Page 1

Customer Care Solutions

RH-20 Series Transceivers

Troubleshooting Instructions

Issue 1 10/2003 Nokia Corporation

Page 2

RH-20 Company confidential

Troubleshooting Instructions CCS Technical Documentation

Page 2 Nokia Corporation. Issue 1 10/2003

Page 3

Company confidential RH-20

CCS Technical Documentation

RF Troubleshooting .......................................................................................................5

Introduction to RF troubleshooting .............................................................................5

RF Key component placement .....................................................................................6

RF Measurement points ...............................................................................................7

GSM900, GSM1800 & GSM1900 Transmitter .............................................................8

Additional information for EDGE troubleshooting .....................................................15

EGSM900, GSM1800 and GSM1900 Receiver ..........................................................23

Synthesizer ...................................................................................................................30

Baseband troubleshooting ............................................................................................35

Main Troubleshooting Diagram ................................................................................37

Phone is dead .............................................................................................................38

Flash Programming Fault ..........................................................................................39

Phone is jammed ........................................................................................................40

SIM card fault (Insert SIM / Card rejected) ...............................................................42

Keypad Fault ..............................................................................................................43

Display Fault ..............................................................................................................45

Illumination fault .......................................................................................................46

Charger Fault .............................................................................................................47

Accessory Fault .........................................................................................................48

Audio Fault ................................................................................................................49

Camera Troubleshooting ..............................................................................................53

Camera Fault ..............................................................................................................54

Camera troubleshooting diagram .................................................................................54

FM Radio troubleshooting ...........................................................................................55

FM Radio troubleshooting diagram ...........................................................................56

Draft 2 8/03 Copyright Nokia. All rights reserved.. Page 1

Page 4

RH-20 Company confidential

CCS Technical Documentation

Page 2 Copyright Nokia. All rights reserved. Draft 2 8/03

Page 5

Company confidential RH-20

CCS Technical Documentation

RF Troubleshooting

Introduction to RF troubleshooting

Measurements should be done using Spectrum analyzer with high-frequency highimpedance passive probe (LO-/reference frequencies and RF power levels) and Oscilloscope with a 10:1 probe (DC-voltages and low frequency signals).

The RF-section is build around one RF-ASIC (HELGO N500). For easier troubleshooting,

this RF troubleshooting document is divided into sections.

Before changing HELGO, please check the following things: supply voltages are OK and

serial communication coming from baseband to HELGO.

Please note that the grounding of the PA module is directly below PA-module so it is difficult to check or change. Most RF semiconductors are static discharge sensitive! So

ESD protection must be taken care of duriong repair (ground straps and ESD soldering

irons). HELGO and PA are moisture sensitive so parts must be pre-baked prior to soldering.

Apart from key components described in this document here are a lot of discrete components (resistors, inductors and capacitors) which troubleshooting is done by checking if

soldering of the component is done properly (for factory repairs checking if it is missing

from PWB). Capacitor can be checked for shortening and resistors for value by means of

an ohmmeter, but be aware in-circuit measurements should be evaluated carefully.

Please be aware that all measured voltages or RF levels in this document are rough figures. Especially RF levels varies due to different measuring equipment or different

grounding of the used probe. When using RF probe usually a good way is to use metallic

tweezers to connect probe ground to PWB ground as close to measurement point as possible.

Issue 1 10/2003 Nokia Corporation. Page 5

Page 6

RH-20 Company confidential

A

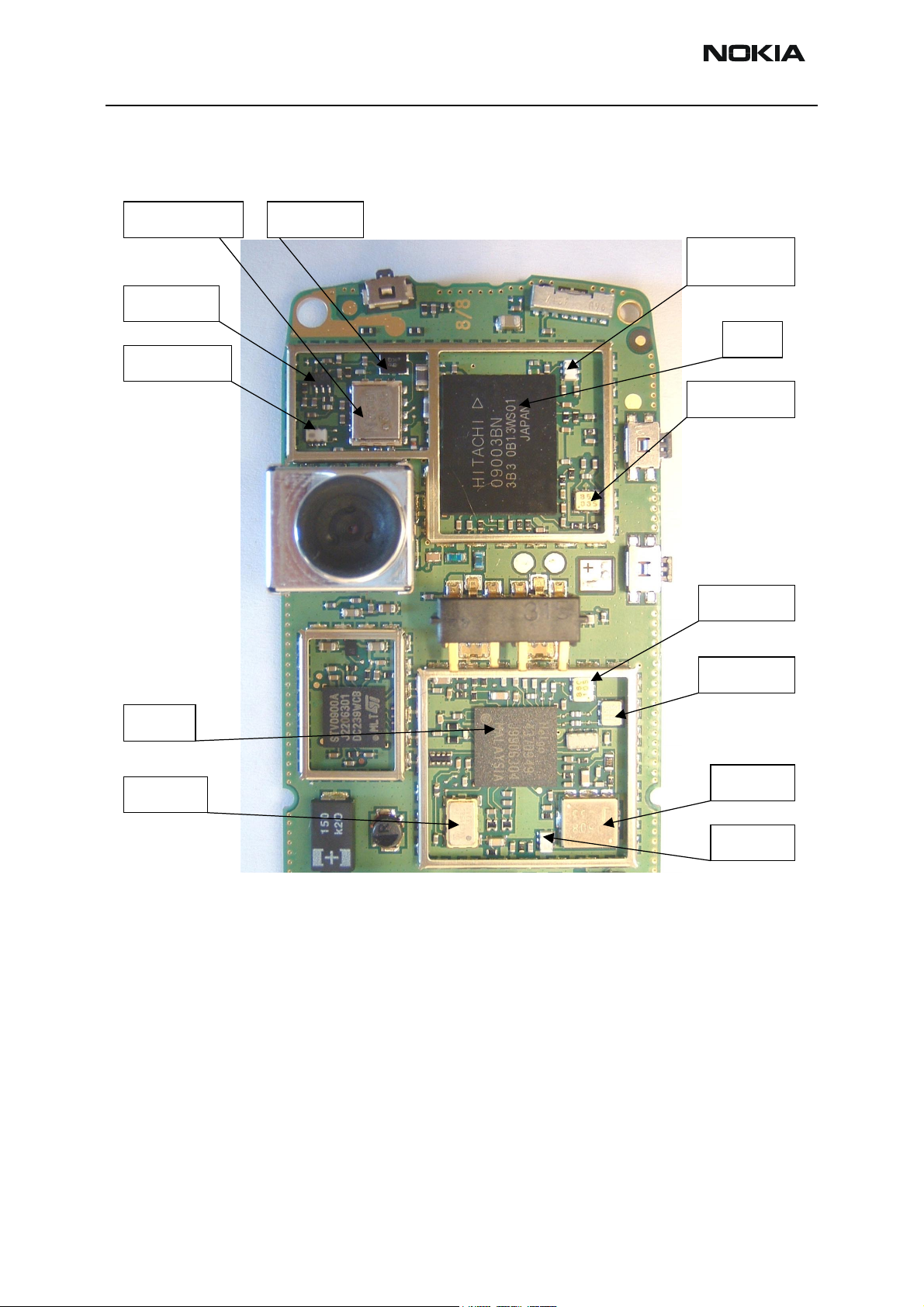

RF Key component placement

Figure 1: Component placement 1

ntenna switch

1900 RX Lna

1900 RX balun

1900 RX Saw

CCS Technical Documentation

1900/1800

TX Balun

TX 900 saw

PA

Helgo

VCTCXO

1800 RX Saw

900 RX Saw

VCO

VCO Balun

Page 6 Nokia Corporation. Issue 1 10/2003

Page 7

Company confidential RH-20

t

A

A

A

A

A

CCS Technical Documentation

RF Measurement points

To Antenna

RX 1900 saw out

VANT_2

LNA P

SM Out Rx 900

LNA VCC

VANT_3

SM out 1800Rx

VANT_1

SM In Tx1800/1900

SM In Tx900

VPECTRL3(ALC)

VR2

RFBusEn

RFBusData

RFBusRes

RFBusClk

VR1

VR3

VCTCXO outpu

TXIN/TXIP

TXQN/QP

26MHz

VBATT

Figure 2: Component placement 2

SM out 1900Rx

1800/1900 PA in

VTXB 1800/1900

Pcrtl 1800/1900

MODE

Vpcrtl 900

VTXB 900

900 PA in

I_ref_1800/1900

I_ref_900

VTXLO 900

1900 RX in

1800 RX in

VR 4

900 RX in

VR 6

TXA

TXP

VR 5

VR 7

TXC

Issue 1 10/2003 Nokia Corporation. Page 7

Page 8

RH-20 Company confidential

CCS Technical Documentation

EGSM900, GSM1800 & GSM1900 Transmitter

General instructions for Tx troubleshooting

Kindly refer to the Service Software Section, Service Concept dagram (p.40)

Connect test jig to computer with DAU-9S cable or to FPS-8 Flash Prommer with XCS-4

modular cable.

Make sure that you have PKD-1 dongle connected to computers parallel port.

Connect DC power supply to module test jig with FLC-2 cable.

Attention: When repairing or tuning transmitter use external DC supply with at

least 3A current capability. Set the DC supply voltage to 4.2V.

Connect an RF-cable to the module test jig (MJS-38) RF connector and to measurement

equipment or at least a 10dB attenuator, otherwise the PA may be damaged. Normally a

spectrum analyzer is used as measurement equipment.

Attention: Normally Spectrum analyzer maximum input power is +30dBm. It is recommended to use 10dB attenuator on Spectrum analyzer input to prevent damage.

