Page 1

STARTING & CHARGING SYSTEM

GI

MA

CONTENTS

PRECAUTIONS ...............................................................2

Supplemental Restraint System (SRS) ″AIR

BAG″ and ″SEAT BELT PRE-TENSIONER″...............2

Wiring Diagrams and Trouble Diagnosis.....................2

PREPARATION ...............................................................3

Special Service Tool ....................................................3

BATTERY.........................................................................4

How to Handle Battery ................................................4

METHODS OF PREVENTING OVER-DISCHARGE

CHECKING ELECTROLYTE LEVEL

SPECIFIC GRAVITY CHECK

CHARGING THE BATTERY

Trouble Diagnoses with Battery/Starting/Charging

System Tester ..............................................................7

DIAGNOSTIC RESULT ITEM CHART

STARTING SYSTEM.....................................................10

System Description....................................................10

M/T MODELS

A/T MODELS

Wiring Diagram - START -.........................................11

M/T MODELS

A/T MODELS

Trouble Diagnoses with Battery/Starting/Charging

System Tester ............................................................13

DIAGNOSTIC RESULT ITEM CHART

WORK FLOW

DIAGNOSTIC PROCEDURE 1

DIAGNOSTIC PROCEDURE 2

..........................................................10

...........................................................10

..........................................................11

...........................................................12

..........................................................15

........................................6

............................4

......................................5

..........................9

........................14

..................................16

..................................18

......4

SECTION

MINIMUM SPECIFICATION OF CRANKING

VOLTAGE REFERENCING COOLANT

TEMPERATURE

Construction...............................................................19

Removal and Installation...........................................20

REMOVAL

INSTALLATION

Pinion/Clutch Check ..................................................21

CHARGING SYSTEM....................................................22

System Description....................................................22

Wiring Diagram - CHARGE -.....................................23

Trouble Diagnoses with Battery/Starting/Charging

System Tester ............................................................24

DIAGNOSTIC RESULT ITEM CHART

WORK FLOW

DIAGNOSTIC PROCEDURE 1

DIAGNOSTIC PROCEDURE 2

DIAGNOSTIC PROCEDURE 3

MALFUNCTION INDICATOR

Construction...............................................................31

Removal and Installation...........................................31

REMOVAL

INSTALLATION

SERVICE DATA AND SPECIFICATIONS (SDS).........32

Battery........................................................................32

Starter........................................................................32

Alternator ...................................................................32

......................................................19

...............................................................20

........................................................20

..........................................................27

...............................................................31

........................................................31

SC

........................26

..................................28

..................................29

..................................30

....................................30

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EL

IDX

Page 2

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Supplemental Restraint System (SRS) “AIR

BAG” and “SEAT BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELTPRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS system

uses the seat belt switches to determine the front air bag deployment, and may only deploy one front air bag,

depending on the severity of a collision and whether the front occupants are belted or unbelted. The SRS

system composition which is available to NISSAN MODELA33 is as follows:

I For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steering wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, crash zone sensor, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring

harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harness connector.

NFSC0001

Wiring Diagrams and Trouble Diagnosis

When you read wiring diagrams, refer to the following:

I GI-9, “HOW TO READ WIRING DIAGRAMS”

I EL-11, “POWER SUPPLY ROUTING” for power distribution circuit

When you perform trouble diagnosis, refer to the following:

I GI-35, “HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES”

I GI-24, “HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT”

