Nissan 300zx Electrical System Section EL 1988 Owner's Manual

I

ELECTRICAL SYSTEM

When

0

Read

SECTION

you

read wiring diagrams:

GI

section. "HOW TO READ WIRING DIAGRAMS .

EL

-

CONTENTS

HARNESS CONNECTOR .................................................. EL- 2

STANDARDIZED RELAY

POWER SUPPLY ROUTING

BATTERY

STARTING SYSTEM ..................................................... EL- 17

STARTING SYSTEM . Starter.

CHARGING SYSTEM ..................................................... EL- 23

CHARGING SYSTEM -Alternator

COMBINATION

INSTRUMENT SWITCH

HEADLAMP

EXTERIOR LAMP

INTERIOR LAMP

METER AND GAUGES . Digital Type Combination Meter

METER AND GAUGES . Needle Type Combination Meter

METER AND GAUGES . Needle Type Combination

WARNING LAMPS AND CHIME

TIME CONTROL SYSTEM

WIPER AND WASHER

HORN, CIGARETTE LIGHTER, CLOCK

REAR WINDOW DEFOGGER

AUDIO AND POWER ANTENNA

AUTOMATIC SPEED CONTROL DEVICE (A.S.C.D.)

STEERING WHEEL SWITCH SYSTEM

THEFT WARNING SYSTEM

LOCATION

HARNESS LAYOUT

SPECIAL SERVICE TOOLS

E.C.C.S.

LOCK-UP

ADJUSTABLE

..............................................................

SWITCH

............................................................

.......................................................

........................................................

OF

ELECTRICAL UNITS

....................

CONTROL SYSTEM

SHOCK

ABSORBER

.................................................

................................................

...........................................

.........................................

..................................................

...................................................

......................

......................

Gauge

......................

...........................................

................................................

...................................................

....................................

..............................................

..........................................

.......................... EL-118

......................................

...............................................

.......................................

.....................................................

...............................................

WIRING DIAGRAM REFERENCE CHART

......

AT SECTION

...

FASECTION HEATER AND AIR CONDITIONER

MIRROR

.....................

.....

W

SECTION

HA

SECTION

EL-

3

EL-

5

EL- 9

EL-

18

EL- 26

EL-

32

EL-

34

EL-

35

EL-

54

EL-

59

EL-

65

EL-

83

EL-

86

EL- 90

EL- 98

EL-107

EL-111

EL-112

EL-115

EL-126

EL-146

EL-177

EL-180

EL-195

HARNESSCONNECTOR

Description

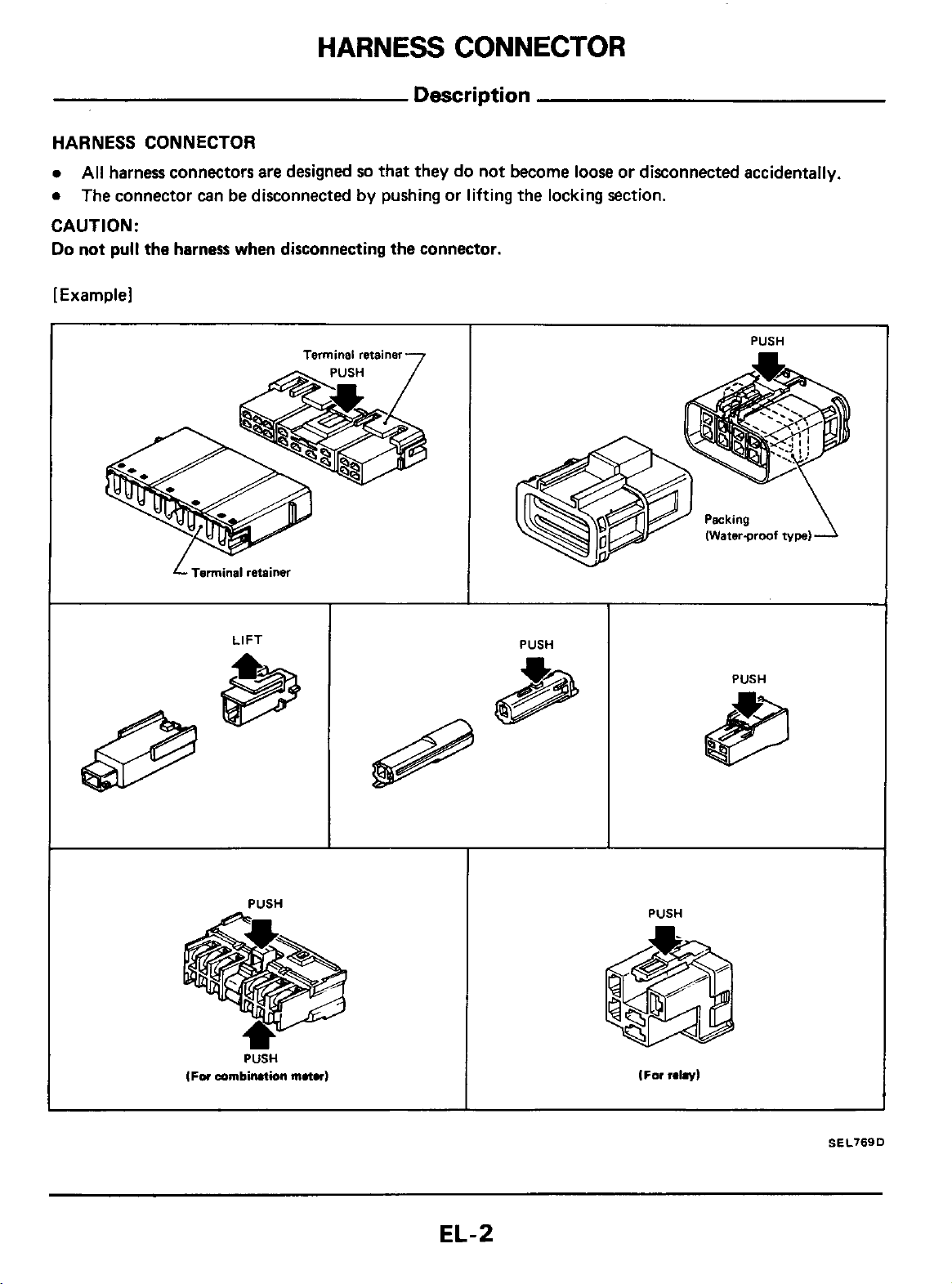

HARNESS CONNECTOR

0

All

harness connectors are designed

0

The connector can be disconnected by pushing or lifting the locking section.

CAUTION:

Do

not

pull

the harness when disconnecting the connector.

[Example]

so

that they do not become

loose

or disconnected accidentally.

Terminal retainer

LIFT

Terminal retainer

PUSH

IWaterprmf type)

PUSH

PUSH

IFw

combinntion

PUSH

PUSH

man)

EL-2

PUSH

SE

L769

D

STANDARDIZED

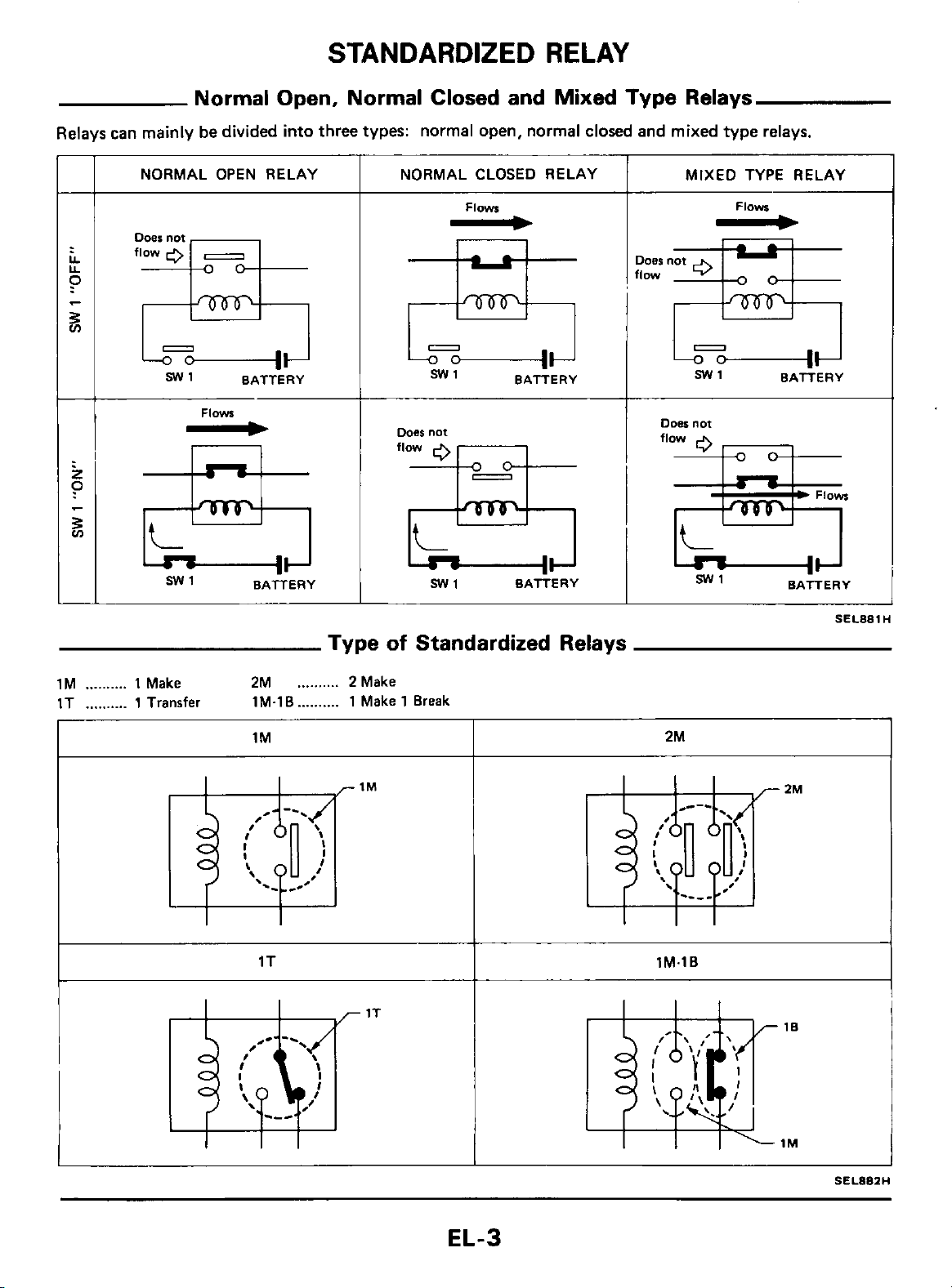

Normal Open, Normal Closed and Mixed Type Relays

RELAY

Relays can mainly

NORMAL OPEN RELAY

000s

not

SW1 BATTERY

-

sw

be

divided into three types: normal open, normal closed and mixed type relays.

~

NORMAL CLOSED RELAY

Does

flow

MIXED TYPE RELAY

Flom

not

0-

J

SW1 BATTERY

Flows

~

Oms

flow

not

ooer

flow

not

0

n

&

23

1

BATTERY

SW1

BATTERY

SWl BATTERY

1M

1T

..........

..........

1

Make

1 Transfer

2M

1M.lB

1M

11

Type

..........

..........

of

Standardized Rela

2 Make

1 Make 1 Break

SEL88lH

'S

2M

1M.16

EL-3

SEL882H

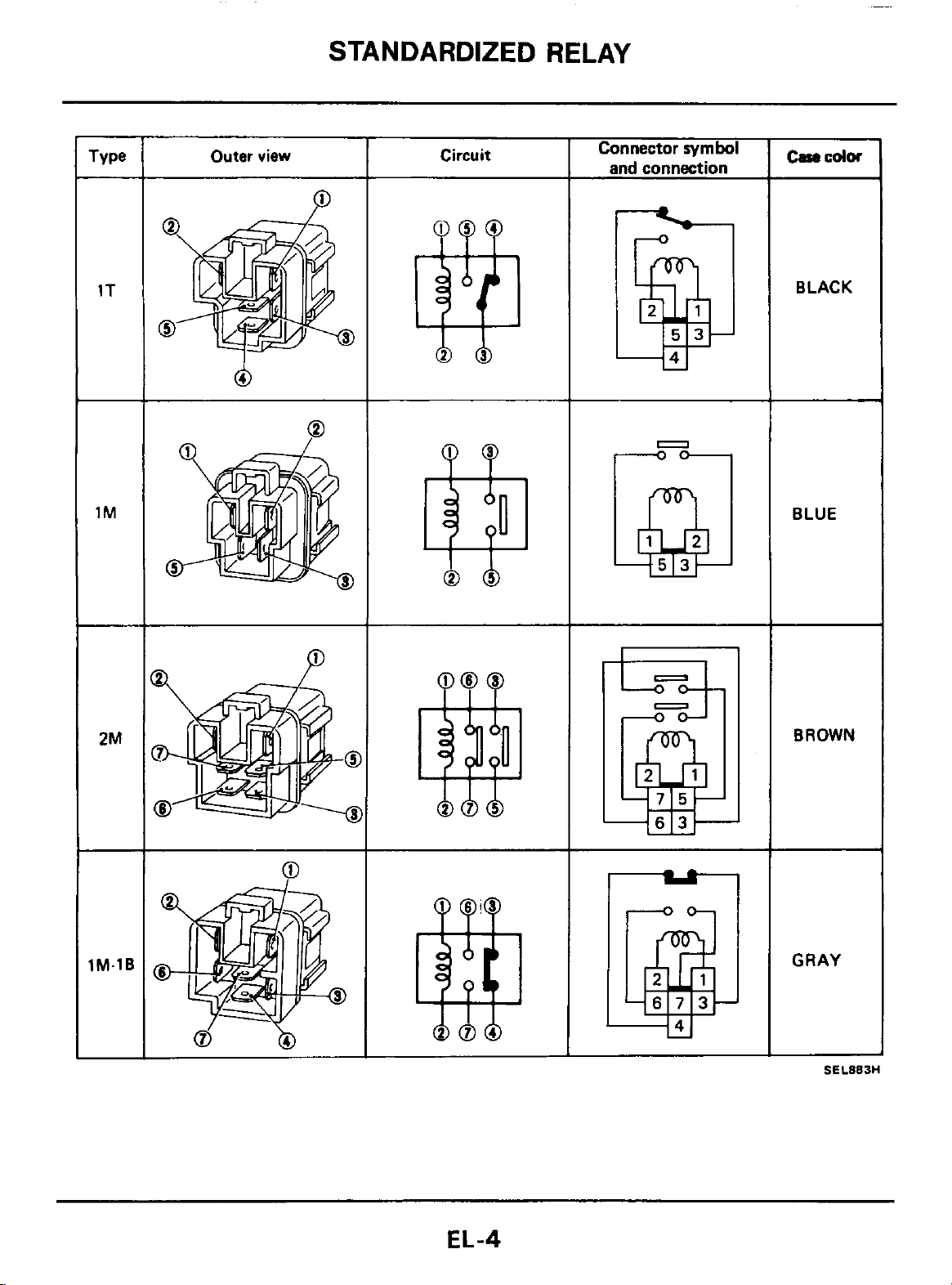

STANDARDIZED RELAY

~

Outer view

Circuit

I54

b

23

Connector

and connection

symbol

BLACK

BLUE

0'

