Nissan 300zx Electrical System Section EL 1984 Owner's Manual

I

ELECTRICAL

SYSTEM

CONTENTS

HOW TO READ DIAGRAMS

STANDARDIZED RELAY

POWER SUPPLY ROUTING

BATTERY.

STARTING SYSTEM

STARTING SYSTEM -Starter

CHARGING SYSTEM

CHARGING SYSTEM - Alternator

COMB IN AT1 ON SWITCH

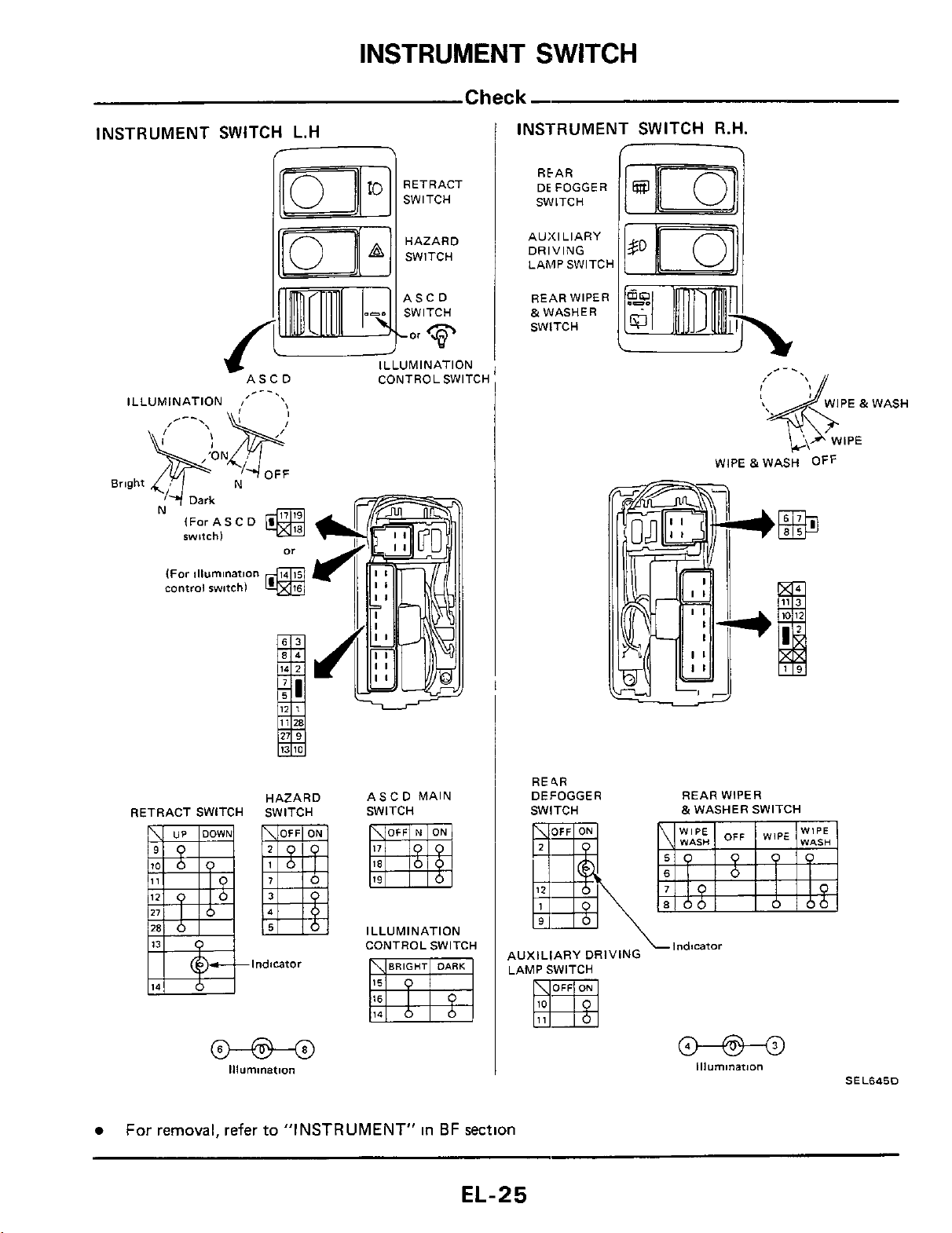

INSTRUMENT SWITCH

HEADLAMP

EXTERIOR LAMP,

INTERIOR LAMP

METER AND GAUGES - Digital Type Combination Meter

METER AND GAUGES - Digital Type Combination Gauge

METER AND GAUGES - Needle Type Combination Meter

METER AND GAUGES

WARNING LAMPS AND CHIME.

VOICE WARNING SYSTEM

TIME CONTROL SYSTEM

WIPER

HORN, CIGARETTE LIGHTER, CLOCK

REAR WINDOW DEFOGGER

AUDIO AND POWER ANTENNA

AUTOMATIC SPEED CONTROL DEVICE (AS

LOCATION OF ELECTRICAL UNITS

HARNESS LAYOUT

AND WASHER

.. ..

.

-

..

.

..

.

-

Needle Type Combination Gauge..

..........

...

....

...

....

.

.

..

...

,.

C

...

.

.

..

.. .. .

... ......

..

..

... ...

.........

.

D

)

.

SECTION

EL

..

..

..

..

..

. ..

....

...

. .

.. EL- 57

..

....

...

...

...

.......

....

..

...

..

..

.

....

.

.

,

.

..

EL-

2

EL-

3

EL-

4

EL-

6

EL- 9

10

ELEL- 15

EL- 17

EL- 23

EL- 25

EL- 26

EL-

34

EL- 38

EL-

41

EL- 65

EL-

68

EL- 71

EL-

76

EL- 81

EL-

89

EL-

92

EL-

93

EL-

95

EL-

97

EL-104

EL-107

HOW

TO

READ DIAGRAMS

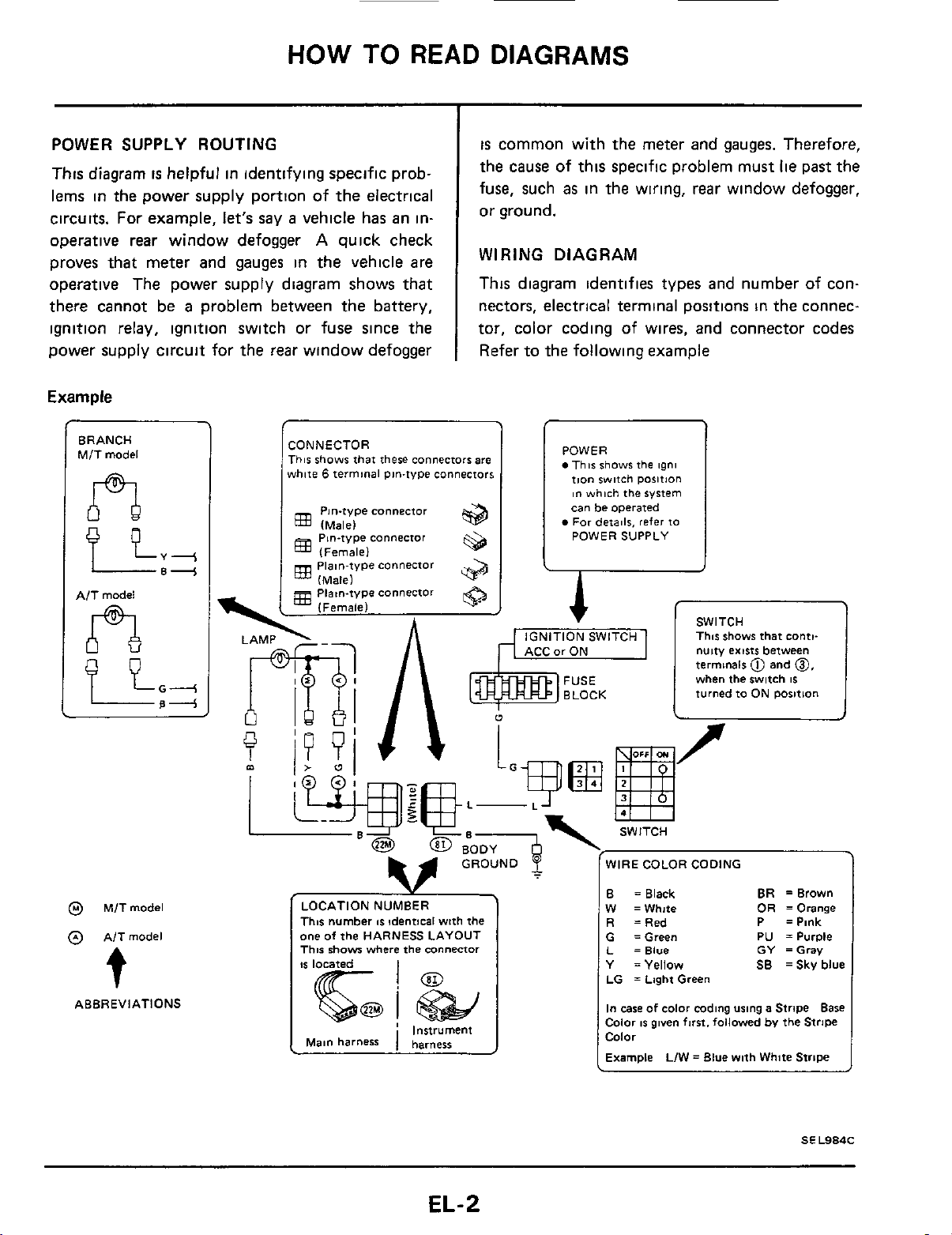

POWER SUPPLY ROUTING

This diagram

lems

in

circuits. For example, let's say

operative

proves that meter and

is

helpful in identifying specific prob-

the power supply portion of the electrical

a

rear

window defogger

gauges

vehicle

in

has

an in-

A

quick check

the vehicle are

operative The power supply diagram shows that

there cannot be

a

problem between the battery,

ignition relay, ignition switch or fuse since the

power supply circuit for the

rear

window defogger

Example

I

is

common with the meter and gauges. Therefore,

the cause of this specific problem must

fuse, such

as

in the wiring, rear window defogger,

or ground.

WIRING DIAGRAM

This diagram identifies types and number of connectors, electrical

terminal

positions in the connec-

tor, color coding of wires, and connector codes

Refer to the following example

lie

past

the

BRANCH

M/T

model

AlT

model

n

@

M/Tmodel

@

AITmodel

t

ABBREVIATIONS

CONNECTOR

This

shows

white

833

gg

This

one

This

that

6

terminal

Pin-type

(Male)

(Female)

Piaan-type

(Male)

Piatn-type

(Female)

number

of

the

show

there

connectors

pin-type

connector

connector

connector

1

IS

!dentical

HARNESS

where

the

connectors

L-

with

the

LAYOUT

mnnenor

are

POWER

This

tion

~n

which

can

For

POWER

A

v

.,

,

,-,.

CarON

shows

witch

the

be

operated

deiailr,

SUPPLY

-..,m

WIRE

B

W

R

G

L

Y

LG

In

case

Color

Color

Example

the

tgni

~osition

system

refer

10

r

I

I

u

COLOR

=

Black

=White

=Red

=Green

=Blue

=Yellow

=

Laghi

of color

IS

given

LIW

SWITCH

This

nutty

termmels

when

turned

f

CODING

Green

coding

fmt.

