Nissan Frontier 2001 Owner's Manual

MANUAL TRANSMISSION

GI

MA

CONTENTS

FS5W71C

PREPARATION ...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools...........................................5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart.........................................6

MANUAL TRANSMISSION

DESCRIPTION.................................................................7

Cross-sectional View...................................................7

ON-VEHICLE SERVICE ..................................................8

Replacing Rear Oil Seal..............................................8

REMOVAL

INSTALLATION

Position Switch Check.................................................8

REMOVAL AND INSTALLATION...................................9

Removal.......................................................................9

Installation..................................................................10

OVERHAUL ...................................................................11

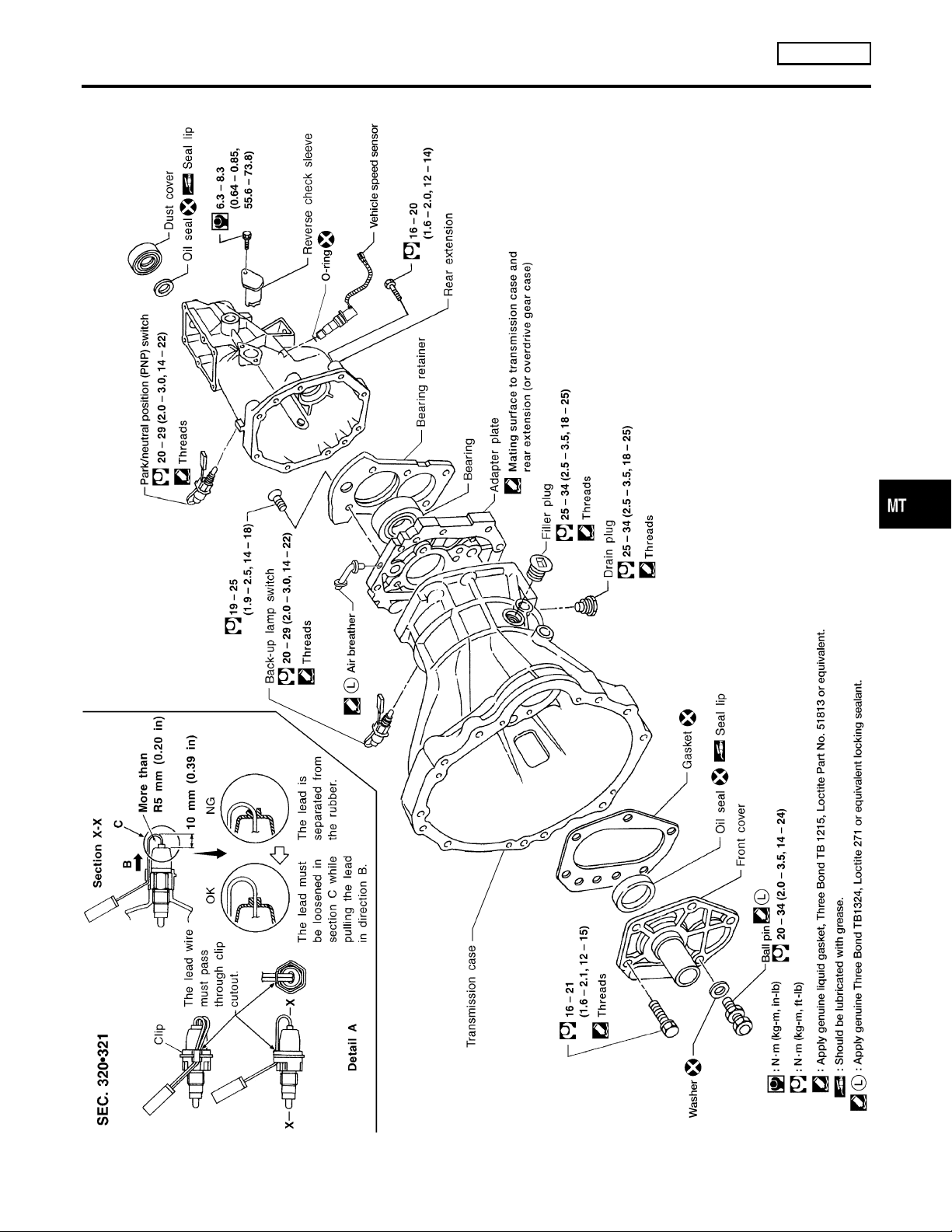

Case Components.....................................................11

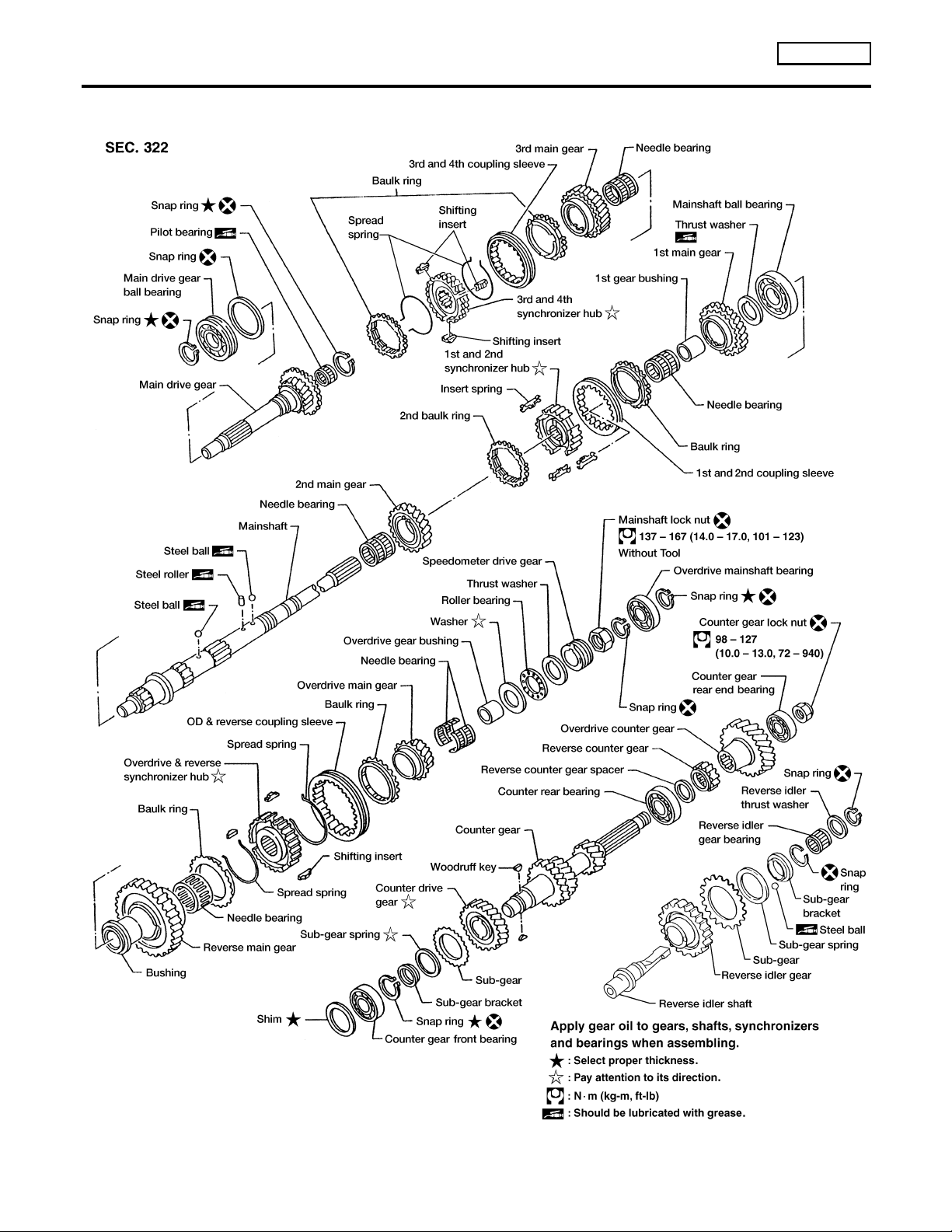

Gear Components .....................................................12

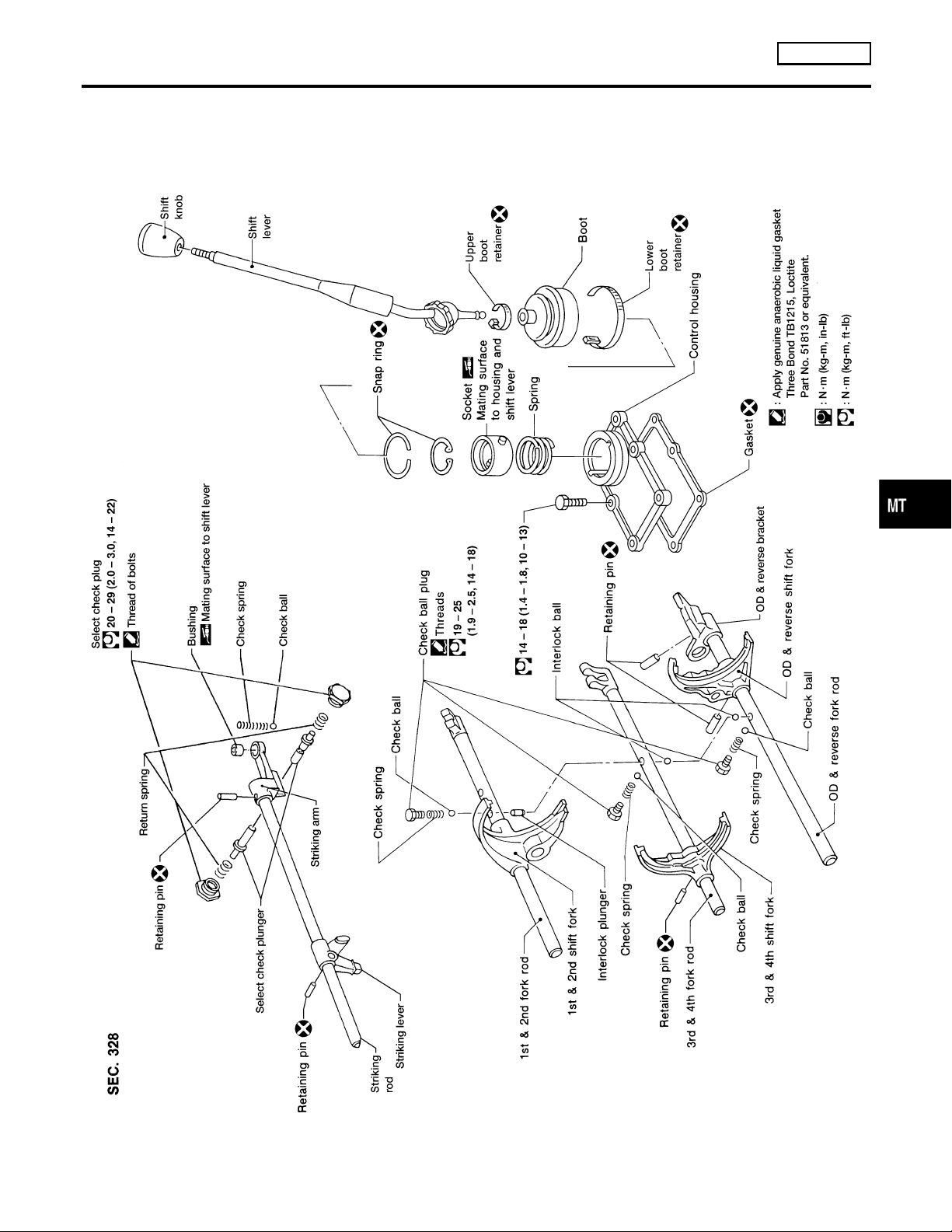

Shift Control Components .........................................13

DISASSEMBLY..............................................................14

Case Components.....................................................14

DISASSEMBLY

Shift Control Components .........................................14

DISASSEMBLY

Gear Components .....................................................15

DISASSEMBLY

INSPECTION..................................................................18

Shift Control Components .........................................18

INSPECTION

Gear Components .....................................................18

INSPECTION

ASSEMBLY....................................................................20

Gear Components .....................................................20

ASSEMBLY

Shift Control Components .........................................26

ASSEMBLY

.................................................................8

..........................................................8

........................................................14

........................................................14

........................................................15

...........................................................18

...........................................................18

.............................................................20

.............................................................26