NFSC0002

SC-2

Page 3

PREPARATION

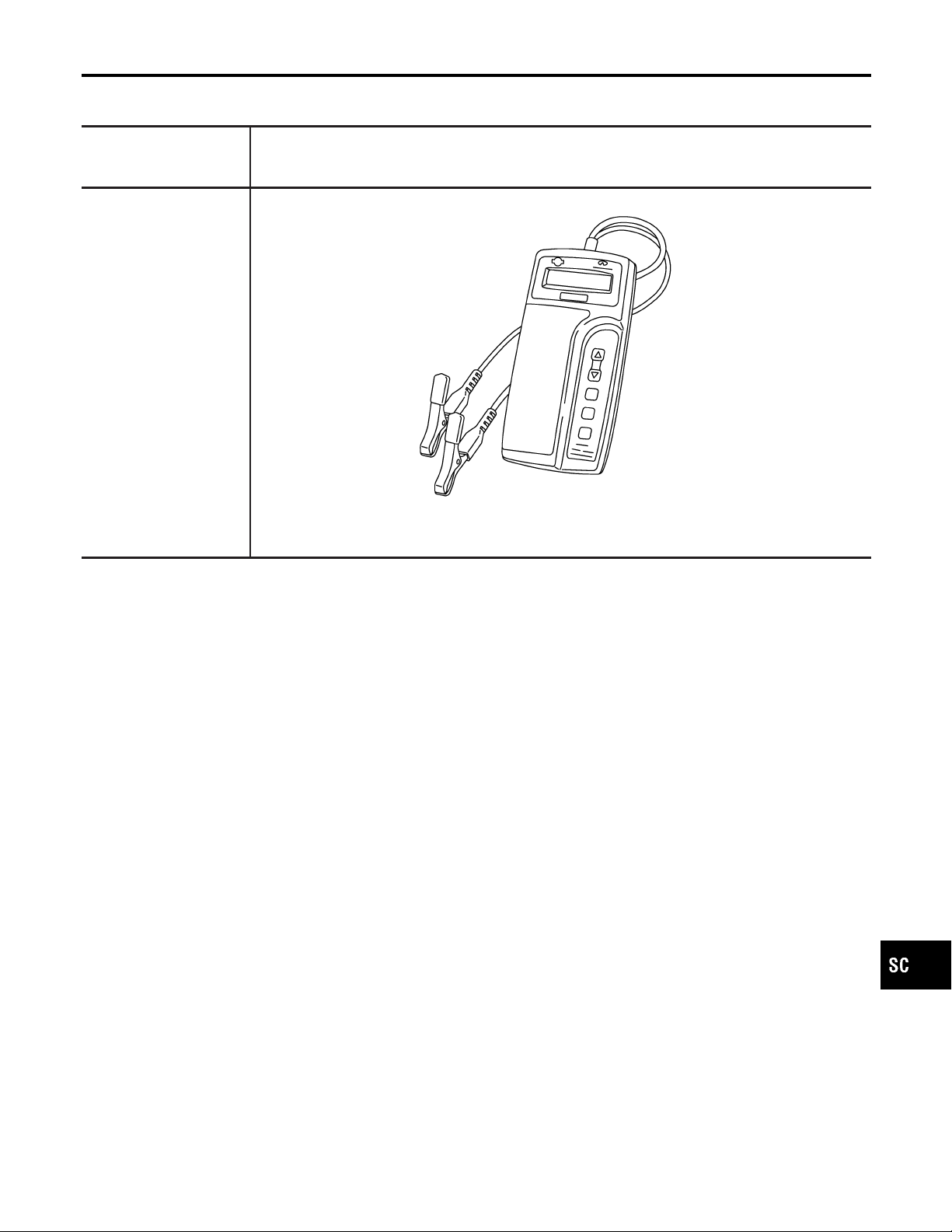

Special Service Tool

Special Service Tool

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

—

(J-44373 Model 620)

Battery/Starting/Charging

system tester

Description

SEL403X

NFSC0017

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EL

SC-3

IDX

Page 4

How to Handle Battery

BATTERY

MEL040F

How to Handle Battery

NFSC0003

CAUTION:

I If it becomes necessary to start the engine with a booster

battery and jumper cables, use a 12-volt booster battery.

I After connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

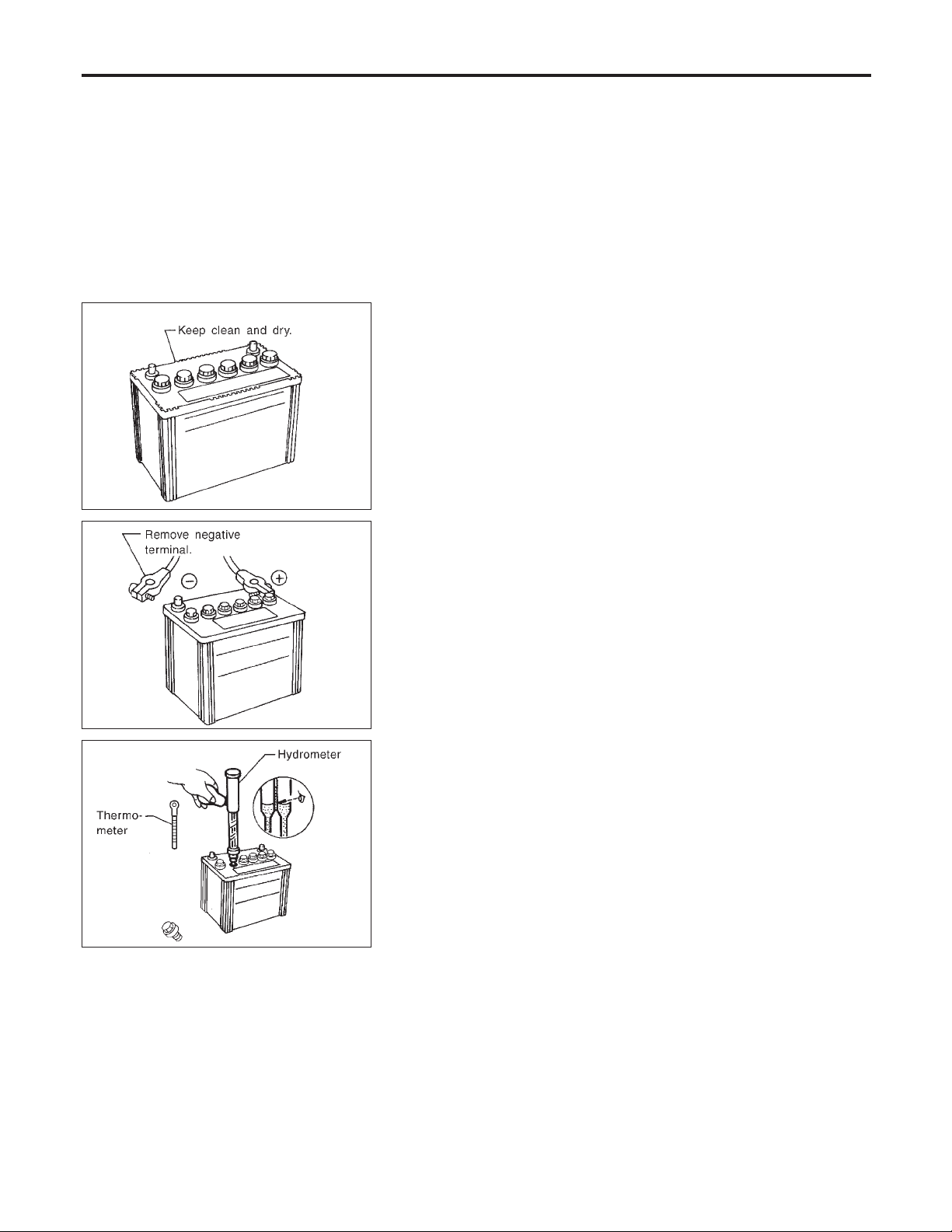

METHODS OF PREVENTING OVER-DISCHARGE

NFSC0003S01

The following precautions must be taken to prevent over-discharging a battery.

I The battery surface (particularly its top) should always be kept

clean and dry.

I The terminal connections should be clean and tight.

I At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance-free”.

I When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle

has an extended storage switch, turn it off.)

MEL041F

MEL042F

I Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

NFSC0003S02

WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub your eyes until you have thoroughly washed your

hands. If acid contacts eyes, skin or clothing, immediately

flush with water for 15 minutes and seek medical attention.

SC-4

Page 5

BATTERY

How to Handle Battery (Cont’d)

I Remove the cell plug using a suitable tool.

I Add distilled water up to the MAX level.