BROWN

GRAY

b

SEL883H

EL-4

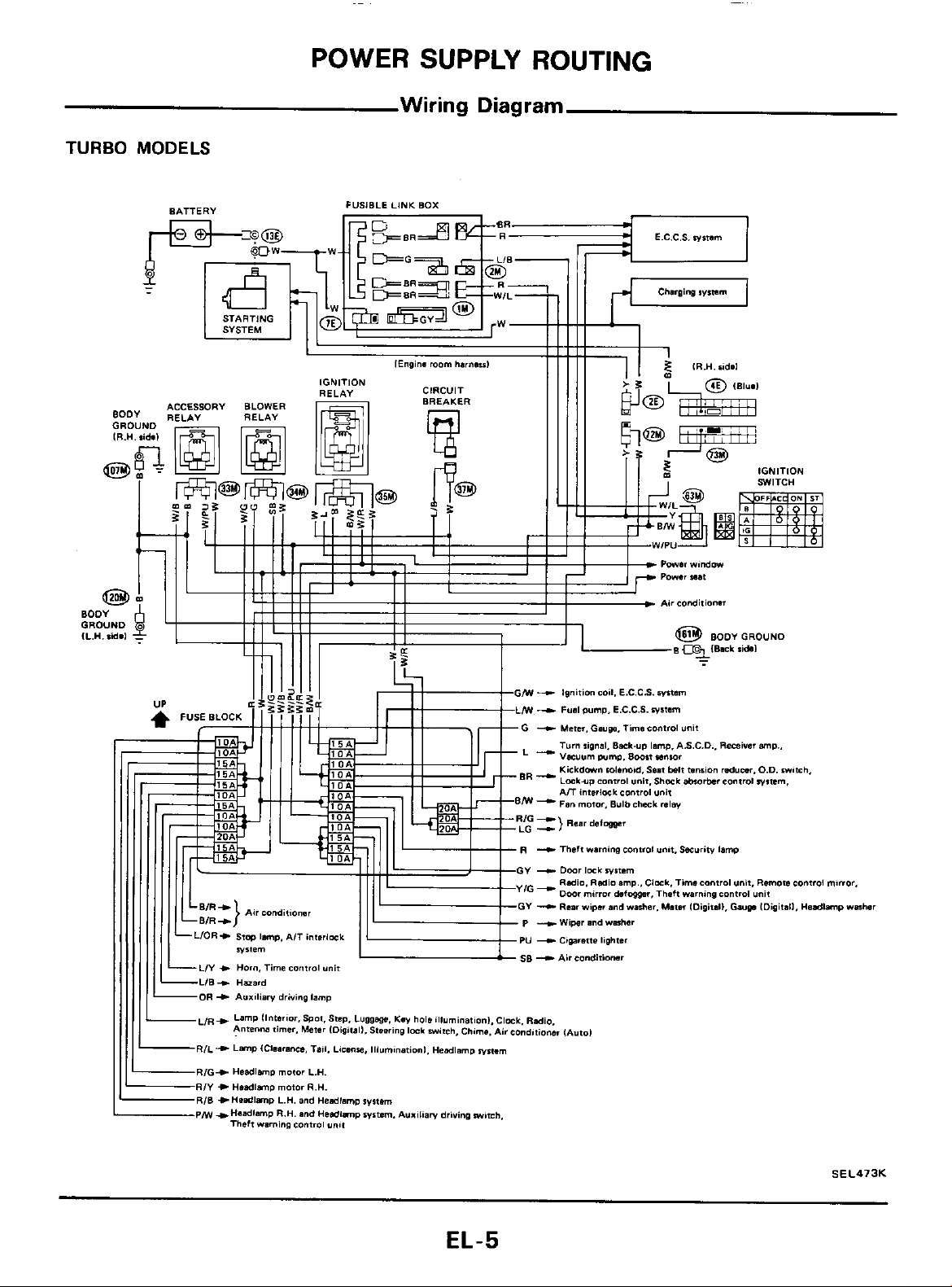

POWER SUPPLY ROUTING

TURBO

MODELS

Wiring

Diagram

EL-5

SEL473K

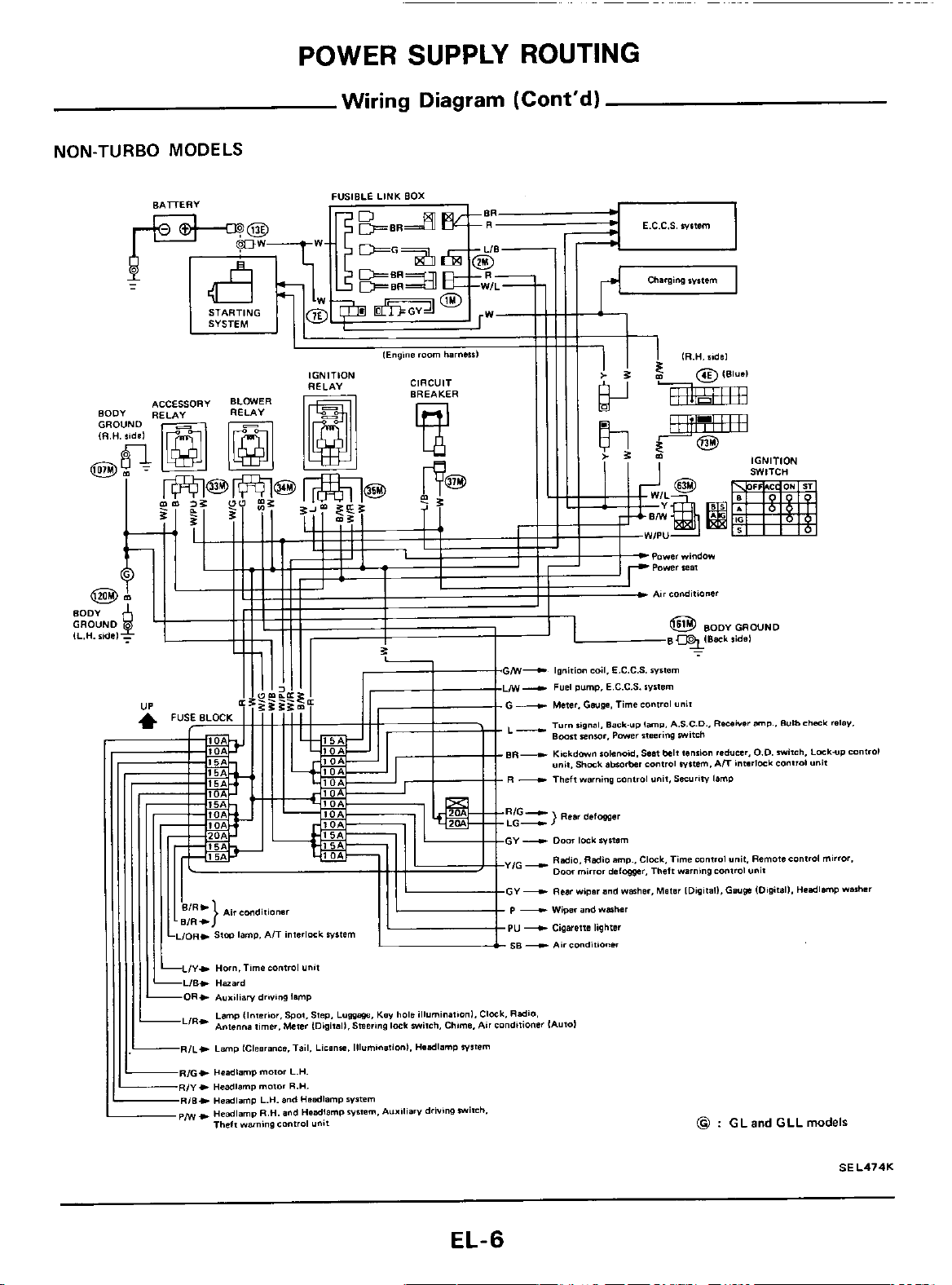

POWER SUPPLY ROUTING

Wiring Diagram (Cont'd)

NON-TURBO

BATrERV

MODELS

STARTING

FUSIBLE LINK

ItNlTlON

RELAY CIRCUIT

BOX

BREAKER

ECCS

wstem

@

BODYGROUND

EL-6

@

:

GL

and

GLL

models

SEL474K

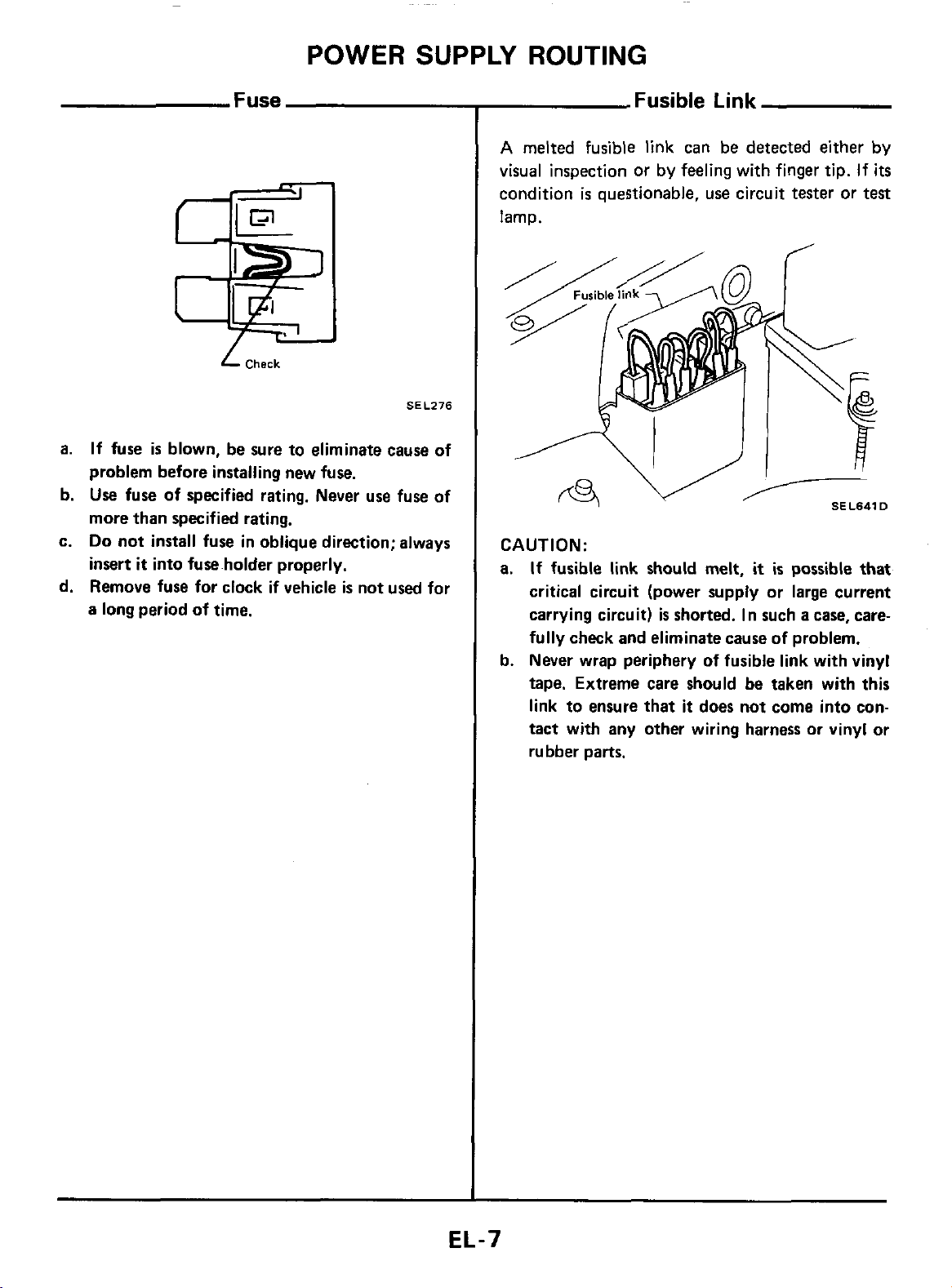

Fuse Fusible Link

Check

a.

If

fuse

is

blown, be sure to eliminate cause of

problem before installing new fuse.

b. Use

c.

d. Remove fuse for clock

fuse

of

specified rating. Never

more than specified rating.

Do

not

install

insert

it

into fuse holder properly.

a long period of time.

fuse

in oblique direction; always

if

POWER

vehicle

is

not used for

use

SUPPLY

SEL276

fuse of

ROUTING

A

melted fusible link can

visual inspection or by feeling with finger tip.

condition

lamp.

CAUTION:

a.

If

critical circuit (power supply or large current

carrying circuit)

fully check and eliminate cause of problem.

b. Never wrap periphery of fusible

tape. Extreme care should be

link to ensure that

tact with any other wiring harness

rubber parts.

is

fusible

questionable,

link

should melt,

is

be

detected either by

use

circuit tester

it

is

shorted. In such a case, care-

link

taken

it

does

not

come into con-

or

possible that

with vinyl

with

or

vinyl or

If

its

test

this

EL-7

Note:

POWER SUPPLY ROUTING

~~

EL-8

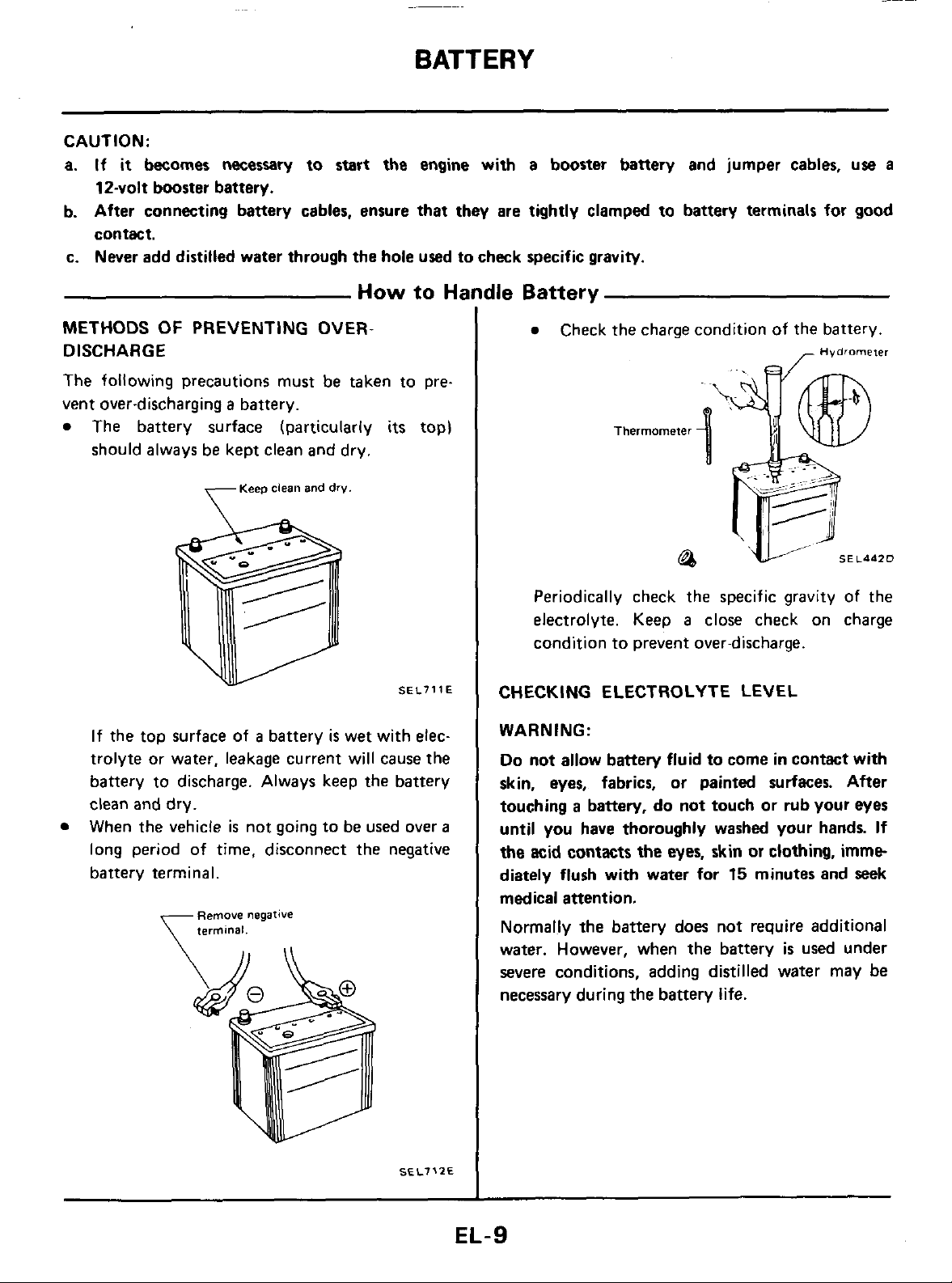

BATTERY

CAUTION:

If

it

a.

b. After connecting battery cables, ensure that they are tightly clamped

contact.

c. Never add distilled water

becomes necessary

12-volt

booster

battery.

to

start the engine with a booster battery and jumper cables,

through

the

hole used to check specific gravity.

to

battery terminals

for

use

a

good

How

METHODS

DISCHARGE

The following precautions must be taken to pre-

vent over-discharging

The battery surface (particularly

should always be kept clean and dry.

If the top surface of a battery

trolyte or water, leakage current will cause the

battery to discharge. Always keep the battery

clean and dry.

When the vehicle

long period of time, disconnect the negative

battery terminal.

OF

PREVENTING OVER-

a

battery.

Keep

clean

is

not going

Remove negative

7

terminal.

and

dry

is

wet with elec-

to

be used over

its

to

top)

Ha

a

Ile Battery

Check the charge condition

Periodically check the specific gravity of the

a

electrolyte. Keep

condition to prevent over-discharge.

CHECK

WARNING:

Do

skin,

touching

until

the acid contacts the

diately

medical attention.

Normally the battery does not require additional

water. However, when the battery

Severe conditions, adding distilled water may be

necessary during the battery life.

I

NG

ELECTROLYTE LEV EL

not

allow battery fluid to come

eyes, fabrics, or painted surfaces. After

a

battery, do not touch or

you

have thoroughly washed your hands.

flush

with water for

close check on charge

eyes,

skin

of

the battery.

