Page 1

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

CONFIDENTIAL

1 (29)

Repairhints

6210/6250

NPE-3/NHM-3

HDa13/S 893

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 2

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

CONFIDENTIAL

2 (29)

GENERAL

-How to use this document

Put the QUICK REPAIR layouts behind this manual.

Now you are able to follow these specifications with graphical layouts and it is easier for you to find the

components and measuring points.

-Component characteristics:

Some components contain important data.

Several described steps are only practicable if you are able to reflash/ realign the phone and/or rewrite

IMEI/SIMlock in certain cases. Please pay attention to separate notes.

-Underfills, broken balls, µBGA

It is not possible to change underfilled components. The trial will damage PCB surely. All replaceable

µBGA-components must be renewed after removing. Reflow is not allowed.

Check soldering points, remove oxidated solderings (broken balls) carefully by enclosing few new solder

before placing new components.

µBGA must be soldered only with NMP approved µBGA-rework machines (e.g. Zevac/OK International).

Use only recommended Fluxtype and an appropriate amount of it.

-PCB handling

Only use appropriate cleaning materials, don`t use scratching or rubbing tools. Clean PCB carefully after

every rework and take great pains over the keyboard area. Don´t make any loose wiring connections

anywhere.

If it is necessary to change any item located under the metal shields, remove the shield first, don´t cut

partially or bend it. Take care: Corners of the lids are sharp, insuries are possible !

Shields and screws must be renewed after removal.

-Realign after repair

Characteristics of replacement parts are different.

To prevent additional faults after repair (eg. low standby time, loosing network etc…) it is necessary

to retune phone values after repair.

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 3

CONFIDENTIAL

3 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

INTRODUCTION

IMPORTANT:

This document is intended for use by authorized NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA 6210/6250 phones.

It contains a lot of collected tips and hints to find failures and repair solutions easily.

It also will give support to the inexperienced technicians.

Saving process time and improving the repair quality is the aim of using this document.

We have build it up based on fault symptoms (listed in "Contents") followed by detailed description for further

analysis.

It is to be used additionally to the service manual and other service information like Service Bulletins, for that

reason it doesn't contain any circuit descriptions or schematics.

All measurements are made using following equipment:

Nokia repair SW : WinTesla Version 6.43

DLL version : 311.03.00

Nokia Module Jig : JBT-13 / MJS-23

Digital multimeter : Fluke 73

Oscilloscope : Hitachi V-1565; Fluke PM 3380A/B

Spectrum Analyzer : Advantest R3162 with an analogue probe

RF-Generator / : Rohde & Schwarz CMU 200

GSM Tester

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If any errors

are found by the reader, NOKIA should be notified in writing, using following procedure :

Please state:

Title of the Document + Issue Number/Date of publication.

Page(s) and/or Figure(s) in error.

Please send to: Nokia GmbH

Service & Analysis Center Europe

Meesmannstr.103

D-44807 Bochum / Germany

Email: training.sace@nokia.com

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 4

CONFIDENTIAL

4 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

Contents

GENERAL 2

INTRODUCTION 3

GENERAL TUNING INFORMATION 5

USER INTERFACE FAILURES 11

SIMCARD FAILURES 13

CHARGING PROBLEMS 14

CONTACT SERVICE 15

PHONE DOES NOT SWITCH ON 17

LOW STANDBY/OPERATION MODE TIME 18

FLASH UPDATE NOT POSSIBLE 18

NO SERVICE PROBLEMS 19

SIGNAL CHARTS 25

FREQUENCY LIST 26

SPECIAL INFORMATION FOR NHM-3 27

CHANGE HISTORY 29

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 5

CONFIDENTIAL

5 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

GENERAL TUNING INFORMATION - DIFFERENCES TO EARLIER PHONES

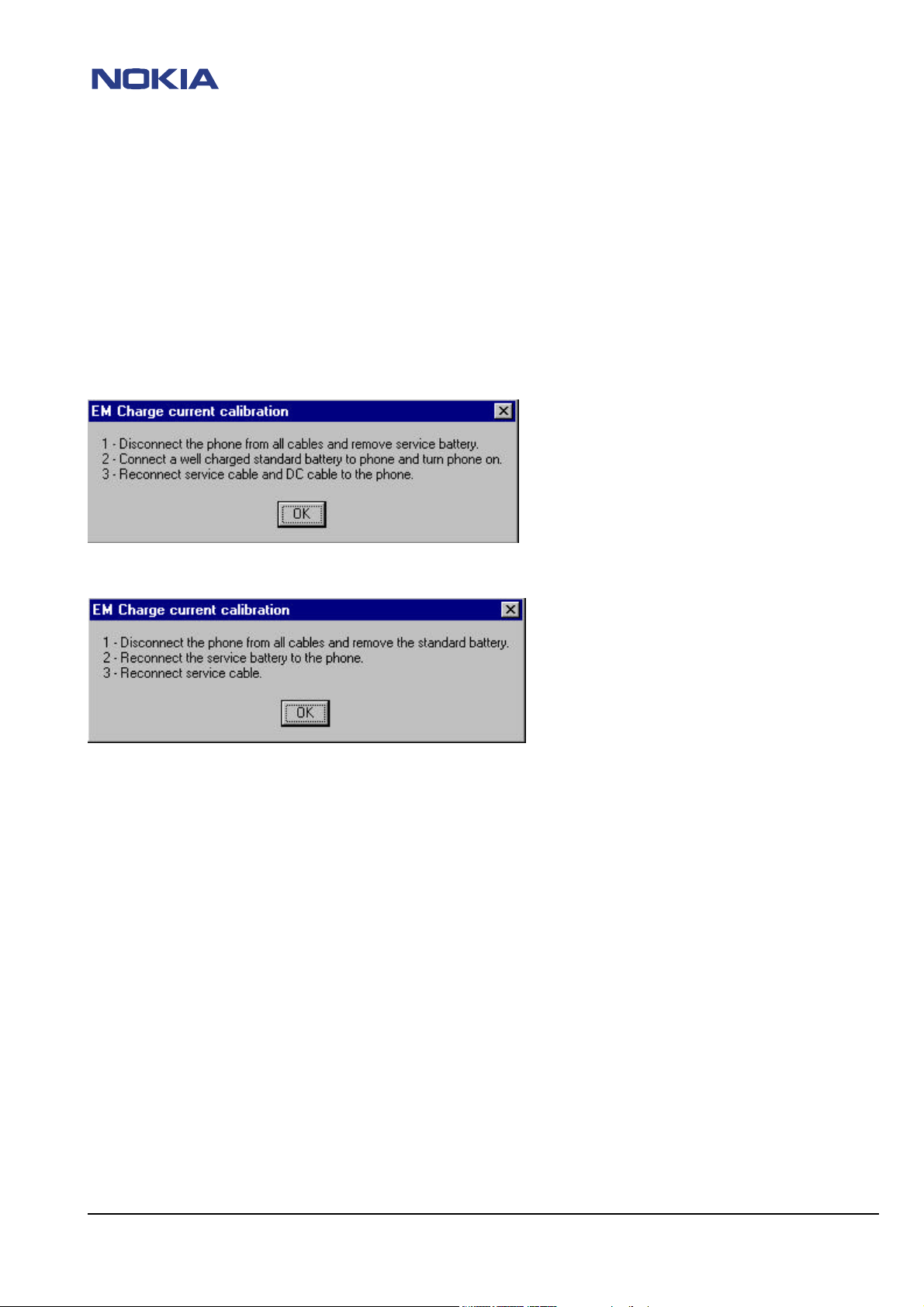

Energy management calibration information

If it is necessary to realign, it is imperative to follow the instructions displayed in the pop-up windows!

