Nissan 300zx Cooling Systems Section LC 1984 Owner's Manual

ENGINE LUBRICATION

&

i

SECTION

CONTENTS

ENGINE LUBRICATION SYSTEM

ENGINE LUBRICATION SYSTEM -Oil Pump

ENGINE LUBRICATION SYSTEM -Oil Pressure Relief Valve

ENGINE LUBRICATION SYSTEM

COOLING SYSTEM

COOLING SYSTEM -Water Pump

COOLING SYSTEM -Thermostat

-

COOLING SYSTEM

COOLING SYSTEM -Cooling Fan

COOLING SYSTEM

SERVICE DATA AND SPECIFICATIONS

SPECIAL SERVICE TOOLS

Radiator

-

Electric Cooling Fan for Turbocharger

-

Lubricating Oil Passage for Turbocharger

(S

D

S

1

COOLING

SYSTEMS

LC

LC-

2

LC-

4

LC-

6

LC-

7

LC-

8

1c-10

1c-11

1c-13

LC-

14

1c-15

1c-16

LC-I

8

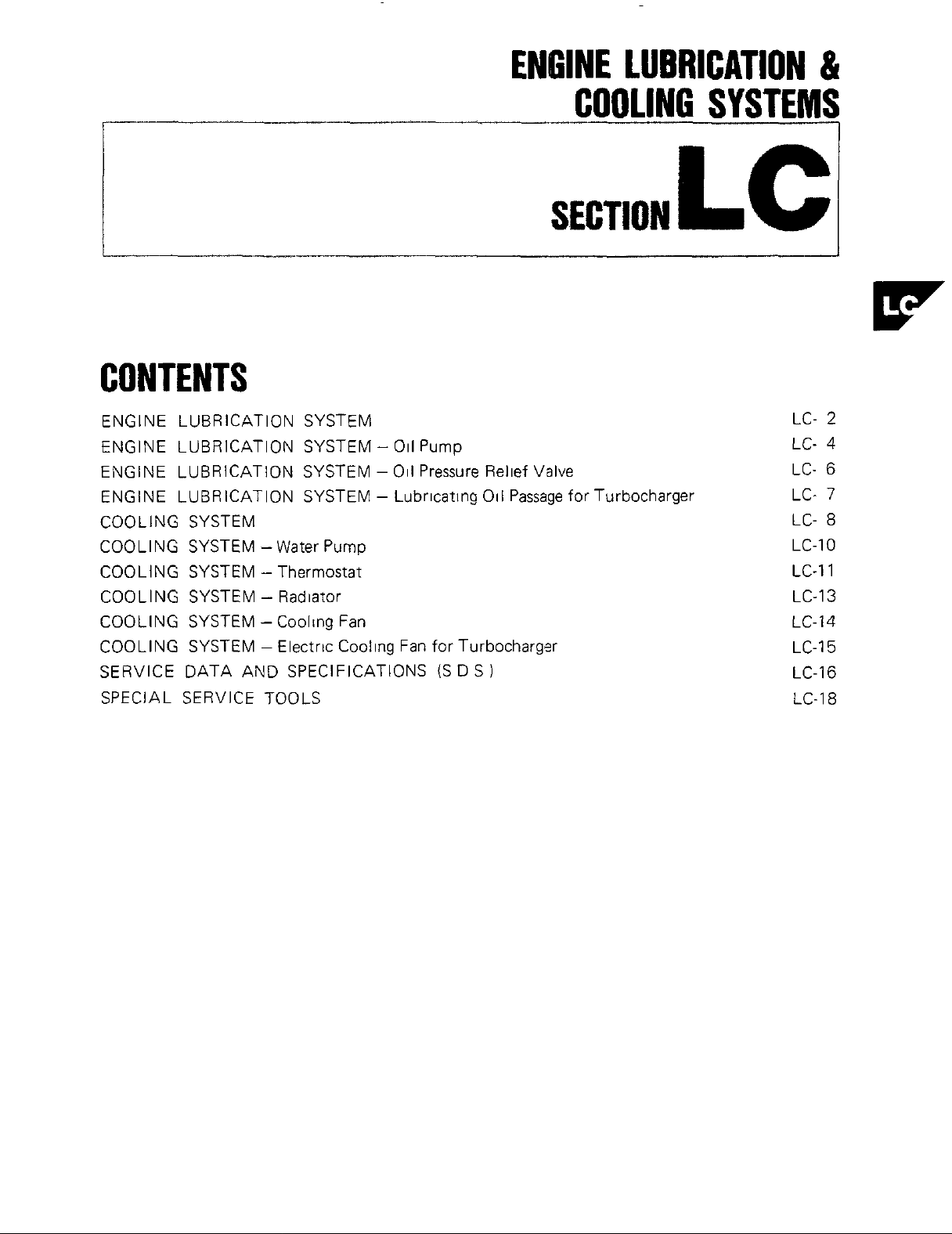

ENGINE LUBRICATION SYSTEM

Lubrication

Circuit

I--

i

r-il

Note

m

f---

011

parrage

011

gallery

in

cylinder

By-parr parrage

Additional lubrication

block

Maan

Crankshaft Cylinder head

CO""eCll"g

rod bearing

+

Piiton

and

cylinder

well

'1

011

gallery

Valve

lifier guide

011

gallery

e

Rockerrhaft Camshaft

+

Rocker

arm

-0

circuit

for

turbocharged model

Turbocharger

+

--/I--

Valve

hfter

1

1

011

pan

11

SLC544

LC-2

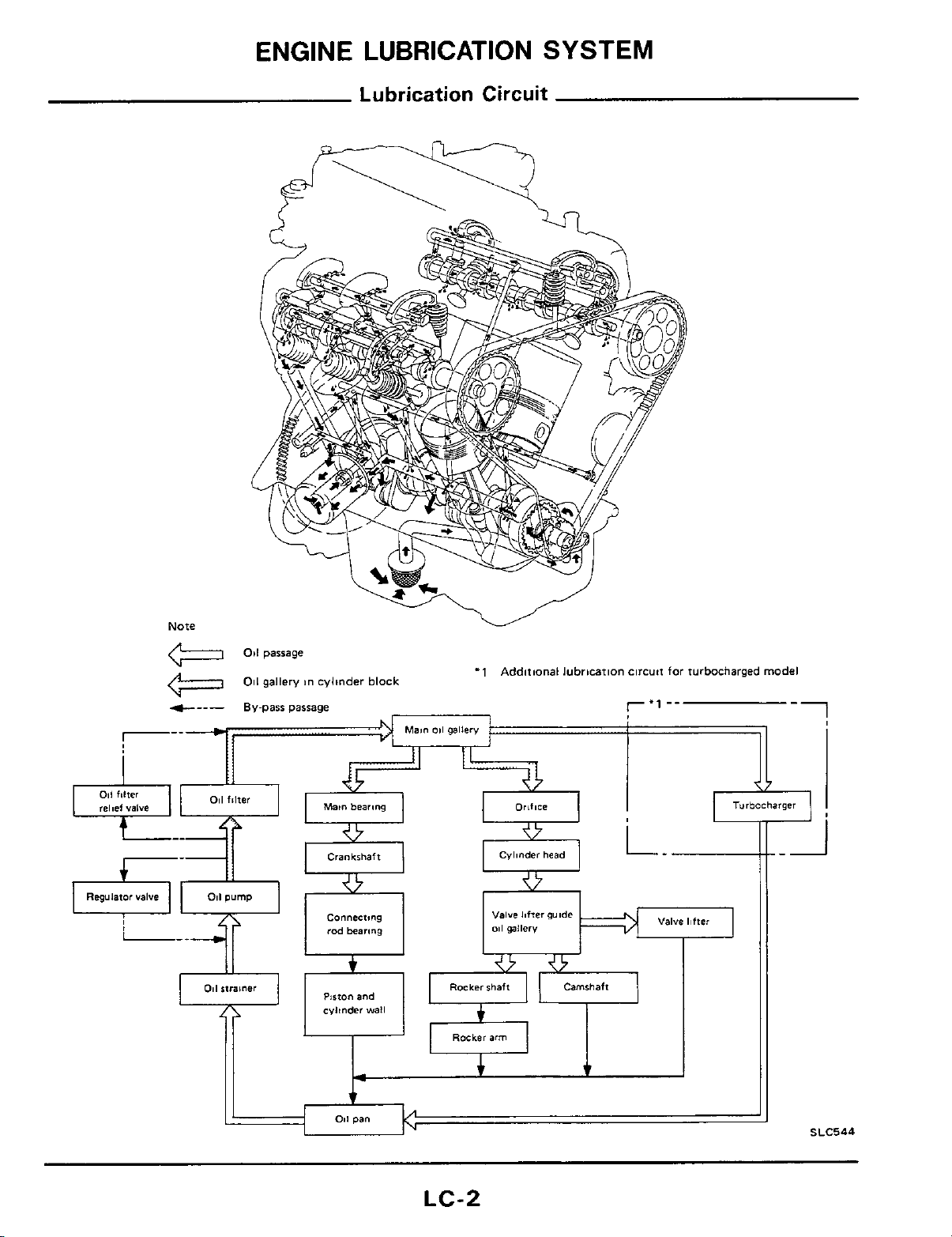

ENGINE

LUBRICATION

SYSTEM

Be

careful not

oil

may be hot

1

Warm up engine

Stop engine and remove

2

to

burn yourself, as the englne and

Oil Pressure Check

oil

pressure switch

SLC545

In-vehicle service)

The above table shows data tested when

1OW-30

77 and 83°C (171 and 181°F). Slight difference

will

perature

and

oil

is

used

and

oil

temperature

be

found because of oil viscosity

If

oil

pump for

difference

oil

is

extreme, check

leaks

or

is

between

oil

oil

passage

SAE

tem-

3

Install pressure gauge

Start engine and check

4

running under no-load

Engine rpm

1,200

2,000

i

Oil

than

4.000

pressure at

78

kPa (0.8 kg/cm2,

ST25051001

600

oil

pressure with engine

Approximate discharge pressure

I

rpm (Idling) should be

11

kPa

PSI)

