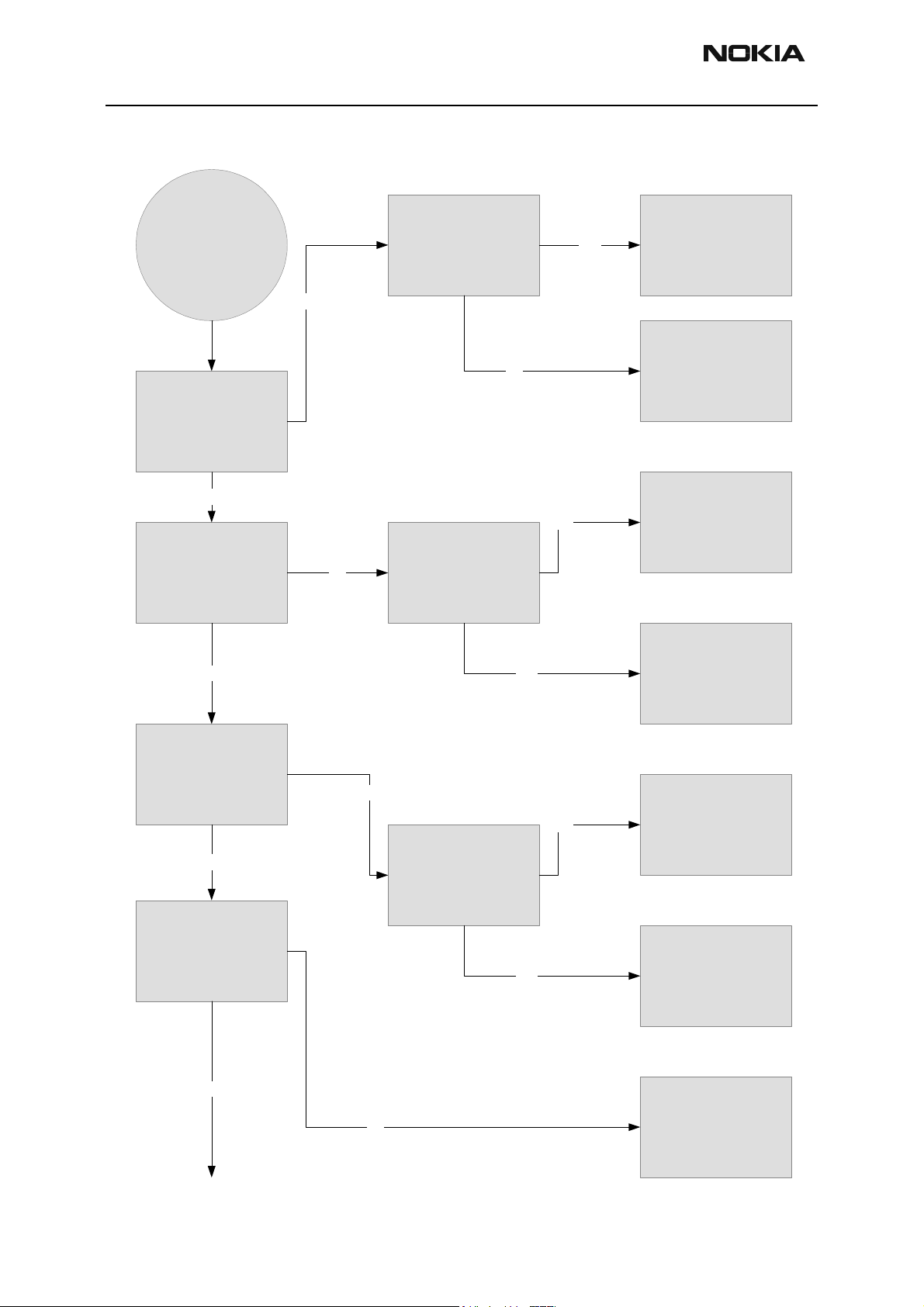

Phone Doesn’t Stay On or Phone is Jammed

Check VBATT, VIO,

Phone is jammed

No

VCORE, VFlash1, VANA,

VR3 capacitors.

Are they OK? (See phone

top view diagram for

capacitor locations).

Yes

Check RSI/BTEMP lines

and VBATT lines.

If OK, change UEM.

Measure VIO, VCORE,

Vflash1, VANA, and VR3

voltages.

Are they OK?

Yes

Measure 32kHz Sleep Clk

from test point.

Is it OK?

Measure 19.2MHz RF Clk

at test point J499.

Is it OK?

Yes

No

Measure 32kHz Clk crystal.

Is it OK?

No

Measure 19.2 MHz Clk

coming from VCTCXO at

C524.

Is it OK?

No

Repair

No

YesYes

No

Change B200

Change UEM

Check G503, C505, C520,

C502, C523, C525, C524,

R511, R510, R512, R520,

R521, R522, R517, R516.

If OK, change G501.

Measure PURX and SleepX

at test points J402 and

J403.

Are they high (1.8V)?

Yes

Yes

No

Change UPP

Change UEM

Page 12 Nokia Corporation Issue 1 05/2002

Page 13

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Phone shuts down after

32 seconds

No

Measure DBusClk 9.6MHz

signal from test point J413.

Is it OK?

Yes

Read phone info.

Is it OK?

No

No

Has the phone been

flashed?

Yes

Measure watchdog signal

CBusDA from test point

J407.

Is it OK?

Change UPP

Yes

Measure FBusRx signal

during phone info read from

test point J412.

Is it OK?

No

NoYes

No

Flash the phone

Change UPP and re-flash

Change UEM and re-flash

Change UEM

Yes

Yes

Measure FBusTx signal

during phone info read from

test point J411.

Retest

Is it OK?

No

Yes

Change UPP

Change UEM

Issue 1 05/2002 Nokia Corporation Page 13

Page 14

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Flash programming

Connections to Baseband

The flash programming equipment is connected to the baseband using test pads for galvanic connection. Test pads are allocated in such a way that they can be accessed when

the phone is assembled. The flash programming interface uses the VPP, FBUSTX, FBUSRX,

MBUS, and BSI connections for connection to the baseband. The connection is through

the UEM, which means that the logic levels correspond to 2.7V. Power is supplied using

the battery contacts.

Baseband power is controlled by the flash prommer in production and in reprogramming

situations. When supply voltage is applied to the battery terminals, the baseband will

power up.

Flash programming procedure

• Phone communicates with prommer via production test pattern, using

signals:

FBUSTX (serial data to phone),

FBUSRX (Serial data from phone),

MBUS (serial clock for FBUSRX)

VPP (External flashing voltage for speed up flashing)

Also BSI line is used when initializing flashing(battery connector)

• When phone has entered flash programming mode, prommer indicates

to UEM that flash programming will take place by writing 8-bit password

to UEM. Prommer will first set BSI to “1” and then uses FBUSRX for

writing and MBUS for clocking. After that, BSI is reset to “0”.

