Page 1

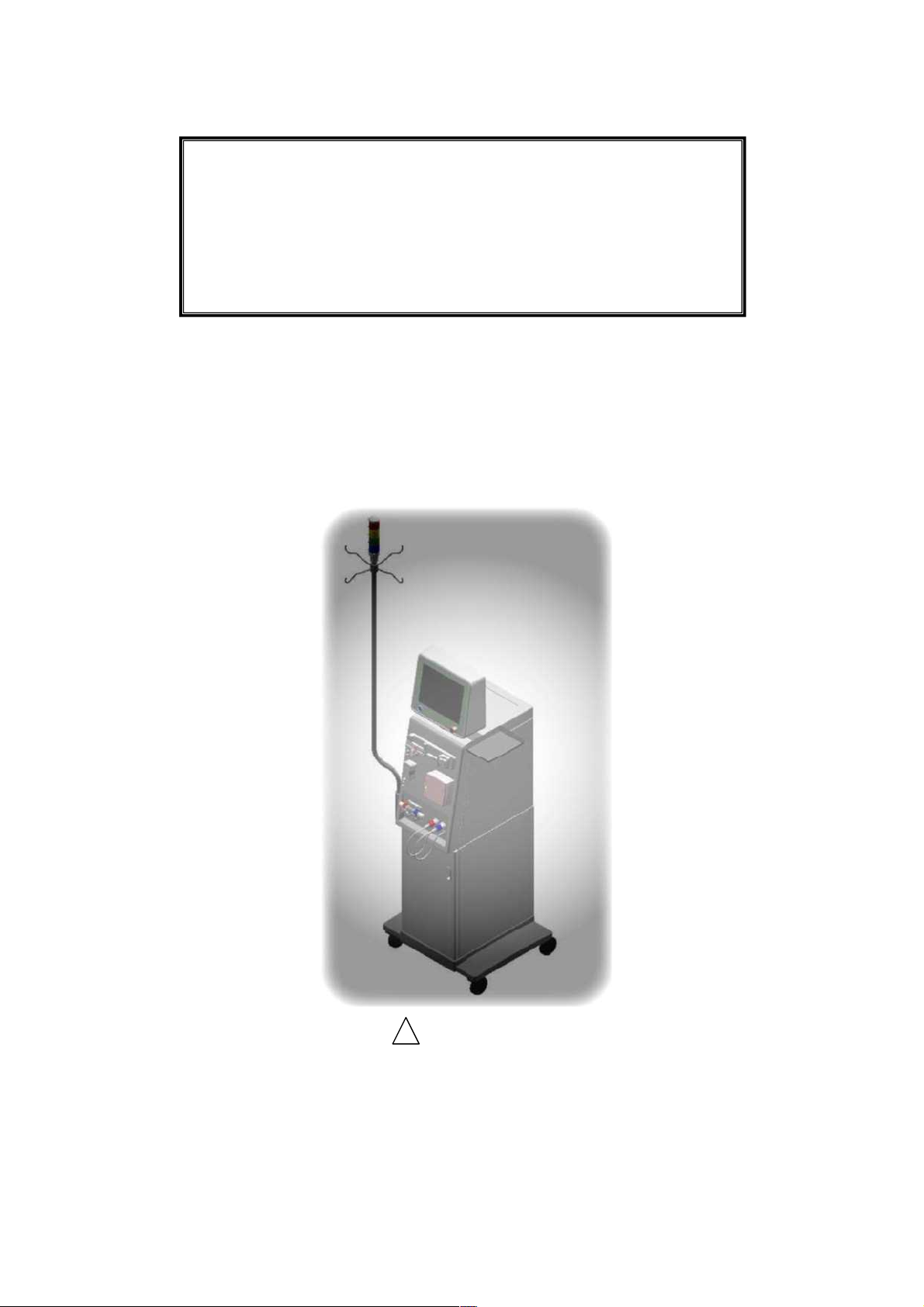

Single patient dialysis machine

SURDIAL 55Plus

Instruction Manual

-- M a i n t e n a n c e M a n u a l - -

!

CAUTION

Read this instruction manual carefully before use.

Improper handling can result in an accident or malfunction.

Use the unit in accordance with this manual.

Keep this manual in a safe place for future reference.

Original Instructions

Page 2

Page 3

Intended Use of This Machine

This machine should be used when physicians prescribe hemodialysis to patients with acute or

chronic renal failure.

Contraindications

This machine is not designed, manufactured, or sold for other use than hemodialysis on patients

with acute or chronic renal failure.

Attention should be paid to contraindications valid for extracorporeal treatment in general.

Safety

Equipment classification and handling precautions

This machine is classified as follows:

1

Type of protection from electric shock······Class I

2

Degree of protection from electric shock······Type B

Ensure to have a protective earth connection with the equipped power plug.

Precaution for fluid penetration

Keep the machine out of water.

Protection against water infiltration······Drip-proof equipment IPX1

Precaution for flammable atmospheres

Do no use this machine in flammable atmospheres..

Preface-1

Page 4

Safety Precautions

Appropriate operation and regular maintenance are essential for safe use of this machine.

Read and understand careful the safety precautions described in this manual before using or servicing

this machine.

The operating procedures and precautions described in this manual are effective only when this

machine is used for its intended purposes. Users shall be liable for all deeds and the safety measures

taken when the machine is used in methods other than specified in this manual.

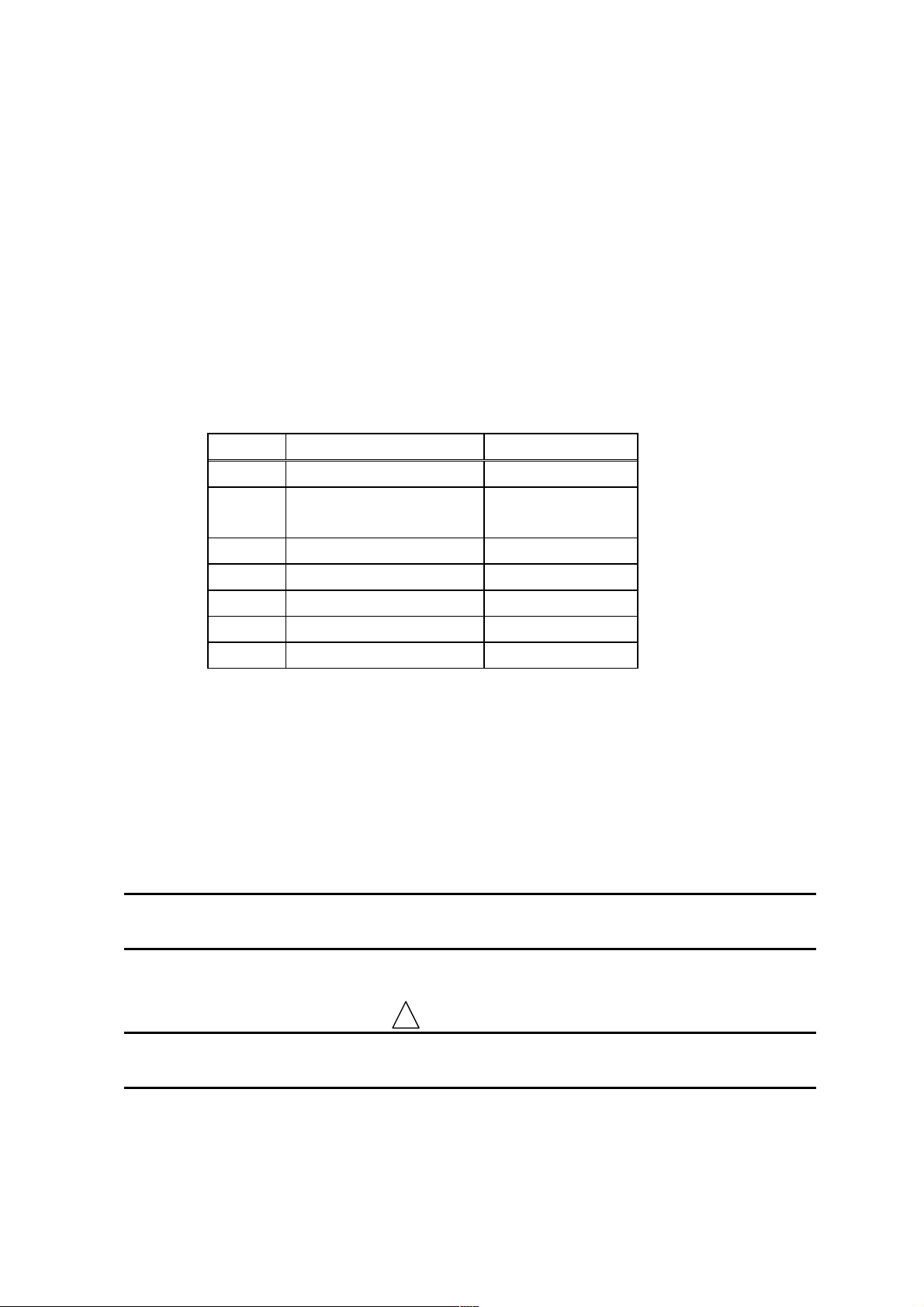

(1) Degree of damage to health and property, and its indication (Alert symbols and signal words)

The degree of the foreseeable damage to health and property when the machine is misused is

classified into the following three categories, and each category is expressed by the following alert

symbol and signal word.

!

DANGER

This indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

!

WARNING

It indicates a potentially hazardous which, if not avoided, could result in death or

injury.

!

CAUTION

This indicates a potentially hazardous, if not avoided, may result in moderate

injury or damage in property.

(2) Note and its indication

NOTE

Indicates note sentences. Make reference when operating or servicing the

machine.

Due to our constant research and improvement, details of the design of the machine described in

this manual may be slightly different from those of the unit you purchased. If you have any question

about the unit you purchased or contents of this instruction manual, please contact the nearest branch

or agency.

