Page 1

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

version 1.1 / 01.02.2000 Page 1 of 41

Page 2

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Introduction

IMPORTANT:

This document is intended for use by authorised NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA 6150 phones.

It contains a lot of collected tips and hints, to find failures and repair solutions easily.

It will also give support to the inexperienced technicians.

Saving process time and improving the repair quality is the aim of using this document.

We have build it up based on fault symptoms (listed in "Contents") followed by detailed description for further analysis.

It is to be used additionally to the service manual and other service information

like Service Bulletins, for that reason it doesn't contain any circuit descriptions or schematics.

All measurements are made with using of following equipment:

Nokia repair SW : Wintesla Version 6.10

DLL version : NSEKM-13 version 2.41.03

Nokia Module Jig : JBS-19

Digital multimeter : Fluke 73

Oscilloscope : Hitachi V-1565; Fluke PM 3380A

Spectrum Analyzer : Advantest R3361C with an analogue probe

RF-Generator / : Rohde & Schwarz CMD 53

GSM Tester

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If any errors are

found by the reader, NOKIA should be notified in writing, using following procedure:

Please state:

Title of the Document + Issue Number/Date of publication

Page(s) and/or Figure(s) in error

Please send to: Nokia GmbH

Service & Analysis Center Europe

Meesmannstr.103

D-44807 Bochum / Germany

Email: ams.sace-training@nokia.com

version 1.1 / 01.02.2000 Page 2 of 41

Page 3

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Contents

INTRODUCTION .................................................................................................................................................. 2

D

OESN'T SWITCH ON

N

OT CHARGING

L

OW STAND-BY TIME

I

NTERMITTENT DOESN'T SWITCH ON

P

HONE SWITCHES OFF ITSELF

S

WITCHES OFF ITSELF - CONTACT SERVICE ON THE DISPLAY

C

ONTACT SERVICE

C

ONTACT SERVICE

C

ONTACT SERVICE

C

ONTACT SERVICE – PPM VALIDITY

C

LOCK TIME OR USER SETTINGS PROBLEMS

B

UZZER FAILURES

I

NTERNAL AUDIO FAILURES

E

XTERNAL AUDIO FAILURES

A

CCESSORY DETECTION FAILURE (HEADSET / CAR KIT ACTIVE

.............................................................................................................................................. 4

..................................................................................................................................................... 7

........................................................................................................................................... 11

....................................................................................................................... 12

................................................................................................................................13

– COBBA

– COBBA

– E

PARALLEL BUS FAILED

..................................................................................................................... 16

SERIAL

EPROM TUNE CHECKSUM FAIL

................................................................................................ 15

............................................................................................... 17

........................................................................................................................ 18

............................................................................................................. 19

................................................................................................................................................ 21

................................................................................................................................... 22

.................................................................................................................................. 24

...................................................................................... 14

)................................................................................... 25

D

ISPLAY FAILURE

K

EYPAD FAILURE

I

SIM CARD ............................................................................................................................................. 30

NSERT

SIM CARD

................................................................................................................................................. 27

.................................................................................................................................................. 29

NOT ACCEPTED

, SIM LOCK

FAILURE

................................................................................................... 32

SIM LOCK DATA NSM-1................................................................................................................................. 34

T

HE PHONE HANGS UP AFTER ENTERING THE

L

OW RECEIVER SIGNAL STRENGTH INDICATOR

N

O SERVICE

C

ALL BREAKS

N

O CALL / SERVICE

N

O OR LOW

........................................................................................................................................................ 36

/ N

O SERVICE

.................................................................................................................................. 39

O.K....................................................................................................................................... 39

TX – P

................................................................................................................................... 39

OWER

PIN-

.......................................................................................................... 36

........................................................................................... 35