• MCU indicates to prommer that it has been noticed, by using the

FBUSTX signal. After this, it reports UP P type ID and is ready to receive

secondary boot code to its internal SRAM.

Page 14 Nokia Corporation Issue 1 05/2002

Page 15

NHP-2

X

rn

n

PAMS Technical Documentation 9. Troubleshooting

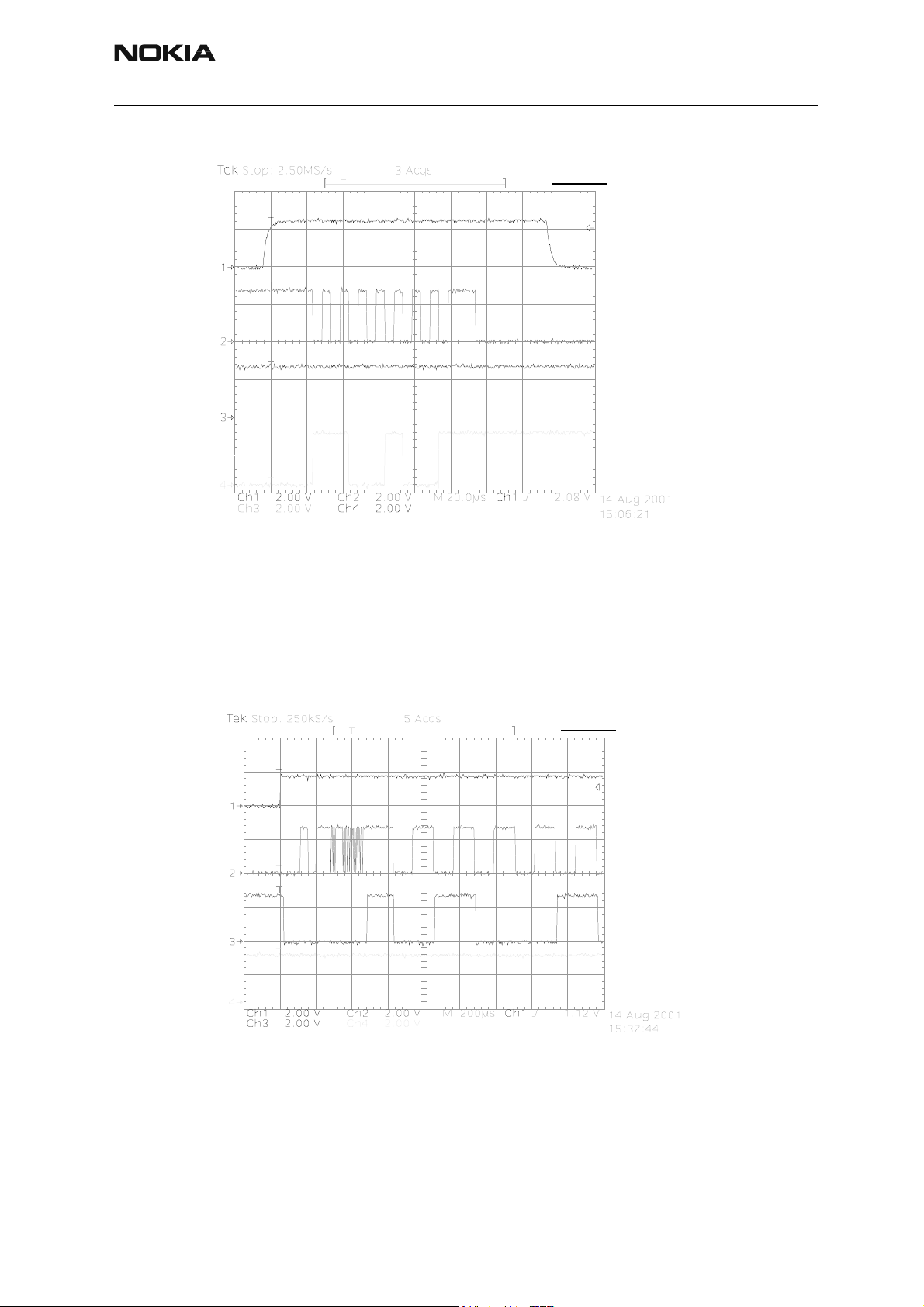

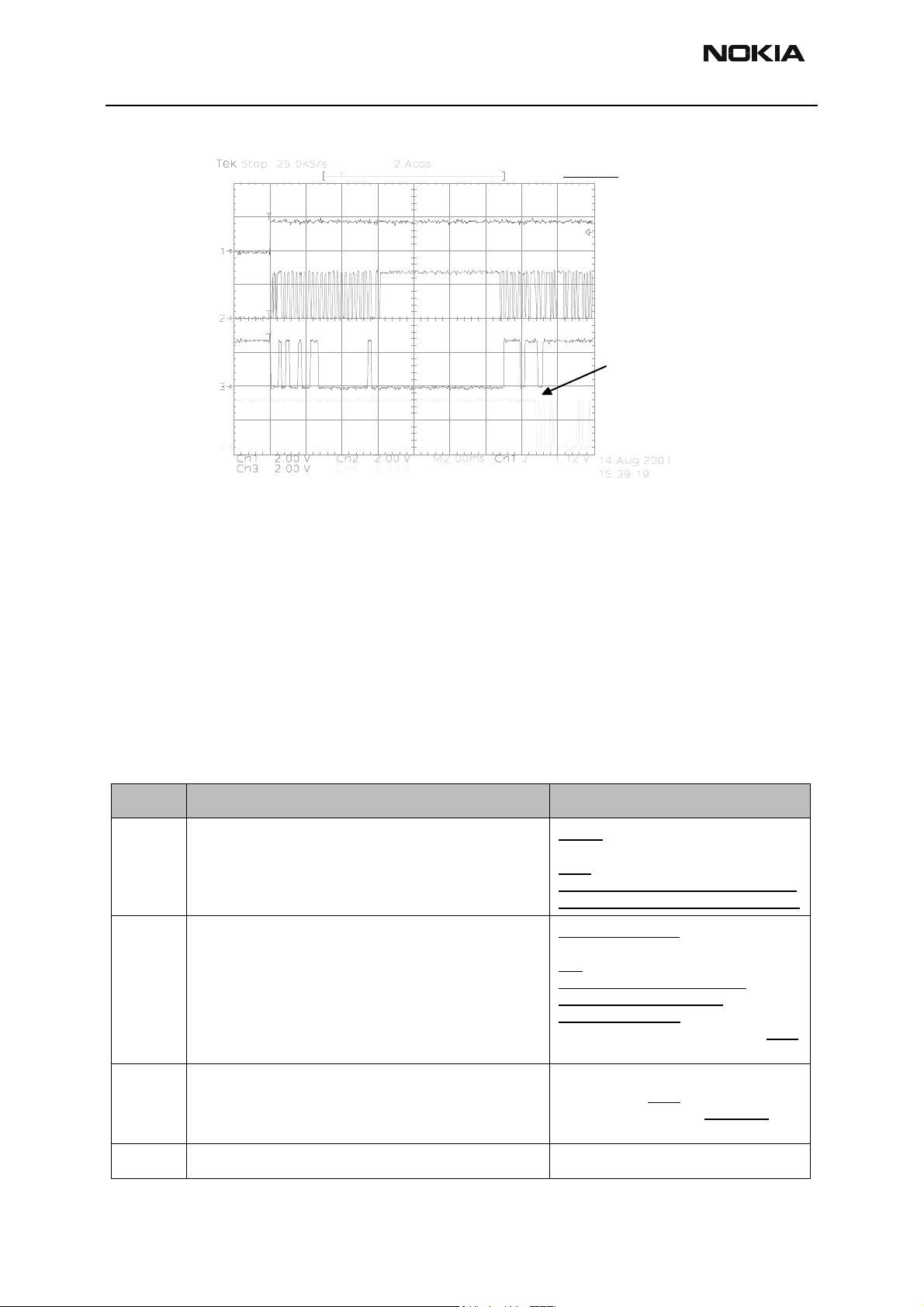

FLASH_1

CH1 = BSI

CH2 = MBUS

CH3 = FBUSTX

CH4 = FBUSR

Measure points

Production test patte

(J396)

Figure 3: Flashing start

• This boot code asks MCU to report prommer phone’s configuration

information, including flash device type. Now, the prommer can select

and send algorithm code to MCU SRAM (and SRAM/Flash self-tests

can be execut ed).

FLASH_2

CH1 = PURX

CH2 = MBUS

CH3 = FBUSTX

CH4 = FBUSRX

Measure points

Production test patter

(J396)

Figure 4: Flashing, continued

Issue 1 05/2002 Nokia Corporation Page 15

Page 16

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

FLASH_3

CH1 = PURX

CH2 = MBUS

CH3 = FBUSTX

CH4 = FBUSRX

Measure points

Produ c tio n te s t pattern

(J396)

Data transfer has

started (Fbus_Rx)

Figure 5: Flashing, continued

Flash programming error codes

• Error codes can be seen from the test results or from Phoenix's flashtool*

• Underlined note means that the connection un der consid eration is being

used for the first time.

• Some error codes may be added later. Here are the most common

ones.

Table 3: Flash programming error codes

Error Description Not working properly

C101

C102

"The Phone does not set FbusTx line high after the startup." Vflash1

VBatt

BSI and FbusRX from prommer to UEM.

FbusTx from UPP->UEM->Prommer(SA0)

"The Phone does not set FbusTx line low after the line has

been high. The Prommer generates this error also when the

Phone is not connected to the Prommer."