Set the phone module to test jig and start Phoenix service sofware

Initialize connection to phone. (use FBUS driver when using DAU9S and COMBOX driver

when using FPS-8)

Select product from the menu

File -> Choose product -> RH-20

From toolbar set operating mode to "Local"

Activate RF controls window from the menu

Testing -> RF Controls

From the RF controls window

- Select band "GSM900" or "GSM 1800" or "GSM1900" (Default = "GSM900")

- Set Active unit to "Tx" (Default = "Rx")

- Set Operation mode to "Burst" (Default = "Burst")

- Set Tx data type to "Random" (Default = "All1")

- Set Rx/Tx channel to 37 on GSM900 band or 700 on GSM1800 band or 661 on

Page 8 Nokia Corporation. Issue 1 10/2003

Page 9

Company confidential RH-20

CCS Technical Documentation

GSM1900 (Defaults)

- Set Tx PA mode to "Free" (Default)

- Set power level to 5 (Default = 19) on GSM900 or to 0 (Default = 15) on GSM1800 or

GSM1900

Issue 1 10/2003 Nokia Corporation. Page 9

Page 10

RH-20 Company confidential

g

g

p

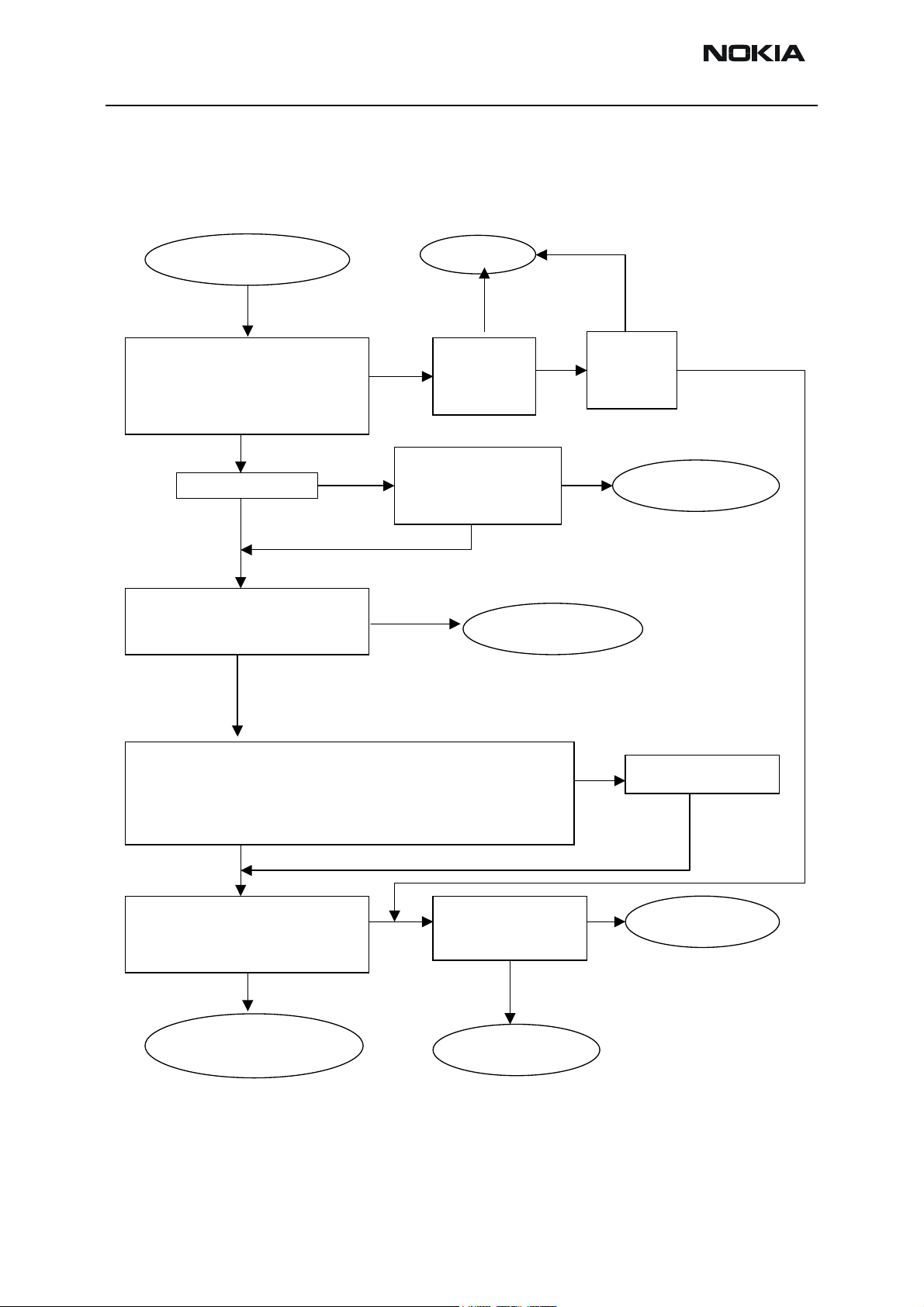

Transmitter troubleshooting diagram

CCS Technical Documentation

Yes

Yes No

Check output signal level:

+32…+33dBm@897.4MHz(GSM900)

+29…+30dBm@1747.8 and 1880MHz

(GSM1800&1900)

OK?

No

No Yes

Yes No

Check with RF probe signal level on

PA input: ~ -1…+5dBm

OK?

No

Yes

Start TX power level tuning and check tuned coefficient values:

Highest level ~0.655…0.831(GSM900); ~0.567…0.782(GSM1800&1900)

Yes

Lowest level ~0.166…0.196(GSM900); ~0.176…0.225(GSM1800&1900)

Base level ~0.137…0.166(GSM900); ~0.132…0.161(GSM1800&1900)

Major differences?

No

Check control voltage with

Yes

oscilloscope:

PA Ctrl voltage >1.5V peak

No

OK?

Yes No

TX Troubleshooting

TX signal found?

PA & Antenna Switch

troubleshooting

Figure 3: Transmitter troubleshooting

TX OK

Check

all power

levels,

OK?

Check output signal

on 500MHz span

Signal found on incorrect

frequency?

Helgo

troubleshootin

Yes

Check control loop

components

OK?

Replace faulty

com

onents

Tune

TX power

levels,

OK?

Synthesizer

troubleshootin

Tune TX coefficient

values

Replace Helgo

Page 10 Nokia Corporation. Issue 1 10/2003

Page 11

Company confidential RH-20

CCS Technical Documentation

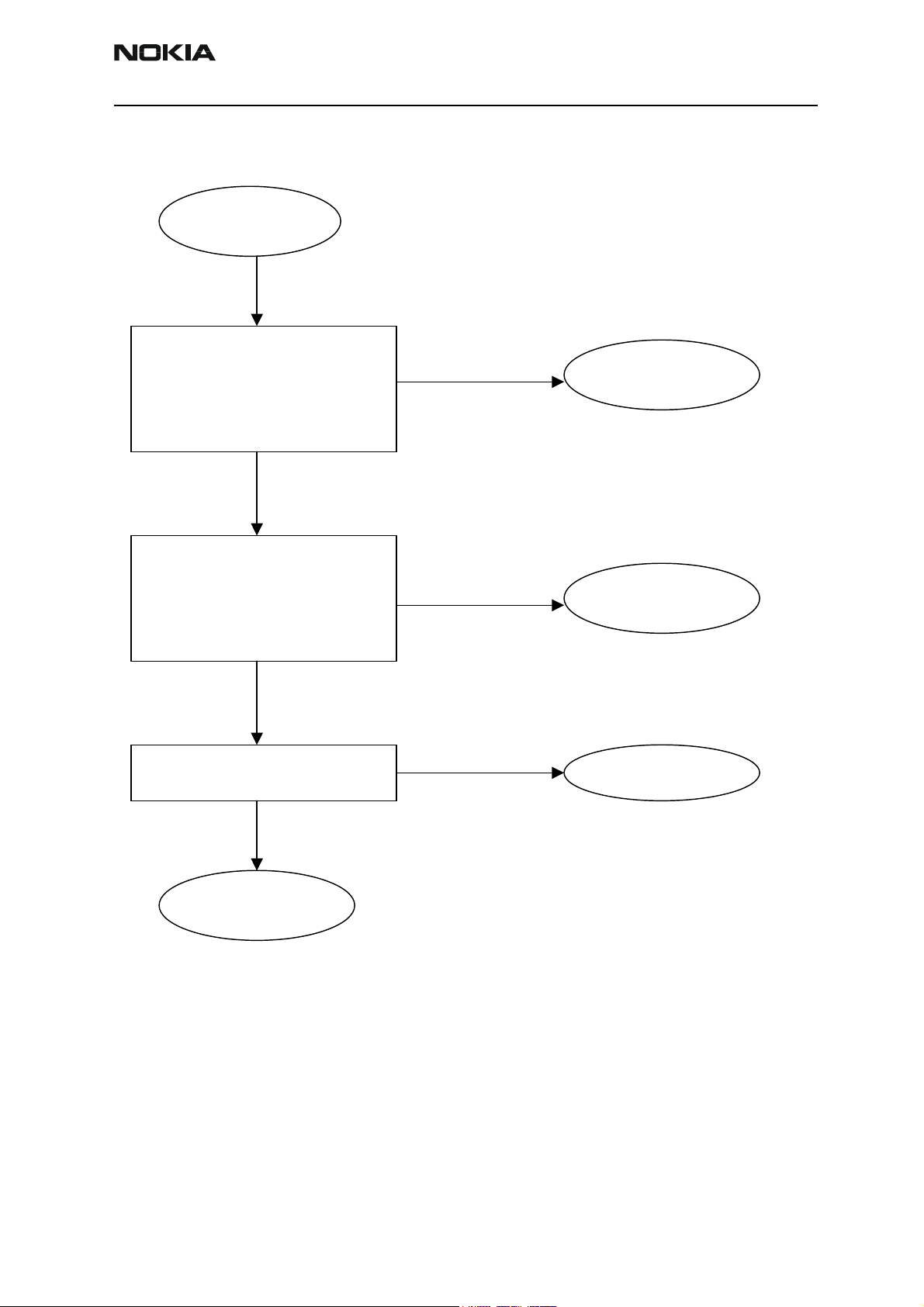

Figure 4: HELGO IC troubleshooting

Check with oscilloscope:

-TXI/TXQ signals

No

-VR1, VR2, VR4, VR5, VR6 =2.8V

-VrefRF01 = 1.35V

-Helgo serial interface

-TXP & TXC signals

OK?

Yes

Check with RF probe:

4G VCO signal output:

No

-3589.6MHz (GSM900)

-3495.6MHz (GSM1800)

-3760MHz (GSM1900)

Level > - 10dBm

OK?

Yes

Yes

Check modulator output components

OK?

