Nissan Sunny 1969 1973 User Manual

N

@J

@o

DXD

@

o

Jl

lIDrnlli

f

feU

I

rnrnJW

I

j

CRAKE

PU3

IS1

RS

i

C

I

lI

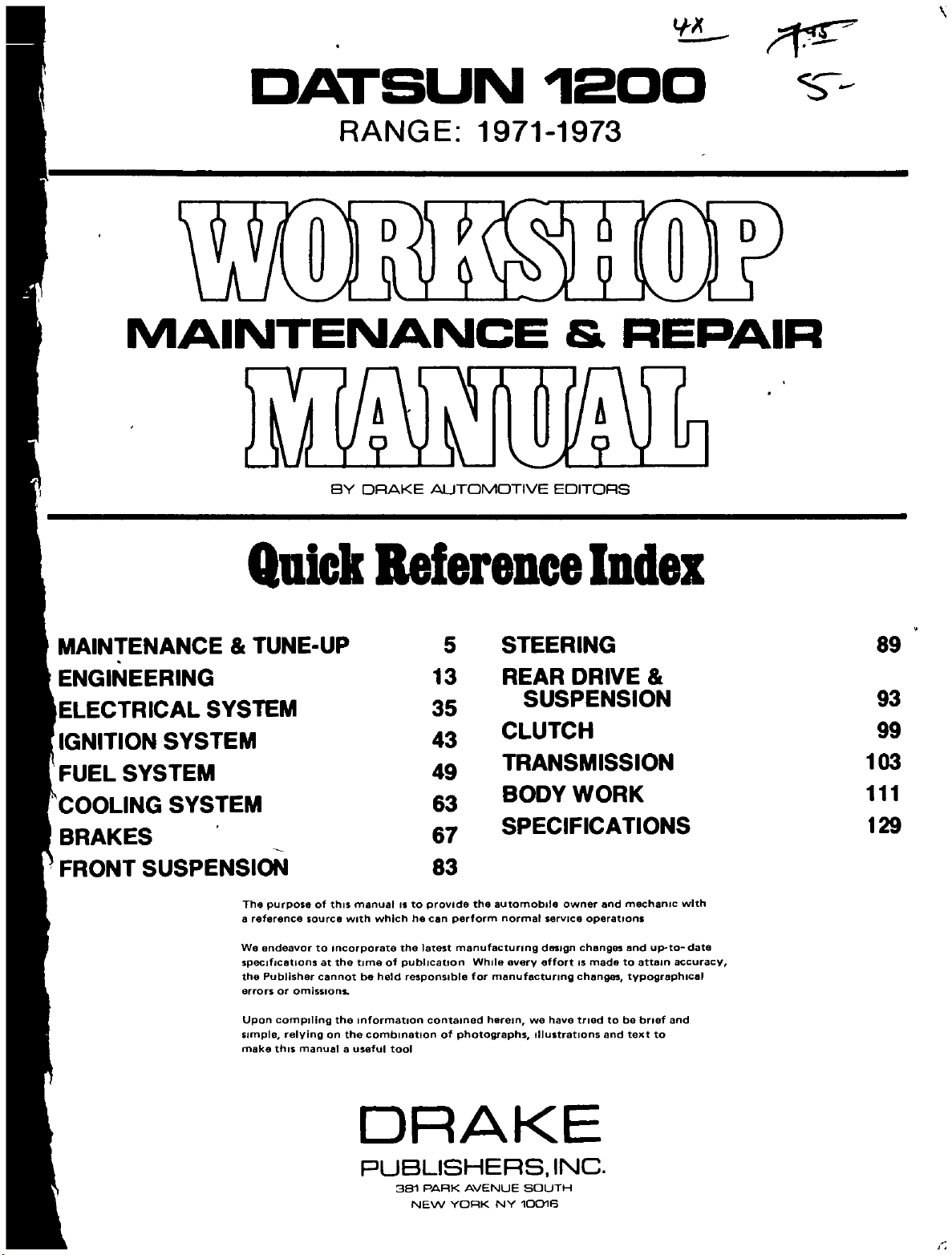

DATSUN

MAINTENANCE

RANGE

BY

DRAKE

1971

AUTOMOTIVE

1200

1973

REPAIR

EDITORS

MAINTENANCE

ENGINEERING

ELECTRICAL

IGNITION

FUEL

COOLING

BRAKES

FRONT

SYSTEM

SYSTEM

SYSTEM

SUSPENSION

Quick

TUNE

SYSTEM

The

purpose

a

reference

We

endeavor

specifications

the

Publisher

errors

Upon

Simple

make

or

omiSSions

compIling

relvlng

thIS

manual

source

UP

of

to

at

cannot

on

Referencelodel

this

manual

with

lOcorporate

time

the

the

information

the

a

useful

which

be

combination

of

held

ISto

he

the

publication

responsible

tool

13

35

43

49

63

67

83

provide

can

latest

contained

5

perform

of

STEERING

REAR

SUSPENSION

CLUTCH

TRANSMISSION

BODY

SPECIFICATIONS

the

automobile

normal

service

manufacturing

While

for

manufacturing

herein

photographs

design

every

effort

we

Illustrations and

have

DRIVE

WORK

owner

operations

changes

IS

madetoattain

changes

tried

and

to

mechanic

and

up

typographical

be

brief

text

to

to

accuracy

and

89

93

99

103

111

129

with

date

DRAKE

PUBLISHERS

PARK

361

NEW

AVENUE

YORK

INC

SOUTH

NY

10016

ISBN

087749

309

X

Pubhshed

DRAKE

381

New

@Drake

Prmtedmthe

PUBLISHERS

Park

York

Pubhshers

III

1973

Avenue

N

Umted

by

South

Y

10016

INC

Inc

1973

StatesofAmenca

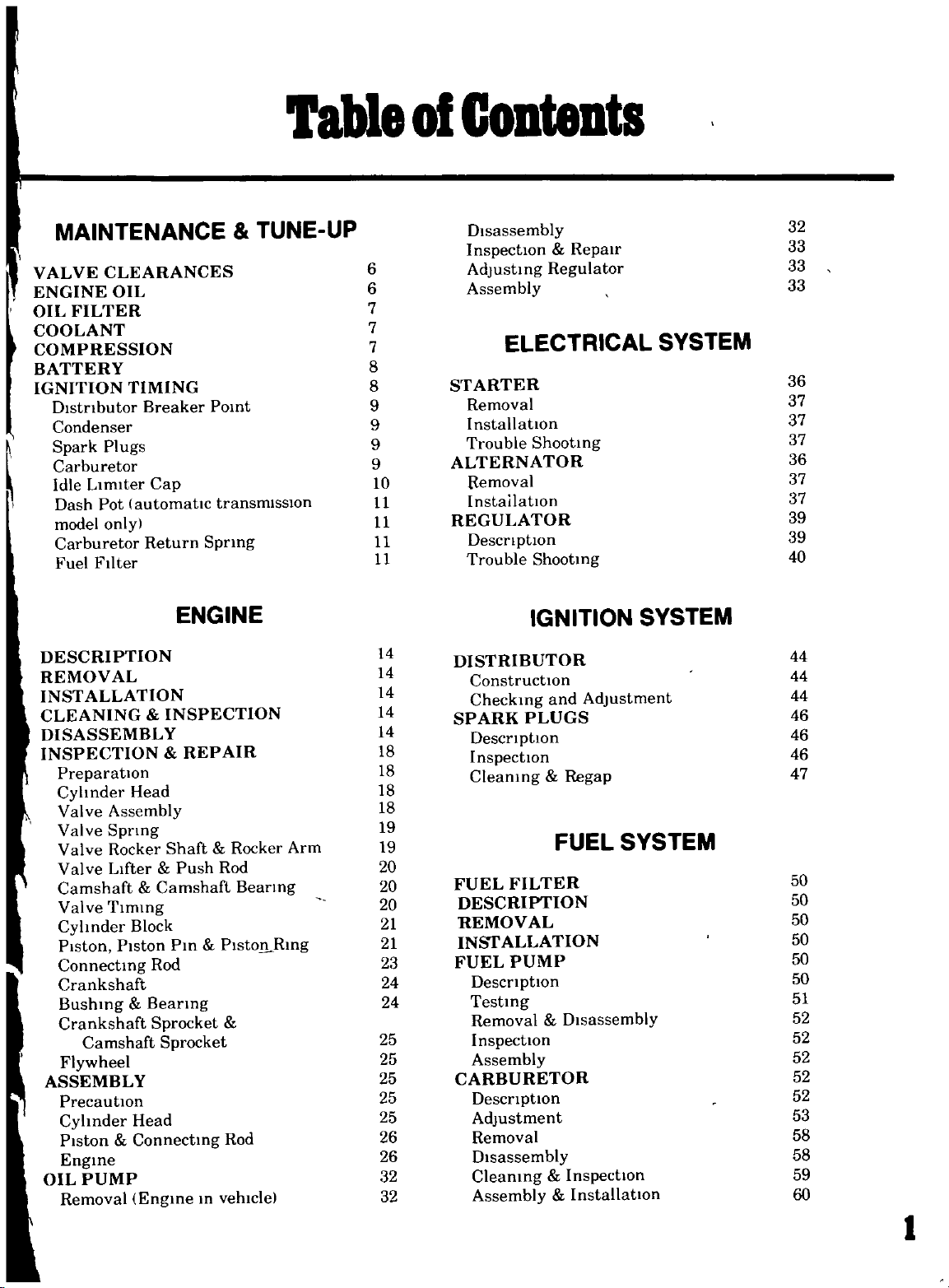

able

of

Contents

MAINTENANCE

VALVE

ENGINE

OIL

COOLANT

COMPRESSION

BATTERY

IGNITION

DIstributor

Condenser

Spark

Carburetor

Idle

Dash

model

Carburetor

Fuel

DESCRIPTION

REMOVAL

INSTALLATION

CLEANING

DISASSEMBL

INSPECTION

PreparatIOn

Cyltnder

Valve

Valve

Valve

Valve

Camshaft

Valve

Cyltnder

PIston

Connectmg

Crankshaft

Bushmg

Crankshaft

Flywheel

ASSEMBL

PrecautIOn

Cyltnder

PIston

Engme

OIL

Removal

CLEARANCES

OIL

FILTER

Plugs

LImIter

Pot

only

Filter

Assembly

Spnng

Rocker

LIfter

Tlmmg

Piston

Camshaft

PUMP

Engme

TUNE

TIMING

Breaker

Pomt

Cap

automatic

Return

transmISSIOn

Sprmg

ENGINE

INSPECTION

Y 14

REPAIR

Head

Shaft

Push

Camshaft

Block

Pm

Rod

Bearing

Sprocket

Sprocket

Y

Head

ConnectIng

m

Rocker

Rod

Bearmg

Rod

vehicle

Plsto

LRmg

Arm

UP

DIsassembly

6

6

7

7

7

8

8

9

9

9

9

10

11

11

11

11

14

14

14

14

18

18

18

18

19

19

20

20

20

21

21

23

24

24

25

25

25

25

25

26

26

32

32

AdJustmg

Assembly

ELECTRICAL

STARTER

Removal

InstallatIOn

Trouble

ALTERNATOR

Removal

InstallatIOn

REGULATOR

DeSCriptIOn

Trouble

DISTRIBUTOR

ConstructIOn

Checkmg

SP

ARK

PLUGS

DeSCriptIOn

InspectIOn

Cleamng

FUEL

DESCRIPTION

REMOVAL

INSTALLATION

FUEL

CARBURETOR

FILTER

PUMP

DeSCriptIOn

Testmg

Removal

InspectIOn

Assembly

DeSCription

Adjustment

Removal

DIsassembly

Cleanmg

Assembly

InspectIOn

RepaIr

Regulator

Shootmg

Shootmg

IGNITION

and

Adjustment

Regap

FUEL

DIsassembly

InspectIOn

InstallatIOn

SYSTEM

SYSTEM

SYSTEM

32

33

33

33

36

37

37

37

36

37

37

39

39

40

44

44

44

46

46

46

47

50

50

50

50

50

50

51

52

52

52

52

52

53

58

58

59

60

I

labl8

of

Contents

Jets

TlOuble

DESCRIPTION

WATER

Hemoval

InstallatIOn

THERMOSTAT

Removal

InspectIOn

Installation

RADIATOR

Hemovdl

InspectIOn

InstallatIOn

Shooting

COOLING

PUMP

BRAKES

SYSTEM

60

60

DESCRIPTION

RECOMMENDATIONS

TROUBLE

64

64

65

65

65

65

65

65

66

66

66

66

DESCRIPTION

RECOMMENDATIONS

TROUBLE

REAR

DIFFERENTIAL

REAR

REAR

RECOMMENDATIONS

FRONT

AXLE

SUSPENSION

SHOCK

Replacement

InspectIOn

SUSPENSION

SHOOTING

STEERING

SHOOTING

REAR

SUSPENSION

DRIVE

ABSORBER

f

I

85

90

90

91

94

94

95

96

96

97

97

FRONT

BRAKE

DISC

Replacement

InspectIOn

ReinstallatIOn

CALIPER

Removal

Disassembly

InspectIOn

Reassembly

ReinstallatIOn

REAR

BRAKE

Hemoval

InspectIOn

Reassembly

HAND

BRAKE

Removal

InspectIOn

RemstallatlOn

ADJUSTMENT

Front

DIcBrake

Rear

Brake

Brake

Hand

Pedal

Brake

BLEEPIN

TROUBLE

PAD

Dlsdssembly

HYD

SHOOTING

BRAKE

Repmr

ReinstallatIOn

HeIght

AULIC

SYsrM

78

79

79

80

68

68

68

68

68

70

70

71

71

72

74

74

74

75

75

75

75

76

77

78

78

78

DESCRIPTION

CLUTCH

Removal

InspectIOn

ReinstallatIOn

Adjustment

CLUTCH

Removal

DIsassembly

InspectIOn

Reassembly

RemstallatlOn

BLEEDING

4

SPEED

3

SPEED

TROUBLE

i

UIQM

RECOMMENDATIONS

ATJ

CLUTCH

PEDAL

MASTER

CLUTCH

CYLINDER

SYSTEM

TRANSMISSION

TRANSMISSION

TRANSMISSION

SHOOTING

C

TRANSMJSSIQ

2

fable

of

Contents

HOOD

I

Removal

InstallatIOn

HOOD LOCK

Removal

Adjustment

LubncatlOn

TRUNK

Removal

Adjustment

TRUNK

DOOR

WIRING

BULB

HEADLAMP

THERMOMETER

OIL

BODY

LOCK

LID

LID

TORSION BAR

CONSTRUCTION

DIAGRAMS

SPECIFICATIONS

FUEL

PRESSURE

WARNINGLAMPS

METER

AND

WORK

AND

IGNITION

112

112

112

112

112

112

114

116

116

116

116

117

118

120

121

122

126

SERVICE

ENGINE

General

Tlghtemng

SpeCIficatIOn

Coohng

Fuel

System

Starter

Alternator

Regulator

Dlstnbutor

IgnItIOn

CLUTCH

NOTES

SPECIFICATIONS

DATA

SpeCificatIOn

Torque

System

Cot

130

134

134

134

135

139

140

142

143

144

145

145

146

174

I

t

I

I

3

aintenIDce

TUDe

up

Ii

