Page 1

OPERATION MANUAL

SINGLE PATIENT DIALYSIS MACHINE

SURDIAL

Manufacturer

NIPRO CORPORATION

3-9-3, Honjo-Nishi, Kita-Ku, OSAKA

531-8510, JAPAN

PHONE +81-6-6372-2331

Version No.0R1121-0801

Page 2

PREFACE

Thank you for purchase of Single Patient Dialysis Machine, SURDIAL.

The Operation Manual is intended to be prepared for correct and safe use of the machine

and not to be intended for description how to manage patient medically.

Be familiar with features of the machine and instructions how to operate it contained in this

manual before use.

Description in this manual is protected by copyright of the manufacturer. Copy, reproduction

or preparation of version in any foreign language of the description partially or wholly shall not

be allowed without obtaining prior approval by the manufacturer.

The life time of this machine is 7 years.

Machine description Life time

Single Patient Dialysis Machine, SURDIAL 7 years

PREFACE

Page 3

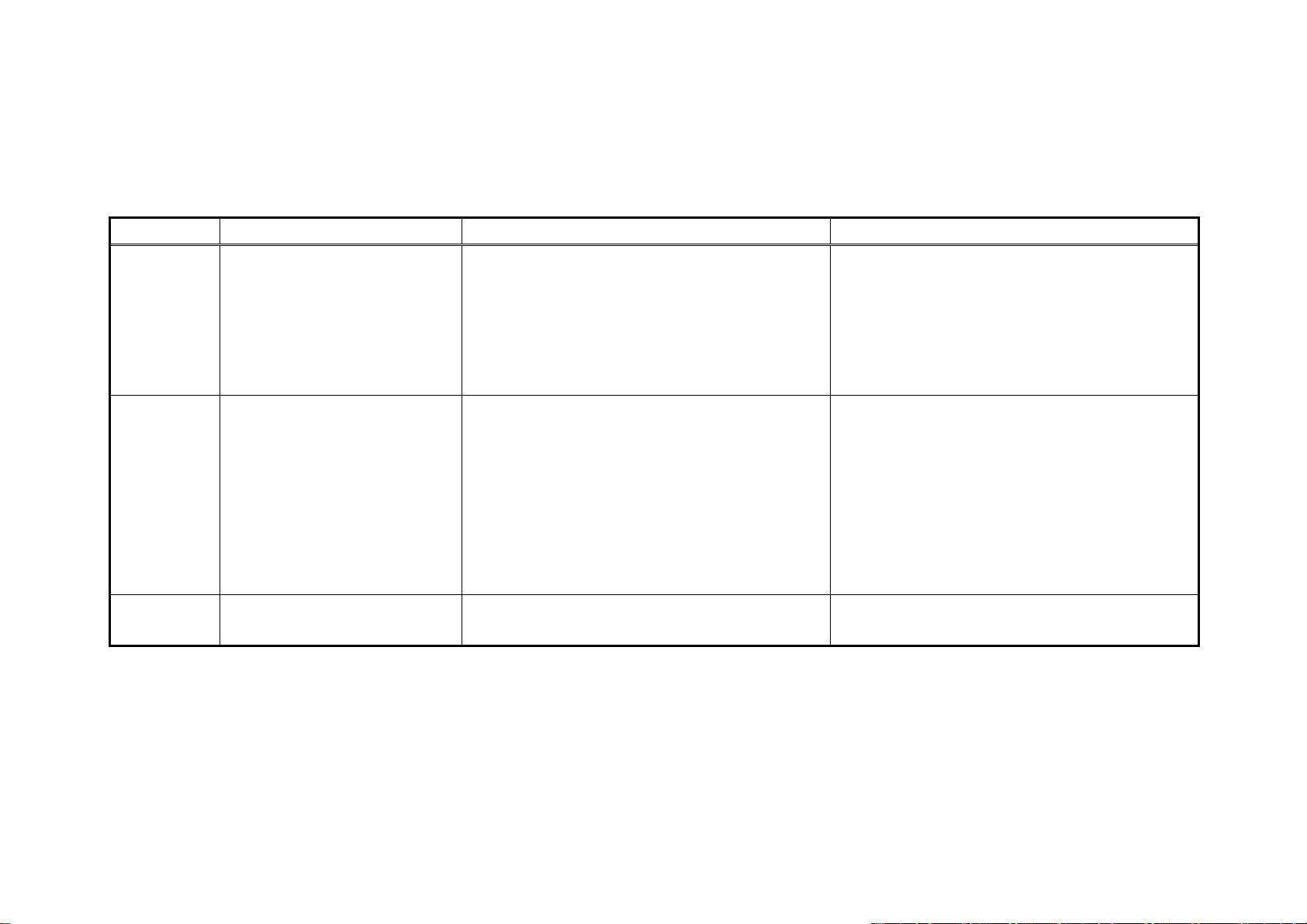

Revision table of SURDIAL OPERATION MANUAL

We revised the following contents in operation manual.

Kindly refer the following contents in operation manual compare as manual from your side.

Page Contents Revision Previous

11-1 11.1.1.Cleaning and

disinfection of machine

enclosure

※ Delete cleaning procedure

using alcohol.

11-1 11.1.2.Cleaning and

disinfection of dialysate

concentrate connectors

and rinse ports

※ Delete cleaning procedure

using alcohol.

21-3 21.2.1.Dialysate flow

Remove blood and/or organic substances from

the machine enclosure using soft cloth wetted

with tepid water or w ater. DO NOT use organic

solvents such as thinner and benzene to

prevent patient damage.

After long term use of dialysate concentrate

connectors and rinse ports, solutes in the

concentrates may isolated to form harmful

crystals and may cause the machine failure.

Clean them using cloth wetted with tepid water

or water regularly. Pull out the ports to this

side to allow easy cleaning.

UFR is≦2.70L/h when dialysate flow rate is

300mL/min.

Remove blood and/or organic substances from

the machine enclosure using soft cloth wetted

with alcohol or water. DO NOT use organic

solvents such as thinner and benzene to

prevent patient damage.

After long term use of dialysate concentrate

connectors and rinse ports, solutes in the

concentrates may isolated to form harmful

crystals and may cause the machine failure.

Clean them using cloth wetted with alcohol or

water regularly. Pull out the ports to this side to

allow easy cleaning.

UFR is≦4.00L/h when dialysate flow rate is

30L/min.