No

HELGO IC

troubleshooting

Replace faulty

component(s)

Baseband

troubleshooting

Synthesizer

troubleshooting

Replace HELGO

Issue 1 10/2003 Nokia Corporation. Page 11

Page 12

RH-20 Company confidential

p

)

p

CCS Technical Documentation

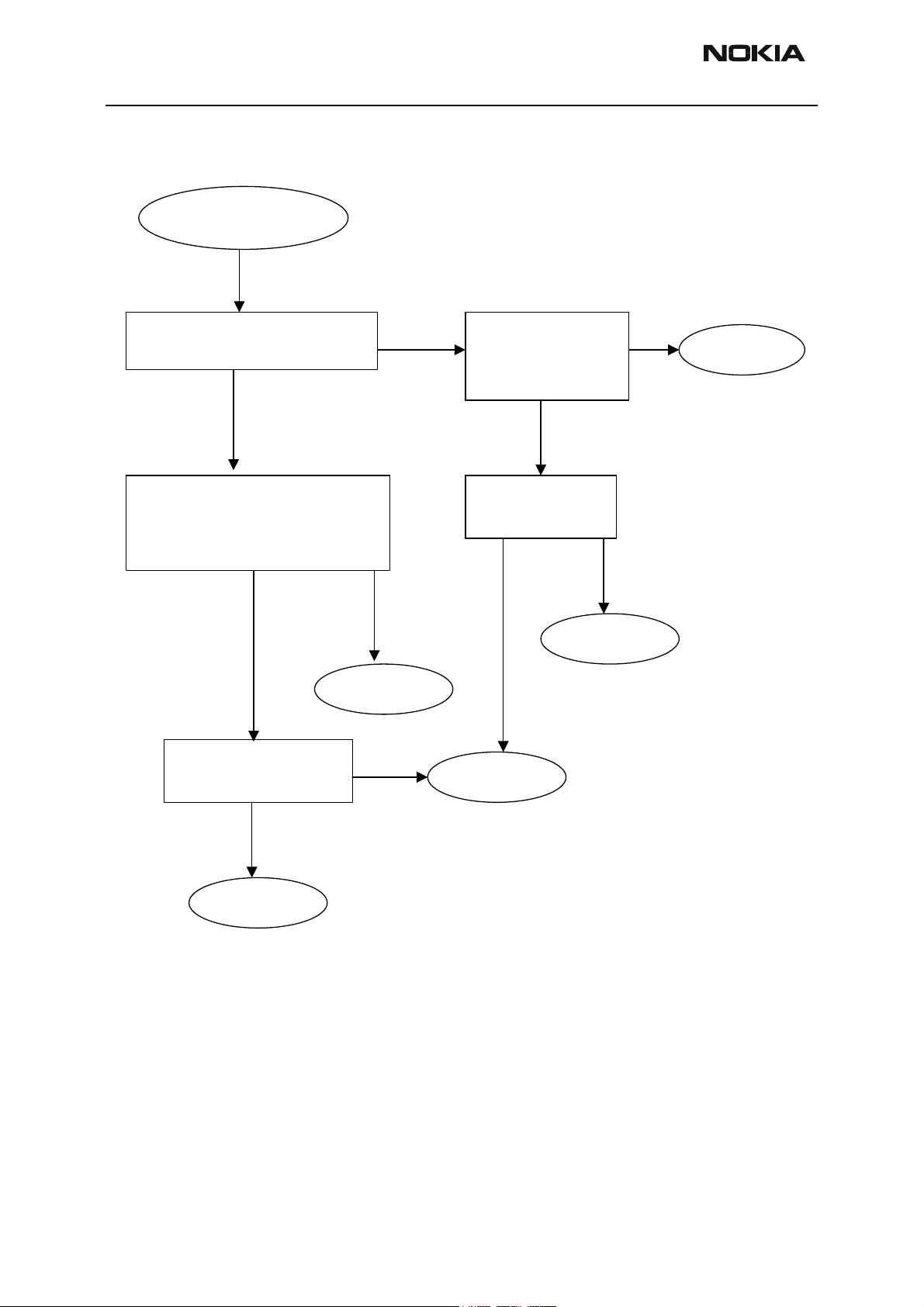

Check with RF probe signal level on PA

Yes Yes

input ~ -1…+5 dBm

OK?

Yes No

Check with oscilloscope:

-VBATT ~4V

-VTXB = 2.8V pulsed

-VPCTRL_900/1800/1900

OK?

Yes

Yes

PA & Antenna Switch

troubleshooting

No

Check components

around PA

OK?

No

Replace faulty

onent(s)

com

Figure 5: PA and Antenna Switch troubleshooting

Check with oscilloscope:

-VANT1 (GSM900)

-VANT2 (GSM1800)

-VANT3 (GSM1900)

OK?

Check VANT line

components

OK?

Yes No

Replace faulty

onent(s

com

Replace PA

Replace

HELGO

Replace ant.

switch

Page 12 Nokia Corporation. Issue 1 10/2003

Page 13

Company confidential RH-20

v

v

CCS Technical Documentation

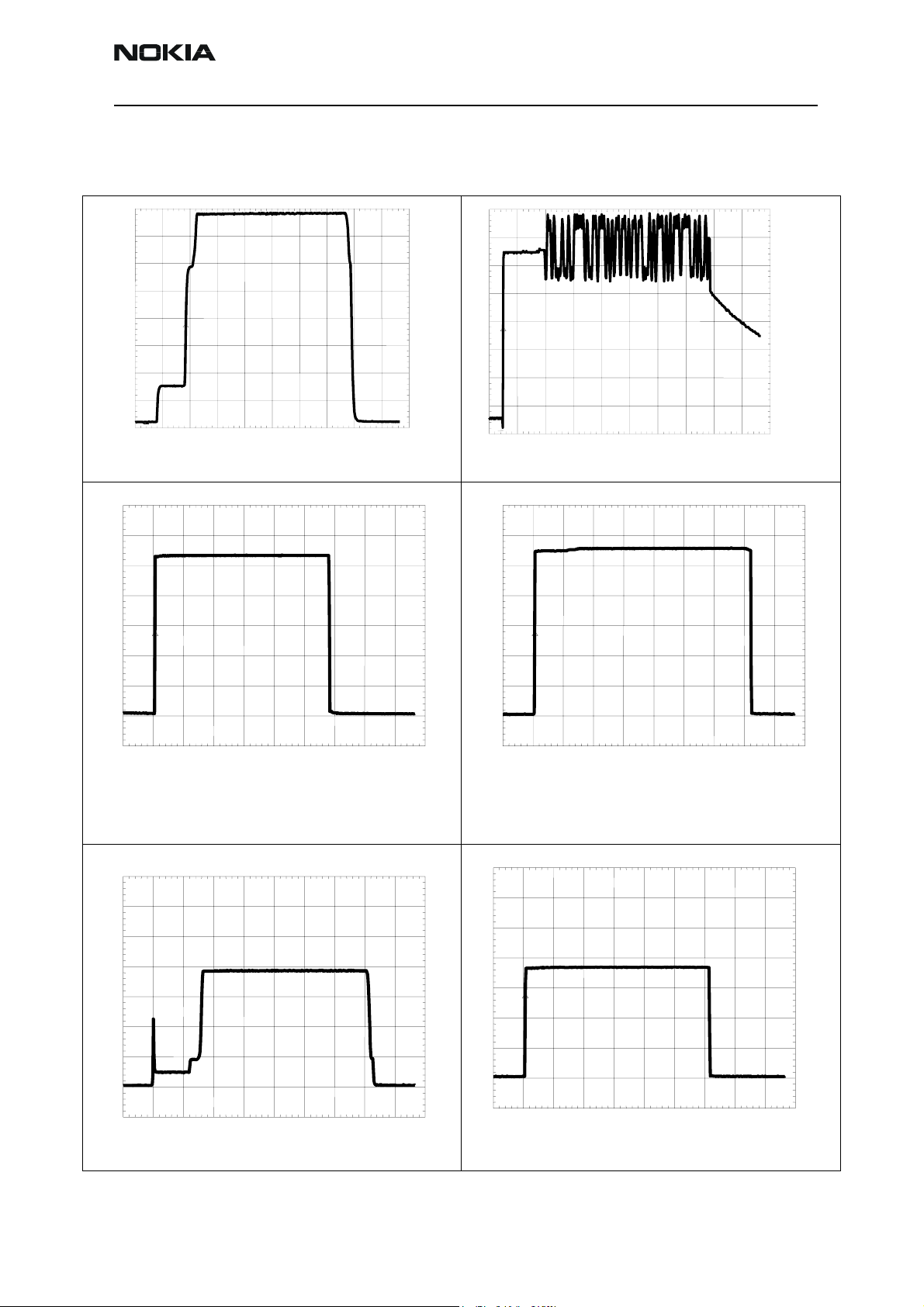

Pictures of transmitter signals

Figure 6: Transmitter signals

TXI

VPC

200mV/di

1

VPCTRL _900 power level high at R703/C703

VPCTRL_1800/1900 power level high at R704/C704

500mV/div 100us/div

VANT_1 / GSM900 TX at C805

VANT_2 / GSM1800 TX at R804

VANT_3 / GSM1900 TX at C806 OV

( no signal/ Flatline on Oscilloscope screen)

100us/di

200mV/div

100us/div

TX I/Q at R516/517 power level high Random data

_

1

500mV/div 100us/div

VANT_1,VANT_2,VANT_3

VTXB_900 at C713

VTXB_1800_1900 at C714

Issue 1 10/2003 Nokia Corporation. Page 13

500mV/div 100us/div

500mV/div MTB 100us/div

TXP at J504

Page 14

RH-20 Company confidential

m

A

Figure 7: Tx out signal, 900 band, burst mode, channel 37

CCS Technical Documentation

Ref Lvl

Ref Lvl

34 dBm

34 dBm

34

21 dB Offset

30

20

10

0

-10

-20

-30

-40

-50

Marker 1 [T1]

28.46 dBm

897.38997996 MHz

RBW 100 kHz

VBW 100 kHz

SWT 2 s

1

RF Att 40 dB

Unit dB

A

1M

-60

-66

Center 897.4 MHz Span 2 MHz200 kHz/

Date: 28.APR.2003 15:09:42

Page 14 Nokia Corporation. Issue 1 10/2003

Page 15

Company confidential RH-20

CCS Technical Documentation

Additional information for EDGE troubleshooting

EDGE mode troubleshooting differs slightly from basic GSM troubleshooting.