ainteDaDee

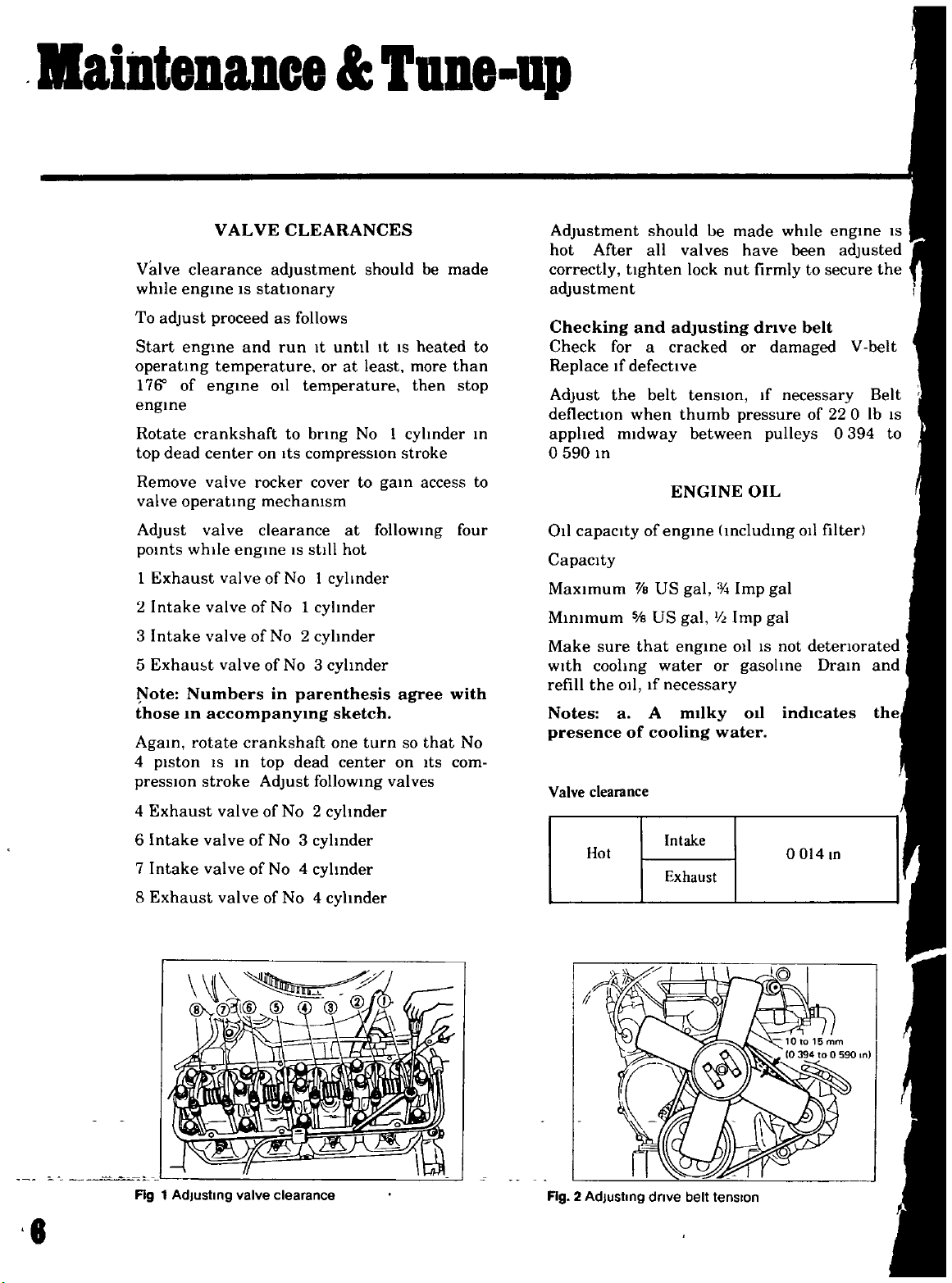

VAL

VE

CLEARANCES

adjust

dead

Exhaust

Intake

Intake

Exham

ote

piston

Exhaust

Intake

Intake

Exhaust

clearance

engme

proceed

engme

temperature

of

engIne

crankshaft

center

valve

operatIng

valve

while

valve

valve

valve

t

valve

Numbers

10

accompanY1Og

rotate

IS

stroke

valve

valve

valve

valve

IS

stationary

and

on

rocker

mechamsm

clearance

engIne

of

of

of

of

crankshaft

In

top

Adjust

of

of

of

of

adjustment

follows

as

run

011

temperature

to

bnng

ItS

compressIOn

cover

IS

still

No

1

No

No

2

No

in

parenthesis

dead

No

No

3

No

4

No

Valve

while

To

Start

operatIng

17S

engIne

Rotate

top

Remove

valve

Adjust

pOints

1

2

3

5

those

AgaIn

4

pressIOn

4

6

7

8

It

until

at

or

No

to

at

hot

1

cylinder

cylinder

cylinder

3

cylInder

sketch

one

center

follOWIng

2

cylinder

cylinder

cylInder

4

cylinder

TUDe

should

least

turn

be

It

IS

heated

more

then

1

cylInder

stroke

access

gaIn

follOWing

agree

that

so

ItS

on

valves

made

with

com

than

stop

four

No

up

Adjustment

hot

After

correctly

should

all

tighten

adjustment

for

the

In

and

a

If

defective

when

midway

of

belt

to

Check

Replace

Adjust

deflectIOn

Checking

In

to

applied

o

590

011

capacity

Capacity

MaXimum

MInimum

Make

With

refill

Notes

presence

Valve

sure

cooling

the

011

a

clearance

Hot

VB

5IB

that

of

US

US

lf

A

cooling

valves

lock

adjusting

cracked

tenSIOn

thumb

between

ENGINE

engIne

gal

gal

engIne

water

necessary

m1lky

Intake

Exhaust

ue

made

nut

pressure

IncludIng

Imp

III

Imp

011

or

water

whIle

have

firmly

drive

or

damaged

If

necessary

pulleys

OIL

gal

gal

not

IS

gasolIne

011

indlcates

been

to

belt

of

011

detenorated

0014

engIne

adjusted

secure

220

0394 to

filter

DraIn

In

IS

the

V

belt

Belt

Ib

IS

and

8

Rg1AdJustmg

valve clearance

Fig

2

AdJustmg

dnve

belt

tension

aintenIDce

une

up

Find

action

b

Oil

dicates

Check

to

H

The

011

Check

any

nece

When

Note

leakage

the

with

dllutton

011

level

mark

filter

for

leakage

sary

mstalhng

Do

may

cause

on

ISofa

011

leaks

IS

replaLe

not

for

extremely

with

If

found

gauge

FILTER

OIL

cartndge

through

found

filter

011

an

overtighten

result

necessary

low

gasoline

below

gasketed

retIghten

as

an

filter

viscosity

L

type

assembly

tIghten

fIlter

011

corrective

mark

flange

shghtly

by

refill

hand

or

COOLANT

rustmg

con

It

used

IS

level

base

tam

wIll

wIth

will

and

system

other

changed

and

product

protect

and

any

not

either

flows

It

not

The

products

the

the

refilled

L

C

in

L

tammg

coohng

The

ethyl

or

or

transfers

passages

If

If

oil

must

coolant

the

Whenever

system

new

L

or

bOll

low

not

year

coolant

IS

al

ethylene

chemical

system

I

C

does

methyl

and

away

temperature

heat

m

the

mIxed

be

be

can

any

should

Check

mhlbltors to

from

not

alcohol

can

thermostat

effiCiently

coohng

wIth

used

throughout

coolant

be

flushed

the

glycol

be

con

corrosIOn

glycerme

evaporate

high

freely

clog

LL

ThiS

seasons

coohng

wIth

the

the

C

of

a

COMPRESSION

cylinder

plugs

test

and

compression

hold

tester

fit

Compression

Note

remove

To

all

pressure

test

spark

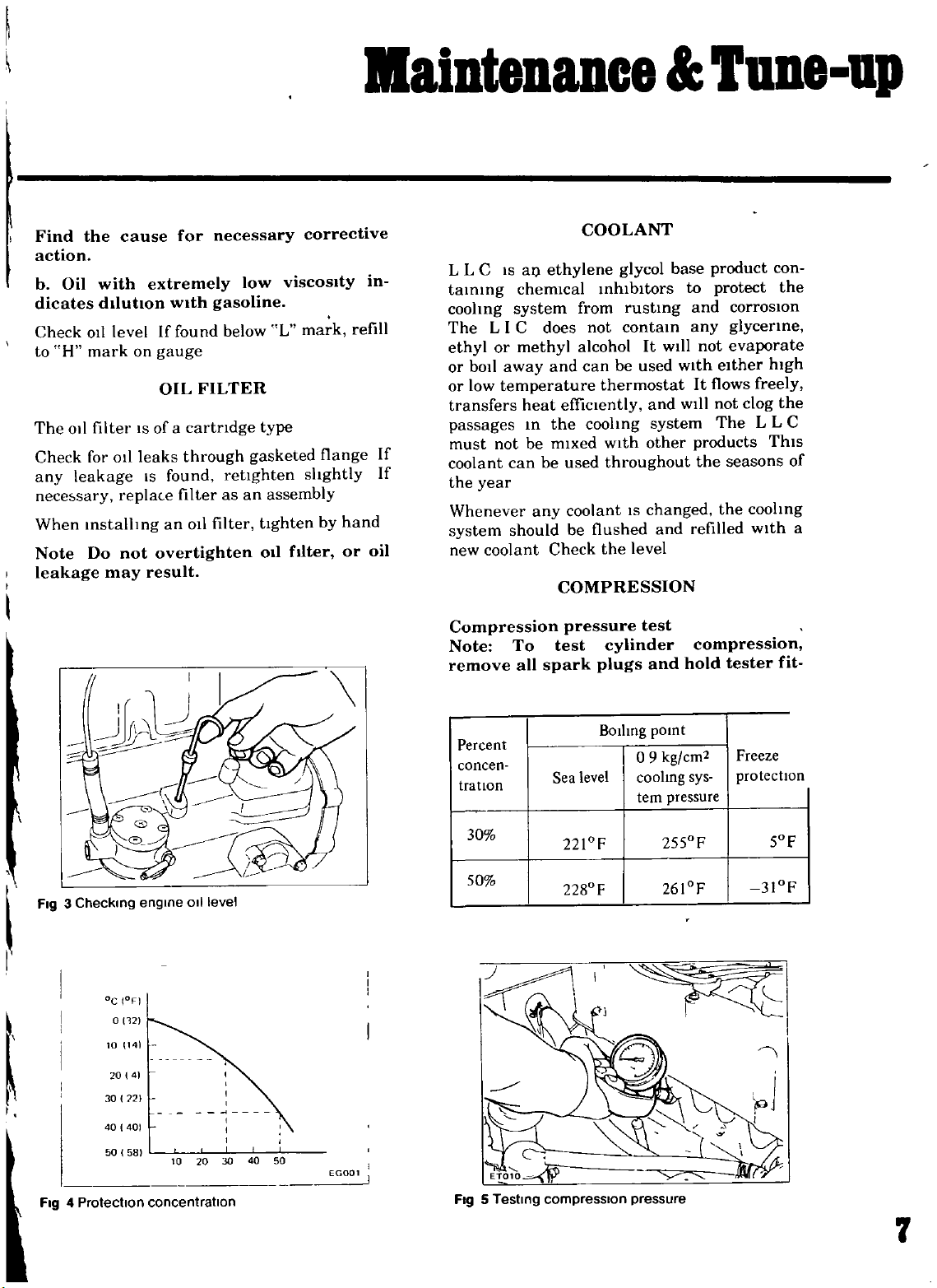

Fig3Checking

I

I

I

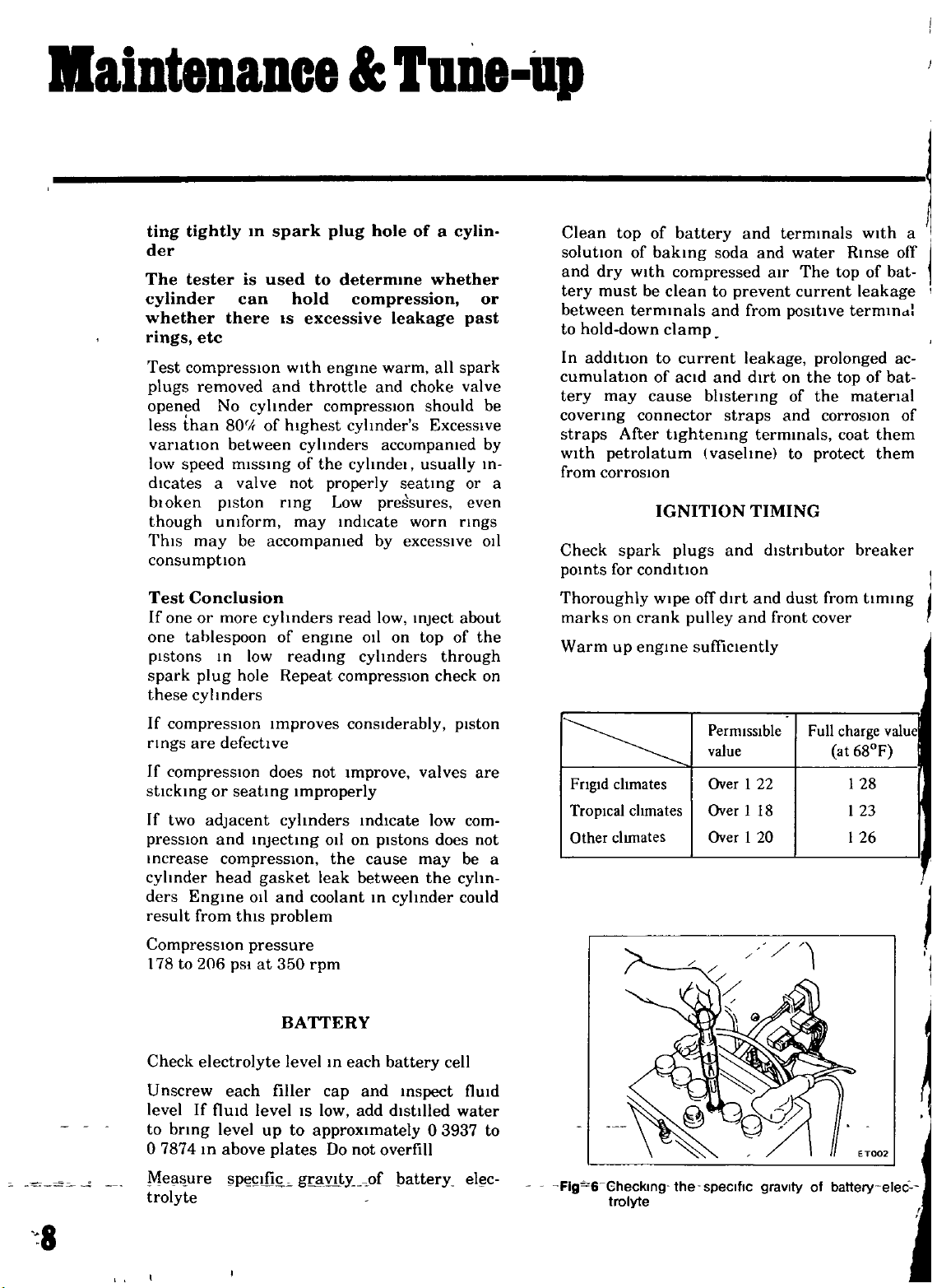

Fig

4

Protection

Oc

0

20141

30

401401

5015BI

engine

OF

121

21

011

10 20

concentration

level

EGOQl

Sea

2210F

2280

BOllIng

level

F

Percent

concen

lion

tra

30

50

I

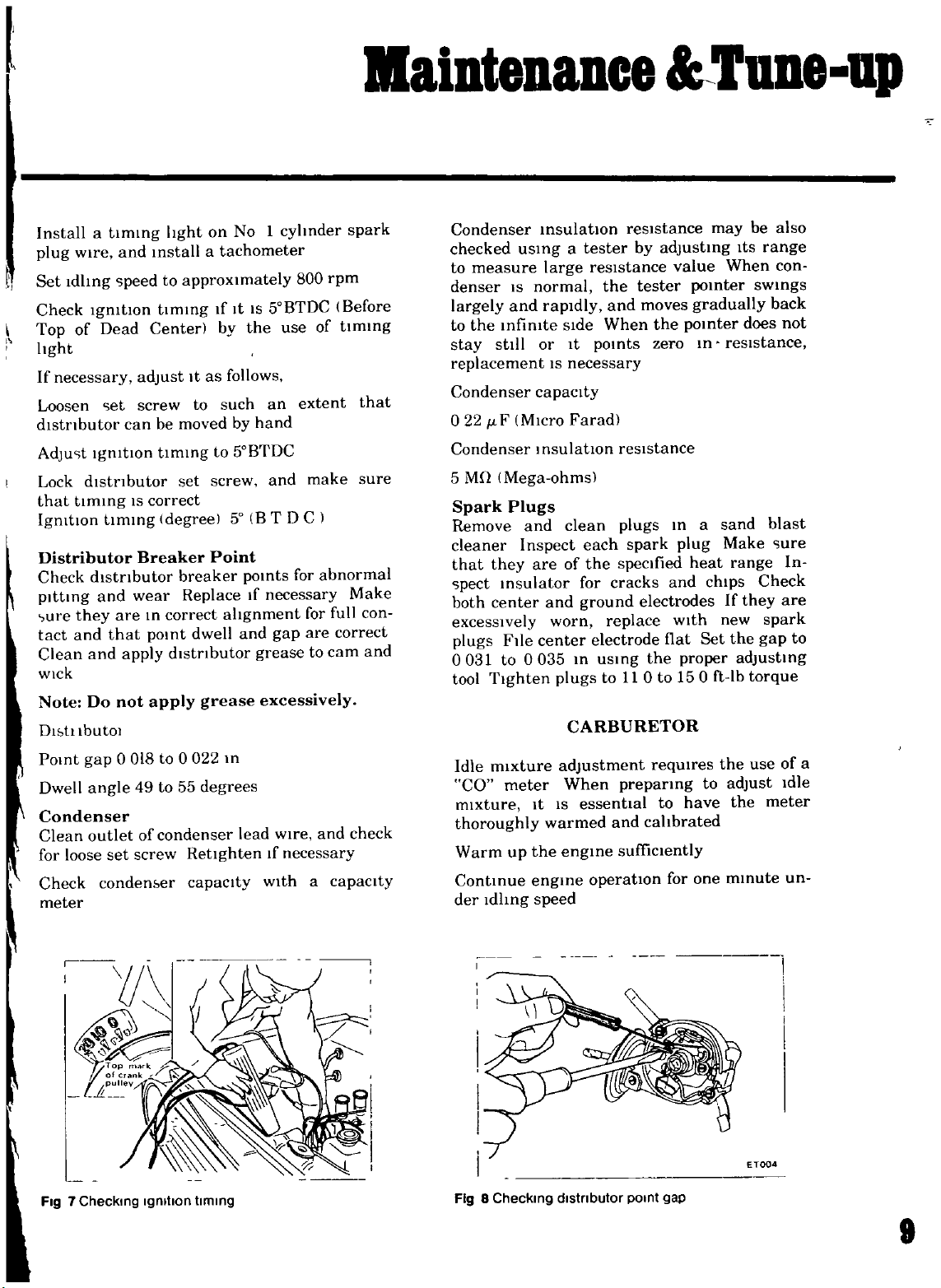

I

Fig5Testing

ETO

104

compressIon

pomt

09

coolmg

tern

pressure

cm2

kg

pressure

2550F

2610F

sys

Freeze

protectIon

50f

31oF

7

aiDtenaDce

TUDe

up

ting

tightly

der

The

tester

cylinder

whether

plugs

etc

compressIOn

removed

rings

Test

opened

less

than

variatIOn

low

speed

dlcates

blOken

though

ThIs

may

consumptIOn

Test

Conclusion

If

one

or

one

tablespoon

plstons

spark

plug

thesecyII

can

there

No

80

between

missing

a

valve

pIston

umform

more

In

hole

nders

m

spark

is

used

IS

wIth

and

cyhnder

of

highest

ring

be

accompamed

cyhnders

of

low

readmg

Repeat

to

hold

excessive

engme

throttle

compressIOn

cyhnders

of

the

not

properly

may

engine

hole

plug

determme

compression

and

cyhnder

cyllndel

Low

indIcate

by

read

011

cyhnders

compressIOn

of

a

whether

leakage

choke

should

s

all

Excessive

warm

accompamed

usually

seating

preSsures

worn

excessive

low

Inject

on

top

through

check

cylin

past

spark

valve

or a

even

rings

about

of

the

or

be

by

10

011

on

Clean

solutIOn

and

tery

between

to

In

cumulatIon

tery

covering

straps

With

from

Check

pOints

dry

must

hold

additIOn

may

petrolatum

corrosIOn

for conditIon

top

down

After

spark

Thoroughly

marks

Warm

on

up

of

of

baking

WIth

be

terminals

clamp

to

of

cause

connector

IGNITION

wipe

crank

engine

battery

soda

compressed

clean

to

and

current

aCId

and

bhstenng

straps

tightening

vasehnel

plugs

and

off

dIrt

pulley

suffiClently

and

and