..........................................6

SECTION

Case Components.....................................................27

ASSEMBLY

SERVICE DATA AND SPECIFICATIONS (SDS).........30

General Specifications...............................................30

Gear End Play...........................................................30

Clearance Between Baulk Ring and Gear................31

Available Snap Rings ................................................31

MAIN DRIVE GEAR BEARING

MAINSHAFT FRONT

COUNTER DRIVE GEAR

OD MAINSHAFT BEARING

Available Shims.........................................................32

COUNTERSHAFT FRONT BEARING

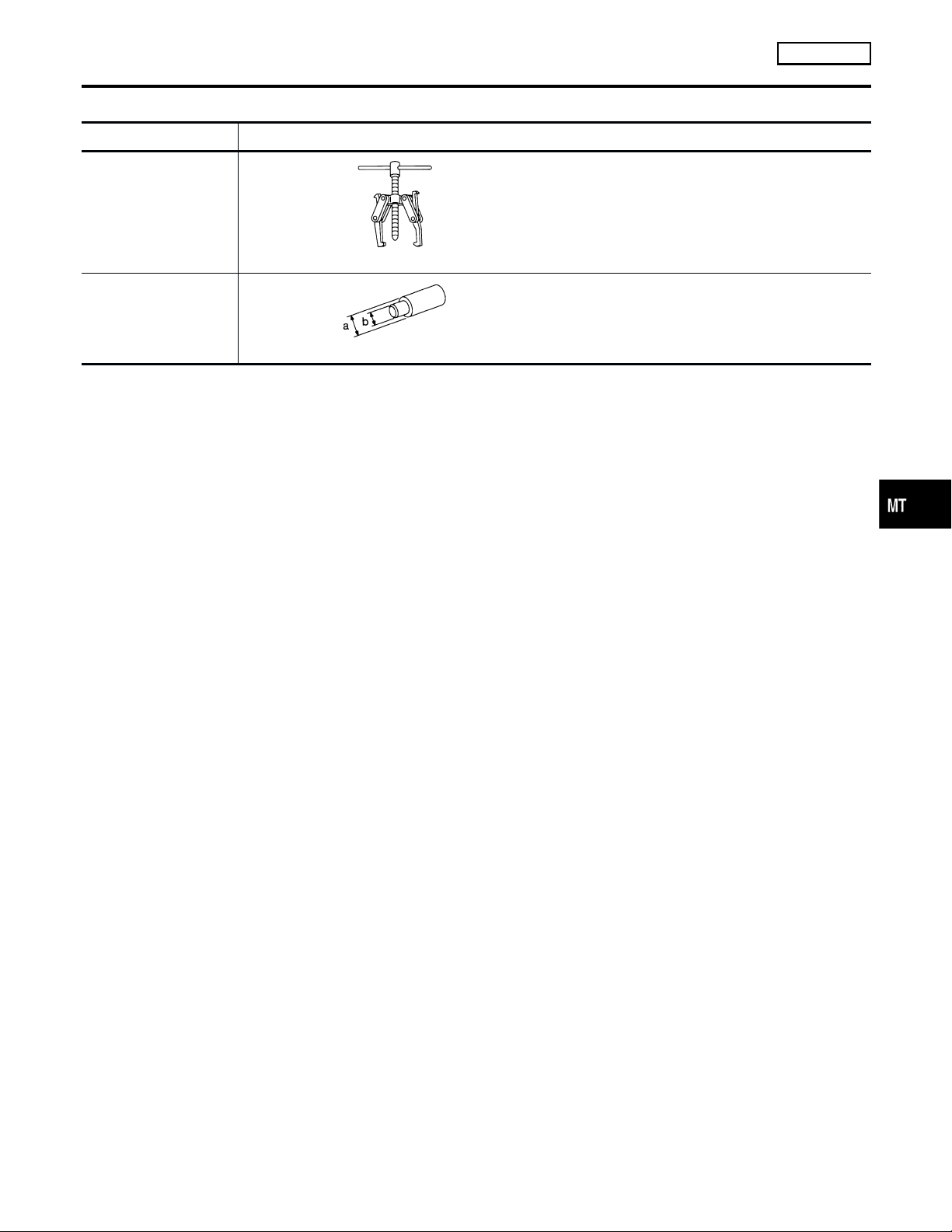

PREPARATION .............................................................33

Special Service Tools ................................................33

Commercial Service Tool...........................................35

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING...................................................36

NVH Troubleshooting Chart.......................................36

MANUAL TRANSMISSION

DESCRIPTION...............................................................37

Cross-sectional View - 2WD Model...........................37

Cross-sectional View - 4WD Model...........................38

ON-VEHICLE SERVICE ................................................39

Replacing Rear Oil Seal - 2WD Model .....................39

REMOVAL

INSTALLATION

Position Switch Check...............................................40

REMOVAL AND INSTALLATION.................................41

Removal.....................................................................41

2WD MODEL

4WD MODEL

Installation..................................................................43

OVERHAUL ...................................................................44

Case Components.....................................................44

Gear Components .....................................................45

Shift Control Components (2/4WD models)..............47

.............................................................27

...............................................................39

........................................................39

...........................................................41

...........................................................42

MT

..................................31

................................................31

.........................................31

......................................32

........................32

FS5R30A

........................................36

EM

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS (Cont’d)