GI

MA

EM

MEL043F

SEL709EA

MEL042FA

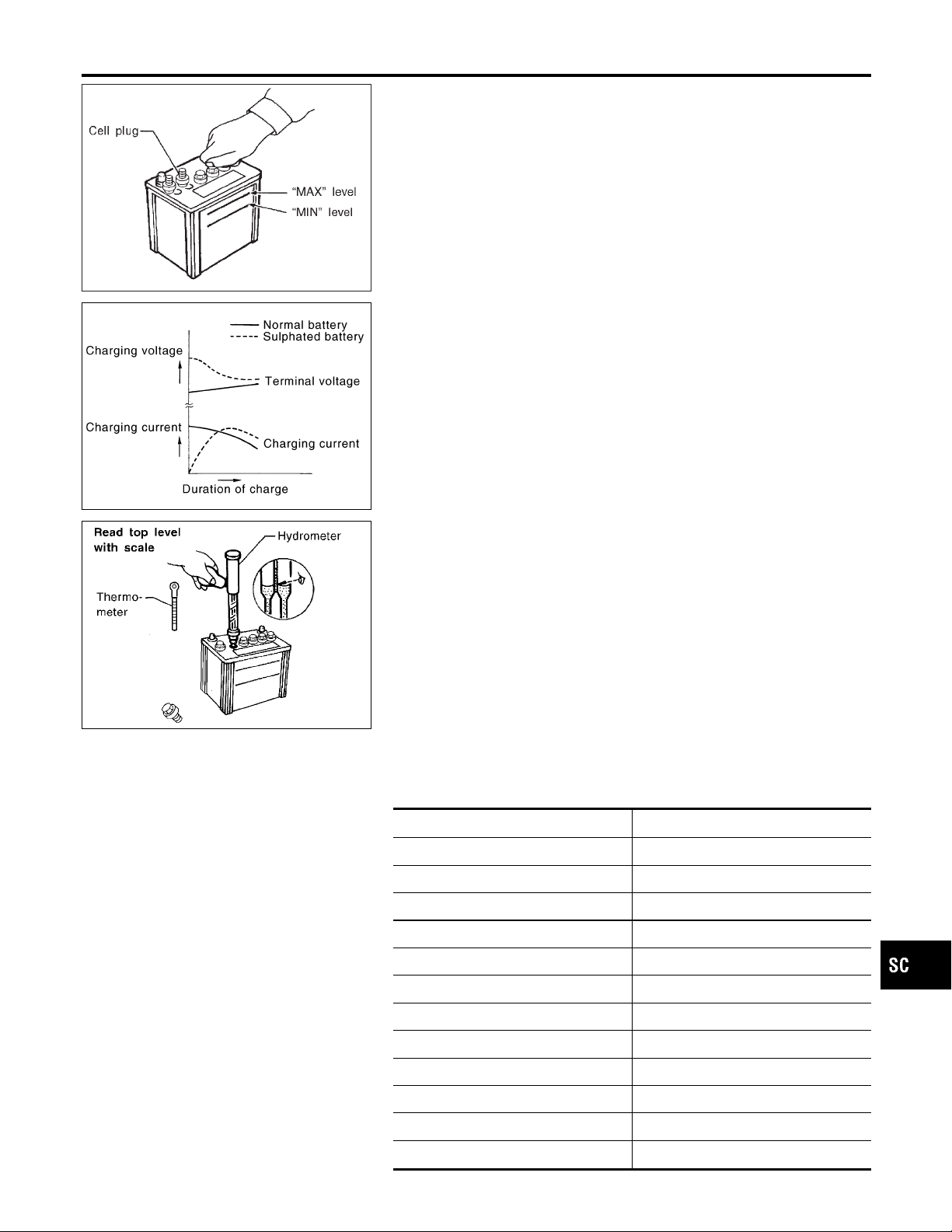

Sulphation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been “sulphated”, note its voltage and current when charging it. As shown in the figure, less

current and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into service by means of a long, slow charge, 12 hours or more, followed by a battery capacity test.

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

2. Use the chart below to correct your hydrometer reading

according to electrolyte temperature.

NFSC0003S0201

NFSC0003S03

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

Hydrometer Temperature Correction

Battery electrolyte temperature °C (°F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) −0.004

16 (60) −0.008

10 (50) −0.012

NFSC0003S0301

SC-5

RS

BT

HA

EL

IDX

Page 6

How to Handle Battery (Cont’d)

BATTERY

Battery electrolyte temperature °C (°F) Add to specific gravity reading

4 (40) −0.016

−1 (30) −0.020

−7 (20) −0.024

−12 (10) −0.028

−18 (0) −0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

CHARGING THE BATTERY

NFSC0003S04

CAUTION:

I Do not “quick charge” a fully discharged battery.

I Keep the battery away from open flame while it is being

charged.

I When connecting the charger,connect the leads first, then

turn on the charger. Do not turn on the charger first, as

this may cause a spark.

I If battery electrolyte temperature rises above 55°C (131°F),

stop charging. Always charge battery at a temperature

below 55°C (131°F).

Charging Rates

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

NFSC0003S0401

Do not charge at more than 50 ampere rate.

NOTE:

The ammeter reading on your battery charger will automatically

decrease as the battery charges. This indicates that the voltage of

the battery is increasing normally as the state of charge improves.

The charging amps indicated above refer to initial charge rate.

I If, after charging, the specific gravity of any two cells varies

more than .050, the battery should be replaced.

SC-6

Page 7

BATTERY

Trouble Diagnoses with Battery/Starting/Charging System Tester

Trouble Diagnoses with

Battery/Starting/Charging System Tester

CAUTION:

When working with batteries, always wear appropriate eye

protection.

NOTE:

I To ensure a complete and thorough diagnosis, the battery,

starter and alternator test segments must be done as a set

from start to finish.

I If battery surface charge is detected while testing, the tester

will prompt you to turn on the headlights to remove the surface

charge.

I If necessary, the tester will prompt you to determine if the bat-

tery temperature is above or below 0°C (32°F). Choose the

appropriate selection by pressing the up or down arrow button,

then press “ENTER” to make the selection.