PURX(also to Safari)

VR3

Rfclock(VCTCXO->Safari->UPP)

Mbus from Prommer->UEM>UPP(MbusRx)(SA0)

FbusTx from UPP->UEM->P rommer(SA 1)

BSI and FbusRX from prommer to UEM.

C103

C104

" Boot serial line fail." Mbus from Prommer->UEM-

>UPP(MbusRx)(SA1)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

"MCU ID message sending failed in the Phone." FbusTx from UPP->UEM->Prommer

Page 16 Nokia Corporation Issue 1 05/2002

Page 17

NHP-2

PAMS Technical Documentation 9. Troubleshooting

C105

C106

C107

C586

C686

Cx81

Cx82

A204

Cx83

Cx84

Cx85

"The Phone has not received Secondary boot codes length

bytes correctly."

"The Phone has not received Secondary code bytes correctly." Mbus from Prommer->UEM-

"The Phone MCU can not start Secondary code correctly." UPP

"The erasing status response from the Phone informs about

fail."

"The programming status response from the Phone informs

about fail."

"The Prommer has detected a checksum error in the message,

which it has received from the Phone."

"The Prommer has detected a wrong ID byte in the message,

which it has received from the Phone."

" The flash manufacturer and device Ids in the existing Algorithm files do not match with the Ids received from the target

phone."

"The Prommer has not received Phone acknowledge to the

message."

"The Phone has generated NAK signal during data block transfer."

"Data block handling timeout"

Mbus from Prommer->UEM>UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

>UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

Flash

Flash

FbusTx from UPP->UEM->Prommer

FbusTx from UPP->UEM->Prommer

Flash

UPP

VIO/VANA?

Signals between UPP-Flash

Mbus from Prommer->UEM>UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

Cx87

Startup

for

flashing

"Wrong MCU ID." RFClock

UPP(Vcore)

