Nissan 300zx Engine Fuel Emission Control System EF EC 1984 Owner's Manual

ENGINE

FUEL

&

-

SECTION

EMISSION

-

EFaEC

CONTENTS

PRECAUTIONS

COMPONENT PARTS LOCATION

ECCS DIAGRAM

ECCS CHART ..

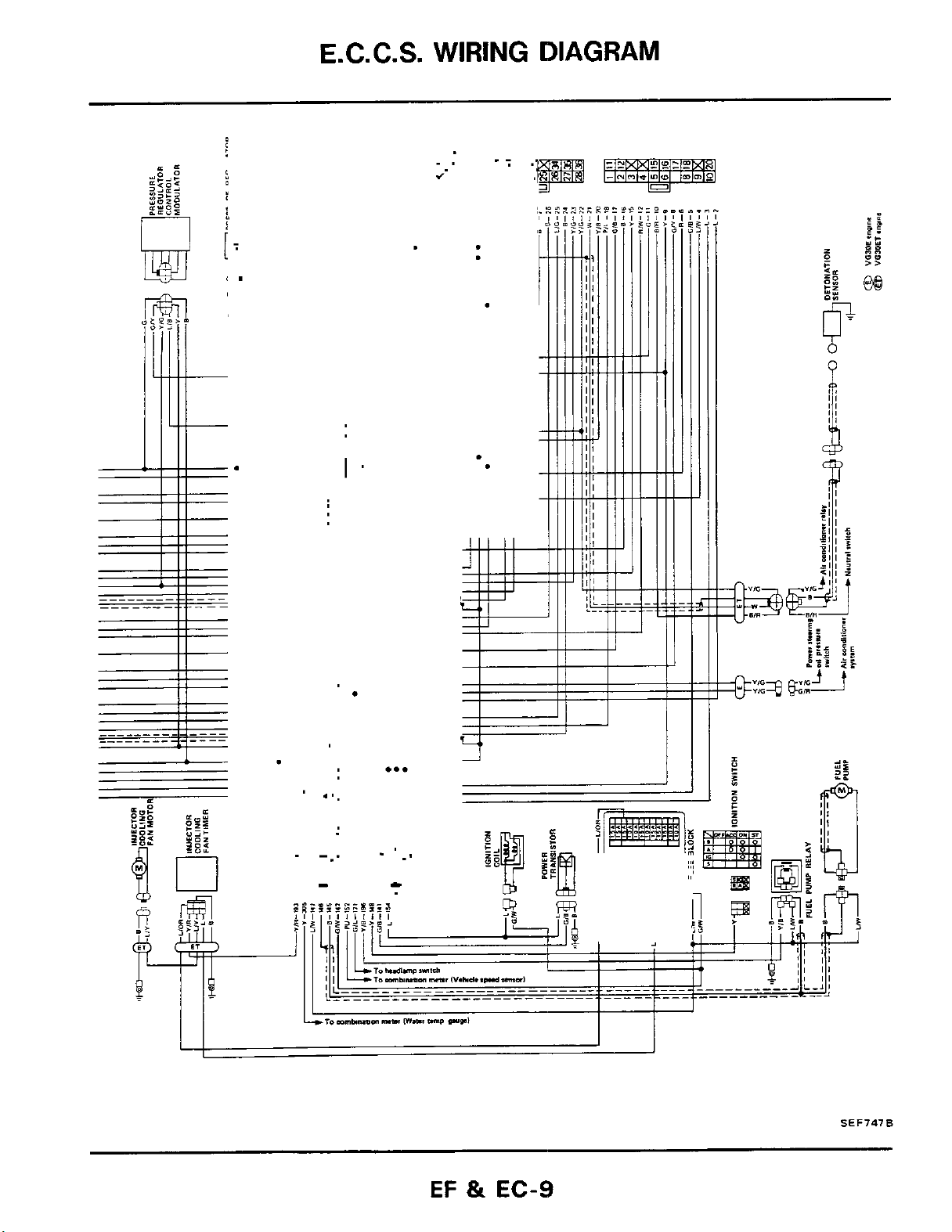

ECC.S WIRING DIAGRAM

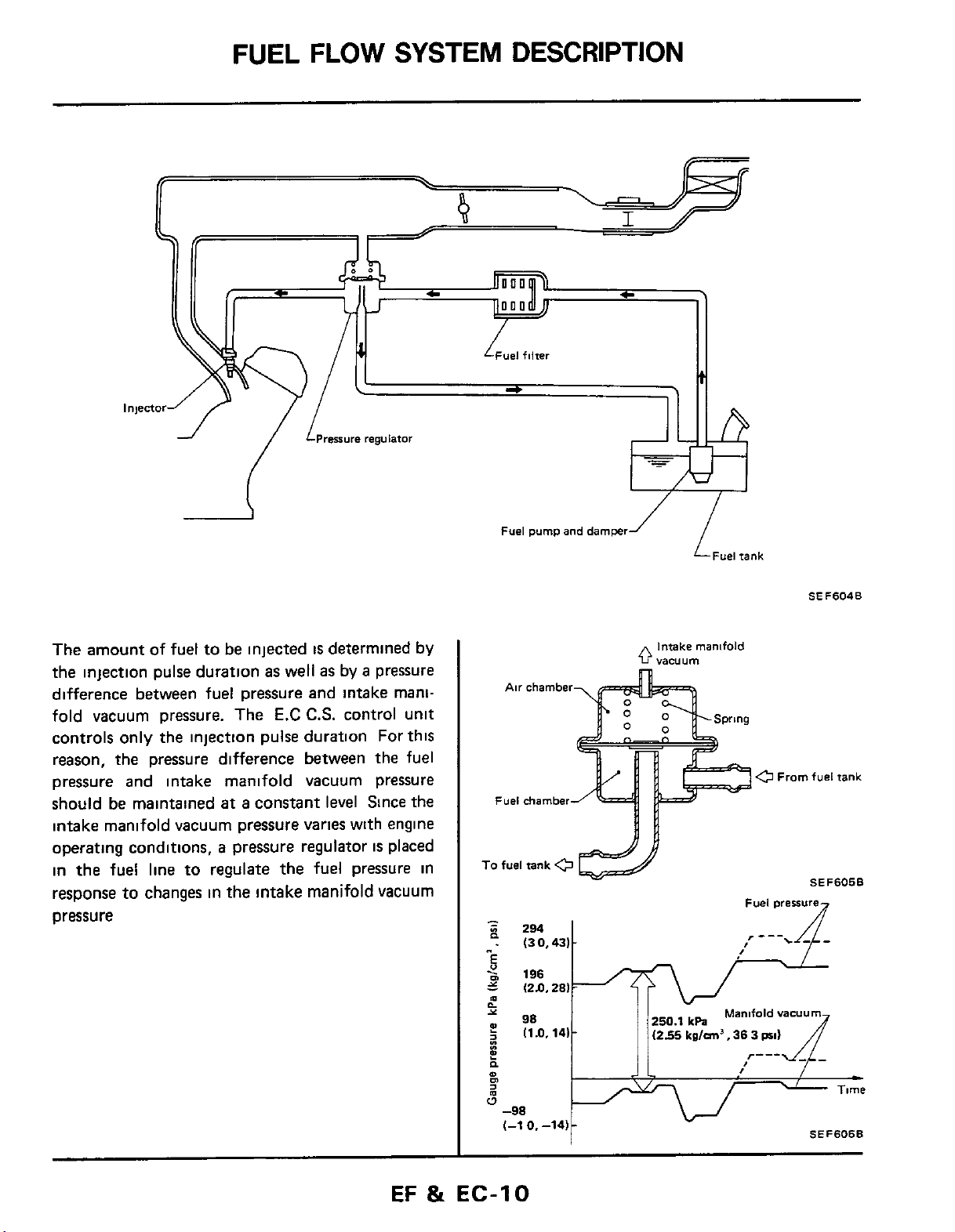

FUEL FLOW SYSTEM DESCRIPTION

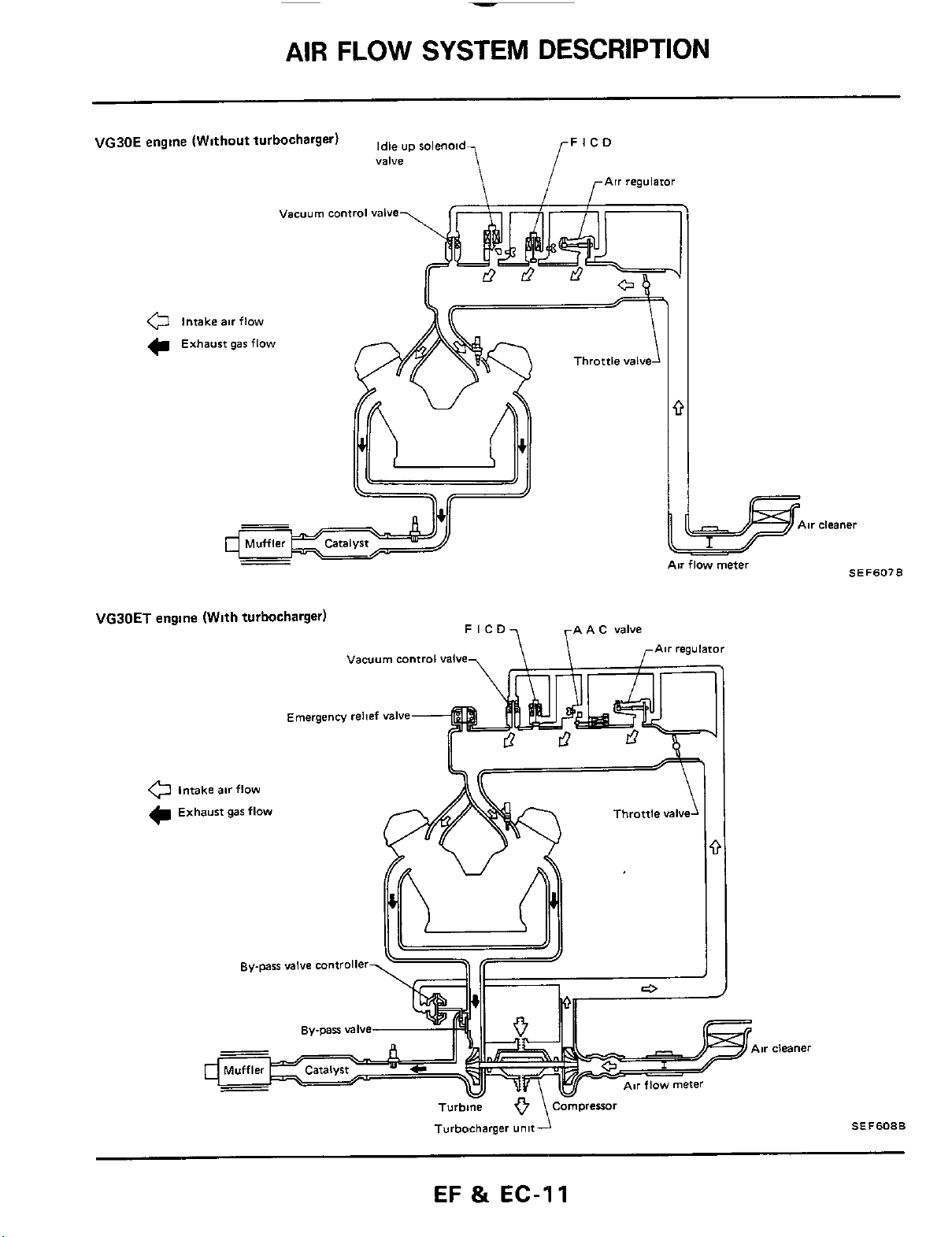

AIR FLOW SYSTEM DESCRIPTION ....

E C C

S.

DESCRIPTION

DIAGNOSTIC PROCEDURE

SE LF-D I AGNOSIS

ELECTRONfC CONTROL SYSTEM INSPECTION

MIXTURE RATIO FEEDBACK SYSTEM INSPECTION

FUEL SYSTEM INSPECTION

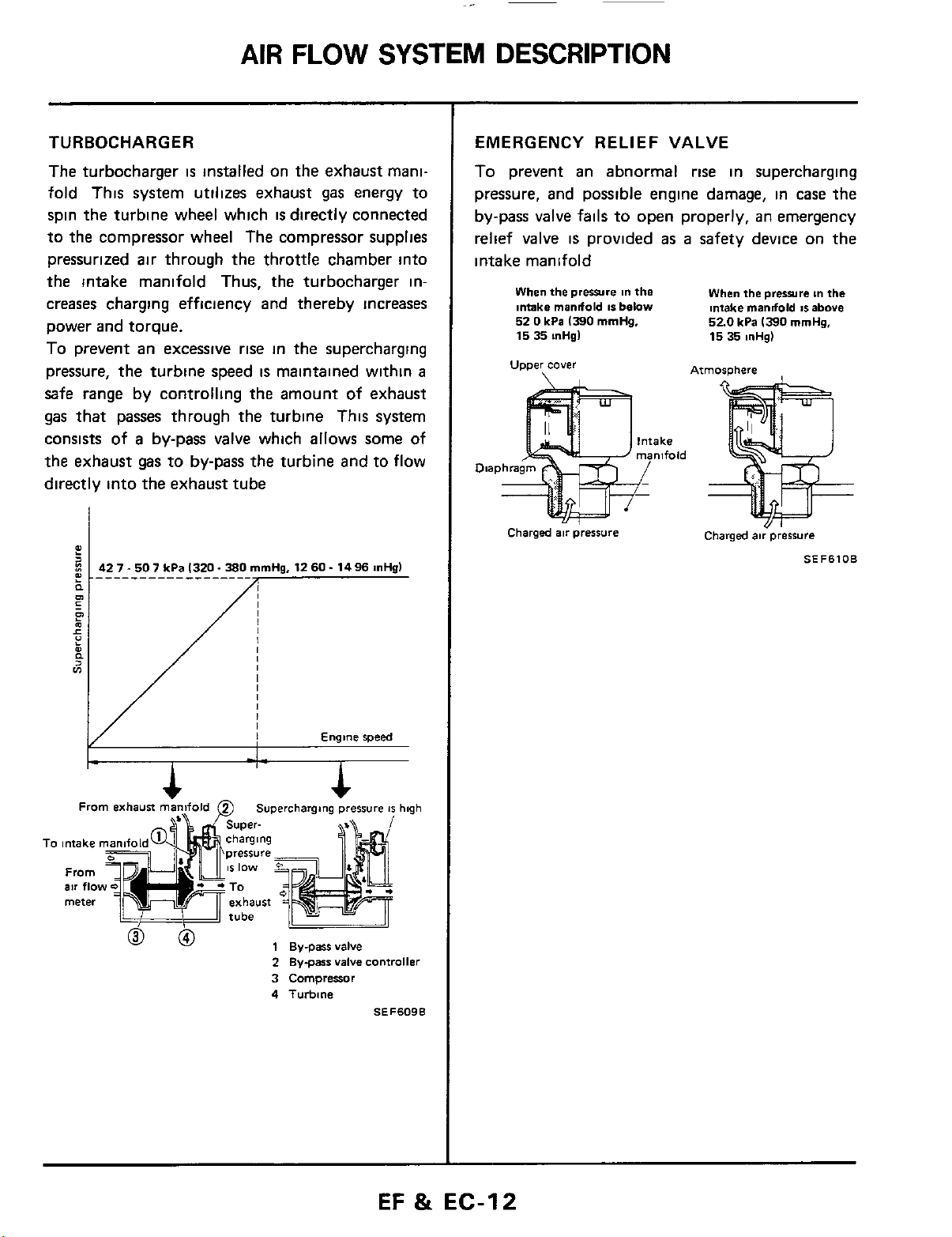

TURBOCHARGER

INJECTOR COOLING FAN (VG30ET)

PRESSURE REGULATOR CONTROL

CRANKCASE EMISSION CONTROL SYSTEM

EXHAUST EMISSION CONTROL SYSTEM

EVAPORATIVE EMISSION CONTROL SYSTEM

SERVICE DATA AND SPECIFICATIONS

. ...