0R1A01-0105

Page 4

PREFACE

CONTENTS

CAUTIONS FOR SAFETY

1. INTENDED USE

2. CONTRAINDICATION

3. CAUTIONS

4. DEFINITIONS

5. SYMBOL FOR SAFETY

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6. INSTALLATION

6.1. Installation environment

6.1.1. Ambient conditions

6.1.2. Power supply

6.1.2.1. When machine power rating is AC 230V

6.1.2.2. When machine power rating is AC 100V

6.1.3. Necessary space requirements to use the machine

6.1.4. Water supply and drainage conditions

6.1.4.1. Water supply pressure

6.1.4.2. Water supply flow rate

6.1.4.3. Water supply temperature

6.1.4.4. Water quality

6.1.4.5. Concentrate line pressure

6.1.4.6. Drainage

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

CAUTION-1~6

1-1~2

2-1~2

3-1~2

4-1~4

5-1~2

6-1~12

6-1

6-1

6-1

6-1

6-1

6-2

6-2

6-2

6-2

6-2

6-2

6-3

6-3

6.2. Unpacking and check of contents

6.3. Procedure for assembling

6.3.1. Cautions

6.3.2. Attachment of I.V. pole, hanger and main lamp

6.3.3. Connector for each concentrate container

6.4. Procedures for tube and plug connections

6.4.1. Connections of fluid supply and drain lines, coupler and power plug

6.4.1.1. Connection of dialysate coupler tubes

6.4.1.2. Connections of drain port of machine side

6.4.1.3. Connection of water supply port

6.4.1.4. Connection of power plug

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

CONTENTS-1

6-4

6-6

6-6

6-6

6-7

6-8

6-8

6-8

6-8

6-8

6-8

Page 5

6.4.2. Connection of each concentrate

6.4.2.1. Connection to execute dialysis operation(before blood line connection)

6.4.2.2. Connection for water rinsing

6.4.2.3. Connection for disinfection

6.4.2.4. Connection for acetic acid rinsing (when acid rinse option is not used)

6.4.2.5. Connection for acetic acid rinsing (when acid rinse option is used)

6.4.2.6. Connection for automatic rinsing (1 or 2)(when acid rinse option is used)

6.4.3. Air purge

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・

・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・

6-9

6-9

6-9

6-9

6-10

6-10

6-10

6-11

6.5. Disinfection of the dialysate circuit

6.6. Disposal of used machine

6.7. Disposal of used packaging materials

6.8. Disposal of blood lines and dialyzer

7. MAIN FUNCTIONS AND COMPONENTS

8. CONSTRUCTION OF MACHINE

8.1. Overall construction

8.1.1. Overall views

8.1.2. Components of machine and their purposes and functions

8.2. Operation panel

8.2.1. Construction of operation panel

8.2.2. Components of operation panel and their purposes and functions

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8-1~14

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

6-12

6-12

6-12

6-12

7-1~2

8-1

8-1

8-3

8-5

8-5

8-6

8.3. Blood line setting panel

8.3.1. Construction of blood line setting panel

8.3.2. Components of blood line setting panel and their purposes and functions

8.4. Power box

8.4.1. Construction of power box

8.4.2. Components of power box and their purposes and functions

8.5. Main lamp assembly

8.5.1. Construction of main lamp assembly

8.5.2. Components of main lamp assembly and their purposes and functions

CONTENTS-2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・

8-9

8-9

8-10

8-11

8-11

8-12

8-13

8-13

8-14

Page 6

9. DISPLAY

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9-1~18

9.1. Layout of display

9.2. Wake up screen

9.3. Rinse screen

9.3.1. Rinse menu

9.3.2. Rinse wait

9.3.2.1. RINSE1: WATER

9.3.2.2. RINSE2:CHEMICAL

9.3.2.3. RNSE3:AUTO1 C&D

9.3.2.4. RINSE4: AUTO2 C&D

9.3.3. Rinse execution

9.3.3.1. RINSE1: WATER

9.3.3.2. RINSE2: CHEMICAL

9.3.3.3. RINSE3: AUTO1 C&D

9.3.3.4. RINSE4: AUTO2 C&D

9.3.4. Rinse end

9.3.4.1. RINSE1: WATER

9.3.4.2. RINSE2:CHEMICAL

9.3.4.3. RINSE3:AUTO1 C&D

9.3.4.4. RINSE4:AUTO2 C&D

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9-3

9-5

9-6

9-6

9-7

9-7

9-7

9-7

9-8

9-9

9-9

9-9

9-9

9-9

9-10

9-10

9-10

9-10

9-10

9.4. Dialysis screen

9.4.1. Dialysis

9.4.2. Priming

9.4.3. Test mode

9.5. SettingⅠ screen

9.6. SettingⅡ screen

9.7. Maintenance menu screen

9.8. Alarm screen

10. ALARM FUNCTIONS AND

10.1. Description of alarms

10.1.1. Functions when error is alerted

10.1.2. Procedure for resetting

10.1.3. Actions to respond to alarm (flow)

10.2. Table of alarms

10.2.1. Meanings of terms contained in “Table of alarms”

10.2.2. Table of alarms

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

RESETTING

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9-11

9-11

9-12

9-13

9-14

9-15

9-16

9-17

10-1~14

10-1

10-1

10-2

10-2

10-3

10-3

10-3~14

CONTENTS-3

Page 7

11. CLEANING AND DISINFECTION

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11-1~8

11.1. Cleaning and disinfection of machine outside

11.1.1. Machine enclosure

11.1.2. Dialysate concentrate connectors and rinse ports

11.2. Cleaning and disinfection of fluid lines

11.3. Disinfection of fluid line inside

11.3.1. Concentration of disinfectant concentrate

11.3.2. Diluted disinfectant concentration and disinfection time

11.3.3. Method to set dilution rate of disinfectant concentrate

11.3.4. Check of residual disinfectant

11.4. Removal of calcium deposit from fluid line inside

11.4.1. Concentration of acetic acid concentrate

11.4.2. Diluted disinfectant concentration and disinfection time

11.4.3. Concentration of acetic acid to be diluted

11.4.4. Method to set dilution rate of acetic acid concentrate

11.4.5. Check of residual acetic acid

11.5. Removal of protein deposit from fluid line inside

11.5.1. Concentration of sodium hypochlorite

11.5.2. Diluted disinfection concentration and disinfection time

11.5.3. Concentration of sodium hypochlorite to be diluted

11.5.4. Check of residual sodium hypochlorite

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11-1

11-1

11-1

11-1

11-2

11-2

11-2

11-3

11-3

11-4

11-4

11-4

11-4

11-5

11-5

11-6

11-6

11-6

11-7

11-7

12. PROCESS FLOW

12.1. Process flow

12.2. Description of process flow

12.2.1. Rinse wait process

12.2.2. Rinse process

12.2.2.1. Water rinse mode

12.2.2.2. Disinfection/rinse mode

12.2.2.3. Acid rinse mode

12.2.2.4. Dwelling mode

12.2.2.5. Prerinse mode

12.2.3. Rinse end process

12.2.4. Dialysis wait process

12.2.5. Prepa

12.2.6. Preparation end process

12.2.7. Dialysis process

12.2.8. Recovery process

12.2.9. Air purge process

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ration process

12-1~4

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12-1

12-2

12-2

12-2

12-2

12-2

12-2

12-2

12-2

12-3

12-3

12-3

12-3

12-3

12-3

12-3

CONTENTS-4

Page 8

13. OPERATION OF MACHINE

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13-1~4

13.1. Check and action before turning on power breaker

13.2. Procedures for machine operation

13.2.1. Machine SW ON

13.2.2. Prerinse

13.2.3. Dialysis

13.2.4. Postrinse

13.2.5. Machine power breaker OFF

14. RINSING

14.1. Selection of rinsing mode

14.2. Setting of rinsing pattern (example: RINSE4 (AUTO2 C&D))

14.3. Connection of concentrates

14.3.1. Connection of concentrates when acid rinse port (option) is not used

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

14.3.1.1. Connection at water rinse

14.3.1.2. Connection at disinfection/rinse

14.3.1.3. Connection at acid rinse

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

14-1~6

・・・・・・・・・・・

13-1

13-3

13-3

13-3

13-4

13-4

13-4

14-2

14-2

14-3

14-3

14-3

14-3

14-3

14.3.2. Connection of concentrates when acid port unit (option) is used

14.3.2.1. Connection at water rinse

14.3.2.2. Connection at disinfection/rinse

14.3.2.3. Connection at acid rinse

14.3.2.4. Connection at auto rinse 1 or 2

14.4. Start of rinsing (example: RINSE4(AUTO2 C&D))

14.5. Completion of rinsing

14.6. Discontinuance of rinsing

15. DOUBLE NEEDLE DIALYSIS

15.1. Setting of dialysate related parameters

15.1.1. Setting of dialysis mode

15.1.2. Setting of dialysate concentration

15.1.2.1. Bicarbonate dialysate

15.1.2.2. Acetate dialysate

15.1.3. Setting of dialysate temperature

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

15-1~20

14-4

14-4

14-4

14-4

14-4

14-5

14-5

14-6

15-2

15-2

15-2

15-2

15-3

15-3

CONTENTS-5

Page 9

15.2. Connection of concentrates

15.2.1. Connection of concentrates to prepare bicarbonate dialysa t e

15.2.2. Connection of concentrate to prepare acetate dialysate

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

15-4

15-4

15-4

15.3. Setting of blood line, dialyzer and syringe

15.3.1. Setting of blood line

15.3.2. Setting of dialyzer

15.3.3. Setting of syringe

15.3.4. Setting of syringe pump

15.3.4.1. Setting of cross-section ratio of syringe

15.3.4.2. Setting of syringe operation stop time

15.3.4.3. Setting of fast-forward volume

15.4. Preparation of machine (preparation process)

15.5. Check of preparation completion of machine (preparation end process)