Preface-2

Page 5

Table of Contents

Intended Use of This Machine

Contraindications

Safety

Safety Precautions

1.····Installation Environment············································································1-1

1.1. Installation environment ··································································································1-2

1.2. Workspace required········································································································1-2

1.3. Electric power equipment································································································ 1-3

1.4. Water supply and drainage requirements ·······································································1-3

2.····Precautions for Maintenance·····································································2-1

2.1. Precautions before handling·························································································· 2-2

2.2. Handling the equipment ································································································ 2-2

2.3. Replacement parts ········································································································ 2-2

2.4. Liability for readjustment and repair ··············································································2-2

3.····Daily Inspection ··························································································3-1

3.1 Daily inspection by operator ·························································································· 3-2

3.2 Monthly inspection ········································································································ 3-2

3.3 Maintenance and inspection by Service Technician······················································ 3-2

3.4 Maintenance by Service Technician·············································································· 3-2

3.5 Inspection after a long-term storage·············································································· 3-2

4.····Maintenance and Inspection Instructions ················································4-1

4.1. Maintenance and inspection instructions······································································· 4-2

4.2. Instructions on the maintenance and inspection log······················································ 4-3

5.····Maintenance and Inspection Log ······························································5-1

6.····Maintenance and Inspection Manual ························································6-1

Table of Contents-1

Page 6

7.····Parts Replacement ·····················································································7-1

7.1 List of parts to be maintained and replaced··································································· 7-2

7.2 Parts replacement during maintenance········································································· 7-9

7.3 Miscellaneous part ········································································································ 7-48

7.4 Powder Bicarbonate Assy (option) ················································································ 7-50

7.5 Hot disinfection with citric acid Assy (option)································································· 7-55

8.····Terminology ································································································8-1

9.····Other Adjustments ·····················································································9-1

9.1 Zero compensation of the blood leak detector (BLD-01) ··············································· 9-2

9.2 Adjustment of Overload Sensitivity in Heparin Pump Assembly···································· 9-5

Table of Contents-2

Page 7

1. Installation Environment

1.1. Surrounding environment

1.2. Workspace required

1.3. Electric power equipment ··············································································· 1-3

1.3.1. For the 230V (AC) unit··············································································1-3

1.3.2. For the 110V (AC) unit··············································································1-3

1.4. Water supply and drainage requirements······················································ 1-3

1.4.1. Water supply pressure ··············································································1-3

1.4.2. Water supply flow ······················································································ 1-3

1.4.3. Water supply temperature ········································································· 1-4

1.4.4. Drainage ···································································································· 1-4

················································································ 1-2

························································································ 1-2

1-1

Page 8

The following conditions are required for the installation environment in order to use this

equipment safely and properly.

1.1. Surrounding environment

During operation

Storage and shipping

(with internal fluid)

Storage and shipping

(without internal fluid)

Surrounding temperature

Surrounding humidity (%)

(°C) 15 to 35 5 to 50 -10 to 50

35 to 80

(non condensing)

Air pressure (hPa)

Do not expose this equipment to direct sunlight.

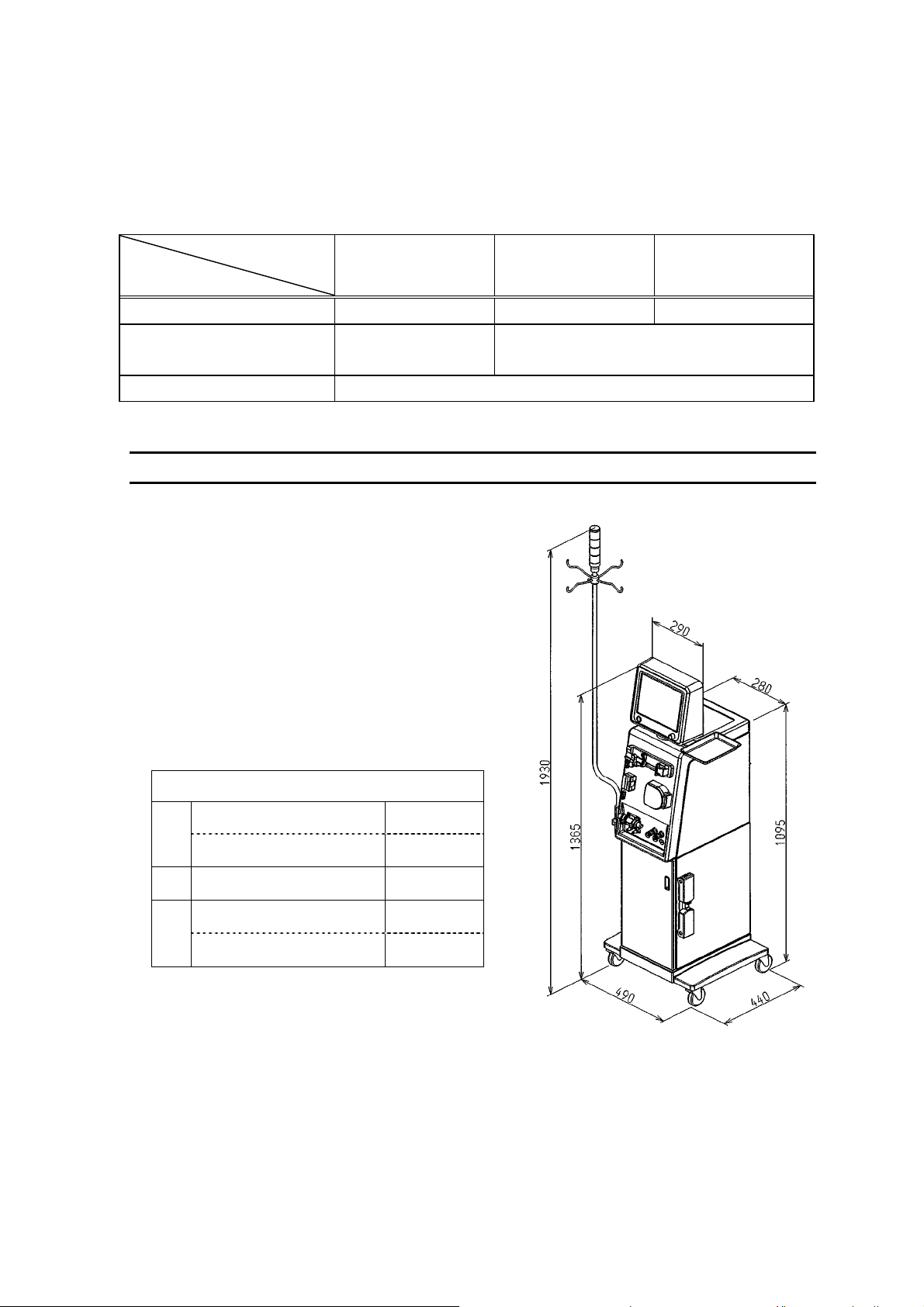

1.2. Workspace required

Prepare a space larger than 5cm, 10cm, and 20cm

above, each side, and back of the equipment,

respectively, with respect to the outside demension.

For ventilation, use a ventilation opening of larger

than φ20cm in diameter or avoid placing an object

next to at least one of the 5 open sides of the

equipment.

Outside demension of the equipment

35 to 85 (non condensing)

795 to 1062

NOTE

1-2

Top

290 mm

W

Wheel part

Wheel part

D

Excluding the infusion stand

490 mm

440 mm

1365 mm

H

Including the infusion stand

1930 mm

Figure 1-1 Outside dimensions of

the equipment

Page 9

1.3. Electric power equipment

1.3.1. For the 230V (AC) unit

The unit requires an 230 V (AC) ±10%, 50/60 Hz power source for proper operation.

A power outlet of 230 V (AC), 10 A or larger with protective earth is required for the standard

machine.

A power outlet of 230 V (AC), 15 A or larger with protective earth is required for the machine

with Hot Citric Option.

Be sure to connect the power plug properly.

1.3.2. For the 110V (AC) unit

The unit requires an 110 V (AC) ±10%, 50/60 Hz power source for proper operation.

A power outlet of 110 V (AC), 15 A or larger with protective earth is required for the standard

machine.

A power outlet of 110 V (AC), 20 A or larger with protective earth is required for the machine

with Hot Citric Option.

Be sure to connect the power plug properly.

!

WARNING

Do not use an AC power plug or adaptor that requires protective earth removal.

Do not use an adaptor for the equipment plug when connecting to the power outlet.

For any problem with the electric power equipment, contact an authorized electrician to check

the wiring.

1.4. Water supply and drainage requirements

Check the following to ensure the proper equipment operation.

1.4.1. Water supply pressure

The normal pressure between 0.05 and 0.74 MPa (0.5 to 7.5 kgf/cm2) is required.

1.4.2. Water supply flow

(1) Standard specification

The water supply flow must be 700 mL/min or higher.

(2) Hot Citric Assy, Variable Dialsate Flow Assy and Mass Flow Assy

The water supply flow must be 900mL/min or higher.

1-3

Page 10

1.4.3. Water supply temperature

(1) Standard specification

A range of 17 to 30°C is necessary.(4 to 30°C with the Heat Exchanger option)

The water supply temperature is minimum 5°C lower than the preset temperature of

dialysate.

(2) Hot disinfection with citric acid Assy, Variable control of dialysate flow Assy and high flow

Assy

A range of 14 to 30°C is necessary. (4 to 30°C with the Heat Exchanger option)

The water supply temperature is minimum 5°C lower than the preset temperature of

dialysate.

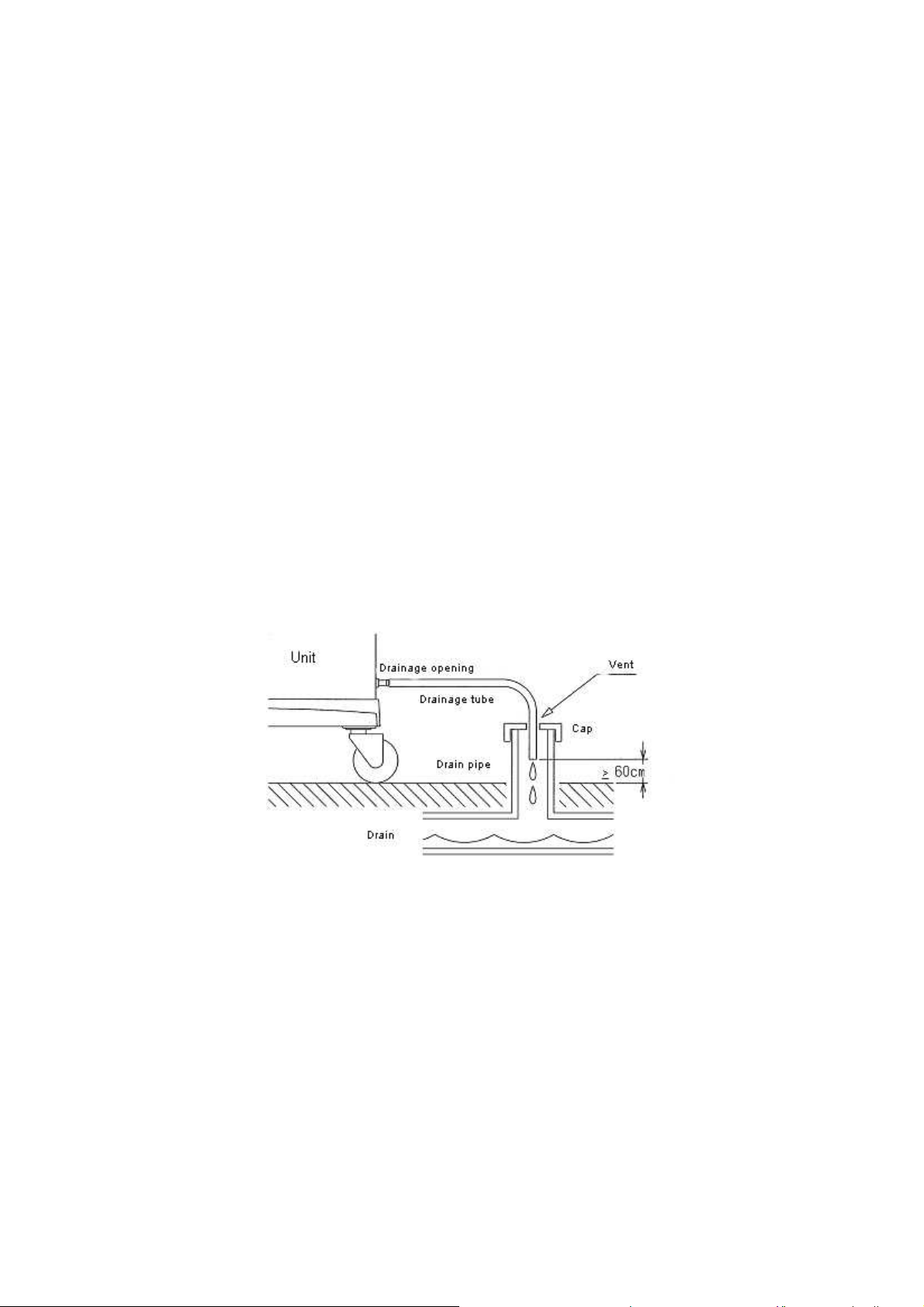

1.4.4. Drainage

Drainage flow must be 1500 mL/min or higher.