..

. . .

. .

..

.

. . . . ...

.

..

..

..

.

.

(S

DS).

..

. . . .

.

..

..

...

. . .

. . . .

CONTROL

..

..

..

...

.

,

.

..

.

SYSTEM

.

.

EF&EC-

.

EF&EC-

EF & ECEF&ECEF&ECEF & EC-10

&

EC-11

EF

,

EF&EC-13

EF

&

EC-28

&

EC-35

EF

EF

&

EC43

EF & EC-60

&

EC-63

EF

EF

&

EC-66

EF

&

EC-69

EF

&

EC-72

. .

EF & EC-74

&

EC-75

EF

,

EF&EC-76

EF

&

EC-79

2

3

4

6

8

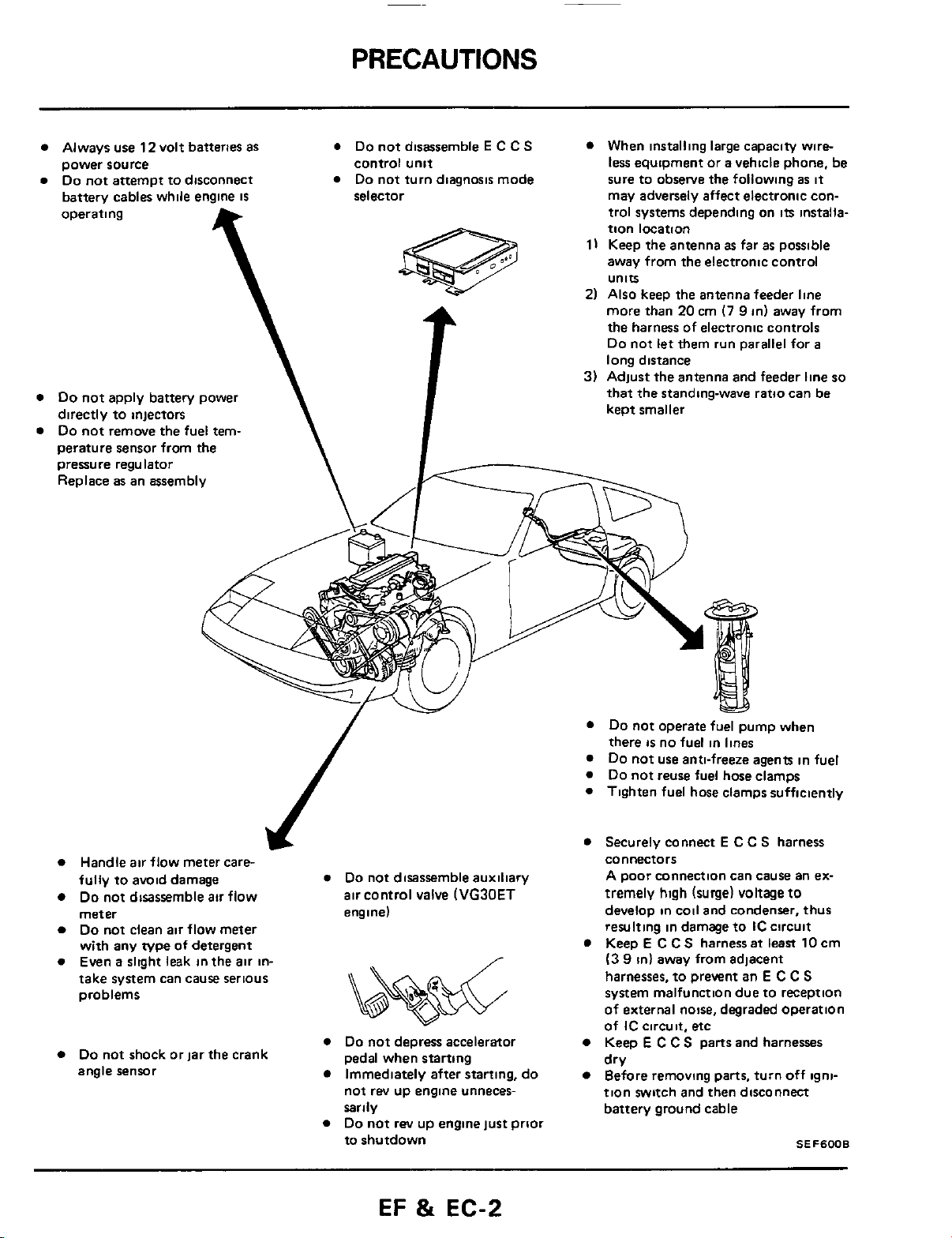

PRECAUTIONS

Always use

power source

Do

not

battery cables while engine

operating

Do

not apply battery power

directly to injectors

Do

not remove the fuel tem-

perature sensor from

pressure regulator

Replace as an assembly

12

volt batteries as

attempt to disconnect

\

the

*

Do

not disassemble E C

control unit

Do

not turn diagnosis mode

\

selector

T

IS

C

S

When installing large capacity wire-

less equipment or a vehicle phone, be

sure to obsetve the following

may adversely affect electronic control systems depending on its

tion location

1)

Keep the antenna as far as possible

away from the electronic control

units

2)

Also keep the antenna feeder line

20

cm

(7

9

more than

the harness of electronic controls

Do

not let them run parallel for

long distance

3)

Adjust the antenna and feeder line

that the standing-wave

keot smaller

in) away from

ratio

can be

as

it

installa-

a

so

\

J

Handle air flow meter care-

fully to avoid damage

Do

not disassemble

meter engine)

Do

not clean

with any type of detergent

0

Even a slight leak in the air

take system can cause serious

problems

Do

not shock or

angle sensor

air

air

flow meter

jar

the crank

flow

in-

*

Do

not disassemble auxiliary

air

control valve

(VG30ET

/

&&%$$?&

Do

not

depress accelerator

pedal when starting

Immediately after starting, do

up

not rev

sarily

Do

to shutdown

engine unneces-

not rev up engine just prioi

Do

not operate fuel pump when

there

is

Do

0

Do

0

Tighten fuel hose clamps sufficiently

Securely connect

connectors

A

tremely

develop in coil and condenser,

resulting in damage to

Keep

(3

harnesses, to prevent an

system malfunction due to reception

of external noise, degraded operation

of

Keep

dry

Before removing parts, turn off ignition switch and then disconnect

battery ground cable

no fuel

not use anti-freeze agents in fuel

not reuse fuel hose clamps

poor connection can cause an ex-

high

E

C C

9

in) away from adjacent

IC

circuit. etc

E

C

in

lines

E

C C

(surge) voltage

S

harness at least

C

S

parts and harnesses

S

IC

E

harness

to

circuit

C C

thus

10

cm

S

SEF6008

EF

&

EC-2

E

C

C

S

conlr01

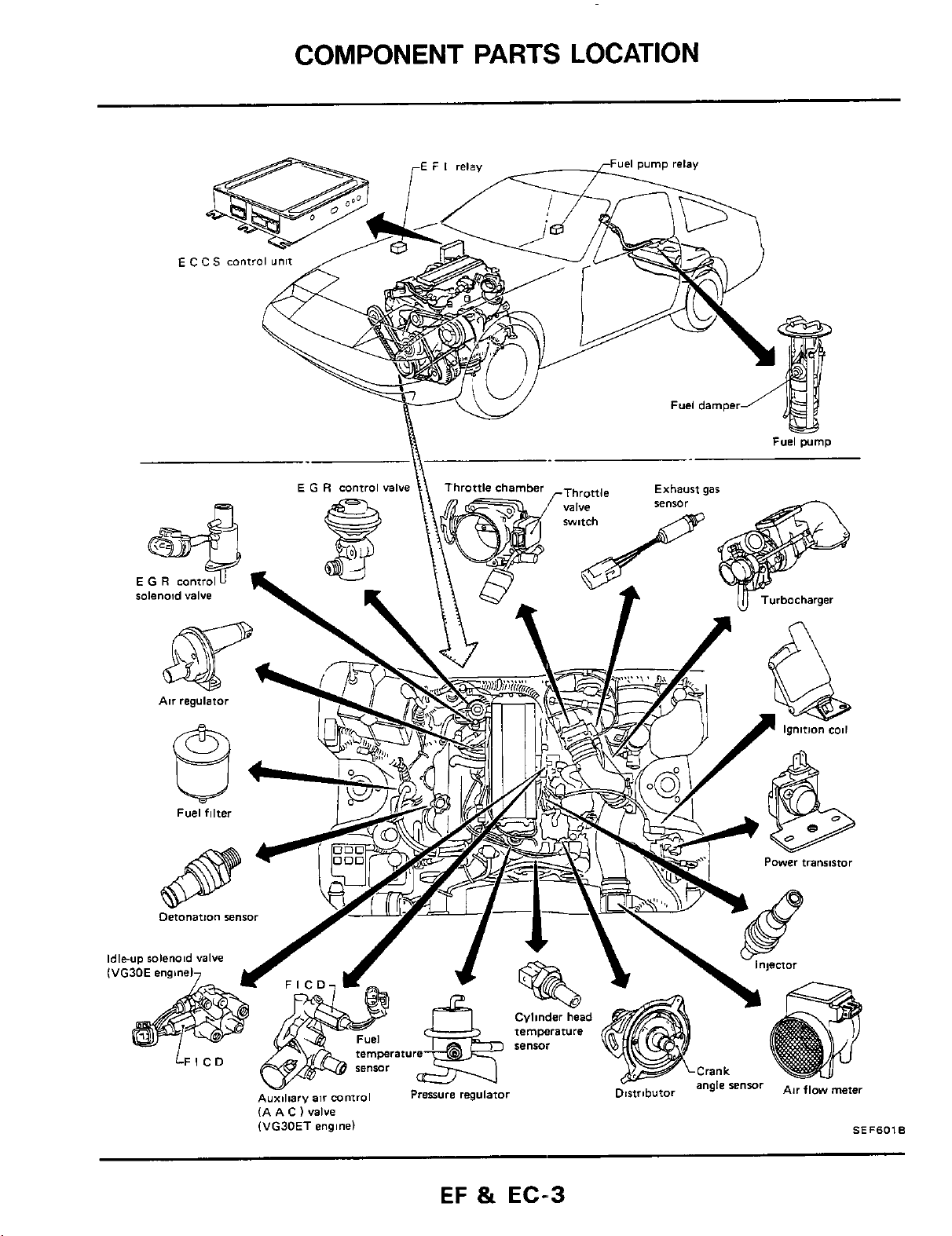

COMPONENT PARTS LOCATION

unit

IA A C

(valve

(VG30ET

engine)

