Page 1

After Sales Technical Documentation

TROUBLESHOOTING

INSTRUCTIONS

FOR NHA–2 & NHA–4

Original, 43/96 NMP Part No. 0275035

Page 2

Troubleshooting Instructions

AMENDMENT RECORD SHEET

After Sales

Technical Documentation

Amendment

Number

Date Inserted By Comments

Page 2

Original, 45/95

Page 3

After Sales

Technical Documentation

TROUBLESHOOTING INSTRUCTIONS

Contents

Introduction Page 4

General Page 4

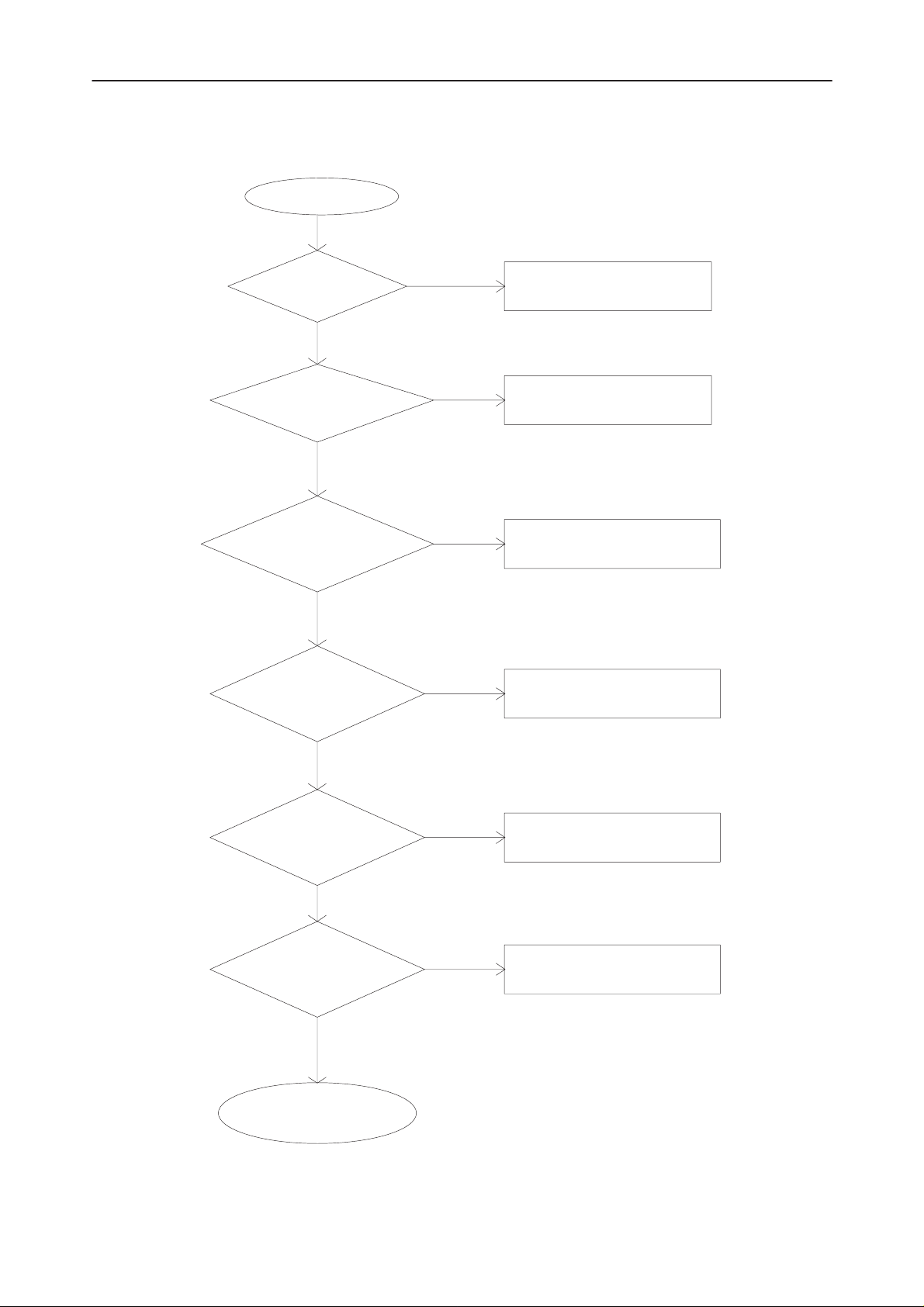

General Chart Page 5

Logic Fault Page 6

Receiver Fault 1 Page 7

Receiver Fault 2 Page 8

Transmitter Fault 1 Page 9

Transmitter Fault 2 Page 10

Earphone Level/Modulation Level Fault Page 11

Display or Keypad Fault Page 12

Call Set–up Fault Page 13

Troubleshooting Instructions

Original, 45/95

Page 3

Page 4

Troubleshooting Instructions

Introduction

General

The purpose is to define fault block of the module and then find out the broken

component. The trouble shooting diagram has been planned so that the fault,

whatever it is, can be found by as simple measurements as possible.

The flow diagrams give you the overview of the blocks. The purpose is that you

proceed through the flow diagram so that, if your answer is YES for the asked

question, go straight to the next level, but if your answer is NO, you have to go

the subbranch.

Required servicing equipment:

– PC for PC locals

– Power supply (2.0 A)

– Digital multimeter

After Sales

Technical Documentation

– Oscilloscope

– RF cables

– Modular cable

– RS232/MBUS adapter

– CMT/Marconi

– RF measuring chassis

The Troubleshooting for NHA–2 consist of 8 consequent checks according to

the following flow diagram.

Page 4

Original, 45/95

Page 5

After Sales

Technical Documentation

General Chart

Troubleshooting Instructions

START

Will turn into

local mode ?