NFSC0018

GI

MA

EM

LC

EC

FE

CL

SEL404X

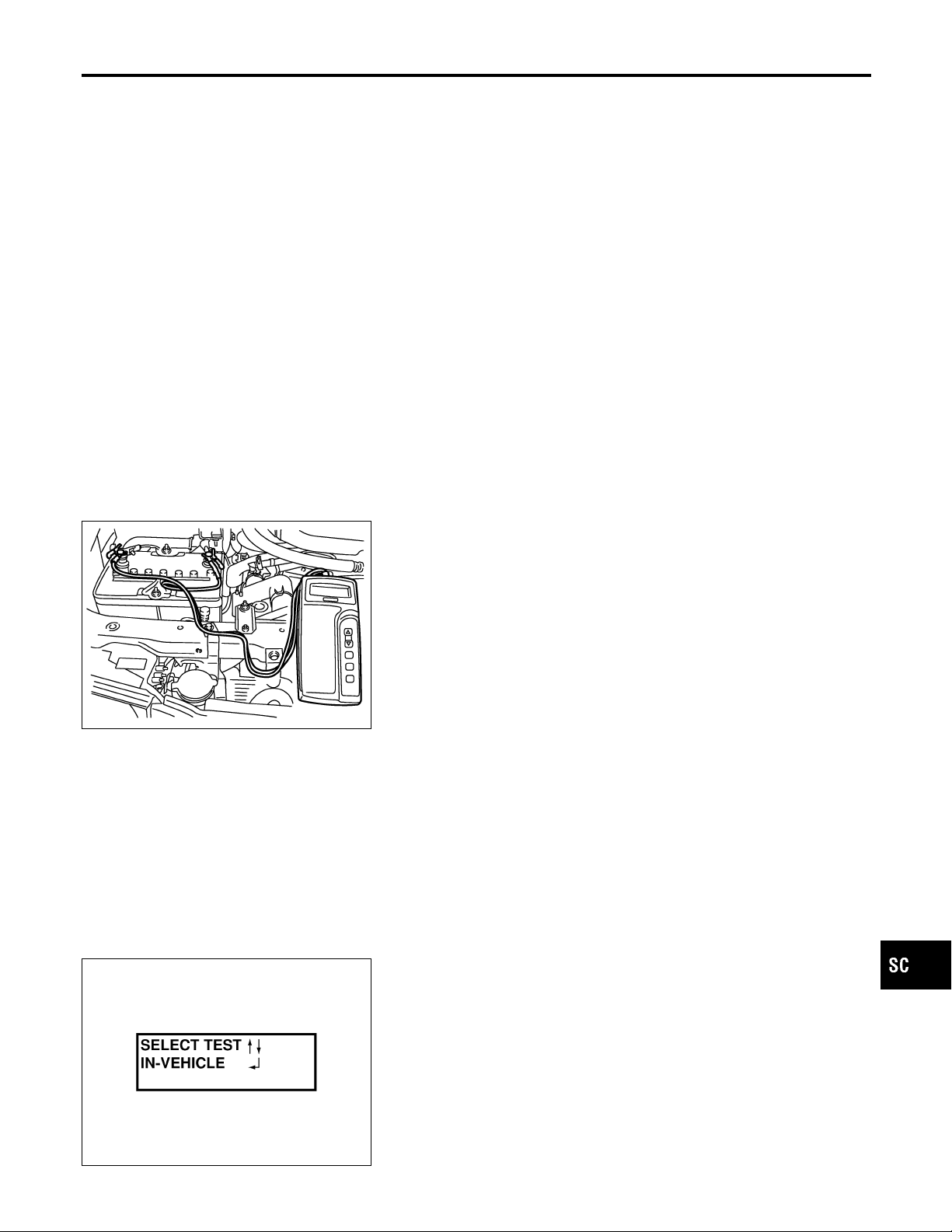

1. Turn off all loads on the vehicle electrical system. Clean or

repair as necessary.

2. Visually inspect the battery, battery terminals and cable ends

with ignition switch in “OFF” position.

NOTE:

The contact surface between the battery terminals, cable ends and

tester leads must be clean for a valid test. A poor connection will

prevent testing and a “CHECK CONNECTION” message will

appear during the test procedures. If this occurs, clean the battery

post and terminals, reconnect them and restart the test.

3. Connect the red tester lead clamp to the positive battery

terminal, and the black to the negative terminal.

MT

AT

AX

SU

BR

ST

RS

BT

HA

SEL405X

4. The tester will turn on automatically. Using the arrow keys,

select “IN VEHICLE” on the tester and then pressthe “ENTER”

key.