DISASSEMBLY..............................................................48

Case Components.....................................................48

DISASSEMBLY

Shift Control Components .........................................49

DISASSEMBLY

Gear Components .....................................................50

DISASSEMBLY

INSPECTION..................................................................54

Shift Control Components .........................................54

INSPECTION

Gear Components .....................................................54

INSPECTION

ASSEMBLY....................................................................56

Gear Components .....................................................56

ASSEMBLY

Shift Control Components .........................................64

ASSEMBLY

Case Components.....................................................65

........................................................48

........................................................49

........................................................50

...........................................................54

...........................................................54

.............................................................56

.............................................................64

ASSEMBLY

SERVICE DATA AND SPECIFICATIONS (SDS).........67

General Specifications...............................................67

Gear End Play...........................................................67

Clearance Between Single Baulk Ring and Gear.....67

DOUBLE BAULK RING

Distance Between Rear Surface of Reverse

Cone and Reverse Baulk Ring..................................68

Available Snap Ring..................................................68

MAIN DRIVE GEAR SNAP RING

MAINSHAFT FRONT SNAP RING

COUNTER GEAR REAR SNAP RING

Available C-ring .........................................................69

MAINSHAFT C-RING

Available Shim and Washer......................................69

TABLE FOR SELECTING PROPER COUNTER

GEAR FRONT BEARING THRUST WASHER

REVERSE IDLER REAR THRUST WASHER

.............................................................65

............................................68

..............................68

.............................68

.......................69

...............................................69

............69

.............70

MT-2

PREPARATION

FS5W71C

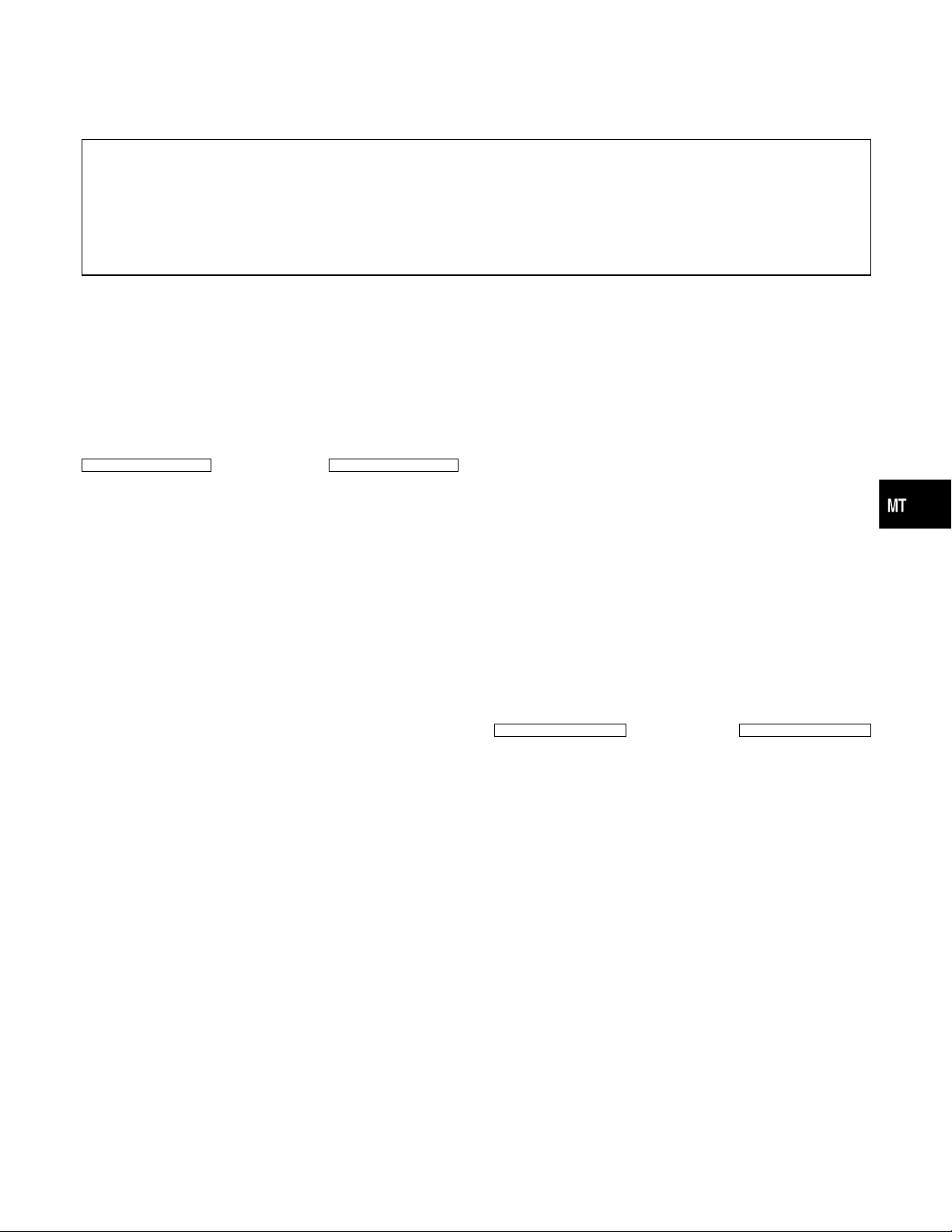

Special Service Tools

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number (Kent-Moore

No.) Tool name

ST23810001

(—)

Adapter setting plate

KV32101330

(See J34286)

Puller

KV31100401

(—)

Transmission press stand

Description

Fixing adapter plate with gear assembly

a: 166 mm (6.54 in)

b: 270 mm (10.63 in)

NT407

Removing overdrive mainshaft bearing

a: 447 mm (17.60 in)

b: 100 mm (3.94 in)

NT408

Pressing counter gear and mainshaft

NEMT0050

GI

MA

EM

LC

EC

FE

CL

ST22520000

(J26348)

Wrench

ST23540000

(J25689-A)

Pin punch

ST30031000

(J22912-01)

Puller

ST23860000

(—)

Drift

NT068

NT409

NT442

NT411

Tightening mainshaft lock nut

a: 100 mm (3.94 in)

b: 41 mm (1.61 in)

Removing and installing fork rod retaining pin

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

Removing and installing 1st gear bushing

Removing main drive gear bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

Installing counter drive gear

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.

AT

TF

PD

AX

SU

BR

ST

RS

BT

ST22360002

(J25679-01)

Drift

NT065

NT065

MT-3

Installing counter gear front and rear end bearings

a: 29 mm (1.14 in) dia.

b: 23 mm (0.91 in) dia.

HA

SC

EL

IDX

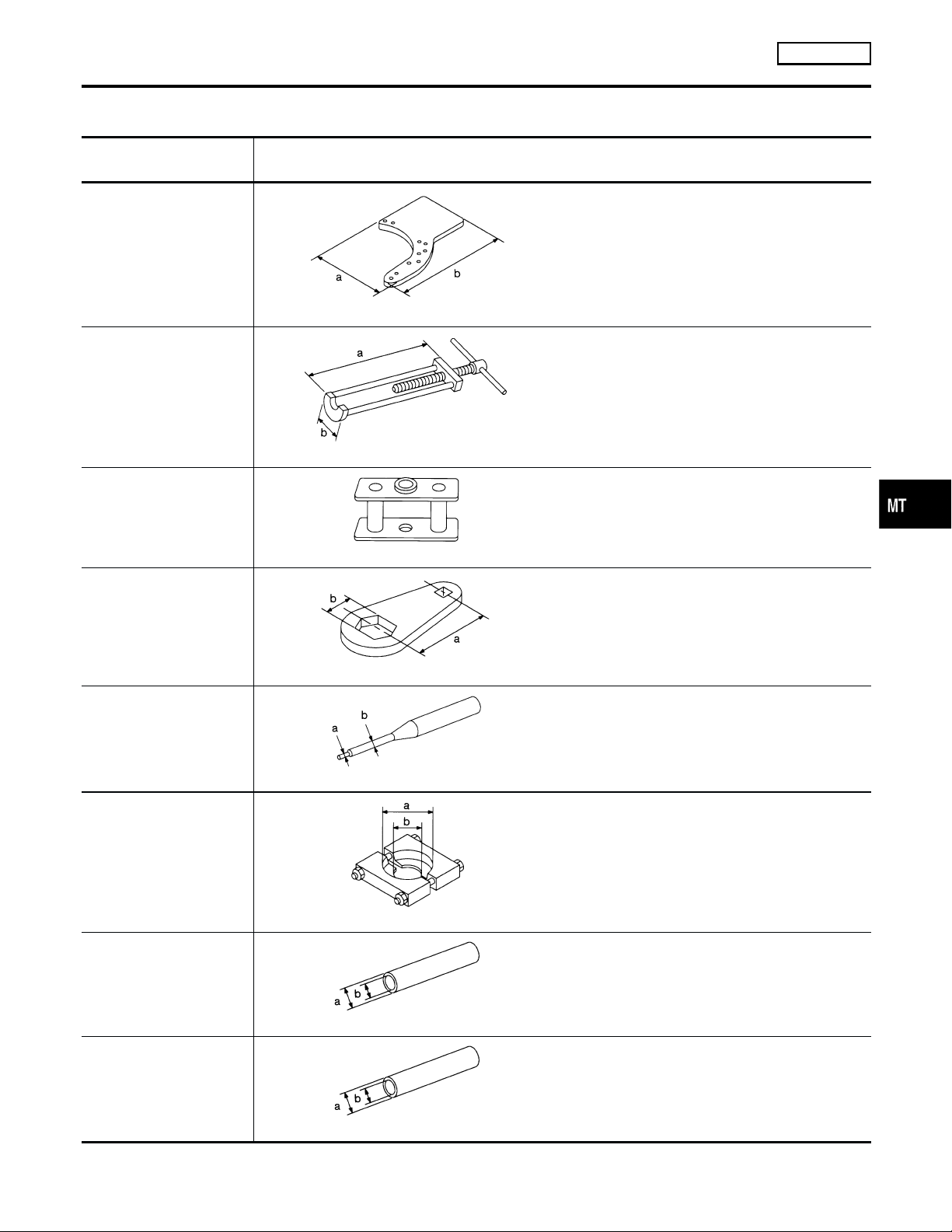

Special Service Tools (Cont’d)

PREPARATION

FS5W71C

Tool number (Kent-Moore

No.) Tool name

ST22350000

(J25678-01)

Drift

ST23800000

(J25691-01)

Drift

ST33400001

(J26082)

Drift

ST33290001

(J34286)

Puller

Description

Installing OD gear bushing

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

NT065

Installing front cover oil seal

a: 44 mm (1.73 in) dia.

b: 31 mm (1.22 in) dia.

NT065

Installing rear oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

NT086

Removing rear oil seal

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

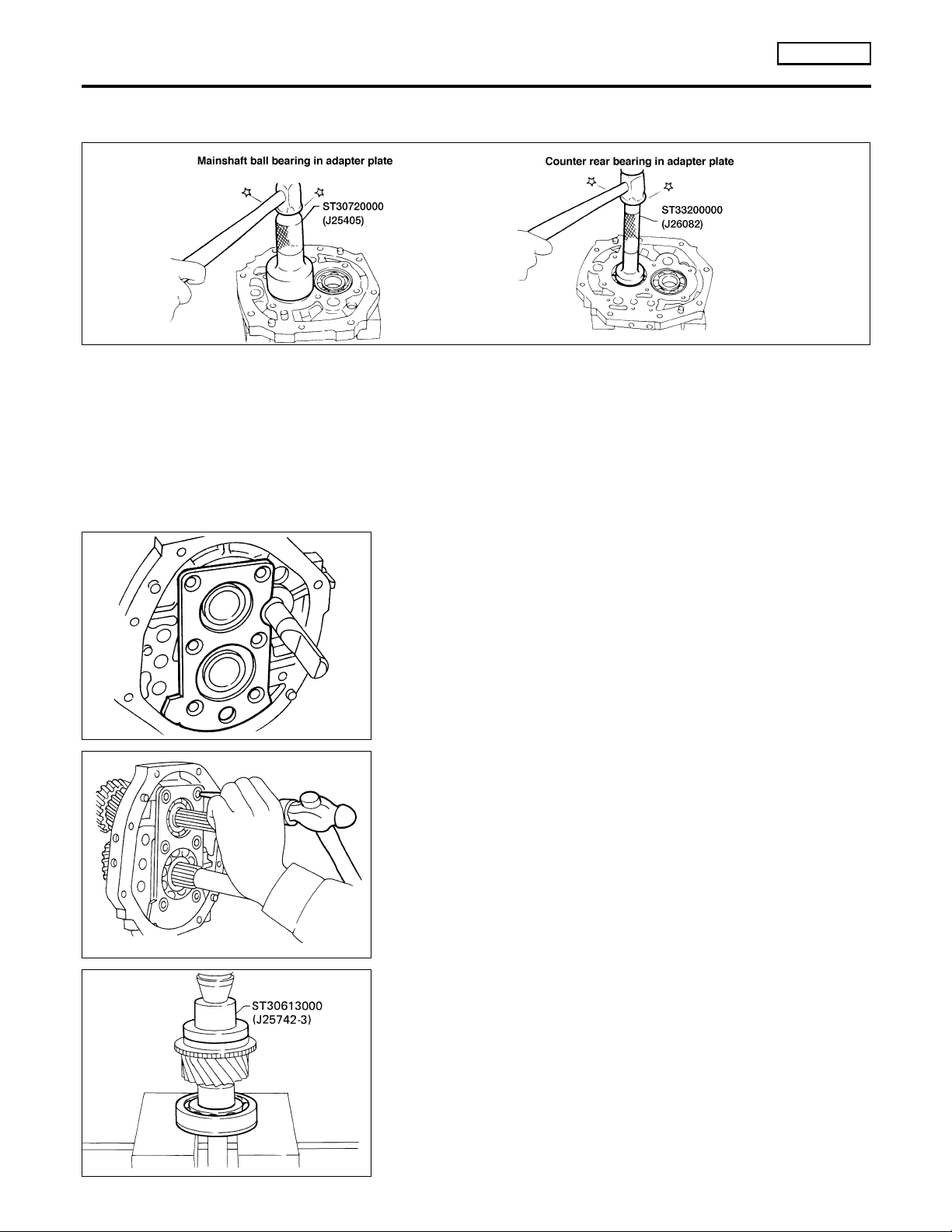

ST30720000

(J25405)

Drift

ST30613000

(J25742-3)

Drift

ST33200000

(J26082)

Drift

NT414

Installing mainshaft ball bearing

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

NT115

Installing main drive gear bearing

a: 71.5 mm (2.815 in) dia.

b: 47.5 mm (1.870 in) dia.

