Page 1

Programmes After Market Services

NPE-4 Series Cellular Phones

3 - Audio System

Original ãNokia Corporation. Page 3-1

Page 2

NPE-4

3 - Audio System PAMS Technical Documentation

Table of Contents

Description Page No.

Introduction ......................................................................................................................................

Abbreviations .................................................................................................................................... 4

Technical overview .......................................................................................................................... 5

Block diagram ............................................................................................................................ 5

Parts list ...................................................................................................................................... 5

DC characteristics .................................................................................................................... 7

Audio function description ............................................................................................................ 7

Audio control ............................................................................................................................. 7

Gain table ................................................................................................................................... 8

Internal audio devices .................................................................................................................... 9

Earpiece ....................................................................................................................................... 9

Earpiece acoustic design ................................................................................................. 10

Earpiece electrical interface .......................................................................................... 12

Microphone ................................................................................................................................ 13

Sketch of microphone acoustic design ....................................................................... 14

Microphone electrical interface .................................................................................... 15

Buzzer .......................................................................................................................................... 16

Buzzer acoustic design .................................................................................................... 17

Buzzer electrical interface ............................................................................................. 18

Vibra specification ................................................................................................................... 19

Vibra electrical interface ................................................................................................. 19

External audio devices .................................................................................................................... 20

Audio accessories ..................................................................................................................... 20

External audio interface ......................................................................................................... 23

External audio interface - electrical interface ................................................................. 23

External audio connector ................................................................................................ 27

External audio signal electrical specification ........................................................... 28

Accessory detection, identification and control .............................................................. 30

Accessory detection .......................................................................................................... 30

Accessory identification .................................................................................................. 30

Accessory control .............................................................................................................31

4

List of Figures

Figure 1 Audio block diagram ................................................................................................. 5

Figure 2 Sketch of earpiece acoustic design ....................................................................... 10

Figure 3 Mechanical assembly of earpiece and vibra ....................................................... 11

Figure 4 Earpiece frequency response - ERP corrected - non DSP corrected ............ 11

Figure 5 DAI receiving frequency response, B4.0 .............................................................. 12

Figure 6 Internal earpiece electrical interface ................................................................... 12

Figure 7 Microphone acoustical design ............................................................................... 14

Figure 8 DAI sending frequency response, B4.0 ................................................................. 14

Figure 9 Internal microphone electrical interface ............................................................ 15

Page 3-2 ãNokia Corporation. Original

Page 3

NPE-4

PAMS Technical Documentation 3 - Audio System

Description Page No.

List of Figures (continued)

Figure 10 Sketch of buzzer acoustic design .......................................................................... 17

Figure 11 Mechanical buzzer asssembly ................................................................................ 17

Figure 12 Typical buzzer frequency response ....................................................................... 17

Figure 13 Buzzer driver circuit .................................................................................................. 18

Figure 14 Vibra driver circuit ..................................................................................................... 19

Figure 15 External microphone interface .............................................................................. 24

Figure 16 External earpiece interface ..................................................................................... 26

Figure 17 Sysyem connector - mechanical outline ............................................................. 28

Figure 18 Carkit audio interface. block diagram .................................................................. 32

List of Tables

Table 1 Parts list ....................................................................................................................... 6

Table 2 Supply voltages .......................................................................................................... 7

Table 3 Possible UEM gains for each input and output ................................................. 8

Table 4 Total UEM gain for each input and output in different audio paths ........... 8

Table 5 UEM ear output specification ................................................................................ 13

Table 6 Microphone input specifications ........................................................................... 16

Table 7 Buzzer driver specifications .................................................................................... 18

Table 8 Vibra driver specifications ....................................................................................... 20

Table 9 Vibra output frequency control ............................................................................. 20

Table 10 HDC-9P interface specifications ........................................................................... 21

Table 11 Selected specifications for HDW-1 BT headset ................................................. 21

Table 12 LPS-1 interface specifications ............................................................................... 22

Table 13 Microphone input specifications, external audio ............................................. 25

Table 14 UEM HF output specifications ............................................................................... 26

Table 15 System connector pin assignment ........................................................................ 28

Table 16 HEADINT voltage value table used for accessory identification ................... 30

Original ãNokia Corporation. Page 3-3

Page 4

NPE-4

3 - Audio System PAMS Technical Documentation

Introduction

This Chapter specifies the Audio hardware for the NPE-4 program.

Abbreviations

UEM Universal Energy Management

UPP Universal Phone Processor

UIF codec User InterFace Codec in UPP

VBAT Main battery voltage

PWM Pulse Width Modulated (signal)

MUX MUltiPlexer

GND Phone ground

LGND GND abbreviation in System connector

SGND Signal ground – reference for microphone

MCU MicroController Unit

PWB Printed Wire Board

ERP Ear Reference Point

MRP Mouth Reference Point

SPL Sound Pressure Level (reference value 20 uPa)

BT BlueTooth

AGC Adaptive Gain Control

DRC Dynamic Range Compressor

ALWE Noise suppressor algorithm

AEC Acoustic Echo Canseler

IMD Insert Moulded Decoration

SCO Syncronous Connection Oriented

LPRF Low Power Radio Frequency (BlueTooth)