EL

IDX

SC-7

Page 8

BATTERY

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

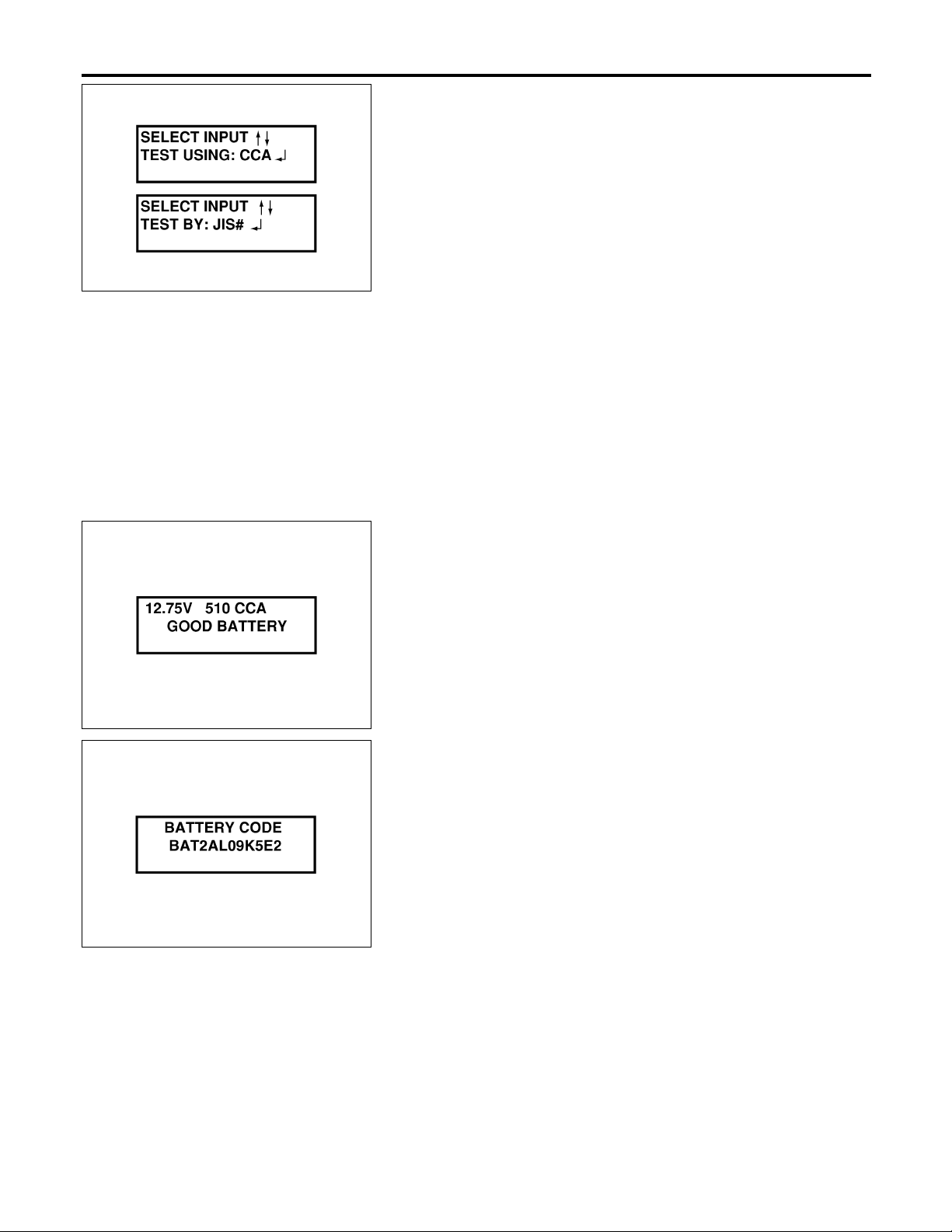

5. Locate the battery type and rating stamped or written on the

top case of the battery to be tested.

NOTE:

The battery type and rating will have either of the following.

CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

JIS: Japanese Industrial Standard.

Battery is stamped with a number such as:

80D26L: 80 (rank of output), D (physical size-depth), 26 (width

in cm). The last character L(post configuration) is not input into

the tester.

SEL406X

The tester requires the rating for the battery be entered exactly

as it is written or stamped on the battery.Do not attempt a CCA

conversion for JIS stamped batteries. JIS must be input

directly.

6. Using the arrow and “ENTER” keys alternately, select the battery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Only use

CCA or JIS.

SEL407X

SEL576X

7. Press “ENTER” to begin the test. Diagnosis results are displayed on the tester. Refer to “DIAGNOSTIC RESULT ITEM

CHART”, SC-9.

8. Press “ENTER”, then test output code is displayed. Record the

test output code on the repair order.

9. Toggle back to the “DIAGNOSTIC SCREEN” for test results.

NOTE:

I If necessary, the tester will ask the user to determine if the

battery has just been charged. Choose the appropriate selection by pressing the up or down arrow button and then press

the “ENTER” button to make the selection.

I When testing a battery installed in a vehicle that has recently

been driven, select “BEFORE CHANGE”.

I If the battery has just been slow charged due to a “CHARGE

& RETEST” decision by the tester, and the tester asks the user

“BEFORE CHARGE/AFTER CHARGE”, select “AFTER

CHARGE”.

SC-8

Page 9

BATTERY

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

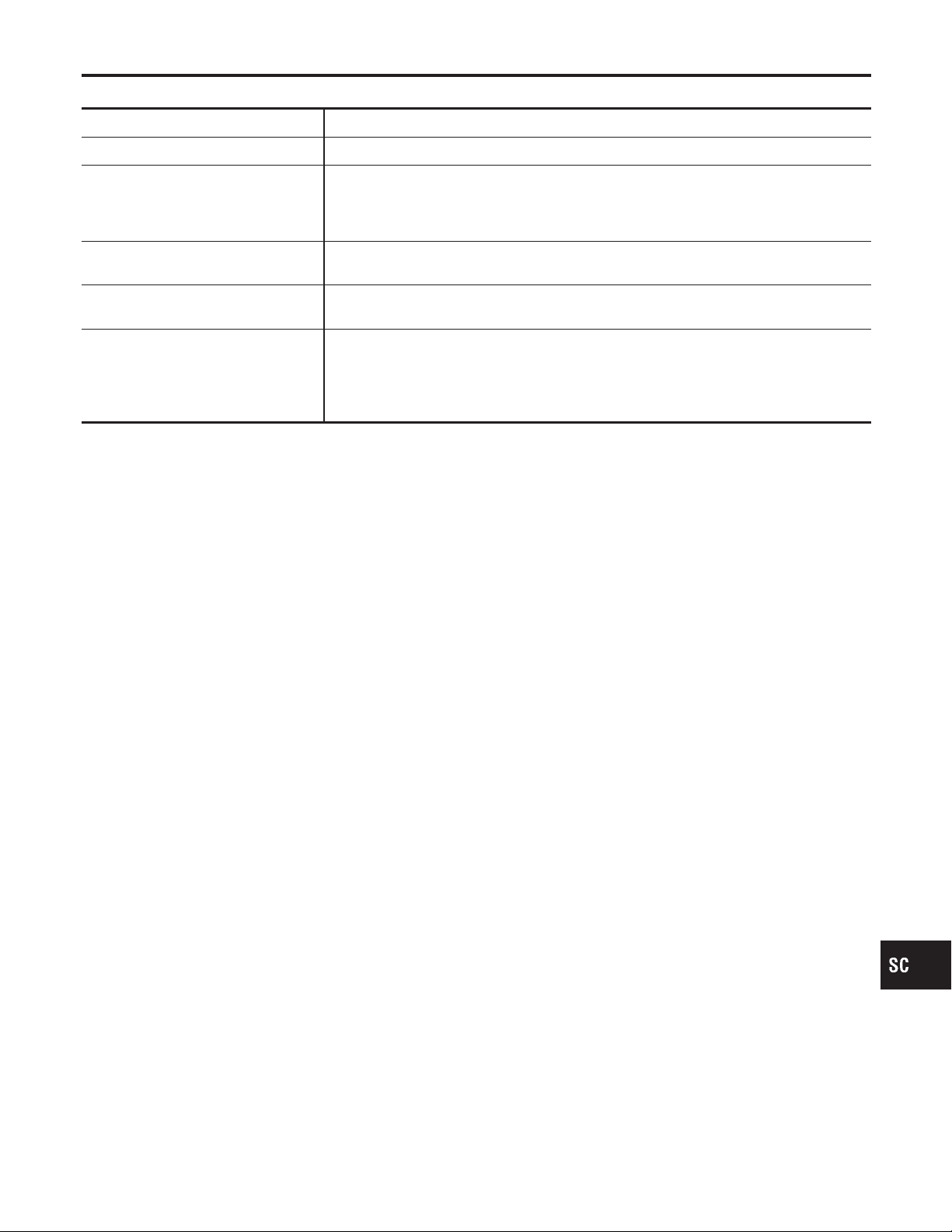

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

GOOD BATTERY Battery is OK, go to “Trouble Diagnoses”, “STARTING SYSTEM”. Refer to SC-13.