~

Hydrometer

in

contact with

rub

your eyes

or

clothing,

15

minutes and seek

is

used under

imme-

If

EL-9

~

BATTERY

0

If

the electrolyte level

a

using

Add

suitable tool.

distilled

water

How

is

low,

remove cell plug

up

to the MAX level.

to

Hand11

SELOOIK

attery (Cont'd)

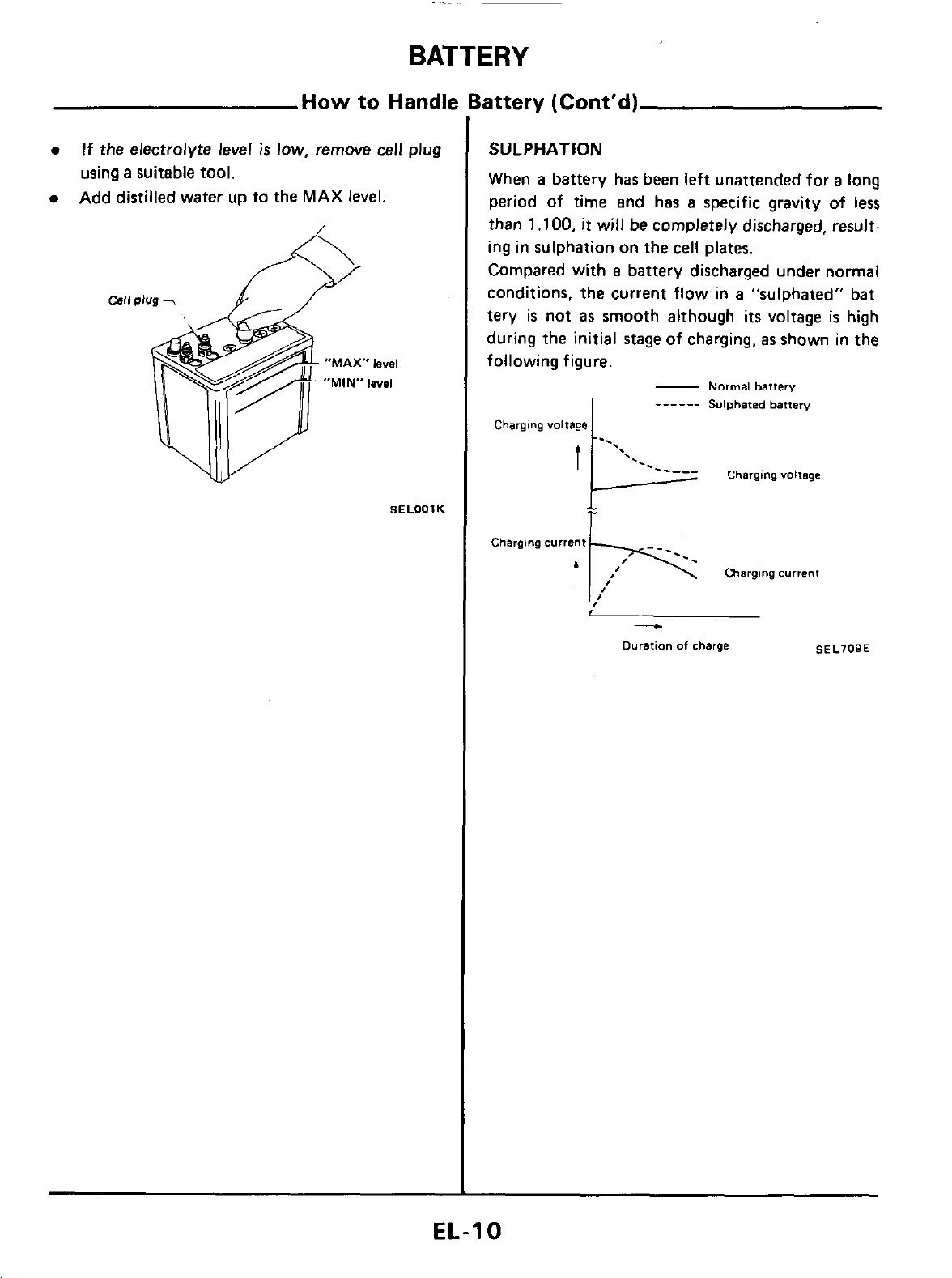

SULPHATION

When a battery has been left unattended for a long

period of time and has

than

1.100.

ing in sulphation on the cell plates.

Compared with

conditions, the current flow in

is

tery

during the initial

following figure.

Chargmg voltage

not

it

will be completely discharged, result-

a

battery discharged under normal

as

smooth although

stage

I-.

A

'.

a

specific gravity

a

"sulphated" bat-

its

voltage

of

charging,

-

______

Normal

Subhated battery

--___

as

battery

Charging

shown in the

voltage

of

is

less

high

I---

+

Charging current

1

Chargingcurrent

-

Duration

of

charge

SEL709E

EL-I

0

BATTERY

Specific Gravity Check

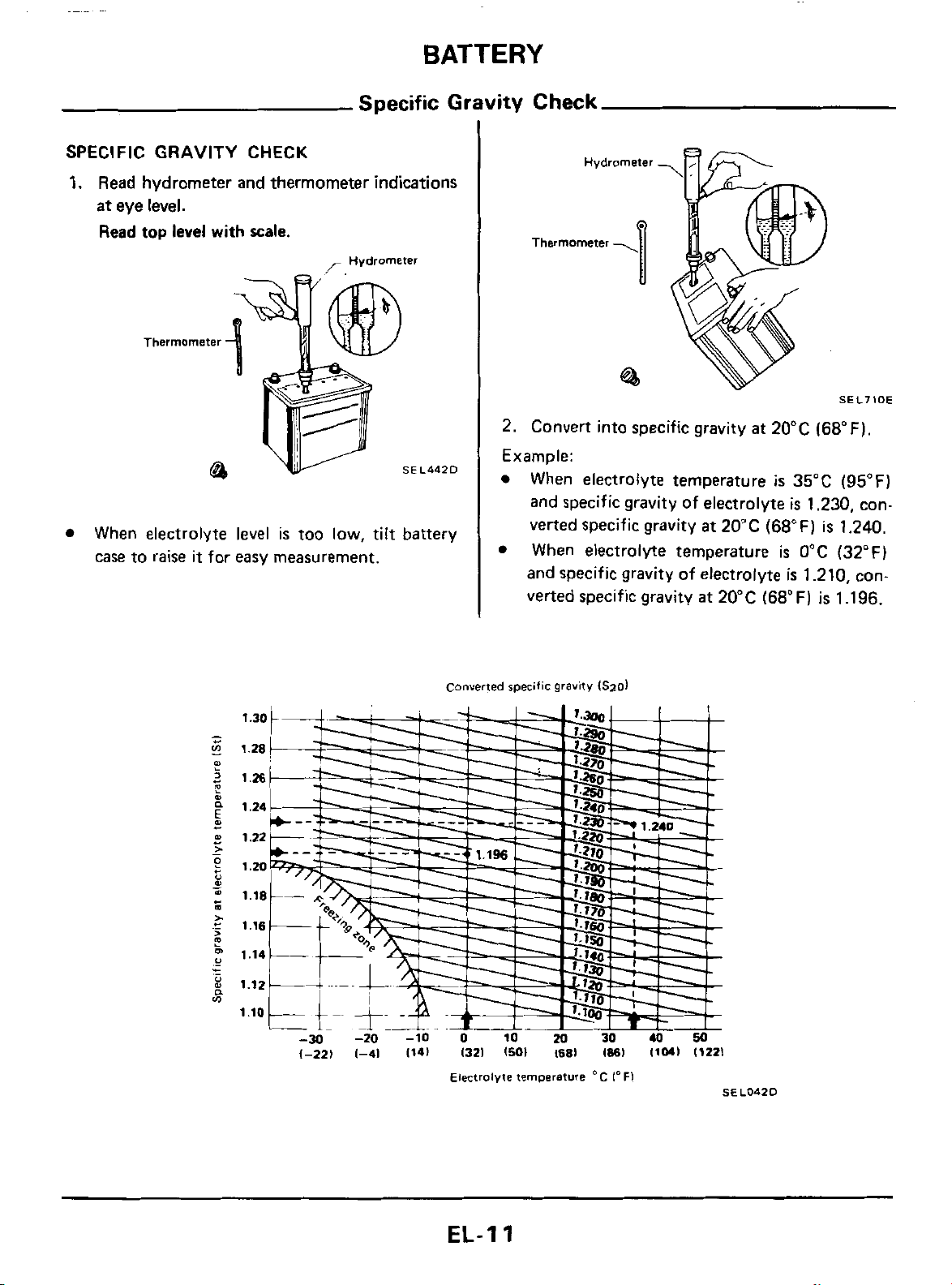

SPECIFIC

1.

Read hydrometer and thermometer indications

at

Read

When electrolyte level

case to raise

GRAVITY

eye

level.

top

Thermometer

CHECK

level

with

scale.

is

too

it

for easy measurement.

~ Hydrometer

I

low,

tilt

SEL442D

battery

Hvdrometer

Thermometer

U

2. Convert

Example:

When electrolyte temperature

and

verted specific gravity

When electrolyte temperature

and specific gravity

verted specific gravity

into

specific gravity at 20°C (68°F).

specific gravity

of

at

of

electrolyte

at

is

electrolyte

20°C (68°F)

20°C (68°F)

SEL710E

35°C (95°F)

is

1.230, conis

1.240,

is

0°C (32” F)

is

1.210. con-

is

1.196.

Converted

specific

gravity

(S201

i

LO420

EL-I

1

BATTERY

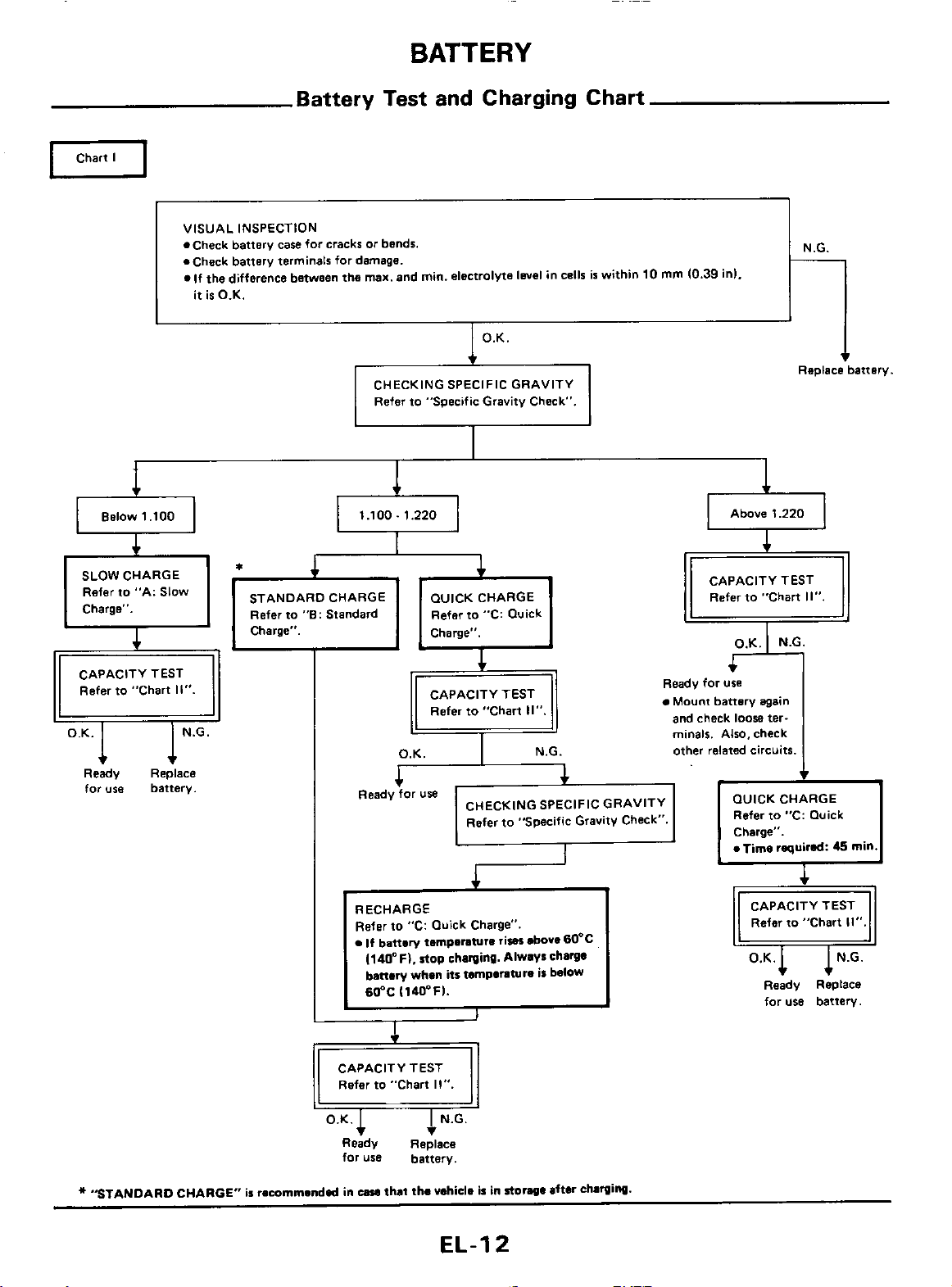

Chart

I

U

iL1

Below

SLOWCHARGE

Battery

VISUAL INSPECTION

Check battery

.Check battery terminals for damage.

If

the difference between the max. and

it

is

O.K.

1.100

care

for cracks

STANDARD CHARGE QUICK CHARGE

Refer

to

"B:

Test

or

bends.

CHECKING SPECIFIC GRAVITY

Refer

11

1.100~1.220

Standard

and Charging Chart

min.

electrolyte level in cells

to "Specific Gravity Check".

Refer to

Charge".

"C:

Quick

is

within

10

mm

10.39

in).

Replace battery.

Above

1.220

CAPACITY TEST

Refer to "Chart

+

11".

Refer to "Chart

Readv Replace

for

use

I('*.

battery.

CAPACITY TEST

Refer

to

Ready

for

use

Refer to "Specific Gravity Check".

I

RECHARGE

Refer to "C: Quick Charge".

If

battery

temperawre

(140°F).

battery

60°C

CAPACITY TEST

Refer to "Chart

Readv Replace

for use battery.

stop

whm

114O'FI.

charping.

its

II".

tmpemNre

"Chart

rise8

Always

11".

.bow.

is

60'C

chew

below

Ready

for

use

Mount

battery again

and check

minals. Also, check

other related circuits.

loore

QUICK CHARGE

Refer

Charge".

.-rime required:

Refer

Ready Replace

for use battery.

ter-

to

"C: Quick

to

1

"Chart

45

min.

(I".

"STANDARD

CHARGE"

is

recommended

in

c.ll

that the vehicle

EL-1

is

in

Itorwe

2

after

charpiw.