As soon as you take an other order as given from WinTesla, the alignment will be failed or will stop and you must begin once

more.

Follow these instructions as shown in pictures and your energy management calibration will work.

First step: (Charge current)

Second step: (Charge current)

If all of the measurements are OK, the values are now adjusted.

If one or more values failed, see charging problems on page #14.

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 6

CONFIDENTIAL

6 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

TX tuning

Has to be tuned in both bands, but only on middle channels :

CH38 – 897,6 MHz for EGSM and CH700 – 1747,8 MHz for PCN.

TX I/Q tuning has to be done for both bands.

Reference are always target- values given from WINTESLA.

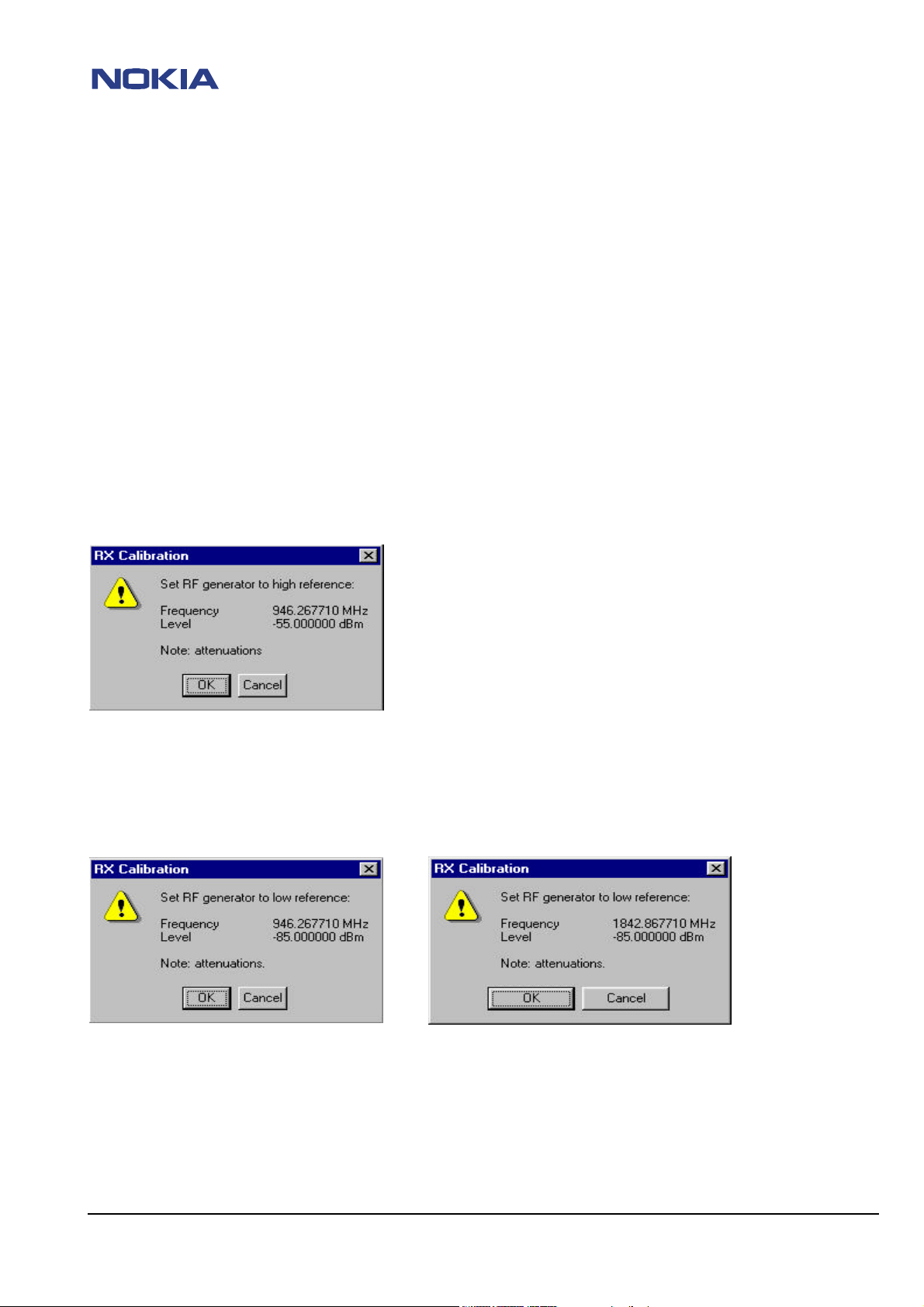

RX calibration

RSSI (Radio / Received Signal Strength Indicator)

The "RX calibration" is used to determine gain at different gain-settings for front-end and Hagar and needs to be done in both

bands, but the calibration only has to be started once, it will automatically proceed to the PCN band after EGSM.

Note: If the frequency in your Wintesla is different from 946.2671 MHz ,you will have to close Wintesla and add or edit

these lines in your tesla.ini file:

[NPE-3_TUNING]

RXChannelGSM =56

TXChannelGSM =38

Restart Wintesla and redo RX Calibration.

Note if the low level in your Wintesla is different from –85dBm, you will have to close Wintesla and add these lines in your

tesla.ini file:

[NPE-3LEVELS]

RSSILow =-85

RSSIHigh =-55

Restart Wintesla and redo RX Calibration

Note : Check if AGC-values are in ascending order (10dBm/step, exception: In PCN mode gainstep 2 to 3 is only ~5dBm)