Receiver OK ?

( SINAD OK )

Transmitter operating

( RF power OK ) ?

Earphone level /

modulation

Yes

Yes

Yes

No

No

No

No

Logic fault

Receiver fault

Transmitter fault

Earphone level or

modulation fault

Is display / keypad

working ?

Call set–up ?

END

Yes

Yes

Yes

No

No

Display or keypad fault

Call set–up fault

Original, 45/95

Page 5

Page 6

Page 6

Logic Fault

Troubleshooting Instructions

Original, 45/95

Logic fault

Power drops off or

does not assume

local mode.

Check clock

signal of N2/pin 61

0.8 Vpp/14.85 MHz

OK ?

YES

Is RESET 0V

in N1/pin 10 ?

YES

Check :

– loading of N1/pin 10

– CRESET N1/pin 20 2.4V

– VCHAR N1/pin 21 0.7 V

NO

NO

Are VL (N1/pin 23)

and VA (N1/pin 2)

3.3 V ?

Check:

– solderings of G600

– loading of CLKIN–line

– C77

– if OK, change G600

Check CLKMCU

of N2/pin 63

3.5 Vpp/2.4 MHz .

OK ?

Check :

– D1/ VA, VL, GND, data and adress lines

– N1/pin 11 TXD 3.3 V

– N1/pin 12 3.3 V

– loading of RXD line

– loading of MBUS line

– if OK, change D1

YES

YES

NO

Is

G600 / VCC

3.6 V ?

NO

Check :

– COFF N1/pin 16 2 Vpp

– VBAT N1/pins 1, 5 and 22 4.8 V

– GND N1/pins 7, 19 and 24

– CREF N1/pin 6 3.3 V

– if OK, change N1

Check :

– loading of VRXI–line

NOYES

Check :

– loading of CLKMCU line

– solderings of N2

– if OK, change N2

– R717 and R718

– VREF–line

– the components

affecting V901 and

V902 d.c. operating

points

Technical Documentation

After Sales

Page 7

After Sales

Technical Documentation

Receiver Fault 1

Check :

– loading of VREF line

– if OK, change N1

Check the components

affecting V901 and

V902 d.c. operating

points

No

Troubleshooting Instructions

Is VREF

( R906 ) 3.3V ?

Are VRXI

and RXBIAS

( V700/c ) 3.65 V

AF signal at

R716 DAF line

Yes

Is VRX

Yes

( V700/b ) 2.6 V ?

( C901 ) 3.7 V ?