Keep the drainage tube 3 m or shorter.

The maximum height of the drain tube is 60 cm, with free outlet to avoid contamination.

1-4

Figure 1-2 Drainage

Page 11

2. Precautions for Maintenance

2.1. Precautions before handling··········································································· 2-2

2.1.1. Service technician····················································································2-2

2.1.2. Well-planned maintenance········································································ 2-2

2.1.3. Clothes ······································································································ 2-2

2.2. Handling the equipment·················································································· 2-2

2.3.

Replacement parts·························································································· 2-2

2.4. Liability for readjustment and repair·······························································2-2

2-1

Page 12

2.1. Precautions to be taken before handling

!

CAUTION

Do not connect the equipment to a patient during maintenance.

2.1.1. Service technician

Only Service technicians who received a technical training of dialysis machines from Nipro, are

allowed to maintain the machine.

Otherwise, a person who is being supervised by a trained technician , is allowed to maintain the

equipment.

2.1.2. Well-planned maintenance

Use of the equipment without planning maintenance, can decrease work efficiency and cause

injury, accident, and errors. It can also interfere with the original purpose, maintenance.

Schedule the time to maintain the equipment, and prepare necessary tools, parts, testing

equipment, and documents in advance.

2.1.3. Clothes

Try to minimize injury and accident by wearing appropriate clothes to work on the equipment.

Select clothes that do not attract a lot of electrostatics. Avoid exposing skin even if the

surrounding temperature is high.

2.2. Handling the equipment

Work in accordance with the instructions.

Read the attached Instruction Manual carefully.

Transport and handle the equipment in accordance with the Manual.

Be sure to check the electric power line, water supply/drainage line, and other connection lines

before working on the equipment.

2.3. Replacement parts

Use the parts specified by the manufacturer.

2.4. Liability for readjustment and repair

A person who readjusted or repaired is liable for consequential events.

2-2

Page 13

3. Daily Inspection

3.1 Daily inspection by operator··········································································· 3-2

3.2 Monthly inspection··························································································· 3-2

3.3 Maintenance and inspection by service technician······································· 3-2

3.4 Maintenance by service technician································································3-2

3.5 Inspection after a long-term storage······························································3-2

3-1

Page 14

!

CAUTION

Do not connect the equipment to a patient during maintenance.

3.1. Daily inspection by operator

Check the following items before and after using the equipment on the same day.

Ensure normal operation of the equipment.

Abnormality, such as leakage around the equipment.

Check loosening of clamps for the water supply opening and drainage opening hoses.

(1) There not being residual chemical solution.

(2) Residual quantities of disinfection or acetic acid solution being enough.

(3) Consumption of disinfection or acetic acid solution being reasonable.

(4) The real concentration of dialysate being reasonable.

(5) There not being abnormal sound, a bad smell, over heat.

(6) The filter of the fan not having blocking.

(7) Foreign substance such as disinfectant stain on the equipment exterior.

(8) Dialysate stain on the equipment. A dialysate stain can cause rust. Wipe it off

immediately.

(9) Abnormality when the start-up test is performed.

(10) If the equipment will be in operation overnight, ensure that the coupler is fit firmly on the

coupler holder.

(11) Confirm that the equipment detects the coupler switch signal.

(12) The syringe must be filled with the preset infusing volume.

3.2. Monthly inspection

Clean the air filter of the fan. (See 7.3.1., 7.3.2.)

3.3. Maintenance and inspection by service technician

Check the working hours. Perform a periodical inspection every 5000 hours or every 6 months.

See “5. Maintenance and Inspection Log” for items to be inspected.

3.4. Maintenance by service technician

Check the working hours. The service technician should maintain the hydrauric line and electrical

board every 5000 hours or every 6 months.

3.5. Inspection after long-term storage

Before starting dialysis treatment after more than 1 month of storage, a disinfection and a water

rinse of minimum 1 hour is required.

Also maintain and inspect the equipment in accordance with “4. Maintenance and Inspection

Instructions.”

3-2

Page 15

4. Maintenance and Inspection Instructions

4.1. Maintenance and inspection instructions······················································· 4-2

4.2. Instructions on the maintenance and inspection log····································· 4-3

4-1

Page 16

!

CAUTION

Do not connect the equipment to a patient during maintenance.

4.1. Maintenance and inspection instructions

The maintenance and inspection log shown in the next chapter is provided to record and keep

the results of maintenance and inspection. The log will help for the future maintenance and

management of the equipment. See “6. Maintenance and Inspection Manual” for the

maintenance and inspection methods. The person who maintains and inspects ( a service

technician or NIPRO personnel ) must record the results in accordance with the instructions

described in 4.2. Make a copy of this form before logging.

4-2

Page 17

4.2. Instructions on the maintenance and inspection log

(1) When to maintain and inspect

Items with the “6” symbol should be inspected every 6 months.

Items with the “6+” symbol should be inspected every 12 months.

(2) Record the model of the equipment.

(3) Record the serial number of the equipment.

(4) Record the duration of the equipment operation.

(5) Record the date when the equipment was installed.

(6) Record the date when the equipment was inspected.

(7) Record the name of the person who inspected.

(8) Enter the results of inspection into the boxes next to the inspection items, using the

following symbols:

Symbol Results of inspection Recording priority

No abnormalities found

X Exchanged 1

A Adjusted 2

T Tightened 3

C Cleaned 4

L Lubricated 5

If two or more maintenance works are performed per item, refer to the above table and use

the symbol with higher priority.

EXAMPLE) When an item is adjusted (A) and cleaned (C), enter “A” into the corresponding

box.

If inspection of an item requires disassembly, draw a circle around the symbol.

(9) Use the “Observation and Notes” column to write information, such as the part exchanged

during maintenance and inspection, when necessary.

Required disassembly for

inspection

NOTE

Execute maintenance and inspection, make sure to keep the maintenance record, and store the

record properly.

!

CAUTION

Dialysate and body fluid can cause infection. Never exchange parts before rinsing the hydraulic

lines.

4-3

Page 18

4-4

Page 19

5. Maintenance and Inspection Log

5-1

Page 20

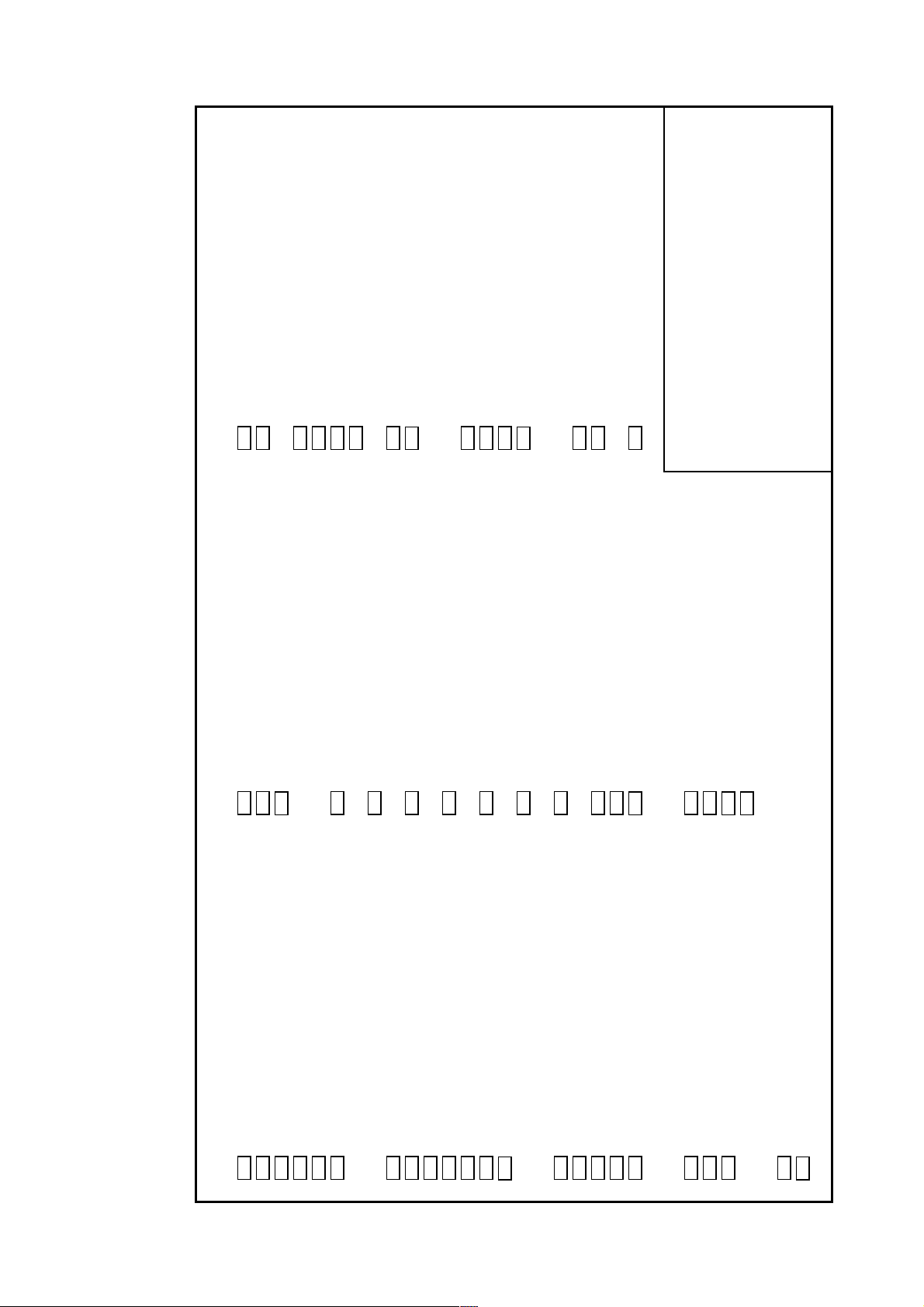

)

2

)