prevent

from

leakage

dirt

terminals

TIMING

and

and

terminals

water

The

atr

current

poSItive

on

of

and

to

dIstributor

dust

front

Rinse

top

termlndl

prolonged

the

top

the

material

corrOSIOn

coat

protect

from

cover

With

bat

of

leakage

of

bat

them

them

breaker

tlmmg

a

off

ac

of

I

I

j

If

compressIOn

are

rings

If

compressIOn

stIcking

If

two

pressIOn

Increase

cylInder

ders

result

defectIve

or

adjacent

and

compreSSIOn

head

Engine

from

CompressIOn

178to206

Check

Unscrew

level

to

07874

Mea

If

bring

ure

electrolyte

flUId

level

In

trolyte

seatIng

this

pSI

each

above

P

Improves

does

cyhnders

mjectmg

gasket

011

and coolant

problem

pressure

at

350

BATIERY

filler

level

up

plates

illL

not

Improperly

011

the

leak

rpm

level

10

cap

IS

low

to

approximately

Do

gravlty

conSiderably

Improve

mdlcate

on

pistons

cause

between

In

cylInder

each

battery

and

Inspect

add

dIstilled

not

overfill

of

pattery

valves

low

does

may

the

03937

piston

cell

water

are

com

not

be

cyhn

could

flUId

el

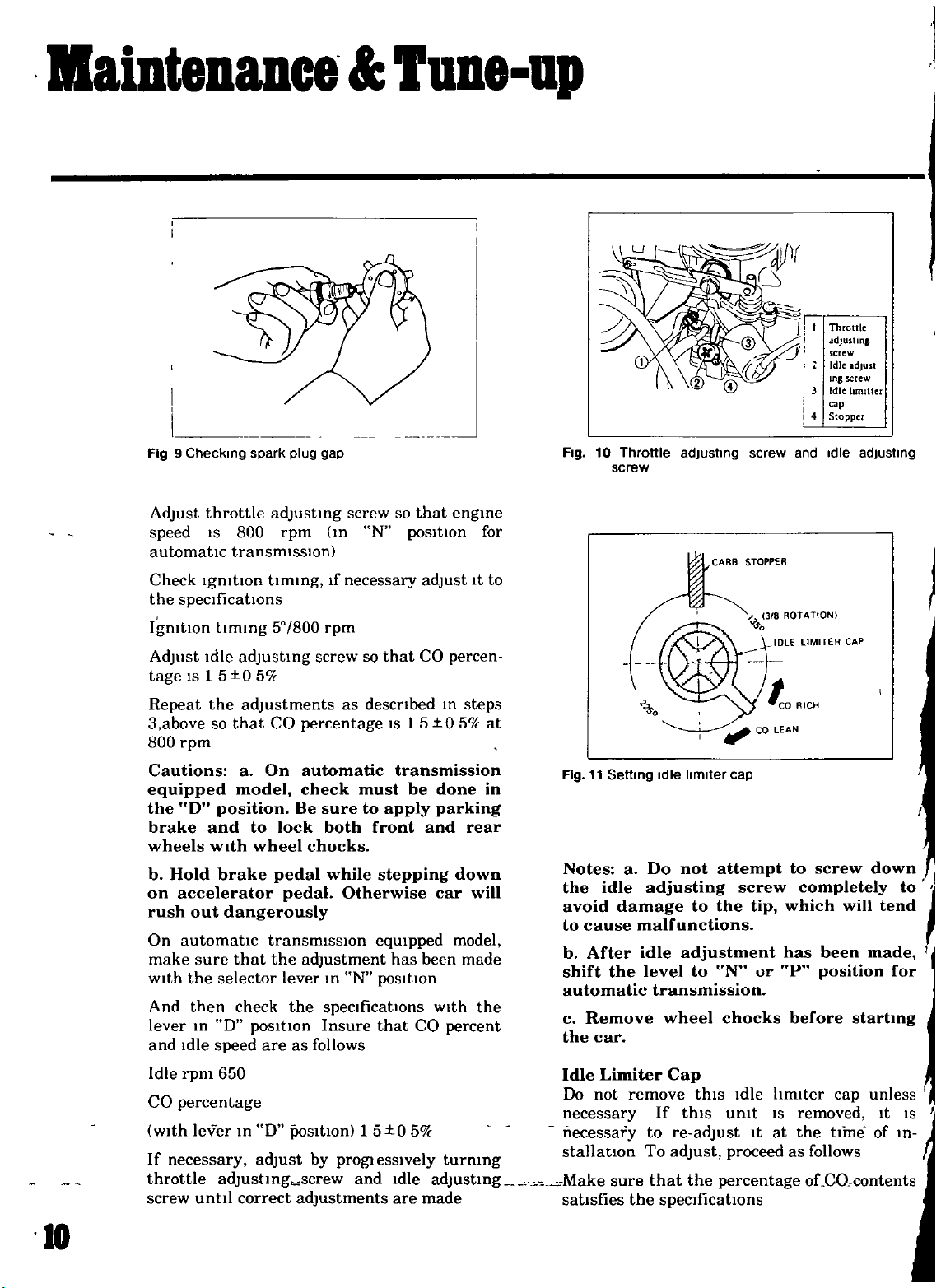

PermIssIble

value

1

chmates

Fngld

TropIcal

Other

a

chmates

clunates

22

Over

OverI18

Over120

Full

charge

at

68OF

128

123

126

value

j

J

I

to

ET002

c

FlgSGheckmg

trolyte

the

speCific

gravity

of

baltery

elec

f

8

l

Install

WIre

plug

Set

Idhng

Check

of

Top

hght

If

necessary

Loosen

dlstnbutor

AdJu

it

Lock

dlstnbutor

that

tlmmg

IgnitIOn

Distributor

Check

pItting

wre

they

tact

and

and

Clean

WIck

Note

Do

DltIIbutOl

POint

gap

Dwell

angle

Condenser

Clean

outlet

for

loose

Check

meter

a

timing

and

ipeed

19mtlOn

Dead

iet

can

IgmtlOn

tImmg

dlstnbutor

and

are

that

apply

not

0

set

condenber

lIght

Install

to

tImmg

Center

adjust

screw

be

tIming

IS

correct

degreel

Breaker

wear

In

correct

pOint

dlstnbutor

apply

018to0

49

to

of

condenser

screw

on

No

a

tachometer

approximately

It

If

IS

the

by

follows

It

as

to

such

moved

set

breaker

to

screw

Point

Replace

by

50BTDC

50

pomts

If

ahgnment

dwell

and

grease

022

In

55

degrees

lead

RetIghten

capacIty

1

cyhnder

800

50BTDC

use

extent

an

hand

and

make

BT

DC

for

necessary

for

are

gap

grease

to

excessively

WIre

If

necessary

a

With

spark

rpm

Before

of

tlmmg

abnormal

Make

full

correct

cam

and

check

capacity

that

sure

con

and

aiDteDaDce

tester

resIstance

the

and

When

pomts

resIstance

each

the

specified

for

cracks

ground

replace

electrode

USIng

to

essential

and

suffiCiently

operatIOn

resistance

by

plugs

spark

110to

preparIng

Condenser

checked

to

measure

denser

largely

to

stay

the

IS

and

Infimte

still

replacement

Condenser

022JF

Condenser

Mn

5

Spark

Remove

cleaner

that

ipect

both

Mega

Plugs

they

msulator

center

excessIVely

File

plugs

0031

to 0035

tool

Tighten

mixture

Idle

CO

meter

mixture

thoroughly

Warm

ContInue

der

up

ldhng

msulatlOn

usmg

large

normal

rapidly

or

IS

capacIty

MIcro

InsulatIOn

ohms

and

Inspect

are

and

worn

center

It

warmed

the

engIne

speed

a

SIde

It

necessary

Farad

clean

of

m

plugs

CARBURETOR

adjustment

When

IS

engme

adjusting

value

tester

moves

the

zero

In

and

electrodes

WIth

flat

the

requIres

to

cahbrated

for

may

pomter

gradually

pomter

m

a

plug

heat

chIps

Set

proper

ft

150

to

have

one

UDe

ItS

When

does

reSIstance

sand

Make

range

If

they

new

the

adjustIng

Ib

torque

the

use

adjust

the

mmute

be

range

swmgs

blast

Check

spark

gap

meter

also

con

back

iure

are

of

up

not

In

to

a

Idle

un

Fig7Checking

Igmllon timing

Fig

8

Checking

dlstnbutor

POint

gap

ETOQ4

I

i

I

I

I

I

I

I

aiDteDaDce

UDe

I

I

I

up

Fig9Checking

Adjust

speed

automatic

Check

the

IgnitIOn

Adjust

tage

Repeat

3

800

Cautions

throttle

1S

IgnitIOn

specIficatIOns

timing

Idle

15t0

IS

the

above

so

rpm

equipped

the

D

position

brake

wheels

b

on

rush

On

make

wIth

And

lever

and Idle

Idle

CO

with

If

throttle

screw

and

wIth

Hold

accelerator

out

automatic

sure

the

then

In

rpm

percentage

lever

necessary

until

brake

selector

speed

650

adJustlng

spark plug

adjusting

800

rpm

transmIssIOn

tlmmg

50

adjusting

5ff

adjustments

that

CO

a

On

model

to

lock

wheel

pedal

pedal

dangerously

transmISSIOn

that

the

lever

check

D

In

posItion

are

D

the

PoSitIOn

adjust

correct

gap

screw

m

If

necessary

800

rpm

screw

as

percentage

automatic

check

Be

sure

both

chocks

while

Otherwise

adjustment

In

N

specificatIOns

Insure

as

follows

by

progIesslvely

screw

adjustments

N

so

that

desctlbed

must

to

apply

front

stepping

eqUIpped

posItion

that

1

5t0

and

that

so

positIOn

adjust

CO

15t05ff

IS

transmission

be

and

has

been

with

CO

5k

Idle

adJustmg

are

made

J

engme

percen

In

steps

done

parking

rear

down

car

model

made

percent

turmng

1t

will

I

the

for

Throttle

sdJustlnl

screw

Idle

adjust

Inlscrew

Idle

Itmlttc

cap

time

adjusting

will

startmg

contents

r

down

tend

made

unless

It

of

to

for

In

JI

I

IS

I

cap

4

Stopper

10

screw

