Nissan 300zx Engine Fuel Emission Control System EF EC 1988 Owner's Manual

EMISSION CONTROL SYSTEM

SECTION

EFaEC

CONTENTS

PRECAUTIONS

ENGINE

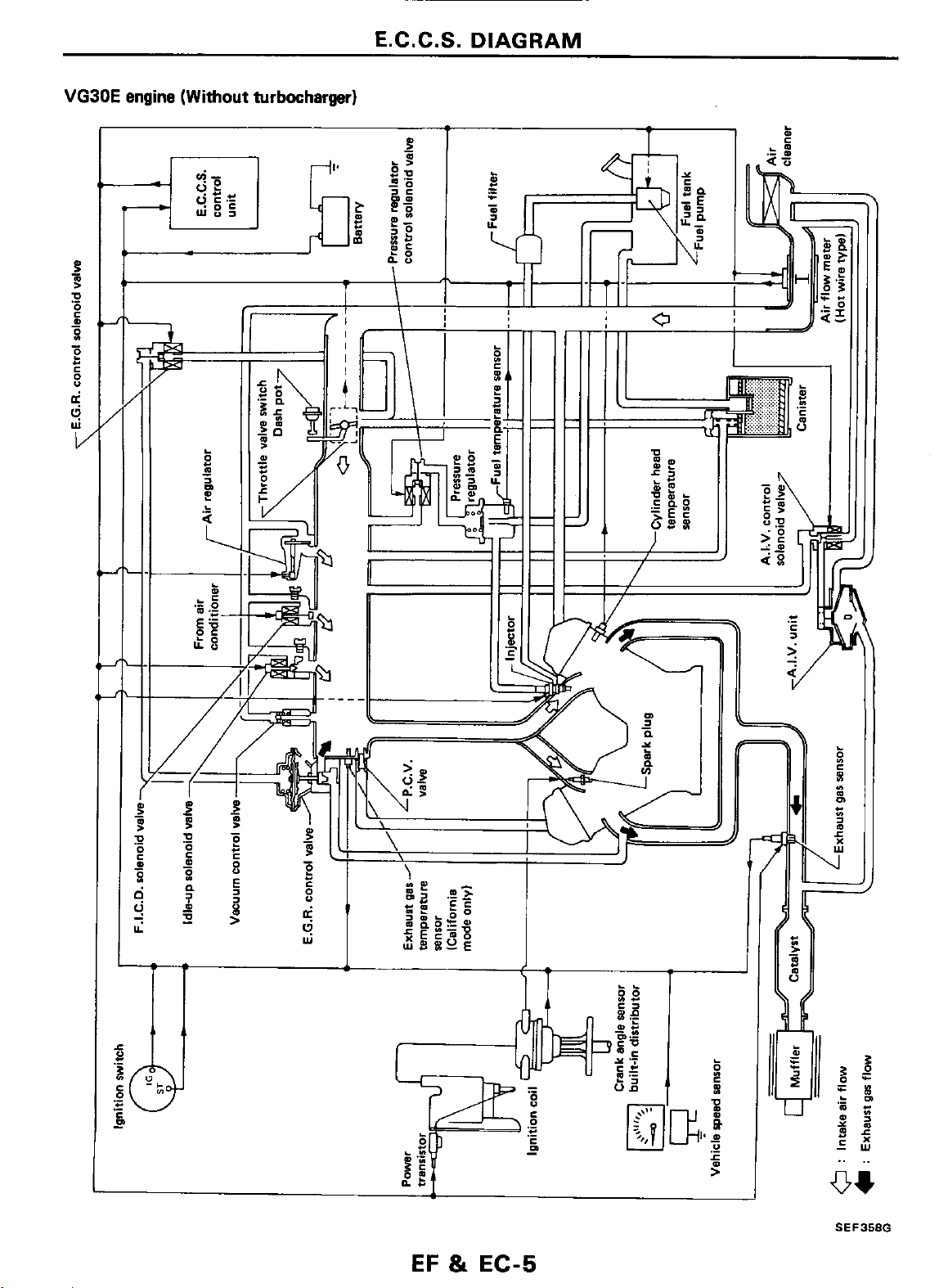

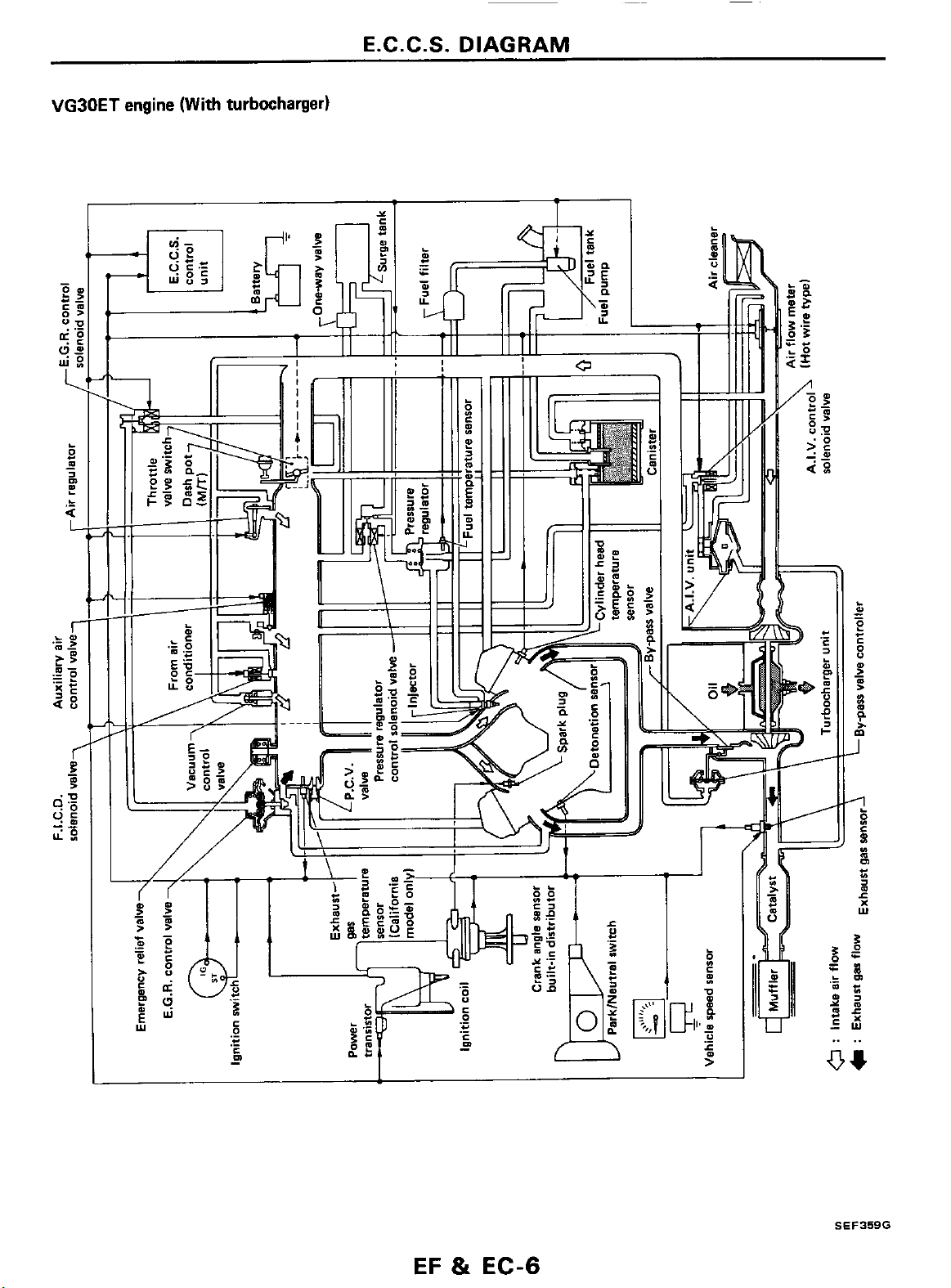

E.C.C.S. DIAGRAM

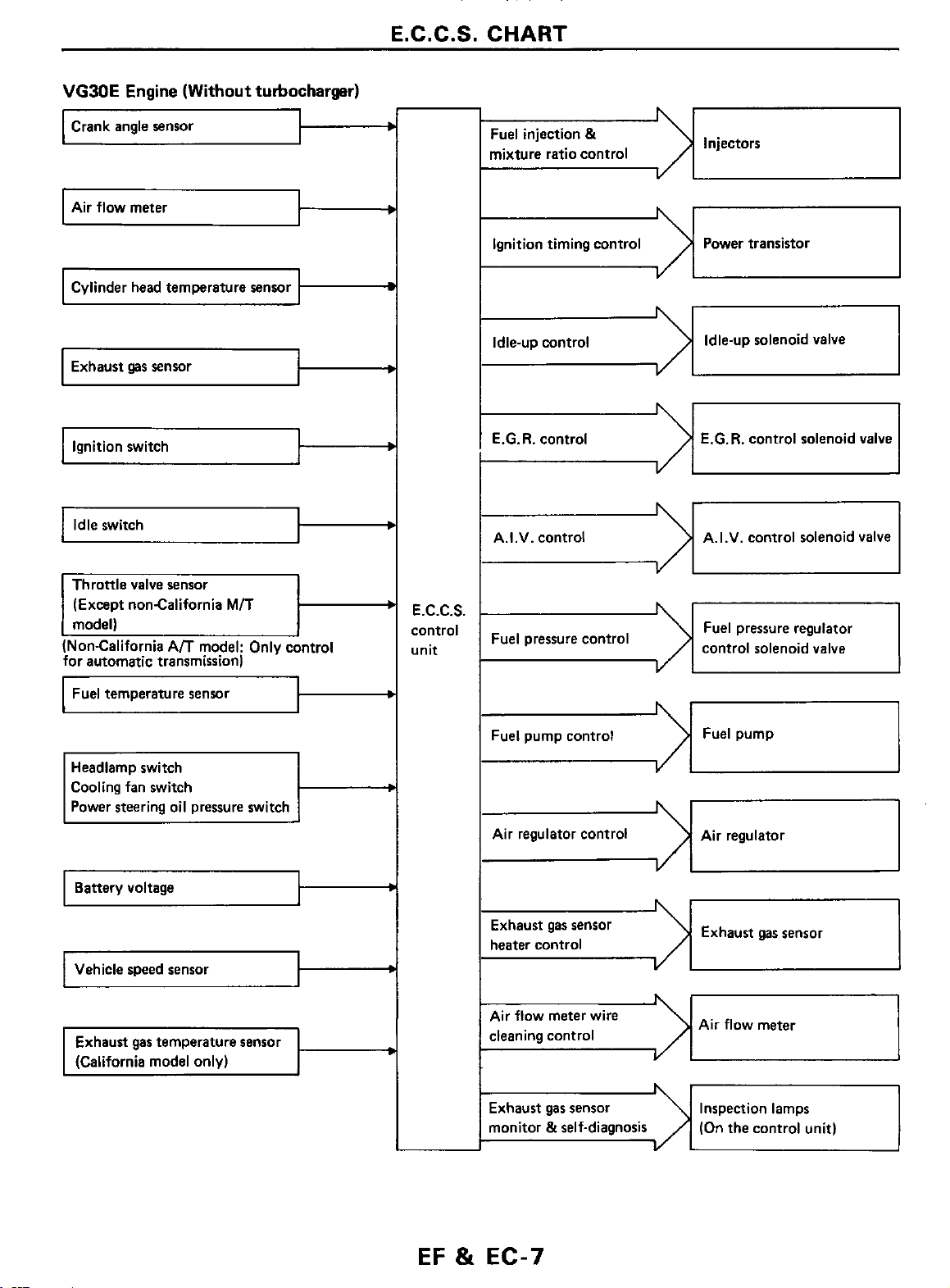

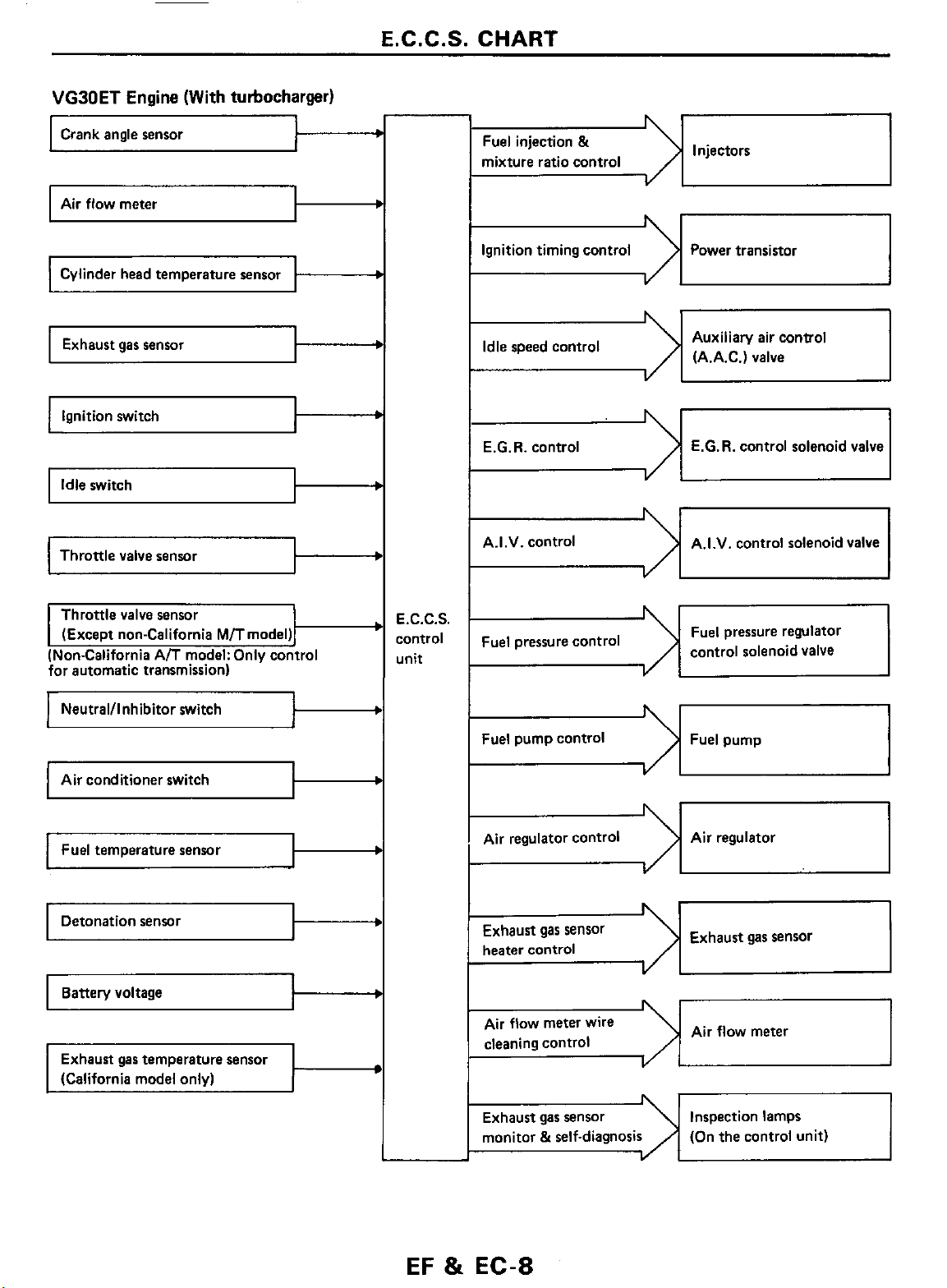

E.C.C.S. CHART

FUEL FLOW SYSTEM DESCRIPTION

AIR FLOW SYSTEM DESCRIPTION

E.C.C.S. CIRCUIT DIAGRAM

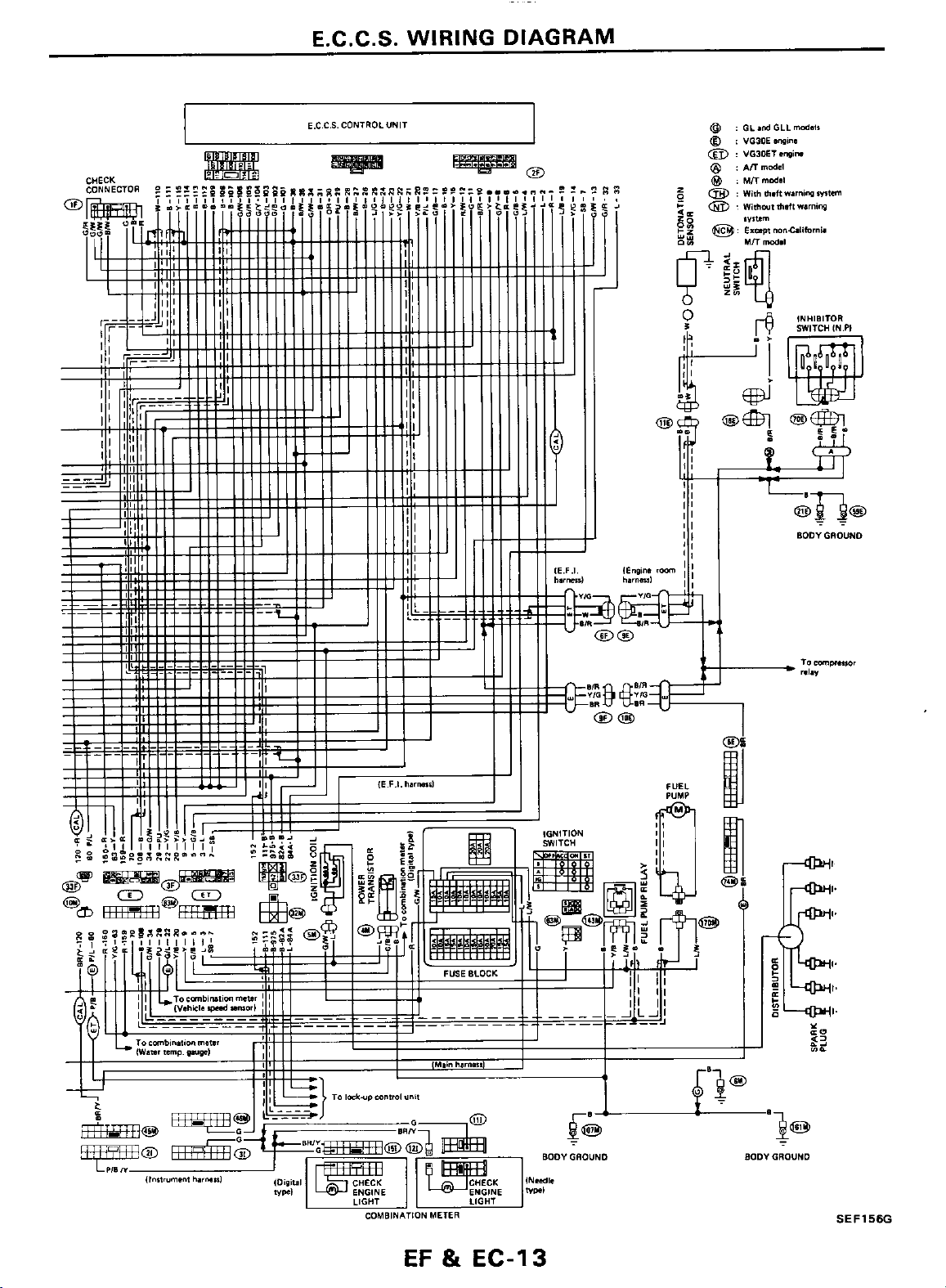

E.C.C.S. WIRING DIAGRAM

E.C.C.S. DESCRIPTION

DIAGNOSTIC PROCEDURE

SELF.DIAGNOSIS

ELECTRONIC CONTROL SYSTEM INSPECTION

AND

CRANK ANGLE SENSOR

AIR FLOW METER

CYLINDER HEAD TEMPERATURE SENSOR

VEHICLE SPEED SENSOR

IGNITION SIGNAL

FUEL PUMP

IDLE SWITCH

ENGINE CONTROL

E.G.R. FUNCTION

EXHAUST GAS SENSOR

DETONATION SENSOR

EXHAUST GAS TEMPERATURE SENSOR

FUEL TEMPERATURE SENSOR

THROTTLE SENSOR

INJECTOR LEAK

START SIGNAL

INJECTOR

POWER SOURCE

......................................................