15.6. Priming process

15.6.1. Setting of saline vial

15.6.2. Priming of saline

15.6.3. Priming of dialyzer with dialysate

15.6.4. Rinsing of blood line and dialyzer

15.6.4.1. When priming function is used

15.6.4.2. When priming function is not used

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

15-5

15-5

15-5

15-5

15-5

15-5

15-7

15-7

15-8

15-8

15-9

15-9

15-9

15-10

15-10

15-10

15-11

15.7. Check of dialysate conductivity

15.8. Setting of UF related parameters

15.9. Connection of patient

15.10. Start of dialysis (dialysis process)

15.10.1. Start of dialysis

15.10.2. Setting of upper and lower venous pressure alarm limits

15.10.3. Setting of upper and lower arterial pressure alarm limits

15.10.4. Setting of upper and lower dialysate pressure alarm limits

15.11. Completion of dialysis (recovery process)

15.11.1. Check of UF completion

15.11.2. Start of blood recovery

15.11.3. Execution of blood recovery

15.11.4. Removal of coupler

15.11.5. Cle

15.11.6. Completion of blood recovery

15.12. Discontinuance of dialysis

15.12.1. Discontinuance of UF

15.12.2. Discontinuance of dialysis

aring away

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

15-12

15-12

15-13

15-14

15-14

15-14

15-14

15-15

15-16

15-16

15-16

15-17

15-17

15-18

15-18

15-19

15-19

15-19

CONTENTS-6

Page 10

16. SINGLE NEEDLE DIALYSIS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

16-1~20

16.1. Setting of dialysate related parameters

16.1.1. Setting of dialysis mode

16.1.2. Setting of dialysate concentration

16.1.2.1. Bicarbonate dialysate

16.1.2.2. Acetate dialysate

16.1.3. Setting of dialysate temperature

16.2. Connection of concentrates

16.2.1. Connection of concentrates to prepare bicarbonate dialysa t e

16.2.2. Connection of concentrate to prepare acetate dialysate

16.3. Setting of blood line, dialyzer and syringe

16.3.1. Setting of blood line

16.3.2. Setting of dialyzer

16.3.3. Setting of syringe

16.3.4. Setting of syringe pump

16.3.4.1. Setting of cross-section ratio of syringe

16.3.4.2. Setting of syringe operation stop time

16.3.4.3. Setting of fast-forward volume

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

16-2

16-2

16-2

16-2

16-3

16-3

16-4

16-4

16-4

16-5

16-5

16-5

16-5

16-6

16-6

16-7

16-7

16.4. Preparation of machine (preparation process)

16.5. Check of preparation completion of machine (preparation end process)

16.6. Priming process

16.6.1. Setting of saline vial

16.6.2. Priming of saline

16.6.3. Priming of dialyzer with dialysate

16.6.4. Rinsing of blood line and dialyzer

16.6.4.1. When priming function is used

16.6.4.2. When priming function is not used

16.7. Check of dialysate conductivity

16.8. Setting of UF related parameters

16.9. Connection of patient

16.10. Setting of single needle dialysis related parameters

16.10.1. Single needle SW ON

16.10.2. Setting of single needle changeover values

16.11. Start of dialysis (dial

16.11.1. Start of dialysis

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

ysis process)

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

16-8

16-8

16-9

16-9

16-9

16-10

16-10

16-10

16-11

16-12

16-12

16-13

16-14

16-14

16-14

16-15

16-15

CONTENTS-7

Page 11

16.11.2. Setting of upper and lower arterial pressure alarm limits

16.11.3. Setting of upper and lower dialysate pressure alarm limits

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

16-15

16-16

16.12. Completion of dialysis (recovery process)

16.12.1. Check of UF completion

16.12.2. Start of blood recovery

16.12.3. Execution of blood recovery

16.12.4. Removal of coupler

16.12.5. Clearing away

16.12.6. Completion of blood recovery

16.13. Discontinuance of dialysis

16.13.1. Discontinuance of UF

16.13.2. Discontinuance of dialysis

17. SEQUENTIAL DIALYSIS

17.1. ON setting of sequential dialysis

17.2. OFF setting of sequential dialysis

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

16-17

16-17

16-17

16-18

16-18

16-19

16-19

16-20

16-20

16-20

17-1~2

17-1

17-1

18. CHECK AND MAINTENANCE

18.1. Check and maintenance by operator

18.1.1. Check and maintenance before and after operation

18.1.1.1. Test mode

18.1.2. Cleaning and disinfection of machine outside

18.1.3. Disinfection and rinsing of fluid line inside

18.1.4. Acetic acid rinsing of fluid lines

18.2. Regular check by engineer

18.2.1. Check before power ON

18.2.2. Check of leakage current

18.2.3. Check of accuracy of pressure sensor

18.2.4. Check of syringe pump

18.2.4.1. Check for fixation of pulley

18.2.4.2. Check for accuracy of syringe pump

18.2.5. Check of accuracy of UF

18.2.6. Check of accuracy of blood leak sensor

18.2.6.1. Visual check of blood leak sensor

18.2.6.2. Zero revisions of blood leak sensor

18.2.7. Che

18.2.7.1. When electronic balance is used

18.2.7.2. When measuring cylinder is used

ck of accuracy of blood pump flow rate

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

18-1~22

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

18-1

18-1

18-1

18-2

18-2

18-2

18-3

18-4

18-5

18-6

18-7

18-7

18-7

18-8

18-9

18-9

18-10

18-11

18-11

18-11

CONTENTS-8

Page 12

18.2.8. Check of accuracy of bubble sensor

18.2.8.1. Preferable method

18.2.8.2. Simple method

18.2.9. Check of accuracy of temperature sensor

18.2.10. Check of accuracy of conductivity cell

18.2.11. Replacement of components of GVS filter (Supply water line)

18.2.12. Replacement of components of electromagnetic valve

18.2.13. Replacement of component of pump

18.2.13.1. Overall views of pump

18.2.13.2. Contents parts list

18.2.13.3. Replace method

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

18-12

18-12

18-12

18-13

18-14

18-15

18-16

18-18

18-18

18-18

18-20

18.3. Maintenance by qualified engineer

19. STORAGE

19.1. Actions before storing machine

19.1.1. Cleaning of enclosure

19.1.2. Priming of formalin solution

19.2. Environmental conditions required to store machine

19.3. Check and test before re-operation of machine

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

20. MACHINE MOVING AND CAUTIONS

21. SPECIFICATIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

19-1~2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

20-1~2

21-1~12

18-22

19-1

19-1

19-1

19-2

19-2

21.1. Specifications for machine

21.1.1. Dimension and weight

21.1.2. Power source

21.1.3. Electric safety

21.1.4. Environment

21.2. Performance of machine

21.2.1. Dialysate flow rate

21.2.2. Deaeration

21.2.3. UFR control

21.2.4. Temperature control

21.2.5. Conductivity control (BICARBONATE)

21.2.6. Conductivity control (ACETATE)

21.2.7. Disinfection control

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

CONTENTS-9

21-1

21-1

21-1

21-1

21-2

21-3

21-3

21-3

21-3

21-3

21-4

21-4

21-5

Page 13

21.2.8. Acid rinse control

21.2.9. Water rinse control

21.2.10. Blood pump

21.2.11. Syringe pump

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

21-5

21-5

21-6

21-6

21.3. Safety monitors

21.3.1. Venous pressure monitor

21.3.2. Dialysate pressure monitor

21.3.3. Bubble detector

21.3.4. Blood leak detector

21.3.5. Temperature monitor

21.3.6. Conductivity monitor

21.4. Specifications for options

21.4.1. Arterial pressure sensor

21.4.2. Backup unit of blood pump for power failure

21.4.2.1. Machine specification

21.4.2.2. Energy cell specification

21.4.3. Heat exchanger

21.4.4. Acid rinse port unit

21.4.5. Hot rinse Assy

21.4.5.1. Hot chemical disinfectant rinse control

21.4.5.2. Hot water rinse

21.4.6. Large single lump assy

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

21-7

21-7

21-7

21-7

21-8

21-8

21-8

21-9

21-9

21-9

21-9

21-9

21-10

21-10

21-10

21-10

21-11

21-11

21.5. Special note

21.5.1. Language

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

22. DATA FOR USE

22.1. Blood tubing set applicable to SURDIAL

22.1.1. A065(A067) / V643

22.1.2. A064(A066) / V643

22.2. Layouts of blood tubing

22.2.1. Model A065(A067) / V643

22.2.2. Model A064(A066) / V643

22.3. Flow chart and components of SURDIAL

22.3.1. Flow chart

22.3.2. Component of SURDIAL

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

22-1~8

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

21-11

21-11

22-1

22-1

22-2

22-4

22-4

22-5

22-6

22-6

22-7

CONTENTS-10

Page 14

CAUTIONS FOR SAFETY

To use the machine (SURDIAL) safely, it shall be operated in

accordance with specified procedures and shall be maintained

regularly after reading and full understanding cautions included in

this Operation Manual.

Procedures for operation and cautions for safety contained in the

manual are only applicable to the case when the machine is used

for specified purpose. It shall be noted that any danger caused by

use of the machine based on any procedures not specified in the

manual shall be responsible for user.