0

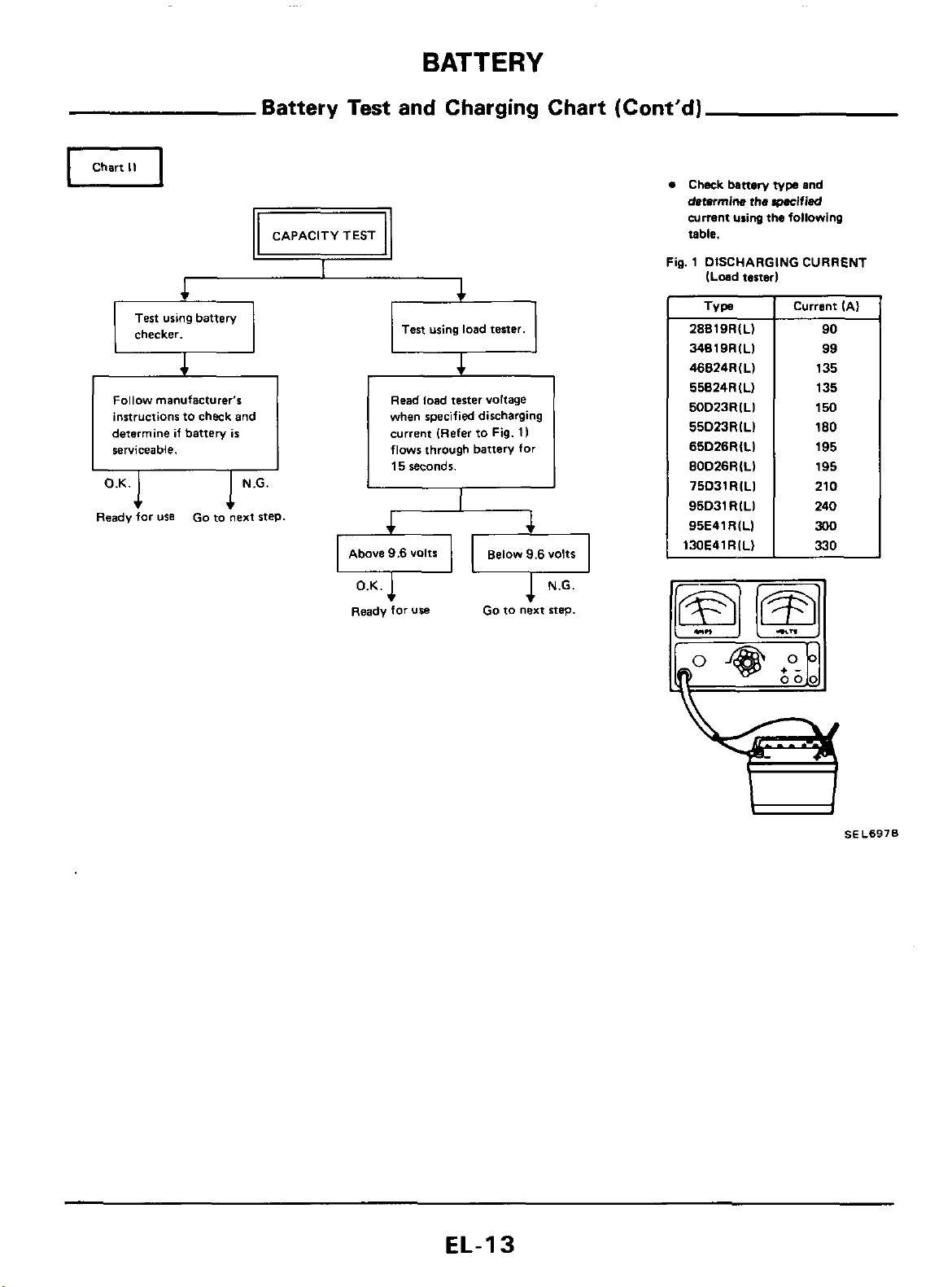

Chart

I1

BATTERY

Battery Test and Charging Chart (Cont’d)

CAPACITY TEST

F

Fig. 1 DISCHARGING CURRENT

Check

battery

dutnmins

current

uiim

table.

(Load tester)

typ

tho

#peifisd

the following

and

Test using battery

checker.

Follow

manufacturer’s

instructions to check and

determine if battery

serviceable.

Ready for

use

Go

is

to

next step

Test using load tester.

Read

load

when specified discharging

current (Refer to Fig. 1)

flows through battery for

15 seconds.

Above

9.6

VOltS

Ready for

Use

4

tester voltage

I

Below 9.6 volts

Go

to next step.

Current (A)

3481 9RlLl

50D23RILl

55D23RIL)

75D31RILI 210

130E41 RIL)

195

240

3w

330

EL-I

3

U

SEL6970

BATTERY

Below

12

to

15voltr

Continue

12 hours.

to

charge for

12

15voltr

ReplaCe battev.

I

CHECKING SPECIFIC GRAVITY

Refer

10

"Specific Gravity Check".

volts

or

above

--

TYPE

$$

cc

mm

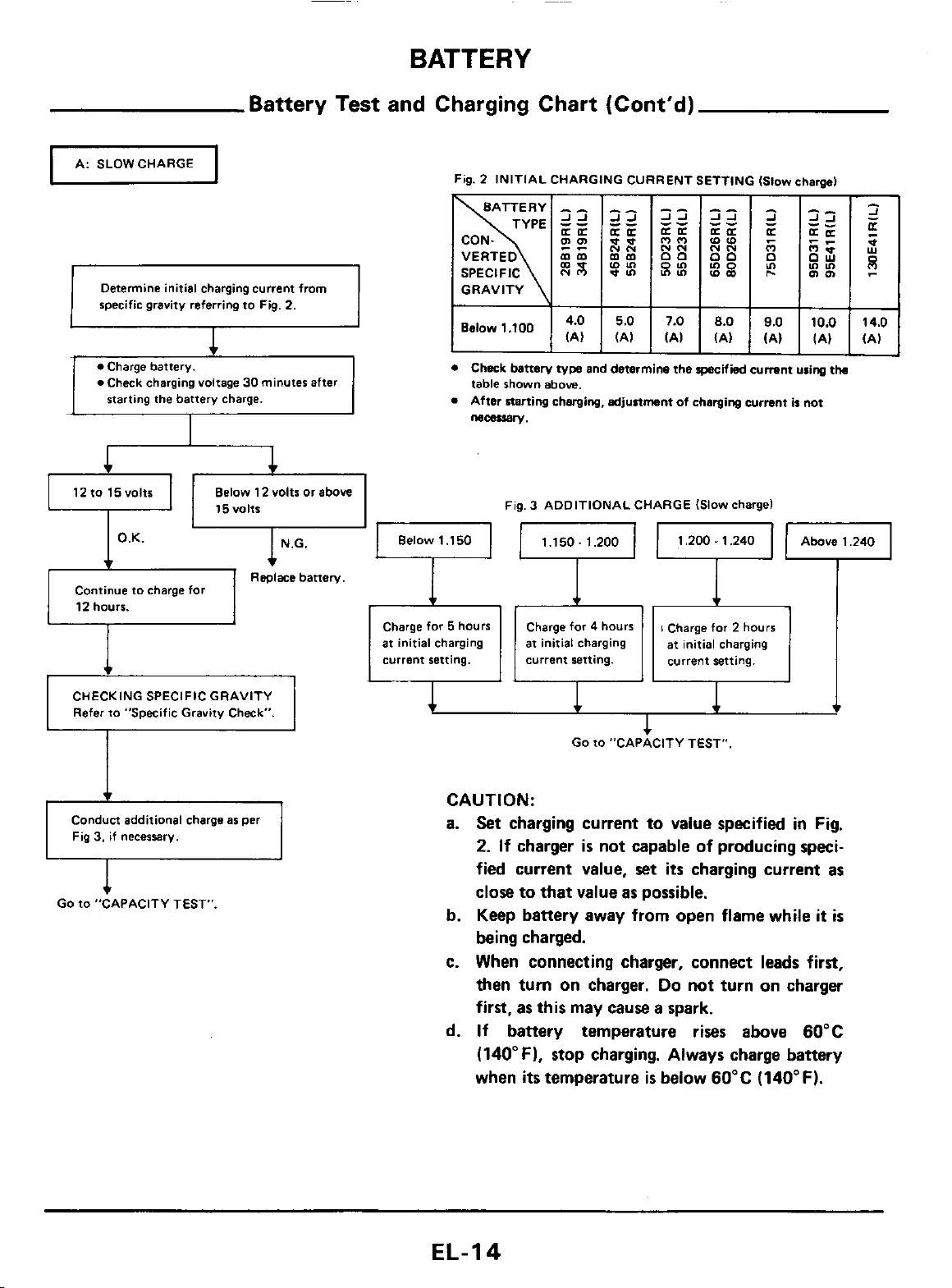

Fig. 3 ADDITIONAL CHARGE

Below 1.150 1.150.1.200 1.200 - 1.240

at

initial charging

current setting. current setting.

--

22

uu

x;:

mm

--

52

KK

no

82

--

22

UK

(DW

El=

(Slow

chargel

-

2

K

~j

22

Uu

6;

-

A

-

Fig

3.

if

necessary.

1

Go

to

"CAPACITY TEST"

GO

to

"CAPACITY TEST".

CAUTION:

a. Set charging current

2.

If

charger

fied current value,

close

to

b.

Keep battery away from open flame while

being charged.

c. When connecting charger, connect leads

then

turn

first,

as

d.

If

battery temperature rises above

(140°F),

its

when

is

that value as possible.

on charger.

this

may

stop

charging. Always charge battery

temperature

to

value specified

not

capable of producing speci-

set

its

charging current

Do

not

turn

on

cause

a spark.

is

below

60°C

(140°F).

charger

in

Fig.

it

first,

60°C

as

is

EL-I

4

Battery Test and Charging Chart (Cont'd)

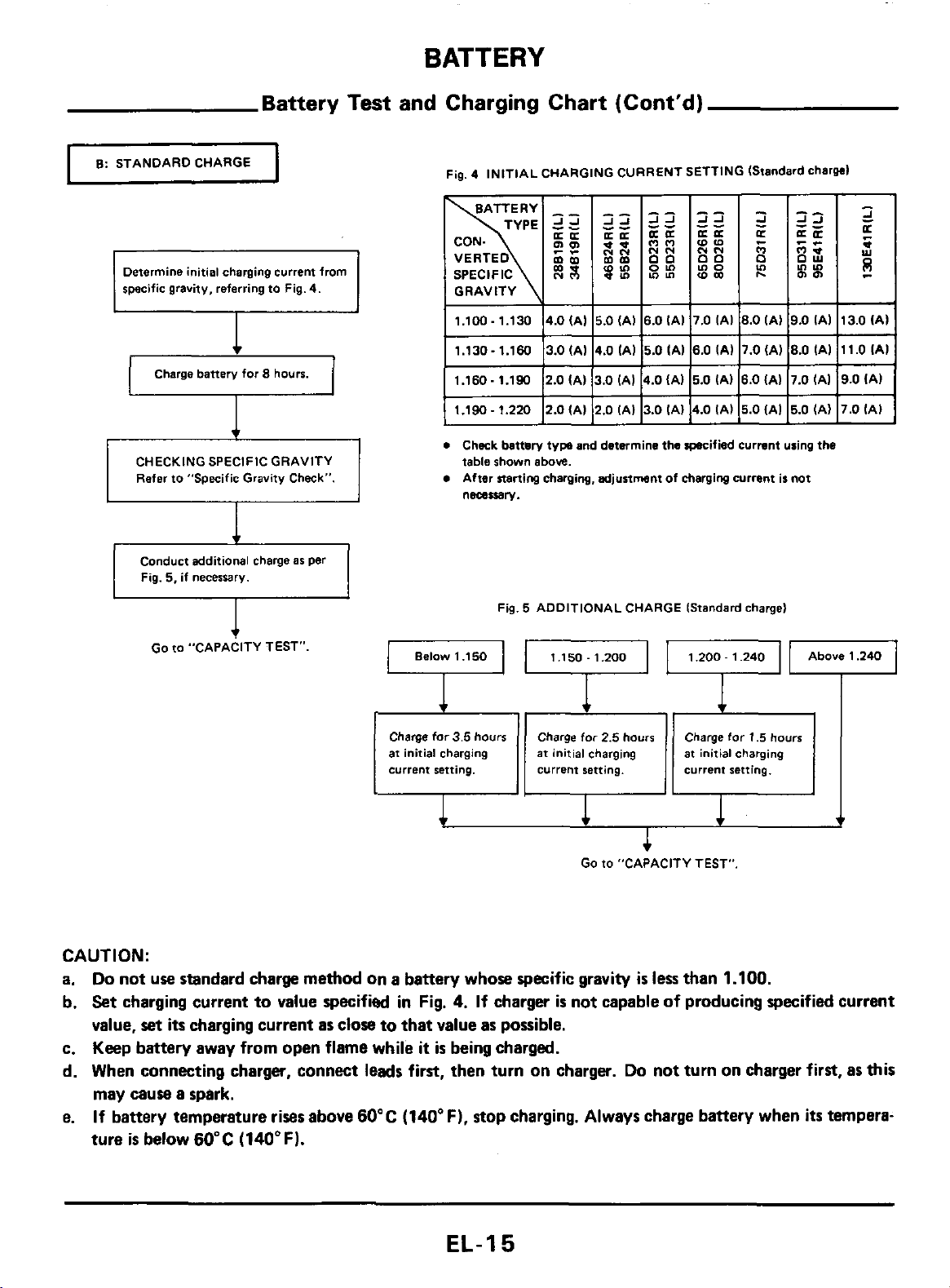

6:

STANDARD CHARGE

Determine initial charging current fmm

specific gravity, referring to Fig.4.

BATTERY

Fig. 4 INITIAL CHARGING CURRENT SETTING (Standard

GRAVITY

4.0

(A)

5.0

(AI

6.0

IAl

7.0

IAl

1.100. 1.130

8.0

IA)

char64

9.0

IAl 13.0 (A)

CHECKING SPECIFIC GRAVITY

Refer

to

"Specific Gravity Check".

Conduct

Fig.

additional charge

5,

if necessary.

I

Go to "CAPACITY TEST".

as

Per

1.130

1.160- 1.190

1.190

Check

table shown above.

After Rening charging.

nmssarv.

""";"""'

r

at initial charging

current retting.

4.0

IAl

5.0

(AI

6.0

IAI

5.0

(A)

IAI

7.0

6.0

5.0

current

-

-

3.0 (AI

1.160

2.0

(AI 3.0 IAl

1.220

2.0

(A) 2.0 IAI 3.0 IAI

battory

tyw

and determine the Ipseified current using tho

Fig. 5 ADDITIONAL CHARGE (Standard charge)

4.0

adjustmnt

(A)

4.0

of charging

TTyF-1

at

initial charging

current retting.

(AI

(AI

(AI

8.0

7.0

5.0

is not

(AI

IAl

(A)

11.0 IAl

9.0

(A)

7.0

(A)

CAUTION:

a.

Do

not

use

standard charge method

b.

Set charging current

value,

set

its

to

value specified

charging current

as

on

close

a

in

to

that value

e. Keep battery away from open flame while

d. When connecting charger, connect

leads

may cause a spark.

e.

If

battery temperature

ture

is

below 60°C

rises

(140°F).

above 60°C

(140"

Go to "CAPACITY TEST".

battery whose specific gravity

Fig.

4.

If

it

is

being charged.

first,

then

charger

as

possible.

turn

on

is

not

charger.

is

less than

capable of producing specified current

Do

not

turn

F), stop charging. Always charge battery when

EL-I

5

1.100.

on

charger

first,

its

tempera-

as

this

I

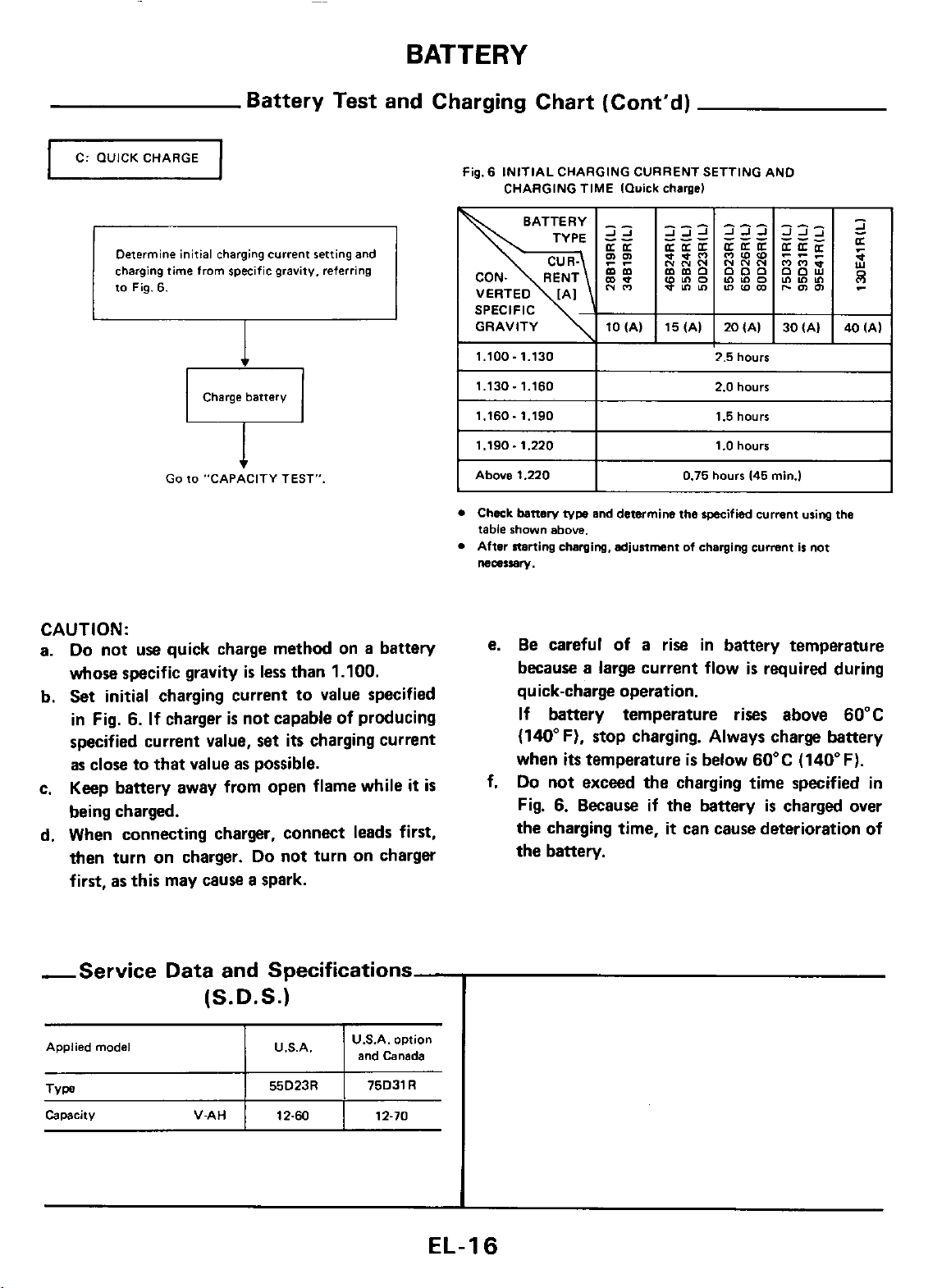

C: RUICKCHARGE

BATTERY

Battery Test and Charging Chart (Cont'd)

I

Fig. 6 INITIAL CHARGING CURRENT SETTING AND

CHARGING TIME IRuick charge)

Determine initial charging

charging time from rpxific gravity, referring

to Fig.