EF

&

SEFBOlB

EC-3

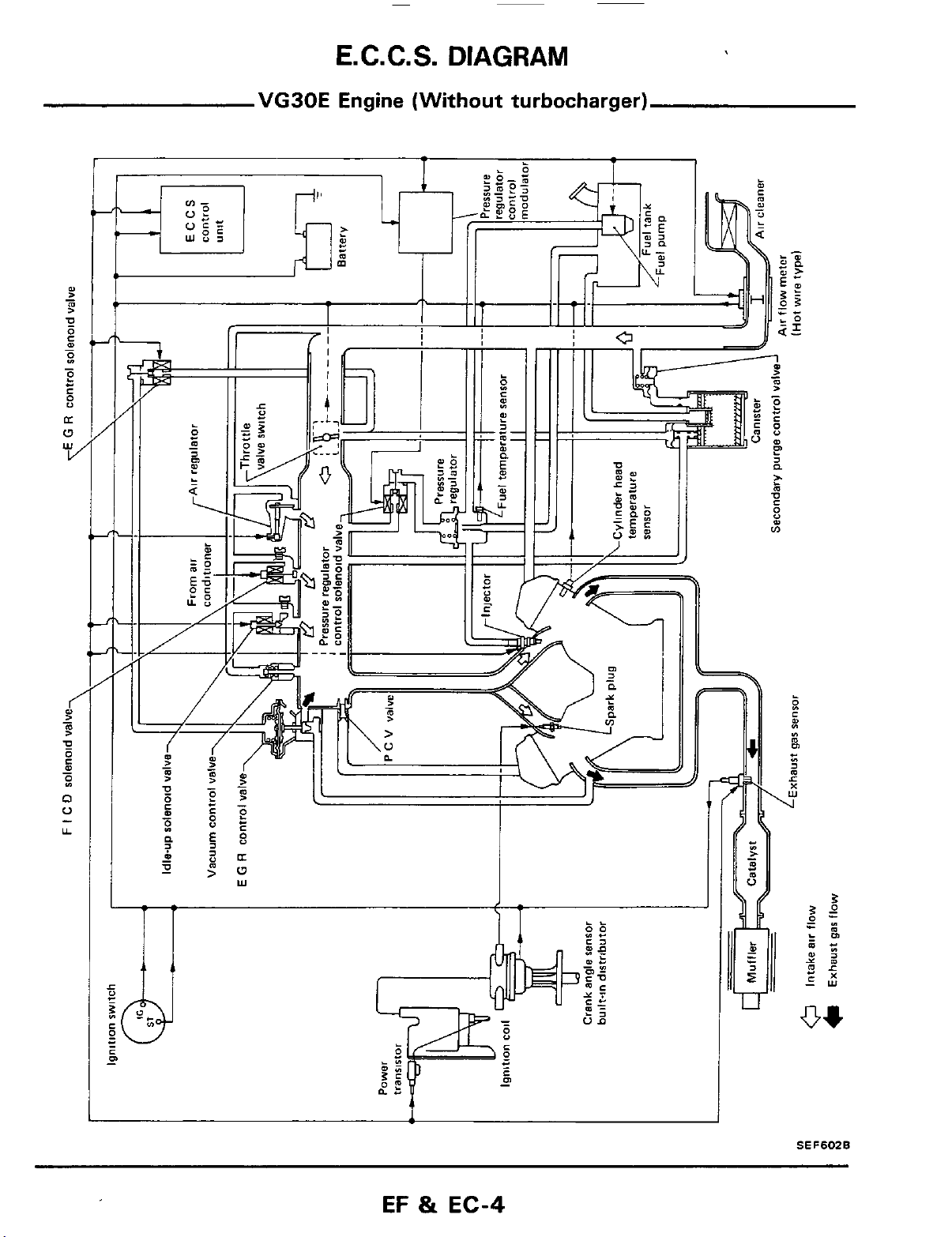

E.

C.C.

S.

DIAGRAM

VG30E

Engine (Without turbocharger)

EF

&

SEF602B

EC-4

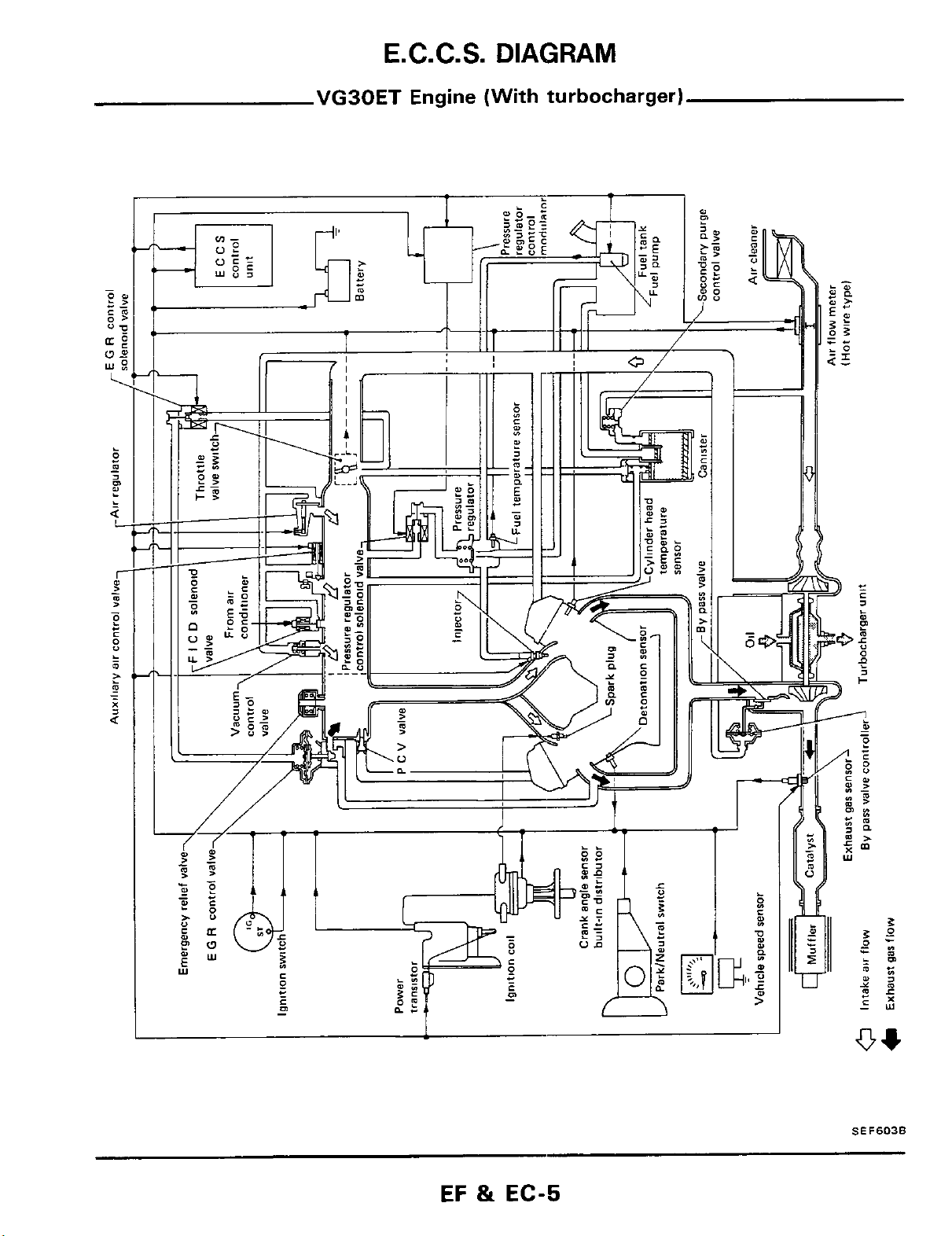

E.C.C.S.

DIAGRAM

VG30ET

Engine

(With turbocharger)

EF

&

L

SEF603B

EC-5

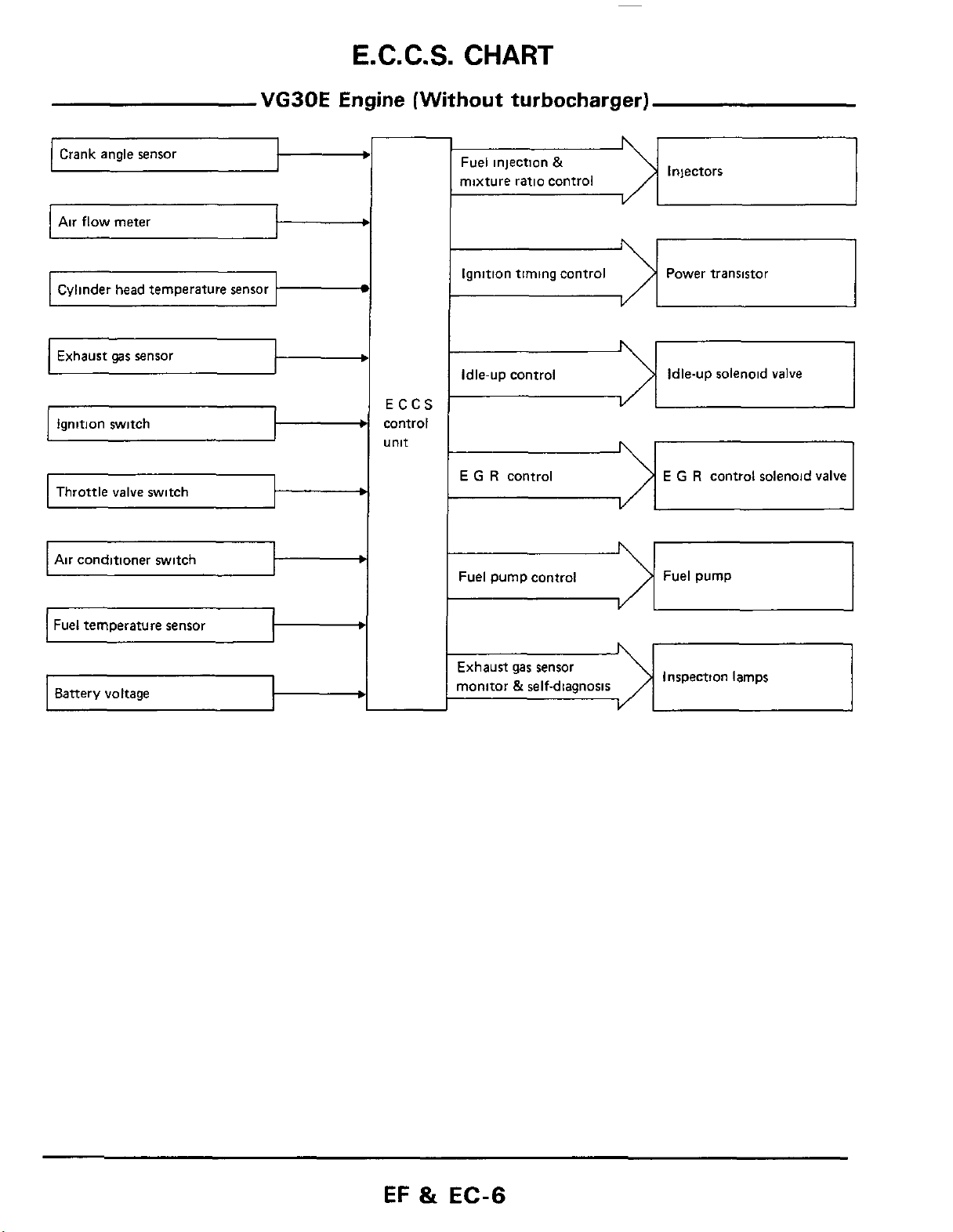

E.C.C.S.

CHART

Crank angle sensor

Exhaust

Throttle valve switch

gas

sensor

VG30E

Engine (Without turbocharger)

-\

t

ECCS

b

control

unit

-b

Fuel injection

mixture ratio control

Ignition timing control Power transistor

Idle-up control Idle-up solenoid valve

E

G

R

&

VI

control

I

Injectors

E G R

1

1

control solenoid valve

Air conditioner switch

Battery voltage

1

t

%el pump control

-1

ixhaust gas sensor

&

nonitor

self-diamosis

Fuel pump

I

Inspection lamps

EF

&

EC-6

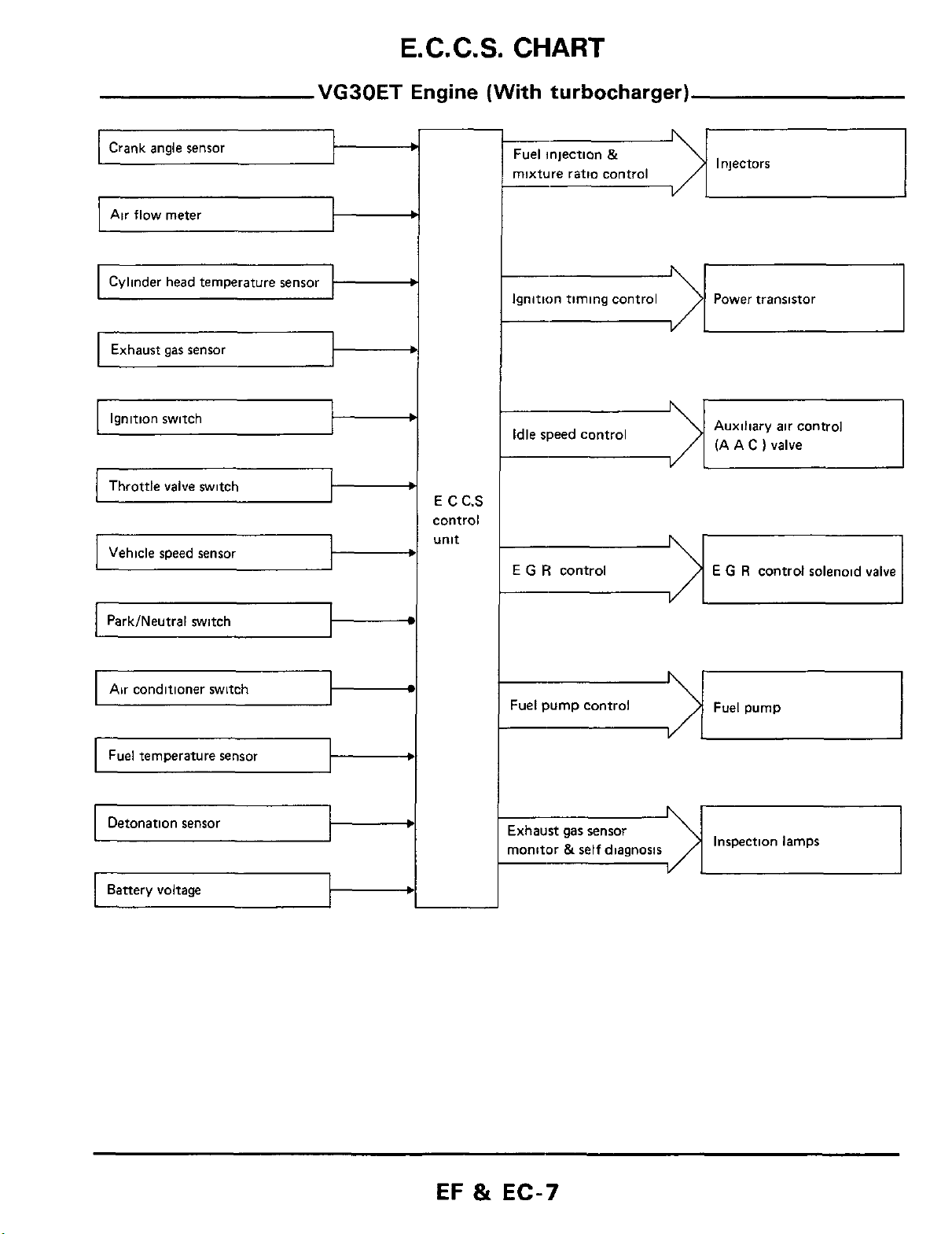

E.