Establish connection to the phone normally (see GSM900/1800/1900 troubleshooting

instructions).

Select product from the menu:

File -> Choose Product -> RH-20

From toolbar set operating mode to “Local”

Activate RF controls window from the menu:

Testing -> RF Controls

From the RF controls window:

Select Band “GSM900” or “GSM1800” or “GSM1900” (Default=”GSM900”)

Set Active unit to “Tx” (Default=”Rx”)

Set Edge “On” (Default=”Off”)

Set Operation mode to “Burst” (Default=”Burst”)

Set Tx data type to “Alternate PN9” (Default=”All1”)

Set Rx/Tx channel to 37 on GSM900 or 700 on GSM1800 or 661 on GSM1900 (Defaults)

Set power level to 8 (Default = 19) on GSM900 or to 2 (Default = 15) on GSM1800 or

GSM1900

NOTE! For GSM900 Edge power levels 5, 6 and 7 are not in use and for GSM1800&1900 Edge power

levels 0 and 1 are not in use.

Issue 1 10/2003 Nokia Corporation. Page 15

Page 16

RH-20 Company confidential

g

g

p

CCS Technical Documentation

TX EDGE Troubleshooting

Yes

Yes No

Check output signal level:

+24…+30dBm@897.4MHz(GSM900)

+22…+29dBm@1747.8 and 1880MHz

(GSM1800&1900)

OK?

No

No Yes

Yes No

Check with RF probe signal level on

PA input:

No

~-8dBm@PCL=8 (GSM900)

~-10dBm@PCL=2 (GSM1800&1900)

OK?

Yes

Start TX Edge power level tuning and check tuned coefficient values:

Highest level ~0.684…0.841(GSM900); ~0.763…0.860(GSM1800&1900)

Yes

Lowest level ~0.333…0.420(GSM900); ~0.323…0.362(GSM1800&1900)

Base level ~0.273…0.313(GSM900); ~0.244…0.313(GSM1800&1900)

Major differences?

No

Check control voltages with

Yes

oscilloscope:

Pa Iref ~2V peak (GSM900)

No

Pa Iref ~2.1V peak (GSM1800@1900)

Mode ~1.8V OK?

Yes No

TX signal found?

PA & ant switch

EDGE troubleshooting

Figure 8: Transmitter EDGE troubleshooting

TX OK

Check

all power

levels,

OK?

Check output signal

on 500MHz span

Signal found on incorrect

frequency?

Helgo EDGE

troubleshootin

Yes

Check EDGE control

loop components

OK?

Replace faulty

com

onents

Tune

TX power

levels,

OK?

Synthesizer

troubleshootin

Tune TX coefficient

values

Replace Helgo

Page 16 Nokia Corporation. Issue 1 10/2003

Page 17

Company confidential RH-20

CCS Technical Documentation

Figure 9: Helgo EDGE troubleshooting

Check with oscilloscope:

-TXI/TXQ signals

No

-VR1, VR2, VR4, VR5, VR6 =2.8V

-VrefRF01 = 1.35V

-Helgo serial interface

-TXP & TXC & TXA

OK?

Yes

Check with RF probe:

4G VCO signal output:

No

-3589.6MHz (GSM900)

-3495.6MHz (GSM1800)

-3760MHz (GSM1900)

Level > - 10dBm

OK?

Yes

Yes

Check modulator output components

and VPECTRL3 signal

No

Helgo EDGE

troubleshooting

Replace faulty

component(s)

Baseband

troubleshooting

Synthesizer

troubleshooting

Replace HELGO

Issue 1 10/2003 Nokia Corporation. Page 17

Page 18

RH-20 Company confidential

p

)

p

Figure 10: Pa & ant switch EDGE troubleshooting

PA & ant switch

EDGE troubleshooting

CCS Technical Documentation

Check with RF probe signal level on PA

input:

~ -8dBm@PCL=8 (GSM900)

~ -10dBm@PCL=2 (GSM1800&1900)

OK?

Yes No

Check with oscilloscope:

-VBATT ~4V

-Iref _900 ~2V peak

-Iref_1800_1900 ~2.1V peak

-VTXB = 2.8V pulsed

-Mode = ~1.8V

OK?

No

Check components

around PA

OK?

Yes No

Yes

Replace PA

Yes Yes

Yes

Check with oscilloscope:

-VANT1 (GSM900)

-VANT2 (GSM1800)

-VANT3 (GSM1900)

OK?

Check VANT line

components

OK?

Replace

HELGO

Replace faulty

onent(s

com

Replace ant.

switch

No

Replace faulty

onent(s)

com

Page 18 Nokia Corporation. Issue 1 10/2003

Page 19

Company confidential RH-20

CCS Technical Documentation

Pictures of EDGE transmitter signals

Figure 11: I_ref_900 power level 8 at R701/C701

Figure 12: VTXB 900 power level 8 at C713

Issue 1 10/2003 Nokia Corporation. Page 19

Page 20

RH-20 Company confidential

Figure 13: I_ref_1800/1900 power level 2 at R700/C700

CCS Technical Documentation

Figure 14: VTXB 1800/1900 power level 2 at C714

Page 20 Nokia Corporation. Issue 1 10/2003

Page 21

Company confidential RH-20

CCS Technical Documentation

Figure 15: TXA 850/1800/1900 at C538

Figure 16: TXI/TXQ signal at C535/C536/R516/R517

Issue 1 10/2003 Nokia Corporation. Page 21

Page 22

RH-20 Company confidential

Figure 17: VPECTRL3 (ALC) signal at C512

CCS Technical Documentation

Page 22 Nokia Corporation. Issue 1 10/2003

Page 23

Company confidential RH-20

CCS Technical Documentation

EGSM900, GSM1800 and GSM1900 Receiver

General instructions for Rx troubleshooting

Connect test jig to computer with DAU-9S cable or to FPS-8 Flash Prommer with XCS-4

modular cable.

Make sure that you have PKD-1 dongle connected to computers parallel port.

Connect DC power supply to module test jig with FLC-2 cable.

Set the DC supply voltage to 4.2V.

Connect an RF-cable to the module test jig (MJS-38) RF connector and to RF signal generator.

Set the phone module to test jig and start Phoenix service sofware.

Initialize connection to phone. (use FBUS driver when using DAU9S and COMBOX driver

when using FPS-8)

Choose product from the menu

File -> Choose product -> RH-20

From toolbar set operating mode to "Local"

Activate RF controls window from the menu

Testing -> RF Controls

From the RF controls window:

- Select band "GSM900", "GSM 1800" or “GSM1900” (Default = "GSM900")

- Set Active unit to "Rx" (Default = "Rx")

- Set Operation mode to "Burst" (Default = "Burst")

For continuous mode:

- Set Operation mode to "Continuous"

- Set AGC to "12: FEG_ON + DTOS_ON + BB_30=Vgain60” (maximum gain setting used

in normal mode)

(Default = "14: FEG_ON + DTOS_ON + BB_42=Vgain72")

- Set Rx/Tx channel to 37 on GSM900 band, 700 on GSM1800 band or 661 on GSM1900

Issue 1 10/2003 Nokia Corporation. Page 23

Page 24

RH-20 Company confidential

(Defaults)

Apply 942.46771 MHz (channel 37 + 67.710 kHz offset), 1842.86771 MHz (channel 700

+ 67.710 kHz offset) or 1960.06771 MHz (channel 661 + 67.71 kHz) –90 dBm signal to

the RF-connector (remember to compensate for cable attenuation).

Measuring with an oscilloscope on "RXI" or "RXQ" following screens should be seen on a

working GSM900 , GSM1800 or GSM1900 receiver:

Figure 18: RX I/Q signal ,burst mode, input level –90dBm.

CCS Technical Documentation

Receiver I or Q burst mode signal (channel 37) measured from testpoint RXI or RXQ with

942.46771 MHz signal, input level –90dBm at RF-connector.

Correct signal amplitudes approximately:

• GSM900~170mVpp

• GSM1800~140mVpp

• GSM1900~160mVpp

Signal part frequency 67.7kHz sine.

DC level of signal part is 1.35V. DC level can variate about +/-100mV between I and Q

signals and between different bands as well.

Page 24 Nokia Corporation. Issue 1 10/2003

Page 25

Company confidential RH-20

CCS Technical Documentation

Figure 19: GSM1900 RX I or Q signal (trace2), burst mode.

GSM1900 receiver burst mode I or Q signal at ch 661 with input signal 1960.067MHz,

level –90 dBm at RF-connector.

Trace2: With wider time scaling both monitoring and own RX bursts are seen, 1st burst

(shorter) is monitoring and 2nd burst (longer) is own RX burst.

Trace1: External LNA VCC supply voltage at burst mode, input level –90 dBm. Measured

from testpoint LNA_VCC.

Issue 1 10/2003 Nokia Corporation. Page 25

Page 26

RH-20 Company confidential

Figure 20: RX I&Q, phase difference 90 deg between signals.

CCS Technical Documentation

Detailed view of GSM900 continuous mode RX I and Q signals measured from testpoints

RXI and RXQ simultaneously.

Used channel 37, input signal 942.46771 MHz, level –90 dBm at antenna port, AGC setting 12.

Phase difference should be 90 degrees between RX I and Q signals at all bands.

Page 26 Nokia Corporation. Issue 1 10/2003

Page 27

Company confidential RH-20

A

q

A

–

A

)

A

CCS Technical Documentation

Troubleshooting diagram for GSM900 receiver

Phone in “Continuous” mode, AGC setting “12”

pply –90dBm

942.46771MHz signal

from generator to

antenna connector

Osilloscope at RX_I

signal 170mVpp DC

offset 1.35***

Fre

uency 67.7kHz

Rx 900 chain

functional

Check

L809,L810

Figure 21: GSM900 receiver troubleshooting

Note! Generator level can be set higher if

needed. Just note that levels will be different

in whole chain respectively.