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 7

CONFIDENTIAL

7 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

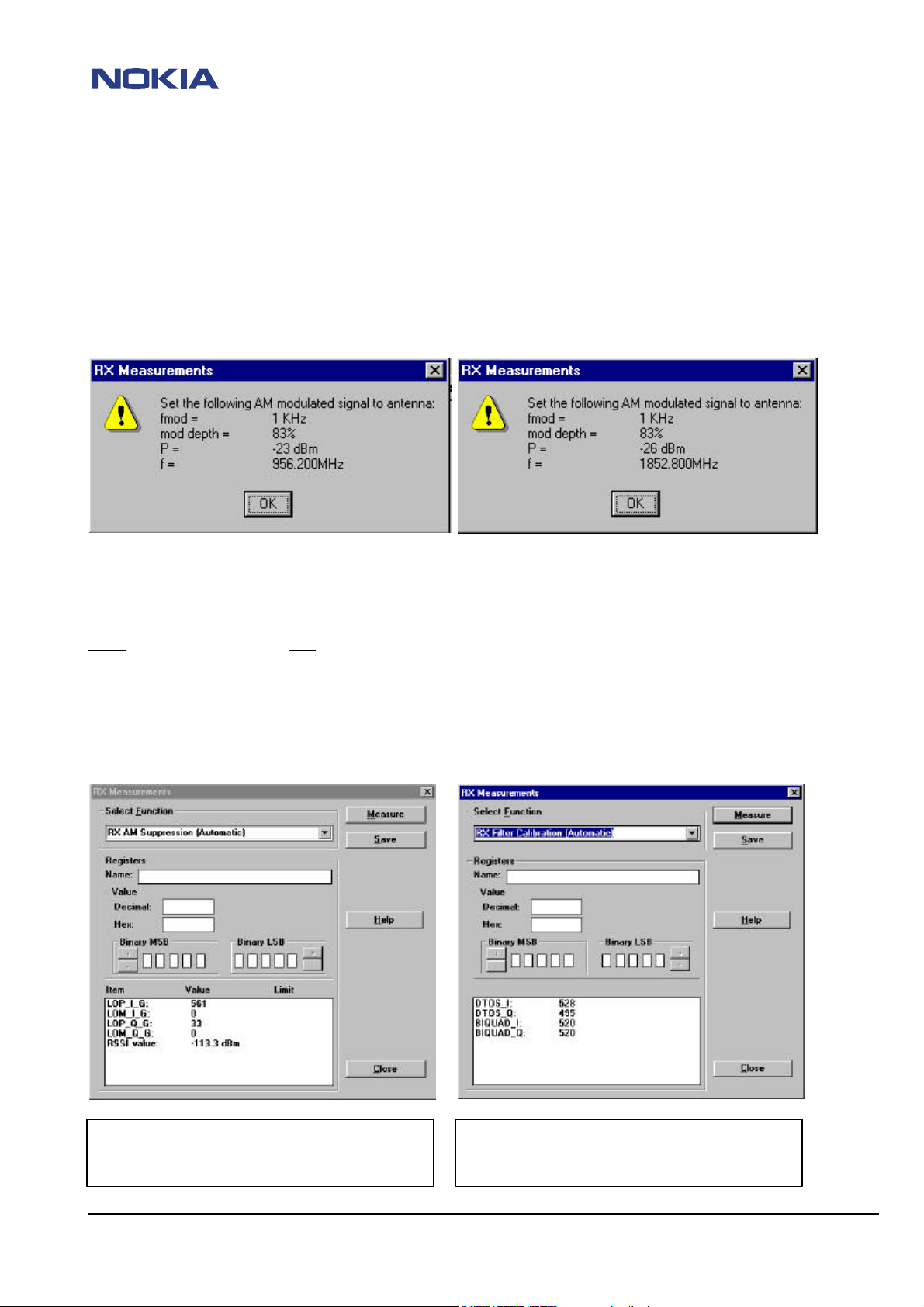

AM suppression tuning

Tune's four Hagar internal resistors of RX demodulator.

Purpose is to minimize the effect of any kind of AM interference to RX performance.

Tuning is automatic but it needs AM-modulated signal to phones` antenna input and has to be done for both bands.

NOTE:

Set the generator to the level or frequency shown in your wintesla window!

NOTE : WINTESLA WILL USE CH.56/700+10MHz INSTEAD OF ALL MANUAL SETTINGS IN TESLA.INI !

Use these settings:

EGSM PCN

Fmod=1kHz Fmod=1kHz

Mod depth=83% Mod depth=83%

P=-23dBm P=-26dBm

F=956.2MHz F=1852.800MHz

AM supression results should be in a range for:

EGSM –86dBm to –130dBm, PCN -95dBm to

–130dBm

© 2001 NMP

Checked by:

RX filter calibration results for AD values should be

in a range between 0 and 1023.

CC Training Group

Approved by:

SACE

Page 8

CONFIDENTIAL

8 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

Description of Signals & Voltages

The cause of this list are some new named signals/voltages in opposite to former names which are used in this document

(where to measure) & for a better understanding in addition to the service manual.

Startup sequence/CCONT section

PWRON/WDDISX (J102/R401) Always high level, only pulled down as long as powerkey is pressed.

PURX (J101) Power-Up-Reset signal from CCONT. When the voltages are stable, this line is on high level

allowing the MAD to run (Masterreset).

CCONTCSX (J100) Chip select for the CCONT. Used when the MAD wants to access the CCONT on the serial

bus (the serial bus is shared with the display) GENSIO-bus.

CCONTINT Interrupt from the CCONT to the MAD; for example: from the Real Time Clock, when a

charger is connected or when an intelligent battery powers the phone up

CHARG_CTRL (J114/C171) Output to the charger, when using 3-wire charging. The duty cycle of this 32Hz signal

switches the output current of the ACP-9 charger.

RFC (J601) Reference Frequency Clock. High stability clock signal for the digital circuits inBaseband

(13MHz)

SLEEPCLK (J112/C113) 32kHz clock generated in CCONT RTC. Used by MAD during sleepmode

SYNTHPWR (J317) Control line from MAD to CCONT. Turns on/off 3 voltage regulators for RF

VCXOPWR/SLEEPX (J331/J333/R305) Control line from MAD to CCONT. Controls the sleep-mode by turning on/off regulators

needed during normal/sleep

VB (J103/C105) Battery voltage

VCORE (C155) Digital baseband supply for the MAD core, 1.7 –1.9V

VBB (J108/C147) Digital baseband supply, 2.7V

VCOBBA (J109/C254) Analog baseband supply, 2.7V (used for audio)

VBATTIR (L121) Battery voltage for supplying IRDA, VIBRA and BUZZER

VBATTRF (L122) Battery voltage for the Power amplifiers (RF)

VBATTUI (L120) Battery voltage for supplying LED’s

VREF (J117/C143) 1.5V reference voltage (+-1,5%) generated by CCONT

VREF_RX (R510) Reference voltage for HAGAR, generated by COBBA

VSYN_1 (J106/C130) Supply voltage for SHF VCO

VSYN_2 (C133) Supply voltage for digital and analog circuits in HAGAR (VLO,VPRE,VBB, VF_RX)

VRX (J104/C136) Supply voltage for HAGAR part of the RX chain

VTX (J107/C142) Supply voltage for the TX chain in HAGAR

VXO (J105/C141) Supply voltage for the VCTCXO and VDIG in HAGAR

VCP (J110/C157) 4,9V supply voltage for PLL charge pump HAGAR

V_IN (F101) Charger input

VPP (C349) 12V input for fast flashing. In normal use, this line of the Flash is used for write protecting

the flash, and is then controlled by MAD with a possible overrule from a voltage detection

circuit. So if the battery is removed, the voltage detector disabled writing to the flash

VIRDA (C139) Regulator (2.7V), that turns the Infrared device and buffers on/off

RAM_BCK (C135) Backup-supply to SRAM. When the phone is turned off, the SRAM gets power from the

RTC-battery, so that data is not lost

BATTIO (V120) Signal used for turning ON an intelligent battery from the phone

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 9

CONFIDENTIAL

9 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

RF part

AFC (R604) Automatic Frequency Control - analog control signal for 26 MHz VCTCXO fine tuning

COBBACLK (J200) 13MHz clock from MAD to COBBA - used for syncronized serial communication between

COBBA and MAD

HAGARRESET (J500/N501) Reset signal from MAD to HAGAR

DET (V800) Detector signal between powerdetector and HAGAR

SCLK (J502/J506) Clock for HAGAR serial programming (26 MHz)

SDATA (J503/J507) Data for HAGAR serial programming

SLE (J501/J505) Serial Latch Enable for HAGAR serial programming (formerly titled as SENA)

RXI, RXQ (R509) The RX baseband signals (after downconversion)