(1) Messages with symbol for safety are classified into the following

three categories:

DANGER

Cases critically causing death or severe injury of user by

misuse of the machine

WARNING

Cases potentially causing death or severe injury of user by

misuse of the machine

CAUTION

Cases potentially causing injury of user and/or loss of property

by misuse of the machine

(2) NOTE

Reference to operation of the machine

Design of the machine may be changed partially based on

improvement of it at any progressive step and the partially

improved design may be different from that contained in the manual.

If you have any question, please contact our branch or agency near

your place without hesitation.

CAUTION-1

Page 15

DANGER

■ Before use of the machine, read and full understand this Operation Manual.

• The machine can be used safely and reliably when operated and

maintained as specified in the manual.

• Before operating the machine, read and full understand the manual to

avoid human injury and the machine damage.

■ Be familiar with procedure how to stop the machine without delay.

• Be familiar with procedure how to stop the machine without delay in

emergency to avoid serious problem occurrence.

• The machine shall be operated by well trained and qualified person only

unless otherwise instructed formally.

Be familiar with procedure how to correct the machine when it is stopped

accidentally.

• Correct the machine as prescribed in the manual after checking the

stopped machine conditions.

DO NOT touch any board, wiring and terminal with hand in all the cases

other than maintenance mode.

• DO NOT touch any non-insulated wiring and terminal.

• DO NOT touch any board with wet hand.

• Disconnect plug from receptacle when any terminal bed is manipulated.

■ Take care of the following when patient is connected to the machine or

disconnect from it.

• DO NOT allow air ingress into patient body.

• DO NOT connect blood line to patient before starting priming operation.

• DO NOT connect blood line to patient during rinsing operation.

• Take care for patient not to be contaminated with harmful virus or

chemical.

• DO NOT connect bloodline to patient during releasing any alarm function.

It may critically causing death or severe injury of patient in this case.

■ Check frequently whether blood line is connected correctly to avoid danger

to patient due to blood leak caused by disconnection of the line when

incorrectly connected, and due to rupture of the line caused by excess

pressure application.

CAUTION-2

Page 16

WARNING

■ DO NOT use any electric wave generating electronic devices in room or

building where the machine is operated.

• DO NOT use electric wave generating electronic devices such as portable

telephone, transceiver and radio controlled toy in hospital to avoid

malfunction of the machine.

• Manage and instruct for the devices not to be brought in and not to be

used in hospital to prevent trouble occurrence.

DO NOT change parameter setting during dialysis excluding the case of

emergency.

• Change parameter setting before connecting the machine to patient.

• Set parameter as intended after full understanding its function.

■ Provide drain port at floor.

• Keep power cord away from floor to avoid electric shock if short-circuit is

caused by water leak.

• Provide drain port at floor near the machine.

Read the manual before starting check and maintenance of the machine.

• Read and full understand the manual before starting check and

maintenance.

• Check and maintain the machine as prescribed in the manual.

• Entrust check and maintenance not prescribed in the manual to

authorized specialist.

■ DO NOT touch any SW unnecessary for the machine operation during

dialysis.

■ DO NOT place the machine at an angle of ≧5°against vertical line under

loading any object on any container support or hunger to prevent falling

down of the machine.

■ DO NOT load any object on any container support or hunger during

transport of the machine.

■ DO NOT place the machine at an angle of ≧10°against vertical line under

unloaded condition to prevent falling down of the machine.

■ DO NOT connect any devices other than approved ones to the machine.

Otherwise, the total leakage current may exceed the acceptable limit.

CAUTION-3

Page 17

■ Injury or death of patient may be caused if the machine is operated,

maintained or calibrated based on any procedure not specified in this

operation manual or if any accessory device not approved by us is used. In

such case, the injury or death is out of our control. The machine shall be

operated, maintained or calibrated by well trained and qualified specialist

based on the procedure specified in this operation manual.

■ Check actual dialysate concentration by meter.

• Check whether dialysate concentration is correct by the test using

osmometer, conductivity meter or flame photometer.

• Check whether dialysate concentration is correctly displayed.

■ Check no residual disinfectant and acid after rinsing completion.

• After disinfection using sodium hypochlorite or peracetic acid; or after

acid rinsing, check whether residue of the disinfectant or acid is

contained in fluid supply and drain lines by the test using test paper or

reagent.

■ DO NOT apply hot rinse without hot rinse option. It might cause breakdown

of the machine.

CAUTION-4

Page 18

CAUTION

■ Before starting the machine installation, read and full understand the

instructions specified in “6. INSTALLATION" of this Operation Manual.

• The machine shall be installed by well trained and qualified person only.

■ Before connecting any optional device to the machine, read and full

understand “Handling Manual” of the device.

• The connection shall be performed by well trained and qualified person

only.

■ DO NOT give shock or impact to display and operation panel.

• Take care not to give shock or impact to display and operation panel

during cleaning.

■ Clean the machine thoroughly before use of it.

• If the machine is used after long term of storage, rinse using water for one

hour or longer.

• If the machine is used after long term of storage without removing water,

rinse well until dirty water is not drained.

■ Take care for the machine to be kept clean.

• If the machine is contaminated with blood, dialysate or rinsing fluid,

remove it by wiping without delay.

• Perform regular cleaning and disinfection.

■ There are the cases that display and process do not respond to operation of

some SW’s under certain conditions. DO NOT operate the SW’s forcibly.

■ Use the color coded dialysate concentrate container. Non- color coded one

is not applicable to the machine.

■ Take care to avoid infection during handling of disposables because there is

possibility of contact with hepatitis virus and/or contaminated drug or

chemical.

■ Use water, dialysate concentrates and substitute of acceptable qualities for

safe and effective operation of the machine.

■ Gap between rollers and housing of blood pump can be adjusted within

allowable range. The adjustment may be required according to size of

rolling tube.

CAUTION-5

Page 19

Chapter 1

APPLICATION

(a) Single patient dialysis machine, SURDIAL is applied to treatment of

patients with acute or chronic renal failure by dialysis when the application

is instructed by doctor.

(b) SURDIAL can be used at both hospital and home.

1-1

Page 20

Chapter 2

CONTRAINDICATION

Any application other than dialysis is contraindicated.

2-1

Page 21

Chapter 3

CAUTIONS

Take care of the followings in use of the machine:

1. The machine shall be operated by well trained technician only.

2. Cautions for installation

(1) Install the machine at place without fear of contact with water.

(2) Install the machine at place without fear of adverse effects caused by abnormal

atmospheric pressure, temperature and/or humidity; insufficient ventilation,

direct exposure to sunlight; and dust, salt and/or sulfur containing air.

(3) Handle the machine under avoiding slant placement, vibration and shock during

installation and transportation.

(4) DO NOT install the machine at chemical storing or gas generating place.

(5) Frequency, voltage and amperage (power consumption) of power supply should

be as specified.

(6) Connect the machine with earth correctly.

3. Cautions prior to starting operation

(1) Check SW contacts, polarity, dial settings, meters and the like to assure correct

operation of the machine.

(2) Check correct connection of the machine with earth.

(3) Check correct connections of all wires.

(4) Take care that operation of the machine combined with other device may cause

adverse effects.

(5) Recheck integrity of lines connected to patient directly.

3-1

Page 22

Cautions during operation

4.

(1) Monitor always whether the machine and patient are maintained normally.

(2) If trouble of the machine or patient is detected, take appropriate actions such as

the machine stop so that the patient is kept safe.

(3) Take care that there is no direct contact of the machine to patient.

5. Cautions after operation

(1) Turn off power after returning operation SW’s, dials and the like to original

positions based on prescribed procedures.

(2) DO NOT forcibly pull any cord and the like to disconnect..

(3) Take care the followings to store or transport the machine:

1) Store the machine at place without fear of contact with water.

2) Store the machine at place without fear of adverse effects caused by

abnormal atmospheric pressure, temperature and/or humidity; insufficient

ventilation, direct exposure to sunlight; and dust, salt and/or sulfur

containing air.

3) Handle the machine under avoiding slant placement, vibration and shock

during storage and transportation.

4) DO NOT store the machine at chemical storing or gas generating place.

(4) Clean accessories, cords, and the like in order and clean them to store.

(5) Store the machine after cleaning it for the next use without any trouble.

6.

If the machine is damaged, indicate the damaged conditions to request

repair by specialist.

7.

DO NOT remodel or modify the machine.

8.

Check and maintenance

(1) Perform regular check and maintenance of the machine and its components.

(2) When the machine is used after storage for some time, check and maintain so that

it can be operated normally and safely.

9.