CODE

version 1.1 / 01.02.2000 Page 3 of 41

Page 4

Doesn't switch on

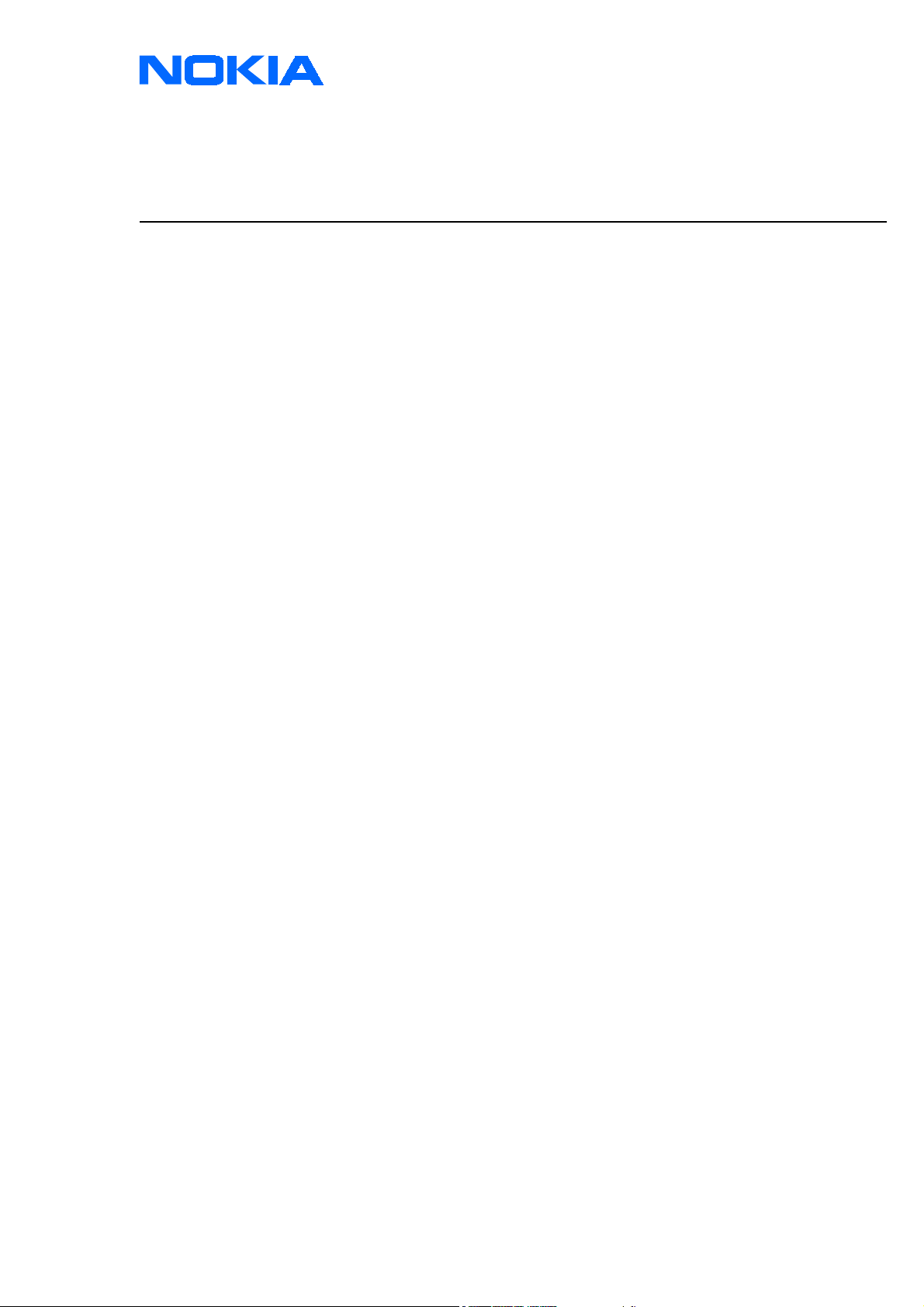

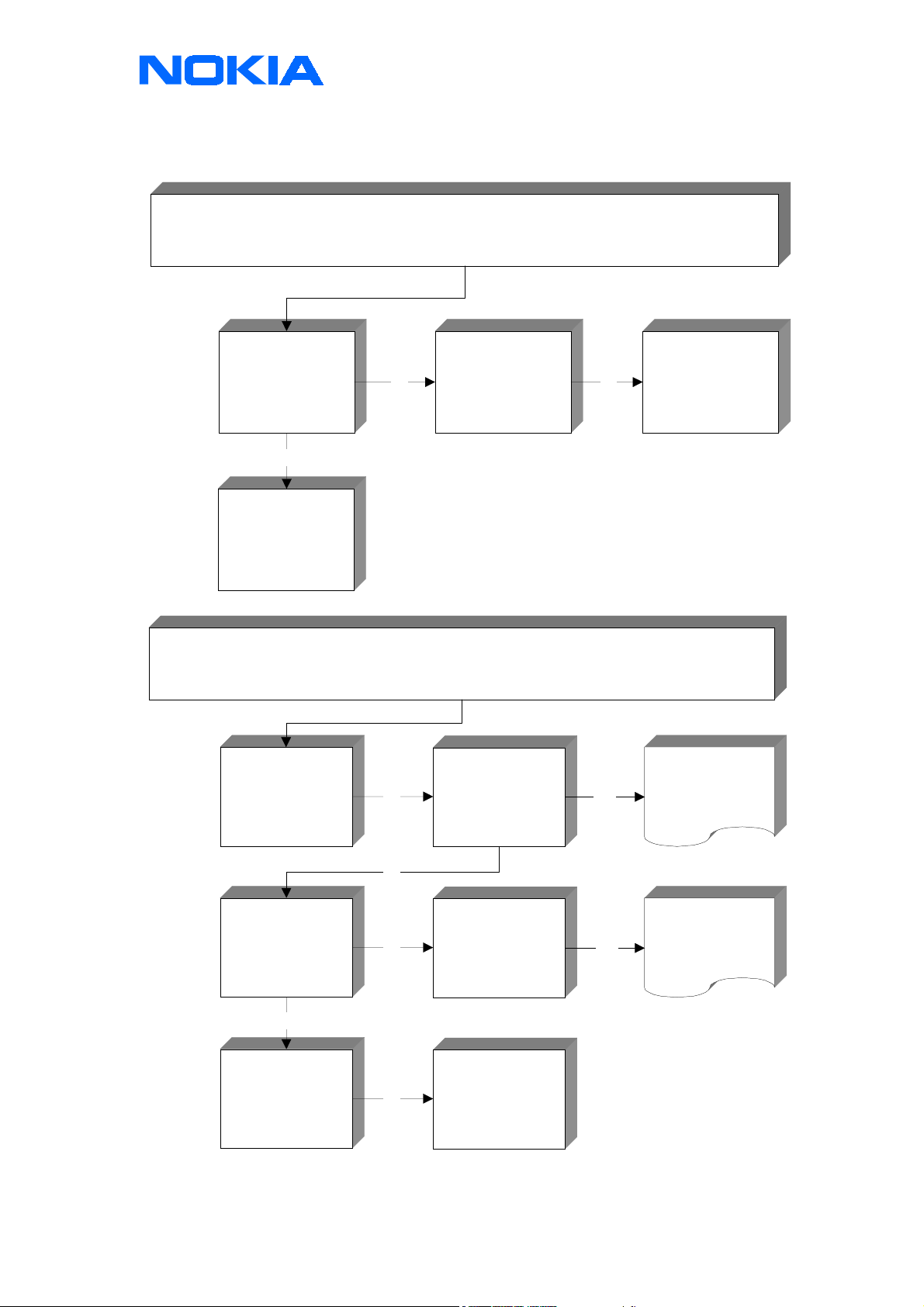

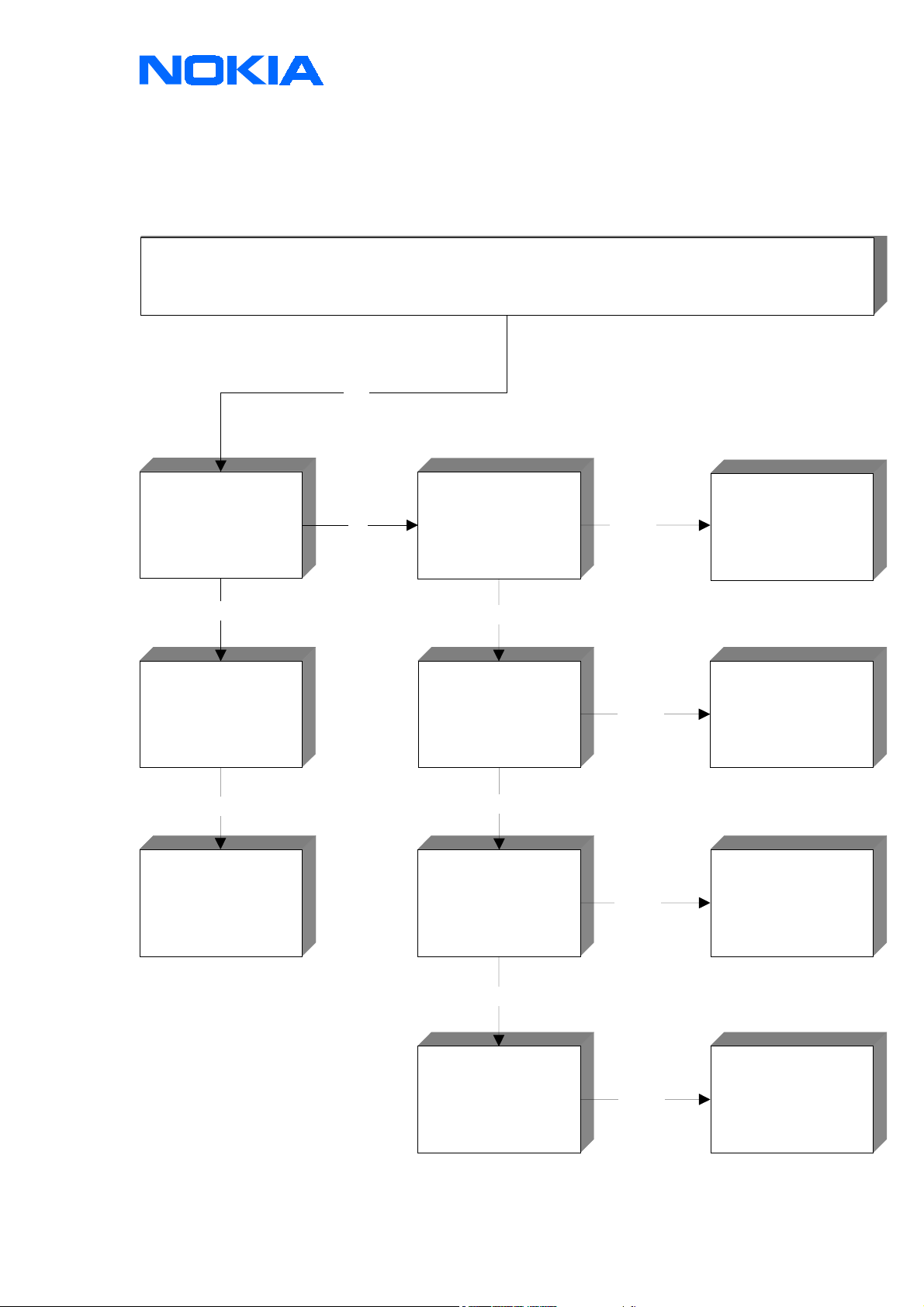

Figure 1: doesn't switch on troubleshooting

Phone doesn't switch on

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Observe power con-

sumption norm. < 6mA

pulsing to 20mA

(without backlights)

Yes

Check VBAT (3,6V)

N100 / 8, 12, ...

Yes

Check 32,768 kHz

N100/46=1,3Vpp (Sinus)

N100/47=2,3Vpp(Square)

Yes

Check DC Volt. PWRONX

N100 / 29 = VBATT (3,6V)

If Pwr button is pressed

PWRONX = 2,9V

Yes

Check DC Volt. PURX

N100 / 54 = 2,8V

D200 / 122 = 2;8V

(after pressin g Pwr b utton)

Yes

Check Sleep clk 32,768kHz

N100/ 4 8 = 2,8Vpp

D200/124=2,8Vpp(square)

Yes

higher

No

No

No

No

No

Check

C680, C682

Check c onnection

to X101

L103

Change

B100

Check:

R118 (10K)

X300

UI-module

Check s ol derings

of N100

or

Change N100

Check s ol derings

of N100

or

Change N100

No

consumption OK

change

N502

Lift L5 60

(VBATT for Pwr

Amp)

OK

N501 or N502

faulty

insert L560

and lift L654 and

Pin 12, 13 of N502

observe the power

consumption

consum ption not OK

change

N501

Check DC Volt SL E EP X

D200 / 113 = 2,8V

N100 / 24 =2,8V

Yes

Check DC Volt VXO

N100 / 25 = 2,8V

G600 / 1 = 2,8V

Yes

Check VCXO 13MHz

G600 / 2 = 1Vpp

D200 / 93 = 0,6Vpp

Yes

Try to flash

the phone

No

No

No

No

Check s ol derings

of D200

or

Change D200

Check s ol derings

of N100

or

Change N100

Change

G600

See Section:

Can't Flash the

phone

version 1.1 / 01.02.2000 Page 4 of 41

Page 5

CONFIDENTIAL

N100 faulty/ poor soldering

Check if voltage on Pin 29 decreases to 700 mV during pressing the Power on button

•

Check if there is a 32.768 kHz square wave on Pin 48

•

Check if PURX Pin 54 goes up to 2.8 V DC

•

Check if VXO Pin 28 goes up to 2.8 V DC

•

B100 faulty 32,768 kHz

Check 32.768 kHz ; 1 Vpp clock signal on B100

•

G650 faulty 13 MHz

Check VXO 2,8V DC on pin 1 from G650

•

Check 13 MHz; 1 Vpp on output pin 2

•

S001 User Interface

Check if voltage on Pin 29 decreases to 700 mV during pressing the Power on button

•

Service & Analysis Center Europe

Training Team

X300 UI Connector bent out

Check if voltage on Pin 29 decreases to 700 mV during pressing the Power on button

•

R118 missing/ poor soldering

Check if voltage on Pin 29 decreases to 700 mV during pressing the Power on button

•

D200 MAD faulty/ poor soldering

Check 32.768 kHz square wave on Pin 124 (comes from CCONT Pin 48)

•

Check 13 MHz on Pin 93 (comes from G650)

•

Check VBB 2.8 V DC

•

Check PURX 2.8 V DC on Pin 122 (comes from CCONT Pin 54)