PWM Pulse Width Modulated

Page 3-4 ãNokia Corporation. Original

Page 5

NPE-4

PAMS Technical Documentation 3 - Audio System

Technical overview

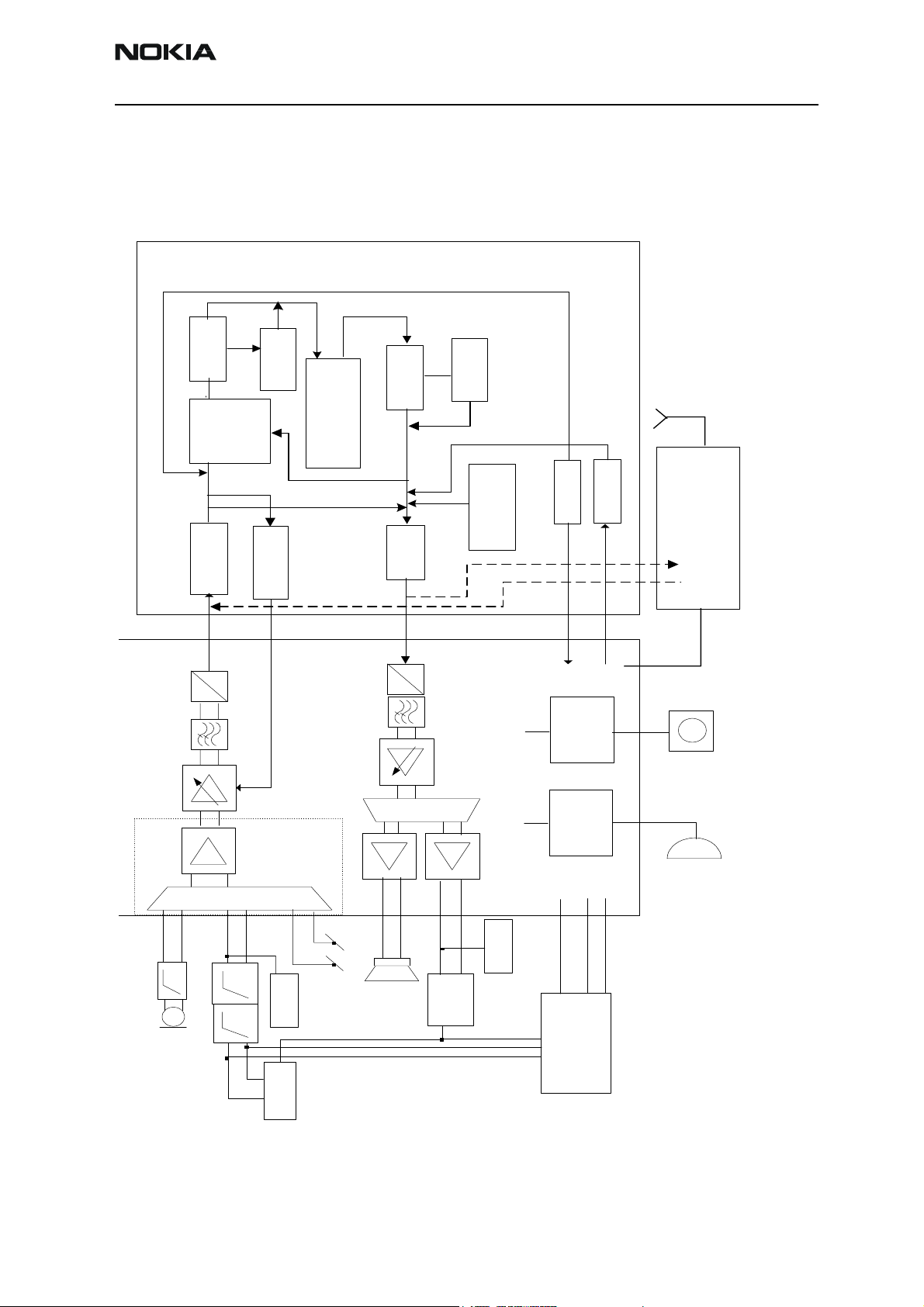

Block Diagram

VAD

U-ALWE /

UDRC

Encoder

Decoder

VAD

D-ALWE /

DRC

UPP

UEM

AEC

Mic Equaliser

MICDATA

D

A

0-22.5dB

filter

Anti-alias

0 / 20 dB

MUX

AGC

Speech codec

Sidetone

SC DAC

Ear

Equaliser

EARDATA

A

D

6 dB

-30 - 0dB

MUX

Tone Generator

6 dB

PWM

PWM

DAI4 Mic

FBUS Tx

Vibra Driver

Buzzer Driver

DAI4 Ear

FBUS Rx

SCO Airlink

BT102

LPRF

CBUS

VIBRA

M

BUZZO

Figure 1. Audio Block diagram

HF

Boomer

+8.2 dB

HFCM

HookInt

MBUS

FBUS Tx

FBUS Rx

CARK-91

MIC1P

HP 1

MIC

MIC1N

MIC2P

MIC2N

HP 3

HP 2

MIC3N

MIC3P

HeadInt

LOOPSET

HEADSET /

EARP

EARPIECE

EARN

Original ãNokia Corporation. Page 3-5

Page 6

NPE-4

3 - Audio System PAMS Technical Documentation

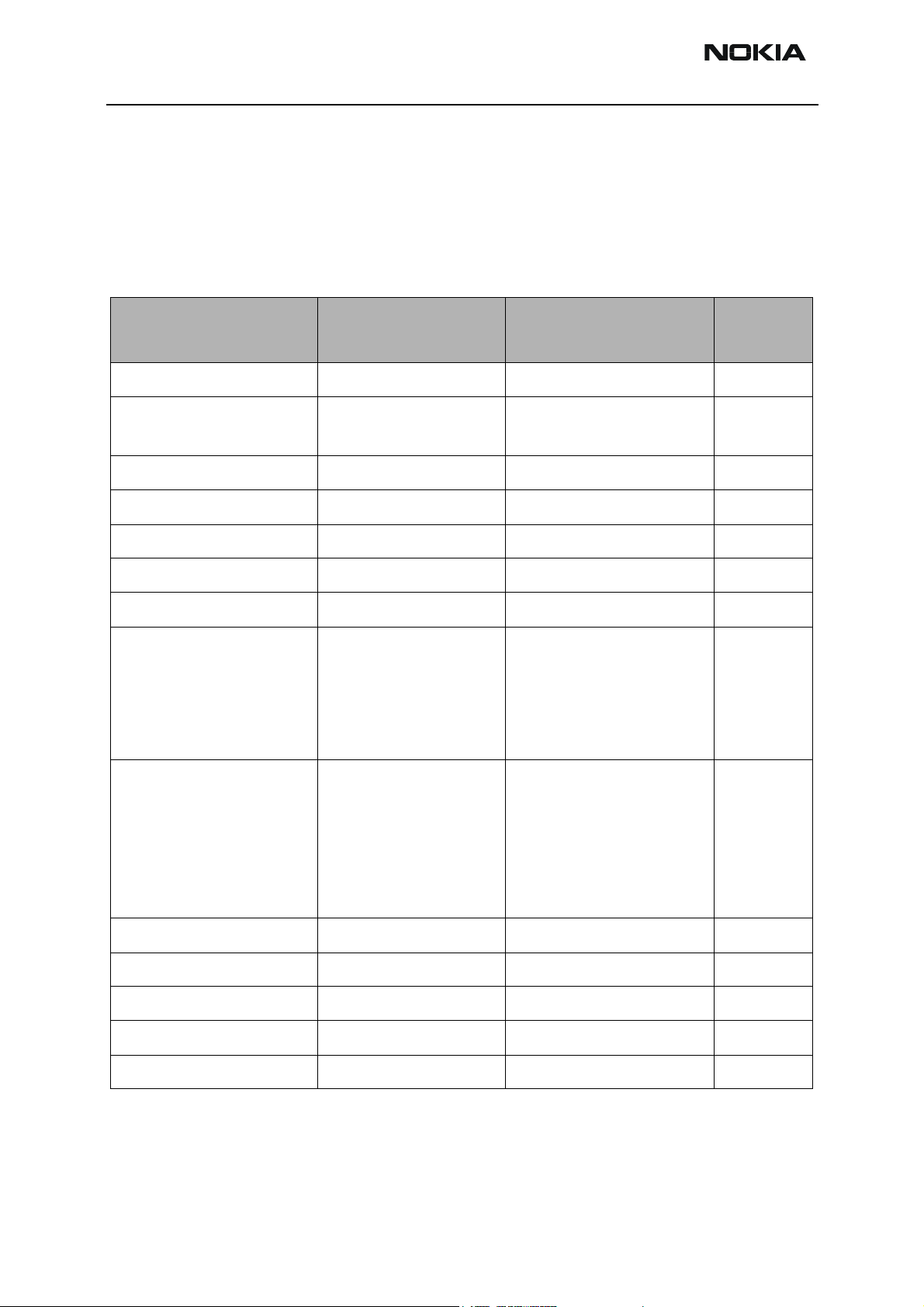

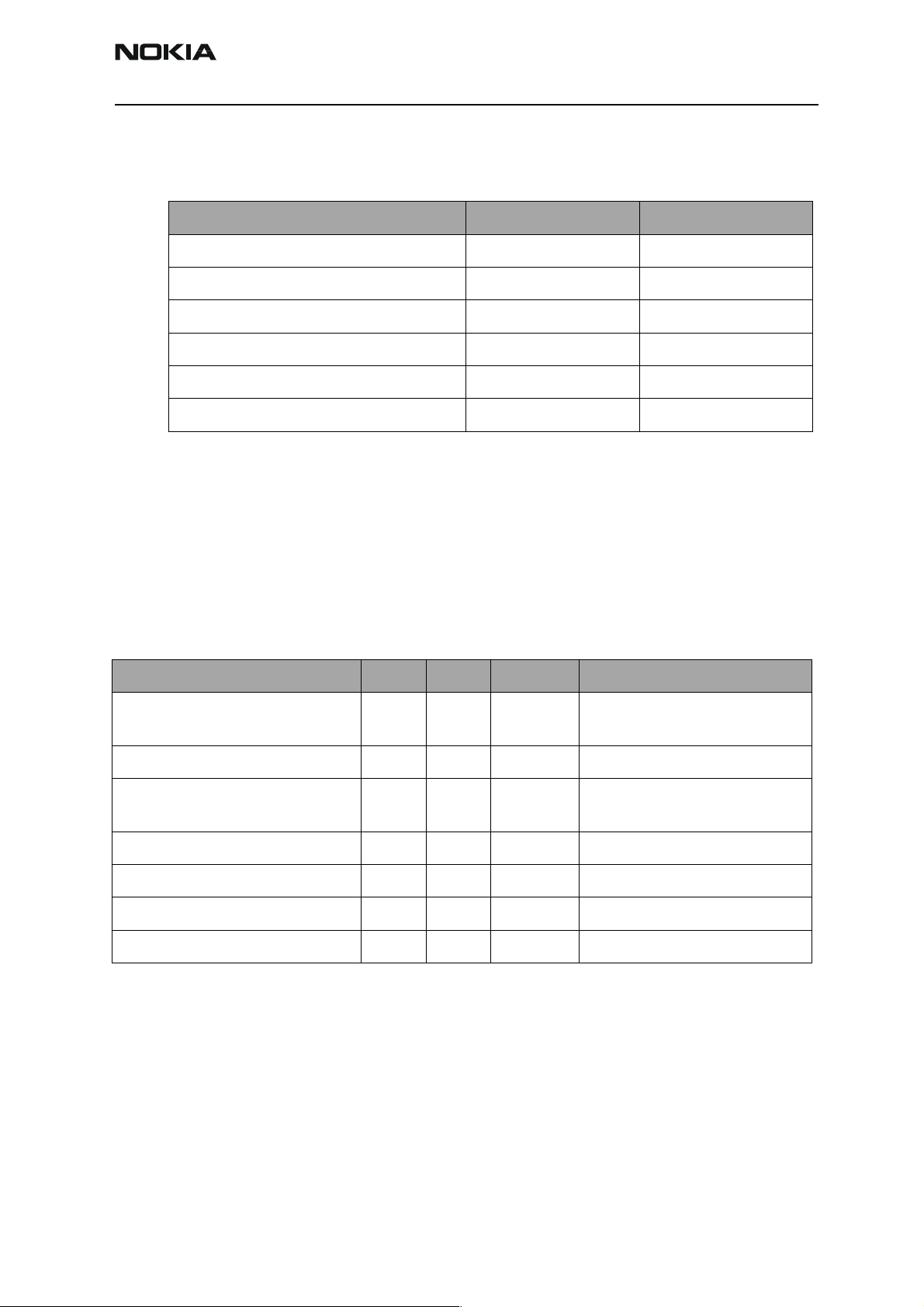

Part List

All involved key parts are listed in the following table. As seen in the table there is only

one vendor for some of the audio and vibration key components.