6.

current

setting

and

c

Go

to

"CAPACITY TEST".

CAUTION:

a.

Do

not

use

quick charge method on a battery

whose

b.

Set

in Fig. 6.

specified current value,

as

e. Keep battery away from open flame while

being charged.

d. When connecting charger, connect leads

then

first.

specific gravity

initial

close to

charging current to value specified

If

charger

that

turn

on charger.

as

this

may

value

cause

is

less

than

1.100.

is

not capable of producing

set

its

charging current

as

possible.

Do

not

turn

on

charger

a

spark.

it

is

first,

SPECIFIC

GRAVITY lO(A)

1.100 - 1.130

I

1.130-1.160

11.160-1.190

I1.190-1,220

Above

1.220

e.

Be careful of a rise in battery temperature

because a large current flow

quick-charge operation.

If

(140°F). stop charging. Always charge battery

when

f.

Do

Fig. 6. Because

the charging time,

the battery.

I

I

I

battery temperature rises above 60°C

its

temperature

not

exceed the charging time specified

15(AI 20(AI 30(A) 401A)

1.5

hours

2.0

hours

1.5 hours

1.0 hours

0.75 hours 145

is

below 60°C (140°F).

if

the battery

it

can cause deterioration of

mi".)

is

required during

is

charged over

I

I

I

in

,Service Data and Specifications

(S.D.S.)

~

Applied model

TYDB

,~~

Capacity V-AH

I

US'A'

I

I

55D23R

I I

12-€4 12-70

U.S.A. option

and Canada

I

I

75031

R

EL-1

I

I

I

6

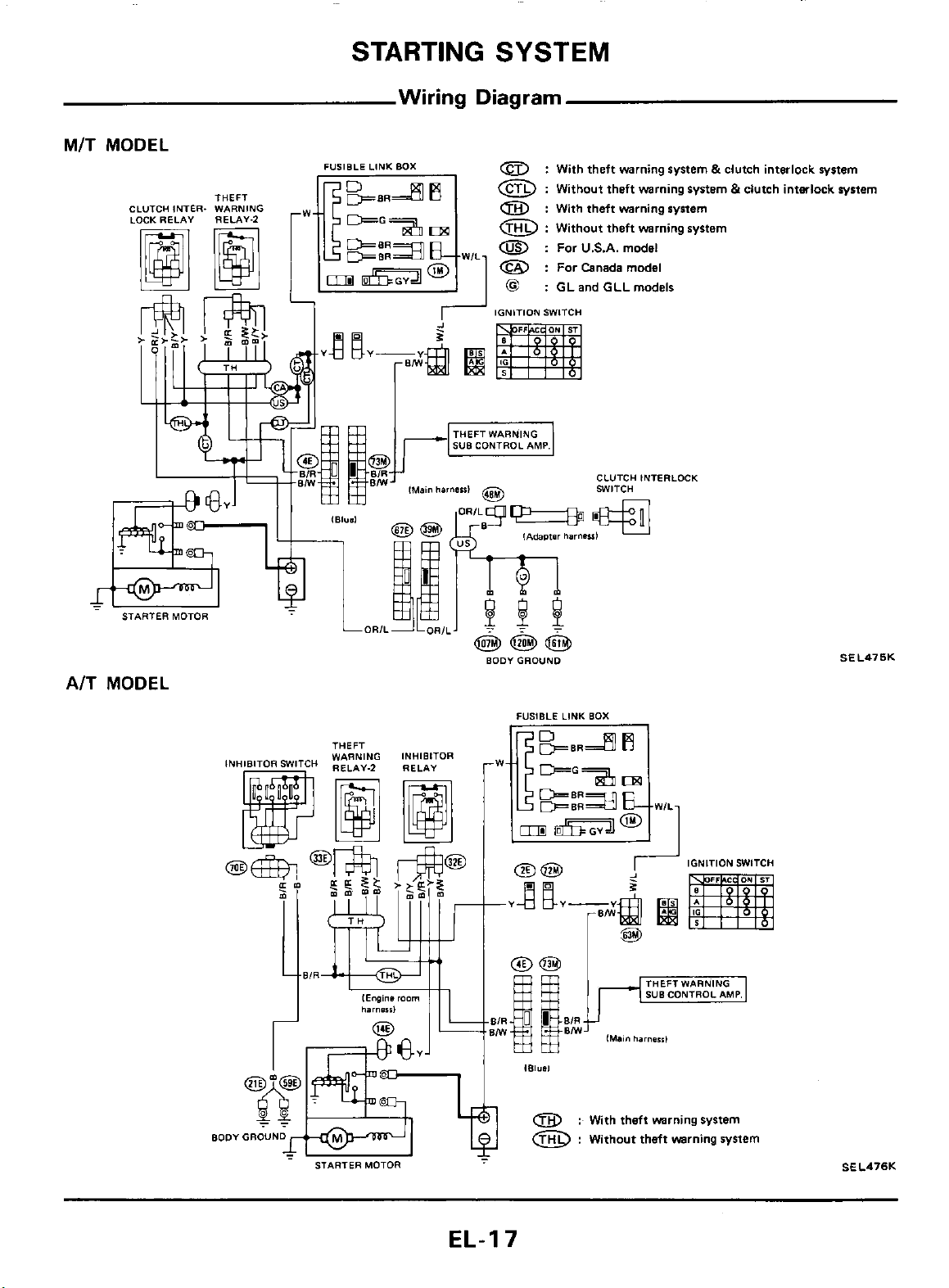

M/T MODEL

CLUTCH INTER. WARNING

LOCI RELAY RELAY-2

THEFT

STARTING

Wiring Diagram

FUSIBLE

LINK

BOX

SYSTEM

:

0

a

a

@

0

a

With theft warning system E dutch interlock system

:

Without theft warning system E clutch interlock system

:

With theft warning system

:

Without theft warning system

:

For

U.S.A.

:

Far

Canada

CLUTCH INTERLOCK

SWlTCH

model

model

AK

MODEL

INHIBITOR

SWITCH

THEFT

:t::F;

INHIBITOR

REL~.Y

,Adom.. ham.ul

BODYGROUND

FUSIBLE LINK BOX

I-EEzzTq

SEL475K

BOO"

! ~ I

GROUND

I

"A67

STARTER

MOTOR

IR

Iw

EL-I

7

:

Without theft warning system

SEL476K

START

IN

G

SYSTEM

Construction

-Start

e

r

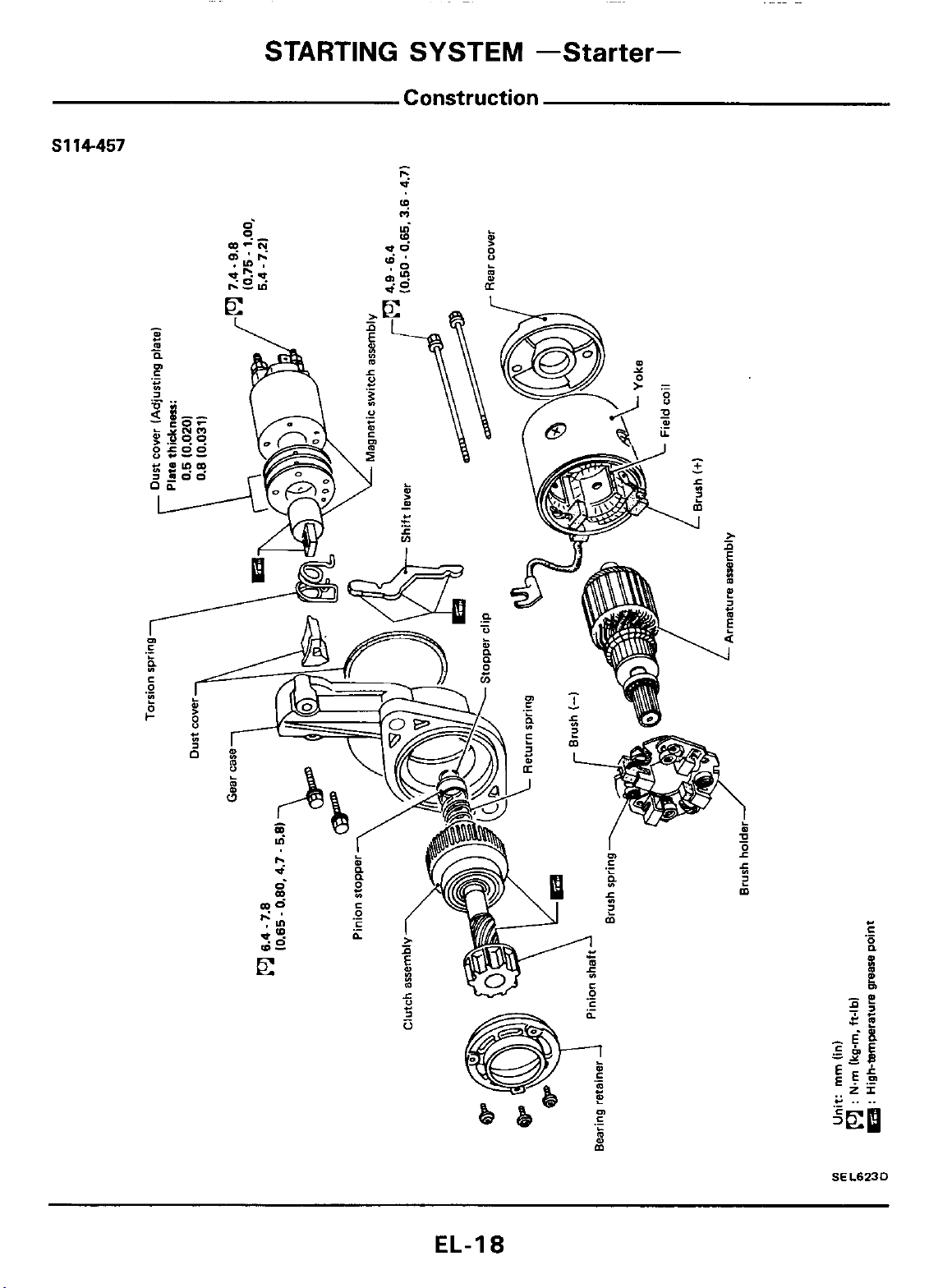

-

EL-I

SEL623D

8

STARTING

SYSTEM

-Starter-

a

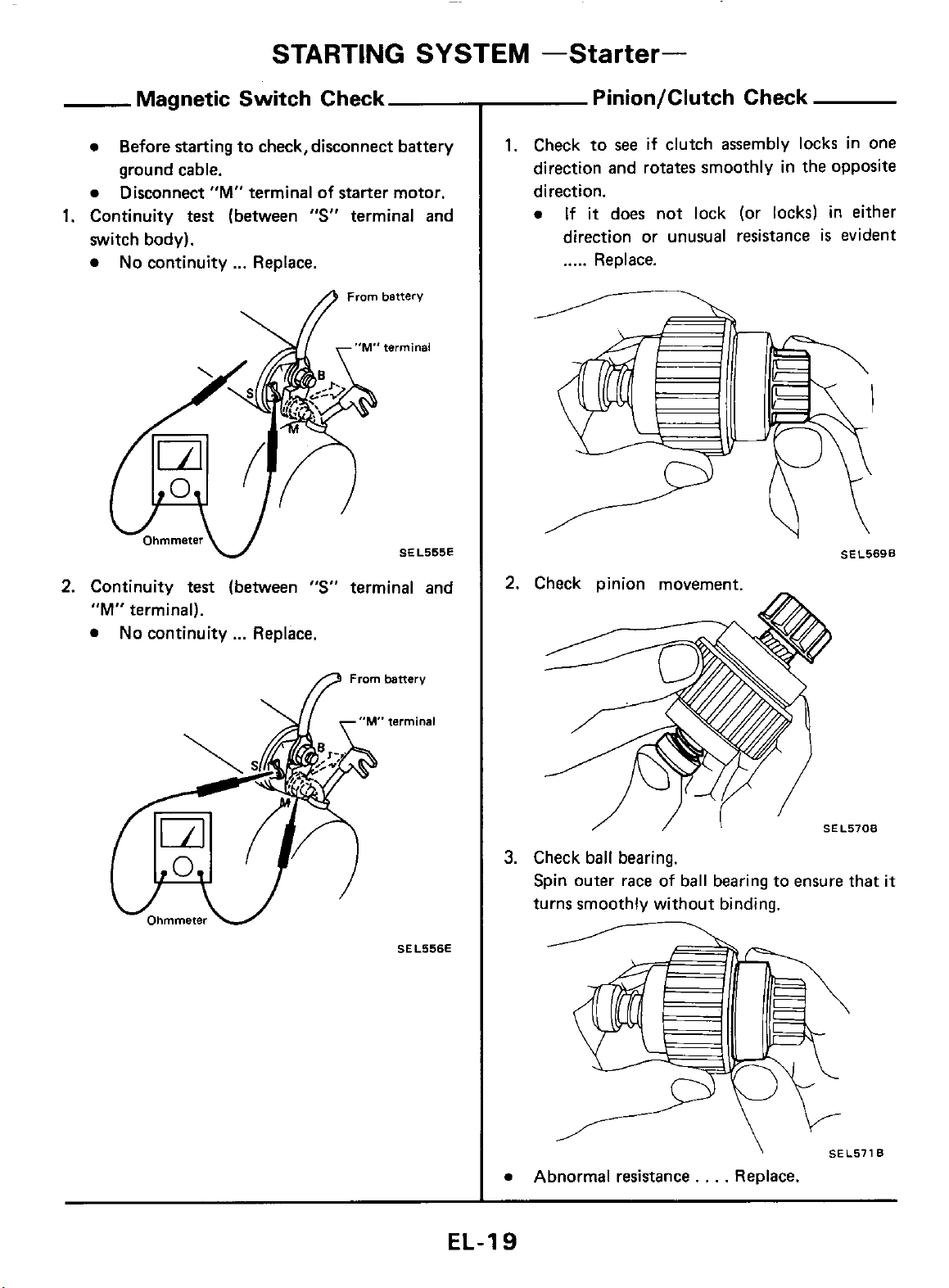

Before starting to check, disconnect battery

ground cable.

a

Disconnect

1.

Continuity

switch body).

No continuity ... Replace.

Magnetic Switch Check

"M"

terminal of starter motor.

test

(between

"S"

terminal and

A

From

banery

Pinion/Clutch Check

1.

Check to

direction and rotates smoothly in the opposite

direction.

a

If

direction or unusual resistance

.....

see

if clutch assembly locks in one

it

does not lock (or locks) in either

is

Replace.

evident

SEL569B

2.

Continuity

"M"

terminal).

No

continuity

test

(between

...

Replace.

"S"

terminal and

,7

Frombanery

3.

Check ball bearing.

Spin outer

turns smoothly without binding.

race

of

ball bearing to ensure that it

a

EL-19

\

Abnormal resistance. . . . Replace.