Read and understand other CAUTIONS contained in the operation manual.

3-2

Page 23

Chapter 4

DEFINITION

Terms contained in this Operation Manual shall be defined as follows:

z “Acetate” means salt required to prepare acetate dialysate which is used for acetate

dialysis.

z “Acid rinsing” means process to rinse dialysate line by passing dilute acetic acid

through it.

z "Arterial pressure (option)" means pressure in arterial drip chamber determined by

pressure sensor connected with the chamber through detection line.

z “Back siphon” means back flow of waste dialysate toward the machine due to

pressure in dialysate drain line is higher than that in the machine, can be caused by

any reason when machine is stopped.

z "Bicarbonate" means salt required to prepare bicarbonate dialysate which is used

for bicarbonate dialysis.

z “Blood leak detector” means device used to detect blood leak to dialysate optically.

z “Blood line” means the circuit used to circulate extracorporeal blood through

dialyzer.

z “Blood pump” means pump used to circulate blood through dialyzer and blood line.

Roller type pump is used in SURDIAL.

z “Bubble detector” means device used to detect air bubble in blood passing through

venous line.

z “Bypass” means process to drain dialysate through bypass line without passing

dialysate through dialyzer.

z “Clamp” means device used to close blood line by clamping when air bubble is

detected in venous line.

z "Concentration" means Na+ concentration in dialysate derived from measurement

of dialysate conductivity.

z “Conductivity sensor” means the sensor used to measure conductivity of dialysate.

z "Dialysate" means solution dissolving various salt used to remove metabolic waste

and excess fluid from blood through dialyzer membrane.

z “Dialysate concentrate connection ports” means those provided with male

connectors each used to connect with each of acetate or A and B concentrates.

z "Dialysate pressure: DP" means pressure at dialyzer inlet determined by referring to

pressure measured at dialysate line by pressure sensor.

z "Dialysis" means process to remove metabolic waste and excessive fluid from a

circulating extracorporeal blood by diffusion.

z “Dialyzer” means device containing membrane through which metabolic waste and

4-1

Page 24

excess fluid are removed.

z DIALYSIS screen : PREPARATION COMPLETION, DIALYSIS and RECOVERY are

enabled by the mode.

z “Disinfection” means process to disinfect dialysate line by passing disinfectant

such as

dilute sodium hypochlorite or peracetic acid solution through it.

z “Disinfectant concentrate connection port” means that provided with male

connector used to connect with disinfectant.

z "Double needle dialysis" means dialysis performed by puncturing artery and vein

using respective needles to circulate blood.

z “Earth” means ground connection.

z PREPARATION screen : message to operator is displayed during preparation

process.

z “Priming” means process to prime dialyzer with saline or the like.

z RINSING (AUTOMATIC RINSING 1) screen : pattern of the disinfection and current

time are displayed.

z RINSING (AUTOMATIC RINSING 2) screen : pattern of the disinfection and current

time are displayed.

z “Rinsing program” means program to allow automatic implementation of water

rinsing, disinfection, acid rinsing and the like in accordance with previously set

sequence and pattern.

z RINSING WAITING screen : list of rinsing patterns is displayed and desired rinsing

mode is selected by the mode.

z RINSING (WATER RINSING) screen : the mode is displayed.

z "Sequential dialysis" means execution of ultrafiltration only without passing

dialysate through dialyzer.

z "Single pump-single needle dialysis" means dialysis performed by puncturing

arteriovenous fistula using single needle under operating of single pump.

z “Syringe pump” means pump designed to load syringe containing heparin which is

infused to blood line at a preset infusion rate through heparin line communicated

with the syringe.

z “Temperature sensor” means the sensors used to measure temperature of supply

water at 2 locations and dialysate at 1 locations.

z "Transmembrane pressure: TMP" means [venous pressure] - [DP].

z TMP is for reference only.

z “TMP off-set” means pressure difference between Venous pressure sensor and

dialysate pressure sensor caused by the setting height difference between both

pressure sensor and other environmental factor. This machine calculate TMP off-set

value as the average pressure difference value (TMP off set = dialysate pressure –

Venus pressure) during 1 round of before first ultra filtration process of beginning

of dialysis, and after 1 hour of dialysis treatment started.

z "Ultrafiltration" means process to remove fluid from a circulating extracorporeal

blood through dialyzer membrane.

z "Venous pressure" means pressure in venous drip chamber determined by

pressure sensor connected with the chamber through detection line.

z “Viscous control system” means system used to prepare dialysate and to control

UF. The principle are next section.

4-2

Page 25

z “Viscous pump” means bellowphragm pump receiving viscous silicone used to

control ultrafiltration (UF) and to prepare dialysate.

z “Water rinsing” means process to rinse dialysate line by passing water through it.

4-3

Page 26

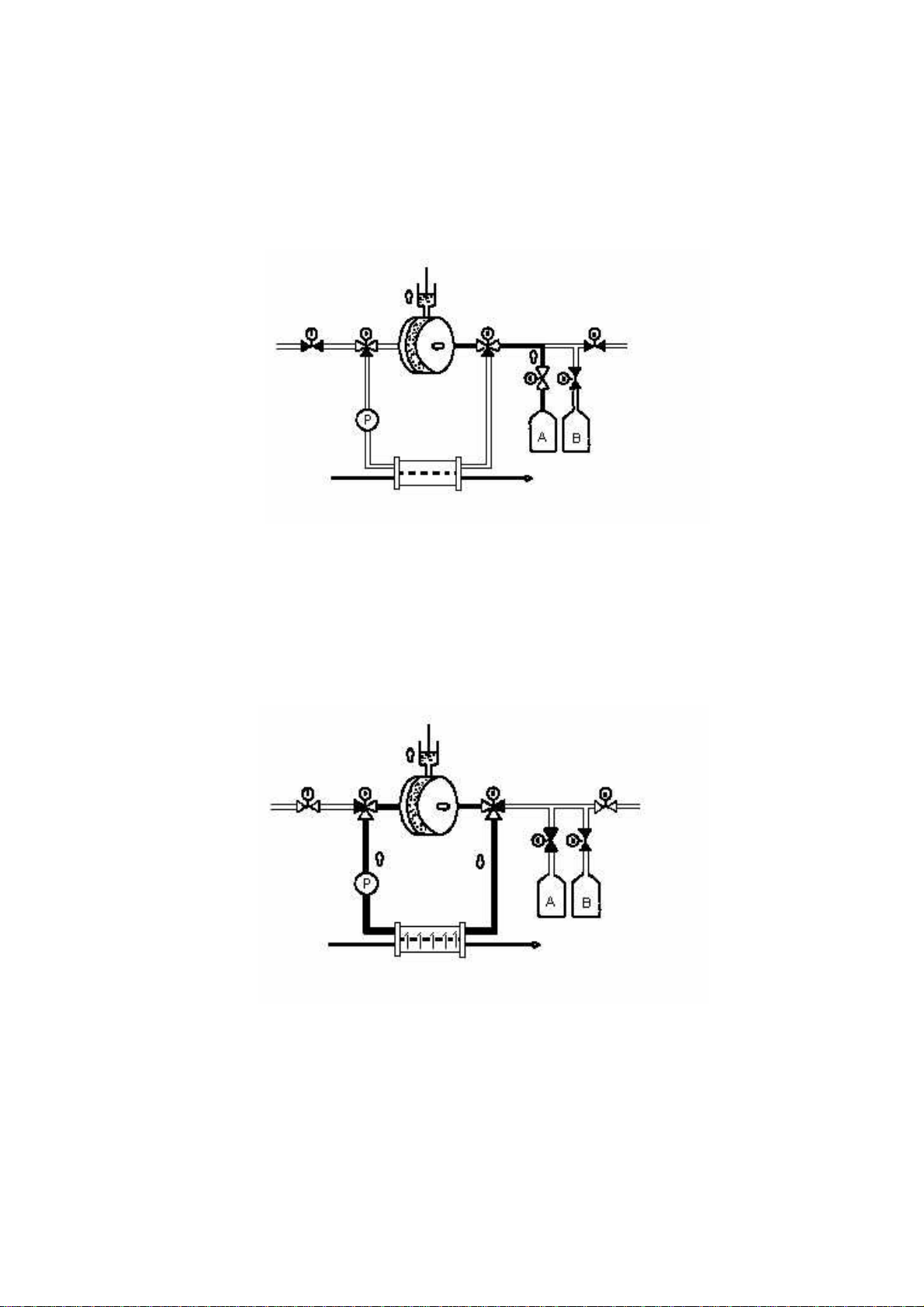

z The principle of VCS (Viscous Control System)

Dialysate mixing

As shown in the below Fig., water is supplied to the right side of the viscous chamber.