Table 1: Parts list

NAME OF THE

SUB-MODULE

Buzzer 1 MCC-03ACS STAR 5140209

Earpiece 2 TYPE: WD 00518/32 U

Earpiece 1 LT 201 KIRK Acoustics 5140233

Microphone assy 1 WM-64-HNY-310 MATSUSHITA 5140225

Vibrator 1 KHN4NB1H MATSUSHITA 6800043

Headset HDC 9P NMP

Loopset LPS-1 NMP

Carkit

- Handsfree unit

- Handsfree earpiece

- Microphone

- Handset unit

COMPONENT

DESIGNATION

CODE: 2403 252 08108

CARK-91

- HFU-2

- HFS-12

- HFM-8

- HSU-1

VENDOR

MATERIAL

CODE

PHILIPS Earpiece Systems 5140067

NMP

Bluuetooth Carkit

- Junction box

- Remote control button

- Handsfree earpiece

- Microphone

- Handset unit

Bluetooth headset HDW-1 NMP 0694064

UEM 4370805

UPP 4370815

Boomer LM4890 National semiconductors 4341221

System connector 5469061

CARK-112

- HFW-1

- CUW-2

- HFS-12

- HFM-8

- HSU-1

NMP 0750135

Page 3-6 ãNokia Corporation. Original

Page 7

NPE-4

PAMS Technical Documentation 3 - Audio System

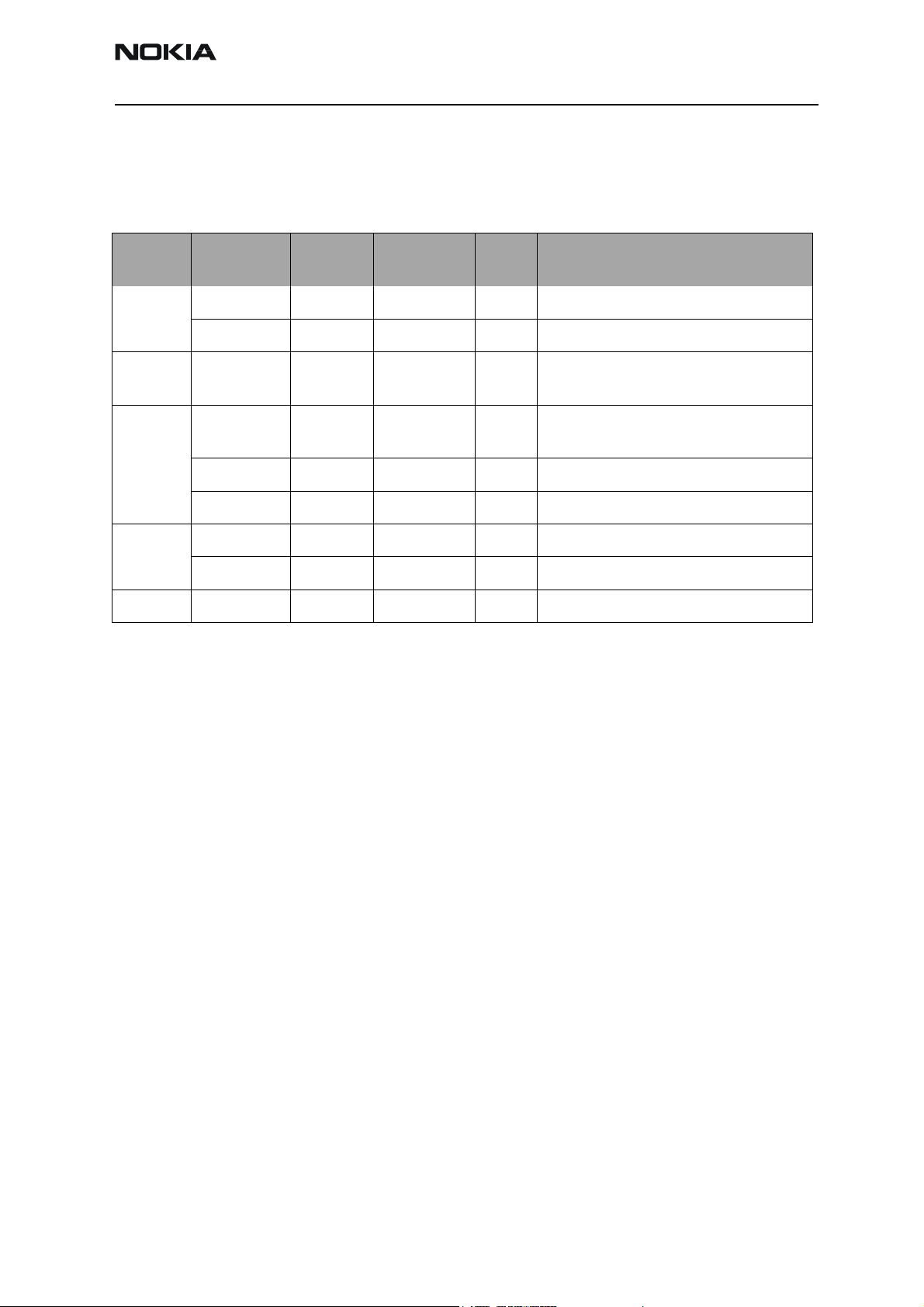

DC Characteristics

The audio relevant supply voltages are shown in the following table:

Table 2:

Line

Symbol

Vana 2.7 2.78 2.86 V (Mic bias buffer)

VBAT 3.1 (SW)

Vflash1 2.7 2.78 2.86 V (DLR3, HEADINT and HOOKINT pull

Vflash2 2.7 2.78 2.86 V (DLR3)

VIO 1.72 1.8 1.88 V (HOOKINT level shifter)

Minimum TYP. /

Nominal

0,005 80 mA Min. due to regulator stability

3.6 5.1 (SW)

(2.9 (HW))

0.005 70 mA Min. due to regulator stability

0.005 1.5 mA Sleep

0.005 40 mA Min. due to regulator stability

Maximum Unit Notes

(5.4 (HW))

Supply Voltages

V (Buzzer and Vibra driver). Min and

max due to SW cut off.

up)

Audio Function Description

Audio control

The audio control and processing is done by the UEM, which contains the audio codec

and the UPP contains DSP blocks, handling and processing the audio data signals.

The audio block diagram is presented in , page .

The UEM supports three microphone inputs and two earphone outputs. The inputs can be

taken from an internal microphone, a headset microphone or a handsfree-unit / Carkit

microphone. The microphone signals from different sources are connected to separate

inputs at the UEM ASIC. Inputs for the microphone signals are differential type.

MIC1 and EAR in/output are used for the internal microphone input and Earpiece output.

The Headset or handsfree unit / Carkit audio is connected to the MIC2 input / HF (single

ended) output. The MIC3/XEAR is connected to GND and not used in the NPE-4 project.

Input and output selection and gain control is performed inside the UEM ASIC (register

AudioCtrl (Gain and routing) and MicBias (microphone bias selection).

Additional gain is added in the DSP SW. This gain is controled by adaptive algorithms

(AGC, DRC, ALWE and AEC) and set as a function of background noise, signal level and

Original ãNokia Corporation. Page 3-7

Page 8

NPE-4

3 - Audio System PAMS Technical Documentation

echo canceling.

In case of BT audio the BT accessory and the phone is connected by both an ACL and SCO

air link. ACL is used for connection commands and SCO for the actual audio transmission.

In both cases the BT module (in accessory and phone) receives the audio signal. In the

phone this signal is routed from BT module over LPRF to DSP where it follows the regular

audio path through out the rest of the system. The BT module and MCU is connected by

the CBUS for exchanging low level information.

All BT Gain adjustments are done in the accessory. DSP tuning is done in UPP, completely

as usually.

Gain Table

The possible gain for each input and output is shown in The gain settings are controlled

in the 16 bit AudioCtrlR register. Note * MIC3 only used for test purposes in NPE-4.. Table

4: Total UEM gain for each input and output in different audio paths (modes). contains

the total gain for each input and output in different audio modes.

The gain settings are controlled in the 16 bit AudioCtrlR register.

Table 3:

UEM Pins Gain (dB)

Input / Output Programmable Fixed UEM To ta l

MIC1 0 to 22.5, step 1.5dB 20 20 to 42.5, step 1.5dB

MIC2 0 to 22.5, step 1.5dB 0 or 20 0 to 22.5 or 20 to 42.5, step 1.5dB

MIC3* 0 to 22.5, step 1.5dB 0 or 20 0 to 22.5 or 20 to 42.5, step 1.5dB

HF (single ended) -30 to 0, step 2dB 6 -24 to 6, step 2dB

EAR -30 to 0, step 2dB 6 -24 to 6, step 2dB

Possible UEM gains for each input and output

Note * MIC3 only used for test purposes in NPE-4.

Table 4: Total UEM gain for each input and output in different audio paths (modes)

Gain Table Normal Mode - Gain dB

UEM Signals ¯Handportable Headset Handsfree (Carkit)

INPUTS MIC1 20 to 42.5, step 1.5dB

MIC2 20 to 42.5 step 1.5dB 0 to 22,5 step 1.5dB

MIC3

OUTPUTS EAR -24 to 6, step 2dB

HF -24 to 6, step 2dB -24 to 6, step 2dB

Page 3-8 ãNokia Corporation. Original

Page 9

NPE-4

PAMS Technical Documentation 3 - Audio System

Deviations in gain performance:

Transmit gain absolute accuracy: -1.0 / 0.0 dB

Transmit gain variation (temperature, supply): +/- 0,7 dB

Transmit gain variation with frequency (300 – 3000 Hz): +/- 0,5 dB

Transmit gain variation with signal level (> -50 dBm0): +/- 0,5 dB

(<-50 dBm0: +/- 1.2 dB)

Receive gain absolute accuracy: +/- 0,5 dB

Receive gain variation (temperature, supply): +/- 0,7 dB

Receive gain variation with frequency (100 – 3000 Hz): +/- 0,5 dB

Receive gain variation with signal level (> -50 dBm0): +/- 0,5 dB

(<-50 dBm0: +/- 1.2 dB)

DSP Gain:

Initially the DSP gain uplink (Mic) is set to 12 dB and 0 dB downlink. This is done in the

Equaliser.

The AGC controled by the DSP is able to reduce the Uplink gain in the UEM by 18 dB

maximum in steps of 1.5 dB.

The DRC can either attenuate the signal or enhance in it in DSP by up to 10 dB.

Note: Local mode gains are uptimised for production testing and are not the same as in

normal mode.

Internal Audio Devices

NPE-4’s internal audio design is described in the following sections.

Earpiece

Receiver solution is selected to be a Kirk Acoustic earpiece. Earpiece design is leak tolerant with a front protection cover directly on the earpiece component. The Earpiece will

be placed in a moulded rubber gasket which seals the front cavity to the IMD Window.

In front of the earpiece and leakholes a shielding material will be placed to prevent dust

particles to migrate onto the earpiece diaphragm. This material consists of a grid material type Saati PES 120/41 from Tradex (It is the same material as in Nokia 8210).

The earpiece is designed to be approved in type approval by type 3.2, low leak artificial

ear (Ear Simulator Type 4195, Low Leakage). No support for type 1 artificial ear is made

(Ear Simulator Type 4185).

Original ãNokia Corporation. Page 3-9

Page 10

NPE-4

3 - Audio System PAMS Technical Documentation

Earpiece Acoustic Design

The earpiece is sealed to the front cover (IMD window) with a rubber gasket. The gasket

is fixed inside the A-cover by the vibra motor assembly.

The Earpiece and gasket is designed to seal perfectly against the front cover. There is no

well defined leakage as known from the NPE-3 project. This is done to have a better performance in the frequency area from 2 – 3.4 kHz and to prevent the possibility of an

acoustic feedback loop inside the phone mechanics.

There is no sealing between the earpiece and the PWB.

There are also holes through the PWB to make the design more leak tolerant by using the

volume between PWB and the B-cover.

A-Cover or window contains front and leakage holes. On the inside of the A-cover a dust

shield is placed. This shield covers both front and leakage holes.