11

Setting

idle

cause

After

the

Remove

car

Limiter

not

sure

Throttle

Idle

a

Do

adjusting

damage

malfunctions

idle

level

transmission

remove

If

to

To

that

the

adjusting

limiter

not

to

adjustment

to

wheel

Cap

this

this

re

adJust

adjust

the

specifications

Fig

to

at

in

Fig

Notes

the

avoid

to

b

shift

automatic

c

the

Idle

Do

necessary

necessary

stallatlon

Make

satisfies

screw

STOPPER

CARB

cap

attempt

screw

the

tip

N

or

chocks

Idle

Unit

It

proceed

percentage

and

to

completely

which

has

P

before

hm1ter

removed

IS

at

the

as

Idle

screw

been

position

follows

oLCO

10

aiDtenuce

be

w

certam

Check

lever

per

2

000

Engme

1

000

Readjust

lflt

falls

rpm

rpm

to

should

to

be

when

within

dash

meet

that

sure

be

pot

It

that

engme

slowed

a

or

the

IS

few

replace

above

correct

m

dash

speed

seconds

pot

reaches

down

It

condItions

TUDe

adjustment

contacts

1

900

from

3

000

with

a new

up

stop

to

to

one

12

Fuel

Fig

Install

sure

Dash

Idle

that

rotatIOn

Pot

Transmission

Check

cracked

operation

strainer

the

or

hmlter

adJustmg

m

the

Automatic

Model

bound

cap

CO

of

dash

ItISalso

screw

RICH

Only

m

pot

posItion

can

d1rectlOn

It

should

essenttal

further

makmg

not

to

check

turn

Carburetor

Check

damage

found

use

Fuel

Filter

Check

depoSIt

All

be

engmes

found

IS

throttle

wIth

for

and

wear

to

Return

or

any

a

contammatlOn

defection

use

a

be

Spring

return

squareness

of

above

cartridge

defective

sprmg

Discard

excessIvely

element

strainer

type

replace

for

sign

spring

beyond

water

as

of

If

If

1t

an

assembly

r

u

IQgiDe

The

A12

valve four

head

bore

full

ber

5

and

opened

alummum

bearmg

dependable

Removmg

the

Open

and

remove

Disconnect

mmal

Removmg

engme

2

wedge

crankshaft

power

hood

hood

the

the

radIator

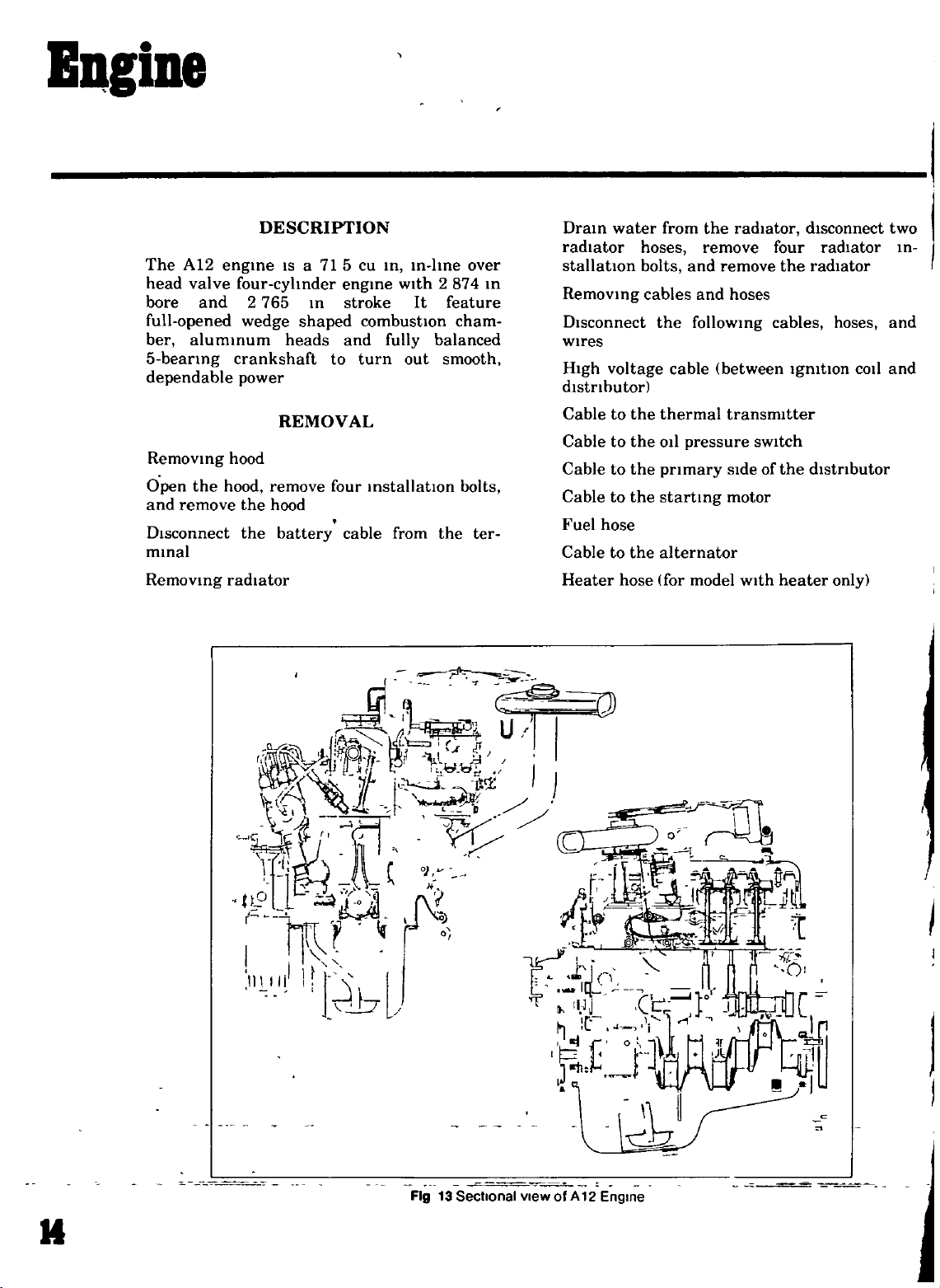

DESCRIPTION

715

IS

a

cyltnder

765

m

shaped

heads

REMOVAL

remove

hood

battery

engine

stroke

and

to

four

cable

cu

m InIme

with

combustIOn

fully

turn

mstallatlOn

from

out

It

over

2874

feature

cham

balanced

smooth

bolts

the

Dram

water

from

the

radiator

radIator

stallatlOn

m

Removmg

Disconnect

wires

High

distributor

Cable

Cable

Cable

Cable

ter

Fuel

Cable

Heater

voltage

to

to

to

to

the

hose

to

the

hose

the

the

the

hoses

bolts

cables

the

and

followmg

cable

thermal

011

pressure

primary

startmg

alternator

for

model

remove

and

remove

hoses

between

transmitter

sW1tch

Sideofthe

motor

With

four

the

cables

Igmtton

heater

disconnect

radIator

radiator

hoses

distributor

only

COlI

two

m

and

and

It

Fig

13

Sectional

I

view

of

A

12

Engine

Bngine

WIres

for accelerator

operatIOn

removing

Lift

Install

removal

the

the

up

the

Disconnecting

model

hydraulIc

DIsconnect

wIthdrawal

Remove

Disconnect

SWItch

D1sconnect

Remove

Remove

carner

Remove

Disconnect

tlOn

the

Model

Remove

remove

In

Remove

and

Suspend

Remove

nuts

Remove

nuts

When

stallation

the

On

the

the

SIde

the

Model

With

of

transmiSSIOn

remote

With

the

the

passenger

Model With

remove

removing

transmiSSIOn

line

four bolts

the

pinS

the

the

the

Will

a1r

engine

INST

engine

clutch

left

from

the

lever

exhaust

the

the

propeller

and

shift

remote

the

control

floor

boot

lever

automatic

from

the

engine

front

rear

nuts

be

carned

cleaner

toward

ALLA

In

wire

hand

dnve

the

clutch

clutch

the

WIre

front

cable

speedometer

shaft

used

Withdraw

lever

control

remote

rod

Sh1ft

WIthdraw

The

control

outer

lever

operatIOn

compartment

transmiSSIOn

both

endsofthe

shIft

rod

With

engine

engine

the

sure

to

be

and

out

more

the

front

TION

reverse

on

nght

model

slave

at

the

tube

to

the

cable

In

the

the

propeller

shIft

rod

lever

the

wire

mounting

mounting

engine

applyaJack

choke

sequence

hand

disconnect

cylInder

JXlrtlOn

back

differential

lever

at

and

lock

carned

IS

cross

installation

installation

mounting

easily

up

shaft

the

remove

pin

beneath

dnve

of

lamp

shaft

The

the

JXlr

and

out

by

electncal

horn

air

The

bolts

CylInder

Jacket

of

in

Clutch

011

pan

Mount

Remove

Side

Install

Mount

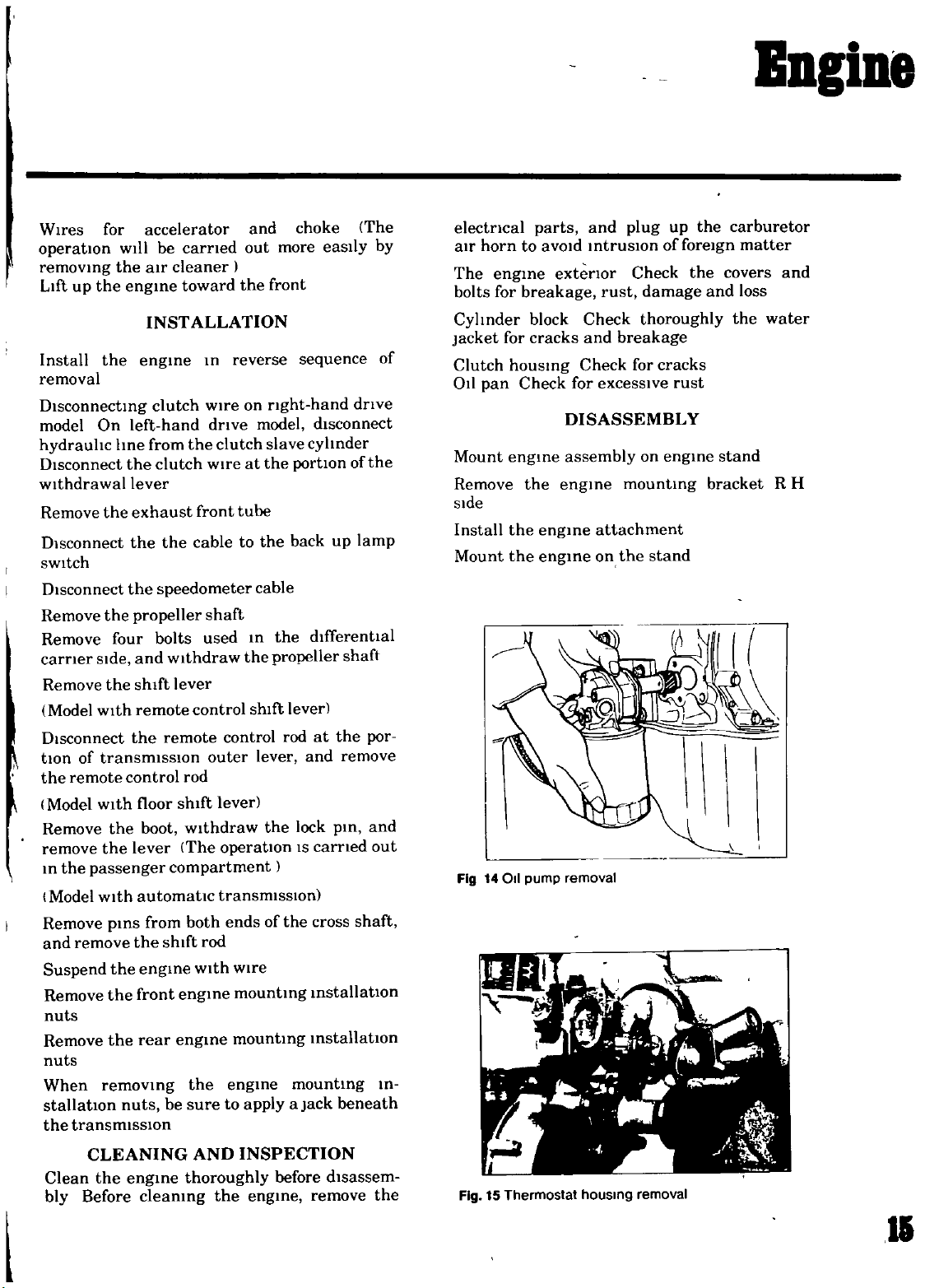

Fig

14011

to

engine

for

breakage

for

hOUSing

Check

engine

the

the

the

pump

parts

block

cracks and

aVOid

extenor

Check

for

DISASSEMBLY

assembly

engine

engine

engine

removal

and

intrusIOn

rust

Check

excessive

attachment

on

plug

of

Check

damage

thoroughly

breakage

cracks

for

on

engine

mounting

the

stand

up

foreign

the

rust

the

and

bracket

carburetor

matter

covers

loss

the

stand

water

R

and

H

l

CLEANING AND

Clean

bly

the

Before

engine

cleaning

INSPECTION

thoroughly

the

engine

before

disassem

remove

the

Fig

15

Thermostat

hOUSing

removal

II

Bngine

Remove

bracket

Remove

Remove

filtel

Remove

dlstnbutor

Remove

Remove

Remove

Remove

Remove

Remove

Remove

Remove

the

L

the

the

the

the

the

the

the

the

the

H

the

the

altel

slde

crankshaft

011

high

on

cap

spark

dlstllbutor

carburetor