By upward movement of piston of the viscous pump during temporally stop of the water

supply, A concentrate (for bicarbonate dialysis) of a volume corresponding to the piston

stroke is aspirated in the right side. By changing the piston stroke, dialysate

concentration can be changed. During the supply and aspiration, used dialysate is

drained from the left side.

UF control

As shown in the below Fig., fresh dialysate prepared in the right side is transferred to

the left side through dialyzer by operating the pump. By upward movement of piston of

the viscous pump, capacity of closed circuit (shown as bold lines) is increased,

generating negative pressure in dialysate compartment of the dialyzer. As the result,

fluid of a volume corresponding to the piston movement is removed from blood. By

changing the piston stroke, it is possible to change UF.

The system is build up so that dialysate preparation and UF control cycle is alternating,

which means that two sets are provided in the system.

【US and JAPAN PATENTS】

4-4

Page 27

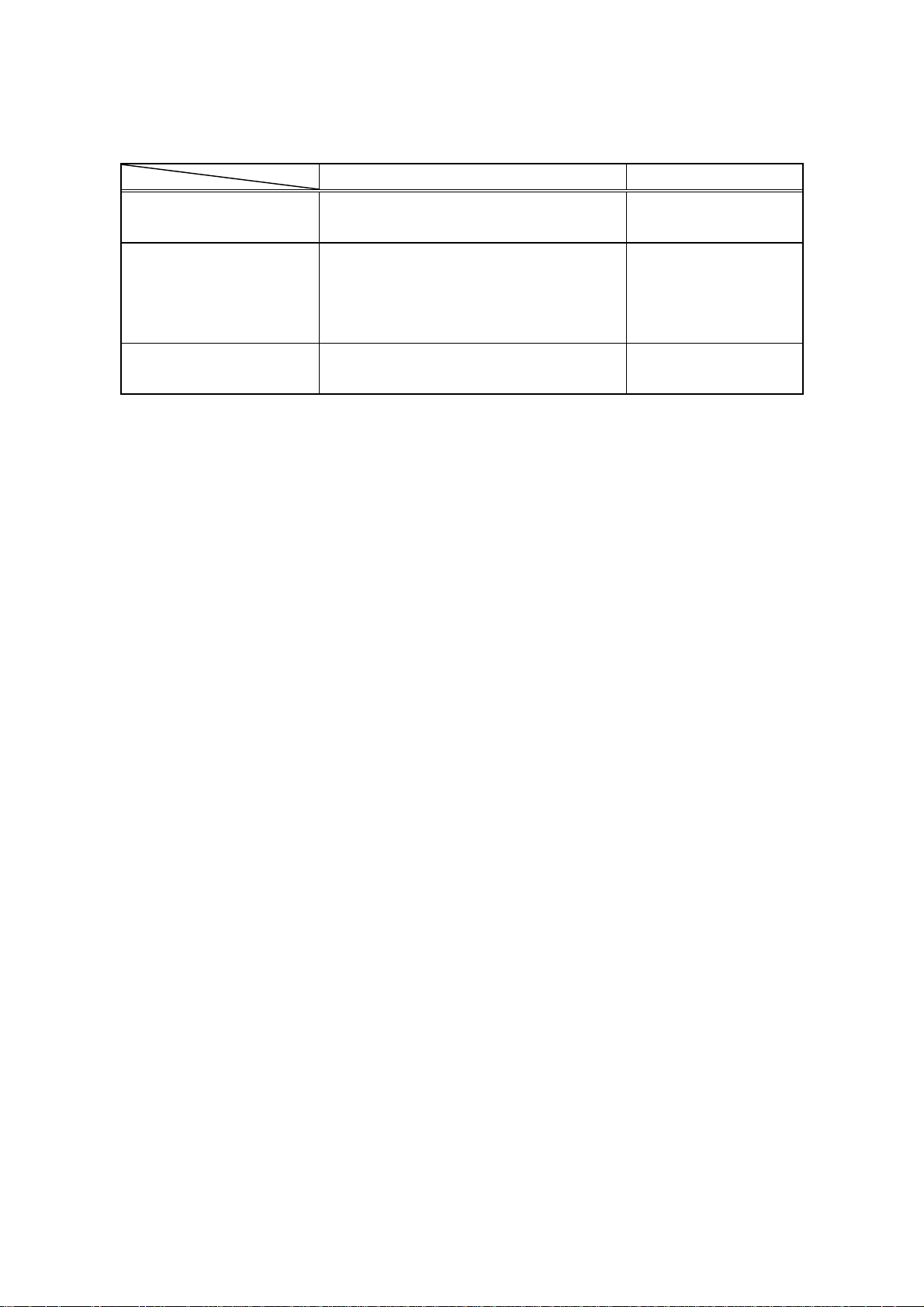

5. SPECIFICATIONS

Specification Required condition

Allowable set range

Allowable indication

range

Accuracy of indicated

value

-400~+400mmHg

Digital indication -400 to

+400mmHg

Indicator indication - -400 ~

+400mmHg

Actual pressure±10mmHg、

or ±10% (F.S.) whichever greater

No

No

Excluding indicator

5-1

Page 28

Chapter 6

INSTALLATION

Environmental condition and methods of unpacking, assembling, connection and wiring required to

install the machine and methods of disposal of used machine and packaging materials are specified

below. These operations should be performed by trained and qualified person(s) only.

6.1. Installation environment

The following requirements should be fulfilled to assure safe and effective use of the machine.

6.1.1. Ambient conditions

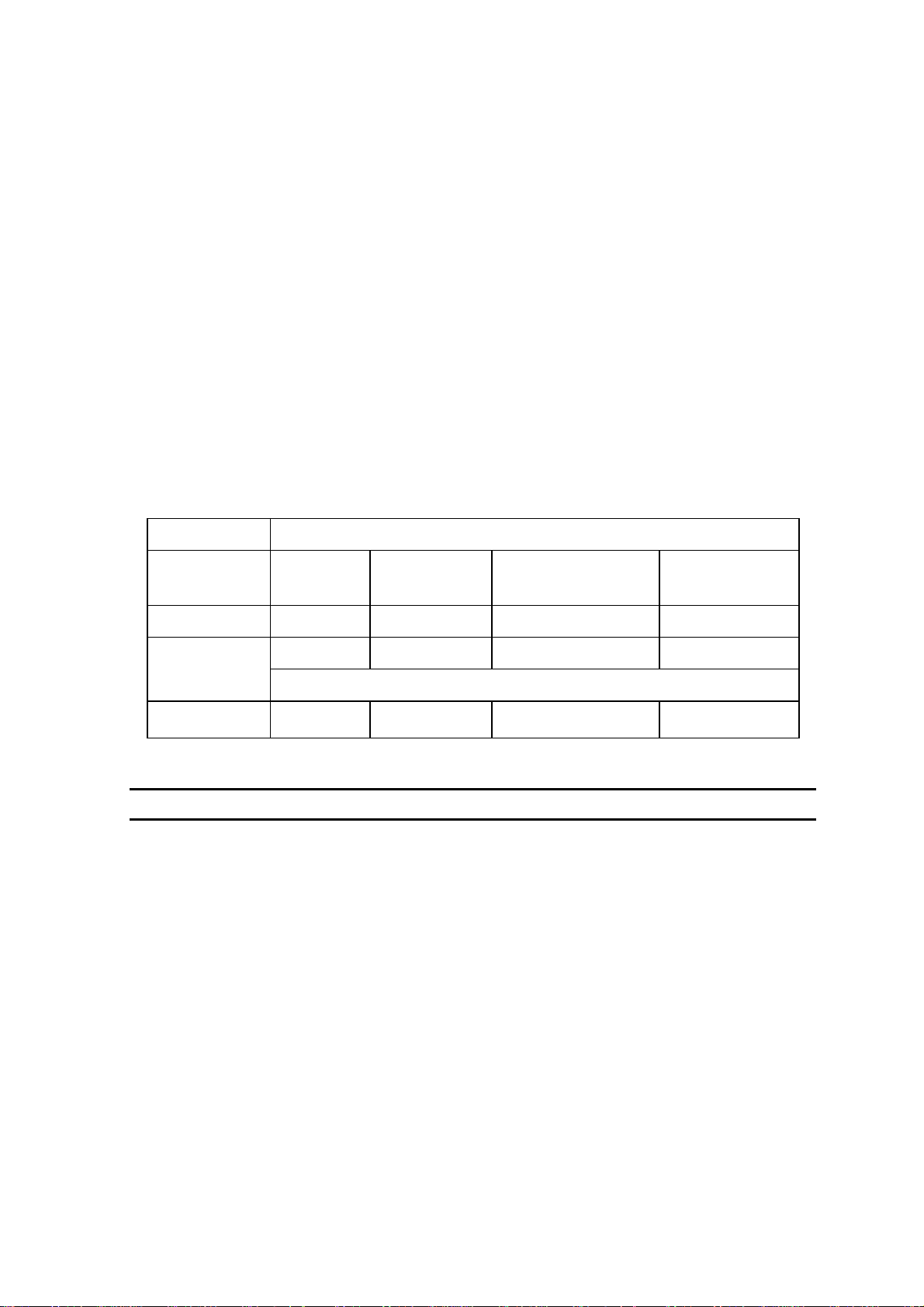

During :