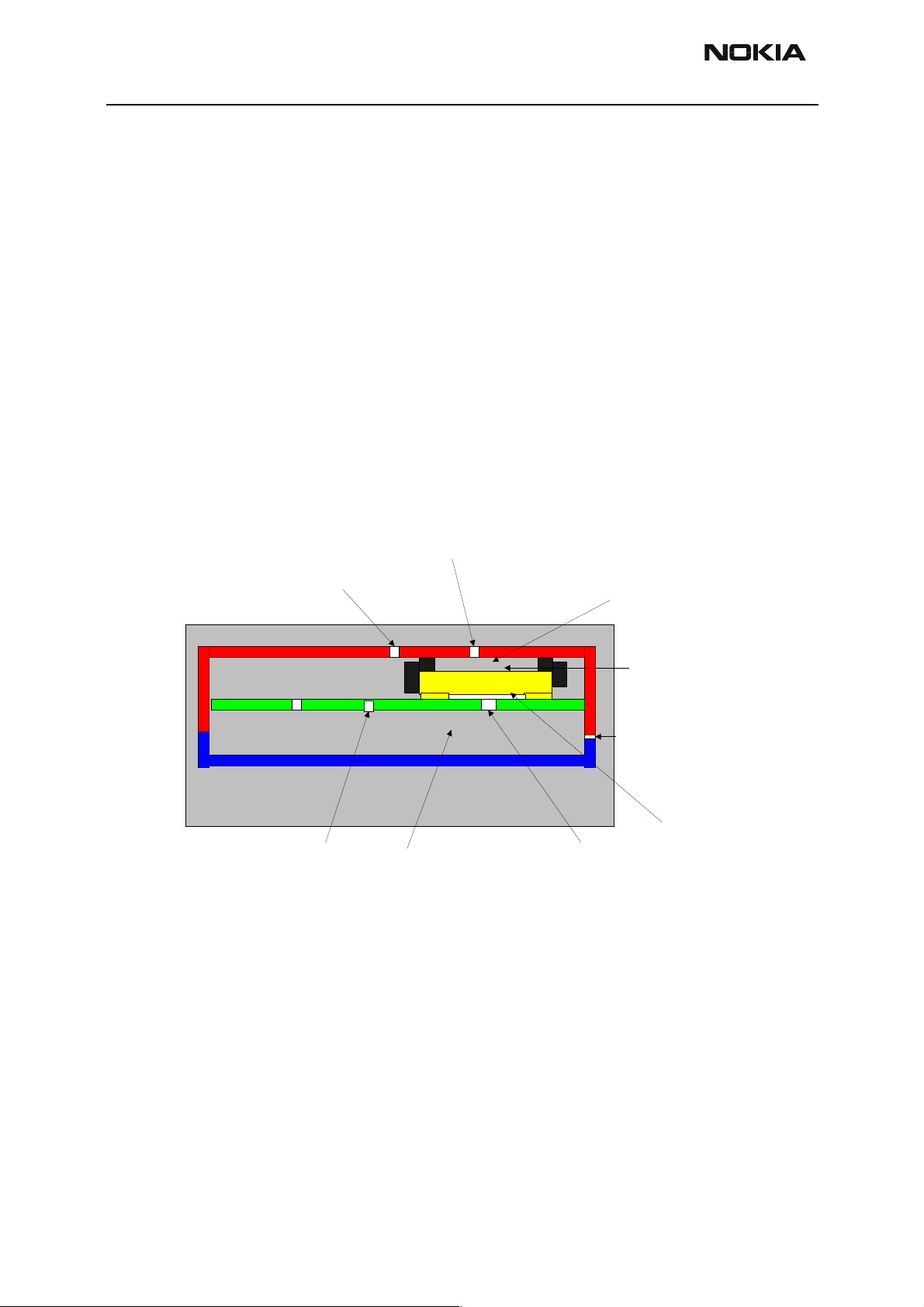

Front Holes on A-Cover

Leakage Holes on A_Cover

Shielding material glued to A cover or IMD Window

Leakage Holes on PCB

Back Volume

Leakage Holes on PCB

Figure 2. Sketch of Earpiece Acoustic Design

Earpiece Front Volume

Leakage Between A_ and B_Covers

(Not well defined)

Opening Between

Earpiece and PCB

Page 3-10 ãNokia Corporation. Original

Page 11

NPE-4

PAMS Technical Documentation 3 - Audio System

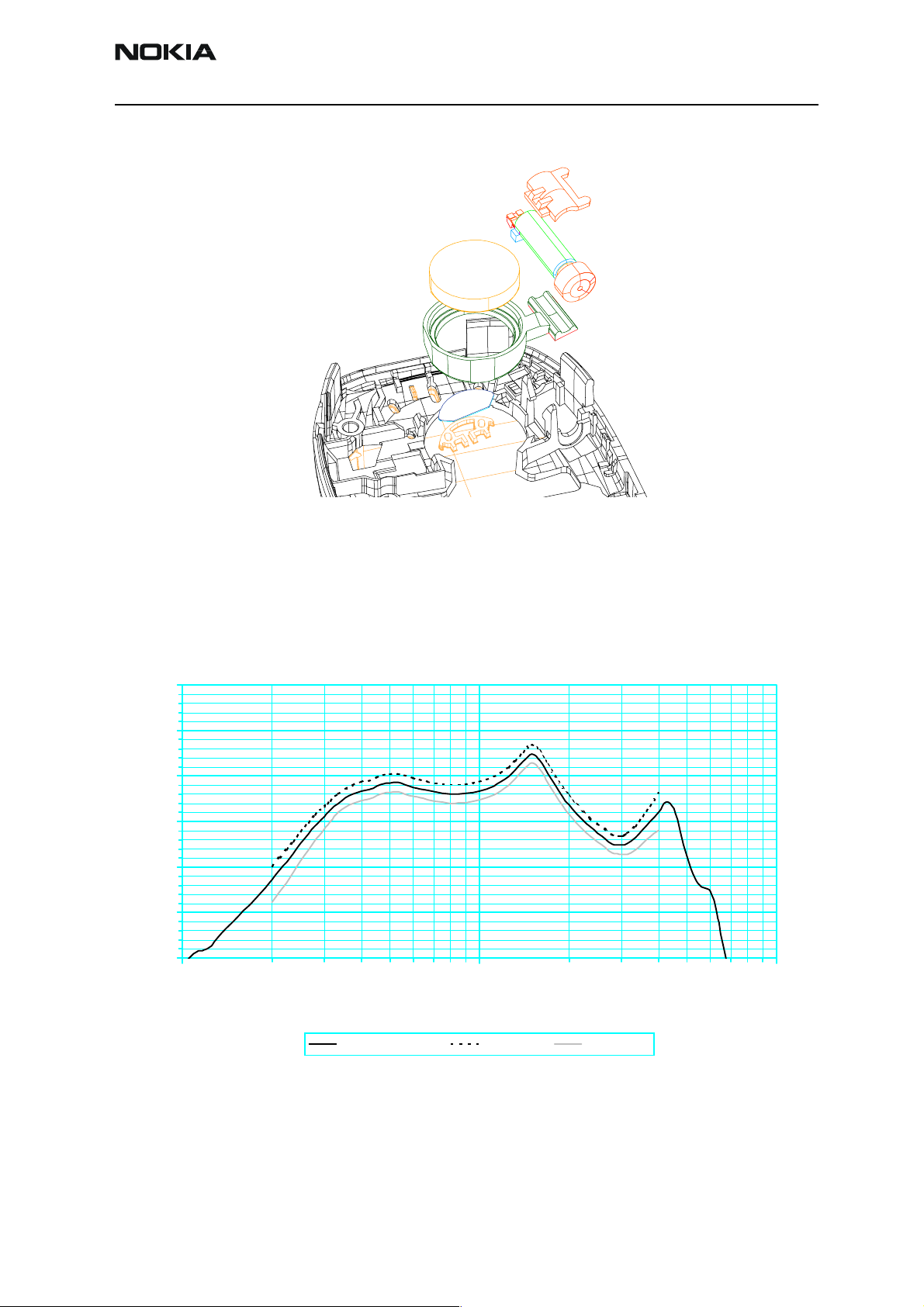

Figure 3. Mechanical assemply of Earpiece and Vibra

Specified frequency response curve for the NPE-4 design (mechanics and Audio):

30

20

10

0

-10

SPL Response [dBPa]

-20

-30

100 1000 10000

Frequency [Hz]

Typical Response Upper Limit Lower limit

Figure 4. Earpiece frequency response - ERP corrected – non DSP corrected

Original ãNokia Corporation. Page 3-11

Page 12

NPE-4

3 - Audio System PAMS Technical Documentation

Absolute Sensitivity (Low leak): 26 dBPa/V ±3dB @ 1kHz. (0 dB on Figure 4. Earpiece frequency

response - ERP corrected – non DSP corrected)

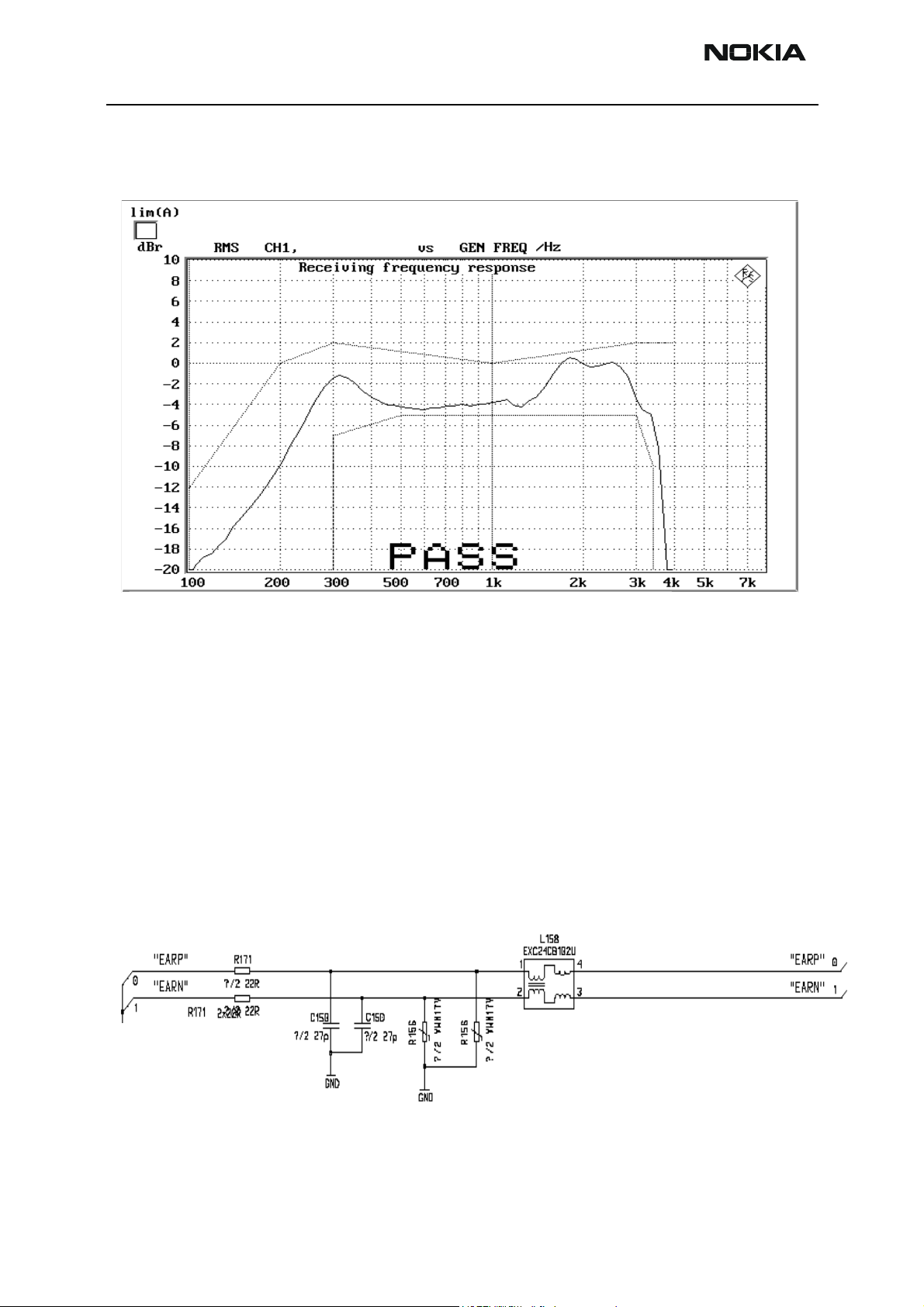

Figure 5. DAI receiving frequency response, B4.0

Earpiece Electrical Interface

Earpiece circuit includes pads for earpiece together with 2 ferrite beads (Common mode

filter), 2 capacitors (900 MHz cut-off filter) and two varistors for ESD protection placed

near the Earpiece.