EMISSION CONTROL PARTS LOCATION

..................................................

.....................................................

..................................

....................................

..........................................

..........................................

...............................................

...........................................

....................................................

.........................................

..............................................

........................................

..............................................

....................................................

..................................................

UNIT

........................................

...............................................

.........................................

..........................................

...................................

.............................................

................................................

................................................

......................................................EF&E

&

GROUND CIRCUIT FOR E.C.U.

..................

.........................

........................

..........................

.................

EF & ECEF & EC-

EF & ECEF&ECEF & ECEF & ECEF & EC-

EF & EC- 12

EF & ECEF & ECEF & ECEF & ECEF & ECEF & ECEF & ECEF & EC-

EF & EC- 92

EF & ECEF & EC-

EF & ECEF & EC-100

EF & EC-104

EF & EC-106

EF & EC-108

EF & EC-112

EF & EC-114

EF & EC-116

EF & EC-118

EF&EC-122

3

4

5

7

9

10

11

14

31

61

82

84

86

88

90

94

96

98

C.120

Contents (Cont'd)

A.I.V. CONTROL SOLENOID VALVE

E.G.R.

IDLE-UP SOLENOID VALVE

A.A.C. VALVE

NEUTRAL/INHIBITOR SWITCH

P.R.

AIR REGULATOR

E.C.U. INPUT/OUTPUT SIGNAL INSPECTION

MIXTURE RATIO FEEDBACK SYSTEM INSPECTION

FUEL SYSTEM INSPECTION

TURBOCHARGER INSPECTION

EVAPORATIVE EMISSION CONTROL SYSTEM

E.G.R. SYSTEM INSPECTION

CRANKCASE EMISSION CONTROL SYSTEM

A.I.V. SYSTEM INSPECTION

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

CONTROL SOLENOID VALVE

......................................

..................................................

....................................

CONTROL SOLENOID VALVE

...............................................

..........................................

.......................................

.........................................

..........................................

...............................

..............................

................................

...........................

..........................

............................

.........................

....................

EF & EC-124

EF & EC-126

EF & EC-128

EF & EC-130

EF & EC-132

EF & EC-134

EF & EC-136

EF & EC-138

EF & EC-143

EF & EC-148

EF & EC-151

EF

&

EC-153

EF

&

EC-155

EF & EC-156

EF & EC-157

EF & EC-159

When

Read

See

you

read wiring diagrams:

GI

EL

section.

section.

"HOW

"POWER SUPPLY R0UTING"for

TO

READ

WIRING

DIAGRAMS

power distribution circuit

.

.

EF

&

EC-2

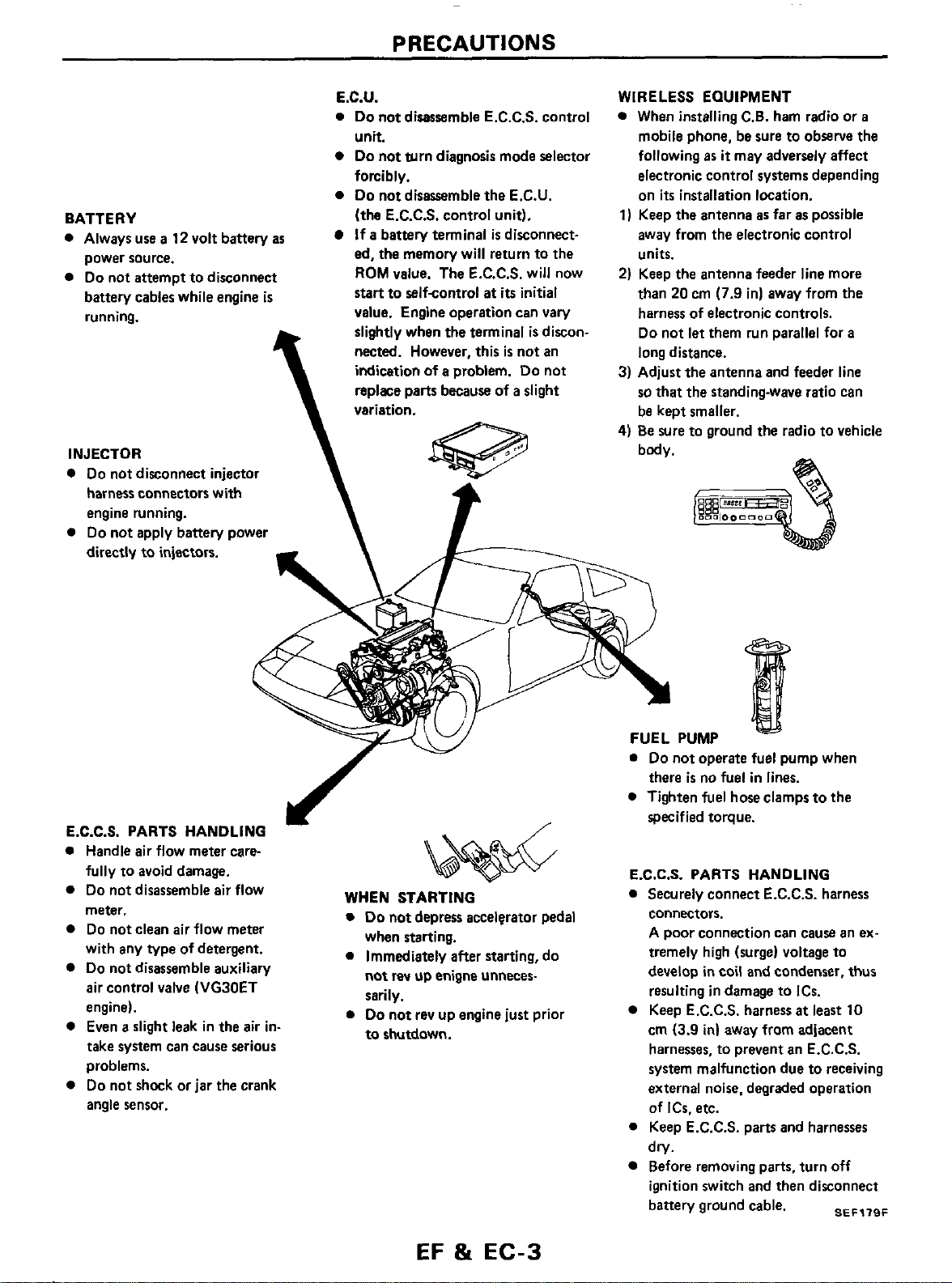

PRECAUTIONS

E.C.U.

a

Do

not disassemble E.C.C.S. control When installing C.B. ham radio or

unit.

a

Do

not turn diagnosis mode selector following

forcibly. electronic control systems depending

a

Do

not disassemble the E.C.U.

BATTERY

Always use

*

power source. ad, the memory will return to the units.

Do

not attempt to disconnect

battery cables while engine

running. value. Engine operation can

a

12

volt battery

as

is

(the E.C.C.S. control unit).

If

a

battery terminal

ROM

value.

The E.C.C.S. will now

start to self-control

slightly when the terminal

nected. However, this

indication

replace parts because of

of

a

is

at

its

problem.

disconnect-

initial

is

not an

Do

a

vary

is

discon-

not

slight

WIRELESS

1)

2)

3) Adjust the antenna and feeder line

4)

INJECTOR

Do

not disconnect injector

harness connectors with

engine running.

Do

not apply battery power

directly to injectors.

EQUIPMENT

a

mobile phone, be sure to observe the

as

it

may adversely affect

on

its

installation location.

Keep the antenna

away from the electronic control

Keep the antenna feeder line more

than

20

em (7.9 in) away from the

harness of electronic controls.

Do

not

let

long distance.

so

that the standing-wave ratio can

be kept smaller.

Be

sure to ground

as

far

as

possible

them run parallel for

the

radio to vehicle

a

E.C.C.S. PARTS HANDLING

Handle air flow meter care-

fully

to

avoid damage.

Do

not disassemble air flow

meter.

Do

not clean air flow meter

with any type of detergent.

Do

not disassemble auxiliary

air control

engine).

Even a slight leak in the air intake system can cause serious

problems.

Do

angle sensor. of

valve

(VG30ET sarily. resulting in damage to

not shock or jar the crank

WHEN STARTING

a

Do

not depress accelerator pedal connectors.

when starting.

a

Immediately after starting, do

not

rev

up enigne unneces-

a

Do

not rev up engine just prior

to shutdown.

FUEL PUMP

a

Do

not operate fuel pump when

there

is

no

fuel in lines.

a

Tighten fuel hose clamps to the

specified toque.

E.C.C.S.

a

a

PARTS HANDLING

Securely connect E.C.C.S. harness

A poor connection can cause an extremely high (surge) voltage to

in

develop

Keep E.C.C.S. harness

cm (3.9

harnesses, to prevent an E.C.C.S.

system malfunction due to receiving

external noise, degraded operation

ICs.

Keep E.C.C.S. parts and harnesses

dry.

Before removing parts, turn off

ignition switch and then disconnect

battery ground cable.

coil and condenser, thus

ICs.

at

least

in\

away

from

adjacent

etc.

10

SEF179F

EF

8t

EC-3

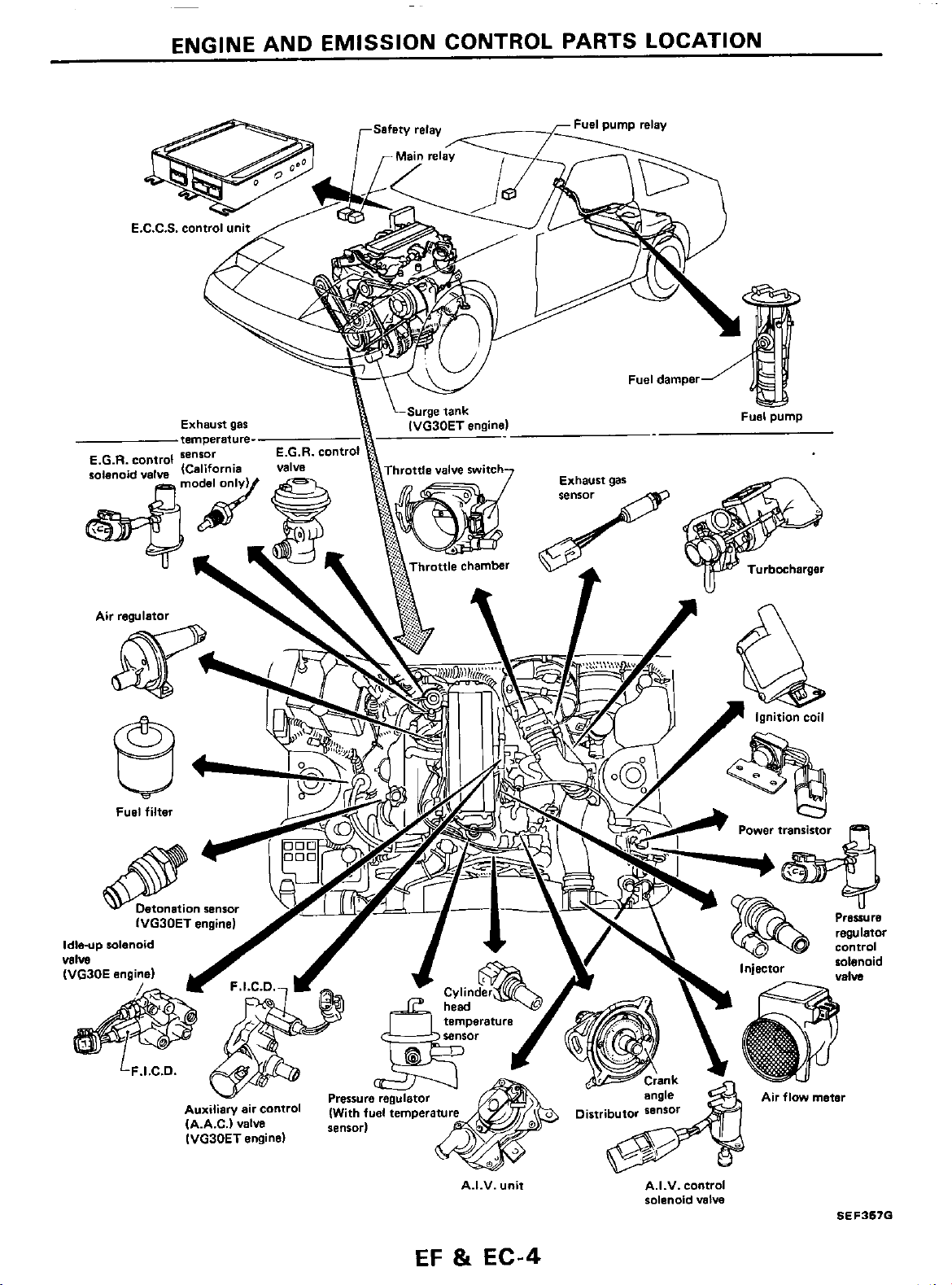

ENGINE AND EMISSION CONTROL PARTS LOCATION

EF

A.I.V.

%I

unit

EC-4

A.I.V.

control

solenoid valve

SEF3570

E.C.C.S.

DIAGRAM

VG30E

engine

(Without

turbochargar)

EF

%t

SEF358G

EC-5

E.C.C.S.

DIAGRAM

VG30ET

engine (With

turbocharger)

EF

&

U

SEF359G

EC-6

E.C.C.S.

CHART

VG30E

Crank angle sensor

Air flow meter

Engine (Without turbocharger)

b

P

+

b

b

Fuel injection

mixture ratio control

Ignition timing control Power transistor

A.I.V. control

&

Injectors

A.I.V. control solenoid

valve

Throttle

(Except nonCalifornia

model1

(Non-California AK model: Only control

for automatic transmission1

Fuel temperature sensor

valve

sensor

MK

1

~

Headlamp switch

Cooling fan switch

Power steering oil pressure switch

Battery voltage

1

Exhaust gas temperature sensor

(California model only1

’

b

b

b

f

E.C.C.S.

control

unit

Fuel pressure control

Fuel pump control Fuel pump

Air regulator control Air regulator

Exhaust

heater control

Air flow meter wire

cleaning control

gas

sensor

YI

Fuel pressure regulator

control solenoid

VL

Exhaust gas sensor

“I

Air flow meter

valve

1

I

EF

Exhaust gas sensor Inspection lamps

&

self-diagnosis

(On the control unit)

%I

nonitor

EC-7

E.C.C.S.

CHART

Crank angle sensor

Air flow meter

+

b

-\

Fuel injection

mixture ratio control

Ignition timing control Power transistor

--

Idle speed control

Ignition switch

-

Idle switch

Throttle

valve

sensor

+

+

E.G.R. control

A.I.V. control A.I.V. control solenoid

&

L

I

Injectors

Auxiliary air cone01

(A.A.C.)

