Page 1

Nokia Customer Care

SERVICE MANUAL

Level 1 and 2

RH-96 Mobile Terminal

1315

Issue 1

COMPANY CONFIDENTIAL

ISSUE 1 09/2006

Copyright © 2006 Nokia. All Rights Reserved.

Page 2

1315 (RH-96)

Nokia Customer Care

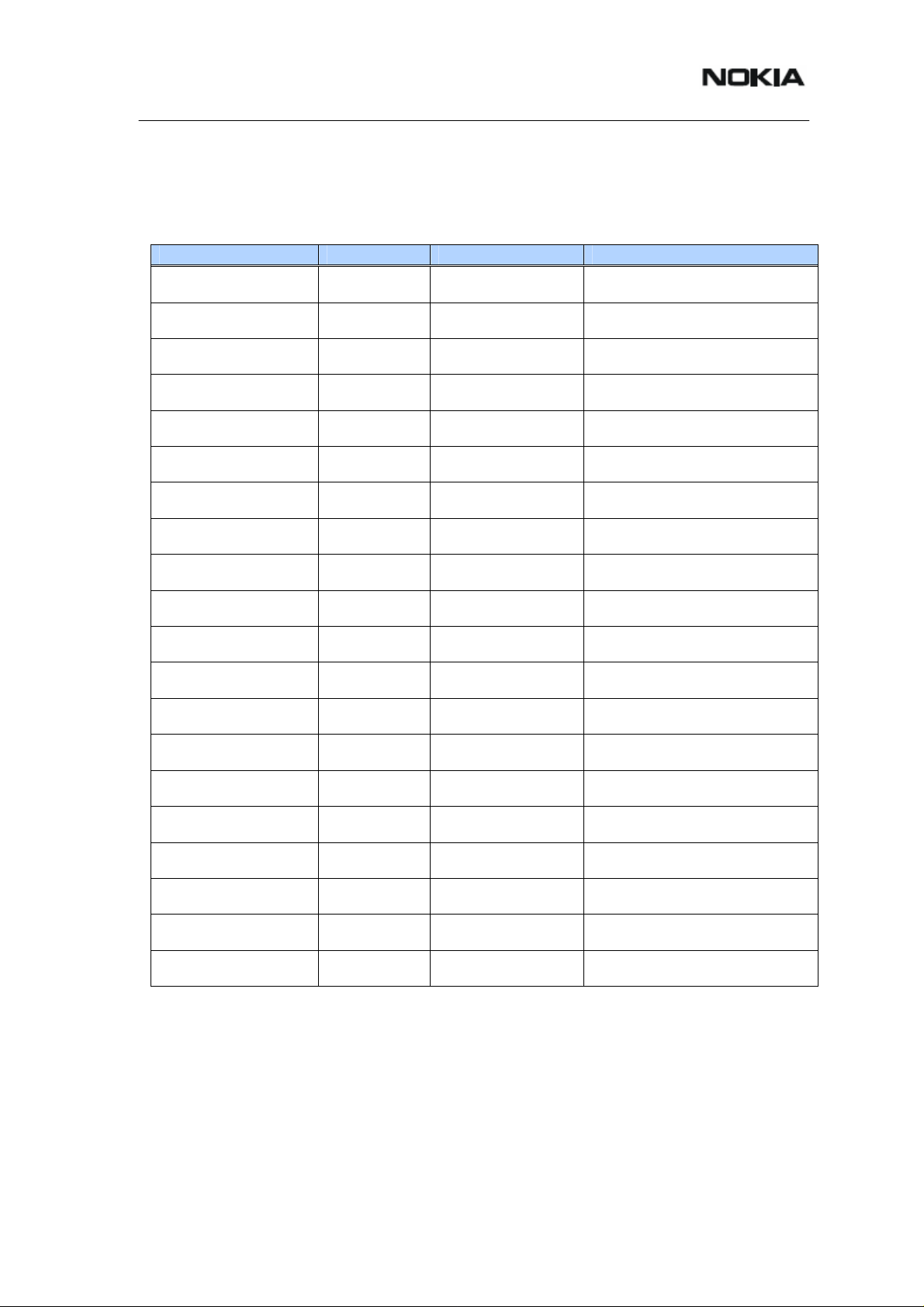

Amendment Record Sheet

Amendment No Date Inserted By Comments

001 09/2006 Frankie Yang Issue 1

Page 2 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 3

1315 (RH-96)