C.

C.S.

CHART

Air flow meter

Cylinder head temperature sensor

Ignition switch

Throttle

valve

switch

VG30ET

I

Engine (With turbocharger)

Fuel injection

mixture ratio control

&

--I

c

b

Ignition timing control Power transistor

b

b

b

b

E

C

C.S

control

unit

-dI

Idle speed control

E

G

R

control

YL

Injectors

Auxiliary air control

C

)

(A A

E G R

valve

control solenoid

I

valve

Park/Neutral switch

Air conditioner switch

I

Fuel pump control Fuel pump

b

b

ixhaust

nonitor

gas

&

sensor

self

diagnosis

Inspection lamps

I

EF

&

EC-7

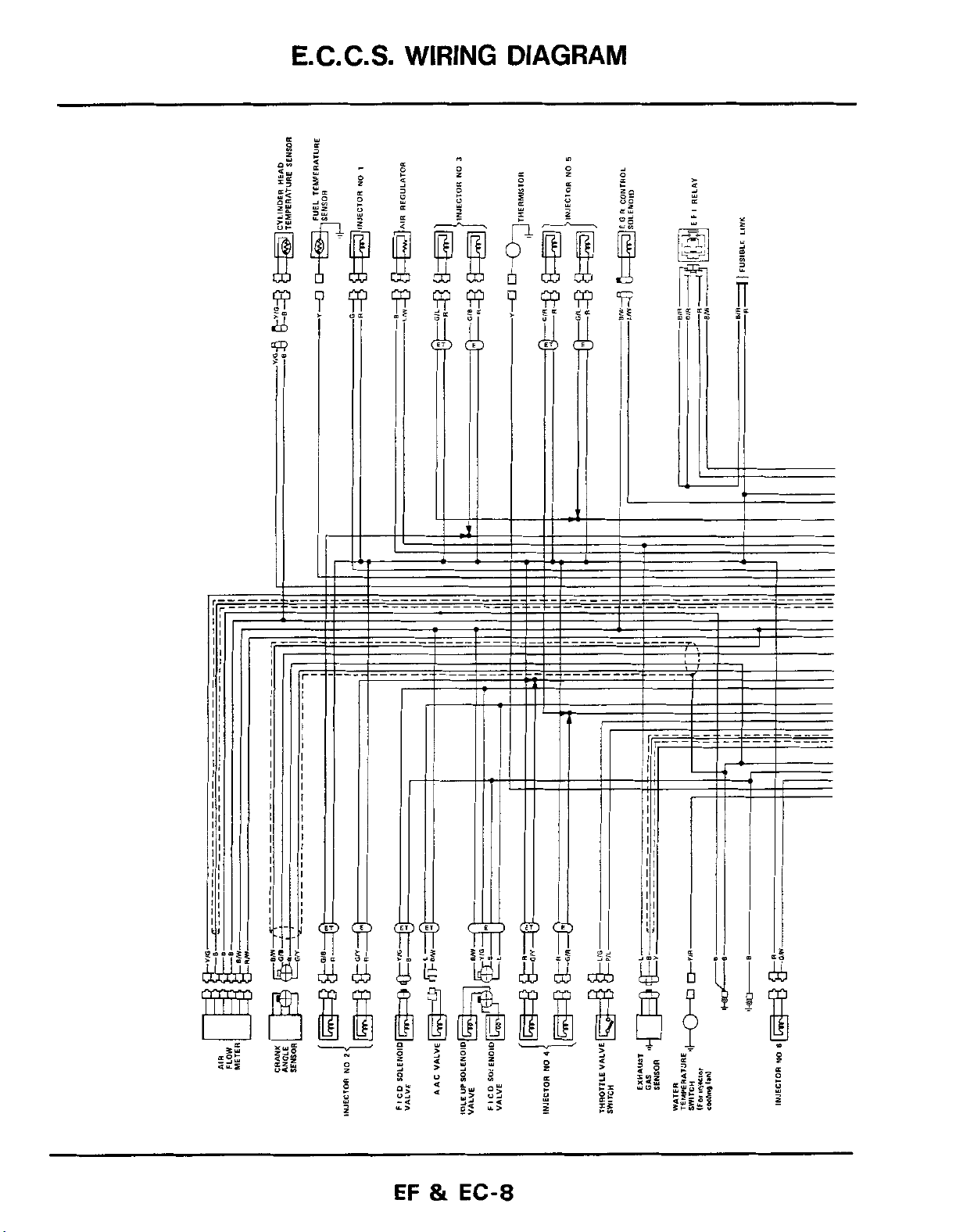

E.C.C.S.

WIRING DIAGRAM

i-

1

EF & EC-8

=

e

Y

2

UI

E.C.C.S.

I'

WIRING

.

DIAGRAM

.

...

SEF747B

EF

&

EC-9

FUEL

FLOW

SYSTEM

DESCRIPTION

The amount of fuel to

the injection pulse duration

difference between fuel pressure and intake manifold vacuum pressure. The

controls only the injection pulse duration For this

reason,

pressure and intake manifold vacuum pressure

should be maintained

intake

operating conditions,

in

response to changes

pressure

the

pressure difference between the fuel

manifold vacuum pressure varies with engine

the fuel line

be

injected

as

at a constant level Since the

a

pressure regulator

to

regulate

in

the intake manifold vacuum

well

E.C

the

is

determined by

as

by a pressure

C.S.

control unit

fuel

pressure in

IS

placed

Fuel

Fuel

pump

chamber

and

damper

’

0

intake

vacuum

iFueirank

manifold

a

Fuel

SEF604B

From

SEF605B

presswe

fuel

tank

EF

&

EC-10

AIR

FLOW

SYSTEM

DESCRIPTION

VG30E

engine (Without turbocharger)

0

Intake

air

flow

C

Exhaust

gar flow

Valve

up

roleno,,,

FlCD

r

Air

cleaner

VGJOET

engine (With turbocharger)

Emergency relief

0

Intake

air

flow

Exhaust

gar

flow

Vacuum

valve

control

valve

cleaner

Turbbne

Turbocharger

-

unit-

\Compresor

EF & EC-11

SE

F

608

B

AIR

FLOW

SYSTEM

DESCRIPTION

TURBOCHARGER

The turbocharger

is

installed on the exhaust manifold This system utilizes exhaust gas energy to

spin the turbine wheel which

is

directly connected

to the compressor wheel The compressor supplies

pressurized air through the throttle chamber into

the intake manifold Thus, the turbocharger increases charging efficiency and thereby increases

power and torque.

To prevent an excessive rise in the supercharging

pressure, the turbine speed

is

maintained within

a

safe range by controlling the amount of exhaust

gas

that passes through the turbine This system

consists of

the

exhaust gas to by-pass

a

by-pass valve which allows some of

the

turbine and to flow

directly into the exhaust tube

EMERGENCY RELIEF VALVE

To

prevent an abnormal

rise

in supercharging

pressure, and possible engine damage, in case

by-pass valve

relief valve

fails

to open properly, an emergency

is

provided

as

a

safety device on the

intake manifold

When

the

Intake

52

0

15

35

Upper

Charged

prwre

mandold

kPa

1390

inHgl

cover

air

pressure

in

IS

below

mmHg.

the

When

the

intake

520

kPa

15

35

Atmosphere

Charged

prerrura

mandold

1390

mrnHg,

mHg)

air pressure

tn

IS

above

SEF6lOB

the

the

From

b==iF

exhausi

To

intake

To

intake

From

From

air

flo

air

flo

meter

meter

h

man2fold

0

Engine

Superchargang

2

Bygars

3

Compressor

4

Turbine

speed

pressure

valve

controller

41

hqh

SEF609B

EF

&

EC-12

E.C.C.S.

DESCRIPTION

E.C.C.S.

E

C

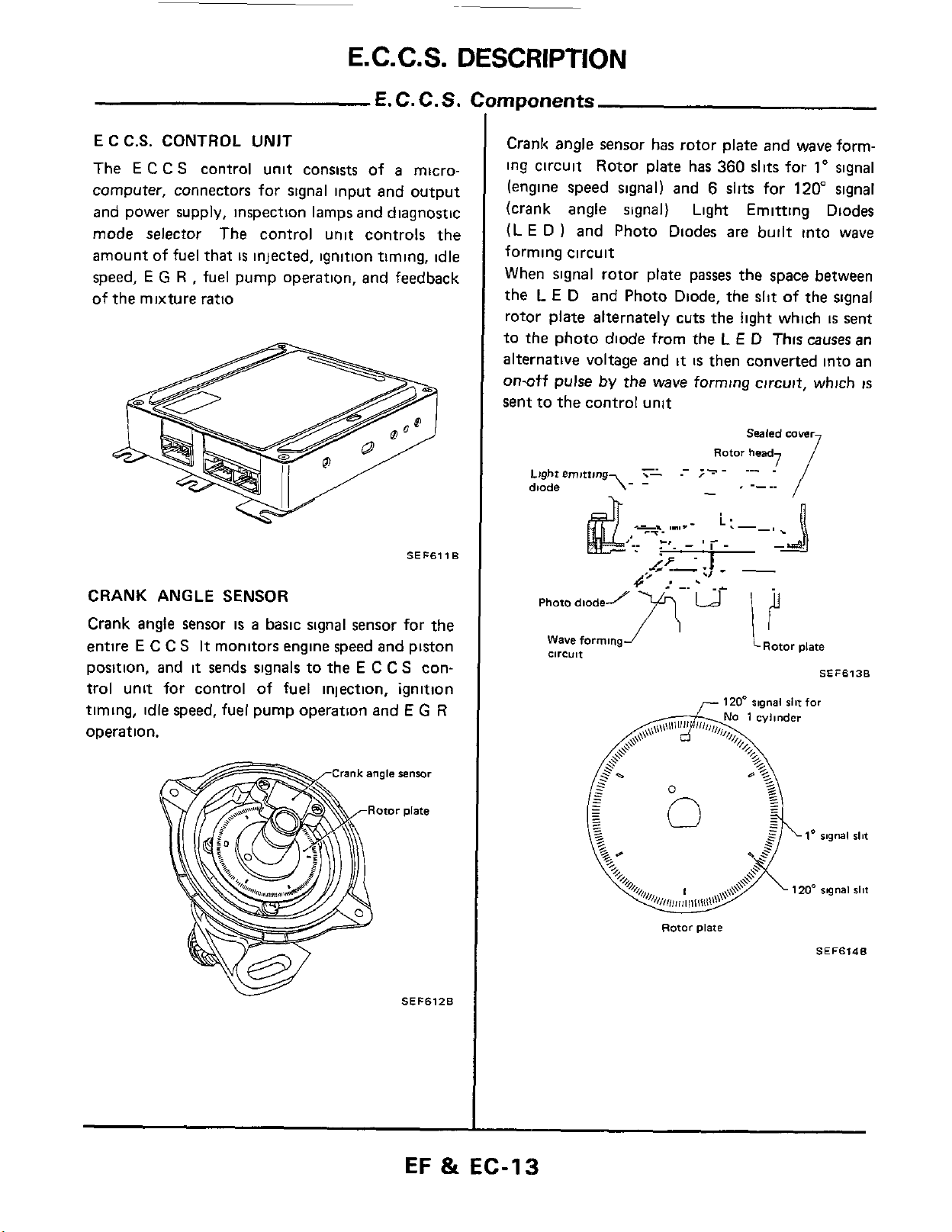

C.S.

CONTROL UNIT

The

E

C

C

S

control unit consists of a microcomputer, connectors for signal input and output

and power supply, inspection lamps and diagnostic

mode selector The control unit controls the

amount

speed,

of

CRANK ANGLE SENSOR

Crank angle sensor

entire

position, and

trol unit for control of

timing, idle speed, fuel pump operation and

operation.

of

fuel that

E G R

the mixture ratio

E

C

,

fuel pump operation, and feedback

It monitors engine speed

C

S

it

sends signals to the E C C S con-

is

injected, ignition timing, idle

SEF611

is

a

basic signal sensor for the

and

piston

fuel

injection, ignition

E

G

R

B

rnponents

Crank angle

ing circuit Rotor plate has

(engine speed signal) and

(crank angle signal) Light Emitting Diodes

(L

E

D ) and Photo Diodes are built into wave

forming circuit

When

the

rotor plate alternately cuts the light which

to

alternative voltage and

on-otf

sent to the control unit

signal

L

E

the

Lighremitring

diode

Phatodlodel

Wave

circurt

sensor

rotor plate passes

D and Photo Diode, the

photo diode from the

pulse by the wave forming circuit, which

has

-.

'I-

1-

.

A.

-7.

l.lll-

I

-,

..

.

ir-

rotor plate and wave form-

360

slits

for

1"

signal

6

slits

for

120"

signal

the

space between

slit

of

the signal

is

sent

L E D

it

is

then converted into an

Rotor

-

.

;--

-

i:--,

_,-

I-

.I

Sealed

head

.--

,

This

mwr

?

.J

-

causes

4,,

fi-.

forming-'

h-

1

,h

'-Rotor

piate

SEFBlJB

an

IS

EF

&

EC-13

Rotor

plate

SEF614B

E.C.C.S.