rocker

manifolds

water

fuel

nator

pump

pump

tensIOn

plugs

cover

thermo

itat

pump

and

engine

pulley

together

cable

assembly

houslllg

With

mounting

the

wIth

the

011

Remove

rods

Remove

Invert

18

Fig

the

Rocker

the

the

rocker

cylInder

engine

shaft

shaft

head

assembly

assembly

assembly

removal

and

push

Fig

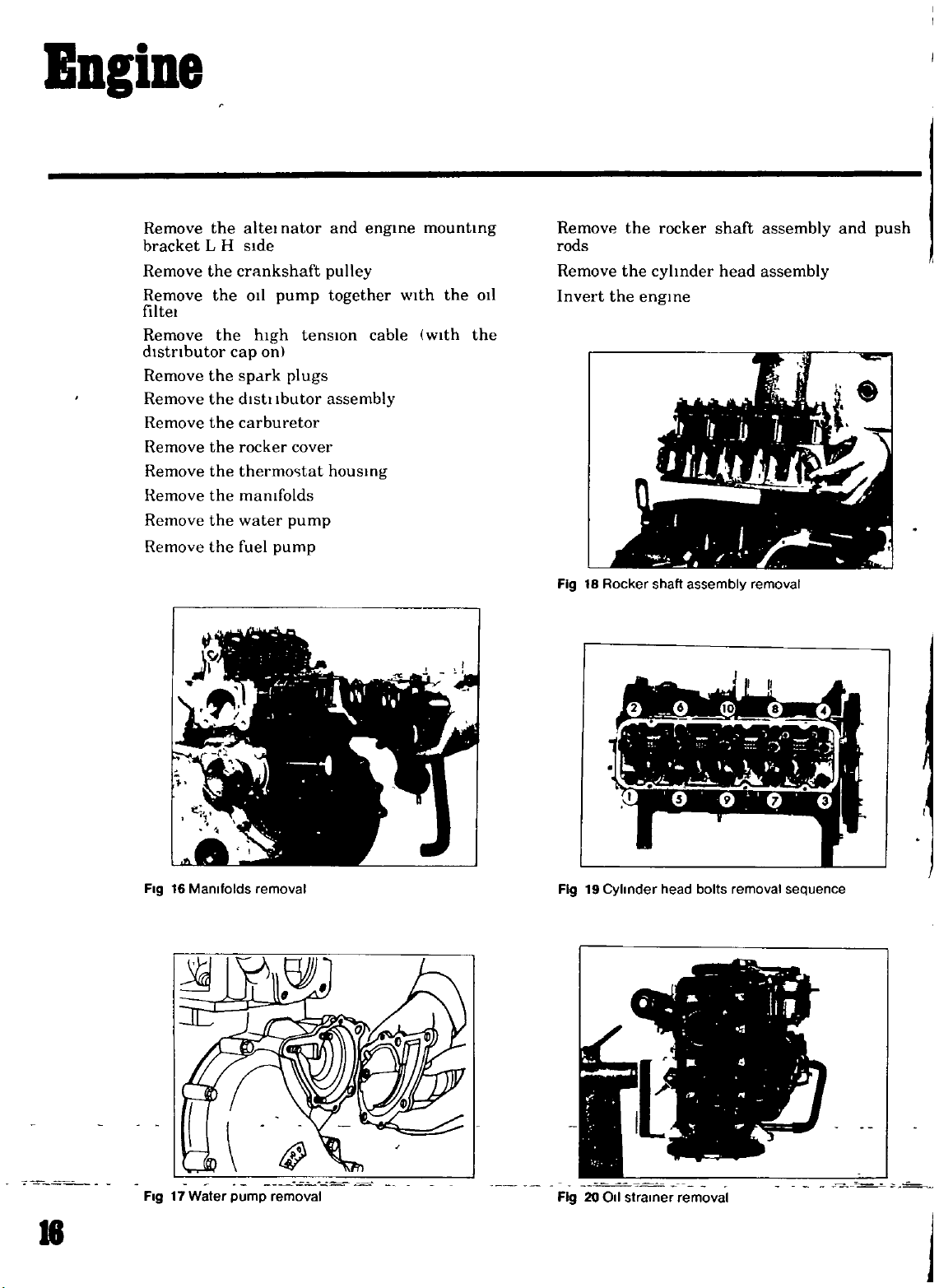

Fig

16

17

Manifolds

Water

pump

removal

removal

l

r

Fig19Cylinder

20

011

Fig

strainer

I

head

bolts

removal

I

w

removal

7

Y

h

L

sequence

1

1

o

18

j

Bneine

Remove

Remove

tenSlOner

Remove

sprockets

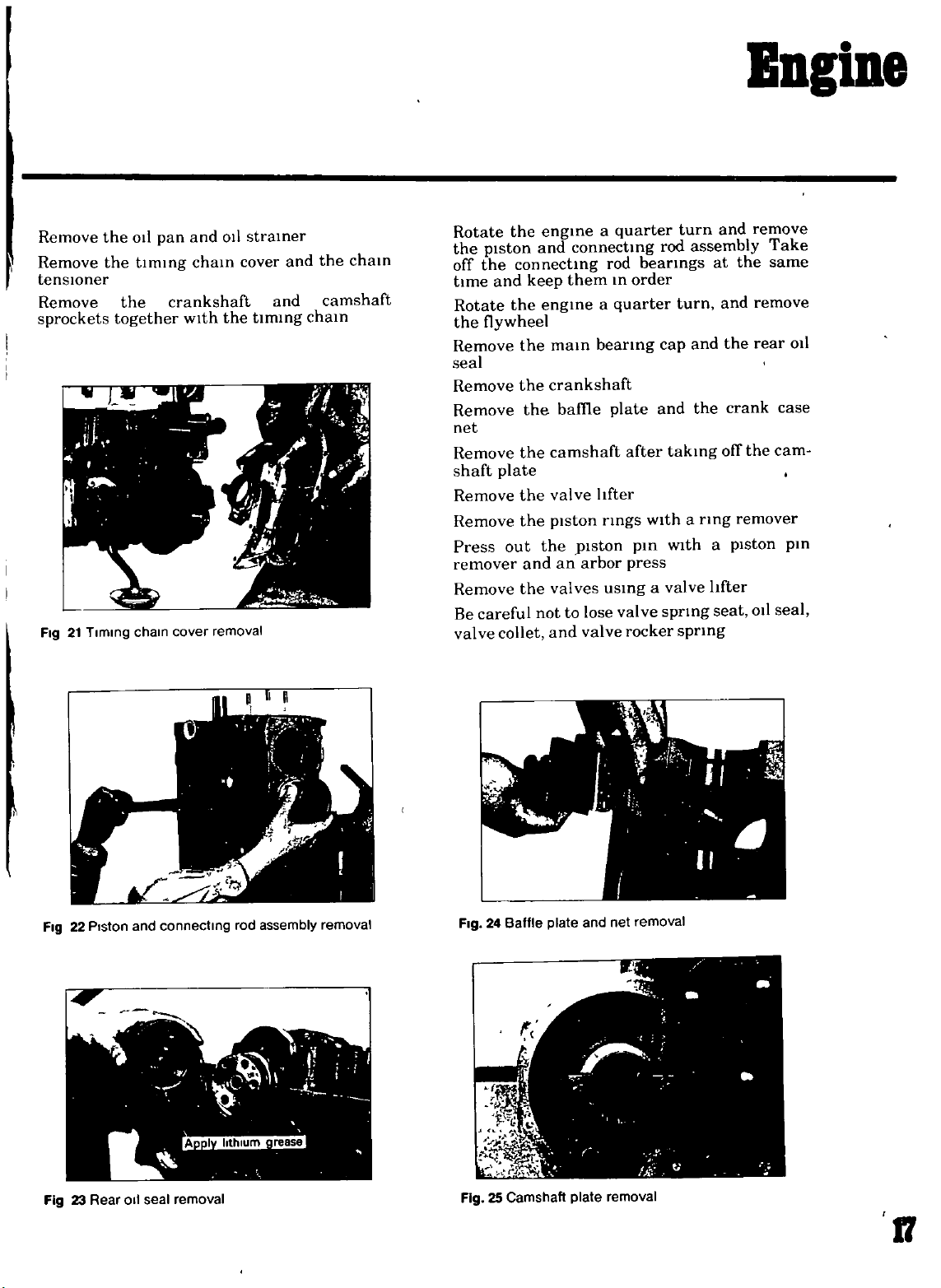

Fig21Tlmmg

the

the

the

together

cham

011

pan

tImIng

and

chaIn

crankshaft

WIth

cover

removal

011

the

straIner

cover

timing

and

and

the

camshaft

chaIn

chaIn

Rotate

the

off

tIme

Rotate

the

Remove

seal

Remove

Remove

net

Remove

shaft

Remove

Remove

Press

remover

Remove

Be

careful

valve

the

piston

the

connectIng

and

the

flywheel

the

the

the

plate

the

the

out

and

the

collet

keep

the

not

engIne

and

engIne

maIn

crankshaft

baffie

camshaft

valve

piston

the

an

valves

to

and

a

connectIng

rod

In

them

a

quarter

bearIng

plate

tfter

rIngs

piston

arbor

USIng

valve

lose

valve

quarter

beatings

order

after

With

pIn

press

a

rocker

rod

cap

and

takIng

With

valve

sprIng

sprIng

turn

assembly

turn

and

the

a

tlng

a

tfter

seat

and

at

and

the

crank

off

the

the

remover

piston

011

remove

remove

rear

Take

same

011

case

cam

pin

seal

I

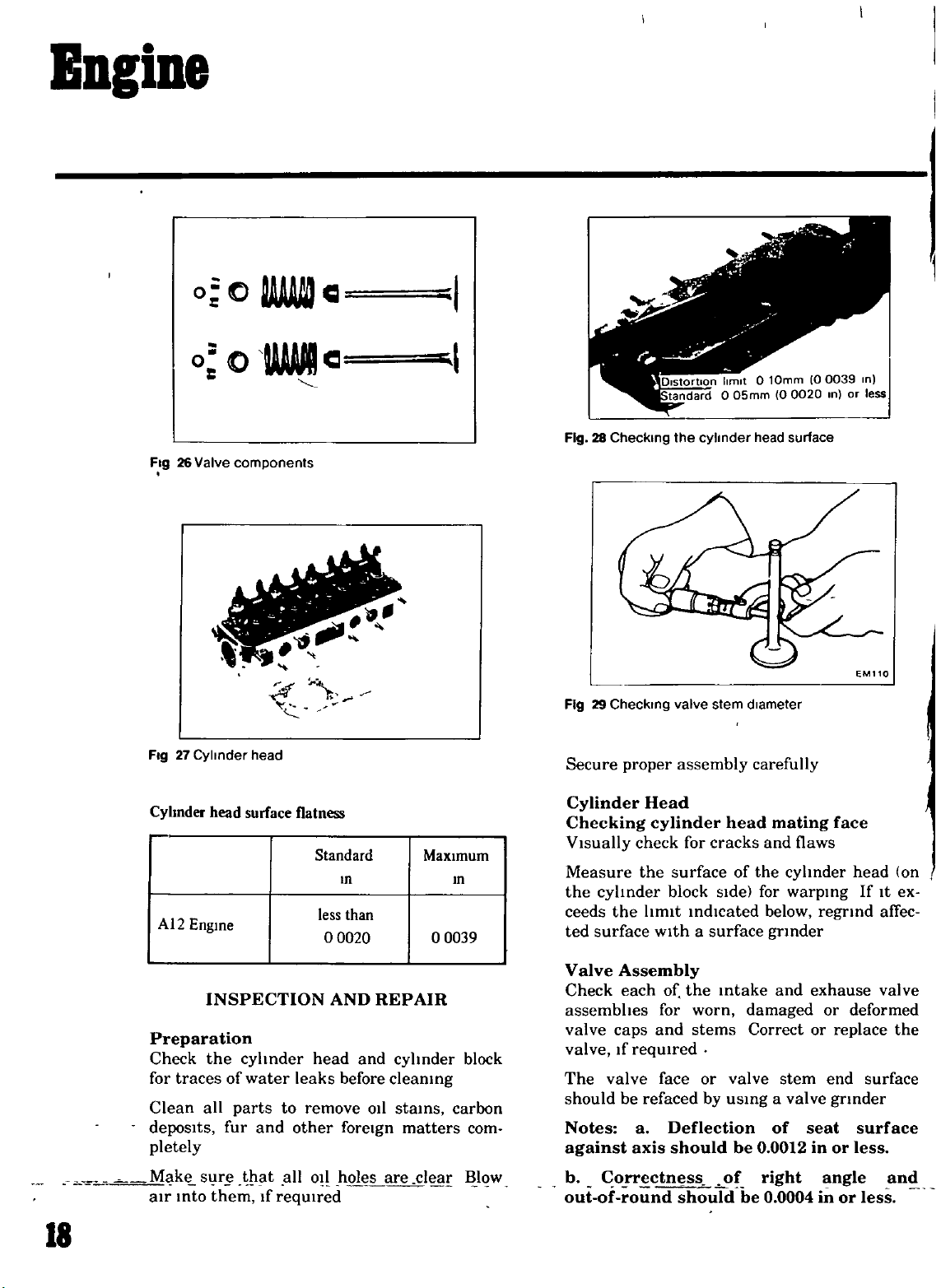

22

PIston

FIg

Fig

and

connectmg

23

Rear

011

seal

removal

rod

assembly

removal

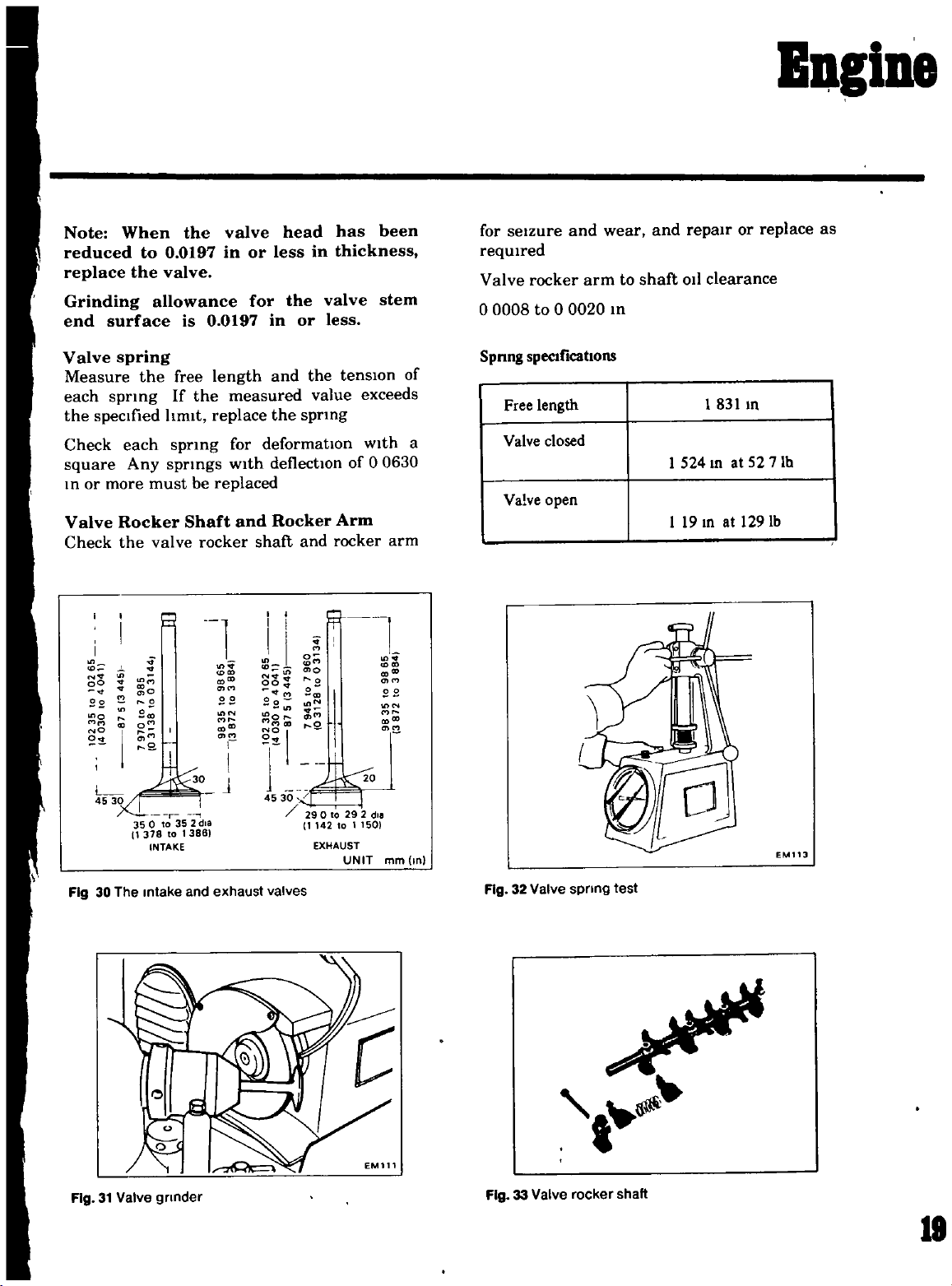

FIg

Fig

24

25

Baffle

Camshaft

plate

plate

and

net

removal

removal

17

Bogioe

Fig

FIg

26

27

0

o

Valve

Cylinder

WAI

o

components

head

WAIl

CI

Cl

I

Fig28Checking

Fig29CheckIng

Secure

proper

the

cylinder

valve

stem

assembly

head

dIameter

carefully

surface

18

Cyhnder

Al2

head

Engme

INSPECTIONAND

Preparation

Check

for

Clean

the

traces

all

depoSits

pletely

k

M

air

slr

Into

them

surface

cyhnder

of

water

parts

fur

and

1at

If

flatness

Standard

less

head

leaks

to

remove

other

all

o

reqUIred

m

than

o

0020 o

REPAIR

and

cylinder

before

cleaning

011

stains

foreIgn

hol

Lare

matters

clear

MaxImum

m

0039

carbon

block

com

Blow

Cylinder

Checking

VIsually

Measure

the

cyhnder

ceeds

ted

surface

Valve

Check

assembhes

valve

valve

The

valve

should

Notes

against

b

out of

Head

cylinder

check

the

the

hmlt

wIth

Assembly

each

for

and

caps

If

reqUIred

face

be

refaced

a

axis

o rr

ctnes

round

for

surface

block

indIcated

a

of

the

worn

stems

Deflection

should

should

head

cracks and

of

SIde

surface

Intake

damaged

Correct

valve

or

by

usmg

be00012

f

be

mating

the

for

below

grinder

a

of

right

0

flaws

cyhnder

warping

and

stem

valve

0004

face

regrind

exhause

deformed

or

or

replace

end

gtlnder

seat

inorless

angle

in

or

head

If

surface

surface

less

It

afTec

valve

the

and

on

ex

IBglne

Note

reduced

replace

Grinding

end

Valve

Measure

each

the

specIfied

Check

square

III

or

Valve

Check

N

00

9E

o

NO

30

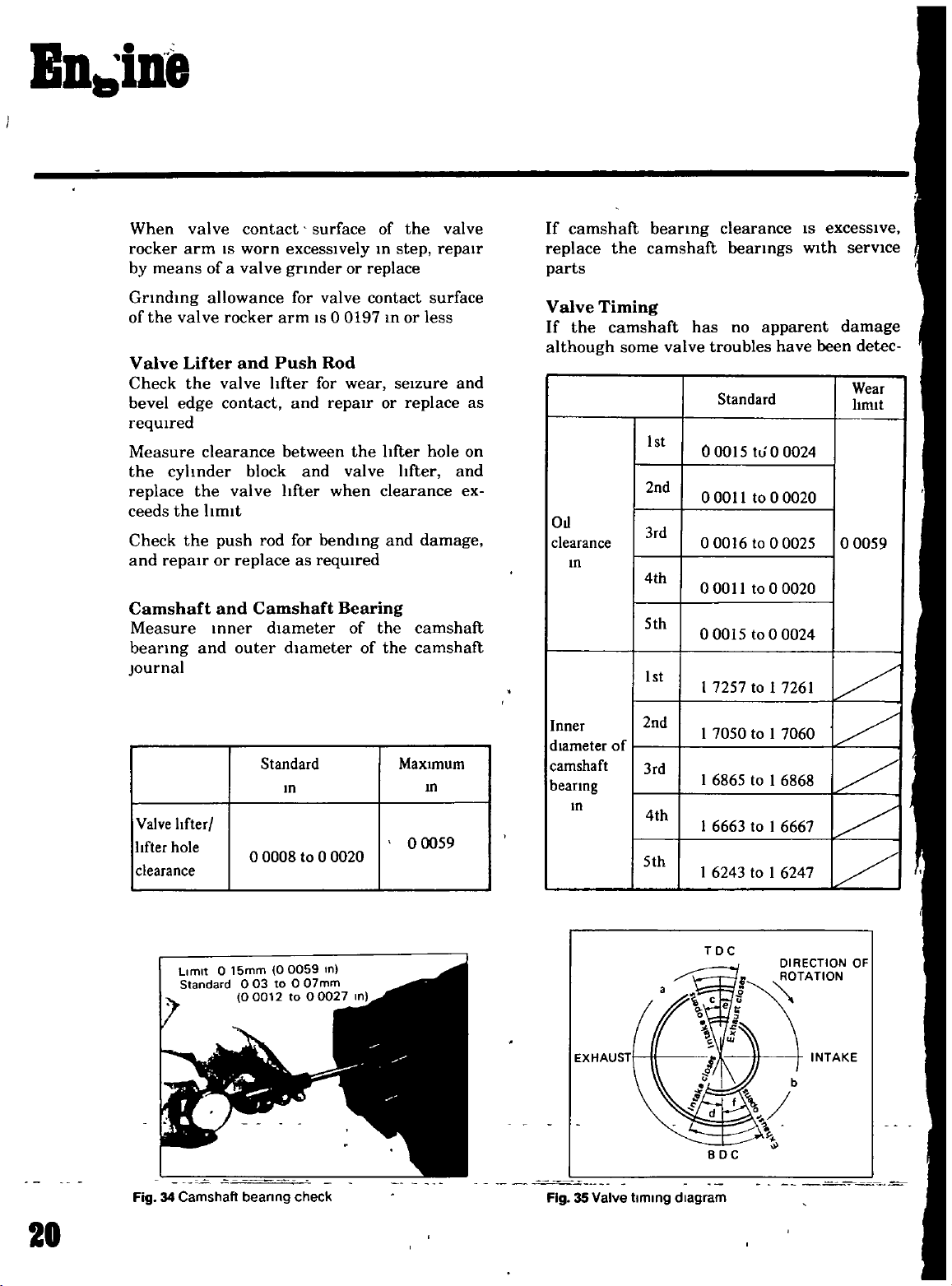

Fig

When

surface

spring

spnng

each

Any

more

Rocker

the

in

I

I

The

the

350

1

to

the

378

Intake

the

0

0197

valve

allowance

is

free

If

hmlt

spnng

sprmgs

must

valve

to

35

1386

to

INTAKE

the

be

Shaft

rocker

I

2dla

and

valve

in

0

0197

length

measured

replace

for

w1th

replaced

and Rocker

1

22

N

I

I

1

exhaust

head

less

or

for

in

and

the

deformatIOn

deflectIOn

shaft

I

Ll

N

00

OtM

Bo

11

l

o

1

45 30

valves

in

the

valve

or

the

value

sprlllg

and

I

gE

cno

r

o

Be

N

l

lit

cnM

Q

l

290to292die

1142to1

EXHAUST

has

thickness

less

tensIOn

of00630

Arm

rocker

UNIT

been

stem

exceeds

with

arm

co

CX

171M

22

N

1501

mm

for

seizure

and

wear

and

repair

or

replace

as

required

Valve

o

0008

Spnng

rocker

specIficatIOns

arm

to

0

0020

of

Free

length

Valve

Valve

32

Valve

closed

open

spring

a

lnl

Fig

shaft

011

to

III

test

clearance

1

831

In

1

524

In

I

19

III

7

Ib

at

52

1291b

at

EM J

Fig

Valve

rocker

31

Valve

grinder

Fig

33

shaft

lB

in1l

Bn

When

rocker

means

by

Grinding

of

the

Valve

Check

bevel

reqUIred

Measure

the

cyhnder

replace

ceeds

the

Check

and

repair

Camshaft

Measure

bearing

Journal

valve

arm

valve

Lifter

the

edge

the

the

IS

ofavalve

allowance

rocker

valve

contact

clearance

valve

hmlt

push

or

replace

and

mner

and

outer

contact

worn

and

block

Camshaft

excessively

grinder

for

arm

Push Rod

hfter

and

between

hfter

rod

for

as

dIameter

diameter

surface

valve

IS

0

for

repair

and

when

bendmg

reqUIred

m

or

replace

contact

0197

wear

the

valve

Bearing

of

of

of

the

step

In

or

seizure

or

replace

hfter

hfter

clearance

and

the

the

valve

repair

surface

less

hole

damage

camshaft

camshaft

and

and

If

camshaft

replace

the

bearmg

camshaft

clearance

bearmgs