GSM_RX (Z700) EGSM RX signal between RX/TX switch and 1st EGSM SAW

GSM_TX (L800) EGSM TX signal between dual-coupler and RX/TX switch

TXP (R512) Transmitter power enable - used for timing of the power loop, Enables the operation

amplifier in HAGAR

TXC (R518) Transmitter power control signal, that controls the level of the output power and the shape

of the burst

VPCTRL_G (V803) Control line for PA output power

TXVDET (C531) Supply voltage for the RF power detector circuit

TXBUF_G (C807) Supply voltage for EGSM TX buffer

TXBUF_P (C829) Supply voltage for PCN TX buffer

LNA_G (C706) EGSM LNA supply voltage, front-end gain on/off

LNA_P (C700) PCN LNA supply voltage, front-end gain on/off

LNAB_G (R708) BIAS for both LNA’s, front-end gain on/off

TXI_0, TXI_180 (R513) Differential In-phase TX signals to the IQ-modulator

TXQ_0, TXQ_180 (R516) Differential quadrature-phase TX signals to the IQ-modulator

TXVGSM (R910/N800) Selects GSM Tx mode in PA and RX/TX Switch

TXVPCN (R911/N800) Selects PCN Tx mode in PA and RX/TX Switch

OUTM_G_TX (L802) Balanced EGSM TX signal between HAGAR and EGSM TX balun

OUTP_G_TX (L802) Balanced EGSM TX signal between HAGAR and EGSM TX balun

OUTM_P_TX (L804) Balanced PCN TX signal between HAGAR and PCN TX balun

OUTP_P_TX (L804) Balanced PCN TX signal between HAGAR and PCN TX balun

INM_GSM_RX (L704) Balanced EGSM RX signal between EGSM RX balun and RF input of HAGAR

INP_GSM_RX (L704) Balanced EGSM RX signal between EGSM RX balun and RF input of HAGAR

INM_LO (T600) Balanced VCO signal between VCO balun and VCO input of HAGAR

INP_LO (T600) Balanced VCO signal between VCO balun and VCO input of HAGAR

INP_PCN_RX (L703) Balanced PCN RX signal between PCN RX balun and RF input of HAGAR

INM_PCN_RX (L703) Balanced PCN RX signal between PCN RX balun and RF input of HAGAR

OSC_DIV/TOUT (C614) Reference divider output (13 MHz) -- RFClock

OSC_IN (G602) Reference frequency input from ref oscillator

OUT_CP (C605) Output of the PLL charge pump

PCS_RX (Z701) PCN RX signal between RX/TX switch and 1st PCN SAW

PCS_TX (L800) PCN TX signal between dual-coupler and RX/TX switch

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 10

CONFIDENTIAL

10 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

Digital/programming part

MBUS (J113/R172) Bidirectional serial bus between MAD and accessory - during flashing, clock signal is

received on this line

MBUS1 (V170) Same as above, but on the “dirty” side of the filter

FBUS(1:0) (V171) FastBus. Consisting of FBUS_RX and FBUS_TX signals. Used for IRDA and accessory

communication. During flashing, the data is transferred on these lines

FBUS_RX(J332/R306) Receive line from the MAD’s point of view

FBUS_TX(J331/R305) Transmit line from the MAD’s point of view

User Interface part

XEAR (L201) Audio output when using carkit or headset

XMIC (L201) Audio input when using carkit or headset

MICN (L200) Negative side of the microphone

MICP (L200) Positive side of the microphone

PD2 (R201) Signal for muting microphone in headset, controlled by MAD

BUZZER (R410) PWM-signal from MAD, controls the buzzer

LCDCD (J328) Signal for controlling if the display is to receive data or control information on the serial

bus

LCDEN (J451) Chip enable signal to the display, informing that data on the serial bus is to the display

driver

LCDRSTX(R430) Reset signal from MAD to display driver

LIGHT (R427) Signal from MAD, that turns on the LED’s for keyboard and backlight

ROW(4:0) (V450) Keyboard matrix scan lines

COL(4:0) (V450) Keyboard matrix scan lines

CARDDET (C127) Used for detecting removal of the battery. When the battery is removed, this signal goes

high before the power is lost, giving the MAD time to power down the SIM-card

SIMIF(4:0) (J300) Serial bus for transferring SIM-data between MAD and CCONT

HEADDET (C211) Used for detection of which accessory has been connected to the system connector by

measuring the voltage on XMIC. Connected to A/D-converter in CCONT, and I/O-pin on

MAD. Data can also be transferred, for example - between MAD and DLR3-cable

HOOKDET (C212) For detecting when the push-button on the headset is pressed

DLR3 (V221) When the DLR3-cable is detected, this signal controls a switch, which gives power to the

cable

SGND (L201) Return line for microphone and earpice when a headset is connected to the phone. When

the DLR3-cable is connected, it changes to a power supply line to the cable, supplying 2.7V

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 11

CONFIDENTIAL

11 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

USER INTERFACE FAILURES

Display failure

Check mechanical appearance of H400 and C451.

Check contact pads on PCB – clean also if necessary

Check VBB 2,7V at C452

Check if Vout 7,6V / 70mVpp at C451 (noise < 100mV), if noise is higher, C451 may be broken.

Change LCD unit if failure persists - probably MAD D301 faulty.

If the LCD shows too much contrast and / or LCD flickers, check if C451 is broken.

If there are vertical or horizontal lines missing, LCD unit electrical defect.

Keypad malfunktion

Check if domesheet contacts are dirty, clean PCB (keypads) if necessary

Check mechanical appearance of domesheet (LCD unit) itself.

Check resistance of ROW and COL lines between the keys (0 Ohm)

Change LCD unit.

If keypad is still malfunctioned - probably MAD D301 faulty.

If keypad crackles when pressing keys, change keypad.

Backlight failure

First check mechanical condition and position of baseband shield, check for shorts, etc.

Check VBATTUI 3,6V at L120

Check VBATTUI 3,6V at R424

Check voltage at V430 (LCD lights) 3,6V and at LED´s V420 – V423

Check voltage at V431 (Key lights) 3,6V and at LED´s V424 – V429

Check voltage at R427 (LIGHT line) – if this fails, MAD D301 or PCB faulty

Note: Different LEDs for LCD (brighter) and keypad backlight.

Clock time problems.

Clock time has to be corrected in short periods.

Check amplitude and frequency of sleepclock oscillator at J112 / C113 should be 3,2Vpp squarewave at 32,768kHz.

If not ok, change B110 and check parts around oscillator :(R110, R111, R112, R113, C110, C111, C112, C113).

Clock time is lost after removing battery.

First try to charge RTC battery, by connecting battery to the phone for app. 10 minutes.

If fault remains, check contact springs of battery or change RTC battery (LCD unit). Check VBACK 3.2V at RTC battery G100

If fault persists, probably CCONT N102 or CHAPS N100 faulty.

32 kHz before and after C113.