Use Daily storage

Temp. (°C)

15 to 35 10 to 40 5 to 50 -10 to 50

Storage for one month

or more; and Transport

with contained fluid

Transport

without fluid

Relative humidity

(%)

Atmospheric

pressure (hPa)

35 to 80 15 to 85 15 to 85 15 to 85

No condensing

795 to

1062

795 to 1062 795 to 1062 700 to 1062

NOTE

Avoid direct exposure of the machine to sunlight

6.1.2. Power supply

6.1.2.1. When machine power rating is AC 230V

The machine is designed to be operated by power supply of AC 230V ± 10%, 50 Hz.

Receptacle conforming to protective earth type plug of AC rating of 230V, ≧ 10 A is required

to connect with the machine. Connect the plug with the receptacle correctly.

6.1.2.2. When machine power rating is AC 110V

The machine is designed to be operated by power supply of AC 110V ± 10%, 50 Hz.

Receptacle conforming to protective earth type plug of AC rating of 110V, ≧ 20 A is required

to connect with the machine. Connect the plug with the receptacle correctly.

6-1

Page 29

WARNING

DO NOT use AC power plug or adapter disconnecting safety earth.

DO NOT connect the machine plug to receptacle through adapter.

If power installation is suspected to have any problem, request check of wiring by electric

engineer.

6.1.3. Necessary space requirements to use the machine

Space above the top of the machine should be ≧ 5 cm, that at each of right and left sides

should be ≧ 10 cm and that at rear side should be ≧ 20 cm.

A ventilation port with a diameter ≧ 20 cm should be provided or any side other than bottom

should be cleared so that the side is completely exposed to atmosphere.

6.1.4. Water supply and drainage conditions

Water supply and drainage conditions should be checked for normal operation of the machine.

6.1.4.1. Water supply pressure

2

Pressure : 0.049 to 0.74 MPa (0.5 to 7.5 kgf/cm

)

6.1.4.2. Water supply flow rate

Flow rate : ≧ 750 mL/min

6.1.4.3. Water supply temperature

Temperature : 17 to 30 °C.

The temperature should be lower than the set dialysate temperature by ≧ 5 °C.

If heat exchanger is used, the temperature should be 5-30 °C which should be lower than the

set dialysate temperature by ≧ 5 °C.

6.1.4.4. Water quality

Supply water must be filtered through a 25 µm filter and the quality must be soft. The quality

must be monitored by regular analysis to maintain the acceptable quality.

WARNING

6-2

Use water of quality meeting AAMI - approved American National Standard for

Haemodialysis System, RD5, 1981, Section 3.2.

Otherwise, patient may suffer from seriously adverse effects.

Page 30

6.1.4.5. Concentrate line pressure

Pressure :

Min : -100 mmHg (136 cm below inlet)

Max : +100 mmHg (136 cm above inlet)

6.1.4.6. Drainage

Drain flow rate : ≧ 1500 mL/min

Drain tube tip must be placed above the machine floor by 0 to 60cm and it should not be

contacted with waste fluid level in drain groove.

6-3

Page 31

6.2. Unpacking and check of contents

WARNING

Unpacking should be performed by at least 2 operators. Otherwise bone fracture may be

caused by drop of the machine on body.

NOTE

Tightening components such as screws and nuts are mm size. If missed, use those of the

same mm size.

(1) Just after unpacking, check conformance of manufacturing No. indicated on the package to

that on the machine.

(2) Check whether the following accessories are provided and whether the machine and

accessories are not damaged.

(a) Hanger (×1)

(b) Main lamp (×1)

(c) Tray (×1)

(e) IV pole (×1)

+O-ring (×2) (d) Main lamp cap (×1)

Fig. 6-1 Accessories

6-4

Page 32

(f) Blood pump handle (×1)

(g) Coupler set (×1)

(h) Disinfectant concentrate

container connection set (×1)

(i) Dialysate concentrate container

connection set

(One for each of A and B)

(j) Dialyzer holder (×1)

(k) Tube holder (×2)

Fig.6-1 Accessories

(L) CL filter (×1)

6-5

Page 33

6.3. Procedure for assembling

6.3.1. Cautions

Take care of the followings at assembling.

(a) Place the machine on horizontal and stable floor.

(b) Sufficient space to assemble should be provided.

(c) Use accessories packaged with the machine and/or designated option to assemble.

6.3.2. Attachment of I.V. pole, hanger and main lamp

6-6

Fig. 6-2 Attachment of I.V. pole

Attach the pole to the machine as shown in Fig. 6-2. Harness can be easily passed through the pole

by binding strand to the machine side connector followed by passing the connector bound strand

through the pole. Engage the connector with the lamp side connector securely.

Wires of the both connectors are colored as shown in the below Table:

Machine side (Letters on tube) Lamp side

Black or white (LAMP) Black or white

Red Red

Page 34

6.3.3. Connector for each concentrate container

Drill concentrate container cap to prepare hole as shown in the below Fig. 6-3.

Then cut off suction port by a depth suitable for the container to make notch as shown in the

below Fig. 6-4.

Concentrate container cap

(Prepare hole of φ18.5mm)

For disinfectant concentrate For A or B concentrate

container container

Fig. 6-3 Connectors for concentrate containers

Fig. 6-4 Preparation of suction port

Cut off

Suction port

NOTE

If the container is provided with 2 ports closed with respective caps, engage the

connector with one of the ports and loosen the cap of the other port to allow air

introduction.

If the container is provided with only one port closed by one cap, engage the connector

with the port and loosen the cap to allow air introduction.

The caps (L and S) are not provided with the machine. Use L or S cap of the containers.

Prepare 3 or 4 connectors for containers receiving A, B and disinfectant concentrates;

and for container receiving acetic acid concentrate as option.

6-7

Page 35

6.4. Procedures for tube and plug connections

6.4.1. Connections of fluid supply and drain lines, coupler and power plug

CAUTION

Before and after tube and plug connection, check whether installation environment

conforms to the requirements specified in 6.1.1 of this operation manual.

Connect dialysate coupler tubes to ports “To dialyzer” and “From dialyzer” securely by

full advancing the tubes followed by banding them.

6.4.1.1. Connection of dialysate coupler tubes

(1) Connect tube at blue band side of coupler to dialysate port “To dialyzer” securely by full

advancing the tube followed by banding.

(2) Connect tube at red band side of coupler to dialysate port “From dialyzer” securely by full

advancing the tube followed by banding.

(3) Cut red band any position. Connect CL filter to cutting point followed by banding.

Connect the side of inject port for CL filter to the edge “From dialyzer”.

6.4.1.2. Connections of drain port of machine side

Use tube of an internal diameter of 8 mm and a length of 2 m or shorter to connect to the port.

Fix the connection securely by strapping with metal clip.

CAUTION

By change of height of the tube free end from drain port placed at floor, dialysate

conductivity may be changed due to change of drain pressure. If the height is changed,

check the conductivity.

6.4.1.3. Connection of water supply port

Use pressure resistant tube of an internal diameter of 8 mm.

Fix the connection securely by strapping with metal clip.

6.4.1.4. Connection of power plug

Insert power plug of the machine in receptacle securely by full advancing the plug.

6-8

Page 36

6.4.2. Connection of each concentrate

6.4.2.1. Connection to execute dialysis operation (before blood line connection)

(1) Load container of A concentrate (or acetate concentrate) and that of B concentrate on

respective container supports.

(2) Connect connectors of the machine for A and B concentrates to respective connectors of the

containers.

(3) Check whether connector of the machine for disinfectant concentrate is connected to rinse

port correctly.