SEL571B

~

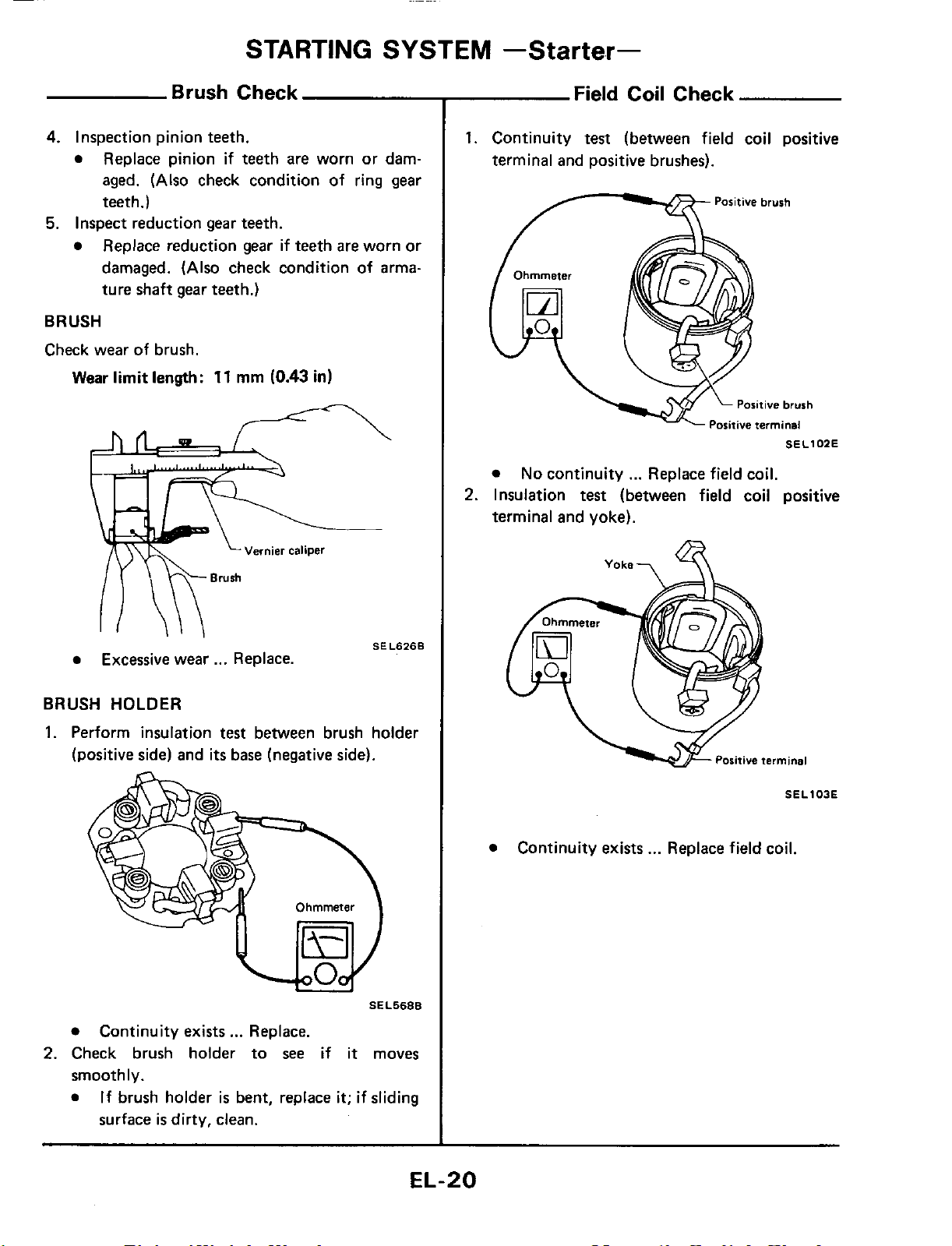

Brush Check

4.

Inspection pinion teeth.

Replace pinion

aged.

teeth.)

5.

Inspect reduction gear teeth.

Replace reduction gear

damaged.

ture shaft

BRUSH

Check wear of brush.

Wear limit length:

(Also check condition of ring

(Also check condition of arma-

gear

teeth.)

STARTING

if

teeth

are

if

teeth are worn or

11

mm

(0.43

SYSTEM

worn or dam-

gear

in)

-Starter-

Field Coil Check

1.

Continuity test (between field coil positive

terminal and positive brushes).

Positive brush

n

/

Ohmmeter

Positive brush

ositive terminal

No

continuity ... Replace field coil.

2.

Insulation

terminal and yoke).

test

(between field coil positive

SEL102E

Excessive wear ... Replace.

BRUSH HOLDER

1.

Perform insulation

(positive side) and

Continuity exists

2.

Check brush holder to

smoothly.

If brush holder

is

surface

dirty, clean.

test

between brush holder

its

base (negative side).

...

Replace.

see

if

is

bent, replace

it

it;

SEL626B

SELS68B

moves

if

sliding

Positive terminal

SE

Continuity exists ... Replace field coil.

L103E

EL-20

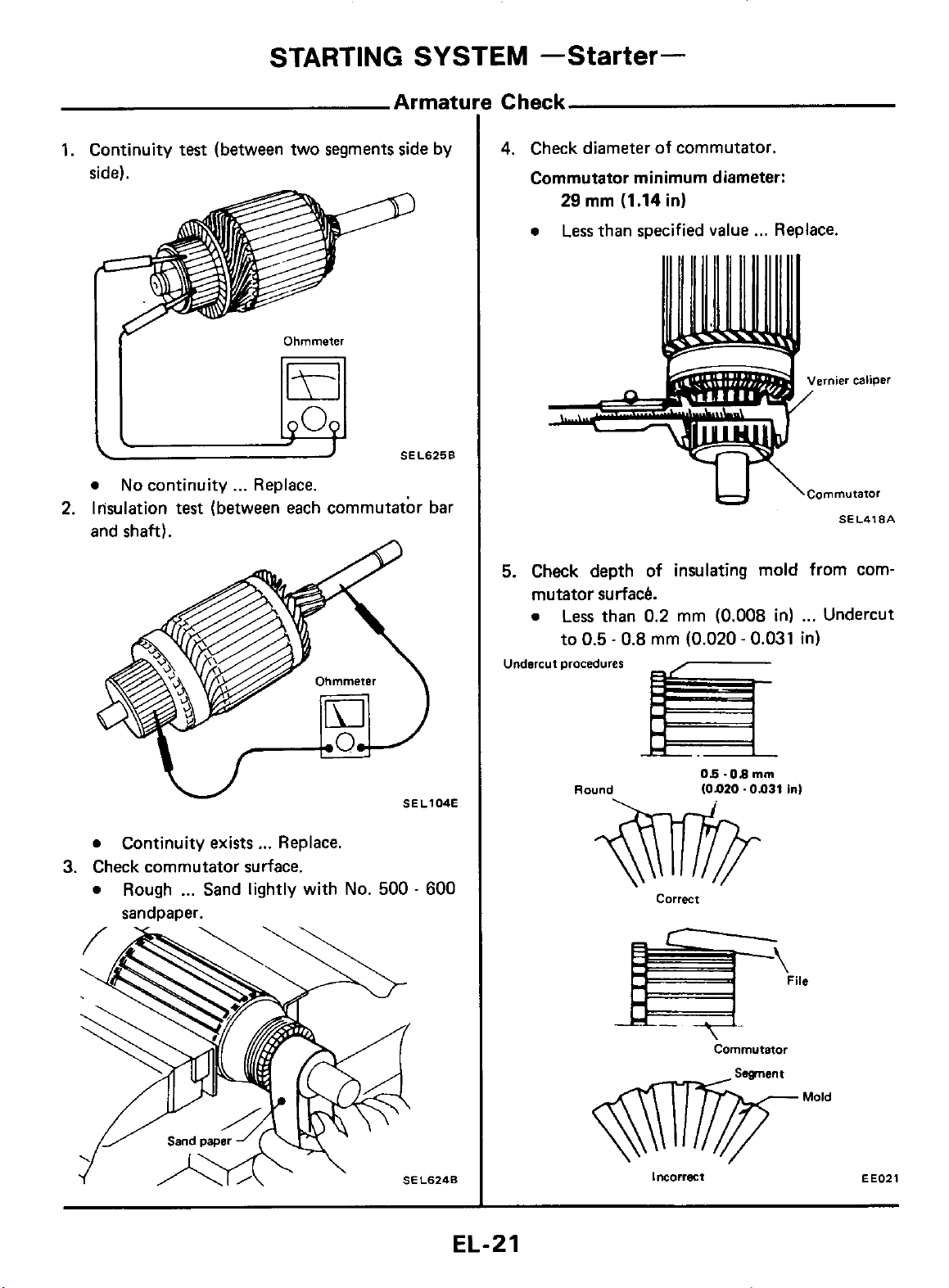

1.

Continuity

side).

a

Ir

STARTING

test

(between two segments side by

Ohmmeter

No

continuity ... Replace. SELSZSB

SYSTEM

Armatu

-Starter-

4.

Check diameter

Commutator minimum diameter:

29

mm

Less

a

than specified value

(1.14

of

commutator.

in)

...

Replace.

2.

lrisulation

and shaft).

a

Continuity exists

3.

Check commutator surface.

a

Rough

sandpaper.

test

(between each commutator bar

...

Sand lightly with No.

...

Replace.

500

-

600

5.

Check depth

mutator surfaci?.

a

Less

0.5

to

Undercut

procedures

Round

of

than 0.2

-

0.8

mm

Correct

\Commutator

insulating mold

mm

(0.008

(0.020 - 0.031

05-OBrnm

101)20~0~31

in) ... Undercut

in1

from

in)

SEL418A

com-

EL-21

Incorrect

Commutator

Mold

EE021

STARTING

SYSTEM

-Starter-

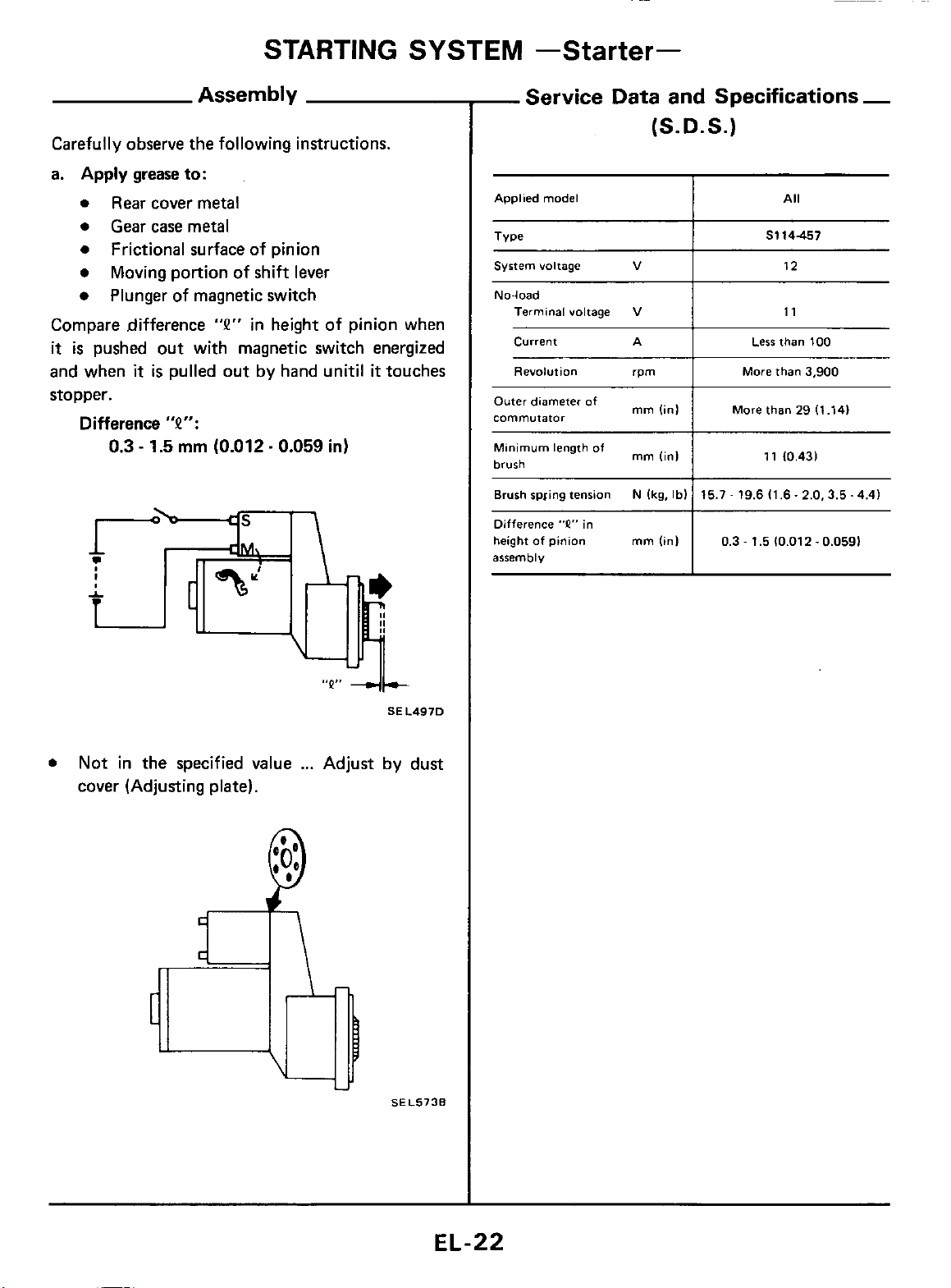

Assembly

Carefully observe the following instructions.

a.

Apply

0

0

0

Compare difference

it

is

and when

stopper.

Difference

grease

to:

Rear cover metal

Gear case metal

Frictional surface of pinion

Moving portion

of

shift lever

Plunger of magnetic switch

"P"

in height of pinion when

pushed out with magnetic switch energized

it

is

pulled out by hand unitil

it

"e":

0.3

-

1.5

mm

(0.012 - 0.059

in)

touches

_.

Service Data and Specifications

(S.D.S.)

Applied model

Type

System voltage

No-load

Terminal voltage

current A

Revolution rpm

Outer

diameter of

commutator

Minimum length

brush

Difference

height of pinion mm

assembly

"P"

in

v

V

mm

of

mrn

(in1

(in1

linl

I

I

I

I

Less

More than

More than 29 (1.141

0.3-

1.510.012-0.0591

All

S114457

12

11

than 100

3,900

11

10.431

-

0

Not in the specified value

cover (Adjusting plate).

SEL497D

...