The low impedance, dynamic type earphone is connected to the differential output (EAR)

in the UEM audio CODEC. On the differential output 2 * 22 Ohm (R171) is placed for

noise reduction and to compensate for the high capacitance of the varistors (1 nF),

which could lead to instability in the UEM.

AUDIO(4:0)

Figure 6. Internal Earpiece Electrical Interface

Page 3-12 ãNokia Corporation. Original

Page 13

NPE-4

PAMS Technical Documentation 3 - Audio System

Ear output specifications from the UEM specifications:

Table 5: UEM Ear output specification

Parameter Te s t c o n d i t i o n Min Typ Max Units

Output swing @ 0dBm0,

GR=-6 dB

Output voltage swing With 60 dB signal to total

Output resistance PDM data with 50 % pulse

Load capacitance EARP to EARN 50 nF

Load resistance EARP to EARN 26 32

Load capacitance EARP to GND 200 pF

Differential offset voltage -50 50 mV

Common voltage level for

EAR output (EARP & EARN)

V

ASwing

distortion ratio

ratio in the DAC input

VCM

EAR

2.36 2.5 V

4.0 V

1.0

1.3 1.35 1.42 V

Microphone

An omni directional microphone (DCT3 type) is used. The microphone is placed in the

system connector sealed in its rubber gasket. The sound port is provided in the system

connector.

pp

pp

W

W

The microphone is delivered from Matsushita with the microphone mounted in the rubber gasket.

A new rubber boot (Microphone gasket) with a harder shore (shore 80 versus shore 50)

will be used, to increase production ease and subsequently the production yield.

The microphone is connected to the differential input (MIC 1) of the UEM.

Original ãNokia Corporation. Page 3-13

Page 14

NPE-4

3 - Audio System PAMS Technical Documentation

Sketch of Microphone Acoustic Design

Systemconector sound outlet

Rubber Gasket Volume

Figure 7. Microphone Acoustical Design

Mic

Absolute Sensitivity: -42 dBV/Pa ±3dB @ 1kHz.

System

connector

Connection

springs

Figure 8. DAI Sending frequency response, B4.0

The desired microphone response is a flat line in 0 dB between 300 Hz and 4 kHz that

roles off as much as possibly outside these frequencies.

Since the microphone response is flat, no DSP equalisation is found necessary.

Page 3-14 ãNokia Corporation. Original

Page 15

NPE-4

PAMS Technical Documentation 3 - Audio System

Microphone Electrical Interface

The microphone electrical circuit includes 2 ferrite beads for common mode noise rejection together with 2 capacitors for filtering the 900 MHz signal and two varistors for

ESD protection placed near the microphone PWB spring pads.

The 10 nF (C155) forms a low pas filter together with the microphone impedance to

make a steeper role off at high frequencies.

Also an extra High pass filter (R152 + C154) is added to limit audible TDMA-noise (217

Hz + harmonics) and to limit the bumpy road noise.

A transistor circuit (V150) on the bias line from UEM is used as the voltage supplier for

minimising the noise level from the UEM bias output.

This gives an decrease in the DC voltage level across the Microphone to typically 1.1 V

(1.3 V re. GND). Using Matsushita microphones as single supplier this will not pose any

problems as the FET in the microphone have little variation on their Vds curves.

The Microphone bias is controlled in the 8 bit AudioBiasR register. The 1 uF (C171) is lessons learned from NPE-3 and simulations shows that this will give an even higher noise

suppression. But it has the risk of oscillating. No difference has been measured on preliminary tests.

AUDIO(4:0)

Figure 9. Internal Microphone Electrical Interface

Original ãNokia Corporation. Page 3-15

Page 16

NPE-4

3 - Audio System PAMS Technical Documentation

UEM microphone input specification:

Table 6: Microphone input specifications

Parameter Symbol Min Typ Max Unit

Microphone amplifier input resistor R

Differential input voltage range for MIC1

input, G =20 dB

Receive Common mode input voltage

range for MIC input

Common mode voltage level V

Differential mode voltage range for

microphone amplifier, at gain = 20dB

Differential load resistance for the

microphone input stage

Transmit gain absolute accuracy GXA -1.0 0.0 dB

Transmit gain variation with programmed

gain, temperature and supply

Common mode rejection ratio CMRR 45 60 dB

M30

V

IN1

V

HFCM

CM

V

OUT

R

OS

GXAGT

V

30 50 kOhm

200 1200 m V

100 m V

1.3 1.35 1.4 V

2.0 V

30 450 kOhm

-0.7 0.7 dB

PP

PP

PP

Buzzer

Alerting tones and/or melodies are generated by a buzzer, which is controlled by a PWM

signal from the UEM. The SPL requirement is to be as good or better than the NPE-3 in

comparison test. The buzzer is delivered from the supplier with an end of line requirement of 102dB (A) at 5cm and 2.5 kHz.

The actual level is found from a comparison with NPE-3 on specific ringing tones.

The buzzer is designed to have the first resonant peak at 2500 Hz. The ringer melodies

will be optimised in DSP so the main frequency of any given melody is shifted to near the

resonant peak. For this optimisation a program called BuzzCalc will be used for the calculation of the dominating frequency of a given ringing melody or tone.

The design of the buzzer is a direct copy from the NPE-3 project. The Buzzer is glued to a

gasket. This final assembly is delivered by STAR. Sound holes are placed in the A-cover

The A-cover is designed to give an optimal SPL by securing the tightness between buzzer

and A-cover.

The buzzer is electrically connected to the PWB by spring contacts.

Page 3-16 ãNokia Corporation. Original

Page 17

NPE-4

PAMS Technical Documentation 3 - Audio System

Buzzer Acoustic Design

Buzzer Resonance

Chamber Volume

Buzzer

Sound Port

Spring Contacts

PCB

Figure 10. Sketch of Buzzer Acoustic Design

The important parameters in this design are the front cavity and the sound portholes.

A-Cover

Rubber

gasket

Figure 11. Mechanical buzzer assemply

The expected A weighted frequency response is (50 % Duty cycle). Tested in a simplified

testbox. Final result expected to lay 2-4 dB below.

Buzzer frequency response

108

106

104

102

100

98

96

SPL / dB(A)

94

92

90

88

0 1000 2000 3000 4000 5000 6000 7000

Freq. / Hz

Figure 12. Typical buzzer frequency response

Original ãNokia Corporation. Page 3-17

Page 18

NPE-4

3 - Audio System PAMS Technical Documentation

Buzzer Electric Interface

The driver circuit is an integral part of the UEM.

UEM

5kOhm

+/- 35%

BUZZPWM

Figure 13. Buzzer driver circuit.

Table 7:

Parameter Variable Min Ty p Max Unit

Output switch resistance Rbuzzo 1.0 2.7 4.5 Ohm

Buzzer driver specifications

VBATDriv

BUZZO

VSADriv2

VBAT

1 uF

BUZZER

12 pF

Output peak sink current Iout VBAT 120 180 350 mA

Output peak sink voltage Uout VBAT 0.5 1.2 V

Output pwm duty cycle Pdcyc 50 %

Buzzer coil resistance Rload 13 16 19 Ohm

Battery voltage VBAT Ni or Li battery 3.03 3.6 5.2 (Ni)

4.2 (Li)

Reverse diode peak current Iforw tp = 10 us 0.35 A

Output frequency Fout, GSM system 0.48 2500 7751 Hz

V

The buzzer is controlled from the UEM by a PWM (Pulse Width Modulated) square wave

signal.

The frequency is produced by a bitstream on register BUZZFREQR that is counted

through a 21 bit accumulator:

BuzzClkout

21

)1)/2/((

+= BuzzFreqRFF

BuzzClk has the same frequency as the CBusClk (1 MHz for GSM).

Page 3-18 ãNokia Corporation. Original

Page 19

NPE-4

PAMS Technical Documentation 3 - Audio System

When buzzer DigEna = 1 then a PWM signal is present at BUZZPWM

The buzzer duty cycle is defined by:

%78125.0*)0:5(Cycle BPWMDCRDuty =

Vibra specification

A vibra alerting device is used to generate a vibration signal for an incoming call. The

vibra is placed in the top of the phone. It is fastened to the A-cover by means of a rubber

gasket and a lid which are pressed into the A-cover see .

The vibra is electrically connected to the PWB by spring contacts.

The vibra is controlled from the UEM by a PWM (Pulse Width Modulated) square wave

signal.

Vibrator Electrical Interface

The driver circuit is an integral part of the UEM.

The two 33 nH inductors are added for decoupling the vibra motor from the RF antenna

field. The two 1 nF capacitors are placed for ESD purposes.

UEM

Vibraclk

Vibra electrical specifications

VBATDriv

5kOhm

+/- 35%

VIBRA

VSADriv2

Figure 14. Vibra driver circuit

1 uF

33nH 33nH

10 nF

VBAT

Vibra

M

1 nF

Operating voltage = 1.0 V – 1.2 VDC (Controlled by the Duty cycle)

Starting Current = max 140 mA

Starting voltage = max 1 VDC

Terminal Resistance = 8.8 Ohm (typical)

Coil = 40 uH (typical)

Typical rpm: 9000 at 1.1 VDC.