Spectrumanalyzer:

ntenna Switch

output GSM900

88dBm

Spectrumanalyzer:

HELGO inputs

GSM900 –89dBm

Oscilloscope

VANT_1…3 0V

Check Antenna

Switch Z800

Spectrumanalyzer:

ntenna Switch

input –88dBm

Oscilloscope:Check

HELGO serial

interface (burst

mode

Check

C809

Check

Baseband

Check SAW

Z809

Check SAW

filter output

Oscilloscope:

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Spectrumanalyzer:

4G VCO output

3769.6MHz

~-30dBm*

Check HELGO

N500

Check

Baseband

Synthesizer

troubleshooting

Check HELGO

N500

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the nearest

PWB ground). Reading

value is represented without

+26 dB compensation.

* Spectrumanalyzer reading

with 1 kohm passive probe

(right value add +26dB)

*** DC-level of RXI/RXQ in

continuous mode will

decrase slowly. The original

level can be restored by

rewriting gain set

ll spectrumanal yzer

Issue 1 10/2003 Nokia Corporation. Page 27

Page 28

RH-20 Company confidential

A

q

A

A

)

A

Troubleshooting diagram for GSM1800 receiver

Phone in “Continuous” mode, AGC setting “12

CCS Technical Documentation

pply –90dBm

1842.86771MHz signal

from generator to

antenna connector

Osilloscope at RX_I

signal 170mVpp DC

offset 1.35***

Fre

uency 67.7kHz

Rx 1800 chain

functional

Check Z808,

L838,L839

Figure 22: GSM1800 receiver troubleshooting

Note! Generator level can be set higher if needed.

Spectrumanalyzer

ntenna Switch

output, GSM1800

-88dBm

Spectrumanalyzer

HELGO inputs

GSM1800 –88dBm

Just note that levels will be different in whole chain

respectively.

Spectrumanalyzer

input –84dBm

Oscilloscope

VANT_1…3 0V

Check Antenna

Switch Z800

ntenna Switch

Oscilloscope:Check

HELGO serial

interface (burst

mode

Check

C809

Check

Baseband

Check Z808

Check SAW

filter output

Oscilloscope

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Spectrumanalyzer

4G VCO output

3685.6MHz

~-30dBm*

Check HELGO

N500

Check

Baseband

Synthesizer

troubleshooting

Check HELGO

N500

ll spectrumanalyzer

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the nearest

PWB ground). Reading

value is represented without

+26 dB compensation.

* Spectrumanalyzer reading

with 1 kohm passive probe

(right value add +26dB)

*** DC-level of RXI/RXQ in

continuous mode will

decrase slowly. The original

level can be restored by

rewriting gain set

Page 28 Nokia Corporation. Issue 1 10/2003

Page 29

Company confidential RH-20

A

q

A

p

A

)

A

CCS Technical Documentation

Troubleshooting diagram for GSM1900 receiver

Phone in “Continuous” mode, AGC setting “12

Figure 23: GSM1900 receiver troubleshooting

pply –90dBm

1960.06771MHz signal

from generator to

antenna connector

Note! Generator level can be set higher

if needed. Just note that levels will be

different in whole chain respectively.

Osilloscope at RX_I

signal 160mVpp DC

offset 1.35***

uency 67.7kHz

Fre

Rx 1900 chain

functional

Spectrumanalyzer:

HELGO inputs

GSM1900 –88dBm

Check LNA

output from C829

–84dBm

Check Balun

T701 output

C808, C807

Spectrumanalyzer:

ntenna Switch

outputs, GSM1900

ut -88dBm

SAW in

Oscilloscope:

VANT_3 2.7V

VANT_1/2 0V

Spectrumanalyzer:

RX_SAW_out –

90dBm (C826)

Oscilloscope:

LNA_VCC 2.6

LNA_P 0V

Check Antenna

Switch Z800

Spectrumanalyzer:

ntenna Switch

input –84dBm

Oscilloscope:Check

HELGO serial

interface (burst

mode

Check Z806

Oscilloscope:

Check R800,

R810, L800

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Check

C809

Check

Baseband

Check HELGO

N500

Check Baseband

Oscilloscope:

VR1,3…6 2.7V

Check HELGO

serial interface

(burst mode)

Spectrumanalyzer:

4G VCO output

3920 MHz

~-30dBm*

Check HELGO

N500

Check

Balun

Check

Baseband

Synthesizer

troubleshooting

Check C808,

L805, C807

Check

HELGO N500

ll spectrumanalyzer

reading values are

measured with 1 kohm

passive probe (use

tweezers to connect the

probe ground to the nearest

PWB ground). Reading

value is represented without

+26 dB compensation.

* Spectrumanalyzer reading

with 1 kohm passive probe

(right value add +26dB)

*** DC-level of RXI/RXQ in

continuous mode will

decrase slowly. The original

level can be restored by

rewriting gain set

Issue 1 10/2003 Nokia Corporation. Page 29

Page 30

RH-20 Company confidential

Synthesizer

General instructions for synthesizer troubleshooting

Connect test jig to computer with DAU9S cable or to FPS-8 Flash Prommer with XCS-4

modular cable.

Make sure that you have PKD-1 dongle connected to computers parallel port.

Connect DC power supply or FPS-8 to module test jig with PCS-1 cable.

Set the DC supply voltage to 4.2V.

Set the phone module to test jig and start Phoenix service sofware

Initialize connection to phone. (use FBUS driver when using DAU9S and COMBOX driver

when using FPS-8)

CCS Technical Documentation

Select product from the menu

File -> Choose product -> RH-20

From toolbar set operating mode to "Local"

Activate RF controls window from the menu

Testing -> RF Controls

From the RF controls window

- Select band "GSM900", "GSM 1800" or "GSM1900" (Default = "GSM900")

- Set Active unit to "Rx" (Default = "Rx")

- Set Operation mode to "Continuous" (Default = "Burst")

- Set Rx/Tx channel to 37 on GSM900 band, 700 on GSM1800 band, 661 on GSM1900

band (Defaults)

Page 30 Nokia Corporation. Issue 1 10/2003

Page 31

Company confidential RH-20

CCS Technical Documentation

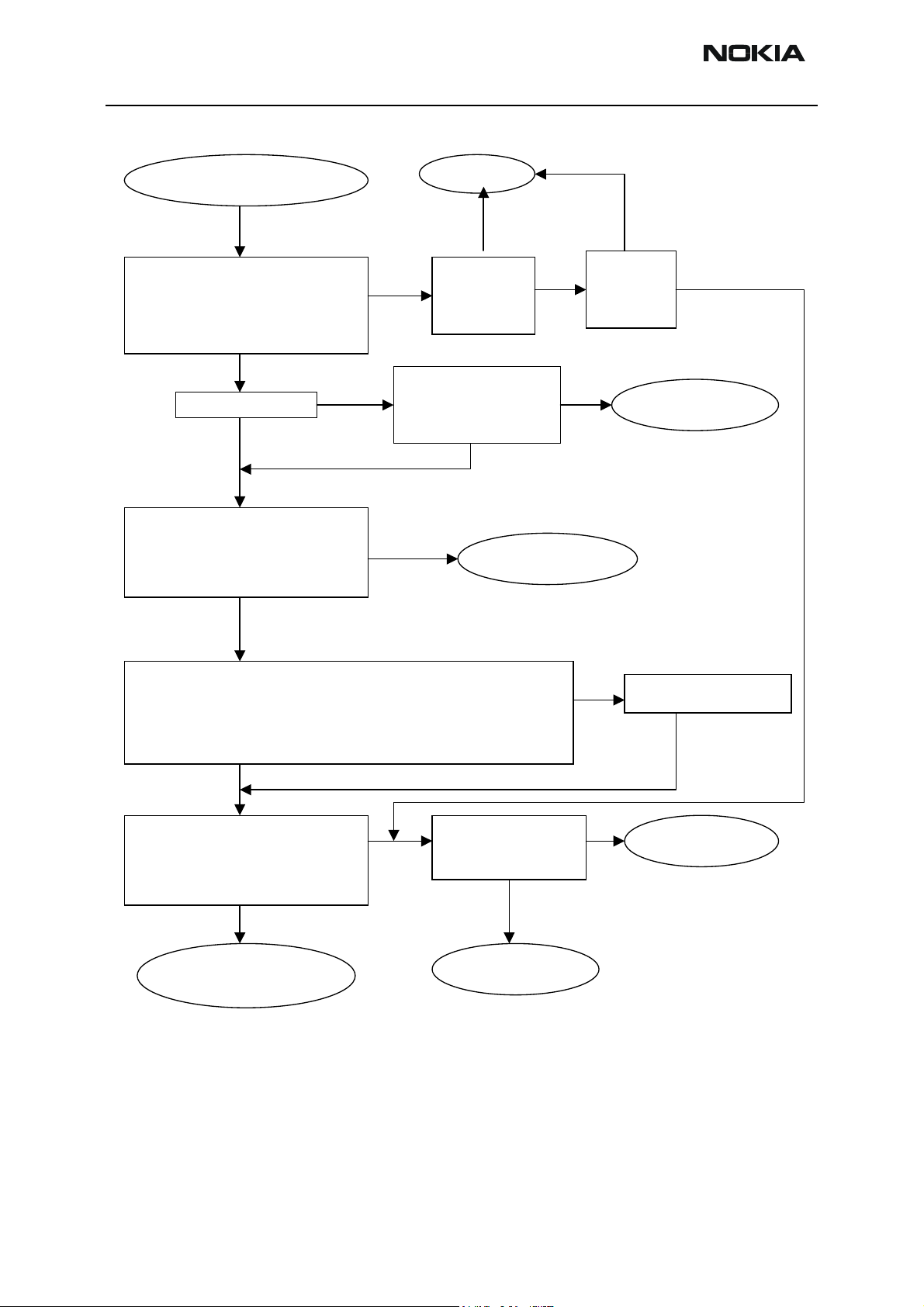

Figure 24: Synthesizer troubleshooting diagram

Synthesizer

troubleshooting

*(When 2.5kOhm passive probe is used,

Yes

correct the measurement by +34 dB

Set with RF controls:

Active Unti = Rx

Operation mode = Continuous

Check with RF probe:

-4G VCO out signal

- 3589.6 MHz (GSM900)

-3495.6 MHz (GSM1800)

- 3760 MHz (GSM1900)

Level >-10dBm (*

OK ?