2

9.Other items to inspect

6.Heparin pump area

6 Dialysate flow rate

(STANDBY, DIALYSIS, RINSING)

(calibration for blood-leak detection)

between displayed and infused volumes

6 Blood leak alarm Stain, leakage, or blockage in filters

alarm

leak

Blood

Observation and Notes

5-2

displayed and actual flow volumes

, or blockage in filters (calibration of the dialysate pressure gauge) 6 Damage/deformation that interfere with functions

leakage

Maintenance and Inspection: 6-month inspection => 6 12-month inspection => 6+

Equipment model: Serial No. of the equipment: Duration of equipment operation:

Date of equipment installation: / / Date of inspection: / / Inspector:

Results of inspection (Inspected: , Disassembled: , Exchanged: X, Adjusted: A, Tightened: T, Cleaned: C, Lubricated: L)

Inspector’s signature:

6 Conditions of connection tubes (bending, etc.) 6 Movement of the heparin pump 6 Bending, leakage, staining, etc of tubes

6 Connection to the drain pipe 6 Loosening of the heparin pump pulley 6 Abnormal sound/smell

6 Presence of damage and connection of cables Consistency

6 Conditions of the grounding conductor 6 Presence of air bubbles in the hydraulic line

6 Damage/deformation that interfere with functions 7.Movements of monitoring and indication alarms 6 Leakage from the hydraulic line

1.Externals, connection tubes, and cables

6 Conditions of the light indicator 6 Temperature-related alarms 6 Filling flow rate (660 to 680 mL/min)

6 Conditions of tubes (bending, etc.) (calibration of concentration indication) 6 Dialysate flow rate

6 Movement of the solenoid valve 6 Venous pressure alarm Tightening the terminal block

6 Movement of the reducing valve (calibration of the venous pressure gauge)

(calibration of temperature indication) 6 Filling complete pressure

2.Water supply, concentrate feeder, and drainage areas 6 Dialysate concentration alarm 0.093 to 0.098 MPa (0.95 to 1.0 kgf/cm

6 Check of the degassing part 6 Arterial pressure alarm 10.Powder Bicarbonate Assy (Option)

6 Movement of the degassing tank (calibration of the arterial pressure gauge) 6 Movement of the solenoid valve

Stain,

6 Conditions of rinse ports 6 Dialysate pressure alarm 6 Bending, leakage, staining, etc of tubes

6 Movement of the solenoid valve 6 Tube error alarm 11.Variable control of dialysate flow Assy and hi Flow Assy (Option)

6 Flow meter display (movement of the air bubble detector) 6 Filling flow rate (880 to 950 mL/min)

6 Movement and leakage in concentrates/UF pumps 6 Insufficient water supply 6 Filling complete pressure

6 Movement during gas purge 6 Alarm buzzer 0.113 to 0.118 MPa (1.15 to 1.2 kgf/cm

3.Closed line area (movement of the blood leak detector)

6 Movement and adjustment during BYPASS

6 Movement of the solenoid valve 6 Short circuit breaker operation

6 Residual disinfectant/acid solution (option) 6 Capacity of the battery for power failure backup

4.Disinfectant/acid solution (option) feeder areas 8.Electric tests

6 Conditions of the tube (bending, etc.) Leakage current

Conditions of the equipment with grounding

between

Consistency

6 Loosening and abnormal sound in the rotating part

5.Blood pump area

Page 21

6. Maintenance and Inspection Manual

6-1

Page 22

3 m

60 cm.

<

Height at the tip of the drain tube:

(2) Length of the drain tube: <

(2) OK if the equipment functions normally

(3) Must not be damaged

(4) Must be connected to a 3P outlet (5) Must not be damaged/deformed

opening and dialyzer coupler must

be closed with a metallic band and

binding band, respectively.

(1) The water supply opening / Drainage

(1) OK if the equipment functions normally

ndicator movements is preset to “1”.

(6) The criteria is applied when the light

conditions

(6) Must light / blinking under the following

Red: lights during the alarm emergence

Yellow: blinking during the standby

process

Green: blinking during the rinse

process

Blue: blinking when timer comp

Exchange the tube with leakage

(1) OK if the equipment functions normally

(2) Must have the movement sound

6-2

Inspection item Inspection method Criteria Note

1. Externals, connection tubes, and cables (1) Conditions of connection tubes.

(1) Visual inspection.

(bending, etc.)

(2) Visual inspection.

(2) Connection to the drain pipe.

(3) Visual inspection.

of cables.

(3) Presence of damage and connection

(4) Visual inspection. (5) Visual inspection.

(4) Conditions of the grounding conductor.

(6) Visual inspection.

with functions.

(5) Damage/deformation that interfere

(6) Conditions of the light indicator.

(1) Visual inspection.

drainage areas

2. Water supply, concentrate feeder, and

(1) Conditions of tubes. (bending, etc.)

(2) Check the movement from MAINTE4.

(2) Movement of the solenoid valve.

Page 23

specified

2

(2) Only a standard specification.

20 mL/min

(4) Adjust using a pinchcock.

(5) Adjust using a pinchcock.

Only a standard specification.

310 mmHg)

(3) Must be 0.037 to 0.041 MPa (280 to

turn on V1, V4, V10 and (V35) from

(3) While water is supplied to the equipment,

MAINTE4. Leave them for approx. 30 sec

and turn OFF V4. Measure the pressure

between the reducing valve and V1.

(4) Must be the PO

(4) Collect the dialysate from the sample port

(5) Water should not exit from the air side

in the standby process.

process.

(5) Visual inspection during the standby

(6) No fluid leakage (7) Must have no stain, leakage, or

(6) Visual inspection during the rinse process. (7) Visual inspection.

blockage

(1) Movement sound must be audible

(1) Operate the equipment manually from

20 mL/min.

between BYPASS and RELE must be

<

coupler line during BYPASS.

(2) Changes in flow must be <

(3) Pumps rotate smoothly

MAINTE4.

process.

(2) Visual inspection during the standby

(3) Perform UF and inspect visually.

(4) Dialysate pressure must be –100 to 0

(4) Short line the FSW connector during the

mmHg

standby process and operate gas purge.

(5) Dialysate must be flowing into the

process.

(5) Visual inspection during the standby

Difference in flow meter displays

Inspection item Inspection method Criteria Note

concentrates/UF pumps.

(3) Movement of the reducing valve.

(4) Check of the degassing part.

(5) Movement of the degassing tank.

(6) Conditions of rinse ports. (7) Stain, leakage, or blockage in filters. 3. Closed line area (1) Movement of the solenoid valve.

(2) Flow meter display.

(3) Movement and leakage in

(4) Movement during gas purge.

BYPASS.

(5) Movement and adjustment during

6-3

Page 24

0.1 ppm.

(2) Use water and measure the flow

volume per min with an electric

balance.

Grease No.: MOLYKOTE

(1) Apply grease on the feed screw part.

BR2 Plus Grease (Dow Corning)

(3) Adjust from MAINTE6 “SYRINGE

RATIO,” if the difference is larger.

10%.

(1) Movement sound must be audible.

MAINTE4.

(1) Operate the equipment manually from

have abnormal sound.

(2) Residual chlorine must be <

min before the water rinse ends in the

(2) Collect a sample from the drain opening 5

(3) OK if the equipment functions normally.

disinfection process.

(3) Visual inspection.

(1) The rotating part should not be loose or

(1) Check the externals and sound.

volume must be 126 to 154 mL/min.

(2) When the display is 140, actual flow

blood line.

(2) Measure the actual flow volume using the

When the display is 330, the actual flow

volume must be 297 to 363 mL/min.

(1) Must move smoothly.

system.

(1) Push the pusher manually to free the

(2) OK if not loose. (3) The difference between the actual and

(2) Tighten the set screw on the pulley. (3) Install a syringe pump with filled with water

preset infusing volumes must be <

and operate at 9.9 mL/hr for 60 min.

6-4

Inspection item Inspection method Criteria Note

areas

4. Disinfectant/acid solution (option) feeder

(1) Movement of the solenoid valve.

(option)

(2) Residual disinfectant/acid solution.

(3) Conditions of the tube. (bending, etc.)

5. Blood pump area (1) Loosening and abnormal sound in the

rotating part.

actual flow volumes.

(2) Consistency between displayed and

6. Heparin pump area

(1) Movement of the heparin pump.

(2) Loosening of the heparin pump pulley. (3) Consistency between displayed and

infused volumes.

Page 25

±0.5 °C.

(1) Difference must be <

2 mEq/L.

out of range.

(2) Difference must be <

(3) Alarm is active when the current level is

out of range.

(4) Alarm is active when the current level is

out of range.

(5) Alarm is active when the current level is

(6)Real Blood leak value must be <150.

(7) Alarm is active.

(8) Alarm is active

(9) OK if buzzer sound is normal. (10) The Real blood leak value is the total

of the specified value of the dummy

simulated filters ±80 ppm.

Turn on the BUBBLE

temperatures in the preparation process.

(1) Compare preset and displayed

(2) Compare displayed and actual

concentration in the preparation

process.

(3) Change the alarm range manually in

Dialysis waiting process.

(4) Change the alarm range manually in

Dialysis waiting process.

(5) Change the alarm range manually in

Dialysis waiting process.

(6) Set the temperature to 36.5 °C in the

preparation process. Read theReal blood

leak value in MAINTE MODE1.

detector.

(7) Remove the tube from the air bubble

DETECTOR switch.

(8) Operate the equipment after decreasing

the water supply to a insufficient level.

the Real blood leak value in MAINTE1.

(9) Check the buzzer sound. (10) Install a simulated blood leak filter. Read

Inspection item Inspection method Criteria Note

(calibration of blood-leak detection)

(calibration of temperature indication)

(1) Temperature-related alarms.

alarms

7. Movements of monitoring and indication

(calibration of concentration indication)

(2) Dialysate concentration alarm.

(calibration of the venous pressure gauge)

(3) Venous pressure alarm.

(calibration of the arterial pressure gauge)

(4) Arterial pressure alarm.

(calibration of the dialysate pressure gauge)

(5) Dialysate pressure alarm.

(movement of the blood leak detector)

(6) Blood leak alarm.

(movement of the air bubble detector)

(7) Tube error alarm.

(8) Insufficient water supply.

(9) Alarm buzzer. (10) Blood leak alarm.

6-5

Page 26

mL/min.

(2) Set the blood pump flow at 150

Set the heparin pump flow at 2.0

mL/h.

Start after charging for 48 hrs.

A new battery allows approx. 30 min

of operation with full charge. The

battery gradually deteriorates

although there is no power failure.

(3) The jig to measure leakage current is

necessary.

The standard of the jig must be in

accordance with JIS-T-1002.

OFF.

(4) The power breaker must be turned

(1) OK if power supply shuts off.

circuit breaker.

(1) Operate the switch to check the short

must operate for >20 min.

(2) The blood pump and heparin pump

and air bubble detector. Turn on the

(2) Attach the blood line on the blood pump

NOTE: It must operate for 20 min,

BLOOD PUMP, HEPARIN PUMP and

considering the time it takes to

complete blood collection in case of

BUBBLE DETECTOR switches. Turn off

the equipment breaker. Mute the buzzer by pressing the

0.5 mA.