E.C.C.S. Components (Cont'd)

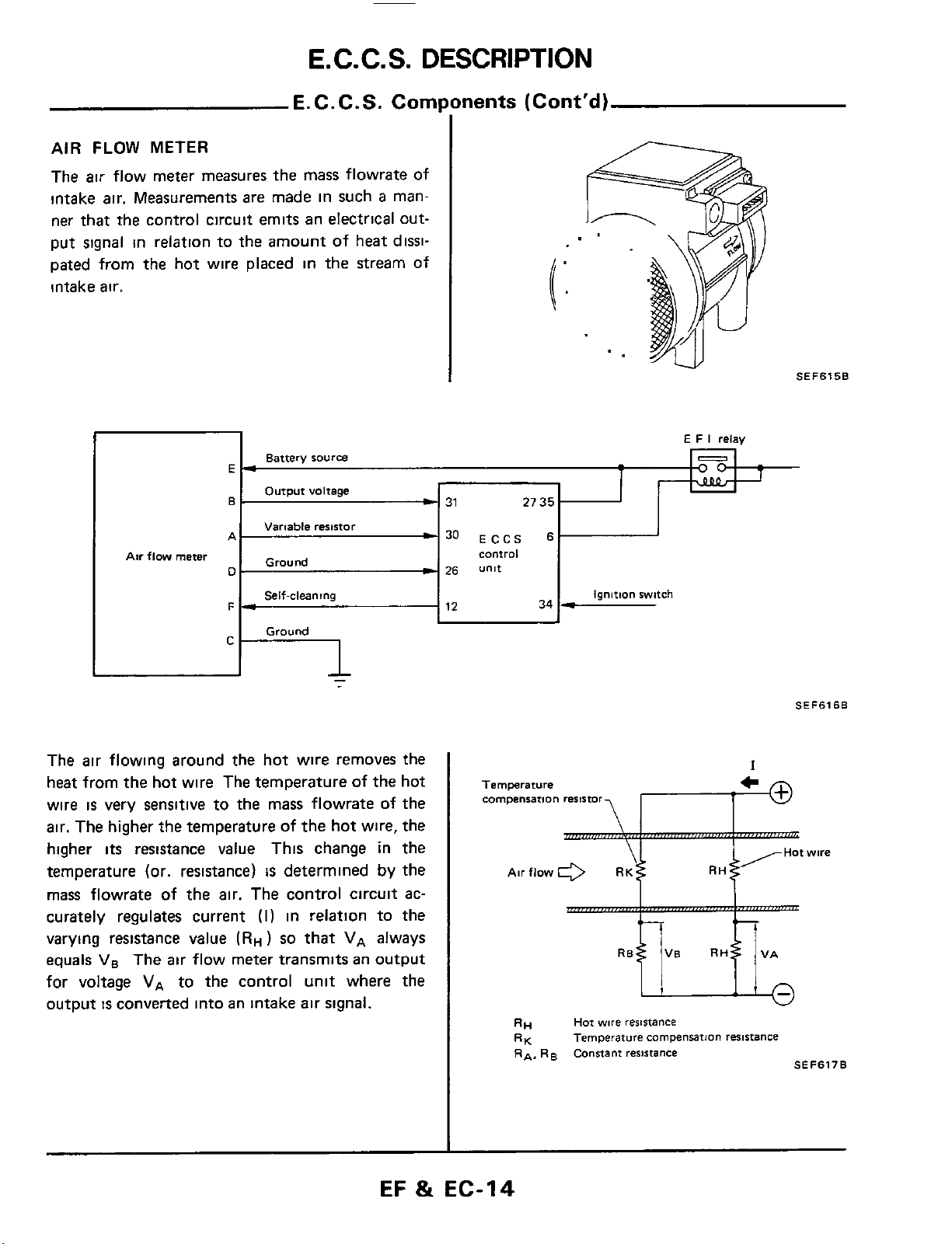

AIR

FLOW

The

air

intake air. Measurements are made in such

ner

that

put signal

pated from the hot wire placed

intake

air.

METER

flow meter measures the mass flowrate of

the control circuit emits an electrical out-

in

relation to the amount of heat dissi-

in

the stream of

DESCRIPTION

a

man-

Battery

Output

Ground

Ground

source

voltage

resistor

Air

flow

meter

El

6-

Variable

A

0.

Self-cleaning

F-

C

-

The air flowing around the hot wire removes the

heat from

wire

air.

The

higher

temperature (or. resistance)

mass flowrate of the air. The control circuit

curately regulates current

varying resistance value

equals

for voltage

output

the

hot wire The temperature of the hot

is

very sensitive to the mass flowrate of the

higher the temperature

its

resistance value This change in the

VB

The air flow meter transmits

VA

to

the control unit where the

is

convened into

an

of

the hot wire, the

IS

determined

(I)

in relation to the

(RH)

so

that

intake air signal.

VA

an

by

always

output

the

ac-

I

31

w30

25

12

-

27

ECCS

comroi

unit

34

Temperature

compensation

RH

RK

RA.

35

6

-

resistor

RB

-

1

ignition

Hot

wore

reststance

Temperature

Constant

reSiiIanCe

E F I

switch

campenration

SEF615B

relay

SEFSlSB

I

twire

resistance

SEFS17B

I

EF & EC-14

E. C. C.

S.

DESCRIPTION

E.C.C.S.

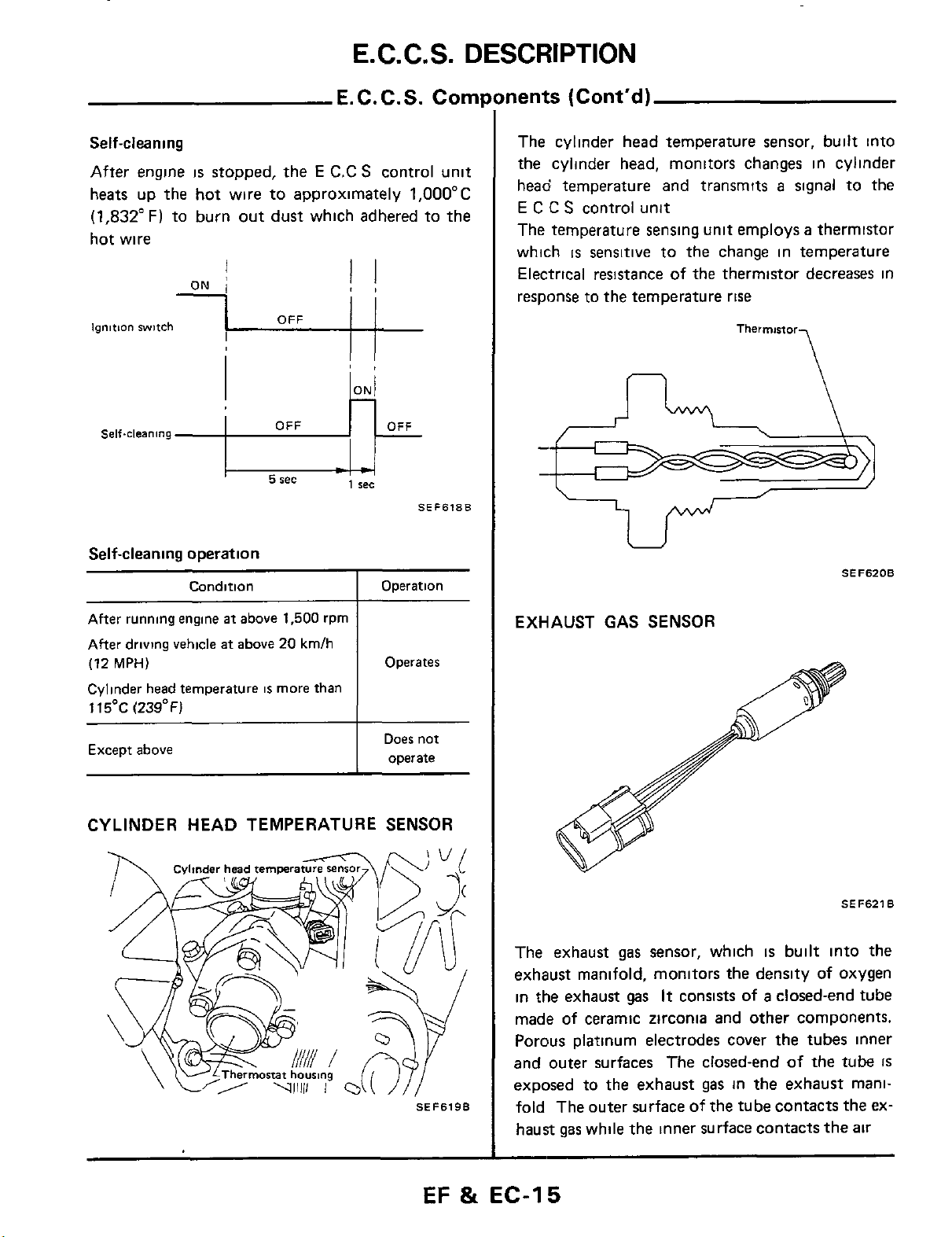

Self-cleaning

After engine

heats up the hot wire to approximately

(1,832"F)

hot wire

Self-cleaning operation

_____~

After running engine

After driving vehicle at above

(12

MPH)

Cylinder head temperature

(239°F)

115OC

is

stopped, the E C.C S control unit

to burn out dust which adhered to the

-

kmlh

-

1

rec

Operation

Condition

~

at

above 1,500 rpm

5

rec

20

is

more than

Corn1

1,OOO"C

SEF618B

Operates

nents (Cont'd)

The cylinder head temperature sensor, built into

the cylinder head, monitors changes in cylinder

a

head temperature and transmits

E

C C S control unit

The temperature sensing unit employs

which

Electrical resistance

response to the temperature

is

sensitive to the change in temperature

of

the thermistor decreases in

rise

Thermmor

signal to the

a

thermistor

U

SEF6208

EXHAUST GAS SENSOR

Except above

Does not

operate

CYLINDER HEAD TEMPERATURE SENSOR

SEF6198

SEF621

The exhaust

exhaust manifold, monitors the density

in

the exhaust

made

of ceramic zirconia and other components.

gas

sensor, which

gas

It

consists

is

built into the

of

a

closed-end tube

of

oxygen

Porous platinum electrodes cover the tubes inner

and outer surfaces The closed-end

exposed to the exhaust

fold The outer surface

haust

gas

while the inner surface contacts the

gas

in the exhaust mani-

of

the tube contacts the ex-

of

the

tube

air

IS

EF

&

EC-15

E.C.C.S.

DESCRIPTION

E.

C. C.

S.

Corn1

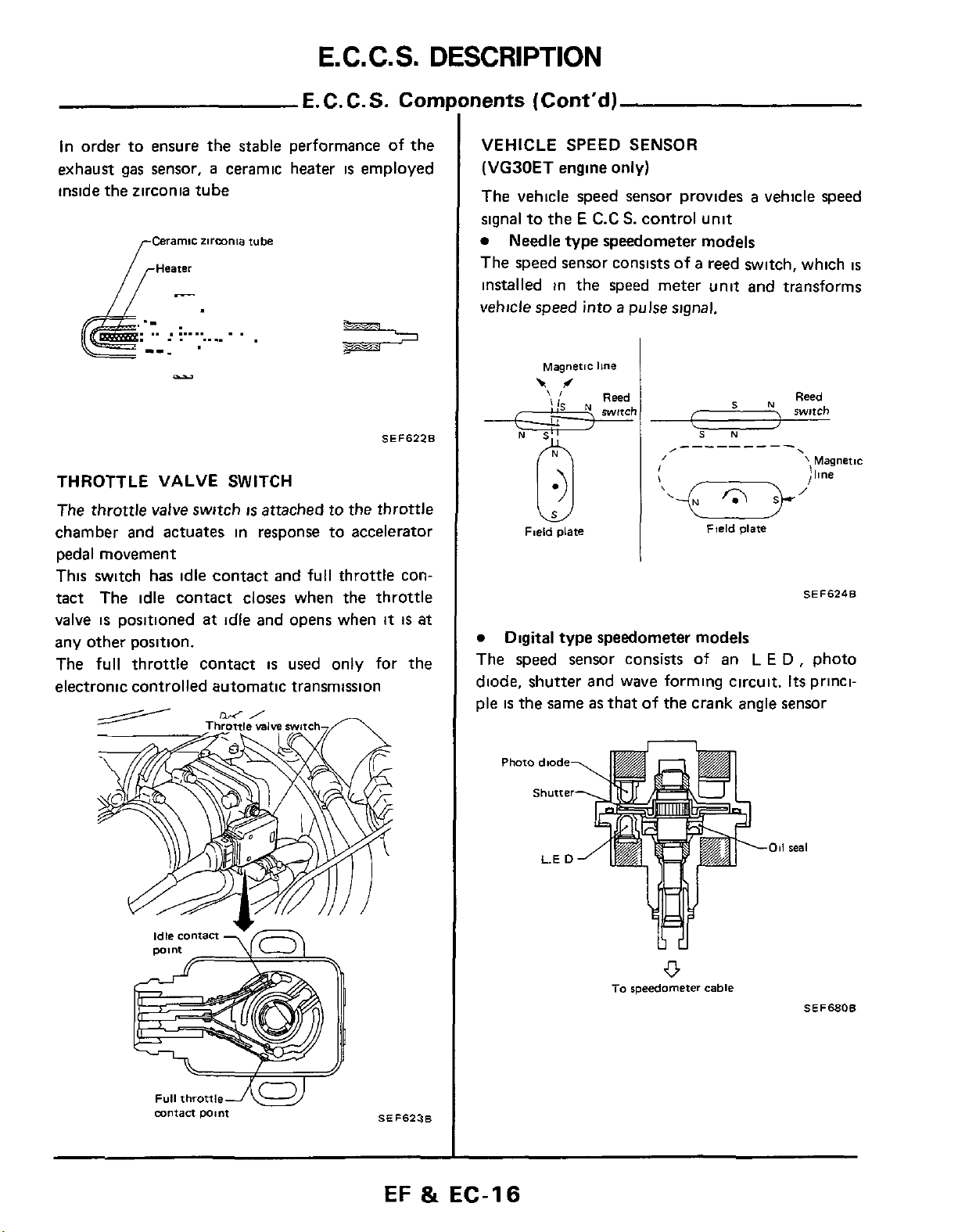

In

order to ensure the stable performance

exhaust

inside the zirconia tube

gas

sensor, a ceramic heater

,-Ceramic

.-

. ..

.

zirmnia tube

.

...

..

. . ..

..

.

.

of

is

employed

the

--_

SEF622B

THROTTLE VALVE SWlTCl

The throttle valve switch

chamber and actuates in

pedal movement

This switch has idle contact and full throttle contact The idle contact closes when the throttle

valve

is

positioned

any other position.