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 12

CONFIDENTIAL

12 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

Vibra failure

Check mechanical appearance of M400

Check VBATTIR 3,6V at L121

Check VBATTIR 3,6V at V440

Check vibra signal at L401. If not ok check VIBRA signal at R444

If signal is ok at R444 change V441, if signal fails,

MAD D301 is probably faulty, or a disconnection between MAD and R444 in VIBRA line is the reason

Buzzer failure

Check mechanical condition of buzzer B400

Check VBATTIR 3,6V at L121

Check buzzer signal at R410

Check buzzer signal in and out at V410

Change buzzer B400 if all of the above works

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 13

CONFIDENTIAL

13 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

SIMcard failures

SIMcard not accepted

Use Wintesla to open normal mode/quick/RF info window - compare shown SIMlock data with the listed entries of the respective

productcode (see SIMlock list).

If shown SIMlock data is the same as in the list – Status is ok und must be set so!

Probably MSIN data field is closed to special IMSI number range, it only can be opened by operator

(refer to general Service Bulletin 065).

If SIMlock data is not the same as in SIMlock list or somehow corrupted, SIMlock-data must be rewritten with the

Nokia-security password.

If SIMlock is corrected or inactive but fault remains - N240 is faulty, or there are probably broken solderings under COBBA change N240 - realign RX / TX values and rewrite SIMlock data and flash the phone after this again.

“Insert SIMcard“ appears in Display

Check X160, if bent or soiled - change if necessary

Check BSI A/D values (ok range 340-350)

Check V160: pin1 – DATA_0, pin3 - VSIM, pin4 - SIMCLK, pin5 – SIMRST_0

Check also R160, C160, C161, C162

Check resistance of SIMlines to GND - change V160, C163, C164 if necessary, probably broken solderings under CCONT N102

Change CCONT N102 and run energy management calibration, if fault persists - probably MAD D301 or PCB faulty.

SIMcard Signals

SIMCLK DATA_0

SIMRST_0 VSIM

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 14

CONFIDENTIAL

14 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

CHARGING PROBLEMS

At first try an energy management calibration; either to define the defective area, or the phone works well after calibration.

(See page #5)

“NOT CHARGING“ appears on display

If calibration failed – check possible failure message:

Battery temperature failed: Check X120, X121, R122 / R123, R124, V120, change N102 if necessary.

Battery size failed: Check X121, X120, R120 / R121, change N102 if necessary.

Battery voltage failed: Check L123 / R105 / C104 / C105, change N102 if necessary

Charge current failed: Check R106, change N100 and / or N102.

Charge voltage failed: Check VCHARGE at voltage devider R102 / R103, if ok – change N102,

if not ok - check X001, R101, F101, L101, change N100 if necessary.

X120 / X121 battery connector, X001 system connector.

Check mechanical condition of connectors – change if necessary.

V_IN line short-circuited to GND

Check resistance of V_IN line at F101 to GND (50 kOhm), if resistance is not ok - remove L101 and check again.

If resistance is ok now - C101 / C102 or N100 should be the reason, if resistance is still not ok – R101 faulty.

CCONT / N102 faulty

Change CCONT N102 if any A/D (calibration) value, is out of limit and DC voltage is ok.

If DC voltages are not ok, check corresponding voltage dividers and battery connectors X120 / X121, always realign RX/TX and

AD values after changing CCONT N102.

Nothing happens if charger is connected

F101 faulty

Check resistance of F101 ( 0 Ohm ).

Check voltage at R103 > 0,4V if charger is connected. If not ok (<0,4V) – check / change X120,X121, F101, R101, R102/R103,

if ok - change N100 and / or N102.

Energy management calibration.

Calibration has to be done always if any part in charging circuit has been replaced.

Try calibration, if charging process stops too early or doesn´t start and if message “NOT CHARGING” appears on Display.

( Also see “General tuning informations“ )

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 15

CONFIDENTIAL

15 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

CONTACT SERVICE

MCU Boot failure

Serial clockline failure

Serial Dataline failure

Connect WDDISX

(R401) to GND

Check Vbb 2.7V at J108/

C147

OK

Check

SLEEPX/VCXOPWR 2.7V

at J333 or J331

OK

Check VXO 2.7V at

J105/C141

OK

Check 13MHz

CLK frequency at C613

OK

Check resistance to GND

F/MBUS lines

J113/331/332

nOK

nOK

nOK

nOK

OK

Continue with section

"Phone does not

switch on"

D301 faulty, swap

Continue with section

"Phone does not

switch on"

Check values at G602,

V600

Check R172, V170, V171,

R305/306,X001

© 2001 NMP

OK

MAD or PCB faulty

OK

Checked by:

CC Training Group

Approved by:

SACE

Page 16

CONFIDENTIAL

16 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

CONTACT SERVICE PROBLEMS

This fault means that the phone software is able to run and thus the watchdog of CCONT N102 can be served. Selftest

functions run when power is switched on and program is executed from FLASH

If any selftest fails, - “CONTACT SERVICE” appears in Display.

Note: Always try SW-update to solve the problem or locate the error - in most of the cases phones are ok after update.

Possible failures:

MCU ROM Checksum failed :

Try to flash the phone. If not ok after flashing – change FLASH D311 if you are authorized to rewrite IMEI and SIMlock data,

if failure persists after changing D311, MAD D301 defect which is not changeable.

CCONT Interface failed :

Probably broken solderings under CCONT N102

If not ok after rework of CCONT, probably MAD D301 or PCB faulty. Run energy management calibration after changing CCONT!

NOTE: For Energy management calibration see also general tuning information page!

COBBA parallel/serial failed

Check VBB 2,7V at C147, VCOBBA 2,7V at C254 & COBBACLK at J200

If all ok – change COBBA N240

If the failure persists after changing COBBA – probably MAD D301 or PCB faulty.

DSP Alive failed

In most of all DSP alive selftest failures MAD D301 is faulty, which is not changeable.

EEPROM tune checksum / security checksum failed

Use Wintesla to check if phonedata like IMEI, product data or PSN are corrupted.

If phone data is ok, try to reset the phone. If phone data is not ok or fault remains after reset, FLASH D311 is faulty.

RTC Battery failed

First try to charge RTC battery by switching on the phone for app. 10 minutes

If fault remains, check contact springs of battery.

In some cases it is necessary to change CCONT N102.

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 17

CONFIDENTIAL

17 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

PHONE DOES NOT SWITCH ON

First check always current consumption: off state 0-2,3mA, sleep mode 2,3-4mA.

If too high – see section „low standby / operation mode time“.

Disable watchdog if phone switches off after 2 or 3 seconds.

Check connectors X001/X120/X121 - change if bent or soiled.

Check VB 3,6V at J103/C105 - if not ok, check/change L123.

Check if PWRON at R401/J102 drops to 0V while pressing powerswitch, if not ok - check/change S402, R401.

Check 32,768kHz at J112/C113, 3Vpp squarewave – (if it is difficult to measure squarewave, because of Basebandshield,

check 32,768 kHz at the other side of C113, 900mVpp sinewave).

If not ok, check/change components around B110, (R110-R113 & C110-C113) and/or change CCONT N102 if necessary.

Check VCORE at C155 – 1,7V – if not ok, change CCONT N102.

Check VBB 2,7V at J108/C147, VXO 2,7V at J105/C141, VREF 1,5V (+-1,5%) at J117/C144 –if not ok, check resistance of lines

to GND and/or change CCONT N102 if necessary.

Check SLEEPX/VCXOPWR 2,7V at J333/J331 - if not ok, MAD is faulty in all probability - swap the phone, because MAD D301 is

not changeable.

Check PURX 2,7V at J101 after pressing powerswitch - if not ok, change CCONT N102.