Adjust by dust

SEL5738

EL-22

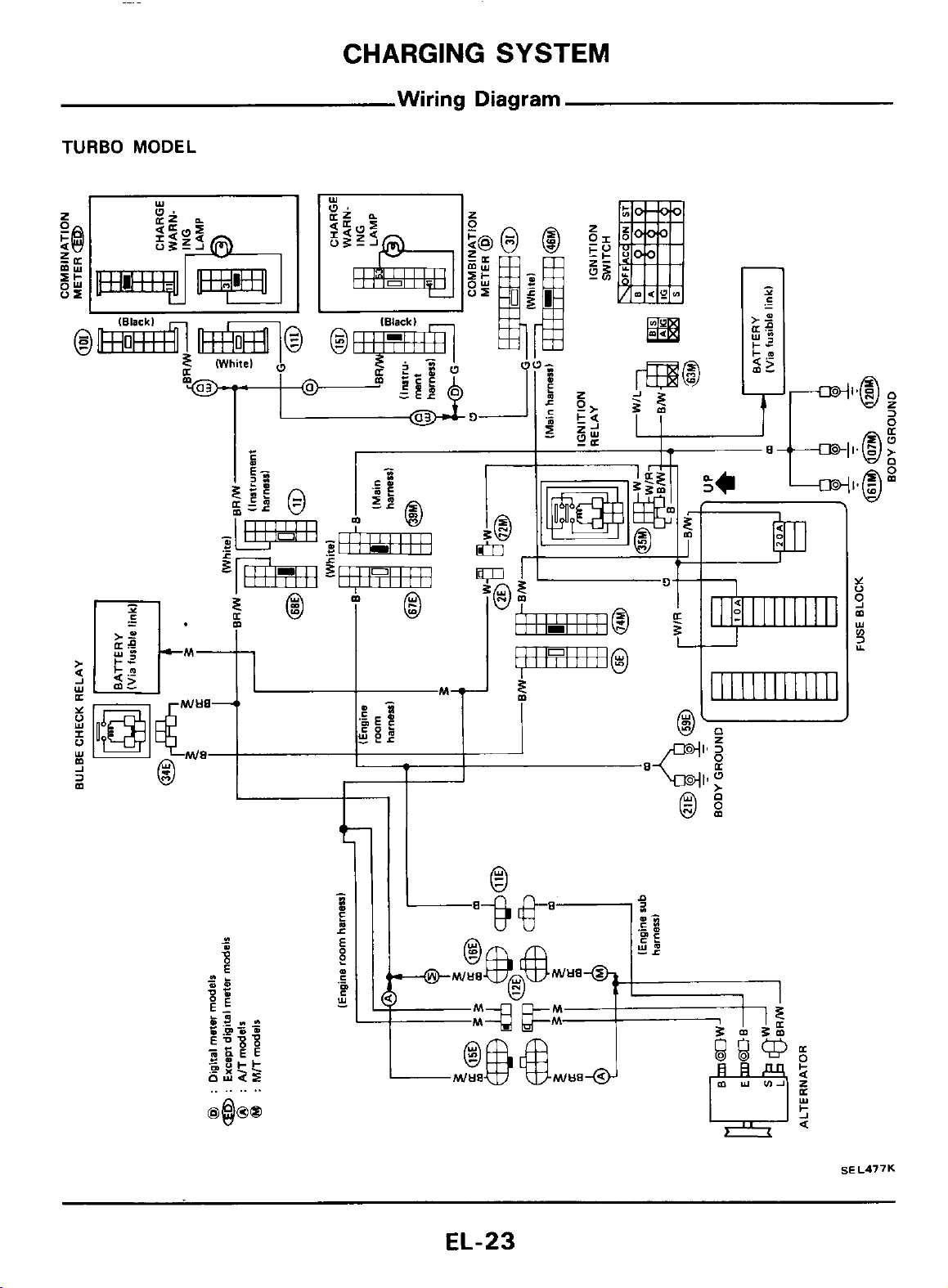

CHARGING

Wiring Diagram

SYSTEM

TURBO

MODEL

EL-23

SE

L477K

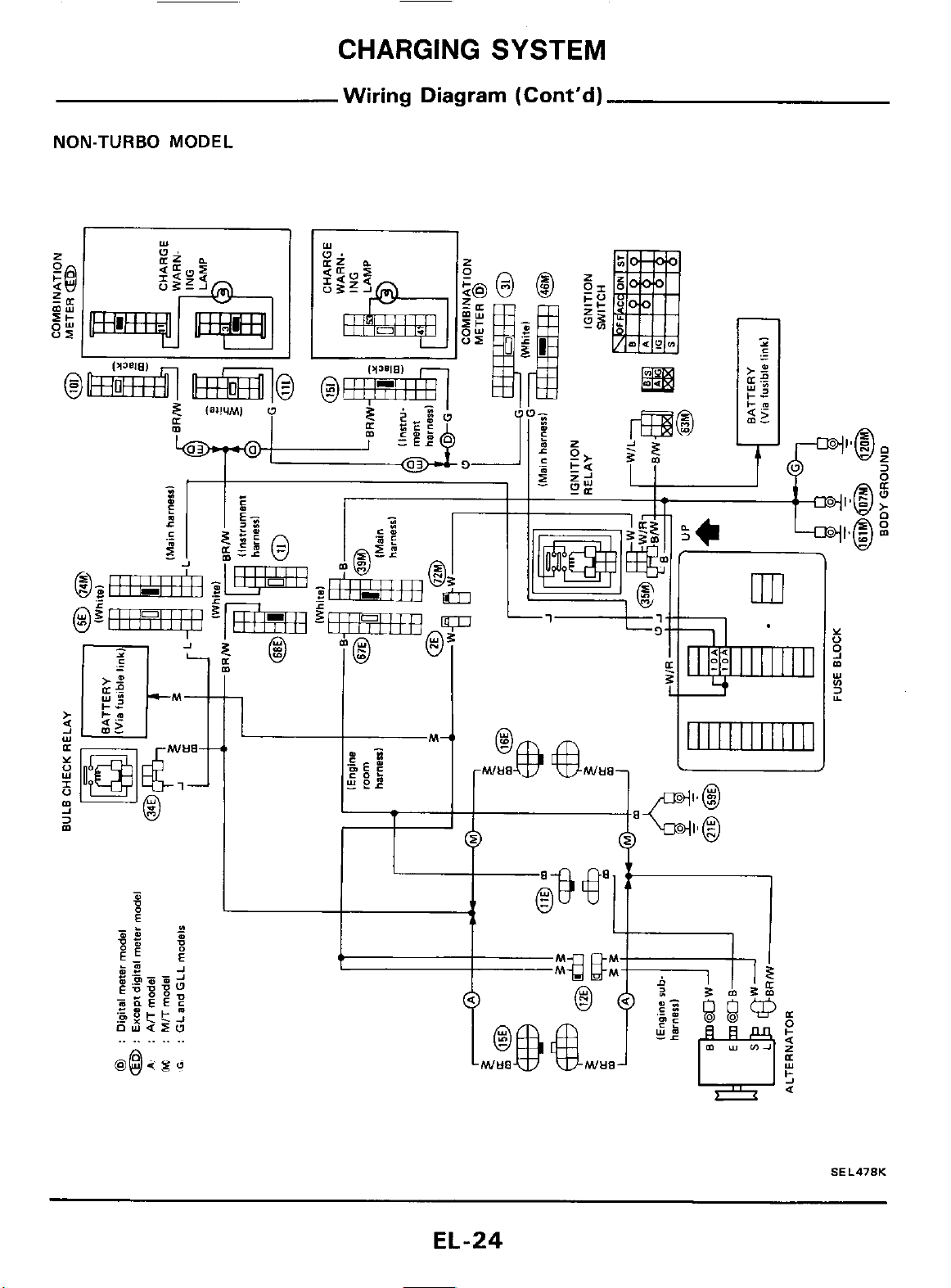

CHARGING

SYSTEM

NON-TURBO

I

MODEL

Wiring

Diagram

(Cont'd)

EL-24

SEL478K

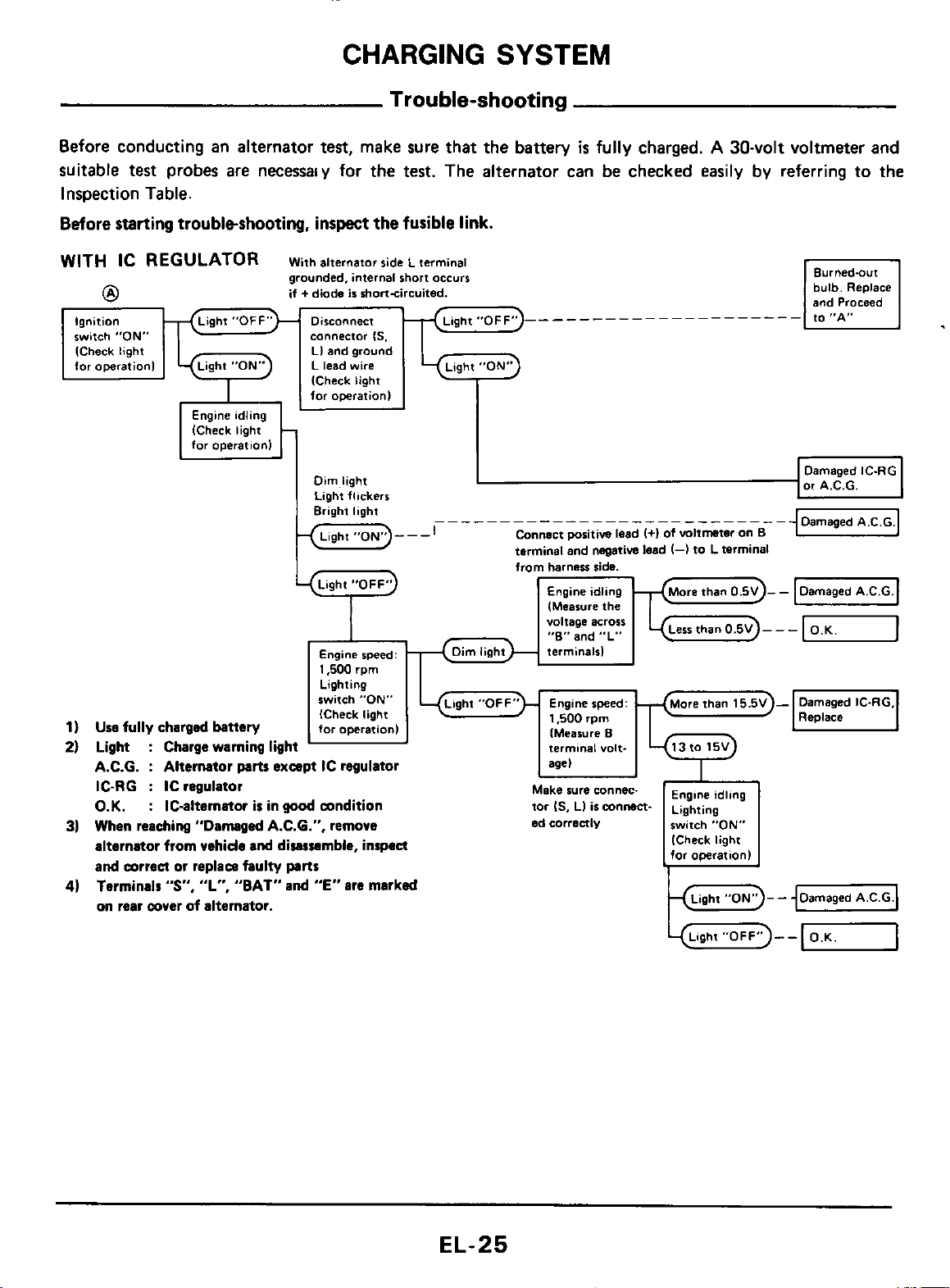

CHARGING

Trouble-shooting

SYSTEM

Before conducting

suitable

test

probes

Inspection Table.

Before

starting

Ignition

switch

"ON"

[Check light

for operation)

trouble-shooting, inspect the fusible

an

alternator test, make

are

necessaiy for the test. The alternator can be checked easily by referring to the

sure

that the battery

is

fully charged. A 30-volt voltmeter

link.

COnneClOr

LI and ground

L lead

IS.

wire

-

_________----_----__-

and

bulb.

Replace

and Proceed

-

"L",

,nary

is

and

"BAT"

in

good

disassemble, inspect

and

1)

Use

fullv charm

2)

Light : Charge warning light

O.K.

31

When reaching "Damaged A.C.6.". remove

alternator from vehide

Terminals

4)

on rear mver of alternator.

:

IC-alternator

"S,

mndition

"E"

am

marked

tor

(S.

ed

correnly

LI

ismnnen-

~i~h~i~~

switch

"ON"

(Check light

for operation)

-

1-1

--TI

EL-25

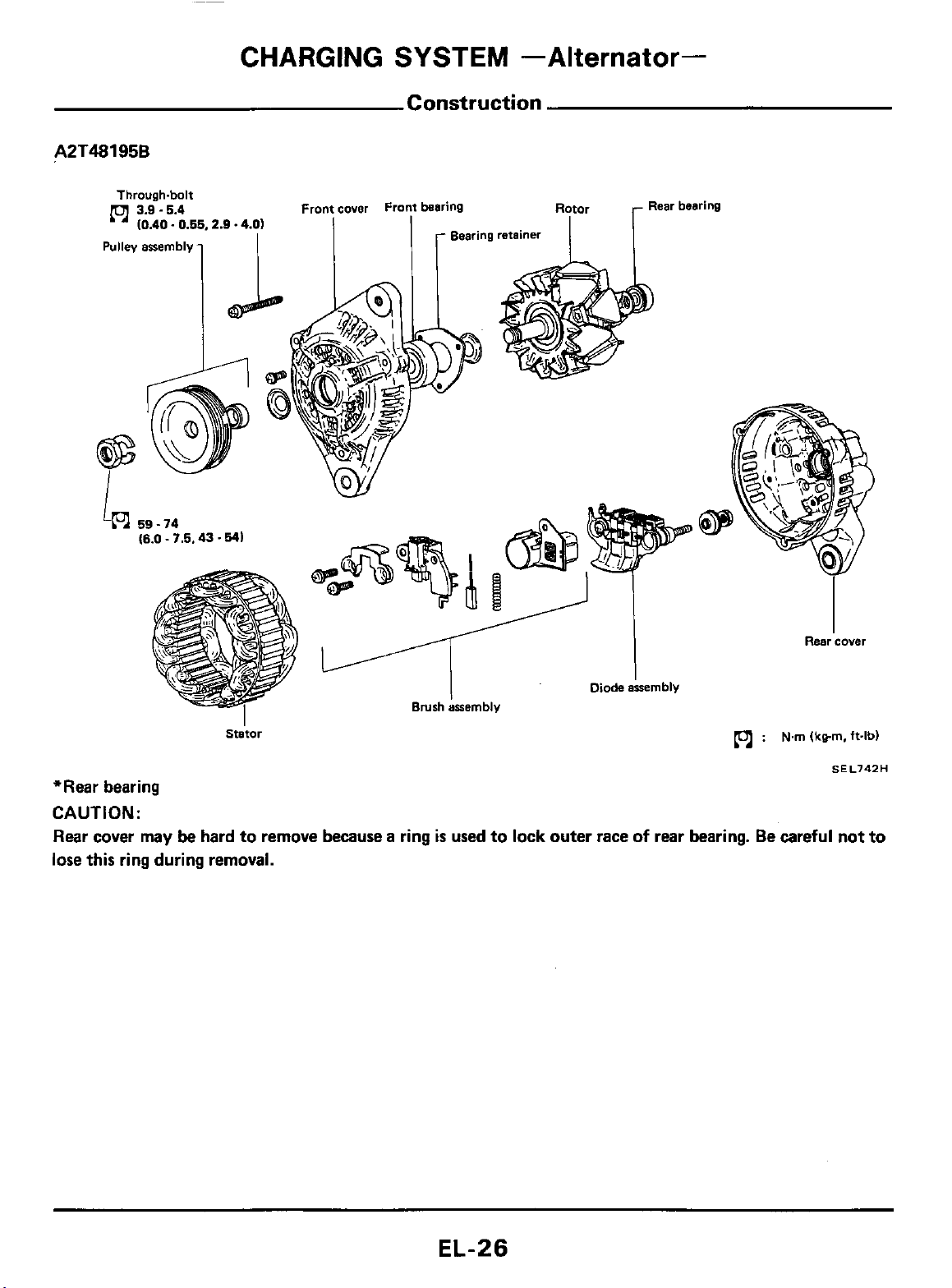

A2T48195B

CHARGING

SYSTEM

Construction

-Alternator-

Through-bolt

3.9

10.40.

Pullw

assembly

(6.0

(6.0

.5.4 Front

0.55,2.9 .4.01

-

7.5.43

7.5.43

.541

.541

-

cover

l

Front baring

Rotor

I

Rear

r

bearing

Rear

'cover

'Rear bearing

CAUTION:

Rear

cover

may

be hard

lose

this ring during removal.

stator

to

remove because a ring

ENrh assembly

is

used

to

Diode assembly

Diode assembly

lock outer race

of

rear

(01

bearing.

:

Nm

Iko-m,ft-lbl

Be

careful not to

SEL742H

EL-26

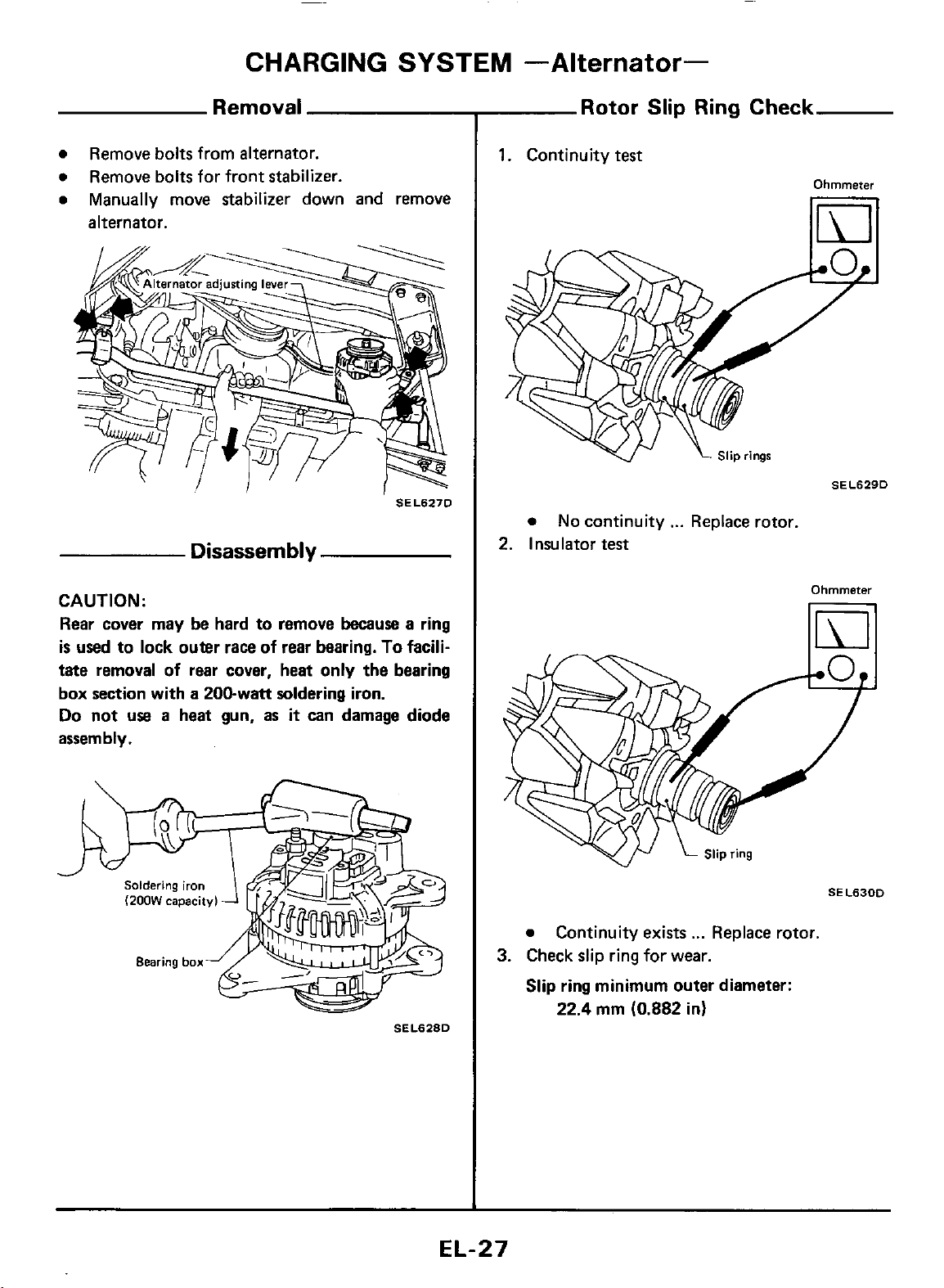

CHARGING

SYSTEM

-Alternator-

Removal

0

Remove bolts from alternator.