Nokia Customer Care

NOKIA

1 3 1 5

RH-96

Transceiver characteristics:

• 800MHz, IS95, CDMA2000 1xRTT

• 96 x 65 pixel color display with 4096 colors

• Removable User Information Module (RUIM), disabled in

non-RUIM markets

• Internal antenna

• Internal vibra

• EVRC Vocoder

• 12 polyphonic MIDI ringtone and 30 pre-loaded ringtones

• Predictive text

• Speakerphone

• 4-way navigation key for easy navigation

• Calendar, alarm clock, calculator, stopwatch, countdown

and voice memo

• 3 pre-loaded games and 5 pre-loaded screensavers

• Downloadable ringtones and wallpapers via BREW

Transceiver with BL-5C 970mAh Li-Ion battery pack

Talk time Standby time Note

Up to 210

minutes

Environmental characteristics:

• Lead-free soldered

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 3

Up to 240

hours

Depends on network

parameters

Page 4

1315 (RH-96)

Nokia Customer Care

Contents Page

General Repair Hints.......................................................................................... 11

Pathfinder on Nokia Online for Technicians.......................................................12

Support Library............................................................................................12

Training........................................................................................................13

Level 1 and 2 e-learning...........................................................................13

Exploded View and Component Disposal.......................................................... 14

Spare Parts Overview......................................................................................... 15

Spare Parts List.................................................................................................. 16

Service Tools......................................................................................................17

Software Update................................................................................................. 18

Point of Sales Flashing................................................................................18

Login Account..............................................................................................19

Login and logout..........................................................................................19

Flashing Instructions....................................................................................21

Disassembly Instructions.................................................................................... 24

Domesheet Exchange Instructions..............................................................27

Display Exchange Instructions......................................................................28

Quick Troubleshooter ......................................................................................... 29

Legend for Quick Troubleshooter.................................................................29

Quick Troubleshooter – Part 1.....................................................................30

Quick Troubleshooter – Part 2.....................................................................31

Go-No-Go Test................................................................................................... 32

Battery Test ........................................................................................................ 32

Forwarding Repairs ............................................................................................ 33

Page 4 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 5

1315 (RH-96)

Nokia Customer Care

Copyright © 2006 Nokia. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents in

this document in any form without the prior written permission of Nokia is

prohibited.

Nokia and Nokia Connecting People are trademarks or registered trademarks

of Nokia Corporation. Other product and company names mentioned

herein may be trademarks or tradenames of their respective owners.

Nokia operates a policy of continuous development. Nokia reserves the right

to make changes and improvements to any of the products described in this

document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or

income or any special, incidental, consequential or indirect damages

howsoever caused.

The contents of this document are provided "as is". Except as required by

applicable law, no warranties of any kind, either express or implied,

including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose, are made in relation to the accuracy, reliability

or contents of this document. Nokia reserves the right to revise this

document or withdraw it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personnel only.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 5

Page 6

1315 (RH-96)

Nokia Customer Care

Warnings and Cautions

Please refer to the product’s user guide for instructions relating to operation,

care and maintenance including important safety information. Note also the

following:

Warnings:

1. IF THE DEVICE CAN BE INSTALLED IN A VEHICLE, CARE MUST BE

TAKEN ON INSTALLATION IN VEHICLES FITTED WITH ELECTRONIC

ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING SYSTEMS.

UNDER CERTAIN FAULT CONDITIONS, EMITTED RF ENERGY CAN

AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE

DEALER/MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE

ELECTRONIC SYSTEMS TO RF ENERGY.

2. THE PRODUCT MUST NOT BE OPERATED IN AREAS LIKELY TO

CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES EG PETROL

STATIONS (SERVICE STATIONS), BLASTING AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING

CELLULAR TELEPHONES, MAY INTERFERE WITH THE FUNCTIONALITY

OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A

PHYSICIAN OR THE MANUFACTURER OF THE MEDICAL DEVICE IF

YOU HAVE ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY

ALSO BE SUBJECT TO INTERFERENCE.

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and that an

anti-static wrist strap is worn.

3. Ensure solder, wire, or foreign matter does not enter the telephone as damage

may result.