E.G.R. control solenoid

valve

I

I

valve

valve

Throttle

(Except nonCalifor

(Non-California Ail model: Only control

for automatic transmission)

Air conditioner switch

Fuel temperature sensor

Detonation sensor

Exhaust gas temperature sensor

(California model only)

valve

sensor

,

b

b

b

E.C.C.S.

control

unit

AI

Fuel pressure control

Fuel pump control Fuel pump

Air regulator control Air regulator

Exhaust gas sensor

heater control

Air flow meter wire

cleaning control

Fuel pressure regulator

control solenoid

Exhaust gas sensor

Air flow meter

valve

I

I

I

EF

Exhaust gas sensor Inspection lamps

(On

&

monitor

EC-8

&

self-diagnosi

the control unit)

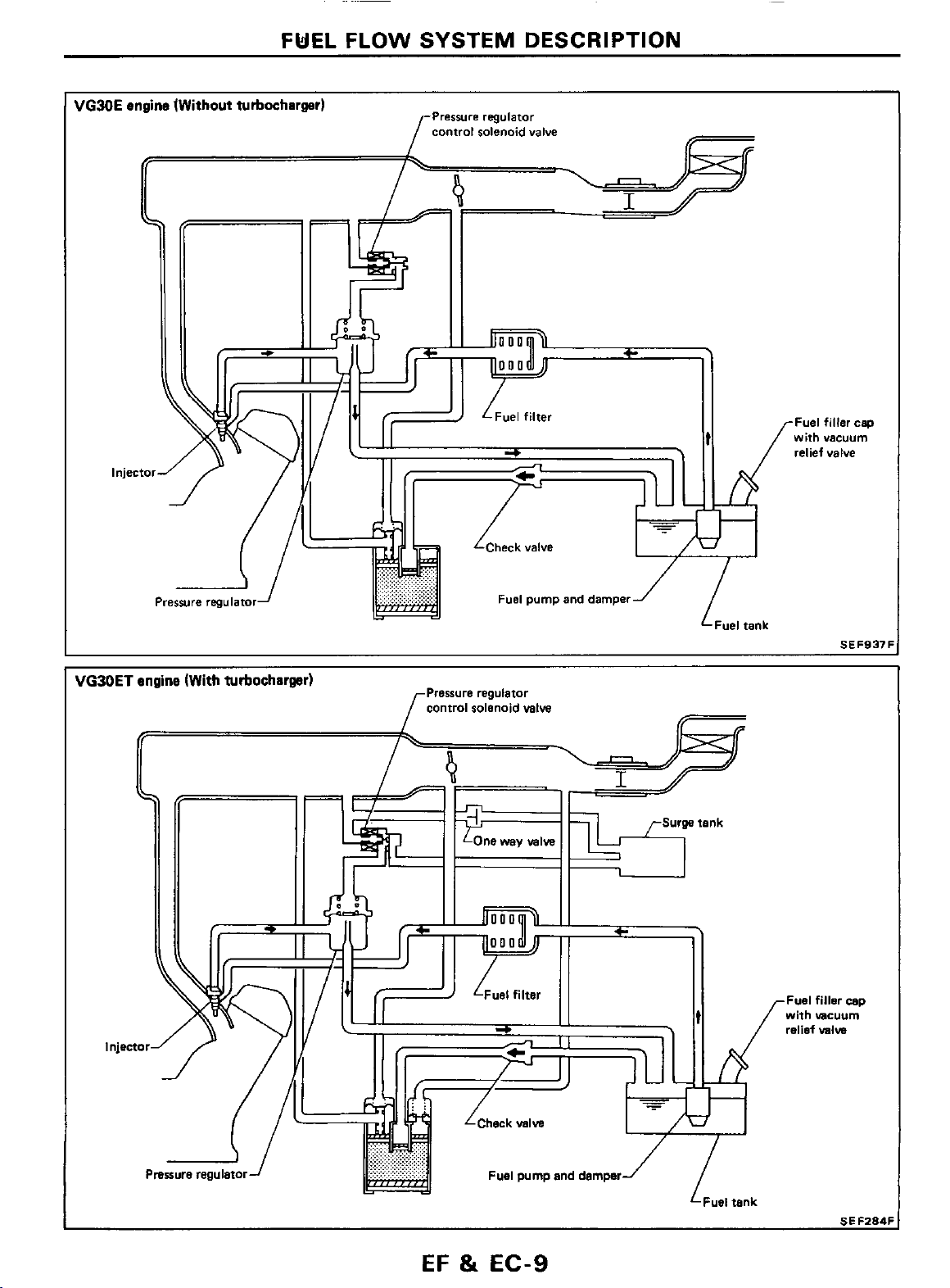

FUEL FLOW SYSTEM DESCRIPTION

VG30E

engine

(Without

turbocharger)

Prerwre

control

regulator

ralenoid

valve

-Fuel filler

with

vacuum

relief valve

cap

SEF937F

EF

&

EC-9

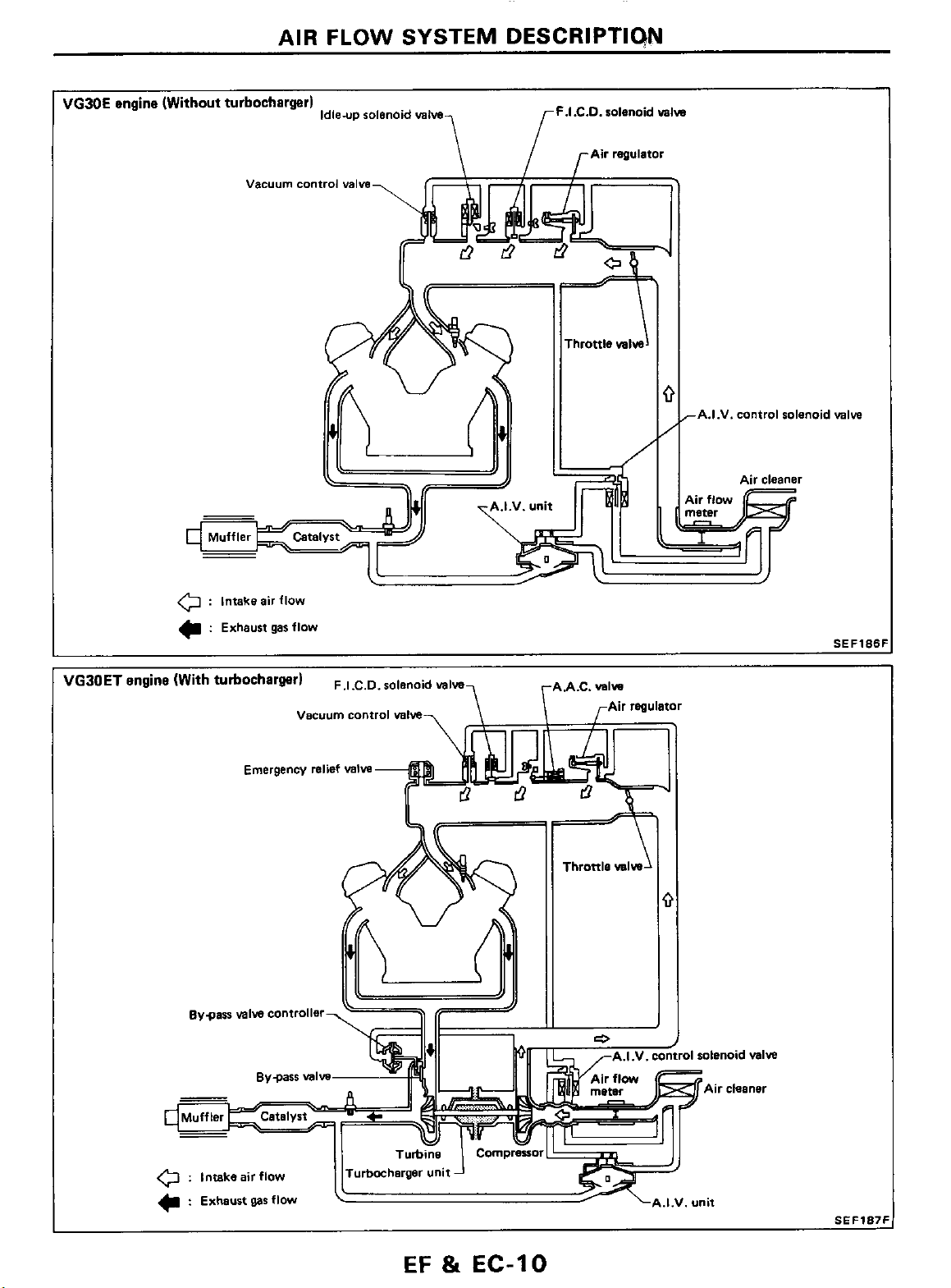

AIR

FLOW

SYSTEM

DESCRIPTIQN

0

:

:

Vacuum control

Intakeairflow

Exhaust gas

flow

valve

Throttle

valve1

I

-A.I.V. control solenoid

Air cleaner

valve

SEF1861

VG30ET

engine (With turbocharger)

Vacuum control

Emergency

Bygas

vdlw

controller

relief

F,I.C,D,

valve

valve

valve,

rAA.C.

valva

ro1

solenoid

valw

a

:

:

Intake

air flow

Exhaustgasflow

EF

&

EC-10

SEF1871

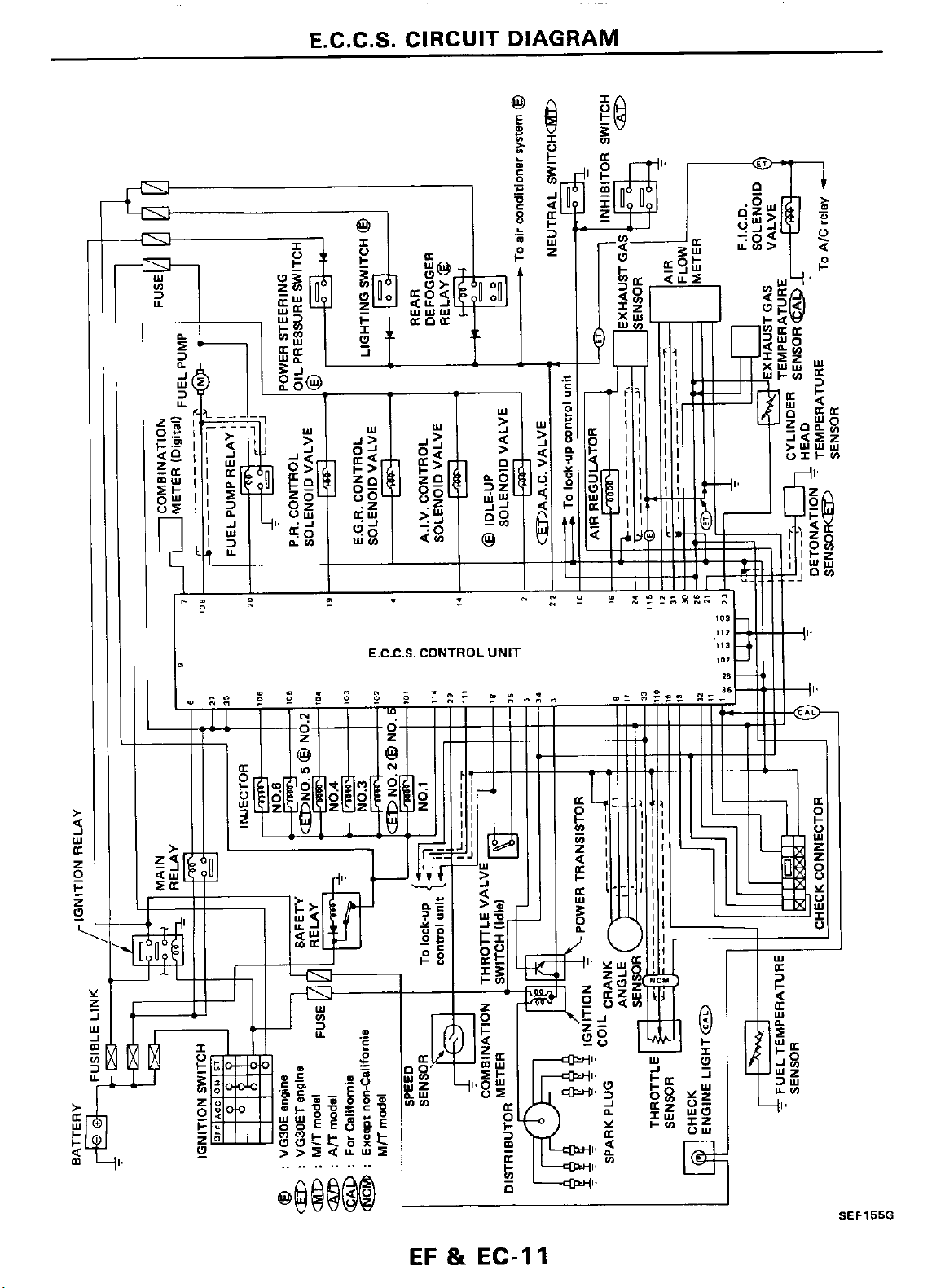

E.C.C.S.

CIRCUIT

DIAGRAM

E.C.C.S.

CONTROL

UNIT

EF

&

EC-11

SEF155G

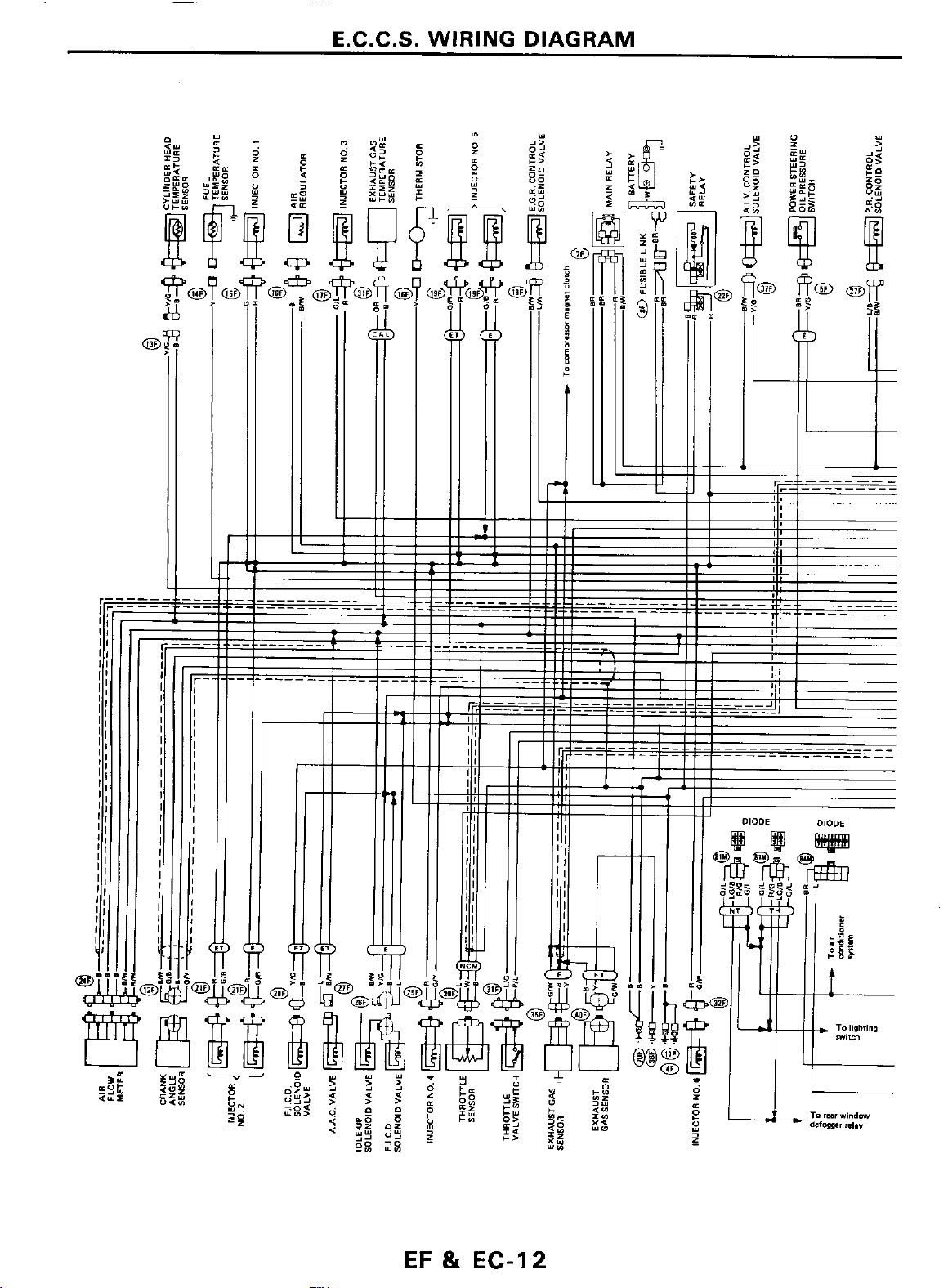

E.C.C.S.

WIRING DIAGRAM

EF

81

EC-12

I

E.C.C.S.

E.C.C.S.

CONTROLVNlT

WIRING DIAGRAM

I

GROUND

SEF156G

SEF6ll8

E.C.C.S.