IS

with

exceSS1ve

service

parts

Valve

If

although

as

on

ex

the

Ot

clearance

In

Timing

camshaft

some

1st

2nd

3rd

4th

5th

1st

valve

has

no

troubles

Standard

00015luOO024

00011

00016

00011

00015

1

7257

apparent

have

0

to

to

00025

to

0

toO

to

I

0020

0020

0024

7261

been

damage

detec

Wear

hm1t

o 0059

Valve

hfter

clearance

34

Fig

hfter

hole

limit

Standard

Camshaft

Standard MaxlIDum

m

o 0008

0151010

003

00012

bearing

00059

to

to

0071010

to

check

00020

m

00027

Inner

diameter

camshaft

m

o

0059

m

beanng

m

EXHAUST

35

Fig

Valve

2nd

of

3rd

4th

5th

timing

1

1

I

1

diagram

TDC

BDC

7050

6865

6663

6243

to

to

to

to

1

7060

1

6868

I

6667

1

6247

DIRECTION

ROTATION

OF

INTAKE

20

ted

I

ttmmg

endmg

plymg

figures

Cylinder

Check

such

Measure

der head

exceeds

Measure

and

walls

compare

as

wear

round

out

of

by

diagram

of

stroke

with

Block

the

cyhnder

cracks

the

matmg

hmlt

the

the

WIth

means

valve

to

specified

and

of

top

face

correct

cyhnder

a

IS

exceSS1ve

of

ttmmg

ensure

for

flaws

a

bormg

head

the

bore

all

advance

cyhnder

for

bore

data

that

cylmders

v1sually

warpmg

1t

for

gauge

rebore

machme

wIth

the

begmmng

are

and

for

block

If

the

out

of

If

wear

the

cyhnder

valve

com

retard

defects

cyhn

warp

round

and

Bogioe

1S

step

by

tool

each

a

m

new

mmor

from

the

Ring

wear

piston

rmg

pIston

of

wh1ch

out

of

When

wlthm the

most

ridge

Piston Piston

Check

as

Measure

and

on

p1ston

Place

or

traveled

be

wear

portIOn

reamer

for

reqUIred

ring

the

piston

rmg

the

used

hmlt

seIzure

Side

groove

part

or

of

or

should

rmg

of

remove

the

other

Pin

clearance

WIth

Clearance

at

cyhnder

round

the

cyhnder

slm11ar

and Piston

scratch

of

the

piston

of

beasfollows

the

bottom

bore

and

the

use

Replace

mstalled

the

It

and

top

of

rmg

and

rmg

wlll

a

a

248

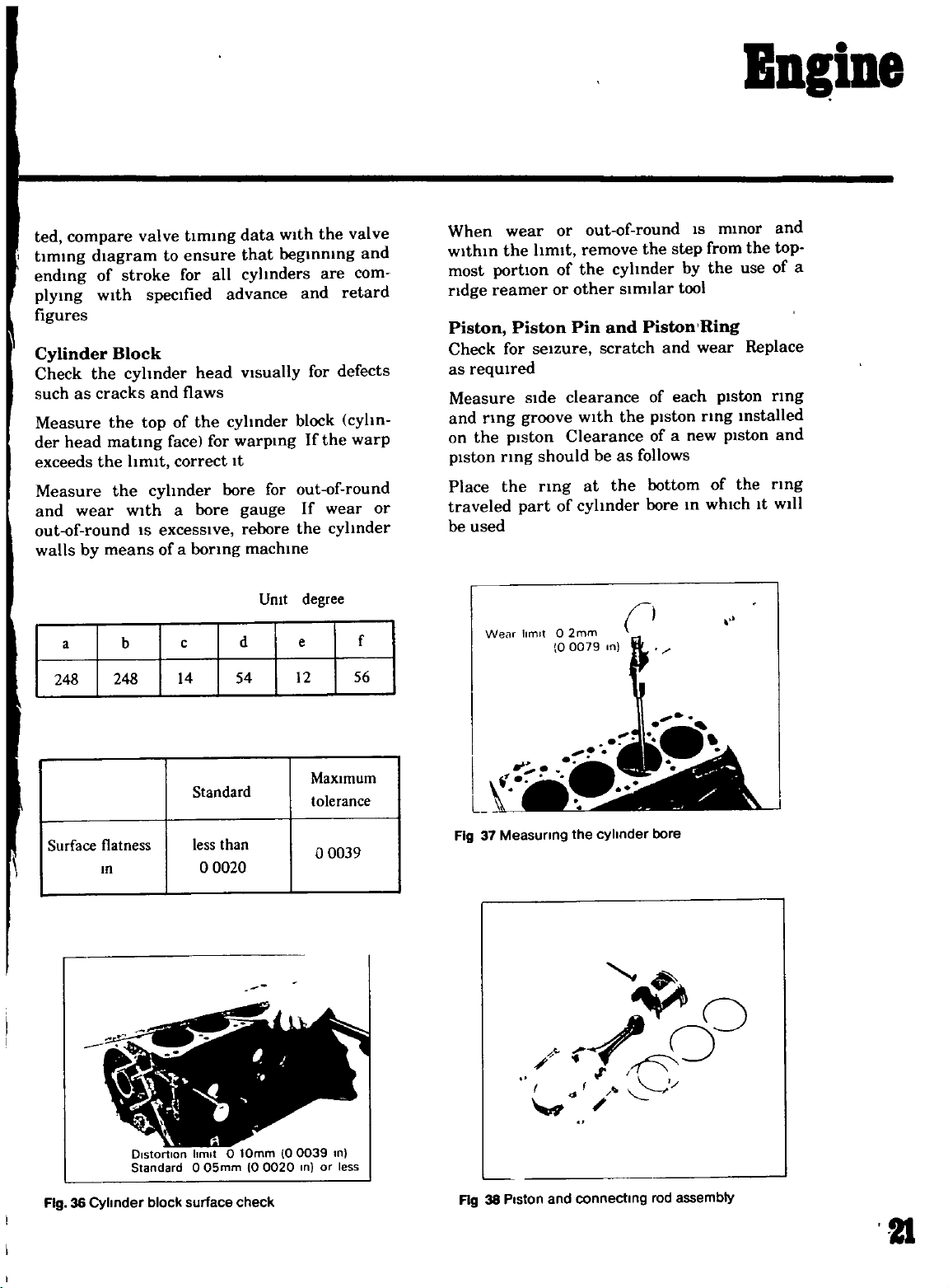

Surface flatness

b

248

m

c

14

Standard

less

Umt

degree

I

limIt

02mm

0

0079

the

In

cylinder

bore

Fig

Wear

37

MeaSUring

d

54

than

o

0020

e

12

MaxImum

tolerance

o

0039

f

56

SAO

O

I

f

I

Fig36Cylinder

Distortion

Standard

block

limIt

0051010

surface

0

101010

100020

check

00039

In

In

or

less

Fig

Piston

and

connecting

38

rod

assembly

II

BogiDe

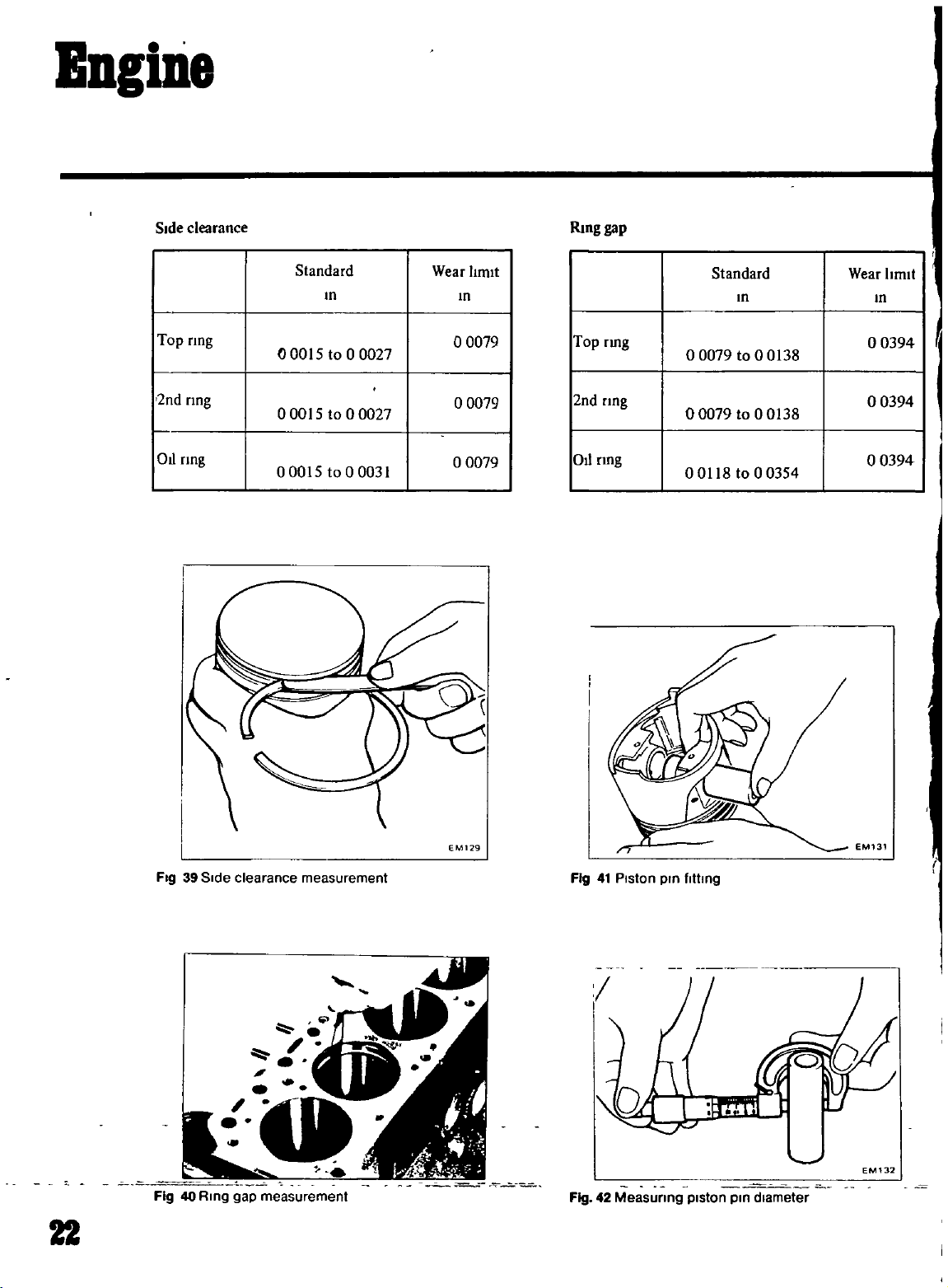

SIde

clearance

Rmg

gap

Top

2nd

Ot

rIng

rIng

rIng

Standard

0015

00015

00015

Wear

limIt

m

to

0

0027

0

to

0027

0

to

0031

o

o

o

m

0079

0079

0079

Top

2nd

OtlrIng

rmg

rIng

00079

00079

00118

Standard

m m

to

0

0138

to

00138

to

00354

Wear

limIt

o

0394

o

0394

o

0394

22

39

Side

Fig

Fig40Ring

clearance

measurement

gap

measurement

EM129

Fig

Fig

41

Piston

42

Measunng

EM131

pin

fitting

pin

diameter

piston

Bngine

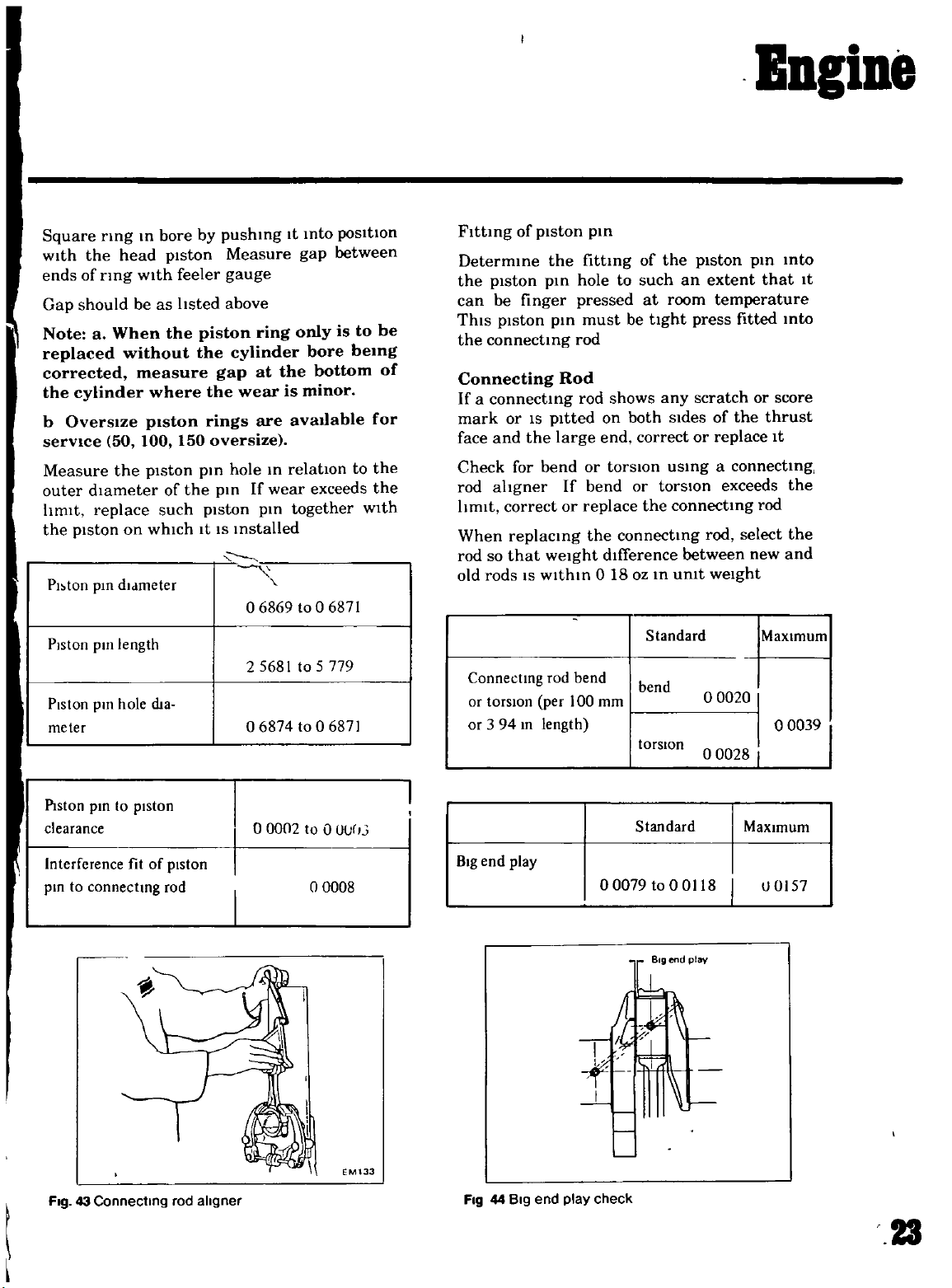

Square

wIth

ends

of

should

Gap

Note

replaced

corrected

the

cylinder

Overs1ze

b

service

Measure

outer

hmlt

the

pIston

PI

ton

PIston

Piston

meter

rmg

the

rmg

a

When

50

the

dIameter

replace

pill

pill

pm

m

bore

head

with

beashsted

without

measure

where

piston

100

piston

such

whIch

on

dldmeter

length

hole

dta

piston

feeler

the

150

of

the

by

pushing

piston

the

gap

the

rings

oversize

pm

pm

piston

It

IS

Measure

gauge

above

ring

cylinder

at

wear

are

hole

If

mstalled

06869

25681

06874

m

wear

pm

It

mto

gap

only

bore

the

minor

is

avaIlable

relation

together

to

to

to

pos1t1on

between

istobe

bottom

exceeds

06871

5779

0

6871

bemg

for

to

the

the

with

of

Flttmg

Determme

the

can

ThIS

the

of

Connecting

If

a

mark

face

Check

rod

hmlt

When

rod

old

rodsISwlthm

piston

piston

be

finger

piston

connectmg

connectmg

or

IS

and

the

for

ahgner

correct

replacing

so

that

Connectmg

or

or

tOrsIon

3

per

94

m

the

pm

pm

Rod

pitted

large

bend

If

or

weight

rod

length

pm

fittmg

hole

pressed

rnust

rod

rod

on

end

or

bend

replace

the

difference

0

bend

100

mm

of

to

such

at

be

shows

both

correct

torsIOn

or

the

connectmg

18

oz

Standard

bend

torsIOn

the

room

tight

any

Sides

usmg

torsIOn

connectmg

m

umt

piston

extent

an

press

scratch

or

rod

between

weIght

o

o 0028

pm

that

temperature

fitted

or

of

the

thrust

replace

a

connectmg

exceeds

rod

select

new

MaXimum

0020

I

mto

1t

mto

score

It

the

the

and

o

00391

PIston

clearance

Interference

pm

FIg43Connecting

pm

to

connectmg

to

fit

piston

of

piston

rod

rod

ahgner

00002

00079

check

Standard

to

0

0118

to

OOUr

j

end

BIg

o

0008

EM133

play

FIg44Big

end

play

MaXImum

I

U0157

23

BogiDe

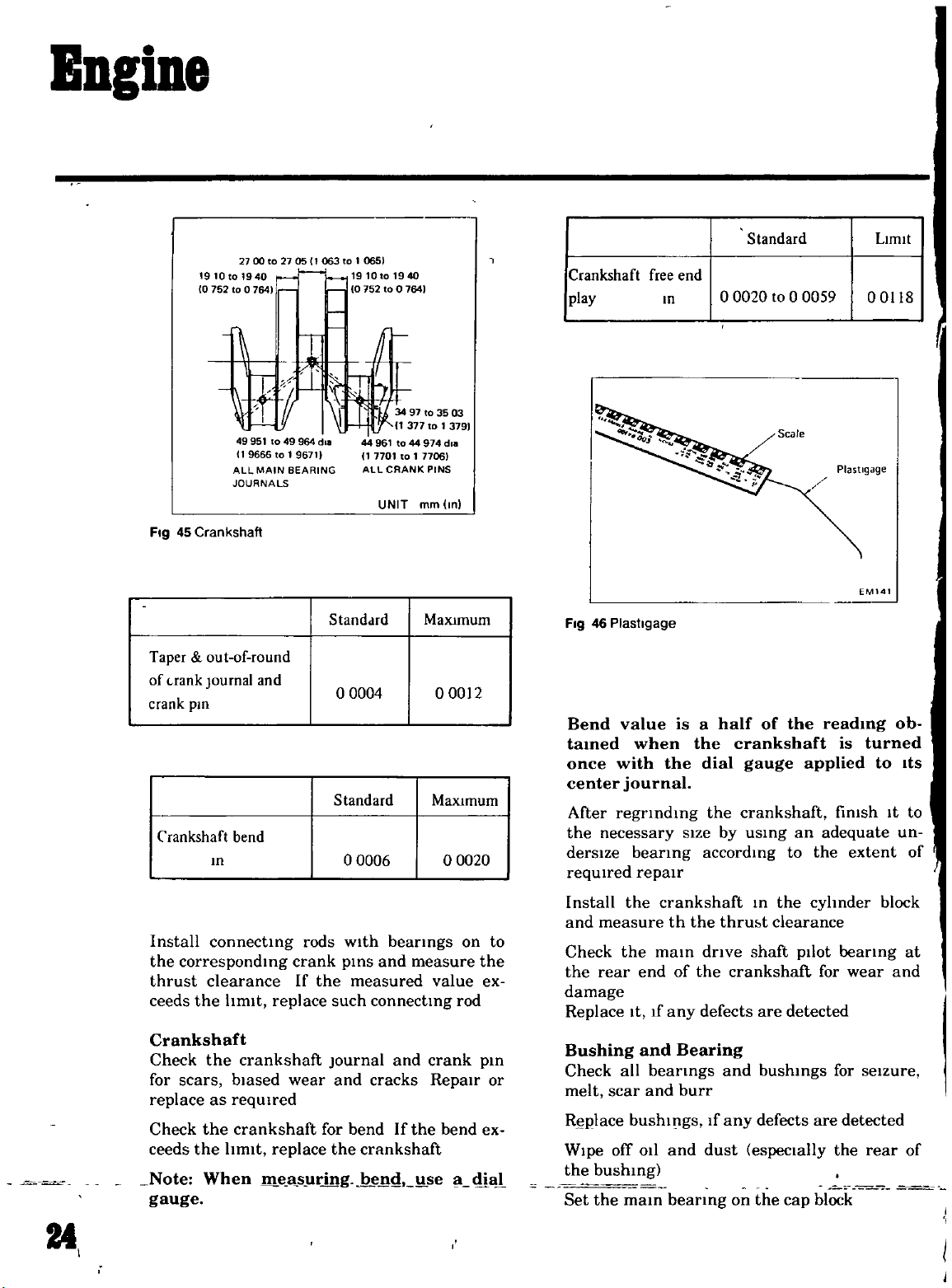

1910to1940 1910to19 40

45

Crankshaft

Fig

Taper

of

uank

crank

pm

Crankshaft

Install

the

corresponding

thrust

ceeds

the

Crankshaft

Check

for

scars

replace

Check

ceeds

the

Note

gauge

27

0752

to

49951to49 964

11

ALL

JOURNALS

out

of

Journal

bend

m

connecting

clearance

hmlt

the

crankshaft

biased

as

reqUired

the

crankshaft

hmlt

When

00to27 05

07641

9666to1

MAIN

round

and

replace