No

VCO out signal level<-10dBm

No

Check output signal on

1 GHz span

Signal found on

incorrect frequency ?

Yes

Yes

Synthesizer

OK

Yes

Check with oscilloscope:

-4G VCO Vcc = 2.7V

No

Check balun

output levels and

solder joints

OK ?

No

Replace

faulty

component(s)

OK ?

No

Yes

Yes

Baseband

troubleshooting

Replace

VCO

Check with oscilloscope:

VCO control voltage

from VCO pin

0V ?

No

Check with oscilloscope:

VCO control voltage

from VCO pin

>4.0 V ?

Yes

Check balun

output levels and

solder joints

OK ?

Yes

Check VCO control

loop components

Yes

OK ?

Replace

VCO

No

Replace

faulty

component(s)

No

Issue 1 10/2003 Nokia Corporation. Page 31

Page 32

RH-20 Company confidential

Pictures of synthesizer signals

Figure 25: 26MHz at G501 pin out

CCS Technical Documentation

Figure 26:

26MHz RFCLK at R420/C420

Page 32 Nokia Corporation. Issue 1 10/2003

Page 33

Company confidential RH-20

CCS Technical Documentation

Figure 27: 1800 TX, channel 512, burst mode

Figure 28: 1900 RX, channel 810, continuous mode

Issue 1 10/2003 Nokia Corporation. Page 33

Page 34

RH-20 Company confidential

Figure 29: VCO output, 1800 band, ch700, RX on, continuous output

CCS Technical Documentation

Page 34 Nokia Corporation. Issue 1 10/2003

Page 35

Company confidential RH-20

CCS Technical Documentation

Baseband troubleshooting

Figure 1: Basic baseband test points

Issue 1 10/2003 Nokia Corporation. Page 35

Page 36

RH-20 Company confidential

CCS Technical Documentation

Page 36 Nokia Corporation. Issue 1 10/2003

Page 37

Company confidential RH-20

CCS Technical Documentation

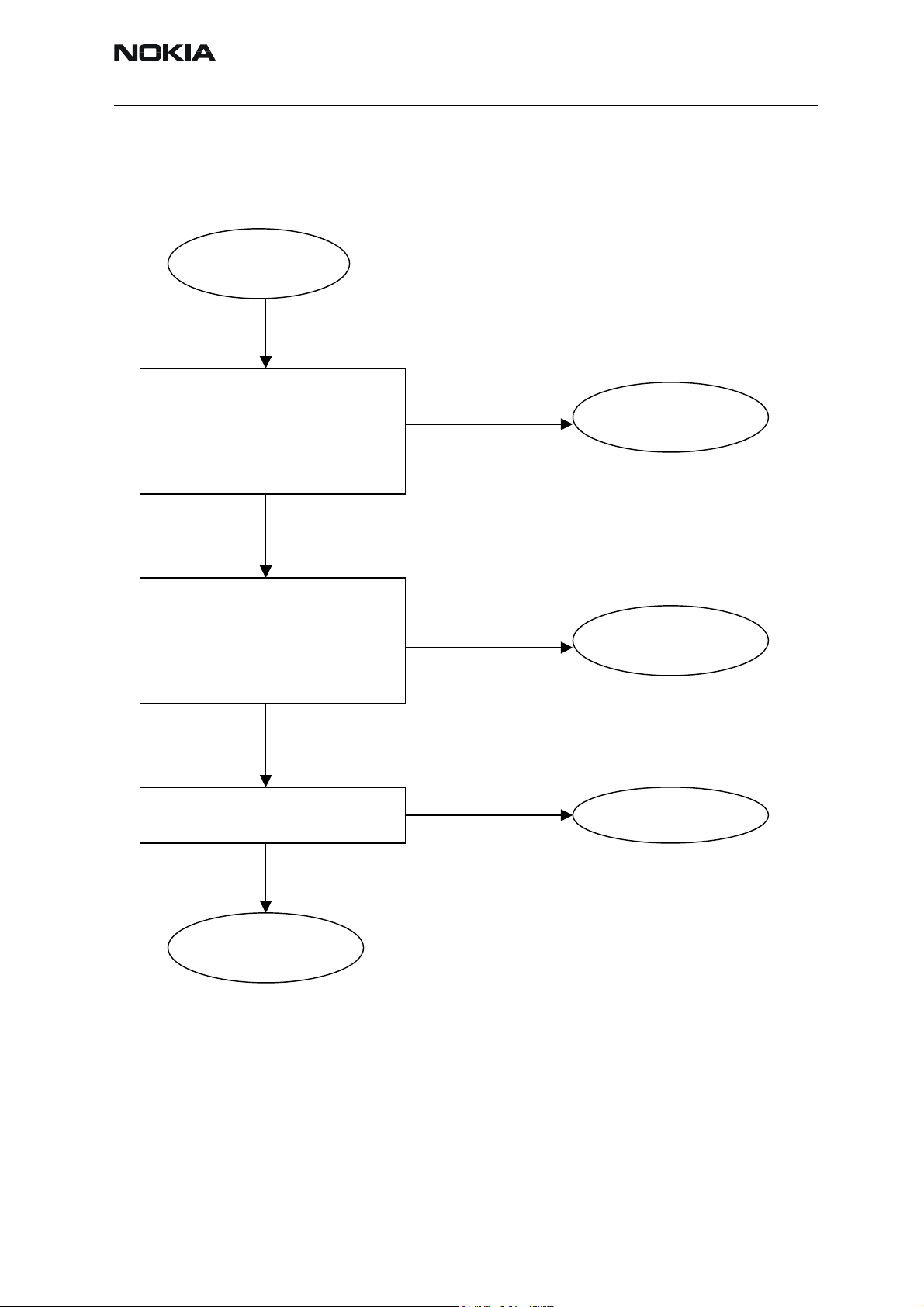

The following diagrams describe baseband troubleshooting.

Main Troubleshooting Diagram

Figure 2: Baseband general troubleshooting

Issue 1 10/2003 Nokia Corporation. Page 37

Page 38

RH-20 Company confidential

Phone is dead

Figure 3: Dead phone troubleshooting

Start

Check X100

Is phone current

0 mA?

No

Yes

(contacts,

solderings). Is it

OK?

Yes

Check L260 -

L265 and C260 -

C265. Are they

OK?

Yes

CCS Technical Documentation

No

No

Change X100

Change defect

ones

Phone current

< 50 mA

No

Phone current

~54 mA

Yes

Is phone in

LOCAL mode ?

Yes

No

No

Check all

VBATT-lines

Is flash

programming

working OK?

No

Check BSI-line including

X100,C100,C240,R202

and R206. Are they OK?

Yes

Yes

Phone is

jammed

Flash fault

Change UEM

Yes

No

Change defect part

End

Page 38 Nokia Corporation. Issue 1 10/2003

Page 39

Company confidential RH-20

CCS Technical Documentation

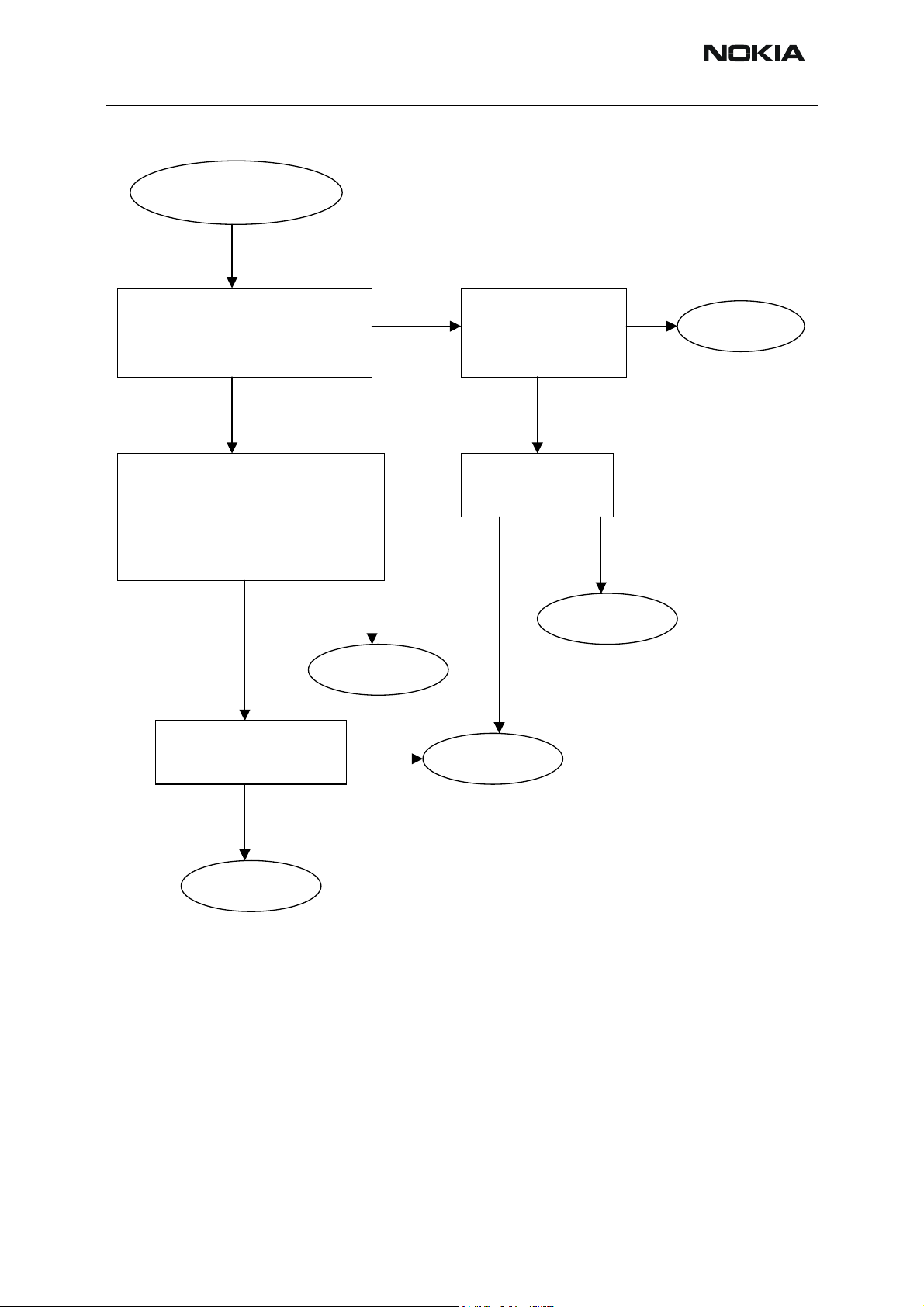

Flash Programming Fault

Figure 4: Flash programming troubleshooting

Start

Is the FBUS

TX-line HIGH

after startup?