The blood pump must stop when the

power failure. This time frame may

vary, depending on the age of the

battery. Exchange the battery if

necessary. Check the following function:

MUTE/RESET switch.

At the same time, check:

sensor detects air bubbles.

· Air bubble detector is on

Remove the blood line from the air bubble

detector.

· Air bubble detector

(3) OK if <

(3) Connect the jig to measure leakage

current to the equipment. Measure the

current in the protective earth conductor

(the grounding conductor of the power

1 Ω.

(4) OK if <

plug) during normal operation.

(4) Use a tester to measure the resistance

between the chamber frame and the

grounding terminal.

6-6

Inspection item Inspection method Criteria Note

backup.

8. Electric tests (1) Short circuit breaker operation.

(2) Battery capacity for power failure

(3) Leakage current.

grounding.

(4) Conditions of the equipment with

Page 27

) when filling is

2

Inspection item Inspection method Criteria Note

tubes. Exchange the tube with leakage.

9. Other items to inspect

(1) Bending, leakage, staining, etc. of (1) Visual inspection. (1) OK if the equipment functions normally.

DIALYSIS, RINSING) present.

(2) Abnormal sound/smell. (STANDBY, (2) Check sounds and smells. (2) OK if no abnormal sounds/smell are

hydraulic line. process.

(3) Presence of air bubbles in the (3) Visual inspection during the standby (3) No air bubbles in the hydraulic line

(4) Leakage from the hydraulic line. (4) Perform the start-up test or the CHECK (4) Test must be completed without a

operation from MAINTE7. problem.

(5) Filling flow rate. (5) In the standby process, measure the (5) Drainage flow rate must be 660 to (5) The system should not complete

drainage flow rate after installing the 680 mL/min. filling within 40 sec.

flow gauge onto the drainage line. Only a standard specification.

(Drainage flow rate: 500 mL/min)

(6) Filling complete pressure. (6) Measure the pressure on the P4- (6) The pressure must be 0.093 to 0.098 (6) Only a standard specification.

discharge side. (FS1-OUT side) Mpa (0.95 to 1.0 kgf/cm

complete.

(7) Dialysate flow rate. (7) Measure the MAX dialysate flow rate. (7) The MAX dialysat flow must be (7) Only a standard specification.

700 mL/min.

(8) Tightening the terminal block. (8) Check the tightening. (8) OK if not loose. (8) The power breaker must be turned

OFF.

6-7

Page 28

) when filling

2

6-8

Inspection item Inspection method Criteria Note

tubes. Exchange the tube with leakage.

10. Powder Bicarbonate Assy (Option)

(1) Movement of the solenoid valve. (1) Check the movement from MAINTE4. (1) Must have the movement sound

(2) Bending, leakage, staining, etc. of (2) Visual inspection. (2) OK if the equipment functions normally.

with functions.

(3) Damage/deformation that interfere (3) Visual inspection. (3) Must not be damaged/deformed

(4) Stain, leakage, or blockage in filters. (4) Visual inspection. (4) Must have no stain, leakage, or

and hi flow Assy (Optional)

blockage

11. Variable control of dialysate flow Assy

(1) Filling flow rate. (1) In the standby process, measure the (1) Drainage flow rate must be 890 to (1) The system should not complete

drainage flow rate after installing the 950 mL/min. filling less than 32 sec.

flow gauge onto the drainage line.

(Drainage flow rate: 500 mL/min)

(2) Filling complete pressure. (2) Measure the pressure on the P4- (2) The pressure must be 0.113 to 0.118

discharge side. (FS1-OUT side) Mpa (1.15 to 1.2 kgf/cm

is complete.

(3) Dialysate flow rate. (3) Measure the MAX level of the dialysate (3) The MAX level must be 800 mL/min.

flow rate.

Page 29

7-1

7. Parts Replacement

7 Parts Replacement ······················································································7-1

7.1 List of parts to be maintained and replaced·················································7-3

7.2 Parts replacement during maintenance·······················································7-8

7.2.1 Water supply filter Assy (F1) ································································7-8

7.2.2 Two-way solenoid valve (V1,V4,V5a,V5b,V6a,V6b,V7a,V7b,V8a

V8b,V9a,V9b,V10,V11,V19,V21)·················7-9

7.2.3 Two-way solenoid valve (V12) ·····························································7-10

7.2.4 Temperature sensor Assy (T) ·······························································7-11

7.2.5 Dialysate pressure sensor Assy (PD)···················································7-12

7.2.6 Conductivity sensor Assy (CD)·····························································7-13

7.2.7 Degassing tank Assy (AS1)··································································7-14

7.2.8 Air elimination tank Assy (AS2) ····························································7-15

7.2.9 Buffer tank Assy····················································································7-17

7.2.10 Magnet gear pump (P1/P2)··································································7-19

7.2.11 Heparin pump Assy (HP)······································································7-23

7.2.12 Blood pump Assy (BP) ·········································································7-26

7.2.13 Sample port Assy (SL)··········································································7-27

7.2.14 Rinse port ·····························································································7-28

7.2.15 Joint of concentrate tank ······································································7-30

7.2.16 Flow sensor Assy (FS1) ·······································································7-32

7.2.17 Flow sensor Assy (FS2/FS4)································································7-33

7.2.18 Coupler Assy ························································································7-34

7.2.19 Blood leak detector Assy (BLD) ···························································7-35

7.2.20 Chamber Assy (Ca/Cb) ········································································7-36

7.2.21 Ultrafiltration pump Assy (UFP)····························································7-37

7.2.22 Pump for A concentrate Assy (P3) ·······················································7-39

7.2.23 Pump for B concentrate Assy (P4) ·······················································7-41

7.2.24 Relief valve Assy (RV)··········································································7-43

7.2.25 Clamp Assy (CLV) ················································································7-44

7.2.26 Other hydraulic components ································································7-46

7.3 Miscellaneous part·······················································································7-47

7.3.1 Air filter··································································································7-47

7.3.2 Air filter 2 ······························································································7-48

7.4 Powder Bicarbonate Assy (option) ······························································7-49

7.4.1 Powder Bicarbonate Cartridge Holder Assy·········································7-49

7.4.2 B powder concentrate air elimination tank Assy (AS3) ························7-51

7.4.3 Pump for B concentrate Assy (P4)·······················································7-52

7.5 Hot disinfection with citric acid Assy (option)···············································7-54

7.5.1 Two-way solenoid valve (V4,V9a,V9b,V11,V19,(V34),(V35))··············7-54

7.5.2 Two-way solenoid valve (V5b,V6a,V6b,V7b,V8a,V8b) ························7-55

7.5.3 Two-way solenoid valve (V5a,V7a)······················································7-56

7.5.4 Two-way solenoid valve (V10) ·····························································7-57

7.5.5 Relief solenoid valve ((V33)) ································································7-58

7.5.6 Conductivity sensor Assy (CD)·····························································7-59

7.5.7 Degassing tank Assy (AS1)··································································7-60

7.5.8 Air elimination tank Assy (AS2) ····························································7-61

7.5.9 Buffer tank Assy····················································································7-63

7.5.10 Magnet gear pump (P1/P2)··································································7-65

7.5.11 Sample port Assy (SL)··········································································7-69

7.5.12 Rinse port ·····························································································7-70

7.5.13 Joint of concentrate tank ······································································7-71

7.5.14 Chamber Assy (Ca/Cb) ········································································7-72

Page 30

7-2

7.5.15 Ultrafiltration pump Assy (UFP)····························································7-74

7.5.16 Pump for A concentrate Assy (P3) ·······················································7-76

7.5.17 Pump for B concentrate Assy (P4) ·······················································7-78

7.5.18 Relief valve Assy (RV)··········································································7-79

7.5.19 Other hydraulic components ································································7-80

7.5.20 Air filter 3 ······························································································7-81

Page 31

7-3

7.1. List of parts to be maintained and replaced

Approximate time to

replace

Code Name of ASSY/Part

Model No. Code No. qty

2 yr Ad libitum

Note

Water supply filter

Assy

93532000 4-030-060 1

1) Filter FI116ATERP265A00 0-201-213 1

F1

2) Packing 01939900124 4-030-066 1

CL filter SSM-3010 0-501-112 1

F2

Coupler line filter SAS-08061 0-501-218 (1)

Option <H>

Two- way s olenoid valve SV2-322-S 2-006-008 2

1) Diaphragm D3A540 0-501-117 2

Best if replace yearly.

V1

V21

2) Valve body D3B1810 0-501-118 2

Two- way s olenoid valve SV2-322-S 2-006-008 1

1) Diaphragm D3A540 0-501-117 1

Best if replace yearly.

2) Valve body D3B1810 0-501-118 1

Two- way s olenoid valve SV2-322-SHW 0-501-126 (1)

Option <H>

1) Diaphragm D3A540 0-501-117 (1)

Best if replace yearly.

V10

2) Valve body D3B1810 0-501-118 (1)

Two- way s olenoid valve SV2-322-S 2-006-008 5 (8)

Option <P><C>

1) Diaphragm D3A540 0-501-117 5 (8)

Best if replace yearly.

2) Valve body D3B1810 0-501-118 5 (8)

Two- way s olenoid valve SV2-422-S 0-501-120 5 (8)

Option <H><P><C>

1) Diaphragm D4A350 0-501-121 5 (8)

Best if replace yearly.

2) Valve body D4B1000 0-501-122 5 (8)

V4

V9a

V9b

V11

V19

(V22)

(V27a)

(V27b)

(V28a)

(V28b)

(V29)

(V30)

(V31)

Two- way s olenoid valve SV2-322-S 2-006-008 6

1) Diaphragm D3A540 0-501-117 6

Best if replace yearly.

2) Valve body D3B1810 0-501-118 6

Two- way s olenoid valve SV2-422-SH 0-501-123 (6)

Option <H>

1) Diaphragm D4A350

0-501-121 (6)

Best if replace yearly.

V5b

V6a

V6b

V7b

V8a

V8b

2) Valve body D4B1021

0-501-124 (6)

Two- way s olenoid valve SV2-322-S 2-006-008 2

1) Diaphragm D3A540 0-501-117 2

Best if replace yearly.

2) Valve body D3B1810 0-501-118 2

Two- way s olenoid valve SV2-422-SHP 0-501-125 (2)

Option <H>

1) Diaphragm D4A350

0-501-121 (2)

Best if replace yearly.

V5a

V7a

2) Valve body D4B1021

0-501-124 (2)

Two- way s olenoid valve SV2-422-S 0-501-120 1 (1)

Option <A>

1) Diaphragm D4A350 0-501-121 1 (1)

Best if replace yearly.

V12

(V17)

2) Valve body D4B1000 0-501-122 1 (1)

Two- way s olenoid valve SV2-322-S 2-006-008 (1)

Option <P>

1) Diaphragm D3A540 0-501-117 (1)

Best if replace yearly.