=

Blue

shows

exists

the

10

using

followed

with

that

between

@

and

switch

ON

rmition

BR

OR

P

PU

GY

SB

a

Stripe

by

White

conti-

0,

16

=Brown

=Orange

=Pink

=Purple

=Gray

=Sky

the

Stripe

Stripe

I

blue

Bare

EL-2

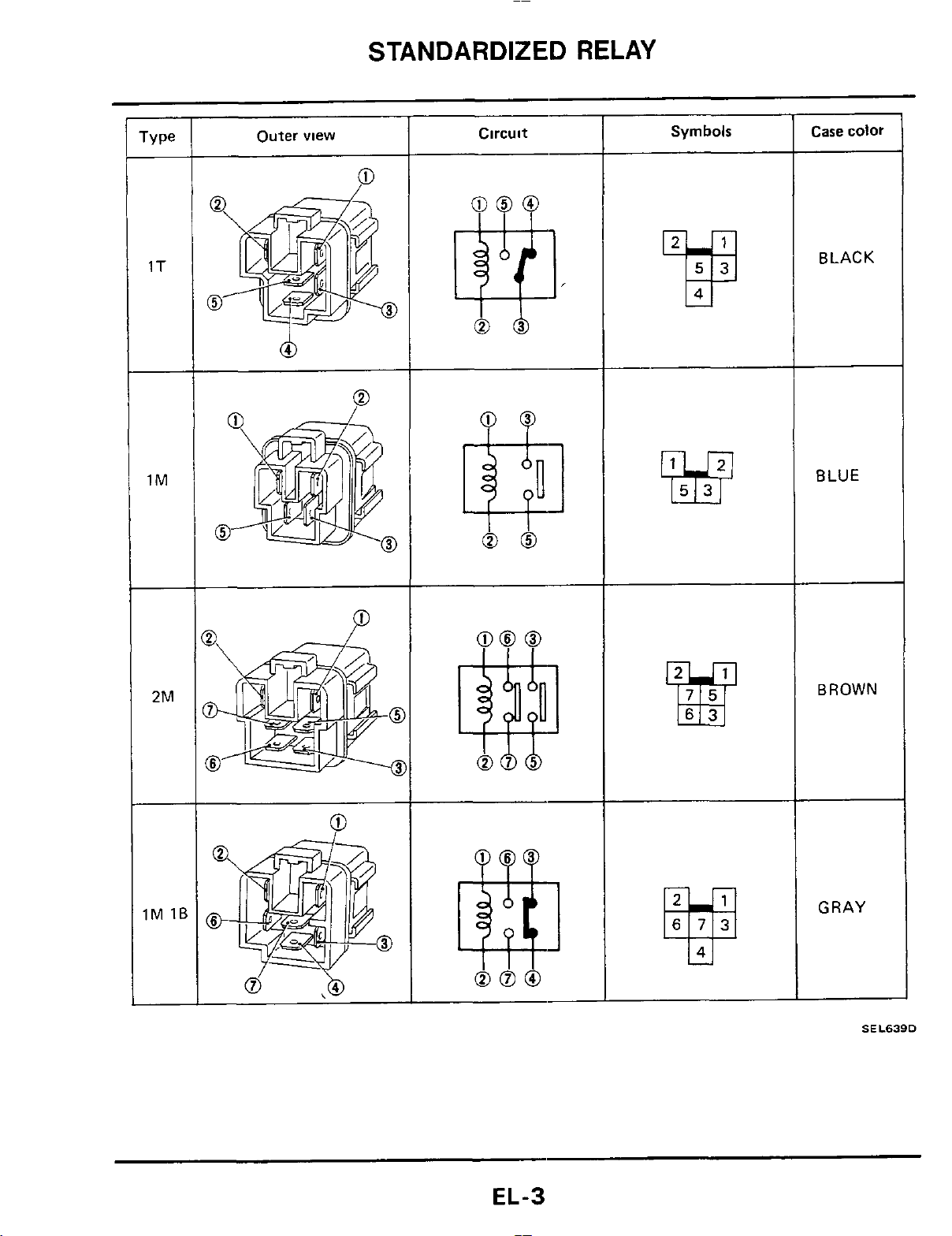

STANDARDIZED RELAY

1T

1M

Outer

view

Circuit

Symbols

Case

BLACK

BLUE

I1

00

color

2M

1M

-

BROWN

1E

d

.b

GRAY

SEL639D

EL-3

~

-

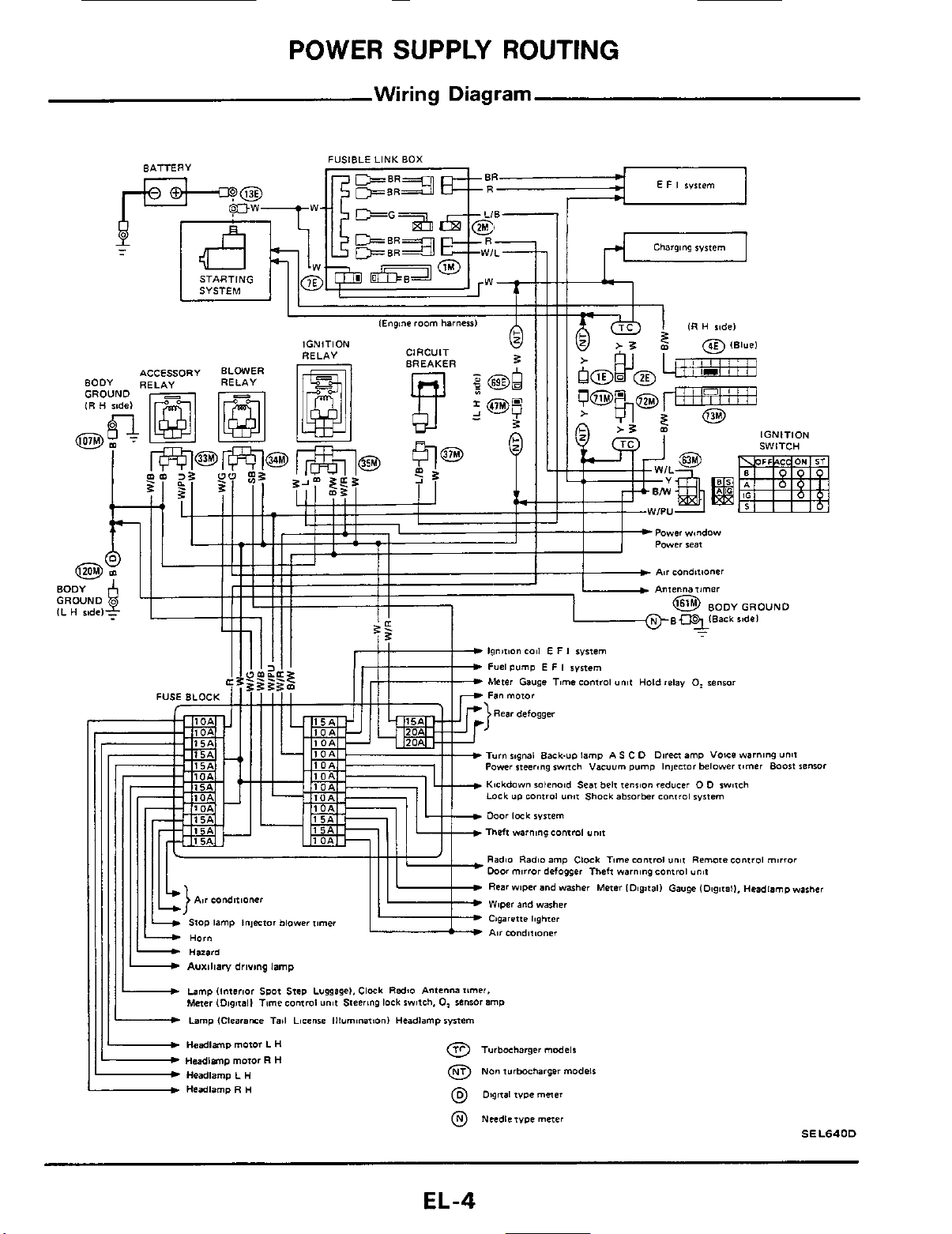

8ATTERY

STARTING

POWER

Wiring Diagram

FUSIBLE

LINK

SUPPLY

BOX

BR

ROUTING

rc-

I

Charging

system

-Power

wmdow

EL-4

POWER

SUPPLY

ROUTING

Fuse

_I

Check

If fuse

a

problem before installing new fuse

b

Use

more than specified rating

Do

c

insert

Remove fuse for clock if vehicle

d

a

is

blown, be sure to eliminate cause of

fuse

of specified rating. Never

not install fuse

it

into fuse holder properly

long period of time.

in

oblique direction, always

SEL276

use

fuse

is

not used for

of

Fusible

A

melted fusible link can

visual inspection or by feeling with finger tip If

condition

lamp

CAUTION

If

a

critical circuit (power supply or large current

carrying circuit)

fully check and eliminate cause

Never wrap periphery

b

tape

link to ensure

tact with any other wiring harness or vinyl or

rubber parts

is

questionable, use circuit tester or

fusible link should melt,

is

Extreme care should

that

Link

be

detected either

it

is

possible that

shorted

it

In

such a case, care-

of

problem

of

fusible link with vinyl

be taken with this

does not come into con-

by

its

test

EL-5

BATTERY

CAUTION:

a.

If

it

becomes necessary to start

12-volt booster battery

b.

After connecting battery cables, ensure that they are tightly clamped

contact

c. Never add distilled water through the hole used to check specific gravity.

the

engine with a booster battery and jumper cables,

Check

to

battery terminals for good

use

a

CHECKING SPECIFIC GRAVITY

1 Read hydrometer and thermal gauge indica-

tions

as

eye

level.

Read top level with scale.

-

Hydrometer

1

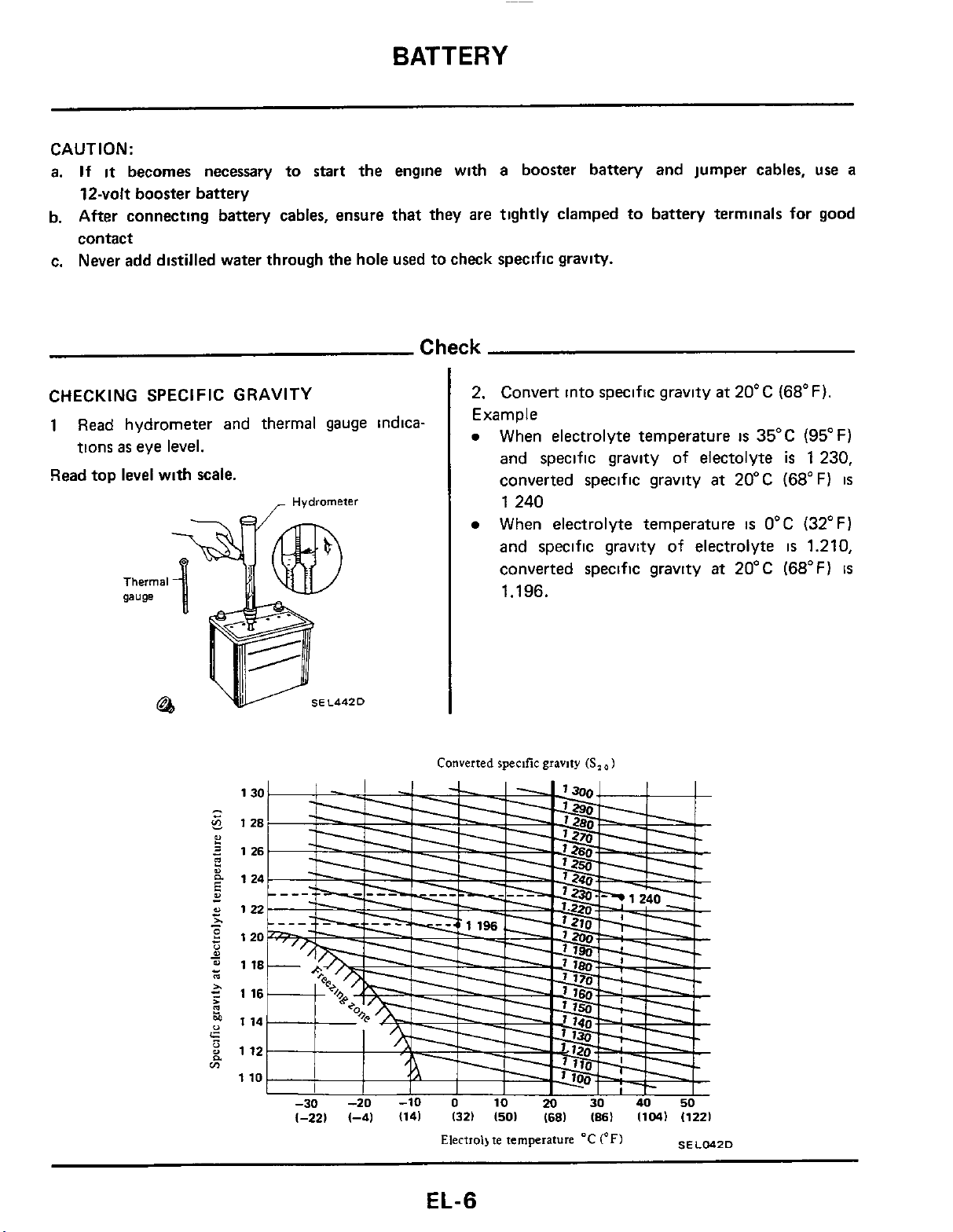

2. Convert into specific gravity

Example

e

When electrolyte temperature

and specific gravity

converted specific gravity

1 240

When electrolyte temperature

and specific gravity of electrolyte

converted specific gravity

1.196.

Converted

specific

gravity

(S,

1

of

electolyte

at

20°C (68°F)

is

35°C (95°F)

at

20°C

is

0°C (32°F)

at

20°C (68°F)

is

1230,

(68°F)

is

1.210,

is

is

1

,

-30

1-221

I I

-20

1-41 1141

-10

0

132)

Electrol)

10

1501

te

I

20

1681

temperature "C

I

30

(86)

('F)

I

1-

40

(104)

I

50

(1221

SELCdZD

EL-6

BATTERY

Full

charging specific

gravity at 20°C

1

26

Check

(68°F)

(Cont’d)

Converted specific

gravity at 20°C

I

I

Recharging necessary

120

(68°F)

I

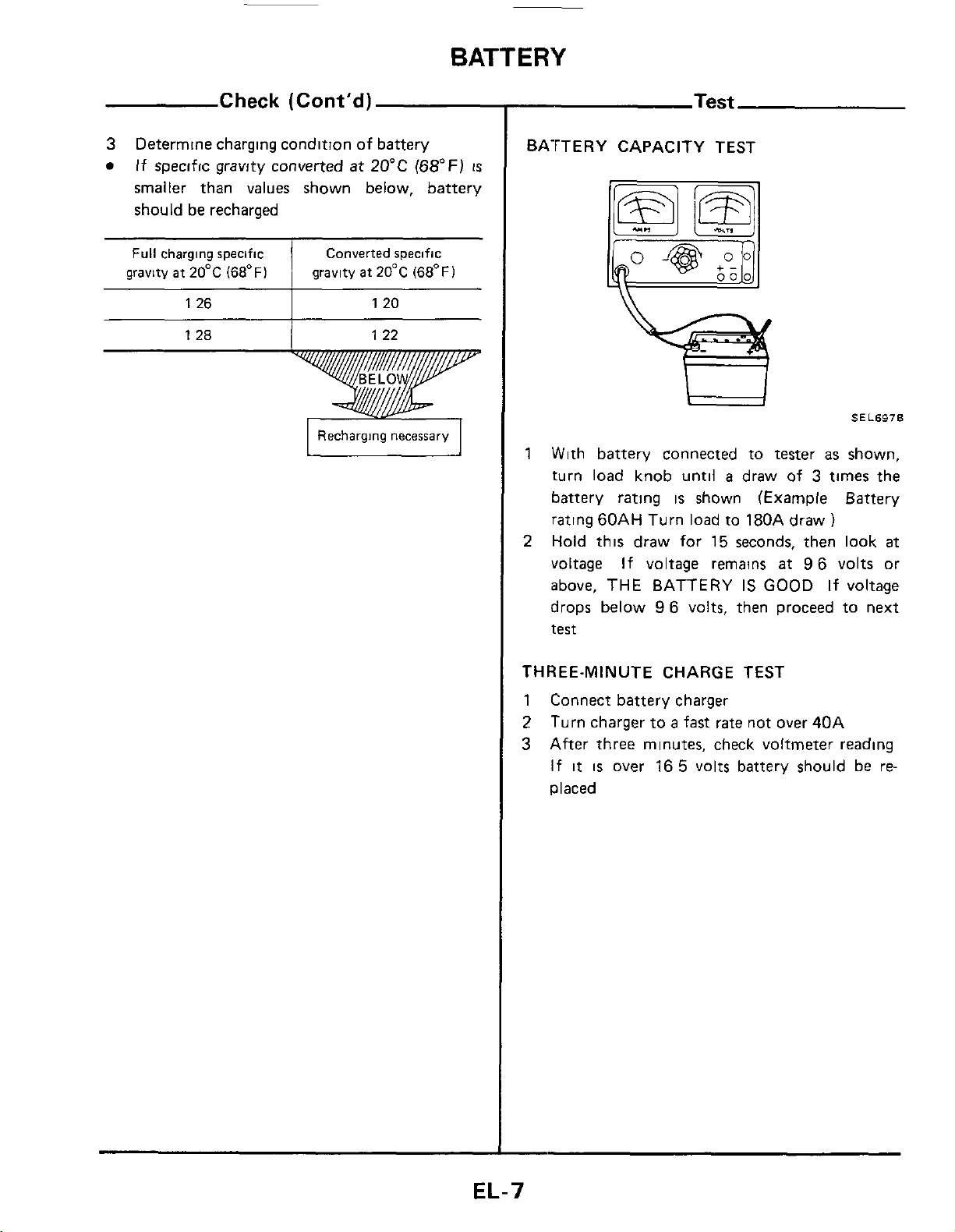

BATTERY CAPACITY TEST

1

With battery connected to

turn load knob until

battery rating

rating

60AH

Hold

2

this draw for

voltage If voltage remains

above,

drops below

test

THE BATTERY

is

Turn load

96

a

shown (Example Battery

to

15

seconds, then

volts, then proceed to next

tester

draw of 3 times the

180A draw

IS

GOOD

at

as

)

96

volts or

If voltage

shown,

look

at

THREE-MINUTE CHARGE

1

Connect battery charger

2

Turn charger to a fast rate not over

3

After three minutes, check voltmeter reading

If

it

is

over

16

5

volts battery should be re-

placed

TEST

40A

EL-7

BATTERY

ling

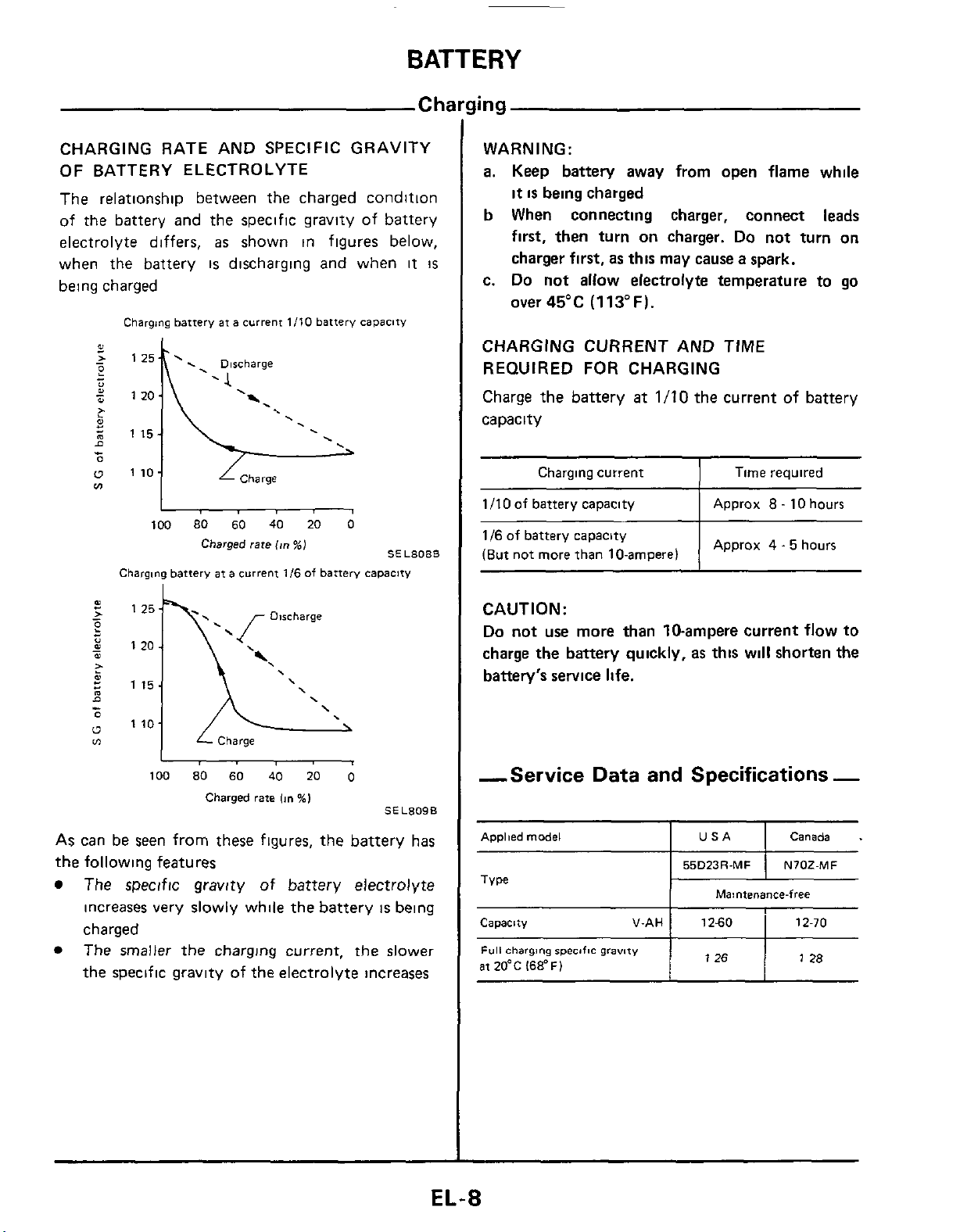

CHARGING RATE AND SPECIFIC GRAVITY

OF

BATTERY ELECTROLYTE

The relationship between

of

the

battery and the specific gravity of battery

electrolyte differs,

when the battery

as

is

the

charged condition

shown

in

figures below,

discharging and when

it

being charged

Charging

Chargtng

100

battery

80

Charged

battery

at

at

a

curreni

60

rare

a

curreni

40

(I"

1/10

%J

116

battery

20

of

battery

capacity

0

SEL8088

capacity

IS

WARNING:

a. Keep battery away from open flame while

it

is

being charged

b

When connecting charger, connect leads

first, then

charger

c.