Check 13MHz Clk frequency (RFC) at C613, if not ok, check values around 26MHz oscillator G602 / V600

Change HAGAR N500 if necessary.

Try to flash the phone - if not ok, see section “FLASH update not possible“.

Note:

It is nessesary to realign all RX/TX values after changing HAGAR N500 and run energy management calibration after changing

CCONT N102.

For Energy managemant calibration see also general tuning information page!

32,687 kHz before and after C613.

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 18

CONFIDENTIAL

18 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

LOW STANDBY / OPERATION MODE TIME

Off state current > 0-2,3mA.

lift L122 (VBATTRF) - check current consumption, if ok - N800 faulty in all probability,

if current is still too high after changing N800. check / change C814, C815, C817.

Lift L123 (VB) - check current consumption – if too high,

VB line faulty

In most cases is CCONT N102 the reason. If fault persists after changing CCONT, it is also possible, that capacitor(s) in VB line

is/are faulty (C105, C122, C123, … ). Check all these components lifting one after the other, with repeated current testing.

If fault persists, probably one of the µBGA / CSP´s and / or PCB should be the reason.

Sleep mode current > 2,3-4mA

Check resistance of all voltage output lines of CCONT N102 to GND

Check component(s) in corresponding line(s) if resistance is not ok

If resistance of voltage lines (from CCONT N102) are ok, but sleep mode current is still too high – change CCONT N102.

Check charging circuit, run energy management calibration.

If calibration fails - continue with section “Not charging“

Align RX / TX values. If calibration fails - continue with section “RX / TX faults”.

Note:

Standby time also depends on network side and users handling, like lights on/off, VIBRA- / WAP activities, games etc.

FLASH UPDATE NOT POSSIBLE

Check if fault code from prommer is one of the following:

MCU boot failure, serial clock/data line failure:

Connect „watchdog disable“ WDDISX R401 to GND.

Check VBB 2,7V at J108/C147 and VXO 2,7V at J105 / C141, if not ok - continue with section “PHONE DOES NOT SWITCH ON“

Check SLEEPX 2,7V at J333 - if not ok - MAD D301 faulty in all probability

Check PURX 2,7V at J101 - if not ok change CCONT N102

Check 13MHz Clk frequency at C613, approximately 800mVpp, if not ok, check values around 26MHz oscillator G602 / V600,

change HAGAR N500 if necessary

Check resistance of MBUS / FBUS lines (J113 / J331 / J332) to GND, also check R172, V170, V171,R305, R306 and check

X001.

If update still not possible – swap the phone, MAD D301 or PCB should be the reason.

Algorithm code fail, alias ID missing:

Update FPS4 box with the latest flash device list and try to update again, if fault remains, check values at MAD D301.

If ok, change FLASH D311

External RAM failure:

Check values at MAD D301, if ok - SRAM D310 faulty and/or change FLASH D311 if necessary.

See chapter “PHONE DOES NOT SWITCH ON”

Note:

It is necessary to run energy management calibration after changing CCONT N102!

For Energy managemant calibration see also general tuning information page (#5).

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 19

CONFIDENTIAL

19 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

NO SERVICE PROBLEMS

No RX EGSM

Use Wintesla to set phone in following mode: Initialise / Local mode / Testing / RF Controls / Gain step value >2 / active unit RXburstmode / Channel 56 (946,2MHz). Set Generator to same frequency, -40dBm.

Check 26MHz reference oscillator frequency at G602, 800mVpp/frequency deviation < 100Hz

Check 946,2MHz at C912, if not ok, check/ change Z900, X900.

Check 946,2MHz at L700, if not ok, check/change Z700.

Check 946,2MHz at V700 in & out, if not ok, check LNA values: VLNAB_G 2,7V at V700, pin 8 and LNA_G 0,7V at pin4, change

HAGAR N500 if necessary.

Check 946,2 MHz at L704 - if not ok, check/change Z703, R702, T700.

Check RXIQ signals at R509, if not ok, check supply values at HAGAR N500: 2,7V at C513 (VXO), C501 (VRX), C503(VSYN_2)

and N501 input 4,9V (VCP). If one or more of these fails, change N102.

Check SDATA at J503/J507, SCLK at J502/J506 and SLE at J501/J505, if not ok MAD D301 faulty

Check VREF (1,5V) at R514 / VREF_RX (1,2V) at R510, if not ok, change N102.

Check frequency of SHF oscillator G600 if possible – refer to EGSM frequencies list.

If all values are ok but no RXIQ signals measurable at R509, HAGAR faulty, or there are probably broken solderings under N500.

If signals at R509 ok, but still no RX calibration possible, check values at COBBA N240:

VBB at C256 (2,7V) and VCOBBA at R245 (2,7V), also check COBBACLK at J200.

If values ok – N240 faulty, or there are probably broken solderings under COBBA.

No RX PCN

Use Wintesla to set phone in following mode: Initialise / Local mode / Testing / RF Controls / Gain step value >2 / active unit RX

burst / Channel 700 (1842,8MHz). Set Generator to same frequency, -40dBm.

Check 26MHz reference oscillator frequency at G602, 800mVpp/frequency deviation < 100Hz

Check 1842,8MHz at X900 and ANT pad of Z900 - change X900 if necessary.

Check 1842,8MHz at C913, if not ok, check solderings of Z900, change if necessary .

Check 1842,8MHz (PCS_RX) at C702 - if not ok, check/change Z701.

Check 1842,8MHz at C712 - if not ok check values of LNA: VLNAB_G = 2,7V at V701, pin 8 (VC) and LNA_P = 0,7V at pin 4 (VCC)

Change V701 if necessary.

Check 1842,8MHz at L703, If not ok, check/change Z702, T701

Check RXIQ signal at R509 - if not ok, check values at HAGAR N500: 2,7V at C513 (VXO), C501 (VRX), C503 (VSYN_2) and

N501 input 4.9V (VCP).

If one or more of these fails - change N102

Check SDATA at J503/J507, SCLK at J502/J506 and SLE at J501/J505, if not ok MAD D301 faulty.

Check VREF (1,5V) at R514 / VREF_RX (1,2V) at R510, if not ok, change N102.

Check frequency of SHF oscillator G600 if possible – refer to EGSM frequencies list.

If there is no possibility to check frequency - check if oscillator works by measuring VCC at C601 (2,7V) and VC at C603, which

varies between 0,7V and 3,8V (see EGSM list).

If VC is 4,8V, the oscillator doesn’t work in all probability, also check T600 and R608.

If all values are ok but no RXIQ signal is measurable at R509, N500 is faulty, or there are probably broken

solderings under HAGAR.

If signal at R509 ok but still no RX calibration possible, check values at COBBA N240: VBB 2,7V at C256 and VCOBBA 2,7V at

R245, also check COBBACLK at J200.

If values are ok, N240 faulty, or there are probably broken solderings under COBBA.