2) Valve body D3B1810 0-501-118 (1)

Relief solen oid valve

SV2-322S13-SRHW 0-501-127 (1)

Option <H>

1) Diaphragm D3A540 0-501-117 (1)

Best if replace yearly.

(V33)

2) Valve body D3B1810 0-501-118 (1)

*1) Hot disinfection with citric acid Assy : <H>

*2) Powder Bicarbonate Assy : <P>

*3) Acid-Rinsing Port Assy : <A>

*4) CF flashing unit : <C>

Page 32

7-4

Approximate time to

replace

Code Name of ASSY/Part

Model No. Code No. qty

2 yr Ad libitum

Note

Two- way s olenoid valve SV2-422-S 0-501-120 (1)

Option <H>

1) Diaphragm D4A350 0-501-121 (1)

Best if replace yearly.

(V34)

2) Valve body D4B1000 0-501-122 (1)

Two- way s olenoid valve SV2-322-S 2-006-008 (1)

Option <P>

1) Diaphragm D3A540 0-501-117 (1)

Best if replace yearly.

2) Valve body D3B1810 0-501-118 (1)

Two- way s olenoid valve SV2-422-S 0-501-120 (1)

Option <H>

1) Diaphragm D4A350 0-501-121 (1)

Best if replace yearly.

(V35)

2) Valve body D4B1000 0-501-122 (1)

SAS-08019 0-504-170 1

T1

SAS-08020 0-504-171 1

T2

SAS-08021 0-504-172 1

T3

Temperature sensor

Assy TYPE A

SAS-08022 0-504-173 (1)

T7 Option <H>

T1

T2

T3

(T7)

1) Sensor holder 9389 2511 0-504-022 3 (1)

Dialysate pressure

sensor Assy

PD-02 0-504-024 1

1) O-ring S-16 0-504-026 1

Replace when disassembled

PD

2) Manifold 93882911 0-504-025 1

SAS-08027 0-504-156 1

CD1

SAS-08028 0-504-157 1

CD2

Conductivity sensor

Assy

SAS-08029 0-504-158 (1)

CD3 Option <P>

1) O-ring P3 2-002-058 6 (3)

2) Sensor holder 9366 3814 0-504-002 2 (1)

9036V336100 0-504-159 1

T4

9036V337100 0-504-160 1

T5

3) Temperature

sensor

9036V453100 0-504-161 (1)

T6

4) O-ring P4 0-504-006 2 (1)

SAS-08030 0-504-161 1

CD1 Option <H>

SAS-08031 0-504-162 1

CD2 Option <H>

Conductivity sensor

Assy

SAS-08032 0-504-163 (1)

CD3 Option <H><P>

1) O-ring P3 2-002-058 6 (3)

2) Sensor holder 90403814001 0-504-164 2 (1)

9036V336100 0-504-167 1

T4

9036V337100 0-504-168 1

T5

3) Temperature

sensor

9036V453100 0-504-169 (1)

T6

CD1

CD2

(CD3)

T4

T5

(T6)

4) O-ring P4 0-504-006 2 (1)

Degassing tank Assy 93612300 0-501-015 1

1) O-ring G50 9-001-121 1

Replace when disassembled

Degassing tank Assy 90402300 0-501-149 (1)

Option <H>

AS1

1) O-ring G50 9-001-121 (2)

Replace when disassembled

Air eliminati on tank Assy 93532400 0-501-024 1

1) Float OLV-2P-1 (special) 0-201-018 1

Best if replace yearly.

2) O-ring G50 9-001-121 2

3) Packing 01930200088 0-201-016 1

Air eliminati on tank Assy 90402400 0-501-149 (1)

Option <H>

1) Float OLV-5 (special) 0-501-153 (1)

Best if replace yearly.

2) O-ring G50 9-001-121 (2)

AS2

3) Packing 01930200088 0-201-016 (1)

*1) Hot disinfection with citric acid Assy : <H>

*2) Powder Bicarbonate Assy : <P>

Page 33

7-5

Approximate time to

replace

Code Name of ASSY/Part

Model No. Code No. qty

2 yr Ad libitum

Note

B powder c onc entrate

air elimin ation tank As sy

90369700 0-501-154 (1)

Option <P>

(AS3)

1) Packing 90364413001 0-501-156 (1)

Replace when disassembled

BTW Assy 93613500 0-501-037 1

1) O-ring G70 9-001-123 1

Replace when disassembled

BTW Assy 90403500 0-501-164 (1)

Option <H>

BTW

1) O-ring G70 9-001-123 (1)

Replace when disassembled

BTD Assy 93613500 0-501-037 1

1) O-ring

G70

9-001-123 1

Replace when disassembled

BTD Assy 90404500 0-501-165 (1)

Option <H>

BTD

1) O-ring G70 9-001-123 (1)

Replace when disassembled

BTB Assy 90364400 0-501-159 1

BTB

1) Packing 90364413001 0-501-156 1

Replace when disassembled

Magnet gear pump MDG-R2RA24H-57 0-501-010 1

1) Spare kit SK-R2N-34A 0-501-012 1

2) Hose connector 93742611 4-023-030 2

Magnet gear pump MDG-R2RA24H-63A 0-501-128 (1)

Option <H>

1) Spare kit 4A400105 0-501-132 (1)

P1

2) Hose connector 93742611 4-023-030 (2)

Magnet gear pump MDG-R2RA24H-57 0-501-010 1

1) Spare kit SK-R2N-34A 0-501-012 1

2) Hose connector 93742611 4-023-030 2

Magnet gear pump MDG-R2BA24H-65A 0-501-129 (1)

Option <H>

1) Spare kit 4A400105 0-501-132 (1)

P2

2) Hose connector 93742611 4-023-030 (2)

Heparin pump Assy 93896500 0-504-035 1 – –

HP

1) Half nut 91936519 0-504-070 1

Blood pump Assy MRP22-011 0-504-200 1

BP

1) Rotor Assy AS49898-01 0-504-179 1

Sample port Assy 93893400 0-501-067 1

1) Packing (B) 01939800472 0-000-060 1

Sample port Assy 90403400 0-501-179 (1)

Option <H>

SL

1) Packing (B) 01939800472 0-000-060 (1)

QJ-2P-H-2

Red silicone rubber

(sleeve: red)

0-501-091 1

Rinse port

(For concentrate)

QJ-NE2P-H-2

Red silicone rubber

(sleeve: blue)

0-501-092 1

1) O-ring QJR22 9-001-103 2

2) Gasket QJR21 9-001-102 2

SAS-08016 0-501-200

(1)

Option <H>

For A concentrate

Rinse port

(For concentrate)

SAS-08017 0-501-201

(1)

Option <H>

For B concentrate

1) O-ring QJR22 9-001-103 (2)

–

2) Gasket QJR21 9-001-102 (2)

Rinse port

(For disinfectant)

SAS-08018 0-501-095 1

1)Tube connector S 93663311001 0-501-096 1

–

2) Packing (A) 91936944004 2-002-066 1

*1) Hot disinfection with citric acid Assy : <H>

Page 34

7-6

Approximate time to

replace

Code Name of ASSY/Part

Model No. Code No. qty

2 yr Ad libitum

Note

QJ-2PNV-H-2

Red silicone rubber

(sleeve: red)

0-501-082 1

Joint of concentrate

tank (Side of the

dialysate)

QJ-NE2PNV-H blue

Red silicone rubber

(sleeve: blue)

0-501-083 1

1) O-ring QJR22 9-001-103 2

2) Gasket QJR21 9-001-102 2

SAS-08013 0-501-189 (1)

Option <H>

For A concentrate

Joint of concentrate

tank (Side of the

dialysate)

SAS-08014 0-501-190 (1)

Option <H>

For B concentrate

1) O-ring QJR22 9-001-103 (2)

–

2) Gasket QJR21 9-001-102 (2)

Joint of concentrate

tank (Side of the

disinfectant)

SAS-08015 0-501-084 1

–

1) Packing (A) 91936944004 2-002-066 1

Flow sensor Assy

SAS-08004 0-504-181 1

FS1

1) Packing 93614615001 0-504-120 2

Flow sensor Assy

SAS-08005 0-504-184 1

(FS2)

FS4

1) Packing 93614615001 0-504-120 2(2)

Option<H>

SAS-08033 0-501-206 1

Red

Coupler Assy

SAS-08034 0-501-207 1

Blue

–

1) Packing 90363014001 0-501-209 2

Blood leak detector Assy

BLD-01 4-030-078 1

BLD

1) Cartridge holder 93444823100 0-504-034 1

Chamber Assy 90361000 0-501-181 1

1) Diaphragm 0193 0700 083 0-501-184 2

2) Hose connector SYKG-002 0-501-011 4

3) O-ring SSM-07046 0-501-016 4

Chamber Assy 90401000 0-501-186 1

Option<H>

1) Diaphragm 0193 0700 083 0-501-184 2

2) Hose connector SYKG-002 0-501-011 4

Ca

Cb

3) O-ring SSM-07046 0-501-016 4

Ultrafiltration pump

Assy

V-10AUM-P1 0-501-048 1

1) Back sheet 1615001500 0-501-049 1

2) Lip seal 1615003300 0-501-050 3

Ultrafiltration pump

Assy

V-10AUM-P1H 0-501-168 (1)

Option <H>

1) Back sheet 1615001500 0-501-049 (1)

UFP

2) Lip seal 1615003300 0-501-050 (3)

Pump for A

concentrate Assy

V-07AUM-P2A 0-501-051 1

1) Back sheet 1640450500 0-501-052 1

2) Lip seal 1640450400 0-501-053 3

Pump for A

concentrate Assy

V-07AUM-P2AH 0-501-169 (1)

Option <H>

1) Back sheet 1640450500 0-501-052 (1)

P3

2) Lip seal 1640450400 0-501-053 (3)

*1) Hot disinfection with citric acid Assy : <H>

Page 35

7-7

Approximate time to

replace

Code Name of ASSY/Part

Model No. Code No. qty

2 yr Ad libitum

Note

Pump for B

concentrate Assy

V-10AUM-P2B 0-501-057 1

1) Back sheet 1615001500 0-501-049 1

2) Lip seal 1615003300 0-501-050 3

discharge rate

0.60[mL/r]

Pump for B

concentrate Assy

V-10AUM-P3B 0-501-170 (1)

1) Back sheet 1615001500 0-501-049 (1)

2) Lip seal 1615003300 0-501-050 (3)

Option <P>

discharge rate

0.30[mL/r]

Pump for B

concentrate Assy

V-10AUM-P2BH 0-501-171 (1)

1) Back sheet 1615001500 0-501-049 (1)

2) Lip seal 1615003300 0-501-050 (3)

Option <H>

discharge rate

0.60[mL/r]

Pump for B

concentrate Assy

V-10AUM-P3BH 0-501-172 (1)

1) Back sheet 1615001500 0-501-049 (1)

P4

2) Lip seal 1615003300 0-501-050 (3)

Option <H><P>

discharge rate

0.30[mL/r]

Powder Bicarbonate

Cartridge Holder

Assy

90369300 0-507-007 (1)

Option<P>

1)Check valve

90369326001

0-507-020

(1)

2)Nozzle packing

90369324001

0-507-023

(2)

–

3)Packing 90369323001 0-507-024 (2)

Other hydraulic

component

– – – – –

1) L-shaped tube B 01930200077 0-501-221 2(8)

Option<P>

2) L-shaped tube C 93893911001 0-501-222 11(4)

Option<P>

3) Reducer hose

connector

90403911001 0-501-223 1(7)

Option<P>

4) T-shaped

connector S

93663916100 0-501-220 3(3)

Option<P>

5) T-shaped

connector

93613911100 0-501-114 23(4)

Option<P>

6) Hose

connector

01930600070 0-501-116 8(3)

Option<H><P><HE>

7) CL filter SSM-3010 0-501-112 1

8) Filter 93663321100 0-501-217 3 (2)

Option <P><A>

9) Silicone tube ø5×ø11 9-004-038 –

30m of Silicon tube

has been used per

one machine.