Do

not

turn

on

first,

as

this

charger.

may

Do

not

cause a spark.

allow electrolyte temperature

turn

to

on

go

over45"C (113°F).

CHARGING CURRENT AND TIME

REQUIRED

Charge the battery

FOR

CHARGING

at

1/10

the current

of

battery

capacity

1/10

of battery

116

of

battery

(But

not more

~~ ~

Charging

current

capacity

capacity

than

10-ampere)

I

Time required

I

Approx

Approx

8

4

-

-

10

5

hours

hours

100

80

60

40

20

0

As

can

Charged

be

seen from these figures, the battery has

rate

(In

%)

the following features

The specific gravity

increases very slowly

of

battery electrolyte

while

the battery

charged

The

smaller the charging current, the slower

the specific gravity of the electrolyte increases

SEL809B

is

being

CAUTION:

not

use

Do

charge the battery quickly, as

more than 10-ampere current flow to

this

will shorten the

battery's service life.

-Service Data and Specifications

Applied

Capacity

Full

charging

at

2O'C

model

specific

168°F)

V-AH

gravi~y

I

1

1x0

126

Ma,ntenance-free

Canada

j

12-70

I

128

-

.

EL-8

STARTING

SYSTEM

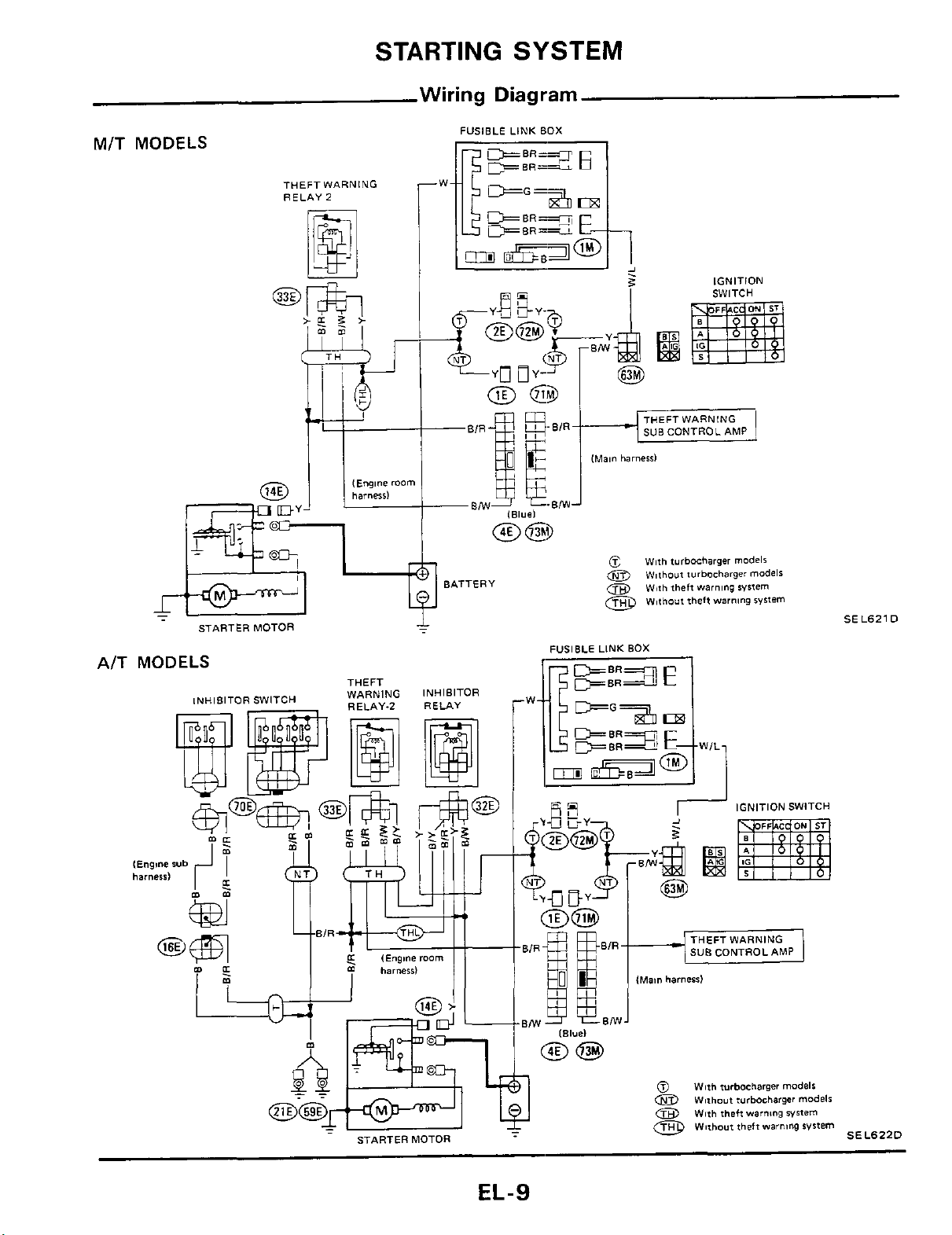

MIT MODELS

THEFT WARNING

RELAY 2

Wiring

FUSIBLE LINK

Diagram

BOX

IGNITION

SWITCH

AIT

-1

-

STARTER MOTOR

MODELS

lNHlBlTOR SWITCH

THEFT

WARNING

RELAY9

BATTERY

INHIBITOR

RELAY

FUSIBLE LINK BOX

.W

EL-9

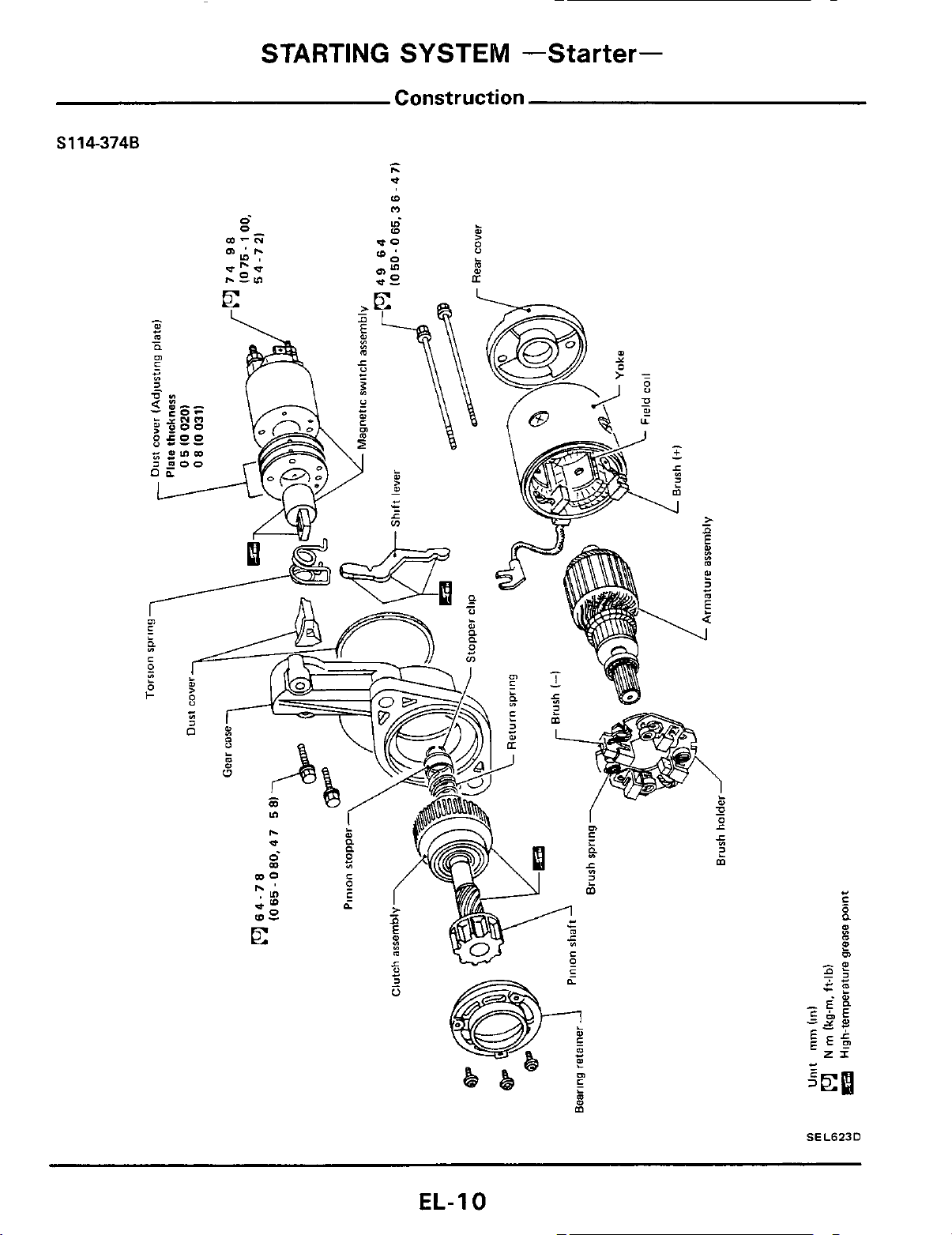

S114-3748

STARTING

SYSTEM

Construction

-Starter-

EL-I

0

SEL623D

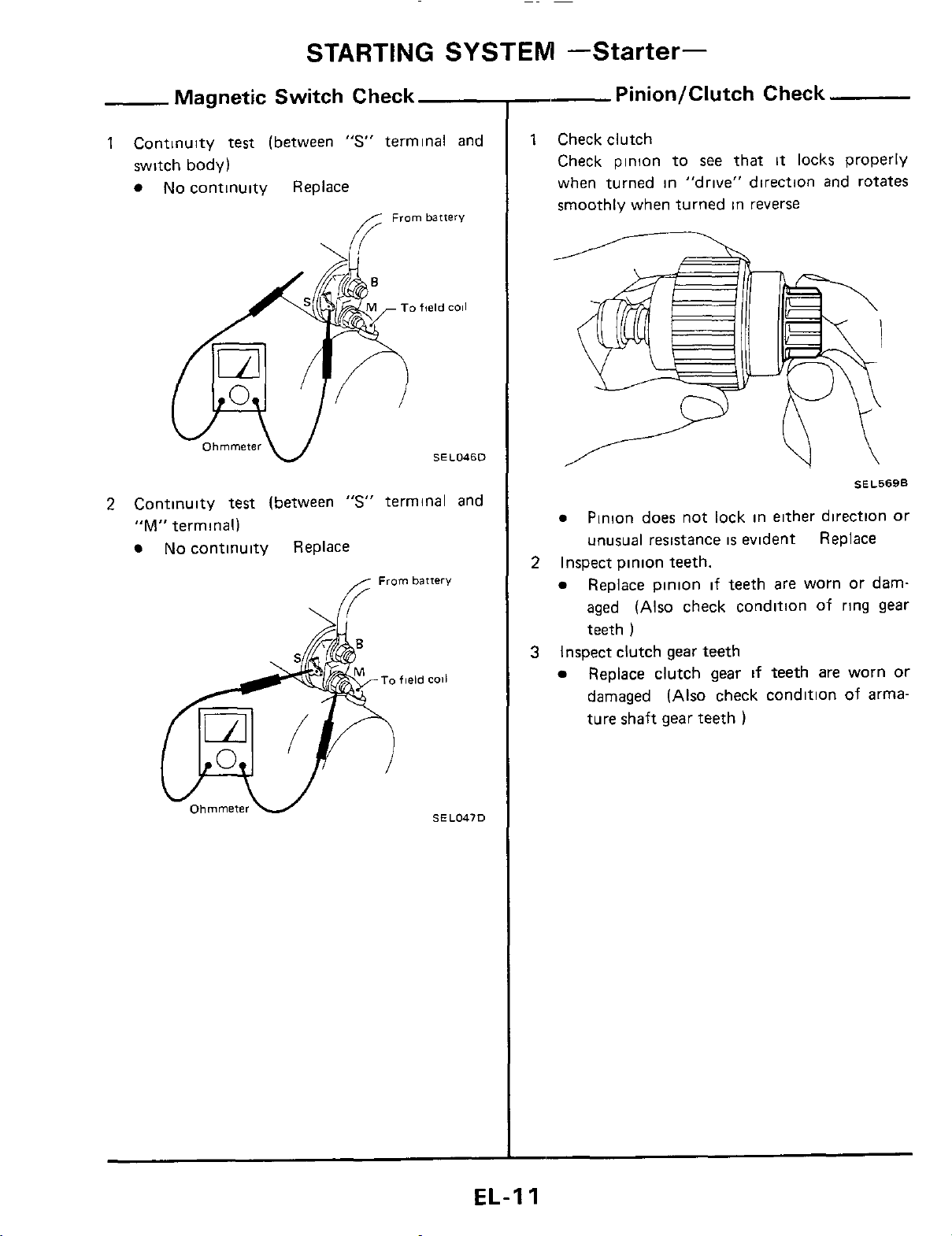

~~

1

Continuity

switch body)

No

2

Continuity

"M"

No

STARTING

Magnetic Switch Check

test

(between

continuity Replace

VL

Ohmrnet

test

(between

terminal)

continuity Replace

"S"

terminal and

From

"S"

terminal and

SYSTEM

battery

Coli

-Starter-

-

1

Check clutch

Check pinion to

when turned in "drive" direction and rotates

smoothly when turned in reverse

2

Inspect pinion teeth.