•

Check SLEEPX 2.8 V DC 0n Pin 113

•

Resolder MAD completely

•

D210 FLASH faulty / poor soldering/ empty

Check VBB 2.8 V DC on Pin 37

•

If power consumption is around 20mA try to flash the phone

•

Resolder FLASH completely

•

L103 faulty/ poor soldering

Check VB on J232 or pin 8 from CCONT

•

X101 / X102 contacts bend out/ dirty

Check if VBATT and Gnd are connected

•

version 1.1 / 01.02.2000 Page 5 of 41

Page 6

CONFIDENTIAL

N501 / N502 short circuit

If there is a short circuit on VBATT, lift L560 and check again

•

If the current is OK one of the two PA is faulty

•

Assemble L560 back and lift L654 and pin 12 and 13 from N502

•

If the current is OK N502 is faulty, if not N501 is faulty

•

If the PCB is burnt, swap the phone

•

C680; C682 / short circuit

Lift the capacitor and check again

•

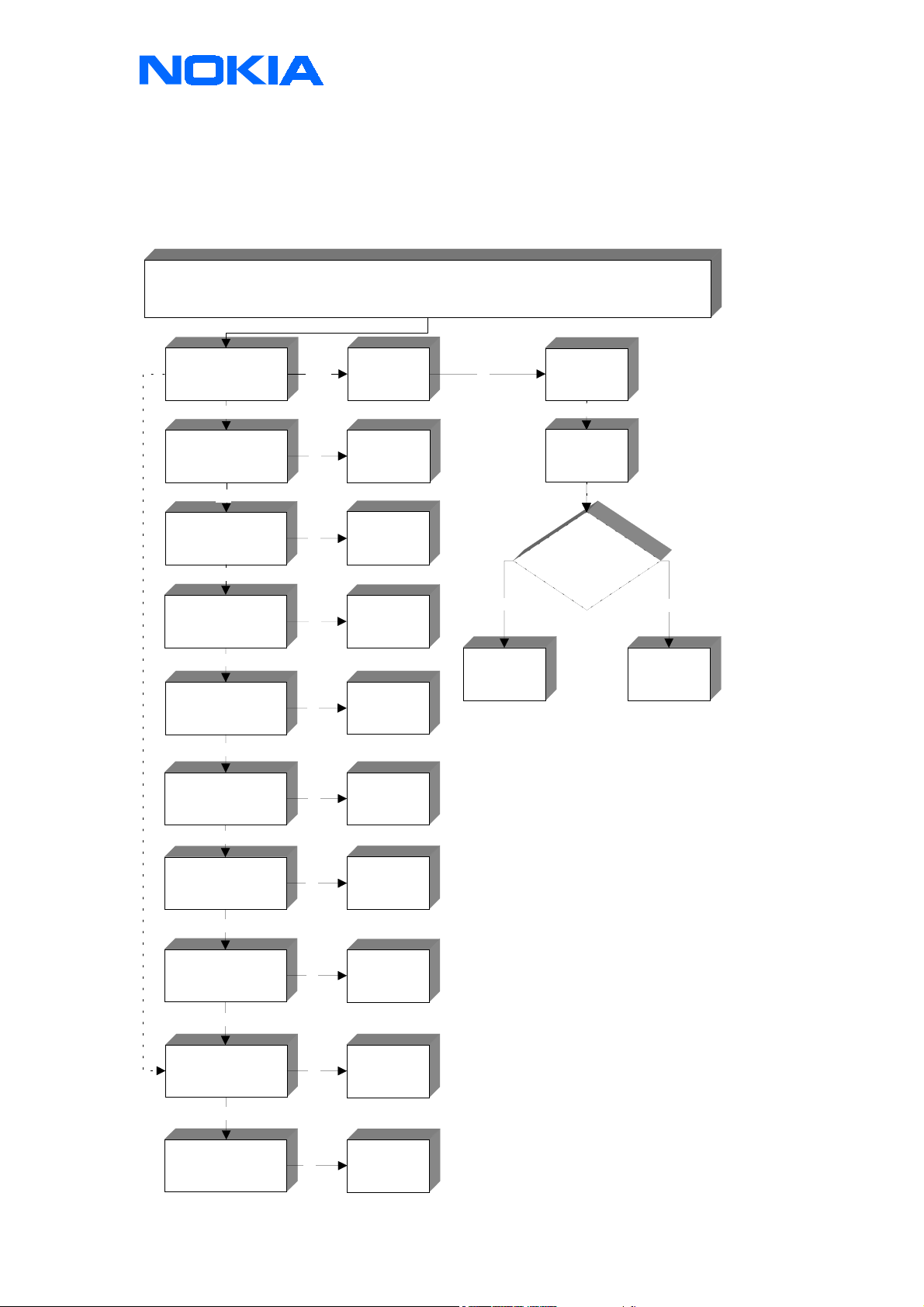

Figure 2: Block diagram of switching on routine

BB Regulator VBB 2.8V

VBATT

Service & Analysis Center Europe

Training Team

VCXO

13 MHz

G600

C213

R103 / R104

VCHAR

BTEMP

R213

SLEEPX

12, 16, ...

60

63

25 VXO 2.8V

24

113

2.8V

55

CCONT

N100

GENSIO

48

124

32 KHz

square

54

122

2.8V

46

47

29

PURX

B100

32 KHz

Crystal

R118

Pwr OnX

from

UI module

MAD2

93

D200

version 1.1 / 01.02.2000 Page 6 of 41

Page 7

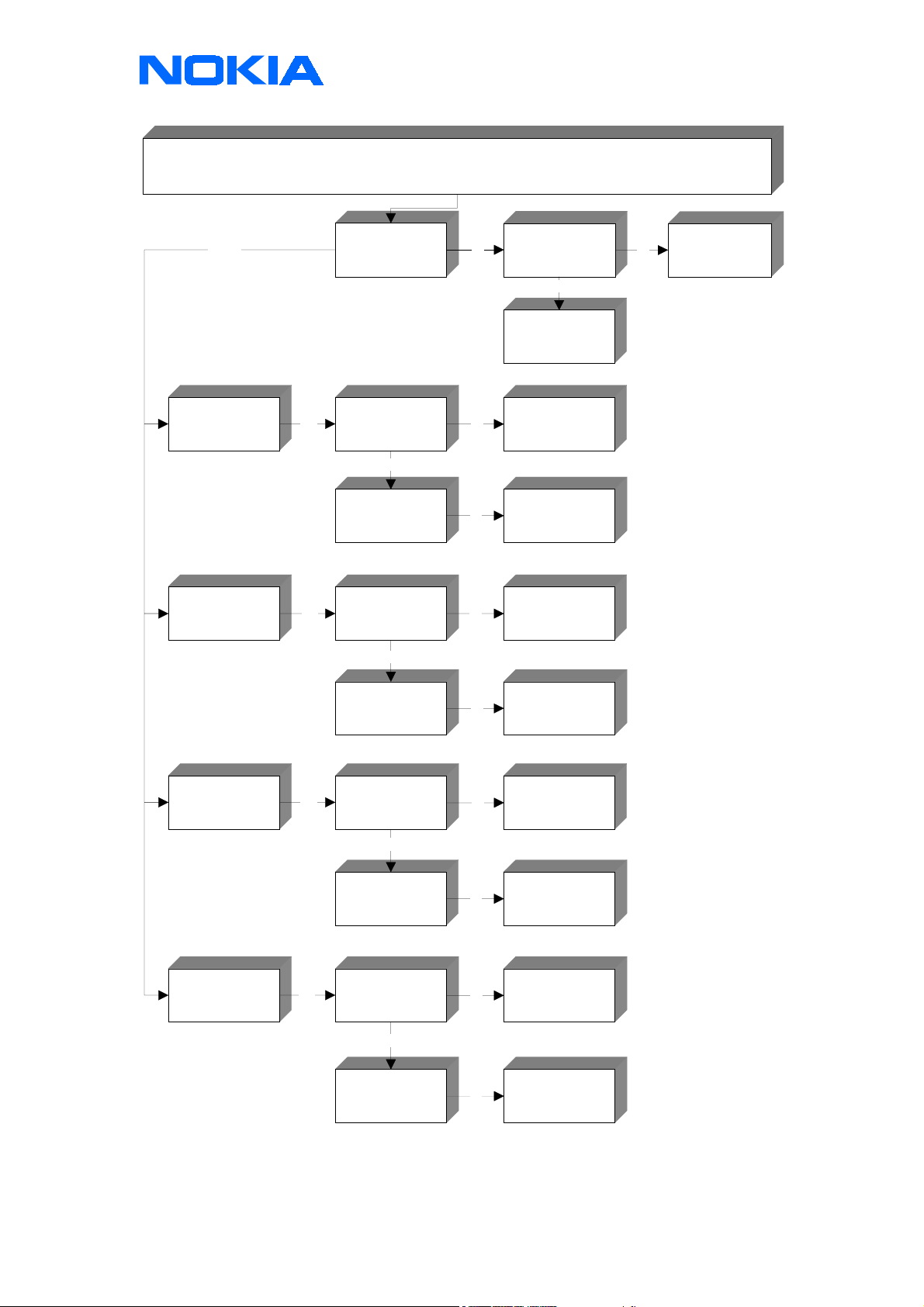

Not charging

check VCH on pi n 1,

16 of N101, CHAPS

CONFIDENTIAL

Service & Analysis Center Europe

Not charging (1)

no confirmation / er r or mes sage / beep is coming from phone, if charger i s

plugged in

Check X100, F101,

check V100, C103 if

VCH is short circuited

Ok

No Ok

L104, L105 if

connection to charger

is open

Training Team

check solderi ngs of

N101 or change if

necessary

Do the battery

management

calibration

check the power

consumption of t he

phone (1-5mA if

phone is swit ched on

wit hout SIM & lights)

Phone doesn't stop charging

if any A/D value is

Ok

No

Ok

wrong, refer to

section not charging

(2)

If the power

consumption is

higher, refer to

section low standby

time

Yes

Yes

not charging (2)

low standby time

No

check DC voltage on

pin 2 of D200, M AD,

switches from 2,8V to

0V, if battery is fully

charged

No

resolder or change

MAD if necessary

version 1.1 / 01.02.2000 Page 7 of 41

Page 8

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

failed

Charger voltage failed

Battery siz e

failed

error message ("not charging") / beep is coming from phone, if charger is plugged in

Not charging (2)

Do the battery

management calibration

check DC voltage on pin

Yes

Yes Ok

60 of N100/ C CONT

if char g e r i s pluged in

nomin al VCH 1:10 (0, 8V)

No

check F101, L104, V100,

C103 and voltage

devider R103, R104

check DC Voltage on pin

62 of N100, C CONT

check DC voltage on pin

9 of N101, CHAPS if

Ok

charger is plugged in

resol d er or change D2 00

resol d er or change N1 00

Ok

Ok

try the c al i b ration aga in

resol d er or change N1 00

(2,8V)

No

if necessary

if necessary

if necessary

Try charging, if no A/D

Ok

value was wrong

Battery temperature

failed

Charge current

failed

check battery, X101,

voltage devider R120,

check DC voltage on pin

Yes

Yes

63 of N100, C CONT

check battery, X102,

voltage devider R120,

check DC voltage on pin

No

try the c al i b ration aga in

R122

No

R122

2 of N100, CCONT

No

check N101, R131 try the c al i b ration aga in

Ok

resol d er or change N1 00

Ok

try the c al i b ration aga in

Ok

resol d er or change N1 00

Ok

Ok

if necessary

if necessary

version 1.1 / 01.02.2000 Page 8 of 41

Page 9

CONFIDENTIAL

F100 faulty

Check resistance of F100 (0Ω)

•

V100 faulty

Check resistance of V100 (50KΩ in circuit)

•

C103 faulty short circuit on Vcharge

Check resistance of C103 (50KΩ in circuit)

•

NOTE! V100 is connected in parallel to C103

•

L104 faulty Vcharge

Check resistance of L104 (0Ω)

•

L105 faulty Charge ground

Check resistance of L105 (0Ω)

•

N101 faulty/ poor soldering

Check PWMOUT on Pin 7 (1 Hz standard charger / 32Hz fast charger)

•

Check if CHARLIM on Pin 9 is 2.8V DC

•

Service & Analysis Center Europe

Training Team

N100 faulty/ poor soldering

Change if any A/D value is out of limit but the DC voltages are ok.