Yes

Is FBUSTX-line

set to LOW after

it has been

HIGH?

Yes

Wrong

manufactor ID

and device ID

No

No

No

Measure BSI-pulse

during Flash

operation. Is it OK?

Yes

Measure FBUSTX-line

during Flash operation

(J411). Is it ~1.8V?.

Yes

Yes

No

No

Check BSI-line including

X100,C100,C240,R202

and R206.

Check R104.

If OK, change UEM

Change UPP

Change Flash

Is phone totally

dead?

No

Phone doesn't

start up or it's

jammed?

No

End (retest)

Yes

Yes

Phone is dead

Phone is

jammed

Issue 1 10/2003 Nokia Corporation. Page 39

Page 40

RH-20 Company confidential

Phone is jammed

Figure 5: Jammed phone troubleshooting (1)

Phone is jammed

CCS Technical Documentation

Measure VIO, VCORE,

VFLASH1, VANA,

VR3 voltages.

Are they OK ?

Yes

Measure 32kHz

SleepClk from t estpoint J404.

Is it OK ?

Yes

Measure 26MHz

RFClk from R420.

Is it OK ?

Check VBATT1-6

VIO,VCORE,VFLASH1,VANA,

No

No

No

VR3 lines.

Are they OK ?

Measure 32kHz

SleepClkfrom B200.

Is it OK ?

Measure 26MHz

RFCLK from G501.

Is i t OK ?

Yes

Yes

No

No

No

Check L260-265,

C260-265,

BSI/BTEMP lines and

VBATT lines

Check BSI/BTEMP

lines . If OK, change

UEM

Check B200,C209,

C210

Change UEM

Check G501,

R520,C540.

If OK change G501

Yes

Measure PURX signal

from testpoint J402.

Is it HIGH (~1.8V) ?

Yes

Phone is

jammed

2

Yes

No

Check R420, C420.

If OK change N500

Change UEM

Page 40 Nokia Corporation. Issue 1 10/2003

Page 41

Company confidential RH-20

AO

CCS Technical Documentation

Figure 6: Jammed phone troubleshooting (2)

Phone is

jammed

2

Phone Shutdown

after 30s

Yes

Measure

watchdog signal

CBUSDA from J414.

Is it OK ?

No

Change

UPP

No

Measure

CBUSClk 1MHz signal

from testpoint J406.

Is it OK ?

Yes

Read phone info.

Is i t OK ?

Yes

No

No

Yes

Retest

Measure FBUSRx

signal during phone info

read from testpoint J412.

Is it OK ?

Yes

No

Change

UEM

Measure FBUSTx

Change

UPP

Change

UEM

Change wv8

1

module or

retest

signal during phone info

read from testpoint J411.

Is it OK ?

Yes

No

Issue 1 10/2003 Nokia Corporation. Page 41

Page 42

RH-20 Company confidential

SIM card fault (Insert SIM / Card rejected)

Figure 7: SIM card troubleshooting

Start

CCS Technical Documentation

Insert SIMor

Card rejected

fault?

No

End

Yes

Set phone to LOCAL

mode. Is it OK?

Yes

Measure VSIM voltage

from X386. Is it ~3.0V?

Yes

Check SIM power-up

sequence. Is it OK?

Yes

No

No

No

Check BSI-line including

X100,C100,C240,R202 and

R206. If OK, change UEM.

Check VSIM-line

(X386,C390,R386,C203).

If OK, change R388.

If still fail, change UEM.

Check SIM lines (X386). If

OK, change R388. If still fail,

change UEM.

Change UPP

Page 42 Nokia Corporation. Issue 1 10/2003

Page 43

Company confidential RH-20

CCS Technical Documentation

Keypad Fault

Figure 8: Keypad troubleshooting (1)

Start

Is the power key

working?

Yes

Is the volume

UP key working?

Yes

Measure voltage

No No

from S302. Is it

HIGH?

Yes

Measure voltage

from S302 when

pressed. Is it

HIGH?

Yes

No

Phone is

jammed

Measure ROW0

No No

line from S300.

Is it ~1.8V?

Yes

Measure COL0

from S300 when

pressed. Is there

50us pulse?

No

Check

R306,C310,S30

2 and line. If OK,

change UEM

Check S302. Is

it OK?

Yes

No

Check S300 and line.

If OK, change Z300.If

still FAIL, change

UPP

Check S300 and

COL0 line. If OK,

change Z300.If still

FAIL, change UPP

Phone is

dead

Change S302

Change UPP

Check S301 and line.

If OK, change Z300.If

still FAIL, change

UPP

Is the volume

Down key

working?

Yes

Measure ROW1

No No

line from S301.

Is it ~1.8V?

Yes

Yes

Continue

Measure COL0

from S301 when

pressed. Is there

50us pulse?

No

Yes

Check S301 and

COL0 line. If OK,

change Z300.If still

FAIL, change UPP

Change UPP

Issue 1 10/2003 Nokia Corporation. Page 43

Page 44

RH-20 Company confidential

Figure 9: Keypad troubleshooting (2)

Continue

Try to change UI

Is the UI-module

keys working?

No

PWB. Are the

keys working

now?

No

Check X301 (solder

joints and spring

contacts). Is it OK?

Yes

No

CCS Technical Documentation

Retest failing

UI-module

Change X301

Yes

Measure ROW0 - Row4

lines from X301. Are

voltage level ~1.8V?

Yes

Measure

SLEEPX-signal from

testpoint J403 when

key is pressed.

Is voltage level

~1.8V?

Yes

When keypad is

pressed, are the

LED's turned on?

No

Check lines ROW0 -

ROW4 from X301.

No

If OK, change Z300. If

still fails, change UPP

No

Illumination

End

fault

Page 44 Nokia Corporation. Issue 1 10/2003

Page 45

Company confidential RH-20

CCS Technical Documentation

Display Fault

Start

Does the display

start?

Yes

No

Figure 10: Display troubleshooting

Try to change

UI-module. Is

the display

working now?

Yes

No

Check X302

(solder joints). Is

it OK?

No

Retest failing

UI-module

Change X302

Yes

Measure VDD (2.7V)

and VDDI (1.8V). Are

they OK?

Yes

Measure RESX(J306)

and CSX (J304)

signals. Are voltage

levels ~1.8V??

Yes

Measure SDA (J305)

and SCLK (J307)

signals. Are voltage

levels ~1.8V?

Yes

No

No

No

Check X302 and

lines again. If OK,

change UEM

Check X302 and

lines again. If OK,

change UPP

Check X302,

R308,R309 and

lines. If OK,

change UPP.

Are the display LED's

working when key is

pressed or enabled by

No

Illumination

fault

Phoenix SW?

End

Issue 1 10/2003 Nokia Corporation. Page 45

Page 46

RH-20 Company confidential

Illumination fault

Figure 11: Backlight troubleshooting

Start

CCS Technical Documentation

Are the display

LED's working?

Yes

Are the

keyboard LED's

working?

Yes

Try to change display.

No

Are the LED's working

now?

No

Check X302 (solder

joints). Is it OK?

Yes

Measure VLED+ and VLED-.

VLED+ = ~7.5V and VLED= ~0.5V when LED driver is

enabled. Are they OK?

(Notice: VLED+=VBATT

when driver is disabled)

Try to change UI PWB.

No

Are the LED's working

now?

No

Check X301 (solder

joints). Is it OK?

Yes

No

No

Yes

No

Retest failing display

Change X302

Check N300, L300, V300, R300,C303,C304.

If not OK, change defect part.

Retest failing UI PWB

Change X301

Yes

End

Measure VLED+. VLED+ =

~7.5V when LED driver is

enabled. Is it OK?

Yes

Check all LED's in UI PWB

(V101 - V106). Are they OK?

Yes

Retest

Check N300, L300, V300, R300,C303,C304.

No

No

If not OK, change defect part.

Change defect parts

Page 46 Nokia Corporation. Issue 1 10/2003

Page 47

Company confidential RH-20

CCS Technical Documentation

Charger Fault

Figure 12: Charging troubleshooting

Start

Battery bars are

working (scroll)

No

Measure voltage

over V100

(TVS).

Is it > 3.0V?

Yes

Read BTEMP value.

Compare it to ambient

temperature.

Is it ~25C?

Yes

Yes

No

No

Check X102, F100,

L100, V100, C106, C110

and line.

Check X100, C100,

R202, R207, C220

and line. Are they

OK?

Yes

No

Retest

Change defect part (if

any), re-calibrate charge

current/voltage. Retest.

Re-calibrate BTEMP with

Phoenix SW. Retest.

Change defect part,

re-calibrate and retest.

Measure charger

current throug F100.

Is it ~350...390mA

(with ACP-7)?

Yes

Retest

No Yes

Check R200. Is it

OK?

No

Change UEM

Change defect part,

re-calibrate charge

current/voltage. Retest.

Issue 1 10/2003 Nokia Corporation. Page 47

Page 48

RH-20 Company confidential

Accessory Fault

Figure 13: Accessory troubleshooting

Start

CCS Technical Documentation

Is accessory detected

when connected to

system connector?

Yes

No

Check system

connector X101

(solder ings, contact

plates). Is it OK?

Yes

Measure ACI-line

(pin3).

Is it ~0.83...1.13V?

Yes

Measure VOUT

voltage (pin4).