Required startup for flashing Vflash1

VBatt

Issue 1 05/2002 Nokia Corporation Page 17

Page 18

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

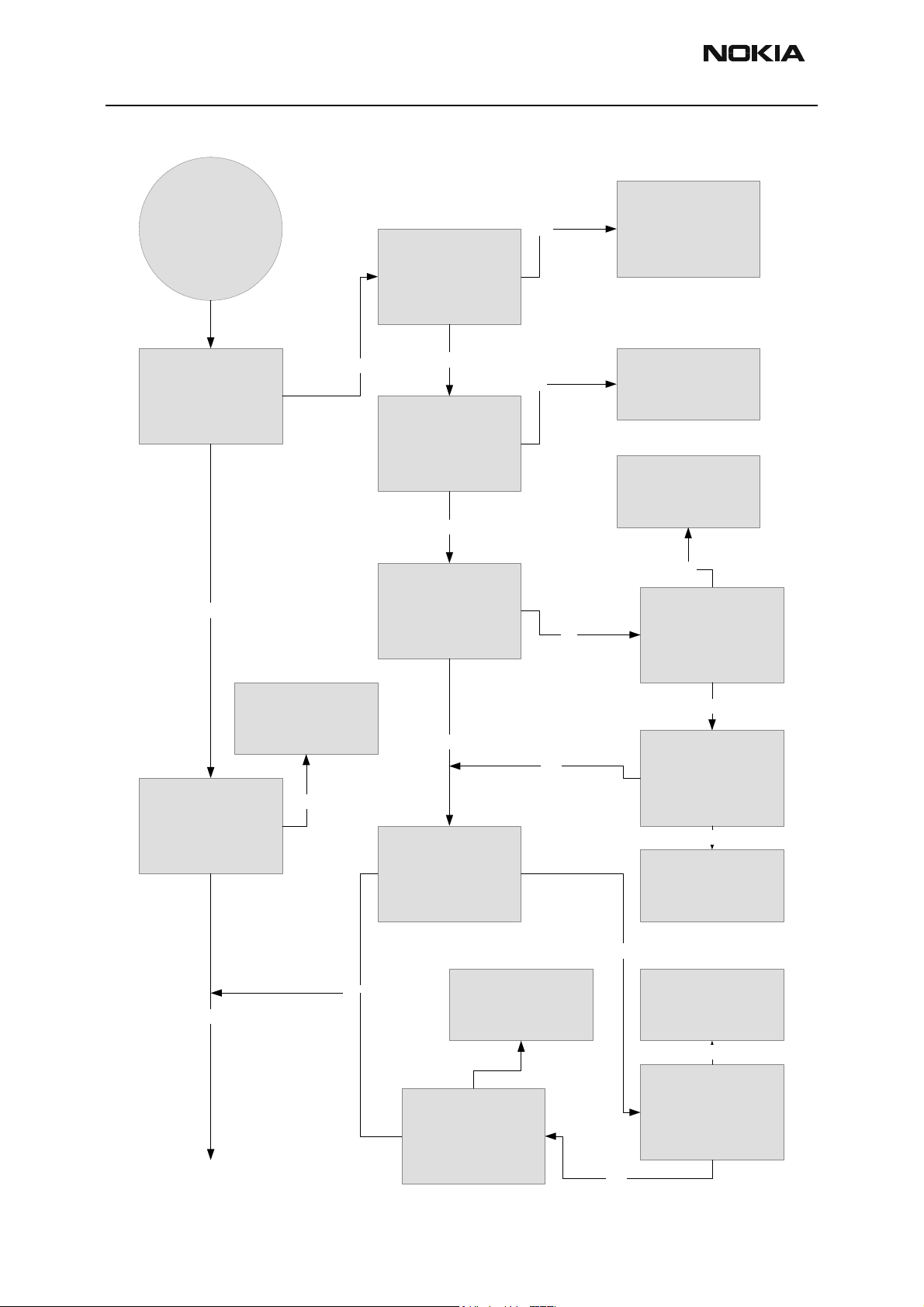

Flash programming

Flash faults

Phone does not set

Flashbus TXD line high

after start up

No

Measure BSI pulse during

Flash programming.

Yes

Measure FBusRx (2.78V)

signal during flash

programming from bottom

connector and test point

J412 (1.8V).

Is it the same?

Measure test point J411

(1.8V) and FBusTx signal

(2.78V) during flash

programming from bottom

connector.

Are they the same?

Is it OK?

Yes

Yes

No

No

No

Check BSI line X101, C230,

R206, C109, R202

Check R102, C103, and

R104.

If OK, then Change UEM.

Change UPP

No

Is there a pulse on J411?

Phone does not set

Flashbus TXD line low after

the line has been high

No

Change UEM

Yes

Measure MBus (2.78V) and

test point J410 (1.8V).

Are they the same?

Yes

Is pulse getting to test point

Yes

J410?

Change UEM

Yes

No

Is there a pulse on

FBusTx?

No

Check R100 and C101.

If OK, then change UEM.

No

Check R101 and C104

No

Is pulse getting to UEM?

Yes

Page 18 Nokia Corporation Issue 1 05/2002

Page 19

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Can you read the

manufacturer ID and the

device ID?

Yes

Is the phone totally dead?

No

Yes

Change Flash

See Phone is dead

flowchart.

Phone doesn't start up or

phone is jammed.

Charging Operation

A Lithium-ion battery with a capacity of 920 mAh is used in NHP-2. Temperature and

capacity information are needed for charge control. These resistors are connected to the

BSI and BTEMP pins of battery connector. The phone has 100 kW pull-up resistors for

these lines so that they can be read by A/D inputs in the phone.

No

No

Retest

Yes

See Phone is jammed

flowchart.

Issue 1 05/2002 Nokia Corporation Page 19

Page 20

NHP-2

4

V100

9. Troubleshooting PAMS Te chnical Documentation

Charging circuitry

The UEM ASIC controls charging, depending on the charger being used and the battery

size. External components are needed for EMC, reverse polarity, and transient protection

of the input to the baseband module. The charger connection is through the system connector interface. NHP-2 baseband is designed to support DCT3 chargers from an electrical point of view. Both two- and three-wire chargers are supported.

(GND)

3(BTEMP)

Figure 6: BLB-3 battery pack pin order

2(BSI)

1 (+)

R200

battery

Figure 7: Charging circuitry

Charger Detection

Connecting a charger creates voltage on VCHAR input of the UEM. When VCHAR input

voltage level is detected to rise above 2 V (VCHdet+threshold) by UEM, charging starts.

VCHARDET signal is generated to indicate the presence of the charger for the SW. The

charger identification/acceptance is controlled by EM SW.

The charger recognition is initiated when the EM SW receives a “charger connected”

interrupt. The algorithm basically consists of the following three steps:

1 Check that the charger output (voltage and current) is within safety limits.

Page 20 Nokia Corporation Issue 1 05/2002

Page 21

NHP-2

)

PAMS Technical Documentation 9. Troubleshooting

2 Identify the charger as a two-wire or three-wire charger.

3 Check that the charger is within the charger window (voltage and current).

If the charger is accepted and identified, the appropriate charging algorithm is initiated.

X100

1, 3

4, 5

F100

1.5A

R107 R108

10K 10K

L100

________

42R/100MHz

D100 C100

C107

10n

Figure 8: Charging circuit

"VCHARIN"

1n0

"PWMO"

0

2

1

CHARGER(4:0

Issue 1 05/2002 Nokia Corporation Page 21

Page 22

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Charger troubleshooting

Connect charger. Make

sure battery is connected.

Battery bar doesn't work

(scroll)

Yes

Measure voltage over

D100. Is it >3.0 Vdc?

Yes

Read BTEMP value. Is it

- 25C (0319)?

Yes

No

No

No

Retest

Check X100, F100, L100,

D100, C100

Change UEM

Remove (fuse) F100 and

measure current.

Is it -350-390 mA?

No

Change UEM

RetestYes

Page 22 Nokia Corporation Issue 1 05/2002

Page 23

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Display and Keyboard

LEDs are used for LCK and keypad illumination in NHP-2. There are six LEDs for the LCD

and six LEDs for the keypad.

A black/white LCD is used in NHP-2. Interface uses 9-bit data transfer. The interface is

similar to DCT3-type interface, except that Command/Data information is transferred

together with the data. D/C bit set during each transmitted byte.

Issue 1 05/2002 Nokia Corporation Page 23

Page 24

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Display faults

Are the UI module's LE Ds

turned on after phone is

turned on or when making a

phone call?

No No

Set phone in Local Mode. Use Phoenix "Message

Sender" and navigate as follows: DEV _HOST ->

DEV_PC -> PN_LIGHT -> OBJ_ROUTING_REQ ->

>LIGHT_CONTROL_TARGER_KBD. Select

Measure VBATT voltage at

R302 and R30. Is it OK?

Yes

OBJ_PC -> UTID -

"LIGHT_STATE_BLINK" and cl ick "Send"

Check VBATT line

Measure UEM signal on

V305, V306, V307, V308,

V314, V315.