•

If DC voltages are wrong, check corresponding voltage dividers

•

Check PWMOUT on Pin 56 (1 Hz standard / 32 Hz fast)

•

X100 faulty/ poor soldering

Check connection of Vcharge; charge ground; charge control

•

X101 BSI; X102 BTEMP

Check connection if battery size or battery temp A/D are out

•

of limit

V102 faulty

Check if there is a short circuit in charge control line

•

Energy management Calibration

If charging stops too early

•

If message “not charging” appears on LCD

•

If any part in charging circuit has been changed

•

If any A/D value is out of limit, check the corresponding

•

DC Voltages on CCONT

version 1.1 / 01.02.2000 Page 9 of 41

Page 10

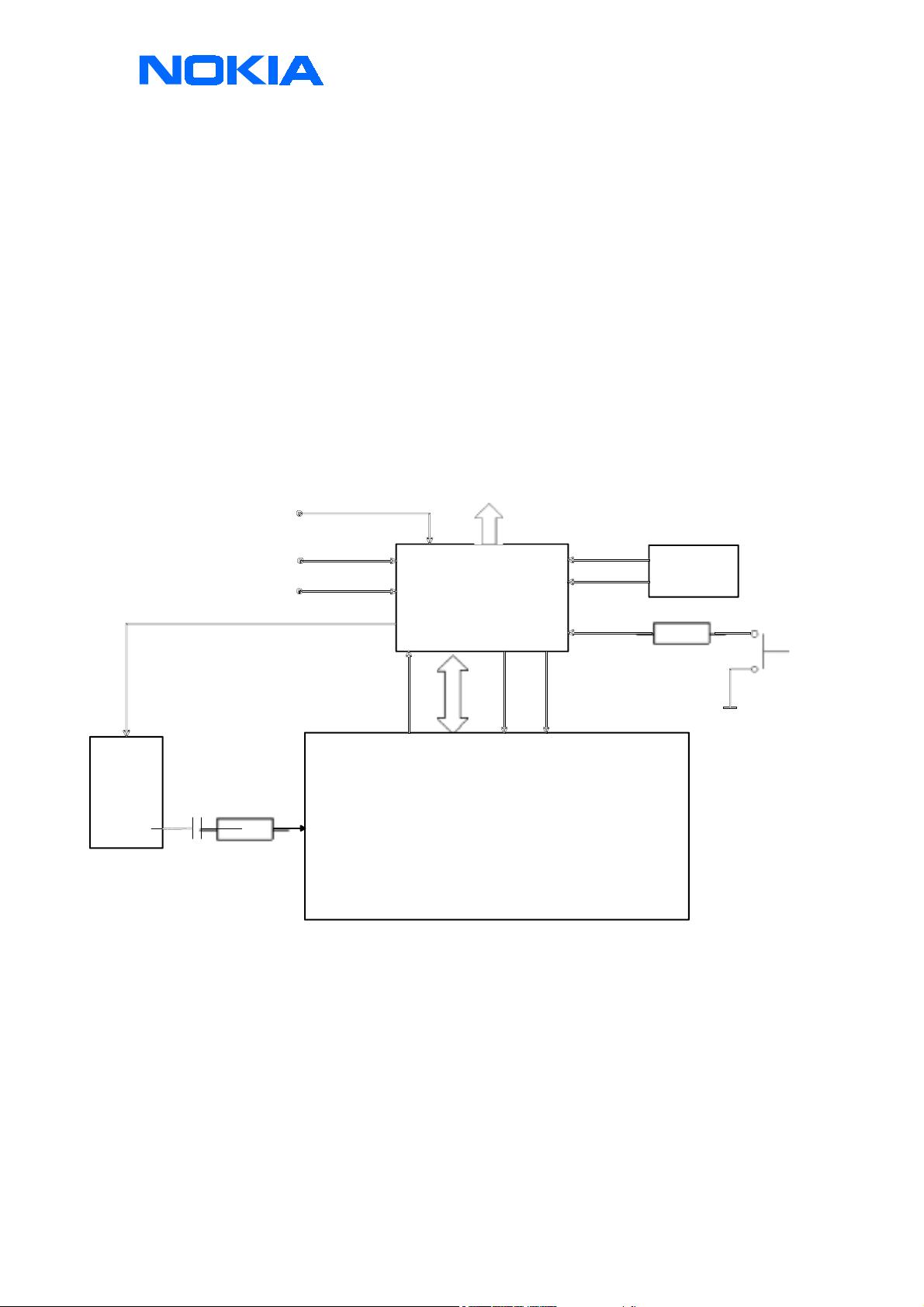

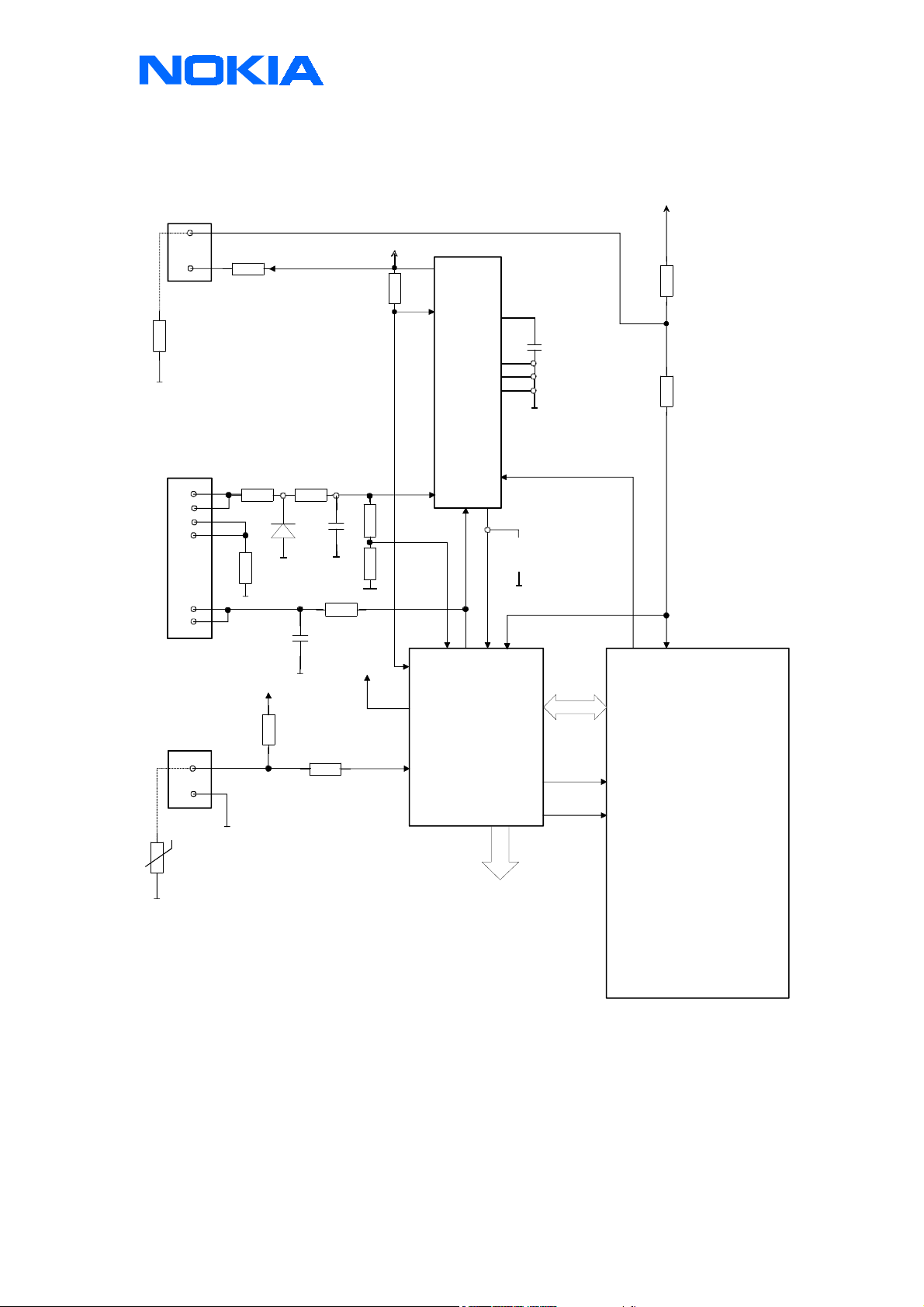

Figure 3: Block diagram of charging concept

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

X101

Battery connector

1

2

BSI Resistor (Inside of Battery)

2.2K .... 18K : NiCd Battery

20K .... 24K : Service Battery

27K .... 51K : 4.1V Lithium Battery

68K .... 91K : 4.2V Lithium Battery

X100

Sysrem Connector

1

3

2

14

4

5

X102

Battery Connector

BTEMP

BGND

T

47K NTC

BTEMP Resistor

inside of Battery

BSI

BVOLT

L103

F101

L105

Charger Ctrl.