DESCRIPTION

Components

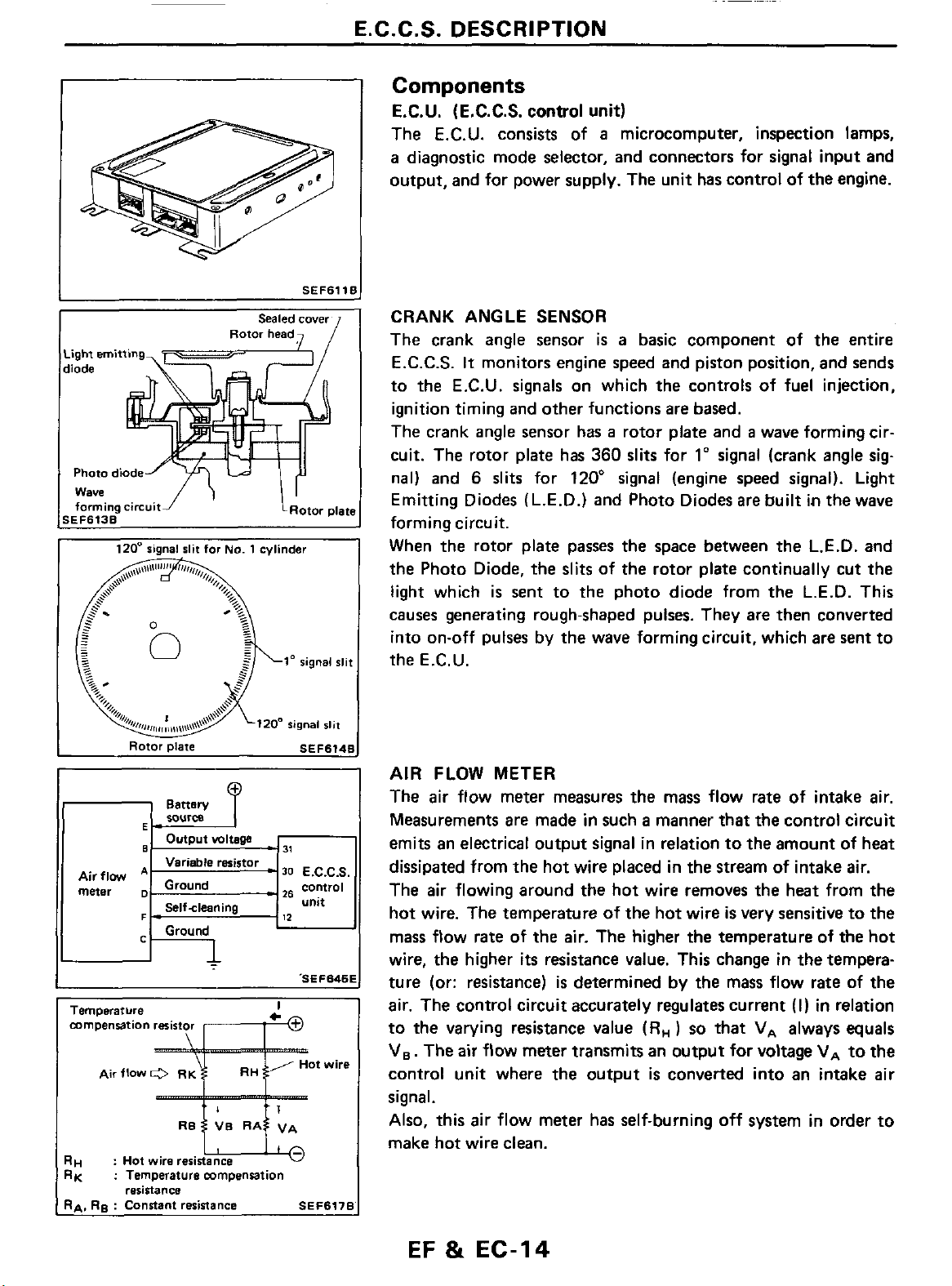

E.C.U. (E.C.C.S. control unit)

The E.C.U. consists of

a

diagnostic mode selector, and connectors for signal input and

output, and for power supply. The unit

a

microcomputer, inspection

has

control of the engine.

lamps,

forming circuit Rotor plate

SEF613B

Rotor plate SEFE148

+

emery

sourcd

E-

Ovtput MltaQe

Ovtput MltaQe

0

Airflw

meter

meter

"

D

D

C

C

1-

I

Temperature

mmpensation resist

Air flow

RH

RK

RA.

:

Hot wire red

:

Temperature mmpensation

resistance

Rs

:

Constant

Variable resistor

Variable resistor

Ground

Selfcleaning

Selfcleaning

-

Ground

Ground

1

-

resistance

-

31

-30

26

12

I

E.C.C.S.

control

unit

'SEF646E

SEF617B

ot wire

CRANK

The crank angle sensor

E.C.C.S.

to the E.C.U. signals on which the controls

ANGLE SENSOR

is

a

basic component of the entire

It

monitors engine speed and piston position, and sends

of

fuel injection,

ignition timing and other functions are based.

a

The crank angle sensor has

cuit. The rotor plate has

nal)

and

6

slits

for

120"

Emitting Diodes (L.E.D.) and Photo Diodes are built

rotor plate and a wave forming cir-

360

slits

for

1"

signal (crank angle

signal

(engine speed signal). Light

in

forming circuit.

When the rotor plate passes the space between the L.E.D. and

slits

the Photo Diode, the

is

light which

sent to the photo diode from the

of the rotor plate continually cut the

L.E.D.

causes generating rough-shaped pulses. They are then converted

into on-off pulses by the wave forming circuit, which are sent to

the E.C.U.

AIR

FLOW

air

The

Measurements are made in such a manner

emits an electrical output signal in relation

dissipated from the hot wire placed

The

air

hot wire. The temperature

mass flow rate of

wire, the higher

I

ture (or: resistance)

air.

The control circuit accurately regulates current

to the varying resistance value

VB.

The air flow meter

control unit where the output

METER

flow meter measures the mass flow rate of intake

that

the control circuit

to

the amount of heat

in

the stream

of

intake

flowing around the hot wire removes the heat from the

of

the hot wire

the

air.

The higher the temperature

its

resistance value. This change

is

determined by

is

very sensitive

in

the tempera-

the

mass flow rate of the

(I)

(RH

)

so

that

V,

always equals

transmits

an output

is

converted into an intake

for

voltage

signal.

Also,

this

air

flow meter has self-burning off system in order to

hot

make

.

wire clean.

the wave

This

air.

to

of

the hot

in

relation

V,

to

sig-

air.

the

the

air

EF

&

EC-14

E.C.C.S. DESCRIPTION

Components (Cont’d)

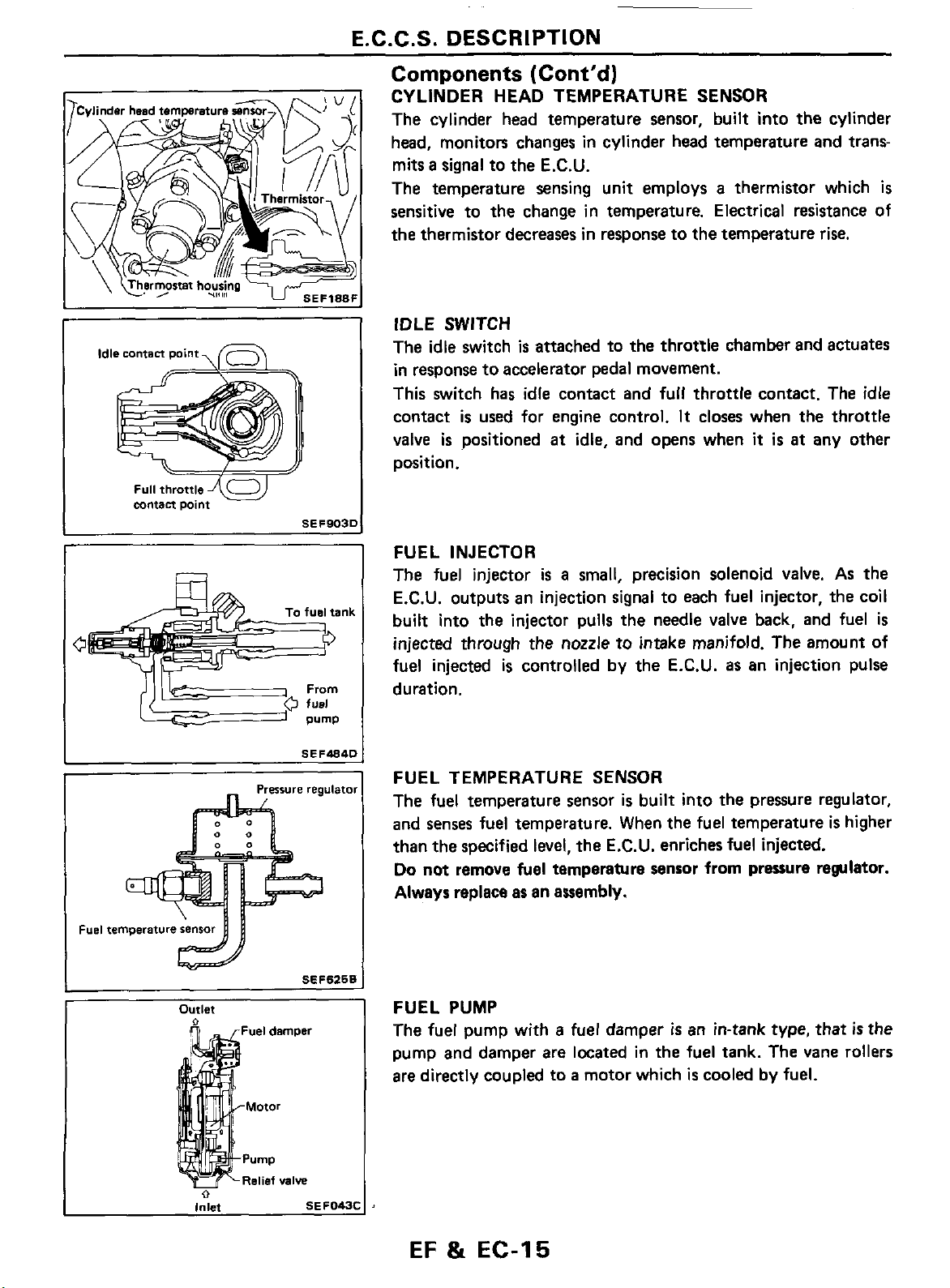

CYLINDER HEAD TEMPERATURE SENSOR

The cylinder head temperature sensor, built into

head, moniton changes in cylinder head temperature and trans-

a

mits

The temperature sensing unit employs a thermistor which

sensitive to the change in temperature. Electrical resistance

the thermistor decreases in response to the temperature

signal to the

E.C.U.

the

cylinder

is

of

rise.

I

a

Idlecontan

R

IDLE SWITCH

.

SEF903D

The idle switch

in response to accelerator pedal movement.

This switch has

contact

valve

position.

is

is

positioned

is

attached to the throttle chamber and actuates

idle

contact and

used for engine control.

at

idle, and opens when

full

throttle contact. The idle

It

closes when the throttle

it

is

at

any other

FUEL INJECTOR

Pressure

SEF4840

regulatol

The fuel injector

E.C.U.

built into the injector pulls the needle valve back, and

injected through the nozzle

fuel

duration.

outputs an injection signal to each

injected

FUEL TEMPERATURE SENSOR

The

fuel

temperature sensor

and senses

than the specified

Do

not

Always

fuel

remove

replace

is

a

small, precision solenoid valve.

fuel

injector, the coil

to

intake manifold. The amount

is

controlled by the

temperature. When the fuel temperature

level,

the

E.C.U.

fuel

temperature

as

an assembly.

E.C.U.

is

built into the pressure regulator,

enriches

sensor

as

an injection pulse

fuel

injected.

from pressure regulator.

As

fuel

is

higher

the

is

of

Outlet

0

0

Inlet

SEF626U

SEF043C

FUEL PUMP

The fuel pump with a fuel

pump and damper are located in the

are directly coupled to

EF

&

EC-15

damper

a

motor which

is

an in-tank type, that

fuel

tank. The vane rollers

is

cooled by

fuel.

is

the

I

Idle-up solenoid

Idle weed adiusring screw1

Y

-

E.C.C.S. DESCRIPTION

Components (Cont’d)

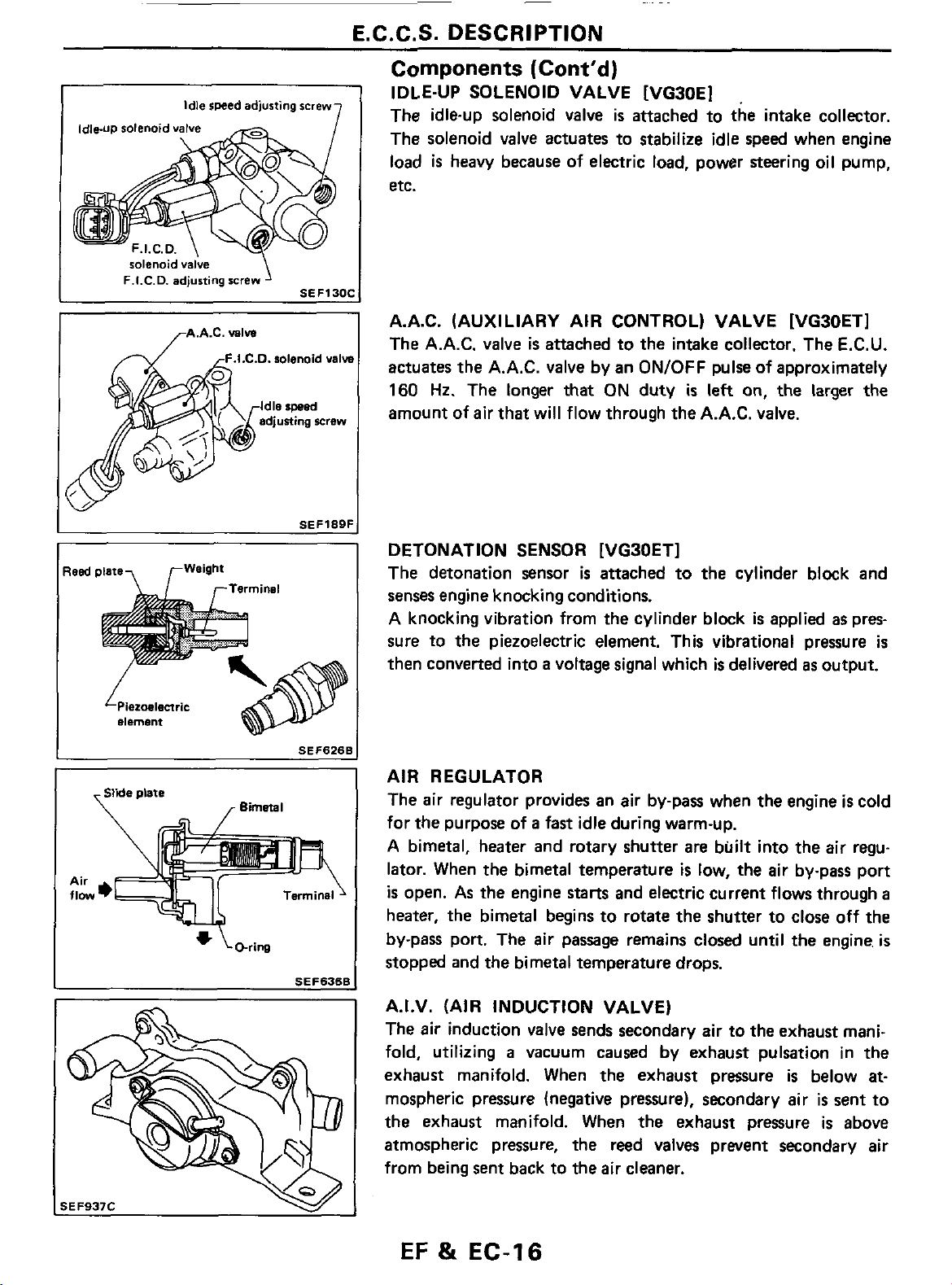

IDLE-UP SOLENOID VALVE [VG30E]

I

The idle-up solenoid valve

The solenoid valve actuates to stabilize idle speed when engine

is

load

etc.

heavy because of electric

is

attached to the intake collector.

load,

power steering oil pump,

I

solenoid

F.I.C.O.

valve

adjusting screw

.I.C.O.

SEFIOOC

solenoid

le

wed

juning

valw

screw

A.A.C. (AUXILIARY

The A.A.C. valve

actuates the A.A.C. valve by an

Hz. The longer that

160

amount of

DETONATION SENSOR IVG30ETl

The detonation sensor

senses engine knocking conditions.

A knocking vibration from the cylinder block

sure to

then converted into a voltage signal which

air

that will flow through the A.A.C. valve.

the

piezoelectric element. This vibrational pressure

is

attached

AIR

CONTROL) VALVE LVG30ETl

to

the intake collector. The E.C.U.

ON

is

attached

ON/OFF

duty

pulse

is

left on, the larger the

to

the

is

delivered

of

approximately

cylinder block and

is

applied

as

pres-

is

as

output.

I

-Slide

olate

SEF626B

SEF636B

AIR REGULATOR

air

The

for the purpose of

A bimetal, heater and rotary shutter are built

lator. When the bimetal temperature

is

heater, the bimetal begins

by-pass

stopped and the bimetal temperature

A.I.V. (AIR INDUCTION VALVE)

The

fold, utilizing

exhaust manifold. When the exhaust pressure

mospheric pressure (negative pressure), secondary

the exhaust manifold. When the exhaust pressure

atmospheric pressure, the reed valves prevent secondary

from being sent back to the

regulator provides

open.

As

the engine starts and electric current flows through

port.

air

induction valve

a

fast idle during warm-up.