Original ãNokia Corporation. Page 3-19

Page 20

NPE-4

3 - Audio System PAMS Technical Documentation

Table 8:

Parameter Variable Min Typ Max Unit

Output swhich resistance Rvibra 1.4 4.2 7.5 Ohm

Output average current Ivibra VBAT 50 80 135 mA

Output peak current Ipeak VBAT 300 mA

Output frequency Fvibra 64 129 520 Hz

Output duty cycle Dvibra 2.9 47 96.9 %

Reverse diode peak current Iforw tp = 10 us 0.30 A

Motor average dc Udc_motor VBAT=3.0 ... 4.5 V 1.0 1.5 2.3 Vdc

Output current high imp Ihiz V_ANA, VBAT -1 1 uA

Vibra driver specifications

Valid frequencies are: 64, 129, 258 and 520 Hz

The duty cycle of the vibra output is selected by the VCLKR register bit #7 .. #4. This is 16

accumulated duty cycles from 2.9 % to 96.9 %

The frequency of the vibra is selected by the VCLKR register bit #D1 and #D0, this clock

is divided down from the 32.768 Hz clock.

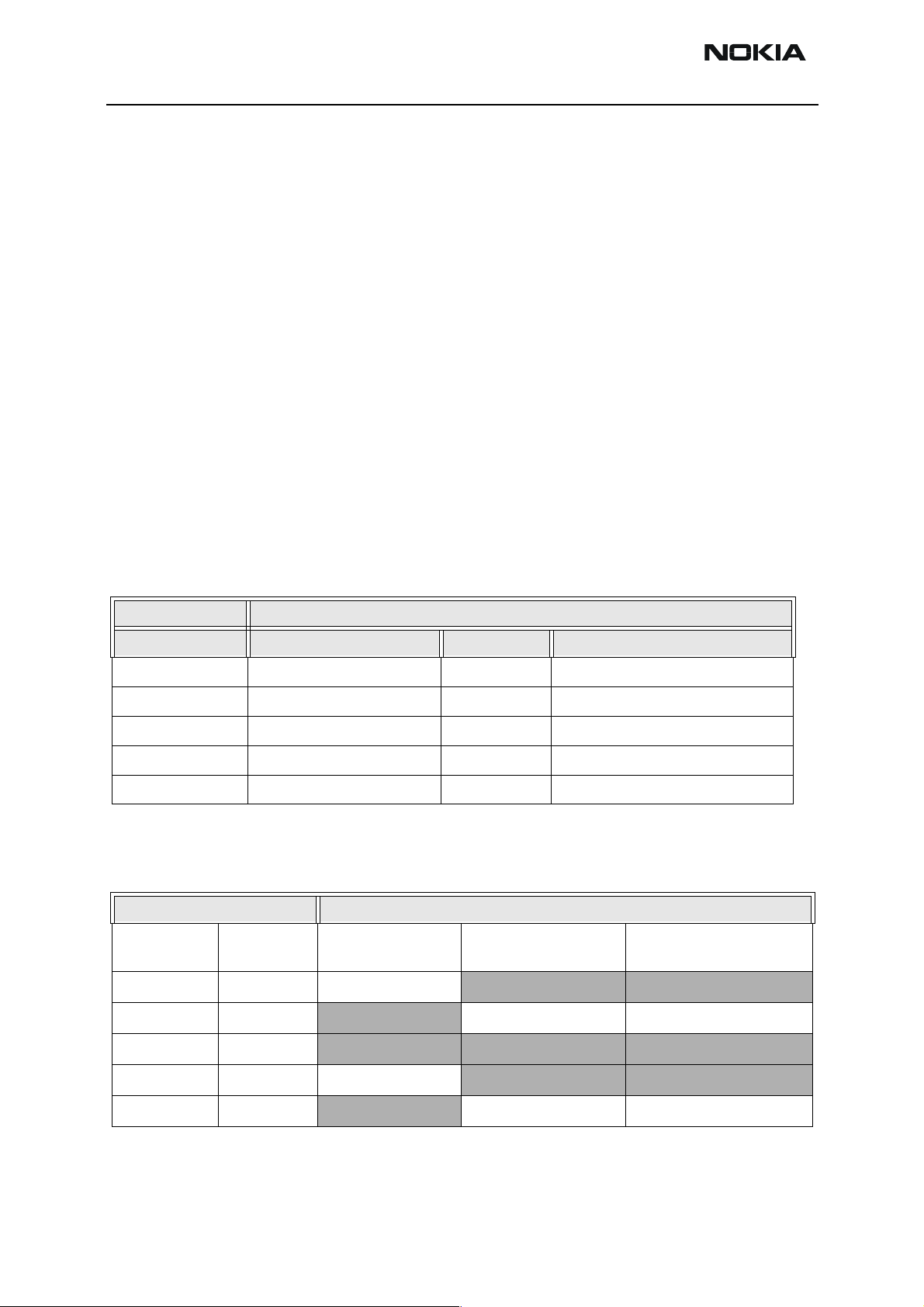

Table 9: Vibra output frequency control

D1 D0 Vibra output frequency

0 0 64,1

0 1 128,5

1 0 258,0

1 1 520,1

External Audio Devices

Audio Accessories

NPE-4 is supporting the following DCT3 and bluetooth audio accessories:

Headsets:

HDC-9P

Headset is the simplest audio accessory to use. It merely only consists of an earpiece, a

microphone, and a swhich which in technical terms is often referred to as a HOOKswhich or Headset button. The HOOK-swhich can be used either to answer in-coming

calls, to end a call or to initiate voice dialling calls.

The Hook interrupt is detected by software polling on the UEM hookInt input pin

Page 3-20 ãNokia Corporation. Original

Page 21

NPE-4

PAMS Technical Documentation 3 - Audio System

HDC-9P is a purely passive audio accessory.

HDW-1

Table 10:

Object Specification Notes

Receiver input impedance 150 Ohm +/- 25 % @ 390 mV at 1 kHz

Maximum Sound pressure level 106 dB SPL at 1 mW

Transmitter output impedance 2200 Ohm +/- 30 % at 1 kHz

Transmitter sensitivity - 43.5 dBV/Pa +/- 3 dB at 1 kHz

XMIC bias voltage 1.5 V Typical

XMIC bias current 1.5 mA Maximum

HDC-9P interface specifications

Bluetooth headset developed in the Tomahawk project.

The BT headset is containing a microphone, a earpiece, bluetooth module and its own

audio codec. HDW-1 is battery supplied

Audio connection is full duplex digital transmission with error correction.

Table 11: Selected specifications for HDW-1 BT Headset

Min Typ Max Unit

Ear signal in Codec after PCM

DAC converter

Ear signal amplifier gain in codec -18 2 12 dB / setting by 2 dB steps

Electroacoustic transfer function

(Rx)

Microphone signal level 3 4 6 mV/Pa

Level at AD input in Codec 58 490 mVrms in codec

Mic. amplifier gain in codec 20 42.5 dB

Noise voltage, microphone 5 uVrms

80 490 mVrms in codec

17 dBPa/V/0.5m

Loopsets:

LPS-1

The Loopset is a hearing aid accessory for hearing impaired persons to use mobile

phones.

It consists of a Wire-loop and a microphone placed in a collar around the person's neck.

This is detected in the mobile as a Headset. In the UI SW it is possible to change profile

Original ãNokia Corporation. Page 3-21

Page 22

NPE-4

3 - Audio System PAMS Technical Documentation

from Headset to Loopset enabling the use of Loopset specific DSP tunings.

The coil amplifier is supplied from MICB2 bias voltage.

No voice dialling from the accessory is possible while there is no hookswhich (voice dialing have to be activated from the phone keypad).

Table 12: LPS-1 interface specifications

Object Specification Notes

Receiver input impedance 100k Ohm +/- 5 % Magnetic loop

Transmitter output impedance 1600 Ohm +/- 30 % at 1 kHz

XMIC bias voltage 1.3 V Maximum

XMIC bias current 400 uA Maximum

Carkits:

CARK-91

The carkit consists of the following components:

MCC-1: Active handset holder with connection for the HFU-2 to mobile

HFU-2: Handsfree unit incl. fast charger, HF – microphone and earpiece amplifiers, interface to handset, datacard and phone and control circuit

HHS-9: Swivel mount

PCH-4J: Mounting cable

HFS-12: Handsfree earpiece, permanently installed in the car.

HFM-8: External handsfree microphone. HFM-8 is an option for the user to have a

separate microphone for the carkit-installation. HFM-8 is designed to be permanently

installed in a car.

The internal microphone in the mobile is muted by a MBUS message from

the HFU-2 when the external microphone is detected in HFU-2.

No data call is possible in HFU-2 while DAU-9 datacable is not supported.

External accessory for Cark-91:

HSU-1: Handset unit with hookswhich. This is a handset used for private conversations without losing the link to the external antenna.

Page 3-22 ãNokia Corporation. Original

Page 23

NPE-4

PAMS Technical Documentation 3 - Audio System

Carkit - 112

The carkit consists of the following components

HFW-1 Bluetooth junctionbox which replaces HFU-2 in the Cark-91 setup

CUW-2 Remote control Button, earpiece volume and hookswhich

And all the components mentioned in Carkit-91 apart from HFU-2 and HSU-1.

Bluetooth carkit developed in the Tomahawk project.

External Audio Interface

The interface is basically a 3-wire solution, which gives two completely separate audiopaths, microphone- and earpiece-signals. The interface is split up into:

External earpiece: XEAR (external earpiece, single ended)

External microphone: XMICP (ex

XMICN (external microphone, negative)

ternal microphone, positive)

External Audio Interface — Electrical Interface

The external audio connections are presented in Figure 15. External Microphone Interface and The hookInt is pulled up by 47 kOhm and the detection is being polled by software on GENIO2 via the Inverter circuit. A 100k Ohm resistor is added to the Hookint line

to avoid DC-clicks in the Uplink path.. A headset or a handsfree unit can be connected

directly to the system connector. The headset microphone bias is supplied from UEM

MICB2 output and fed to the microphone through XMICP line.

Note: MIC3 lines will be disconected from MIC2 and grounded near the UEM.

Original ãNokia Corporation. Page 3-23

Page 24

NPE-4

3 - Audio System PAMS Technical Documentation

XAUDIO(11:0)

GENIO(0)

Figure 15. External Microphone Interface

See Table 13. Microphone input specifications, external audio for the input specifications

for the external microphone.

The external audio interface microphone electrically circuit includes 2 ferrite beads for

common mode rejection together with 2 capacitors for filtering the 900 MHz signal.

An extra Lowpass filter (R167 and C172) for a steeper role-off at higher frequencies and

two high pass filters (C165 and R166 (- 3dB: 234Hz), C164 and R165 (- 3dB: 102Hz)) are

added to limit the audible TDMA-noise and to improve bumpy road noise suppression.

A transistor circuit on the bias line from UEM is used for a voltage supplier for minimising the noise level from the UEM bias output.

The Microphone bias is controlled in the 8 bit AudioBiasR register.