(kglcm2,

196

294 (3.431

392

psi1

(2.281

(4.571

4

more

LC-3

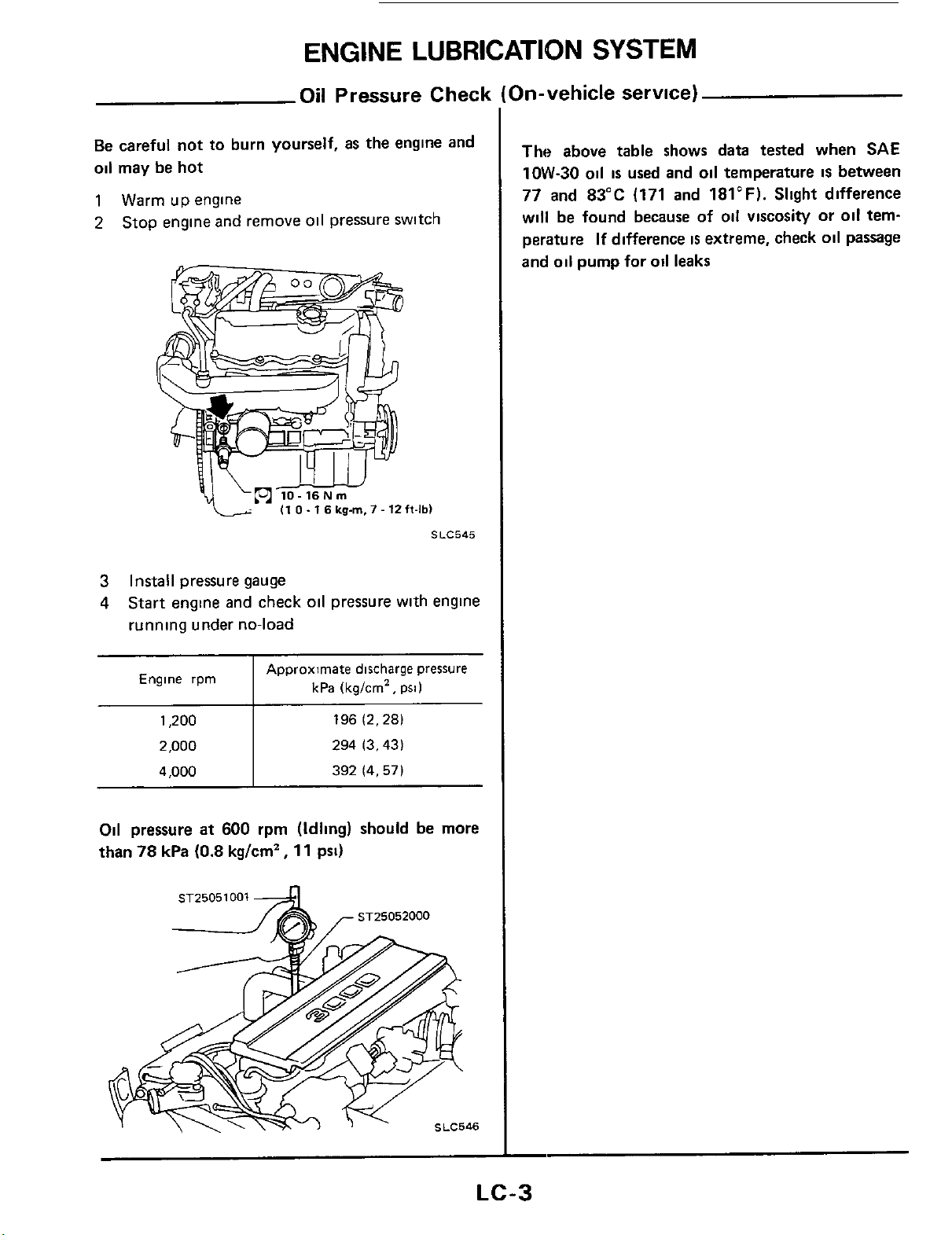

1.

Drain

2.

Remove

In

for removal

3.

Remove

case

ENGINE LUBRICATION SYSTEM

Disassembly and Assembly

1

oil.

oil

pan.

of

on-vehicle service, refer to

in

section

oil

pump assembly

EM

Oil

Pan

-Oil

IO

6.07.4.3-5 1

Pump-

Always replace

When installing

and outer gear.

Be

sure that O-ring

with

new

oil

seal and gasket.

oil

pump, apply engine

is

properly

fitted

on.

Front

oil

to inner

L(nl

12-16

11.2. 16.