NT073

Installing counter rear bearing

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

NT091

MT-4

PREPARATION

FS5W71C

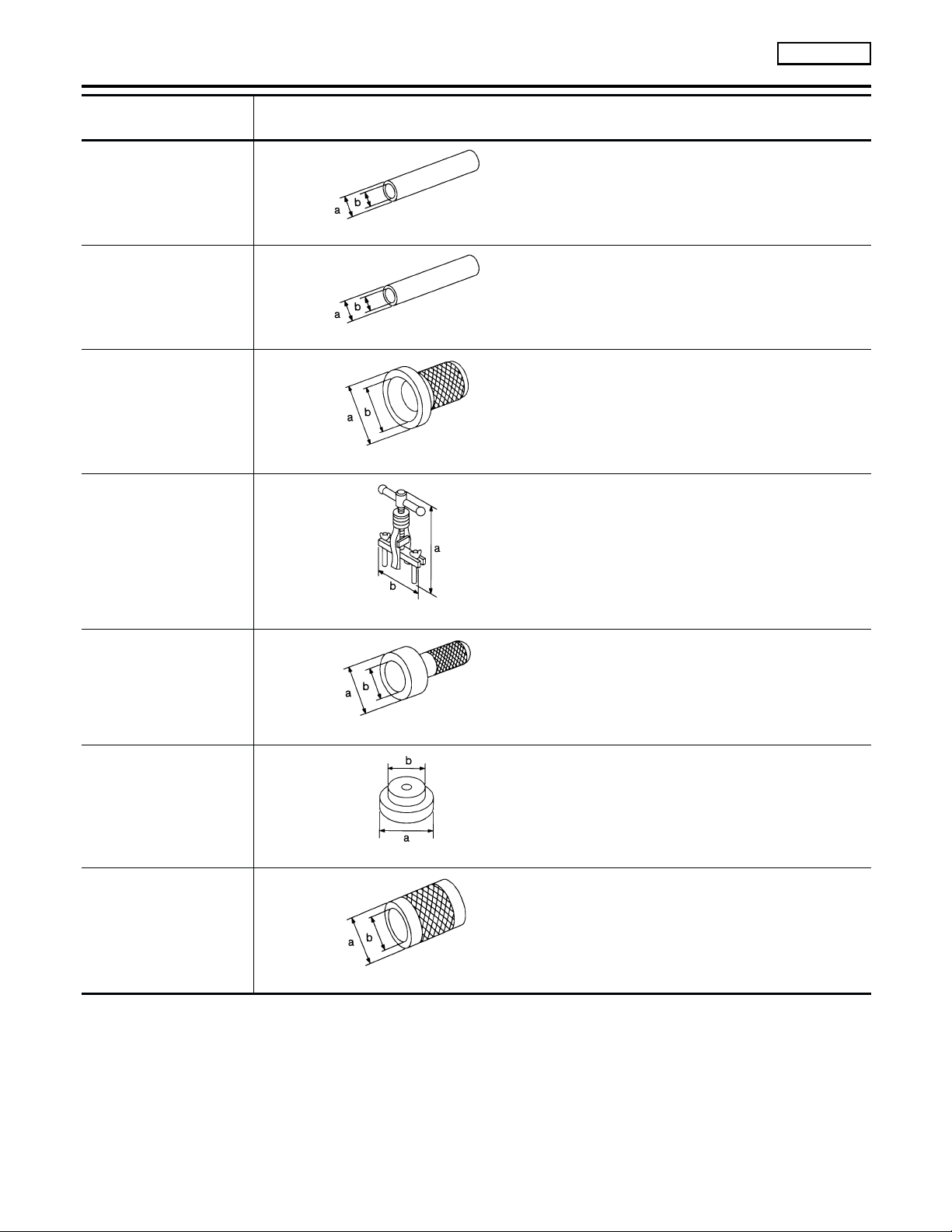

Commercial Service Tools

Tool name Description

Puller

NT077

Drift

NT074

Commercial Service Tools

Removing counter bearings, counter drive and OD

gears

Installing countershaft rear end bearing

a: 40 mm (1.57 in) dia.

b: 30 mm (1.18 in) dia.

NEMT0051

GI

MA

EM

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

MT-5

HA

SC

EL

IDX

NVH Troubleshooting Chart

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING

NEMT0052

FS5W71C

NVH Troubleshooting Chart

NEMT0052S01

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

MANUAL TRANSMISSION

Reference page

SUSPECTED PARTS

(Possible cause)

MT-11

MT-11

MT-13

MT-13

MT-12

MT-12

Refer to MA-37,

“Checking M/T Oil”.

NEMT0052S0101

MT-12

MT-12

Symptom

OIL (Oil level is low.)

OIL (Wrong oil.)

OIL (Oil level is high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

Noise 1 2 3 3

Oil leakage 3122

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

MT-6

INSERT SPRING (Damaged)