Is ( VCC )

1.85 V

N700/pin 4

Yes

Yes

Check :

– R717

– loading of RXI line

– RXBIAS line

Check IF demodulator circuit

C727, solderings of N700,

N700/pin 9 and R716

L704, C723, R712, R715, C722,

C706 and C705

Check :

– the operation between

– V703 d.c. voltages

3–5–10–11

at different pins

Check :

– solderings of N700

– 2nd IF line N700/

– N700 d.c. voltages

45 MHz ?

Is there at

C705 – 34dBm*/

No

Yes Yes

Yes

Earphone

level fault

Check R702,

V700 d.c. operation

point

No No

Check solderings of Z703,

L706, C706, Z702, V701

and C716

Check level at

45 MHz. OK ?

C706 – 51dBm*/

*measured with 10:1 divider

Original, 45/95

Receiver fault

Noise or AF signal

at X1/pin 9 XEAR

No No No No No

Simplex sens.

( TX off ) OK?

Yes

Yes

Transmitter

No

TX spectrum

fault

OK ?

Test point

2.5 – 4.0 V

RXVCO, middle channel

No

fault 2

Receiver

Yes

filter Z700

Replace duplex

Yes

Injektion level

at C709 – 16dBm*

No

Check solderings of

Yes

V601, C600, C602

and C709

?

Is there at

44.55 MHz

N700/pin 2 – 28dBm*/

No

Check solderings

of R636, C749, C718,

C719 and L710.

Check also N700/

pins 1 and 2.

Yes

Yes

Is there level

at Z703 – 63dBm* ?

No

Check the operation

between the aerial

and Z703

Page 7

Page 8

Troubleshooting Instructions

Receiver Fault 2

Receiver fault 1

After Sales

Technical Documentation

*measured with 10:1 divider

Check L603

– 1.9 V. OK ?

Yes

Are N650/

pins 4 and 14

2.8 V ?

Yes

Control signals

of N650/pins 8, 11, 12,

13, 19 ( pin 8 –17dBm*/

14.85 MHz )

OK ?

Yes

Check d.c voltages :

V601/c (3.7V) b (2.0V) e (1.3V)

V602/c (3.2V) b (1.6V) e (0.9V)

OK ?

No

No

No

No

Check –VMOD line

between display module

( or –VOUT pad ) and

V603 anode

Check :

– L605, V605, R646, R647

– loading of N650/pins 4 and 14

Check following lines :

– D1/pin 13 ( SDATA )

– D1/pin 17 ( SCLK )

– D1/pin 18 ( SLE )

– D1/pin 26 ( SLD )

Check G600 and C669

Check :

– V700/b ( RXBIAS ) 2.6 V

– V604 d.c voltages

– the components affecting

V601 and V602 d.c.

operating points

Yes

Resistance

between N650/pin 3

and V603 8.2 Kohm

Yes

Is RXVCO

oscillating at

V602 collector ?

( – 28 dBm* )

Yes

Is level to

prescaler N650/

pin 6 – 30dBm* ?

Yes

Check the critical components

of VCO : C604, V603, C614,

C613, C612, C601

No

No

No

Fault in loop filter

Check the critical components

of VCO : C604, V603, C614,

C613, C612, C601

C600, R600, R614 or

the freguency of VCO

is substantially off

the mark ( C604, V603,

C614, C613, C612, C601 )

Page 8

Original, 45/95

Page 9

After Sales

Technical Documentation

Transmitter Fault 1

Check loading

of TXS line.

If OK, change D1.

Check

3.3V

TXS D1/pin 21

Check :

– V654 and V651

– the components affecting

operating points

V654 and V651 d.c.

Troubleshooting Instructions

Check the operation

between the components

R625 and C662.

Measure level at L653

–17dBm*/90 MHz

Check the operation

between the components

C662 and C804.

Yes Yes

3.5 V

Check V662

collector ( TSYN )

Yes

Current

consumption

level >= 450mA

of biggest power

No No No No

Yes

error

frequency

Power OK,

Transmitter fault

but transmitter

*measured with 10:1 divider

Is there

Check duplex filter

Z700 TX port solder

joint, path from

V805 collector

Check the operation

of G600 and its

eeprom values

Yes

90 MHz ?

about 3 V at

testpoint TXVCO

and at L653 –17dBm*/

No

Check the operation of

the differential amplifier

Transmitter fault 2

( V807, V809, V808 )

No

–19dBm* ?

Is there at

V662 collector

No

Check the critical

Yes

4 V.

Check that

collector is

VCONT at V803

Yes

components of

the amplifier V803

No

Yes

Is there at

–14dBm* ?