3 Inspect clutch

Pinion/Clutch Check

see

that

it

locks properly

Pinion does not lock in either direction or

unusual resistance

Replace pinion if teeth are worn or damaged (Also check condition

teeth

)

gear

Replace clutch gear

damaged (Also check condition

ture shaft gear teeth

is

evident Replace

teeth

if

teeth

)

of

are

SEL569B

ring

gear

worn or

of

arma-

SEL047D

EL-I

1

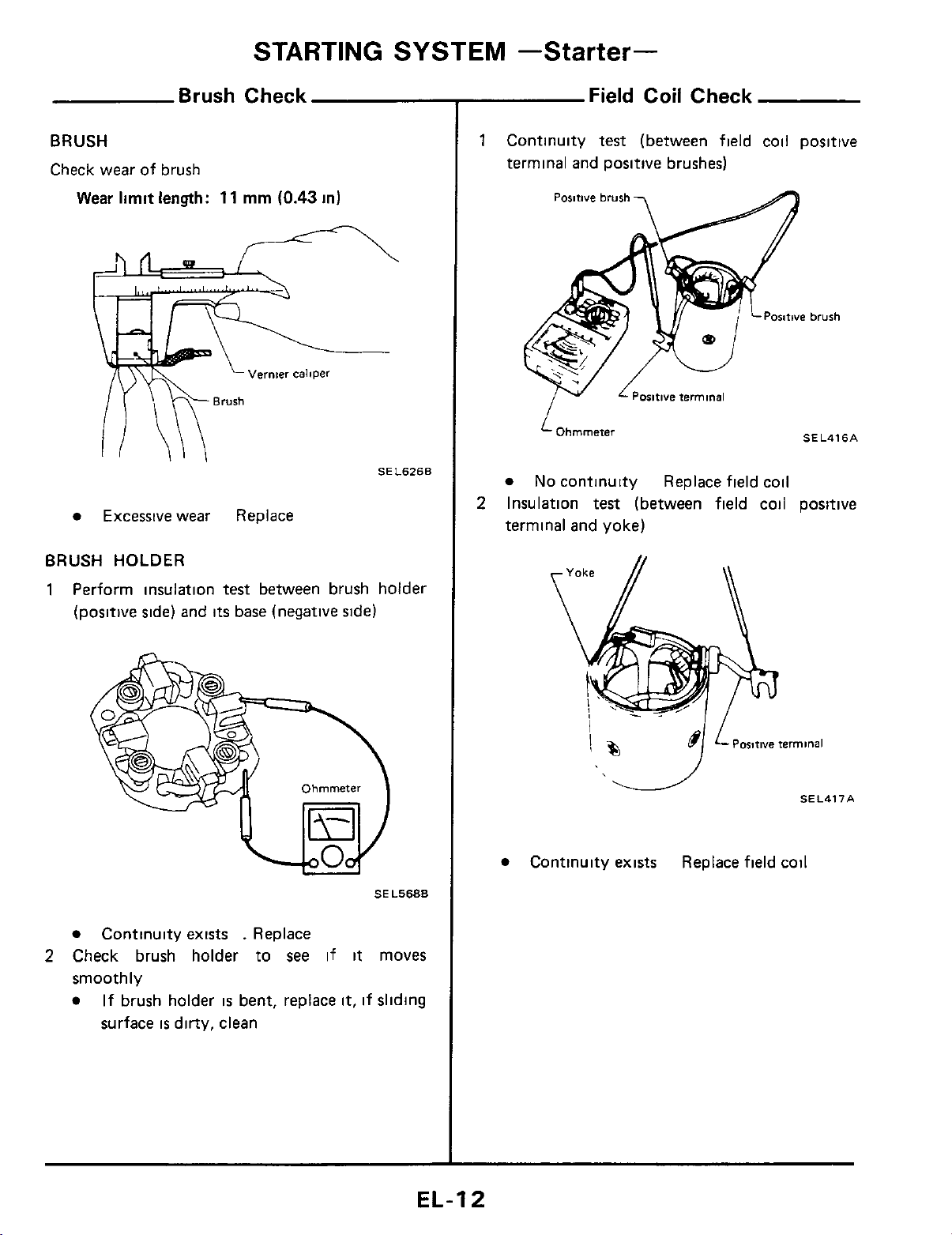

STARTING

SYSTEM

-Starter-

Brush Check

BRUSH

Check wear of brush

Wear

limit

length:

Excessive wear Replace

11

mm

Vernier

(0.43

caliper

in)

SEL626B

Field

Continuity test (between field coil positive

terminal and positive brushes)

‘Ohmmeter

No continuity Replace fielk ~

Insulation test (between field coil positive

terminal

and

Coil Check

ositive

yoke)

terminal

SELUq6A

:oil

BRUSH

1

2

HOLDER

Perform insulation test between brush holder

(positive side) and

Continuity exists . Replace

Check brush

smoothly

If

brush

surface

is

its

base (negative side)

holder

holder

dirty, clean

is

to

see

if

bent, replace

it,

it

if

SE

L568B

moves

sliding

I

Postwe

1%

Continuity exists Replace field coil

terminal

EL-I

2

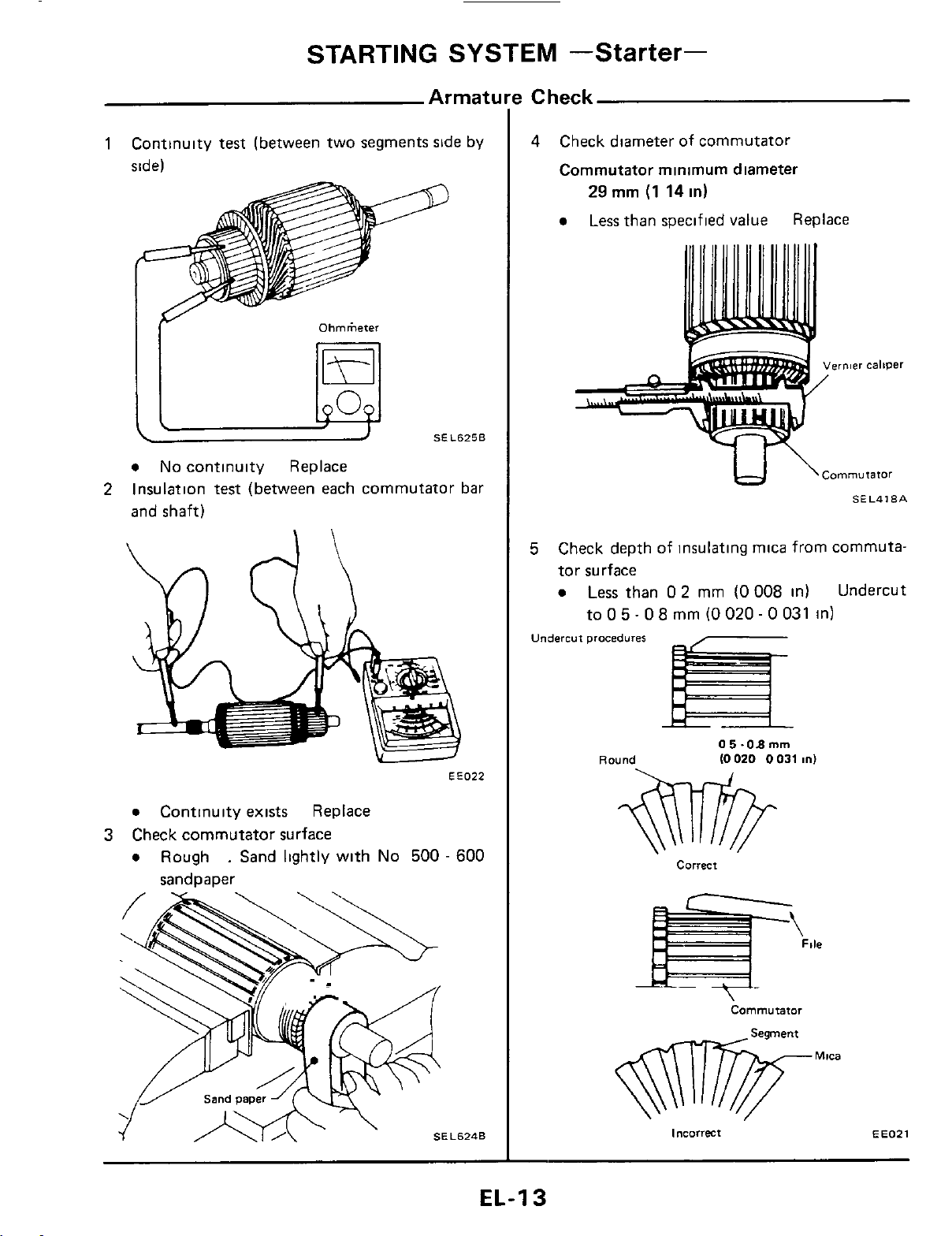

Continuity

1

side)

STARTING

test

(between two segments side by

SYSTEM

!

Check

4

-Starter-

Check diameter

Commutator minimum diameter

29

mm

Less

than specified value Replace

(1

of

commutator

14 in)

IY

a

Insulation

2

and shaft)

No

continuity Replace

test

(between each commutator bar

Ohrnketer

EE022

Check depth

5

tor surface

a

Less

than 0 2 mm

to 0

5.0

Undercut procedures

Round

vernier

tJ

of

insulating mica from commuta-

(0

008

8

mrn (0

020

0

5

-08

(0

020 0 031

-

\Cornmurator

SEL418A

in) Undercut

0

031

in)

mm

in)

caliper

a

Continuity exists Replace

3 Check commutator surface

a

Rough . Sand lightly with

sandpaper

No

500 - 600

EL-1

3

Correct

incorrect

Commutator

EEOZI

STARTING SYSTEM

-Starter-

Reassembly

Carefully observe the following instructions

between

"P":

-

1.5

mm

to:

the

(0

012.

lever

front edge

0.059

of

the pinion

in)

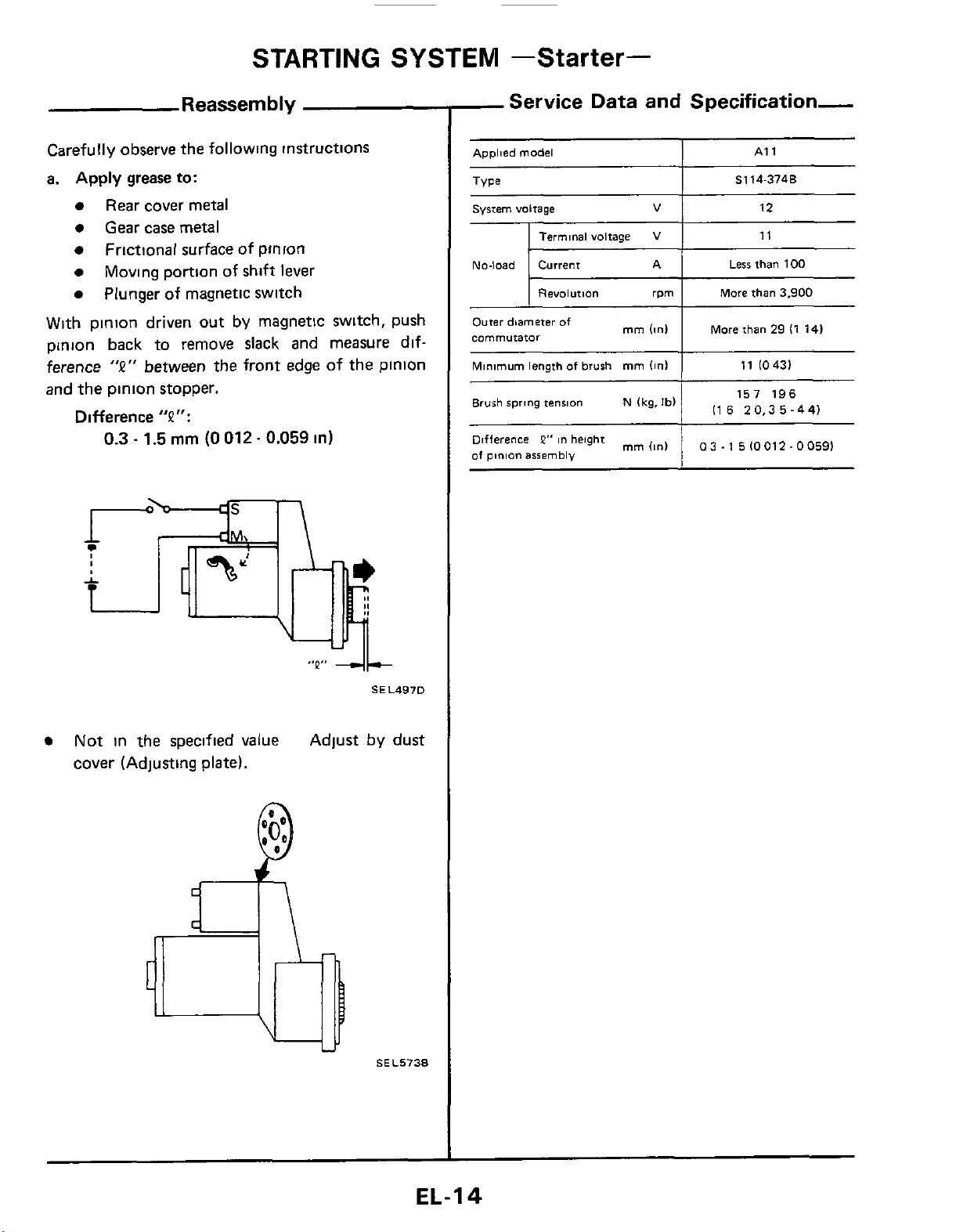

a. Apply grease

Rear cover metal

Gear case metal

Frictional surface of pinion

Moving portion of shift

Plunger of magnetic switch

With

pinion driven out by magnetic switch, push

pinion back to remove slack and measure difference

and the pinion stopper.

"2"

Difference

0.3

-

Service Data and Specification-

Applied

model

I

Revolution

Outer diameter

commutator

Minimum length

Brush spring tension

Difference

of

pinion

P"

assembly

of

of

in

brush

height

rpm

mm

(in1

mm

(In)

N

(kg.

mm(in1

I

Less

I

Mare than 3.900

More than 29 (1 141

I

11

Ibl

1

1

157 196

116 20.35-44)

03-1510012-00591

A1 1

than

10431

100

-

-

Not

in the specified value Adjust

cover (Adjusting plate).

"Q"