VREF

V100

R120

L104

C103

R122

Current

Shunt

R104

R103

R116

VCH

VB

VB

R131

Chargedet.

1,16

2 ICHAR

8,12,16,21,

27,28,57

63

12

5

2,3,4

6,11,13

14,15

N101

CHAPS

710

VBACK

PWMOUT 1Hz / 32Hz

VCHAR

60 56 46 62

N100

CCONT

BB and RF

Regulators

8

9

2.5V DC min

DataClk 49

DataSelX 50

DataI/O 51

CCONTInt 52

Purx 54

C104

CHARLIM

G100

RTC Battery

Battery Type (BSI)

VBB

2

MCUGENOUT

119 DataSCLK

116 GenCCONTCSX

118 GenSDIO

123 CCONTInt

122 Purx

95

CardDetX

R120

R122

D200

MAD2

version 1.1 / 01.02.2000 Page 10 of 41

Page 11

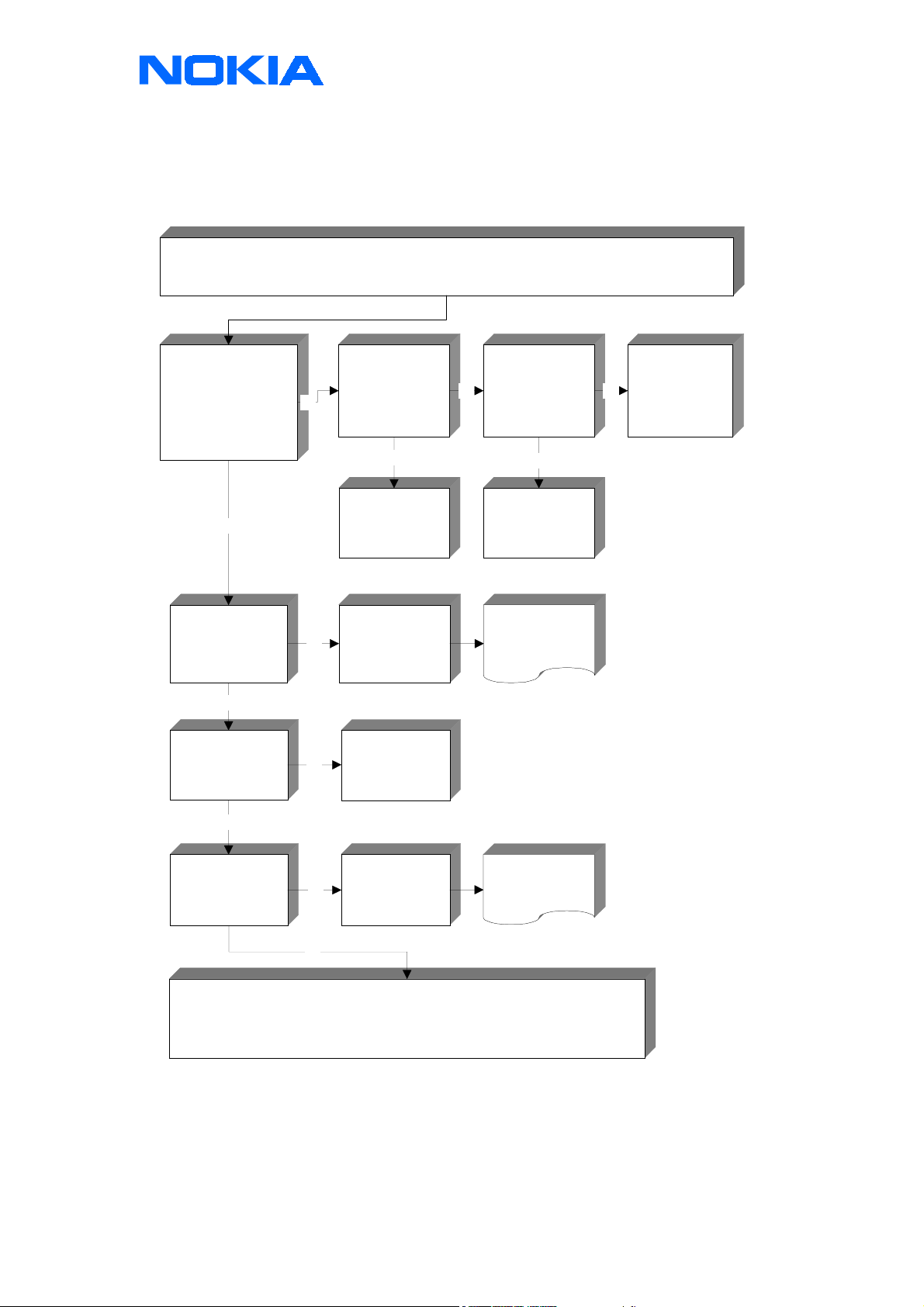

Low Stand-by time

CONFIDENTIAL

Low standby time

(battery is Ok)

Service & Analysis Center Europe

Training Team

check power

cons ump tion of the

phone:

Off state > 0-1mA

sleep mode > 1- 5 mA

Call mode >

200-500mA (lev el 19 / 5)

Ok

check the charging

circuit, use battery

management

calibration

Ok

check if sleep mode

function works

properly

No

change N5 50 , if

cons ump tion is Ok

refer to section "not

No

charging (2)" if any

A/D value is wrong

resold er or change

No

lift L560 lift L103

Ok

D200, MAD if

necessary

No No

change N100,

CCONT if

cons ump tion is Ok

"not charging (2)"

check C142,

C610-12, C105,

N101, change if

necessary

Ok

section

Ok

Calibrate RX and TX

values of the phone

Note: The standby time depends also on the network side, like: PRP (paging repeat

period time), signal strength (min -98dBm), location updates

and on the user handling of the phone (lights on or of, memory acti viti es, games etc.)

No

Ok

refer to section

receiver /

transmitter failure

section "receiver /

transmitter failure"

N501 / N502 / N100 / N101 / D200 / Battery calibration - faulty

Check the current consumption in different operation modes

•

version 1.1 / 01.02.2000 Page 11 of 41

Page 12

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Figure 4: current consumption values

Function mode Minimum current in mA Maximum current in mA

Off state 0 1,35

Sleep mode 1 5

Call mode GSM 900 250 440

Call mode GSM 1800 200 420

Disconnect the PA's N501 / N501 lift L560 and check the current again

•

Check if the current consumption comes from the first or second side of CCONT lift L103

•

Check C105, C142 or N101

•

Check solderings of the MAD

•

Change MAD

•

calibrate battery value if charging stops too early or battery is too hot after charging (see also chapter "Not charging)

•

Note! The Standby-time depends on the network side and on the user handling

Intermittent doesn't switch on

D210 FLASH faulty

Check if the handset switches on after removing the battery for few seconds

•

or after connecting it with the charger or headset

D210 Flash internal fail

•

version 1.1 / 01.02.2000 Page 12 of 41

Page 13

Phone switches off itself

CONFIDENTIAL

Phone intermittend switches off

Yes

Service & Analysis Center Europe

Training Team

Check if this happens

only w ith 5V S IM-cards

and if the phone work s

probably w ith 3V S IM's

Yes

Check the 5V

supply voltage on

C131 with an

oscilloscope

Yes

Change C131 if the

noise is higher than

350mVpp

Check X101 and

No Wrong

X102, if poor soldered,

bent, soiled or old

version

No

Check amplitude of

32,768KHz square

wave at pin 124 of

MAD (2,8Vpp)

No

Check amplitude of

13MHz at pin 93 of

MAD (600mV pp)

Wrong

Wrong

Resolder, or change

the connector

Change or check

soldering of B100,

N100, R154, C101,

C102

Change or check

soldering of G650,

V600...