9.121

I

N

rn

lkg-m

ft-lbl

SLC547

R

(1

6

-2

1.12-151

LC-4

R

4.5 I04

-05.2

R

9

N

-361

rn

Ikg-m

ft-lbl

SLC548

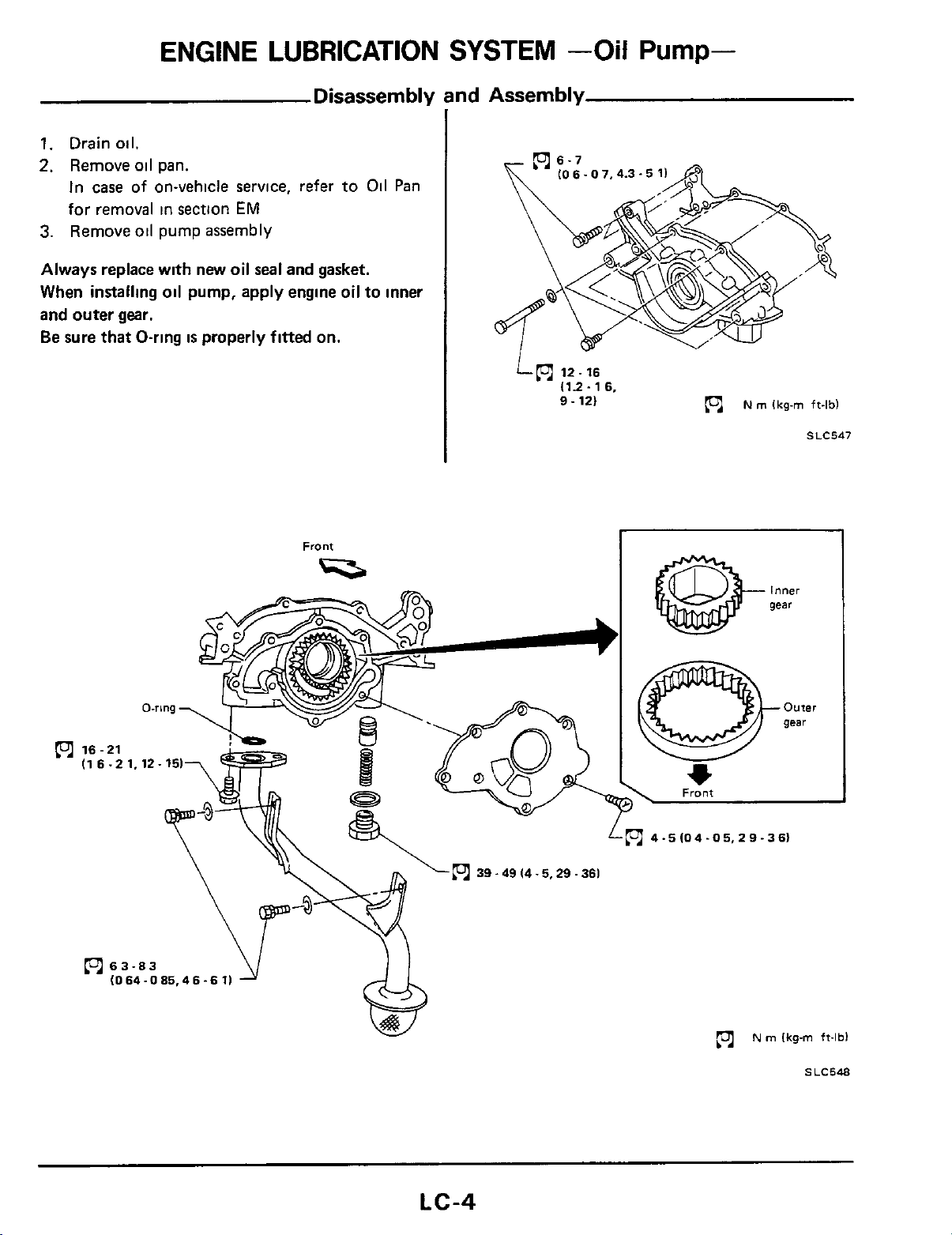

ENGINE

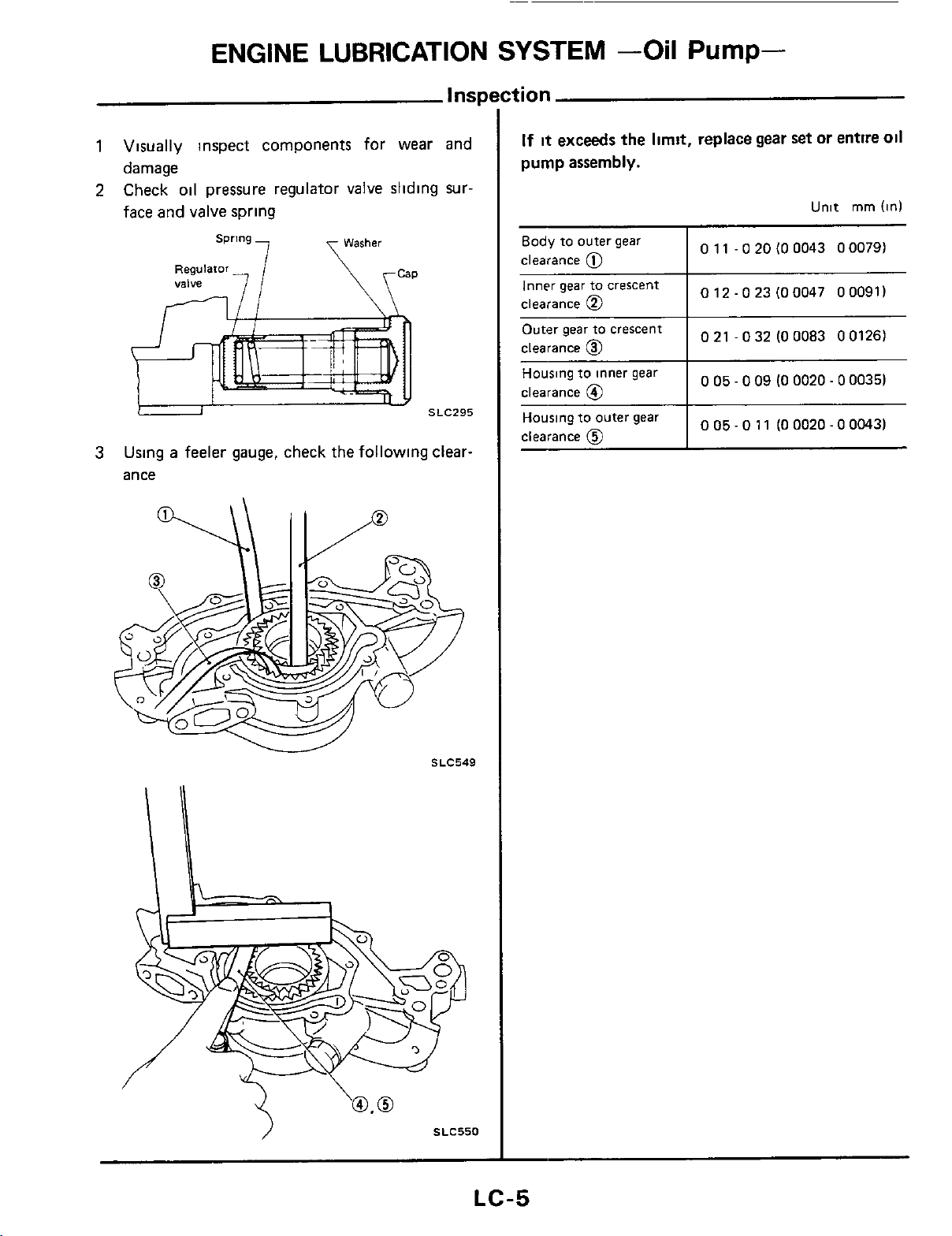

Visually inspect components for wear and

damage

oil

Check

face and valve spring

pressure regulator valve sliding sur-

Spr'ng

7

Regulalor,

valve

,/

LUBRICATION

\

Washer

SYSTEM

tion

If

it

exceeds the limit, replace gear set or entire

pump assembly.