The full throttle contact

electronic controlled automatic transmission

at

is

attached to the throttle

response to accelerator

idle

and opens when

is

used

only for the

it

is

at

nents

VEHICLE SPEED SENSOR

(VG30ET

The vehicle speed sensor provides a vehicle speed

signal

The speed sensor consists of

installed

vehicle

The speed sensor consists of

diode, shutter and wave forming circuit.

ple

(Cont'd)

engine

to

the

Needle

in

speed

Magnetic

\#

\I

i

:

!'

N

S"

Field

0

plate

Digital type speedometer models

is

the same

only)

E

C.C

S.

control unit

type speedometer models

a

reed switch, which

the speed meter unit and transforms

into

a

pulse signal.

line

Reed

sw17CI

i

Field

plate

an

as

that

of

the crank angle sensor

L E D

SEF624B

,

photo

Its

princi-

IS

Full

throttle

contact

p0,nt

SEF623B

EF

&

EC-16

To

speedometer

0

cable

011

seal

SEFS80B

E.

C.

C.

S.

DESCRIPTION

E.C.C.S. Corn

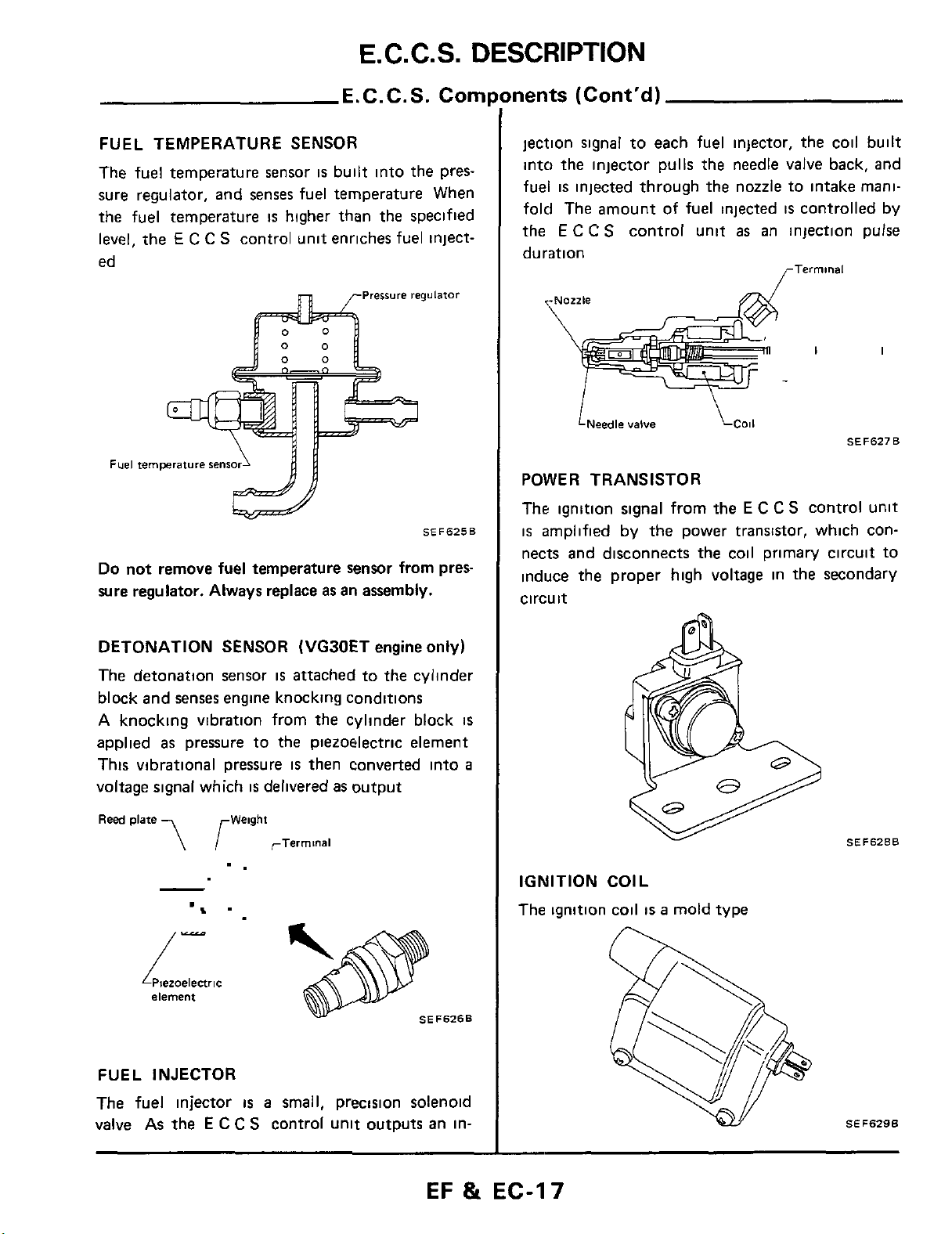

FUEL TEMPERATURE SENSOR

The fuel temperature sensor

sure regulator, and senses fuel temperature When

the fuel temperature

level, the

ed

Fuel

Do not remove fuel temperature sensor from pressure regulator. Always replace as

E

C C

temprature

S

$ens

IS

control unit enriches fuel inject-

is

built into the pres-

higher than the specified

Pressure

an

assembly.

regulator

SEF625B

lnents (Cont’d)

jection signal to each fuel injector, the coil built

into the injector pulls the needle valve back, and

fuel

is

injected through the nozzle to intake mani-

fold The amount of fuel injected

the

E

C C

S

control unit

duration

<-Nozzle

as

is

controlled by

an injection pulse

\

LNeedle

POWER TRANSISTOR

The ignition signal from the

is

amplified by the power transistor, which connects and disconnects the coil primary circuit to

induce the proper high voltage in the secondary

circuit

valve

E

C C

SEF627B

S

control unit

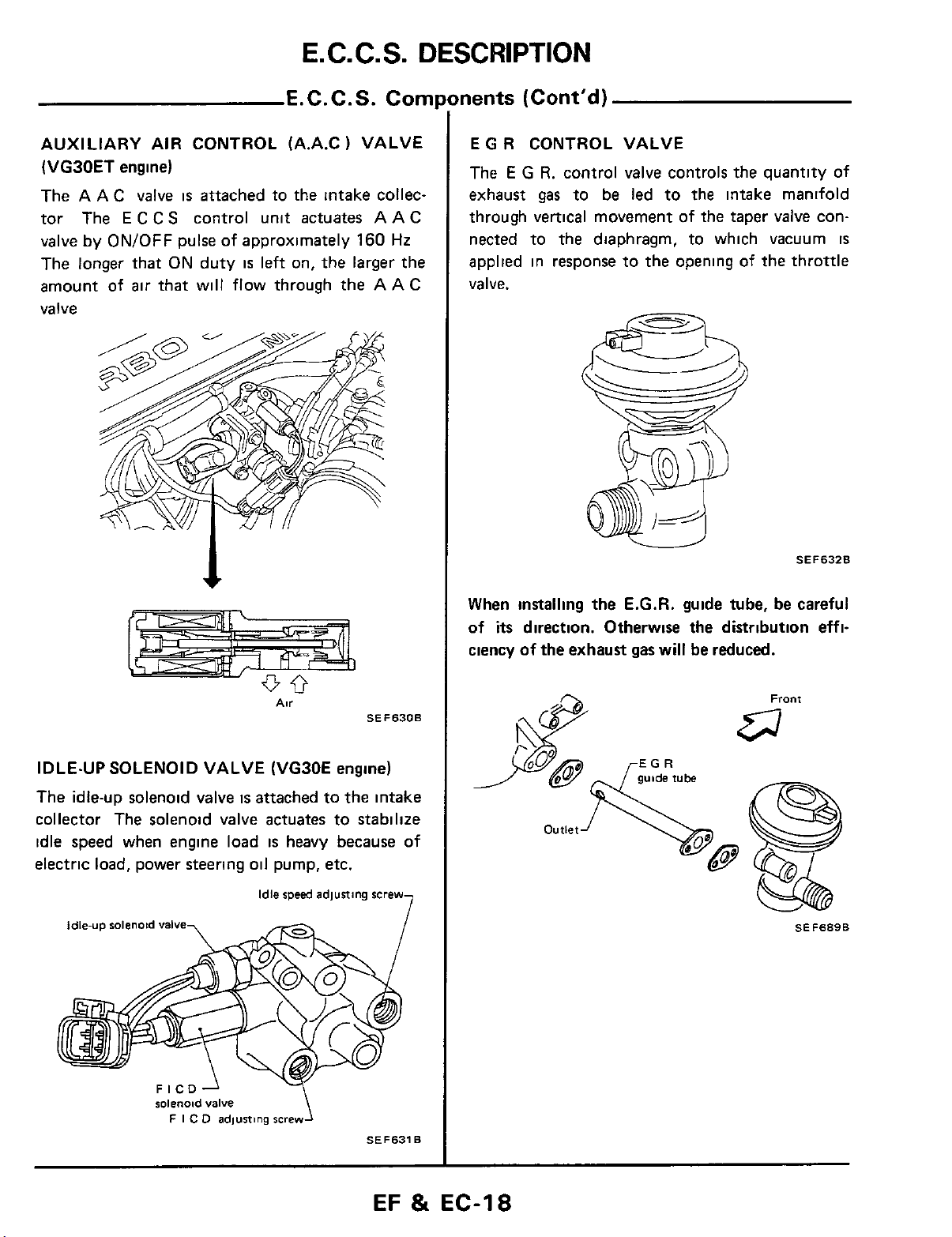

DETONATION SENSOR

The detonation sensor

block and senses engine knocking conditions

A

knocking vibration from the cylinder block

applied

This vibrational pressure

voltage signal which

Reed

plate

as

pressure to the piezoelectric element

is

,,

,-Weight

(VG30ET

is

attached to

IS

then converted into

delivered

rTerminal

as

output

engine only)

the

-.

/-

Piezoelectric

element

FUEL INJECTOR

cylinder

is

a

SEFSZSB

IGNITION COIL

The ignition coil

IS

a

mold type

SEFSZBB

The

fuel

injector

valve As the

E

C C

is

a

small, precision solenoid

S

control unit outputs an in-

EF

&

EC-17

E. C. C.

S.

DESCRIPTION

E.C.C.S. Corn1

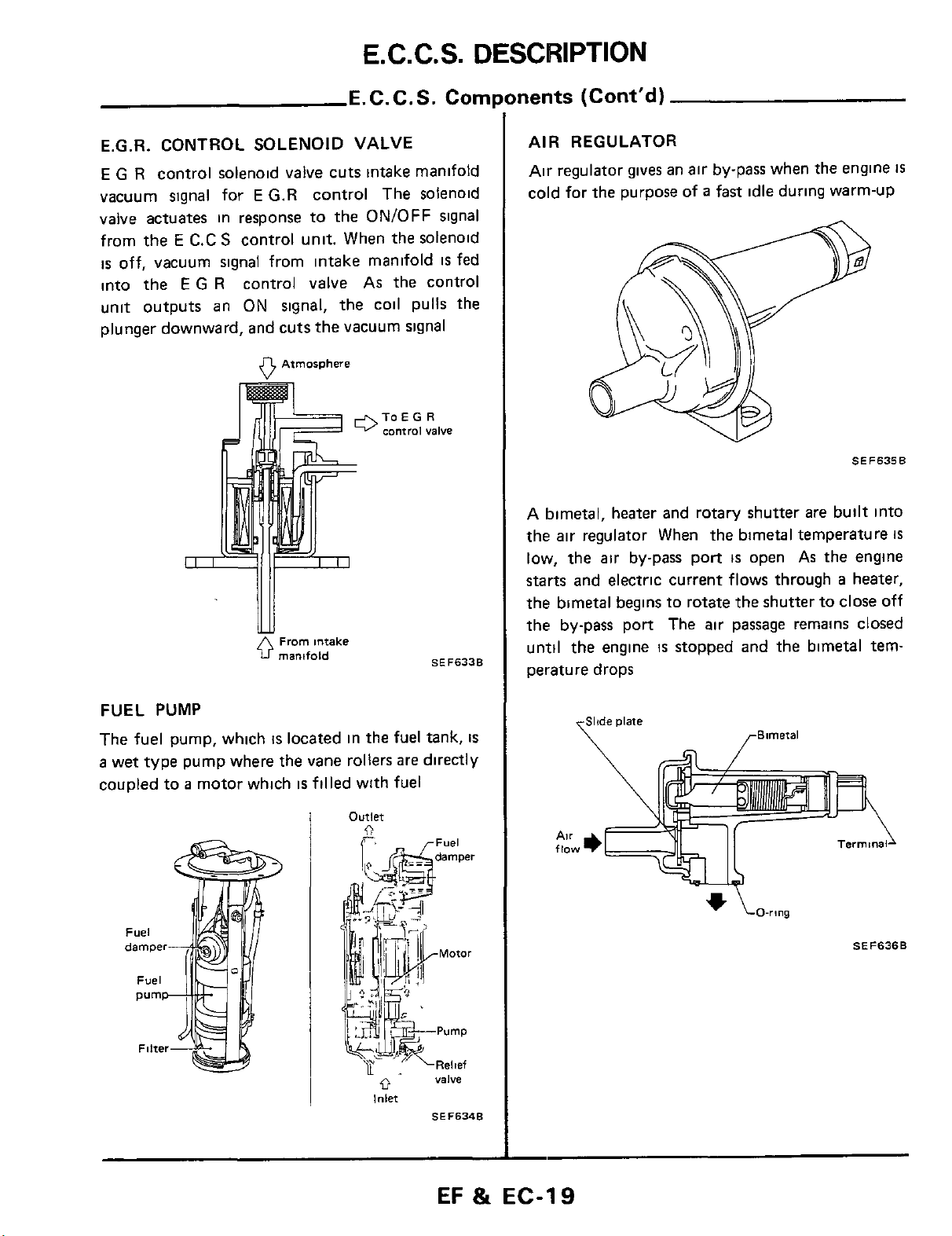

AUXILIARY AIR CONTROL (A.A.C 1 VALVE

A

A C

engine)

valve

is

attached to the intake collec-

E

C

CS

control unit actuates

is

left

air

that will flow through the

on, the

AAC

160

Hz

larger

A A C

the

(VG30ET

The

tor The

valve by ON/OFF pulse of approximately

The longer that ON duty

amount of

valve

nents (Cont'd)

E

G R CONTROL VALVE

The

E G R.

exhaust

through vertical movement of the taper valve connected to the diaphragm, to which vacuum

applied in response to the opening

valve.

control valve controls the quantity of

gas

to be led to the intake manifold

of

the throttle

IS

1

AV

IDLE-UP SOLENOID VALVE (VG30E

The idle-up solenoid

collector The solenoid valve actuates to stabilize

idle speed when engine load

electric load, power steering oil pump, etc.

ldleup

solenoid

valve

valve

is

attached to

is

heavy because of

idle

speed

adiuning

SEF630B

engine)

the

intake

screw

7

When

of

ciency of the exhaust gas will be reduced.

installing

its

direction. Otherwise the distribution

the

E.G.R.

guide tube, be careful

SEF632B

effi-

SEF689B

FICDJ

solenoid

F

I

C

valve

D

adjusling

screw

SEF631

EF

B

8i

EC-18

E.