replace

me

9671

BEARING

rods

crank

If

wear

8

sJlring

0651

1063to1

0752to0

dl

44 961to44

1

7701to1

ALL

S

tanddrd

o

0004

Standard

o 0006 o

wIth

pinS

the

measured

such

connecting

Journal

and

cracks

for

bend

the

crankshaft

jJncldtSe

7641

34 97

1

377

CRANK

UNIT

bearings

and

measure

and

If

the

to

3503

to

1

974 dl

7706

PINS

mm

MaXimum

00012

MaxJmum

value

crank

Repair

bend

3791

m

0020

on

rod

the

pin

ex

dial

Llmtl

00118

EM141

Crankshaft

play

free

Standard

end

0

m

o0020

0059

to

Fig46Plasllgage

extent

wear

turned

to

block

It

ob

Its

to

un

of

at

and

Bend

tamed

once

center

After

the

derSize

reqUIred

Install

and

to

ex

Check

the

value

when

with

journal

regrInding

necessary

bearing

the

measure

the

rear

repair

end

isahalf

the

size

crankshaft

th

main

of

the

dial

the

by

according

the

thruht

drIve

the

crankshaft

of

crankshaft

gauge

crankshaft

uSing

In

clearance

shaft

the

the

an

to

pilot

readmg

is

applied

fimsh

adequate

the

cyhnder

beating

for

damage

It

1f

Replace

all

scar

bushings

off

bushing

the

main

and

bearIngs

and

011

Bushing

or

Check

melt

Rgj

Jlace

Wipe

the

Set

defects

any

Bearing

burr

and

bearing

If

dust

and

any

on

detected

are

bushings

defects

especially

the

cap

are

block

for

detected

the

seIzure

rear

of

14

Cut

and

gettmg

Install

1

them

Tlghtentng

36to43ftlb

Note

when

Remove

plastlgage

printed

Crankshaft

Sprocket

Check

Replace

a

plastIgage

place

clear

the

together

Be

the

the

tn

tooth

defective

It

m

parallel

of

the

on

cap

with

torque

sure

not

plastIgage

cap

at

Its

the

plastIgage

Sprocket

surfaces

to

the

011

hole

the

the

to

is

and

widest

sprocket

wIdth

with

assembly

specified

turn

Inserted

measure

part

envelope

and

for

flaws

the

of

the

torque

wIdth

wIth

the

bearing

crank

and

tighten

crankshaft

the

Camshaft

and

of

wears

pm

the

scale

Install

check

for

replace

Check

deViated

Check

and

If

the

the

stretch

defective

Flywheel

Check

the

flywheel

replace

Measure

surface

IfItexceeds

Check

and

with

tooth

wear

Replace

Note

to

392

Replace

F

the

camshaft

run

the

camshaft

camshaft

replace

cham

clutch

for

If

necessary

deVtat10n

If

necessary

out

at

ItS

damage

a

dial

0

0079

surfaces

the

the

for

roller

diSC

gauge

sprocket

If

sprocket

thrust

camshaft

damage

the

of

m

replace

of

ring

It

Imks

contact

and

the

gear

exceeds

deViatIOn

wear

clutch

1t

ring

m

posItion

00039

locatmg

excessive

Replace

surface

Repair

dISC

gear

at

about

Ingine

and

tn

If

It

IS

plate

wear

cham

of

the

or

contact

for

flaw

356

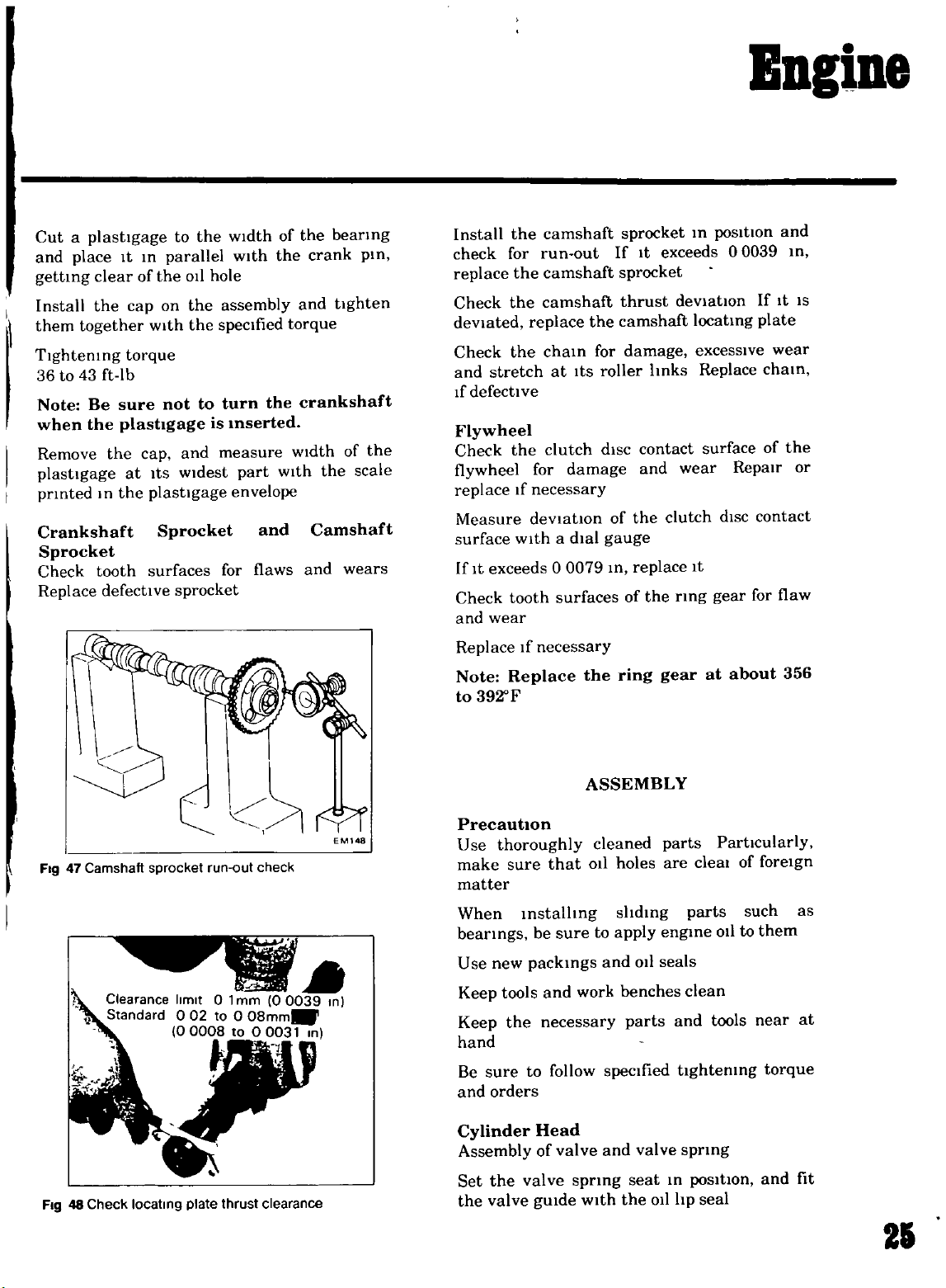

Fig

Fig

47

48

Camshaft

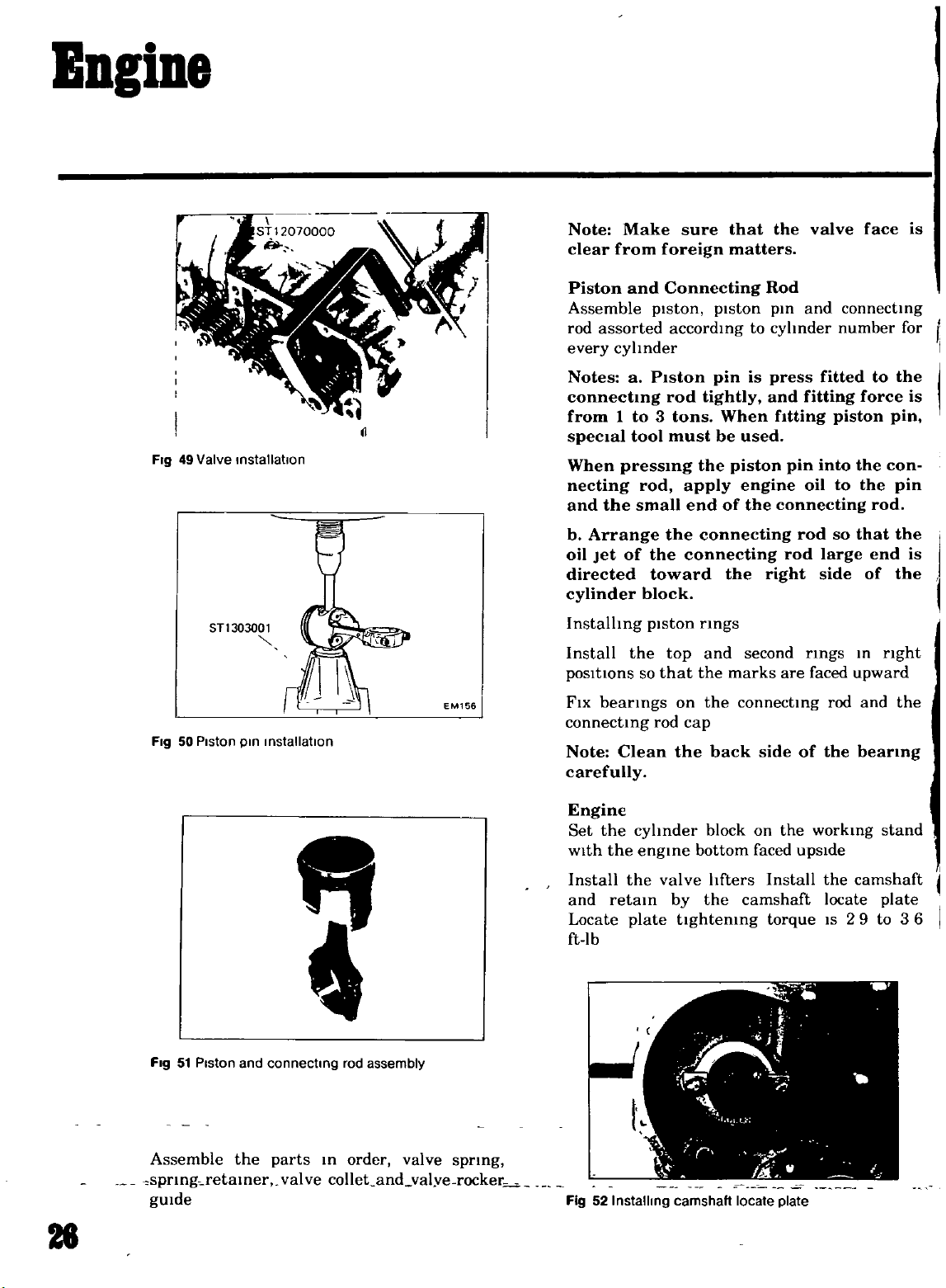

Clearance

Standard

1

Check

sprocket

locatmg

limit

0

0

02

0008

plate

t

0

to

thrust

runout

1

0

to

mm

check

08mm

0

0031

clearance

00039

ASSEMBLY

EM148

m

m

PrecautIOn

Use

thoroughly

make

matter

When

bearings

Use

new

tools

Keep

Keep

hand

Be

sure

and

orders

Cylinder

Assembly

the

Set

the

valve

sure

mstalltng

packmgs

the

to

Head

valve

gUIde

that

be

sure

and

necessary

follow

of

valve

work

sprmg

with

cleaned

011

holes

sltdmg

to

apply

and

benches

specified

and

the

011

seals

parts

valve

seat

011hpseal

parts

are

cleal

parts

engme

clean

and

tIghtemng

sprmg

m

poSItIon

PartIcularly

of

foreign

such

011tothem

tools

near

torque

and

as

at

fit

21

BDgiDe

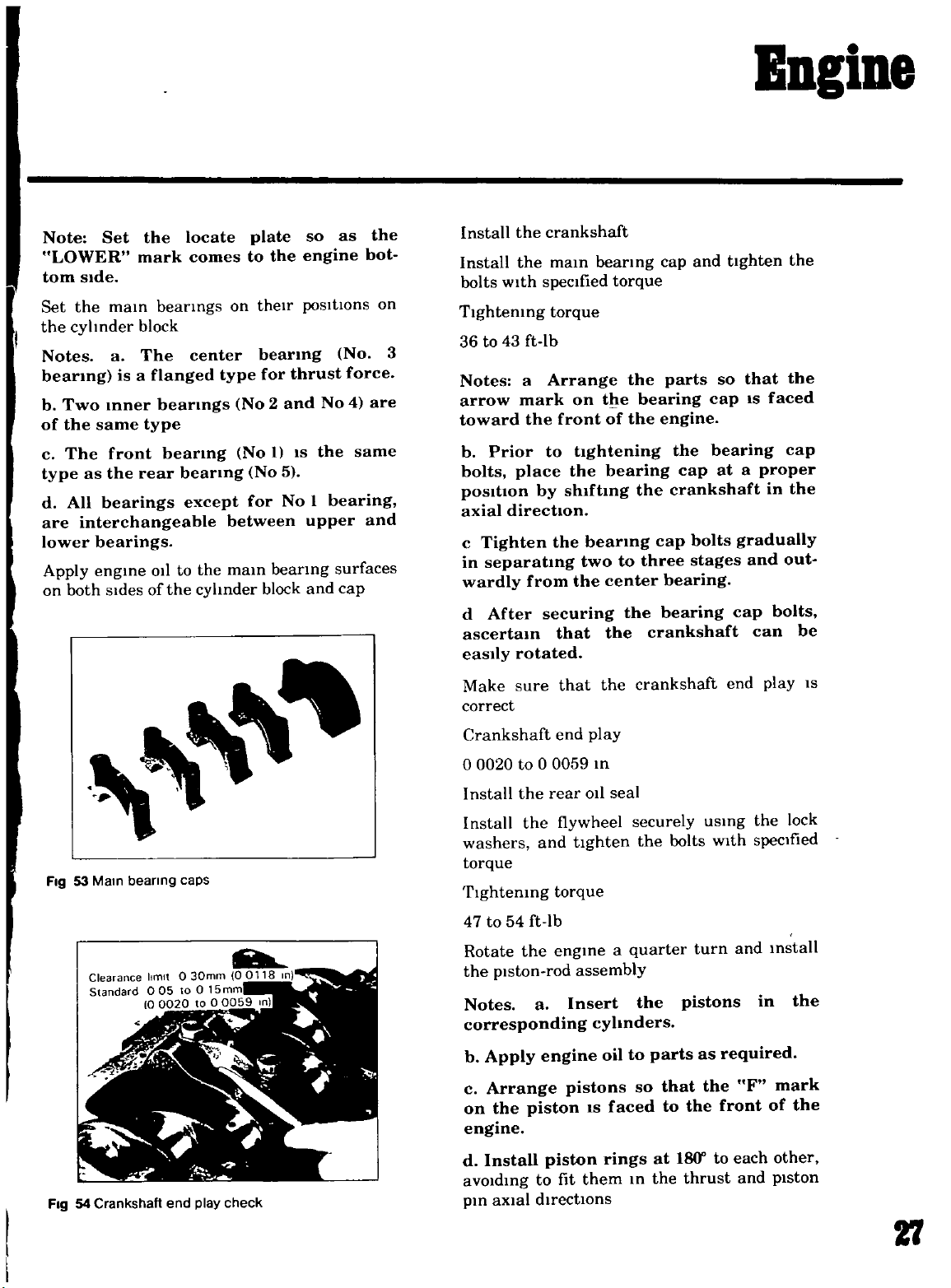

Note

clear

Make

from

sure

foreign

that

matters

the

valve

face

is

Fig

Fig

Piston

Assemble

rod

every

Notes

connectmg

from

speCIal

49

Valve

installatIon

When

necting

and

b

oil

directed

cylinder

STl

303001

InstallIng

Install

pOSItIOns

EM156

FIX

connecting

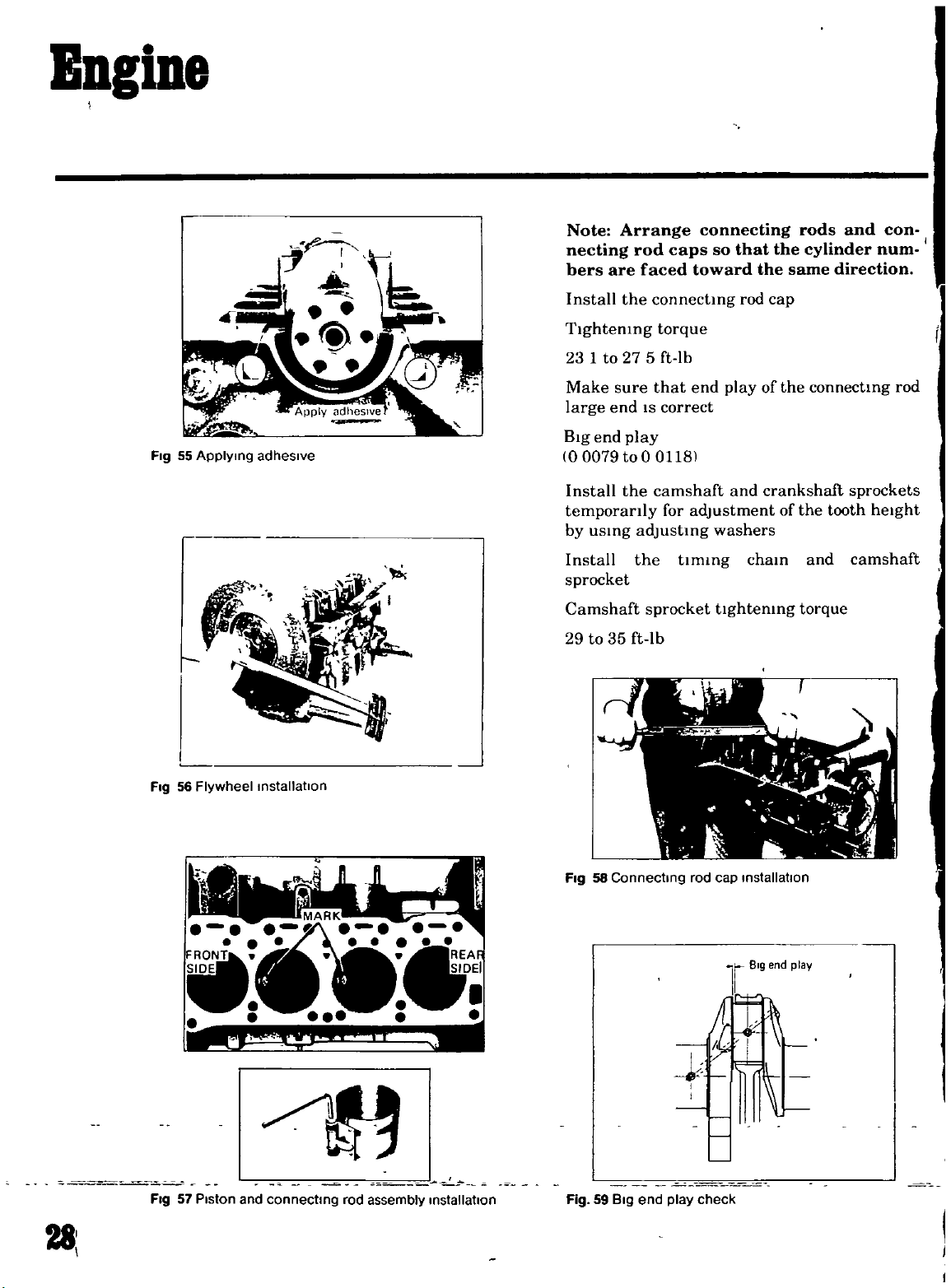

Piston

50

pin

installation

Note

and

assorted

cylInder

1

pressmg

the

Arrange

of

Jet

bearings

Clean

a

to

tool

small

the

pIston

P1ston

3

rod

the

toward

block

piston

so

rod

Connecting

piston

accordmg

pin

rod

tightly

tons

must

the

apply

end

the

connecting

connecting

rmgs

and

top

that

the

on

the

cap

the

back

Rod

to

is

and

When

be

used

piston pin

engine

of

the

the

right

second

marks

connecting

side

and

pm

cyhnder

press

fitted

fitting

fitting

into

oil

connecting

rod

rod

large

side

rings

are

faced

of

connecting

number

piston

to

so

upward

rod

the

to

force

pin

the

con

the

rod

that

end

of

In

nght

and

bearmg

for

the

is

pin

the

is

the

the

carefully

28

51

FIg

Assemble

spnng

gUIde

Piston

retamer

and

the

connecting

parts

valve collet

rod

assembly

In

order valve

and

sprmg

valverocker

Engine

the

Set

WIth

Install

and

Locate

ft

Fig52Installing

cyhnder

the

engine

the

retain

plate

lb

valve

by

tightemng

camshaft

block

bottom

hfters

the

on

faced

camshaft

locate

the

Install

torque

plate

workmg

upSIde

the

locate

IS

camshaft

2 9

stand

plate

to

3 6

Bogine

Note

LOWER

tom

side

Set

the

the

cylinder

Notes

bearmg

b

Two

of

the

c

The

as

type

d

All

are