When DLR-3 cable is not connected there is a 330 Ohm pulldown resistor from SGND

(XMICN) to L-GND (R172). When DLR-3 is connected Vflash2 voltage of 2.78 V is used as

supply for the data cable on SGND line.

Page 3-24 ãNokia Corporation. Original

Page 25

NPE-4

PAMS Technical Documentation 3 - Audio System

Connections for MIC3 are grounded near the UEM and not as shown in Figure 15. External Microphone Interface connected to MIC2 lines.

Table 13: Microphone input specifications, external audio

Parameter Symbol Min Typ Max Unit

Microphone amplifier gain for MIC 2 / Handsfree MicG2 0 22,5 dB

Microphone amplifier gain for MIC 2 / Headset MicG2 22.5 42,5 dB

Microphone amplifier input resistor R

Differential input voltage range for MIC2 input,

G =20 dB

Differential input voltage range for MIC2 input,

G =0 dB

Receive Common mode input voltage range for

MIC input

Common mode voltage level V

Differential mode voltage range for microphone

amplifier, gain 20 dB

Differential load resistance for the microphone

input stage

Transmit gain absolute accuracy GXA -1.0 0.0 dB

Transmit gain variation with programmed gain,

temperature and supply

Common mode rejection ratio CMRR 45 60 dB

MIC

V

IN2

V

IN2

V

INCMR

CM

V

OUT

R

GS

GXAGTV -0.7 0.7 dB

30 50 kOhm

200 m V

2.0 V

100 m V

1.3 1.35 1.4 V

2.0 m V

30 450 kOhm

PP

PP

PP

PP

From the UEM output a Boomer circuit is added to give enough output swing to the

headset. The boomer is coupled as differential input single ended output. The differntial

input is using HF / HFCM output from the UEM.

The Boomer is controled by UPP GENIO14. This control signal enables and disables the

boomer wich have a internal circuit for uptimal and clickfree startup.

The boomer timing is mostly controled by C176. The nearly clickless operation has been

made by timing in the MCU SW (A 12 msec delay between UEM and Bommer startup and

a 1 sec delay between boomer and UEM shutdown has be made.)

The Gain of the circuit is controled by R176 / R 180 and R177 / R 178. Leading to a

Boomer HW gain of approximately 3 dB.

Original ãNokia Corporation. Page 3-25

Page 26

NPE-4

3 - Audio System PAMS Technical Documentation

Filtering in the boomer circuit:

Highpass: -3dB point = 234 Hz

Lowpass: -3dB point = 3386 Hz

The 15 Ohm with a load of 150 Ohm reduce the output level with approximately 0.8 dB.

XEAR circuit includes 1 ferrite bead HF filter, 1 capacitor (900 MHz cut-off filter) and

one 10 nF capacitor (C?? (R161)) placed near the system connector for EMC purposes.

On the single ended output 15 Ohm (R183) is placed to compensate for the high capacitance of the 10 nF condensator, which could lead to instability in the Boomer.

The hookInt is pulled up by 47 kOhm and the detection is being polled by software on

GENIO2 via the Inverter circuit. A 100k Ohm resistor is added to the Hookint line to avoid

DC-clicks in the Uplink path.

10n

10n

UEMUPP

68k

68k

15

C?? (R161)

10n

GND

Figure 16. External Earpiece Interface

Table 14: UEM HF output specifications

Parameter Test condition Min Typ Max Unit

Output voltage swing

single ended mode

Output voltage swing fully

differential mode

Output resistance (0 Hz

to 4 kHz)

Parasitic load resistance HF to HFCM (with external audio

with 60 dB signal to total distortion

ratio

with 60 dB signal to total distortion

ratio

PDM Data with 50 % pulse ratio in

the DAC input

circuitry)

1.0 V

2.0 V

1 Ohm

10 nF

PP

PP

Load resistance HF to HFCM or VSA (with

30 45 Ohm

headset)

Page 3-26 ãNokia Corporation. Original

Page 27

NPE-4

PAMS Technical Documentation 3 - Audio System

Table 14: UEM HF output specifications

Parameter Test condition Min Typ Max Unit

Offset voltage -50 50 mV

Common voltage level for

HF output (HF and

HFCM)

Pull down resistor value in

HF output

Pull down swhich

resistance in HFCM

output

VCM

R

PD

R

SW

HF

0.75 0.8 0.85 V

3 10 25 kOhm

400 Ohm

HEADINT and HOOKINT are ‘interrupts input’ in UEM.

Headint is used to identify the type of accessory that is connected to the system connector. The interrupt is generated by pulldown resistors in the respective accessories.

Hookint is used for detecting the hook swhich of the headset.

HF is the audio output through which audio can be routed to either Headset-earpiece or

Carkit earpiece. HF is wired as single ended output, which in reality performs the audioamplification.

MIC2P, MIC2N, MIC3P and MIC3N are all inputs to the microphone amplifier in the

UEM. In short form the main difference for the listed inputs are:

MIC2P, MIC2N: Rated to audio signals up to 2 Vpp (with gain 0 dB). Used for Headset

and Carkit microphone.

MIC3P, MIC3N: Rated to audio signals up to 2 Vpp (with gain 0 dB). Used for FM Radio

Both types of inputs can be wired and used to either fully differential or singled-ended

operation, however the fully differential configuration is chosen for the DCT3 interface.

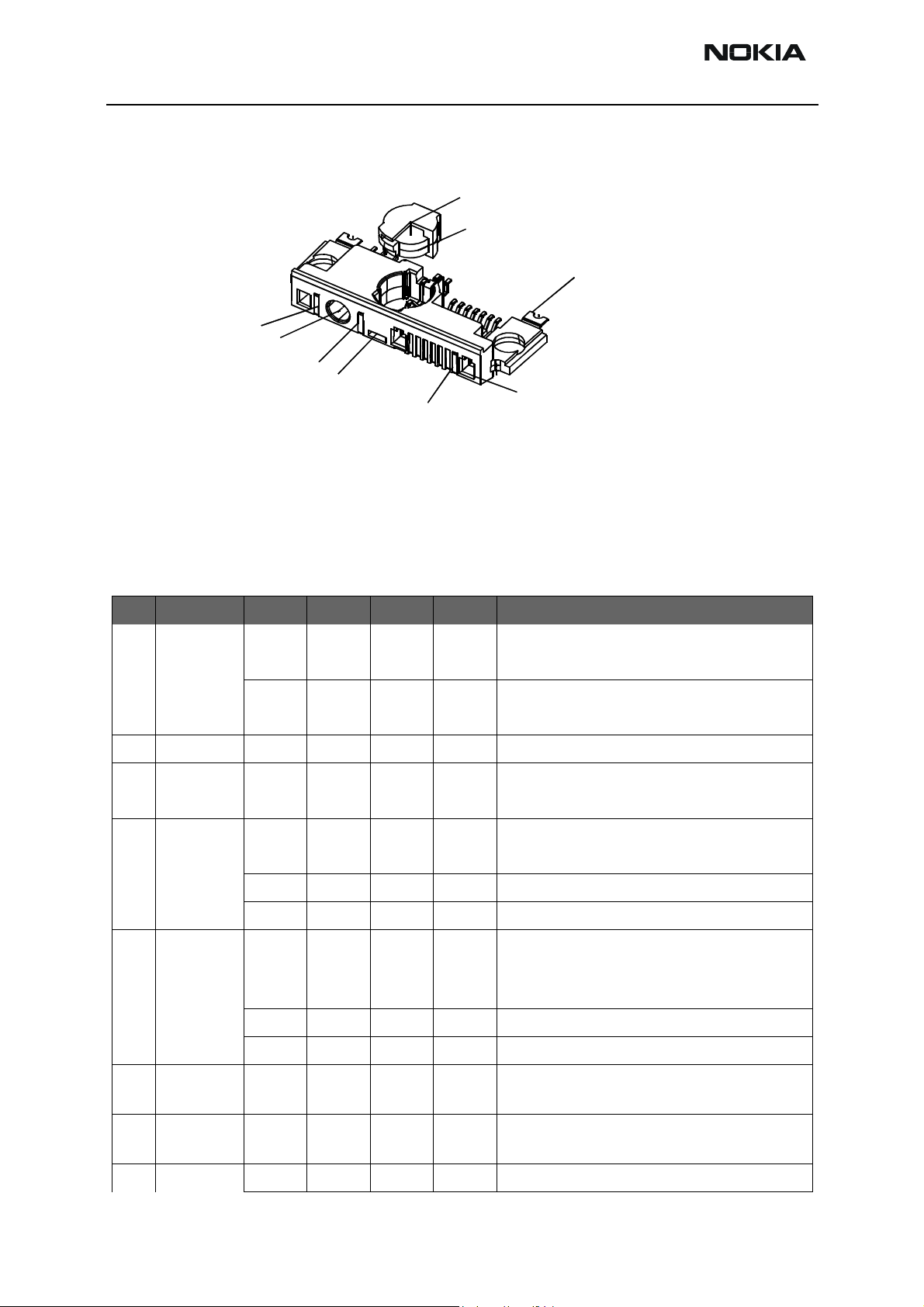

External Audio Connector

The accessibility to the external audio interface is reached by the system connector.

Original ãNokia Corporation. Page 3-27

Page 28

NPE-4

2

4

3 - Audio System PAMS Technical Documentation

The configuration for the bottom connector is shown in the following figure.