Note: After changing COBBA, HAGAR and/or CCONT it is necessary to realign all RX,TX -and AD values,

and rewrite IMEI and SIMlock data (COBBACHANGE)

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 20

CONFIDENTIAL

20 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

NO SERVICE PROBLEMS

EGSM/PCN no RX

Change Z700

First check 26 MHz at G602 (700mVpp,+/-100Hz) Check SHF (list) and/or VC/VCC 2.7V (C601)

No service

(GSM900)

Check 946,2MHz at

Z900 (antennapad)

Check 946,2MHz at

C912

OK

Check 946,2MHz at

L700

OK

Check 946,2MHz at

V700

nOK nOK

OK

nOK nOK

nOK nOK

0.7-3.8V

Check/change X900

Check/change Z900

Check

LNAB_G at V700/701, VC (2.7V)

at pin8, 2,7V at pin4.

LNA_G = 0.7V

LNA_P =0.7V

No service

(GSM 1800)

Check 1842,8 MHz at

Z900 (antennapad)

Check 1842,8MHz at

Check 1842,8MHz at

Check 1842,8MHz at

C913

C702

C712

OK

OK

nOKnOK

OK

Change Z701

Check/change Z703,

R702, T700

© 2001 NMP

OK

Change

V700/701

Check 946,2MHz at

nOK nOK

L704

OK

Check RX IQ at R509 Check RX I/Q at R509

Check VBB 2.7V at C256, R245,

VCOBBA (2,7V) and COBBACLK at

Change N500

Check supply voltages

at N500: C513 (VXO);

C501 (VRX);

C503 (VSYN_L)

At N501: (VCP) 4.8V

Check

SDATA J503

SLE J501

SCLK J502

J200

nOKOK

Change N500

nOKnOK

Swap PCBChange N240

OK

Check 1842,8MHz at

L703

OK

Checked by:

CC Training Group

Check/change Z702

T701

Approved by:

SACE

Page 21

CONFIDENTIAL

21 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

NO SERVICE PROBLEMS / TX POWER

First of all: Try to calibrate RX / TX values to define the fault area, or phone works well after calibration

No or low TX power EGSM

Use Wintesla to set phone in following mode: Initialise / Local mode / Testing /RF Controls / active unit TX / Channel 38

(897,6MHz).

Check 26MHz reference oscillator frequency at G602 (800mVpp, frequency deviation < 100Hz)

CheckTXBUF_G at C807 – 2,7Vpp squarewave - see signal page #27

Check TXIQ signals at C525 / C526, refer to signals shown on page #27.

If not ok, check values at COBBA N240 (see COBBA N240 chapter page #24).

Check 897,6 MHz at T800 pin 4 and 6. If not ok, check signals at HAGAR N500 (see HAGAR N500 chapter)

Check 897,6 MHz at N800 pin 8. If not ok,check / change parts like T800,V801, Z802, Z800.

Check 897,6 MHz at L800 pin 1. If not ok, check values at N800.

Check 897,6 MHz at X902 (Antenna pad). If not ok, check / change X900.

Check L800 in & out, check also signal at Z900 in & out and TXVGSM: 2,7Vpp squarewave at C910 (sets Z900 into TX-mode).

No or low Tx power PCN

Use Wintesla to set phone in following mode: Initialise / Local mode / Testing /RF Controls / active unit TX / Channel 700

(1747,8MHz).

Check 26MHz reference oscillator frequency at G602 (800mVpp, frequency deviation < 100Hz).

Check TXBUF_P at C829 – 2,7V squarewave – see signal page #27

Check TXIQ signals at C525 / C526, refer to signals shown on page #27.

If not ok check values at COBBA N240 (see COBBA N240 chapter, page #24)

Check 1747,8MHz at T840 pin 4 and 6. If not ok check signals at HAGAR N500 (see HAGAR N500 chapter).

Check 1747,8MHz at N800 pin 8. If not ok check / change parts like T840,V802, Z800.

Check 1747,8MHz at L800 pin 2. If not ok, check values at N800.

Check 1747,8MHz at X902 (Antenna pad). If not ok, check / change X900.

Check L800 in & out, check also signal at Z900 in & out and TXVPCN: 2,7Vpp squarewave at C911 (sets Z900 into TX-mode).

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 22

CONFIDENTIAL

22 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

NO TX

Check 26 Mhz at G602-

No TX

Check

CH38/897.6MHz at

OK OK

T800, pin 4/6

nOK nOK

Change N240

700mVpp/+/- 100hz, check SHF,

check Vbatt RF at L122

Check TX I/Q signals

nOK

Check TXC at C529

at R513/516

nOK

Change N240

Check

SDATA at J503

SLE at J501

SCLK at J502

If not OK, swap

OK

Check

OKOK

CH700/1747.8 MHz

at T840, pin 4/6

Change N102

Check 897.6MHz at

N800, pin8

OK

Check 897.6MHz

at L800, pin1

OK

Check 897.6MHz at

antennapad Z900

OK

Check 897.6MHz

at X902

nOK

nOK

nOK

nOK nOK

nOK

nOK

Check TXP at C524

Check/change

T840/Z800/V801

Check/change

T800/Z802/Z800/V801

N800 3.6V VBATT_RF, pin3,6

TXV_PCN 2.7Vpp sqw., pin 1

TXV_GSM 2.7Vpp sqw., pin 2

Vpc 1-1.6Vpp sqw.pin 7

Check/change

L800/Z900

Change X900

OK

nOK

nOK

nOK

Change N500

Check 1747,8MHz

at N800, Pin8

OK

Check 1747.8MHz at

L800, pin2

OK

Check 1747.8MHz at

antennapad Z900

OK

Check 1747.8 at X902

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 23

CONFIDENTIAL

23 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

SHF OSCILLATOR PROBLEMS

This causes problems in EGSM and PCN mode (RX/TX).

If the phone has no service because of too low TX power (eg. approximately 5dBm in the highest powerlevels) and / or there are

strange A/D values in the RSSI measurements – check (if possible) the SHF frequency with a spectrum analyzer

and /or the RX calibration A/D values (also see pictures below) if there might be something unusual like a cutted SHF oscillator

frequency amplitude and / or the gain readings in RX calibration are lower as normal, - approximately about values of 10 to 20.

If this is the case, check the periphery – capacitors of SHF Oscillator G602 in VC circuit (C603, C604, C605)

Check their resistance to GND (approximately 3MOhm at R612 to GND in normal case / otherwise the value should be in lower

kOhm range (around 10k):

Left picture shows a normal SHF frequency amplitude – right side in defect case

Left picture shows normal gain readings – right picture in defect case (RX Calibration):

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 24

CONFIDENTIAL

24 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

COBBA / N240 faulty

Check VBB 2,7V at C256 and VCOBBA 2,7V at R245

Check 13MHz COBBACLK at J200, probably broken solderings under COBBA / N240.

Realign Rx / Tx values after rework of COBBA N240.

HAGAR / N500 faulty

Check voltages at HAGAR:

VXO 2,7V at C533

VCP 4,7V at N501 (output)

VSYN_2 2,7V at C503

VRX 2,7V at C501

VREF 1,5V at C143

Check 26MHz reference oscillator frequency at G602:

800mVpp – frequency deviation < 100Hz.

Check TXIQ signals at R513/C525 (TXI 0/180) and R516 / C526 (TXQ 0/180)

Check SDATA at J503/J507, SCLK at J502/J506 and SLE (SENA) at J501/J505 (refer to signals shown on page #27)

Check TXC at C529 (diagram on page #25)

Check TXP at R512, 3Vpp squarewave/ 217Hz

Check frequency of SHF oscillator / G600 – refer to EGSM frequency list

If all values are ok but no TX - signal is measurable at T800, there are probably broken solderings under HAGAR, or N500 is

faulty.