4+

SEL497D

by

dust

SEL5738

EL-I

4

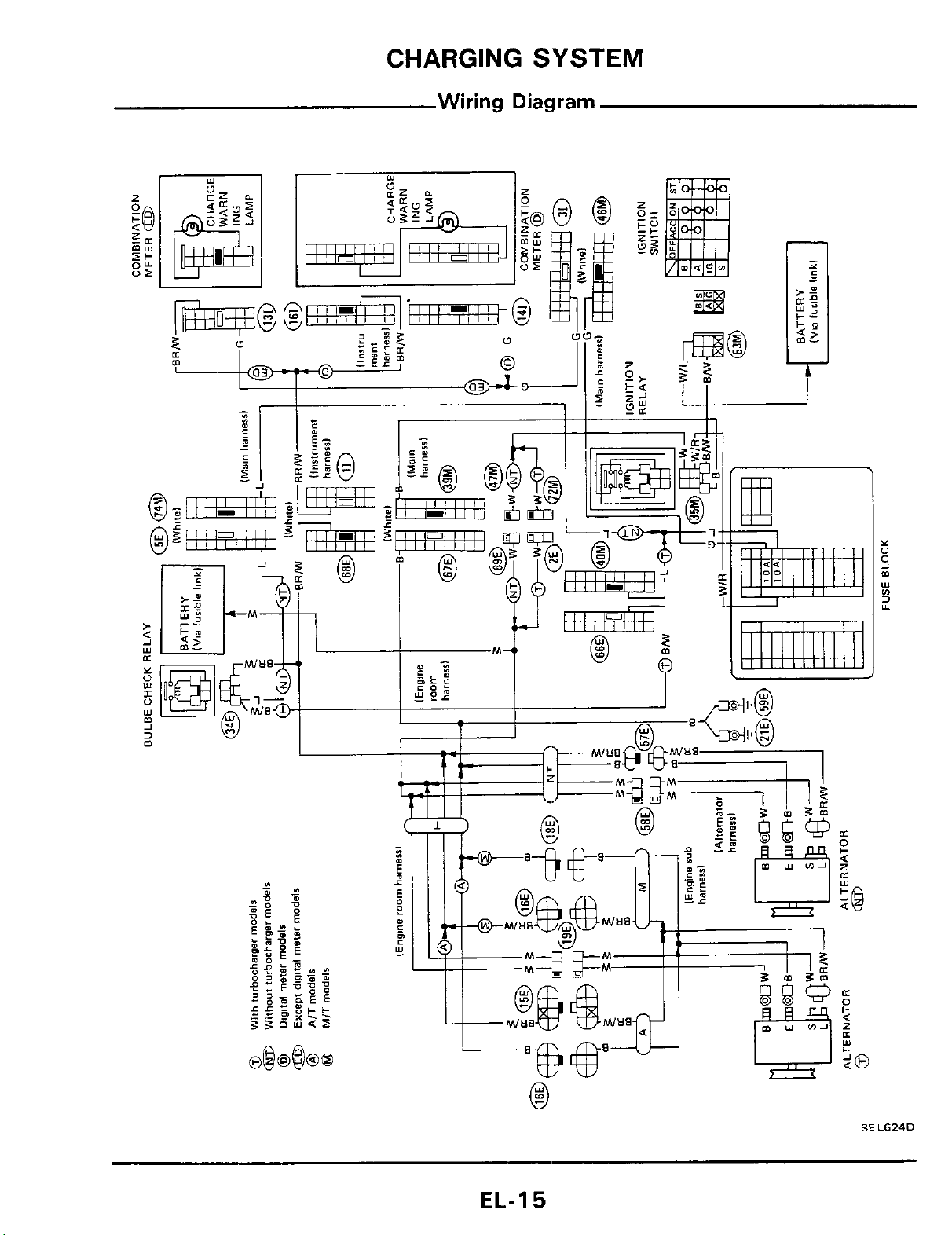

CHARGING

Wiring Diagram

SYSTEM

EL-I

SEL6240

5

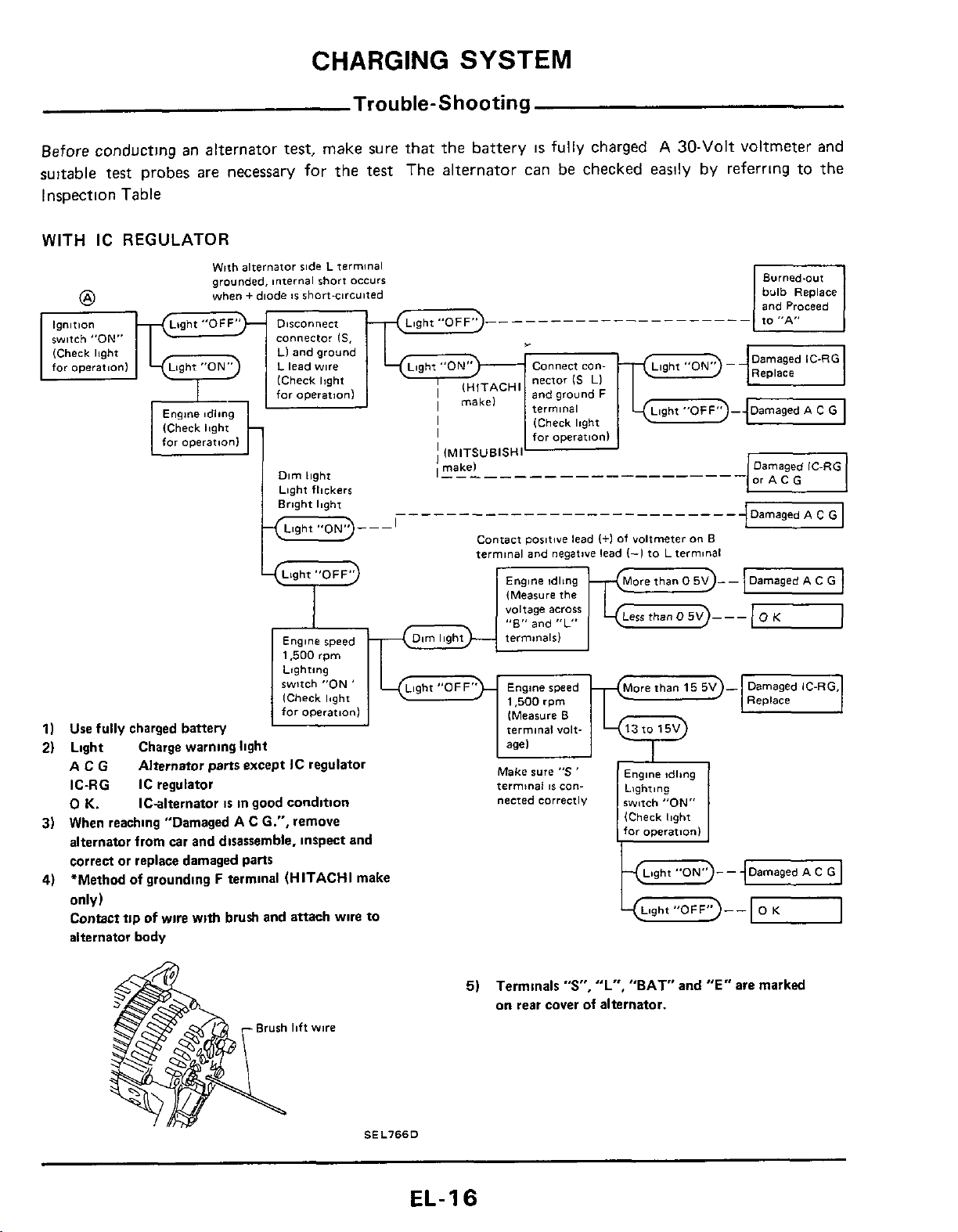

CHARGING

Trouble-Shooting

SYSTEM

Before conducting an alternator test, make sure

that the

battery

IS

suitable test probes are necessary for the test The alternator can

Inspection Table

WITH

@

Ignition

witch

(Check

for

operatton1

IC

REGULATOR

"ON"

light

Wpth

alternator

grounded,

when

+

side L terminal

internal

short

diode

IS

short-circuited

occurs

-

cOnneCtor

Ll

L

lead

far

IS.

and

ground

w~re

I

operation1 and

lH,TACHl

I

I

I

(MITSUBISHI

'

makel

I

-

- - - - - - -

J

Connect

nector

[Check

for

..........................

Lqht

"OFF"

9

Engine

speed

1,500

rpm

Contact

terminal

poiitwe

and

(Measure

"oltage

"E"

and

fully charged A 30-Volt voltmeter and

be

checked easily by referrmg to the

bulb

Replace

and

Proceed

con-

IS

LI

ground

F

Itght

operation1

- -

- -

lead

negative

the

acres

"L"

(+I

lead

of

--------

voltmeter

(-1

to

L

terminal

on

-

B

IC-RG

0

K.

When reaching "Damaged

only)

Contact

alternator body

IC

regulator

IC-alternator

tip

of

wlre

with

16

In

good condltlon

A

C G.", remove

brush and attach

Brush

lift

wire

wire

to

SEL766D

EL-1

Make

termmal

nected

Terminals

5)

on rear cover

6

sure

"S

8s

con-

COrreCtly

"S",

'

"L",

of

alternator.

Engine

tdltng

Lighting

$witch

"ON,,

(Check

light

for

operatlonl

-0

Light"0FF"

"BAT" and

--

"E"

are marked

OK

CHARGING

SYSTEM

Construction

-Alternator-

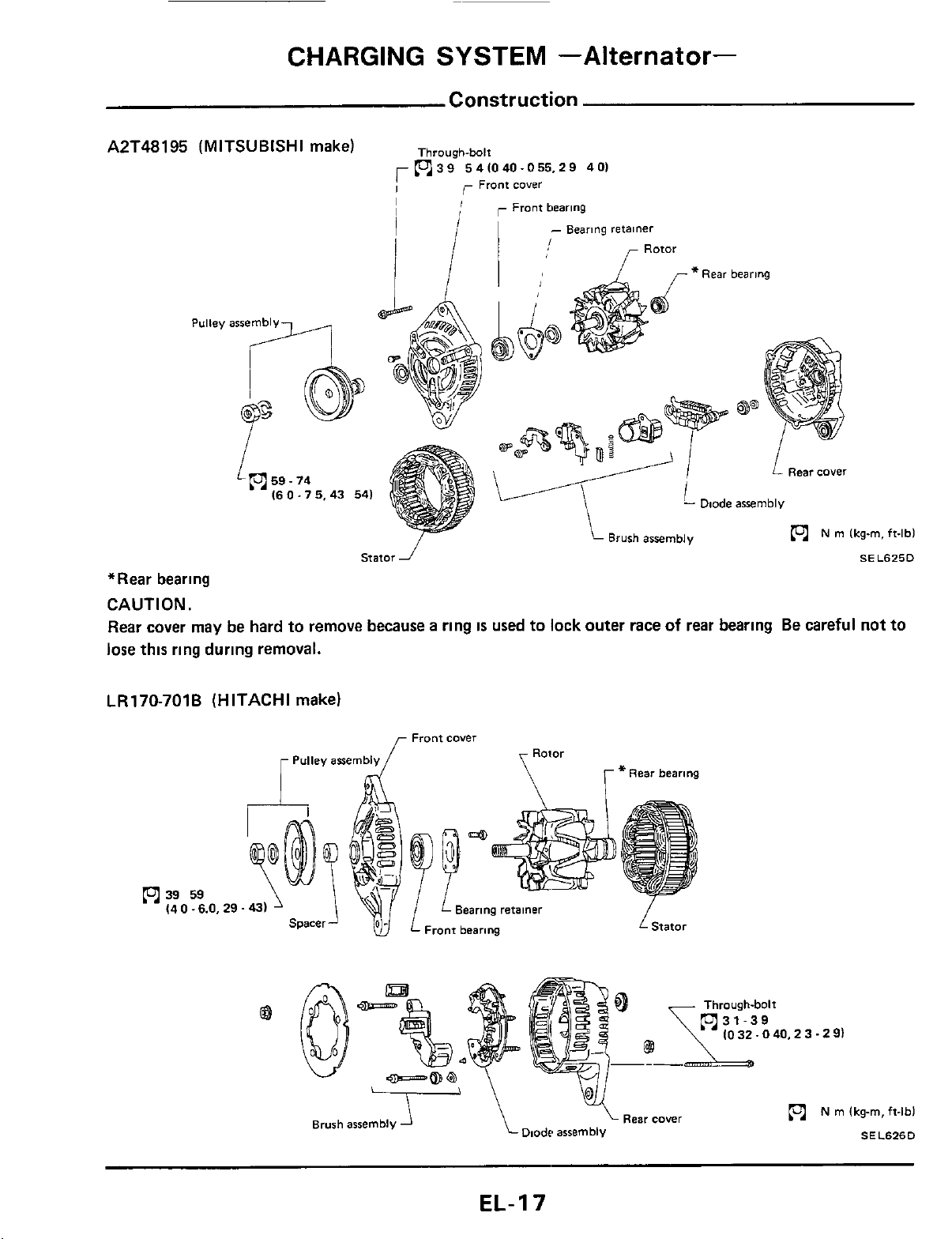

A2T48195 (MITSUBISHI make)

16

0.7

5,43 54)

*Rear bearing

CAUTION.

Rear cover may be hard to remove because a ring

lose this ring during removal.

Through-bolt

m39 541040-055.29 401

r

I

,-

Front

cover

-

~ear~ng

retainer

is

used to lock outer race

-

Diode assembly

("1

N m lkg-rn.

of

rear bearing Be careful not to

it-lbl

SEL625D

LR170-701B (HITACHI make)

n

39 59

(4

0

-6.0,

29.43)

("1

N

m

Ikg-m,

ft-lbl

Dlodt, assembly SEL626D

EL-I

7

____ ____

CHARGING

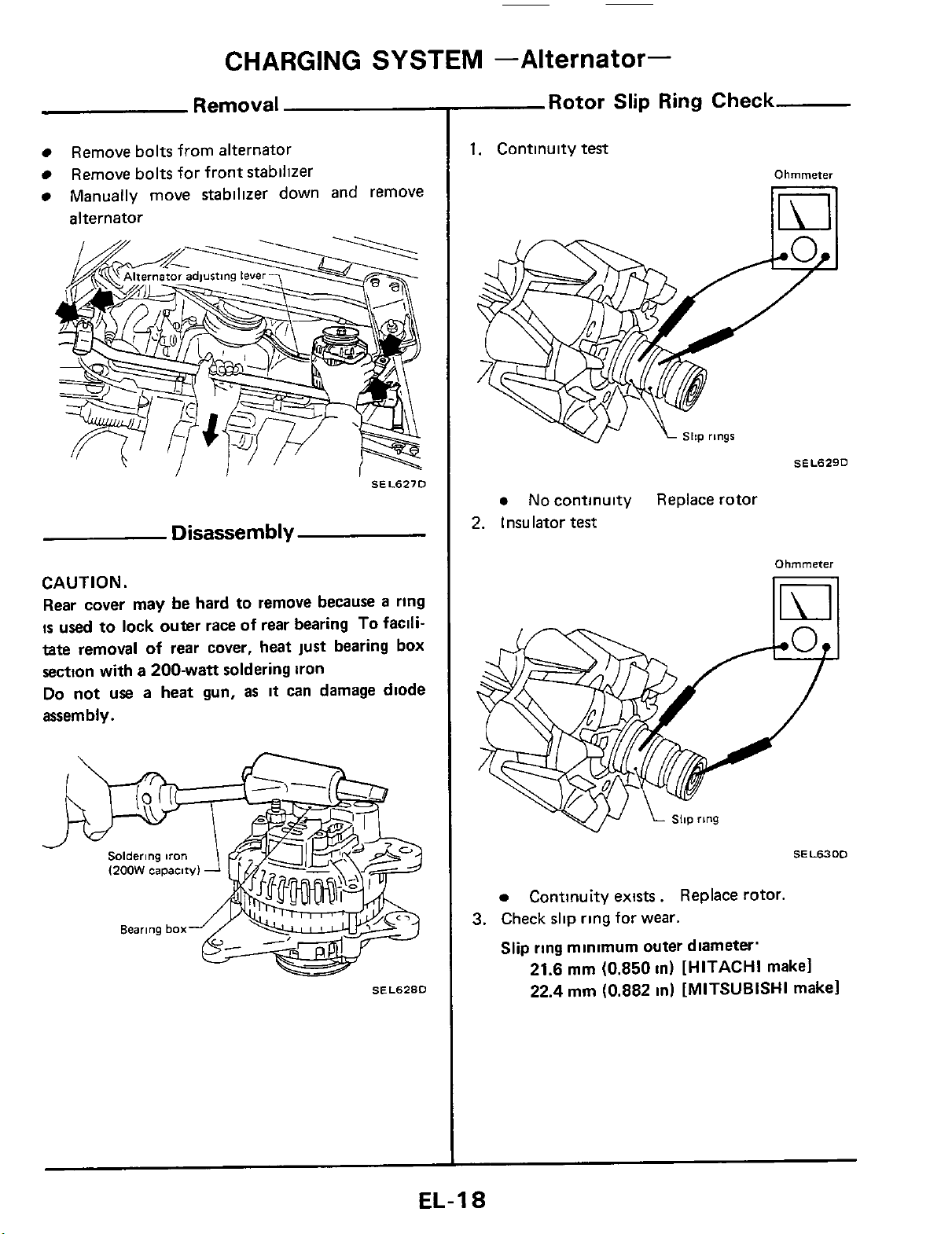

Removal

Remove bolts from alternator

Remove bolts for front stabilizer

Manually

alternator

move

stabilizer down and remove

Disassembly

SYSTEM

1.

SEL627D

2.

-Alternator-

Rotor Slip Ring Check

Continuity

No

Insulator

test

continuity Replace rotor

test

Ohmmeter

SEL629D

CAUTION.

Rear

cover may be hard to remove because a ring

IS

used to lock outer race

tate

removal

section with

Do

not

assembly.

of

rear cover, heat just bearing box

a

200-wan soldering iron

use a heat gun,

of

rear bearing

as

it

can damage diode

To

facili-

SEL628D

Continuity exists. Replace rotor.

3.

Check slip ring for wear.

Slip ring minimum outer diameter.