Is the signal OK?

Yes

No

Change UEM

Change LEDs

Page 24 Nokia Corporation Issue 1 05/2002

Page 25

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Are the display module

LEDs turned on when

phone is turned on or when

making a phone call?

Measure VBATT voltage at

No No

Set phone in Local Mode. Use Phoenix

"Message Sender" and navigate as foll ows:

DEV_HOST -> DEV_PC -> PN_LIGHT ->

OBJ_ROUTING_REQ -> OBJ_PC -> UTID ->

LIGHT_CONTROL_TARGER_DISPLAY.

Select "LIGHT_STATE_BLINK " and click

R302 and R300.

Is it OK?

Yes

LIGHT_CONTROL_REQ ->

"Send"

Measure UEM signal on

V300, V301, V302, V303,

V310, V311.

Is the signal OK?

No

Check VBATT line

Change UEM

Yes

Change LEDs

Issue 1 05/2002 Nokia Corporation Page 25

Page 26

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Does the display start?

No Yes

Set phone in Local Mode. Use Phoenix

"Message Sender" and navigate as foll ows:

DEV_HOST -> DEV_PC -> PN_TEST ->

OBJ_ROUTING_REQ -> OBJ_PC -> UTID ->

TEST_DISPLAY_SEt -> NUM_SB: ->

TEST_SB_UI_DISPLAY_PATTERN ->

"TEST_PATTERN_ALTPIXELS" and clic k

Try changing display

module.

Does it work?

No

TEST_UI_TEST_REQ ->

SB_LENGTH. Select

"Send"

Check test points J307,

J308, and J309.

Are signals OK?

(Refer to Display Section).

No

Retest

Change UPP

Yes

Change Display

Page 26 Nokia Corporation Issue 1 05/2002

Page 27

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Keypad faults

Is the power key working?

Measure voltage at S300

when power key is pressed.

Is it High?

No No

Measure voltage at S300.

Is it High?

Yes

Yes Yes

No

Check S300. Is it OK?

No

Check S300, C305, and

R304.

If OK, change UEM.

See Phone is

Dead flowchart

Change S300

See Phone is

Jammed

flowchart

Issue 1 05/2002 Nokia Corporation Page 27

Page 28

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Are the UI module keys

working?

Change keypads module.

Is it working?

No

Measure ROW 0-4 signals

between UPP and Z300.

Are they -1.8V?

Yes

Measure ROW 0-4 signals

between Z300 and

keypads.

Are they -1.8V?

No

No

RetestNo Yes

Make sure there are no

shorts on Z300.

If OK, change UPP.

Change Z300

Yes

Make sure there are no

shorts on Z300.

If OK, change UPP.

Page 28 Nokia Corporation Issue 1 05/2002

Page 29

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Is the volume UP key

working?

Yes

Is the volume DOWN key

working?

No No

Measure S0 (P00) of UPP

Hold down the UP key and

Measure S0 (P15) of UPP

No No

at S301.

Is it 1.8V?

Yes

remeasure.

Is it 1.8V?

Yes

at S301.

Is it 1.8V?

No

Check S301 lines.

If OK, change UPP.

Change UPP

Change S301

Check S301 lines.

If OK, change UPP

Audio

Yes

Hold down the DOWN key

and remeasure.

Is it 1.8V?

Yes

No

Change UPP

Change S301

Audio control and processing in NHP-2 is accomplished by UEM, which contains the

audio codec, and by UPP, which contains the MCU and DSP blocks, handling and processing the audio data signals.

The baseband supports three microphone inputs and two earpiece outputs. Microphone

Issue 1 05/2002 Nokia Corporation Page 29

Page 30

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

inputs are MIC1, MIC2, and MIC3. MIC1 input is used for the phone’s internal microphone; MIC2 input is used for headsets or loopset. MIC3 input is used for third-party

accessories (2.5mm Jack).

Every microphone input can have either a differential or single-ended AC connection to

UEM circuit. In NHP-2, the internal microphone (MIC1) is differential, whereas MIC2 and

MIC3 microphones for accessory detection are single-ended. The microphone signals

from different sources are connected to separate inputs at UEM. Inputs for the microphone signals are differential type. Also, MICBIAS1 is used for MIC1 and MIC3 and

MICBIAS2 is used for MIC2.

Accessories

NHP-2 supports single-ended external audio accessory connection. Headset and data

cables can be connected directly to the system connector or 2.5mm jack supporting TTY/

TDD or third-party accessories. Detection of different accessories is made in analog mode

by reading the DC voltage value of its corresponding AD converter. The following table

indicates accessory detection levels.

Columbia Accessory Detection Table Limits

ADC Upper

Accessory ADC Lower Limit

Type Voltage Hex Voltage Hex HEADINT KEYB1 Detection answer/end call

Value Value Value Value

HEADINT

HDC_9P 0.50V 0x012 400mV 0x094 X N/A

HEADINT N/A

HDE-1 0.50V 0x012 400mV 0x094 X N/A

HEADINT N/A

LPS-1 0.50V 0x012 400mV 0x094

HEADINT N/A

DLR-3P 500mV 0x0B9 850mV 0x13A

JBA-4 900mV 0x14B 1400mV 0x202 X N/A

Third Party

Acc. 0.50V 0x012 1.0V 0x170 N/A X

GenIO21 N/A

TTY/TDD 2.40V 0x374 2.78V 0x3FF N/A X

Limit ADC used Interrupt Interrupt to

HOOKIN

T

X

X

N/A

N/A

HEADINT N/A

GenIO21 N/A

Page 30 Nokia Corporation Issue 1 05/2002

Page 31

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Audio Troubleshooting

Earpiece failure

Is the earpiece working?

No Yes

Change earpiece.

Is it working now?

No

Set phone in LOCAL mode. Use

Phoenix "Baseband Audio

Control" and set the following:

Enable Tx, Enable Rx, Select

MIC2 (0dB), Enable earpiece

only. Inject 1KHz sine signal

200mVpp on XEAR.

Is the signal coming out of

the UEM on EARP and

EARN?

No

Retest

Check R161, R159, C156,

R173, C154, C155, R152,

R154, C150, C152.

If OK, change UEM.

Yes

Check R150, C180, and

If OK, change earpiece.

C161.

Issue 1 05/2002 Nokia Corporation Page 31

Page 32

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Microphone failure

Is the microphone working?

No Yes

Change the microphone. Is

it working now?

No

Set phone in Local Mode.

Use Phoenix "Baseband

Audio Control" and set the

following: Enable Tx,

Enable Rx, Select MIC1,

Enable HF only (single-

ended). Talk through the

microphone.

Measure MICB1 voltage

from MICP pads on bott o m

connector. Is it -2.1V?

Yes

No

Retest

Check C195, R176, C176,

R167, C174, C175, R172,

R164, C170, C172. If OK,

change UEM.