V660 collector

No

Is there at

No

Check the components

affecting V804 d.c.

operating point

–4dBm*

V803 collector

( biggest power ) ?

YesYes

Is there

+2dBm* ?

at V804 collector

Original, 45/95

Check the

components

affecting V805

d.c. operating

point

Page 9

Page 10

Page 10

Transmitter fault 1

Transmitter Fault 2

Troubleshooting Instructions

Original, 45/95

Resistance between

N650/pin 17 and V659

cathode is about 5 Kohm

Fault in loop filter

Check d.c.voltages

Yes Yes

V657/c (2.7V) b (2.7V) e (2.0V)

V658/c (1.8V) b (1.1V) e (0.5V)

OK ?

NoNo

Check the components

affecting V657 and V658

d.c. operating points

Check the critical

components of VCO :

V659, C663, C659, L651,

C675. Check also C686,

C637 and N650/pin 15.

Technical Documentation

After Sales

Page 11

After Sales

Technical Documentation

Earphone Level/Modulation Level Fault

ST 1.7 Vpp

SAT 420mVpp

MOD

LPIN

Troubleshooting Instructions

X1/pin 9

XEAR

330 mVpp

pin 52 pin 53 pin 55

pin 51

EMPI EMPO

pin 50

COMO

pin 49

COMI

pin 47

ATTO

120 mVpp 120 mVpp 190 mVpp 190mVpp 270 mVpp 270 mVpp 540 mVpp

pin 35

XEAR

pin 34

VOLI

pin 32

EXPO

pin 29

EXPI

pin 28

FILO

Original, 45/95

– voice modulation 2.9 kHz

– volume 3

– comp. on

– XMIC line 60 mV / 1 kHz

Signals levels of N2

pin 46

XMIC

140 mVpp

pin 27

DAF

140 mVpp 200 mVpp 200 mVpp 140 mVpp 140 mVpp 330 mVpp

Page 11

Page 12

Troubleshooting Instructions

Display or Keypad Fault

Display or keypad fault

After Sales

Technical Documentation

Display OK ?

Yes

Check :

– loading of –VOUT

– soldering of X2/pin 5

No

No

Change the

display module

Display OK ?

Lights OK ?

–VOUT OK ?

Pulses to

0V on COL 0–3

lines

Yes

Yes

Yes

Check:

– X2/pins 1 and 15 ( VBAT )

– X2/pins 4 and 16 ( GND )

– X2/pin 3 ( LCDCLK ) 2Vpp / 80 kHz

– X2/pin 7 ( RESET ) 3.3 V

–the operation of E, R_W and RS lines

–the operation of DB (3:0) lines

No

–the operation of XPWRON N1/pin 13

and PWRON N1/pin 9

–the operation of XPWROFF line

N1/pin 14

No No

D1/pin 52

lights line at

+3.3 V with

lights on

Yes

Check the operation of

switches V42 and V43.

Check also the components

V30 – V41.

No

Check COL 0–3 lines

from D1 to keyboard

Check load in the

lights line.

If OK, change D1.

Page 12

Yes

ROW 0–5 lines are to carry

3.3 V and pulses to 0V when

corresponding key depressed.

Check those lines.

Original, 45/95

Page 13

Original, 45/95

Call set–up fault

Call Set–up Fault

After Sales

Technical Documentation

Will the phone

assume SERV –mode ?

Check:

– the operation of ST signal

– the operation of SAT signal

– the operation of Transmitter

– the operation of TXI line

– the operation of Synthesizer

– the operation of VCO

– if OK, change N2

Yes

No

Subscriber

data OK ?

RSSI

operative ?

Data detection

of N2 operative ?

Yes

Yes

Yes

No

No

No

If the reprogramming

impossible, check D2

control lines and

solder joints.

Check N700/12/RSSI line

and the operation of

D1 A/D converters ( pins 78–85 ).

Inspect the signal path from

N700/pin 9 DAF to N2/ pin27.

Check also other lines

from N2.

Troubleshooting Instructions

Page 13

Replace N2.

Page 14

Troubleshooting Instructions

After Sales

Technical Documentation

This page intentionally left blank.

Page 14

Original, 45/95

Loading...

Loading...