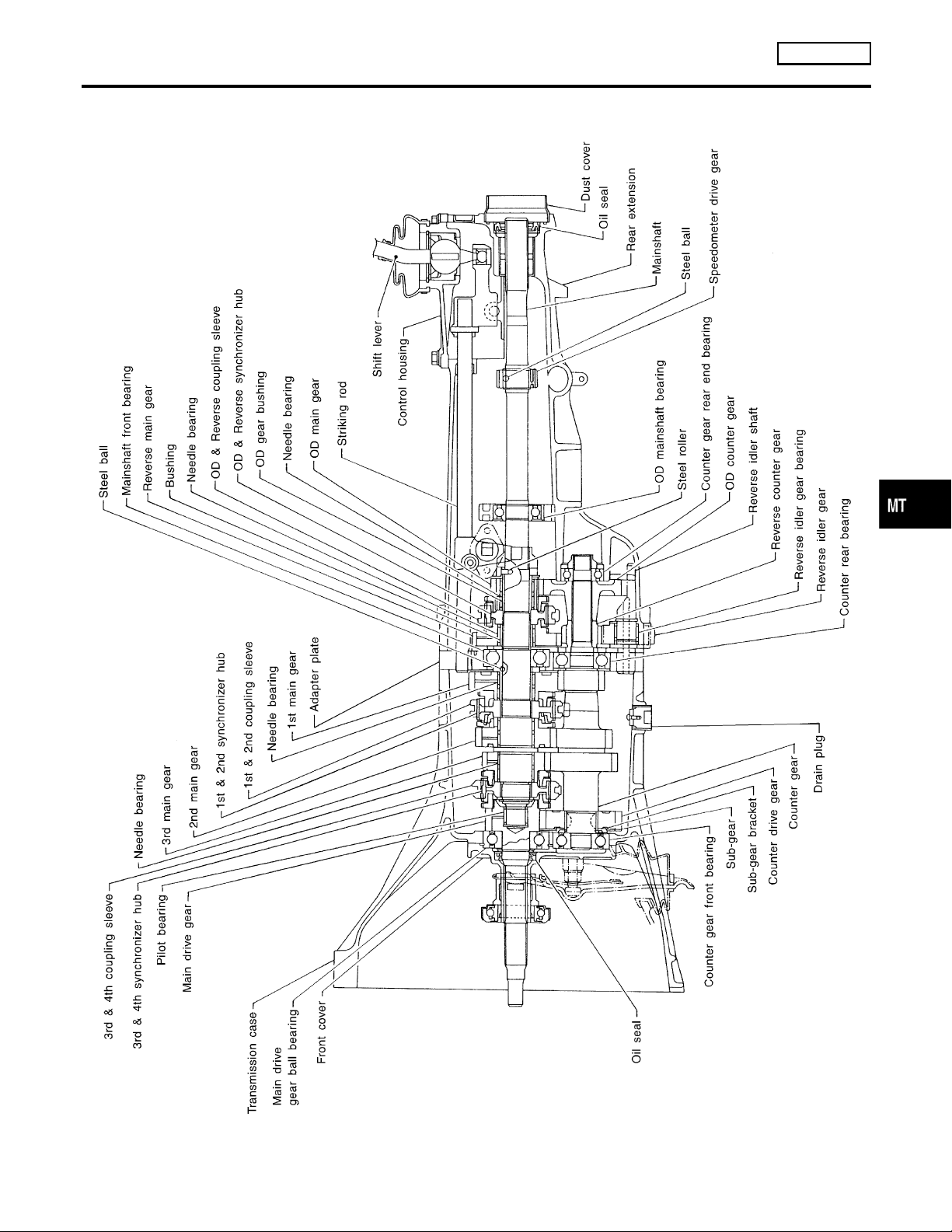

DESCRIPTION

NEMT0053

FS5W71C

Cross-sectional View

Cross-sectional View

NEMT0053S01

GI

MA

EM

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

MT-7

SMT153D

HA

SC

EL

IDX

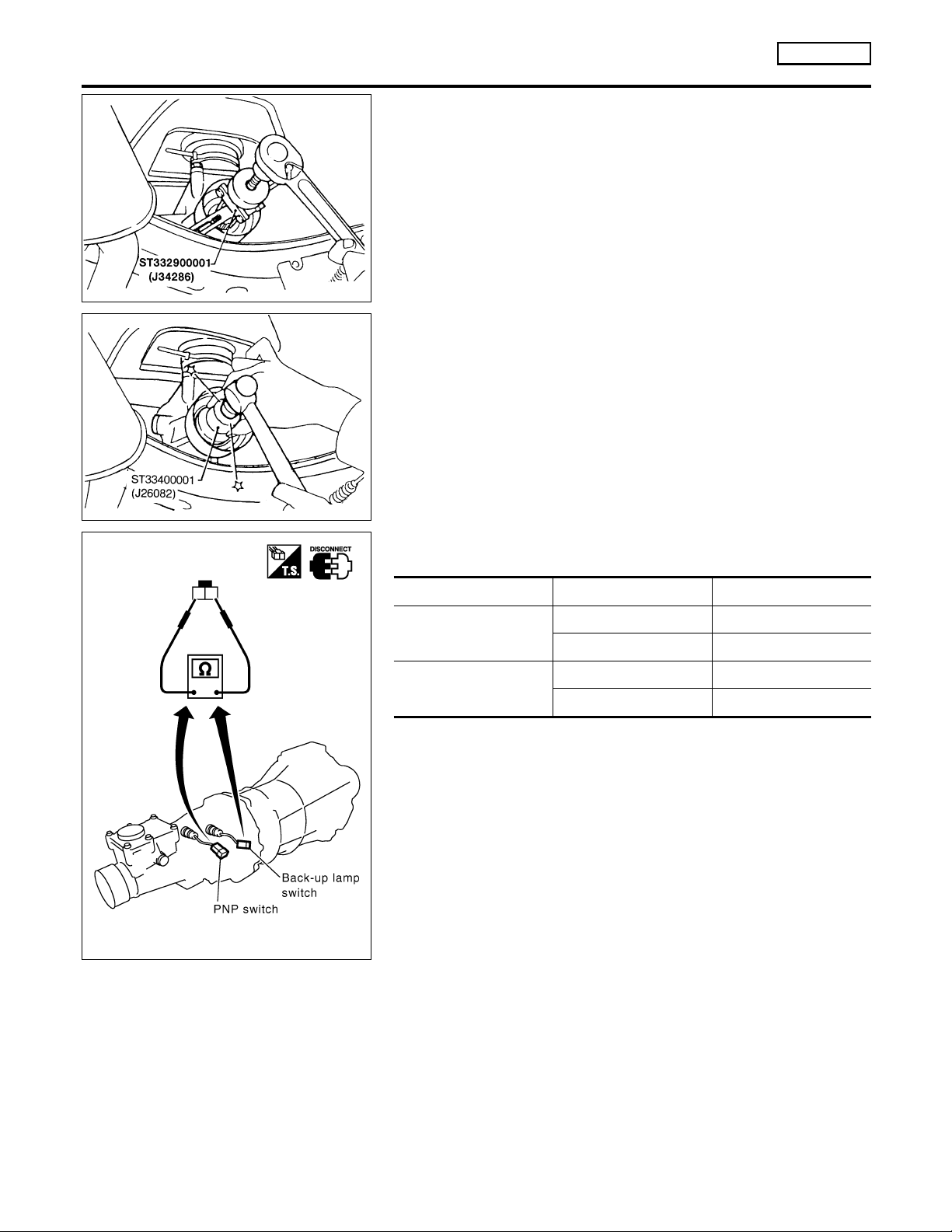

Replacing Rear Oil Seal

ON-VEHICLE SERVICE

FS5W71C

AMT079

SMT480CA

Replacing Rear Oil Seal

REMOVAL

NEMT0054

NEMT0054S01

1. Remove the propeller shaft. Refer to PD-9, “ Removal and

Installation”.

2. Remove rear oil seal using Tool.

쐌 Always replace with a new seal once it has been removed.

INSTALLATION

NEMT0054S02

1. Install new oil seal until it stops.

쐌 Apply multi-purpose grease to seal lip of oil seal before

installing.

2. Install any part removed.

Position Switch Check

NEMT0055

쐌 Check continuity.

SMT981D

Switch Gear position Continuity

Back-up lamp switch

Park/neutral position

(PNP) switch

Reverse Yes

Except reverse No

Neutral Yes

Except neutral No

MT-8

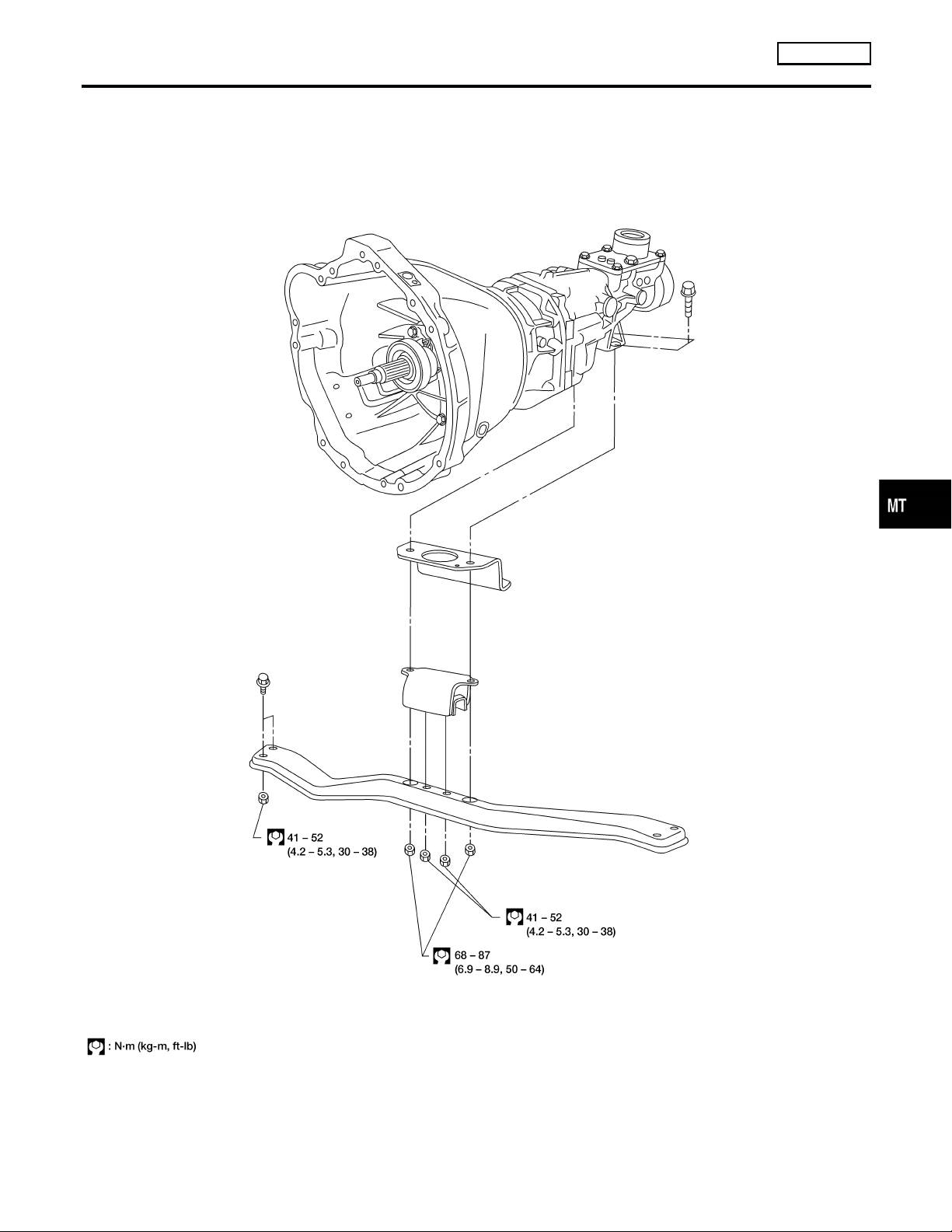

REMOVAL AND INSTALLATION

NEMT0056

FS5W71C

Removal

Removal

NEMT0056S01

GI

MA

EM

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

WMT030

CAUTION:

Before separating the transmission from the engine, remove

the crankshaft position sensor (OBD) from the transmission.

Be careful not to damage sensor edge or ring gear teeth.

MT-9

HA

SC

EL

IDX

Removal (Cont’d)

REMOVAL AND INSTALLATION

NOTE:

To prevent oil spills, drain transmission oil before removing

transmission or insert plug into rear oil seal after removing

propeller shaft.

쐌 Be careful not to damage spline, sleeve yoke, and rear oil

seal when removing propeller shaft.

1. Remove battery negative terminal.

2. Remove the crankshaft position sensor (OBD) from transmission upper side.

3. Remove the clutch operating cylinder from transmission.

4. Disconnect the vehicle speed sensor, back-up switch, and

park/neutral position (PNP) switch harness connectors.

5. Remove the starter motor from transmission.

6. Disconnect the exhaust hanger.

7. Remove the propeller shaft. Refer to PD-9, “Removal and

Installation”.

FS5W71C

SMT099A

AMT190

8. Remove the shift lever.

9. Support the engine by placing a jack under the oil pan.

쐌 Do not place jack under oil pan drain plug.

10. Remove the transmission crossmember.

11. Separate the transmission from the engine.

WARNING:

Support manual transmission while removing it.

Installation

NEMT0056S02

1. Tighten bolts securing transmission.

Bolt No. Tightening torque N·m (kg-m, ft-lb) mm (in)

1 39 - 49 (4.0 - 5.0, 29 - 36) 65 (2.56)

2 39 - 49 (4.0 - 5.0, 29 - 36) 58 (2.28)

3* 16 - 22 (1.6 - 2.2, 12 - 16) 25 (0.98)

4 16 - 22 (1.6 - 2.2, 12 - 16) 16 (0.63)

*: With nut

2. Tighten clutch operating cylinder to the specified torque. Refer

to CL-5, “CLUTCH SYSTEM”.

MT-10

OVERHAUL

NEMT0057

FS5W71C

Case Components

Case Components

NEMT0057S01

GI

MA

EM

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

MT-11

WMT055

HA

SC

EL

IDX

Gear Components

OVERHAUL

FS5W71C

Gear Components

NEMT0057S02

MT-12

AMT156

OVERHAUL

FS5W71C

Shift Control Components

Shift Control Components

CAUTION:

To avoid damage when replacing shift knob, remove shift lever

with knob, as assembled.