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are

correctly re-fitted after servicing and alignment. Ensure all

cables and wires are repositioned correctly.

Page 6 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 7

1315 (RH-96)

Nokia Customer Care

For Your safety

QUALIFIED SERVICE

Only qualified personnel may install or repair phone equipment.

ACCESSORIES AND BATTERIES

Use only approved accessories and batteries. Do not connect incompatible

products.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read its user’s guide for detailed safety

instructions. Do not connect incompatible products.

ESD protection

Nokia requires that product service points have sufficient

ESD protection (against static electricity) when servicing products.

Any product of which the covers are removed must be handled with

ESD protection. The SIM card can be replaced without ESD

protection if the product is otherwise ready for use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD.

Resistors, too, can be damaged by static electricity discharge.

All ESD sensitive parts must be packed in metallized protective bags

during shipping and handling outside any ESD Protected Area

(EPA).

Every repair action involving opening the product or handling the

product components must be done under ESD protection.

ESD protected spare part packages MUST NOT be opened/closed

out of an ESD Protected Area.

For more information and local requirements about ESD protection

and ESD Protected Area, contact your local Nokia After Market

Services representative.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 7

Page 8

1315 (RH-96)

Nokia Customer Care

Battery information

Note that a new battery's full performance is achieved only after two or three

complete charge and discharge cycles!

The battery can be charged and discharged hundreds of times but it will eventually

wear out. When the operating time (talk-time and standby time) is noticeably shorter

than normal, it is time to buy a new battery.

Use only batteries approved by the phone manufacturer and recharge the battery

only with the chargers approved by the manufacturer. Unplug the charger when not

in use. Do not leave the battery connected to a charger for longer than a week,

since overcharging may shorten its lifetime. If left unused a fully charged battery will

discharge itself over time.

Temperature extremes can affect the ability of your battery to charge.

For good operation times with Ni-Cd/NiMh batteries, discharge the battery from time

to time by leaving the product switched on until it turns itself off (or by using the

battery discharge facility of any approved accessory available for the product). Do

not attempt to discharge the battery by any other means.

Use the battery only for its intended purpose.

Never use any charger or battery that is damaged.

Do not short-circuit the battery. Accidental short-circuiting can occur when a

metallic object (coin, clip or pen) causes direct connection of the + and – terminals

of the battery (metal strips on the battery) for example when you carry a spare

battery in your pocket or purse. Short- circuiting the terminals may damage the

battery or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer or

winter conditions, will reduce the capacity and lifetime of the battery.

Always try to keep the battery between 15°C and 25°C (59°F and 77°F). A phone

with a hot or cold battery may temporarily not work, even when the battery is fully

charged. Batteries' performance is particularly limited in temperatures well below

freezing.

Do not dispose of batteries in a fire!

Dispose of batteries according to local regulations (e.g. recycling). Do not dispose

as household waste.

Page 8 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 9

1315 (RH-96)

Nokia Customer Care

Care and Maintenance

The product is a product of superior design and craftsmanship and should be

treated with care. The suggestions below will help you to fulfill any warranty

obligations and to enjoy this product for many years.

Keep the phone and all its parts and accessories out of the reach of small children.

Keep the phone dry. Precipitation, humidity and all types of liquids or moisture can

contain minerals that will corrode electronic circuits.

Do not use or store the phone in dusty, dirty areas. Its moving parts can be

damaged.

Do not store the phone in hot areas. High temperatures can shorten the life of

electronic devices, damage batteries, and warp or melt certain plastics.

Do not store the phone in cold areas. When it warms up (to its normal temperature),

moisture can form inside, which may damage electronic circuit boards.

Do not drop, knock or shake the phone. Rough handling can break internal circuit

boards.

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean the

phone.

Do not paint the phone. Paint can clog the moving parts and prevent proper

operation.

Use only the supplied or an approved replacement antenna. Unauthorized

antennas, modifications or attachments could damage the phone and may violate

regulations governing radio devices.

All of the above suggestions apply equally to the product, battery, charger or any

accessory.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 9

Page 10

1315 (RH-96)

Nokia Customer Care

Company Policy

Our policy is of continuous development; details of all technical modifications will be

included with service bulletins.

While every endeavour has been made to ensure the accuracy of this document,

some errors may exist. If any errors are found by the reader, NOKIA MOBILE

PHONES Business Group should be notified in writing.