21.6

mm

22.4

mm

(0.850

(0.882 in)

in)

[HITACHI

[MITSUBISHI

Ohmmeter

IWI

SEL630D

makel

makel

EL-I

8

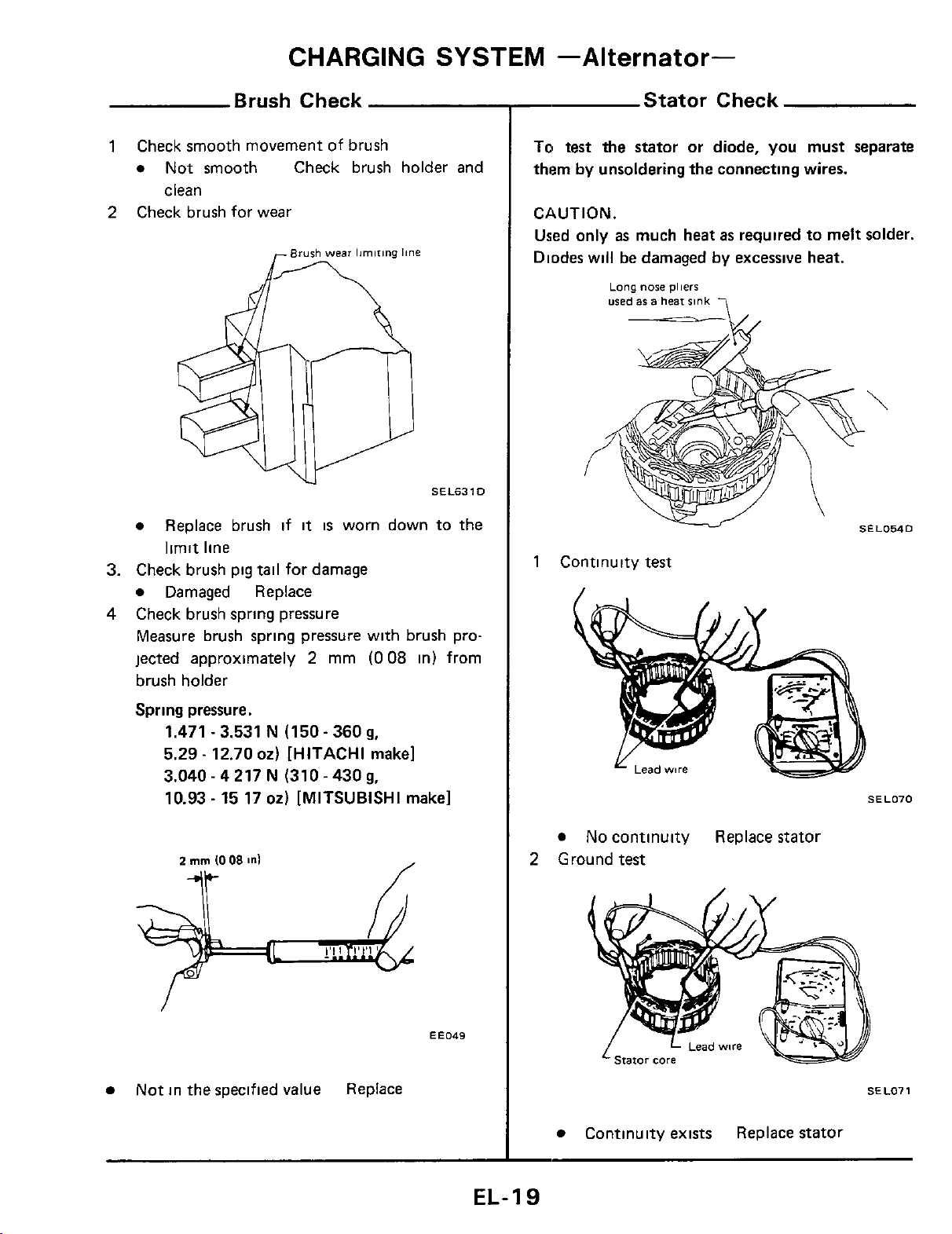

CHARGING

SYSTEM

-Alternator-

Brush Check

Check smooth movement of brush

1

Not smooth Check brush holder and

clean

2

Check brush for wear

Replace brush

limit line

3.

Check brush pig

Damaged Replace

4

Check brush spring pressure

Measure brush spring pressure with brush projected approximately

brush holder

if

tail

for damage

it

is

worn down to the

2

mm

(008

SEL631D

in) from

-

To

test

them

by

CAUTION.

Used only

Diodes will

1

Continuity test

Stator

the

stator

unsoldering the connecting wires.

as

much heat

be

damaged by excessive heat.

Long

nose

used

a$

a

heal

-1,

Check

or

diode, you must separate

as

required to melt solder.

pliers

sink

/

\

SEL054D

Spring pressure.

1.471 - 3.531 N (150 - 360

5.29 - 12.70

3.040 - 4 217 N (310 - 430

10.93 - 15 17

2

mm

(0

08

02)

[HITACHI make]

02)

[MITSUBISHI make]

in1

9,

9,

IP-

Not in the specified value Replace

EE049

2

y_

Lead

wire

No

continuity Replace stator

Ground

test

Continuity exists Replace stator

-

SEL070

SE

LO7

1

EL-19

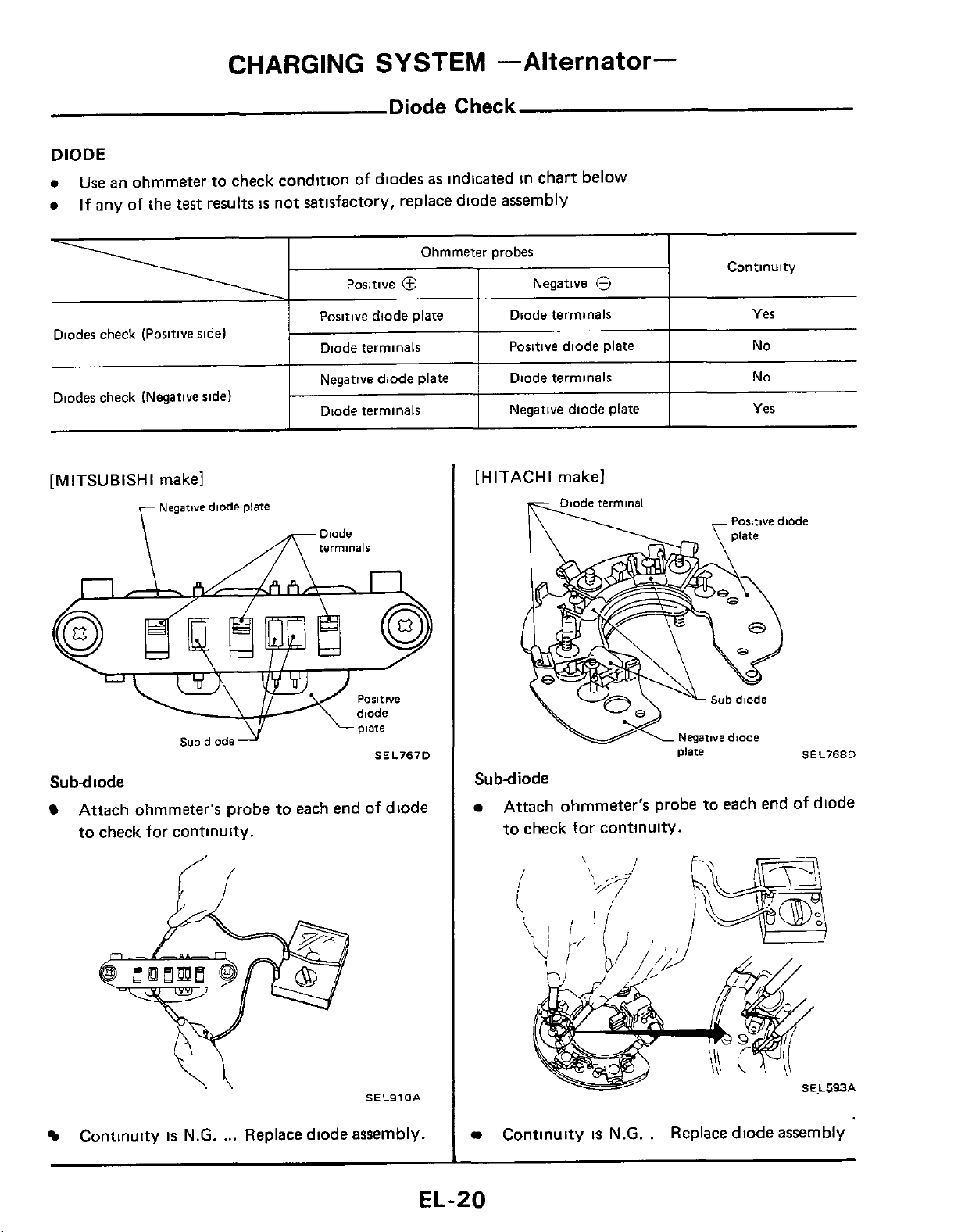

CHARGING

SYSTEM

-Alternator-

Diodes check (Positive side)

Diodes check (Negative side)

[

MlTSUBlSHl

makel

Negatwe

diode

\

plate

Diode

~ositive

Positive diode plate Diode terminals

Diode terminals Positive diode plate

Negative diode plate Diode terminals

Diode terminals Negative diode plate

0

Check

Ohmmeter probes

[HITACHI makel

Negative

8

Continuity

Yes

No

No

Yes

Sub

dlode

Subdiode

Attach ohmmeter's probe to each end of diode

to check for continuity.

Continuity

is

N.G. ... Replace diode assembly.

piate

SEL767D

SEL910A

Subdiode

Attach ohmmeter's probe

to check for continulty.

Continuity

is

N.G. . Replace diode assembly

SEL768D

to

each end of diode

EL-20

CHARGING SYSTEM

-Alternator-

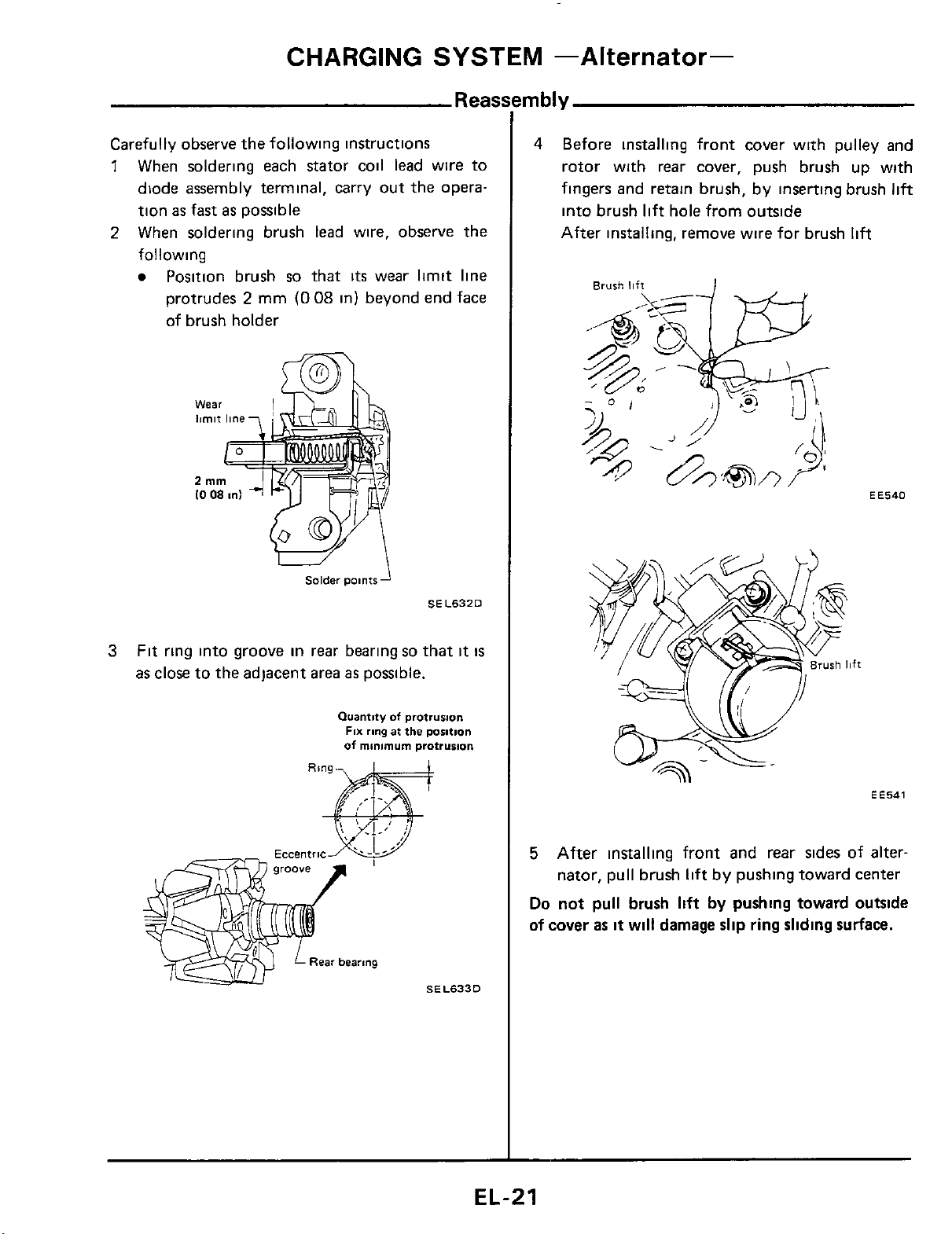

Carefully observe the following instructions

1

When soldering each stator coil lead wire to

diode assembly terminal, carry out the operation

as

fast

as

possible

2

When soldering brush lead wire, observe the

following

Position brush

protrudes

2

mm

so

(0

that

08

its

wear limit line

in)

beyond end face

of brush holder

Reasi

mbly

4

Before installing front cover with pulley and

rotor with

fingers and retain brush, by inserting brush

into brush

After installing, remove wire for brush

rear

cover, push brush up with

lift

hole from outside

lift

lift

EE540

Solder

Fit ring into groove in rear bearing

3

as

close to the adjacent

area

points

as

possible.

Quantity

FIX

ring

of

minimum

so

that

of

prorrusion

at

the

protrusion

SEL6320

it

position

is

5

After installing front and rear sides of alter-

nator, pull brush

Do

not pull

of

cover

as

it

brush

will damage

lift

by pushing toward center

lift

by pushing toward outside

slip

ring

sliding surface.

EE541

EL-21

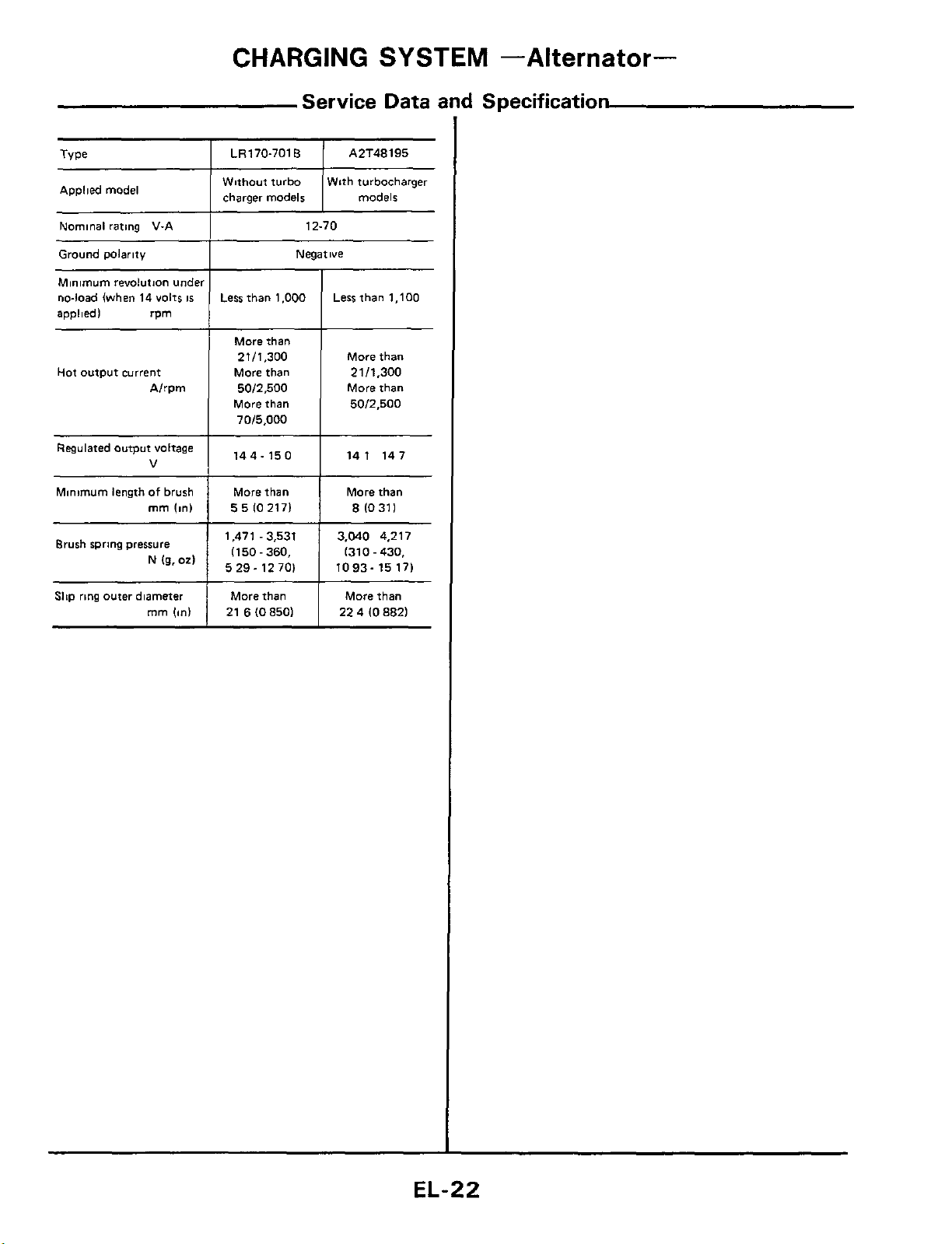

CHARGING

Service Data and Specification

SYSTEM

-Alternator-

Applied

model

Nominal rating V-A

Ground wlarity

Minimum

no-load (when 14 volts

applied) rpm

Hot output current

Regulated output voltage

Minimum length

Brush spring pressure

Slip ring outer diameter

revolution

Alrpm

V

of

rnm

N

1%

mm

undt

brush

(m)

02)

Ion)

LR170-701B

W8thout turbo With turbocharger

charaer models models

12-70

Negative

IS

Less than 1.000

More than

2111,300

More than

5012,500

More than

7015,000

144-150

More than

55102171

1,471 - 3,531

1150-360.