NEMT0057S03

GI

MA

EM

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

MT-13

HA

SC

WMT040

EL

IDX

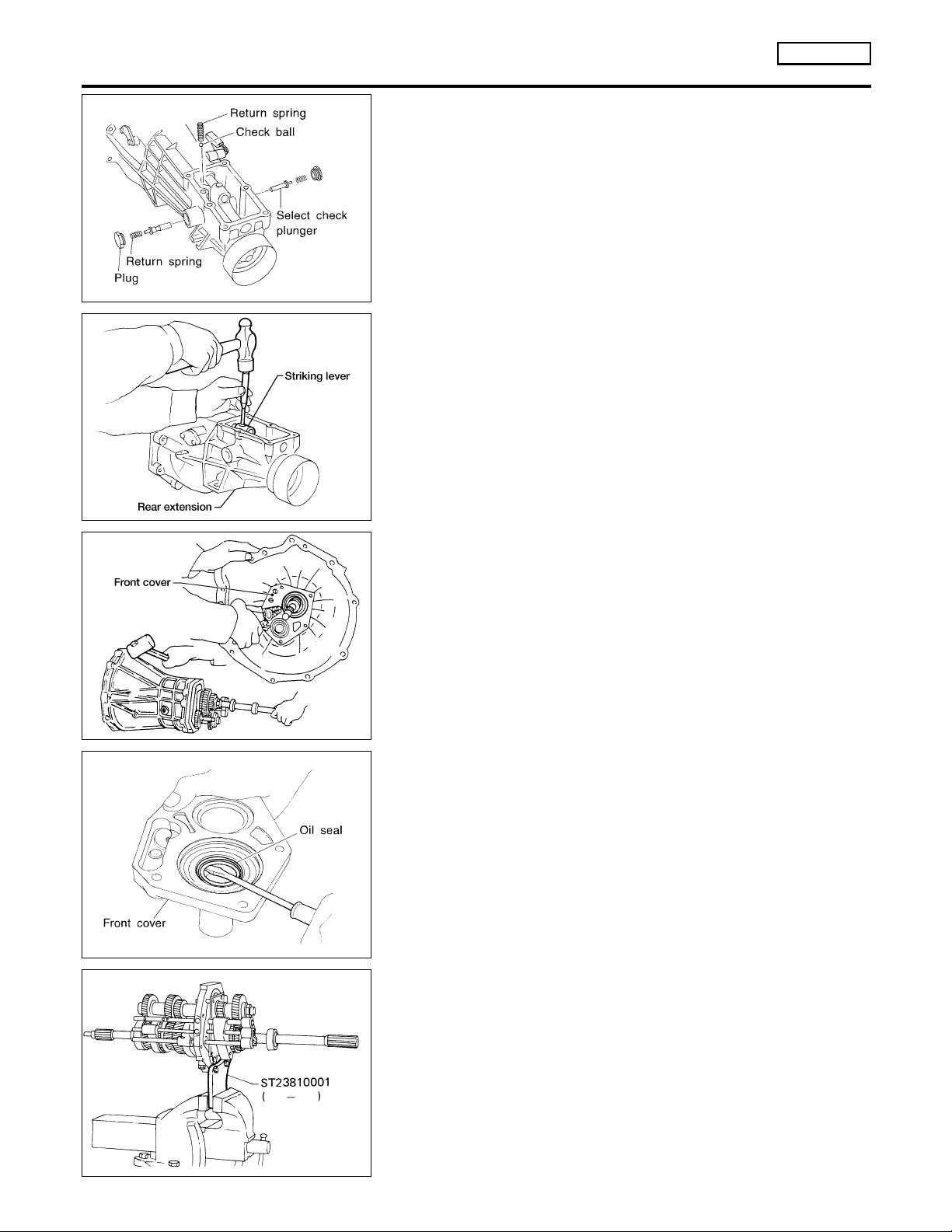

Case Components

SMT161D

DISASSEMBLY

FS5W71C

Case Components

DISASSEMBLY

1. Remove rear extension.

a. Remove control housing, check ball, return spring plugs, select

check plungers and return springs. Also remove reverse check

plug, check spring and check ball.

쐌 Be careful not to lose check balls.

b. Drive out striking lever retaining pin.

c. Remove striking lever from striking rod.

d. Remove rear extension by lightly tapping on it.

NEMT0058

AMT132

AMT131

SMT166D

2. Remove front cover, gasket, counter gear front bearing shim

and main drive gear ball bearing snap ring.

3. Separate transmission case from adapter plate by lightly tapping on it.

4. Remove oil seal from front cover.

쐌 Be careful not to damage mating surface of front cover.

SMT545A

Shift Control Components

DISASSEMBLY

1. Set up Tool on adapter plate.

2. Remove striking rod from adapter plate.

3. Remove check ball plugs, check springs, and check balls.

NEMT0059

MT-14

DISASSEMBLY

Shift Control Components (Cont’d)

4. Drive out retaining pins. Then drive out fork rods and remove

interlock balls.

FS5W71C

GI

MA

EM

SMT984

SMT025

SMT174A

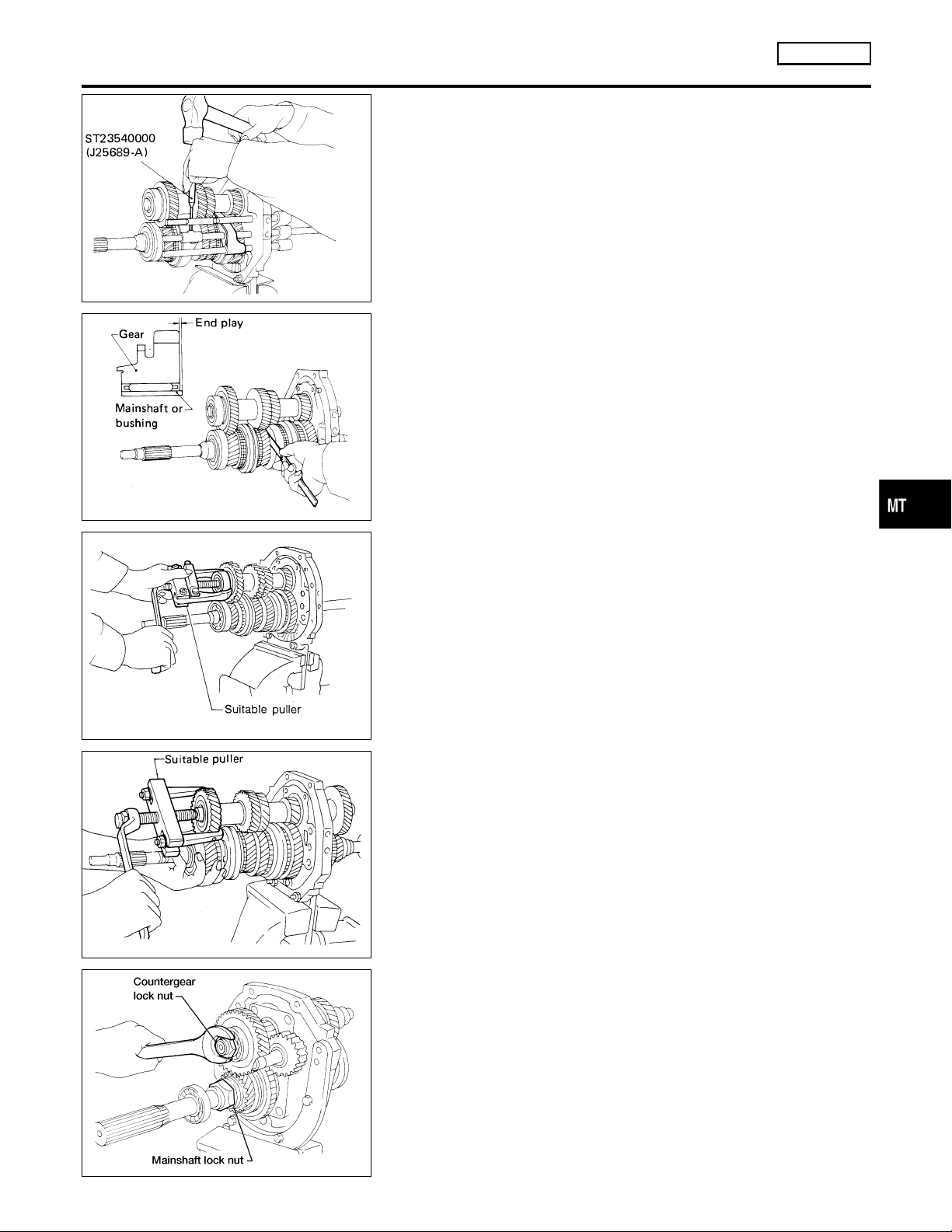

Gear Components

DISASSEMBLY

1. Before disassembly, measure the end play of each gear.

쐌 If end play is not within the specified limit, disassemble and

inspect the parts.

쐌 Replace any part which is worn or damaged. Refer to “Gear

End Play”, MT-30.

2. Mesh 2nd and reverse gear, then remove counter gear front

bearing using a suitable puller.

3. Remove snap ring, then remove sub-gear bracket, sub-gear

spring and sub-gear.

4. Remove counter drive gear together with main drive gear

assembly using a suitable puller.

쐌 When removing main drive gear assembly, be careful not

to drop pilot bearing or baulk ring.

5. Remove snap ring, then remove 3rd and 4th synchronizer

assembly and 3rd main gear.

NEMT0060

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

SMT162A

AMT133

6. Disassemble parts at rear of adapter plate as follows:

a. Release staking on both countergear and mainshaft lock nuts,

then loosen both nuts.

Mainshaft lock nut: Left-hand thread

MT-15

RS

BT

HA

SC

EL

IDX

Gear Components (Cont’d)