Is the signal going to the

UEM at MICP and MICN at

C170 and C172?

Yes

Is the signal going out of

the UEM at XEAR, pin 10

on the bottom connector

(X100)?

Yes

No

No

If connection is OK at C170

and C172, then change

microphone.

Check R160 and C164. If

OK, change UEM.

Retest

Page 32 Nokia Corporation Issue 1 05/2002

Page 33

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Vibra failure

Is vibra working?

Measure VBATT voltage

pin 1 of M300. Is it OK?

Yes

Set phone in Local Mode. Use Phoenix "Message

Sender" and navigate as follows: DEV_HOST ->

Dev_PC -> PN_ACCESSORY ->

PN_OBJ_ROUTING_REQ -> PN_OBJ_PC ->

UTID_100 -> ACC_VIBRA_CTRL_REQ. Select

"ACC_ON" and click "Send".

Measure UEM signal on

pin 2 of M300.

Is the signal OK?

NoNo

No

Check VBATT line

Change UEM

Change vibraYes

Issue 1 05/2002 Nokia Corporation Page 33

Page 34

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Buzzer failure

Is buzzer working?

Measure VBATT voltage

from B302. Is it OK ?

Yes

Set phone in Local Mode.

Use Phoenix "Baseband

Audio Control". Under

Buzzer on Frequency and

Duty cycle input 20.

Check signal on pin 2 of

B302. Is the signal OK?

NoNo

No

Check VBATT line

Change UEM

Change buzzerYes

Page 34 Nokia Corporation Issue 1 05/2002

Page 35

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Receiver fault finding

PCS

RFA

LOA

Cell

RFA

UHF

VCO

PCS

LNA

Cell

LNA

ALFRED

Figure 9: Receiver block diagram

General instructions for RX troubleshooting

Start Phoenix software and use it to start the wanted RX-mode of the mobile phone.

Troubleshooting flowchart is divided into three steps: general checking, local checking,

and RX-chain checking. Notice that before changing ASICs or filter, all solderings and

missing components must be checked visually. After any possible component changes,

the phone must be retuned.

Path of the received signal

AMPS

CDMA

IF

128.1MHz

AMPS

IF XTL

CDMA

IF SAW

VGA

IQ

DEMOD

ADC

I

BBFIL/BBAMP

Q

BATMAN D

Block level description of the receiver:

(Antenna/ext RF) Antenna Switch – Diplexer – Duplexer – Low Noise Amplifier (LNA) –

RX band filter – First mixer – 128.1 MHz RX IF filter – IF-amplifier – second mixer – 614

kHz low-pass filter – adjustable IQ amplifier – Baseband.

Issue 1 05/2002 Nokia Corporation Page 35

Page 36

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Fault finding charts for receiver chain

AMPS

Using Phoenix,

configure phone AGC

& audio routing to

make SINAD

measurement

Apply 881.49 MHz =

ch 383 -116dBm,

8kHz dev, 1kHz sine

signal to external

RF-connector X800.

YES

Connect HS to cellular

tester; open audio

AF: 1kHz sine signal,

meas SINAD

AF:>12 dB

NO

AMPS RX-chain OK

YES

Check UHF Vc (from

C509) V: 1.8...2.1V

YES

Check RXVHF Vc

(from C715),

V:0.7...1.3

Using Phoenix,

readjust AGC to

obtain proper Rx I/Q

level

NO

NO

Start synthesizer

troubleshooting

Start synthesizer

troubleshooting

Apply 881.49 MHz

-30dBm, sine signal to

external RF-connector

X900.

Page 36 Nokia Corporation Issue 1 05/2002

Page 37

NHP-2

d

of

ou

t

PAMS Technical Documentation 9. Troubleshooting

Note!

Check input level at

diplexer (Z805) input

YES

NO

Change EXT RF

connector

Check all soldering

and components in

antenna circuit before

changing.

Check input level at

duplex filter. You also

can check level at

diplexer output.

YES

Check input level at

LNA input (L750)

YES

Check RF level at cell

band filter input.

NO

NO

NO

Change diplexer

(Z805)

Change duplex filter

(Z804)

Change Alfred N750

Note!

Check all soldering an

discrete components

front end.

Note!

Check all

solderings and

discrete

components

around Alfred

before changing.

YES

Check RF level at

C_Mix_IN

YES

NO

Change Alfred N750

Note!

From beginning to

C_Mix_IN input, y

should see strong

RF signal level at

881.49 MHz. Exac

level is difficult to

define due to

variable

impedances in RX

path. Also, the

probe type used

affects results.

Issue 1 05/2002 Nokia Corporation Page 37

Page 38

NHP-2

r

9. Troubleshooting PAMS Te chnical Documentation

Check RF level at RX

IF filter input

at 128.1 MHz

YES

Check RF level at RX

IF filter output

at 128.1 MHz

Check RF level at

NO NO

NO

PCS_Cell_LO

at 1009.59 MHz

YES

Change UHF PLL

(N501)

Change RX IF filter

(Z752)

Note!

Check all discrete

components and

voltages around

Alfred.

Start UHF synthesize

troubleshoot

YES

Check RX I and Q

signals at I:

R707,R708,R709,

R710

YES

Check UEM and start

baseband

troubleshoot

Check RF level by

NO NO

L701 without having

electrical contact at

256.2 MHz

YES

Change Batman

(N701)

Start synthesizer

troubleshoot

Page 38 Nokia Corporation Issue 1 05/2002

Page 39

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Cell CDMA

Troubleshooting 128.1 MHz IF Saw Filter

Since the same physical signal path is used for both analog and digital modes at the

lower band, there is no need for additional troubleshooting in the digital mode. So if the

digital mode at the lower band is not working properly, start the analog mode troubleshooting.

PCS

st

Only EXT RF connector –> 1

IF needs separate troubleshoot at upper band. After down

conversion (RF –> 128.1 MHz) both lower and upper band use same signal path.

Issue 1 05/2002 Nokia Corporation Page 39

Page 40

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

.

Using Phoenix,

configure RX to

ch 600 and set

appropriate gain.

Apply 1960.0 MHz =

ch 600 -50dBm signal

to external

RF-connector X800.

YES

Check RX I and Q

signals at I:

R707 - R710

NO

Check UHF Vc (from

C509) V: 2.2 ...2.6V

YES

Check RXVHF Vc

(from C715)

V: 0.7 ...1.3

YES

NO

NO

PCS RX-chain is OK

Start synthesizer

troubleshooting

Start synthesizer

troubleshooting

YES

Page 40 Nokia Corporation Issue 1 05/2002

Page 41

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Check input level of

diplexer (Z805)

YES

Check input level of

duplex filter (Z803)

YES

Check RF level at

LNA input (at duplex

filter RX output port)

NO

NO

NO

Change EXT RF

connector

Change diplexer

(Z805)

Change duplex filter

(Z803)

Note!