No

Check VBB 2,8V DC

on pin 55 of N100

Wrong

Change or check

soldering of N100,

C107

version 1.1 / 01.02.2000 Page 13 of 41

Page 14

CONFIDENTIAL

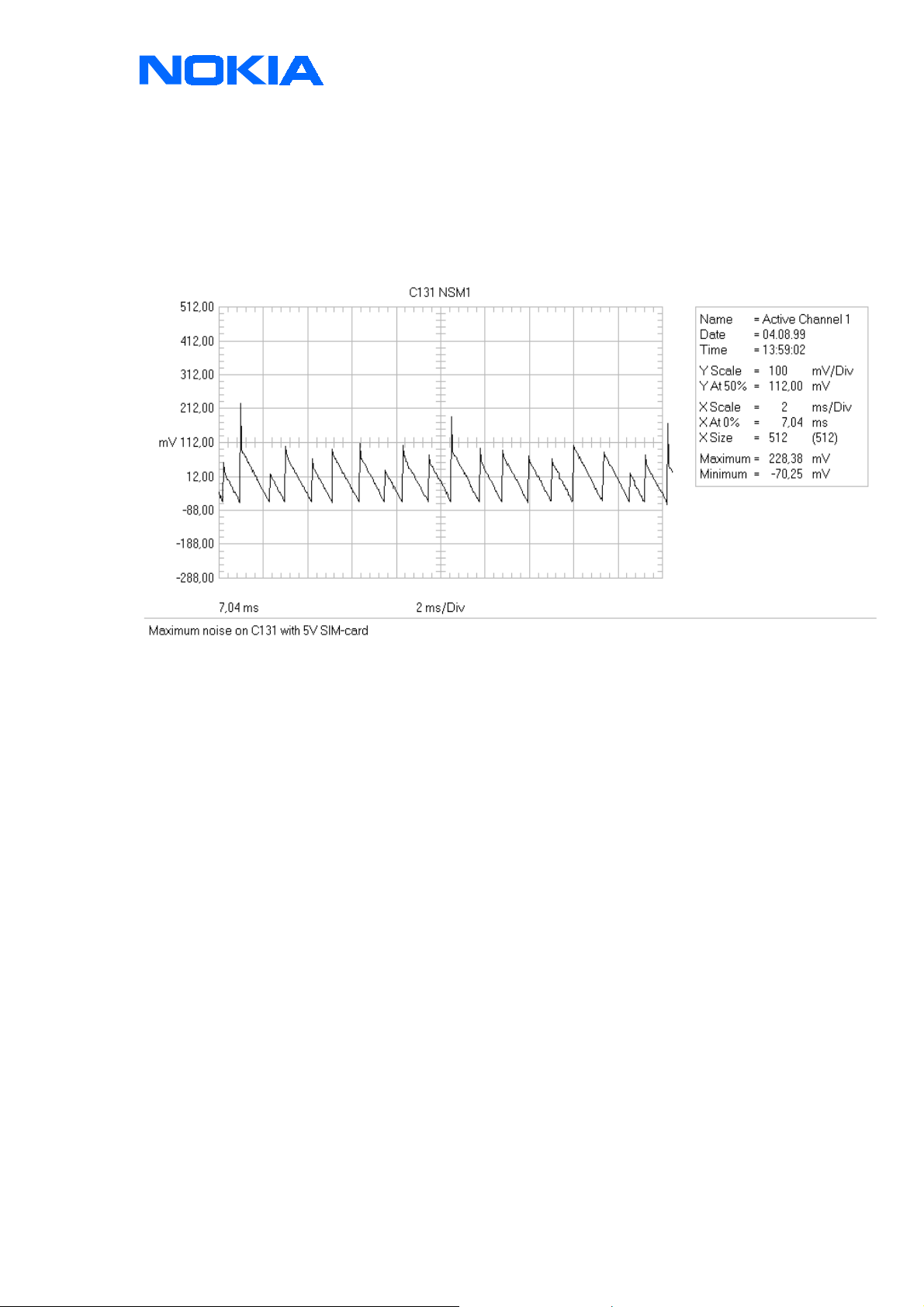

C131 10μF/10V

Check if the handset works with 3V SIM-cards

•

Check if the 5V voltage over the capacitor C131 is around 4,8V-5,2V with

•

maximal 350mVpp noise overlap (look at the diagram below)

Figure 5: maximal noise o n C131

Service & Analysis Center Europe

Training Team

Switch off itself - contact service on the display

D200 MAD faulty / poor soldering

Check the amplitude of the 32,768 kHz square wave on pin 124 (comes from CCONT pin 48)

•

Check the amplitude of the 13 MHz clock frequency pin 93 (from G650)

•

Check VBB 2,8V DC

•

Resolder MAD

•

Internal error of MAD

•

version 1.1 / 01.02.2000 Page 14 of 41

Page 15

CONFIDENTIAL

Contact service – COBBA parallel bus failed

Contact Service

Check via WINTESLA / Testing / Sel ftest

which kind of selftest is fail

COBBA parallel bus

failed

Yes

Service & Analysis Center Europe

Training Team

check COBBACLK

13MHZ/ 3,2Vpp on

pin 45 0f COBBA

Ok

check VBB 2,8V on

pin 27, 53 of COBBA

Ok

Check VCOBBA 2,8V

DC on pin 7, 12, 21,

25 of COBBA

Ok

Check soldering of

MAD or change MAD

No

No

No No

Check COBBA Clk on

pin 144 of MAD

Check VBB 2,8V DC

on pin 55 of N100,

CCONT

Check VCOBBA 2,8V

DC on pin 22 of

N100, CCONT

No

No

Change or check

soldering of MAD

check soldering or

change N100, C107

Change or check

soldering of N100,

C133

Ok

Check soldering of

COBBA or change

COBBA

version 1.1 / 01.02.2000 Page 15 of 41

Page 16

Contact service – COBBA serial

Contact Service

Ch eck via W INTES LA / Testing / S elf test

which kind of selftest is faulty

COBBA Serial

bus failed

Yes

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Check VBB 2 ,8V

DC on pin 27, 53

of COBBA

Ok

Check VCOBBA

2,8V DC on pin 7,

12, 21, 25 of

COBBA

Ok

Check soldering

of COBBA or

change CO BBA

Ok

Check soldering

of MAD or change

MAD

No

No

Check VBB 2 ,8V

DC on pin 55 of

N100, CCONT

Check VCOBBA

2,8V DC on pin

22 of N100

No

No

Change or check

solder ing of

N100, C140

Change or check

solder ing of

N100, C133

N250 COBBA faulty / poor soldering

Check VBB 2,8V DC on pin 27, 53 from COBBA

•

Check VCOBBA 2,8V DC on pin 7,12,21,25, from COBBA

•

Check COBBACLK 13MHz 3,2Vpp pin 45 from COBBA

•

Resolder COBBA

•

Internal error of COBBA

•

Note! Rewrite SIMLOCK and IMEI entries with use of the Nokia security SW (SSSW) and make a SW-update or send these

phones to the SACE, if this procedure is not permitted to you

version 1.1 / 01.02.2000 Page 16 of 41

Page 17

CONFIDENTIAL

Contact service – Eeprom tune checksum fail

Contact Service

Check via WINTESLA / Testing / Selftest

which kind of selftest is fail

EEPROM tune

checksum fail

Yes

Service & Analysis Center Europe

Training Team

Check via WINTESLA >

product information, if

any phone data, like:

IMEI, product code,

PSN, etc. is corrupted

change the EEPROM if

it is permitted to you to

Reset the phone (don't

No

Yes No

rewrite the IMEI

use the full factory set if

it is not permitted to you

to rewrite the IMEI)

EEPROM

internal fault

send this phone to the

SACE if it is not

permitted to you to

rewrite the IMEI

refer to General

Service Bulletin

037!!!

Phone is Ok, if

CONTACT SERVICE

dissapears

D230 Eeprom faulty

Check with Wintesla if IMEI or product data are corrupted

•

Don’t use the "Full factory set" with Wintesla, otherwise the IMEI will be changed to question marks

•

Change the Eeprom if it's permitted to you and write all ID data (IMEI, product code…) back

•

If you aren't allowed to change the Eeprom and the IMEI is missing, write a note with a little comment, and send it

•

together with the phone to the SACE

version 1.1 / 01.02.2000 Page 17 of 41

Page 18

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Note! Rewrite SIMLOCK and IMEI entries with use of the Nokia security SW (SSSW) and make a SW-update or send these

phones to the SACE, if this procedure is not permitted to you

Contact service – ppm validity

Contact Service

Check vi a WINTESLA / Tes t ing / Selftest

which kind of selftest is fail

PPM v alidity fail

try to flash the phone

check soldering or

change D200,

SW / D210 Flash faulty / poor soldering

Check if the fault disappears after a SW-update

•

Resolder D210 Flash

•

Internal error of Flash

•

Yes

not OK

FLASH

OK

phone is OK, if

CONTACT

SERVICE dissapears

after flashing

version 1.1 / 01.02.2000 Page 18 of 41

Page 19

Clock time or user settings problems

Clock time problems / wrong ringingtone speed

check 32,768KHz

clock frequency on

pin 48 of N100,

CCONT

Check soldering or

change B100, R 154 ,

C101, C102, N100

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Clock time / Ringing tone is too fast or too slow

32,786 kHz Sleep oscillator

Check that the sleepclk 32.768 kHz square wave frequency on pin 48 CCONT is not higher or lower

•

Check the crystal B100, R154, C101, C102, N100

•

Clock freezes after switching on the phone

Yes

Check the

CCONTINT

impulse on pin

52 of N100,

CCONT

Ok

Check the

CCONTINT

impulse on pin

123 of D200,

MAD

No

No

resolde r C CONT

or change if

solderings are

esolder MA D or

r

change if

solderings are

Ok

Ok

version 1.1 / 01.02.2000 Page 19 of 41

Page 20

CONFIDENTIAL

Clock freezes after power on

CCONTINT short circuit / break

Check the CCONTINT impulse on pin 52 CCONT or pin 123 MAD (see the diagram below)

•

Check pin 52 CCONT pin 123 MAD short circuit or break

•

Figure 6: CCONTINT impulse

Service & Analysis Center Europe

Training Team

Loose of clock time after removal of battery

Backupbattery

keeps the clock

running for min.

10 minutes

No

Check the DC

voltage 2,8V -

3,3V on G100,

backupbattery

No

Check the

springcontacts if

they are bent or

soiled

No

Change G100,

backupbattery

Yes

correct or clean

the contacts

version 1.1 / 01.02.2000 Page 20 of 41

Page 21

CONFIDENTIAL

Service & Analysis Center Europe

Looses clock time if the battery is empty or removed for a few minutes

G100 Back up battery faulty / disconnected

Check the voltage 2,8V-3,3V over the back up battery connected to the PCB in the service modus

•

Check the spring contacts

•

Clean the contacts for the back up battery on the board

•

Buzzer failures

Buzzer failure

check buzzer signal 1Vpp

on B001, buzzer

use WINTESLA / testing /

audio / level 1, 1000Hz

Ok

change B001, buzzer

Training Team

check 32,768KHz on pin

48 of N100, CCONT if

speed of buzzer is too

slow or fast

No

check contacts and

solder of X300

Ok

check buzzer signal

200mV pulses on pin 97

of D200, MAD (use same

settings)

not Ok not Ok

Change B100

not Ok

No

resolder or change X300 if

any spring is bended

resolder or change MAD if

necessary

check solder of R154,

C101, C102 or change

N100 if necessary

B001 / UI-module

Check buzzer signal about 1Vpp pulses (use WINTESLA / testing / audio

•

Level 1, 1000Hz)

Change component if signal is ok

•

version 1.1 / 01.02.2000 Page 21 of 41

Page 22

CONFIDENTIAL

X300, board to board connector

Check soldering

•

Check contact springs, change component if bent

•

D200, MAD

Check buzzer signal on Pin 97 (200mV pulses) use WinTesla / testing / audio

•

Level 1, 1000Hz

B100, 32.768 kHz crystal

Change component if ringing tone speed is too low or high if a call comes in.