Please state:

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

Please send to:

NOKIA CORPORATION

Nokia Mobile Phones Business Group

Nokia Customer Care

PO Box 86

FIN-24101 SALO

Finland

Page 10 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 11

1315 (RH-96)

Nokia Customer Care

General Repair Hints

This section provides general hints on repairs:

Read the tutorials or user guide on www.Nokia.com > Choose your location >

Support > Product Support. Select the appropriate mobile terminal model to

become familiar with the Nokia product.

y Take adequate ESD precautions before starting repairs, e.g. work in an ESD

Protected Area, and that an anti-static wrist strap is worn.

y Use gloves to avoid corrosion and fingerprints.

y Protect windows and displays with a film to avoid dust and scratches.

y Use a lint-free cloth when cleaning the LCD module (e.g. Micro-Fiber cloth).

y Use a soft cloth/ESD brush and Isopropanol when cleaning the pads. Do not

use a glass fiber pencil as it will scratch the surface and will lead to corrosion.

y Reuse mechanical parts that are not soldered if they did not repair the failure

(except shielding lids and bent parts).

y Make sure to replace the shielding lids with new ones when removing them,

so that the high-frequency leakage does not affect the device.

y Always use original Nokia spare parts.

y Check the soldering joints of the parts causing problems (e.g. soldered

connectors or switches) and resolder them if necessary (Level 2 only).

y Remove redundant soldering flux after repair.

y Meet the torque requirements when assembling the terminal (see also

"Torques for transceiver assembly" document found on Nokia Online).

y Always use properly functioning test equipment to test to be sure if it is the

mobile terminal and not faulty equipment causing the malfunction.

y A UIM card is required for all Go-No-Go tests.

y Make a note of the Item code causing the malfunction when making fault log

entries. Also complete the appropriate part code from the assembly if

needed.

y Note that some malfunctions could be software related and resolved by a

software update.

y Refer to additional documents available on Nokia Online (NOL).

Note: Check Nokia Online (NOL) for latest news and files on a regular basis.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 11

Page 12

1315 (RH-96)

Nokia Customer Care

Pathfinder on Nokia Online for Technicians

Support Library

In addition to the information in this Service Manual, refer to the main

documentation database Nokia Online (NOL) that houses additional information,

such as multimedia content (video clips and interactive tutorials).

Navigate to the Support Library section as follows:

Nokia Online > Care Services > Support Library > Under the Select Category

pulldown menu select > Support Library. Under the Subcategory pull-down menu

select the appropriate product number. Under the second the Subcategory

pull-down menu select Field Service Bulletins. Download the latest Service

Bulletins available.

Available product documentation for each product may include:

y Instructions

y General Service Bulletins

y Product related documents

y Spare Part Service Bulletins

y Service Tools Service Bulletins

y Common Software Service Bulletins

Note: Reviewing the Service Bulletins will indicate if existing documents have

become obsolete. All new information must be processed and implemented as soon

as possible.

Page 12 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 13

1315 (RH-96)

Nokia Customer Care

Training

Level 1 and 2 e-learning

Content formerly found on Nokia CarePoint, such as Online Troubleshooting,

Product Information, Videos - Disassembly/Reassembly can now be found on

the Nokia Online website.

Navigate to the Training section as follows:

Nokia Online > Care Services > Training

Level 1 and 2 e-learning courses offer quick product overviews and support on

repair and use of Nokia mobile terminals:

Overview and Guides Disassembly and Assembly Troubleshooting

Basic information about

the mobile terminal,

features and

technologies

Recommendation: Download the newest versions of very large files, e.g. videos,

Phoenix packages or Service Manuals only once and distribute them for further

use.

Instructions on disassembling

and reassembling the mobile

terminal

Step-by-step instructions

on locating and repairing

the most common

problems with the mobile

terminal

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 13

Page 14

1315 (RH-96)

Nokia Customer Care

Exploded View and Component Disposal

Refer to the image below for the recommended ecologically sound disposal of

components. Colorized components show the different categories.

Page 14 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 15

1315 (RH-96)

Nokia Customer Care

Spare Parts Overview

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 15

Page 16

1315 (RH-96)

Nokia Customer Care

Spare Parts List

Refer to the latest Service Bulletins (spare parts, SWAP units and service tools) on

the Nokia Online website for the 1315.