SMT547A

WMT033

DISASSEMBLY

FS5W71C

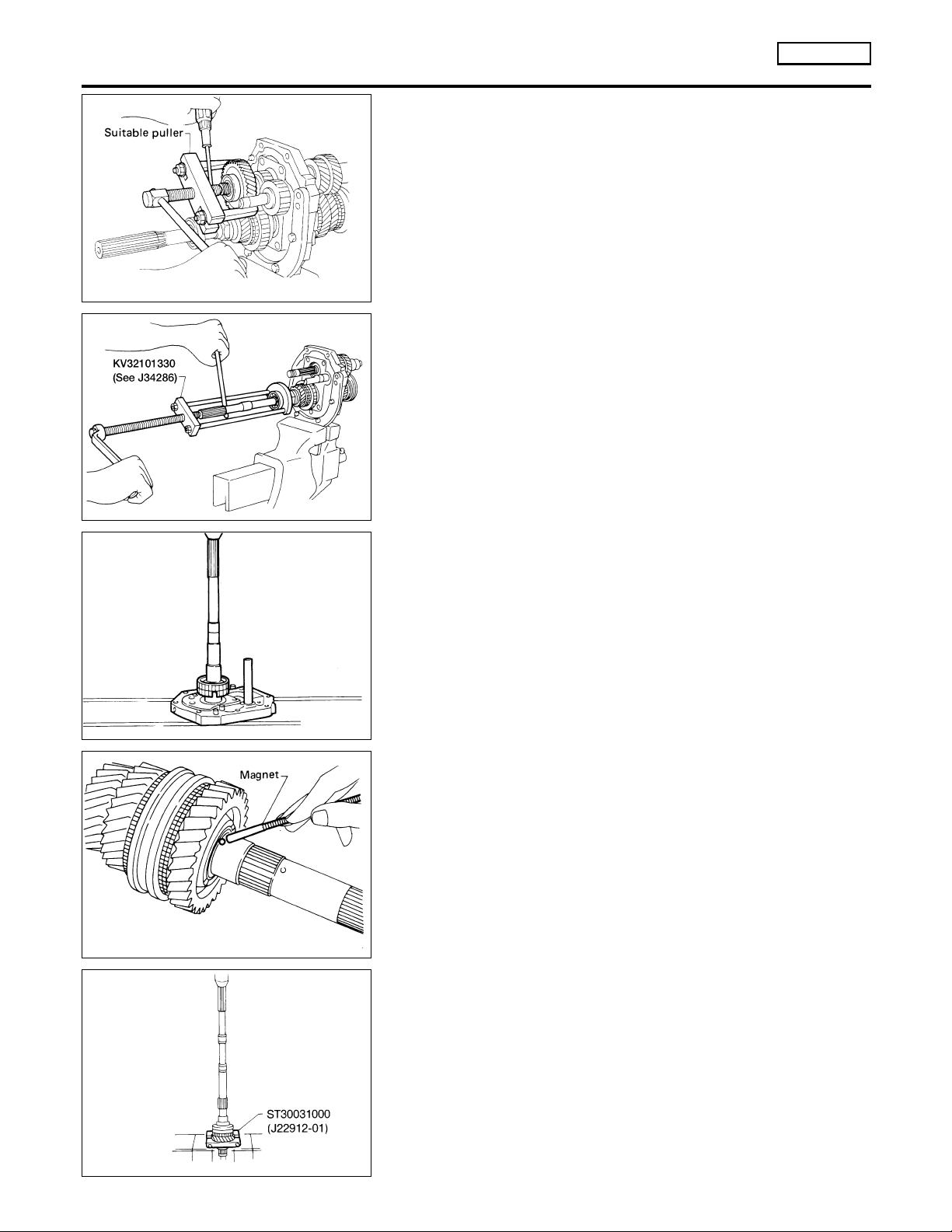

b. Remove overdrive counter gear together with counter gear

rear end bearing using a suitable puller.

c. Remove reverse counter gear and spacer.

d. Remove snap rings from reverse idler shaft, then remove

reverse idler gear, thrust washers and reverse idler gear bearing.

e. Remove snap ring and pull out overdrive mainshaft bearing,

then remove snap ring. (2WD model)

f. Remove mainshaft lock nut.

g. Remove speedometer drive gear and steel ball. (2WD model)

h. Remove thrust washer, steel roller, roller bearing and washer.

i. Remove overdrive main gear, needle bearing and baulk ring

(overdrive).

j. Remove counter gear by tapping on rear end of counter gear.

k. Press out overdrive gear bushing and overdrive & reverse

synchronizer assembly.

l. Remove reverse main gear and needle bearing.

m. Press out reverse gear bushing.

SMT554A

SMT383A

TM049A

7. Remove thrust washer, steel ball, 1st main gear and needle

bearing.

쐌 Be careful not to lose steel ball.

8. Press out 1st gear bushing together with 2nd main gear using

Tool.

Remove 2nd gear needle bearing.

MT-16

DISASSEMBLY

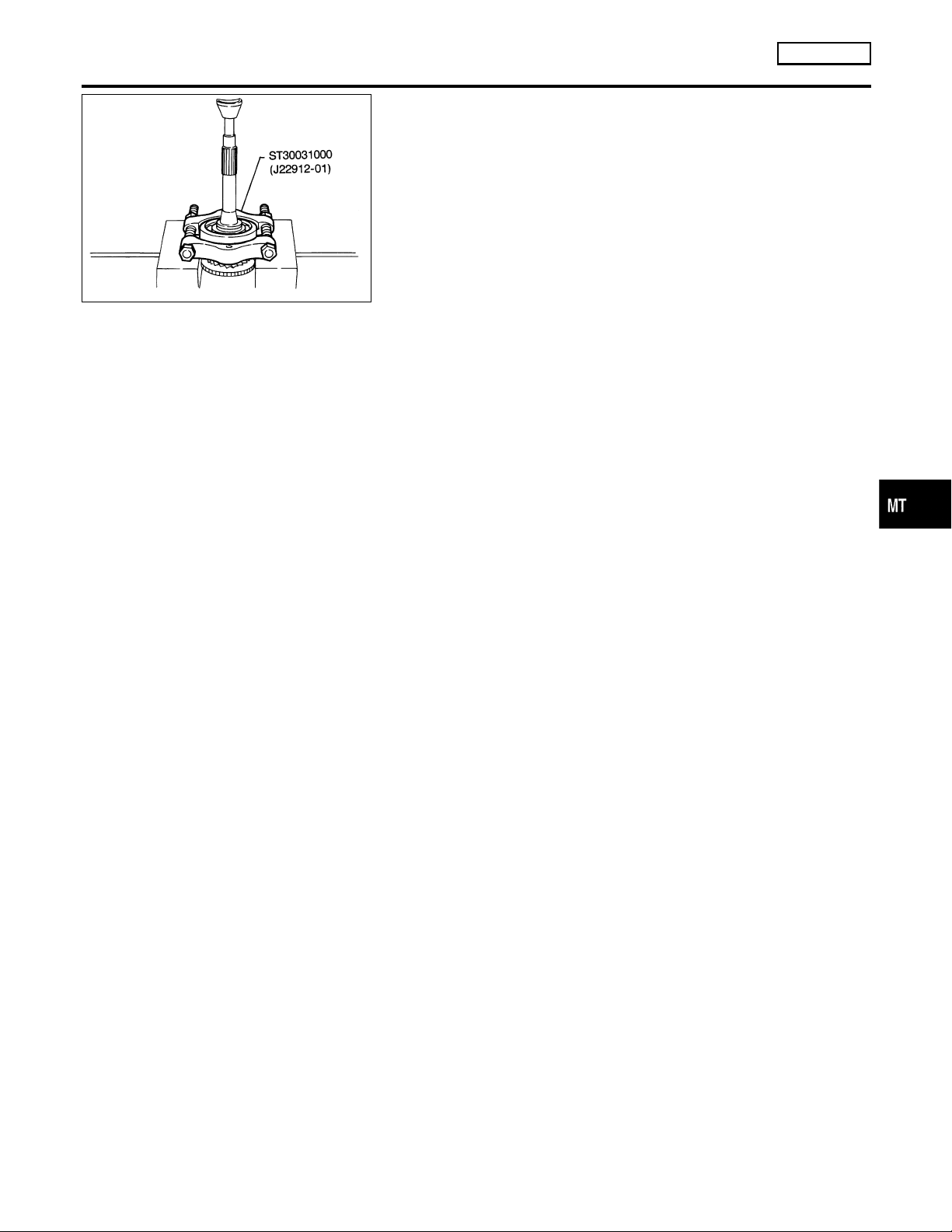

9. Remove main drive gear ball bearing.

a. Remove snap ring.

b. Remove main drive gear ball bearing.

FS5W71C

Gear Components (Cont’d)

GI

MA

EM

SMT420A

LC

EC

FE

CL

AT

TF

PD

AX

MT-17

SU

BR

ST

RS

BT

HA

SC

EL

IDX

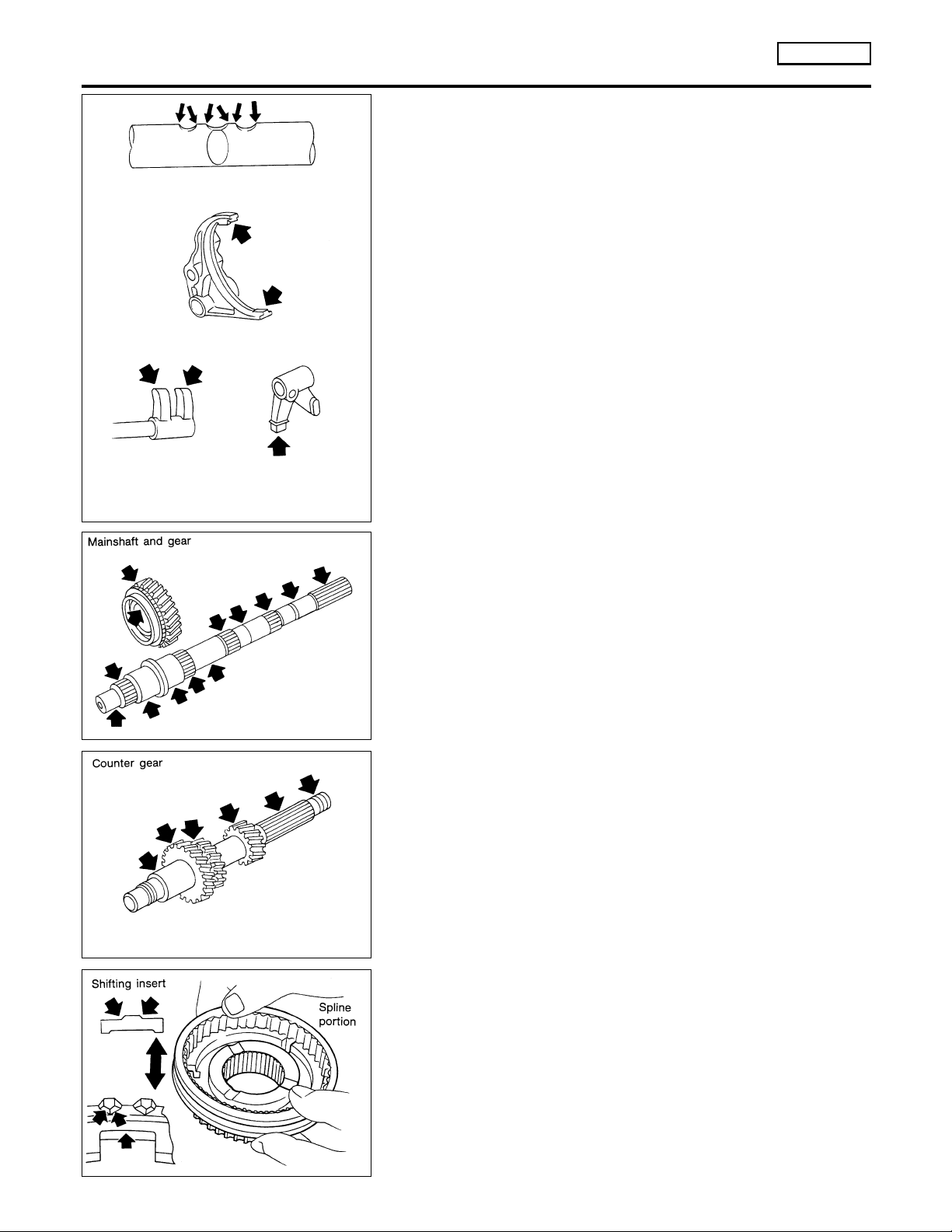

Shift Control Components

INSPECTION

FS5W71C

Shift Control Components

INSPECTION

쐌 Check contact and sliding surfaces of fork rods for wear,

scratches, projections and other damage.