(4) If acid rinse option is used, check whether connector for acetic acid concentrate is

connected to rinse port correctly.

CAUTION

Connect each concentrate connector, rinse port and the like securely. Otherwise, trouble

such as water leak or air aspiration may be caused.

During acetate dialysis (B concentrate is not used), connect connector for B concentrate

to corresponding rinse port placed at upper part of the machine.

6.4.2.2. Connection for water rinsing

(1) Check whether all connectors are connected to rinse ports.

CAUTION

Connect each concentrate connector, rinse port and the like securely. Otherwise, trouble

such as water leak or air aspiration may be caused.

Connect all 3 connectors of the machine for A, B and disinfectant concentrates to

respective rinse ports. If acid rinse option is used, connect acetic acid concentrate

connector to corresponding rinse port.

6.4.2.3. Connection for disinfection

(1) Connect connector placed at rear side of the machine for disinfectant concentrate to

container for disinfectant concentrate.

(2) Check whether connectors of the machine for A and B concentrates are connected to

respective rinse ports securely.

(3) If acid rinse option is used, check whether connector for acetic acid concentrate is

connected to rinse port correctly.

CAUTION

Connect each concentrate connector, rinse port and the like securely. Otherwise, trouble

such as water leak or air aspiration may be caused.

6-9

Page 37

6.4.2.4. Connection for acetic acid rinsing (when acid rinse option is not used)

(1) Connect connector placed at rear side of the machine for disinfectant concentrate to

container for acetic acid concentrate.

(2) Check whether connectors of the machine for A and B concentrates are connected to

respective rinse ports securely.

CAUTION

Connect each concentrate connector and the like securely. Otherwise, trouble such as

water leak or air aspiration may be caused.

6.4.2.5. Connection for acetic acid rinsing (when acid rinse option is used)

(1) Connect connector placed at rear side of the machine for acetic acid concentrate to

container for the concentrate.

(2) Check whether 3 connectors for A, B and disinfectant concentrates are connected to

respective rinse ports securely.

CAUTION

Connect each concentrate connector and the like securely. Otherwise, trouble such as

fluid leak or air aspiration may be caused.

6.4.2.6. Connection for automatic rinsing (1 or 2) (when acid rinse option is used)

(1) Connect connector placed at rear side of the machine for disinfectant concentrate to

container for the concentrate.

(2) Connect connector placed at rear side of the machine for acetic acid concentrate to

container for the concentrate.

(3) Check whether connectors of the machine for A and B concentrates are connected to

respective rinse ports securely.

CAUTION

Connect each concentrate connector, rinse port and the like securely. Otherwise, trouble

such as water leak or air aspiration may be caused.

Use disinfectant and acetic acid concentrates of specified concentrations.

6-10

Page 38

6.4.3. Air purge

The machine is shipped after filling fluid line with air. To install the machine, remove air in

accordance with the procedures shown in message screen of display. The air is removed

automatically within 7 to 10 minutes.

CAUTION

Before starting air purge, check whether water supply is enabled. If disabled, pump may

be damaged due to unloaded operation.

NOTE

When the machine is turned on after long term, date and time may be initialized and E50

RAM INITIALIZE error may be occurred to initialize SETTING 1 screen. Because RAM

back up battery is emptied. The check and re-input should be performed by well trained

person.

RAM back up battery is rechargeable. It is full charged by power on the machine about 22

hours continuously. It is emptied by turn off the machine about 7 - 10 days.

(1) Check whether all connectors are connected to respective rinse ports correctly.

(2) Check whether water can be supplied.

(3) The air purge process is enabled during rinse wait mode only. Select the mode.

(4) Press [F・5] SW to display maintenance mode menu.

(5) Press [F・3] or [F・4] SW to select "MODE9” followed by pressing [F・1] SW.

(6) After checking display of [MAINTE 9], press [F・1] SW to start the air purge process.

(7) To terminate the process forcibly during its execution, press [F・1] SW.

(8) Upon completion of the process, it is shown in the message screen.

[MAINTE MENU(4/5)]

MODE9:MACHINE FILLING PROCEDURE

MODE10:ALARM HISTORY

MODE9 MODE10 P.UP P.DOWN DISP.

F・1 F・2 F・3 F・4 F・5

[MAINTE 9]

GO TO RINSE WAITING MODE

PRESS START SW TO FILL MACHINE

STARTMENU

F・1 F・2 F・3 F・4 F・5

[MAINTE 9]

FILLING

STOP

F・1 F・2 F・3 F・4 F・5

[MAINTE 9]

END OF FILLING

MENU

F・1 F・2 F・3 F・4 F・5

6-11

Page 39

6.5. Disinfection of the dialysate circuit

Be sure to disinfect the dialysate circuit before use of the machine.

6.6. Disposal of used machine

Procedures how to dispose materials of the machine are described below:

(a) Resin such as electrical circuit board and silicone oil; rubber and electric wire should be

disposed as industrial waste. If the disposal is covered by regional regulation, dispose them

based on it.

(b) To distinguish iron from stainless steel, use magnet because the iron is attracted by it, while

the stainless steel is not so. The iron is surface finished by painting or plating to prevent rust

formation.

6.7. Disposal of used packaging materials

Dispose used packaging materials after separating to groups of wood, styrol foam, corrugated

board and the like.

6.8. Disposal of blood lines and dialyzer

Dispose used blood lines and dialyzer by suitable manners specified by hospital or medical

facilities to prevent risk of infection.

6-12

Page 40

Chapter 7

MAIN FUNCTIONS AND COMPONENTS

Main functions and components of the machine are as follows:

(1) Preparation of bicarbonate dialysate

(2) Preparation of acetate dialysate

(3) Ultrafiltration control by viscous control system (VCS)

(4) Sequential dialysis

(5) One clamp single needle dialysis

(6) Rinsing program

(7) Blood pump (three roller type)

(8) Bubble detector

(9) Clamp

(10) Auto self check

(11) Blood leak detector

(12) Auto gas purge

(13) Message screens of display

(14) Auto priming

(15) Drain from dialyzer

(16) Check of leak from closed circuit

(17) Main lamp

(18) Double syringe pump

(19) Arterial pressure sensor (option)

(20) Backup for blood pump at power failure (option)

(21) Heat exchanger (option)

(22) Acid rinse port (option)

(23) Hot rinse-programming (option)

7-1

Page 41

Chapter 8

CONSTRUCTION OF MACHINE

8.1 Overall construction

8.1.1 Overall views

Main

Operation

Blood line setting

Front view

Fig. 8-1-1 Front and right side views of SURDIAL

8-1

Right side

Page 42

y

Power suppl

Rear side view Left side view

Fig. 8-1-2 Rear and left side views of SURDIAL

8-2

Page 43

V

8.1.2 Components of machine and their purposes and functions

No. Component Purpose and function

1 Sampling port

2 Rinse port for A

concentrate

3 Connector for A

concentrate

4 Rinse port for B

concentrate

5 Connector for B

concentrate

6 Flow meter

7 Dialysate return tube Tube used to return used dialysate to port “From

8 Dialysate supply tube Tube used to supply fresh dialysate to port “To

9 Dialysate return coupler

10 Dialysate supply coupler Coupler used to connect fresh dialysate supply tube to

11 Bypass connector Connector used to bypass ports “From Dialyzer” and

12 Limit SW for bypass

connector

13 Coupler holder

14 Dialysate flow rate

regulating needle valve

15 Container support

16 Port “From Dialyzer”

17 Port “To Dialyzer”

Port used to take dialysate sample

Port used to connect to connector of A concentrate

container during rinsing operation

Connector used to connect connector of bicarbonate A

concentrate container

Port used to connect connector of B concentrate

container during rinsing operation

Connector used to connect connector of bicarbonate B

concentrate container

Meter use to indicate flow rate of dialysate supplied to

dialyzer

Dialyzer”

Dialyzer”

Coupler used to connect used dialysate return tube to

dialyzer

dialyzer

“To Dialyzer” when couplers Nos. 9 and 10 are set to

the machine during rinsing operation

SW used to detect whether coupler is received in

coupler holder

Holder used to receive coupler during rinsing operation

alve used to regulate dialysate flow rate in closed

circuit

Support used to load dialysate concentrate container

Port used to return used dialysate from dialyzer

Port used to supply fresh dialysate to dialyzer

8-3

Page 44

No. Component Purpose and function

18 Water supply port

19 Drain port

20 Port for connector of

disinfectant concentrate

connector

21 Connector for disinfectant

concentrate container

22 Blood leak sensor