Is it ~2.8V?

Yes

Retest

No

No

No

Repair solderings or check contact

plates if dirty. Retest.

ACI-Accessory

Check ACI- line (L106,R103,R102,R109,C103).

If not OK, change defect part and retest.

Check VOUT-line (N100, L107, R103, C101,

C102, C112).

If not OK, change defect part and retest.

Non-ACI Accessory

End

Measure ACI-line

(pin3).

Is it ~0V?

Yes

Measure VOUT

voltage (pin4).

Is it ~0V?

Yes

Retest

No

No

Check ACI- line (L106,R103,R102,R109,C103).

If not OK, change defect part and retest.

Check that regulator N100 enable-pin is

LOW-state.

If not OK, check ACI-line again

Page 48 Nokia Corporation. Issue 1 10/2003

Page 49

Company confidential RH-20

CCS Technical Documentation

Audio Fault

Figure 14: Audio troubleshooting (1)

Audio fault s

Is earpiece

working ?

Yes

No Yes

Change old UI -module back.Set

phone to LOCAL mode. Using

Phoenix Audiotest set EXT IN, HP

Try to change

UI- module. Is it working

now ?

No

OUT, LOOP ON

Check earpiece

cont act springs from

old UI-module and

change earpiec e and

foam to old UI-

module.

Retest .

Measure DC-

offset voltage between earpiece

pads J310/J311 and GND. Is it

~1.38V ?

Yes

Measure

MICB2 voltage from

XMICP (L102 input).

Is it ~2.1V ?

Yes

No

No

Check L150, C155,

R151, R152 and line.

If OK change UEM

Check L102, C116,

C150, R153, C159,

R158 and line.

If OK change UEM.

Audio fault s

2

Earpiece

2

Issue 1 10/2003 Nokia Corporation. Page 49

Page 50

RH-20 Company confidential

Figure 15: Audio troubleshooting (2)

Earpiece

2

Connect EXT audio

signal 1kHz (s ine,

200mVpp) between

XMICP and XMICN

pads (X101, 9/10)

CCS Technical Documentation

Measure sine

signal from earpiece

pads (J310,J311).

Is It ~880mVpp ?

Yes

Change UPP

Retest

No

Measure sine

signal to UEM (R155).

Is it ~130mVpp ?

No

Yes

Check C154. If OK

change UEM

Check C154, R155,

C156, R154, C159,

R158, R159 and lines.

Page 50 Nokia Corporation. Issue 1 10/2003

Page 51

Company confidential RH-20

CCS Technical Documentation

Figure 16: Audio troubleshooting (3)

Audio fault s

2

Is microphone

working ?

Yes

Try to change new

No Yes

UI-module. Is it working

now ?

No

Restore old UI module. Set phone to

LOCAL mode. Using Phoenix

Audiotest set HP IN, EXT OUT,

LOOP ON

Measure MICB1-

voltage from MICP pad.

Is it ~2.1V ?

Yes

No

Check mic contact springs

from old UI module.

If not OK replace

microphone in old UI

module with new one.

Retest .

Check L101, C151,

C152, C153, R156,

R157.

If OK change UEM

Audio fault s

3

Check C151, R157,

C153 and line.

If OK change UEM if

still fail change UPP

Issue 1 10/2003 Nokia Corporation. Page 51

Page 52

RH-20 Company confidential

Figure 17: Audio troubleshooting (4)

Audio faults

3

CCS Technical Documentation

IHF speaker

working ?

Yes

END

Check C160,

C161, C169,

C166, R163,

L151, L152, C164

and IHF PA out put

lines .

Retest .

Try to change new C-

No

Set phone to loc al mode with Phoenix.

Set buzzer ON, vol "9" and freq. to 1kHz.

cover assembly. Is it

Restore old C-cover.

No

Yes

level between IHF

pads J156/J157 to

GND. Is it ~1.8V ?

working now?

No

Measure DC-

IHF speaker or

Yes

Check signal in C161.

contact springs

fault.

Retest .

Yes

Measure AC-

level between IHF

pads (J156,J157).

Is it ~1.0Vrms ?

No

Is it OK ?

Yes

contact springs

Yes

Check C161,

C160, R163,

C169, C170,

No

R170, C171.

change UEM

Speaker

faults.

Retest .

If OK then

Check IHF PA

controls on J152,

J153, J154.

Is it OK ?

No

Change UPP

Yes

Change IHF

PA (N150)

Page 52 Nokia Corporation. Issue 1 10/2003

Page 53

Company confidential RH-20

CCS Technical Documentation

Camera Troubleshooting

Figure 18: Component placement

Figure 19: Trace layout

Issue 1 10/2003 Nokia Corporation. Page 53

Page 54

RH-20 Company confidential

Camera Fault

Camera troubleshooting diagram

CCS Technical Documentation

Page 54 Nokia Corporation. Issue 1 10/2003

Page 55

Company confidential RH-20

CCS Technical Documentation

FM Radio troubleshooting

Figure 20: FM Radio Component layout

Figure 21: Trace layout.

Issue 1 10/2003 Nokia Corporation. Page 55

Page 56

RH-20 Company confidential

Figure 22: FM radio block layout.

Components L103, L104, L105, C107, C108, C109, C117, C162, C163, R164, R165, R166

and R167 are not shown in the picture. Those components are placed in baseband section, near audio amplifier N150.

CCS Technical Documentation

FM Radio troubleshooting diagram

Notes to "FM Radio troubleshooting diagram"

Use 1MHz 1X probe when measuring Audio and clock signals with oscilloscope.

Use active RF probe when measuring frequencies with spectrum analyzer.

Note 1. RF test signal parameters:

- Amplitude, A, –67.0 dBm

- Carrier frequency, f

- Deviation, ∆f, 75 kHz

- Modulating frequency f

- FM stereo, mode R=L, pilot state ON

, 98,000 MHz

c

, 1,000 kHz (RF generator internal)

m

Page 56 Nokia Corporation. Issue 1 10/2003

Page 57

Company confidential RH-20

CCS Technical Documentation

Figure 23: FM radio troubleshooting diagram

Set phone into local mode.

Start FM radio.

Does

the radio

start ?

YES

Connect RF test signal (note1)

Set radio channel to 98.0 MHz

Set radio volume to max.

Measure

Audio signal

from C162 and

C163.

Is it 1kHz

0.5–0.8Vp–p?

NO

Check

C107, C108,

C109, C117 ,

L105,C367,C378,

C379, L358.

Measure signal

from C162, C163

Is it 1kHz

0.5–0.8

Vp–p?

NO

Check

R359,R360,

V356, V357,

L356,L357,C357,

C358,C362.

Measure

signal from

J103, J104,

OK ?

NO

Change

N356.

Measure signal

from J103 and J104.

Is it

OK ?

Check

NO NO

YES

YES

YES

YES

C374, C375, R375,

R358 and measure

32kHz clock signal

from J359,

retest starting.

Start OK ?

YES

Check

R164,

R165, R166,

R167, L103,L104

Measure

signal from J103

and J104.

Is it

0.015–0.3

Vp–p?

YES

OK, RETEST IN FLALI

NO

Measure

voltages from

pins 7 and 34,

is it –2.7 V ?

Retest starting.

Start OK now ?

Set

Radio and RF generator

to 87.5 and 108.0 MHz.

Measure Audio from

C162 and C163.

Are both cases

1 kHz 0.5 – 0.8 Vp–p ?

NO

Check

V356, V357, L356,

L357, C357, C358, C362,

R359, R360.

T est again with

87.5 and 108.0 MHz.

Measure audio from

C162 and C163.

Both

OK?

NO

Change

V356 and 357.

BOTH !

Retest with

87.5 and 108.0 MHz.

Measure audio from

C162 and C163.

Both OK ?

NO

NO

(pins 5,6,7,8,9,11,

12,13,17,33,34,35,

Check

N356 solders

36, 37.

Start OK

now ?

YESYES

YES

YES

NO

Change

N356.

Radio start

OK

now?

NO

Baseband digital

fault (UPP)

YES

Audio

Amplifier

failure

(N150)

NO

Change

radio module TB4

OK, RETEST IN FLALI

E Nokia Corporation

Issue 1 10/2003 Nokia Corporation. Page 57

Page 58

RH-20 Company confidential

Diagrams of FM radio signals

Figure 24: Oscilloscope screen shot, Audio output

CCS Technical Documentation

Signal 1: Audio output from PWB test points J103 and J104, with FM test signal, volume

100%.

Signal 2: Audio output from FM radio pins 22 and 23(same as in C162 and C163), with

FM test signa

Figure 25: FM radio clock from test point J359, 32 kHz frequency clock signal, when radio is on.l

Page 58 Nokia Corporation. Issue 1 10/2003

Page 59

Company confidential RH-20

CCS Technical Documentation

Figure 26: FM frequency from FM radio pin 37, the other end of L358, with FM test signal

15:51:49 03 JUL 2002

PEAK

LOG

10

dB/

MKR 97.9280 MHz

#AT 0 dBREF -20.0 dBm

-71.03 dBm

SWEEP

CONT SGL

FREE RUN

VIDEO

LINE

WA SB

CORR

SC FS

CENTER 98.0000 MHz SPAN 300.0 kHz

#RES BW 10 kHz VBW 10 kHz #SWP 1.00 sec

EXTERNAL

SYNC CRD

TV TRIG

Figure 27: VCO frequency from FM radio pins 3 and 4, the other ends of V356 and V357, with FM test signal

10:46:24 03 JUL 2002

PEAK

LOG

10

dB/

WA SB

CORR

SC FS

#AT 10 dBREF .0 dBm

MKR

196.440 MHz

-9.40 dB

MEAS UNCAL

SWEEP

CONT SGL

FREE RUN

VIDEO

LINE

EXTERNAL

SYNC CRD

CENTER 196.450 MHz SPAN 1.000 MHz

#RES BW 10 kHz #VBW 10 kHz #SWP 20.0 msec

TV TRIG

Issue 1 10/2003 Nokia Corporation. Page 59

Page 60

RH-20 Company confidential

CCS Technical Documentation

This page left blank intentionally.

Page 60 Nokia Corporation. Issue 1 10/2003

Loading...

Loading...