Replace battery.

REPLACE BATTERY

BAD CELL-REPLACE

GOOD-RECHARGE

CHARGE & RETEST

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery test again with Battery/Starting/Charging system tester. If second test result is

“Replace Battery”, then do so. Perform battery test again to confirm repair.

Replace the battery. Perform battery test again with Battery/Starting/Charging system

tester to confirm repair.

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.)

Perform battery test again with Battery/Starting/Charging system tester.

Perform the slow battery charging. (Initial rate of charge is 10A for 12 hours.)

Perform battery test again with Battery/Starting/Charging system tester to confirm repair.

NOTE:

If the tester asks the user “BEFORE CHARGE/AFTER CHARGE”, select “AFTER

CHARGE”.

NFSC0018S01

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC-9

EL

IDX

Page 10

System Description

STARTING SYSTEM

System Description

M/T MODELS

NFSC0021

NFSC0021S01

Power is supplied at all times

I through 40A fusible link (letter C, located in the fuse and fusible link box)

I to ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

I through terminal 5 of the ignition switch

I to clutch interlock relay terminal 5.

With the ignition switch in the ON or START position, power is supplied

I through 15A fuse [No. 20, located in the fuse block (J/B)]

I to clutch interlock relay terminal 1.

When the clutch pedal is depressed, ground is supplied to clutch interlock relay terminal 2 through the clutch

interlock switch and body grounds E11, E22 and E53.

The clutch interlock relay is energized and power is supplied

I from terminal 3 of the clutch interlock relay

I to terminal 2 of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

A/T MODELS

NFSC0021S02

Power is supplied at all times

I through 40A fusible link (letter C, located in the fuse and fusible link box)

I to ignition switch terminal 1.

With the ignition switch in the ON or START position, power is supplied

I through 15A fuse [No. 20, located in the fuse block (J/B)]

I to park/neutral position relay terminal 1.

Also, with the ignition switch in the START position, power is supplied

I from ignition switch terminal 5

I to park/neutral position relay terminal 5.

Ground is supplied, with the selector lever in the P or N position

I to park/neutral position relay terminal 2

I through park/neutral position switch.

The park/neutral position relay is energized and power is supplied

I from ignition switch terminal 5

I through park/neutral position relay terminals 5 and 3

I to terminal 2 of the starter motor windings.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

SC-10

Page 11

STARTING SYSTEM

Wiring Diagram — START —

M/T MODELS

Wiring Diagram — START —

NFSC0005

NFSC0005S03

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC-11

EL

IDX

MEL434R

Page 12

Wiring Diagram — START — (Cont’d)

STARTING SYSTEM

A/T MODELS

NFSC0005S04

SC-12

MEL835P

Page 13

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester

Trouble Diagnoses with

Battery/Starting/Charging System Tester

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter

and alternator test segments must be done as a set from start to

finish.

1. Turn off all loads on the vehicle electrical system.

2. Perform battery test with Battery/Starting/Charging system

tester. Refer to SC-7.

3. Press “ENTER” to begin the starting system test.

NFSC0019

GI

MA

EM

LC

EC

FE

CL

SEL408X

SEL409X

SEL410X

4. Start the engine.

5. Diagnosis result is displayed on the tester. Refer to “DIAGNOSTIC RESULT ITEM CHART”, SC-14.

NOTE:

I If the starter performs normally but the engine does not start,

perform engine diagnosis.

I For intermittent “NO CRANK” or “NO STARTER OPERATION”

incidents, go to DIAGNOSTIC PROCEDURE 2.

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC-13

EL

IDX

Page 14

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

CRANKING VOLTAGE NORMAL Go to “WORK FLOW”, SC-15.

CRANKING VOLTAGE LOW Go to “WORK FLOW”, SC-15.

CHARGE BATTERY

REPLACE BATTERY

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.)

Perform battery test again with Battery/Starting/Charging system tester. Refer to SC-7.

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery test again with Battery/Starting/Charging system tester. Refer to SC-7. If second test

result is “REPLACE BATTERY”, then do so. Perform battery test again to confirm repair.

NFSC0019S01

SC-14

Page 15

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

WORK FLOW

NFSC0019S02

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

*1 SC-7

*2 SC-19

*3 SC-16 *4 SC-18

SC-15

SEL411X

EL

IDX

Page 16

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

DIAGNOSTIC PROCEDURE 1

Check “B” Terminal Circuit

1 CHECK POWER SUPPLY FOR STARTER MOTOR “B” TERMINAL

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition OFF.

4. Check that the starter motor connector E202 terminal 1 (B/R) connection is clean and tight.

5. Check voltage between starter motor B terminal E202 terminal 1 (B/R) and ground using a digital circuit tester.

OK or NG

OK © GO TO 2.

NG © Check harness between the battery and the starter motor for open circuit.

NFSC0019S03

NFSC0019S0301

SEL961XA

2 CHECK BATTERY CABLE CONNECTION QUALITY (VOLTAGE DROP TEST)

1. Check voltage between starter motor B terminal E202 terminal 1 (B/R) and battery positive terminal using a digital cir-

cuit tester.

SEL962XA

OK or NG

OK © GO TO 3.

NG © Check harness between the battery and the starter motor for poor continuity.