-

12 701

5 29

More

than

21

6

IO

850)

Less

3,040 4,217

I310

1093- 15 17)

More

22 4

A2T48195

than

1,100

More than

21 11,300

More than

5012,500

141 147

More than

8

10311

-

430,

than

10

8821

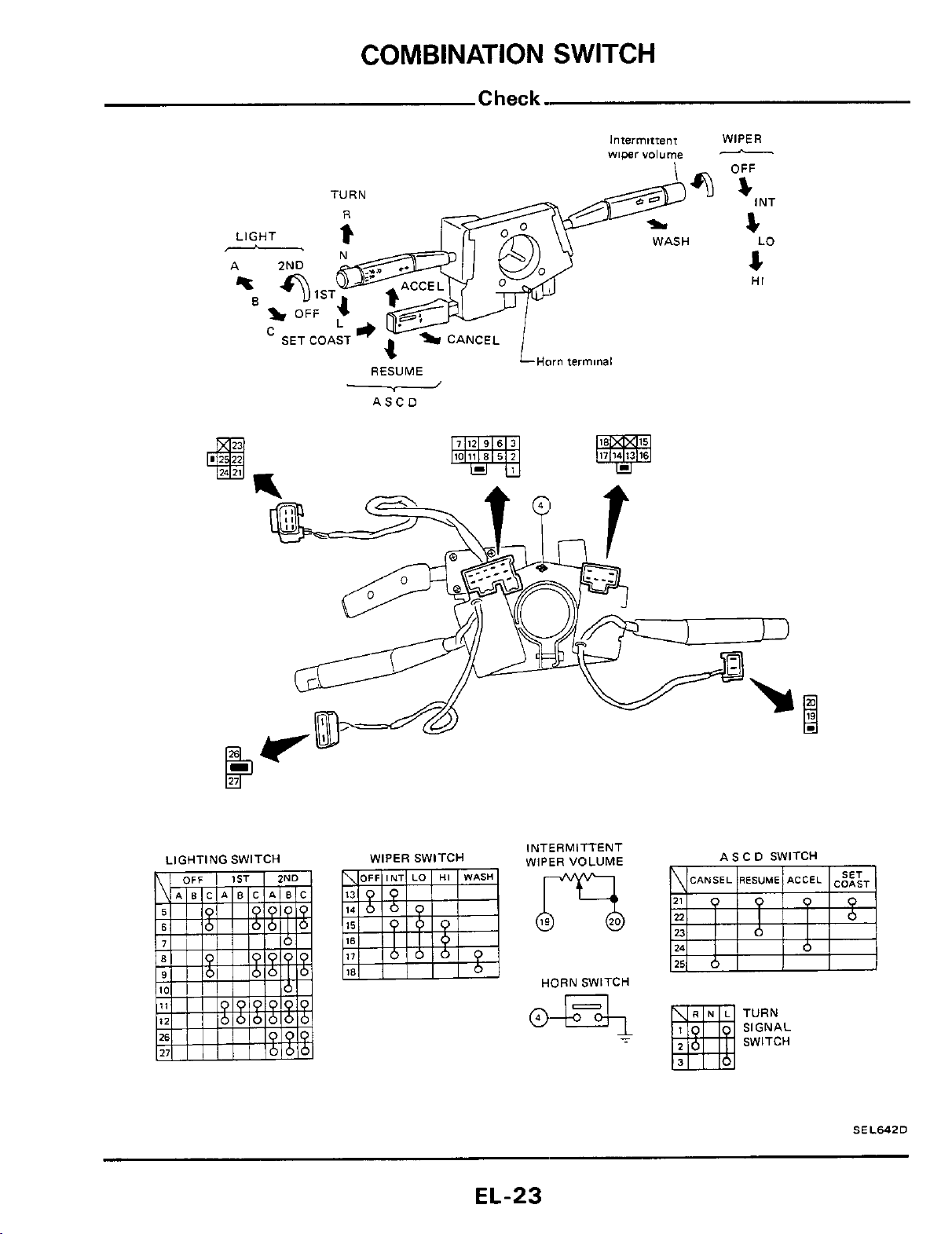

COMBINATION SWITCH

TURN

RESUME

ASCD

Horn

terminal

Intermittem

wimrvolume

WASH

WIPER

OFF

s

L

4

INT

LO

HI

LIGHTING SWITCH

WIPER SWITCH

INTERMITTENT

WIPER VOLUME

HORN SWITCH

EL-23

AS C D SWITCH

TURN

-

SIGNAL

SWITCH

SEL64ZD

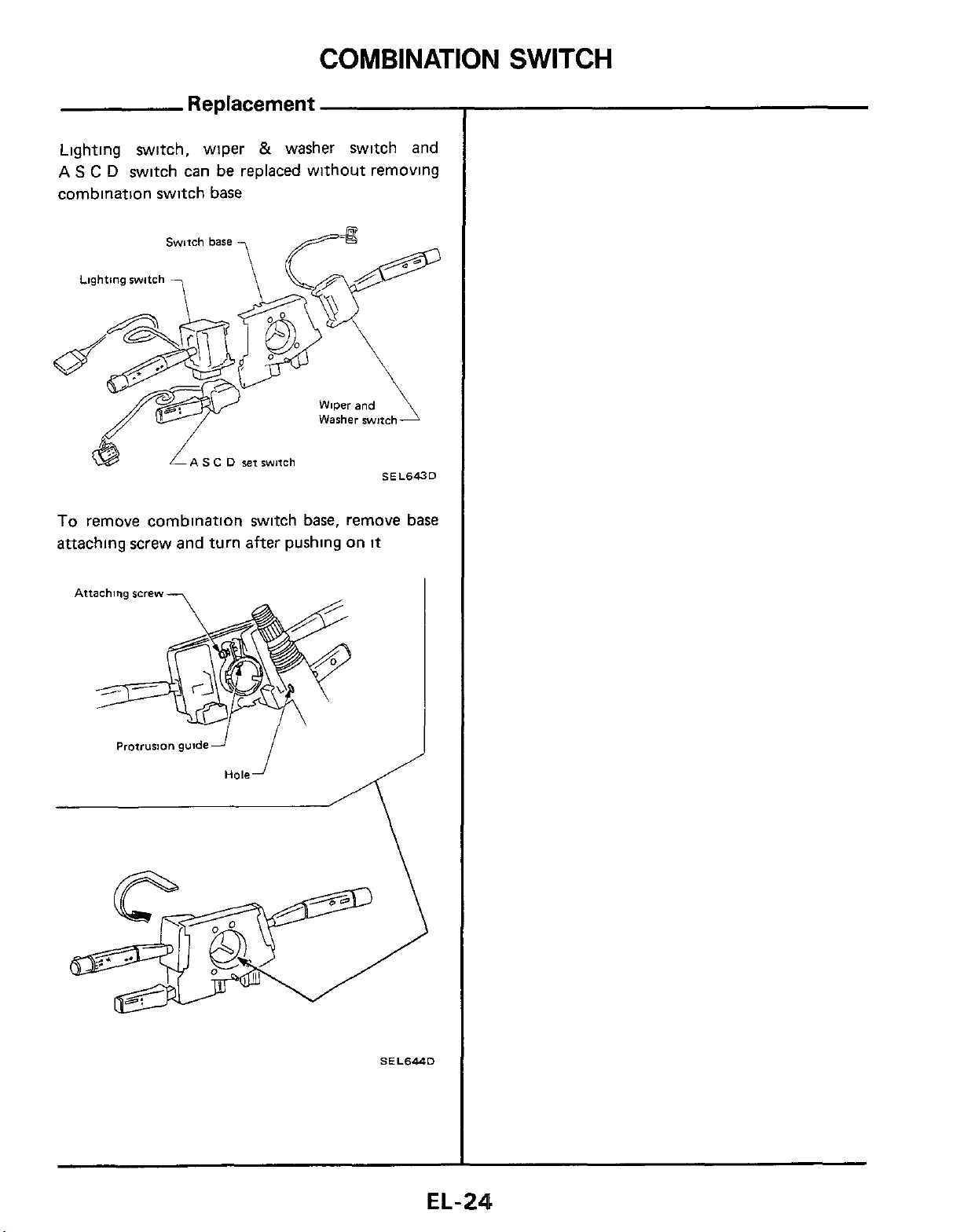

Replacement

COMBINATION

SWITCH

Lighting switch, wiper

AS

C

D

switch can

&

washer switch and

be

replaced without removing

combination switch base

Swtch

base

Lighting switch

Washer swmh

A

S

C

D

sei

switch

To

remove combination switch base, remove base

attaching screw and turn after pushing on

Attaching screw

it

SEL643D

Protrusion gu!dei

Hole

SEL644D

EL-24

INSTRUMENT SWITCH

INSTRUMENT

-'+

Dark

N

(For ASC

switch)

(Far

illuminafion

control

swifchl

p7J-q

OFF

D

RETRACT

SWITCH

HAZARD

SWITCH

INSTRUMENT SWITCH

m

E:EGGER

SWITCH

REAR WIPER

&WASHER

SWITCH

[WJ]

R.H.

refer

HAZARD

to

"INSTRUMENT"

RETRACT SWITCH SWITCH

For

removal,

ASCD MAIN

SWITCH

I

LLUMlNATlON

CONTROL SWITCH

BRIGHT

DARK

El

in

BF

section

EL-25

RE4R

DEFOGGER

SWITCH

AUXILIARY DRIVING

LAMP SWITCH

REAR WIPER

&WASHER SWITCH

0

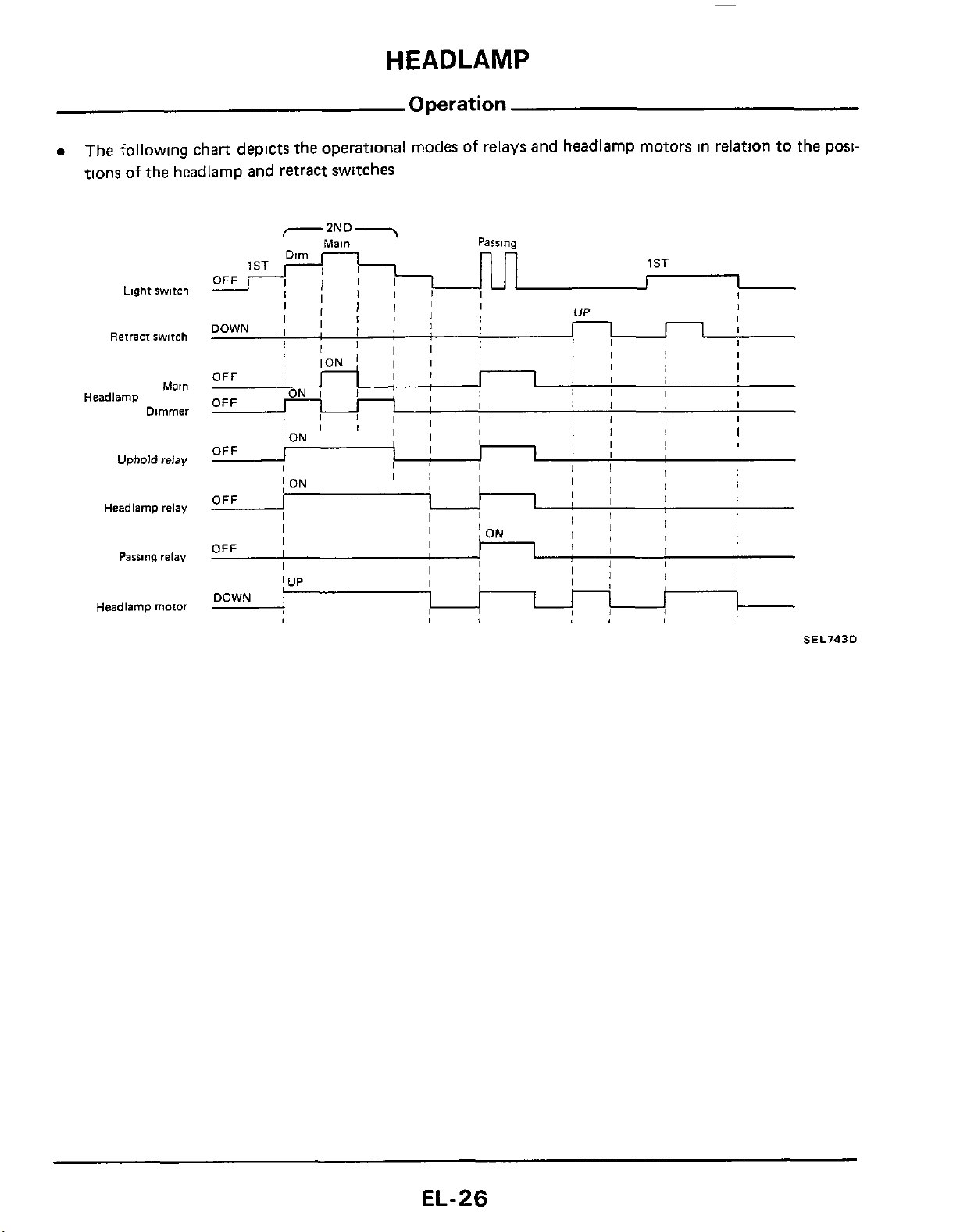

The

nons

following

of

the headlamD and retract switches

chart depicts the operational modes

HEADLAMP

Operation

of

relays

and headlamp motors in relation

to

the posi-

Light switch

Retract switch

Headlamp

Dimmer

Uphold

Headlamp relay

Pasrlng

Headlamp mofor

Mal”

relay

relay

OFF

OFF

OFF

OFF

OFF

DOWN

-2ND

II

j

ON

I

I I

I

ON

I

I

I

I

I

UP

7

Main

111

I

Ill

I

I1

I

Parsing

1

ST

nn

I I

1

I

I

I

I

,

I

I

I

I

I

UP

1

I

1

I

I

I

II

I

I

1

I

I

I

,

1

1

1

I

I

I

1

1

I I

I I

I

I

!