•

If you pick a ringing tone from the menu, the speed is normal.

In this case, also the clock is running wrong if the phone is switched off.

•

Internal Audio Failures

Internal audio failure

Service & Analysis Center Europe

Training Team

speaker doesn't

work

(receiving audio)

microphone

doesn't work

check impedance

Yes

of speak er (30

Ohm)

Ok

resolder or change

X300 if an y sp r ing

is bent

check contacts

and impedance of

Yes not Ok

microphone (800

Ohm)

Ok

check soldering

and conta cts of

X100

Ok

check MIC BIAS

voltage, 2,8V DC if

audio is active

Ok

not Ok

not Ok

not OK

not Ok

change speaker

check soldering of

N250, COBBA or

change if

necessary

change

microphone

resolder or change

if necessary

change C266

check if MIC N or

MIC P is short

circuited to ground

Ok

check solder of

N250, COBBA or

change if

necessary

not Ok

change V103

version 1.1 / 01.02.2000 Page 22 of 41

Page 23

CONFIDENTIAL

Speaker

No / quiet / distorted receiving audio signal

Check the mechanic of speaker, contacts, membrane, soiling

•

Check resistance of speaker (about 30Ω)

•

Microphone

No / quiet / distorted transmitting audio signal

Check contacts of microphone

•

Check resistance of microphone (about 800Ω)

•

X300

Check soldering

•

Check contacts (change connector if bent)

•

X100

Check microphone spring contacts

•

Check soldering

•

Service & Analysis Center Europe

Training Team

V103

Check resistance from MIC N or MIC P to ground (about 1KΩ and 2KΩ)

•

change component if resistance is 0

Ω

C266

Check MIC BIAS voltage 2.8V DC collector V 250 if audio is active (use WinTesla / testing / audio)

•

version 1.1 / 01.02.2000 Page 23 of 41

Page 24

External Audio Failures

CONFIDENTIAL

External audio failures

Service & Analysis Center Europe

Training Team

XEAR failure

(receiving audio)

XM IC failure

(transmitting

audio)

check X100

Yes not oK

Yes not oK

if poor soldered

or soi led

contacts

oK

check L107

(0 Ohm)

check X100

if poor soldered

or soi led

contacts

oK

not oK

resolder or clean

X100,

change if

necessary

change L107

resolder or clean

X100,

change if

necessary

check L106 (0

Ohm)

not oK

change L106

L106

Check resistance of coil (0Ω), if there is no XMIC

•

L107

Check resistance of coil (0Ω), if there is no XEAR

•

X100

Check soldering

•

Check contacts (soiling)

•

version 1.1 / 01.02.2000 Page 24 of 41

Page 25

CONFIDENTIAL

Accessory detection failure (headset / car kit active)

Accessory detection failure

(headset / car kit active)

check if XMIC

headset is

detected

Yes not oK

(X100 pin 8) i s

short circui ted to

ground

oK

Service & Analysis Center Europe

Training Team

change V102

car kit is

detected

check if there is a

liquid damage

around X100,

V102, V101, L105

check R257,

R256, R261

check if XEAR

Yes not oK

(X100 pin 10) i s

short circui ted to

ground

oK

check R259,

R260

not oK

not oK

resolder or

change if

necessary

change V102

resolder or

change if

necessary

V102

Check the resistance of XMIC to ground if headset is detected

•

Check the resistance of XEAR to ground if car kit is detected

•

Change component if resistance is low

•

R259 / R260

Check soldering and resistance of components if car kit is detected

•

(45KΩ / 22KΩ inside PCB)

R256 / R257 / R261

Check soldering and resistance of components if headset is detected

•

(2,2KΩ, 45KΩ, 22KΩ inside PCB)

version 1.1 / 01.02.2000 Page 25 of 41

Page 26

CONFIDENTIAL

Liquid damage

Check if there is a liquid damage around X100, V101, V102 and L105)

!

Figure 7: Block diagram of audio switching concept

VBB 2.8V

R259

R260

R261

C261 C260

VCOBBA 2.8 V

107 HOOKDET

MAD2

D200

108 HEADDET

CCONT

64 EAD

N100

Service & Analysis Center Europe

Training Team

System Connector

X100

XEAR 10

SGND 9

XMIC 8

V102

V102

V102

R256

R254

R257

C255

R252

C254

C272

C253

C258

C257

2 AUXOUT

3 HF

58 MIC 3P

62 MIC 1P

61 MIC 1N

57 MIC 3N

COBBA

N250

version 1.1 / 01.02.2000 Page 26 of 41

Page 27

Display Failure

contrast

dissapears,

missing segments

Yes

CONFIDENTIAL

Display failure

change elastomer

not oK

change LCD, if

elastomer change

doesn't help

Service & Analysis Center Europe

Training Team

strange signs on

LCD, "dark" LCD

during start up is

missing

black line on LCD

after phone is

switched off

Yes

Yes

not oK

check contacts

and solderin gs of

X300

check LCD reset

on pin 36 of MAD

add a 4,7M Ohm

resistor to C6 on

user i nterface

(piggypack)

not oK

not oK

resolder or change

X300 if any s pr ing

is bent

resolder M AD or

change if

necessary

refer to service

bulletin 009 NSE-1

version 1.1 / 01.02.2000 Page 27 of 41

Page 28

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Elastomer

Change Elastomer to recommended blue ShinEtsu elastomer MSG in Tape & Reel. Do not touch elastomer with bare

•

hands (see SB035 NSM-1).

Figure 8: different types of elastomers

DO NOT USE #5409131 #9780252

ANY LONGER Recommended Elastomer

LCD / UI Module

Change LCD if elastomer change doesn't help

•

The PCB version UE4_13 makes better contact between PCB and the Elastomer, pad size of the LED's is modified

•

Figure 9: different types of LCD's

Philips LCD Seiko LCD

N0 capacitors capacitors inside

version 1.1 / 01.02.2000 Page 28 of 41

Page 29

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

X300

Check solderings

•

Check contacts (change connector if bent)

•

D200

If there are wrong signs on LCD and the filled LCD during start up is missing, check LCD reset on JBS-19 Test Pin 25 or

•

D200/ 36 during start up

UI-module

Check LCD contact pads, clean if soiled

•

Change if elastomer and LCD change do not help

•

Keypad failure

Keypad failure

check contacts

and solderings of

X300

oK

check keys on UI

module

oK

check ROW and

COL lines of D 200,

MAD

not oK

not oK

not oK

resolder or cha nge

X300 if any spring

is bent

change module if

any key is

damaged

resolder MAD or

change if

necessary

X300

Check soldering

•

Check contacts (change connector if bent)

•

D200

• Check ROW (5:0) and COL (4:0) lines

UI-module

• Check keys on UI, change UI-module if any keydome is damaged

version 1.1 / 01.02.2000 Page 29 of 41

Page 30

Insert SIM CARD

CONFIDENTIAL

Insert SIM card

the phone does n't register the SI M card

Service & Analysis Center Europe

Training Team

check s olderings and cont acts of

X300, SIM ca rd reader

oK

check pin 95 of D200 MAD, if BSI

is connected

oK

check pin 120 (SIMDATA ), pin

126 (SIMCLK), pin 127(SIMRST),

pin 128 (SIMIOC) and pi n 129

(SIMPWR) of D200, M AD

oK

check pin 43 (SIMDATA), pin 38

(SIMCLK), pin 42 (SIMRST), pin

36 (VSIM) of N100, CCONT

not oK

not oK

not oK

not oK

resolder X300 or

change if any

contact is bent

check solderings

and contacts of

connector X101

resolder MAD or

change if necessary

resolder CCONT or

change if necessary

not oK

not oK

not oK

swap t h e phone if

any wire to the SIM

card reader has torn

off

check the battery

contacts, clean if

soiled

change V104 if SIM

-DATA, -CLO CK,

-RESET or VSIM is

short circuited to

ground

X302, SIM card reader

Check soldering

•

Check contacts (change connector if bent)

•

X101, battery connector

Check BSI connection to D200 / 95 CardDetX

•

version 1.1 / 01.02.2000 Page 30 of 41

Page 31

CONFIDENTIAL

D200, MAD

Check SIM card -DATA (Pin120), -Clock 3,25MHz (Pin 126), -Reset (Pin 127), -IOC (Pin 128)

•

and -Power (Pin 129)

N100, CCONT

SIM card -DATA (Pin 43), -Clock 3,25MHz (Pin 38), -Reset (Pin 42) and VSIM 3V/5V DC

•

(Pin 36) depends on SIM card

V104

Change component if SIM -DATA, -Clock, -Reset or VSIM is short circuited to

•

ground

Service & Analysis Center Europe

Training Team

version 1.1 / 01.02.2000 Page 31 of 41

Page 32

CONFIDENTIAL

SIM card not accepted, SIM LOCK failure

SIM card not accepted (SIM LOCK active)

SIM card not

accepted

appears on

LCD after

entering the

PIN code.

Yes

Service & Analysis Center Europe

Training Team

open

WINTEASLA

and activate

quick /RF -info

compare the data

entries MCC+MNC

Yes Ok

with the listed

entries of t he

respective product

code

not oK

SIM LOCK is oK!

correct the SIM

LOCK settings

with use of the

Nokia security SW

(SSSW) or send

those phones to

the SACE

if SIMLOCK is not

active, but

phone still doesn't

accept SIM,

change N250,

COBBA

!!!Take note!!!

if the Msin data field is

closed to any special

IMSI number range,

the operator is

ONLY

allowed to open the

SIM LOCK!!!(see

General SB065)

correct the SIM LOCK

settings with use of

the Nokia security SW

(SSSW) aft er

changing of C OBBA

or send those phones

to the SACE

If message "SIM Card not accepted" appears on LCD after entering PIN code,

•

a SIM LOCK is activated in this phone.