NEMT0061

SMT075C

SMT386A

SMT550A

Gear Components

INSPECTION

Gears and Shafts

쐌 Check shafts for cracks, wear and bending.

쐌 Check gears for excessive wear, chips and cracks.

Synchronizers

쐌 Check spline portion of coupling sleeves, synchronizer hubs,

and gears for wear, chips, and cracks.

쐌 Check baulk rings for cracks and deformation.

쐌 Check shifting inserts for wear and deformation.

쐌 Check insert spread springs for deformation.

NEMT0062

NEMT0062S01

NEMT0062S02

SMT427C

MT-18

INSPECTION

Gear Components (Cont’d)

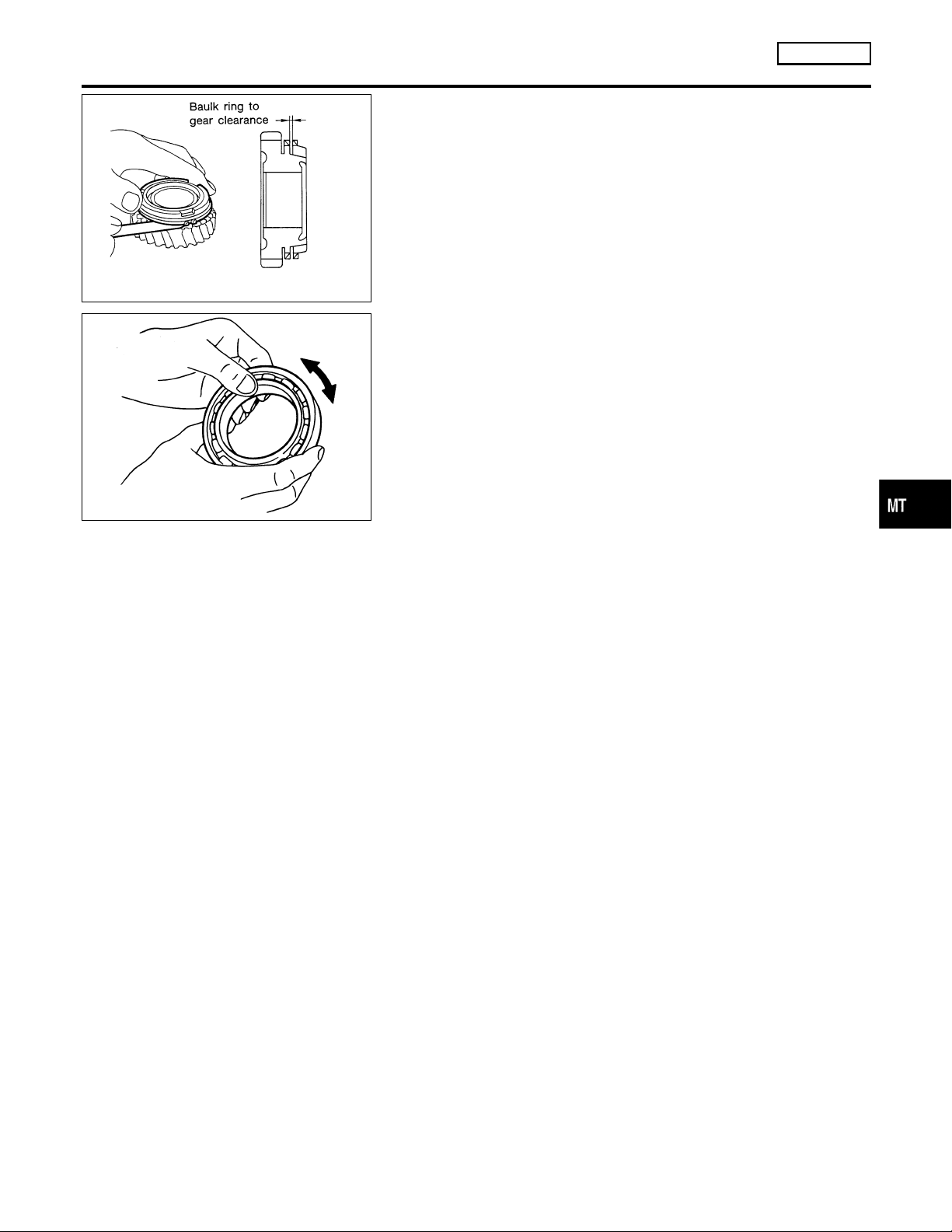

쐌 Measure baulk ring wear.

1) Measure clearance between baulk ring and gear.

Clearance between baulk ring and gear:

Refer to “Clearance Between Baulk Ring and Gear”,

MT-31.

쐌 If the clearance is less than the wear limit, replace baulk ring.

FS5W71C

GI

MA

EM

SMT140

SMT418A

Bearings

쐌 Make sure all bearings roll freely and are free from noise,

cracks, pitting or wear.

NEMT0062S03

LC

EC

FE

CL

AT

TF

PD

AX

MT-19

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Gear Components

ASSEMBLY

Gear Components

ASSEMBLY

FS5W71C

NEMT0063

AMT185

SMT778C

SMT674C

1. Install bearings into case components.

2. Assemble adapter plate parts.

쐌 Install oil gutter on adapter plate and expand on rear side.

쐌 Install bearing retainer.

a. Insert reverse idler shaft, then install bearing retainer.

b. Tighten each screw, then stake each one at two points.

3. Install main drive gear ball bearing.

a. Press main drive gear ball bearing.

SMT425A

MT-20

ASSEMBLY

Gear Components (Cont’d)

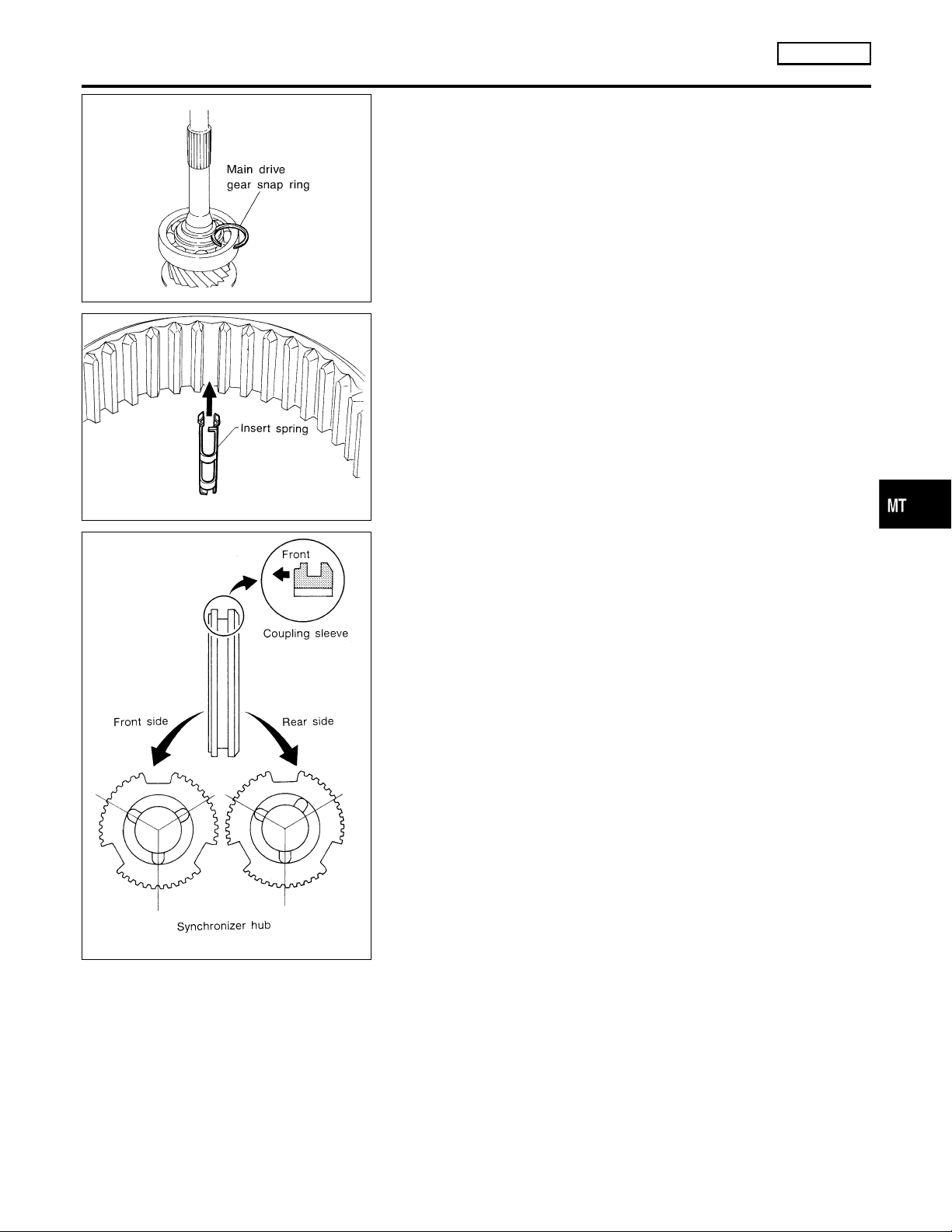

b. Select and install proper main drive gear snap ring to achieve

proper clearance of groove.

Allowable clearance of groove:

0 - 0.13 mm (0 - 0.0051 in)

Main drive gear bearing snap ring:

Refer to “MAIN DRIVE GEAR BEARING”, MT-31.

FS5W71C

GI

MA

EM

SMT170D

SMT054C

4. Assemble synchronizers.

쐌 Assemble the 1st and 2nd synchronizer.

쐌 Check coupling sleeve and synchronizer hub orientation.

LC

EC

FE

CL

AT

TF

PD

AX

SMT206C

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MT-21

Loading...

Loading...