The

air

a

vacuum caused by exhaust pulsation in the

an

air by-pass when the engine

into

is

low, the

to

rotate the shutter to close off the

passage remains closed until the engine.

drops.

sends

secondary air

air

to

the exhaust mani-

is

air

air

cleaner.

is

the air regu-

by-pass port

below at-

is

sent to

is

above

cold

a

is

air

EF

&

EC-16

Holder

~

%nwr

element (Titania)

-

C

I

-

-

:I

c

-

*

.-

r

Le

Rich-

I

E.C.C.S. DESCRIPTION

Components (Cont'd)

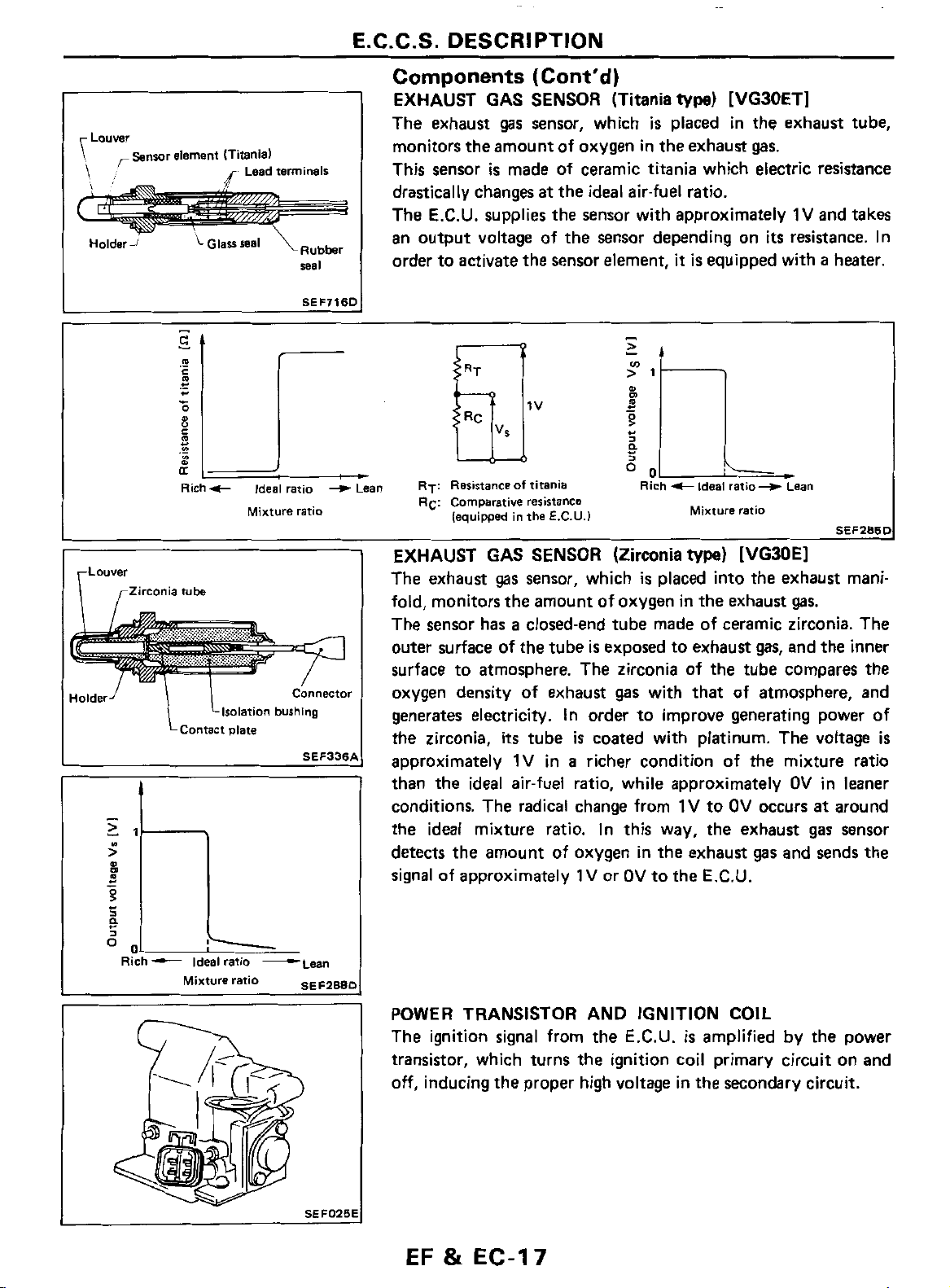

EXHAUST GAS SENSOR

The exhaust

monitors the amount of oxygen in the exhaust

Lead terminals

SEF716D

This sensor

drastically changes

E.C.U.

The

an

output voltage of the sensor depending on

order to activate the sensor element,

I--.

ideal

ratio

+

L~~~

Mixture ratio [equipped

I

SEF336A

RT: Resistanceof titania Rich C Ideal ratio+ Lean

Rc:

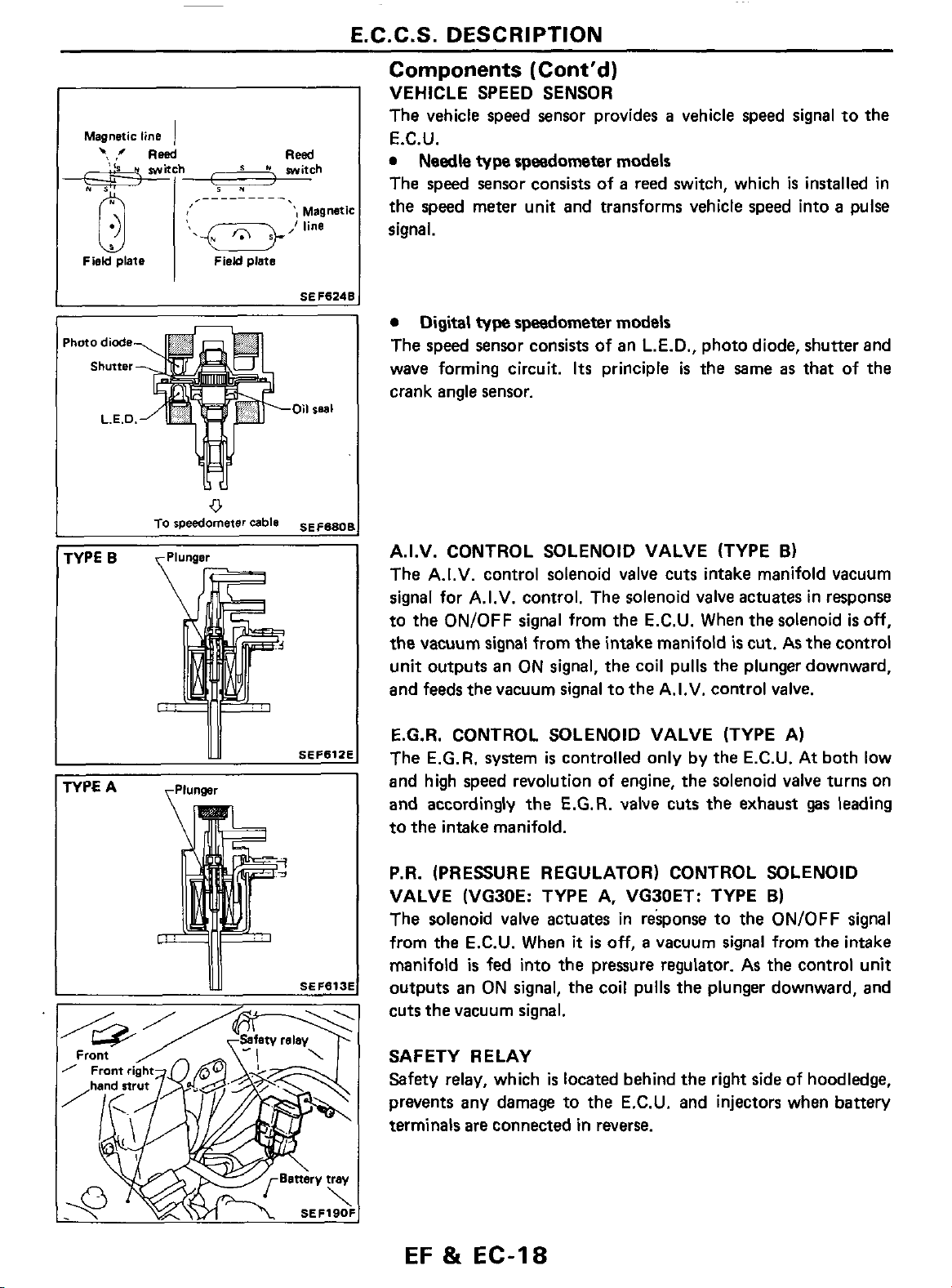

EXHAUST GAS SENSOR

~~ ~

The exhaust

fold, monitors the amount of oxygen

The sensor has a closed-end tube made of ceramic zirconia. The

outer surface of

surface to atmosphere. The zirconia of the tube compares the

oxygen density of exhaust gas with that of atmosphere, and

generates electricity. In order to improve generating power of

the zirconia,

approximately

than the ideal air-fuel ratio, while approximately

conditions. The radical change from

the ideal mixture ratio. In this way, the exhaust gas sensor

detects the amount of oxygen

signal of approximately

is

supplies the sensor with approximately

fq,"

Comparative resistance

(Titania

gas

sensor, which

made of ceramic titania which electric resistance

at

the

ideal

type)

is

placed in the exhaust

air-fuel ratio.

it

IVG30ETI

is

equipped with a heater.

gas.

1V

its

resistance. In

tube,

and takes

~~1-

in

the

E.C.U.)

gas

sensor, which

the

tube

its

tube

1V

in a richer condition of the mixture ratio

(Zirconia

is

is

exposed to exhaust gas, and

is

coated with platinum. The voltage

in

1 V

or

OV

Mixture ratio

Wpe)

placed into

in

the exhaust

1V

to

the exhaust

to the

E.C.U.

[VG30El

the

exhaust mani-

OV

occurs

gas

and sends the

gas.

OV

at

SE FZBS

the

inner

in leaner

around

I

D

is

Mixture ratio SEF288D

I

I

POWER TRANSISTOR AND IGNITION

The

ignition

transistor, which turns the ignition coil primary circuit on and

off, inducing the proper high voltage

signal from the

E.C.U.

in

COIL

is

amplified by the power

the

secondary circuit.

EF & EC-17

E.C.C.S. DESCRIPTION

Components (Cont'd)

VEHICLE SPEED SENSOR

The vehicle speed Sensor provides a vehicle speed signal to the

E.C.U.

Needle

,--------->

0;

Field

plate

<%-/'

Field plate

',

Magnetic

line

The speed Sensor consists

the speed meter unit and transforms vehicle speed into

signal.

type

spaadometer models

of

a

reed switch, which

is

installed in

a

pulse

0

speedometer

cable

TYPE

To

B

1

-

TYPE

A

TPlunger

Oil

seal

SEFeBOB

SEFBlZE

Digital

The speed sensor consists

wave forming circuit. Its principle

crank angle sensor.

A.I.V. CONTROL SOLENOID VALVE (TYPE

The A.I.V. control solenoid valve cuts intake manifold vacuum

signal for A.I.V. control. The solenoid valve actuates in response

to the ON/OFF signal from the

the vacuum signal from the intake manifold

unit outputs an ON signal, the coil pulls the plunger downward,

and feeds the vacuum

E.G.R. CONTROL SOLENOID VALVE (TYPE A)

The

and high speed revolution of engine, the solenoid valve turns on

I

and

to the intake manifold.

type

speedometer models

E.G.R.

accordingly the

syStem

of

an

L.E.D.,

is

E.C.U.

signal

to the

is

controlled only by the

E.G.R.

A.I.V.

valve cuts the exhaust

photo diode, shutter and

the same

When the solenoid

control valve.

is

cut.

E.C.U.

as

that

B)

As

the control

At both low

as

of the

is

off,

leading

P.R. (PRESSURE REGULATOR) CONTROL SOLENOID

VALVE (VG30E: TYPE A, VG30ET: TYPE

The solenoid valve actuates in response to

the

from

manifold

1

SEF613E

outputs an ON signal, the coil pulls the plunger downward, and

cuts the vacuum signal.

SAFETY RELAY

Safety relay, which

prevents any damage to the

terminals are connected

EF

E.C.U.

is

fed into the pressure regulator.

&

EC-18

When

it

is

located behind

in

is

off,

E.C.U.

reverse.

B)

the

ON/OFF signal

a

vacuum

signal

the

right

and injectors when battery

from the intake

As

the control unit

side of hoodledge,

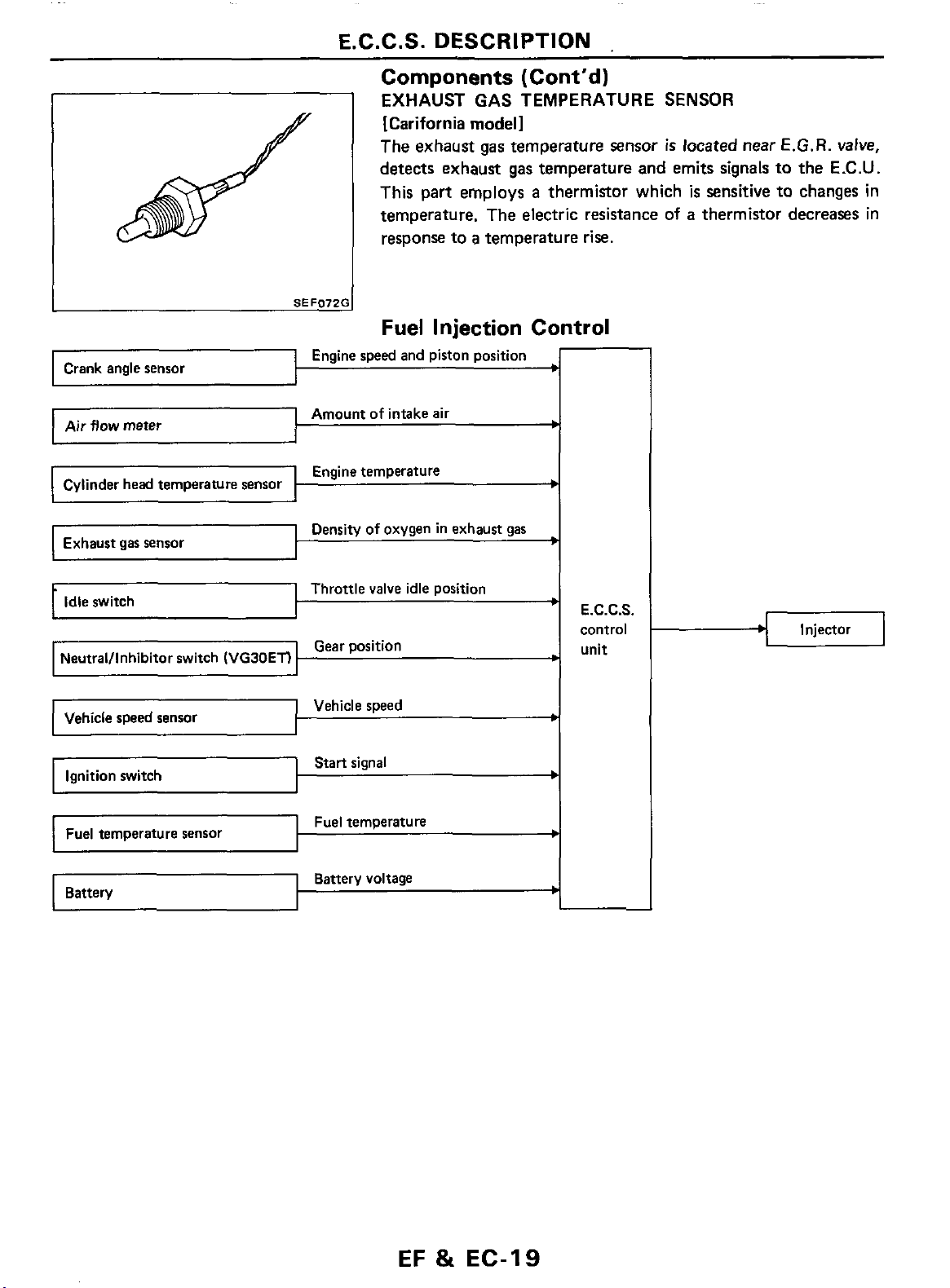

Crank angle sensor

E.C.C.S. DESCRIPTION

Components (Cont'd)

EXHAUST

[Carifornia

The exhaust gas temperature sensor

detects exhaust gas temperature and emits signals to the E.C.U.

This part employs

temperature. The electric resistance

response to

SEF072G

Fuel

Engine speed and piston position

GAS

model]

a

temperature rise.