C.

C.

S.

DESCRIPTION

E.C.C.S. Components (Cont’d)

E.G.R. CONTROL SOLENOID VALVE

E

G

R

control solenoid valve cuts intake manifold

vacuum signal for

valve actuates in response to the ON/OFF signal

from

the

E

C.C

is

off, vacuum signal from intake manifold

into the

unit outputs an ON signal, the coil pulls the

plunger downward, and cuts the vacuum signal

E

G

E

G.R

control The solenoid

S

control unit. When the solenoid

R

control valve

9

Atmosphere

From

0

intake

manifold

As

the control

ToEGR

control

is

fed

valve

SEF6336

AIR REGULATOR

Air regulator gives an

cold for the purpose of a fast idle during warm-up

A bimetal, heater and rotary shutter

the air regulator When the bimetal temperature

low,

the air by-pass port

starts

the bimetal begins to rotate the shutter

the by-pass port The air passage remalns closed

until the engine

perature drops

and electric current flows through a heater,

air

by-pass when the engine

SE

are

built into

is

open As the engine

to

close off

is

stopped and the bimetal tem-

F635

IS

is

B

FUEL PUMP

The fuel pump, which

a

wet type pump where the vane rollers are directly

coupled to

a

motor which

is

located in the

is

filled with fuel

1

Outlet

fuel

tank,

A

IS

SEF636B

EF

&

EC-19

E.C.C.S.

DESCRIPTION

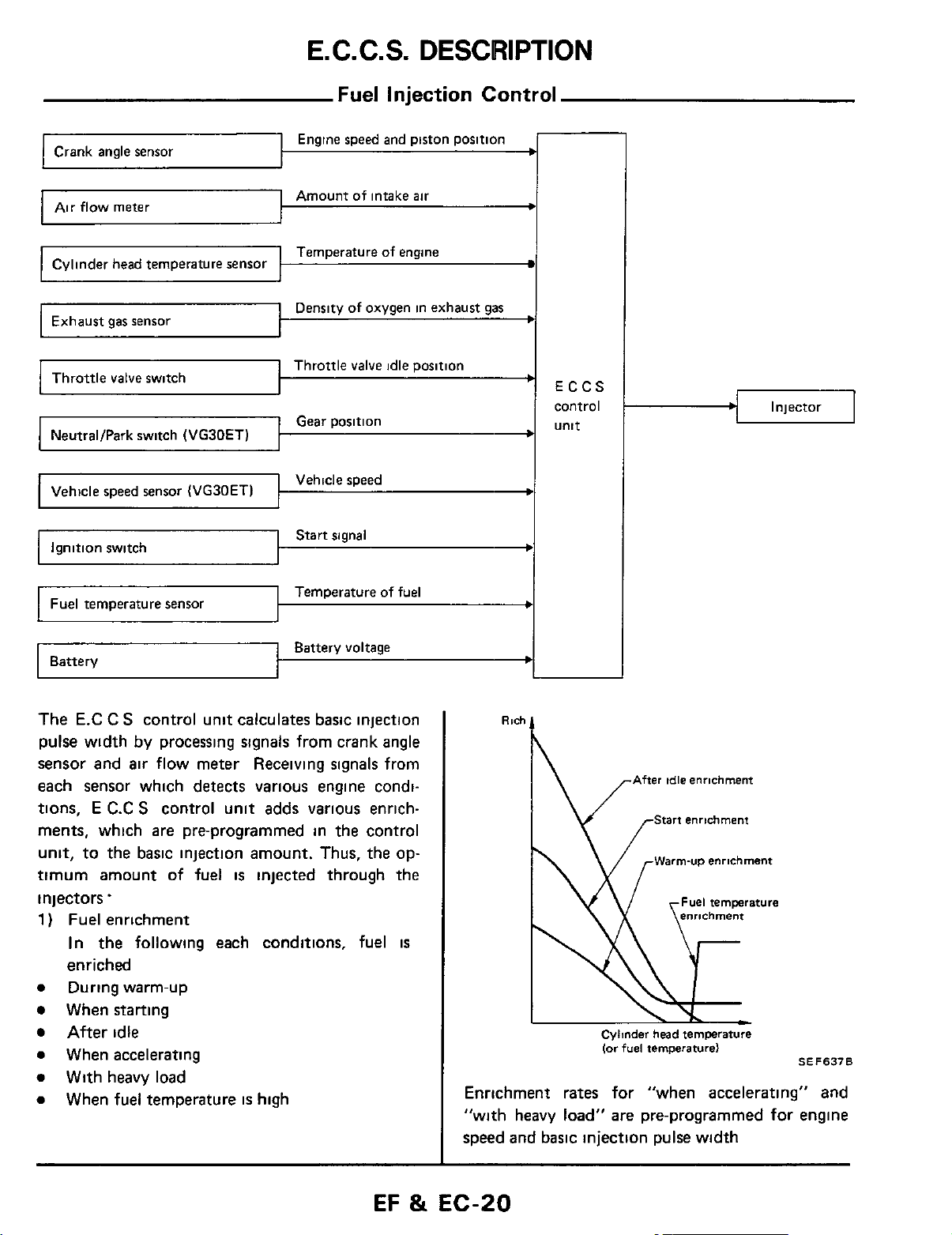

Fuel Injection Control

Engine

speed

and piston

position

Air

flow

I I

Cylinder

Exhaust

Throttle

NeutraVPark

I

Battery

meter

head

temperature

gas

sensor

valve

switch

switch (VG30ET)

sensor

Amount

Temperature

Density

Throttle

Gear

position

I

Vehicle

Start

signal

Temperature

Battery

of

intake

of

of

oxygen

valve

speed

of

voltage

engine

idle

fuel

air

in

exhaust

position

gas

I

'

ECCS

control

unit

.I

Injector

The

E.C

C

S

control unit calculates basic injection

pulse

width

by

processing signals from crank angle

sensor and air flow meter Receiving signals from

each sensor which detects various engine conditions,

ments, which are pre-programmed

unit,

timum

E

C.C

S

control

to

the basic injection amount. Thus,

amount

of

fuel

unit

adds various enrich-

is

injected through the

in

the control

the

op-

injectors.

1

)

Fuel

enrichment

In

the following each conditions,

fuel

is

enriched

e

During warm-up

When starting

After idle

e

When accelerating

e

With heavy load

e

When fuel temperature

is

high

Rlch

'

Enrichment rates

"with

heavy load" are pre-programmed

\/

Cylmder

(or

fuel

for

.-Warm-u~

head

temperature

temperature1

"when accelerating" and

speed and basic injection pulse

enrichment

width

for

SE

F637

engine

0

EF

&

EC-20

E.

C.

C.

S.

DESCRIPTION

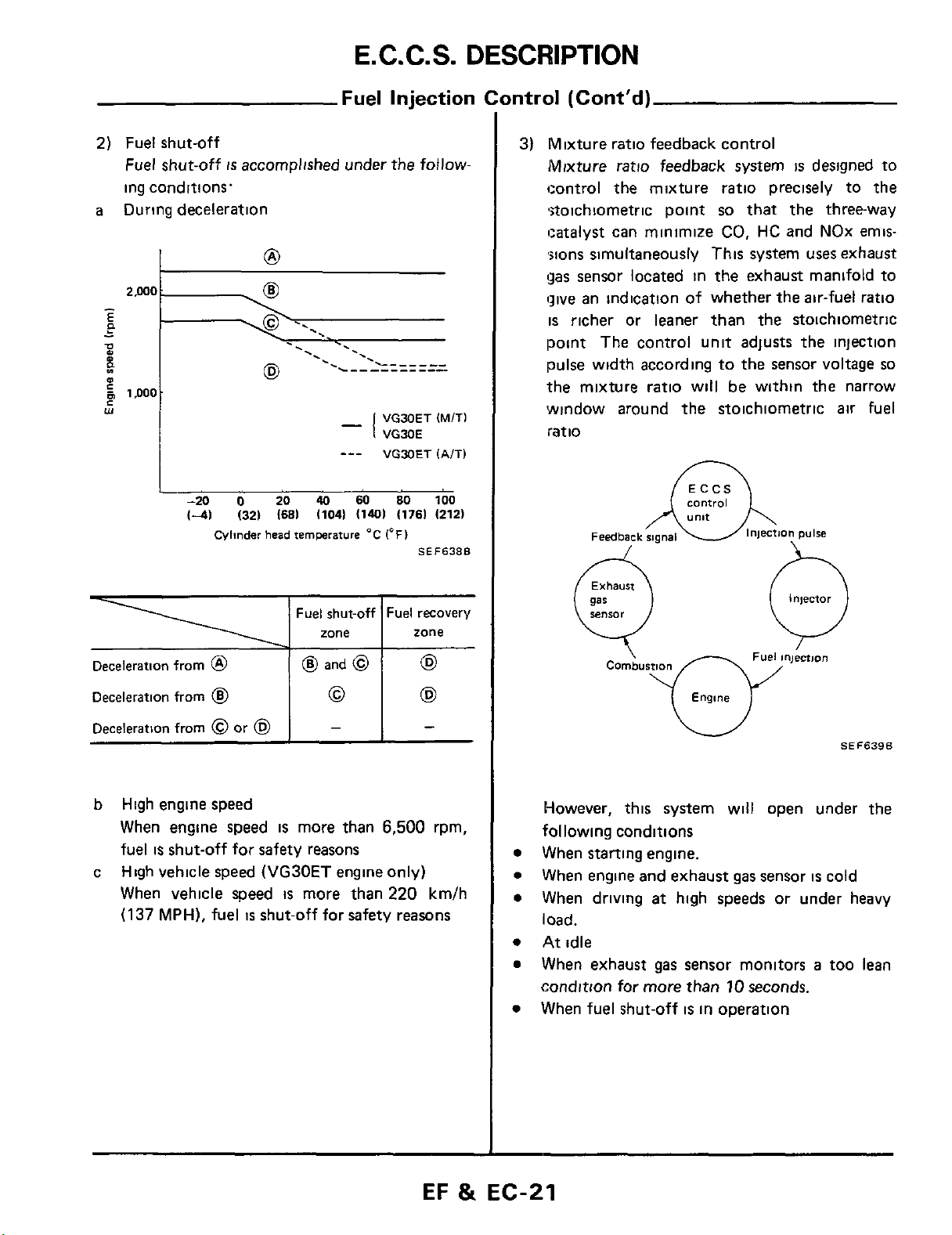

2)

Fuel

shut-off

Fuel

shut-off

ing conditions.

a

During deceleration

-

-20

(-41

Fuel

is

accomplished under the follow-

-..

.

.

._

.

.

_--

0

1321

Cvlinder

head

40 60

20

(681

11041

IemPerature "C

Injection

'.

VG30ET (MITI

VG30E

VGXIET

SO

(1401

(1761

1°F)

IA/Tl

100

12121

SEF638B

mtrol (Cont'd)

3)