interchangeable

lower

Apply

on

bearings

engIne

both

Set

maIn

a

is

lOner

same

front

the

bearings

sIdes

the

mark

bearIngR

block

The

a

flanged

bearmgs

type

bearmg

rear

OIltothe

of

the

locate

comes

center

bearmg

except

cyltnder

on

type

No2and

No

between

mam

plate

to

theIr

bearmg

for

No

for

bearIng

block

the

1

thrust

IS

5

No

so as

engine

posItIOns

No

No

the

I

bearing

upper

surfaces

and

cap

force

4

same

bot

are

and

the

Install

Install

bolts

on

Tlghtemng

3

36to43ftIb

Notes

arrow

toward

b

bolts

posItIon

axial

c

in

wardly

d

ascertam

easily

Make

correct

the

the

with

a

mark

Prior

place

direction

Tighten

separatmg

After

rotated

sure

crankshaft

mam

specified

torque

Arrange

the

to

by

the

from

securing

that

on

front

tightening

the

shlftmg

bearmg

two

the

that

bearmg

torque

the

the

of

the

bearing

to

center

the

the

the

crankshaft

cap

parts

bearing

engine

the

cap

three

bearing

bearing

crankshaft

and

cap

the

cap

crankshaft

bolts

stages

tighten

so

that

bearing

at

a

gradually

and

cap

end

IS

proper

can

play

faced

in

bolts

the

the

cap

the

out

be

IS

Fig

Fig

53

54

Mam

Crankshaft

bearing

end

caps

play

check

Crankshaft end

0020

nstalI

to

the

0

rear

the

and

o

I

Install

washers

torque

Tlghtemng

47to54ftIb

piston

the

rod

a

Rotate

the

Notes

corresponding

b

c

on

Apply

Arrange

the

engine

piston

engine

d

Install

avoIdIng

aXial

pIn

piston

to

directIOns

0059

011

flywheel

tighten

torque

engine

assembly

Insert

pistons

IS

fit

them

play

In

seal

securely

a

quarter

the

cyhnders

oil

to

so

faced

rings

In

the

parts

at18Y

the

that

to

bolts

turn

pistons

as

the

thrust

USIng

with

required

the

front

to

and

F

each

and

the

lock

specIfied

mstall

in

the

mark

of

the

other

pIston

27

Bagine

Fig55ApplYing

adhesive

Note

Arrange

necting

bers

are

Install the

Tlghtenmg

1

to

23

Make

large

Big

00079

Install

end

275ft

sure

end

play

to

the

temporarily

by

usmg

Install the

sprocket

Camshaft

29to35

rod

caps

faced

connectmg

torque

lb

that

correct

IS

0

0118

camshaft

for

adJustmg

tlmmg

sprocket

ft

lb

connecting

so

that

toward

rod

end

play

and

adjustment

washers

cham

tlghtemng

the

the

same

cap

of

the

crankshaft

of

rods

cylinder

direction

connectmg

the

tooth

and

torque

and

con

num

sprockets

height

camshaft

rod

L

and

installation

connecting

rod

assembly

0

installation

FIg58Connecting

59

Big

Fig

end

play

rod

check

cap

installation

FIg56Flywheel

c

57

Piston

FIg

281

dIfference

HeIght

AdJustmg

tluckness

washer

Bogine

that

the

and

located

of

camshaft

crankshaft

both

its

mating

crankshaft

and

tighten

of

43

down

at

to

the

the

58

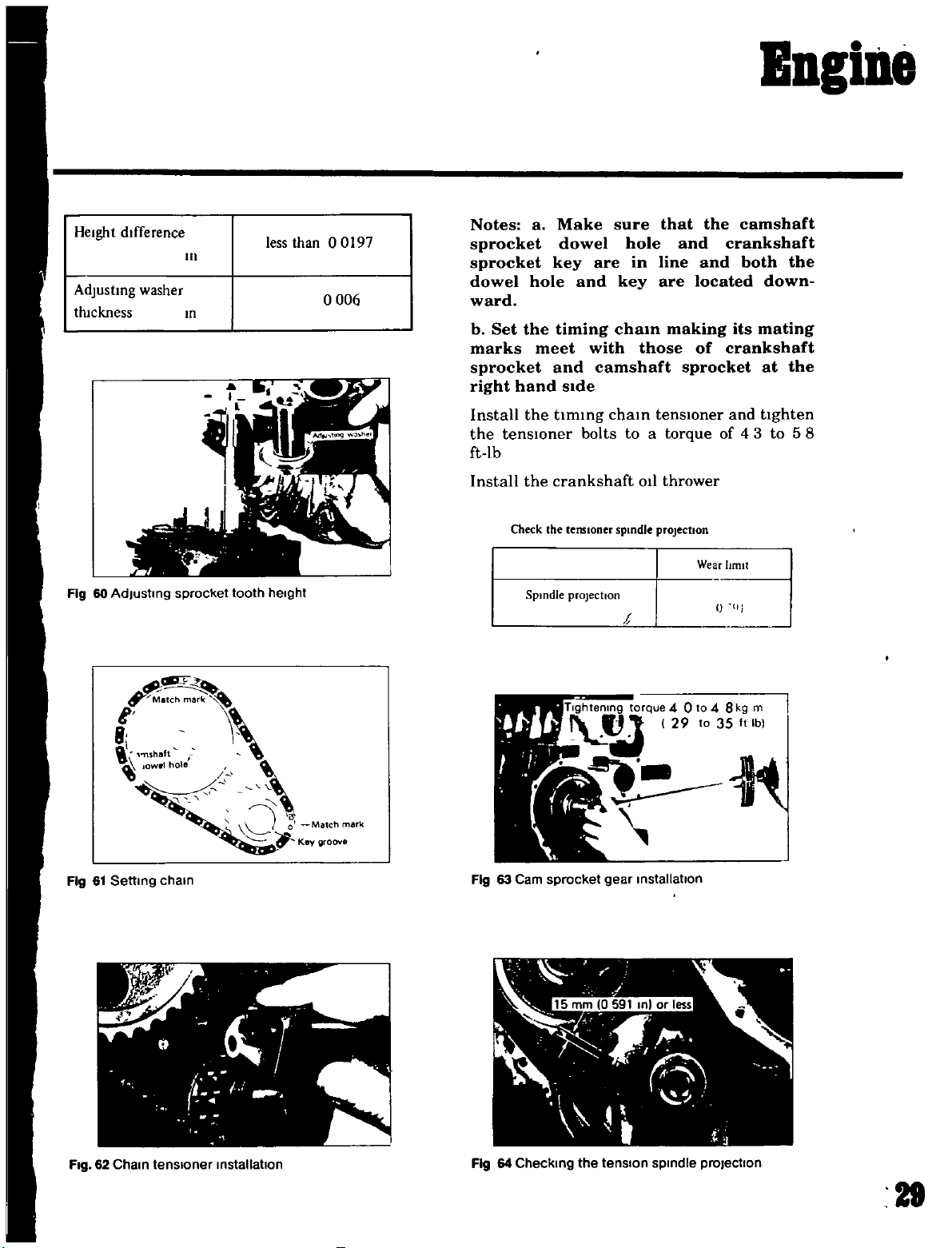

Notes

less

III

than00197

sprocket

sprocket

dowel

m

0006

ward

b

marks

sprocket

right

Install

the

ft

Install

Set

Ib

a

hole

the

hand

the

tenslOner

the

Check

key

timing

meet

and

tlmmg

crankshaft

the

Make

dowel

side

temloner

and

with

bolts

sure

are

key

cham

camshaft

cham

to

spondle

hole

in line

those

a

011

and

are

making

sprocket

tenslOner

torque

thrower

projection

60

AdJustmg

Fig

e

8

Fig61Settmg

r

f

0

Wear

limit

sprocket

tooth

heIght

Spindle

projection

t

a

IT

Match

mark

Tlsnaft

1

hol

0w

cham

0

k

Matohma

0

0

Key

groove

Fig

63

Carn

sprocket

gear

mstallatlon

Fig

tt

f

I

I

l

r

I

4

Cham

62

tensloner

Installation

Fig

64

Checkmg

the

tension

spindle

projection

21

BDgiDe

Install

front

the

Install

agent

front

cover

to

the

the

both

cover

new

011

front

011

seal

disassembled

IS

surfaces

seal

cover

to

should

of

the

front

be

applYing

the

gasket

cover

replaced

the

The

when

seahng

The

stallatIOn

and

bolt

ItS

on

cyhnder

the

other

for

the

head

bolt

center

head

one

IS for

uses

IS for

nght

two

types

center

the

other

all

Side

posItIOns

has

a

nght

I

of

in

SIde

The

mark

Cylmder

bloLk

Side

Stecl

heet

Tlghtemng

to51

36

Install

the

gasket

Apply

seahng

gasket

tlOns

of

011

pan

2 9

to

4 3

Invert

head

assembly

Note

cylinder

It

on

gasket

Tighten

peclfied

torque

ft

lb

the

ot

especIally

the

011

pan

tlghtemng

ft

lb

the

engine

Apply

block surface

and

apply

top

the

torque

strainer

agent

on

torque

and

gasket

sealing

cylinder

Sealmg

on

the

and

sealing

and

agent

both

front

Install

agent

Place

head

the

011

surfaces

and

the

overall

agent

bolts

not

pan

rear

the

required

uSing

of

the

por

cyhnder

the

gasket

to

the

to

the

v

Bolt

number

j

lor

E

u

pt

CD

65

Head

FIg

Fig66Tlghtenmg

bolt

O

segment

sequence

rmg

o

L

Dlaml

031111003189

03492to0

1

nlltilatlOn

tl

hh

f

T

3555

rJ

T

1M

ot

rhJ

30

Cylinder

head

Side

Jomt

sheet

Remarks

Install

Be

careful

because

WIth

WIthout

thIS

sealing

J

applymg

not

SIde

agent

to

has

damage

sealing

the

prevIOusly

agent

push

been

rod

Side

provIded

4

cylmder

head

h

block

block

ad

gasket

CYlmder

Cylinder

ItI

o

rtng

mserted

To

be

mto

hole

Cylinder

m

Loading...

Loading...