Note: After changing COBBA, HAGAR and/or CCONT it is necessary to realign all RX,TX -and AD values,

and rewrite IMEI and SIMlock data (COBBACHANGE)

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 25

CONFIDENTIAL

25 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

SIGNAL CHARTS

Serial data (RX Burst mode) Serial clock (RX Burst mode)

Serial Latch enable (RX Burst mode) TX power control TXC

TX power enable TXP TX_IN phase /Quadrature phase (0/180°)

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 26

38

60

3

0

CONFIDENTIAL

26 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

FREQUENCY LIST

Channel TX RX VCO - TX VCO VCO - RX VCO

MHz MHz MHz VOLT MHz VOLT

1

124

512

700

885

890,2

897,6

902

914,8

1710,2

1747,8

1784,8

935,2

942,6

947

959,8

1805,2

1842,8

1879,8

3560,8

3608

3659,2

3420,4

3495,6

3569,6

VC at C603

1,7

2,01

2,34

0,84

1,3

1,77

3740,8

3788

3839,2

3610,4

3685,6

3759,6

VC at C603

2,81

3,2

2,03

2,36

2,66

975

976

977

978

979

980

981

982

983

984

985

986

987

988

989

990

991

992

993

994

995

996

997

998

999

1000

1001

1002

1003

1004

1005

1006

1007

1008

1009

1010

1011

1012

1013

1014

1015

1016

1017

1018

1019

1020

1021

1022

1023

880,2

880,4

880,6

880,8

881

881,2

881,4

881,6

881,8

882

882,2

882,4

882,6

882,8

883

883,2

883,4

883,6

883,8

884

884,2

884,4

884,6

884,8

885

885,2

885,4

885,6

885,8

886

886,2

886,4

886,6

886,8

887

887,2

887,4

887,6

887,8

888

888,2

888,4

888,6

888,8

889

889,2

889,4

889,6

889,8

890

925,2

925,4

925,6

925,8

926

926,2

926,4

926,6

926,8

927

927,2

927,4

927,6

927,8

928

928,2

928,4

928,6

928,8

929

929,2

929,4

929,6

929,8

930

930,2

930,4

930,6

930,8

931

931,2

931,4

931,6

931,8

932

932,2

932,4

932,6

932,8

933

933,2

933,4

933,6

933,8

934

934,2

934,4

934,6

934,8

935

3520,8

3521,6

3522,4

3523,2

3524

3524,8

3525,6

3526,4

3527,2

3528

3528,8

3529,6

3530,4

3531,2

3532

3532,8

3533,6

3534,4

3535,2

3536

3536,8

3537,6

3538,4

3539,2

3540

3540,8

3541,6

3542,4

3543,2

3544

3544,8

3545,6

3546,4

3547,2

3548

3548,8

3549,6

3550,4

3551,2

3552

3552,8

3553,6

3554,4

3555,2

3556

3556,8

3557,6

3558,4

3559,2

3560

1,46

1,51

1,56

1,61

1,66

1,7

3700,8

3701,6

3702,4

3703,2

3704

3704,8

3705,6

3706,4

3707,2

3708

3708,8

3709,6

3710,4

3711,2

3712

3712,8

3713,6

3714,4

3715,2

3716

3716,8

3717,6

3718,4

3719,2

3720

3720,8

3721,6

3722,4

3723,2

3724

3724,8

3725,6

3726,4

3727,2

3728

3728,8

3729,6

3730,4

3731,2

3732

3732,8

3733,6

3734,4

3735,2

3736

3736,8

3737,6

3738,4

3739,2

3740

2,66

2,69

2,72

2,75

2,78

2,81

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 27

CONFIDENTIAL

27 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

Special information for NHM-3

This phone is build so that it can withstand a fall of 3 metres height without harmful effects – what certainly

does not mean that you should test this feature on purpose.

Further more the phone endures drops into water of 0.5metres depth up to 1minute at a water temperature of not

more than 50°C. Therefore the speaker, buzzer and microphone are sealed. Take care not to destroy these seals if you have

to change one of the above mentioned item, don´t even touch the seals!

To ensure water resistance, covers with gaskets must not be used more than three times after tightening the screws.

Check always appearance of gasket around systemconnector and battery cover, change parts in case of doubt!

It is absolutly necessary to use always new screws to assemble the phone, because gaskets around screws are surely

damaged after tightening them! Order / torque of tightening screws: middle screws at 12Ncm, top screws at 25Ncm and

then bottom screws at a torque of 25Ncm.

Note that accessories do not fulfill the same tough specifications as the phone is made for.

Do not connect any electrical item ( eg. charger, carkit ) to the phone if it is still damp!

The usage of NPE-3 Repair-Hints for NHM-3 phones is possible without any problems.

Schematics of both phones differ only in few points ( eg. varistors in Xmic-line, some more components around LNA… ),

and almost all itemcodes are the same.

Because of different systemmodul-forms you have to use MJS-23 Jig with XRC-3 Rf-cable for testing and adjustment.

If you have to make energy management calibration ( eg. after changing Ccont or any part of the charging circuit ), be

sure that you are using dll 311.04.00 or later, else the tuning of battery size won´t work and you will get the following

failure message:

One of the most conspicuous differences between NPE-3 and NHM-3 is the systemconnector, which is connected via

flexfoil to Pcb. Further more a batteryconnector similar to the one in NSM-2/3 is used. The Simcard-holder is combined

with the shielding of the baseband as well as the antenna is one part with the shielding of the poweramplifier. The RFconnector is constructed flexible, so that a fall does not result in torn off traces.

If it is necessary to change any item with help of a soldering machine ( eg µBGA-components, shieldings, poweramplifier…),

you have to remove the display assy first, which is connected to PCB with a flexfoil. This can be done easily with help of a

Metcal Soldering Station MX500 equipped with a soldering tip SMTC 162.

Hot air should not be used to desolder anything ever since using Pcb with microvias, which will crack rapidly if exposed to

too high temperature!

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 28

CONFIDENTIAL

28 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

To remove the flexfoil release clips of display assy first and turn it around, so that you have access to the soldering points

of the foil. Now you can desolder the flexfoil easily.

Before soldering a new display ( do not use the old one! ) clean careful the soldering points. Add few new solder to the pads

and enclose only a little bit of flux.

Bend the flexfoil a little bit at the perforation, so that it is easier to hold the display in correct position. Do not touch the

contacts of the flexfoil with bare fingers!

Heat up the soldering points for approximately 10 seconds. Check connection visually ( especially at the top of the flex for

shorts to ground ) and clip display on Pcb. Never bend the flexfoil for more than 90°!

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Page 29

CONFIDENTIAL

29 (29)

HDa-13/S 893 Repairhints

Service & Analysis Center Europe Introduction Version 1.2 Approved

SACE CC Training Group Date 2001-03-16

CHANGE HISTORY

Originator Status Version Date Comment

CC-TrainingGroup

CC-TrainingGroup

CC-TrainingGroup

Draft 0.1 24.01.2001 First draft version for the repair group

Approved

Approved

1.0 06.02.2001 First approved version

1.2 09.03.2001 Display information added

© 2001 NMP

Checked by:

CC Training Group

Approved by:

SACE

Loading...

Loading...