Rubber boot

Microphone

3

8

13

Contact 1

DC-jack

2,3,4

Contact 5

Microphone port

Contacts

8...13

Contact 14

14

Figure 17. System connector – mechanical outline

External Audio Signal Electrical Specification

Table 15: System connector pin assignment

Pin Name Min Typ Max Unit Notes

1 VIN

0

0

0

8.5

850

16.9

1.0

V

mA

Vpeak

Apeak

Unloaded Fast Charger

Supply current

Unloaded Standard Charger

Supply current

Solderable element,

2 pcs

Cable/Cradle connector

guiding/fixing hole, 3 pcs

2 L-GND 0 0 0 V Supply ground DC Jack

3 VIN

4 CHRG_

CTRL

0

0

0

1.7

8.5

850

0.8

2.9

V

mA

V

Unloaded Fast Charger DC Jack

Supply current

Charger control (PWM) dig. Low DC Jack

Charger control (PWM) dig. High

1 32 37 Hz PWM frequency for a fast charger

1 99 % PWM duty cycle

5 CHRG_

CTRL

0

1.7

0.8

2.9

V

Charger control (PWM) dig. Low Bottom

charger contacts

Charger control (PWM) dig. High

1 32 37 Hz PWM frequency for a fast charger

1 99 % PWM duty cycle

6 MICP 0 2 100 mV Connected to UEM MIC1P input. (re.

SGND)

7 MICN 0 2 100 mV Connected to UEM MIC1N input. (re.

SGND)

8 XMIC 2.0 2.2 kW Input AC impedance

Page 3-28 ãNokia Corporation. Original

Page 29

NPE-4

PAMS Technical Documentation 3 - Audio System

Table 15: System connector pin assignment

Pin Name Min Typ Max Unit Notes

1 Vpp Maximum signal level

0 1.55 V Mute (output DC level)

2.5 2.9 V Unmute (output DC level)

100 600 µA Bias current from UEM

2 Vpp

9 SGND 330 W Resistance to phone ground, return path for

10 XEAR 47 W Output AC impedance (ref. LGND)

10 µF Series output capacitance

16 300 W Load AC impedance to GND (Headset) pin

4.7 10 kW Load AC impedance to GND (Accessory)

1.0 Vpp Maximum output level (no load)

6.8 kW Load DC resistance to GND (Accessory)

16 1500 W Load DC resistance to GND (Headset) pin

2.78 2.8 2.86 V DC voltage (47k pull-up to Vflash1)

Microphone signal (Gain 0 dB)

Connected to UEM MIC3P + MIC2P input

XMIC. When the DLR-3 datacable is

connected, SGND swhiches to be a supply

line for the cable (2.8V)

#14

pin #14

pin #14

#14

HEAR 0 14 220 mV

11 MBUS

12 FBUS_R

X

13 FBUS_TX

14 L-GND 0 0 V Supply ground

0

2.0

0

2.0

0.1

1.7

0.8

2.8

0.8

2.8

0.8

2.8

V Serial bi-directional control bus.

V Fbus receive. Serial Data

V Fbus transmit. Serial Data

Earphone signal

Connected to UEM HF output

Baud rate 9600 Bit/s

Phone has 4.7kW pull up resistor in UEM

Baud rate 9.6k-230.4kBit/s

Phone has 220kW pull down resistor

Baud rate 9.6k-230.4kBit/s

Phone has 47kW pull up resistor in UEM

Original ãNokia Corporation. Page 3-29

Page 30

NPE-4

3 - Audio System PAMS Technical Documentation

Accessory Detection, Identification and Control

Accessory Detection

Accessories are detected when the XMIC signal is loaded with either DLR3, Loopset or

Headset. The interrupt is generated by pulldown resistors in the respective accessories.

Carkit 91 is detected via communication on the MBUS line.

BT accessories are connected after BT connectivity is chosen in UI. Communication with

UEM is done over the CBUS lines.

Accessory Identification

The voltage on the XMICP is used to identify which type of accessories that are connected to the system connector. See Table 16: HEADINT Voltage Value Table used for

Accessory Identification. The HEADINT interrupt is detected in the UEM and this voltage

level is used to determine the type of accessory.

A voltage is measured on the HeadInt input on the UEM. This signal is multiplexed to an

A/D converter in the UEM. From this level an Accessory server recognises the type of

accessory and chooses the relevant audio accessory tuning if applicable. If the detection

voltage window is as described in Table 16: HEADINT Voltage Value Table used for Accessory Identification for headset and loopset the microphone bias is enabled.

If DLR3 is used the detection voltages are as in Table 16: HEADINT Voltage Value Table

used for Accessory Identification, no bias for the microphone is enabled and 2.8 V DC for

DLR3 is supplied.

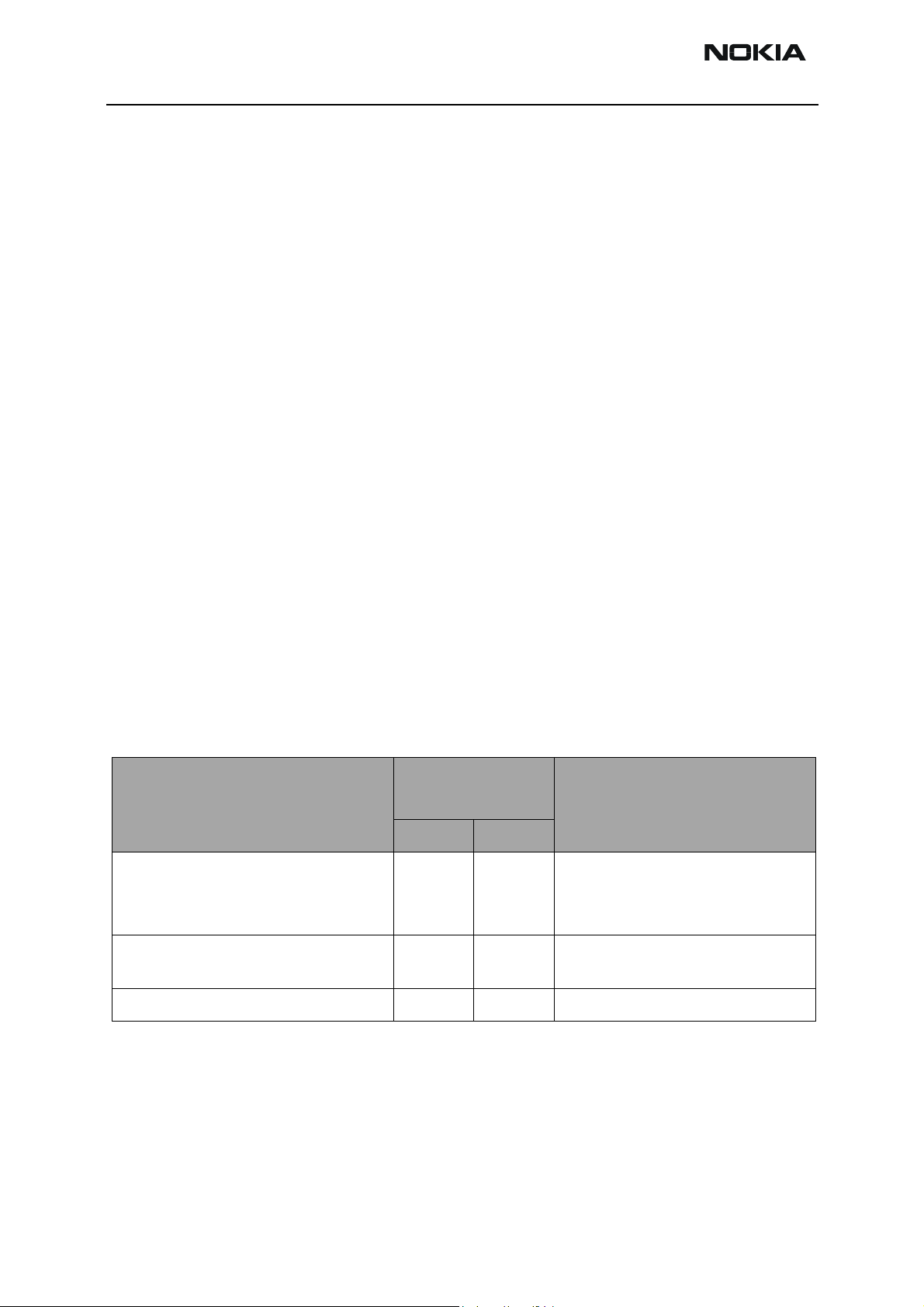

Table 16: HEADINT Voltage Value Table used for Accessory Identification

ACCESSORY CONNECTED HEADINT

VOLTAGE LEVEL

MIN MAX

Headset HDC-9P and Loopset LPS-1 19 mV 300 mV Without MBias

Varying with microphone FET

working line.

Carkit CARK-91 Detected and acknowledged by the

phone on MBUS

NOTES

DLR3 300 mV 800 mV

Page 3-30 ãNokia Corporation. Original

Page 31

NPE-4

PAMS Technical Documentation 3 - Audio System

Accessory Control

Headset and Loopset

In the HDC-9P the headset-button is electrically connected across the XEAR and L-GND

lines. When the Headset button is activated, XEARP is short-circuited to L-GND and a

HOOKINT interrupt is detected in the UEM. This is used to lift the receiver, to put it down

or initiate voice call.

HDW-1 is a Bluetooth Headset. The BT headset is recognised by the phone after a BT

search for any BT component in the vicinity has been performed and a connection is set

up via the BT module in both phone and accessory.

In case of BT audio the BT accessory and the phone is connected by both an ACL and SCO

air link. ACL is used for connection commands and SCO for the actual audio transmission.

In both cases the BT module (in accessory and phone) receives the audio signal. In the

phone this signal is routed from BT module over LPRF to DSP where it follows the regular

audio path through out the rest of the system. The BT module and MCU is connected by

the CBUS for exchanging low level information.

Carkit

CARK-91

The carkit communicates with the phone through the system connector via the MBUS

lines. No interrupts are detected on the HeadInt or HookInt. Headint is disabled so a voltage on the XMIC line is not able to initiate the interrupt. All communication is controlled

in the HFU-2 unit. Voice dialling is only possible in CARK-91 via phone "name" softkey.

The HFU-2 sends an MBUS registration messages to the phone when the HFU-2 is powered up. This message includes an identification number for the HFU-2 box. The phone

will send an acknowledge message and communication are set-up.

The HFU-2 box includes power amplifier for Earpiece (nom. gain 26 dB) and preamplifier

for Microphone (nom. gain 30 dB).

Original ãNokia Corporation. Page 3-31

Page 32

NPE-4

3 - Audio System PAMS Technical Documentation

HFS-12

HFM-8

UEM

MBUS

HFU-2

26 dB

Audio

Interface

30 dB

External

audio sheet

System

connector

EMI Filter

System

connector

MCC-1

MBUS

Figure 18. Carkit audio interface. Block diagram.

Control

circuit

MBUS

MBUS

CARK-64

This carkit is a passive kit and is just a holder for the phone. No detection is done anywhere.

CARK-112

This is a Bluetooth carkit. The BT Carkit is recognised by the phone after a BT search for

any BT component in the vicinity has been performed and a connection is set up via the

BT module in both phone and accessory.

In case of BT audio the BT accessory and the phone is connected by both an ACL and SCO

air link. ACL is used for connection commands and SCO for the actual audio transmission.

In both cases the BT module (in accessory and phone) receives the audio signal. In the

phone this signal is routed from BT module over LPRF to DSP where it follows the regular

audio path through out the rest of the system. The BT module and MCU is connected by

the CBUS for exchanging low level information.

Voice dialling is only possible in CARK-112 via phone "name" softkey.

Page 3-32 ãNokia Corporation. Original

Loading...

Loading...