SC-16

Page 17

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

3 CHECK STARTER MOTOR GROUND CIRCUIT (VOLTAGE DROP TEST)

1. Check voltage between starter motor case and battery negative terminal using a digital circuit tester.

GI

MA

EM

LC

EC

FE

CL

SEL372Y

OK or NG

OK © Starter motor “B” terminal circuit is OK. Further inspection necessary. Refer to “WORK

FLOW”, SC-15.

NG © Check the starter motor case and ground for poor continuity.

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC-17

EL

IDX

Page 18

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

DIAGNOSTIC PROCEDURE 2

Check “S” Terminal Circuit

1 CHECK POWER SUPPLY FOR STARTER MOTOR “S” TERMINAL

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition OFF.

4. Disconnect starter motor connector.

5. Check voltage between starter motor connector E203 terminal 2 (B/R) (M/T models) or E201 terminal 2 (B/R) (A/T

models) and ground using a digital circuit tester.

OK or NG

OK © GO TO 2.

NG © Check the following.

I 40A fusible link (letter C, located in fuse and fusible link box)

I Park/neutral position relay

I Harness for open or short

NFSC0019S0401

=NFSC0019S04

SEL373Y

2 CHECK “S” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

1. Connect starter motor connector.

2. Check voltage between starter motor connector E203 terminal 2 (B/R) (M/T models) or E201 terminal 2 (B/R) (A/T

models) and battery positive terminal using a digital circuit tester.

SEL973Y

OK or NG

OK © Starter motor “S” terminal circuit is OK. Further inspection necessary. Refer to “WORK

FLOW”, SC-15.

NG © Check harness between the battery and the starter motor “S” terminal for poor continuity.

SC-18

Page 19

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERATURE

Engine coolant temperature Voltage V

=NFSC0019S05

GI

−30°C to −20°C (−22°F to −4°F) 8.2

−19°C to −10°C (−2°F to 14°F) 8.7

−9°C to 0°C (16°F to 32°F) 9.1

More than 1°C (More than 34°F) 9.4

Construction

MA

EM

LC

NFSC0006

EC

FE

CL

MT

AT

AX

MEL208O

SU

BR

ST

RS

BT

HA

EL

IDX

SC-19

Page 20

Construction (Cont’d)

STARTING SYSTEM

SEL457T

Removal and Installation

REMOVAL

1. Remove air duct assembly.

2. Remove harness protector from engine room harness.

3. Disconnect starter harness.

4. Remove starter bolts (two).

5. Remove starter.

INSTALLATION

To install, reverse the removal procedure.

MEL209O

NFSC0007

NFSC0007S01

NFSC0007S02

SEL458T

SC-20

Page 21

STARTING SYSTEM

Pinion/Clutch Check

Pinion/Clutch Check

1. Inspect pinion teeth.

I Replace pinion if teeth are worn or damaged. (Also check

condition of ring gear teeth.)

2. Inspect reduction gear teeth.

I Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

I If it locks or rotates in both directions, or unusual resistance is

evident, replace.

NFSC0008

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC-21

EL

IDX

Page 22

System Description

CHARGING SYSTEM

System Description

The alternator provides DC voltage to operate the vehicle’s electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 3 (S) through:

I 120A fusible link (letter A, located in the fuse and fusible link box), and

I 10A fuse (No. 70, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle’s electrical system. Output voltage

is controlled by the IC regulator at terminal 3 (S) detecting the input voltage. The charging circuit is protected

by the 120A fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

I through 10A fuse [No. 30, located in the fuse block (J/B)]

I to combination meter terminal 24 for the charge warning lamp.

Ground is supplied to terminal 68 of the combination meter through terminal 2 (L) of the alternator. With power

and ground supplied, the charge warning lamp will illuminate. When the alternator is providing sufficient voltage with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

NFSC0009

SC-22

Page 23

CHARGING SYSTEM

Wiring Diagram — CHARGE —

Wiring Diagram — CHARGE —

NFSC0010

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC-23

EL

IDX

MEL836P

Page 24

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester

Trouble Diagnoses with

Battery/Starting/Charging System Tester

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter

and alternator test segments must be done as a set from start to

finish.

1. Turn off all loads on the vehicle electrical system.

2. Perform battery and starting system test with Battery/Starting/

Charging system tester.

3. Press “ENTER” to begin the charging system test.

4. Start engine.

NFSC0020

SEL417X

SEL418X

5. Press “ENTER” until “LOADS OFF REV ENGINE 5 SEC” is

displayed.

6. Raise and hold the engine speed at 1,500 to 2,000 rpm for

about 5 seconds, then return to the engine to idle.

Once the increase in engine rpm is detected, press “ENTER”

to continue.

NOTE:

I If after 30 seconds an increase in engine idle speed is not

detected, “RPM NOT DETECTED” will display.

I Some engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect this

without any other action being taken. If this occurs, continue on

with the testing process. The final results will not be affected.

SEL419X

7. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

8. When complete, the tester will prompt you to turn on the following electrical loads.

I Heater fun set to highest. Do not run the A/C or windshield

defroster.

I Headlamp high beam

I Rear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads.

SC-24

Page 25

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

9. Press “ENTER” to continue.

GI

MA

EM

SEL420X

SEL421X

SEL422X

10. Raise and hold the engine speed at 1,500 to 2,000 rpm for

about 5 seconds, then return the engine to idle. Once the

increase in engine rpm is detected, press “ENTER” to continue.

NOTE:

If after 30 seconds an increase in engine idle speed is not detected,

“RPM NOT DETECTED” will be displayed. Press “ENTER” to

restart the test.

11. Diagnostic result is displayed on the tester. Refer to “DIAGNOSTIC RESULT ITEM CHART”, SC-26.

12. Press “ENTER” then test output code is displayed. Record the

test output code on the repair order.

13. Toggle back to the “DIAGNOSTIC SCREEN” for test results.

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

SEL577X

BT

HA

EL

IDX

SC-25

Page 26

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

CHARGING SYSTEM NORMAL Charging system is normal and will also show DIODE RIPPLE test result.

NO CHARGING VOLTAGE Go to “WORK FLOW”, SC-27.

LOW CHARGING VOLTAGE Go to “WORK FLOW”, SC-27.

HIGH CHARGING VOLTAGE Go to “WORK FLOW”, SC-27.

DIODE RIPPLE NORMAL Diode ripple is OK and will also show CHARGING VOLTAGE test result.