If you change whole

tube, you need 30m.

10) Silicone tube ø3 ×ø6 2-002-071 –

6.5m of Silicon tube

has been used per

one machine.

If you change whole

tube, you need 6.5m.

11) Plug 93893020004 0-501-216 (1)

Option <H>

–

12) Concentrate

line filter

SAS-08062 0-501-219 (4)

Option <H><P><A>

Lithium battery CR2032 0-502-220 1

Use something which

has no conductivity

for removal.

–

Ni-cd battery 20KR-CH(3AH) 0-502-085 1

*1) Hot disinfection with citric acid Assy : <H>

*2) Powder Bicarbonate Assy : <P>

*3) Acid-Rinsing Port Assy : <A>

*4) Heat Exchanger Assy : <HE>

NOTE 1) This list doesn’t guarantee the performance of parts within the indicated time frame.

The time to exchange parts, is especially depending on the used concentration of disinfectants.

2) This list shows approximate time when parts have to be replaced except for electric components.

Page 36

7.2 Parts replacement during maintenance

7.2.1 Water supply filter Assy (F1)

7.2.1.1 Overall configuration

6

Assy

7.2.1.2 List of components

No. Name Model No. Code No. Note

1 Cap 93619318 0-201-210

2 Hose connector 93619319 0-201-212

3 Packing 01939900124 4-030-066

4 Filter FI116ATERP265A00 0-201-213

5 Body 93619320 0-201-211

6 Water supply filter Assy 93532000 4-030-060

7.2.1.3 How to replace parts

(1) Disassemble the Water supply filter Assy by turning the cap

(2) Replace the filter

(3) Reassemble by turning the cap

4

and packing

3

.

1

clockwise.

1

counterclockwise.

7-8

Page 37

9

8

6

8

9

8

6

7.2.2. Two-way solenoid valve

(V1,V4,V5a,V5b,V6a,V6b,V7a,V7b,V8a,V8b,V9a,V9b,V10,V11,V19,V21)

7.2.2.1 Overall configuration

11

Assy

7.2.2.2 List of components

No. Name Model No. Code No. Note

1 Actuator Assy – –

2 Core – –

3 Pacless pipe – –

4 Sound damp sheet – –

5 Spring – –

6 Plunger – –

7 Diaphragm support – –

8 Diaphragm D3A540 0-501-117

9 Valve body D3B1810 0-501-118

10 Screw M3×45P2 0-501-119

11 Two-way solenoid Valve SV2-322-S 2-006-008

7.2.2.3 How to replace parts

(1) Unscrew the 2 screws

(2) Remove the diaphragm

(3) Replace the diaphragm

plunger

.)

(4) Reassemble and tighten the screws (

10

. to remove the valve body

from the plunger

and valve body

10

) to the torque of 0.69 N.m (7 kgf.cm).

.

.

. (Enchase the diaphragm

firmly to the

7-9

Page 38

8

8

8

6

2

7.2.3. Two-way solenoid valve (V12)

7.2.3.1 Overall configuration

1

7.2.3.2 List of components

Assy

No. Name Model No. Code No. Note

1 Actuator Assy – –

2 Core – –

3 Pacless pipe – –

4 Sound damp sheet – –

5 Spring – –

6 Plunger – –

7 Diaphragm support – –

8 Diaphragm D4A350 0-501-121

9 Ring – –

10 Valve body D4B1000 0-501-122

11 Screw – –

12 Two-way solenoid Valve

TYPE B

SV2-422-S 0-501-120

7.2.3.3 How to replace parts

(1) Unscrew the 2 screws

(2) Remove the diaphragm

(3) Replace the diaphragm

plunger

.)

11

to remove the valve body

from the plunger 6.

and valve body

(4) Reassemble and tighten the screws

11

to the torque of 0.69 N.m (7 kgf.cm).

10

.

10

. (Enchase the diaphragm

firmly to the

7-10

Page 39

7.2.4 Temperature sensor Assy (T)

7.2.4.1 Overall configuration

Assy

4

7.2.4.2 List of components

No. Name Model No. Code No. Note

1 Sensor holder 93892511 0-504-022

T1 harness 9036V333100 0-504-174

2

T2 harness 9036V334100 0-504-175

T3 harness 9036V335100 0-504-176

T7 harness 9036V426100 0-504-177

3 Hose connector 01930600070 0-501-116 Use arbitrarily.

4 Temperature sensor

Assy

SAS-08019 0-504-170 T1

SAS-08020 0-504-171 T2

SAS-08021 0-504-172 T3

SAS-08022 0-504-173 T7

7.2.4.3 How to replace parts

(1) Pull out the thermistor 2 . (Pull to the right by

referring to the figure on the right.)

(2) The flange part of the thermistor 2 should stop at

the bump located inside of the sensor holder 1.

(See the figure on the right.)

(3) Insert the Hose connector 3 .

Sensor holder

1

Thermistor

2

Bump

7-11

Page 40

7.2.5. Dialysate pressure sensor Assy (PD)

7.2.5.1 Overall configuration

7.2.5.2 List of components

9

Assy

No. Name Model No. Code No. Note

1 Manifold 93882911 0-504-025

2 O-ring S-16 0-504-026

3 Pressure transducer – –

4 Base plate – –

5 Spacer – –

6 Dialysate pressure

sensor board

7 Screw M3×12 0-504-031 With a plain washer and

8 Board cover 93882914 0-504-032

9 Dialysate pressure

sensor Assy

– –

a spring lock washer

PD-02 0-504-024

7.2.5.3 How to replace parts

!

CAUTION

Do not touch the surface of the pressure transducer of the dialysate pressure sensor. It can

cause malfunction.

(1) Remove the board cover 8 .

(2) Unscrew the 2 screws 7 .

(3) Remove the pressure transducer 3 from the manifold 1, using a precision flathead

screwdriver, etc.

(4) Replace the manifold

(5) Reassemble and tighten the screws

1

and O-ring 2.

7

to the torque of 0.69 N.m (7 kgf.cm).

7-12

Page 41

7.2.6 Conductivity sensor Assy (CD)

7.2.6.1 Overall configuration

11

Assy

7.2.6.2 List of components

No. Name Model No. Code No. Note

1 Sensor holder 93663814 0-504-002

2 O-ring P3 2-002-058 Silicone rubber

3 Pin 93153812 2-002-060

4 Screw M3×8 0-201-085 With a plain washer and

a spring lock washer

5 CD1/CD2 harness - -

6 O-ring P4 0-504-006 Silicone rubber

7 Collar 93733820 0-504-007

T4 harness 9036V336100 0-504-159

8

T5 harness 9036V337100 0-504-160

T6 harness 9036V453100 0-504-161

9 Pressor - -

10 Screw M3×8 0-201-085 With a plain washer and

a spring lock washer

5

11 Conductivity sensor

Assy

SAS-08027 0-504-156

SAS-08028 0-504-157

SAS-08029 0-504-158

CD1,

CD2,

CD3,

excluded

5

excluded

5

excluded

7.2.6.3 How to replace parts

(1) Unscrew the 6 screws 4 and 2 screws 10.

(2) Remove the pin 3 and temperature sensor 8 from the sensor holder 1 .

(3) Remove the O-ring 2 from the pin 3 and replace.

(4) Remove the O-ring 6 from the temperature sensor 8 and replace.

(5) Reassemble and tighten the screws 4 to the torque of 0.39 N.m (4 kgf.cm).

O-ring

Chamfering

!

CAUTION

The chamfer side of the collar 7 should be inserted

to direction of the O-ring 6. Inserting into the wrong

side can cause leakage.

7-13

Page 42

7.2.7 Degassing tank Assy (AS1)

7.2.7.1 Overall configuration

×4

7.2.7.2 List of components

9

Assy

×4

×4

No. Name Model No. Code No. Note

1 Case (1) 91933411 0-201-010

2 Wire net 91933015 0-201-013

3 O-ring G50 9-001-121 fluoro rubber

4 Float 93442313 0-201-012

5 Case(2)-L 91933412 0-201-011

6 Screw M4×15 0-201-126 With a plain washer and

7 Plain washer For M4 0-201-132

8 Nut For M4 0-201-127

9 Degassing tank Assy 93612300 0-501-015

7.2.7.3 How to replace parts

(1) Unscrew the 4 screws

(2) Replace the O-ring

(3) Reassemble in the reverse order.

6

.

3

.

7-14

a spring lock washer

Page 43

7.2.8 Air elimination tank Assy (AS2)

7.2.8.1 Overall configuration

18

Assy

7.2.8.2 List of components

No. Name Model No. Code No. Note

1 Case (1) 91933411 0-201-010

2 Wire net 91933015 0-201-013

3 O-ring G50 9-001-121

4 Plate 01939700069 0-201-017

5 Ring – –

6 Float – –

7 Float switch shaft – –

8 Mesh 01930200089 0-501-030

9 Packing 01930200088 0-201-016

10 Case 93312412 0-201-015

11 Nut – –

12 Screw M4×20 0-201-133

13 Nut

14 Tube – –

15 Pin – –

For M4

0-201-127

fluoro rubber

With a plain washer and

a spring lock washer

7-15

Page 44

No. Name Model No. Code No. Note

16 Connector – –

17 Float switch Assy OLV-2P-1 (Special) 0-201-018

18 Air elimination tank Assy 93532400 0-501-024

Consists of

5 , 6 , 7 , 11

7.2.8.3 How to replace parts

(1) Unscrew the 4 screws

(2) Remove the ring 5 and float 6.

(3) Replace the float 6 and 2 O-rings 3. (Bring the float with the insert side up.)

(4) Reassemble in the reverse order.

12

.