0

Remove bolts for front stabilizer.

0

Manually move stabilizer down

alternator.

Disassembly

and

remove

SEL627D

1.

Continuity test

0

No

2.

Insulator

Rotor

continuity

Slip Ring Check

test

...

Replace rotor.

Ohmmeter

SEL629D

CAUTION:

Rear cover may be hard to remove

is

used

to lock outer race of rear bearing.

tate

removal of rear cover, heat only the bearing

box section with a

Do

not

use

a

heat gun,

assembly.

200-watt

soldering

as

it

because

iron.

can damage diode

a

To

facili-

SEL628D

ring

0

Continuity exists ... Replace rotor.

3.

Check slip ring for wear.

Slip ring minimum outer diameter:

22.4

mm

(0.882

in)

Ohmmeter

SEL630D

EL-27

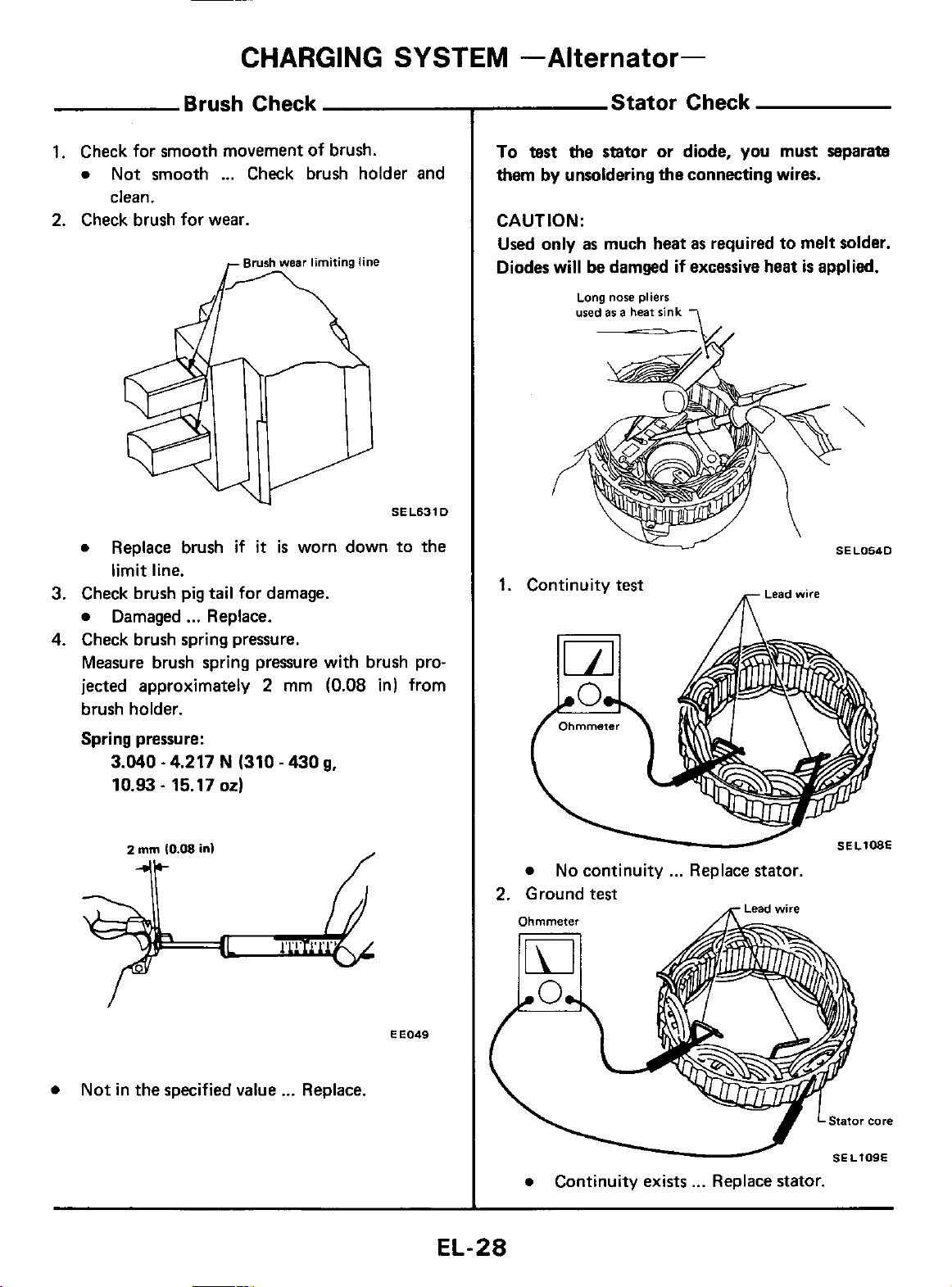

~

Brush Check

1.

Check for smooth movement

e

Not smooth

clean.

2.

Check brush for wear.

...

CHARGING

of

brush.

Check brush holder and

SYSTEM

SEL631D

-Alternator-

Stator

To

test

the stator

by

them

CAUTION

Used only as much heat

Diodes will

unroldering the connecting wires.

:

be

Long

used as a

or

damged

nose

pliers

heat

rink

if

-J/.

Check

diode,

excessive heat

you

must separate

as

required to melt solder.

is

applied.

e

Replace brush

limit line.

3.

Check brush

Damaged

4.

Check brush spring pressure.

Measure brush spring pressure with brush projected approximately

brush holder.

Spring pressure:

3.040

10.93 - 15.17

2

pig

-

4.217 N (310

mm

(0.08

tail

...

Replace.

02)

in1

if

it

is

worn down to the

for damage.

2

mm

-

430

(0.08

g,

in) from

1.

Continuity

2.

Ground

test

m

No

continuity ... Replace stator.

test

Lead

wire

EE049

e

Not

in

the specified value

...

Replace.

e

Continuity exists ... Replace

stator.

EL-28

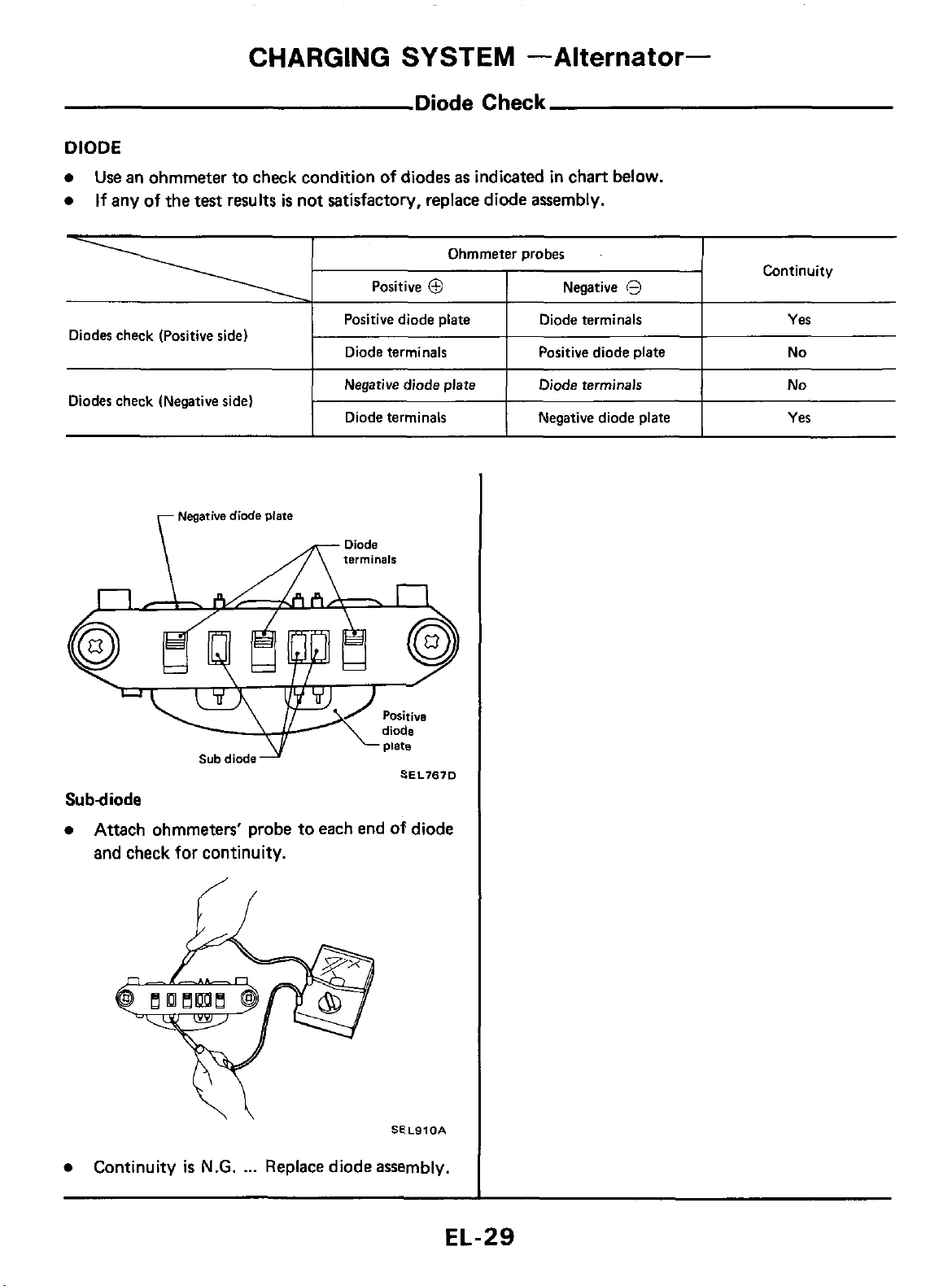

CHARGING

SYSTEM

-Alternator-

DIODE

Use an ohmmeter

If

any

of

the test results is not satisfactory, replace diode assembly.

Diodes check (Negative side)

Negative

to

diode

r

\

Diode

check condition of diodes

Positive

Positive diode plate Diode terminals Yes

Diode terminals Positive diode plate No

Negative diode plate

Diode terminals

Plate

0

Check

as

indicated in chart below.

Negative

Diode terminals No

Negative diode plate Yes

13

Sub

diode

Subdiode

Attach ohmmeters' probe

and check

Continuity is

for

continuity.

N.G.

plate

SEL767D

to

each end

...

Replace diode assembly.

of

SELOIOA

diode

EL-29

~~

CHARGING

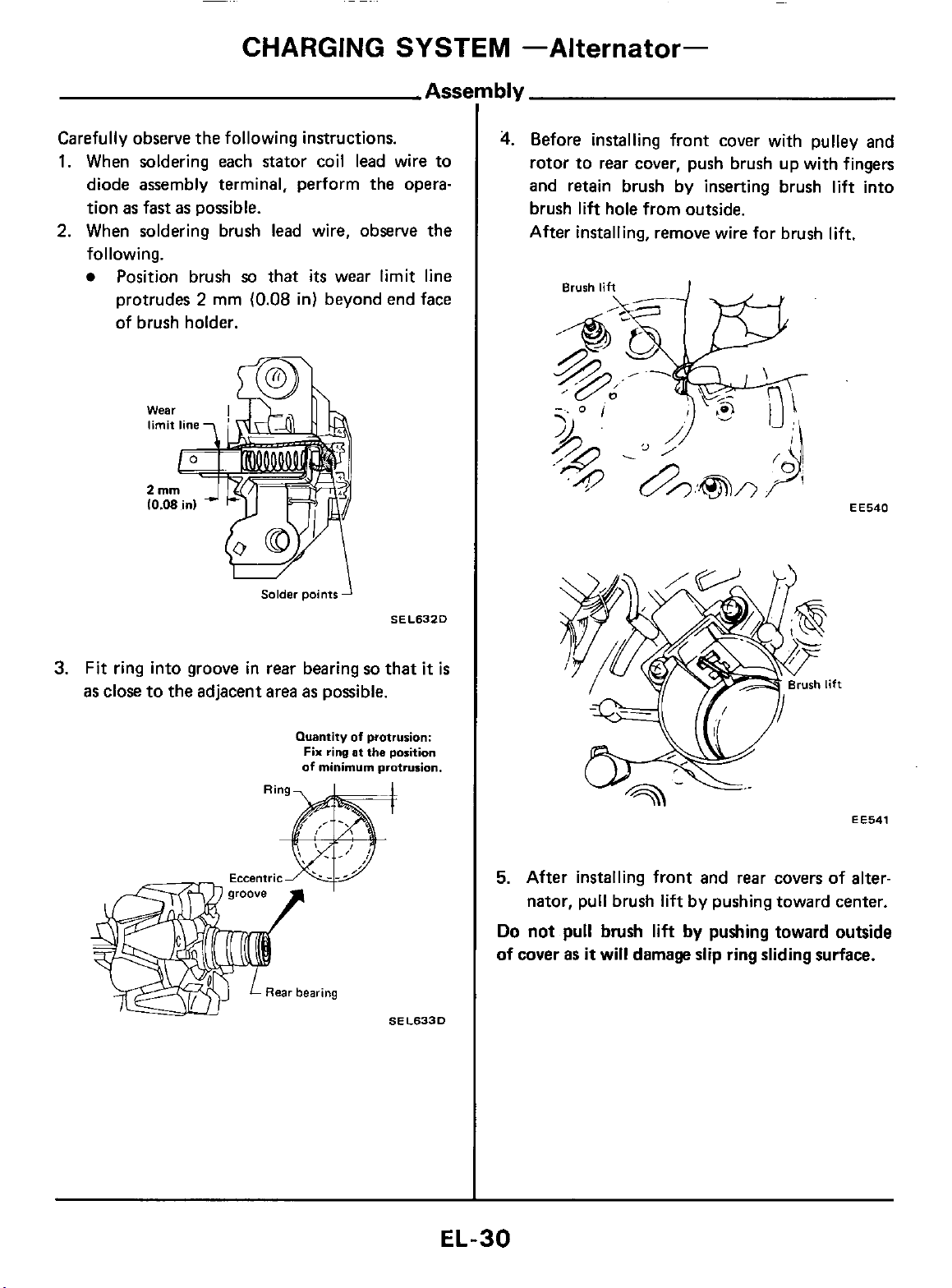

Carefully observe the following instructions.

1.

When soldering each stator coil lead wire to

diode assembly terminal, perform the opera-

as

fast

as

tion

2.

When soldering brush lead wire, observe the

following.

Position brush

protrudes

of brush holder.

possible.

so

2

mm

(0.08

that

its

wear limit line

in) beyond end face

SYSTEM

Assf

ibly

4.

-Alternator-

Before installing front cover with pulley and

rotor to rear cover, push brush up with fingers

and retain brush by inserting brush lift into

lift

brush

After installing, remove wire for brush

hole from outside.

lift.

3.

Fit ring into groove

as

close to the adjacent

Solder

in

points

rear

bearing

area

as

possible.

Quantity

of

Fix ring at the psition

of

minimum protrusion.

SEL632D

so

that

protrusion:

it

is

5.

After installing front and rear covers of alter-

lift

nator, pull brush

Do

not

pull

of cover

as

it

brush

will damage

by pushing toward center.

lift

by

pushing toward outside

slip

ring sliding surface.

EE541

EL-30

Loading...

Loading...