Note: Service Bulletins must be checked on daily basis to ensure that up-to-date

order codes are used.

Page 16 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 17

1315 (RH-96)

Nokia Customer Care

Service Tools

CA-82DS Data Service Cable (USB)

This cable provides connection from the USB port

of the personal computer or notebook to the DB9

connector of the Flash Adapter.

CA-83DS Data Service Cable (Serial)

This cable provides connection from the serial

port of the personal computer or notebook to the

DB9 connector of the Flash Adapter.

SF-93 Flash Adapter

This device allows Point of Sale (POS) locations

to flash the mobile terminal.

SS-91 Domesheet Alignment Jig

This jig is used to align the adhesive domesheet

assembly onto the PWB in the proper location

during domesheet replacement.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 17

Page 18

1315 (RH-96)

Nokia Customer Care

Software Update

Point of Sales Flashing

Please follow the service manual to use the Flash Adapter. Check always for the

latest version of flash software, which is available on NOKIA Online.

Charger

Data Service Cable (USB)

Flash Adapter

Service SW

It is very important to follow this connection and removal procedure, otherwise, the

contact pins of the Flash Adapter will be damaged.

1. Connect the Flash Adapter to the mobile

terminal, starting from the battery connector

side.

2. Press it down until the two locking tabs are

locked.

Page 18 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 19

1315 (RH-96)

Nokia Customer Care

3. Af ter flashing is finished, slide these two

locking tabs backward at the same time to

unlock them.

4. Unplug the adapter and remove it from the

mobile terminal.

Flashing function in Service Software is used for software upgrade to download

mobile terminal images from PC to target mobile terminal. Mobile terminal images

include ARMPRG, Boot Code, Application Code, Language Pack and File System.

Users only need to select the necessary images to upgrade but not all images

every time. Before the upgrade process, user can select the “automatic

backup/restore user data” function to backup or restore files of phonebook,

messages and call register, if necessary.

Login Account

To start flashing, user has to login by entering a pair of user name and password.

1255 software will provide appropriate functions according to the log in information

based on different service level. If user wants to log in via different username and

password, please log out first. See below table for login account information.

Service Level User name Password

Level 1 chuck delta

Level 2 captain toctoc

Login and logout

z Three ways to access login screen:

Initiate 1255 Service Software by launching RH79CCS12RXXX.exe.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 19

Page 20

1315 (RH-96)

Nokia Customer Care

Or click on login icon

Or select Login from File menu

z Login screen appears (level 1 and 2 only):

z Two ways to logout:

Click on logout icon.

Page 20 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 21

1315 (RH-96)

Nokia Customer Care

Or select Logout from File menu.

Flashing Instructions

z How to access Flashing screen

Select an active phone. Note that ‘Offline’ means you can use service software

functions while the mobile terminal is not connected, e.g. edit phonebook and

data which is saved in local drive of your service PC or Notebook.

Click on Bundle Flashing tab.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page

21

Page 22

1315 (RH-96)

Nokia Customer Care

Or select Bundle Flashing in Phone menu.

z Window displaying requirements for Bundle Flashing

z Select image files

Click button which is next to “Latest Version” to browse a folder in your PC.

Service software would automatically find the latest version bundle image in this

folder. Or click button which is next to “Bundle File Path” to browse a bundle

image file in your PC.

Note that the users can only flash file system and language pack images which

are compatible with the operator setting value of the connected phone, i.e. a

Unicom phone can’t flash Vivo’s language or file system images.

Page 22 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 23

1315 (RH-96)

Nokia Customer Care

z Decide which images are to be updated

Activate or deactivate check boxes in front of the image texts to check the one

you want to update, and uncheck the one don’t need to update.

z Check the Automatic backup/restore user data or phonebook data box

z Start to upgrade

Click the Update button.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 23

Page 24

1315 (RH-96)

Nokia Customer Care

Disassembly Instructions

Dental Tool

Dental Tool

SORX T6 Tweezers

1. Tools for disassembly and reassembly. 2. Protect the display surface with a film.

3. Press the Release Button and remove the

B-cover.

SRT - 6

TweezersSORX T6

- 6 SRT

4. Place the SRT-6 into the gap between

A-cover and D-cover . Lever to separate the

snaps of A-cover and D-cover.