7-16

Page 45

7.2.9 Buffer tank Assy

7.2.9.1 Overall configuration

×4

×4

×4

11

BTW Assy

×4

12

BTD Assy

13

BTB Assy

7-17

Page 46

7.2.9.2 List of components

No. Name Model No. Code No. Note

1 Lower tank 91936937 0-201-020

2 O-ring G70 9-001-123 fluoro rubber

3 Upper tank (B) 91936955 0-201-021

4 Screw M4×15 0-201-126

5 Nut For M4 0-201-127

6 Case 90364411001 0-501-160

7 Packing 90364413001 0-501-156

8 BTB lid 90364412001 0-501-162

9 BTB bracket 90364414001 0-501-163

10 Screw

11 BTW Assy 93613500 0-501-037

12 BTD Assy 93613500 0-501-037

13 BTB Assy 90364400 0-501-159

M4×15

0-201-126

With a plain washer and

a spring lock washer

With a plain washer and

a spring lock washer

7.2.9.3 How to replace parts

BTW Assy

11

/ BTD Assy

(1) Unscrew the 4 screws

(2) Replace the O-ring 2 .

(3) Reassemble in the reverse order.

13

BTB Assy

(1) Unscrew the 4 screws

(2) Replace the

Packing

(3) Reassemble in the reverse order.

12

4

.

10

.

7

.

7-18

Page 47

7.2.10 Magnet gear pump (P1/P2)

7.2.10.1 Overall configuration

7.2.10.2 List of components

40

Assy

No. Name Model No. Code No. Note

1 Motor 1430101300 0-501-130

2 Magnet retaining ring MDG0519 0-501-131

5 Rear casing – –

6 Magnet can – –

7 Mounting plate – –

8 Bracket – –

9 Driven gear – –

10 Idler gear – –

11 Gear case – –

12 Straight pin – –

13 Front bearing – –

14 Rear bearing – –

15 Front plate – –

16 Rear plate – –

17 Pump head – –

18 Gasket A – –

7-19

Page 48

No. Name Model No. Code No. Note

8

7

9

2

5

r

19 Gasket B – –

20 Packing B – –

21 Packing C – –

22 Retainer spring – –

23 O-ring – –

32 Small screw – –

35 Small screw – –

36 Small screw – –

37 Hose connector 93742611 4-023-030

38 Spare kit SK-R2N-34A 0-501-012 Consists of

9

10 , 13

,

39 Pump body set MDG-R2RA100-34B 0-201-167 Consists of

2 , 5

to 23,

40 Magnet gear pump MDG-R2RA24H-57 0-501-010

to16,

1

32 , 36

7.2.10.3 How to replace parts

18

.

Driven gea

Forceps

35

to remove the pump part from the motor 1 .

32

to remove the pump head

2

using a forceps, etc. Remove the retainer spring

1

.

!

CAUTION

Remove the magnet retaining ring 2 gently

and slowly. It can deform when excessive force

is applied.

20

, bracket 8,

(1) Unscrew the 3 small screws

(2) Unscrew the 4 small screws

(3) Remove the gasket A

(4) Unscrew the 3 small screws 36. Remove the mounting plate 7, packing B

and gasket B

1

from the pump part.

(5) Remove the rear casing 5 while leaving the packing C 21 on the rear casing 5 . (Liquid

may be present inside the rear casing 5.)

To remove the rear casing 5 , turn the front bearing 13 and rear casing 5 . If the rear

bearing

14

is retained inside the rear casing 5, hold the shaft of the driven gear 9 and

pull it out.

(6) Remove the magnet retaining ring

also.

Hang around the

magnet retaining

ring

Magnet

retaining ring

23

,

2

(7) Remove the magnet can 6 from the driven gear 9. Store the magnet can 6 in a place

where no iron powder, etc. will come in contact.

14

(8) Disassemble in the order of rear bearing

gear case

11

, straight pin

12

, front plate

, rear plate 16, driven gear 9 , idler gear 10,

1

, and front bearing

13

. Handle these parts

carefully. Clean and store them in a place where no dust, etc. will come in contact.

7-20

Page 49

5

23

(9) Attach the O-ring

to the front bearing 13 and rear bearing 14. Apply a thin layer of

silicone grease on the O-ring 23 in advance.

(10) Attach the straight pin

12

to the front bearing 13.

(11) Assemble in the order of front plate

plate

16

, and rear bearing

14

and mount them to (10). Holes of these parts should align.

Be sure to insert the driven gear 9 and the idler gear 10 in the direction shown below:

Driven gear (9)

1

, gear case 11, driven gear 9 , idler gear 10, rear

Front bearing side

Idler gear (10)

Rear bearing side

(12) Insert the magnet can 6 into the driven gear 9 and place the magnet retaining ring 2

using a forceps, etc.

Forceps

!

CAUTION

If the magnet retaining ring 2 is loose, it can

Squeeze in advance.

Magnet

retaining ring

Driven

gear

come out. Enchase while squeezing it.

Enchase the magnet retaining ring 2 firmly

into the gap of the projected driven gear.

(13) Insert the retainer spring

5

firmly. Do not turn the rear casing

22

into the gap of the rear bearing 14, and attach the rear casing

5

when attaching. It should be positioned straight

ahead.

(14) Put the gasket B

19

on the front bearing 13, so that the holes align. Attach the bracket 8

so that the two gaps are aligned.

(15) Install the gasket A

screws

32

to tack.

18

to the front bearing 13 and attach the pump head

17

. Use the 4 small

7-21

Page 50

8

2

Convex

Check the

Check the

direction.

Align the

shapes.

Convex

!

CAUTION

When installing the gasket

18

, check the

direction, so that the holes in the front bearing

13

and gasket

1

match, as shown in the

figure on the left.

Installing in the wrong directory can cause

pump malfunction or water leakage.

Concave

(16) Install the packing B

36

. Tighten with a torque of 0.59 N.m (6 kgf.cm).

(17) Install the pump head

0.78 N.m (8 kgf.cm).

Tighten the small screws

specified torque at the end.

Order of tightening

Concave

Body

20

and mounting plate 7 on the bracket 8 using the 3 small screws

17

using the 4 small screws

32

slowly and diagonally, using equivalent force. Tighten up to the

3

. Tighten the screws to the torque of

!

CAUTION

Pump head

When installing the pump head

17

, do not

tighten with a higher torque than specified or

Small screw

avoid tightening only one side. It can damage

the screw part of the front bearing

13

.

(18) Install the reassembled pump part to the motor 1 using the 3 small screws

35

.

7-22

Page 51

7-23

7.2.11 Heparin pump Assy (HP)

7.2.11.1 Overall configuration

7.2.11.2 List of components

No.

Name Model No. Code No Note

1 Pusher E 93896511 0-504-036

2 Button 93896538 0-504-037

3 Coil spring No.1043 0-504-038

4 Pin 93896537 0-504-039

5 Screw M3×8 0-201-091

With a plain washer and

a spring rock washer

6 Metal fitting 93896533 0-504-041

7 Harness holder B 93886530 0-504-042

8 Screw M3×8 0-201-091

With a plain washer and

a spring rock washer

9 Sensor blacket 93886536 0-504-044

10 Limit switch SS-01 0-504-045

11 Screw M2.3×12 0-201-096

With a plain washer and

a spring rock washer

12 Screw M3×8 0-201-091

With a plain washer and

a spring rock washer

13 Syringe holder 93886513 0-504-048

14 Shaft A 93896524 0-504-049

15 Screw M4×8 0-504-050

50

Assy

Page 52

7-24

No.

Name Model No. Code No Note

16 Coil spring No.1145 0-504-051

17 Stopper 93886535 0-504-052

18 Screw M3×8 0-201-091

With a plain washer and

a spring rock washer

19 Syringe base 93896532 0-504-054

20 Packing 93146537 0-504-055

21 Screw M4×16 0-504-056

With a spring rock

washer

22 Chassis 93886514 0-504-057

23 Motor plate 93886515 0-504-058

24 Screw M4×8 0-201-071

With a plain washer and

a spring rock washer

25 Stepping motor KT42JM4-004 4-028-013

26 Screw M3×8 0-201-091

With a plain washer and

a spring rock washer

27 Timing pulley 10XL037 0-504-062

28 Timing pulley 12XL037 0-504-063

29 Timing belt 70-XL-025U 0-204-043

30 Setscrew M4×4 0-504-065

31 Screw M3×8 0-504-066

32 Plate 93886520 0-504-067

33 Plate 2 93886529 0-504-068

34 Shaft 93896519 0-504-069

35 Half nut 91936519 0-504-070

36 Clutch spring 91936523 0-504-071

37 Spring case 93146521 0-504-072

38 Screw M3×10 0-504-073

With a plain washer and

a spring rock washer

39 Rotation detection

sensor

– –

40 Dog 93896534 0-504-075

41 Bearing RF-1450ZZ 0-504-076

42 Feed screw 93896517 0-504-077

43 Housing 93896516 0-504-078

44 Guide shaft 93896518 0-504-079

45 Limit switch SS-01 0-504-045

46 Screw M2.3×12 0-201-096

With a plain washer and

a spring rock washer

47 Nut 93886523 0-504-082

48

Lever 91936927 0-504-083

49

O.L spring 01930600121 0-504-084

50

Heparin pump Assy 93896500 0-504-035

Page 53

7-25

7.2.11.3 How to replace parts

(1) Loosen the setscrews

30

(4 in total). Remove the pulley

28

from the feed screw

42

and the

pulley

27

from the stepping motor

25

.

(2) Unscrew the 4 screws

24

and disassemble into chassis

22

, motor plate

23

, and housing

43

.

(3) Push the shaft

34

in the housing

43

part to remove the feed screw

42

.

(4) Unscrew the 4 screws

31

.

(5) Open a space between the lever

48

(resin part) and the metal part of the housing

43

part by

inserting a flathead screw driver, etc. Insert a screwdriver, etc. while pressing and squeezing the

spring inside the housing by hand.

(6) Rotate the shaft

34

by 90 degrees, and replace the half nut

35

.

(7) Reassemble in the reverse order.

Page 54

7-26

7.2.12 Blood pump Assy (BP)

7.2.12.1 Overall configuration

7.2.12.2 List of components

No.

Name Model No. Code No. Note

1 Housing Assy AR02672-01 0-504-178

2 Rotor Assy AS49898-01 0-504-179 Rotational handle built-in

3 Screw M5×10 0-504-180

With a plain washer and

a spring rock washer

4 BP cover Assy SAS-08035 0-504-190

With pin

5 Motor FY6PF6G-303 0-504-191

6 Blood pump Assy MRP22-011 0-504-200

7.2.12.3 How to replace parts

[How to replace Rotor Assy]

(1)

Pull open the handle of the Rotor Assy

2

.

(2) Remove the Hex socket head cap screw with captive washer

3

.

(3) Pull out the Rotor Assy

2

.

(4) Reverse above procedure when mounting parts.

[How to replace BP cover Assy]

(1)

Remove carefully the pin

4

to upper side (the knurling side of the pin) of the BP cover Assy.

(2)

Insert the pin

4

(the knurling side is upper) when mounting the BP cover Assy.

!

CAUTION

Replace maximum 3 times the BP cover Assy to prevent a decline of fixed power of the pin.

Remove the pin very carefully because holes of the Housing are sometimes transformed

when the pin is removed by force.

6

Assy

Page 55

7.2.13 Sample port Assy (SL)

7.2.13.1 Overall configuration

6

7.2.13.2 List of components

Assy

No. Name Model No. Code No. Note

1 Body 01930400069 0-201-044