Check all soldering and

components in antenna

circuit before changing.

Note!

Check all soldering and

discrete components of

front end.

Note!

Before replacing Alfred,

check all the solderings

and components around

N750.

YES

Check RF level at

PCS band filter (Z750)

input

YES

Change Alfred (N750)???NO

Issue 1 05/2002 Nokia Corporation Page 41

Page 42

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Check RF level at

P_MIX_IN

YES

Check RF level at RX

IF filter input

at 128.1 MHz

YES

Continue

troubleshooting Cell

Band

NO

NO

Change PCS band

filter Z750

Check RF level at

PCS_Cell_LO at

2088.1 MHz

YES

Change UHF PLL

(N501)

NO

Start UHF synthesizer

troubleshooting

Note!

Check all discrete

components and

voltages around

Alfred.

Page 42 Nokia Corporation Issue 1 05/2002

Page 43

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Transmitter fault finding

RX

SPLIT BAND

SAW FILTER

Hi BAND

Lo BAND

CELL

SAW

Filter

Detector

HORNET

TX_RF_AGC

( UPP )

TOMCAT

P_DET

P_REF

WHIP

ANT.

Internal

ANT.

Ant.

Switch

RF

Conn.

RX

PCS DUPLEXERCELL DUPLEXER

Isolator

Diplexer

Isolator

SNAPPER

PA

SHARK

PA

Figure 10: Transmitter block diagram

General instructions for TX troubleshooting

PCS

DVR

CELL

DVR

UHF LO

ROBIN

UP CONV

Current Mirror

PA_AGC

( UPP )

IF AGC

PWROUT

(UEM)

19.2

MHz

CLK

VHF PLL

TX_ IF_AGC

( UPP )

DATA

SIO

Enable

Filter &

Resonator

CLK

Div By 2

I/Q

MODBBFilter

VHF SYNTH

2

I

inputs

Q

2

Always use RF-cable connected from external RF-connector to analyzer via (rf-power)

attenuator. This is important to protect analyzer against excessive rf-power and to prevent unwanted rf-power from leaking to the cellular frequencies.

Start Phoenix software and select TX mode. It is recommended that you select mid channel (383 for AMPS/CDMA or 600 for PCS) and appropriate power level.

Note: Tune the phone after any component change.

Path of the transmitted signal

AMPS/Cell CDMA

UEM TX I/Q DA-converters -> I/Q modulator and VGA (Robin) -> IF ->

Upconverter + driver - EXT Driver amp > BPF -> PA -> (Power detector) -> Duplex-filter

-> Diplexer -> EXT RF-connector -> Cyclops -> Antenna

PCS (ONLY DUALBANDER)

UEM TX I/Q DA-converters -> I/Q modulator and VGA (Robin) -> IF-> Upconverter +

driver ->Balun -> BPF -> PA-> (Power detector) -> Duplex-filter -> Diplexer ->

EXT RF-connector -> Cyclops -> Antenna

l

Power detection and power control circuit belongs under power control part of this

guide.

Issue 1 05/2002 Nokia Corporation Page 43

Page 44

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Fault finding charts for transmitter

AMPS

Start Phoenix software and set phone to the Analog mode. Set channel 383 and Powerlevel 2. Connect RF-cable to Ext RF connector and connect cable to Spectrum analyzer

input and measure RF level. Please notice insertion loss of the cable and attenuations.

Page 44 Nokia Corporation Issue 1 05/2002

Page 45

NHP-2

PAMS Technical Documentation 9. Troubleshooting

AMPS, PL2, CH383

Visual check of TX

block

-PA and up converter

-TX SAW

-Duplex filter

-Passive components

OK

Check LO-signal

(1009.59 MHz) @ up

converter and TX VHF

(346.2 MHz) @ N601

NO

Start synthesizer

troubleshooting

OK

Check supply voltage

-VR2

-VR3

-VR6

-VR1B

OK

Check TXi/q signals

Test points

R626 - R629

OK

NO

NO

Check UEM and UPP

(baseband)

Check UEM

(baseband)

Check TX RF (836.49

MHz) output power

and @ up converter

RF: 0 dBm +/- 6 dB

OK

NO

Change Robin

Issue 1 05/2002 Nokia Corporation Page 45

Page 46

NHP-2

r

9. Troubleshooting PAMS Te chnical Documentation

Check TX SAW input

and output power

IL: -3dB

OK

Is Itot 700...800 mA?

Check PA output

power and gain.

Output power: -28

dBm

Gain: -30 dB

OK

Check Isolator Z802

insertion loss

IL< 0.3 dB

NO

NO

NO

Change TX SAW filte

Z604

Change PA

N801

Change Isolator

Z802

OK

Check duplexer Z803, diplexer

Z805, and RF connector X800

insertion loss

Dupl IL -2.2 dB

Dipl -0.35 dB

RF conn -0.1 dB

OK

Start Power control

troubleshooting

Cell CDMA

The transmitter chain is exactly same as AMPS mode, except control current. Thus, it is

important that AMPS has no faults.

NO

Change Z803 or Z805

or RF connector

Page 46 Nokia Corporation Issue 1 05/2002

Page 47

NHP-2

PAMS Technical Documentation 9. Troubleshooting

PCS (only dualbander)

PCS mode and Cell CDMA mode have a common RF modulator, making it important that

Cell CDMA mode has no faults.

PCS Cell CDMA,

+24 dBm, CH600

Is Cell CDMA mode

OK?

OK

Check LO-signal

2088.1 MHz @ T775

and TX VHF

116.2 MHz @ N750

OK

Check supply voltage

_VR2

-VBATTRF

-VR3

-VR6

-VR1B

OK

NO

NO

NO

Start AMPS

troubleshooting

Start synthesizer

troubleshooting

Check UEM and UPP

(baseband)

Check TX RF (1880

MHz) output power

@T603 output

RF: 0 dBm +/- 6 dB

OK

Check Z601 input and

output power IL: -3 dB

OK

NO

NO

Change Robin

Change Z601

Issue 1 05/2002 Nokia Corporation Page 47

Page 48

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Is Itot 350...450 mA?

Check PA output

power and gain.

Output power: -27

dBm

Gain: -30 dB

OK

NO

Change PA

N960

Check Isolator Z801

insertion loss

IL< 0.3 dB

OK

Check duplexer Z804

diplexer Z805 and RF

connector X800 insertion

loss

Dupl IL -2.2 dB

Dipl -0.35 dB

RF conn -0.1 dB

OK

Start Power control

troubleshooting

NO

NO

Change Isolator

Z801

Change Z804 or Z805

or RF connector

Power control loop

Basically power detection is done with circuitry and power control is done inside Robin

and PA. Power detection is basically similar for both bands, except both bands have individual couplers.

Page 48 Nokia Corporation Issue 1 05/2002

Page 49

NHP-2

Detected voltages are described in the next table and diagram.