Injection Control

TEMPERATURE SENSOR

is

located near E.G.R. valve,

a

thermistor which is sensitive to changes in

of

a

thermistor decreases in

~

Air

flow

meter

Exhaust gas sensor

NeutraI/lnhibitorrvvItch(VG30;;;]

I I

7

1

Amount

Engine temperature

Density

Throttle valve idle position

Gear position unit

Vehicle speed

Start signal

Fuel

of

intake air

of

oxygen in exhaust gas

temperature

b

'

b

b

+

E.C.C.S.

control

Injector

1

Battery voltage

EF

&

EC-19

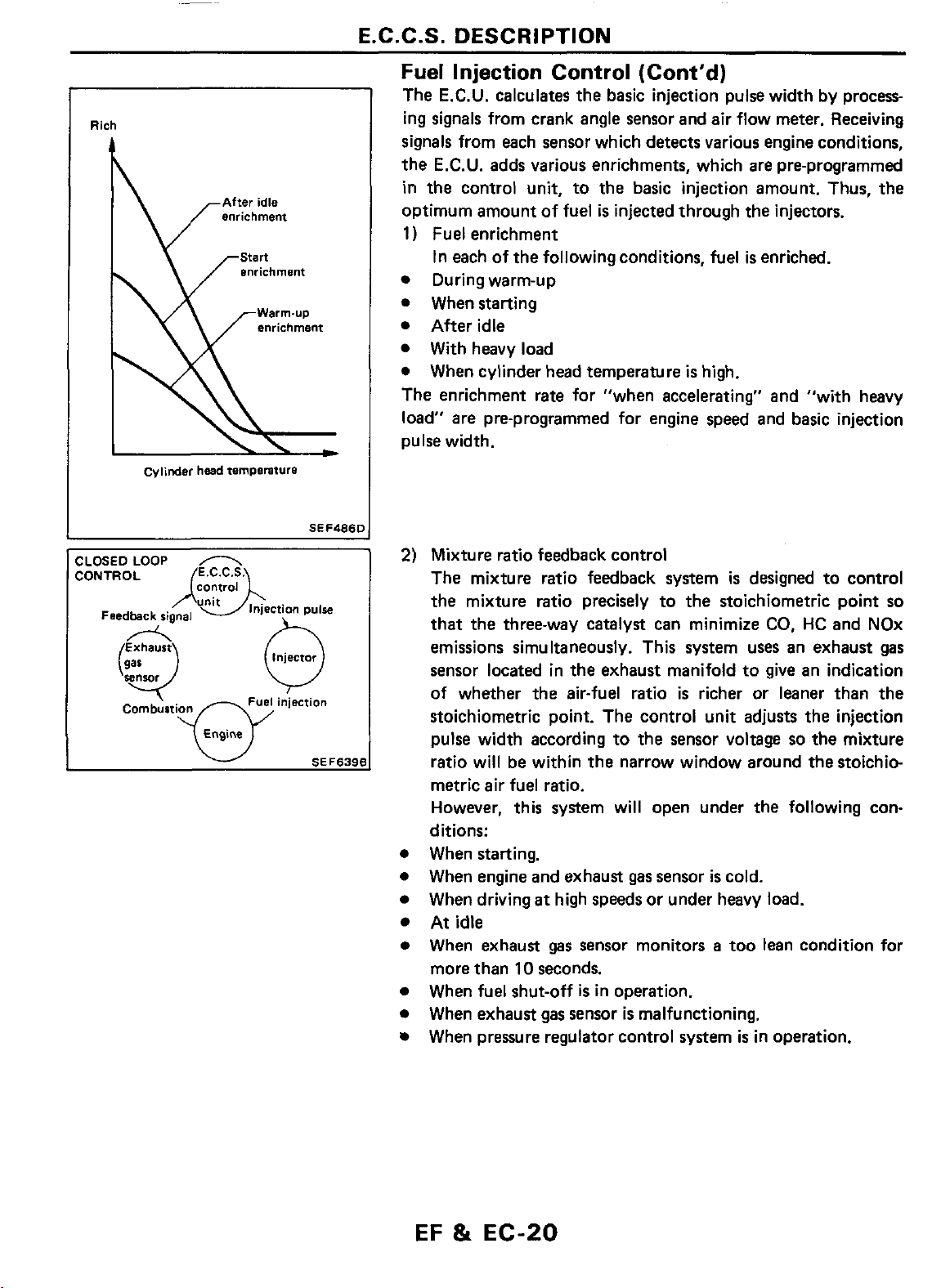

E.C.C.S. DESCRIPTION

Rich

A

cylinder

CLOSEOLOOP

I

CONTROL

Feedback

A

I

head

'E.C.C.Sj

lfd

signal

enrichment

enrichment

temperature

n

injector

injection

SEF4860

Fuel

The E.C.U. calculates the basic injection pulse width by process-

ing signals from crank angle sensor and air flow meter. Receiving

signals from each sensor which detects various engine conditions,

the E.C.U.

in

optimum amount of fuel

1)

The enrichment rate for "when accelerating" and "with heavy

load" are pre-programmed for engine speed and basic injection

pulse width.

2)

I

I

Injection Control (Cont'd)

adds

various enrichments, which

the

control unit, to

Fuel enrichment

In each of the following conditions,

During warm-up

When starting

After idle

With

heavy

When cylinder head temperature

Mixture ratio feedback control

The mixture ratio feedback system

the mixture ratio precisely to the stoichiometric point

that the three-way catalyst can minimize CO, HC and NOx

emissions simultaneously. This system uses

sensor located in the exhaust manifold

of

whether the air-fuel ratio

stoichiometric point. The control unit adjusts

pulse width according

ratio will be within the narrow window around thestoichiometric

However, this system will open under the following con-

ditions:

When

When engine and exhaust gas sensor

When driving

At

idle

When exhaust

more than

When fuel shut-off

When exhaust gas sensor

When pressure regulator control system

load

air

fuel ratio.

starting.

at

10

seconds.

the

basic injection amount.

is

injected through the injectors.

is

is

to

the

sensor voltage

high speeds or under heavy load.

gas

sensor monitors a too lean condition for

is

in operation.

is

malfunctioning.

are

pre-programmed

Thus,

fuel

is

enriched.

high.

is

designed to control

an

exhaust gas

to

give an indication

richer or leaner than the

the

so

the mixture

is

cold.

is

in operation.

the

so

injection

EF

&

EC-20

Group

injection

No.

1

cylinder

u

No. Z cyltndn-

No.

3cylind.r-

NO.

4 cylinder-

5

cylinderb

No.

No.

6

cylinderb

C

1

engine

cycle4

e

Simultaneous iniection

No.

cylinder

No.

z

cylinder-

No.

3

cylinder-

No.4cy1inderu

No.

5

cylinder-

N~.

6cylinder-n-n-i-,

n

C

1

engine

n

cycle

n

_I

SEFMOB

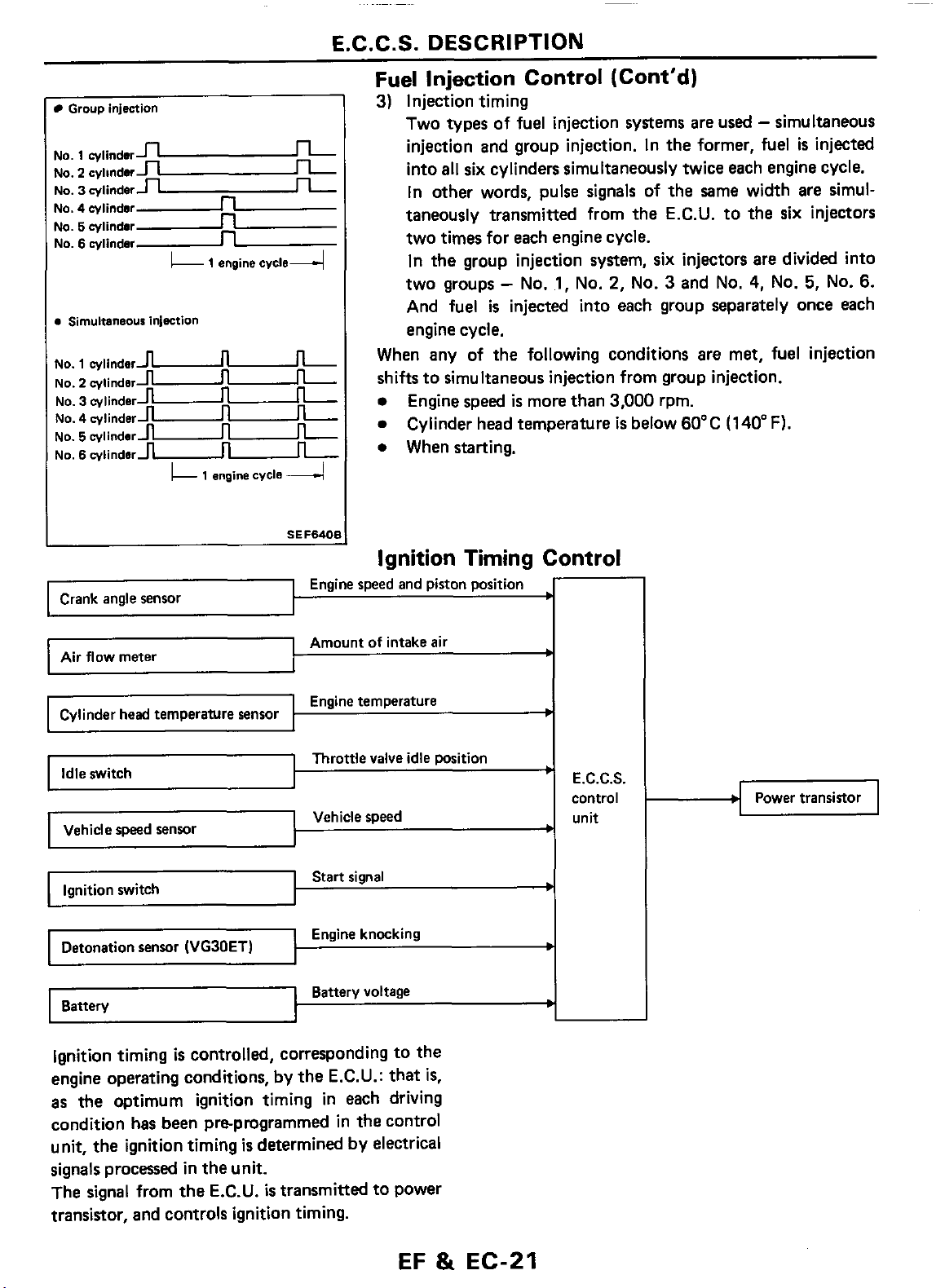

3)

Injection timing

Two types of fuel injection systems are used - simultaneous

injection and group injection. In the former,

all

into

six cylinders simultaneously twice each engine cycle.

fuel

is

injected

In other words, pulse signals of the same width are simultaneously transmitted from the E.C.U. to the six injectors

two times for each engine cycle.

are

In the group injection system, six injectors

-

No.

1,

No.

2,

two groups

And fuel

No. 3 and

is

injected into each group separately once each

No.

divided into

4,

No.

5,

No. 6.

engine cycle.

When any of the following conditions are met, fuel injection

shifts to simultaneous injection from group injection.

Engine speed

Cylinder head temperature

*

When starting.

is

more than

3,000

is

below

rpm.

60°C

(140°F).

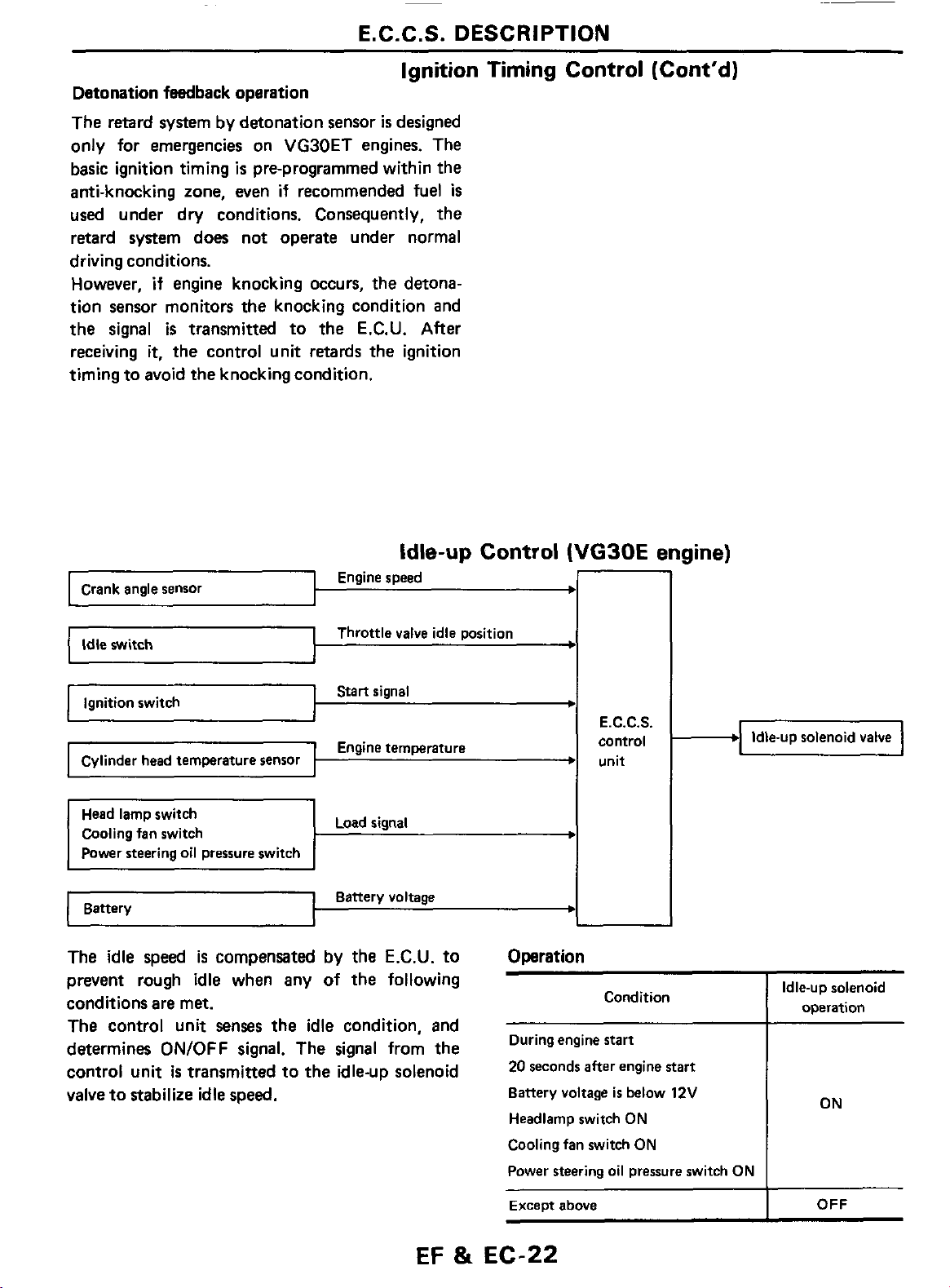

Crank angle sensor

Air flow meter

Idle switch

Ignition switch

Battery

Engine speed and piston position

Amount

Engine temperature

Throttle

Vehicle speed

Start signal

Engine knocking

j

Battery voltage

of

intake air

valve idle wsition

t

t

t

’

E.C.C.S.

control Power transistor

unit

b

t

EF

&

EC-21

Detonation feedback operation

E.C.C.S. DESCRIPTION

Ignition Timing Control (Cont'd)

The retard system by detonation sensor

only

for emergencies on VG30ET engines. The

is

basic ignition timing

anti-knocking zone, even if recommended fuel

used under dry conditions. Consequently, the

retard system does not operate under normal

driving conditions.

However, if engine knocking occurs, the detonation sensor monitors the knocking condition and

is

the signal

receiving

timing to avoid the knocking condition.

transmitted to the E.C.U. After

it,

the control unit retards the ignition

pre-programmed within the

is

designed

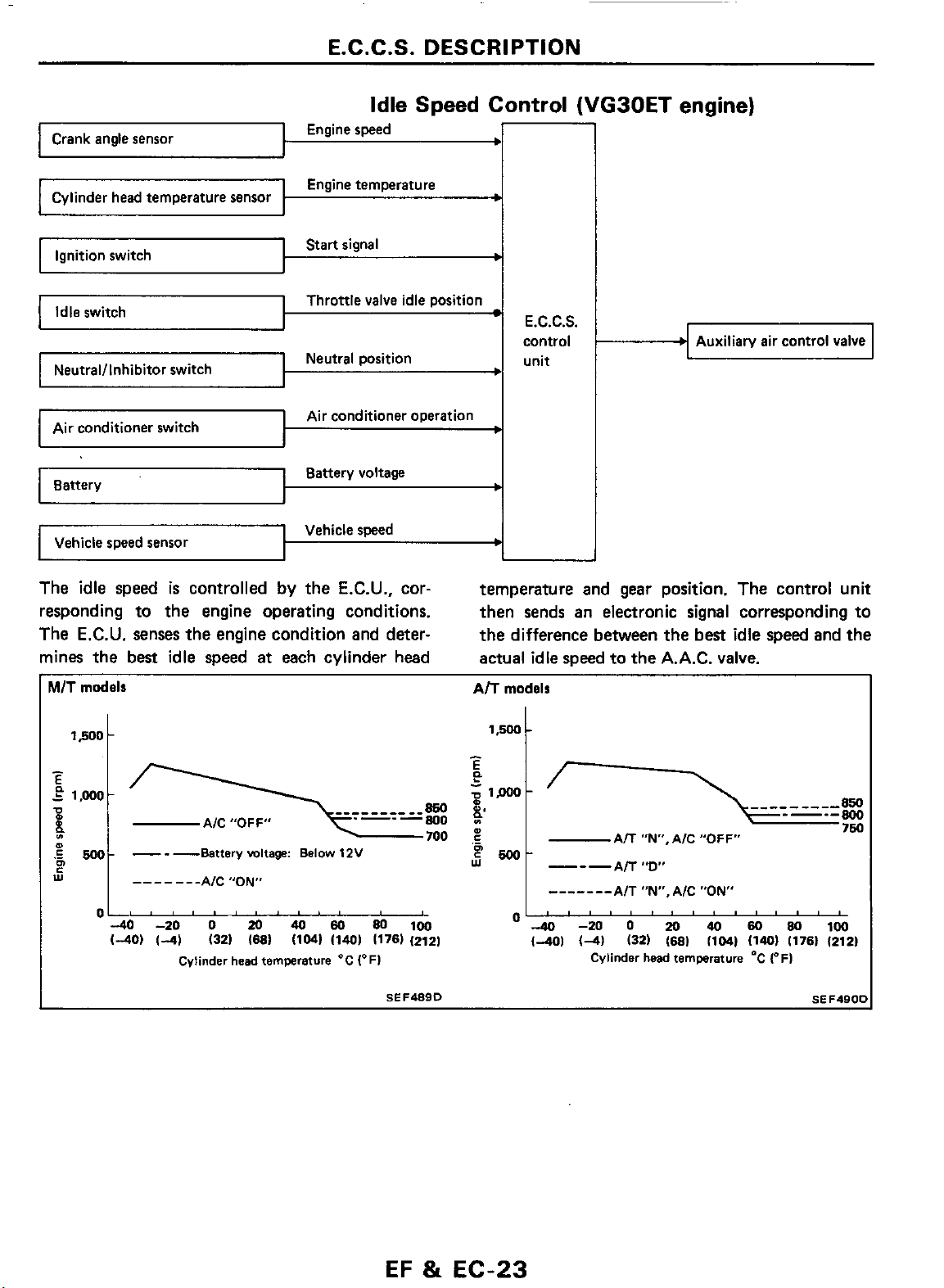

Idle-up

is

Control

(VG30E

engine)

Throttle

Engine temperature

Head lamp switch

Cooling fan switch

Power steering oil pressure switch

Battery

prevent rough idle when any of the following

conditions are met.