Initialise phone into normal mode and activate

•

Quick/ RF-info

(WinTesla)

compare the SIM LOCK entries with the references from the operator

N100, CCONT

Refer to insert SIM Card procedure

•

version 1.1 / 01.02.2000 Page 32 of 41

Page 33

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

N250, COBBA

Change COBBA if all SIM LOCK entries and SIM card signals

•

from CCONT are ok

Note! Rewrite SIMLOCK and IMEI entries with use of the Nokia security SW (SSSW) and make a SW-update or send this

phones to the SACE, if this procedure is not permitted to you

Figure 10: No SIMLOCK set to the phone

Figure 11: SIMLOCK is set to operator OLA France

version 1.1 / 01.02.2000 Page 33 of 41

Page 34

CONFIDENTIAL

Service & Analysis Center Europe

SIM LOCK DATA NSM-1

Figure 12: List of current SIM LOCK phones NSM-1

Product-Code NSM- 1 SIM-LOCK-DATA Operator

0502586

0502581

0502570

0502582

0502571; 0503476

0502587

0502824

0503022

0503126

0503138

0503160

0503142

0503710, 0503711

0503712; 0503932

0503765

0503808; 0503931

0503611

0501437; 0501438; 0501677; 0501678;

0501883; 0501884; 0501885; 0501886;

0501887; 0501888; 0502205; 0502206;

0502207; 0502208; 0502209; 0502238;

0502239; 0502240; 0502241; 0502242;

0502243; 0502348; 0502420; 0502426;

0502427; 0502583; 0502584; 0502585;

0502589; 0502590; 0502690; 0502691;

0502774; 0502996; 0502997; 0503110;

0503488; 0503504; 0503709; 0503933;

0503975; 0504079; 0504166; 0504167;

Mcc+Mnc 21401

Msin 0000000000

Mcc+Mnc 23433

Msin 0000000000

Mcc+Mnc 26803

Msin ??????????

Mcc+Mnc 23430

Msin ??????????

Mcc+Mnc 23205

Msin ??????????

Mcc+Mnc 2140;

Msin ??????????

Mcc+Mnc 20420

Msin 0000000000

Mcc+Mnc 20416

Msin 0000000000

Mcc+Mnc 23201

Msin ??????????

Mcc+Mnc 26801

Msin ??????????

Mcc+Mnc 21403

Msin ??????????

Mcc+Mnc 26806

Msin ??????????

Mcc+Mnc 23202

Msin ??????????

Mcc+Mnc 28602

Msin ??????????

Mcc+Mnc 20810

Msin ??????????

Mcc+Mnc 28601

Msin ??????????

Mcc+Mnc 28010

Msin ??????????

NO SIM-LOCK

AIRTEL

ORANGE

OPTIMUS

ONE2ONE

CONNECT

MOVISTAR

DUCHTONE

PROXIMUS

MOBILKOM

TELECEL

AMENA

TMN

Maxmobil

Telsim

SFR (GID1=2456)

Turkcel

SFR

Training Team

version 1.1 / 01.02.2000 Page 34 of 41

Page 35

CONFIDENTIAL

The phone hangs up after entering the PIN co de

Phone SW hangs up after entering the PIN code

Yes

check the

amplitude of the

32,768 kH z clock /

2,8Vpp on pin 124

of D200, MAD

Ok

check the

amplitude of the

13MHz clock on

pin 93 of D200,

MAD

No

No

Service & Analysis Center Europe

Training Team

resolder CCONT

or change if

solderings are Ok.

check G600,

change if

necessary

Ok

check VBB 2,8V

DC on pin 59 of

N100, CCONT

Ok

check solderi ngs

of MAD or

change if

necessary

No No

check C 140,

change if

necessary

D200 MAD faulty / poor soldering

Check the amplitude of the 32,768 kHz square wave on pin 124 (comes from CCONT pin 48)

•

Check the amplitude of the 13 MHz clock frequency pin 93 (from G650)

•

Check VBB 2,8V DC

•

Resolder MAD

•

Internal error of MAD

•

check solderi ngs

of CCONT or

change if

necessary

version 1.1 / 01.02.2000 Page 35 of 41

Page 36

Low receiver signal strength indicator

Antenna faulty / wrong - Tuning

Check the code of the antenna label (see below)

•

Check the receiver signal indicator with a new antenna

•

Retune the handset

•

Figure 123: Antenna codes

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

NMP

CODE

DESCRIPTION

TYPE CODE

NOTE

(Stamped in

helix antenna)

0660178 ANTENNA FXD

DGPxxxxx NSM-1*

890-960/1710-1880 MHz

0660160 ANTENNA FIXED HELIX

SGSxxxxx NSE-1/3*

890-960 MHz

0660145 HELIX 1710-1880 MHz PCN SPNxxxxx NSK-1/3*

No service

13 MHz VCTCXO G650 out of range

Check the 13 MHz reference frequency pin 15 N600 (SUMMA) or pin 2 from G650, set first the module in service

•

mode, a frequency error higher +-50Hz can create deviation of the IF frequencies

X560 Antenna connector mechanical faulty

Check the handset with the external antenna

•

Check the resistance "0Ohm" from the internal antenna pad to the "in" pin from X560

•

B100 32,768 kHz crystal

Check the amplitude of the 32,768 kHz square wave on pin 48 from CCONT

•

version 1.1 / 01.02.2000 Page 36 of 41

Page 37

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Figure 13: Sleepclock signal

No RX (no rx calibration…RSSI reading fixed value)

MAD / COBBA / R263 faulty

Check if the 13 MHz IF frequency on pin 22 & 23 COBBA changes the amplitude if the generator frequency level is

•

changed

Check if the RXC impulse on pin 36 N600 (SUMMA) changes the amplitude if the generator frequency level is changed

•

Check R263 if any or low signal is measurable

•

Change MAD

•

Change COBBA (Remember SIM-LOCK data and new update after change)

•

No RX (no rx calibration…RSSI readings -> high difference)

Z560 Duplexer faulty / poor soldering

Check the rx signal on the ANT pin and on the out going pins RX-G or RX-D

•

Check that the signal attenuation between duplexer "in" and "out" is around 2dbm-5dbm depending on the receiver

•

band

Resolder the duplexer or change it

•

No RX (no rx calibration…RSSI reading highest value)

Z600 / Z601 faulty / poor soldering

Check the 73 MHz IF frequency on Z600

•

Check the components C511, C512, L503, L504 if the signal amplitude is different between the two lines

•

check the soldering of Z600 or change it

•

check the 13 MHz IF frequency on Z601, around 3dbm attenuation between signal-in and signal-out

•

check the soldering of Z601 or change it

•

version 1.1 / 01.02.2000 Page 37 of 41

Page 38

CONFIDENTIAL

Service & Analysis Center Europe

No RX (no rx calibration…RSSI reading highest value)

N600 SUMMA faulty / poor soldering

check the UHF- and VHF oscillator frequency

•

check the control-lines for the PLL, pin 5, 6, 7 from N600 (see the diagrams below)

•

check the UHF-VC on pin 21 N600 1,9V-3.2V depending on the channel

•

check the VHF-VC on pin 12 N600 2,6V check the 5V VCP supply voltage drop over R606 (normal 0,2V)

•

change the N600 SUMMA

•

Figure 14: PLL-SCKL Signal

Training Team

Figure 15: PLL-SDAT Signal

Figure 16: PLL-SENA Signal

version 1.1 / 01.02.2000 Page 38 of 41

Page 39

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

Call breaks / No service

G550 UHF Oscillator out of range or high spurious emission

check the UHF frequency on G550 for high spurious or deviation

•

check the UHF-VC on pin 21 N600 1,9V-3.2V depending on the channel

•

check the 5V VCP supply voltage on pin 13, 22 from N600 SUMMA or pin 32 from CCONT

•

check R507 10Kohm, C542 1nF

•

No Call / service OK

N100 CCONT faulty

check if the "Insert SIM-card" message appears sometimes on the display

•

check if it's possible to read the saved phone numbers of the SIM-card

•

Resolder CCONT

•

Change CCONT

•

No or low TX–Power

N501 / N502 / X 560 faulty

Check the power supply Vbat N502 pin 2,3,4,12,13 / N501 pin 4,6,11,12,13

•

Check the input power on pin 8 N501/ pin 6 N502 depend on the band (nominal 0dbm)

•

Check the outgoing power on pin 12 or 13 N501/ N502

•

Check the TX-Power control on pin 9 N501/ N502 ,1Vpp-1,5Vpp / 0,4..V - 0,9..V DC depend on the power-level (see the

•

diagram below)

Change the PA if no or too low power comes out

•

Check the TX-Power on the antenna IN/OUT pads from X 560

•

Check the X560 connector if it has a high attenuation

•

version 1.1 / 01.02.2000 Page 39 of 41

Page 40

Figure 17: TX-Control Signal

CONFIDENTIAL

Service & Analysis Center Europe

Training Team

version 1.1 / 01.02.2000 Page 40 of 41

Page 41

CONFIDENTIAL

Service & Analysis Center Europe

Change history

Orginator Status Version Date Comment

Jose

Marquez

Holger Klein approved 1.1 01.02.2000 SIM-LOCK entries up-dated

Draft 0.2 20.09.1999 First public version

Draft 0.3 01.10.1999 Example for AMS

approved 1.0 19.10.1999 SIM-LOCK entries up-dated

Flow-charts corrected

Training Team

version 1.1 / 01.02.2000 Page 41 of 41

Loading...

Loading...