5. Repeat step 4 on the other side of the mobile

terminal.

6. Insert the SRT-6 into the gap between

A-cover and D-cover. Slip the SRT-6 to

separate the snaps between A-cover and

D-cover.

Page 24 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 25

1315 (RH-96)

Nokia Customer Care

7. Repeat step 6 on the other side of the

mobile terminal.

9. Remove the keymat.

8. Remove A-cover and take out the Engine.

10. Use a TORX T6 screwdriver to loos en and

remove the six Torx screws (T1.8x6), in the

order shown. Use torque driver set to 25Ncm

@ 700 rpm. The tolerance is +/-2Ncm. For

re-assembly, screws can be replaced in

reverse order.

11. Remove the LCD Module Shielding Assy.

12. Remove the Receiver (earpiece) from LCD

Module Shielding Assy.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 25

Page 26

1315 (RH-96)

Nokia Customer Care

13. Carefully grip both sides of the device and

gently pull out the PWB Module vertically from

D Cover As sembly.

15. Use the dental tool to remove the Vibrator. 16. Use the tweezers to remove the DC Jack.

14. Use the dental tool gently to unsnap SAM

Module and pull up to remove it from the

D-cover.

17. Use the tweezers to remove the

Microphone.

18. Without touching the connector, pee l off the

rubber cap of earphone jack.

Note: The speaker is an integral part of the SAM Module to ensure optimum RF

performance and must not be replaced individually. To assemble the mobile terminal,

follow the “Disassembly Instructions” in reverse order.

Page 26 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 27

1315 (RH-96)

Nokia Customer Care

Domesheet Exchange Instructions

1. Use the SRT-6 to lift the domesheet. 2. Remove the domesheet.

3. Place a new domesheet on the Domesheet

Alignment Jig.

5. Press firmly on the PWB to ensure correct

bonding of the domesheet.

4. Align the guide pins and place the PWB on

the Jig.

6. Inspect to ensure proper adhesion of

domesheet to PWB.

Note: After using the heatgun, the domesheet needs to be replaced.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 27

Page 28

1315 (RH-96)

Nokia Customer Care

Display Exchange Instructions

1. Protect the LCD Module by covering it with a

piece of film.

3. Remove the LCD Module.

2. Disconnect the BTB connector.

Page 28 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 29

1315 (RH-96)

Nokia Customer Care

Quick Troubleshooter

Legend for Quick Troubleshooter

This legend is valid for all parts of the Quick Troubleshooter.Follow the steps until the

problem is solved. If these steps do not resolve the problem, you are not authorized to

proceed.

Only marked components can be changed.

Starting point of repair activities regarding the observed

fault symptoms.

Follow the arrows step by step.

Pads or contacts: Check optical and mechanical

condition particularly for corrosion. Clean if necessary.

Measure component for electrical functionality and

change if needed (Level 2 only).

Pads or contacts: Check optical and mechanical

condition particularly for corrosion. Clean with ESD

brush only, if necessary.

No more actions possible. Send product to the

appropriate service supplier with higher service level.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 29

Page 30

1315 (RH-96)

Nokia Customer Care

Quick Troubleshooter – Part 1

Page 30 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 31

1315 (RH-96)

Nokia Customer Care

Quick Troubleshooter – Part 2

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 31

Page 32

1315 (RH-96)

Nokia Customer Care

Go-No-Go Test

After a visual check, a Go-No-Go test must be carried out to guarantee the

functionality of the mobile terminal if the unit has been opened.

Battery Test

A battery tester allows you test the capacity of Nokia batteries. Refer to the

information on the Nokia Online website.

Page 32 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Page 33

1315 (RH-96)

Nokia Customer Care

Forwarding Repairs

When forwarding the mobile terminal for repairs to a higher level service supplier

use a swap carton as shown below.

1. Always Protect the window with a protection

film.

3. Add repair documentation to the swap carton,

e.g. completed service note.

2. Put the unit under the stretch film.

4. Fold the swap carton as shown.

Note: There are two different sizes of swap cartons for common mobile terminals.

Issue 1 09/2006 © 2006 Nokia Corporation Company Confidential Page 33

Page 34

1315 (RH-96)

Nokia Customer Care

This page intentionally left blank.

Page 34 © 2006 Nokia Corporation Company Confidential Issue 1 09/2006

Loading...

Loading...