T

N

PAMS Technical Documentation 9. Troubleshooting

Note!

Is PWRDET vs.

output power OK?

See chart below.

YES

NO

Check VR2.

Check PWRDET

circuitry.

See

PWRDET

vs. Output

power curve

Is DAC value vs.

PWRDET (mV) OK?

NO

Check UEM

(baseband)

YPICAL DETECTED VOLTAGES AT POWER LEVELS PL2…PL10 FOR DUALBANDER

800A 800D 1900D

Pout TXPWRDET Pout TXPWRDET Pout TXPWRDET

PL dBm dac mV dBm dac mV dBm dac mV

2 26.5 633 1671 27.3 696 1839 27.3 662 1746

3 22.5 393 1038 23.3 433 1142 23.3 405 1069

4 18.5 237 625 19.3 261 688 19.3 245 648

5 14.5 141 372 15.3 155 410 15.3 147 387

6 10.5 82 215 11.3 90 237 11.3 84 222

7 6.5 46 120 7.3 50 132 7.3 46 122

8 - - - 3.3 27 70 3.3 24 64

9 - - - -0.7 13 33 -0.7 11 30

10 - - - -4.7 5 12 -4.7 5 12

OTE: DAC VALUES MAY VARY ABOUT +/- 20%

Issue 1 05/2002 Nokia Corporation Page 49

Page 50

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

2000

1800

1600

1400

Detected voltage [mV]

1200

1000

800

600

400

200

0

246810

Power level

800A

800D

1900D

Page 50 Nokia Corporation Issue 1 05/2002

Page 51

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Synthesizer fault finding

There are four oscillators generating the needed frequencies for RF-section. 19.2 MHz

reference oscillator, 1 GHz and 2GHz UHF VCO, TX VHF VCO, and RX VHF VCO. RX VHF

frequency is fixed 256.2 MHz and TX VHF has two fixed frequencies: 246.2 MHz for lowband and 416.2 MHz for upper band. UHF VCO's operating frequencíes are controlled by

PLL-circuit of LMX2370I. All locals are locked to stable 19.2 MHz reference oscillator.

The frequency range for UHF VCO is two separate bands. The output frequency range for

the lower band is from 997.11 MHz to 1022.07 MHz. In upper band, the output frequency

range from the UHF VCO is from 2058.1 MHz to 2118.05 MHz.

It is practical to check out the synthesizer status by measuring control voltage of the

VCO from the Integrator capacitor. If the voltage is stable and reasonable, local oscillators are running correctly.

19.2 MHz reference oscillator

The 19.2 MHz oscillator frequency (G790) is controlled by UEM. This 19.2 MHz signal is

connected to Batman/Robin and there in PLL-circuits and to UPP.

All synthesizers use divided VCTCXO signal as a reference signal for Phase locked loop to

provide correct LO-frequency.

Baseband needs a reference signal where it can generate the necessary clock signals and

VCTCXO output signal is also buffered and connected to UPP.

Issue 1 05/2002 Nokia Corporation Page 51

Page 52

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Fault finding chart for 19.2 MHz oscillator

Start Here!

2 Change VCTCXO

OK

2.No

Is VCTCXO

oscillating?

19.2 MHz

1.No

OK

1 Check voltage

C505

2.78 V

OK

RX VHF VCO

The RX VHF VCO signal is used to generate receiver Intermediate frequency. RX VHF VCO

has one fixed frequency 256.2 MHz. Operating frequency is locked in Phase-locked Loop.

RX VHF VCO output signal is fed to Batman. Inside, the Batman signal is divided for

Phase detector and RX parts. Before I/Q-modulator frequency is divided by 2.

No

OK

Check resistor

Page 52 Nokia Corporation Issue 1 05/2002

Page 53

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Fault finding chart for RX VHF VCO

Measure oscillator frequency over L701 coil. Don´t connect probe to pads!

AMPS, CH383

4

Change Batman

NO

NO

OK

TX VHF Synth

The TX VHF VCO signal is used to generate transmitter Intermediate frequency. TX VHF

VCO has two fixed frequencies: 346.2 MHz for lower band and 416.2 MHz for upper

band. Operating frequency is locked in Phase-locked Loop and frequency is divided by

two before modulator.

3

Check loop filter

components:

C701,R714,C715,

R703,R702,C704

1

3.No YES

3.No

OK

Start Here.

Is oscillator locked to

256.2 MHz?

OK

OK 2.No

2

Check resonator

components:

V701,C716,L701, and

DC block C702

OK

Issue 1 05/2002 Nokia Corporation Page 53

Page 54

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Fault finding chart for TX VHF VCO

AMPS, CH383 -> TX VHF frequency 346.2 MHz

PCS, CH600 -> TX VHF frequency 416.2 MHz

4

Check components:

C612,C613,C632

R607,R605,R606

O

K

4

.

N

o

5

Change

Robin

OK

3

Check resonator

components:

V601,C631,L611,

C630,C629,V602,

C637,C638

OK

5.No

1

Start Here

Is oscillator locked to

346.2 MHz or 416.2

MHz?

o

N

.

3

2.No OK

K

O

s

e

Y

UHF Synthesizer

The UHF synthesizer consists of an external UHF VCO, loop filter and integrated PLL in

LMX2370 N501. IC contains stages like counters, prescaler, divider by two, phase and frequency comparator, and a charge pump circuit.

The output frequency of the VCO depends on the DC-control voltage, which is controlled

by PLL-circuit inside N501.

2

Check operating

voltage:

2.78 V at R609

No

OK

Check:

R609

Page 54 Nokia Corporation Issue 1 05/2002

Page 55

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Fault finding chart for UHF Synthesizer

Change VCO

OK

Change N501

3.No

4.No

Is frequency locked?

2.No

OK

Check loopfilter

components and

balun

START HERE

1.No

OK

Check VCO operating

voltage: 2.78V

No

OK

Is EVM OK?

No OK

1

Check loopfilter

components

Check r esistor R515

Yes

NoYes

OK

Issue 1 05/2002 Nokia Corporation Page 55

Page 56

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Test Point Diagrams

Test points (TPD) are illustrated in the following diagrams.

Figure 11: Test points — top view A

Page 56 Nokia Corporation Issue 1 05/2002

Page 57

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Figure 12: Test points — top view B

Issue 1 05/2002 Nokia Corporation Page 57

Page 58

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Figure 13: Test points — bottom view A

Page 58 Nokia Corporation Issue 1 05/2002

Page 59

NHP-2

PAMS Technical Documentation 9. Troubleshooting

Figure 14: Test points — bottom view B

Issue 1 05/2002 Nokia Corporation Page 59

Page 60

NHP-2

9. Troubleshooting PAMS Te chnical Documentation

Page 60 Nokia Corporation Issue 1 05/2002

Loading...

Loading...