EXCESS RIPPLE DETECTED

DIODE RIPPLE NOT DETECTED Go to “WORK FLOW”, SC-27.

Replace the alternator. Perform “DIODE RIPPLE” test again using Battery/Starting/

Charging system tester to confirm repair.

NFSC0020S01

SC-26

Page 27

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

WORK FLOW

NFSC0020S02

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC-27

EL

IDX

SEL423X

Page 28

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

DIAGNOSTIC PROCEDURE 1

Check “L” Terminal Circuit

NFSC0020S03

NFSC0020S0301

1 CHECK “L” TERMINAL CONNECTION

Check to see if “L” terminal is clean and tight.

OK or NG

OK © GO TO 2.

NG © Repair “L” terminal connection. Confirm repair by performing complete Battery/Starting/

Charging system test.

2 CHECK “L” TERMINAL CIRCUIT

1. Disconnect alternator connector.

2. Apply ground to alternator connector A2 terminal 2 (BR) with the ignition switch in the ON position.

SEL966X

OK or NG

OK © Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG © Check the following.

I 10A fuse [No. 30, located in fuse block (J/B)]

I CHARGE lamp

I Harness for open or short between combination meter and fuse

I Harness for open or short between combination meter and alternator

SC-28

Page 29

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

DIAGNOSTIC PROCEDURE 2

Check “B” Terminal Circuit

1 CHECK “B” TERMINAL CONNECTION

Check to see if “B” terminal is clean and tight.

OK or NG

OK © GO TO 2.

NG © Repair “B” terminal connection. Confirm repair by performing complete Battery/Starting/

Charging system test.

2 CHECK ALTERNATOR “B” TERMINAL CIRCUIT

Check voltage between alternator B terminal E46 terminal 1 (B/R) and ground using a digital circuit tester.

OK or NG

OK © GO TO 3.

NG © Check the following.

I 120A fusible link (letter A, located in fuse and fusible link box)

I Harness for open or short between alternator and fusible link

=NFSC0020S04

NFSC0020S0401

SEL967XA

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

3 CHECK “B” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between alternator B terminal E46 terminal 1 (B/R) and battery positive terminal using a digital circuit tester.

SEL968XA

OK or NG

OK © Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG © Check harness between the battery and the alternator for poor continuity.

BR

ST

RS

BT

HA

EL

IDX

SC-29

Page 30

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont’d)

DIAGNOSTIC PROCEDURE 3

Check “S” Terminal Circuit

=NFSC0020S05

NFSC0020S0501

1 CHECK “S” TERMINAL CONNECTION

Check to see if “S” terminal is clean and tight.

OK or NG

OK © GO TO 2.

NG © Repair “S” terminal connection. Confirm repair by performing complete Battery/Starting/

Charging system test.

2 CHECK ALTERNATOR “S” TERMINAL CIRCUIT

Check voltage between alternator connector A2 terminal 3 (B/R) and ground using a digital circuit tester.

SEL969X

OK or NG

OK © GO TO 3.

NG © Check the following.

I 10A fuse (No. 70, located in fuse and fusible link box)

I Harness for open or short between alternator and fuse

3 CHECK “S” TERMINAL CONNECTION QUALITY (VOLTAGE DROP TEST)

Check voltage between alternator connector A2 terminal 3 (B/R) and battery positive terminal using a digital circuit tester.

SEL970X

OK or NG

OK © Replace the alternator. Confirm repair by performing complete Battery/Starting/Charging

system test.

NG © Check harness between the battery and the alternator for poor continuity.

MALFUNCTION INDICATOR

NFSC0020S06

The IC regulator warning function activates to illuminate

“CHARGE” warning lamp, if any of the following symptoms occur

while alternator is operating:

I Excessive voltage is produced.

I No voltage is produced.

SC-30

Page 31

CHARGING SYSTEM

Construction

Construction

NFSC0012

GI

MA

EM

LC

EC

FE

CL

MT

SEL974Y

Removal and Installation

REMOVAL

1. Remove engine undercover RH.

2. Remove side inspection cover RH.

3. Remove radiator.

4. Loosen belt idler pulley.

5. Remove drive belt.

6. Disconnect alternator harness connector andA/C compressor

harness connector.

7. Remove alternator upper bolt and lower bolt.

INSTALLATION

To install, reverse the removal procedure.

NFSC0013

NFSC0013S01

NFSC0013S02

AT

AX

SU

BR

ST

RS

BT

HA

MEL384KA

EL

IDX

SC-31

Page 32

Battery

SERVICE DATA AND SPECIFICATIONS (SDS)

Battery

Type 80D26L

Capacity V-AH 12-55

Cold cranking current A

(For reference value)

582

Starter

M0T87281 M0T87181

Type

Applied model M/T A/T

System voltage 12V

Terminal voltage 11.0V

No-load

Minimum diameter of commutator 28.8 mm (1.134 in)

Minimum length of brush 7.0 mm (0.276 in)

Brush spring tension 18.3 - 24.8 N (1.87 - 2.53 kg, 4.12 - 5.58 lb)

Clearance between bearing metal and armature shaft Less than 0.2 mm (0.008 in)

Clearance between pinion front edge and pinion stopper 0.5 - 2.0 mm (0.020 - 0.079 in)

Current Less than 90A

Revolution More than 2,800 rpm

MITSUBISHI make

Reduction gear type

NFSC0014

NFSC0015

Alternator

Type

Nominal rating 12V-110A

Ground polarity Negative

Minimum revolution under no-load (When 13.5 volts is applied) Less than 1,100 rpm

Hot output current (When 13.5 volts is applied)

Regulated output voltage 14.1 - 14.7V

Minimum length of brush More than 6.00 mm (0.2362 in)

Brush spring pressure 1.000 - 3.432 N (102 - 350 g, 3.60 - 12.34 oz)

Slip ring minimum outer diameter More than 26.0 mm (1.024 in)

Rotor (Field coil) resistance 2.16 - 2.46Ω

LR1110-723V

HITACHI make

(More than 35A/1,300 rpm)

More than 70A/1,800 rpm

More than 91A/2,500 rpm

More than 110A/5,000 rpm

NFSC0016

SC-32

Loading...

Loading...