Body

to

outer gear

clearance

(i7

-Oil

Pump-

I

011

-020(00043

Unit

rnrn

000791

oil

(in)

Using a feeler gauge, check

ance

the

following clear-

SLC295

Outer gear

to

crescent

0

21

-

0

32

(0

0083 0 0126)

SLC550

LC-5

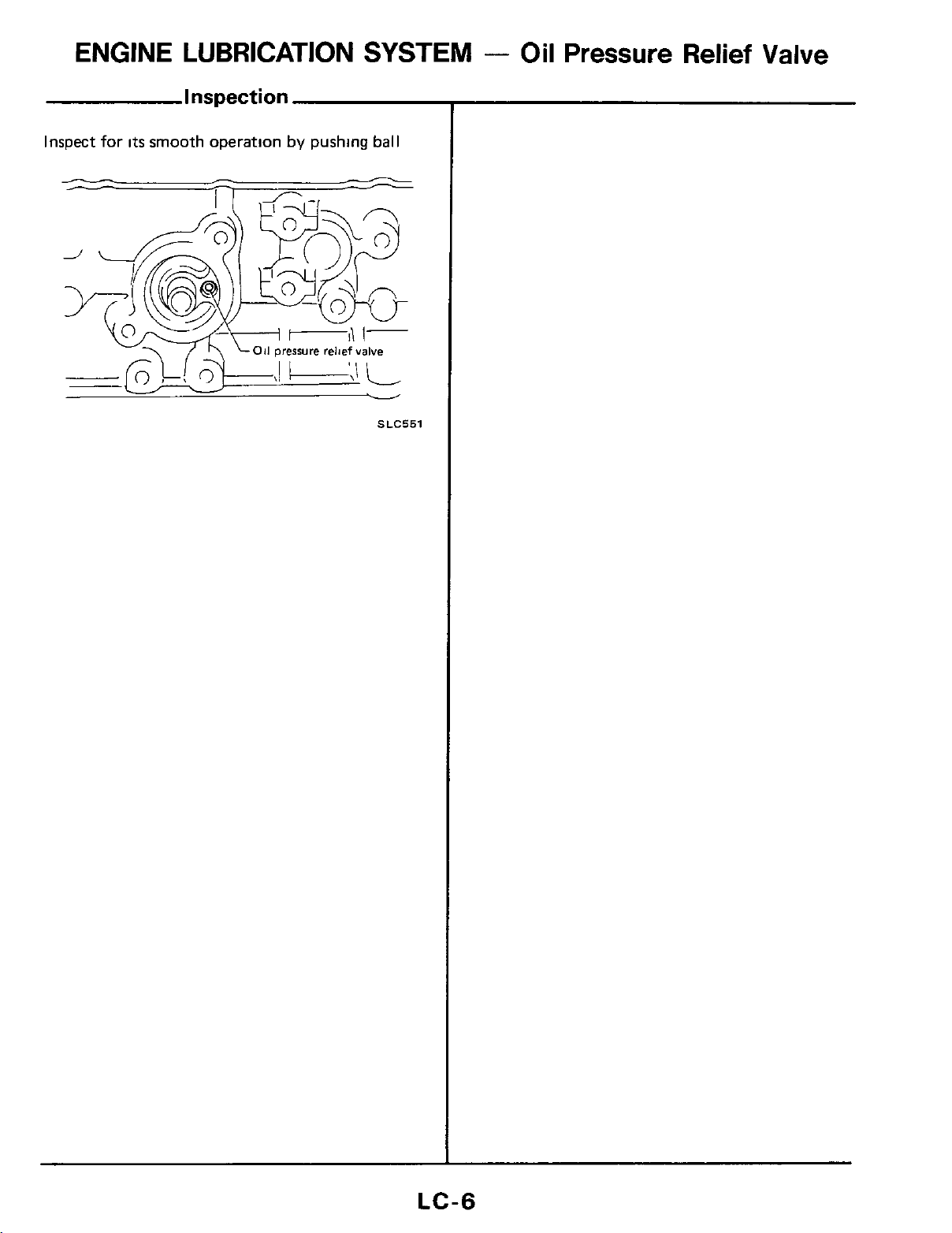

ENGINE LUBRICATION SYSTEM

Inspection

Inspect for

its

smooth

operation

by

pushing ball

1

-

Oil

Pressure Relief Valve

--

_A

SLC551

LC-6

Loading...

Loading...