I I

I I

I/

1,

!I

I

I

I

I

~

I

I

I

,

,

I

I

I

I

SEL743D

EL-26

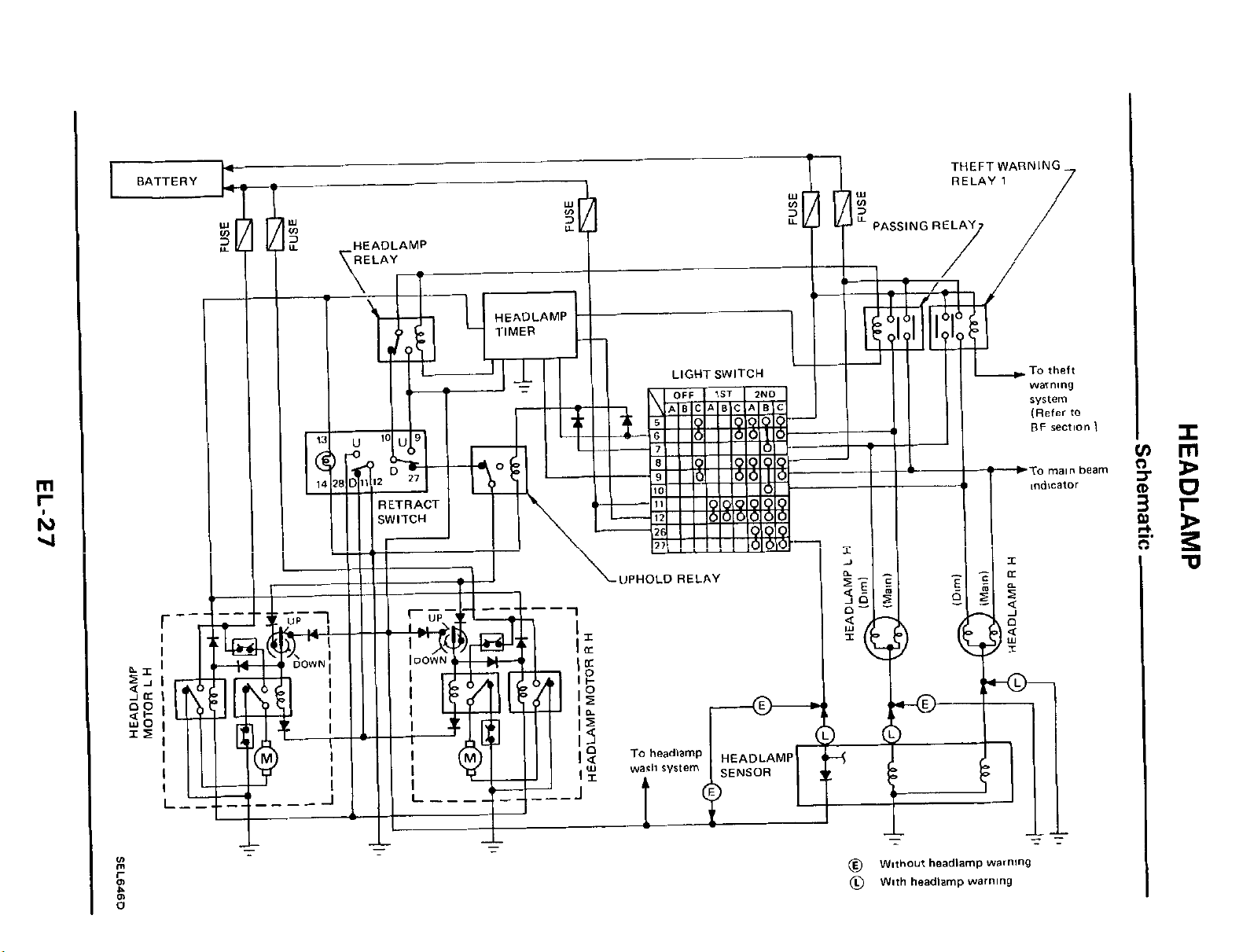

BATTERY

-

TI

"$

7;

PASSING RELAY

THEFT WARNING

RFI

AV

1

'/'

'

7

r

--,

I

II

I

k=a-J

\-UPHOLD RELAY

1V.

I

@

Wnihoul headlamp

0

Wnh headlamp warning

warning

HEADLAMP

R

MOTOR

HEADLAMP

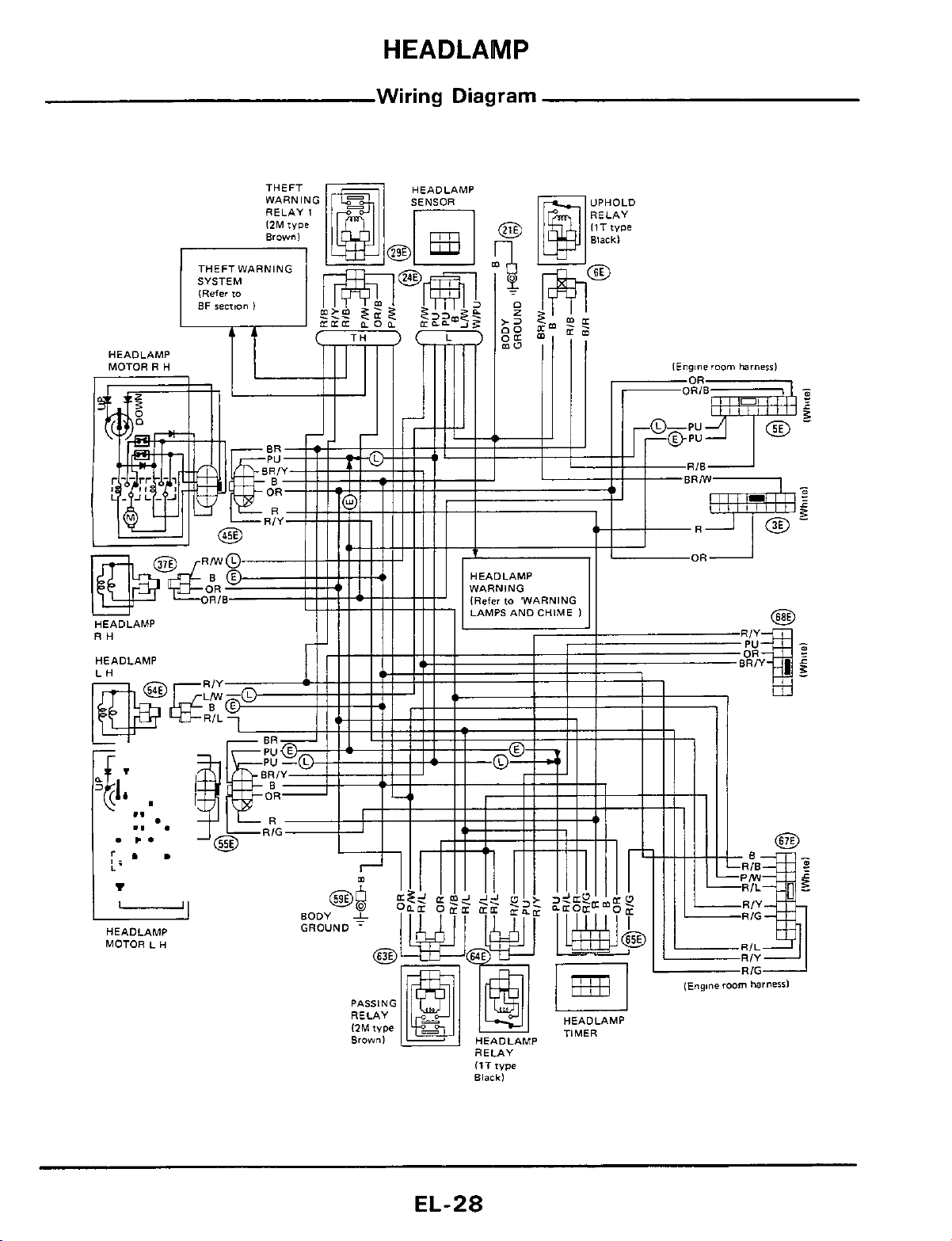

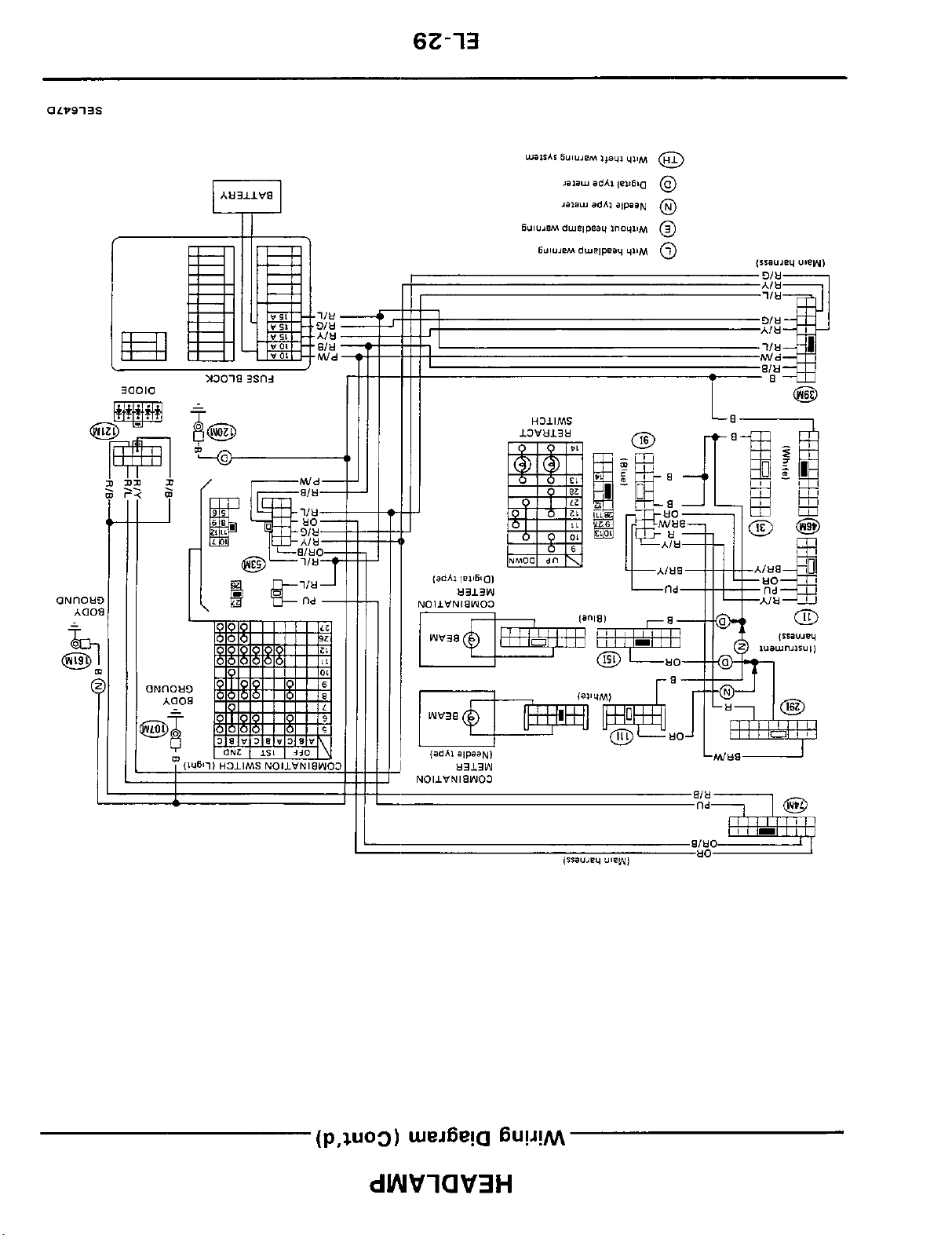

Wiring Diagram

H

RH

HEADLAMP

HEADLAMP

MOTOR L H

RELAY

type

ItT

Black)

HEADLAMP

EL-28

L

,

sin

Mld

u

f

HEADLAMP

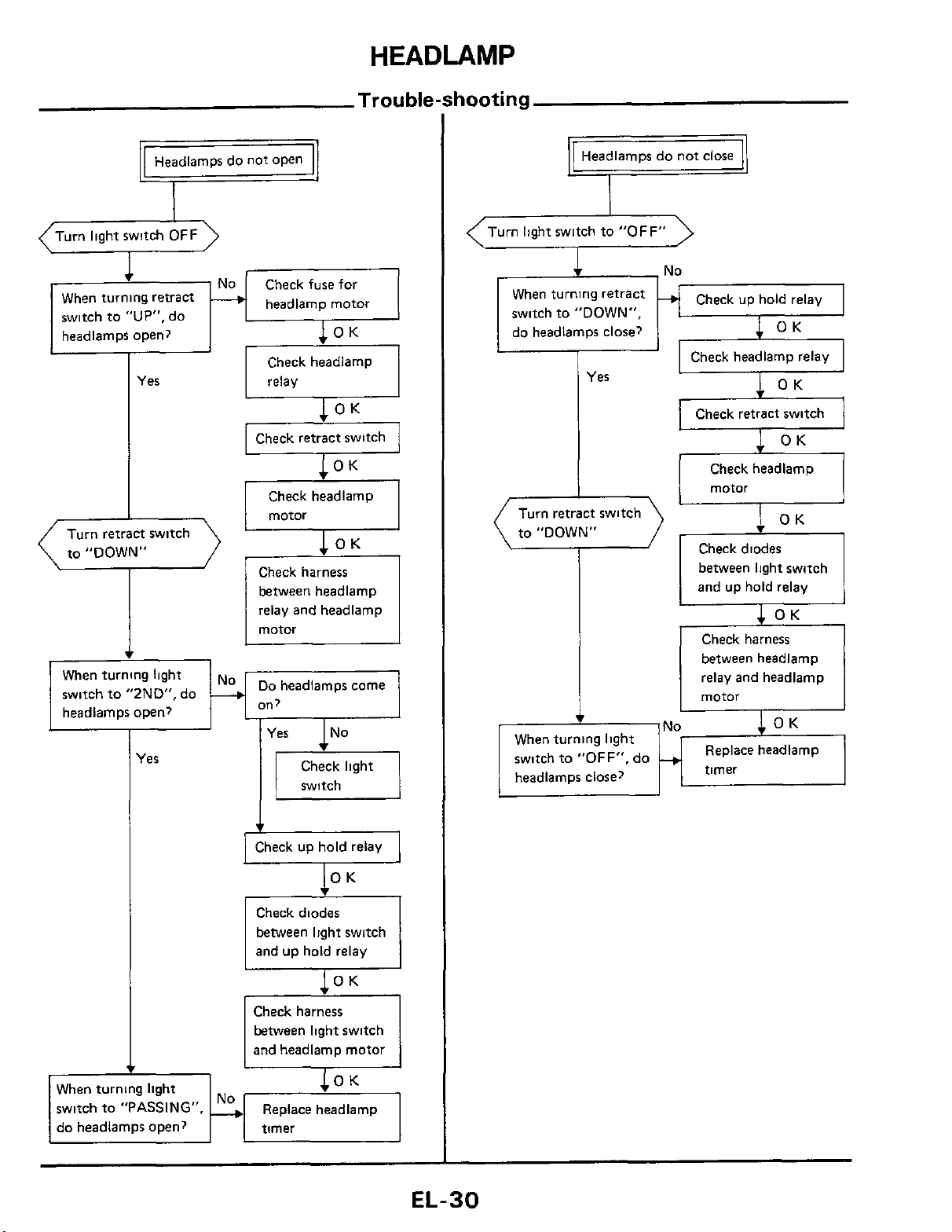

Trouble-shooting

Headlamps do not close

F

When turning retract

switch to

headlamps open?

Turn retract switch

to "DOWN"

When turning light

r

switch to "ZND", do

I

headlampsopen?

I

"UP",

Yes relay

(es

do

I

headlamp motor

Check headlamp

Check headlamp

motor

between headlamp

relay and headlamp

motor

on,

switch

(Turn light switch

When turning retract

switch to "DOWN",

do headlamps close?

I

I

When turning light

switch to "OFF". do

headlamps close?

~

c

v

Yes

to

-

-No

"OFF"

-

\

No

Check headlamp relay

Check retract switch

Check headlamp

Check diodes

between light switch

and up hold relay

1

Check harness

between headlamp

relay and headlamp

motor

Replace headlamp

-.

timer

-

OK

Check up hold relay

1

lo

Check diodes

between light switch

and up hold relay

OK

between light switch

and headlamp motor

When turning light

switch to "PASSING", Replace headlamp

do headlamps open?

I

EL-30

Loading...

Loading...