The control unit senses the idle condition, and

determines

control unit

valve

to stabilize idle speed.

ON/OFF

is

transmitted to the idle-up solenoid

signal. The signal from the

Load signal

Battery voltage

valve

idle position

-4

.I

Condition

During engine start

20

seconds after engine start

Battery voltage

Headlamp switch

Cooling fan switch

Power steering oil pressure switch

is

below

ON

12V

ON

Idle-up solenoid

Idle-up solenoid

operation

ON

ON

valve

I

EF

Except above

%t

EC-22

OFF

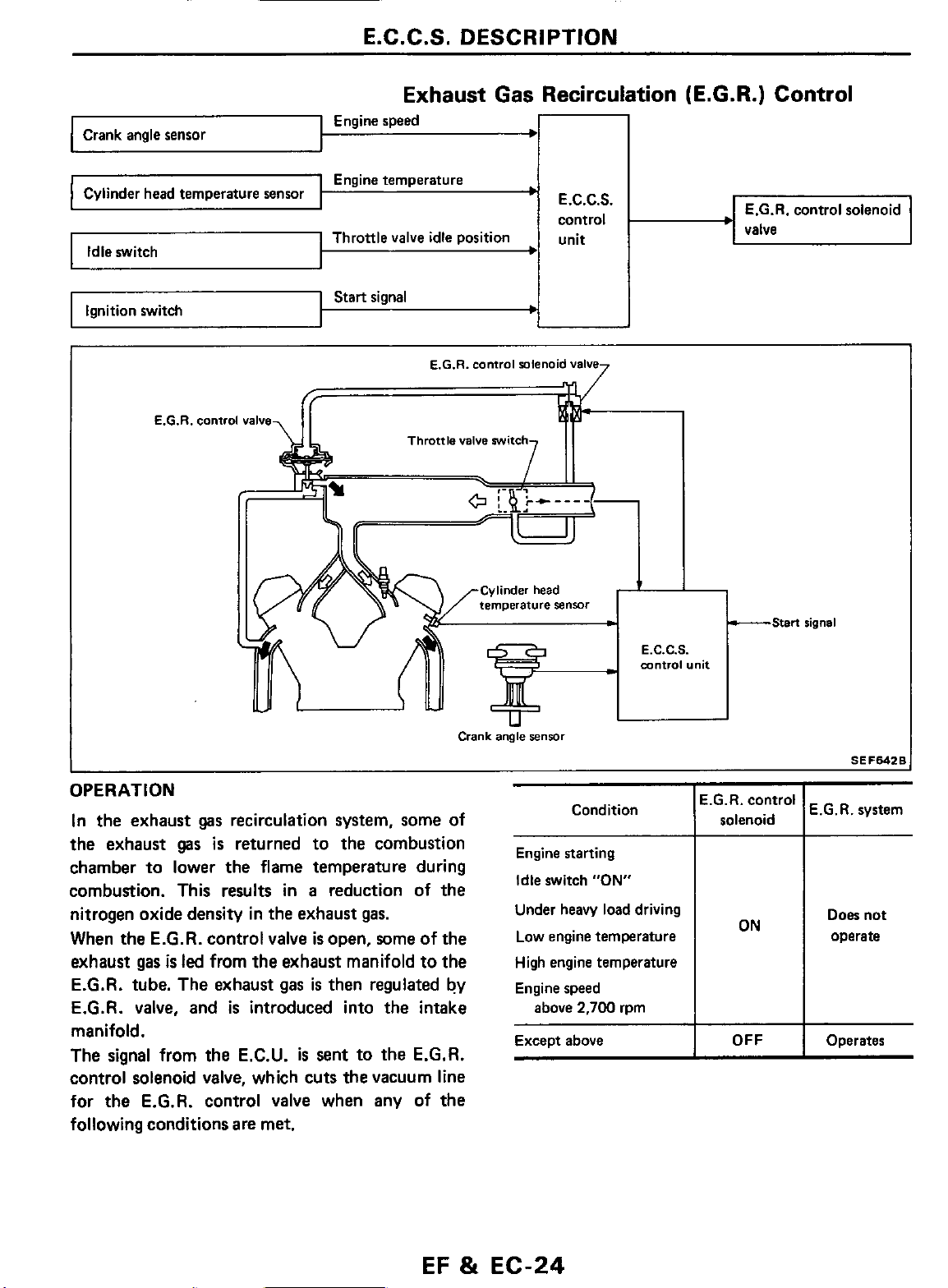

Crank angle sensor

I

Neutralllnhibitor switch

I I

E.C.C.S. DESCRIPTION

Idle SDeed Control (VG30ET engine)

Engine speed

J

Engine temperature

Start signal

Throttle valve idle position

Neutral position

Air conditioner operation

I

*

i

I

E.C.C.S.

control

unit

Auxiliary

air

control valve

Battery

Vehicle speed sensor

I

The

idle

speed

responding to the engine operating conditions. then sends

The E.C.U. senses the engine condition and determines the best idle speed

WT

models

1,500

t

is

controlled

----Battery

_______

AIC

wltew:

"ON,'

Battery voltage

Vehicle speed

I

by

the E.C.U., cor-

at

each cylinder head actual idle speed to the

Below

12V

.

I

temperature and

the

difference between the best idle

A/T

models

an

electronic

gear

position. The control unit

signal

A.A.C.

corresponding to

weed

valve.

and the

Cylinder

head

temperature

'C

("FI

SEF489D

EF

&

EC-23

Cylinder

head

temperature

'C

('FI

SEF490C

E.C.C.S. DESCRIPTION

Crank angle sensor

Idle switch

E.G.R.

control

valve

Engine speed

Engine temperature

Throttle valve idle position

Start signal

E.G.R.

control solenoid valve,

Cylinder head

temperature

b

'

b

E.C.C.S.

control

unit

snmr

E.G.R. control solenoid

valve

Start

signal

In the exhaust

nitrogen oxide density in the exhaust

When the

exhaust

E.G.R.

E.G.R.

gas

tube. The exhaust gas

valve,

E.G.R.

is

led

and

gas

recirculation system, some of

gas.

control valve

is

open, some of the

from the exhaust manifold to the

is

then regulated by

is

introduced into the intake

manifold.

The signal from the

E.C.U.

is

sent to the

E.G.R.

control solenoid valve, which cuts the vacuum line

for the

E.G.R.

control

valve

when any

of

the

following conditions are met.

Crank angle

Under heavy load driving

Low

High engine temperature

Engine speed

Except above

sensor

Condition

engine temperature

above

2,700

rpm

E.G.R. control

solenoid

ON

OFF

SEFMZB

!.G.R. system

Does

not

operate

Operates

EF

%t

EC-24

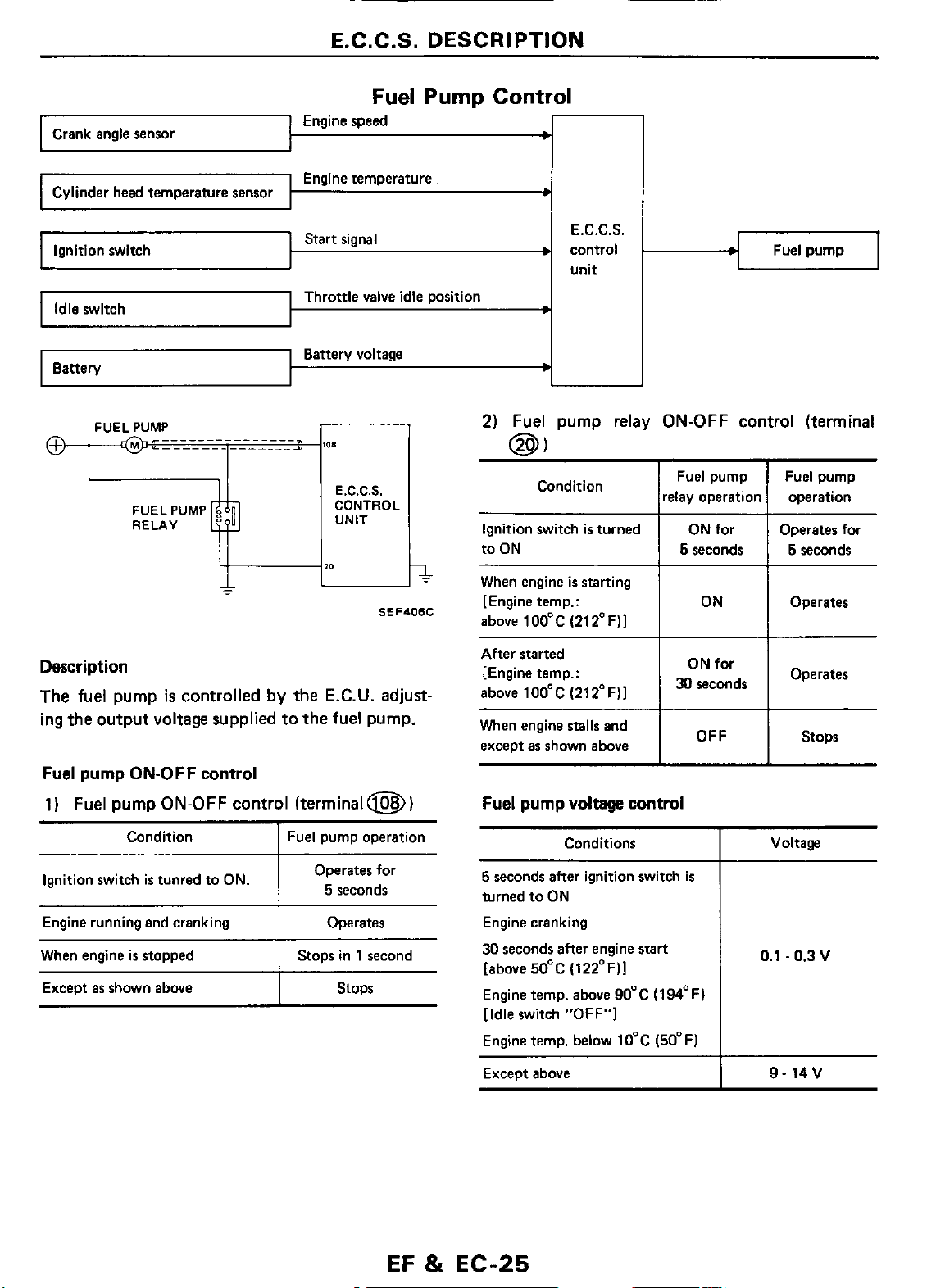

E.C.C.S.

DESCRIPTION

Crank angle sensor

Ignition switch

Idle switch

Battery

FUEL PUMP

RELAY

Fuel

Engine speed

Start signal

Throttle

Battery voltage

valve

E.C.C.S.

CONTROL

UNIT

Pump

idle position

Control

I

control

+

unit

2)

Fuel

pump relay

@)

Condition

Ignition switch

to

ON

E.C.C.S.

is

turned

I

ON-OFF

Fuel pump Fuel pump

relay operation

control (terminal

I

operation

Operates

5 seconds

for

Description

fuel

The

ing the output voltage supplied

Ignition switch

Engine running and cranking

When engine

Except

pump is controlled

Condition Fuel pump operation

is

tunred to

is

stopped

as

shown above

by

ON.

the

E.C.U.

to

the

fuel

pump.

Operates for

5

seconds

Operates

Stops in 1 second

stops

adjust-

When engine

[Engine temp.:

above 100°C (212OF)I

After started

[Engine temp.:

above 100°C (212'F)I

When engine

except

Fuel pump

5

seconds

turned to

Engine cranking

30

seconds after engine

[above 5OoC (122"FIl

Engine temp. above 90°C (194OF)

[Idle switch "OFF"]

Engine temp. below 10°C (5OOF)

is

starting

stalls

as

shown above

voltage

Conditions

after

ON

and

I

control

ignition switch

start

ON

30

is

ON

for

seconds

OFF

I

Operates

I

Voltage

0.1

-

Operates

stops

0.3

V

EF

&

EC-25

Except above

1

9-14V

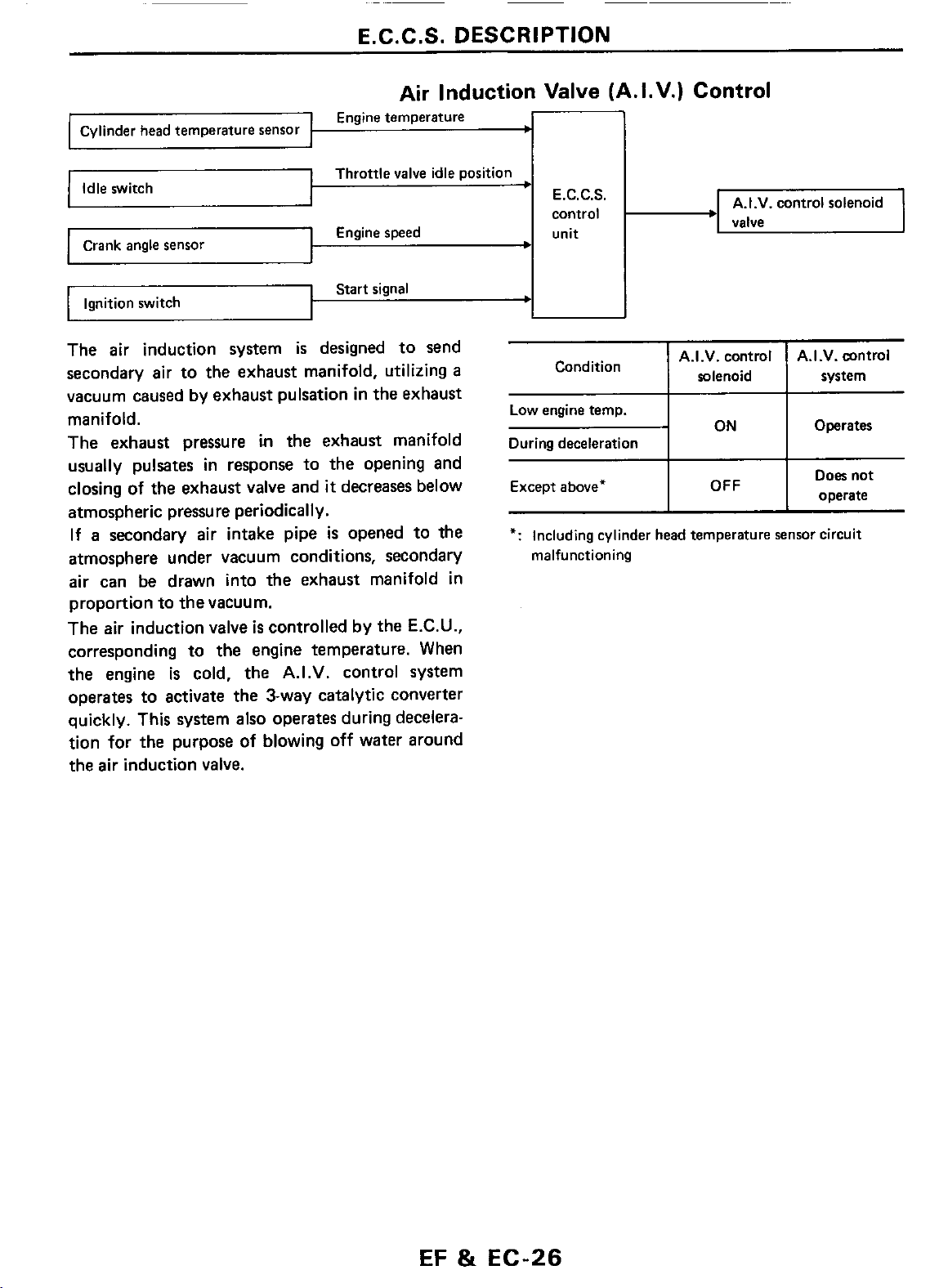

E.C.C.S. DESCRIPTION

Engine temperature

Idle switch

Crank angle sensor

The air induction system

secondary air to the exhaust manifold, utilizing

vacuum caused by exhaust pulsation in the exhaust

manifold.

The exhaust pressure

usually pulsates in response to the opening and

closing of the exhaust

in

the exhaust manifold

valve

Throttle valve idle position

Engine speed

Start signal

is

designed to send

and

it

decreases

below

a

t

’

E.C.C.S.

control

unit

Condition

Low

engine temp.