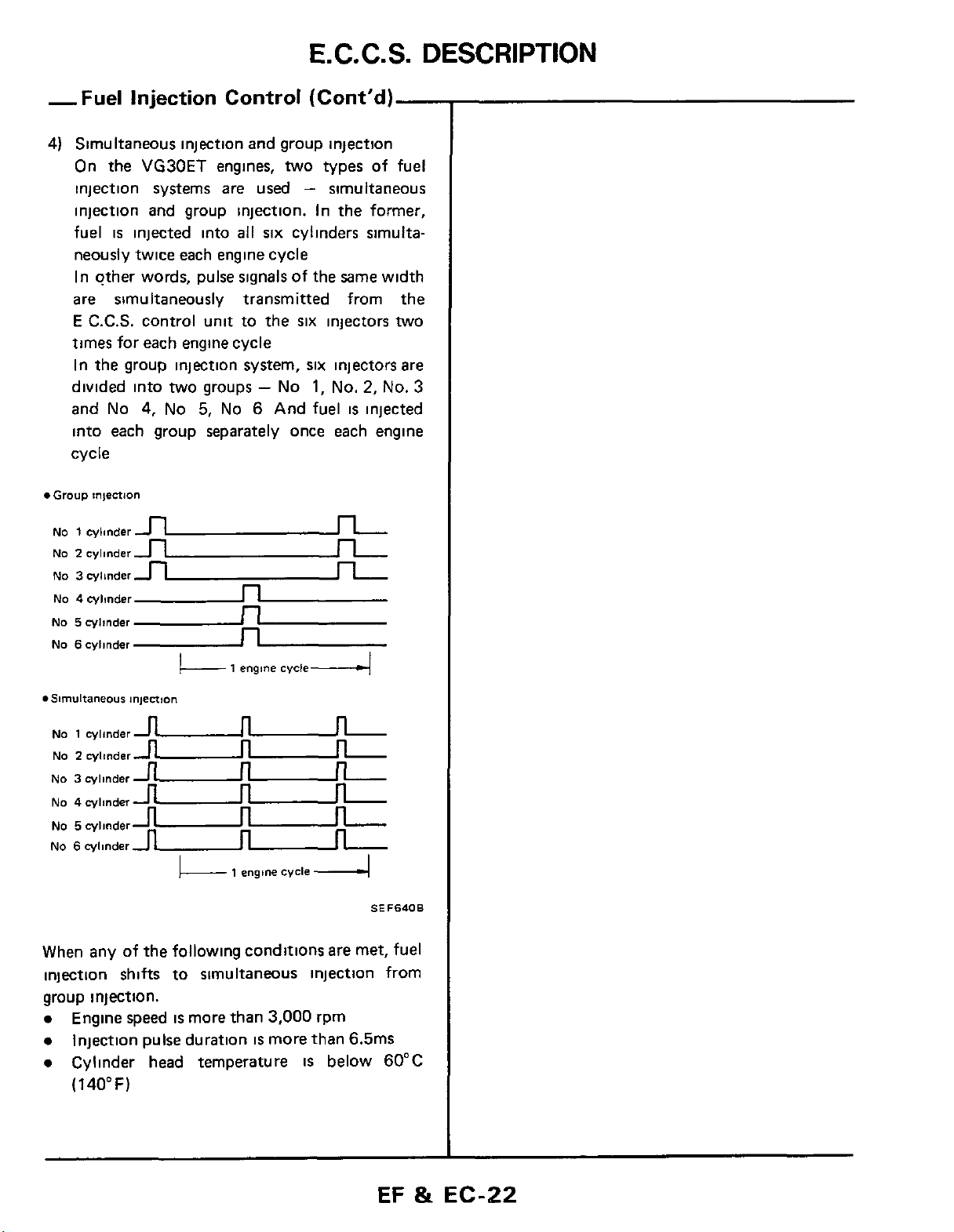

Mixture ratio feedback control

Mixture

control the mixture ratio precisely to the

*stoichiometric point

!catalyst can minimize

';ions simultaneously This system

gas

give an indication of whether the air-fuel ratio

is

point The control unit adjusts the injection

pulse

the mixture ratio will be within the narrow

window around the stoichiometric

ratio

ratio

feedback system

so that the three-way

CO,

senwr located in the exhaust manifold to

richer or leaner

width according

than

eontroi

to

the sensor voltage so

is

HC

and NOx emis-

uses

the stoichiometric

designed to

exhaust

air

fuel

Deceleration from

Deceleration from

Deceleration from 0 or

b

High engine speed

When engine speed

fuel

is

High vehicle speed

c

When vehicle speed

(137

MPH), fuel

@

@

shut-off for safety reasons

@

and

0

@

is

(VG30ET

is

is

shut-off for safety

-

more than 6,500 rpm,

engine

more than

@

62

(E9

-

only)

220

reasons

km/h

Injector

0

Combustm

Engme

However, this system will open under the

following conditions

When starting engine.

When engine and exhaust

When driving

load.

At idle

When exhaust

condition for more than

When fuel shut-off

at

high speeds or under heavy

gas

sensor monitors a too lean

is

gas

sensor

10

seconds.

in omration

is

cold

EF

&

EC-21

E.C.C.S.

DESCRIPTION

-Fuel

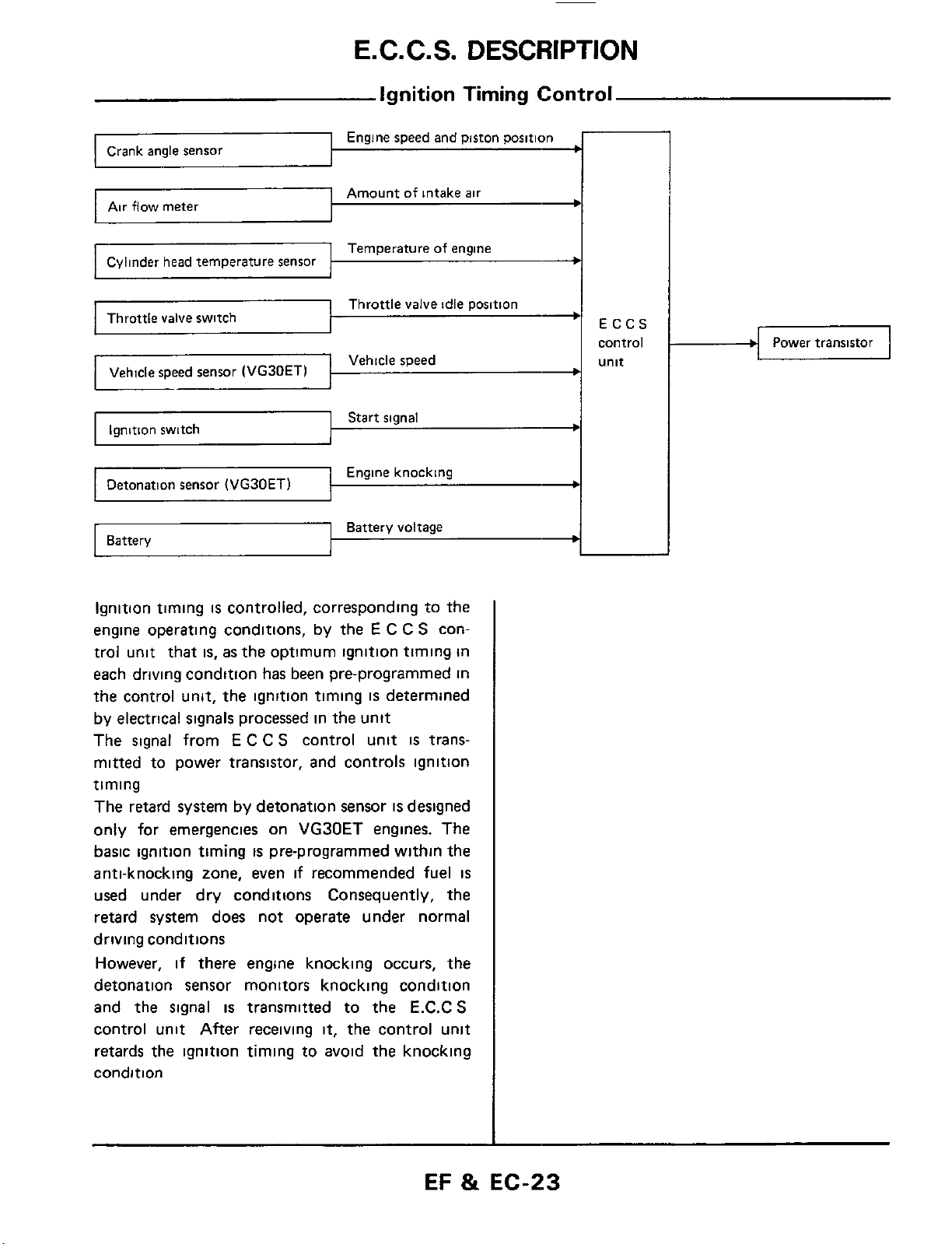

4)

Simultaneous injection and group injection

On

injection systems

injection and group injection. In the former,

fuel

neously twice each engine cycle

In other words, pulse signals

are simultaneously transmitted from the

E

times for each engine cycle

In the group injection system, six injectors are

divided into

and

into each group separately once each engine

cycle

Group

NO

1

NO

2

No

3

No

4

No 5 cylinder

No

6cylinder

injection Control (Cont'd)-

the

VG30ET

is

injected into

C.C.S. control unit to the six injectors

two

No

4,

No

injection

cylmder

cylindercylinder

cylmdern

u

-

engines,

are

groups

5,

No

two

types

used

-

simultaneous

all

six cylinders simulta-

of

the same width

-

No

1,

No.

2,

6 And

fuel

is

n

_n

L-

1

engine

cvcle4

of

fuel

two

No.

3

injected

.

Slrnultaneous

No

1

NO 2 cylinder

No

3

No

4

No

5

No

6

When any

injection shifts to simultaneous injection from

group injection.

Engine speed

Injection

Cylinder head temperature

(1

cylinder

cylinder

cylinder

cylinder

cylinder

40"

F)

ln,ect,On

u

-

u

u

u

u

I

of

the following conditions are met, fuel

is

pulse

duration

1

engm

more than

is

cycle

I

SEF640B

3,000

more than 6.5ms

rpm

IS

below 60°C

EF

&

EC-22

E.

C.

C.

S.

DESCRIPTION

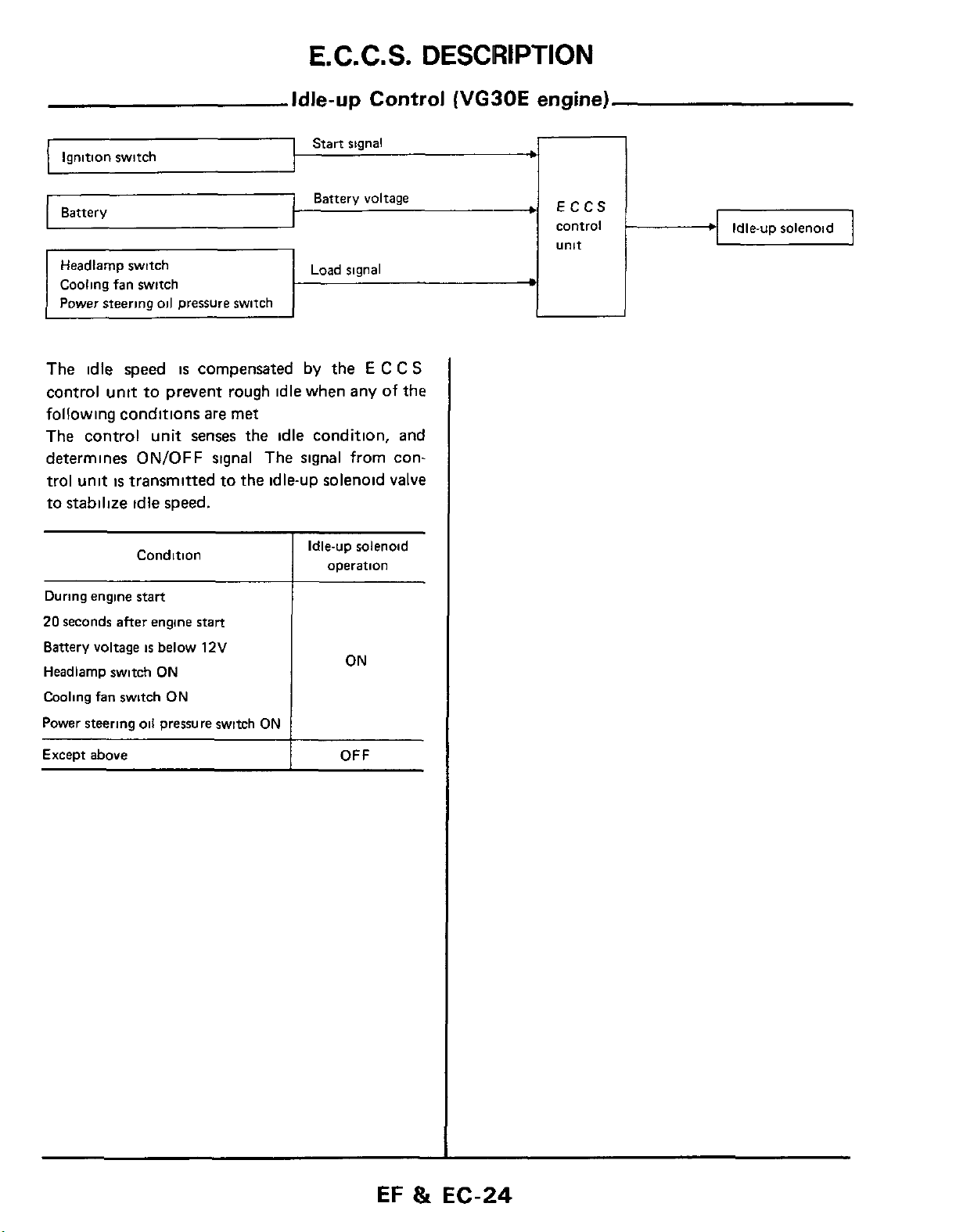

Ignition Timing Control

Crank angle sensor

Air flow meter

Cylinder head temperature sensor

Vehicle speed sensor

I

Ignition switch

Detonation sensor

Battery

~

(VG30ETl

Engine speed and piston position

Amount of intake

Temperature of engine

Throttle valve idle position

Vehicle

1

Start signal

Engine knocking

Battery voltage

speed

air

Power transistor

I

Ignition timing

engine operating conditions, by the

trol unit that

each driving condition has been pre-programmed in

the control unit, the ignition timing

by electrical signals processed in the unit

The signal from

mitted to power transistor, and controls ignition

timing

The retard system by detonation sensor

only for emergencies on VG30ET engines. The

basic ignition timing

anti-knocking zone, even

used under dry conditions Consequently, the

retard system does not operate under normal

driving conditions

However,

detonation sensor monitors knocking condition

and

the signal

control unit After receiving

retards the ignition timing to avoid the knocking

condition

is

controlled, corresponding to the

E

C C S con-

is,

as

the optimum ignition timing in

IS

determined

E

C C S control unit

is

pre-programmed within the

if

recommended fuel

if

there engine knocking occurs, the

is

transmitted to the E.C.C

it,

the control unit

is

is

designed

trans-

is

S

EF

&

EC-23

E.C.C.S.

DESCRIPTION

Idle-up Control

Ignition switch

Battery

~-

Headlarnp switch Load signal

Cooling fan switch

Power steering

The idle

oil

speed

pressure switch

is

compensated

control unit to prevent rough idle when any of the

are

following conditions

met

The control unit senses the idle condition, and

determines

trol unit

is

ON/OFF

transmitted to the idle-uD solenoid valve

signal The signal from con-

to stabilize idle speed.

Condition

Start signal

Battery voltage

by

the

E

C

Idle-up solenoid

operation

C

S

(VG30E

engine)

ECCS

control

unit

During engine start

20

seconds after engine

Battery voltage

Headlarnp switch

Cooling fan switch

Power steering oil pressure switch

Except above

is

below

ON

ON

start

12V

ON

ON

OFF

EF

8t

EC-24

Loading...

Loading...