During deceleration

Except above*

~

tl

A.I.V.

solenoid

OFF

A.I.V. control solenoid

valve

control

ON

A.I.V. control

system

Operates

Does

operate

not

EF

&

EC-26

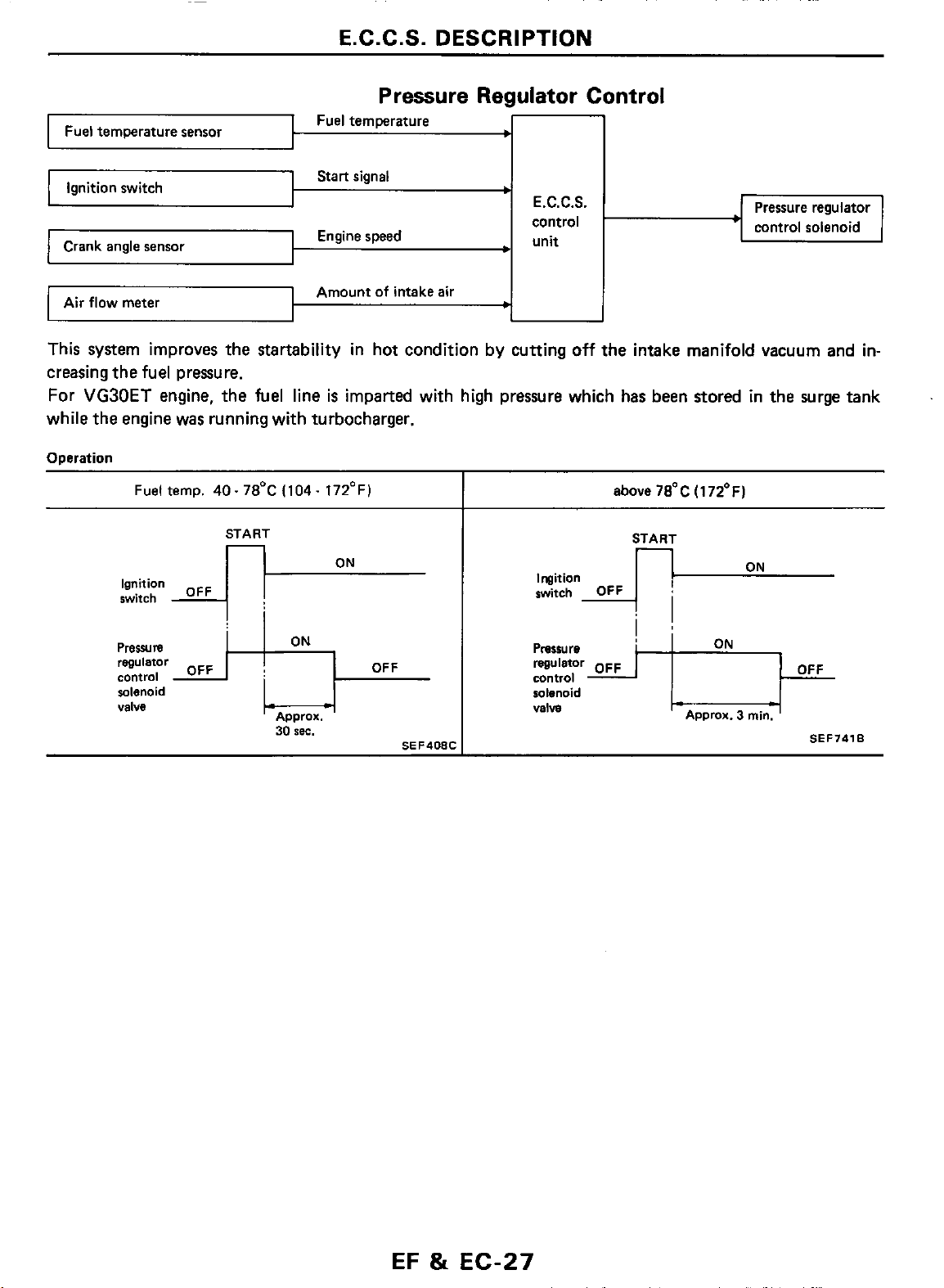

E.C.C.S. DESCRIPTION

Fuel temp.

40-

78'C

Fuel temperature

Start signal

Engine speed

Amount

(104.

172OF)

of

intake air

c

c

E.C.C.S. Pressure regulator

control control solenoid

unit

above

78OC

(172'F)

I

control

solenoid solenoid

valve

Amrox. Approx. 3 min.

30

sec.

SEF408C

regvlmor

control

valw

SEF7418

EF

&

EC-27

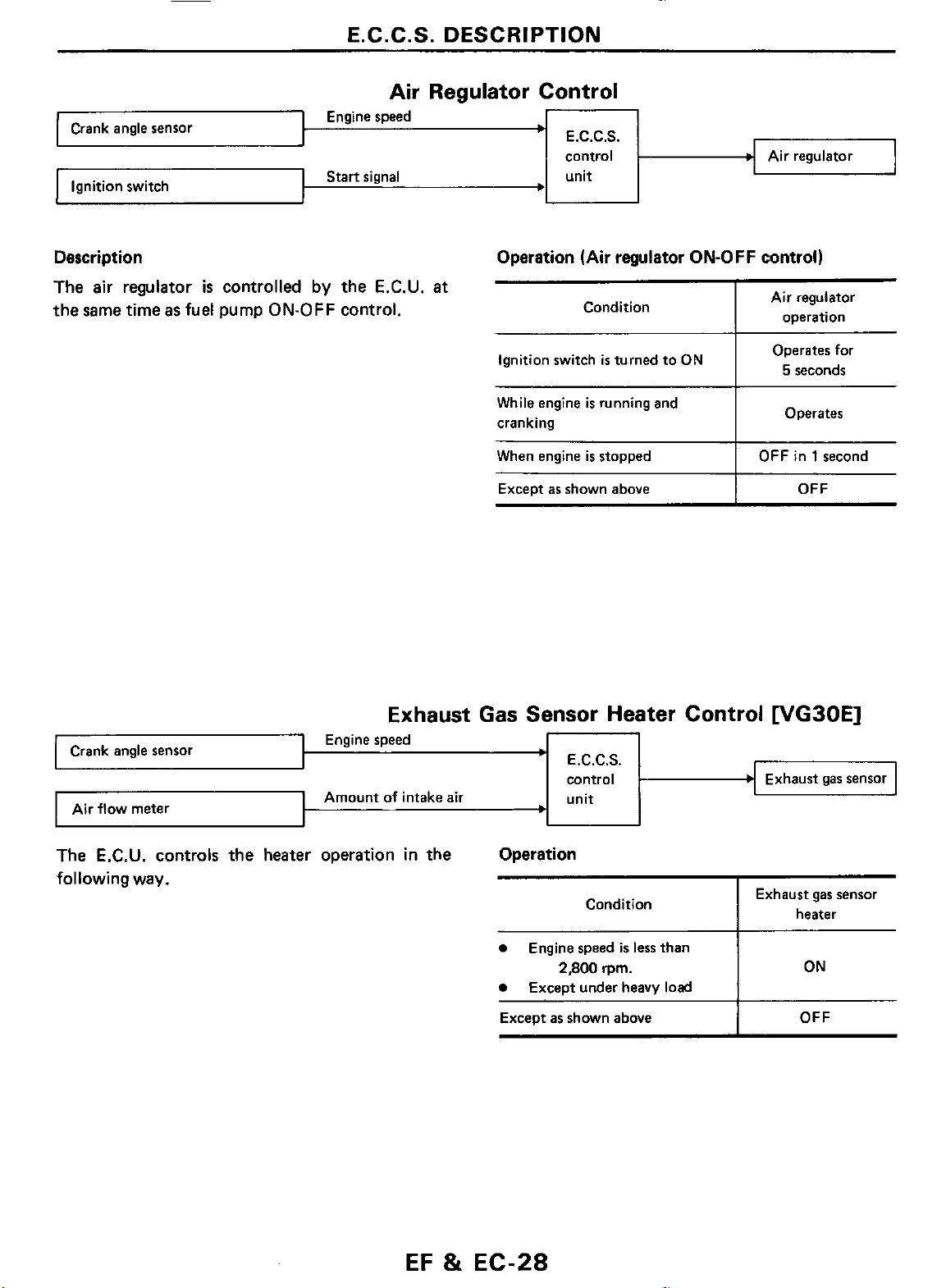

Ignition switch

E.C.C.S. DESCRIPTION

Engine speed

’

E.C.C.S.

control

Start signal unit

Air regulator

Description

The

air regulator

the same time

as

is

fuel

controlled

pump

ON-OFF

by

the

E.C.U.

control.

at

Operation (Air regulator

Condition

Ignition switch

While

engine

cranking

When engine

Except as shown above

is

turned

is

running and

is

stopped

to

ON-OFF

ON

control)

Air regulator

I

I

I

OFF

operation

Operates

5

seconds

Operates

in

1

OFF

fot

second

following

way.

Engine speed

Amount

of

intake air

’

E.C.C.S.

control

unit

Condition

0

Engine speed

2,800

0

Exceot under heavv

Except

as

shown above

rprn.

is

-

less

than

load

Exhaust gas sensor

Exhaust gas sensoi

heater

ON

I

OFF

EF

&

EC-28

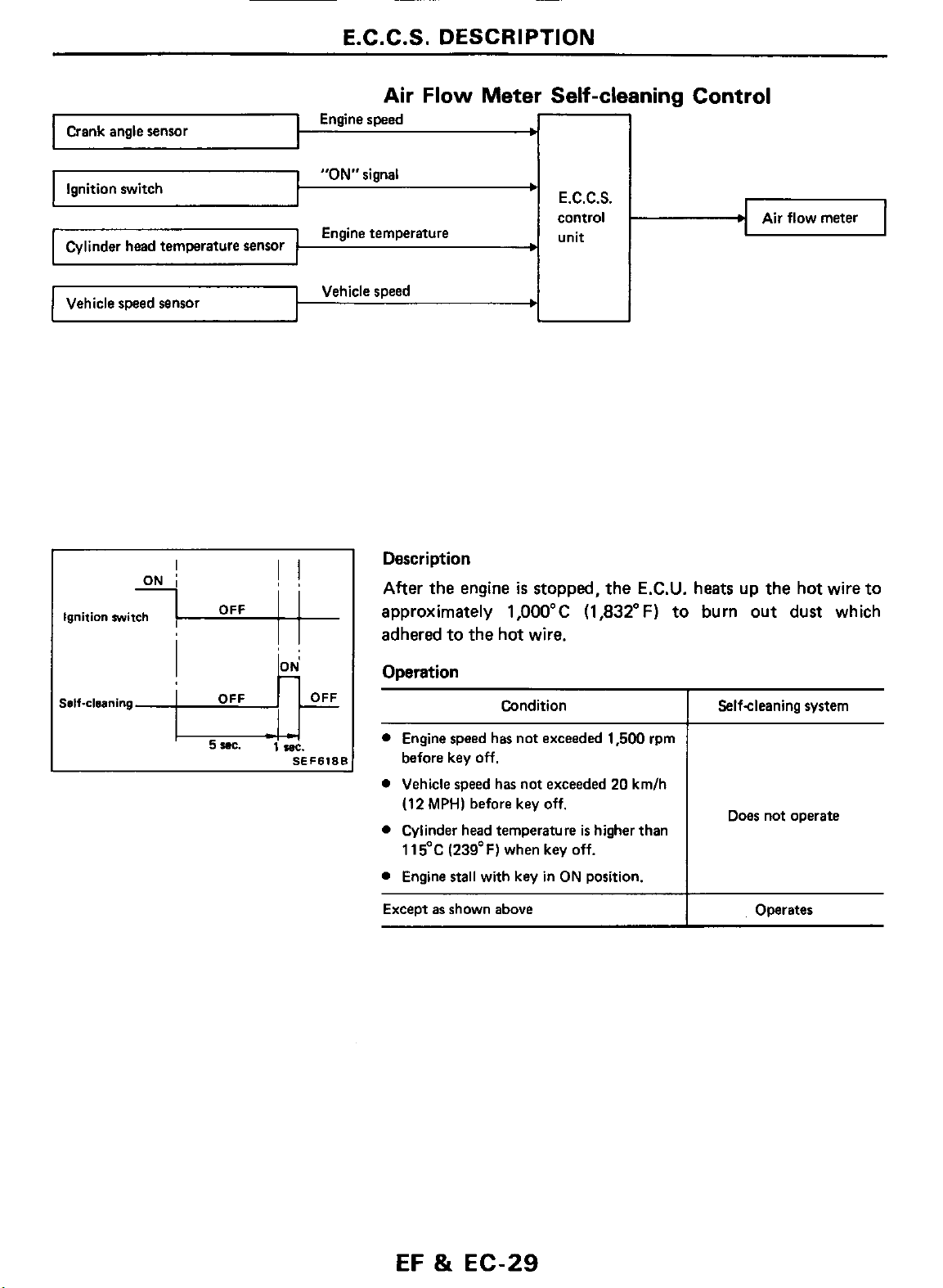

Ignition switch

Cylinder head temperature sensor

I

E.C.C.S.

Air

Engine speed

"ON"

signal

Engine temperature unit

I

DESCRIPTION

Flow

Meter

Self-cleaning Control

E.C.C.S.

control

Air flow meter

Vehicle speed sensor

I

ON

I

'

ON

'

Ignition witch

Ignition

Self-clsaning

Self-clsaning

1

witJ+

1

1

OFF

OFF

OFF

5nc.

Vehicle speed

II

II

I,

I1

~ ~

I

-b

iw.

SEFBIRI

Description

After the engine

approximately

adhered to the hot wire.

Omration

Engine speed has not exceeded 1.500 rpm

before key

Vehicle speed has not exceeded 20 kmlh

MPH)

(12

Cylinder head temperature

115OC (239OF) when key

Engine

stall

is

l,OOO"C

Condition

off,

before key

with key in

stopped, the E.C.U. heats

(1,832"F) to burn out dust which

off.

is

higher than

off.

ON

position.

up

the hot wire to

Selfcleaning system

Does

not operate

Except

EF

as

shown above

8t

EC-29

Operates

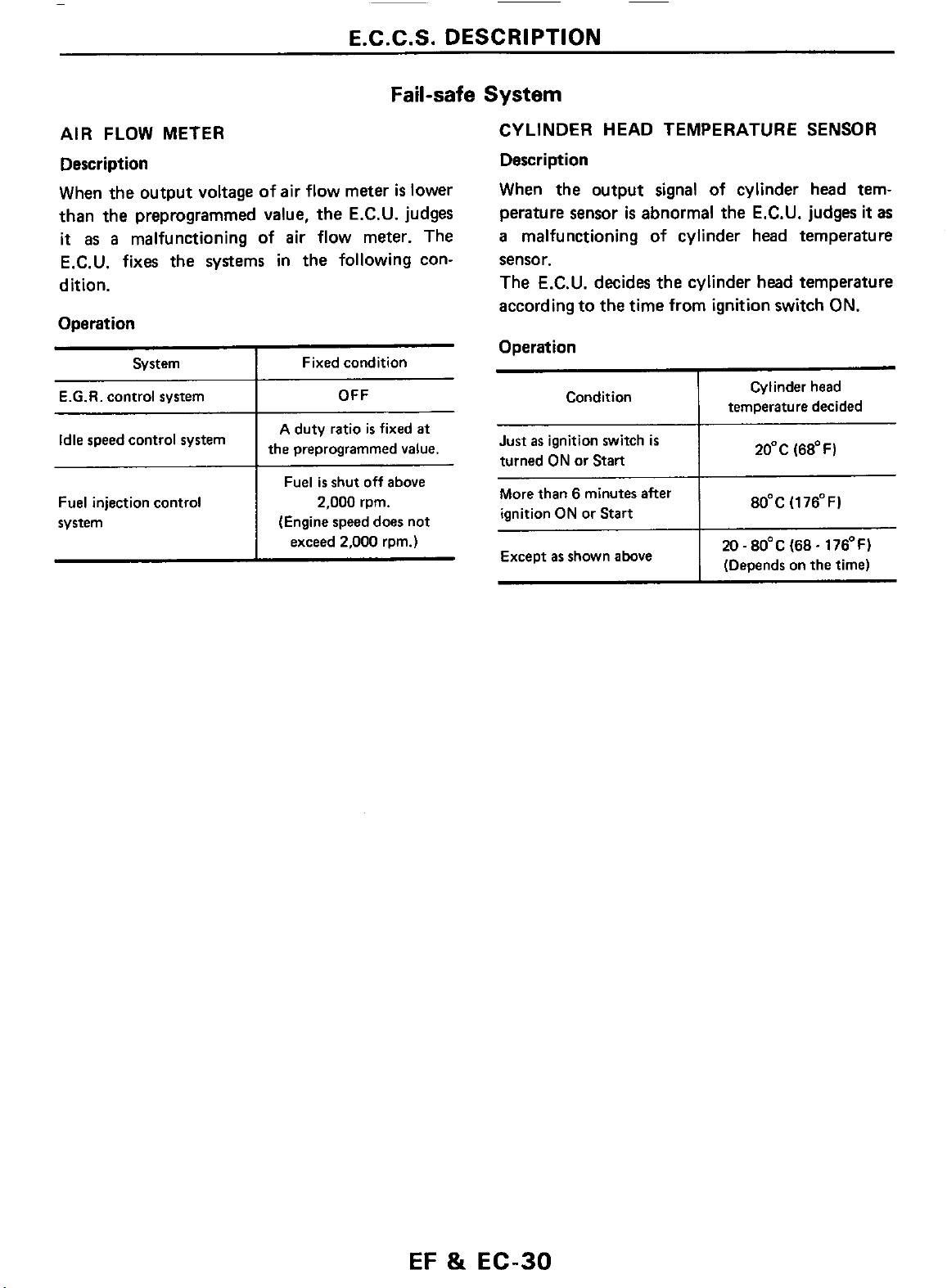

E.C.C.S.

DESCRIPTION

AIR FLOW METER

Description

When the output voltage of air flow meter

than the preprogrammed value,

it

as

a

malfunctioning of

the

E.C.U. fixes

dition.

Operation

Svstem

E.G.R. control svstem

Idle speed control system

Fuel injection control

system

systems

I

I

the preprogrammed value.

the

E.C.U. judges

air

flow meter. The

in

the following con-

Fixed condition

OFF

A

duty ratio

Fuel

(Engine speed does not

exceed 2.000 rpm.)

is

is

shut off above

2.000 rpm.

Fail-safe

is

lower

fixed

at

System

CYLINDER HEAD TEMPERATURE SENSOR

Description

When the output signal of cylinder head tem-

perature sensor

a

malfunctioning of cylinder head temperature

sensor.

The E.C.U. decides the cylinder head temperature

according to

Operation

Condition

Just

as

ignition switch

turned

ON

or

More than 6 minutes after

ignition

Except

ON

as

shown above

is

abnormal the E.C.U. judges

the

time from ignition switch

I

is

Start

or

Start

I

I

I

ON.

Cylinder head

temperature decided

2OoC(68'F)

80°C

(176'F)

20

-

80°C

(68

-

176'F)

(Depends on the time)

it

as

EF

&

EC-30

Loading...

Loading...